Patents

Literature

344 results about "Sharp tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

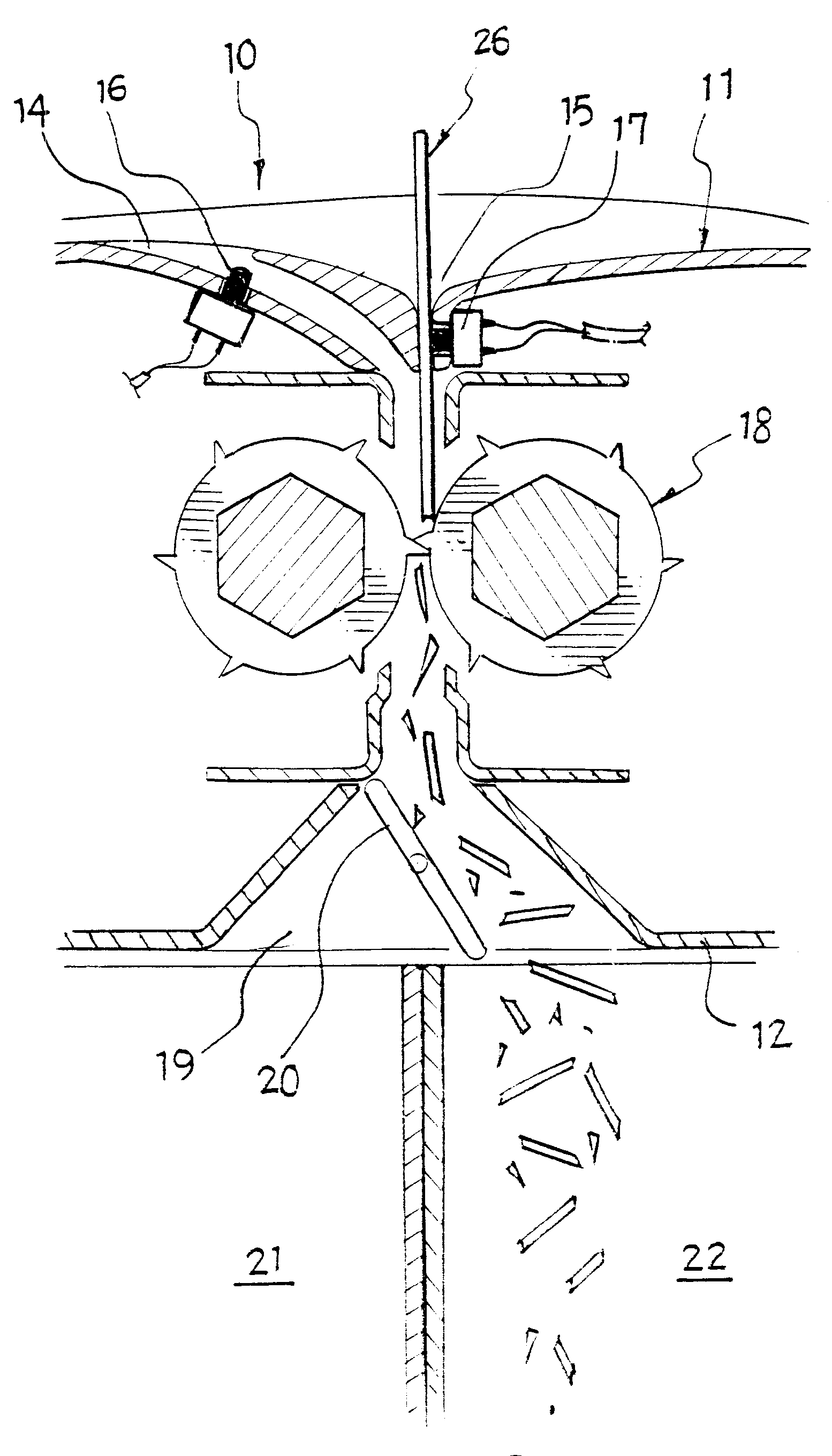

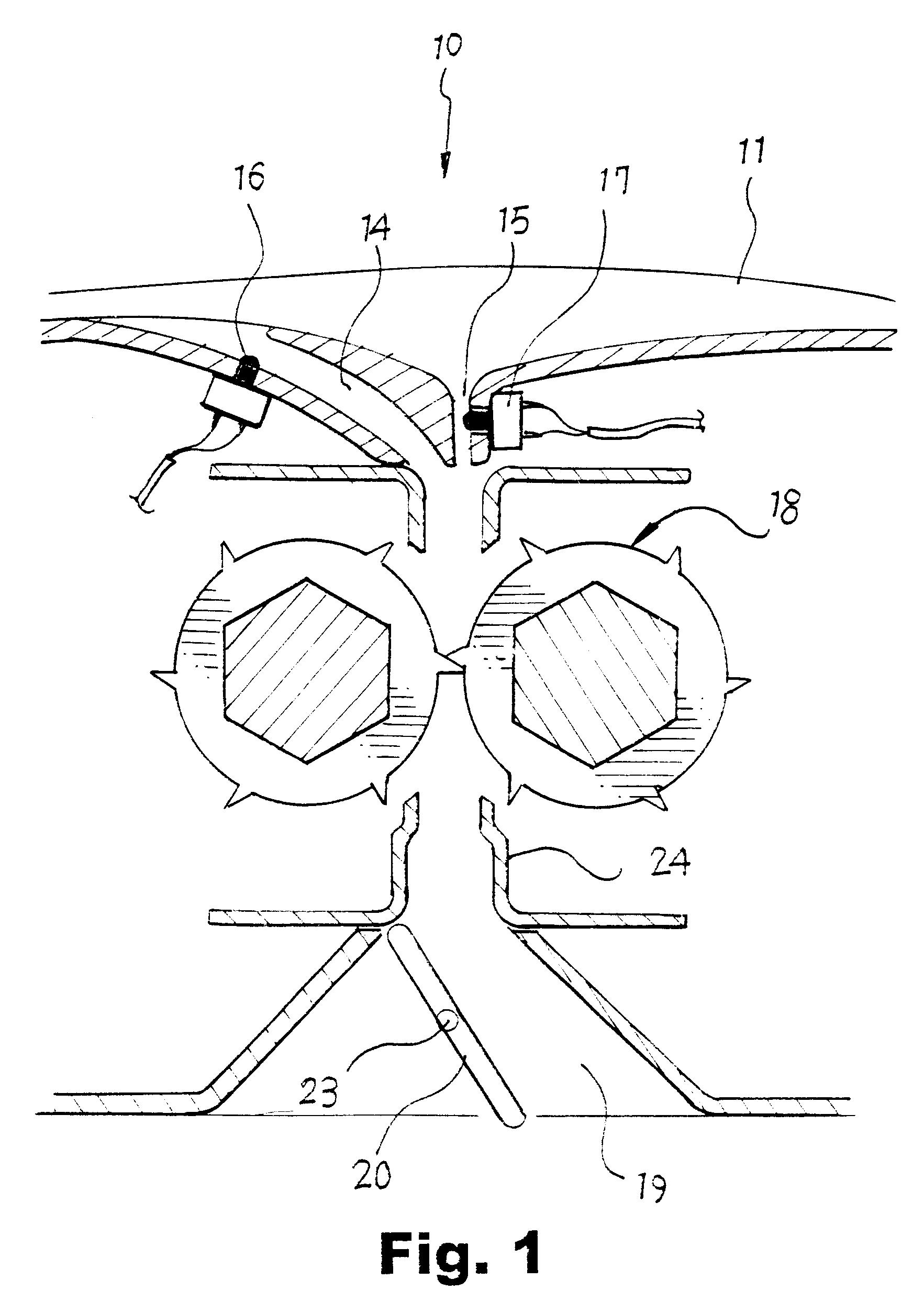

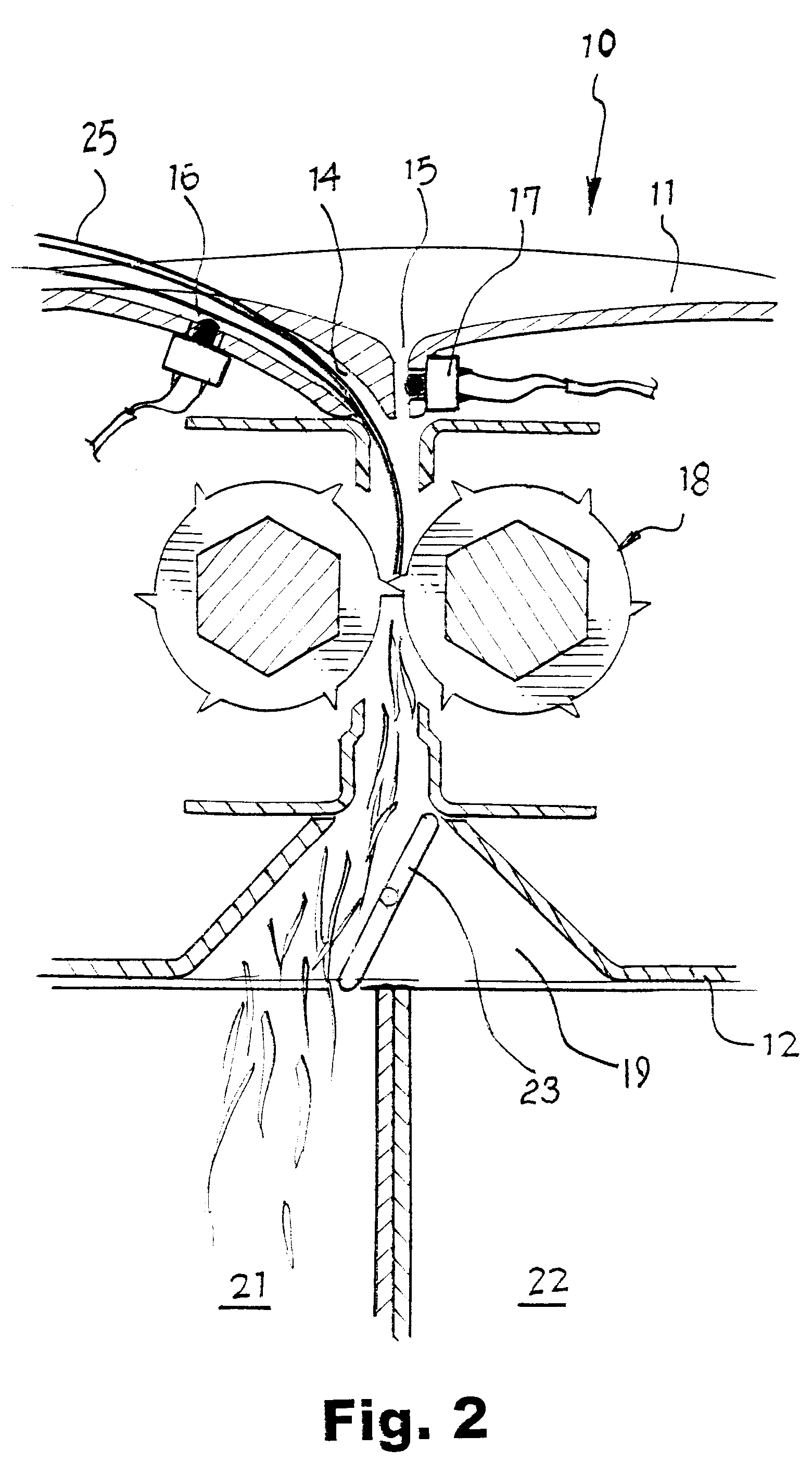

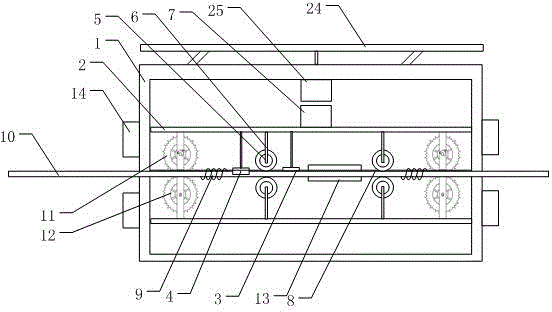

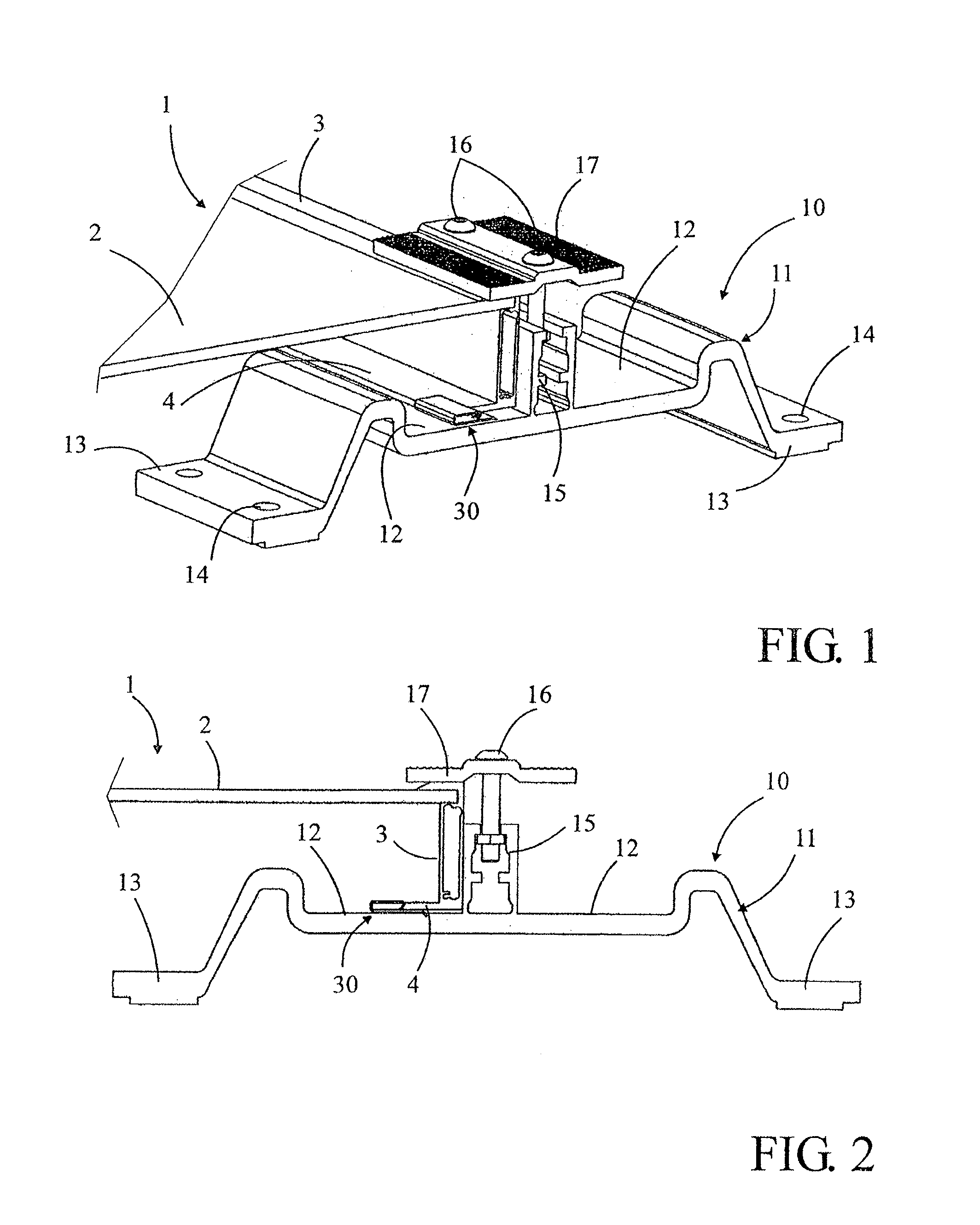

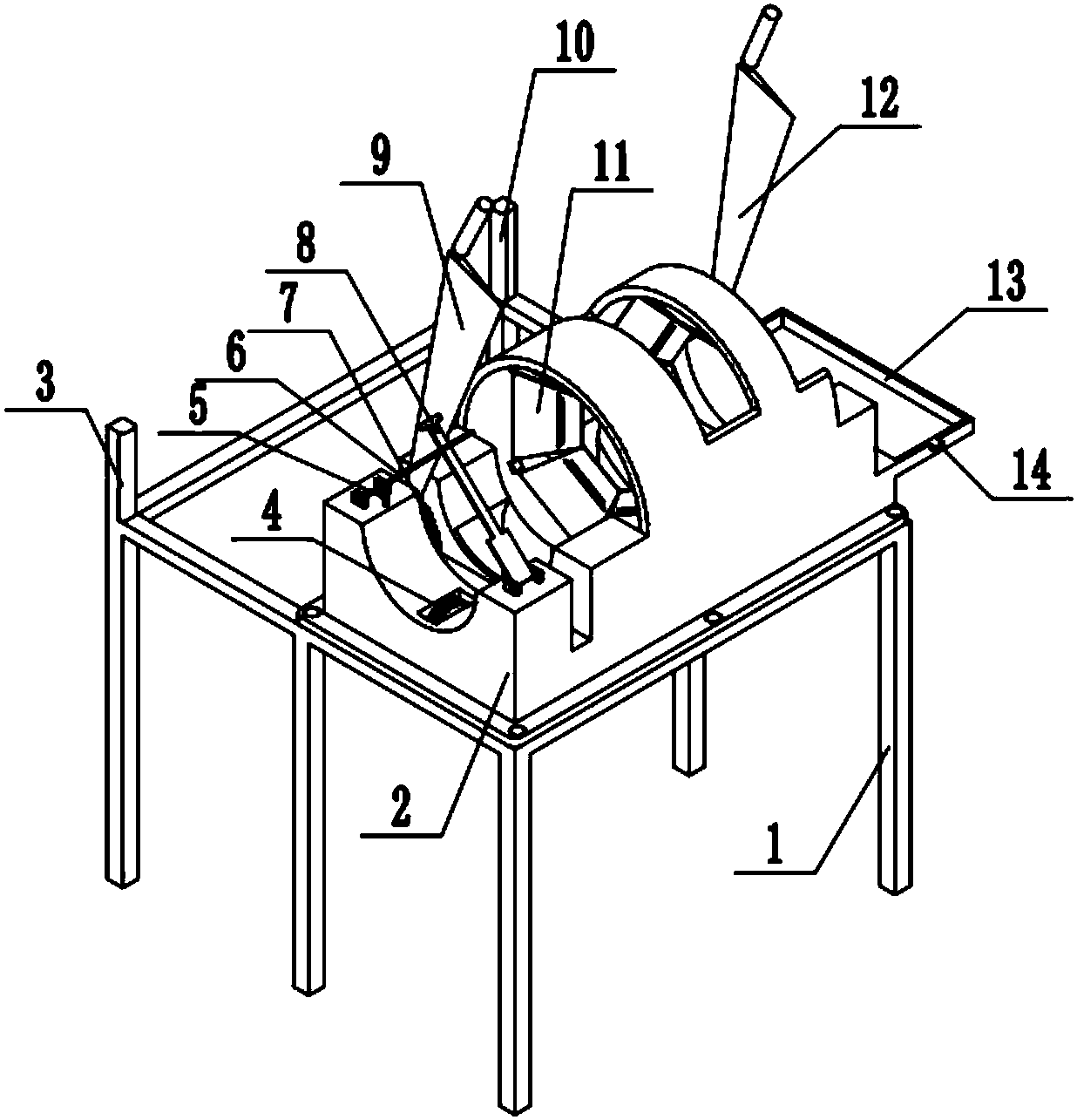

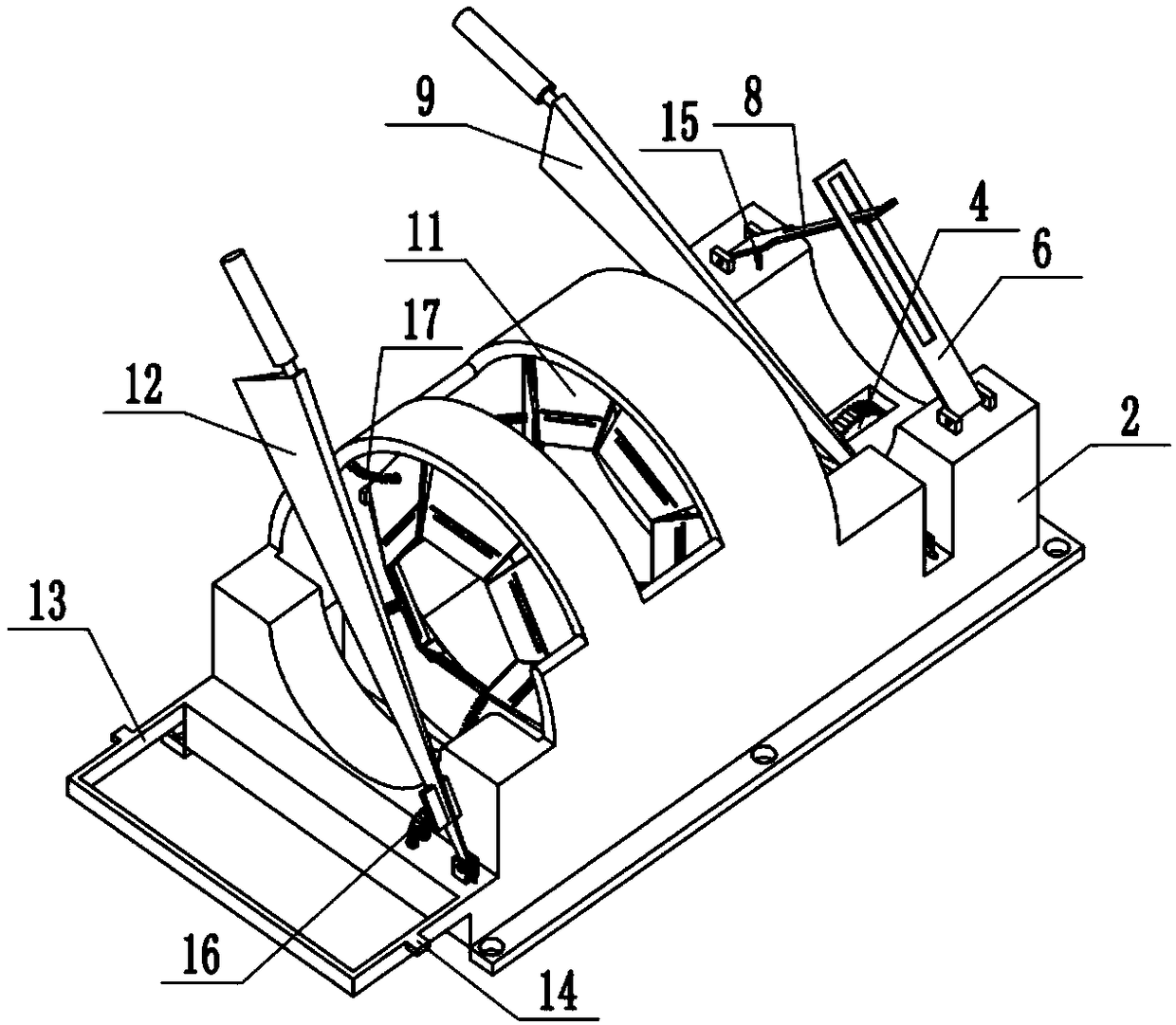

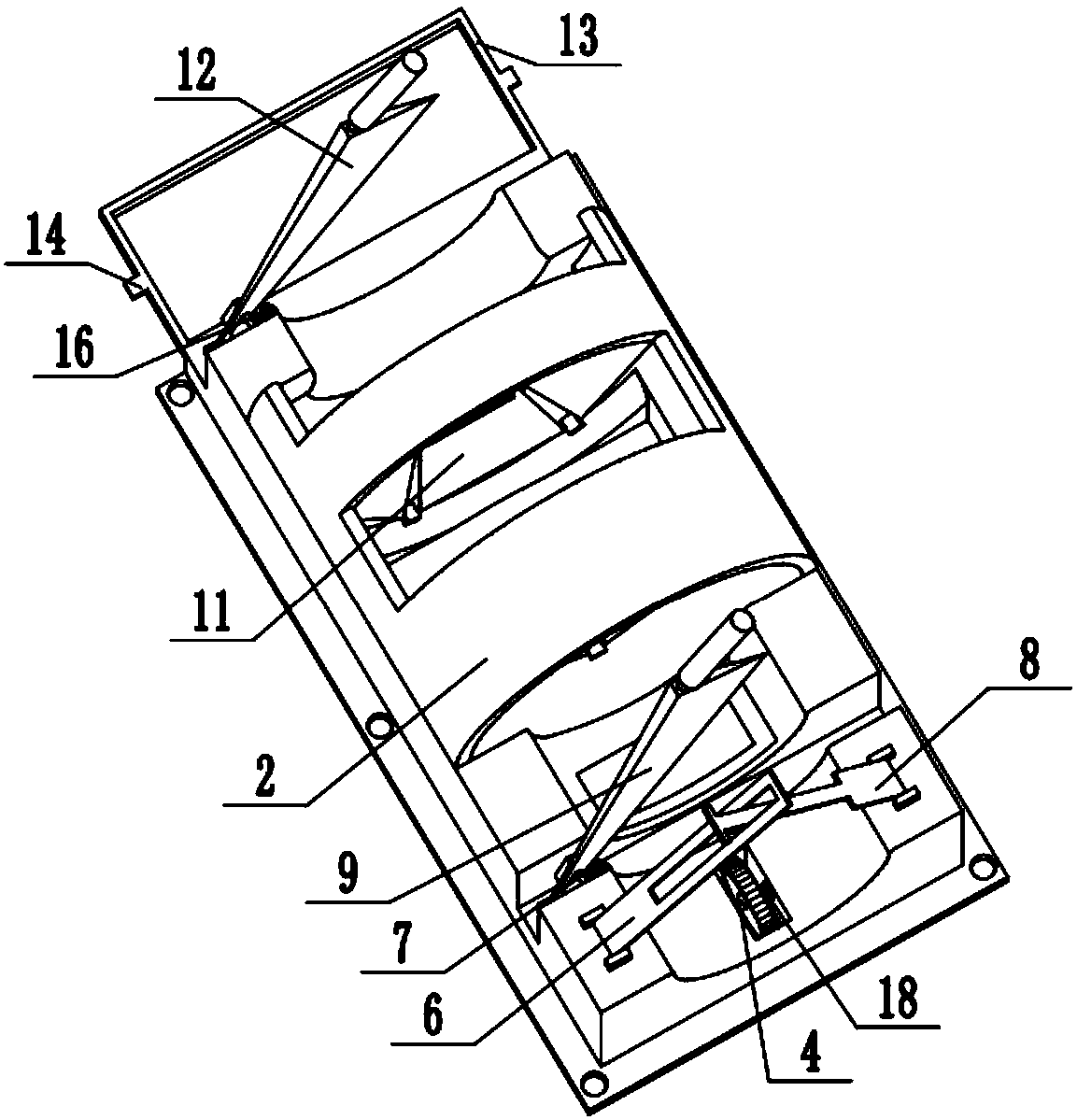

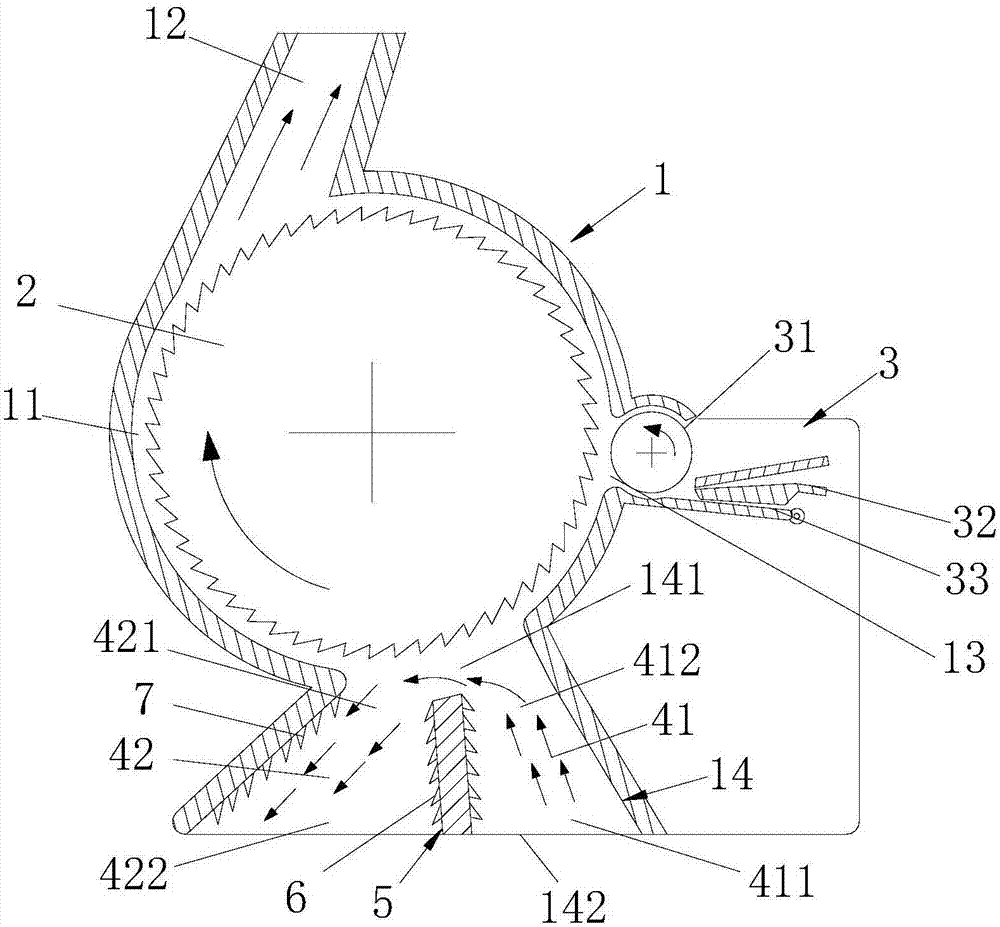

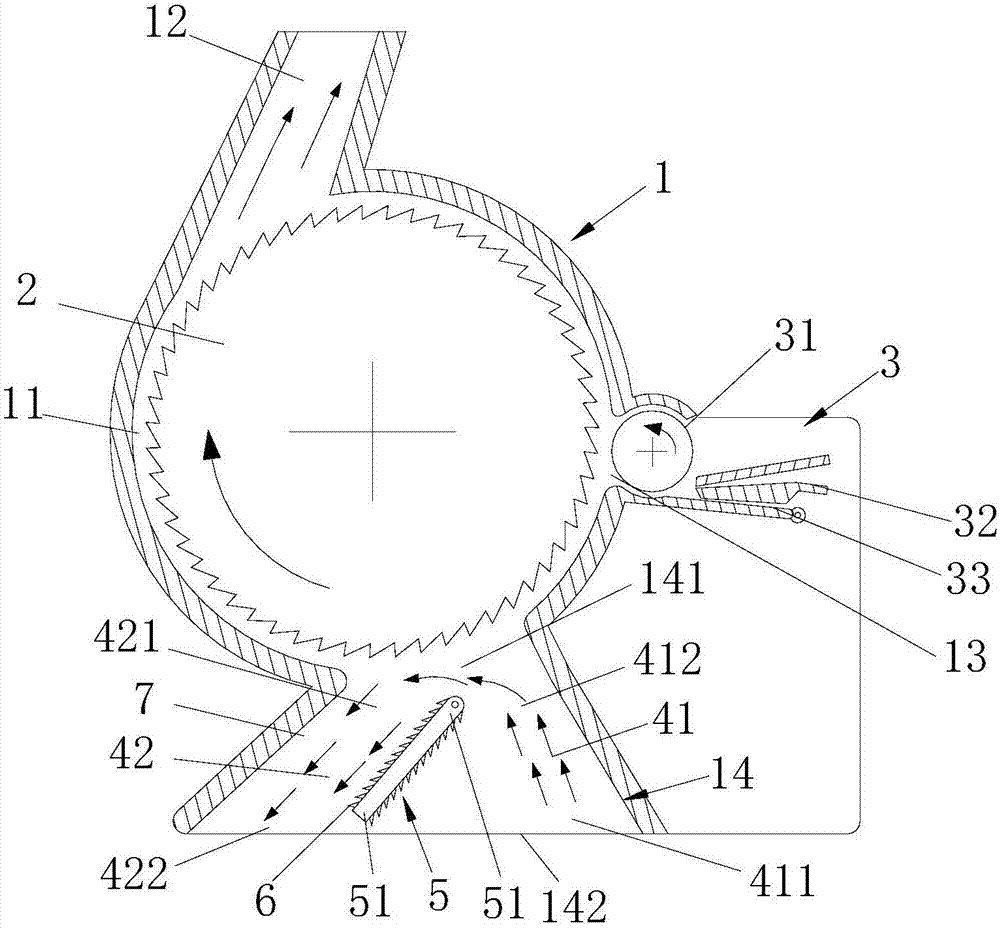

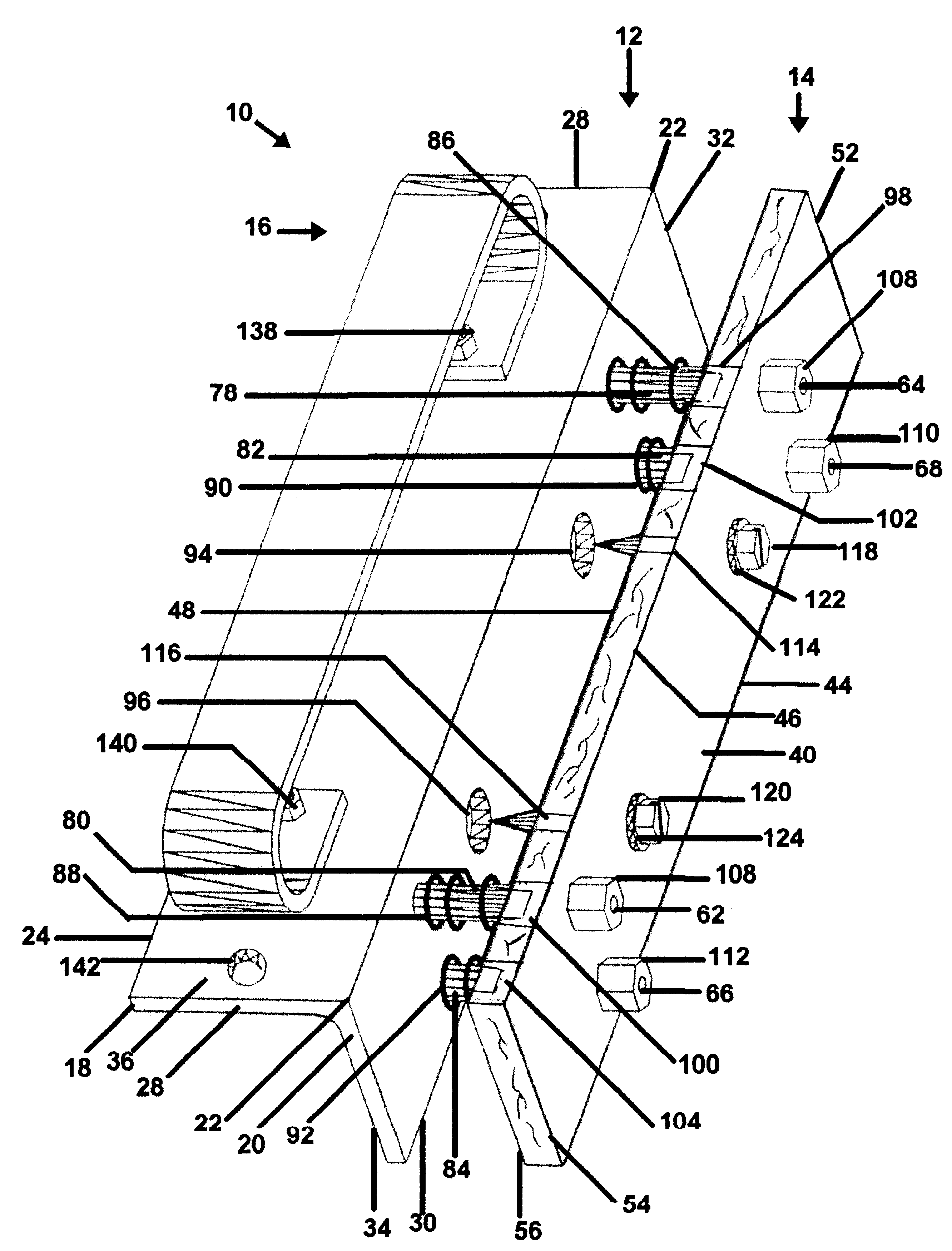

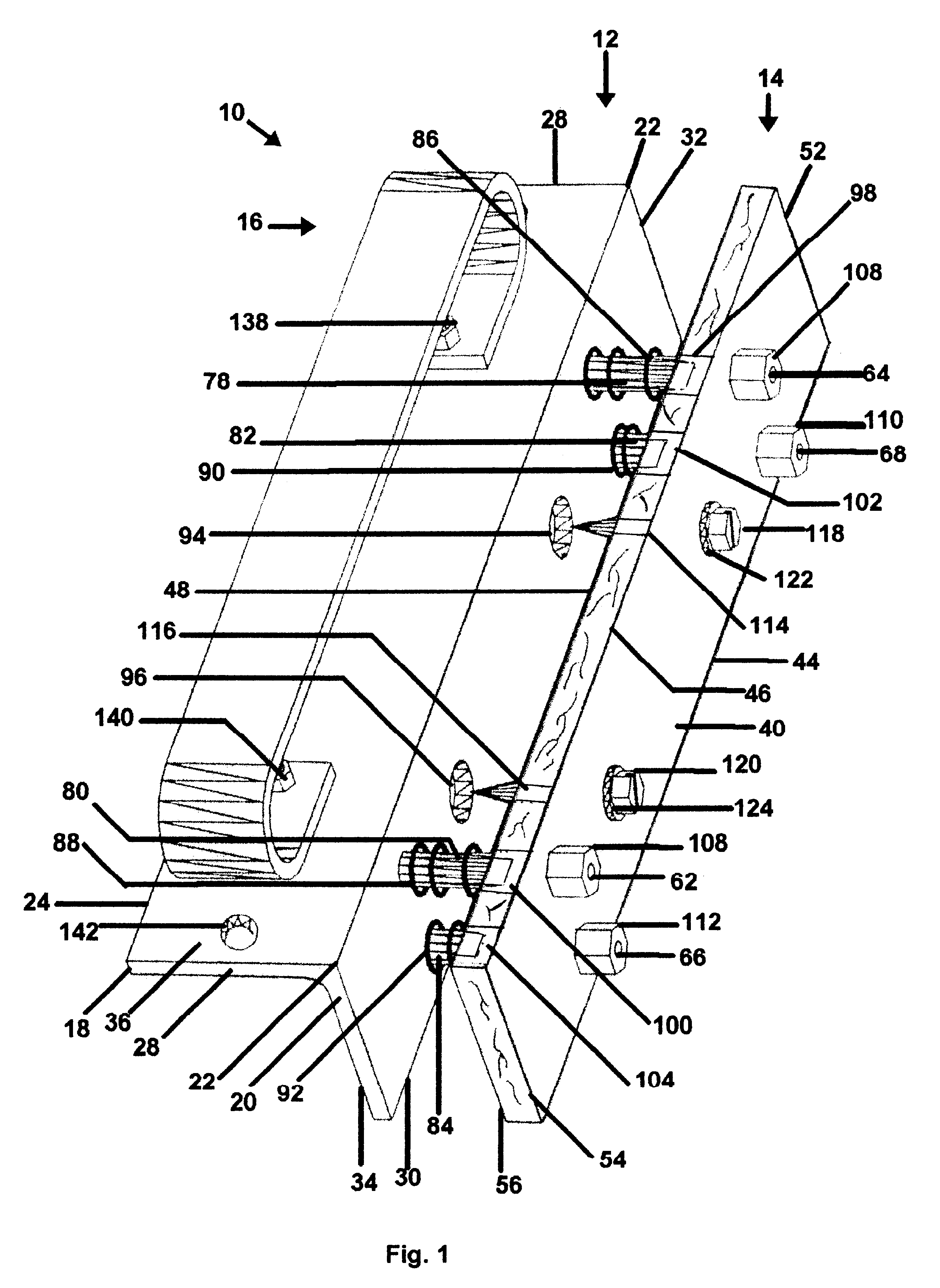

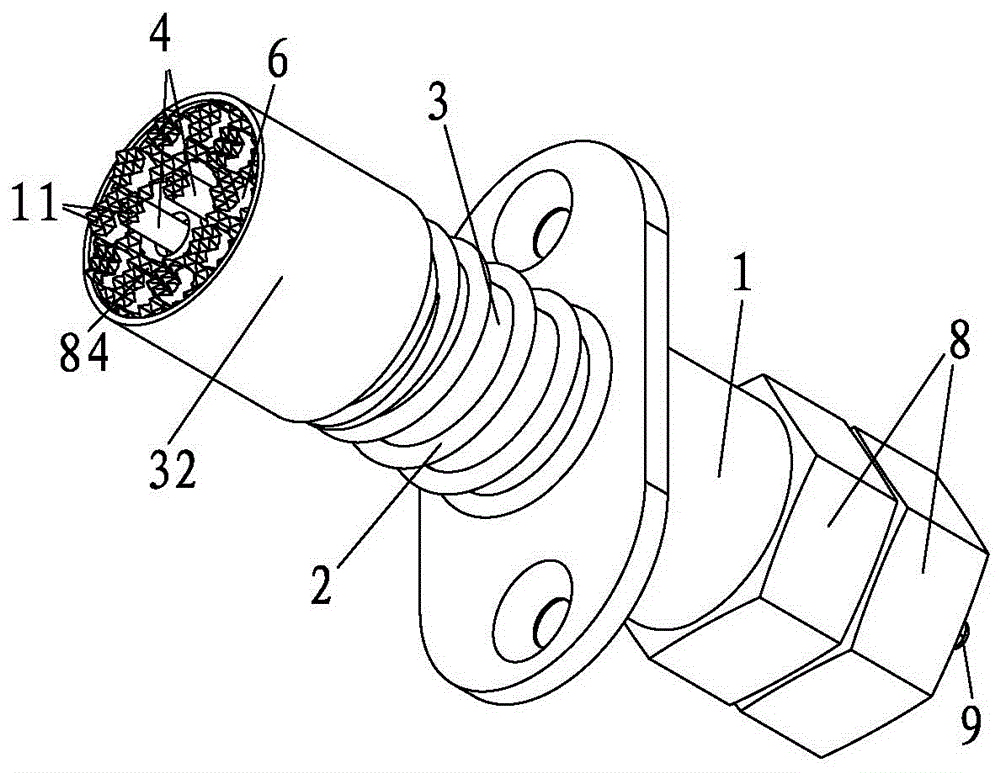

Dual-functional medium shredding machine structure

This invention is related to a dual-functional medium shredding machine structure, specifically designed for shredding or destroying paper printed with data to be destroyed, optical discs containing data to be destroyed, or expired credit cards. This invention mainly implements a pair of shredding roller blades with sharp teeth as shredding means, and is characterized by providing separate feeding inports, including a paper inport for feeding paper in an inclined orientation, and a disc inport for feeding discs in a vertical orientation, wherein the inports are each led to the same shredding roller blades such that, regardless of the type of substance being fed by the user, the paper or the discs can both be shredded by the shredding roller blades, and the shredded scraps are dispensed to separate collectors through an identical exit by means of an auto-revolving switch plate; and a touch switch at each of the inports such that, while feeding the paper or the discs, the touch switch activates the shredding roller blades to perform shredding task, and drives the switch plate so as to dispense shredded scraps of different substance into different collectors.

