Patents

Literature

34results about How to "Improve carding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

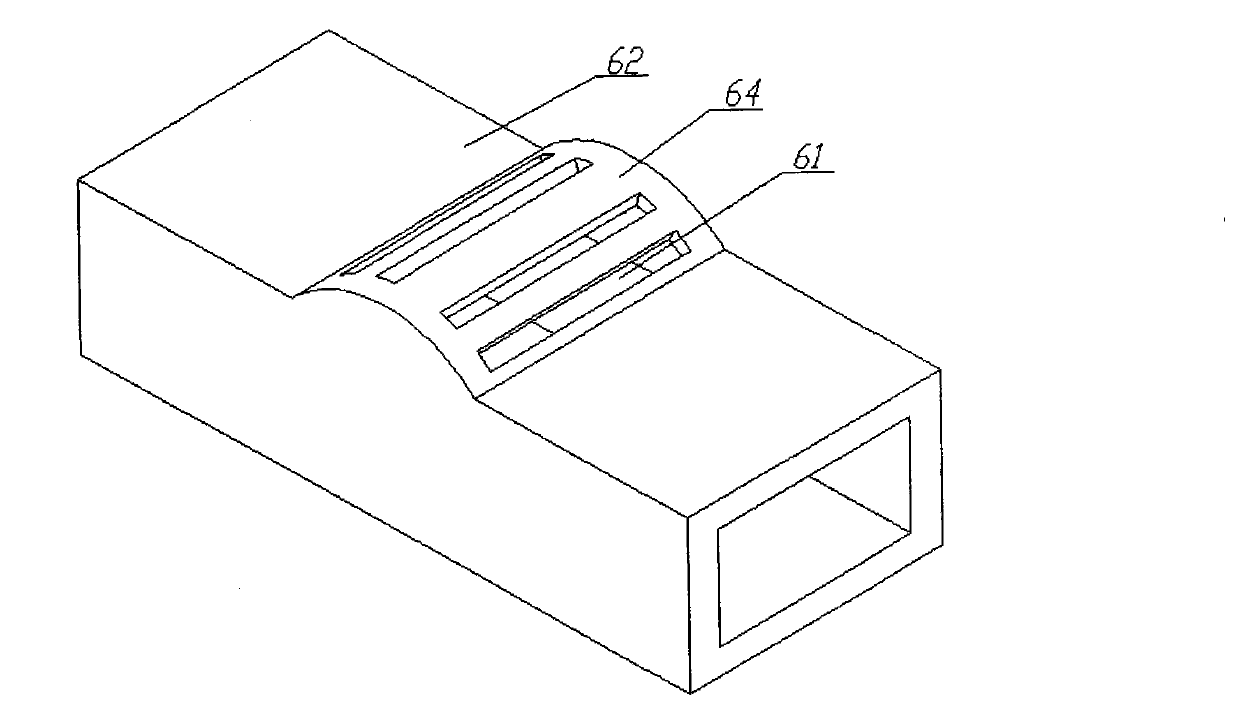

Impurity-removing carding device for rotor spinning machine

PendingCN107190374AEasy dischargeReduce bring backContinuous wound-up machinesOpen-end spinning machinesYarnFiber

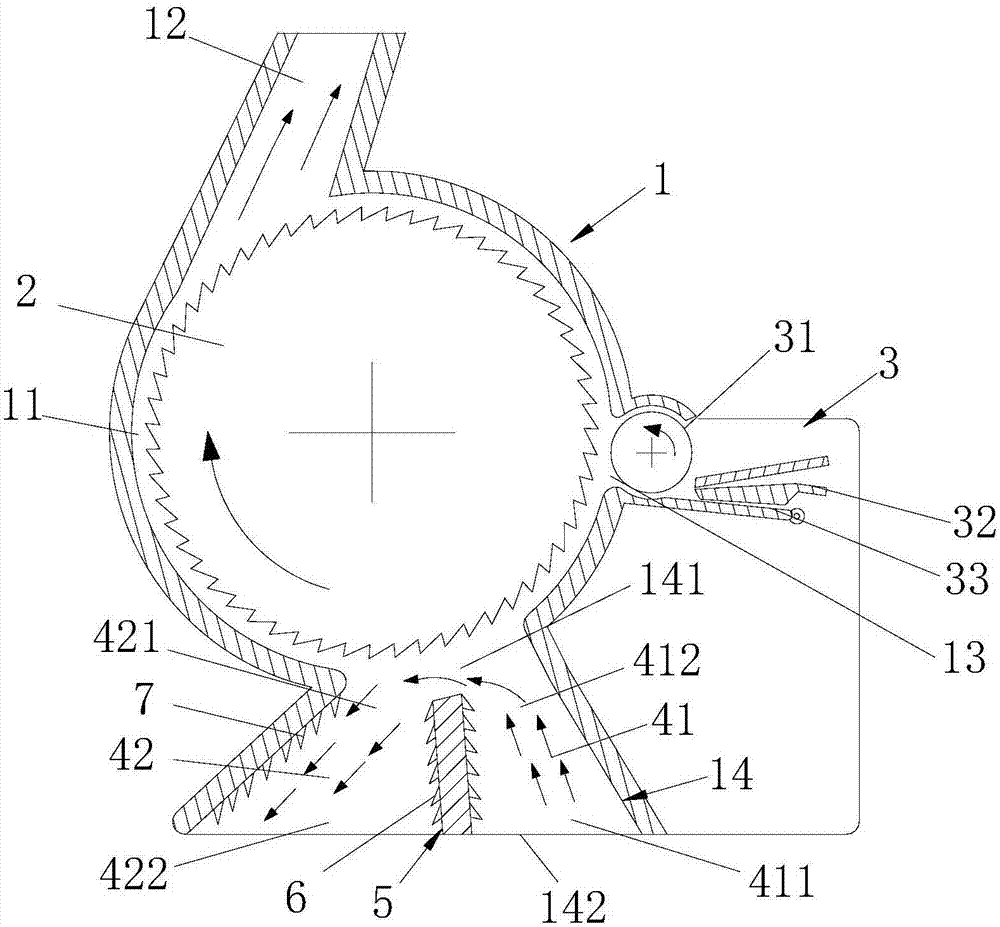

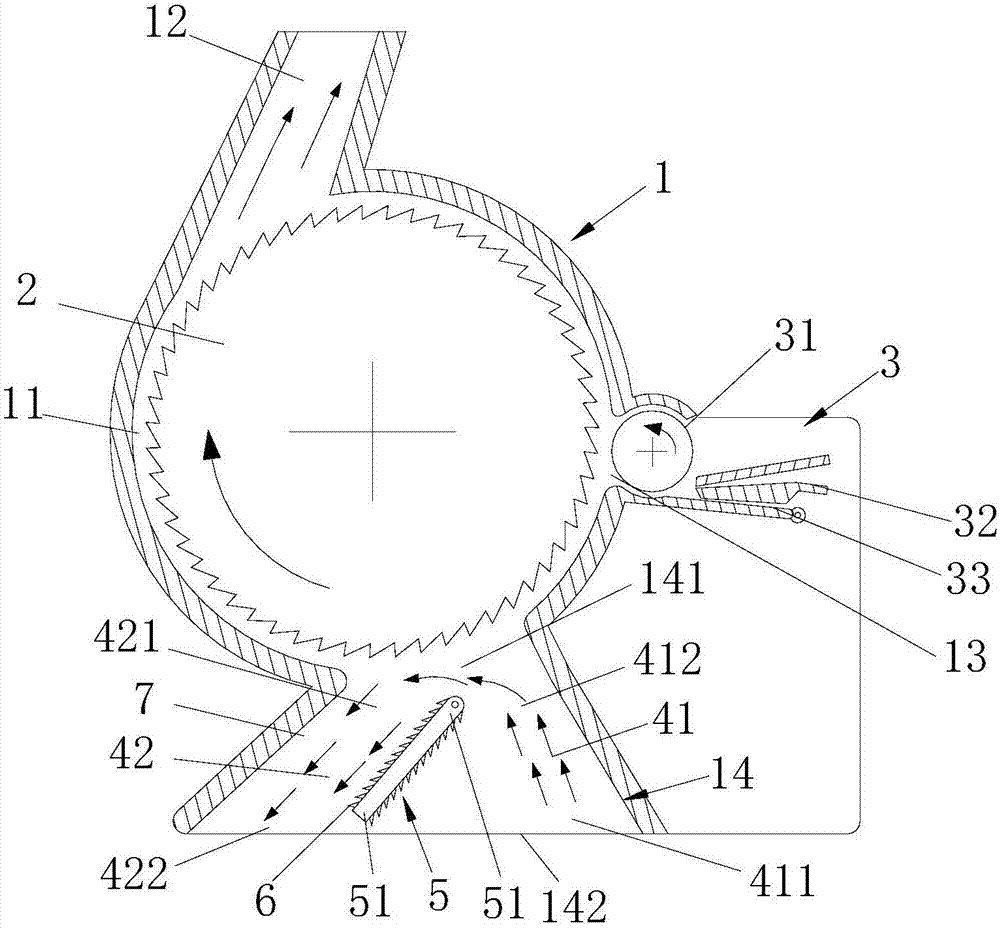

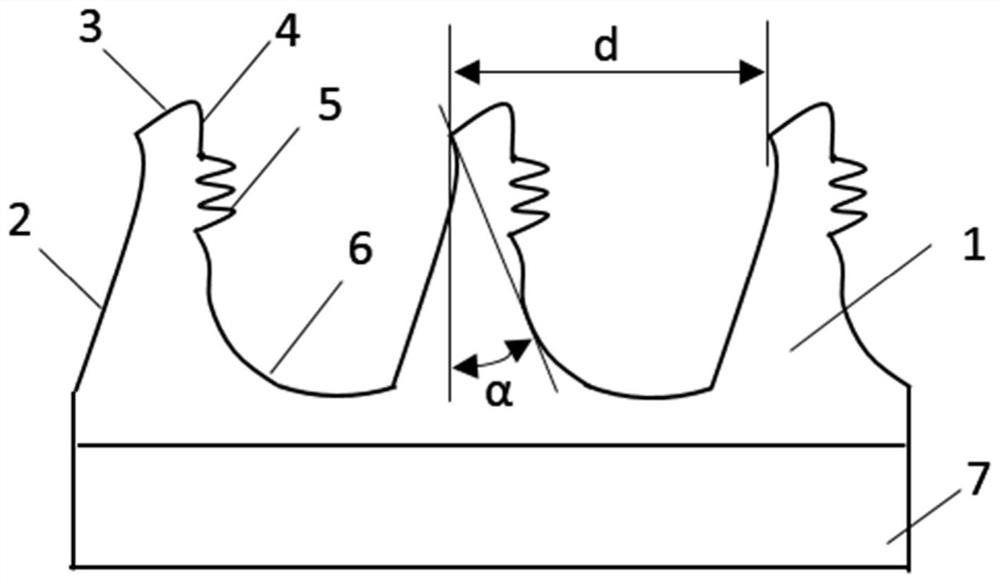

The invention discloses an impurity-removing carding device for a rotor spinning machine. The device comprises a shell and a carding roller, the shell is provided with a fiber transporting channel, a feeding channel and an impurity removing channel, the impurity removing channel comprises an impurity inlet and an impurity outlet, the impurity removing channel is internally provided with a spreader plate making the impurity removing channel divided into an air current channel and an impurity air current channel, on end of the spreader plate is located at the impurity inlet, the impurity inlet is divided into an air current channel outlet and an impurity air current channel inlet, the other end of the spreader plate is located at the impurity outlet, and the impurity outlet is divided into an air current channel inlet and an impurity air current channel outlet; card clothing is laid on the surface of the spreader plate, and the card clothing comprises sharp teeth arranged in the direction facing the impurity outlet. The size of the air flow channel is adjusted, so that the size of an air current is controlled, and the phenomenon that impurities low in density are brought back into a carding cavity by an air replenishment air current is prevented; in this way, the carding effect is improved, and the phenomenon that the quality of yarn spun through the next few steps is lowered is prevented.

