Patents

Literature

146results about How to "Reduce site occupancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical compound for treating wastewater containing complex heavy metals and/or radioactive substances and application of pharmaceutical compound

ActiveCN102730812AHas a bactericidal effectRapid sedimentation to removeWater/sewage treatment by flocculation/precipitationAutomatic controlDithiophosphoric acid

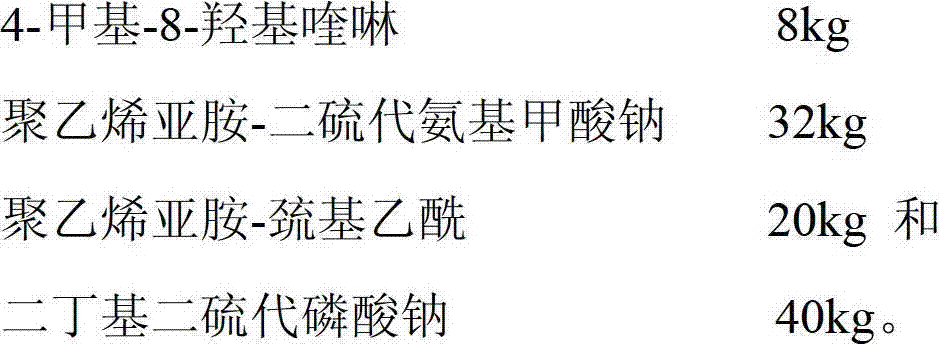

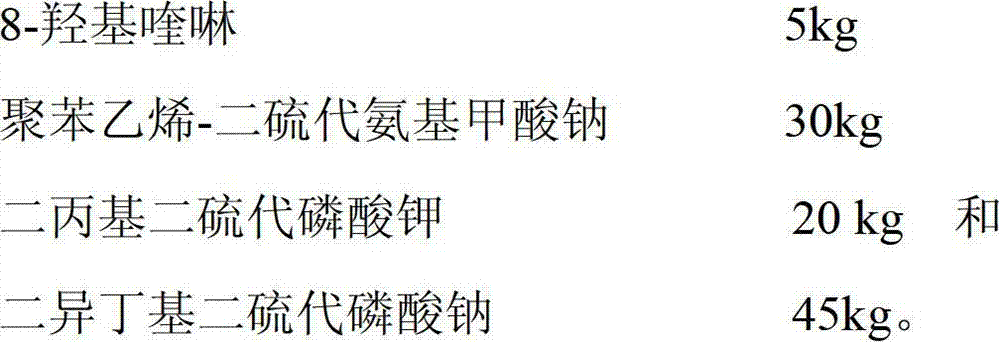

The invention discloses a pharmaceutical compound for treating wastewater containing complex heavy metals and / or radioactive substances and application of the pharmaceutical compound. The pharmaceutical compound comprises one of 8-hydroxyquinoline and derivatives of 8-hydroxyquinoline or a composition of any two of 8-hydroxyquinoline and the derivatives of 8-hydroxyquinoline, one of polyamine-dithiocarbamates or a composition of any two of the polyamine-dithiocarbamates, and one of dihydrocarbyl dithiophosphates or a composition of any two of the dihydrocarbyl dithiophosphates, wherein the mass fractions of the three components are respectively 1% to 90%, 1% to 90% and 1% to 98%. The pharmaceutical compound is dissolved in water and then the pharmaceutical compound solution is added into wastewater to be treated, and the amount of the pharmaceutical compound is 0.5 to 2 times larger than the theoretical amount of heavy metals and radioactive substances in the wastewater; and a metal complex is formed after sufficient stirring, and finally, the wastewater treatment can be completed by filtering separation. The pharmaceutical compound and the application of the pharmaceutical compound provided by the invention have the advantages of obvious effects, less investment, low cost, no site restriction, remote automatic control and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for rapidly producing high-quality organic fertilizer by virtue of high-temperature aerobic secondary fermentation

ActiveCN103980017AIncrease temperatureShorten the timeBio-organic fraction processingOrganic fertiliser preparationMicroorganismOrganic fertilizer

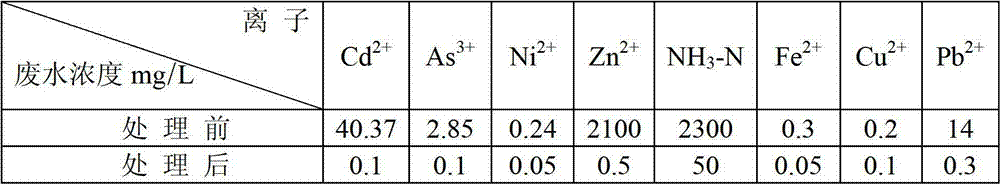

The invention discloses a method for rapidly producing a high-quality organic fertilizer by virtue of high-temperature aerobic secondary fermentation and relates to the technical field of microorganism application. The method comprises the following steps: A, raw material preprocessing; B, zymocyte preparation, namely a, preparation of high temperature zymocyte: 1, preparation of stock culture of the high-temperature zymocyte, 2, preparation of sterilizing materials of the high-temperature zymocyte, 3, inoculation of the stock culture of the high-temperature zymocyte, 4, fermentation of the stock culture of the high-temperature zymocyte, and 5, secondary fermentation, and b, preparation of middle-temperature and low-temperature zymocyte; C, inoculation of the high-temperature zymocyte; D, temperature rising and fermentation; E, sterilization; F, fermentation at a high temperature; G, inoculation of the middle-temperature and low-temperature zymocyte; H, cooling and secondary fermentation. The method has the characteristics of having short fermentation cycle, less investment and low cost, and being capable of rapidly preparing organic wastes into the high-quality organic fertilizer, and is applicable to rapidly processing various organic wastes; the prepared high-quality organic fertilizer can be used as a base fertilizer for planting of crops such as rice, fruits, vegetables and melons and fruits.

Owner:湖南百威生物科技股份有限公司

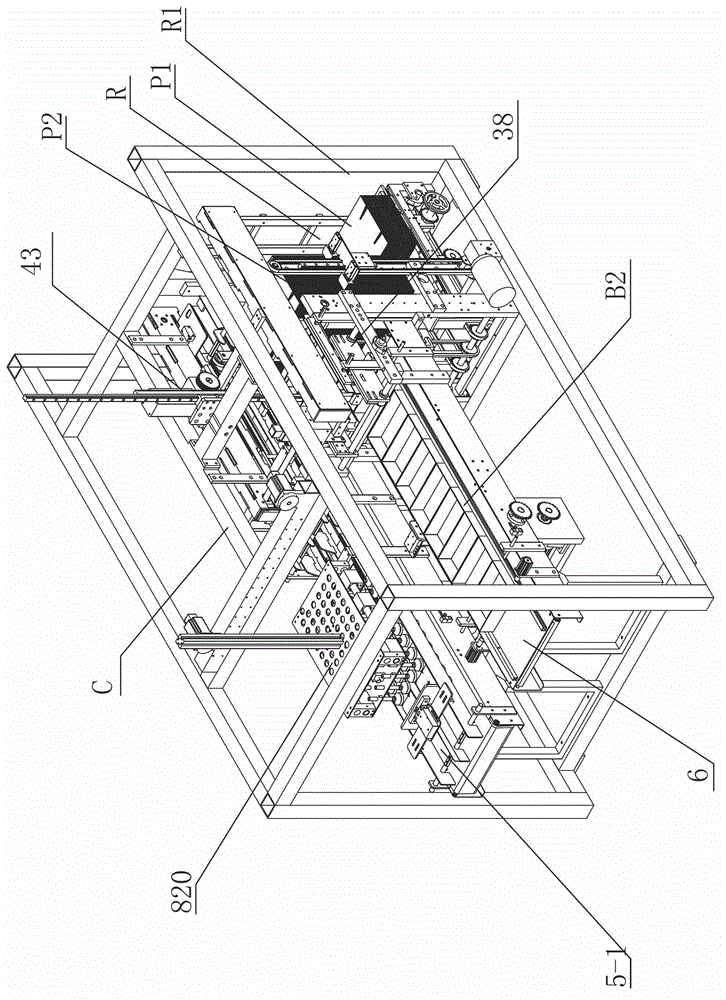

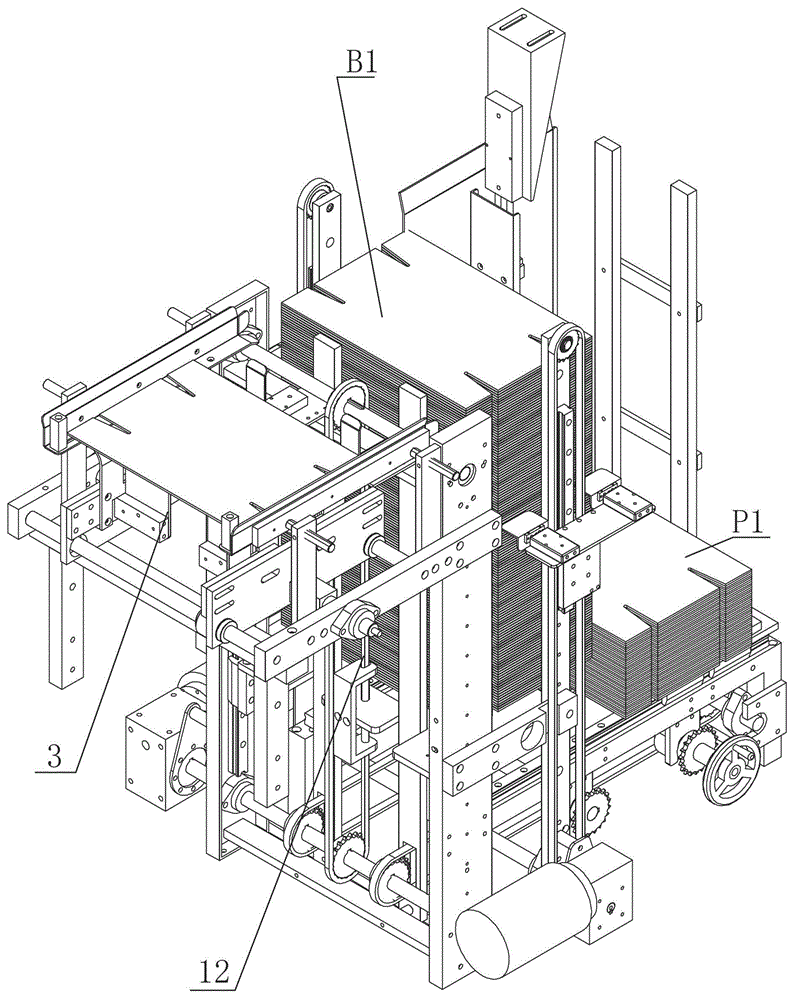

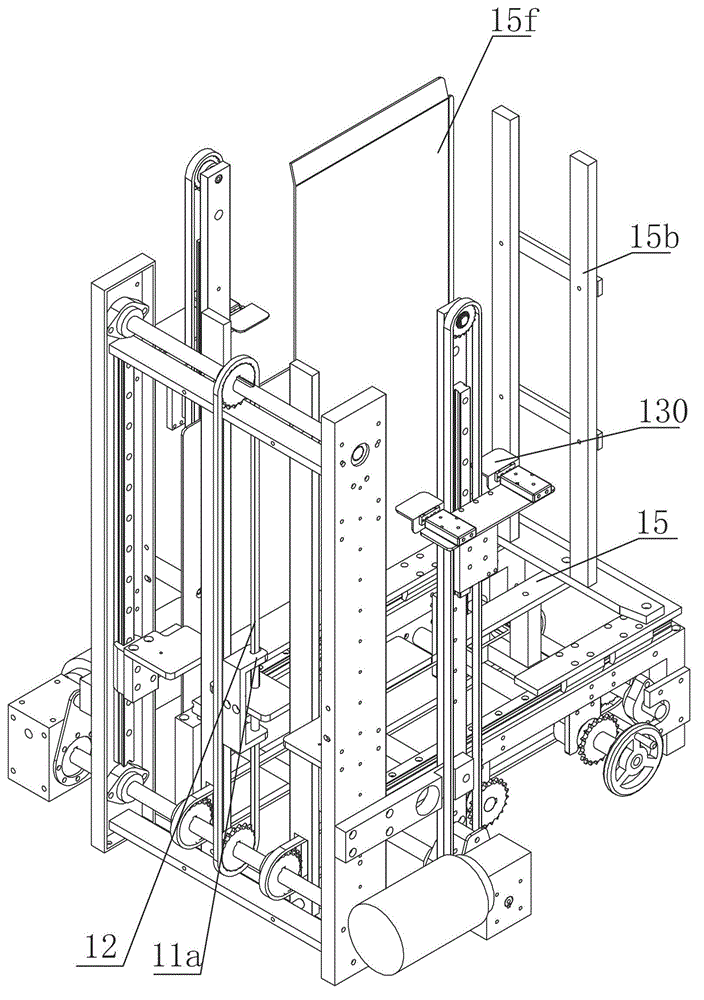

Boxing machine

The invention provides a boxing machine, which comprises a paper overlapping area, a paper conveying device, a carton forming die at a high position, a carton pressing die, a carton conveying device, an article sorting and combining device and an article boxing machine, and is used for extracting boxed articles from an article boxing region into cartons in a carton boxing region. The boxing machine can be used for realizing continuous work of carton forming, article grouping and boxing comprehensively, is suitable for being combined into an upper article production line or packing production line, and has the advantages of small size, simple structure, small floor occupation and high efficiency.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP +1

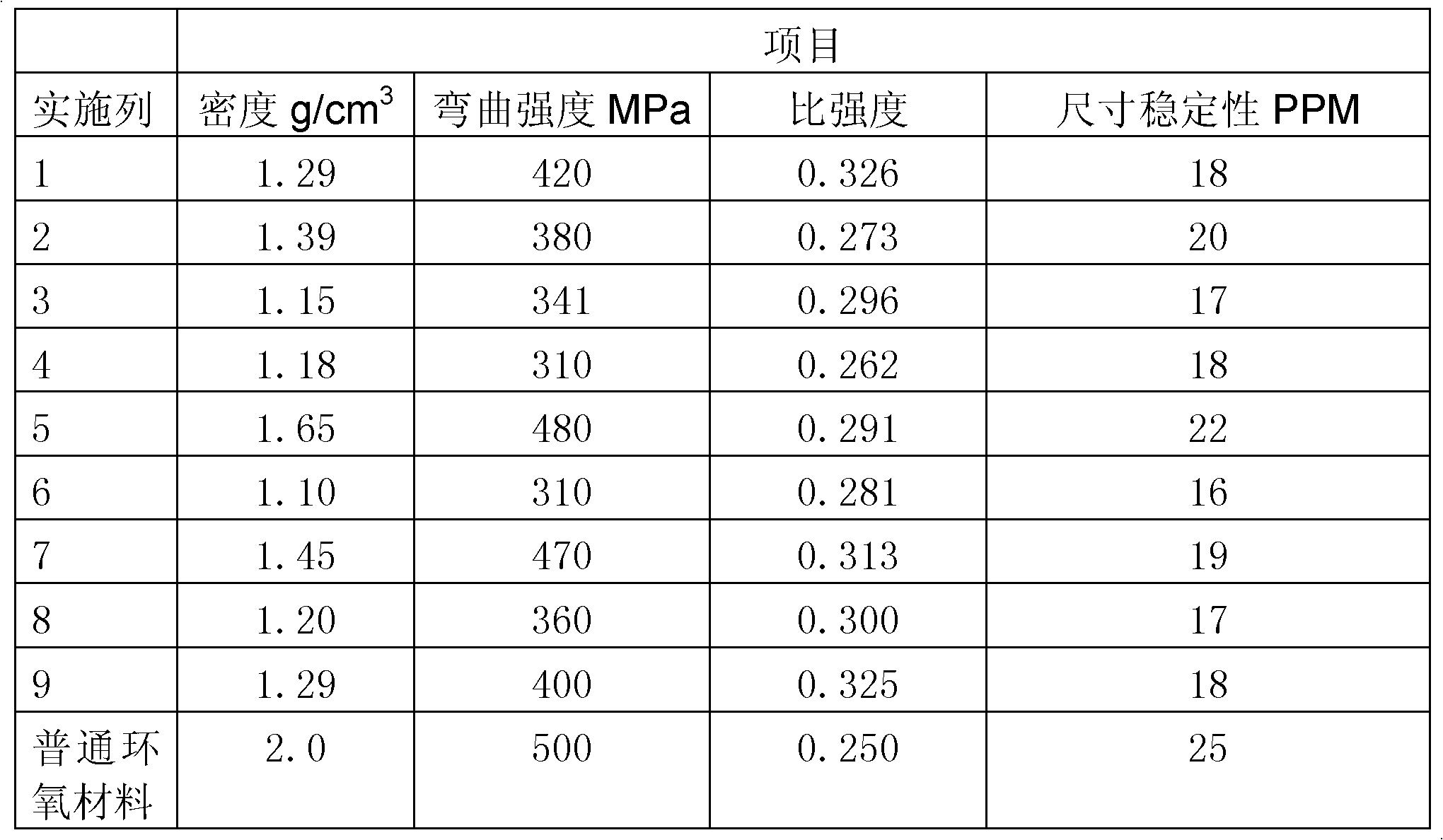

Lightweight high-strength composite material and preparation method thereof

ActiveCN102276960AGuaranteed qualityImprove yield rateLaminationLamination apparatusGlass fiberEpoxy

The invention discloses a lightweight high-strength composite material. The lightweight high-strength composite material is prepared by soaking a reinforcing material into mixed solution, laminating and thermally curing, wherein the mixed solution comprises the following components in part by weight: 125 parts of epoxy resin, 35.0 to 80.0 parts of solvent, 2.5 to 35 parts of curing agent, 0.01 to0.50 part of accelerator; 0.5 to 5 parts of coupling agent, 0.05 to 0.1 part of surfactant and 5 to 50 parts of hollow glass microsphere; and the reinforcing material is electronic-grade glass fiber cloth. The invention also discloses a preparation method of the composite material. According to the technical scheme, the lightweight high-strength composite material and the preparation method thereof have the advantages of simple formula, capacity of directly mixing and processing, light weight and high strength.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Method for changing sludge to organic fertilizer

InactiveCN1562904AOvercome the disadvantage of high energy consumptionOvercome the disadvantage of high consumptionClimate change adaptationExcrement fertilisersSludgeAnimal feces

The invention relates to a mud treatment technology, particularly to method transforming mud into organic fertilizer. In the invention, mud is stirred to pulp, then is screened, feces of birds and beasts is dried and fine grinder, then to be mixed and smelted with mud, cut and prilled, the grains are dried by drying machine, then to be packed.

