Side gate intelligent flexible automatic separation equipment for molded cluster plastic parts

An automatic separation and plastic technology, which is applied in the field of intelligent and flexible automatic separation equipment for side gates after forming of cluster plastic parts, can solve the problems of small operation space, time-consuming and labor-intensive, and increase the difficulty of manual separation, so as to ensure product quality and high efficiency. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

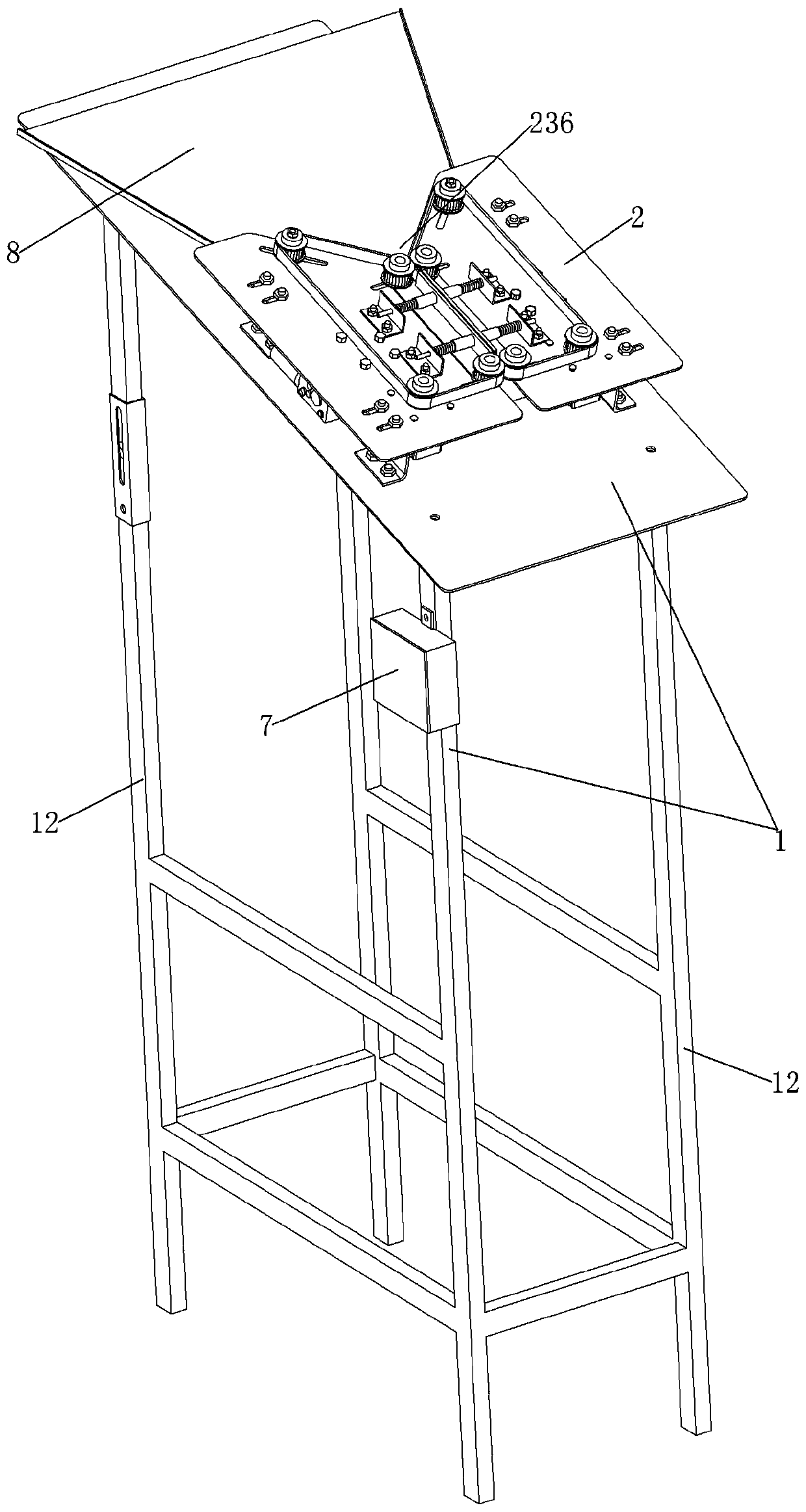

