Patents

Literature

126results about How to "Control feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of thin-wall tubular product of particle-reinforced aluminum-based composite material

ActiveCN101737574AReduce plasticityFix production issuesRigid pipesSolution treatmentRoom temperature

The invention relates to a preparation method of a thin-wall tubular product of a particle-reinforced aluminum-based composite material, which comprises the steps of: 1, preparing a tube blank by adopting a mixing and casting process and a powder metallurgy process; 2, homogenizing the tube blank, turning and stripping, carrying out a high-temperature compression deformation test to obtain a suitable processing deformation condition; 3, spinning the tube blank for finite element number value simulation, optimizing process parameters, and thermally spinning and warmly spinning; and 4, carrying out solution treatment on the obtained tubular product, and ageing after water hardening at room temperature. The tubular product prepared by the invention has larger diameter wall thickness ratio, smooth internal surface and outer surface without defects, uniform wall thickness and better interface combination between reinforced particles and a base body of the thin-wall tubular product. The method has short procedure, labor saving of the processing mode, energy saving and environmental protection, simple process, low raw material cost, suitability for large-scale production and better popularization value, and can be widely applied to the preparation of high-strength light tubular products in the fields of aerospace, vehicles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

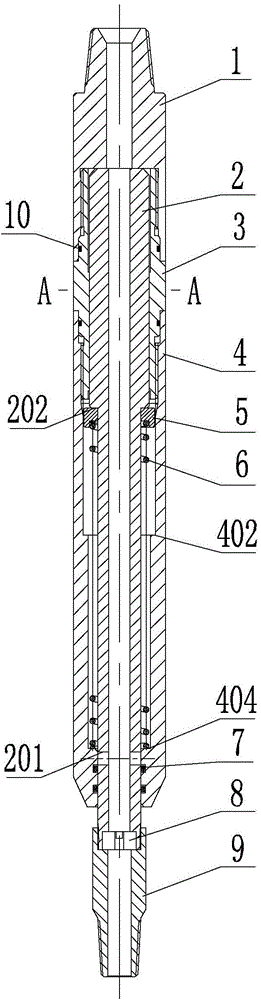

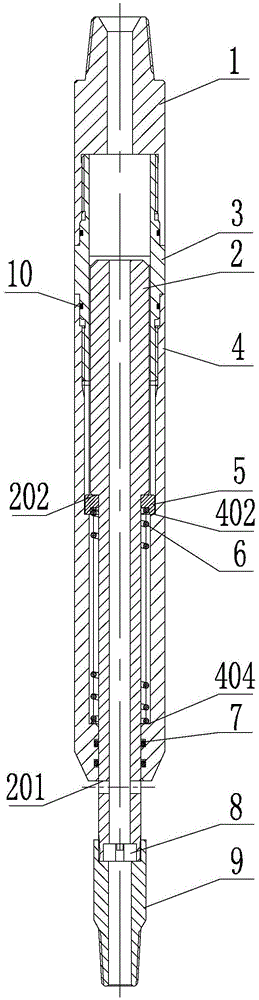

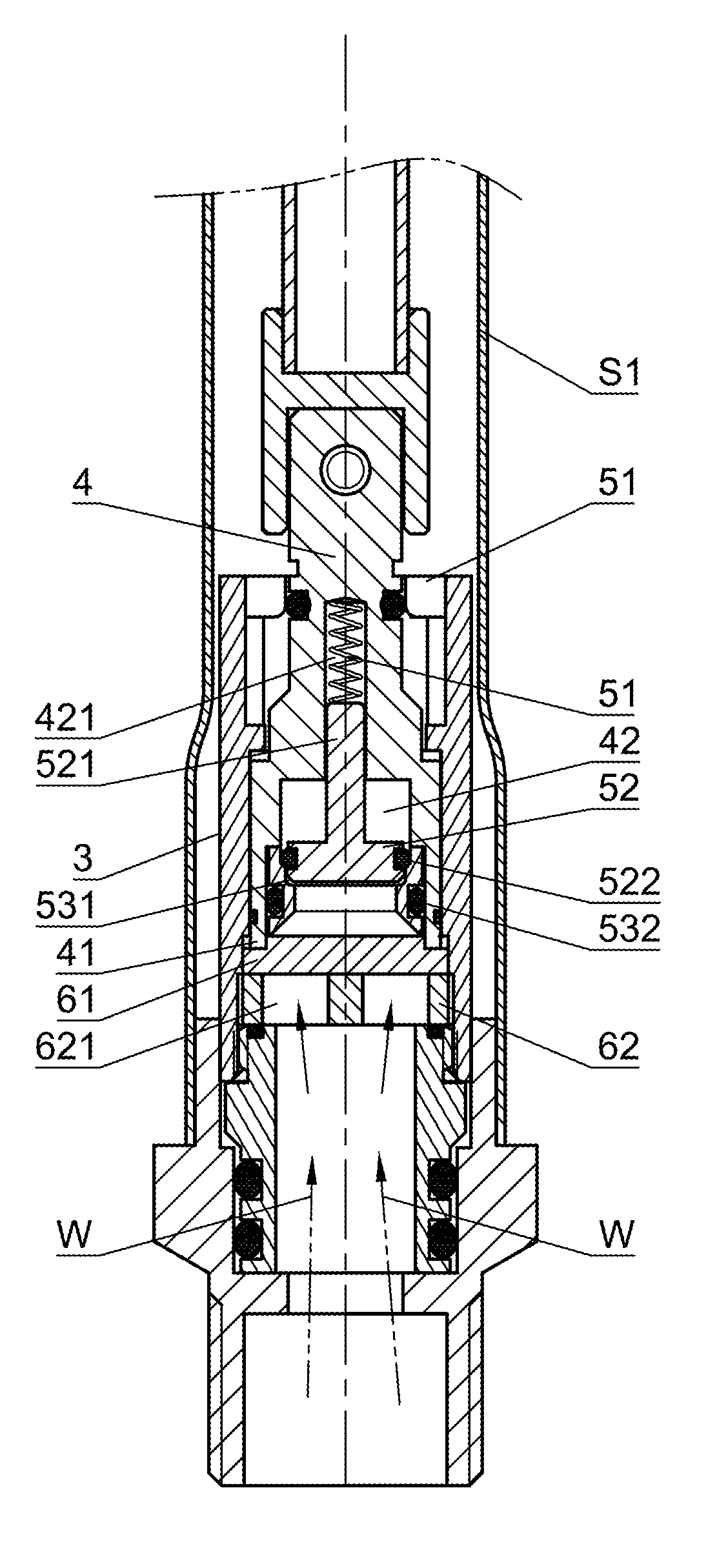

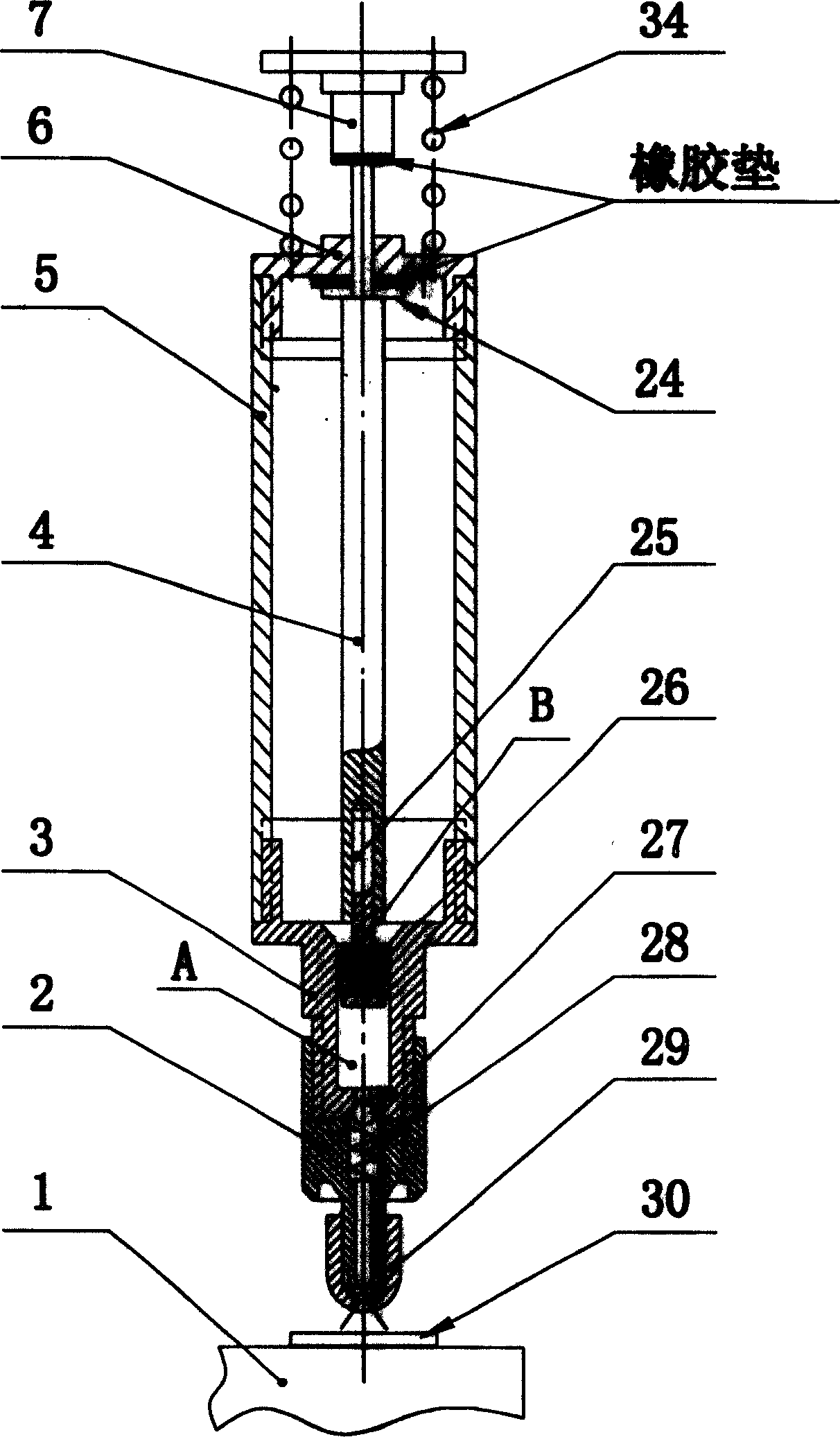

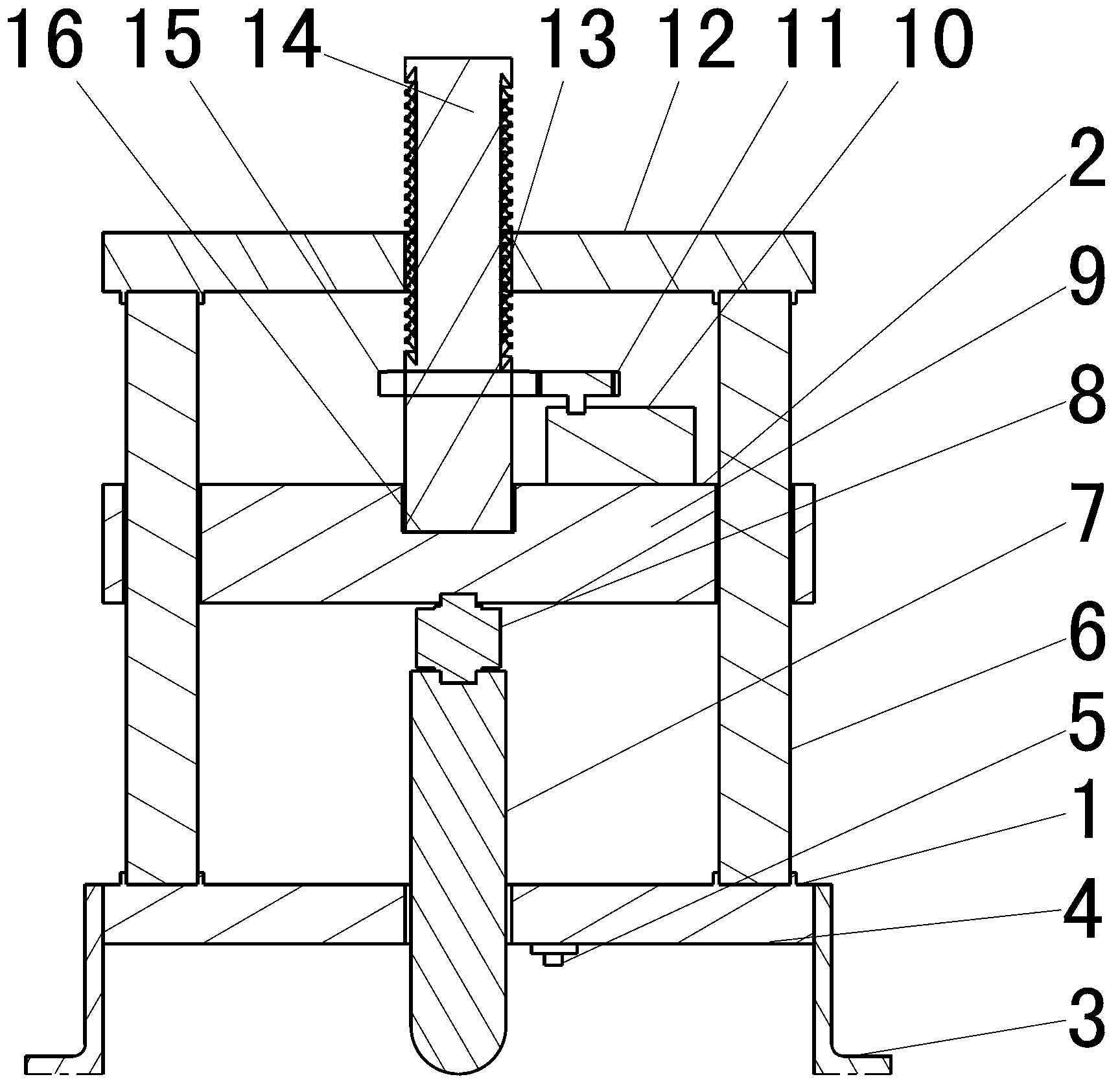

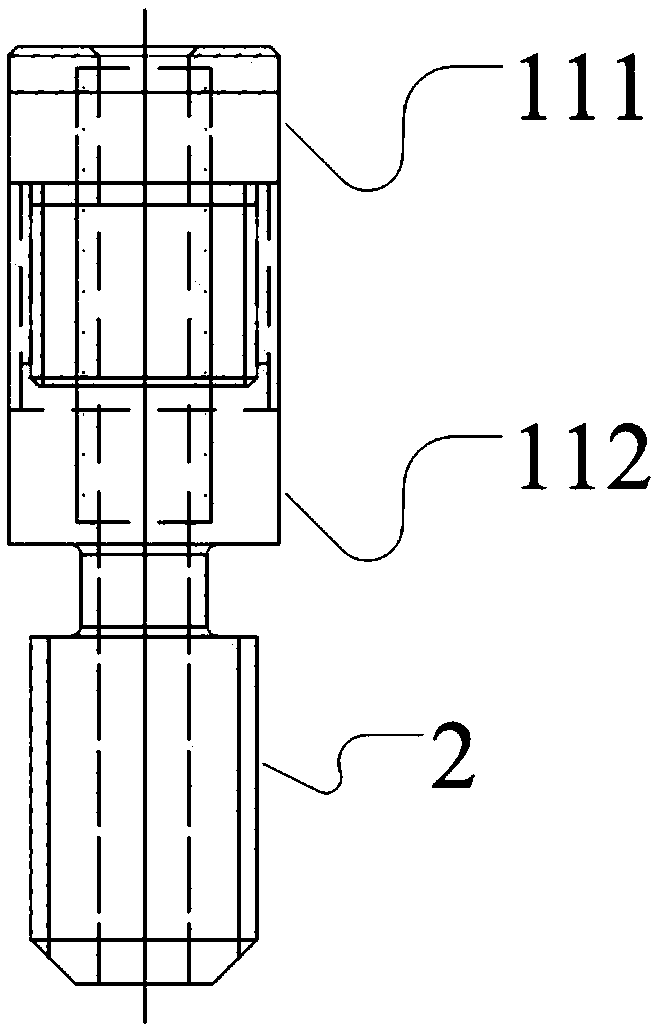

Drilling pressure pushing pressurizer

ActiveCN104405321ALower the pressure valueControl feedDrilling rodsDrilling casingsUpper jointEngineering

The invention a drilling pressure pushing pressurizer which comprises an upper joint, a lower joint, a shell, a piston and a throttling ring, wherein the shell is a hollow barrel; one end of the shell is connected with one end of the upper joint; the piston is arranged in the inner cavity of the shell in a manner of moving up and down; one end, which is far away from the upper joint, of the piston extends out of the shell; the extending end of the piston is in sliding sealed fit with the shell and is connected with one end of the lower joint; the throttling ring is connected with the extending end of the piston and is used for generating throttling pressure difference; through holes are respectively formed in the upper joint, the piston, the throttling ring and the lower joint and are connected with one another in sequence to form a liquid guide channel; at least one pressure release hole penetrating from the through hole in the piston to the outer wall of the piston is formed in the lower part of the piston and retracts into or extends out of the shell along with the up-and-down sliding of the piston. The drilling pressure pushing pressurizer realizes drilling pressure adjustment and can judge the completion of hole drilling on the ground.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

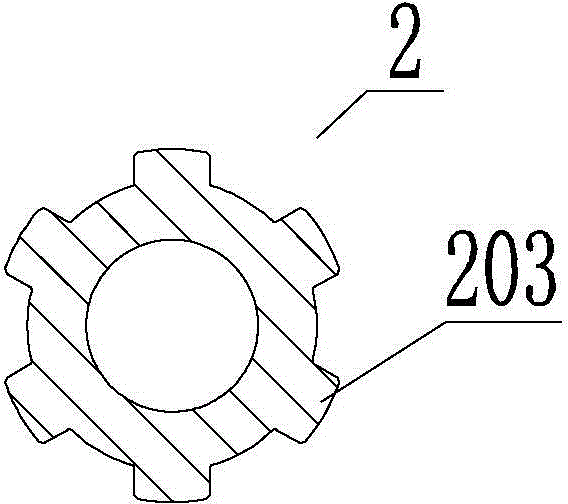

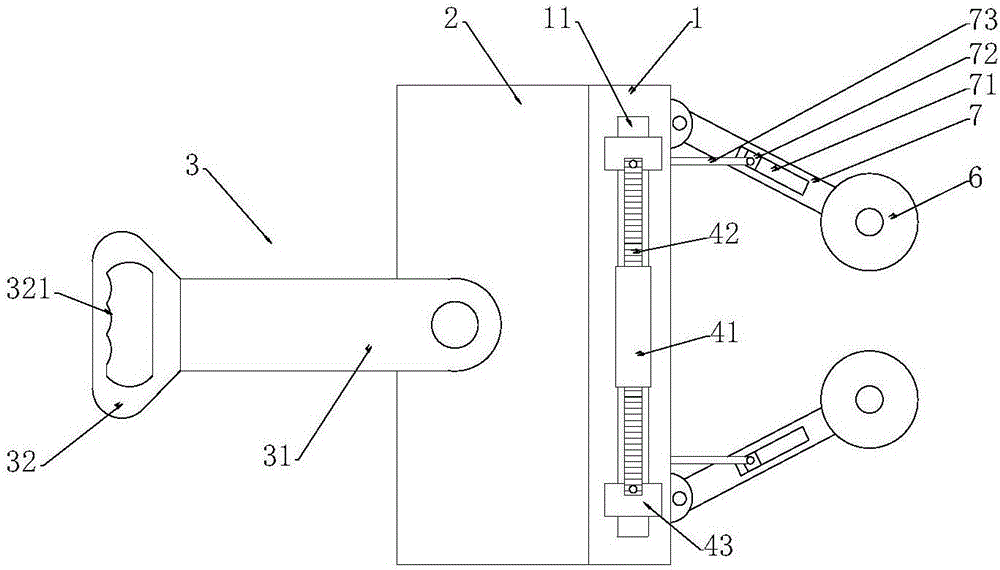

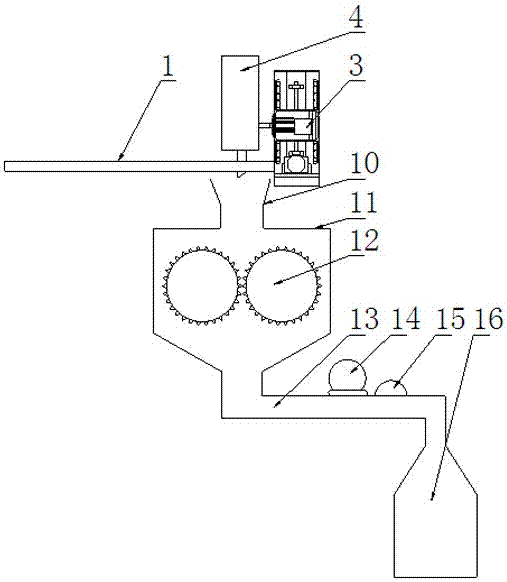

Manual cable stripping tool

InactiveCN107181209AControl feedAvoid damageApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a manual cable stripping tool including a cutting part, a connecting part and an operating part that are successively connected, cutting knife feeding mechanisms are symmetrically arranged at the left and right sides of the cutting part, the cutting knife feeding mechanisms include screw rod sleeves, screw rods, first slide blocks, and bar-shaped blocks, the two screw rods are respectively connected with the upper and lower ends of each screw rod sleeve, the screw rods are connected with the first slide blocks, the cutting part is provided with a first slide groove matched with the first slide blocks, the first slide blocks are slidably clamped with the first slide groove, the two sides of the cutting part are provided with the bar-shaped blocks that are connected between the corresponding two first slide blocks in the vertical direction, knife rests are fixed at the center positions of the inner side surfaces of the bar-shaped blocks and are provided with cutters. The manual cable stripping tool can effectively complete the cable skin stripping work, is easy to control the feed, and avoids damage to the cable cores of the cutters.

