Tobacco leaf processing technology adopting stemming, slitting and redrying

A technology of re-curing tobacco leaves and processing technology, which is applied in the fields of tobacco, solid separation, and tobacco preparation. It can solve the problems of difficulty in controlling the size of tobacco leaves and tobacco stems, difficulty in controlling the temperature and moisture of tobacco leaves, and large loss of tobacco leaves. Toasting process, improving the utilization rate of tobacco leaves, reducing the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

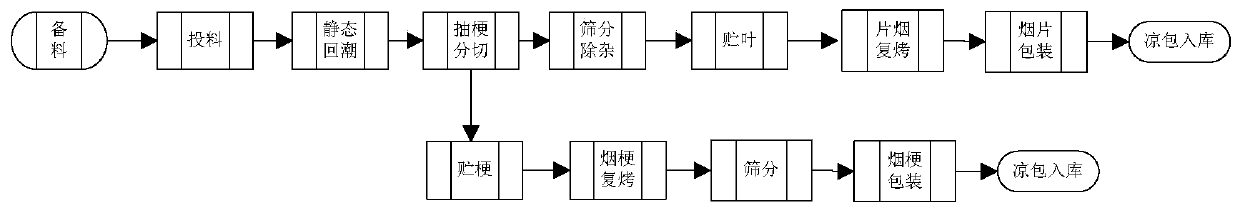

[0031] Such as figure 2 As shown, according to the formula and process requirements, the original tobacco frame is put into the production line, and the moisture and temperature of the tobacco leaves are controlled by static moisture regain. Tobacco moisture and temperature. When the moisture content of the raw tobacco is greater than 13%, spread the raw tobacco on the spreading table with the stem end facing outwards, and feed the raw tobacco from the spreading table into the mesh belt rehydration machine, and control the hot air temperature and humidification rate of the mesh belt rehydration machine. The amount of water is used to control the moisture content and temperature of the raw tobacco at the outlet; when the moisture content of the raw tobacco is less than 13%, the raw tobacco enters the vacuum humidifier for rehydration, and the vacuum degree is controlled to be 2.3±0.2KPa for one time, and the vacuum degree for humidification is 7.0±1.0KPa. After stopping the s...

Embodiment 2

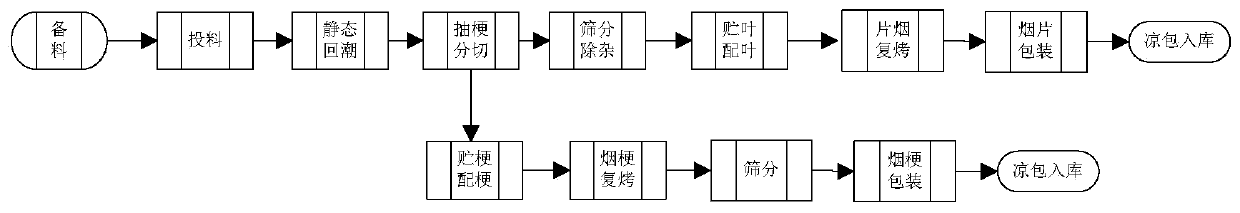

[0037] Such as image 3 As shown, the single-grade raw tobacco is sorted and stacked neatly in the frame. Further, the raw tobacco is prepared and framed according to the formula and process requirements in the raw material resurgence section, and put into the production line. Tide machine to control the moisture and temperature of the tobacco leaves. When the moisture content of the raw tobacco is greater than 13%, spread the raw tobacco on the spreading table with the stem end facing outwards, and feed the raw tobacco from the spreading table into the mesh belt rehydration machine, and control the hot air temperature and humidification rate of the mesh belt rehydration machine. The amount of water is used to control the moisture content and temperature of the raw tobacco at the outlet; when the moisture content of the raw tobacco is less than 13%, the raw tobacco enters the vacuum humidifier for rehydration, and the vacuum degree is controlled to be 2.3±0.2KPa for one time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com