Patents

Literature

52results about How to "Does not hinder rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

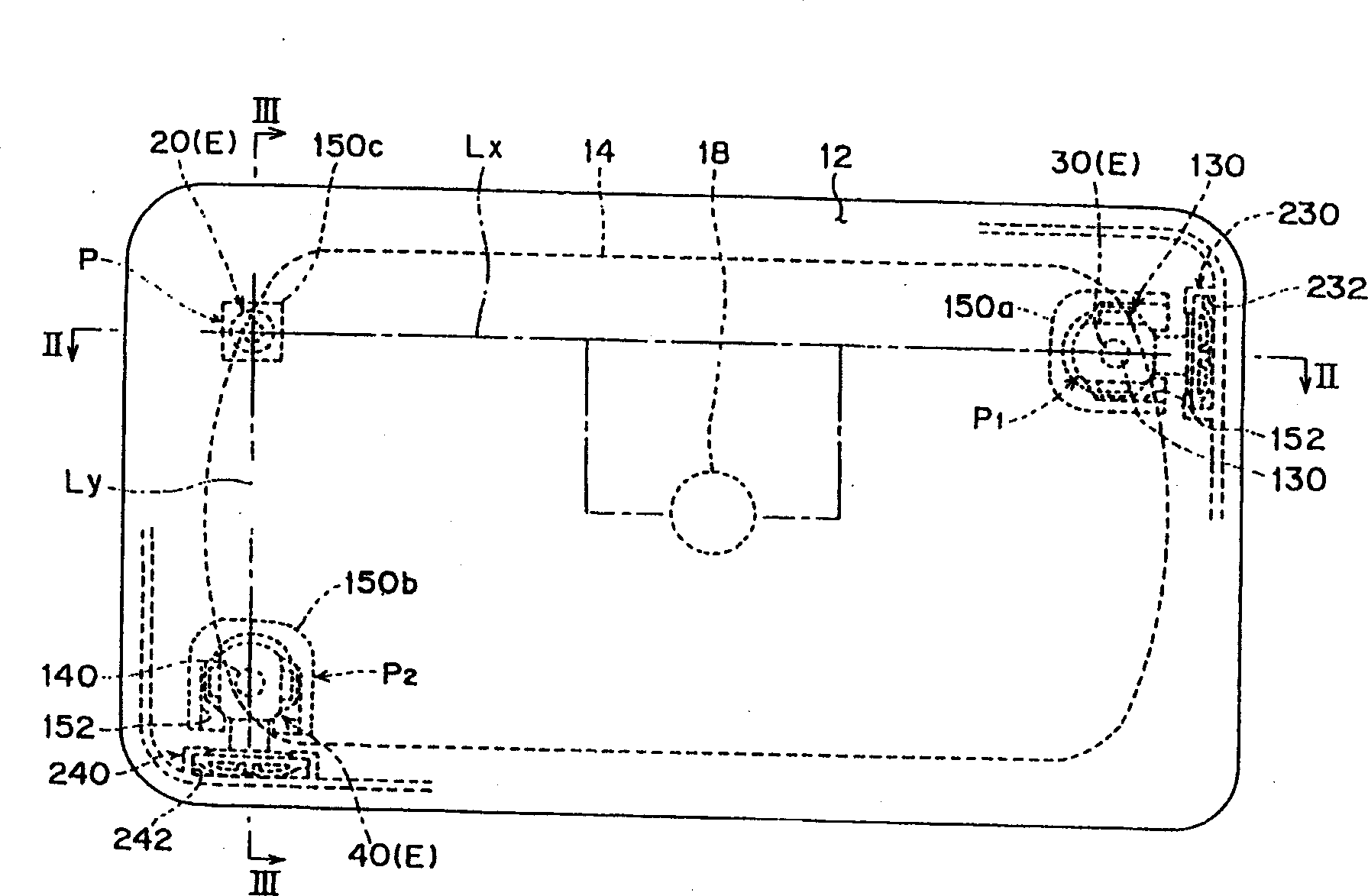

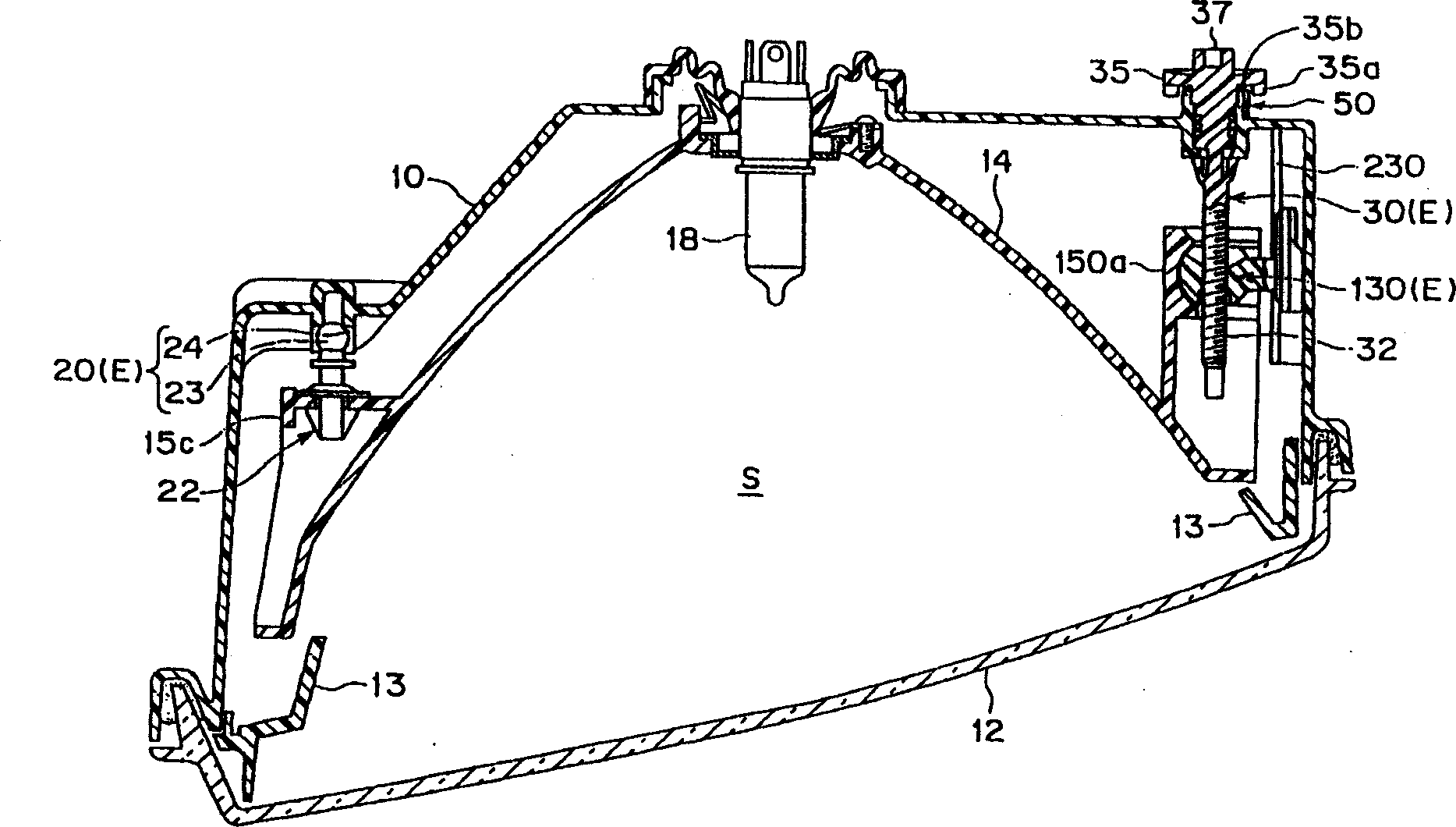

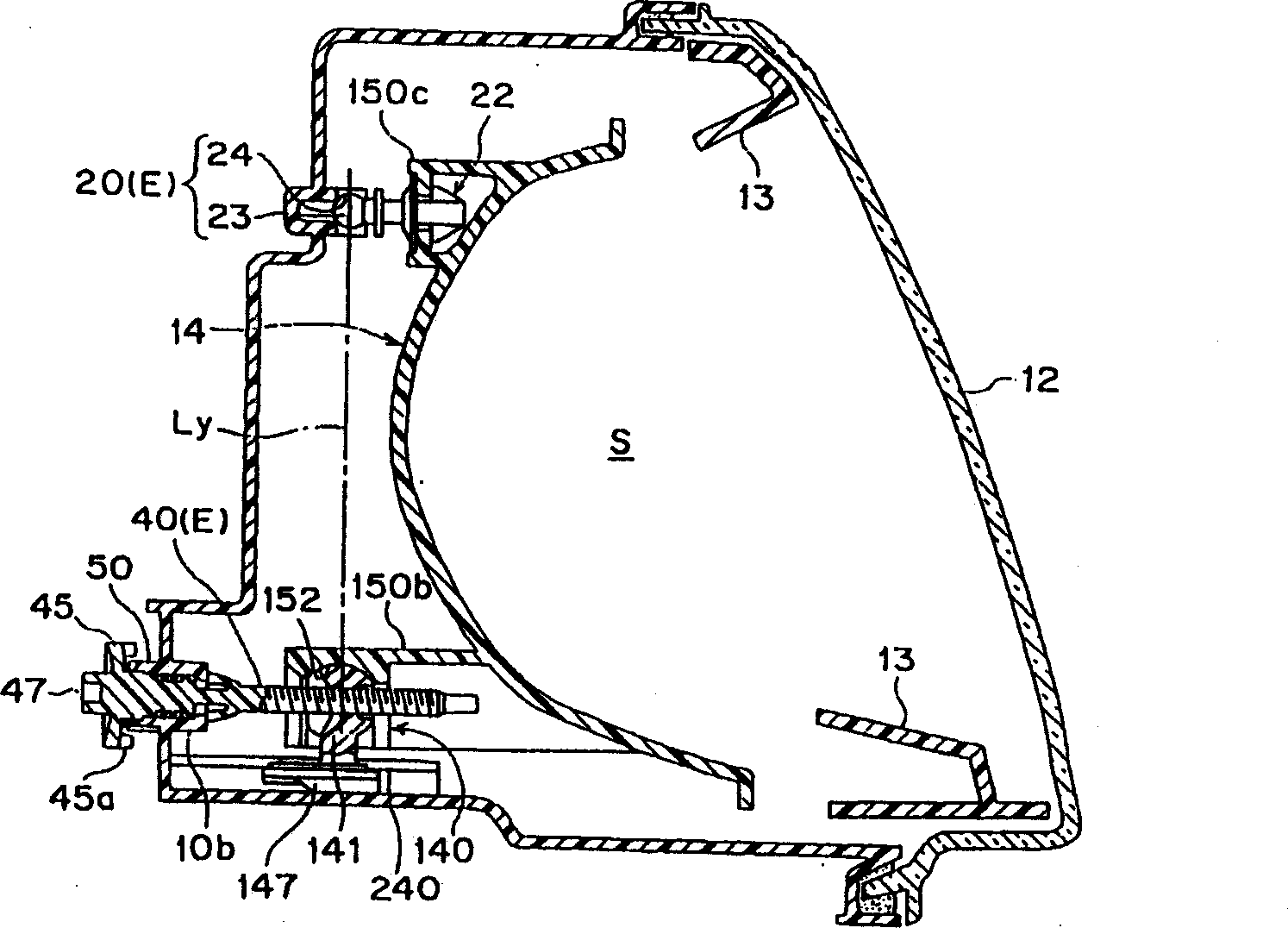

Reflector-movable front-lighting lamp for automobile

InactiveCN1362594ADoes not hinder rotationGuaranteed normal slidingVehicle headlampsPoint-like light sourceMovable typeMiniaturization

The invention provides a compact head lamp for reflector movable type automobile capable of preventing vibrations of a reflector and smoothly rotating an aiming screw. In this head lamp, a nut sliding guide 230 equipped to a bracket 150a in a reflector 14 side, screwed with a screw 30, and guides a nut member 130 moving forward / backward in relation to rotations of the screw 30 is provided on a lamp body. A stress releasing means having a ball joint structure is provided between the nut member 130 composing a aiming point P1 and the bracket 150a. The sliding guide 230 carries the weight of the reflector 14, guarantees sliding of the nut member 30. Torsional moment is not generated on the nut member 30, so that vibrations of the reflector 14 can be suppressed, and smooth rotations of the screw can be ensured.

Owner:KOITO MFG CO LTD

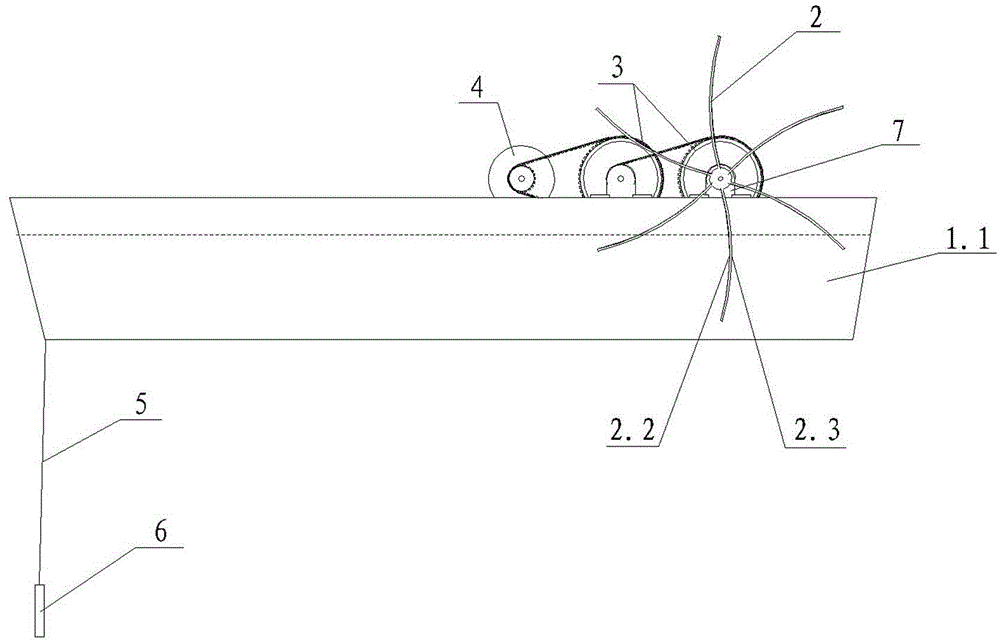

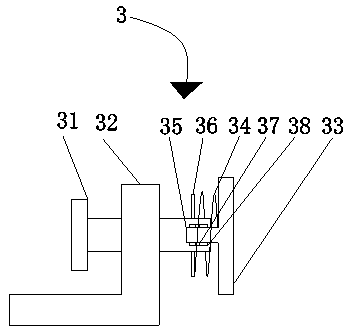

Shield-arc welding device with aerating device inside tube

InactiveCN101486125AEasy to useGuarantee welding qualityWelding accessoriesGas-filled tubeArc welding

The invention discloses a gas shielded welding device with an air charging device inside a tube. The gas shielded welding device comprises a locking device with a chuck for clamping a pipeline to be welded, a drive mechanism for driving the chuck to rotate, the air charging device inside the tube for charging protective gas from a pore space of the pipeline to be welded, and an air charging pipe communicated with the air charging device inside the tube. The gas shielded welding device has the advantages that the device has a semiautomatic structure and convenient operation, and can improve welding quality.

