Discharging device of carding machine

A carding machine and carding technology, used in deburring devices, textiles and papermaking, fiber processing, etc., can solve problems such as high operating costs, low production efficiency, and damage to the length of the fluff, and enhance the ability to obtain fluff. The strength is not easy to break, and the effect of reducing the damage to the length of the fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

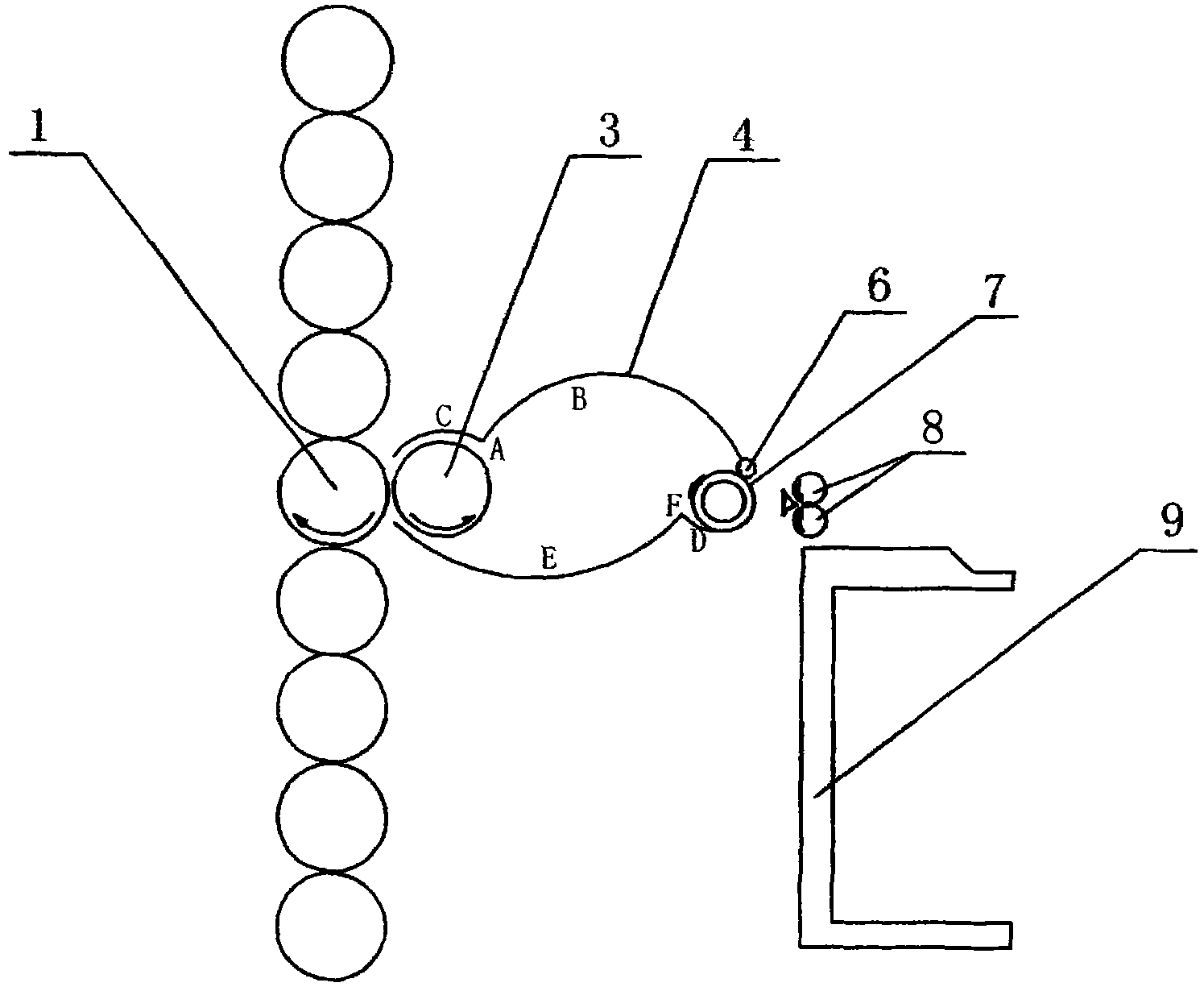

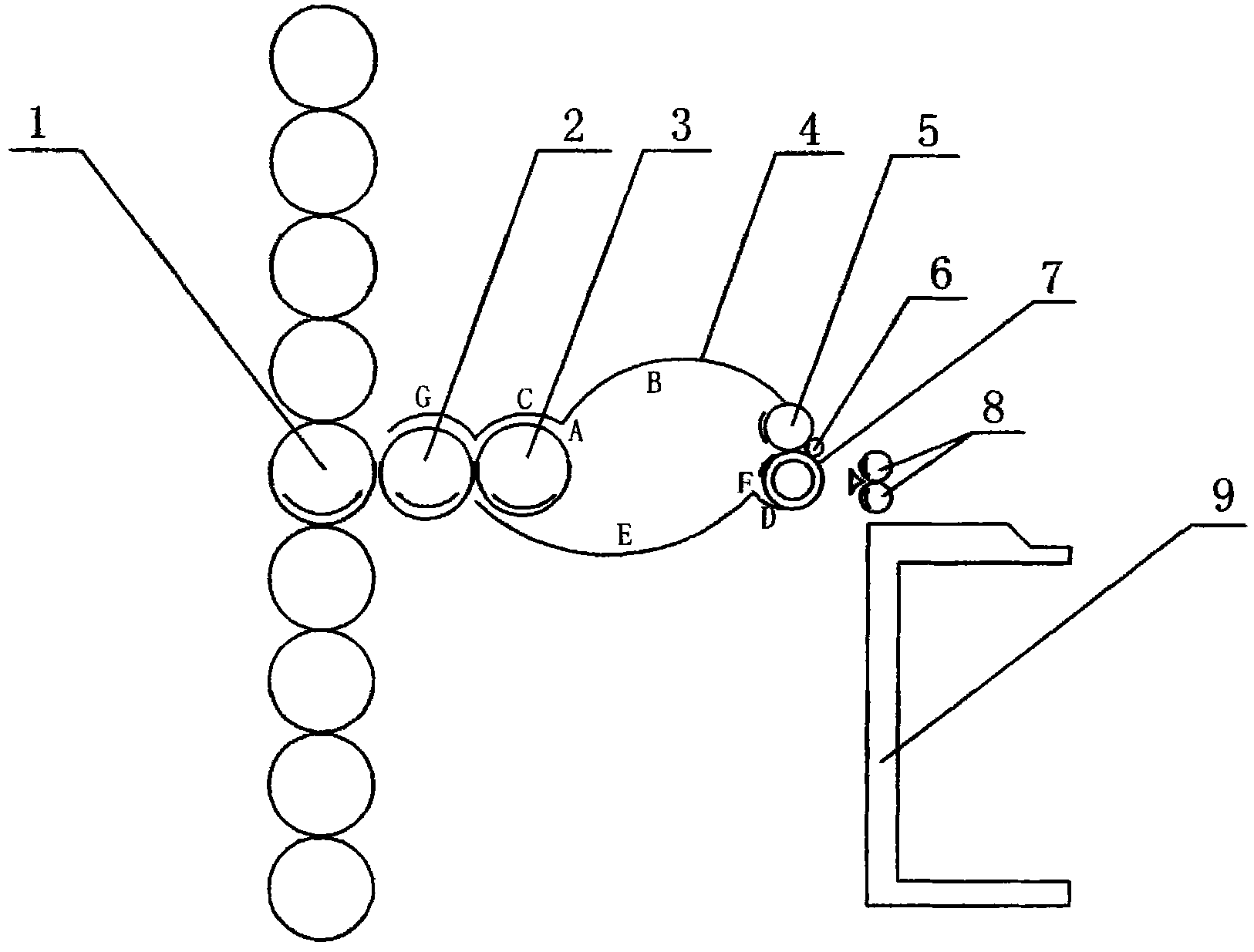

[0021] figure 1 The structure of one embodiment of the present invention is shown.

[0022] like figure 1 As shown, the machine discharge device according to one embodiment of the present invention includes a fairing 4 , a high-speed depilling roller 3 and a dust