Patents

Literature

51results about How to "Won't pull out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

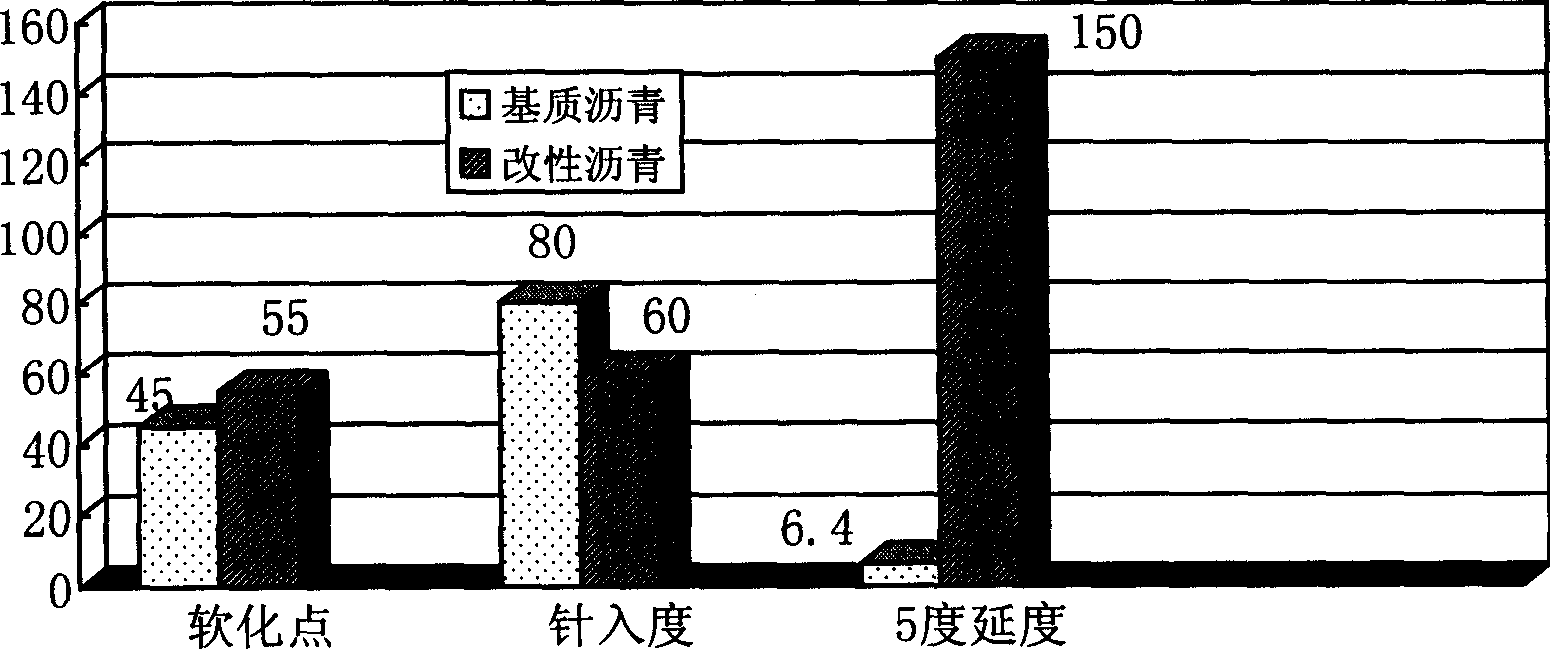

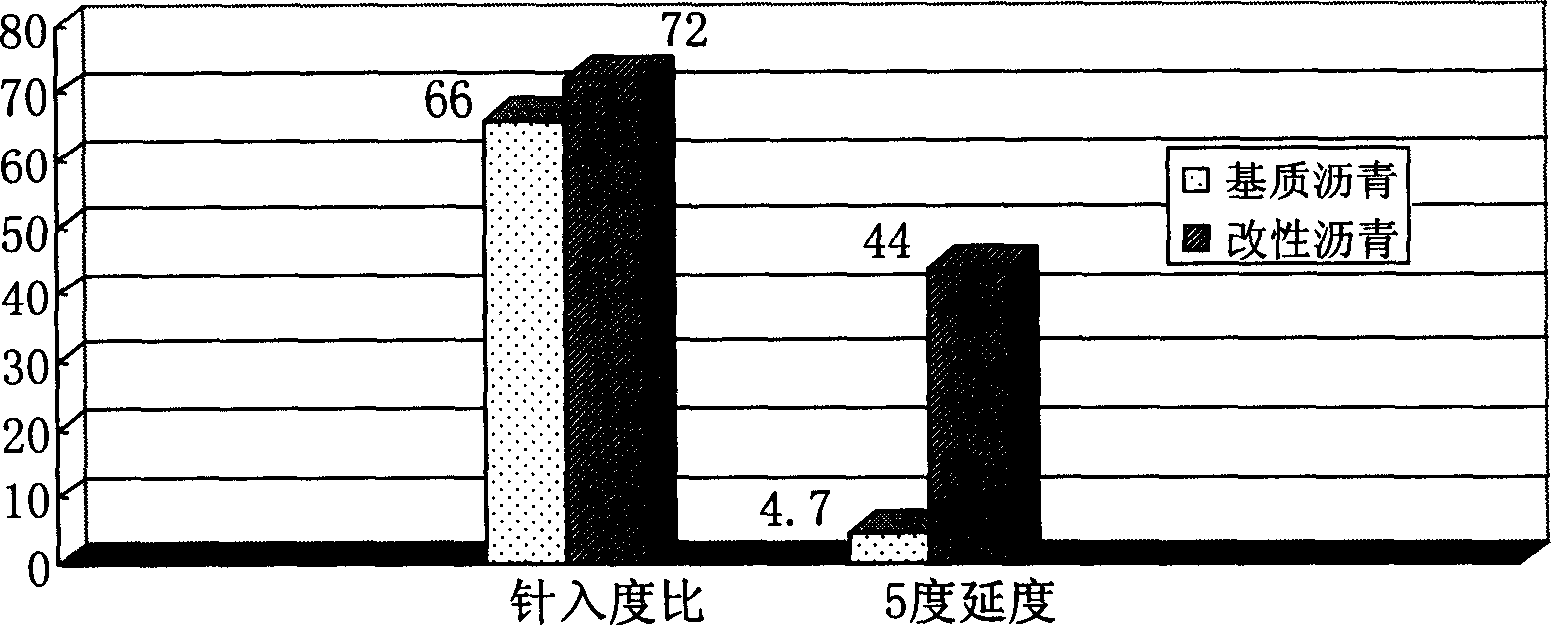

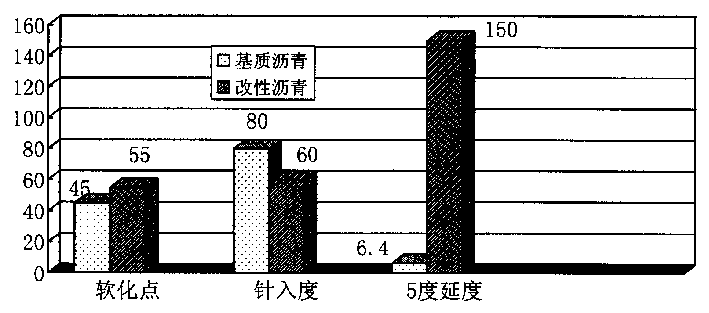

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

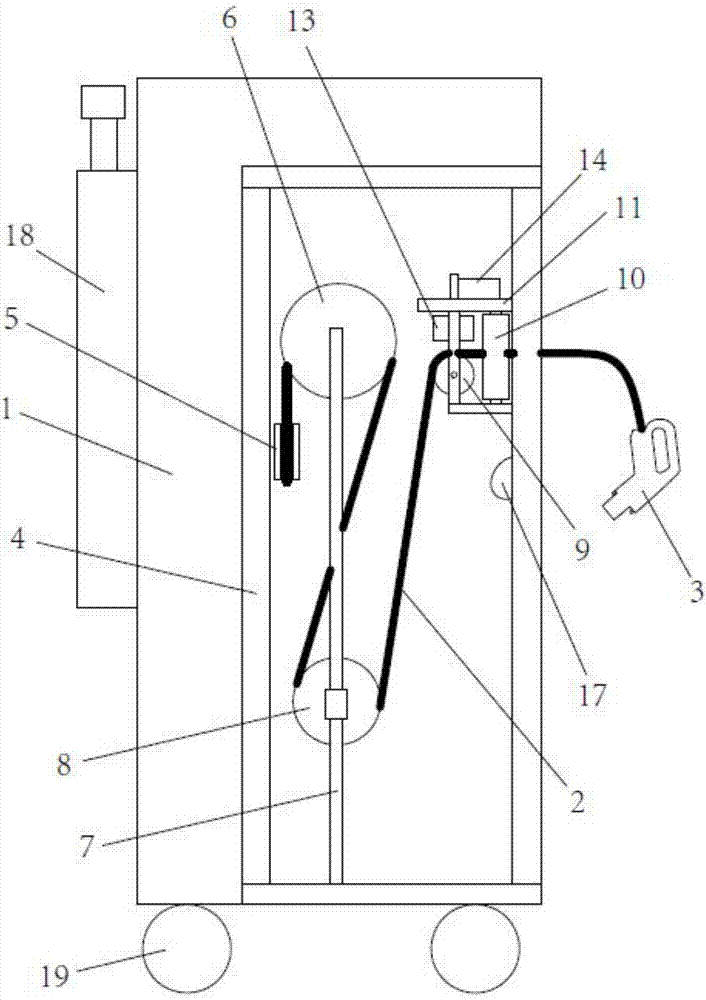

Easy-to-store charging pile device

PendingCN107310421AIncreased durabilityExtended service lifeCharging stationsElectric vehicle charging technologySteering wheelElectric wire

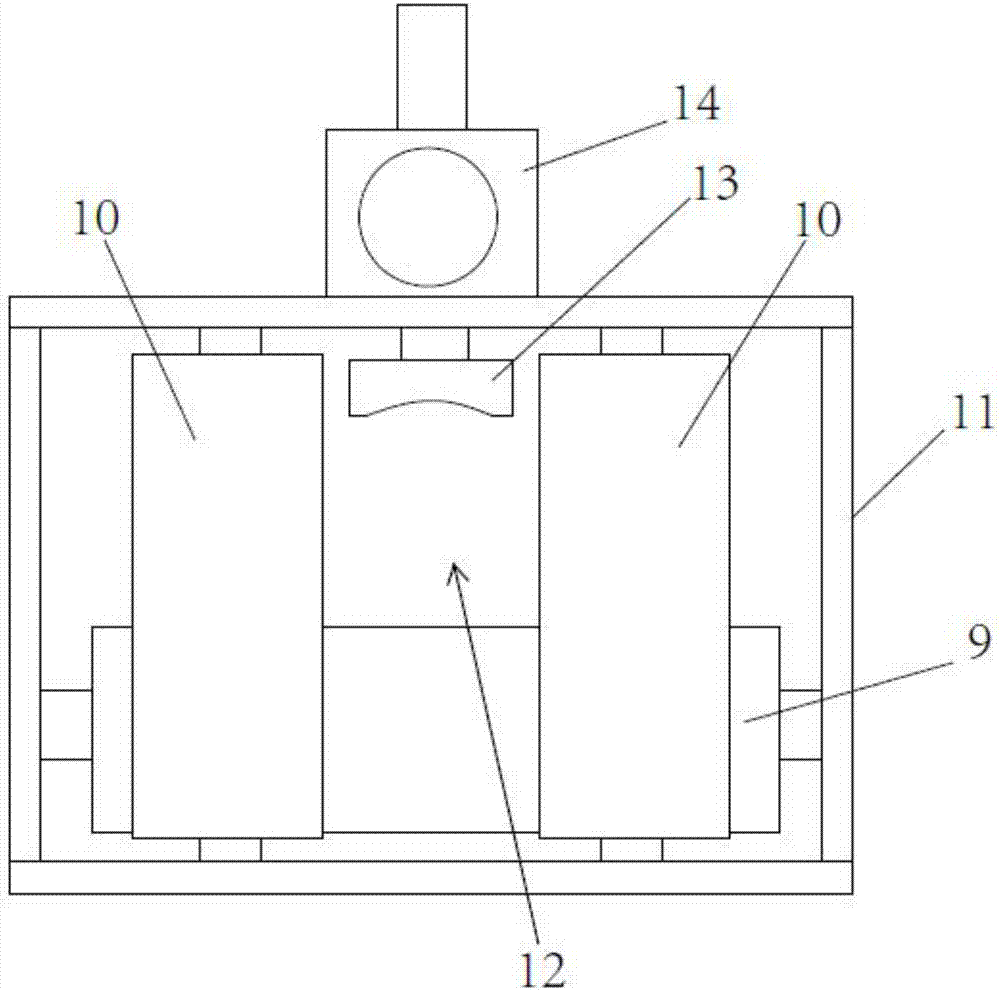

The invention discloses an easy-to-store charging pile device. The charging pile device comprises a charging pile body, wherein a charging wire is arranged at one side of the charging pile body; a charging gun is arranged at one end of the charging wire; the charging wire is arranged in a storage box; a wire inlet is formed in the surface, which is at one side of the charging pile body, of the storage box; a first steering wheel is arranged in the storage box at one side of the wire inlet; a second steering wheel is arranged in the storage box at the upper part of the first steering wheel; a weight balancing rolling wheel is arranged in the storage box at the lower part of the first steering wheel and arranged on a rotating shaft; guide sleeves are respectively arranged on two ends of the rotating shaft and sleeved on a guide pillar; the guide pillar is fixedly arranged on the bottom of the storage box; a wire outlet is arranged in the surface of the storage box along the weight balancing rolling wheel arranging direction; and a horizontal roll and two vertical rolls are arranged on the wire outlet and arranged in a cage. By utilizing the charging pile device disclosed by the invention, the charging wire is effectively stored and protected from being damaged.