Owner:浙江天力久田管业有限公司

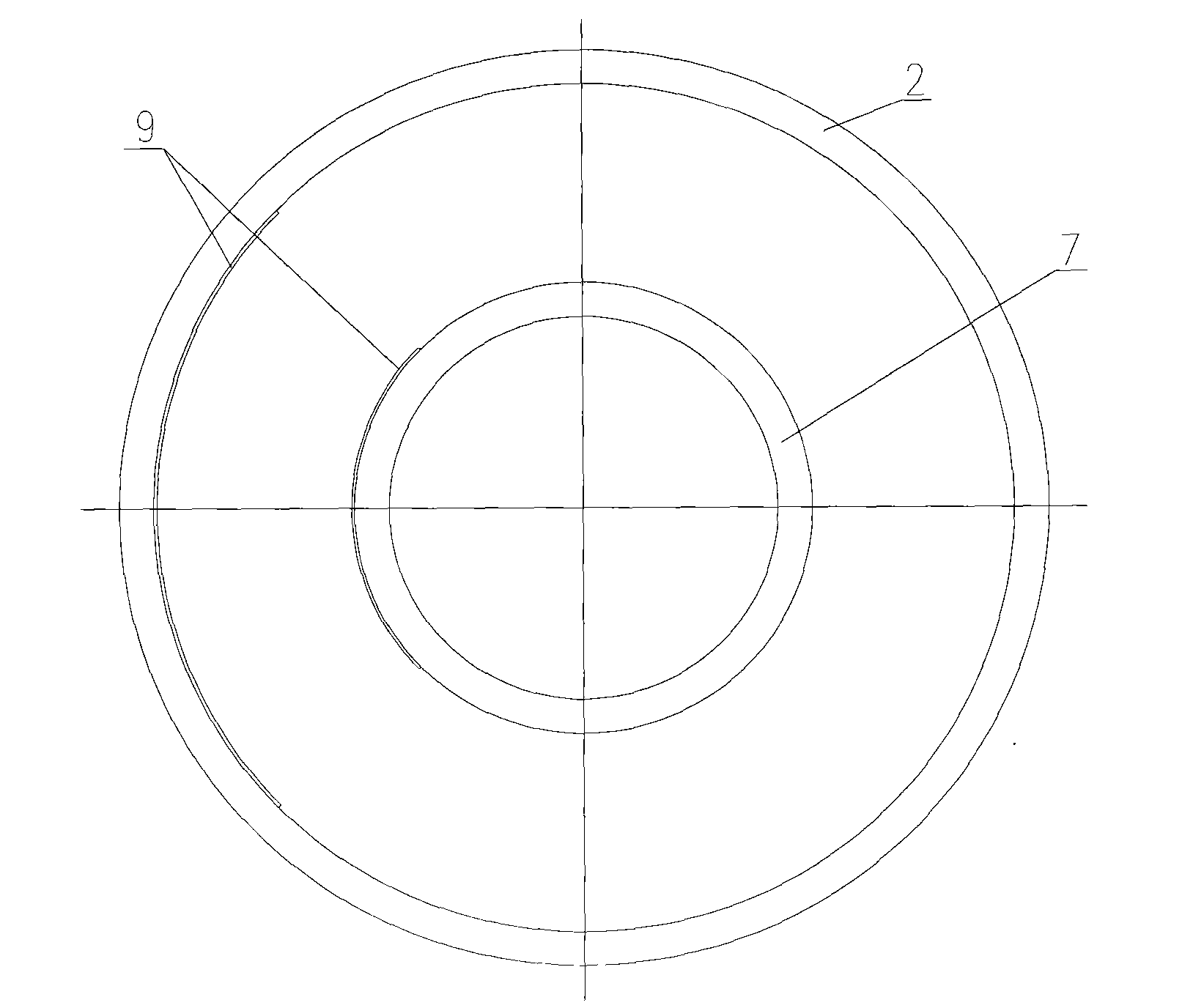

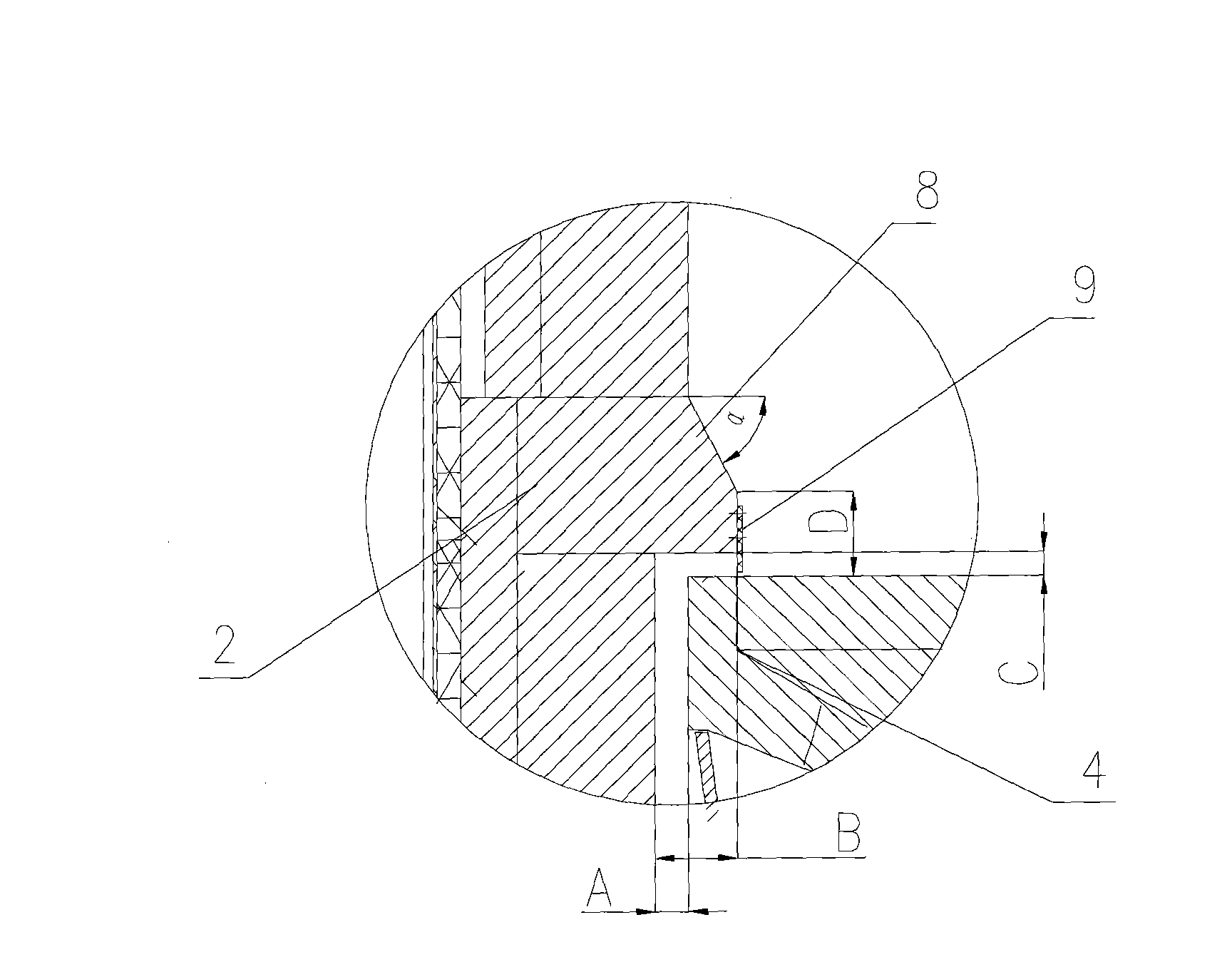

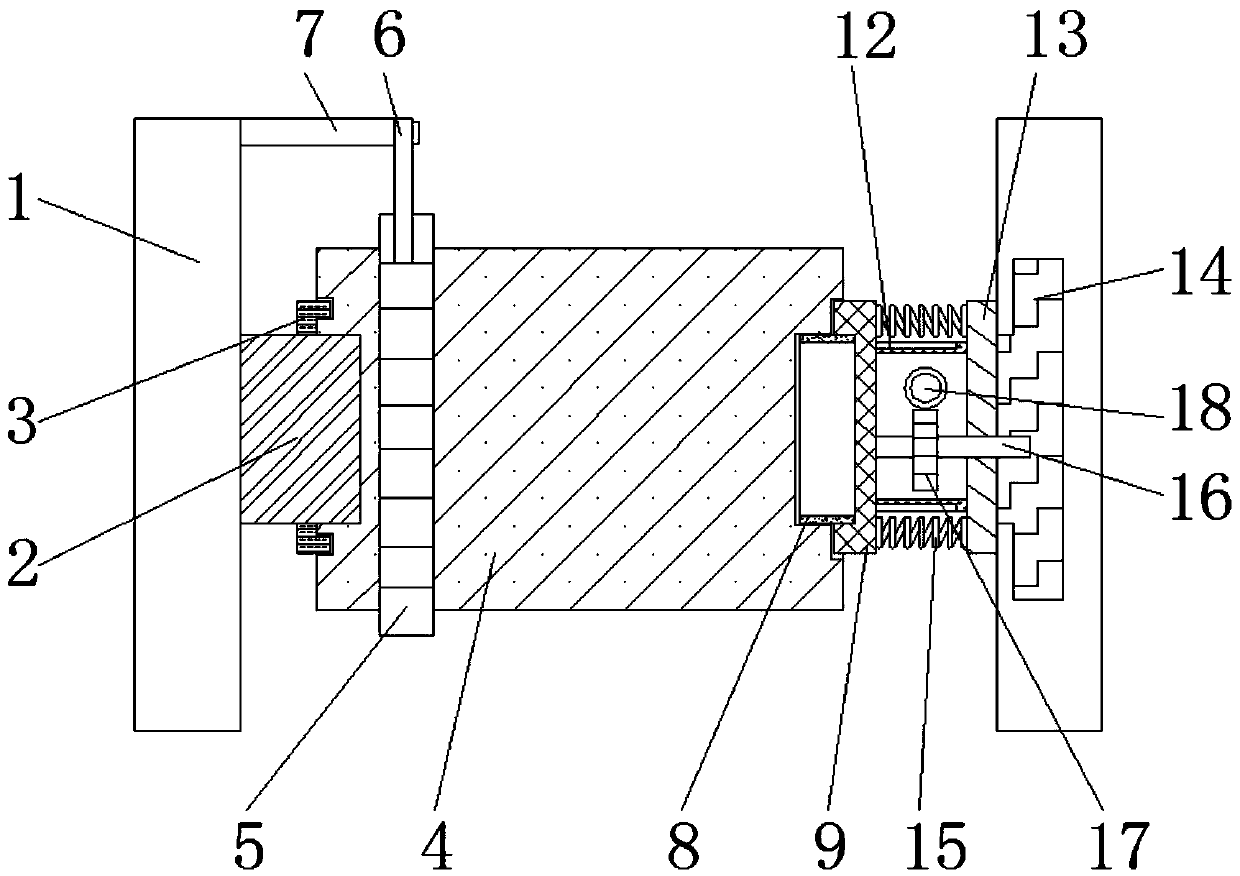

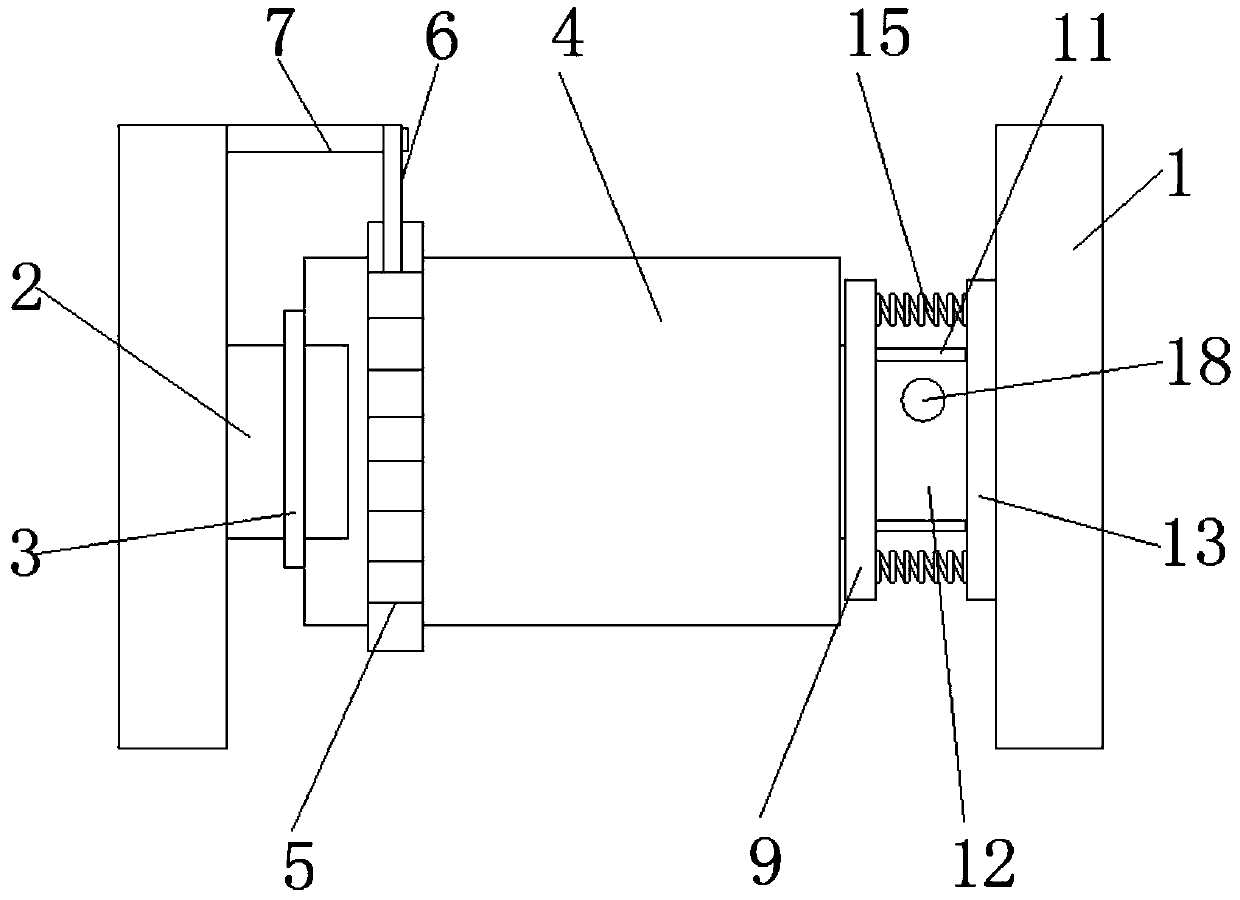

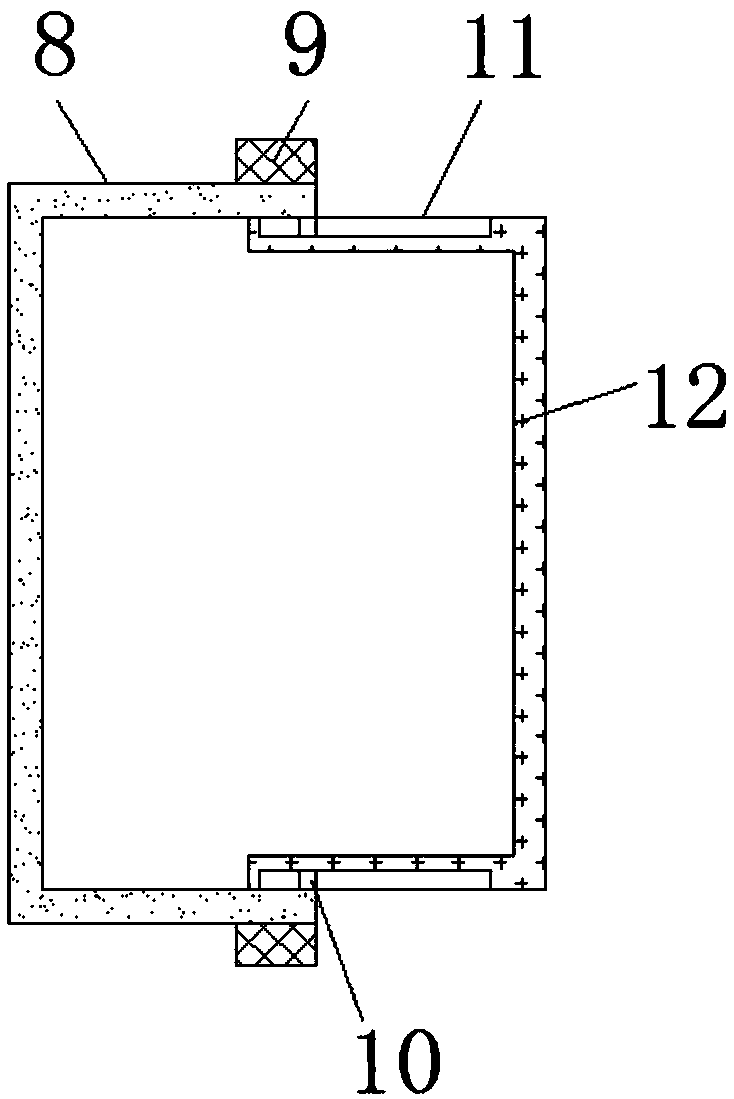

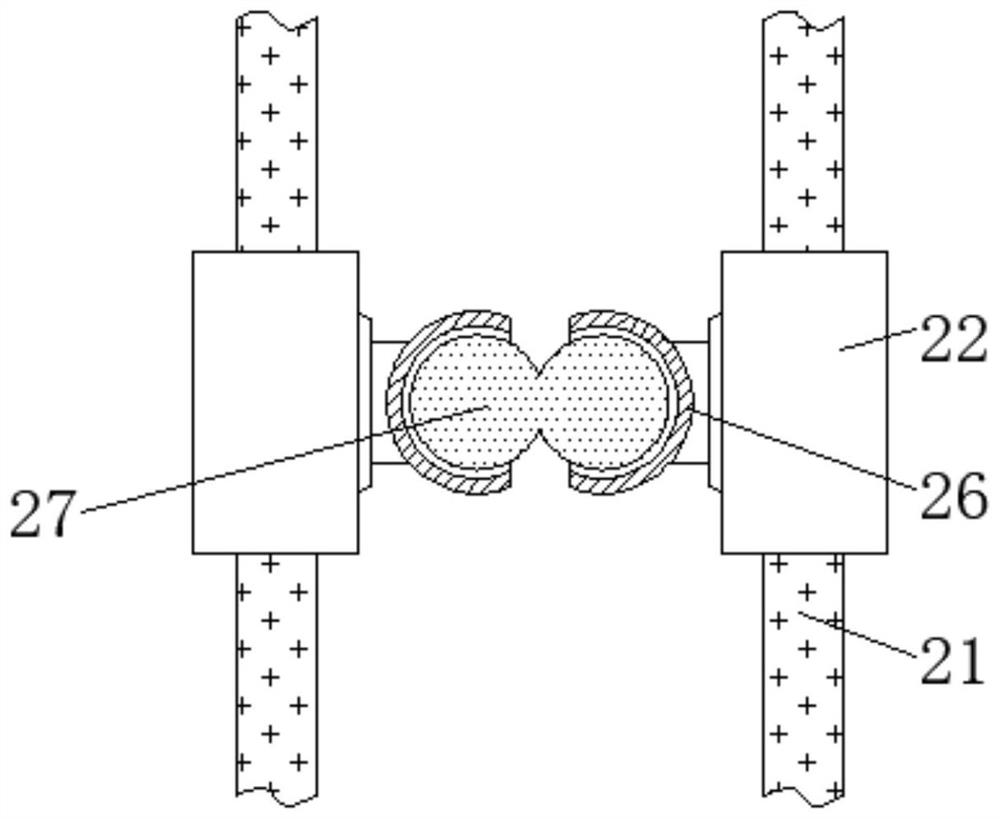

Novel shaft-end sealing structure of concrete mixer

InactiveCN102494139AGood sealing effectExtended service lifeEngine sealsCement mixing apparatusMechanical engineering

The invention discloses a novel shaft-end sealing structure of a concrete mixer. A movable sealing ring sleeved on a mixing shaft is arranged on a portion, which is located on the inner side of a mixing barrel, of the mixing shaft, a fixed sealing ring sleeved on the mixing shaft is arranged on the mixing barrel, the movable sealing ring and the fixed sealing ring are pressed by a spring which is arranged on the mixing shaft or the mixing barrel and axially stretches and retracts on the mixing shaft, so that an end surface of the movable sealing ring hermetically contacts with an end surface of the fixed sealing ring, and both end surfaces, which contact with each other, of the movable sealing ring and the fixed sealing ring are located on the inner side of the mixing barrel. As the movable sealing ring and the fixed sealing ring are pressed by the spring so that surface contact sealing is formed, the sealing contact surfaces are located in the mixing barrel, sand in the mixing barrel cannot enter a portion, which is connected with the mixing barrel, of the mixing shaft and a portion which is located out of the mixing barrel, and a sealing effect is good.

Owner:SHANDONG MIX MACHINERY EQUIP

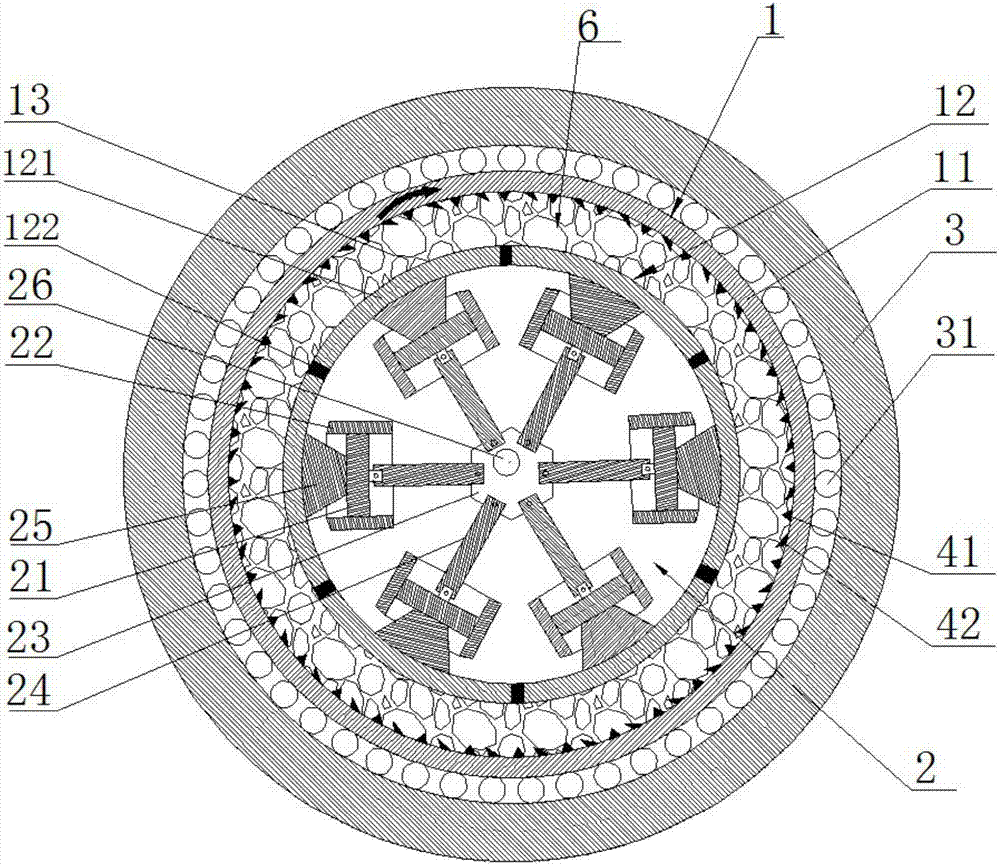

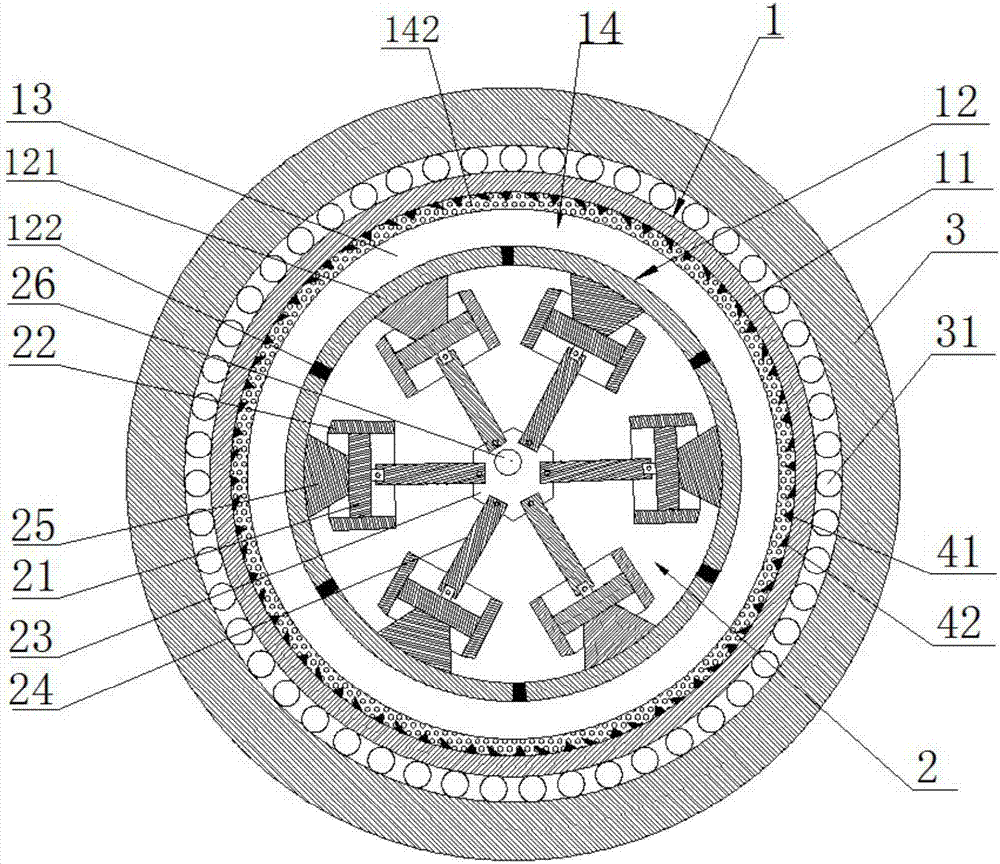

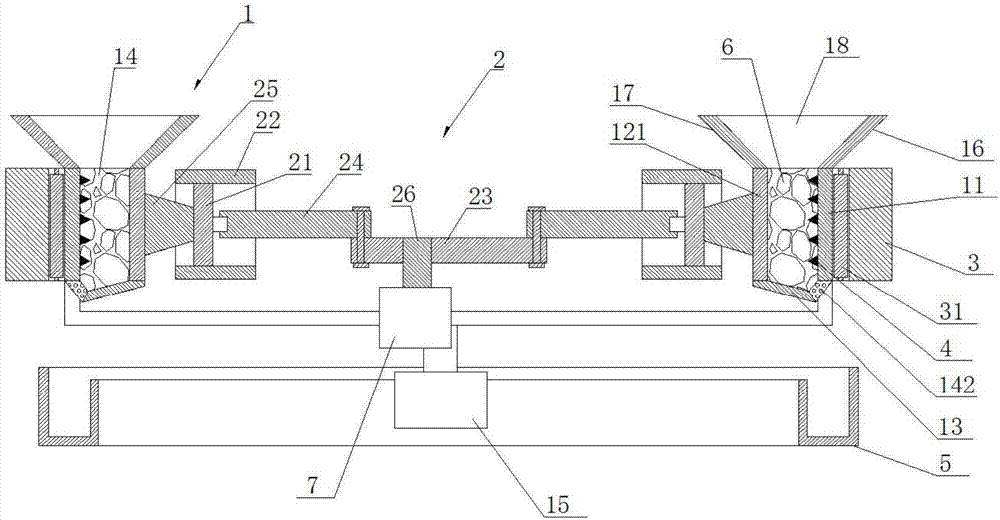

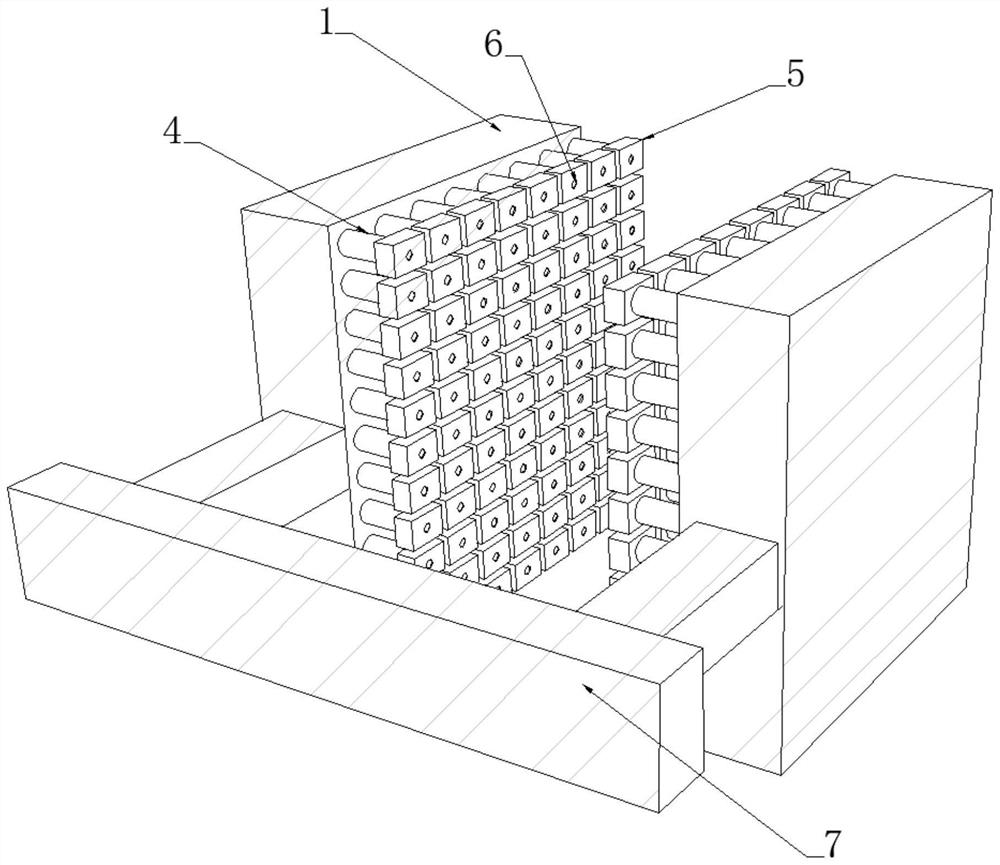

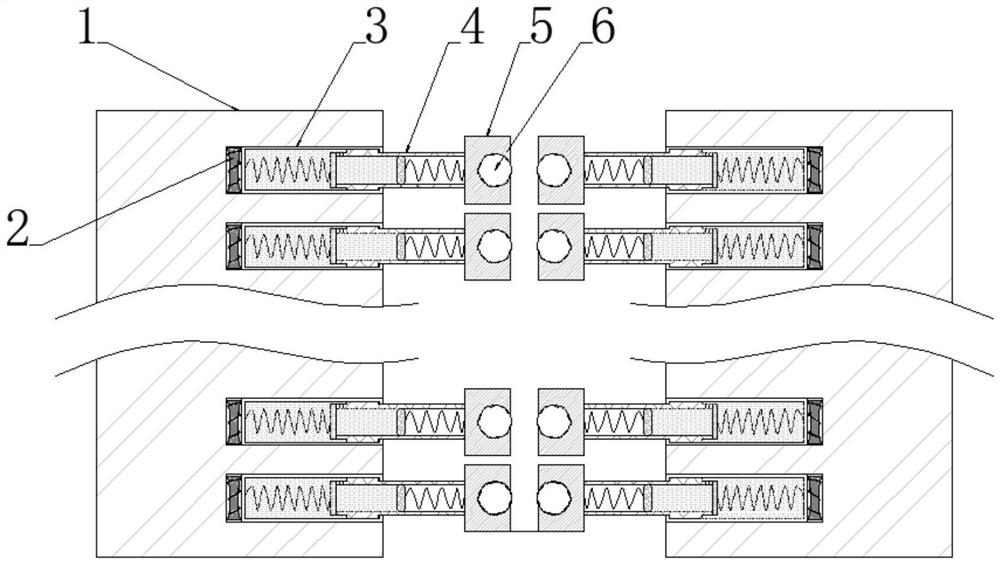

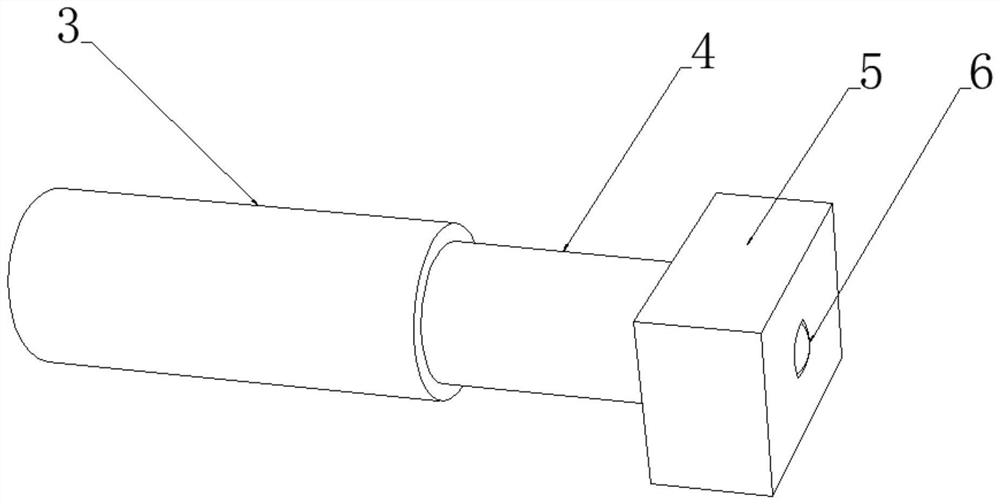

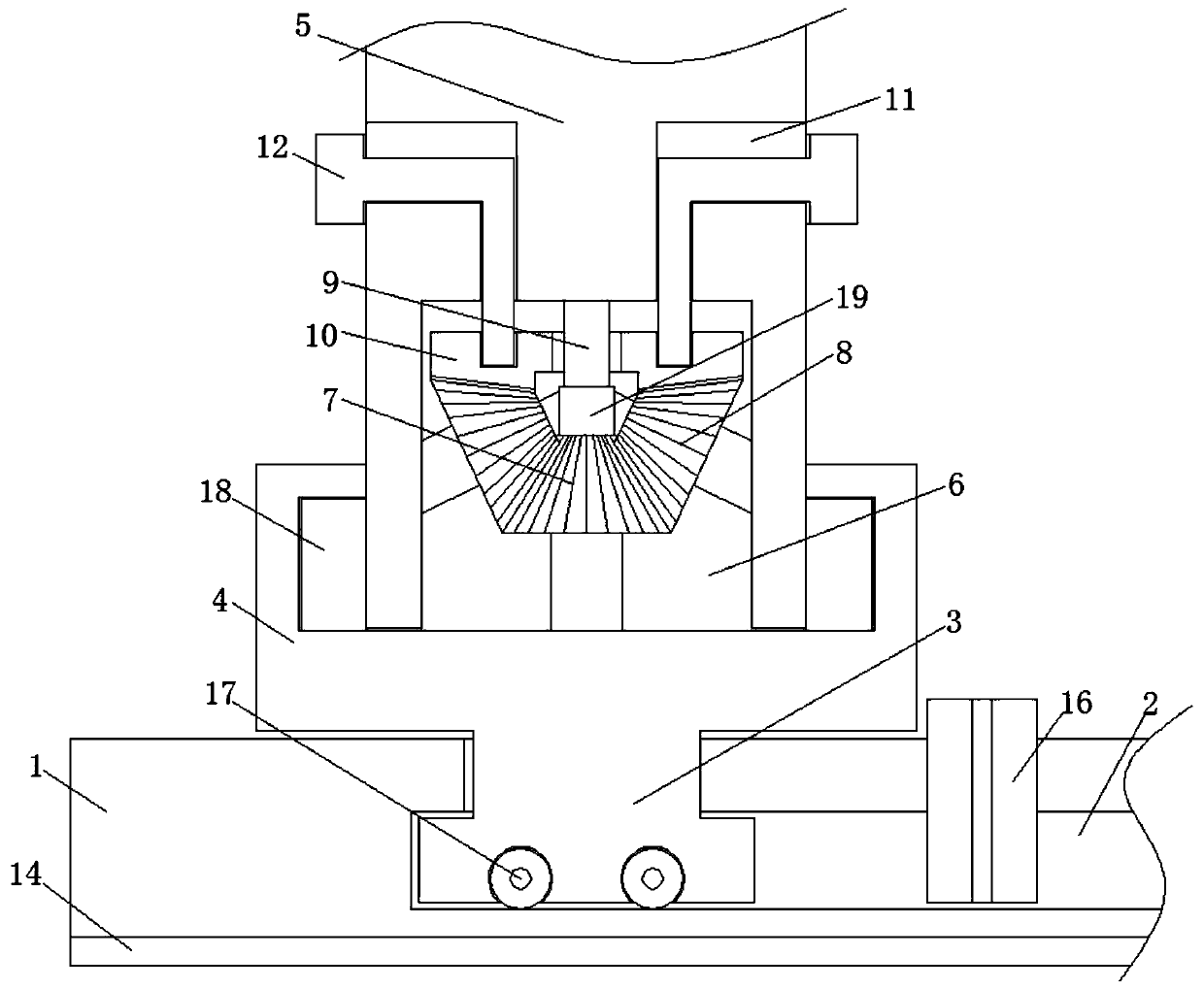

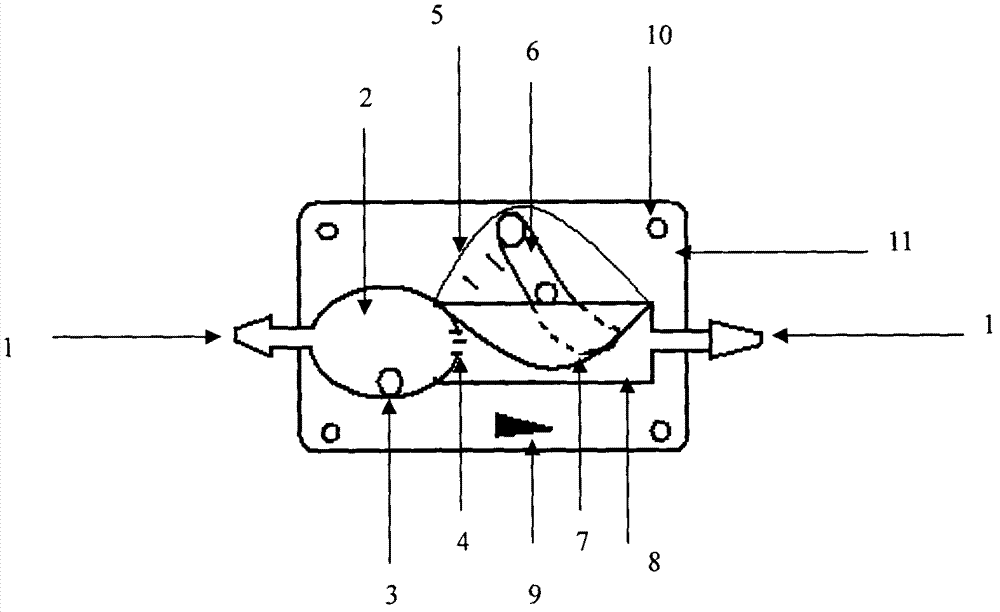

Crusher

InactiveCN107029821AEvenly brokenImprove energy utilizationGrain treatmentsElectric machineryEngineering

The invention relates to a crusher, comprising a crushing device and a driving device; the crushing device comprises an outer plate, an inner plate and a bottom plate; the outer plate, the inner plate and the bottom plate are enclosed into a horizontal annular crushing chute; the outer plate is composed of a The first motor drives and rotates; the inner plate is formed by connecting a plurality of pressing plates in sequence through elastic connecting bodies; the inner side of the outer plate in the annular breaking trough is provided with crushing tines; A turntable, a plurality of pistons facing the pressure plate respectively and sleeves slidingly matched with the pistons; one end of a first connecting rod is hinged on the piston, and the other end is hinged on the turntable; one end of a second connecting rod is connected to the piston, The other end is connected to the pressing plate; the turntable is driven to rotate by a rotating shaft eccentrically arranged on the turntable; the crusher can significantly improve the energy utilization rate, with small vibration, low noise, and even crushing.