Owner:CHONGQING SANXIA CABLE GRP

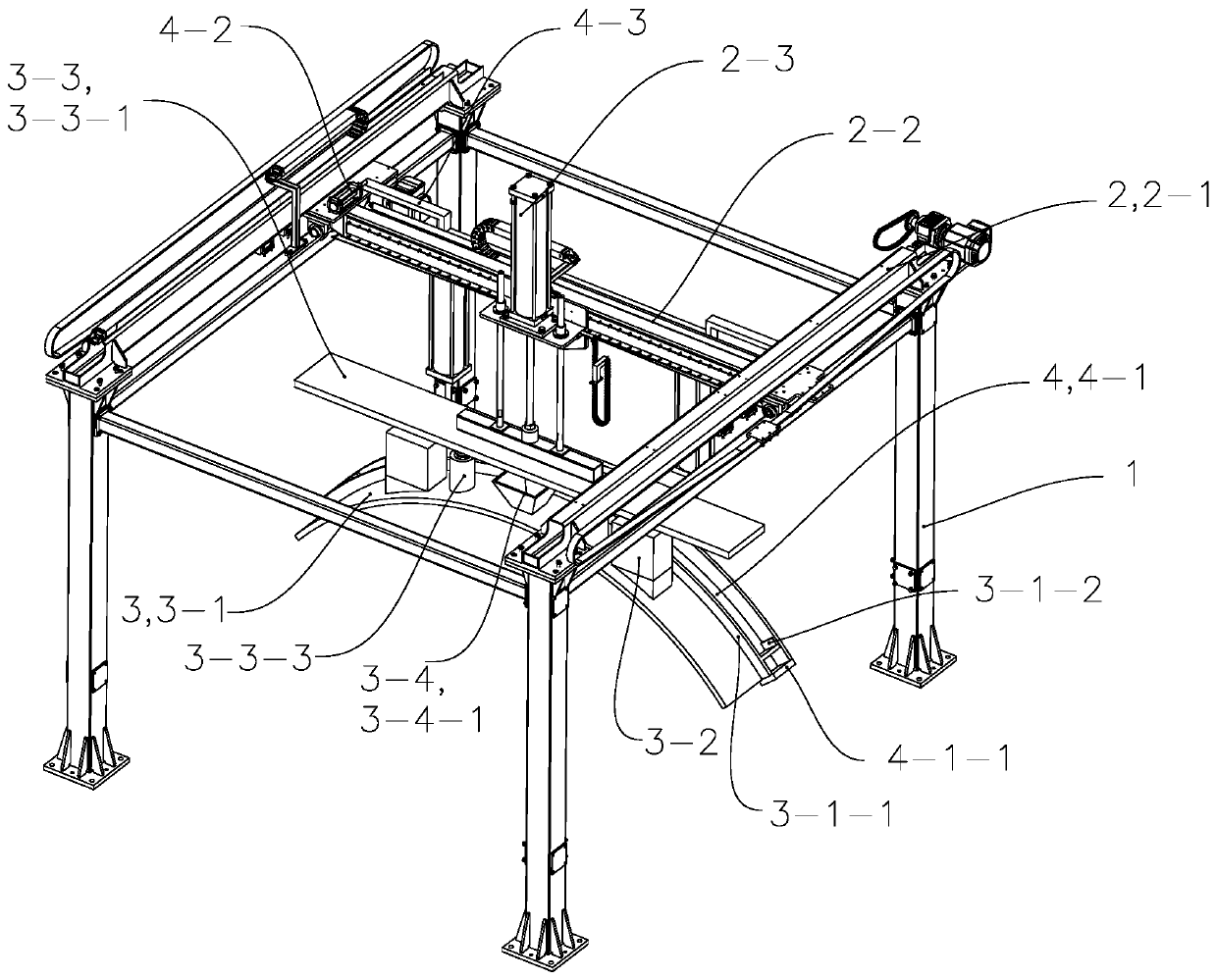

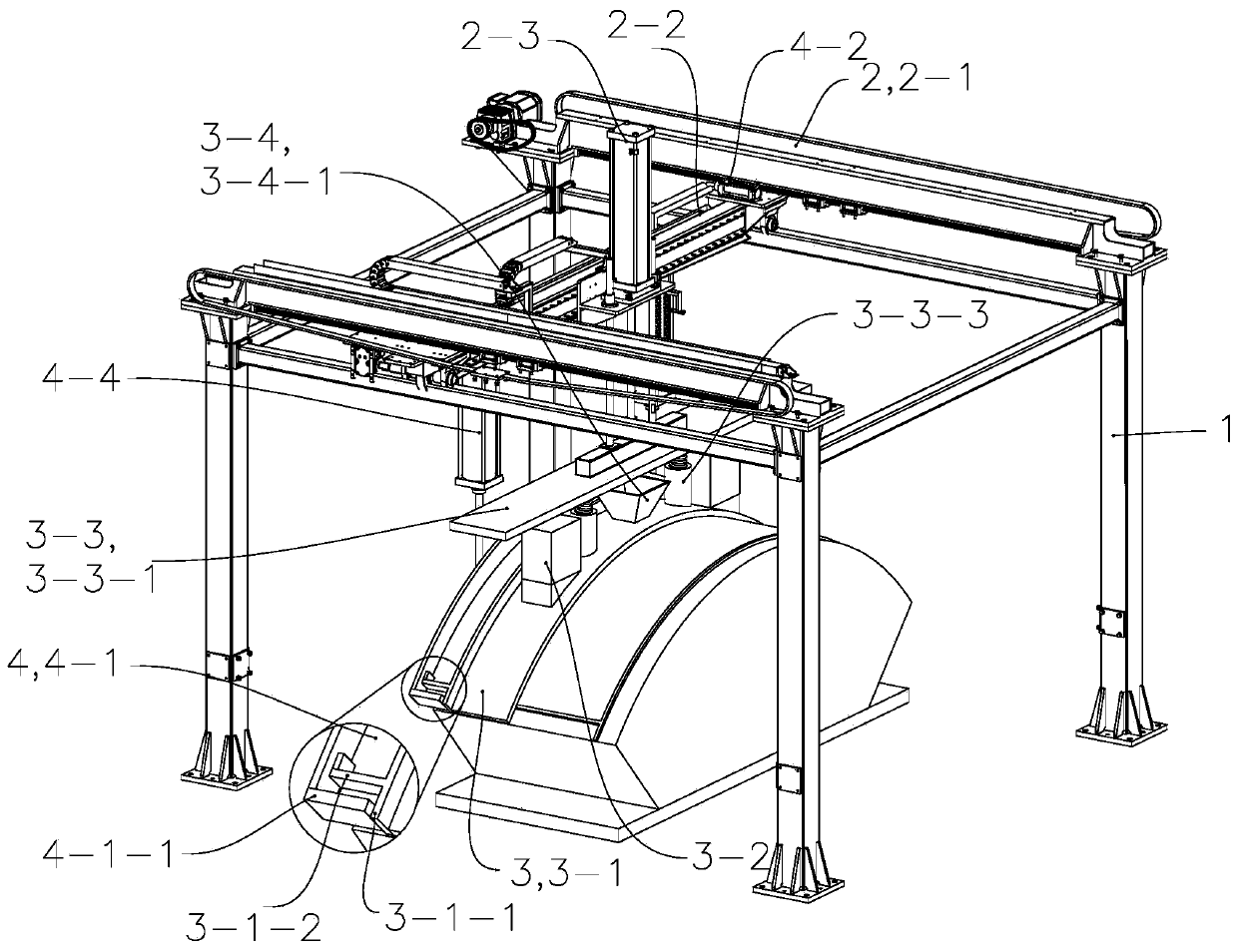

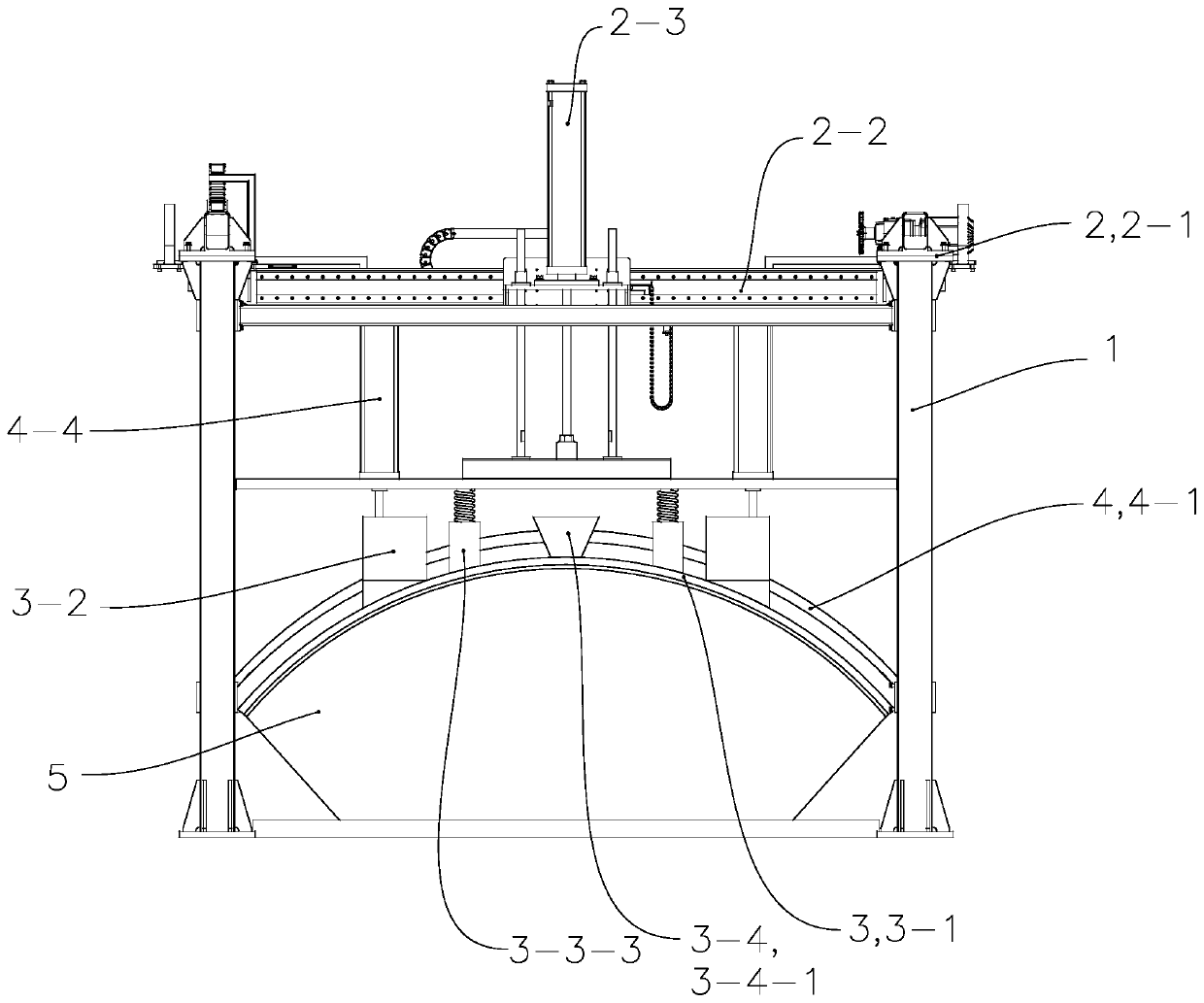

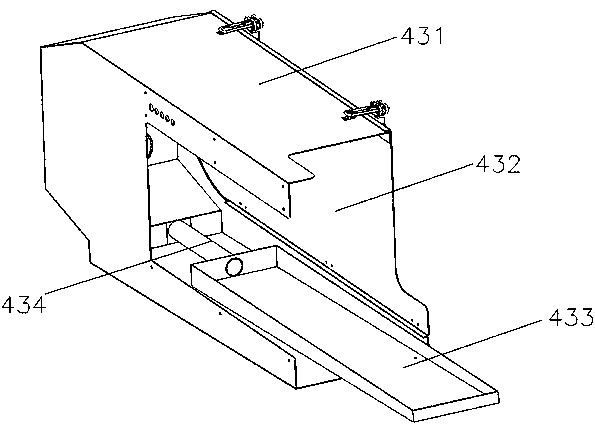

Subway duct piece arc surface troweling device

PendingCN110228122AShorten troweling timeShorten production timeCeramic shaping apparatusEngineeringPortal frame

The invention relates to a subway duct piece arc surface troweling device. A three-dimensional movement mechanism is installed on a portal frame, a troweling machine head is installed on the three-dimensional movement mechanism, the troweling machine head is provided with a troweling flat plate, the troweling flat plate is a circular arc-shaped plate which is the same as the circular arc surface of a subway duct piece, and the three-dimensional movement mechanism drives the troweling flat plate to be arranged coaxial with the circular arc surface of the subway duct piece; and after the troweling flat plate is driven to move in the width direction of the arc surface of the subway duct piece, the arc surface of the subway pipe piece is troweled in the moving process of the troweling plate, the width of the same subway iron pipe piece is far less than that of the arc length, the troweling time of the subway pipe piece is shortened, the production time of the subway pipe piece is shortened, and the production efficiency of the subway pipe piece is further improved.

Owner:徐州新通预制构件制造有限公司

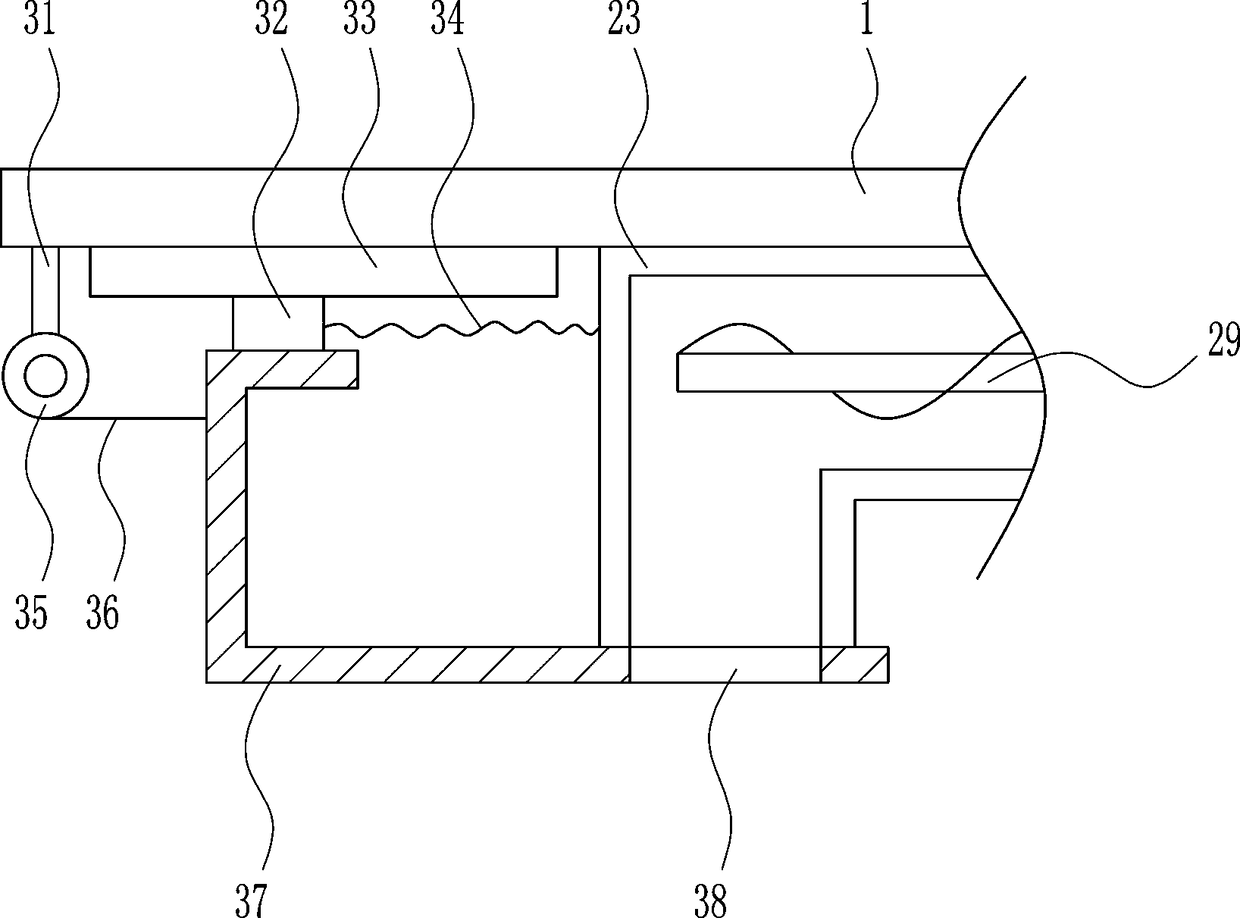

Edge cutting waste collection device

InactiveCN106985179AAvoid cloggingStable deliveryGrain treatmentsMetal working apparatusWaste collectionWaste recovery

The invention discloses an edge cutting waste collection device which comprises an edge cutting mechanism, a waste crushing mechanism and a waste recovery mechanism. The edge cutting mechanism comprises an edge cutting plate, an edge cutting knife, an edge cutting motor and an edge cutting cover. A groove opening matched with the edge cutting knife is formed in the edge cutting plate. The edge cutting knife is located in the groove opening and mounted on an output shaft of the edge cutting motor. The edge cutting knife is covered with the edge cutting cover. The edge cutting motor of the edge cutting mechanism is mounted on a cutting knife feed adjusting mechanism. The waste crushing mechanism is arranged below the edge cutting knife and connected with the waste recovery mechanism. According to the edge cutting waste collection device, edge cutting waste is recovered after being crushed through the waste crushing mechanism, a fan and a heater of the waste recovery mechanism further prevent cloth blocking, and conveying is smooth; and the cutting knife feed adjusting mechanism is arranged, a lead screw is driven by a motor to drive a cutting knife mechanism to ascend and descend, the feed amount is controlled, the edge cutting waste collection device is suitable for products of different thicknesses and materials, the edge cutting effect is optimized, and the edge cutting waste collection device is worth of wide popularization.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

Efficient spraying tower with anti-blocking function for waste gas treatment

ActiveCN109603373AControl feedAffect the effect of dust removalGas treatmentUsing liquid separation agentSludgeLiquid storage tank

The invention relates to an efficient spraying tower with an anti-blocking function for waste gas treatment. The efficient spraying tower comprises a tower body, an air inlet, an air outlet, a fillerlayer, a spraying mechanism, a controller and a liquid storage tank, and further comprises a dredging mechanism and an adjusting mechanism. The dredging mechanism comprises a supporting rod and two vibrating assemblies; each vibrating assembly comprises a first motor, a supporting rod, an eccentric wheel, a moving plate, a vibrating rod and two springs; the adjusting mechanism comprises two adjusting assemblies, and each adjusting assembly comprises a baffle and a moving unit; each moving unit comprises a second motor, a fixed block, a rotating shaft and a movable block. According to the efficient spraying tower with the anti-blocking function for waste gas treatment, the filler layer can be dredged through the dredging mechanism, the filler layer is prevented from being blocked by sludge,and the dust removal effect is prevented from being affected; through the adjusting mechanism, the amount of waste gas can be controlled so that the waste gas and reagents can be in full contact, andthe dust removal effect is improved.

Owner:蒋宗霞

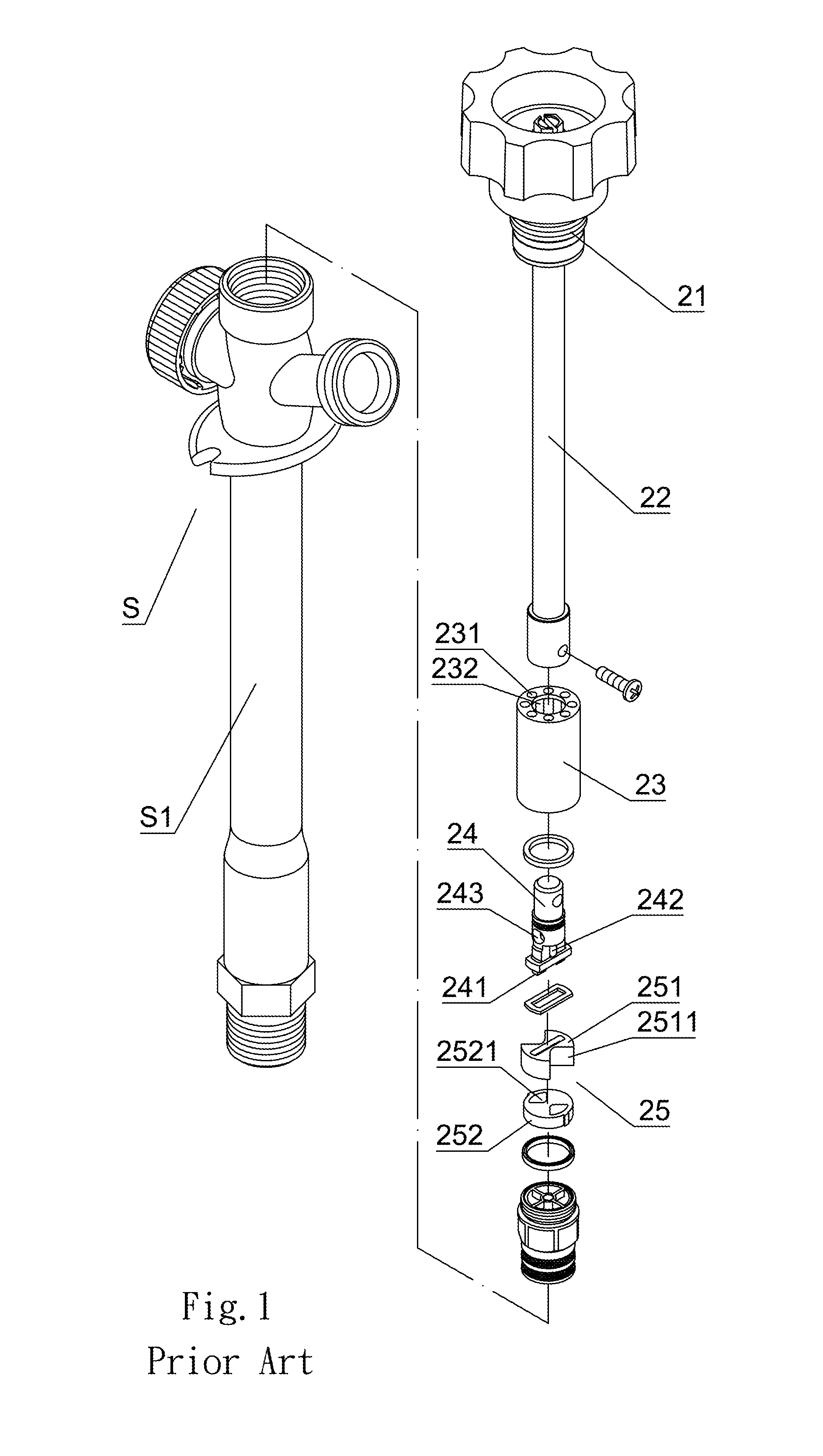

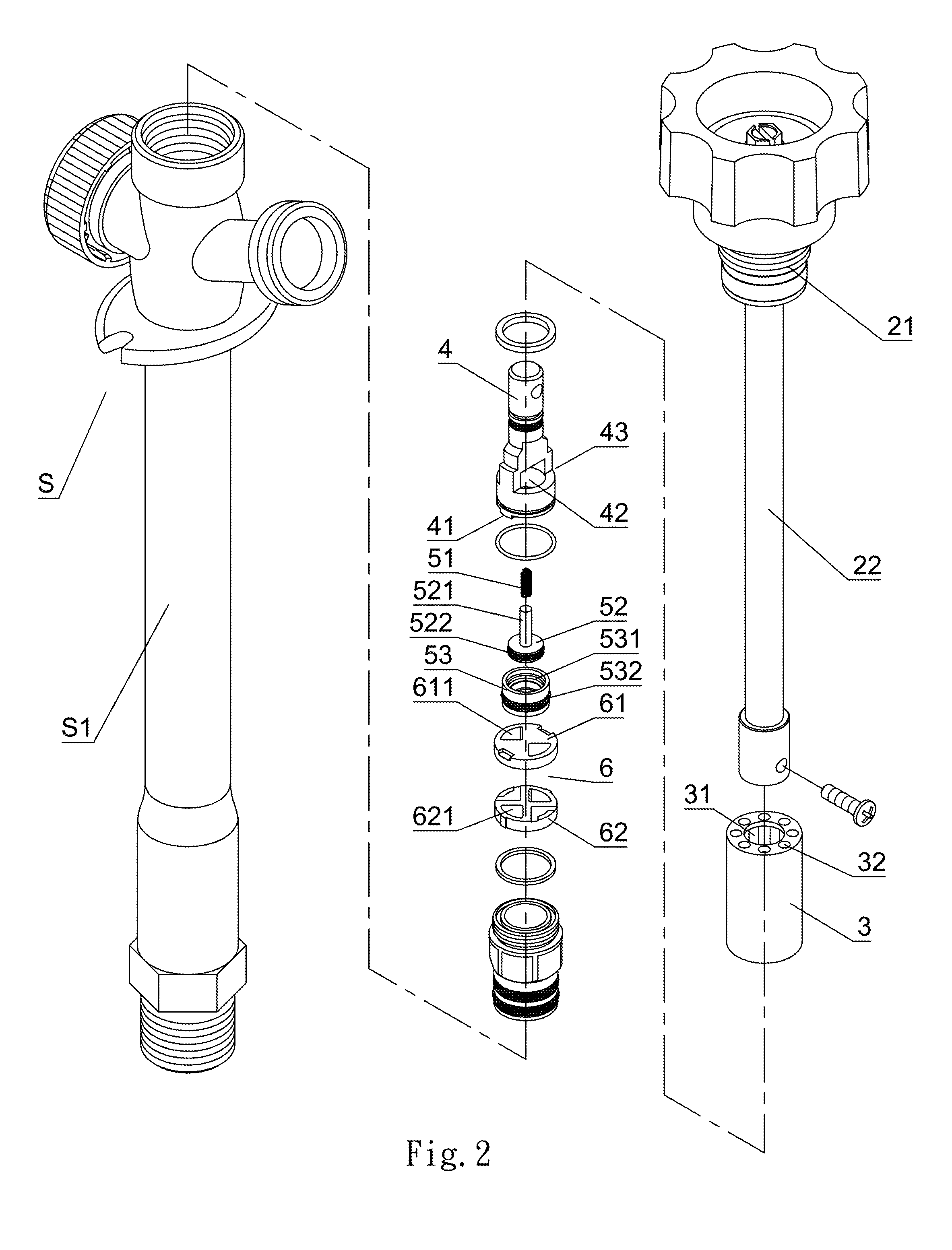

Outlet valve for a frost-preventing faucet

An improved outlet valve for a frost-preventing faucet substantially employs an axial slot defined at a central top inside the inlet passage for being inserted by an elastic element and an axial post. A first stop ring is disposed around the stop valve. The first stop ring and the stop valve are inserted into a limiting slot of a hollow stop sleeve disposed under the stop valve. A second stop ring disposed around the stop sleeve is inserted into a lower section of an inner wall of the inlet passage. A bottom of the second stop ring is disposed above a top of the top porcelain. Cooperating the subject improved configuration with the top porcelain allows the water to be supplied upward since outlet gates of the bottom porcelain and the top porcelain stay abreast without a blockage. When a water pressure is larger than a rebounding force of the elastic element, the stop valve upwardly compresses the elastic element. Thereby, the water travels through the inlet passage disposed at the middle section of the plug and enters into an outlet hole at the top end of the tubular receiving valve seat. The water is further upwardly guided into a supplying pipe of the faucet. When the water pressure is smaller than the rebounding force of the elastic element, the elastic element compresses the stop valve. Thereby, an axial post of the stop valve is downwardly inserted into the limiting slot of the stop sleeve for impeding the water flow, so that the porcelain valve unit is prevented from freezing, and the water pressure is capable of controlling a feeding of the water flow.

Owner:WU HUNG NENG

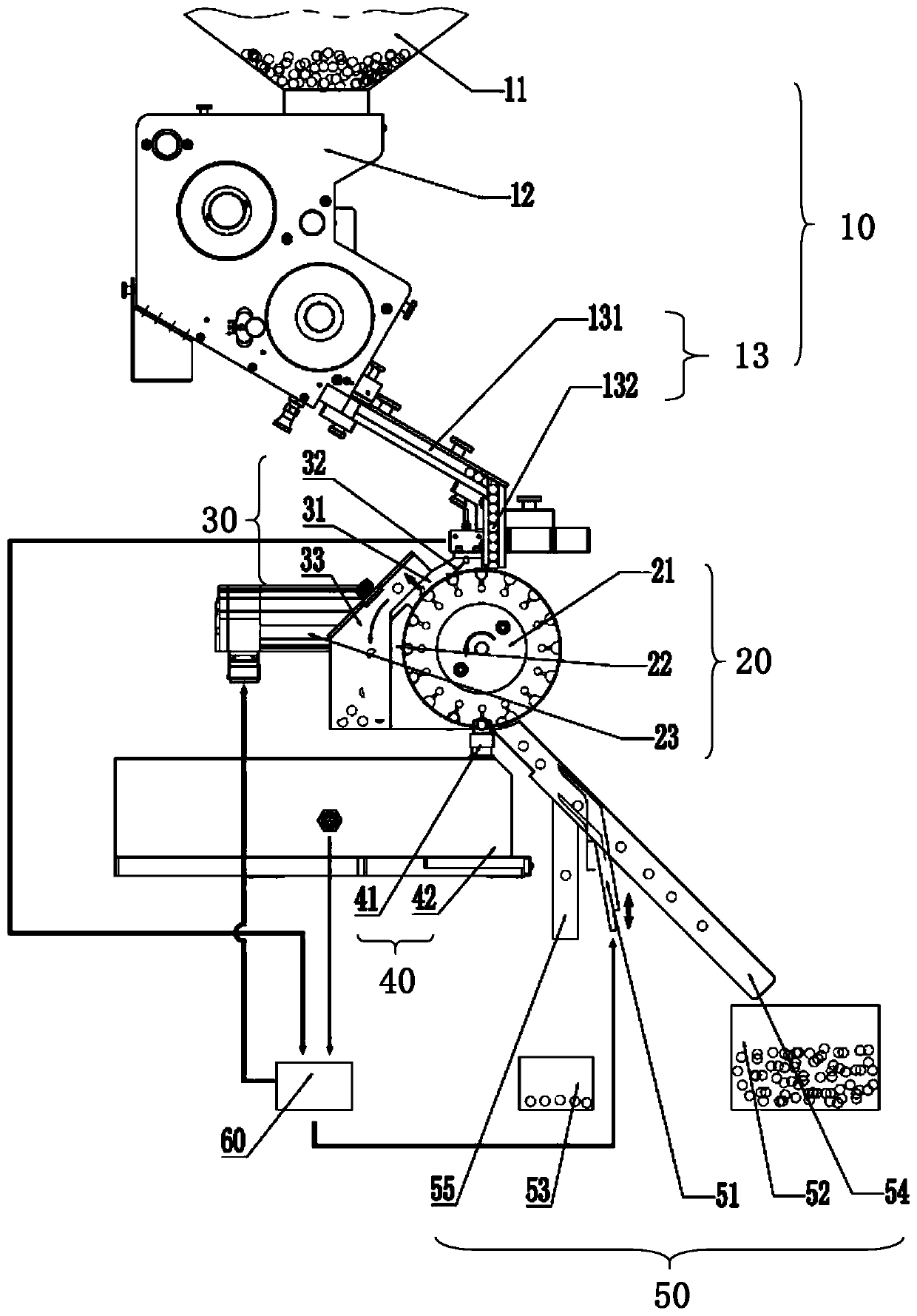

Tea leaf cooling machine

InactiveCN103636824AGuaranteed qualityControl feedPre-extraction tea treatmentEngineeringMouth shape

The invention discloses a tea leaf cooling machine. The tea leaf cooling machine comprises a rack and a polygonal gauze element roller which is in a horn mouth shape at the length direction; the small end of the horn mouth is a material inlet of the polygonal gauze element roller; the large end of the horn mouth is a material outlet of the polygonal gauze element roller; the polygonal gauze element roller is supported on a support holder 4 of the rack by a rotary shaft of the polygonal gauze element roller; the rack is provided with a motor; the motor is connected with the polygonal gauze element roller in a drive mode by a drive pair; one side at the material inlet in the polygonal gauze element roller, is provided with a blocking blade; a tea leaf passing clearance is formed between the outer edge of the blocking plate and the inner wall of the polygonal gauze element roller; one side of the polygonal gauze element roller is provided with a plurality of heat radiation fans in the length direction. With the tea leaf cooling machine provided by the invention, the tea leaf cooling time can be shortened, uniform moisture of tea leaves is guaranteed, and the tea leaf quality is better guaranteed.