Owner:JIANGSU SHENYI ELECTRIC CO LTD

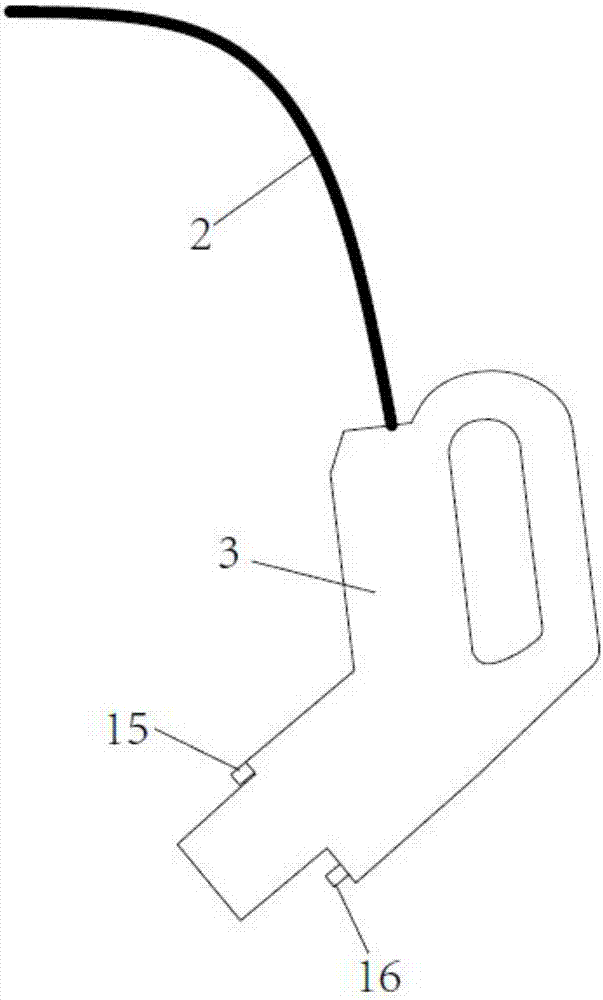

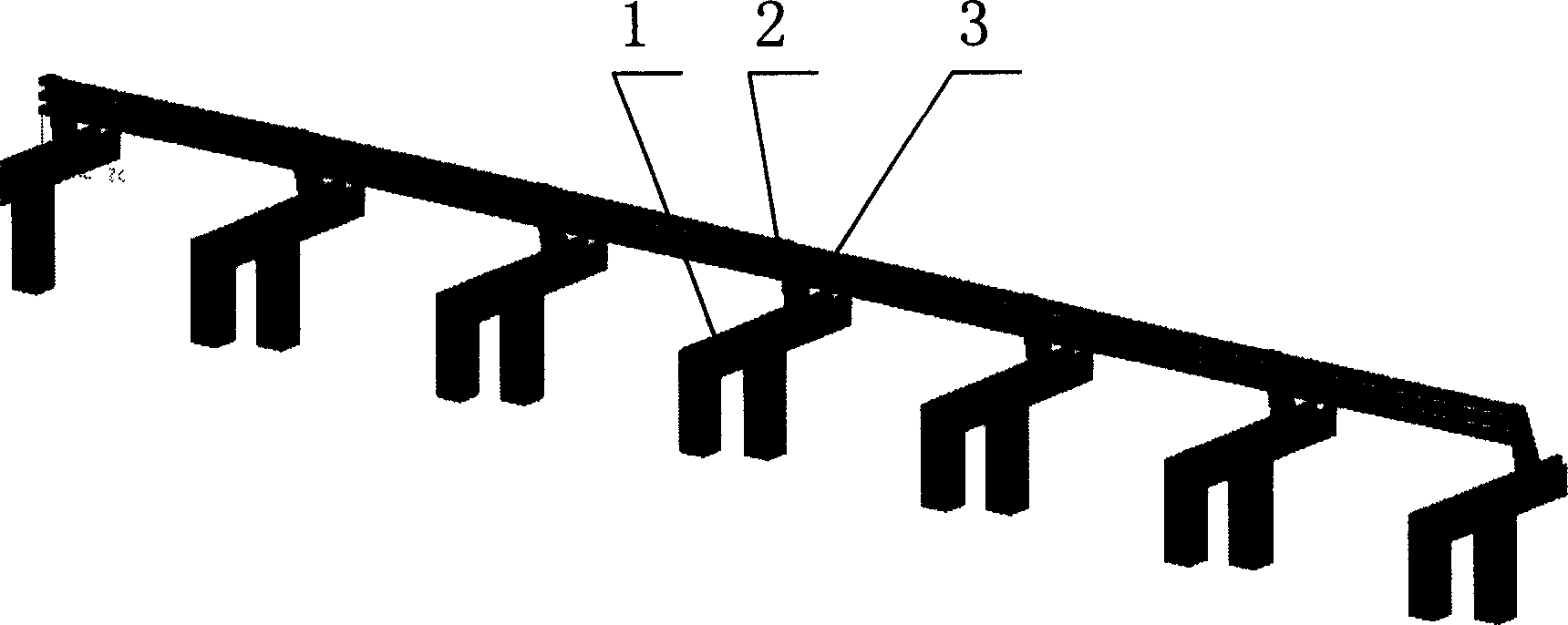

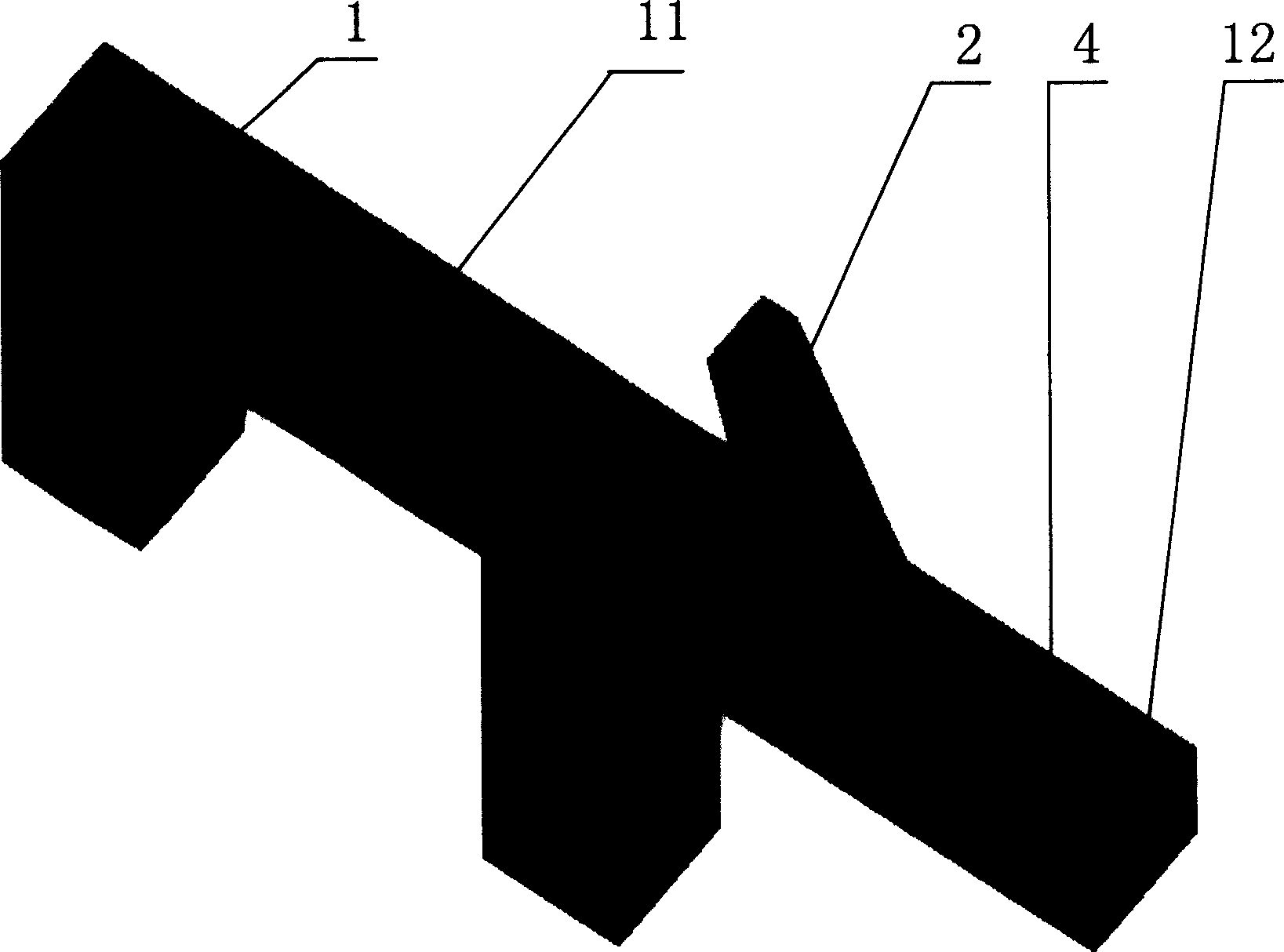

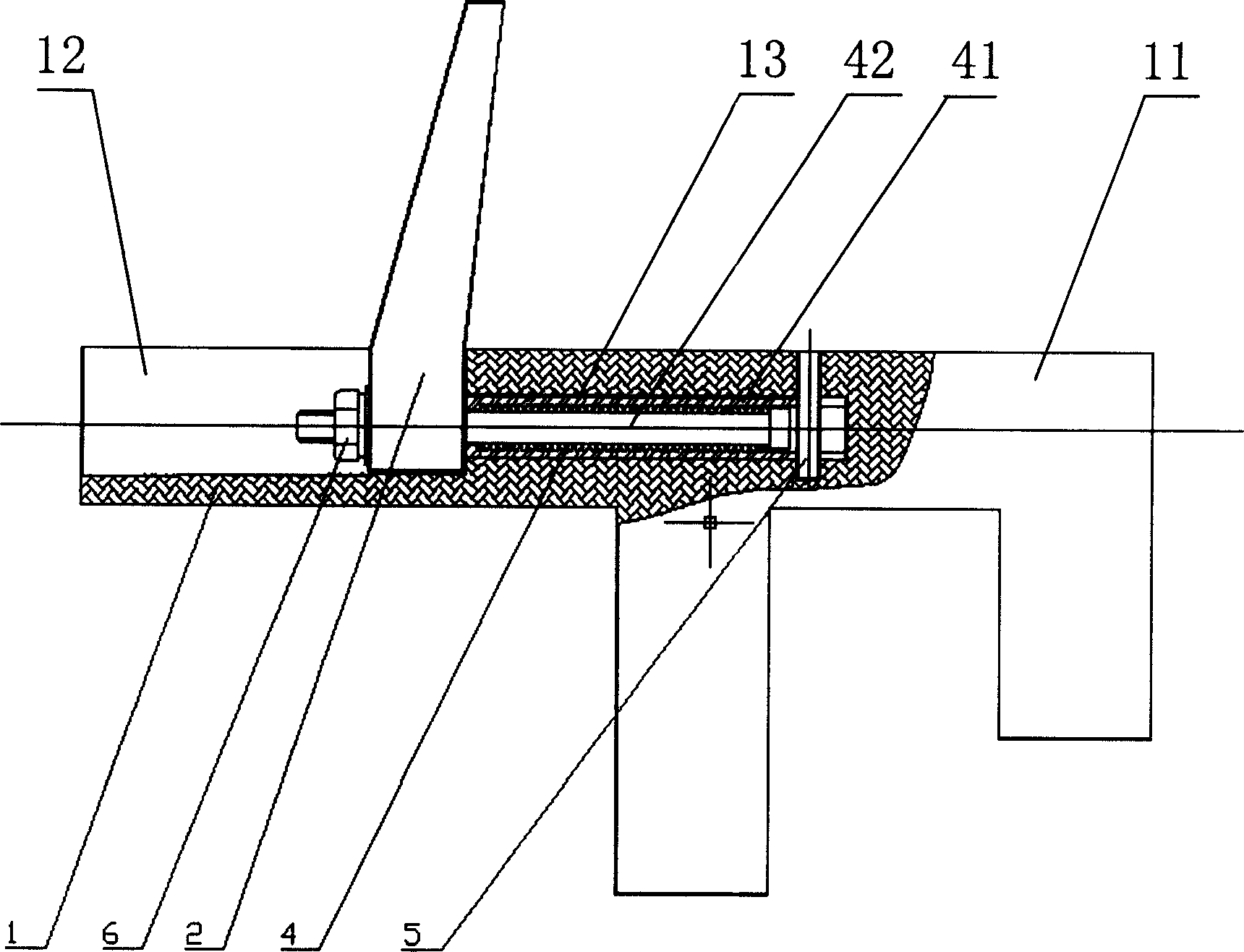

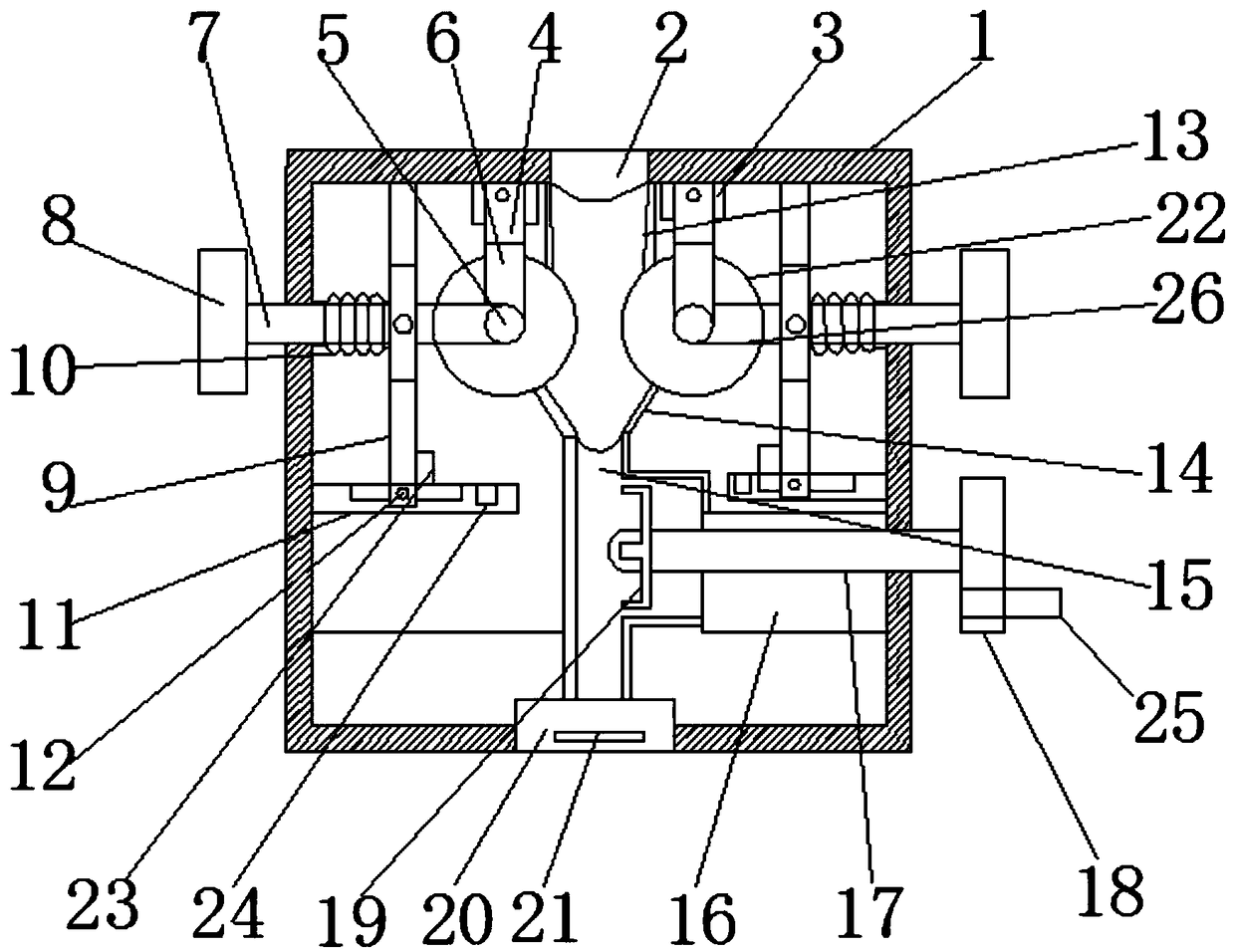

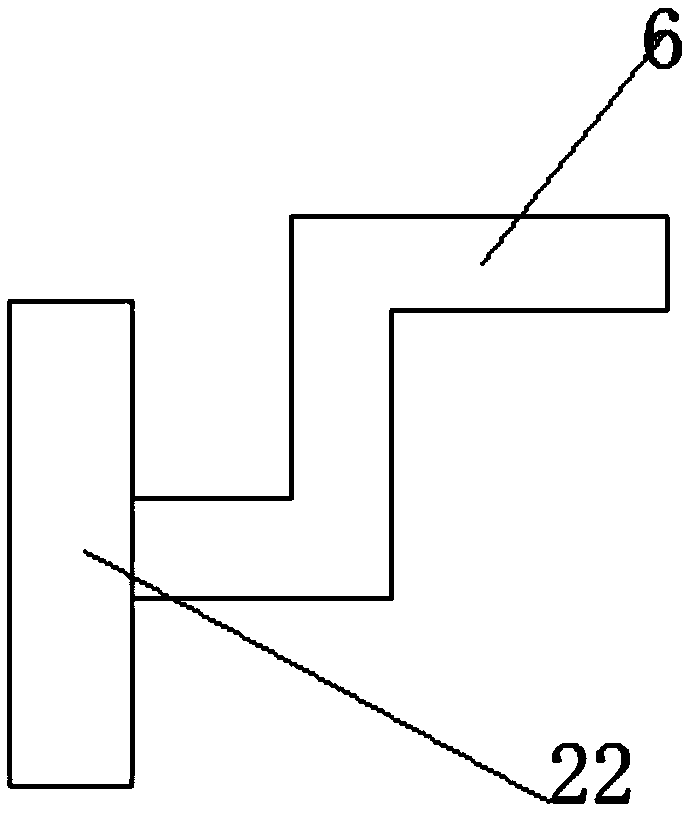

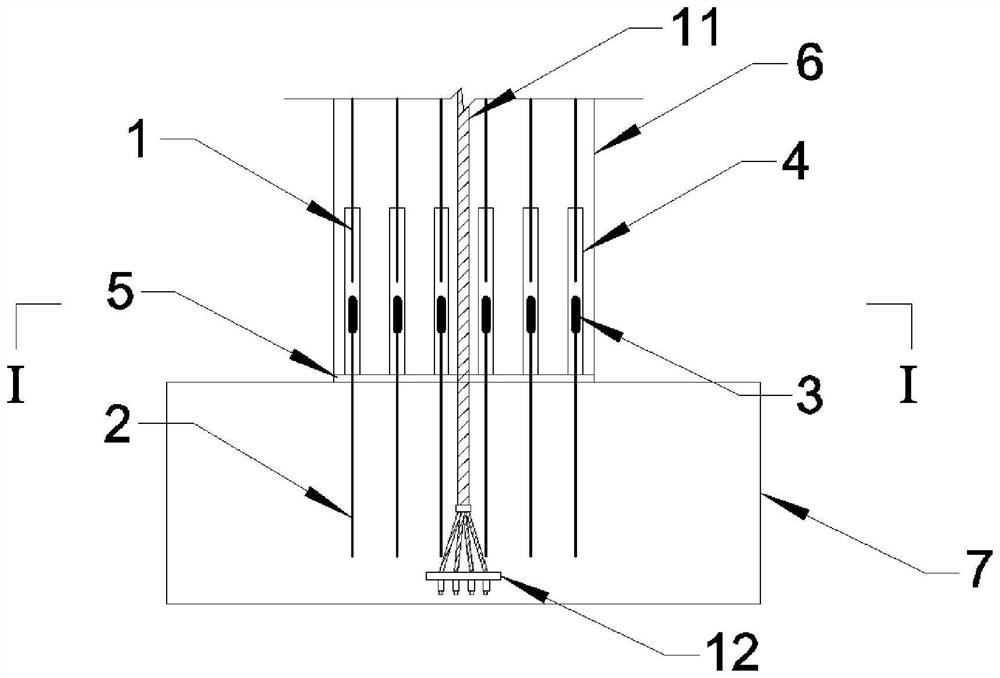

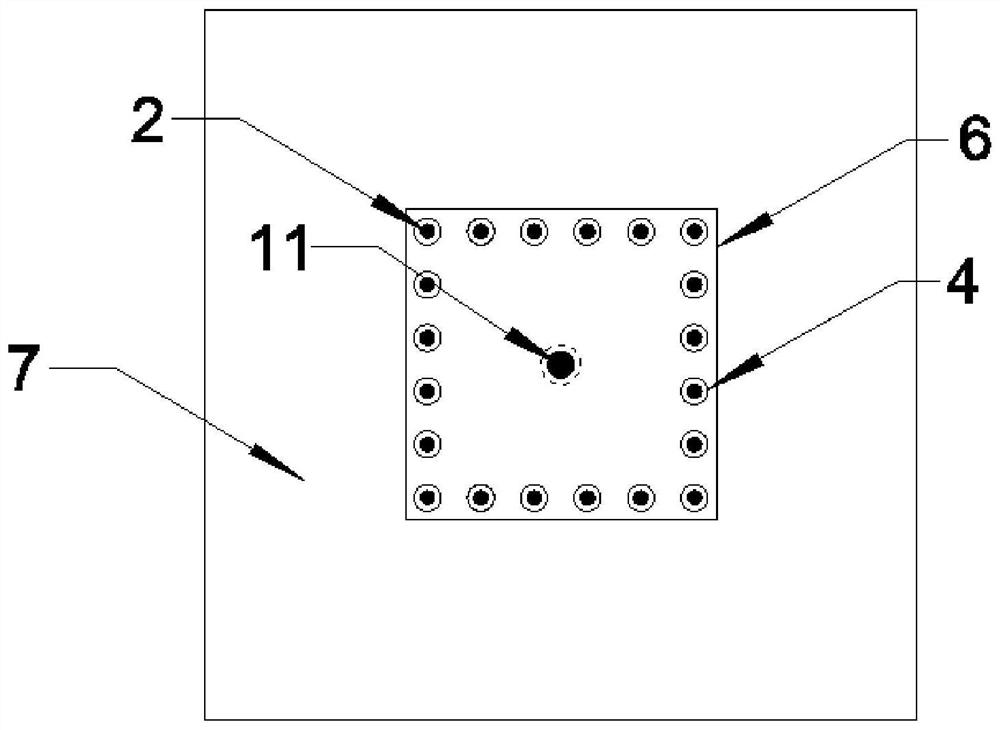

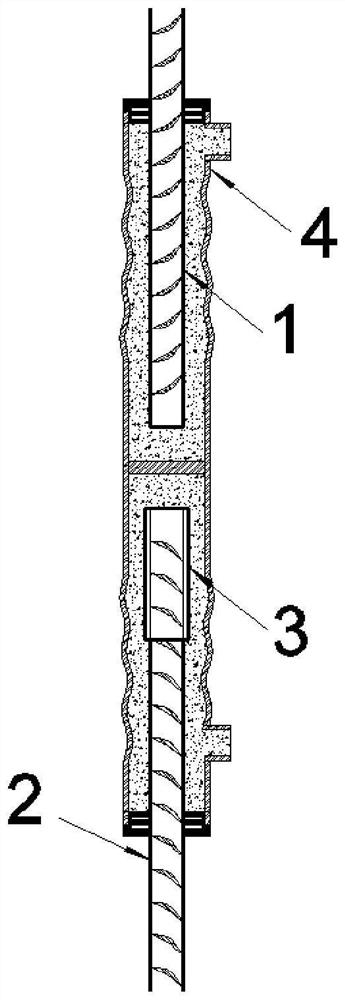

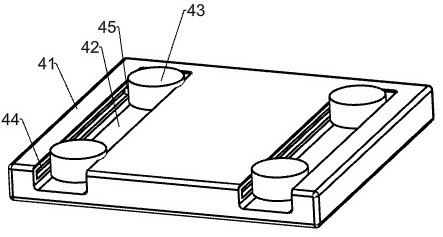

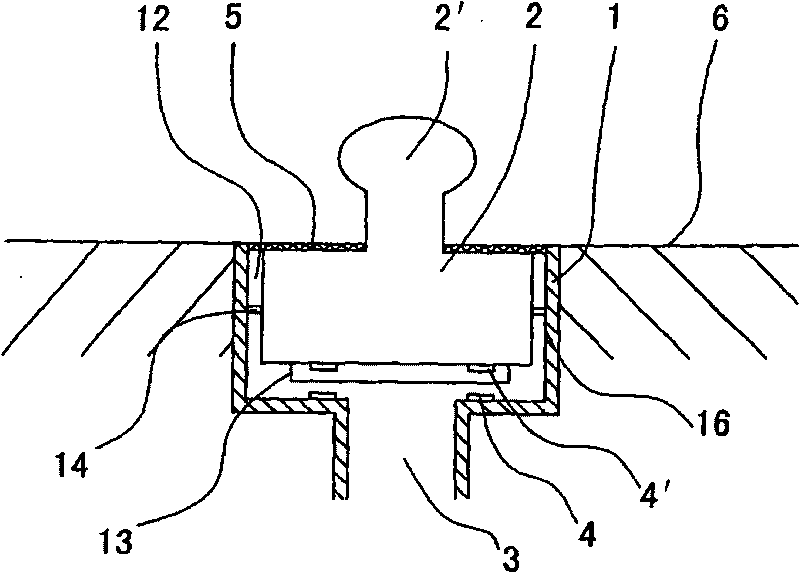

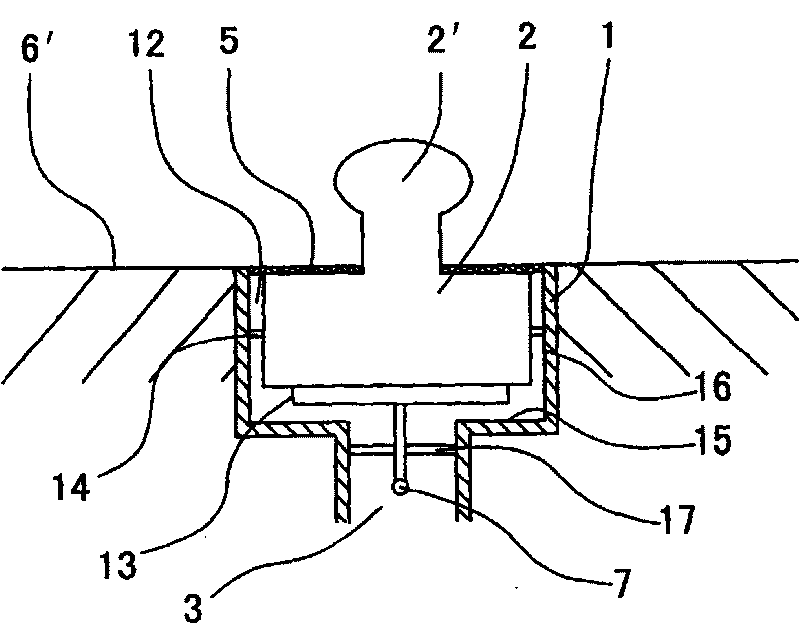

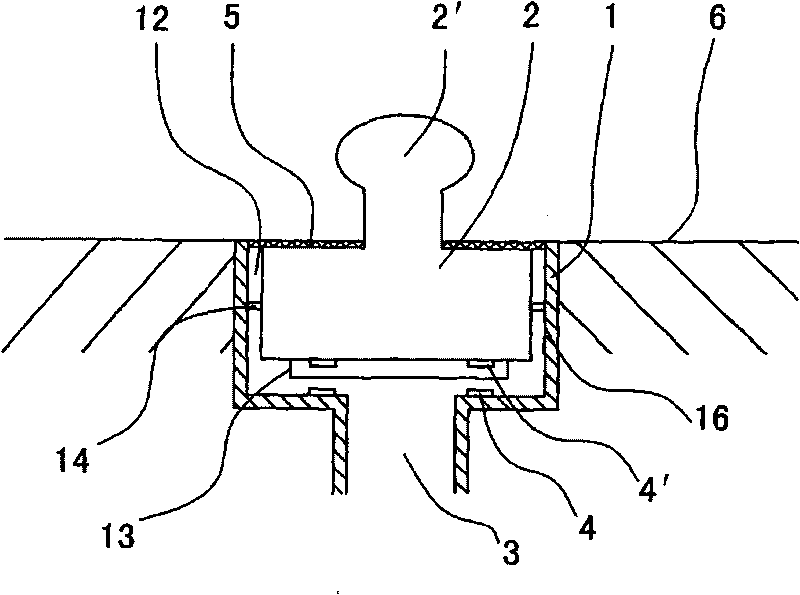

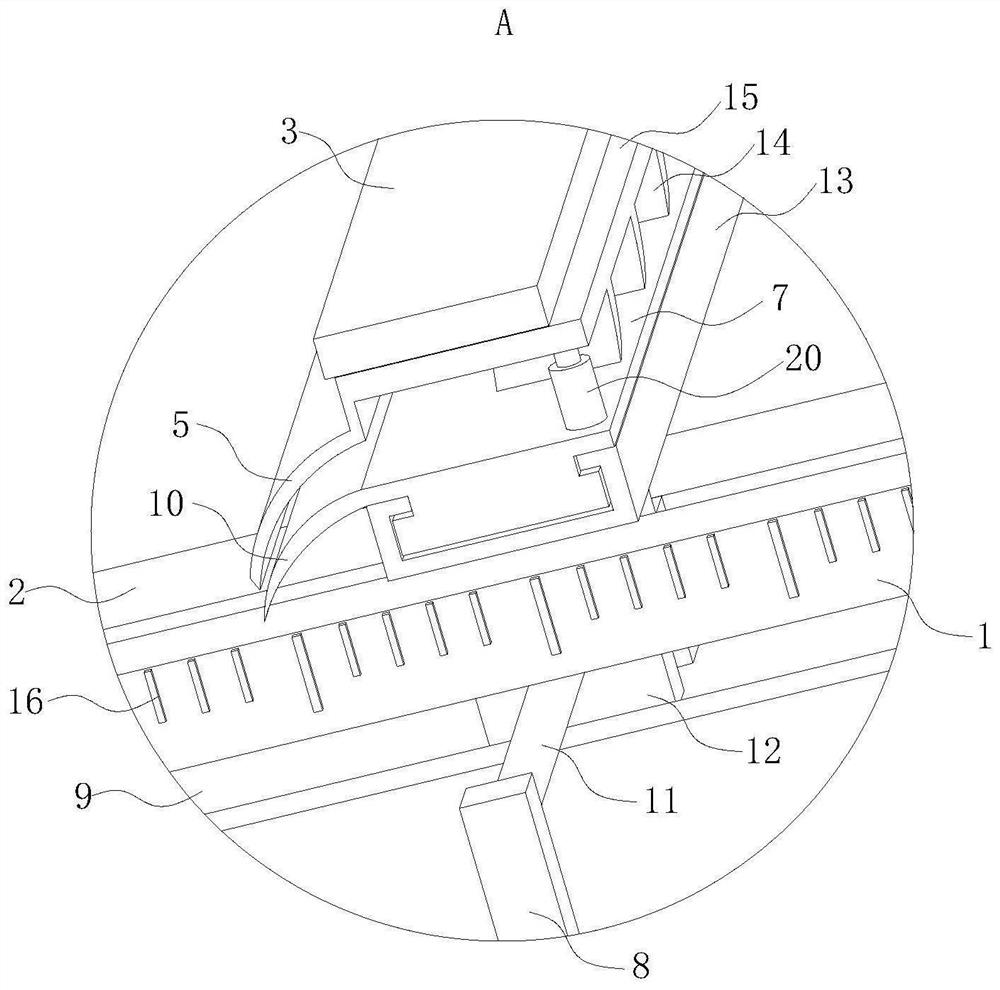

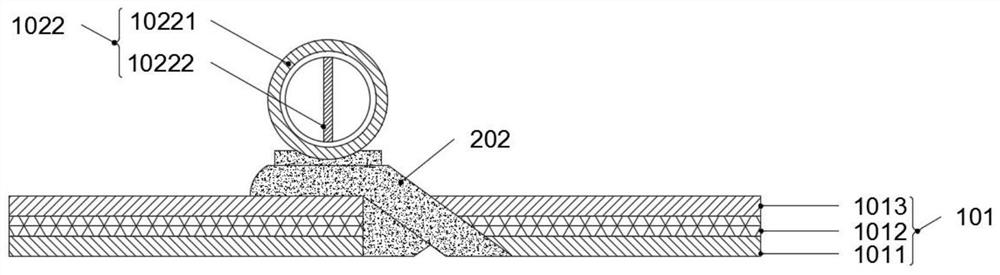

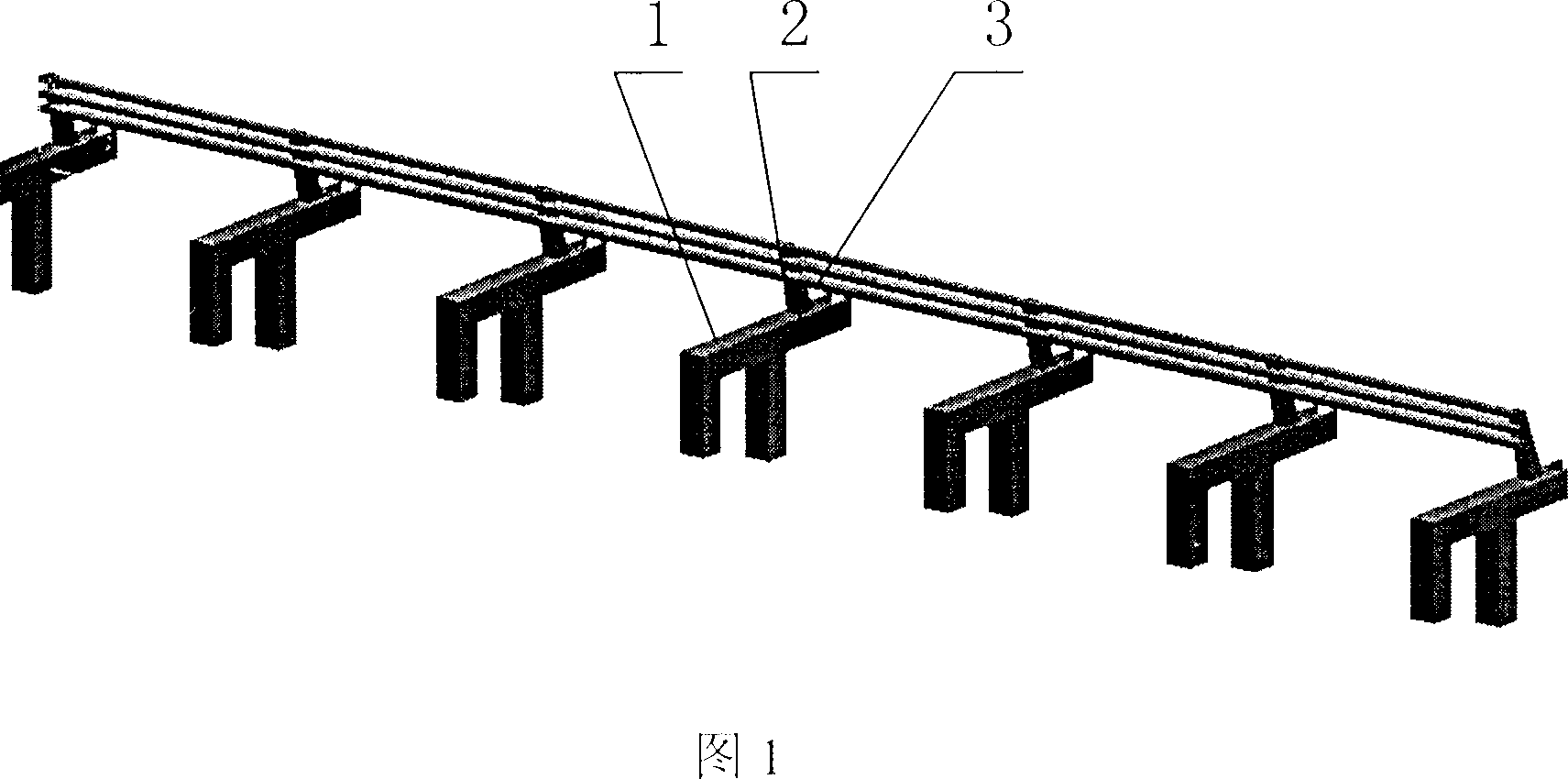

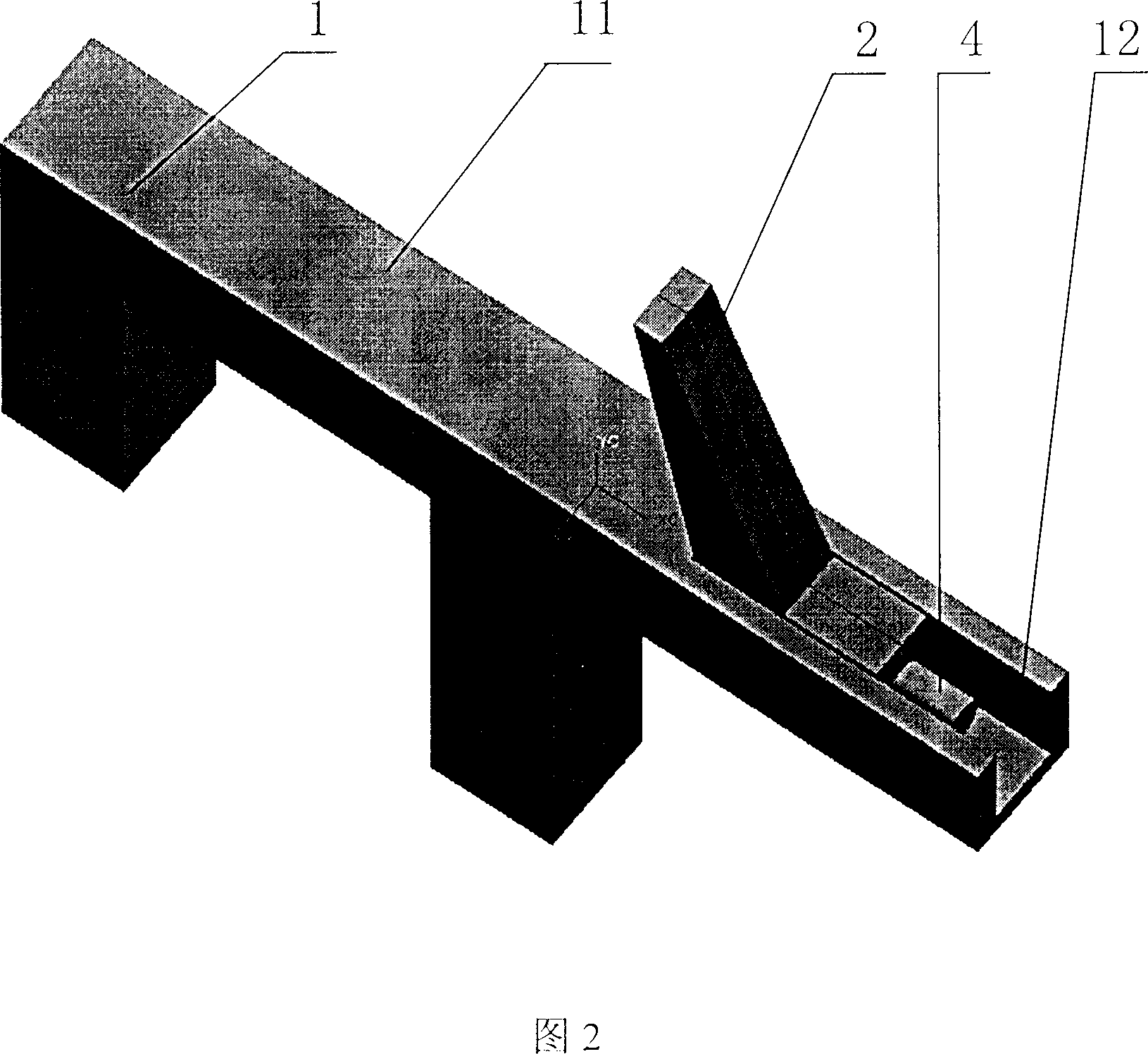

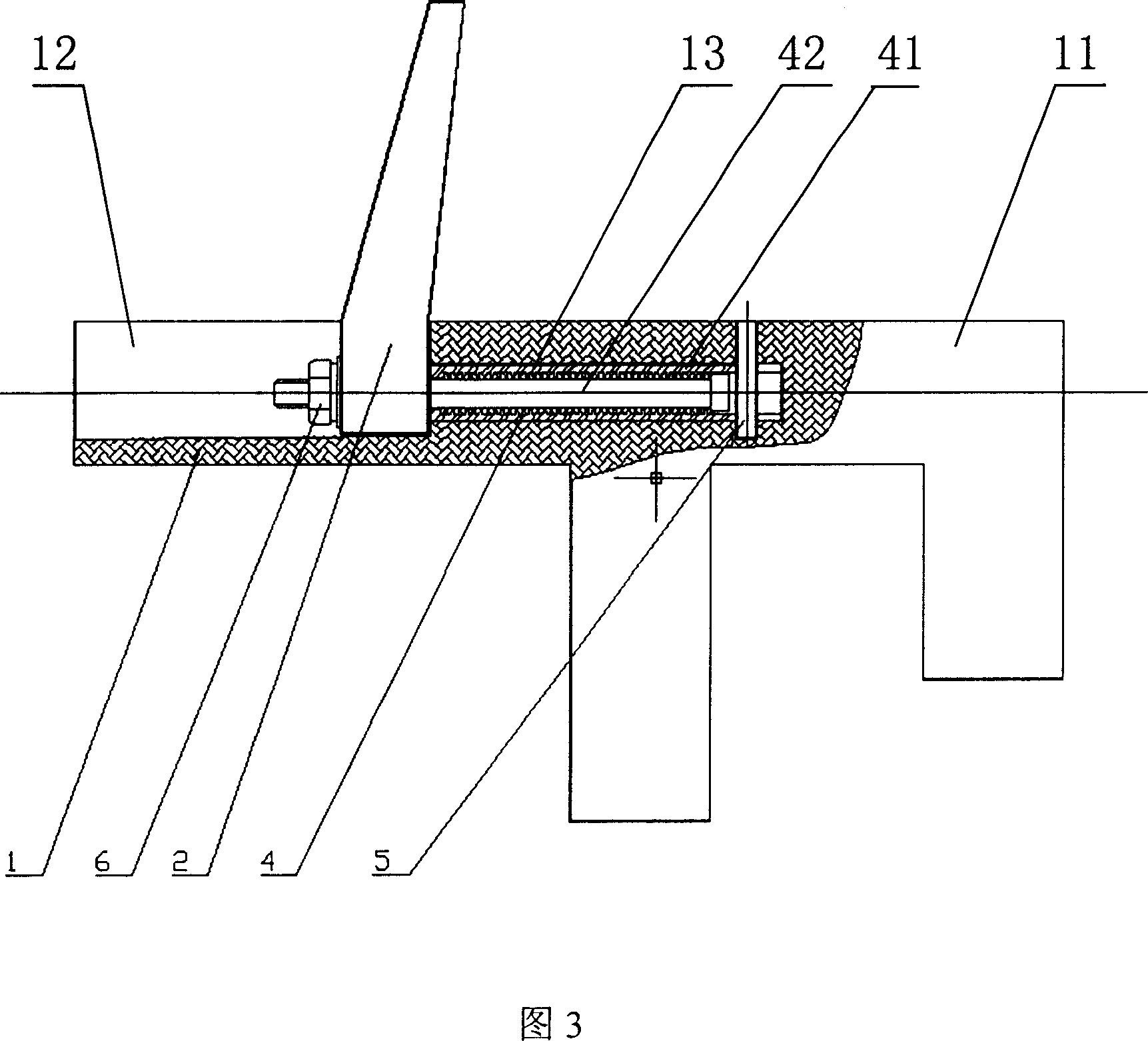

Crashproof guard bar

InactiveCN1632229AGood orientationWon't pull outBridge structural detailsRoadway safety arrangementsEnergy absorbingEnergy absorbers

An anti-collision guardrail, comprising a guardrail foundation (1), a column (2), a beam (3) and an energy-absorbing threaded part (4), the guardrail foundation (1) is F-shaped, placed horizontally in the roadbed, and the guardrail foundation (1 ) on the foundation beam (11) on the rear section to open a guide groove (12), in the foundation beam (11) at the front end of the guide groove (12), a hole (13) is provided along the longitudinal direction, and a hole (13) is set in the hole (13). The energy-absorbing threaded part (4), the column (2) is arranged in the guide groove (12) and connected with the energy-absorbing threaded part (4), the beam (3) is arranged in front of the column (2) and connected with the column (2) . The invention has the characteristics of firm foundation, no encroachment on the effective driving road surface, buffering and energy absorbing effect when the vehicle collides with the guardrail, reduced collision intensity and good guiding ability, and can minimize the damage to the vehicle and passengers caused by the collision. It is especially suitable for highway anti-collision barriers and bridge anti-collision barriers on cliffs.