Owner:ZHEJIANG SCI-TECH UNIV

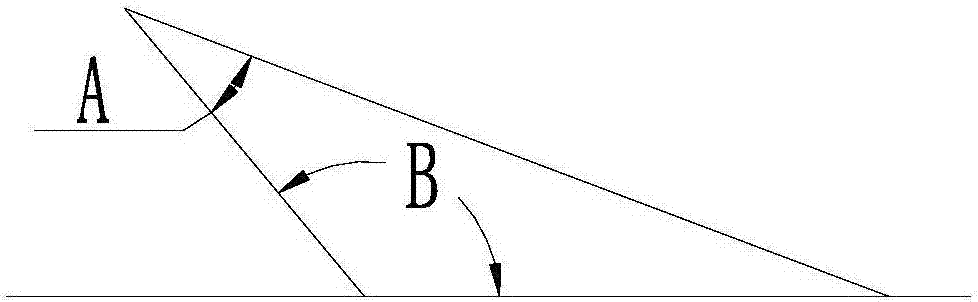

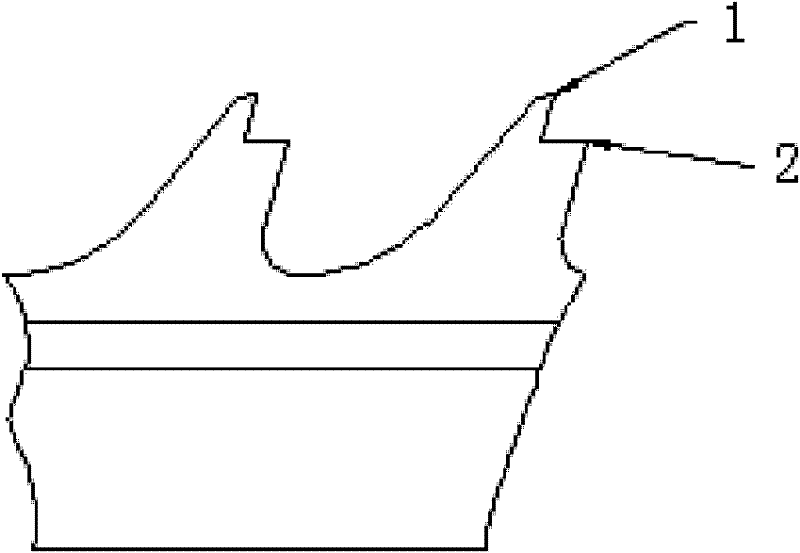

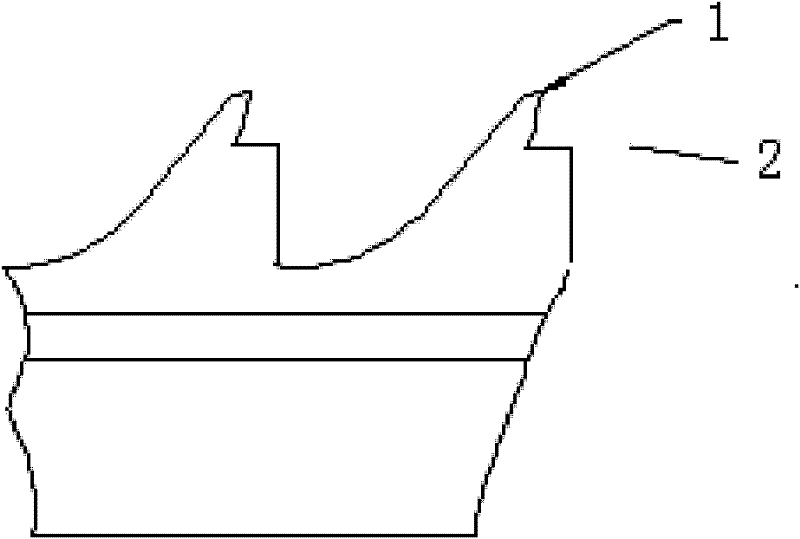

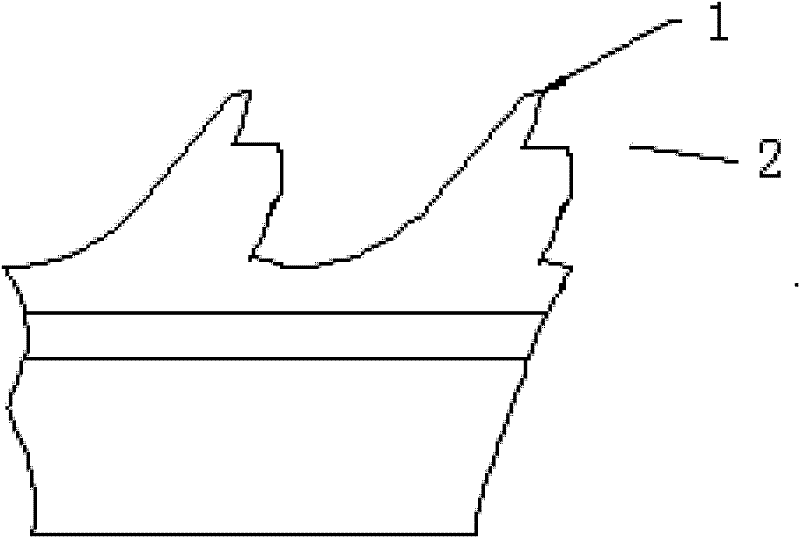

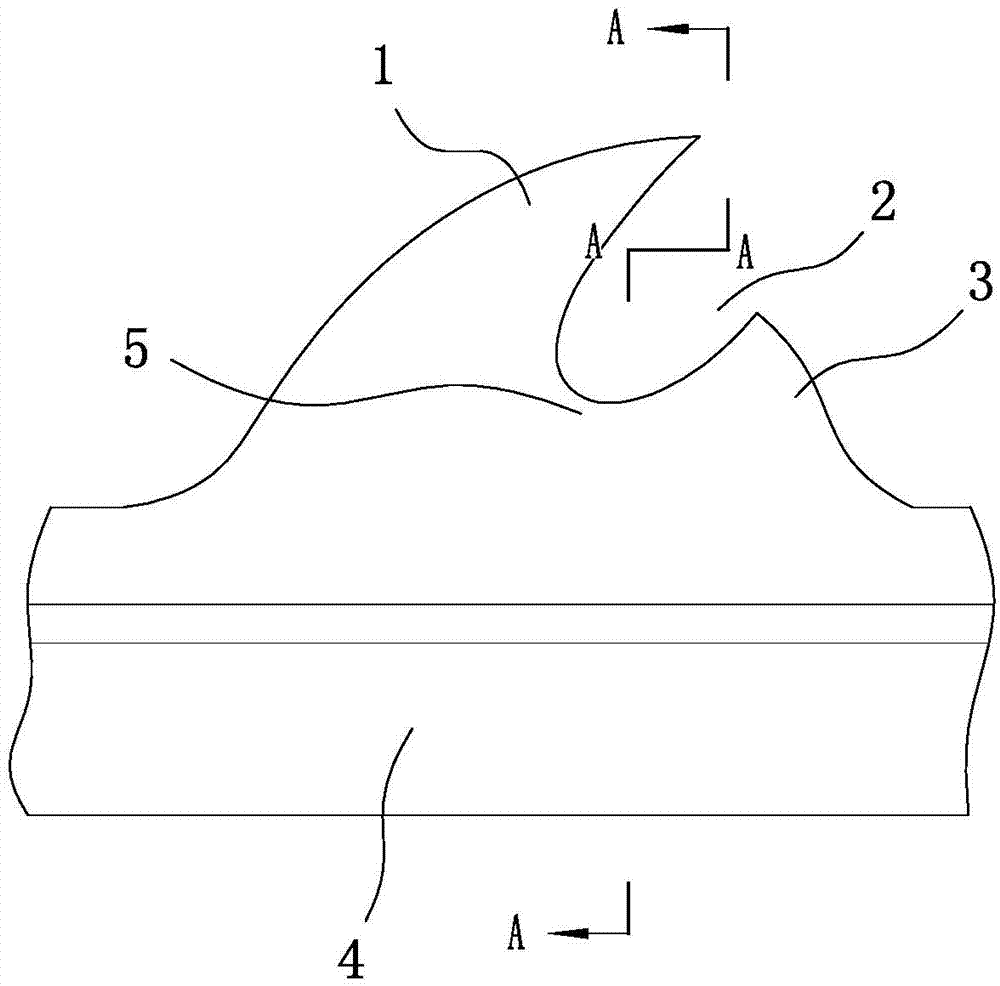

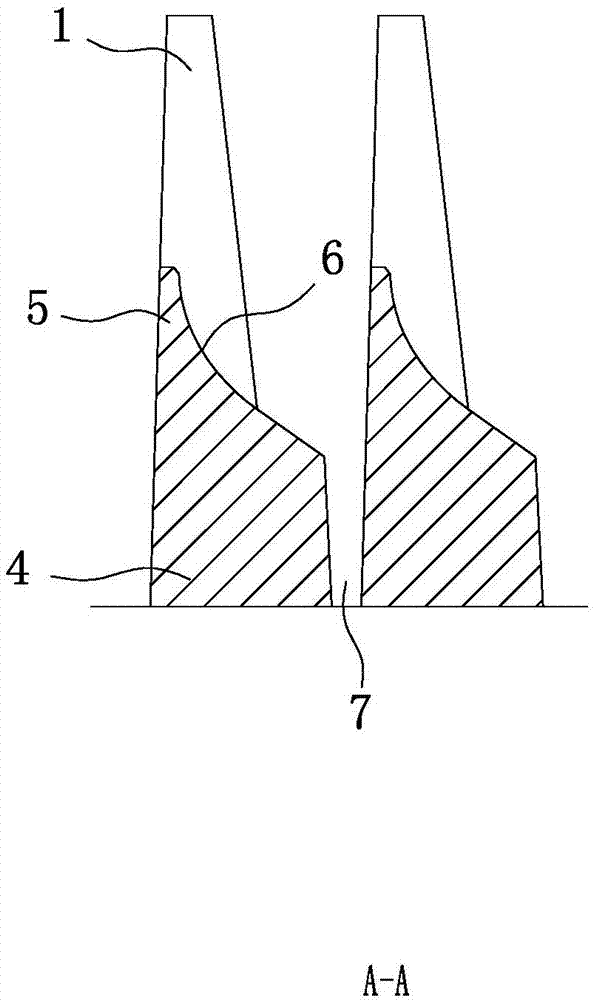

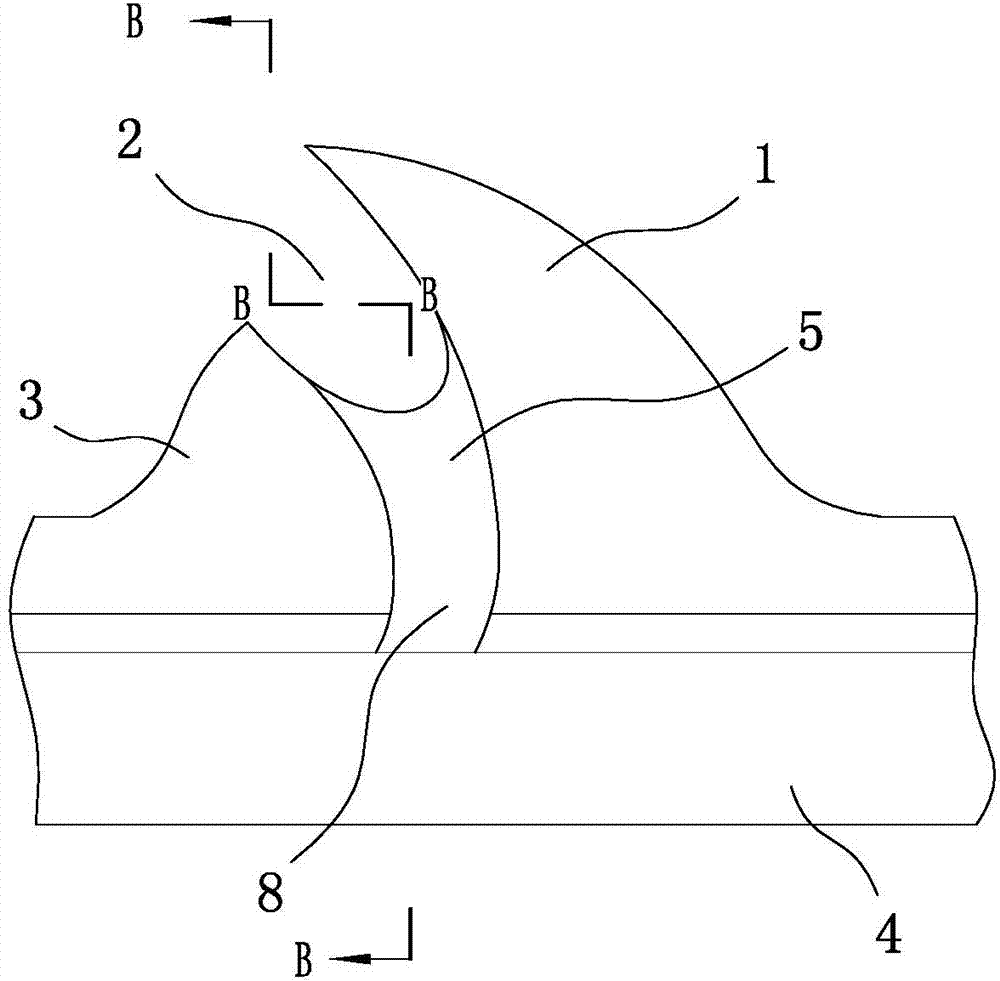

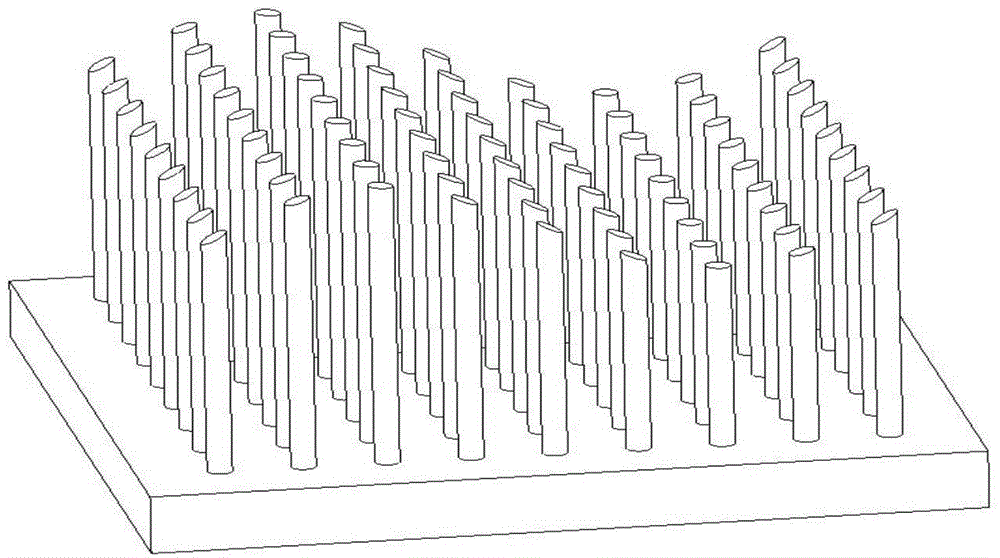

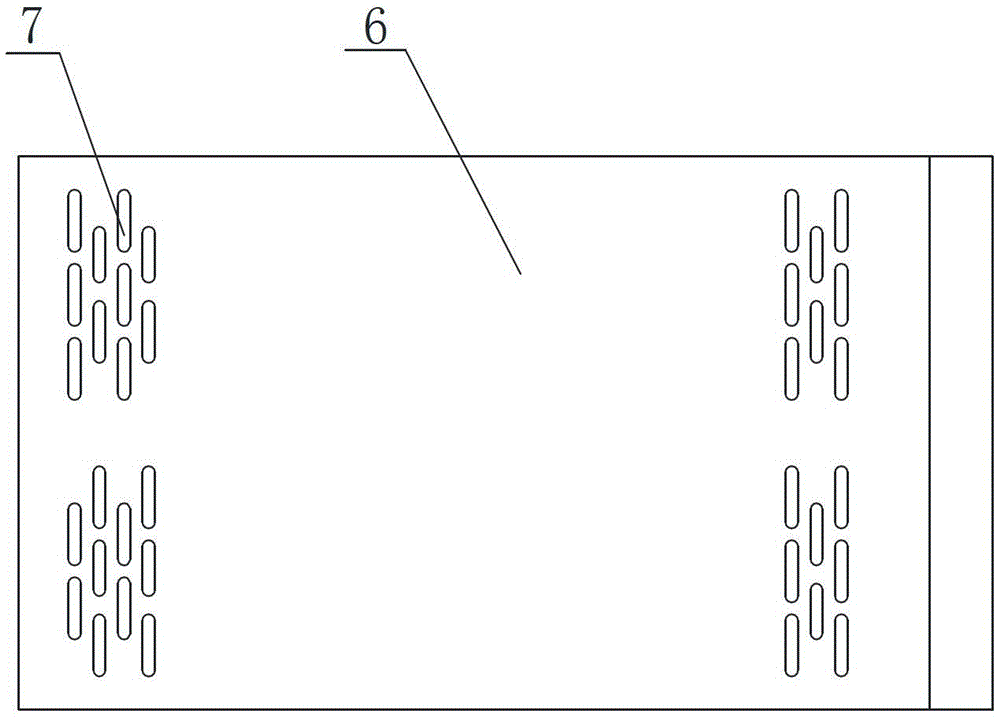

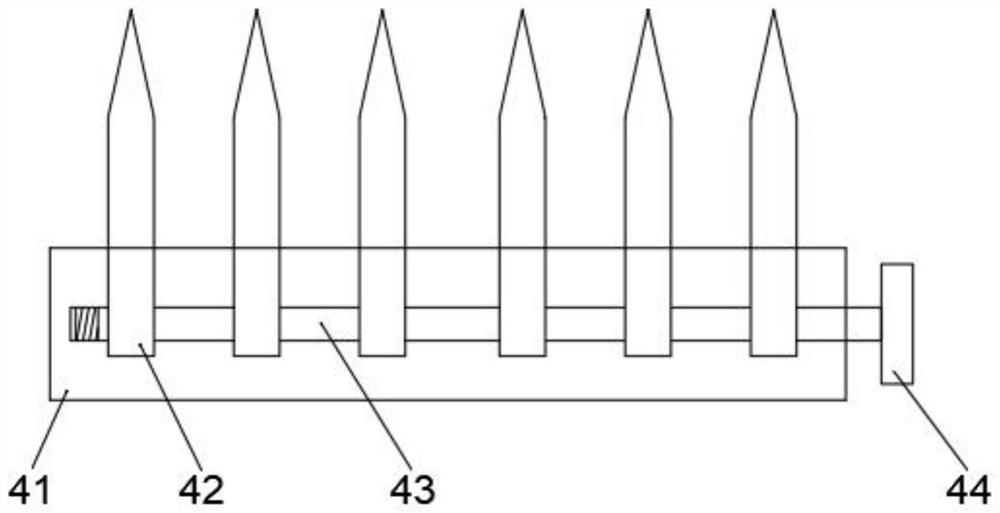

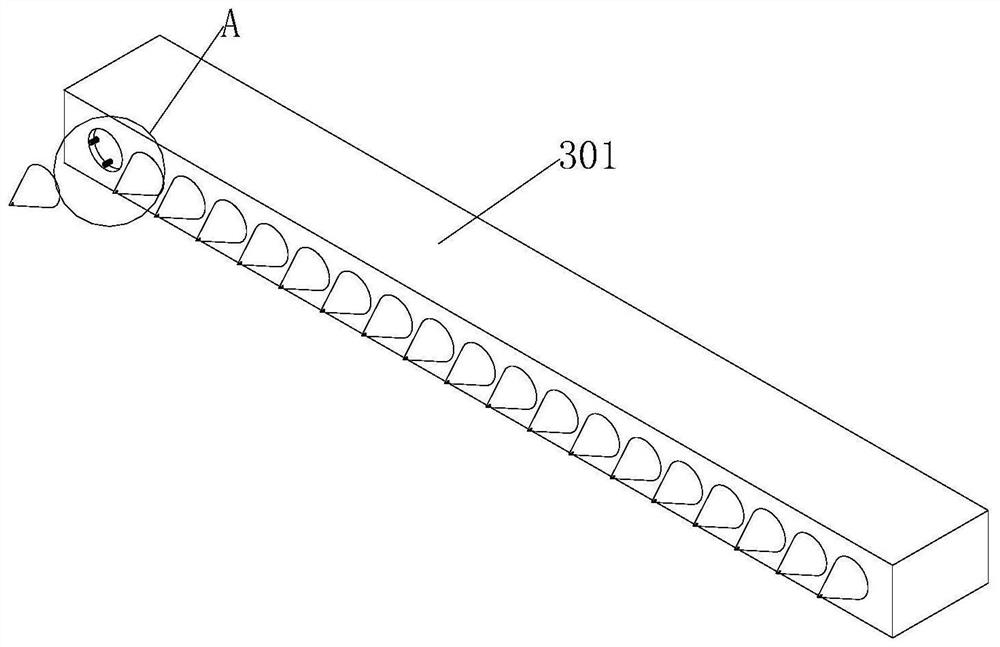

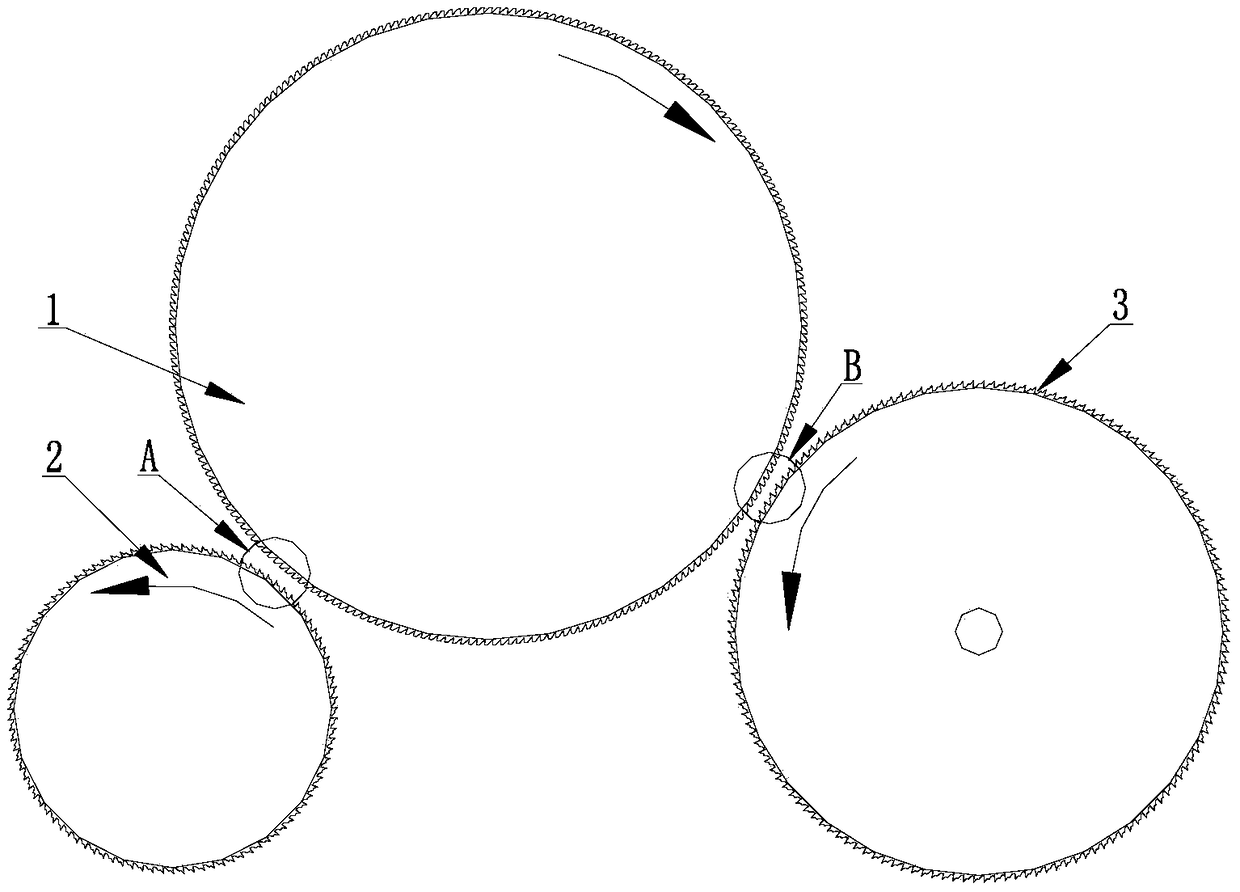

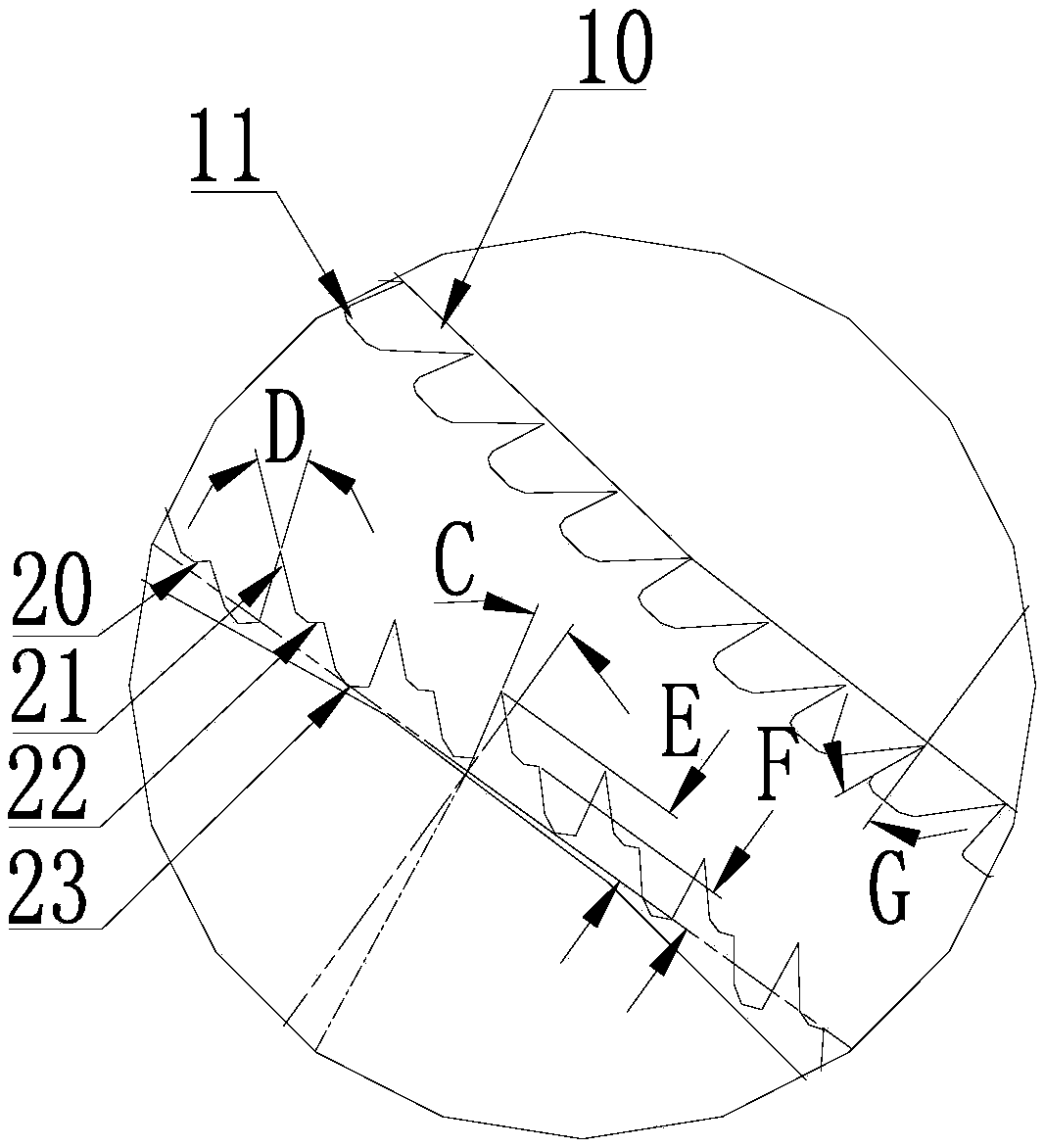

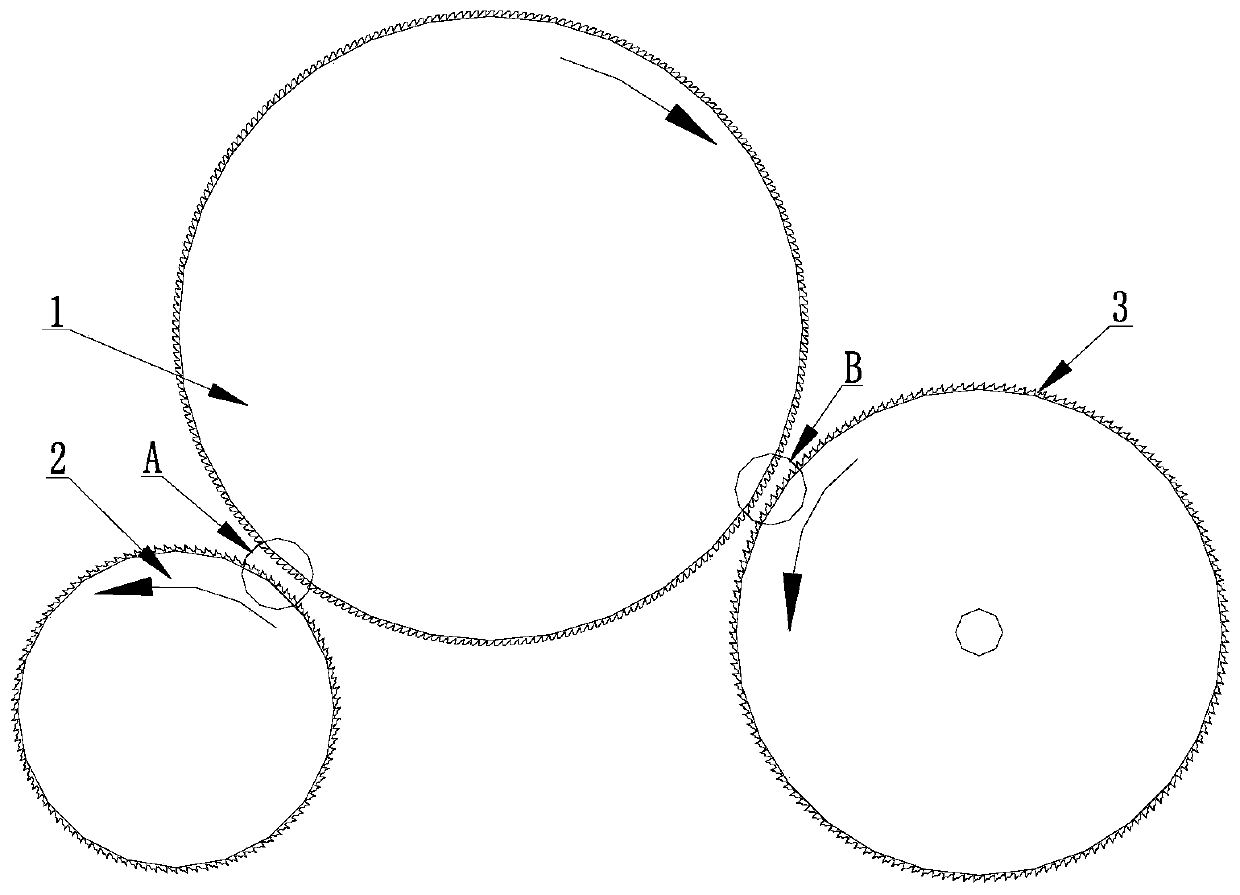

High-density cotton carding metallic card clothing

The invention provides high-density cotton carding metallic card clothing comprising main comb teeth raised from a base part, wherein a tooth flank towards a carding direction of the main comb teeth is raised so as to form lateral teeth with a tooth height smaller than the height of the main comb teeth. The technical scheme is as follows: the tooth flank towards the carding of original comb teeth is raised and provided with lateral teeth so as to form a structure of one tooth root and double comb teeth; in the carding process of fibers, the fibers are supported by the lateral teeth to ensure that the fibers are gathered at a carding layer area of the main comb teeth so that an overall carding effect of the comb teeth is improved; in the mean time, the main comb teeth are assisted by the lateral teeth on the fiber carding; and therefore, the tooth density of the metallic card clothing is increased by more than 30%.

Owner:金轮针布(江苏)有限公司

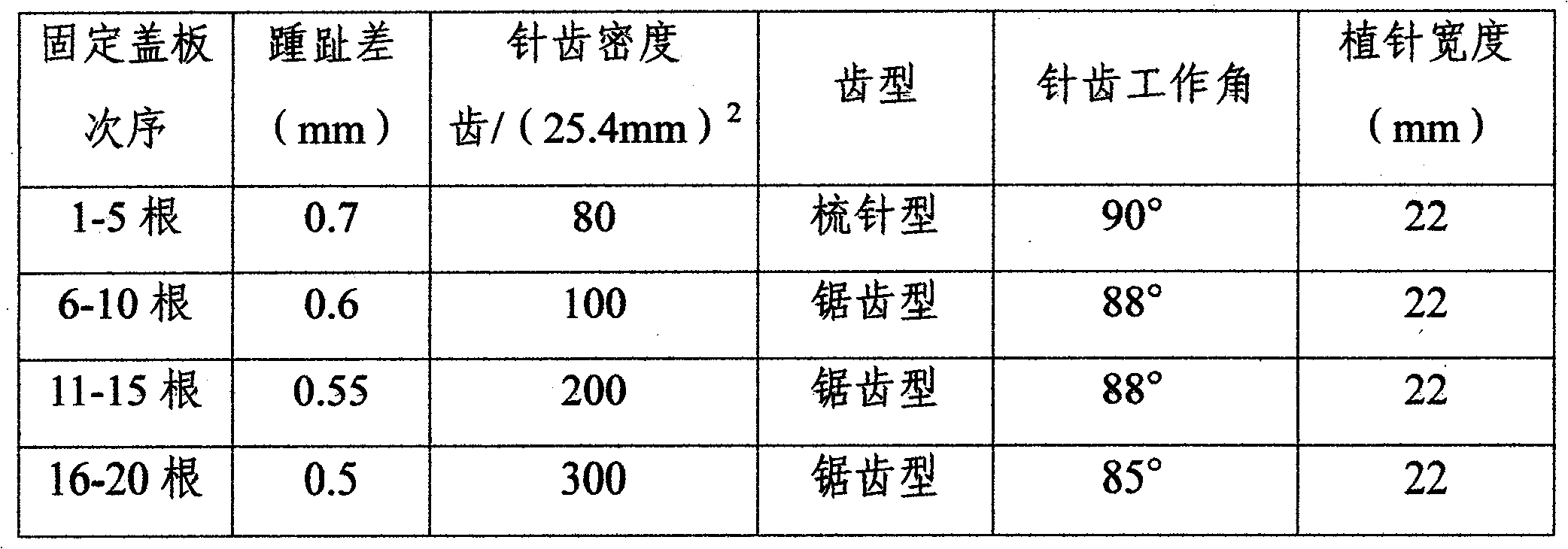

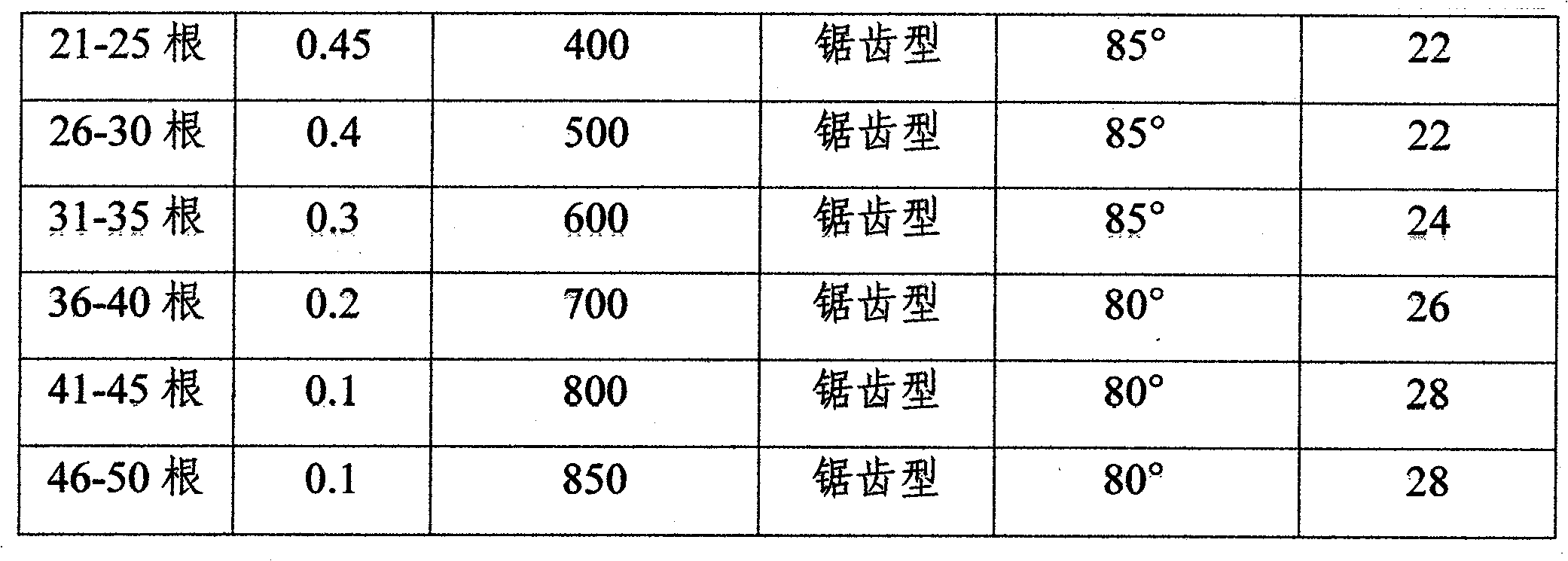

Novel fully-fixed cover board carding machine

The invention provides a novel fully-fixed cover board carding machine, relating to the technical field of the manufacture of a carding machine. By taking the idea which meets the 'gradual carding' of the carding machine as the key technology and being matched with a cotton net cleaner, the invention provides the design scheme of the 'novel fully-fixed cover board carding machine'. The whole device is provided with 50 fixed cover boards and 6 cotton net cleaners, wherein the 10 fixed cover boards are respectively arranged among every 2 cotton net cleaners; and the heels and toes of the fixed cover boards are sequentially reduced, the density of the needle teeth is gradually increased, the needling width of the cover boards is gradually increased, and the work angles of the needle teeth are gradually reduced from the back to the front, so that carding capability is gradually enhanced. The first cotton net cleaner is a guide board type, and the second-sixth cotton net cleaners are static types. The novel fully-fixed cover board carding machine changes the conventional structure that a main carding region is additionally provided with a movable cover board, thereby further enhancing the carding capability of the carding machine and the impurity-removing and short flock-removing capability of the cotton net cleaner, being good for improving the carding effect, and further improving the carding quality and the yield of the carding machine.

