Thick-wall cast steel exhaust manifold casting process

An exhaust manifold and casting process technology, which is applied in the field of thick-wall cast steel exhaust manifold casting technology, can solve the problems of inability to meet the high temperature resistance of the thick-wall cast steel exhaust manifold and unsuitable for automobile exhaust manifolds. , to achieve the effect of reducing the risk of cold insulation, good mechanical properties, and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

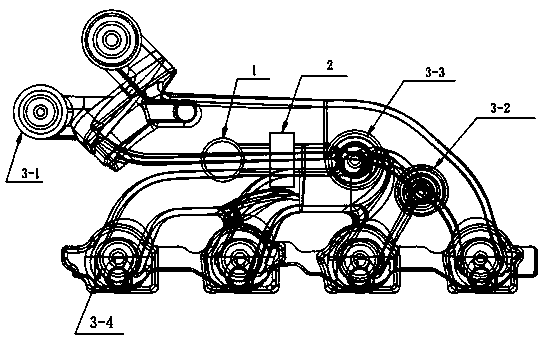

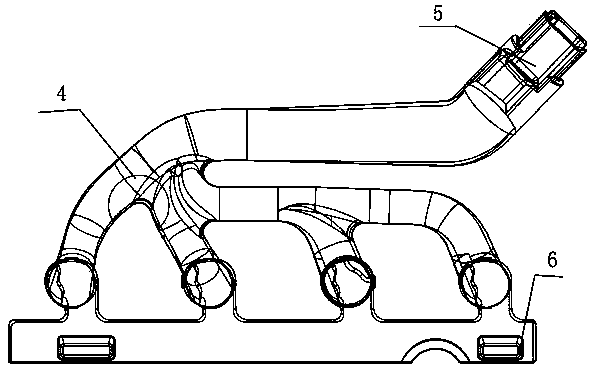

[0041] This embodiment provides a thick-wall cast steel exhaust manifold casting mold including sand mold, riser, sand core and pouring system; refer to figure 2 , the sand core is provided with two sand-shooting openings, that is, number 5 and number 6 in the figure; refer to figure 1, the pouring system includes a straight pouring rod 1 and a runner, the straight pouring rod 1 is vertically connected to the runner, a filter 2 is set in the middle of the runner, and a filter 2 is set at the end of the runner into the riser. The sand core is matched with the sand mold, the sprue connected with the runner is set in the sprue 1, the riser includes four large surface risers 3-4, two triangular flanges Riser 3-1, a fire inlet riser 3-3 and a thermal insulation riser 3-2. Fire inlet riser 3-3 and insulation riser 3-2 are all provided with riser neck, and riser neck is provided with easily broken groove. The fire inlet riser 3-3 and the inner runner are of an integrated structur...

Embodiment 2

[0044] A method for casting a thick-walled cast steel exhaust manifold provided in this embodiment, using the casting model in Embodiment 1, includes the following steps:

[0045] S1: Core making:

[0046] Hot core making: Use coated sand doped with 30% chromite sand as the raw material of the cavity core, heat the core box to 200°C, shoot sand into the core box for 4-6 seconds through two sand injection ports, and the shell will form. Curing, vibrating to pour out the uncured coated sand in the inner cavity of the sand core. After 180 seconds, the sand core is cured and taken out of the core box to ensure that the thickness of the sand shell is 6-8mm;

[0047] Cold core: heat and mix the dried sand, liquid phenolic resin, and liquid polyisocyanate resin according to the weight ratio of dry sand: liquid phenolic resin: liquid polyisocyanate resin at a ratio of 98:1:1, and the temperature is 20°C, and then join the cold core machine to form under the catalysis of triethylamine...

Embodiment 3

[0054] A method for casting a thick-walled cast steel exhaust manifold provided in this embodiment, using the casting model in Embodiment 1, includes the following steps:

[0055] S1: Core making:

[0056] Hot core making: Use coated sand doped with 30% chromite sand as the raw material of the cavity core, heat the core box to 230°C, shoot sand into the core box for 4-6 seconds through two sand injection ports, and the shell will form. Curing, vibrating to pour out the uncured coated sand in the inner cavity of the sand core. After 180 seconds, the sand core is cured and taken out of the core box to ensure that the thickness of the sand shell is 6-8mm;

[0057] Cold core: heat and mix the dried sand, liquid phenolic resin, and liquid polyisocyanate resin according to the weight ratio of dry sand: liquid phenolic resin: liquid polyisocyanate resin at a ratio of 123:1:1, and the temperature is 40°C, and then join the cold core machine to form under the catalysis of triethylamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com