Modified asphalt material for road and its prepn

A technology for modifying asphalt and roads, which is applied to building insulation materials, building components, buildings, etc. It can solve problems such as unsatisfactory heat resistance and aging resistance, complex modification processing technology, and reduced temperature sensitivity, so as to achieve good adhesion. Adhesion and anti-stripping properties, improved weather resistance and UV resistance, and the effect of high viscosity of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

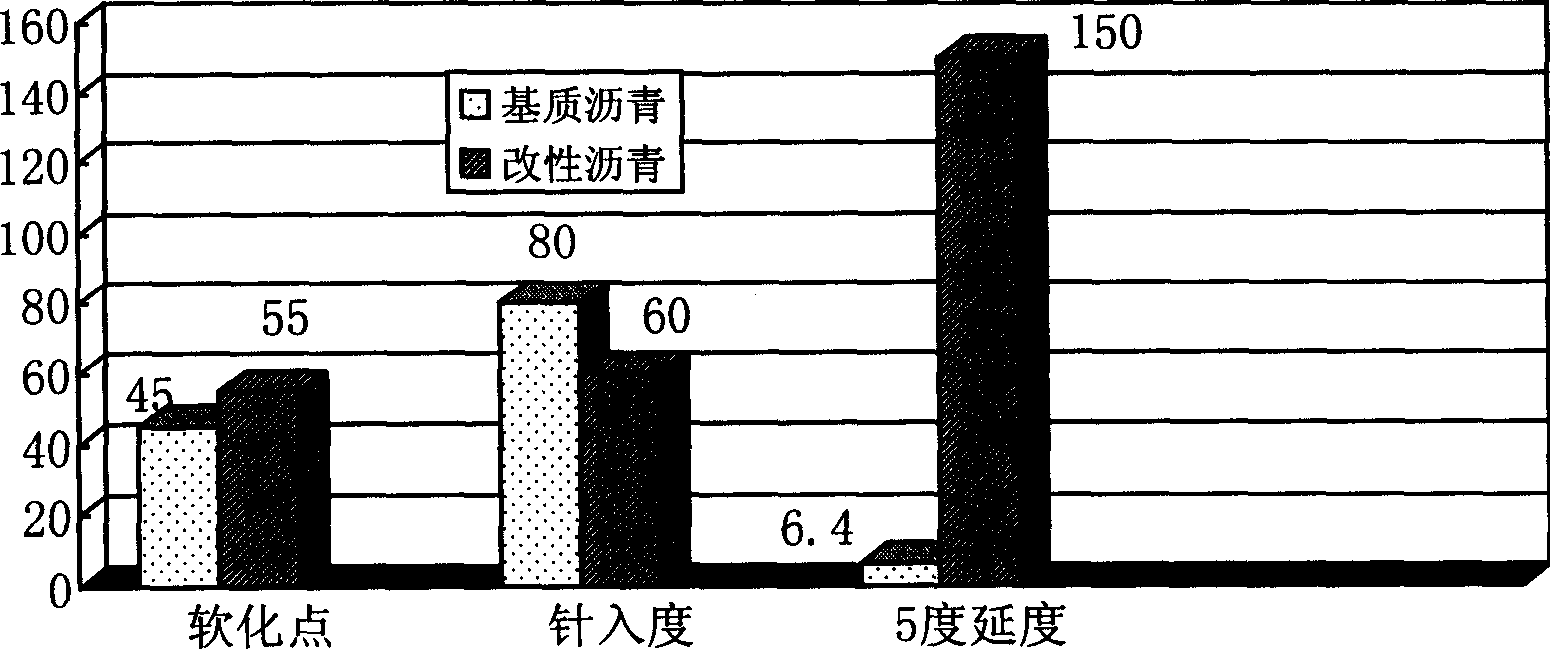

Embodiment 1

[0033] Heat 76wt% base asphalt to heat up and melt until it can flow. Pay attention to constant stirring to avoid local overheating. While stirring, add 9wt% powdered styrene-butadiene rubber, 10wt% natural asphalt ore, and 5wt% organic metal soap, and then maintain the temperature at 160 ° C ~ 200 ° C And rotating speed 3000rpm~5000rpm, high-speed shearing and mixing for 40min~60min, filter, sample preparation, elemental analysis, FT-IR analysis, thermal analysis, optical micrography, scanning electron microscope photography, four-component determination, wax content determination, Softening point, penetration, elongation determination and mass loss, penetration ratio and elongation determination after rotary film oven aging test.

