Patents

Literature

181results about How to "Control feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

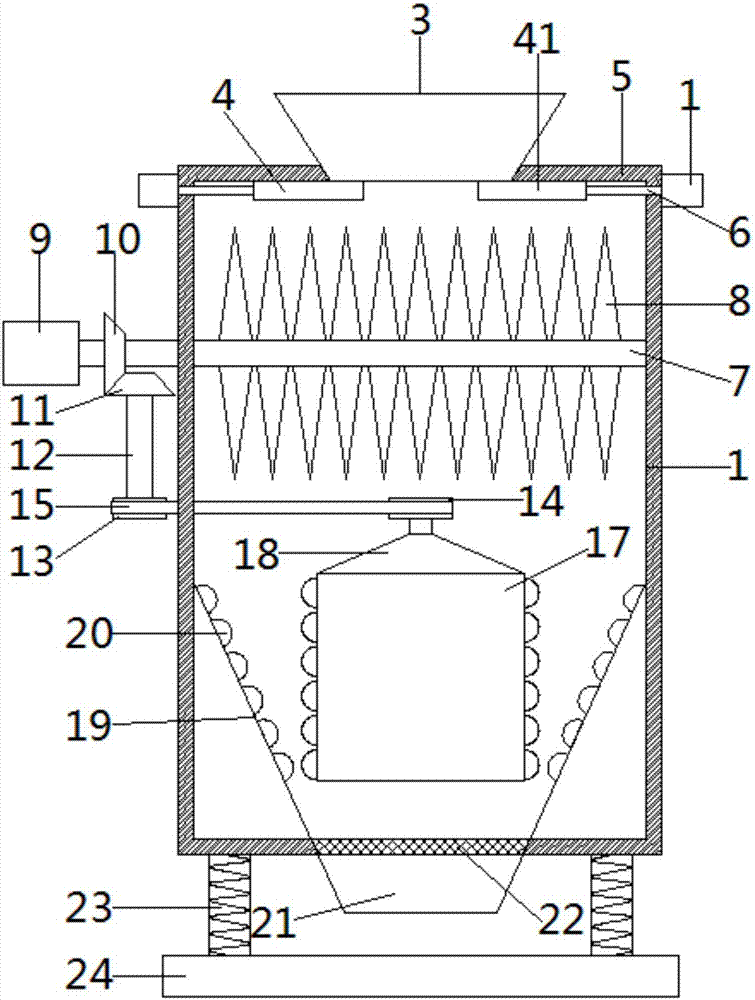

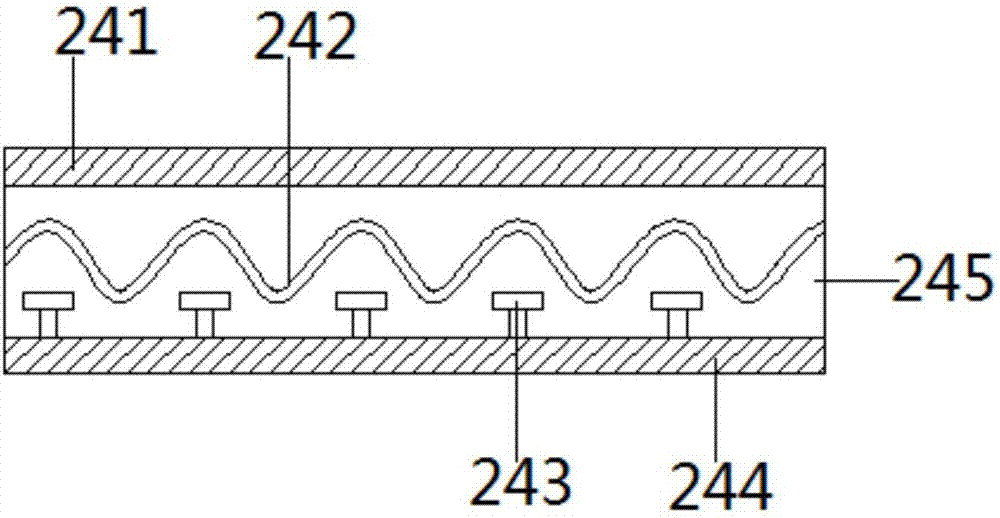

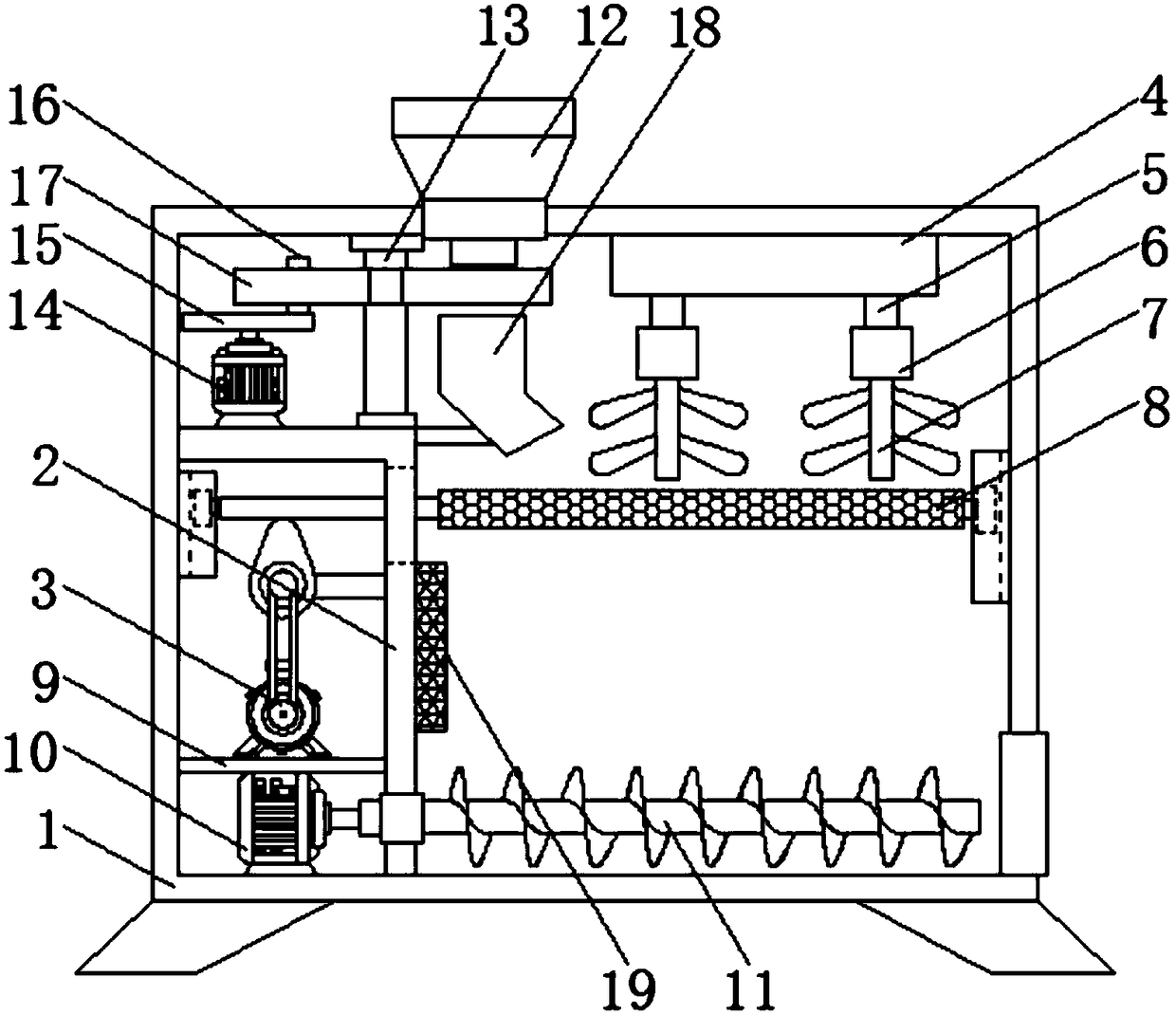

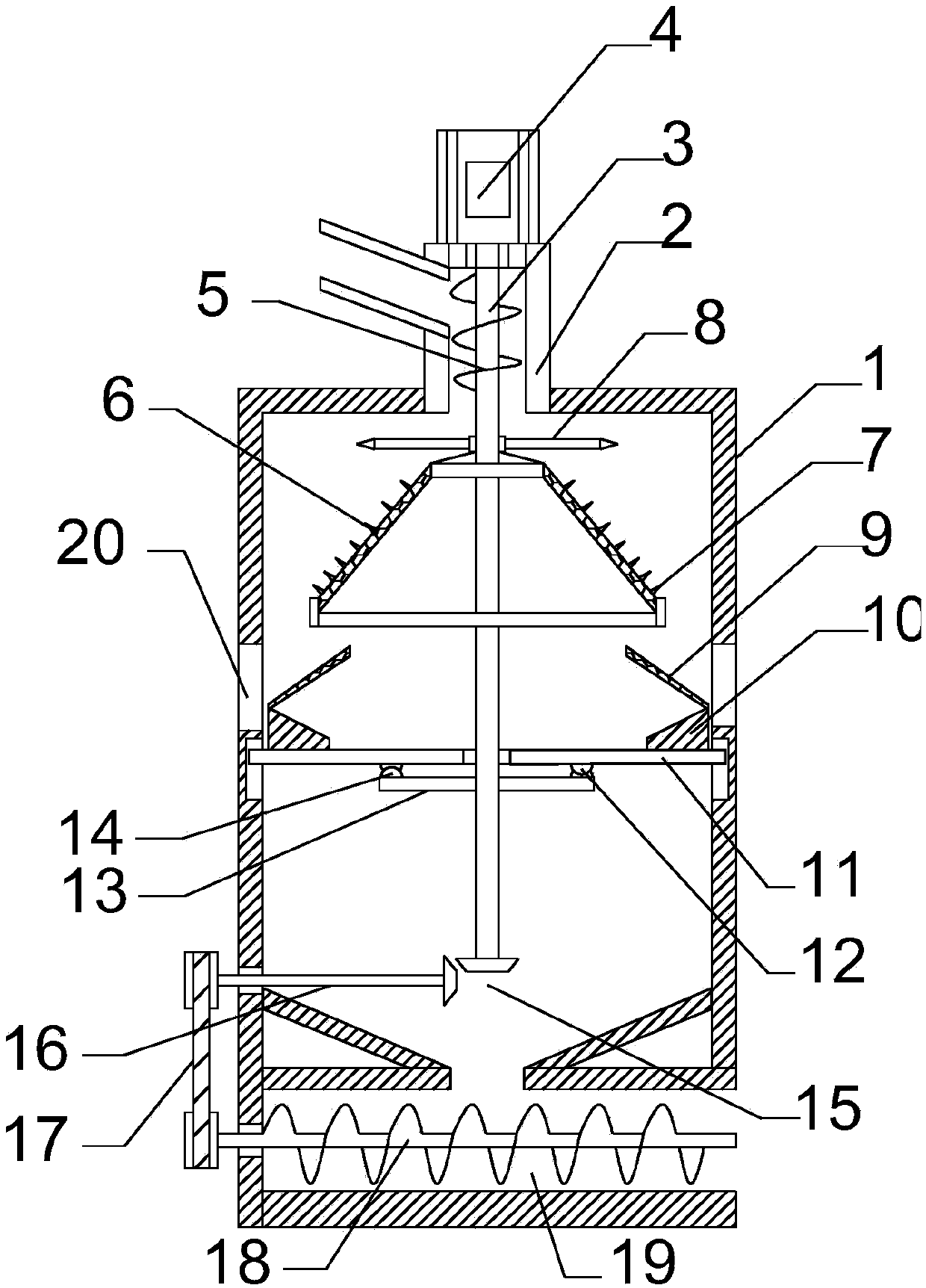

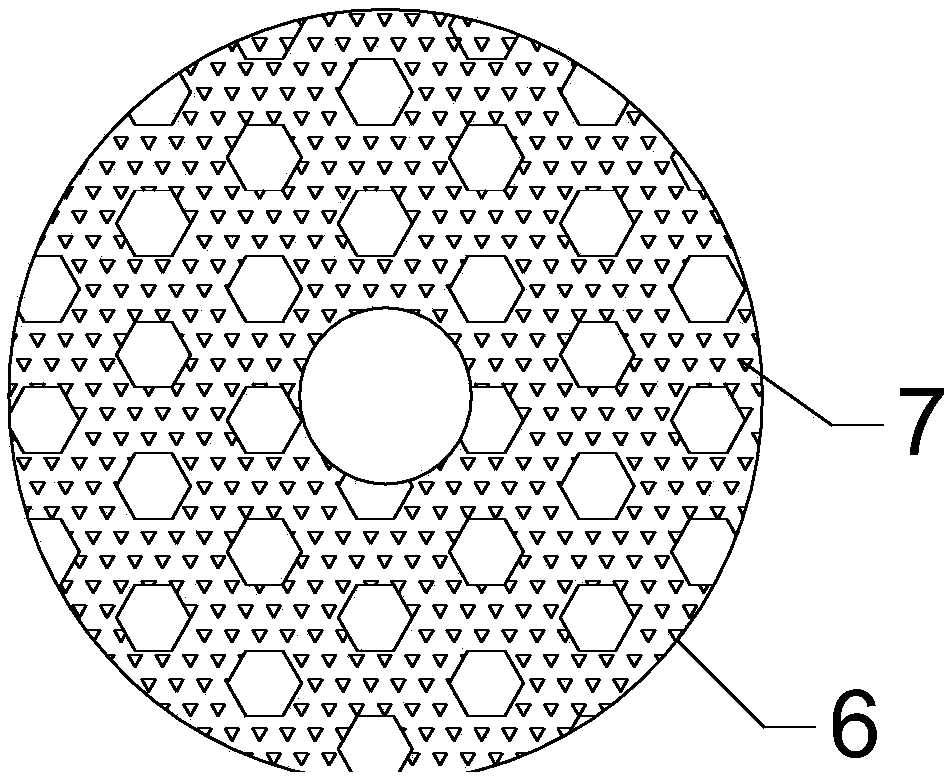

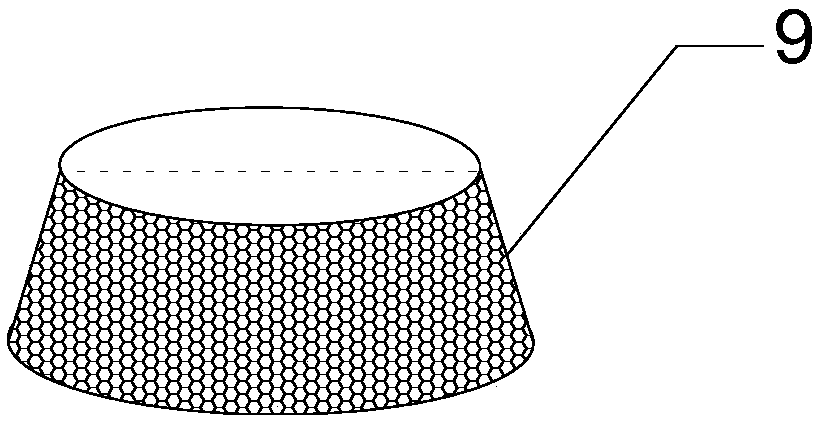

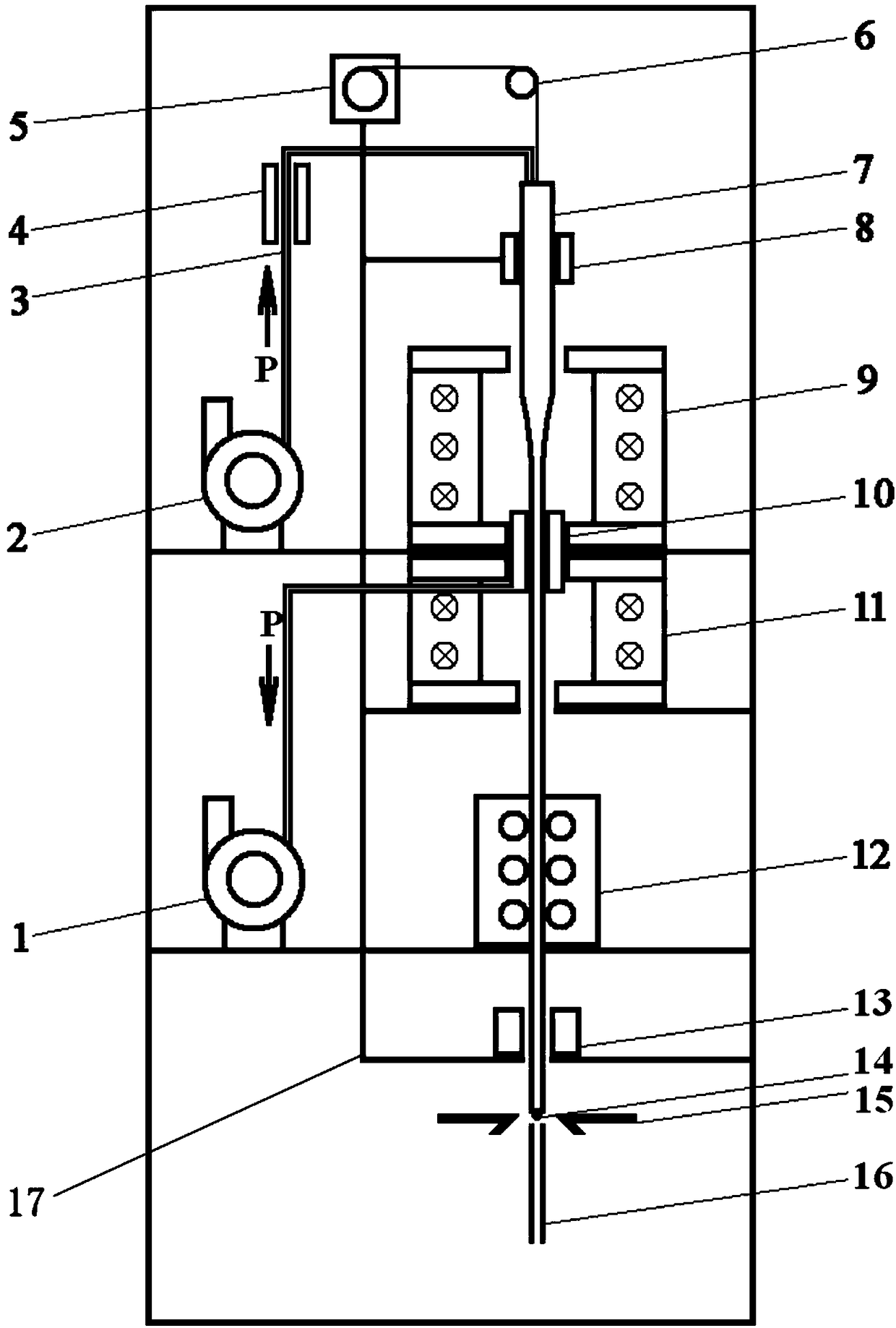

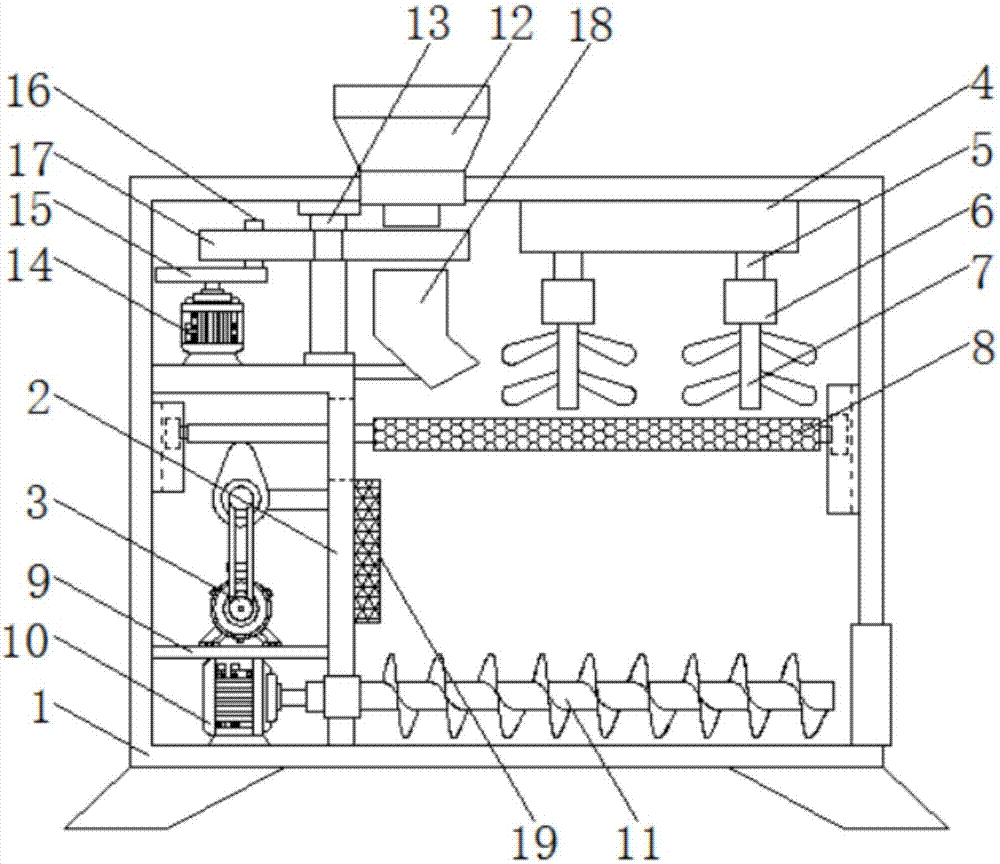

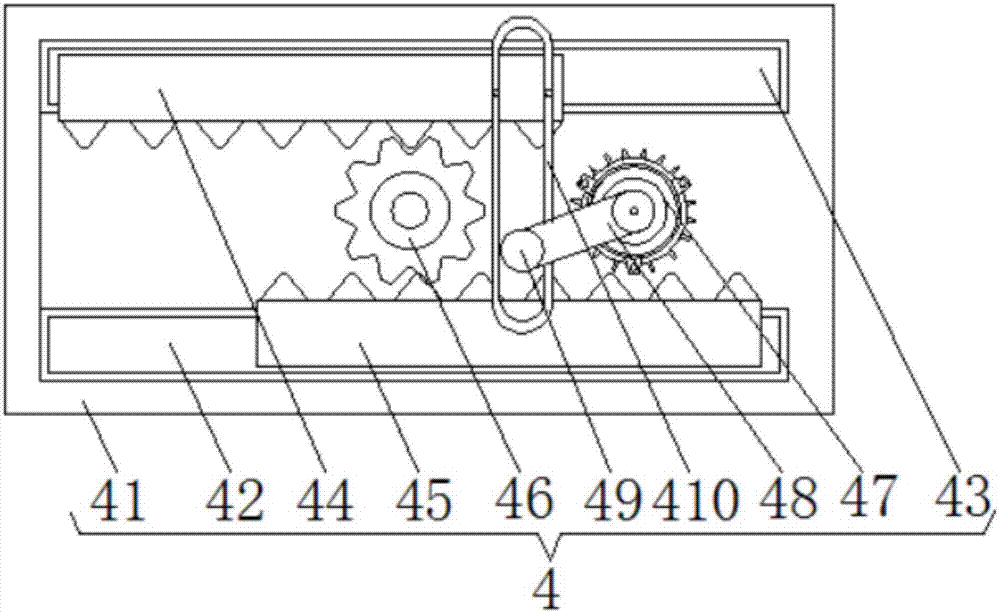

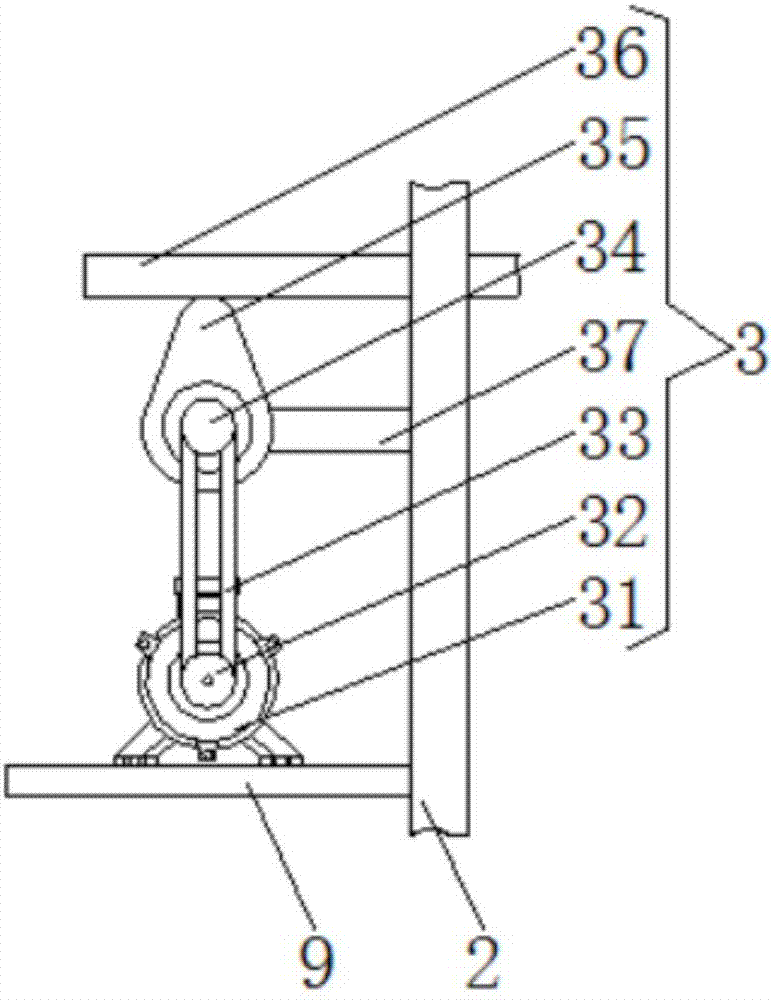

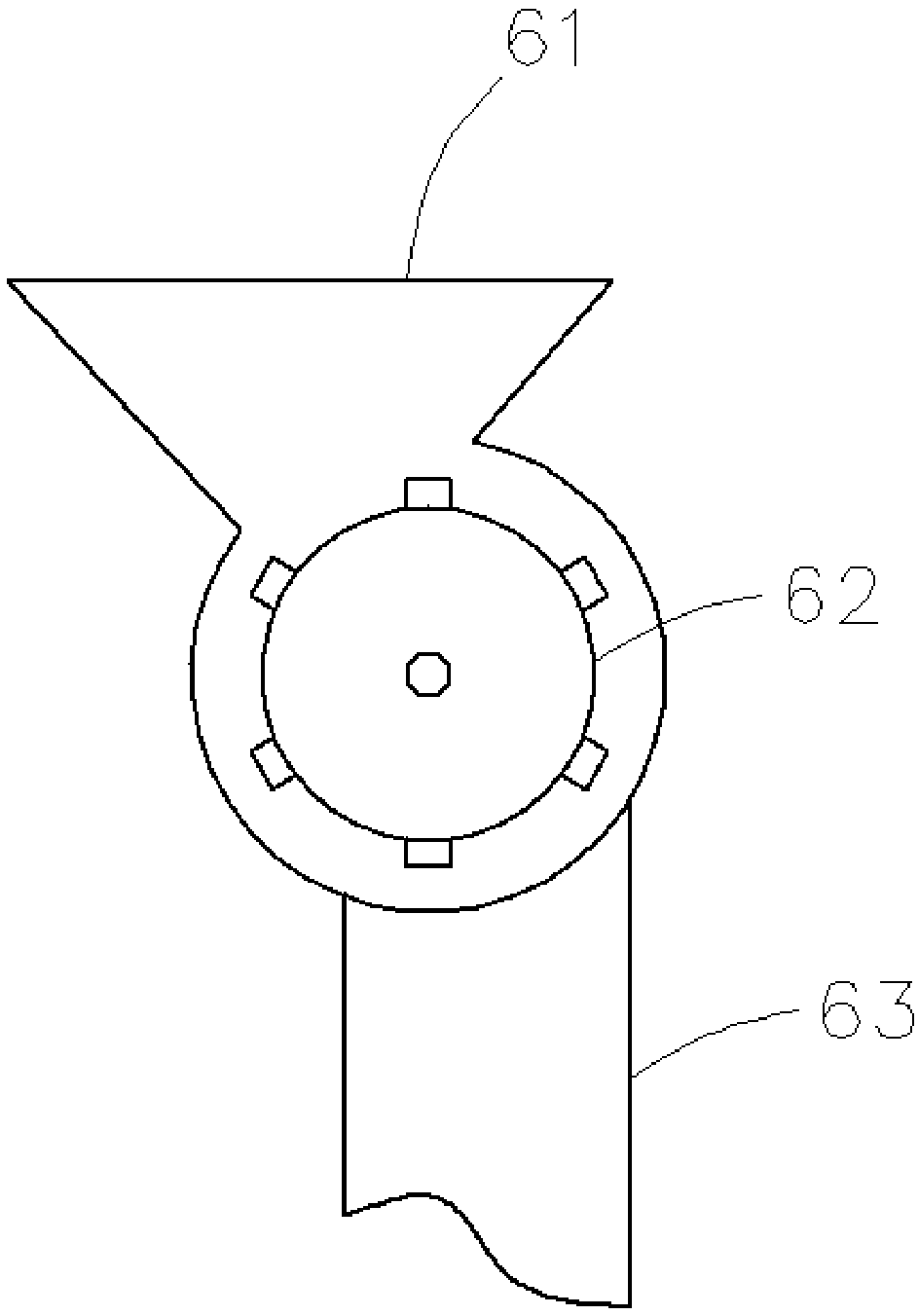

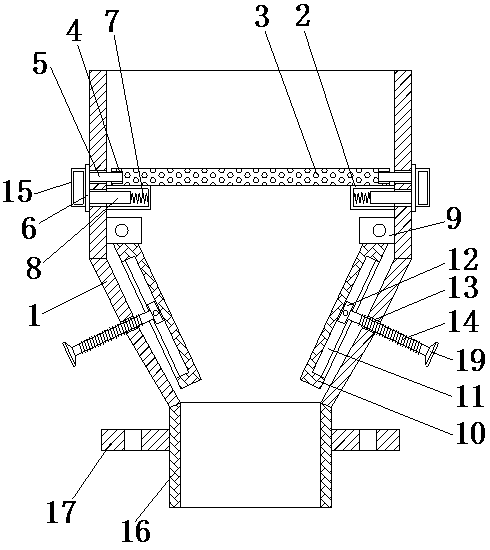

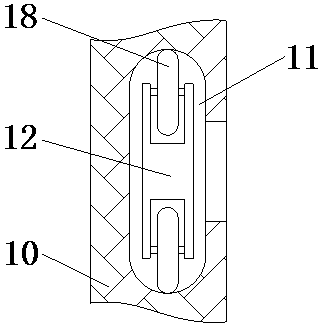

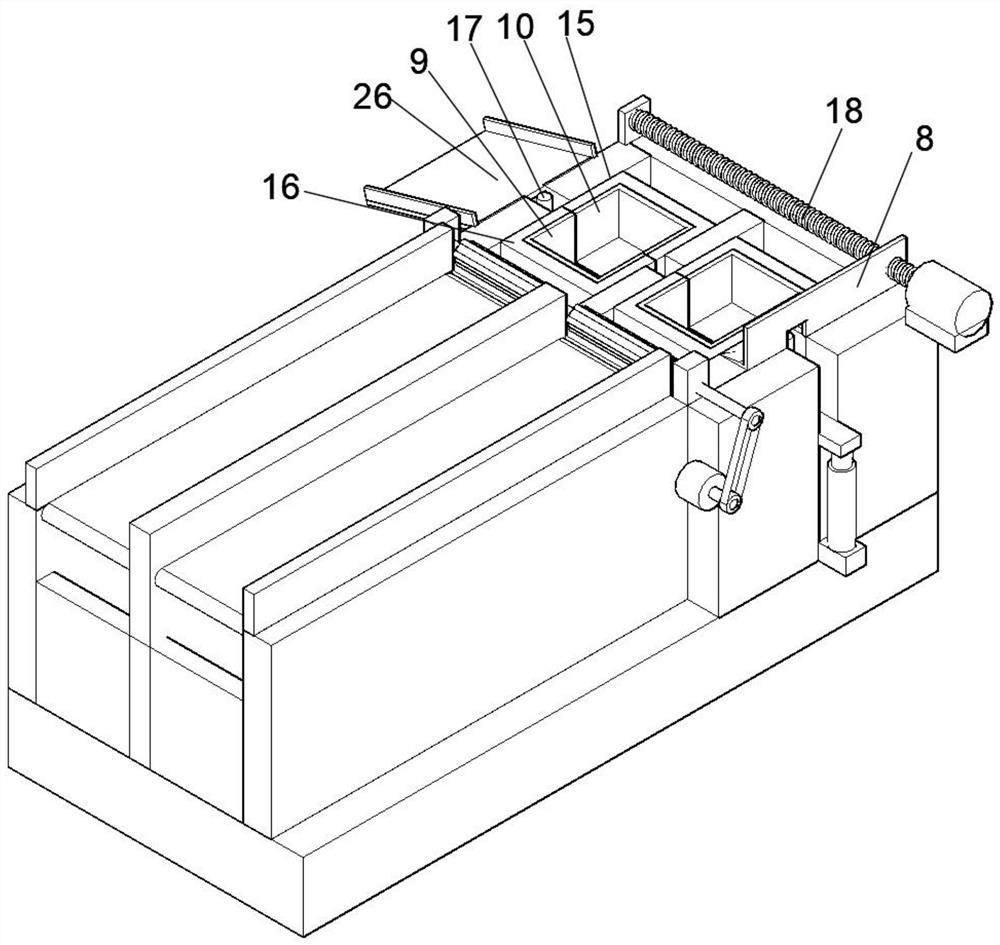

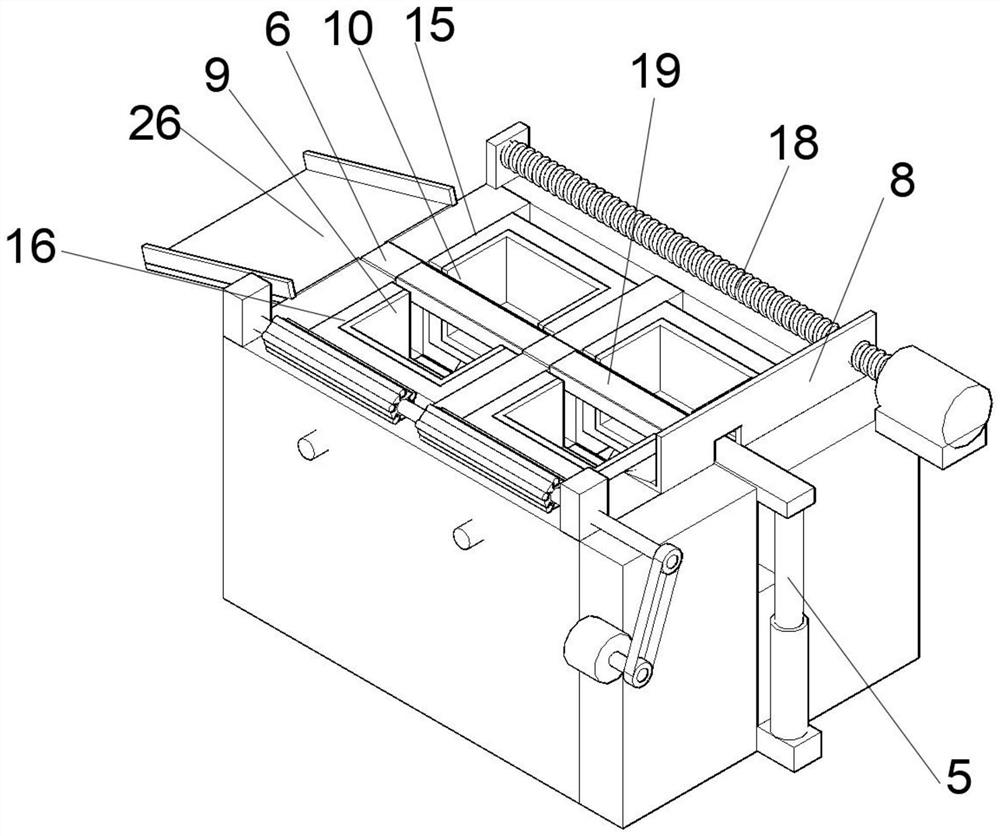

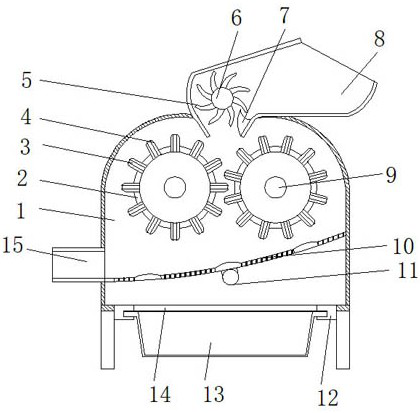

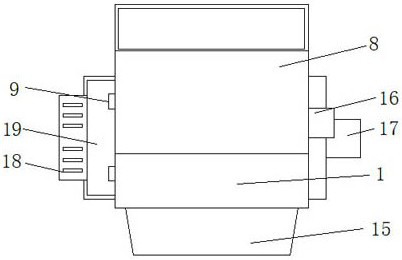

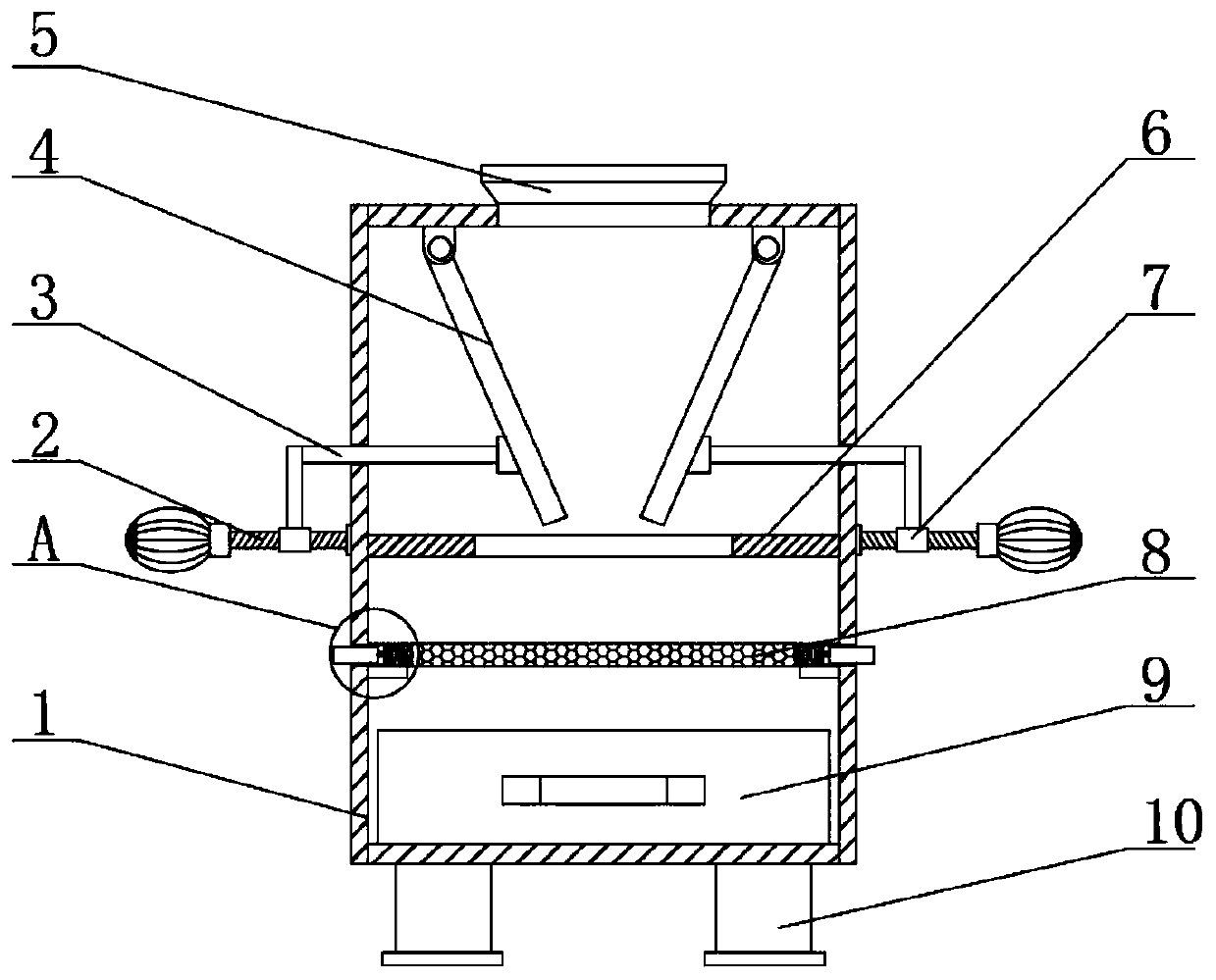

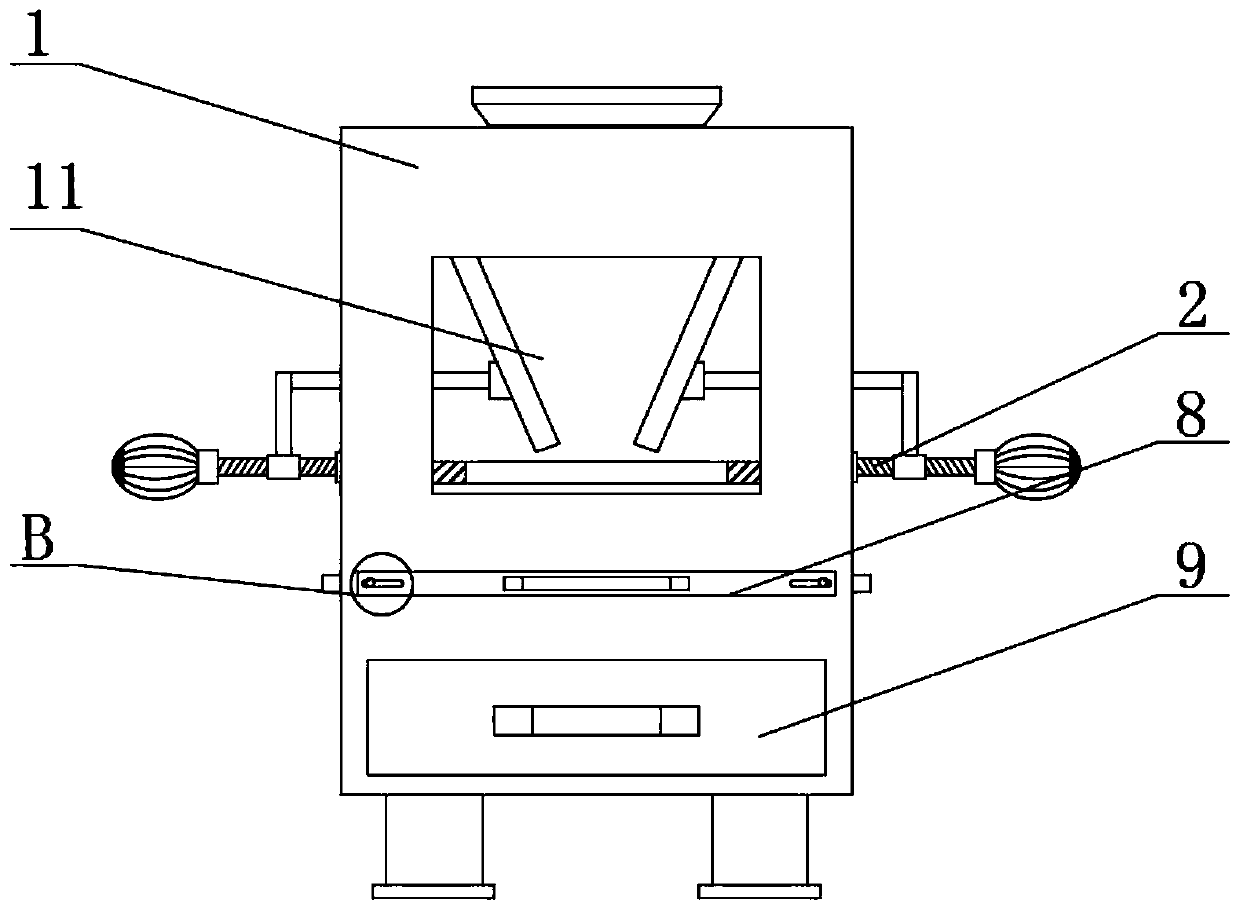

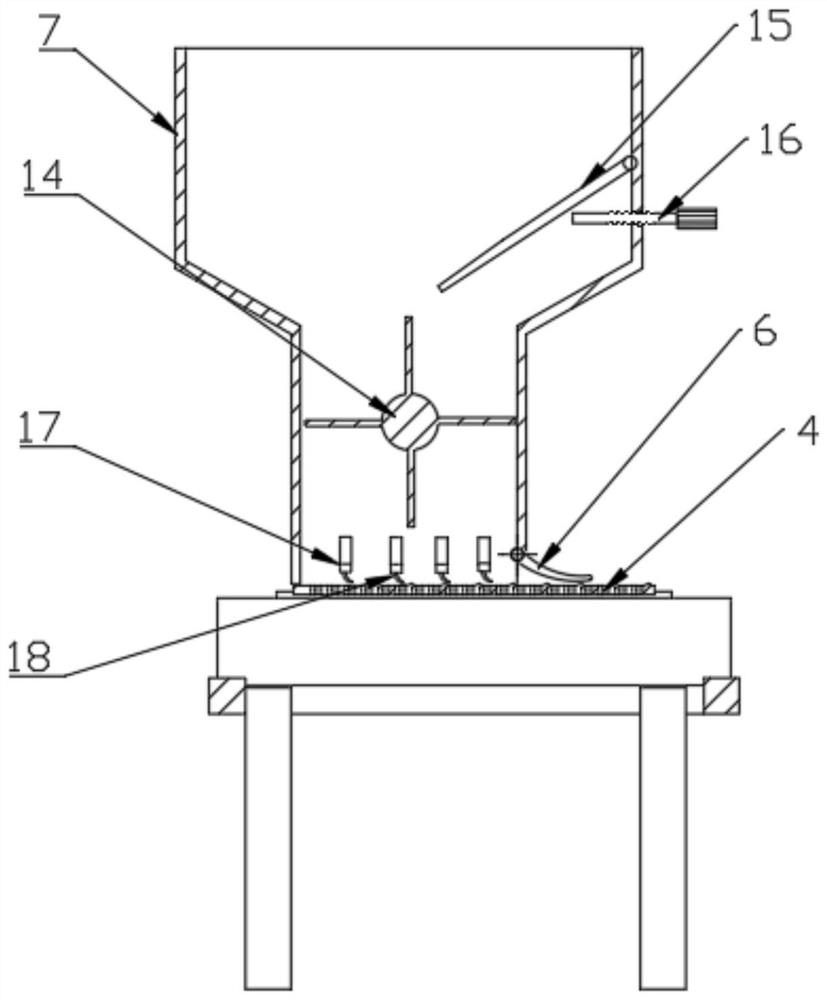

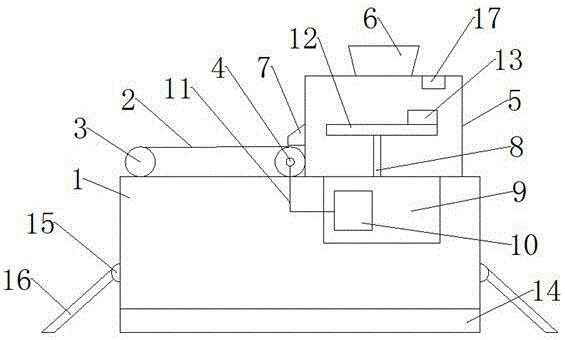

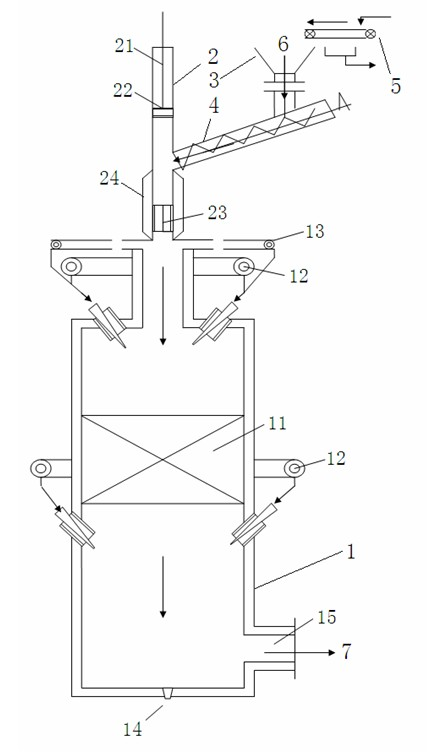

Damping smashing device for traditional Chinese medicine processing

InactiveCN107469969AAvoid corrosionExtended service lifeGrain treatmentsEngineeringEnergy consumption

The invention discloses a shock-absorbing crushing device for traditional Chinese medicine processing, which comprises a machine body, the outer wall of which is covered with a ceramic layer, a circular feeding port is opened on the upper side of the machine body, and a feeding hopper is connected to the feeding port , the bottom of the feed hopper matches the size of the feed port, and the left and right feed baffles are respectively arranged at the left and right ends of the lower side of the feed port, and the left feed baffle and the right feed The baffle is a semicircular baffle arranged symmetrically. This invention is a shock-absorbing crushing device for processing traditional Chinese medicine, which can control the feeding amount and feeding speed, and effectively improve work efficiency. Two crushing mechanisms are arranged inside the machine body. The material is fully crushed, and the two crushing mechanisms are driven by one motor, which effectively reduces energy consumption, greatly improves the crushing efficiency, and makes the medicinal materials crushed more fully. In addition, it can effectively reduce the vibration generated during the operation of the device and improve the operation of the device. stability.