Owner:陈茂铨

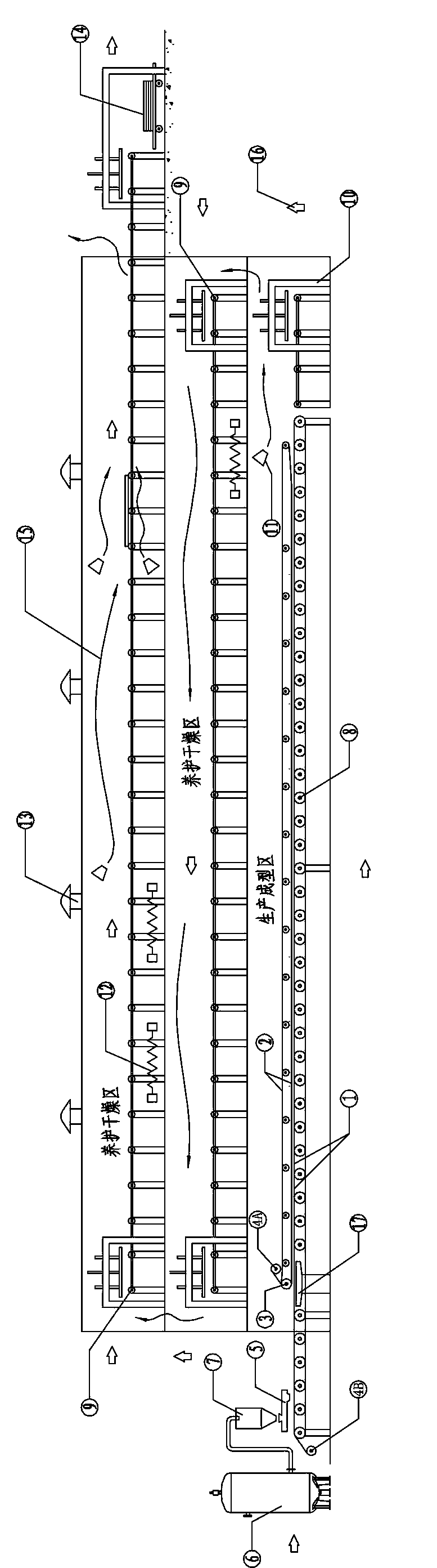

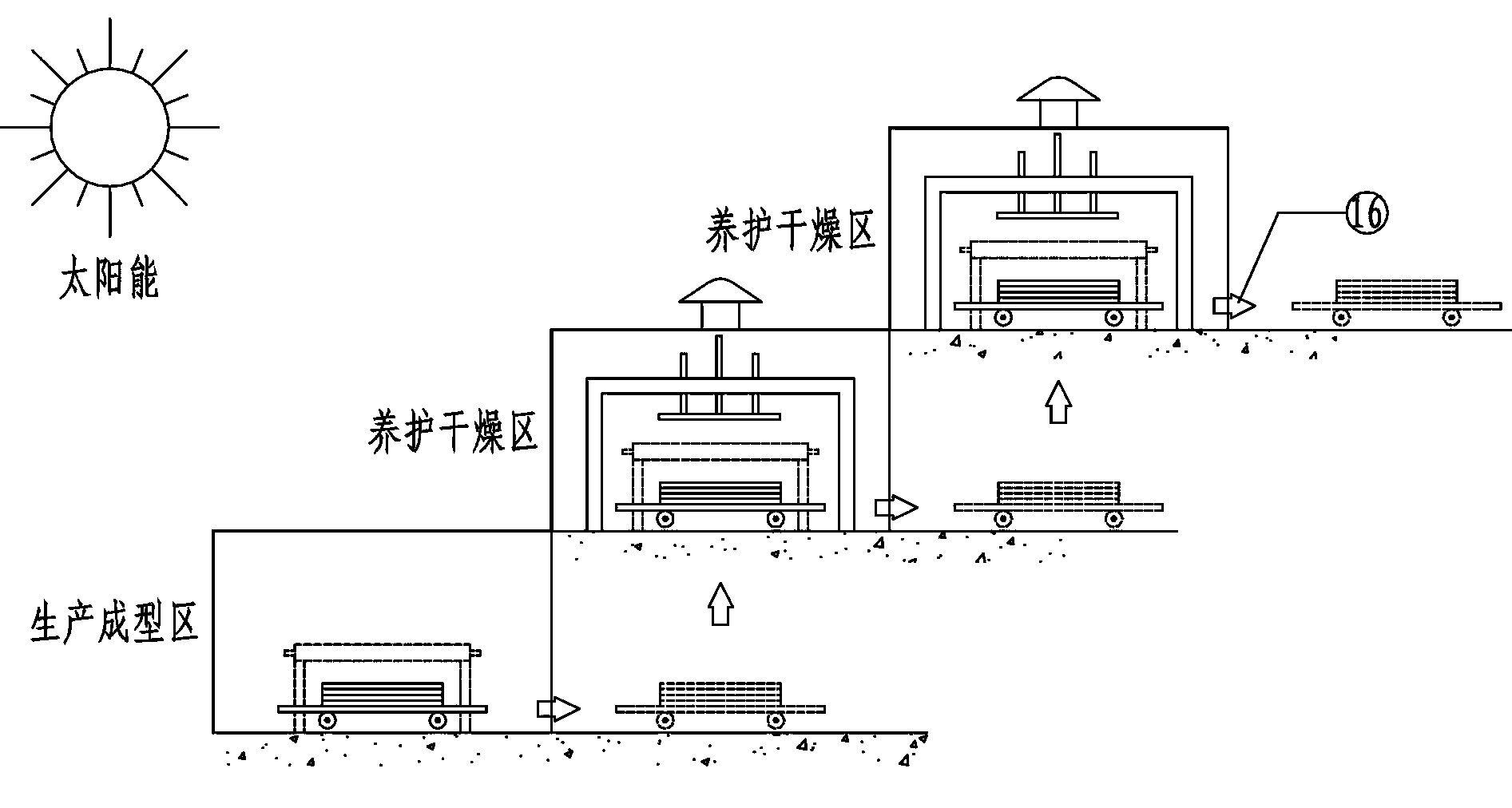

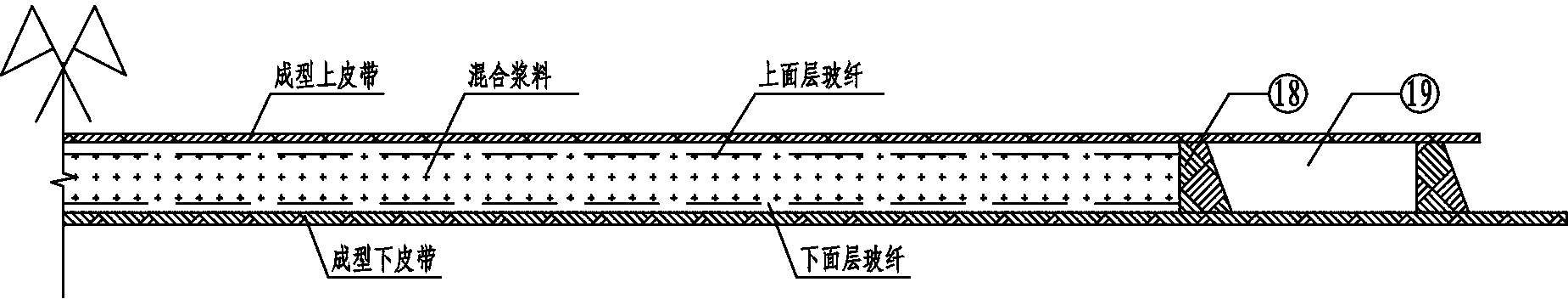

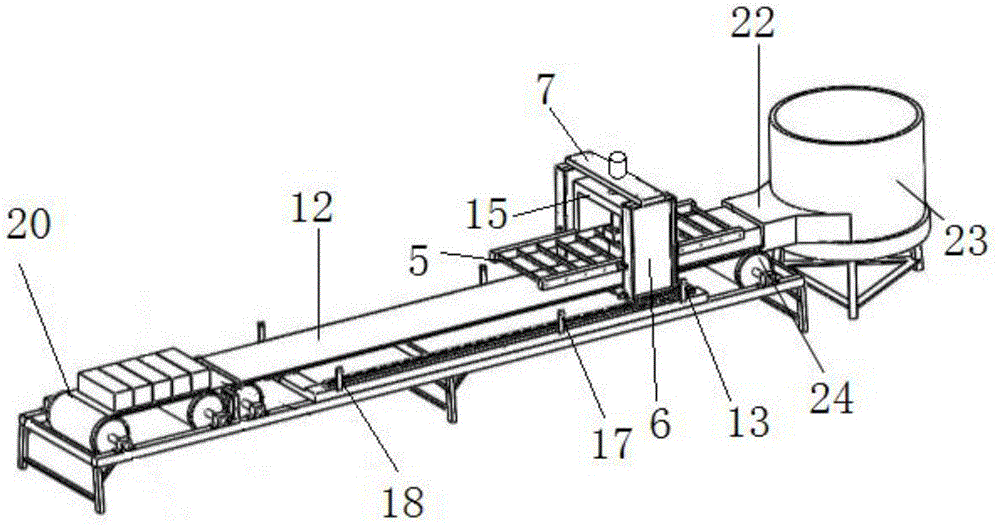

Production line and method for manufacturing building decorative sheet

ActiveCN103586973AEfficient use ofHigh compressive strengthRoof covering using slabs/sheetsRoof covering using tiles/slatesGlass fiberProduction line

The invention relates to a production line and method for manufacturing a building decorative sheet. The production line comprises a production forming area, a maintenance area and a drying area, wherein the three areas are arranged in a sealed space capable of collecting sunlight and are mutually communicated, the steps of production formation, maintenance and drying of the sheet can be finished in the same sealed space, solar energy is fully utilized, the heat efficiency is improved by 65%-85%, and energy is saved. According to the method for manufacturing the building decorative sheet, the sheet is formed through a conveying belt, glass fibers cover the two surfaces of the sheet, the forming method is simple and rapid, and the compressive strength and flexural strength of the manufactured sheet are high. In addition, the production line is suitable for air hardening sheets, hydraulicity sheets and sheets with both air hardening performance and hydraulicity.

Owner:包头市兼强轻型板业有限责任公司

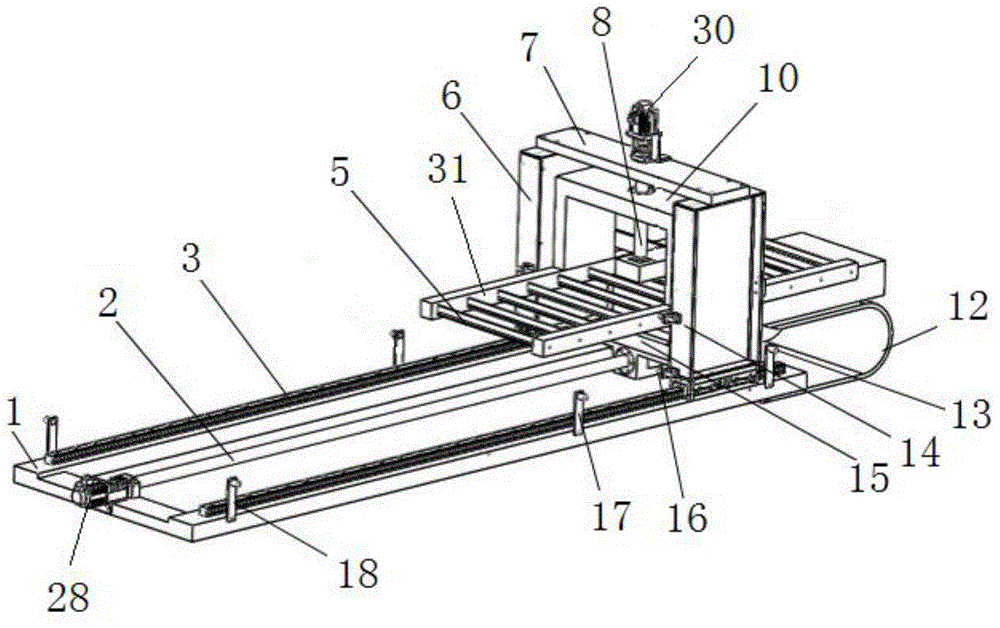

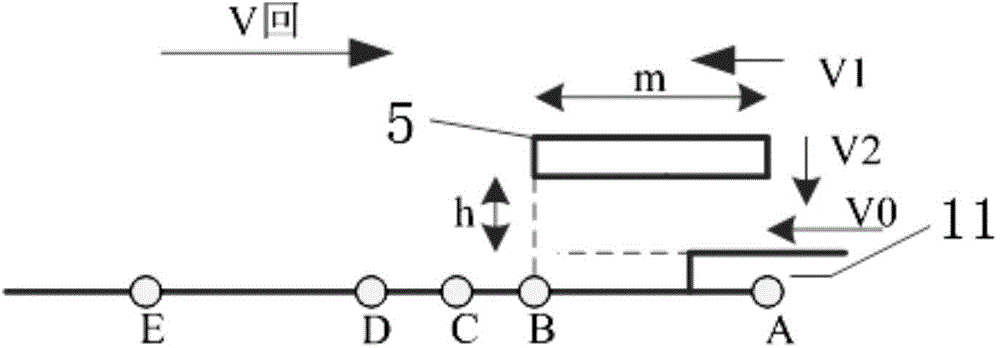

Automatic green brick cutting device and cutting method thereof

ActiveCN104875277ARealize continuous automatic cuttingSquare shapeCeramic shaping apparatusBrickMechanical engineering

The invention discloses an automatic green brick cutting device. The automatic green brick cutting device comprises a clay strip conveying mechanism, a moving mechanism and a cutting mechanism arranged on the moving mechanism, wherein the cutting mechanism cuts clay strips and pushes the cut clay strips away in the state that the relative speed of the moving mechanism and the clay strip conveying mechanism is zero. With the adoption of the structure, the automatic green brick cutting device and the cutting method have the advantages as follows: (1), conveying is not required to be stopped when the clay strips are cut in the clay strip cutting process, and the clay strips are continuously and automatically cut off; (2), the relative speed of the cutting mechanism and the clay strips is zero in the moving direction of the clay strips, so that clay strip green bricks are square during cutting, the whole mechanism is compact, and the small area is occupied.

Owner:山东信开源科技创新发展有限责任公司

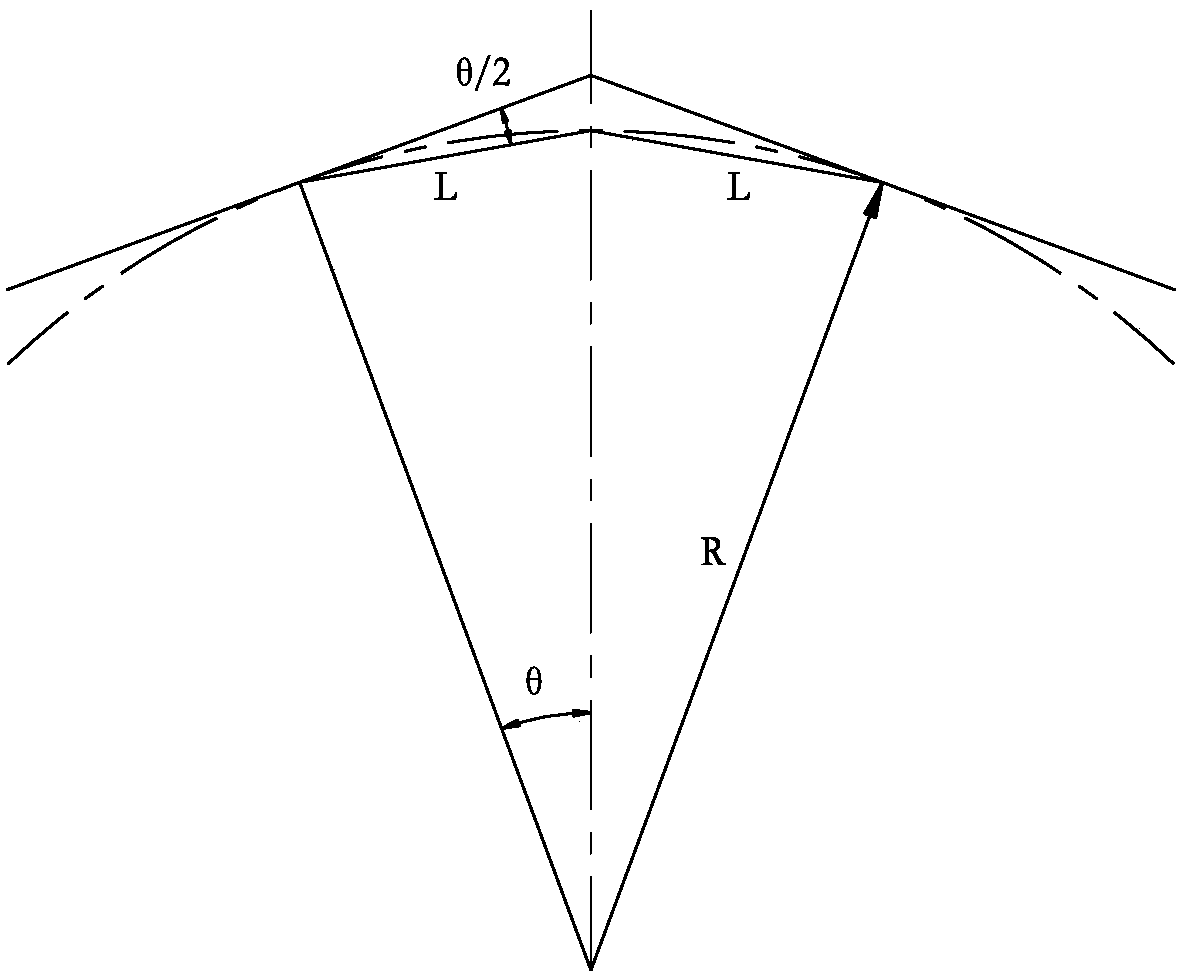

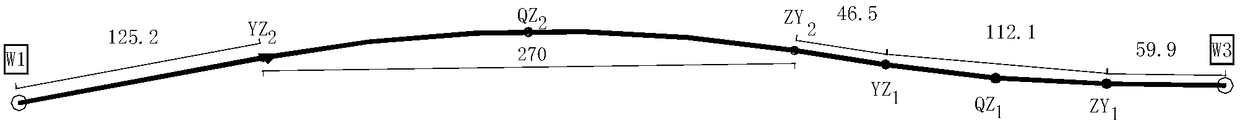

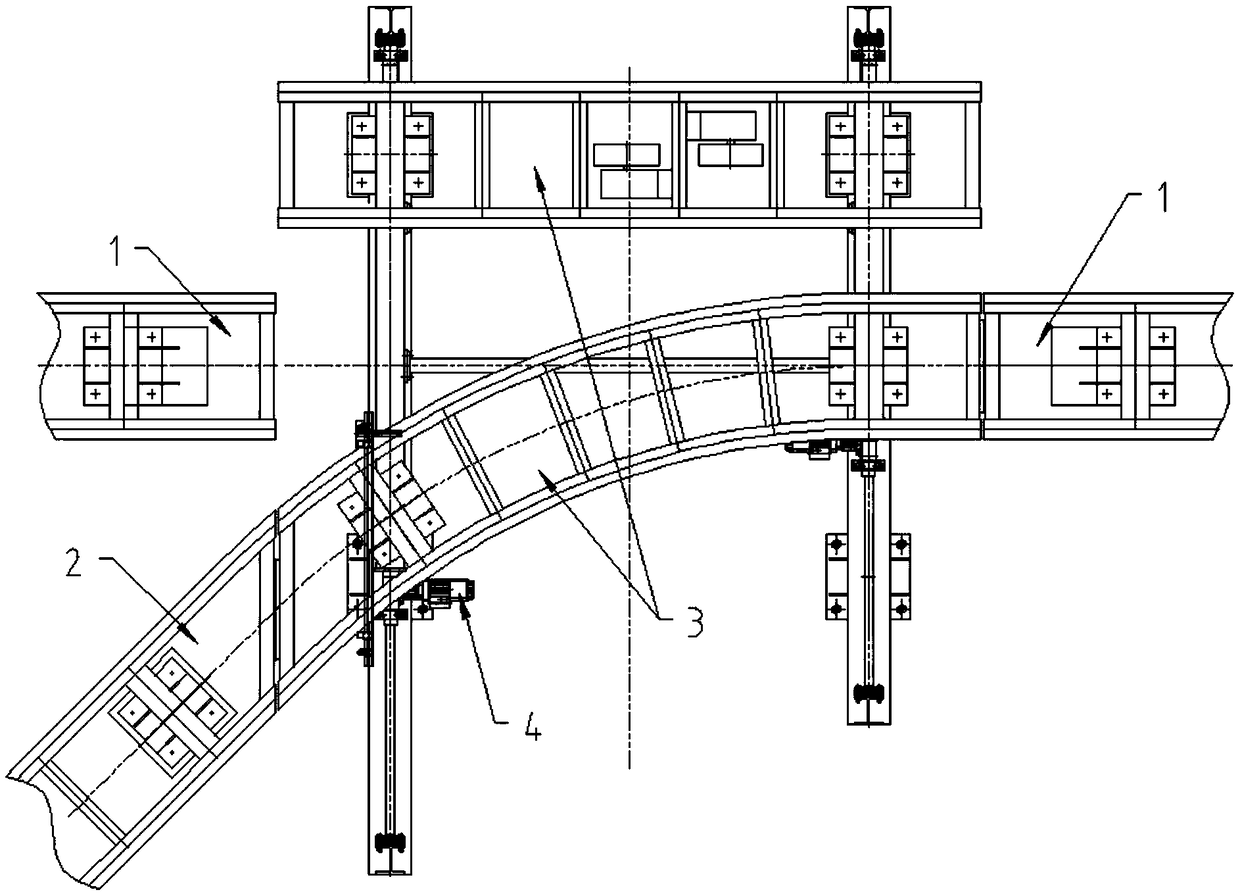

Curve staring method of concrete curve jacking pipe

InactiveCN108104829AShorten construction timeReduce site occupancyPipe-jointsRigid pipesStaringEconomic benefits

The invention relates to a curve starting method of a concrete curve jacking pipe, and belongs to the technical field of building projects. The curve starting method is used for solving the problem ofcurve starting control in the jacking process of the concrete curve jacking pipe. According to the curve starting method of the concrete curve jacking pipe, on the basis that the curve jacking trackof the concrete jacking pipe by a pipe jacking machine, follow-up two sections of curve starting pipes and rectifying systems such as auxiliary rectifying is controlled, it is ensured that in the curve section construction process, the concrete curve jacking pipe jacks forwards at a stable curvature radius by calculating the opening amount of the curve section, the situation that measuring and rectifying work needs to be conducted manually when each curve starting pipe reaches the initial point of the curve section curve starting mileage is avoided, and thus the construction time is shortened.The concrete curve jacking pipe reduces occupation of a great deal of fields, and outstanding economic benefits are brought.