Owner:湖北龙王垭茶业有限公司

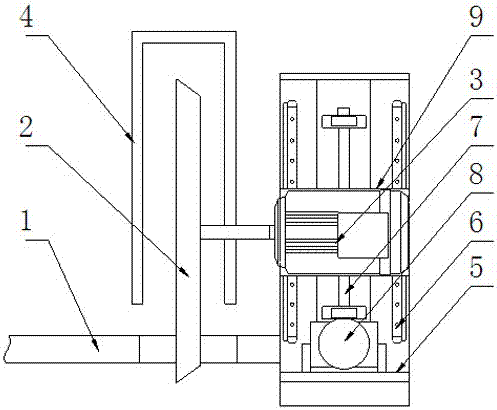

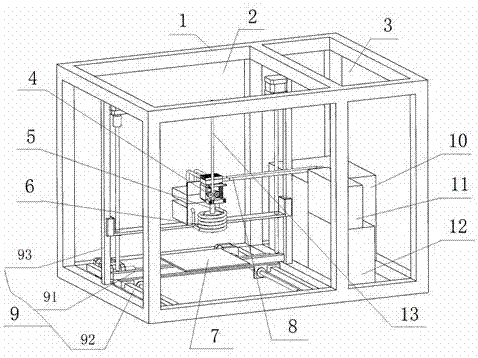

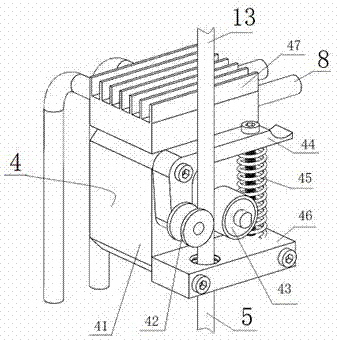

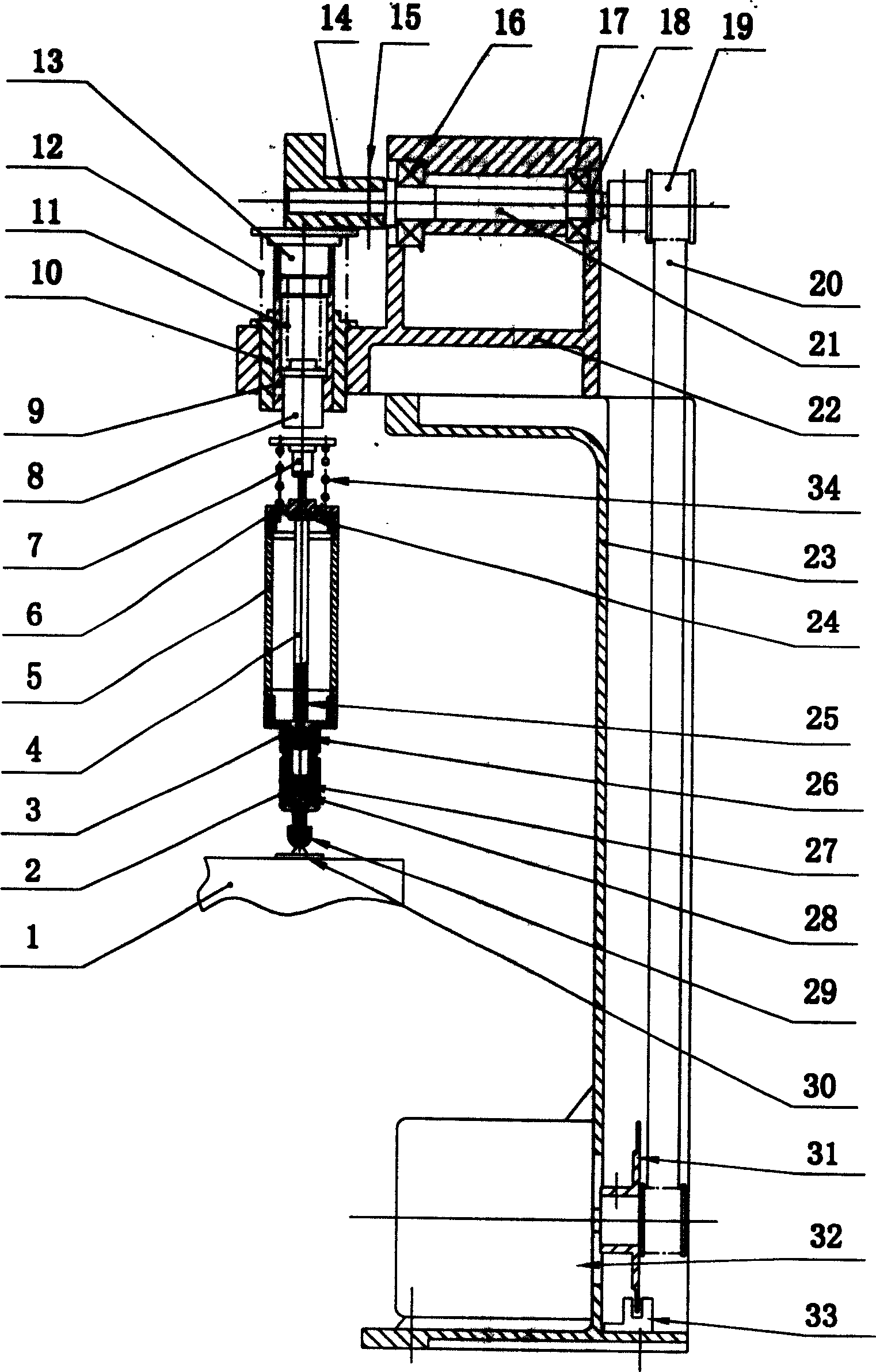

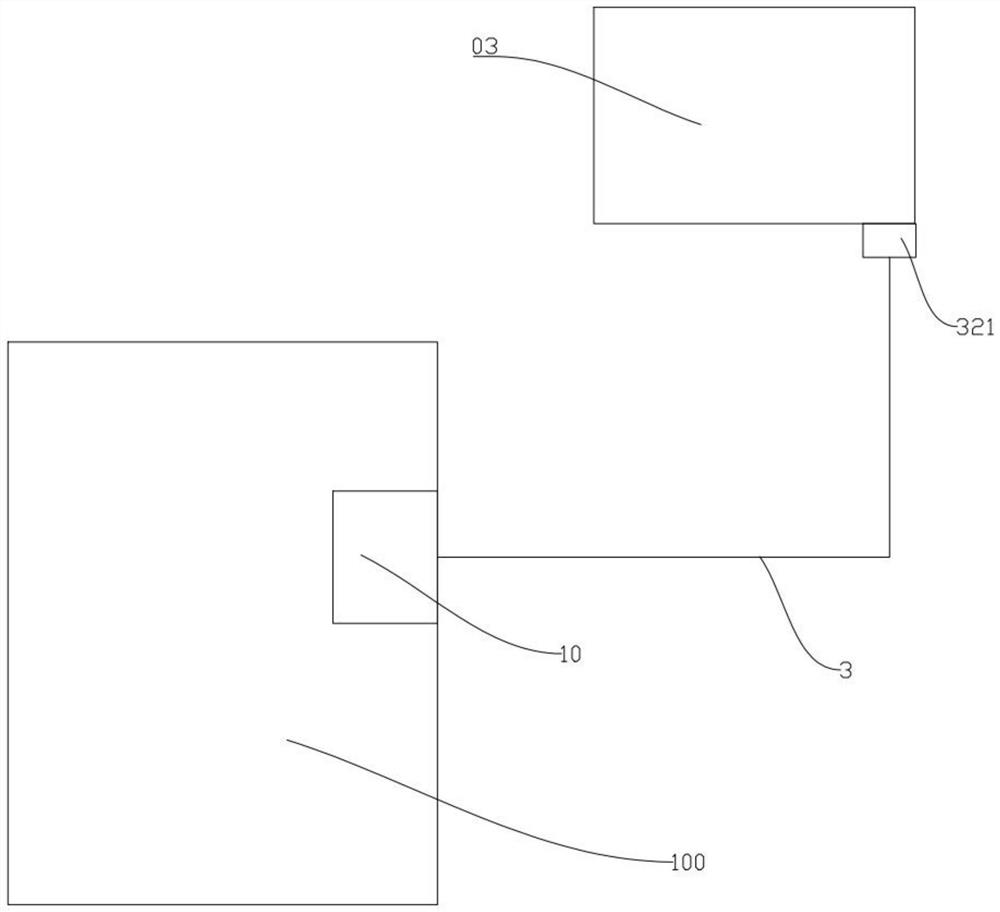

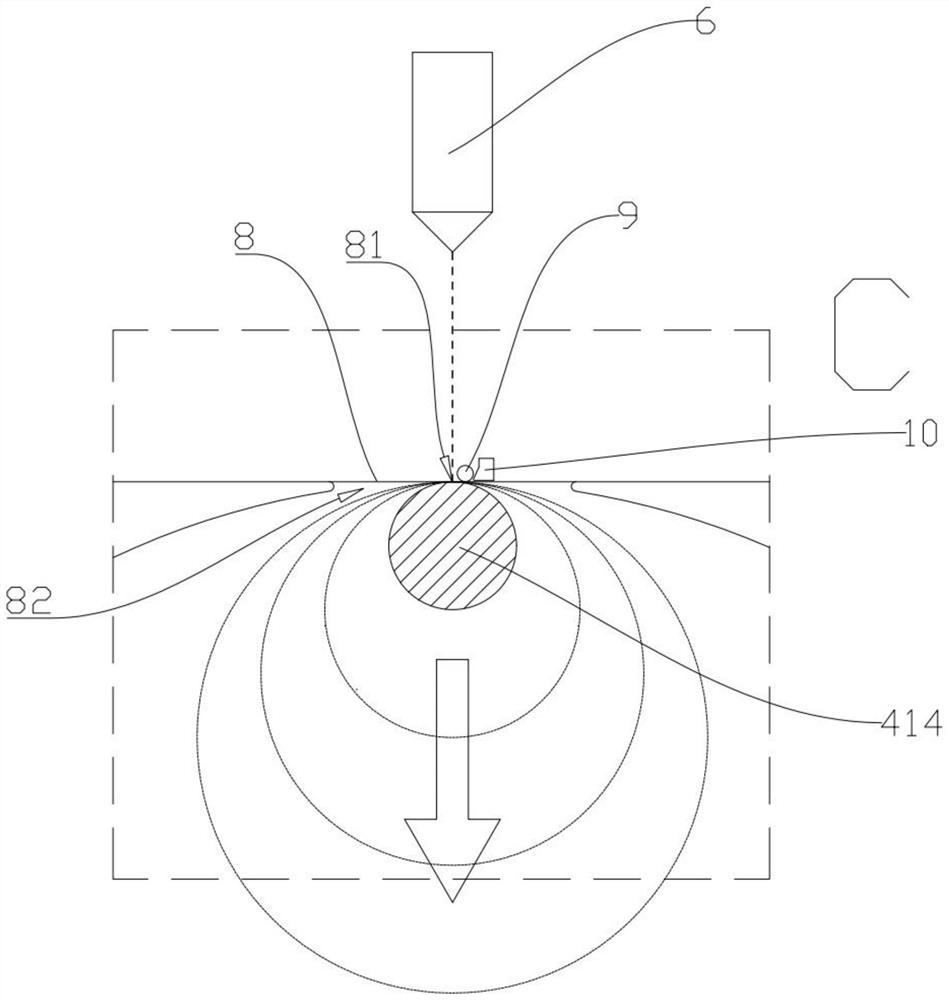

3D (three-dimension) printer for printing vitreous body and printing method

InactiveCN107285609ABroaden your optionsControl feedAdditive manufacturing apparatusGlass shaping apparatusHigh energyControl system

The invention relates to a 3D (three-dimension) printer for printing a vitreous body and a printing method. The 3D printer is composed of a frame, a printing silo and a control cooling silo; the printing silo is connected with the control cooling silo and arranged in the frame; the inner part of the printing silo is provided with a delivering mechanism, a nozzle printing mechanism, a sensing heating device, a printing bottom plate, a cooling medium guide flow pipe and a three-dimensional movement mechanism; the inner part of the control cooling silo is provided with a cooling device, a control system and a power supply. By applying the 3D printer for printing the vitreous body and the printing method, the selection scale of the printing raw material is enlarged; the sensing heating method has the significant advantages of high working efficiency, high energy utilization rate, quick temperature rise, control easiness, small equipment volume, pollution free and others; besides, the printer and the printing device have the advantages of simple and reliable structure, high automatic degree, control easiness, strong practicability and others.

Owner:贵州云上左岸科技有限公司

Method and device for adding precise trace amount of reagent and even coverage

InactiveCN1540306AReduce dosageUniform coveragePreparing sample for investigationSurgeryMotor driveDrive shaft

The device includes mechanisms of screwdown, power driven and spraying reagent. Motor drives rotation of transmission shaft, generating up and down motion of punch. The punch promotes injection mechanism to spray reagent. Atomized reagent is sprayed on tissue of slice or surface of object to be tested having certain area so as to form an even covered reagent film. Advantages of the invention are: (1) thin film of reagent covers surface of object to be tested, small dosage is needed; (2) changing distance between the injection mechanism and the surface of object can change size of covered area.

Owner:庞全

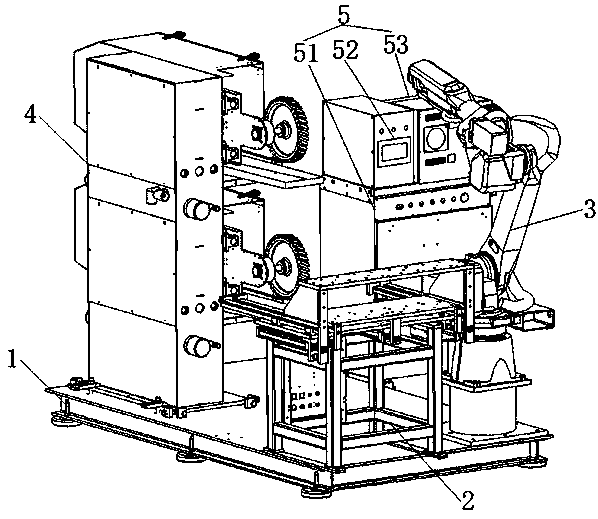

Robot polishing workstation

PendingCN109623587AHigh degree of automationMany adjustable parametersGrinding carriagesGrinding drivesWorkstationGolf club

The invention discloses a robot polishing workstation. The robot polishing workstation comprises a base, an upper and lower platform component, a robot body, a polishing machine and a control cabinet,wherein the upper and lower platform component, the robot body and the polishing machine are all disposed on the base, the upper and lower platform component comprises an upper platform and a lower platform, the robot body comprises a robot big arm and a robot forearm, the polishing machine comprises a mounting plate and a vertical cabinet which is provided with at least one polishing machine module, the polishing machine modules correspond to dust suction devices one by one, and the control cabinet is connected with the upper and lower platform component, the robot body and the polishing machine. The robot polishing workstation has high automation degree and many adjustable parameters, and is provided with a spindle drive mechanism, a grinding force control mechanism, a wheel feed control feed mechanism, a belt tension adjuster, a deviation adjustment device and the dust suction devices, thereby fully meeting the grinding requirements of golf club heads and other workpieces, and remarkably avoiding the grinding yield decrease and grinding efficiency reduction caused by workpiece deformation and wear to an abrasive belt and a polishing wheel.

Owner:DONGGUAN ZHAOLIANG WELDING EQUIP TECH

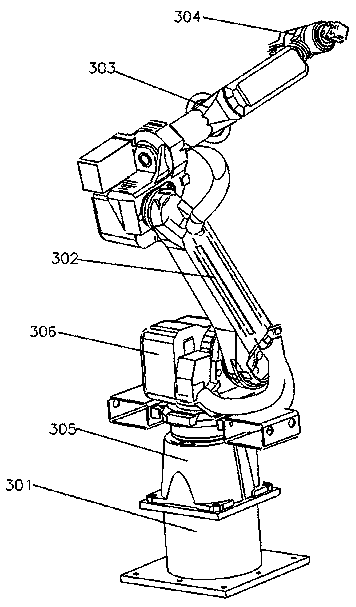

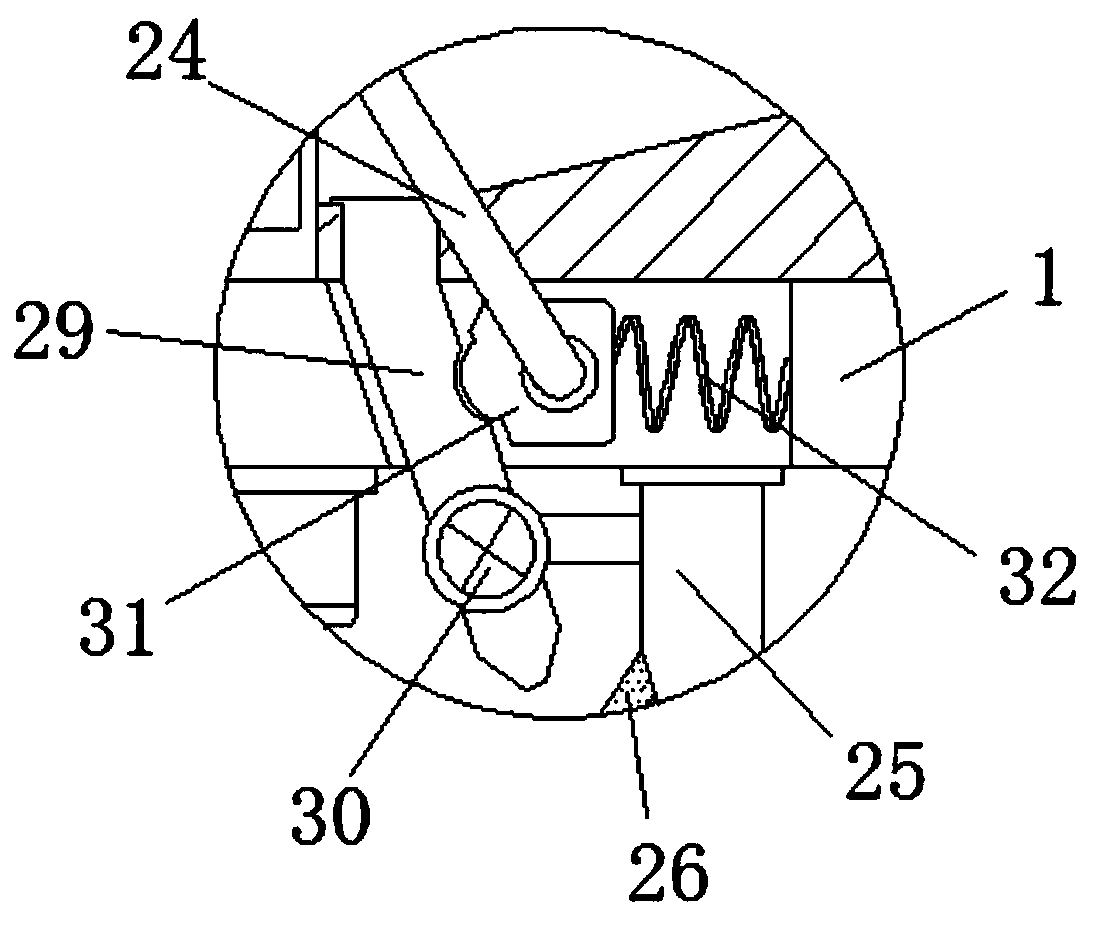

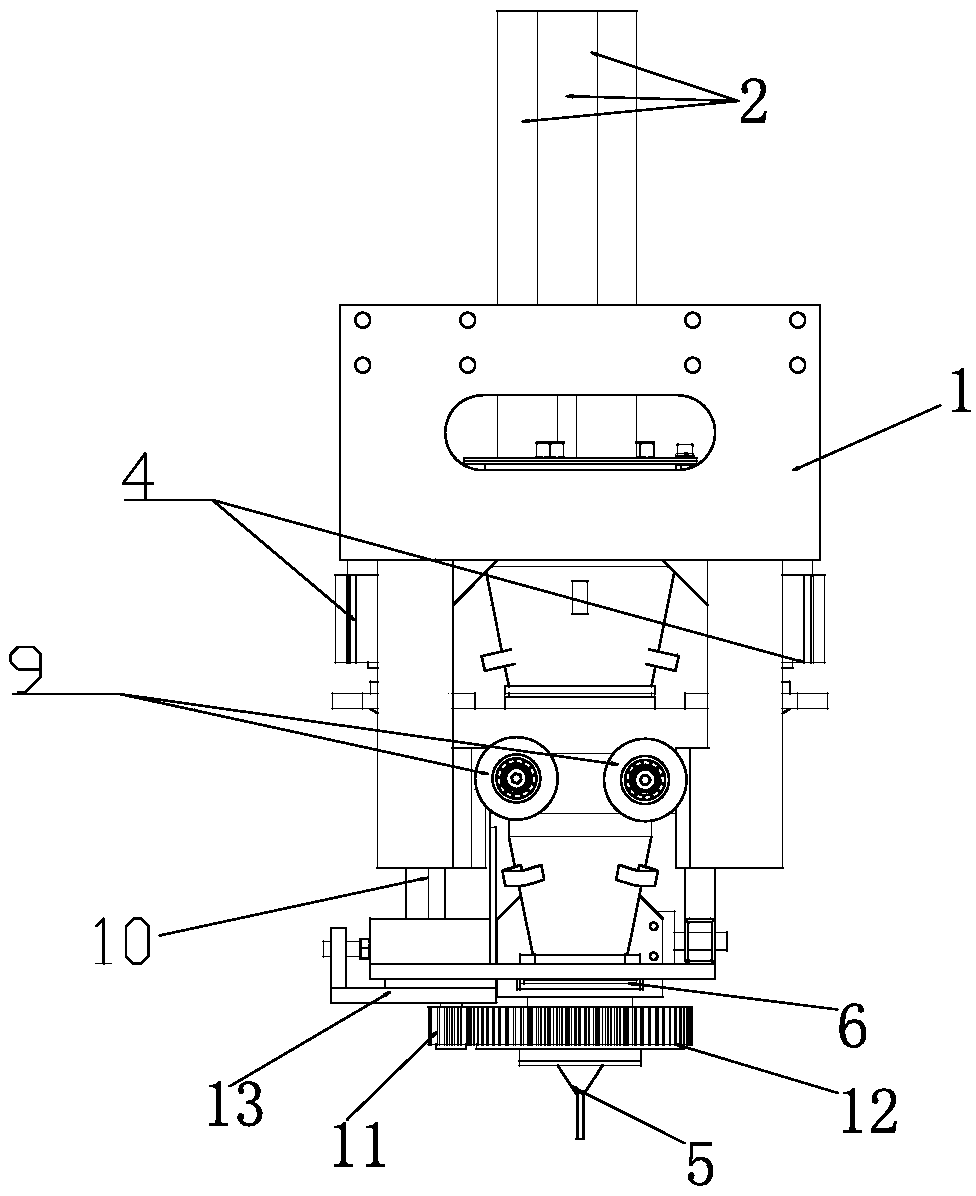

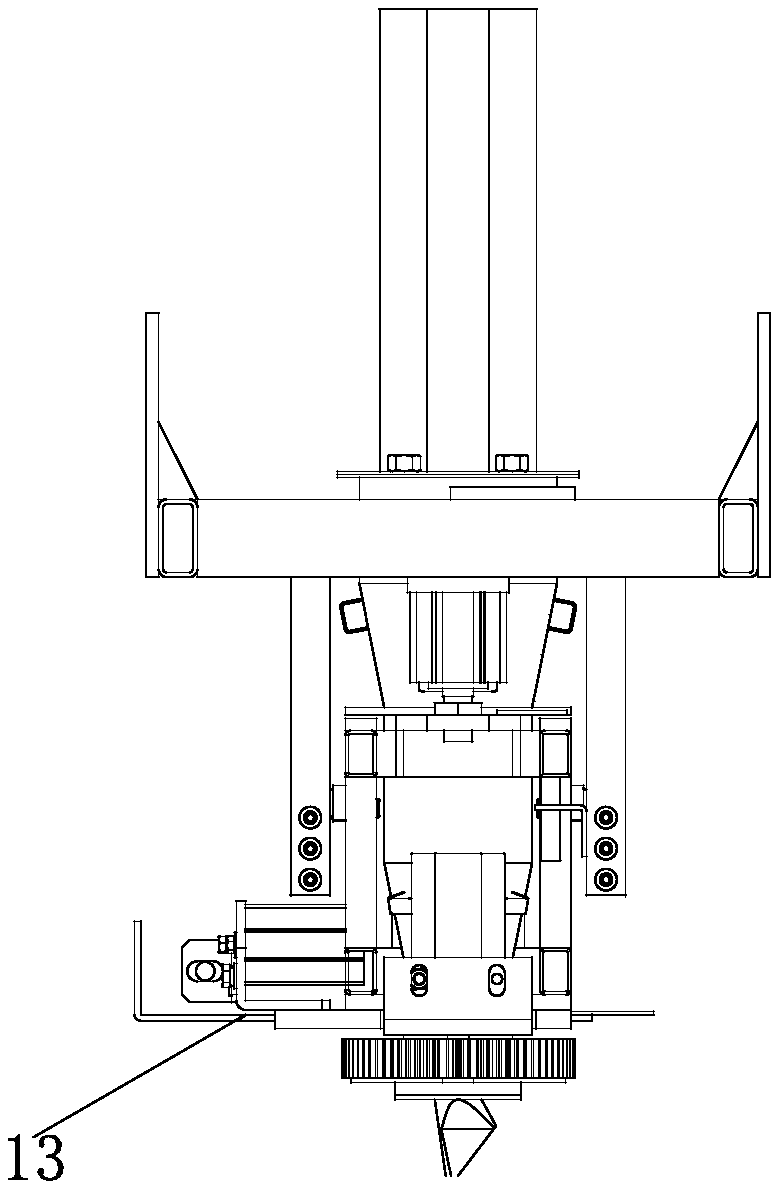

Dismantling robot for residual refractory brick in rotary kiln and dismantling method

ActiveCN109780871ARealize demolition workReduce labor intensityLinings repairManipulatorBrickControl system

The invention discloses a dismantling robot for a residual refractory brick in a rotary kiln and a dismantling method, and belongs to the technical field of industrial robots. The robot comprises a bearing moving system, a displacement system, a locking system, a feeding system, a feedback system and a control system. According to the dismantling robot, four feeding boxes are mounted on a machineframe, and the dismantling of the residual refractory brick is completed by using the coordination work of all systems; and the dismantling robot is a very typical electro-mechanical integrated system, technologies such as mechanical, electronic, control and sensing are integrated, the robot meets the relevant requirements of the cleaning of the residual refractory brick of the rotary kiln, the cleaning operation of the residual refractory brick can be completed efficiently, meanwhile, a kiln body is not damaged, and the automation and intelligence of the dismantling of the residual refractorybrick are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