Owner:MICHILIN PROSPERITY

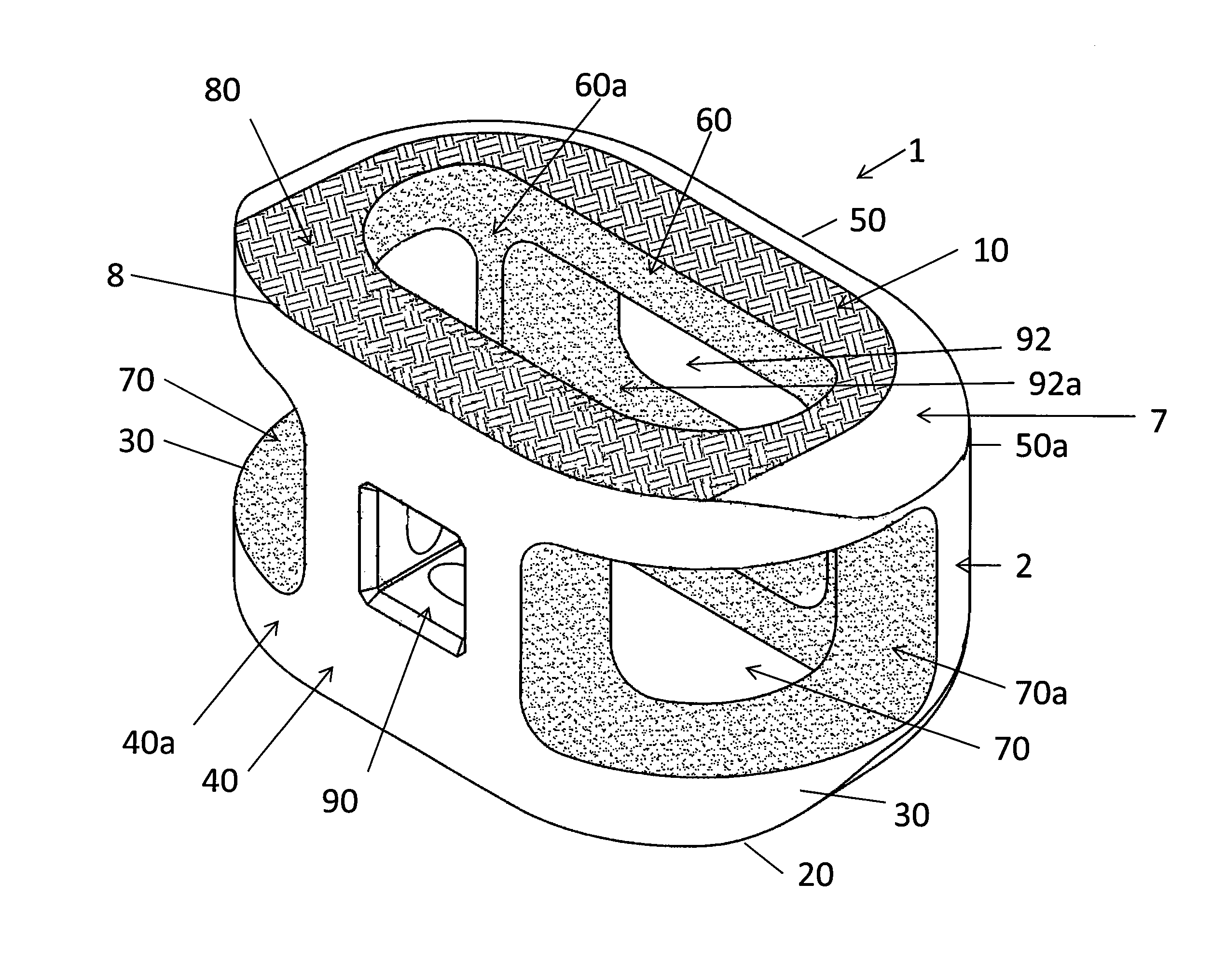

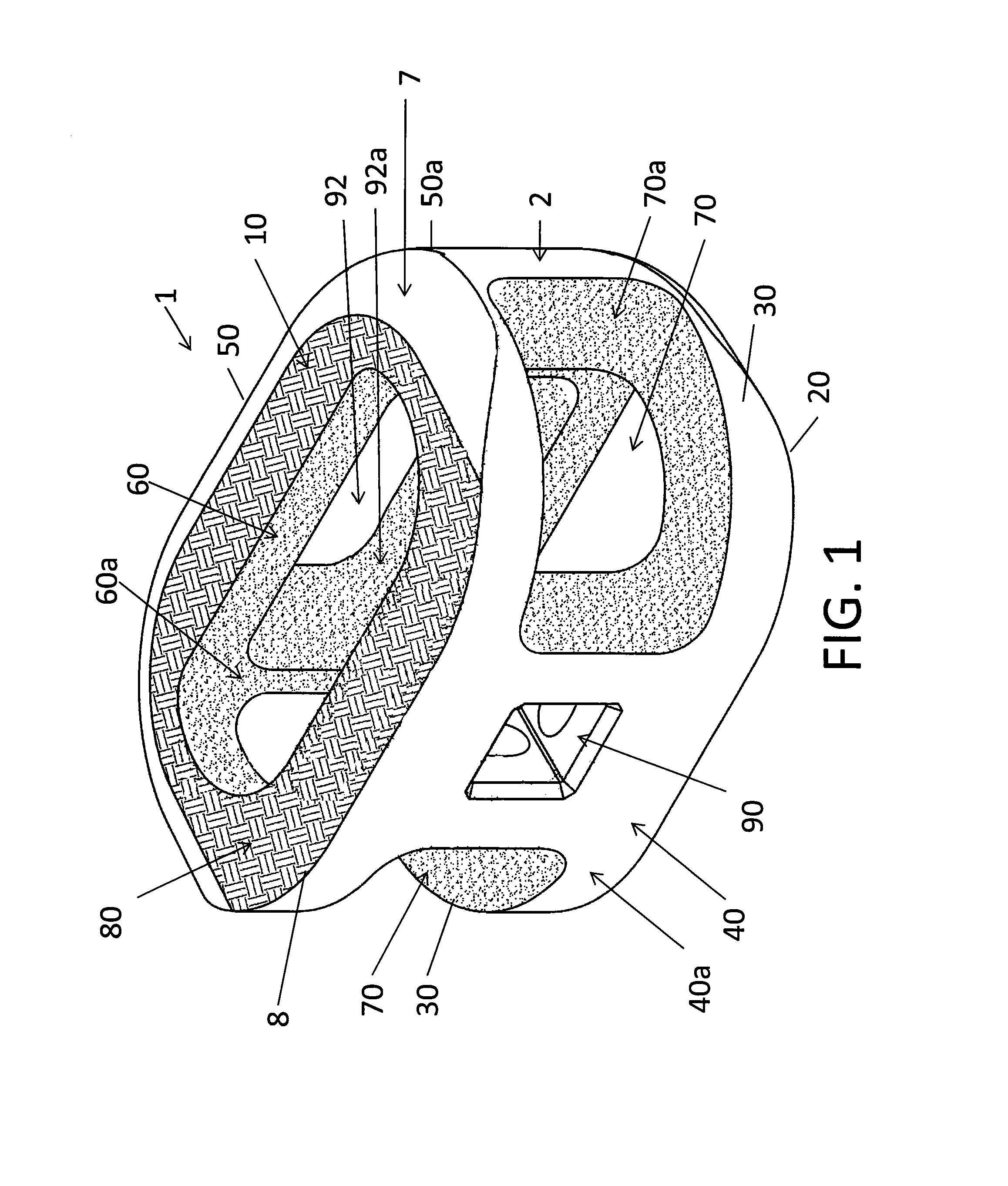

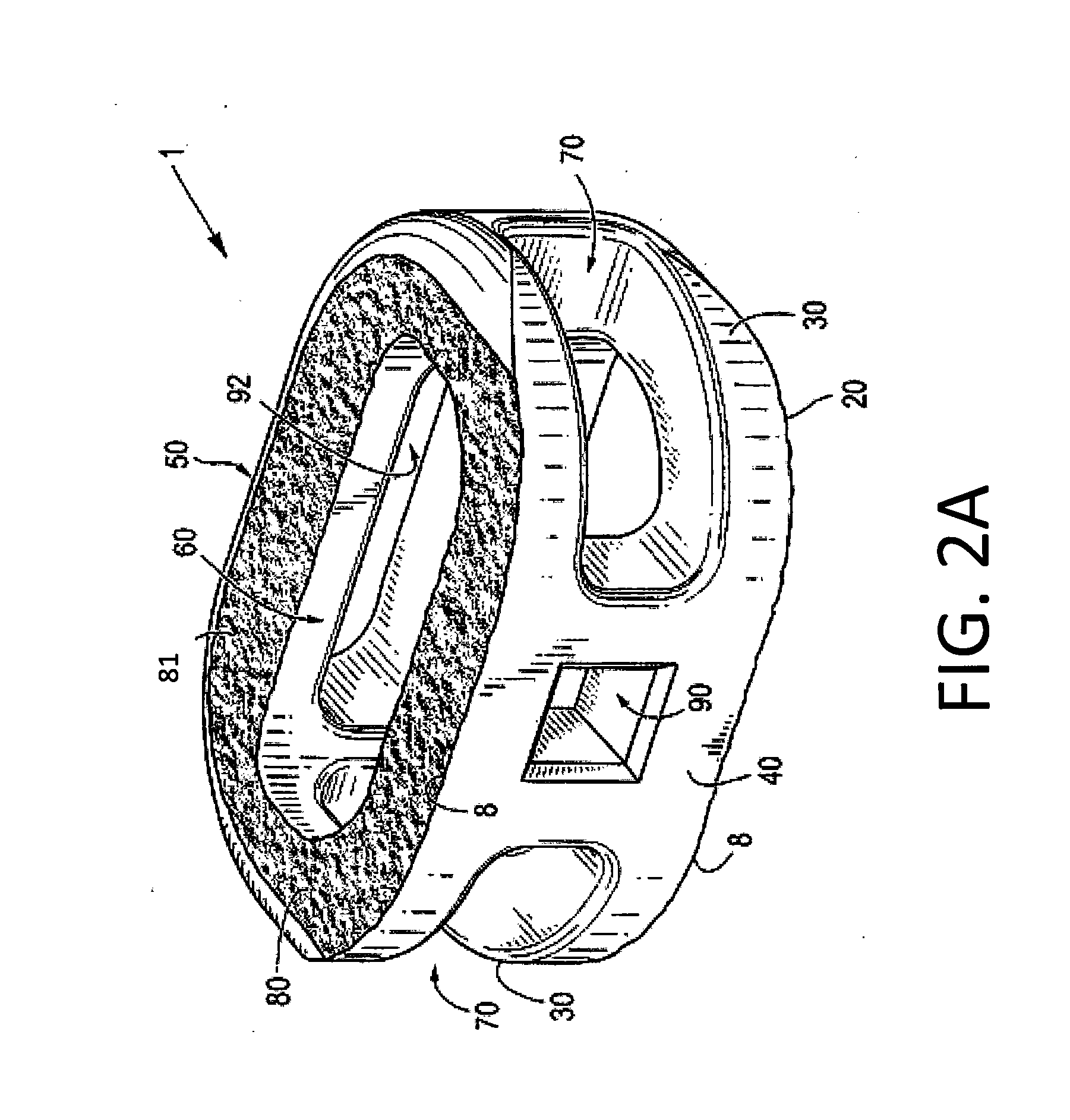

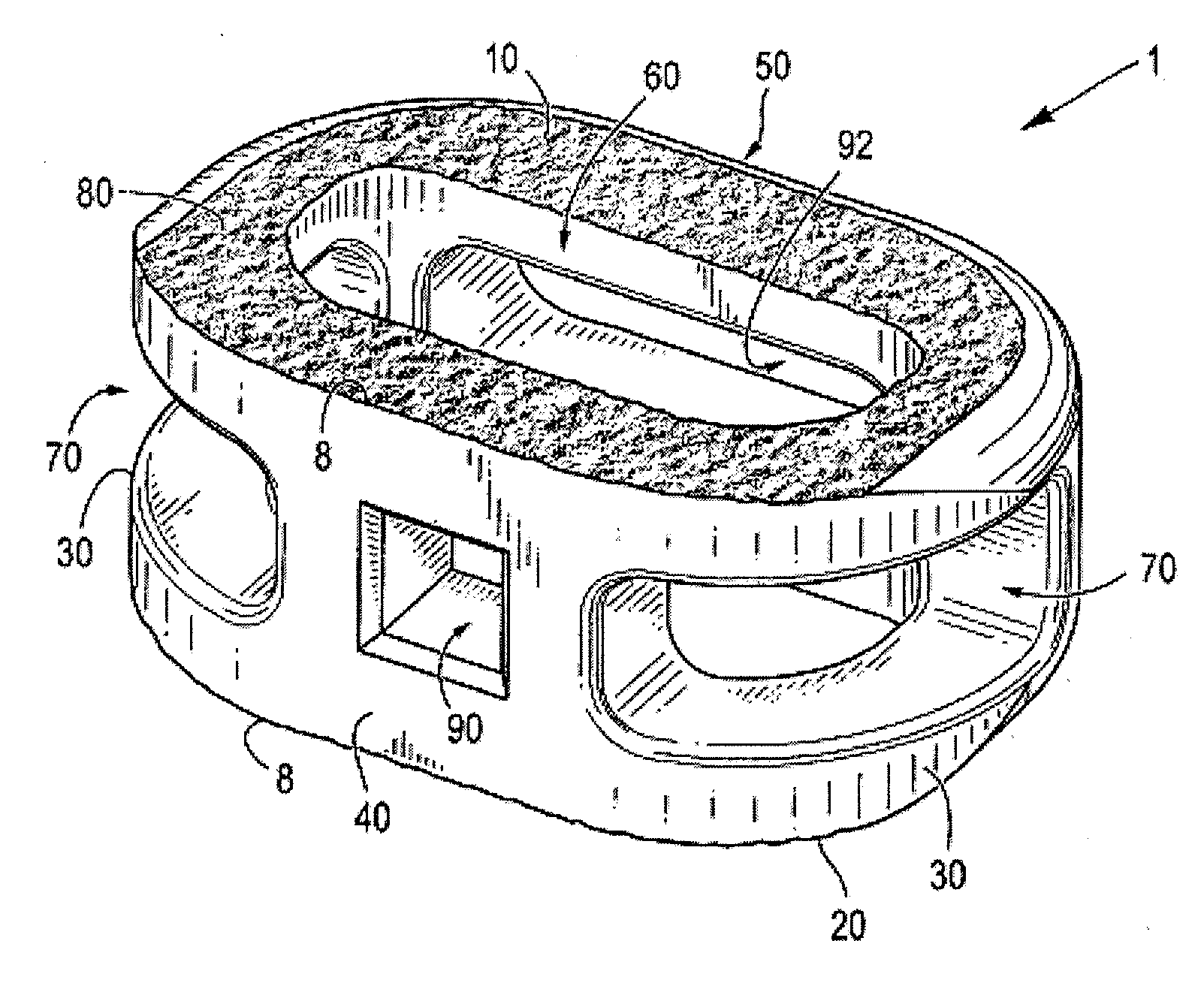

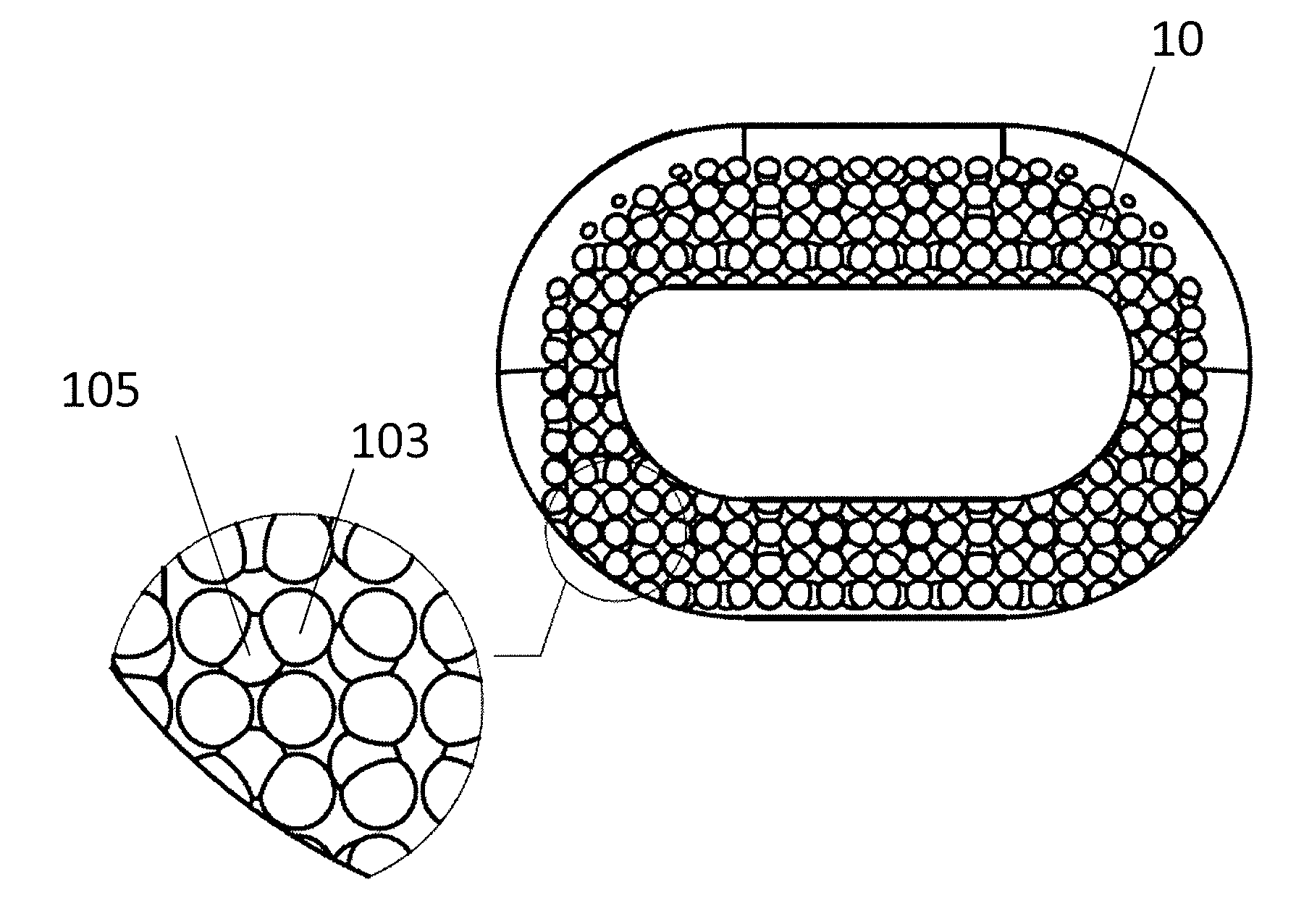

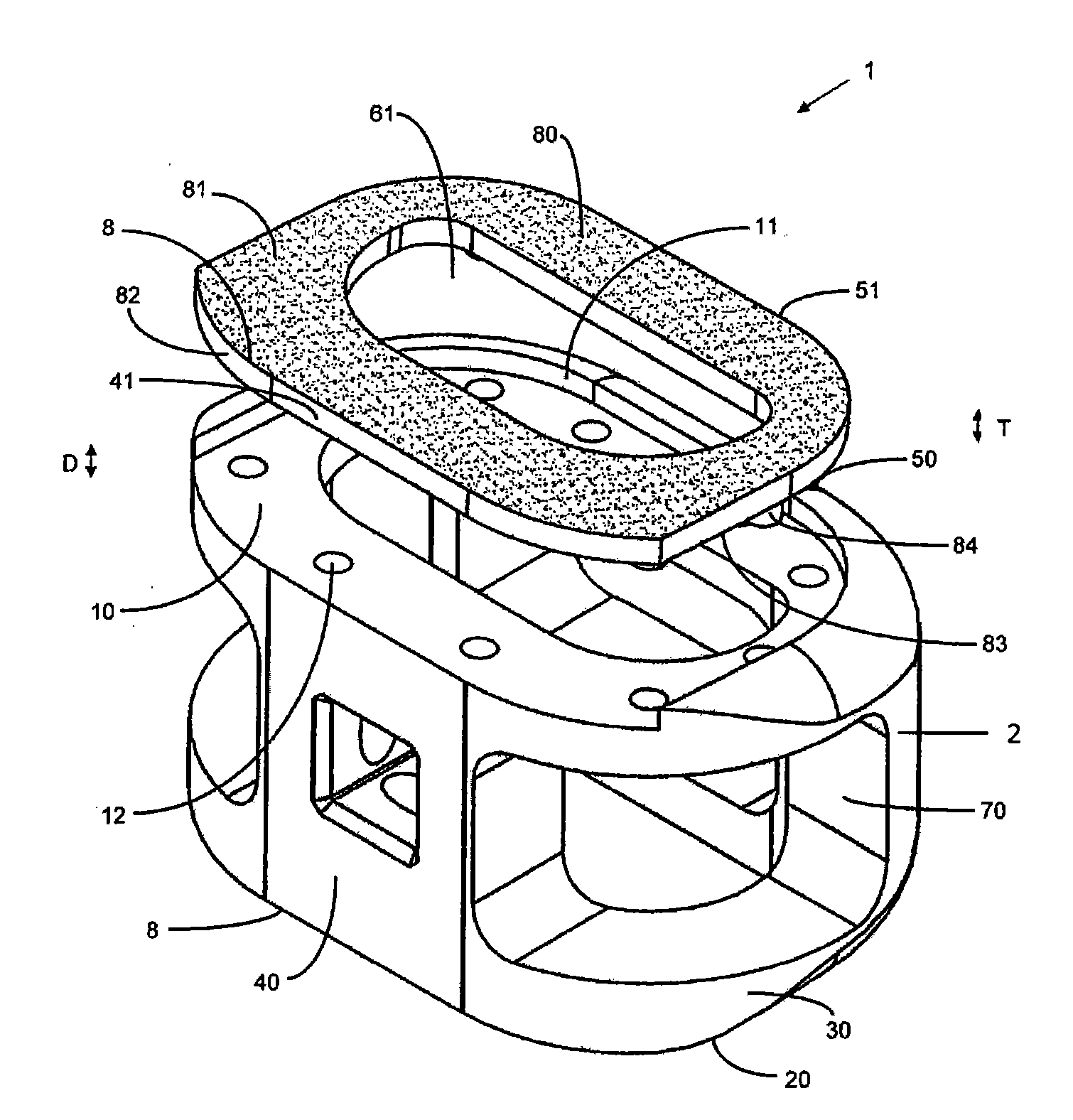

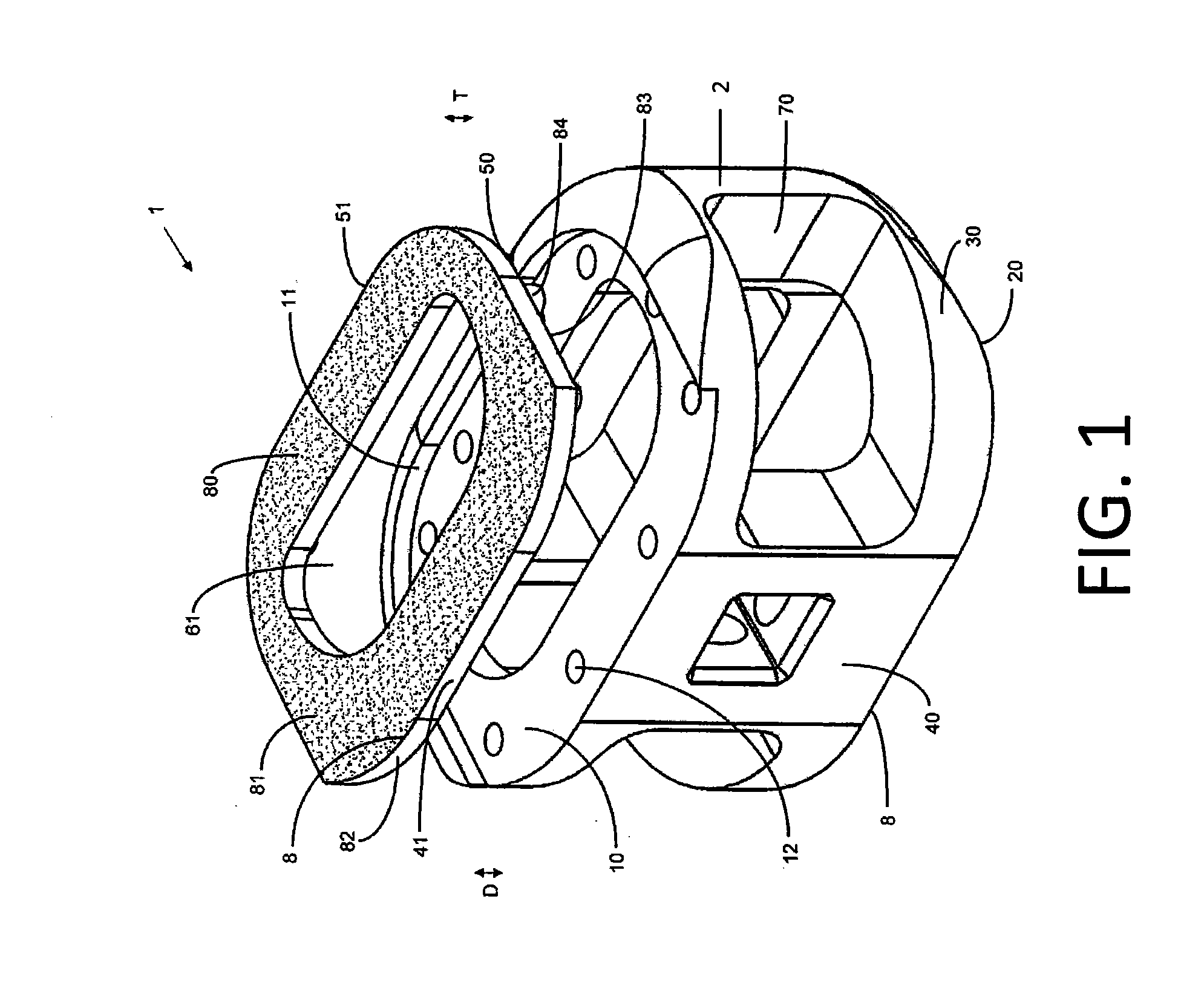

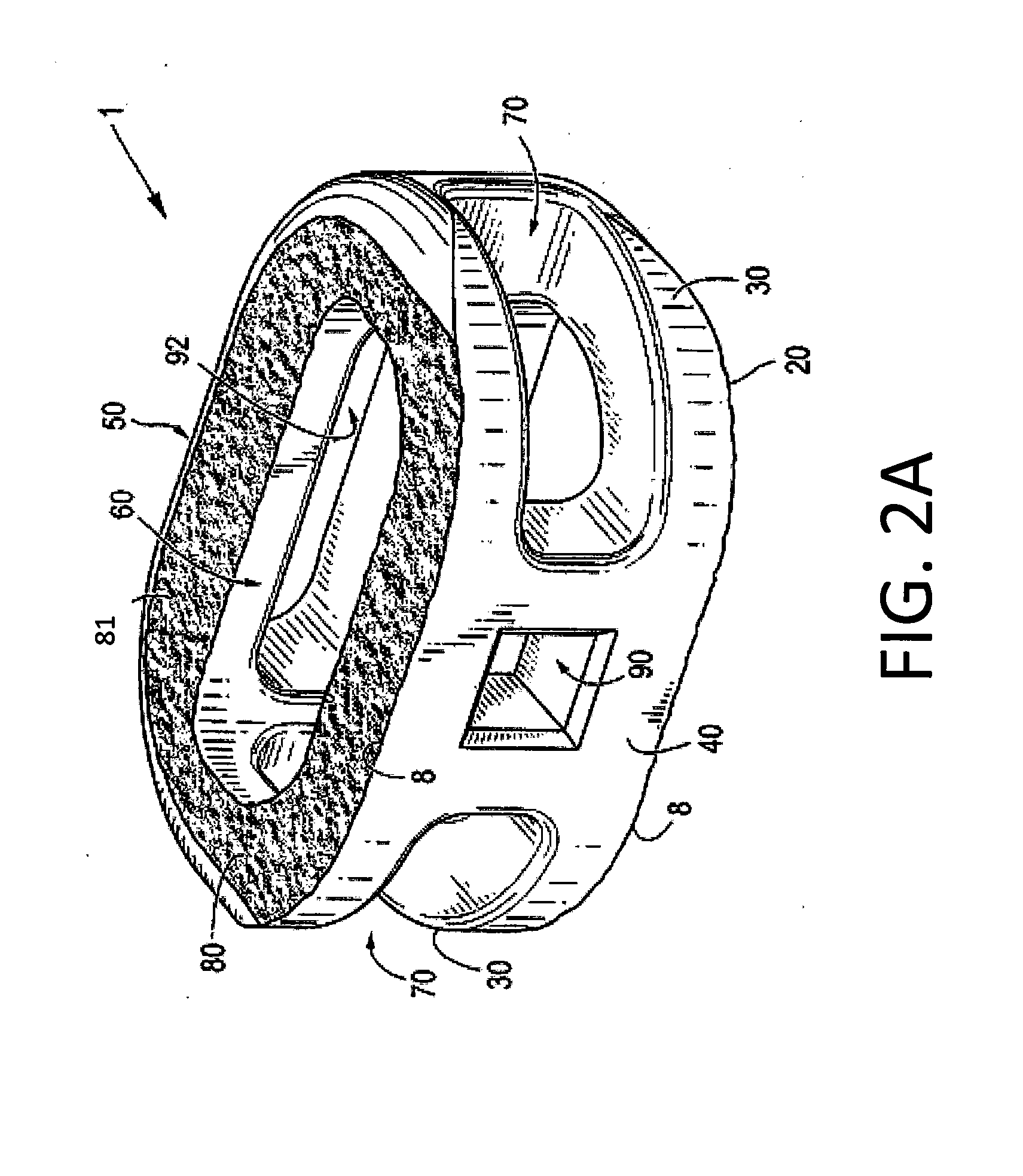

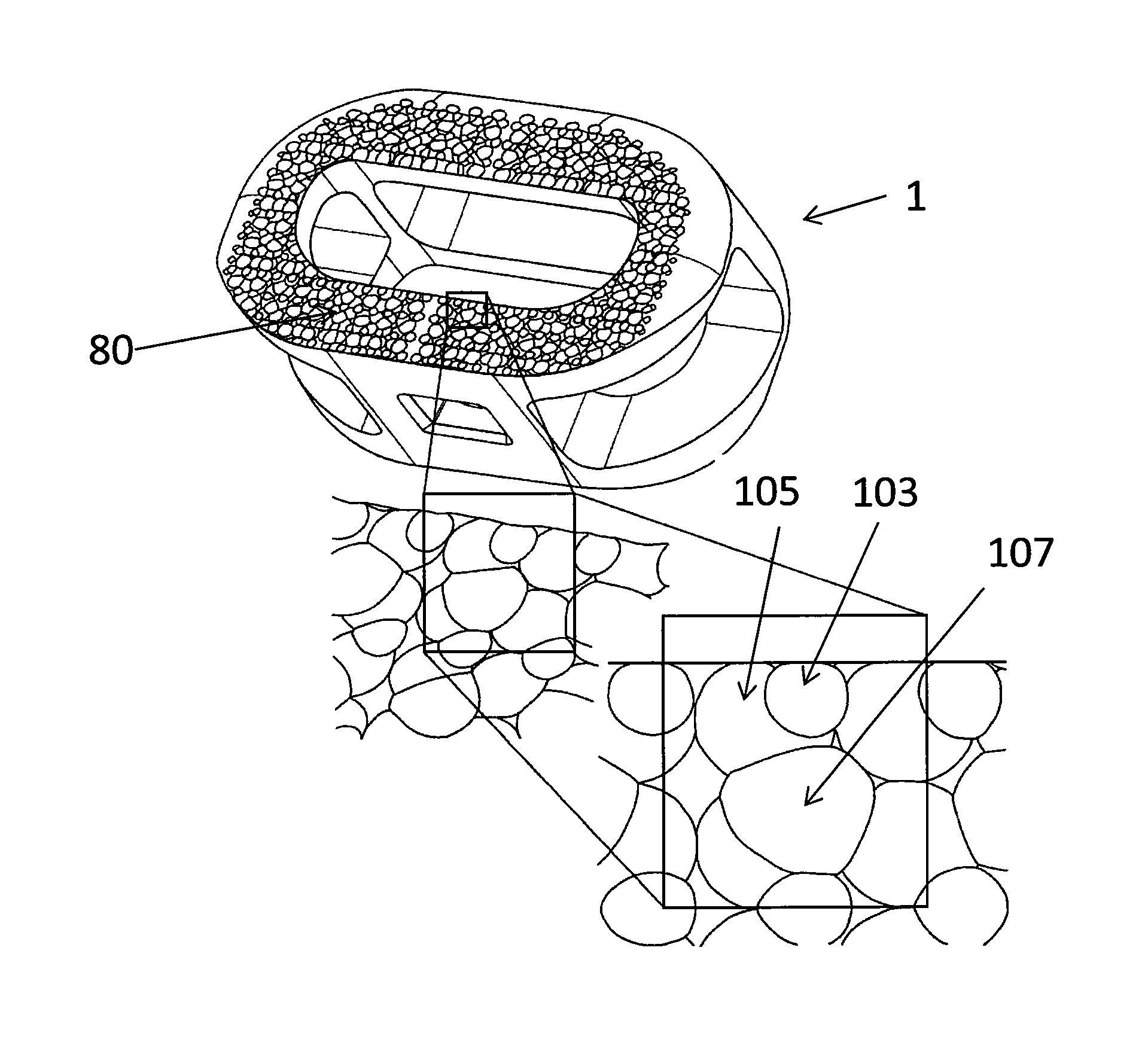

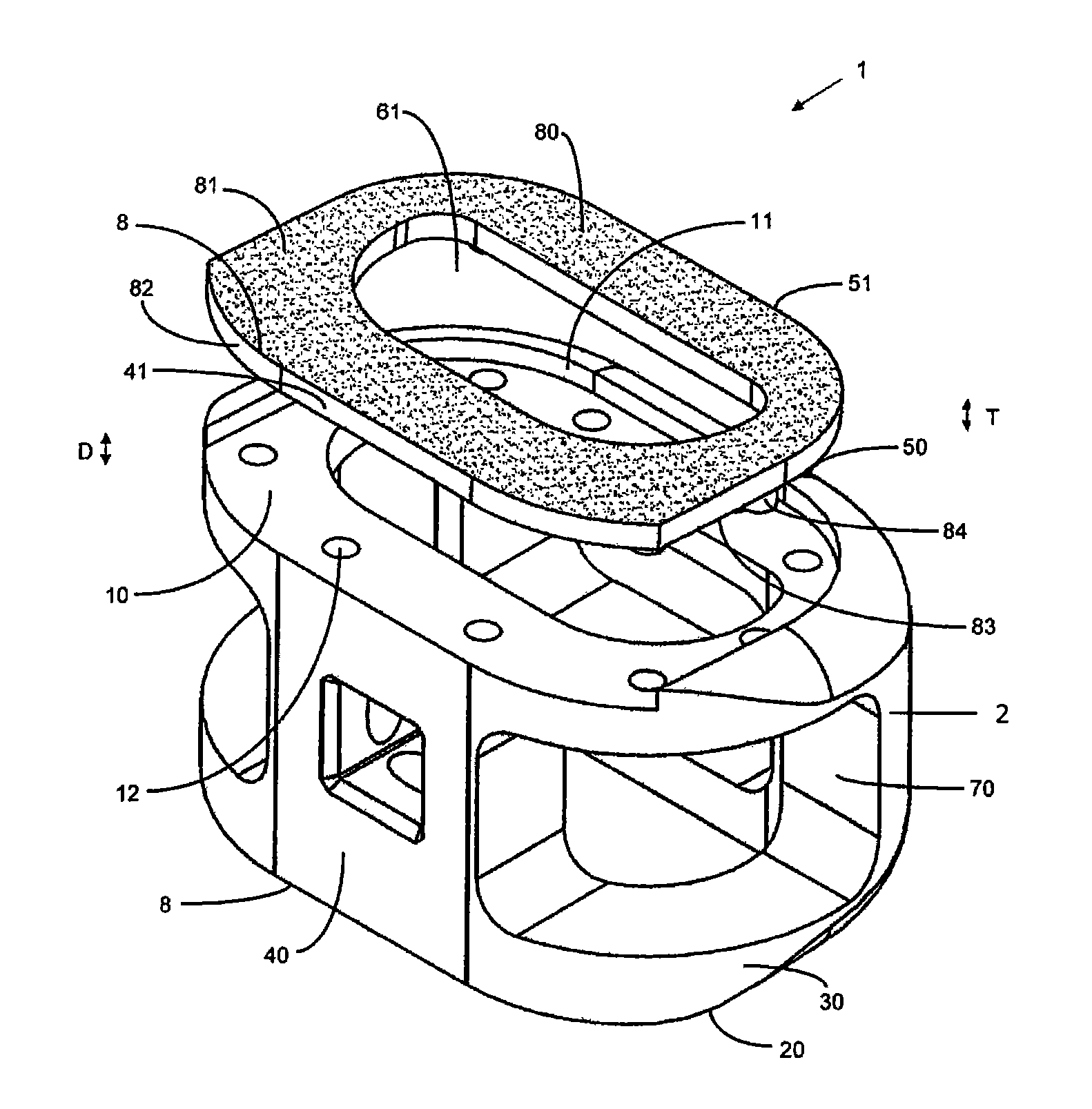

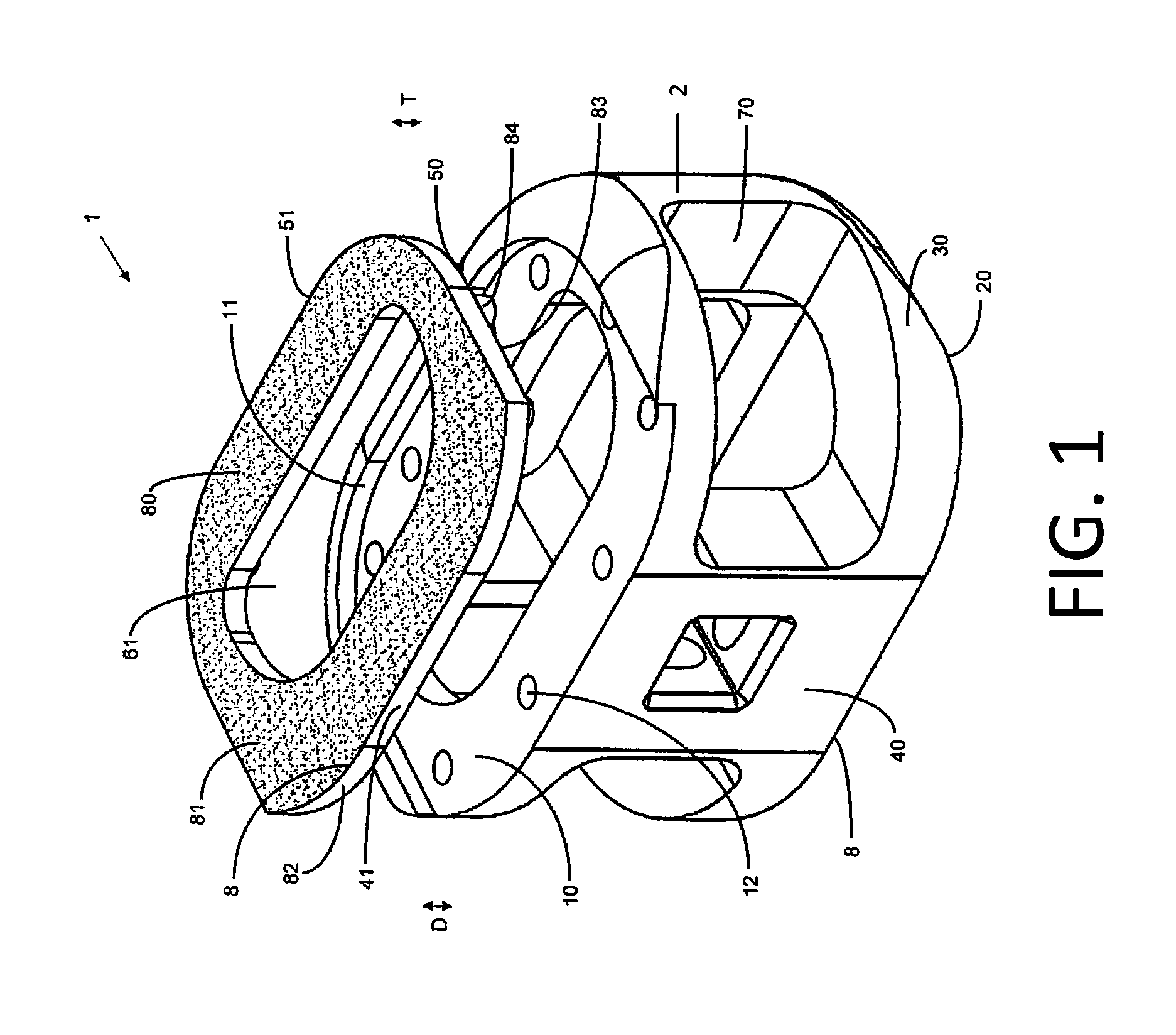