Owner:SHANGHAI MUNICIPAL CONSTR

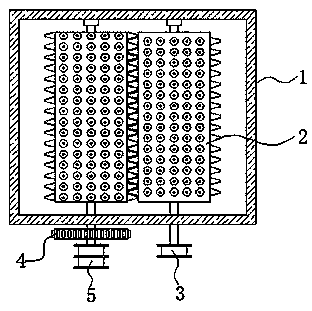

Continuous remediation equipment for remediating heavy metal composite soil based on biomineralization

InactiveCN111420977AEasy to crushConducive to uniform thicknessSievingScreeningSoil remediationEnvironmental engineering

The invention discloses continuous remediation equipment for remediating heavy metal composite soil based on biomineralization. The invention relates to the technical field of soil remediation, existing soil remediation equipment is diverse and messy and large in field occupation, the soil remediation is easily influenced by factors such as soil thickness, humidity and biological content, in orderto solve the problems that an existing grinding and screening device is not beneficial to efficient and rapid repairing, the following scheme is provided, the continuous remediation equipment comprises a smashing mechanism, a grinding mechanism, a screening mechanism, a mixing mechanism, a feeding mechanism and a driving mechanism, the grinding mechanism is located below the smashing mechanism, the screening mechanism is located below the grinding mechanism, and the mixing mechanism is located below the screening mechanism. According to the remediation equipment, automatic soil feeding is facilitated, continuous operation is facilitated, soil is smashed, screened and mixed, the thickness, humidity and biological content of the soil can be kept balanced accordingly, overall efficient remediation of the soil is facilitated, and the equipment is high in integration degree, small in occupied area and high in practicability.

Owner:安徽新之图科技发展有限公司

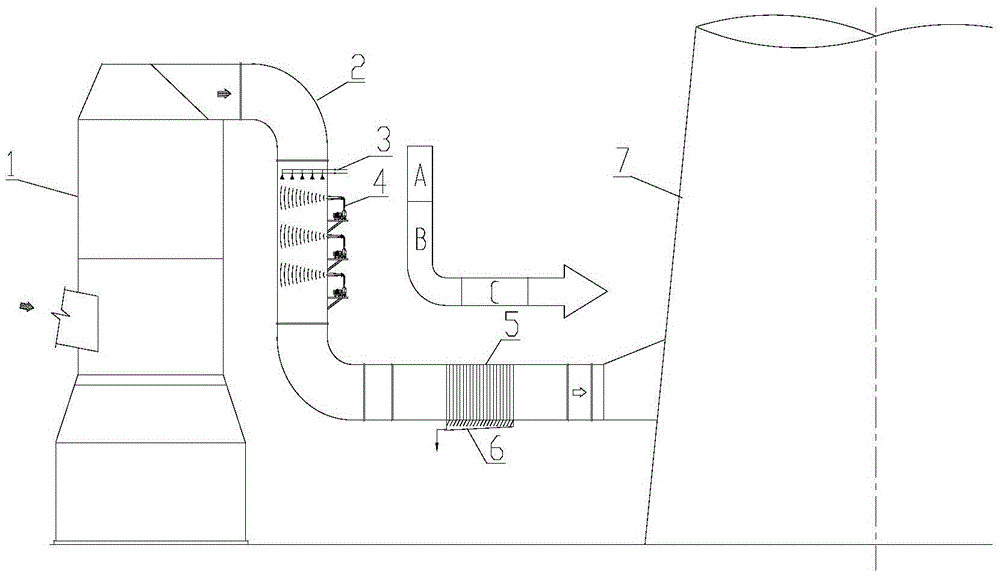

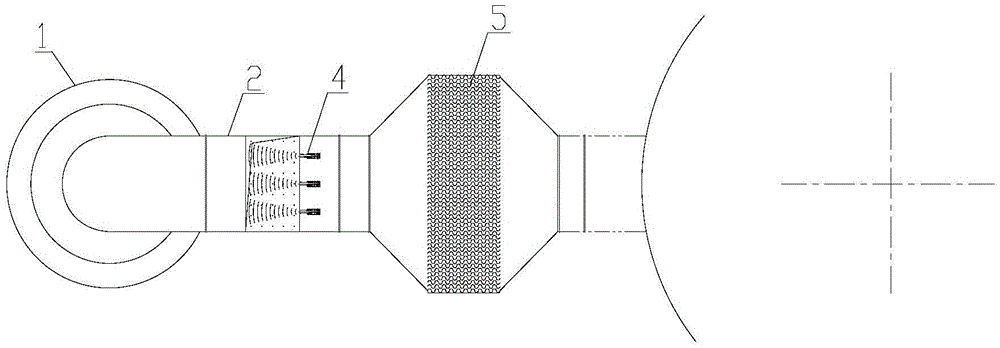

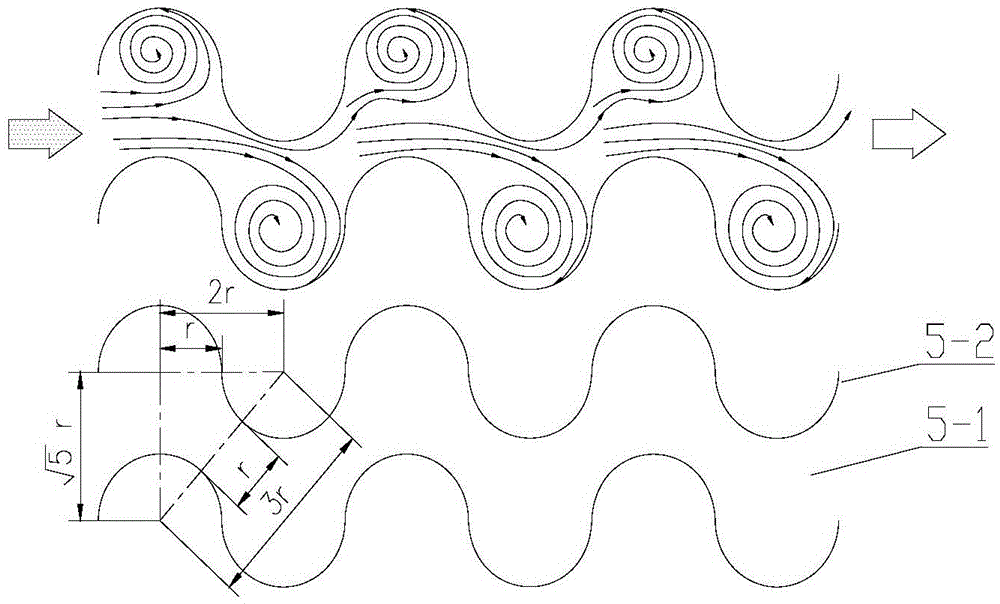

Wet method dedusting device

InactiveCN105413379AReduce power consumptionReduce drainageCombination devicesWater dischargeMetallic materials

The invention discloses a wet method dedusting device. The wet method dedusting device comprises a supersonic wave atomizer used for spraying fine water mist towards a smoke flow channel to form a supersonic wave atomization region, a sound wave generator arranged at the lower position of the supersonic wave atomizer according to the smoke flow direction and used for establishing a sound field in the smoke flow channel to form a sound wave coagulation region, and a liquid drop catcher arranged at the lower position of the sound wave generator according to the smoke flow direction used for catching coagulated dust-containing liquid drops after going through the supersonic wave atomization region and the sound wave coagulation region to form a dust collection region. The place occupation, the total cost and operation expenses of the dedusting device after wet method desulphurization can be lowered greatly, waste water discharge of wet method dedusting is reduced, and ultraclean discharge of a chimney is achieved. In addition, because there is no high voltage electrostatic apparatus, internal members can be made of non-conductive corrosion-resistant non-metallic materials, and there are discharge burning operation risks.

Owner:FUJIAN LONGKING

High-temperature quick fermentation process for organic fertilizer

InactiveCN106957187AIncrease temperatureShorten the timeBio-organic fraction processingClimate change adaptationChemistryCrop

The invention discloses a high-temperature quick fermentation process for an organic fertilizer, and relates to the technical field of application of microorganism. The technological processes are as follows: A, pretreatment of raw materials; B, preparation of a zymophyte agent: a, preparation of high-temperature zymophyte agent: 1, preparing original stocks of the high-temperature zymophyte agent; 2, preparing sterilizing materials of the high-temperature zymophyte agent; 3, inoculating the original stocks of the high-temperature zymophyte agent; 4, fermenting high-temperature original stocks; 5, carrying out secondary fermentation; b, preparation of medium-low temperature zymophyte agent; C, inoculation of high-temperature zymophyte agent; D, warming fermentation; E, sterilization; F, high-temperature fermentation; G, inoculation of medium-low temperature strains; H, cooling and secondary fermentation. The high-temperature rapid fermentation process has the characteristics of short fermentation period, less investment, low cost, and capability of quickly producing organic wastes into high-quality organic fertilizers, and is suitable for quickly treating various organic wastes. The produced high-quality organic fertilizer can be used as basic fertilizers for planting crops such as paddy rice, fruits, vegetables, and melons and fruits.

Owner:郭建云

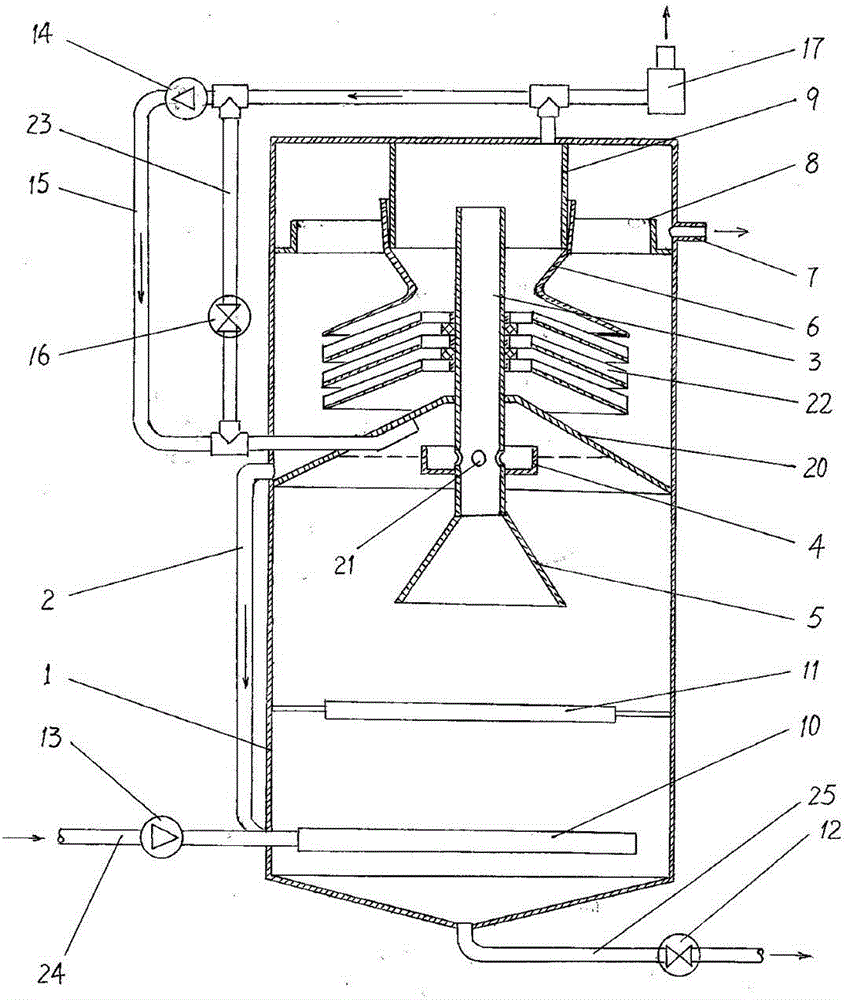

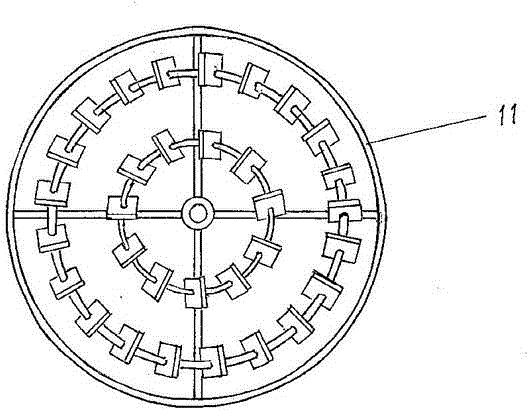

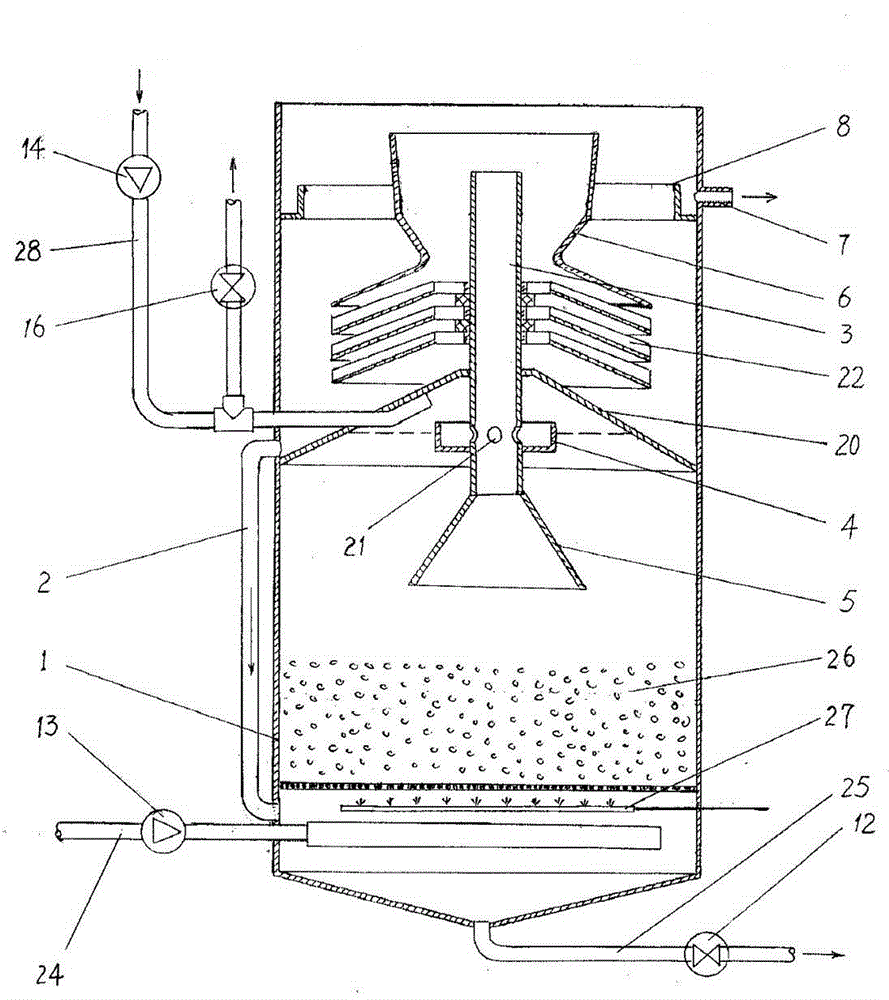

Efficient pulse biological reaction device

ActiveCN104803473AImprove the mixing effectIncrease gas production rateTreatment with anaerobic digestion processesSustainable biological treatmentWater blockEngineering

The invention relates to an efficient pulse biological reaction device. The efficient pulse biological reaction device is characterized in that a gas-collecting hood, a flow guide cylinder, an effluent weir, a precipitation plate, a middle spacing plate, a gas stripping pipe and a water blocking disk are arranged in a pot body, wherein a gas hole is formed in the gas stripping pipe, and the height of the gas hole does not exceed that of the side edge of the water blocking disk; an exhaust opening is formed in the top of the pot body surrounded by the gas-collecting hood, a gas return pipe is connected to the exhaust opening, and the gas return pipe is inserted to a tapered top region on the bottom surface of the middle spacing plate from the side part of the pot body; a flow guide grid and a water distributing device are arranged at the bottom of the pot body, the water distributing device is connected with a feed pipe on the outer side of the pot body; a return passage for transporting upper liquid back to the pot body through the bottom of the pot body is arranged at the upper part, corresponding to the outside edge of the middle spacing plate, of the pot body. The biological reaction device disclosed by the invention can generate gas stripping pulse automatically so as to have a good stirring function on sludge in the pot body, and creates a good uniform growing environment for the anaerobic reaction of microorganisms, so that the pulse biological reaction device disclosed by the invention keeps higher processing efficiency and has a higher gas-generating rate by using the sludge.

