Method for preparing massive compact high-pure single-phase Y2SiO5 ceramic block material at low temperature

A ceramic material and densification technology, which is applied in the field of low-temperature preparation of bulk dense and high-purity single-phase Y2SiO5 ceramic materials, achieves the effects of low sintering temperature, simple equipment and short holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

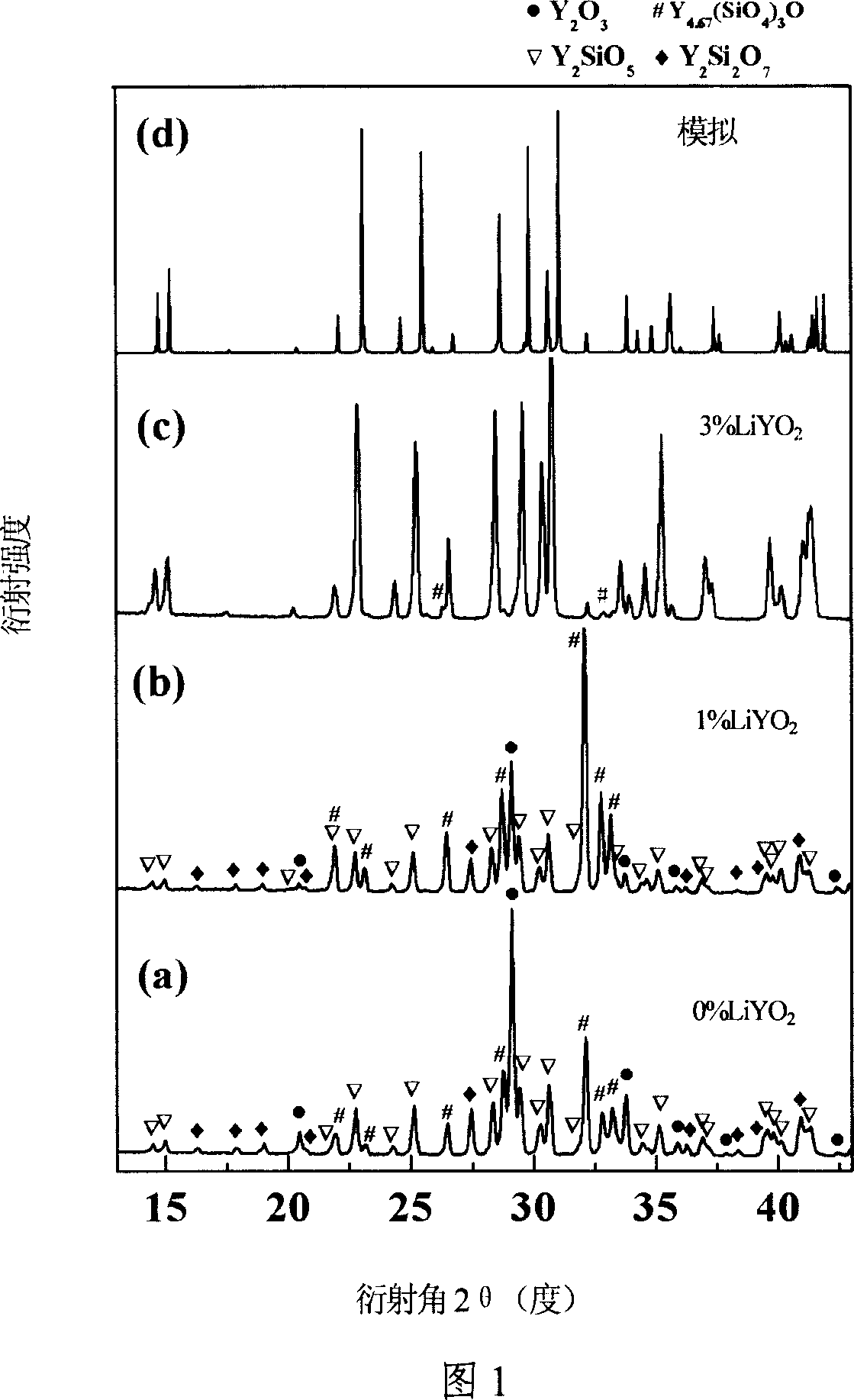

[0020] The raw material is SiO 2 , Y 2 o 3 Powder and additive LiYO 2 Powder, the powder particle size is 5μm. 6 g SiO 2 , 25 grams Y 2 o 3 Powder and additive LiYO 2 The powders were mixed in isopropanol with magnetic stirring for 5 hours, where the additive LiYO 2 The contents are respectively 0%, 1%, and 3% of the total mass. After mixing, the powder is dried and calcined in a high-temperature air electric furnace at 1450°C for 1.5 hours. Analysis of LiYO by X-ray Diffraction 2 Content vs. Y 2 SiO 5 Effect of ceramic synthesis reaction (Fig. 1), (a) in Fig. 1 represents LiYO 2 X-ray diffraction curve with zero content, (b) represents LiYO 2 X-ray diffraction curve with 1% content, (c) represents LiYO 2 X-ray diffraction curve with 3% content, (d) represents the simulation theory Y 2 SiO 5 The X-ray diffraction curve; it can be seen from the figure that with LiYO 2 The addition of SiO 2 / Y 2 o 3 The reaction speed between them is significantly increased. ...

Embodiment 2

[0026] The difference from Example 1 is:

[0027] The raw material is SiO 2 , Y 2 o 3 Powder and additive LiYO 2 Powder, the powder particle size is 2μm. 13 g SiO 2 , 50g Y 2 o 3 Powder and additive LiYO 2 The powders were mixed in isopropanol with magnetic stirring for 5 hours, where the additive LiYO 2 The content is 3 grams. After mixing, the powder is dried and calcined in a high-temperature air electric furnace at 1500°C for 1.5 hours to obtain pure Y 2 SiO 5 ceramic powder.

[0028] Will Y 2 SiO 5 The ceramic powder was milled by a planetary ball mill for 10 hours. Both the milling tank and the milling medium were made of agate. The milling speed was 350 rpm. The ball milling medium was separated from the powder and dried to obtain an ultrafine powder with a particle size of 0.03-2 microns.

[0029] Then the dry powder is cold isostatically pressed to obtain a green body, the molding pressure is 280 MPa, and the green body with an initial relative density o...

Embodiment 3

[0033] The difference from Example 1 is:

[0034] The raw material is SiO 2 , Y 2 o 3 Powder and additive LiYO 2 Powder, the powder particle size is 10μm. 8 g SiO 2 , 30 g Y 2 o 3 Powder and additive LiYO 2 The powder was mixed in isopropanol with magnetic stirring for 8 hours, in which the additive LiYO 2 The content is 1.5 grams. After mixing, the powder is dried and calcined in a high-temperature air electric furnace at 1400°C for 4 hours to obtain pure Y 2 SiO 5 ceramic powder.

[0035] The calcined powder is milled by a planetary ball mill for 20 hours. Both the milling tank and the milling medium are made of agate. The milling speed is 250 rpm. The milling medium is separated from the powder and dried to obtain an ultrafine powder with a particle size of 0.03-2 microns. .

[0036] Then the dry powder is cold isostatically pressed to obtain a green body, and the cold isostatic pressing pressure is 200 MPa to obtain a green body with an initial relative densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com