Owner:雷正保

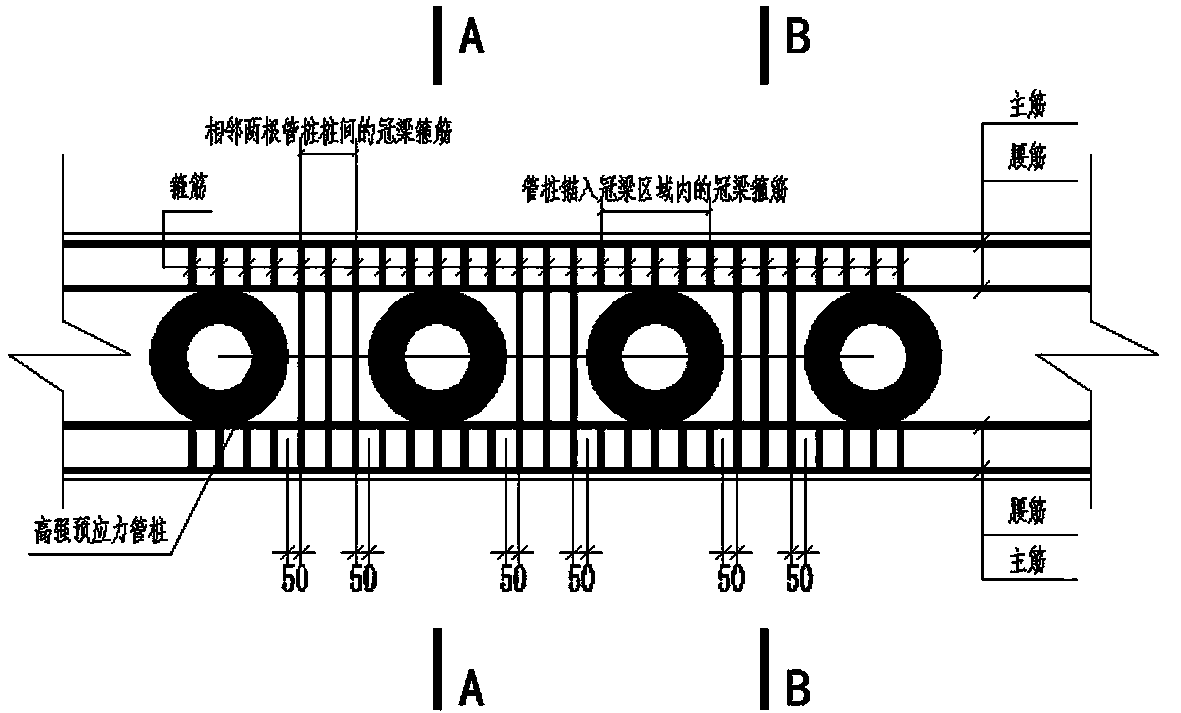

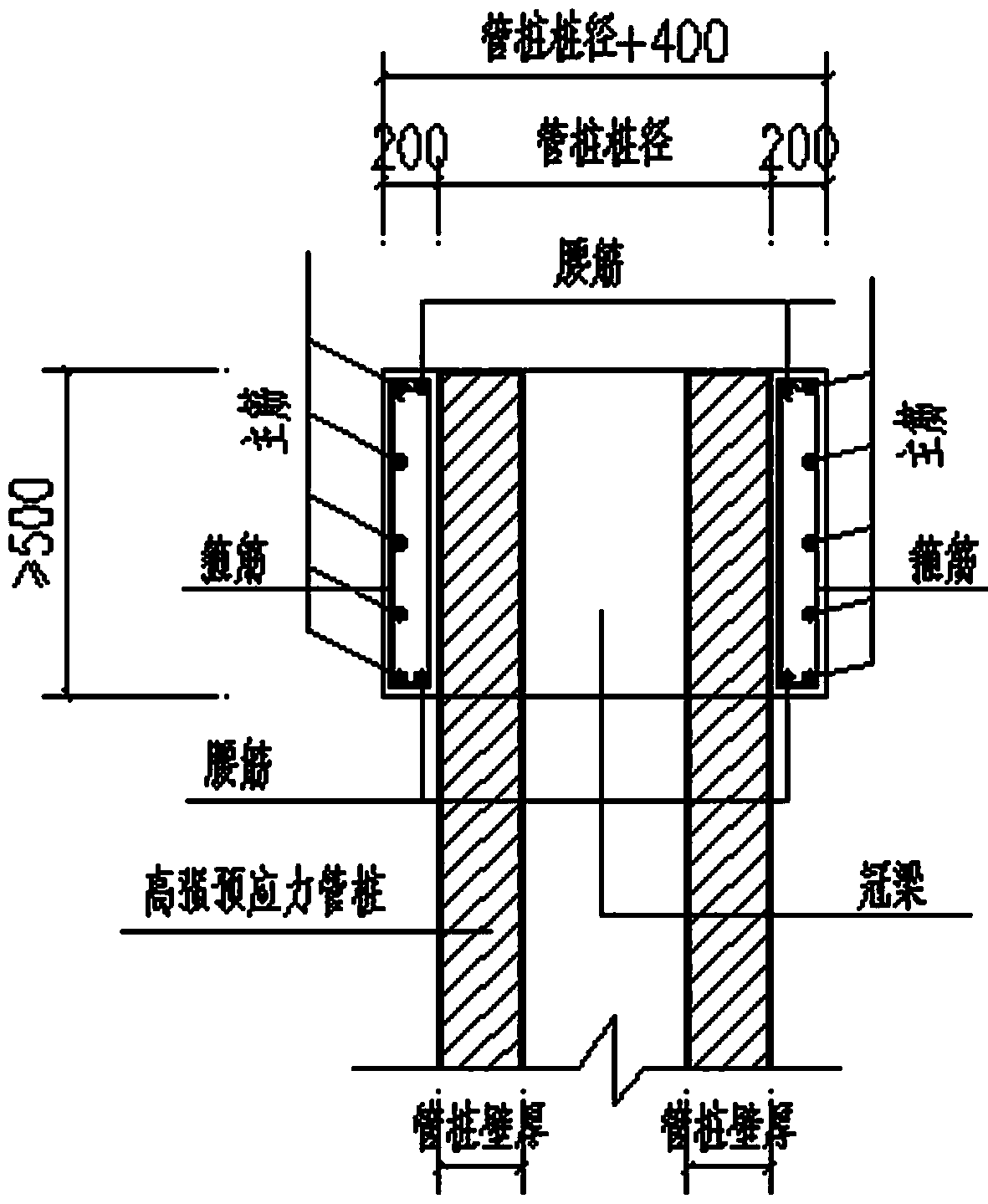

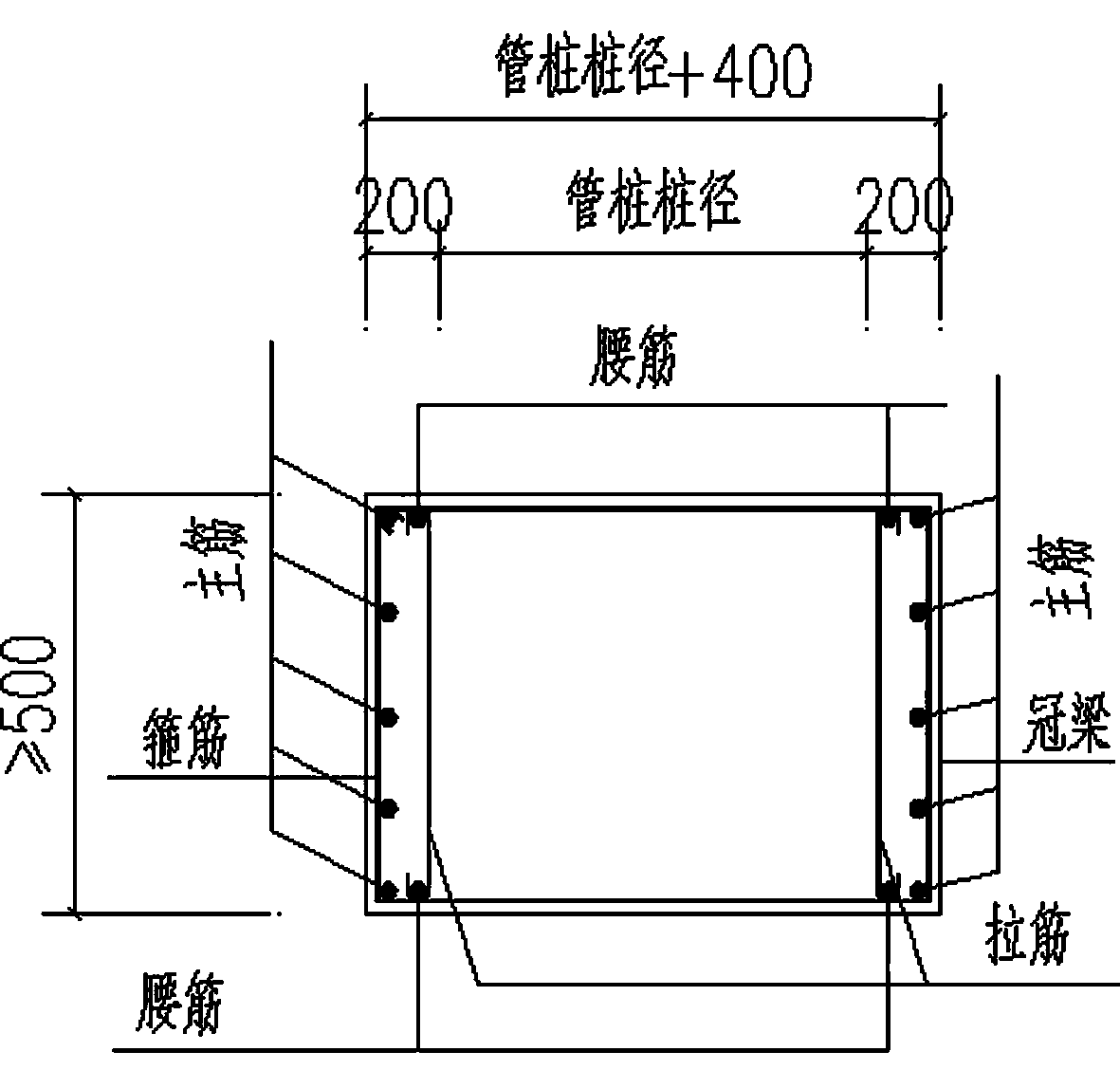

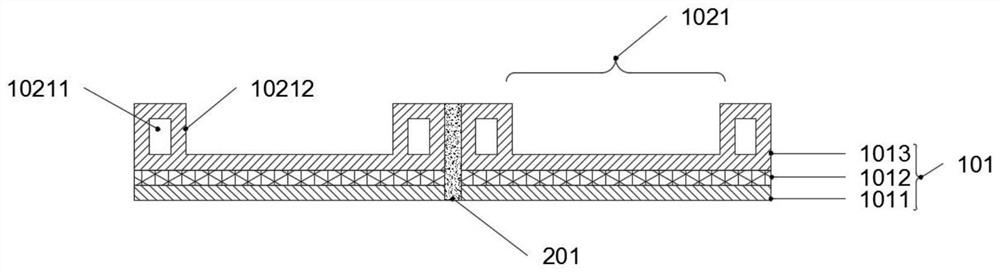

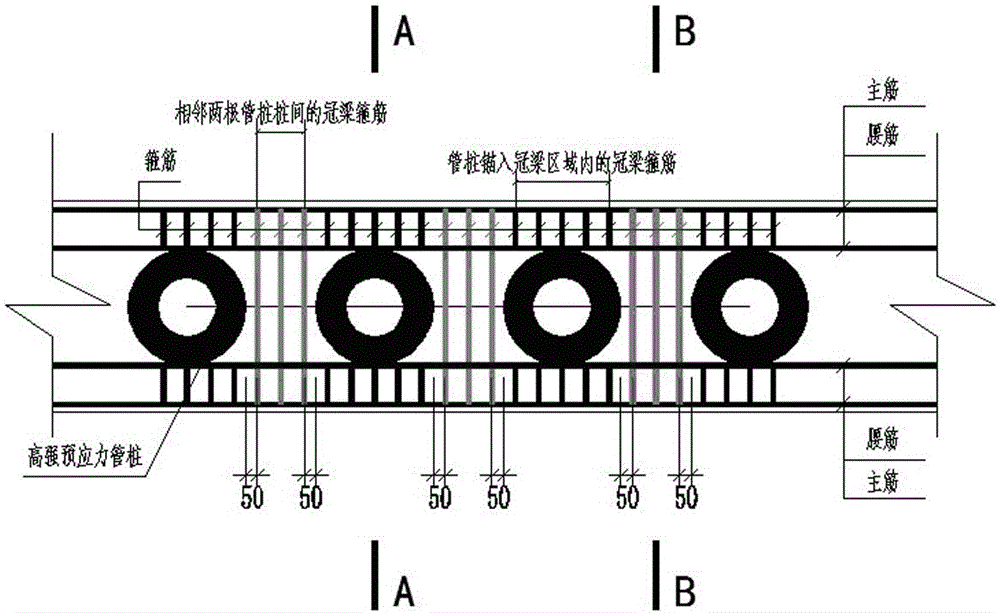

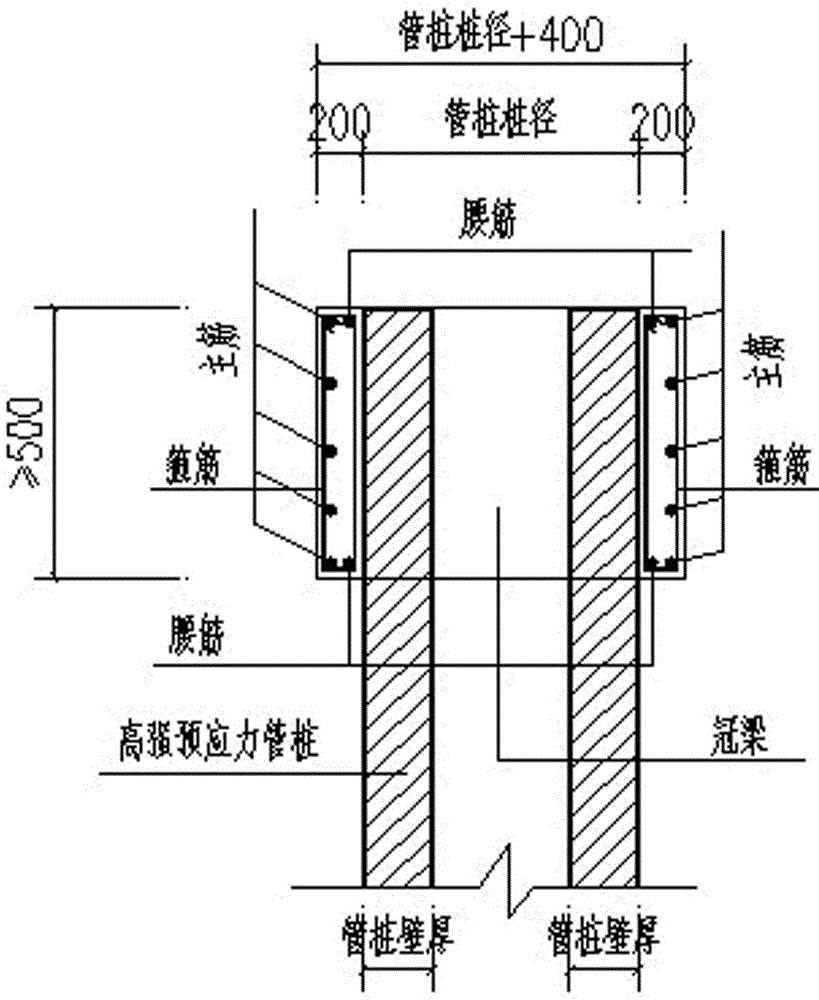

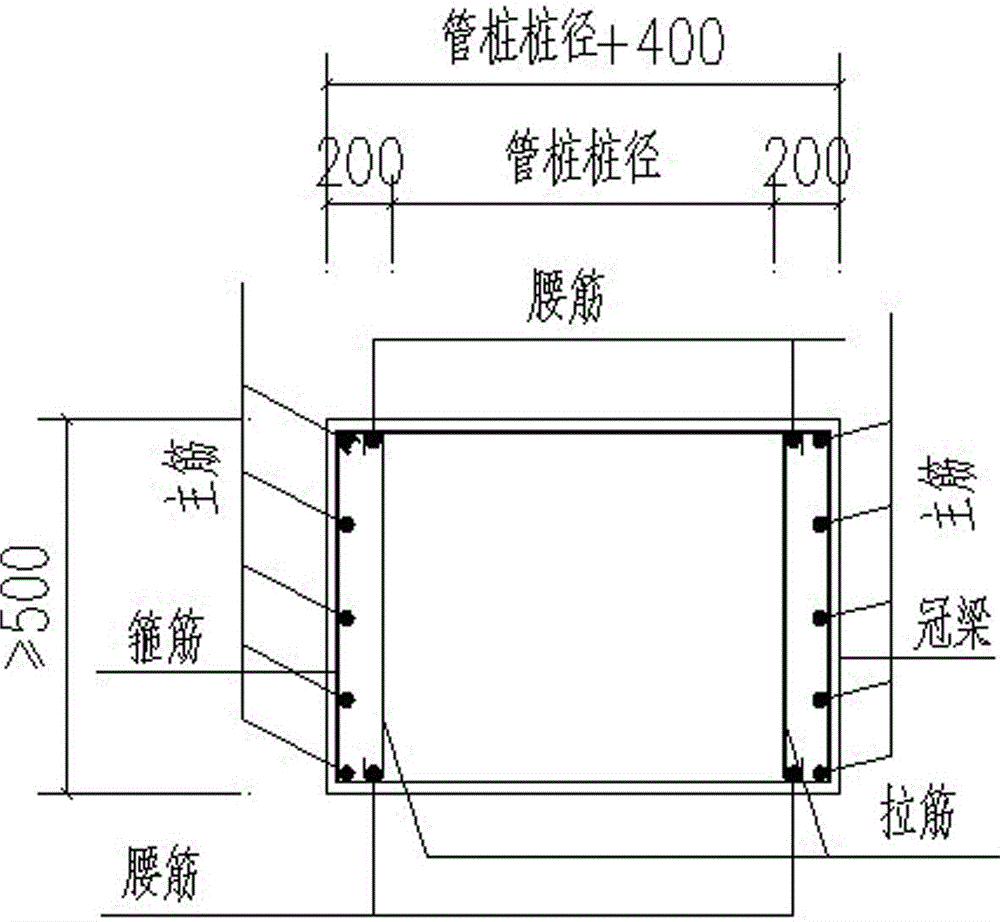

Pile top crown beam structure of high-strength prestress pipe pile for supporting foundation pit and construction method thereof

ActiveCN103452120ASaving on reinforced concreteShorten the construction periodExcavationsRebarCushion

The invention relates to a pile top crown beam structure of a high-strength prestress pipe pile for supporting a foundation pit and a construction method thereof. The structure is characterized in that a crown beam is arranged at the tops of high-strength prestress pipe piles, the length of the part, inserted into the crown beam, of each high-strength prestress pipe pile is the same as the height of the crown beam, the height of the crown beam is not lower than 500mm, the width of the crown beam is 400mm more than the diameter of each pipe pile, the two ends of the crown beam respectively extend by 200mm out of the edge of each pipe pile, longitudinal stress reinforced bars of the crown beam are arranged near the edges of the inner side and outer side of the foundation pit, web bars are attached with the edge of each pipe pile, a bidirectional two-leg hoop bar and two additional vertical pull bars are arranged between the crown beams of the two adjacent high-strength prestress pipe piles, the hoop bar is 50mm away from the edge of each pipe pile, and two independent bidirectional two-leg bars are arranged in the area, anchored into the crown beam, of each high-strength prestress pipe pile. The method comprises the following steps of excavating earth to the bottom of the cushion layer of the crown beam, measuring and paying off, casting the cushion layer, binding the reinforced bars, supporting a formwork, casting concrete, airing water and curing, removing the formwork, and excavating the earth of the lower layer.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

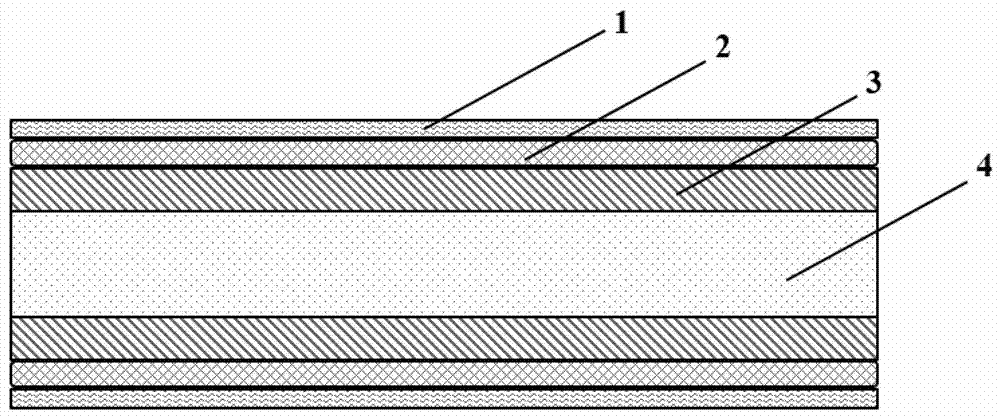

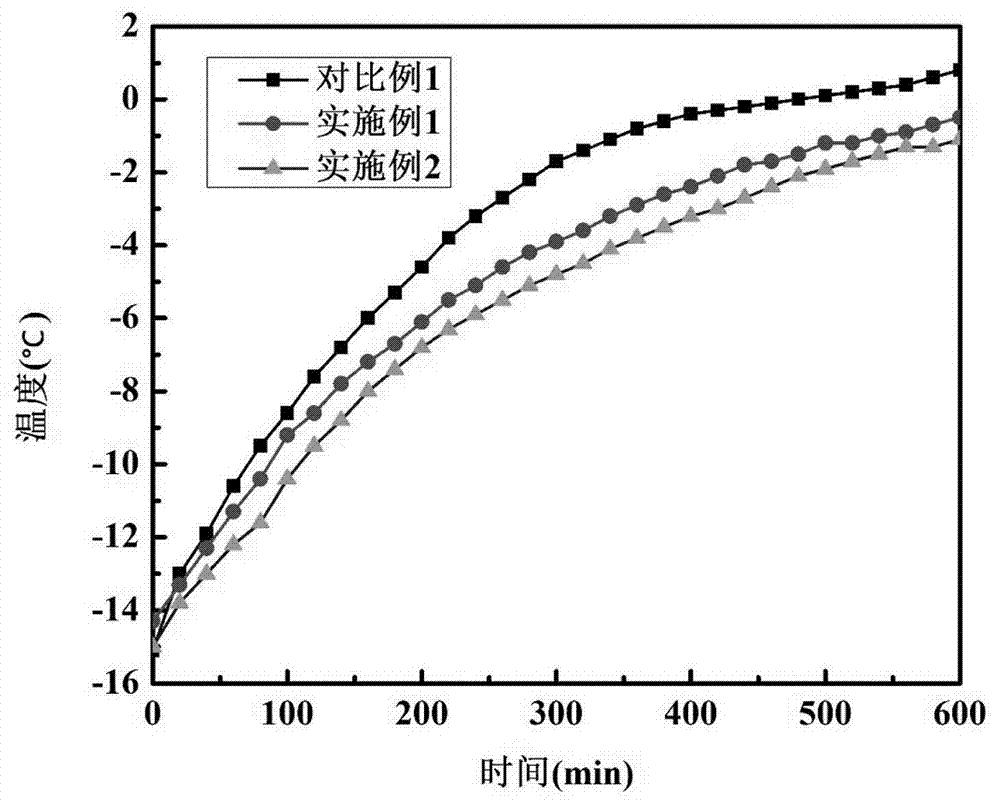

Environment-friendly type vacuum heat insulation plate

ActiveCN107387944AAvoid punctureStop radiationThermal insulationSynthetic resin layered productsGlass fiberEngineering

The invention relates to an environment-friendly type vacuum heat insulation plate. The environment-friendly type vacuum heat insulation plate comprises a heat insulation core material located on the inner side, a reflecting type air insulation membrane located on the outer side and a protecting layer located between the heat insulation core material and the reflecting type air insulation membrane. The heat insulation core material comprises 40-95wt% of glass fibers, 2-40wt% of kieselguhr, 2-40wt% of attapulgite and 1-5wt% of a binding agent. By adoption of the composite core plate prepared from the kieselguhr, the attapulgite and the glass fibers, the problem that a packaging bag is damaged and consequently the vacuum degree is decreased can be solved, the technical process can be simplified, and the production cost of the core material is reduced.