Owner:孙鹏子

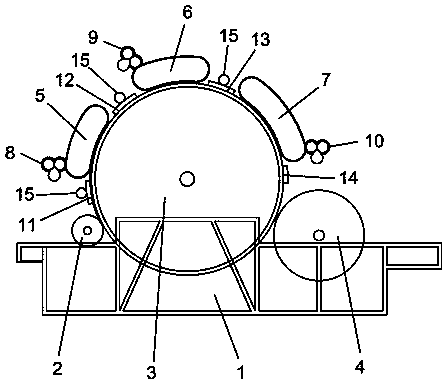

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

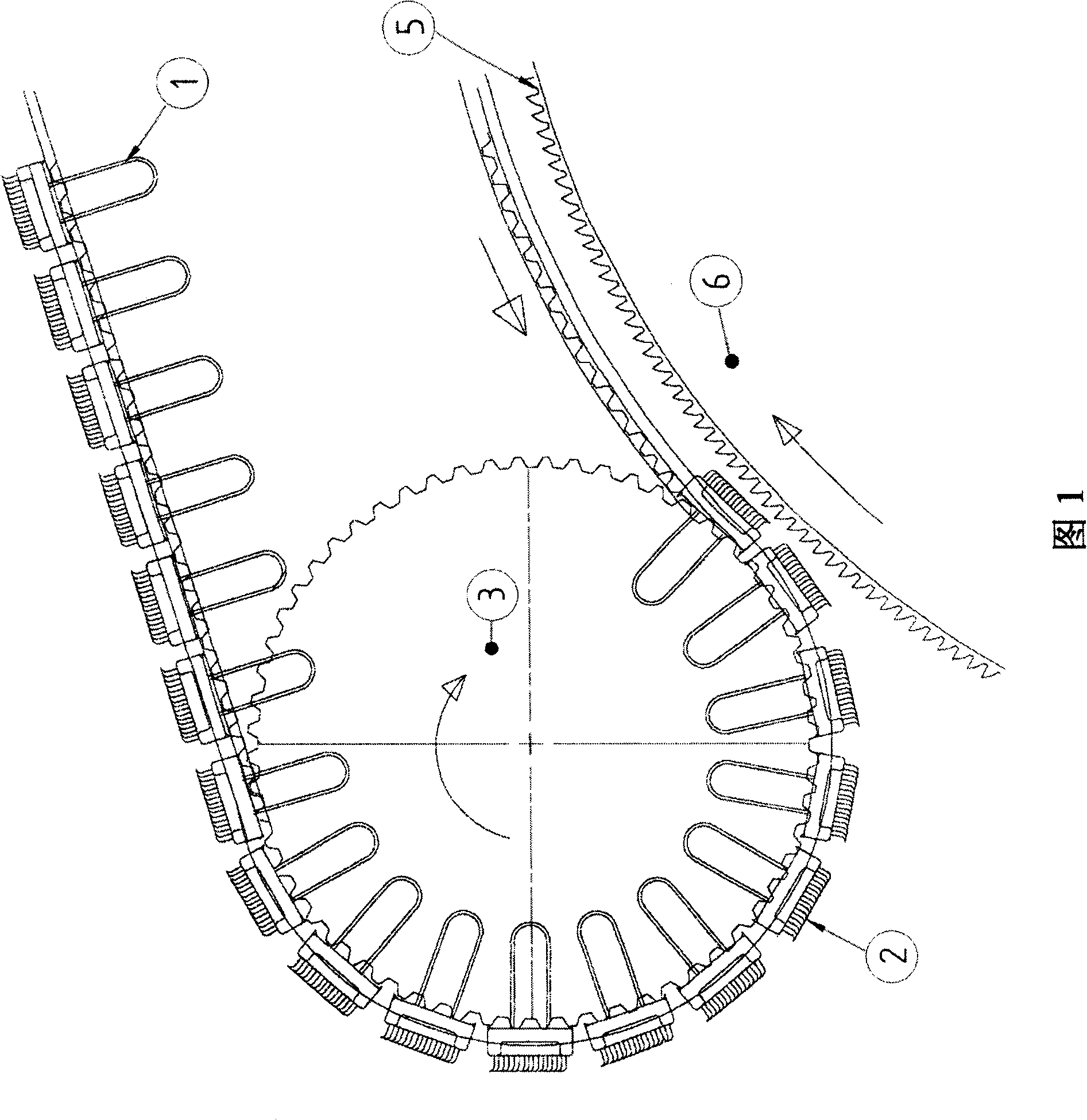

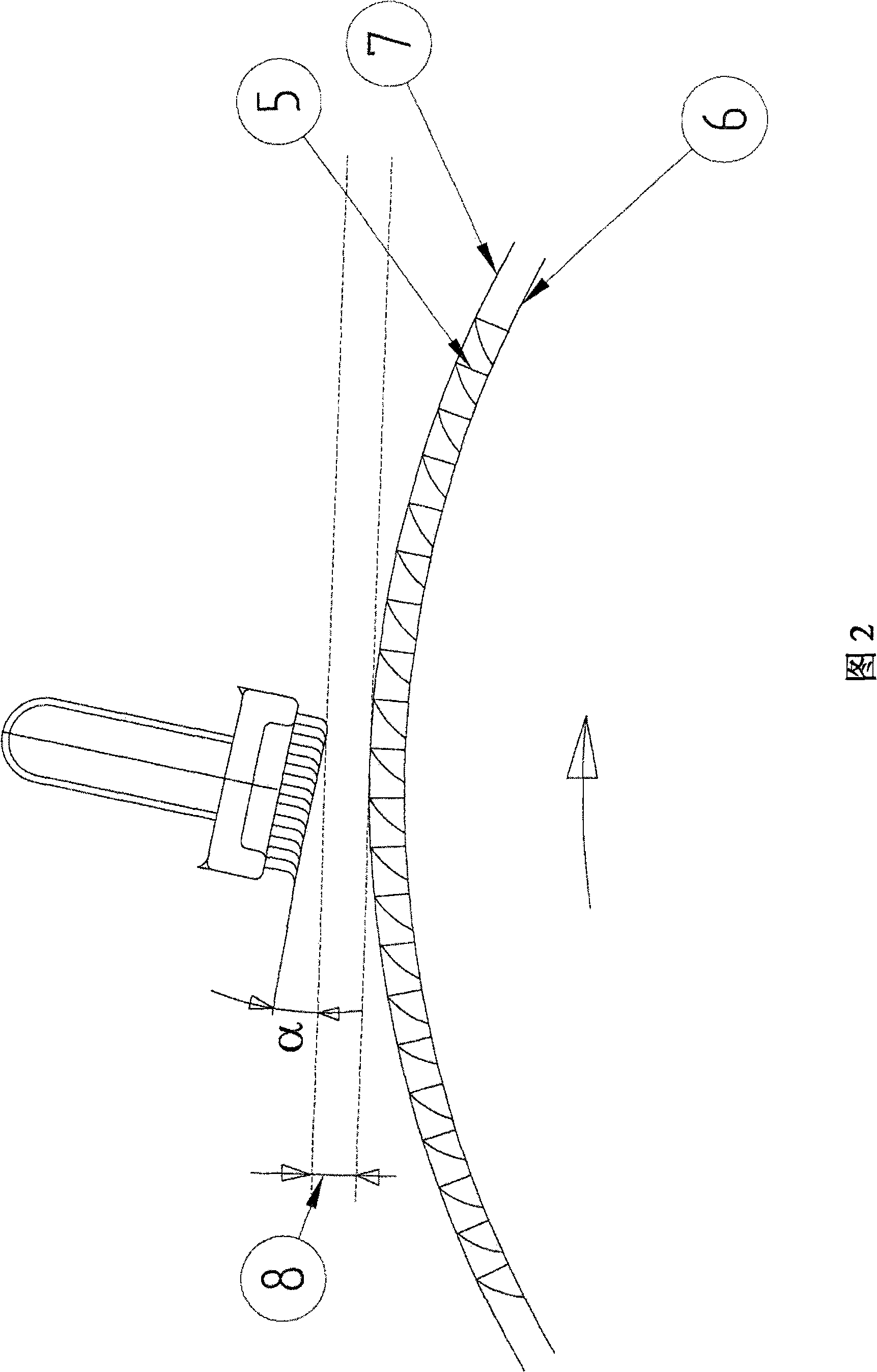

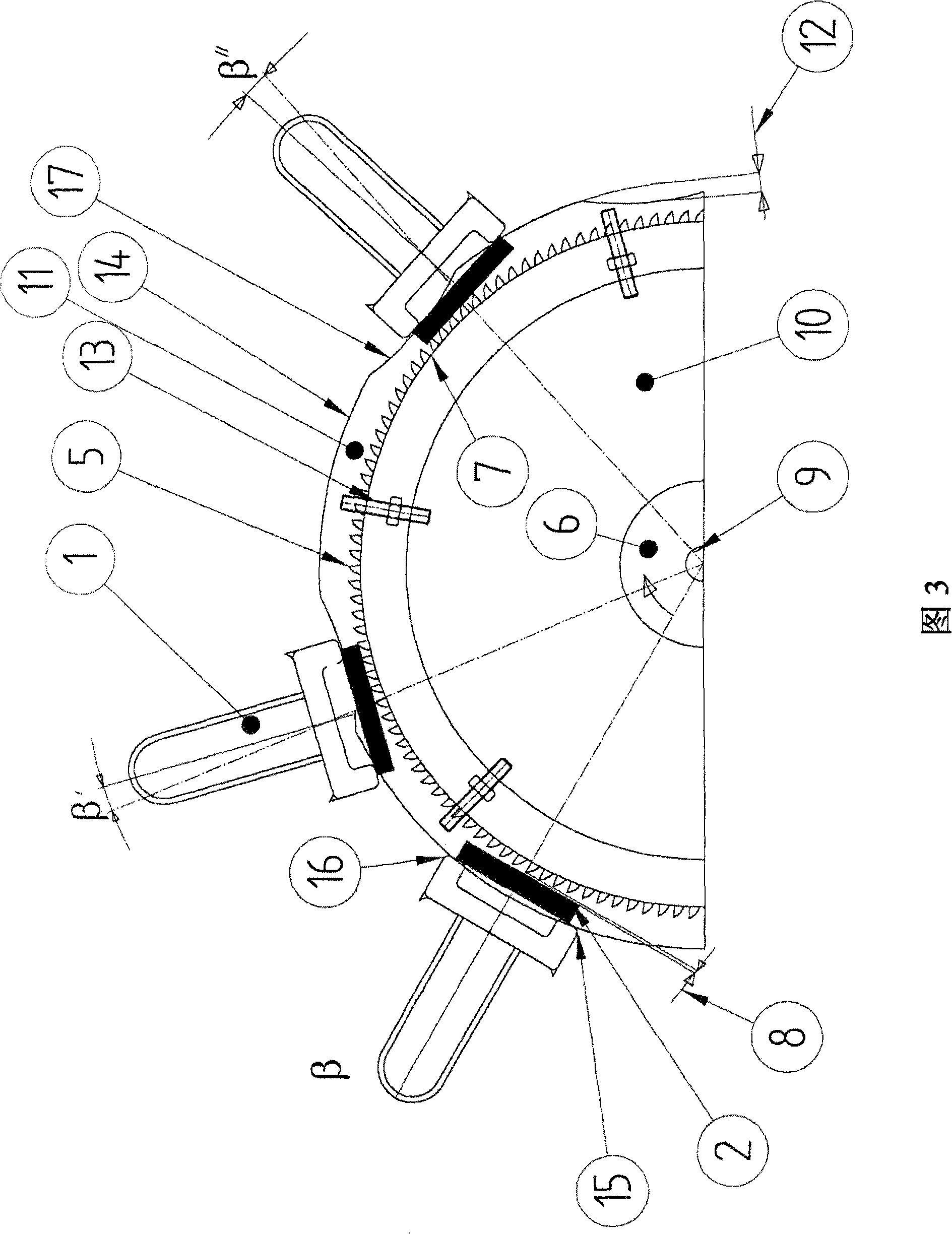

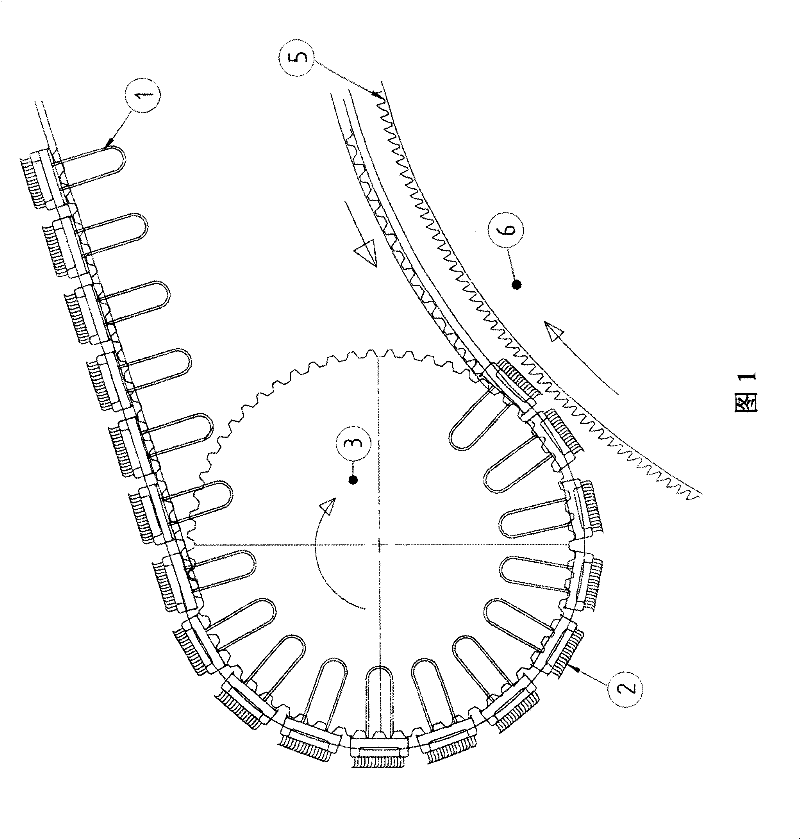

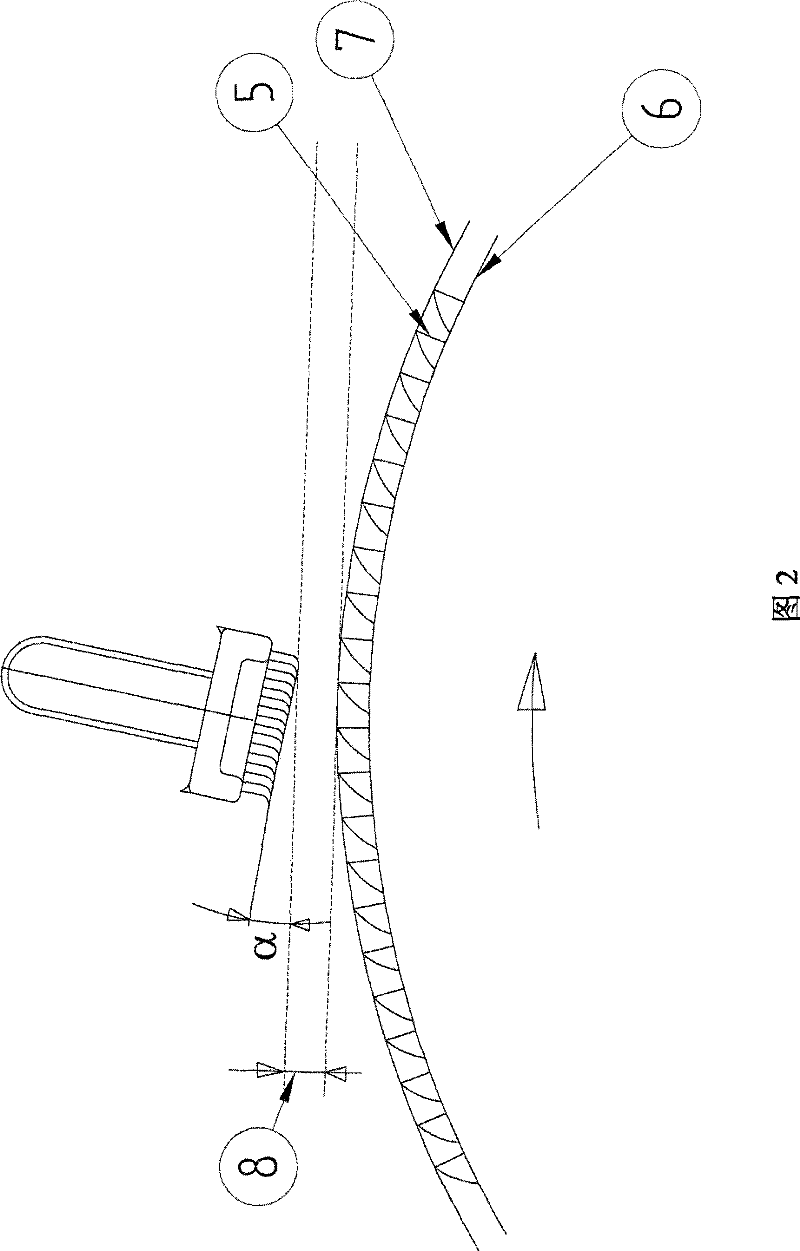

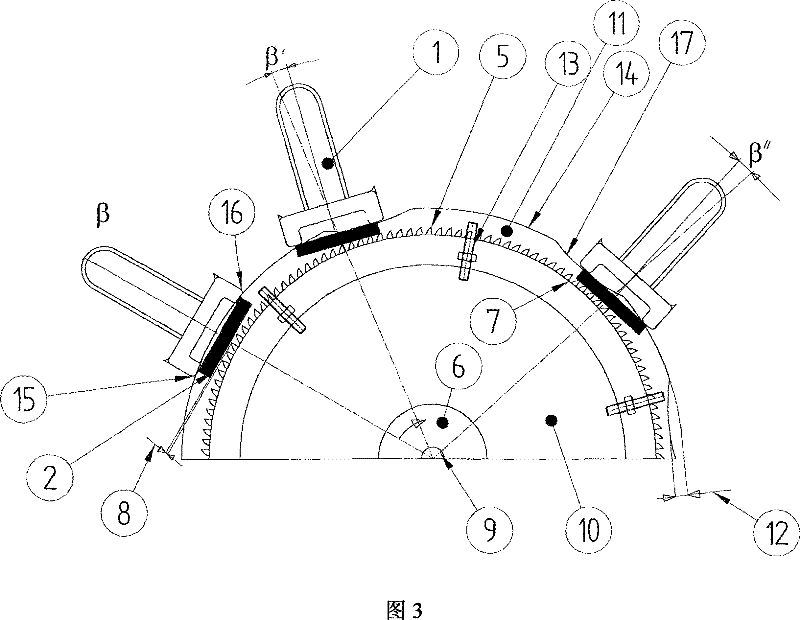

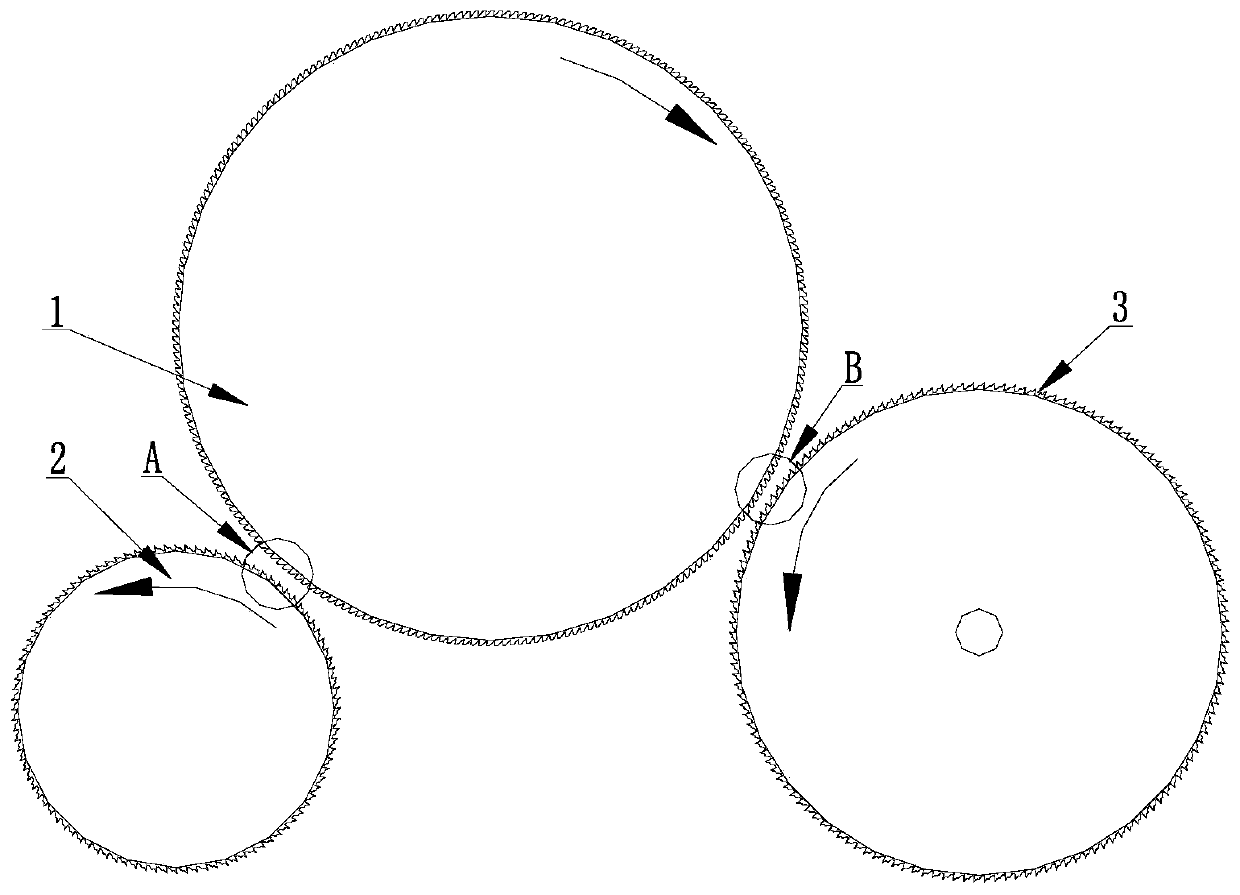

Dynamic carding method and device thereof

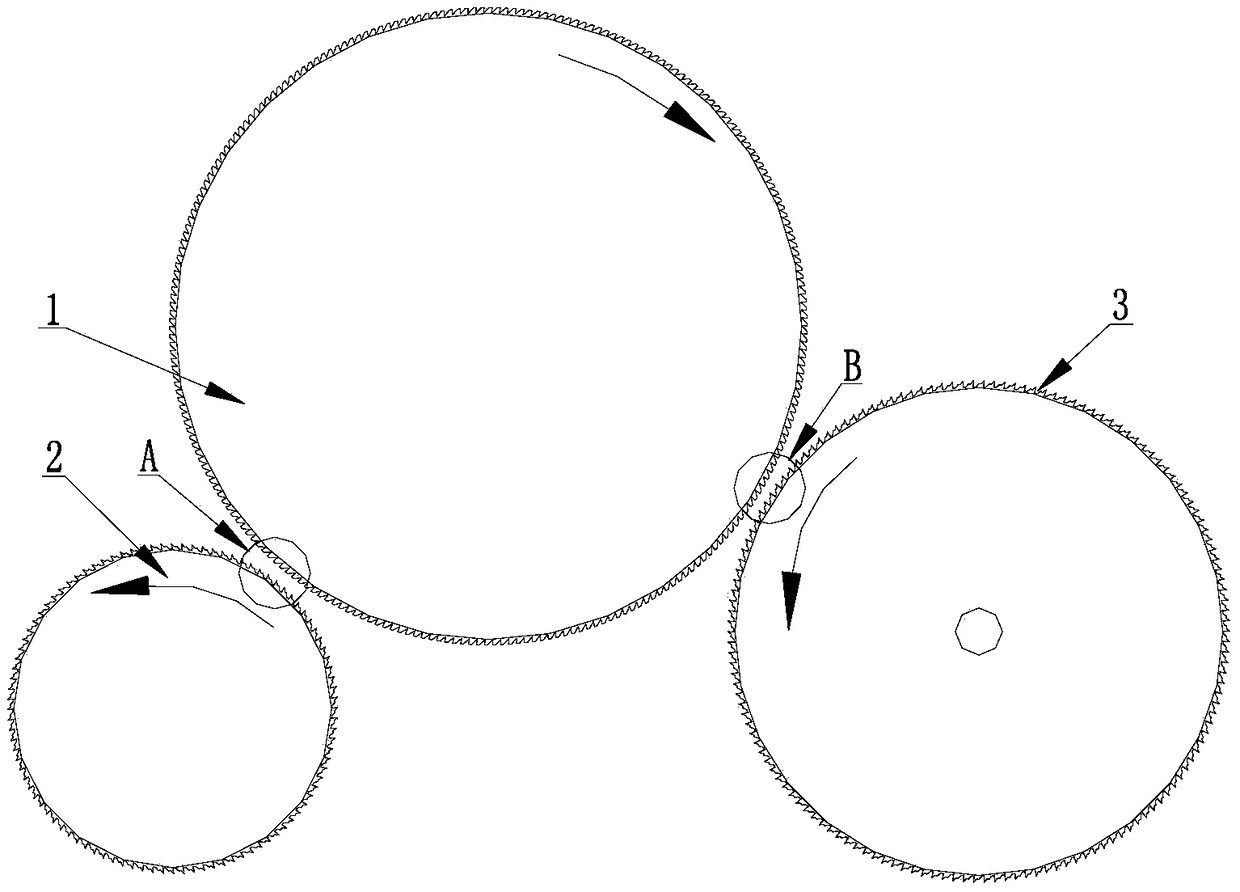

The invention relates to a dynamic carding method for carding fibers with a carding machine having card-flat rods fitted with card clothing moves the card-flat rods in a carding zone in relation to the peripheral surface of a swift along a scheduled path and a device thereof; wherein, at least one card clothing moves instantaneously in a direction deviated from the scheduled path at least one time passing through the carding zone, and then returns to the scheduled path. The feature of the device for carding fibers according to the carding method of the invention is that the invention comprises a device that makes at least one card clothing deviate instantaneously from the scheduled path, and then return to the scheduled path.

Owner:HERGETH H

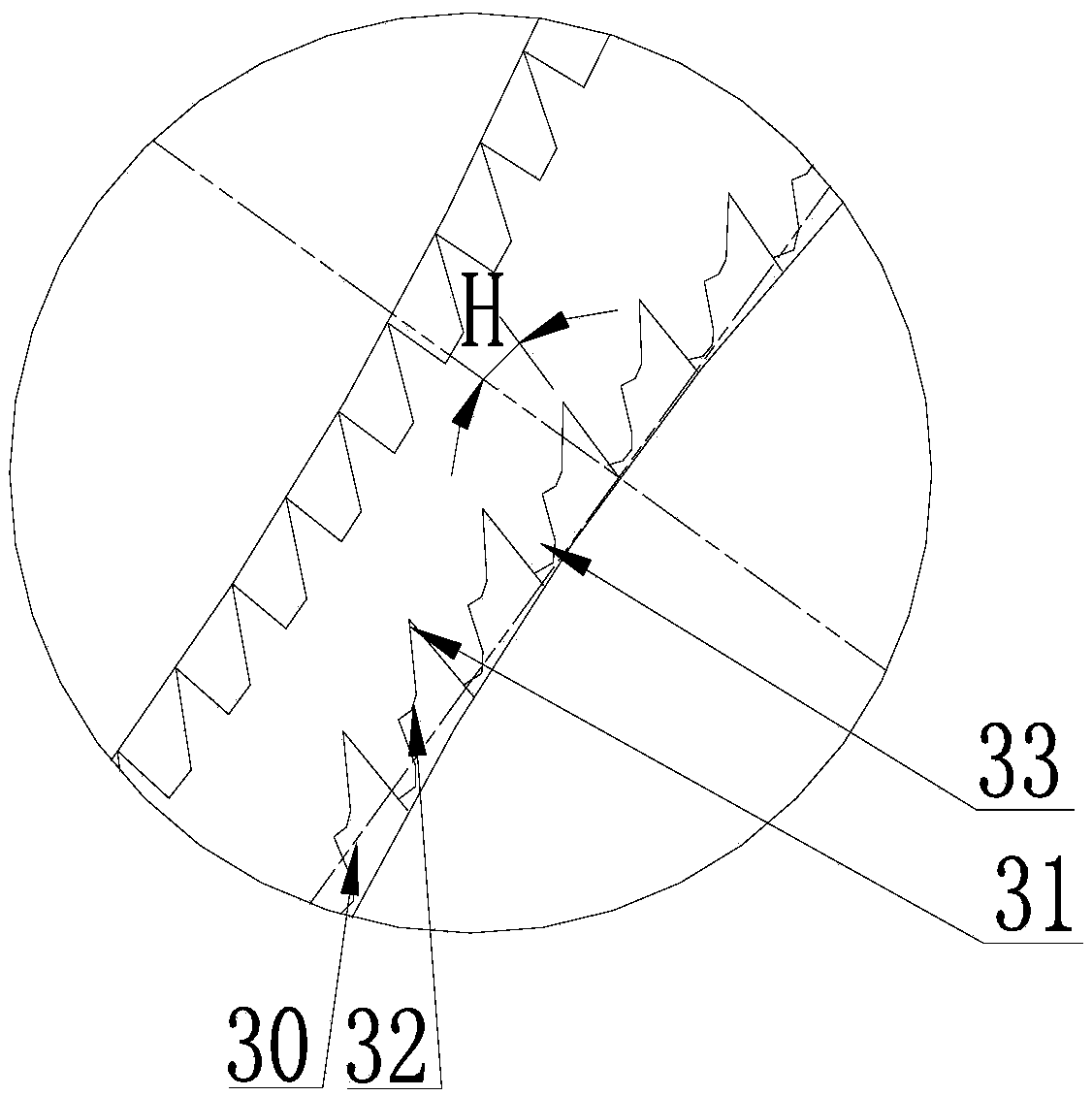

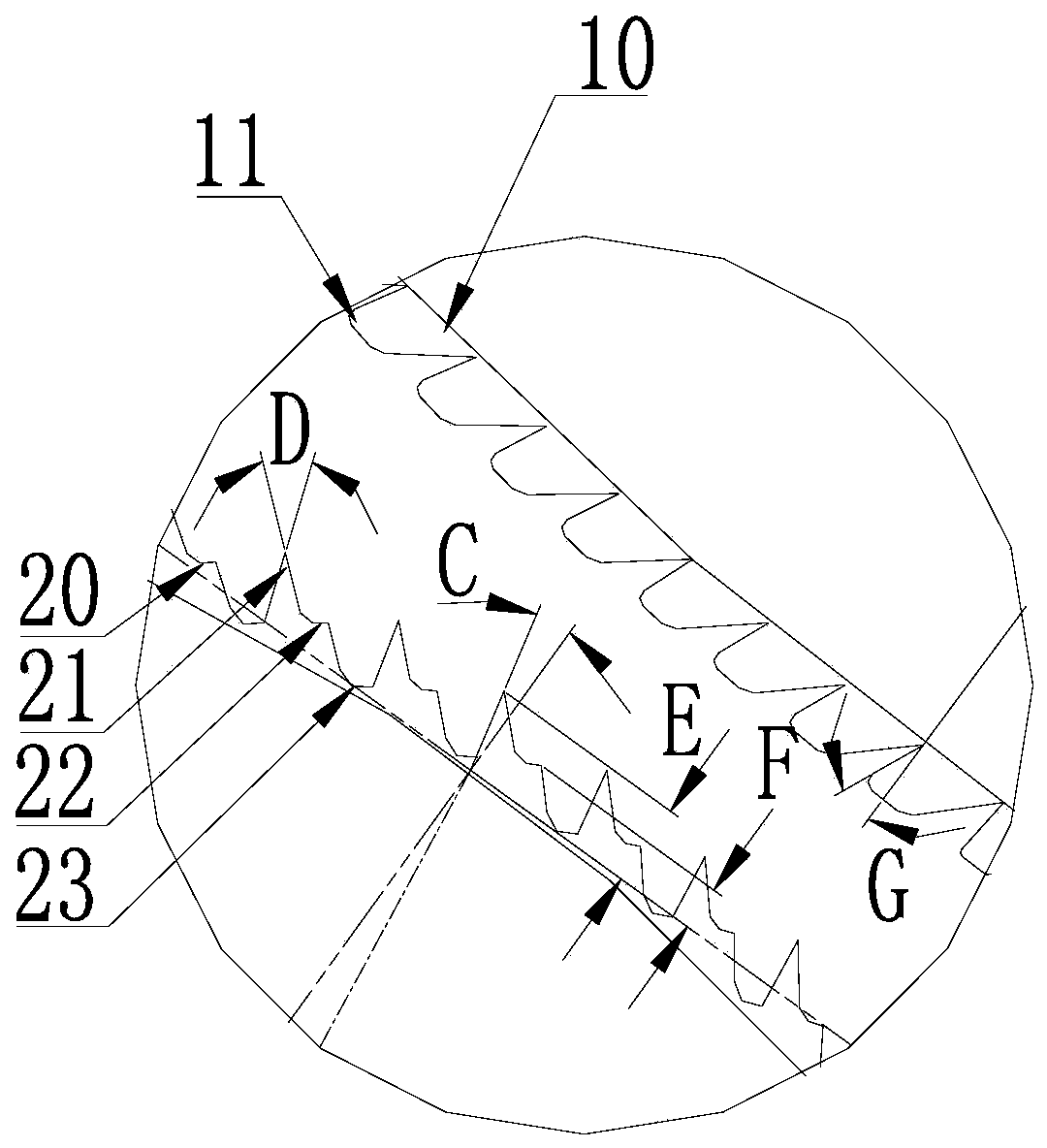

Metal card clothing of carding machine

The invention discloses metal card clothing of a carding machine. The metal card clothing comprises a base portion, the base portion is evenly provided with main teeth, the front portions of the main teeth are provided with auxiliary teeth, notches are formed between the main teeth and the auxiliary teeth, the main teeth are arc back teeth with arc work faces, the auxiliary teeth are E-shaped teeth, and the main teeth are connected with the auxiliary teeth through a transition plate. The impurity tolerance capacity of the metal card clothing can be improved, fiber damage and cylinder winding phenomena are reduced, the metal card clothing can replace elastic card clothing in the carding process, and carding efficiency of wool is improved.