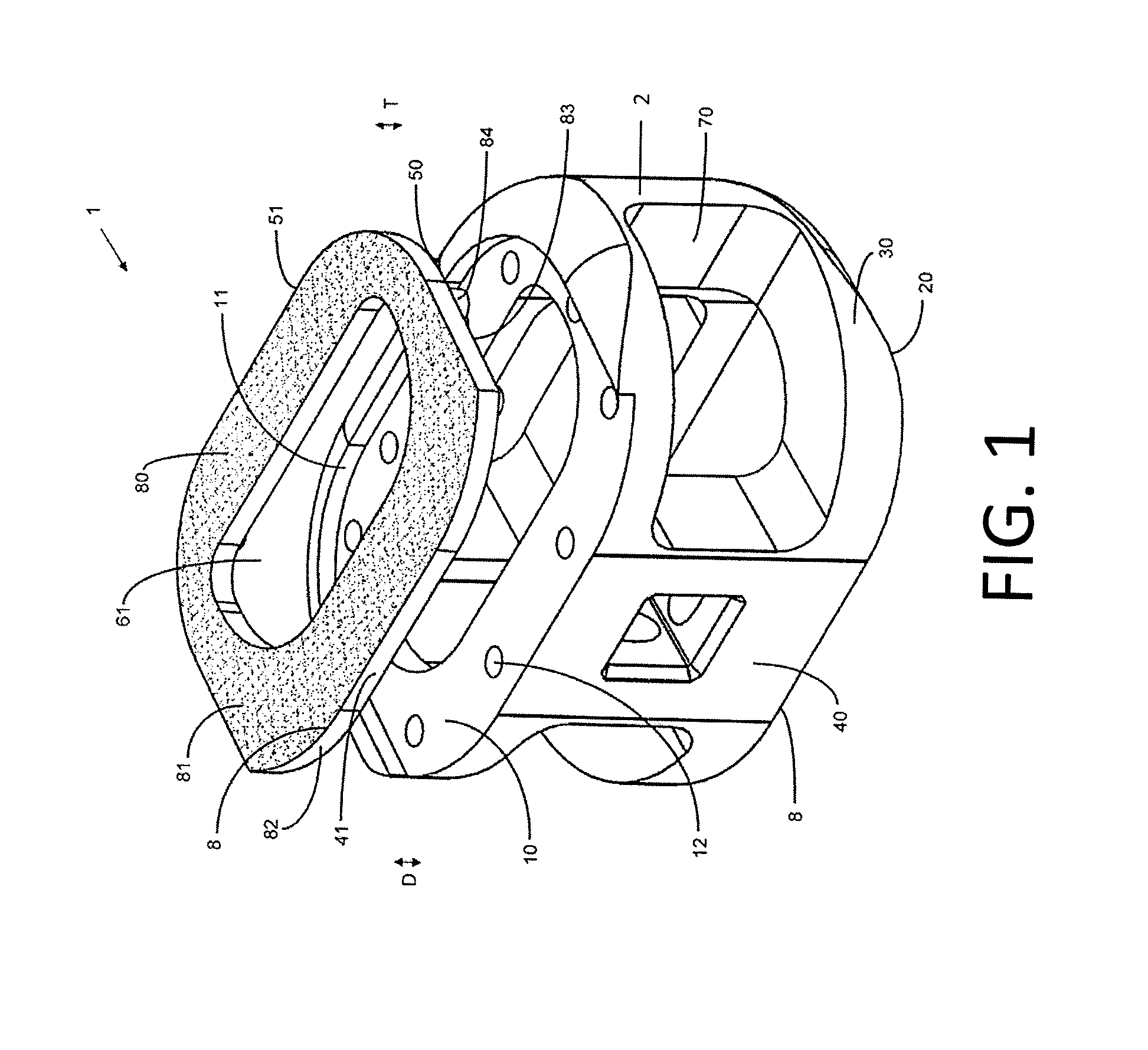

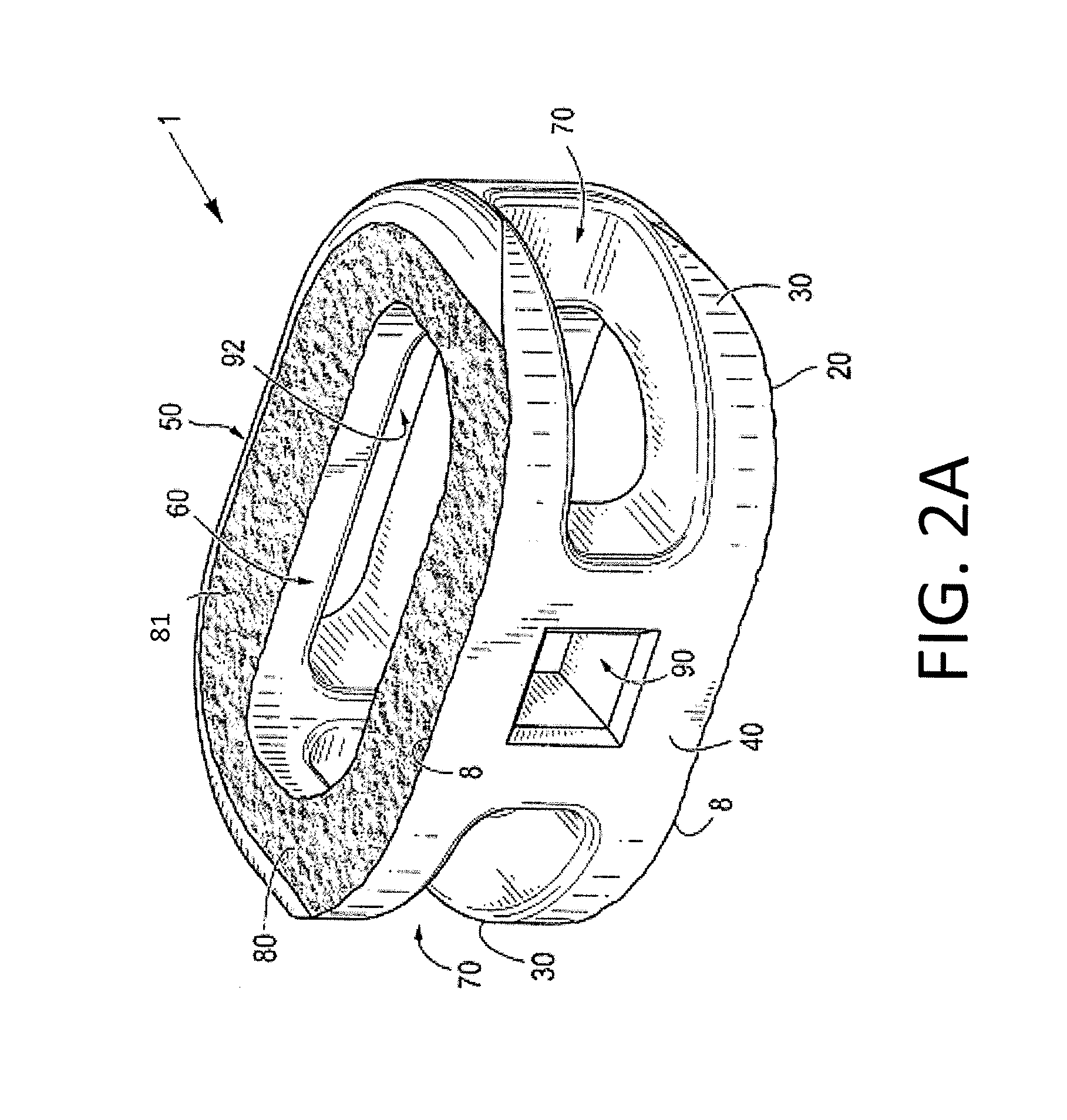

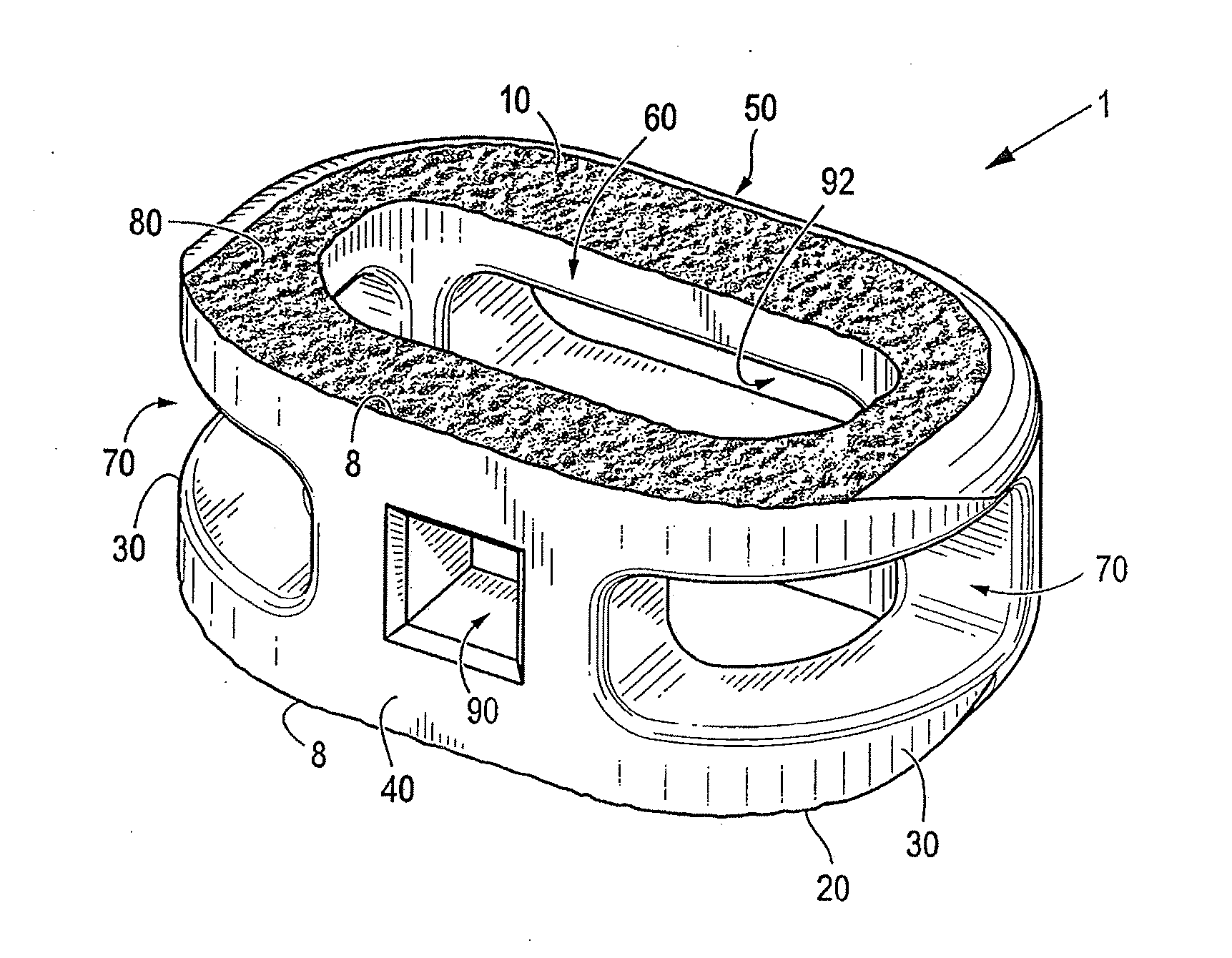

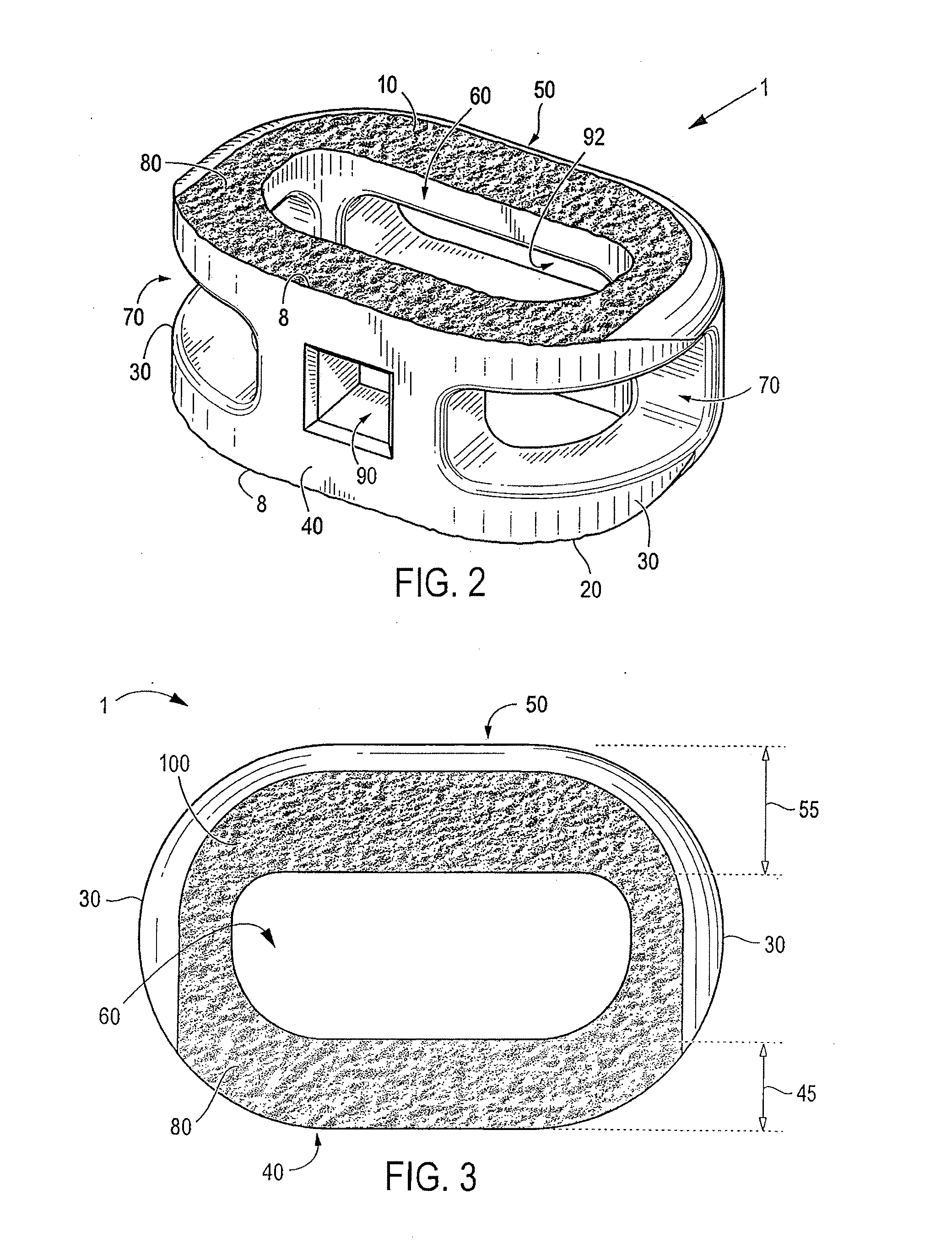

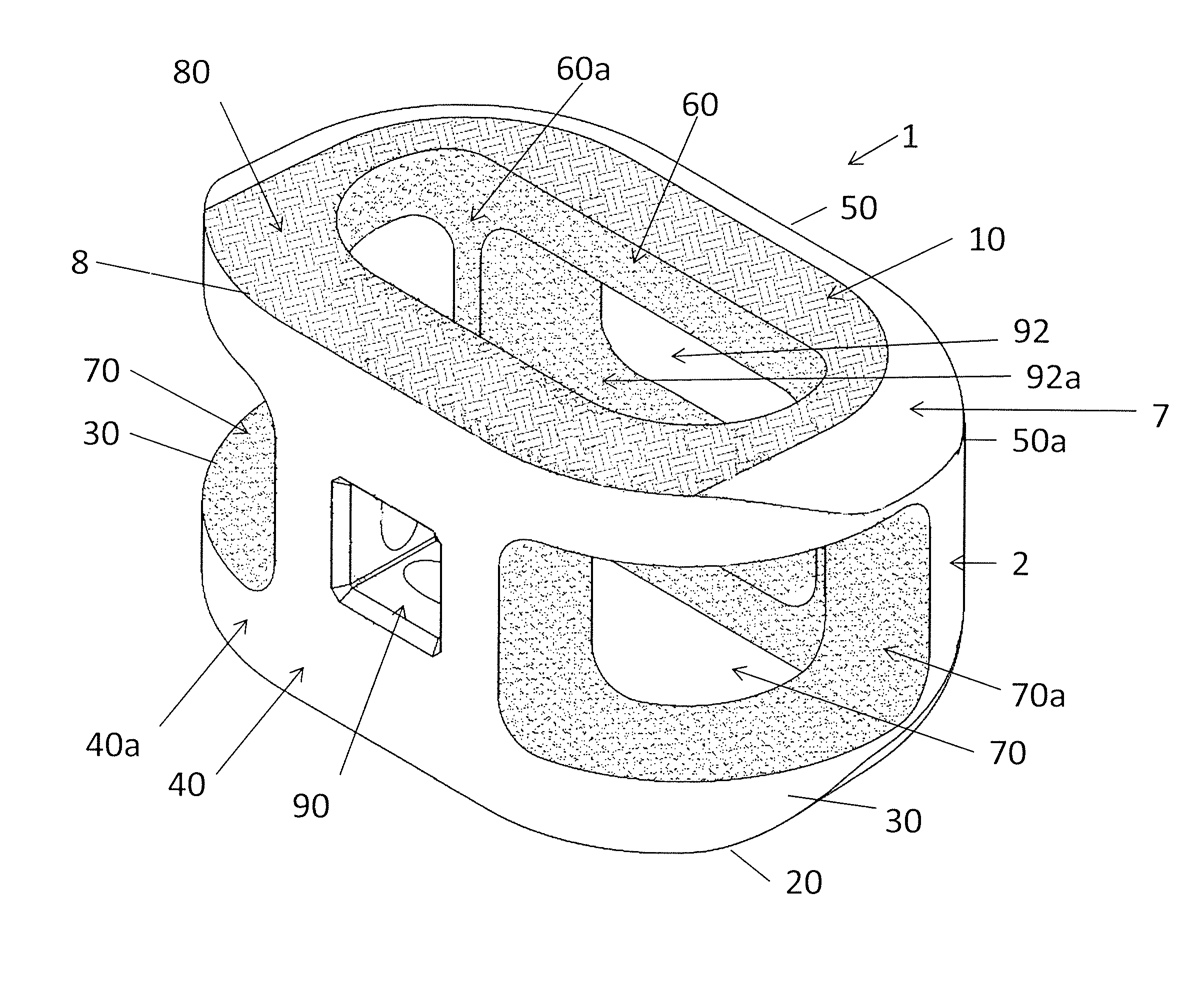

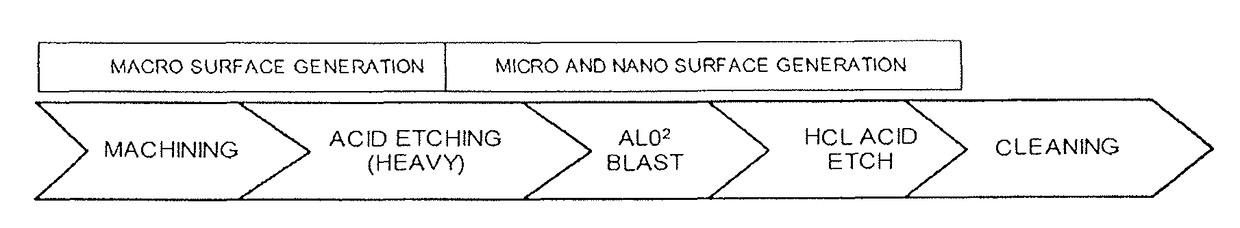

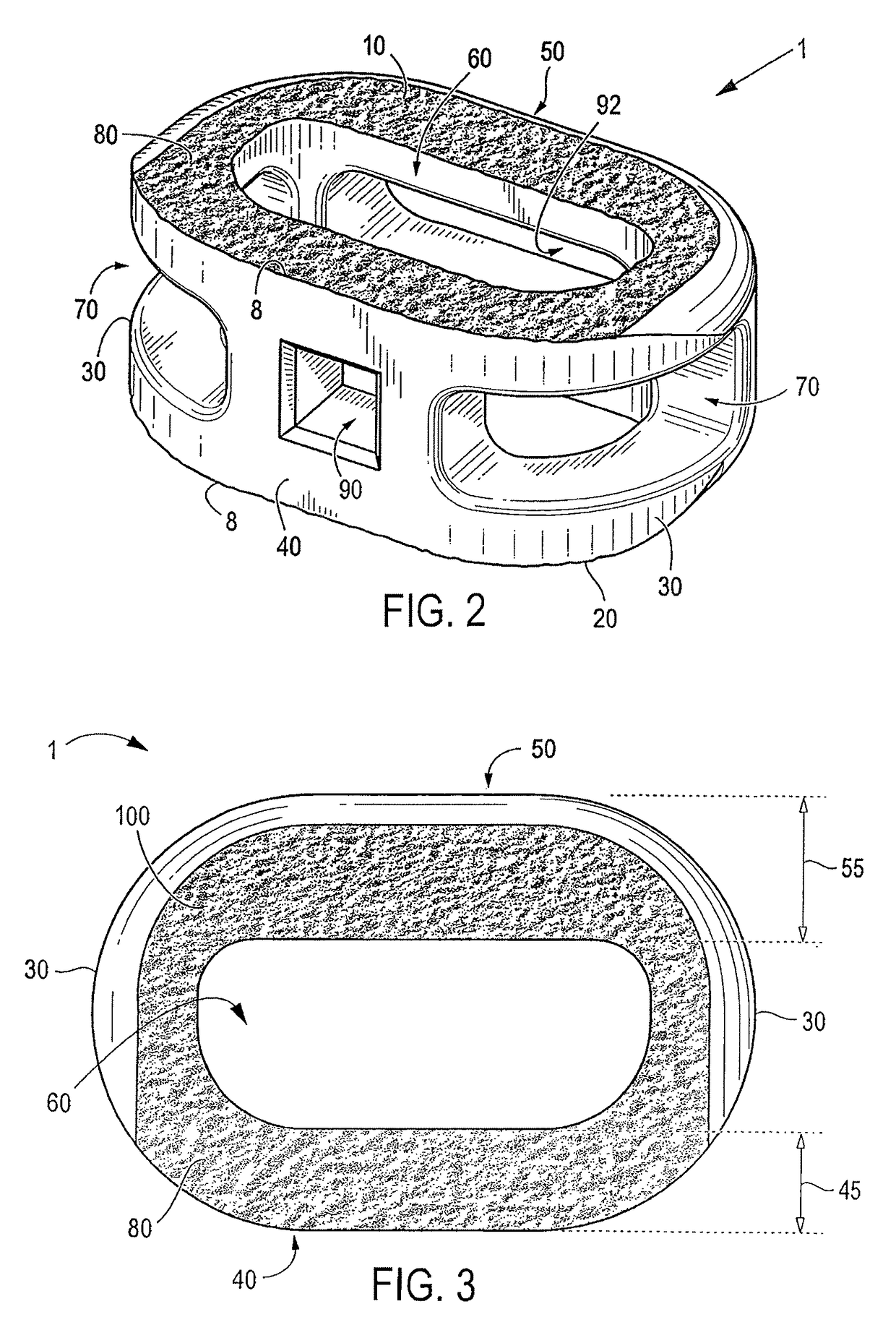

Implants having three distinct surfaces

ActiveUS20120316650A1Positively influence naturally occurring biological bone remodelingPositively fusion responseBone implantSpinal implantsRough surfaceBone structures

