Patents

Literature

89results about How to "Stable at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

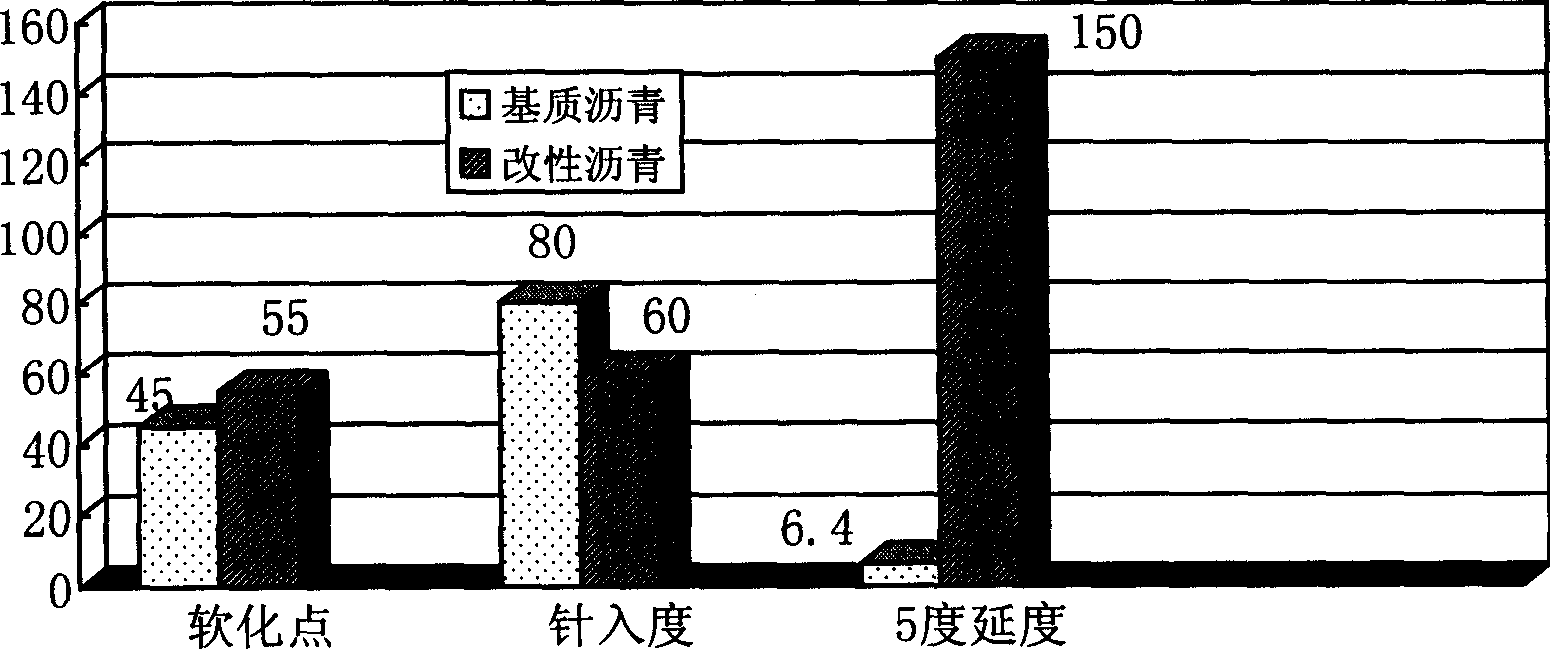

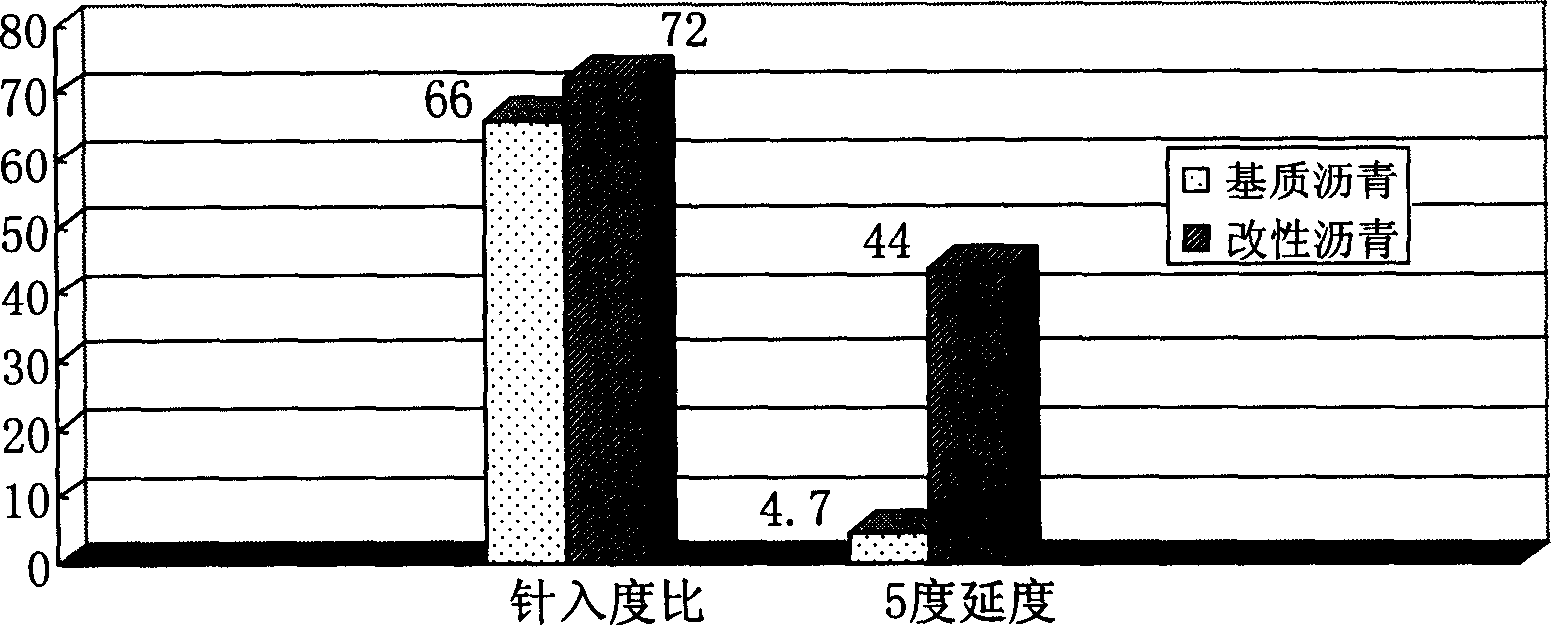

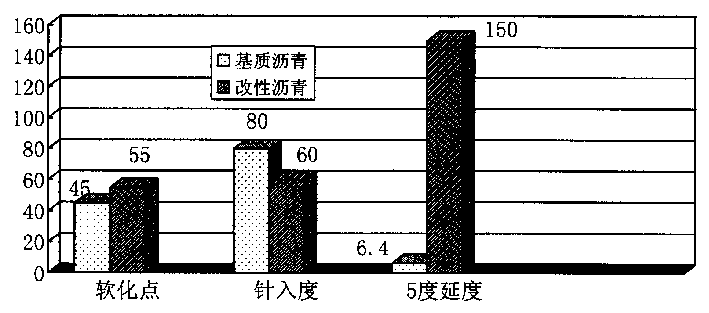

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

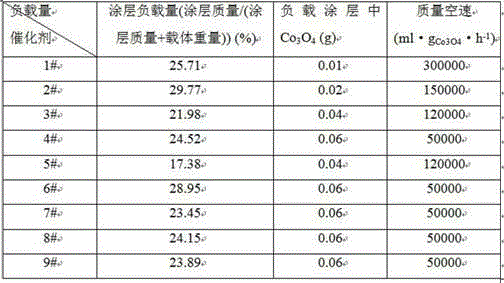

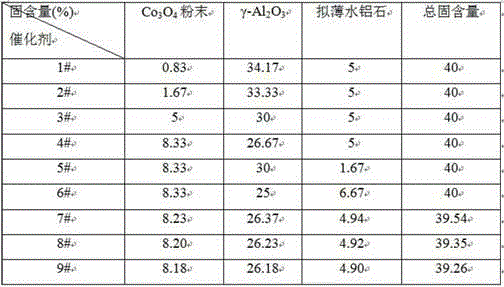

Monolithic catalyst for catalytic combustion of propane, and preparation method thereof

The invention relates to a monolithic catalyst for catalytic combustion of propane, wherein a coating slurry prepared from an active component, a co-catalyst, pseudo bohemite and gamma-Al2O3 is coated on a monolithic carrier and then high-temperature calcination is performed to form the monolithic catalyst, the monolithic carrier is a cordierite honeycomb ceramic, the active component of the catalyst is Co3O4, and the co-catalyst is one or a plurality of materials selected from ZrO2, CeO2 and La2O3. According to the present invention, the catalyst is mainly used for the catalytic combustion of low-carbon chain alkanes, has characteristics of high thermal stability, low price and simple process, and is suitable for application in industrial production; and according to the preparation method, the Co3O4 powder catalyst is used to prepare the monolithic catalyst, such that the generation of the inert component CoAl2O4 is reduced, the reproduction of the activity of the powder catalyst is ensured, and a certain reference is provided for the preparation of the catalysts.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Special-purpose welding rod for built-up welding of hot work die restoration

ActiveCN105033507AImprove toughnessImprove crack resistanceWelding/cutting media/materialsSoldering mediaWear resistantOxidation resistant

The invention provides a special-purpose welding rod for built-up welding of hot work die restoration. The special-purpose welding rod comprises a coating and a welding core. Nanometer chromium-nitride powder is added into alloy powder and a fine nitride interstitial phase is formed in deposited metal, so that the deposited metal has excellent toughness and crack-resistant performances. Meanwhile, yttrium oxide is added into the alloy powder, so that the deposited metal can be purified, occluded foreign substances can be spheroidized, formation of the nitride strengthening phase can be promoted, and the anti-fatigue performance of the deposited metal is improved. When the welding rod is used for restoring the hot work die, the obtained deposited metal has the excellent high-temperature anti-oxidation performance, wear-resistant performance, cleanliness and anti-fatigue performance.

Owner:SHANDONG UNIV

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

High-performance forsterite refractory raw material and preparation method thereof

The invention relates to a high-performance forsterite refractory raw material and a preparation method thereof. The method comprises the following steps: mixing 65-85 weight percent of fine magnesite powder with 15-35 weight percent of siliceous raw material fine powder, adding 1-10 weight percent of binding agent, and ball-milling for 1-3 hours to obtain a ball-milling material; then adding water being 3-10 weight percent of the ball-milling material into the ball-milling material, stirring, pressing to form a blank body, drying, and calcining at 1200-1400 DEG C to obtain a calcining material; grinding the calcining material to the particle size smaller than 0.045mm, and adding an additive being 0.2-2 weight percent of the calcining material and the binding agent being 1-10 weight percent of the calcining material, and ball-milling to obtain a secondary ball-milling material; and adding 3-10 weight percent of water into the secondary ball-milling material, stirring, pressing to form a blank body, drying, and secondary calcining at 1450-1650 DEG C to obtain the high-performance forsterite refractory raw material. The raw material has the advantages of wide sources, low production cost and easiness in sintering, and the prepared high-performance forsterite refractory raw material has large volume density, low porosity and stable high temperature properties.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing tungsten carbide-zirconium oxide-aluminum oxide composite knife material

The invention belongs to the technical field of material science and relates to a preparation method of a tungsten carbide-zirconia-alumina composite cutting tool material. In the invention, submicron-scale ZrO2 particles and nano-scale Al2O3 powder are added to the sub-micron-scale WC matrix, and the micro-scale VC and TaC particles are used as inhibitors. A new type of composite tool material with ZrO2 and Al2O3 as the matrix as the matrix. By adding submicron ZrO2 particles and nano-Al2O3, the high temperature stability and oxidation resistance of the WC matrix are improved. The composite tool material has high comprehensive mechanical properties, and its hardness, flexural strength, and fracture toughness can reach: 18GPa , 880MPa and 13MPa.m1 / 2.

