Patents

Literature

155results about How to "Guaranteed ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20090101242A1Improve toughnessHigh tensile strengthFurnace typesHeat treatment furnacesWater basedNiobium

Owner:TENARIS CONNECTIONS

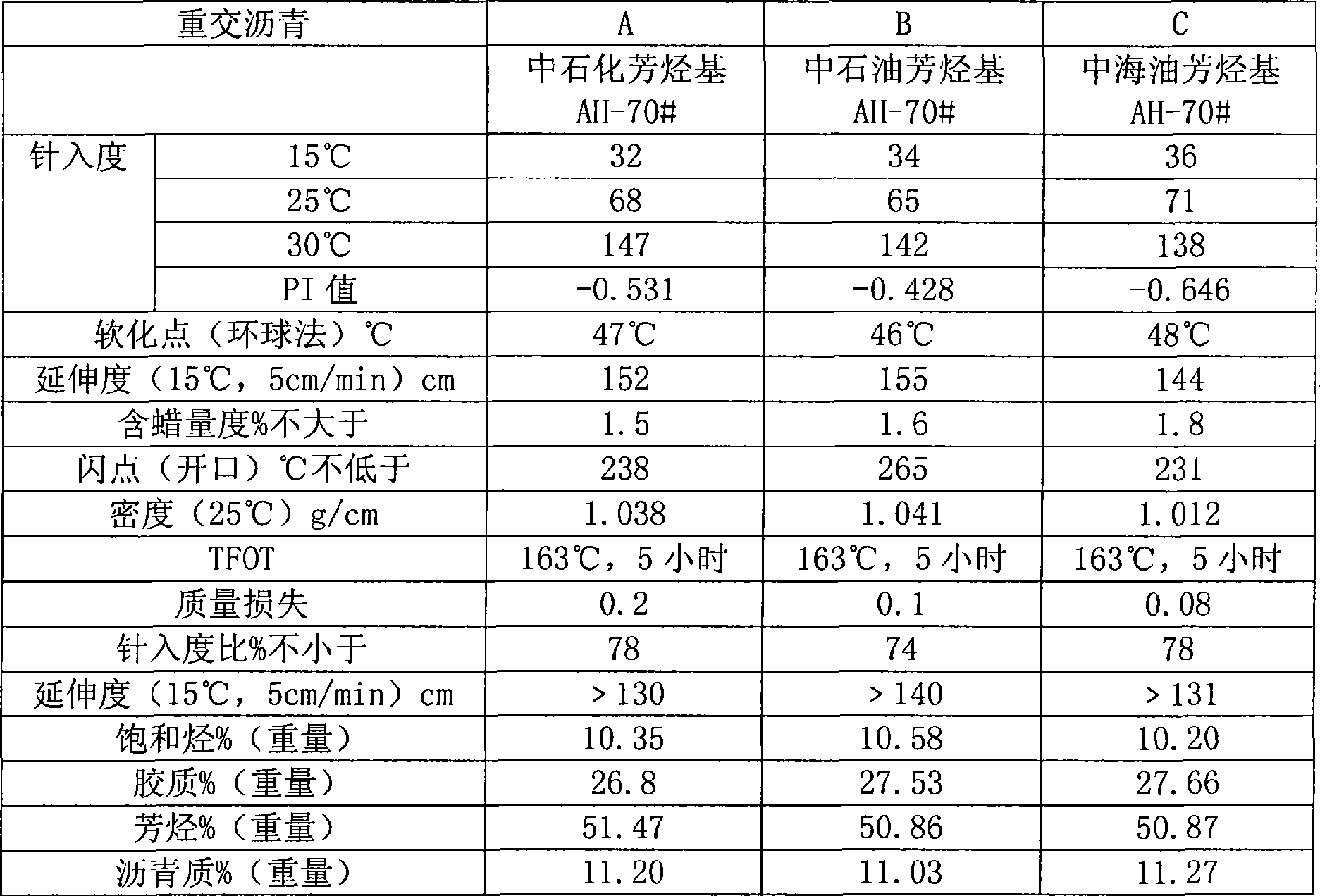

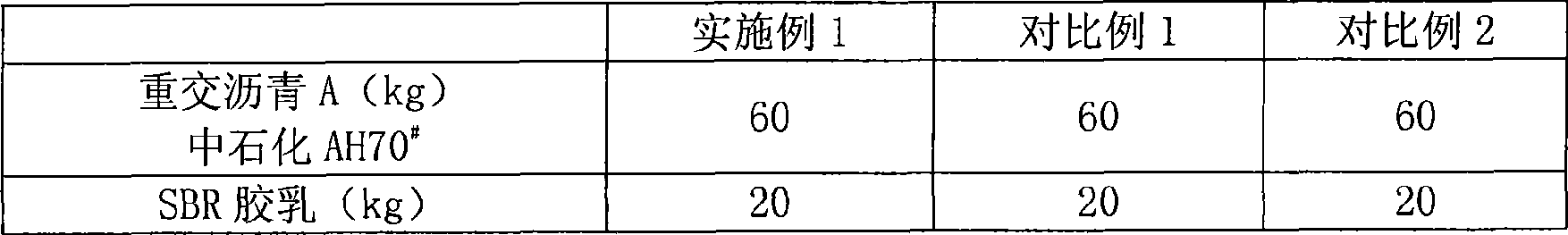

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

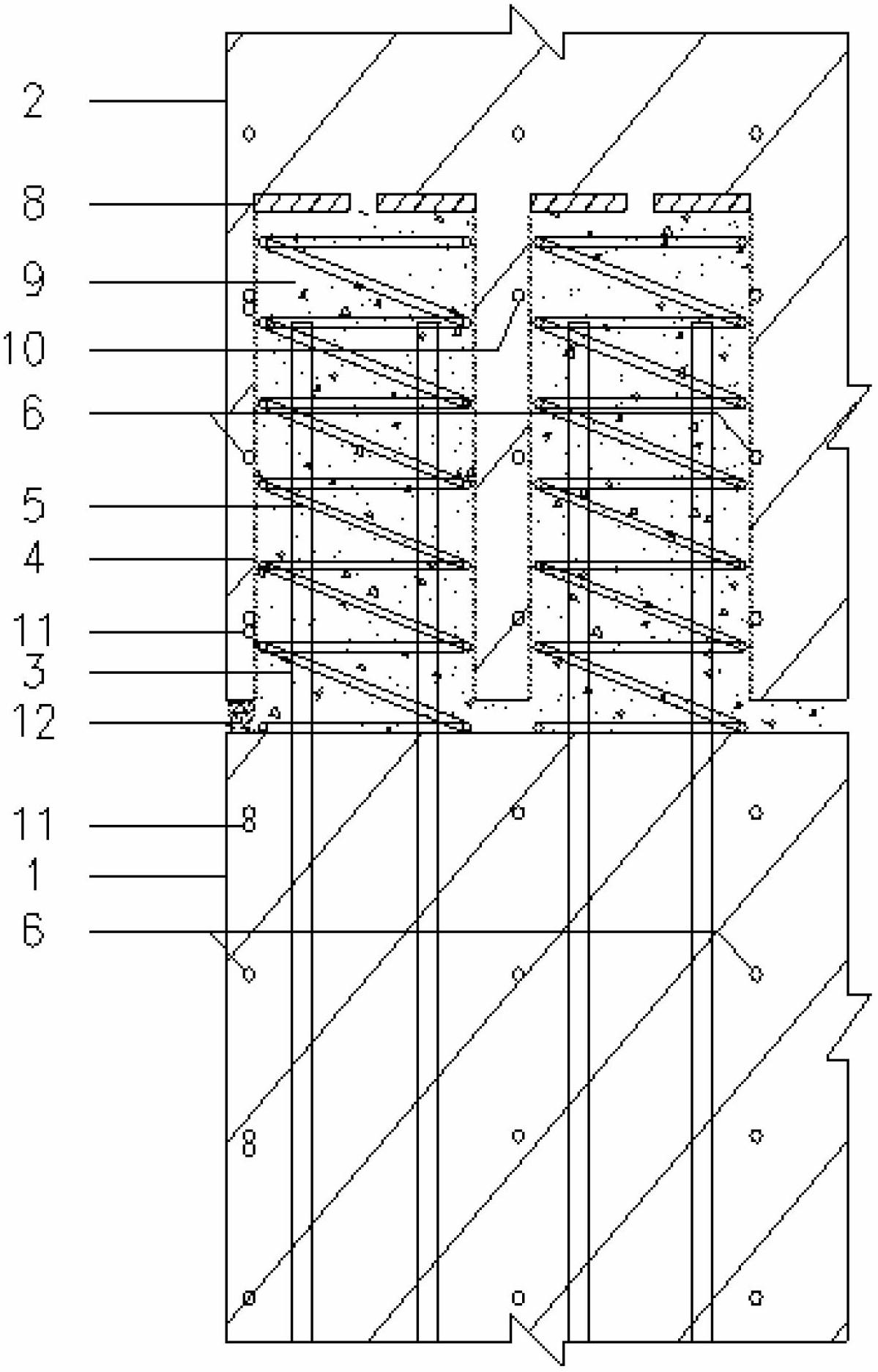

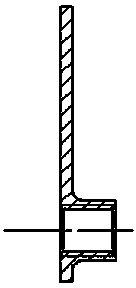

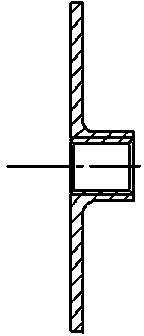

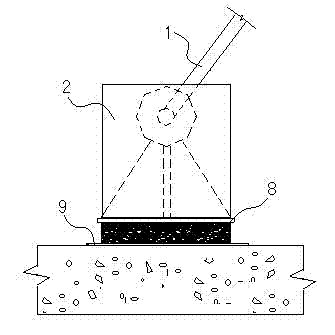

Connecting structure for assembly type concrete shear wall edge member

InactiveCN102691365AImprove the anchoring effectGuaranteed carrying capacityWallsShock resistanceRebar

The invention discloses a connecting structure for an assembly type concrete shear wall edge member. vertical connecting reinforcing steel bar, which can be provided with an upset head, is reserved through a hole reserved in a large-diameter metal bellows, and is sleeved with a continuous spiral stirrup; then the vertical connecting reinforcing steel bar and the continuous spiral stirrup are commonly inserted into the large-diameter metal bellows; and fine aggregate concrete (or a grounding material) is poured into the metal bellows, so that the reliable connection of the edge member is realized. Due to reliable anchoring of the vertical connecting reinforcing steel bar, the optimization of the diameter, the quantity and the plane arrangement of the vertical connecting reinforcing steel bar, and the increase of the wet joint area on a splicing surface, full exertion of the bearing capacity of the shear wall is ensured; and multiple effective restrain for the subsequentlly-poured fine aggregate concrete (or the grouting material) is formed by the shear wall stirrup, a horizontal tie bar, the metal bellows and the continuous circular spiral stirrup, and thus the integral performance of the part is remarkably improved. According to the connecting method for the edge member, which is provided by the invention, the stress continuousness of the vertical steel reinforcing bar is ensured, the deformaility and the ductility performance of the vertical steel reinforcing bar are remarkably improved, and the shock resistance of the assembly type concrete shear wall is improved. Meanwhile, the method is simple in manufacturing process and facilitates the practice and application.

Owner:SOUTHEAST UNIV

Electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates

The invention discloses an electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates and belongs to the technical field of electroplating. An electroplating solution used by the method comprises the following components according to mass concentration: 170-350g / L of nickel salt, 5-50g / L of cobalt salt, 0.5-4g / L of sodium borohydride,20-60g / L of ethylenediamine and 30-50g / L of buffering agents. The Ni-Co-B alloy coatings prepared from the electroplating solution have high throwing power and excellent corrosion resistance performance; the micro hardness of the Ni-Co-B alloy coatings can reach 1000HV.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

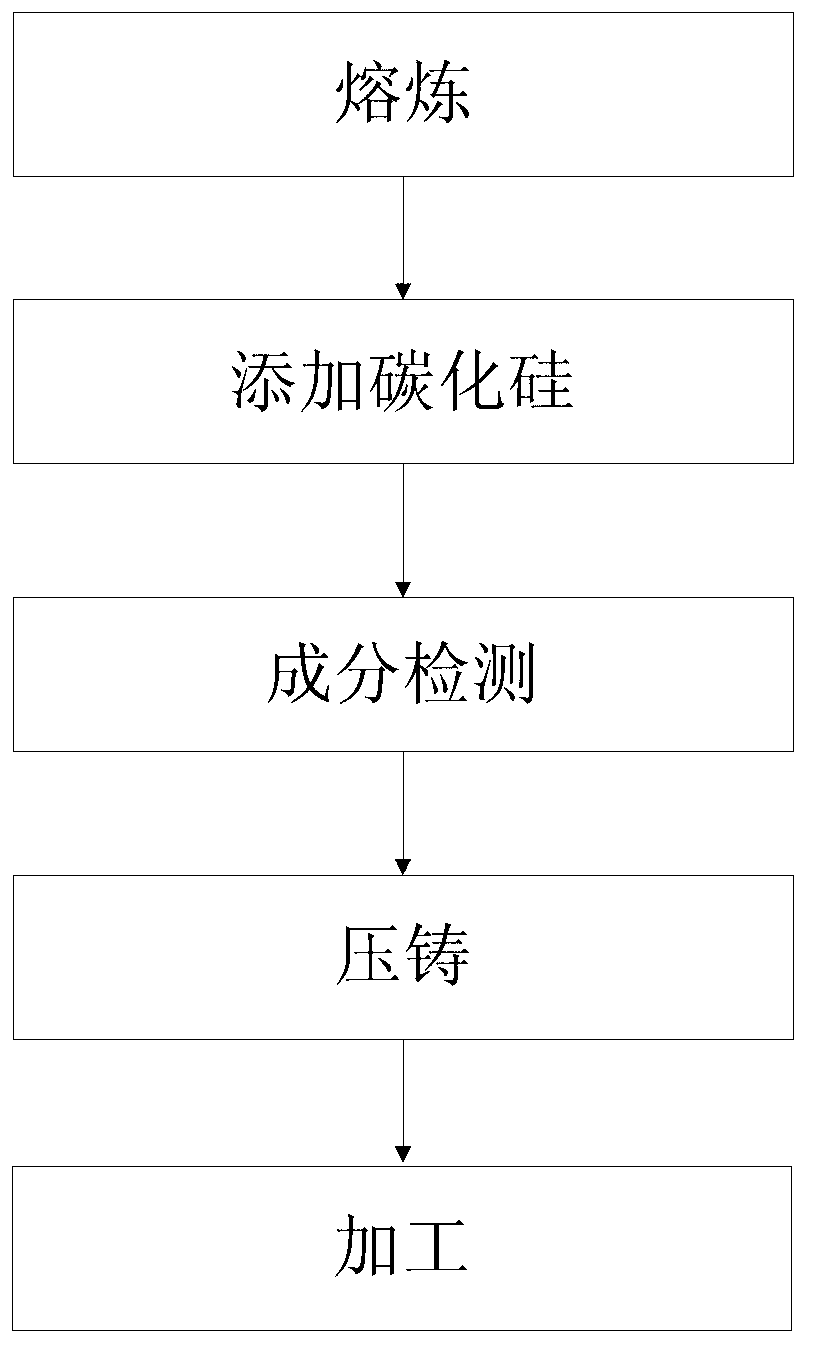

Preparation method of nanoscale silicon carbide magnesium alloy material

ActiveCN103320631AGuaranteed CorrosionGuaranteed ductilityTransportation and packagingMetal-working apparatusManganeseHardness

The invention provides a preparation method of a nanoscale silicon carbide magnesium alloy material. The nanoscale silicon carbide magnesium alloy material is prepared by uniformly dispersing and distributing a light nanoscale silicon carbide material through particle fine treatment in the magnesium alloy material. The nanoscale silicon carbide magnesium alloy material comprises the following components in percentage by weight: 1-1.5% of nanoscale silicon carbide, 10-11.5% of aluminum, 1.1-1.8% of zinc, 0.05-0.2% of manganese, less than or equal to 0.2% of inevitable impurities, and the balance of magnesium. According to the preparation method of the nanoscale silicon carbide magnesium alloy material provided by the invention, higher solid solubility is formed in a magnesium alloy substrate by means of characteristics of high hardness and wear resistance and the like of nanoscale silicon carbide, so that the stretching and compressing yield strength is enhanced while the welding performance, corrosion resistance and malleability of the nanoscale magnesium alloy material are ensured.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