Owner:郑小华

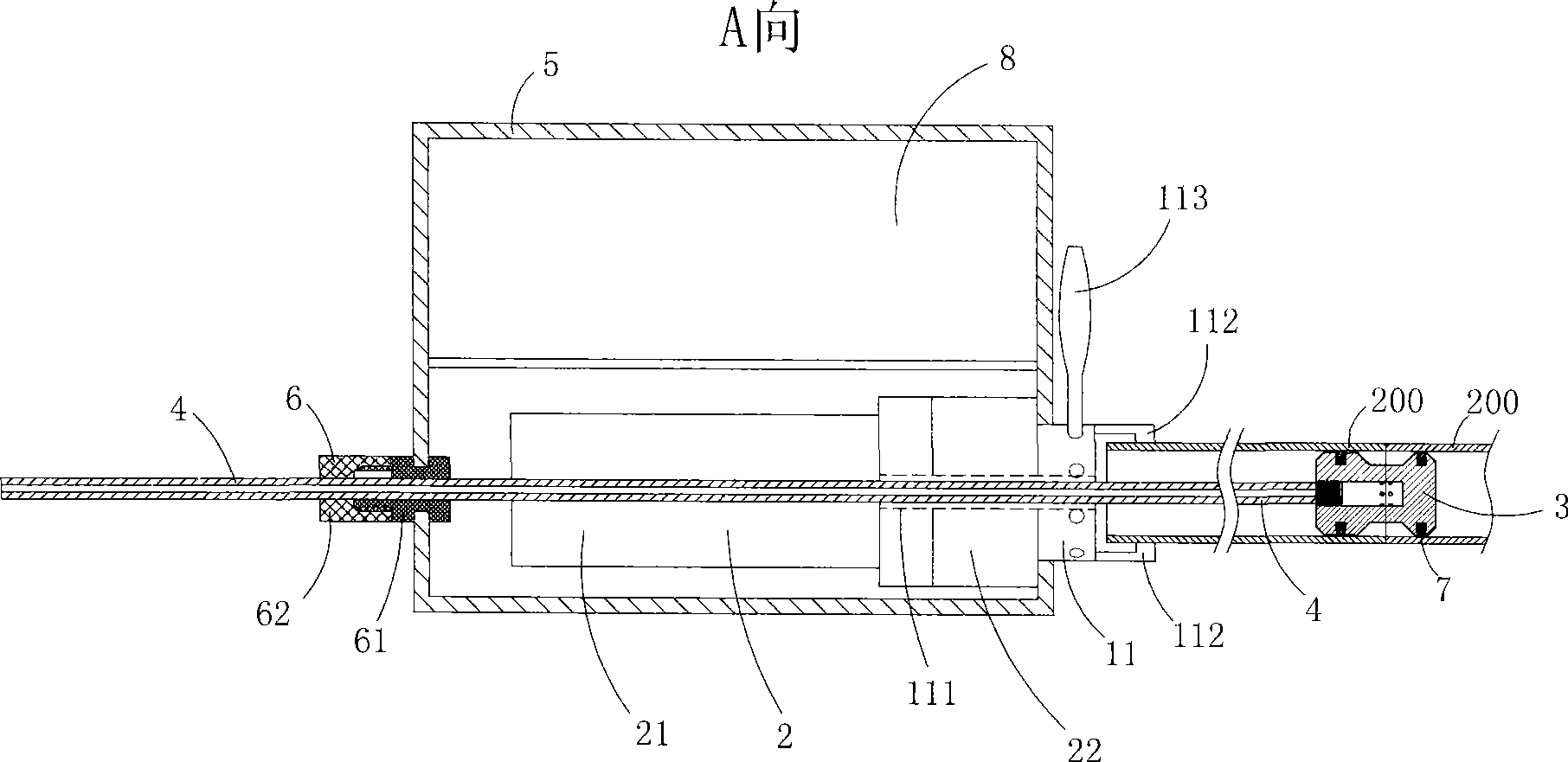

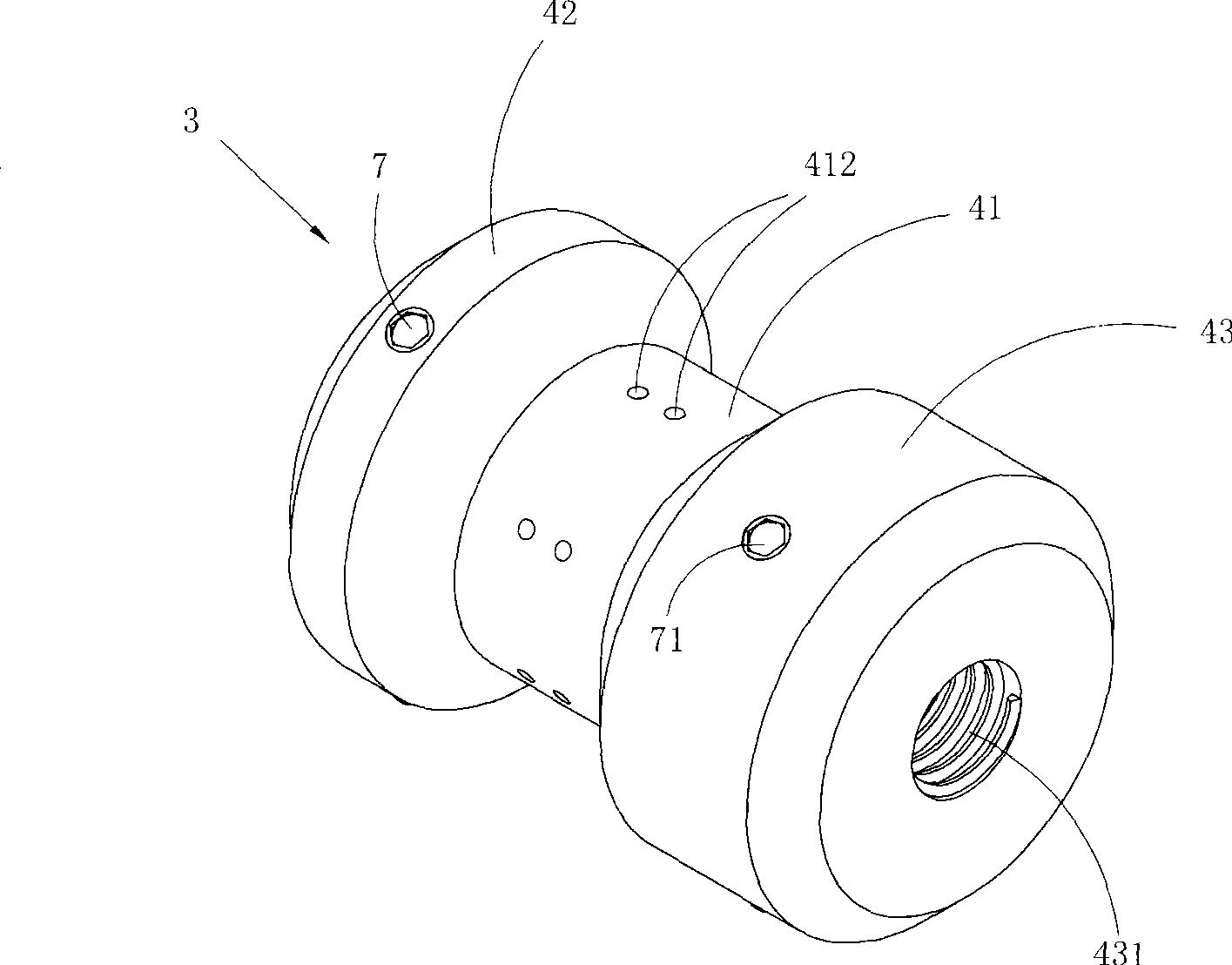

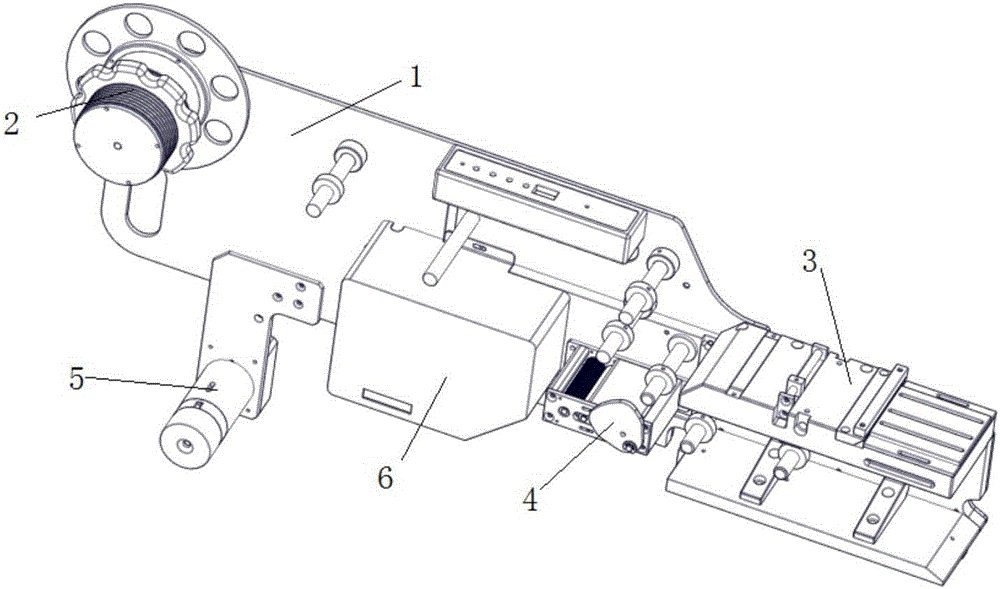

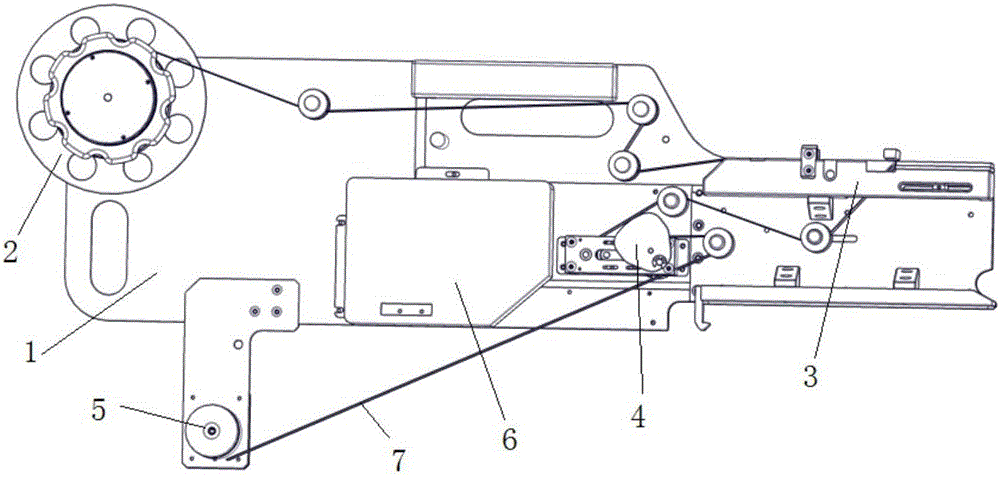

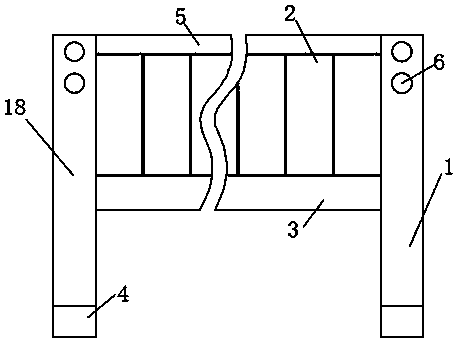

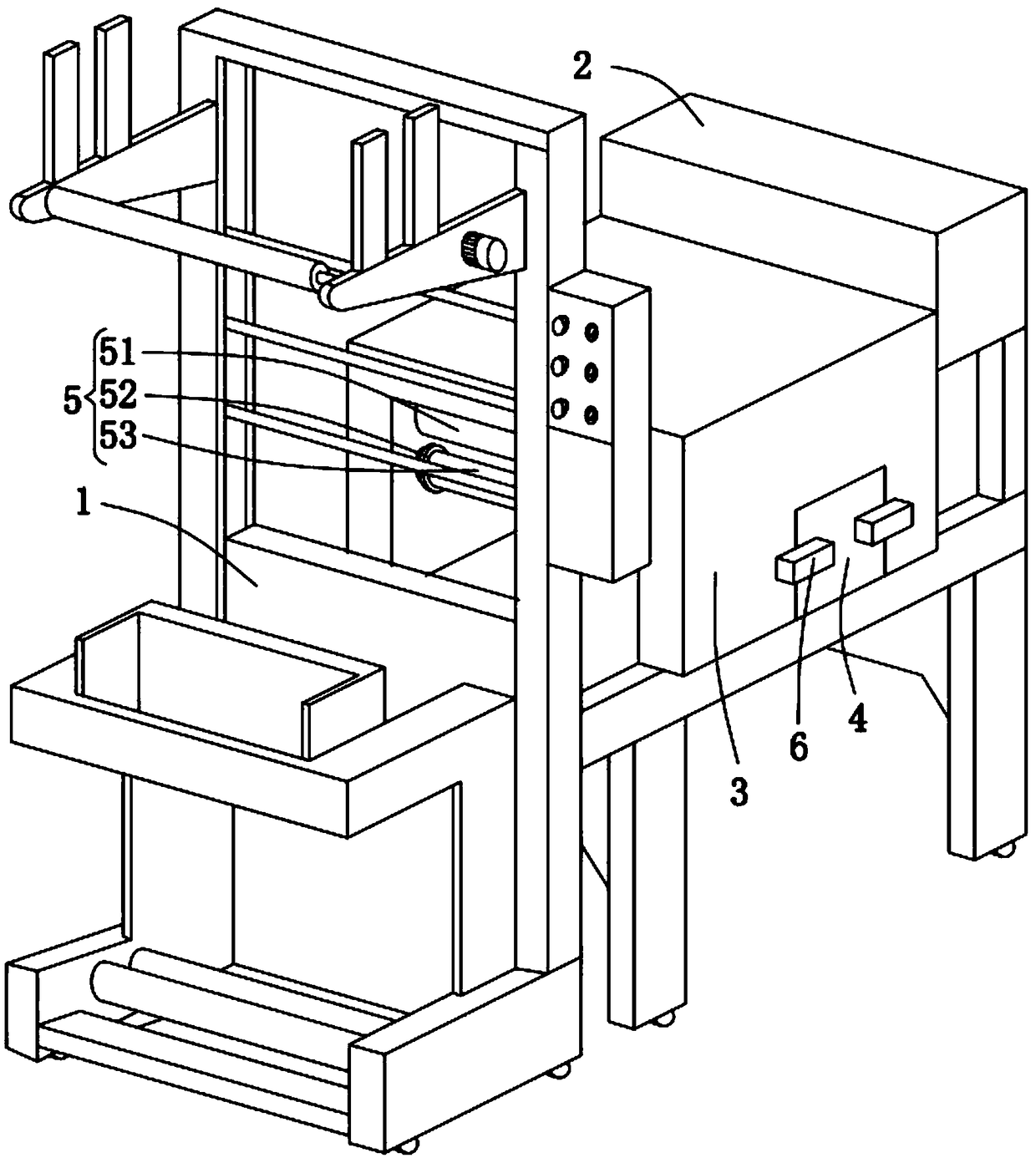

Label stripping mechanism, emptying module and label stripping method for automatically tightening strips

ActiveCN106184952ASimple structureEasy to operateLabelling machinesWebs handlingEngineeringIntelligent control

The invention provides a label stripping mechanism, an emptying module and a label stripping method for automatically tightening strips, and belongs to the technical field of machining equipment. The emptying module consists of a fixed base, a motor, an inner baffle plate, a roller, a locking ring and a turntable; and the label stripping mechanism includes a frame, and the emptying module, a label stripping plate module, a collecting module and a waste recovery module mounted on the frame. The label stripping mechanism has the advantages of intelligent control and capability of stripping labels without manual operation, can automatically tighten the strips, and greatly improves the label stripping efficiency and quality.

Owner:吴凯旋

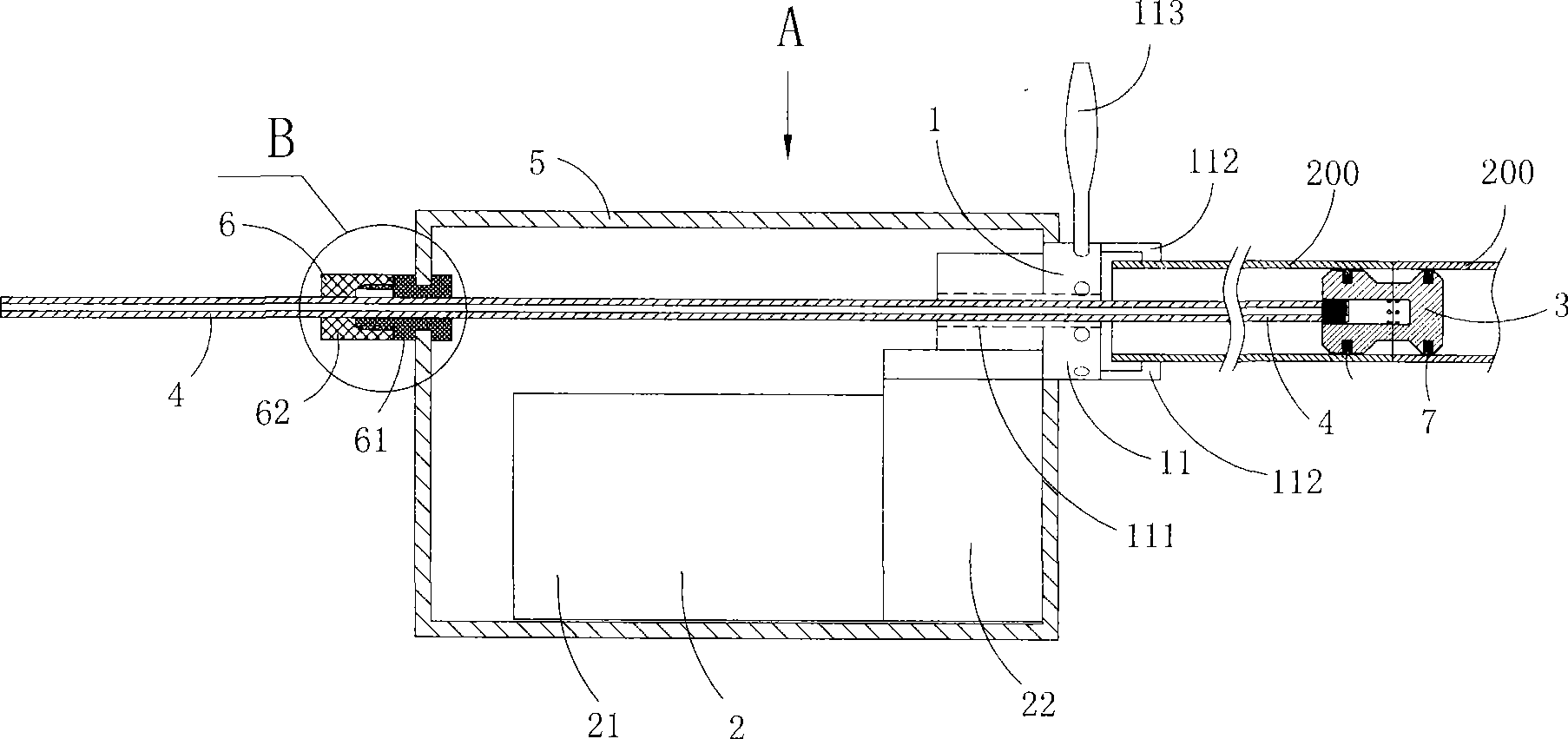

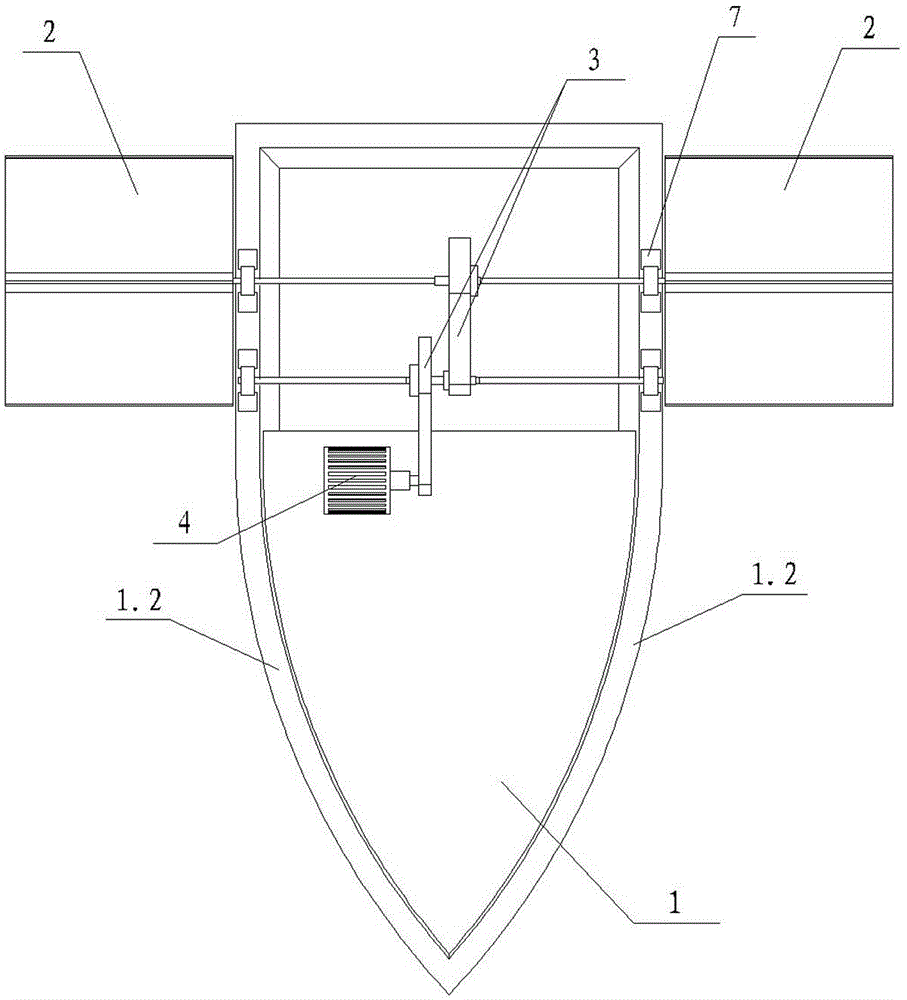

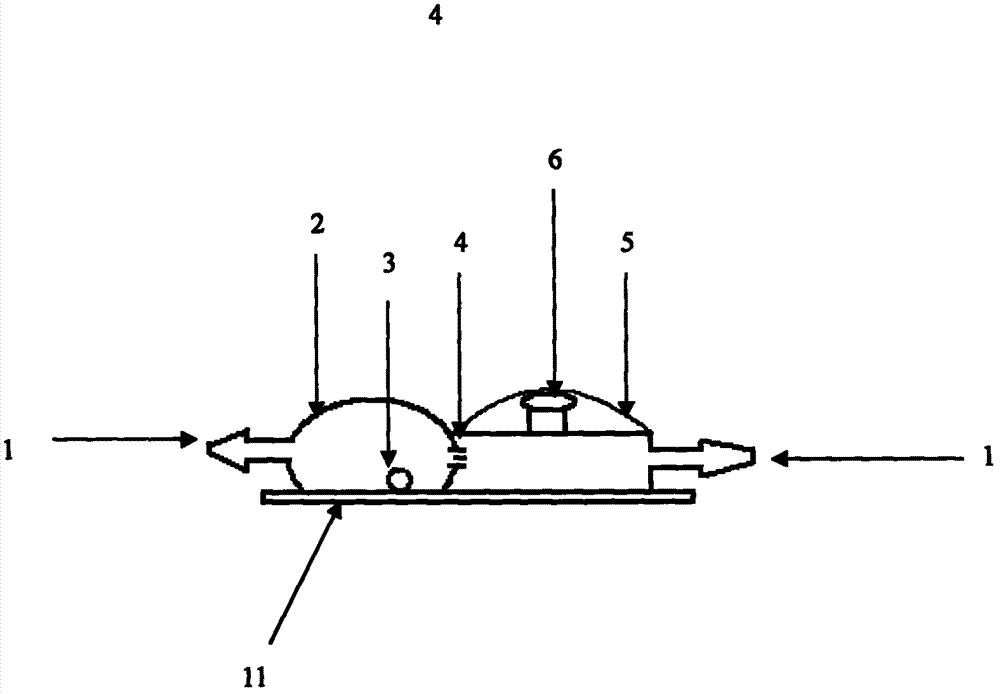

Floating body type dual-impeller tidal current energy power generating device

InactiveCN103334860ADoes not hinder rotationSimple structureWaterborne vesselsHydro energy generationImpellerMooring system

The invention discloses a floating body type dual-impeller tidal current energy power generating device, comprising a floating body (1), impellers (2), a speeder (3) and a power generator (4); the impeller shafts of the two impellers are horizontally arranged; the two impellers (2) are arranged at two sides of the floating body (1) respectively, and are connected with the input end of the speeder (3); the out put end of the speeder (3) is connected with a power shaft of the power generator (4); and a mooring system is arranged at the front end of the floating body (1) provided with a water injecting chamber (1.1). The horizontally arranged impeller shafts have the flow guiding function and part of the impellers is arranged above the water, so the tidal current energy power generating device is high in automatic power generating efficiency for water, and convenient to mount and maintain.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

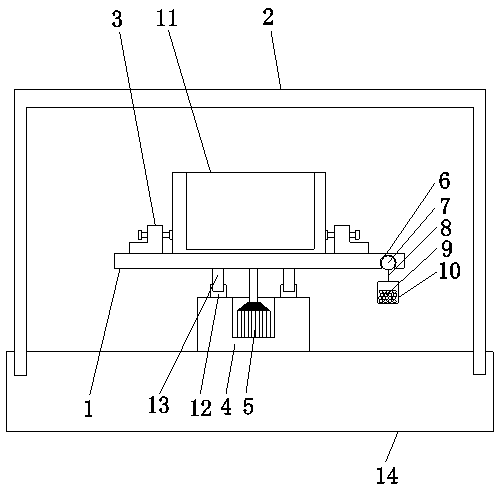

Gas shielded welding device with in-pipe charging device

InactiveCN101486125BEasy to useGuarantee welding qualityWelding accessoriesSemi automaticEngineering

The invention discloses a gas shielded welding device with an inflatable device in a pipe, comprising: a locking device with a chuck for clamping a pipe to be welded; a driving mechanism for driving the chuck to rotate; a An inflatable device for inflating shielding gas from the cavity of the pipe to be welded; and an inflatable tube communicated with the inflatable device in the pipe. The invention has the advantages of semi-automatic structure, relatively convenient operation and improved welding quality.

Owner:浙江天力久田管业有限公司

Specimen display box for biological teaching

The present invention relates to the technical field of biological teaching, especially to a specimen display box for biological teaching The box comprises a pedestal, a transparent upper cover is arranged at the upper end of the pedestal, a U-shaped base is arranged at the middle portion of the upper end of the pedestal, the upper end of the U-shaped base is provided with circular slide rails, the U-shaped base is internally provided with a motor, the output shaft of the motor is provided with a support plate, siding columns are arranged at the lower end of the support plate, the support plate is provided with a transparent glass dish, the transparent glass dish is provided with spacing mechanisms comprising L-shaped plates, one side of each L-shaped plate is provided with one bolt, one end of each bolt is provided with one baffle, one circular trough is arranged at the internal portion of one end of each bolt, one pressure reduction plate is arranged at the internal portion of each circular trough, the outer side of each circular trough is provided with one annular groove, each annular groove is internally provided with one slide block, and springs sleeve the outer sides of the bolts between the baffles and the pressure reduction plates. The specimen display box for biological teaching has an omnibearing display function and has a sterilization drying effect.

Owner:成都酷爱睿工业产品设计有限公司

Hand-held branch trimming device

The invention discloses a hand-held branch trimming device, and relates to the technical field of branch trimming equipment. The device comprises a bearing structure, the outer wall of the bearing structure is provided with a fastening structure and an extension rod, the upper portion of the bearing structure is provided with a motor, an output shaft end of the motor is provided with a circular cutter, and the lower portion of the bearing structure is provided with a clamping structure. The hand-held branch trimming device has the advantages that a user can stand on an original position to trim trees, and meanwhile the device can also be adjusted for trimming according to the heights of the to-be-trimmed trees.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

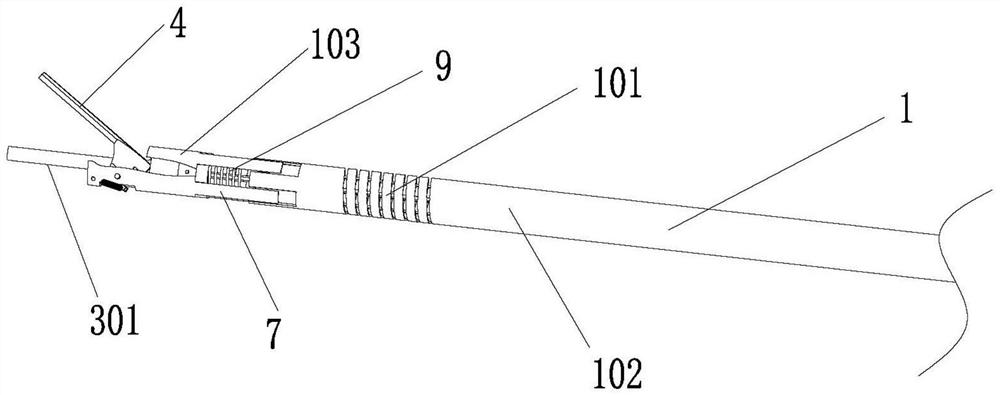

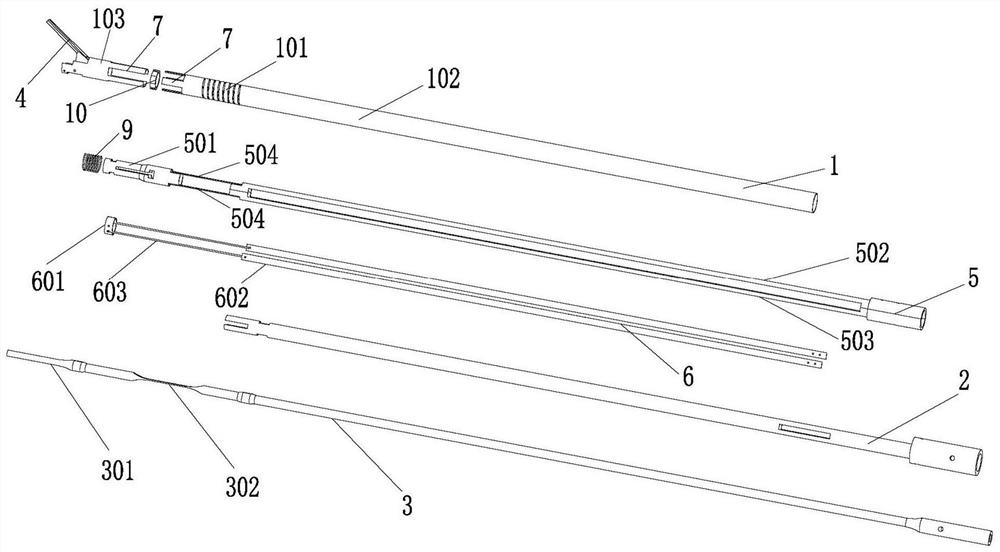

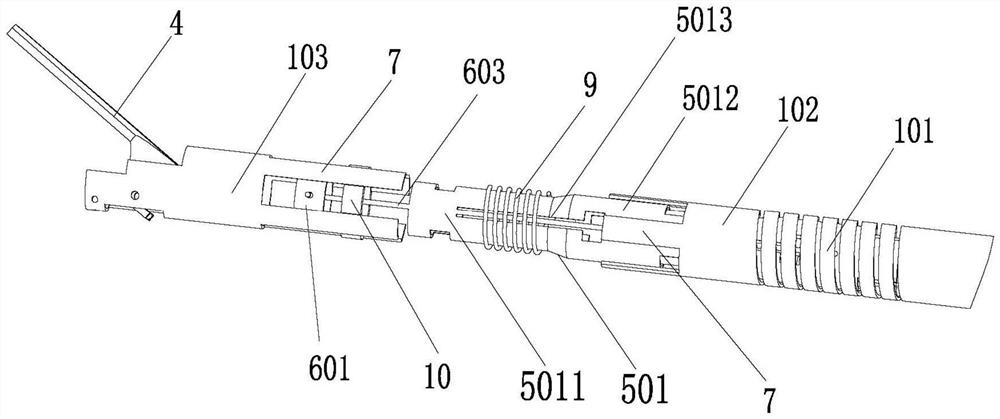

Sleeve assembly and ultrasonic knife

The present invention discloses a sleeve assembly and an ultrasonic knife. The sleeve assembly comprises an outer sleeve, an inner sleeve, an ultrasonic guide rod, a clamping arm, a bent pipe fitting and a stretching assembly, and the outer sleeve is provided with a bent part which is driven by axial movement of the bent pipe fitting to be bent; a tool bit of the ultrasonic guide rod extends out of the far end of the outer sleeve and forms a clamping mechanism capable of being opened and closed with the clamping arm, the stretching assembly drives the outer sleeve and drives the clamping arm to move axially, and in the moving process of the clamping arm, after the near end of the clamping arm is limited by the end face of the far end of the bent pipe fitting, pivot rotation is generated at the same time to achieve clamping of the clamping mechanism; and the bent pipe fitting, the stretching assembly and the ultrasonic guide rod are in flexible connection with the corresponding positions of the bent part, and the outer sleeve can drive the clamping arm to rotate around the axis of the ultrasonic guide rod through autorotation in the bending or straight state. According to the integrated sleeve assembly, opening, closing and autorotation of the clamping mechanism and bending of the sleeve assembly can be achieved at the same time, and the use flexibility and control precision of the clamping mechanism are improved.