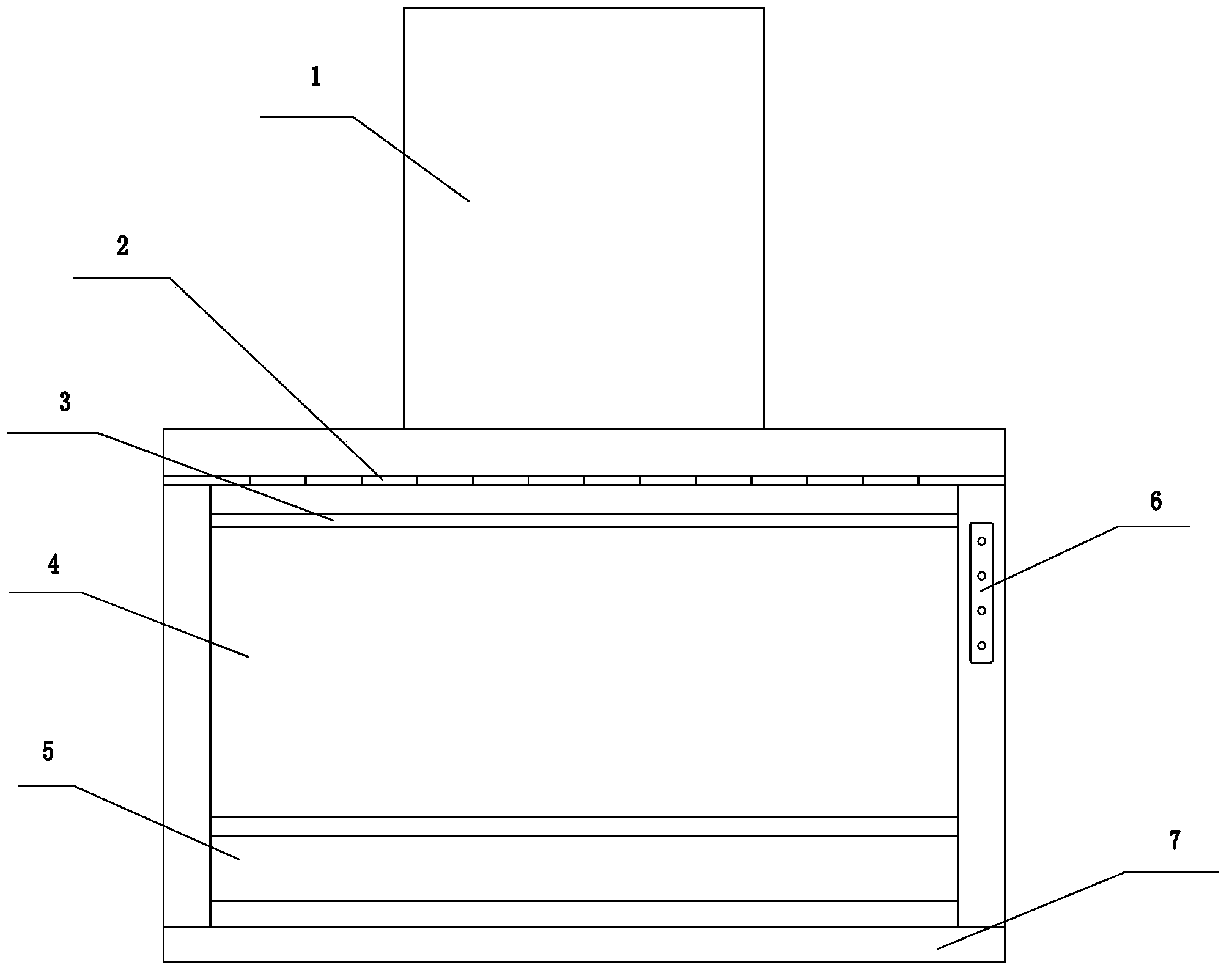

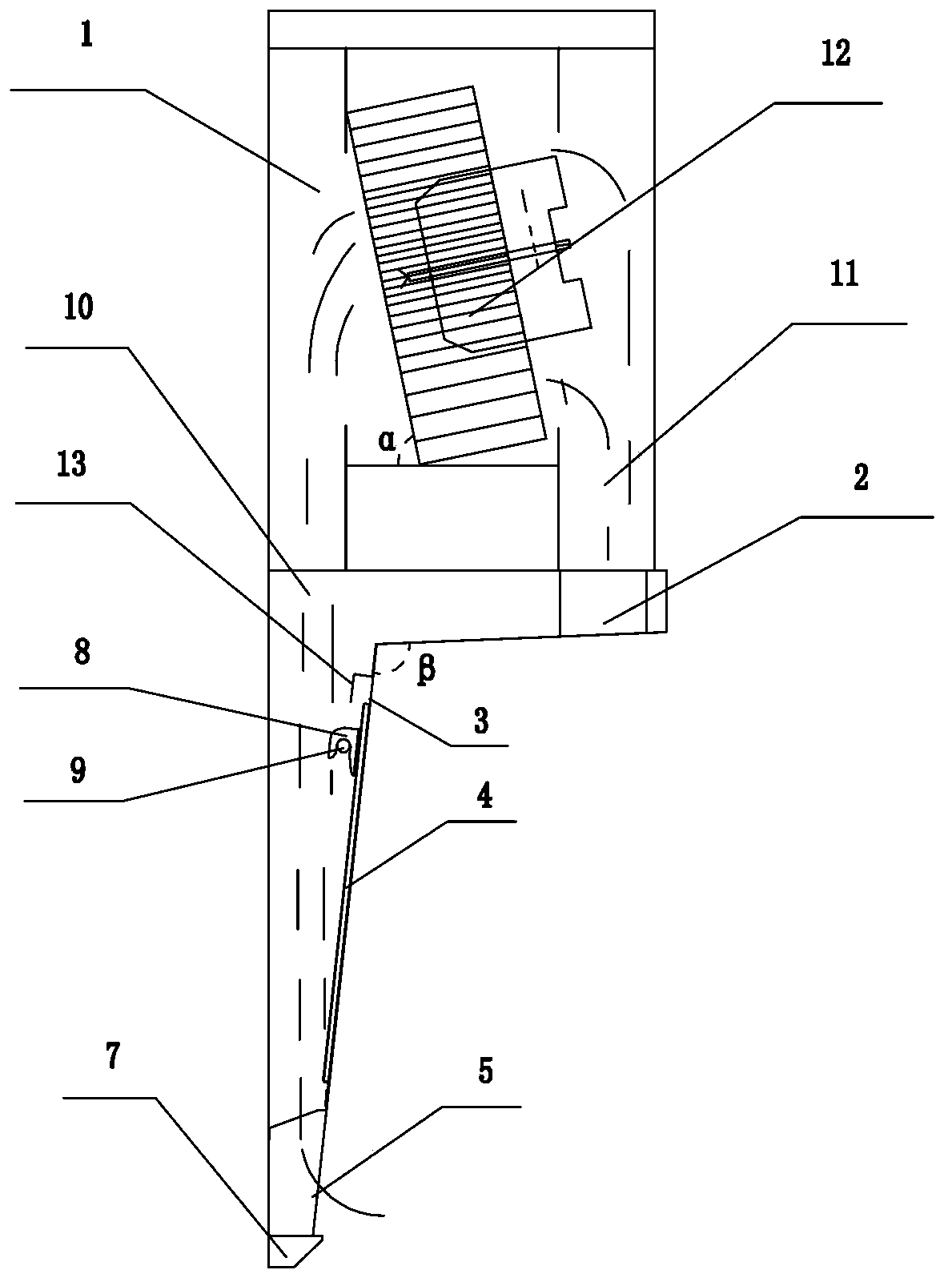

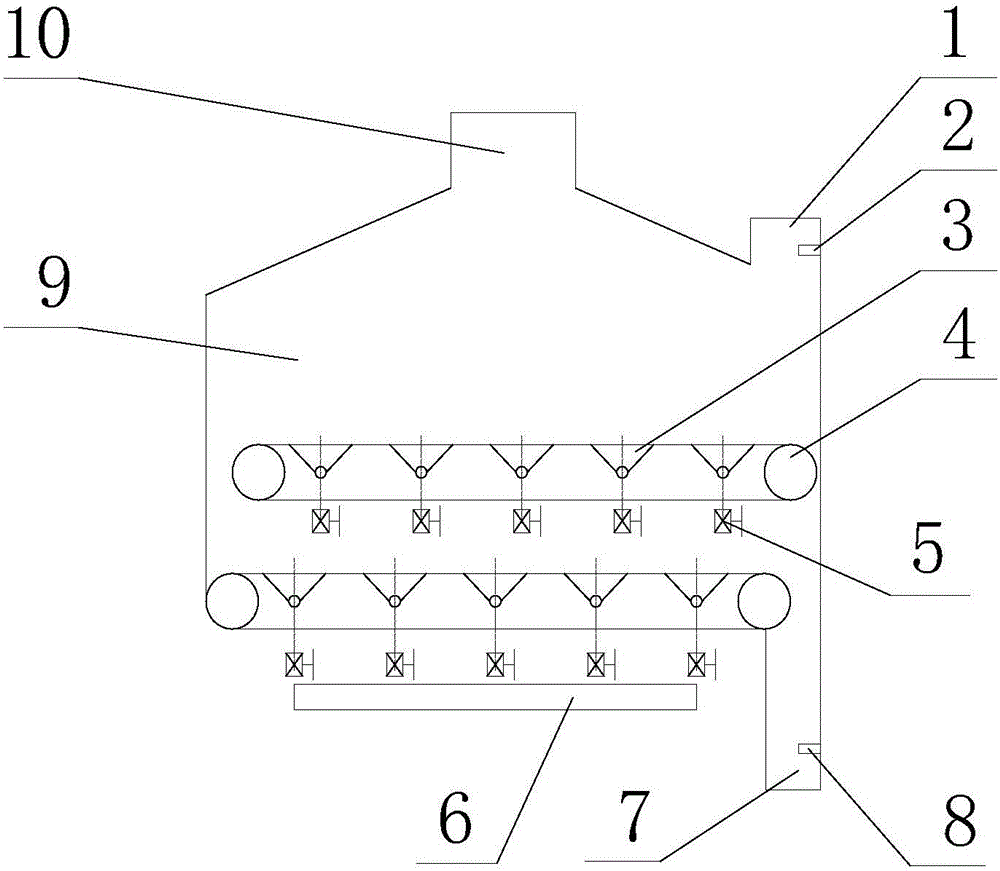

Straight-draught range hood with double-air-inlet blower

InactiveCN104296207AEffective control of feedControl feedDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

A straight-draught range hood with a double-air-inlet blower belongs to the field of range hoods and overcomes the shortcomings that a conventional range hood is poor in suction and exhaust effects and narrow in use space. The straight-draught range hood comprises a case consisting of a transverse case body and a vertical case body which are connected with each other, wherein a first vertical air duct is formed in the interior hollow part of the vertical case body; a first smoke inlet and a second smoke inlet which are communicated with the first vertical air duct are respectively formed in the upper part and the lower part of the vertical case body; an exhaust fume collecting hood is arranged on the case; an oil cup is arranged at the lower part of the case; the blower is arranged in the exhaust fume collecting hood; the air outlet of the blower is formed in the upper part of the exhaust fume collecting hood and communicated with the outside; the included angle beta between the transverse case body and the inner side surface of the vertical case body is smaller than 135 degrees and larger than 90 degrees; an air inlet is formed in each of two sides of the blower; the first vertical air duct is communicated with one of the air inlets of the blower; the transverse case body is provided with a third smoke inlet penetrating the transverse case body; and the third smoke inlet is communicated with the other air inlet of the blower through a second vertical air duct in the exhaust fume collecting hood. The straight-draught range hood is large in use space, good in suction and exhaust effects and excellent in energy-saving effect.

Owner:成都前锋电子有限责任公司

Full-automatic intelligent fish skin cutting and stripping method

Owner:CHINA JILIANG UNIV

Water purification device with automatic feeding

InactiveCN108585263AControl feedImprove purification qualityTreatment involving filtrationMultistage water/sewage treatmentCouplingEngineering

The invention discloses a water purification device with automatic feeding. The water purification device comprises a box body; an outer box is arranged at the outer side of the upper part of the boxbody; the upper part of the outer box and the top end of the box body form a feeding bin; the upper part and the lower part of the box body are respectively provided with a containing cavity and a discharge bin; the lower part of the containing cavity communicates with a dirt discharge bin; the upper part of the feeding bin is provided with an end cover; the middle part of the upper end of the endcover is provided with a pull ring; a second motor is arranged at the upper part of the inner side of the right wall of the outer box; a second motor is connected with a screw rod through a coupling;a first slide block is arranged on the screw rod; the left side of the upper end of the box body is provided with a feeding gap; a mounting groove is arranged in the upper wall of the box body; and atransmission mechanism is arranged in the mounting groove. The device provided by the invention is reasonable in structure design and can realize timed and quantitative control of the feeding amountof sewage and a flocculant, the feeding is automatic, the distribution ratio of the flocculant to the sewage is reasonable, the sewage purification quality is improved, and simultaneously, the problemof discharging of purified water and the treatment and discharging of sewage are reasonably solved.

Owner:ZHEJIANG XIAYUAN INFORMATION TECH CO LTD

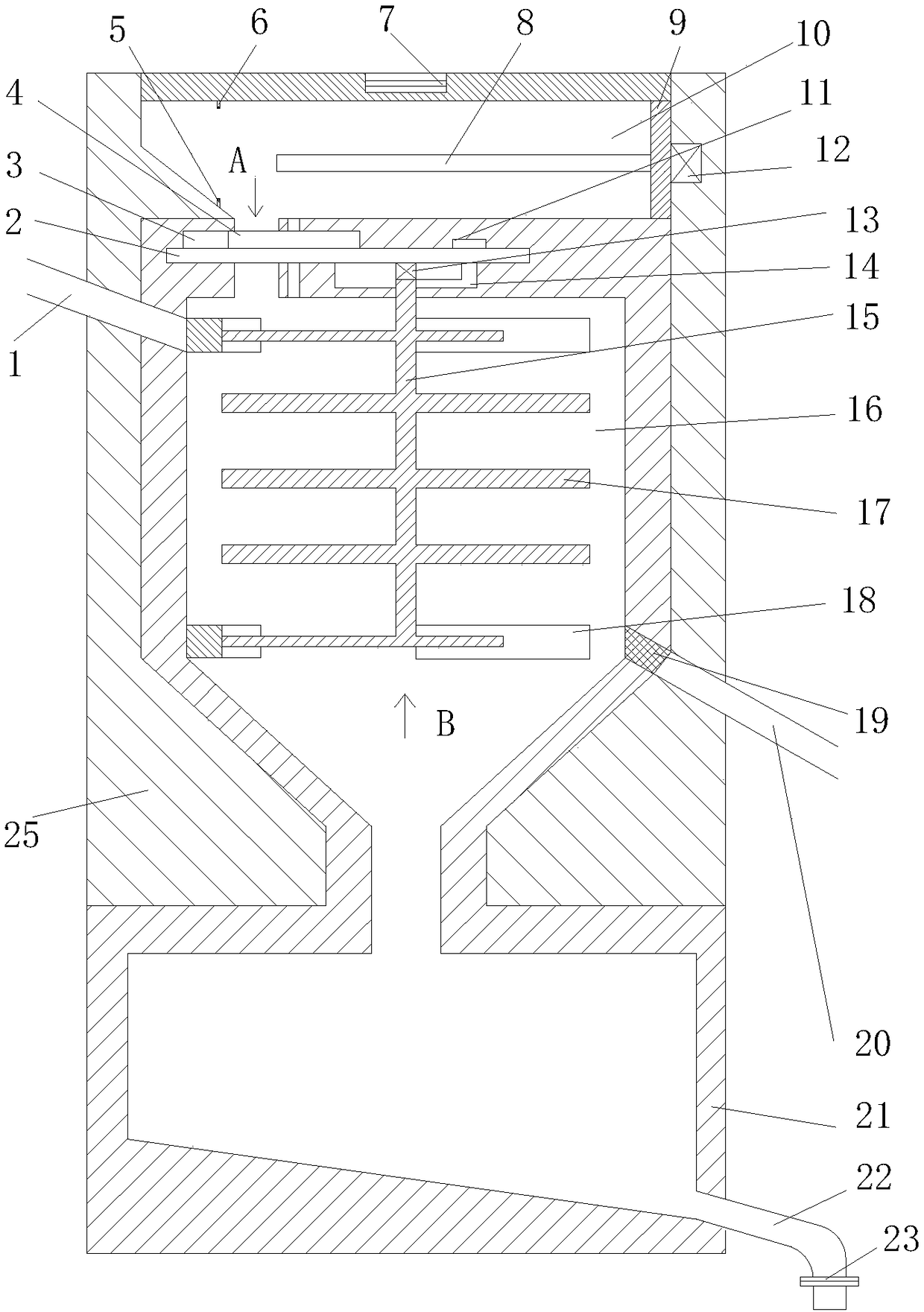

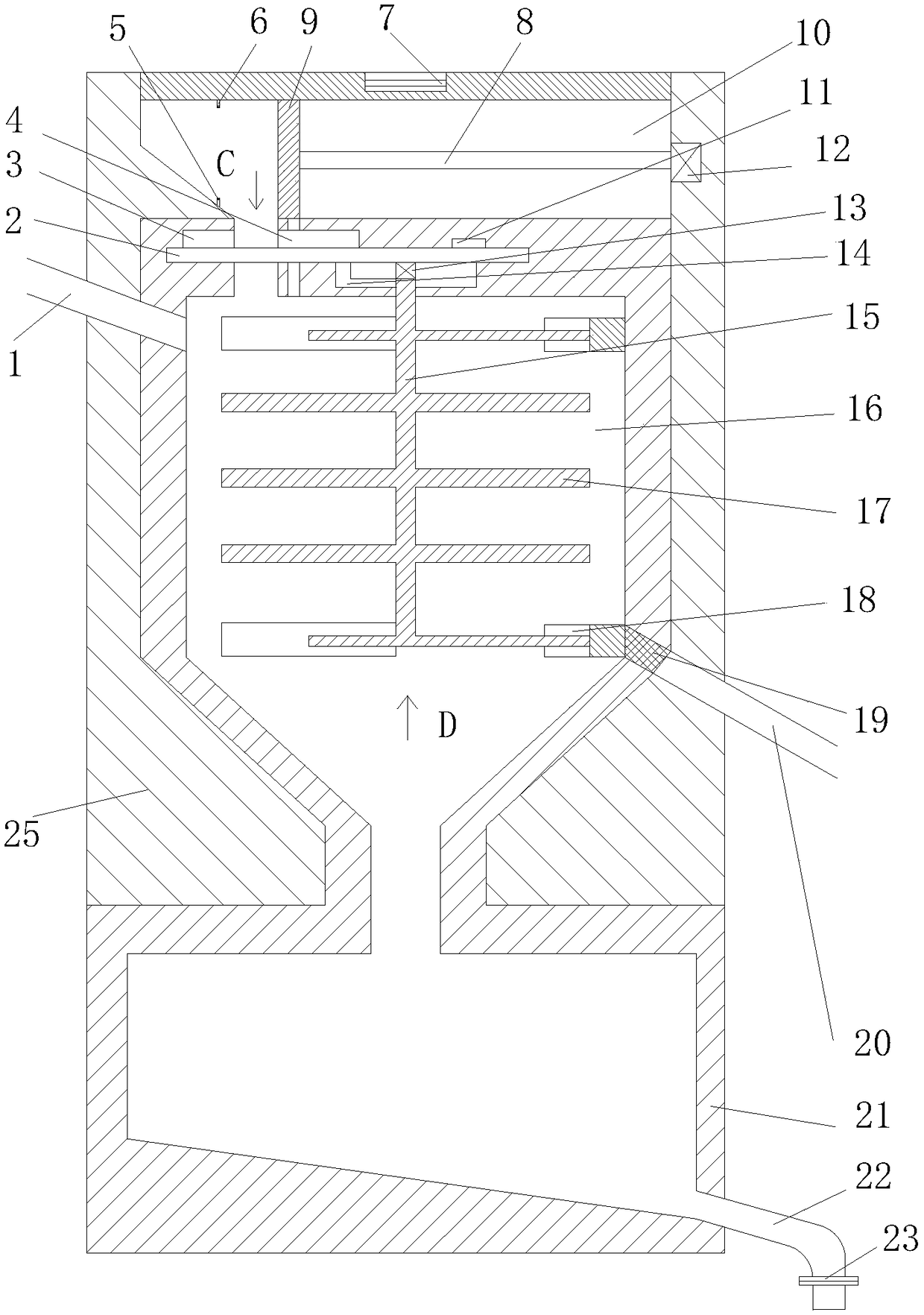

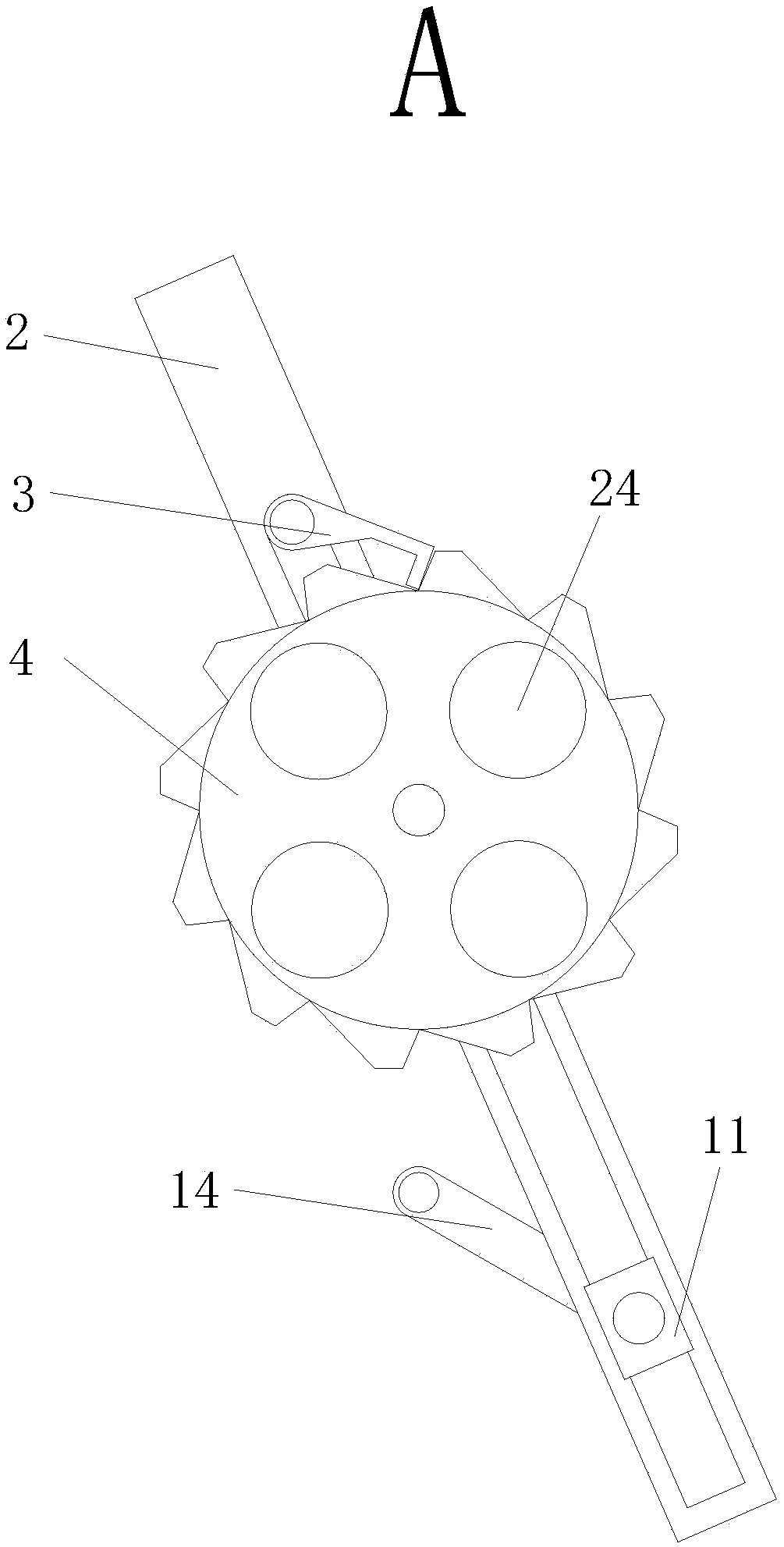

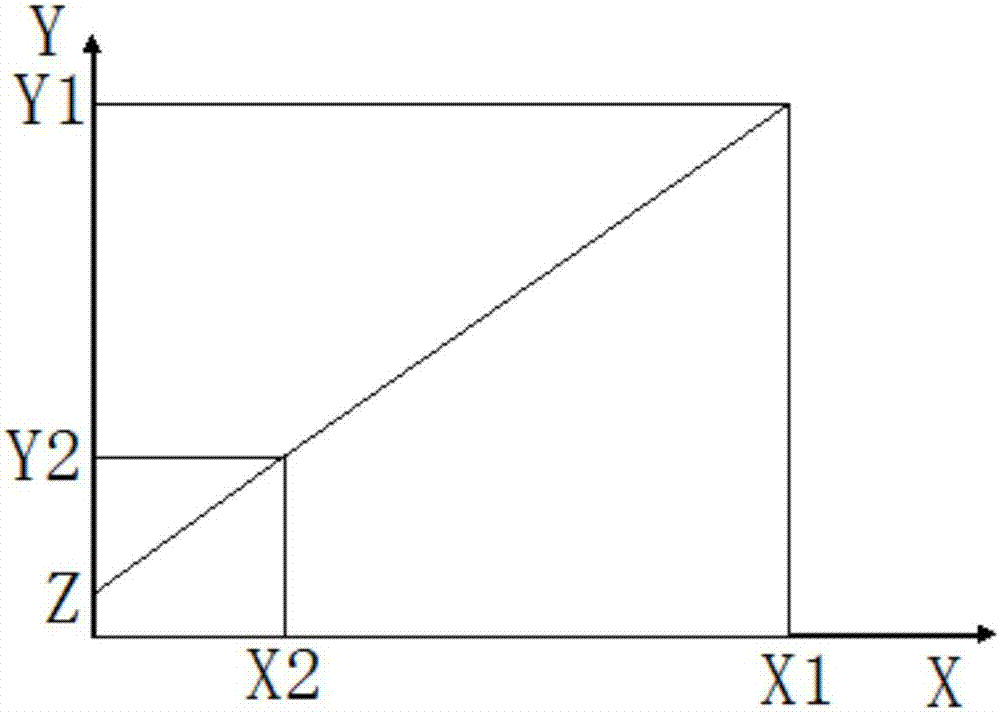

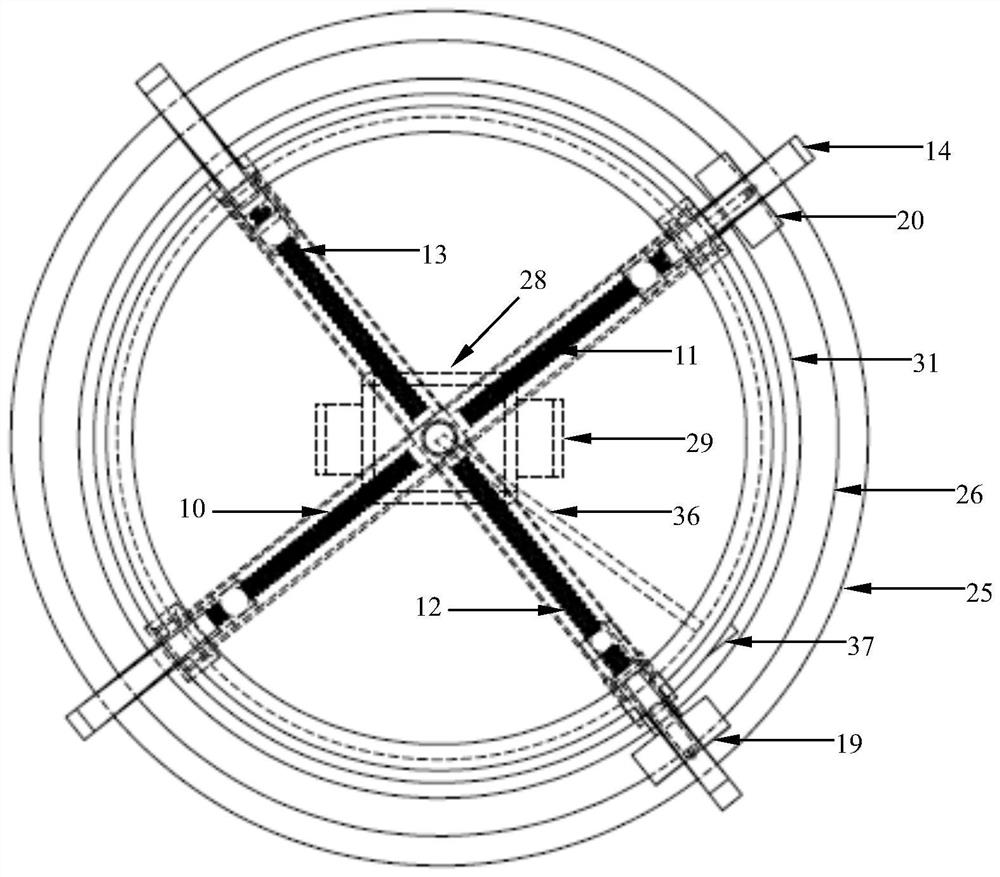

Ring rolling mill rolling process feeding control method and system

ActiveCN107971436AAvoid problems such as response lagControl feedMetal rollingManipulatorEngineering

The invention discloses a ring rolling mill rolling process feeding control method. The method comprises the steps that the section width and the height of a ring piece blank are measured in real time; according to the real-time section width of the ring piece blank, axial rolling force is adjusted according to the function relation obtained in advance between the section width and the height of the ring piece blank, so that the height and the section width of the ring piece blank conform to the function relation between the section width and the height. By the application of the ring rollingmill rolling process feeding control method, the feeding amount can be controlled precisely, the problems of response lag and the like generated by observation of a manipulator are avoided, the product quality is improved remarkably, the size stability of products is improved, and the appearance is more structured. The invention further discloses a ring rolling mill rolling process feeding controlsystem which has the above technical effects as well.

Owner:SOUTHWEST ALUMINUM GRP

Garbage drying device

The invention discloses a garbage drying device. The garbage drying device comprises a feed port, a discharge port, an inlet moisture meter and an outlet moisture meter; moist garbage enters a fire grate in a drying chamber from the feed port, and moves along with the fire grate; intake ports are uniformly formed below the fire grate; hot smoke sprayed by the intake ports is used for drying the garbage, and is conveyed into the drying chamber by a tail gas pipe; and the flow is controlled by the openness of intake port valves. The hot smoke and water vapor evaporated from the garbage are discharged by an exhaust port. The garbage drying device uses the tail gas afterheat of a garbage combustion boiler without excessively consuming other heat for detecting the water content of the fed and discharged garbage in real time to prevent combustion of the garbage in the drying chamber, returns and controls the water content of the garbage in real time to control the openness of the valves to control the intake quantity of tail gas, improves the utilization efficiency of the tail gas, and adopts a multi-layer fire grate overturning mechanism to deeply feed the tail gas into the garbage layer to achieve good drying effect.

