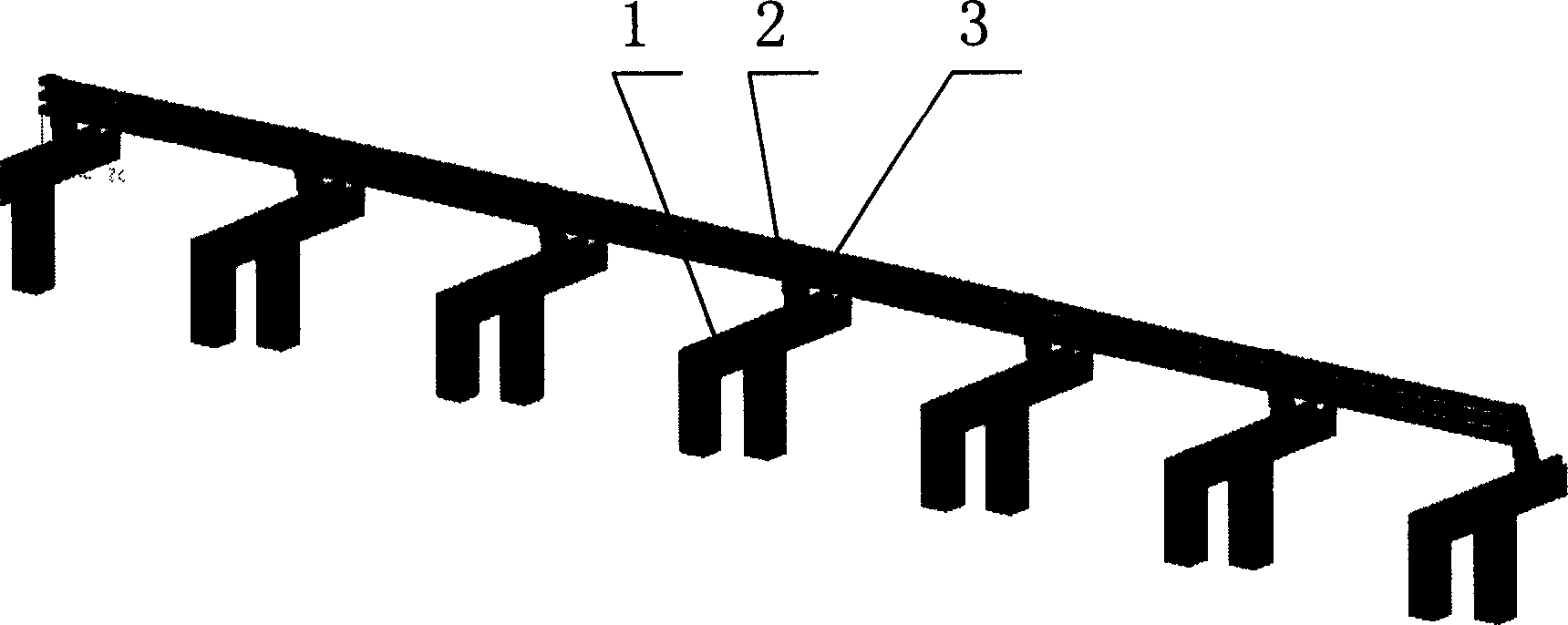

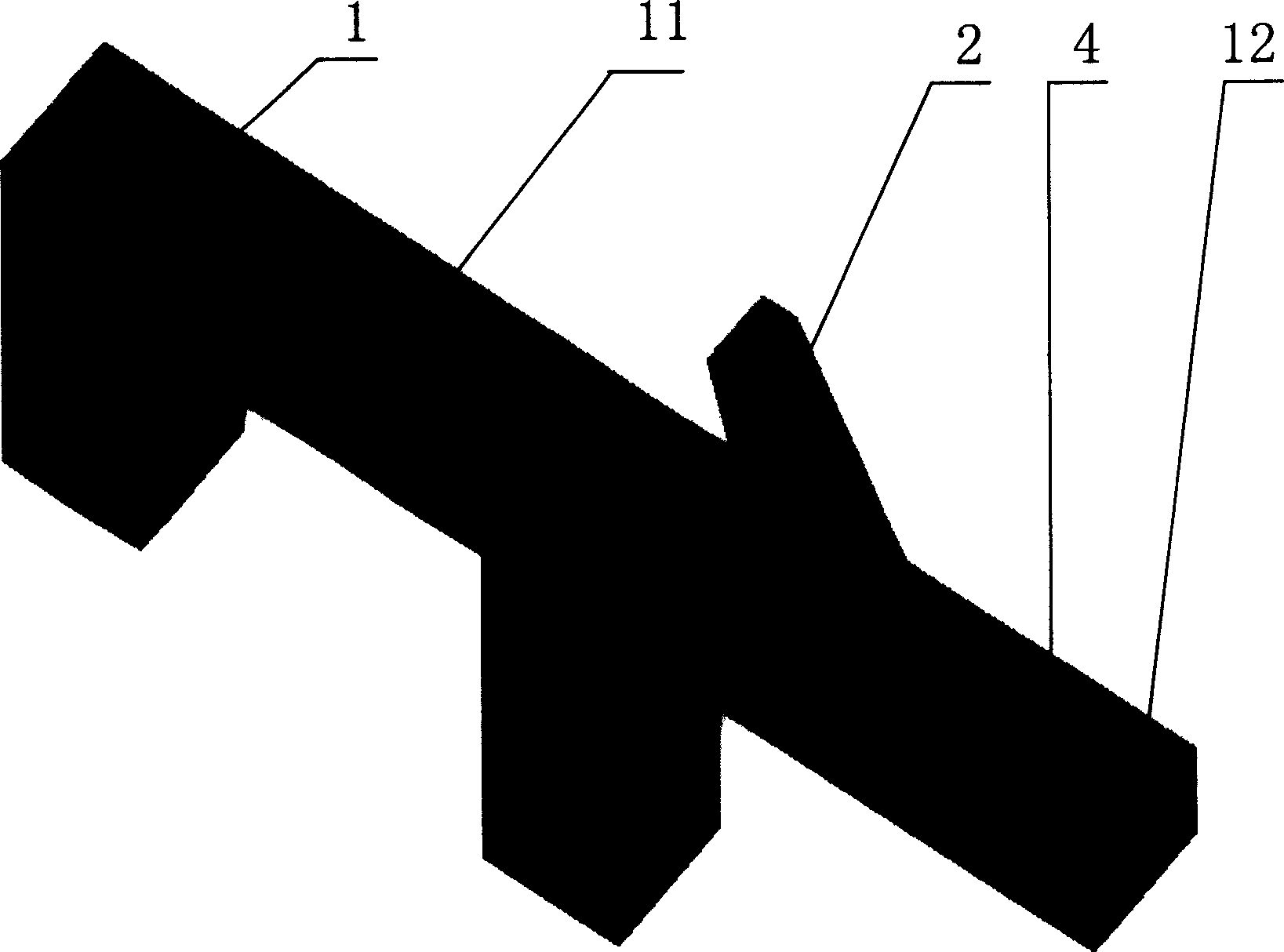

Crashproof guard bar

An anti-collision guardrail and guardrail technology, applied in bridge parts, roads, bridges and other directions, can solve the problems of vehicle rollover, reduction of the effective height of guardrails, large windward area, etc., and achieve the effect of good guiding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