Owner:SHANDONG UNIV

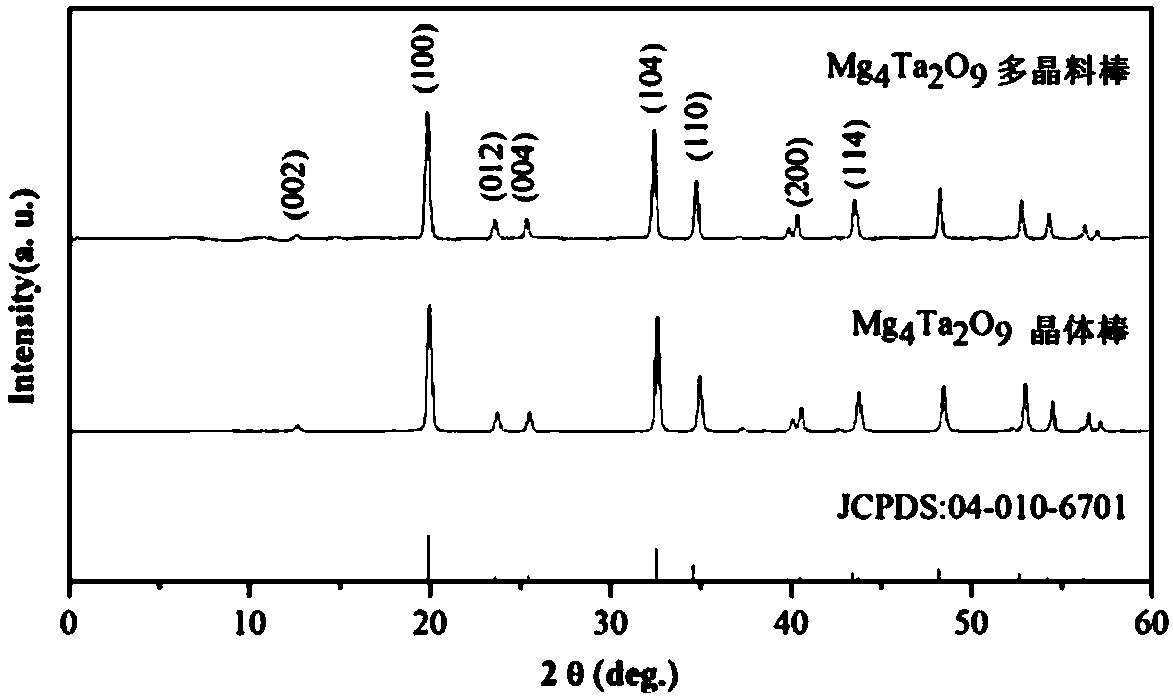

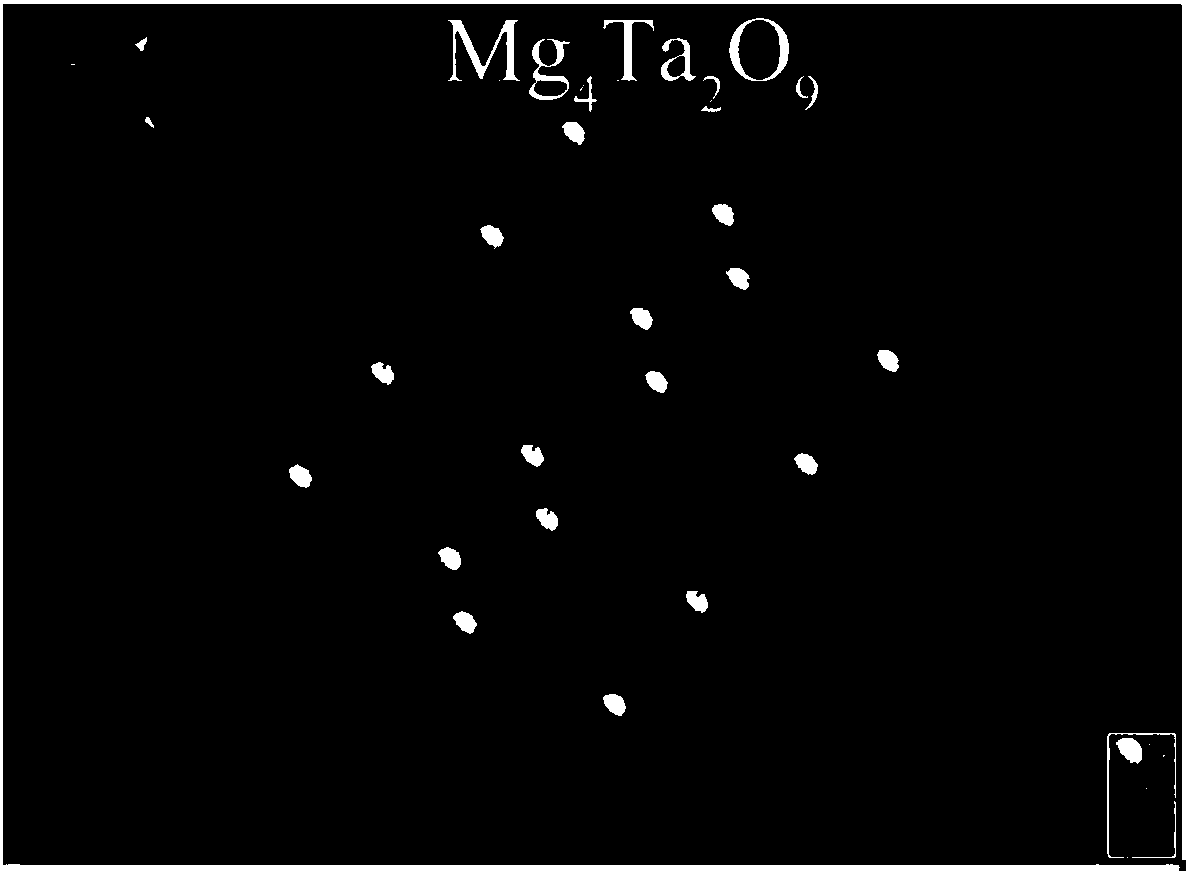

Intrinsic luminescent scintillation crystal magnesium tantalum oxide, and preparation method and use thereof

ActiveCN108221055AStable structureImprove flicker performancePolycrystalline material growthBy zone-melting liquidsHexagonal crystal systemScintillation crystals

The invention provides a scintillation crystal magnesium tantalum oxide. The chemical formula of the crystal is Mg4Ta2O9, the crystal belongs to a hexagonal crystal system and has an ilmenite structure, the scintillation light yield is 16000 photons / M eV, the decay time is 5 [mu]s, and the energy resolution is 6.2%. The invention also provides a use of the Mg4Ta2O9 as a scintillation crystal material, and a preparation method of the Mg4Ta2O9. The preparation method comprises the following steps: MgO and Ta2O5 which are used as initial powders are uniformly mixed according to a molar ratio of 4.04:1, and are processed to form a raw material rod, the raw material rod is pre-sintered to obtain a pure-phase, dense and uniform polycrystalline rod, and the colorless and transparent rod-shaped crystal having a size of phi 4 mm * L 62 mm grows by adopting an optical floating zone technology. The method has the advantages of stable melting zone, simplicity in operation, effectiveness in inhibition of the volatilization of MgO, and maintenance of uniform composition and stable crystal quality.

Owner:SHANGHAI INST OF TECH

Plasma arc overlaying alloy powder used for heat-working die

ActiveCN105081612AHigh deposition speedImprove productivityPlasma welding apparatusWelding/cutting media/materialsCrack resistanceOxidation resistant

The invention provides plasma arc overlaying alloy powder used for a heat-working die. The overlaying alloy powder is iron-base alloy powder; the raw material comprises, by mass, 1%-2% of nano chromium nitride powder and 2%-5% of yttrium oxide powder. By adding the nano chromium nitride powder into the iron-base alloy powder, fine nitride interstitial phases are formed in overlaying metal, and the overlaying metal is made to be good in toughness and crack resistance; meanwhile, the yttrium oxide is added into the alloy powder, so that the overlaying metal and glomeration inclusion are purified, nitride strengthening phases are promoted to form, and the fatigue resistance of the overlaying metal is improved. The heat-working die is repaired through the alloy power in combination with the plasma arc overlaying technique, the obtained overlaying metal is excellent in high-temperature oxidation resistance, abrasive resistance and cleanliness and is good in fatigue resistance.

Owner:SHANDONG UNIV

Metal powder cored wire specially used for hot-working die repair

ActiveCN105081610ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaElectrolysisHigh carbon

The invention provides a metal powder cored wire specially used for hot-working die repair. The metal powder cored wire comprises a wire pipe wall and powder wrapped by the wire pipe wall. The powder is composed of, by mass, 4-8 parts of electrolytic manganese, 2-6 parts of 45# silicon iron, 1-4 parts of ferrotitanium, 20-35 parts of chromium metal, 20-30 parts of high-carbon ferro-chrome, 0-5 parts of graphite, 2-6 parts of ferrovanadium, 12-18 parts of ferromolybdenum, 2-4 parts of tungsten powder, 4-8 parts of nickel powder, 1-2 parts of nanometer chromium nitride powder, 2-6 parts of yttrium oxide powder, 1-2 parts of potassium feldspar and 1-4 parts of sodium fluosilicate. The nanometer chromium nitride powder is added, fine nitride interstitial phases are formed in deposited metal, and therefore the deposited metal has good toughness and anti-cracking capacity; yttrium oxide is added to the alloy powder, the deposited metal is purified, inclusions are nodulized, a nitride strengthening phase is promoted to be formed, and the anti-fatigue performance of the deposited metal is improved. A hot-working die is repaired through a gas metal arc welding technology in which the metal powder cored wire is combined with full-argon gas shielding. The obtained deposited metal has excellent high-temperature oxidation performance, abrasion resistance and cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

Laser cladding alloy powder for repairing and remanufacturing hot-working die

ActiveCN105132913AHigh temperature hardnessGood toughness, crack resistanceMetallic material coating processesRare-earth elementYttrium

The invention provides laser cladding alloy powder for repairing and remanufacturing a hot-working die. In order to solve the problem that nickel-based or cobalt-based thermal spraying powder is expensive, iron-based alloy powder is adopted in the invention. While the iron-based alloy is formed through replacing pure iron with waste steel, the reutilization of the waste is realized. However, as the impurity content in the waste steel is high, the removal of phosphorous, carbon and sulphur is required in the refining process so as to obtain molten steel of which the components and temperature are qualified. The traditional method usually removes the impurities through slagging in the form of furnace slag, but has the problems of high heat energy requirement, large metal losses and serious splashing. In order to solve the problems, a traditional slag former is replaced by yttrium oxide, and waste steel impurities and glomeration inclusions are removed through the purifying functions of rare-earth elements. Meanwhile, deposited metal is endowed with excellent anti-fatigue performance.