Owner:邢献军

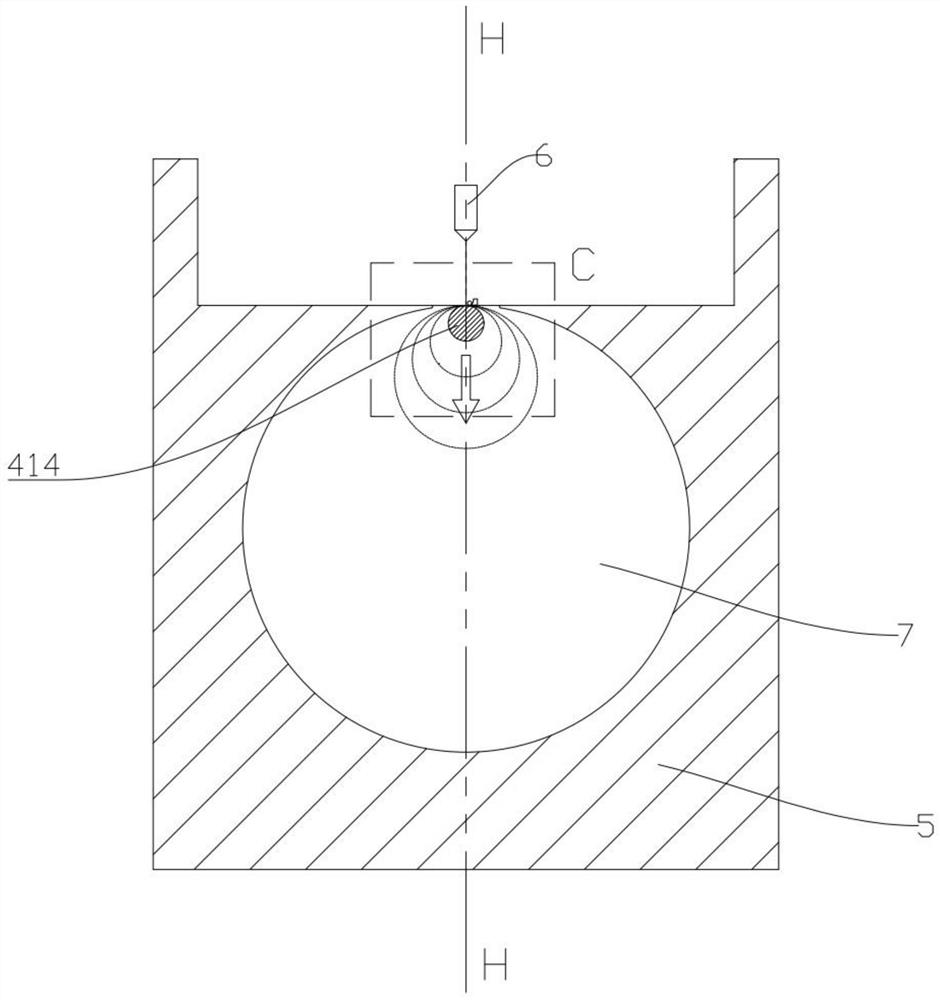

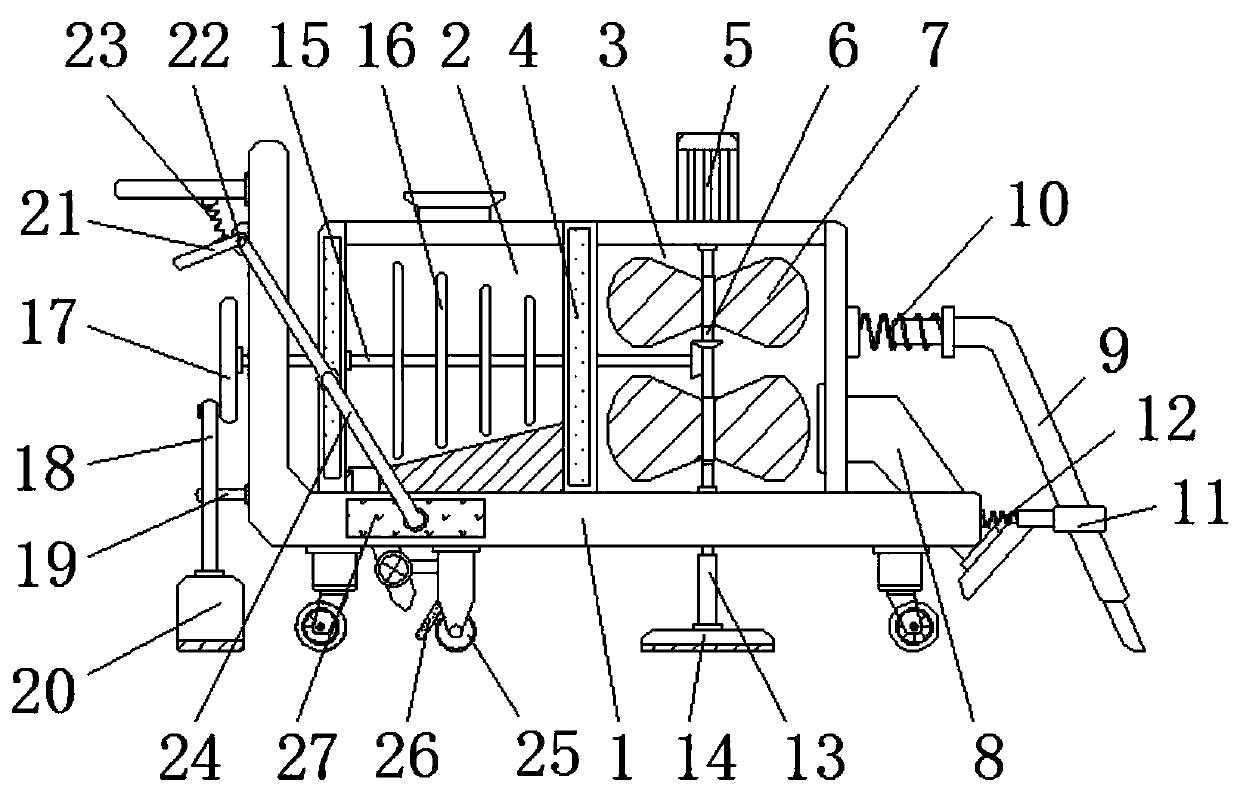

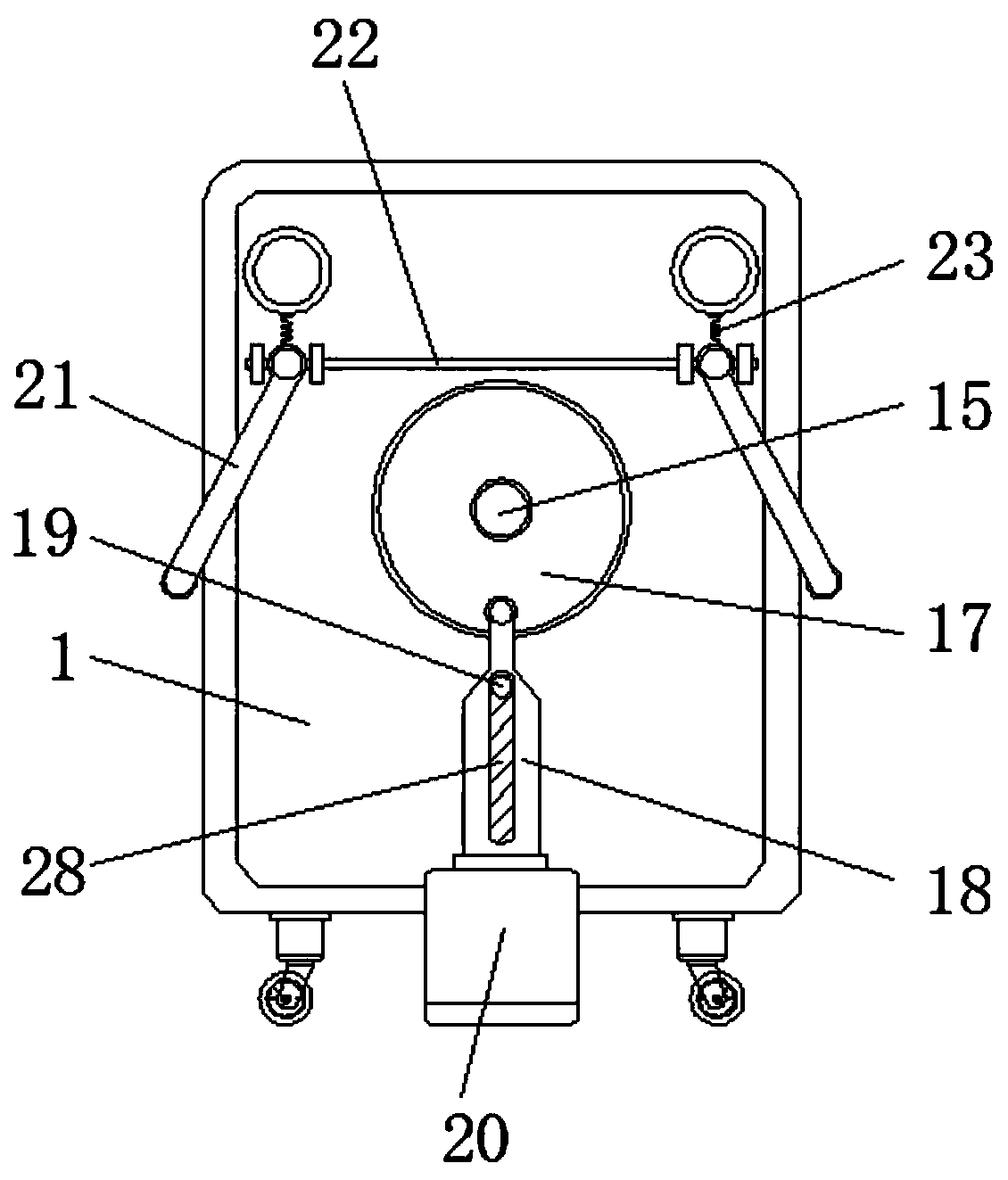

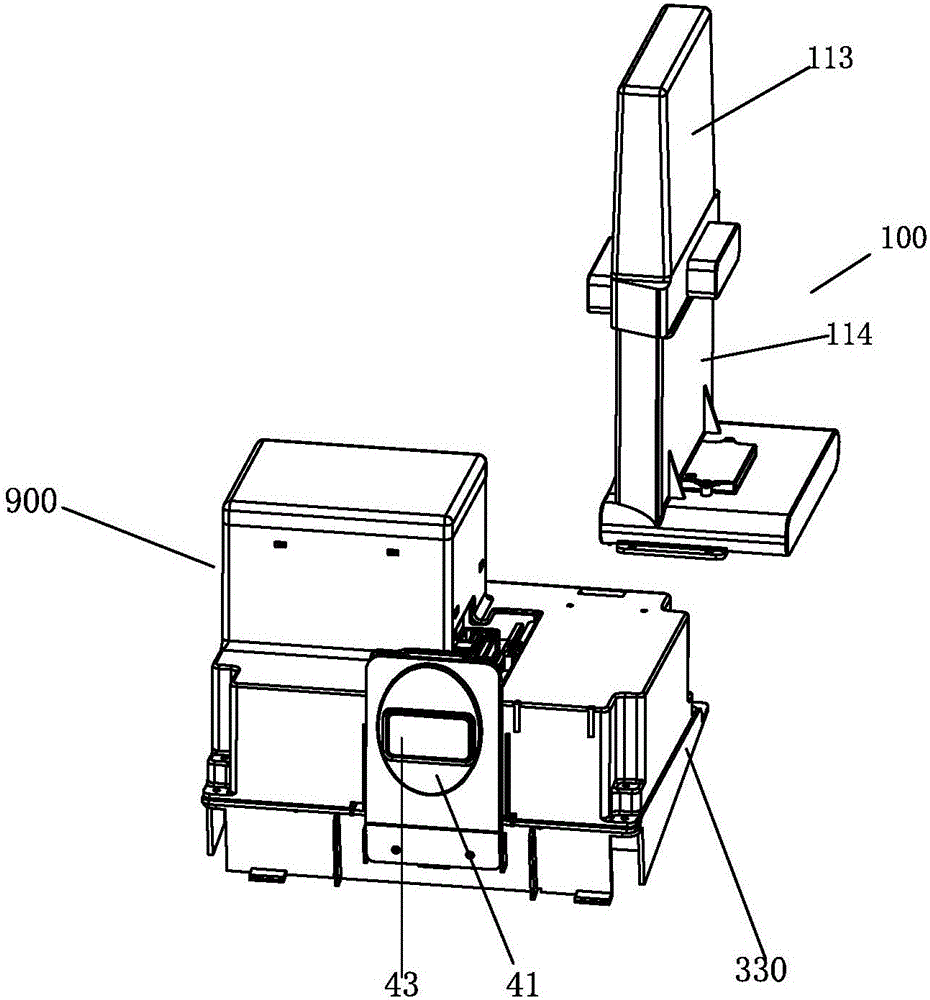

Basic shaft type SLM metal printer

ActiveCN112719300ASimple structureEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingEngineering

The invention discloses a basic shaft type SLM metal printer which comprises a printer body and a metering powder feeding device. The printer body comprises a rack; a powder cylinder is arranged in the middle of the rack; the powder cylinder is cylindrical, and the extending direction of the powder cylinder is parallel to the horizontal plane; a basic shaft driving device is arranged in the powder cylinder; the basic shaft driving device is used for driving the basic shaft to rotate and / or move up and down; the powder cylinder is provided with a long-strip-shaped opening, crack pieces are connected to the two sides of the long-strip-shaped opening, and a gap is formed between the two crack pieces; a powder scraping roller is arranged on one side below the gap; and a powder supplementing mechanism is further arranged in the powder cylinder. The basic shaft type SLM metal printer is simple in structure and convenient to use, complex components such as a powder laying device and a powder scraping device are omitted, the requirements for machining symmetry and the like of some rotating components are well met, the quality of printed and machined products is guaranteed, the temperature stress of workpieces in the printing process is controlled, automatic feeding is achieved, and the printing efficiency is improved.

Owner:嘉兴意动能源有限公司

Municipal engineering road crack filling device capable of filling according to crack radian

The invention discloses a municipal engineering road crack filling device capable of filling according to crack radian. The municipal engineering road crack filling device capable of filling accordingto the crack radian comprises a moving plate, a heating plate motor and a first connecting rod; a material mixing box is fixedly mounted above the moving plate; an air placing chamber is connected tothe right side of the material mixing box; a heating plate is mounted in the internal wall of the material mixing box; a motor is fixedly mounted above the air placing chamber; a material dischargingpipe is mounted under the material mixing box; a valve is mounted under the material discharging pipe; a connecting hole is formed in the surface of the moving plate; and a fifth spring is fixed between a first rotating shaft and a fixing sleeve. According to the municipal engineering road crack filling device capable of filling according to the crack radian, by arranging a locating rolling sheetand the material discharging pipe, the locating rolling sheet can roll in a crack under the pushing of the moving plate; and meanwhile, under cooperation of the material discharging pipe above the locating rolling sheet, slurry is discharged to a material stopping plate and flows into the crack to enable the slurry to be conveniently filled with the rolling of the locating rolling sheet; and therefore, the filling effect of the device is improved.

Owner:无锡市鸣腾建设工程股份有限公司

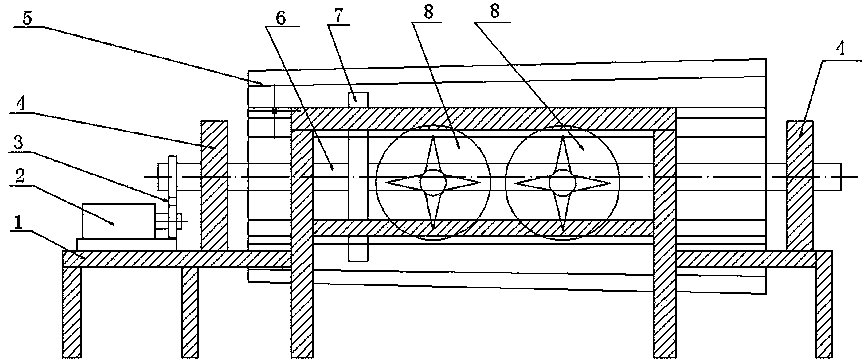

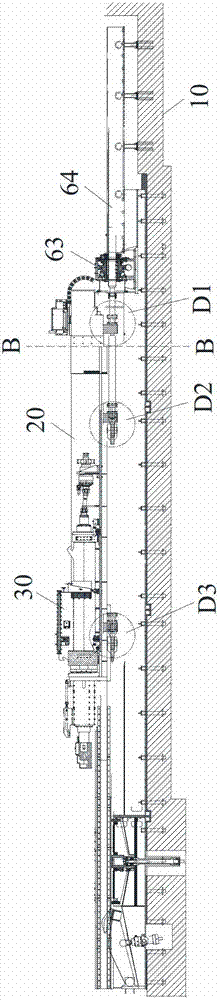

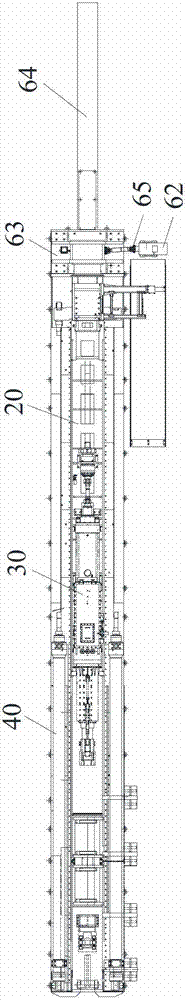

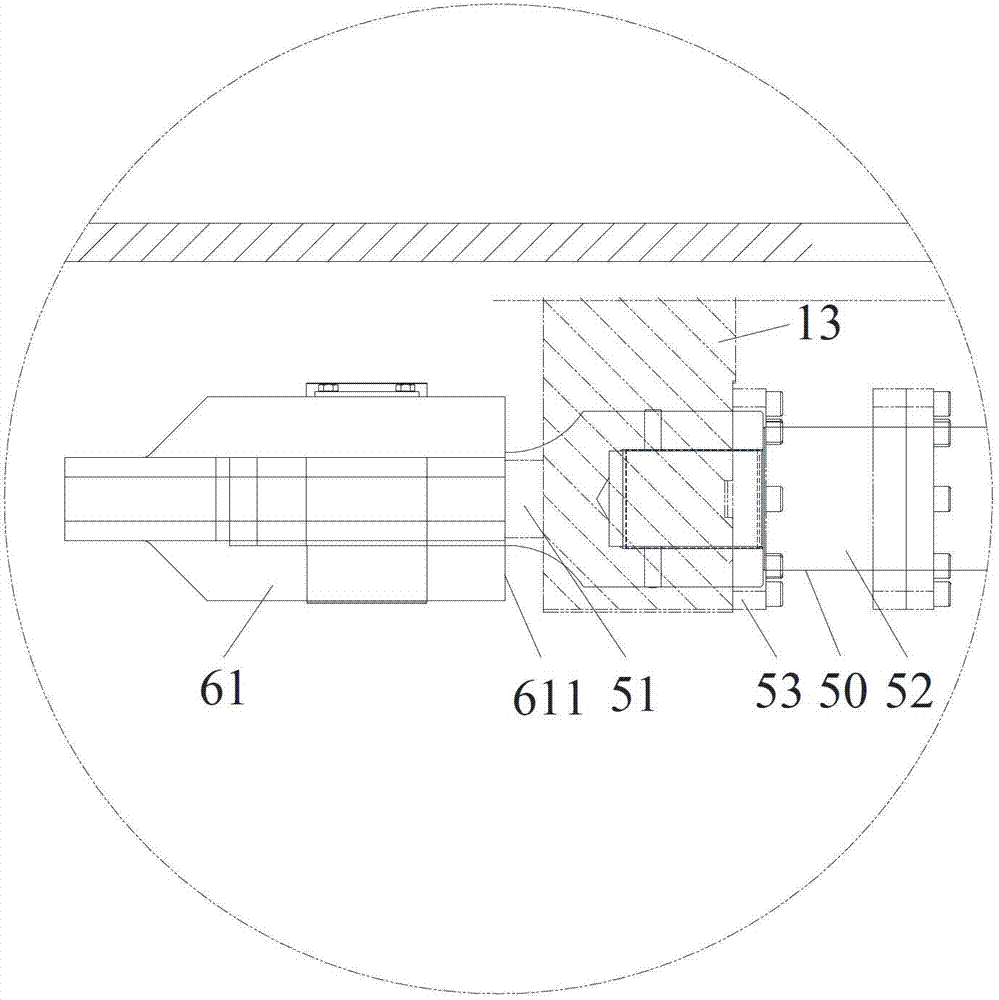

Feeding system of hot pilger mill

ActiveCN102873111AControl feedMeets rolling feed requirementsMetal rolling arrangementsHydraulic cylinderInternal pressure

A feeding system of a hot pilger mill comprises a support platform, a conveyer, a feeder and a feeding hydraulic cylinder, wherein the conveyer is erected on the support platform, and the feeding hydraulic cylinder is arranged on the conveyer and drives the conveyer to slide on the support platform. The feeding system of the hot pilger mill is characterized by further comprising an adjustable stopping device and a contact buffer portion, the adjustable stopping device comprises a drive portion and a stopping portion, the stopping portion moves along the sliding direction of the conveyer under the drive action of the drive portion, the contact buffer portion is connected with the conveyer and is positioned in the rear of the stopping portion all the time, and when contacting with the stopping portion, the contact buffer portion sends signals to the feeding hydraulic cylinder to enable the feeding hydraulic cylinder to change internal pressure, so that the conveyer slows down or stops.

Owner:TAIYUAN HEAVY IND

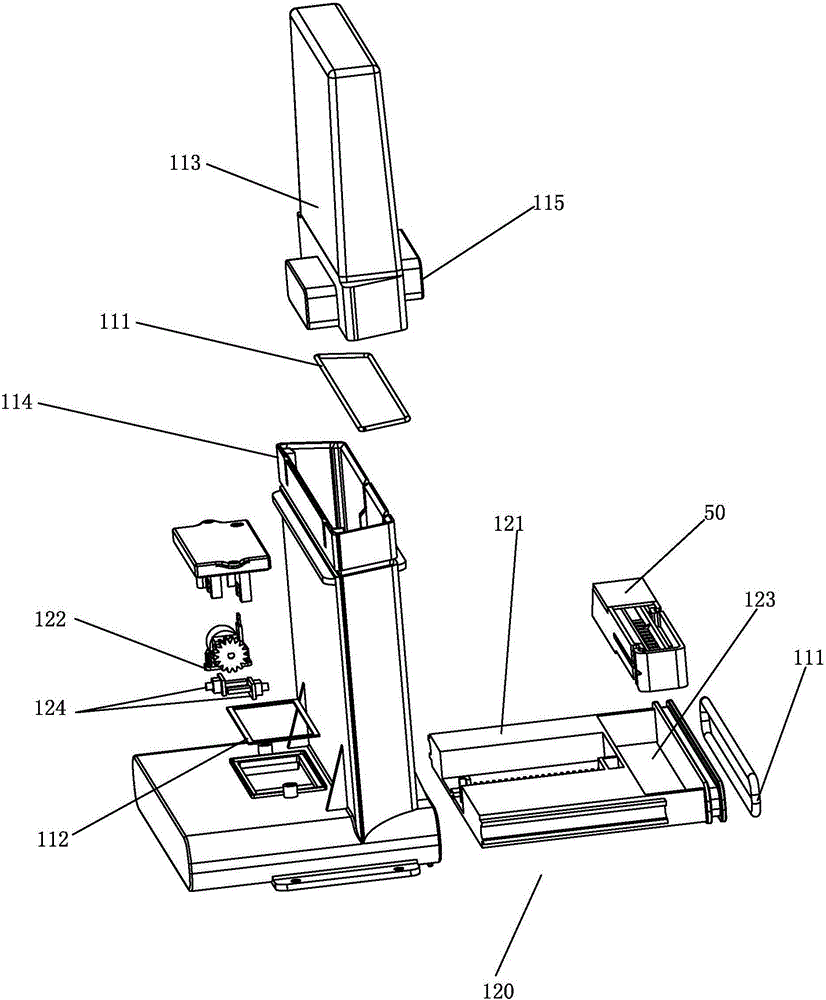

Intelligent urine detector, urinal and urine detection method

ActiveCN106198516AAchieve readAddressing deficiencies in manual urine testingMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesArtificial urineEngineering

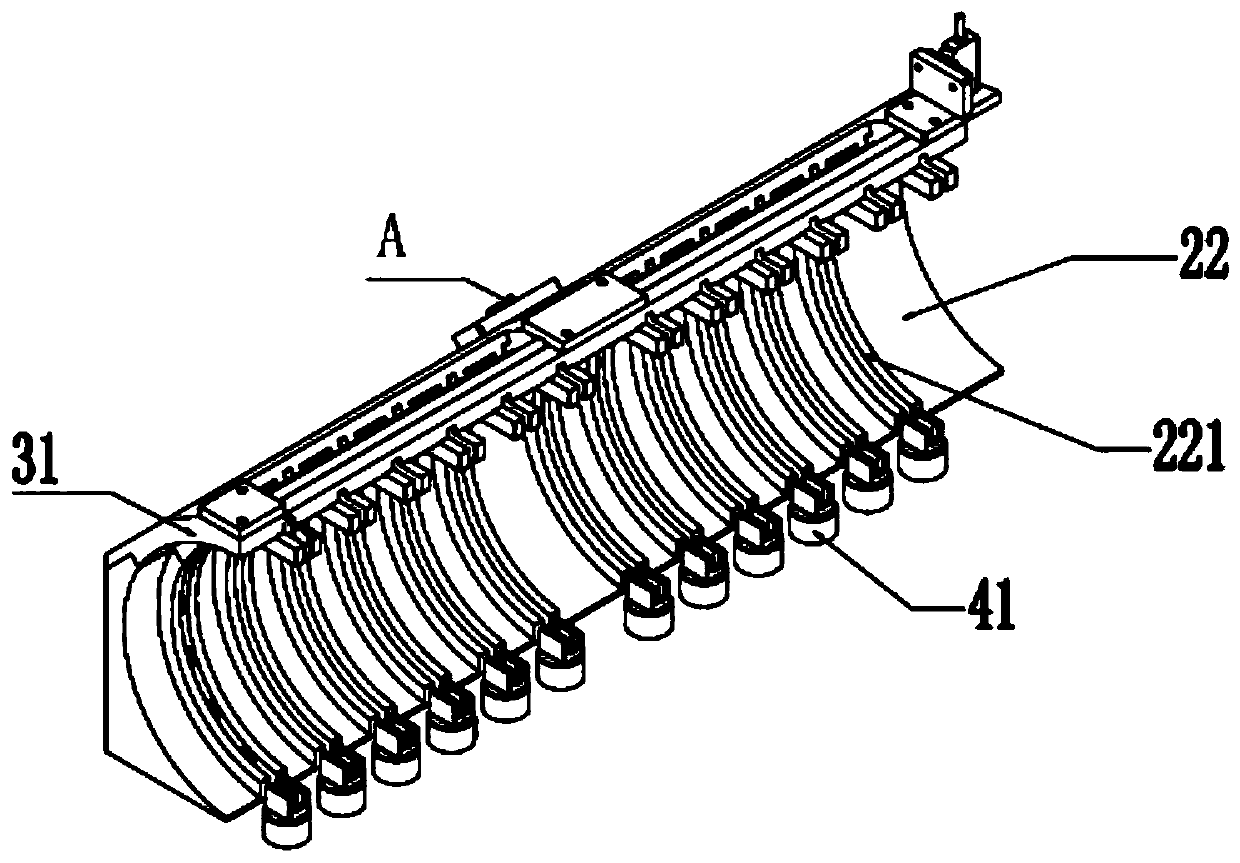

The invention relates to an intelligent urine detector, a urinal and a urine detection method. The intelligent urine detector comprises: a feeding mechanism comprising a storage box and a pushing unit, wherein the storage box is filled with a plurality of test paper boxes, and the pushing unit is used for pushing the test boxes to a two-dimensional conveying mechanism; the two-dimensional conveying mechanism which is controlled to move along a first direction to realize feeding or discharging or is controlled to move along a second direction to realize urine taking or supplied urine information reading; a scanning mechanism used for reading the urine information in the test paper boxes; and a control mechanism connected with the feeding mechanism, the conveying mechanism and the scanning mechanism to control coordinative work of all the mechanisms in order to realize intelligent urine detection. The intelligent urine detector, the urinal and the urine detection method effectively overcome the disadvantages of artificial urine detection, and realize feeding, automatic urine taking, urine information reading and discharging through adopting the cooperation of the feeding mechanism, the two-dimensional conveying mechanism, the scanning mechanism and the control mechanism.

Owner:JOMOO KITCHEN & BATHROOM

Ovality detection device and detection method

The invention discloses an ovality detection device and an ovality detection method. The device comprises a machine frame, a rotating platform arranged on the machine frame, a driving device, a probeassembly and a control assembly, the upper surface of the rotating platform is used for containing an object to be measured, the probe assembly comprises at least one probe, and each probe can reciprocate in at least one plane a in the radial direction of a circle b; each probe can be in contact with the outer edge or the inner edge of an object to be measured, the object to be measured is fixed through sliding friction force at the contact position, and the control assembly is connected with each probe and can control each probe to do reciprocating motion. According to the method, the maximumdiameter point of a to-be-detected object is clamped through a probe assembly, whether the same point is clamped by forward and reverse rotation or not is observed in a forward and reverse rotation mode, and the ovality of the to-be-detected object is checked. The device and method have the advantages of being reasonable in design, simple, practical, convenient to operate, controllable and adjustable in precision and small in environmental interference.

