Patents

Literature

44results about How to "Realize automated separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for cleaning and recycling oil stains on water surface

InactiveCN106351196AGuarantee personal safetySave human effortWater cleaningGeneral water supply conservationDrive shaftFuel tank

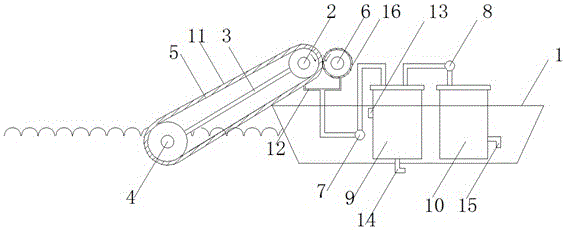

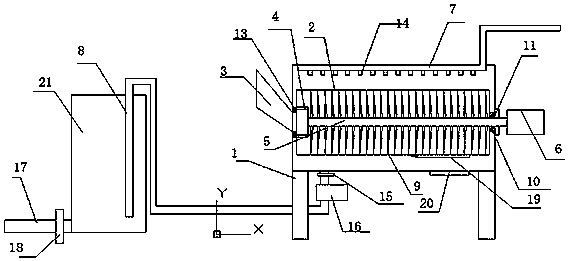

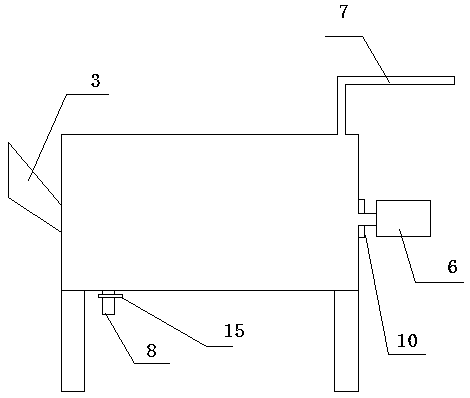

The invention relates to the technical field of water surface oil absorption, in particular to a water surface oil pollution removal and recovery device, comprising a hull, an upper transmission wheel fixed on the hull, a universal drive shaft, a lower transmission wheel, a conveyor belt, and a squeeze roller for the upper transmission wheel , the first oil pump, the second oil pump and the oil-water separation tank and oil storage tank arranged on the hull, the upper transmission wheel is powered by the engine, the upper transmission wheel is connected to the lower transmission wheel through the cardan shaft, and the transmission belt is respectively connected with the upper transmission wheel and the lower transmission wheel. The periphery of the transmission wheel is surrounded to form a closed ring, and the oil-absorbing felt is installed on the transmission belt. The extrusion roller contacts and rotates with the oil-absorbing felt on the upper transmission wheel to squeeze out the oil. There is an oil collection tank at the oil outlet, and the outlet of the oil collection tank leads to the first oil pump. The oil from the outlet of the first oil pump passes through the oil-water separation tank, the second oil pump and then enters the oil storage tank. Using the device of the invention can remove oil stains on the water surface in a large area with high efficiency, guarantee the safety of personnel, and make the recovered oil have high purity.

Owner:GUANGXI UNIV

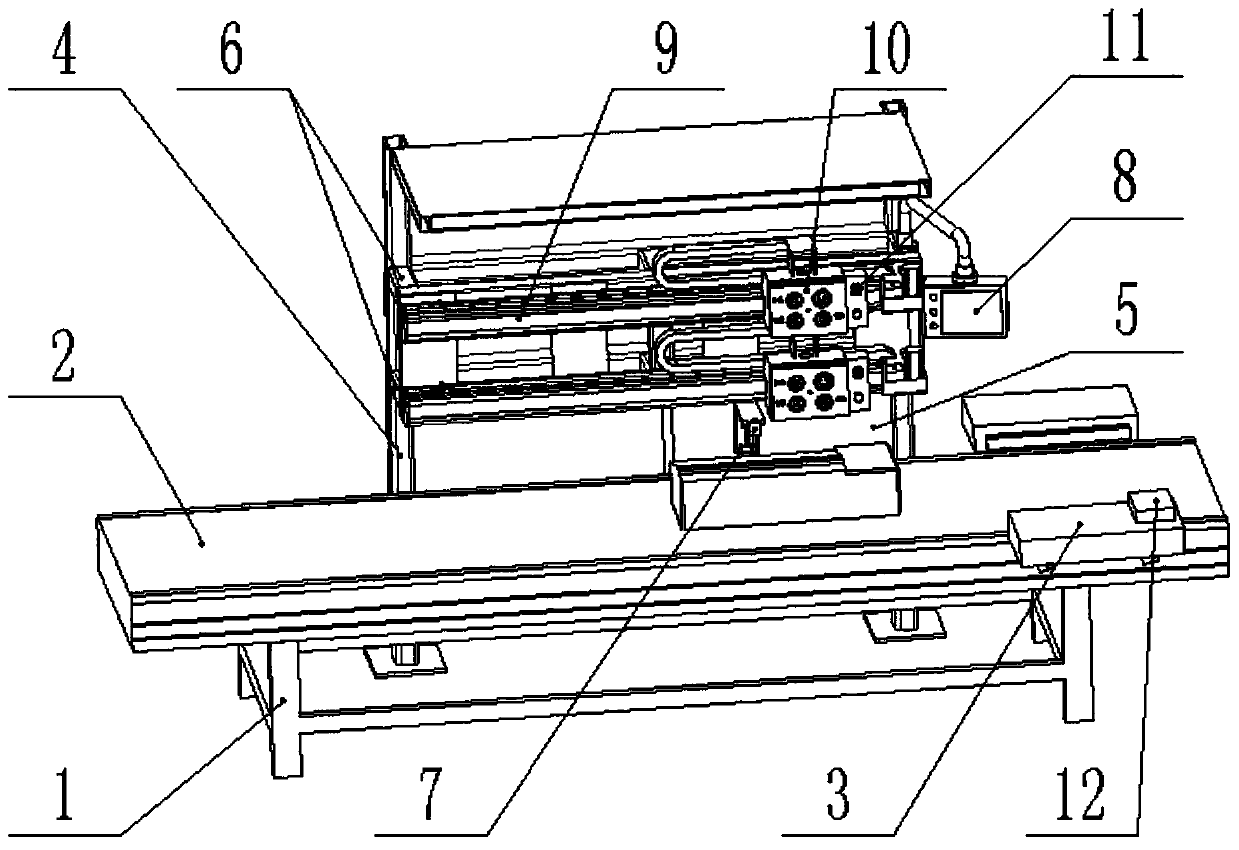

Automatic fly maggot separation machine

ActiveCN106332845ARealize automated separationWith obstacle avoidanceAnimal husbandryMaggotMachine vision

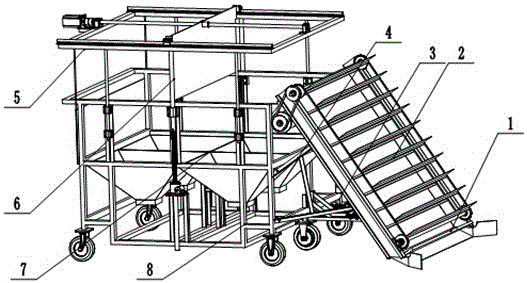

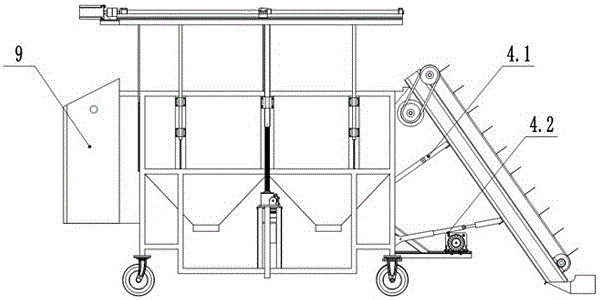

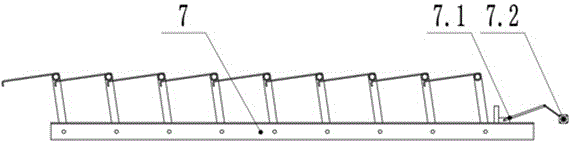

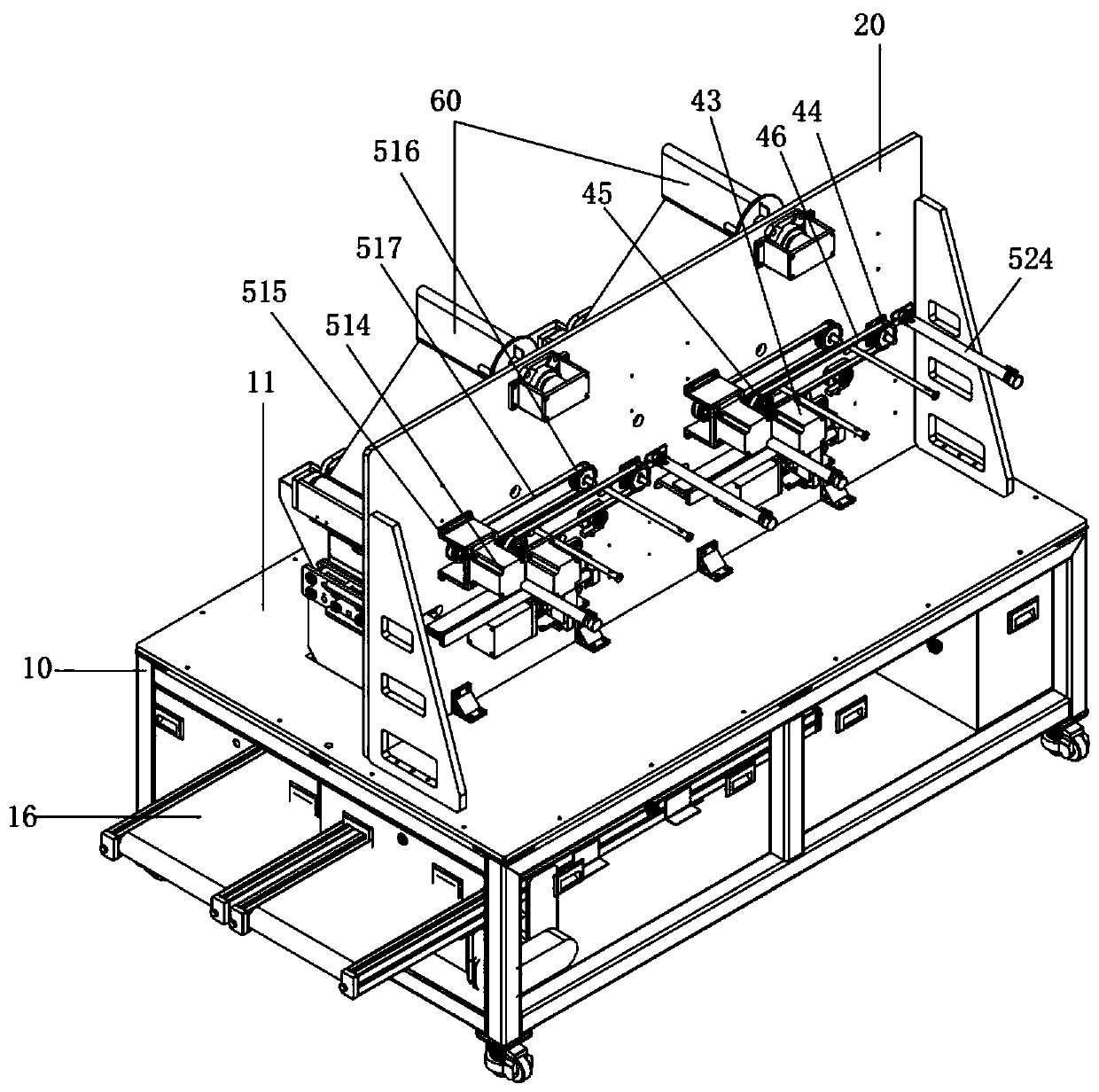

The invention discloses an automatic fly maggot separation machine. The automatic fly maggot separation machine is characterized in that a reversing scraper conveying system is arranged at the front end of the separation machine, and is used for conveying the material on ground into a material hopper of the separation machine; a machine vision detection system is arranged on a support frame at the front end of the conveying system, and is used for detecting the material and fly maggot densities before operation in real time; a conveying belt obstacle-crossing assembly is arranged between the reversing scraper conveying system and a separation machine body; a louver vibration device is arranged on the separation machine body; ultrasonic obstacle-avoiding modules are arranged around the separation machine body. The automatic fly maggot separation machine has the advantages that the fly maggots and material slag can be automatically separated, and the automatic walking in a fly maggot culture greenhouse and the separation and collection of fly maggots can be simultaneously completed; by adopting the machine vision detection system, the fly maggot density can be monitored in real time, the material charging speed is automatically controlled, and the separation effect is promoted.