Owner:SHANDONG UNIV

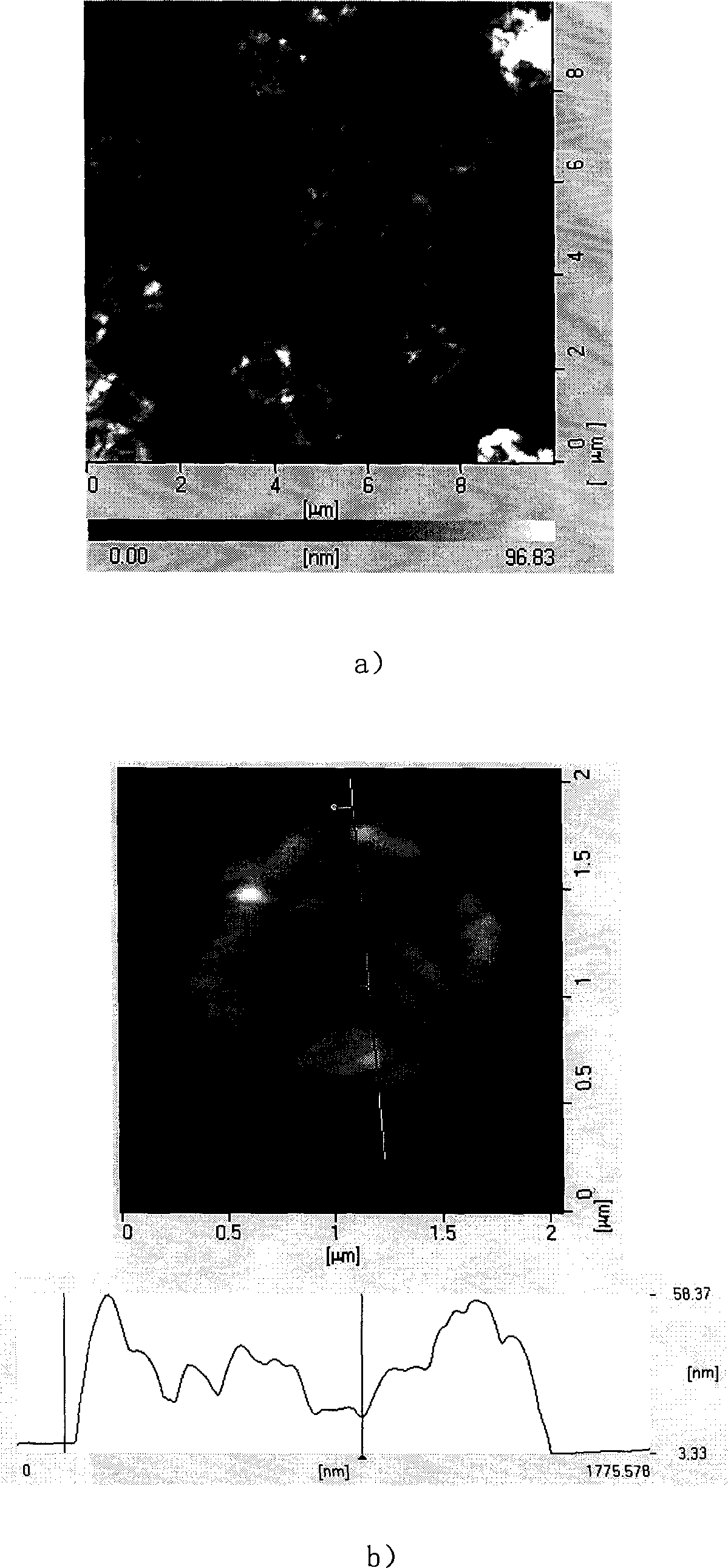

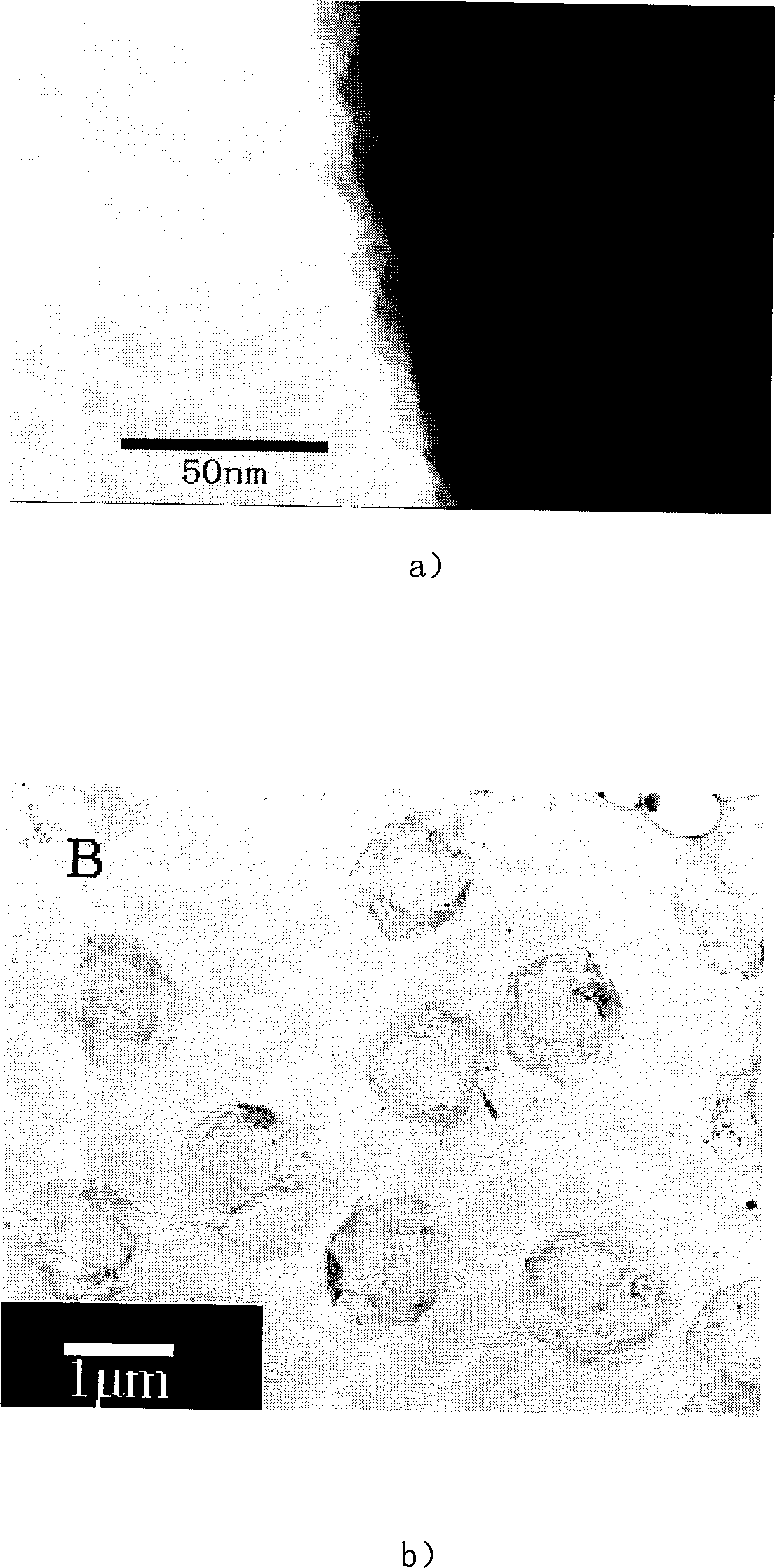

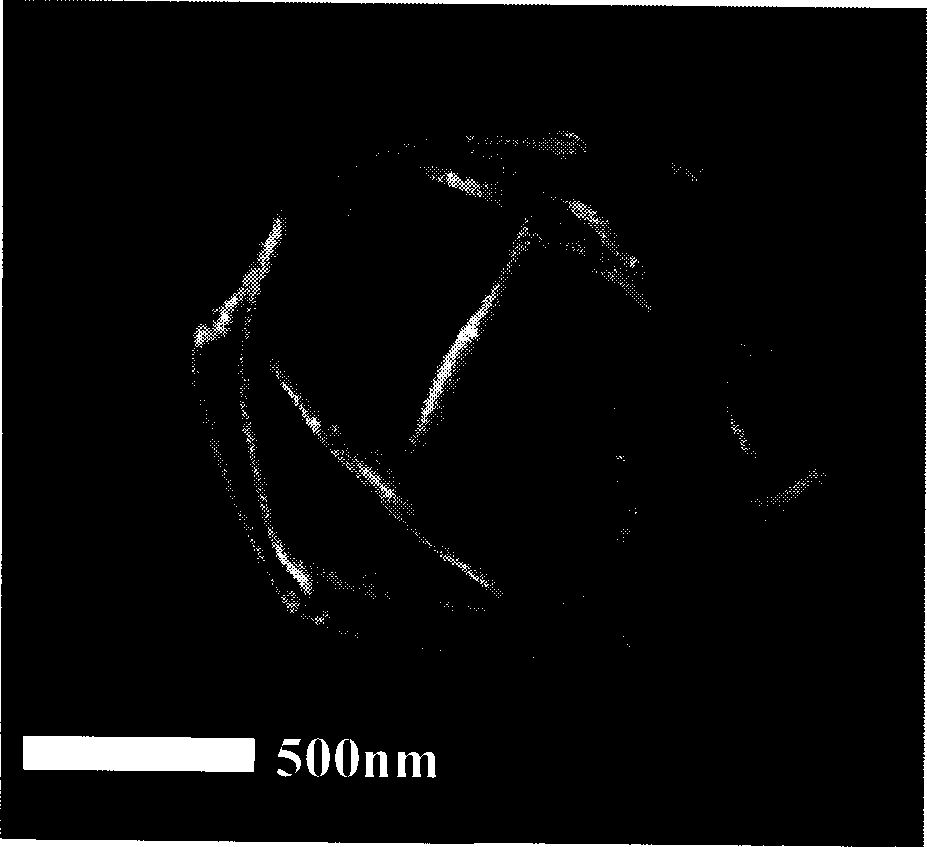

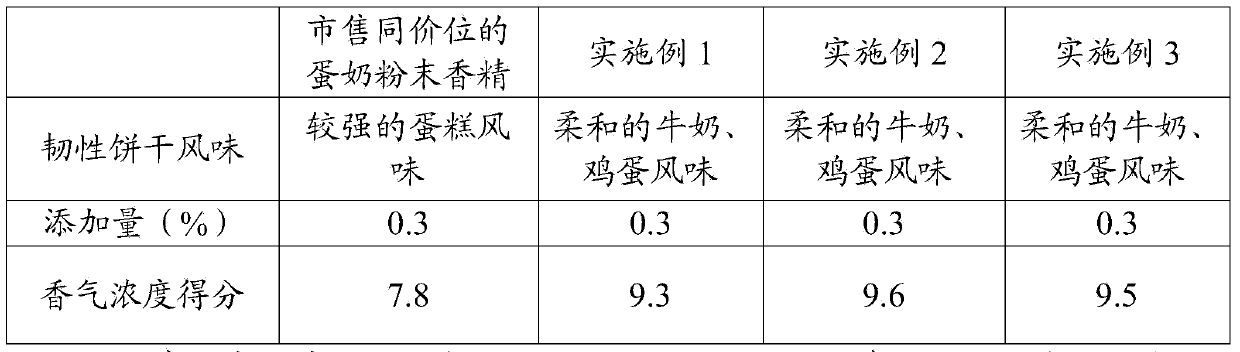

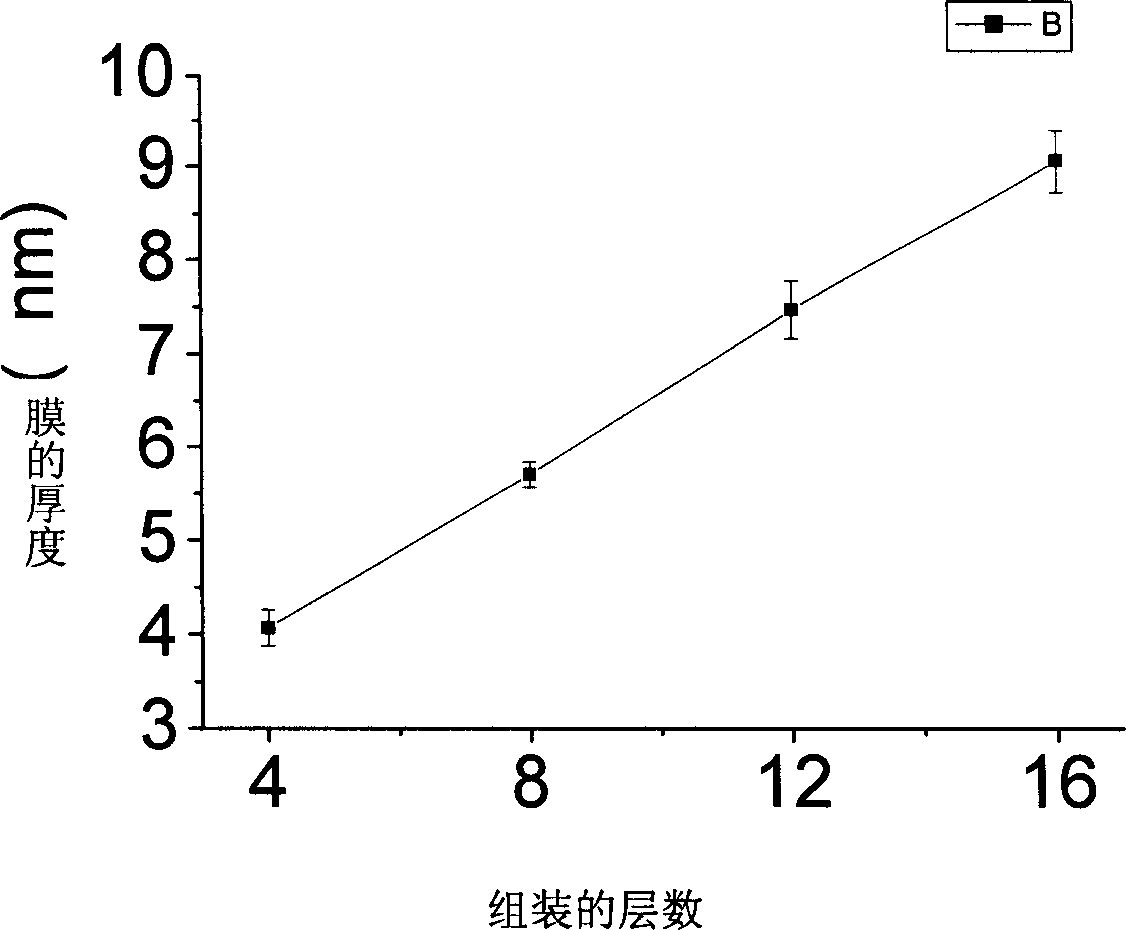

Layer-by-layer microcapsule assembling process based on mutual covalent action

InactiveCN1772365AQuick responseCapsular wall controllableMicroballoon preparationMicrocapsule preparationSilica particleHydrofluoric acid

The layer-by-layer microcapsule assembling process based on mutual covalent action includes: the reaction of two kinds of polymer on the surface of aminated silica grains to obtain super thin polymer film in multilayer structure; and subsequent eliminating inorganic grains with hydrofluoric acid to obtain hollow microcapsule with wall of covalent cross-linked multilayer film structure. The microcapsule thus obtained has the features of adjustable wall thickness of nanometer or submicron level, high strength, high stability and acid, alkali and salt corrosion resistance, and easy functionalization. The microcapsule may be used in medicine, dye, cosmetics, sensor and other fields.