An interbody spinal implant having at least three distinct surfaces including (1) at least one integration surface having a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures; (2) at least one graft contact surface having a coarse surface topography including micro features and nano features; and (3) at least one soft tissue surface having a substantially smooth surface including nano features. Also disclosed are processes of fabricating the different surface topographies, which may include separate macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

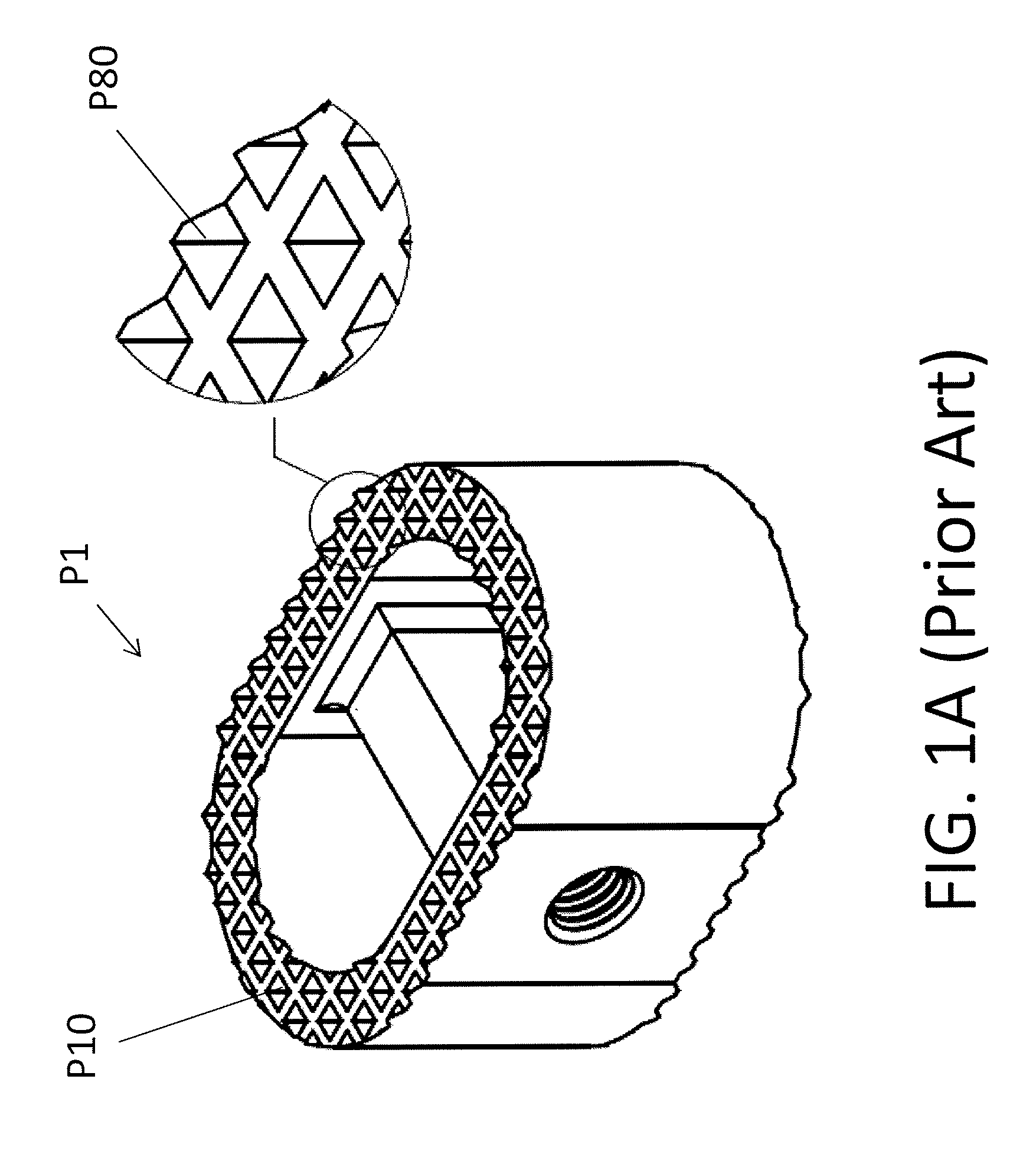

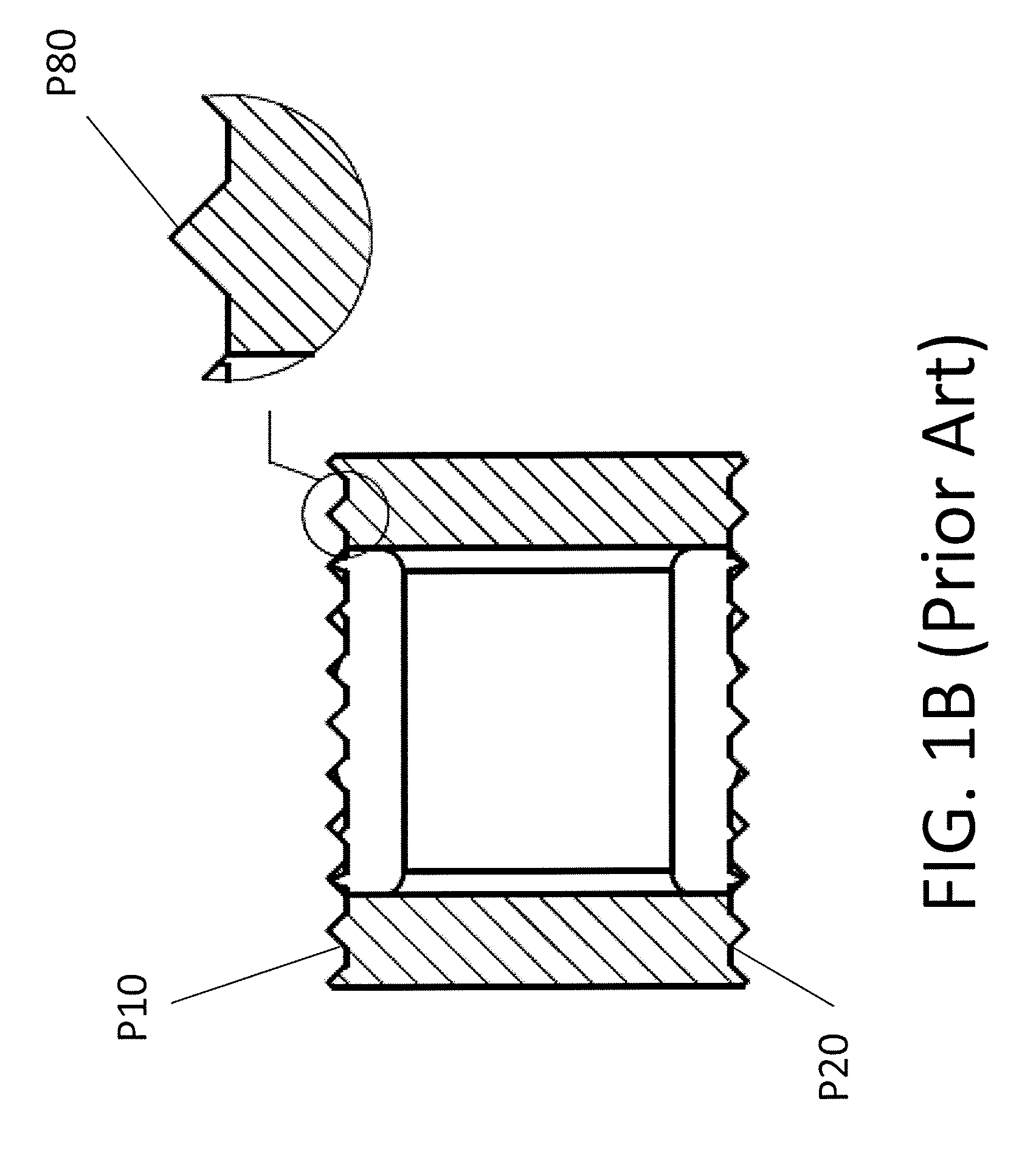

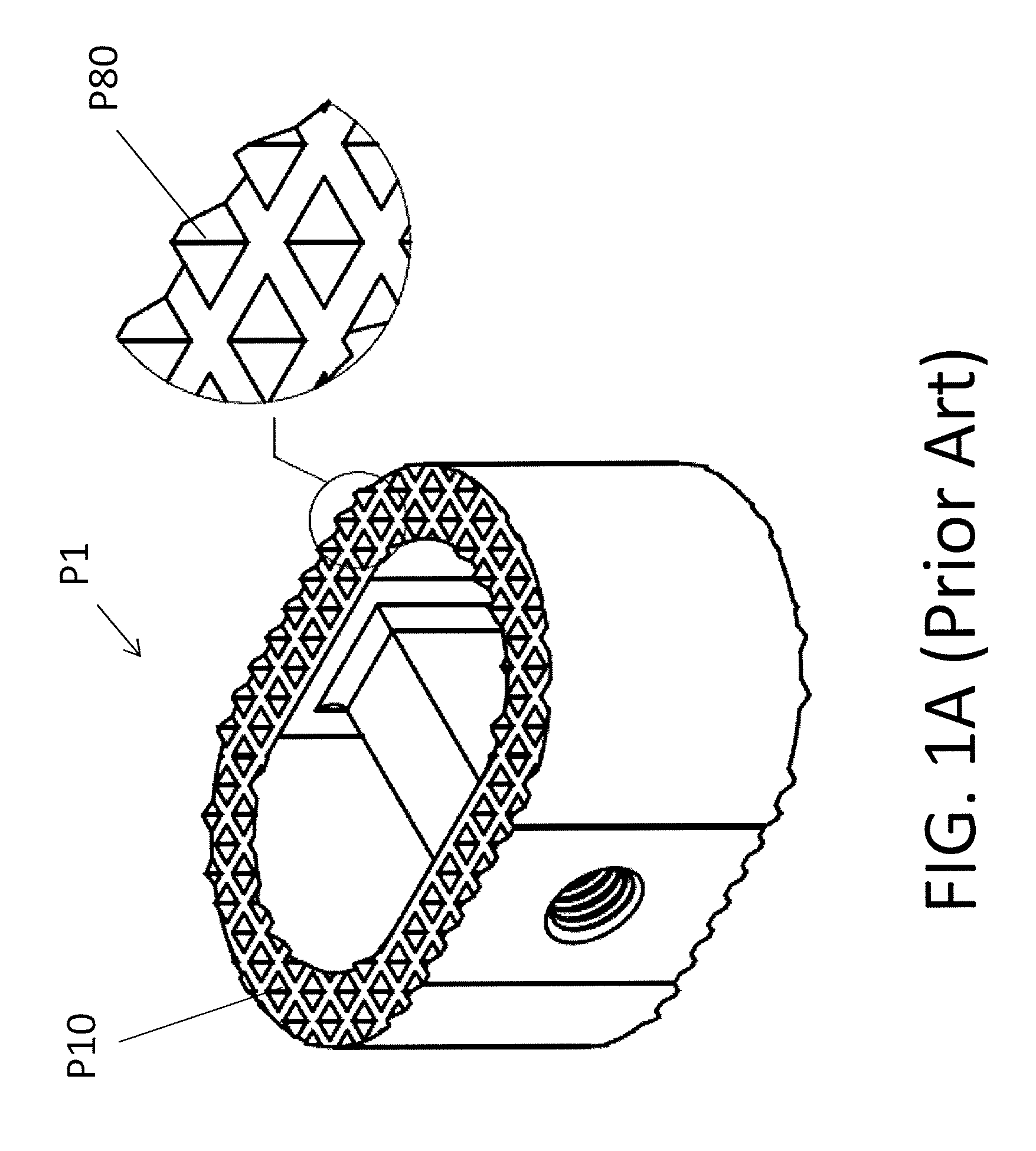

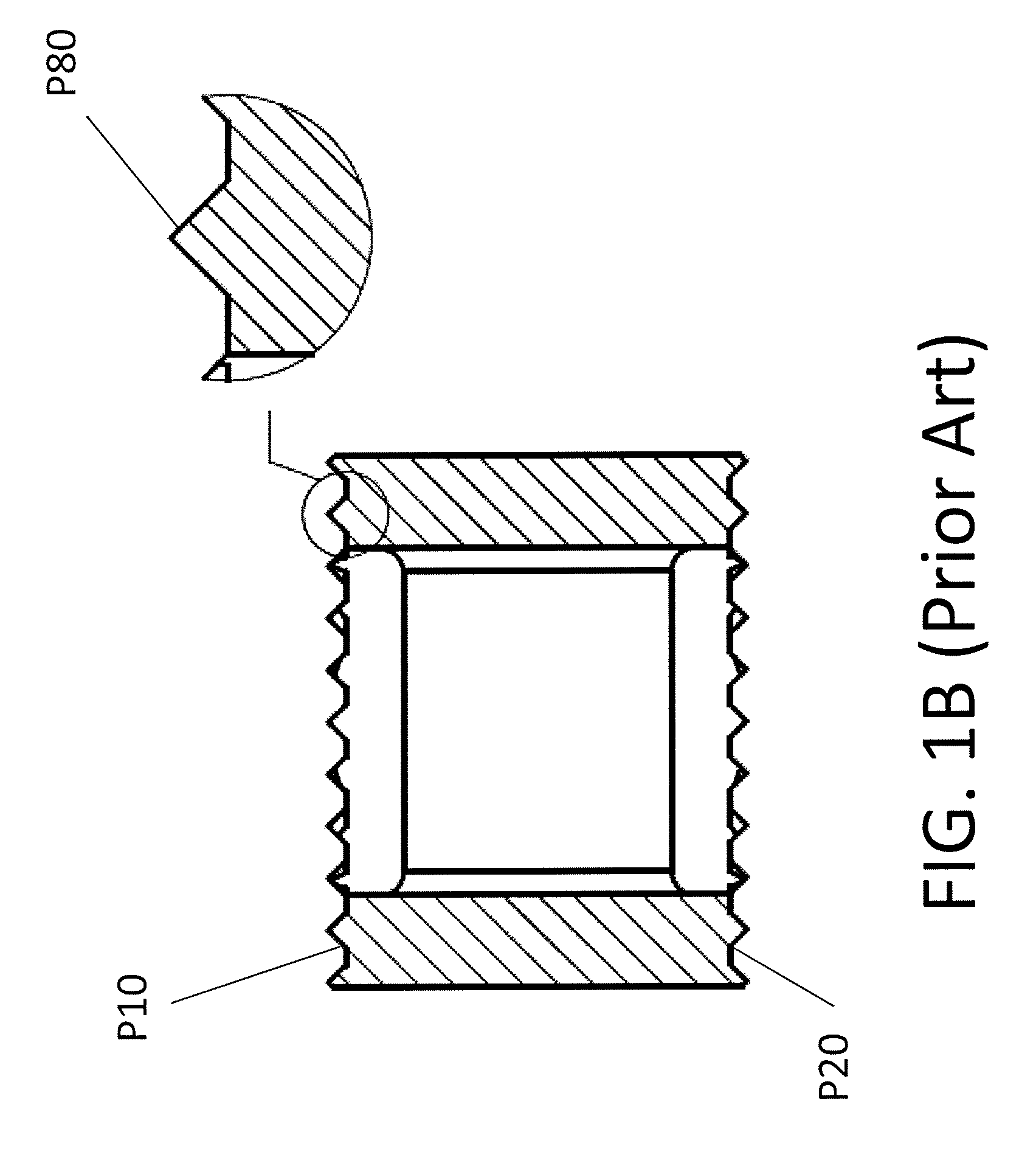

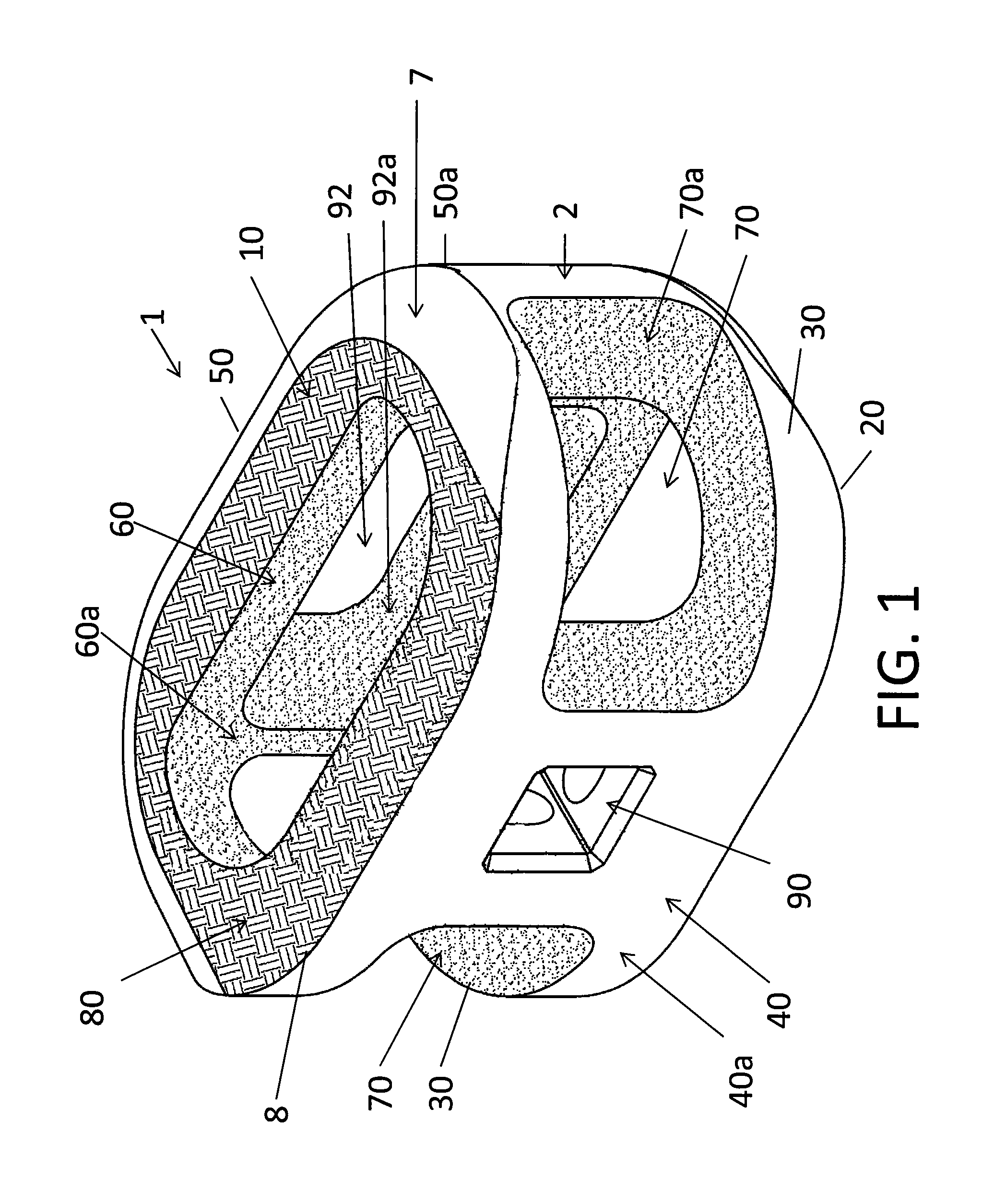

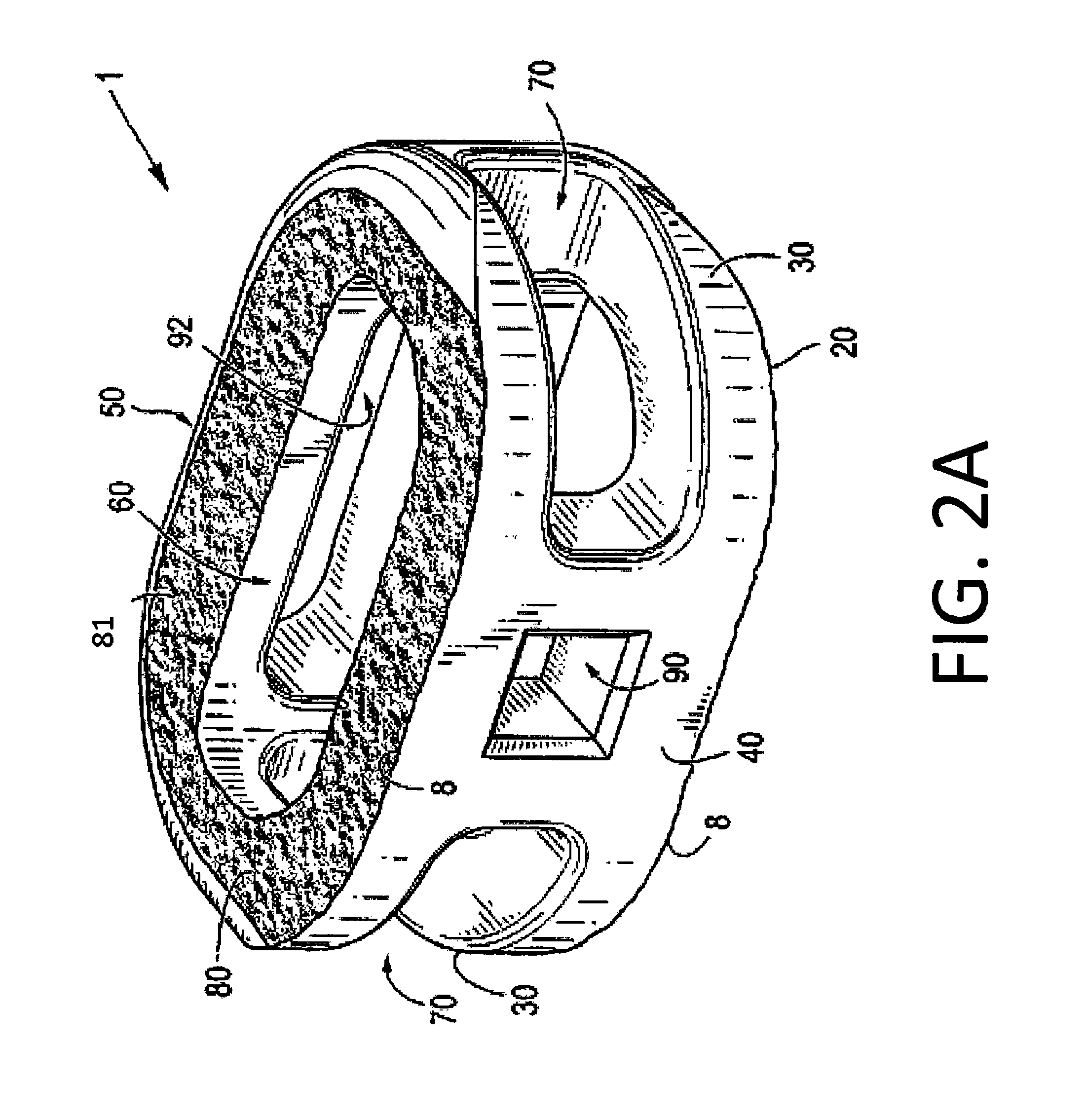

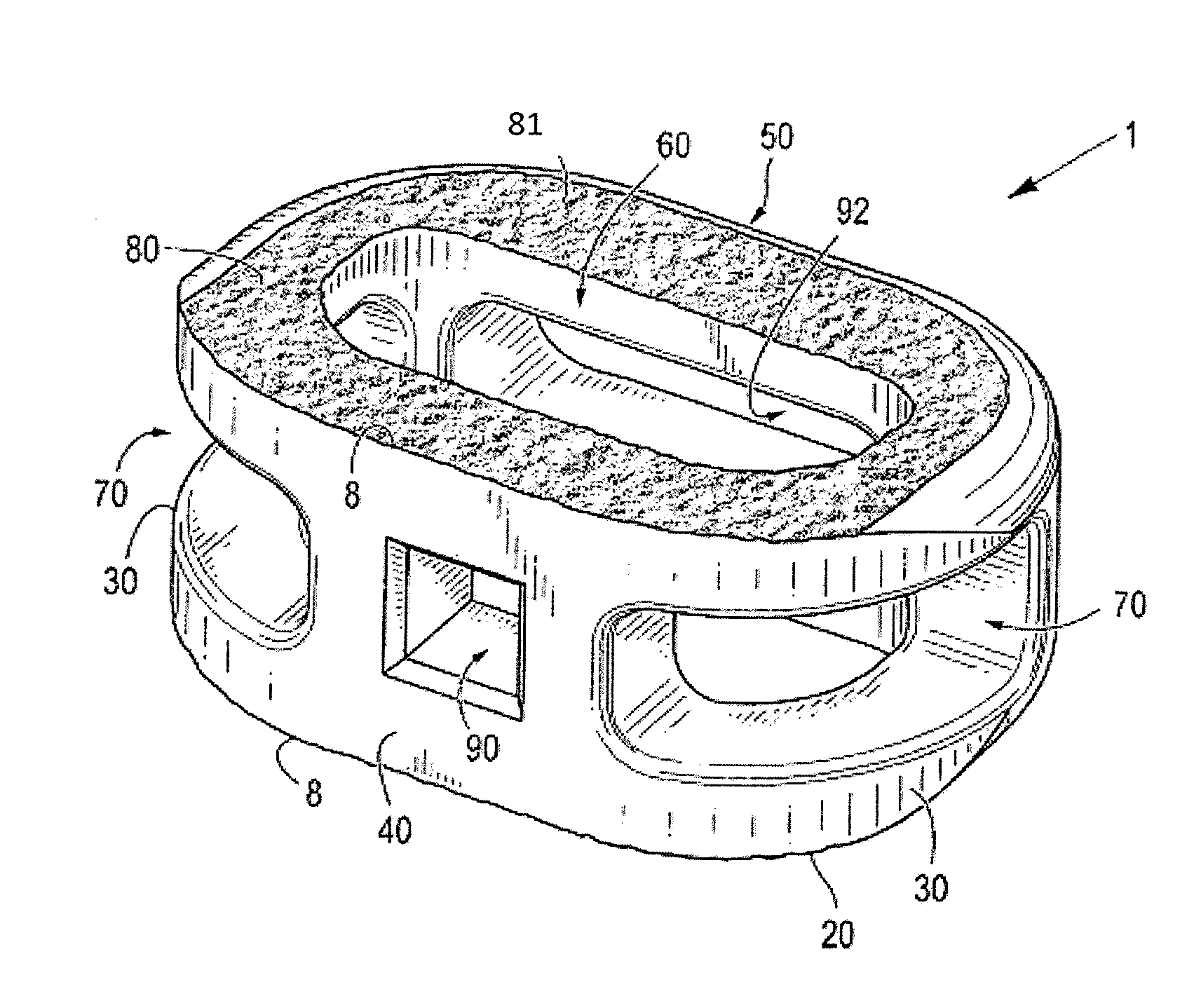

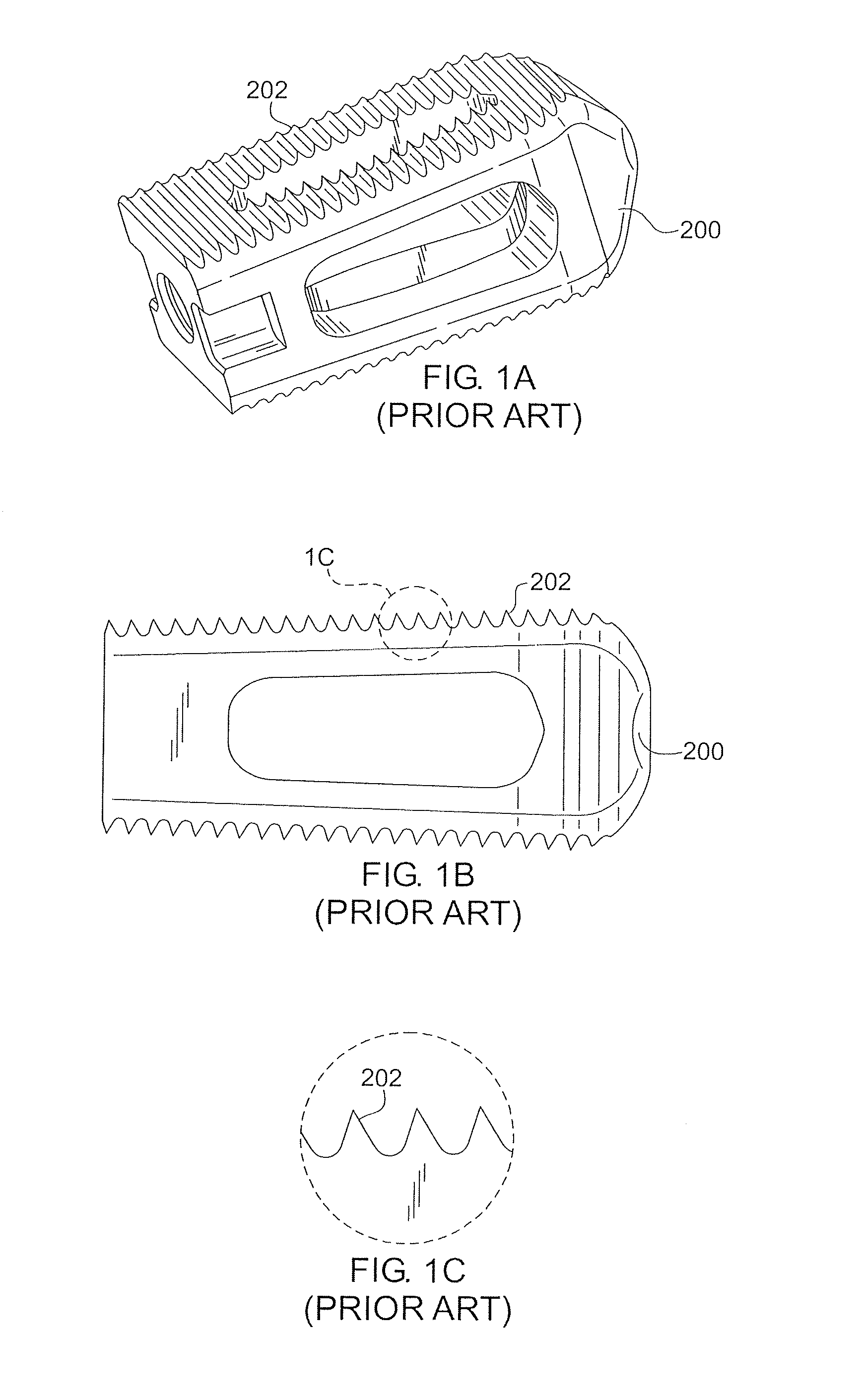

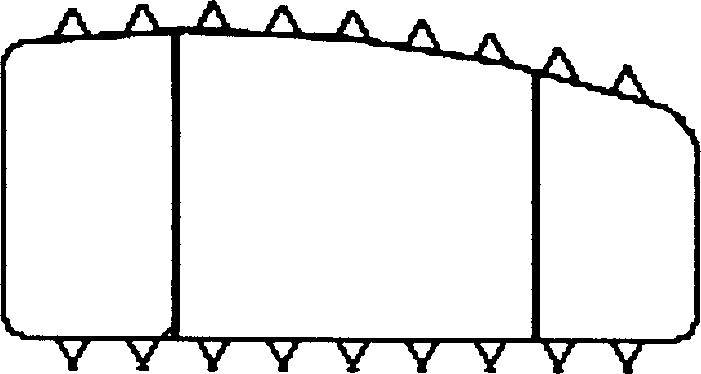

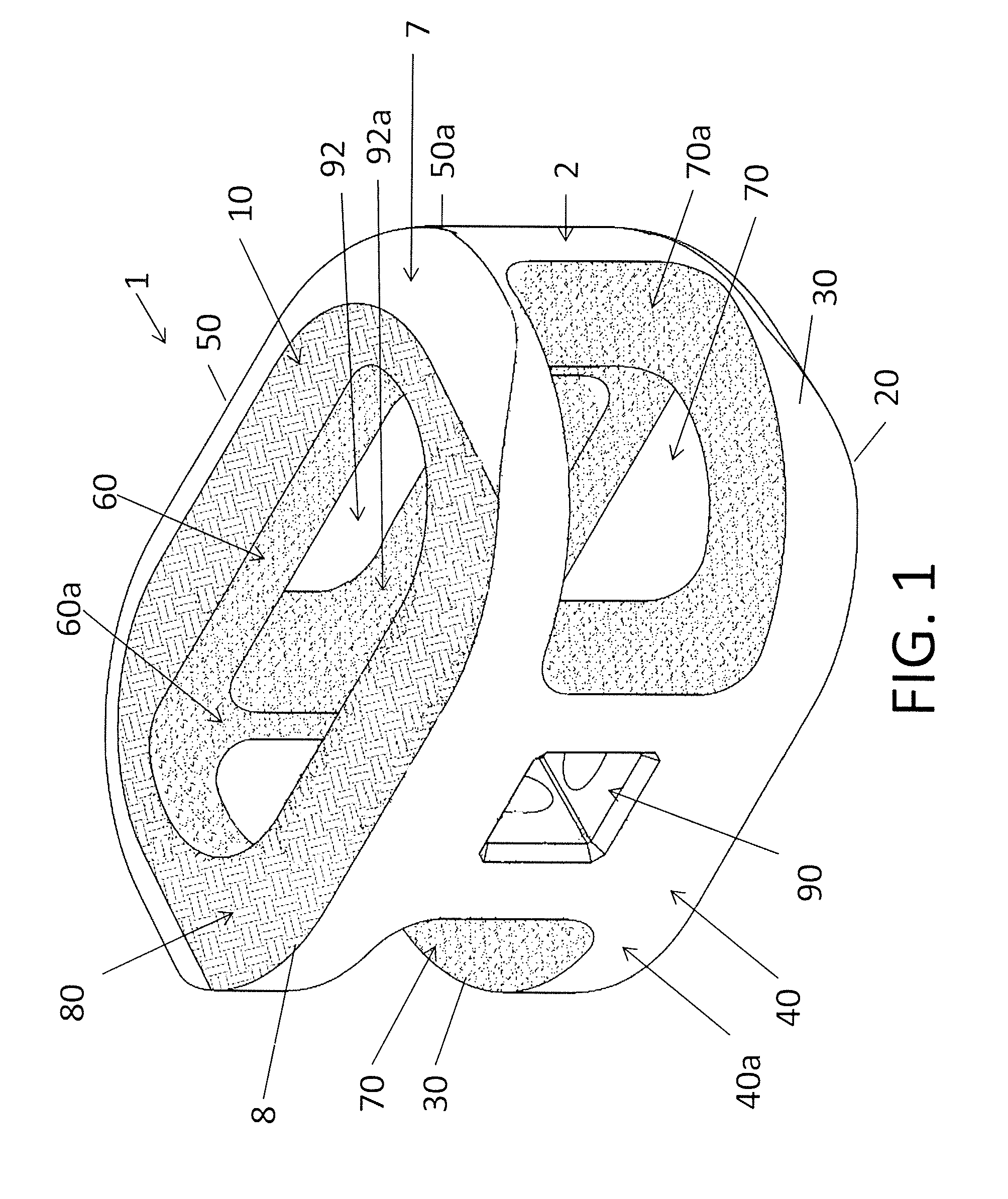

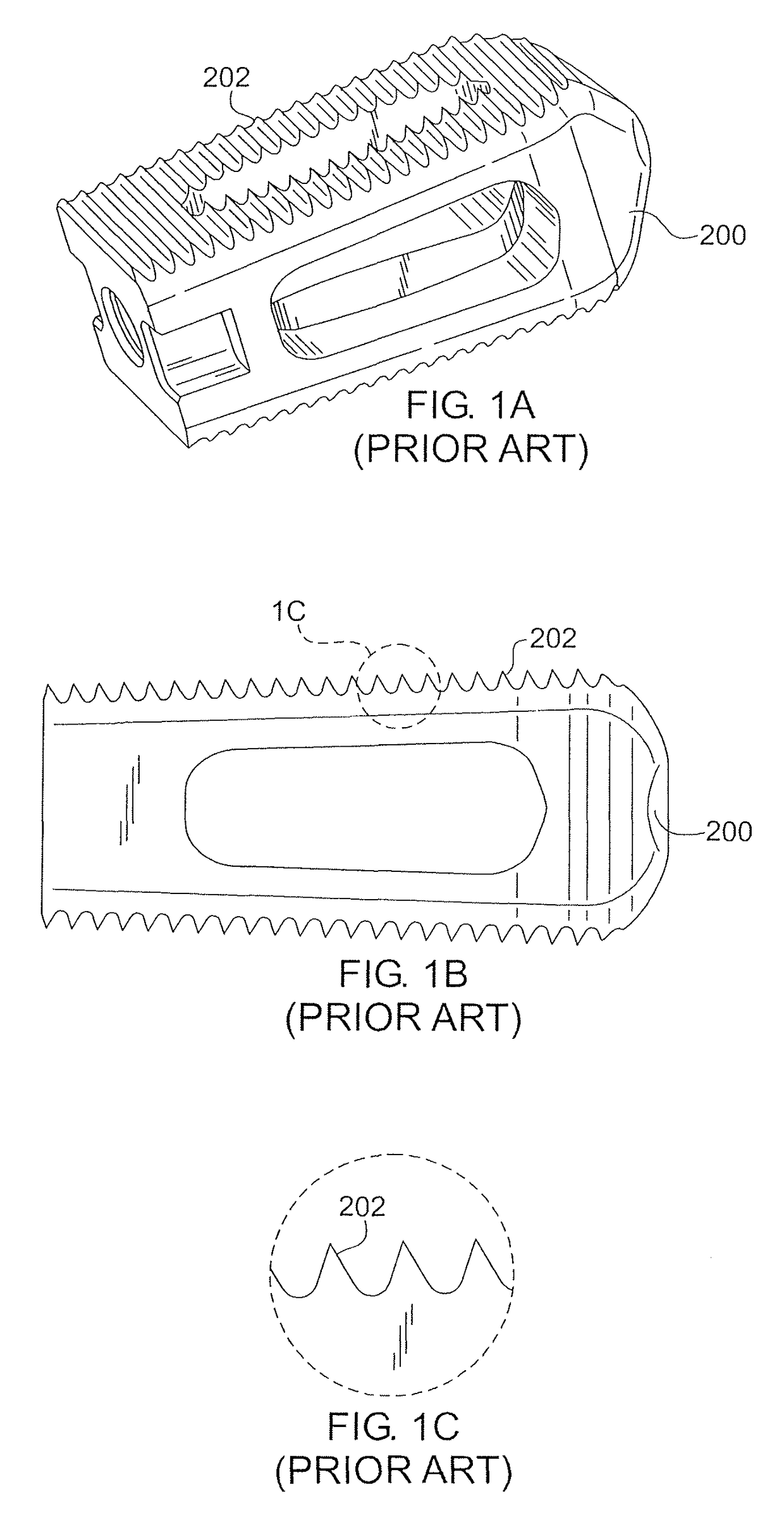

Implants with integration surfaces having regular repeating surface patterns

ActiveUS20130006363A1Increase frictionImplant stabilityBone implantSpinal implantsSurface patternBone structure

An interbody spinal implant, such as a solid-body or composite implant. The implant has at least one integration surface with a roughened surface topography including a repeating pattern, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebral endplates and to inhibit migration of the implant. The repeating pattern is formed of at least three at least partially overlapping repeating patterns. The repeating patterns may radiate at a fixed distance from at least one point and may include recesses having a slope of thirty degrees or less relative to the integration surface. Also disclosed are processes of fabricating the integration surfaces.

