Prefabricating, splicing and connecting structure for partially unbonded grouting sleeve and construction method

A grouting sleeve and prefabricated assembly technology, applied in the direction of structural elements, building structures, building components, etc., can solve the problems affecting the application of prefabricated assembled bridge piers, low displacement ductility, etc., so as to change dynamic characteristics, ensure ductility, and reduce residuals. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

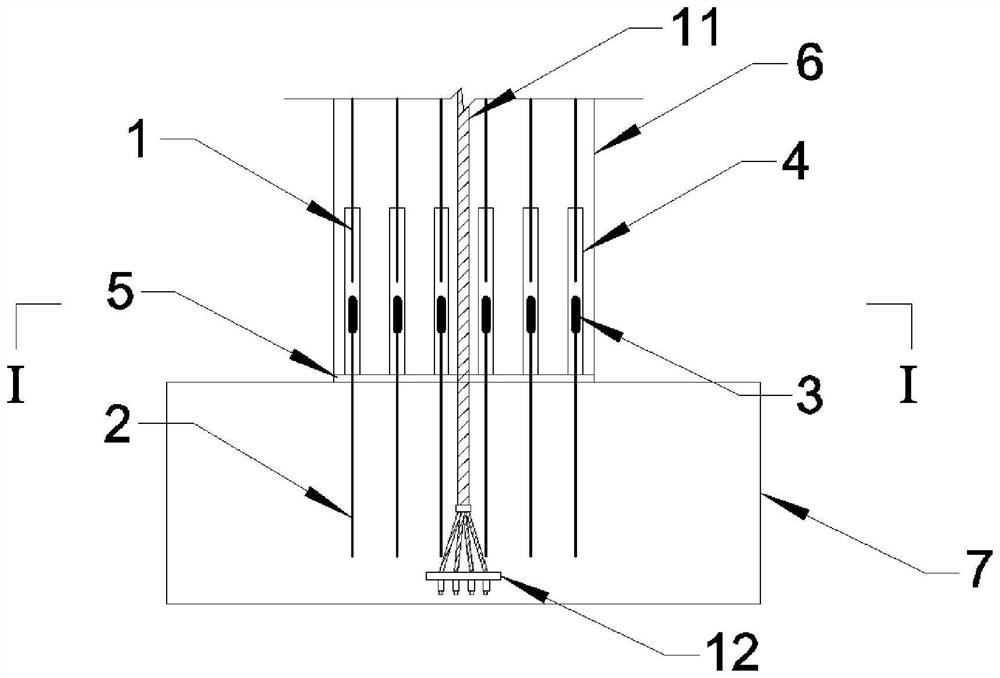

[0072] This embodiment provides a prefabricated assembled connection structure of a partially bonded grouting sleeve.