Owner:SICC CO LTD

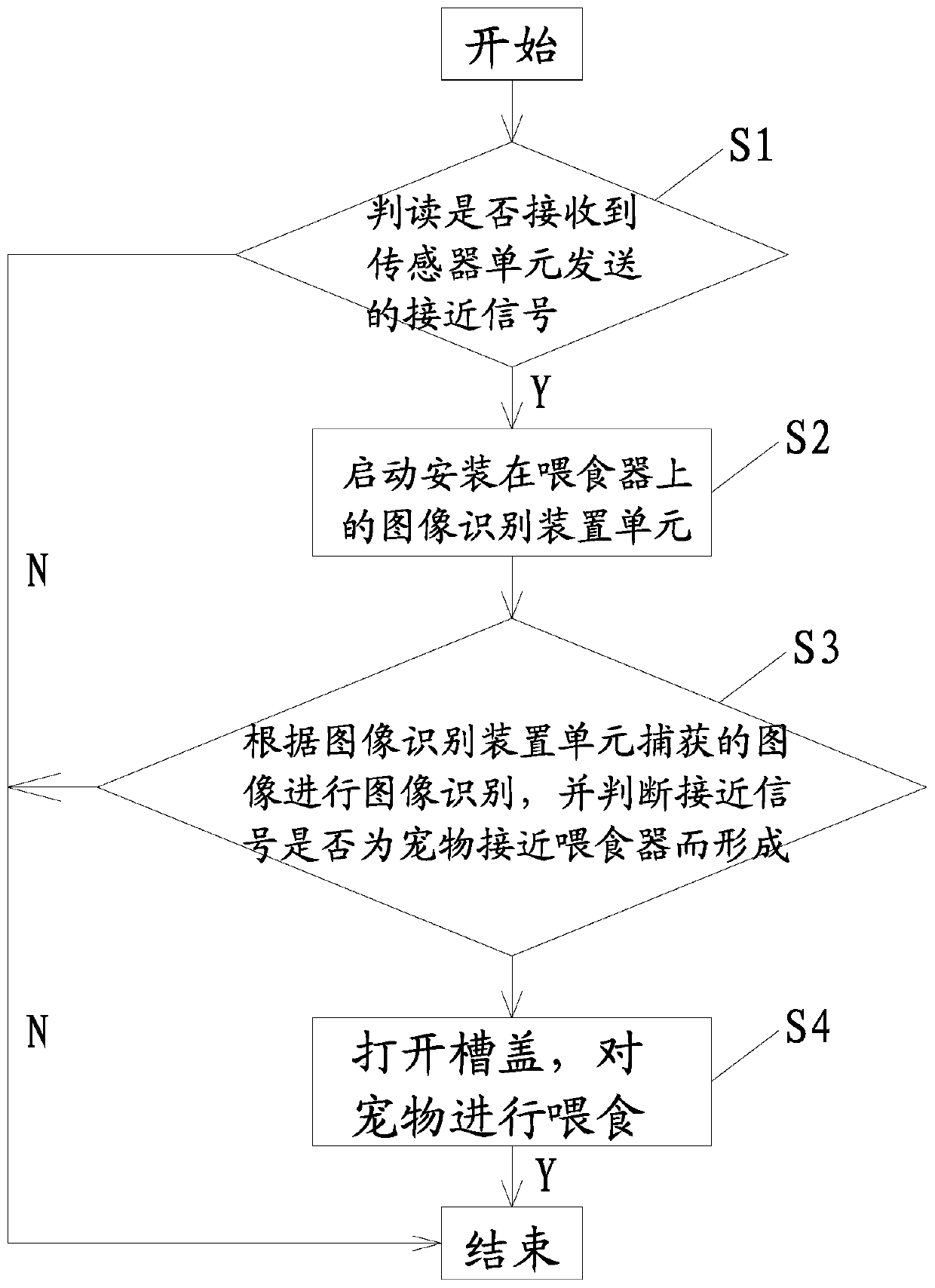

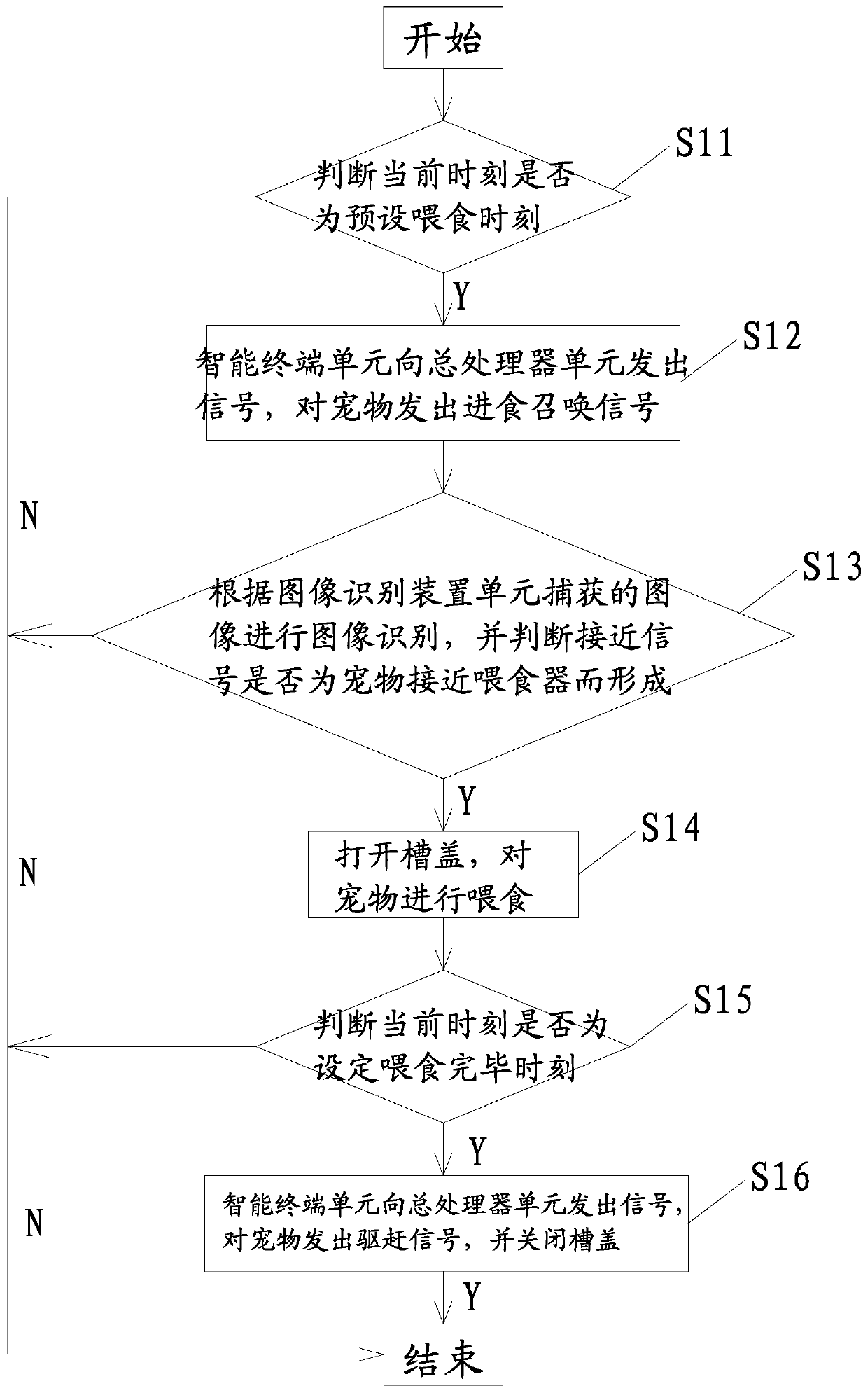

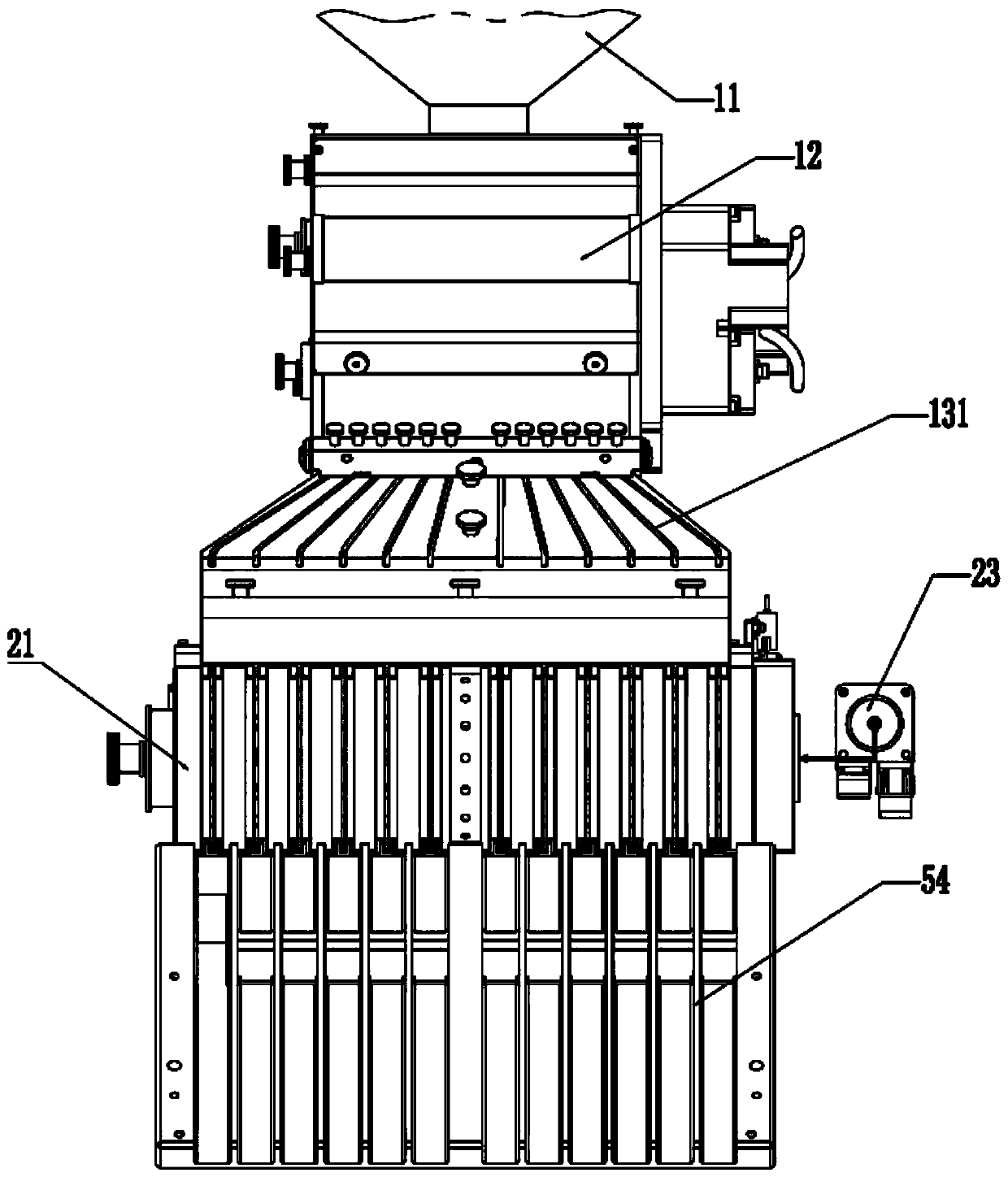

Pet automatic feeding method and device

PendingCN111149718ASimple structureEasy to useAnimal feeding devicesCharacter and pattern recognitionControl theoryCompanion animal

Owner:HUAQIAO UNIVERSITY

Small product weighing device

PendingCN111174879AGuaranteed accuracyShorten weighing timeWeighing apparatus with automatic feed/dischargeSortingControl cellProcess engineering

The invention relates to a small product weighing device. The device comprises a feeding mechanism, a conveying and transferring mechanism, a fragment removing mechanism and a weighing mechanism, wherein the feeding mechanism comprises a hopper, a stirring mechanism and a sequencing mechanism, the conveying and transferring mechanism comprises a transferring hub, a guiding seat and a servo motor,the fragment removing mechanism comprises a guiding fork, a triggering mechanism, an air blowing device and a collecting box a, and the weighing mechanism comprises a weighing platform and a weighingsensor; the discharging mechanism comprises a discharging sliding groove a, a discharging sliding groove b, a removing door, a collecting box b and a collecting box c; the device further comprises a control unit, the trigger mechanism and the weighing sensor transmit signals to the control unit, the control unit can send instructions to the air blowing device, the servo motor and the removing door, and products meeting the weight requirement and products not meeting the weight requirement are separated. The problem that disturbance airflow is generated around the weighing platform due to vacuum leakage and the problem that the production efficiency is affected due to the fact that the stabilization time is long when small products are weighed are solved.

Owner:SHANGHAI QUNTIN-TECH CO LTD

Material distributor

The invention belongs to the technical field of ceramic production, and in particular relates to a material distributor. The material distributor comprises a frame, a feeding tube, a silo, a lifting device, a discharge port, a discharge port gate, a discharge port gate driving device, and a discharge port driving device. The silo comprises two cylinders sleeved to each other, and the two cylindersare respectively an upper cylinder and a lower cylinder, wherein the upper cylinder and the lower cylinder are slidably connected. The upper cylinder is fixedly connected to the frame, and the feeding tube is disposed at an upper end of the upper cylinder and communicates with the upper cylinder. The lifting device is fixedly connected to the frame, and an output end of the lifting device is fixedly connected to the lower cylinder body. The discharge port is disposed at a lower end of the lower cylinder and communicates with the lower cylinder body, and the discharge port gate is disposed between the two. The discharge port gate driving device is disposed on the lower cylinder body, and drives the discharge port gate to open or close a communication passage between the discharge port andthe lower cylinder body. The discharge port driving device is disposed on the lower cylinder. The material distributor has the advantages of simple structure and convenient operation.

Owner:FOSHAN BAOYAN MACHINE MFG

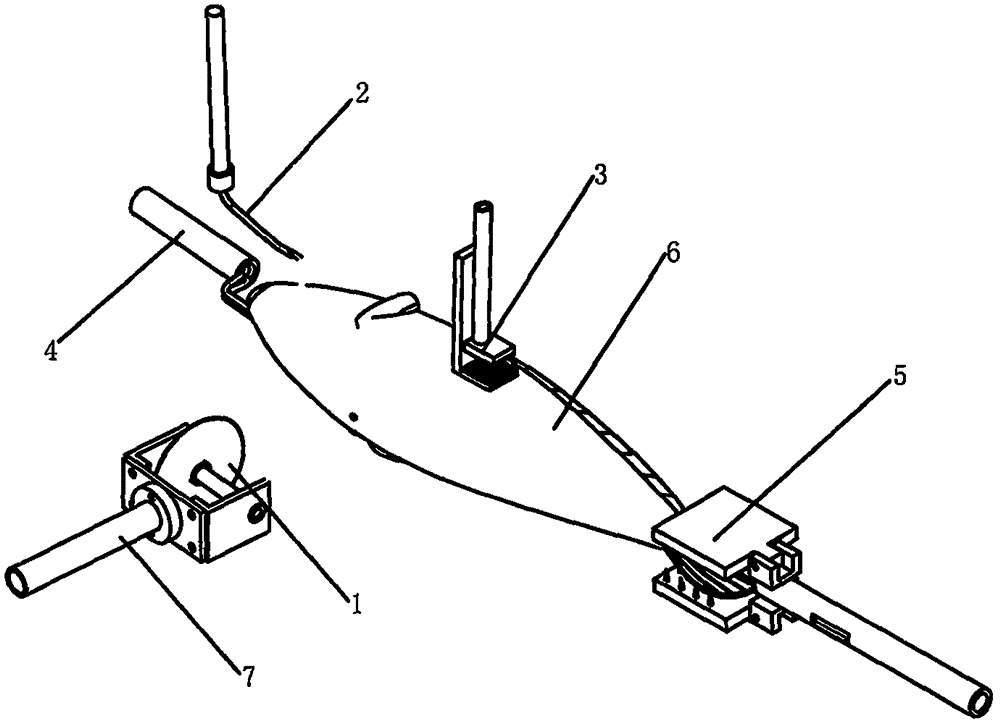

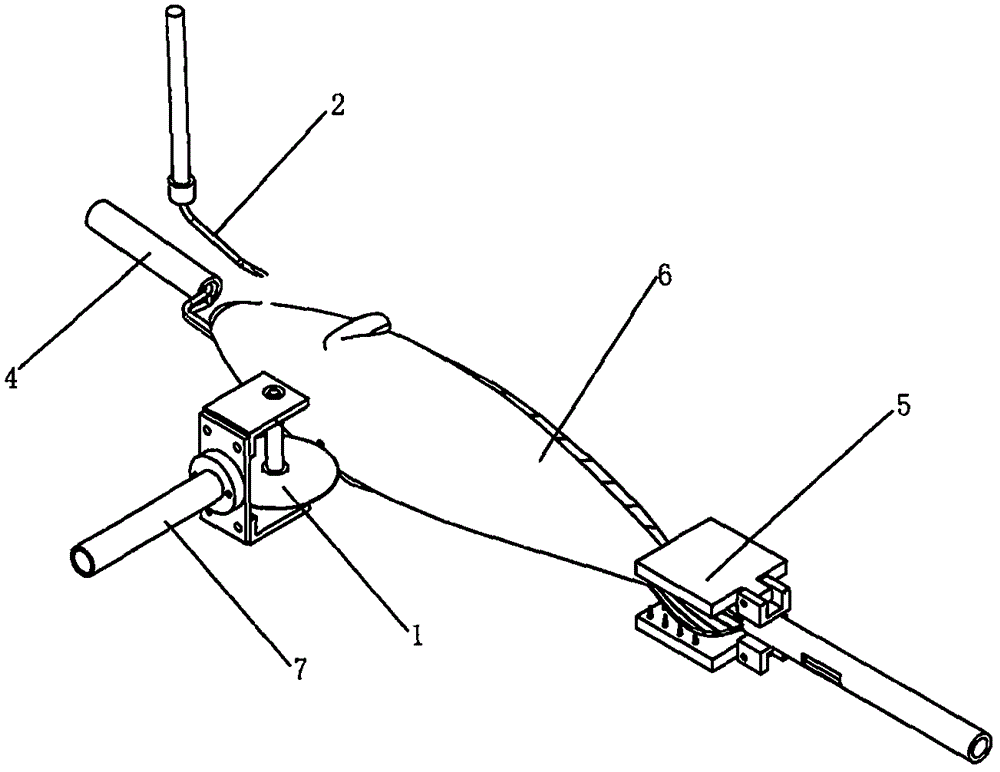

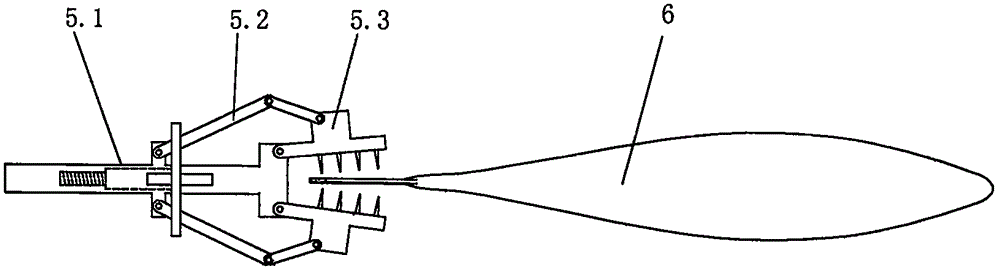

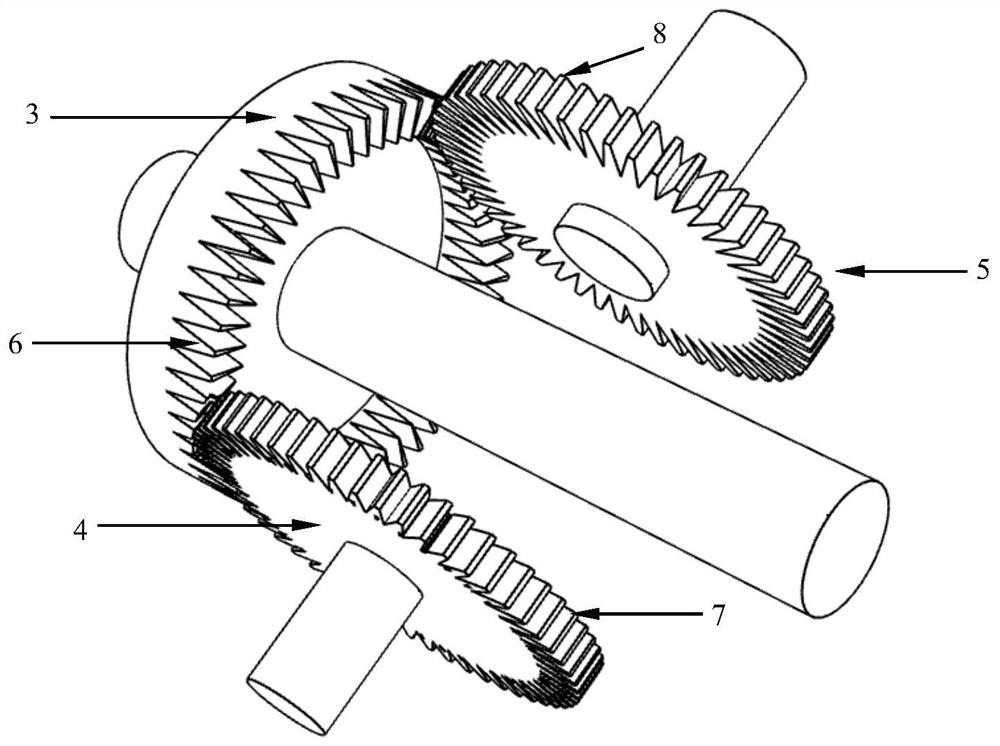

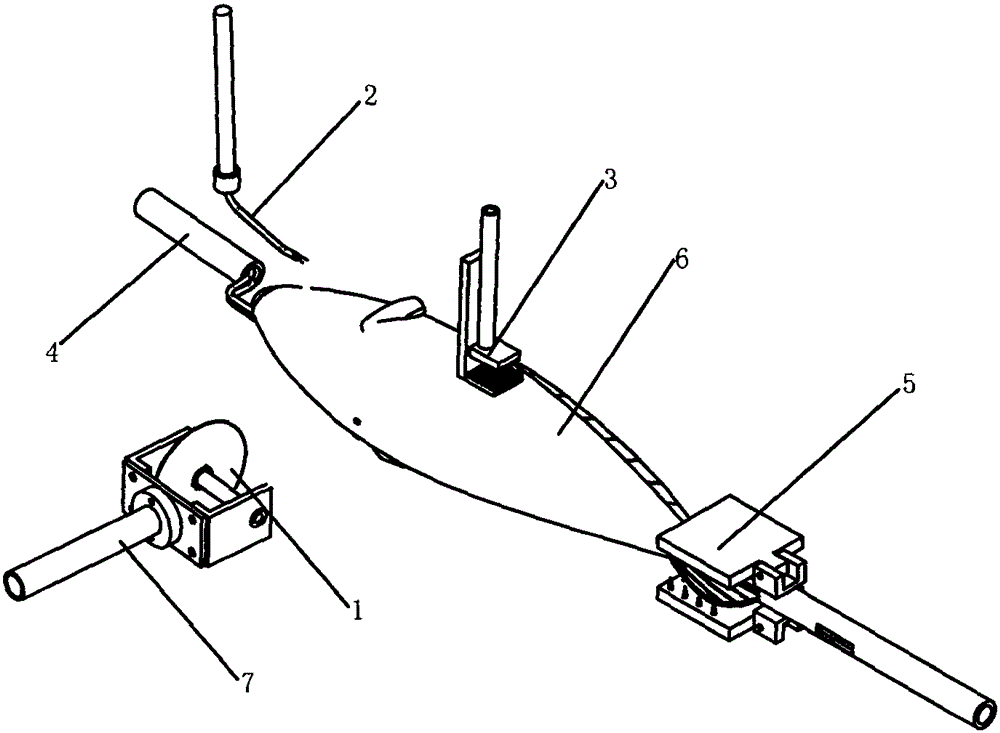

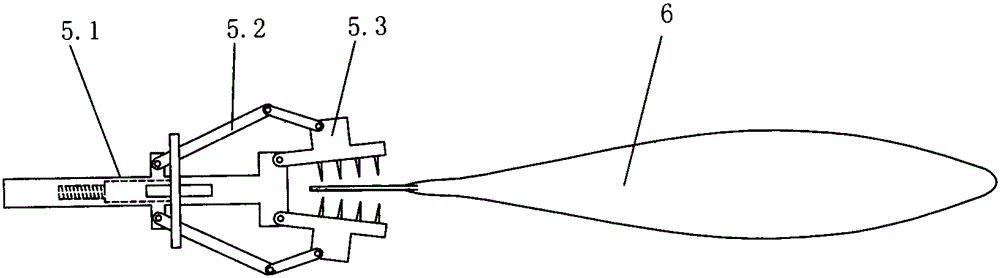

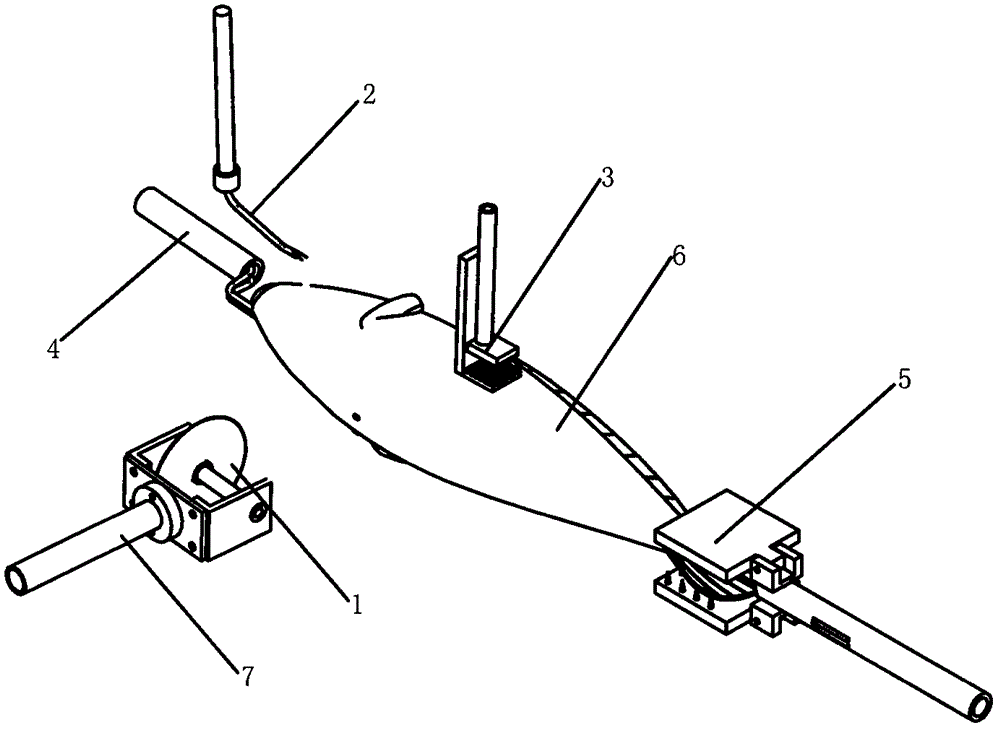

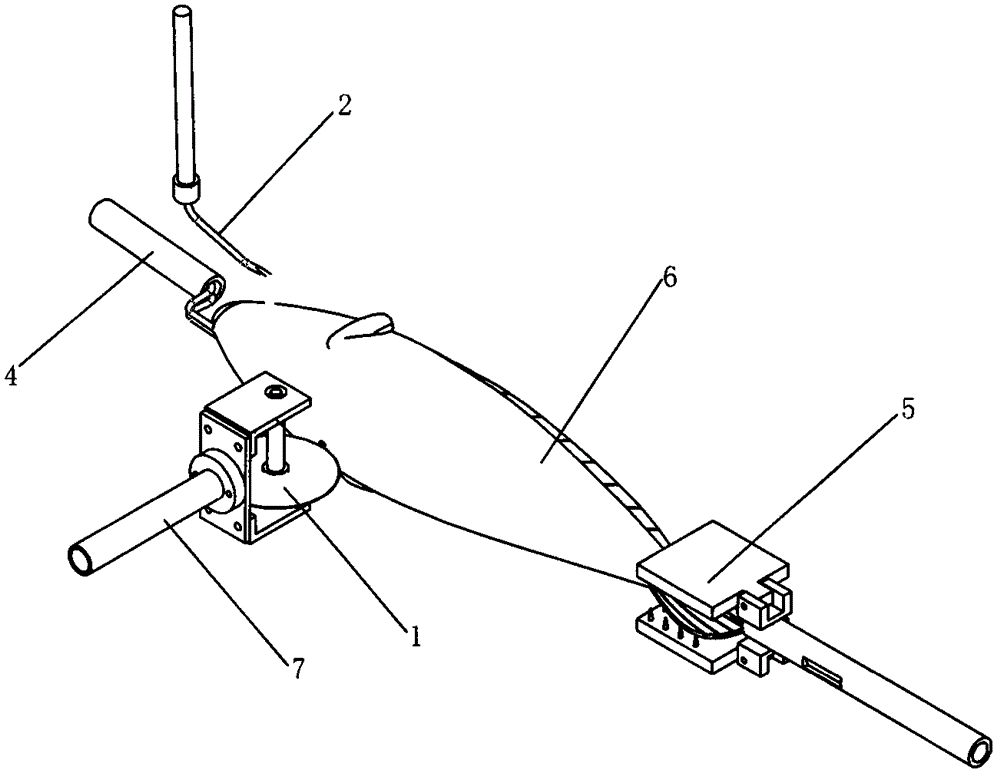

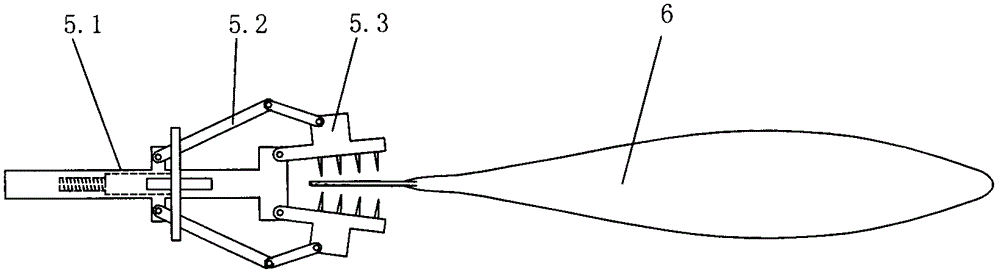

Fish skin separation method based on three-dimensional scanning

The invention discloses a fish skin separation method based on three-dimensional scanning, which is based on a fish skin separation device. The fish skin separation device comprises a holding mechanism, a circular cutting knife (1), a separation knife (2) and a skin-stripping mechanism (3). The holding mechanism comprises a gill hook (4) and a tail clamp mechanism (5). The circular cutting knife is arranged at an eccentric position of a central axial line between the gill hook and the tail clamp mechanism. The separation knife and the skin-stripping mechanism are arranged at the side of the gill hook. The fish skin separation method includes the steps of scanning fish body through a three-dimensional image to obtain circular cutting position and path, separation path, longitudinal cutting path and stripping path; holding the to-be-skinned fish body in a horizontal manner front-and-back by the holding mechanism, circularly cutting the fish body around the fish body through the circular cutting knife; separating fish skin from fish body by the separation knife being stretched into the fish body from cut marks at the circularly cut position; longitudinally cutting the fish skin in the length direction of the fish body by means of the circular cutting knife; and finally removing the fish skin by the skin-stripping mechanism. The fish skin separation method achieves automatic separation of the fish skin, increases stripping efficiency of the fish skin and avoids damage on the fish skin.