Owner:高彦峰

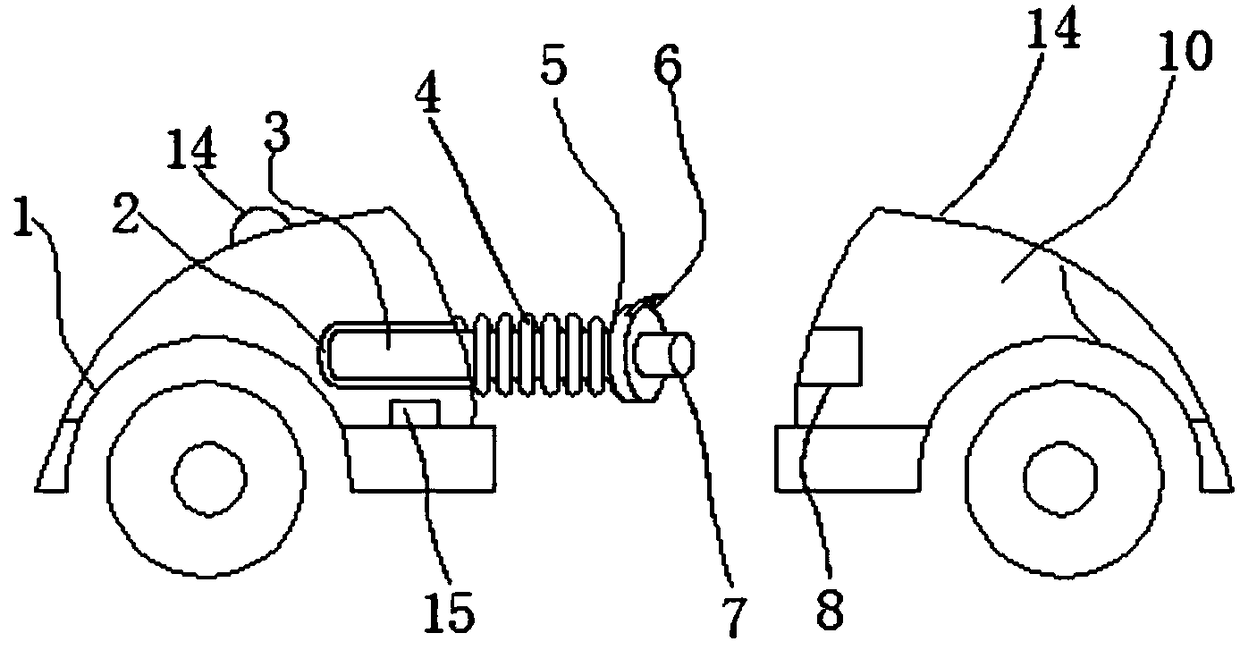

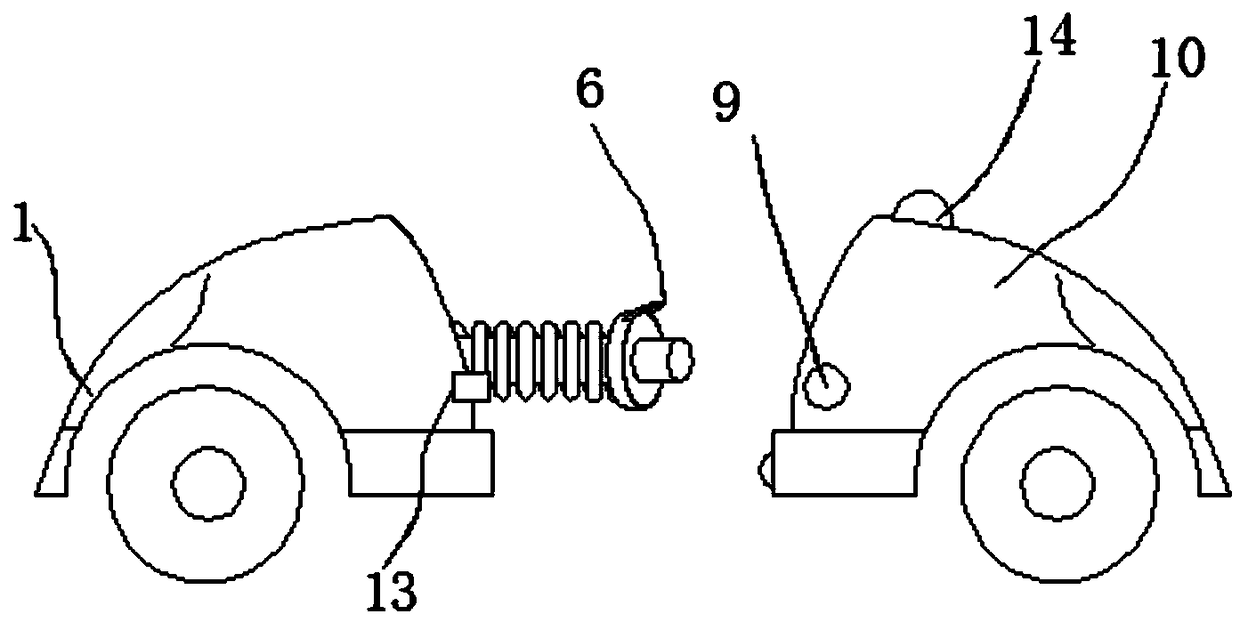

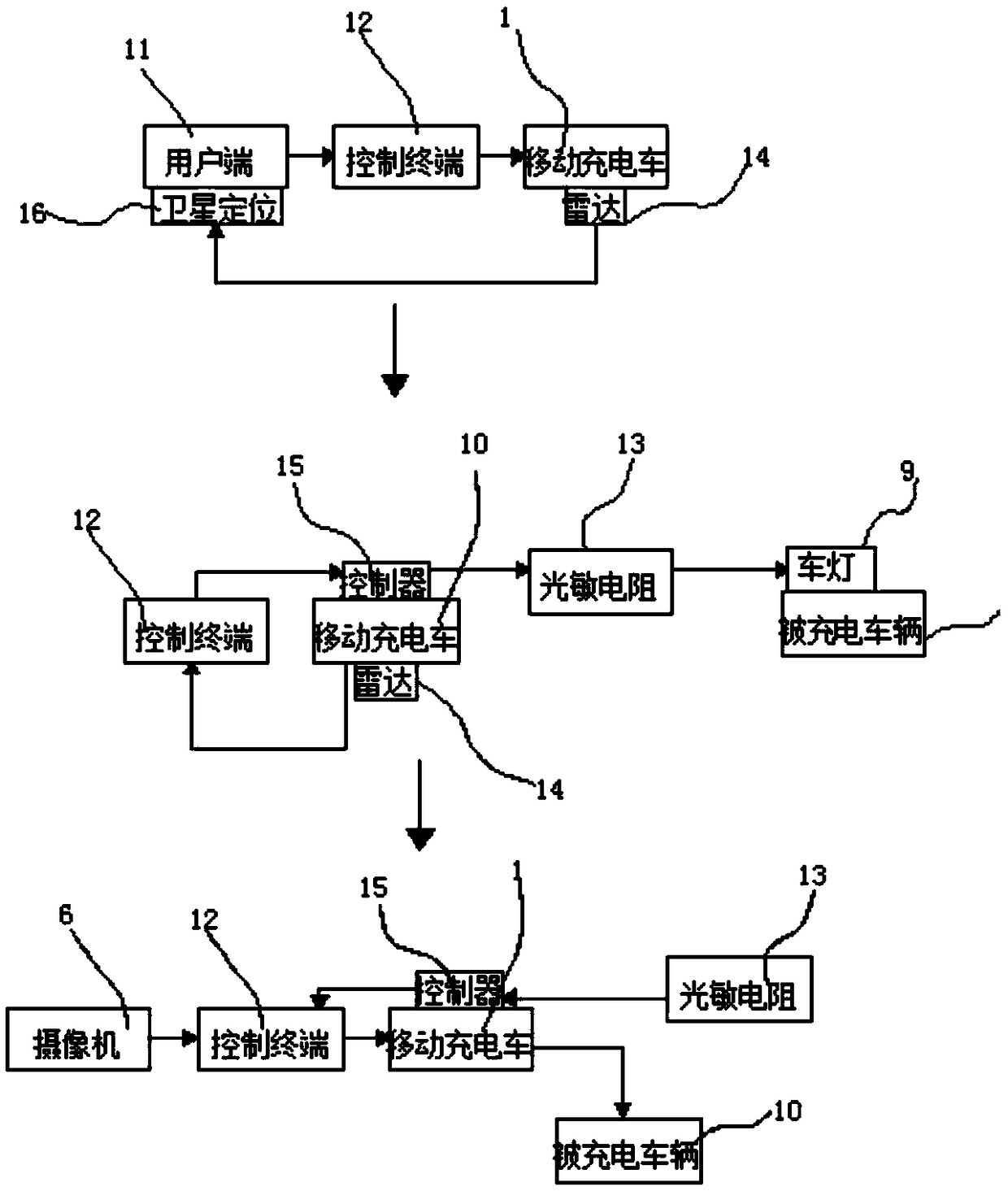

New energy vehicle unmanned driving automatic-butting-type energy storage charging device

InactiveCN109398145AResolution cycleSolve difficultyCharging stationsElectric vehicle charging technologyElectrical resistance and conductanceRadar

The invention discloses a new energy vehicle unmanned driving automatic-butting-type energy storage charging device. The new energy vehicle unmanned driving automatic-butting-type energy storage charging device comprises an unmanned driving charging vehicle body, a charged vehicle and a remote control terminal; and the vehicle tail of the charged vehicle is provided with a charging port, vehicle lamps are mounted on the two sides of the vehicle tail of the charged vehicle correspondingly, a radar is mounted on the upper surface of the unmanned driving charging vehicle body, a guiding hole is formed in the position, corresponding to the charging port, of the vehicle head of the unmanned driving charging vehicle body, a guiding column is inserted into the guiding hole, one end of the guidingcolumn is exposed outside the guiding hole, and the circumferential exterior of the exposed part of the guiding column is connected with a compensation spring in an inserted mode. The magnetic attraction mode is replaced with a photoresistor mode, only a photoresistor pair is completely aligned with the vehicle lamp remote control terminal, a charging signal can be received, when the photoresistor pair is completely aligned with the vehicle lamp, a charging plug is aligned with the charging port, and thus alignment is more convenient without deviation.

Owner:瑾圣新能源(上海)有限公司

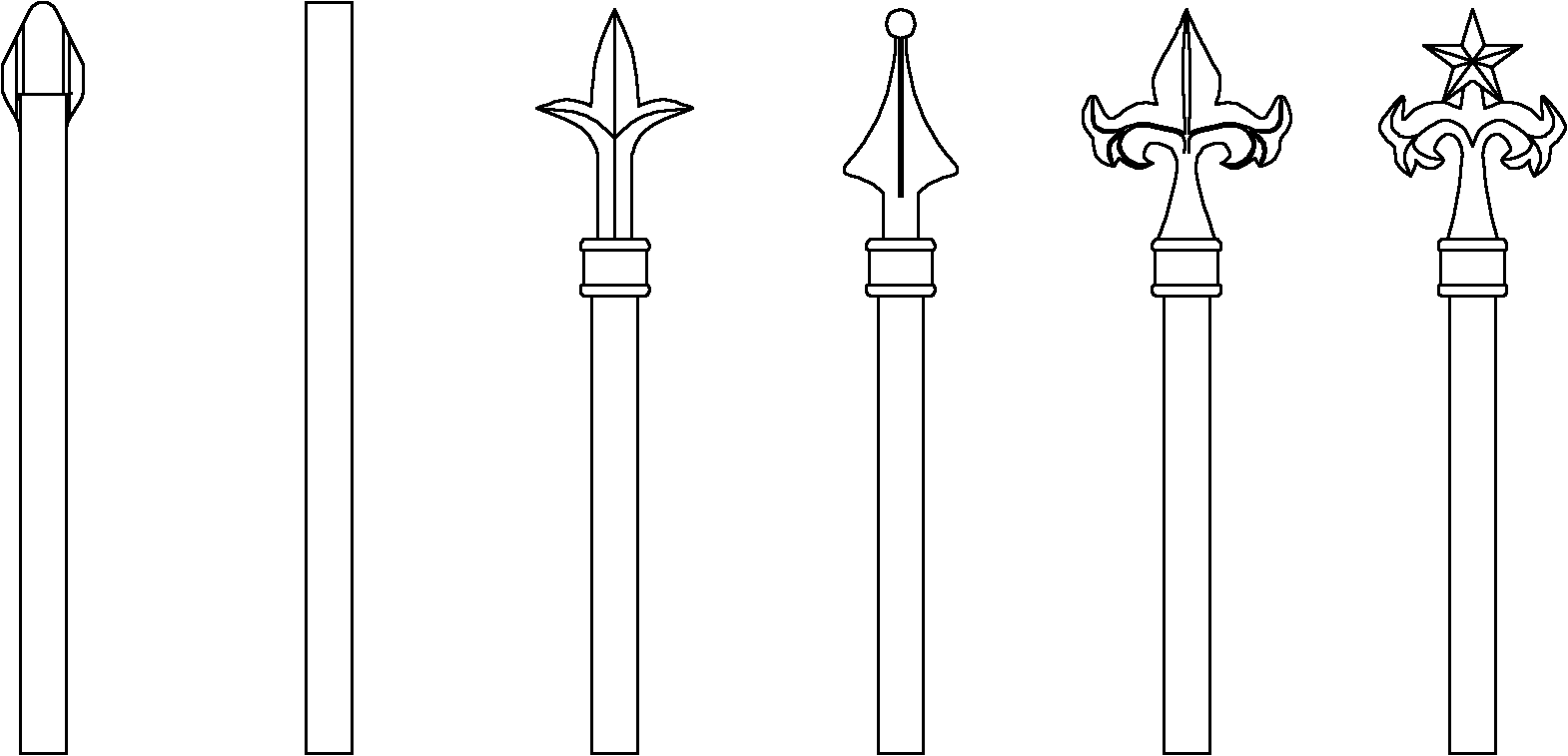

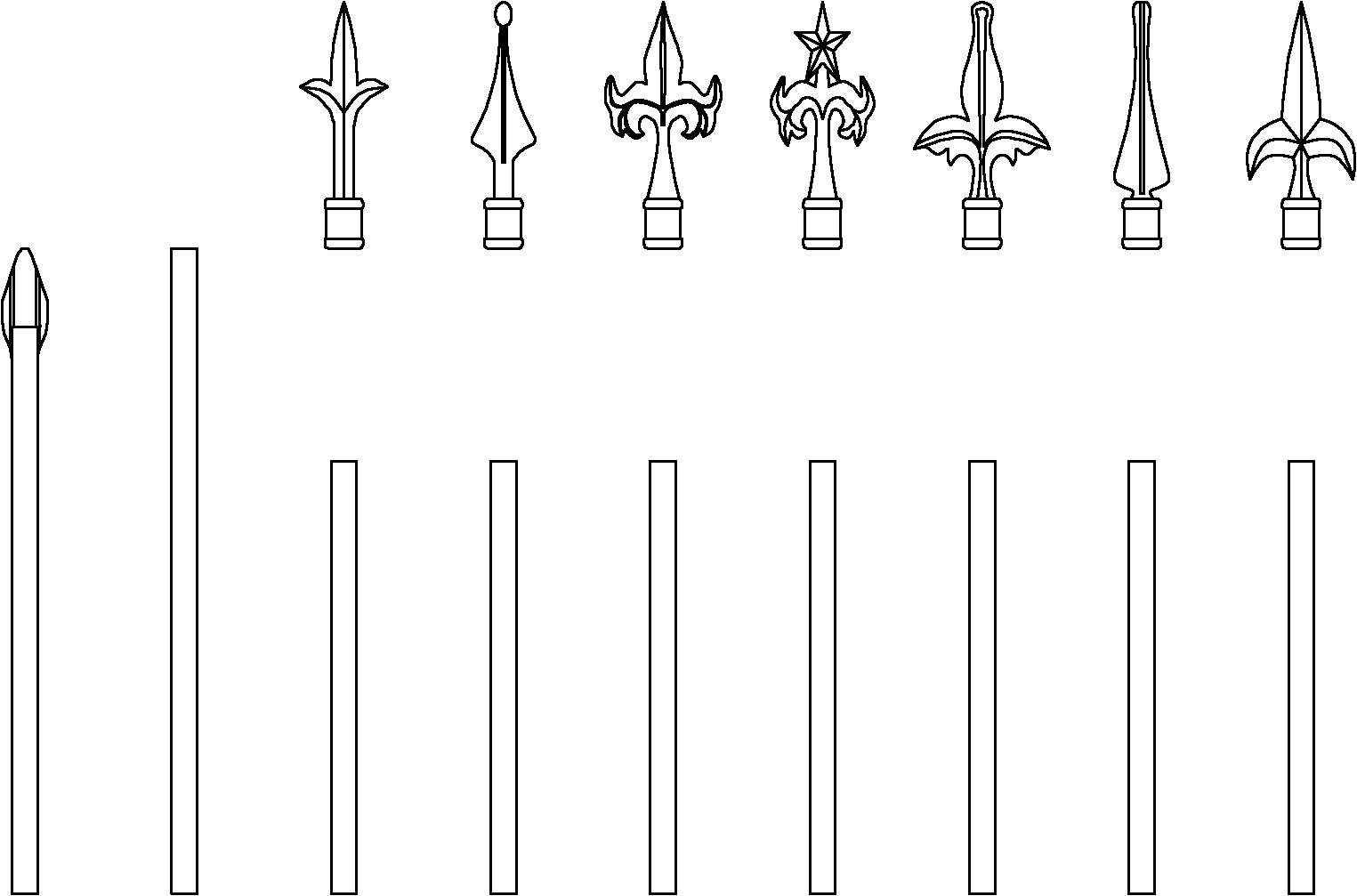

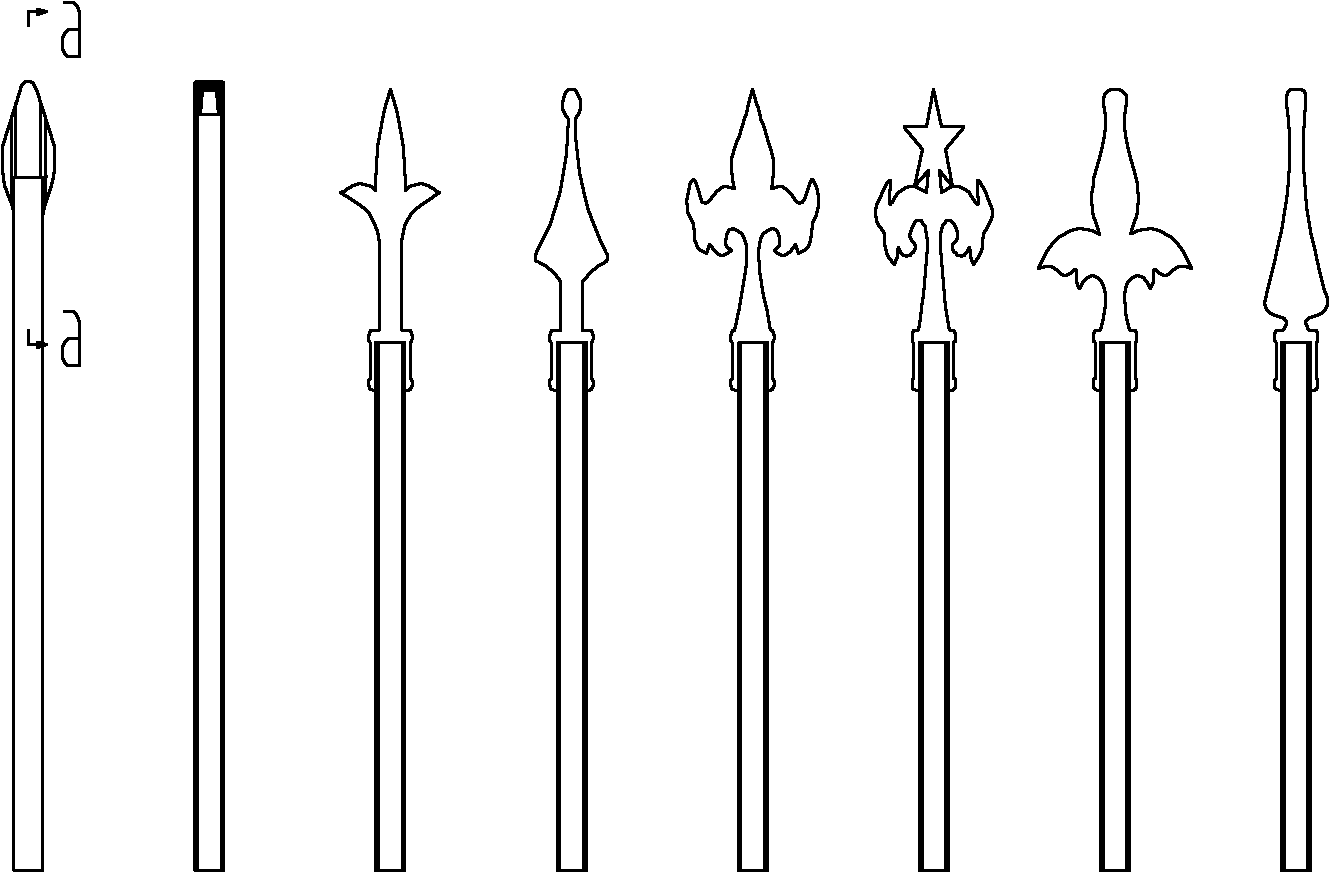

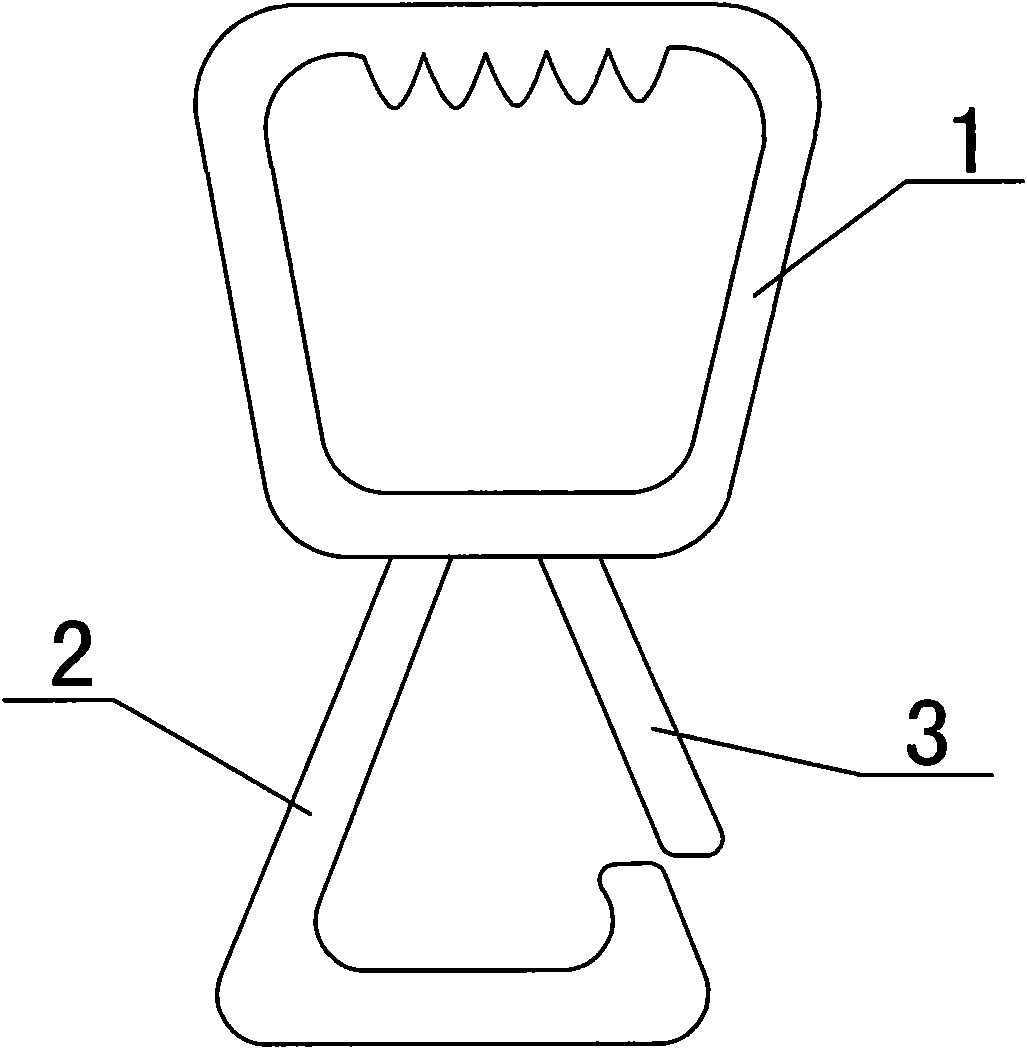

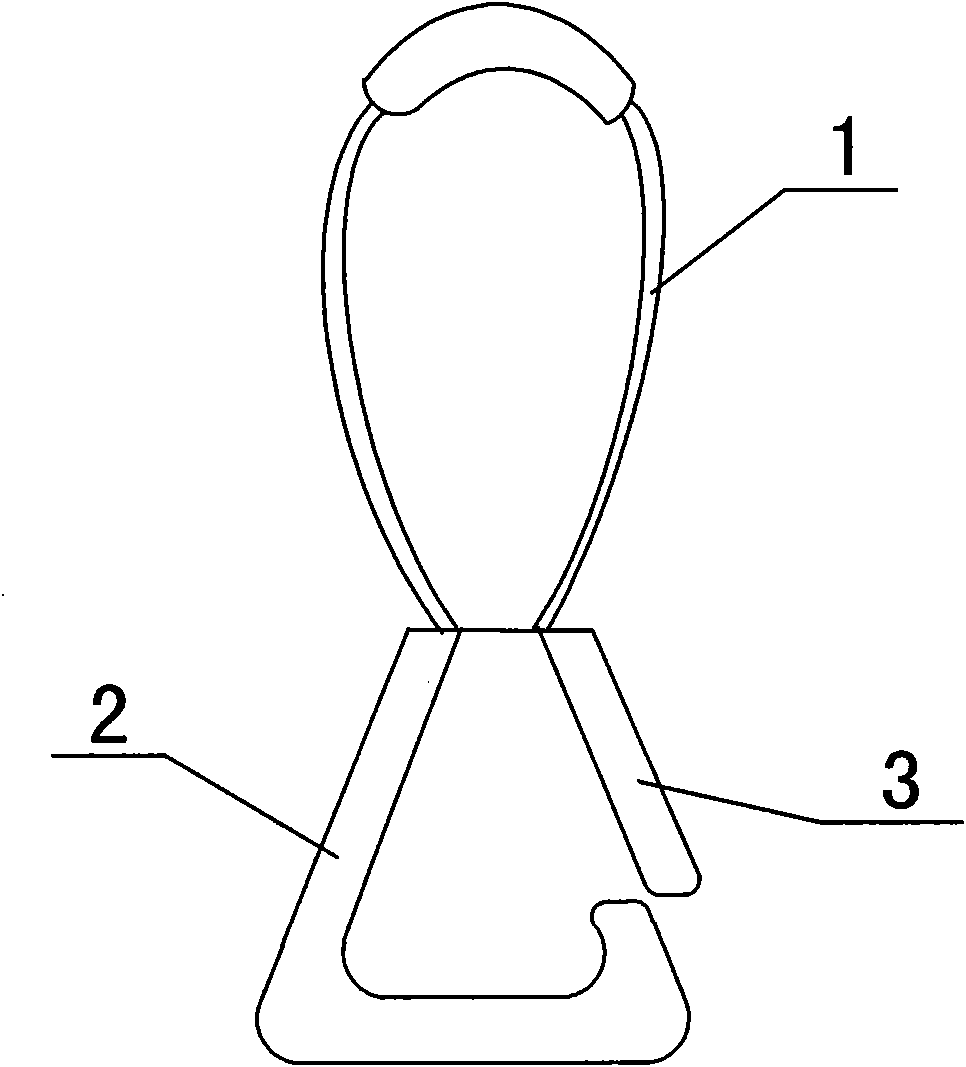

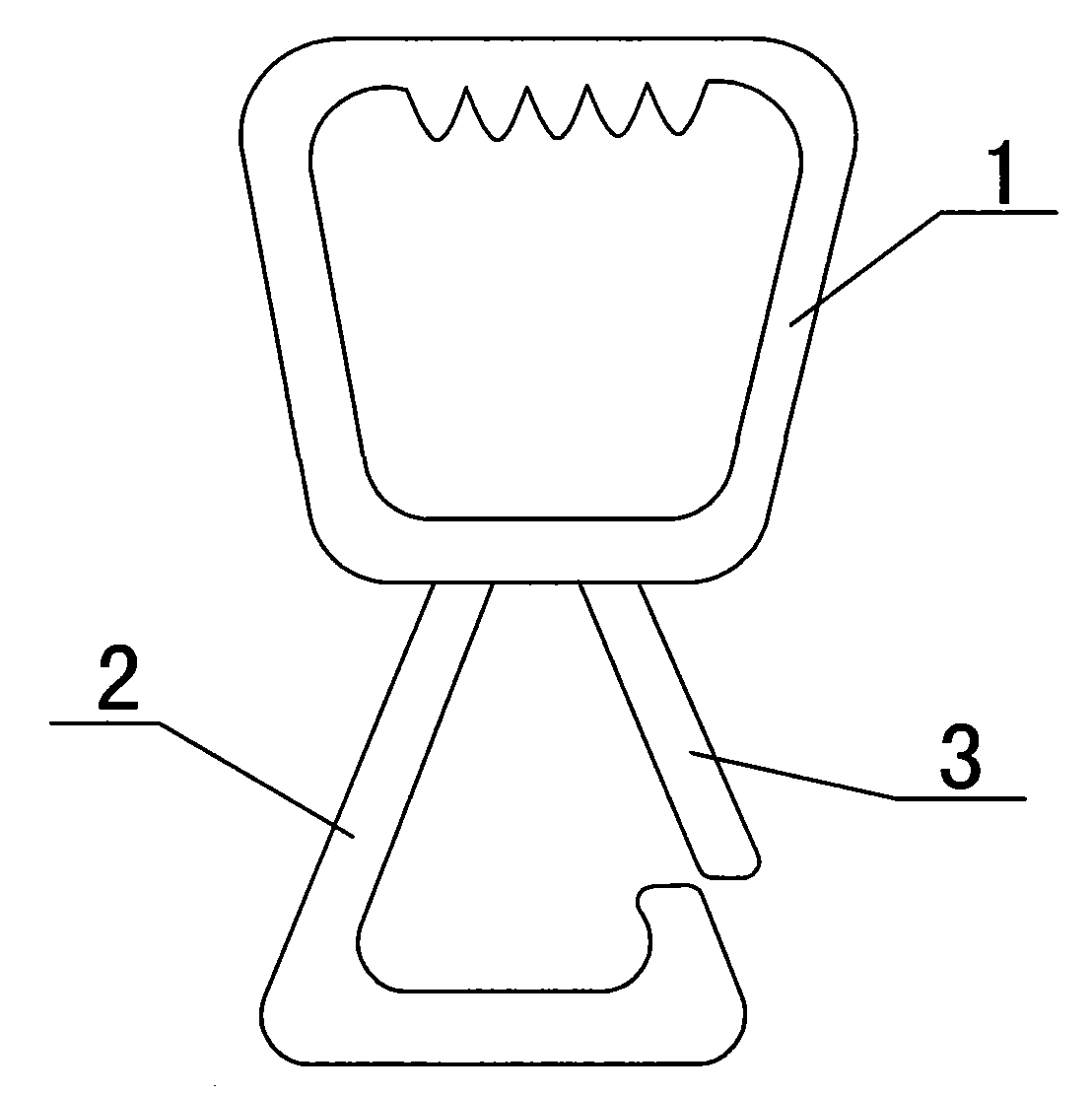

Assembly type fence lance

The invention relates to an assembly type fence lance, in particular to a lance assembled on a fence. The fence lance comprises a vertical column and a lance, wherein the lower end part of the lance is a joint type inverted cone bulge, the joint type inverted cone bulge is inserted into a hole of the vertical column in close fit, and the lower end face of the lance is provided with a blind hole. Because the lower end part of the lance is the joint type inverted cone bulge inserted into the hole of the vertical column in close fit, the vertical column can not be pulled out easily. Moreover, the invention has the advantages of convenient installation and attractive appearance.