Owner:ZHEJIANG UNIV

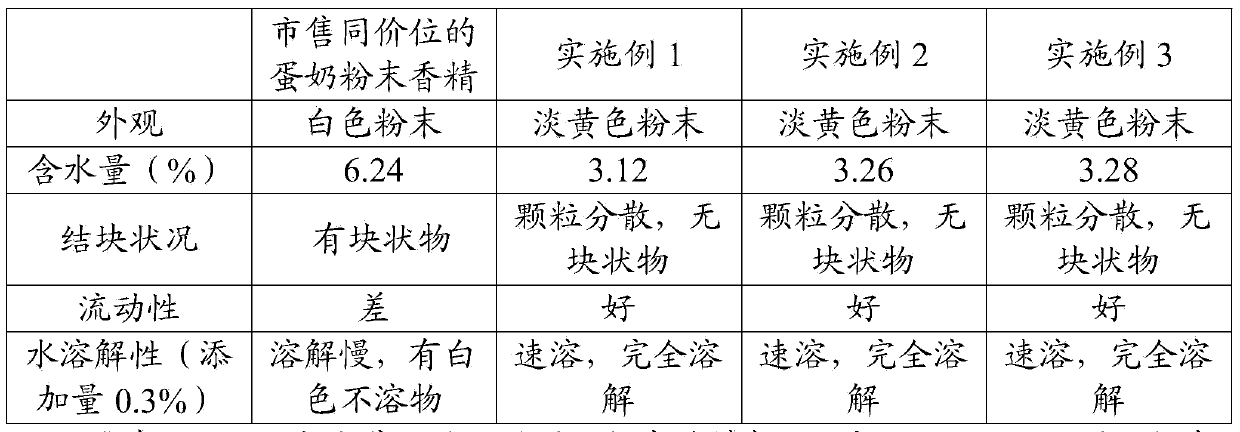

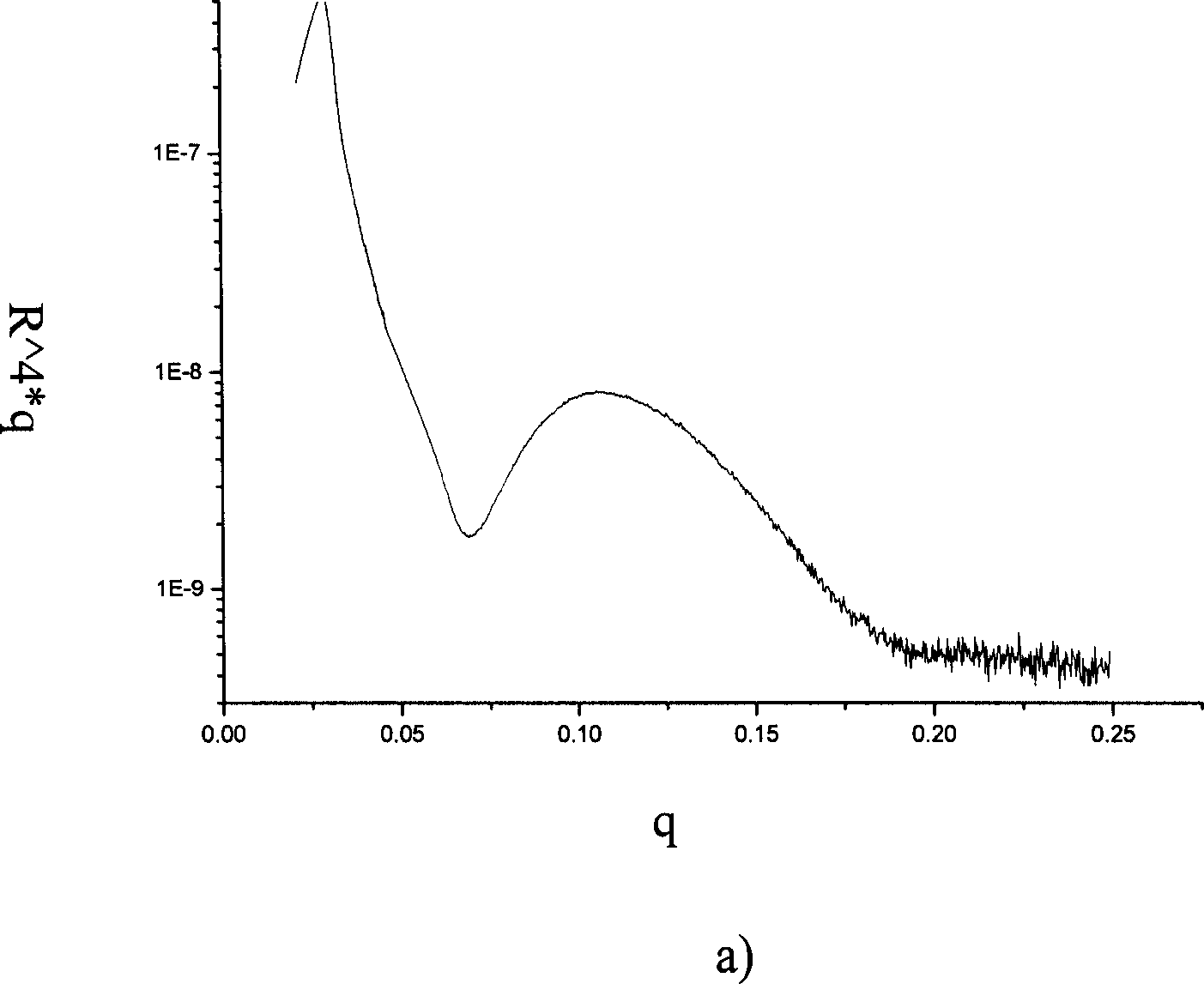

Egg-milk powder essence composition and preparation method thereof

ActiveCN104187546AImprove high temperature stabilityHigh nutritional valueFood preparationYolkPhospholipase

The invention discloses an egg-milk powder essence composition and a preparation method thereof. The egg-milk powder essence composition comprises the following components in parts by weight: 35-50 parts of enzymatic hydrolysate, 35-44 parts of maltodextrin, 4-6 parts of starch sodium octenylsuccinate, 1-3 parts of glucose powder, 0.2-0.4 part of sodium alginate, 0.1-0.3 part of sodium carboxymethylcellulose, 4-6 parts of an egg-milk essence base and 1.5-3.5 parts of palm oil, wherein the enzymatic hydrolysate is mainly prepared by the step of carrying out heating and enzymolysis on raw materials, wherein milk and egg pulp are used as the raw materials, and protease and phospholipase are used as catalysts. According to the egg-milk powder essence composition, flavors of the milk, egg white and egg yolk are naturally and realistically integrated; meanwhile, the egg-milk powder essence composition has excellent high temperature resistance and can be used for directly perfuming baking foods, candies, milk products and leisure foods so as to enable the baking foods, candies, milk products and leisure foods to have the egg-milk flavor.

Owner:GUANGZHOU FLOWER FLAVOURS & FRAGRANCES

Covalent layer-by-layer self-assembling process for constructing polymer film on planar substrate

InactiveCN1772797AQuick responseOptimal Control StructureLamination ancillary operationsSynthetic resin layered productsEpoxyPolymer science

The covalent layer-by-layer self-assembling process for constructing polymer film on planar substrate includes the first reaction of the substrate of surface aminated quartz or silicon chip and polymer with side radical containing epoxy group to form one layer of nanometer superthin film on the substrate by means of covalent bond; the subsequent reaction to polymer with side radical containing amino group to form one other layer of nanometer superthin film; and repeating the reaction with these two kinds of polymer solution to form superthin polymer film in multilayer structure, with each of the layers possessing thickness capable of being regulated in subnanometer level. The present invention has the features of simple technological process, adjustable film thickness, easy functionalizing, acid, base and organic solvent resistance of the film, high stability, etc. and is expected to find application in electronics, medicine, chemical and other fields.

Owner:ZHEJIANG UNIV

Light colour cementitous material for road and its preparation method

InactiveCN1478843AImprove plasticizing effectRaw materials are easy to obtainTemporary pavingsAdhesivesRoad surfacePolyresin

Owner:SOUTH CHINA UNIV OF TECH

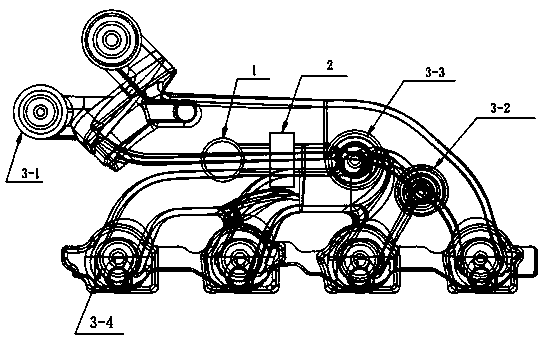

Pure crystalline acne-removing amino acid face cleansing cream and preparation method thereof

ActiveCN107260609ALower crystallization temperatureGood moisturizing effectCosmetic preparationsToilet preparationsFlavorSURFACTANT BLEND

The invention discloses pure crystalline acne-removing amino acid face cleansing cream and a preparation method thereof. The mild easy-to-spread-and-use pure crystalline acne-removing amino acid face cleansing cream is prepared from the following raw materials by mass: 1) 15-40% of a surfactant which is a mixture of two or more than two of an anionic surfactant, a zwitterionic surfactant and a nonionic surfactant, 2) 5-30% of a moisturizing agent, 3) 1-8% of a conditioner, 4) 1-15% of an anti acne composition, 5) 0.1-0.5% of flavor and 6) balance of deionized water. The product has the advantages of stable quality, easy spreading and use, weak acidity, mildness and strong cleaning power. After the pure crystalline acne-removing amino acid face cleansing cream is used, face is clean, not dry and not tight, and the use feeling after use of the product is greatly improved.

Owner:GUANGZHOU OUSIA IND CO LTD

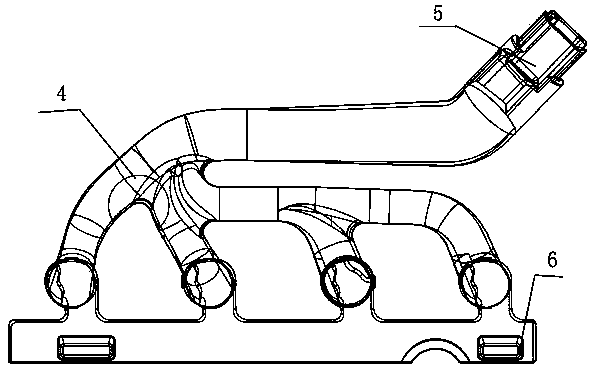

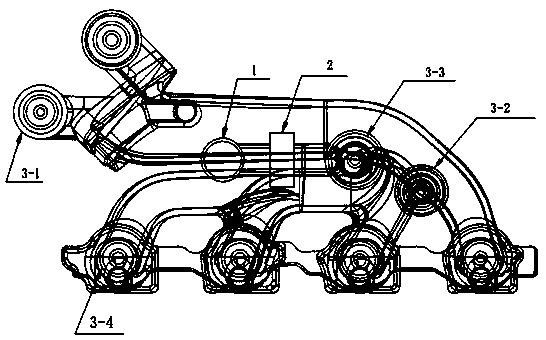

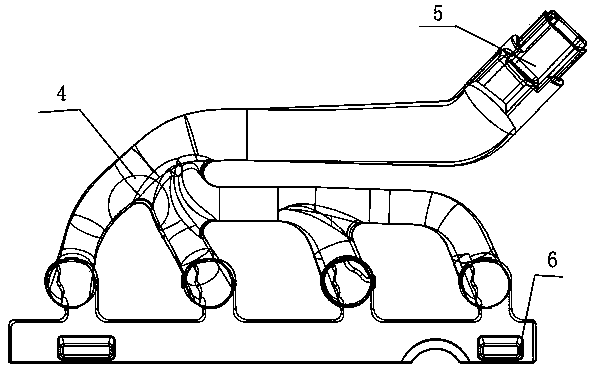

Thick-wall cast steel exhaust manifold casting process

ActiveCN108655348AReality GuaranteeComplex structureFoundry mouldsFoundry coresPass rateCasting mold

The invention discloses a thick-wall cast steel exhaust manifold casting process and belongs to the technical field of exhaust manifold casting. According to the thick-wall cast steel exhaust manifoldcasting process, a thick-wall cast steel exhaust manifold casting mold and method are included. The casting mold comprises a sand mold, feeder heads, a sand core and a pouring system. The sand core is provided with multiple sand jetting openings. The pouring system comprises a sprue bar, a cross gate and an ingate. The sprue bar communicates with the cross gate in a perpendicular manner. A filteris arranged in the middle of the cross gate. The feeder heads comprise the large-face feeder heads, the triangular flange feeder heads, the fire inlet feeder head and the heat preservation feeder head. The fire inlet feeder head is arranged at the tail end of the cross gate. The thick-wall cast steel exhaust manifold casting process is good in mechanical performance, uniform in wall thickness andresistant to high temperature. The thick-wall cast steel exhaust manifold casting mold and method are included. The wall thickness of a casting ranges from 5.5 mm to 6.5 mm, and the weight ranges from 8 Kg to 12 Kg. Technical requirements are met; performance is stable; the problem that molding is difficult to achieve when common casting processes are adopted is solved; and the qualification rateof products is high.

