Liquefied air energy storage and thermoelectric power generation coupling system and working method thereof

A technology for thermoelectric power generation and air liquefaction, which is applied in liquefaction, refrigeration and liquefaction, generator/motor and other directions, and can solve the problems of low energy storage system efficiency, increased system complexity, and environmental thermal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

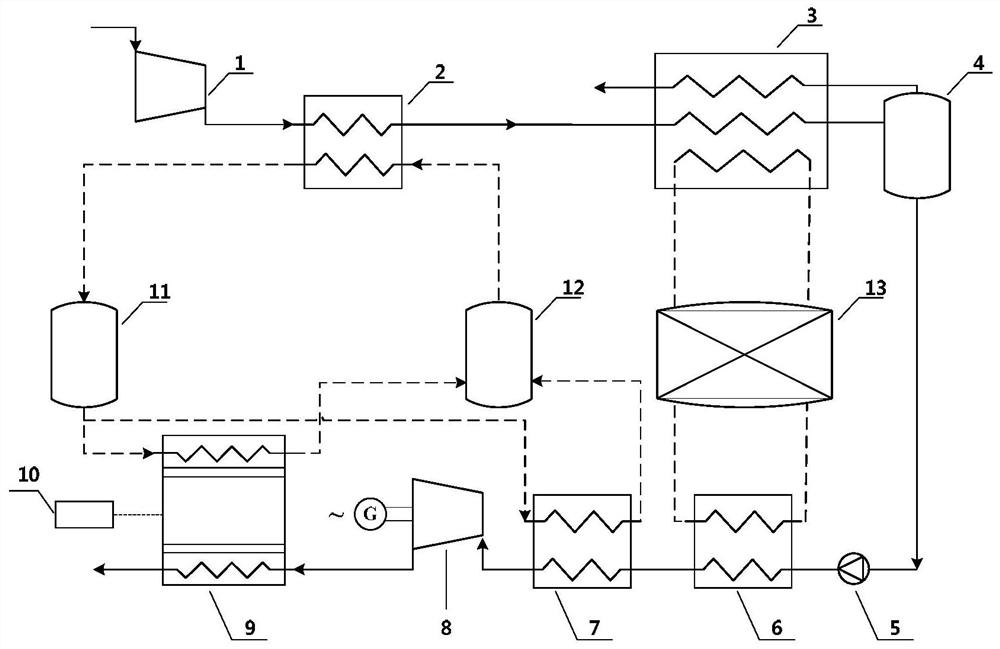

Embodiment 1

[0038] see figure 1 , the liquefied air energy storage-thermoelectric power generation coupling system of the present invention includes an air compressor 1, a post-stage air cooler 2, a cold box 3, a liquid air storage tank 4, a cryogenic liquid pump 5, an air vaporizer 6, and a pre-stage Air reheater 7, air expander 8, thermoelectric power generation device 9 and other main components also include high temperature heat storage tank 11, normal temperature heat storage tank 12 and a low temperature cold storage tank 13. The applicable working conditions of this embodiment are: the exhaust temperature of the air expander 8 is relatively low and must not be higher than the ambient temperature, so as to ensure the efficient operation of the thermoelectric power generation device.

[0039]The air inlet of the air compressor 1 is connected to the ambient atmosphere, and the exhaust port of the air compressor 1 is connected to the hot end of the after-stage air cooler 2 and the hot ...