Owner:WUXI DIF TECH

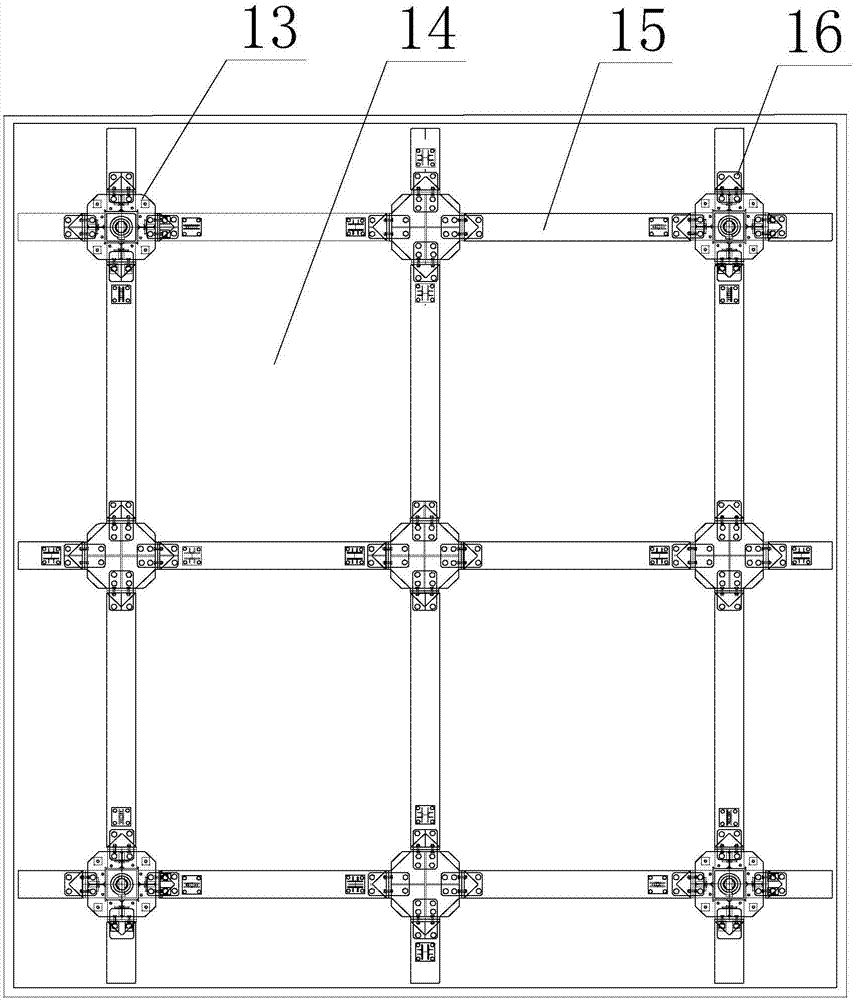

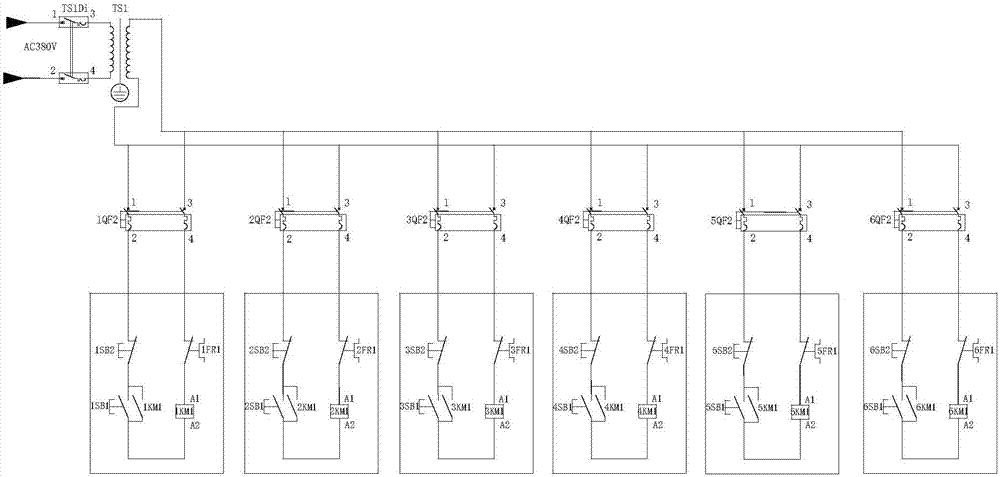

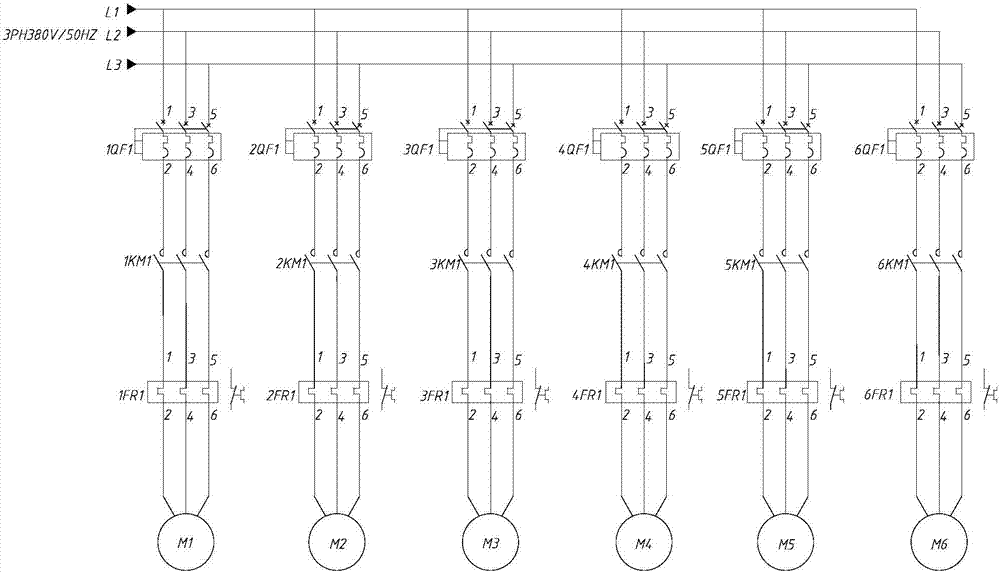

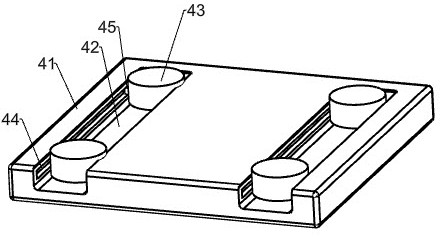

Modular design and quick assembly super high-rise building jacking form and jacking method

ActiveCN107130794AQuick assemblySave installation timeForms/shuttering/falseworksEngineeringModular design

The invention discloses a modular design and quick assembly super high-rise building jacking form and a jacking method. The modular design and quick assembly super high-rise building jacking form comprises a plurality of shaft ways. The shaft ways are parallel to one another, jacking platforms are mounted on the shaft ways, the shaft ways and the jacking platforms are combined with one another to obtain jacking forms, and jacking can be carried out by each jacking platform or the multiple jacking platforms. The modular design and quick assembly super high-rise building jacking form and the jacking method have the advantages that the modular design and quick assembly super high-rise building jacking form and the jacking method are in systematic, integrated and modular designs, mature and standard devices can be sufficiently utilized, and accordingly the purposes of quick construction and the optimal comprehensive economic benefit indexes can be achieved; the modular design and quick assembly super high-rise building jacking form and the jacking method are short in mounting and jacking preparation time, effects of optimal work efficiency and economic benefits can be realized, steel platforms can be integrally and locally jacked, precision control in service procedures can be greatly improved, and jacking requirements of the steel platforms at different locations can be met without influence on the integral construction progress.

Owner:SICHUAN HUASHI GRP CO LTD +2

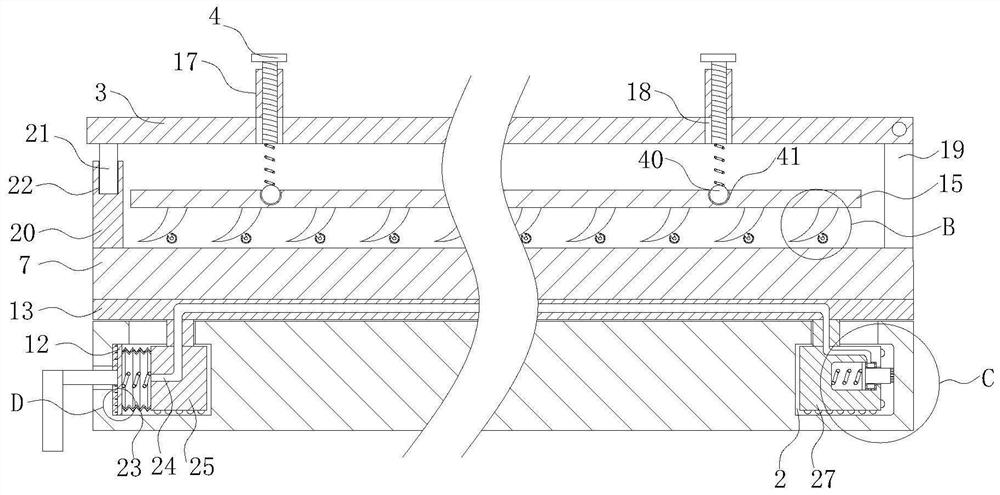

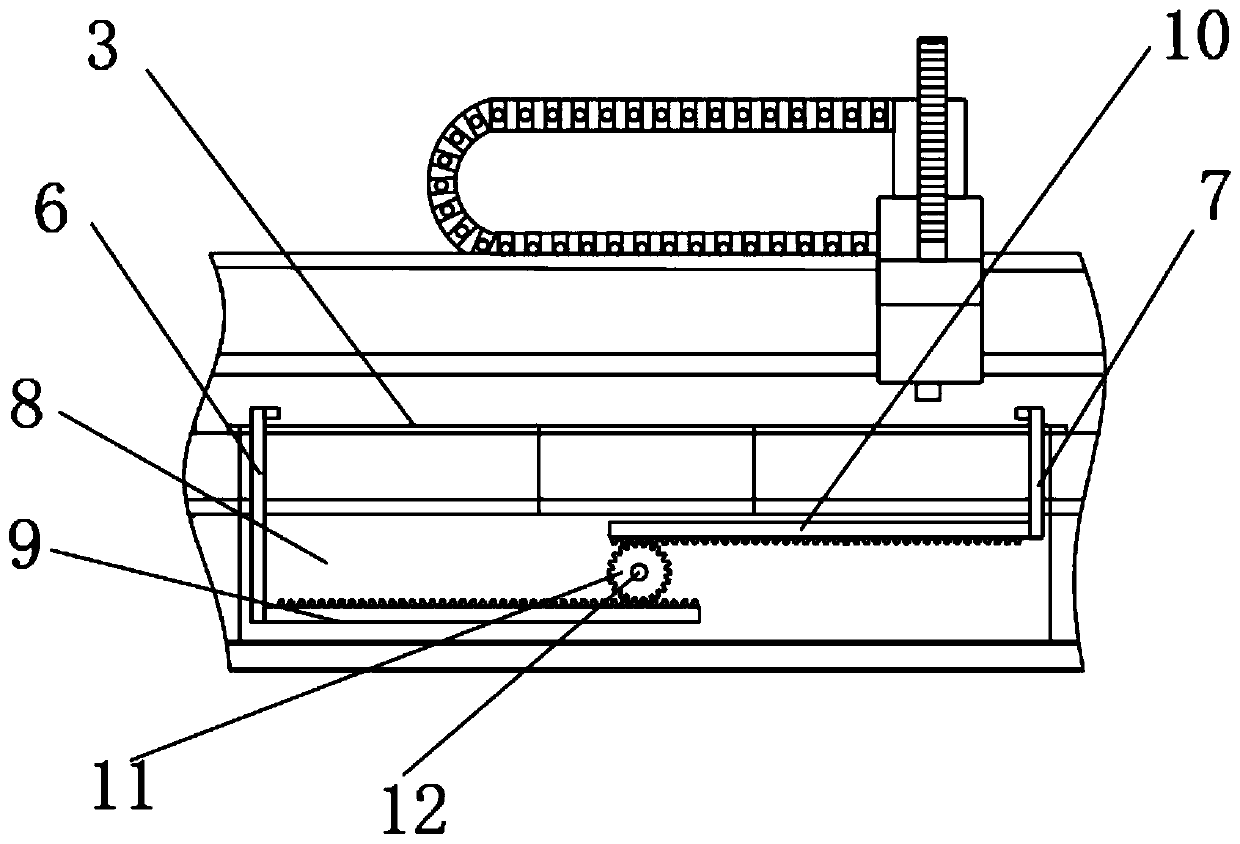

High-stability wire harness winding device for automobile electric pedal

InactiveCN108944691AIncrease frictionWon't pull outSteps arrangementElectric/fluid circuitPull forceEngineering

The invention provides a high-stability wire harness winding device for an automobile electric pedal, and relates to the technical field of wire harness winding devices. The high-stability wire harness winding device for the automobile electric pedal comprises a device box. A wire inlet is formed in the top of the device box. Mounting blocks are fixedly mounted at the top of the inner wall of thedevice box. Rotating rods are movably mounted on the mounting blocks. Rotating shafts are movably mounted at the ends, away from the mounting blocks, of the rotating rods. A mounting table is fixedlymounted on the right side of the inner wall of the device box. A rotating rod is arranged on the right side of the device box in a penetrating mode. According to the high-stability wire harness winding device for the automobile electric pedal, movable rods are arranged and movably connected with driving rods, and thus friction force between rotating wheels and a wire harness is increased; a rotating button is arranged, and thus the wire harness is in a fixed state; and springs are arranged, and thus the springs provide pull force for moving rods.

Owner:芜湖勇沃汽车部件有限公司

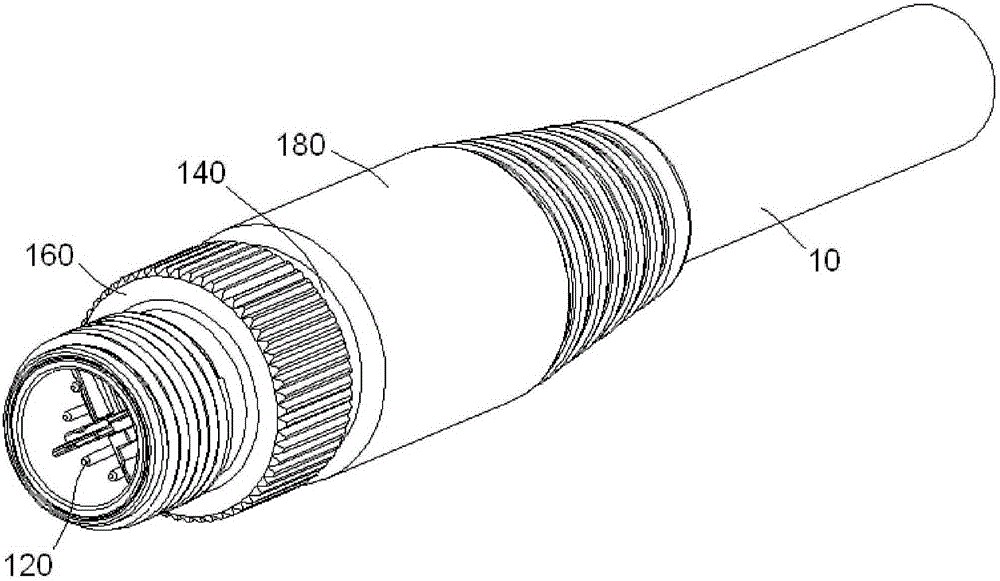

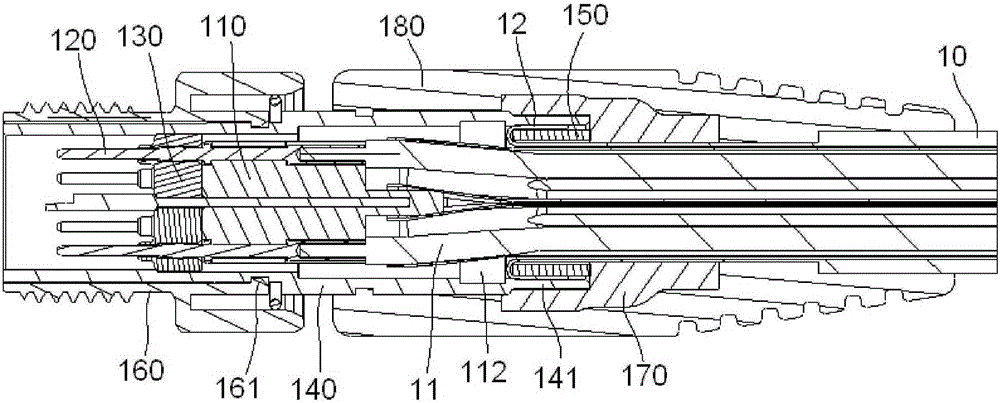

Connector

InactiveCN106450944AImprove joint strengthSimple structureRelieving strain on wire connectionTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a connector. The connector comprises an insulation body; a conductive terminal, which is disposed on the insulation body, and is suitable for being electrically connected with a conductor exposed out of a cable; and a shielding bushing, which is disposed on the insulation body in a sleeved manner. The shielding bushing is an integrated part, and is suitable for accommodating the conductive terminal and the insulation body. The shielding bushing is the integrated part, and therefore the connector has advantages of simple structure, good shielding performance, and ability of reducing production costs.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Anti-drop power plug and socket assembly for material bending machine

InactiveCN112018565AFirmly connectedGuaranteed to workCoupling device detailsElectrical resistance and conductanceRubber membrane

The invention relates to an anti-drop power plug and socket assembly for a material bending machine and belongs to the technical field of material bending machines. The anti-drop power plug and socketassembly for the material bending machine comprises a plug; the bottom of the plug is fixedly connected with two symmetrical insertion pieces; electromagnets are fixedly connected to the inner wallsof the tops of the insertion pieces; resistors electrically connected with the electromagnets are fixedly connected to the inner walls of the inner sides of the insertion pieces; negative plates electrically connected with the resistors are fixedly connected to the inner walls of the inner sides of the insertion pieces. According to the anti-drop power plug and socket assembly for the material bending machine of the invention, a rubber film and a limiting groove are matched for use; when the plug is pulled vigorously by an external force, the plug can quickly move upwards under the action of external force, large centrifugal force is generated, so that a piston block moves downwards and extrudes an electrorheological fluid; the rubber film is extruded and expanded by the electrorheologicalfluid; and the rubber film is clamped with the limiting groove, so that the effect of limiting the plug from falling off is achieved, electric power stable connection of the material bending machineis guaranteed, and normal work of the material bending machine is guaranteed.

Owner:李顺清

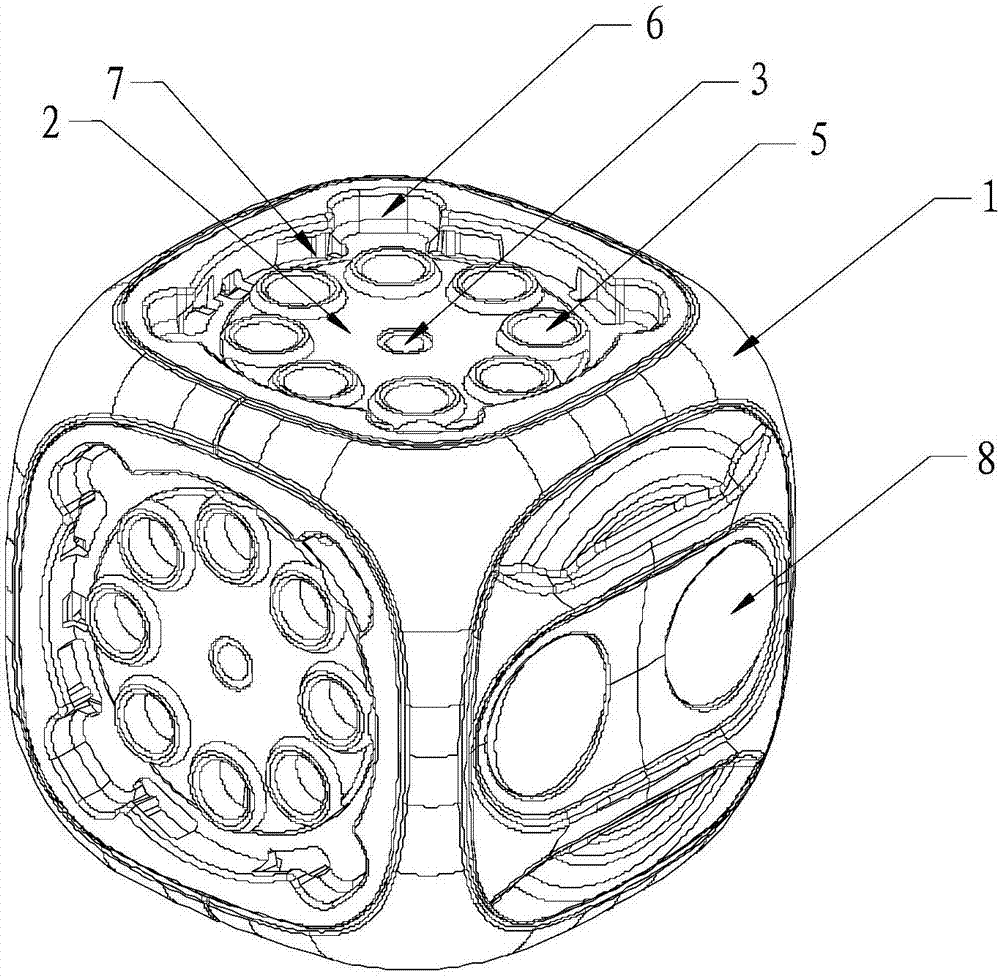

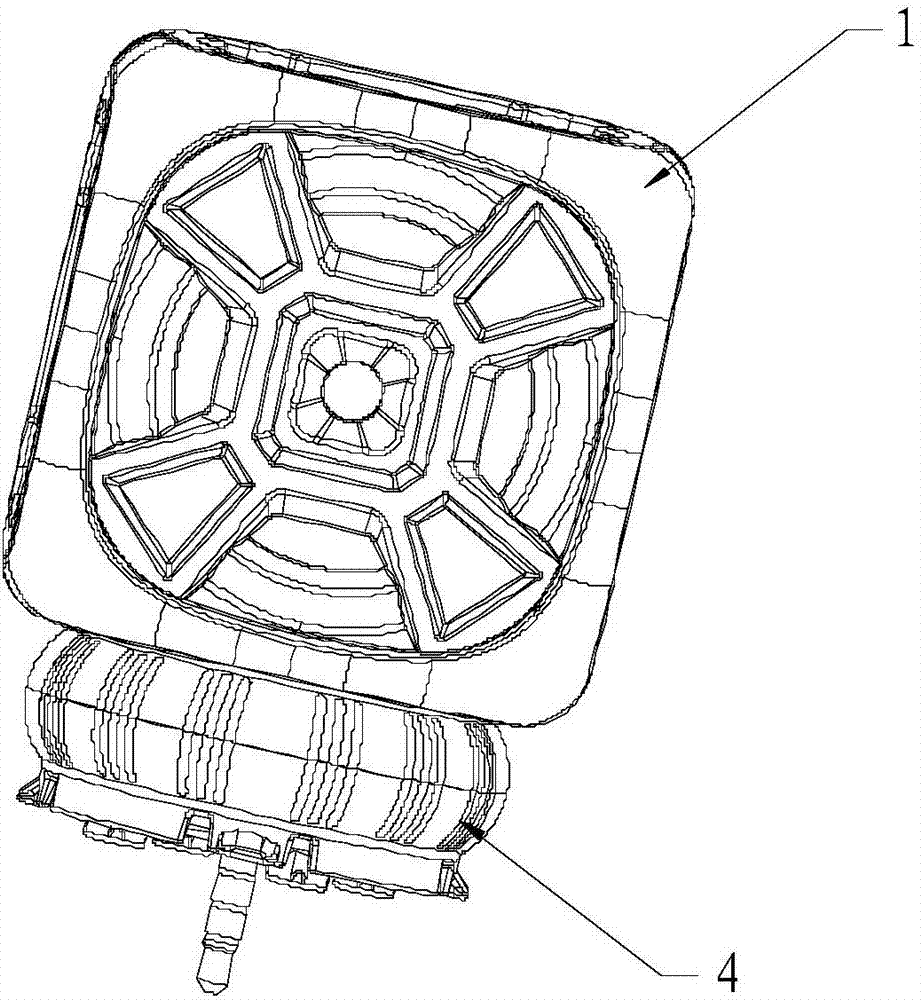

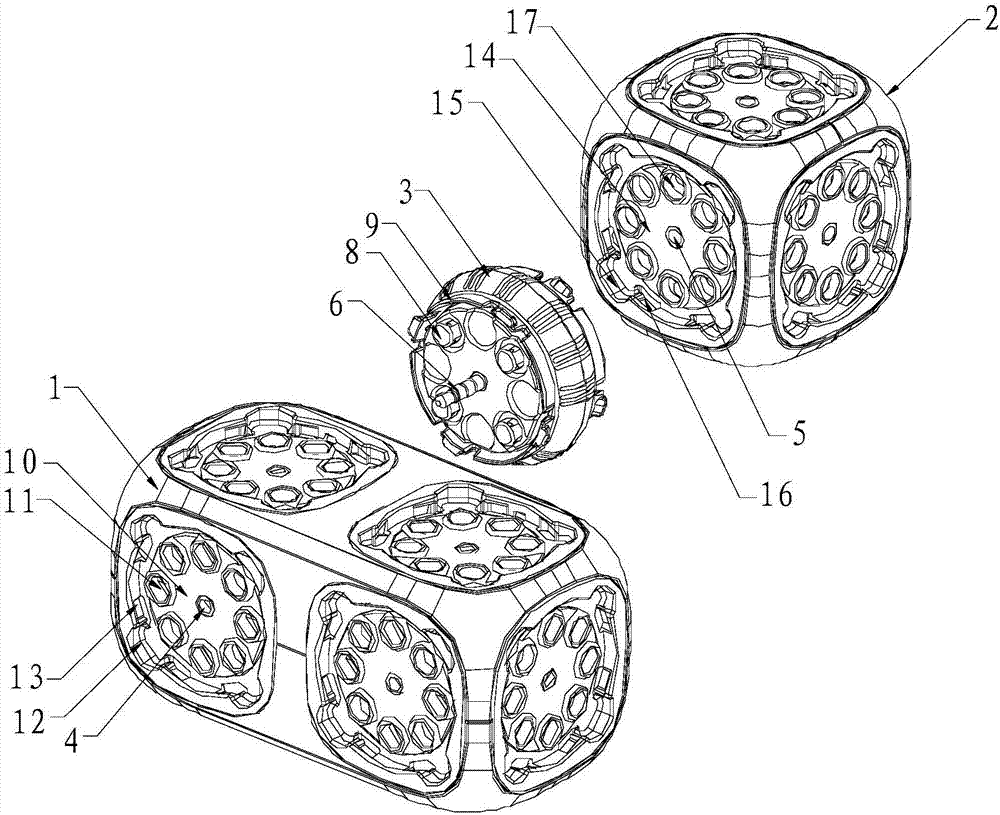

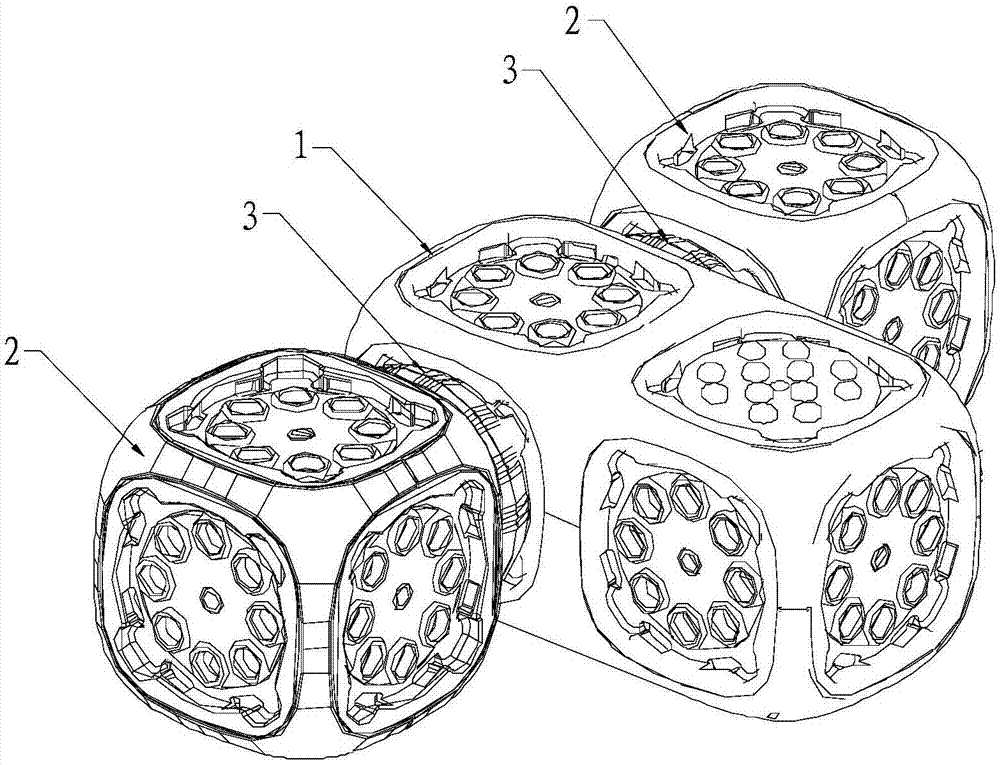

Basic module of intelligent electronic building block

PendingCN107485866AEnsure safetyEasy to rotate and installToysConstruction engineeringElectrical connection

The invention relates to a basic module of an intelligent electronic building block. The basic module comprises a module body and a control main board arranged in the module body; the module body is provided with a mounting part, a fixing part and a connecting port; one side of the module body is recessed inwards to form the mounting part; the fixing part is arranged in the mounting part and used for being fixedly connected with an electronic building block connecting piece, and the connecting port is formed in the mounting part and electrically connected with the control main board. The basic module can be in circuit connection and data transmission with the electronic building block connecting piece so that various functions of the electronic building block can be achieved, all electronic device parts are not exposed, and the safety of children during playing is greatly guaranteed.