Owner:CHINA JILIANG UNIV

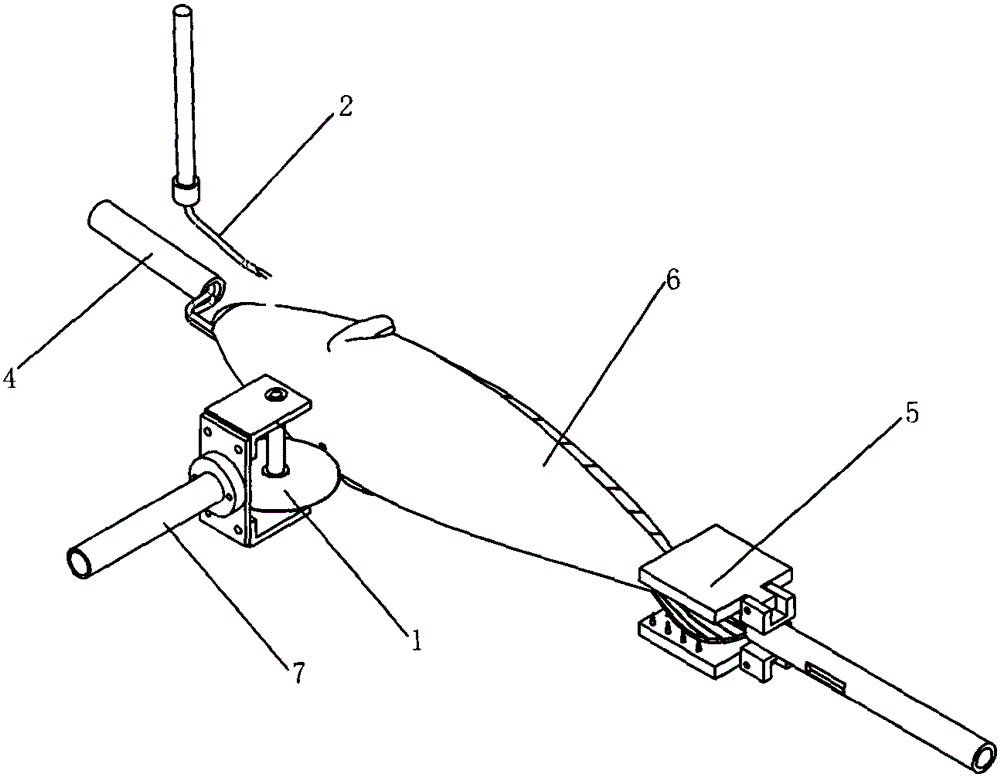

Full-automatic intelligent fish skinning method

The invention discloses a full-automatic intelligent fish skinning method based on a fish skinning device. The fish skinning device comprises a clamping mechanism, a girdling knife (1), a separating knife (2) and a skinning mechanism (3), wherein the clamping mechanism comprises a fish gill hook (4) and a tail clamping mechanism (5); the girdling knife is located at the eccentric position of the central axis between the fish gill hook and the tail clamping mechanism; the separating knife and the skinning mechanism are located on the side of the fish gill hook. The fish skinning method comprises the steps of clamping, recognizing and scanning, annular cutting, fish skin separating, longitudinal cutting and skinning. The full-automatic intelligent fish skinning method realizes automatic fish skin separation, improves the fish skinning efficiency and prevents the fish skin from being broken.

Owner:CHINA JILIANG UNIV

Water conservancy dam cement stirring device

InactiveCN108312335AImprove stabilityControl feedCement mixing apparatusPolymer chemistryFixed frame

The invention relates to a stirring device and particularly relates to a water conservancy dam cement stirring device. The technical problem to be solved by the invention is to provide a water conservancy dam cement stirring device which is capable of fully stirring and is high in stability and simple to operate. The invention provides such a water conservancy dam cement stirring device. The waterconservancy dam cement stirring device comprises a support frame, a motor, a first rotating shaft, a first flat belt, a first belt wheel, a first bearing block, a second belt wheel, a first contact wheel, a first cam wheel and the like, wherein the support frame is arranged on the right side of the top of a fixed frame; a second bearing block is arranged at the middle part of the left wall of thefixed frame; the first bearing block is arranged at the middle part of the right wall of the fixed frame; a second rotating frame is mounted between the second bearing block and the first bearing block. Through the water conservancy dam cement stirring device, the effects of fully stirring cement and improving the stirring stability are achieved; a stirring frame moves up and down and is matchedwith stirring blades, so that the stirring blades can fully stir the cement; a baffle can achieves an effect of controlling the feeding amount of the cement raw material; the cement stirring stabilityis improved.

