Starch separation device used for processing sweet potato sheet jelly

A technology for sweet potato flour and starch, applied in grain processing and other directions, can solve the problems of poor separation effect and incomplete starch separation, and achieve the effects of automatic separation, reduction of production cost and improvement of separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

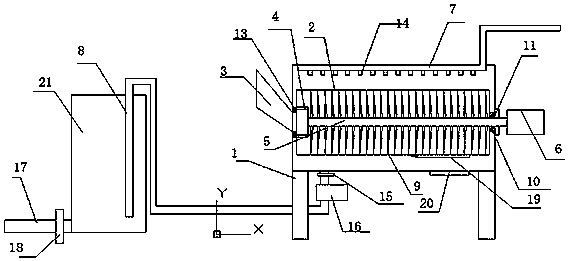

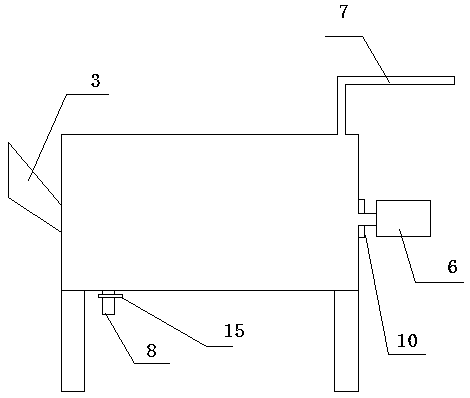

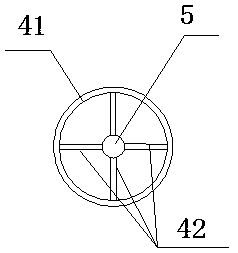

[0017] like Figure 1-3 As shown, a starch separation device for processing sweet potato flour skin, comprising an outer cylinder 1, a separation cylinder 2, a feeding hopper 3, an installation shaft frame 4, a transmission shaft 5, a motor 6, a water pipe 7, and a discharge pipe 8, which is characterized in that : The separation cylinder 2 is installed in the outer cylinder 1, one end of the transmission shaft 5 is installed on the mounting shaft frame 4, the other end of the transmission shaft 5 is connected with the motor 6, and the separation cylinder 2 is provided with Stirring teeth 9, a transmission gear 10 is provided on one side of the separating cylinder 2, a matching gear 11 is installed on the transmission shaft 5, and the transmission gear 10 is matched with the matching gear 11. A feeding hopper 3 is provided on one side, the feeding hopper 3 is connected with the separating cylinder 2, and a supporting bearing 13 is connected on one side of the separating cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com