Flexible base layer bituminous road surface

A technology of asphalt pavement and flexible base, which can be applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of residual deformation, damage, cracks, etc., and achieve the effect of strengthening stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

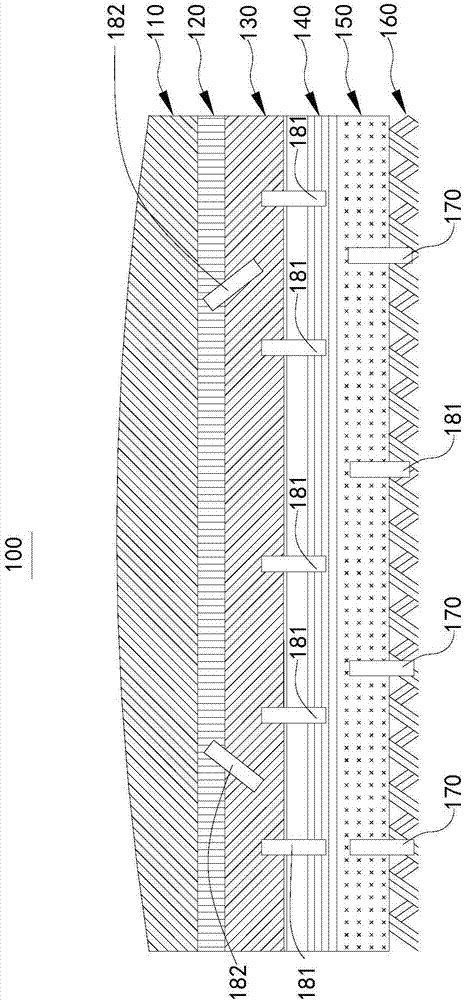

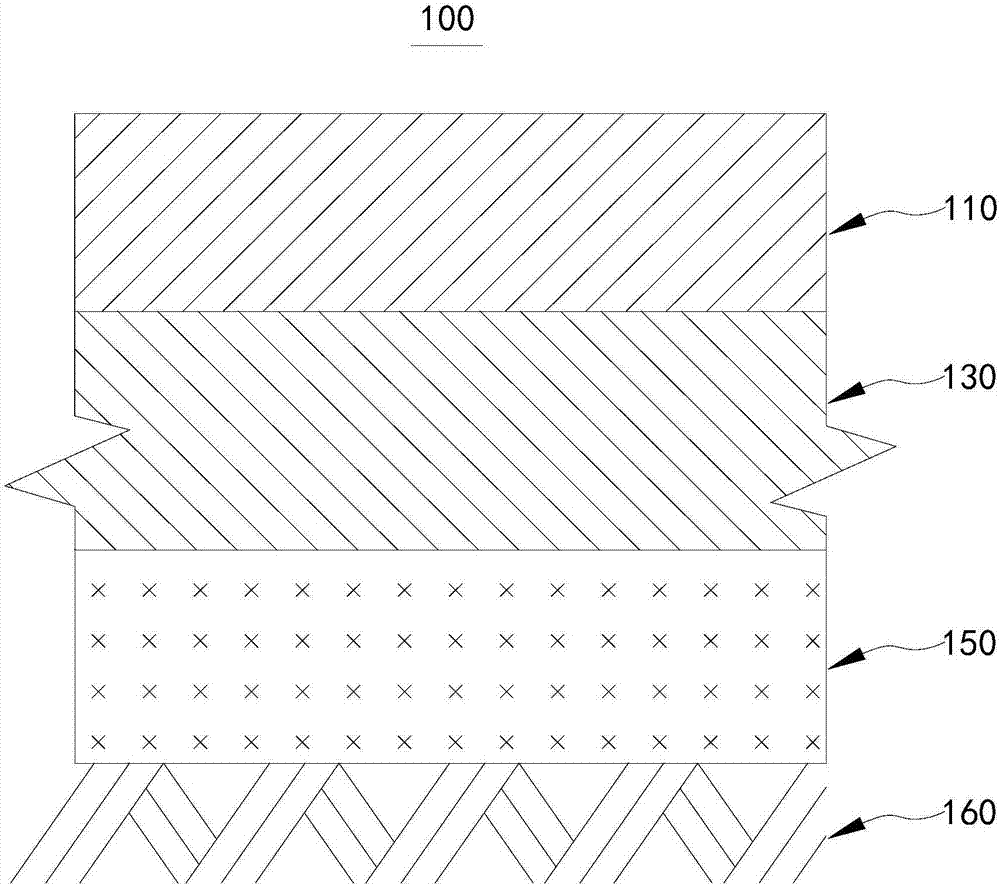

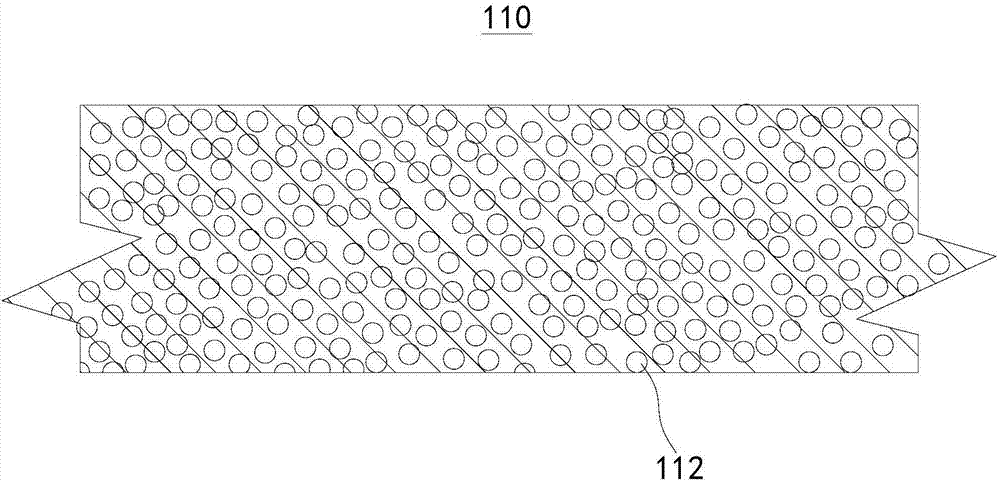

[0044] Please refer to figure 1 , figure 1 A structural schematic diagram of a flexible base asphalt pavement 100 provided in this embodiment, from figure 1 It can be seen that the flexible base asphalt pavement 100 includes a surface layer 110 , a base layer 130 , a cushion layer 150 and a soil foundation 160 arranged in sequence from top to bottom.

[0045] From figure 1It can also be seen that the thickness of the flexible base asphalt pavement 100 gradually decreases along the direction from the middle to both sides in the width direction; the flexible base asphalt pavement 100 also includes a first reinforcement column arranged between the soil foundation 160 and the cushion 170 and a first dredging pipe 181 ; the flexible base asphalt pavement 100 also includes a second dredging pipe 182 arranged on the base 130 . What needs to be explained here is that the invention finds through long-term research and tests that existing road surface cracks, fractures, etc. have the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com