Owner:河北通持水务科技有限公司

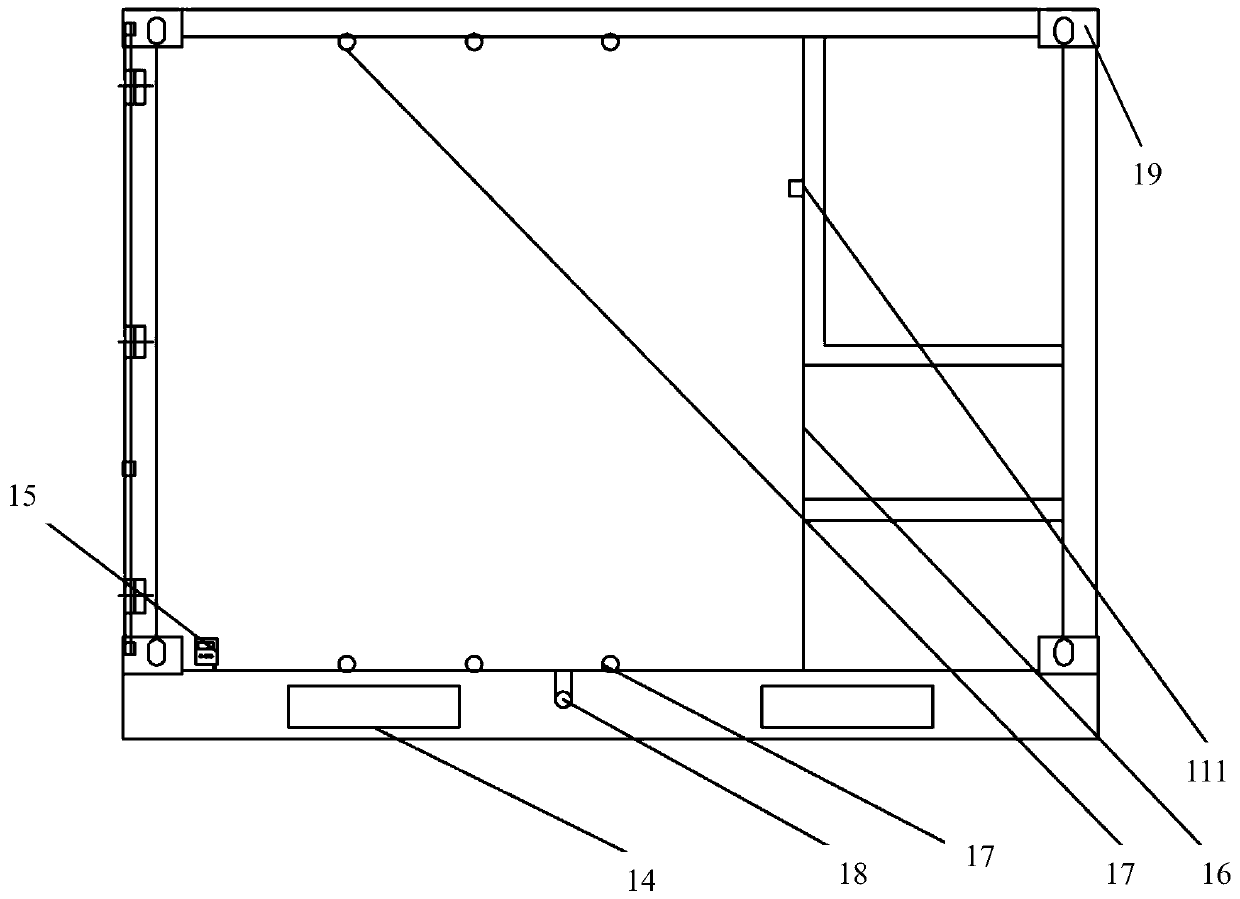

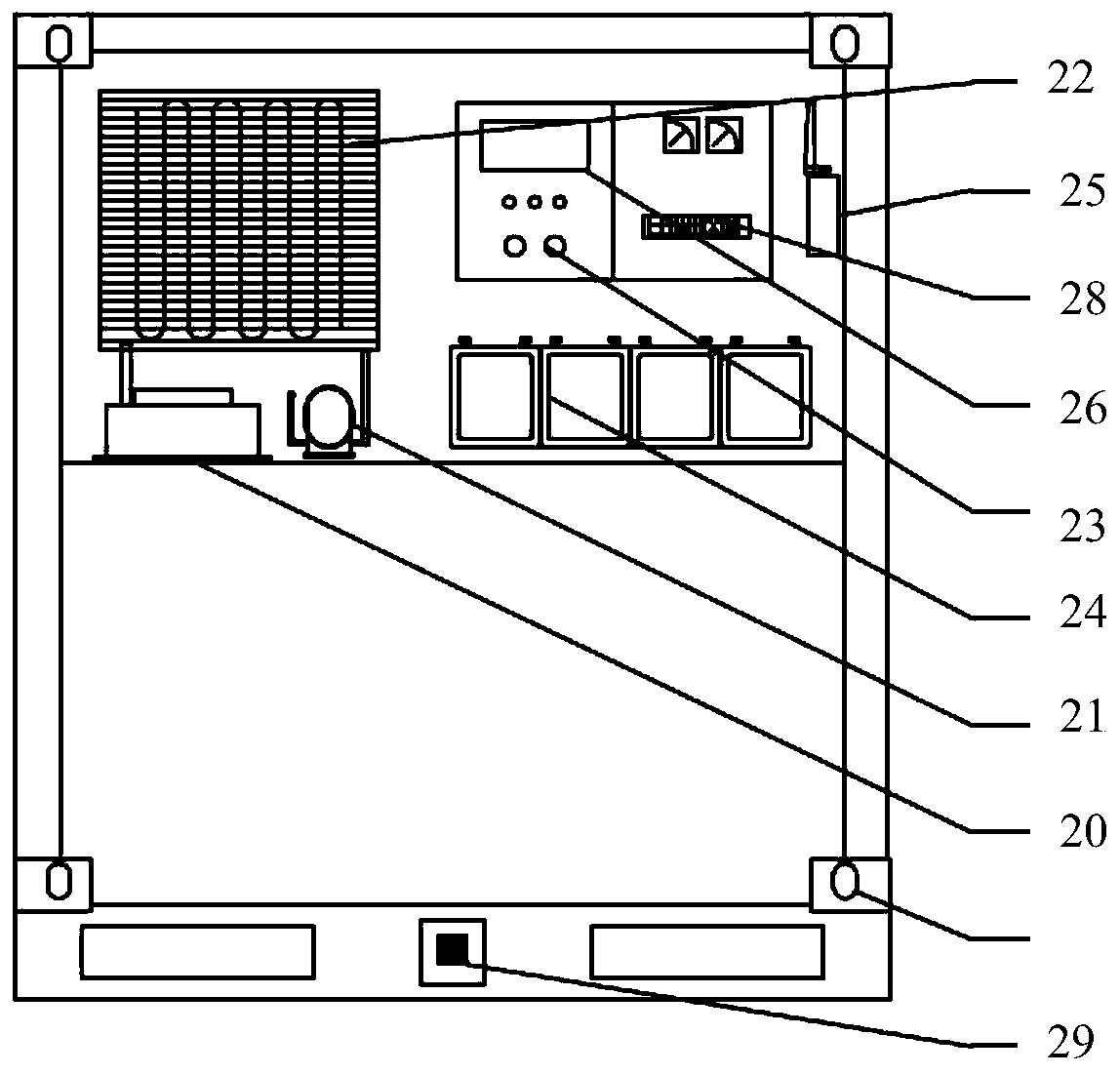

Cold chain container control system

PendingCN110515327ASolve quality problemsSolve efficiency problemsProgramme controlComputer controlCold chainControl system

The invention belongs to the field of cold chain transportation industry, and discloses a cold chain container control system. The control system comprises a heat preservation box body, a refrigeration module, a power management module, a monitoring module and a cloud platform management module. The box body stores and transports cargoes; the refrigeration module controls the temperature in the box body through heat exchange inside and outside the box body; the power management module is used for controlling the power supply mode of a power supply and supplying power to other systems in the box body; the monitoring module is used for monitoring various parameters of the box body and sending the parameters to the cloud platform management module; and the cloud platform management module isused for analyzing the received parameters and feeding back instructions to the monitoring module. The cold chain container control system is suitable for common logistics transportation, reliable inwork, efficient and convenient, and solves the problems of low transportation quality, low efficiency, low economical efficiency and the like caused by the fact that traditional cold-chain freight transportation only depends on special vehicles or heat preservation equipment.

Owner:刘师洋 +1

Polyurethane fiber coating device used on elasticizer

InactiveCN101974817AReduce manufacturing costGuaranteed tensionYarnEngineeringMechanical engineering

The invention discloses a polyurethane fiber coating device used on an elasticizer which has low production cost and can directly finish composite coating of fiber filament on the elasticizer. The device comprises a proto-filament frame, a first guide pressing arm, a proto-filament roller, a molding frame, a pedestrian pedal and a stand, wherein the proto-filament roller is matched with the first guide pressing arm; a heating box is arranged on an input part for synthetic fiber filament between the molding frame and the stand; the stand is sequentially provided with a twister, a second guide pressing arm, a first tension roller, a polyurethane fiber drum, a traction roller, a composite filament deformation air spout, a third guide pressing arm and a second tension roller from top to bottom; the first tension roller is matched with the second guide pressing arm; and the second tension roller is matched with the third guide pressing arm.

Owner:JIANGSU SHUNSIDA TEXTILE

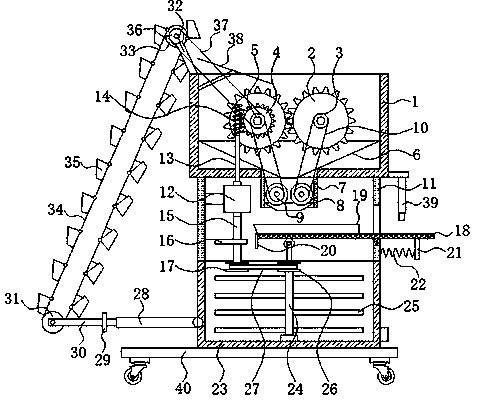

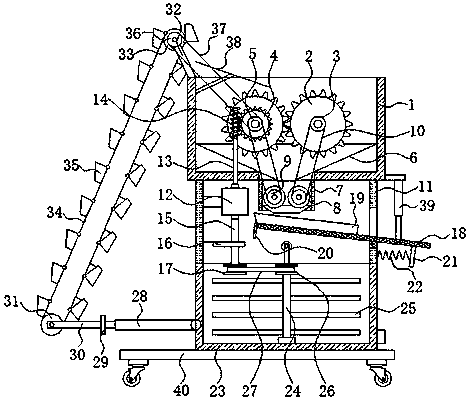

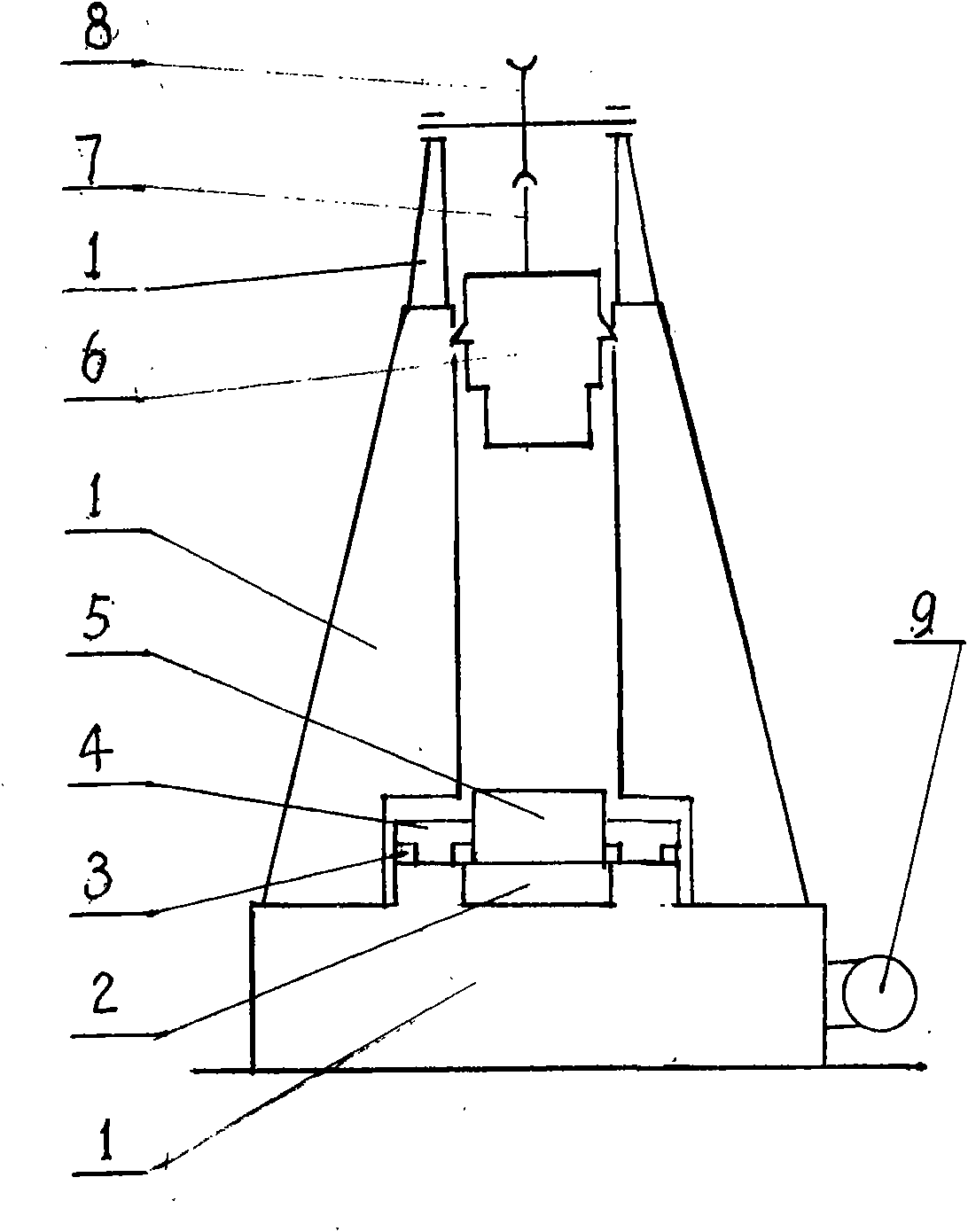

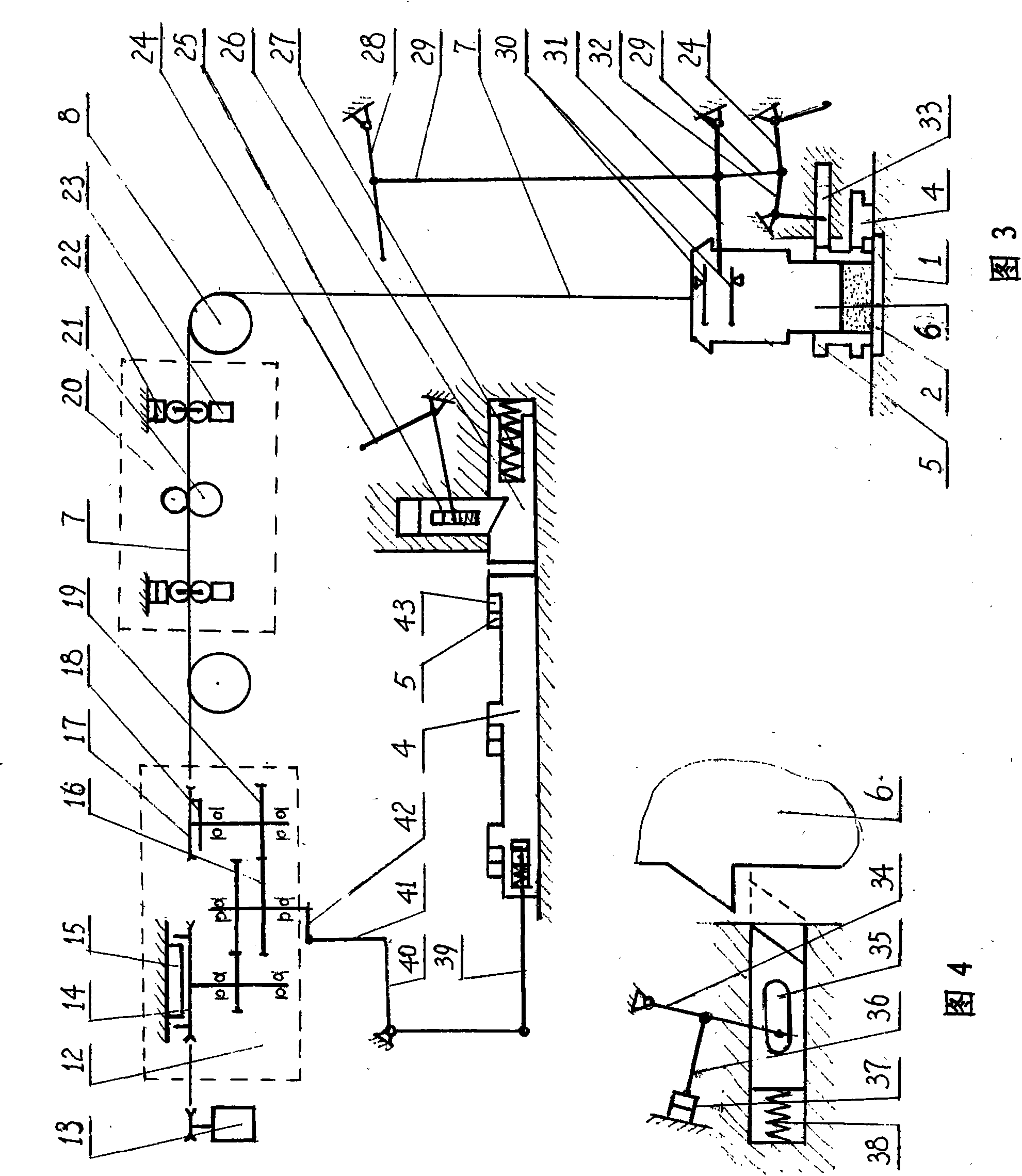

Impact brick making method and device

InactiveCN101913194AReduce energy consumptionReduce site occupancyShaping conveyorsShaping press ramBrickGear wheel

The invention discloses impact brick making method and device. The device comprises a rack (1), a main motor (13), a speed changing device (12), a feeding device (11), a brick box (5) and a rotary conveying device (10) of the brick box. The device is characterized in that the top end of the rack is fixedly provided with a fixed pulley (8), one end of a pull rope (7) is connected with a gravity hammer (10) through a shock absorber, and the other end of the pull rope is connected with a rope winder (17) after penetrating through a rope tautening device (20); the rope winder is provided with a torsional spring (18), the rope winder is coaxially and fixedly connected with a lifting driven gear (19) of the speed changing device, and partial area from a lifting drive gear (16) of the speed changing device to a gear root is provided with no teeth; a shaft of the lifting drive gear is fixedly connected with a crank (42), and the crank is connected with a brick box moving and locating device through a connecting rod (41); and the feeding device (11) and the rotary conveying device of the brick box are installed under the rack, a bearing plate (2) is fixedly connected on the rack below the gravity hammer, and a gravity hammer stopping mechanism is also installed on the rack.

Owner:冉春晖

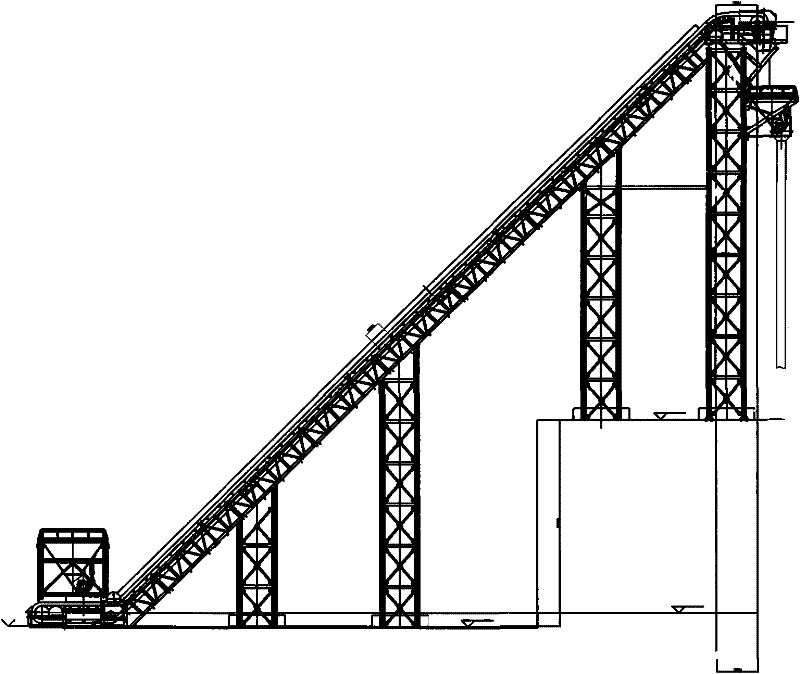

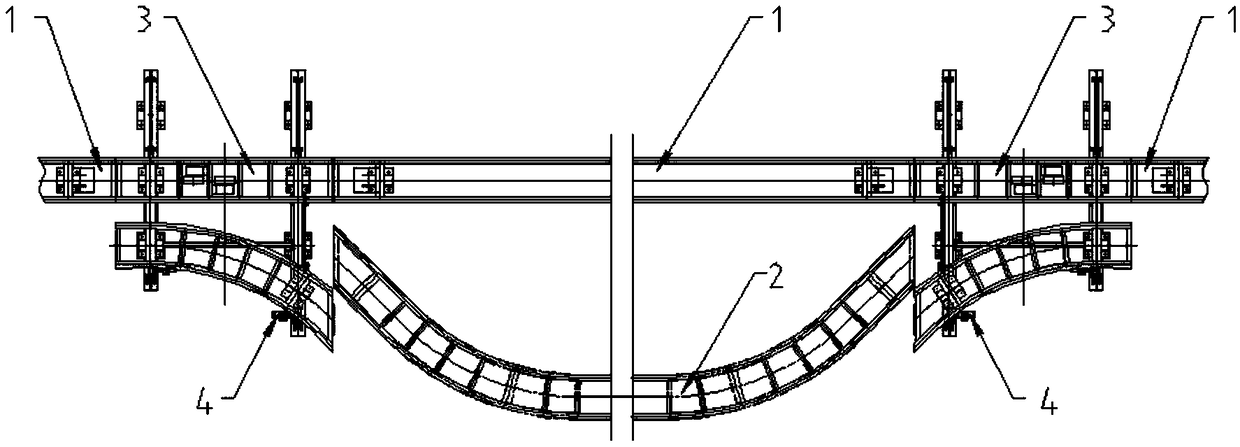

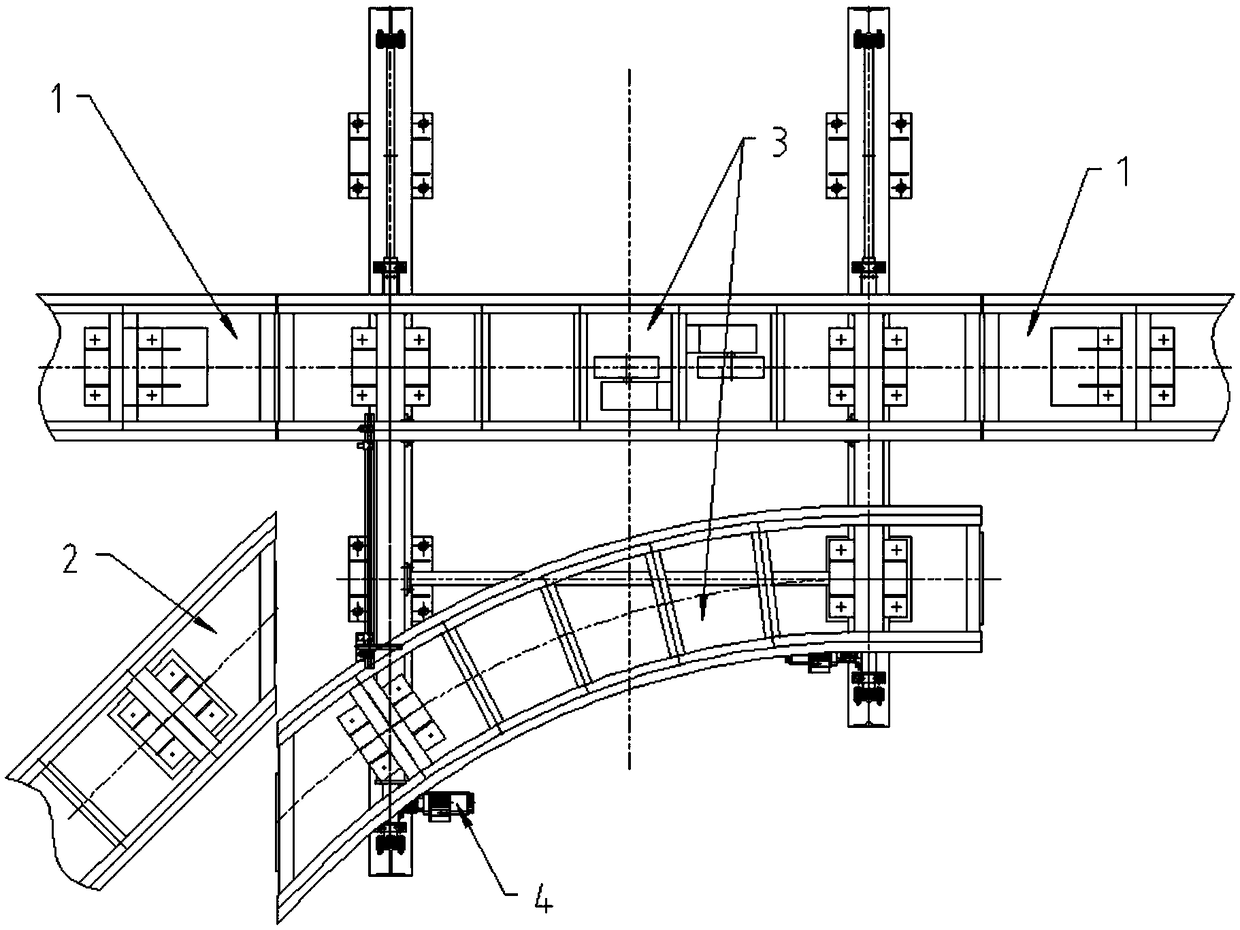

High inclination-angle undulating flange belt conveyor capable of conveying roller compacted concrete

InactiveCN102476745AShorten the lengthReduce production and installation costsCleaningRoller-compacted concreteEngineering

The invention relates to a high inclination-angle undulating flange belt conveyor capable of conveying roller compacted concrete, and the conveyor comprises an upper horizontal section, a lower horizontal section and an inclined section, wherein the upper horizontal section is connected with the inclined section through adopting a convex arc sectional rack, and the lower horizontal section is connected with the inclined section through adopting a concave arc sectional rack; the high inclination-angle undulating flange belt conveyor is characterized in that: the upper horizontal section is provided with a forced beating device (21); and the improved beating device has good beating effect, so the defects of more concrete adhesion and size loss are solved.