Owner:JINHUA ACAD OF AGRI SCI +1

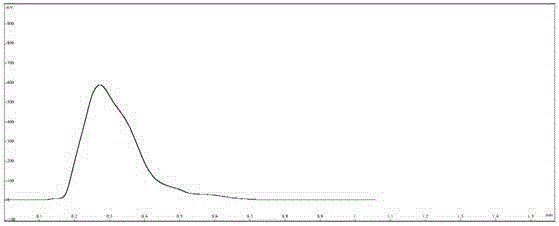

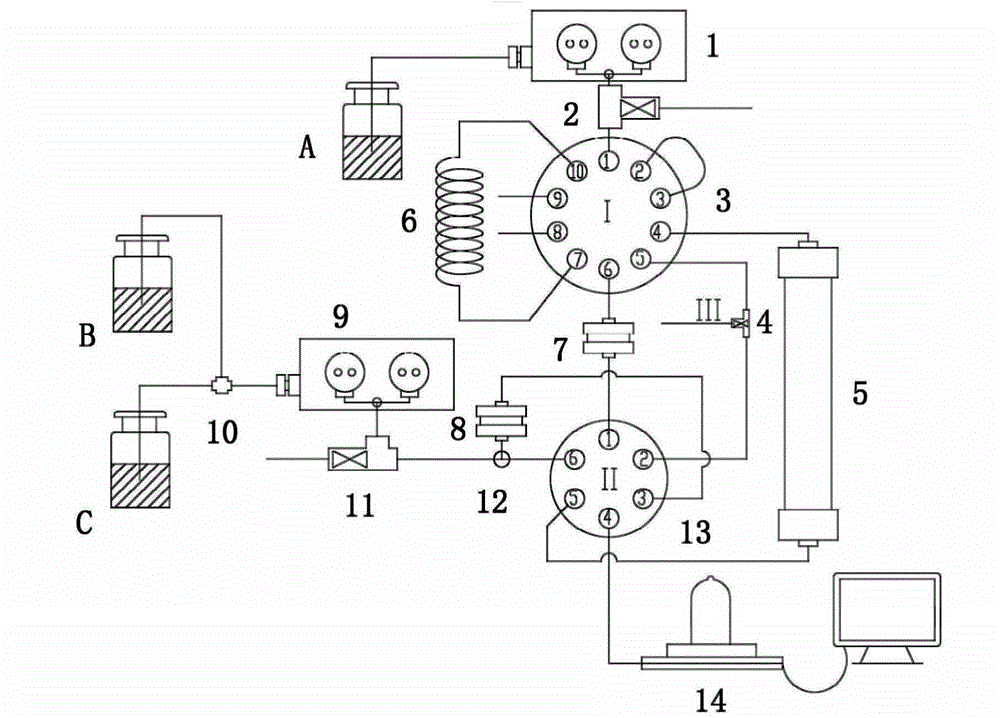

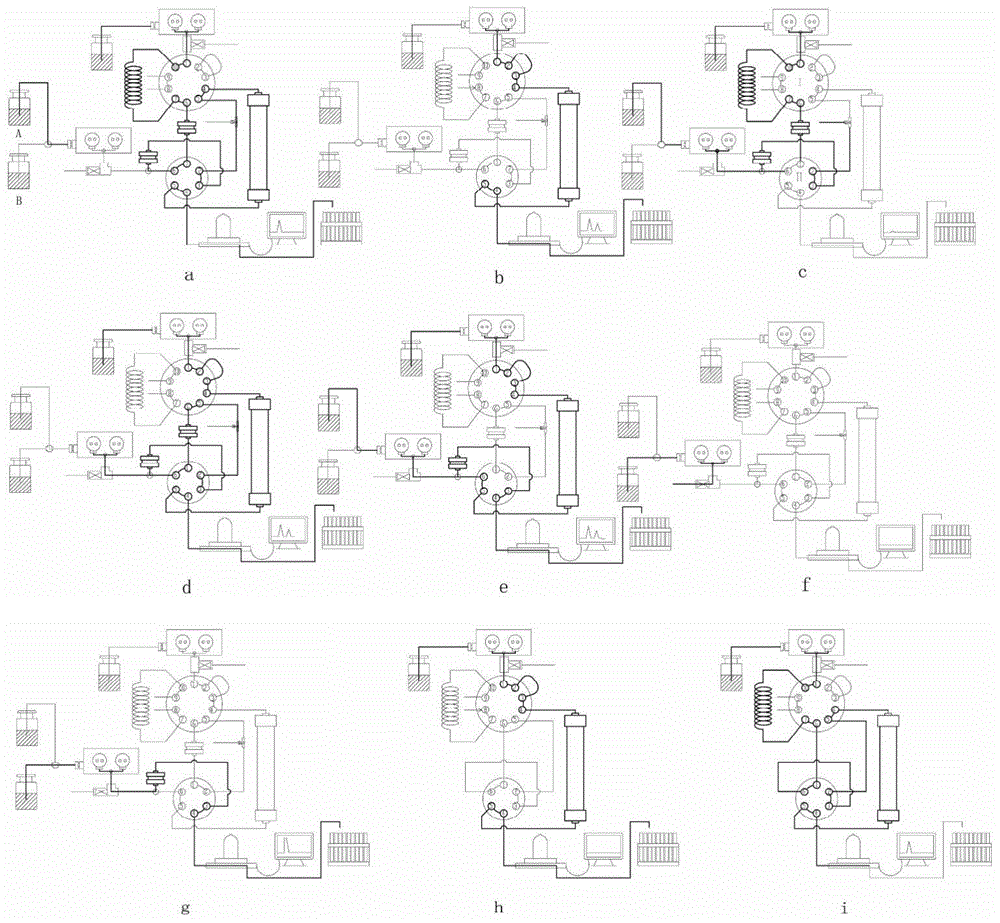

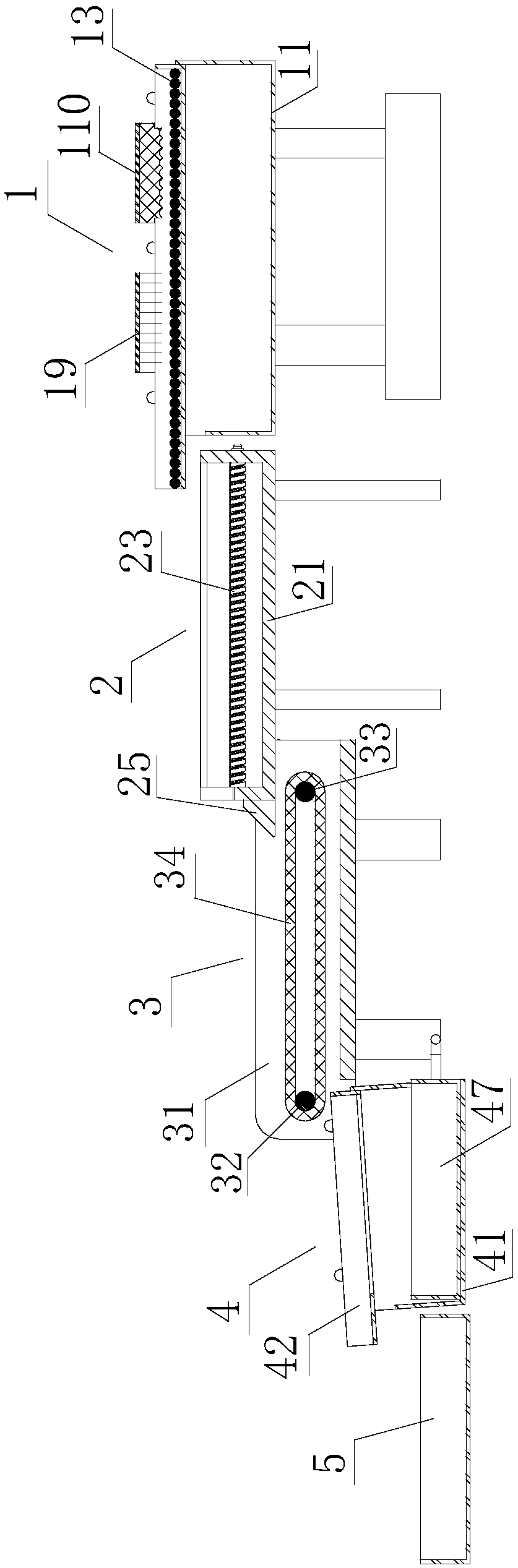

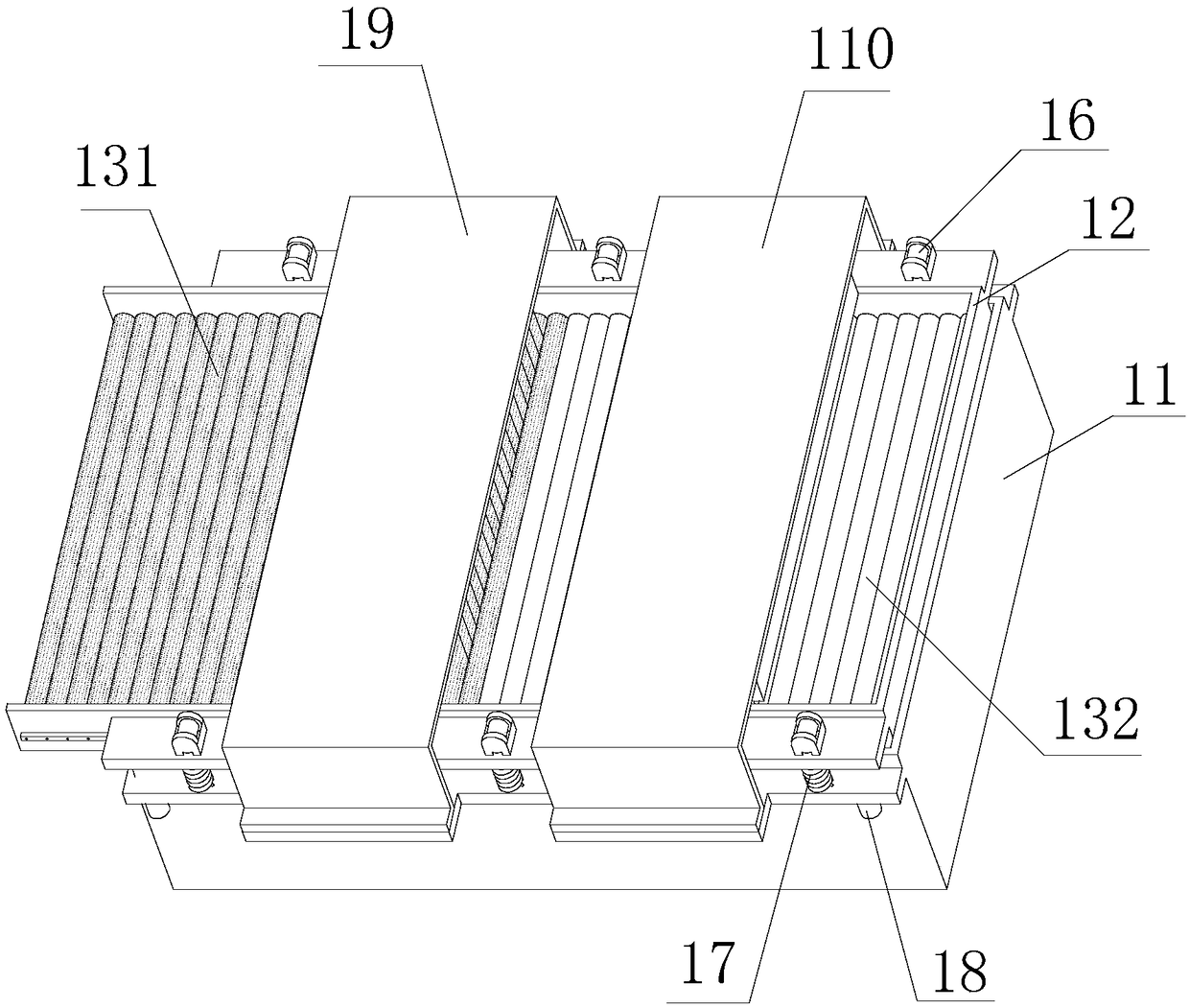

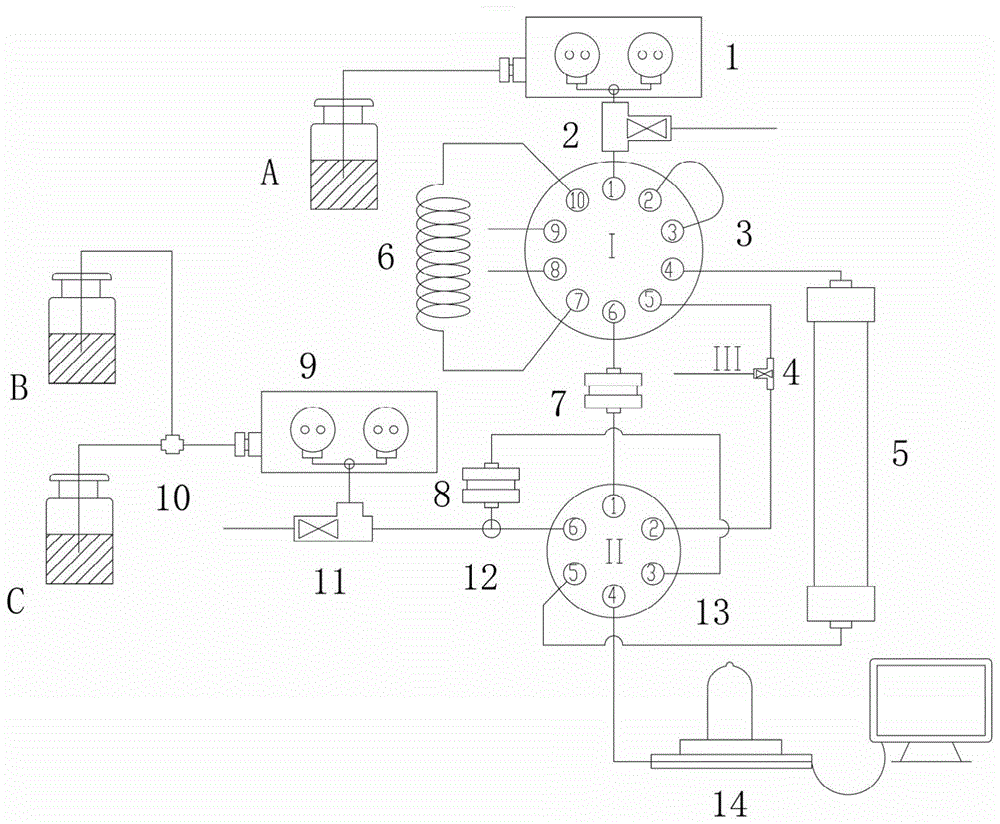

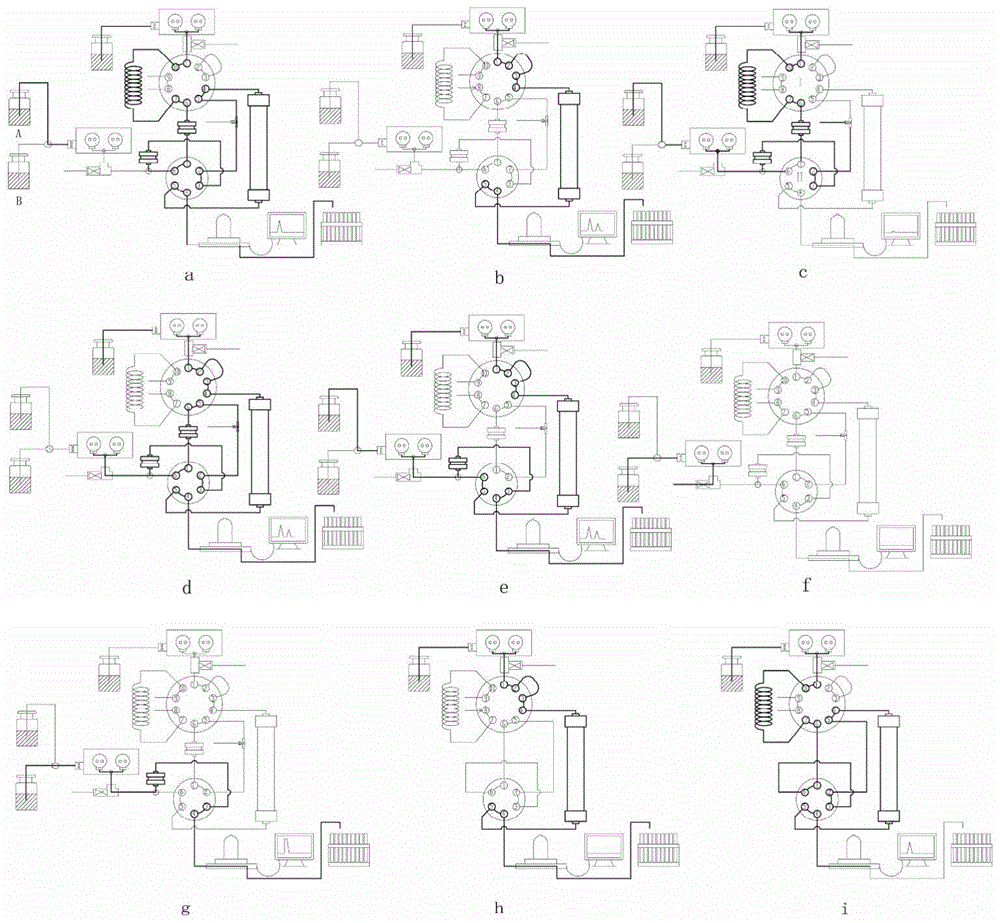

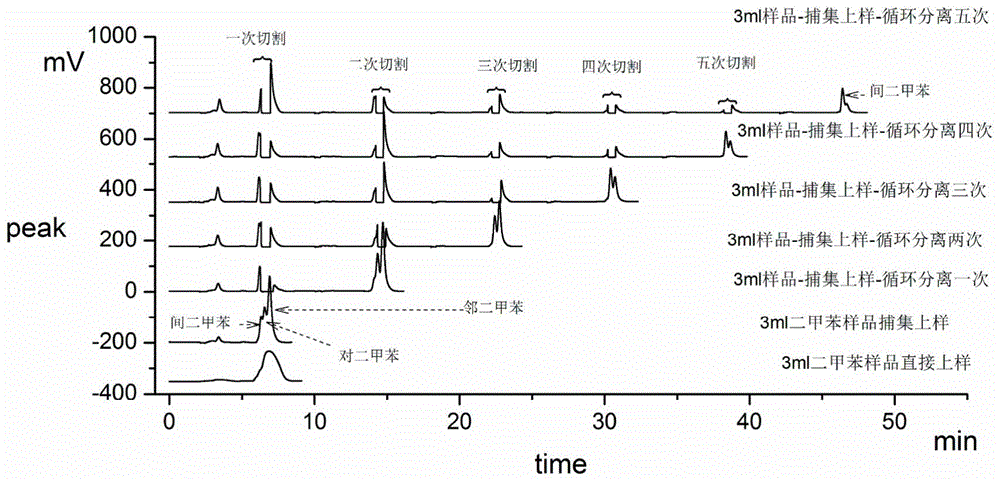

Preparative circulating chromatography apparatus

ActiveCN104422735AExtended service lifeSmall dead volumeComponent separationChromatographic separationNatural product

A preparative circulating chromatography apparatus can be applied in chromatographic separation preparation of target components in a complex sample and is mainly advantaged in that: (1) with pre-treatment and concentration of an on-line sample, large-volume sampling on the premise of a high column efficiency can be achieved; (2) through position exchange between a separation column and a trapping column, circulating separation and purification of the target components are achieved and the preparative circulating chromatography apparatus is less in circulating dead volume and column efficiency loss; and (3) through concentration-elution of a finish product through the trapping column, a separation-concentration integrated process is achieved, wherein the three functions are achieved through adjustment of an adsorption performance of the trapping column and valve exchange. Compared with a conventional preparative chromatography method, the apparatus has significant advantages on separations of natural products, drugs and chemical products, especially on separation and preparation of micro-scale targeted components and unstable components in a mixture.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

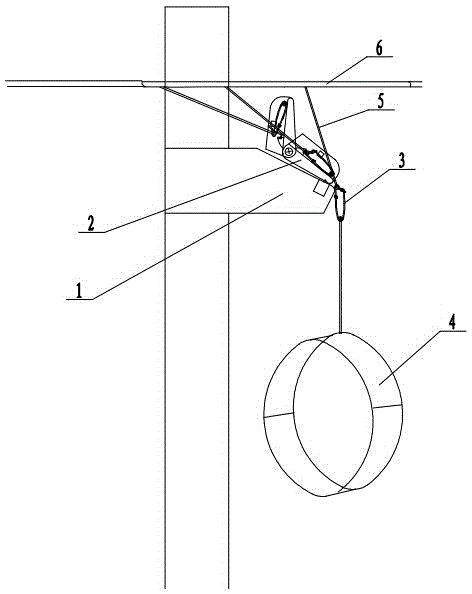

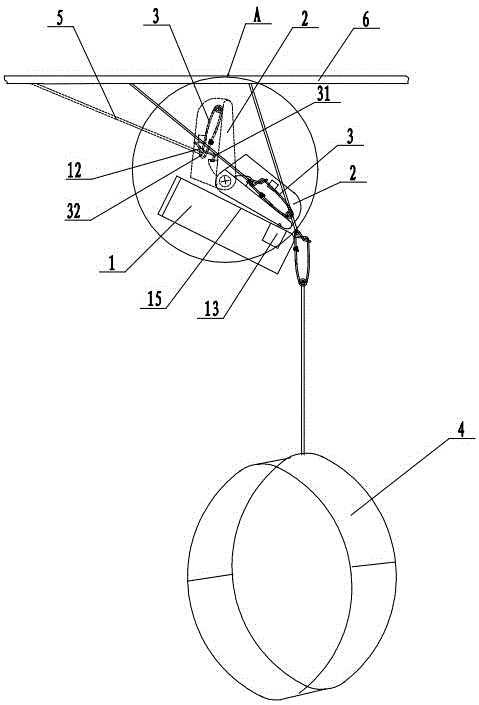

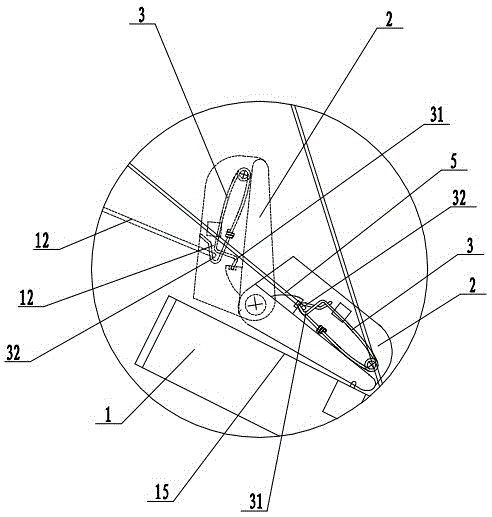

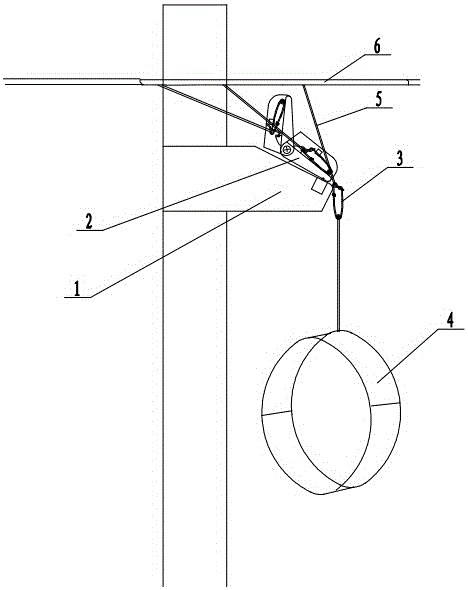

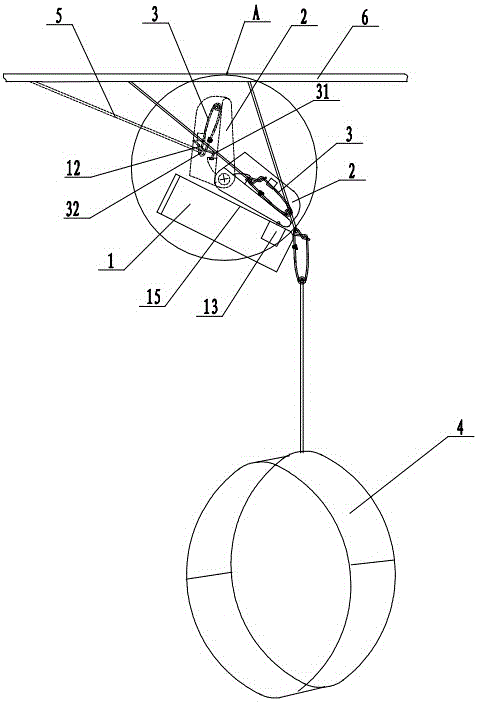

Automatic crab trap releasing device

InactiveCN105059482AOut of automatic implementationAutomated separationTowing/pushing equipmentFisheryStructural engineering

The invention relates to an automatic crab trap releasing device. Problems of great labor intensity, high cost and low efficiency caused by manually releasing the traditional crab trap are mainly solved. The automatic crab trap releasing device comprises a fixed seat and an unhooking device, wherein a lifting hook comprises a clamping part and a releasing part; a crab trap is connected with a supporting rope through the lifting hook; the unhooking device is hinged on the fixed seat; the unhooking device comprises a bottom plate, a stopping plate and a stopping block; a unhooking slot is formed in the bottom plate; the unhooking slot comprises a sliding-in end and a releasing end; the stopping block is fixedly connected with the bottom plate; a clamping slot is formed in the stopping block; the lifting hook is in clamping fit with the clamping slot; the supporting rope is connected with the releasing part; the releasing part of the lifting hook is pulled by the supporting rope to slide into the unhooking slot; the clamping part of the lifting hook is pushed in the clamping slot so as to drive the unhooking device to rotate for a certain angle around a hinging center; the supporting rope is separated from the lifting hook through a rope releasing opening; and the lifting hook is released from the unhooking device. As the releasing device can be used for releasing the crab trap, the automatic crab trap releasing device provided by the invention is advantaged in that the labor intensity of the releasing device is low, the cost of the device is saved, the production effect of the device is extremely high, and automatic separation is effectively realized.