Owner:INNOLCON MEDICAL TECH SUZHOU

Anti-falling gripper for robot

InactiveCN113910271AImprove stabilityHigh elastic limitGripping headsElectrically conductiveEngineering

The invention discloses an anti-falling gripper for the robot, and belongs to the technical field of robots. The robot can adapt to objects in different shapes by arranging multiple clamping modules, clamping blocks are pushed through electric rods to clamp the objects, friction blocks are used for making contact with the clamping blocks to push sliding rods to move backwards, electrorheological fluid and first springs in the clamping module are extruded, the electrorheological fluid is controlled to be solidified through a controller, the clamping module is kept stable, meanwhile, the situation that an object is damaged due to too large clamping force is avoided, unstable current is generated by a radiation metal rod and a conductor rail through rotation of a ball in a spherical cavity, and therefore whether the clamping module is clamped or not is judged; and after the controller controls the electrorheological fluid to be liquefied, repulsive force is generated in cooperation with an electromagnet, so that the clamping module is tightly attached to the object, and the stability of the device is further improved.

Owner:张旭

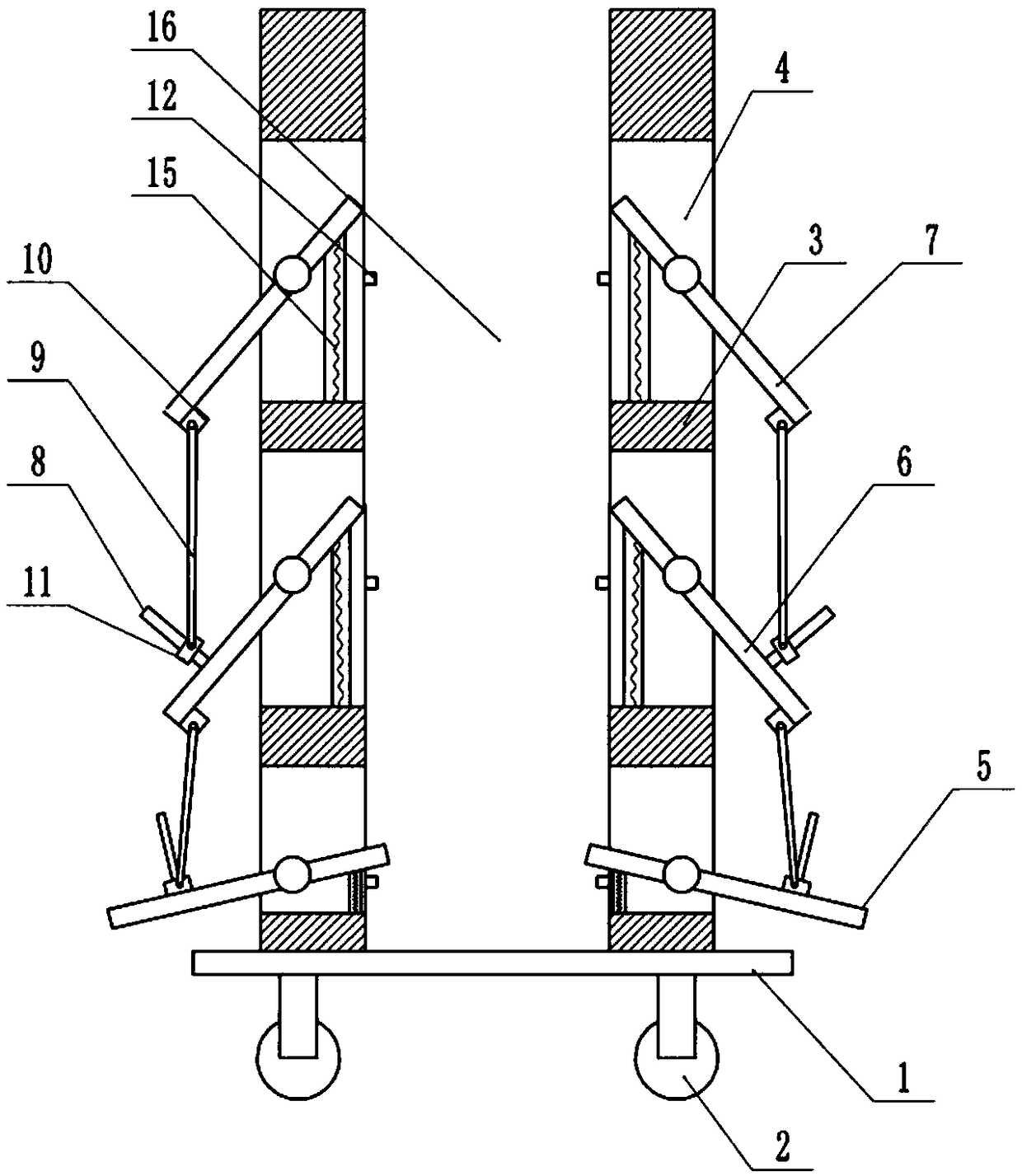

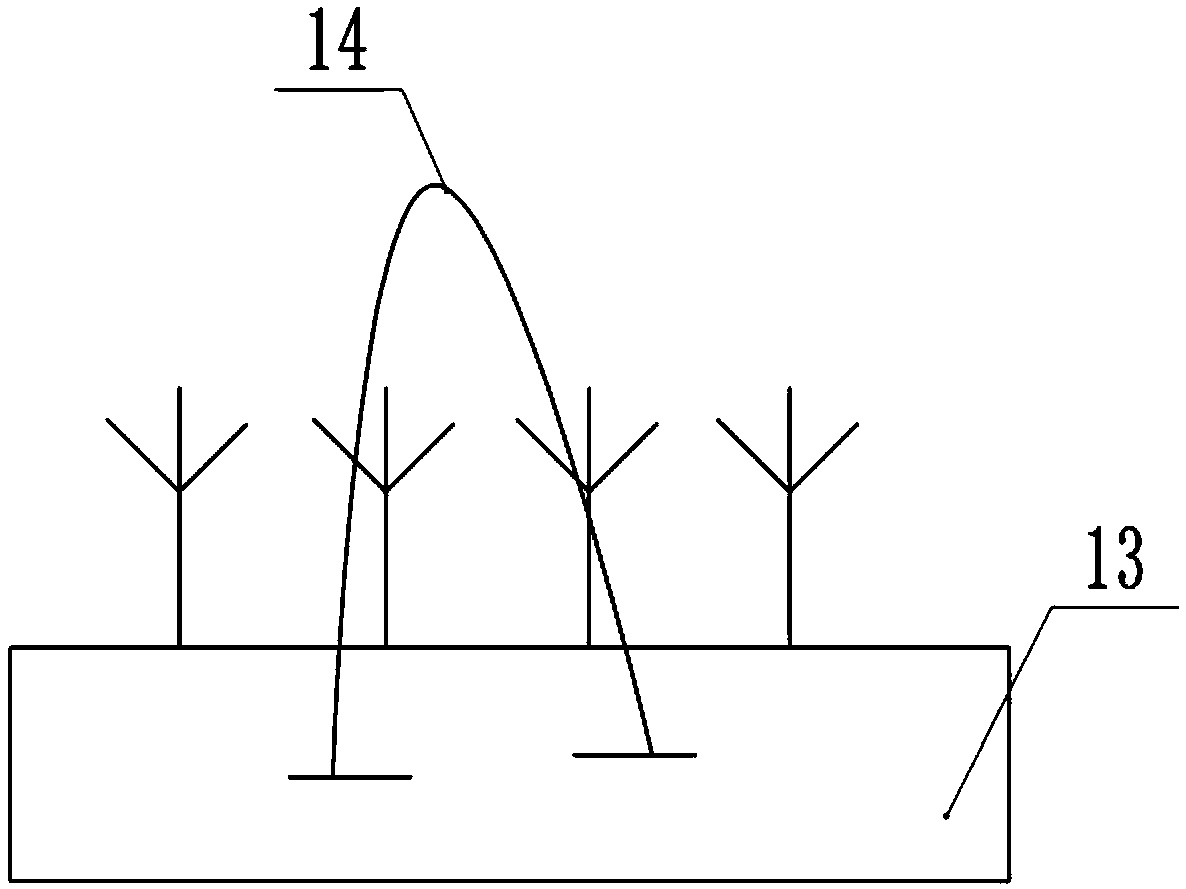

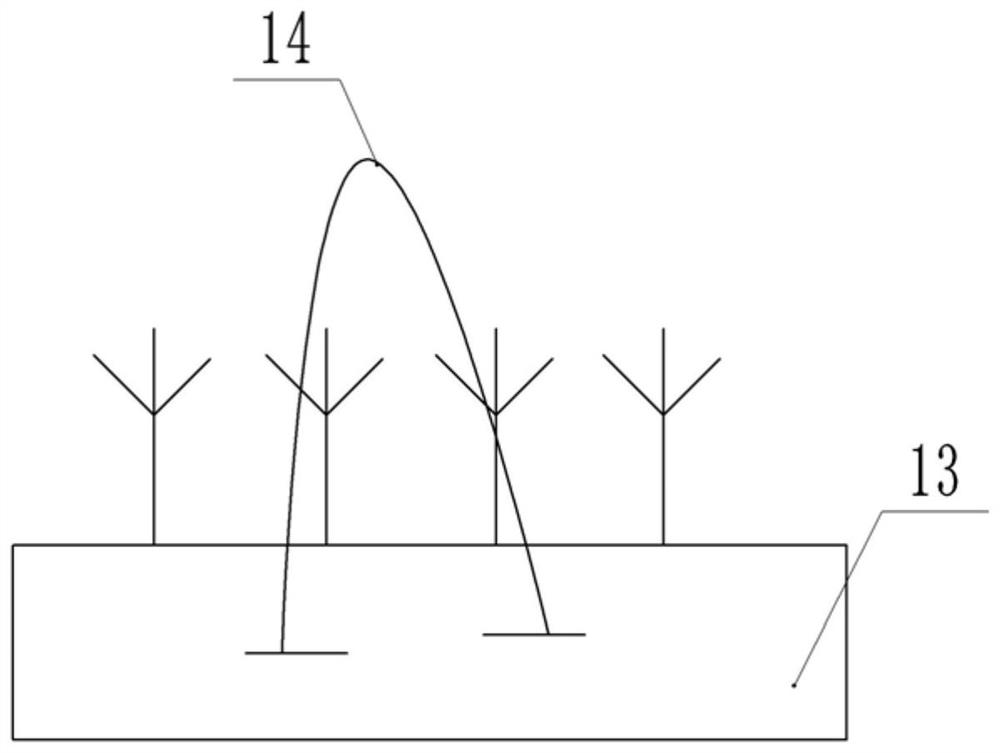

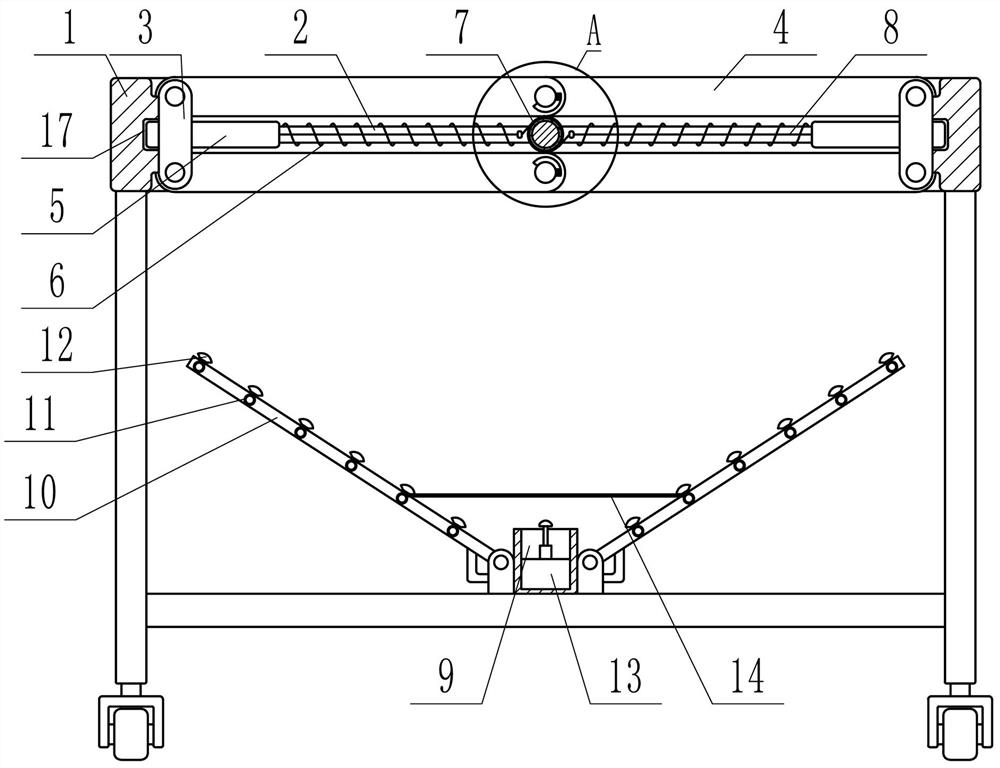

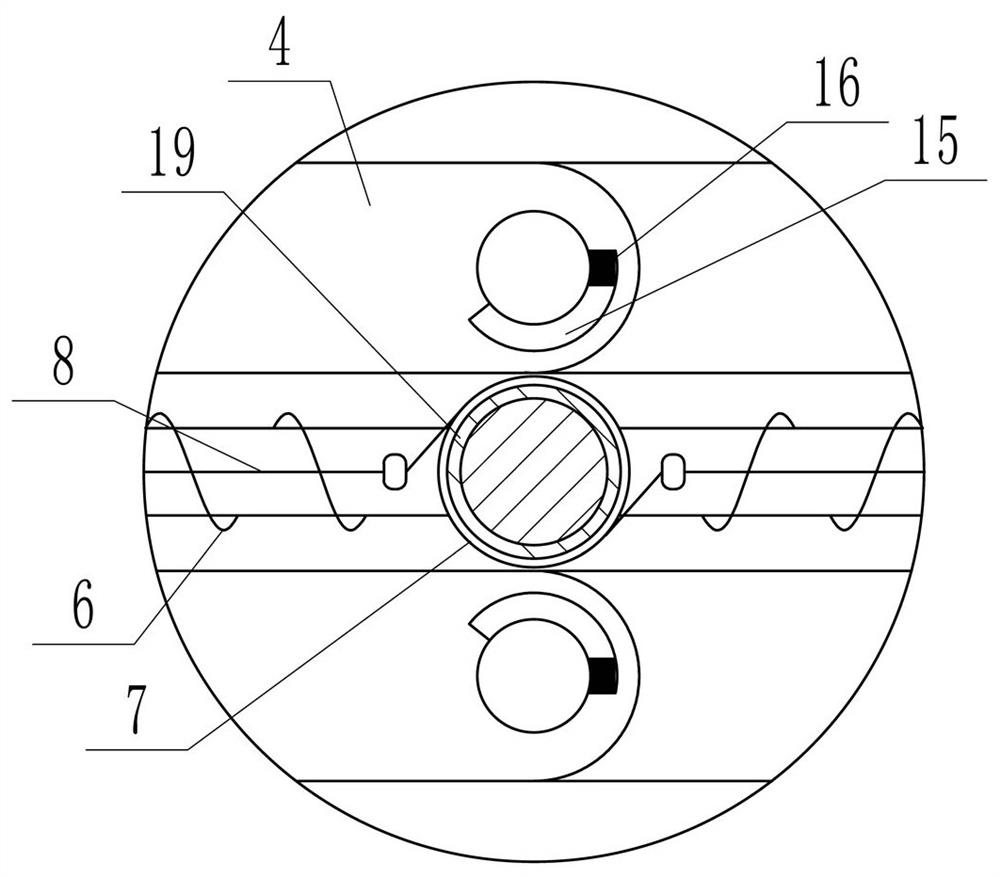

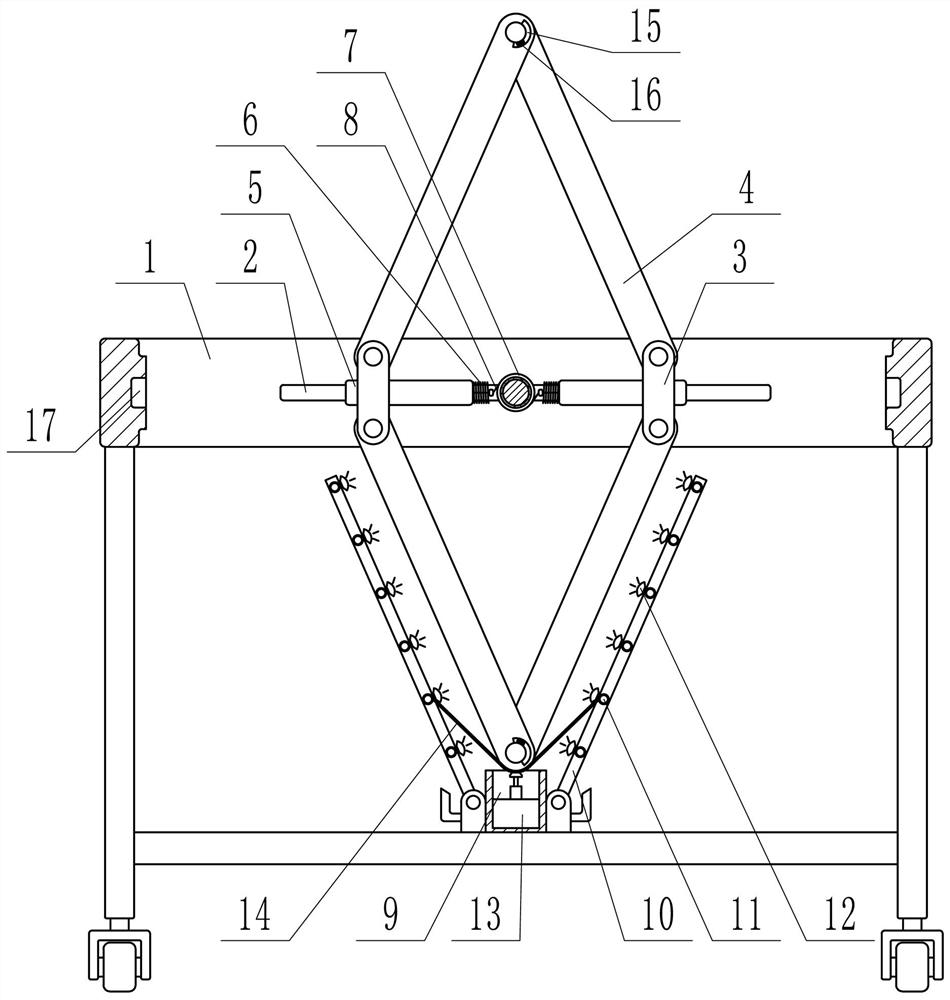

Cultivation planting method for scrophularia ningpoensis

ActiveCN108617451AImprove space utilizationEasy to placeFertilising methodsRoot crop cultivationEngineeringScrophularia ningpoensis

The invention relates to a cultivation planting method for scrophularia ningpoensis. The method comprises the steps of preparing seedbeds and preparing a seedbed frame; and the method specially comprises the following steps: a, performing preparation at the earlier stage: selecting a bottom plate and a pair of clamping plates, and forming through holes in each clamping plate; and preparing supporting plates, limit blocks, fixing blocks, sliding rods, sliding sleeves, springs, connecting rods and the seedbeds; b, installing the bottom plate and the clamping plates; c, installing the supportingplates: enabling each supporting plate to be rotatably connected in the corresponding through hole, and installing each spring in the corresponding through hole; d, connecting the supporting plates: installing the corresponding sliding rod on one end, far away from placing space, of each supporting plate, and installing the corresponding sliding sleeve on each sliding rod; installing the corresponding fixing block on one end, far away from the placing space, of each supporting plate; and enabling two ends of each connecting rod to be separately and rotatably connected with the corresponding fixing block and the corresponding sliding sleeve which are located on adjacent supporting plates; and e, installing the limiting blocks. The method provided by the invention realizes an effect that a plurality of layers of seedbeds can be placed on the seedbed frame, thereby improving a space utilization rate.

