Impurity-removing carding device for rotor spinning machine

A rotor spinning machine and carding technology, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, can solve problems such as accelerated rotor wear and yarn grade degradation, and achieves Effects that enhance guidance, improve quality, and reduce likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

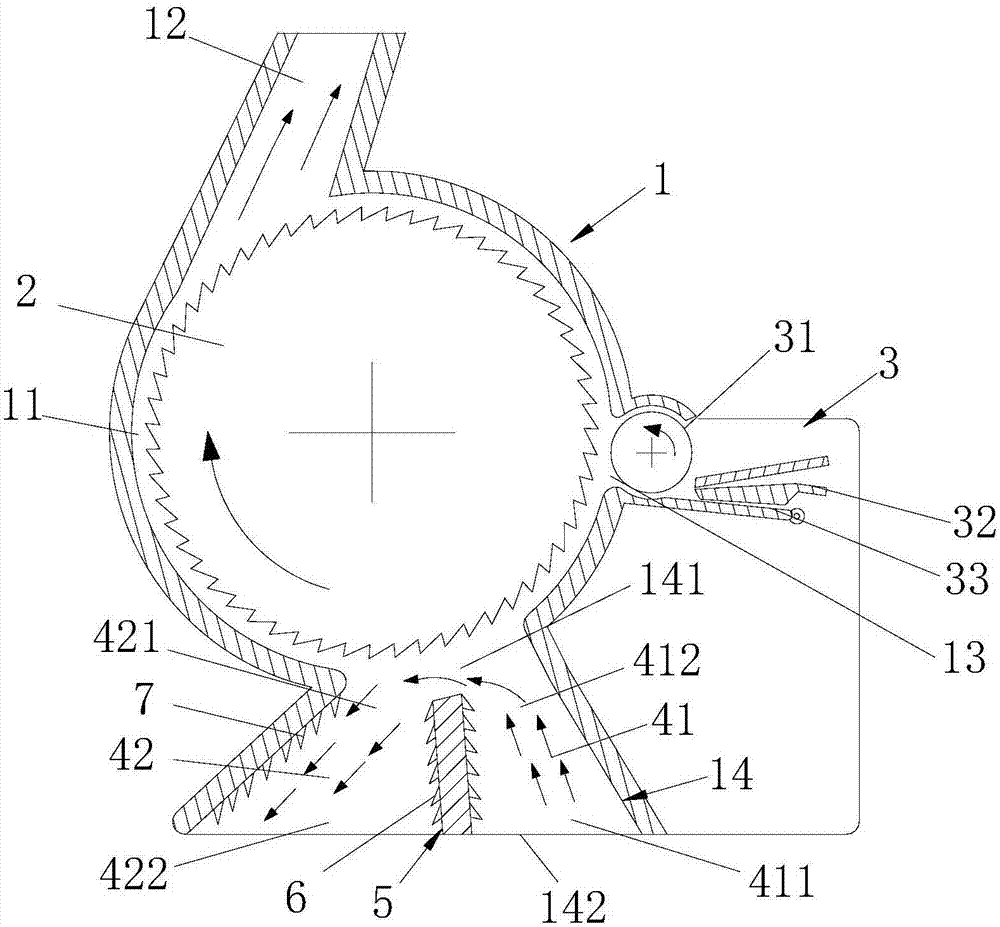

[0027] Embodiment one: if figure 1 , 2 As shown, the present embodiment includes a housing 1 with a carding chamber 11, and a carding roller 2 is installed in the carding chamber 11, and the housing 1 is provided with conveying fiber passages 12 communicated with the carding chamber 11 respectively. , feeding channel 13 and miscellaneous passage 14, feeding mechanism 3 is installed at feeding passage 13 places, miscellaneous passage 14 is positioned at housing 1 below, miscellaneous passage 14 comprises the miscellaneous inlet 141 near the carding chamber 11, and Away from the miscellaneous outlet 142 of the combing cavity 11 . The conveying fiber channel 12 is docked with the rotor, and the feeding mechanism 3 includes a feeding roller 31 , a feeding horn 32 , and a feeding plate 33 . The fiber strip is fed from the feeding horn 32, passes through the feeding plate 33 and the feeding roller 31, enters the carding chamber 11, and is decomposed into single fibers and single f...

