Preparative circulating chromatography apparatus

A circulating chromatography and preparative technology, which is applied in the field of circulating preparative liquid chromatography, can solve the problems of poor practicability and large investment of preparative equipment, and achieve automatic separation, simplification of manpower, and small dead volume between columns Effect

Active Publication Date: 2015-03-18

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Existing technologies are often only applicable to the application of analytical chromatography, but are not practical for preparative equipment, and the transformation of technology often requires a large amount of investment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

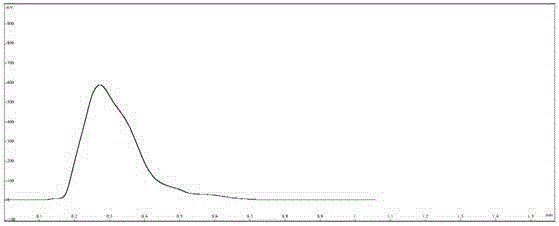

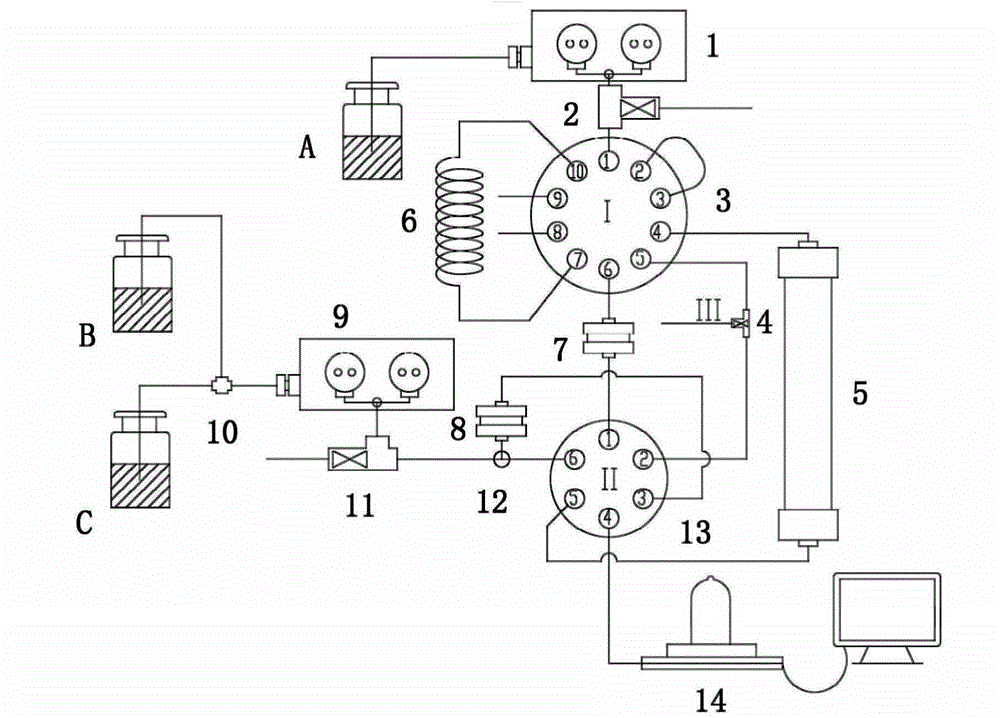

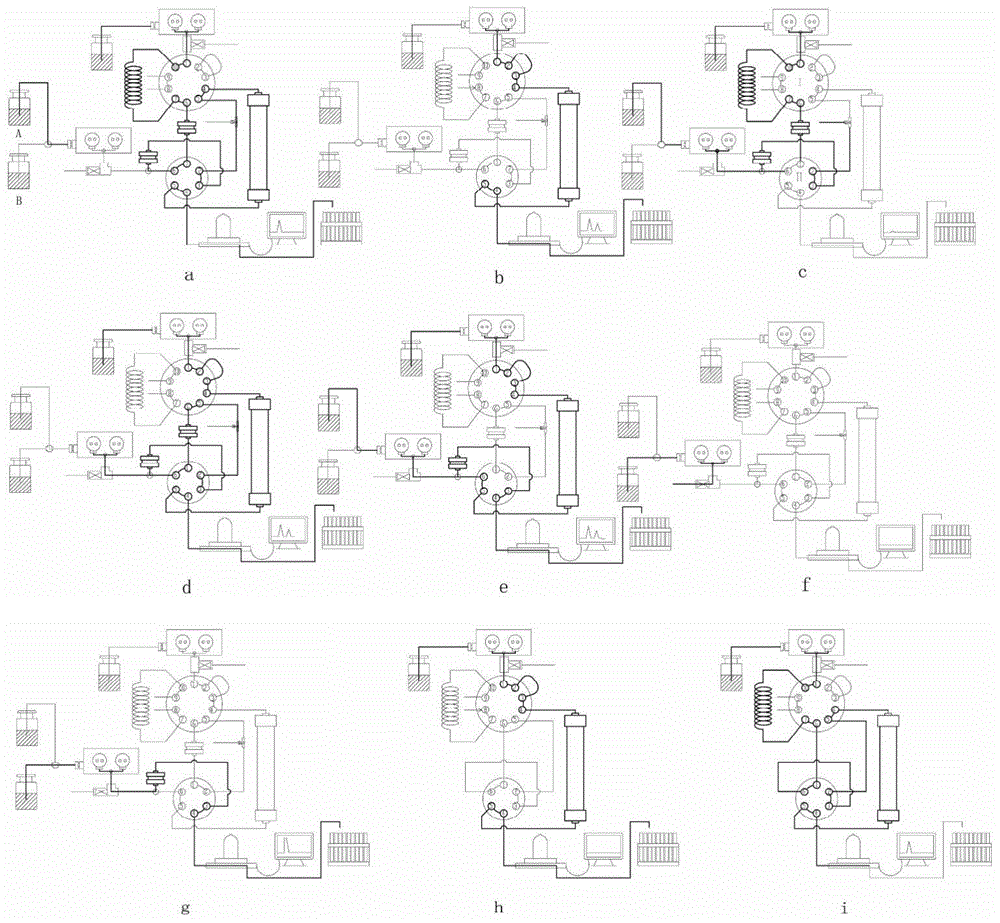

A preparative circulating chromatography apparatus can be applied in chromatographic separation preparation of target components in a complex sample and is mainly advantaged in that: (1) with pre-treatment and concentration of an on-line sample, large-volume sampling on the premise of a high column efficiency can be achieved; (2) through position exchange between a separation column and a trapping column, circulating separation and purification of the target components are achieved and the preparative circulating chromatography apparatus is less in circulating dead volume and column efficiency loss; and (3) through concentration-elution of a finish product through the trapping column, a separation-concentration integrated process is achieved, wherein the three functions are achieved through adjustment of an adsorption performance of the trapping column and valve exchange. Compared with a conventional preparative chromatography method, the apparatus has significant advantages on separations of natural products, drugs and chemical products, especially on separation and preparation of micro-scale targeted components and unstable components in a mixture.

Description

technical field [0001] The invention is a circulating preparative liquid chromatography device for complex sample separation. Background technique [0002] In the separation and preparation of natural products, drugs or chemical products, preparative liquid chromatography is the most common and effective separation method. However, there are still many problems in the application of this technology: (1) The composition of the target substance is The content in the mixed sample is very low, and there are too many components other than the target component; (2) The target component is unstable due to cumbersome transfer process or environmental factors such as light, heat, and oxygen during the pretreatment or drying process of the sample (3) The sample solubility is poor, resulting in a small sample volume, a waste of solvent, or volume overload when a large volume sample is loaded, which affects the separation effect; (4) The sample is dissolved in a solvent with strong elut...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N30/02G01N30/38

Inventor 肖红斌邹晓伟刘丹高明哲

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com