Pile top crown beam structure of high-strength prestress pipe pile for supporting foundation pit and construction method thereof

A technology for prestressed pipe piles and foundation pit support, which is used in infrastructure engineering, excavation, construction, etc., can solve problems such as crown beams being easily pulled out, waste of reinforced concrete, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

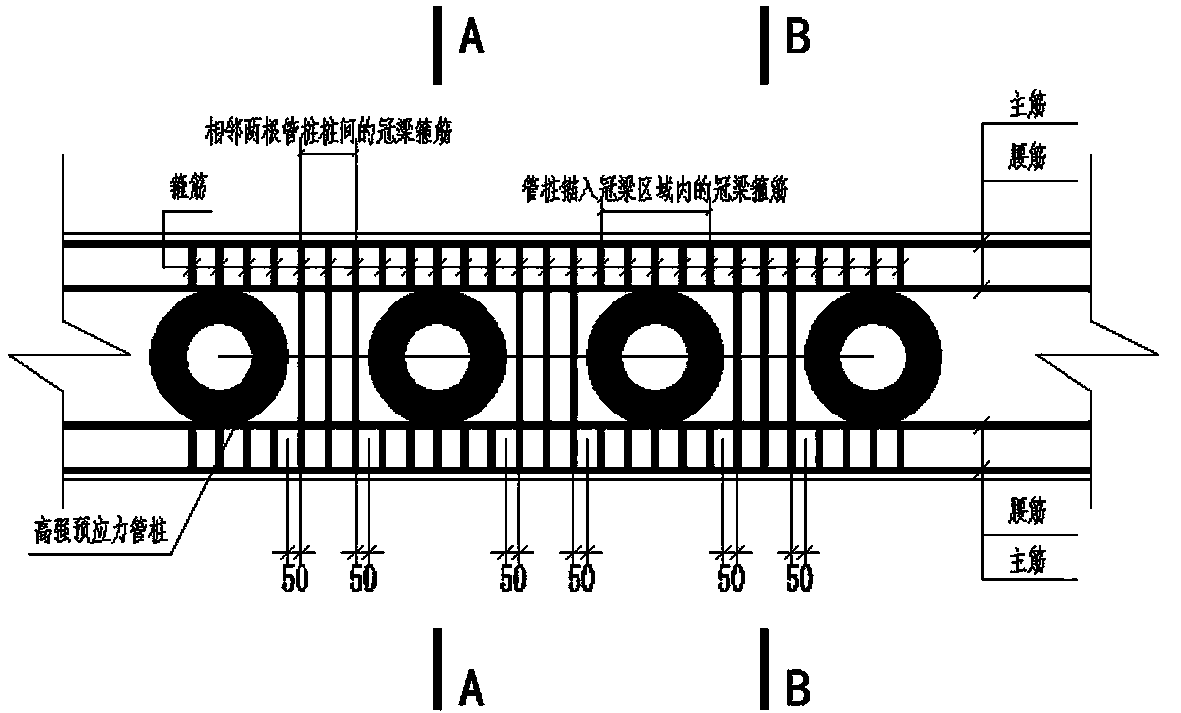

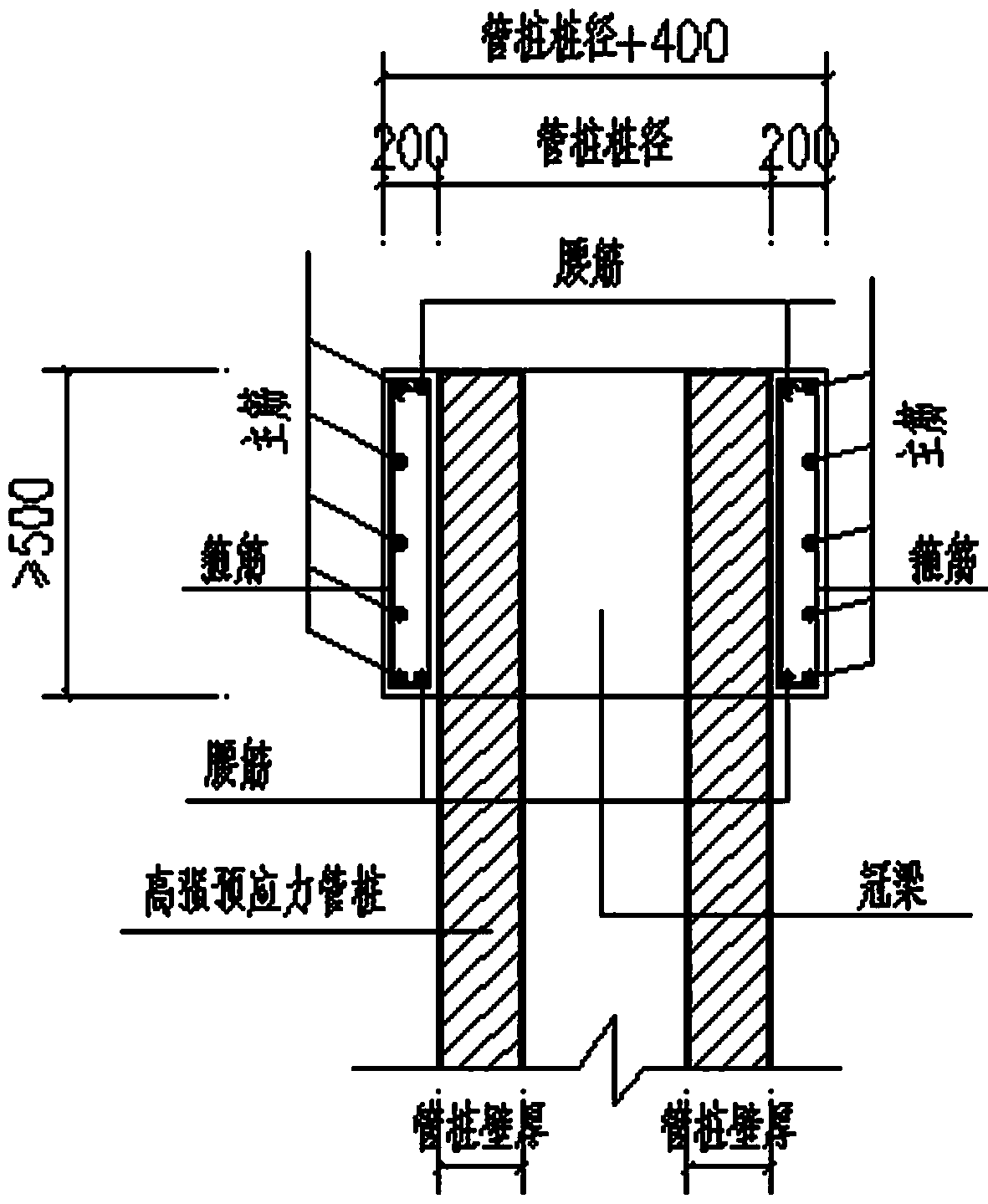

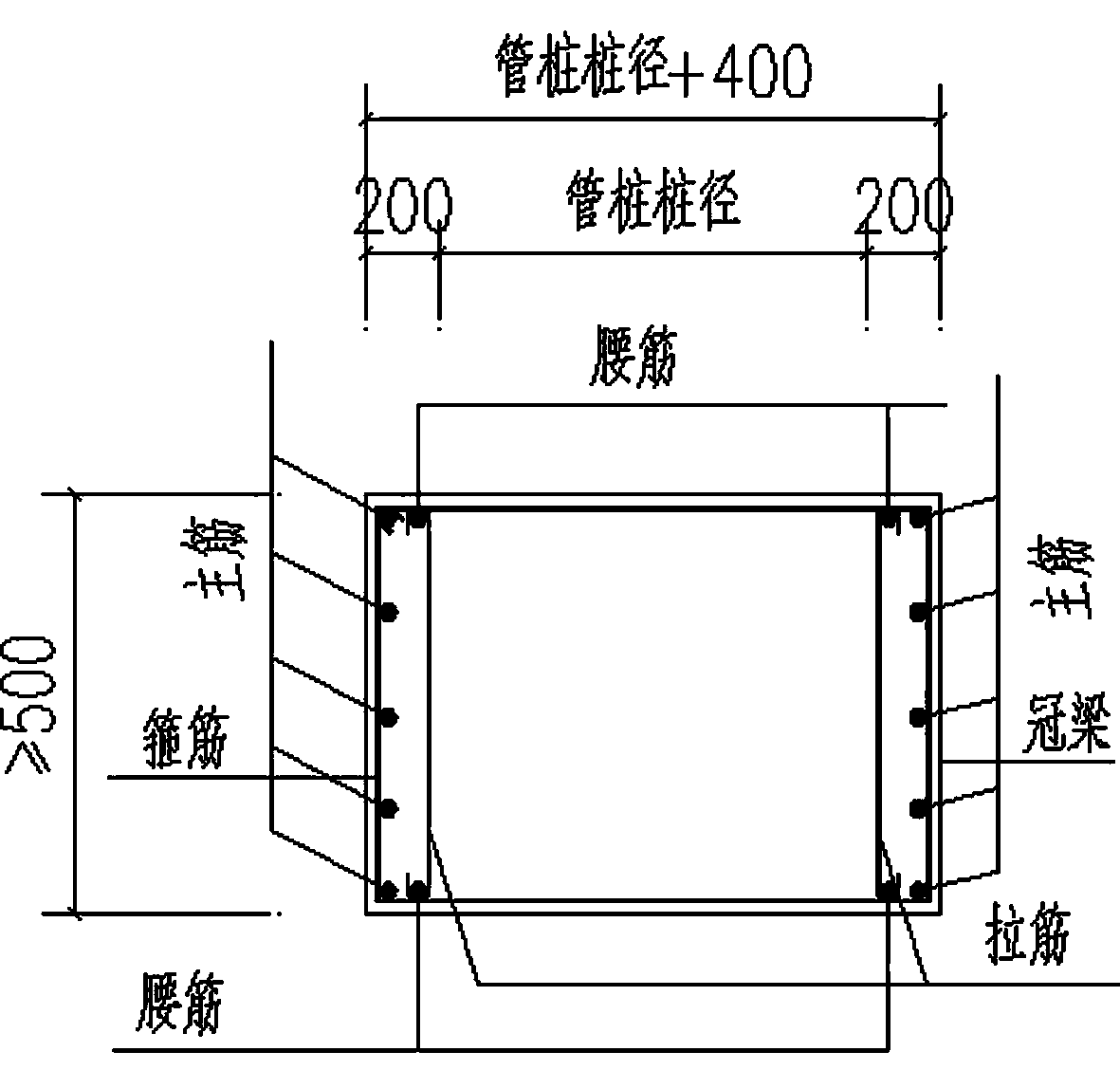

[0024] according to figure 1 , figure 2 , image 3 The pile top crown beam structure of a high-strength prestressed pipe pile used for foundation pit support is shown, and its structural characteristics are as follows:

[0025] The crown beam is set on the top of the high-strength prestressed pipe pile, and the length of the high-strength prestressed pipe pile anchored into the crown beam is the same as the height of the crown beam; The waist bar of the beam is attached to the edge of the pipe pile; in the crown beam area between two adjacent high-strength prestressed pipe piles, a two-way two-leg hoop and two vertical tie bars are set, and the stirrup is 50mm away from the edge of the pipe pile ; In the crown beam area where the high-strength prestressed pipe pile is anchored into the crown beam, two independent two-way two-leg hoops are set.

[0026] The height of the crown beam is not less than 500mm, and the width is the pipe pile diameter + 400mm, that is, the edge of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com