Owner:单开禹

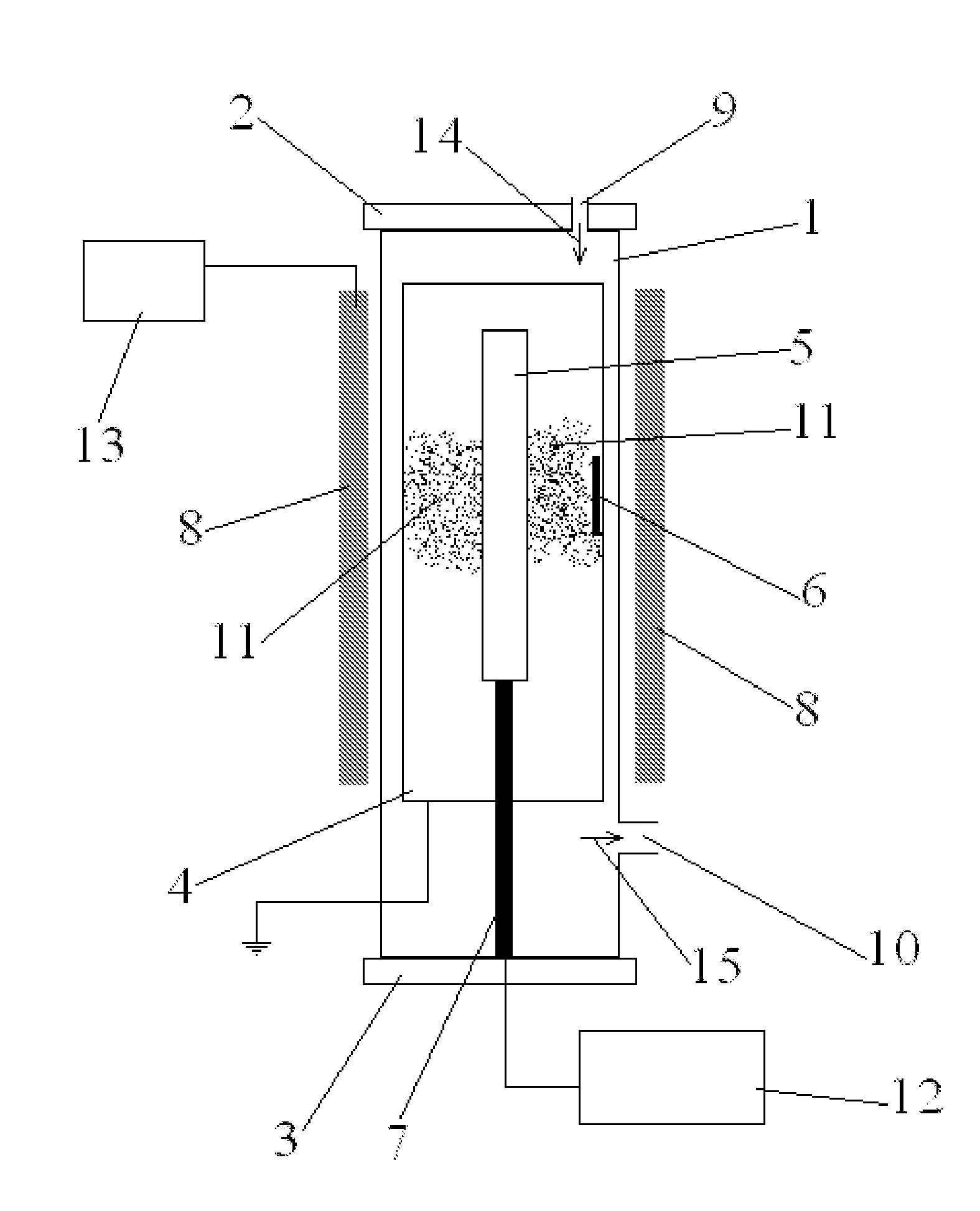

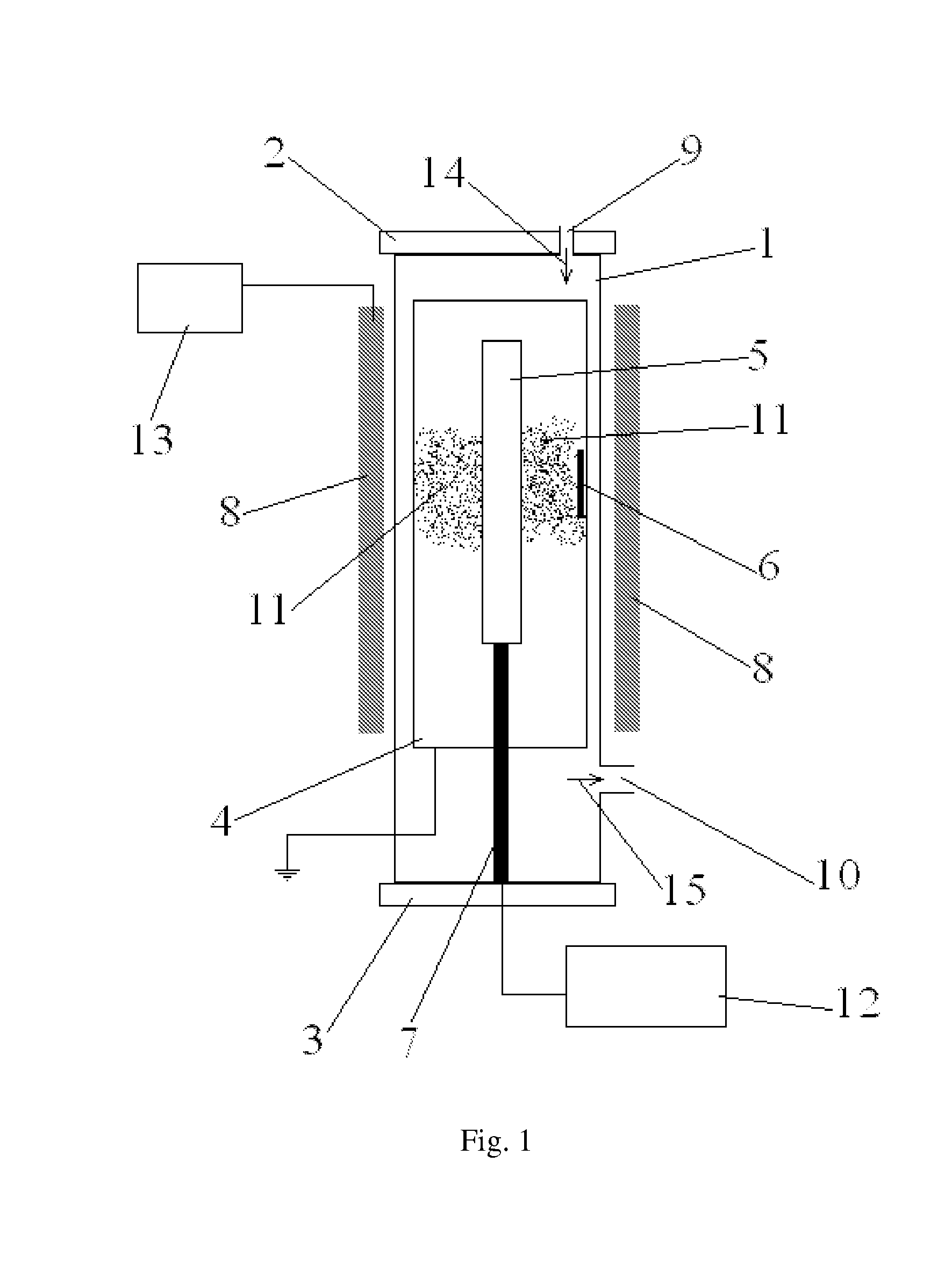

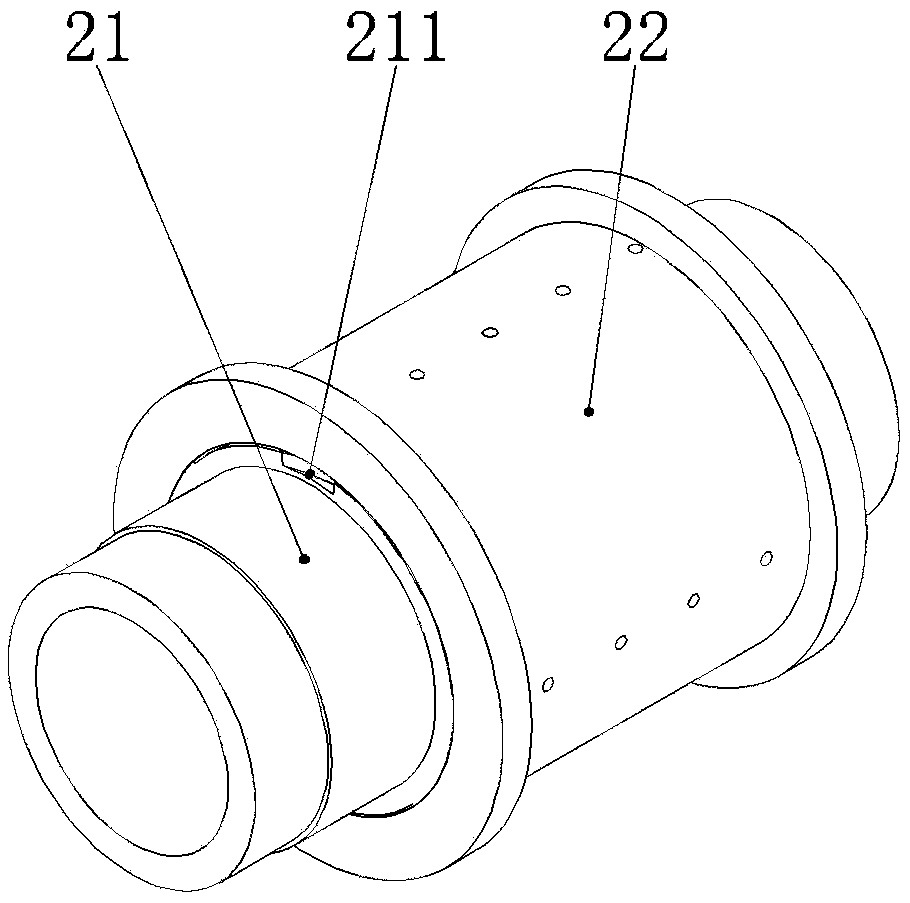

Method for growing carbon nanowalls

InactiveUS20090274610A1Control feed rateMaterial nanotechnologyCarbon compoundsCarbon nanowallsProduct gas

A method for growing carbon nanowalls on a base material is disclosed. The method comprises mixing a predetermined amount of a hydrocarbon gas with a predetermined amount of at least one non hydrocarbon gas; placing said base material in a reaction chamber having a first portion and a second portion, first portion is extended from a first end of reaction chamber to first end of base material; creating a radical in reaction chamber which comprises a hydrocarbon radical and a non hydrocarbon radical; applying the radical to the base material; and growing carbon nanowalls on said base material based on said hydrocarbon radical.

Owner:GHOANNEVISS MAHMOOD +2

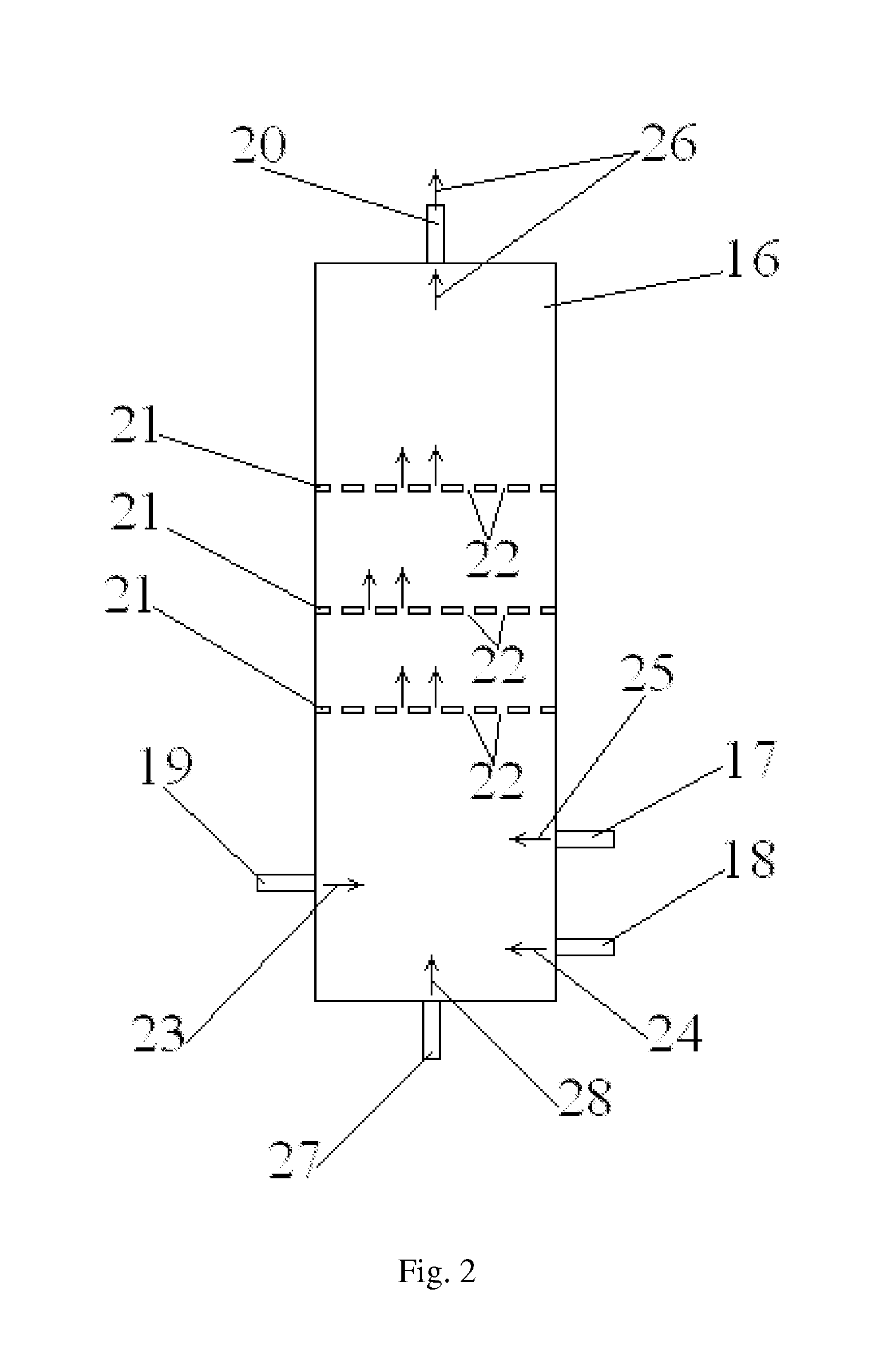

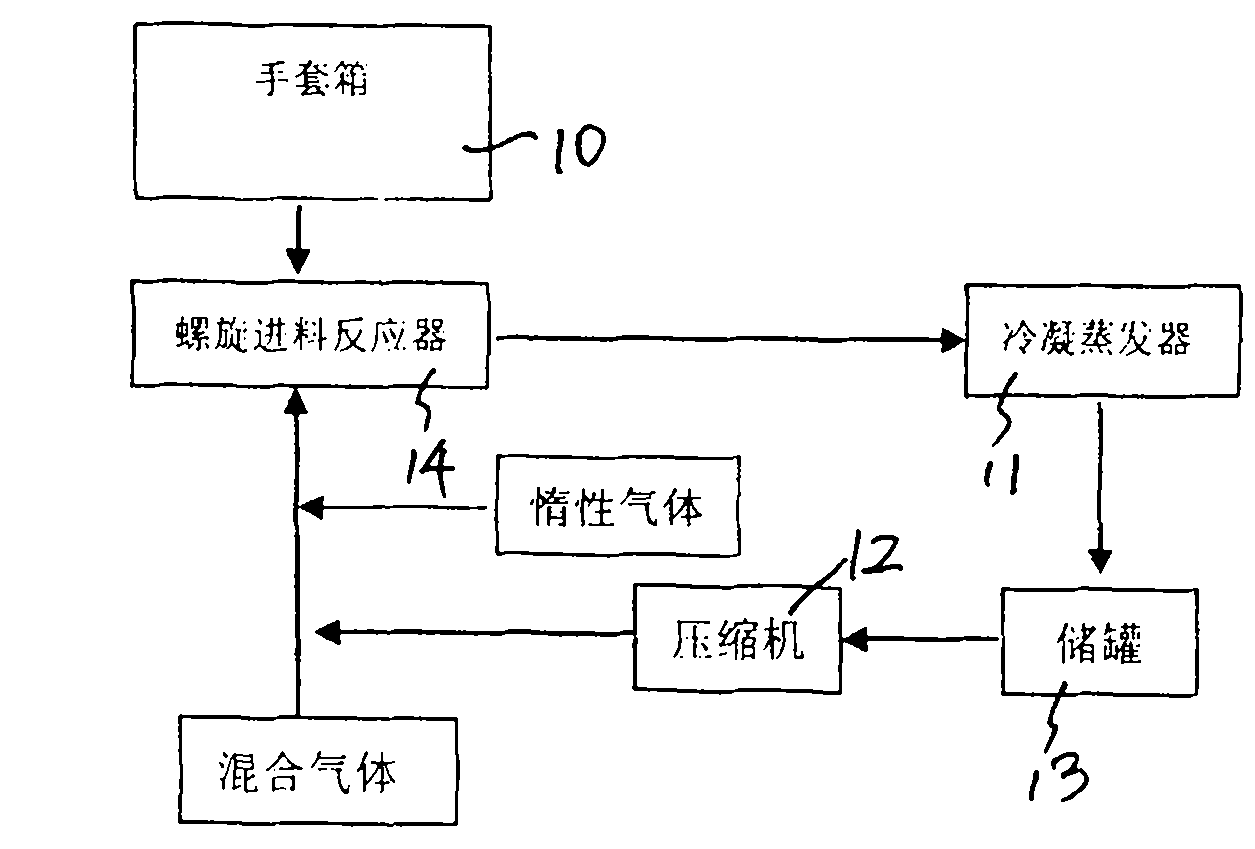

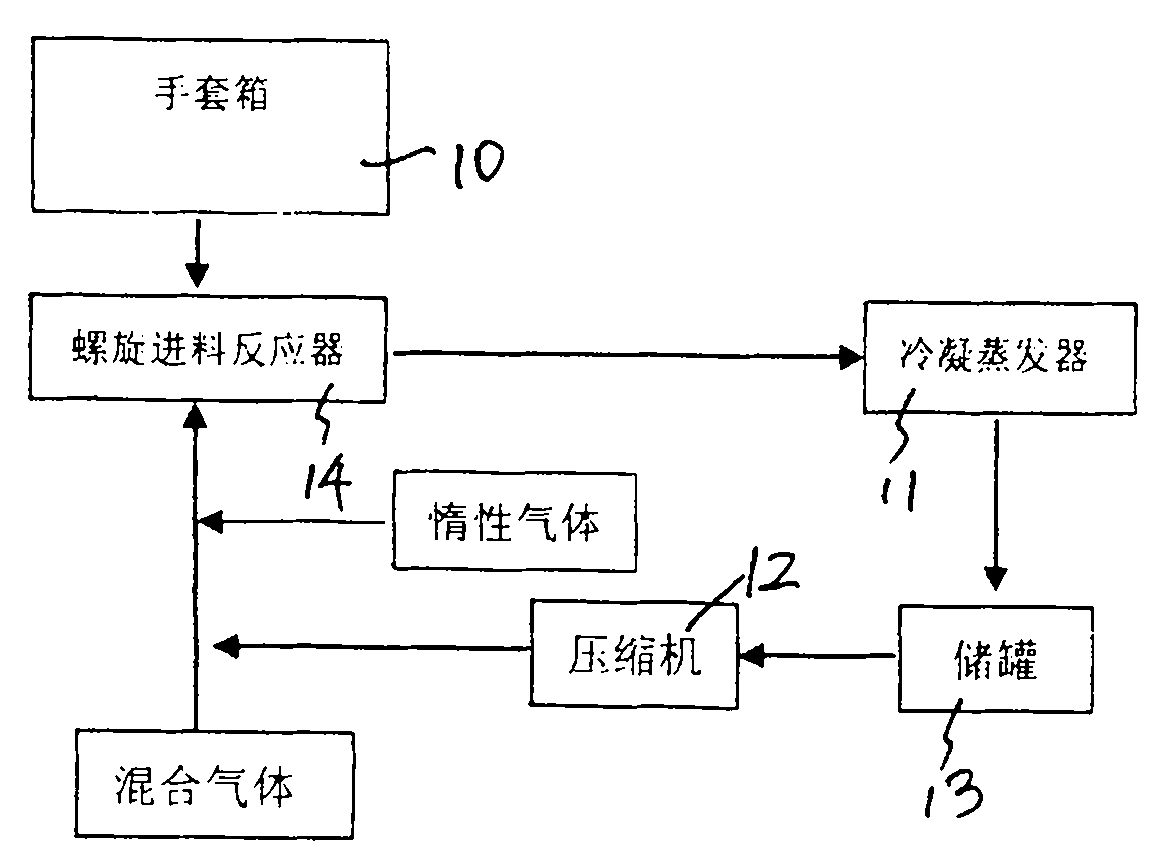

Preparation process of high-purity phosphorus pentafluoride

ActiveCN101844754AEffective control of feed rateControl feed ratePhosphorus halides/oxyhalidesPhysical chemistryHydrogen chloride

The invention discloses a preparation process of high-purity phosphorus pentafluoride, which comprises the following steps of: firstly adding phosphorous pentachloride into a feed hopper of a spiral feeder under the protection of dry gas in a glove box to assemble a gas circulation loop, and simultaneously adding inert gas into the gas circulation loop in advance; starting a spiral stirring reaction furnace, simultaneously injecting mixed gas of hydrogen fluoride and fluorine gas into the spiral stirring reaction furnace, and controlling the reaction process by controlling the rotation frequency of the phosphorous pentachloride in the spiral feeder, the temperature of gas flow at the outlet of the spiral stirring reaction furnace and the pressure of the gas circulation loop; freezing the phosphorus pentafluoride gas and the hydrogen fluoride gas generated in the reaction process and unreacted hydrogen fluoride gas by a condenser-evaporator, and collecting high-purity phosphorus pentafluoride gas after reaction. The method is simple and effective and can be operated easily.