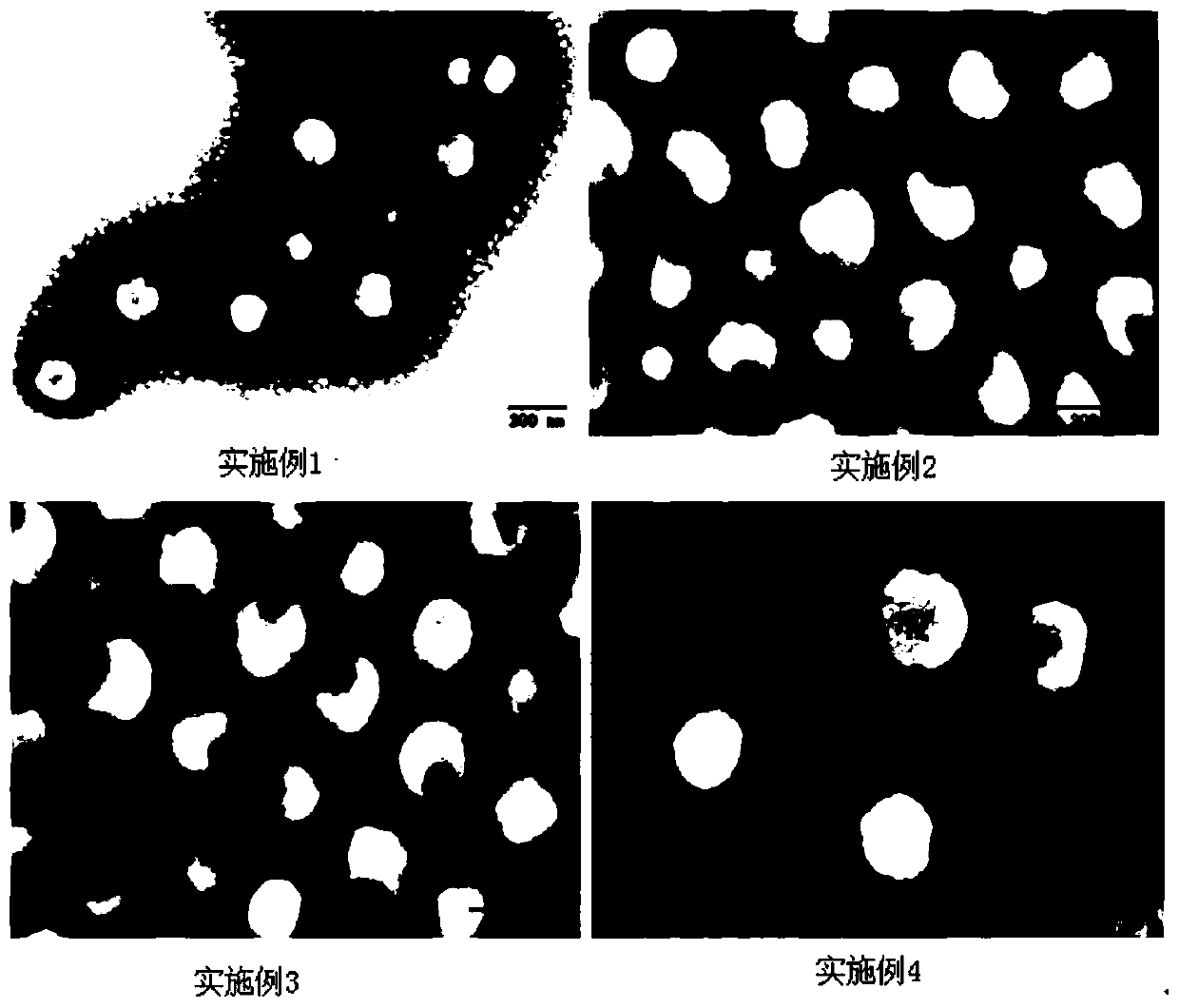

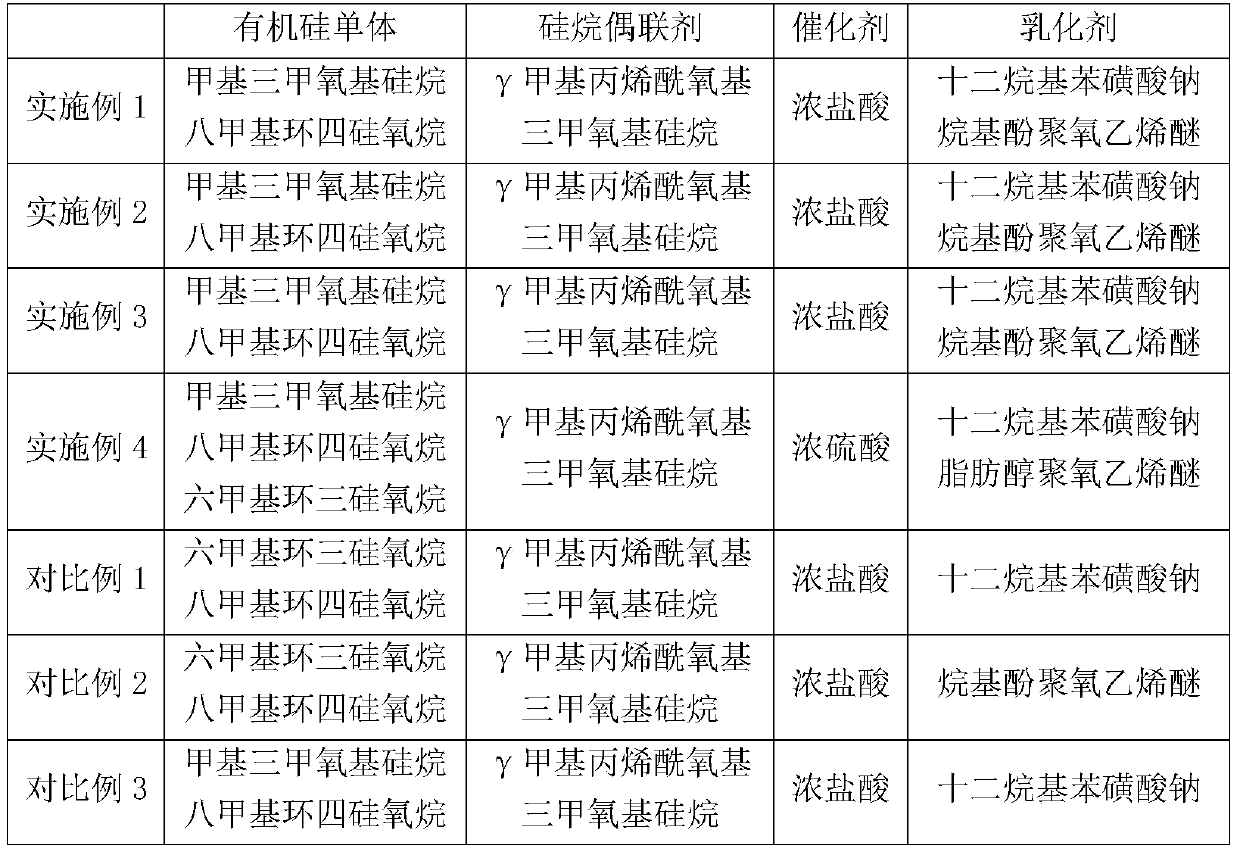

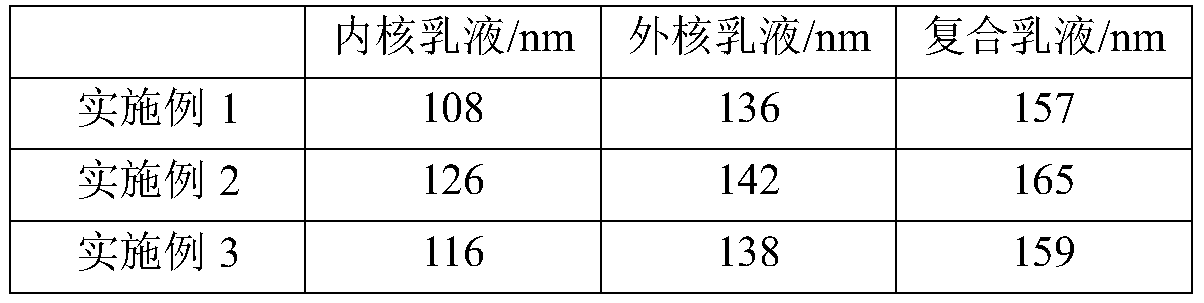

Preparation method of ACR elastic resin with core-shell structure

The invention discloses a preparation method of ACR elastic resin with a core-shell structure. The ACR elastic resin comprising a polysiloxane core layer and a polyacrylate shell layer is obtained through a core-shell emulsion polymerization method. The preparation method comprises the preparation steps of the core-layer polysiloxane core emulsion: mixing an organosilicone monomer, a silane coupling agent, a catalyst, deionized water and an emulsifier, emulsifying, introducing nitrogen to remove oxygen, carrying out polymerization reaction, and regulating the pH value to 6-8 after the reactionis ended, and thus obtaining the polysiloxane core emulsion. Polysiloxane latex particles have more excellent elasticity at low temperature; meanwhile, the organosilicone monomer in the preparation stage of the polysiloxane core emulsion comprises methyltrimethoxysilane; an acrylate silane coupling agent is selected, cross-linked structures described in the specification are formed inside and outside polysiloxane emulsion elastic particles in the polymerization reaction process respectively, and the elastic performance of polysiloxane at the low temperature of -25 DEG C or less is improved onthe basis that the ductility of polysiloxane is guaranteed through the structures.

Owner:YIBIN TIANYUAN GRP CO LTD +1

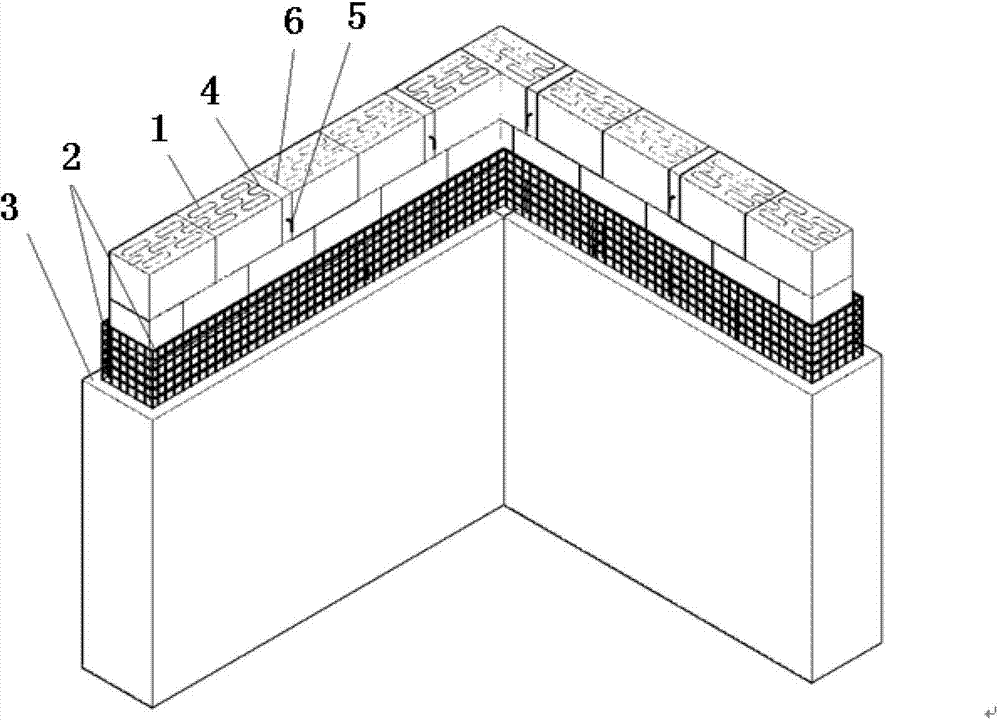

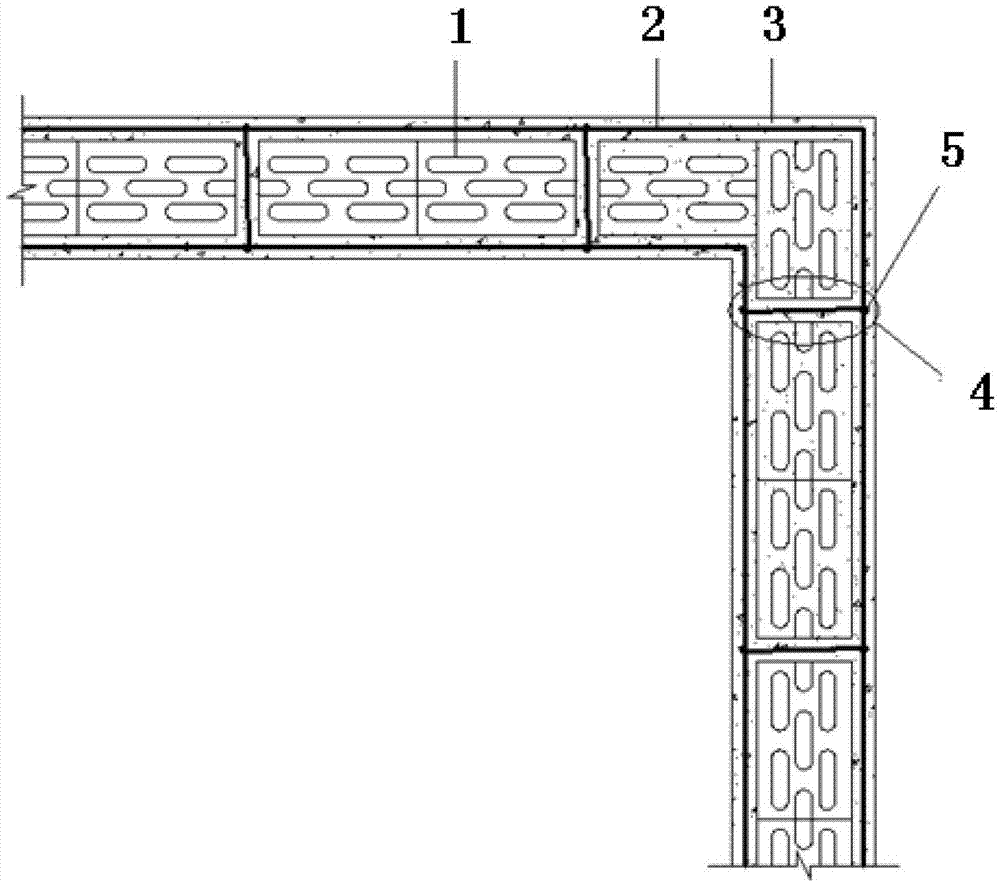

Energy-saving wall with connecting keys and recycled concrete wall panels holding insulation block masonry, and manufacturing method of energy-saving wall

The invention relates to an energy-saving wall with connecting keys and recycled concrete wall panels holding insulation block masonry and a manufacturing method of the energy-saving wall, and belongs to the technical field of constructional engineering. The energy-saving wall mainly comprises insulation block masonry, a wire mesh frame, recycled concrete, and connecting keys. The insulation block masonry is built first in construction. Wire mesh is bent and is fixed by tie bars reserved on the insulation block masonry so that the wire mesh frame is formed. A formwork is erected and the recycled concrete is poured, and accordingly the energy-saving wall with the connecting keys and the recycled concrete wall panels holding the insulation block masonry is formed. The energy-saving wall built with the recycled concrete is economical, practical, energy-saving and environment-friendly. Different from the traditional energy-saving wall, the energy-saving wall is provided with the concrete wall panels and the wire mesh on two sides of the insulation block masonry and is better in thermal insulation, acoustic insulation and energy saving. The energy-saving wall complies with the energy saving and environment protection design, and the development trend of modern architecture, and is widely applicable to the field of constructional engineering.

Owner:BEIJING UNIV OF TECH

Construction method for municipal road, pavement structure and road pavement

InactiveCN106958177AImprove waterproof performanceImprove ductilityPaving reinforcementsIn situ pavingsEpoxyPonding

The invention discloses a municipal highway, a road surface structure and a construction method of the highway pavement, including the highway, on which there are altogether an epoxy resin asphalt layer, an FRT layer, a concrete layer, coal gangue, a lime layer, a slag soil base, steel bars, Reinforced grid mesh, pouring vertical steel columns inside the road, so as to avoid the dislocation between the road surface and the roadbed after a long time, the upper surface of the lime layer is bonded to the middle layer of the paved road surface and the asphalt concrete on the upper layer of the road surface and pressed together In fact, during road construction, because the FRP waterproof layer has good water resistance, it can avoid the uneven settlement caused by the accumulation of water penetrating into the roadbed, and then can ensure the smoothness of the road surface. The epoxy resin laid on the surface of the road The asphalt layer makes the road surface have good ductility, so that the road surface will not crack during the long-term extrusion.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

Method for machining stainless steel singe dual-lug support plate nut

The invention relates to a method for machining a stainless steel singe dual-lug support plate nut. The method includes the steps of the step A, machining a cold heading mould, the step B, trimming, the step C, tapping and the step D, shell nosing, wherein the step A includes the step A1 of primary heading and the step A2 of final heading. The method is advanced, easy to adopt, and capable of ensuring malleability and flowability of materials; the percent of pass of riveting of machined parts can reach 100%, and the parts can meet assembling requirements.

Owner:JIANGXI HONGDU AVIATION IND GRP

Truss imitating type damper structure transfer layer

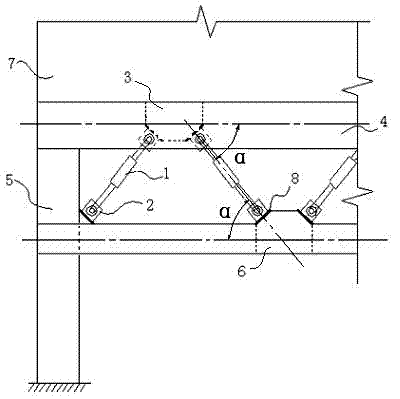

InactiveCN102383503AControlling Earthquake ResponseSolve the problem of severe interlayer stiffness mutationShock proofingClassical mechanicsDamper

The invention discloses a truss imitating type damper structure transfer layer, which is a truss type combination structure formed by a frame column, a transferring beam, a floor beam and damper. Upper portion structures of shear walls and the like are constructed on the transferring beam, stagger beam bodies form a beam system of the transferring beam, and stagger beam bodies form a beam system of the floor beam. The beam system of the transferring beam and the beam system of the floor beam are respectively provided with secondary beams. The secondary beams are provided with supports, a support under the beam system of the transferring beam and a support above the beam system of the floor beam are connected through a damper which is installed in inclined mode, and soft base cushions and cushion boards are sequentially installed between the supports and the secondary beams. The truss imitating type damper structure transfer layer breaks through a quake-proof design and research method, and a mixed damping device is composed of the damper, the soft base cushions and the supports, thereby reducing earthquake influence of a transfer layer structure. The truss imitating type damper structure transfer layer is simple in structure, economical and practical and has great popularization value.