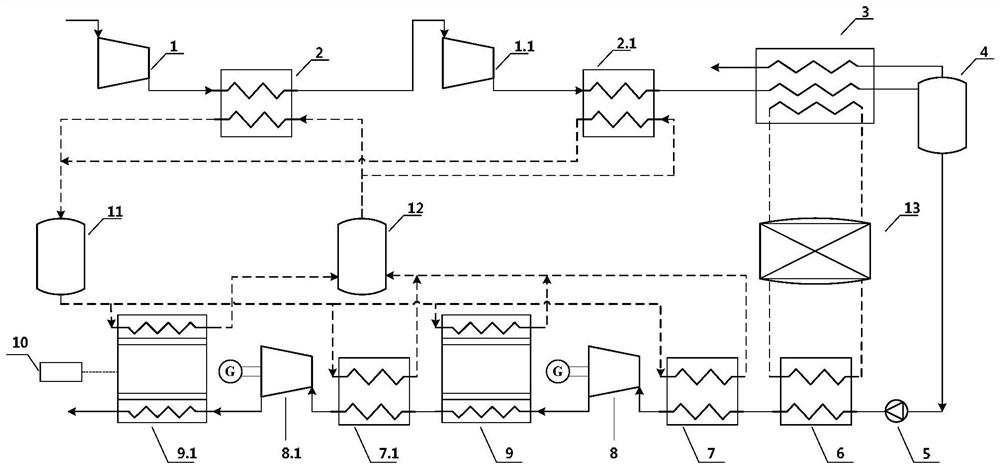

Embodiment 2

[0054] figure 2 It is a schematic diagram of a coupling system adopting a two-stage compression and two-stage expansion scheme in the present invention. Compared with Embodiment 1, the improvement is that the air compression device consists of a first-stage air compressor 1, a first-stage after-stage air cooler 2, The second-stage air compressor 1.1 and the second-stage after-stage air cooler 2.1 are composed and connected in sequence. The outlet of the hot end of the second-stage after-stage air cooler 2.1 is connected with the inlet of the hot end of the cold box 3; the air expansion device and the temperature difference The power generation device consists of a first-stage front air reheater 7, a first-stage air expander 8, a first-stage thermoelectric power generation device 9, a second-stage front air reheater 7.1, a second-stage air expander 8.1 and a first-stage The second-stage thermoelectric power generation device 9.1 is composed and connected in sequence, and the o...

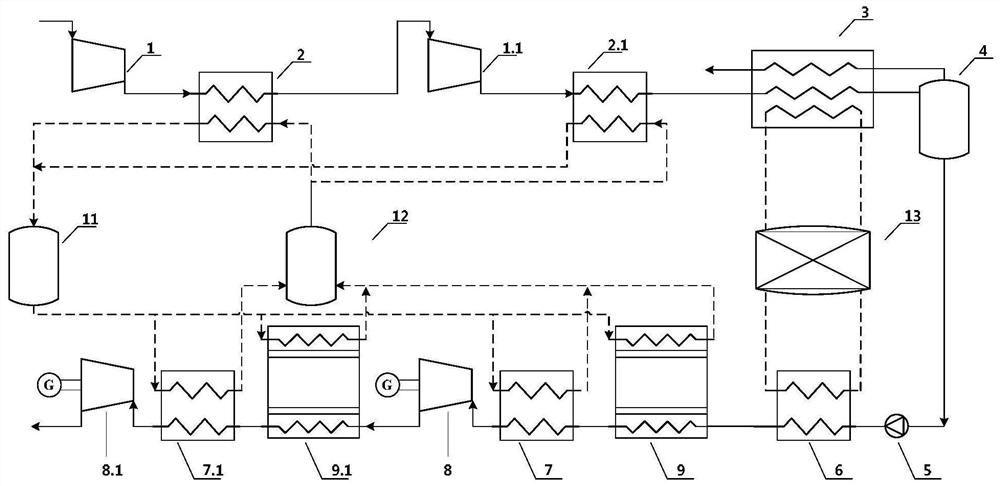

Embodiment 3

[0056] image 3 It is a schematic diagram of the pre-stage thermoelectric power generation device of the present invention, and its improvement compared with Example 2 is that the thermoelectric power generation device is no longer installed at the outlet of the last-stage air expander, but the inlet of the air reheater before the first stage Install a thermoelectric power generation device; the outlet of the air vaporizer 6 is sequentially connected with the first-stage thermoelectric power generation device 9 cold-end heat exchanger, the first-stage pre-stage air reheater 7 cold end, the first-stage air expander 8, and the second-stage 9.1 cold end heat exchanger of the thermoelectric power generation device, 7.1 cold end of the second-stage pre-stage air reheater are connected with the second-stage air expander 8.1, and the outlet of the second-stage air expander 8.1 is communicated with the atmosphere. The working method of the system is the same as that of Embodiment 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com