Owner:JIANGSU JIUJIUJIU TECH

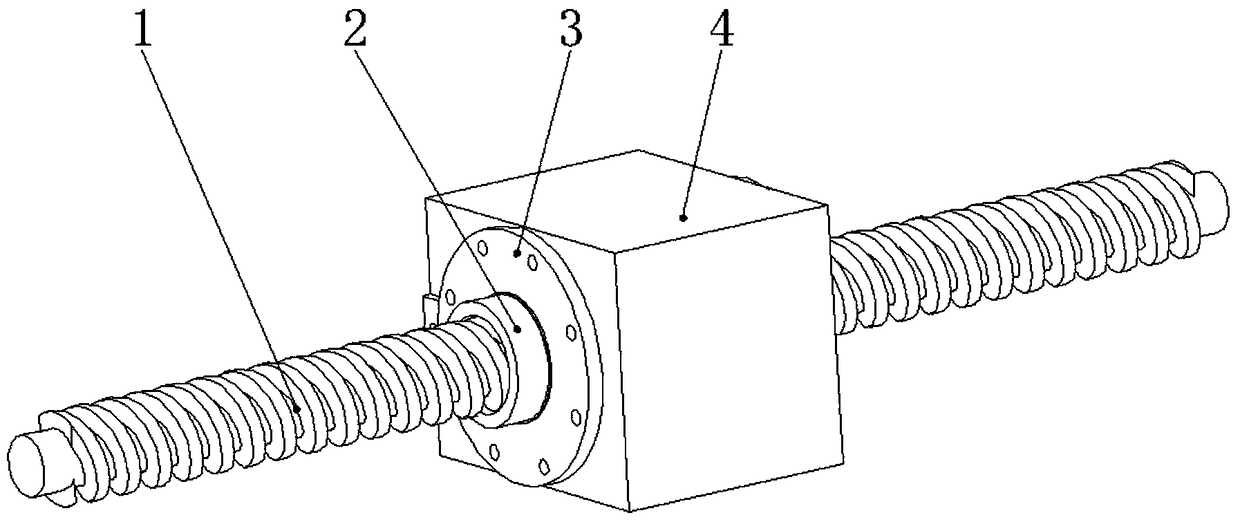

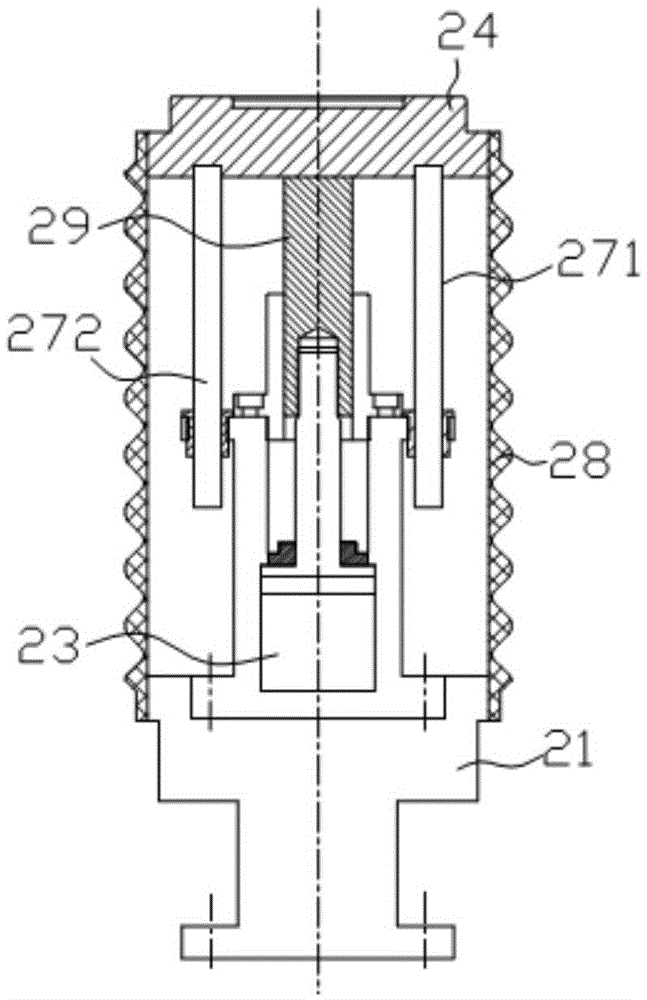

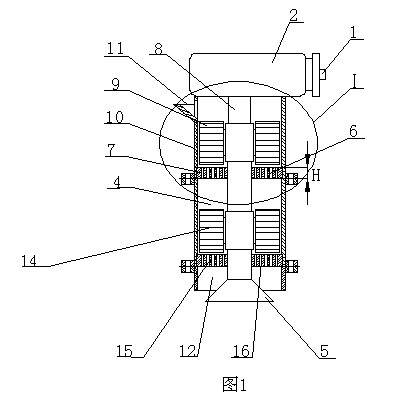

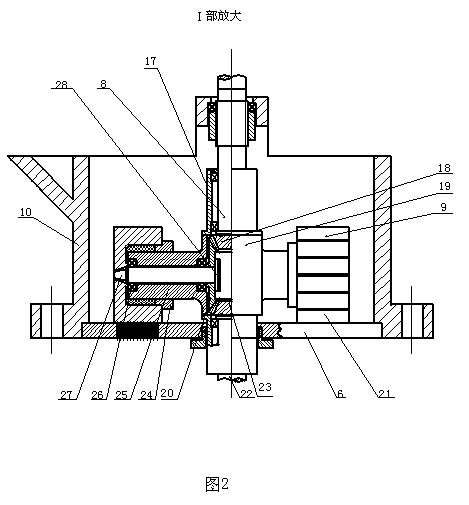

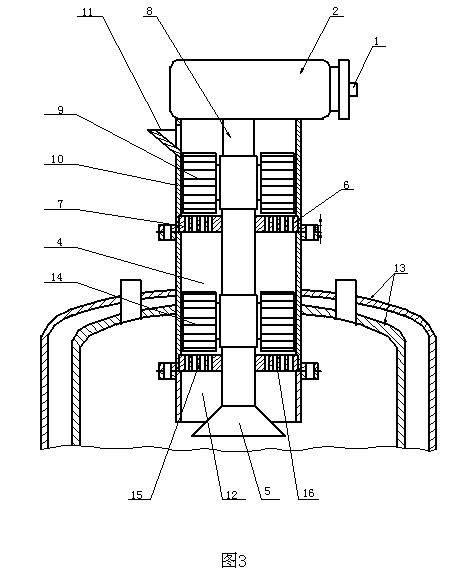

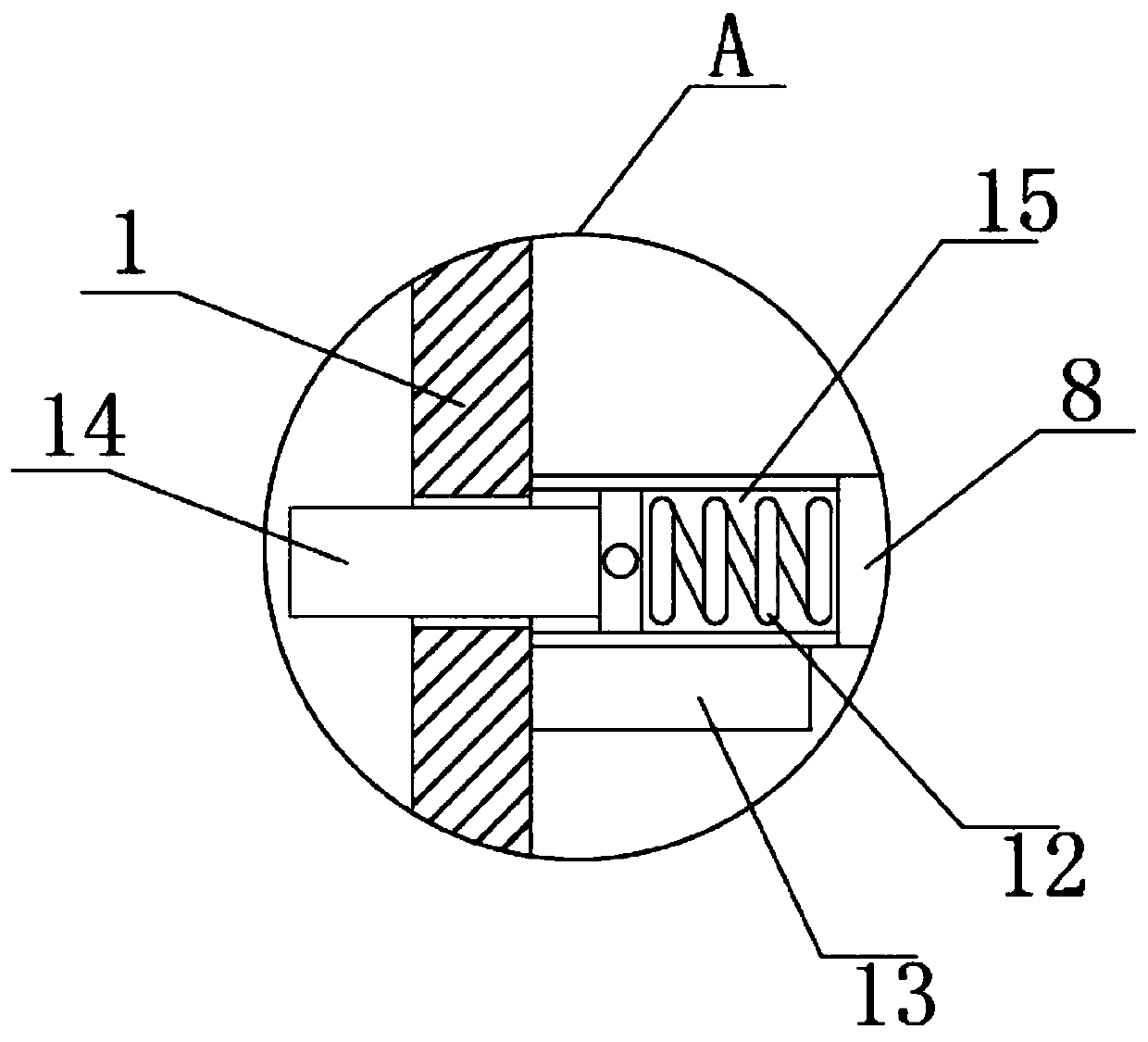

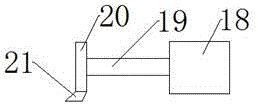

Nut drive type static pressure lead screw pair

ActiveCN108788878AImprove superiorityAvoid direct connectionFeeding apparatusMetallic LeadOil supply

The invention discloses a nut drive type static pressure lead screw pair, and relates to the technical field of static pressure spiral transmission. The nut drive type static pressure lead screw paircomprises a lead screw and a static pressure nut which are mutually matched, and further comprises static pressure composite bearings arranged at the two ends of the static pressure nut. Each static pressure composite bearing comprises at least one annular oil cavity formed in the axial end portion of the static pressure composite bearing, connected with the static pressure nut and used for achieving axial supporting of the static pressure nut, an annular oil supply groove A formed in the axial end portion of the static pressure composite bearing, connected with the static pressure nut and used for supplying oil to an oil film oil supply groove, and at least three radial oil cavities which are formed in the radial direction of the static pressure composite bearing, matched with the lead screw and used for achieving radial supporting of the static pressure nut. The nut drive type static pressure lead screw pair has the beneficial effects that limitation on the feeding speed due to the lead screw shaft critical rotation speed is avoided; reasonable oil supply of the nut drive type static pressure lead screw pair is achieved, and direct connection between an oil pipe and the static pressure nut is avoided; and axial and radial static pressure supporting of the static pressure nut is achieved, and the superior performance of the static pressure lead screw pair is improved.