Owner:王伟囊

Full-automatic intelligent fish skin cutting and stripping method

Owner:CHINA JILIANG UNIV

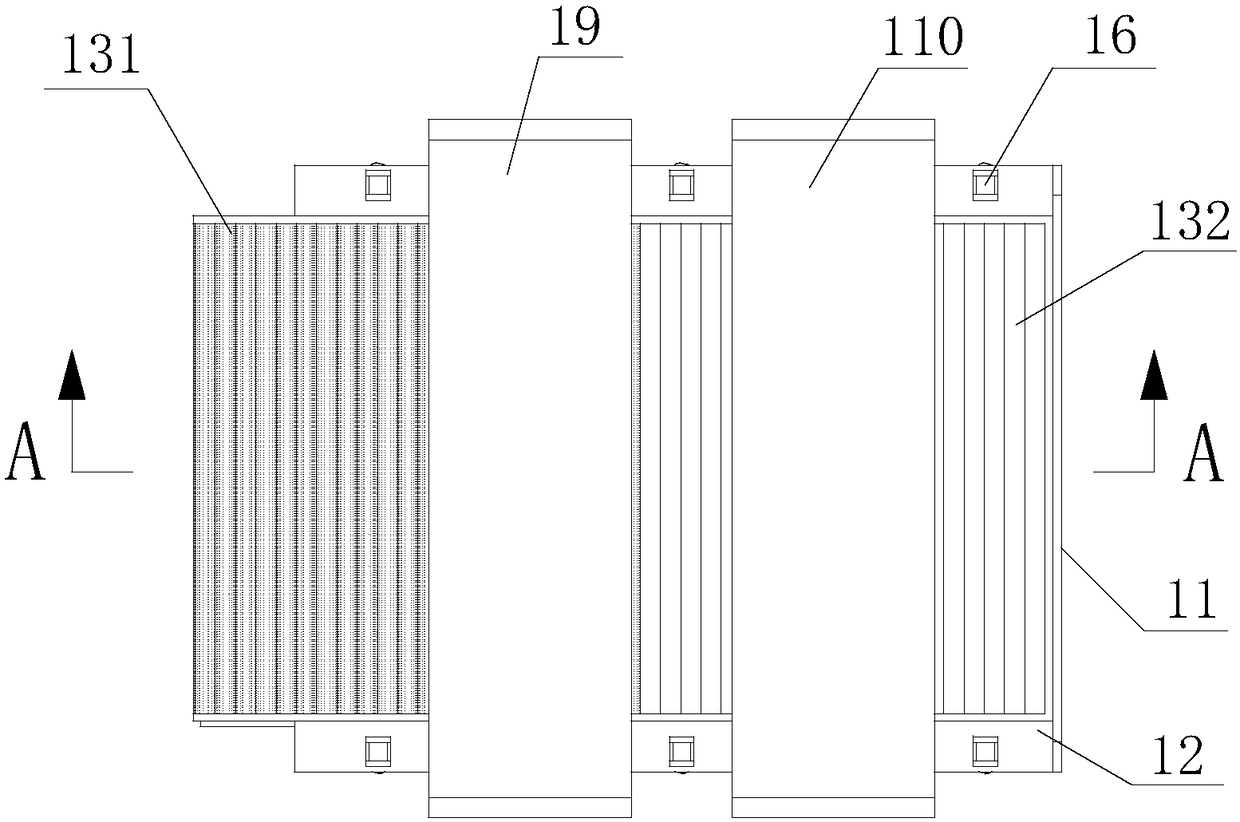

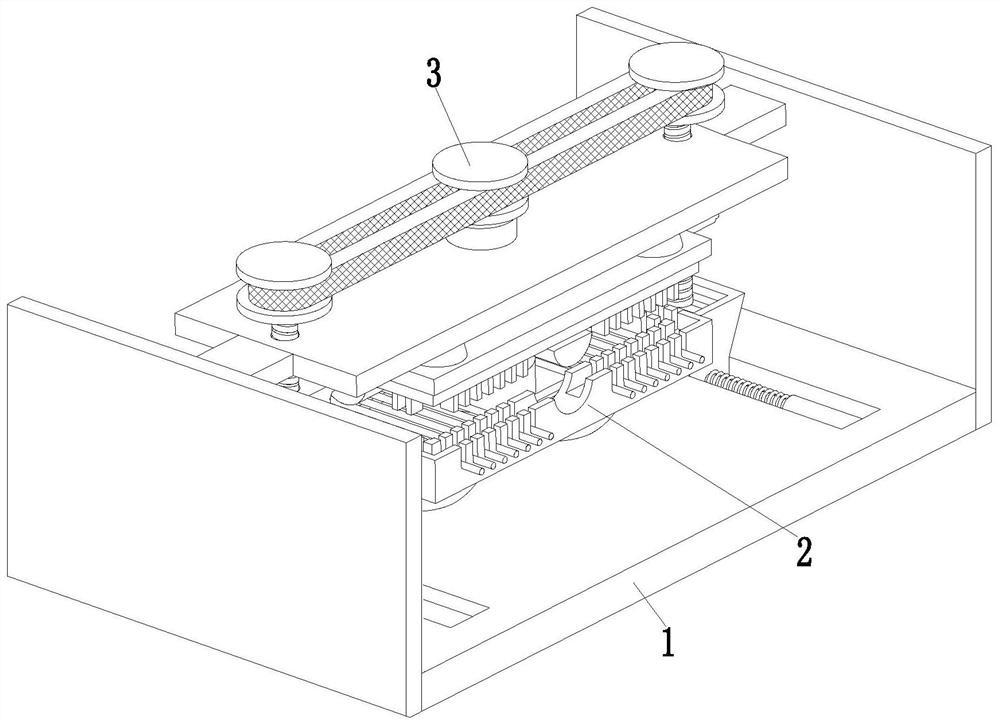

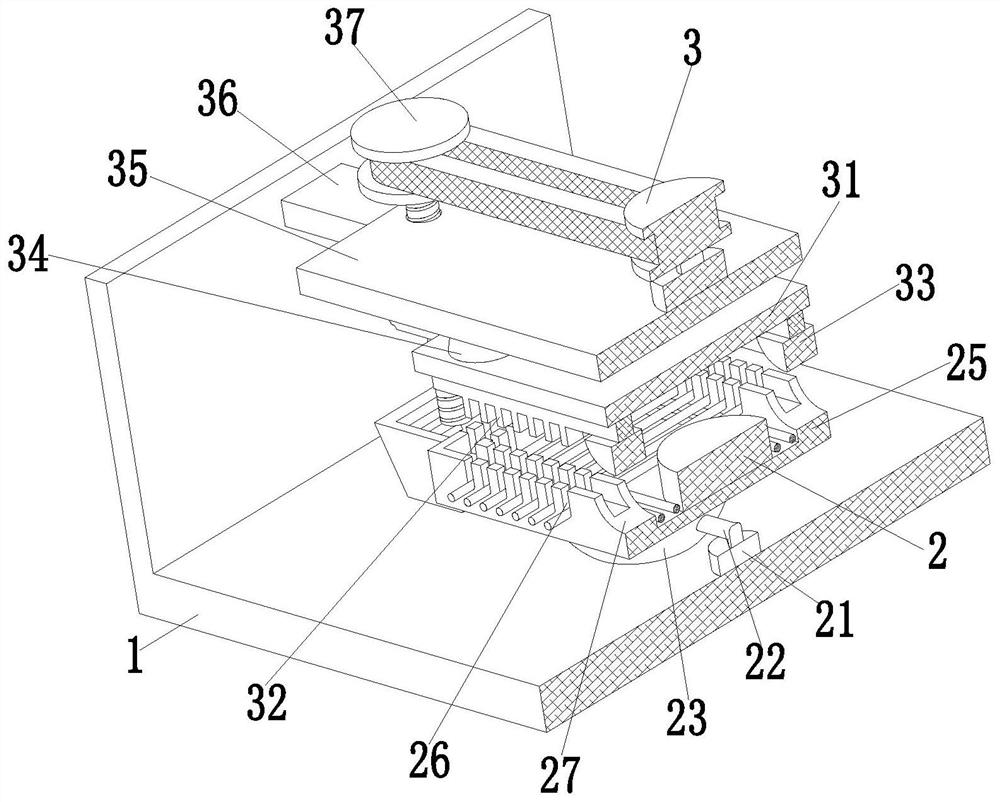

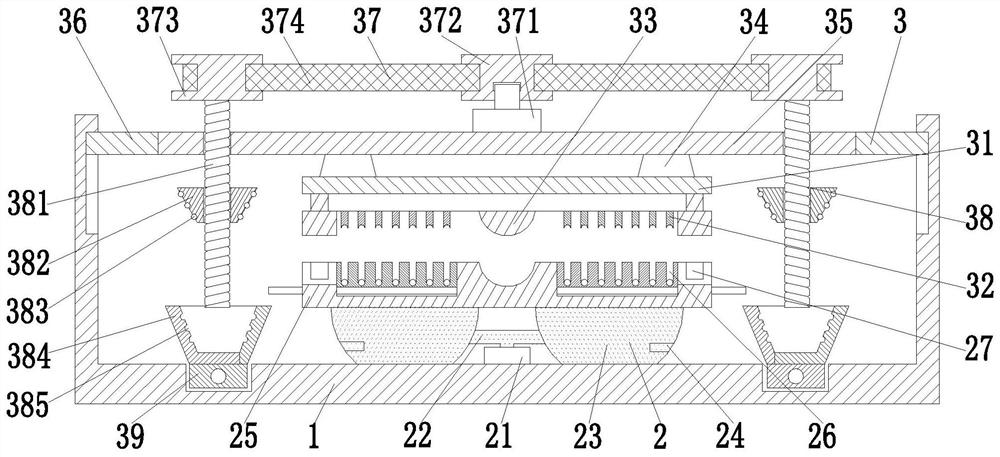

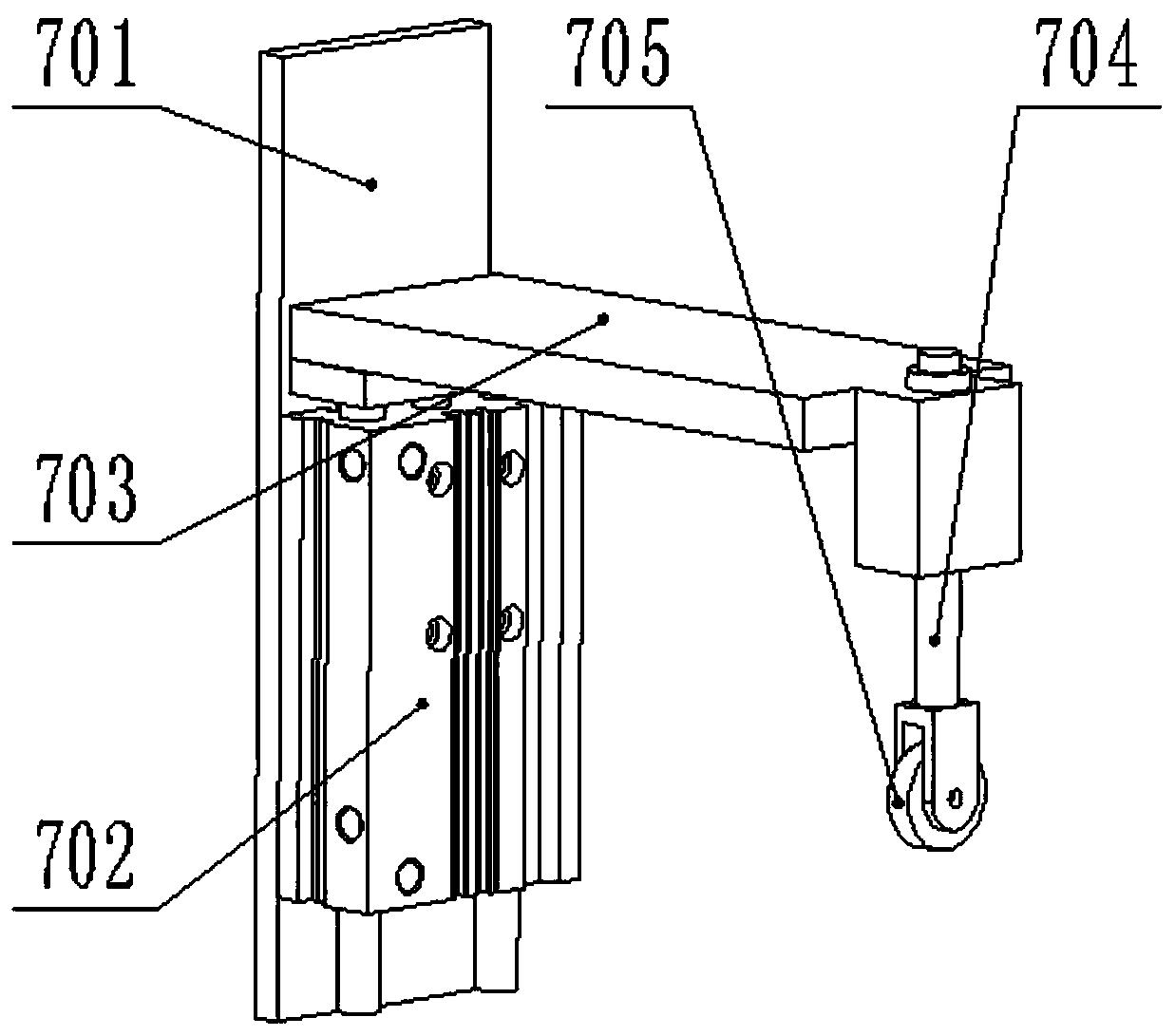

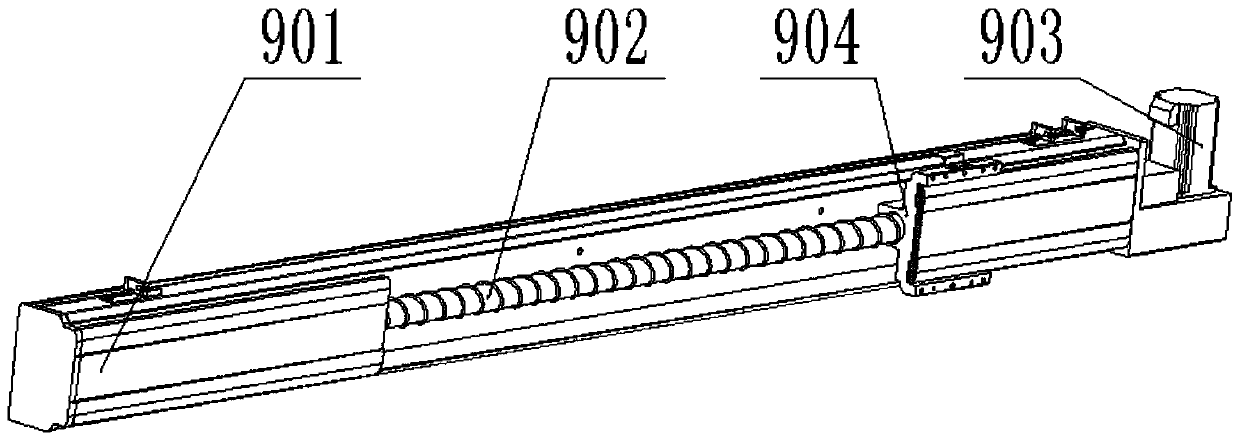

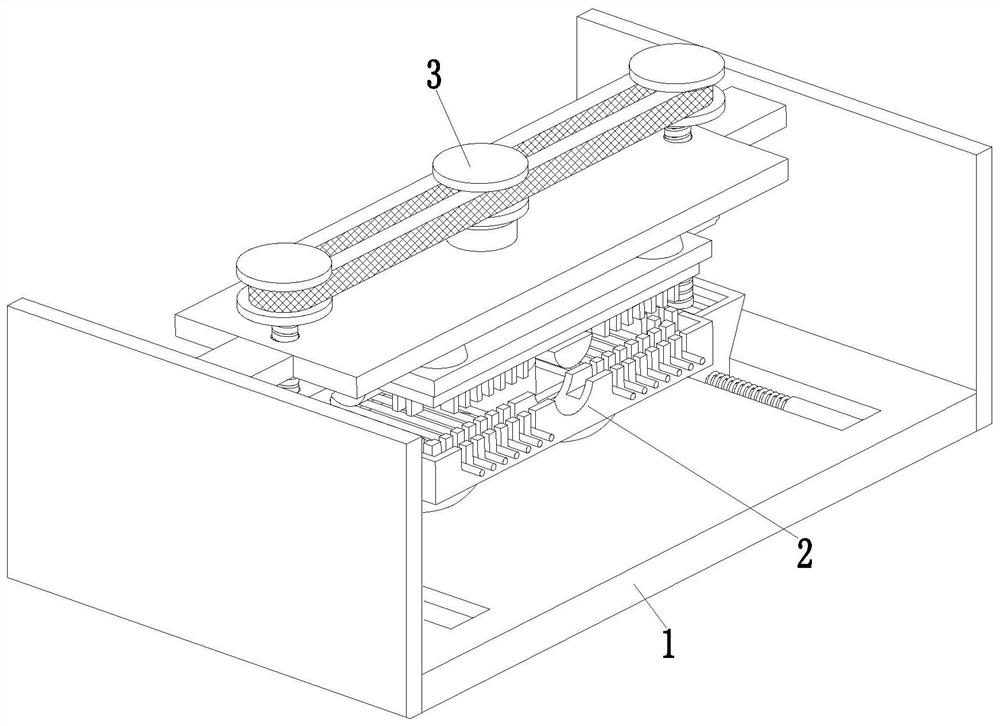

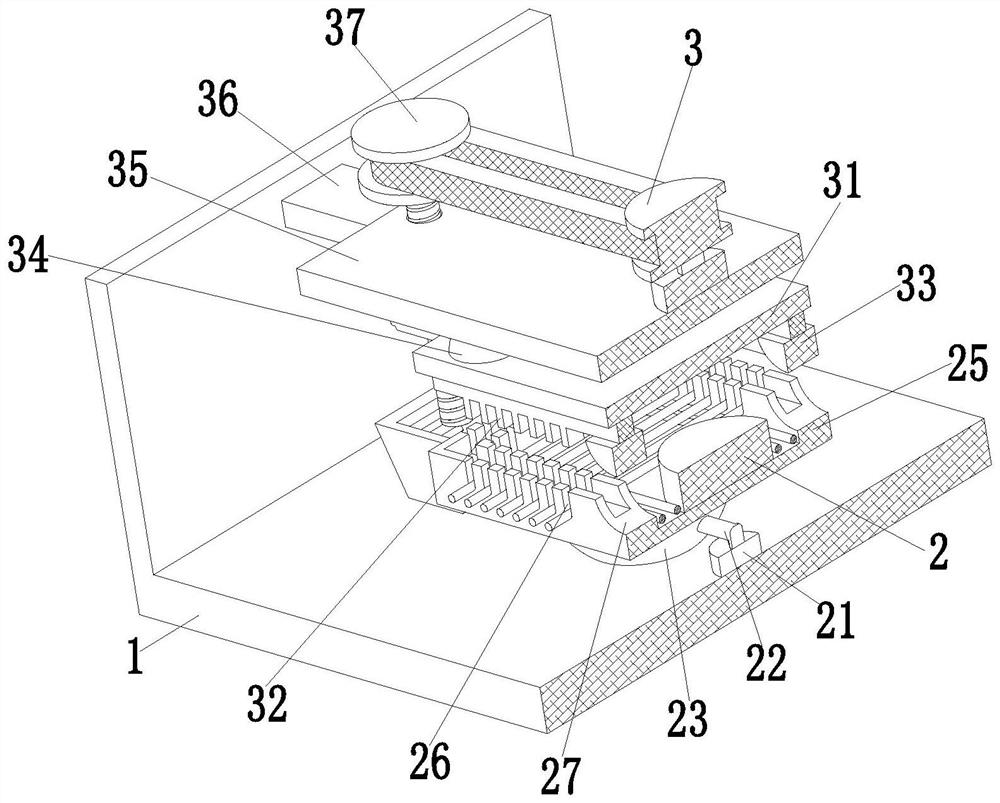

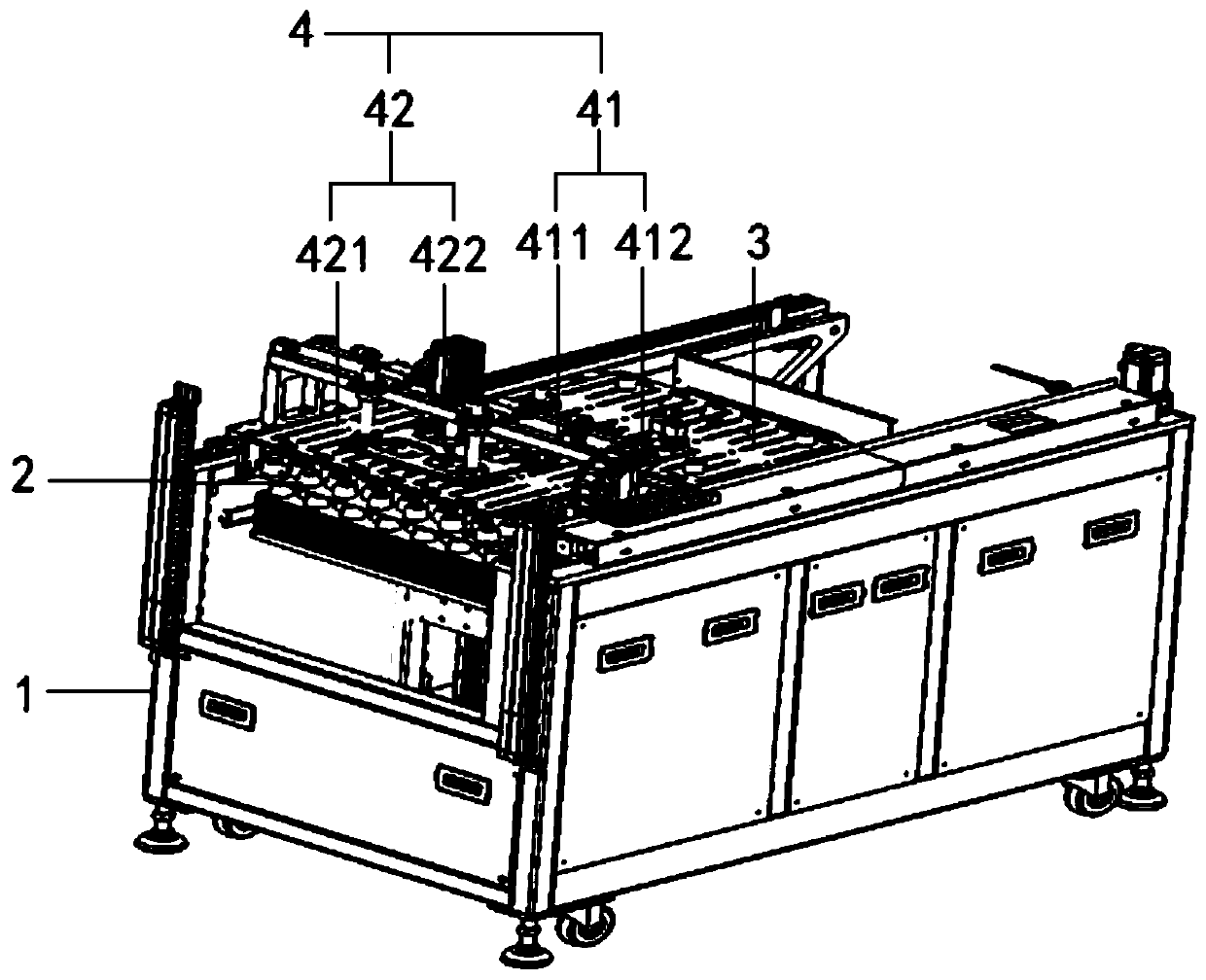

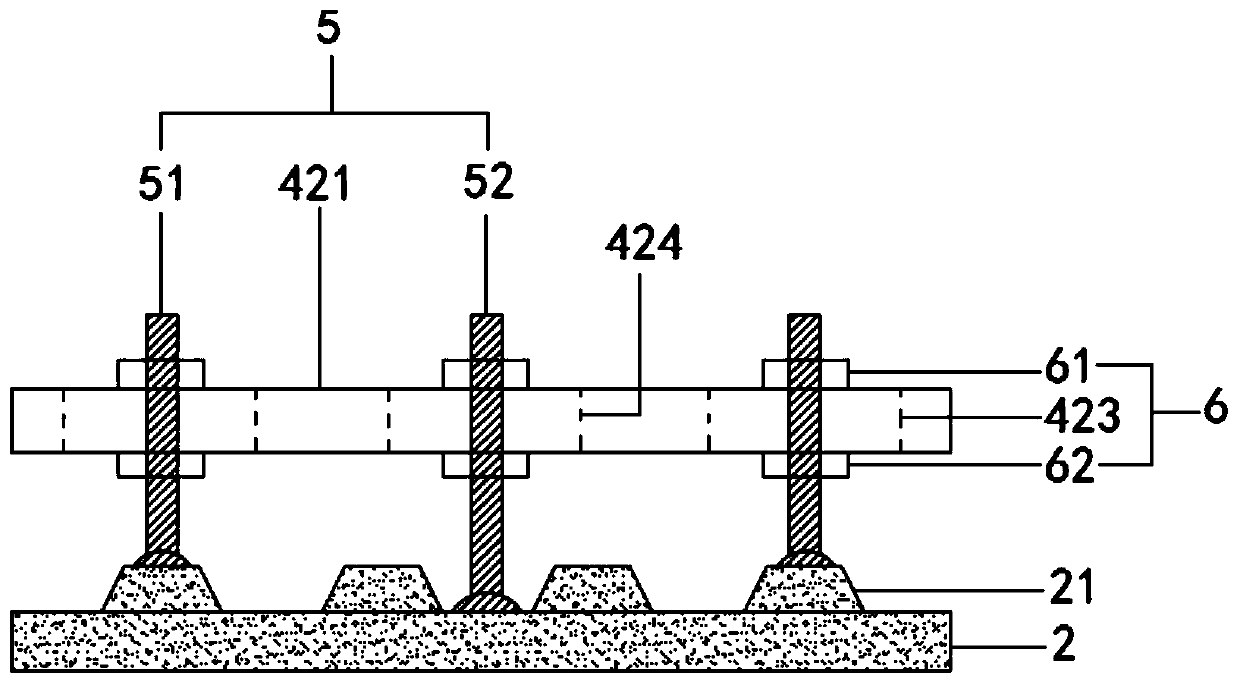

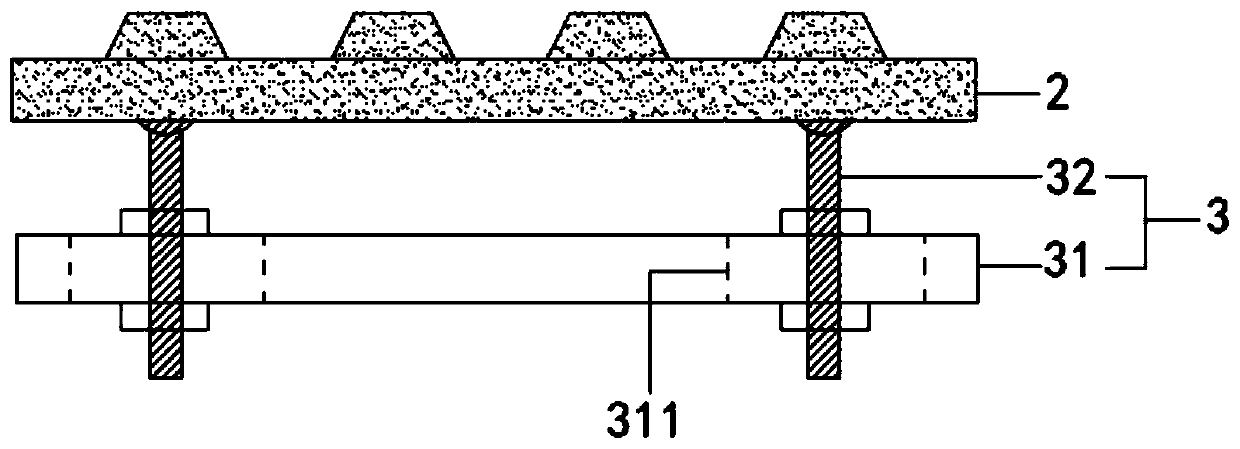

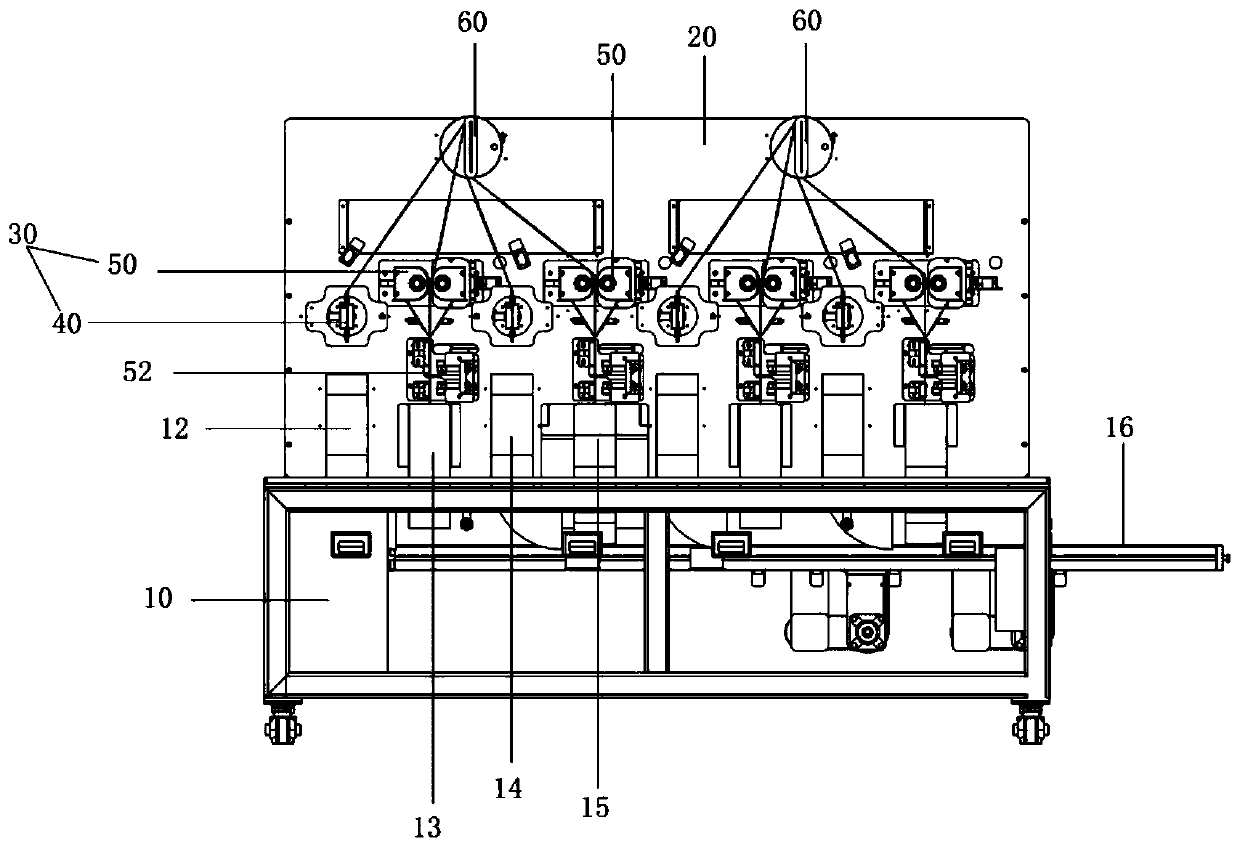

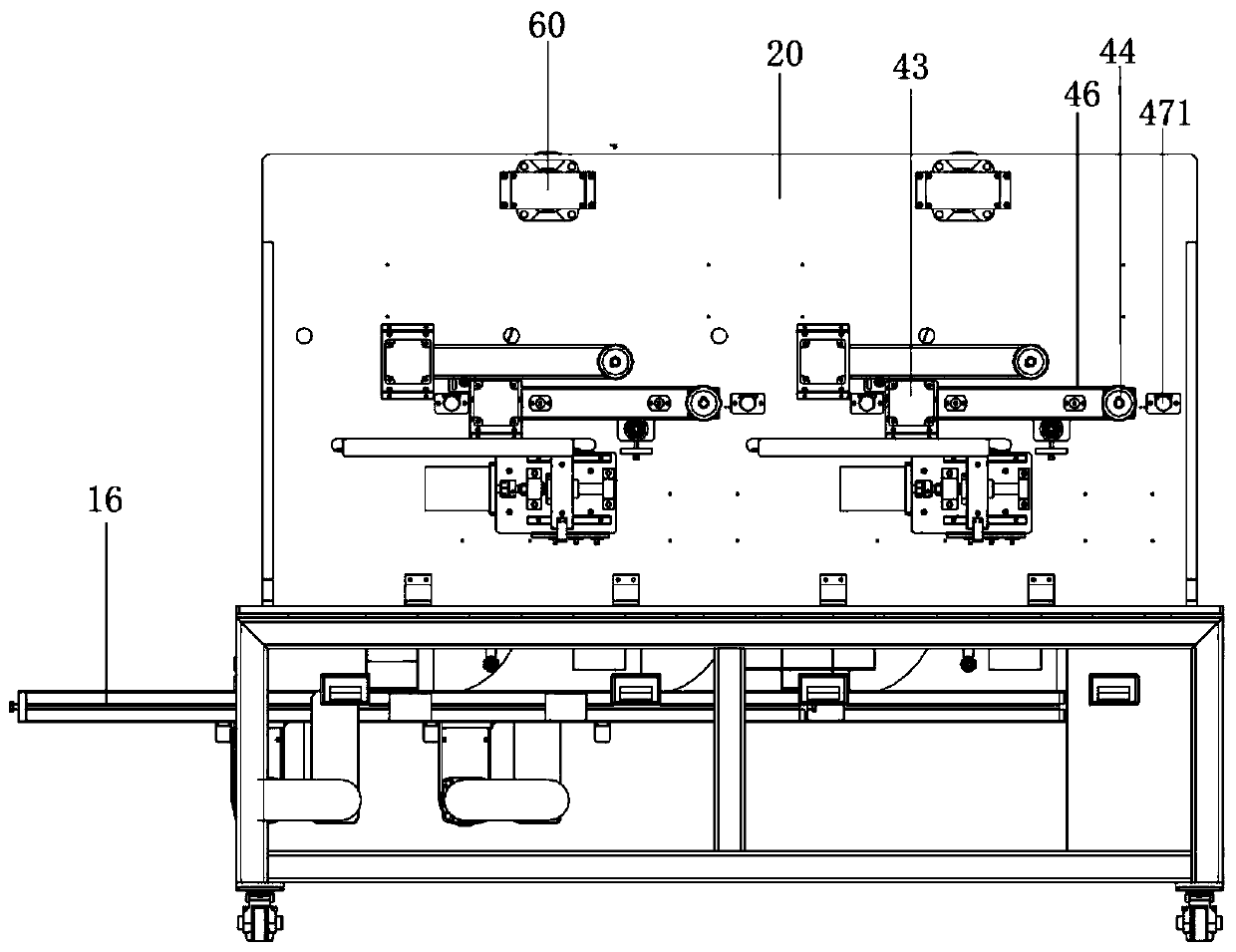

Side gate intelligent flexible automatic separation equipment for molded cluster plastic parts

The invention relates to side gate intelligent flexible automatic separation equipment for molded cluster plastic parts. Two synchronous belt transmission devices on two symmetrically arranged separation support plates on a support form a driving lead-in mechanism for the plastic parts. A V-shaped lead-in opening can lead an injection molding device into an inlet of a material passing channel, andthen a main runner waste rod of the injection molding device is clamped by clamping sections of two synchronous belts in the middle of the driving lead-in mechanism. Along with rotation of the synchronous belts, the injection molding device is horizontally pushed along the material passing channel to be in contact with a roller brush. The rotating roller brush brushes an injection molded productfrom the injection molding device, and the injection molded product falls into a lower discharging hole to be recycled, so that the automatic separation and recycling of the product are realized. Synchronous belt tensioning devices arranged on the clamping sections of the two synchronous belts can provide enough clamping force for the two clamping sections. The side gate intelligent flexible automatic separation equipment for molded cluster plastic parts realizes automatic separation of injection molding devices, the separation effect is good, the efficiency is high, the roller brush cannot scratch the products, the product quality is guaranteed, and the side gate intelligent flexible automatic separation equipment for molded cluster plastic parts is suitable for comprehensive popularization.

