Combined wall with connecting keys and waste brick masonries filled in regenerated concrete wall boards and fabrication method of combined wall

A technology of recycled concrete and brick masonry, applied to walls, building components, buildings, etc., can solve problems such as poor thermal insulation performance, weak earthquake resistance, and large amount of bricks, and achieve improved earthquake resistance, ductility guarantee, and energy saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

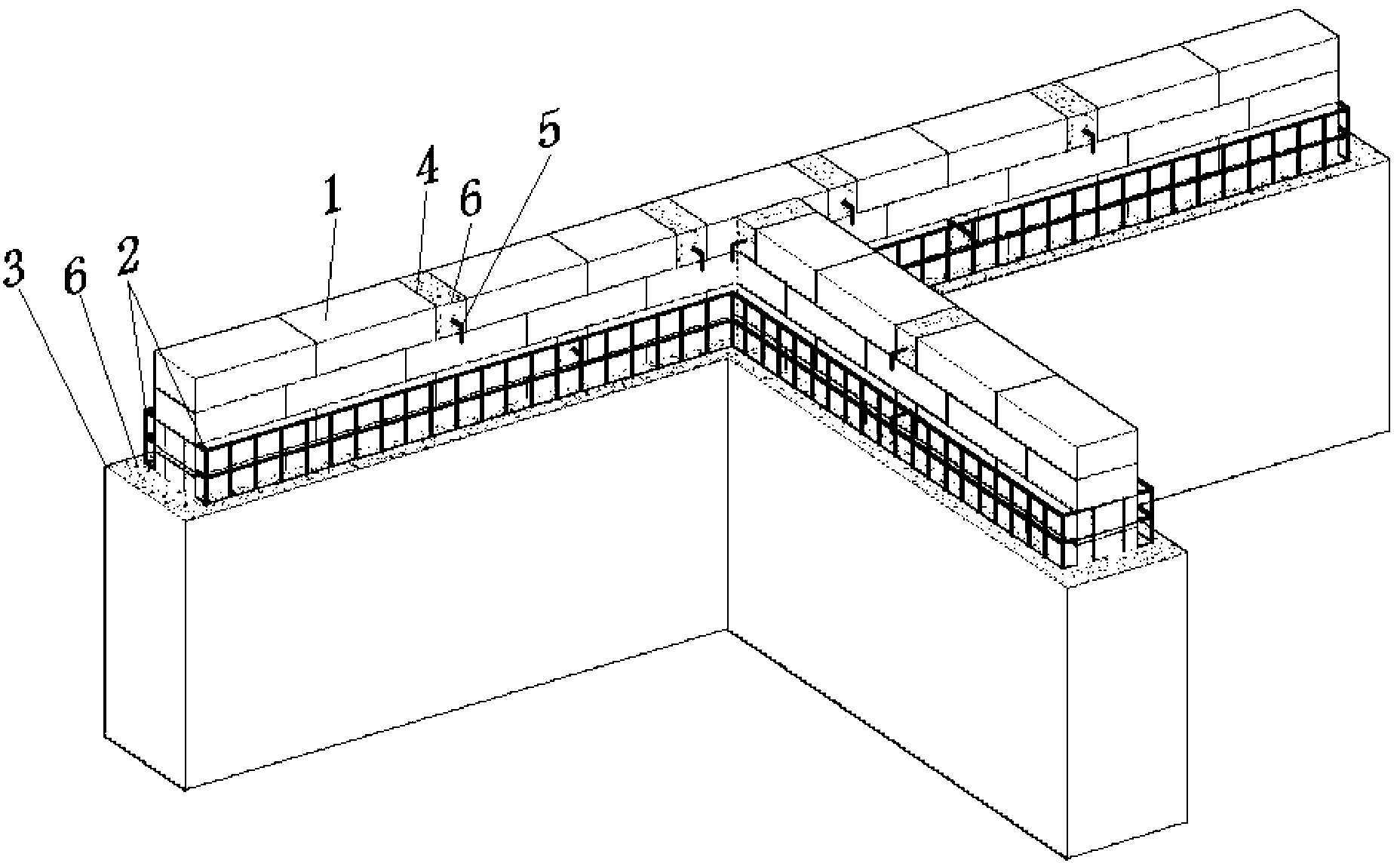

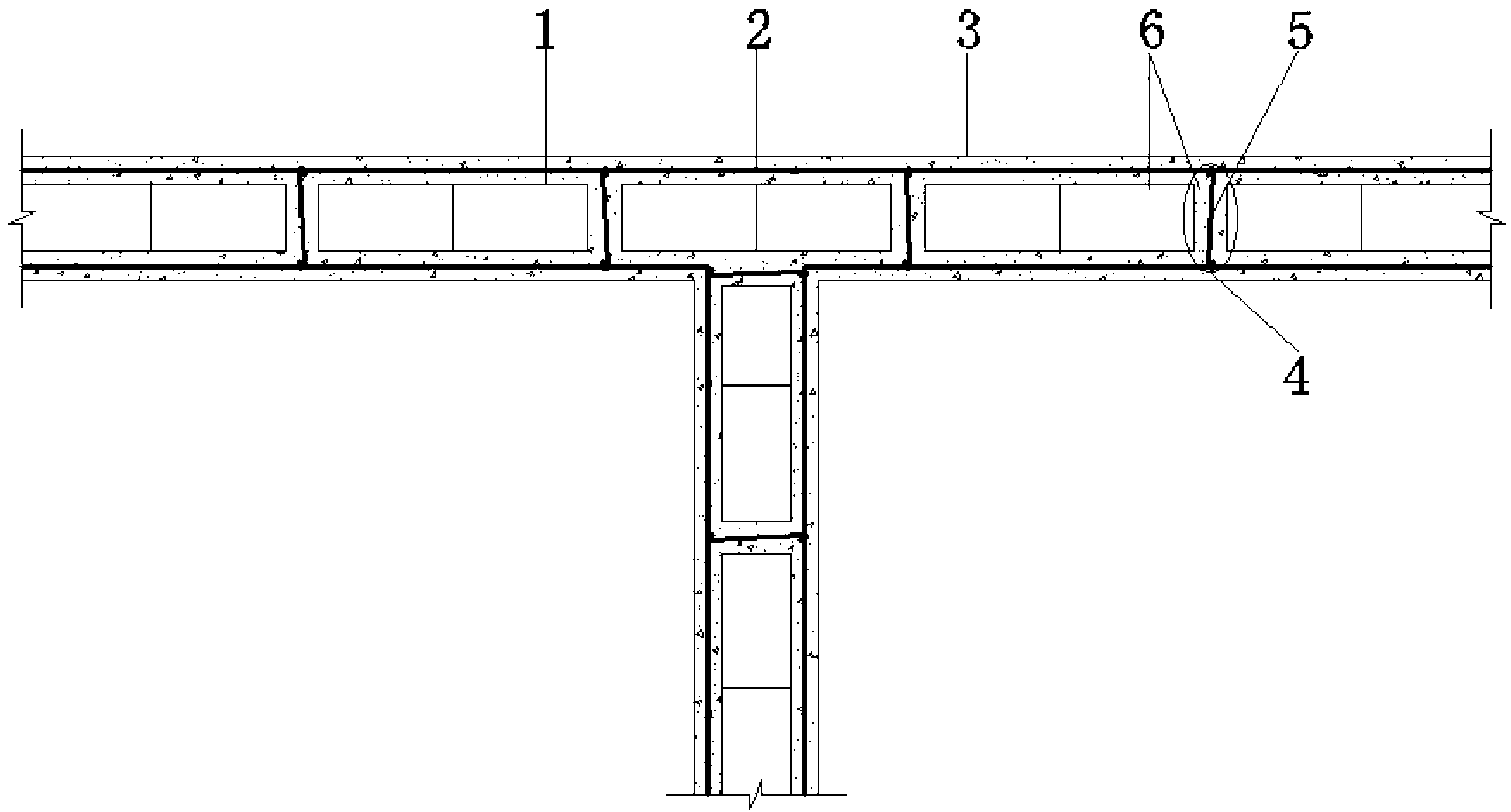

[0032] Such as Figure 1 to Figure 5 As shown, the recycled concrete wall panels with connection keys are filled with waste brick masonry composite walls, mainly composed of waste brick masonry 1, steel wire mesh skeleton 2, recycled concrete wall panels 3, and link keys 4. The composite wall is a composite wall formed by regenerating concrete wall panels 3 formed after pouring through link keys 4, and sandwiching waste brickwork 1 between recycled concrete wallboards 3; inside the composite wall along the waste brickwork 1 The surrounding edge is embedded with a steel mesh skeleton 2, which is formed by bending the steel mesh 7 and then welding or binding. The steel mesh skeleton 2 is a closed hollow shape, and the inside of the closed hollow shape is made of waste bricks. body 1; the steel wire mesh sheet 7 on both sides of the waste brick m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com