cage 7 . The high-speed stripping roller 3 is set adjacent to the central carding roller 1 of the carding machine, and is used to strip the fluff combed on the central carding roller 1, and throw the fluff into the fairing 4 by the centrifugal force of high-speed rotation . Fairing 4 is made up of upper wall B, lower wall E and two side walls, is used for closing the space between described high-speed depilling roller 3 and dust cage 7. And the dust cage 7 is used for absorbing the fluff in the fairing 4 .

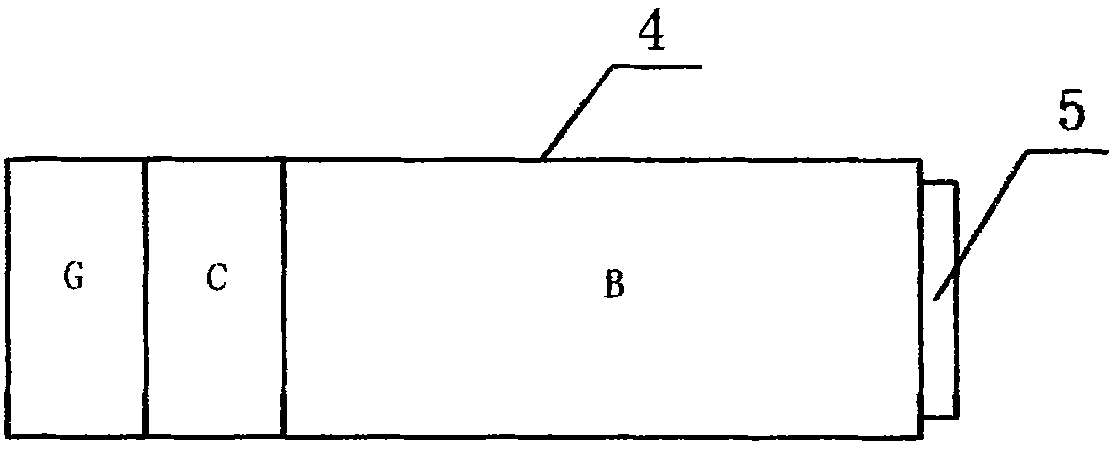

[0023] The fairing 4 is located between the high-speed depilling roller 3 and the dust cage 7, and includes four walls. The upper wall B of the fairing 4 is a curved surface protruding upward, the lower wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com