Owner:CHIAN JIANGXI CORP FOR INT ECONOMIC & TECHN COOPERATION

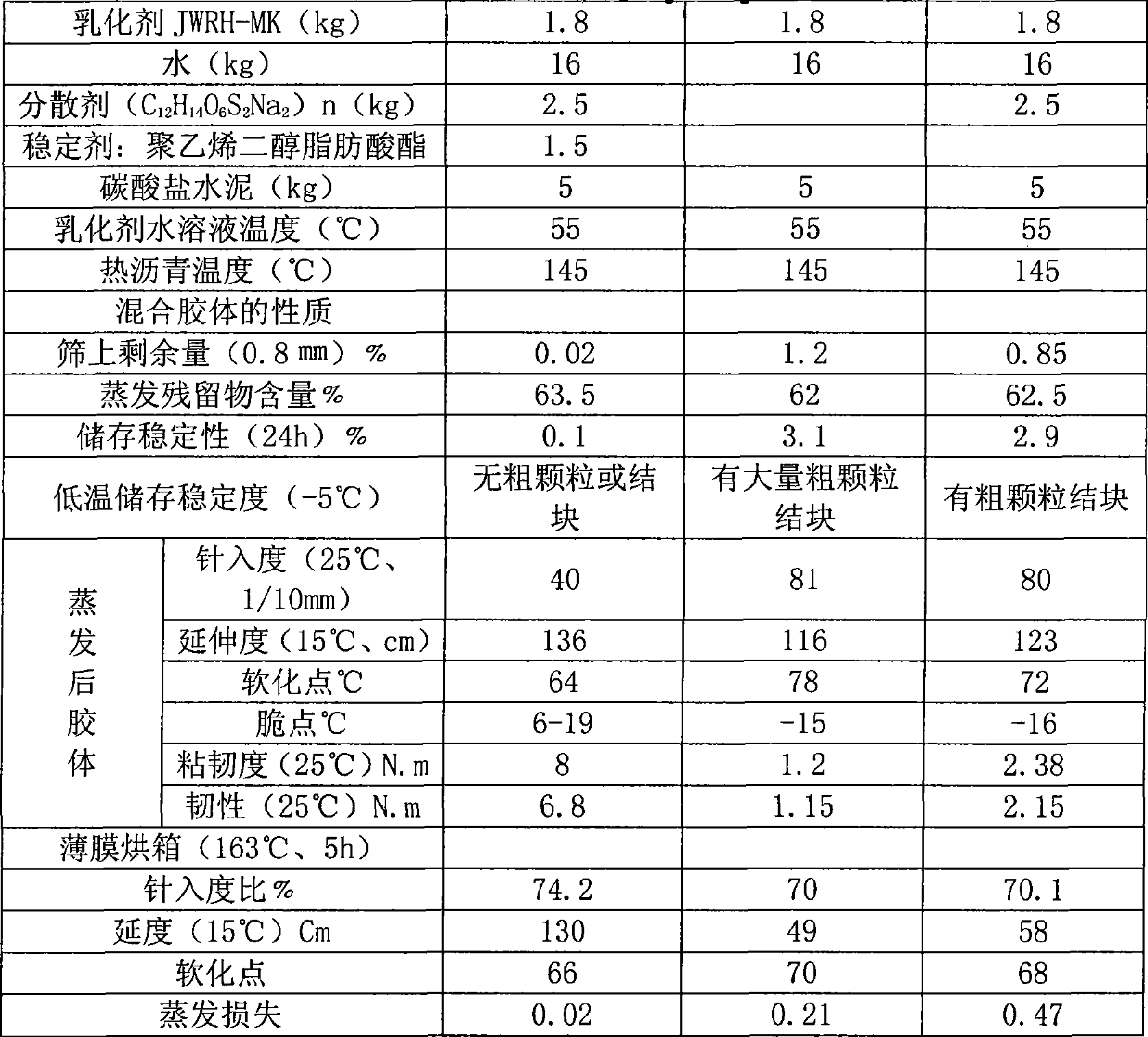

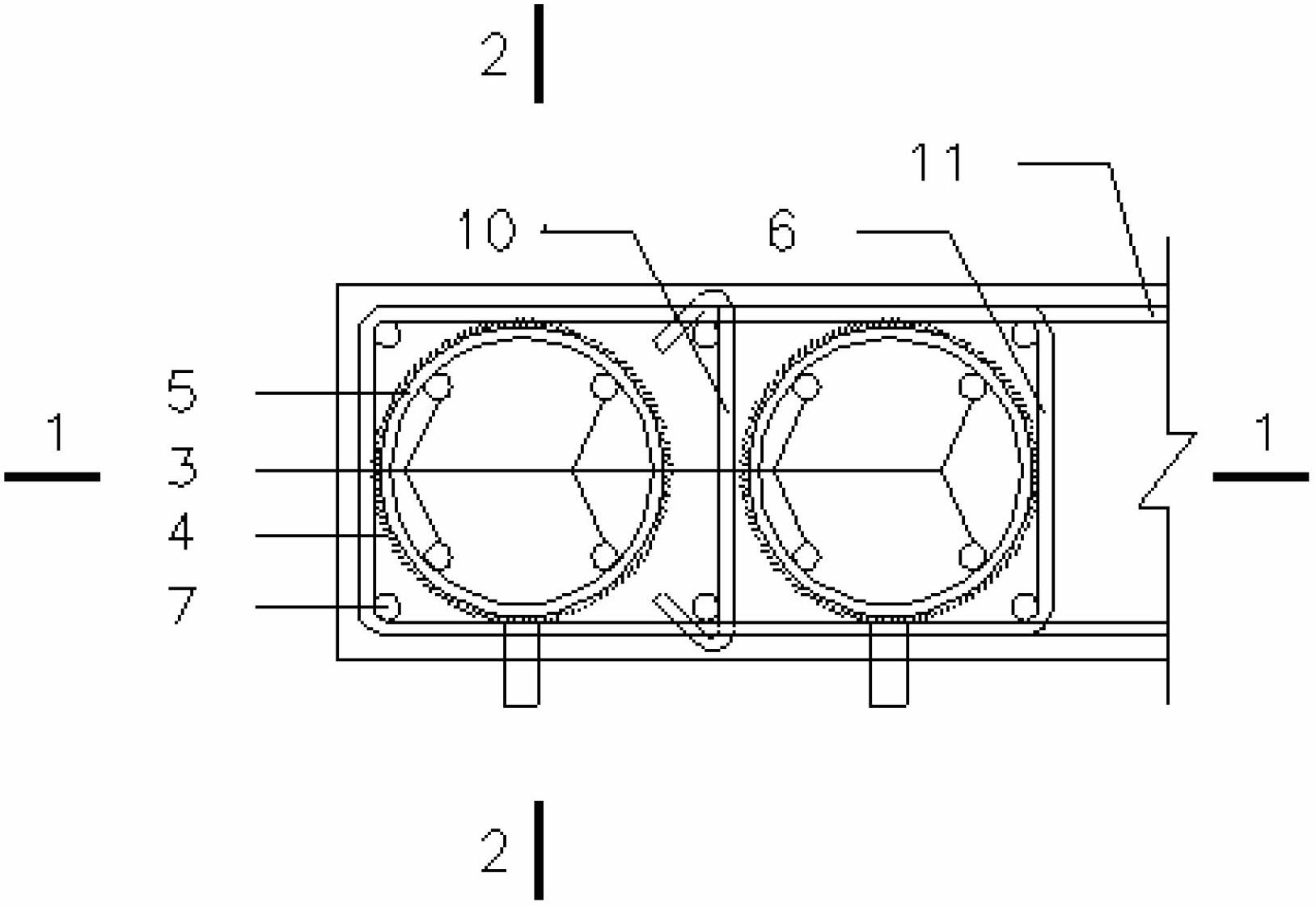

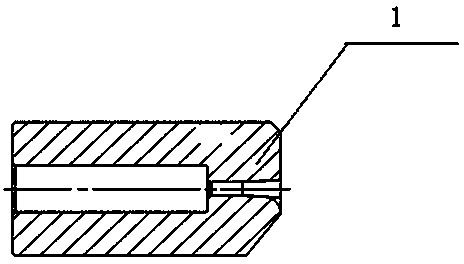

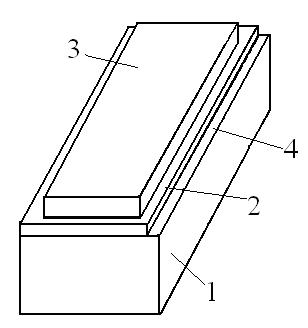

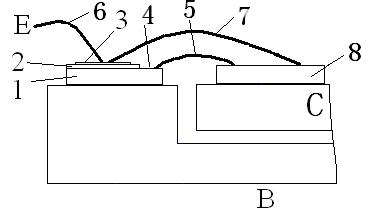

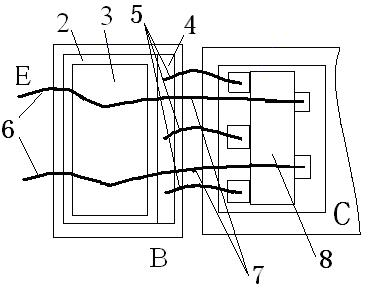

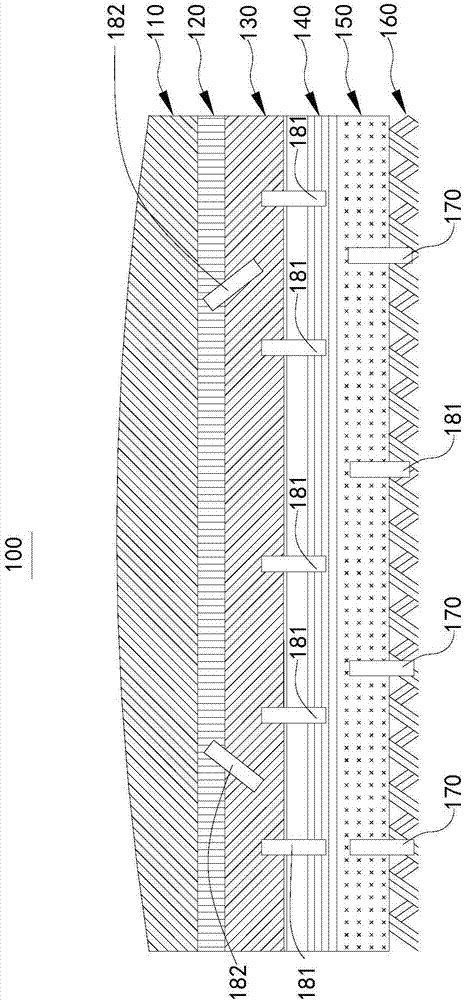

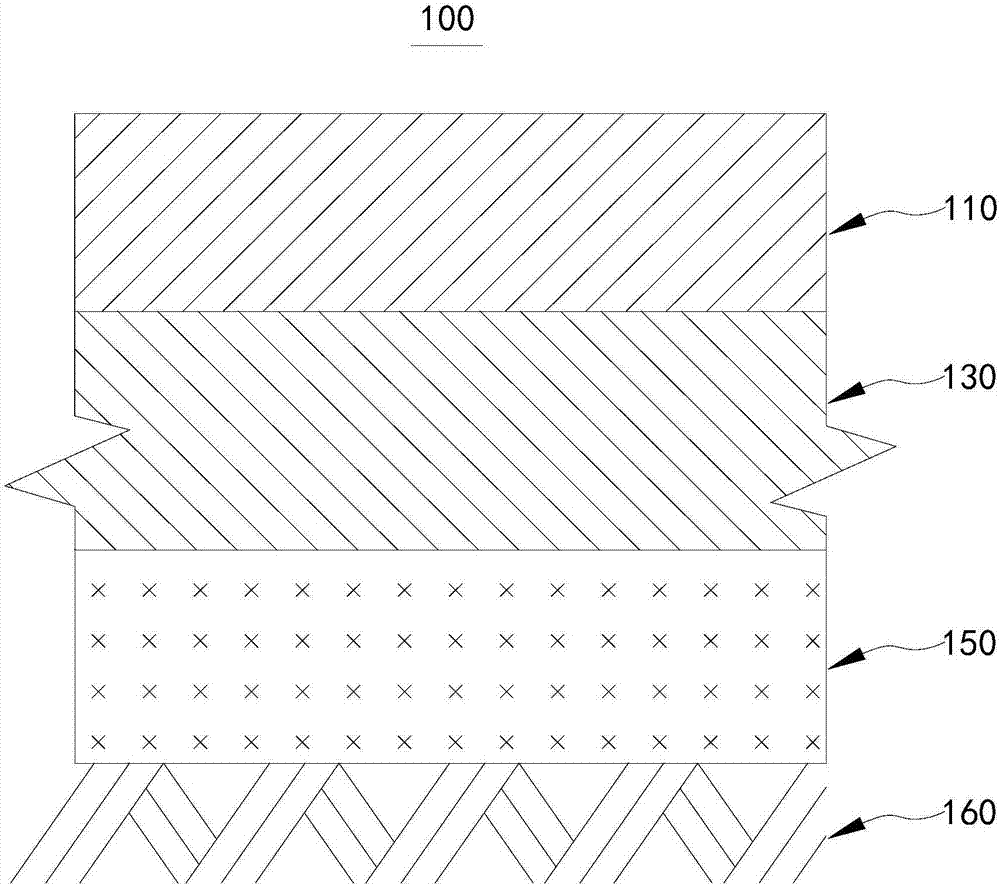

A microwave power transistor internal matching network and its manufacturing method

ActiveCN102280439AImprove performanceImprove frequency performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMicrowave

The invention discloses an internally matching network for a microwave power transistor and a manufacturing method of the internally matching network. The internally matching network comprises an internally matching mass optical memory (MOM) capacitor, a lower electrode outgoing line (5), a first upper electrode outgoing line (6) and a second upper electrode outgoing line (7), wherein the lower electrode outgoing line (5) of the MOM capacitor is led out of the upper surface (4), which is exposed by photoetching, of a lower electrode, and the other end of the lower electrode outgoing line is connected with a grounding pin of a tube core (8) transistor. The internally matching network has the advantages that the lengths of the electrode outgoing lines are shortened, the performance of the internally matching transistor is improved, a manufacturing process of the internally matching power transistor is simplified, the difficulty of the process is reduced, the utilization rate of a tube shell is improved, and the development period is shortened.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

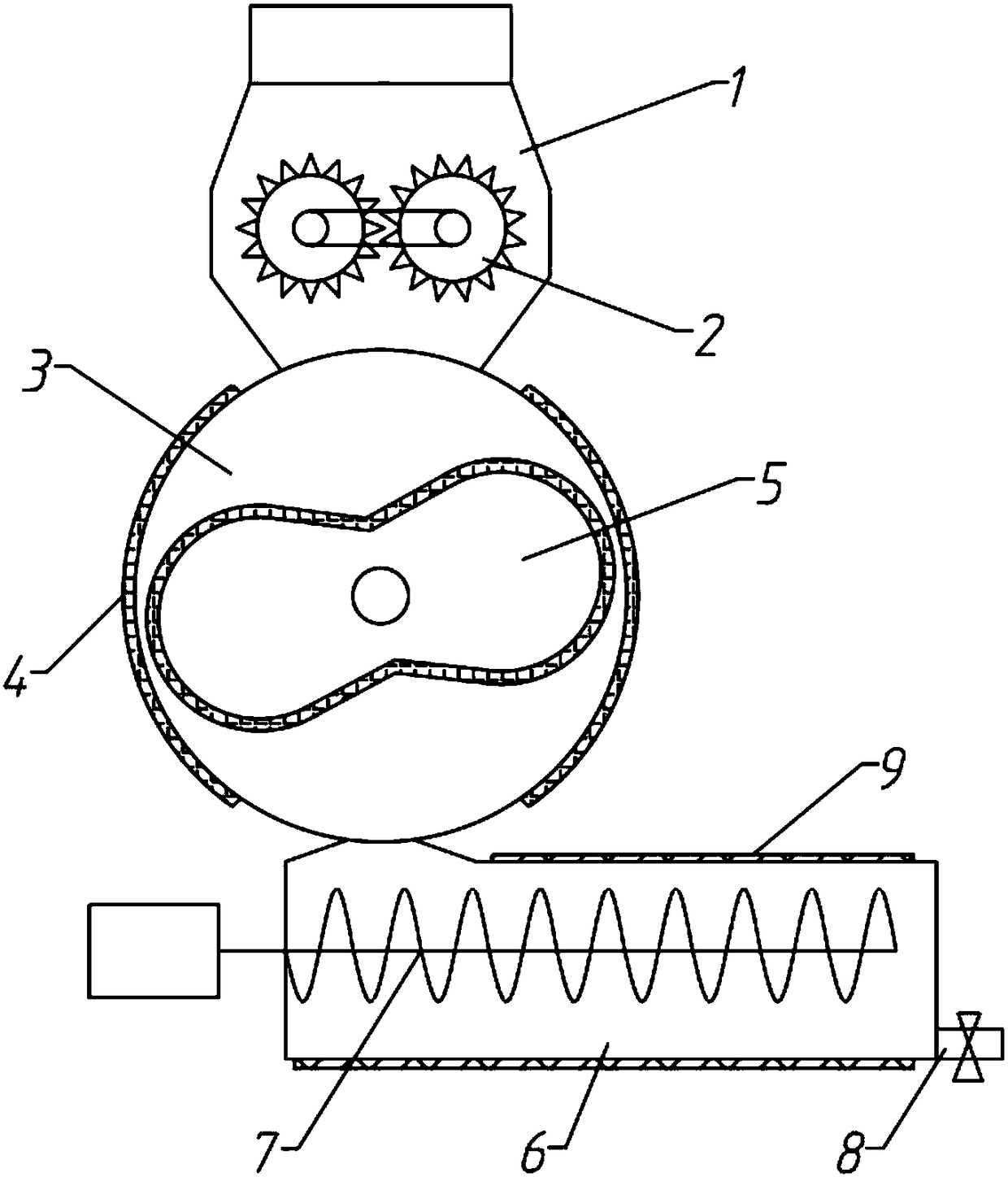

Waste rubber softening device for rubber production

InactiveCN108527704ASoften evenlyReduce lossPlastic recyclingMechanical material recoveryWaste rubberHeat losses

The invention relates to the technical field of rubber production, in particular to a waste rubber softening device for the rubber production. The waste rubber softening device comprises a feed pipe,a heating cavity and a flow-guiding pipe. Waste rubber is used as production raw materials, environment is protected, and energy is saved. The waste rubber is smashed by a smashing knife in the feed pipe, falls into the heating cavity, and is convenient to heat. An outer heating piece and an inner heating piece generate heat, and raw material particles falling into a grinding cavity fall on a grinding wheel; not only are heating and softening carried out, but also part of the raw material particles moves following the grinding wheel, and is in contact with the inner wall of a tank body to be heated and softened, so that uniform heating and softening of the rubber are realized. The softened rubber flows into the bottom of the heating cavity, is squeezed by the grinding wheel, and flows intothe flow-guiding pipe. The rotating shaft rotates to drive screw blades to rotate to stir the rubber so as to ensure the ductility. An insulating layer of the outer wall reduces heat loss to keep thetemperature.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