Owner:TITAN SPINE

Implants with integration surfaces having regular repeating surface patterns

ActiveUS8758443B2Prevent and minimize damageIncrease frictionBone implantSpinal implantsSpinal columnBone structure

An interbody spinal implant, such as a solid-body or composite implant. The implant has at least one integration surface with a roughened surface topography including a repeating pattern, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebral endplates and to inhibit migration of the implant. The repeating pattern is formed of at least three at least partially overlapping repeating patterns. The repeating patterns may radiate at a fixed distance from at least one point and may include recesses having a slope of thirty degrees or less relative to the integration surface. Also disclosed are processes of fabricating the integration surfaces.

Owner:TITAN SPINE

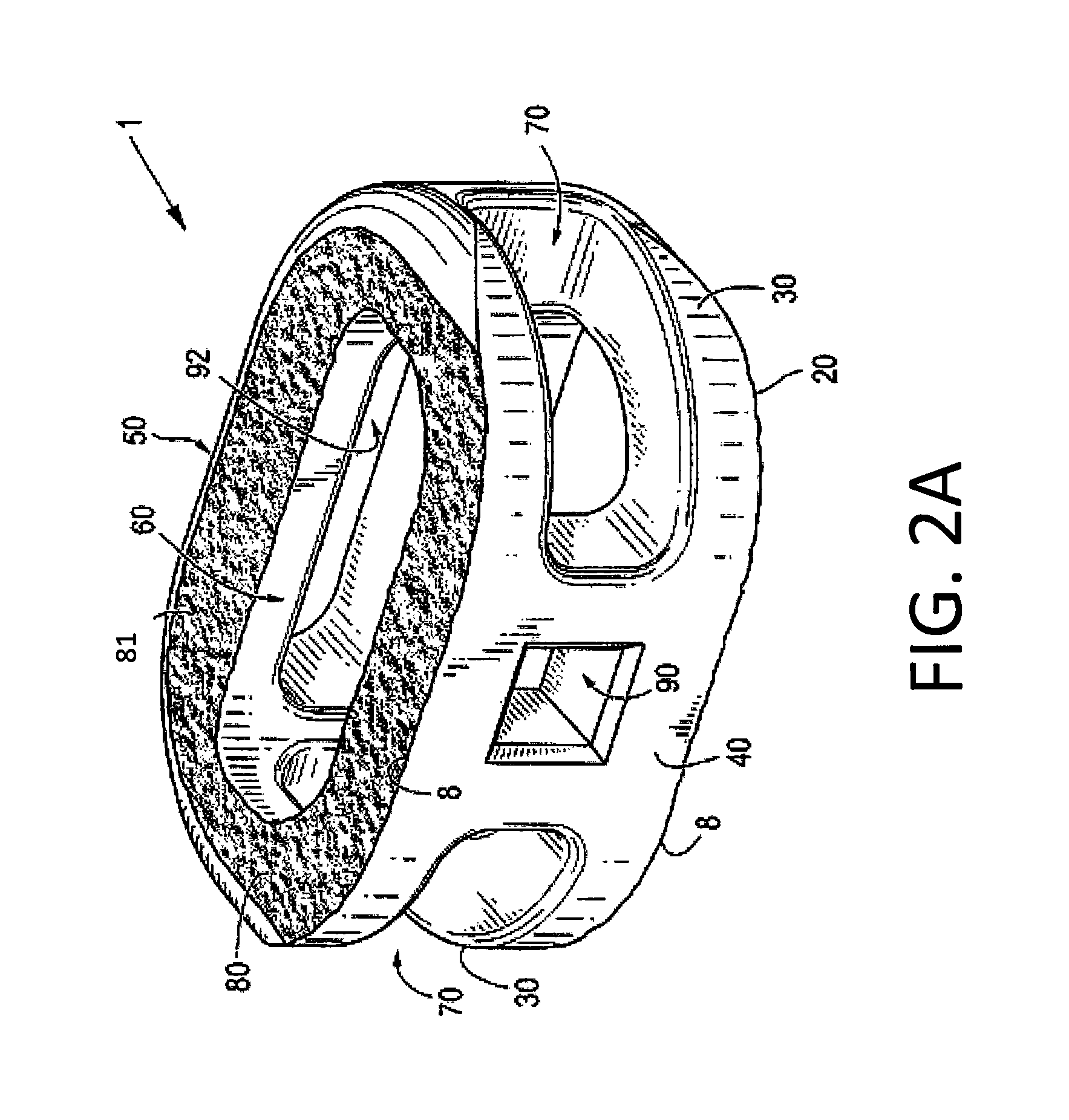

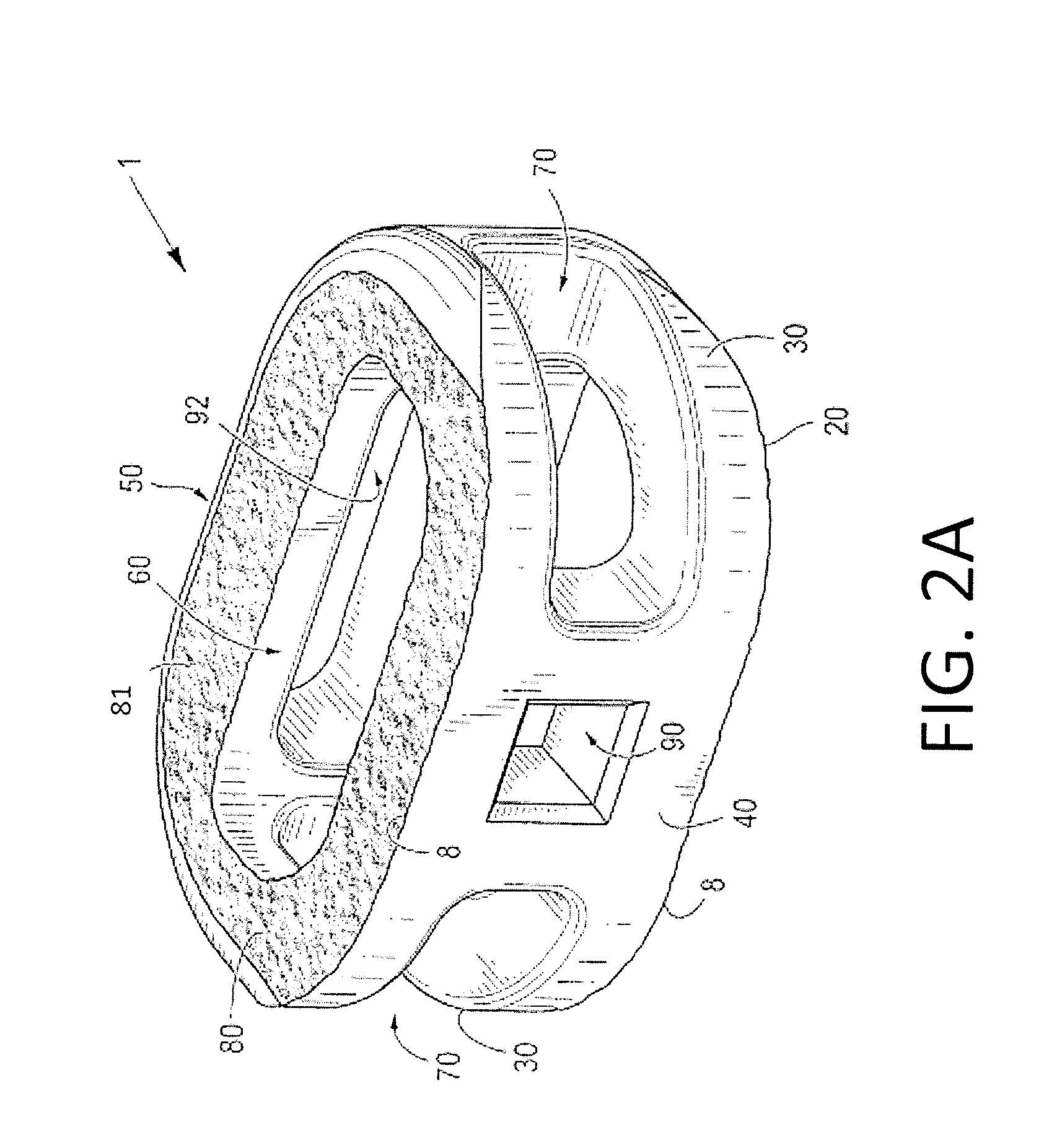

Composite implants having integration surfaces composed of a regular repeating pattern

ActiveUS20120316651A1Inhibit migrationBone implantDecorative surface effectsRough surfaceBone structure

A composite interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions; a first integration plate affixed to the top surface of the body; and an optional second integration plate affixed to the bottom surface of the body. At least a portion of the first integration plate, optional second integration plate, or both has a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction, inhibit migration of the implant, and promote bone growth. Also disclosed are processes of fabricating a roughened surface topography, which may include separate and sequential macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

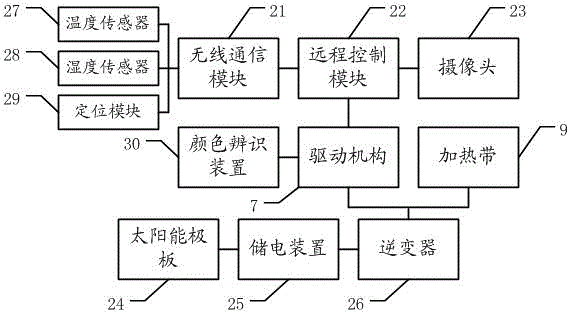

Ice and snow removing device of power transmission line

ActiveCN104882841AEliminate icingRemove snowOverhead installationApparatus for overhead lines/cablesEngineeringOverhead line

The invention discloses an ice and snow removing device of a power transmission line. The ice and snow removing device is arranged on an overhead line, wherein a box body of the ice and snow removing device is internally provided with a scrapping plate, a hairbrush assembly, a heating belt sleeving the external part of the overhead line, an upper ice removing wheel and a lower ice removing wheel. Under the driving of a driving mechanism, the ice and snow removing device moves on the overhead line through a pulley set. Gears of the upper ice removing wheel and the lower ice removing wheel form certain extrusion forces to coating ice, and circumferential ice removing sharp teeth remove the coating ice on the power transmission line, so that rapid ice removing is realized; in addition, the heating belt is used to heat the external part of the overhead line, so that ice removing is convenient. The scrapping plate and the hairbrush assembly are capable of clearing scattered ice and accumulated snow on the overhead line, and in this way, the ice and snow removing device can effectively removing the coating ice and the accumulated snow on the overhead line, reduce the pressure caused by the e coating ice and the accumulated snow and ensure the normal power supplying in an icy and snowing day.

Owner:BINZHOU POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Implants having three distinct surfaces

ActiveUS8814939B2Avoid abrasionsAvoid lacerationsBone implantSpinal implantsRough surfaceBone structure

An interbody spinal implant having at least three distinct surfaces including (1) at least one integration surface having a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures; (2) at least one graft contact surface having a coarse surface topography including micro features and nano features; and (3) at least one soft tissue surface having a substantially smooth surface including nano features. Also disclosed are processes of fabricating the different surface topographies, which may include separate macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

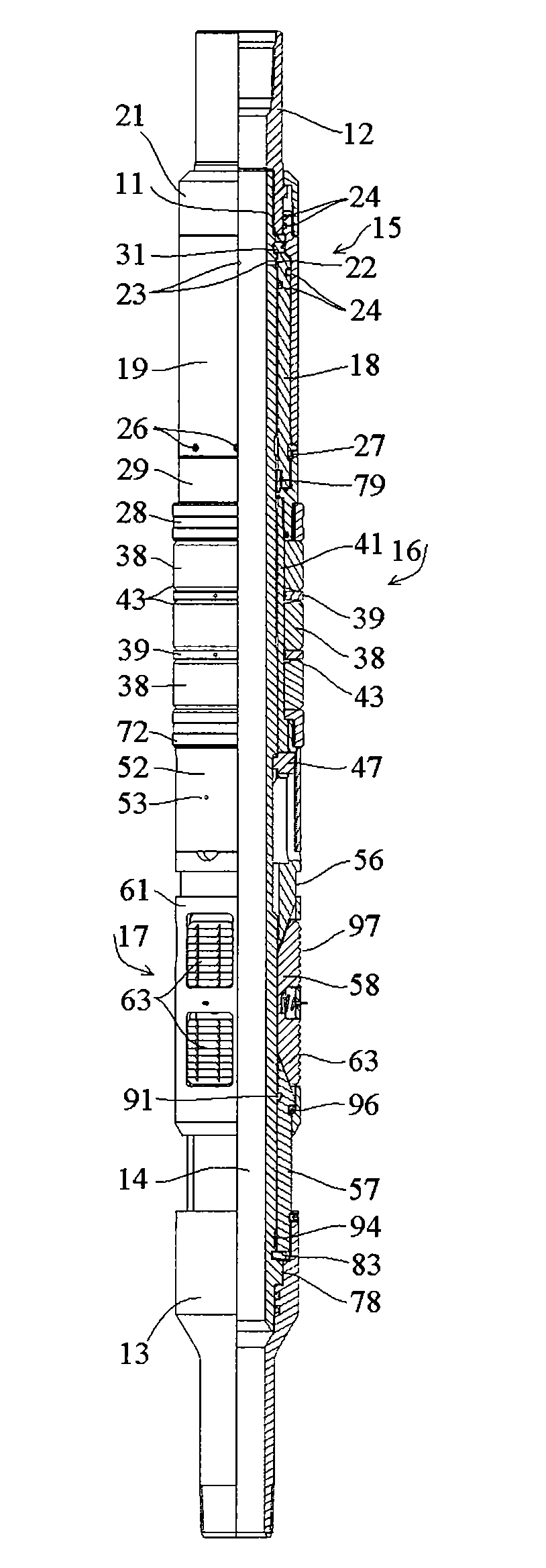

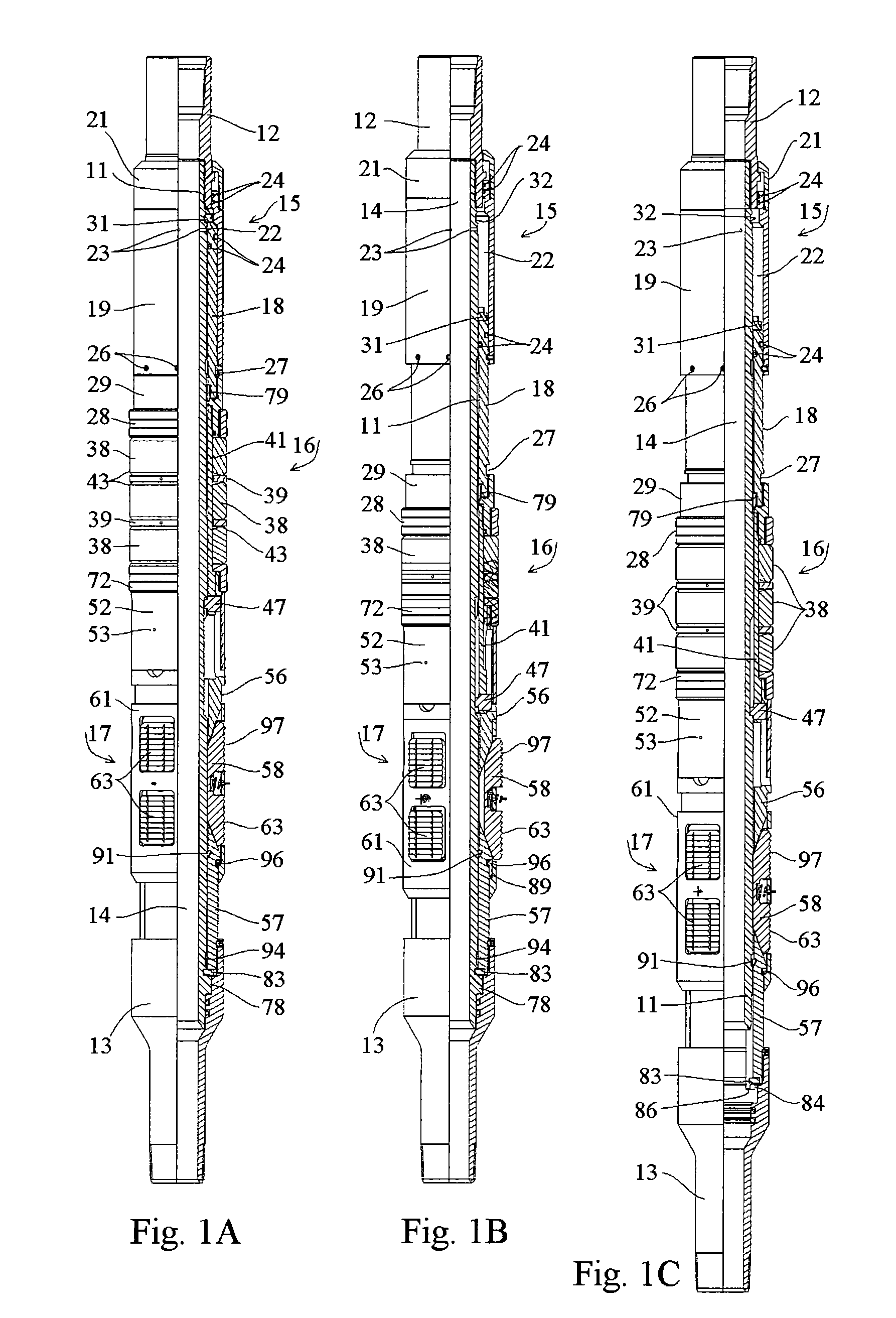

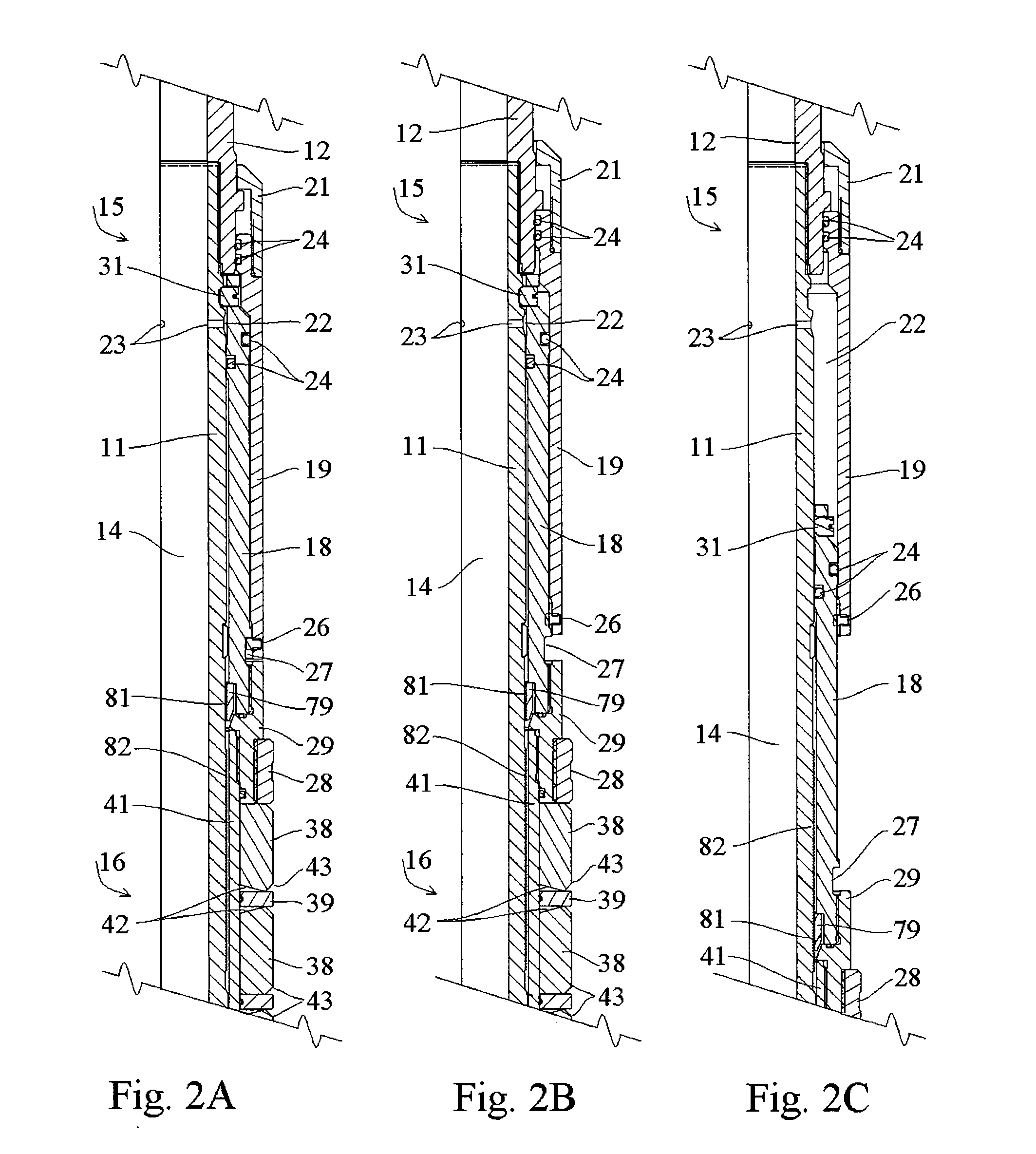

Downhole packer tool with dummy slips

ActiveUS20120160522A1Simple andFacilitated releaseFluid removalSealing/packingEngineeringSharp tooth