Owner:WUXI ZHONGWANG 4D TECH

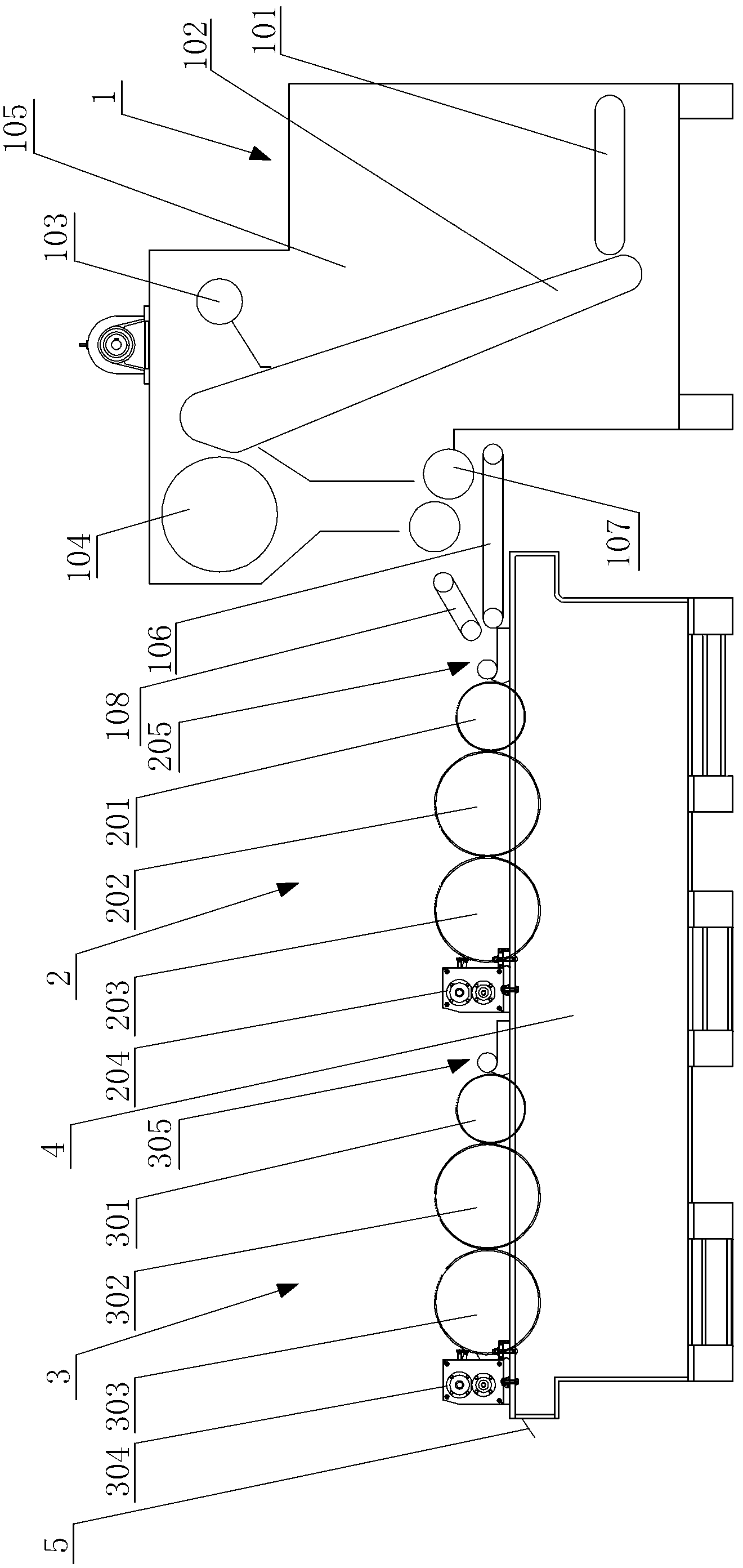

Non-woven carding machine used for spinning absorbent cotton

ActiveCN103290531ALine speed setting is reasonableConsistent vertical and horizontal strengthCarding machinesAbsorbent cottonMechanical engineering

The invention relates to carding machines, and discloses a non-woven carding machine used for spinning absorbent cotton. The non-woven carding machine used for spinning absorbent cotton comprises a feeding mechanism, a carding mechanism and a stripping mechanism. The stripping mechanism comprises a stripping roller, and the carding mechanism comprises a cylinder and a doffer, wherein the cylinder is located in front of the doffer and is connected with the doffer, a movable cover plate is arranged above the cylinder, a first front fixing cover plate and a second front fixing cover plate are arranged in front of the cylinder, the first front fixing cover plate is located below the second front fixing cover plate, a rear fixing cover plate is arranged behind the cylinder, the stripping roller is located behind the doffer, a cluttering roller and a flattening roller are sequentially arranged between the doffer and the stripping roller, and the cluttering roller is close to the doffer. The combination mode of the cover carding and cluttering roller cluttering can greatly improve the carding effect of the previous non-woven carding machine and effectively remove impurities such as cotton shells mixed in raw materials.

Owner:青岛东佳纺机(集团)有限公司

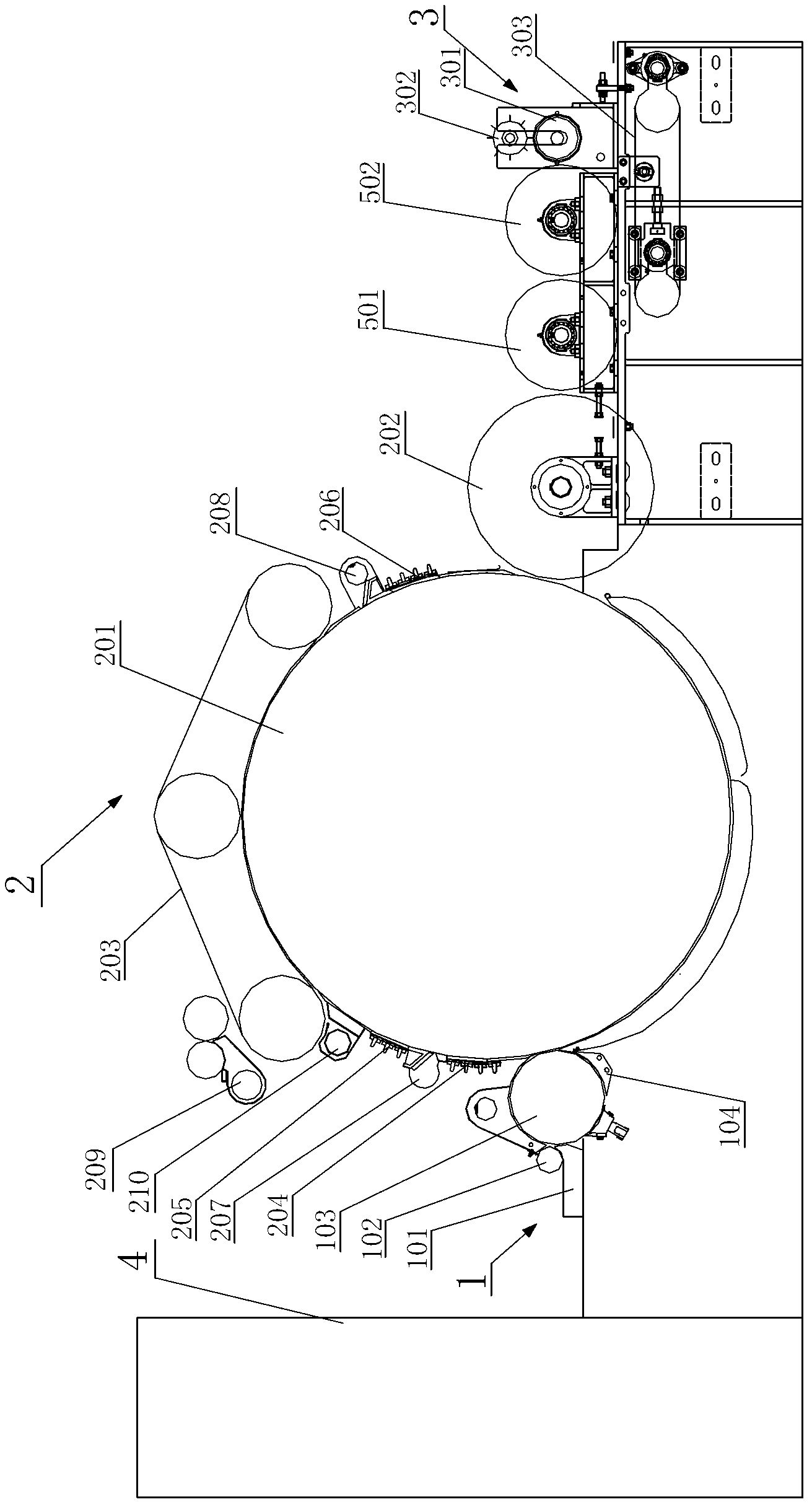

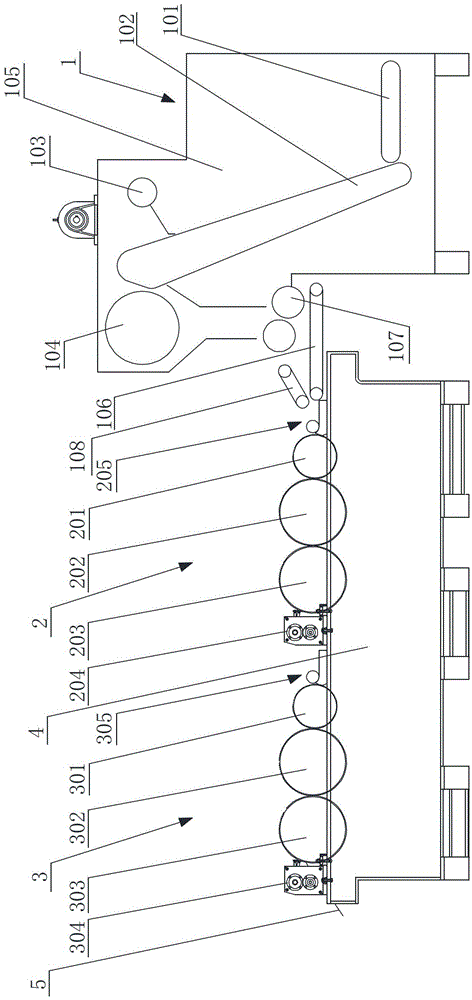

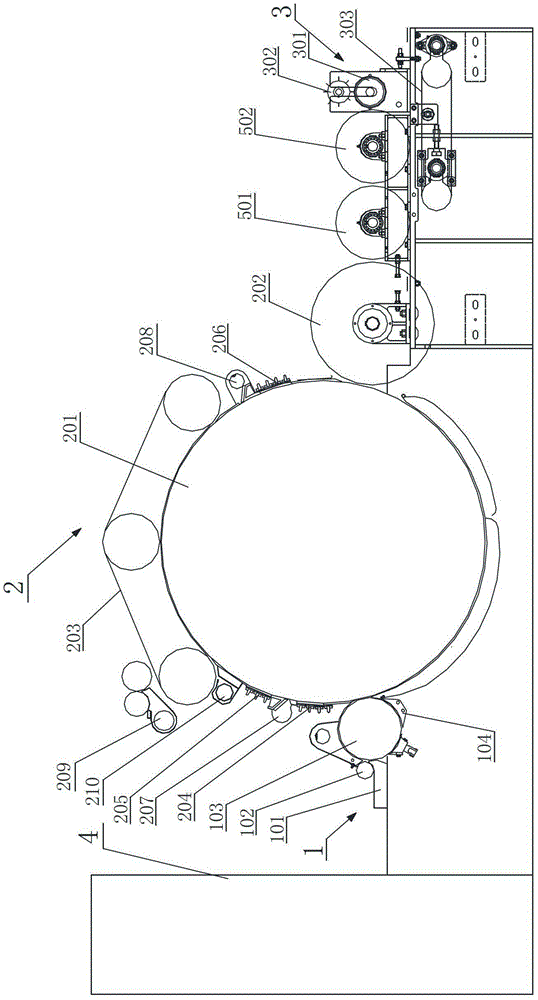

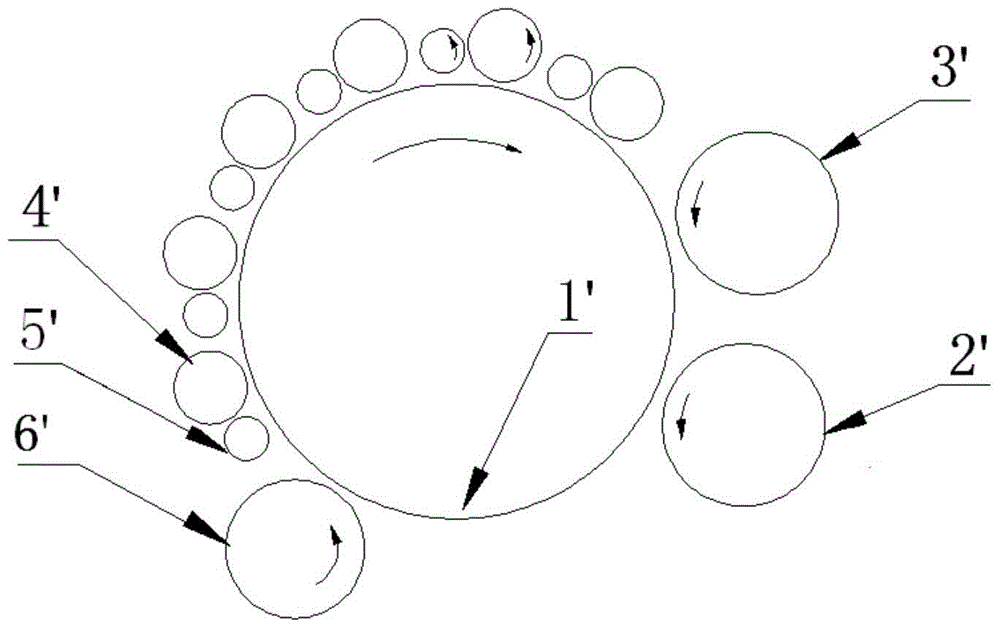

Double-throwing-coarse cashmere carding machine

ActiveCN103290532AGood thickening effectImprove carding effectCarding machinesDiameter ratioPulp and paper industry

The invention discloses a double-throwing-coarse cashmere carding machine. The double-throwing-coarse cashmere carding machine comprises a feeding mechanism and a carding mechanism, wherein the carding mechanism is composed of a front-stage carding unit and a rear-stage carding unit, the rear-stage carding unit is located right at the back of the front-stage carding unit, and the feeding mechanism, the front-stage carding unit and the rear-stage carding unit are connected in sequence. Each stage of carding unit of the carding mechanism comprises a licker-in, a cylinder and a doffer, wherein the licker-in, the cylinder and the doffer are arranged linearly, and a peeling cutter is at the back of the doffer and is closely near the doffer. In each stage of carding unit of the carding mechanism, the roller diameter ratio among the licker-in, the cylinder and the doffer is 250: 380: 380, and the linear speed ratio between the licker-in and the cylinder is 1:1.55-1:1.6. The double-throwing-coarse cashmere carding machine adopts a double-stage carding method, the throwing-coarse effect is obviously improved, and the carding effect of the cashmere carding machine and the extraction efficiency of dehaired wool are largely improved.

Owner:青岛东佳纺机(集团)有限公司 +1

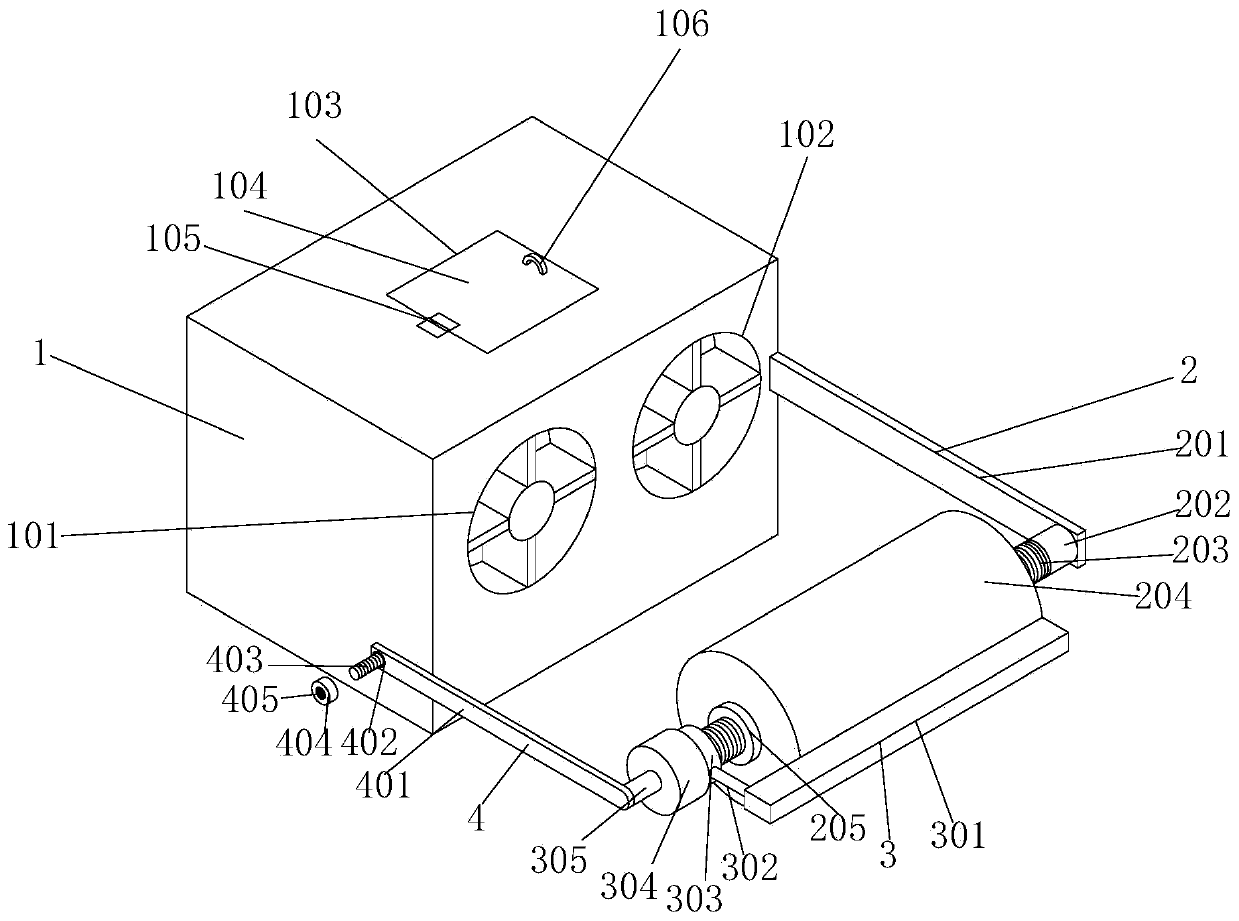

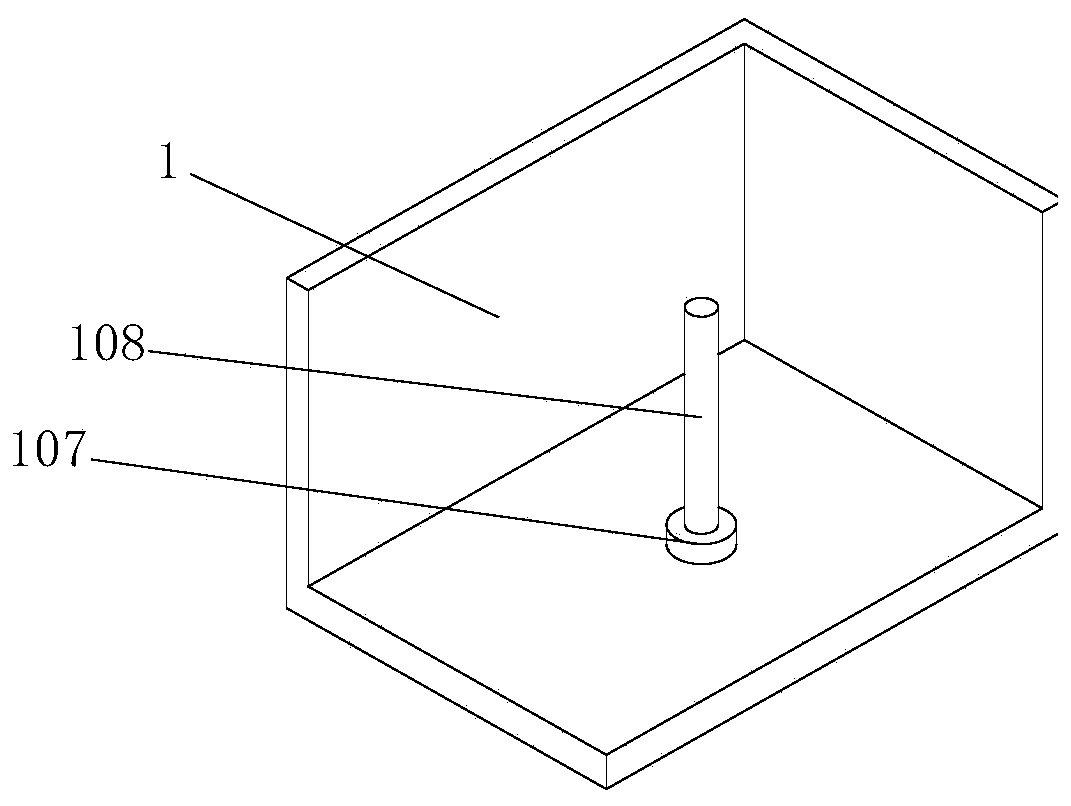

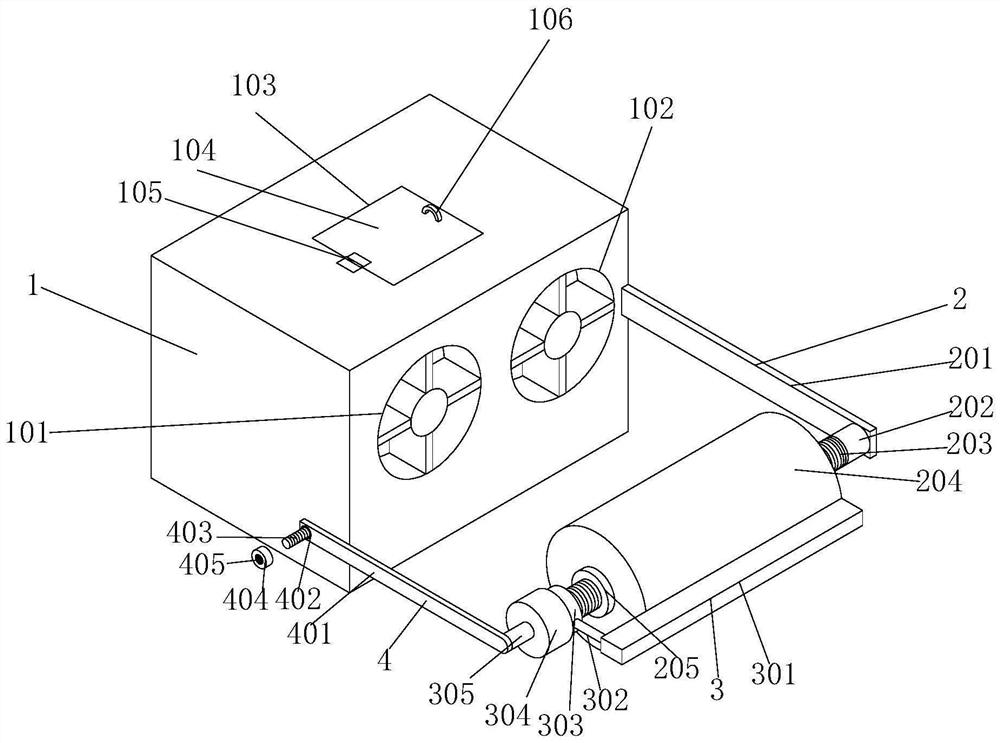

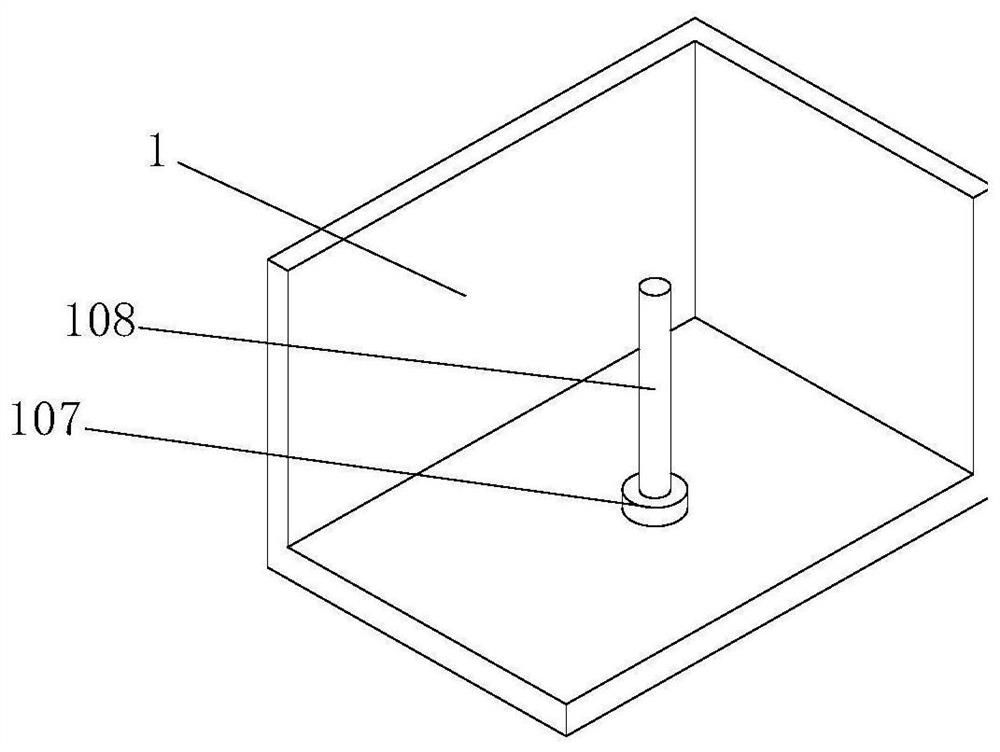

Carding machine capable of protecting cotton fibers

The invention relates to the technical field of carding machines, and discloses a carding machine capable of protecting cotton fibers. The carding machine comprises a shell, a fixing device, a cardingdevice and a handling device, wherein the shell comprises a first fan, a second fan and a through hole; a substrate is fixedly installed on the lower inner wall of the shell; a heating rod is fixedlyinstalled on the upper surface of the substrate; a fixing device is arranged in front of the shell; the fixing device comprises a fixing rod, a round rod and a first thread groove; a cotton fiber barrel is arranged on the outer side of the round rod; the carding device is arranged at the right end of the fixing device; the carding device comprises a cotton comb, a connection rod and a bearing; round grooves are formed in the front of the cotton comb; springs are connected to the round grooves; cotton comb teeth are arranged at the front ends of the springs; the connection rod is arranged on the left surface of the cotton comb; the bearing is fixedly connected to the left end of the connection rod; the inner ring of the bearing is sleeved on the round rod; a bearing sleeve is sleeved on the outer ring of the bearing; a motor is arranged at the front end of the bearing sleeve; ad the bearing sleeve is fixedly connected to the output shaft of the motor. The efficient carding machine hasthe advantages of good carding effect, high carding speed and the like