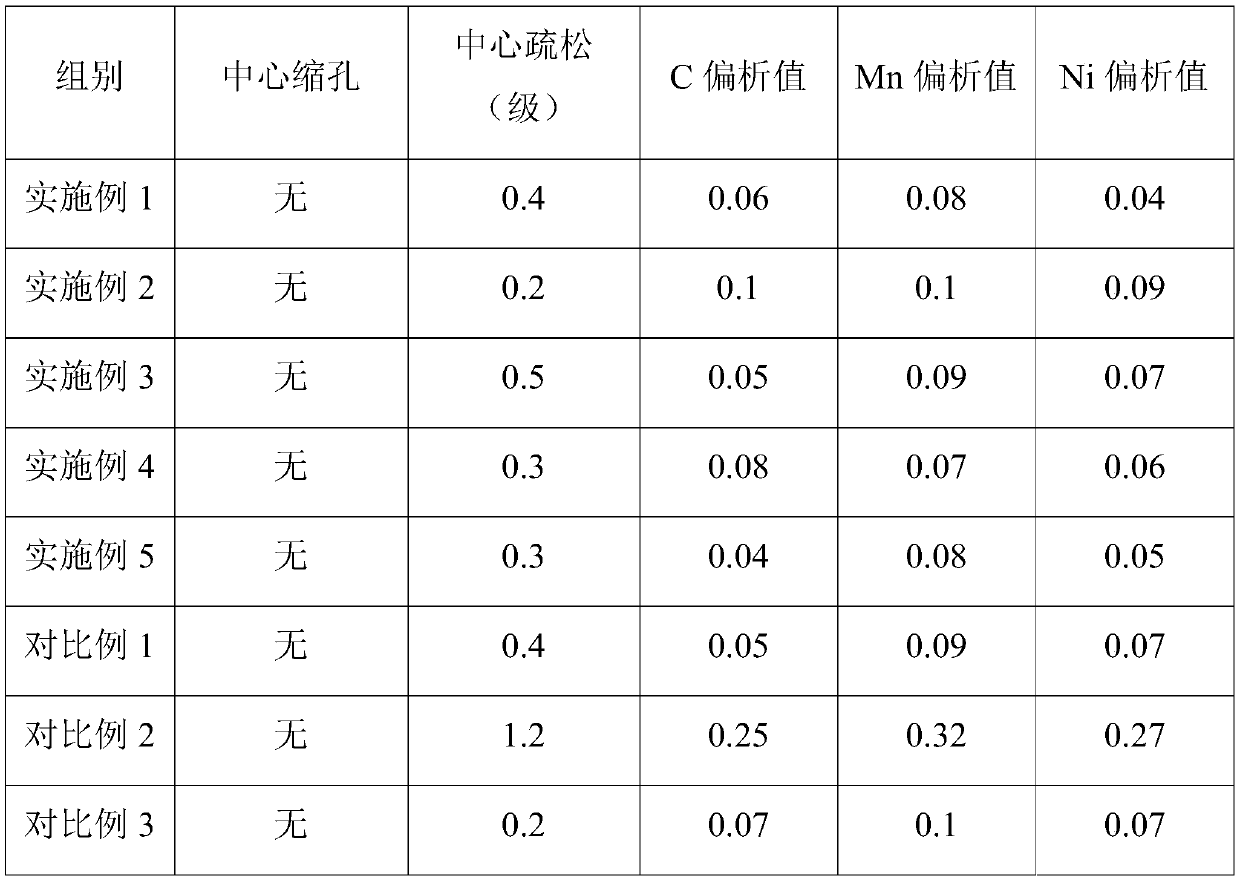

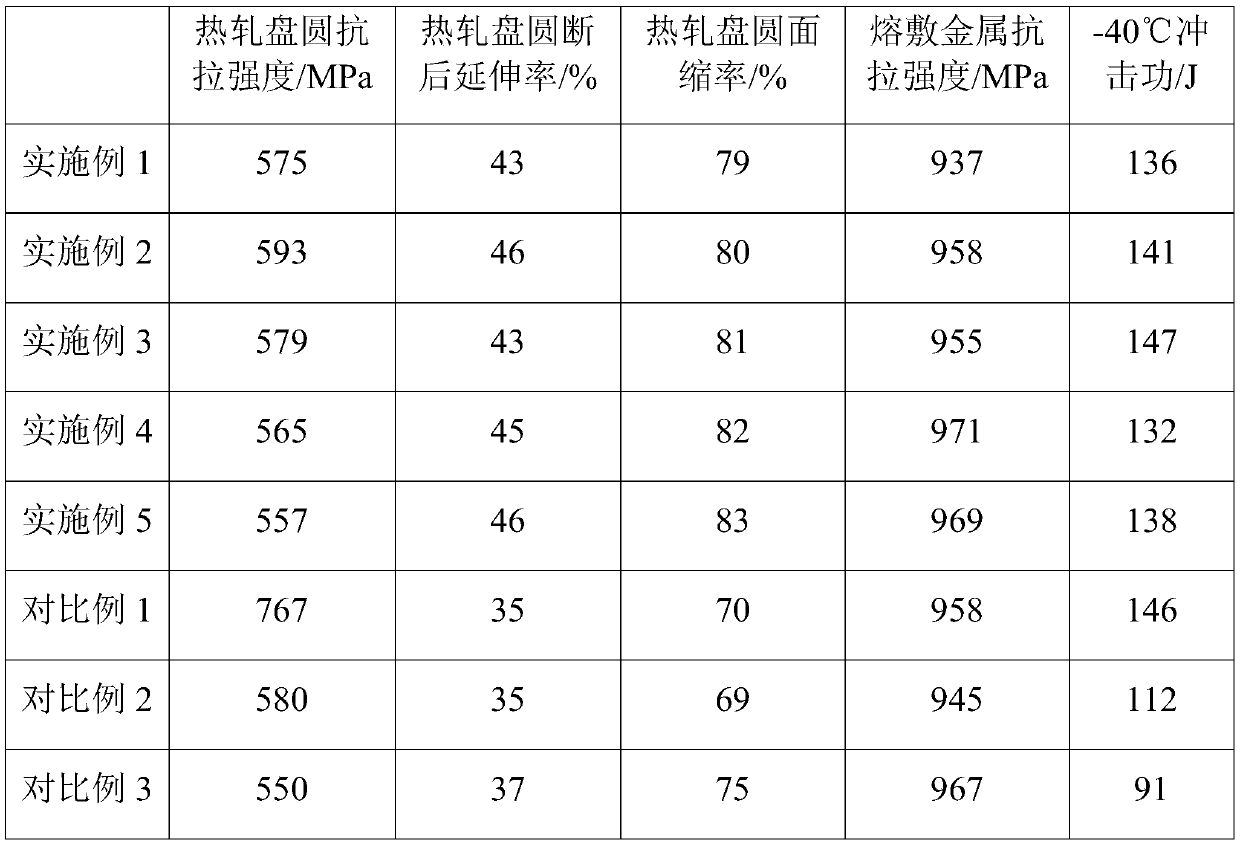

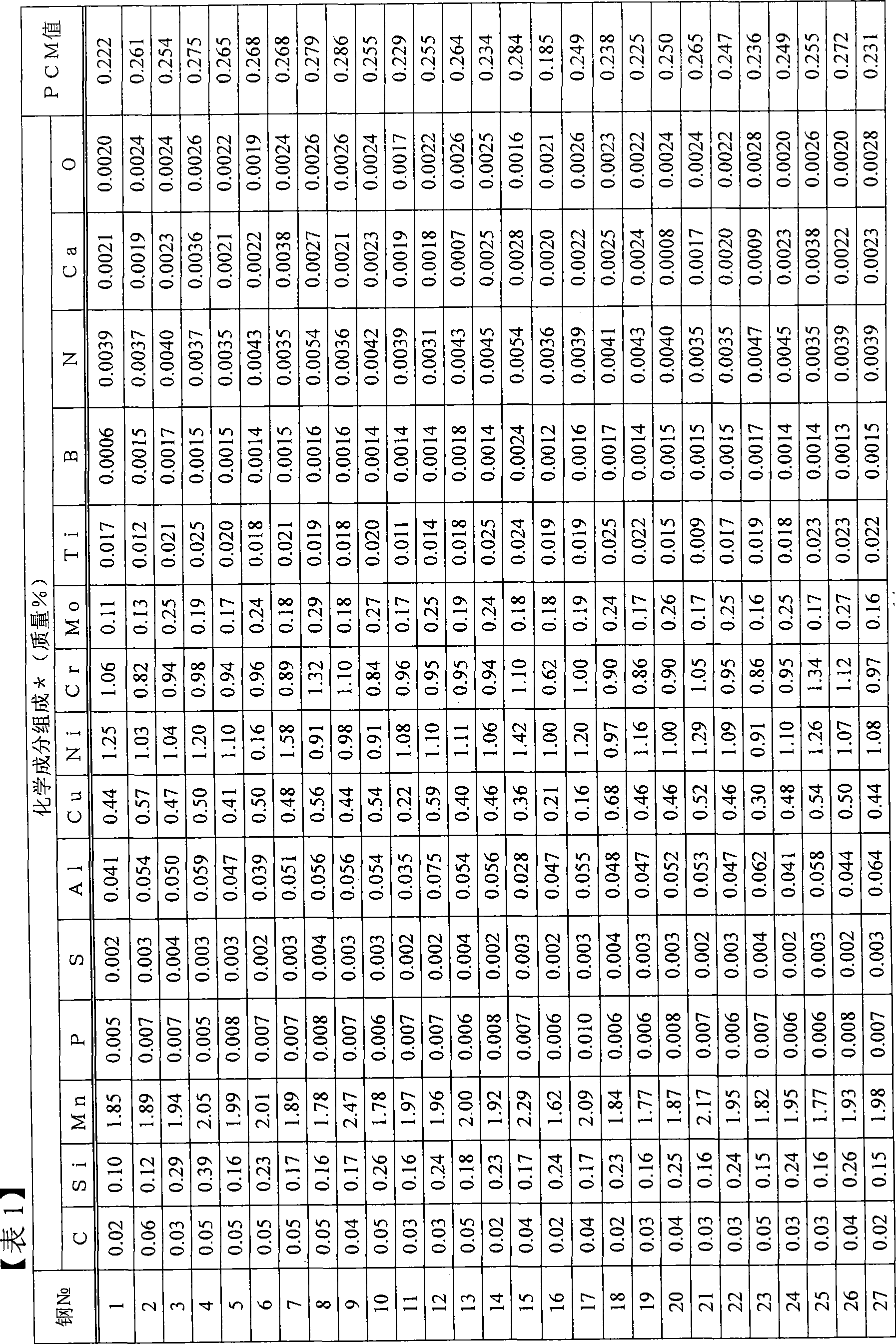

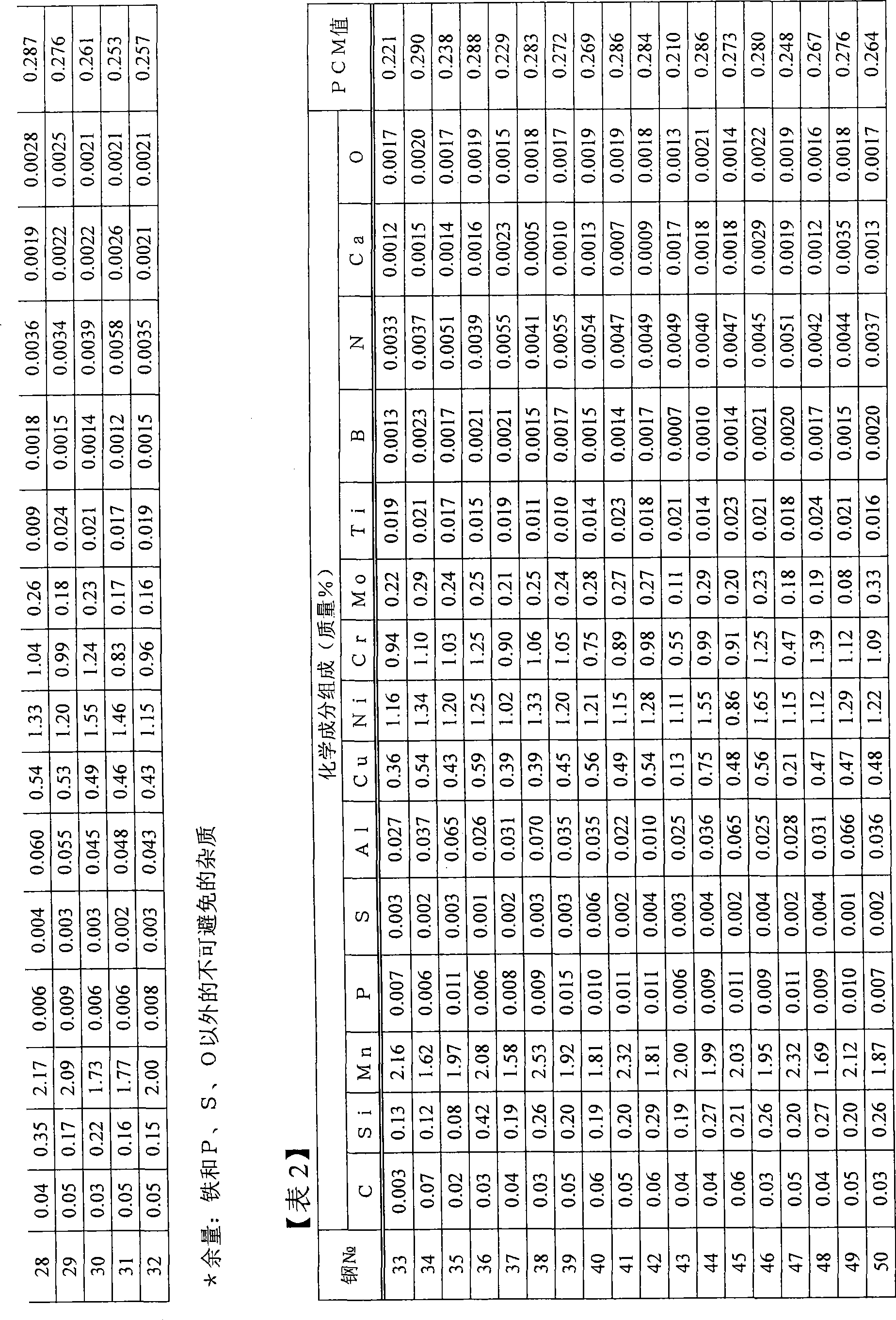

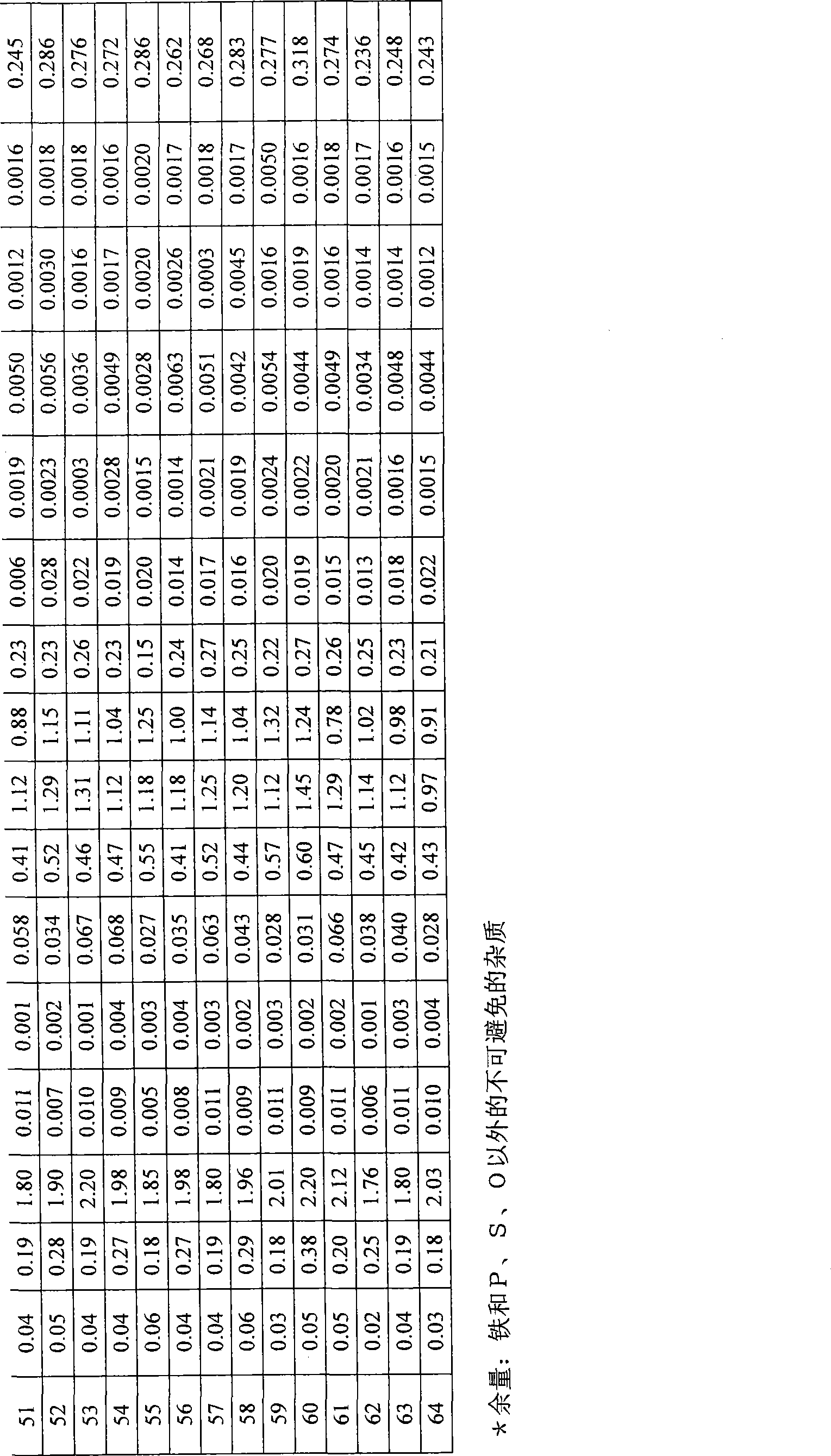

Hot-rolled wire rod for 90-kilogram-grade welding wire and production method thereof

ActiveCN111041346AImproved toughness and plasticityImprove welding performanceFerrite pearlitePlasticity

The invention relates to the technical field of metallurgy, and particularly discloses a hot-rolled wire rod for a 90-kilogram-grade welding wire and a production method thereof. The hot-rolled wire rod comprises the components of C, Si, Mn, Ni, Mo, Cr, V, Ti, Al, N, Zr and the balance Fe and inevitable impurities. The hot-rolled wire rod for the 90-kilogram-grade welding wire is prepared throughthe procedures of steelmaking, continuous casting, heating, rolling, laying and cooling. According to the method, through component adjustment and process optimization, the prepared hot-rolled wire rod meets the requirements of the wire rod for the 90-kilogram-grade welding wire, a ferrite+pearlite structure suitable for drawing is obtained, and the strength, toughness and plasticity of the wire rod are good so that the annealing process can be omitted in the welding wire processing process, welded deposited metal has moderate strength, the low-temperature impact energy is good, the productionefficiency is high, and the wide application prospect is achieved.