Owner:玉环市几偶孵化器有限公司

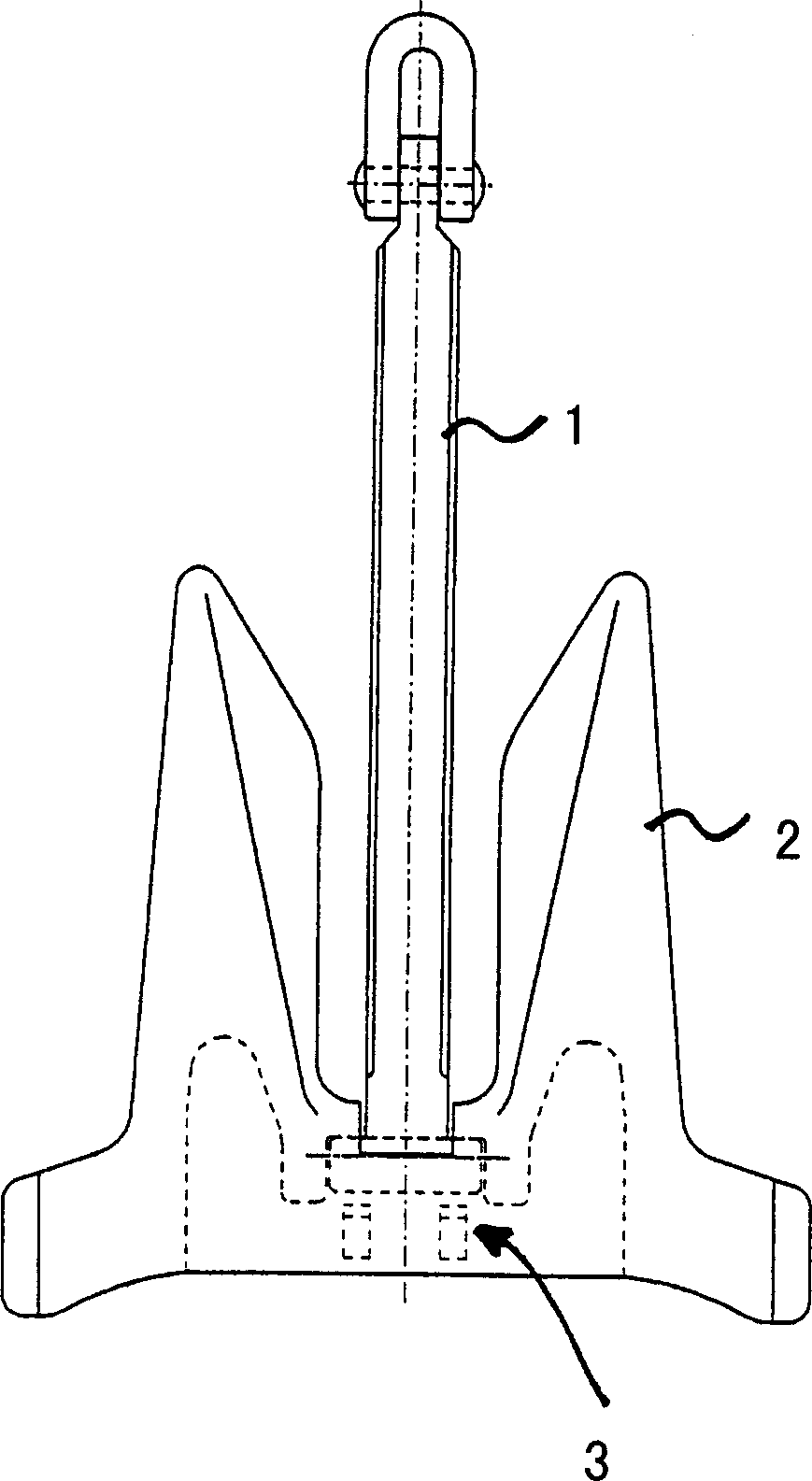

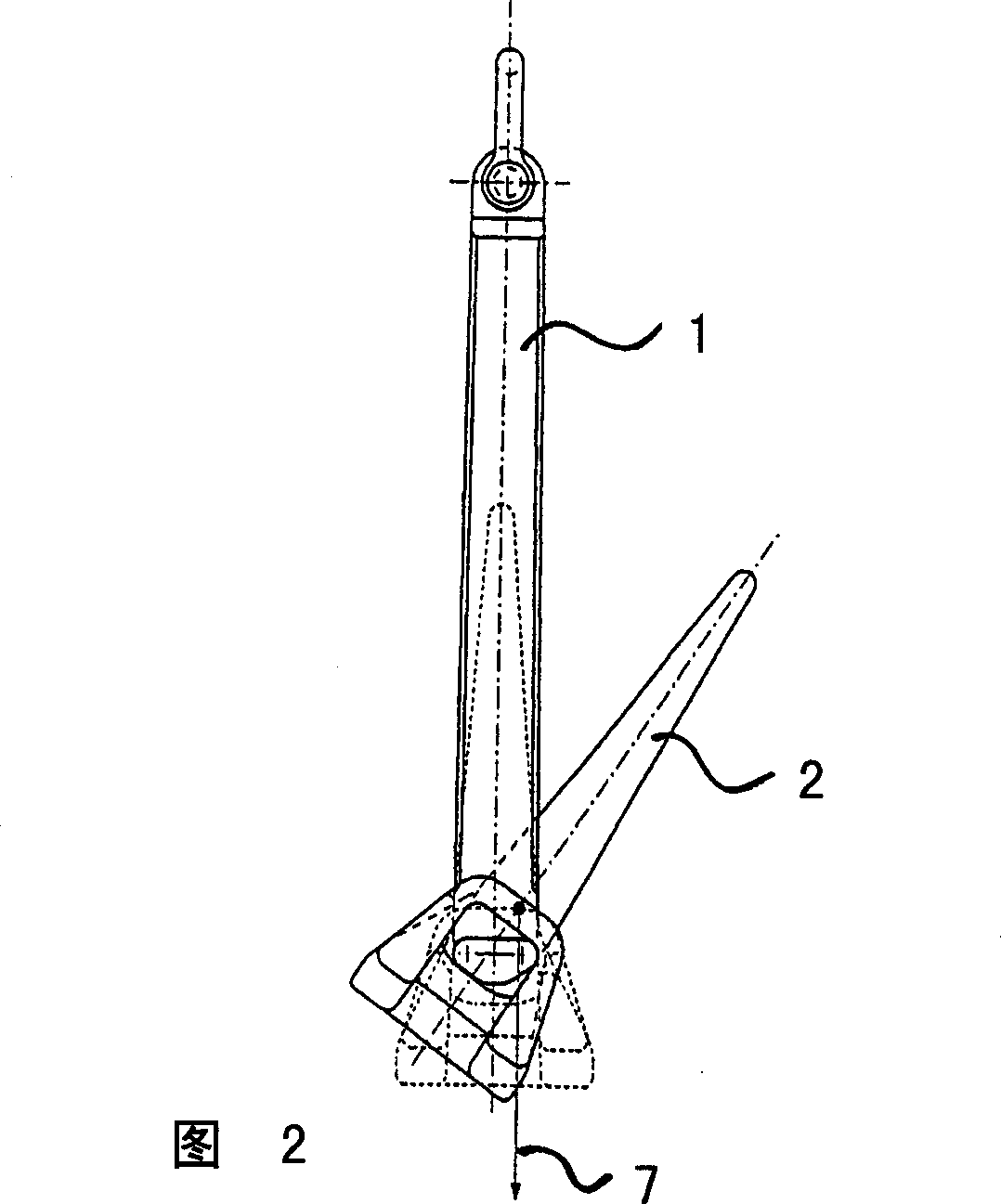

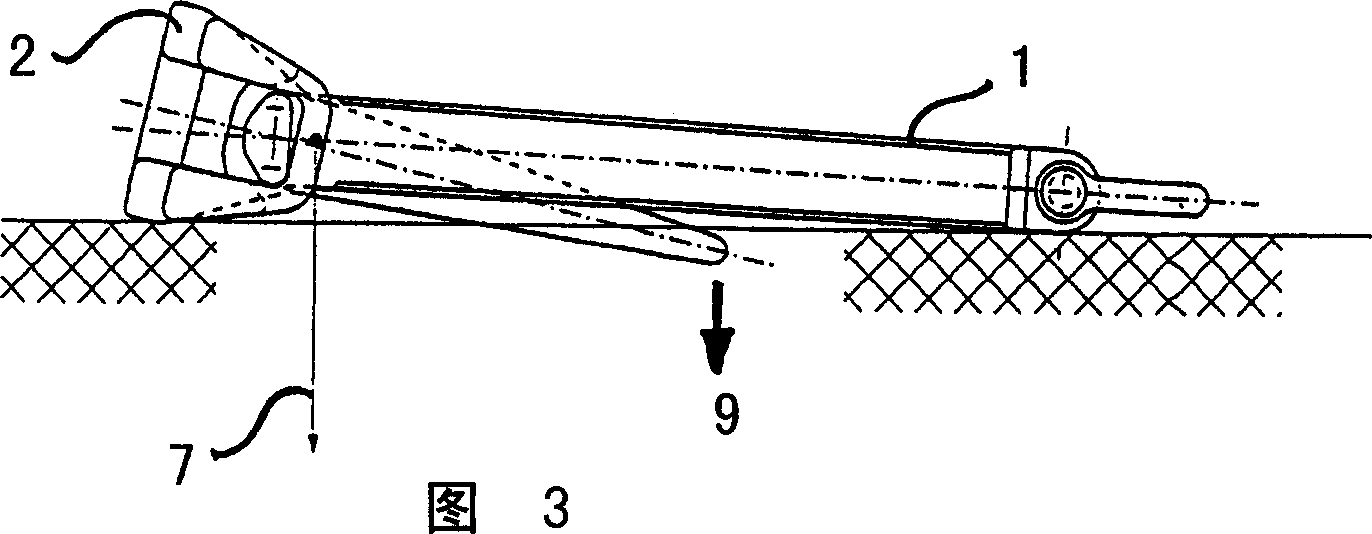

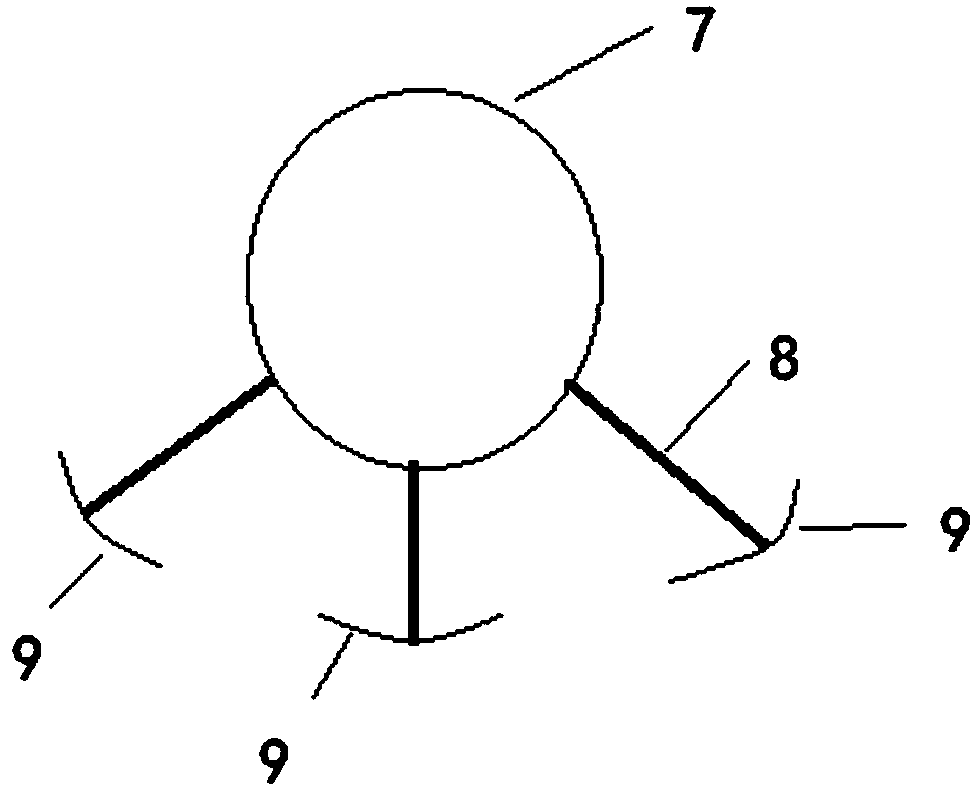

Anchor

The anchor has a shaft (1) and a pivoting head (2) with flukes. Two spaced pivot points are provided, which are eccentrically arranged. The centre of mass (7) of the anchor head lies between and over both pivot points, when the anchor head is vertically on the anchor shaft.