Owner:QINGDAO UNIV OF SCI & TECH +1

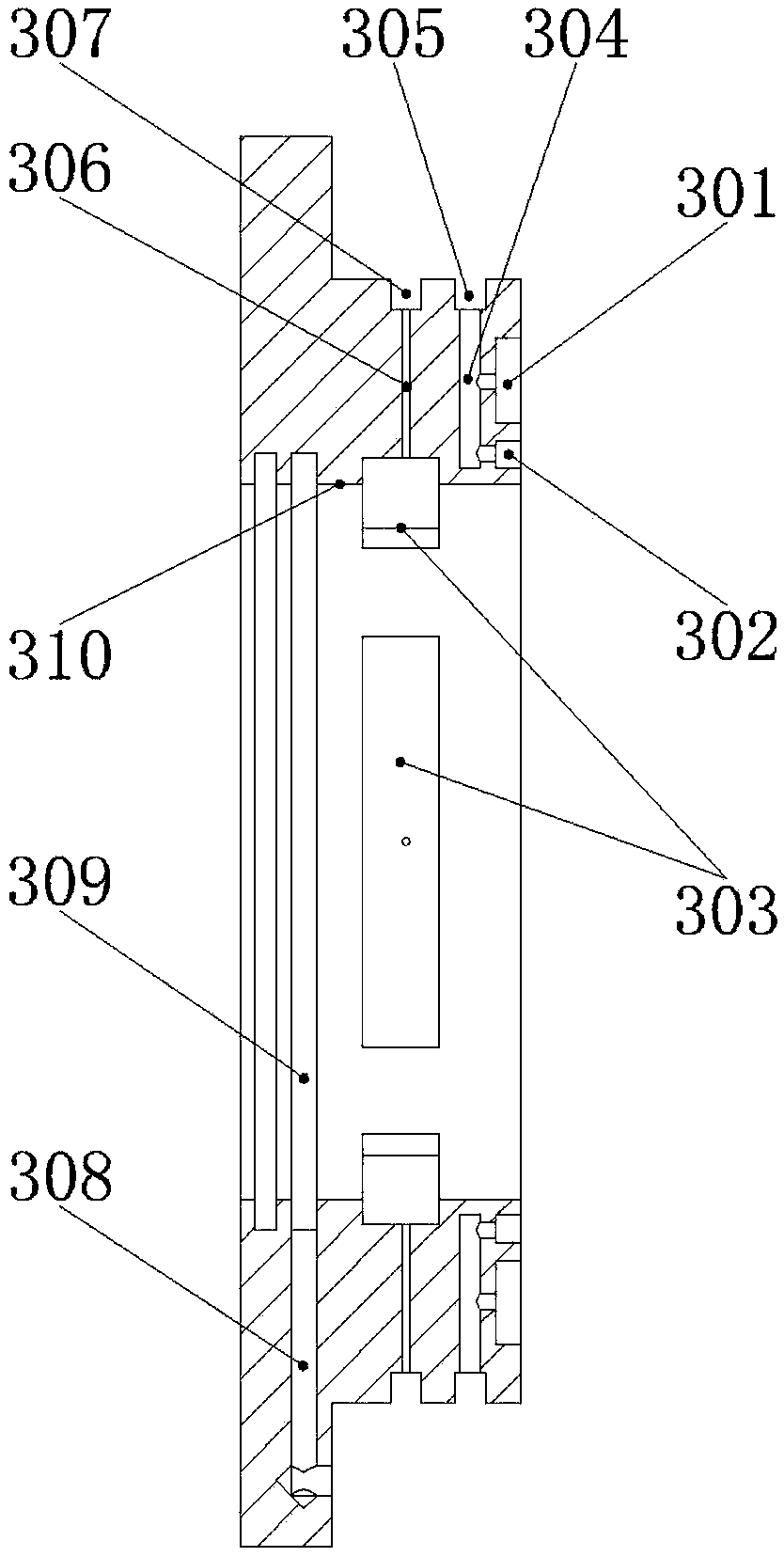

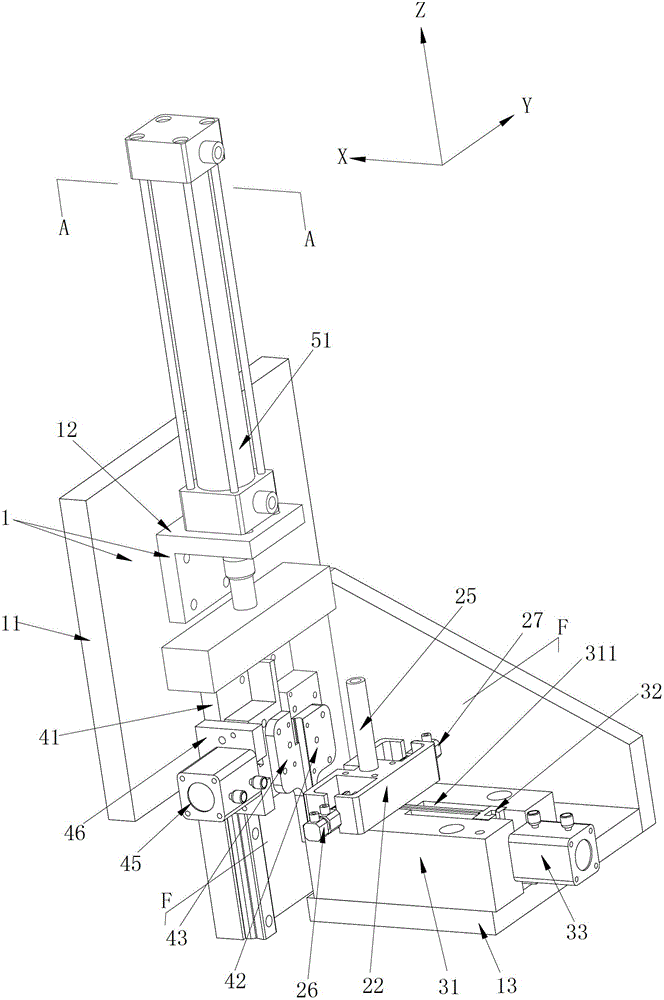

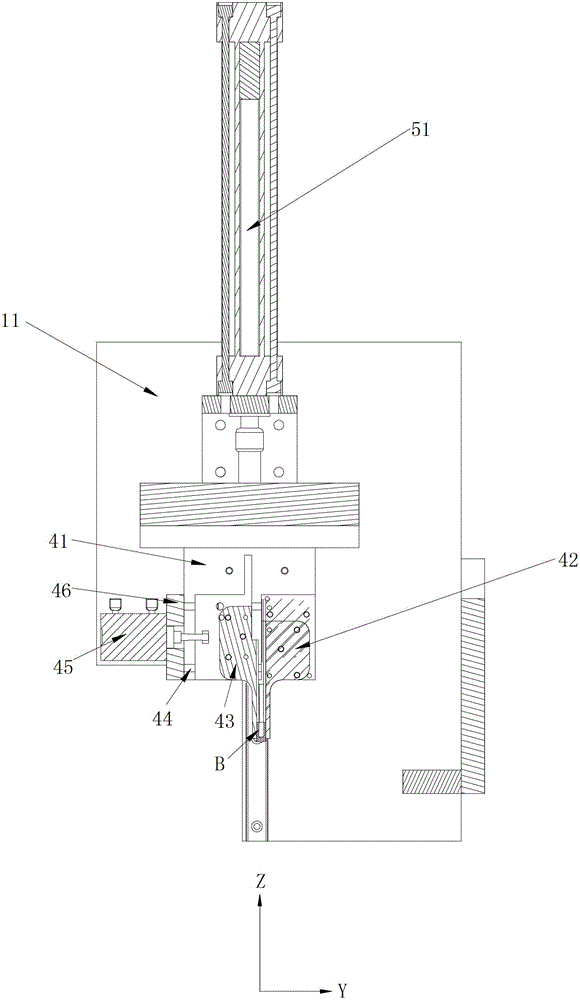

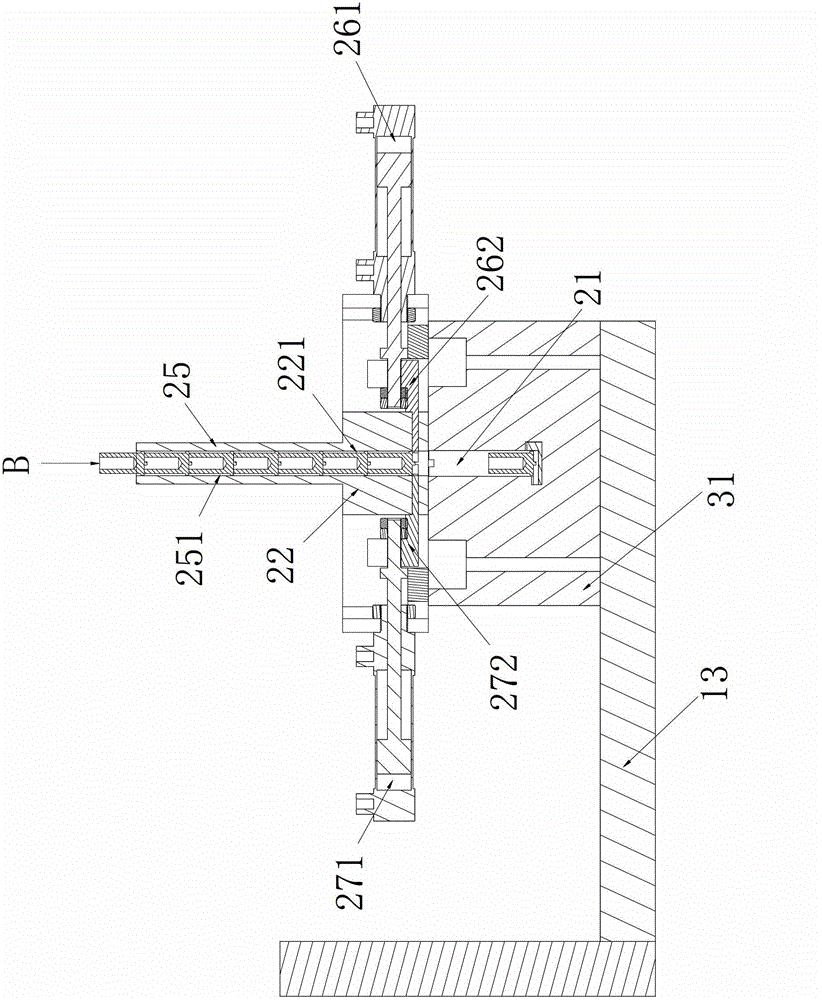

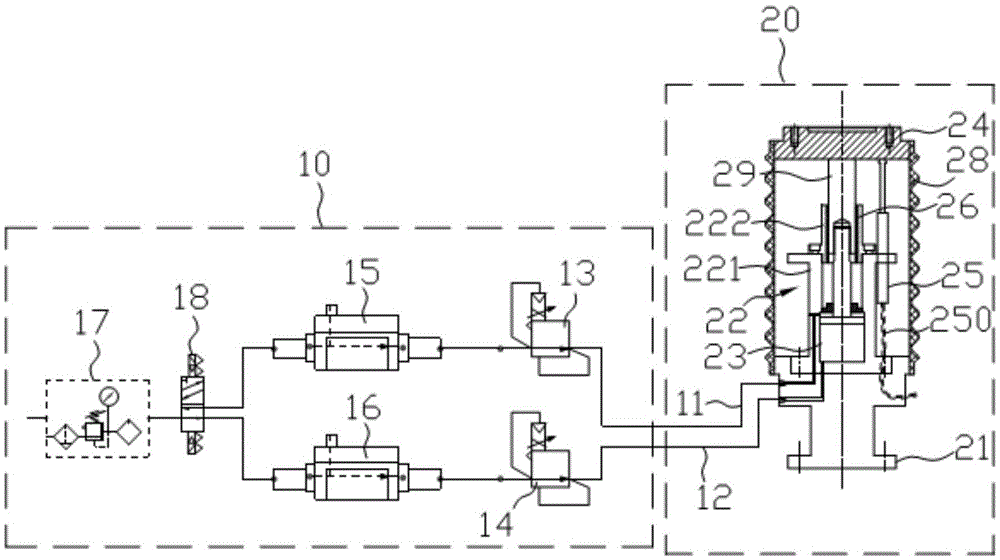

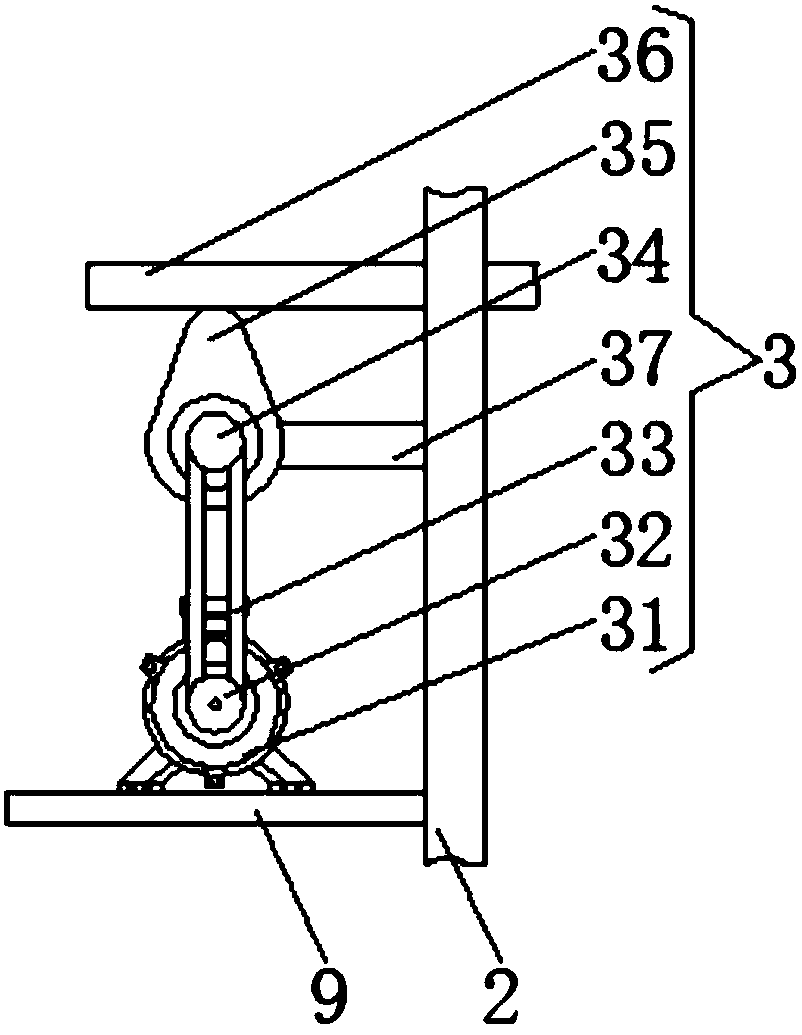

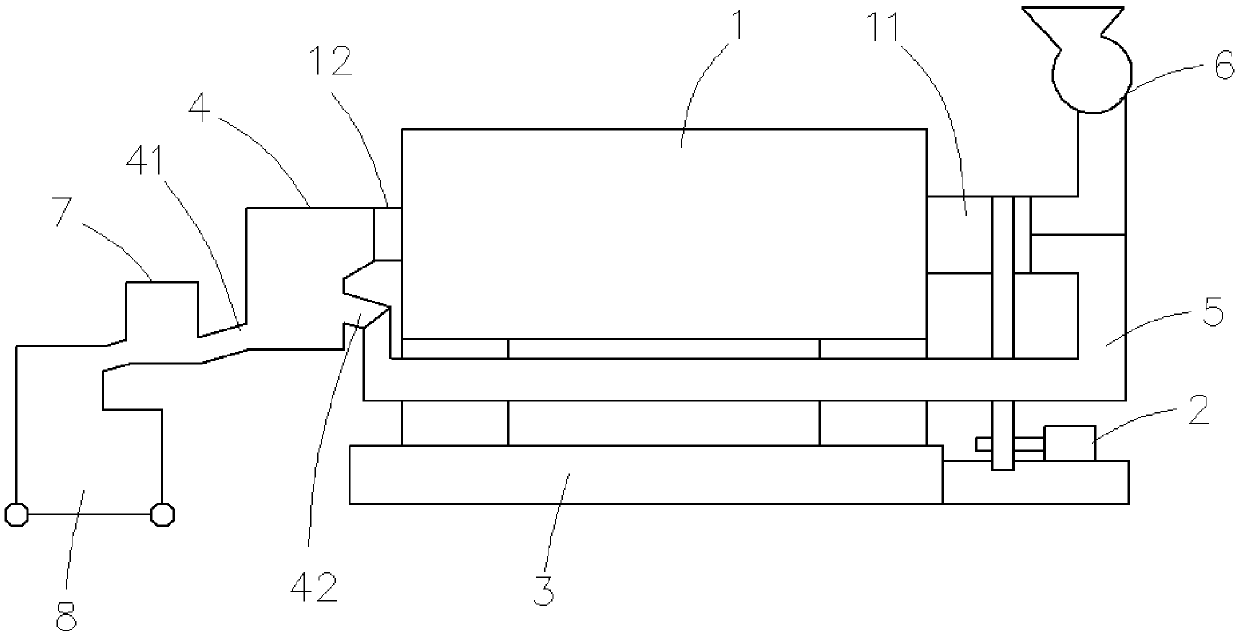

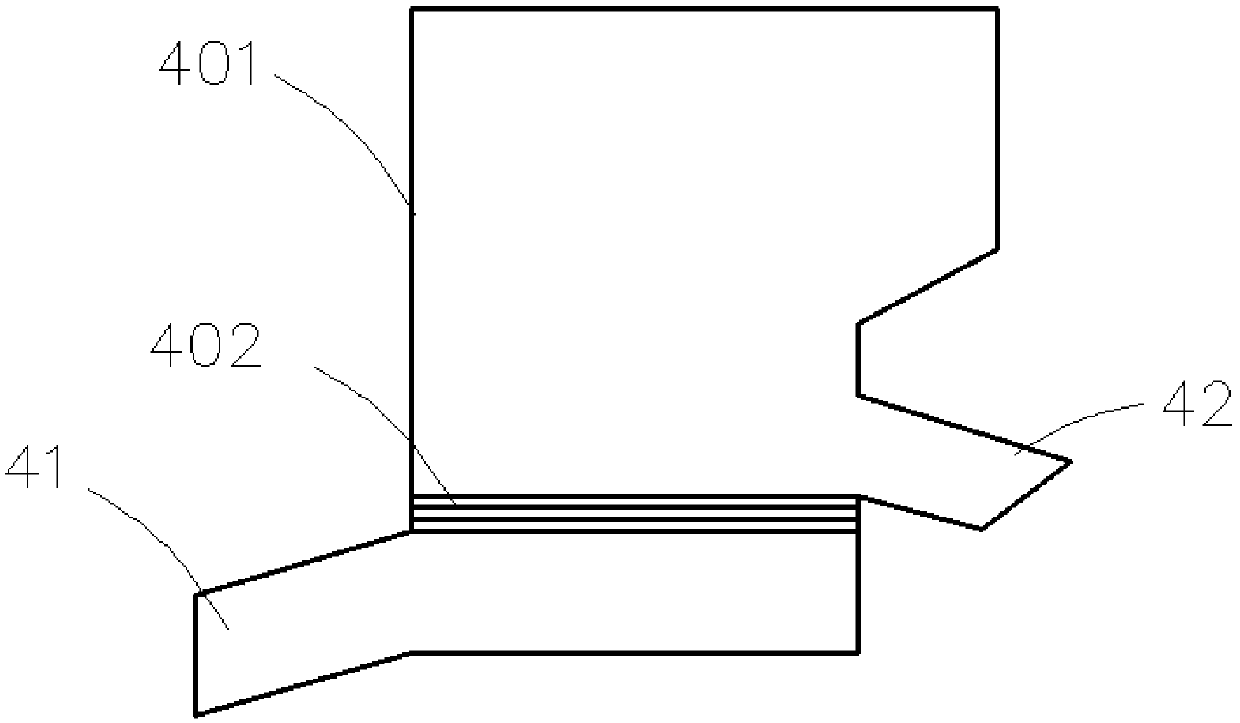

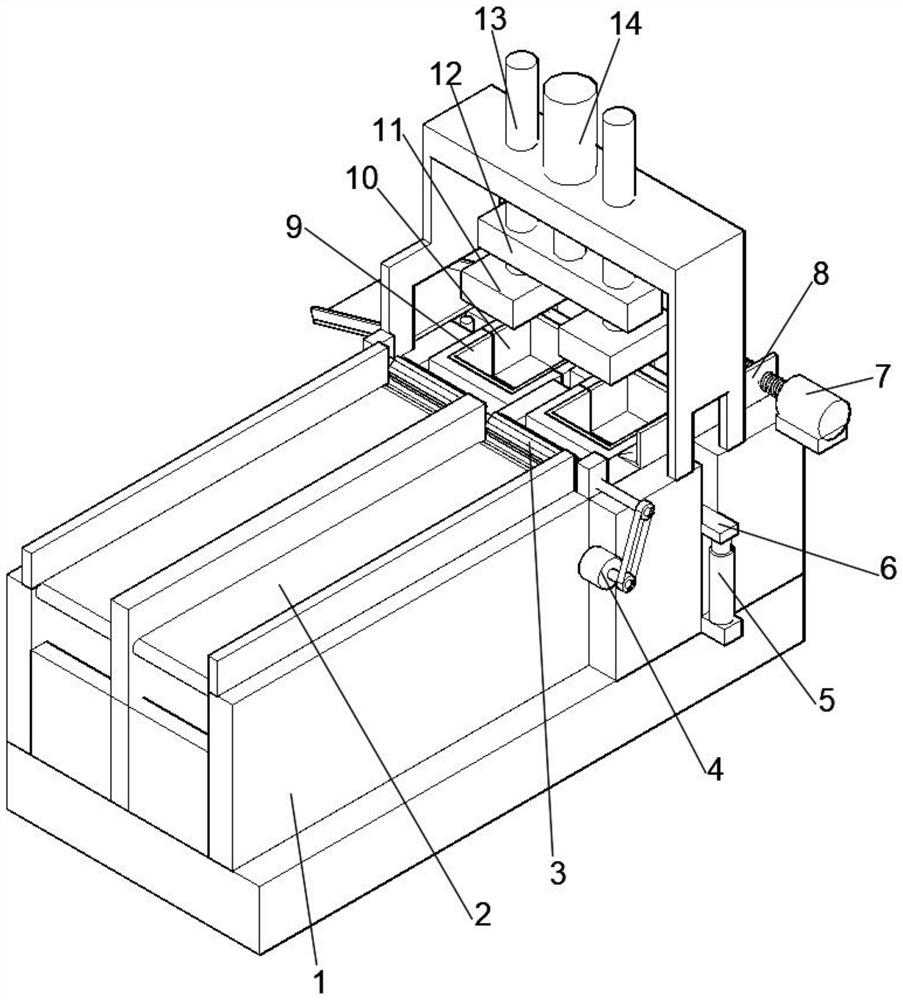

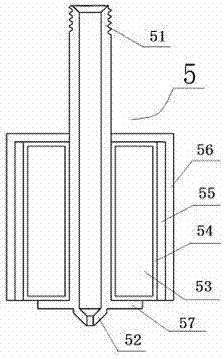

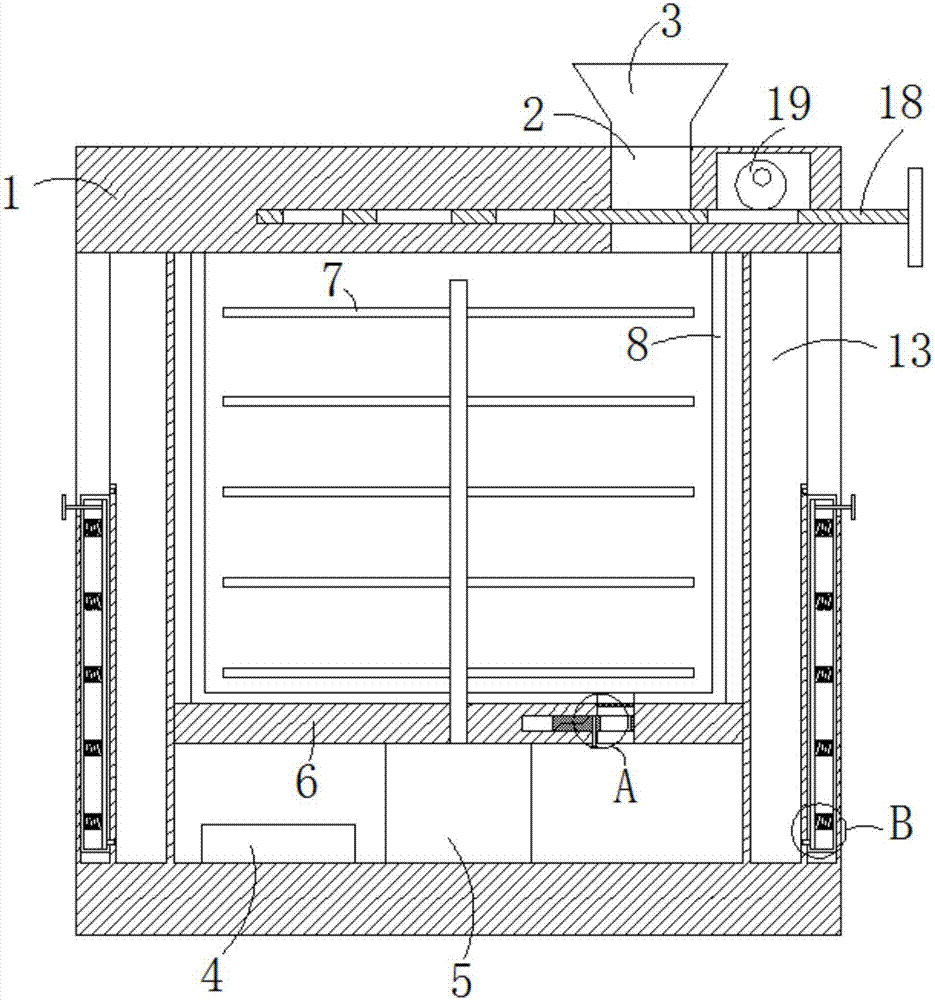

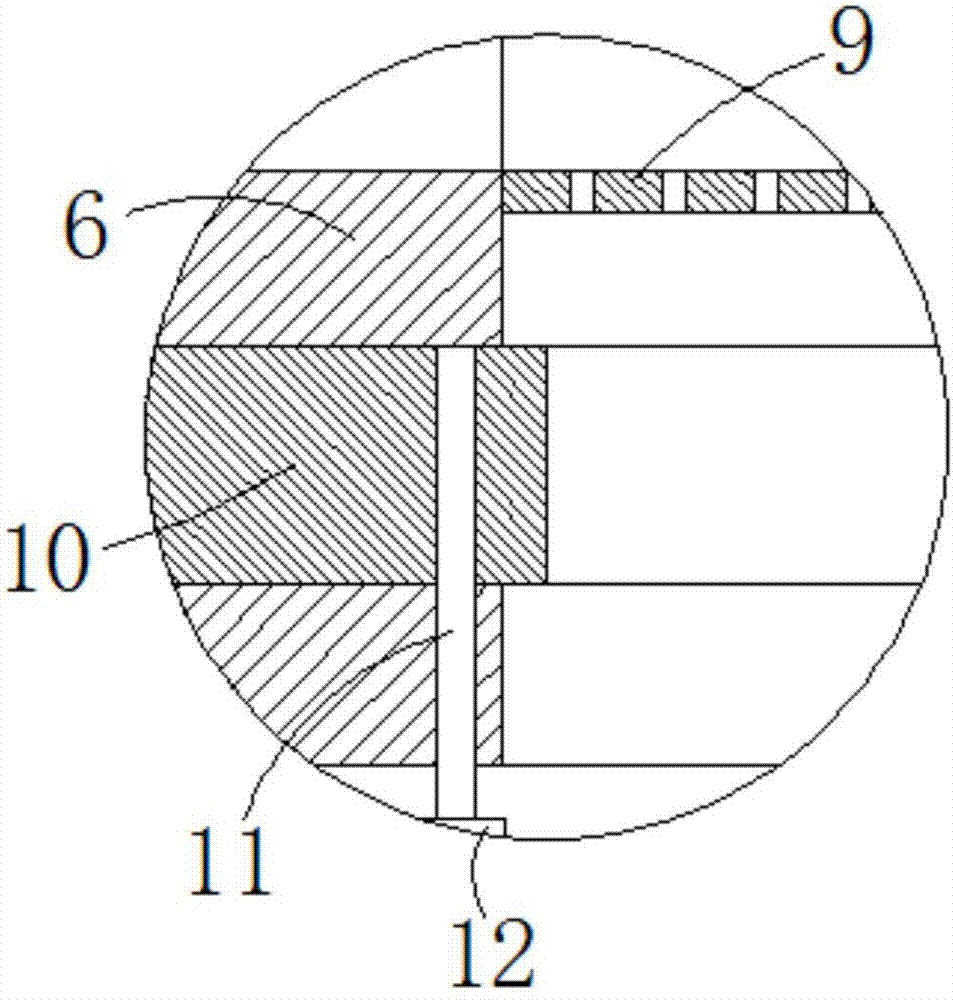

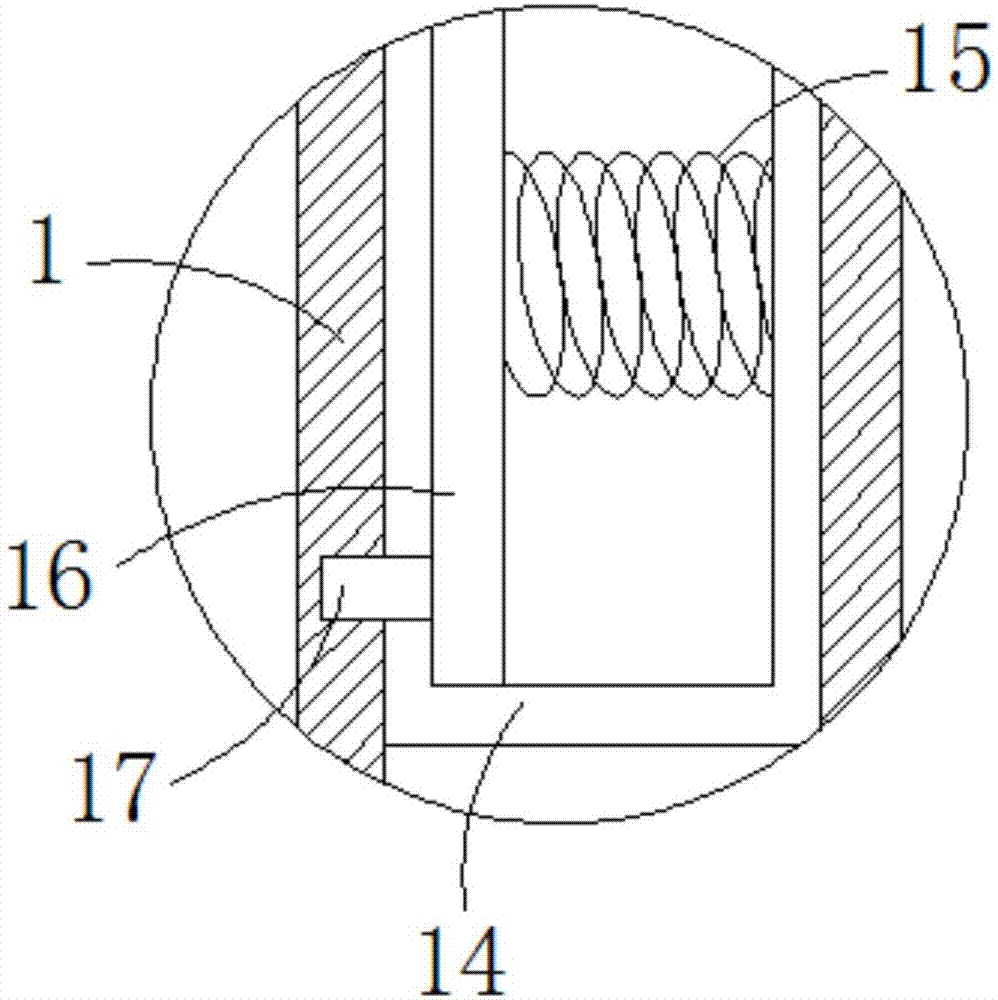

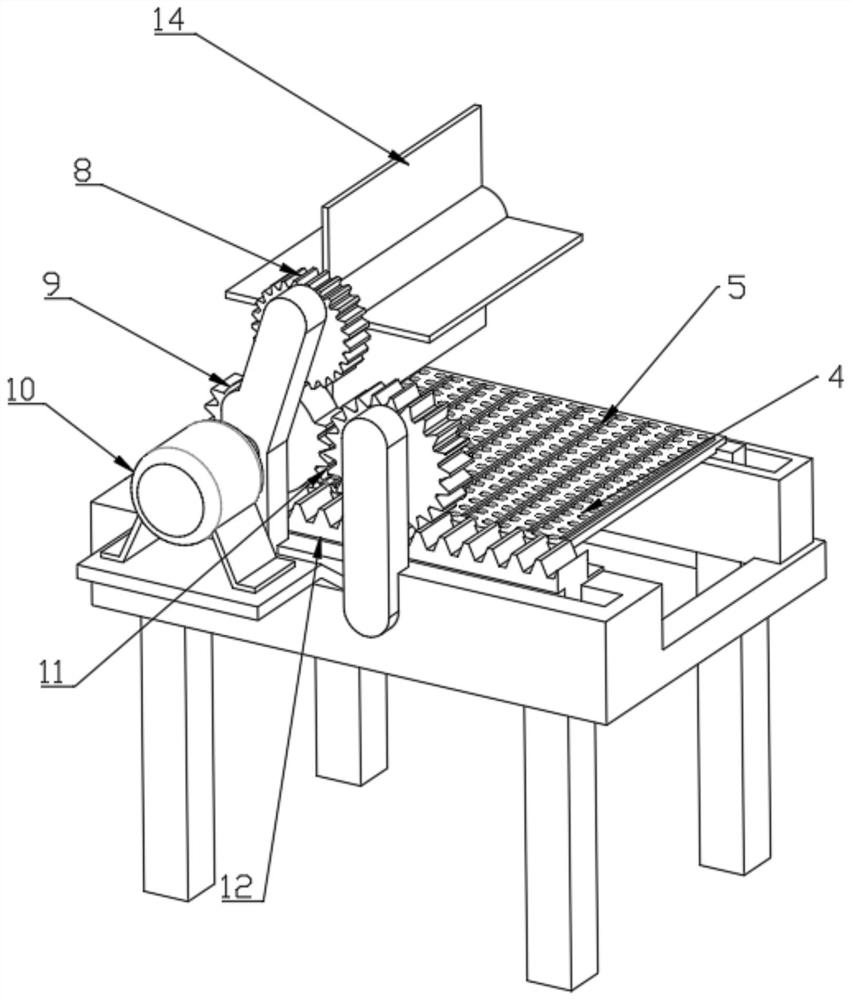

Automatic feeding device for stud welding

The invention discloses an automatic feeding device for stud welding. The automatic feeding device for stud welding comprises a machine frame, a longitudinal placing device for placing studs to be welded, a transverse pushing device for installing the longitudinal placing device and capable of transversely moving back and forth between a first position and a second position of a horizontal workstation of the machine frame, a longitudinal pushing device capable of longitudinally moving back and forth between a third position and a fourth position of a vertical workstation of the machine frame, a movable clamp fixed at the lower end of the longitudinal pushing device and capable of clamping a stud pushed to the second position by the transverse pushing device when the longitudinal pushing device moves to the third position, and a controller for performing data transmission and connected with the longitudinal placing device, the transverse pushing device, the longitudinal pushing device and the movable clamp. The automatic feeding device for stud welding is high in working efficiency, free of workpiece blockage, small in noise and electricity-saving, and can help to save the production cost.

Owner:佛山市玛雅数控设备有限公司

Constant force compensation device

ActiveCN105458857AControl feed rateEdge grinding machinesAutomatic grinding controlConstant forceEngineering

The invention discloses a constant force compensation device. The constant force compensation device comprises a constant force control part and a constant force execution part. The constant force control part comprises an air source, an air inlet and outlet pipe connected with the air source, an electrical proportional valve arranged on the air inlet and outlet pipe and a digital flow controller. The constant force execution part comprises a fixing flange, an air cylinder fixed to the fixing flange and a tool installation flange driven by the air cylinder; and displacement of the tool installation flange is monitored by a sensor. When the constant force execution part meets conditions like workpiece deformation, compensation for the workpiece deformation can be carried out through the constant force control part, and therefore it is guaranteed that the running speed of the constant force execution part is stable, and pushing force applied outwards is constant. When the working direction of the constant force execution part changes, an electromagnetic valve in the constant force control part conducts reversing on inlet and outlet air of the air cylinder and then conducts compensation for the constant force execution part, and it is guaranteed that action force output by the constant force execution part keeps constant all the time. By means of the constant force compensation device, it can be effectively guaranteed that a polishing tool or other tools apply the contact action force to products.

Owner:ZHEJIANG WANFENG TECH DEV CO LTD

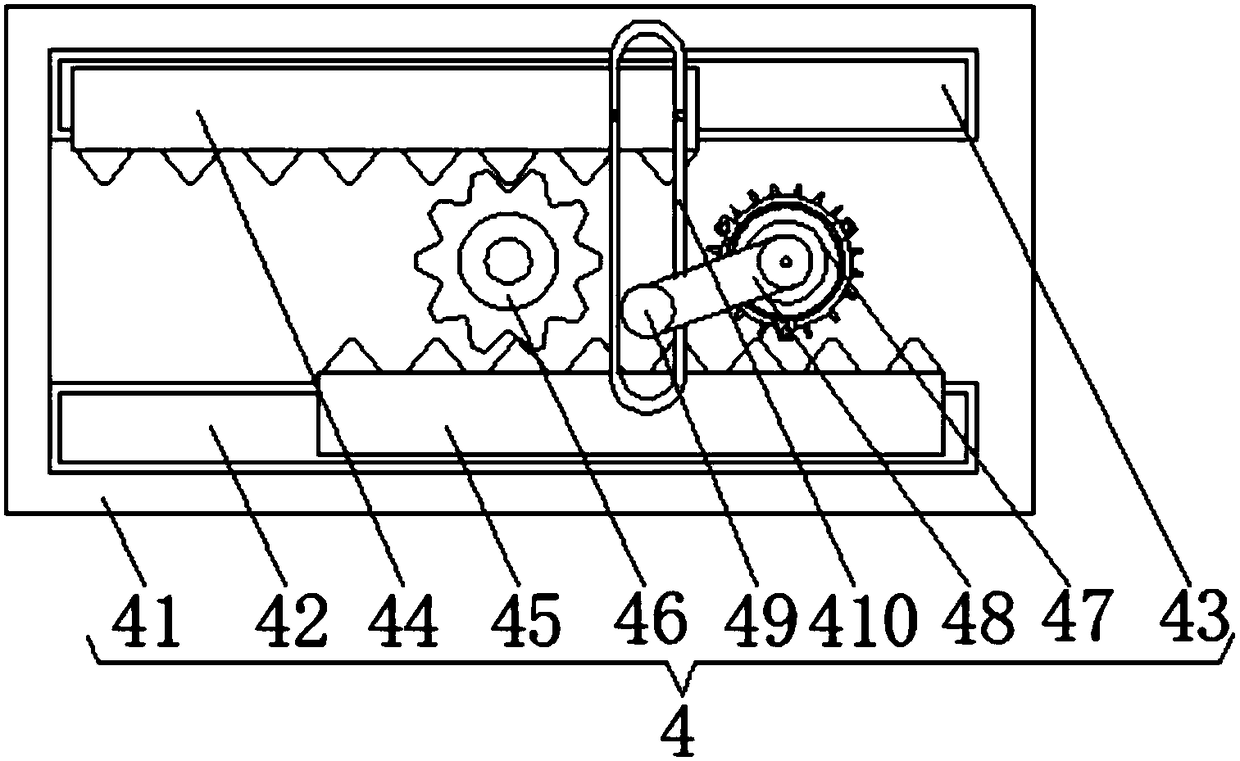

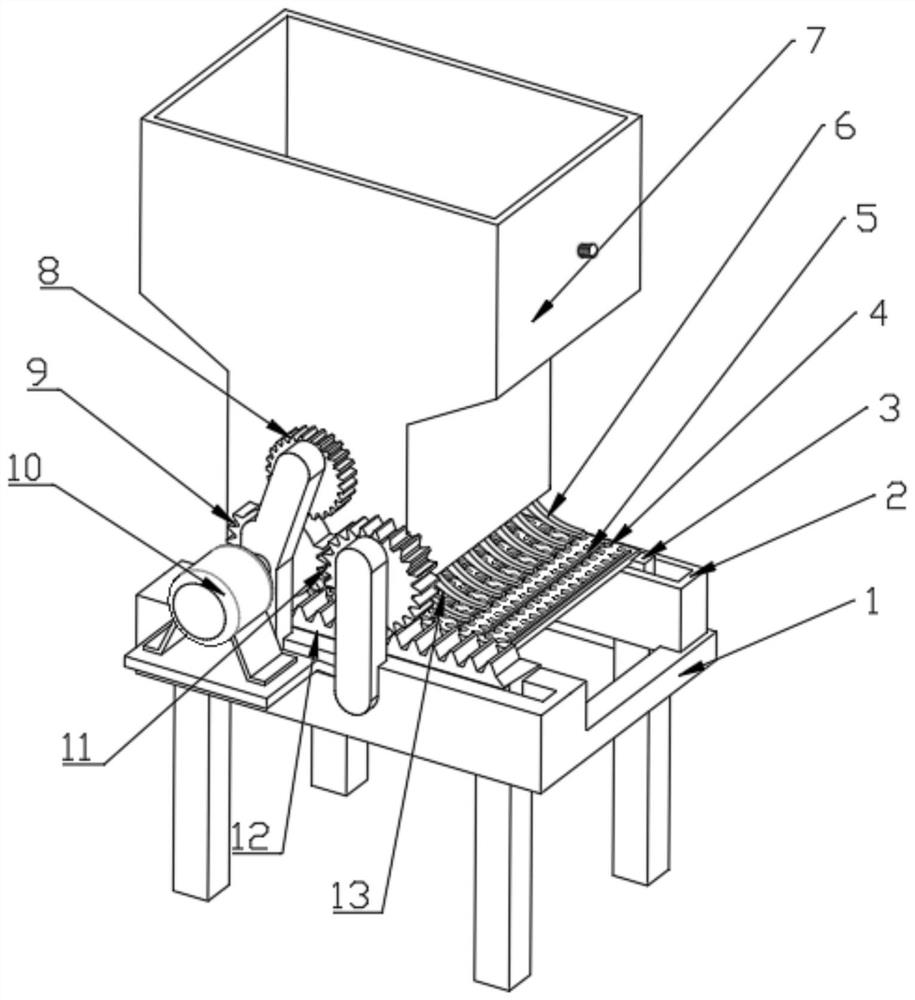

Sieving method for processing sweet potato powder

InactiveCN108188023AHigh speedReduce the amount of manual laborSievingScreeningEngineeringFeeding tube

The invention discloses a sieving method for processing sweet potato powder. The sieving method comprises the steps that the sweet potato powder is poured from a feeding hopper, and a rotary table isdriven by rotation of a motor to rotate; a rotating rod is driven by the rotation of the rotary table to perform circular motion, and a grooved pulley is driven by the rotating rod to perform intermittent rotation, so that the bottom of the feeding hopper is intermittently blocked; the sweet potato powder is fell down to the surface of a sieving mesh through a feeding tube, a first belt pulley isdriven by the work of a vibrating motor to rotate, and a second belt pulley is driven by the rotation of the first belt pulley to rotate through a belt. According to the sieving method for processingthe sweet potato powder, the sieving mesh is driven by the work of the vibrating motor to move and sieve the sweet potato powder, manual sieving is not required, the labor capacity is reduced, the speed of sieving is accelerated, and the working efficiency is improved; and the rate of feeding is controlled to enable the sweet potato powder to be intermittently and continuously fed, the stacking ofthe sweet potato powder due to too fast feeding is prevented to lead the device cannot work normally, and the use effect of the device is improved.

