High-efficiency carding system for nonwovens

A carding and non-woven technology, which is applied in the field of high-efficiency carding system, can solve the problems of low output, poor fiber web appearance and uniformity, etc., and achieve the goal of increasing fiber transfer, improving carding performance, and efficient carding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

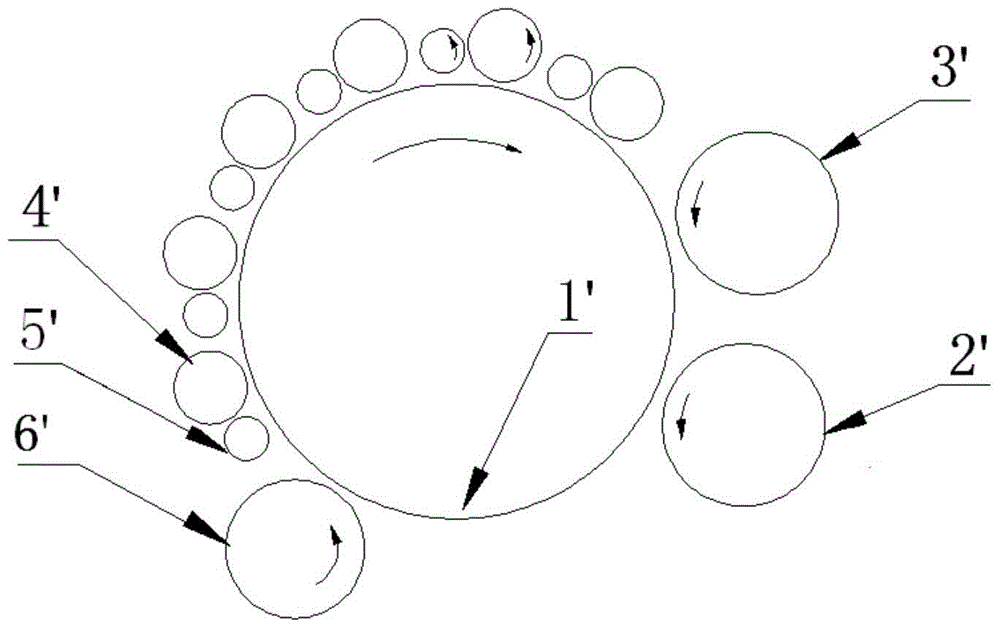

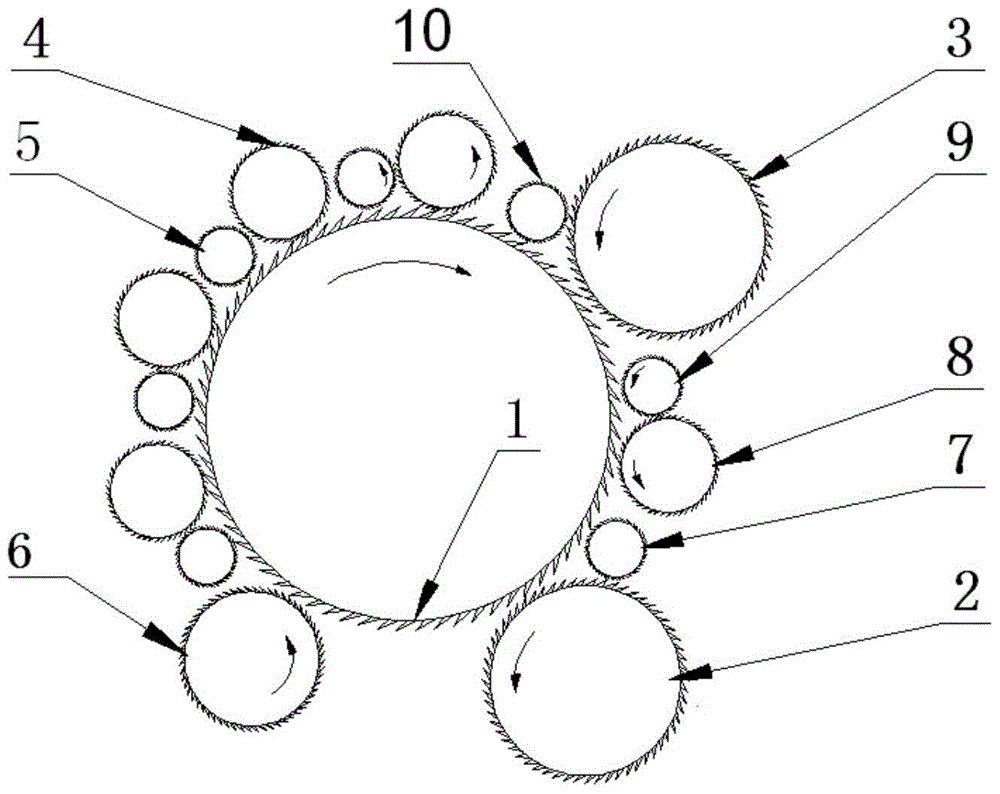

[0022] A non-woven high-efficiency carding system of the present embodiment includes a cylinder 1, a lower doffer 2, an upper doffer 3 installed on the frame main body, a plurality of carding units composed of a work roll 4 and a stripping roll 5, And the transfer roller 6, between the lower doffer 2 and the upper doffer 3, there is a buffer carding unit for the surface high-speed airflow generated by the high-speed rotation of the branch cylinder 1, and the buffer carding unit includes a group of buffer work rolls 8 and buffer stripping rollers 9. The buffer stripping roller 9 is located between the buffer work roller 8 and the upper doffer 3 . An upwind roll 10 is provided between the upper doffer 3 and the closest work roll 4 , and a leeward roll 7 is provided between the lower doffer 2 and the buffer work roll 8 . The distance between the buffer work roll 8 and the cylinder 1, between the buffer stripping roller 9 and the cylinder 1, and between the buffer work roll 8 and ...

Embodiment 2

[0026] A nonwoven high-efficiency carding system of this embodiment is different from Embodiment 1 in that the distance between the buffer work roll 8 and the cylinder 1 is 0.10 m, and the distance between the buffer stripping roller 9 and the cylinder 1 is 0.10 m. The gauge is 0.20mm, and the gauge between the buffer work roll 8 and the buffer stripping roller 9 is 0.20mm.

Embodiment 3

[0028] A nonwoven high-efficiency carding system of this embodiment is different from Embodiment 1 in that the distance between the buffer work roll 8 and the cylinder 1 is 0.25mm, and the distance between the buffer stripping roller 9 and the cylinder 1 is 0.25 mm. The gauge is 0.35mm, and the gauge between the buffer work roll 8 and the buffer stripping roller 9 is 0.40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com