Crusher

A crusher and crushing device technology, which is applied in grain processing and other fields, can solve the problems of low energy utilization rate, uneven crushing, loud noise, etc., and achieve the effect of improving energy utilization rate, good crushing effect, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

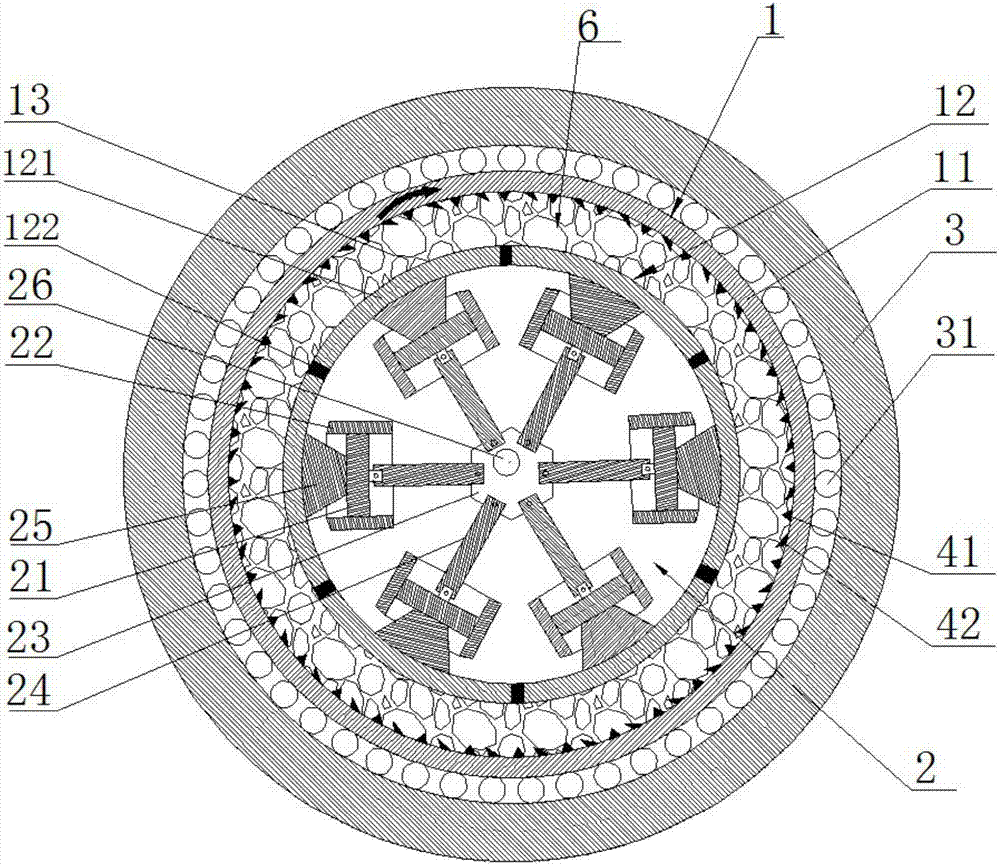

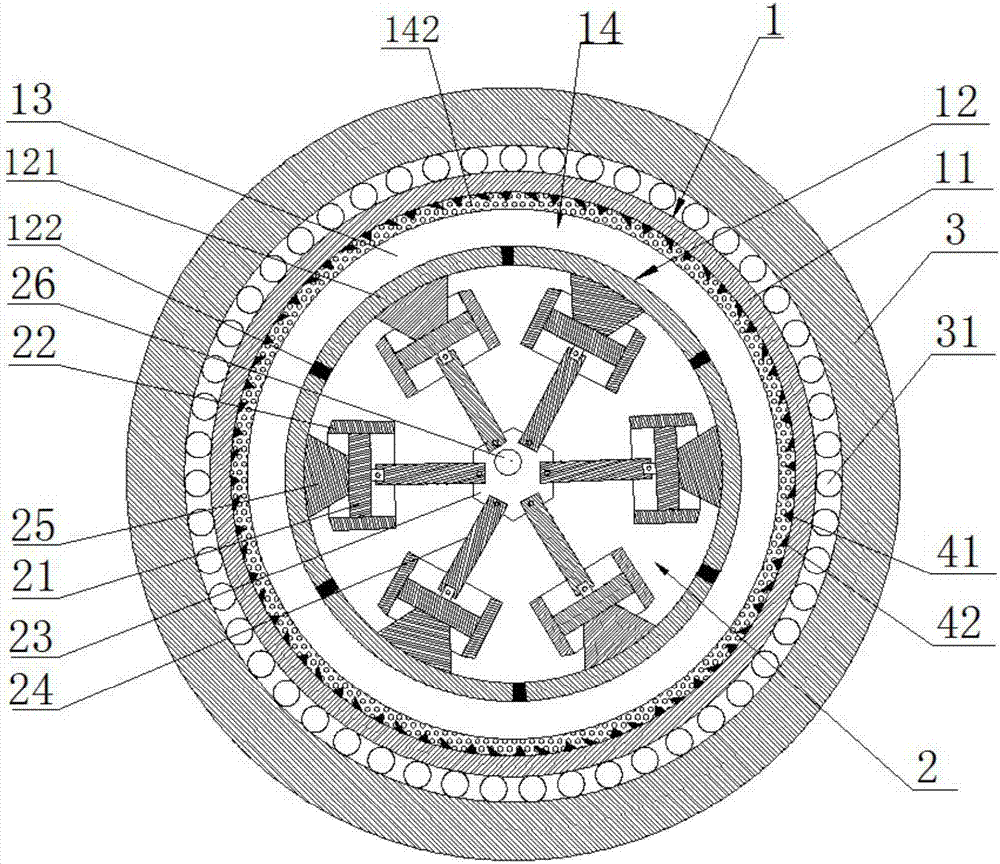

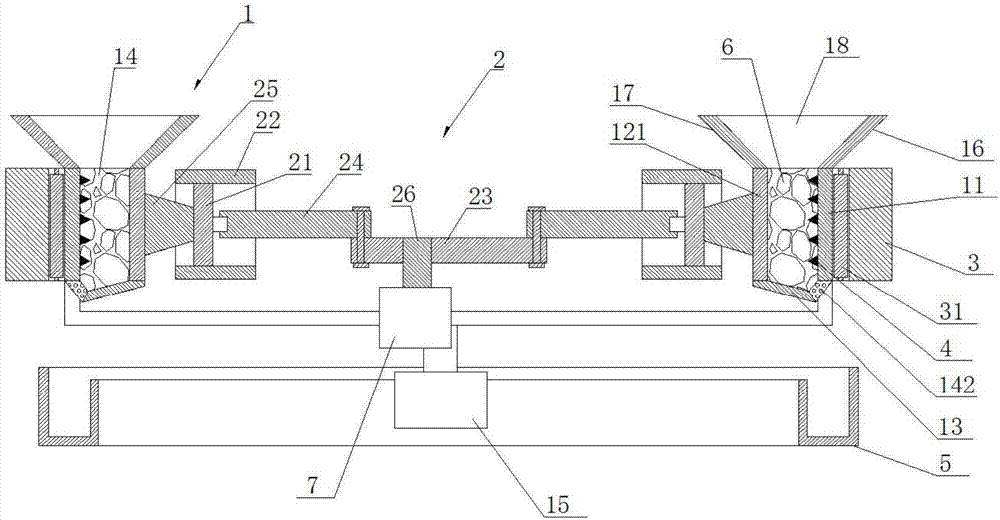

[0031] Such as Figures 1 to 3 As shown, a crusher includes a crushing device 1 and a driving device 2; the crushing device 1 includes an outer plate 11, an inner plate 12 and a bottom plate 13; the outer plate 11, the inner plate 12 and the bottom plate 13 are all ring-shaped, and the The outer plate 11, the inner plate 12 and the bottom plate 13 surround a horizontal annular crushing chute 14; the outer plate 11 is driven to rotate by a first motor 15; in this embodiment, a support is connected below the side plate 11, and the first motor 15 passes The bracket drives the side plate 11 to rotate; the inner plate 12 is formed by sequentially connecting multiple pressing plates 121 through elastic connectors 122; The setting of the connecting body 122 can prevent the leakage of materials while ensuring the independent movement of each pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com