Owner:中国安能集团第一工程局有限公司

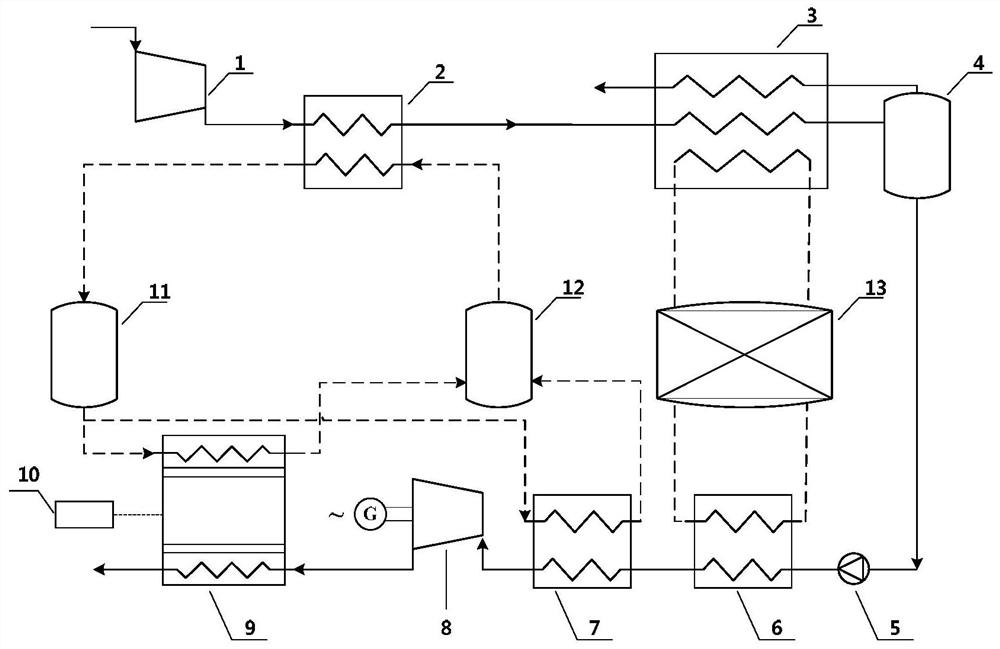

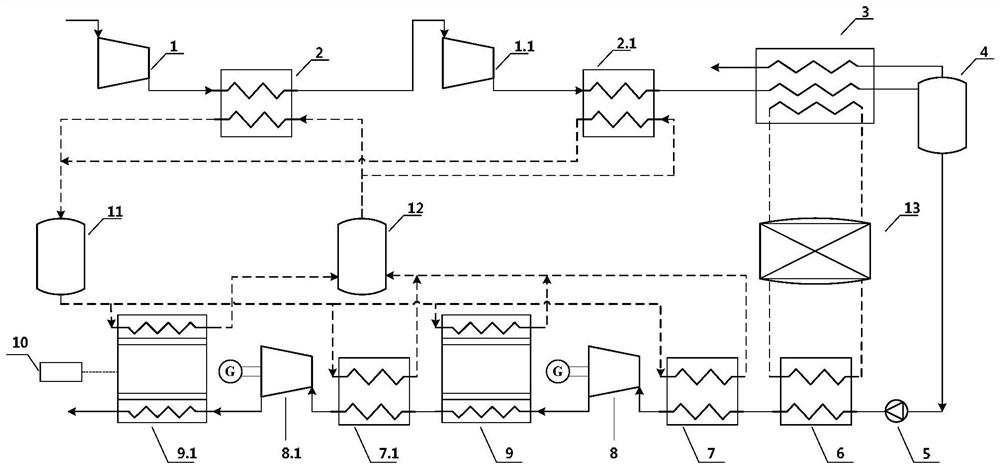

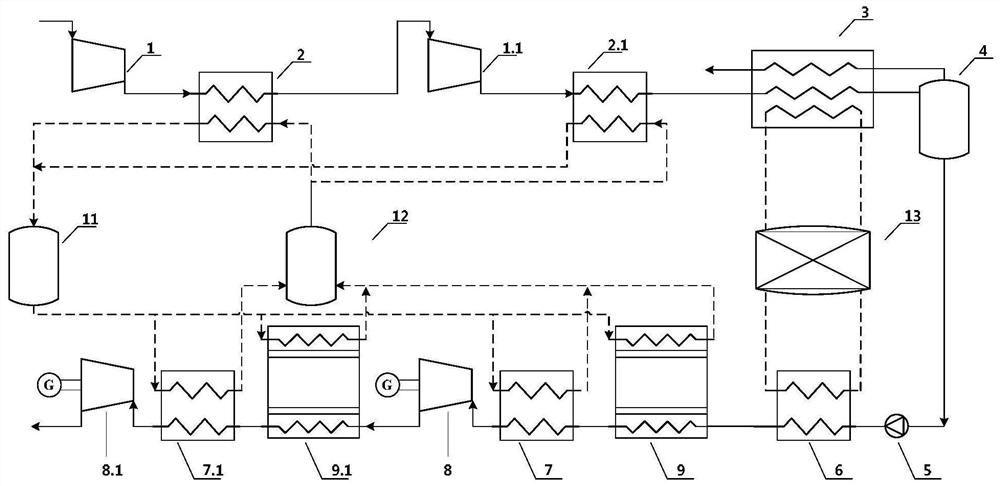

Liquefied air energy storage and thermoelectric power generation coupling system and working method thereof

ActiveCN112855292AReduce temperature lossEasy to solveReciprocating combination enginesSolidificationEnvironmental geologyStorage energy

The invention discloses a liquefied air energy storage and thermoelectric power generation coupling system and a working method thereof. The system comprises an air compression device, an air liquefaction device, a liquid air pressurizing gasification device, an air expansion device, a thermoelectric power generation device and a heat and cold storage device. According to the working method of the system, in the energy storage stage, the air compression device, the air liquefaction device and the heat and cold storage device are in a working state to consume external electric energy to realize air liquefaction storage and compression heat recovery; and in the energy release stage, a supercritical working mode is adopted, the liquid air pressurizing gasification device, the air expansion device, the thermoelectric power generation device and the heat and cold storage device are in the working state, power is supplied outwards through the air expansion device and the thermoelectric power generation device, and liquid air gasification latent heat recovery is completed. The semiconductor thermoelectric power generation device is introduced into the liquefied air energy storage system, compression waste heat and expansion waste cold are used for driving the thermoelectric power generation device to output extra electric energy, the operation efficiency of the system can be improved, and waste heat emission can be reduced.

Owner:XI AN JIAOTONG UNIV

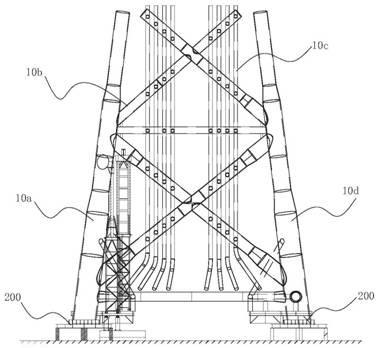

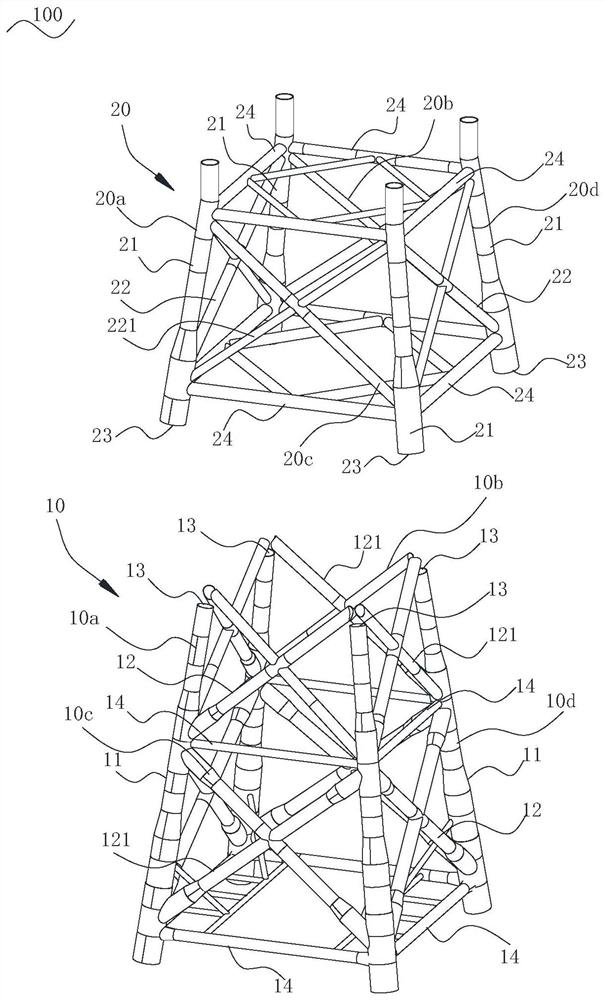

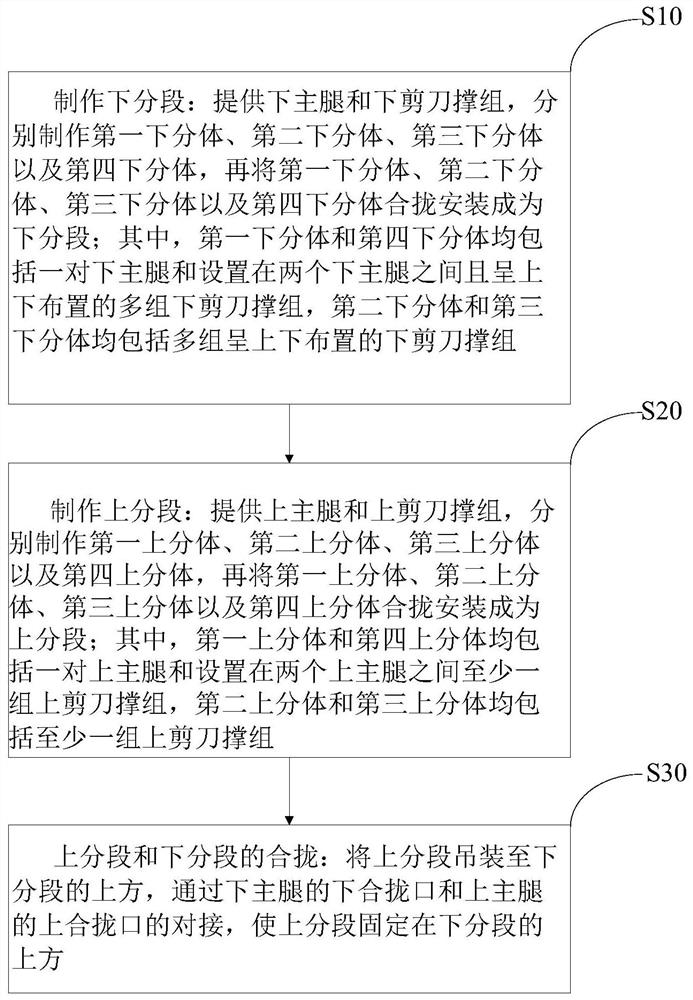

Jacket and jacket construction method

PendingCN112709253AImprove securityReduce site occupancyFoundation engineeringButt jointOffshore construction

The invention provides a jacket and a jacket construction method. The jacket can be divided into an upper segment and a lower segment for segmented manufacturing. After the two segments are manufactured, the two segments are folded and fixed. In the whole construction process, only butt joint operation of an upper folding opening and a lower folding opening exists in high-altitude operation, the high-altitude operation amount is greatly reduced, and the safety of construction operation is improved. Meanwhile, according to the jacket and the jacket construction method, the turnover operation of the segments is avoided, and the jacket can be positioned in advance according to offshore construction and transportation requirements. In addition, the upper segment and the lower segment of the jacket can be constructed and constructed at the same time, the site occupation of raw materials can be reduced, time can be saved, the project manufacturing period can be shortened, and the production efficiency can be improved.

Owner:烟台铁中宝钢铁加工有限公司 +1

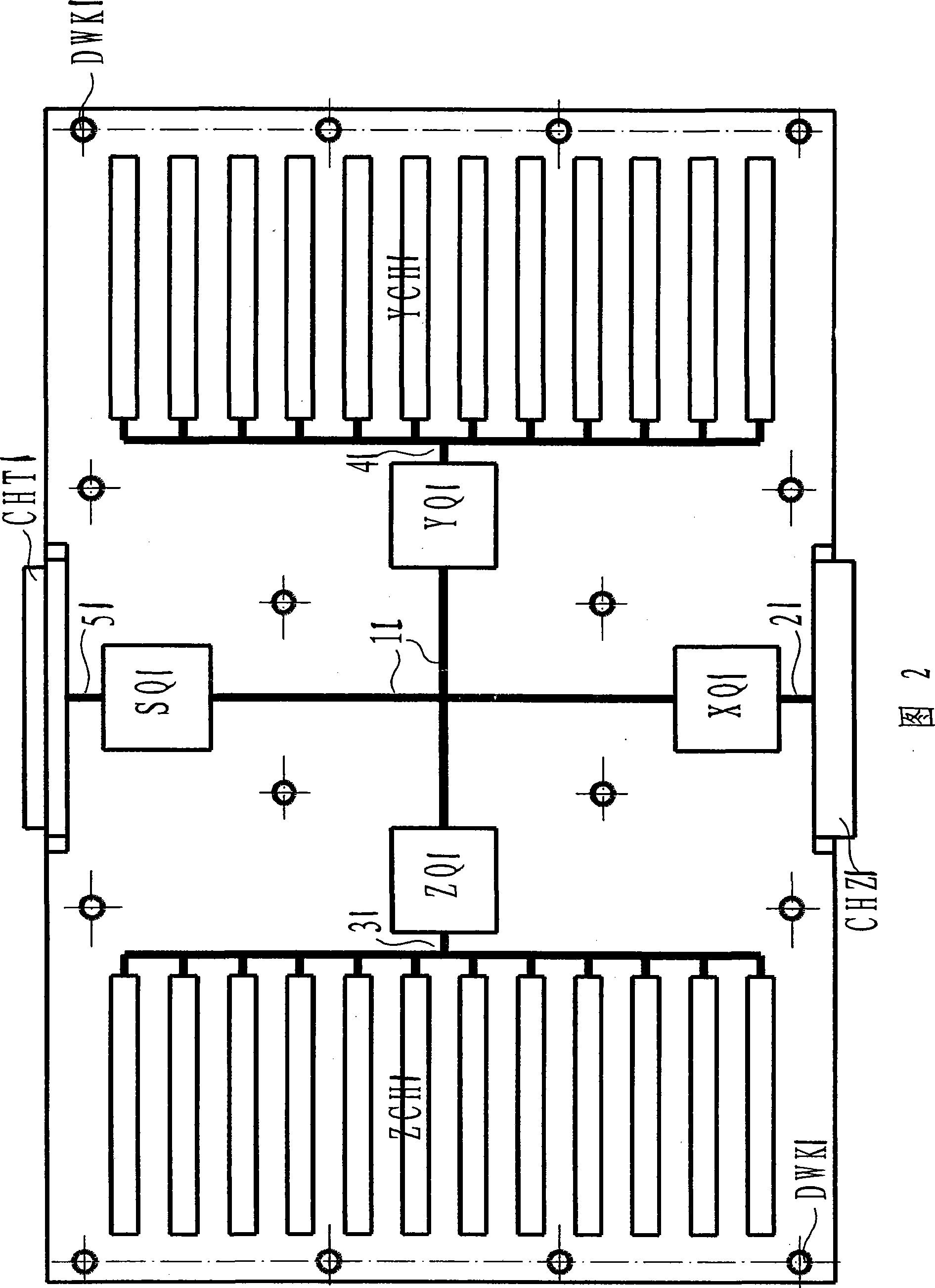

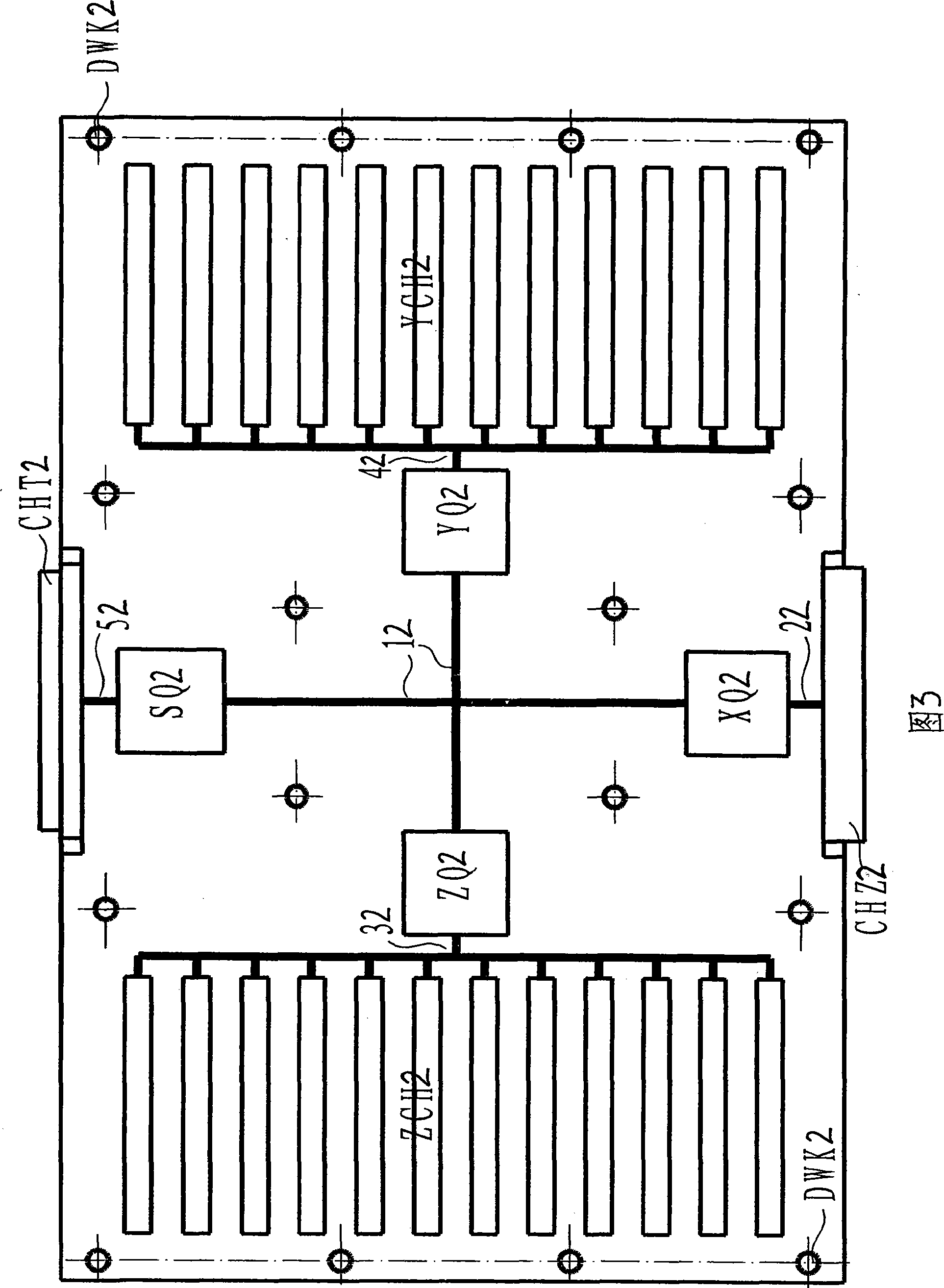

Expansion structure of bus socket and expansion method thereof

InactiveCN101446935AGuaranteed uptimeHigh precisionElectric digital data processingEngineeringCard reader

The invention provides an expansion structure of a bus socket and an expansion method thereof. the expansion structure comprises an expansion mainboard, wherein, a first plug body that can be connected with a computer mainboard is arranged at one side of the expansion mainboard, and a first socket body is arranged at the other side of the expansion mainboard; first left slot groups and first right slot groups connected in parallel are matched and arranged between the first socket body and the first plug body, at least four first left slots connected in parallel are arranged in every first left slot group, and at least four first right slots connected in parallel are arranged in every first right slot group; the first right slot group and the first left slot group are respectively connected with a primary shared device, and the primary shared devices are switched with a card reader after being connected in parallel; a first sub-control panel is matched and arranged on the expansion mainboard and is connected with a main control panel, and the main control panel is also connected with the computer mainboard. The expansion method of the bus socket include the steps as follows: preparation, the socketing and installation of the expansion mainboard, the socketing and installation of an expansion sub-board, the assembling and controlling of the primary shared devices, secondary shared devices and third-level shared devices, etc.

