Preparation method of high-nuclear yeast powder essence

A production method and technology of powder flavor, applied in the fields of application, food preparation, food science, etc., can solve the problems of aroma and meaty taste, and achieve the effect of strong aroma, rich calcium, and stability under high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

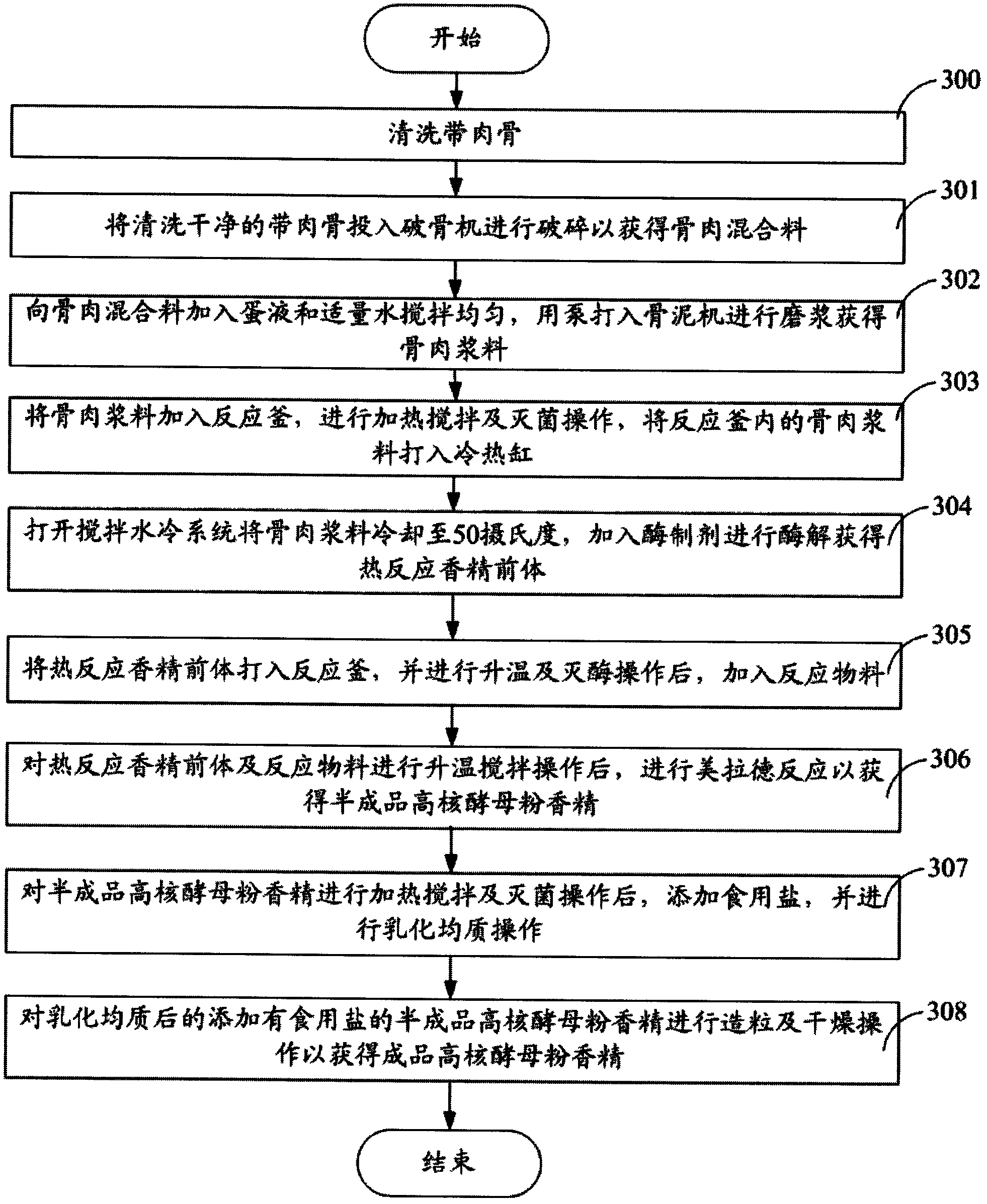

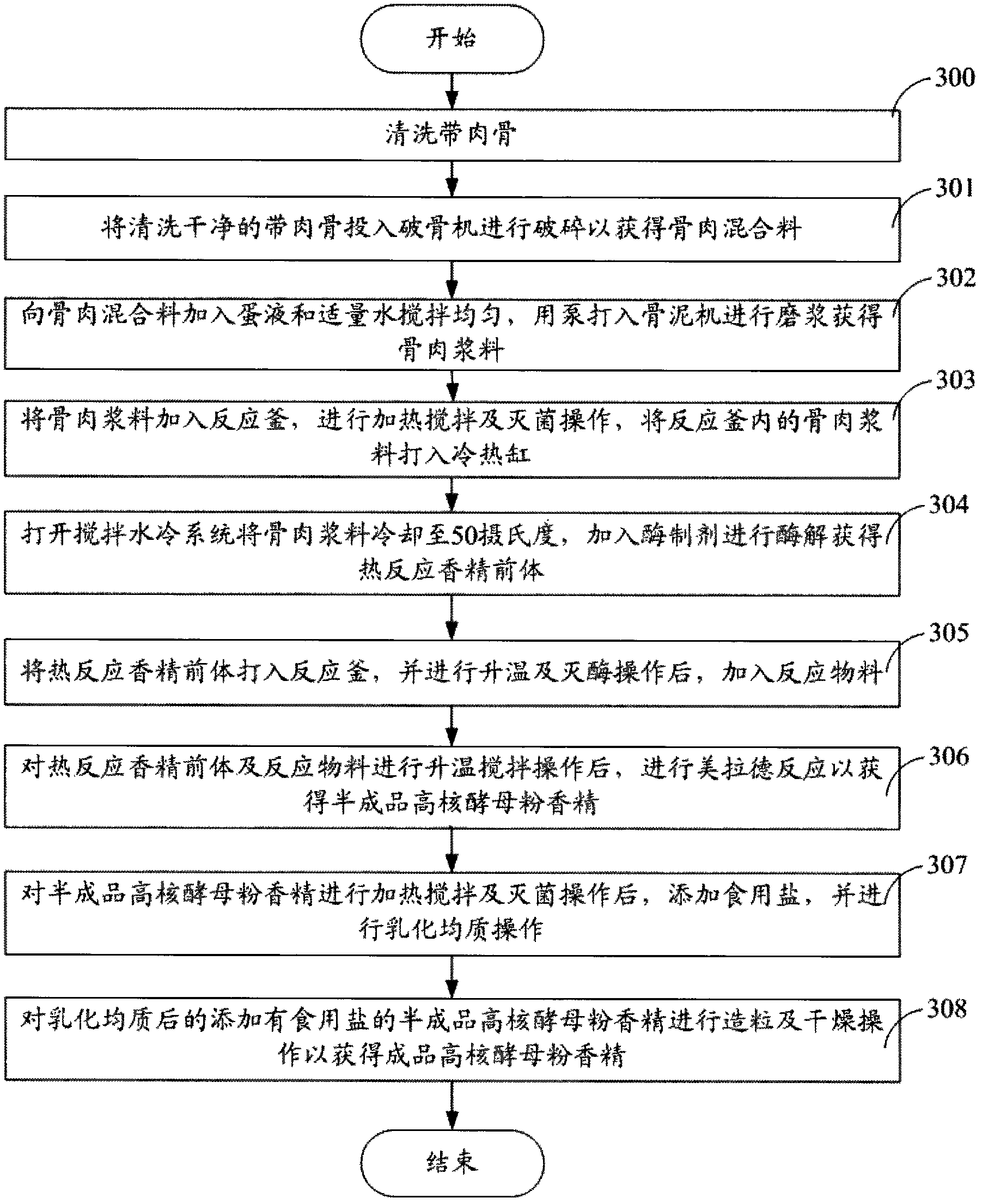

[0017] The production method of the prokaryotic yeast powder essence provided by the present invention uses meat and bone as the main raw material to pulverize, refine, add enzyme preparations for enzymolysis, add auxiliary materials including prokaryotic yeast extract, and then perform Maillard reaction to obtain semi-finished products High nuclear yeast powder flavor, dry and granulate the semi-finished high nuclear yeast powder flavor to make the finished high nuclear yeast powder flavor. The specific steps of the production method of the high nuclear yeast powder essence provided by the invention are as follows, please refer to figure 1 :

[0018] Step S300, cleaning the bone with meat. Among them, the bones with meat are beef bones, chicken bones, pork bones, fish bones and the like.

[0019] Step S301, putting the cleaned fleshy bone into a bone crusher for crushing to obtain a bone-meat mixture.

[0020] Step S302, adding egg liquid and an appropriate amount of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com