Owner:HEBEI IRON AND STEEL

780 mpa low yield ratio round steel pipe for building structure with excellent shock resistance and production process

The steel pipe not only satisfies predetermined expression, but also regulates chemical composition, and satisfies following conditions (A)-(C): (A) the central portion for removing the surface portion 2mm from the front and the back face of the steel pipe has an average Vickers hardness from 230 to 310; (B) in microscopic constitution of steel pipe, bainitic ferrite structure is over 80% in area, martensitic phase is below 5% in area; (C) average Vickers hardness Hv of the surface portion 2mm from the front and the back face of the steel pipe is below 1.3 times of the average hardness Hv of the central portion. According to the construction, high strength and low yield ratio can be realized in the mean time, tractility can be ensured by reducing hardness on external surface of the steel pipe due to bending machining in steel pipe forming, cracking resistance in welding can be improved because of improved shock resistance for steel pipes with highest tensile strength at 780MPa for building reinforcement.

Owner:KOBE STEEL LTD

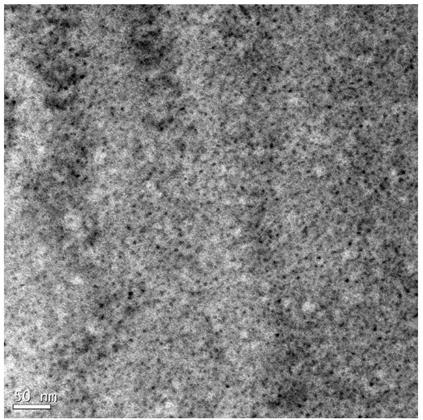

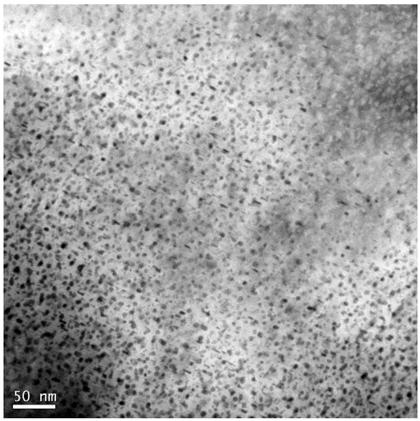

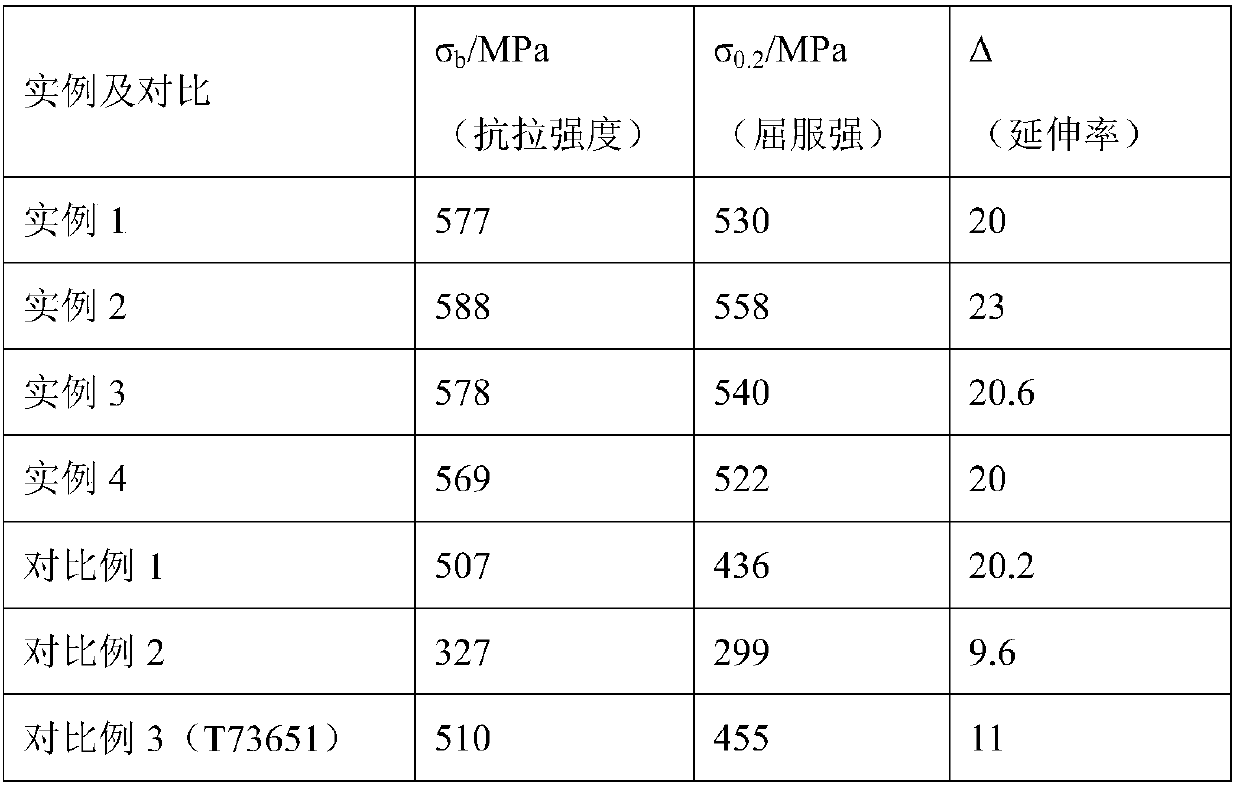

Heat treatment method for synchronously improving strength and ductility of 7-series aluminum alloy plate

ActiveCN109628861AEasy to replyGood recrystallization effectFurnace typesHeat treatment furnacesSolution treatmentUltimate tensile strength

The invention relates to the technical field of aluminum alloys, in particular to a heat treatment method for synchronously improving strength and ductility of a 7-series aluminum alloy plate. According to the heat treatment method, a 7-series aluminum alloy hot-rolled plate is adopted as a treated object, solution treatment, pre-aging treatment, retrogression heating treatment and re-aging treatment are adopted in sequence, and a product is obtained. When the design process is applied to an aluminum alloy 7050 plate, the strength of extension of the obtained product ranges from 565 MPa to 590MPa, the yield strength of the obtained product ranges from 520 MPa to 560 MPa, and the ductility of the obtained product ranges from 20% to 23.5%. The strength and ductility of an alloy can be improved at the same time. In addition, the continuous temperature increase and heating manner is adopted, a large amount of time can be saved in the retrogression heating treatment stage, and the production efficiency is improved.

Owner:湖南思力行科技有限公司

Environment-friendly furniture board manufacturing process

InactiveCN109500938ALow ductilityWeak elasticityWood veneer joiningWood stock bendingProduction lineSolid wood

The invention provides an environment-friendly furniture board manufacturing process. The preparation method of environment-friendly furniture boards comprises the following steps of material selection, cutting, board laminating, cold press molding, mold bending forming, drying shaping, hot press molding, grinding finishing and paint spraying, wherein the paint spraying step comprises primer spraying, primer grinding and topcoating. Through the environment-friendly furniture board manufacturing process, solid wood boards are subjected to cold pressing and bending forming through a cold press,the cost for purchasing high-frequency bending processing production line equipment is omitted, the manufacturing process is simplified, and the production cost is reduced. By means of the solid woodboard cold pressing molding method, a molded product does not have excessive glue lines, the overall effect of the product is ensured, and the natural beauty and curvy beauty of the solid wood productare represented. The environment-friendly furniture board manufacturing process has the characteristics that the painting process is simple, operation is safe, the appearance is attractive, the costis low, and the process has no pollution to environment and does no harm to human bodies. Sustainable development of furniture production is promoted. Manmade harm to health can be reduced.

Owner:成都千佳世纪家具有限责任公司

MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and welding process of MIG welding solid-core welding wire

PendingCN114289929AReduce surface tensionRealize all position weldingArc welding apparatusWelding/cutting media/materialsManganeseUltimate tensile strength

The invention relates to an MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and a welding process of the MIG welding solid-core welding wire. According to the technical scheme, the MIG welding solid-core welding wire for the high-manganese austenite low-temperature steel comprises the following chemical components: 0.20-0.60 wt% of C; si is less than or equal to 0.05 wt%; the content of Mn is 20-32 wt%; the content of Ni is 0.1 to 2 weight percent; the content of Cr is 0.1 to 1.8 wt%; the content of Cu is 0.55 to 1.00 wt%; the content of W is 0.5 to 1.9 weight percent; the content of Mo is 1.3 to 3.0 wt%; the content of Al is 0.5 to 2 weight percent; nb + V + Ti + B + RE < = 0.5 wt%; p < = 0.002 wt%; s < = 0.001 wt%; and the balance of Fe and inevitable impurities. Full-automatic and all-position welding can be achieved, the welding efficiency is high, forming is good, and the mechanical property is excellent; the strength of weld metal formed through inert gas protection is matched with that of high-manganese austenite low-temperature steel, the forming performance is good, the low-temperature toughness is excellent, and the technical requirements for the strength and ultralow-temperature toughness of the LNG storage tank at the working temperature of-196 DEG C can be met.