Embodiment 2

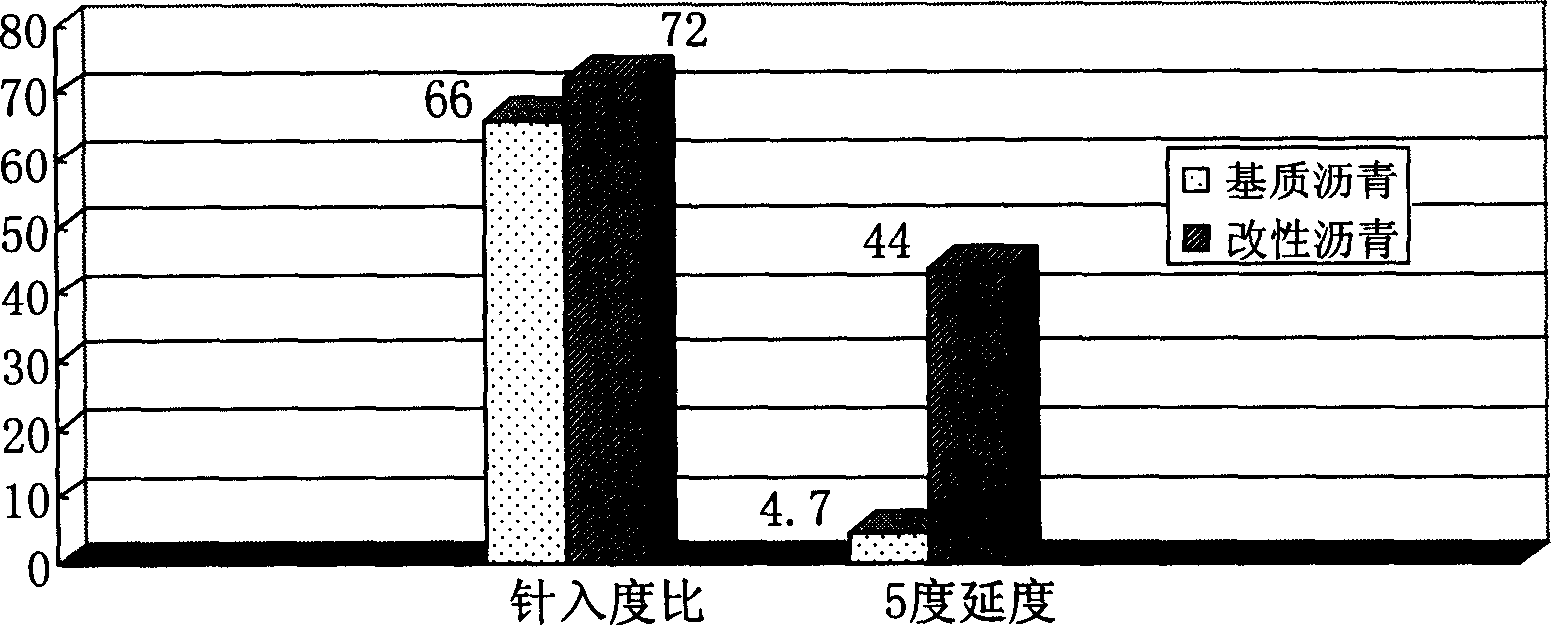

[0035] Heat 96wt% base asphalt to heat up and melt until it can flow. Pay attention to continuous stirring to avoid local overheating. While stirring, add 2wt% powdered styrene-butadiene rubber, 1wt% natural asphalt ore, and 1wt% organometallic soap, and then maintain the temperature at 160 ° C ~ 200 ° C And rotating speed 3000rpm~5000rpm, high-speed shearing and mixing for 40min~60min, filter, sample preparation, elemental analysis, FT-IR analysis, thermal analysis, optical micrography, scanning electron microscope photography, four-component determination, wax content determination, Softening point, penetration, elongation determination and mass loss, penetration ratio and elongation determination after rotary film oven aging test.

Embodiment 3

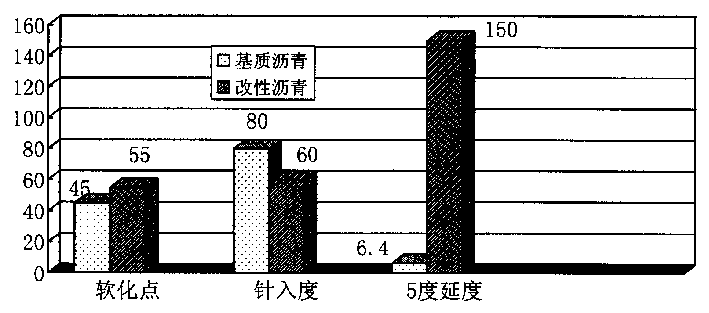

[0037]Heat 84wt% base asphalt to heat up and melt until it can flow, pay attention to constant stirring to avoid local overheating, add powdered styrene-butadiene rubber 7.3wt%, natural asphalt ore 8wt%, organometallic soap 0.7wt% while stirring, and then maintain the temperature at 160℃~ 200°C and rotating speed 3000rpm-5000rpm, high-speed shear mixing for 40min-60min, filter, sample preparation, elemental analysis, FT-IR analysis, thermal analysis, optical micrography, scanning electron microscope photography, four-component determination, wax content Determination, softening point, penetration, elongation determination and mass loss, penetration ratio and elongation determination after rotary film oven aging test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com