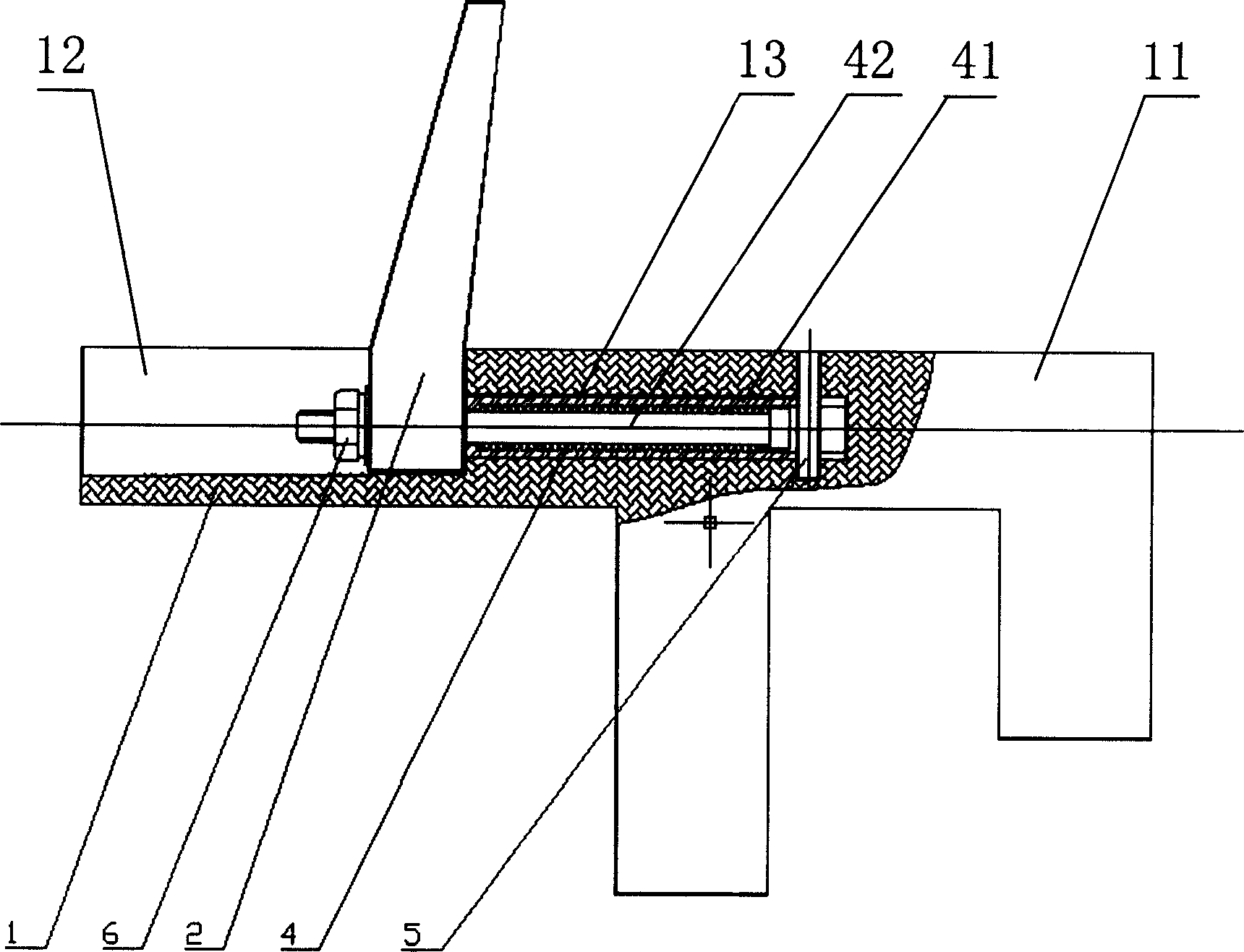

Method used

Image

Examples

Embodiment Construction

[0024] According to the momentum theorem, if a particle changes its velocity sharply in a very short time, while its position remains almost unchanged, the particle is subject to a collision. Assuming that the mass of the objects participating in the collision remains unchanged during the collision, the time interval Δt is integrated by Newton's law, and the change of momentum is equal to the impulse, namely:

[0025] I'=mv s ′ The momentum of the particle after the collision

[0026] I = mv s The momentum of the particle before the collision

[0027] P = ∫ t t ′ Fdt The momentum of the particle

[0028] I'-I=P

[0029] During the entire collision process, F is a variable, which is a function of time, but it can be approximately considered to be a constant value in each time interval Δt, then:

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com