Owner:安吉县安信信息有限公司

Centrifugal sand screening device

The invention discloses a centrifugal sand screening device. The device comprises a shell, the top of the shell communicates with a feeding pipe, a rotating shaft is arranged in the feeding pipe, andthe part, located in the feeding pipe, of the rotating shaft is fixedly connected with a spiral blade; and a crushing cutter is fixedly connected to the position, located below the spiral blade, of the rotating shaft, and a conical sieve is arranged below the crushing cutter. According to the device, the spiral blade and a variable-frequency motor are arranged so that the feeding speed can be controlled, and the sand sieving effect can be guaranteed; the conical sieve and crushing teeth arranged on the conical sieve are arranged, the separation speed of large-mass waste residues such as stonescan be increased under the action of centrifugal force, and the screening efficiency can be improved; sand blocks are crushed through the rotating crushing teeth so that the waste of sand materials can be avoided; an annular sieve which moves up and down is arranged to carry out secondary sieving on the waste residues, and residual fine sand can be recycled; and a spiral discharging roller whichis in linkage with the rotating shaft is arranged so that synchronous discharging can be realized, discharging can be thorough, and the efficiency of sand sieving operation can be improved.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

Rolling wheel extruder for preparing cylindrical particle fuels

The invention discloses a rolling wheel extruder for preparing cylindrical particle fuels, which comprises a receiving barrel. A first transmission shaft is perpendicularly mounted in the receiving barrel and connected with a transmission part in a power transmission box, a first group of rolling wheels is mounted on the first transmission shaft and includes at least two rolling wheels which are respectively mounted on two sides of the first transmission shaft, a first circular steel disc is mounted in the receiving barrel and located below the first group of rolling wheels, a plurality of first cylindrical through holes are arranged on the first circular steel disc, a raw material inlet is arranged at the upper end of the receiving barrel, and a fuel outlet is arranged at the lower end of the receiving barrel. The rolling wheel extruder is specially used for providing the fuels for a gas producer, the fuels are high in hardness and low in cost and can replace natural gas, fuel oil, lump coal and coke, and accordingly production cost of gas is lowered.

Owner:孔令增

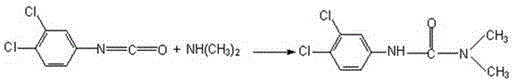

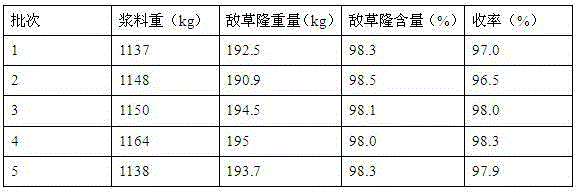

Industrial production method for continuously preparing Dailon

ActiveCN102746194AControl feed rateUrea derivatives preparationOrganic compound preparationMethods of productionCascade reaction

The invention relates to a production method of a pesticide product, particularly an industrial production method for continuously preparing Dailon. A multi-kettle-cascade reactor is adopted, the reaction raw materials isocyanate and dimethyl amine are continuously fed into the reaction kettle in the form of dilute solutions to react, and the product is discharged by overflow. The invention overcomes the defects of low productive capacity, low control stability and the like in the intermittent reaction apparatus, and has the characteristics of high yield and good product quality; and the reaction yield is higher than 97%, and the product content is higher than 98%.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Glass tube secondary drawing apparatus and method thereof

ActiveCN108516668ARich preparation methodEasy to adjustGlass reforming apparatusHeating furnaceMaterials science

The invention belongs to the technical field of special glass preparation and specifically relates to a glass tube secondary drawing apparatus and a method thereof. according to the drawing method, aglass tube is sent through a feed system into a heating furnace of a drawing system and is softened downwards under the action of gravity; the glass tube enters an annealing furnace through a mould and is drawn under the action of a tractor; the glass tube is sealed by a plugging structure, and pressure in the glass tube and the mould is controlled; by an online detection device, internal and external diameters of the secondary tube are detected on line; when the internal and external diameters of the secondary tube meet preset requirements, a tube cutter is started to cut off the secondary tube; the glass tube is sealed by a plugging structure and drawing continues; when the internal and external diameters of the secondary tube do not meet preset requirements, temperature of the heating furnace and drawing speed of the tractor are regulated until the internal and external diameters of the secondary tube meet the preset requirements. The size of the secondary tube drawn by the above method is easy to regulate and control, and glass varieties are convenient to replace. The apparatus and the method are suitable for multi-varieties and small-batch preparation of special glass tubes, preparation methods of glass tubes are enriched, and the operation is simple.

Owner:CHINA BUILDING MATERIALS ACAD

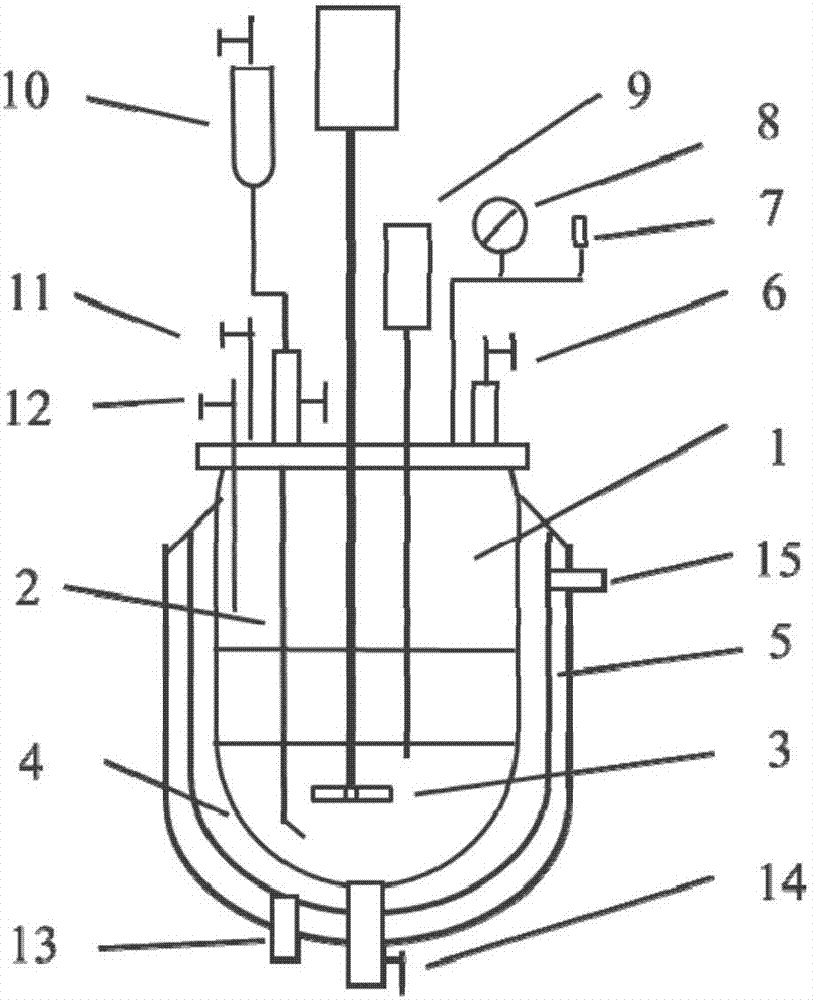

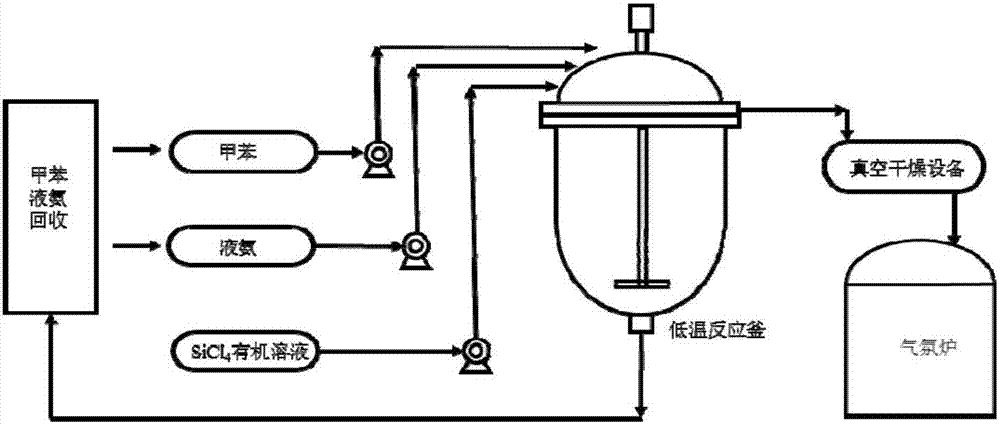

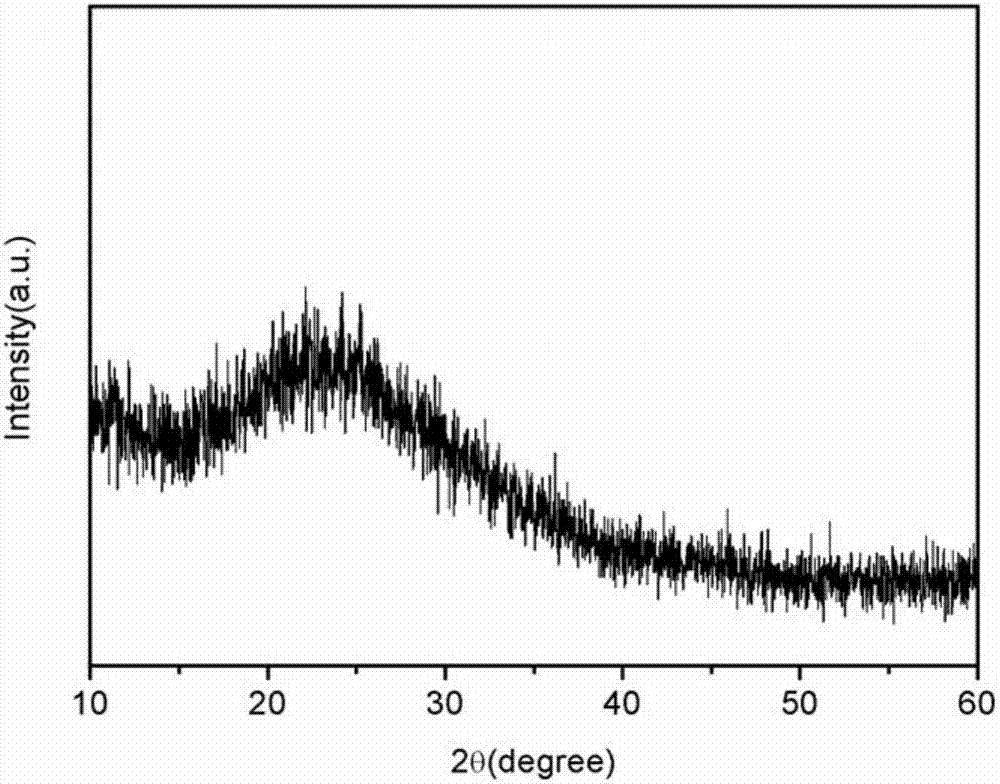

Preparation method of alpha-phase silicon nitride powder

ActiveCN107954723AEasy to cleanSimple internal structureNitrogen compoundsChemical/physical/physico-chemical stationary reactorsInterfacial reactionReaction rate

The invention discloses a preparation method of alpha-phase silicon nitride powder. The preparation method comprises the following steps: (1) reacting silicon tetrachloride with liquid ammonia in a two-liquid-phase interface of an organic solvent and the liquid ammonia to obtain a precursor which is silylimine, wherein the organic solvent is methylbenzene or a mixture of the methylbenzene and dimethylbenzene; (2) carrying out thermal decomposition on the silylimine to obtain non-shaped silicon nitride powder; and (3) carrying out crystallization treatment on the non-shaped silicon nitride powder in step (2) to obtain the alpha-phase silicon nitride powder. In the method, silicon tetrachloride reacts with the liquid ammonia on the two-liquid-phase interface of the organic solvent and the liquid ammonia, the silicon tetrachloride is diluted at low temperature, the reaction rate can be reduced by control over feeding speed, synthesis of the precursor can be controlled effectively, the circumstance that aggregates are formed by the precursor is avoided, the reaction area is expanded by interfacial reaction, and the speed of NH4Cl dissolved in the liquid ammonia is increased. The prepared alpha-Si3N4 powder is controllable in crystal form and morphology, grain sizes are distributed uniformly, a technological process is simple, and production requirements can be met.

Owner:浙江英德赛半导体材料股份有限公司

Screening robot used for sweet potato flour processing

The invention discloses a screening robot used for sweet potato flour processing, and relates to the technical field of sweet potato flour processing. The screening robot used for sweet potato flour processing comprises a shell. A partition frame is fixedly connected to the left side of the bottom of the inner wall of the shell. A partition plate is fixedly connected between the right side of theinner wall of the partition frame and the left side of the inner wall of the shell. A vibrating device is fixedly connected to the top of the partition plate. The right side of the top of the vibrating device penetrates through the right side of the partition frame and extends out of the partition frame. The side, located outside the partition frame, of the vibrating device is fixedly connected with a sieve screen. According to the screening robot used for sweet potato flour processing, the sieve screen is driven by a vibrating motor to move to screen sweet potato flour, and manual screening is not needed, so that the workload of workers is reduced, the screening speed is increased, and the working efficiency is improved; and the discharging speed is controlled so that sweet potato four can be discharged intermittently and continuously, the situation that sweet potato flour accumulation is caused by an excessively high discharging speed, and consequentially, the screening robot cannotwork normally is avoided, and the using effect of the screening robot is improved.

Owner:安吉县安信信息有限公司

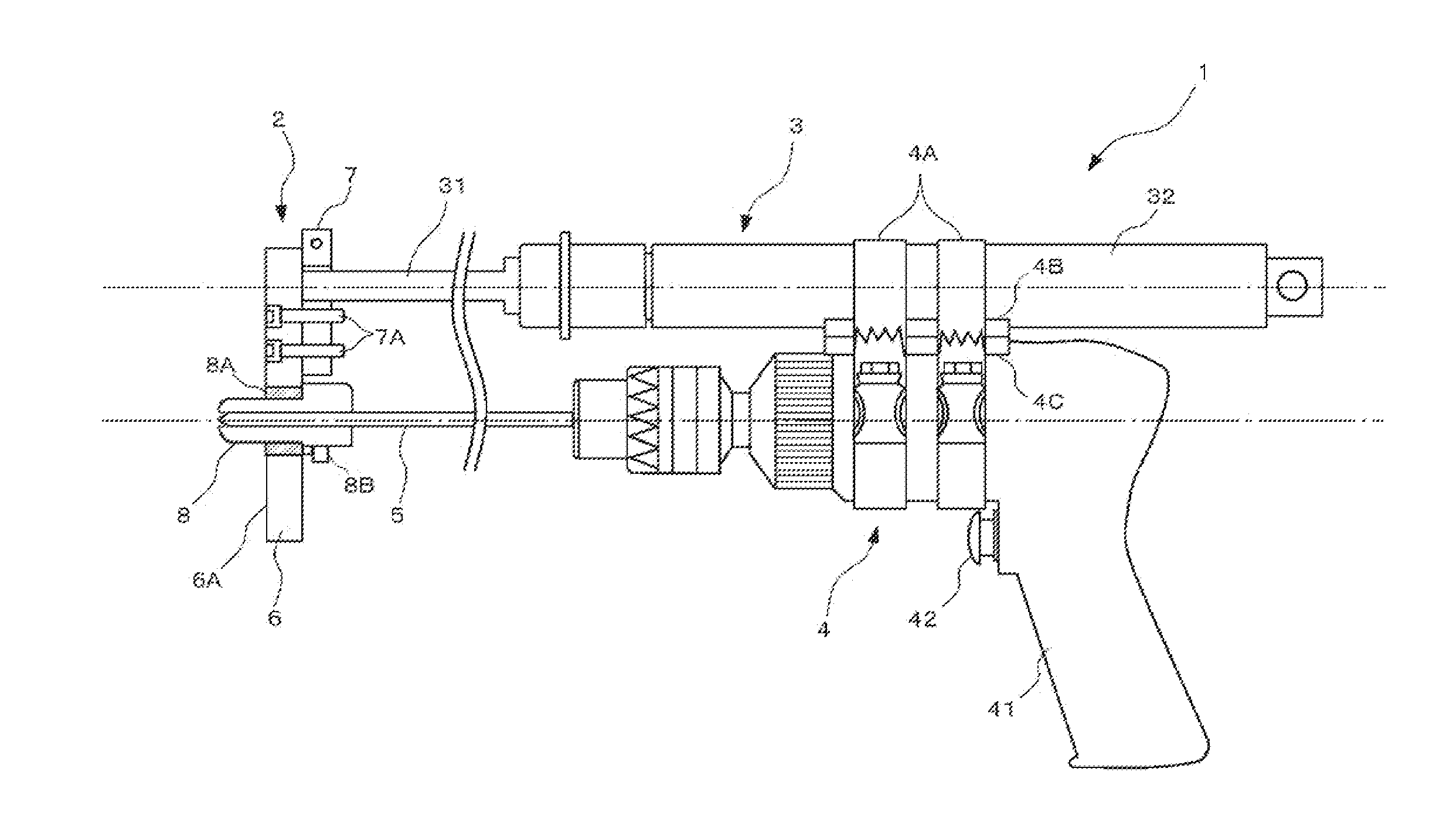

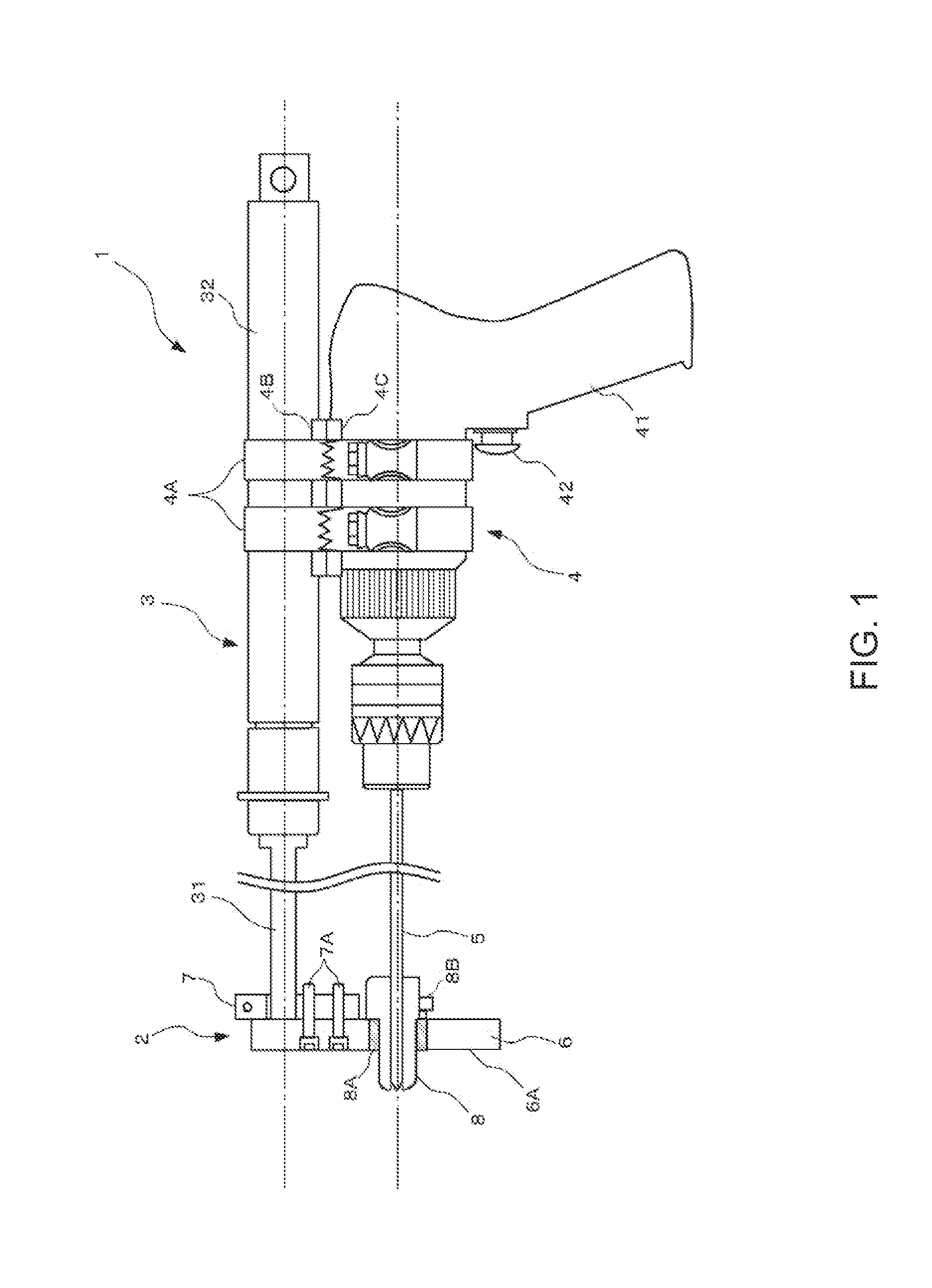

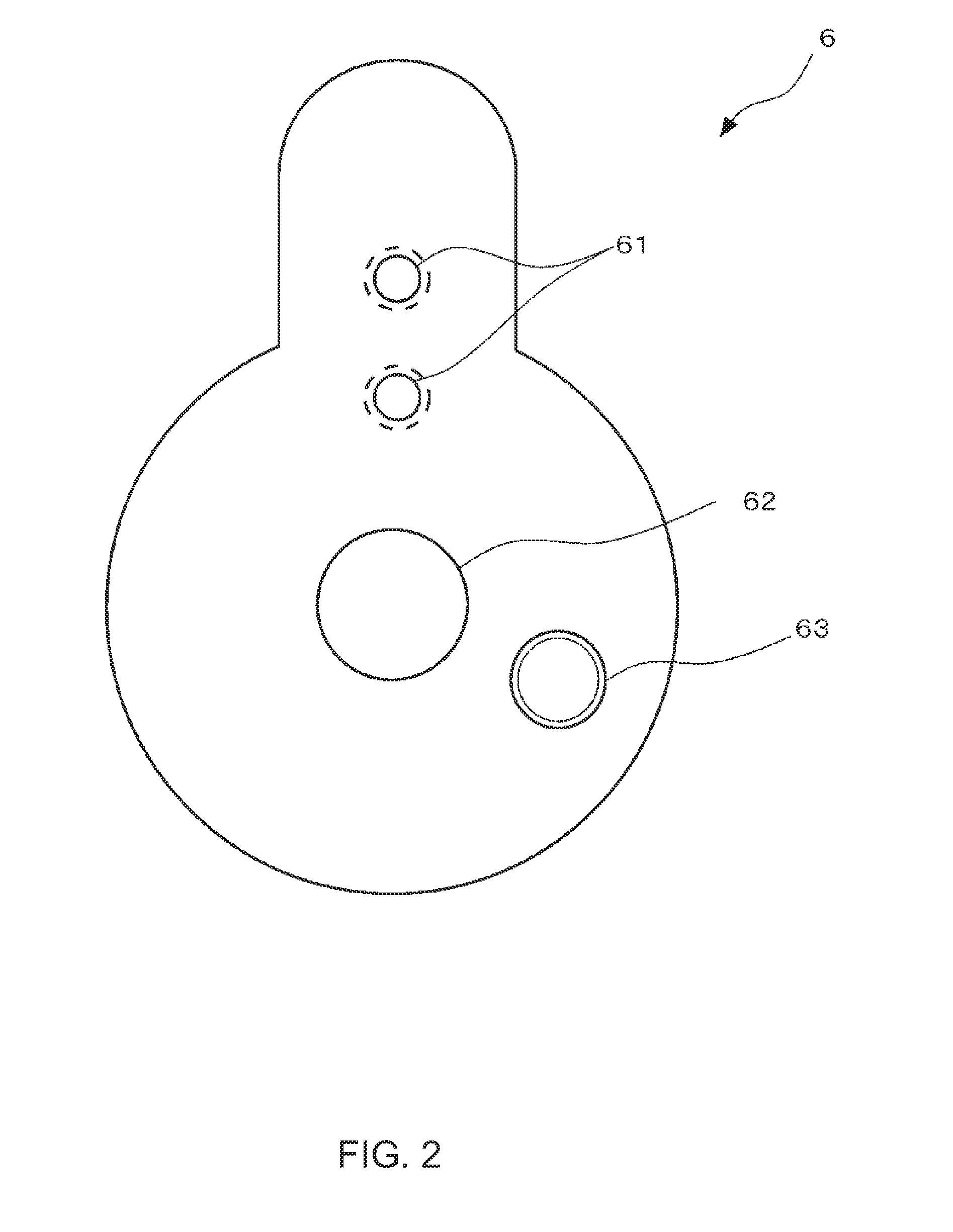

Hand drill

InactiveUS20120141218A1Avoid stratificationControl feed rateDrilling/boring measurement devicesThread cutting machinesDrill holeEngineering

The object of the invention is to provide a hand drill that capable of suppressing delamination that occurs when drilling holes in an object, as well as being more compact. The hand drill has a base member, a damper, a drill and drill blade. The base member has a contact surface that comes in contact with an object being drilled, and a drill bushing. The damper comprises a piston rod and a cylinder, and extends or contracts in its own axial direction. The tip end section of the piston rod is fastened to the base member. The drill is fastened to the cylinder and displaces together with the cylinder. The drill blade is installed in the drill so that it is parallel to the axial direction of the damper. When the damper is in the extended state, the tip end of the drill blade is located at the tip end of the drill bushing.