Owner:浙江黎盛新材料科技有限公司

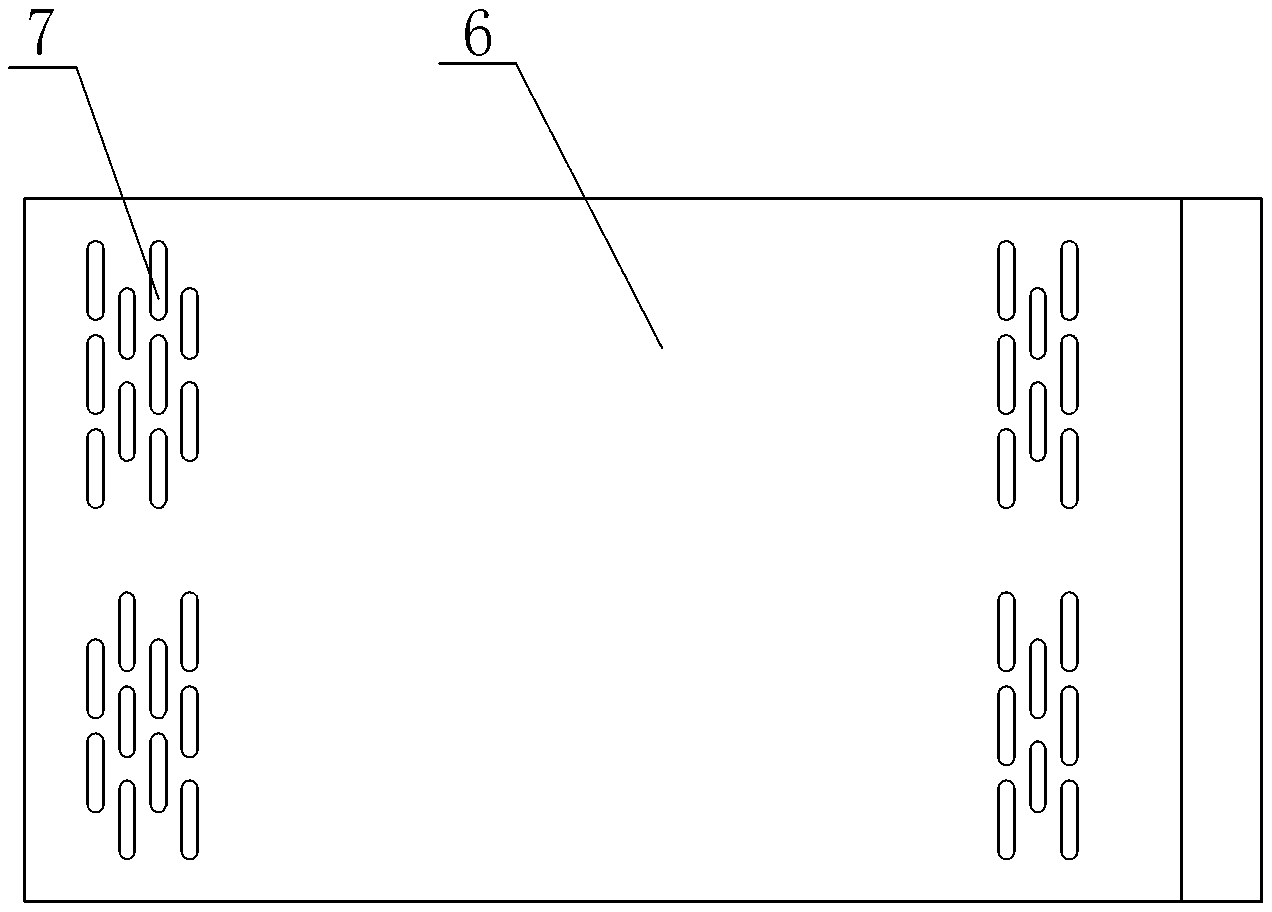

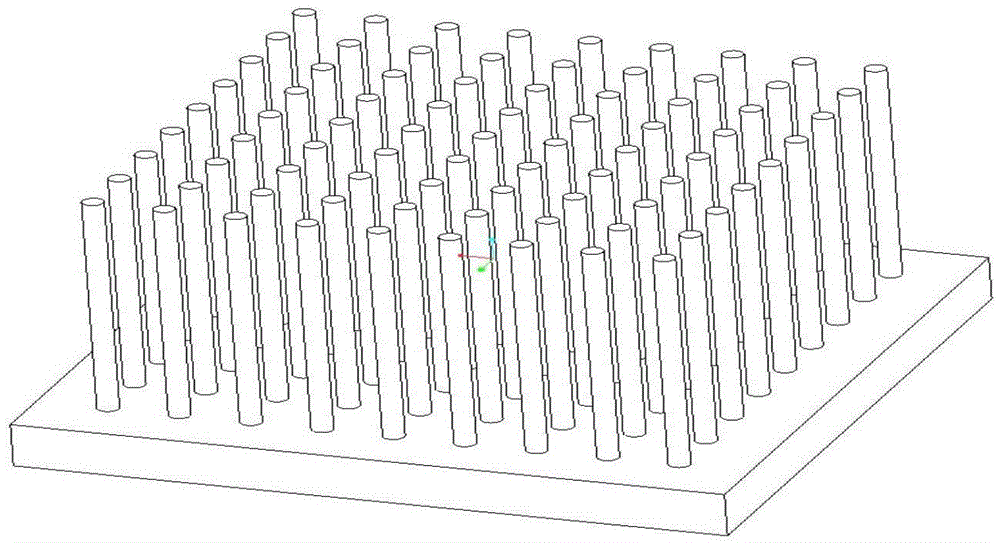

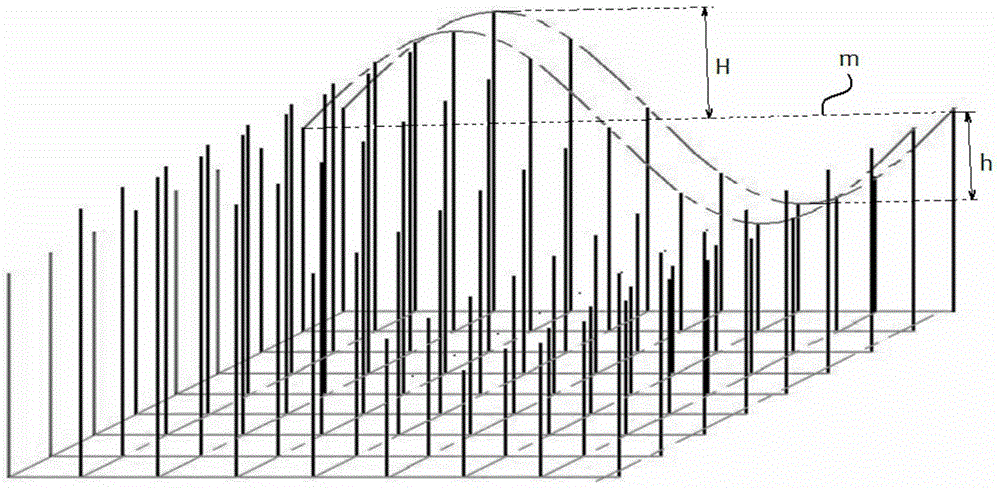

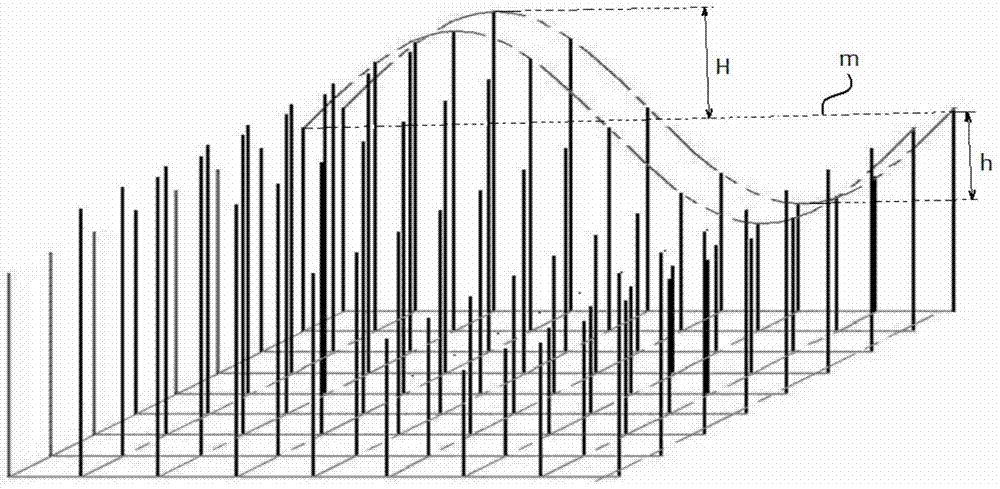

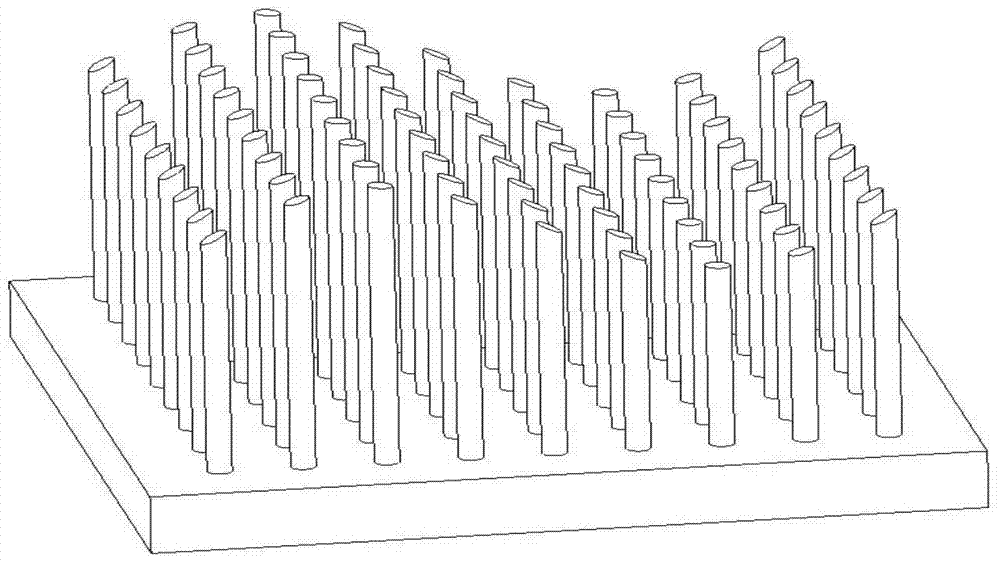

Unequal-height tooth carding cloth

ActiveCN104805542AMinimizes carding damageAffect quality efficiencyCarding machinesCardingEngineering

The invention provides an unequal-height tooth carding cloth, which consists of unequal-height tooth carding cloth units, wherein the surface of the tooth top of the carding cloth of each unequal-height tooth carding cloth unit is in a wavy way. By adopting the technical scheme, the unequal-height tooth carding cloth has the advantages that the carding and loosening functions are realized, the carding damage to fibers is reduced, the amount of short fibers is reduced, the carding quality is improved, the stereo multi-layer surface carding state is formed, and the technical purposes of high carding yield and high carding quality are realized.

Owner:EASTERN LIAONING UNIV

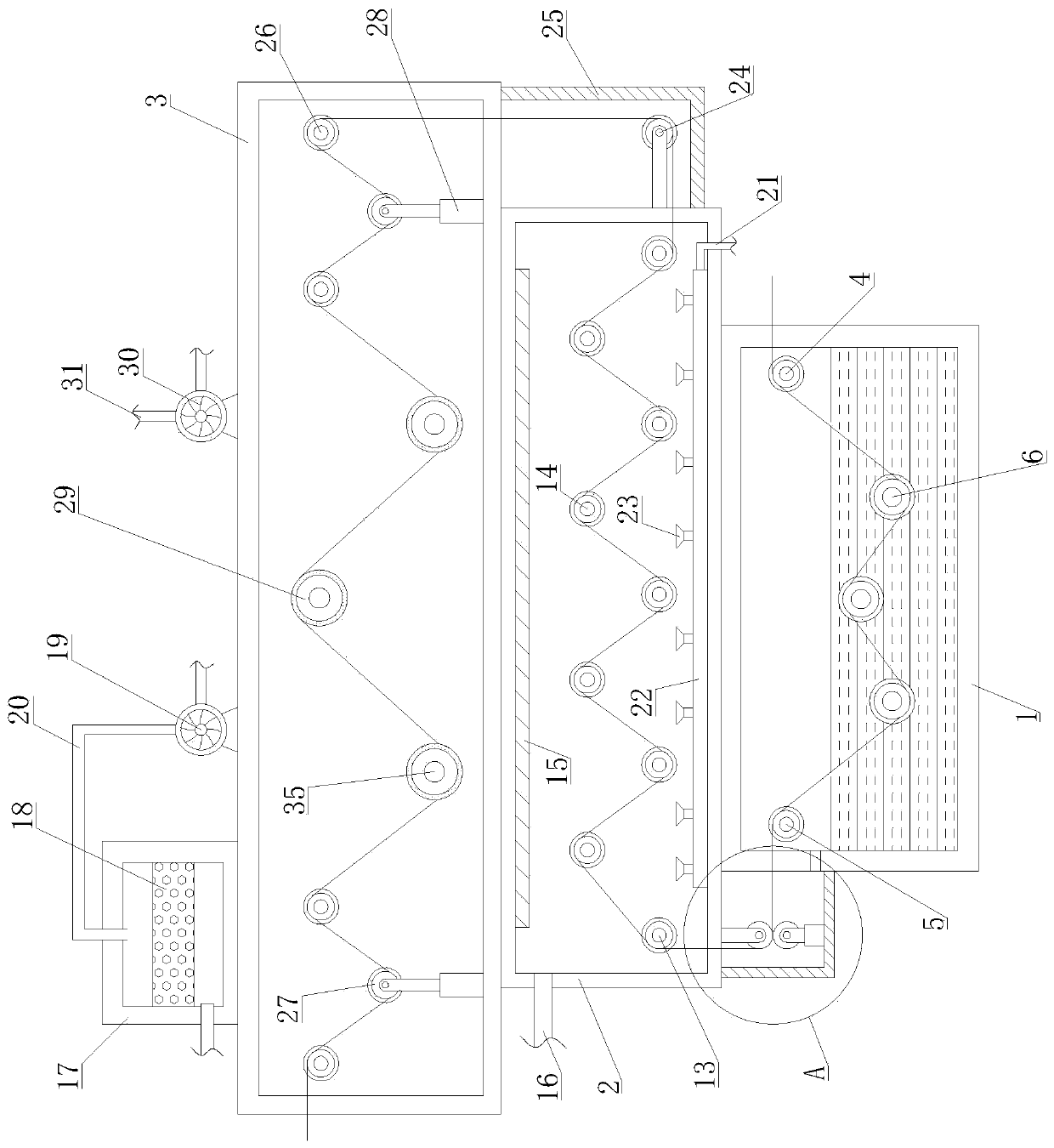

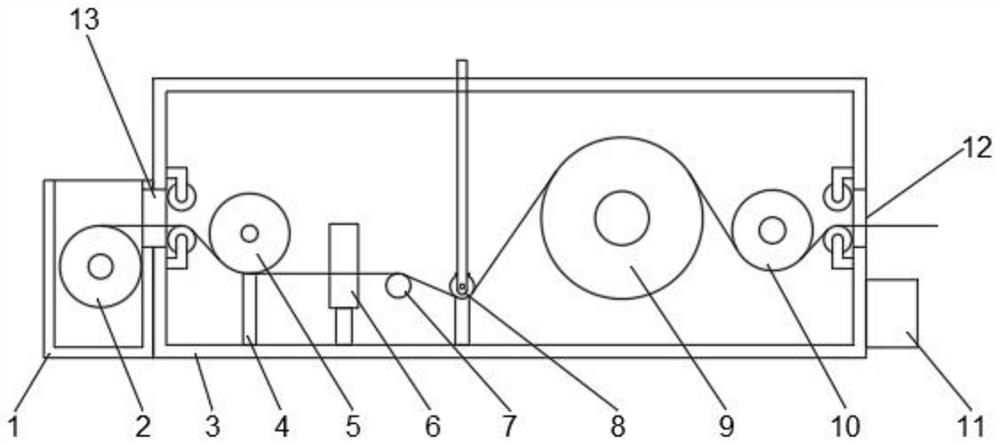

Automatic yarn combing device for liquid control yarn production

PendingCN111304851AExtended delivery pathAchieve recyclingLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnIndustrial engineering

The invention discloses an automatic yarn combing device for liquid control yarn production. The automatic yarn combing device comprises a combing and cleaning box, a drying box and a yarn combing box; a cleaning roller is arranged in the combing and cleaning box and immersed in water solution; a first water extruding roller is arranged on the drying box; a second water extruding roller is arranged below the first water extruding roller; a first guide roller is arranged on the drying box; a first drying roller and a second drying roller are arranged in the drying box; a heating device and an air separation piece are arranged in the drying box; an air spraying head is arranged on the air separation piece; a first air extractor is arranged on the yarn combing box and provided with a conveying pipe and an air return pipe; a dehumidifying box is arranged on the yarn combing box and provided with a dehumidifying device; tension devices are arranged on two sides in the yarn combing box and provided with tension rollers; and second guide rollers are arranged on the yarn combing box and positioned on two sides of the tension rollers. The automatic yarn combing device is various in function, simple in operation and convenient to use, integrates the functions of combing, cleaning, drying, brushing and absorbing, and is excellent in yarn combing effect, and the yarn production efficiencyis improved.

Owner:SUZHOU KANGFU INTELLIGENT TECH CO LTD

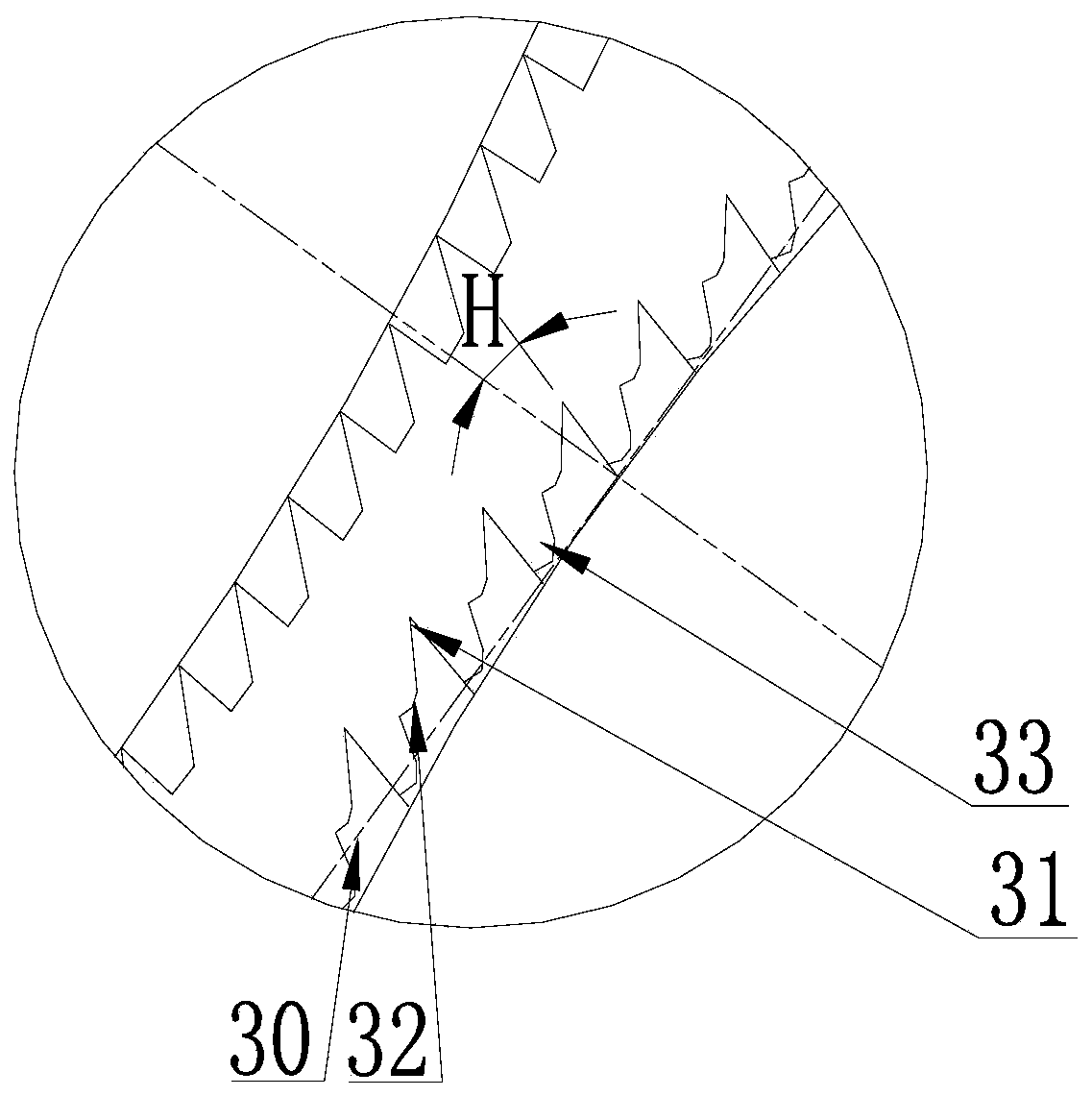

Metal card clothing for carding superfine fibers

The invention relates to a metal card clothing for carding superfine fibers, which comprises a base part, and a plurality of needle teeth are sequentially arranged on the base part; tooth tops of the pin teeth are of an inclined tooth top structure, and inclined tooth top faces are arranged at the tops of the tooth tops. A first working surface is arranged on one side of each pin tooth, and the first working surfaces are in smooth connection with the oblique tooth tip surfaces; second working surfaces, stepped inclined edge tooth surfaces and arc surfaces are sequentially arranged on the other sides of the pin teeth, and the second working surfaces are in smooth transition connection; and the arc surfaces of the needle teeth are in smooth transition connection with the second working surfaces of the adjacent needle teeth, so that a complete carding area is formed, and the carding, impurity removal and transfer processes of the superfine fibers are completed. Compared with the prior art, the device is simple in structure and high in applicability, superfine fibers can be effectively prevented from being deposited and wound around the roller, the card clothing carding work efficiency is effectively improved, manual cleaning is not needed, and the labor intensity is greatly reduced.

Owner:DONGHUA UNIV +3

Oscillating opening fiber carding method

The invention discloses an oscillating opening fiber carding method. The oscillating opening fiber carding method comprises the following steps: a, a fiber layer unwound from a fiber roll is fed to alicker roller by a feeding roller to perform opening, and the long fibers in the fiber layer are fully opened and loosened under the oscillating opening action of opening needle teeth; b, the fiber layer is striped by a cylinder after the fiber layer is opened by the licker roller, and the fiber is subjected to oscillating opening further; c, the stripped fiber layer enters a cylinder-cover platecarding area with the cylinder, and are carded into singe fibers; d, the carded fiber layer goes out of the cylinder-cover plate carding area, and enters a cylinder-doffer carding area, and oscillating carding is performed on the fibers between cylinder blunt scaly needle teeth and doffer carding needle teeth; e, the condensed fiber layer is stripped by a stripper roller to form a fiber net, the fiber net is gathered by a bell mouth and is squeezed by a big pressing roller to form slivers. The oscillating opening fiber carding method is suitable for caring when the fiber material has a low thread density or when the fiber strength is low, can prevent the fibers from being stuffed, and can improve the carding effect of low damage and the strong release of the soft and weak fibers.

Owner:DEZHOU HENGFENG TEXTILES

Double Throwing Coarse Cashmere Carding Machine

ActiveCN103290532BGood thickening effectImprove carding effectCarding machinesDiameter ratioPulp and paper industry

The invention discloses a double-throwing-coarse cashmere carding machine. The double-throwing-coarse cashmere carding machine comprises a feeding mechanism and a carding mechanism, wherein the carding mechanism is composed of a front-stage carding unit and a rear-stage carding unit, the rear-stage carding unit is located right at the back of the front-stage carding unit, and the feeding mechanism, the front-stage carding unit and the rear-stage carding unit are connected in sequence. Each stage of carding unit of the carding mechanism comprises a licker-in, a cylinder and a doffer, wherein the licker-in, the cylinder and the doffer are arranged linearly, and a peeling cutter is at the back of the doffer and is closely near the doffer. In each stage of carding unit of the carding mechanism, the roller diameter ratio among the licker-in, the cylinder and the doffer is 250: 380: 380, and the linear speed ratio between the licker-in and the cylinder is 1:1.55-1:1.6. The double-throwing-coarse cashmere carding machine adopts a double-stage carding method, the throwing-coarse effect is obviously improved, and the carding effect of the cashmere carding machine and the extraction efficiency of dehaired wool are largely improved.