Owner:楼利波

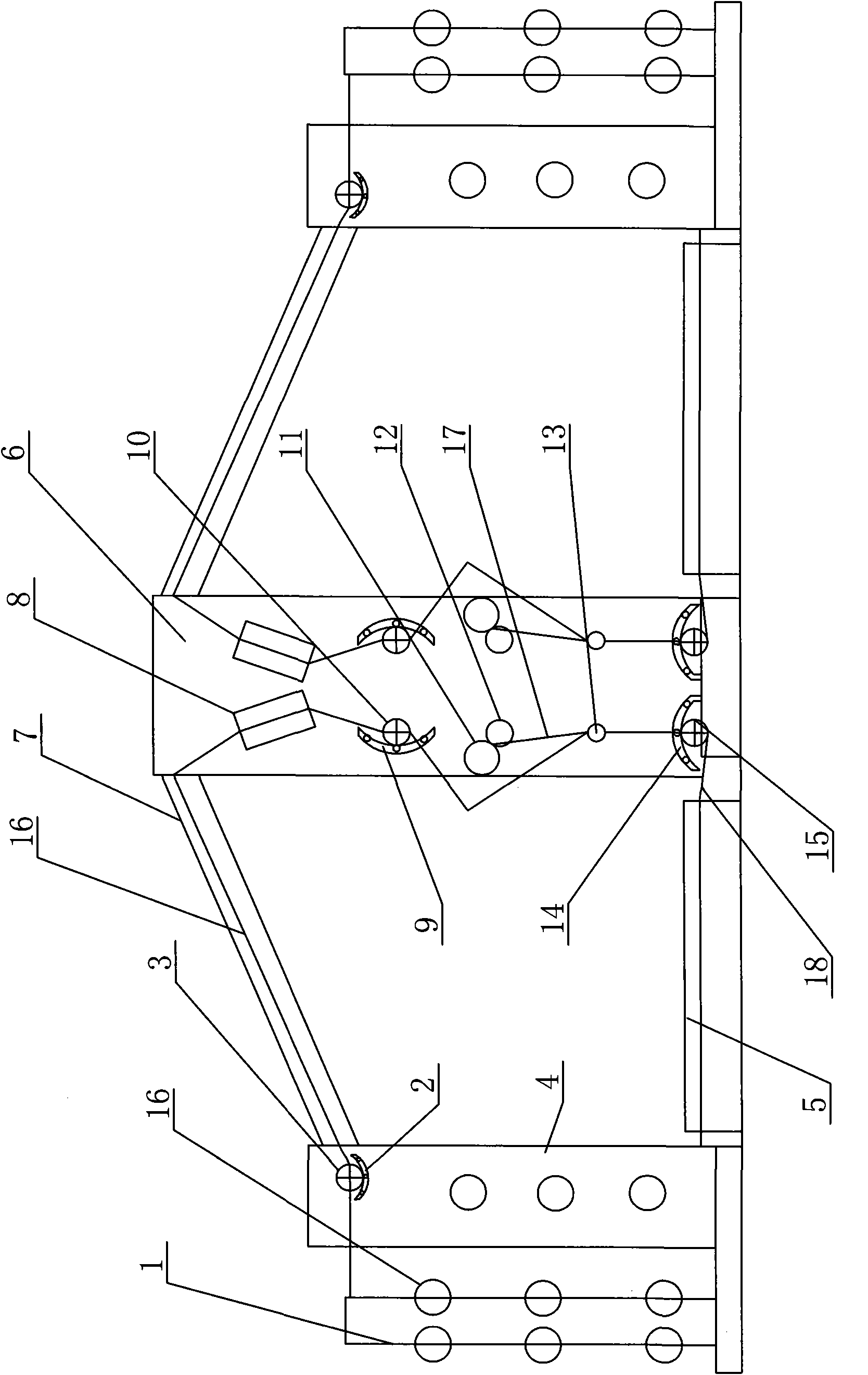

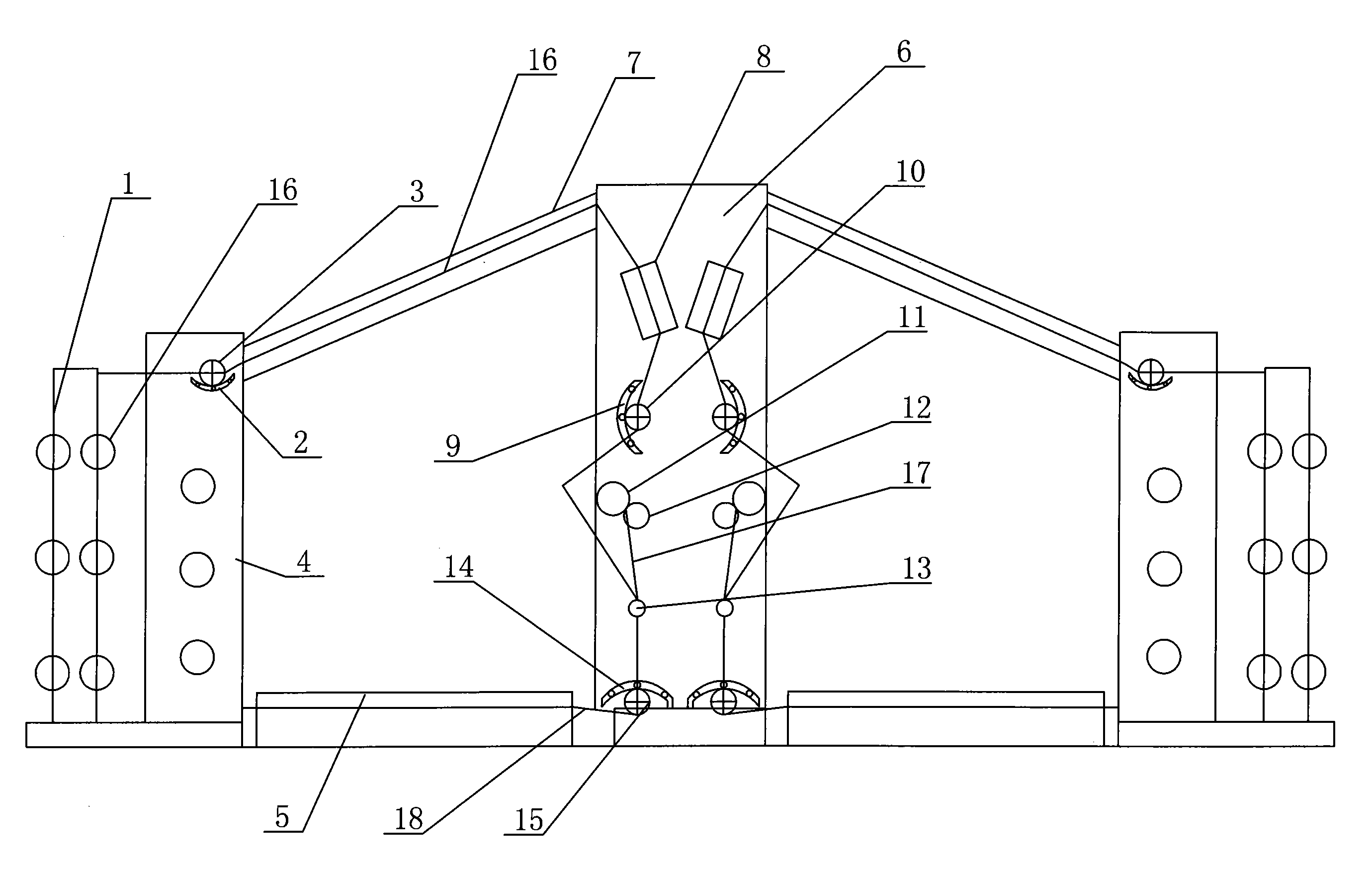

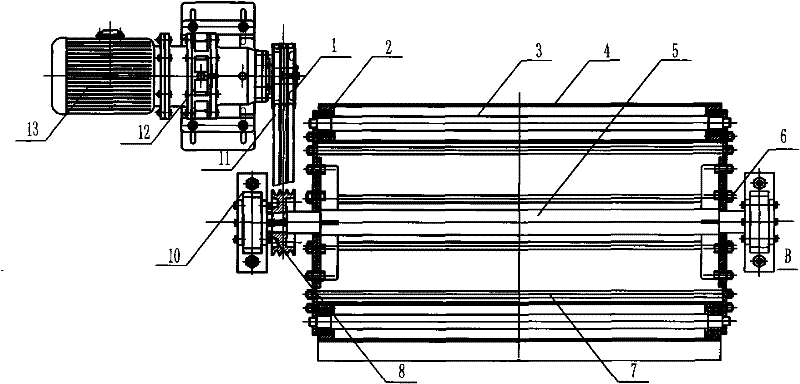

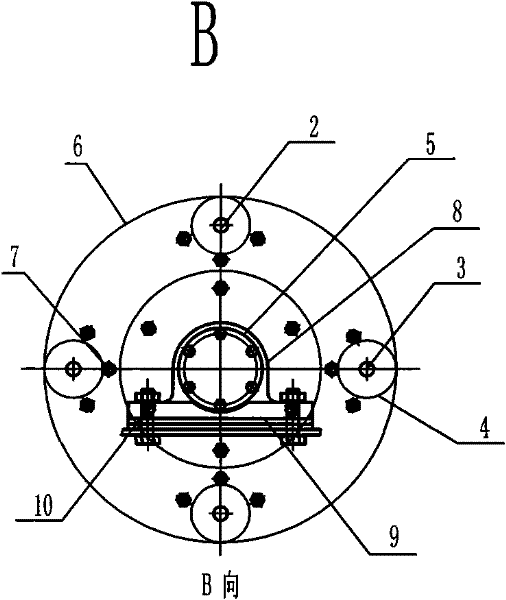

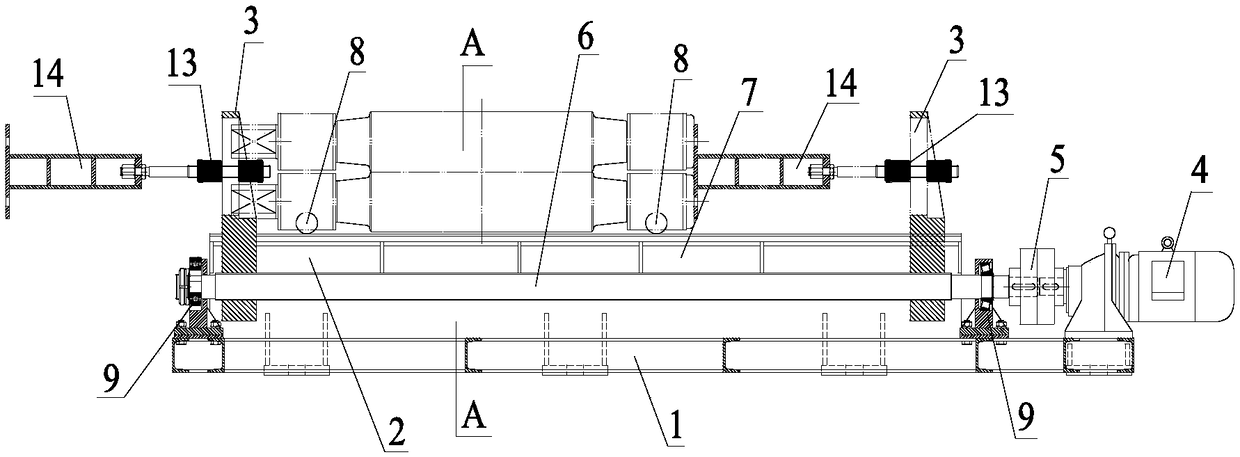

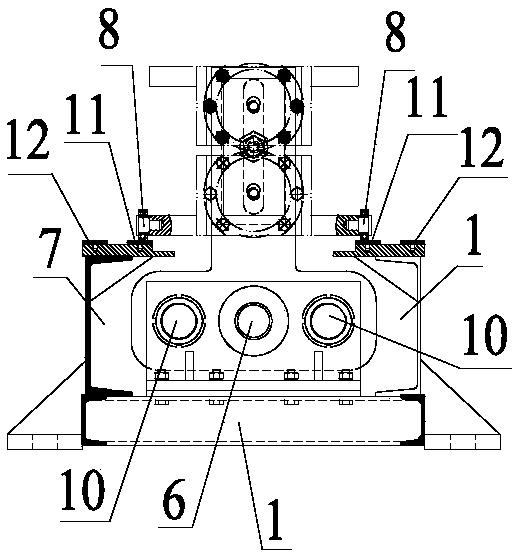

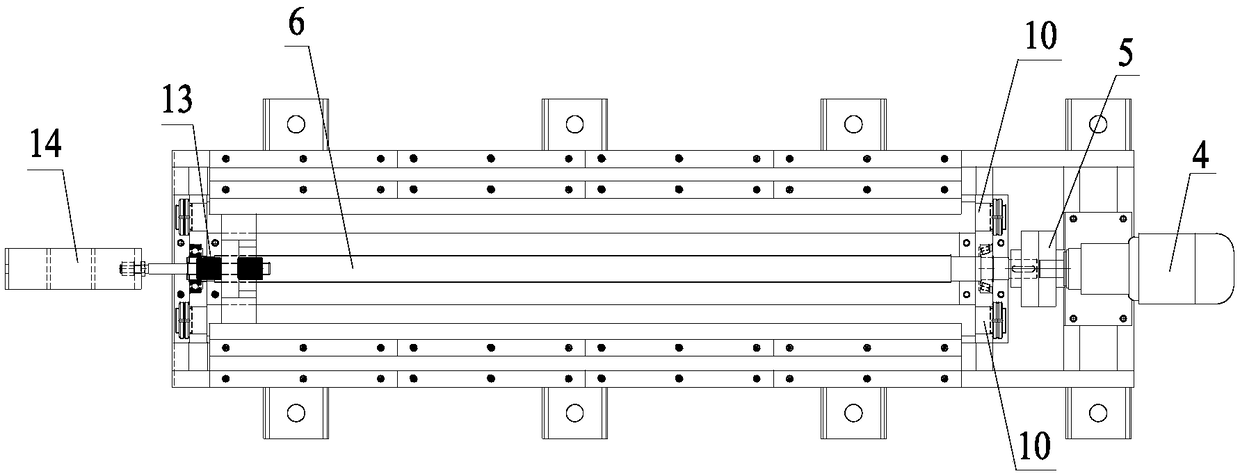

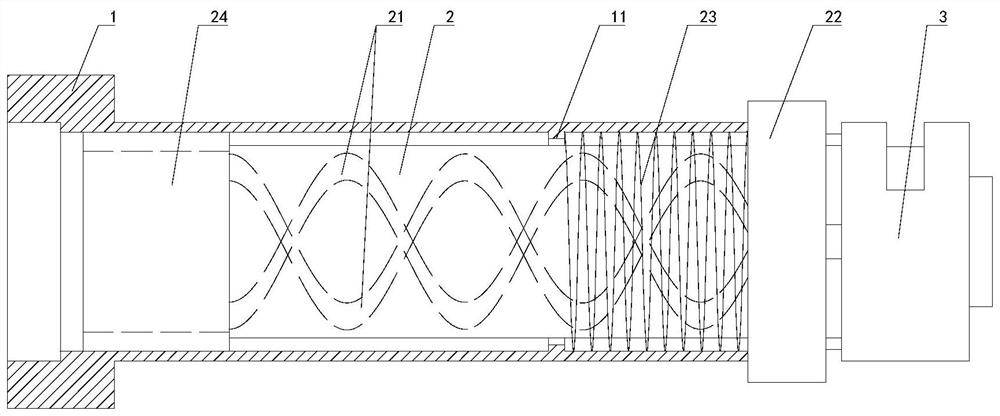

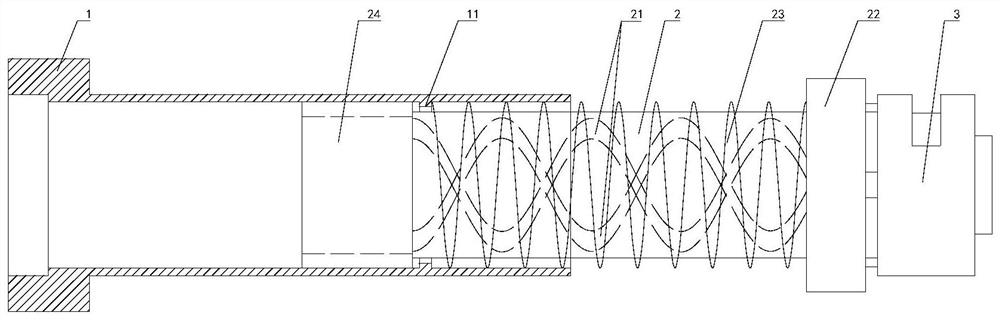

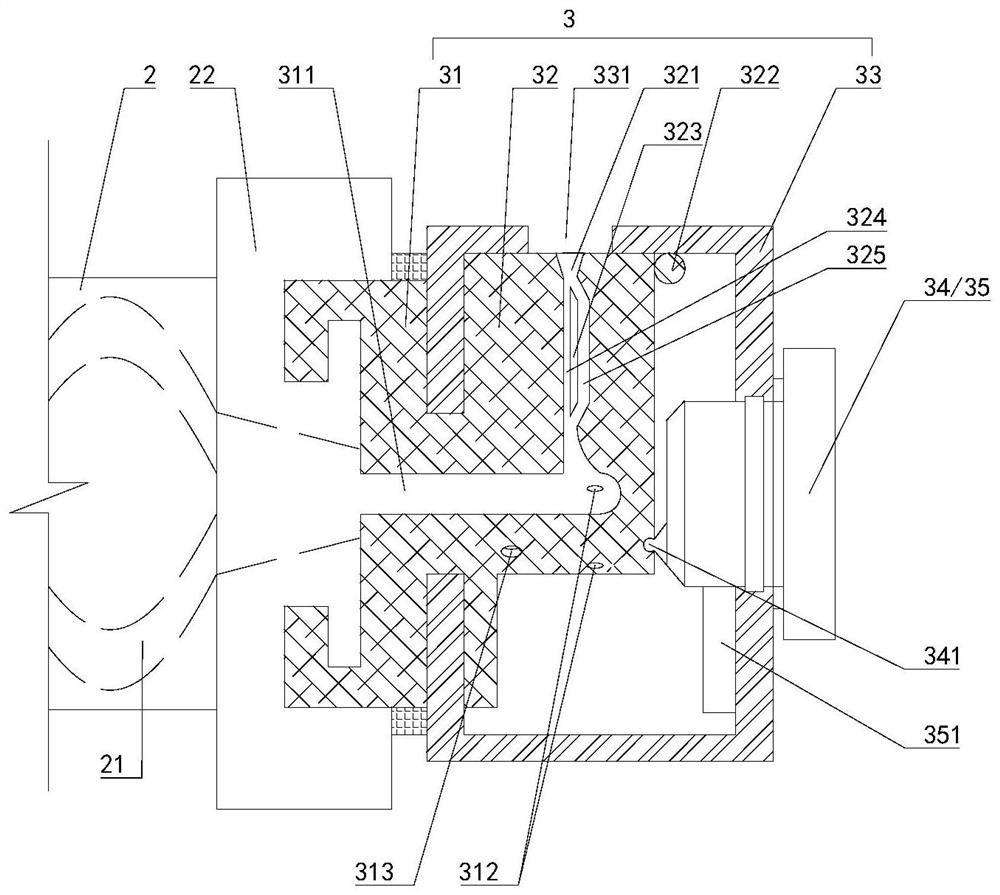

Quick roll changing device for working roll or supporting roll of hot rolling production line, and changing method

InactiveCN108994084AImprove efficiencyReduce site occupancyMetal rolling stand detailsMetal rolling arrangementsProduction lineWork roll

The invention relates to the field of hot rolling, and discloses a quick roll changing device for a working roll or a supporting roll of a hot rolling production line. The quick roll changing device for the working roll or the supporting roll of the hot rolling production line comprises a rack, wherein a sliding frame is arranged on the rack and comprises two sliding baffle plates symmetrical leftand right; a cycloidal pin wheel speed reducer is fixedly arranged on the rack and is connected with a screw rod through a pin coupler; the screw rod sequentially penetrates through the lower parts of the two sliding baffle plates through threaded connection; the sliding frame further comprises two roll changing platforms parallel to the screw rod; the two roll changing platforms are located on two sides of the screw rod; and two rows of rollers of the working roller or the support roller are located on the two roll changing platforms. The invention further discloses a changing method of thequick roll changing device for the working roll or the supporting roll of the hot rolling production line. The quick roll changing device for the working roll or the supporting roll of the hot rollingproduction line, and the changing method provided by the invention support the changing of the working roll or the supporting roll, and is accurate in control, fast in roll changing speed and low inworking intensity; and the device is simple in design and low in cost.