Owner:WUHAN UNIV OF SCI & TECH

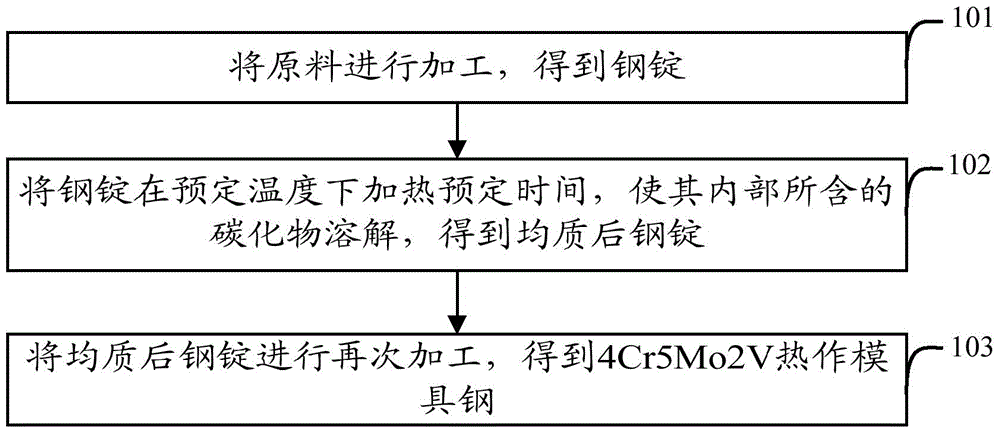

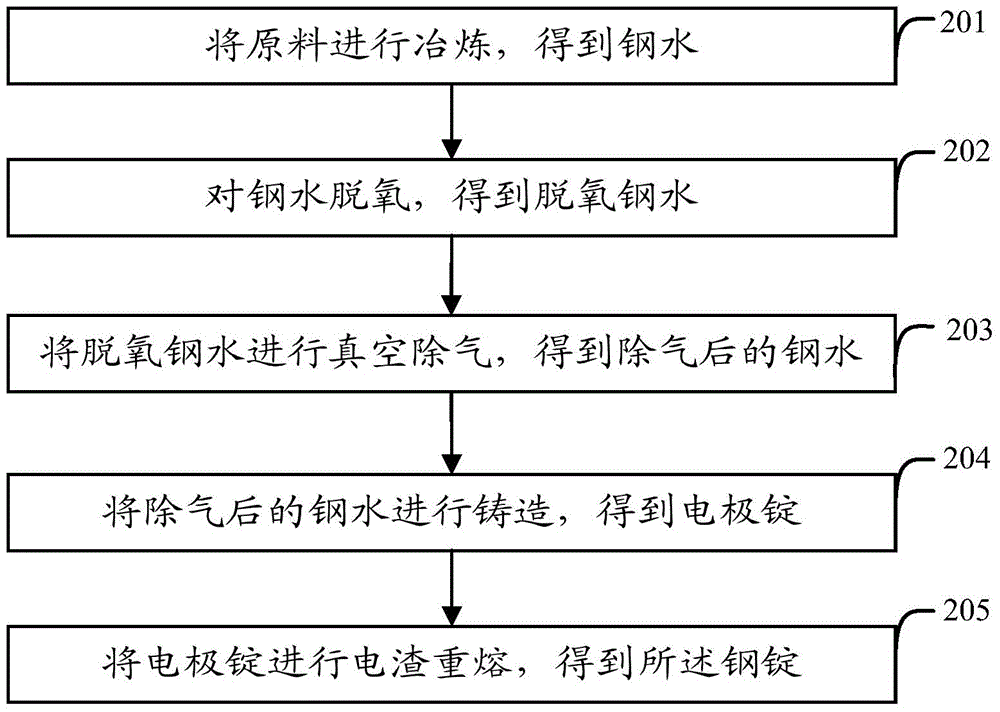

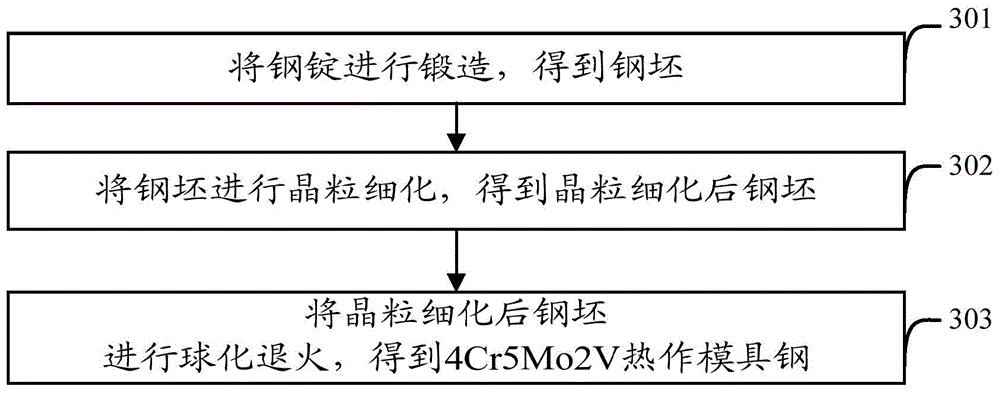

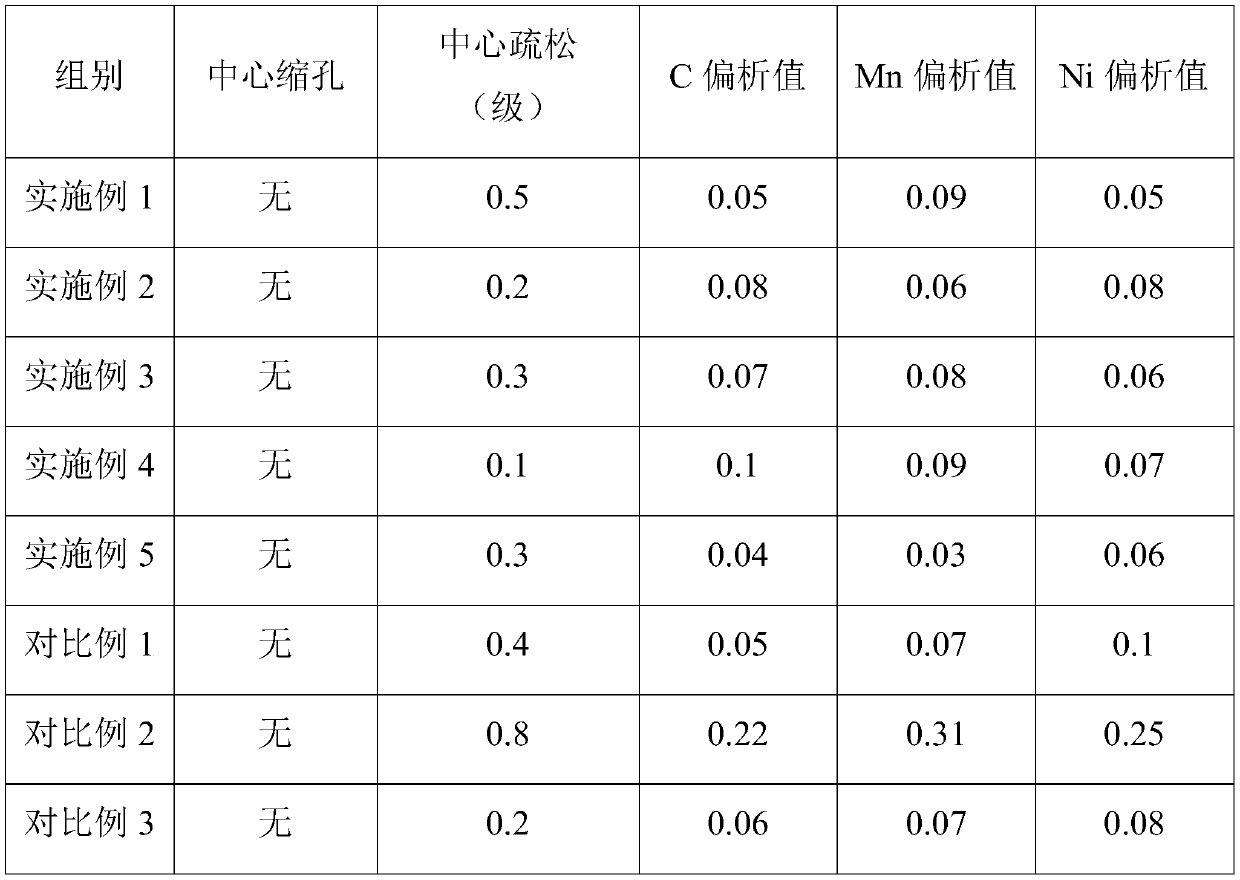

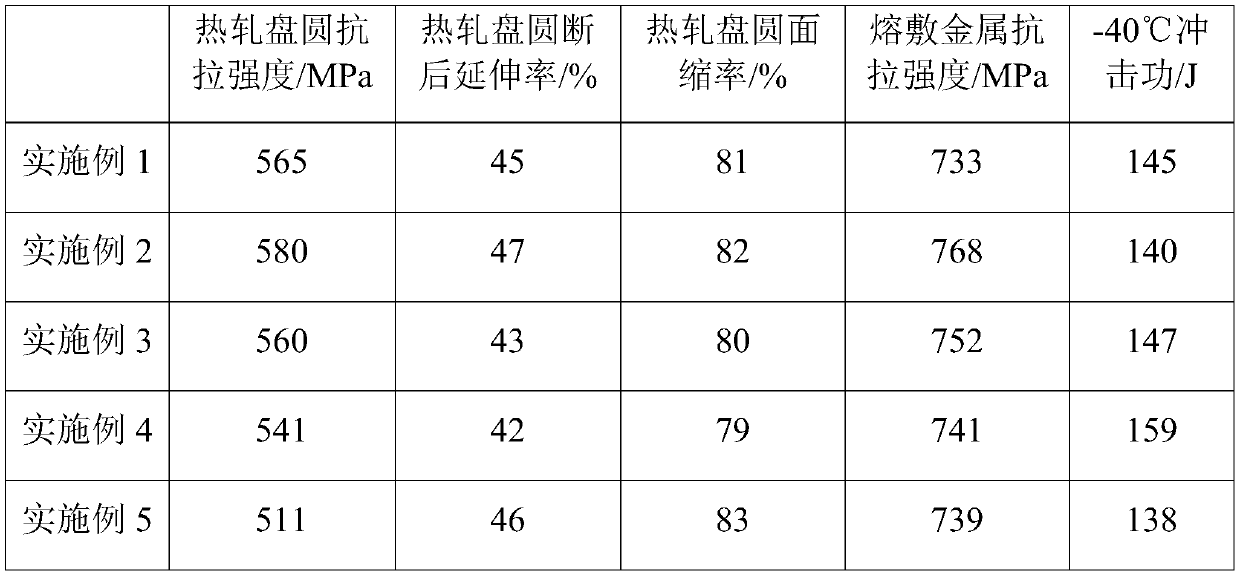

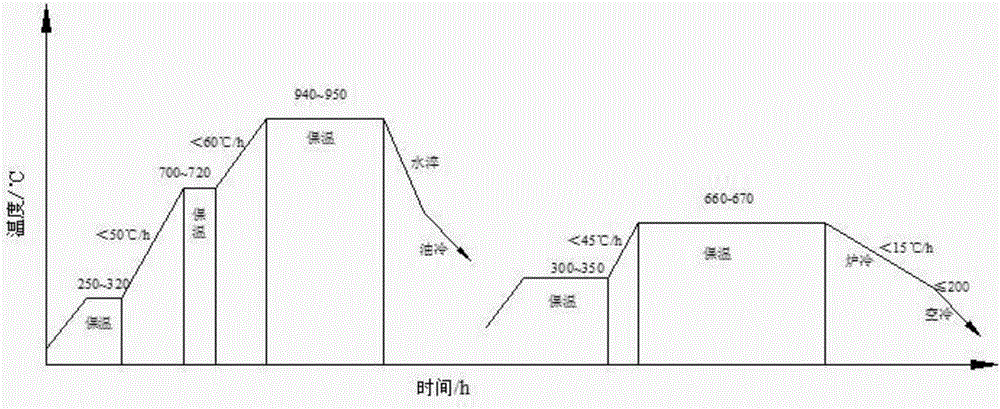

Method for producing 4Cr5Mo2V hot work die steel

The invention relates to the technical field of metallurgy, and in particular relates to a method for producing 4Cr5Mo2V hot work die steel. The method comprises the following steps: processing a raw material so as to obtain steel ingots, heating the steel ingots for a reset time at a preset temperature so as to melt carbide inside the ingots to obtain homogenized ingots, and further processing the homogenized ingots so as to obtain the 4Cr5Mo2V hot work die steel. Due to adoption of the method for producing the 4Cr5Mo2V hot work die steel, the phenomenon that the machined 4Cr5Mo2V hot work die steel is cracked or fractured at early stage is avoided. In addition, in the process that the ingots are heated and the carbide inside the ingots is dissolved, the internal tissue inside the ingots is uniform, the stress of the internal tissue of the ingots is reduced, and macrosegregation can be eliminated to a certain extent.

Owner:北京会盛百模具材料技术有限公司

Hot-rolled wire rod for 70-kilogram-level welding wire and production method thereof

The invention relates to the technical field of metallurgy, and particularly discloses a hot-rolled wire rod for a 70-kilogram-level welding wire and a production method thereof. The hot-rolled wire rod comprises the following components: C, Si, Mn, Ni, Mo, Cr, V, Ti, Al, Zr and the balance of Fe and inevitable impurities, and the hot-rolled wire rod for the 70kg-grade welding wire is prepared through the procedures of steelmaking, continuous casting, heating, rolling, spinning and cooling. Component adjustment and process optimization are carried out, the prepared hot-rolled wire rod meets the requirements of a wire rod for a 70-kilogram-level welding wire, and a ferrite and pearlitic structure suitable for drawing is obtained; the strength, the toughness and the plasticity of the wire rod are good; and therefore the annealing procedure can be omitted in the welding wire machining process, deposited metal obtained after welding is moderate in strength, good in low-temperature impact energy and high in production efficiency, and the wide application prospect is achieved.

Owner:HEBEI IRON AND STEEL

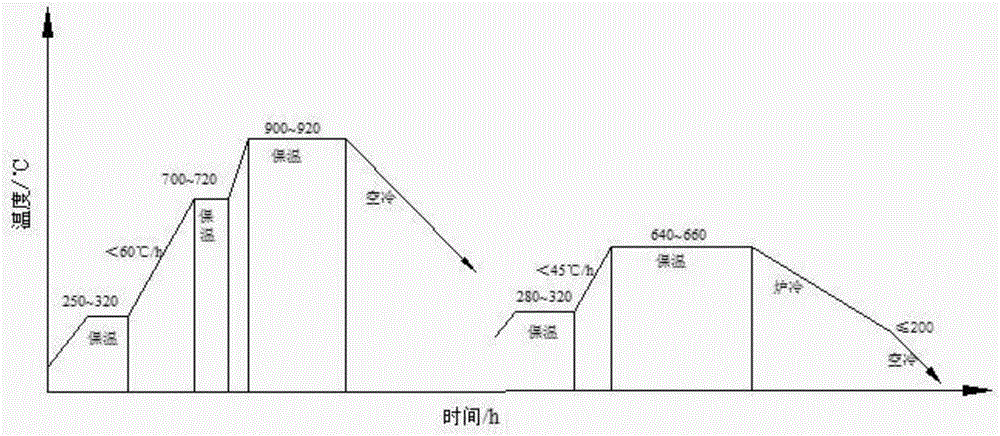

Heat treatment method of forged piece of industrial steam turbine rotor

InactiveCN106086360AGuaranteed quenching effectHigh strengthFurnace typesHeat treatment furnacesWater coolingUltimate tensile strength

The invention discloses a heat treatment method of a forged piece of an industrial steam turbine rotor. The heat treatment method comprises preheat treatment and quenching and tempering treatment. Preheat treatment comprises the steps of normalizing and tempering, and quenching and tempering treatment comprises the steps of quenching and tempering. During quenching of the quenching and tempering treatment, the temperature is raised in a ladder heating manner, a cooling manner of combining water cooling and oil cooling is adopted during cooling, and the tempering temperature and the cooling speed are decreased through tempering. The heat treatment method of the forged piece of the industrial steam turbine rotor is more reasonable in process, the large-diameter forged piece of the industrial steam turbine rotor can be treated, the obtained strength of the large-diameter forged piece of the industrial steam turbine rotor can reach the grade of 670 MPa, obdurability matching is better, and then the efficiency of an industrial steam turbine unit is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

Processing method for bend forming of boards

InactiveCN103568449AEasy to processCooperate accuratelyLaminationLamination apparatusMaterials processingMachining process

The invention belongs to the field of board material processing technology, and especially relates to a processing method for bend forming of boards. The processing method comprises following steps: material selection; board combination; hot press molding; height cutting; polishing and organizing; spraying of a priming paint; polishing of a priming paint layer; and spraying of a finishing coat. According to the processing method, cross-band veneers and surface veneers are bonded in a criss-cross staggered manner along the texture direction, and then are subjected to hot press molding using a thermocompressor. Load carrying capability is increased 3 to 4 times because that an original texture structure is changed. One-step hot press molding is adopted in the processing method, so that, begin from raw materials production cost is reduced, processing processes of the boards are simplified, production efficiency is increased, and cost is reduced.

Owner:MEXARTS HOME TIANJIN

Palladium-silver alloy material for dental department

InactiveCN103205594AImprove corrosion resistanceGuaranteed ductilityImpression capsDentistry preparationsGold alloysMechanical property

The invention discloses palladium-silver alloy for repairing an oral cavity. Alloy ingredients are optimized by an alloy material. Compared with the prior art, the obtained material has the advantages of good mechanical property, good corrosion resistance, low sensitization, and beautiful color and luster under the premise of not reducing the alloy property and clinical use effect; and the cost is just 1 / 4 to 1 / 3 of gold alloy.

Owner:SICHUAN QIHE PRECIOUS METALS CO LTD

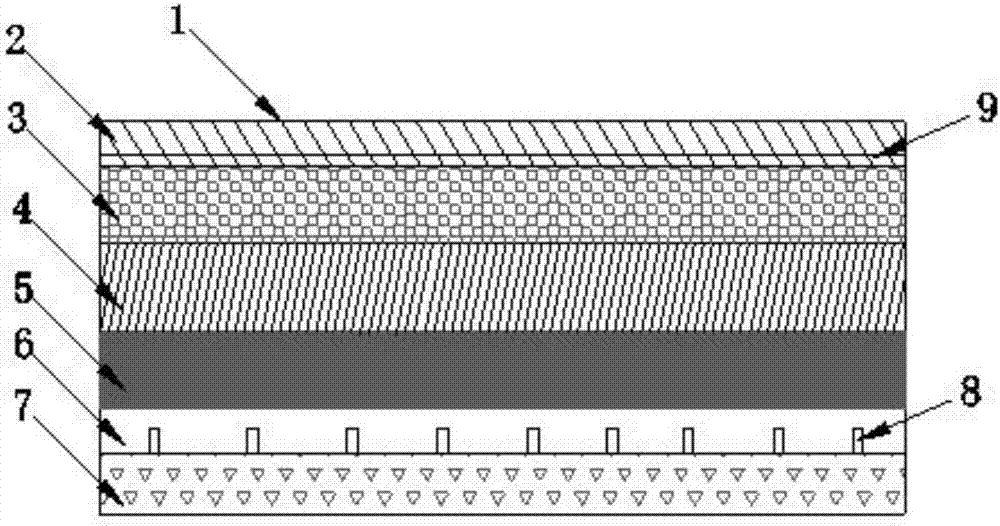

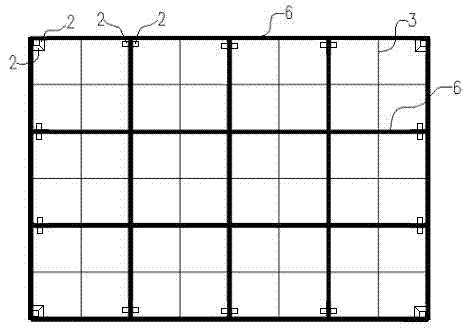

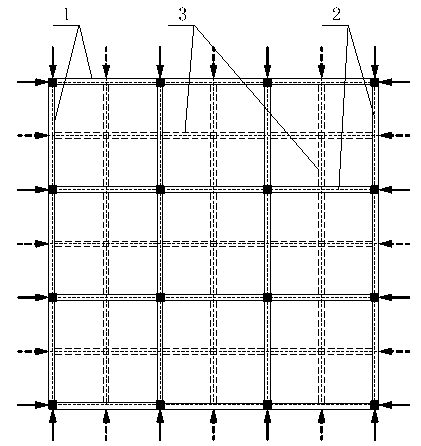

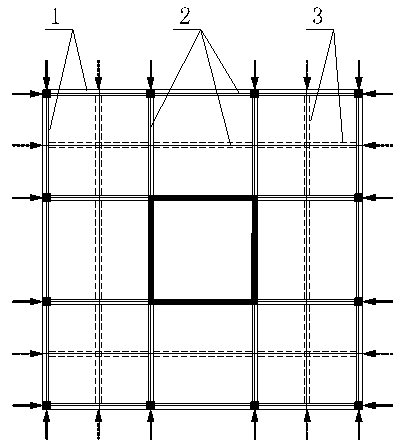

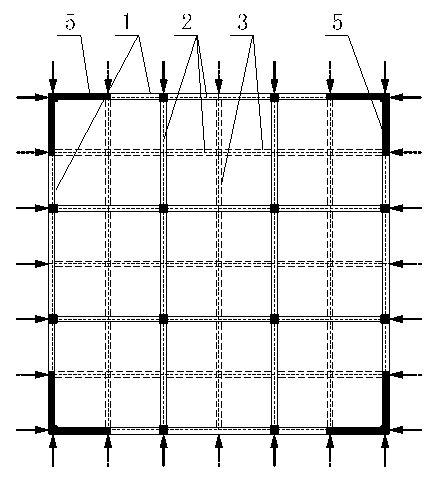

Full-prefabricated assembly type steel-concrete composite floor system and design calculation method

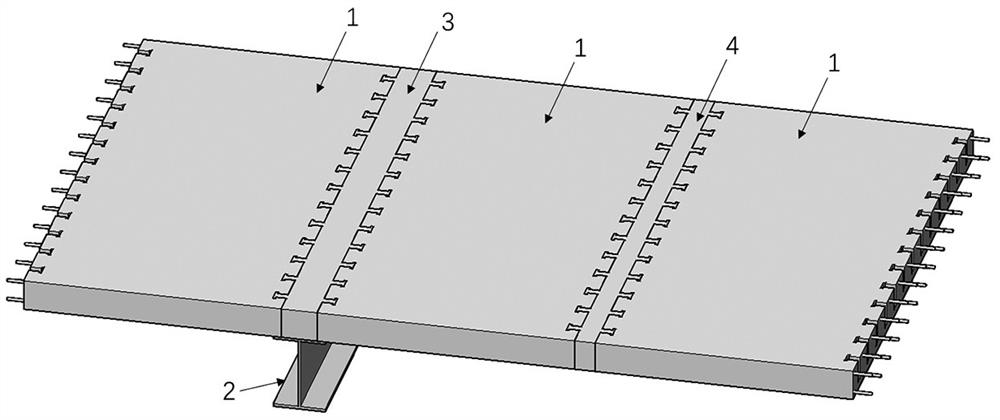

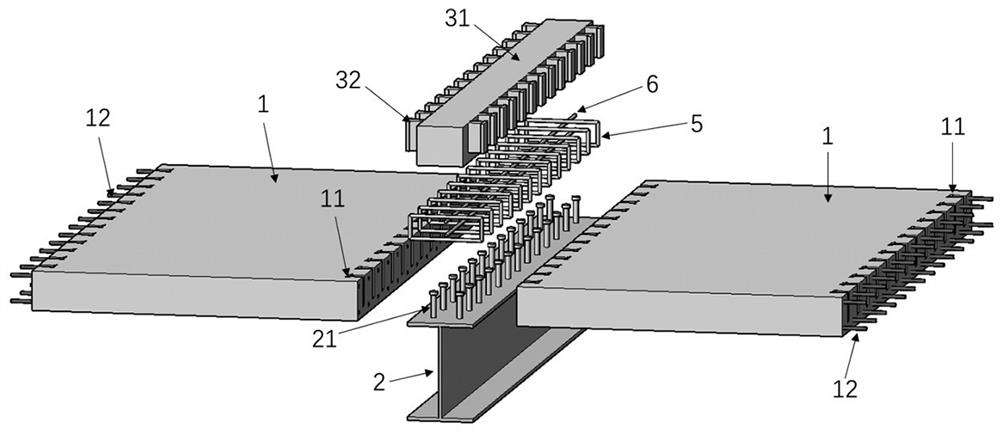

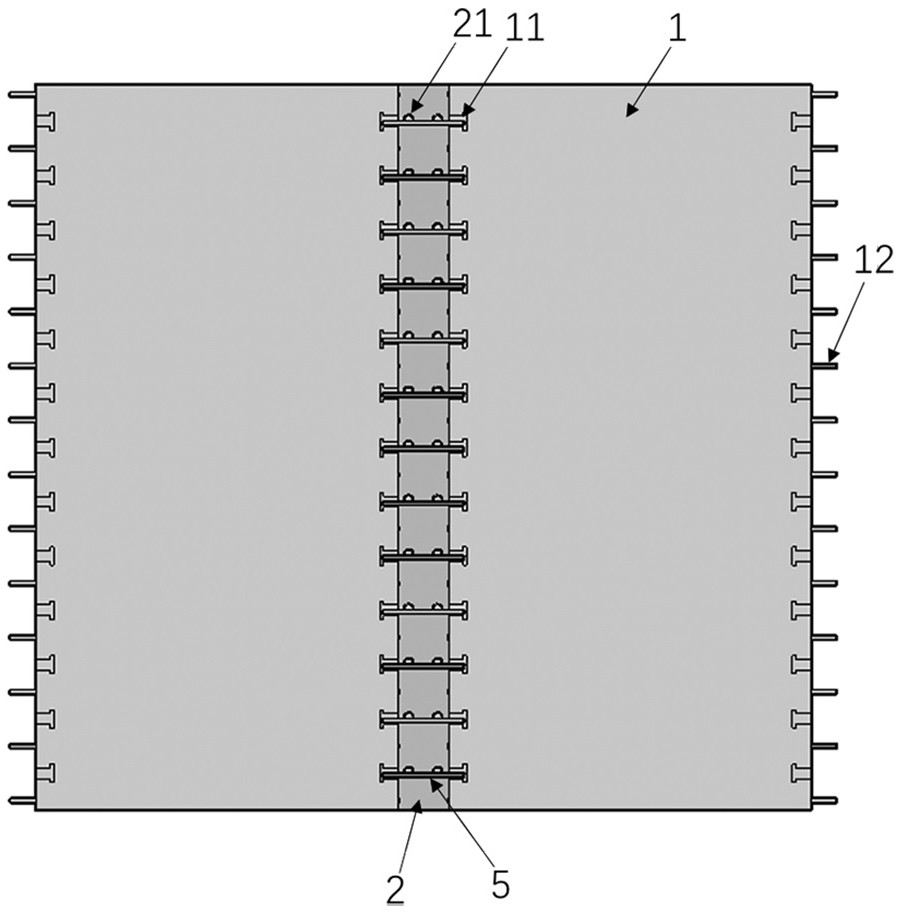

ActiveCN113202219AIncreased shear strengthGuaranteed carrying capacityGeometric CADFloorsFloor slabArchitectural engineering