Owner:青岛东佳纺机(集团)有限公司 +1

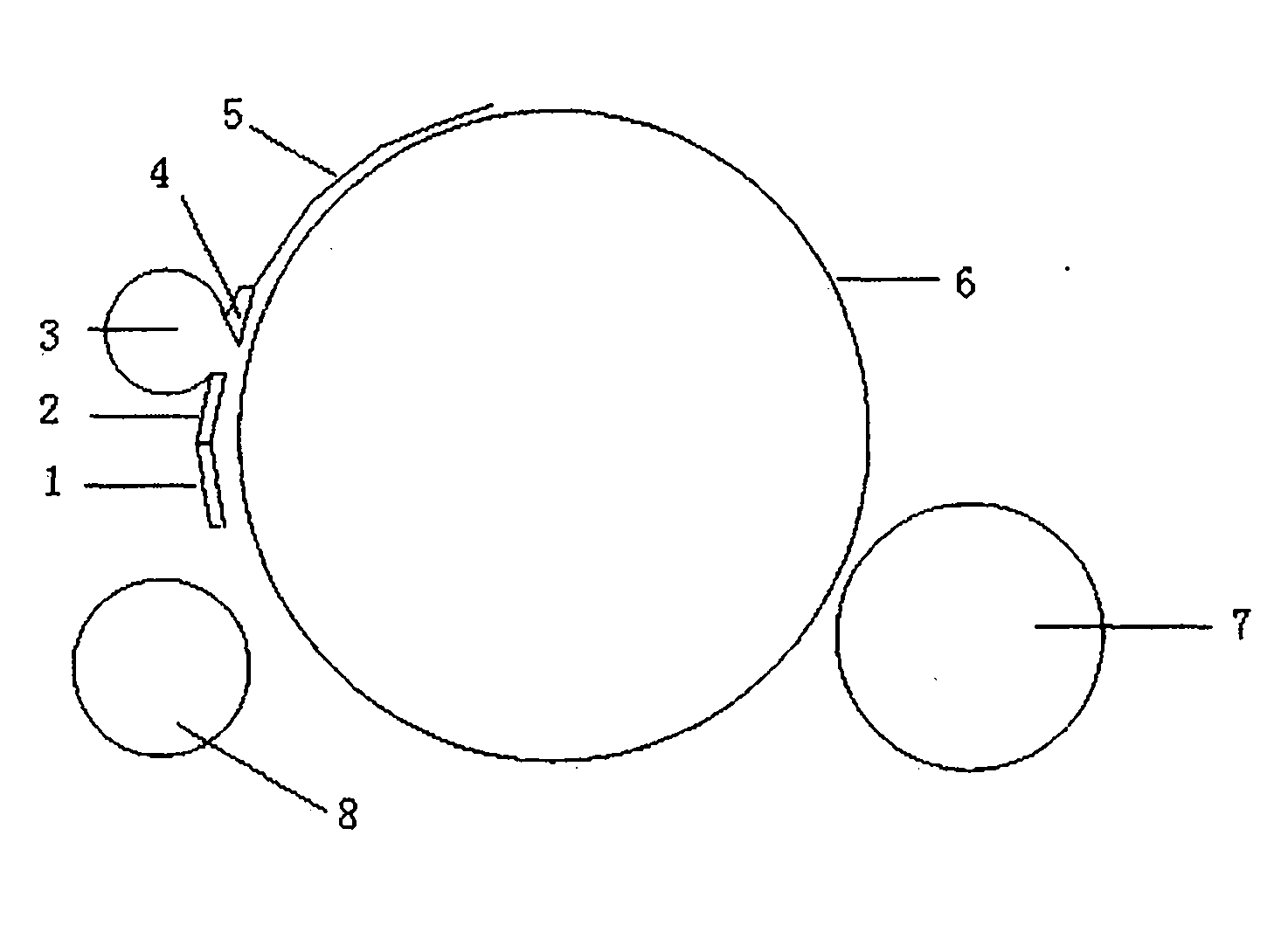

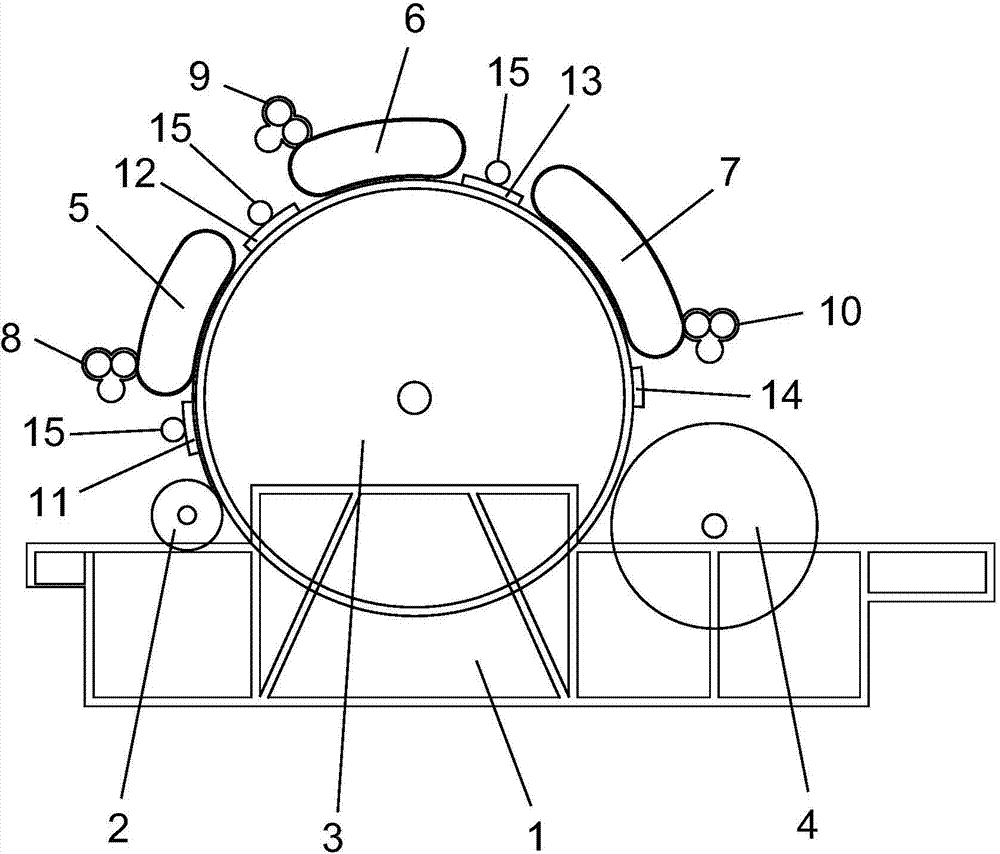

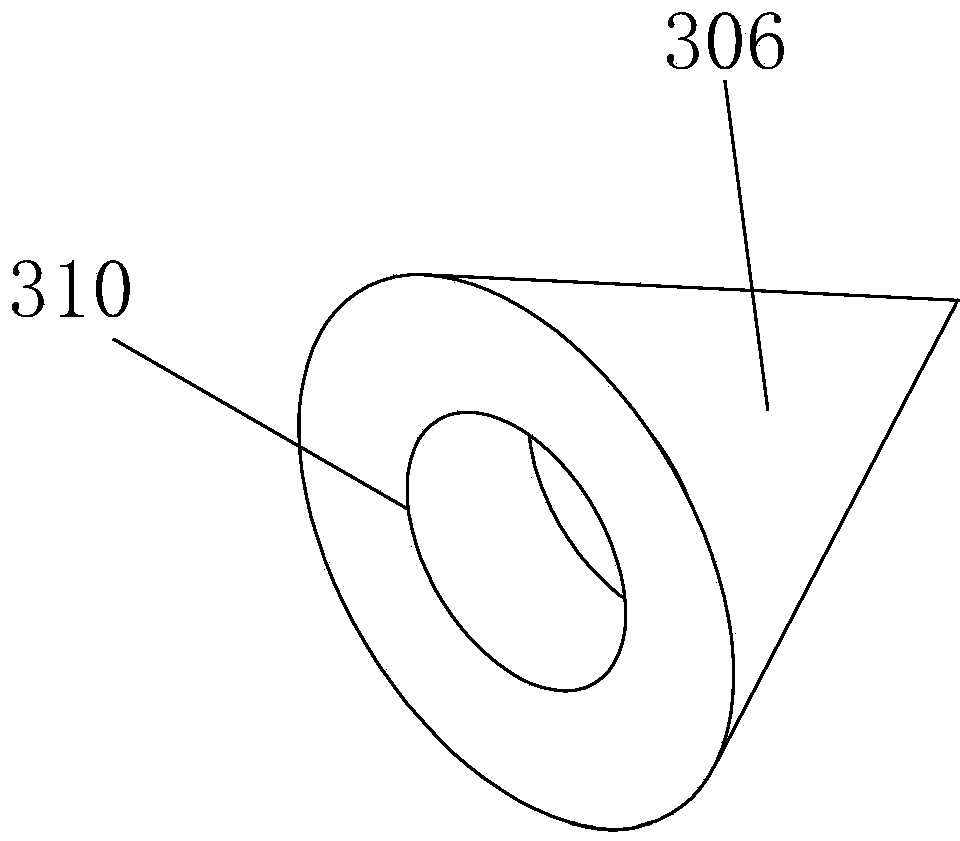

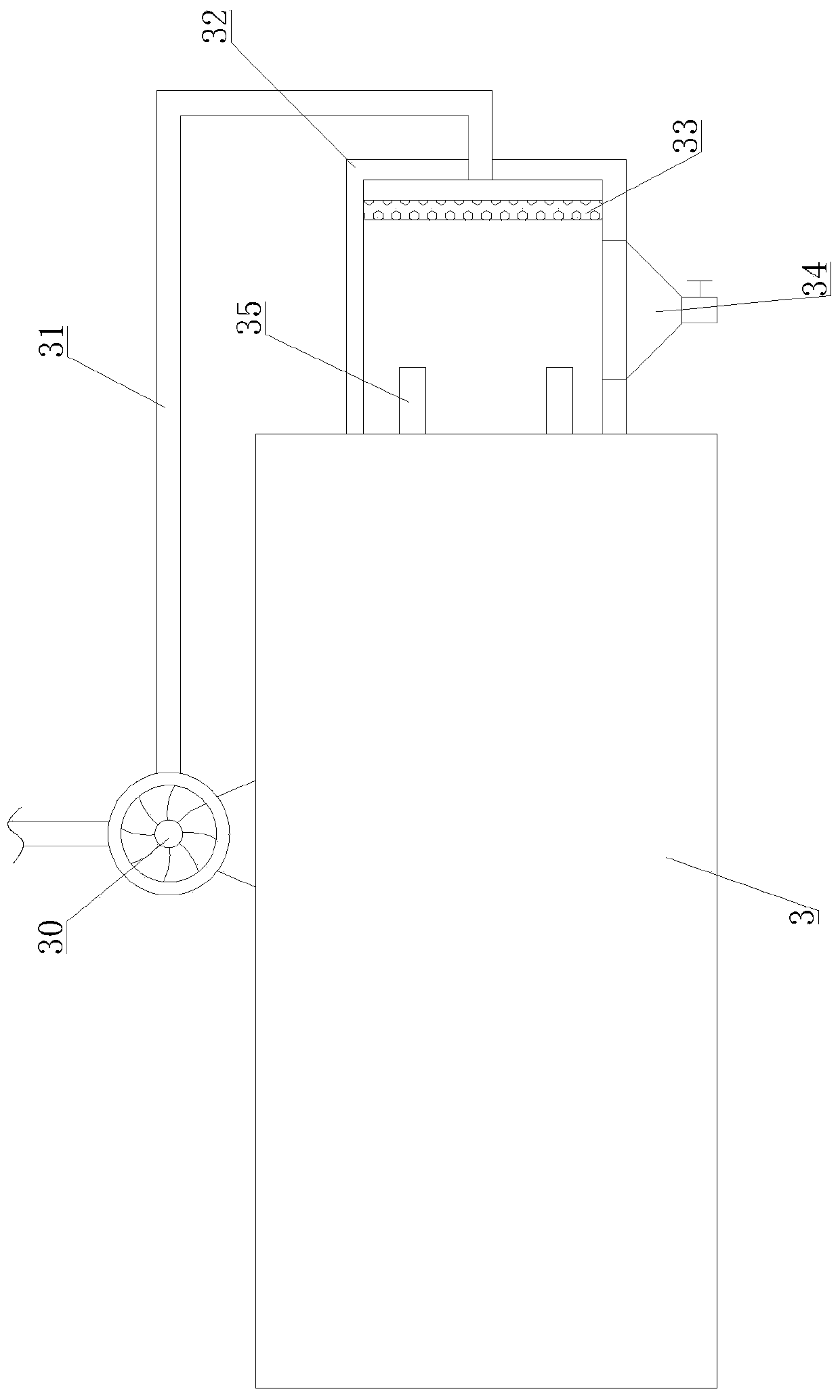

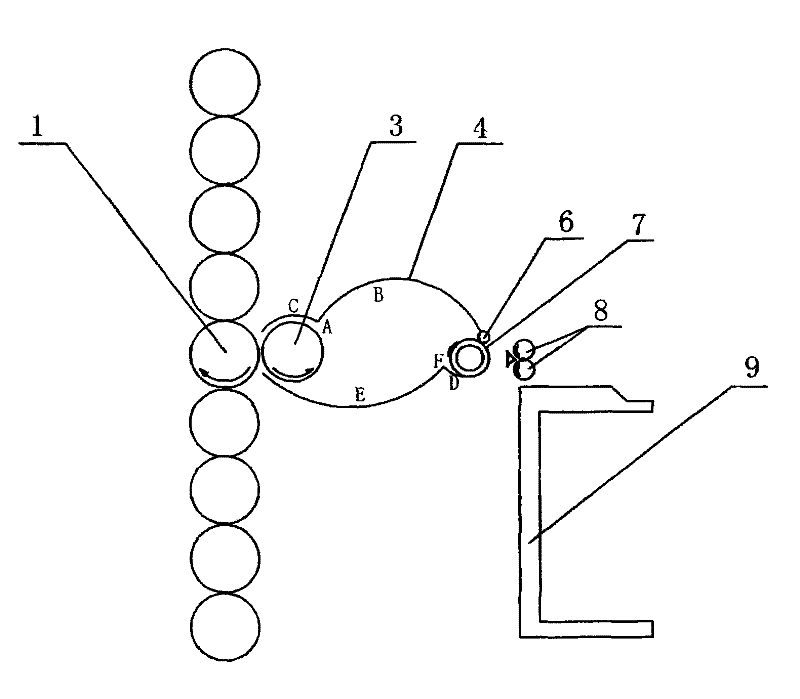

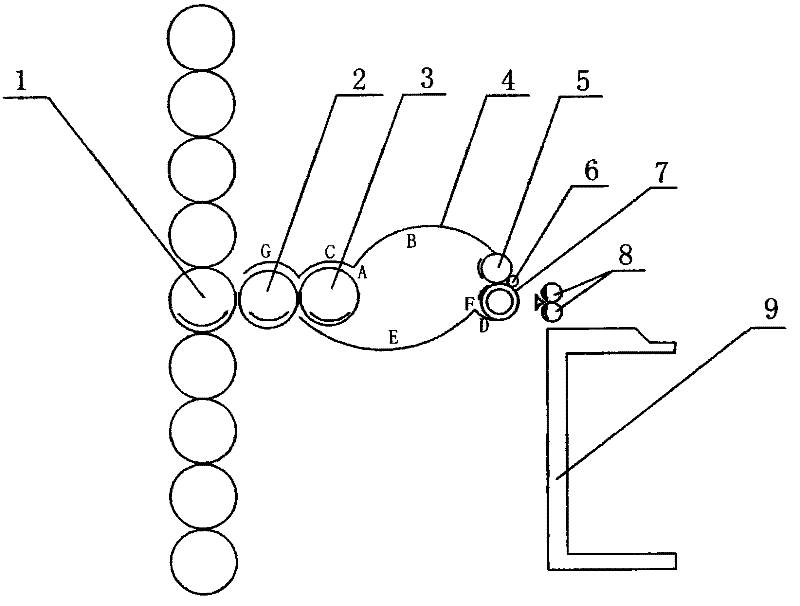

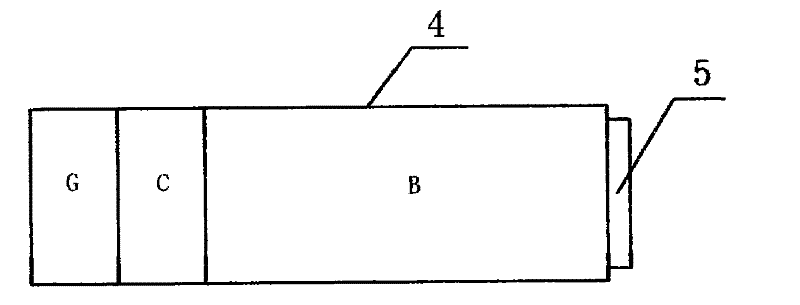

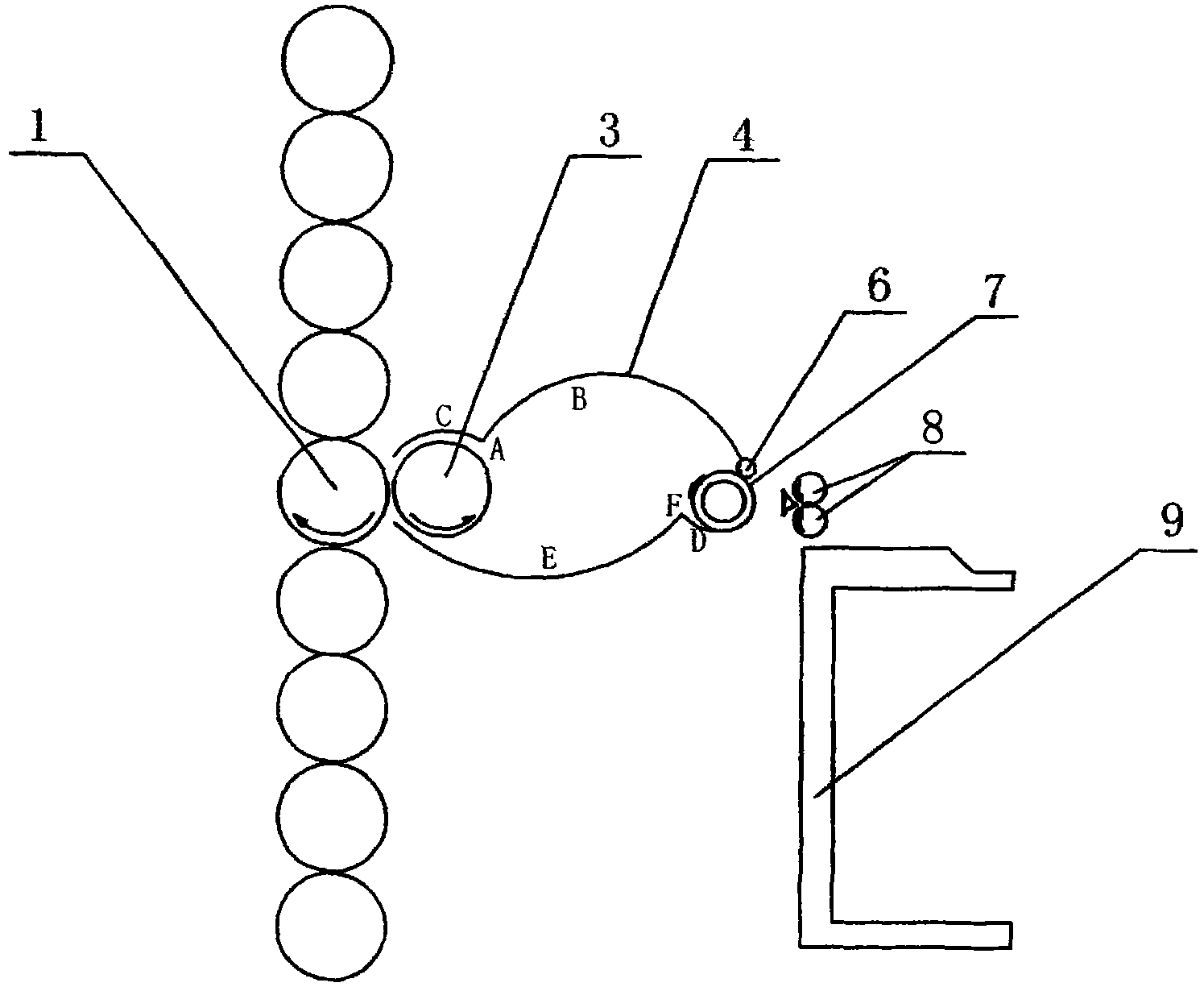

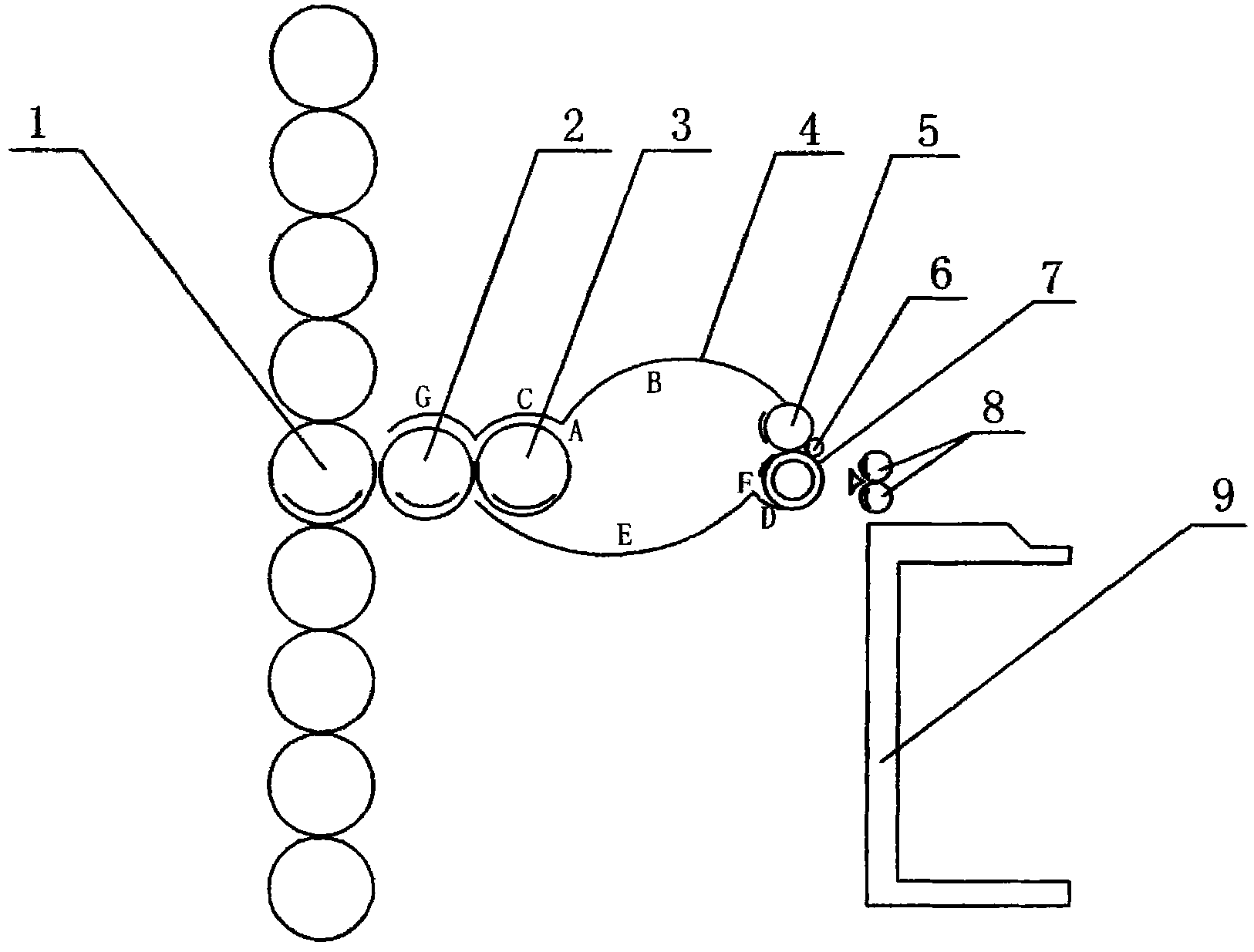

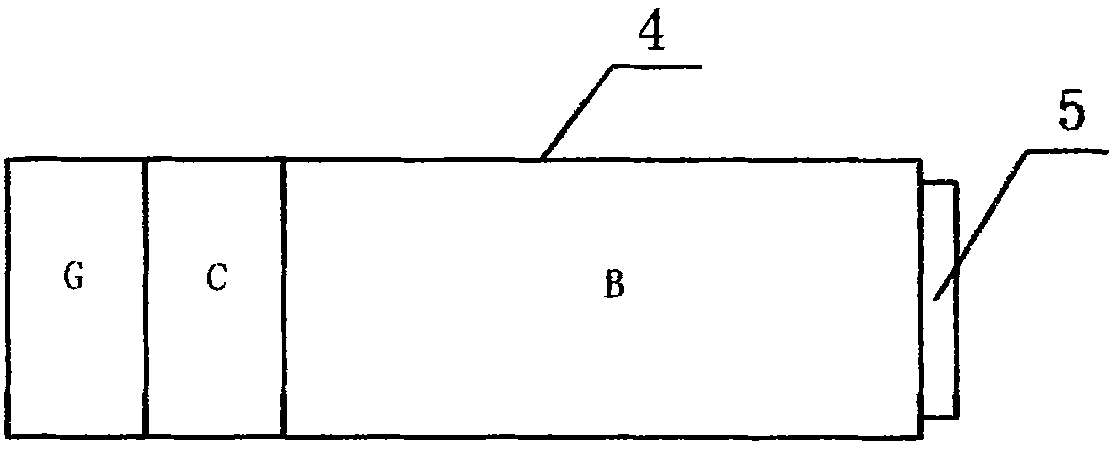

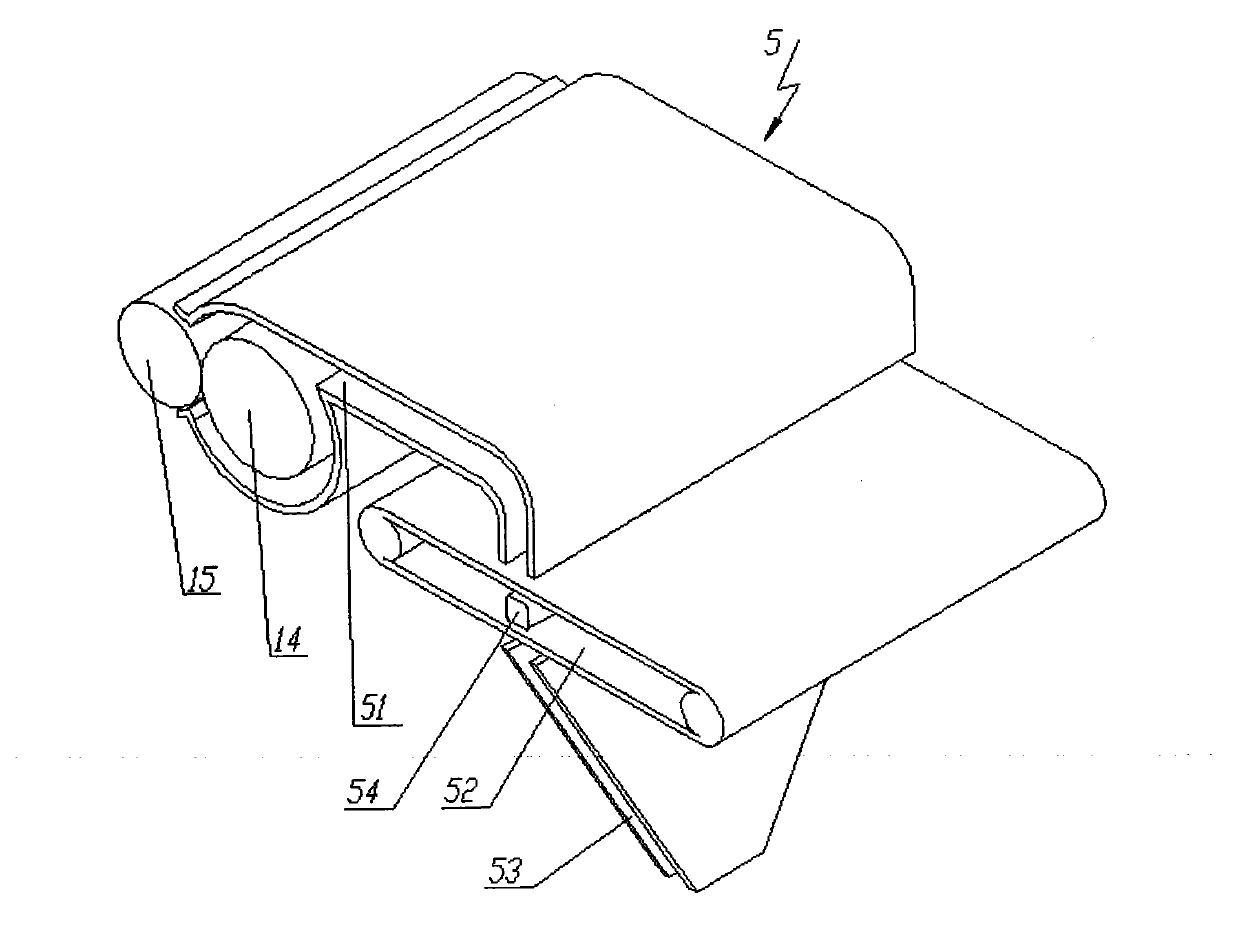

A kind of unloading device of carding machine

ActiveCN101994171BEnhanced ability to fling into fluffReduce in quantityCarding machinesLow speedOutput device

An outlet device of a carding machine, comprising a high-speed dehairing roller (3), a fairing cover (4) and a dust cage (7). Wherein the upper wall (B) of the fairing (4) is a curved surface protruding upward, the lower wall (E) is a curved surface protruding downward, and both side walls are planes. A low-speed doffer (5) is arranged between one end of the upper wall (B) and the dust cage (7), the axis of the low-speed doffer (5) is parallel to the axis of the dust cage (7), and the low-speed doffer ( 5) Adjacent to the dust cage (7). The present invention overcomes the deficiencies in the prior art, solves the technical problems that have not been solved for a long time in this field, significantly improves the carding effect, can card high-quality fluff, improves the economic benefits of products and can reduce the cost of carding. Costs have produced outstanding advances in technology.

Owner:HANGZHOU YUANDESHAN SCIENTIFIC & TECHNICAL CO LTD

Nonwoven Cards for Spinning Absorbent Cotton

ActiveCN103290531BLine speed setting is reasonableConsistent vertical and horizontal strengthCarding machinesEngineeringAbsorbent cotton

The invention relates to carding machines, and discloses a non-woven carding machine used for spinning absorbent cotton. The non-woven carding machine used for spinning absorbent cotton comprises a feeding mechanism, a carding mechanism and a stripping mechanism. The stripping mechanism comprises a stripping roller, and the carding mechanism comprises a cylinder and a doffer, wherein the cylinder is located in front of the doffer and is connected with the doffer, a movable cover plate is arranged above the cylinder, a first front fixing cover plate and a second front fixing cover plate are arranged in front of the cylinder, the first front fixing cover plate is located below the second front fixing cover plate, a rear fixing cover plate is arranged behind the cylinder, the stripping roller is located behind the doffer, a cluttering roller and a flattening roller are sequentially arranged between the doffer and the stripping roller, and the cluttering roller is close to the doffer. The combination mode of the cover carding and cluttering roller cluttering can greatly improve the carding effect of the previous non-woven carding machine and effectively remove impurities such as cotton shells mixed in raw materials.