Owner:FUJI JUKOGYO KK

Adjustable ball grinding mill

InactiveCN110586260AQuality improvementImprove working conditionGrain treatmentsEngineeringMechanical engineering

The invention relates to an adjustable ball grinding mill which comprises a cylinder, a motor and a base. The cylinder is horizontally erected on the base. The motor is in drive connection with the cylinder, a feeding inlet is formed in one end of the cylinder, a first discharging outlet is formed in the other end of the cylinder, the adjustable ball grinding mill further comprises a screening device, a returning device and a feeding device, the inlet end of the screening device communicates with the discharging outlet of the cylinder, a second discharging outlet and a returning opening are formed in the screening device, one end of the returning device communicates with the returning opening, and the other end of the returning device communicates with the feeding inlet. Due to cooperationof the returning device and the screening device arranged at the discharging end of the cylinder, materials conforming to the standards are screened to be discharged, and materials not conforming tothe standards are recycled to the cylinder and ground again; due to cooperation of a metering device and a feeding mechanism, the feeding speed of the feeding end of the cylinder is controlled, and the ball grinding mill is kept at the best working state.

Owner:台山市金昊贸易有限公司

Raw material feeding hopper for injection molding of disposable lunch box

The invention discloses a raw material feeding hopper for injection molding of a disposable lunch box. The raw material feeding hopper comprises a feeding hopper, the tops of two sides of the inner cavity of the feeding hopper are fixedly connected to cushion blocks, the top of the cushion block is provided with a filtering plate, two sides of the filtering plate are provided with clamping slots,a clamping rod is arranged in the inner cavity of the clamping slot, one end, far away from the inner cavity of the clamping slot, of the clamping rod passes through the feeding hopper and extends toout of the feeding hopper, one end, outside the feeding hopper, of the clamping rod is fixedly connected to a connection plate, and the inner wall of the cushion block is fixedly connected to a spring. The raw material feeding hopper filters raw materials and prevents impurities from entering the processing equipment. The filtering plate is easy to disassemble and clean. Through cooperation of a connection block, a baffle, a chute, a sliding plate, a threaded hole and a threaded rod, the diameter of the inner chamber of the feeding hopper can be adjusted according to demands of a user, thus the feeding flow of the raw material is adjusted, the feeding rate is controlled and the orderly processing of raw materials is achieved.

Owner:HENAN OWEN PACKING PROD CO LTD

Automatic discharging and stamping equipment

InactiveCN112496127AAvoid getting stuck in the moldAvoid damageMetal-working feeding devicesPositioning devicesHydraulic cylinderStructural engineering

The invention discloses automatic discharging and stamping equipment. The equipment comprises a machine body, and a feeding mechanism, a stamping mechanism and a material taking mechanism are arrangedon the machine body; the feeding mechanism comprises a conveying belt; and the stamping mechanism is arranged at one side of the conveying belt and comprises an upper die and a lower die, the lower die is formed by splicing a first lower die body and a second lower die body, and the bottom of the first lower die body and the bottom of the second lower die body are sleeved with a first supportingframe and a second supporting frame correspondingly. The material taking mechanism comprises a control panel, the control panel is arranged below the first supporting frame and the second supporting frame, and a first hydraulic cylinder is installed at one side of a pushing plate. The first lower die body and the second lower die body are opened towards the two sides, a stamped part is unlocked, the part is ejected out through upward movement of the pushing plate, automatic discharging is conducted, convenience and rapidness are achieved, the situation that the part is clamped in a die is avoided, damage to the part is reduced, and the product quality is improved.

Owner:HEFEI DEJIE ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

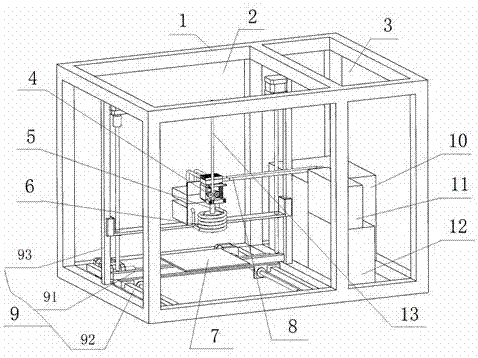

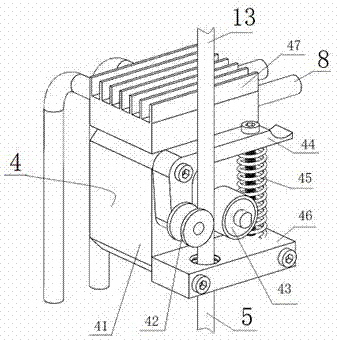

3D (three-dimension) printer for printing vitreous body and printing method

InactiveCN107285609ABroaden your optionsControl feedAdditive manufacturing apparatusGlass shaping apparatusHigh energyControl system

The invention relates to a 3D (three-dimension) printer for printing a vitreous body and a printing method. The 3D printer is composed of a frame, a printing silo and a control cooling silo; the printing silo is connected with the control cooling silo and arranged in the frame; the inner part of the printing silo is provided with a delivering mechanism, a nozzle printing mechanism, a sensing heating device, a printing bottom plate, a cooling medium guide flow pipe and a three-dimensional movement mechanism; the inner part of the control cooling silo is provided with a cooling device, a control system and a power supply. By applying the 3D printer for printing the vitreous body and the printing method, the selection scale of the printing raw material is enlarged; the sensing heating method has the significant advantages of high working efficiency, high energy utilization rate, quick temperature rise, control easiness, small equipment volume, pollution free and others; besides, the printer and the printing device have the advantages of simple and reliable structure, high automatic degree, control easiness, strong practicability and others.

Owner:贵州云上左岸科技有限公司

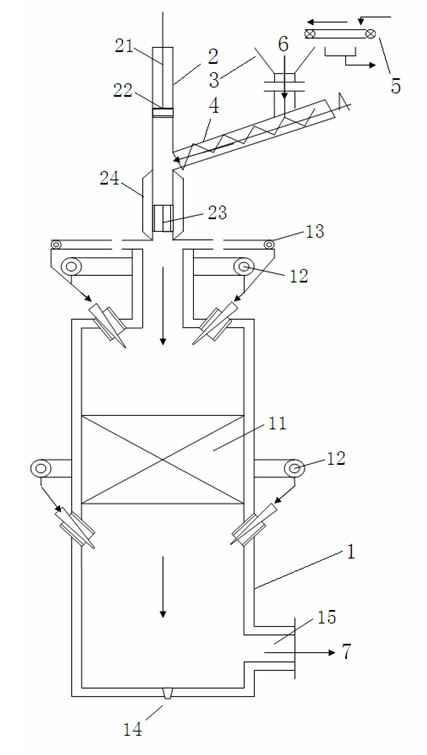

Graphene synthetic apparatus

The invention discloses a graphene synthetic apparatus. The graphene synthetic apparatus comprises a box body, wherein a material inlet is formed in a top plate of the box body, the side wall of the material inlet is fixedly connected with a feeding funnel, the material inlet is provided with a material control mechanism, the upper surface of a box body bottom plate is fixedly connected with a heater and a motor, the inner side wall of the box body is fixedly connected with a horizontal plate, an output shaft of the motor penetrates through a through hole on the side wall of the horizontal plate and is fixedly connected with a plurality of stirring rods, the outer side of the stirring rod is provided with a loading bucket, the lower surface of a loading bucket bottom plate is fixedly connected to the upper surface of the horizontal late, a first material outlet hole is formed in the loading bucket bottom plate, a second material outlet hole corresponding to the first material outlet hole is formed in the side wall of the horizontal plate, and the side wall of the second material outlet hole is fixedly connected with a filter plate with a plurality of filter holes. The graphene synthetic apparatus can effectively control the feeding speed of materials, can also facilitate the synthesis of the graphene, and is worth of popularization.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

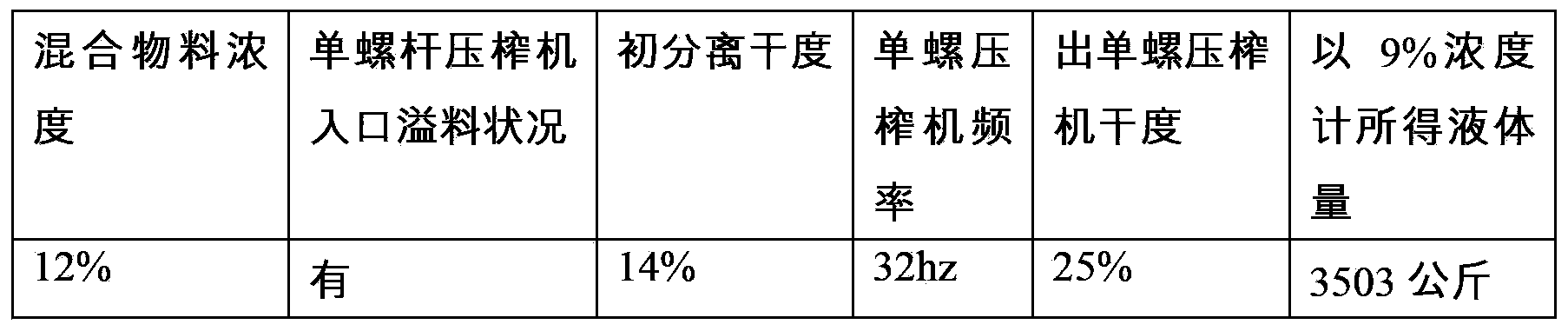

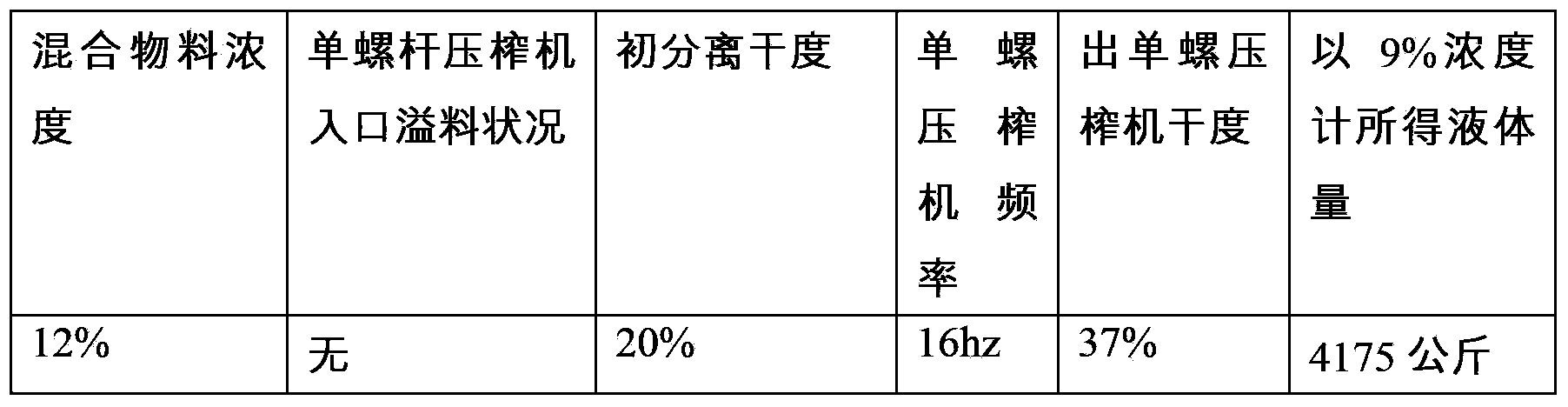

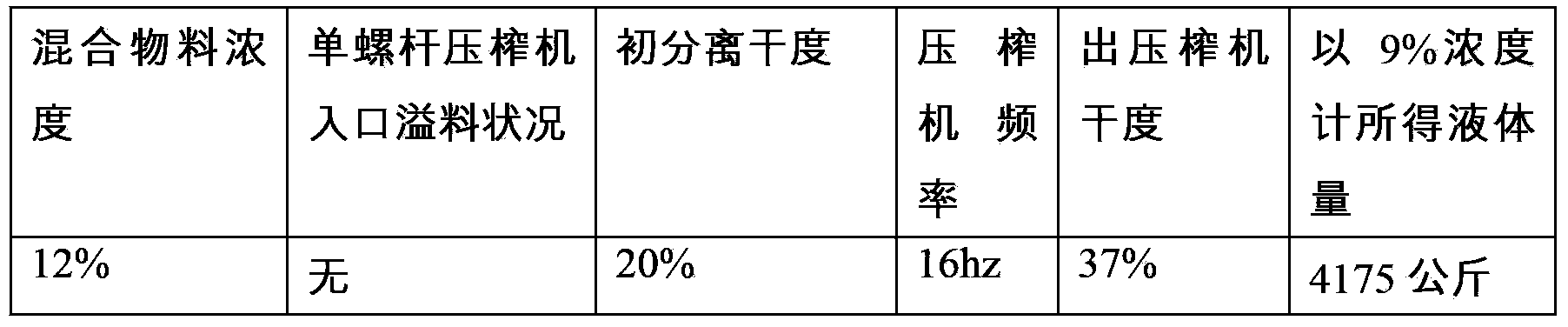

Method for increasing solid-liquid separation rate of raw tobacco powder raw material in tobacco reconstituting process

The invention provides a method for increasing the solid-liquid separation rate of a raw tobacco powder raw material in a tobacco reconstituting process. The method comprises the following steps: adding water into the tobacco powder raw material to form a solid-liquid mixed production material of which the water content is 85-90 percent, pumping the solid-liquid mixed production material into a centrifugal extruder through a volume pump, and processing at the rotating speed of 1,000-1,500 revolutions per minute to obtain an extruded dry material and a wet material; sieving the wet material in a linear and rotary way at the flux of 6,750-9,000 kilograms per hour to obtain a vibratory sieving procedure extracting solution and a vibratory sieving dry material, mixing the vibratory sieving dry material and the extruded dry material, and introducing the mixture into a single screw squeezer for squeezing to obtain a dry material of which the dryness is 37-38 percent and a squeezing procedure extracting solution; and mixing the squeezing procedure extracting solution and the vibratory sieving procedure extracting solution to obtain a tobacco powder raw material extracting solution of which the concentration is 8-10 percent. According to the method, specific to a crushed tobacco leaf raw material with high tobacco ash content, a dry material of which the dryness is over 37 percent can be obtained during solid-liquid separation.

Owner:杭州利群环保纸业有限公司

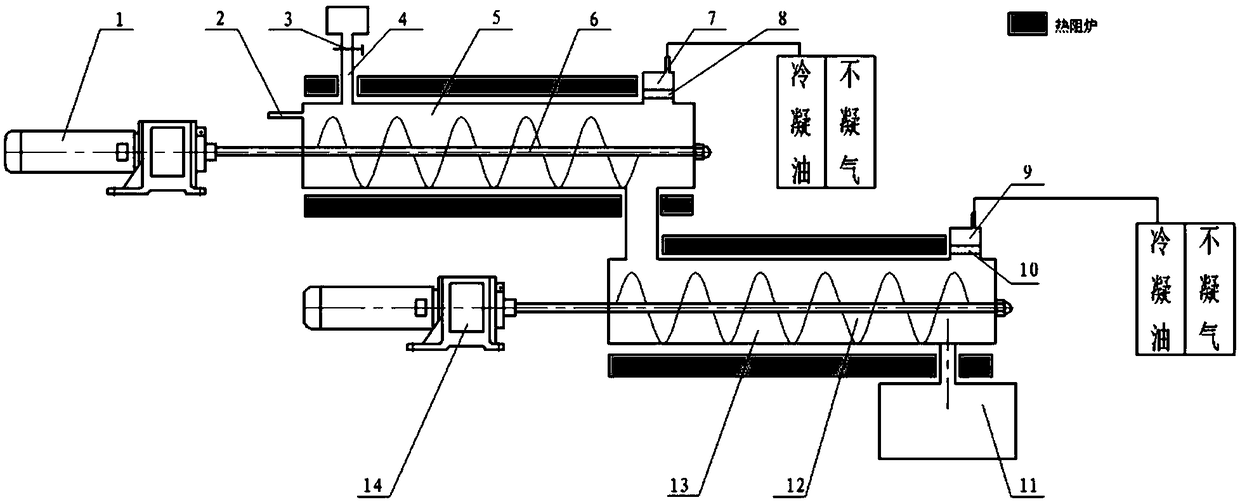

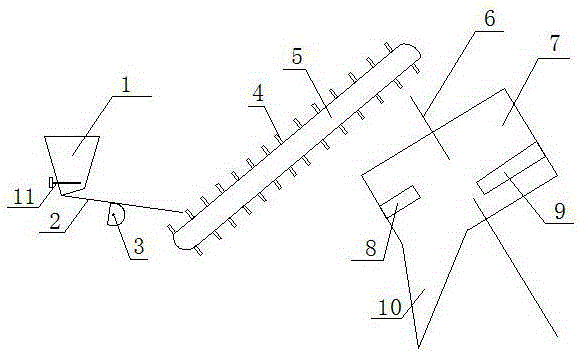

Algal biomass continuous sectional catalytic pyrolysis reaction device

InactiveCN108624344AControl feed rateThe effect of stabilizing successive primary responsesBiofuelsSpecial form destructive distillationCatalytic pyrolysisCombustion

The invention discloses an algal biomass continuous sectional catalytic pyrolysis reaction device which comprises an initial-section reaction device and a tail-section reaction device. The initial-section reaction device is formed by connecting a motor shaft with an initial-section spiral propeller positioned in an initial-section reactor, a gas incoming pipe is arranged on the initial-section reactor, a feeding device is arranged at an end close to a motor, and an exhaust pipe is arranged on the upper portion of the discharging end of the initial-section reactor; the tail-section reaction device is formed by connecting a motor shaft with a tail-section spiral propeller positioned in a tail-section reactor, an exhaust pipe is arranged on the upper portion of the discharging end of the tail-section reactor, and a collection container is arranged on the lower portion of the discharging end of the tail-section reactor. The discharging end of the initial-section reactor is connected with the feeding end of the tail-section reactor, so that sectional pyrolysis is realized during continuous feeding, a primary product semicoke is timely pyrolyzed further, convenience is brought to collecting products of every stage, and composition and physiochemical property of algal biomass pyrolysis products and combustion characteristics of bio-oil can be known more comprehensively.