Owner:广州启麟智能科技有限公司深圳分公司

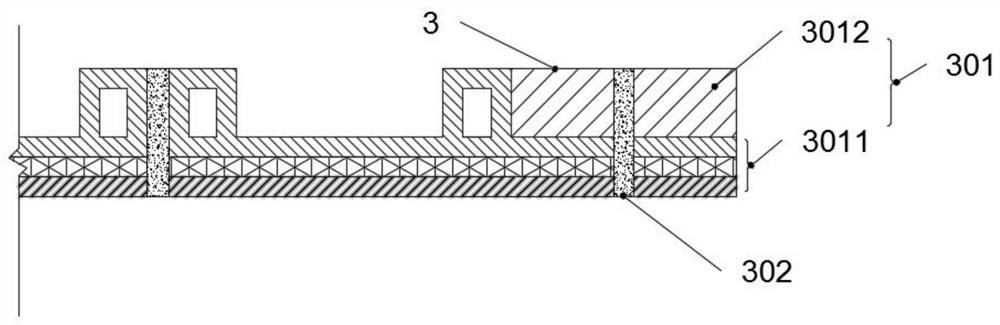

Prefabricating, splicing and connecting structure for partially unbonded grouting sleeve and construction method

PendingCN114000656AAdequate bonding and anchoringPhenomena that allow slippageBridge structural detailsBridge erection/assemblyBridge engineeringArchitectural engineering

The invention relates to the technical field of bridge engineering, in particular to a partially unbonded grouting sleeve prefabricating, splicing and connecting structure and a construction method. According to the method, a layer of anti-corrosion lubricating grease is smeared on the bearing platform overhanging steel bar with a certain length in the grouting sleeve, the sleeve with the corresponding length sleeves the bearing platform overhanging steel bar, and the two ends of the sleeve are subjected to water sealing treatment through flexible sealant, so that the bearing platform overhanging steel bar in the grouting sleeve forms a steel bar unbonded section with a certain length. The connection stress of the pier and the bearing platform in normal use is guaranteed, and the energy dissipation capacity of the pier can be improved through sliding friction of the bearing platform overhanging steel bar in the grouting sleeve under the action of an earthquake. Meanwhile, the whole system has the advantages of simple structure, convenience in construction, high economical efficiency and the like, and is convenient to popularize and apply.

Owner:TONGJI UNIV

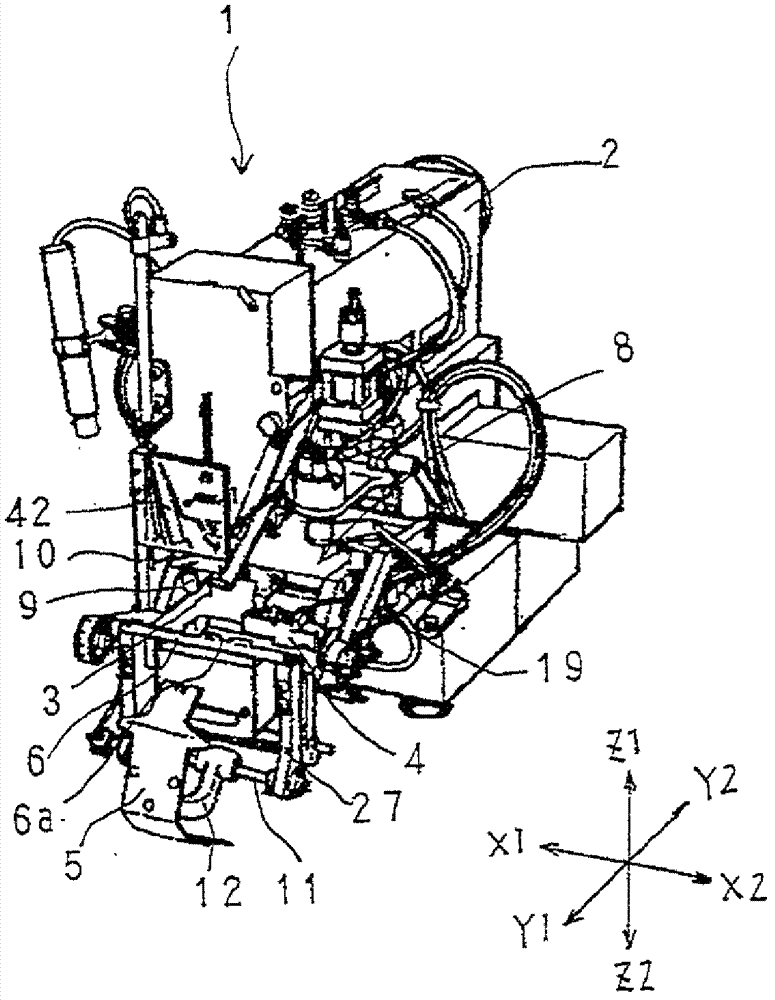

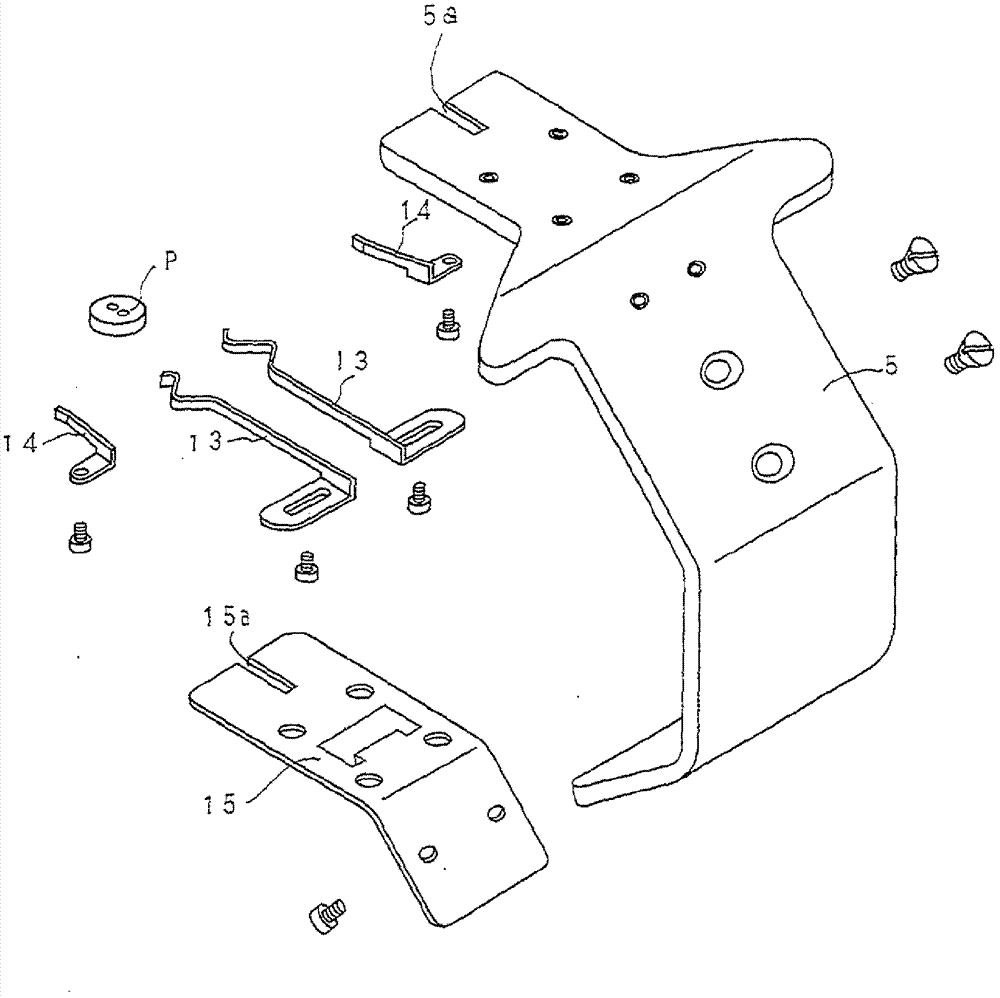

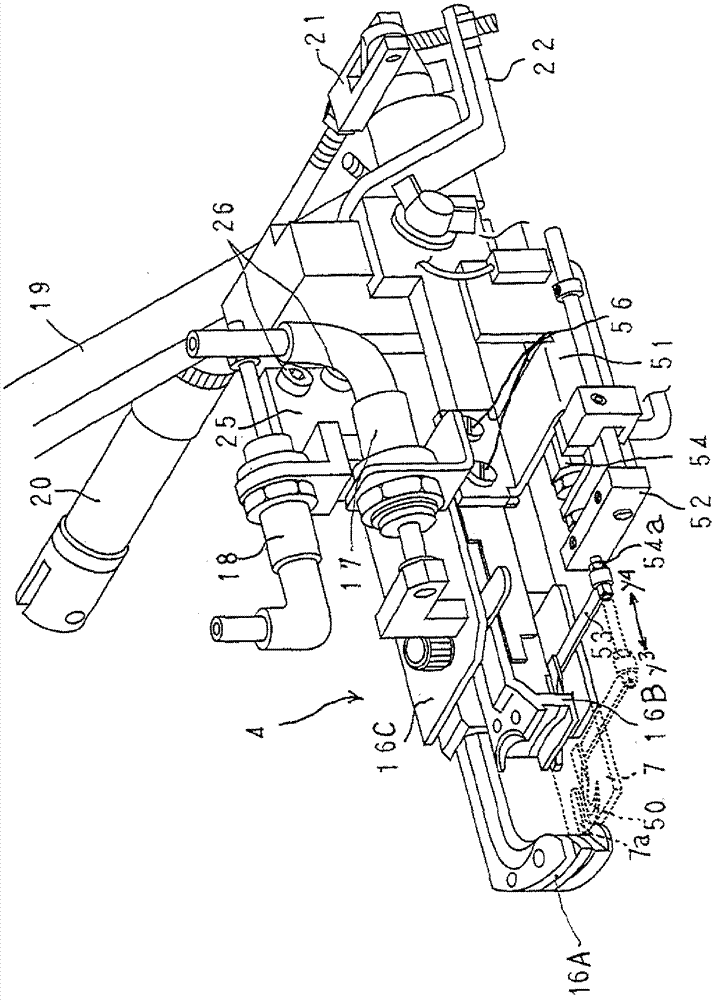

Button sewing method and sewing machine for sewing buttons

InactiveCN102733099AAvoid getting in the wayWon't pull outNeedle severing devicesEngineeringSewing machine

The present invention relates to a button sewing method and a sewing machine for sewing buttons, wherein the button sewing method comprises the following continuously-implemented steps of: disposing an outer button, a lining button and a cloth on a carrier plate; enabling the two buttons to independently move and simultaneously sewing the buttons on the cloth; keeping the cur-off state of a cut-off end portion of a sewing thread for sewing buttons and keeping the state of the outer button and the cloth; enabling two button supporters to move away from each other; overturning the two buttons to be in a vertical posture; folding the end portion of the cloth hanging downwards due to overturning; repeatedly performing winding first needle motion, and winding second and third needle motions for alternatively threading at both sides of the sewing thread for sewing buttons; cutting off portion of the thread wound at the periphery of the outer button after winding second needle motion; and enabling the two supporters to perform reverted return overturning, thereby enabling the two buttons to be in a horizontal or substantially horizontal posture.

Owner:YAMATO SEWING MASCH MFG CO LTD

Portable handle for shopping bag

The present invention discloses a portable handle for a shopping bag, which comprises an annular portable handle, and is characterized in that the portable handle for shopping bag also comprises an annular hook with a lock, and the annular hook and the annular portable handle are connected as a whole. When the portable handle for shopping bag provided by the invention is used, the lock on the annular hook is opened, and a plurality of shopping bags can be hung on the annular hook, then the lock is buckled up. A plurality of shopping bags can be conveniently carried by using the portable handle provided by the invention, and the loss of shopping bags can not be caused; people are comfortable to carry shopping bags using the portable handle for shopping bag, marks can not be left on the hands of people, and people do not feel pain. Besides, the present invention has the advantages of simple structure, convenient use, low cost, easy promotion and so on.

Owner:上海市复兴高级中学

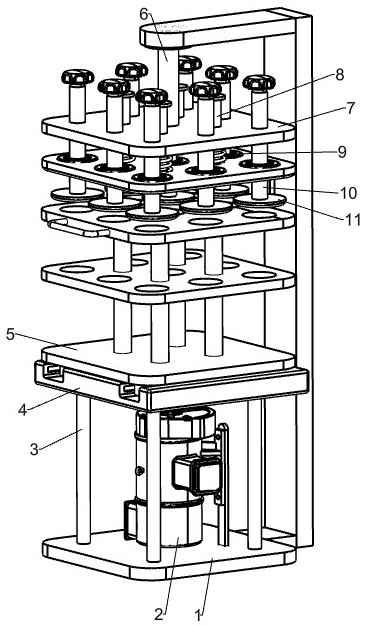

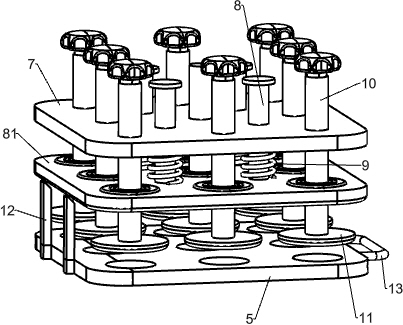

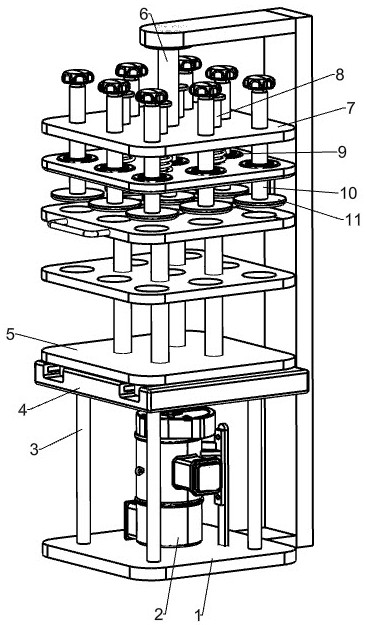

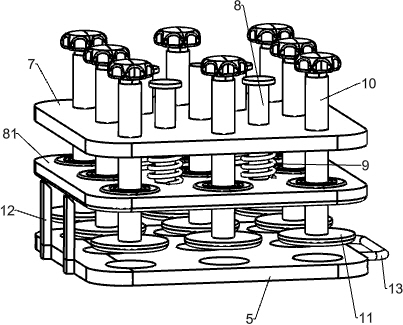

Medicine shaking device for medical care

ActiveCN111603984AEase of useEasy to placeRotating receptacle mixersTransportation and packagingElectric machineryTest tube

The invention relates to a medicine shaking device, in particular to a medicine shaking device for medical care. The medicine shaking device for medical care has the functions of shaking a plurality of liquid medicines and shaking a single liquid medicine. The medicine shaking device for medical care comprises a support, a rotating assembly, a discharging assembly, a test tube rack and a fixing assembly; the rotating assembly is installed in the support and rotates through power provided by a motor; the discharging assembly is installed on the rotating assembly and conducts discharging in a pulling mode; the test tube rack is mounted on the discharging assembly; the fixing assembly is mounted in the support and is used for fixing test tubes in a pulling manner. Medicaments in all test tubes can be mixed conveniently and quickly by controlling the rotation of a gear motor; the test tube rack cannot be pulled out through the cooperation of a linear groove and a sliding shaft, so that thetest tubes filled with the medicaments can be better placed.

Owner:江苏长江慧信息技术有限公司

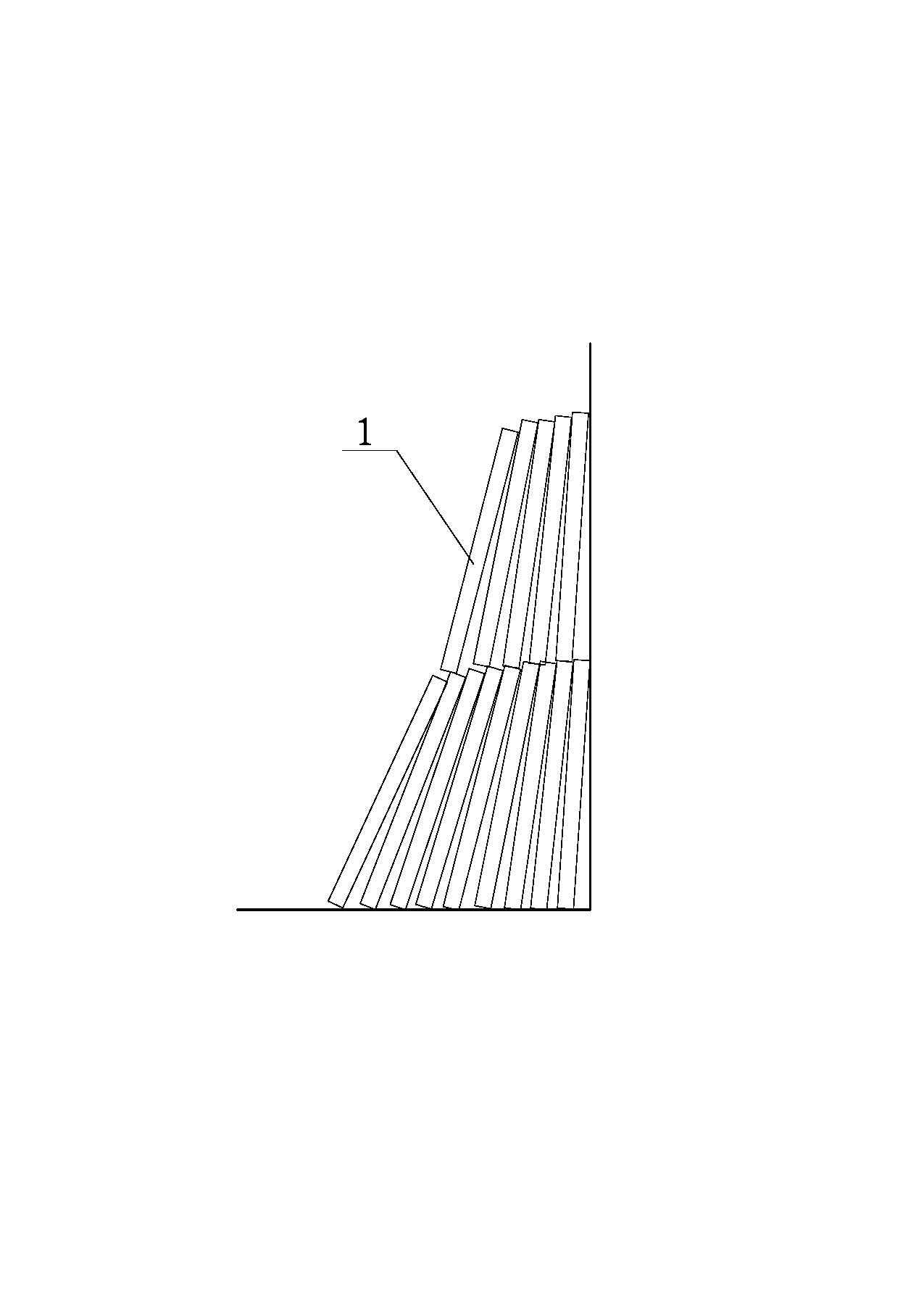

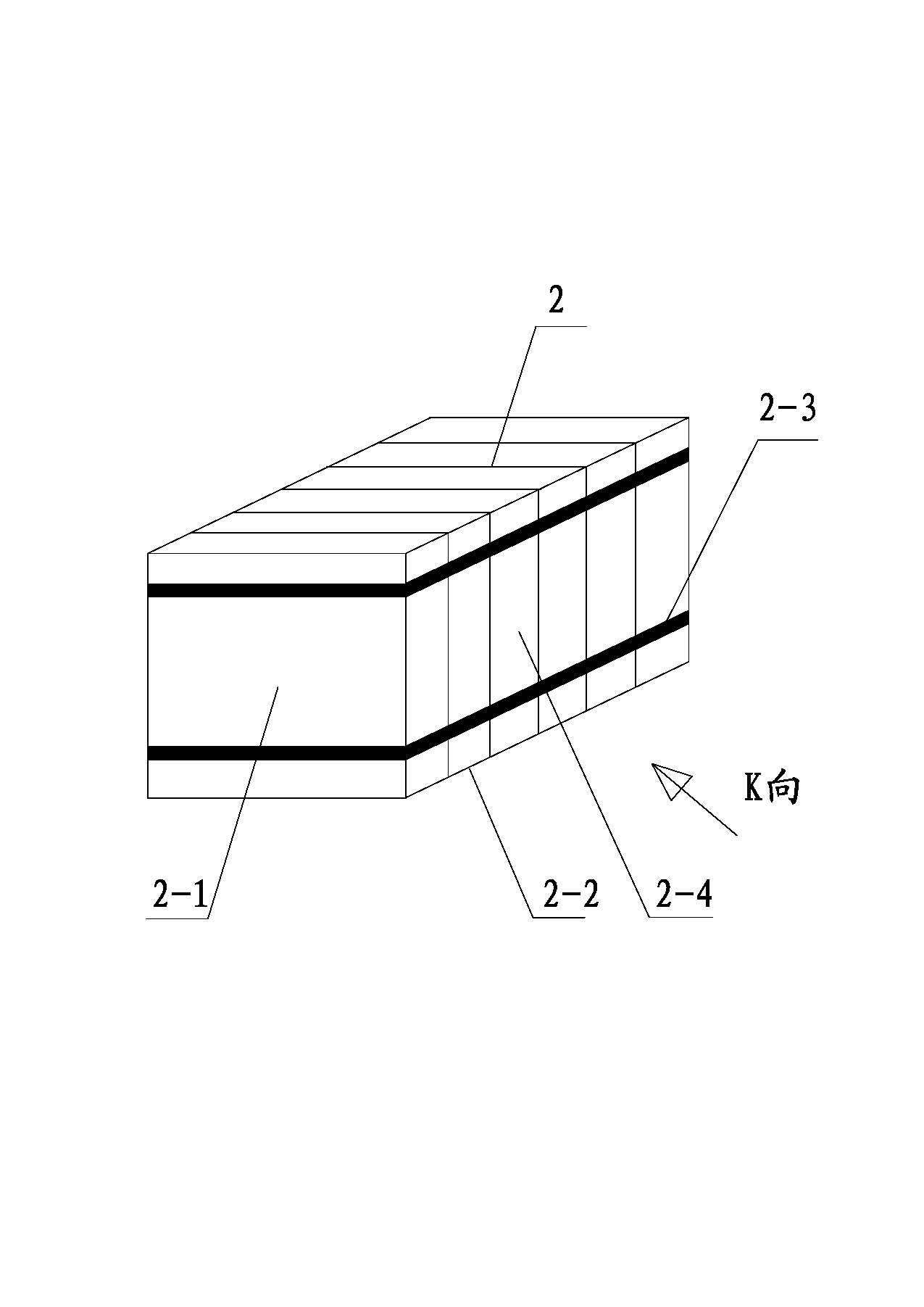

Ceramic tile stack, and stacking method and device for ceramic tiles

InactiveCN102673884AIncrease the number of palletizing layersEfficient use ofStacking articlesContainers with multiple articlesBrickEdge surface

The invention relates to a ceramic tile stack, and a stacking method and device for ceramic tiles, and belongs to the field of storage of the ceramic tiles. The ceramic tile stack comprises brick packages, wherein the brick packages are placed with the bottom edges facing downward. The ceramic tile stack is characterized in that the brick packages cling together to form a ceramic tile flexible container, support body are placed on the ground or table-board of a stacking area, the ceramic tile flexible container is placed on the support bodies with the bottom edge facing downward, and a ceramic tile flexible container is further placed above the bottom ceramic tile flexible container. The support bodies are arranged between upper and lower ceramic tile flexible containers. The support bodies are arranged such a way that the support bodies can support the ceramic tile flexible containers and an inserting and supporting gap exists between the support bodies and the bottom edge surface of the ceramic tile flexible container transversely. The invention has the beneficial effects that the brick packages are not scattered under the effect of strapping tapes by way of strapping the brick packages together to form the ceramic tile flexible containers; the ceramic tile flexible containers are stacked together and do not collapse; the number of the stacking layers of the ceramic tiles can be improved greatly, the space of a warehouse is utilized effectively and the labor intensity of workers is greatly reduced.

Owner:山东润科机电设备有限公司

Water channel sewage plunger

The invention discloses a water channel sewage plunger which can be used for water channel ponding and can automatically return plunger after draining. The water channel sewage plunger is provided with a base; a taphole is arranged in the base and is provided with a plug; the lower part of the base is provided with a water outlet; a water chamber (12) is arranged between the periphery of the plug (2) and the perisporium (16) of the taphole; the plug (2) is arranged above the water outlet; and the bottom of the plug and the bottom surface (15) of a base (1) are respectively provided with magnetic parts (4' and 4). The invention is suitable for serving as water channel plungers.

Owner:王兆保

Molding material

InactiveCN107216582ASmall compression deformationFactors that reduce wearCarbon nanotubePolyvinyl chloride

The invention discloses a molding material. The molding material comprises carbon nanotubes, polytetrafluoroethylene, polyvinyl chloride, calcium carbonate, chlorinated polyethylene, a composite stabilizing agent, titanium dioxide, a modifier, polyethylene wax and stearic acid. The molding material provided by the invention has good anti-compression performance and wear resistance.

Owner:SICHUAN OCEAN PLASTIC CO LTD

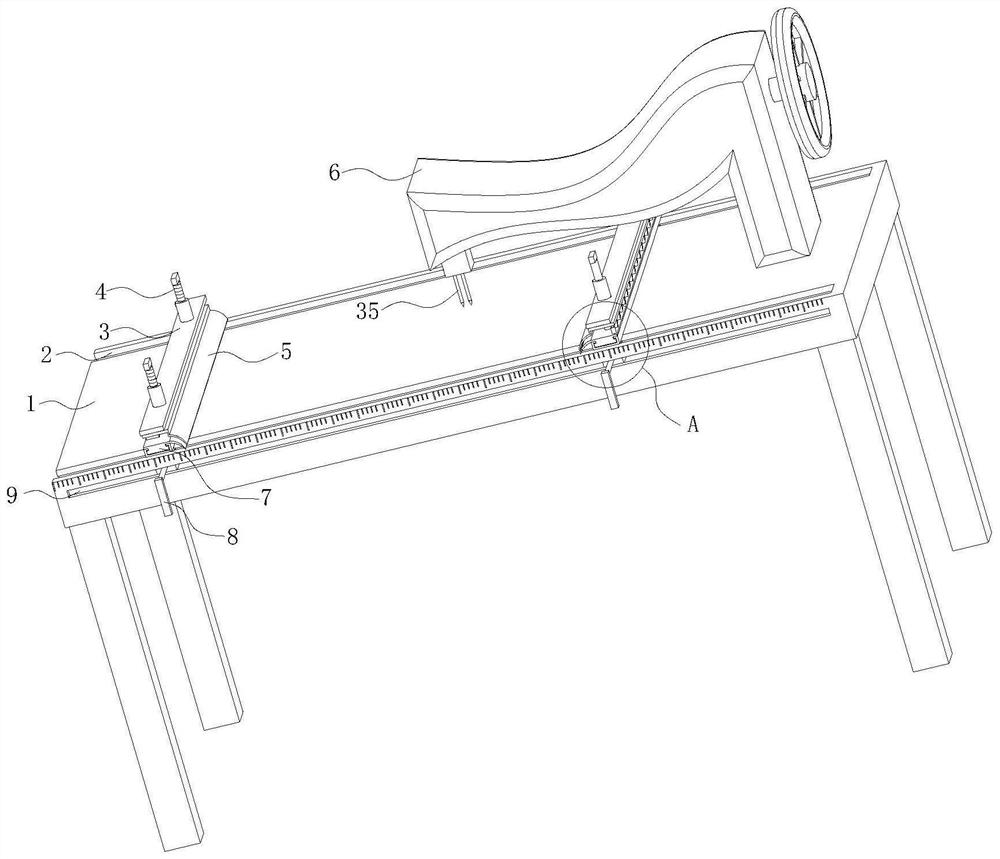

Double-chain stitch sewing machine

The invention belongs to the technical field of double-chain stitch sewing machines, and particularly relates to a double-chain stitch sewing machine which comprises a working platform, a machine base and machine needles, wherein the machine base is fixedly mounted on the upper surface of the working platform; the two groups of machine needles are arranged at the end part of the machine base; horizontal sliding rails are arranged on the front side and the rear side of the upper surface of the working platform; a first sliding block is arranged in the horizontal sliding rail located at the front end in a sliding mode; and a second sliding block is arranged in the horizontal sliding rail located at the rear end in a sliding mode. An elastic pressing plate can press two sides of fabric needing to be sewn to the top of a guide sliding plate, then the position of the fabric is fixed, and then the guide sliding plate is pushed to slide in a limiting sliding groove body, so that threading of the machine needles can be more straight, the stitch neatness of sewn clothes is improved, and thus the quality of the clothes is improved. The device is particularly suitable for being used by a sewing novice, and the situation that a hand is punctured by the needles when the novice puts the fabric needing to be sewn to be close to the machine needles and tightly presses the fabric on the working platform with the hand is avoided.