Owner:黄启康

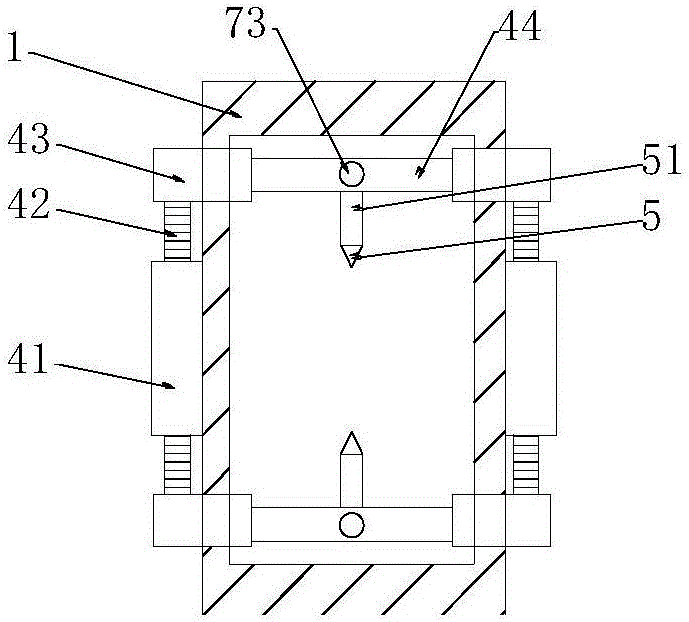

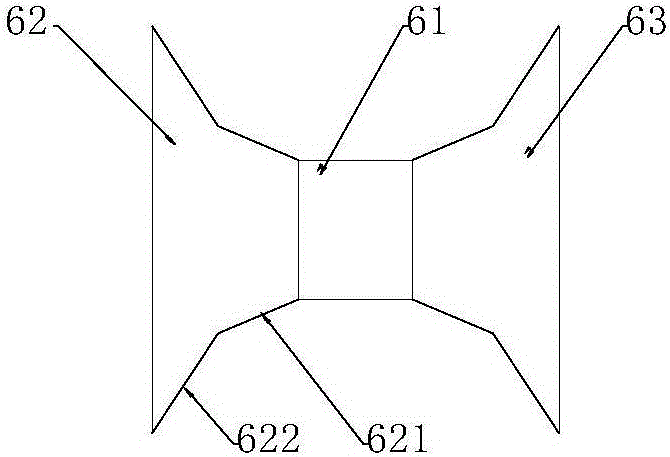

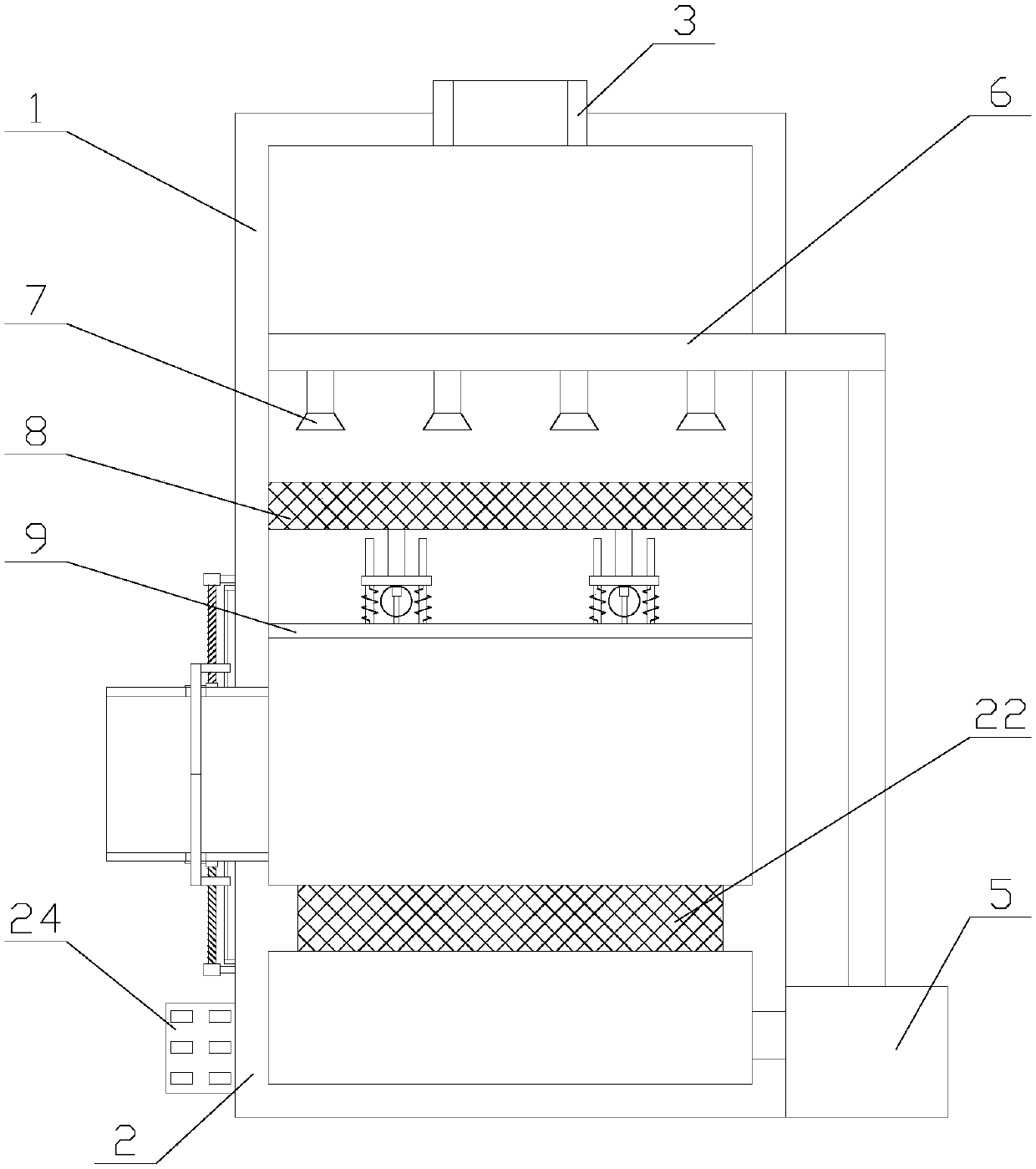

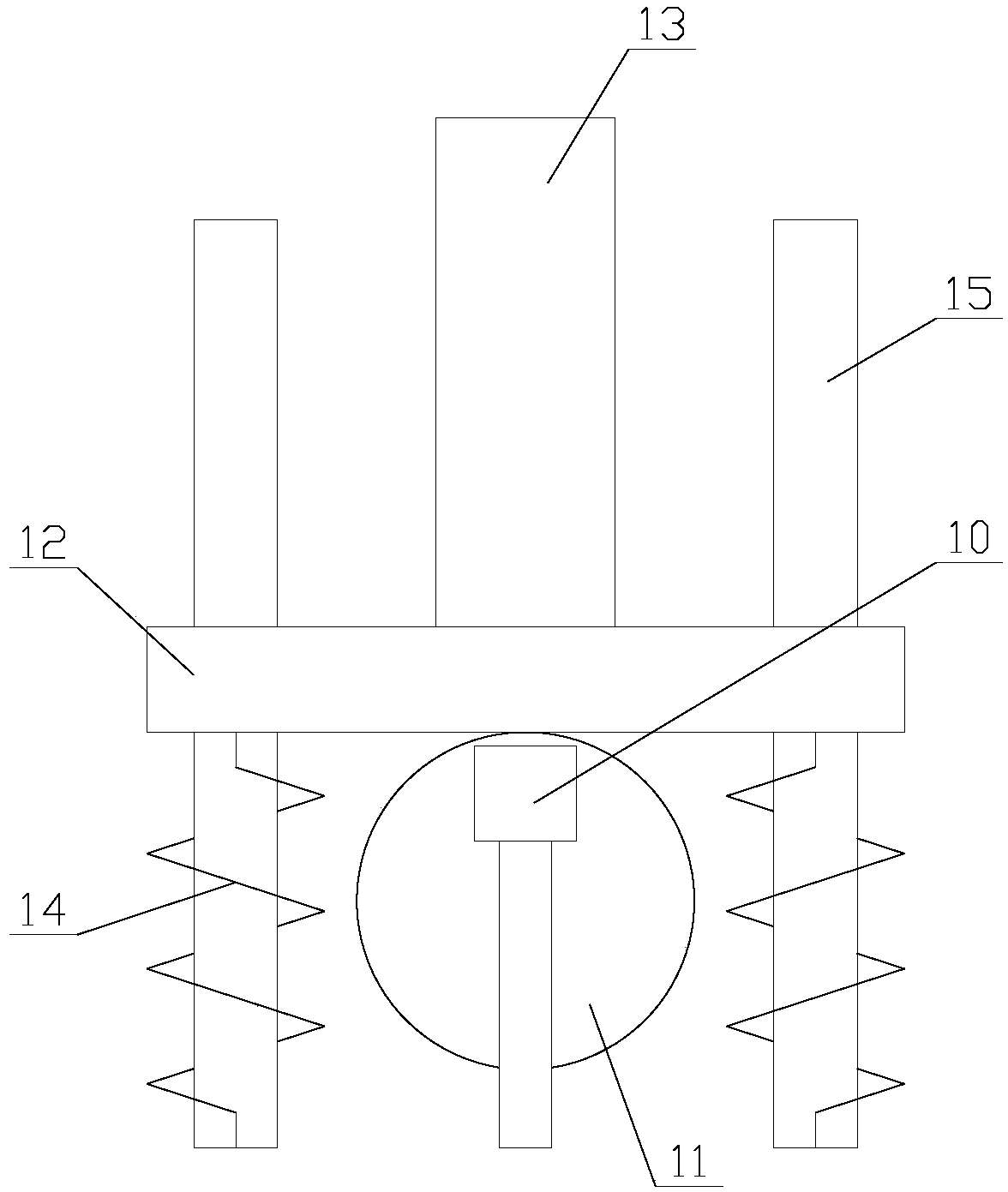

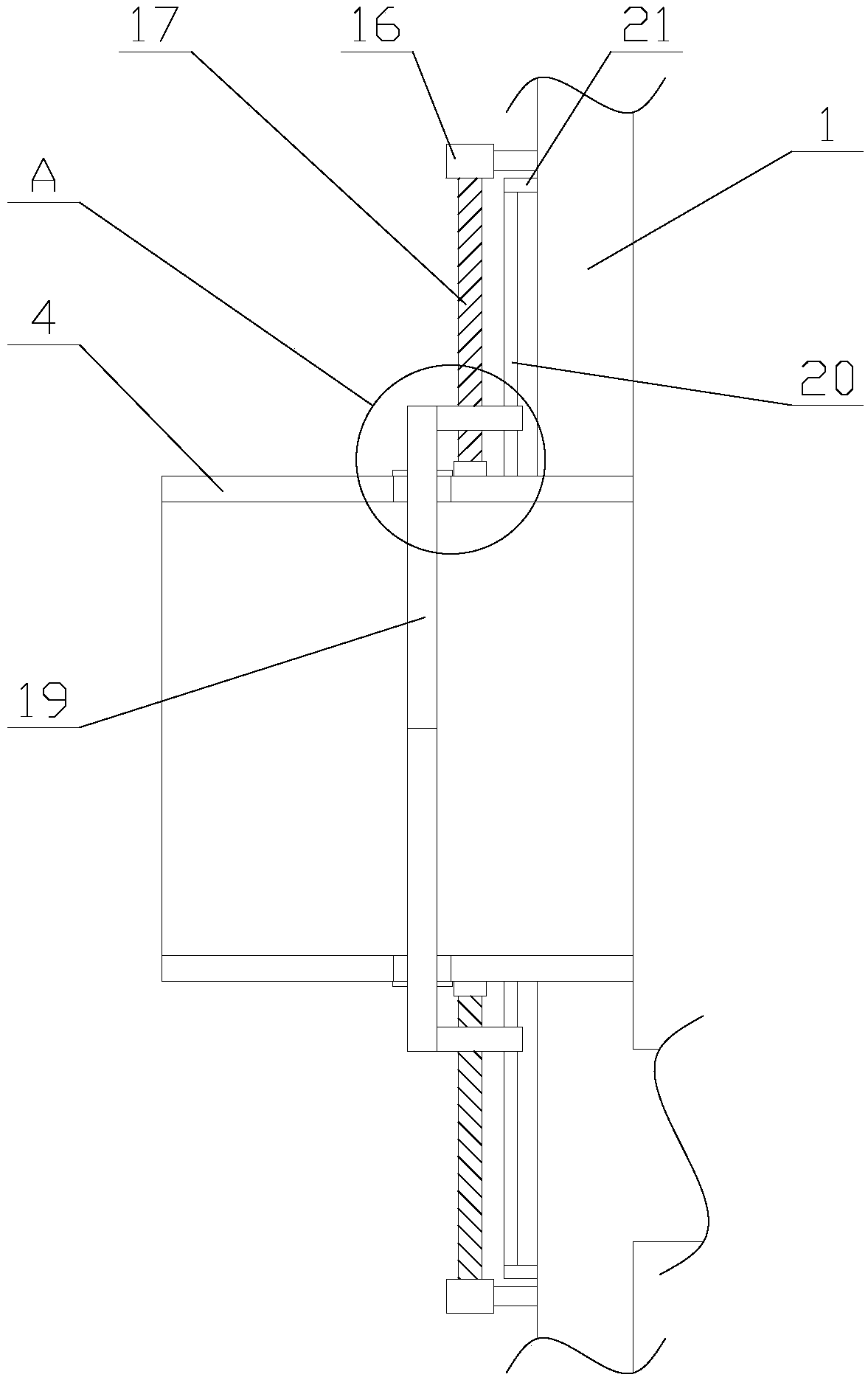

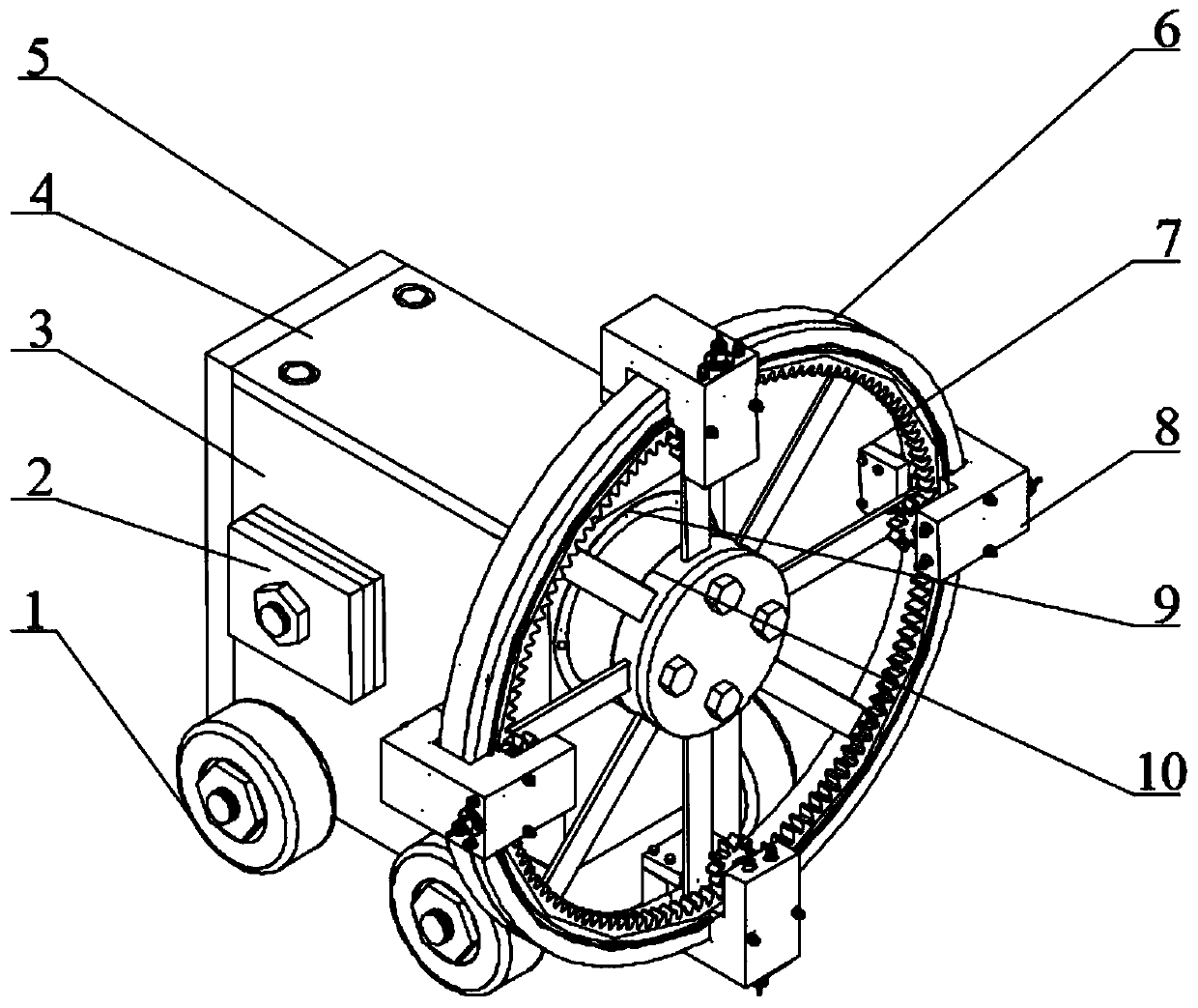

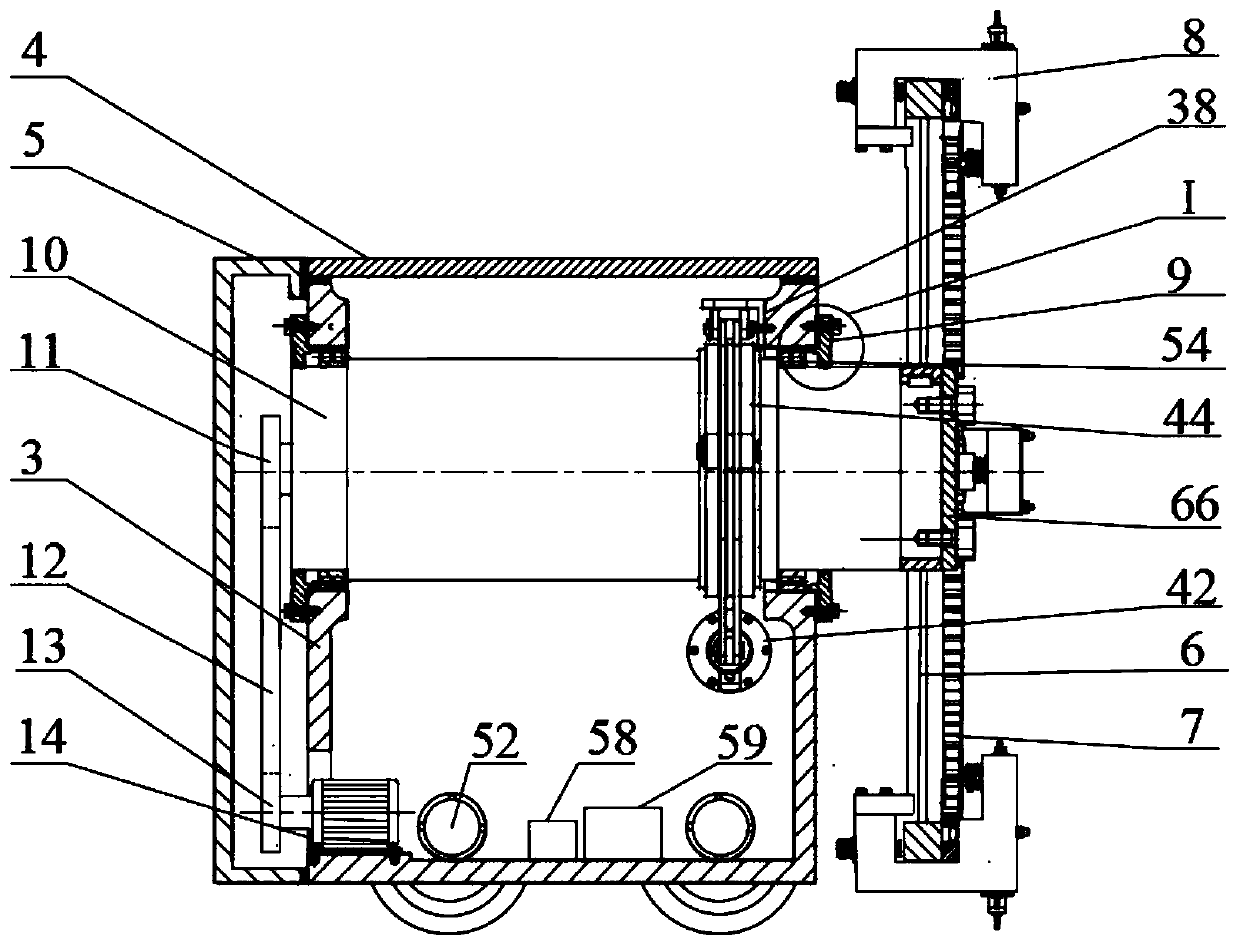

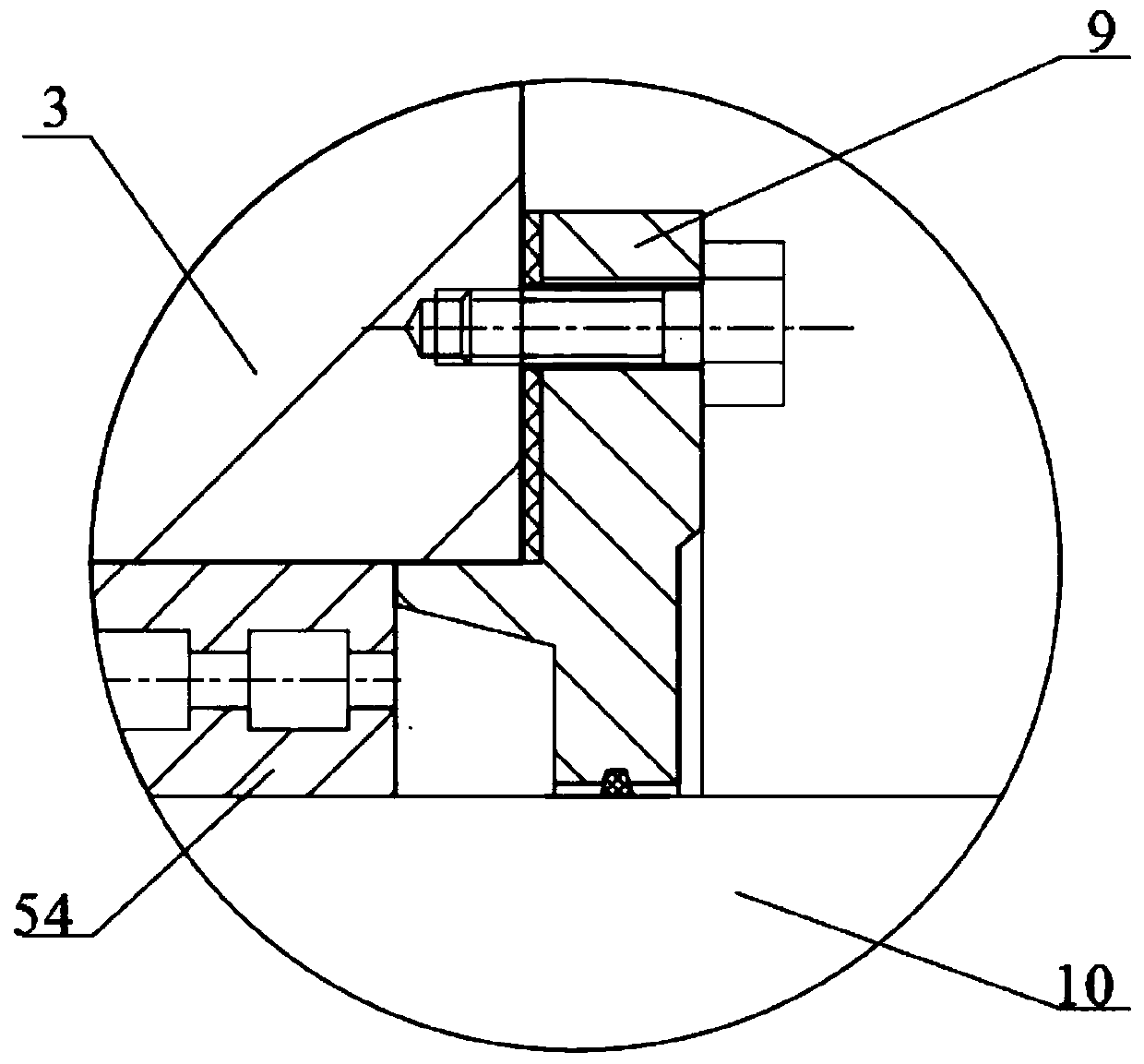

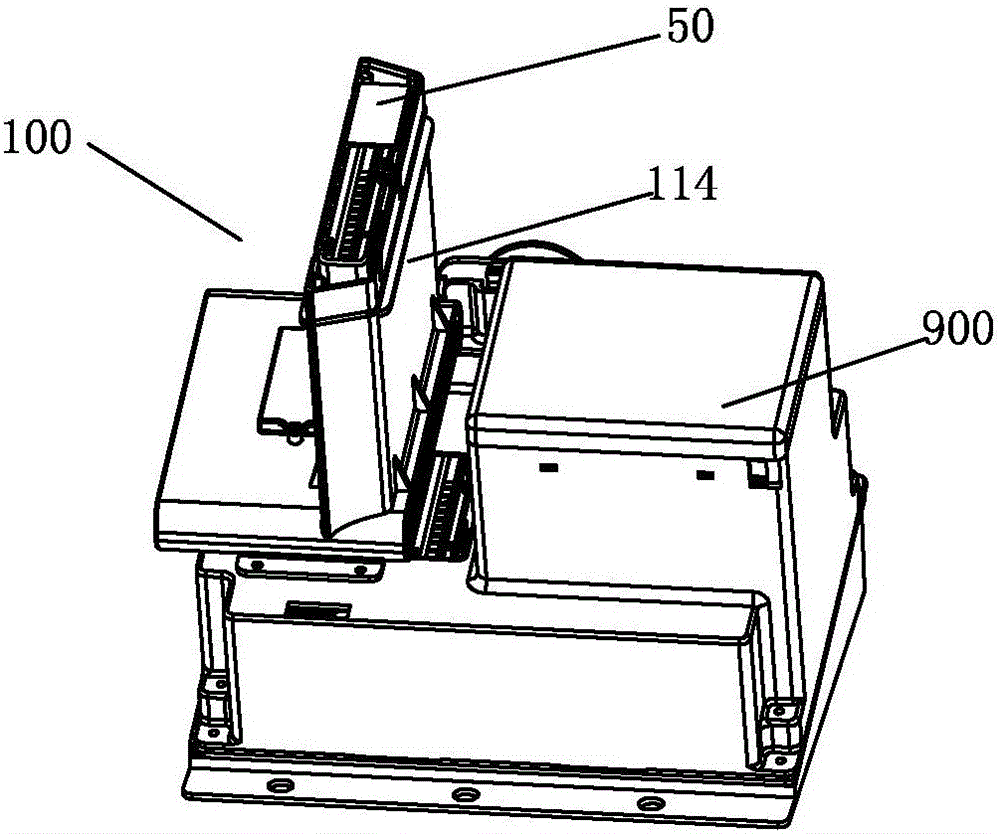

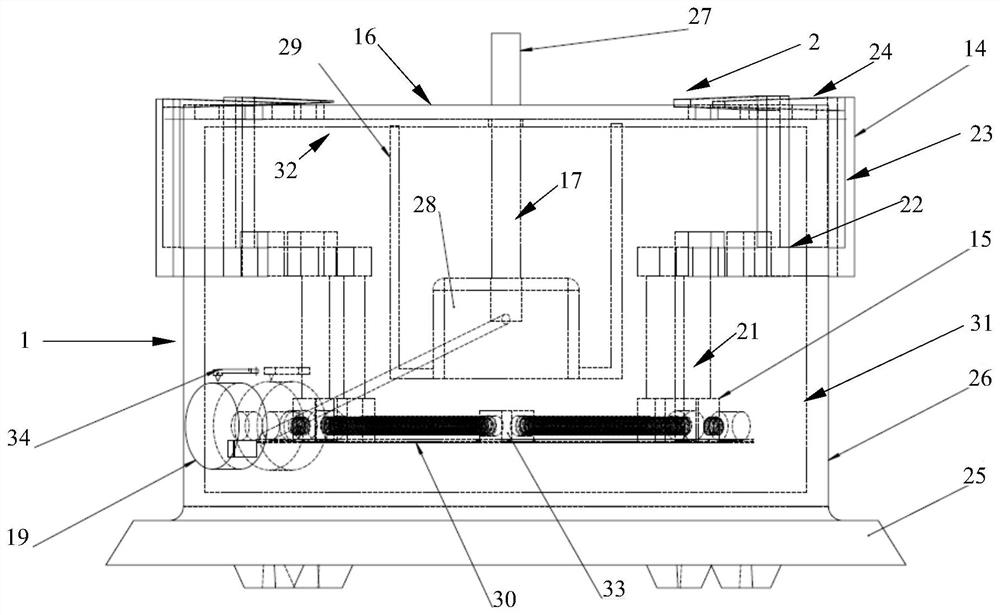

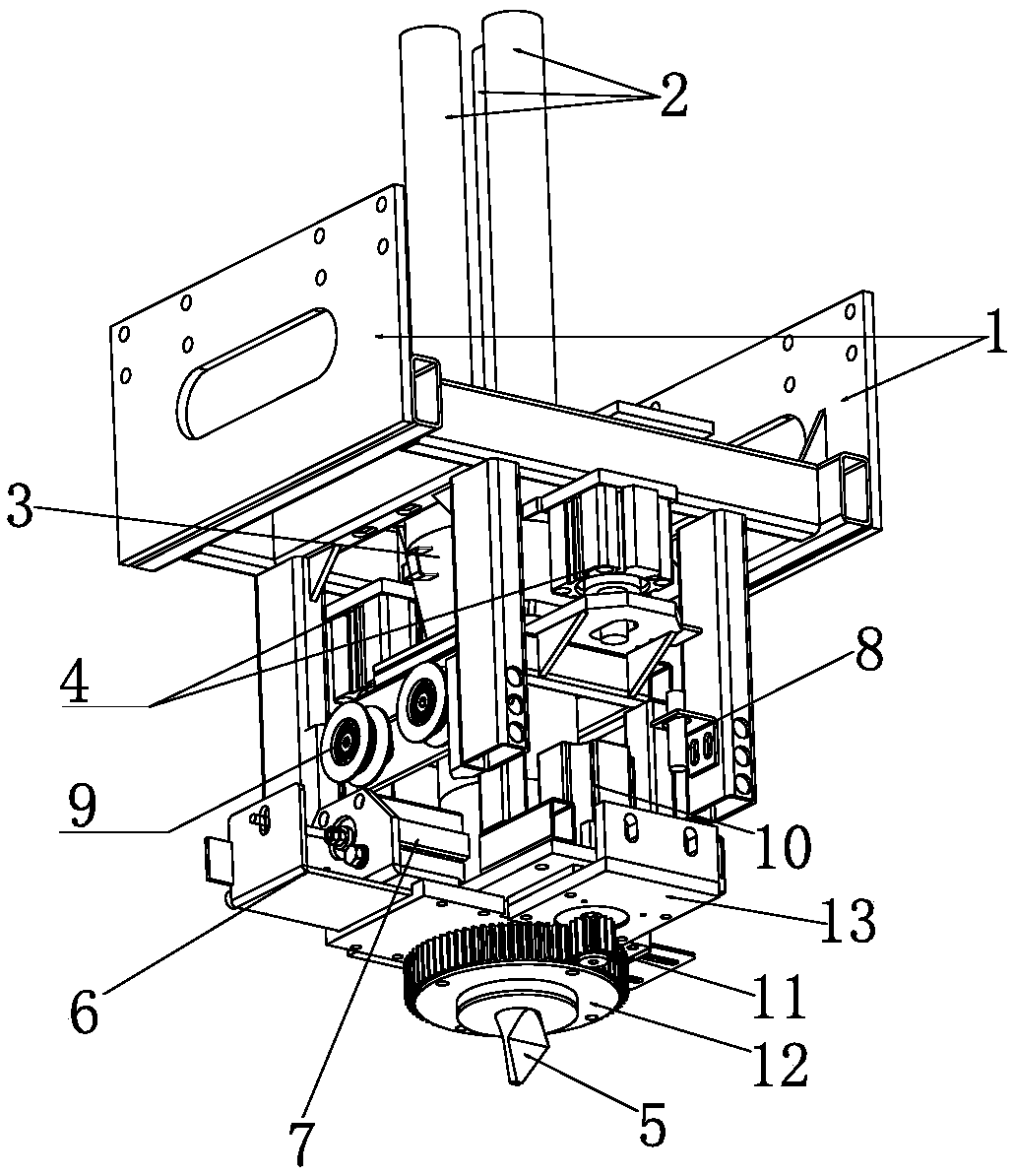

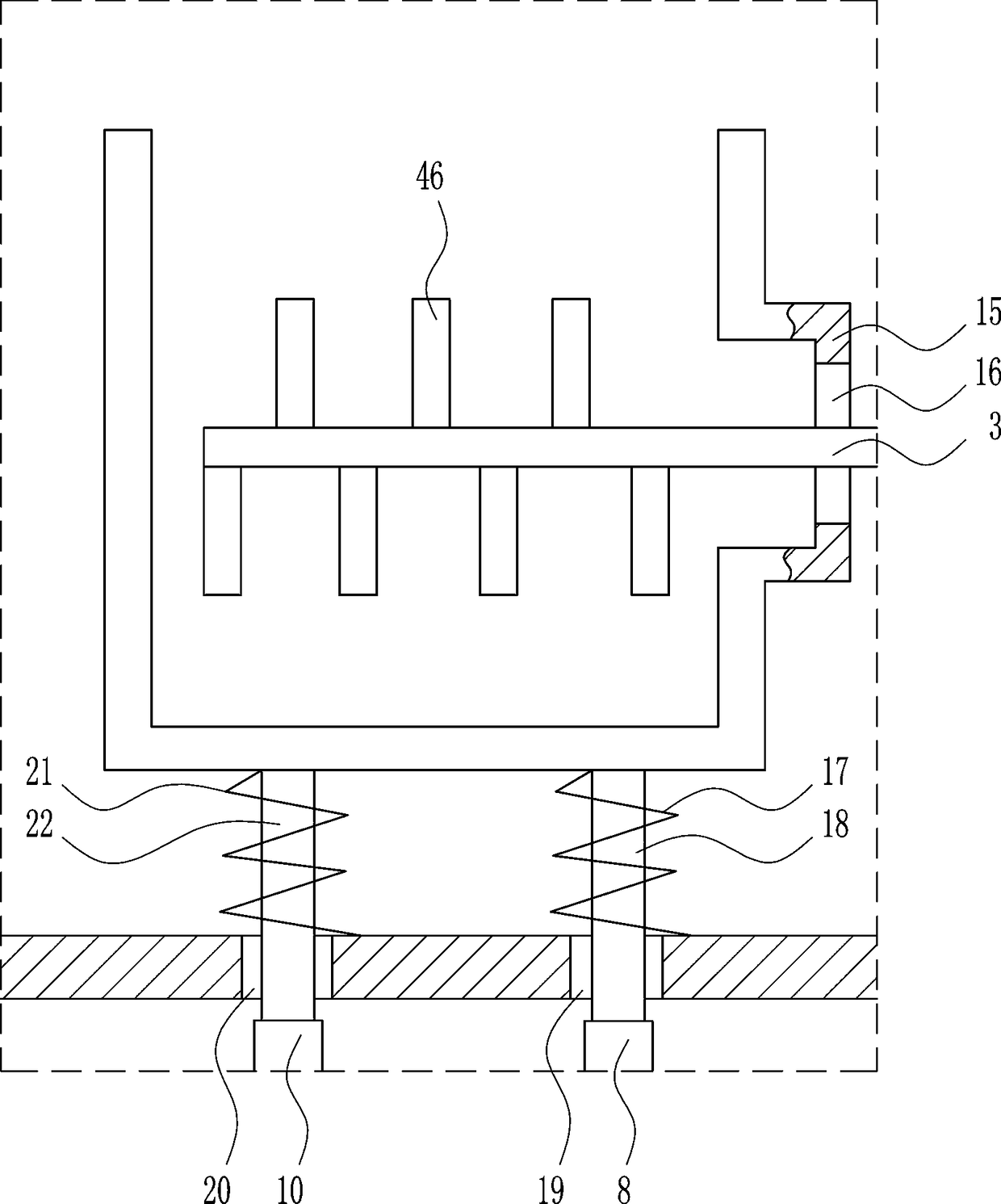

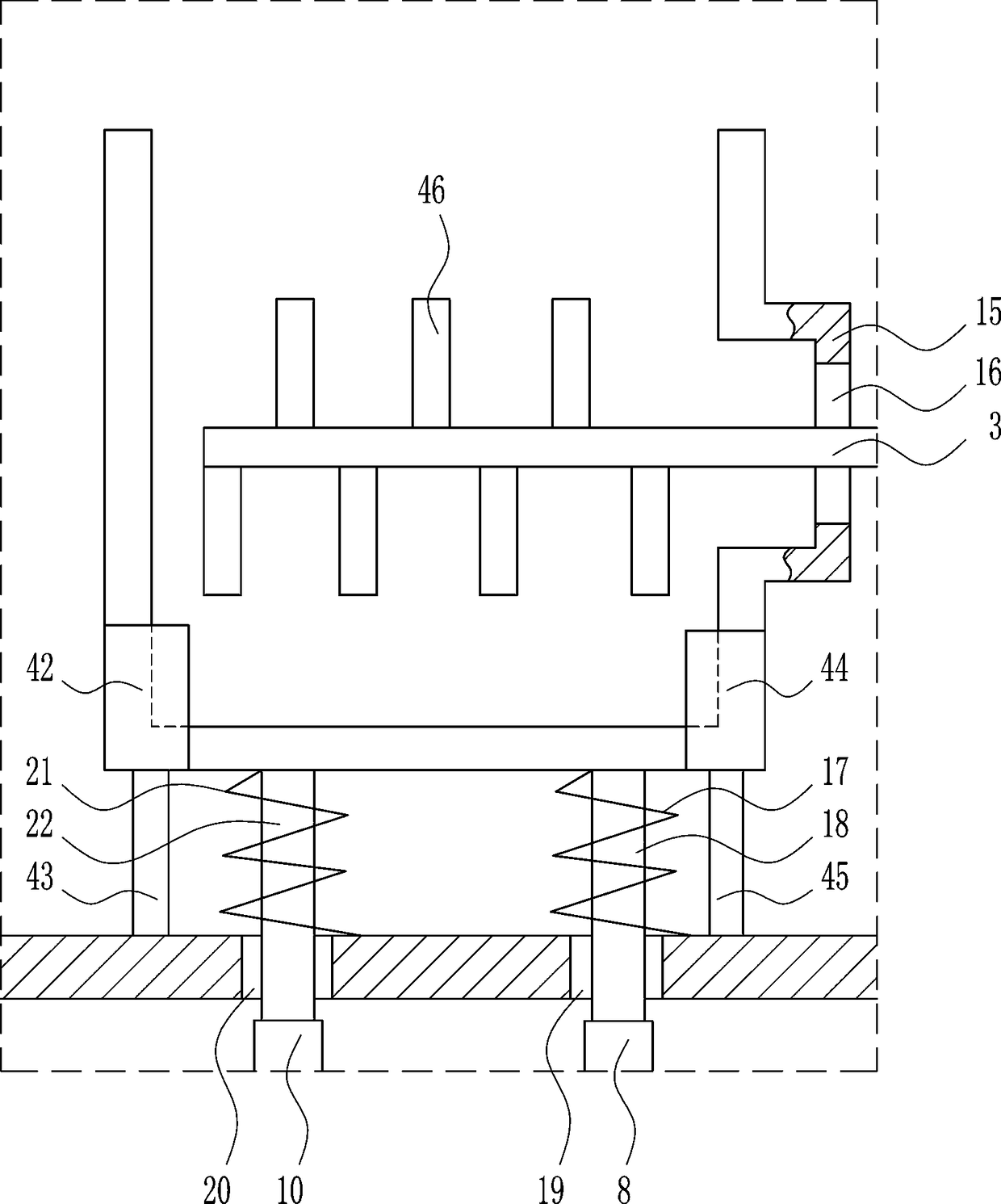

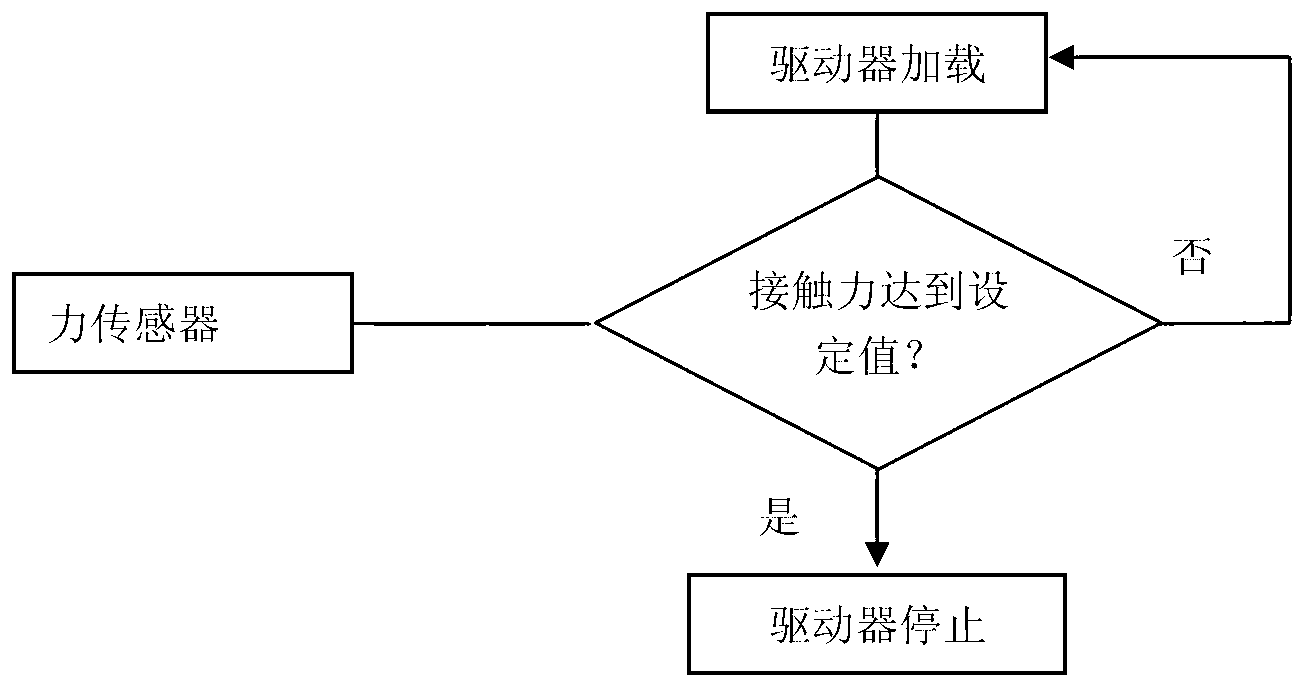

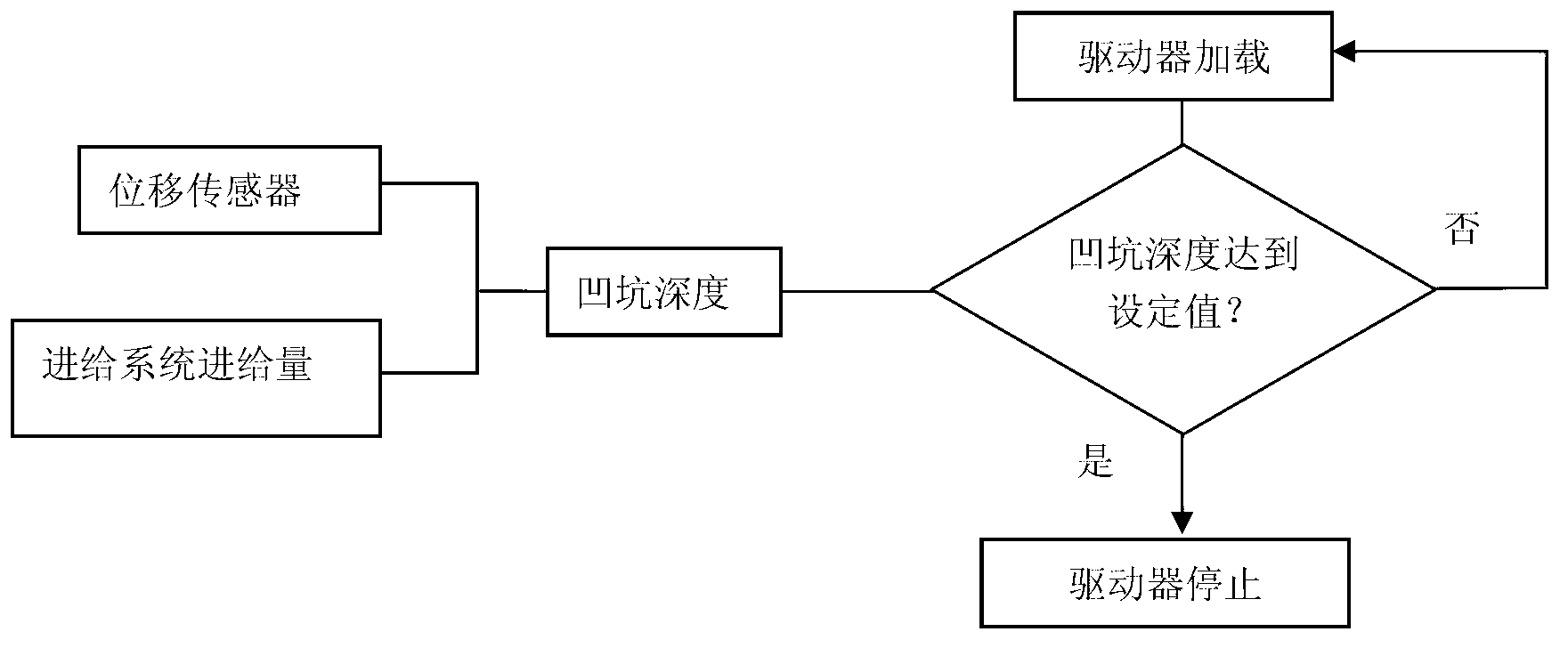

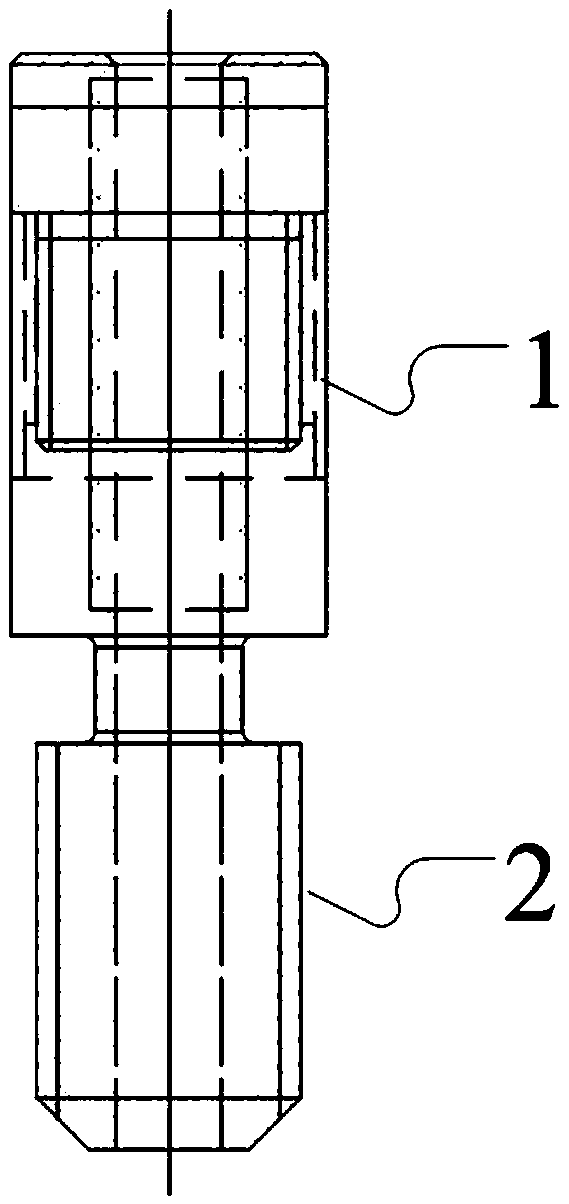

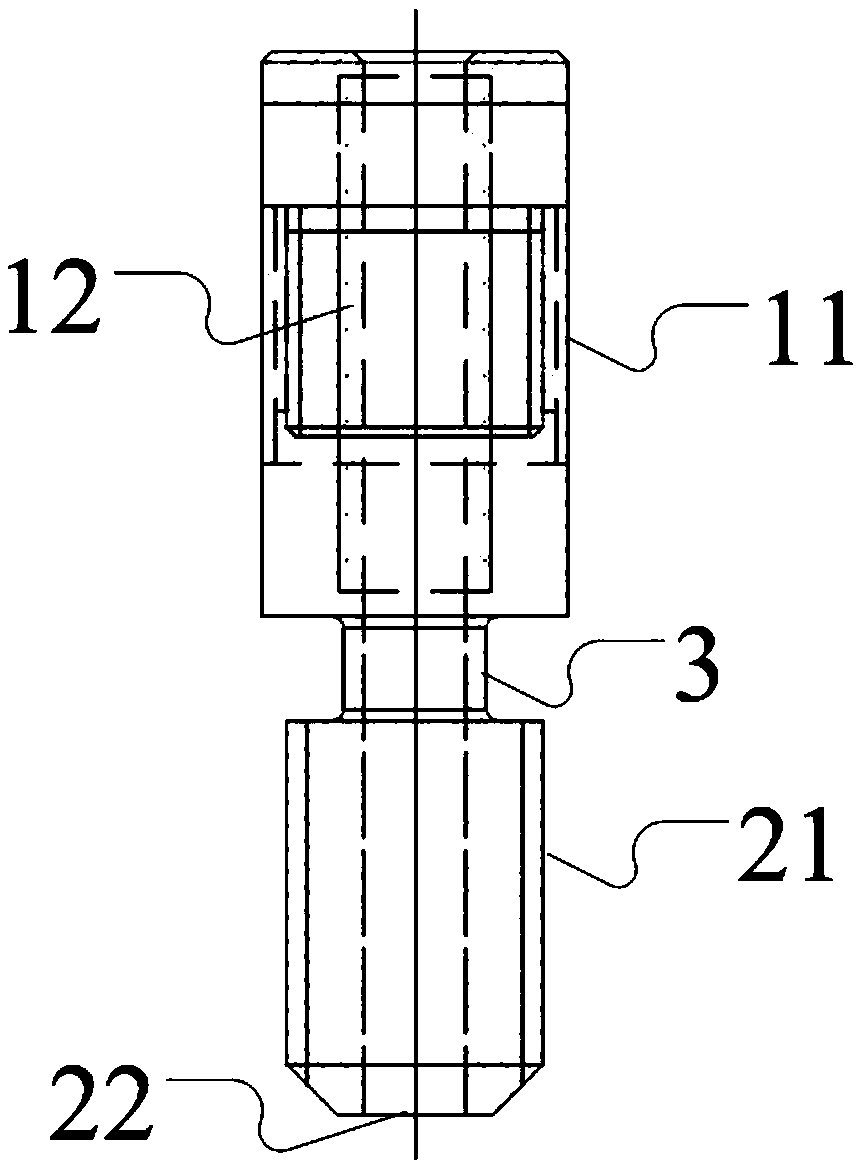

Static indentation damage prefabrication testing machine for composite material structures

InactiveCN102706754AAchieving Prefabricated DamageControl feedMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringMechanical engineering

The invention relates to a static indentation damage prefabrication testing machine for composite material structures, which comprises a supporting component, a pressure head, a pressure head feeding component and a measuring and controlling component, wherein the pressure head feeding component is connected with the supporting component and further in transmission connection with the pressure head; the measuring and controlling component is connected with the pressure head feeding component; and the pressure head is aligned with a test piece. Compared with the prior art, the static indentation damage prefabrication testing machine has a simple integral structure, is convenient to move and is suitable for prefabricating static indentation damages of the large-scale composite material structures.

Owner:SHANGHAI JIAO TONG UNIV

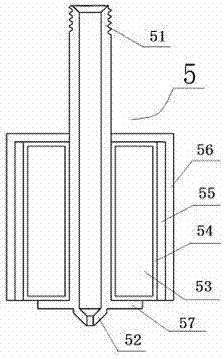

Throat pipe structure for 3D printer, nozzle device and desktop grade 3D printer

PendingCN109514860AControl the amount of extrusionControl feedManufacturing heating elements3D object support structures3d printTitanium

The invention discloses a throat pipe structure for a 3D printer, a nozzle device and a desktop grade 3D printer. The throat pipe structure comprises a heat dissipating cold area and a heating hot area. The heat dissipating cold area comprises a titanium throat pipe outer pipe body and a polytetrafluoroethylene throat pipe inner pipe body. The polytetrafluoroethylene throat pipe inner pipe body issleeved with the titanium throat pipe outer pipe body. The heating hot area comprises a heating block connecting area and a nozzle connecting area. The heating block connecting area is located on theouter side of the heating hot area. The nozzle connecting area is located below the heating hot area. The heating hot area further comprises a heat insulating area connected with the titanium throatpipe outer pipe body so that the range of the heating hot area in the throat pipe structure can be reduced and the extrusion amount of printing materials can be controlled. The throat pipe structure solves the technical problem that the printing effect is poor. The 3D printer is simple in structure, convenient to install, high in precision and stable in quality.

Owner:SHANGHAI FUSION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com