Owner:青岛东佳纺机(集团)有限公司

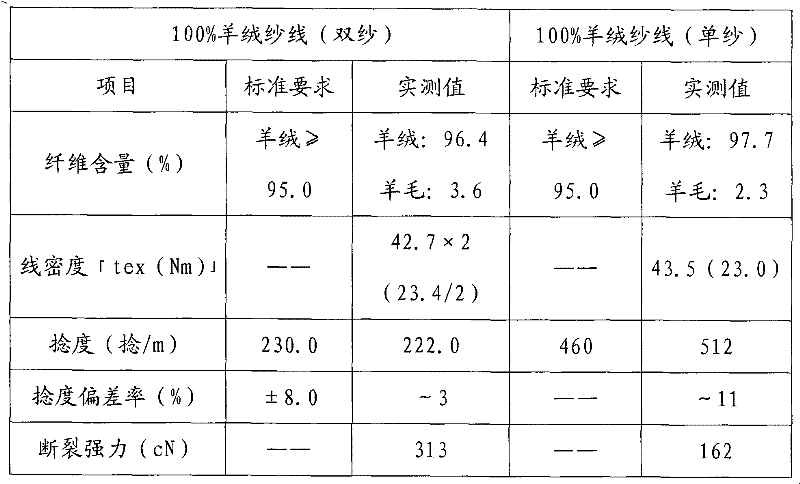

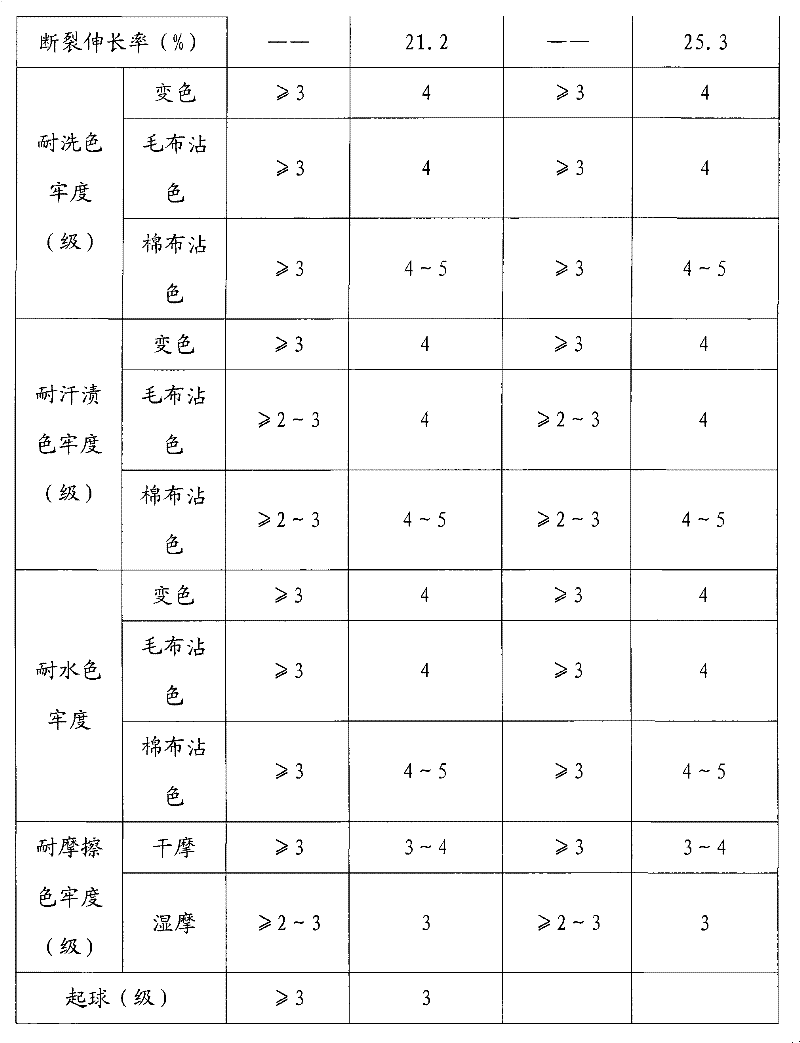

Cashmere yarn with high tensile stretch and production technology thereof

ActiveCN101586278BAvoid damageHigh elongation at breakFibre cleaning/openingWool fibre washing/scouringYarnSingle fiber

The invention belongs to the technical field of knitting yarns and production technology thereof, in particular relates to a cashmere yarn with high tensile stretch and production technology thereof. The production technology of the cashmere yarn with high tensile stretch includes the followings: in cashmere washing step, drying is carried out at the low temperature of 40 DEG C to 50 DEG C so as to reduce the power damage of cashmere single fiber; in carding step, the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG so that the striking point direction of cubing rolls is changed and the length damage of cashmere is reduced; in dying step, drying is carried out at the low temperature of 50 DEG C to 70 DEG C so as to further reduce the power damage of cashmere single fiber; in spinning step, the twist factor of the single yarn used is 90% to 98%. In the invention, drying is carried out at the low temperature of 40 DEG C to 50 DEG C both incashmere washing step and in dying step, and the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG in carding step, thereby reducing the damage of cashmere to the maximum and guaranteeing high breaking elongation, rebound degree and force of cashmere.

Owner:湖州珍贝羊绒制品有限公司

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are successively mounted on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are successively mounted on the top of the cylinder from front to back and correspond to the rack; a gap is formed between the first carding region cover plate and the second carding region cover plate; and a gap is also formed between the second carding region cover plate and the third carding region cover plate. The carding machine is provided with the three carding cover plates, three carding regions are formed, the first carding region has main effects of neatening, smoothly carding fibers and preliminarily discharging impurities andlower piles, the second carding region is further used for neatening, carding the fibers and preliminarily discharging the impurities and the lower piles, the third carding region has main effects ofprecisely carding and further discharging the impurities and lower piles, each of the three carding region cover plates is provided with a cover plate cleaning device, the three carding region cover plates can be cleaned independently, and after being cleaned, the carding cover plates can be rapidly and efficiently used in carding operation. The carding machine is divided into three portions, radian occupied by each carding cover plate is also reduced, the carding cover plates can be cleaned as quickly as possible, the cover plate cleaning efficiency is further improved, and a carding effect is ensured.

Owner:乐陵市佳和纺织有限公司

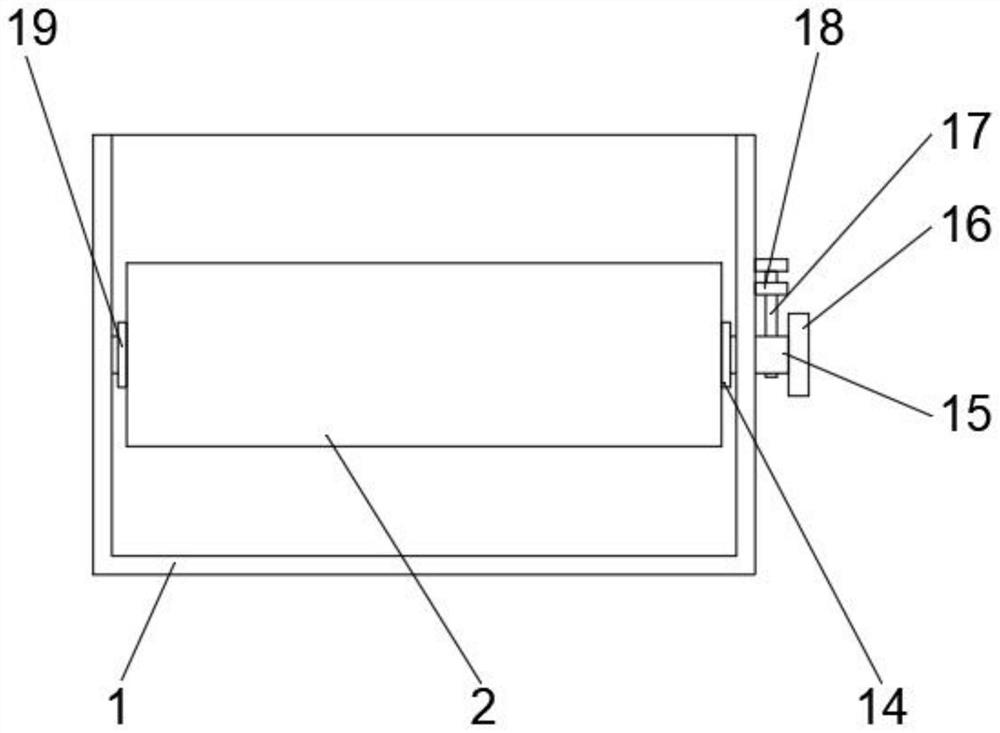

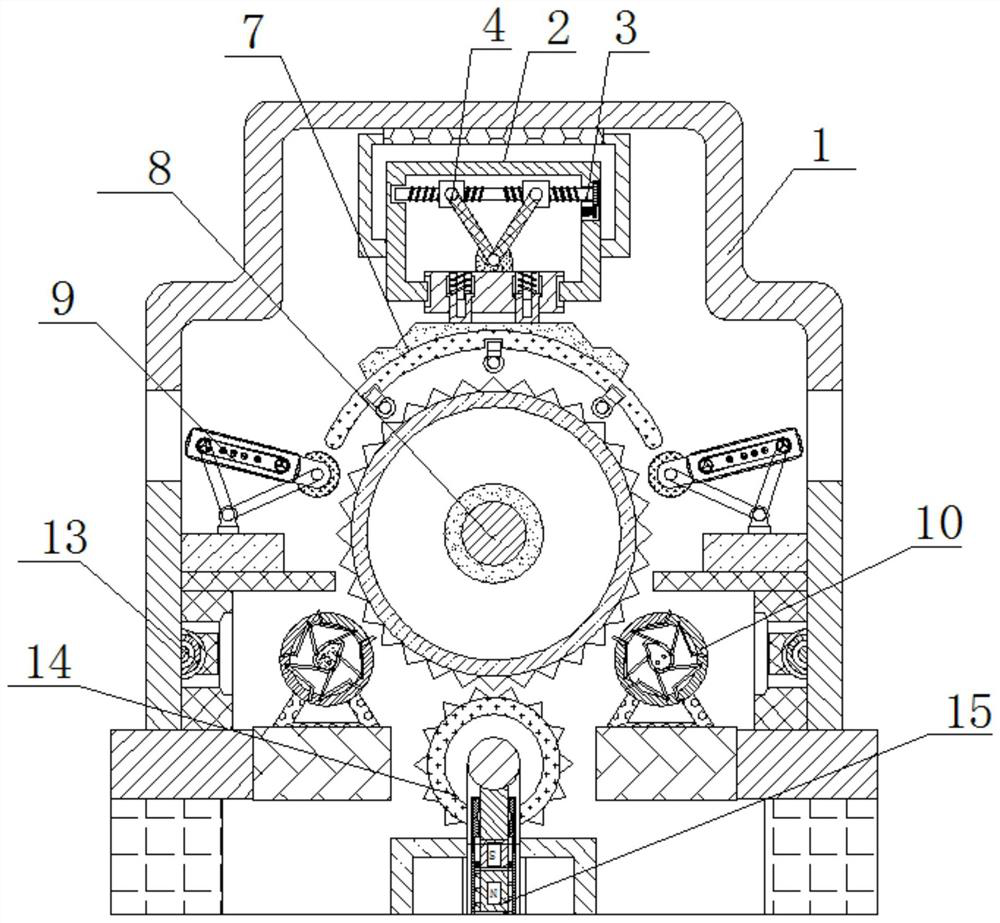

Cotton carding device with cotton box and impurity removing function

PendingCN112626653AImprove cleanliness and qualityImprove carding effectCarding machinesAgricultural engineeringCotton thread

The invention discloses a cotton carding device with a cotton box and an impurity removal function, and relates to the cotton carding device. The cotton carding device specifically comprises the cotton carding box and a cotton feeding box fixed on the side surface of the cotton carding box; a cotton feeding roller wound with cotton threads is arranged in the cotton feeding box; a feeding port is formed in one side, facing the cotton feeding box, of the cotton carding box; a discharging port is formed in the other side of the cotton carding box; a licker-in, an impurity removing mechanism, a guide roller, a tension adjusting device, a cylinder and a doffer are sequentially installed in the cotton carding box in the direction from the feeding port to the discharging port; a dust collector is fixedly installed at the bottom end of the outer wall of the side, facing the discharging port, of the cotton carding box through bolts; and the air suction end of the dust collector extends into the cotton carding box. The cotton carding device has the beneficial effects that the impurity removing mechanism is arranged in the cotton carding box, impurity removing work can be conducted on the surfaces of cotton threads, and the cleanliness and quality of the cotton threads are improved.

Owner:湖北智盛纺织科技有限公司

Energy-saving and environment-friendly adjustable carding machine

InactiveCN112176463AAvoid using directlyImprove work efficiencyContinuous processingCarding machinesFiberEngineering

The invention relates to the technical field of textile machinery, and discloses an energy-saving and environment-friendly adjustable carding machine. The energy-saving and environment-friendly adjustable carding machine comprises a rack, a movable support is movably connected with the lower portion of the rack, a threaded shaft is movably connected with the inner top of the movable support, a connecting rod is hinged to the lower portion of the threaded shaft, and a movable block is movably connected with the lower portion of the connecting rod. Through power-on and power-off of an electromagnet, the distance between a licker-in and a cylinder is changed, long fibers and short fibers are distinguished, the distinguishing process can be reduced in the subsequent steps, direct use is achieved, and the working efficiency is improved; the movable block is integrally driven to move downwards through the matching of the threaded shaft and the connecting rod, the distance between a cover plate and the cylinder is reduced, so that the carding effect of the device is better; and a rotating wheel drives a cleaning rod to rotate, thus the cleaning rod makes contact with the surface of the cylinder to clean the cylinder, and meanwhile a dust suction fan sucks impurities into an impurity collecting box to be treated in a centralized mode.

Owner:南京启庆电子商务有限公司

A carding machine for protecting cotton wool

The invention relates to the technical field of carding machines, and discloses a carding machine capable of protecting cotton fibers. The carding machine comprises a shell, a fixing device, a cardingdevice and a handling device, wherein the shell comprises a first fan, a second fan and a through hole; a substrate is fixedly installed on the lower inner wall of the shell; a heating rod is fixedlyinstalled on the upper surface of the substrate; a fixing device is arranged in front of the shell; the fixing device comprises a fixing rod, a round rod and a first thread groove; a cotton fiber barrel is arranged on the outer side of the round rod; the carding device is arranged at the right end of the fixing device; the carding device comprises a cotton comb, a connection rod and a bearing; round grooves are formed in the front of the cotton comb; springs are connected to the round grooves; cotton comb teeth are arranged at the front ends of the springs; the connection rod is arranged on the left surface of the cotton comb; the bearing is fixedly connected to the left end of the connection rod; the inner ring of the bearing is sleeved on the round rod; a bearing sleeve is sleeved on the outer ring of the bearing; a motor is arranged at the front end of the bearing sleeve; ad the bearing sleeve is fixedly connected to the output shaft of the motor. The efficient carding machine hasthe advantages of good carding effect, high carding speed and the like

Owner:浙江黎盛新材料科技有限公司

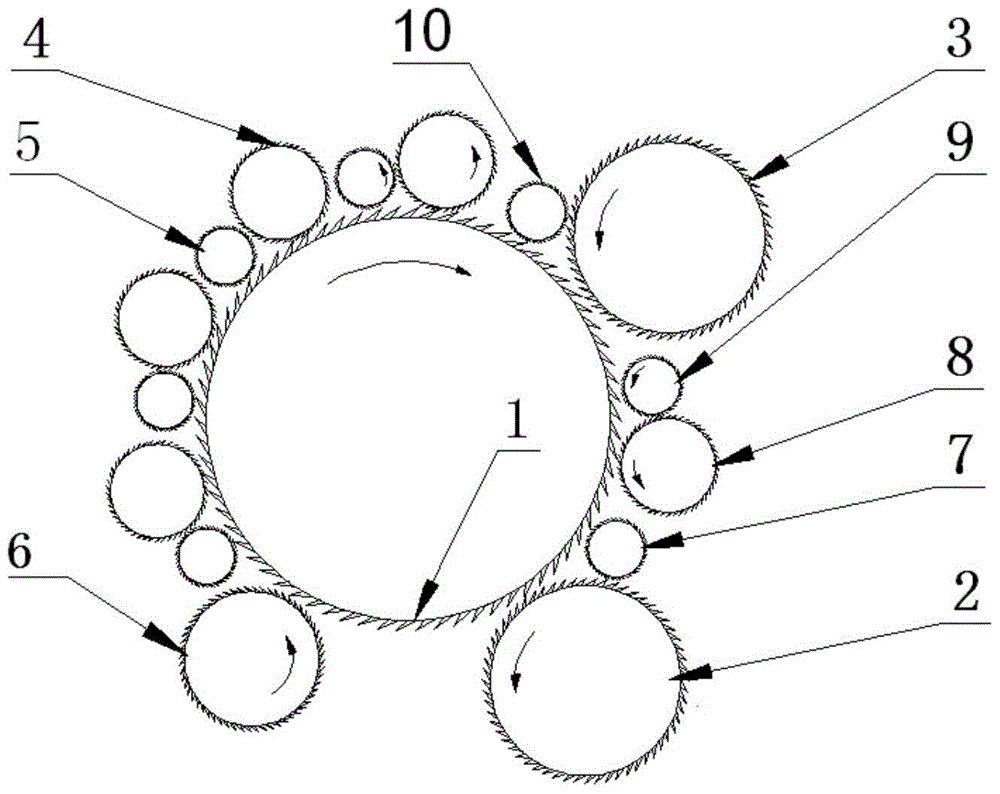

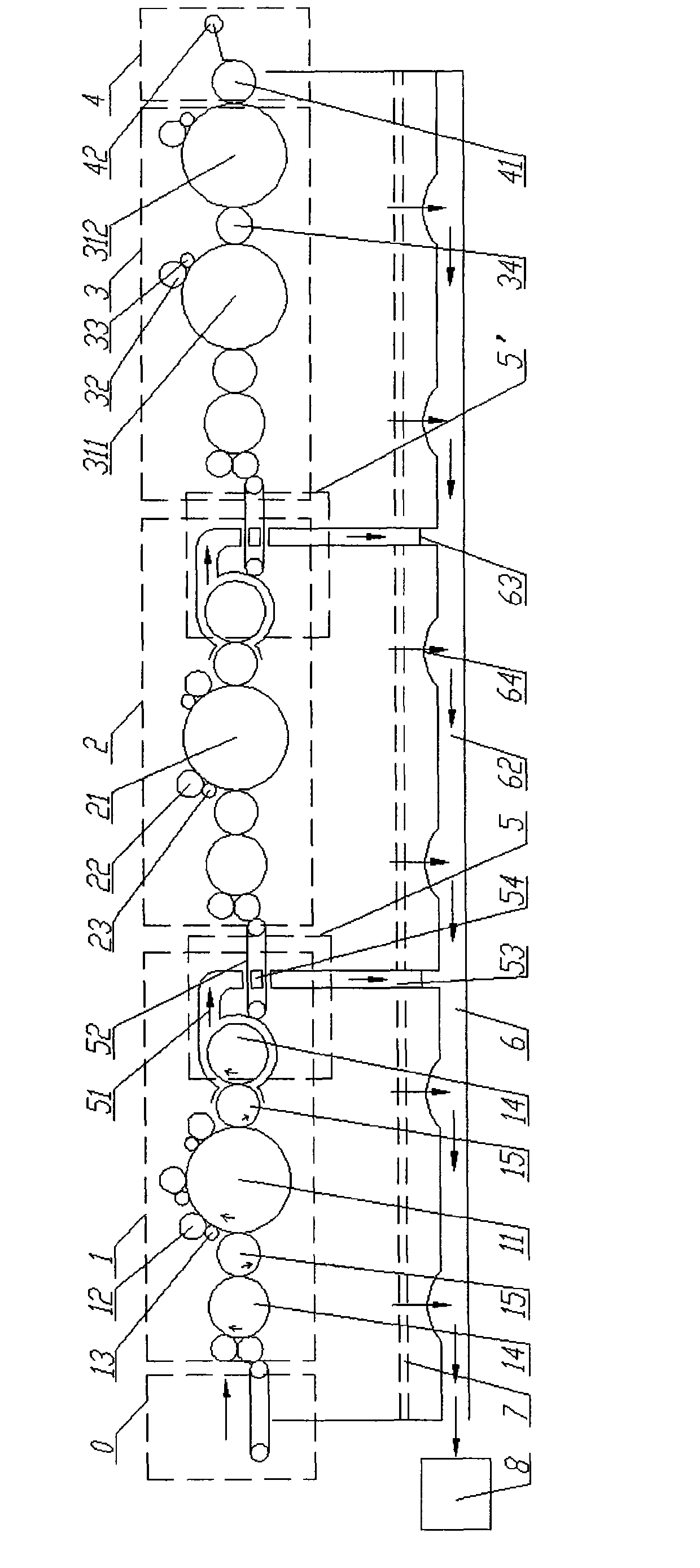

High-efficiency carding system for nonwovens

The invention discloses a non-woven efficient carded web formation system. The system comprises a cylinder, a lower doffer, an upper doffer, a plurality of carding units and a transferring roller which are installed on a rack body, wherein the carding units are formed by work rollers and stripping rollers; a buffer carding unit used for shunting surface jet stream generated by high-speed rotation of the cylinder is arranged between the lower doffer and the upper doffer and comprises a group of buffer work rollers and a group of buffer stripping rollers; and the buffer stripping rollers are arranged between the buffer work rollers and the upper doffer. The non-woven efficient carded web formation system can overcome the defects of low yield, poor fiber web appearance and uniformity and the like in the prior art, effectively improve the carding performance of a carding machine and the uniformity of a doffer output fiber web, increase the fiber transfer quantity between the cylinder and the doffers, and achieve efficient carded web formation of the complete carding machine.