The invention discloses a full-prefabricated assembly type steel-concrete composite floor system and a design calculation method. The floor system comprises prefabricated concrete floors (1), an H-shaped steel beam (2), beam-slab UHPC tenon-and-mortise connection nodes (3) and slab-slab UHPC tenon-and-mortise connection nodes (4), wherein shear-resistant slotted holes (11) are formed in the two sides of each prefabricated concrete floor (1) in the slab thickness direction; stud connecting pieces (21) are welded on the upper flange of the H-shaped steel beam (2); the two prefabricated concrete floors (1) are connected with the H-shaped steel beam (2) through the beam-slab UHPC tenon-and-mortise connection nodes (3); and every two adjacent prefabricated concrete floors (1) are connected through the plate-plate UHPC tenon-and-mortise connection nodes (4). According to the design provided by the invention, the ultra-high performance concrete UHPC is adopted for connection between the prefabricated concrete floors and the H-shaped steel beam and connection between the prefabricated concrete floors, and the fabricated floor system has the advantages of simple structure, reliable performance, convenience and rapidness in construction, green and environmental protection, and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

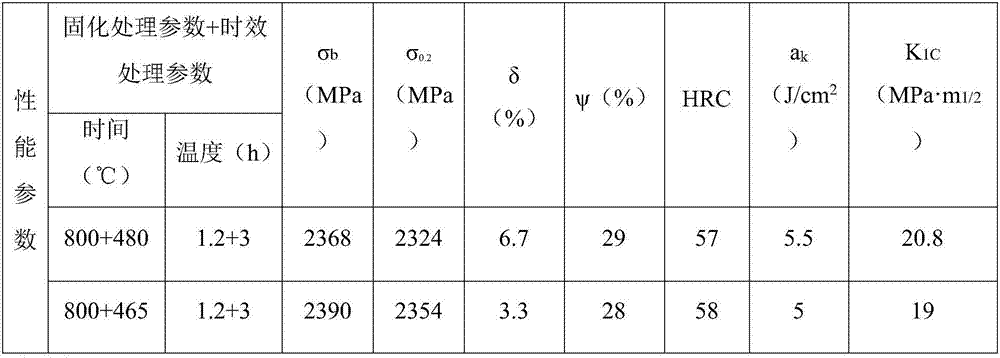

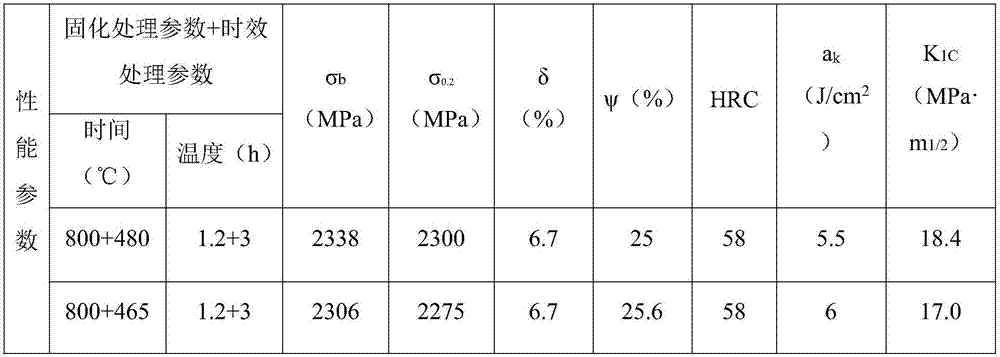

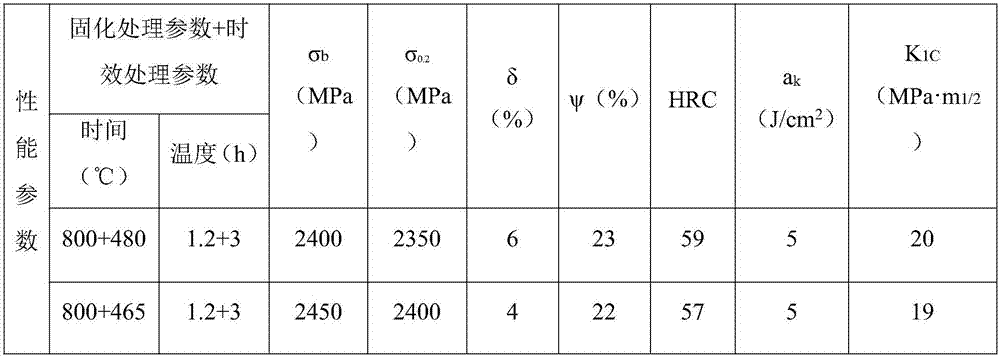

Preparation method of novel cobalt-free material for high-strength aviation part

The invention aims to provide a preparation method of a novel cobalt-free material for a high-strength aviation part. The novel cobalt-free material for the high-strength aviation part comprises, by weight, 16.0%-20.0% of Ni, 4.0%-6.0% of Mo, 2.5%-3.5% of Ti, no more than 0.01% of C, no more than 0.05% of Al, no more than 0.05% of Si, no more than 0.05% of Mn, no more than 0.01% of S, no more than0.05 % of P, no more than 0.01% of O, no more than 0.01% of N, and the balance Fe and inevitable impurities. The novel cobalt-free material has high strength, the tensile strength sigma b is equal toor higher than 2300 MPa, the yield strength sigma 0.2 is equal to or higher than 2200 MPa, delta>=3%, the percentage of area reduction psi is equal to or higher than 20%, the Rockwell hardness HRC is56-59, the impact toughness ak is equal to or higher than 5 J / cm <2>, and the breaking tenacity K1C is equal to or higher than 15 MPa.ml1 / 2. Compared with traditional cobalt-containing maraging steel, consistent tensile strength and yield strength can be achieved, meanwhile, the characteristic of high tenacity of the maraging steel is ensured, consumption of cobalt resources is lowered, the preparation cost is reduced, energy shortages are relieved accordingly, and the application and development of the maraging steel are widened.

Owner:苏州汉汽航空科技有限公司

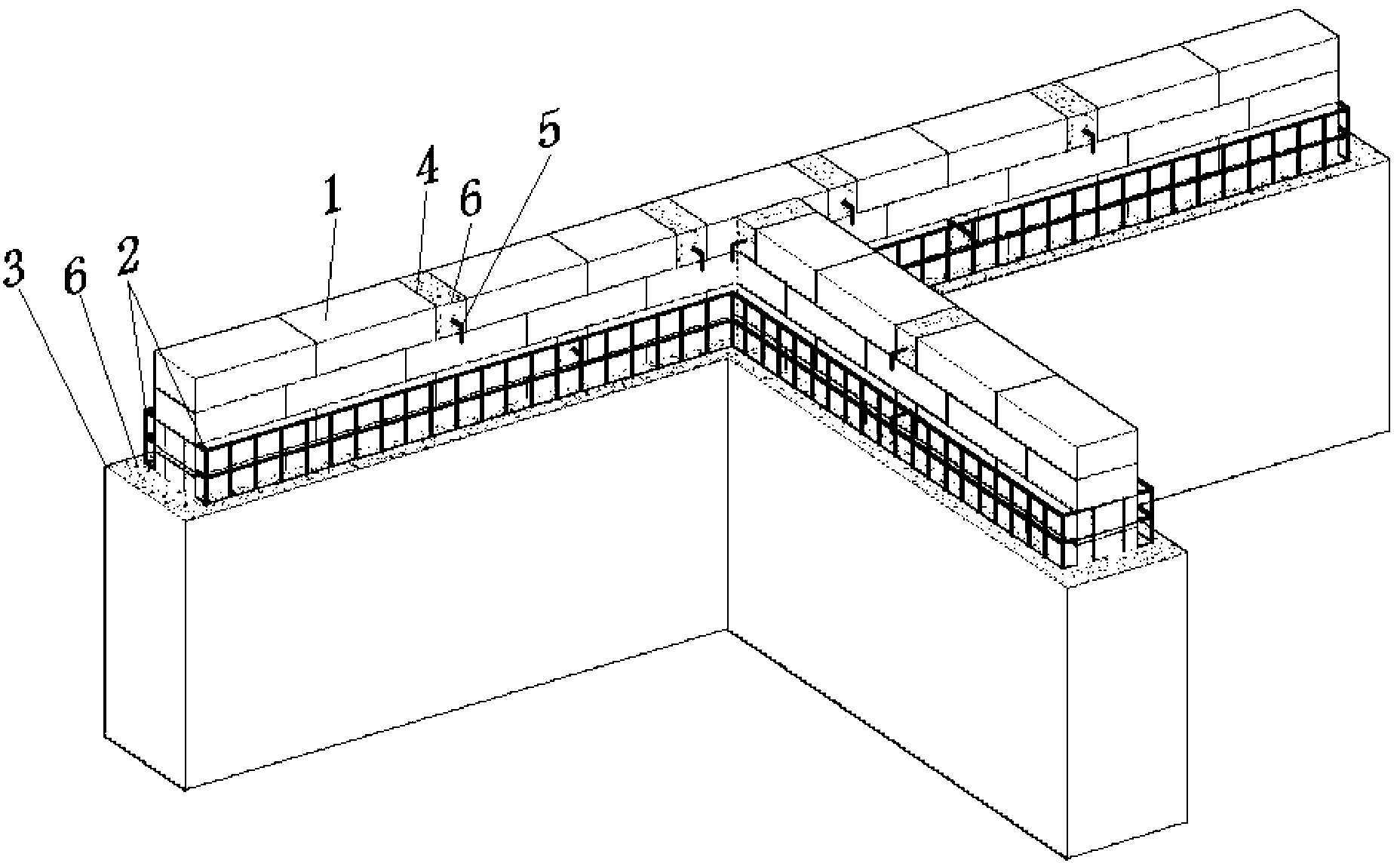

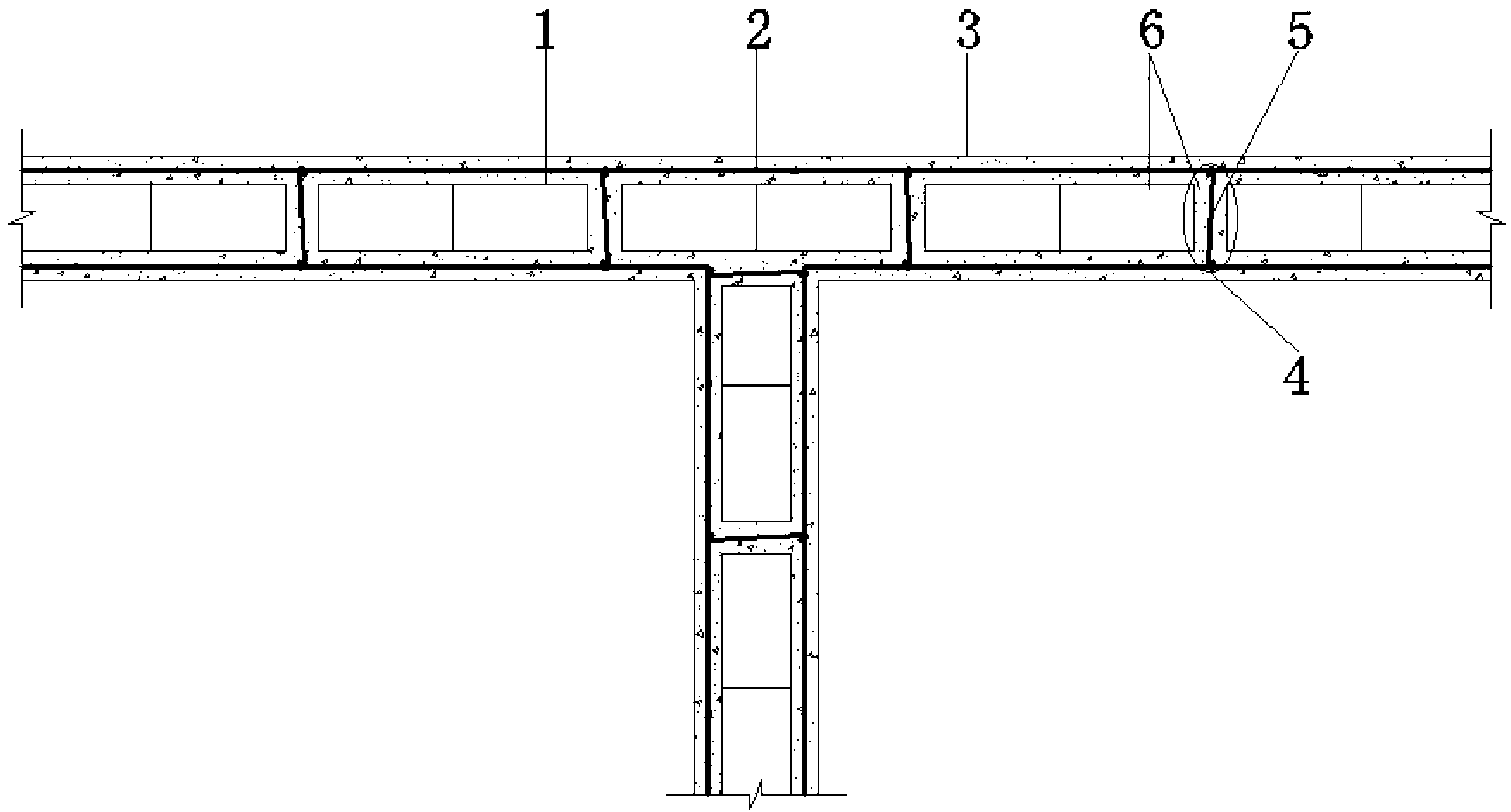

Combined wall with connecting keys and waste brick masonries filled in regenerated concrete wall boards and fabrication method of combined wall

The invention relates to a combined wall with connecting keys and waste brick masonries filled in regenerated concrete wall boards and a fabrication method of the combined wall, belonging to the technical field of construction engineering. The combined wall mainly comprises the waste brick masonries, a steel wire mesh framework, the regenerated concrete wall boards and the connecting keys. During fabrication, the waste brick masonries are built according to design size, steel wire meshes are bent and fixed by using preserved tie bars on the waste brick masonries to form the steel wire mesh framework, templates are erected and then regenerated concrete is poured to form the combined wall with the connecting keys and the waste brick masonries filled in the regenerated concrete wall boards. Most materials used by for fabricating the combined wall are construction wastes and are economic, practical, energy-saving and environmental-friendly; the transverse steel wires of the steel wire mesh framework are dense, the shear resistance is good and the wall body is prevented from being damaged due to brittle shear; and different from the traditional brick masonry walls, the bearing capacity, the ductility and the like of the wall body are guaranteed since the steel wire meshes and the concrete are filled in the wall body, the goals of reinforcing house integrity and improving the overall shock absorbing and energy dissipating performance are realized, the combined wall is suitable for village and town buildings and the application prospect is wide.

Owner:BEIJING UNIV OF TECH

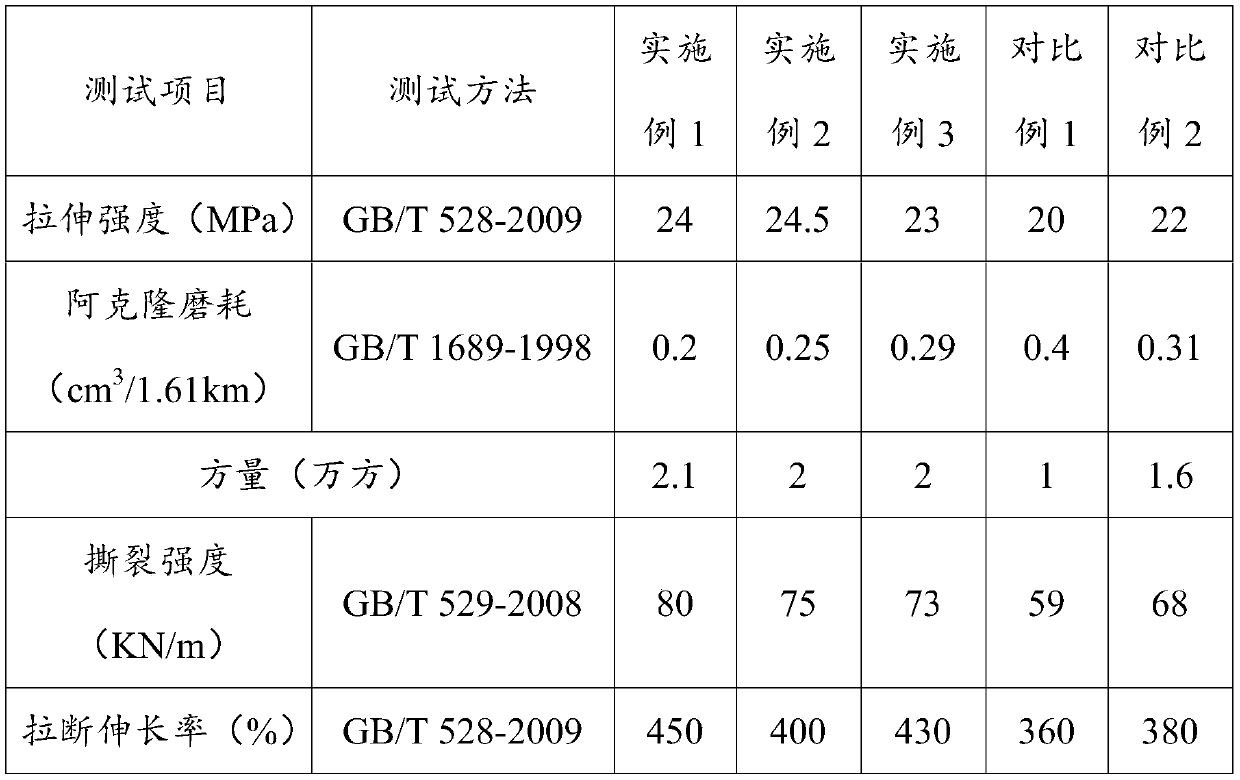

Wear-resistant nitrile rubber composition and application thereof

The invention discloses a wear-resistant nitrile rubber composition and application thereof. The composition comprises the following components in parts by weight: 100 parts of carboxylated nitrile rubber, 0.5-5 parts of a vulcanizing agent, 5-10 parts of zinc oxide, 3-8 parts of organic modified nano silicon dioxide, 1-3 parts of stearic acid, 1-6 parts of an accelerant, 0.5-2 parts of an anti-aging agent, 30-80 parts of carbon black and 5-15 parts of solid coumarone resin. All the components are matched, abrasion resistance, strength and ductility can be considered at the same time, are usedfor preparing the pump truck split piston, the average square amount is obviously increased, the service life of the piston is greatly prolonged, and remarkable application value is achieved.