Owner:新乡市日正电子材料有限公司

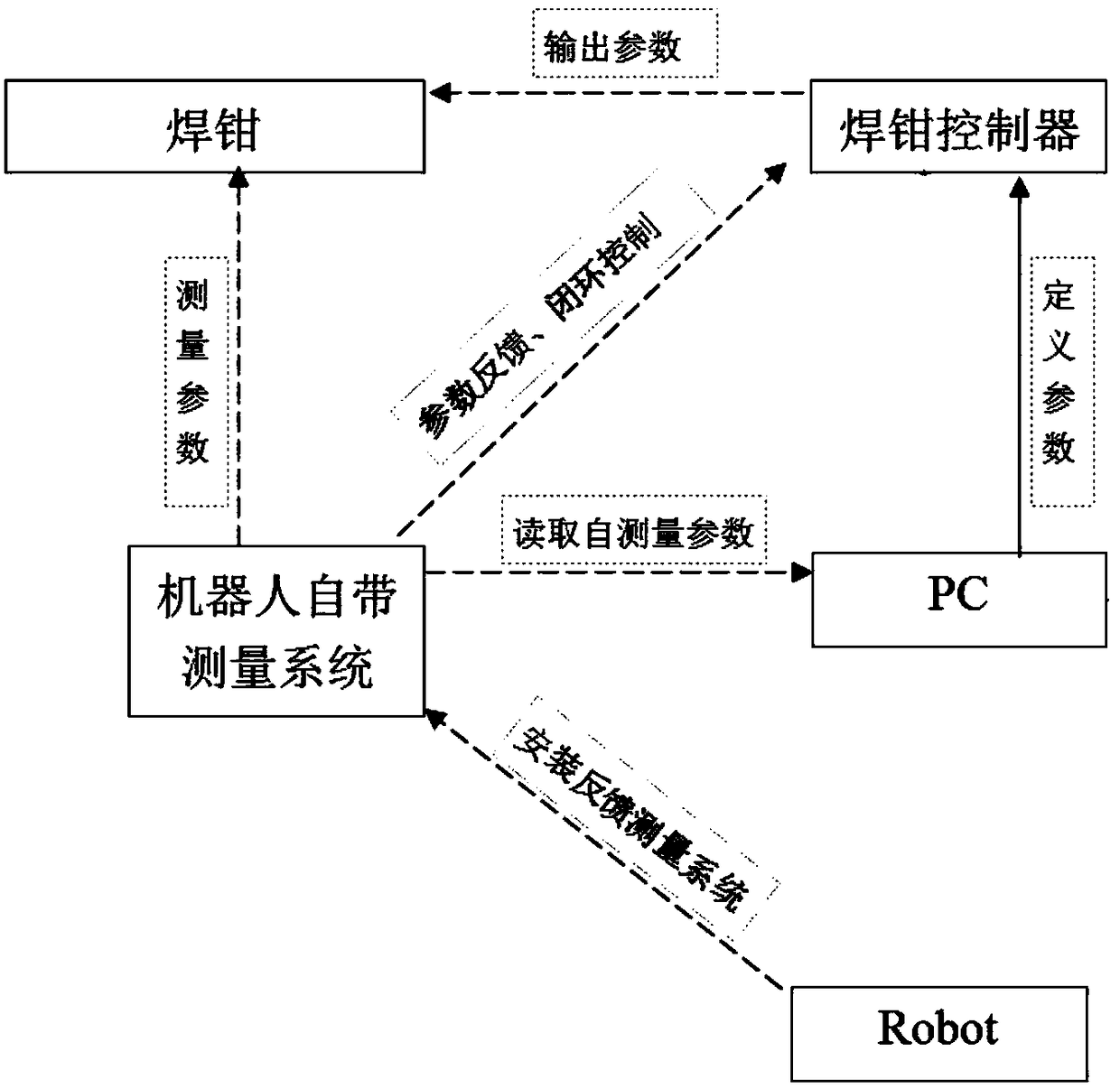

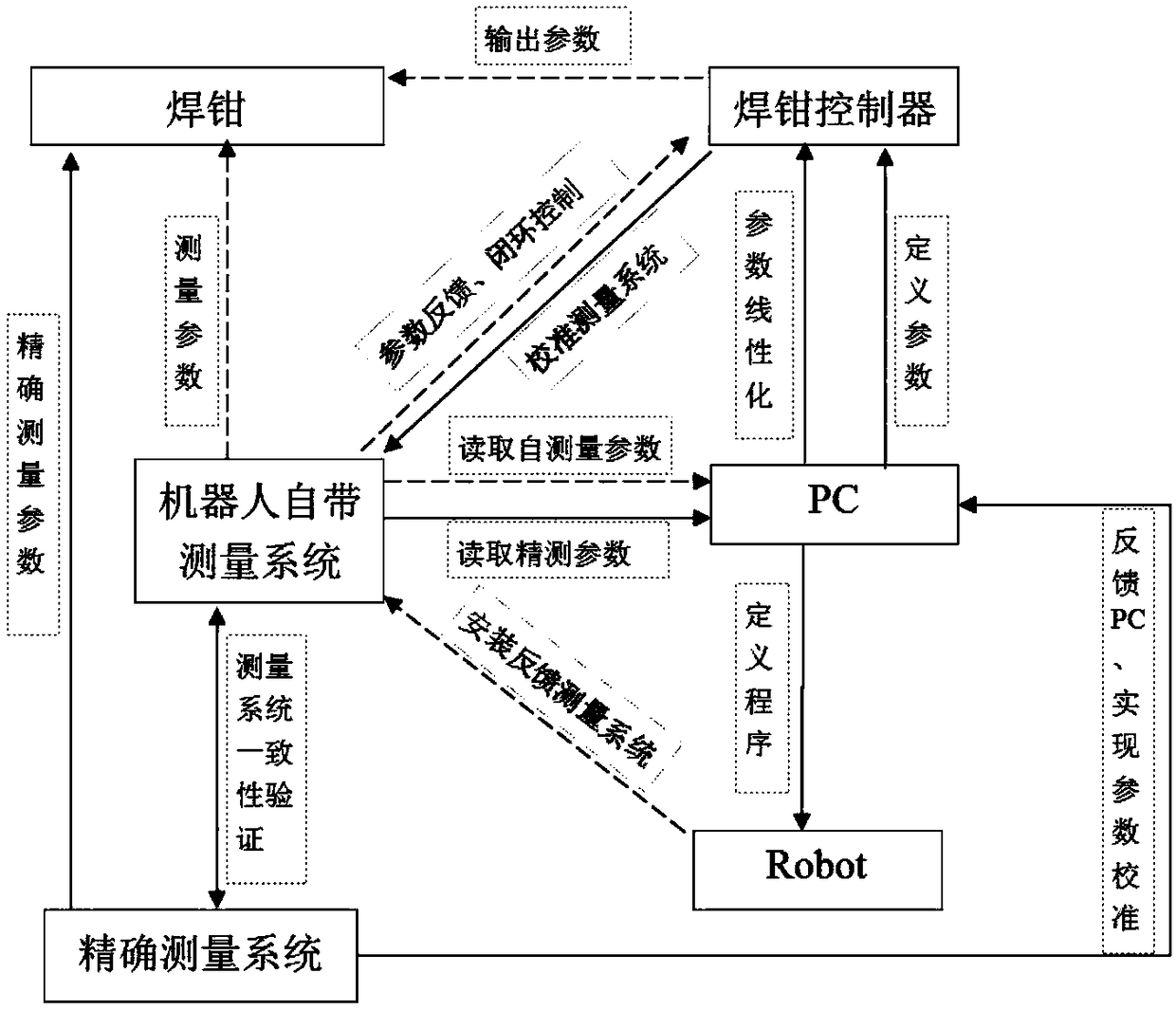

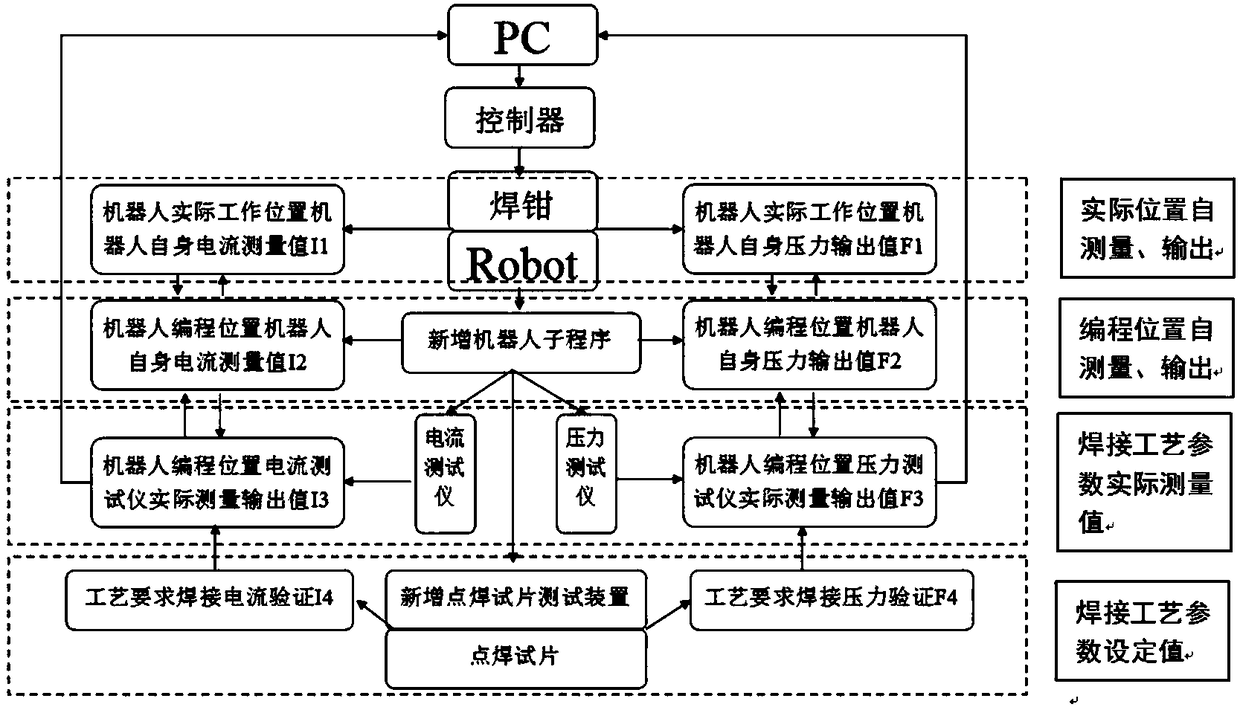

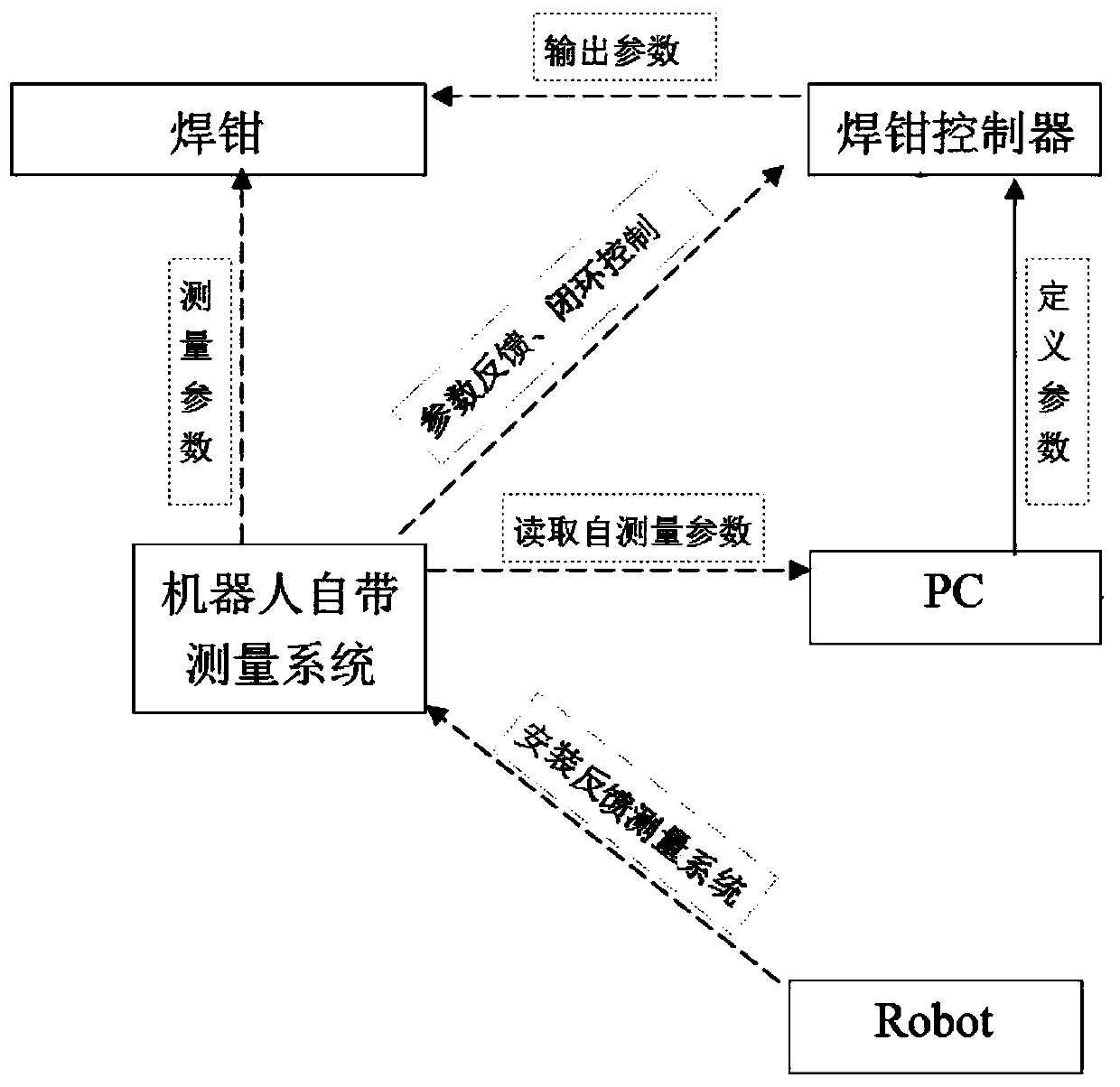

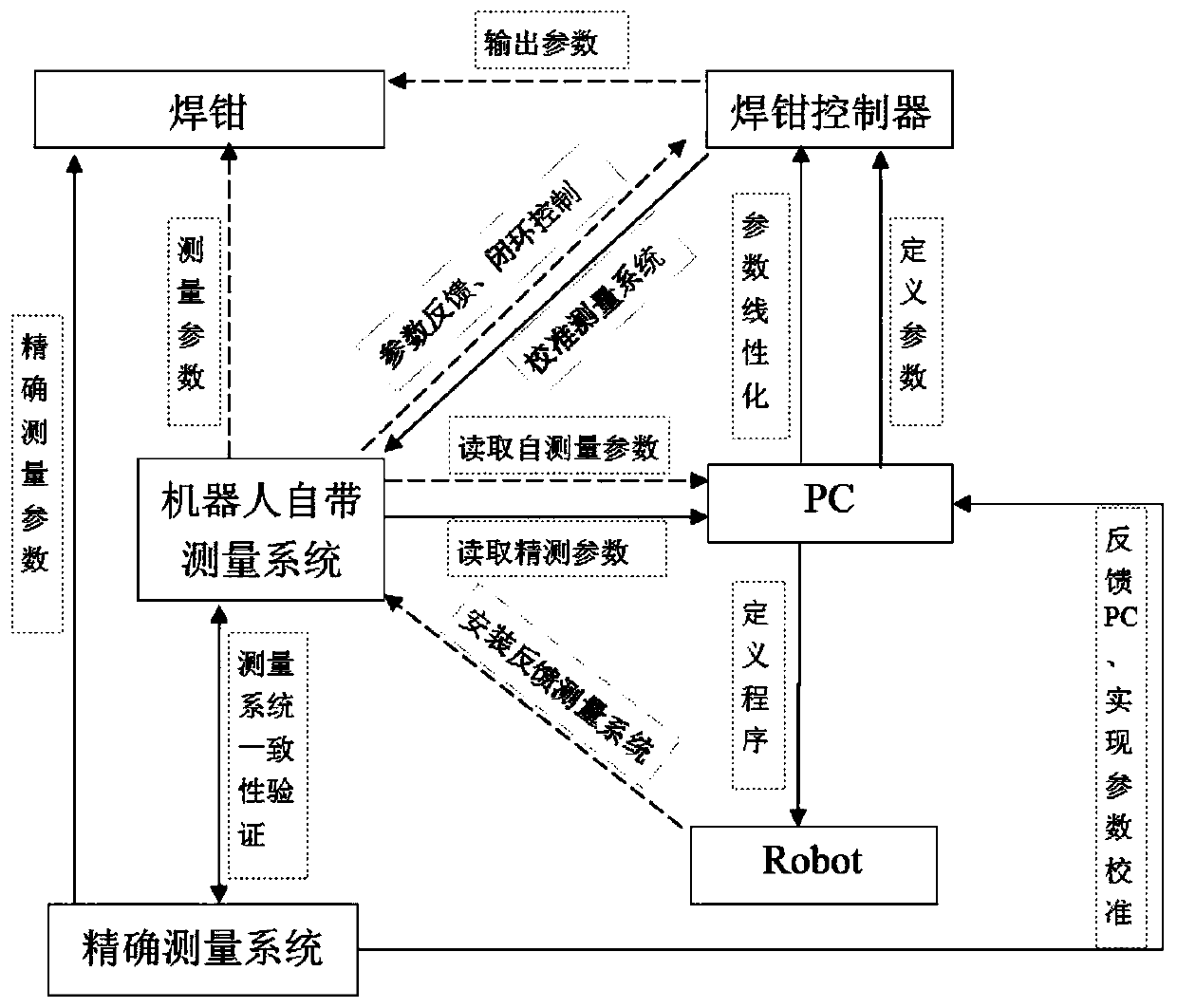

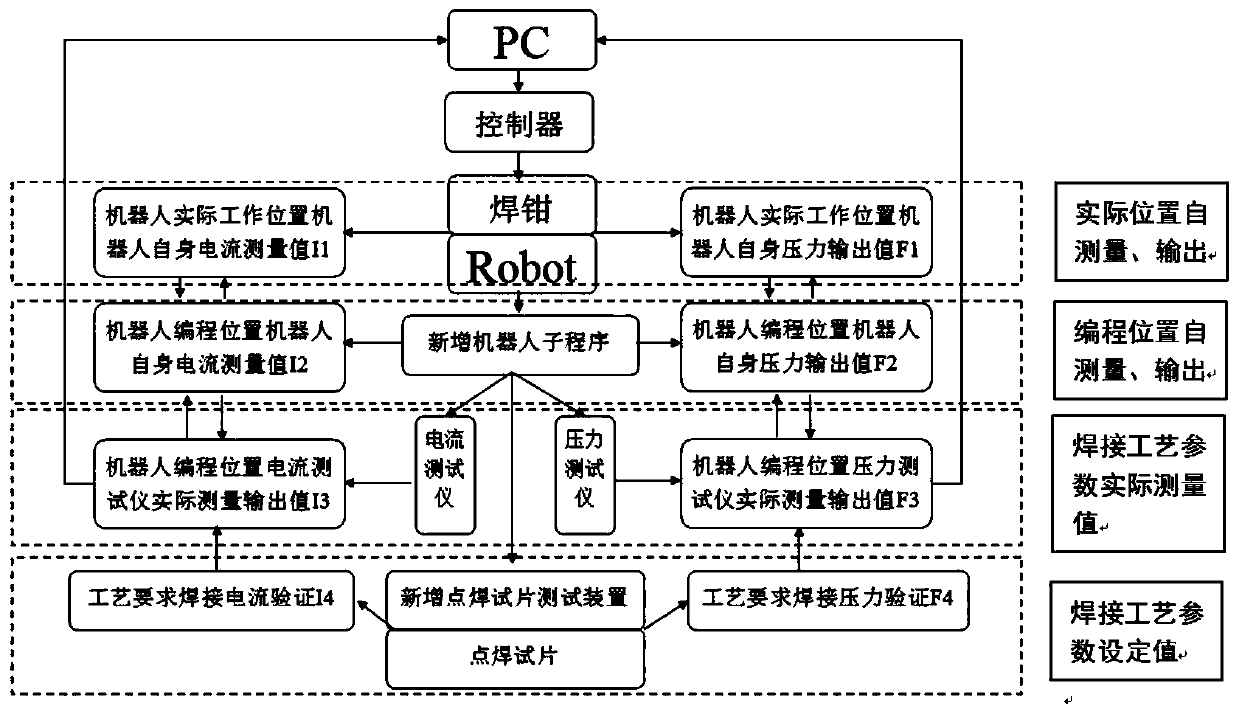

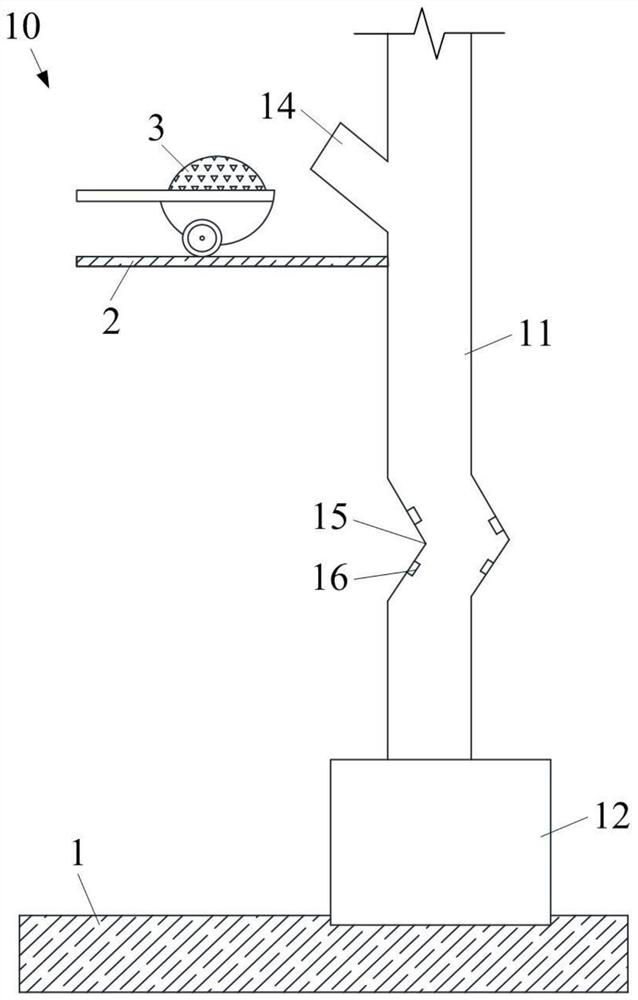

Robot resistance spot-welding technological parameter testing and control method

ActiveCN108161198AEnsure consistencyReduce participationWelding monitoring devicesElectrical resistance and conductancePower flow

The invention relates to the field of mechanical welding, in particular to a robot resistance spot-welding technological parameter testing and control method. The robot resistance spot-welding technological parameter testing and control method comprises the steps that S1, measuring position transfer verification is carried out; S2, empty spot welding is carried out; S3, actual measurement is carried out; S4, a program position output parameter of the S2 and an actual position output parameter of S3 are subjected to parameter linearization; and S5, a technological parameter setting value is verified. The robot resistance spot-welding technological parameter testing and control method has the following beneficial effects that according to the technical scheme, the robot resistance spot-welding technological parameter testing and control method comprises empty spot and practical spot welding parameter comparison verification, so that the parameter output conformability of the parameters on the two situations is ensured; a fixing bracket of a welding testing instrument is designed and manufactured, so that artificial participation is reduced, and the operational safety performance is improved; a welding test piece fixing bracket is designed and manufactured, so that the history that a welding test piece can not be verified is ended; robot parameter definitions are increased, and welding current and welding pressure test automation separation is realized; and a robot program is designed and written, so that the operational flexibility is ensured, and personnel participation is reduced.