Owner:TEXPROIL S R L SUCURSAL COLOMBIA

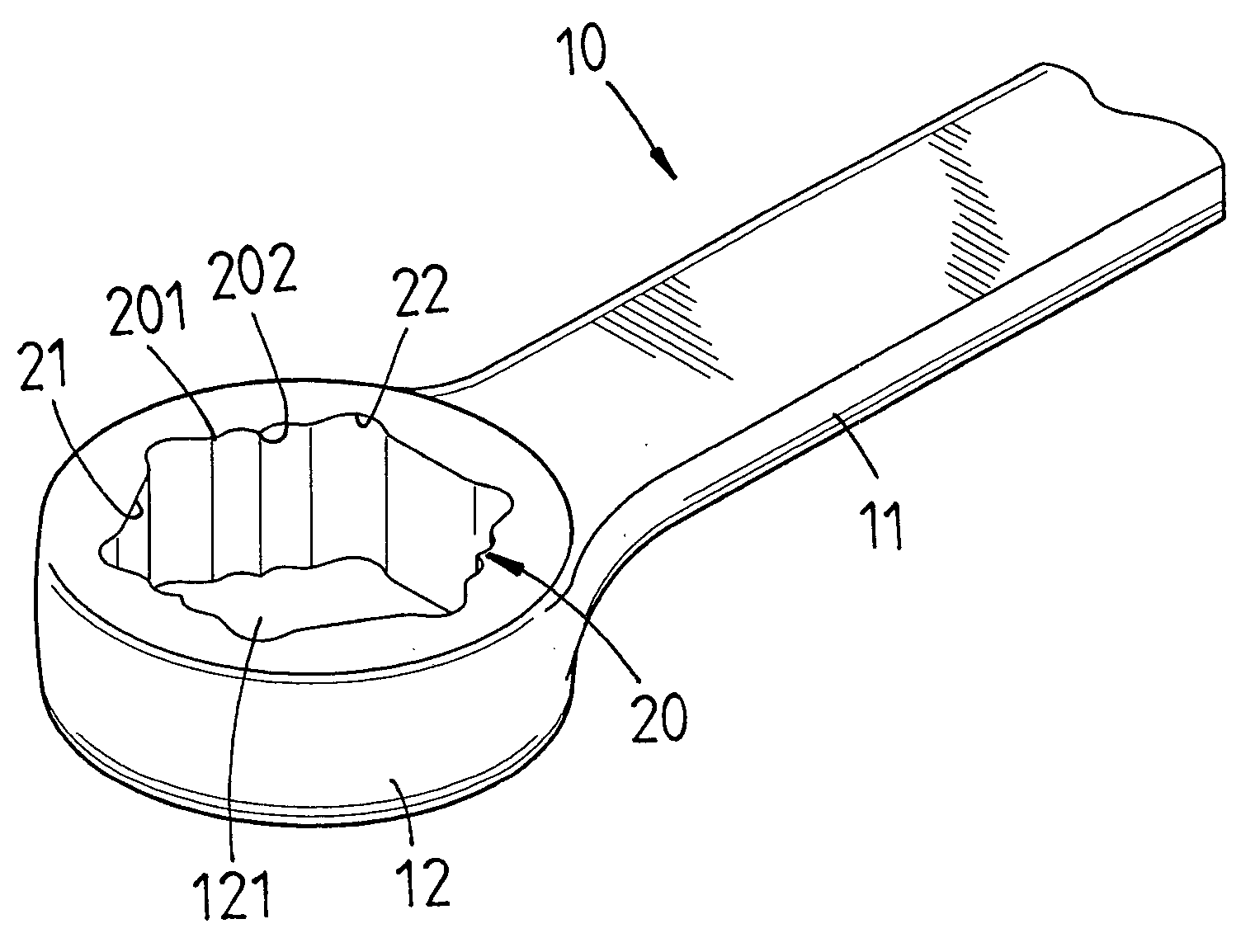

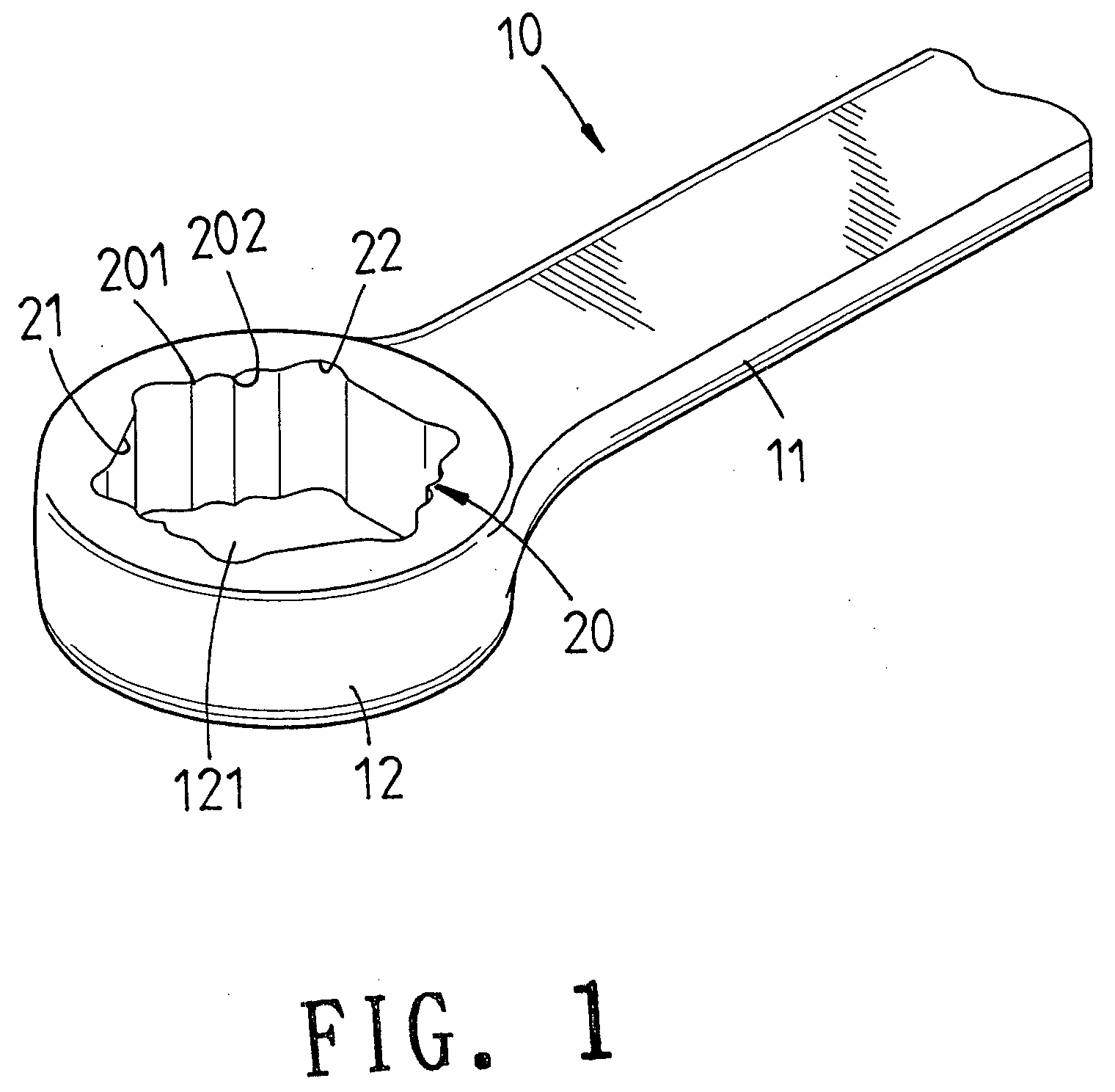

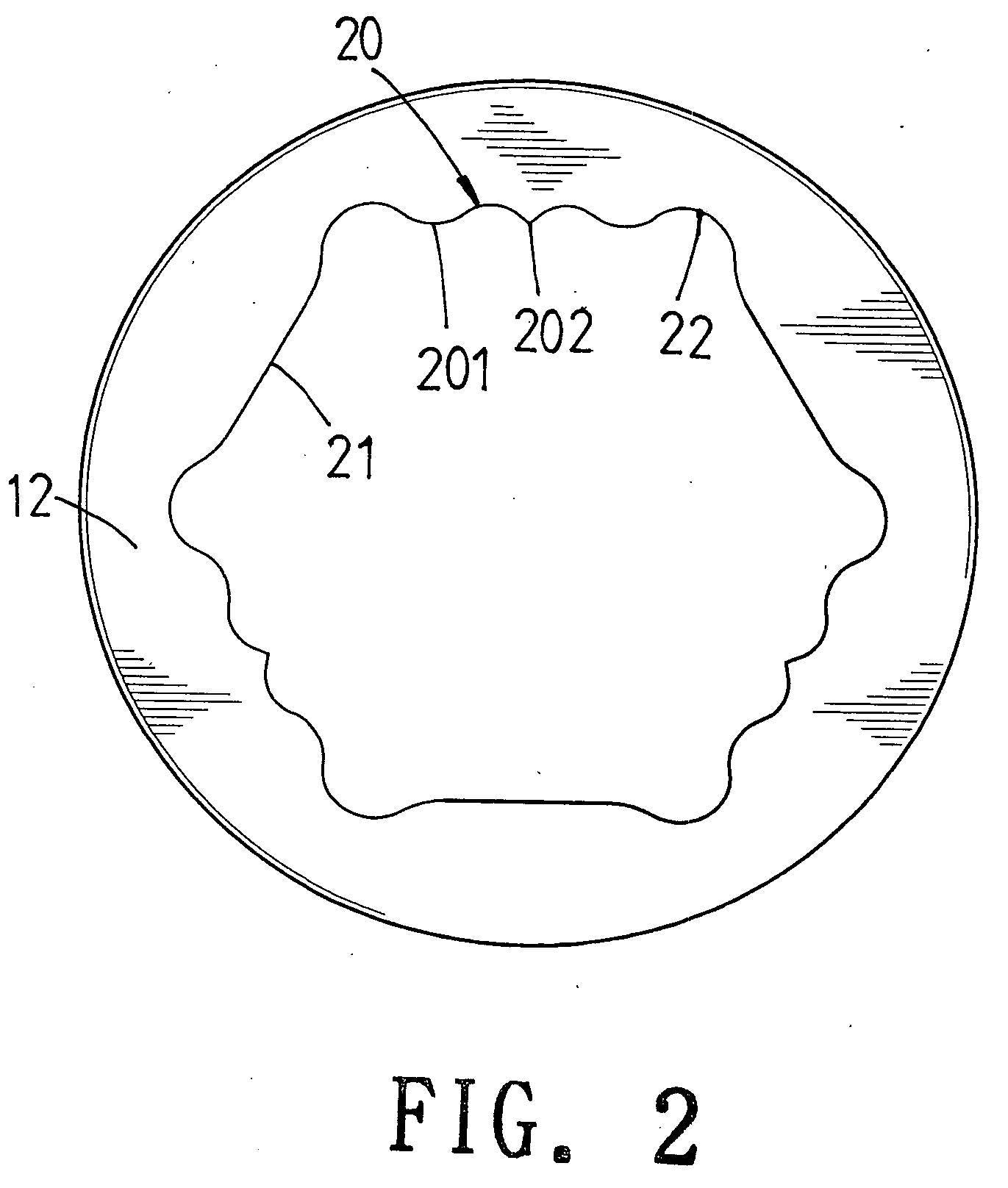

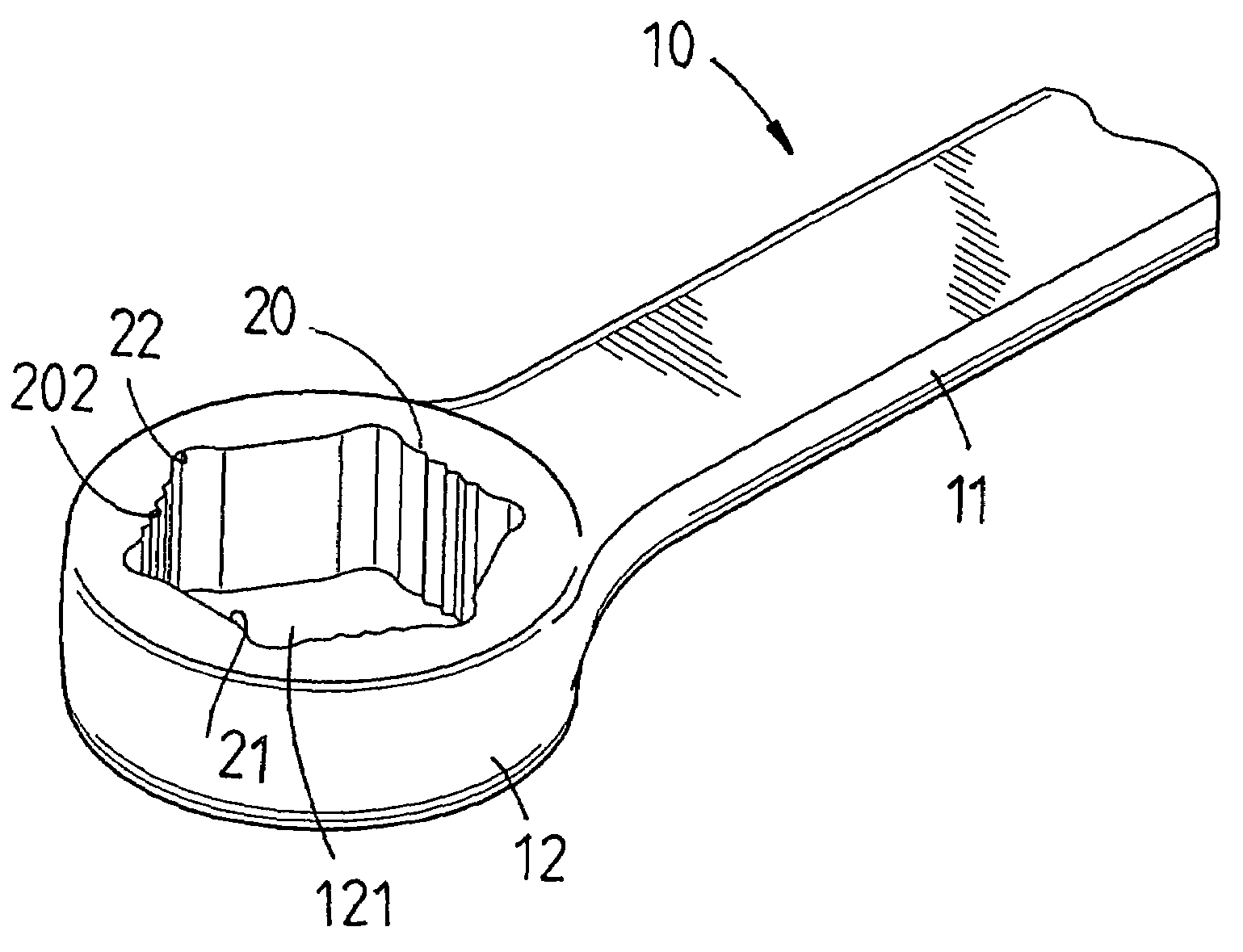

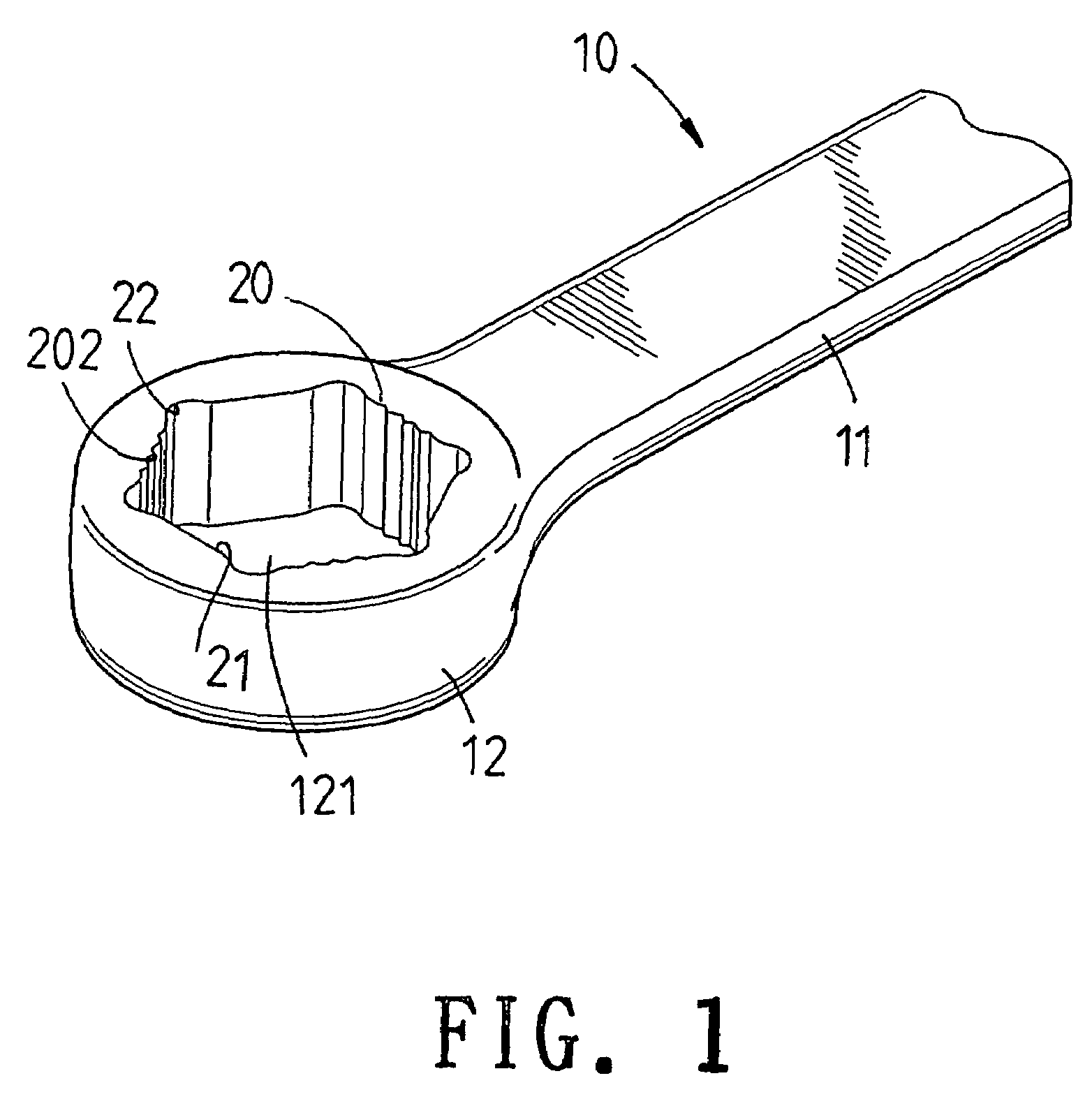

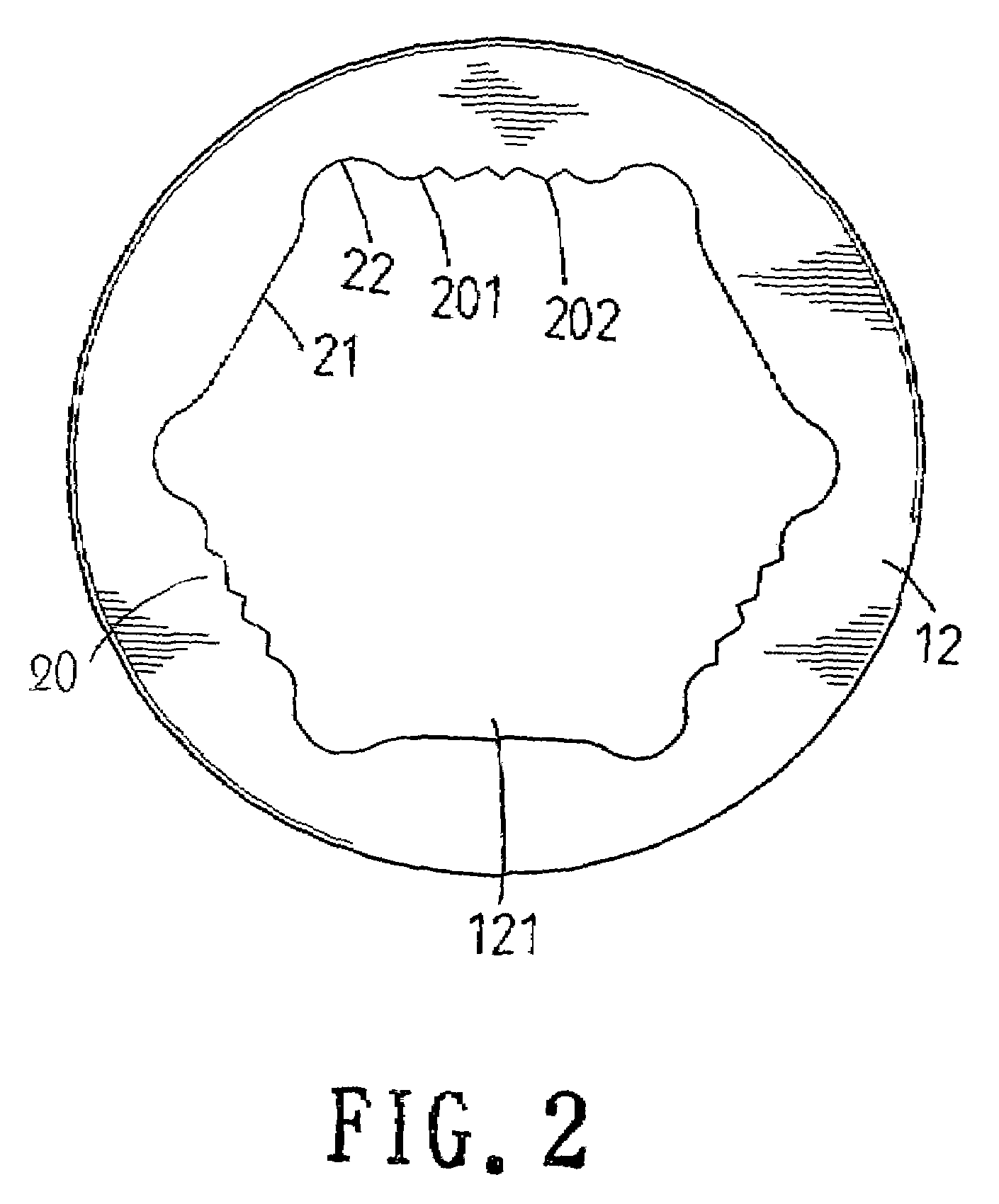

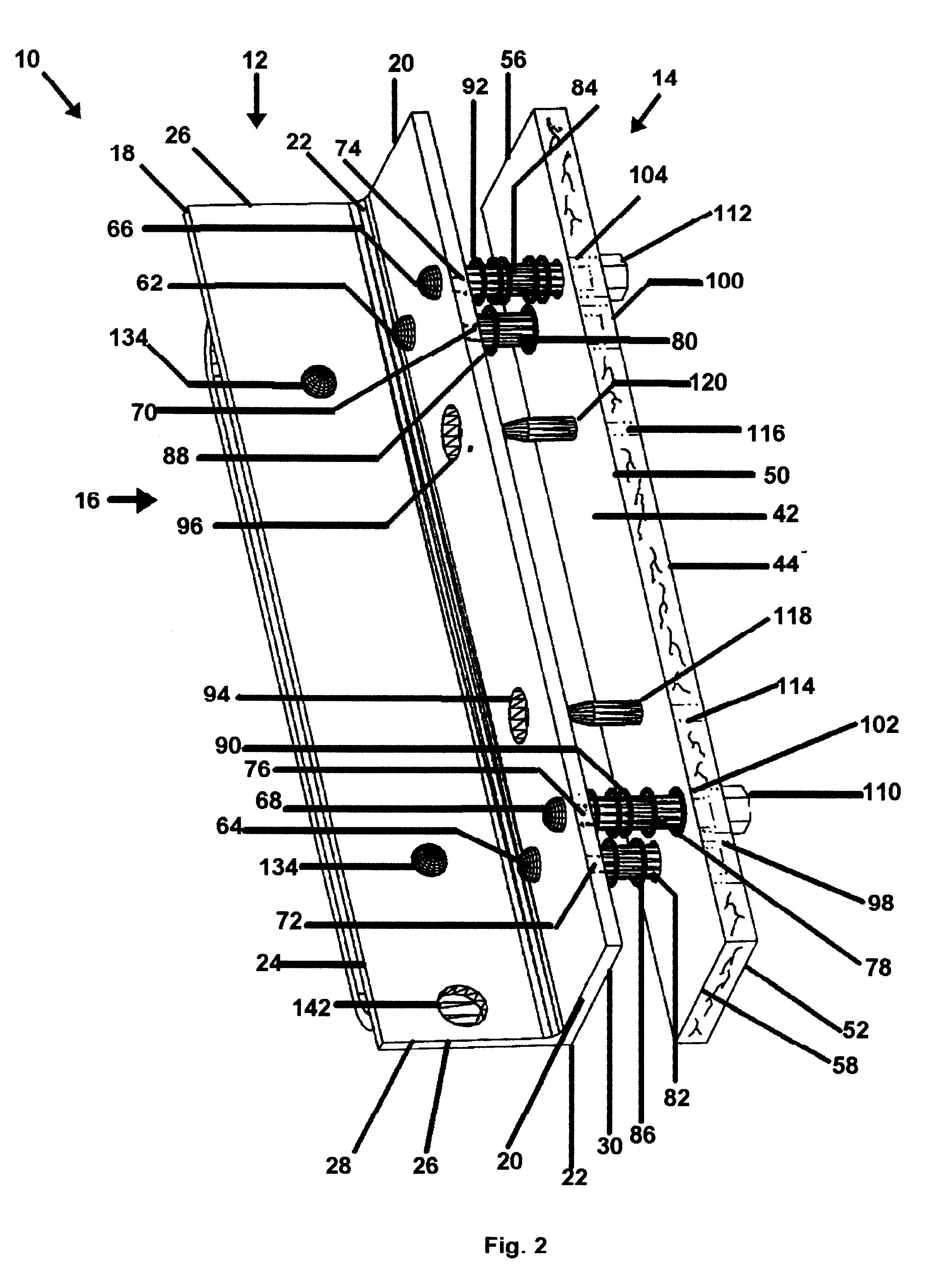

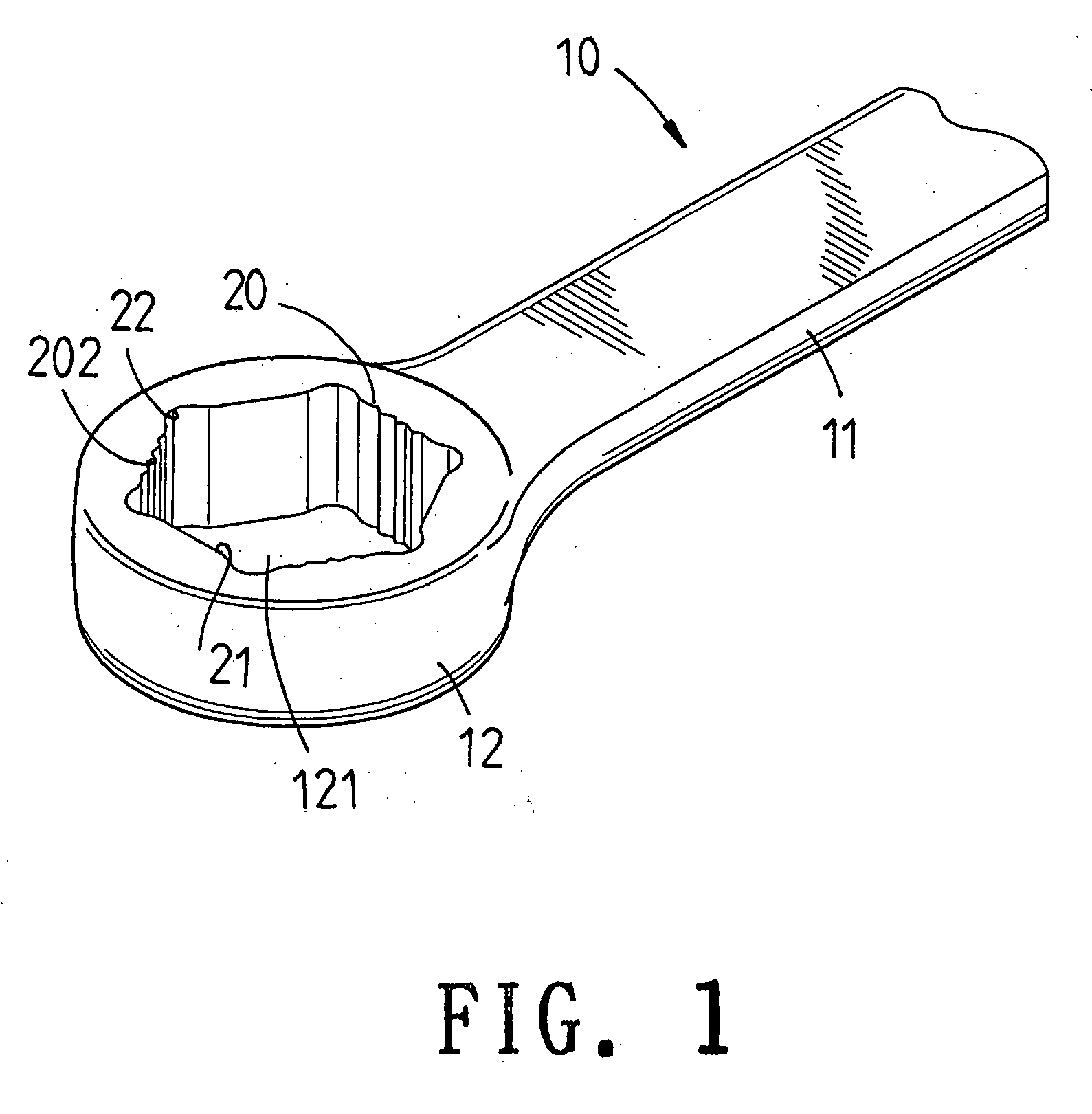

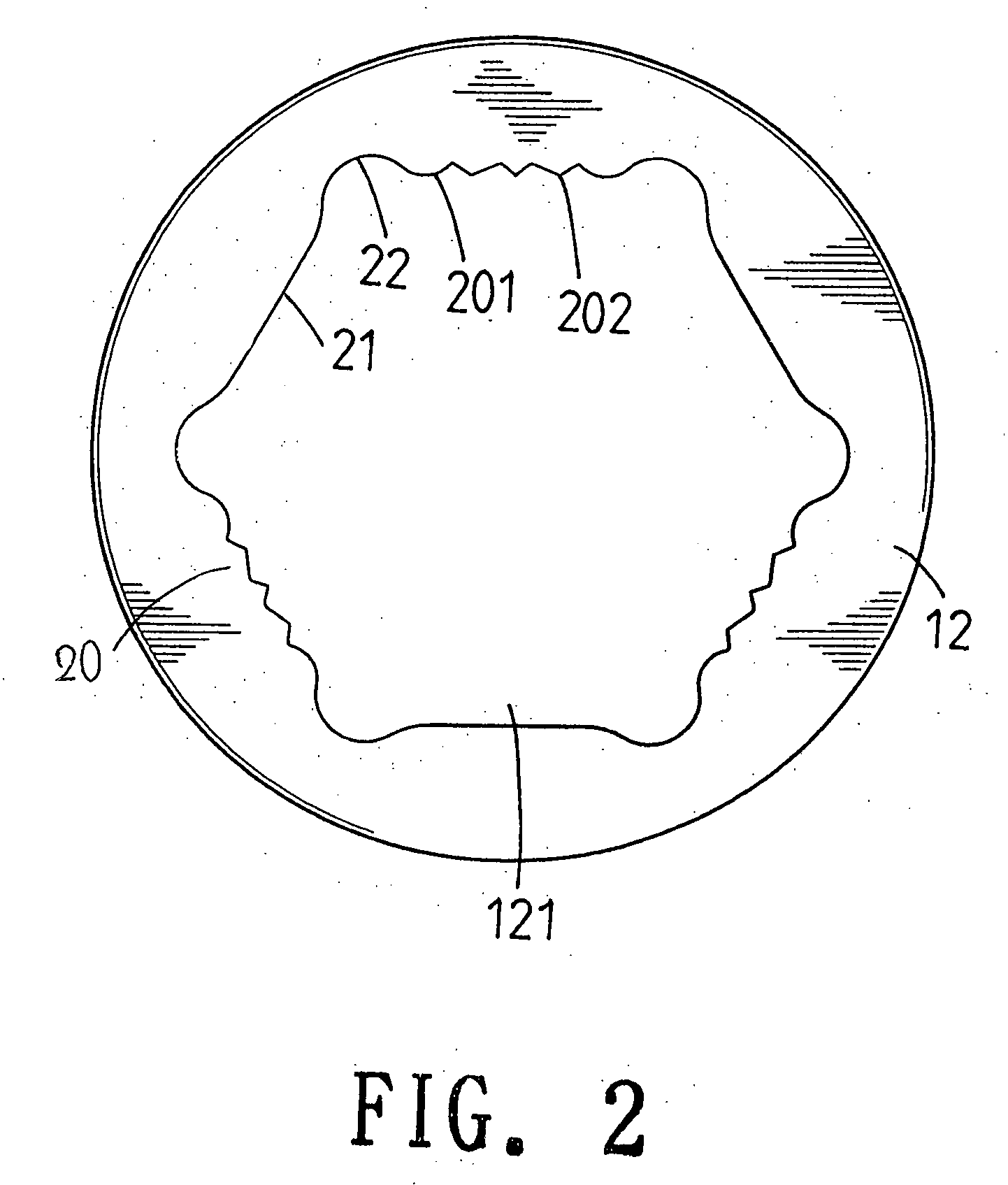

Clamping device for providing high twisting forces and low damage to screw device

A clamping device for providing high twisting forces and low damage to a screw device comprises a handle; a driving portion formed with a space; the space including at least two resisting portions and at least two adhesion portions; the resisting portions and adhesion portions being alternatively arranged; each of the connection of the resisting portion and the adhesion portion being formed with a recess for receiving apexes of a screw means so as to prevent the screw means from damage; and each resisting portion having two cambered protrusions at two ends and one sharp tooth between the two cambered protrusions; the apexes of cambered protrusions and the sharp tooth being collinear. Furthermore, the driving portion can be used to a sleeve so that sleeve has the same function of the driving portion. Thereby it is preferred that there are three resisting portions and three adhesion portions.

Owner:HSIEH CHIH CHING

Composite implants having integration surfaces composed of a regular repeating pattern

A composite interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions; a first integration plate affixed to the top surface of the body; and an optional second integration plate affixed to the bottom surface of the body. At least a portion of the first integration plate, optional second integration plate, or both has a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction, inhibit migration of the implant, and promote bone growth. Also disclosed are processes of fabricating a roughened surface topography, which may include separate and sequential macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

Process of fabricating composite implants having integration surfaces composed of a regular repeating pattern

InactiveUS20130306591A1Inhibit migrationDecorative surface effectsBone implantRough surfaceBone structures

Processes of fabricating a roughened surface topography on a composite interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions; a first integration plate affixed to the top surface of the body; and an optional second integration plate affixed to the bottom surface of the body. At least a portion of the first integration plate, optional second integration plate, or both has a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction, inhibit migration of the implant, and promote bone growth. The process steps may include separate and sequential macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

Friction-fit spinal endplate and endplate-preserving method

ActiveUS20150018958A1Add seatsImprove visualizationBone implantJoint implantsRough surfaceBone structure

An interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions. At least a portion of the top surface, the bottom surface, or both surfaces has a roughened surface topography including both micro features and nano features, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebrae and to inhibit migration of the implant. The roughened surface topography typically further includes macro features and the macro features, micro features, and nano features overlap. Also disclosed are methods of using such implants and processes of fabricating a roughened surface topography on a surface of an implant. The process includes separate and sequential macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

Clamping device for providing high twisting forces and low damage to screw device

A clamping device for providing high twisting forces and low damage to a screw device comprises a handle; a driving portion formed with a space; the space including at least two resisting portions and at least two adhesion portions; the resisting portions and adhesion portions being alternatively arranged; each of the connection of the resisting portion and the adhesion portion being formed with a recess for receiving apexes of a screw means so as to prevent the screw means from damage; and each resisting portion having two cambered protrusions at two ends and three sharp teeth between the two cambered protrusions; the apexes of cambered protrusions and sharp teeth being collinear. Furthermore, the driving portion of the present invention can be used to a sleeve so that sleeve has the same function of the driving portion. Thereby it is preferred that there are three resisting portions and three adhesion portions.

Owner:HSIEH CHIH CHING

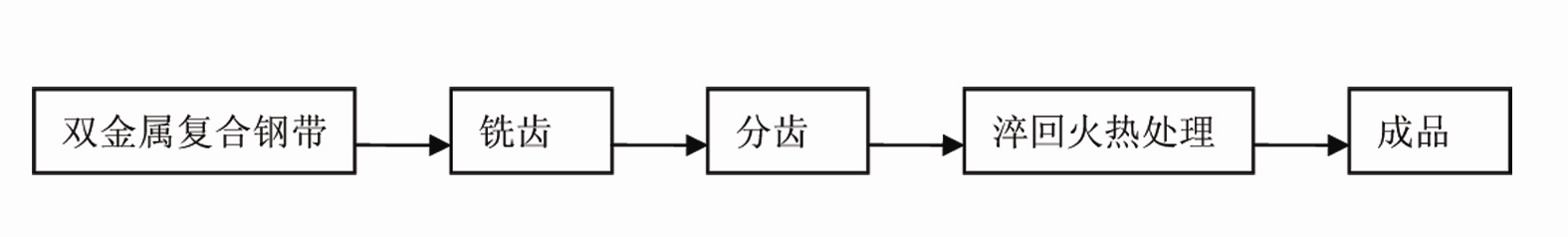

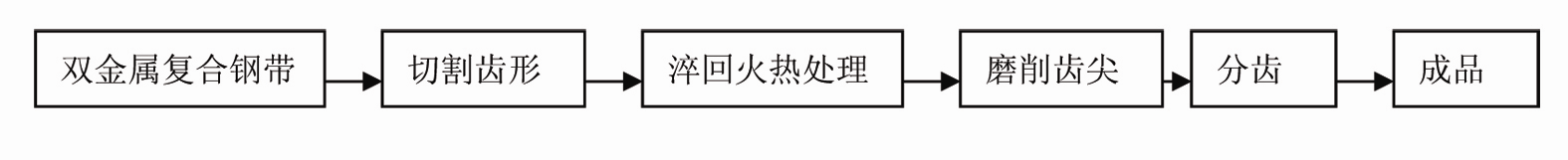

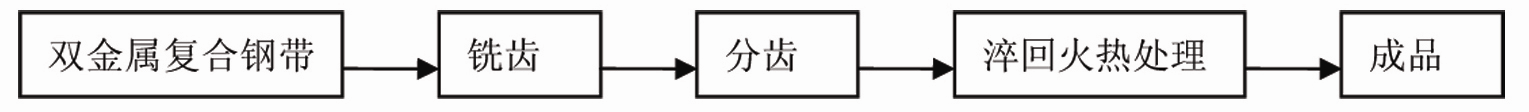

Making method for sawteeth of dual metal saw

InactiveCN102000884ASolve the problem of easy overheatingImprove cutting efficiencyMetal sawing tool makingPunchingWire cutting

The invention relates to a making method for cutting sawteeth of a dual metal saw. The making method comprises the following steps of: performing laser cutting or punching or linear cutting forming on a dual metal composite steel band serving as a saw raw material according to the tooth shape; quenching and tempering the cut saw so as to enhance the hardness of a tooth part; grinding and milling a front corner and a rear corner of the thermally processed sawtooth-shaped tooth part so as to form sharp tooth tips; and dividing the teeth. By adopting laser cutting to form the sawtooth, the making method improves the production efficiency, reduces the machining cost and simultaneously solves the problem of overheating of the quenched tooth tips caused by burrs on the tooth tips; furthermore, as the tooth part is separately milled to form the sharp tooth tips, the saw in the use has no run-in period, thereby improving the cutting efficiency of the dual metal saw and prolonging the service lifetime of the dual metal saw.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