Owner:武汉钢铁有限公司

Spray maintenance telescopic spray head

ActiveCN111672647AReduce site occupancyReduce construction difficultyMovable spraying apparatusSpray nozzlesStructural engineeringWater supply

The invention provides a spray maintenance telescopic spray head. The spray maintenance telescopic spray head comprises a connecting pipe, the connecting pipe is connected with a water supply pipe, asliding body is slidably connected in the connecting pipe, under the action of water pressure, the sliding body partially extends out of the connecting pipe, under the action of no water pressure, thesliding body retracts in the connecting pipe, a water channel is arranged in the sliding body, a spray head device is rotatably connected to the tail end of the sliding body, the spray head device communicates with the water channel, and the spray head device swings left and right under the action of water pressure by taking a central shaft of the sliding body as a rotating shaft. According to the spray maintenance telescopic spray head, the technical effects that the site occupancy rate is greatly reduced, the construction difficulty and the construction cost are greatly reduced due to sitesaving, the telescopic swing spray head has no interference with formwork erecting and detaching of cast-in-place components, formwork erecting and detaching are conveniently and rapidly carried out,the construction efficiency is improved, the economic benefit is obvious, the spray area of the spray head is increased through the swing spray head, the spraying effect is better, the curing effect is improved, the strength of the components is guaranteed, and water resources are saved are achieved.

Owner:湖北省清江路桥建筑有限公司

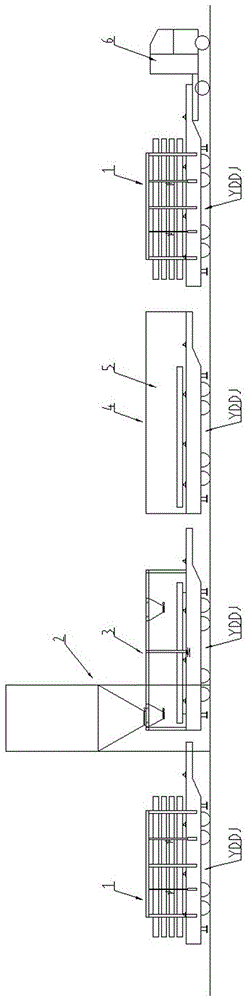

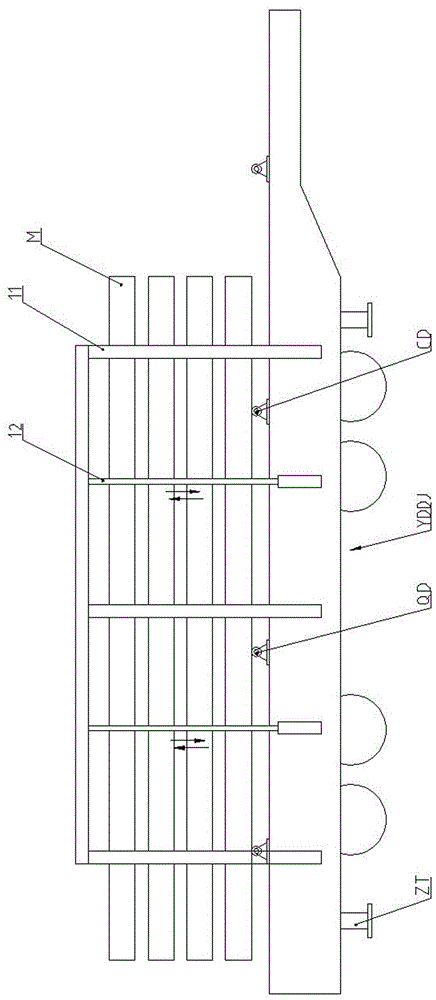

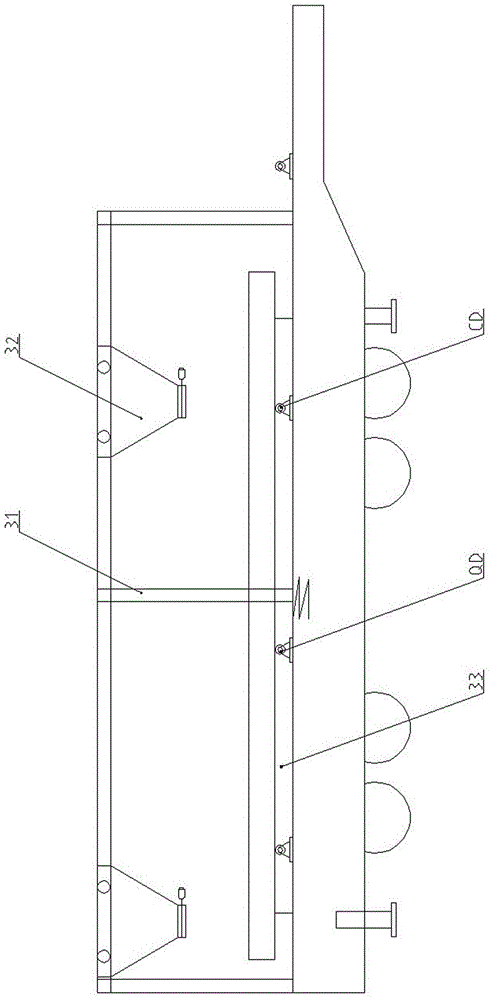

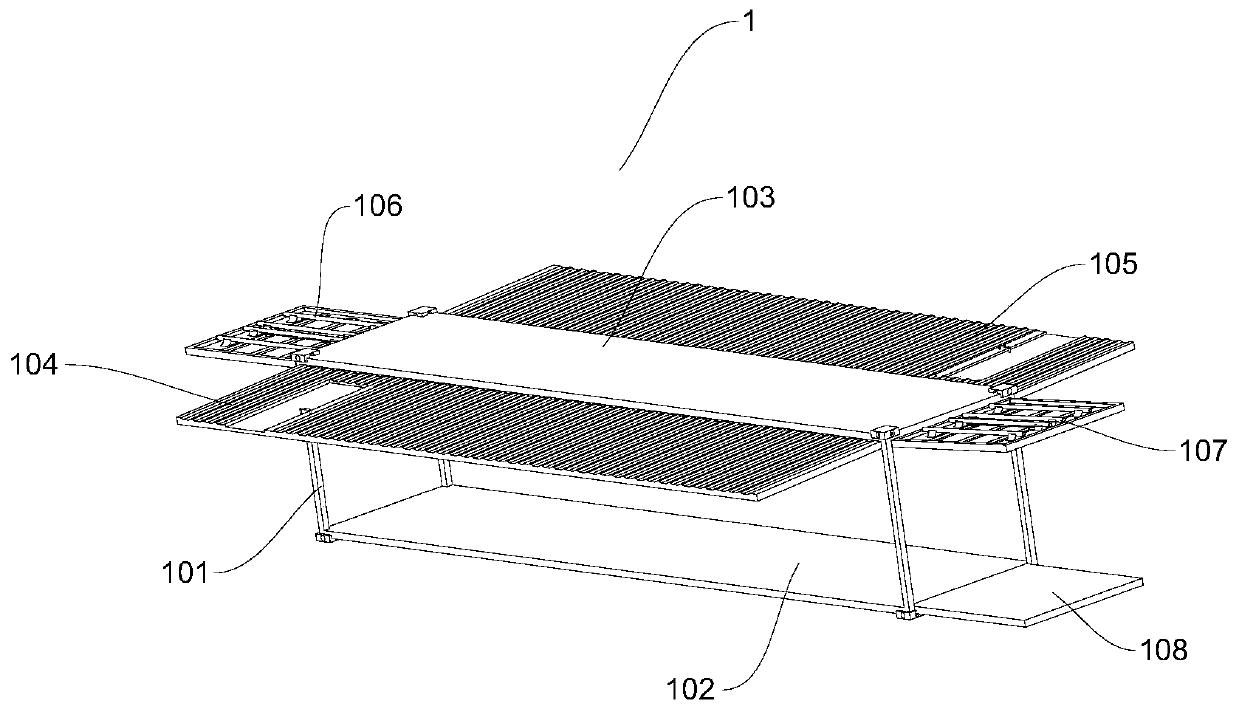

PC component production system

PendingCN106827221AReduce site occupancyMeet site needsCeramic shaping plantsFeeding arrangmentsRebarEngineering

The invention discloses a PC component production system. The system at least includes mobile die table stations, a mobile mortar storage tank and a burden distribution and vibrating station; the die table stations and the burden distribution and vibrating station are arranged in sequence, the mortar storage tank is arranged at the burden distribution and vibrating station, the die table stations and the burden distribution and vibrating station are all provided with conveying devices, a vibrating device capable of vertically lifting is arranged on the burden distribution and vibrating station, die tables are conveyed from the die table stations to the burden distribution and vibrating station for reinforcing steel bar assembly, burden distribution and vibrating to form PC components, and then the PC components are sent out. The die table stations are used for storing the die tables and serve as a die table warehouse; the burden distribution and vibrating station is used for changing the horizontal arrangement mode of reinforcing steel bar assembly, burden distribution and vibrating of a fixed production line into the vertical arrangement mode, the mobile mortar storage tank is arranged at the burden distribution and vibrating station to complete the steps of reinforcing steel bar assembly, burden distribution and vibrating at one working position of the burden distribution and vibrating station, space occupation is reduced, and the site need is met. Simply by dragging a mobile chassis to a project site through a headstock and then arranging the mobile chassis well, the production can be performed, and the system has the advantages of being timely in production and construction.

Owner:湖南东方红住宅工业有限公司 +1

Method for preparing fermented soy sauce with pure flour

The invention discloses a method for preparing fermented soy source with pure flour, comprising the following steps of: mixing flour and water to stir to obtain a mixture; putting mixture into a fermenting tank after being subjected to cooking, cooling, inoculating and starter-making; naturally fermenting the mixture for 3-4 months, carrying out sterilization treatment, filtering and clarifying to obtain the soy source. According to the method disclosed by the invention, the pure flour is used as the raw material, cooked and cooled and then is inoculated with multi-enzyme strains required by starchy materials; after starter-making for 3-4 days, the pure flour is put into the fermenting tank and salt water at a temperature of about 18 DEG C is added for high-salt liquid-state natural fermentation; after fermentation for 3-4 months, the soy source with golden yellow color, thick state, rich flavor and sweet and salty taste is obtained and is suitable for steaming, cooking, frying and mixing of various dishes.

Owner:JIANGSU SUMEI FOOD

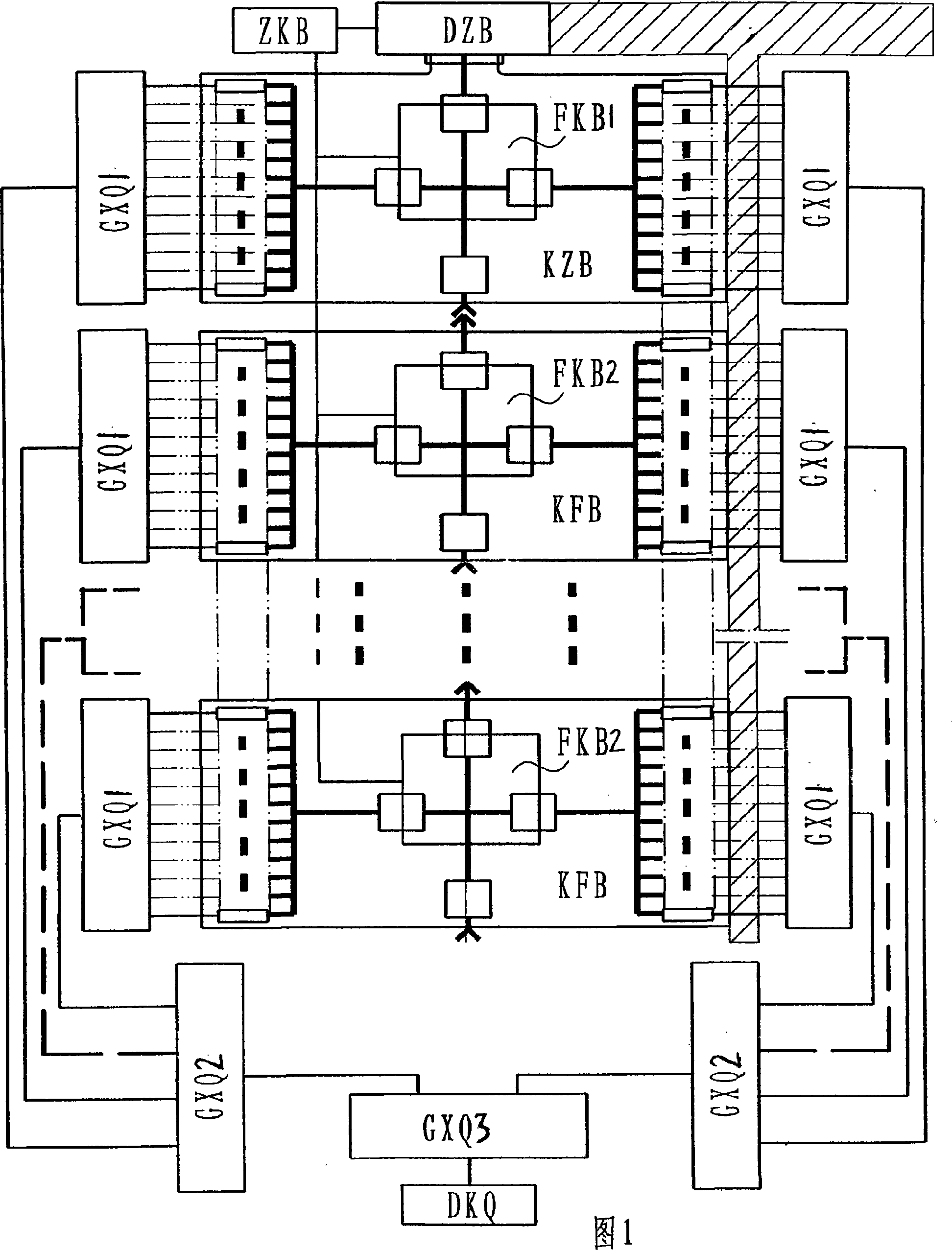

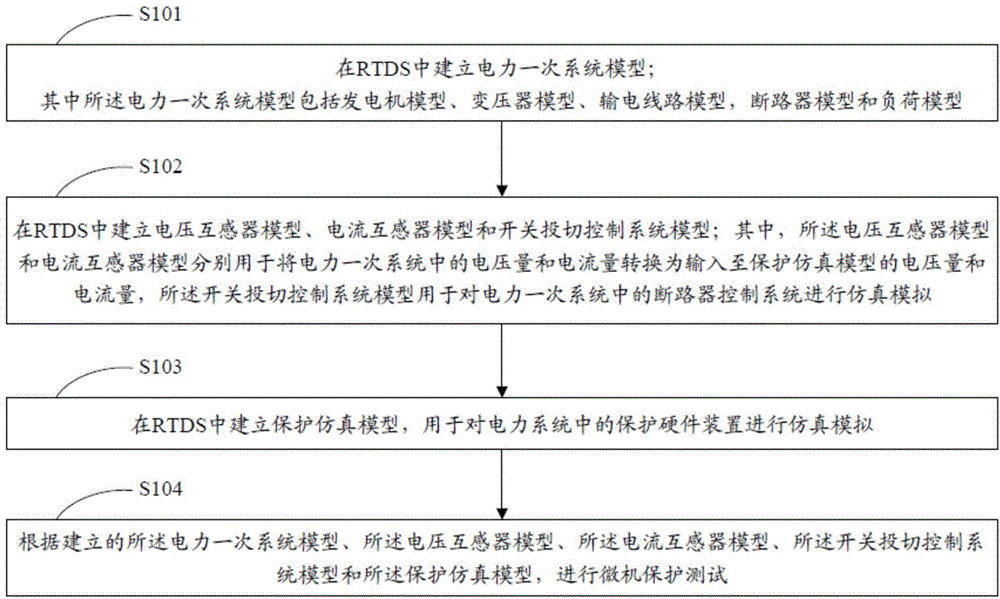

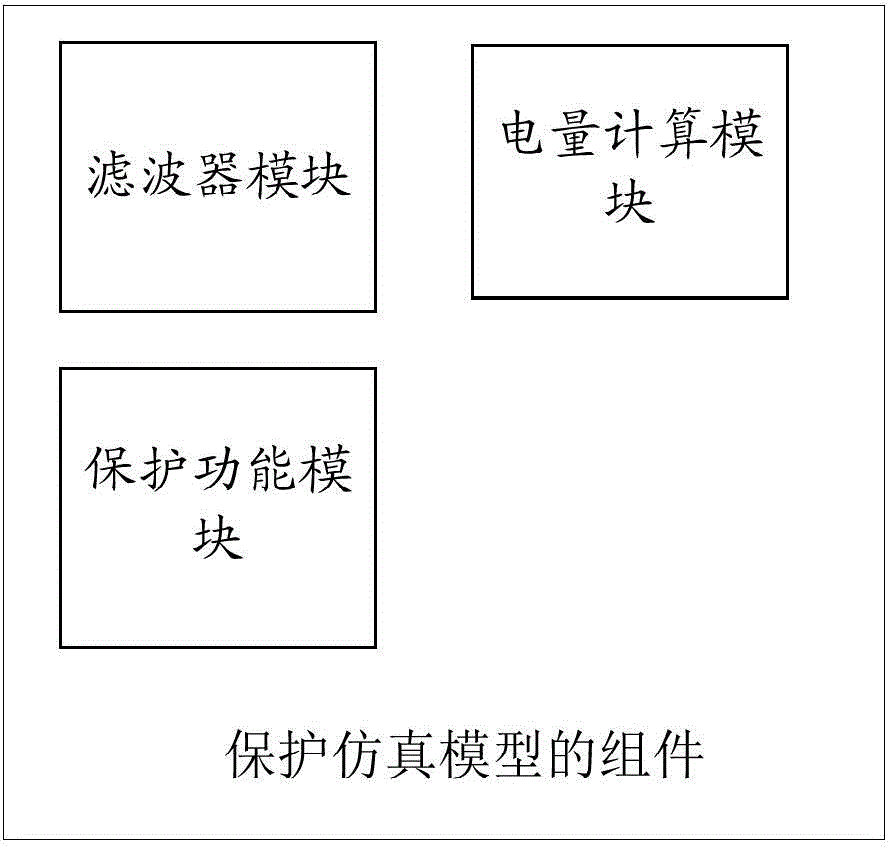

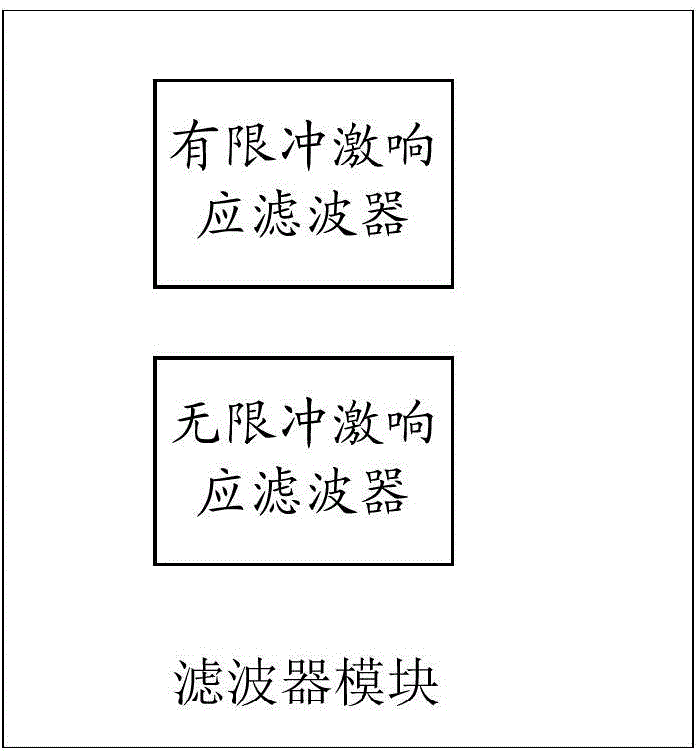

RTDS-based microcomputer protection integrated test method

ActiveCN103605292AReduce volumeShort construction periodSimulator controlElectric power systemEngineering