Owner:SINO TRUK JINAN POWER

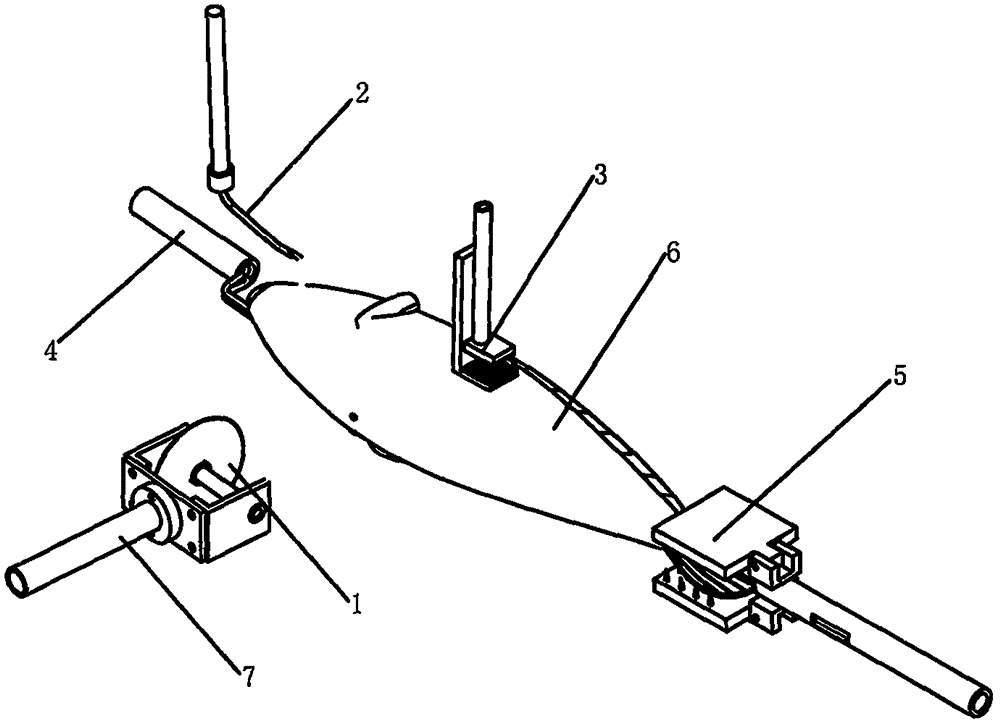

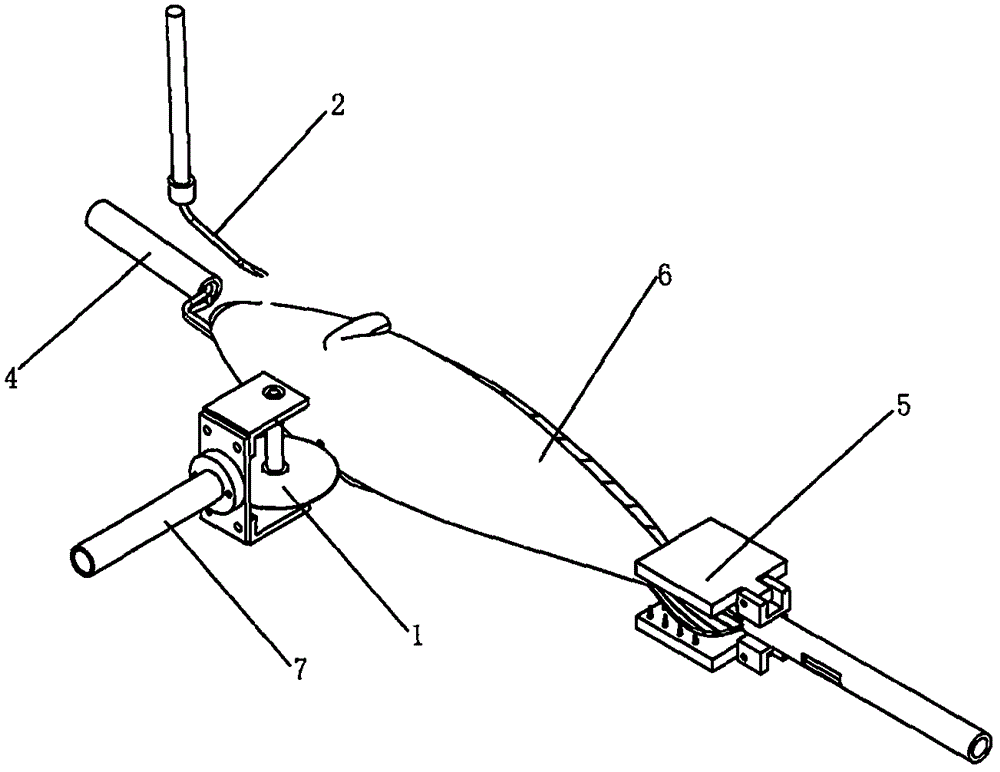

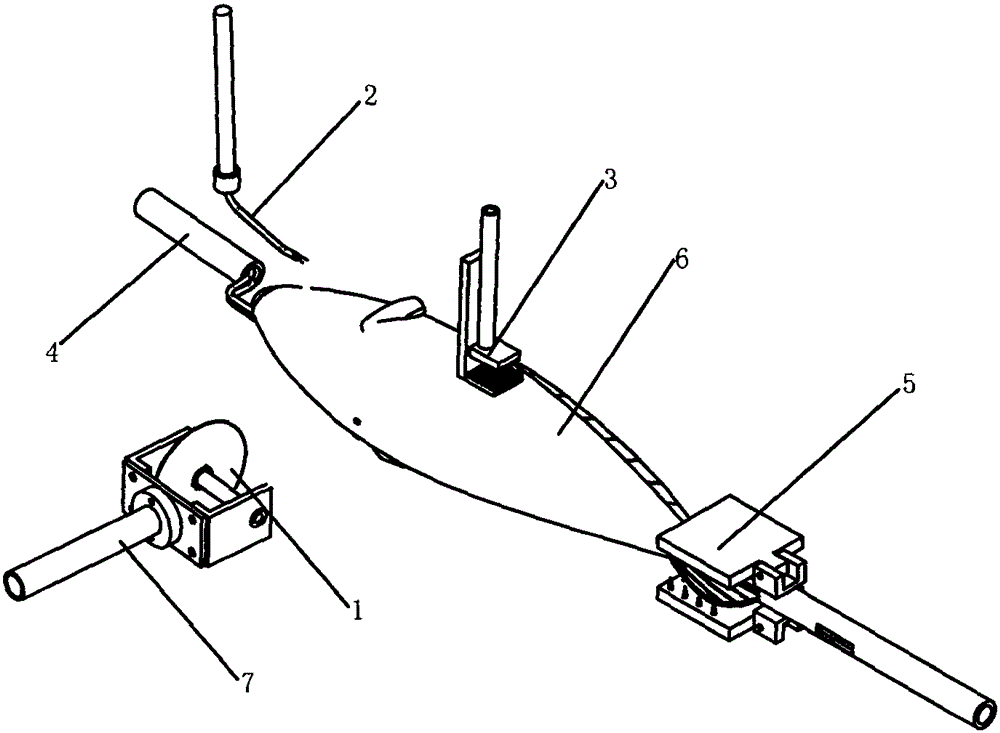

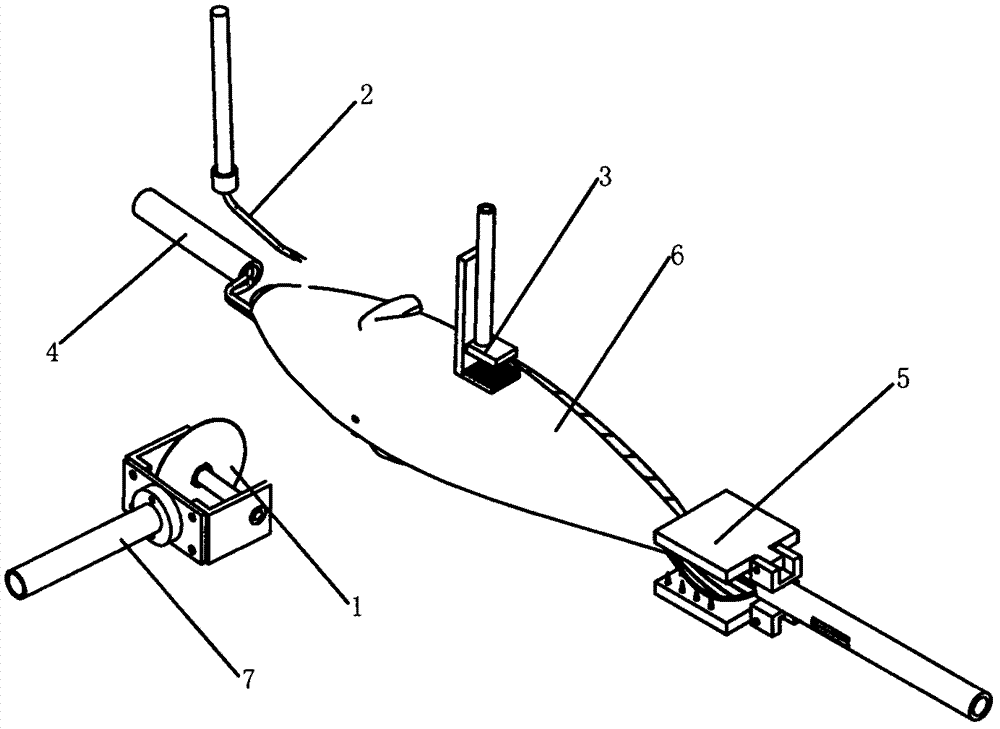

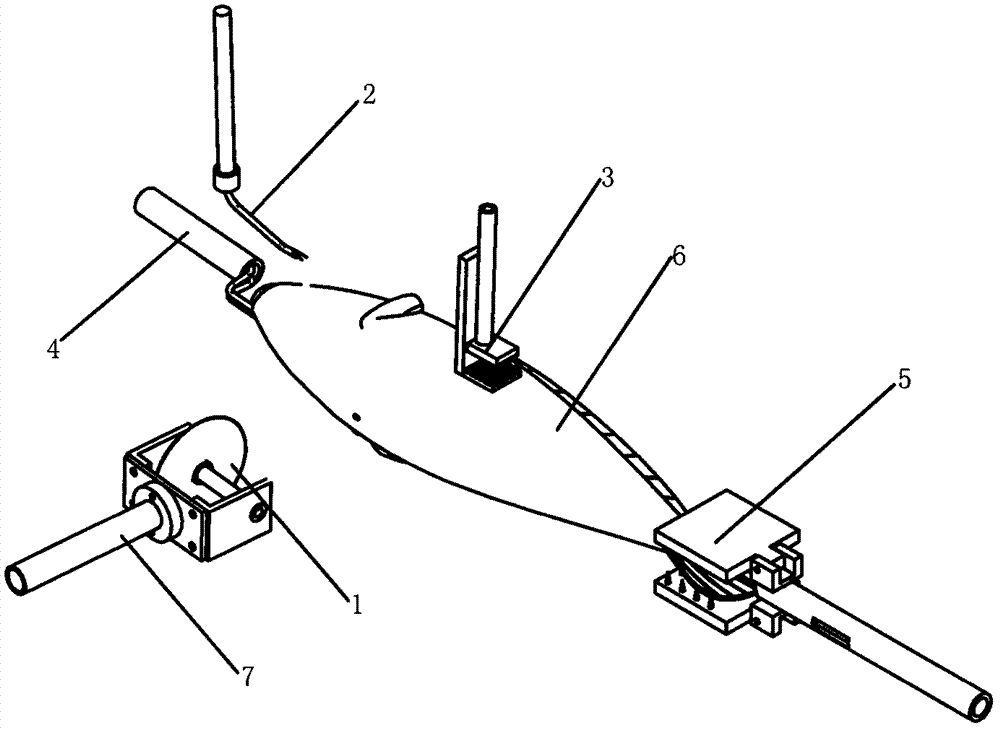

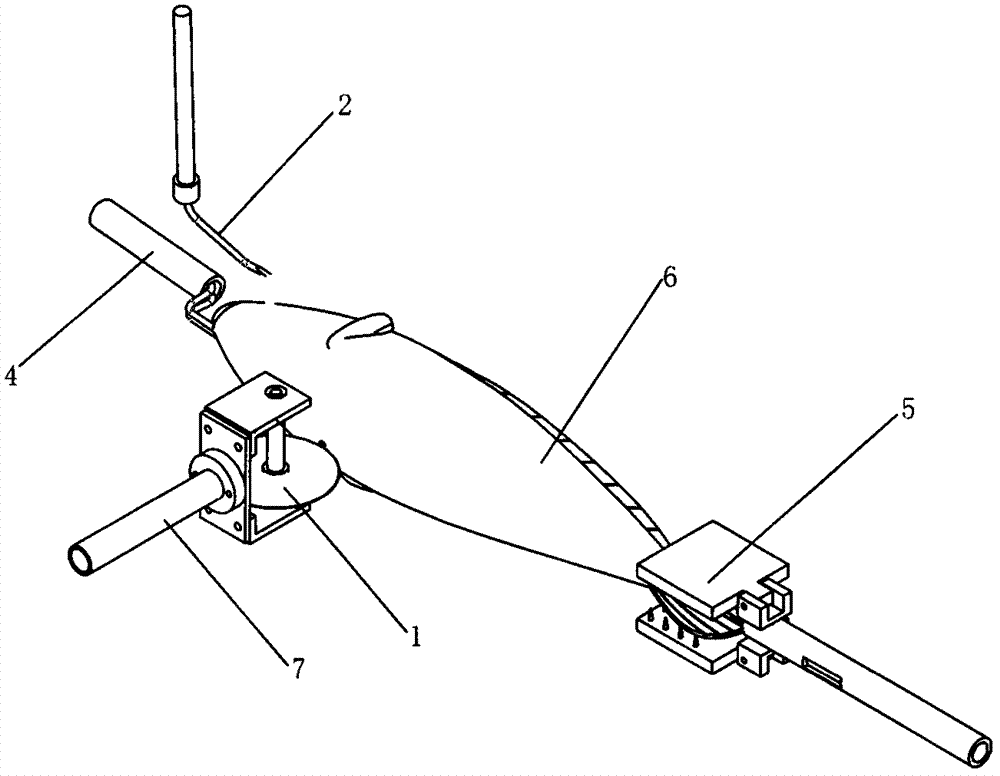

Fish skin separation method based on three-dimensional scanning

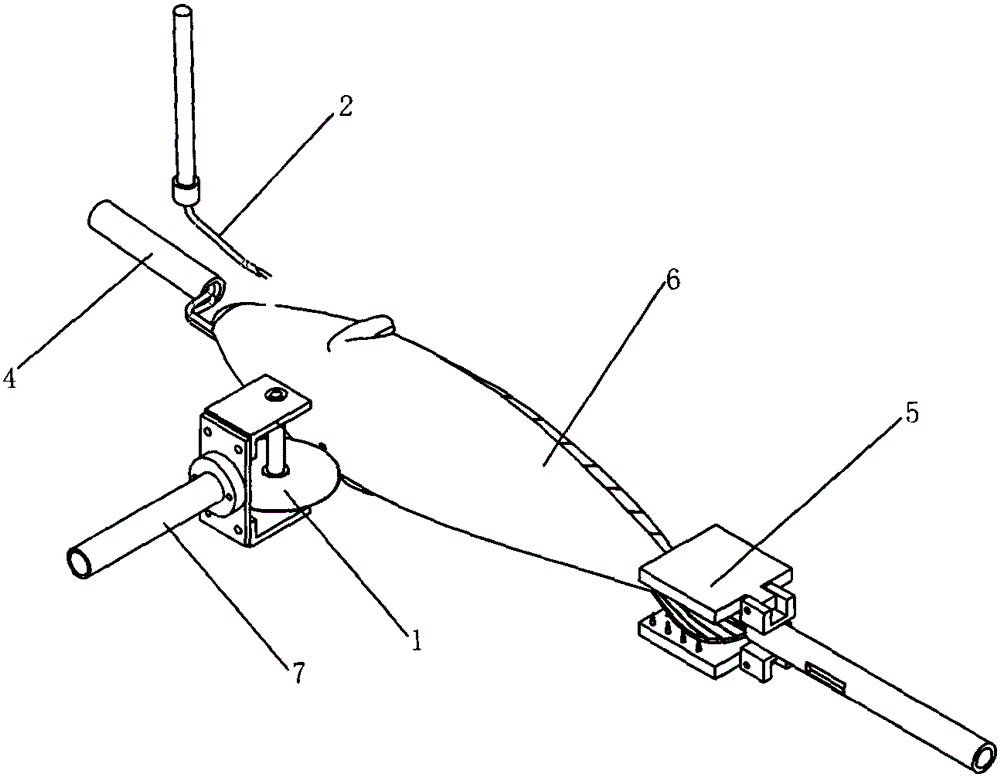

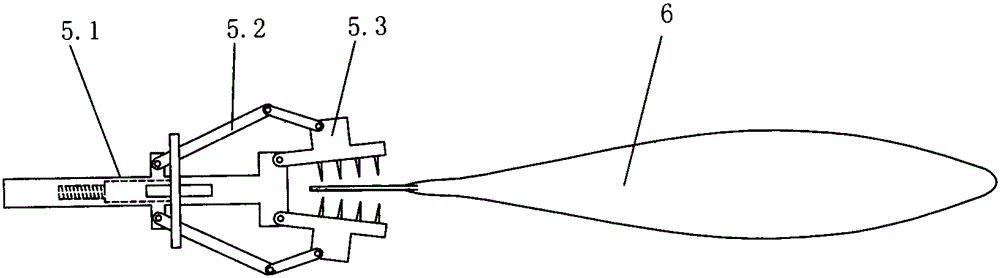

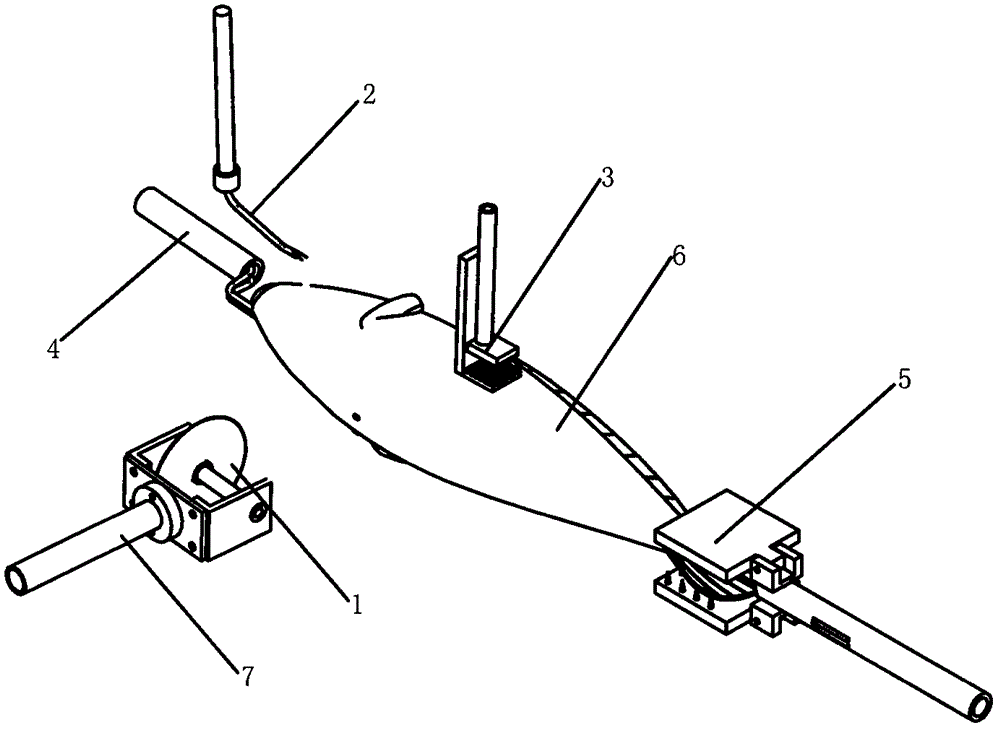

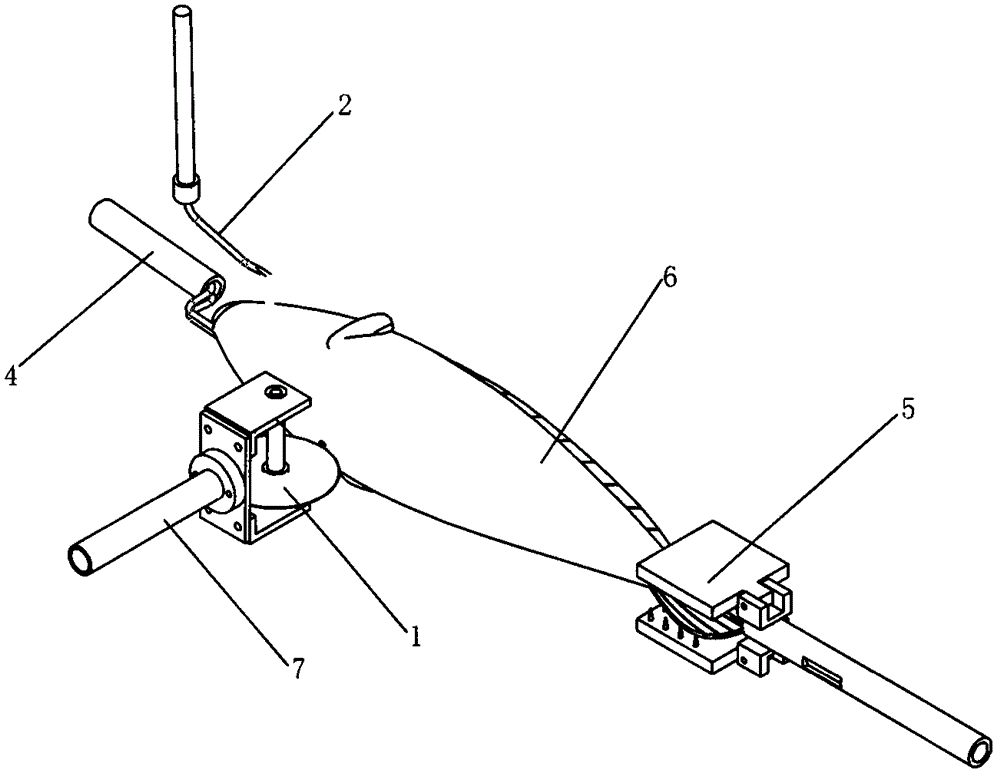

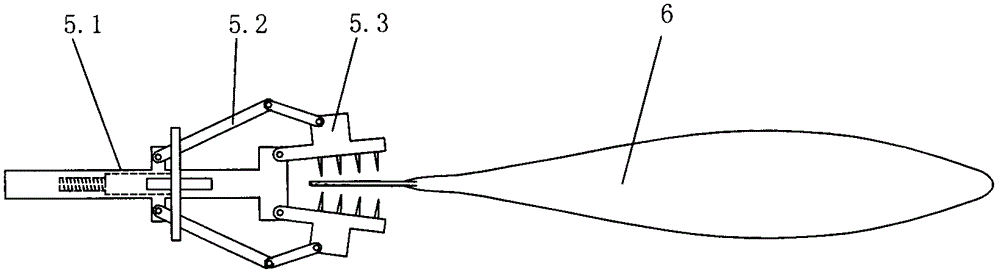

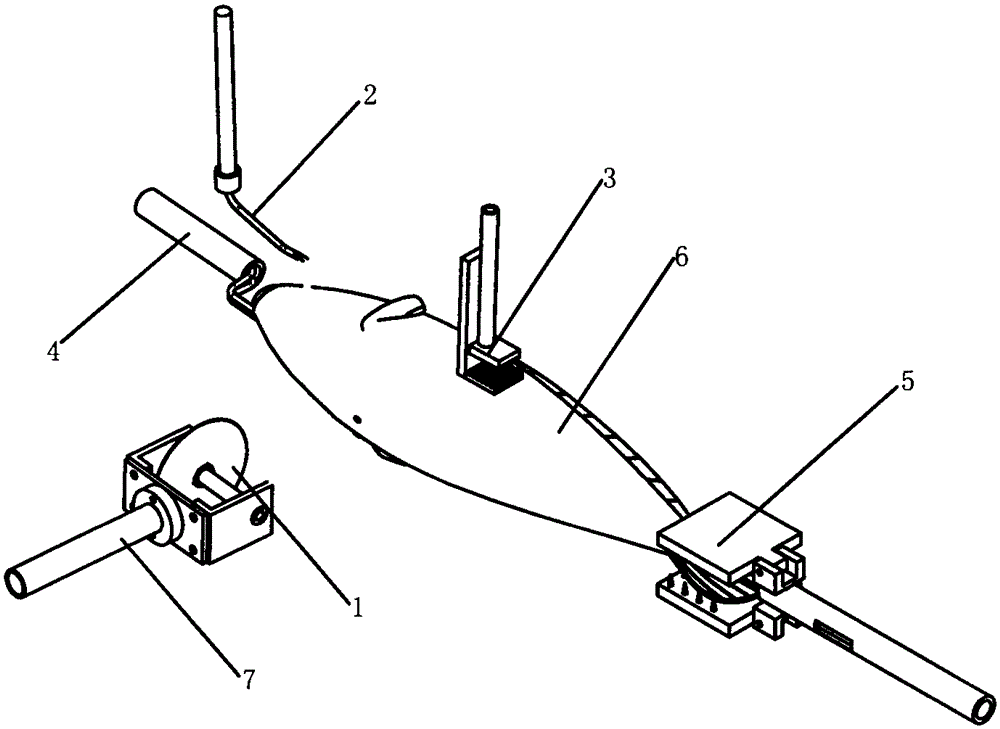

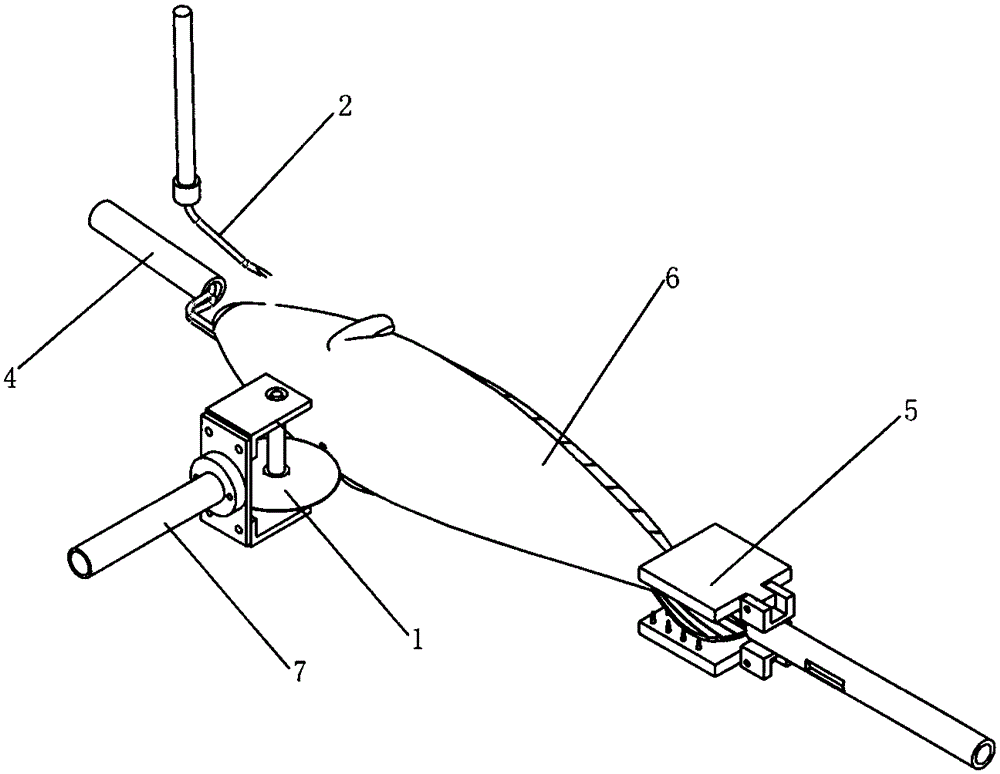

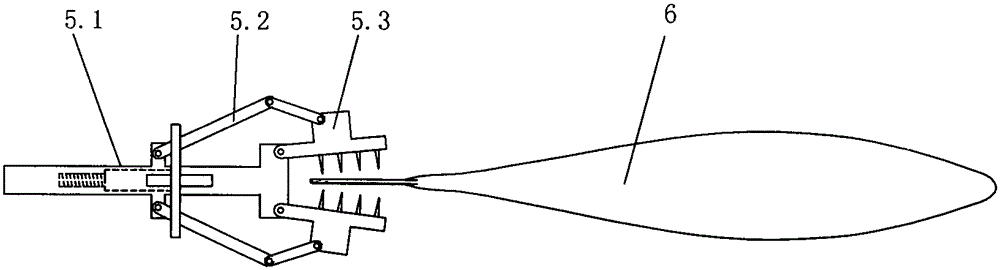

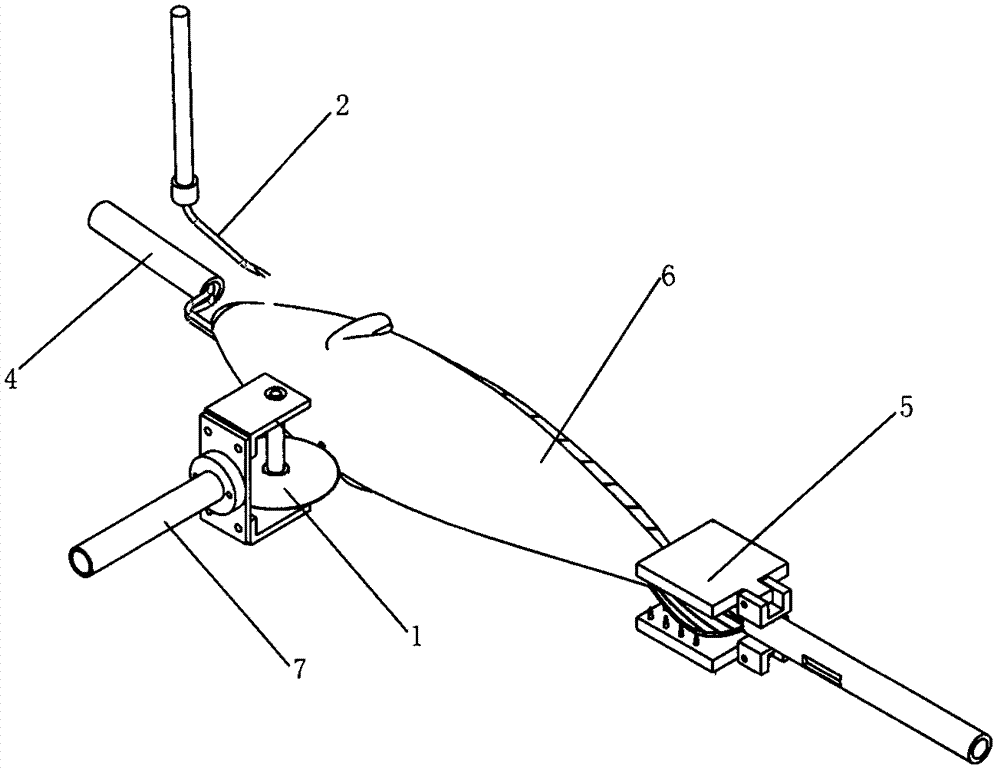

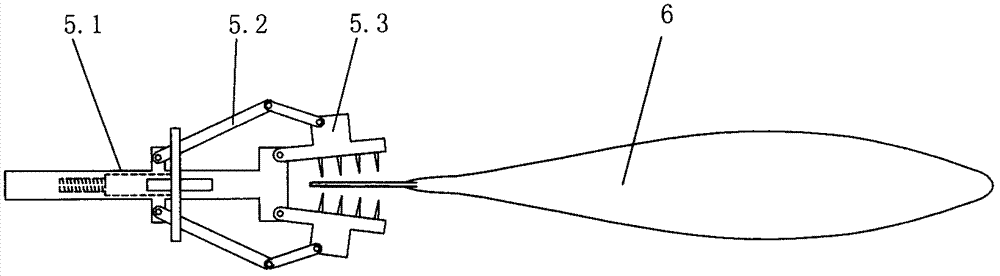

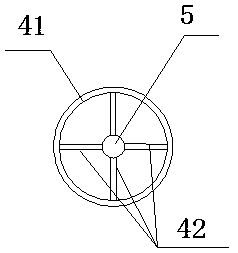

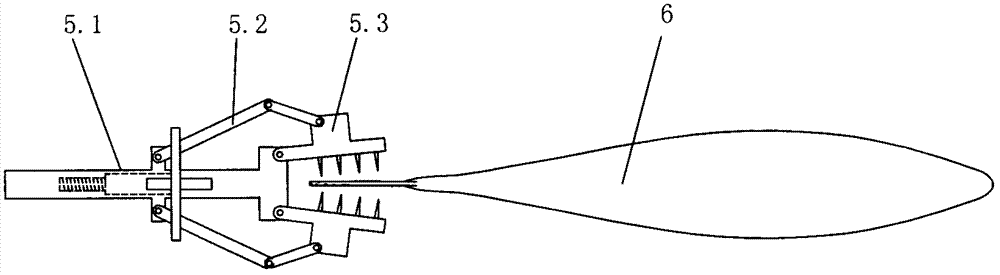

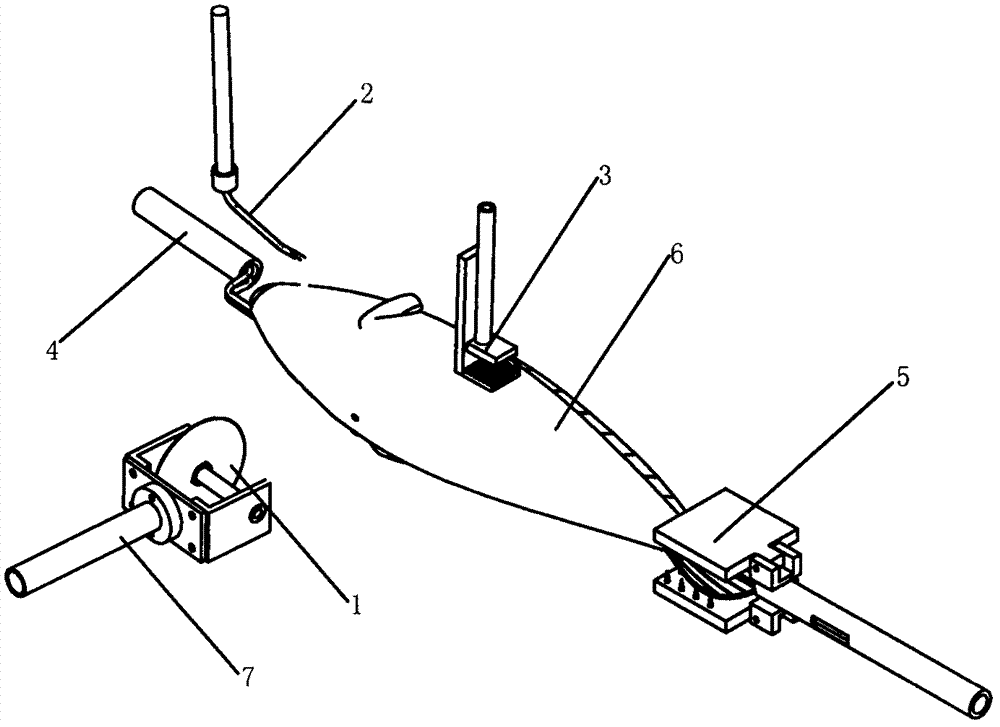

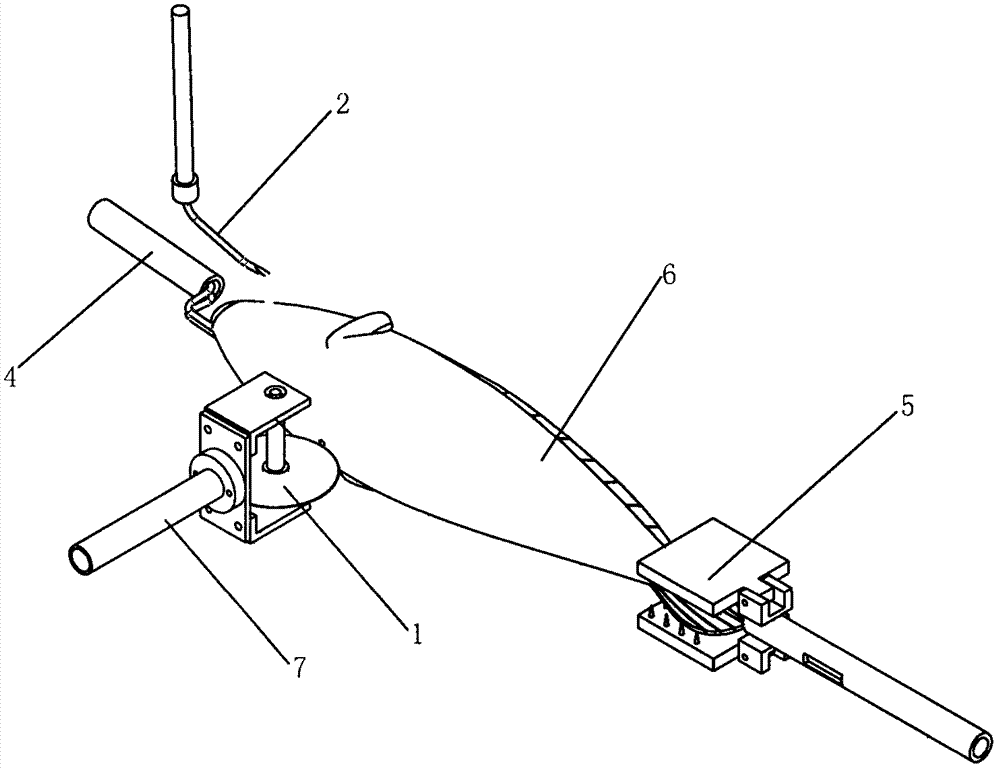

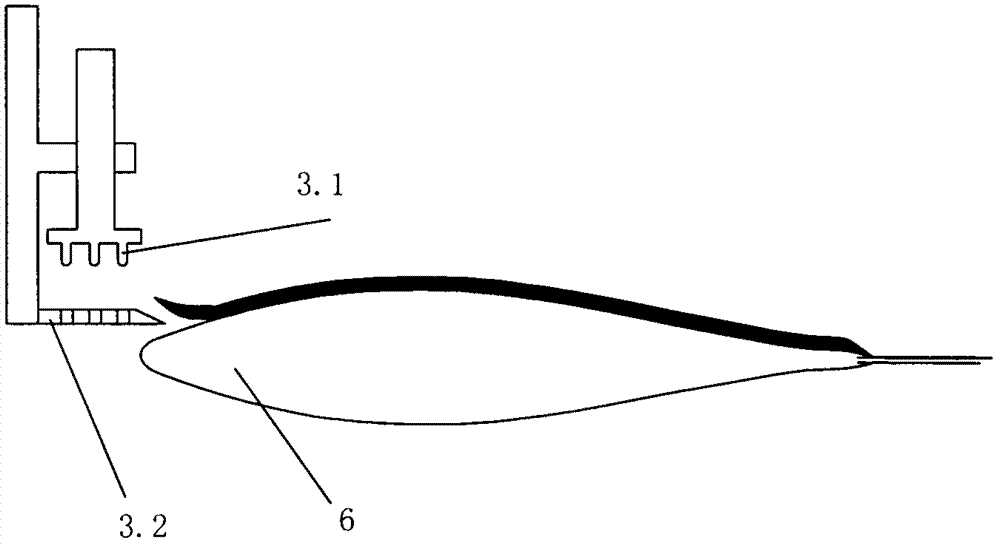

The invention discloses a fish skin separation method based on three-dimensional scanning, which is based on a fish skin separation device. The fish skin separation device comprises a holding mechanism, a circular cutting knife (1), a separation knife (2) and a skin-stripping mechanism (3). The holding mechanism comprises a gill hook (4) and a tail clamp mechanism (5). The circular cutting knife is arranged at an eccentric position of a central axial line between the gill hook and the tail clamp mechanism. The separation knife and the skin-stripping mechanism are arranged at the side of the gill hook. The fish skin separation method includes the steps of scanning fish body through a three-dimensional image to obtain circular cutting position and path, separation path, longitudinal cutting path and stripping path; holding the to-be-skinned fish body in a horizontal manner front-and-back by the holding mechanism, circularly cutting the fish body around the fish body through the circular cutting knife; separating fish skin from fish body by the separation knife being stretched into the fish body from cut marks at the circularly cut position; longitudinally cutting the fish skin in the length direction of the fish body by means of the circular cutting knife; and finally removing the fish skin by the skin-stripping mechanism. The fish skin separation method achieves automatic separation of the fish skin, increases stripping efficiency of the fish skin and avoids damage on the fish skin.

Owner:CHINA JILIANG UNIV

Lotus fresh and lotus core separating device for core-removed lotus seeds as traditional Chinese medicine material

ActiveCN108378379AHelps vibrate in halfEfficient separationSievingScreeningEngineeringTraditional Chinese medicine

The invention discloses a lotus fresh and lotus core separating device for core-removed lotus seeds as a traditional Chinese medicine material. Lotus fresh can be vibrated to be open along a joint side through an initial vibration device, and can be vibrated to be open in two parts conveniently, so that the lotus cores and the lotus fresh can be effectively separated; after being processed by theinitial vibration device, the lotus cores and the lotus fresh are sent into a lotus core guiding device; the lotus cores and the lotus fresh are conveyed through each lotus guiding passage way which consists of guiding threaded rods in same direction at same speed, so that the lotus cores and the lotus fresh can be further separated, and subsequent vibration screening is facilitated; the lotus cores can be automatically screened out through a lotus core and lotus fresh screening device; the lotus cores are stored in a lotus core collecting box; and the lotus fresh is conveyed to a lotus freshcollecting box, and can be made into lotus seed powder, so that the waste of tiny lotus fresh is avoided. The lotus fresh and lotus core separating device disclosed by the invention is reasonable in structural design, and automatic separation of the lotus cores from partial lotus flesh, of the lotus seeds of which the middle parts are removed, can be realized.

Owner:安徽道源堂中药饮片有限公司