Owner:BROM VOLVES MAINTENANCE

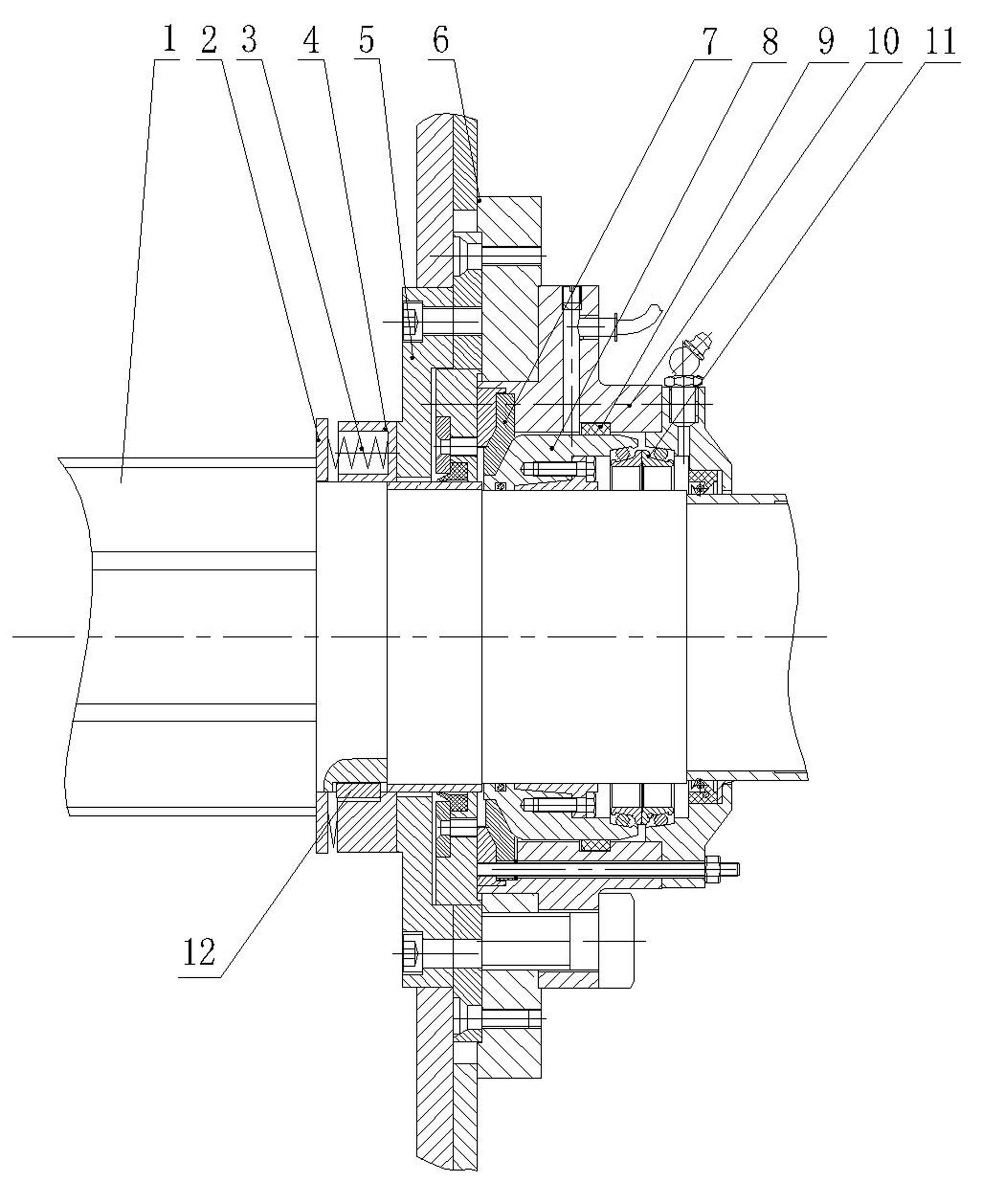

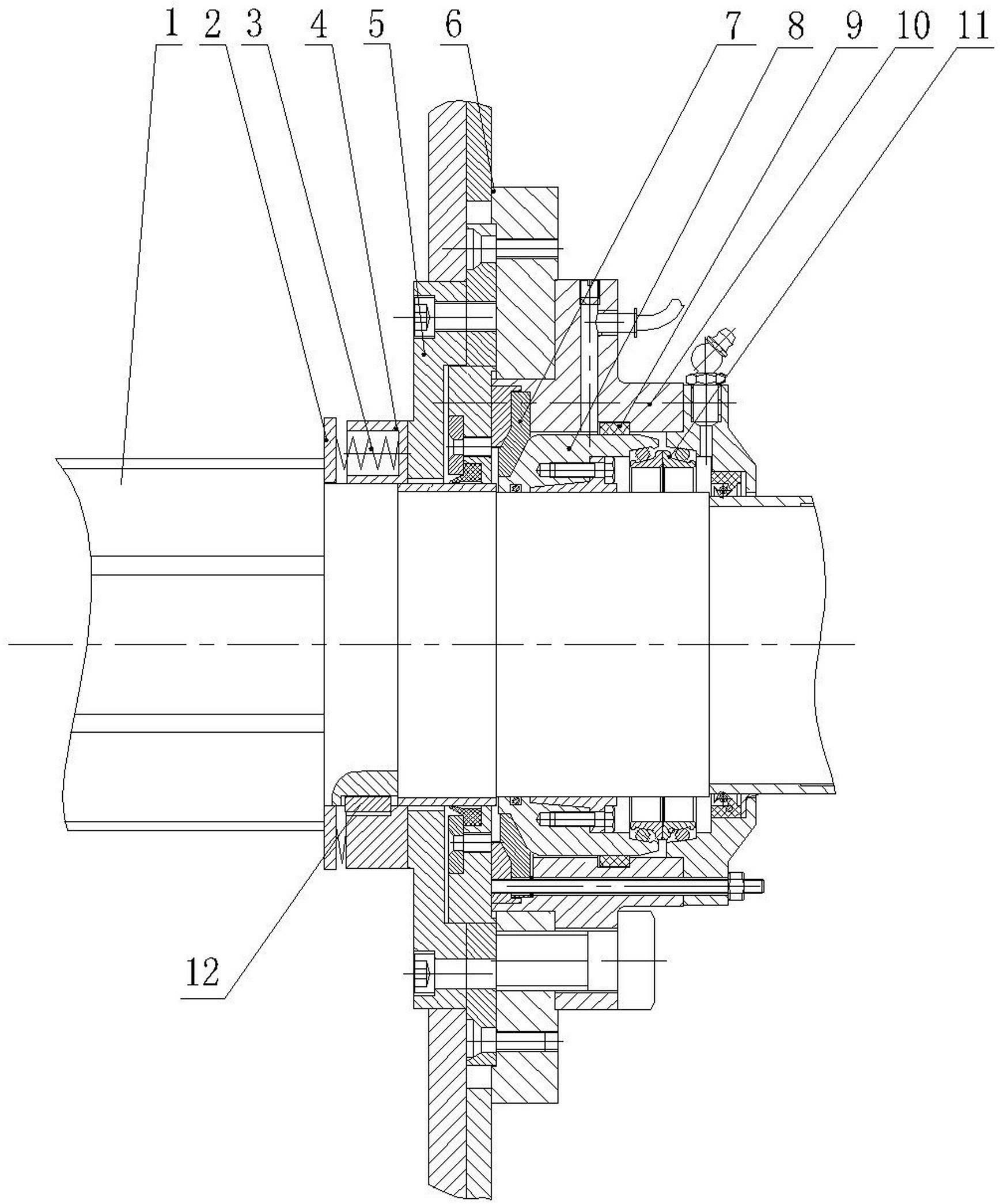

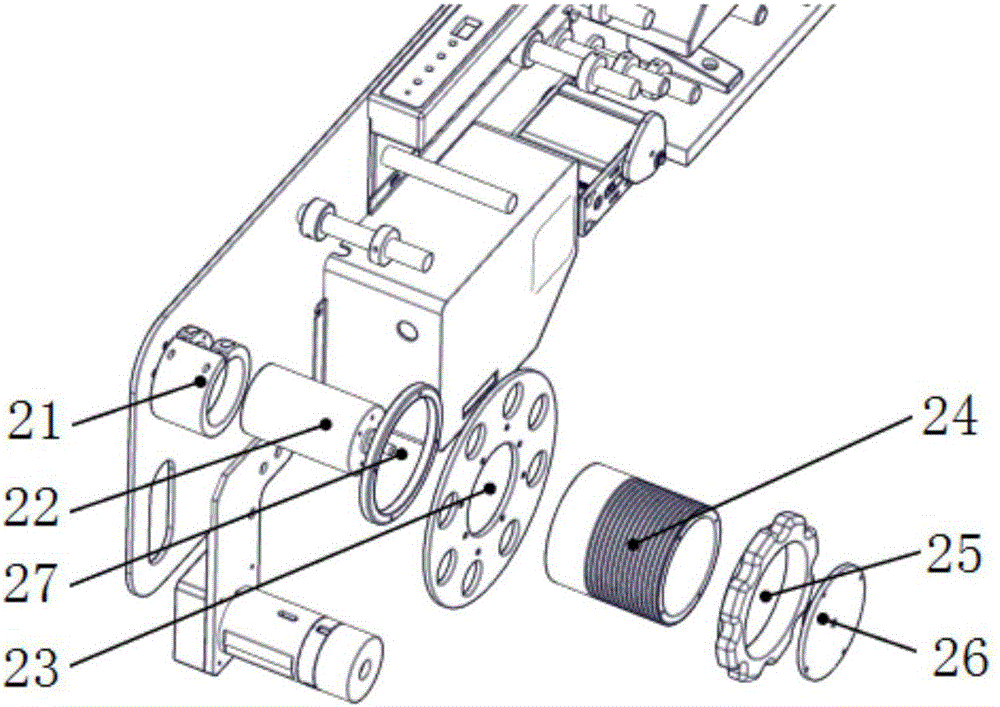

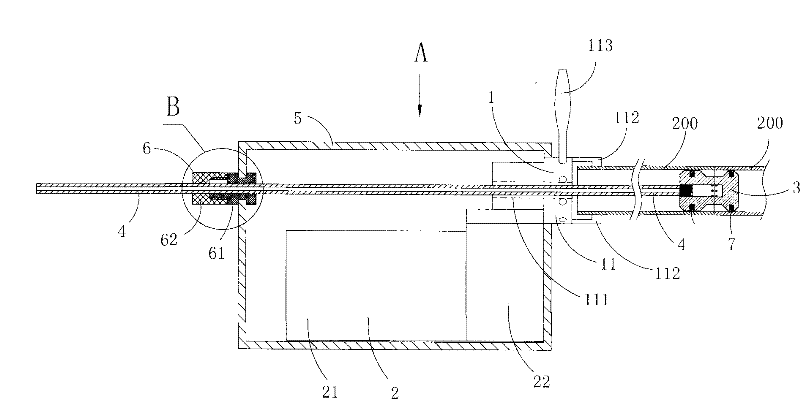

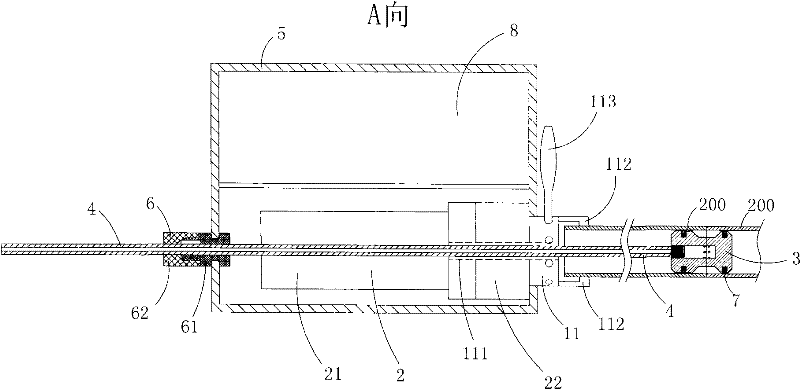

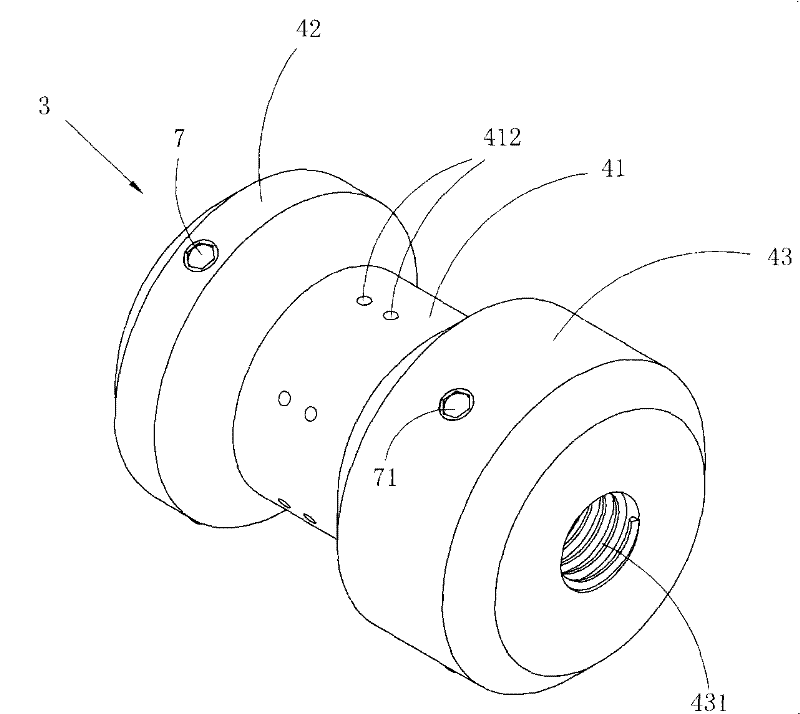

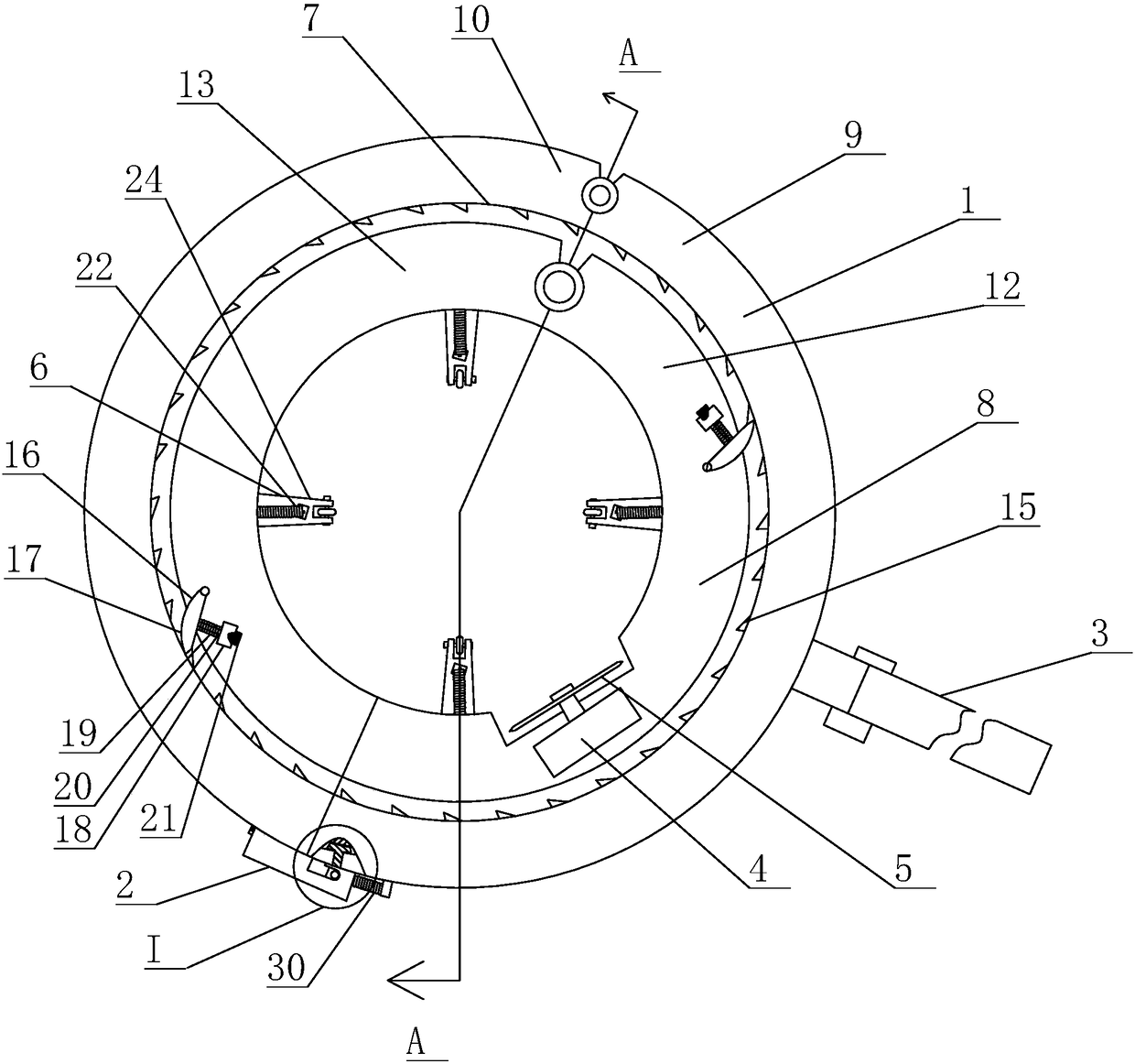

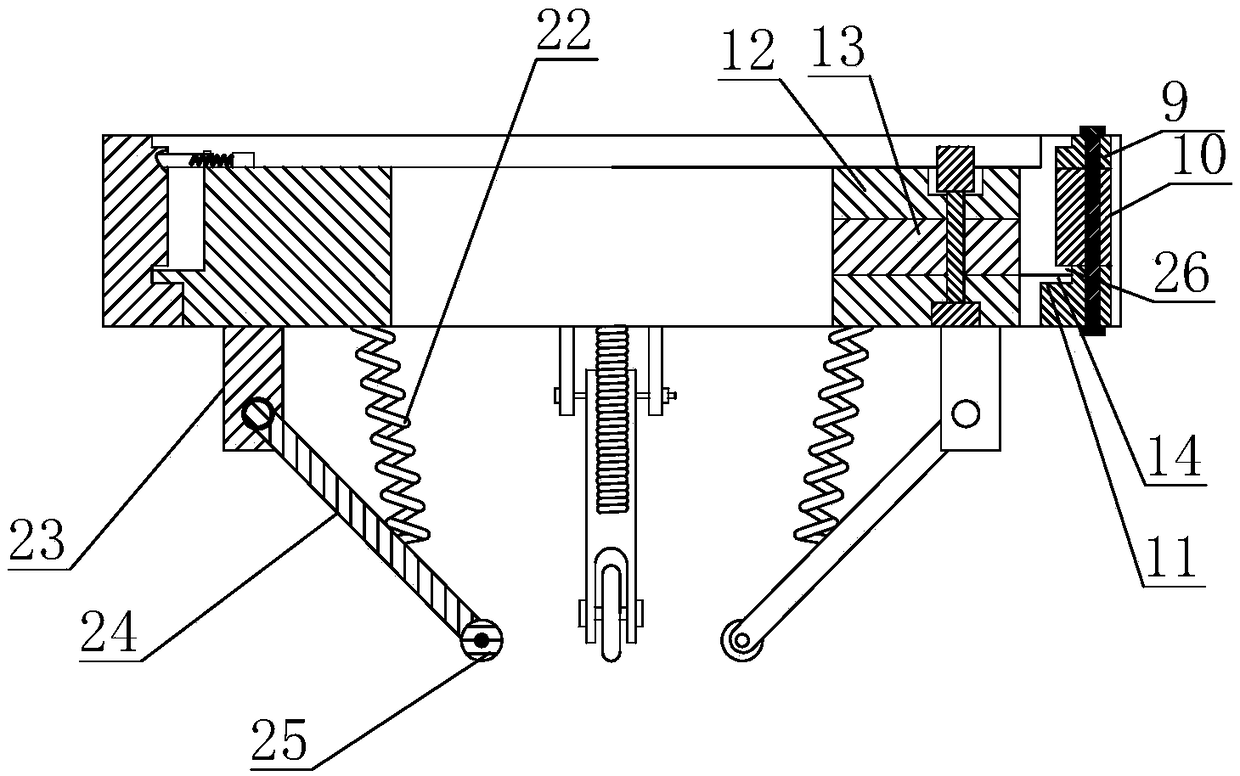

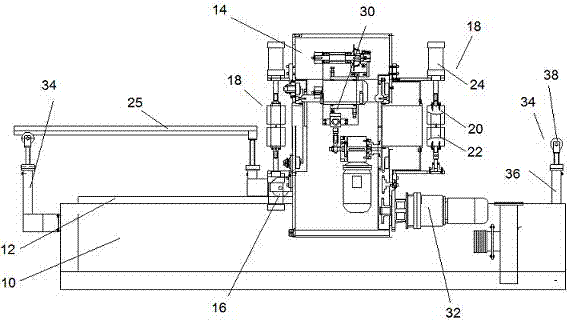

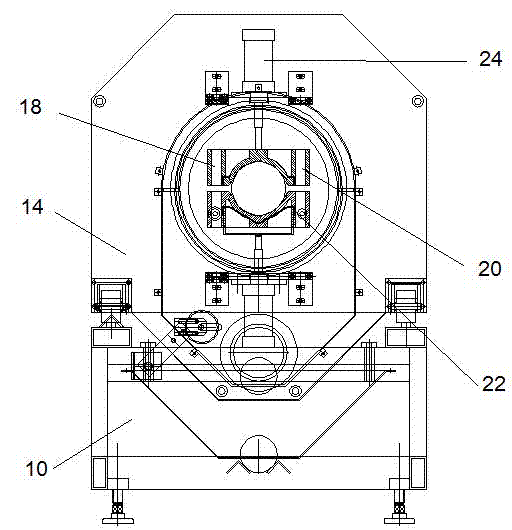

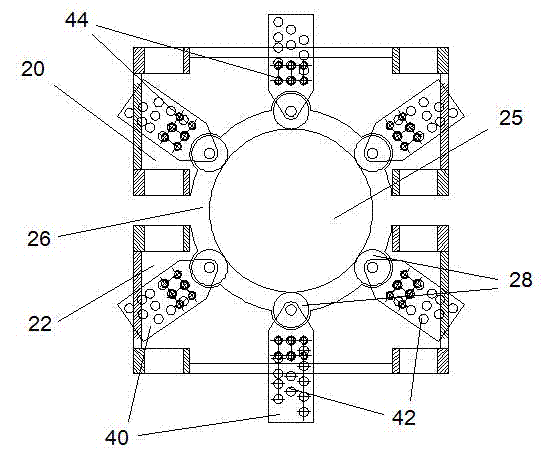

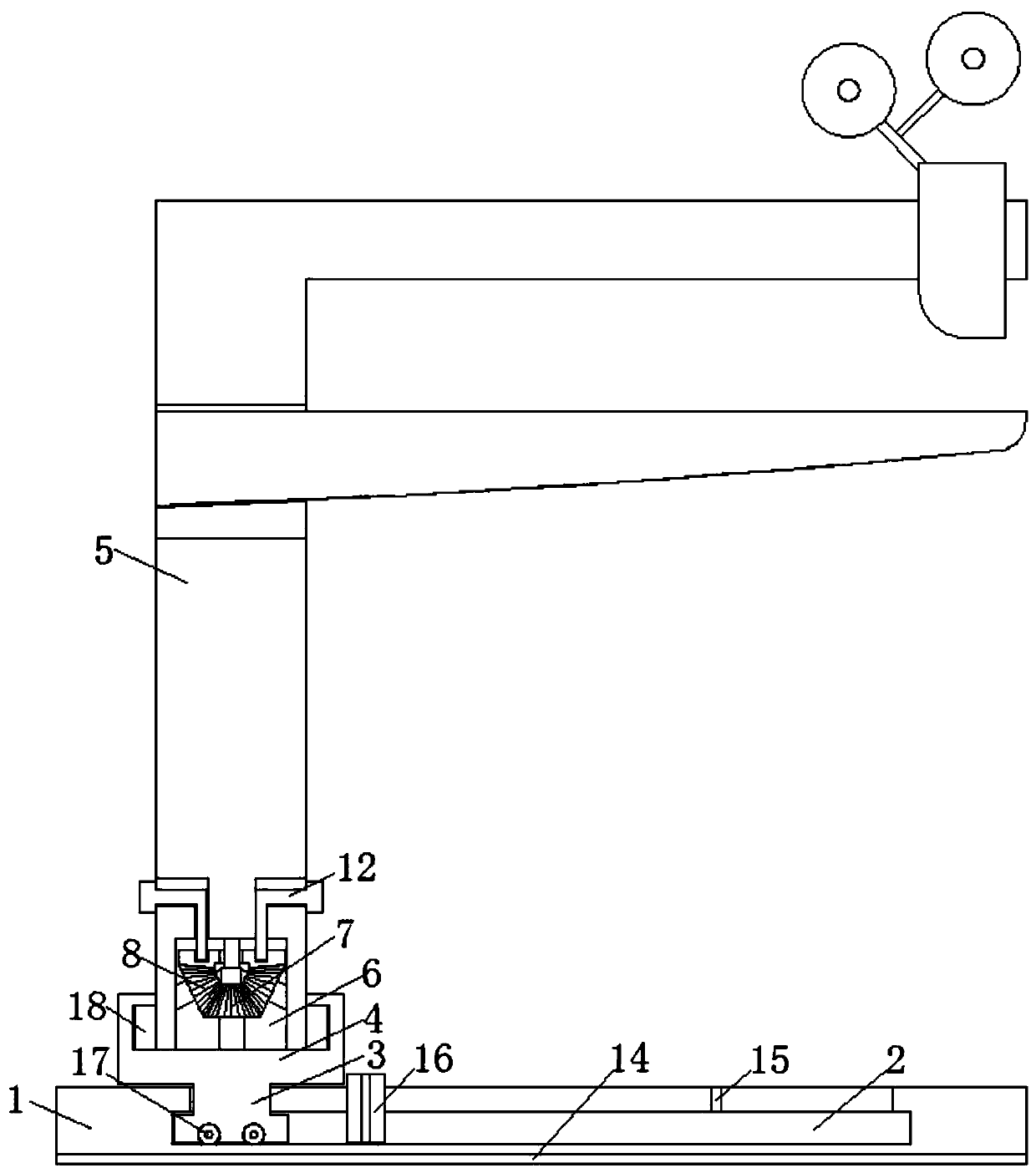

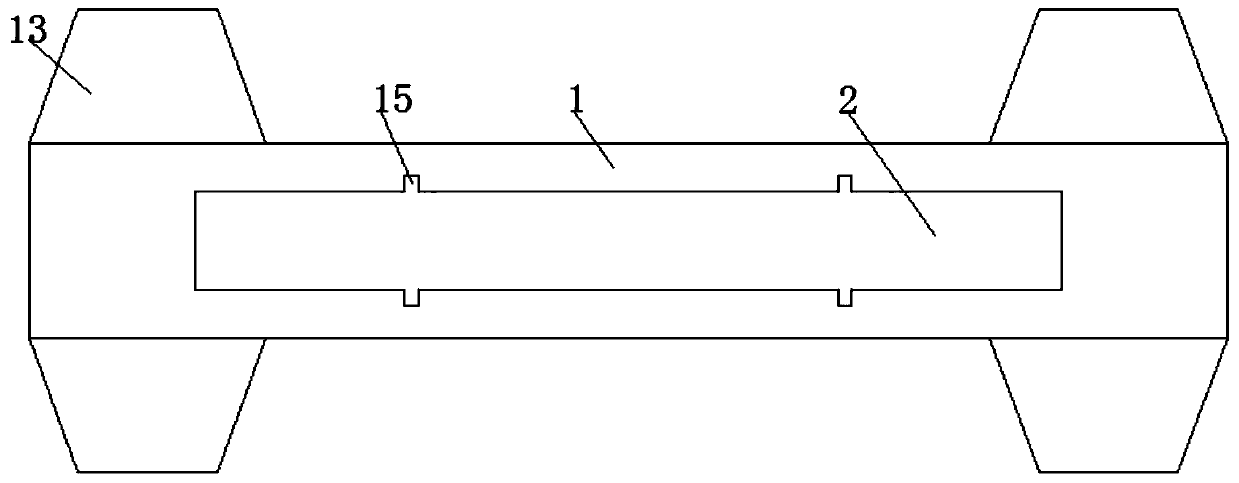

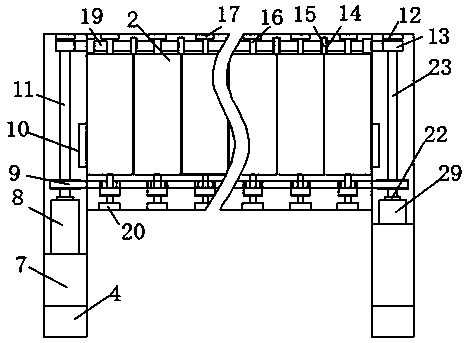

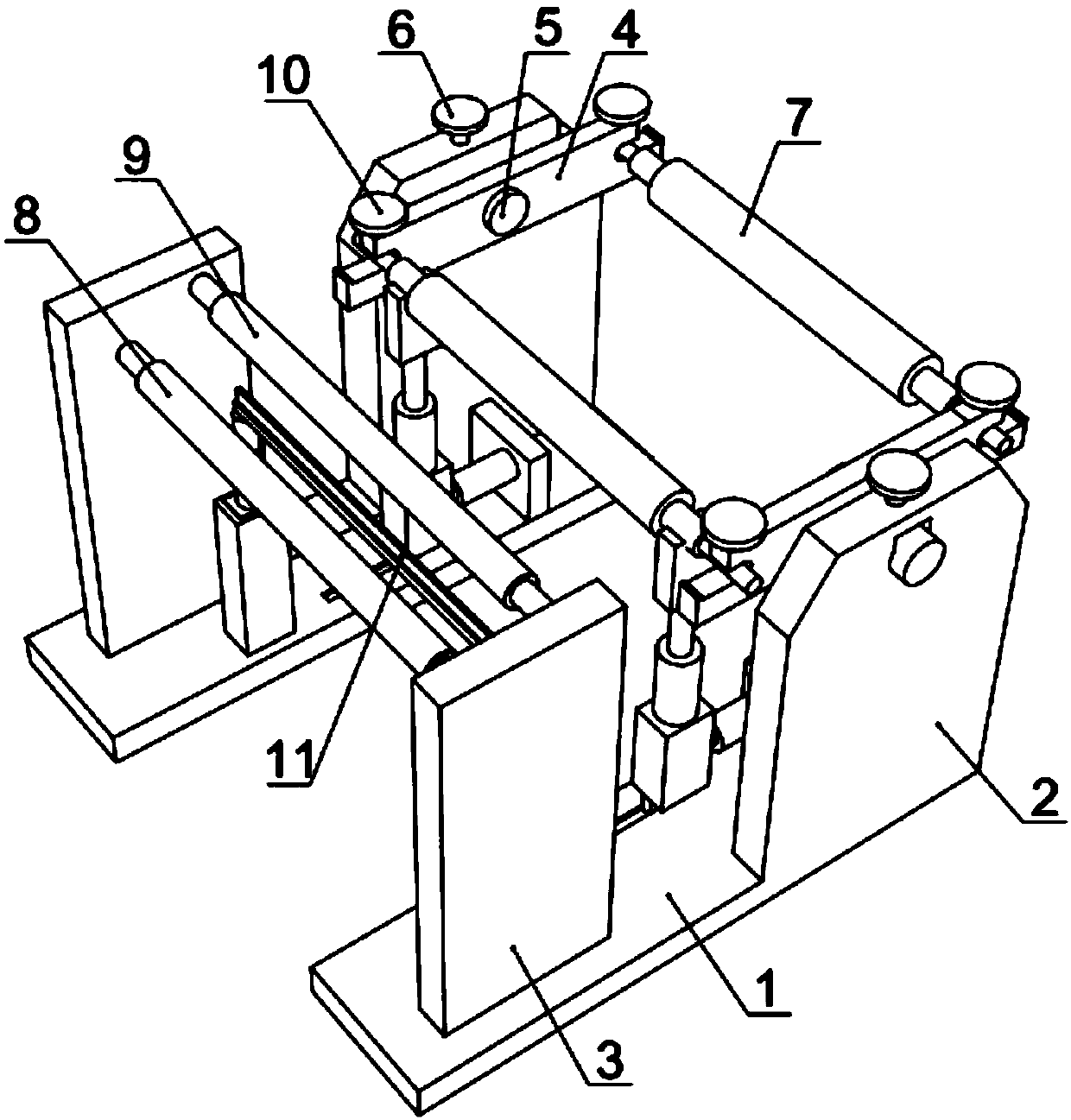

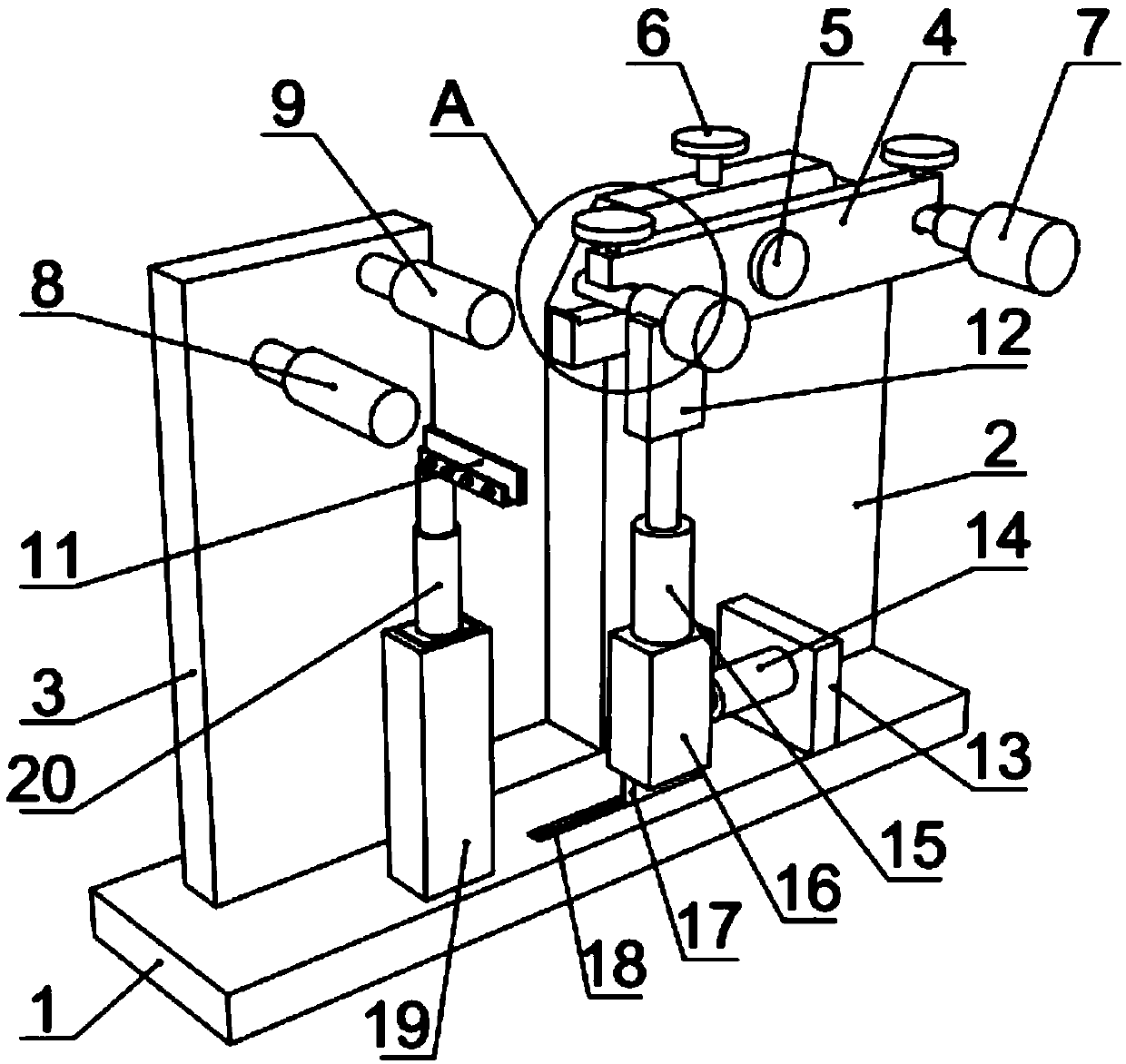

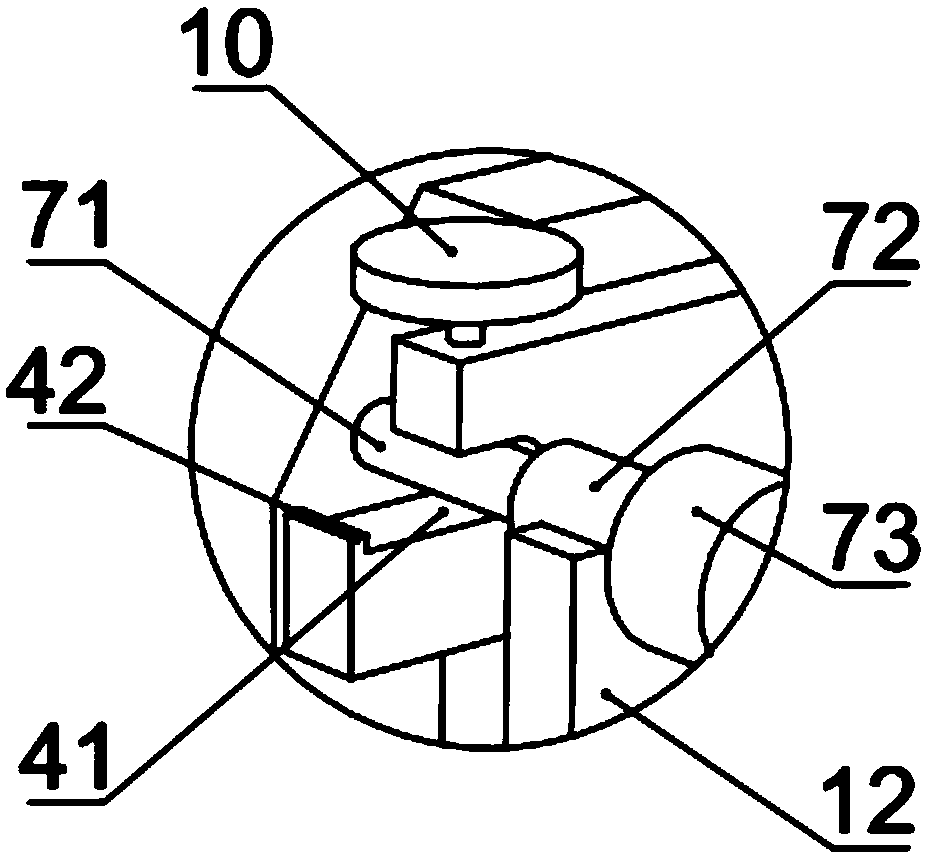

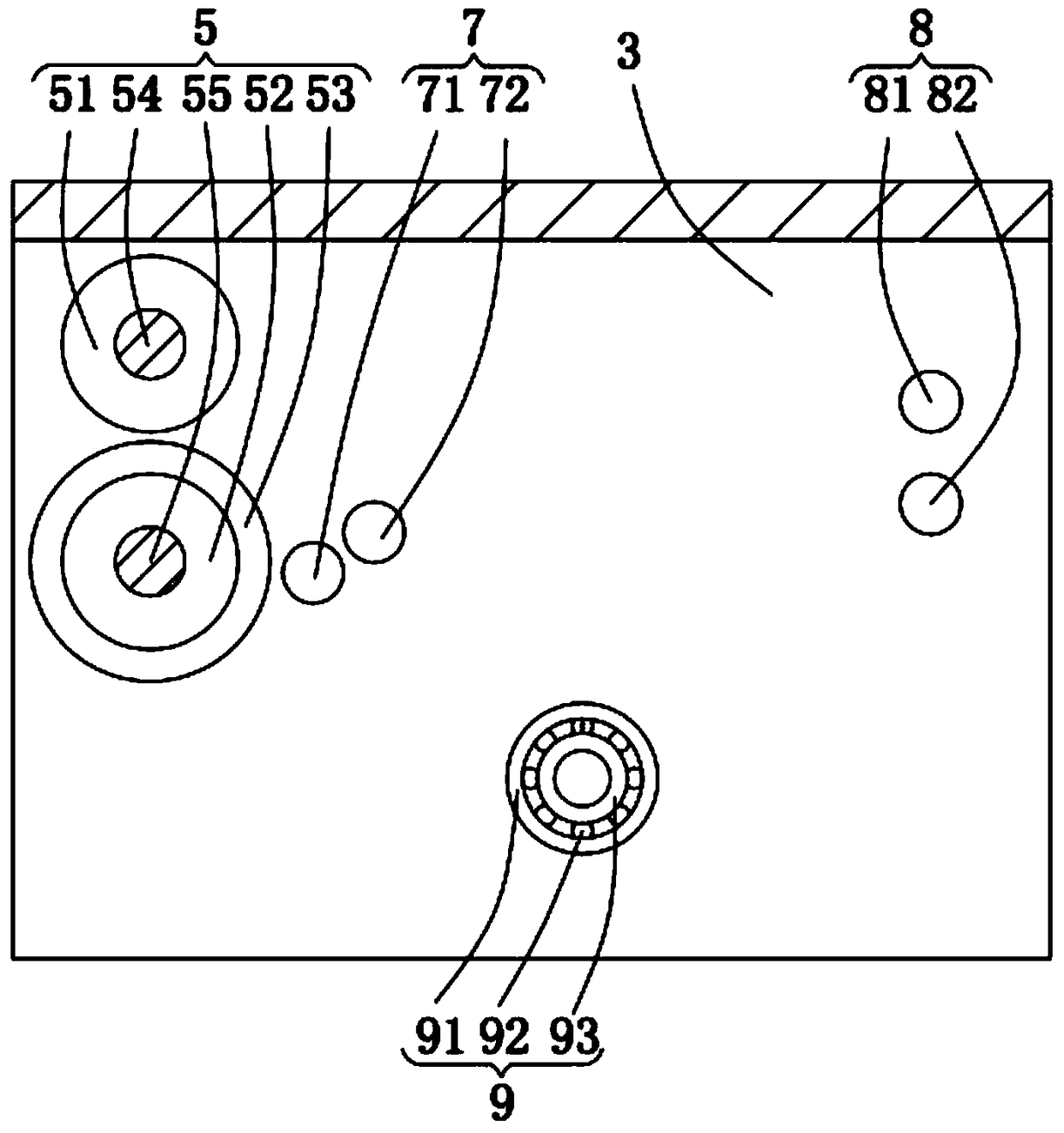

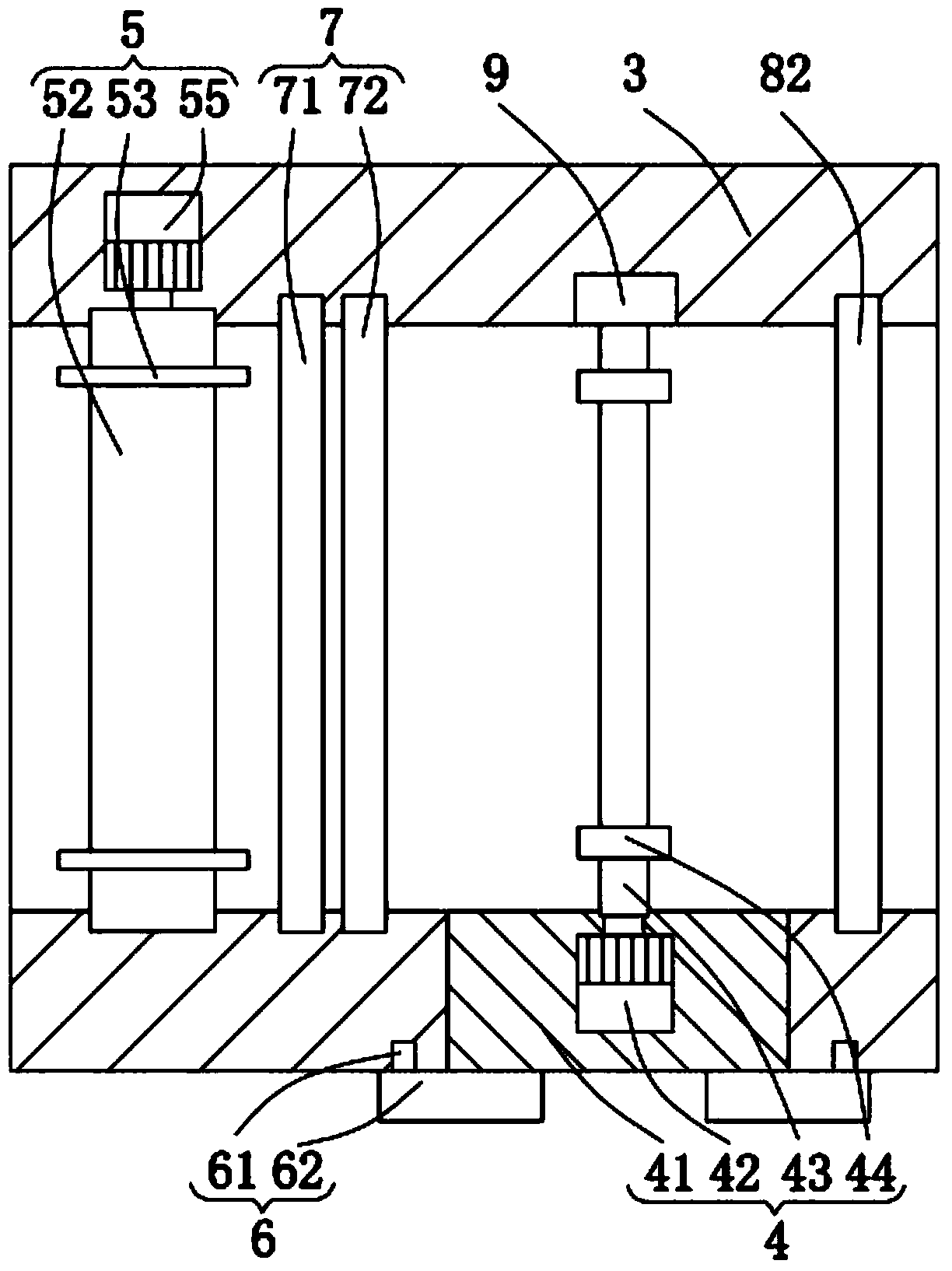

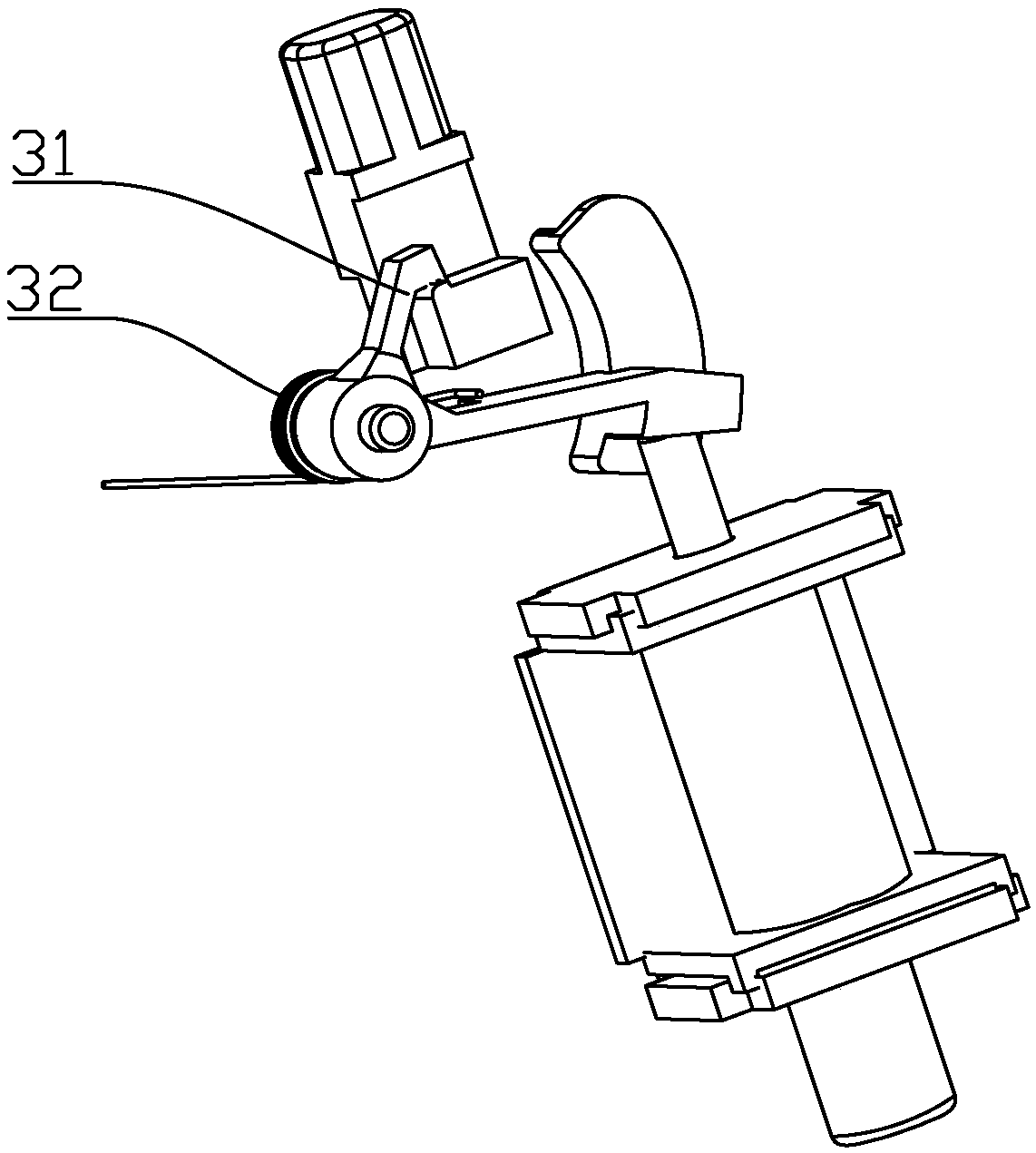

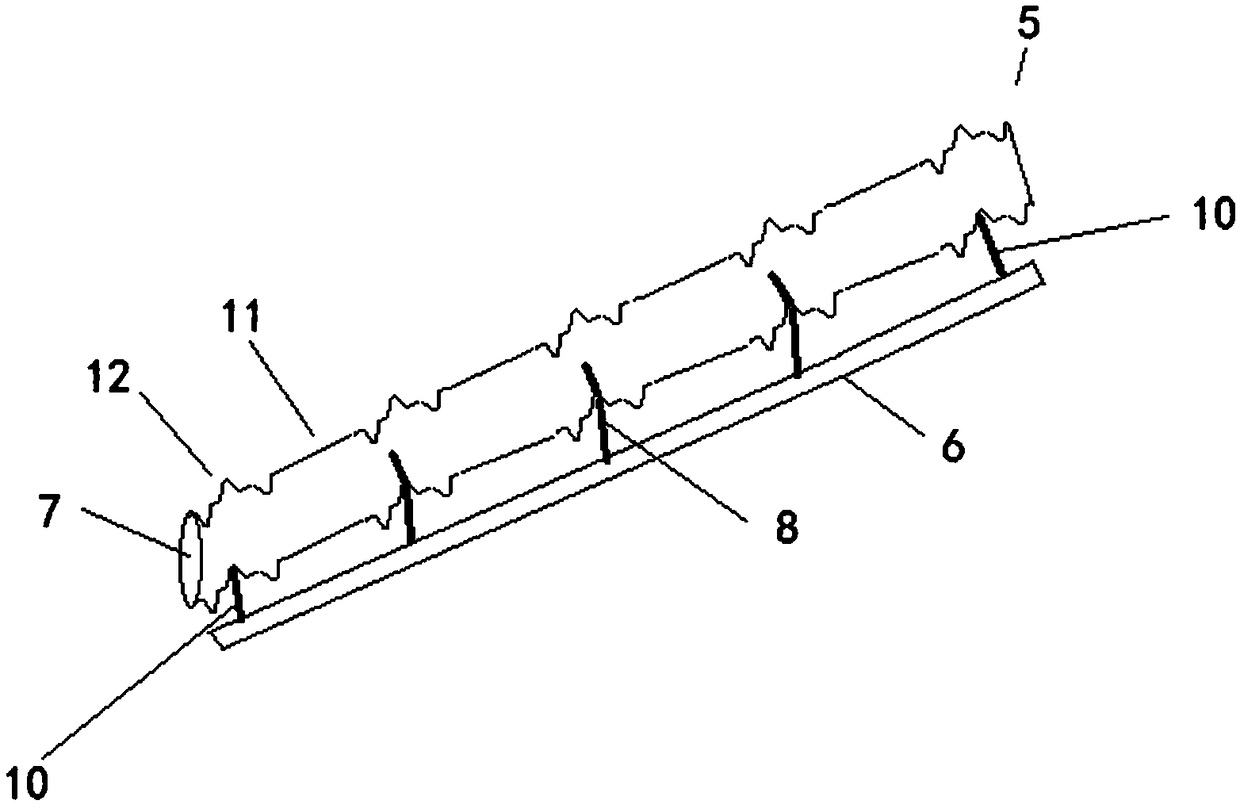

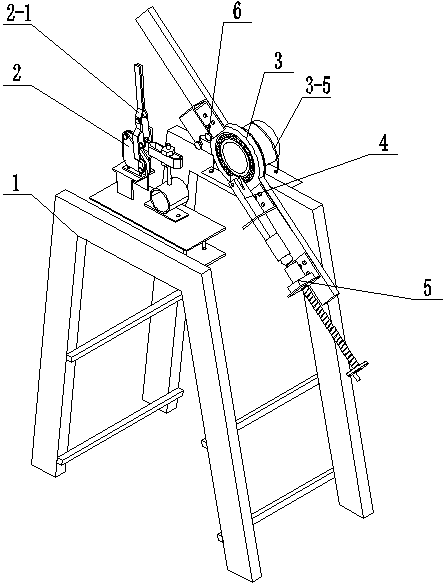

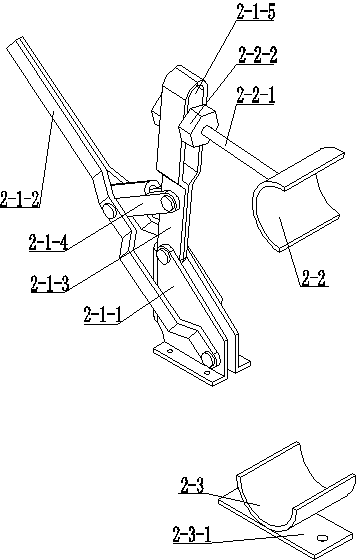

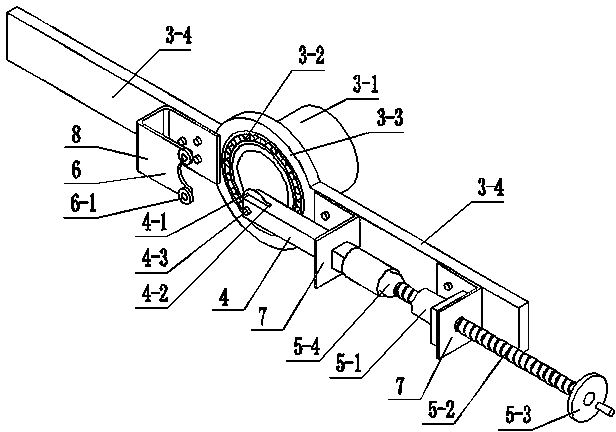

Spiral pipe cutting machine

InactiveCN102962752ALow costImprove cutting effectGrinding carriagesGrinding machinesEngineeringMechanical engineering

The invention provides a spiral pipe cutting machine. The spiral pipe cutting machine is used for cutting a pipe, comprises a rack and is characterized in that the rack is provided with a cutting table capable of horizontally moving along the rack; along the moving direction of a pipe to be cut, at least one of both the front and rear ends of the cutting table is provided with a pressing mechanism for pressing the pipe to be cut; the pressing mechanism comprises at least three rollers which are arranged along the peripheral wall of the pipe to be cut and are abutted against the peripheral wall of the pipe to be cut to press the pipe to be cut; and the middle of the cutting table is provided with a cutting mechanism for cutting the pipe to be cut. According to the spiral pipe cutting machine provided by the invention, by the roller, the rotation of the pipe is not blocked when the pipe to be cut is clamped, so that the cutting on the pipe can be efficiently completed. The spiral pipe cutting machine provided by the invention can be implemented by simple transformation on the basis of an original cutting machine and has the advantages of low cost, good cutting effect, simplicity of operation and the like.

Owner:昆山圣源机械有限公司

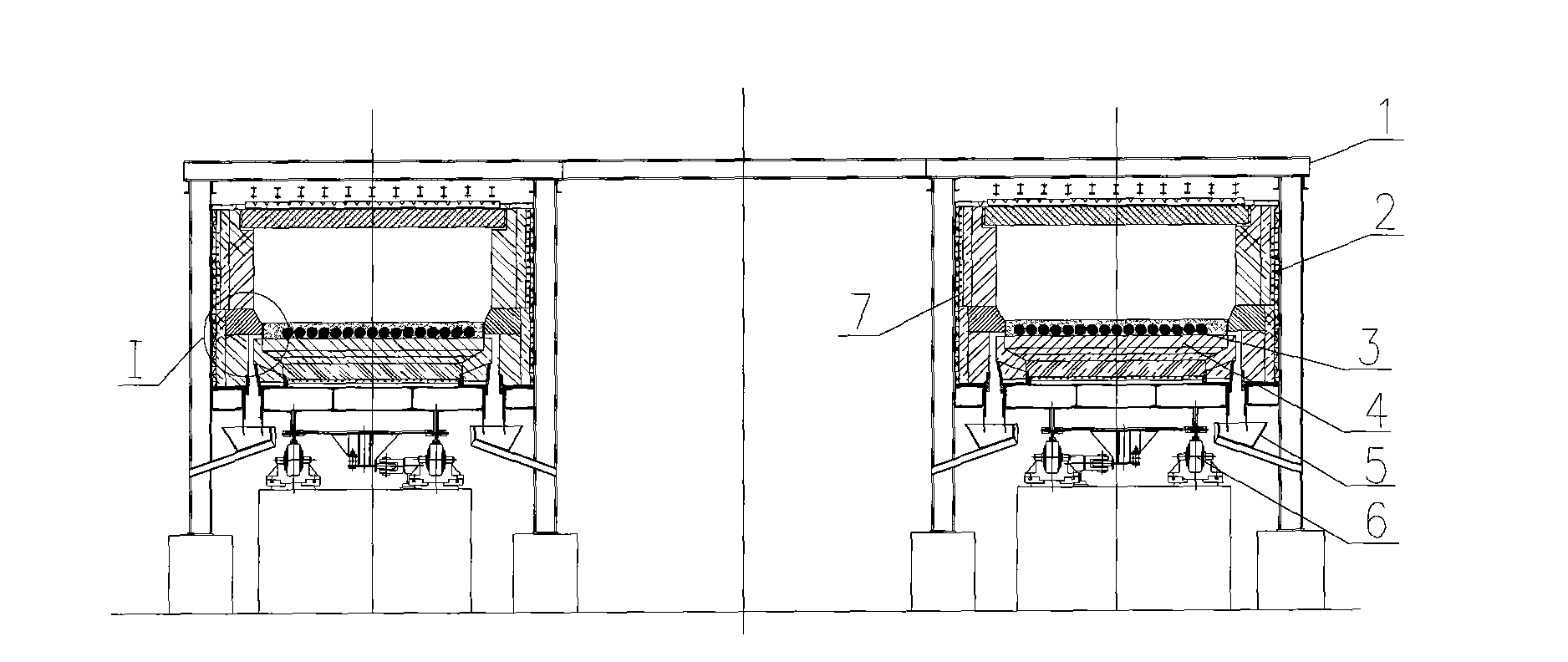

Annular reduction furnace capable of not leaking material at furnace bottom

The invention discloses an annular reduction furnace capable of not leaking material at furnace bottom. The annular reduction furnace comprises a furnace frame, an outer furnace wall, a furnace bottom, a water seal tank, a furnace bottom mechanism and an inner furnace wall, a circle of humps is respectively provided at the part of the inner and outer furnace walls above the furnace bottom, the humps and the furnace bottom coincide partially along the horizontal direction, and a certain gap is formed between the humps and the furnace bottom along the vertical direction. The annular reduction furnace capable of not leaking material at furnace bottom sets a leakage-proof structure in the inner and outer furnace walls, and the leakage-proof structure can not hinder the rotation of the furnacebottom and can effectively prevent the material from entering the water seal tank in the spreading process and the roasting and reduction process so as to reduce the cleaning work of the water seal tank.

Owner:顾玲

Manual box nailing machine facilitating angle adjustment

InactiveCN110027252AImprove adaptabilityIt is convenient to change the angle direction of processingPaper-makingBox making operationsMachiningComputer engineering

The invention discloses a manual box nailing machine facilitating angle adjustment and belongs to the field of box nailing machines. The manual box nailing machine facilitating angle adjustment comprises a bottom plate. A limiting sliding groove is formed in the top of the bottom plate. A connecting sliding block is connected into the limiting sliding groove in a sliding manner. The top of the connecting sliding block extends to the top of the limiting sliding groove. A fixed connecting block is fixedly connected to the top of the connecting sliding block. By pushing a body of the box nailingmachine, the body of the box nailing machine is moved to the right side of the bottom plate, then an inserting ring is pushed upwards, the body of the box nailing machine is rotated, therefore the machining angle direction of the body of the box nailing machine is changed conveniently, the box nailing machine can change the machining angle of the box nailing machine according to the use requirement of users, the adaptive capacity of the box nailing machine is improved, the application range of the box nailing machine is enlarged, when the position of a paper box is not conducive to machining,the machining position can be changed for machining the paper box, a user can use the machine conveniently, and the production efficiency is improved.

Owner:珠海市祥英纸品包装有限公司

Publicity board for public management

ActiveCN109036174ADifficult to cleanReduce management difficultyCleaning using toolsIdentification meansCurrent managementEngineering management