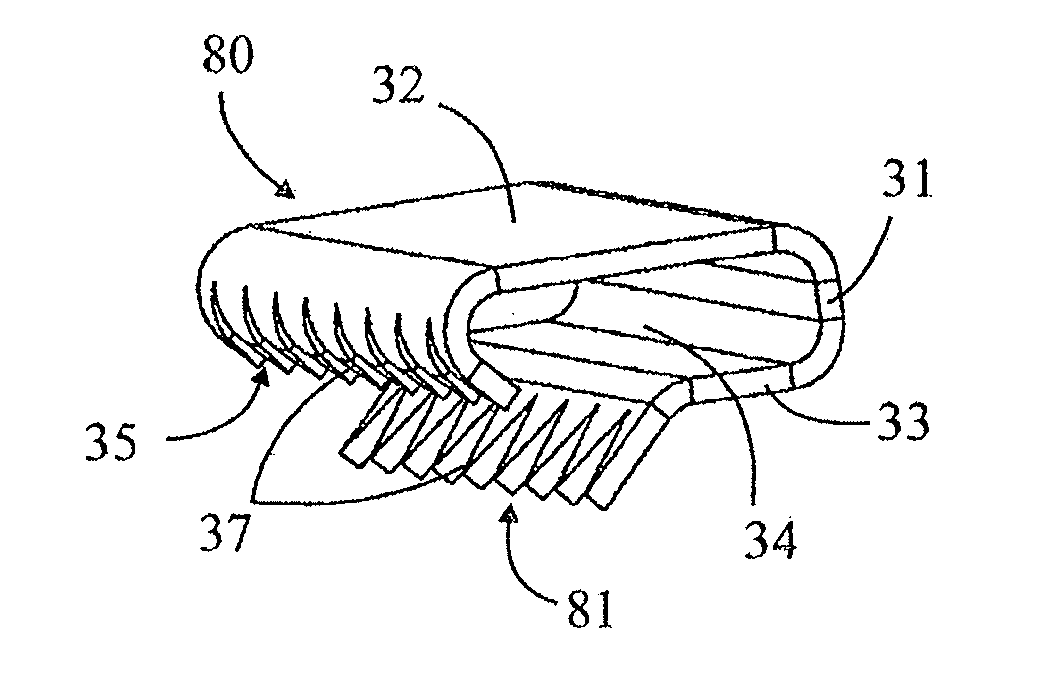

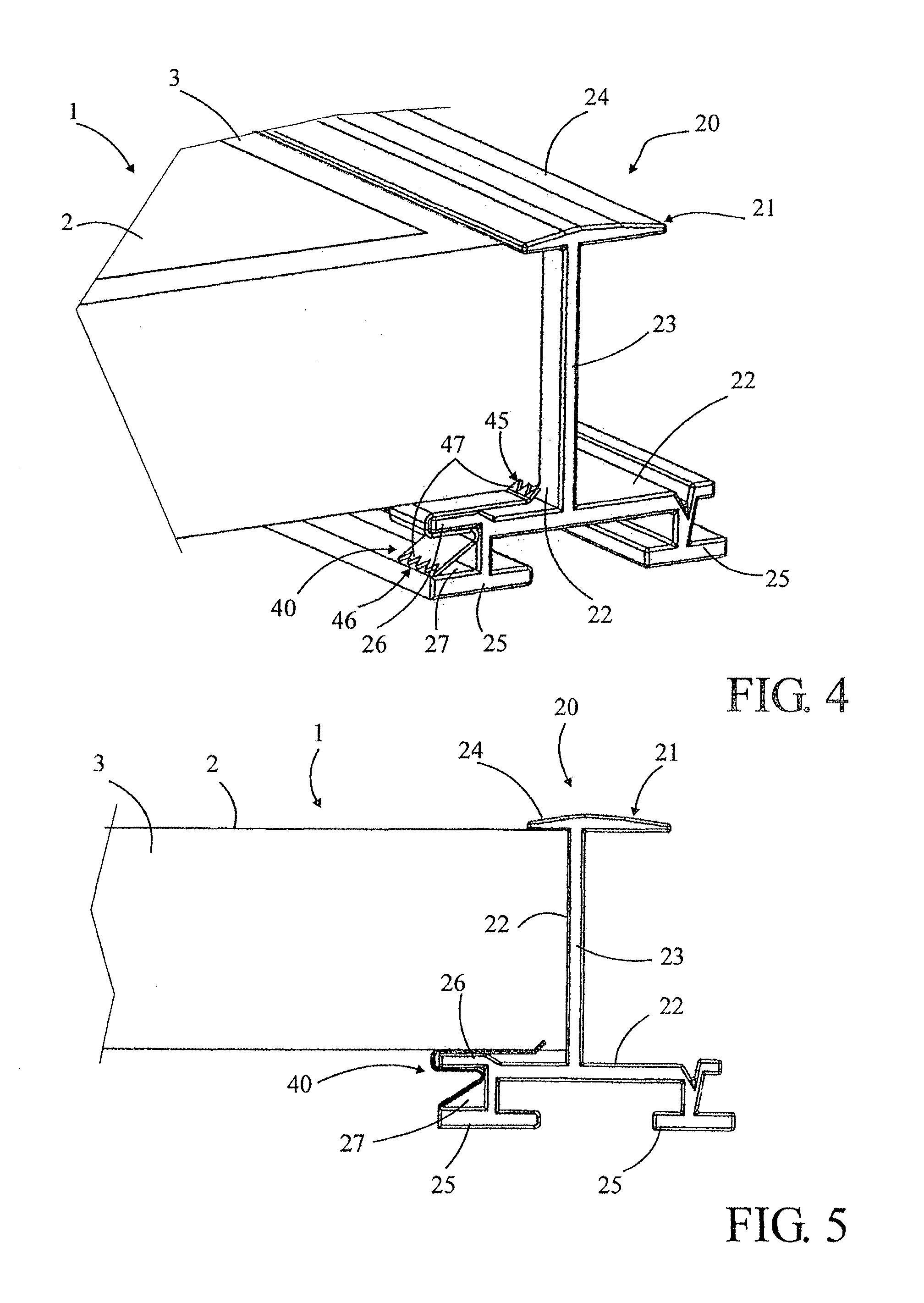

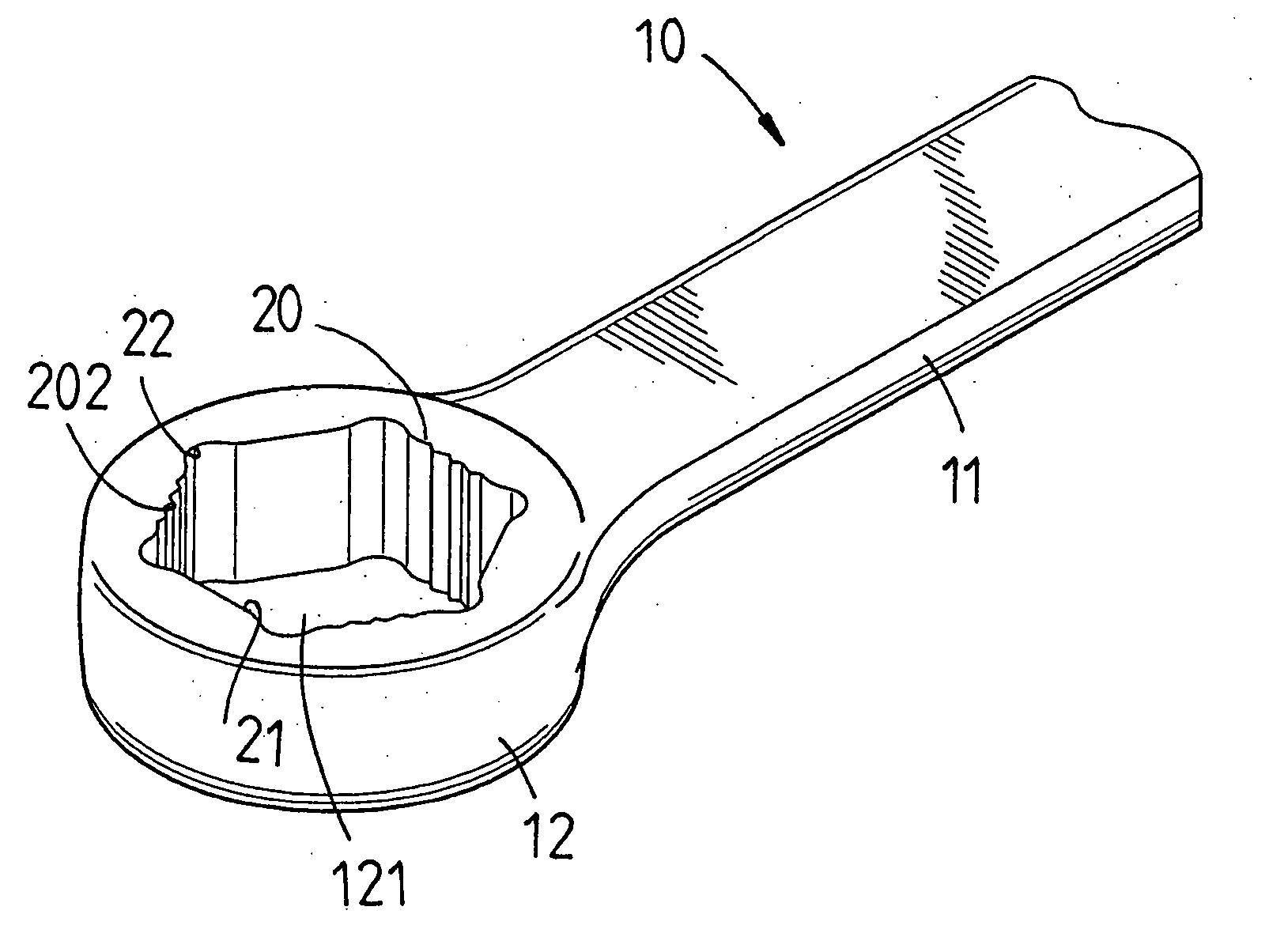

Separate connection device for grounding electrical equipment comprising a plurality for separate electrical components

ActiveUS20130335877A1Lower requirementShort intervention timePhotovoltaic supportsSolar heating energyIn planeEngineering

A separate connection device (40) intended to be inserted between a metal frame (3), of an electrical component (1), and a metal supporting structure (20) in order to connect, electrically and separately, the frame to the supporting structure. The connection device (40) comprises a metal blade manufactured from spring steel which comprises two self-connecting end areas (45, 46) arranged in separate planes and comprising a set of sharp teeth (47) arranged in order to be embedded within the metal material and formed on a folded section of the metal blade so that the sets of teeth (37,47) extend in opposite directions and in planes intended to intersect the planes of the frame (3) and of the supporting structure (20) when the connection device is mounted.

Owner:MOBASOLAR

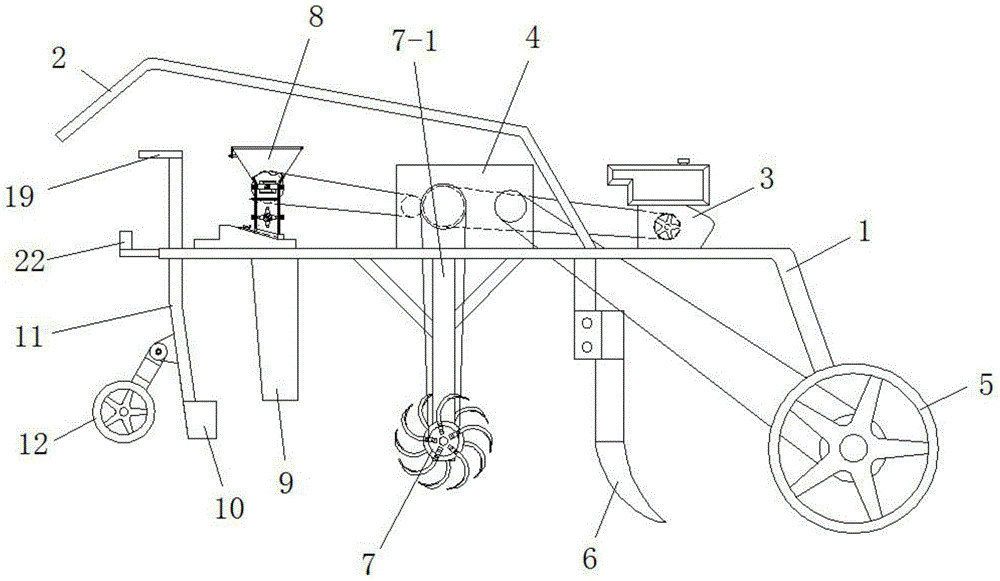

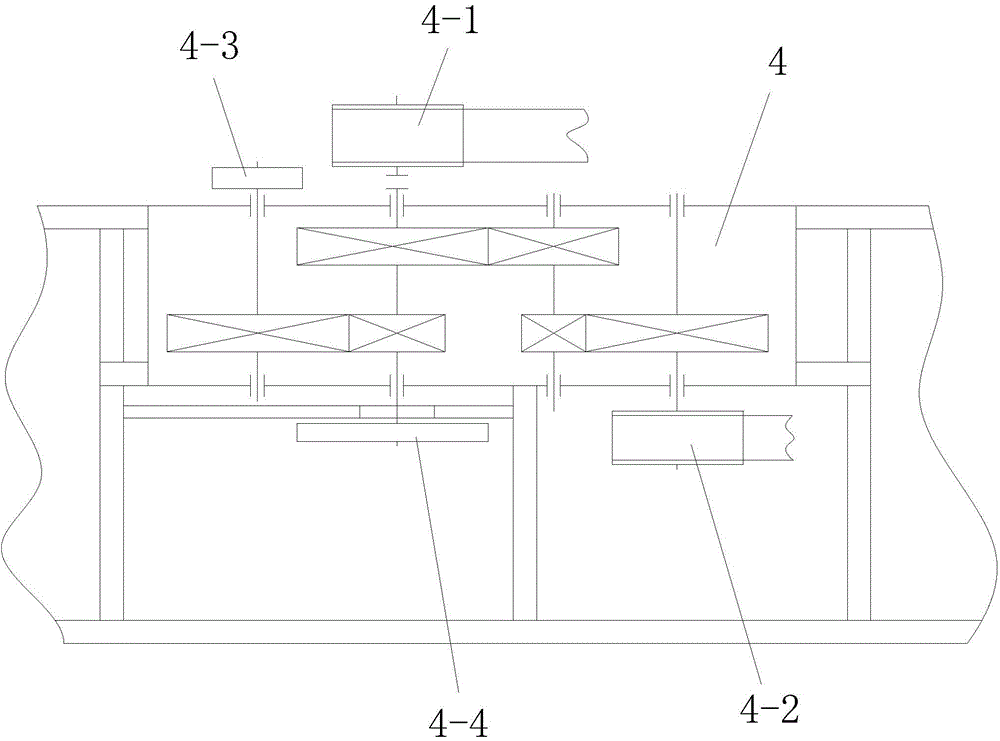

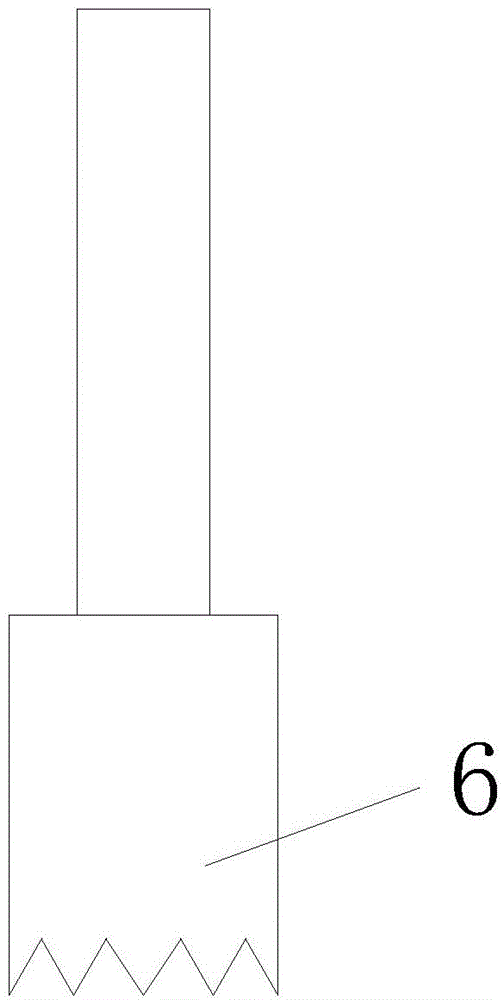

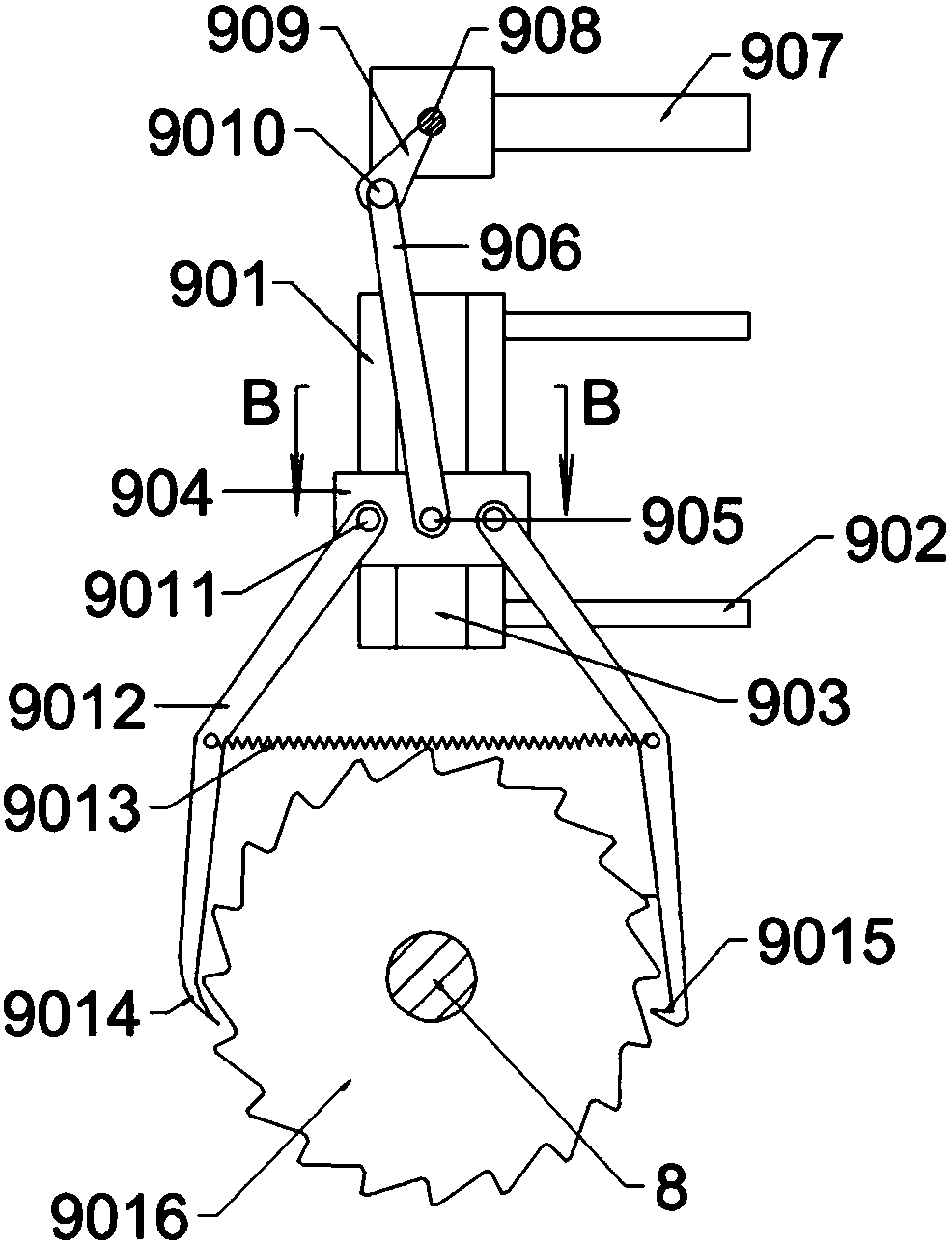

Furrowing and deep-fertilizing machine for orchards

InactiveCN104663097AAdjustable depthSolve the shortcoming of easily producing residual soil at the bottom of the ditchPlantingFertiliser distributersAgricultural engineeringOrchard

A furrowing and deep-fertilizing machine for orchards comprises a rack and a hand grab, wherein a diesel engine and a gearbox in transmission connection with the diesel engine are mounted on the rack, a travelling wheel is mounted at the front end of the rack, a ground breaking shovel is mounted behind the travelling wheel, a row of sharp tooth-shaped structures are arranged at the bottom end of the ground breaking shovel, and the top end of the ground breaking shovel is fixed at the bottom of the rack; a furrowing device is mounted behind the ground breaking shovel and comprises a fixed bracket fixed at the bottom of the rack and a rotating base rotationally connected to the bottom of the fixed bracket, and rotary tiller blades for furrowing are fixed on the rotating base at intervals; a fertilizing device is mounted on the rack behind the furrowing device, a baffle plate is mounted between the fertilizing device and the furrowing device and fixed at the bottom of the rack, a covering shovel is mounted behind the fertilizing device and is mounted at the rear end of the rack through a covering shovel handle, a ground wheel is fixed on the covering shovel handle, and the covering shovel handle can be moved up and down to control the furrowing depth.

Owner:浙江机电职业技术学院

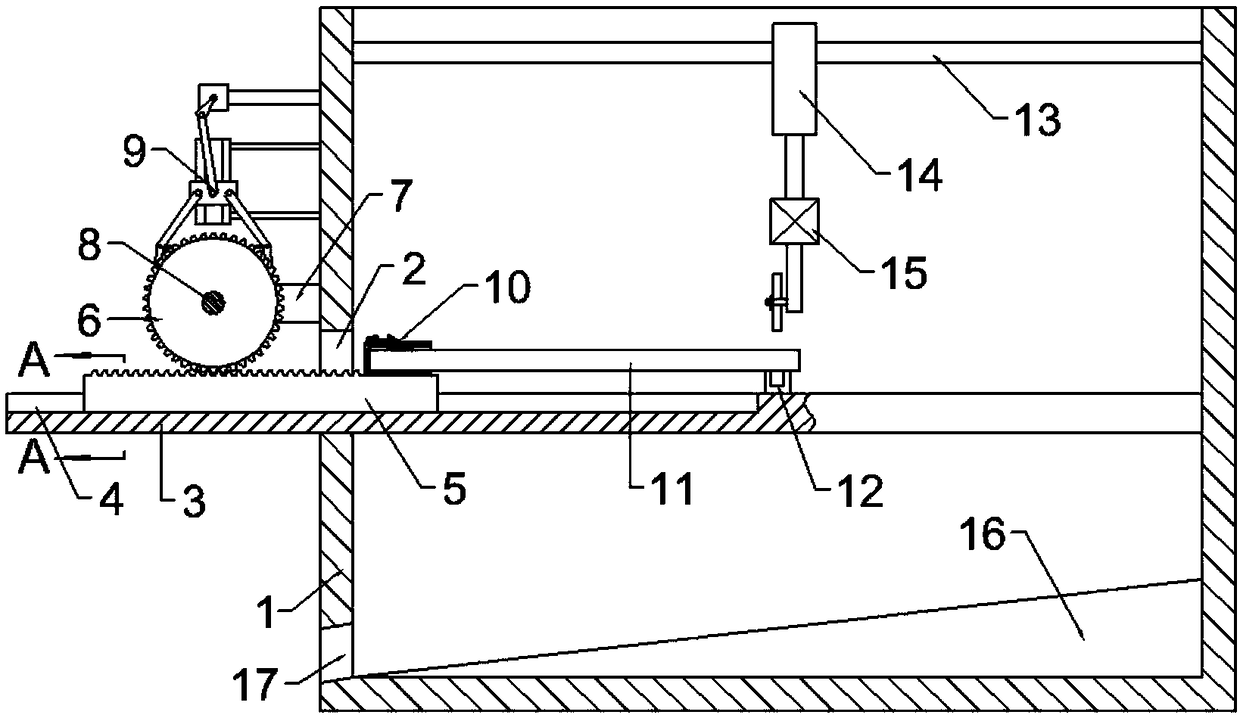

Working method of long-strip-shaped material equidistant cutting device with ratchet wheel auxiliary feeding function

InactiveCN108480743ARealize intermittent equidistant feedingRealize fixed installationMetal-working feeding devicesProfiling/shaping machinesEngineeringEquidistant

The invention provides a working method of a long-strip-shaped material equidistant cutting device with a ratchet wheel auxiliary feeding function. The long-strip-shaped material equidistant cutting device comprises a processing machine shell, the top of the processing machine shell is open, a feeding and discharging through hole is formed in the left side wall of the processing machine shell, a feeding supporting plate is fixedly connected to the interior of the feeding and discharging through hole, the left end of the feeding supporting plate extends to the outer side of the processing machine shell, and the right end of the feeding supporting plate is fixedly connected with the right side wall of the interior of the processing machine shell; a first moving groove with an upward openingis formed in the feeding supporting plate, a first rack is arranged in the first moving groove, and the upper side of the first rack meshes with a first gear; and a first support frame is fixedly connected to the left side wall of the processing machine shell, and a first rotation shaft is rotatably connected to the first support frame. The working method has the following beneficial effects thatwhen a moving block moves upwards, a connecting plate can drive two second rotating rods to move upwards, a sharp tooth on the left side has no acting force on a ratchet wheel, and a hook body can hook the ratchet wheel to enable the ratchet wheel to rotate anticlockwise.

Owner:杨艳

Interverterbral fusion implement

InactiveCN1436518ANo foreign body reactionPromote bone fusionInternal osteosythesisProsthesisHuman bodyBiocompatibility Testing

The interverterbral fusion implement for cervical vertebra anterior operation is one hollow column with polygonal or circular cross section, holes on side wall and sharp teeth on the upper and the lower surfaces. It is made of polymer material capable of being absorbed by human body, poly(DL-lactic acid), poly(L-lactic acid), polyglycolic acid or their copolymer. It has determined early-stage locking effect, late-stage bone fusion effect, good biocompatibility and proper mechanical structure, and may be self-degraded after being fused with vertebra. It results in no rejection and may be also used in thoracic vertebra and lumbar vertebra operation.

Owner:成都迪康中科生物医学材料有限公司

Process of fabricating implants having three distinct surfaces

InactiveUS20130292357A1Avoid abrasionsAvoid lacerationsBone implantDecorative surface effectsBone structureTopography

Processes of fabricating different surface topographies, which may include separate macro processing, micro processing, and nano processing steps, in order to produce an interbody spinal implant having at least three distinct surfaces including (1) at least one integration surface having a roughened surface topography including macro features, micro features, and nano features, without sharp teeth that risk damage to bone structures; (2) at least one graft contact surface having a coarse surface topography including micro features and nano features; and (3) at least one soft tissue surface having a substantially smooth surface including nano features.

Owner:TITAN SPINE

Sugarcane peeling and section cutting device

PendingCN108284478AImprove peeling efficiencyIntegrity guaranteedVegetable peelingMetal working apparatusEngineeringUltimate tensile strength

The invention discloses a sugarcane peeling and section cutting device, and belongs to the field of agricultural product processing. The sugarcane peeling and section cutting device is composed of a support, a device rack, a first sugarcane stop rod, a sharp tooth gear, a first baffle spring, a first baffle, first cutting-off tool springs, a second baffle, a first cutting-off tool, a second sugarcane stop rod, peeling tools, a second cutting-off tool, a storage bag supporting rod, a storage bag stop block, a second baffle spring, second cutting-off tool springs, peeling tool springs and a stepping motor. The sugarcane peeling and section cutting device is high in automation degree, the labor intensity is relieved, and the sugarcane peeling efficiency is improved; the integral design of thestructure is reasonable, the peeling and section cutting work of the whole sugarcane can be finished through one-time operation, the whole operation process is clean and sanitary, and direct usage cannot be influenced for eaters. According to the purpose of cooperation of the unique design of the first baffle and the second baffle and usage of tension springs, the sugarcane is downwards closely attached to a sugarcane positioning clamping arc step, the sharp tooth gear rotates and drives the non-peeled sugarcane to move inwards, and the attaching force is increased.

Owner:祝凯旋

Impurity-removing carding device for rotor spinning machine

PendingCN107190374AEasy dischargeReduce bring backContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention discloses an impurity-removing carding device for a rotor spinning machine. The device comprises a shell and a carding roller, the shell is provided with a fiber transporting channel, a feeding channel and an impurity removing channel, the impurity removing channel comprises an impurity inlet and an impurity outlet, the impurity removing channel is internally provided with a spreader plate making the impurity removing channel divided into an air current channel and an impurity air current channel, on end of the spreader plate is located at the impurity inlet, the impurity inlet is divided into an air current channel outlet and an impurity air current channel inlet, the other end of the spreader plate is located at the impurity outlet, and the impurity outlet is divided into an air current channel inlet and an impurity air current channel outlet; card clothing is laid on the surface of the spreader plate, and the card clothing comprises sharp teeth arranged in the direction facing the impurity outlet. The size of the air flow channel is adjusted, so that the size of an air current is controlled, and the phenomenon that impurities low in density are brought back into a carding cavity by an air replenishment air current is prevented; in this way, the carding effect is improved, and the phenomenon that the quality of yarn spun through the next few steps is lowered is prevented.