Embodiment 2

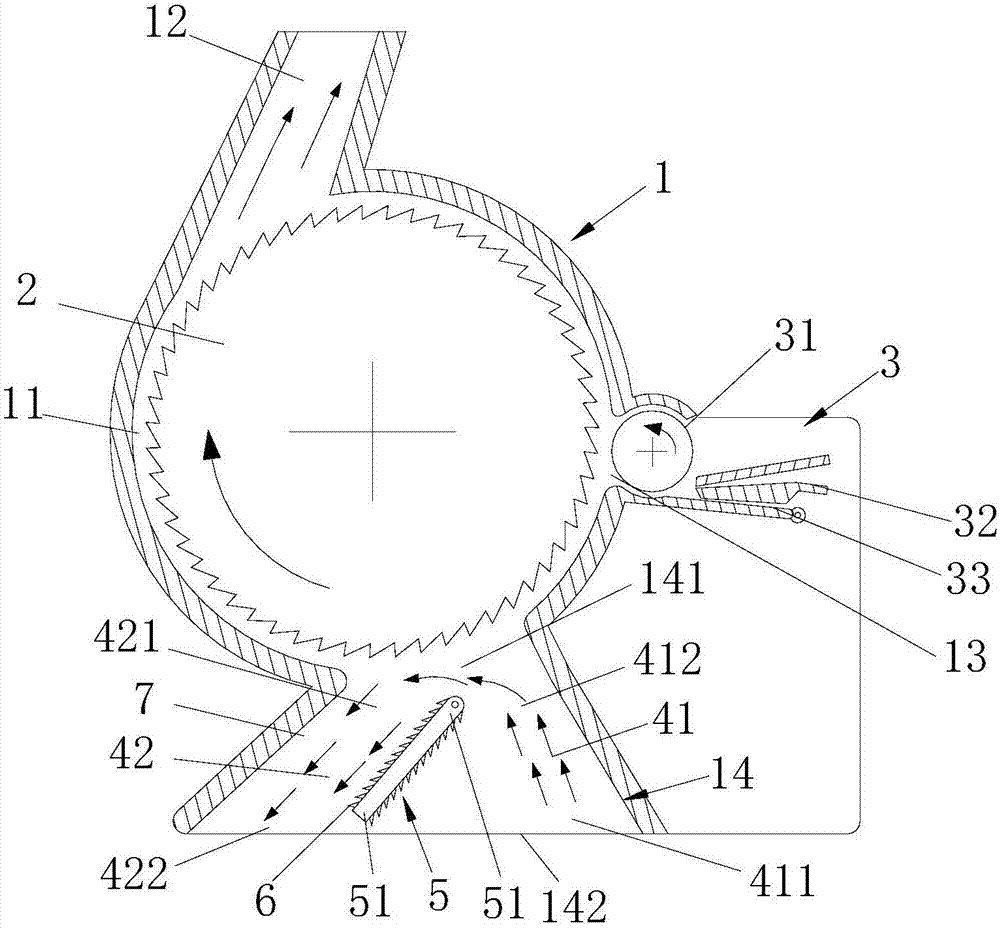

[0038] Embodiment two: if image 3 , 4 As shown, the difference from Embodiment 1 is that the end of the diverter plate 5 located at the miscellaneous inlet 141 is a hinged end 51, and the hinged end 51 is hinged in the miscellaneous discharge channel 14 through a rotating shaft; The end of 142 is swing end 52 . By pulling the splitter plate 5 , the splitter plate 5 is rotated around the rotating shaft, thereby changing the size of the air flow channel 41 and the impurity air flow channel 42 . Among them, the hinged end 51 is located in the middle of the miscellaneous inlet 141, and the miscellaneous inlet 141 is evenly divided into the outlet 412 of the air flow channel and the inlet 421 of the impurity air flow channel. Facts have proved that such a separation ratio can bring the best effect of removing impurities. , and can reduce the generation of backflow airflow, thereby preventing impurities from entering the carding chamber 11 due to backflow airflow. Wherein, takin...

Embodiment 3

[0039] Embodiment three: as Figure 5 As shown, the difference from Embodiment 2 is that the splitter plate 5 is a fan-shaped structure, the end of the fan-shaped structure close to the center of the circle is the hinged end 51, and the end of the fan-shaped structure close to the arc is the swing end 52; the card clothing 6 is laid On the surface where the radius of the fan-shaped structure is located; the central angle of the splitter plate 5 is 60°. Wherein, the central angle can also be selected within the range of 30° to 60°. When the tip angle of the tines is 40° and the tooth back angle is 130°, if the central angle is 30°, the impurity content of the fibers discharged from the conveying fiber channel 12 is 0.005%; if the central angle is 45°, the fiber conveying channel The impurity content of the fibers discharged from 12 is 0.004%; if the central angle is 60°, the impurity content of the fibers discharged from the conveying fiber channel 12 is 0.003%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com