Owner:JIANGSU UNIV

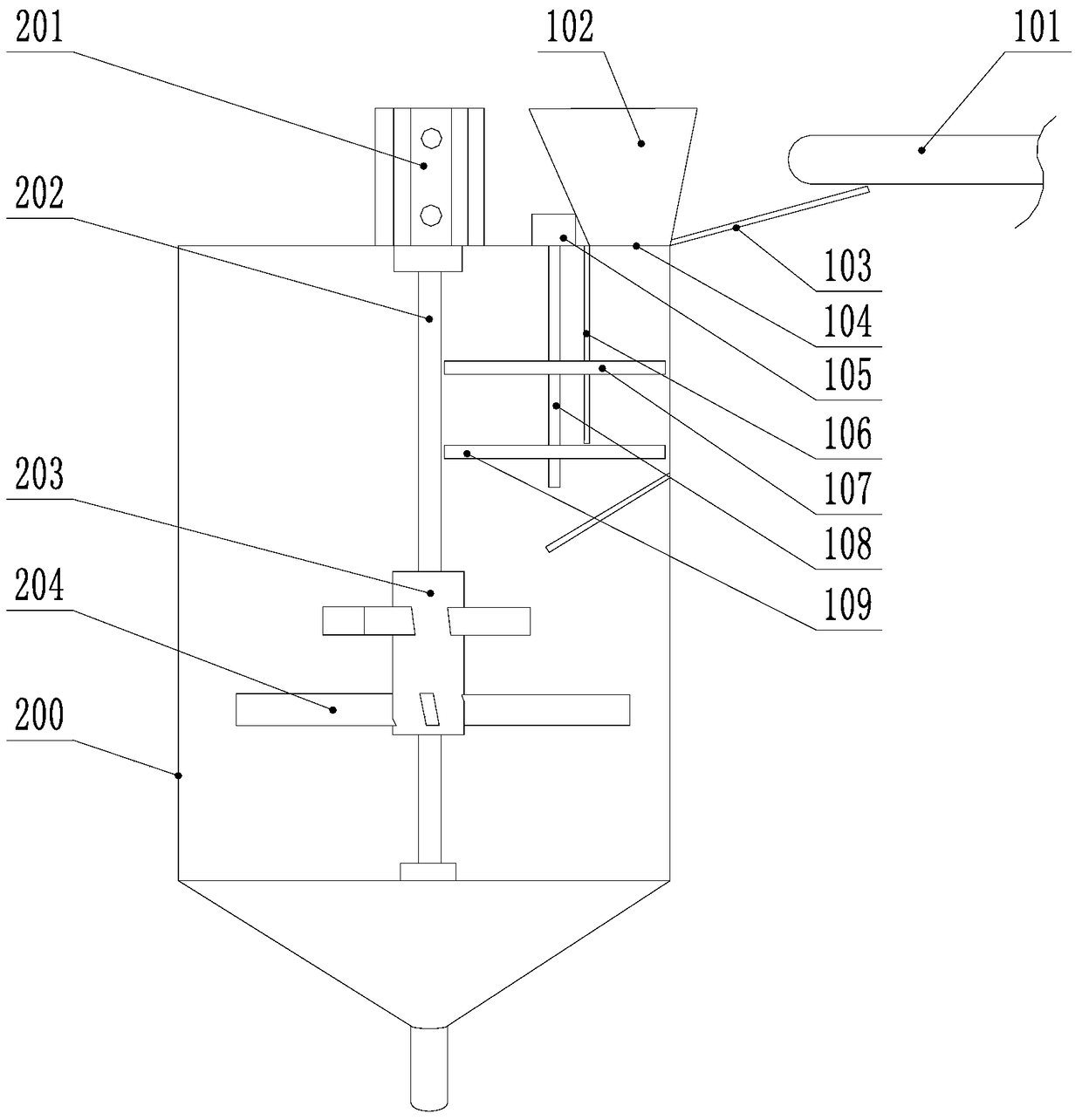

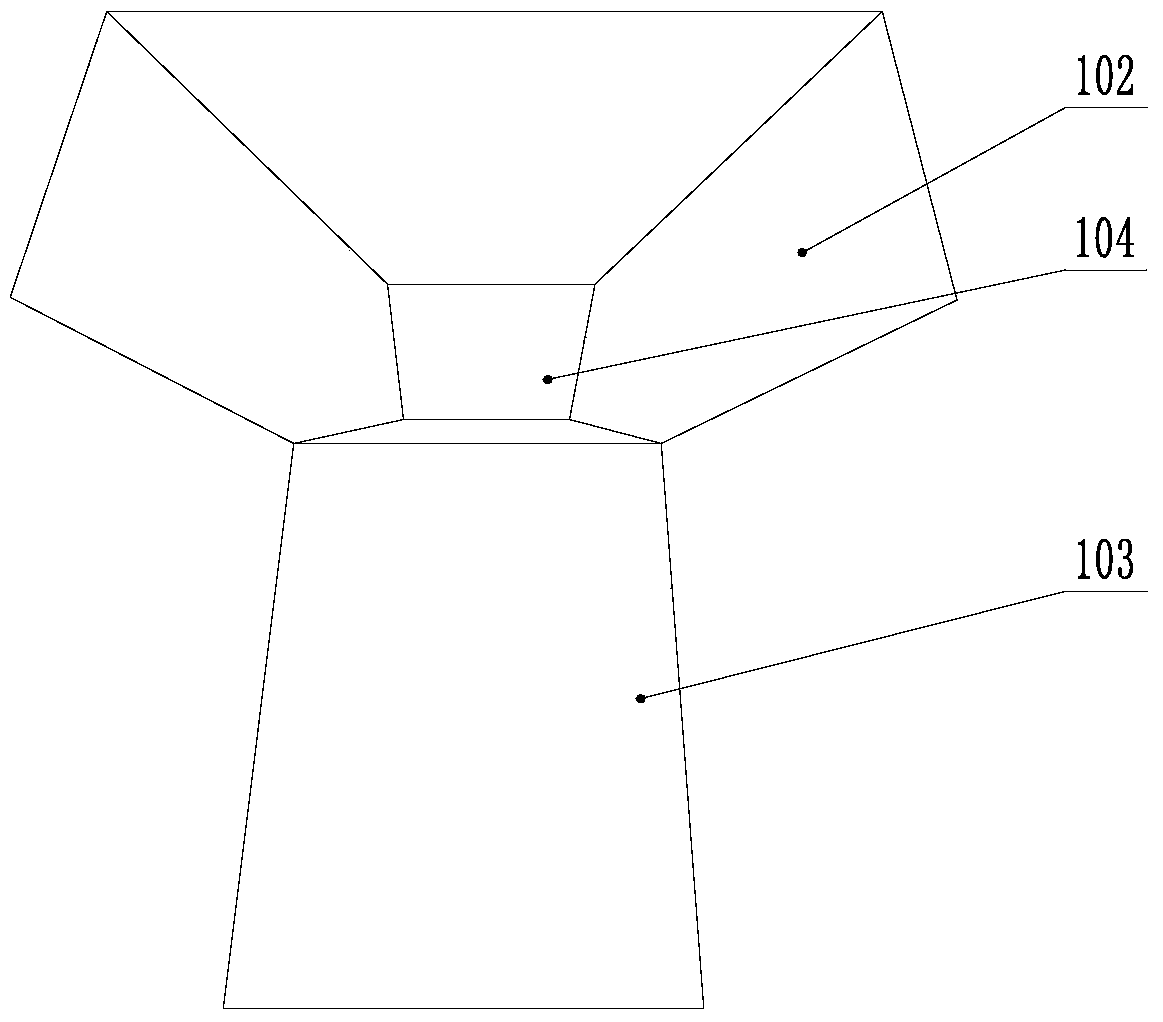

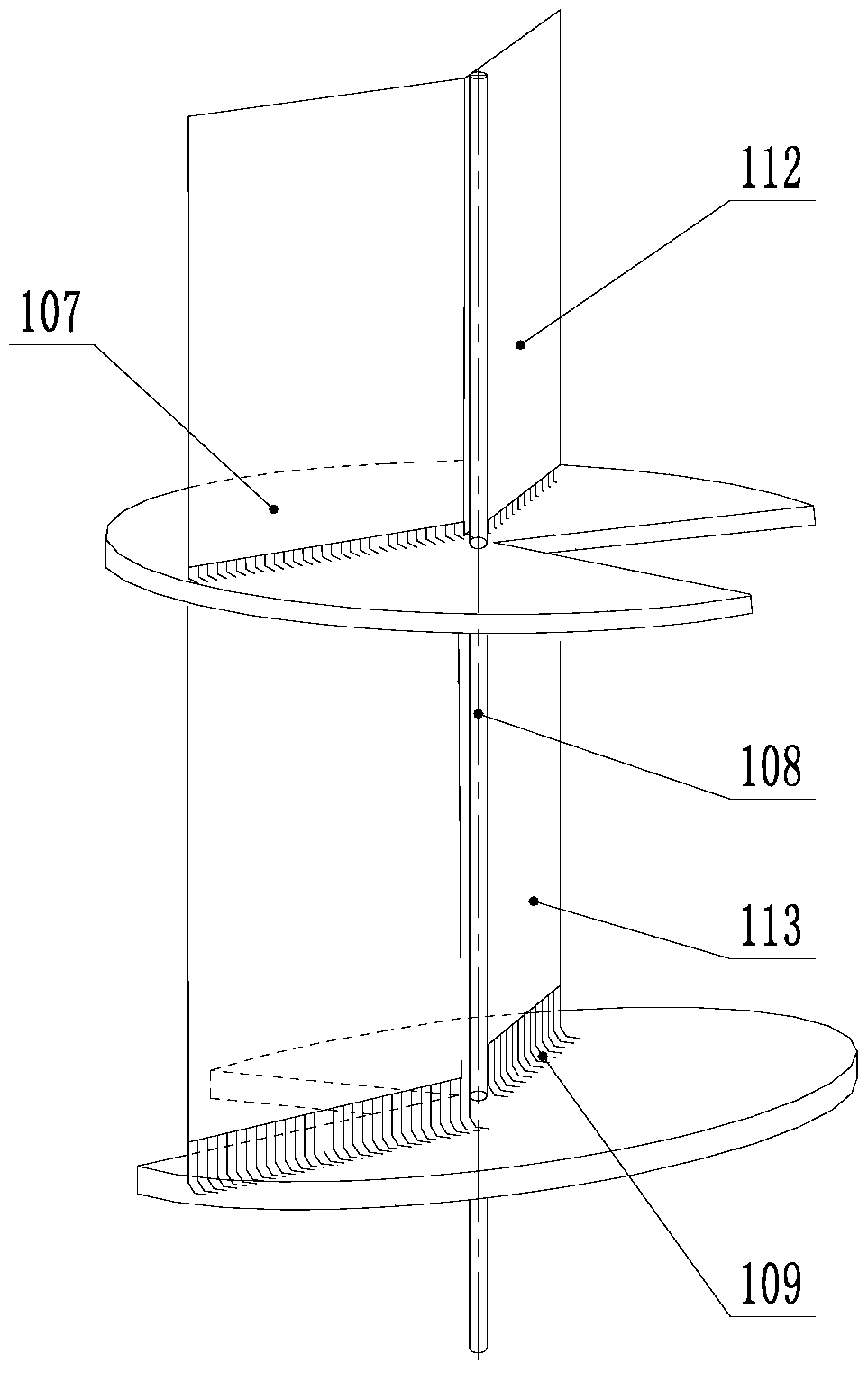

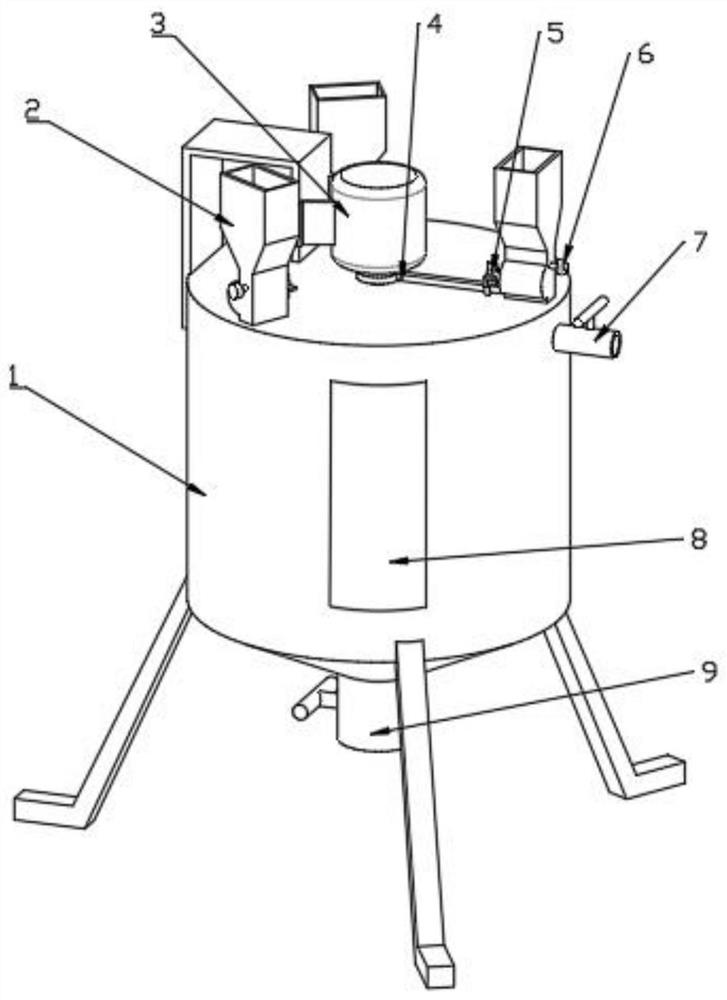

paint mixer

ActiveCN105597594BReduce pollutionReduce the probability of contracting occupational diseasesRotary stirring mixersMixer accessoriesSupporting systemProcess engineering

The invention provides a paint mixer, and belongs to the field of paint processing. The paint mixer comprises a stirring system, a feed system, and a supporting system; pigment delivered by a pigment conveyer belt is delivered into a feeding channel via a baffle plate and a guide plate; and feeding speed is controlled accurately via combination of a feed control device in the feeding channel. Accurate control of the adding amount of raw materials is capable of obtaining a mixture with more accurate concentration and improving product quality; and more full mixing of the raw materials can be realized via combination of double stirring blades of the stirring system arranged in the upper part and the lower part.

Owner:山东丰元锂能科技有限公司

Opening device for polypropylene staple fiber non-woven geotextile manufacturing

ActiveCN111809275ARealize the opening processImprove separation efficiencyFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberPolypropylene

The invention discloses an opening device for polypropylene staple fiber non-woven geotextile manufacturing, and relates to the technical field of building material production. The opening device aimsat solving the problems that when an opening device in the prior art is used, the separation effect between opened impurities and fibers is poor, and the opening quality is affected. The device specifically comprises a shell, wherein a feeding hopper is fixedly mounted at the top of the shell, a discharging pipe is fixedly mounted at the bottom of the side face of the shell, two rollers are mounted in the shell through bearings, and a driving mechanism in transmission connection with the two rollers is fixedly mounted on the side face of the shell. According to the invention, the rollers andopening teeth which rotate oppositely in the shell are used for pulling and loosening incoming raw materials for realizing opening treatment of raw materials, the opened raw materials enter the surface of a filtering mechanism, impurities obtained by opening the raw materials are filtered through vibration, operation is easy and convenient, the separation efficiency between fibers and impurities is improved, and the opening quality and efficiency are improved.

Owner:潍坊驼王实业有限公司

Screening device for silicon monoxide composite negative electrode material

The invention discloses a screening device for a silicon monoxide composite negative electrode material, and belongs to the technical field of composite negative electrode materials. The screening device comprises a box body; rotating plates are rotationally connected inside the box body; connecting rods are fixedly welded on one side of the bottoms of the rotating plates; screw rods are symmetrically arranged on two sides of the box body; fixed plates are welded on the inner wall of the box body; fixed blocks are fixedly welded on two sides of the inner wall of the box body; a filter screen is connected to one side of each fixed block in a sliding manner; mounting grooves are formed in two sides of each filter screen; an insertion block is movably inserted in one side of each mounting groove; and a spring is fixedly mounted in each mounting groove. Through the coordinated use of the screw rods, the connecting rods and the rotating plates, the feeding quantity and the feeding speed canbe effectively controlled, and the blocking is avoided, so that the screening efficiency is improved, and through the coordinated use of the insertion blocks and the springs, the filter screens can be quickly dismounted and replaced, convenience is brought to a user, and the practicability is high.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD +1

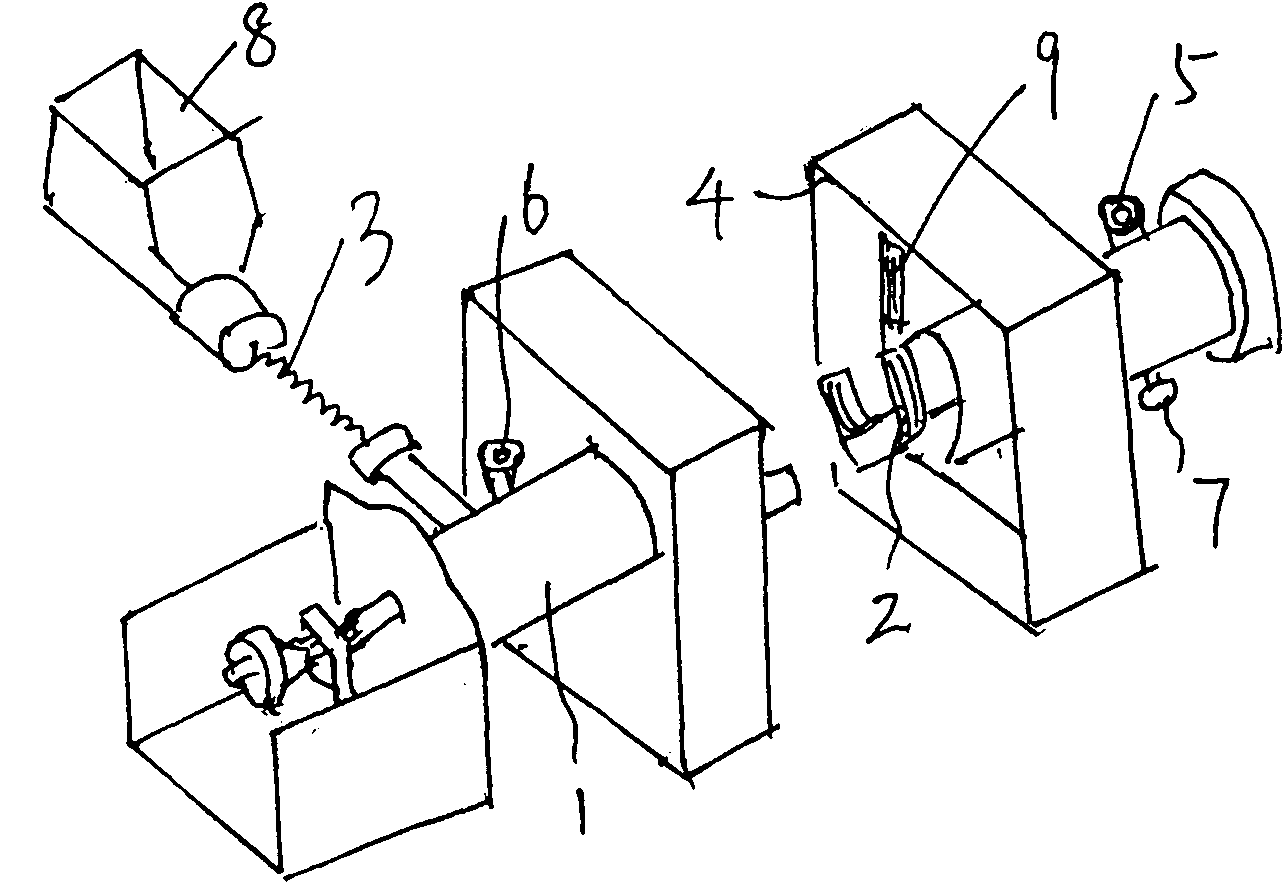

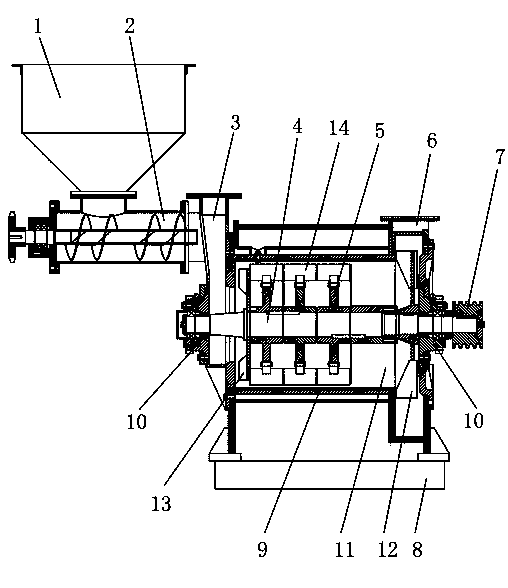

Smashing device for manufacturing amino molding plastic

InactiveCN103372487AControl feed rateImprove crushing efficiencyGrain treatmentsMechanical engineeringPulverizer

The invention discloses a smashing device for manufacturing amino molding plastic. The smashing device comprises a rack, wherein a housing case is arranged on the rack; a main shaft penetrates through the rack and is connected with two end surfaces of the housing case through a bearing saddle; both ends of the housing case are respectively provided with a feeder and a discharging device; the housing case is internally provided with a smashing cavity; the smashing cavity is internally provided with a knife rest on the main shaft; blades are distributed on the knife rest in the circumferential direction. The smashing device is characterized in that the blades are in clearance fit with the inner wall of the smashing cavity, and the clearances ranges from 1mm to 2mm; each circle of blades distributed in the circumferential direction are designed into a group, and the clearance between each two adjacent groups of blades is 0.5mm-1.5mm. The smashing device has the beneficial effects of being capable of increasing smashing efficiency and controlling the feeding speed of materials, so that the feeding speed is matched with the practical capacity of a smashing machine.

Owner:WUXI ZHONGWANG 4D TECH

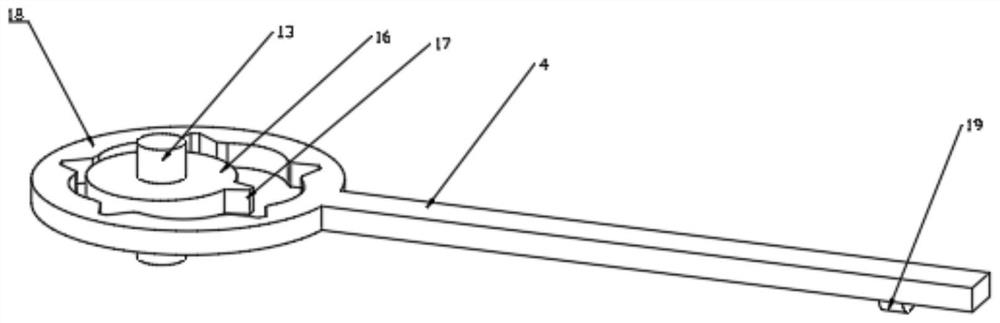

Concrete raw material screening device

The invention is applicable to the technical field of concrete, and provides a concrete raw material screening device. The screening device comprises a machine frame used for supporting and mounting,a hopper fixedly installed on the machine frame and used for containing concrete raw materials, a sieve plate slidably arranged on the machine frame below the hopper and used for sieving the concreteraw materials, a feeding roller rotationally arranged in the hopper and used for controlling feeding of the concrete raw materials, and a driving part connected with the feeding roller and the sieve plate through transmission parts and used for driving the feeding roller to rotate for feeding and driving the sieve plate to slide for screening, wherein the transmission parts comprise a first gear,an intermittent gear, a second gear and a rack, the rack is at least fixed to one end of the non-sliding side of the sieve plate, the first gear, the intermittent gear and the second gear are rotationally connected to the machine frame, and the second gear is meshed with the rack. The screening device has the advantages of simple structure, convenient operation, energy conservation, good synchronism, high screening efficiency and convenience in popularization and implementation.

Owner:李淑敏

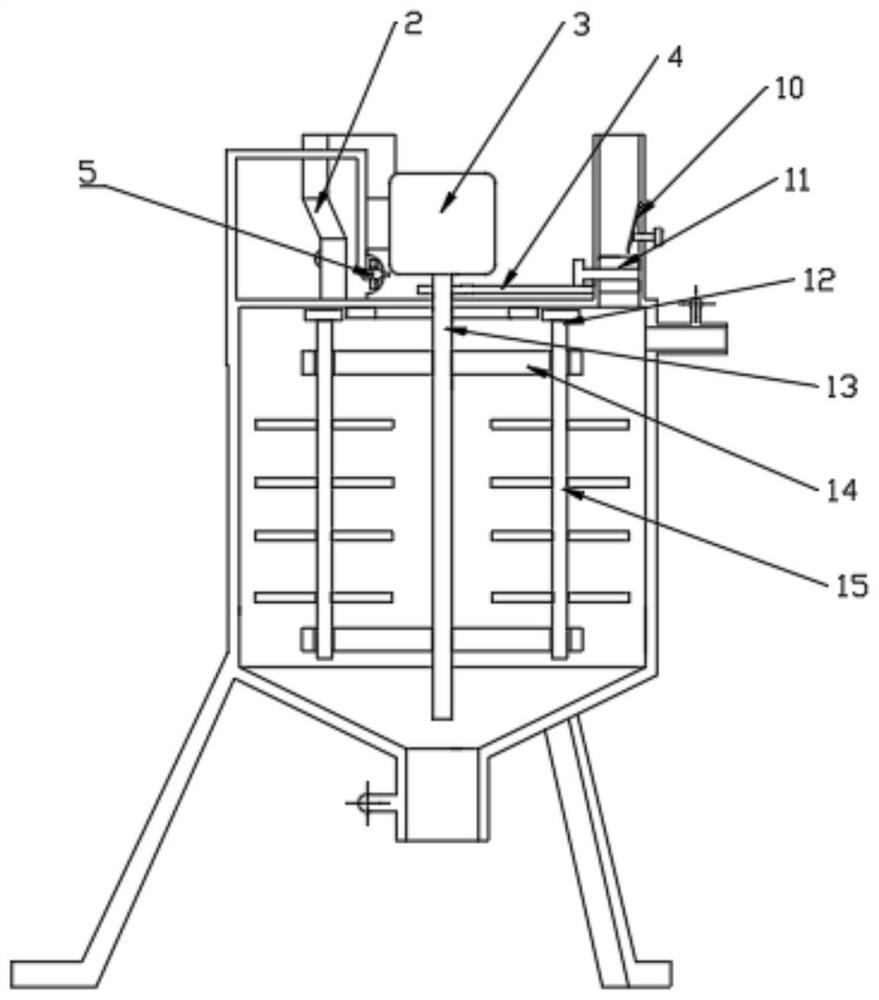

Textile dye mixing device

InactiveCN112221375AFor continuous mixingImprove mixing uniformityRotary stirring mixersTransportation and packagingStructural engineeringMechanical engineering

The invention is suitable for the technical field of textile equipment, and provides a textile dye mixing device which comprises a mixing barrel body, in which a mixing space is formed; a rotating shaft which is rotationally arranged in the mixing barrel body and is connected with the plurality of stirring rods; at least one solid hopper which is communicated with the non-central position of the top of the mixing barrel body, wherein a feeding roller for conveying raw materials is arranged in the solid hopper; a driving part which is arranged on the mixing barrel body and is used for driving the rotating shaft to rotate, wherein at least one poke rod is connected to the driving part, one end of the feeding roller extends out of the solid hopper and is coaxially and fixedly connected with apoke blade, the poke rod rotates to intermittently poke the poke blade to control feeding, a water inlet pipe and a discharging pipe are arranged on the mixing barrel body, and valves for controllingflow are arranged on the water inlet pipe and the discharging pipe. The device has the advantages of simple structure, convenient operation, energy saving, good synchronism, and realization of multi-ratio control.

Owner:温翠真

FPC feeding robot

ActiveCN105775665AThe device is compactSimple design principleConveyorsControl devices for conveyorsDrive motorManufacturing efficiency

The invention discloses an FPC feeding robot. The FPC feeding robot comprises a rack and a conveying belt. The conveying belt is arranged on the rack. Conveying wheels are arranged in the conveying belt. A rotating speed sensor is arranged on one conveying wheel. A bin is arranged at the right ends of the conveying wheels. A feeding hopper is arranged at the upper end of the bin, and a discharging hopper is arranged at the lower end of the bin. A push rod is arranged in the bin. A drive motor is connected to the lower end of the push rod. The drive motor is provided with a frequency modulation speed changer connected with the rotating speed sensor through a wireless network. A material supply tray is arranged at the upper end of the push rod. A material pushing device is arranged on the material supply tray. The whole device is compact in structure, the design principle is simple, very high using value is achieved, and FPC feeding can be well finished. The FPC manufacturing efficiency is greatly improved, the FPC feeding robot can well adapt to different feeding speeds for material supply, a very high automation degree and a very high intelligent degree are achieved, and the FPC feeding robot is worthy of popularization.

Owner:华粹智能装备有限公司

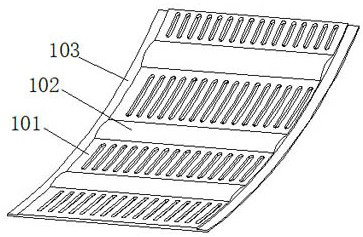

Tea color selection machine with shred screening function

InactiveCN105341196AImprove qualityEasy feedingPre-extraction tea treatmentSortingEngineeringPore diameter

The invention discloses a tea color selection machine with a shred screening function. The tea color selection machine comprises a feed hopper, a vibration feed feeder, a conveyor belt, a sorting channel, a sorting chamber, an image collection device, a sorting electric control air injection device and a control host. The vibration feed feeder is arranged under the feed hopper. One end of the conveyor belt is arranged under the vibration feed feeder, and the other end of the conveyor belt is arranged above the sorting channel. The sorting chamber is arranged on the sorting channel. The image collection device and the sorting electric control air injection device are arranged in the sorting chamber. The image collection device and the sorting electric control air injection device are connected with the control host. The vibration feed feeder is composed of a screening plate and a vibrator. The screening plate inclines by 5-15 degrees from the feed hopper end towards the conveyor belt end, holes with a pore diameter of 0.4-0.6cm are arranged in the screening plate, and the end, close to the feed hopper, of the screening plate is hinged to the feed hopper. The vibrator is arranged under the screening plate. The vibrator is composed of a rotating shaft and an eccentric wheel arranged on the rotating shaft. The tea color selection machine is convenient to feed, the feed speed can be controlled conveniently, tea shreds can be screened, and the screened tea has high quality.

Owner:四川雅安雅泉茶业有限公司

Device for preparing sulfur dioxide by directly burning raw sulfur

InactiveCN102115044ASolve non-flammableSolve technical problems of incomplete combustionSulfur compoundsSocial benefitsMolding machine

The invention discloses a device for preparing sulfur dioxide by directly burning raw sulfur. The device for preparing the sulfur dioxide by directly burning the raw sulfur comprises a raw sulfur continuous burning furnace; a sulfur noodle extrusion molding machine is arranged on the top of the raw sulfur continuous burning furnace; the sulfur noodle extrusion molding machine is connected with a propulsion feeder; and a raw sulfur funnel is arranged on the propulsion feeder. By the device for preparing the sulfur dioxide by directly burning the raw sulfur, the technical problem that the raw sulfur is difficult to burn and cannot be burned totally is solved effectively; the amorphous, flowable and difficult burning characteristics of the raw sulfur are changed into moldable, static and incendive characteristics, so that the raw sulfur can be burned and is easy to burn, and SO2 can be prepared directly; meanwhile, the high-performance retention high-temperature gas heat is recycled, so a feasible method for treatment and economic utilization of the raw sulfur is found. The device is a reliable way for relieving the burden of the environment as the raw sulfur is continuously increased; and the device has better economic prospect and good social benefit.

Owner:江苏中显集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com