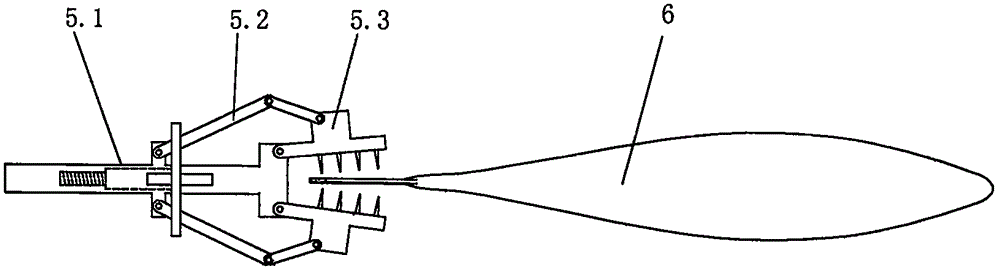

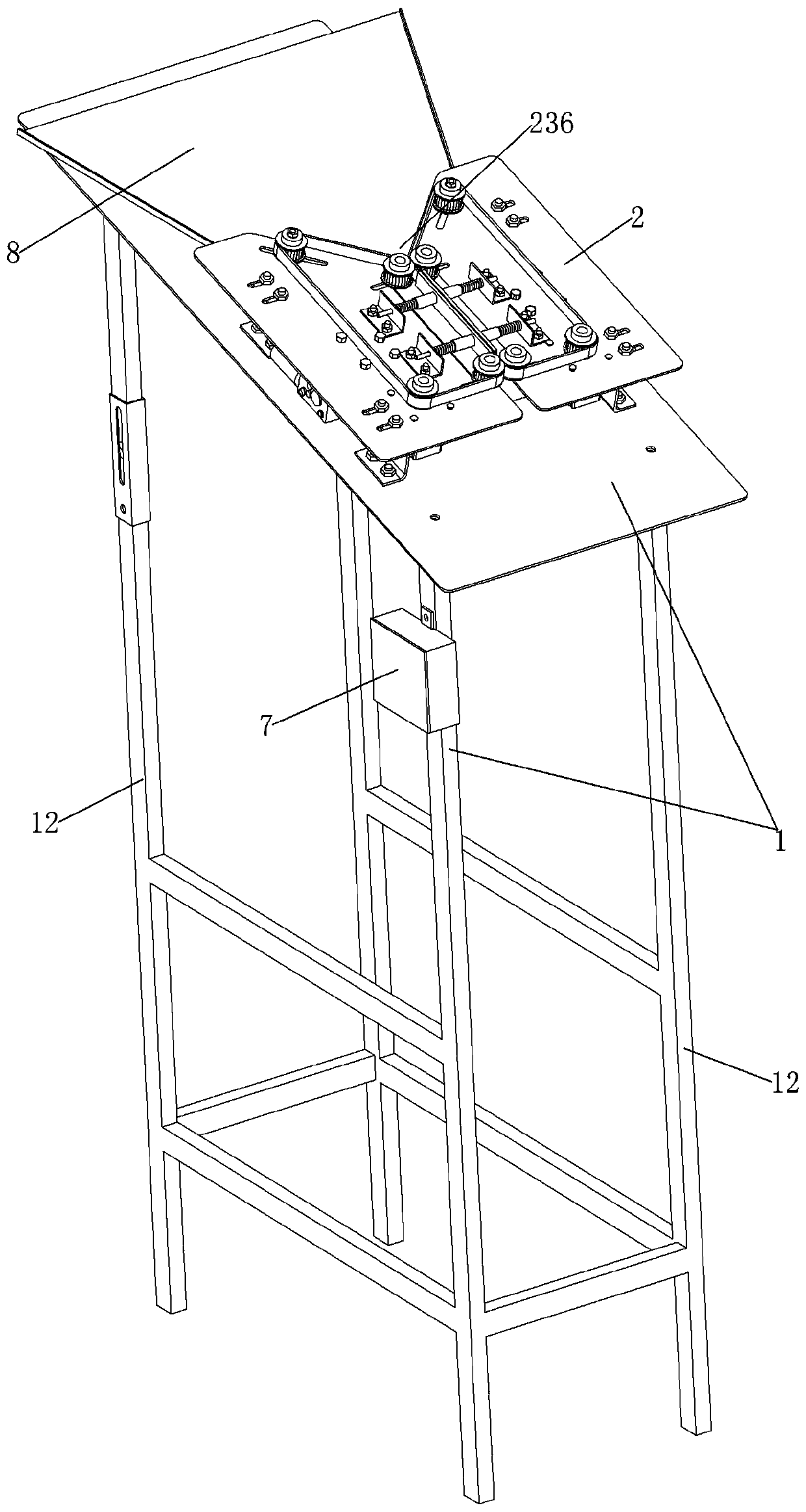

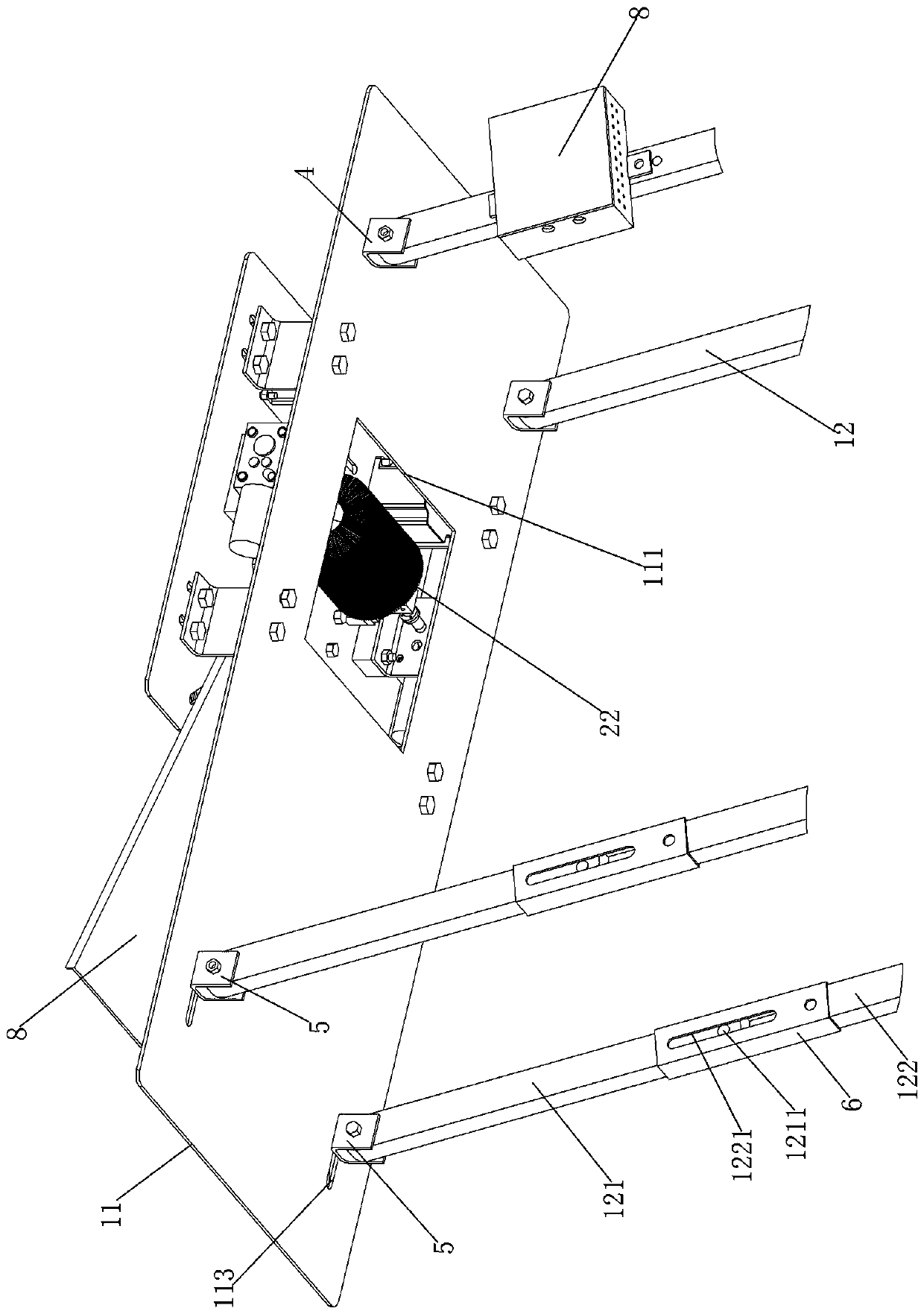

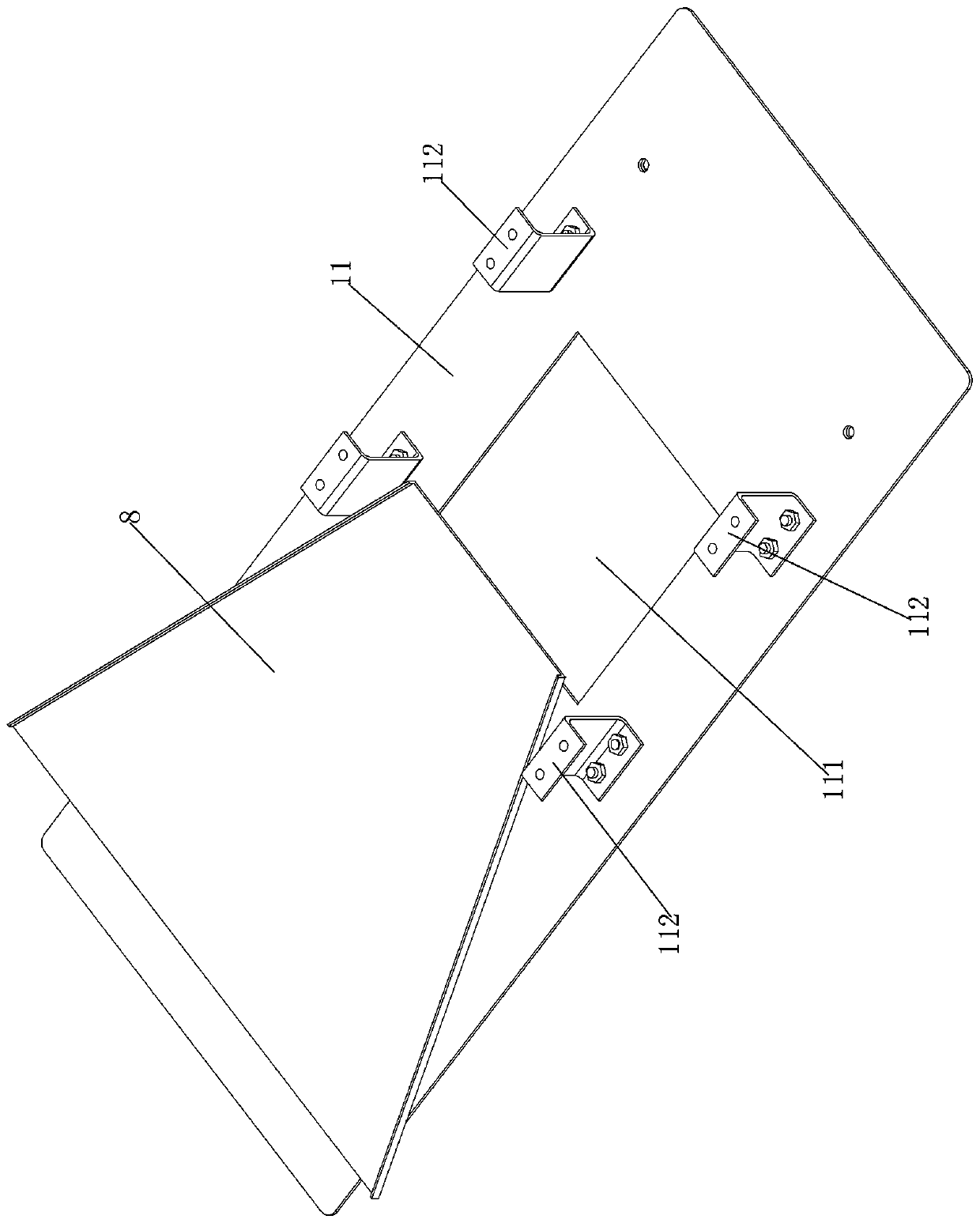

Full-automatic intelligent fish skinning method

The invention discloses a full-automatic intelligent fish skinning method based on a fish skinning device. The fish skinning device comprises a clamping mechanism, a girdling knife (1), a separating knife (2) and a skinning mechanism (3), wherein the clamping mechanism comprises a fish gill hook (4) and a tail clamping mechanism (5); the girdling knife is located at the eccentric position of the central axis between the fish gill hook and the tail clamping mechanism; the separating knife and the skinning mechanism are located on the side of the fish gill hook. The fish skinning method comprises the steps of clamping, recognizing and scanning, annular cutting, fish skin separating, longitudinal cutting and skinning. The full-automatic intelligent fish skinning method realizes automatic fish skin separation, improves the fish skinning efficiency and prevents the fish skin from being broken.

Owner:CHINA JILIANG UNIV

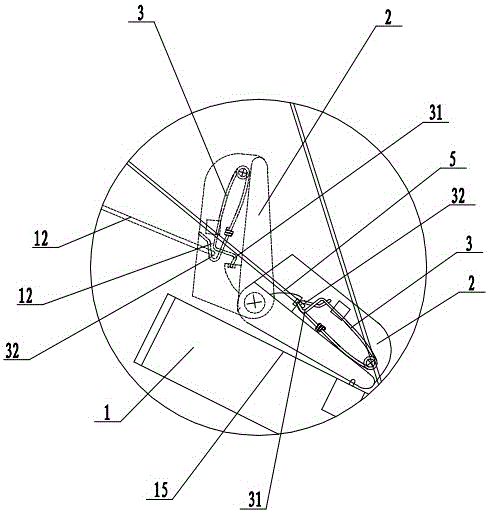

Auxiliary manufacturing system for concrete prefabricated part

InactiveCN112497436AReduce wasteQuality improvementDischarging arrangementMouldsArchitectural engineeringWorking environment

The invention relates to an auxiliary manufacturing system for a concrete prefabricated part. The auxiliary manufacturing system comprises a supporting frame, an outer wall mold and a clamping adjusting mechanism, the supporting frame is of a C-shaped structure with an upward opening, the outer wall mold is arranged in the middle of the upper end face of the supporting frame, and the clamping adjusting mechanism is connected to the outer wall mold. The problems that a prefabricated part die of an existing device is poor in sealing performance, slurry leakage and liquid leakage are likely to happen during concrete pouring, concrete waste is likely to be caused, flowing-out concrete is difficult to clean, and a messy working environment is caused to a workshop can be solved, and the problemsthat an existing device cannot automatically separate the mold from the prefabricated part after the prefabricated part is formed, and the mold needs to be manually disassembled, so that labor forceis wasted, efficiency is low, and the manufacturing efficiency of the concrete prefabricated part is affected can be solved.

Owner:王蒙蒙

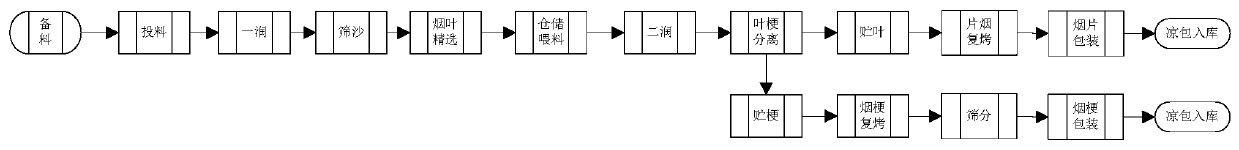

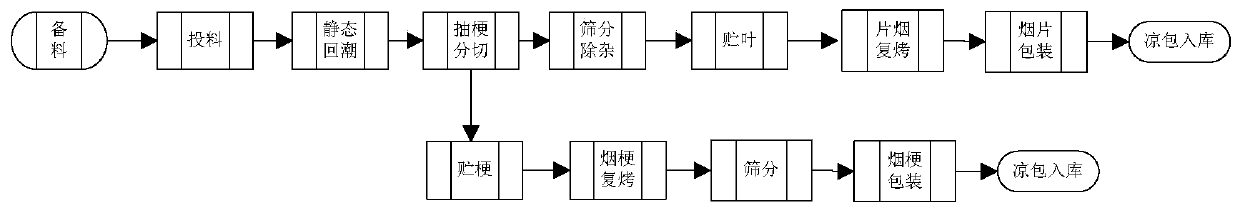

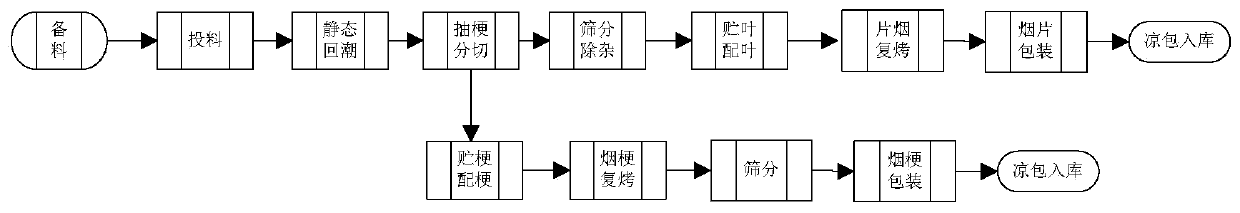

Tobacco leaf processing technology adopting stemming, slitting and redrying

The invention relates to a tobacco leaf processing technology adopting stemming, slitting and redrying, and belongs to the technical field of tobacco processing. The processing technology provided bythe invention comprises the steps of material preparing and moisture regain, stemming and slitting, storage, tobacco leaf redrying and packaging, and tobacco steam redrying and packaging, wherein during static moisture regain, vacuum moisture regain and mesh belt moisture regain are matched for controlling the moisture and temperature of tobacco leaves, and stemming and slitting replace the traditional leaf-threshing air separating; and after stemming and slitting, tobacco leaves and tobacco stems respectively enter a leaf storage cabinet and a steam storage cabinet to be temporarily stored for moisture balancing and production, and redrying, boxing, cooling-packaging and warehousing are respectively carried out. According to the processing technology, static moisture regain replaces roller moisture regain, roll screening replaces roll sand screening, stemming and slitting replace threshing air separating, a group of storage feeding is reduced, then the problems that the threshing redrying production line is high in energy consumption, large in occupied area, large in tobacco leaf loss, large in noise, large in dust mount, and the like are solved, and the technology has the advantages of low investment and high yield.