Owner:POWER DISPATCHING CONTROL CENT OF GUANGDONG POWER GRID CO LTD

Pasted fur tobacco rapid fermenting process

ActiveCN101972039AReduce temperature differenceIncrease the speed of fermentation reactionTobacco treatmentPolypropylene meshMaterial consumption

The invention discloses a pasted fur tobacco rapid fermenting process which is characterized in that the temperature of a sealed storehouse is set to be 35-40 DEG C and the humidity is set to be 70-85 percent; white fur tobacco stems are dipped in pasted rice water and then stacked in the storehouse, repeatedly stacked 3-4 times, turned and subjected to moisture release for completing the fermentation; and in a last moisture release process, the fermented tobacco is dried through a polypropylene mesh tape dryer until the water content in percent by weight is 20-24 percent and then packaged and stored. The method can reduce the labor and material consumption of the pasted fur tobacco during the production, and improve the quality stability among different batches of products.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Chemical adsorbent for processing heavy metal waste water

PendingCN109019741AReduce dosageEasy to handleWater contaminantsWater/sewage treatment using germicide/oligodynamic-processIron powderSorbent

The invention provides a chemical adsorbent for processing heavy metal waste water. The Chemical adsorbent for processing heavy metal waste water comprises the following components in parts by mass: 5to 25 parts of calcium oxide, 15 to 40 parts of an inorganic polymer flocculant, 1 to 25 parts of sulfur-containing iron powder, 3 to 30 parts of sodium percarbonate, and 1 to 10 parts of an organicpolymer flocculant. The adsorbent of the invention is simple to use and operate, the conditions are easy to control, the dosage of the medicament is small, and the sedimentation speed is fast.

Owner:OCHEMATE MATERIAL TECH CO LTD

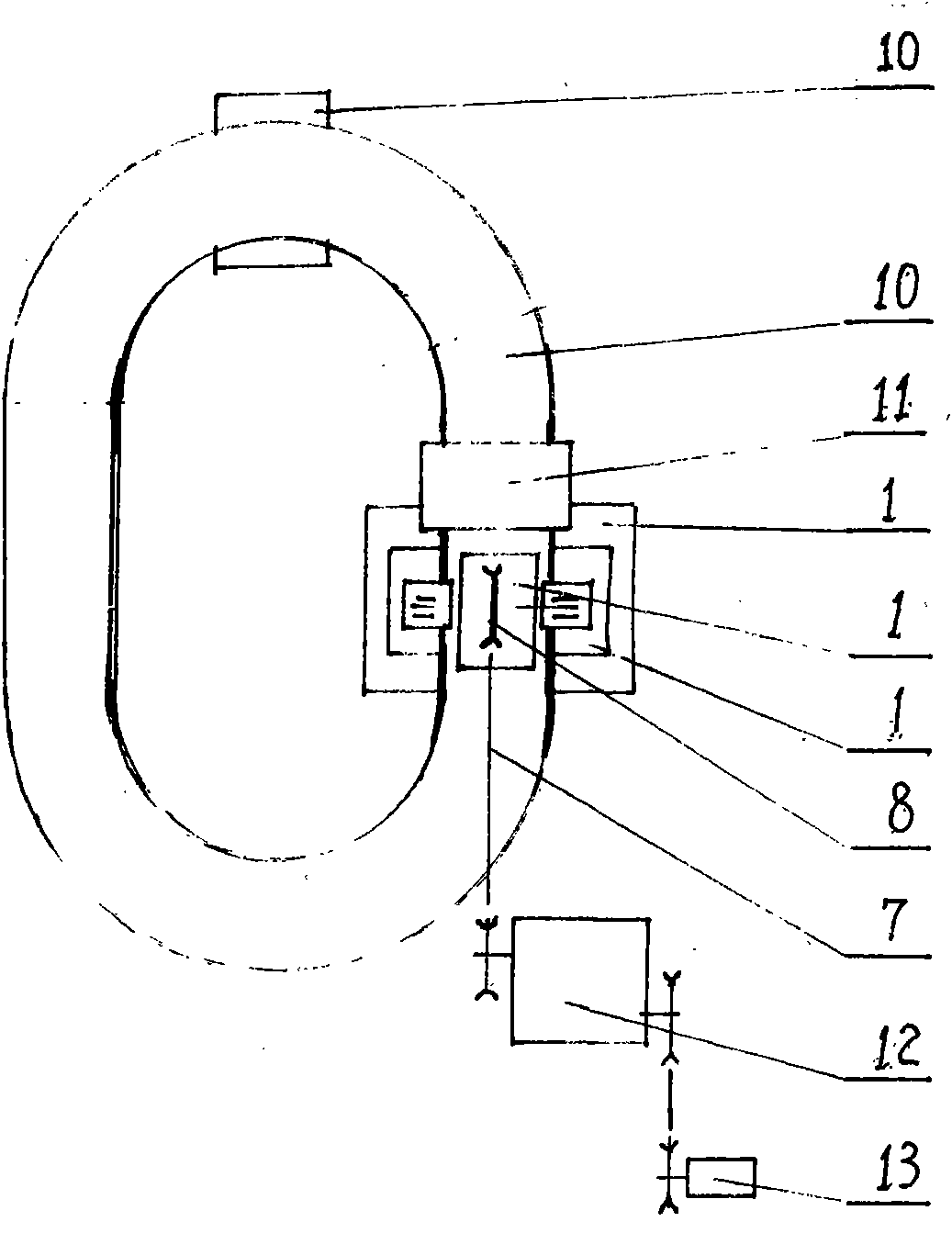

Track-change device of roller coaster

The invention provides a track-change device of a roller coaster. The track-change device comprises a main track, a rotating track and a drive device, wherein the area surrounded by the main track isan overhaul area, and a plurality of overhaul tracks are arranged in the overhaul area; the rotating track is arranged on the main track, the rotating track is provided with a rotation shaft, and therotating track is rotatably arranged on the main track by adopting the rotation shaft as the axis; the drive device drives the rotating track to rotate, wherein under the non-overhaul state, two endsof the rotating track are connected with and fixed with the main track, and serve as one part of the main track; and when track-change overhaul is needed, the drive device drives the rotating track torotate along the rotation shaft and enables one end of the rotating track to be connected with the overhaul tracks. With the device, while the track-change overhaul of the plurality of overhaul tracks is realized, the integral occupied area of the device can be effectively reduced, the overhaul and maintenance cost of the roller coaster is effectively reduced, and the overhaul period is effectively shortened.

Owner:北京中冶设备研究设计总院有限公司

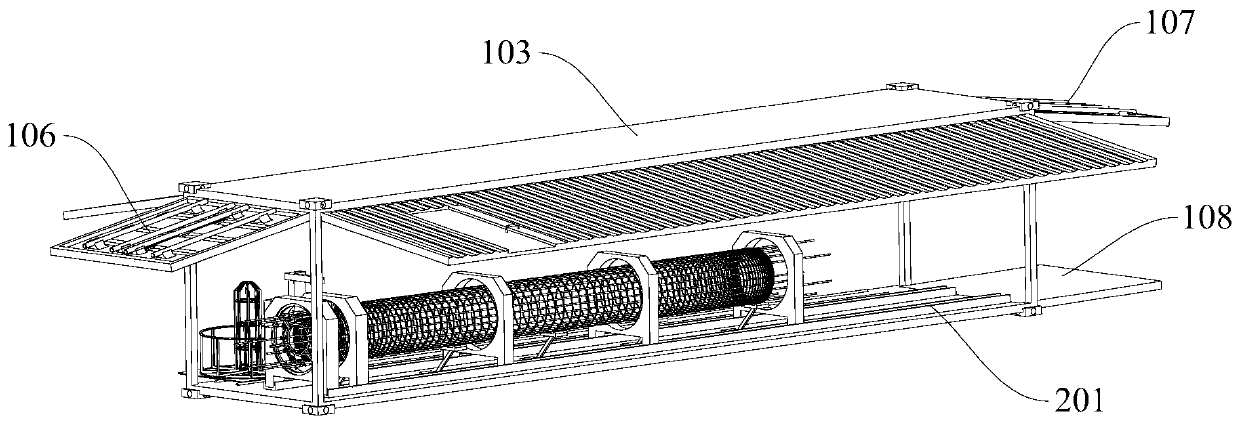

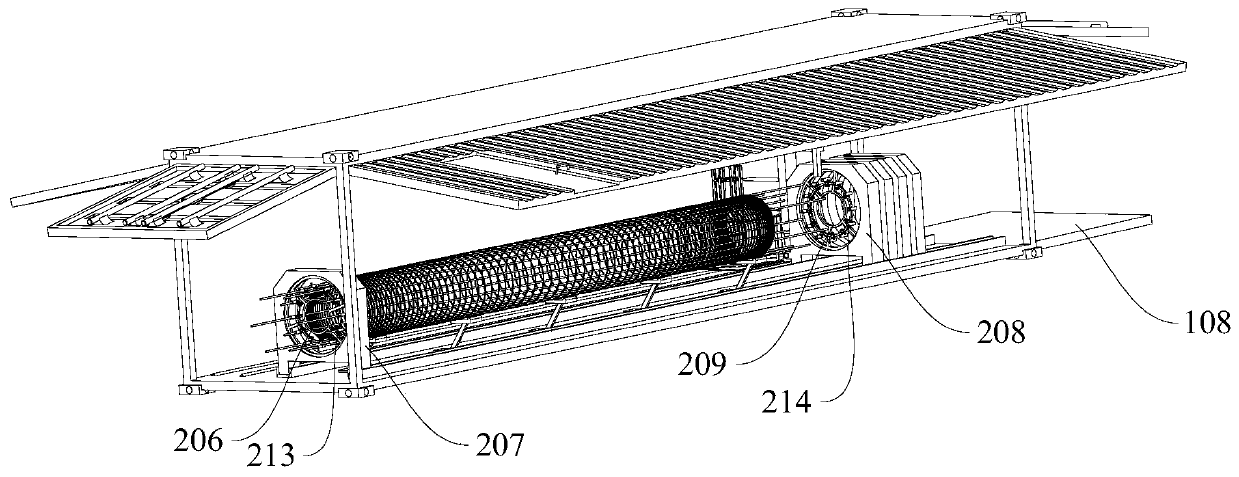

Reinforcement cage manufacturing device

The invention discloses a reinforcement cage manufacturing device. The reinforcement cage manufacturing device comprises a box body and a reinforcement cage manufacturing mechanism, wherein the box body comprises a framework, a bottom plate arranged at the bottom of the framework, a top cover arranged at the top of the framework, a left side door leaf, a right side door leaf, a rear end door leafpivoted to the top of the rear end of the framework, a front end door leaf pivoted to the top of the front end of the framework and a supporting door leaf pivoted to the bottom of the front end of theframework, wherein the left side door leaf and the right side door leaf are pivoted to the top of the left side and the top of the right side of the framework respectively, the bottom plate can be used for placing the reinforcement cage manufacturing mechanism, the reinforcement cage manufacturing mechanism comprises a guide rail which is detachably arranged on the bottom plate, a rotary disc mechanism matched with the guide rail in a sliding mode and a moving mechanism, and the supporting door leaf can be opened to enable the top surface of the supporting door leaf and the top surface of thebottom plate to be in the same horizontal direction so that the guide rail can extend to the top surface of the supporting door leaf. According to the device, the automatic on-site production of a reinforcement cage can be realized, the transportation cost is reduced, the occupied space of the site is reduced by means of the modular design, and whole hoisting is facilitated.

Owner:浙江坤德创新岩土工程有限公司

Attraction material device and manufacturing method thereof

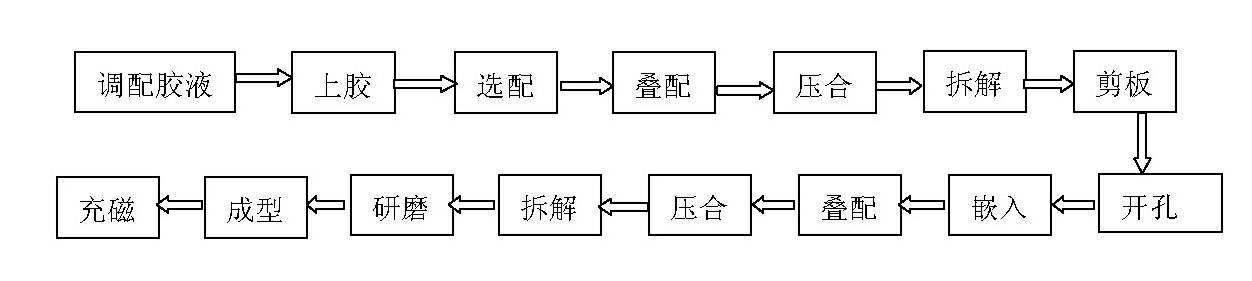

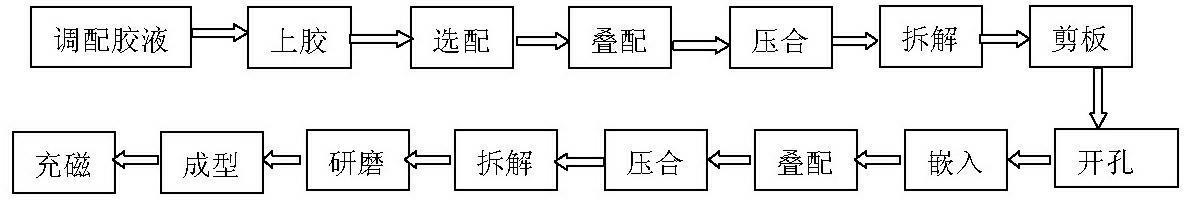

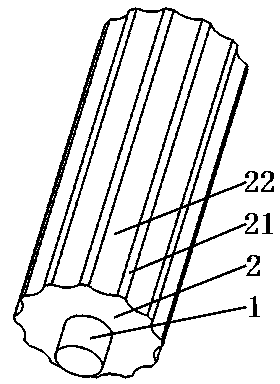

ActiveCN102173173AImprove bending strengthImprove flatnessLamination ancillary operationsLaminationUV resistanceChemical resistance

The invention relates to an attraction material device and a manufacturing method thereof. The manufacturing method comprises the following steps of: blending glue solution; gluing; selecting; overlapping; pressing; disassembling; shearing a plate; holing; embedding; overlapping; pressing; disassembling; grinding; forming; and magnetizing. The attraction material device comprises an attracting part and a closing part, wherein the attracting part consists of a substrate and magnets embedded in the substrate; the magnets are parallelly distributed in a plurality of rows in the substrate; and the closing part consists of a substrate and iron sheets embedded in the substrate. By the manufacturing method for the attraction material device, the production efficiency is high, equipment investment is low and the occupied area is small; and the manufactured attraction material device has a mild color of faint yellow, good UV resistance, chemical resistance and bending strength, good flatness without concave-convex feel, good cohesive property and large attraction force.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

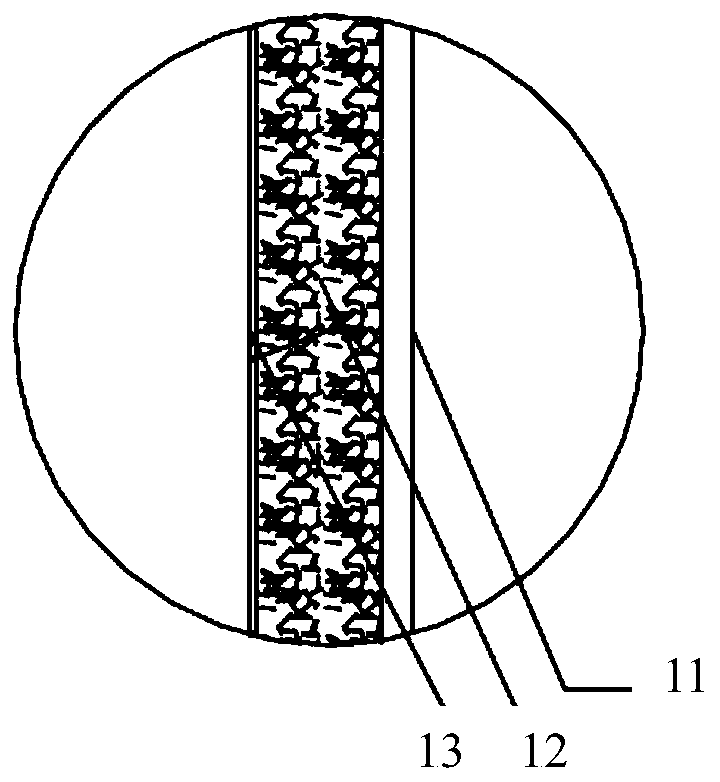

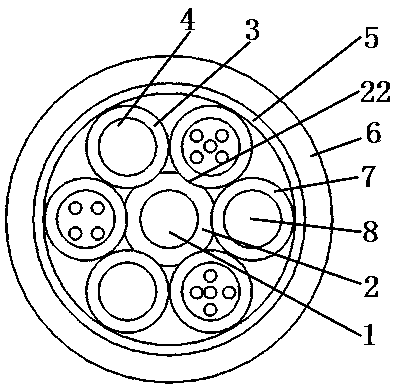

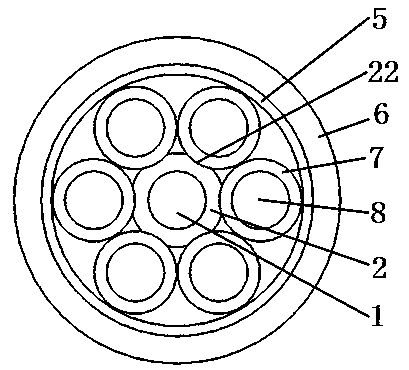

Optical cable of improved structure

InactiveCN104049329AEasy and intuitive to take outShorten the extraction processFibre mechanical structuresEngineeringProtection layer

The invention belongs to the technical field of cables, and relates to an optical cable of an improved structure. The optical cable comprises loose tubes, insulated core wires, a protection layer and a sheath layer wrapping the protection layer in an extrusion molding mode. One or more optical fibers are arranged in each loose tube, and a conductor is arranged in each insulated core wire. The optical cable is characterized by further comprising a supporting component located in the center of the optical cable. The supporting component is composed of a reinforcing part in the center and a supporting part wrapping the reinforcing part, the outer edge of the supporting part is composed of protruding strips and concave grooves, and the protruding strips and the concave grooves are distributed alternately. Just a part of each loose tube is located in the corresponding groove, just a part of each insulated core wire is located in the corresponding groove, and every two adjacent loose tubes or every two adjacent insulated core wires or the loose tubes and the corresponding adjacent insulated core wires are tangent or spaced. The optical cable has the main advantages of being simpler in structure, smaller in outer diameter, lighter in weight, lower in cost, easier to produce and construct and better in impact resistance and pressure resistance.

Owner:尹红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com