Owner:徐州力达缝纫设备制造有限公司

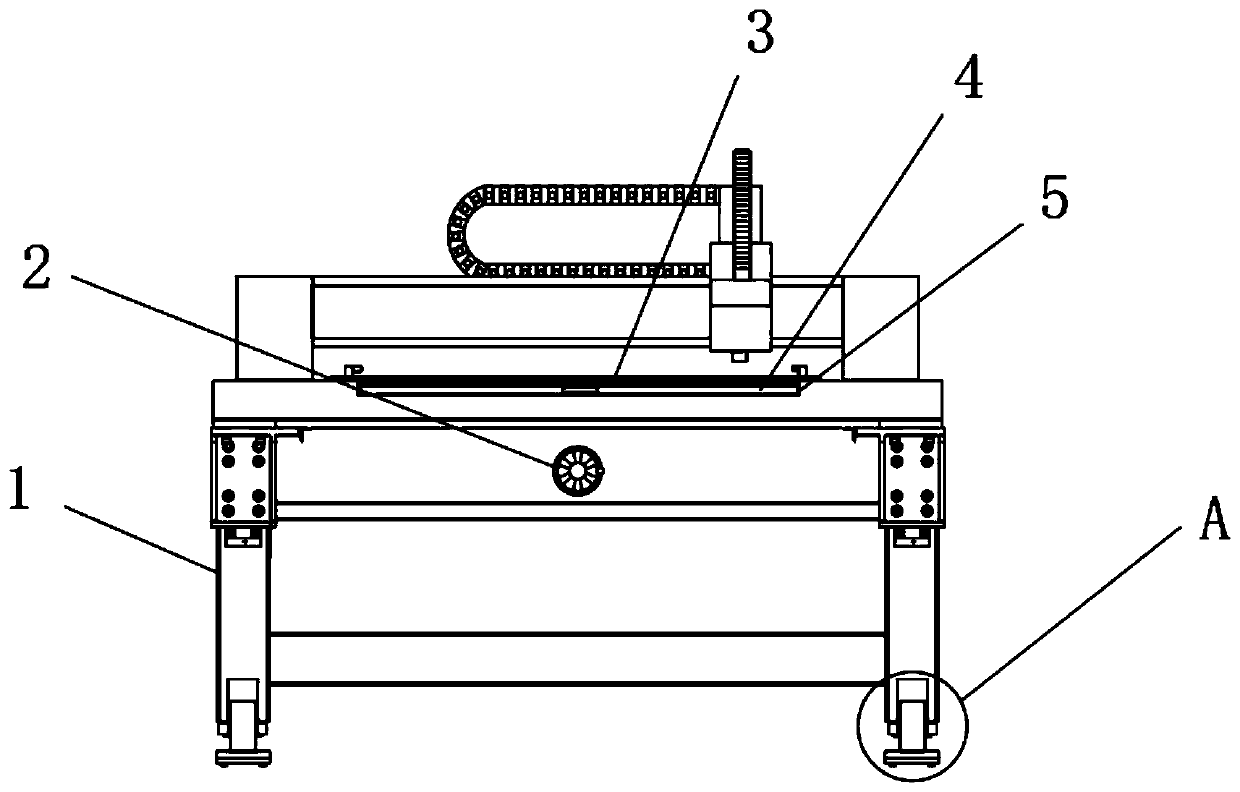

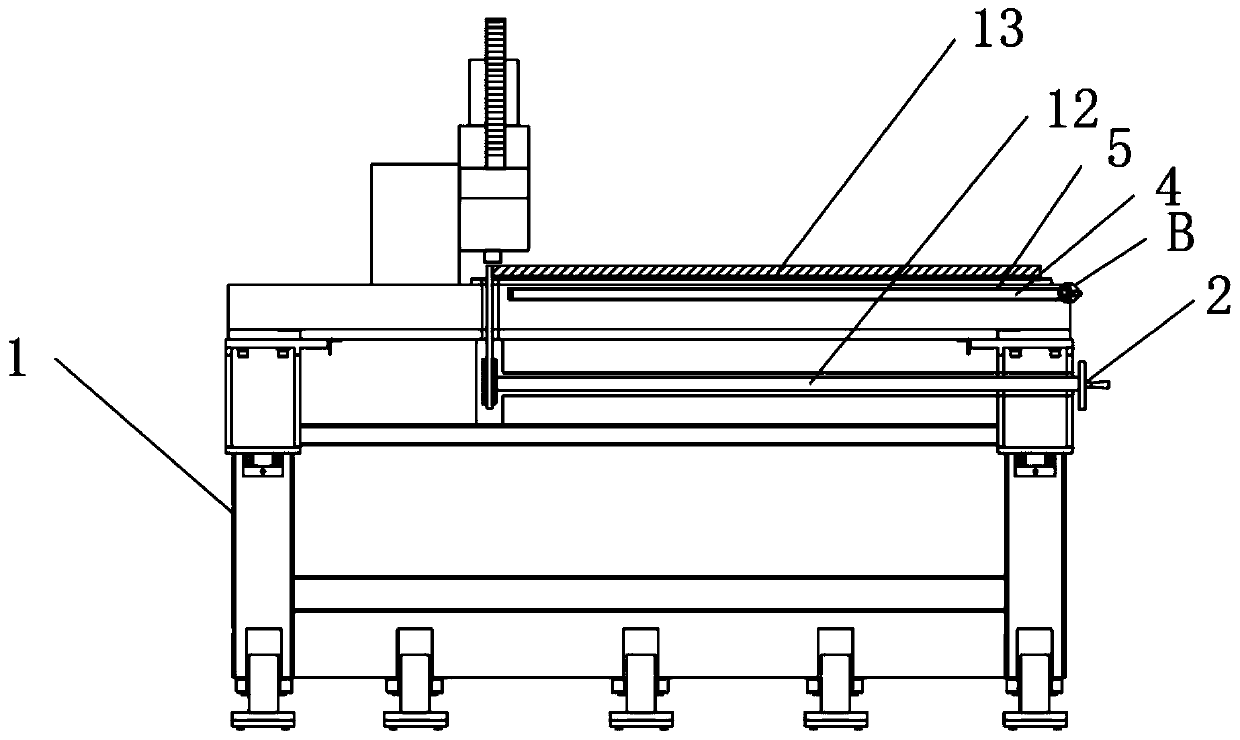

Stable cutting laser cutting machine

The invention discloses a stable cutting laser cutting machine which comprises a laser cutting machine main body, a clamping mechanism, a limiting mechanism and a stabilizing mechanism. The clamping mechanism comprises a limiting slot. The limiting slot is formed in one end of the inner wall of the laser cutting machine main body, an operating table is arranged on the surface of the top end of thelaser cutting machine main body, a first limiting rod is arranged at one end of the inner wall of the limiting slot, the top end of the first limiting rod penetrating the inner wall of the laser cutting machine main body is located on the outer side of the operating table, a first limiting rack is arranged at the end, located on the inner side, of the limiting slot, of the first limiting rod, anda second limiting rod is arranged at the other end of the inner wall of the limiting slot. Compared with the prior art, the stable cutting laser cutting machine has the beneficial effects that by designing the stable cutting laser cutting machine, the separation distance between clamping plates can be adjusted in cooperative use and a cut object is clamped effectively, so that the using effect ofthe laser cutting machine is better, the problem that the laser cutting machine is small in application range is solved, and the stable cutting laser cutting machine is high in practicality.

Owner:江苏觅科激光设备有限公司

Intelligent electronic toy block

The invention relates to an intelligent electronic toy block which comprises a control device, electronic toy block basic components and connecting pieces. Control motherboards are arranged in the control device, first fixing mounting portions and first connecting ports are arranged on each side surface of the control device, and the first connecting ports are electrically connected with the control motherboards; a second fixing mounting portion and a second connecting port are arranged on one side surface of each electronic toy block basic component, and electronic devices which are electrically connected with the corresponding second connecting port are arranged on the other side surface of each electronic toy block basic component; a first insertion component, a second insertion component and connecting positioning portions are arranged at two ends of each connecting piece, and each first insertion component and the corresponding second insertion component are electrically connected with each other; the connecting pieces are inserted in the first connecting ports by the first insertion components, the second insertion components are inserted in the second connecting ports, the connecting positioning portions at the two ends of each connecting piece are matched with the corresponding first fixing mounting portion and the corresponding second fixing mounting portion and are connected with the control device and the corresponding electronic toy block basic components. The intelligent electronic toy block has the advantages that circuit connection and data transmission can be easily and quickly implemented by the intelligent electronic toy block, and the intelligent electronic toy block is high in safety and interestingness.

Owner:广州启麟智能科技有限公司深圳分公司

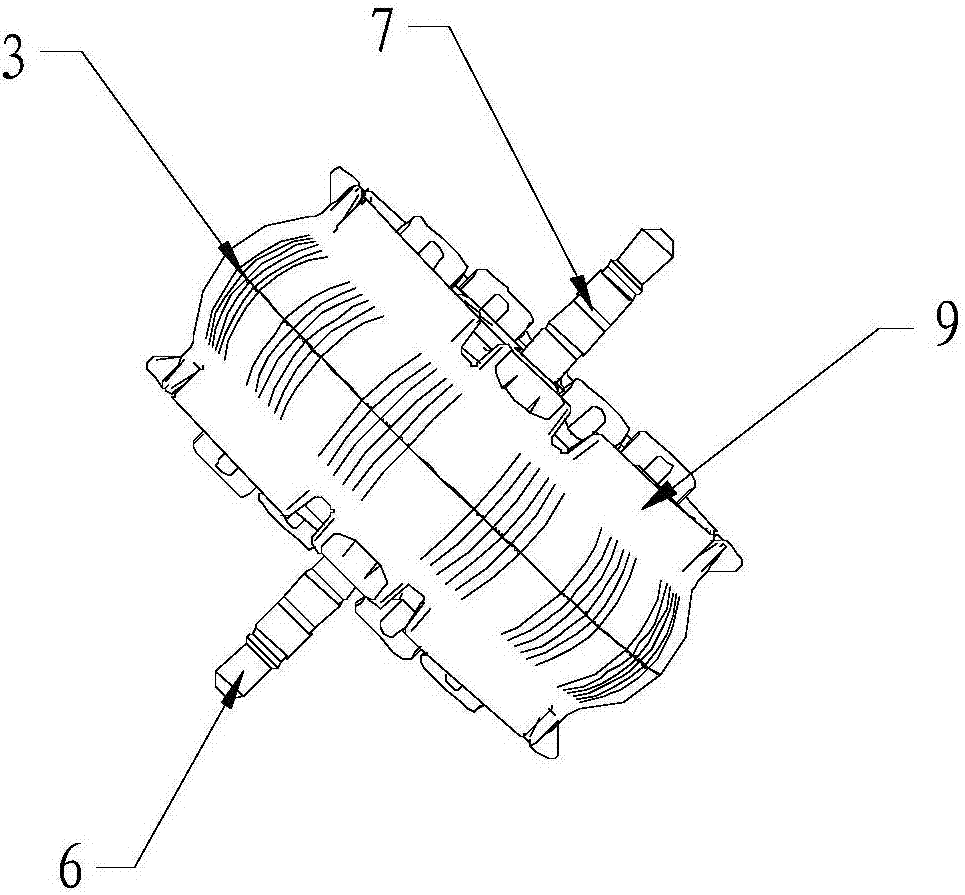

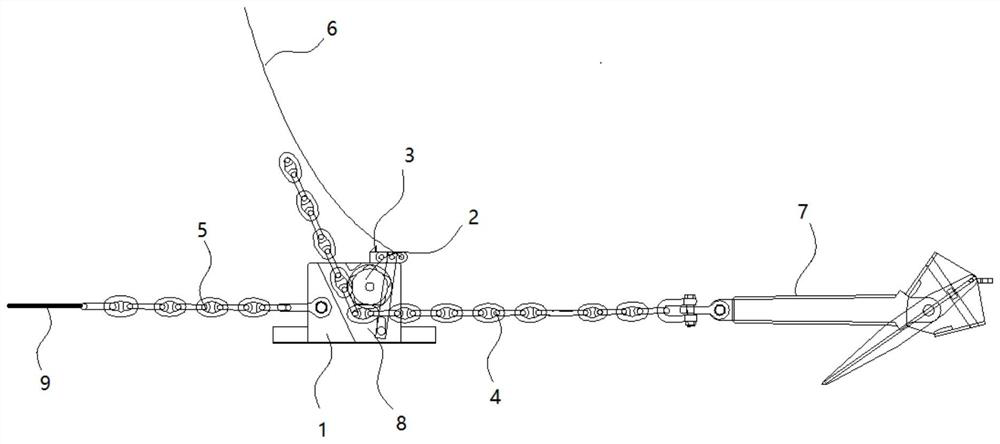

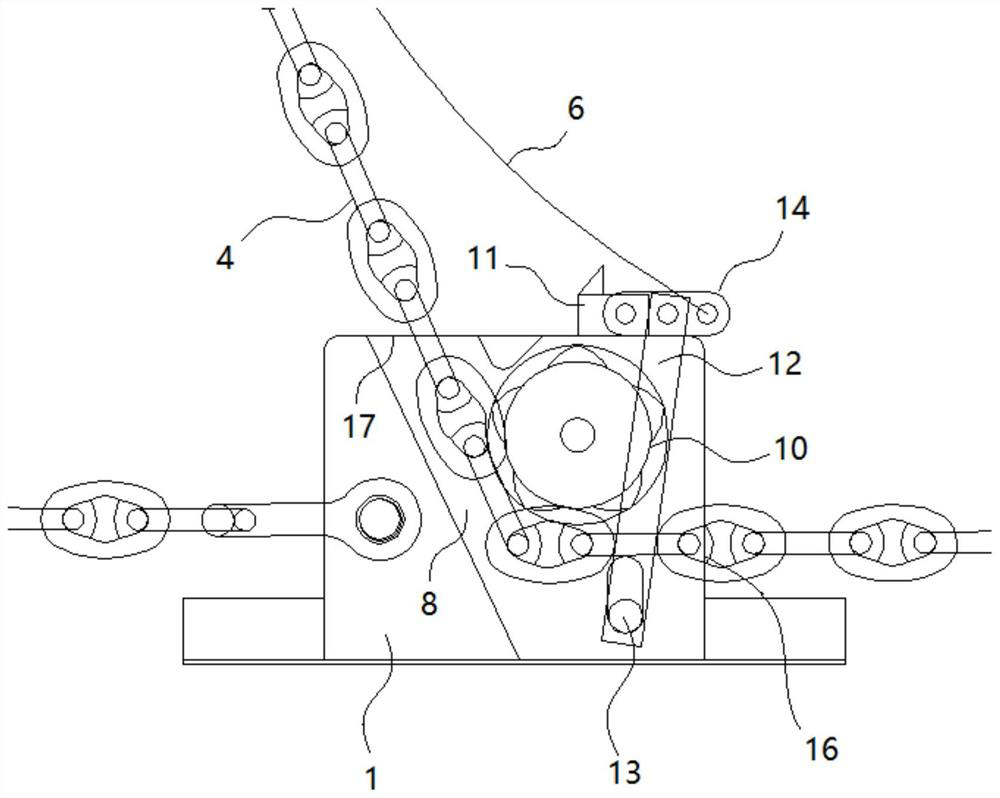

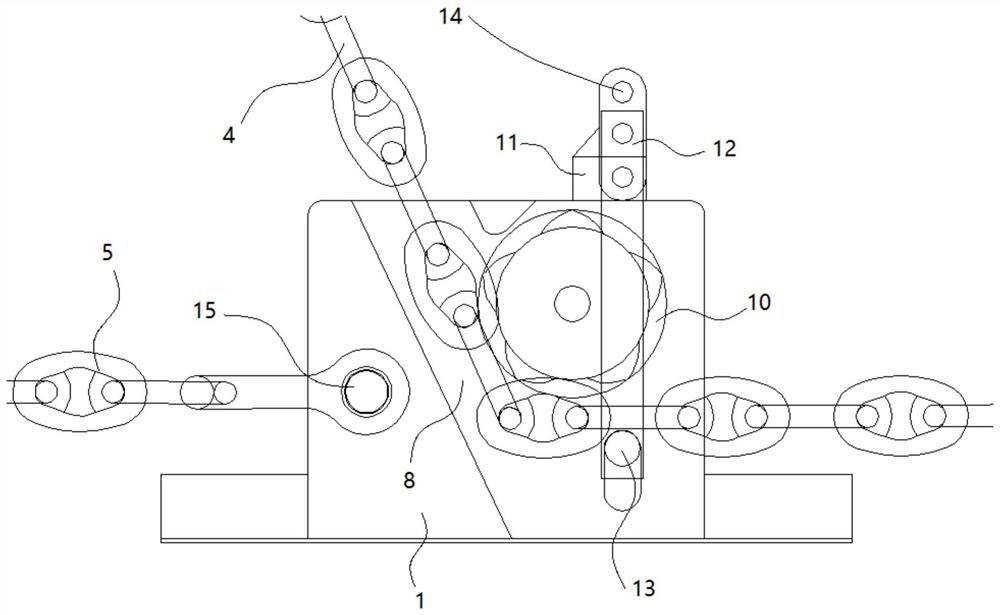

Catenary adjusting device and mooring system

ActiveCN114228904AReduce lossesReduced Power RequirementsAnchor handling/lashingTetherMooring systemEngineering

The invention relates to the technical field of catenary mooring systems, and provides a catenary adjusting device and a mooring system.The catenary adjusting device comprises a main body with a hollow inner cavity; the guide piece is arranged in the inner cavity of the main body, and a receding channel is formed in the area between the guide piece and the inner wall of the main body; an inlet of the receding channel is located in the side face of the body, an outlet of the receding channel is located in the top face of the body, and the receding channel is suitable for changing the extending direction of the driving anchor chain after the driving anchor chain penetrates. According to the adjusting device, after the driving anchor chain penetrates out of the receding channel, the driving anchor chain extending horizontally is forced to change the direction, the driving anchor chain extending to the water surface is made to extend in the vertical direction, the traction force is made to be equal to the pre-tensioning force, force loss is reduced, the requirement for the power of a winch is lowered, the size of the winch is reduced, and the service life of the winch is prolonged. The installation difficulty is reduced and the cost is saved; and moreover, component force in the vertical direction can be avoided, the anchor cannot be pulled out, and the reliability of the mooring anchor can be improved.

Owner:HUADIAN HEAVY IND CO LTD

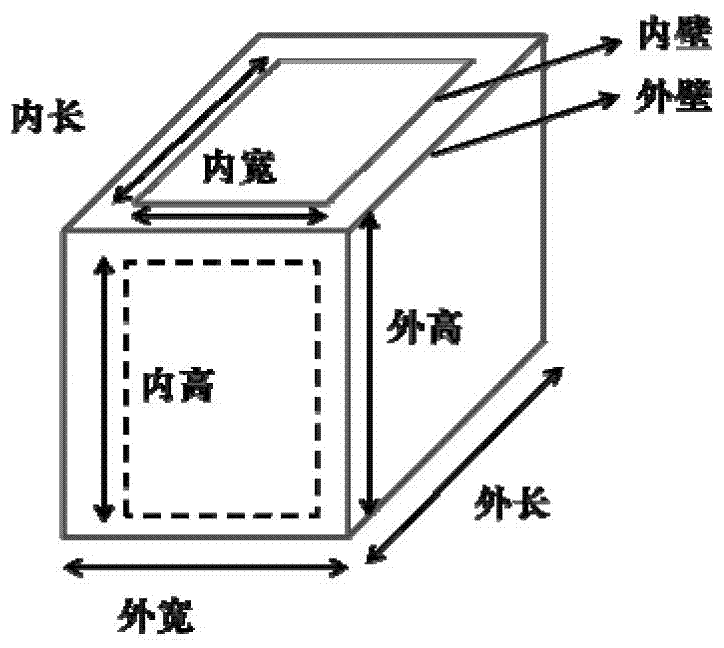

Continuous fiber prepreg tape inner layer wall reinforced corrugated pipe and production equipment thereof

InactiveCN113665140ASmall expansion coefficientDimensional temperature resistanceRigid pipesPipe connection arrangementsFiberWelding

The invention discloses a continuous fiber prepreg tape inner layer wall reinforced corrugated pipe. The corrugated pipe comprises a composite pipe body, a pipe body welding body and a pipe end butt joint opening, and the composite pipe body is composed of a continuous fiber prepreg tape reinforced composite inner layer wall and a structure stiffening corrugated pipe. The composite inner layer wall is composed of an anti-corrosion plastic inner layer, a continuous fiber prepreg tape reinforcing layer and a transition plastic layer, the structure stiffening corrugated pipe is composed of a plastic pipe of a concave structure and a plastic pipe of a circular structure, and the plastic pipe of the concave structure is composed of a built-in hollow body and a plastic supporting body. The plastic pipe of the circular structure is composed of a plastic circular pipe and reinforcing inner ribs. The pipe body welding body comprises an end face butt-joint type body and a lap welding type body. The pipe end butt joint opening comprises a pipe joint and a pipe bell mouth, the pipe joint is formed by inserting a reinforced composite inner layer wall pressure-bearing layer into a pipe end plastic pipe body inner wall in a welding manner, and the pipe bell mouth is composed of a pipe joint, an electric melting sealing belt for preventing an in-pipe medium from leaking and an electric melting plastic fusion ring in butt joint through the pipe end.

Owner:谭燕

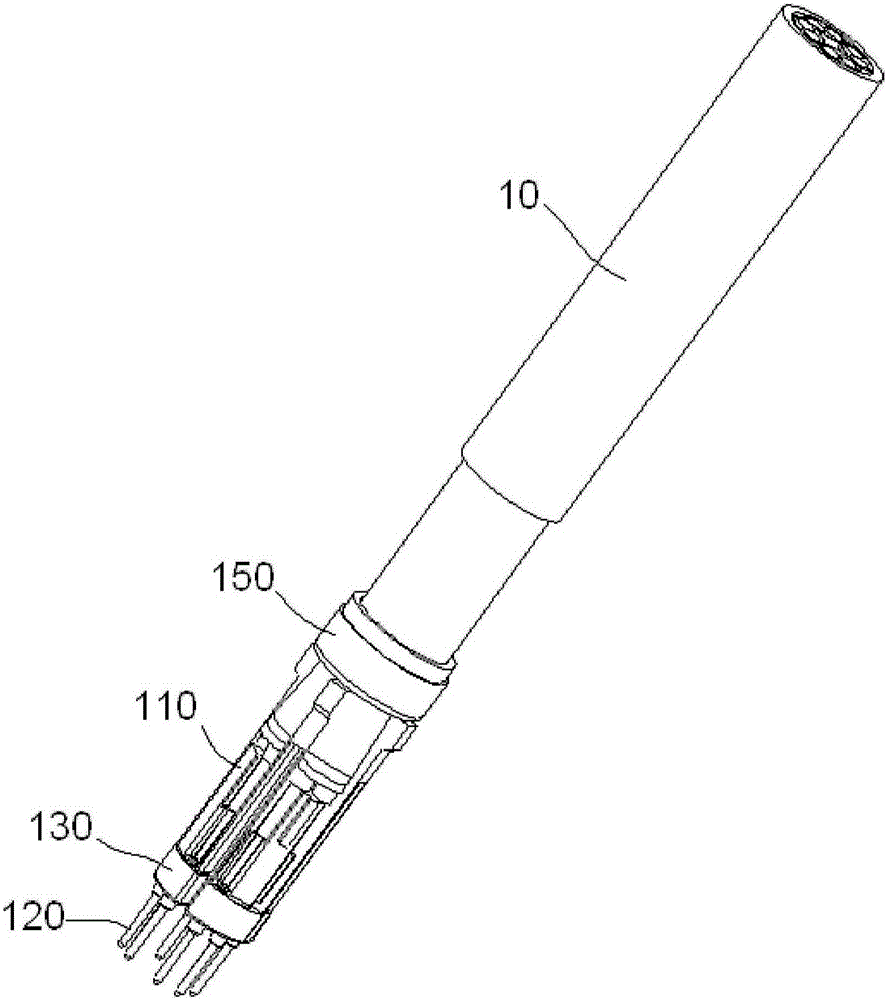

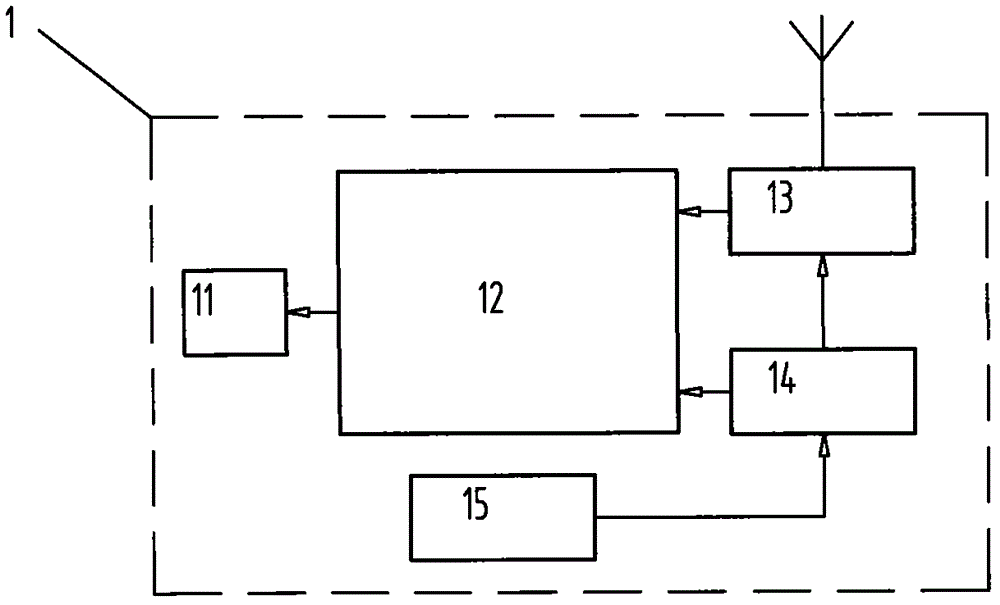

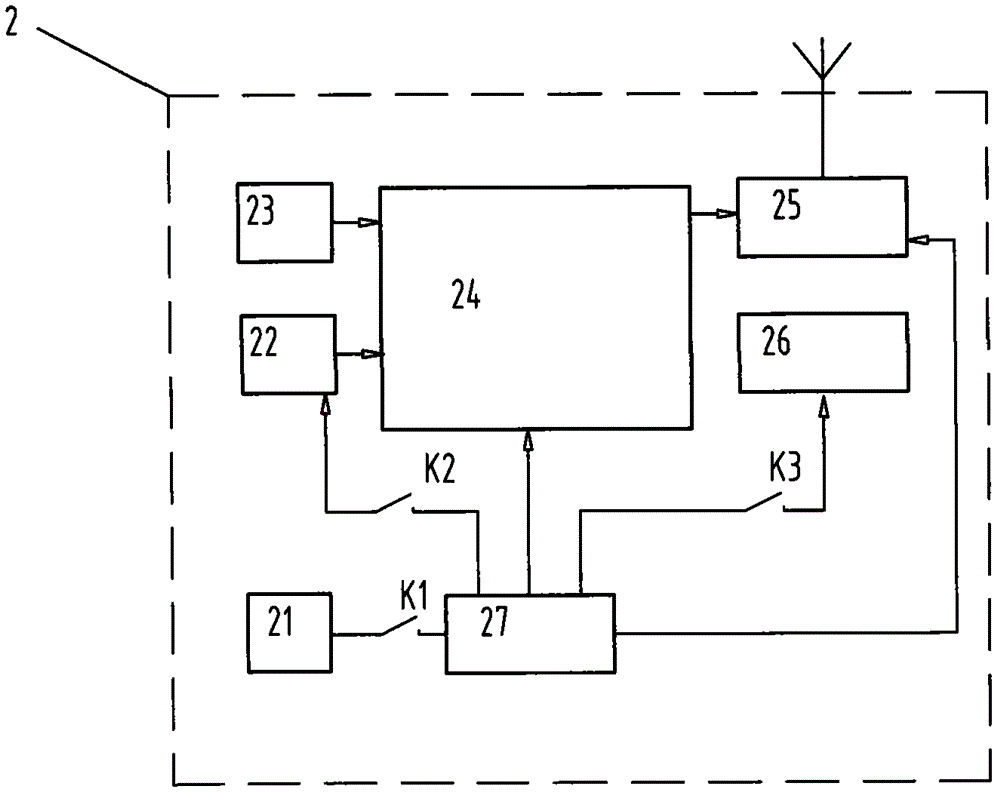

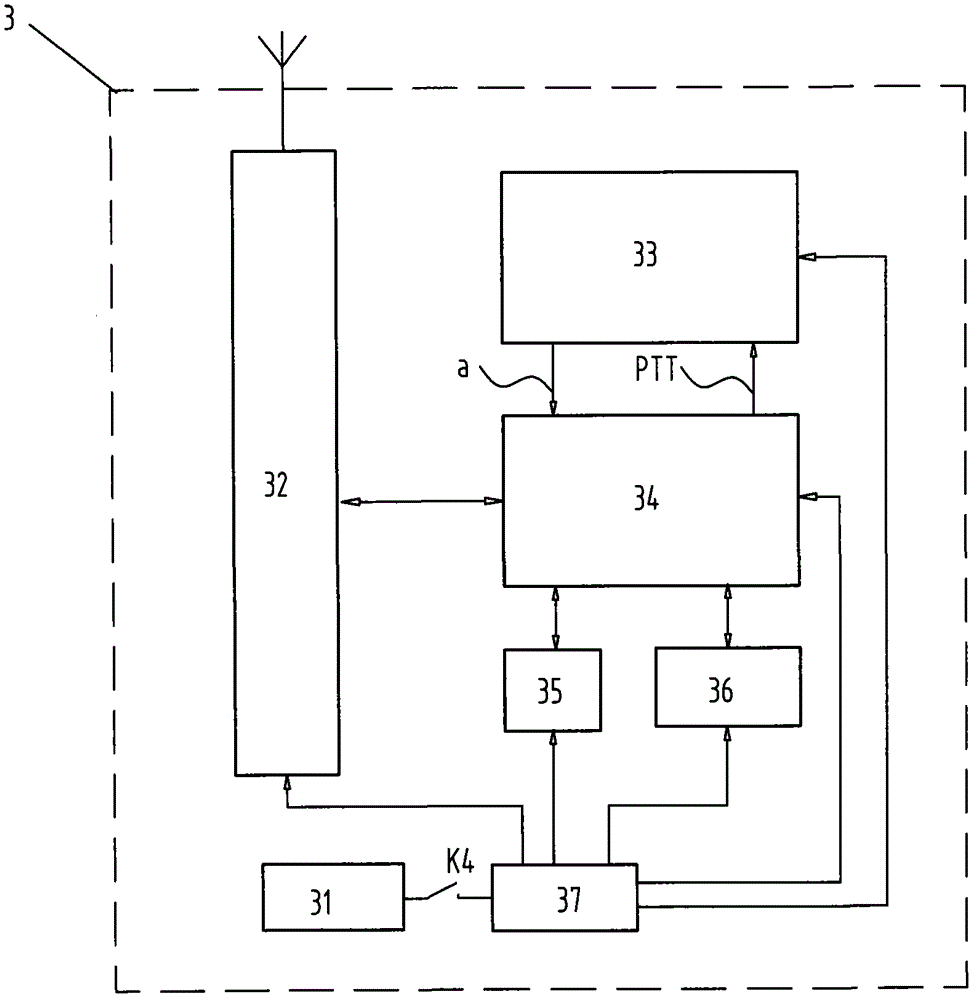

An audio-visual forensics intercom system terminal

InactiveCN103248967BWon't killWon't pull outClosed circuit television systemsStations for two-party-line systemsComputer hardwareWireless transmission

The invention relates to an audio-video-position evidence obtaining intercom system terminal which comprises an insert earphone, an information acquisition head and a host and is characterized in that the insert earphone and the information acquisition head are connected with the host by adopting wireless transmission signals; the information acquisition head is used for acquiring field audio and video information; a satellite positioning module of the host is used for acquiring field positioning information; the audio, video and position information is stored in a storage of the host by a main control module of the host; and a play or call state of a talkback voice module in the host is automatically controlled by the main control module of the host according to a call instruction of a wearer. The audio-video-position evidence obtaining intercom system terminal does not occupy hand of the wearer in the evidence obtaining and talkback process and is particularly suitable to use as necessary equipment for law-enforcement and duty personnel.