Owner:NANYANG FEILONG AUTOMOBILE PARTS CO LTD

Preparation method of zirconium manganese doped hexa- aluminate catalyzer

InactiveCN101108340ASimple processLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminateIsobutanol

The invention discloses a preparation method of manganese zirconium mixing hexaaluminate catalysts, which mixes and stirs cyclohexane, Isobutanol, OP-10 emulsifier and water according certain volume ratio to prepare reverse microemulsion system; the invention adopts zirconium nitrate, manganous nitrate, aluminium nitrate and carbowax as material to mix and dissolve in deionized water, add into the prepared reverse microemulsion system, drip urea and ammonia precipitant according to certain volume ratio, to produce lodgment; prepare catalyst forequarter by high pressure kettle critical drying agent, manganese zirconium mixing hexaaluminate catalyst of good dispersing, less block and of platy shape is ahcieved after being baked in muffle furnace; the preparation method has simple technics, low cost, small size of crystal grain and stable high temperature.

Owner:GUANGDONG UNIV OF TECH

Novel highly effective heat-insulating material and preparation method thereof

InactiveCN101200629AGood plasticity at low temperatureImprove insulation effectOther chemical processesChemical industryMetallurgyRefrigeration

Novel efficient heat preservation material and a preparation method thereof relate to the fields of steel metallurgy, refrigeration, construction etc and concretely relate to novel heat preservation material and a preparation method thereof. The present invention is that 10 to 30 portions of inorganic nanometer materials, 20 to 40 portions of organic macromolecular latex, 10 to 20 portions of the materials with low thermal conductivity coefficient, 5 to 8 portions of anti-cracking agent, 1 to 5 portions of high temperature reinforcing agent, 0.1 to 2 portions of thickening agent, 0.01 to 1 portion of defoaming agent, 2 to 10 portions of film-forming additive, 0.05 to 3 portions of wetting dispersant and 10 to 20 portions of water are mixed to be made into a prepared material. The present invention has the characteristics of good low-temperature plasticity, high temperature stability, convenient use, good heat preservation performance and long service life.