Owner:CHANGSHA ZHONGJING MACHINERY

Flexible base layer bituminous road surface

The invention relates to the field of buildings and civil engineering, in particular to a flexible base layer bituminous road surface. The problem that in the relative technology, the road condition quality is poor is solved. The flexible base layer bituminous road surface comprises a surface layer, a base layer, a cushion layer and an earth base which are sequentially arranged from top to bottom. The surface layer comprises a bituminous concrete surface layer body, a bituminous macadam surface layer body and a bituminous injecting gravel surface layer body; the base layer is at least formed by evenly mixing a bituminous mixture, bituminous injecting macadam and ABS particles; the cushion layer comprises a grading macadam layer body which forms a dense structure by mixing macadam of different particle diameters and being subjected to compaction; the thickness of the flexible base layer bituminous road surface is gradually reduced in the direction from the middle of the flexible base layer bituminous road surface to the two sides in the width direction; and the flexible base layer bituminous road surface further comprises first reinforcing column bodies, first unchoking pipes and second unchoking pipes, wherein the first reinforcing column bodies and the first unchoking pipes are arranged between the earth base and the cushion layer, and the second unchoking pipes are arranged on the base layer. The flexible base layer bituminous road surface can be well used under the long-time and high-load condition.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

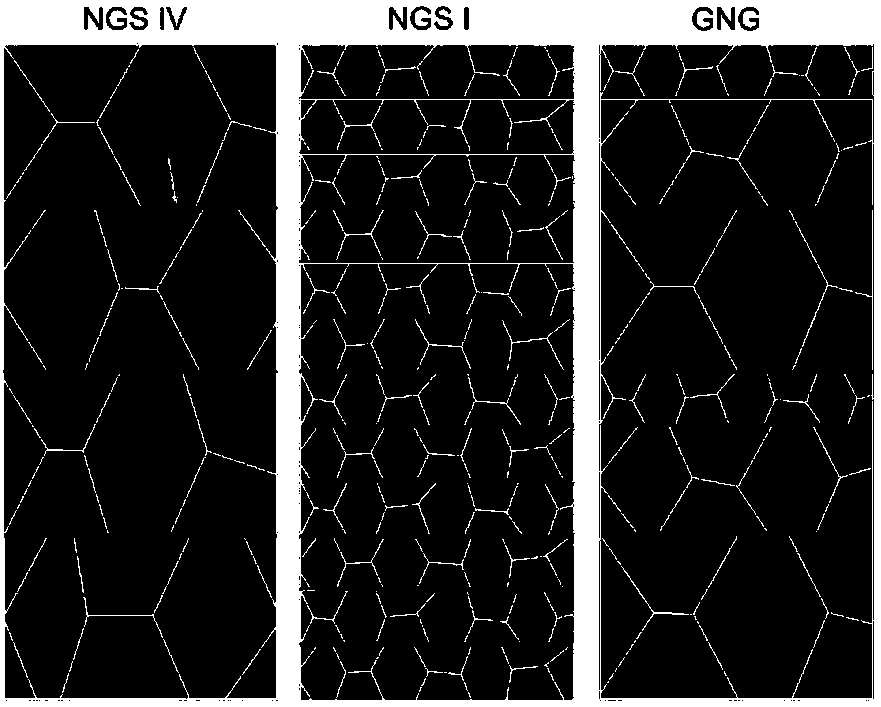

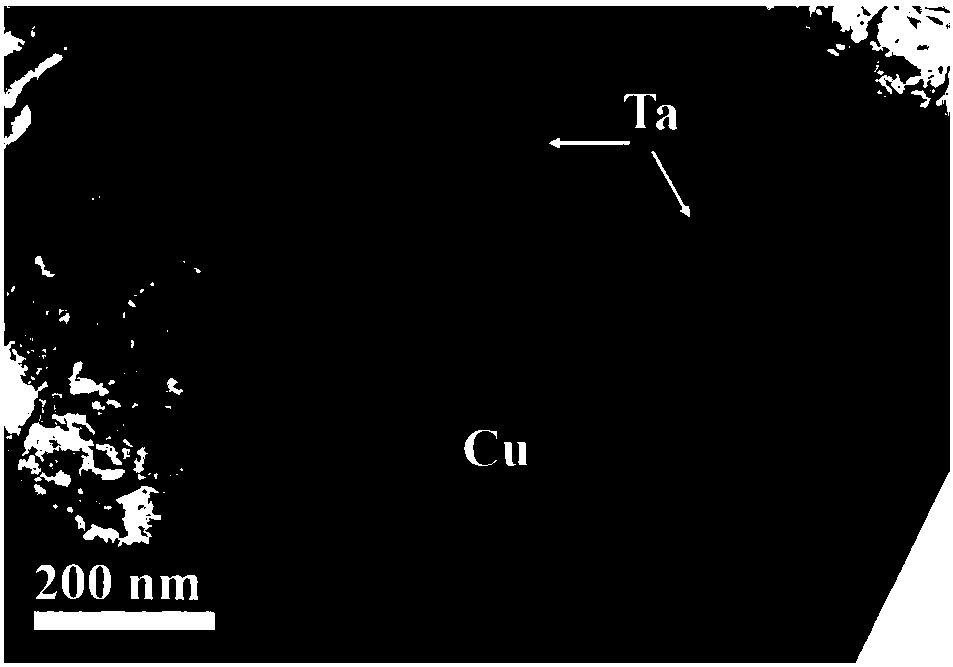

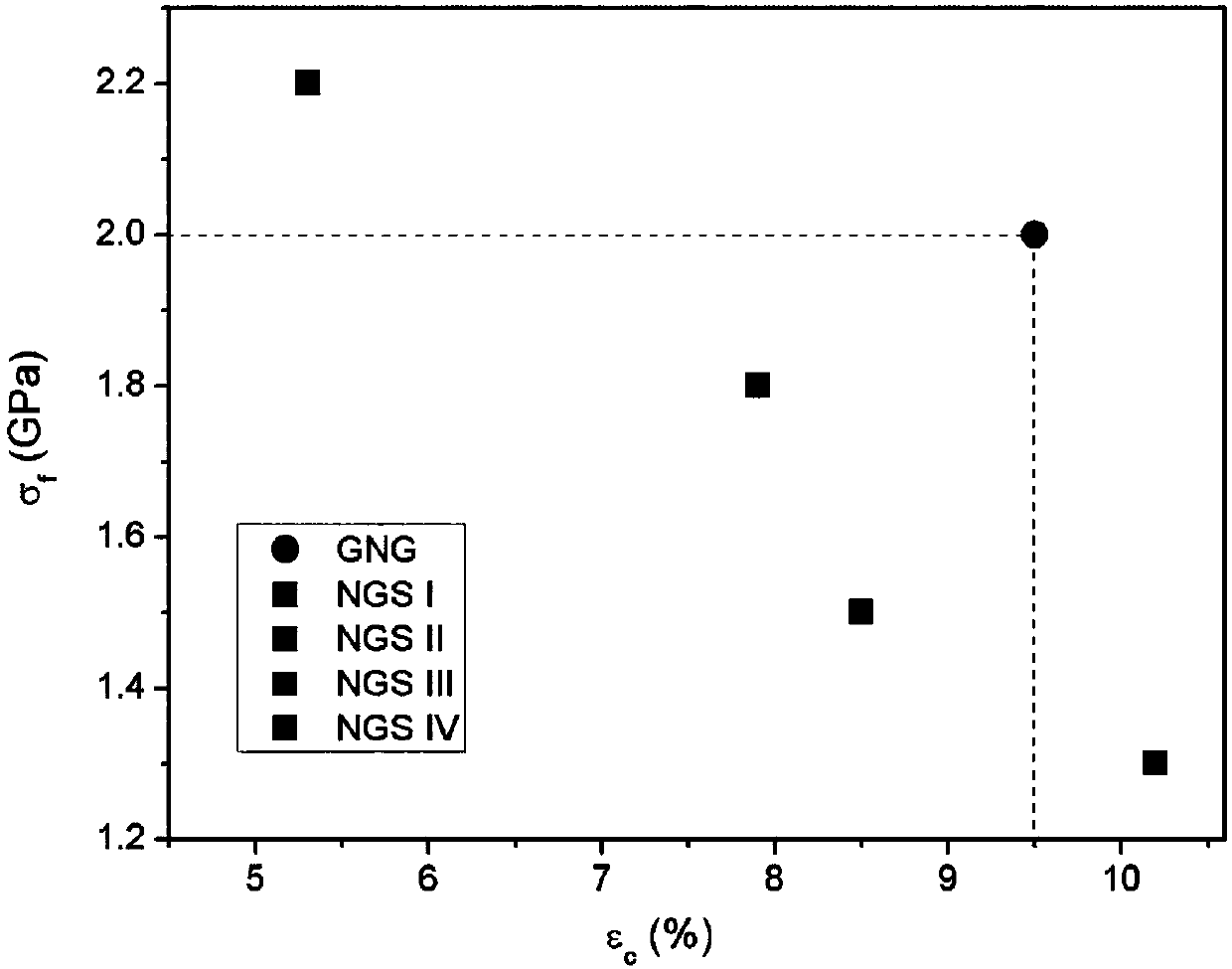

Preparation method of metal thin film having high strength and high ductility

InactiveCN107641790AHigh strengthImprove ductilityVacuum evaporation coatingSputtering coatingMicro nanoHigh intensity

The invention discloses a preparation method of a metal thin film with both coating thickness and grain size of a gradient structure. The metal thin film has high strength and high ductility and presents excellent comprehensive mechanical performance. Different from conventional top-down methods, a new path is opened, and a bottom-up method is adopted to prepare the thin film in micro-nano scale and of the gradient structure; in other words, high-vacuum direct-current magnetron sputtering technology is utilized, an ultrathin separation layer (1nm Ta) with high thermostability is introduced ingeniously, a metal thin film is separated into a multilayer structure with gradient changing thickness, gradient distribution of grain size is further improved through medium-temperature annealing, then a non-homogeneous gradient-structure thin film with both the coating thickness and the grain size in gradient changing is obtained. A thin coating provides high strength, and a thick coating maintains high ductility, so that the gradient thin film has the advantages of high strength and high ductility. The preparation method has high suitability and can be popularized to various other metal andmetal compound thin films. The preparation method is clean, pollution-free and low in cost and has good realizing effect.

Owner:NANJING UNIV

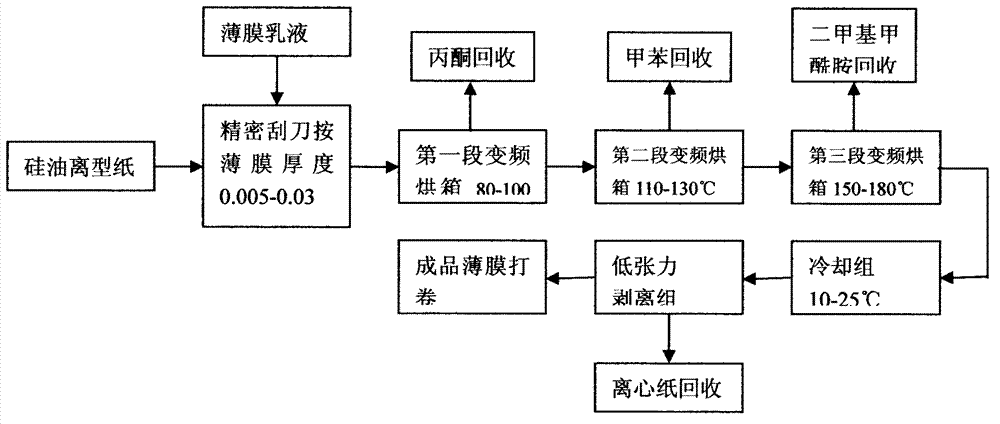

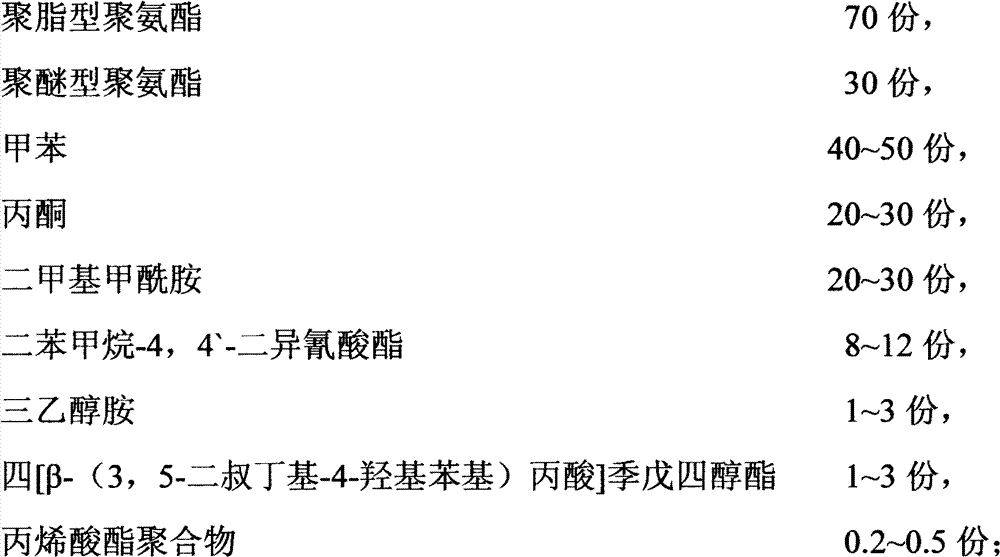

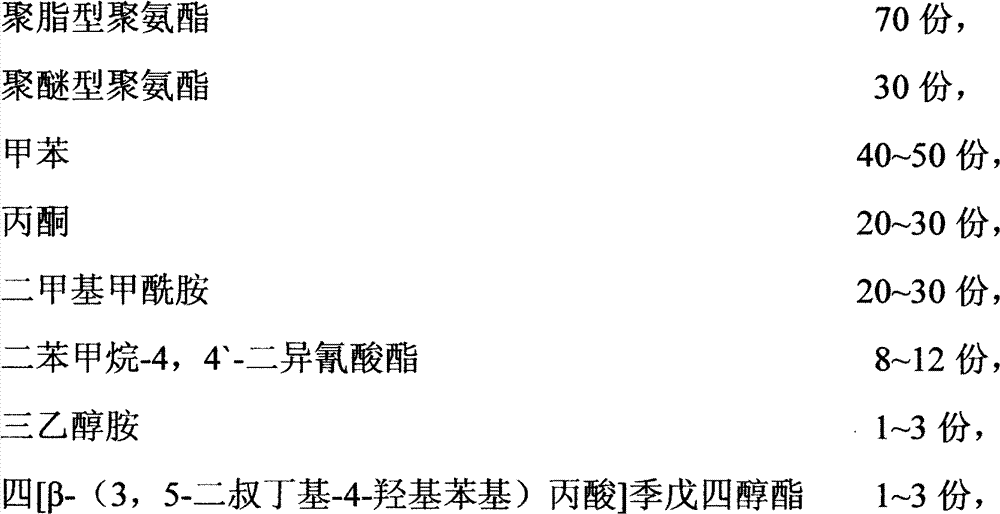

Degradable thin film with waterproof and moisture permeable function

The invention discloses a degradable thin film with a waterproof and moisture permeable function. The degradable thin film is obtained by drying a slurry emulsion, and the slurry emulsion is formed by the following components by weight parts: 70 parts of polyester type polyurethane, 30 parts of polyether polyurethane, 40-50 parts of toluene, 20-30 parts of acetone, 20-30 parts of dimethylformamide, 8-12 parts of diphenylmethane-4,4'-diisocyanate, 1-3 parts of triethanolamine, 1-3 parts of tetra-[beta-(3,5-ditertiary butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester and 0.2-0.5 part of acrylate polymer; the slurry emulsion is processed by using the following process to form the degradable thin film; and the process comprises the following steps of: coating the slurry emulsion on the surface of silicone oil release paper; and sequentially drying under a low-speed flowing air atmosphere under the conditions of 80-100 DEG C, 110-130 DEG C and 150-180 DEG C to obtain the degradable thin film. The degradable thin film disclosed by the invention guarantees the flexibility and the malleability, and also accelerates the forming of the thin film to improve the moisture permeable performance of the thin film.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Pre-stress constraint concrete structure and manufacture method thereof

InactiveCN103184765AImprove integrityImprove seismic performanceBuilding material handlingPre stressPre stressing

The invention discloses a pre-stress constraint concrete structure and a manufacture method thereof. When the four categories of concrete structures of a concrete frame structure, a concrete frame-tube structure, a concrete frame-shear structure or a concrete truss-tube structure is manufactured, pre-stress ribs which are in parallel with axle lines of main beams are arranged in all main beams, thus each pre-stress rib is enabled to penetrate through all the main beams in the same axle line on the same plane, meanwhile constraint reinforced ribs are configured in the main beams, so that the main beams are enabled to form constraint beams, when the concrete strength of the poured main beams in a same layer reaches designed strength, the pre-stress ribs of all the main ribs in the same layer are subjected to tensioning and anchoring, the pre-stress ribs are all enabled to be in a tensioning state, the main beams on all different horizontal surfaces of the concrete structure are manufactured according to the method, and the pre-stress constraint concrete structure is manufactured and obtained. The pre-stress constraint concrete structure has the advantages of high bearing force in an overall structure, excellent rigidity, remarkable performance of seismic resistance, a small component cross section and lower constructional cost.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com