The invention discloses a publicity board for public management, and belongs to the field of publicity for public management. The publicity board for public management solves the problems that existing publicity boards for public management are mostly located outdoors, dust is easily attached to the surfaces of the publicity boards, and the publicity boards are usually at high positions and are not easily cleaned. When the publicity board is in use, the publicity board can be cleaned while running, and great convenience can be brought to management staff; moreover, a stereoscopic triangular structure is adopted for the publicity board, the publicity board has one more side than an existing publicity board, more publicity slogans can be displayed, the replacement frequency is reduced, and the management difficulty of the management staff can be reduced; the full-automatic structure is adopted for the overall device, only mounting work is needed, the publicity board does not need to be taken care of in the later period, and the current management requirement can be better met.

Owner:鲍建永

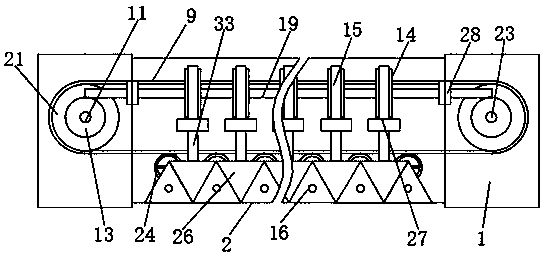

Cloth winding mechanism of cloth printing machine

InactiveCN109592461AIncrease productivityEasy to liftArticle deliveryWebs handlingHydraulic cylinderConductor Coil

The invention provides a cloth winding mechanism of a cloth printing machine, and belongs to the technical field of printing machines. The cloth winding mechanism includes a base, a pair of first supporting plates arranged at the upper portion of the base and two cloth winding rollers arranged between the first supporting plates, each cloth winding roller comprises a cloth winding shaft, a supporting shaft connected to both ends of the cloth winding shaft and a fixing shaft connected to the supporting shaft, rotating shafts are arranged at the upper portions of the first supporting plates in apenetrating mode, first fastening bolts for fixing the rotating shafts are arranged at the tops of the first supporting plates, and supporting plates are fixedly connected with the rotating shafts; and transverse U-shaped fixing grooves are formed in the two ends of each supporting plate, the fixing shafts are mounted in the fixing grooves, second fastening bolts for fixing the fixing shafts arearranged above the fixing grooves, sliding seats are further arranged on the base, first vertical hydraulic cylinders are arranged at the upper parts of the sidling seats, the top ends of the first vertical hydraulic cylinders are connected with supporting blocks, and damping grooves matched with the supporting shafts in a clamped mode are formed in the supporting blocks. The cloth winding mechanism can support the cloth winding rollers and prevent the cloth winding rollers from shaking up and down, the two end wear is small, the cloth winding is neat, and the long time stopping for replacingthe cloth winding rollers does not need.

Owner:苏州极数印花科技有限公司

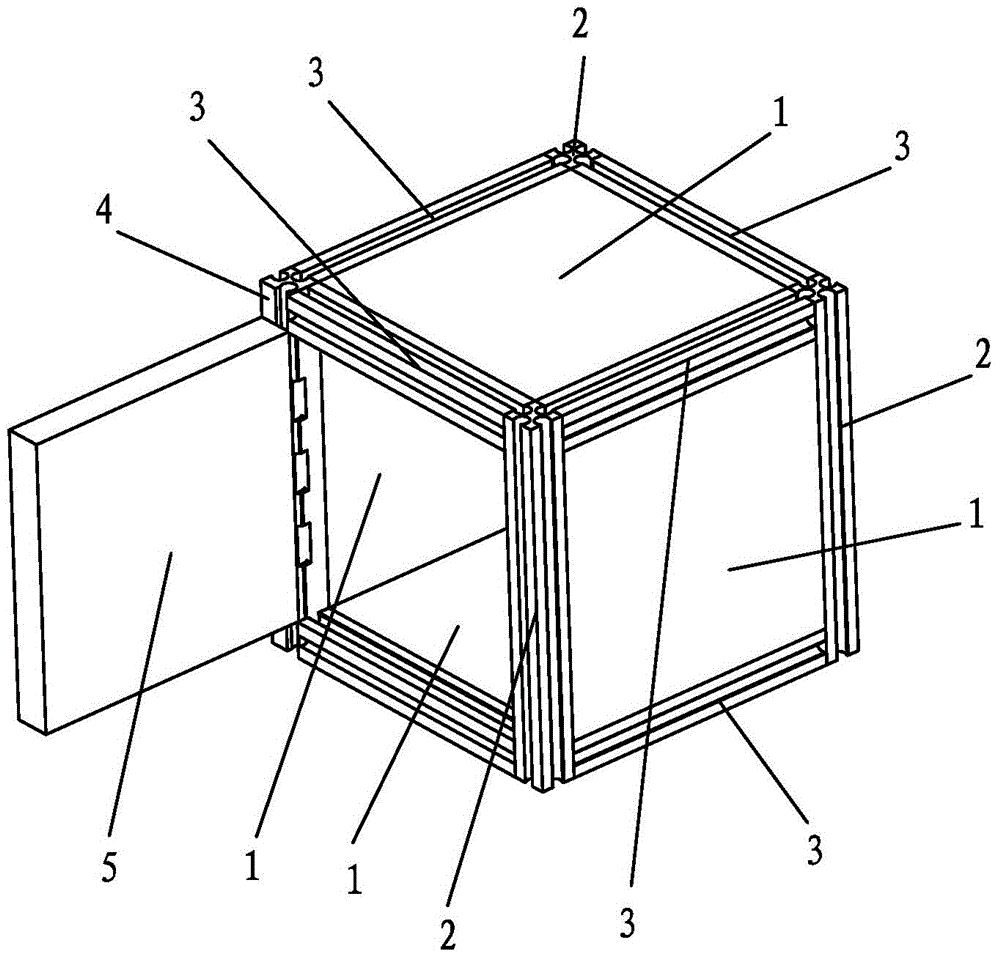

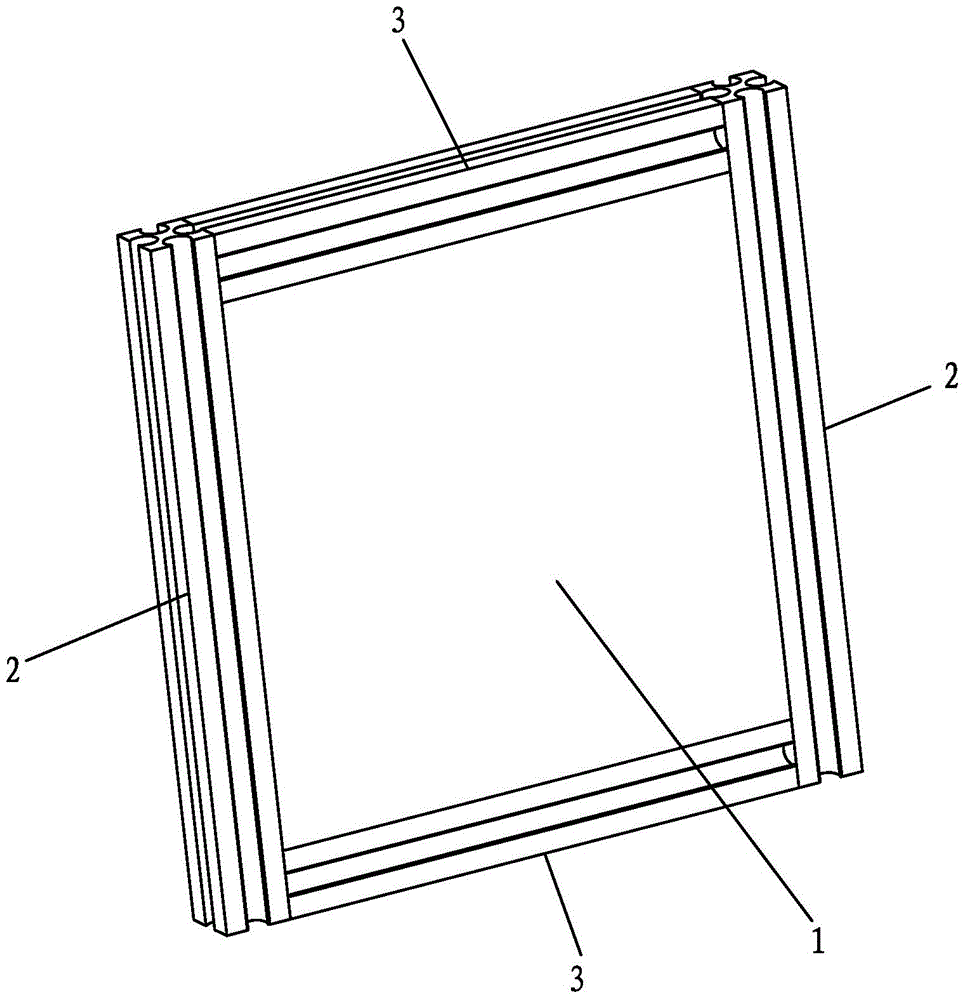

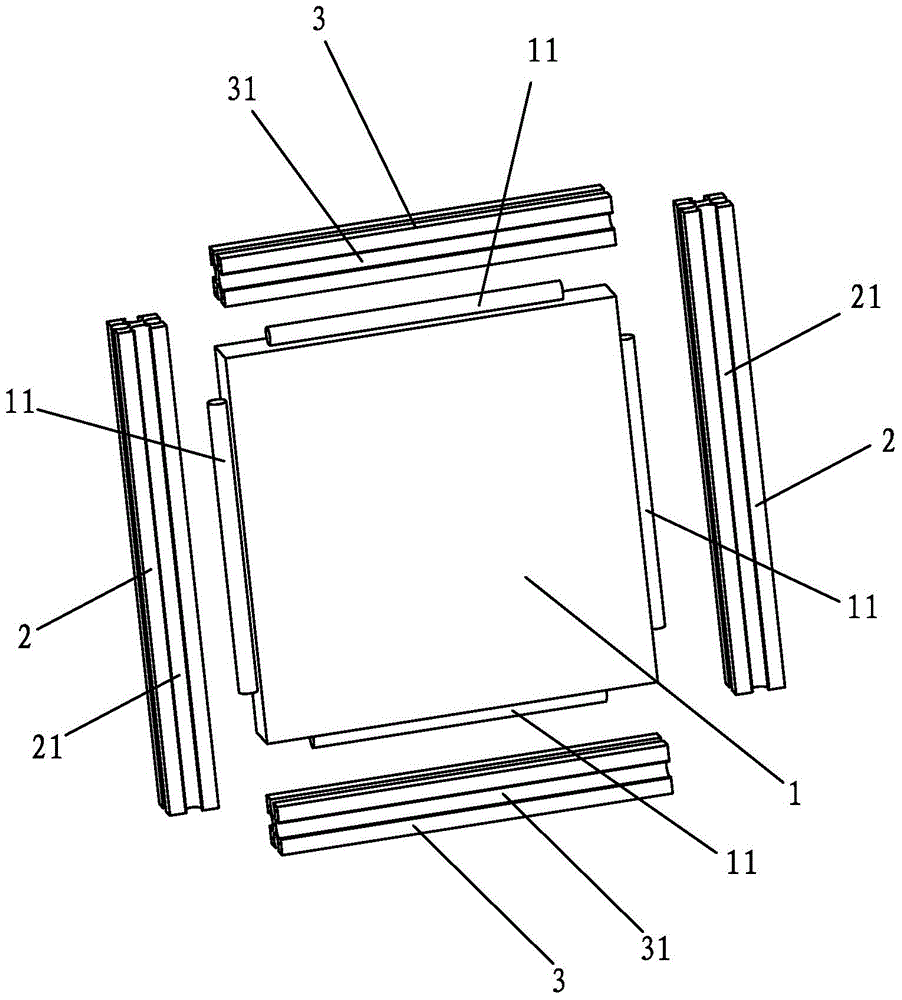

Splicing component convenient to splice

Owner:ZHONGSHAN LIFANGTI INTELLIGENT HOUSEHOLD

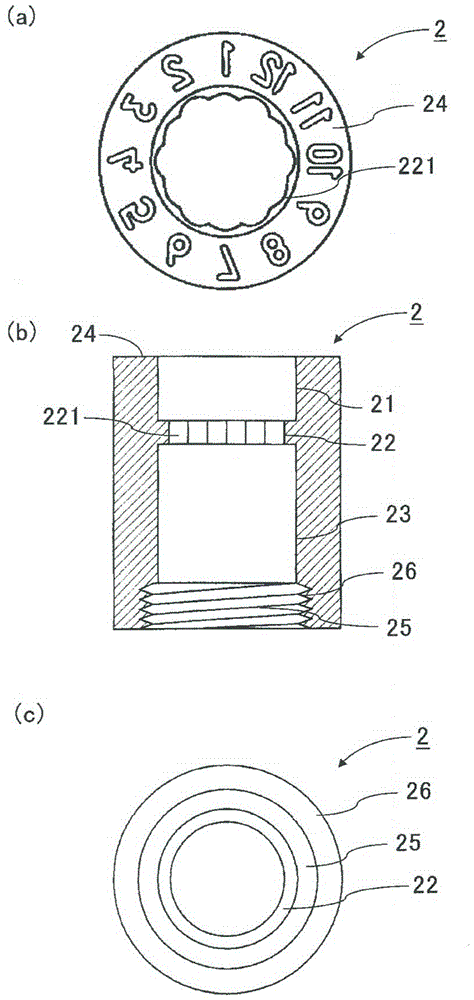

In-mold detachable stamping device

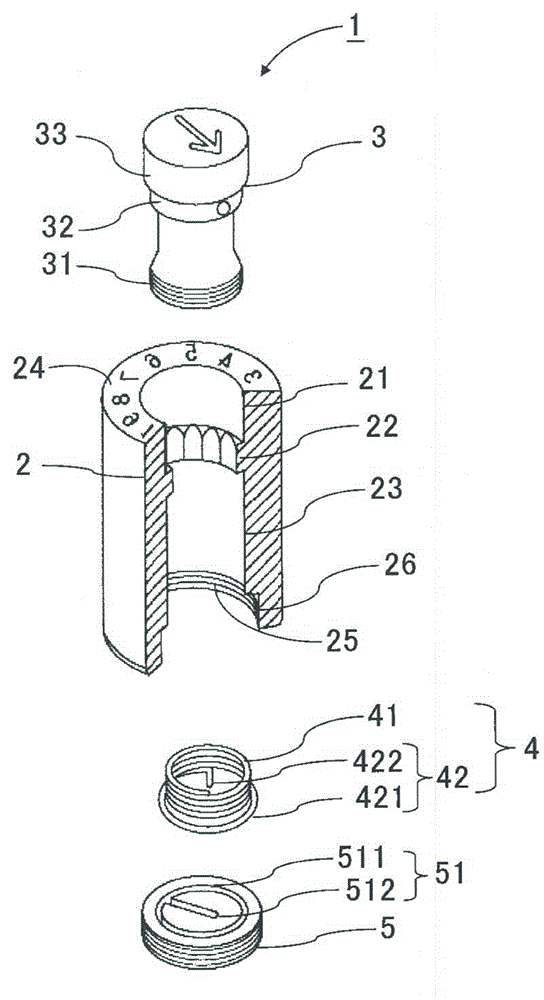

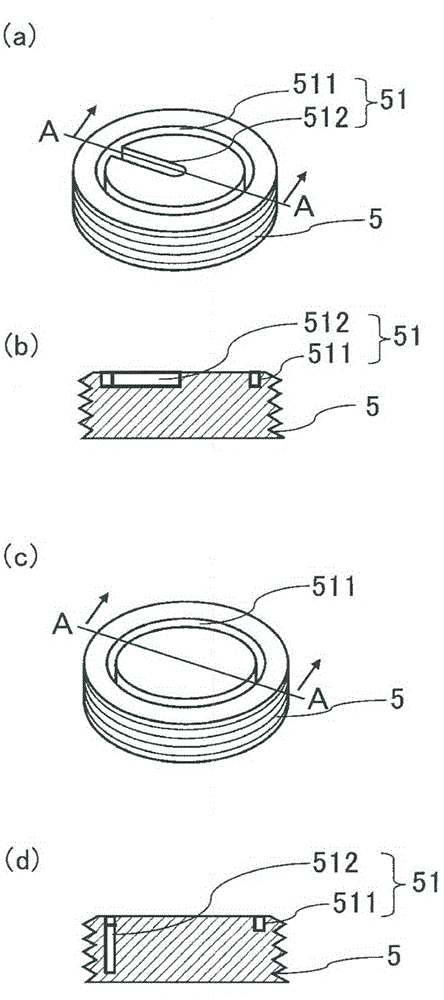

[Problem] To provide an in-mold detachable stamping device, in which rotation of the indicator does not lock even after repeated rotation to change the stamp mark. [Solution] A stamping device: which is provided with a roughly cylindrical outer marking shell that is fitted into a shaping mold, an indicator that is fitted inside said outer marking shell and is capable of angular displacement around the axial line, a cover that screws onto the lowermost section of the outer marking shell, and a spring for biasing the indicator with a downward force; and in which the stamp marking section is formed on surfaces of the outer marking shell and the indicator. The in-mold detachable stamping device is characterized in that: the indicator is provided with an indicator section that faces onto the inner surface of the mold, a positioning section extending downward from the indicator section, and a shaft section extending downward from the positioning section; the shaft section has a threaded part at the lower end; the spring has an engaging section that engages with the indicator and a fixing section that is fixed to the cover; the pitch of the spring in the engaging section and the pitch of the threaded section are equal; and the engaging section is engaged with the threaded section.

Owner:URATANISHOJI

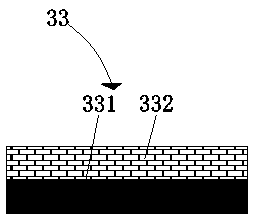

Waterproof roll molding equipment

The invention relates to the field of roll molding, in particular to waterproof roll molding equipment. The waterproof roll molding equipment comprises a machine body, a discharge shell, a shell body,a fixing mechanism, a pressing mechanism, a limiting mechanism, a first guide mechanism, a second guide mechanism and a clamping mechanism; through cooperative use of the fixing mechanism and the pressing mechanism, after rolls are molded, films are fixed on the fixing mechanism, and the rolls and the films pass through a first pressing roller and a second pressing roller; the positions of the rolls and the films are limited through limiting rings, so that the rolls are compounded with the films during molding to reduce procedures, and the production efficiency is improved; and through a guidance effect of the first guide mechanism and the second guide mechanism, the positions of the rolls and the films are limited, and the rolls and the films are guided, so that the rolls and the films conveniently correspond in position to prevent the position deviation caused by deviation of the two.