Owner:正纺科技(广州)有限公司

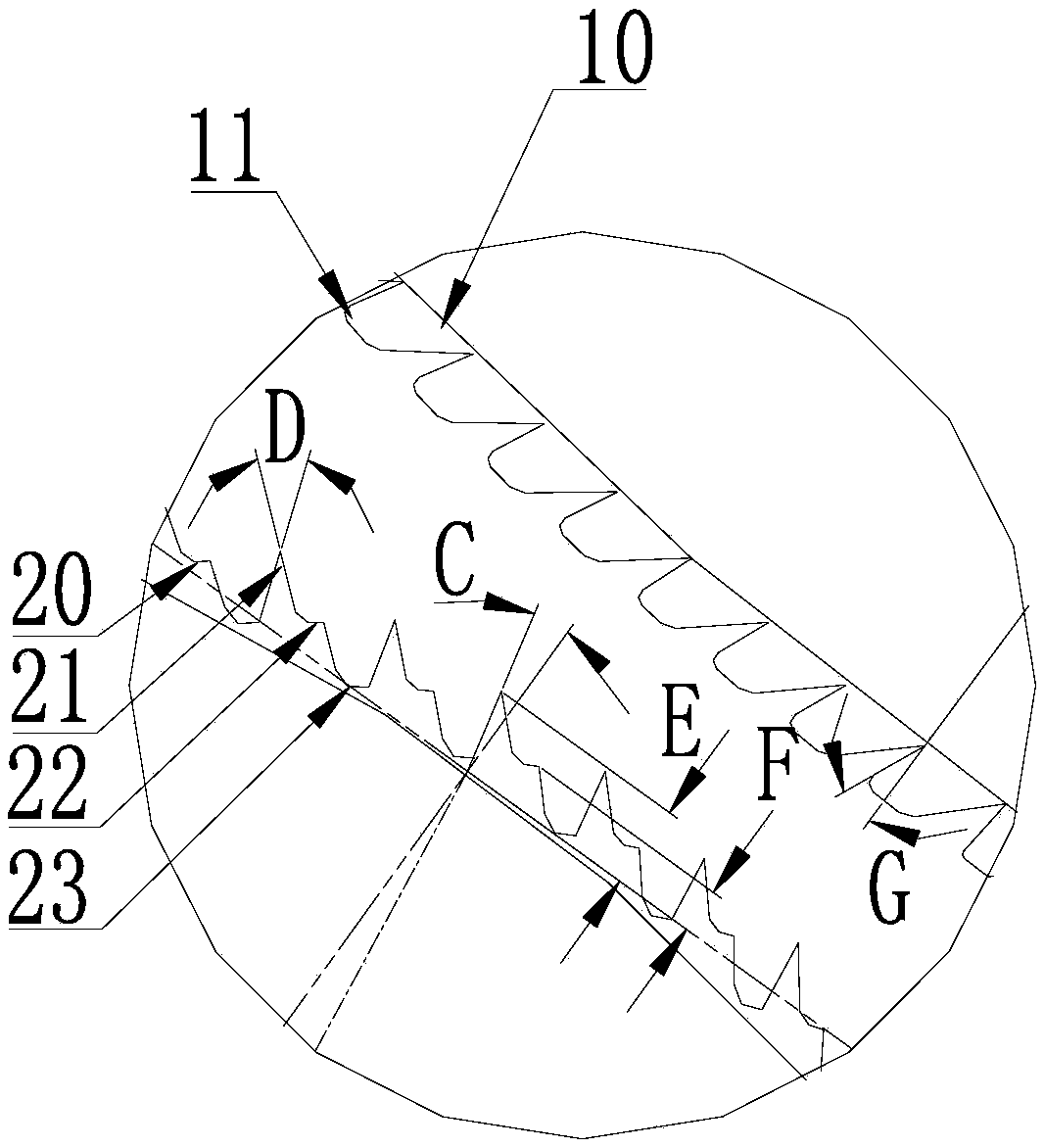

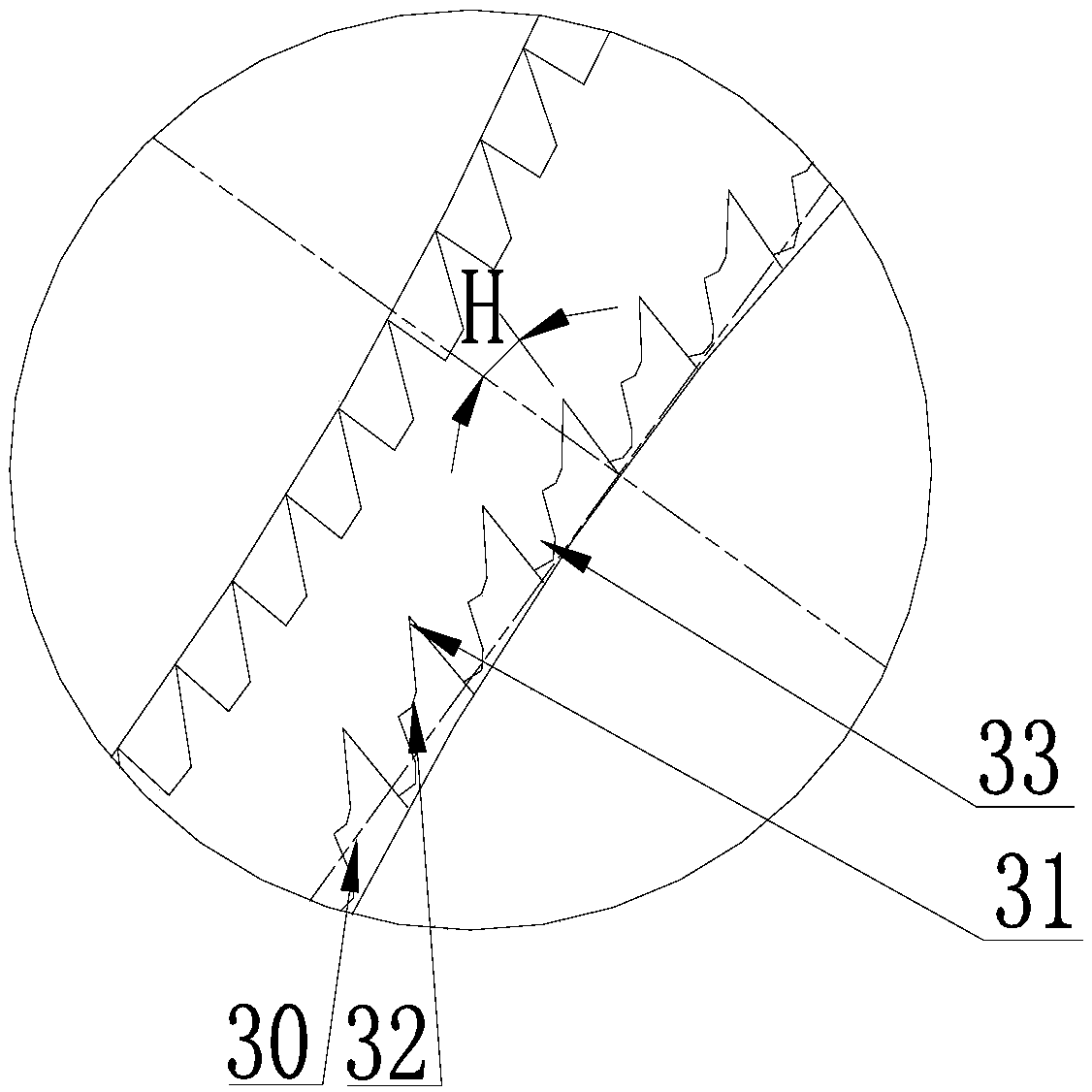

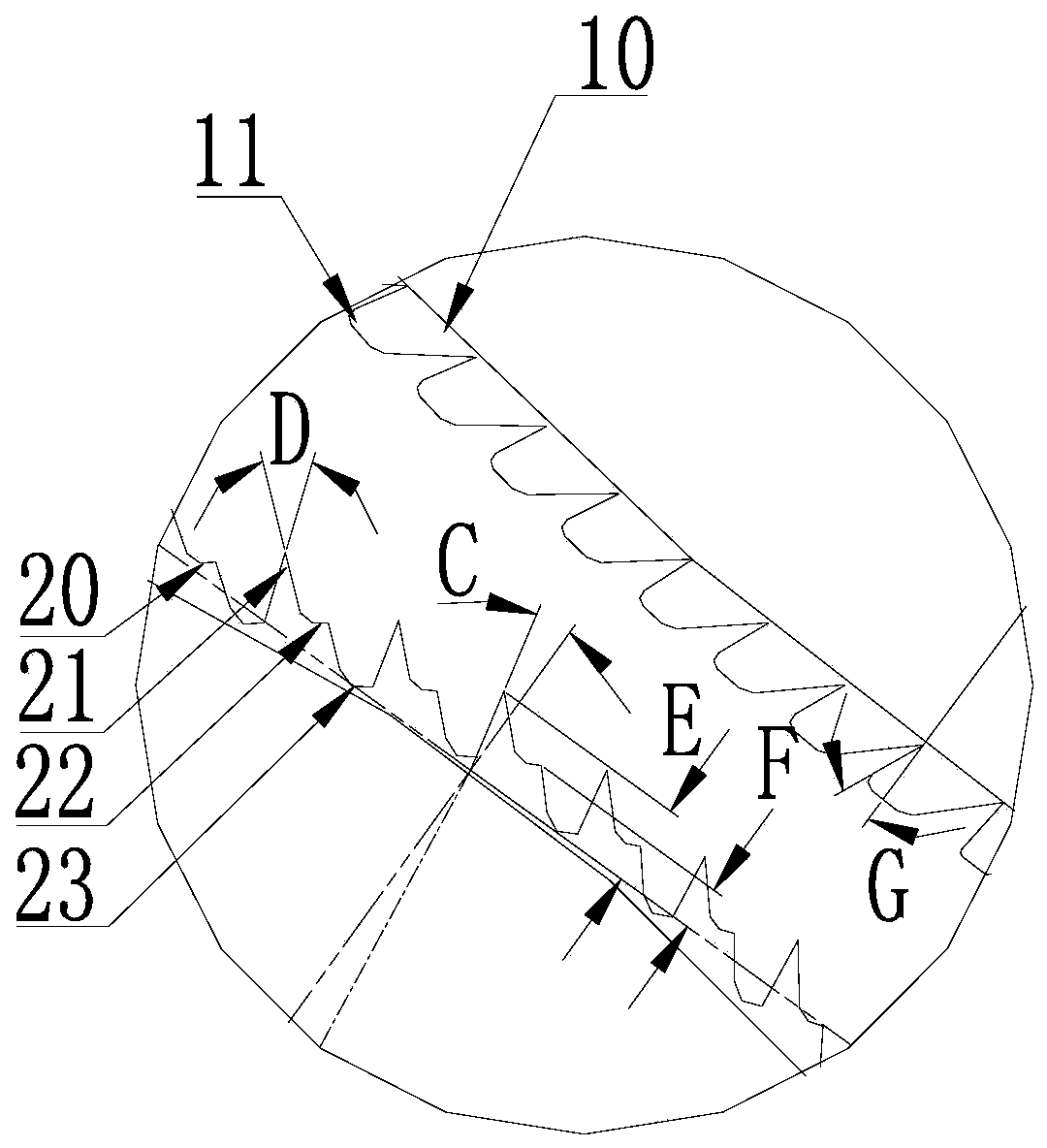

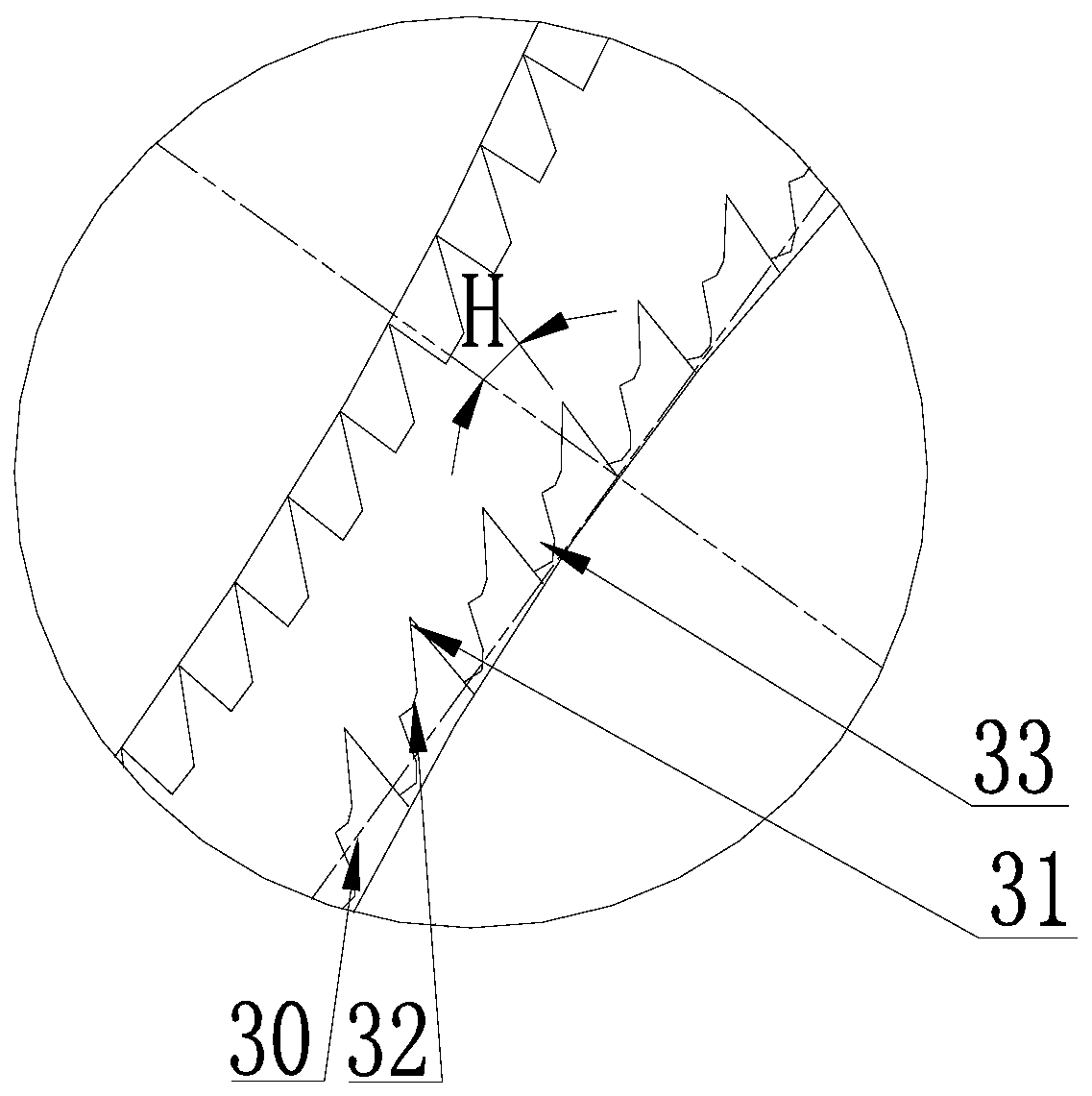

Oscillation type loosening plant dyed fiber carding mechanism

The invention discloses an oscillation type loosening plant dyed fiber carding mechanism which comprises a piercing roller, a cylinder and a doffer. By conducting cooperation design on needle tooth structures on the surfaces of the piercing roller, the cylinder and the doffer, needle teeth of the piercing roller are designed into a double-peak structure, and fiber clusters are subjected to low-damage oscillation type loosening; the needle teeth of the cylinder are designed into a blunt-scale-shaped structure with a smooth tooth top, a low-damage hitting platform is provided for oscillation type loosening of fiber clusters on the surface of the piercing roller, and the fiber clusters on the surface of the piercing roller are effectively stripped off; needle teeth of the doffer are designedinto a double-peak structure, fibers are secondary carded, meanwhile the blockage of the fibers in the needle teeth is effectively avoided, the carding effect of the plant dyed fibers is effectively improved, and the subsequent processing quality is improved. The carding mechanism is reasonable in structure and simple in transformation, is an ideal carding mechanism special for plant dyeing, and is easy to use and popularize on a large area.

Owner:DEZHOU HENGFENG TEXTILES

Non-contour tooth card clothing

The invention provides an unequal-height tooth carding cloth, which consists of unequal-height tooth carding cloth units, wherein the surface of the tooth top of the carding cloth of each unequal-height tooth carding cloth unit is in a wavy way. By adopting the technical scheme, the unequal-height tooth carding cloth has the advantages that the carding and loosening functions are realized, the carding damage to fibers is reduced, the amount of short fibers is reduced, the carding quality is improved, the stereo multi-layer surface carding state is formed, and the technical purposes of high carding yield and high carding quality are realized.

Owner:EASTERN LIAONING UNIV

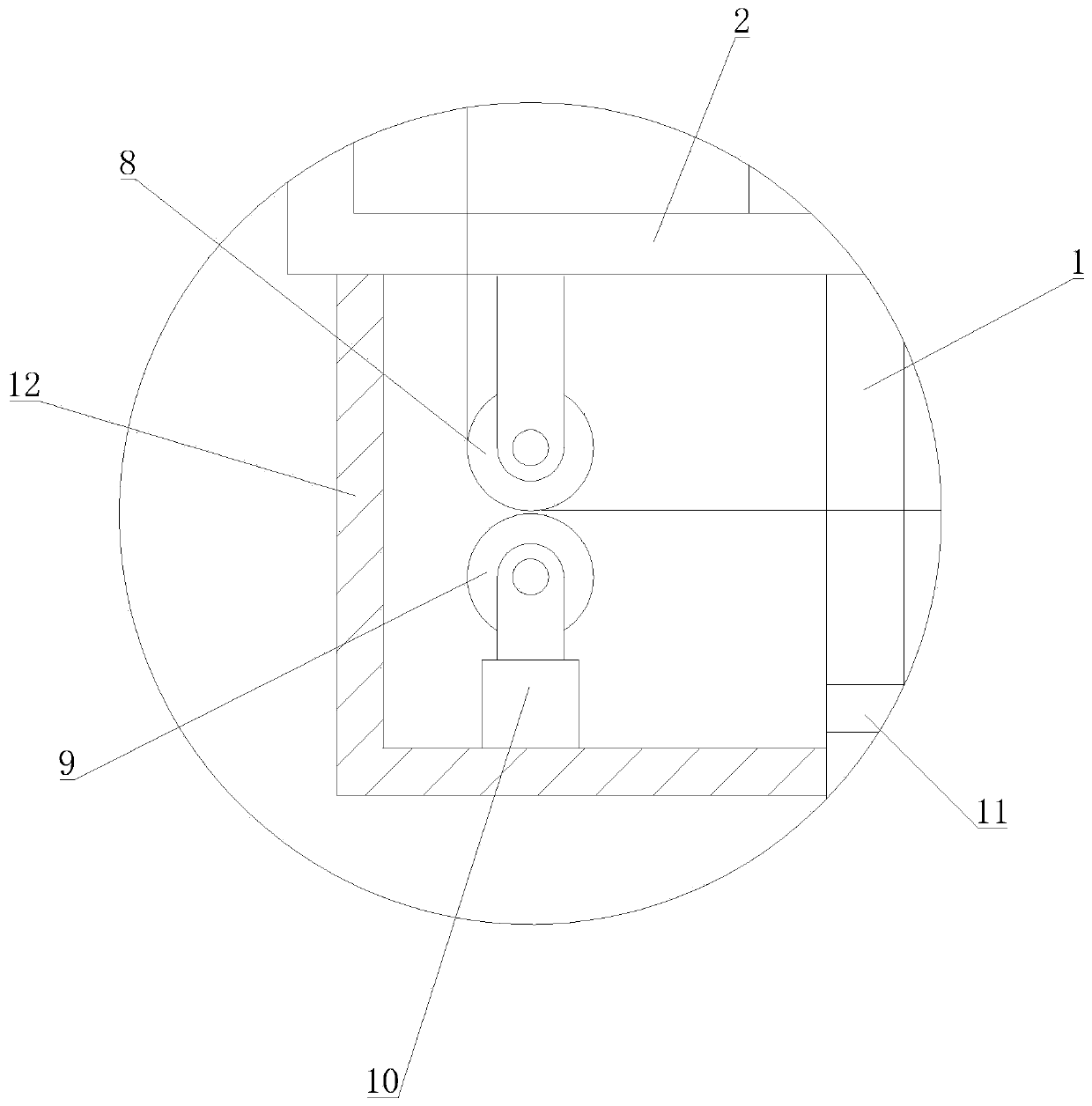

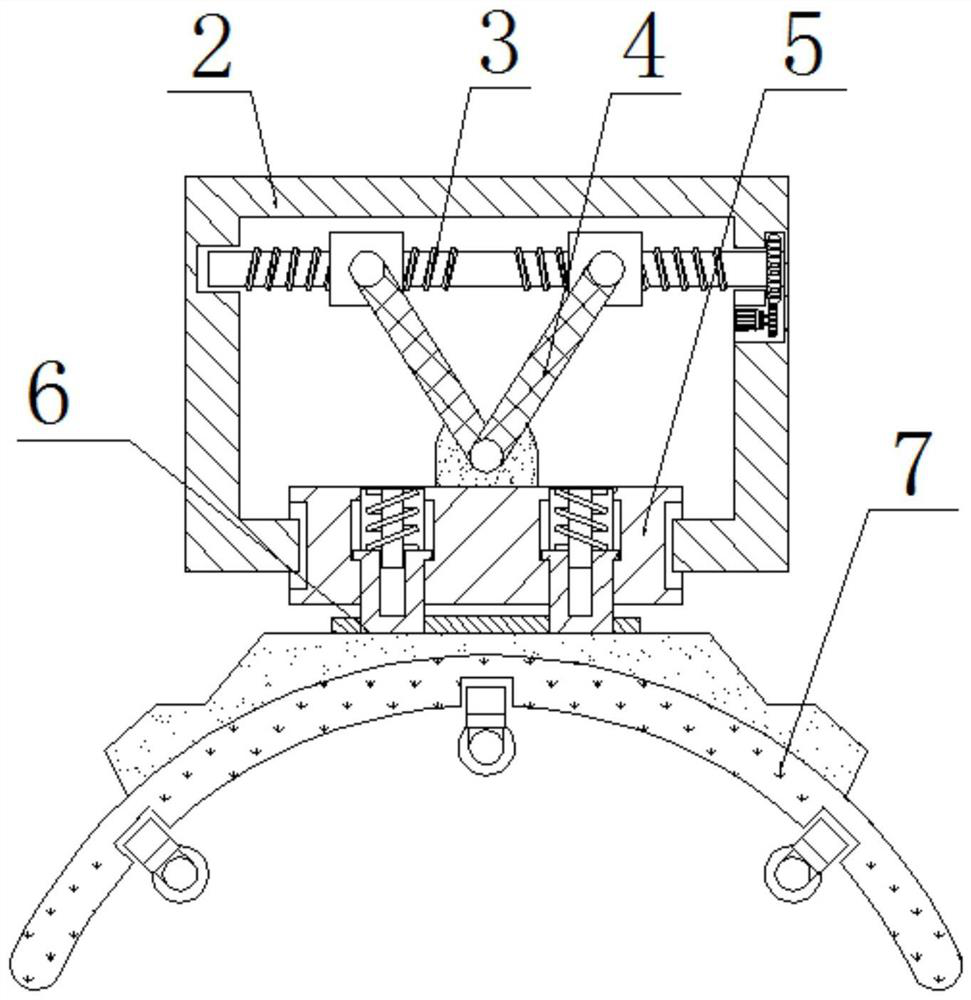

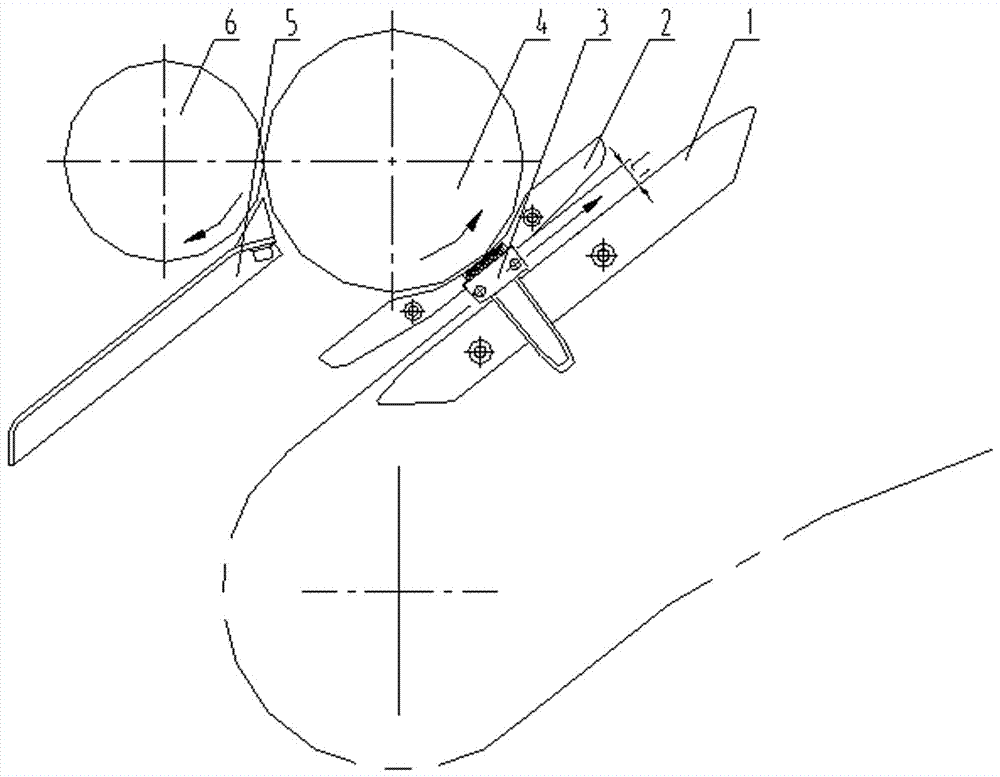

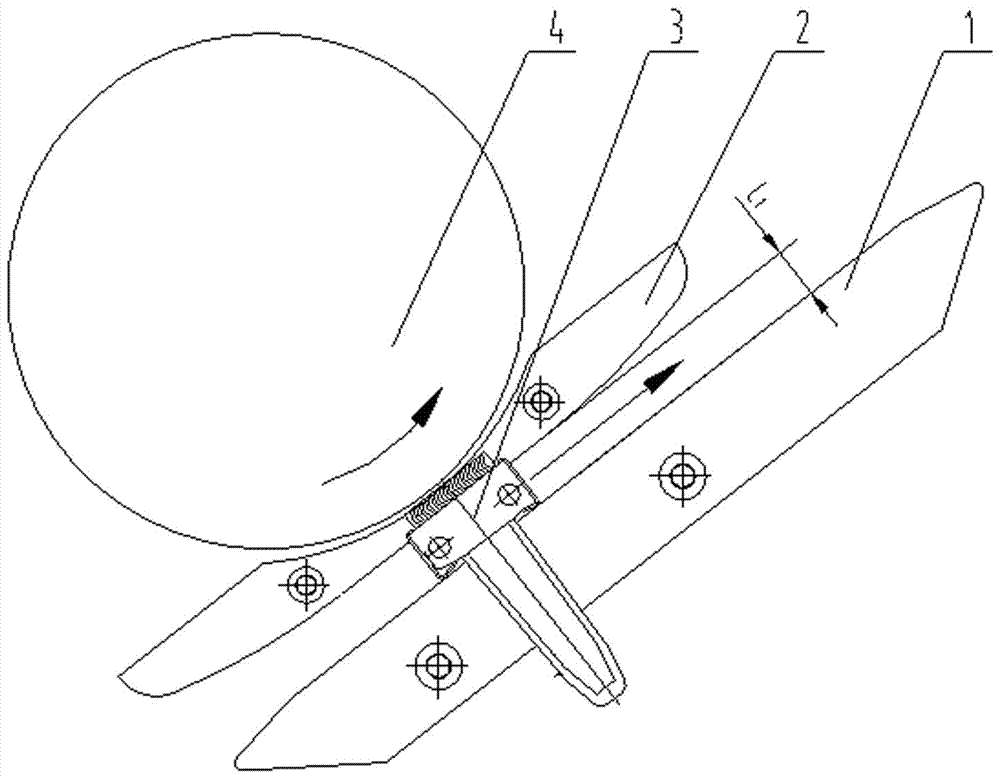

Supporting structure for movable cover plate

InactiveCN107268122AThe limit is safe and reliableOvercome the disadvantages of not being able to self-regulateCarding machinesGasketGeotechnical engineering

The invention discloses a supporting structure for a movable cover plate. The supporting structure comprises a supporting block, the supporting block is connected with a bracket through a bolt, a spring, a gasket, a limiting nut and a fastening nut, wherein the bolt is sleeved with the spring, the gasket, the limiting nut and the fastening nut in sequence from top to bottom. A bolt penetrating-installing hole machined in the supporting block is a stepped hole, the aperture of the upper end and the aperture of the lower end of the bolt penetrating-installing hole are larger than the aperture of the middle section, and the spring is located in a cavity in the lower end of the stepped hole; the aperture of an upper end hole of the stepped hole is larger than the maximum outer diameter of an upper end cap of the bolt, and the depth of the upper end hole of the stepped hole is larger than the thickness of the upper end cap of the bolt; the bracket is fixed to a supporting bracket leg through a bolt. The supporting structure for the movable cover plate elastically supports, limits and protects the movable cover plate during normal operation of the movable cover plate.

Owner:ZHENGZHOU HONGDA NEW TEXTILE MACHINERY

An oscillating carding mechanism for opening vegetable dyed fibers

The invention discloses an oscillation type loosening plant dyed fiber carding mechanism which comprises a piercing roller, a cylinder and a doffer. By conducting cooperation design on needle tooth structures on the surfaces of the piercing roller, the cylinder and the doffer, needle teeth of the piercing roller are designed into a double-peak structure, and fiber clusters are subjected to low-damage oscillation type loosening; the needle teeth of the cylinder are designed into a blunt-scale-shaped structure with a smooth tooth top, a low-damage hitting platform is provided for oscillation type loosening of fiber clusters on the surface of the piercing roller, and the fiber clusters on the surface of the piercing roller are effectively stripped off; needle teeth of the doffer are designedinto a double-peak structure, fibers are secondary carded, meanwhile the blockage of the fibers in the needle teeth is effectively avoided, the carding effect of the plant dyed fibers is effectively improved, and the subsequent processing quality is improved. The carding mechanism is reasonable in structure and simple in transformation, is an ideal carding mechanism special for plant dyeing, and is easy to use and popularize on a large area.

Owner:DEZHOU HENGFENG TEXTILES

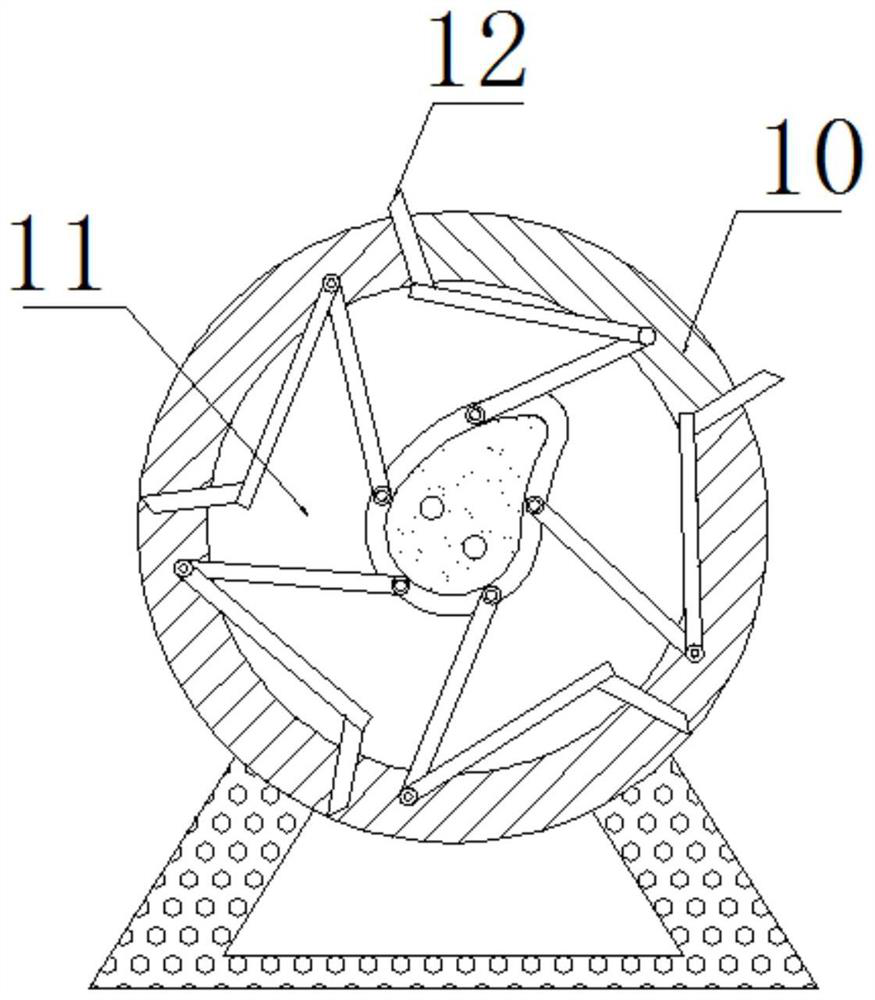

Discharging device of carding machine

ActiveCN101994171AEnhanced ability to fling into fluffReduce in quantityCarding machinesLow speedEconomic benefits

The invention discloses a discharging device of a carding machine. The device comprises a high-speed wiper roll (3), a fairing (4) and a dust cage (7), wherein the upper wall (B) of the fairing (4) is an upwards protruded curved surface while the lower wall (E) is a downwards protruded curved surface; both of the two side walls of the fairing (4) are planes; a low-speed doffer (5) is arranged between one end of the upper wall (B) and the dust cage (7); the axis of the low-speed doffer (5) is parallel to that of the dust cage (7); and the low-speed doffer (5) is arranged adjacently to the dust cage (7). The discharging device overcomes the disadvantages in the prior art, solves the technical problems which are not solved for a long time in the field, obviously improves the carding effect, can card high-quality fluff, improves the economic benefit of a product, can reduce the carding cost and brings brilliant progress technologically.

Owner:HANGZHOU YUANDESHAN SCI & TECHNICAL CO LT

Heterogeneous animal fiber carding machine

InactiveCN101608353BProtection lengthProtected growthCarding machinesAnimal fiberMechanical engineering

The invention discloses a heterogeneous animal fiber carding machine which sequentially comprises an automatic feeder, 2-6 sections of carding machines and an output mechanism. The heterogeneous animal fiber carding machine is characterized in that an air draft net curtain device is arranged between every two adjacent sections of carding machines; the air draft net curtain device comprises a reticular transport curtain which is horizontally installed, a special-shaped air draft cover, an air draft pipe, an air draft pipeline and a negative pressure source; wherein the air draft pipeline comprises a main air channel which is evenly provided with air suction holes and connected with the negative pressure source, and a branch air channel; a main cylinder of the carding machines is provided with 1-4 pairs of working rolls and wiper rolls, and the number of the working rolls and the wiper rolls is reduce progressively from the feeding direction of the carding machine to the output direction; screens are arranged under all the sections of carding machines; the air suction holes are positioned under the screens, and the number of the air suction holes is not less than the that of the sections of the carding machines.

Owner:吴孔希

Dynamic carding method and device thereof

InactiveCN101275311BEasy to replaceImprove carding effectCarding machinesCardingMechanical engineering

The invention relates to a dynamic carding method for carding fibers with a carding machine having card-flat rods fitted with card clothing moves the card-flat rods in a carding zone in relation to the peripheral surface of a swift along a scheduled path and a device thereof; wherein, at least one card clothing moves instantaneously in a direction deviated from the scheduled path at least one time passing through the carding zone, and then returns to the scheduled path. The feature of the device for carding fibers according to the carding method of the invention is that the invention comprises a device that makes at least one card clothing deviate instantaneously from the scheduled path, and then return to the scheduled path.

Owner:HERGETH H

A kind of oscillating type opening fiber carding method

ActiveCN108998863BAvoid damagePrevent stuffingCarding machinesUltimate tensile strengthMaterials science

The invention discloses an oscillating opening fiber carding method. The oscillating opening fiber carding method comprises the following steps: a, a fiber layer unwound from a fiber roll is fed to alicker roller by a feeding roller to perform opening, and the long fibers in the fiber layer are fully opened and loosened under the oscillating opening action of opening needle teeth; b, the fiber layer is striped by a cylinder after the fiber layer is opened by the licker roller, and the fiber is subjected to oscillating opening further; c, the stripped fiber layer enters a cylinder-cover platecarding area with the cylinder, and are carded into singe fibers; d, the carded fiber layer goes out of the cylinder-cover plate carding area, and enters a cylinder-doffer carding area, and oscillating carding is performed on the fibers between cylinder blunt scaly needle teeth and doffer carding needle teeth; e, the condensed fiber layer is stripped by a stripper roller to form a fiber net, the fiber net is gathered by a bell mouth and is squeezed by a big pressing roller to form slivers. The oscillating opening fiber carding method is suitable for caring when the fiber material has a low thread density or when the fiber strength is low, can prevent the fibers from being stuffed, and can improve the carding effect of low damage and the strong release of the soft and weak fibers.

Owner:DEZHOU HENGFENG TEXTILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com