Owner:HONGQI FURNACE CHARGE HENAN

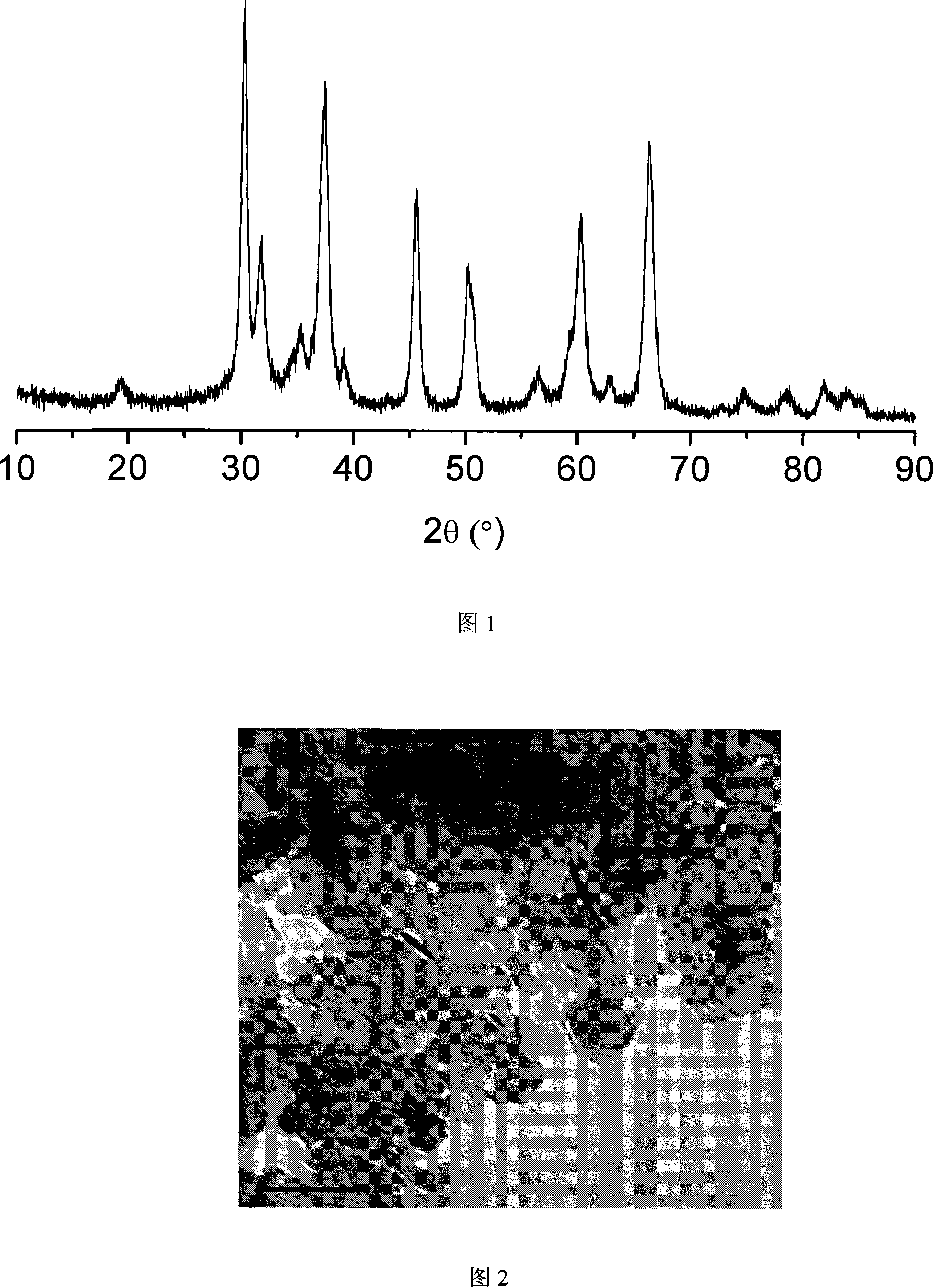

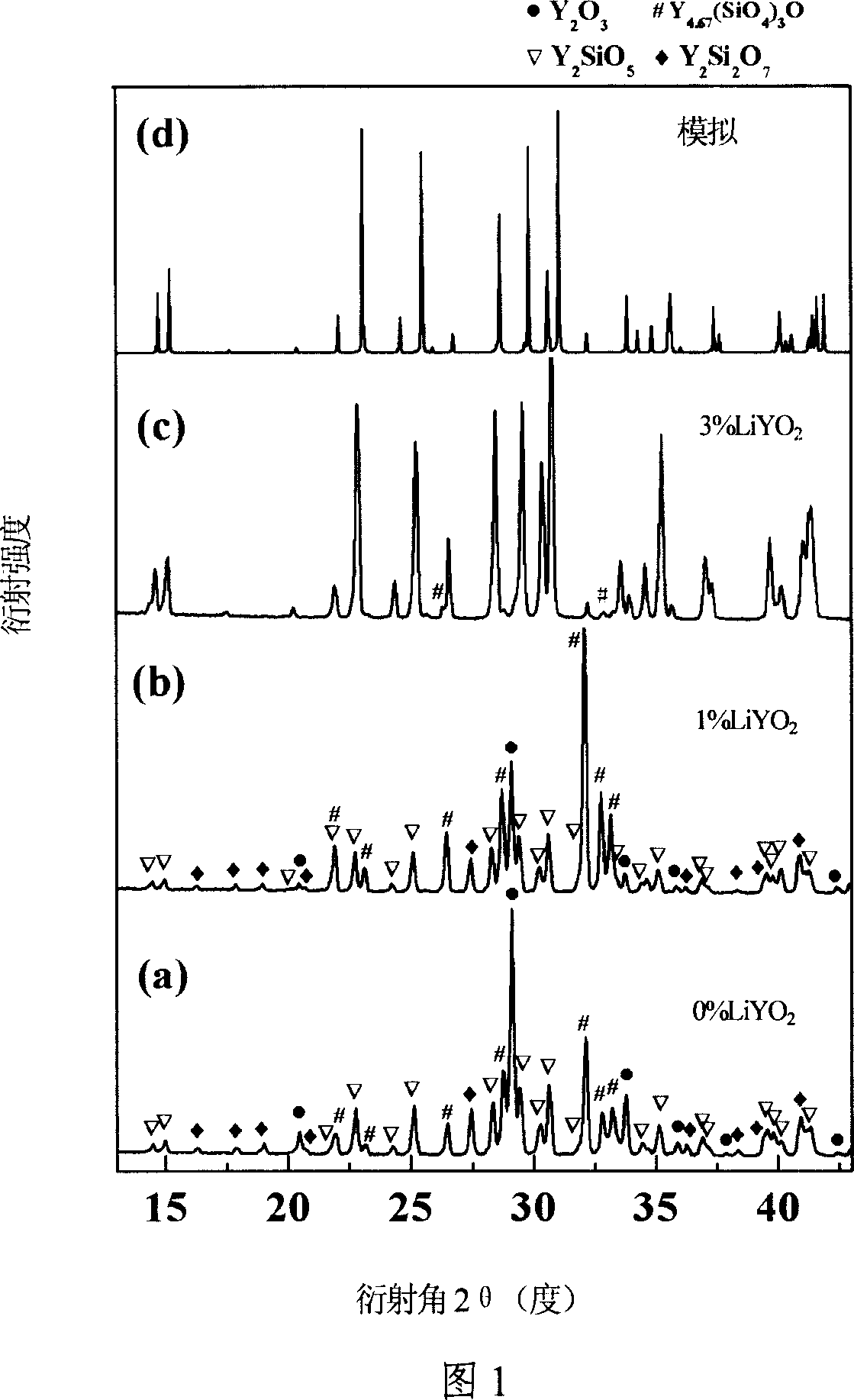

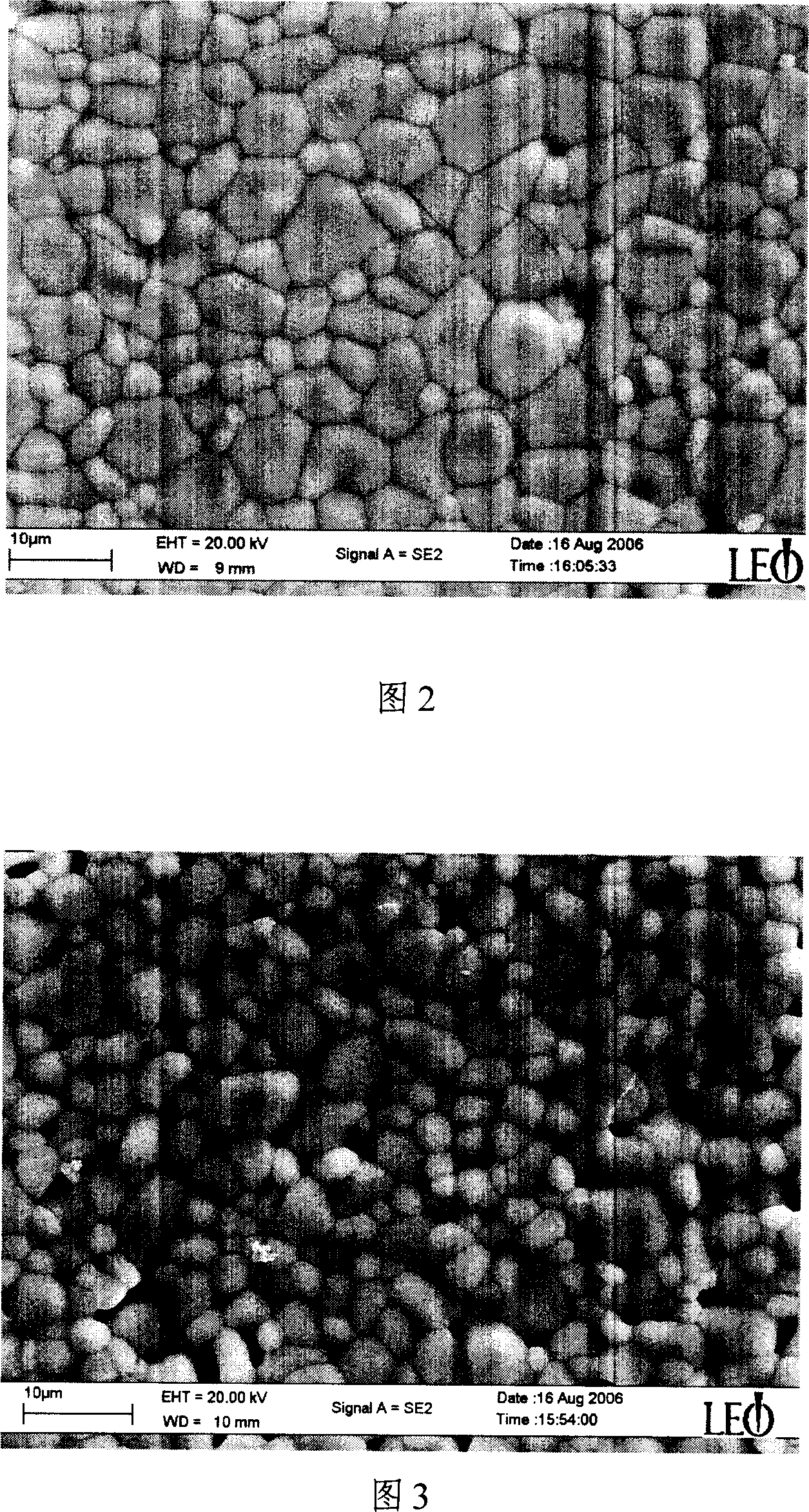

Method for preparing massive compact high-pure single-phase Y2SiO5 ceramic block material at low temperature

InactiveCN101143782ASynthesis temperature is lowHigh purityManufacturing technologyOxidation resistant

The invention relates to a manufacturing technology of novel highly pure Y2SiO5 ceramic material, in particular to a manufacturing method for a highly pure massive and compact single-phase Y2SiO5 ceramic material. A LiYO2 additive is added into the mixed raw materials of Y2O3 and SiO2 in a proportion of 0.2-10.0 percent that of total weight of Y2O3< / SUB, SIO2 and LiYO2. Following a homogenous mixing, the mixture then go through sintering treatment at a temperature between 1250 DEG C and 1600 DEG C for 1-5 hours to obtain highly pure single-phase Y2SiO5 powder. The powder is ground then to obtain ultrafine powder and the ultrafine powder is allowed to be fed into high-strength steel moulds for single-phase cooling and isostatic cool pressing to obtain green compact with a relative density of 45-65 percent. Finally the green compact can be sintered in a high temperature combustion furnace or an oxygen furnace at a temperature between 1100 DEG C and 1600 DEG C for 0.5-2.5 hours to get finished product with a 85-100 percent density that of a theoretical density. The invention allows manufacturing highly pure massive and compact single-phase Y2SiO5 ceramic material under relatively low temperature conditions and the product can be used as a high temperature sintered material, an oxidation resistant protective coating etc,, which has a substantial market potential in aeronautic and astronautic fields.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

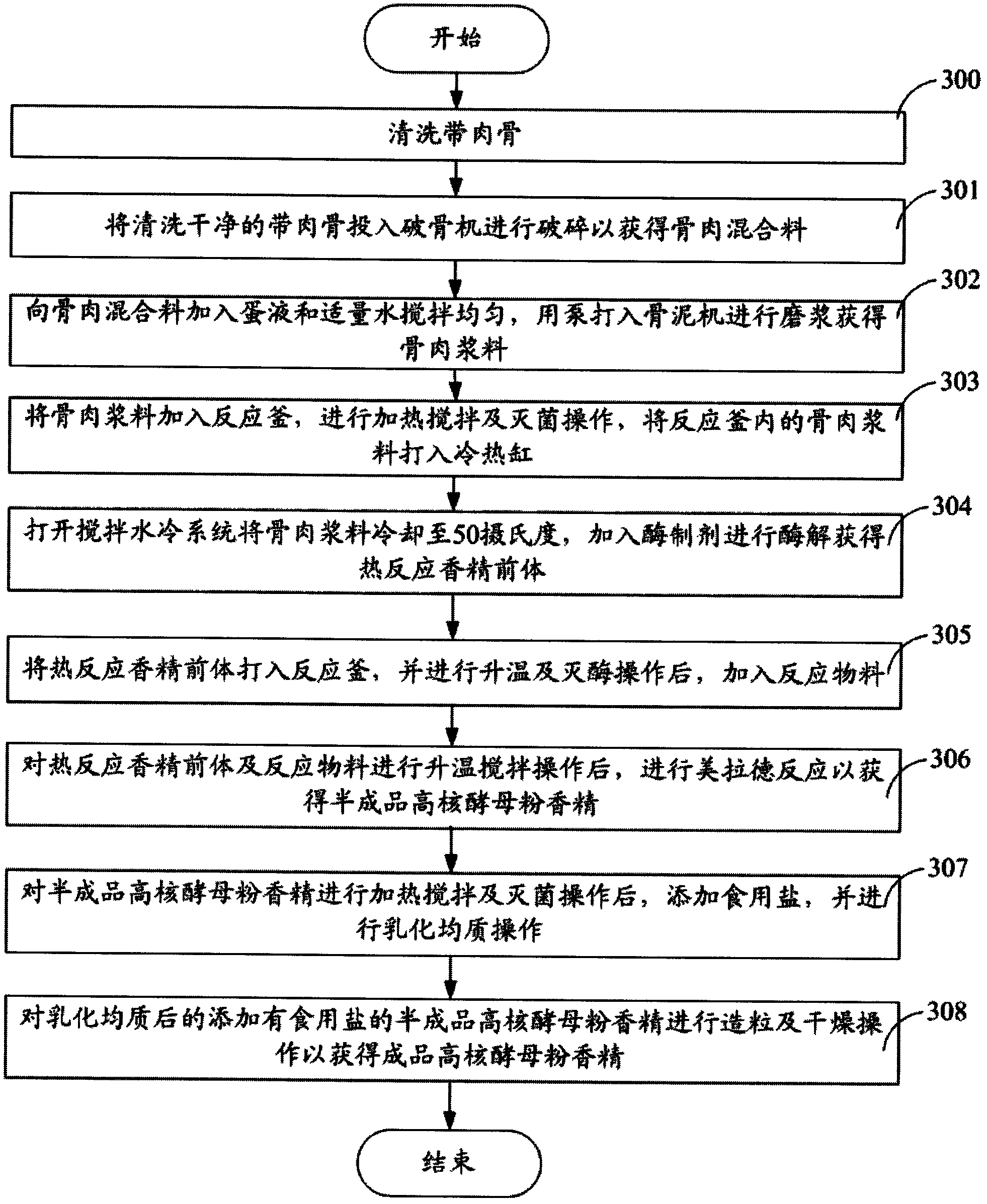

Preparation method of high-nuclear yeast powder essence

The invention relates to a preparation method of high-nuclear yeast powder essence, which comprises the following steps that: bone with meat is cleaned; the cleaned bone with meat is put into a bone breaking machine, and bone and meat mixture is obtained; egg cream and water are added into the bone and meat mixture to be stirred uniformly, the mixture is fed into a bone mill to be pulped, and bone and meat sauce is obtained; the bone and meat sauce is added into a reaction vessel to be heated, stirred and sterilized, and the bone and meat sauce in the reaction vessel is fed into a cooling and heating jar; a stirring water-cooled system is turned on to cool the bone and meat sauce to be 50DEG C, enzyme preparation is added in, enzymatic hydrolysis is carried out, and a thermal reaction essence precursor is obtained; the thermal reaction essence precursor is fed into the reaction vessel, heated, inactivated and added with reaction materials; the thermal reaction essence precursor and the reaction materials are heated and stirred, Maillard reaction is carried out, and semi-finished high-nuclear yeast powder essence is obtained; and the semi-finished high-nuclear yeast powder essence is heated, stirred, sterilized, added with edible salt, emulsified, homogenated, granulated and dried, and finished high-nuclear yeast powder essence is obtained.

Owner:NINGXIA JINDAO FOOD

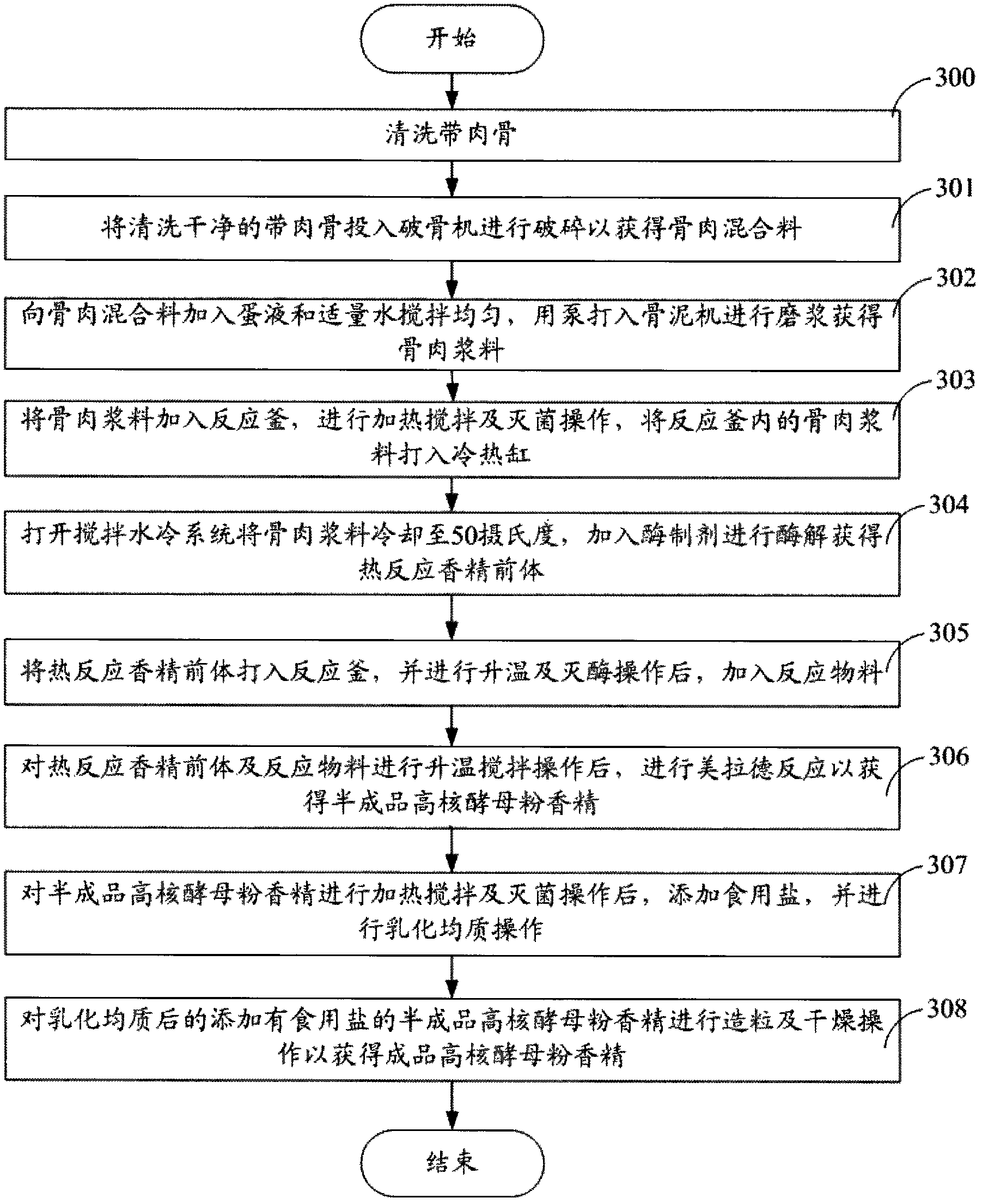

Environment-friendly nano antifouling algicide and preparation method thereof

InactiveCN106797955AReduce manufacturing costLow toxicityBiocideDead animal preservationWater basedWater source

The embodiment of the invention discloses an environment-friendly nano antifouling algicide and a preparation method thereof. The environment-friendly nano antifouling algicide is prepared from the following raw materials by mass percent: 5 to 10 percent of water-based nano silver dispersoid size, 10 to 20 percent of 4,5-dichloro-N-octyl-4-isothiazoline-3-one, 5 to 10 percent of 2-octyl-4-isothiazoline-3-one, 5 to 10 percent of benzimidazole, 3 to 5 percent of emulsifier, 5 to 8 percent of antifreeze, 1 to 3 percent of penetrant, 1 to 3 percent of amine neutralizer, 1 to 3 percent of thickener, 5 to 10 percent of solubilizing stabilizer, 5 to 10 percent of synergist, 5 to 8 percent of ethanol and 20 to 30 percent of deionized water. The environment-friendly nano antifouling algicide and the preparation method thereof disclosed by the invention have the characteristics of low manufacturing cost, low toxicity, safety for water source and environment, and are of great significance for saving energy, protecting the environment and creating a harmonious relationship between human and nature.