Owner:ZHEJIANG SCI-TECH UNIV

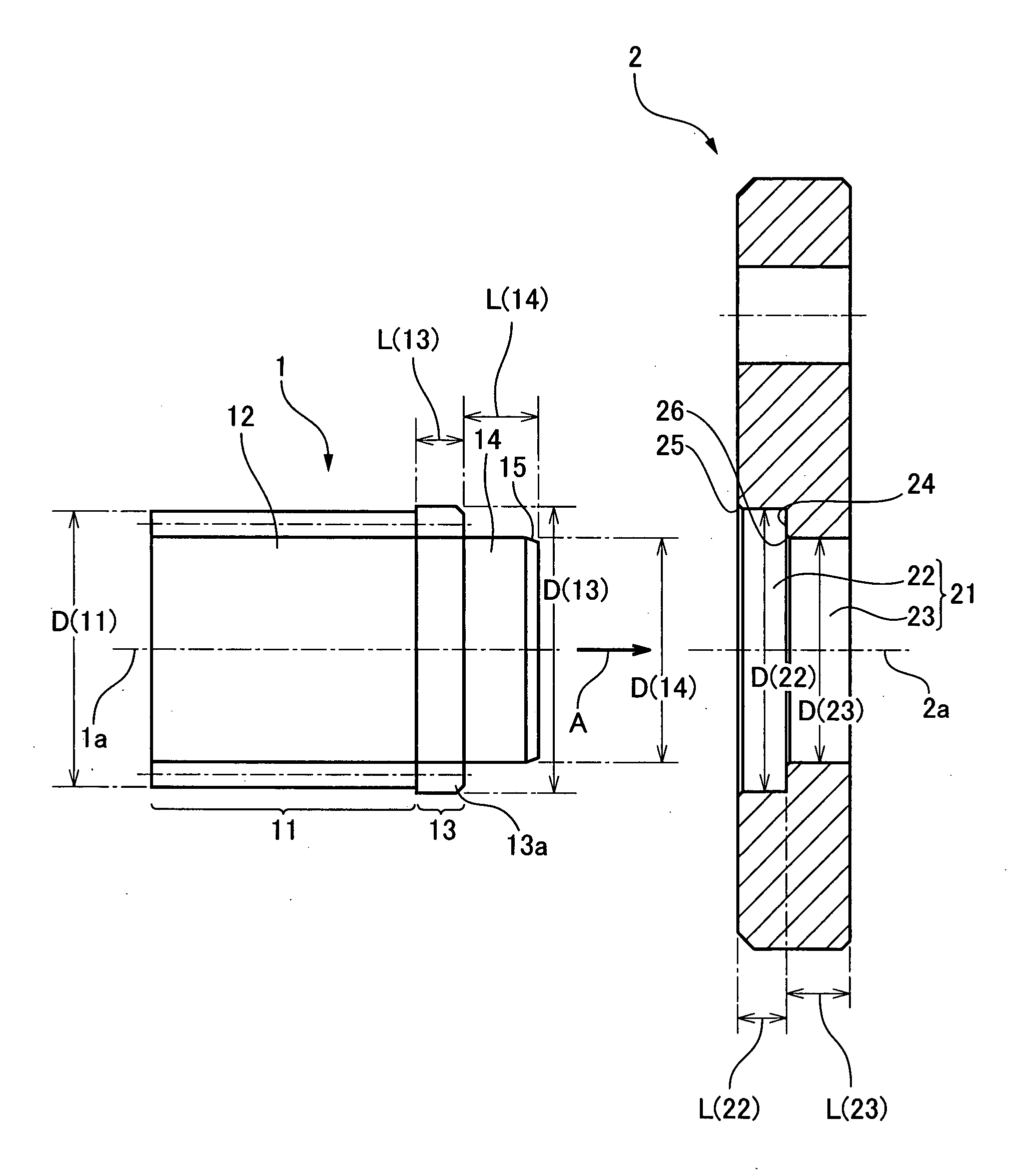

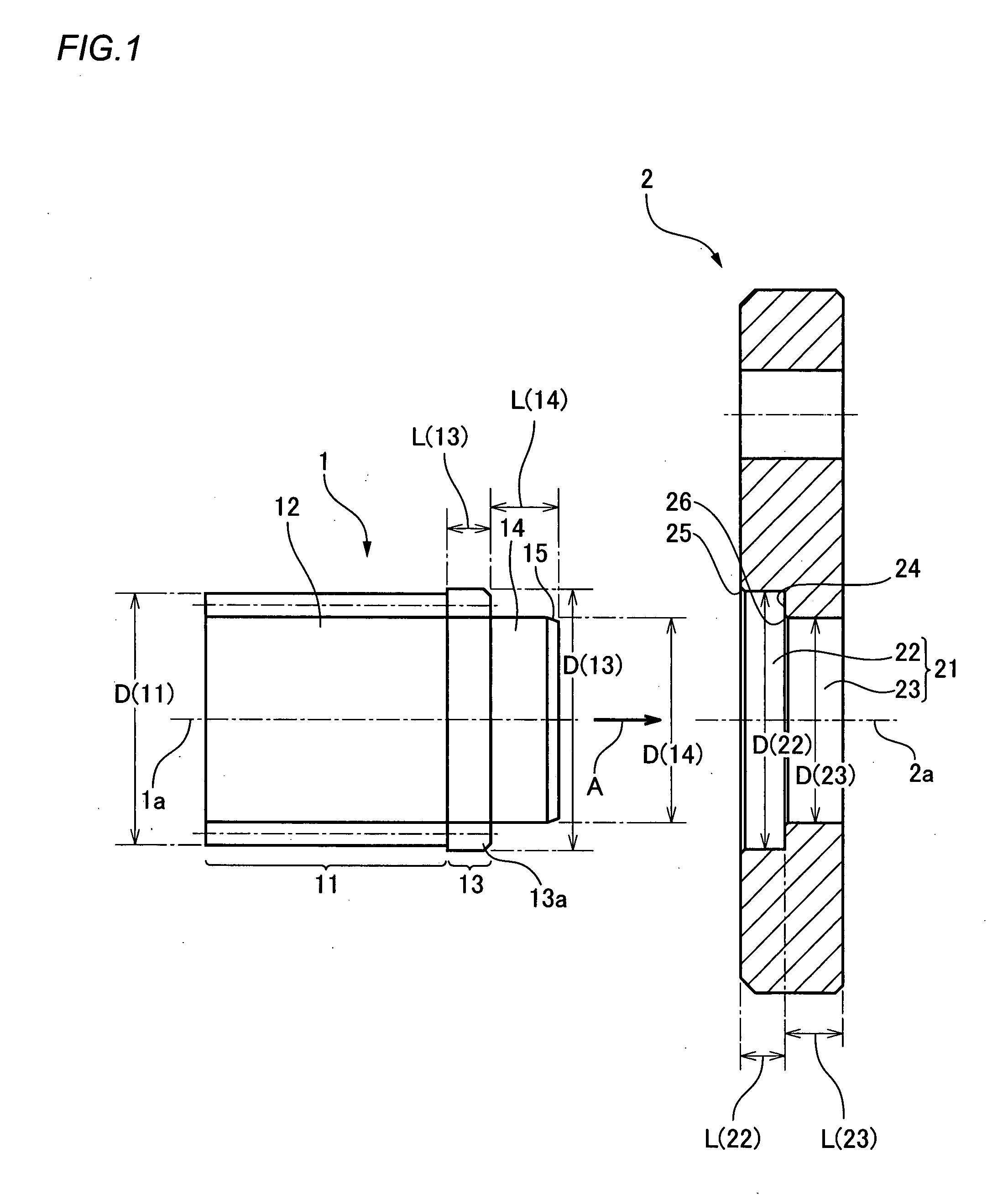

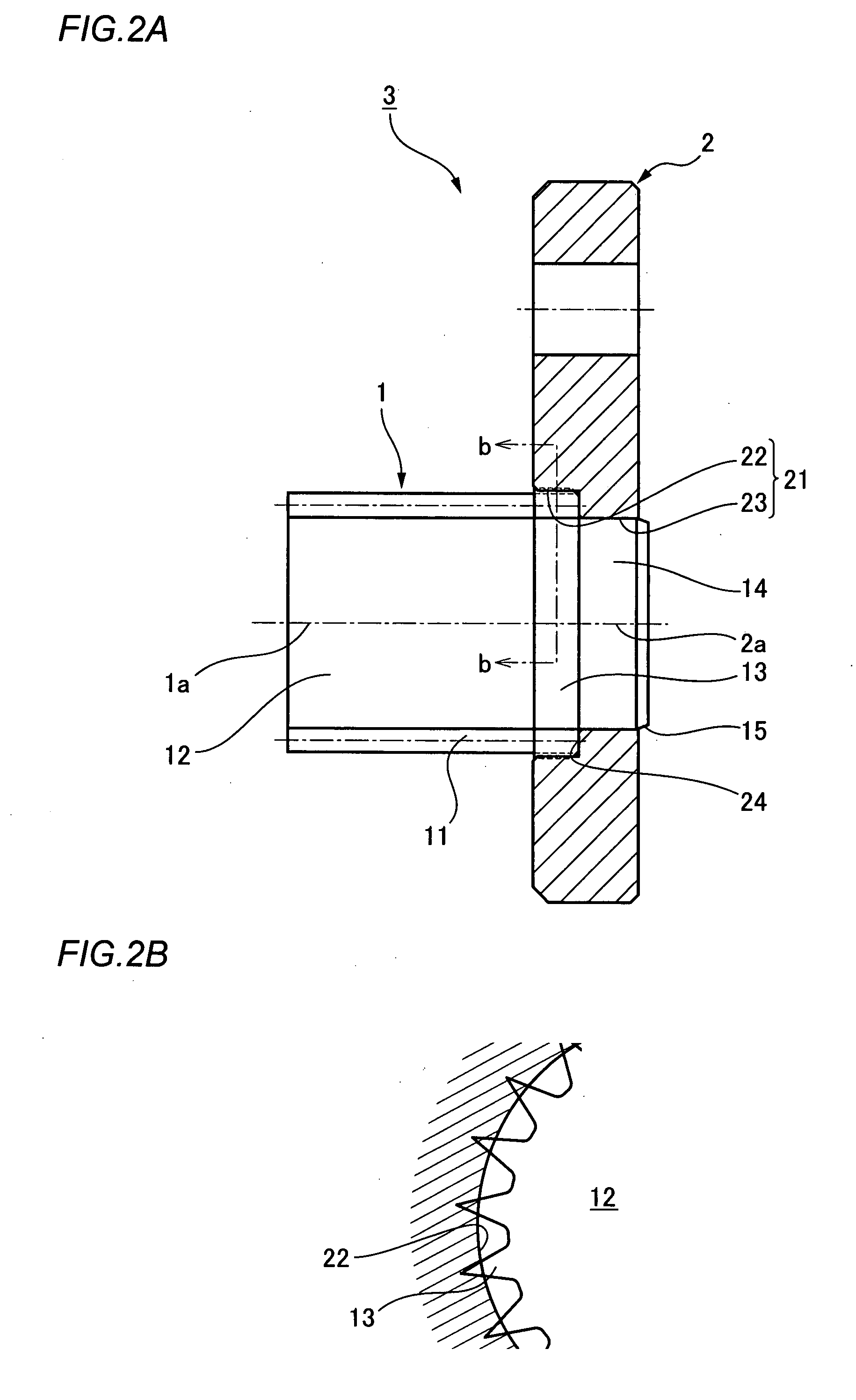

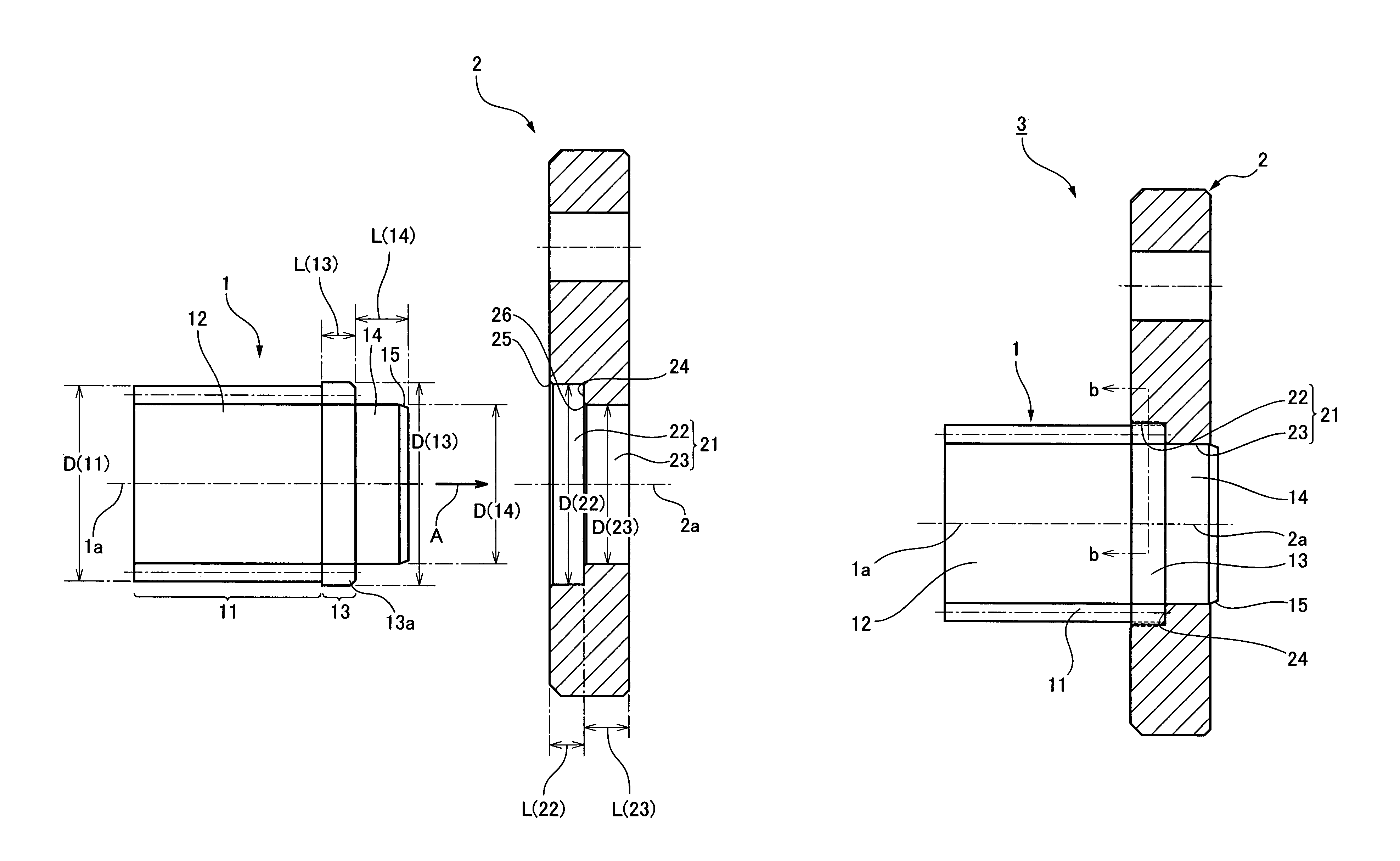

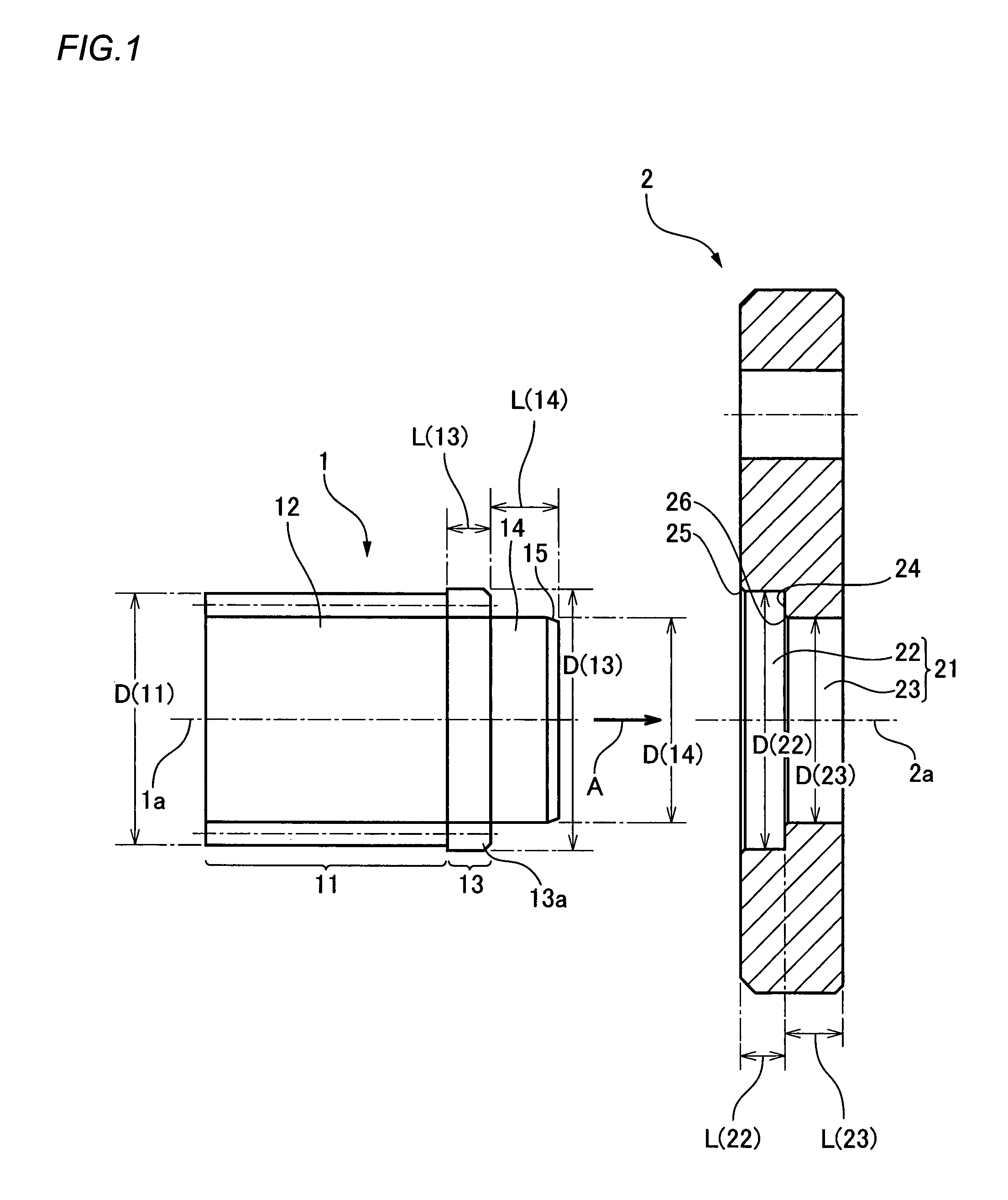

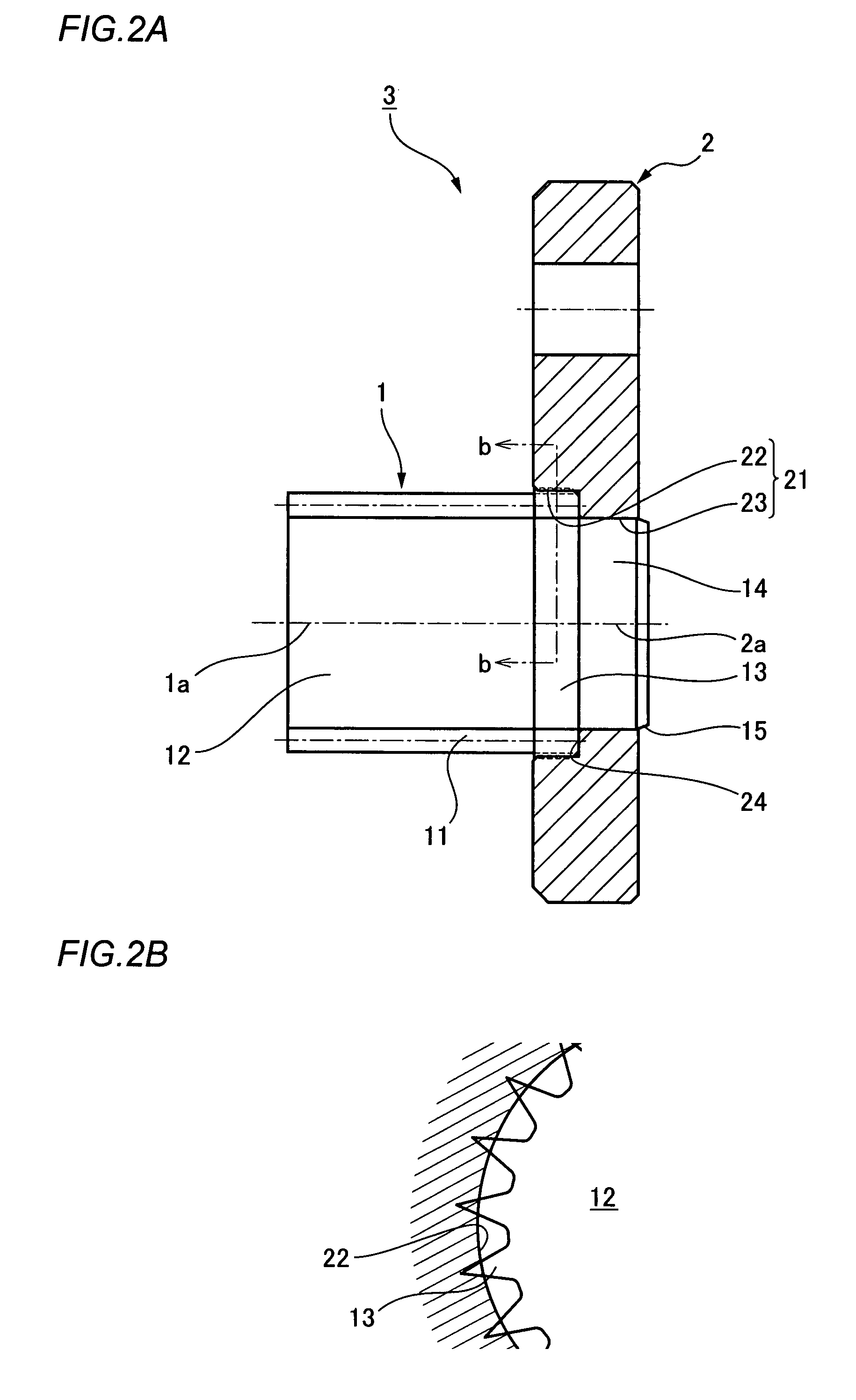

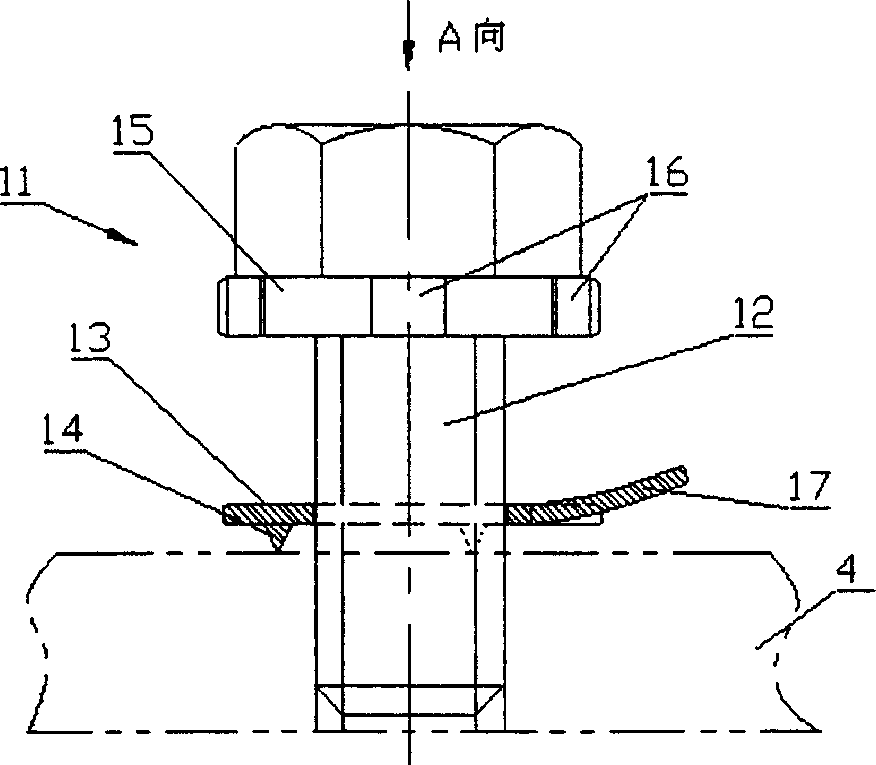

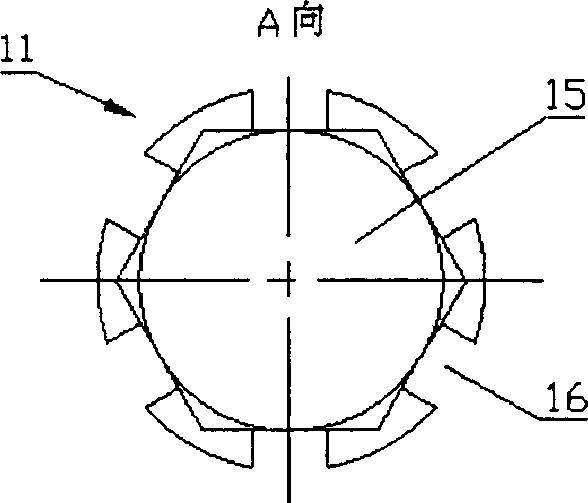

Method of fastening gear and structure of the same

ActiveUS20080028612A1Improve fastening strengthPortable liftingCouplings for rigid shaftsEngineeringPinion

In a fastening method of press-fitting and fixing an axial end section of a second-stage pinion (1) into a circular opening (21) of a first-stage planetary carrier (2), at first press-fitting external teeth (13a), which have an addendum circle larger than an addendum circle of the other pinion part and has a sharp tooth top, are generated through manufacturing of tooth-cutting at an outer circumferential section of the axial end portion of the second-stage pinion (1). Then, a press-fit bore (22) that has a smaller diameter than the addendum circle of the press-fitting external teeth (13a), is formed at the circular opening (21) of the first-stage planetary carrier (2). The press-fitting external teeth (13a) are then press-fitted into the press-fit bore (22) so that tooth tops thereof cut into an inner circumference surface of the press-fit bore (22) to secure fastening strength between the second-stage pinion (1) and the first-stage planetary carrier (2).

Owner:HARMONIC DRIVE SYST IND CO LTD

Process for fabricating bioactive vertebral endplate bone-contacting surfaces on a spinal implant

ActiveUS9848995B2Add seatsImprove visualizationBone implantJoint implantsRough surfaceBone structure

An interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions. At least a portion of the top surface, the bottom surface, or both surfaces has a roughened surface topography including both micro features and nano features, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebrae and to inhibit migration of the implant. The roughened surface topography typically further includes macro features and the macro features, micro features, and nano features overlap. Also disclosed are methods of using such implants and processes of fabricating a roughened surface topography on a surface of an implant. The process includes separate and sequential macro processing, micro processing, and nano processing steps.

Owner:TITAN SPINE

Rough milling cutter for rotor and wheel groove of steam turbine and manufacturing technology of rough milling cutter

ActiveCN103418822AGuaranteed StrengthHigh strengthMilling cuttersManufacturing technologyMilling cutter

The invention provides a rough milling cutter for the rotor and the wheel groove of a steam turbine and a manufacturing technology of the rough milling cutter. The milling cutter comprises blade parts adopting an integral structure and a shank part, wherein a plurality of cutting edges arranged along spiral lines are uniformly distributed on the blade parts in the circumferential direction; the blade parts are axially and hierarchically arranged at three stages along the milling cutter; cutting edges comprise main blades and auxiliary blades, which are distributed in a staggered manner; the main blades are whole blades penetrating through a first-stage part and a second-stage part, and adopt the structure of a postwave blade with sharp teeth, which are used for opening chip-separation grooves; the first-stage part of the auxiliary blades is a boss, the height of which is lower than that of the first-stage part of the main blades; the second-stage part of the auxiliary blades adopts the structure of a clearance angle with sharp teeth, which are not used for opening chip-separation grooves; the third-stage part of the blade parts is a coping part. The rough milling cutter has the advantages that the defects that the removing amount of metal is large, the cutting stroke is long, and the tipping is easy to occur in positions with major diameters are overcome, the security and reliability of the cutter are enhanced, so that the milling cutter has a stable machining process, high efficiency and excellent anti-tipping performance, and is suitable for roughly opening various V-shaped grooves, the repeated utilization rate of the cutter is high, the cutter can be reused through coping for 3 to 5 times, and the cost of cutter is reduced.

Owner:DONGFANG TURBINE CO LTD

Box handling grip

An improved temporary hand held grip for engaging the edge of a cardboard, Styrofoam or wooden box that includes a right angle body to mate with the edge of a box and a plurality of teeth that penetrate a box contiguous to the edge of a box and just off side the edge. Each improved grip includes an attached leather strap connected to one angle side of the right angle body to aid in handling a box. The improvedgrip contains sufficient space to allow the fingers to grip the entire invention so as to prevent losing control of it when using it. The plurality of teeth are easily adjustable if it becomes necessary to adjust the depth of their penetration into the surface of the box being handled so as not to damage the contents of the box being handled while retaining a firm grip on the box. The improved grip also provides a means of preventing injuries from the sharp teeth by retracting when pressure is released when not being used tohandle a box.

Owner:JORDENING HAROLD GENE

Clamping device for providing high twisting forces and low damage to screw device

A clamping device for providing high twisting forces and low damage to a screw device comprises a handle; a driving portion formed with a space; the space including at least two resisting portions and at least two adhesion portions; the resisting portions and adhesion portions being alternatively arranged; each of the connection of the resisting portion and the adhesion portion being formed with a recess for receiving apexes of a screw means so as to prevent the screw means from damage; and each resisting portion having two cambered protrusions at two ends and three sharp teeth between the two cambered protrusions; the apexes of cambered protrusions and sharp teeth being collinear. Furthermore, the driving portion of the present invention can be used to a sleeve so that sleeve has the same function of the driving portion. Thereby it is preferred that there are three resisting portions and three adhesion portions.

Owner:HSIEH CHIH CHING

Method of fastening gear and structure of the same

ActiveUS8020299B2Improve fastening strengthPortable liftingCouplings for rigid shaftsEngineeringPinion

Owner:HARMONIC DRIVE SYST IND CO LTD

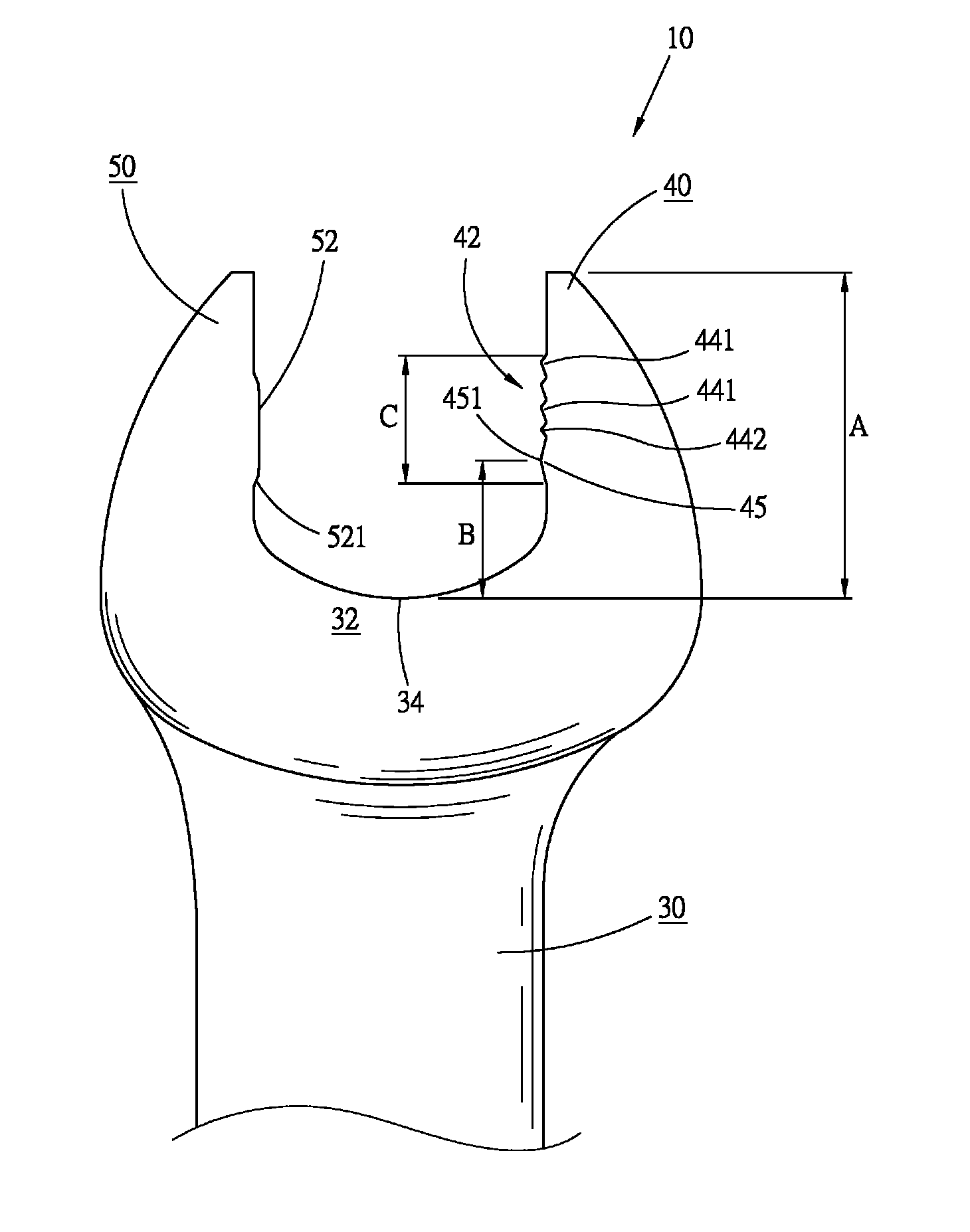

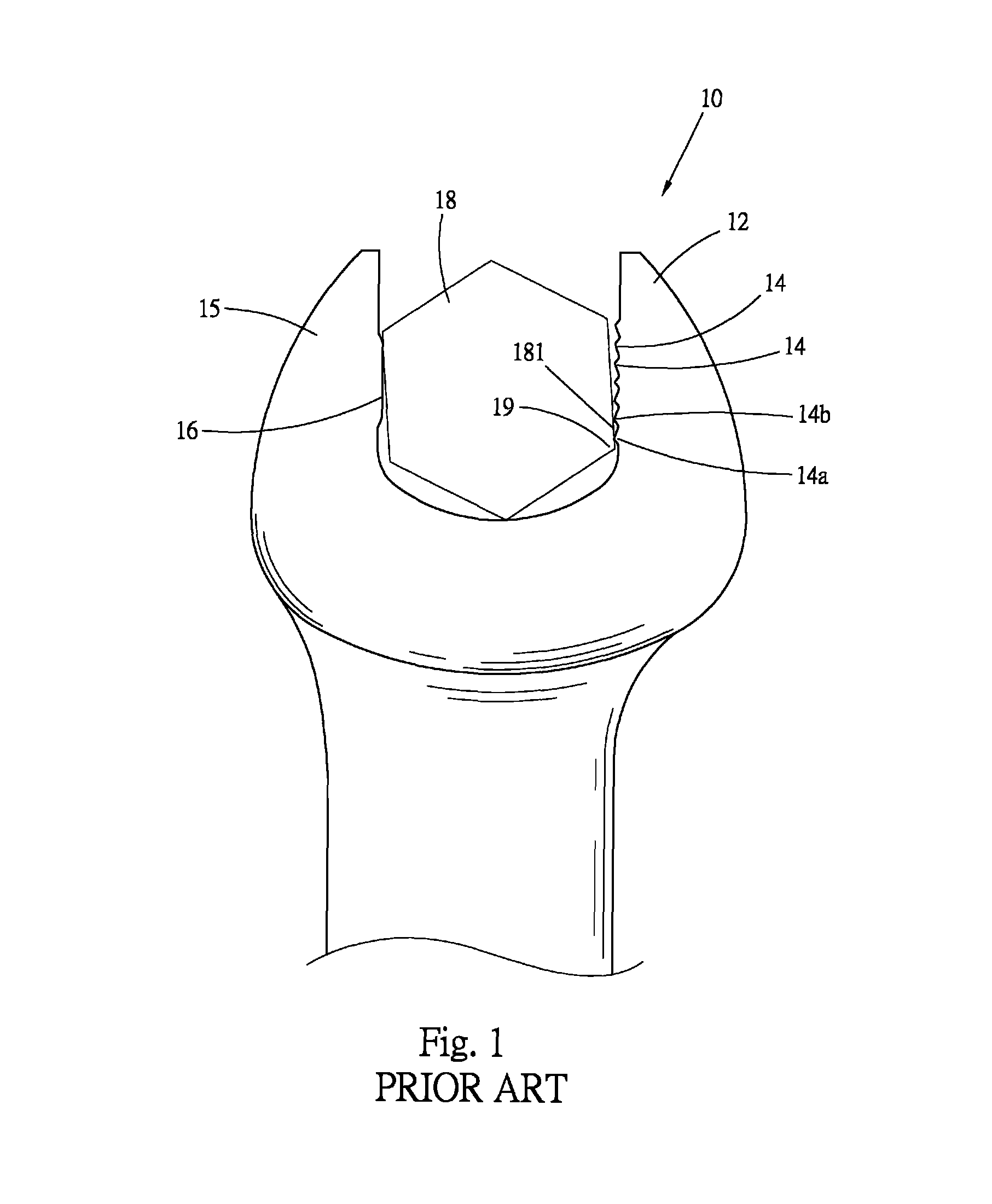

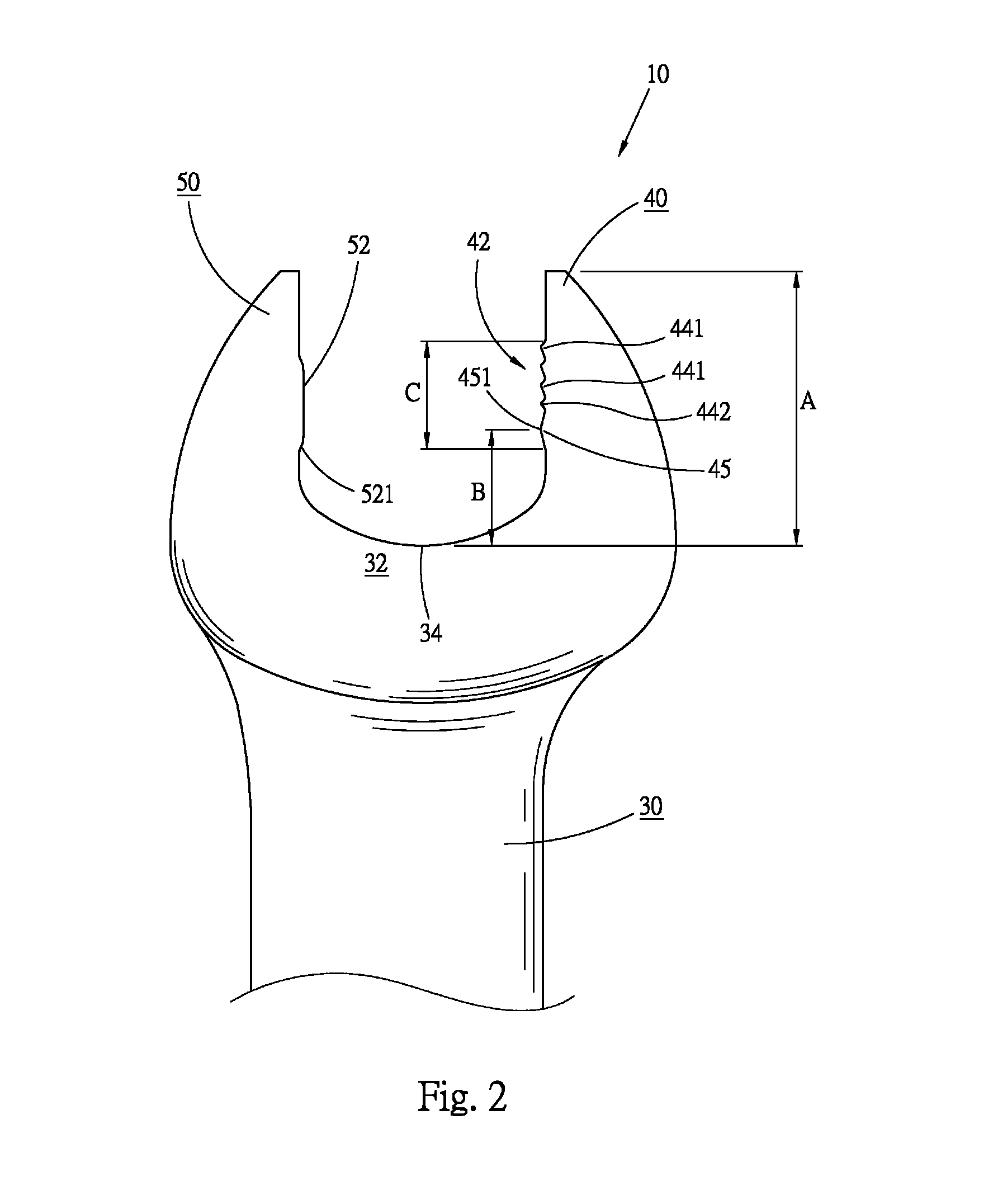

Open-end wrench

ActiveUS8667873B2Improve structural strengthNot easy to damageSpannersWrenchesEngineeringTooth position

The present invention is related to an open-end wrench including a first jaw and a second jaw and a throat section connected between rear ends of the two jaws. A toothed section is disposed on the inner side of the first jaw. The toothed section has multiple sharp teeth and a wide tooth positioned behind the sharp teeth. The wide tooth has a largest width among all the teeth. The bottommost point of the throat section is spaced from a front end of the first jaw by a first length. The bottommost point of the throat section is spaced from the tooth crest of the wide tooth by a second length, which ranges from ⅓ to ½ the first length. The toothed section has a length, which is about ⅖ the first length. The width of the wide tooth is 0.325 to 0.375 the length of the toothed section.

Owner:KABO TOOL COMPANY

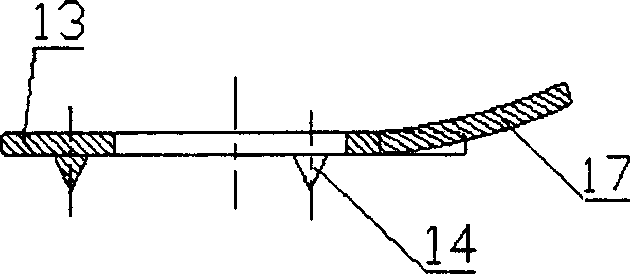

Full automatic subassembly of lock bolt

A lock bolt component consists of bolt and gasket sheathed on periphery of bolt screw. It features that sharp tooth to lock with bearing surface of connected piece is set on front side of gasket and positioning element to lock with slot nut external peripheral wall of bolt is set on back side gasket periphery.

Owner:赖起兵

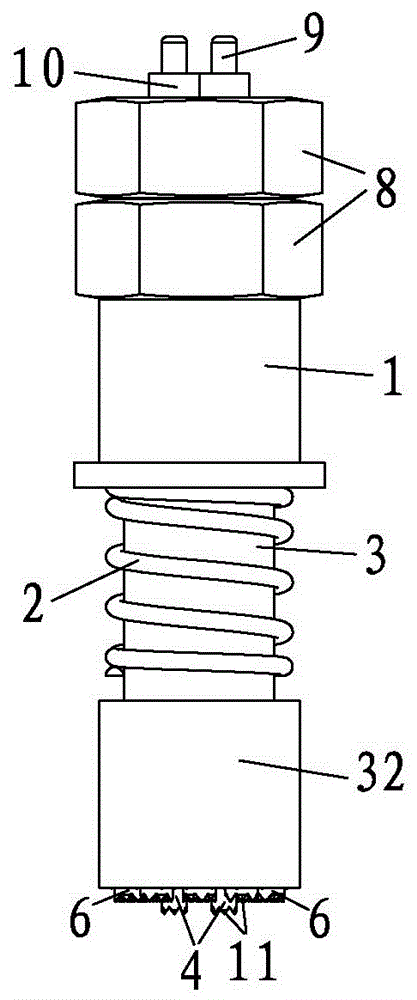

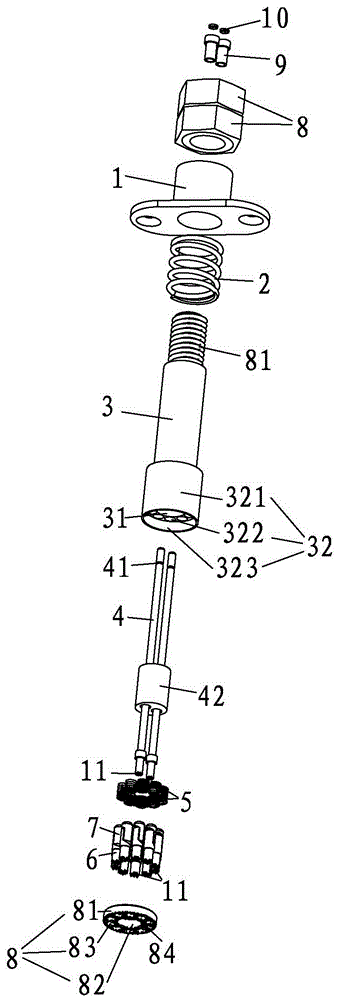

Probe

ActiveCN106129665AResolve connectionSolve fever problemElectrical measurement instrument detailsElectrical testingPower batteryEngineering

The invention belongs to the technical field of batteries, and especially relates to a probe. The probe comprises a probe base, a first spring, a current probe rod, a voltage probe, a second spring, a current probe, an expansion head, and a probe end cover. The first spring and the probe seat are sequentially disposed on the current probe rod in a sleeving manner. The current probe rod is provided with a hollow cavity. One end of the voltage probe passes through the hollow cavity to extend out of the current probe rod. An end part of the current probe rod is provided with an accommodation part, and the accommodation part comprises an accommodation part body, an accommodation hole, and an accommodation groove, wherein the accommodation hole and the accommodation groove are disposed on the accommodation part body. The second spring is disposed in the accommodation hole, and the current probe and the expansion head are cooperatively connected, and are inserted into the second spring. The other ends of the current probe and the voltage probe are respectively provided with a sharp tooth part. The probe cover covers the accommodation groove. The arrangement of the above structure enables the probe to solve a problem of the connection of an electrode lug and a power supply during the formation and capacity grading of large-capacity power batteries.

Owner:DONGGUAN YINGZHIBAO ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com