Owner:CHONGQING SHUAINENG SCI & TECH

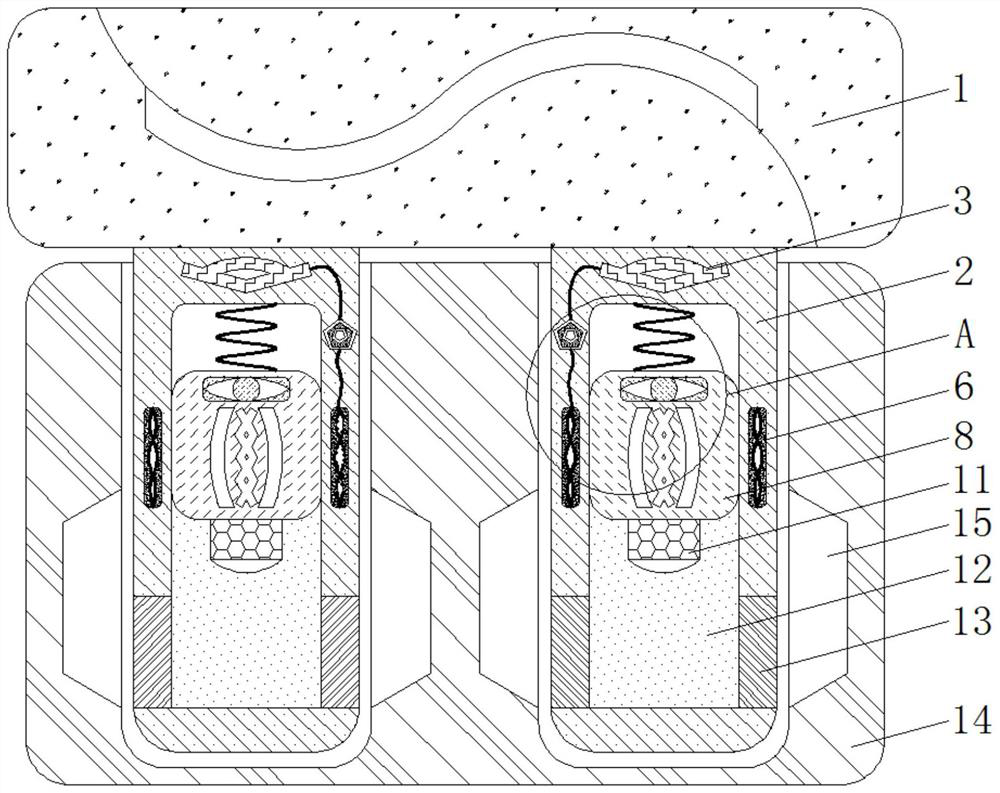

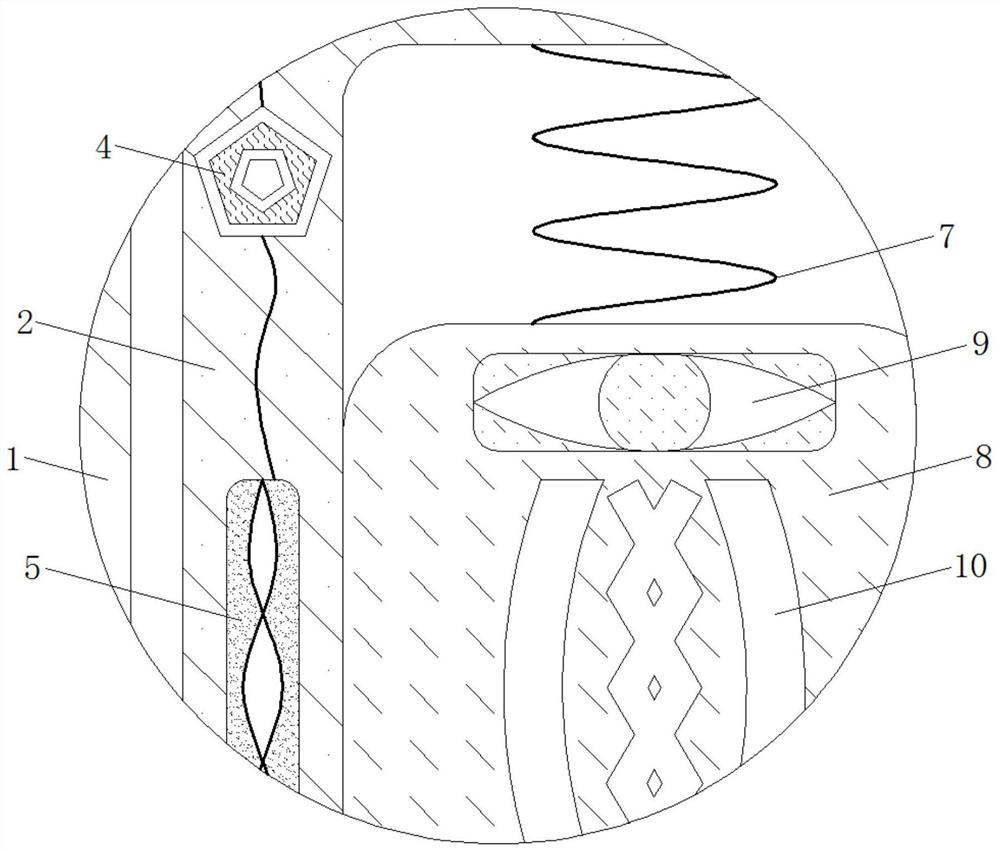

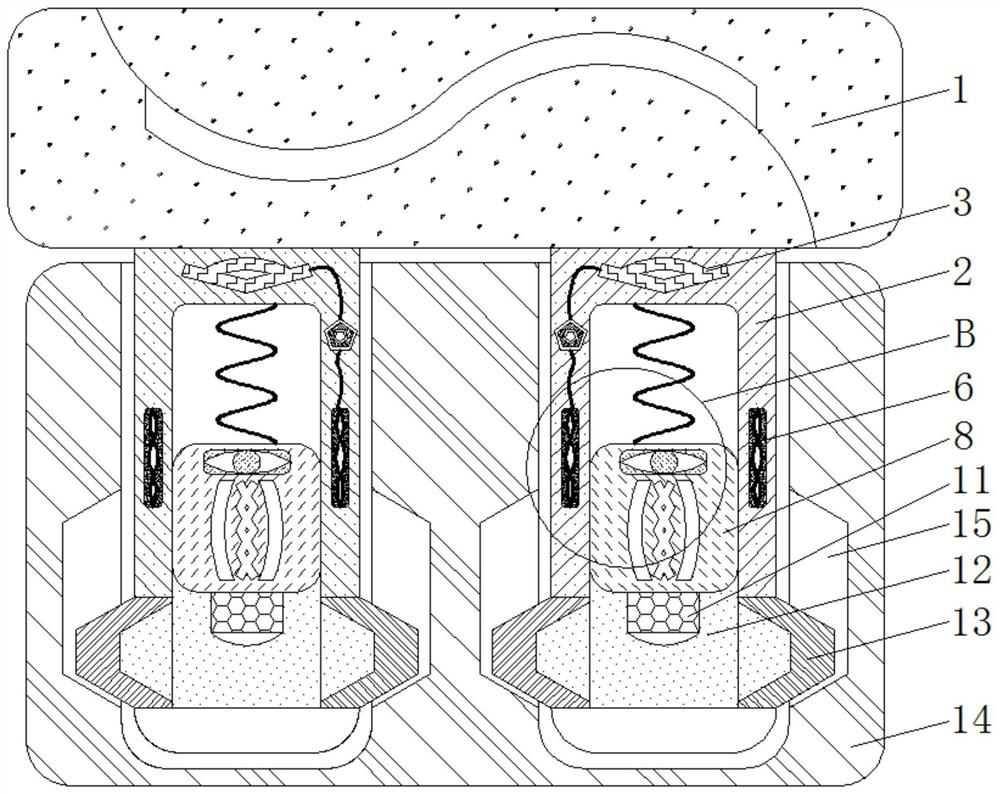

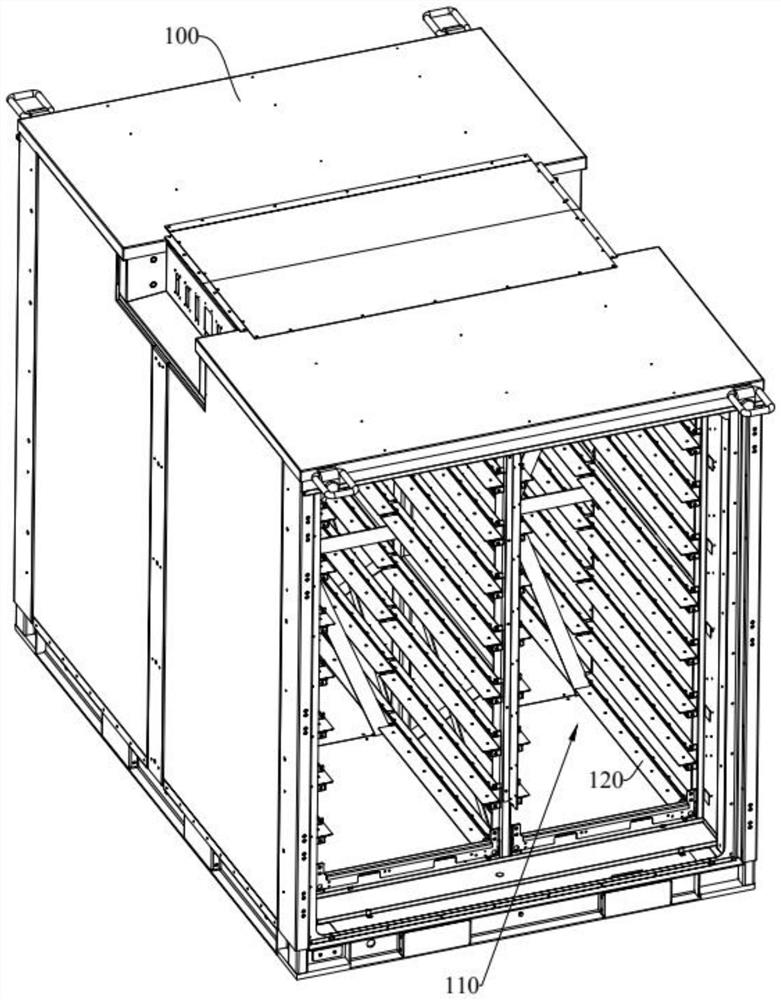

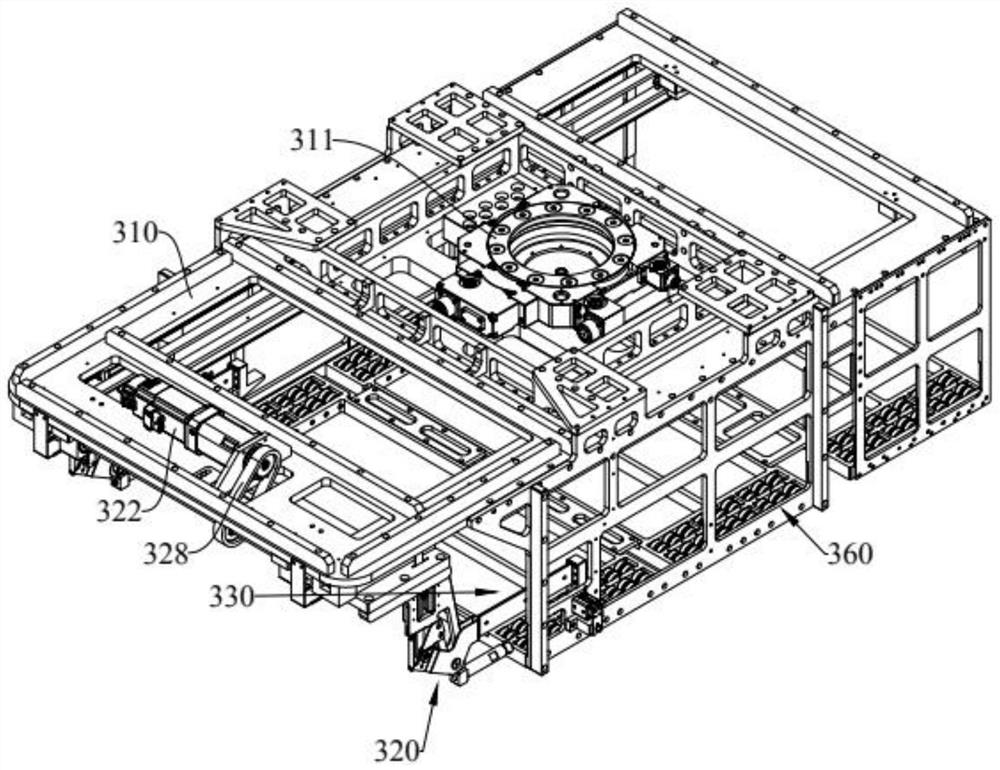

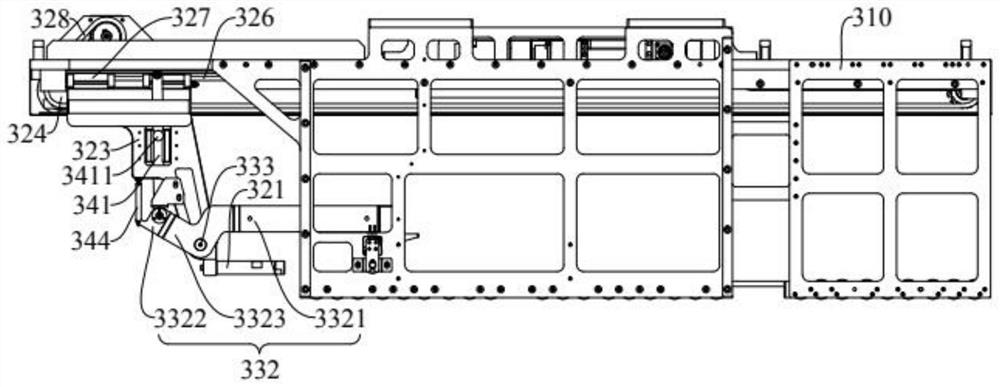

Carrier and battery cabinet entering system

PendingCN114852472AWon't pull outEasy to resetCell component detailsVehicular energy storageControl engineeringMechanical engineering

The invention belongs to the technical field of battery production equipment, and discloses a carrier and a battery cabinet entry system.The carrier comprises a box body, a pushing assembly, a reset assembly and an avoiding assembly, an opening is formed in one end of the box body, a battery can be moved into the box body from the opening, and the pushing assembly comprises a pushing rod and a first driving part; the first driving piece can drive the push rod to move in the length direction of the box body so as to push the battery out of the box body from the opening, the reset assembly comprises a first check block, and the first check block is provided with a first working position capable of abutting against the side, close to the opening, of a second check block located on the battery and a second working position away from the second check block; the first check block is connected to the push rod, and the avoiding assembly can enable the first check block to be converted from the first working position to the second working position. The reset assembly is arranged on the carrier to reset the battery, the reset mode is simple and convenient, manual participation is not needed in the reset process, and therefore the production efficiency is greatly improved.

Owner:苏州博众仪器科技有限公司

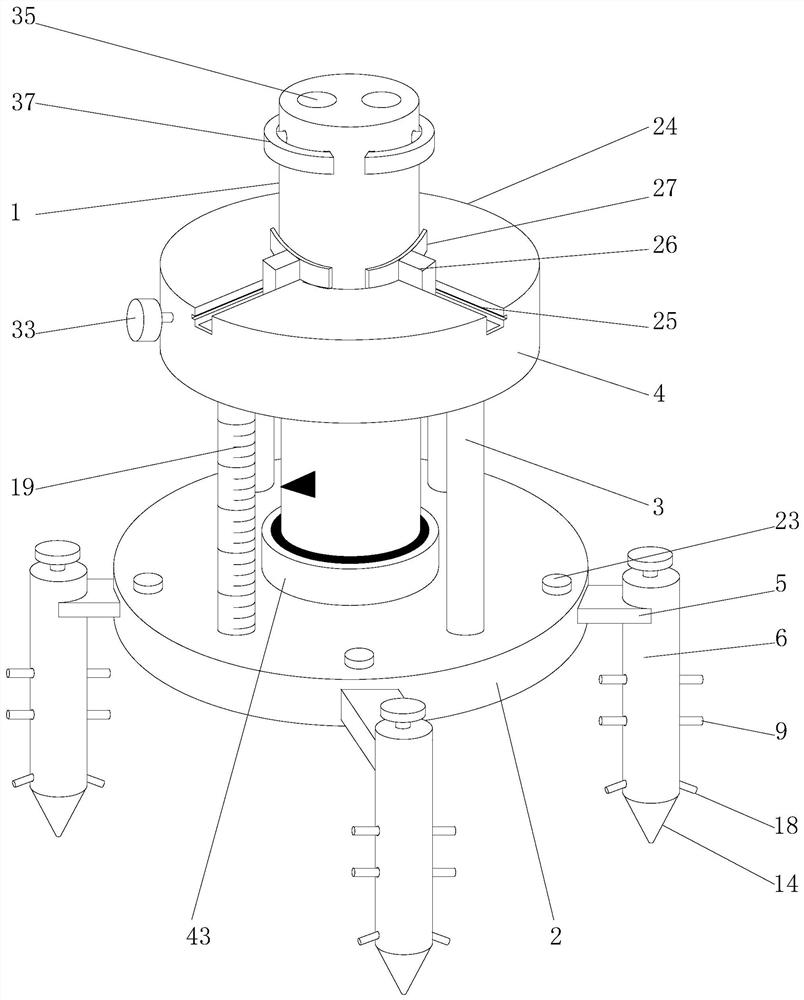

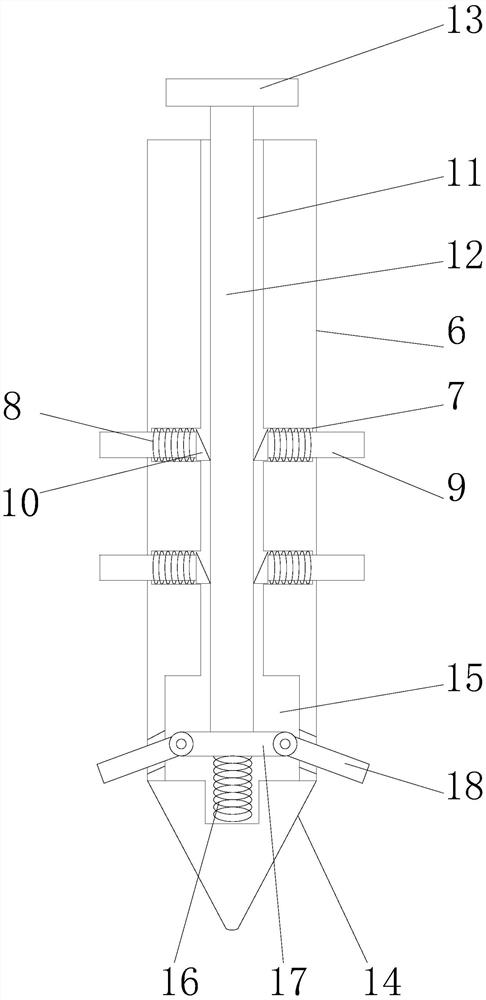

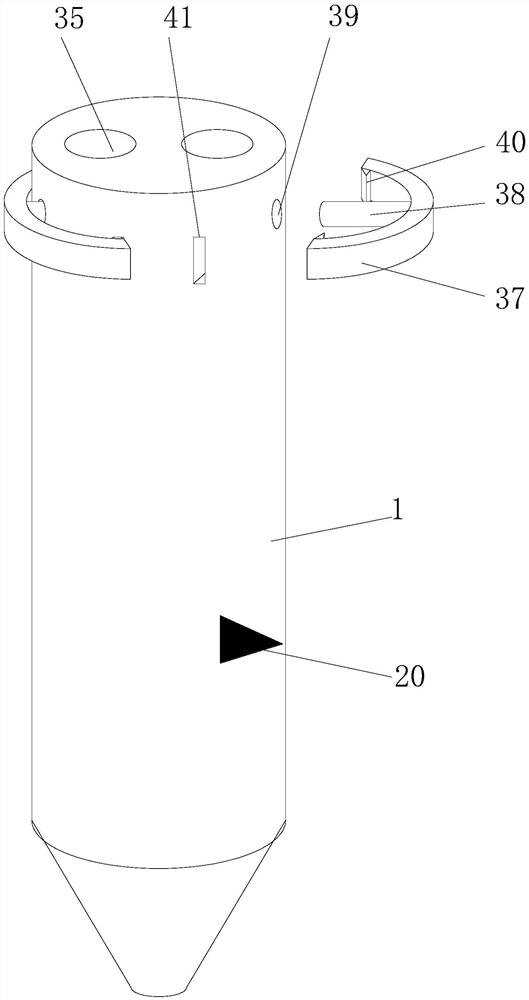

Electric power grounding pile for electric power engineering

ActiveCN113871908AWon't pull outImprove gripConnection contact member materialStructural engineeringPower engineering

The invention provides an electric power grounding pile for electric power engineering, which relates to the technical field of electric power engineering. The electric power grounding pile comprises a pile body and a fastening frame, the pile body is installed on the inner side of the fastening frame, the fastening frame comprises a base, a supporting rod and a clamping assembly, the supporting rod is arranged on the top of the base, and the clamping assembly is arranged above the supporting rod. A supporting arm is installed on the outer side of the base, and a ground inserting cylinder is arranged on the outer side of the supporting arm. A sliding hole is formed in the side wall of the ground inserting cylinder. The pile body is inserted into the base and the inner side of the clamping assembly, during installation, a ground inserting cylinder is inserted into the ground, then the pile body penetrates through the inner side of a fastening frame to be inserted into the ground, the pile body is locked in cooperation with the clamping assembly, in the process, through the action of the ground inserting cylinder, a threaded rod is inserted into a threaded inner groove, the threaded rod jacks up a triangular block in the inserting process, the poking rod is pushed to extend out of the ground inserting cylinder and is fixed in soil, so that the pile body is stabilized and cannot be influenced by side force, road holding force is provided, and the poking rod cannot be pulled out and is more reliable.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

A medicine shaking device for medical care

ActiveCN111603984BEasy to placeTest tube rack pulled outRotating receptacle mixersTransportation and packagingPharmacy medicineNursing care

The invention relates to a medicine shaking device, in particular to a medicine shaking device for medical care. The technical problem to be solved by the present invention is to provide a medicine shaking device for medical care with the functions of shaking multiple medicine liquids and single medicine liquid. A drug shaker device for medical care, comprising: a bracket; a rotating assembly installed in the bracket and powered by a motor to rotate; a feeding assembly installed on the rotating assembly and discharging by pulling; a test tube rack , installed on the feeding assembly; the fixing assembly, installed in the bracket, fixes the test tube by pulling. The present invention can mix the medicaments in all the test tubes by controlling the rotation of the deceleration motor, which is convenient and fast, and the test tube rack will not be pulled out through the cooperation of the slot and the sliding shaft, so that the medicaments can be better placed of test tubes.

Owner:江苏长江慧信息技术有限公司

A pile top crown beam structure and construction method of high-strength prestressed pipe piles used for foundation pit support

The invention relates to a pile top crown beam structure of a high-strength prestress pipe pile for supporting a foundation pit and a construction method thereof. The structure is characterized in that a crown beam is arranged at the tops of high-strength prestress pipe piles, the length of the part, inserted into the crown beam, of each high-strength prestress pipe pile is the same as the height of the crown beam, the height of the crown beam is not lower than 500mm, the width of the crown beam is 400mm more than the diameter of each pipe pile, the two ends of the crown beam respectively extend by 200mm out of the edge of each pipe pile, longitudinal stress reinforced bars of the crown beam are arranged near the edges of the inner side and outer side of the foundation pit, web bars are attached with the edge of each pipe pile, a bidirectional two-leg hoop bar and two additional vertical pull bars are arranged between the crown beams of the two adjacent high-strength prestress pipe piles, the hoop bar is 50mm away from the edge of each pipe pile, and two independent bidirectional two-leg bars are arranged in the area, anchored into the crown beam, of each high-strength prestress pipe pile. The method comprises the following steps of excavating earth to the bottom of the cushion layer of the crown beam, measuring and paying off, casting the cushion layer, binding the reinforced bars, supporting a formwork, casting concrete, airing water and curing, removing the formwork, and excavating the earth of the lower layer.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Crashproof guard bar

InactiveCN1317457CWon't pull outExtended collision timeBridge structural detailsRoadway safety arrangementsRoad surfaceEngineering

A crashproof guard bar includes a guard bar base (1), a column (2), a bridging beam (3) and an energy-absorbing screw thread member (4). The guard bar base (1) is F type and is set across the road bed. The rear segment of the basic bridging beam (11) on the guard bar base (1) is disposed with a guide groove (12). A hole (13) is disposed in the basic bridging beam (11) at the front end of the guiding groove (12) along longitudinal direction, and is disposed with the energy-absorbing screw thread member (4). The column (2) is disposed in the guide groove (12) and is connected to the energy-absorbing screw thread member (4). The bridging beam (3) is disposed in front of the column (2) and is connected with the column (2). The invention has firm base, will not occupy effective running road surface, can generate buffer energy-absorbing function when the vehicle crashes the guard bar, and can crash intensity and has good guide ability, and can farthest reduce the damage to the vehicle and passenger from the crash. The invention is especially adapted for the pavement anti-collision guard bar on cliff and bridge anti-collision guard bar.

Owner:雷正保

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com