Owner:上海鹏图抗菌新材料有限公司

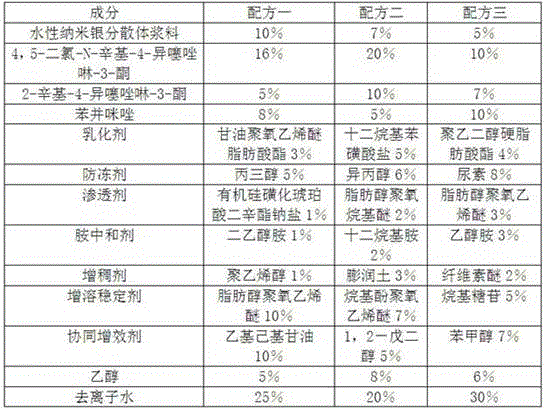

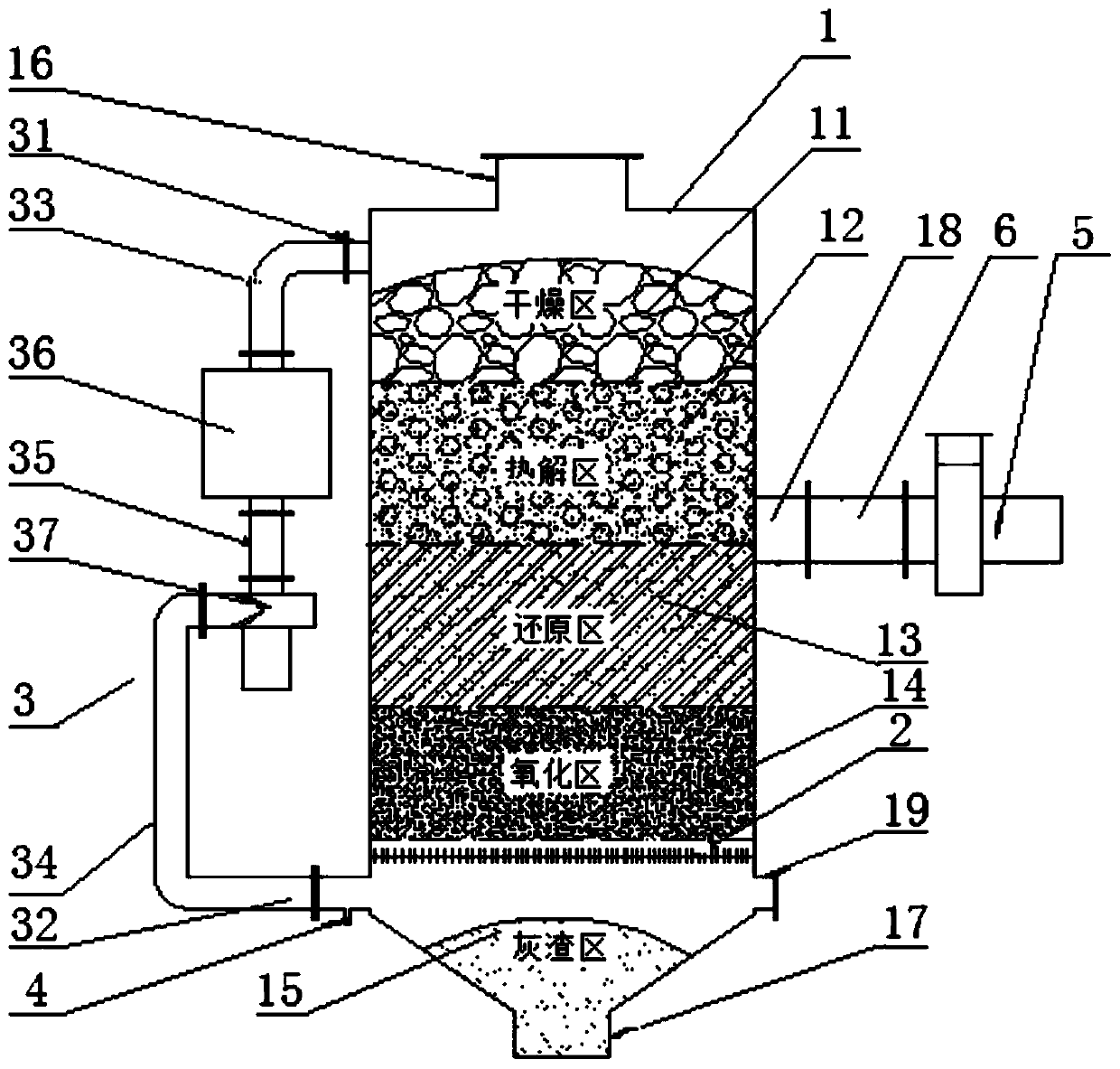

Domestic waste gasification device and process

InactiveCN109705923AEliminate exhaust gasIncrease heatGranular/pulverulent flues gasificationSlagProcess engineering

The invention relates to the technical field of humidity regulation, more particularly to a domestic waste gasification device and a process. The domestic waste gasification device comprises a gasification furnace; a material inlet is arranged at that top of the gasification furnace, an ash-slag outlet is arranged at the bottom of the gasification furnace, a gasification gas outlet is arranged atthe side wall of the gasification furnace, and domestic garbage enters a drying zone, a pyrolysis zone, a reduction zone and an oxidation zone in turn for treatment, so that the obtained ash-slag is discharged through the ash-slag outlet and the obtained gasification gas is discharged through the gasification gas outlet; a fire grate is arranged at the junction of the oxidation zone and the ash-slag zone, a backdraft device for drying and filtering the gas is communicated between the drying zone and the ash-slag zone, the backdraft device is provided with a backdraft suction port communicatingwith the drying zone and a backdraft air outlet communicating with the ash-slag zone, the backdraft air outlet is arranged below the grate, and an igniter is arranged besides the side of the backdraft air outlet. The invention extracts the mixed gas at the top of the gasification furnace, dries and removes water vapor, thereby facilitating the continuous gasification reaction of the gasificationfurnace; the gasified gas after filtration and purification is ignited and then enters the furnace to effectively avoid the deflagration phenomenon.

Owner:GUANGDONG UNIV OF TECH

Composite protection structure for channel

InactiveCN101100845AEasy constructionImprove construction progressCoastlines protectionArtificial water canalsWear resistanceMaterials science

A ditch protection structure includes a bottom anti-leaking layer of clay or film, a middle layer of sand and gravel, a top layer of modified concrete of multi holes. The modified concrete contents in weight of 200-500 lot cement, 1000-1800 lot gravel of particle size of 5-80mm, 100-180 lot water and modify agent in a content of 2%-30% of water. The structure could be paved by paving machine for large area and is of low shrink index, anti-break under low temperature and stable under high temperature, good impact and wear resistance.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