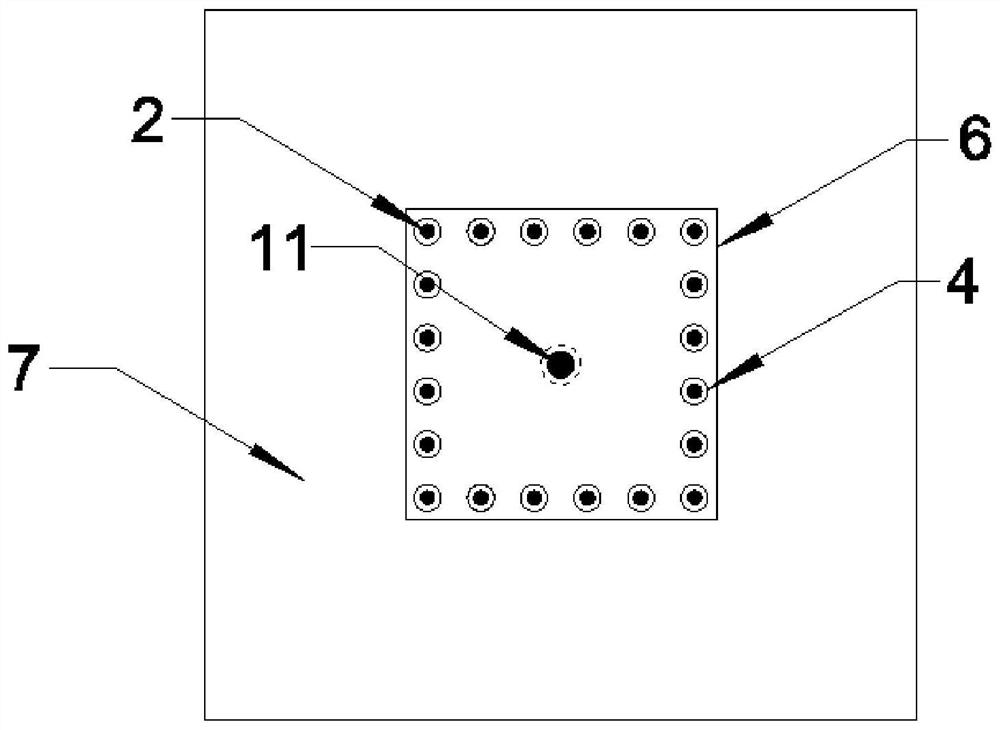

[0073] Such as Figure 1-4 As shown, a prefabricated and assembled connection structure of a part of the unbonded grouting sleeve, including the main reinforcement of the pier 1 and the overhanging steel bar 2 of the cap that need to be anchored and connected, the casing 3 for the unbonded treatment of the overhanging steel bar 2 of the cap, The grouting sleeve 4 pre-embedded at the bottom of the pier 6.

[0074] The bottom of the pier 6 and the top of the cap 7 are provided with a cushion 5, and the order from top to bottom is the pier 6, the cushion 5, and the cap 7;

[0075] Part of the unbonded grouting sleeve prefabricated assembly connection structure is fixed on the pier 6, cushion layer 5 and cap 7;

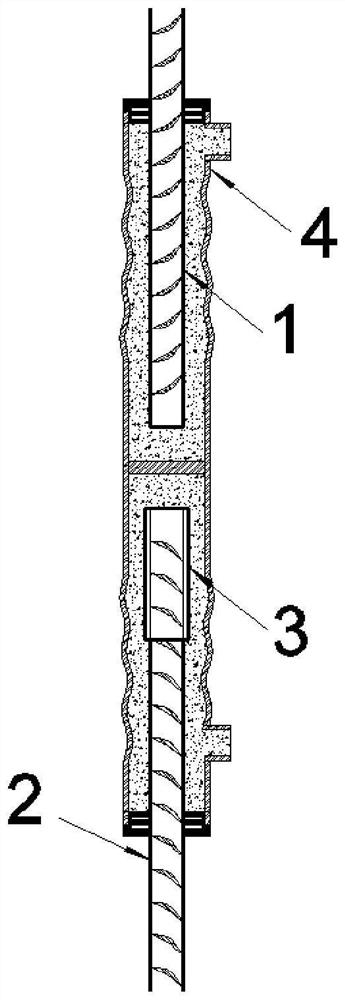

[0076] The upper part of the grouting sleeve 4 is the main bar section of the grouting sleeve pier, and the lower part is the section of the extended ...

Embodiment 2

[0083] This embodiment provides a construction method for a prefabricated assembled connection structure of a partially bonded grouting sleeve.

[0084] A construction method for a partially bonded grouting sleeve prefabricated assembled connection structure, comprising the following steps:

[0085] (S1) Bind the pier reinforcement cage, connect the main reinforcement 1 of the pier with the grouting sleeve 4, cast the concrete of the pier 6 pier body and reserve 11 tunnels for unbonded prestressed tendons, and maintain for 28 days;

[0086] (S2) Construction of cap 7, in which anti-corrosion grease is applied to the non-bonded section 10 of the steel bar of the protruding steel bar 2 of the cap that is used to connect with the inner grouting sleeve 4 of the bridge pier 6, and the sleeve 3 of the corresponding length is coated on the The upper and lower ends of the casing 3 are water-sealed with flexible sealant, and the casing 3 is fixed by spring clips 8. At the same time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com