Owner:HONGTA TOBACCO GRP

A treatment system for printing and dyeing sewage

InactiveCN104355423BExtended service lifeEasy to separateWater treatment parameter controlMultistage water/sewage treatmentWater sourceEngineering

The invention discloses a treatment system for printing and dyeing sewage and sludge. The treatment system comprises a blow-off pipeline, a spiral separator, a filter screen device, a garbage treatment device, a first separation pool, a second separation pool and an oil-water separator, wherein the blow-off pipeline is connected to the cavity of the spiral separator; the garbage treatment device comprises a garage transportation belt and a garbage truck; the garbage transportation belt is arranged directly under the outlet end of a spiral discharger arranged on the spiral separator; the garbage truck is arranged at the garbage outlet of the garbage transportation belt. Through secondary separation of the second separation pool and tertiary separation of the oil-water separator, oil and water are thoroughly separated, the separation effect is good, a large number of water sources are saved, solid-phase garbage can be separated and disposed through the arrangement of the spiral separator and the garbage treatment device, a circular rotatable filter screen is arranged, and the filter screen is in multi-point contact with sewage, so that the filtering effect is good, and the service life of the filter mesh is also relatively long.

Owner:JIANGSU SHUANGYING TEXTILE TECH

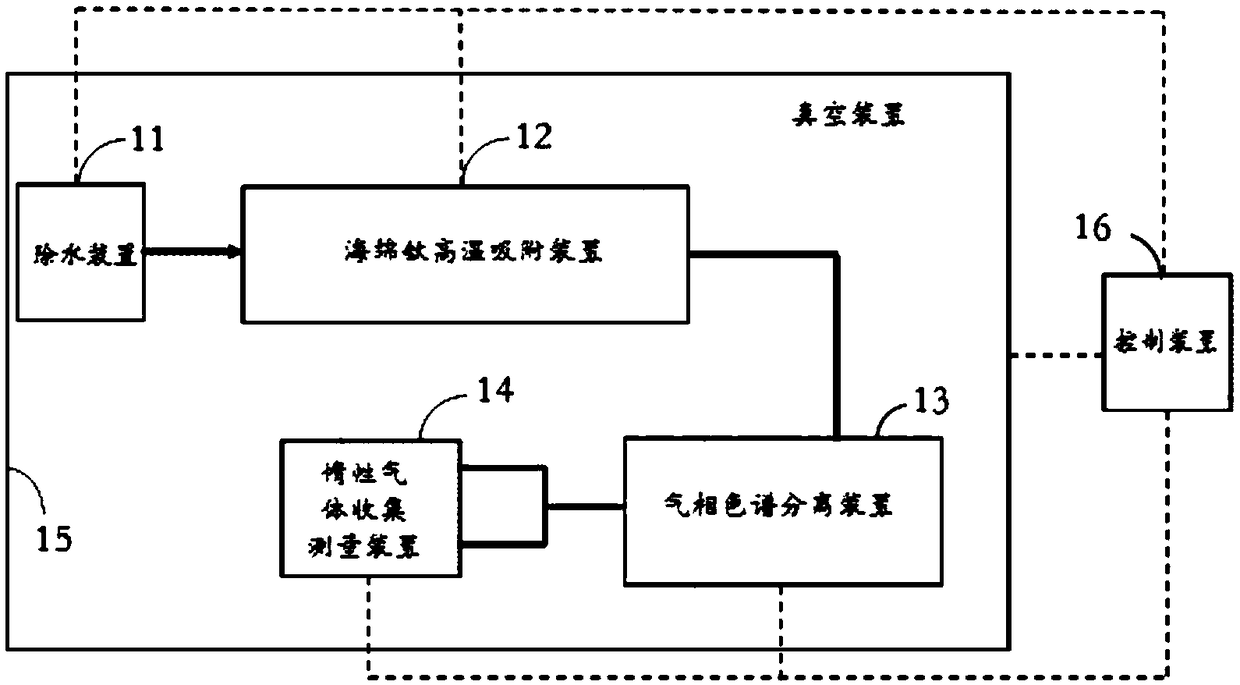

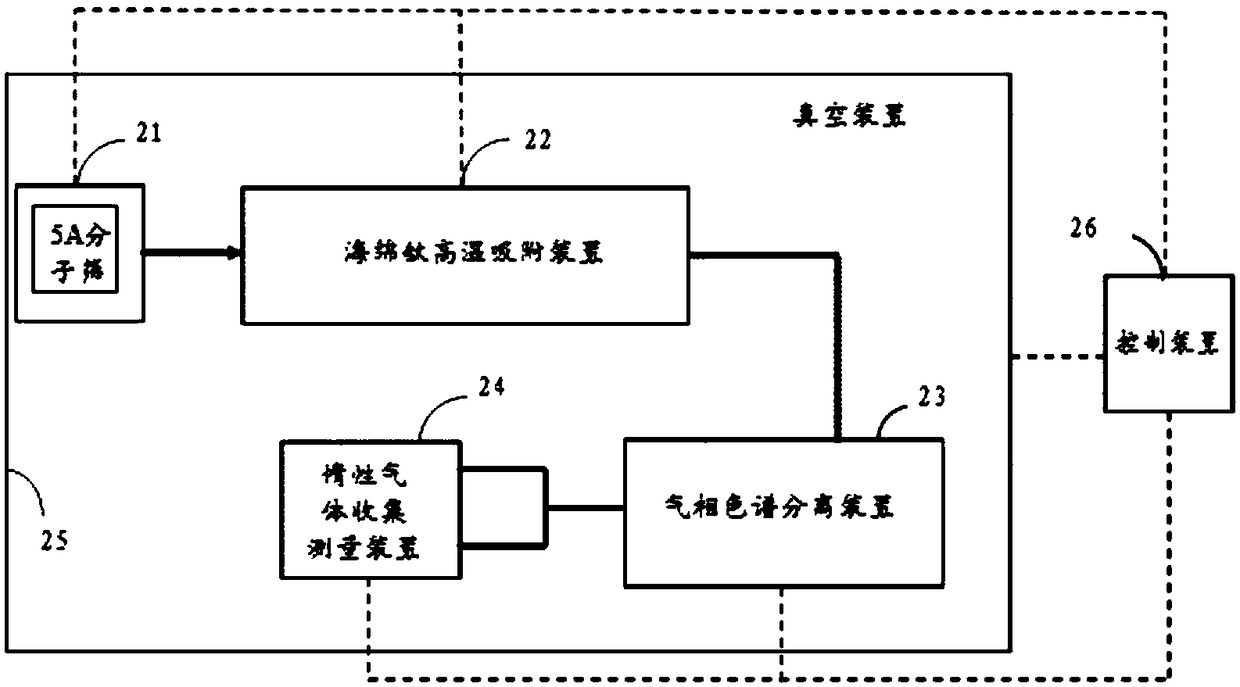

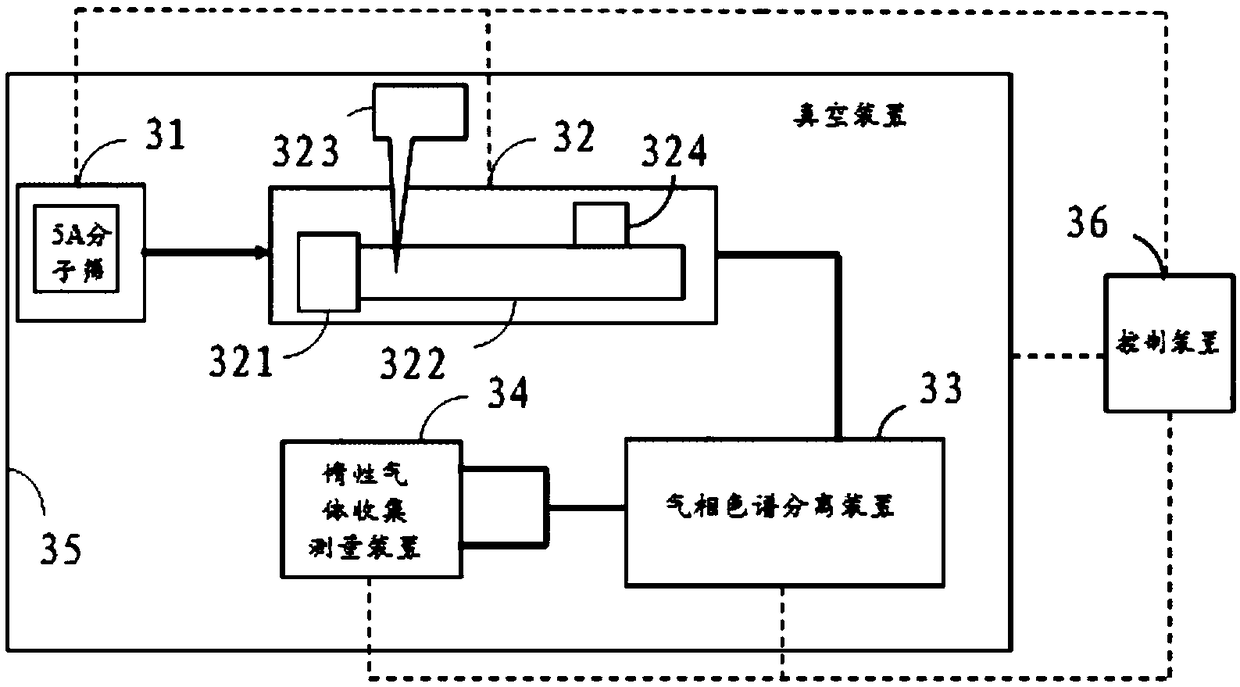

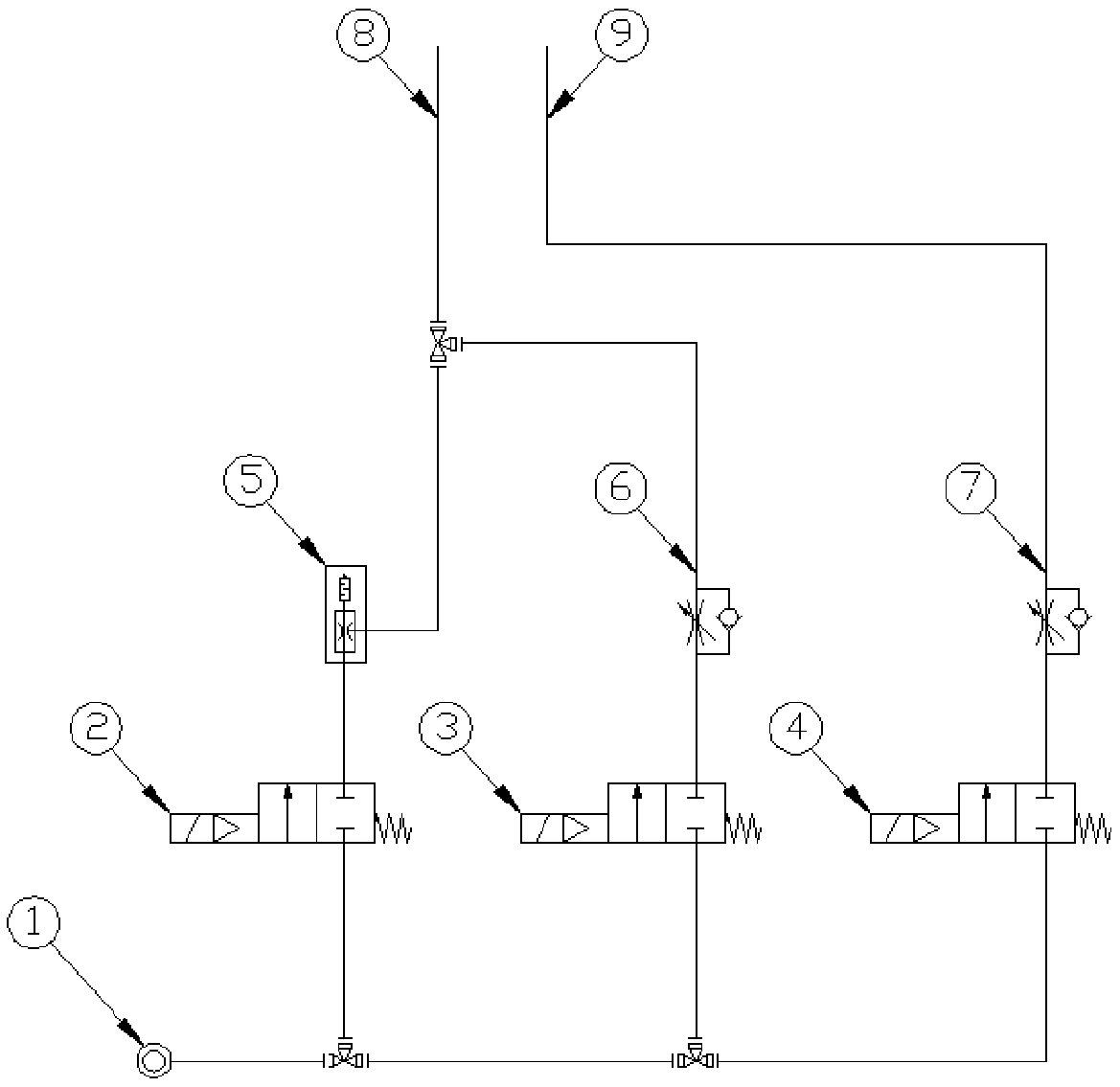

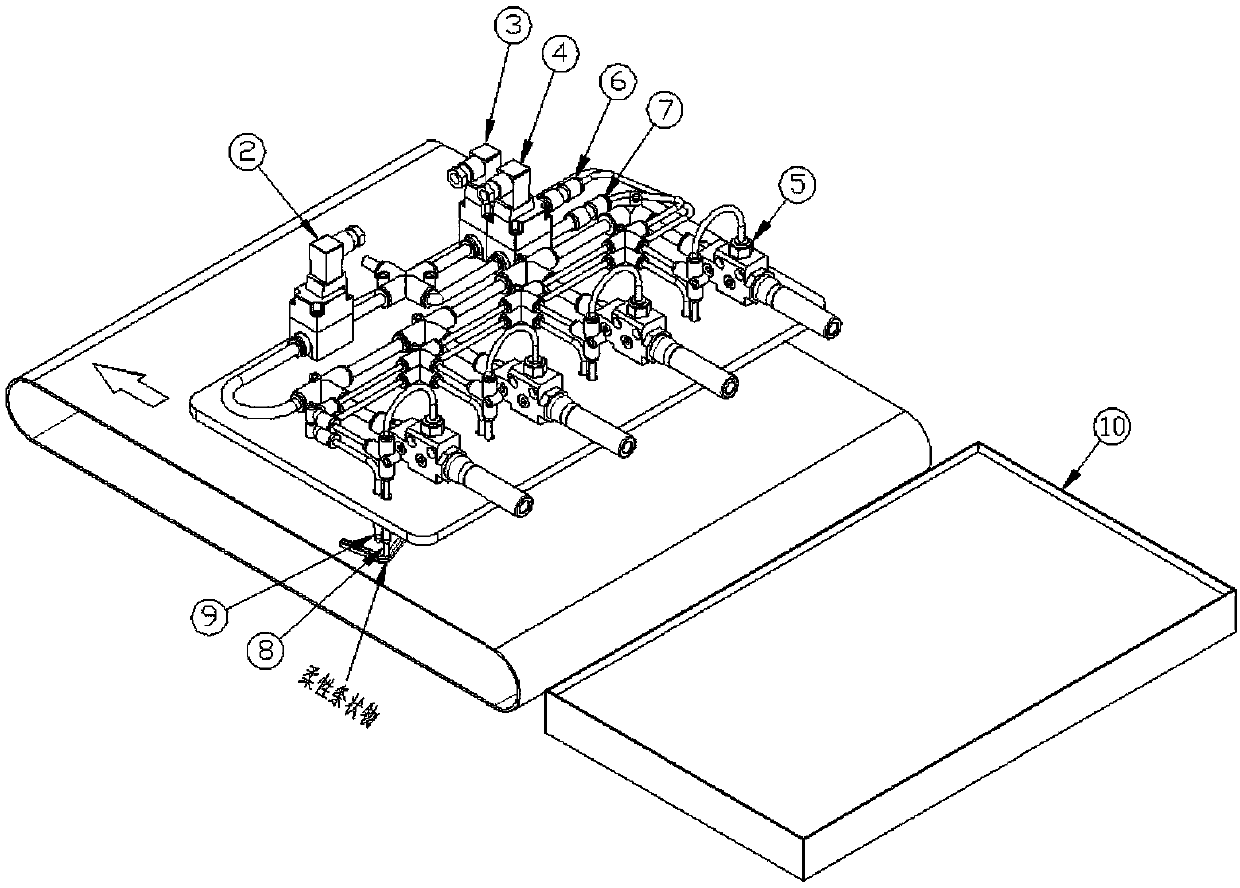

System for automatic separation of inert gas in small gas quantity environment sample

ActiveCN109323909ARealize automated separationPreparing sample for investigationAutomatic controlMeasurement device

The invention discloses a system for automatic separation of inert gases in a small gas quantity environment sample. The system comprises a vacuum device, a control device, a water removing device, asponge titanium high-temperature adsorption device, a gas chromatography separation device, and an inert gas collecting and measuring device. The vacuum device is used for enabling the system to be ina vacuum state. The control device is used for realizing automatic control of the whole inert gas separation. The water removing device is used for removing water and carbon dioxide from the small gas quantity environment sample gas under the control of the control device. The sponge titanium high-temperature adsorption device is used for removing active gases in the small gas quantity environment sample gas under the control of the control device. The gas chromatography separation device is used for separating argon gas and krypton gas in the small gas quantity environment sample gas under the control of the control device. The inert gas collecting and measuring device is used for collecting and measuring the argon gas and the krypton gas separately. According to the system for automaticseparation of the inert gases in the small gas quantity environment sample, automatic simultaneous extraction and separation of the krypton gas and the argon gas in the small gas quantity environmentsample can be realized, and problems that an inert gas extraction and separation is long in time consumption and complex in operation, complex samples of components cannot be processed, sample processing efficiency is low, and manual operation error rate is high are solved.

Owner:UNIV OF SCI & TECH OF CHINA

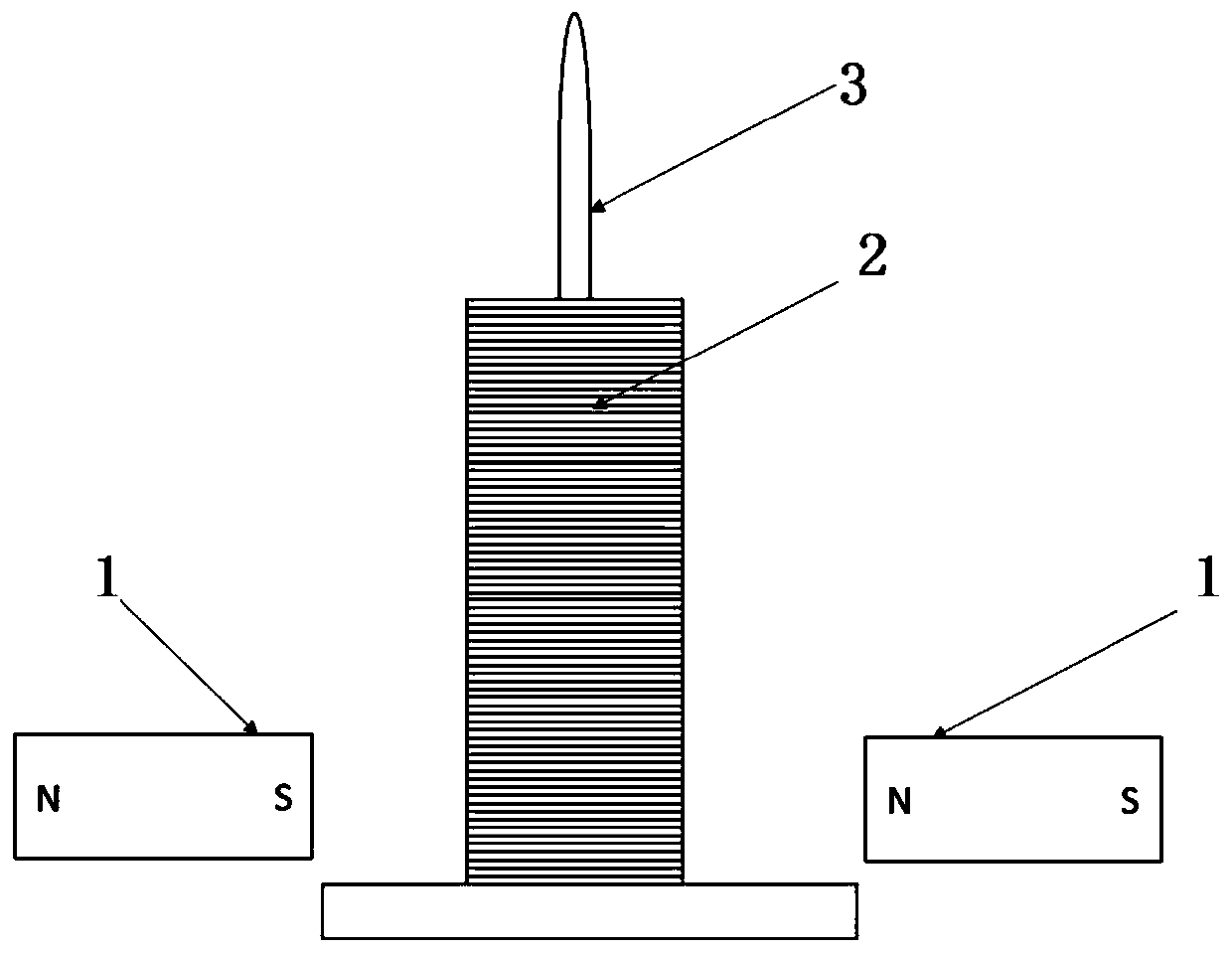

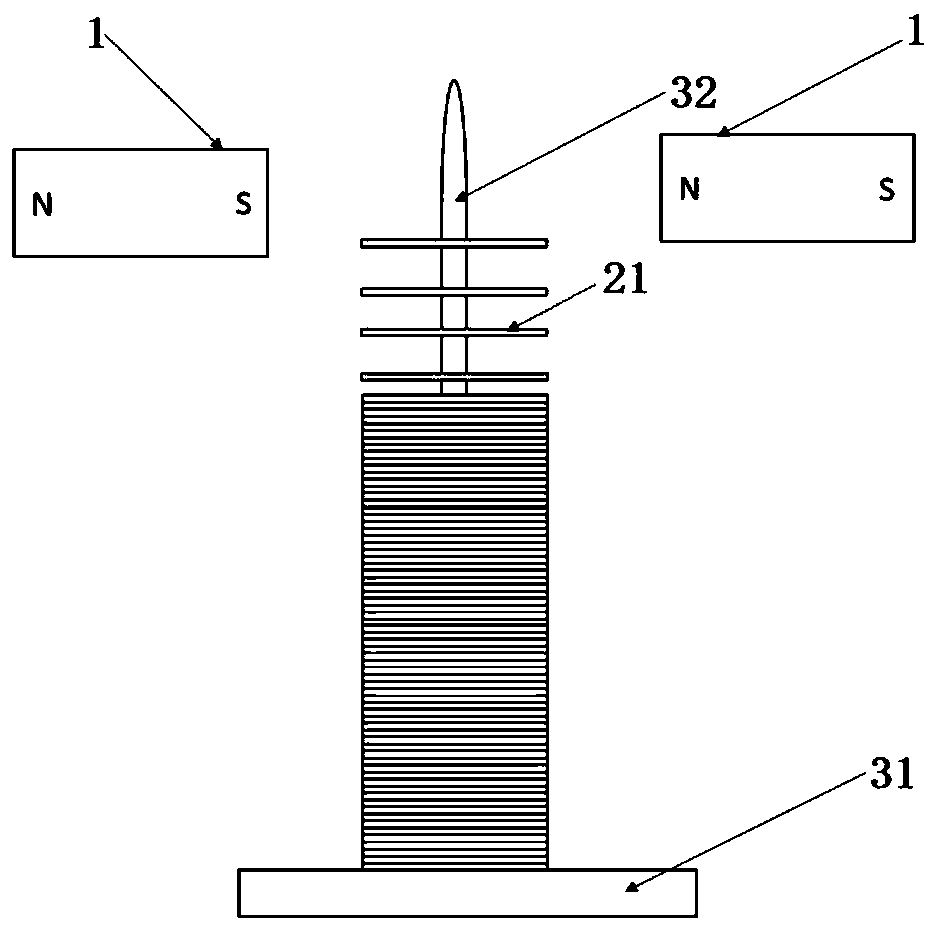

Metal sheet separation device based on magnetic field

The invention discloses a metal sheet separation device based on a magnetic field. The metal sheet separation device aims to solve the technical problems that metal sheet separation equipment in the prior art is large in size, high in energy consumption, prone to errors and prone to damage metal sheets. The metal sheet separation device based on the magnetic field comprises at least one pair of magnetic field generation units, wherein the two magnetic field generation units in each pair of magnetic field generation units are located on the two sides of a sheet stack body formed by stacking a plurality of metal sheets to be separated correspondingly and generate magnetic fields correspondingly, and the magnetic poles of the ends, close to the sheet stack body, of the two magnetic fields areopposite. The metal sheet separation device is simple in structure and small in size, the metal sheets are magnetized through the two magnetic field generation units, then every two adjacent metal sheets repel each other, and under the combined action of repulsive force and gravity, and the plurality of metal sheets located between the two magnetic field generation units can reach a suspended separation state, so that the effect of separation is achieved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Automatic printing line of flexible circuit board

ActiveCN114143977ASpeed up the printing processAvoid pollutionConductive pattern formationFlexible circuitsProcess engineering

The invention discloses a flexible circuit board automatic printing line which comprises a material distributing device, a printing device, a feeding device and a discharging device, the material distributing device comprises a feeding material bearing table, a spacer material bearing table and a sheet separating mechanism, and the sheet separating mechanism comprises a spacer grabbing assembly, an original sheet grabbing assembly and a first control module. The first control module controls the spacer grabbing assembly and the raw sheet grabbing assembly to act alternately. The printing device comprises a vacuum printing platform used for placing a flexible circuit board original sheet and a printing mechanism arranged above the vacuum printing platform. The separating mechanism can separate the spacers and the flexible circuit board raw sheets from the spacers and the flexible circuit board raw sheets which are stacked alternately and convey the flexible circuit board raw sheets to the printing device for printing; according to the automatic printing line for the flexible circuit board, automatic separation of the spacer and the flexible circuit board original sheet is achieved, so that the printing progress of the flexible circuit board original sheet is accelerated, manual feeding can be replaced, and pollution to the flexible circuit board original sheet is avoided.

Owner:赤壁市万皇智能设备有限公司

Full-automatic fish skin stripping method

The invention discloses a full-automatic fish skin stripping method based on a fish skin stripping device. The fish skin stripping device comprises a clamping mechanism, an annular cutting knife (1), a separating knife (2) and a skin stripping mechanism (3); the clamping mechanism comprises a gill hook (4) and a tail clamping mechanism (5), the annular cutting knife is located at the eccentric position of a central axis between the gill hook and the tail clamping mechanism, and the separating knife and the skin stripping mechanism are located at the gill hook side; a fish body to be skinned is horizontally clamped front and back through the clamping mechanism, the annular cutting knife performs annular cutting around the fish body, the separating knife stretches into the fish body from the annular cutting position to separate fish skin from the fish body, then the annular cutting knife performs longitudinal cutting on the fish skin in the length direction of the fish body, and in the skin stripping process of the skin stripping mechanism, the tail clamping mechanism is loosened. According to the full-automatic fish skin stripping method, automatic separating of the fish skin is achieved, the fish skin stripping efficiency is improved, and the fish skin is prevented from being destroyed.

