FPC feeding robot

A robot and material feeding technology, which is applied in the field of robots, can solve the problems of material waste and the inability to automatically adjust the amount of material supplied, and achieve the effect of simple design principle, good use value, high automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

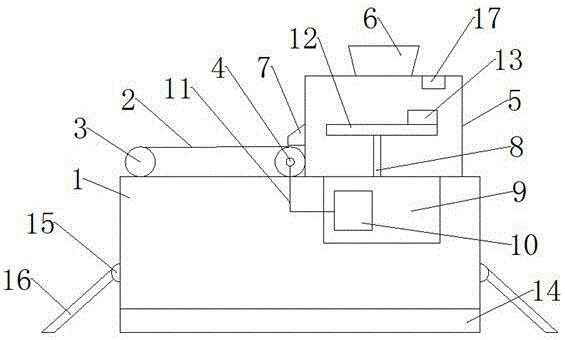

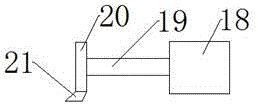

[0014] Example: see figure 1 and figure 2 , the present invention provides a technical solution: a FPC feeding robot, including a frame 1 and a conveyor belt 2, the conveyor belt 2 is arranged on the frame 1, a transmission wheel 3 is arranged inside the conveyor belt 2, and a speed sensor is arranged on the transmission wheel 3 4. The feeding speed can be well measured by the sensor. The right end of the transmission wheel 3 is provided with a silo 5, the upper end of the silo 5 is provided with a feed hopper 6, the lower end of the hopper 5 is provided with a discharge hopper 7, and the hopper 5 is provided with a Push rod 8, drive motor 9 is connected to the lower end of push rod 8, frequency modulation transmission 10 is arranged on drive motor 9, speed sensor 4 is connected with frequency modulation transmission 10 through wireless network 11, can well control the speed of drive motor 9, push rod 8. A feeding tray 12 is arranged on the upper end, and a pushing device 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com