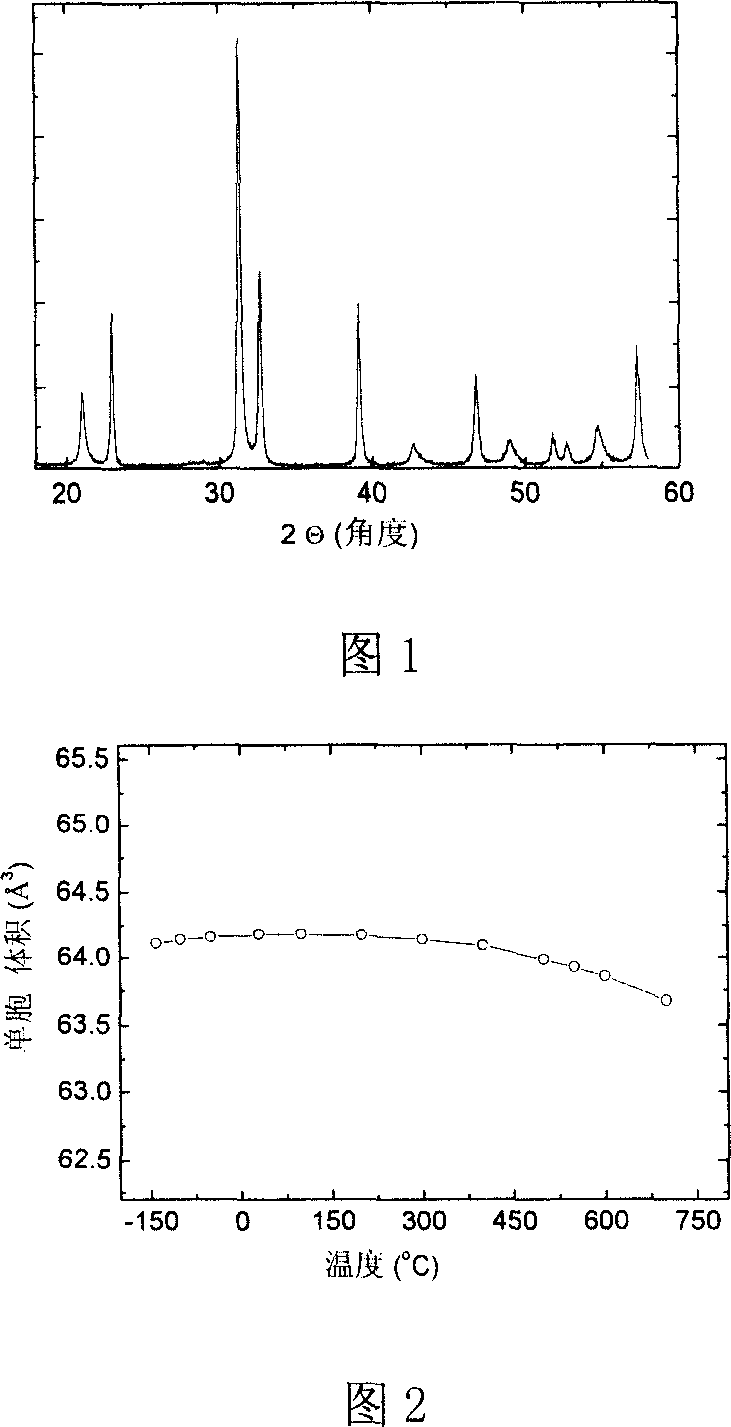

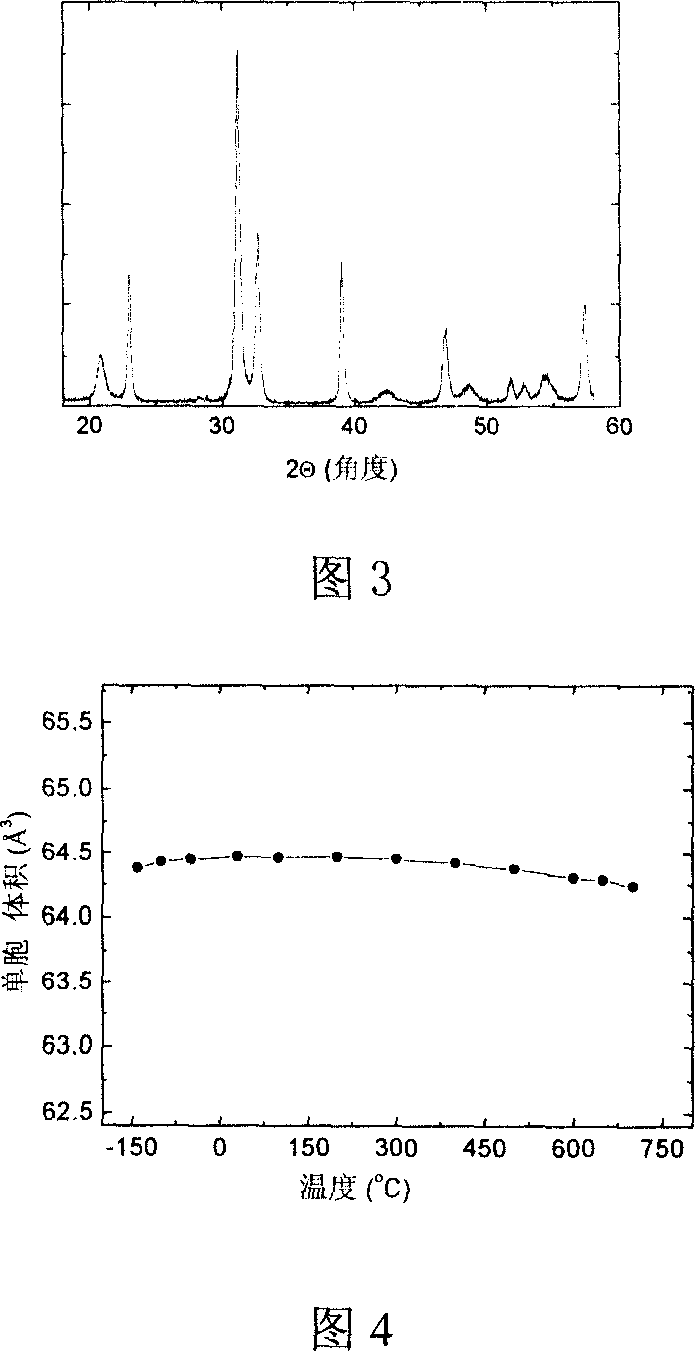

Zero-expansion material

This invention relates to a not expanding material used at minus 140 to 700 deg, belongs to non-metal material region. The invention takes PbO, TiO2, Bi2O3, Fe2O3 and ZnO as precursor, utilize high temperature solid phase method to prepare ( 1 - X - Y) PbTiO3 - xBiFeO3 - yBi ( Zn1 / 2Ti1 / 2) O3 powder body, require the X is not less than 0.0 and not greater than 0.2, and Y is not less than 0.0 and not greater than 0.4; accordingly weigh the PbO, TiO2, Bi2O3, Fe2O3, and ZnO, then ball mill in ethanol solution for 1 to 48 hours for intensive mixing, drying and squashing to make sheet, calcining at 700 to 1300 deg for 1 to 24 hours, the offspring after calcining ball mill at ethanol solution for 1 to 48 hours, then drying again and squashing for sheet, calcining at 800 to 1300 deg for 1 to 48 hours, cooling, the finished product after grinding is zero expanding material PbTiO3 - BiFeO3 - Bi ( Zn1 / 2Ti1 / 2) O3.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of high-temperature-softening-resistant, high-strength and high-conductivity copper-based composite material molded part

ActiveCN114293051AEvenly distributedRaise the high temperature softening temperatureMaterial nanotechnologyTungsten/molybdenum carbideCarbonizationMolybdenum carbide

The invention relates to the field of powder metallurgy, in particular to a preparation method of a high-temperature-softening-resistant high-strength high-conductivity copper-based composite material molded part, which comprises the steps of precursor powder preparation, nano molybdenum carbide-copper composite powder preparation, green body forming and combined densification. Nano molybdenum carbide particle reinforced copper-based composite powder is prepared through a co-precipitation-co-reduction-selective carbonization process, a composite material blank is prepared through a cold isostatic pressing forming process, and a copper-based composite material forming part with high strength, high conductivity, high wear resistance and high softening temperature is obtained after high-temperature sintering and deformation machining combined densification. The nanoscale molybdenum carbide particles in the copper-based composite material are stable at high temperature, can hinder dislocation movement at room temperature and high temperature, are remarkable in dispersion strengthening effect, have small influences on the electric conduction and heat conduction performance of the material and are excellent in comprehensive performance, and the copper-based composite material has important application prospects in the fields of heat dissipation grooves, electric resistance welding electrodes, nuclear reactor high-temperature-resistant high-heat-conduction components and the like.

Owner:北京科大京都高新技术有限公司

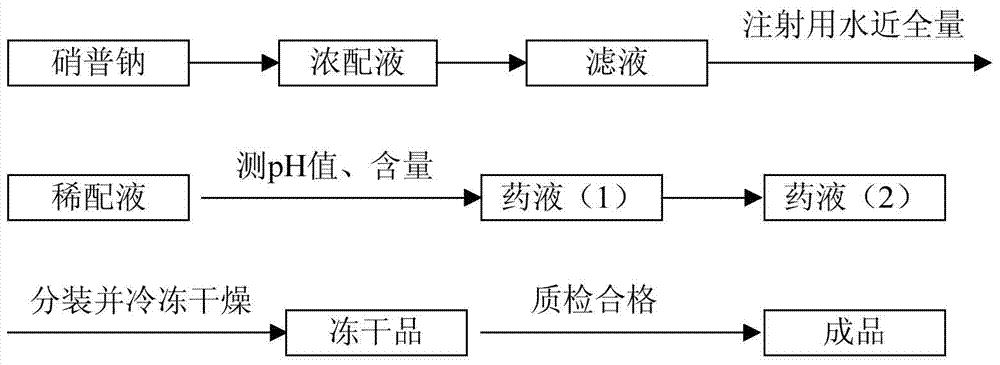

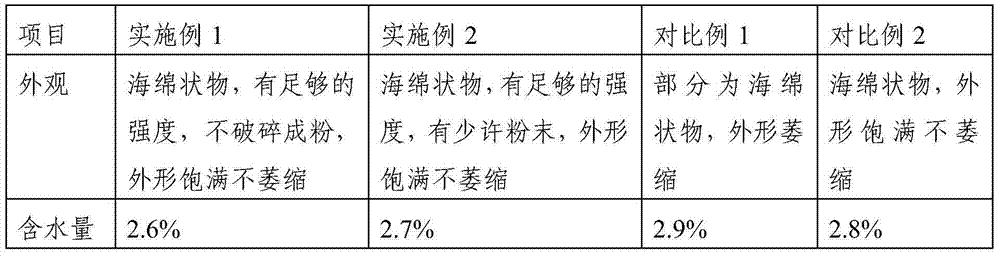

Preparation method of sodium nitroprusside injection

InactiveCN103768096AUniform escapeBlock strong hygroscopicityHeavy metal active ingredientsPowder deliveryActivated carbonPenicillin

The invention provides a preparation method of sodium nitroprusside injection. The preparation method comprises the following steps: (1) accurately weighing sodium nitroprusside according to a mass volume ratio of each 50g of sodium nitroprusside: added water for injection enabling a solution to reach 100mL, adding the water for injection to the sodium nitroprusside so as to dissolve the sodium nitroprusside into a 20%-30% concentrated solution, adding 0.1-0.2% of activated carbon, stirring for 15-25 minutes, and carrying out coarse filtration so as to remove carbon; (2) supplementing the water for injection, and then carrying out refined filtration by using a filtering membrane; and (3) respectively filling the solution subjected to refined filtration into sterile penicillin bottles, partially stoppering, putting in freeze-drying equipment, and carrying out freeze-drying according to a freeze-drying curve. The preparation method has the advantages that proper temperature, pressure and heating rate are adopted in a preparation process, the intense moisture absorption of an inner loose structure of the product is avoided, the product is prevented from absorbing moisture again after being dried, the occurrence of the shrunk product is reduced, and the percent of pass is increased; and additives for improving surface activity do not need to be added, the risk caused by impurity introduction is reduced, and the production efficiency is improved.

Owner:YOUCARE PHARMA GROUP

Compact forsterite fire-resistant raw material and preparation method thereof

InactiveCN103044043AWide variety of sourcesReduce manufacturing costPhysical chemistryMixed materials

The invention relates to a compact forsterite fire-resistant raw material and a preparation method of the compact forsterite fire-resistant raw material. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: mixing 69wt%-85wt% of talcum powder, 13wt%-30wt% of fine powder of magnesian raw material, and 0.2wt%-2wt% of an additive to prepare a mixed material; then adding 1wt%-10wt% of a bonding agent relative to the mixed material, and ball-milling the mixed material and the bonding agent in a ball mill for 1-3 hours to prepare a ball-milled material; then adding 3wt%-10wt% of water relative to the ball-milled material in the ball-milled material, stirring for 10-30min, forming a blank body by pressing and drying; and finally calcining the dried blank body at 1350-1650 DEG C, keeping the temperature for 1-3 hours, and then obtaining the compact forsterite fire-resistant raw material. The compact forsterite fire-resistant raw material disclosed by the invention has the characteristics of being low-cost in production and easy to sinter, and the prepared compact forsterite fire-resistant raw material has large volume density, low porosity and stable high temperature property.

Owner:WUHAN UNIV OF SCI & TECH

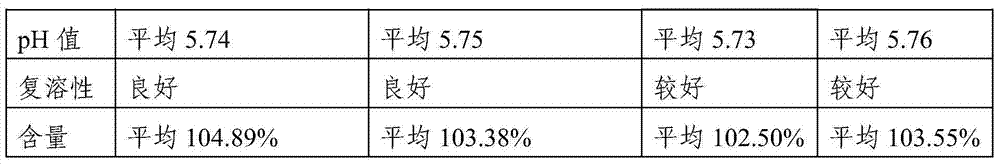

Method for preparing diamond coating on surface of cobalt-containing hard alloy and tool and die with diamond coating

ActiveCN111041448AImprove uniformity of implantationImprove the "mosaic" effectVacuum evaporation coatingSputtering coatingThermal dilatationHigh density

The invention relates to a method for preparing a diamond coating on the surface of cobalt-containing hard alloy and a tool and mold with a diamond coating. According to the invention, the surface ofa sample is subjected to sand blasting and cleaning treatment, an ideal basis is provided for high density and homogenization of diamond particles in an ultrasonic grinding and crystal planting stageand a mechanical riveting 'inlaying' effect of a grown diamond coating, the crystal planting uniformity and the 'inlaying' effect are improved, a ternary nitride coating with high aluminum content isselected as an insertion layer, the insertion layer is stable at high temperature, does not react with a surrounding medium, and has almost zero solid solubility to cobalt, the coefficient of thermalexpansion of the insertion layer is between the coefficient of thermal expansion of the diamond coating and the coefficient of thermal expansion of a hard alloy matrix, a cobalt element in the hard alloy matrix can be effectively prevented from diffusing outwards, the nucleation interface strength of the diamond coating and the quality of the diamond coating are improved, and therefore the film-substrate binding force of the diamond coating and the quality of the diamond coating are effectively improved.

Owner:CONPROFE TECH GRP CO LTD +2

A Casting Process of Thick-walled Cast Steel Exhaust Manifold

The invention discloses a thick-wall cast steel exhaust manifold casting process and belongs to the technical field of exhaust manifold casting. According to the thick-wall cast steel exhaust manifoldcasting process, a thick-wall cast steel exhaust manifold casting mold and method are included. The casting mold comprises a sand mold, feeder heads, a sand core and a pouring system. The sand core is provided with multiple sand jetting openings. The pouring system comprises a sprue bar, a cross gate and an ingate. The sprue bar communicates with the cross gate in a perpendicular manner. A filteris arranged in the middle of the cross gate. The feeder heads comprise the large-face feeder heads, the triangular flange feeder heads, the fire inlet feeder head and the heat preservation feeder head. The fire inlet feeder head is arranged at the tail end of the cross gate. The thick-wall cast steel exhaust manifold casting process is good in mechanical performance, uniform in wall thickness andresistant to high temperature. The thick-wall cast steel exhaust manifold casting mold and method are included. The wall thickness of a casting ranges from 5.5 mm to 6.5 mm, and the weight ranges from 8 Kg to 12 Kg. Technical requirements are met; performance is stable; the problem that molding is difficult to achieve when common casting processes are adopted is solved; and the qualification rateof products is high.

Owner:NANYANG FEILONG AUTOMOBILE PARTS CO LTD

Preparation method for titanium-coated ternary cathode material

ActiveCN107204456AStable charge and discharge cycleStable at high temperatureCell electrodesLithium chlorideTitanium nitride

The invention discloses a preparation method for a titanium-coated ternary cathode material. The preparation method comprises the following steps: taking lithium chloride, nickel chloride, manganese chloride and cobalt chloride as raw materials, and forming metal carbonate precipitate by taking ammonium carbonate as a precipitating agent; sealing, pressurizing and reacting through nano-titanium dioxide, and performing organic titanium aerating and sintering reaction to obtain the titanium-coated ternary cathode material; finally, obtaining the titanium-coated ternary cathode material in an active state under the action of ultraviolet activation. The ternary cathode material prepared by the invention has the advantages of stable charging and discharging circulation, high-temperature stability, low cost, low environmental pollution and the like.

Owner:宝鸡钛普锐斯钛阳极科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com