Owner:中建新越建设工程有限公司

Coal mine hoisting winch capable of replacing drum conveniently

The invention discloses a coal mine hoisting winch capable of replacing a drum conveniently. The hoisting winch comprises a fixed plate and a lead screw; the fixed plate is provided with a first fixedblock; the first fixed block is connected with a first fixed ring; moreover, the first fixed ring and the drum are connected with each other; the drum is provided with a ratchet wheel; the ratchet wheel is connected with a connecting rod through a pawl; the right side of the drum is provided with a fixture block; the fixture block and a second fixed ring are connected with each other; moreover, sliding blocks are arranged under the fixture block; moreover, each sliding block and a corresponding sliding chute are connected with each other; the sliding chutes are formed in a second fixture block; the second fixture block is connected with a turning block through a connection block; the lead screw is arranged on the second fixed ring; the lead screw is connected with a worm gear; and the worm gear is connected with a worm. According to the coal mine hoisting winch capable of replacing the drum conveniently, the first fixed ring and the second fixed ring are correspondingly fixed to the left side and the right side of the drum, so that the rotation of the drum cannot be hindered when the drum is fixed.

Owner:GUIZHOU UNIV

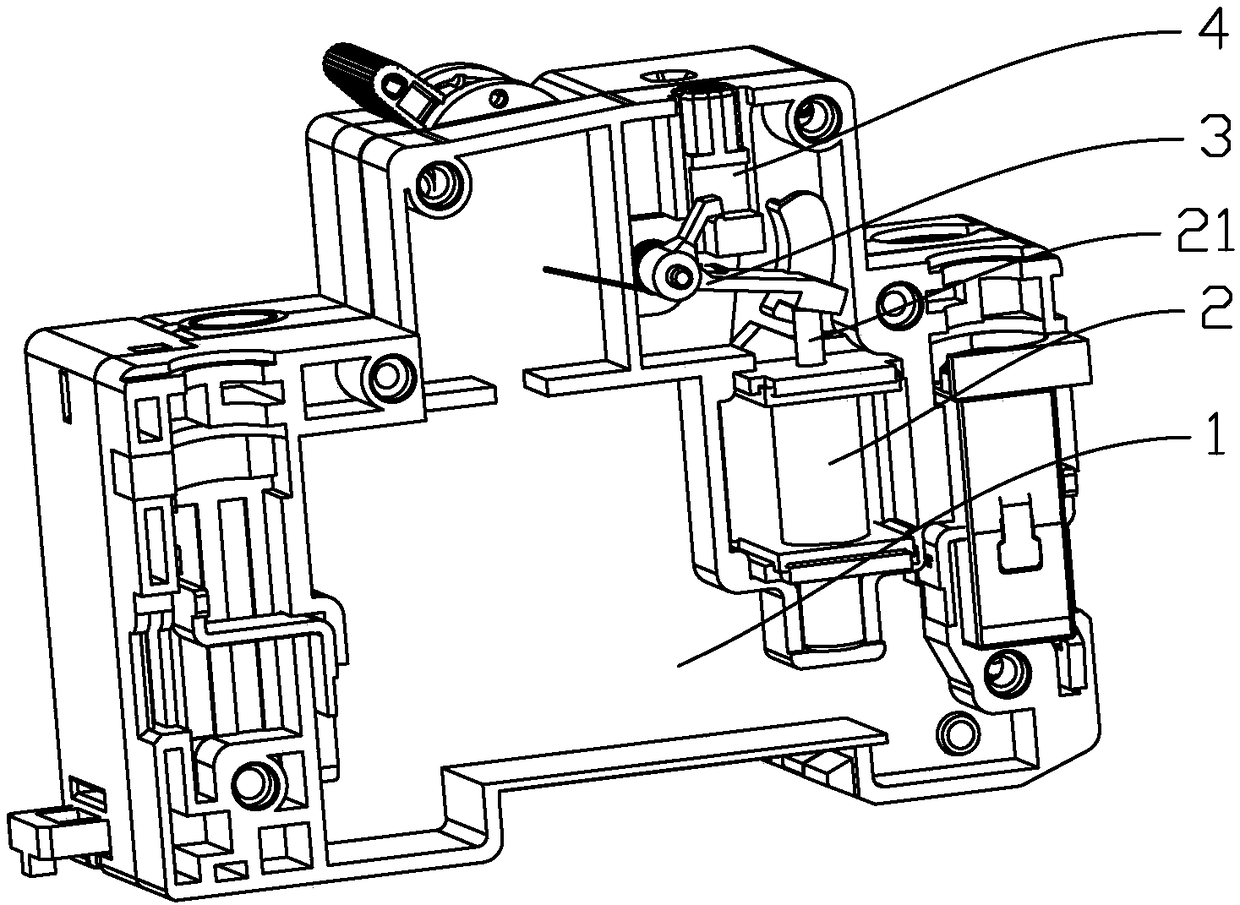

Tripping mechanism of electric leakage breaker

PendingCN108417465ADoes not hinder rotationAvoid direct contactProtective switch operating/release mechanismsEngineeringMechanical engineering

The invention discloses a tripping mechanism of an electric leakage breaker. The tripping mechanism comprises a housing, an electric leakage tripping device, a resetting member and a tripping connecting rod, wherein the electric leakage tripping device, the resetting member and the tripping connecting rod are arranged in the housing. The resetting member is internally provided with a resetting spring and is snapped with the housing through the resetting spring. The electric leakage tripping device comprises a moving iron core which can attract extendably. The tripping connecting rod is hingedwith the housing. Furthermore the tripping connecting rod is in the movement track of the moving iron core and is arranged in a manner of pushing the moving iron core. One end, which is far from the moving iron core, of the tripping connecting rod is provided with a hook which is buckled with or abuts against the resetting member. The tripping connecting rod is provided with a tripping connectingrod resetting spring which always drives the hook to buckle with the resetting member. The tripping mechanism is advantageous in that the tripping connecting rod has an elastic function force for resetting; the resetting member can be better fixed; and spring of the resetting member in a normal working state is prevented.

Owner:浙江九策智能电气有限公司 +1

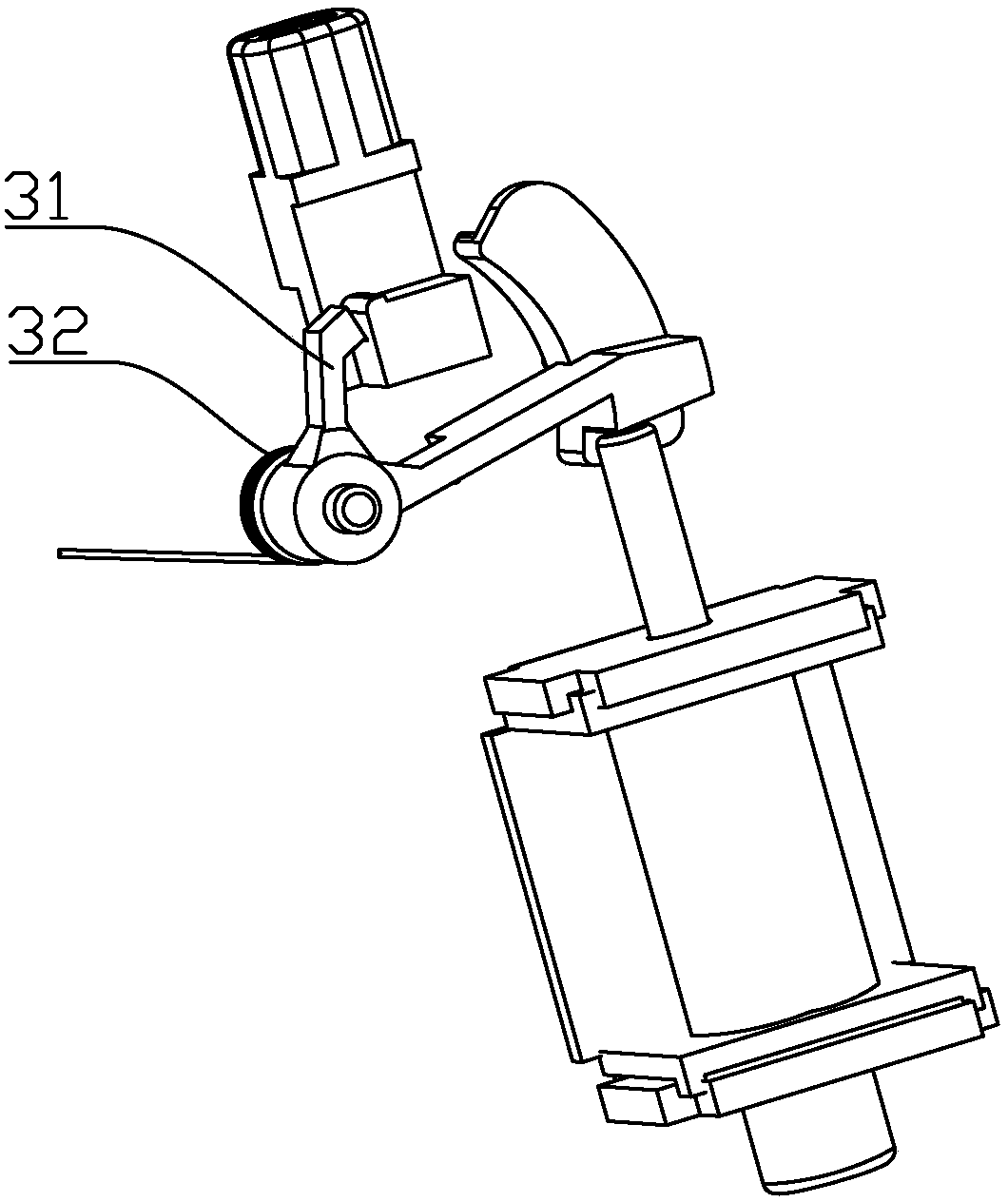

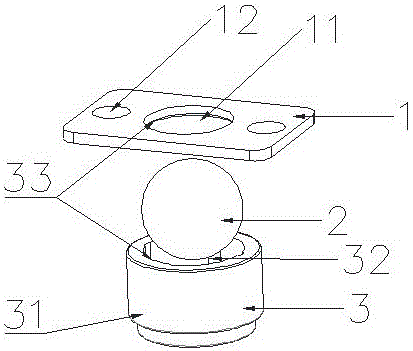

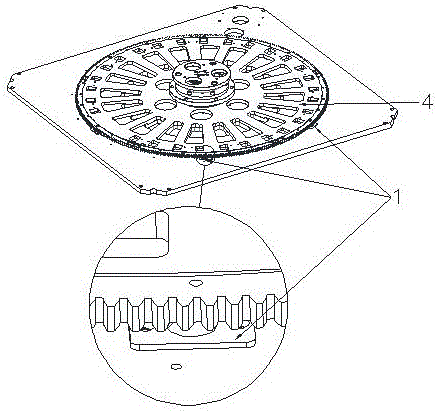

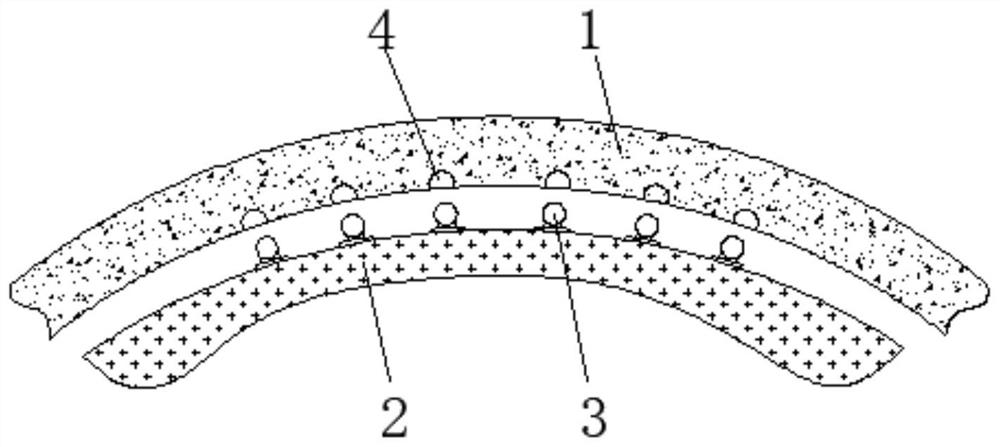

Automatic orientated balance mechanism for circular-disc-shaped structure

InactiveCN106015316ASwivel movement without hindrancePrevent disengagementBall bearingsCircular discWhole body

The present invention relates to the field of mechanical devices, in particular to an automatic orientation balance mechanism for a disc-shaped structure, which includes a steel ball anti-slip piece, a steel ball and a steel ball base; the steel ball base is an engineering plastic cylinder as a whole; the inside of the cylinder is A number of grooves are provided; the grooves are arranged parallel to the generatrix of the cylinder, and an arc-shaped chamfer is arranged on the inner wall of the bottom of the cylinder, and the radian of the arc-shaped chamfer is equal to the arc of the surface of the steel ball; the steel ball It is arranged above the steel ball base, and the steel ball anti-off sheet is fixed above the steel ball by screws; the steel ball anti-off sheet is sheet-shaped, and is provided with a steel ball hole and a fixing hole, and the diameter of the steel ball hole is smaller than the diameter of the steel ball. The invention has the advantages that the mechanism can maintain the balance of the large disk, increase the load capacity of the large disk, and at the same time not hinder the rotation of the disk, and has a simple structure and is convenient to use.

Owner:迈为医疗技术(深圳)有限公司

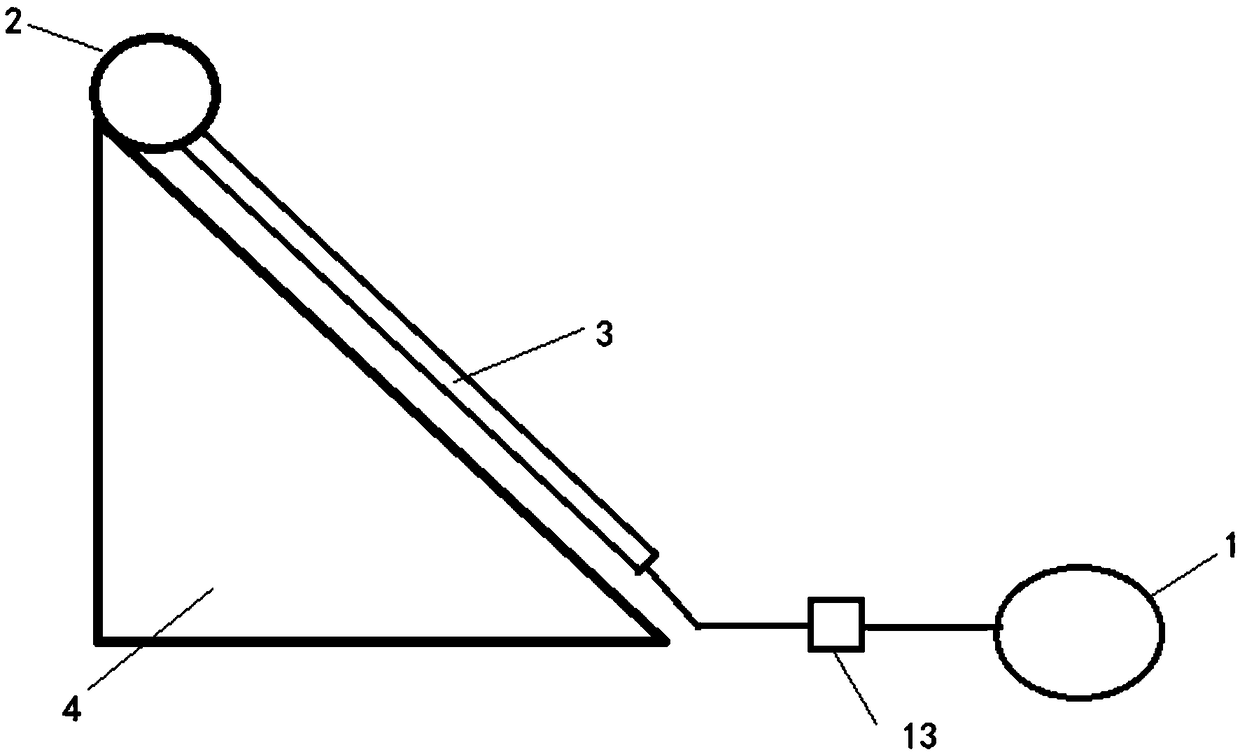

Explosion-proof solar water heater

ActiveCN108253641AHigh strengthImprove transportation capacitySolar heating energySolar heat collector detailsEngineeringSolar heat

The invention discloses an explosion-proof solar water heater. The explosion-proof solar water heater comprises a cold water tank, a hot water tank, a solar heat collector and a bracket, wherein the solar heat collector is arranged on the bracket, and the two ends of the solar heat collector are connected with the cold water tank and the hot water tank correspondingly. The explosion-proof solar water heater is characterized in that the hot water tank is arranged at the upper end of the bracket, the cold water tank is arranged at the lower end of the bracket, the solar heat collector comprisesa plurality of solar heat collecting pipes, the upper end of each solar heat collecting pipe is inserted into the hot water tank, and the lower end of each solar heat collecting pipe is connected withthe cold water tank through a pump.

Owner:敏达环保科技(嘉兴)有限公司

A kind of cultivation and planting method of Scrophularia scrophulariae

ActiveCN108617451BImprove space utilizationEasy to placeFertilising methodsRoot crop cultivationAgricultural engineeringScrophularia

Owner:玉环市几偶孵化器有限公司

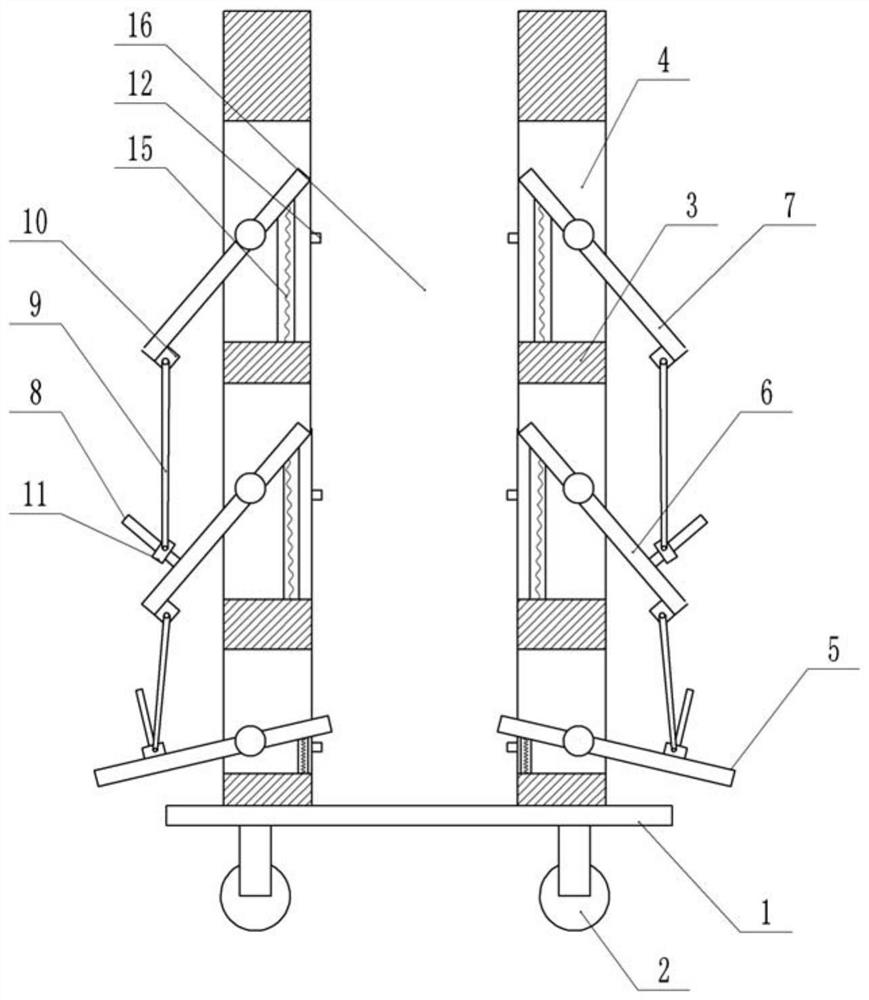

Emergency transfer bed

The invention relates to an emergency transfer bed, which can effectively solve the problems of incomplete disinfection and low efficiency of an existing transfer bed. According to the technical scheme, the transfer bed comprises a horizontal rectangular frame, an upper bed plate and a lower bed plate are arranged in the rectangular frame, each bed plate is formed by hinging two flat plates, the bed plates can protrude outwards from the joint positions of the flat plates, the bed plates can be supported when being horizontal, when protruding outward, the bed plates can be driven to rotate around a central axis, a material box with an upward opening is arranged below the bed plates and is arranged in the length direction of the bed plates, a plurality of connecting rods are hinged to the left side and the right side of the material box respectively, a plurality of spraying pipes perpendicular to the connecting rods are evenly distributed on the connecting rods on the same side at intervals in the length direction of the connecting rods, spraying heads are arranged on the spraying pipes, the material box is provided a water pump which can pump water to the spraying pipes, the connecting rods on the left side and the right side are fixed through a pull rope, and the pull rope can be pressed and the water pump can be driven to pump liquid when the lower bed plate is changed into a V shape.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

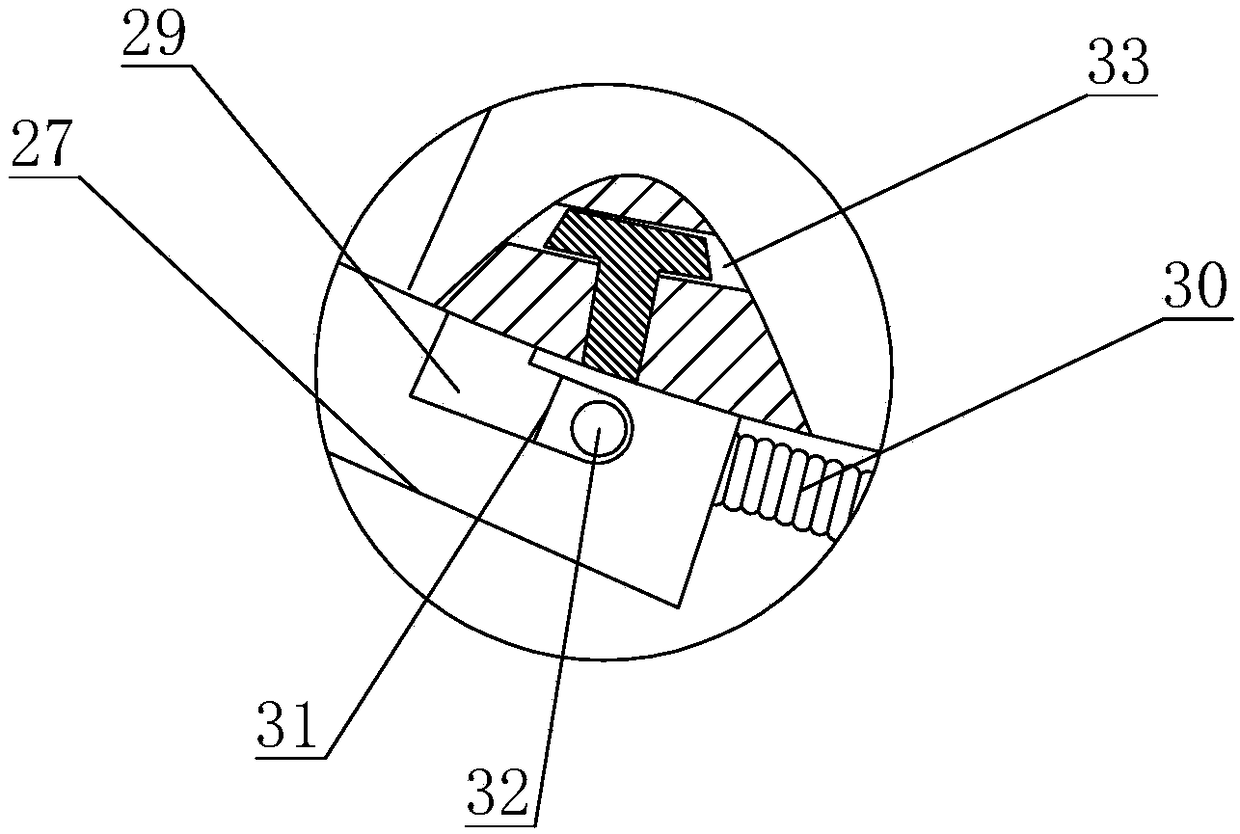

Novel ventricular shunt pipe pressure control valve

InactiveCN103357110BDoes not hinder rotationAdjust the liquid flow rateValvesEngineeringTitanium alloy

The invention relates to a novel ventricular shunt pipe pressure control valve. The technical scheme includes that two liquid storage sacs which are communicated in the middle are disposed on a rigid base, and the side of each liquid storage sac is provided with a shunt pipe interface; a titanium alloy ball (3) added in one sac can be retained by a retaining board after rolling and falling down so as not to enclose the outlet of the liquid storage sac; a flexible partition board (7) added in the other sac is additionally provided with a control valve (6) on the outer side thereof so as to allow the fingers to rotate a pressure control valve to control the inner pressure of the sac. The novel ventricular shunt pipe pressure control valve is simple to operate and free of affect of the magnetic force. The inner pressure of the sac can be changed according to the position changes of a patient, complications after the ventricular and peritoneal shunt are greatly reduced, the probability of reoperation of the patient is reduced, so that medical cost is saved, and clinical practical value and economic benefit highly are produced. As is shown in the attached figure of the abstract, the control valve is composed of two liquid storage sacs, one is provided with the titanium alloy ball, and the other is provided with the flexible partition board.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

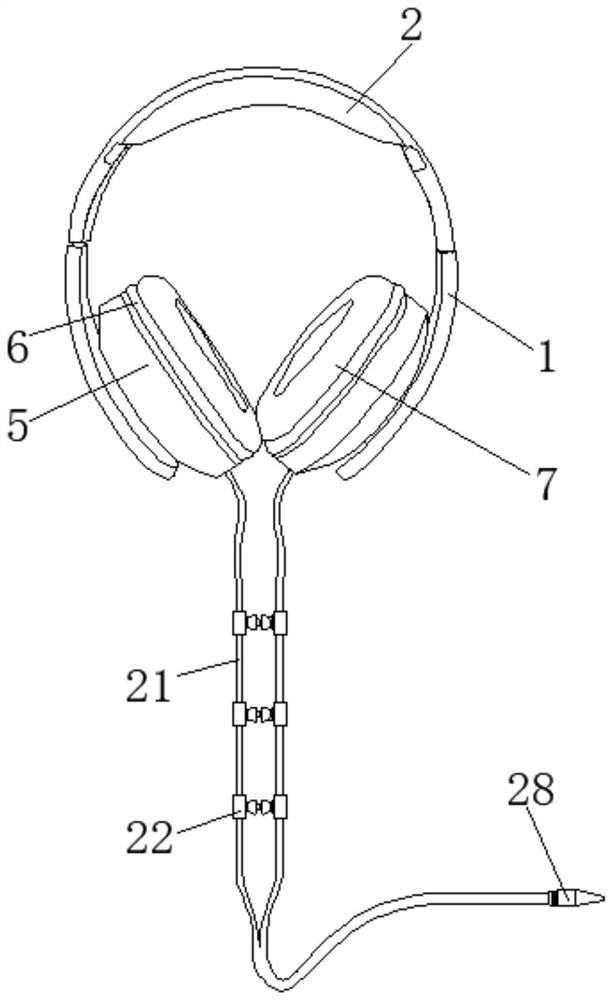

Single-wire and double-wire interchangeable earphone capable of accommodating double-wire earphone into single-wire earphone

PendingCN114302282APlay a protective effectNoise isolationEarpiece/earphone attachmentsEngineeringHeadphones

Owner:江西瑞声电子有限公司

Wire cutter

InactiveCN104113018ANeat and beautiful sectionAchieve fixationApparatus for removing/armouring cablesElectric power systemEngineering

The invention discloses a wire cutter and relates to the field of power system line maintenance. The wire cutter comprises an operating table, the operating table is provided with a rotating device and a retention pressing device corresponding to the position of the rotating device, the retention pressing device comprises a manual opening and closing module fixed on the operating table, the manual opening and closing module is connected with an upper formwork, and a lower formwork bolt is connected to the operating table corresponding to the upper formwork. The rotating device comprises a cylindrical base, the outer portion of the base is sleeved with a bearing, the bearing is sleeved with a turntable, two connecting plates are symmetrically fixed on the circumference of the turntable, one connecting plate is respectively provided with a knife rest with a blade and a feeding device through two first bent plates, the rear end of the knife rest is hinged to the front end of the feeding device, and the other connecting plate is provided with a pressing wheel device relative to the blade. The wire cutter can rapidly cut an aluminum stranded wire of an iron core aluminum stranded wire outer layer and does not damage a steel core, and a broken line part is tidy and attractive.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com