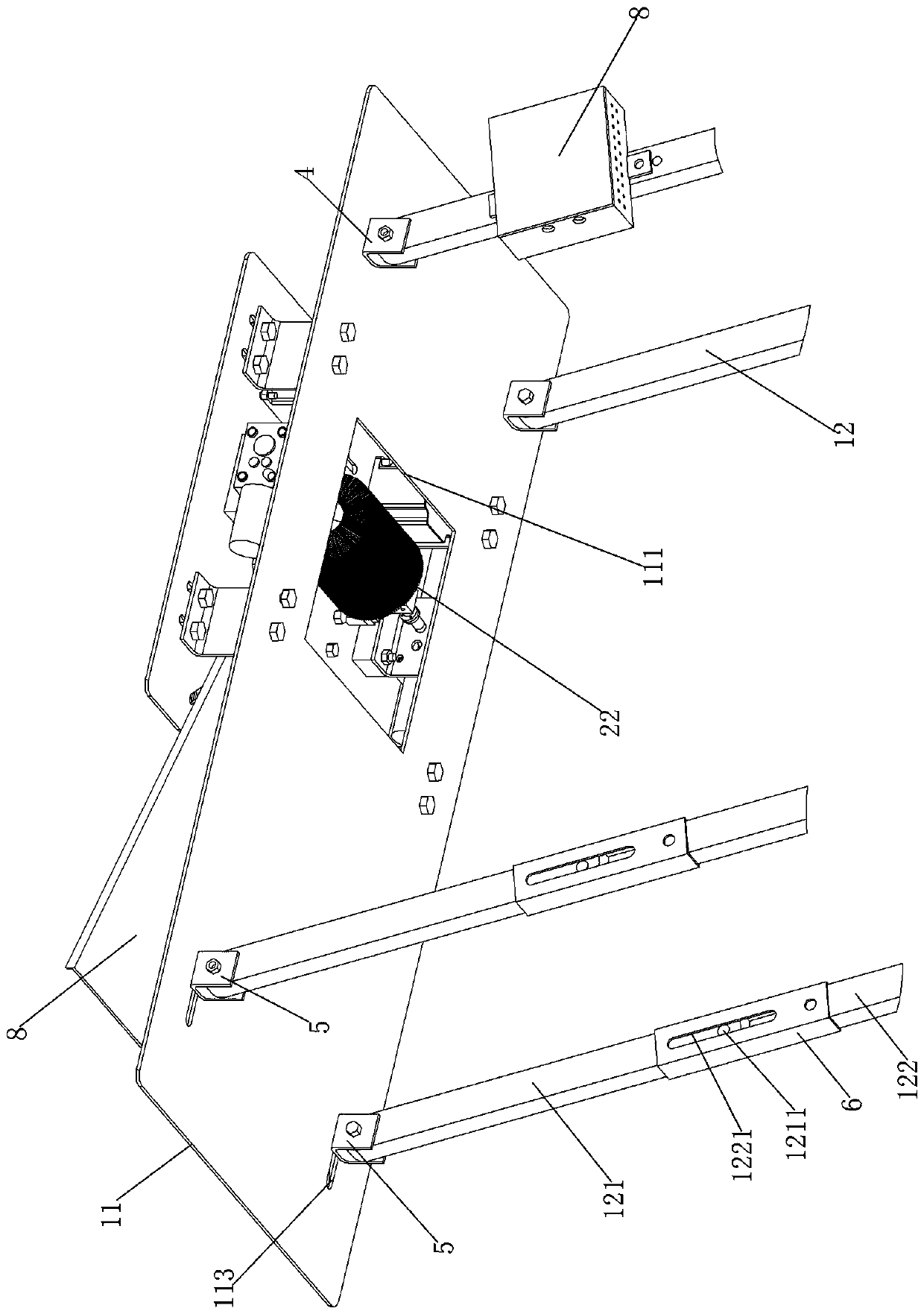

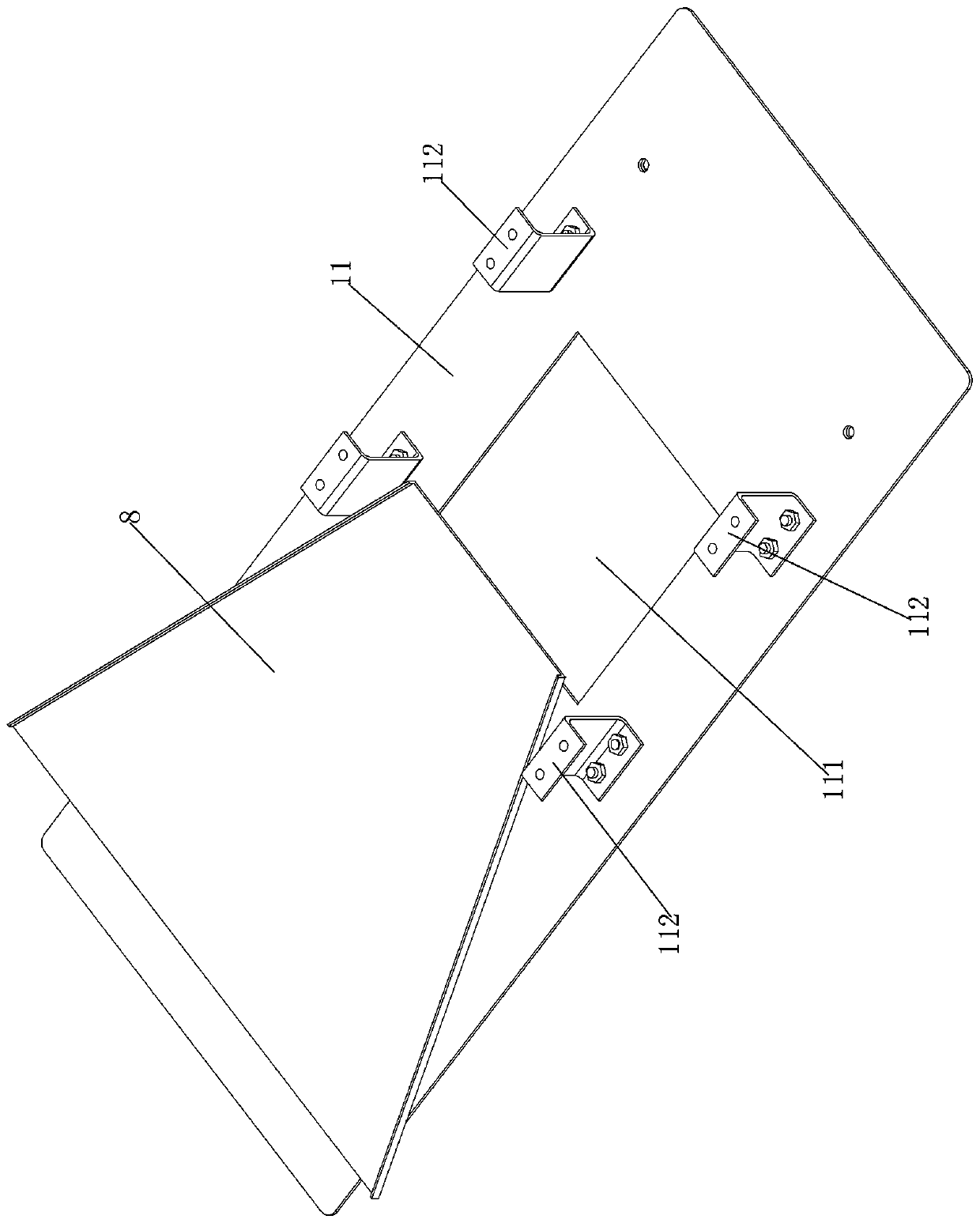

[0032] Embodiment 1, refer to the accompanying drawings (1-12) of the description, an intelligent and flexible automatic separation equipment for side gates after cluster plastic parts are formed, characterized in that: the automatic separation equipment includes a bracket and a device separation device, and the bracket includes The support base plate and the legs fixedly connected to the four corners of the support base plate, wherein the height of the two legs at the rear end of the support base plate is greater than the height of the front two legs, the support base plate is fixed on the upper ends of the four legs obliquely, and the middle part of the support base plate is opened There is a blanking hole, and the upper surface of the supporting base plate on both sides of the blanking hole is symmetrically provided with supporting connectors;

[0033]The device separation device is arranged above the blanking hole of the support base plate, and includes two identical rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com