Owner:CHINA JILIANG UNIV

Electric safety test follower device for air conditioner sub-machine

PendingCN109752617AElectric shock preventionImprove detection efficiencyMaterial analysis by optical meansElectrical testingTest powerElectricity

The invention discloses an electric safety test follower device for an air conditioner sub-machine, belonging to the technical field of detection of air-conditioning equipment. The device comprises aworkbench, wherein a transport channel is provided on the workbench, one end of the workbench is provided with a centering device, one side of the transport channel is provided with a detection follow-up device, the detection follow-up device is matched with the transport channel; the detection follow-up device comprises a fixing bracket, the side of the fixing bracket away from the transport channel is fixedly mounted with a control box, the side of the fixing bracket adjacent to the transport channel is provided with two mounting brackets, lower side of the mounting brackets adjacent to thetransport channel is fixedly mounted with a grounding conduction mechanism, the upper side of the mounting brackets away from the transport channel is fixedly mounted with a touch screen operation box, follow-up electrifying modules parallel to the transport channel are provided on the mounting brackets, the grounding conduction mechanism is matched with the sub-machine to be detected on the transport channel, the follow-up electrifying modules are connected with a test power supply box, the test power supply box is provided with a control switch, and the touch screen operation box is electrically connected to the follow-up electrifying modules.

Owner:山东红宝自动化有限公司

A kind of crab cage automatic detachment device

InactiveCN105059482BOut of automatic implementationAutomated separationTowing/pushing equipmentProduction effectEngineering

The invention relates to an automatic crab trap releasing device. Problems of great labor intensity, high cost and low efficiency caused by manually releasing the traditional crab trap are mainly solved. The automatic crab trap releasing device comprises a fixed seat and an unhooking device, wherein a lifting hook comprises a clamping part and a releasing part; a crab trap is connected with a supporting rope through the lifting hook; the unhooking device is hinged on the fixed seat; the unhooking device comprises a bottom plate, a stopping plate and a stopping block; a unhooking slot is formed in the bottom plate; the unhooking slot comprises a sliding-in end and a releasing end; the stopping block is fixedly connected with the bottom plate; a clamping slot is formed in the stopping block; the lifting hook is in clamping fit with the clamping slot; the supporting rope is connected with the releasing part; the releasing part of the lifting hook is pulled by the supporting rope to slide into the unhooking slot; the clamping part of the lifting hook is pushed in the clamping slot so as to drive the unhooking device to rotate for a certain angle around a hinging center; the supporting rope is separated from the lifting hook through a rope releasing opening; and the lifting hook is released from the unhooking device. As the releasing device can be used for releasing the crab trap, the automatic crab trap releasing device provided by the invention is advantaged in that the labor intensity of the releasing device is low, the cost of the device is saved, the production effect of the device is extremely high, and automatic separation is effectively realized.

Owner:王伟囊

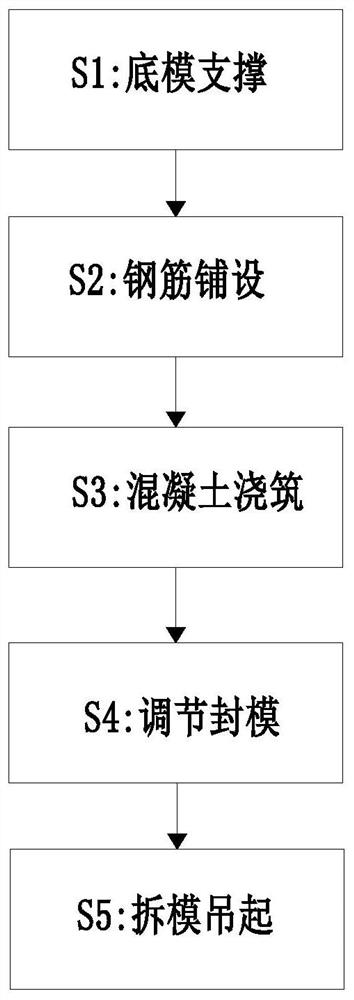

Concrete prefabricated part manufacturing method

InactiveCN112497444AReduce wasteQuality improvementMouldsAuxillary shaping apparatusConstruction engineeringWorking environment

The invention relates to a concrete prefabricated part manufacturing method. The manufacturing method uses an auxiliary concrete prefabricated part manufacturing device, the auxiliary concrete prefabricated part manufacturing device comprises a supporting frame, an outer wall mold and a clamping adjusting mechanism, the supporting frame is of a left square bracket-shaped structure with an upward opening, the outer wall mold is arranged in the middle of the upper end face of the supporting frame, and the clamping adjusting mechanism is connected to the outer wall mold. According to the manufacturing method, the problems that a prefabricated part die of an existing device is poor in sealing performance, slurry leakage and liquid leakage are likely to happen during concrete pouring, concretewaste is likely to be caused, flowing-out concrete is difficult to clear, and a messy working environment is caused to a workshop can be solved, and the problems that an existing device cannot automatically separate the die from the prefabricated part after the prefabricated part is formed, the die needs to be manually disassembled, labor force is wasted, efficiency is low, and the manufacturing efficiency of the concrete prefabricated part is affected can be solved.

Owner:王蒙蒙

A method for testing and controlling process parameters of robot resistance spot welding

ActiveCN108161198BEnsure consistencyReduce participationWelding monitoring devicesProcess engineeringSpot welding

The invention relates to the field of mechanical welding, in particular to a robot resistance spot-welding technological parameter testing and control method. The robot resistance spot-welding technological parameter testing and control method comprises the steps that S1, measuring position transfer verification is carried out; S2, empty spot welding is carried out; S3, actual measurement is carried out; S4, a program position output parameter of the S2 and an actual position output parameter of S3 are subjected to parameter linearization; and S5, a technological parameter setting value is verified. The robot resistance spot-welding technological parameter testing and control method has the following beneficial effects that according to the technical scheme, the robot resistance spot-welding technological parameter testing and control method comprises empty spot and practical spot welding parameter comparison verification, so that the parameter output conformability of the parameters on the two situations is ensured; a fixing bracket of a welding testing instrument is designed and manufactured, so that artificial participation is reduced, and the operational safety performance is improved; a welding test piece fixing bracket is designed and manufactured, so that the history that a welding test piece can not be verified is ended; robot parameter definitions are increased, and welding current and welding pressure test automation separation is realized; and a robot program is designed and written, so that the operational flexibility is ensured, and personnel participation is reduced.

Owner:SINO TRUK JINAN POWER +1

Magnetic separation vertical transportation system and method for solid waste on construction site

PendingCN113262878ARealize automated separationImprove classification efficiencyMagnetic separationVertical ductsTransit systemWaste collection

The invention discloses a magnetic separation vertical transportation system and method for solid waste on a construction site, and relates to the technical field of classified recycling, clearing and transporting of the solid waste on the construction site. The problems that concrete blocks in existing solid waste contain a large amount of iron waste, and if the iron waste is not classified and separated, the use performance of products obtained after the concrete blocks are recycled can be affected are solved. The system comprises a waste transportation pipeline detachably connected to the outer side of a building main body structure, a waste collection device connected to the bottom of the waste transportation pipeline, and an electromagnetic device fixed to the inner side of the waste transportation pipeline. The method comprises the steps: throwing solid waste through the waste throwing opening, performing a circuit where the electromagnetic device arranged on the inner side of the waste conveying pipeline is located, enabling the electromagnetic device to adsorb and separate iron waste in the solid waste, and collecting the other solid waste in the waste collecting device and conveying the waste away from a construction site; and turning off the power supply, so that the electromagnetic device releases the iron wastes, and the iron wastes are separated.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

A preparative circulating chromatography device

ActiveCN104422735BRealize the loadNo volume overloadComponent separationChromatographic separationNatural product

A preparative circulating chromatography apparatus can be applied in chromatographic separation preparation of target components in a complex sample and is mainly advantaged in that: (1) with pre-treatment and concentration of an on-line sample, large-volume sampling on the premise of a high column efficiency can be achieved; (2) through position exchange between a separation column and a trapping column, circulating separation and purification of the target components are achieved and the preparative circulating chromatography apparatus is less in circulating dead volume and column efficiency loss; and (3) through concentration-elution of a finish product through the trapping column, a separation-concentration integrated process is achieved, wherein the three functions are achieved through adjustment of an adsorption performance of the trapping column and valve exchange. Compared with a conventional preparative chromatography method, the apparatus has significant advantages on separations of natural products, drugs and chemical products, especially on separation and preparation of micro-scale targeted components and unstable components in a mixture.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fully automatic fish skin separation method

The invention discloses a full-automatic fish skin separating method based on a fish skin separating device. The fish skin separating device comprises a clamping mechanism, a girdling knife (1), a separating knife (2) and a skinning mechanism (3), wherein the clamping mechanism comprises a fish gill hook (4) and a tail clamping mechanism (5); the girdling knife is located at the eccentric position of the central axis between the fish gill hook and the tail clamping mechanism; the separating knife and the skinning mechanism are located on the side of the fish gill hook; three-dimensional image scanning is performed on a fish body to obtain the annular cutting position and path, the separating path, the longitudinal cutting path and the skinning path; the fish body to be skinned is horizontally clamped by the clamping mechanism in tandem, the girdling knife conducts annular cutting around the fish body, the separating knife extends into the fish body from the incision at the annular cutting part to separate the fish skin from the fish body, then the girdling knife longitudinally cuts the fish skin in the length direction of the fish body, and the tail clamping mechanism releases in the skinning process of the skinning mechanism. The full-automatic fish skin separating method realizes automatic fish skin separation, improves the fish skinning efficiency and prevents the fish skin from being broken.

Owner:CHINA JILIANG UNIV

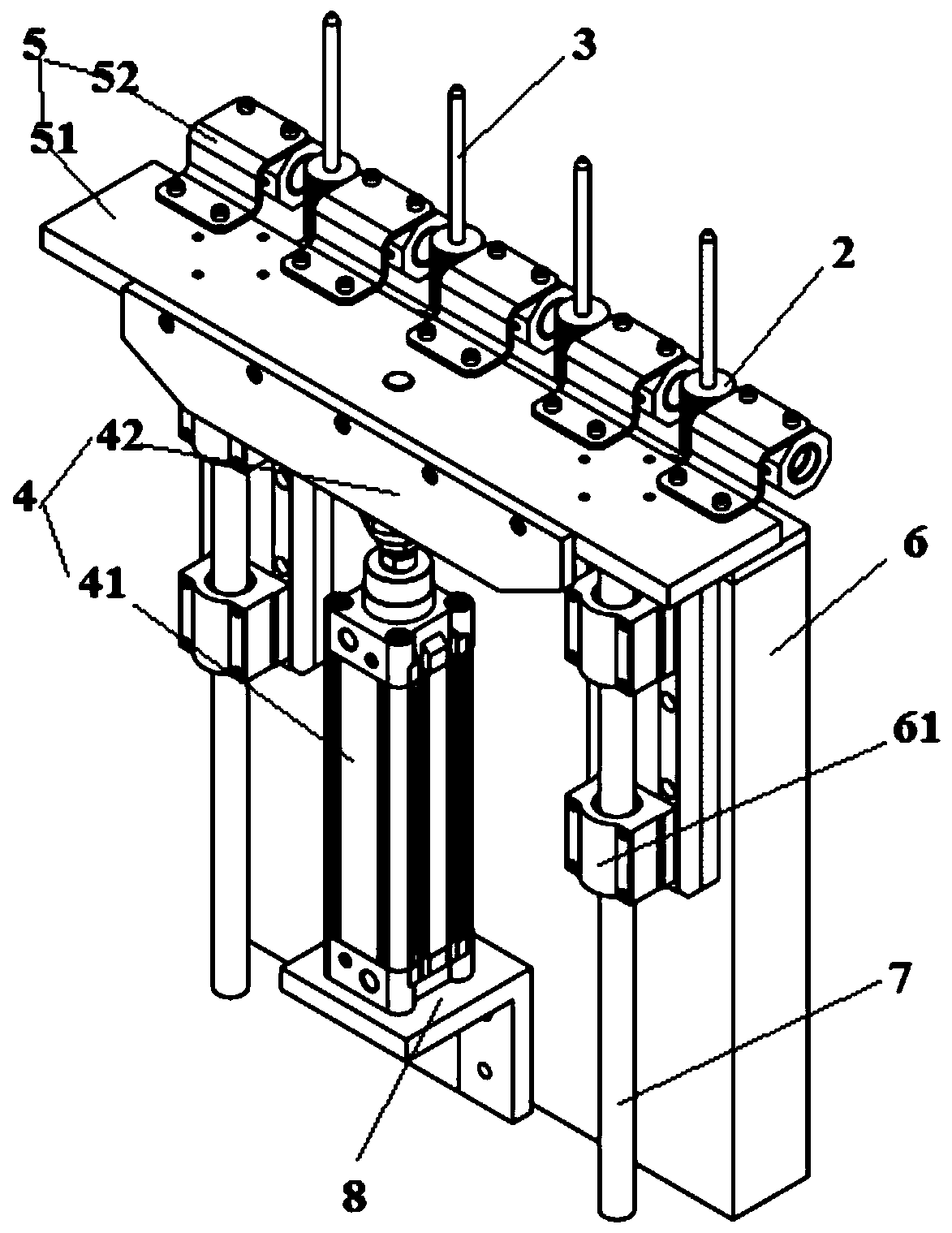

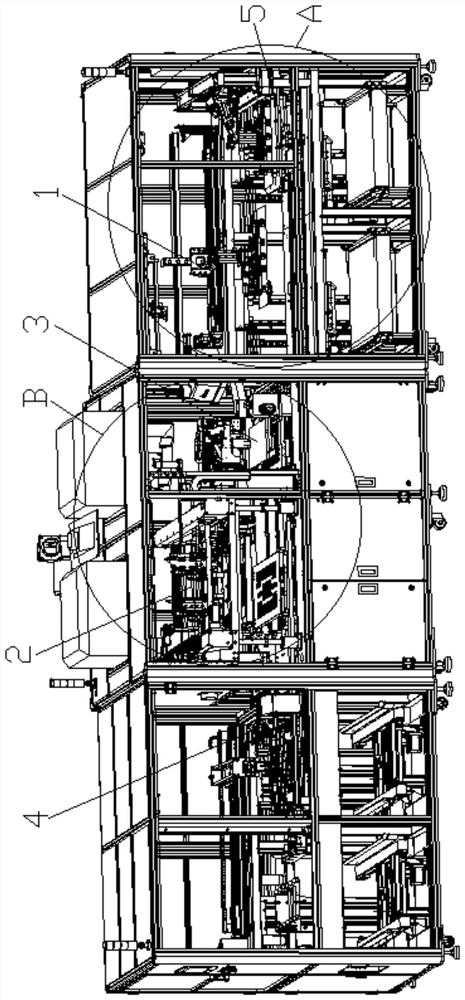

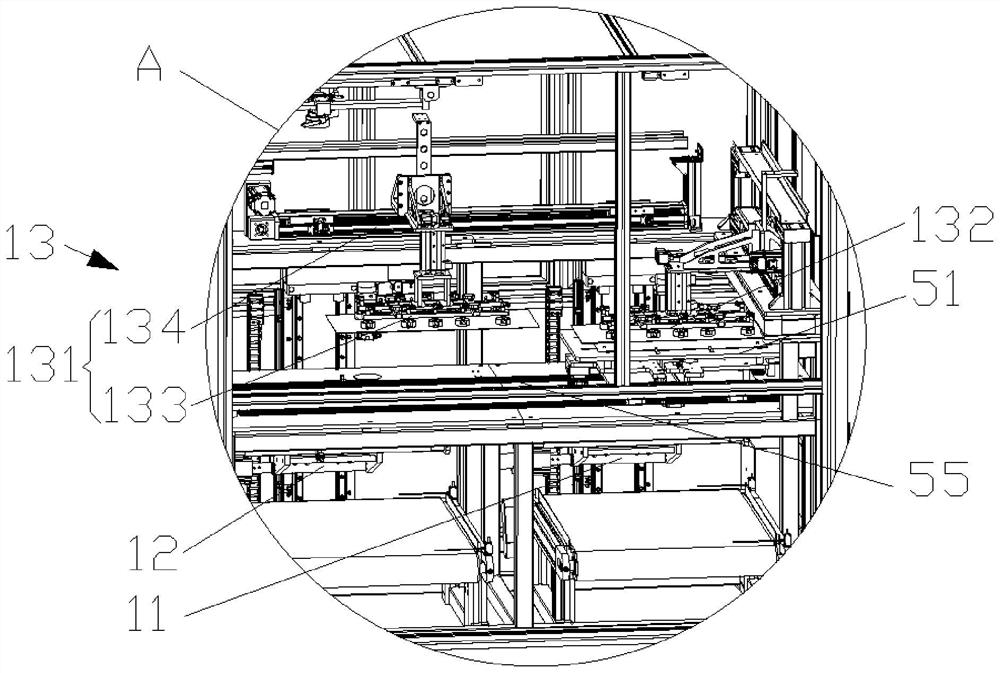

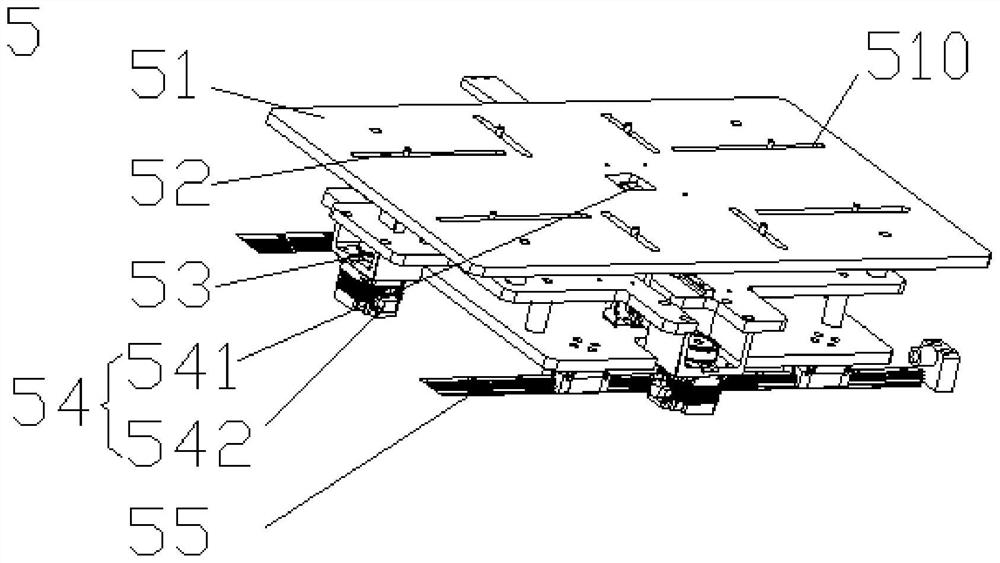

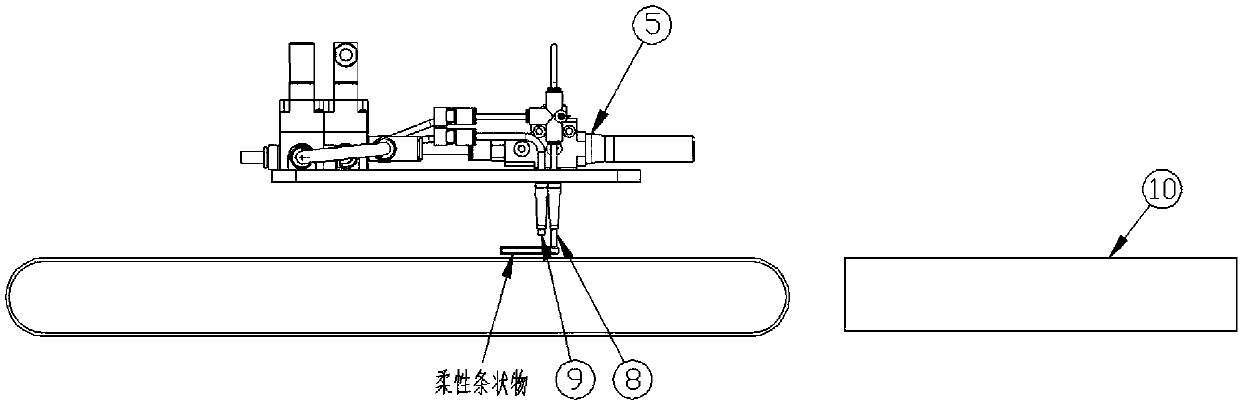

Automatic suction and separation device and method of flexible strip-shaped food

ActiveCN109693937ARealize automated separationImprove separation efficiencyLoading/unloadingConveyor partsEngineeringFood processing

The invention discloses an automatic suction and separation device and method of flexible strip-shaped food, and belongs to the field of food processing. The single flexible strip-shaped food is separated from a to-be-separated flexible strip-shaped food set through the separation device, specifically, the single flexible strip-shaped food is sucked through a separating and sucking part to achieveprimary separation, then the adhered food which possibly exists is separated through blowing by a separating and air blowing part to achieve secondary separation, then the food is placed on a conveying device, and is conveyed to the next processing procedure through the conveying device, so that automatic separation of the flexible strip-shaped food is realized; and a separation matrix is composed of the plurality of separation devices, so that the separation efficiency is improved, and then the problems that the food is secondarily polluted, the labor cost is high, the labor intensity is high and the working efficiency is low due to the adoption of an all-manual mode are solved.

Owner:TAIZHOU ANJOY FOODS +3

Distribution table for plastic trays

PendingCN110920994ARealize automated separationImprove separation efficiencyPackagingStacking articlesEngineeringMechanical engineering

The invention provides a distribution table for plastic trays. A distribution table body is arranged first and provided with a taking station and a distribution station, multiple plastic tray bodies are stacked on the taking station, and the distribution station is provided with a distribution mechanism. The distribution mechanism comprises a distribution plate and multiple distribution suction cups, the distribution plate is fixedly installed on the distribution station, and the distribution suction cups are detachably installed on the distribution plate. The taking device is erected on the distribution table body and comprises a horizontal moving mechanism and a lifting mechanism, the lifting mechanism comprises a lifting plate and a second driving part, the second driving part and the lifting plate are installed on the horizontal moving mechanism, and the lifting plate ascends and descends under driving of the second driving part and is provided with multiple taking suction cups facing the plastic tray bodies. Compared with the prior art, the distribution table for the plastic trays has the advantages that the stacked plastic trays are automatically separated, and compared withmanual separation, the separation efficiency is improved.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

Starch separation device used for processing sweet potato sheet jelly

InactiveCN107670807ARealize automated separationImprove separation efficiencyGrain treatmentsDrive shaftGear wheel

The invention relates to a starch separation device used for processing sweet potato sheet jelly. The starch separation device comprises an outer cylinder, a separation cylinder, a feed hopper, a mounting shaft frame, a transmission shaft, a motor, a water pipe and a discharge pipe. The starch separation device is characterized in that the separation cylinder is installed in the outer cylinder, atransmission gear is arranged on one side of the separation cylinder, a matching gear is installed on the transmission shaft, the transmission gear is matched with the matching gear, and the feed hopper is arranged on one side of the outer cylinder and connected with the separation cylinder; one side of the separation cylinder is connected with a supporting bearing, and the supporting bearing is installed in the outer cylinder; a water pipe is arranged on the outer cylinder and provided with spray nozzles; and the discharge pipe is arranged below the outer cylinder and provided with a first electromagnetic valve, and the discharge pipe is connected with a material collection barrel. By arranging the starch separation device used for processing the sweet potato sheet jelly, automatic separation of starch is realized, the separation efficiency is improved, and meanwhile the production cost is reduced.

Owner:湖南新食康农业发展有限公司

Automatic separation device for winding type battery pole piece separation

PendingCN111146525ARealize automated separationSimple structureSolid waste disposalWaste accumulators reclaimingThin membranePole piece

The invention discloses an automatic separation device for winding type battery pole piece separation. The device comprises a rack and a mounting plate arranged on the rack; a separation mechanism anda discharging device corresponding to the separation mechanism are arranged on the mounting plate; the separation mechanism comprises two thin film storage devices and two pole piece storage devices;the thin film storage devices and the pole piece storage devices are arranged in a staggered mode, and the discharging device is arranged in the middle of the top of the separation mechanism. According to the invention, a winding type battery pole piece to be separated is arranged on the discharging device, a thin film on the battery pole piece is recycled through a thin film storage device, anda positive pole piece and a negative pole piece are recycled through a pole piece storage device, thereby achieving the automatic separation of the battery pole piece is achieved. The device is simplein structure, convenient to use and rapid to operate, and the thin film storage device and the pole piece storage device are arranged in a staggered mode, so the device is more reasonable in layout,more compact in structure and more convenient and rapid to operate.

Owner:湖北德普智能装备有限公司

Fully automatic intelligent fish skinning method

The invention discloses a full-automatic intelligent fish skinning method based on a fish skinning device. The fish skinning device comprises a clamping mechanism, a girdling knife (1), a separating knife (2) and a skinning mechanism (3), wherein the clamping mechanism comprises a fish gill hook (4) and a tail clamping mechanism (5); the girdling knife is located at the eccentric position of the central axis between the fish gill hook and the tail clamping mechanism; the separating knife and the skinning mechanism are located on the side of the fish gill hook. The fish skinning method comprises the steps of clamping, recognizing and scanning, annular cutting, fish skin separating, longitudinal cutting and skinning. The full-automatic intelligent fish skinning method realizes automatic fish skin separation, improves the fish skinning efficiency and prevents the fish skin from being broken.

Owner:CHINA JILIANG UNIV

Fish skin automatic peeling device

The invention discloses an automatic fish skin peeling device, which comprises a clamping mechanism, a ring cutter (1), a separating knife (2) and a peeling mechanism (3). The clamping mechanism includes fish gill hooks arranged at the same level (4) and the tail clip mechanism (5), the ring cutter (1) is located at the eccentric position of the central axis between the gill hook (4) and the tail clip mechanism (5), and the separation knife (2) And the skinning mechanism (3) is located at the side of the gill hook; the fish body (6) to be peeled is clamped horizontally by the clamping mechanism, and the ring cutter (1) is used to make circular cuts around the fish body, and the separation knife (2) Stretch into the fish body from the kerf at the annular cutting place to separate the fish skin from the fish body, then cut the fish skin longitudinally by the ring cutter (1) along the length direction of the fish body, and peel off the fish skin by the peeling mechanism 3 afterwards. The invention realizes the automatic separation of the fish skin and obtains the whole fish skin, improves the peeling efficiency of the fish skin and avoids the damage of the fish skin.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com