Magnetic separation vertical transportation system and method for solid waste on construction site

A technology for solid waste and construction site, which is applied in the field of magnetic separation vertical transportation system for solid waste at construction site, can solve the problems affecting the performance of concrete block products, and achieves the goal of improving the efficiency of classification and recovery, and the speed of adsorption and separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

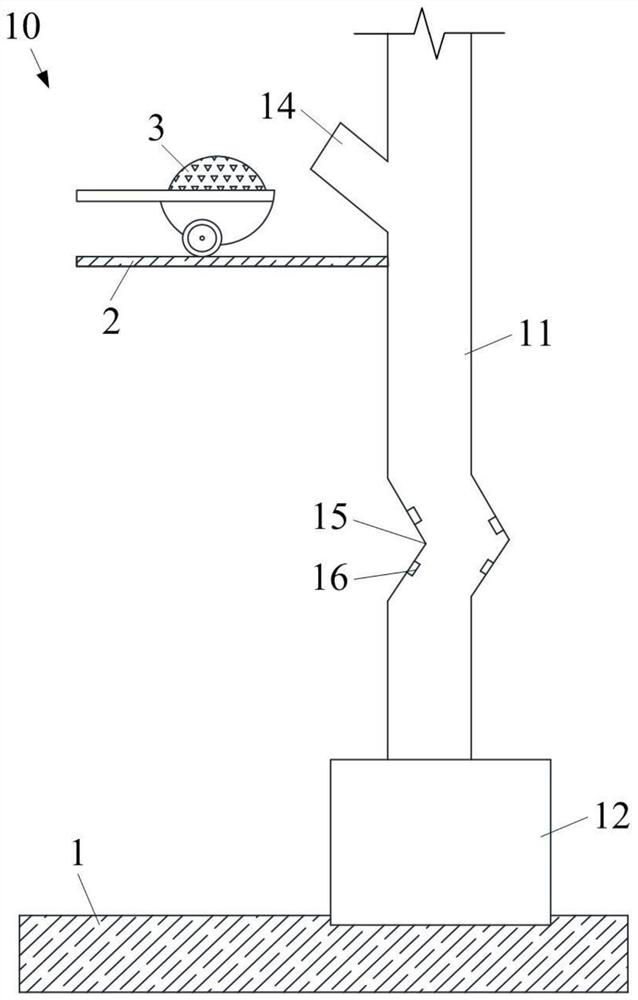

[0025] combine figure 1 The magnetic separation vertical transportation system 10 of the construction site solid waste of the present invention is illustrated, which includes:

[0026] The waste transportation pipeline 11 is vertically arranged and detachably connected to the outside of the main building structure. The side walls of the waste transportation pipelines 11 corresponding to each floor 2 are provided with a waste delivery port 14 communicating therewith;

[0027] The waste collection device 12 is arranged at the bottom of the waste transportation pipeline 11 and communicates with it;

[0028] The electromagnetic device 16 is fixed inside the waste transportation pipeline 11 .

[0029] The magnetic sorting vertical transport system 10 for solid waste at the construction site of the present invention includes a waste transport pipeline 11 detachably connected to the outside of the building main structure, a waste collection device 12 connected to the bottom of the ...

Embodiment 2

[0036] combine figure 1 Illustrate the magnetic separation vertical transportation method of the construction site solid waste of the present invention, the specific steps are as follows:

[0037] The magnetic separation vertical transportation device for solid waste at the construction site as described in Embodiment 1 is installed outside the main structure of the building, and the solid waste 3 crushed on each floor 2 is thrown into the waste transportation pipeline 11 through the waste delivery port 14, The solid waste 3 is transported vertically downward along the waste transportation pipeline 11 under the action of gravity, so that the circuit of the electromagnetic device 16 installed inside the waste transportation pipeline 11 is conducted, and the electromagnetic device 16 absorbs and separates the iron in the solid waste 3 waste, and the remaining solid waste 3 is collected in the waste collection device 12 and transported away from the construction site;

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com