Patents

Literature

50 results about "Stripping - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

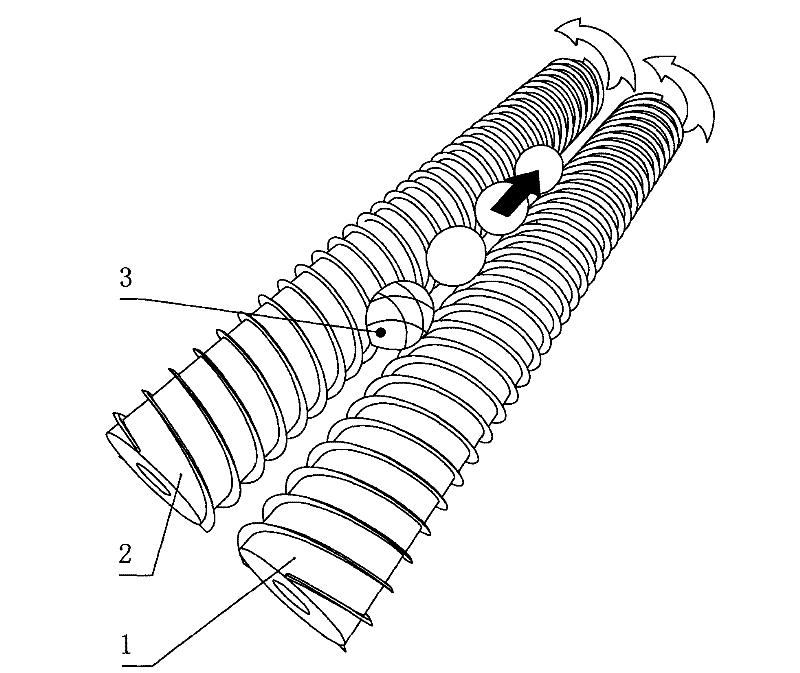

Method for stripping off green husk of nut through mechanized dry process

The invention discloses a method for stripping off green husks of nuts through a mechanized dry process and relates to a fruit processing technique, in particular to a processing technique for stripping off the green husks of the nuts. Crossed reticular knife marks are cut on the surfaces of fermented mature green nuts through two spiral knife rolls which have opposite spiral directions and rotate in the same direction at different speeds, and then the spiral knife rolls rotate to apply tangential force and axial force on the nuts to rotate and turn over the nuts so as to enable the green husks to be split and separated from the surfaces of the nuts. Since the spiral knife rolls have sharp edges, when the spiral knife rolls cut into the green husks, sap in the green husks is not squeezed out and is prevented from contaminating the exterior surfaces of the nuts during processing. Though the entire green husk stripping motions are equivalent to simulated manual stripping actions, the mechanized high-efficiency application of the green husk stripping action is realized. Therefore, the invention provides the effective method for stripping the green husks of the nuts through the dry process.

Owner:YUNNAN SARDE TECH +1

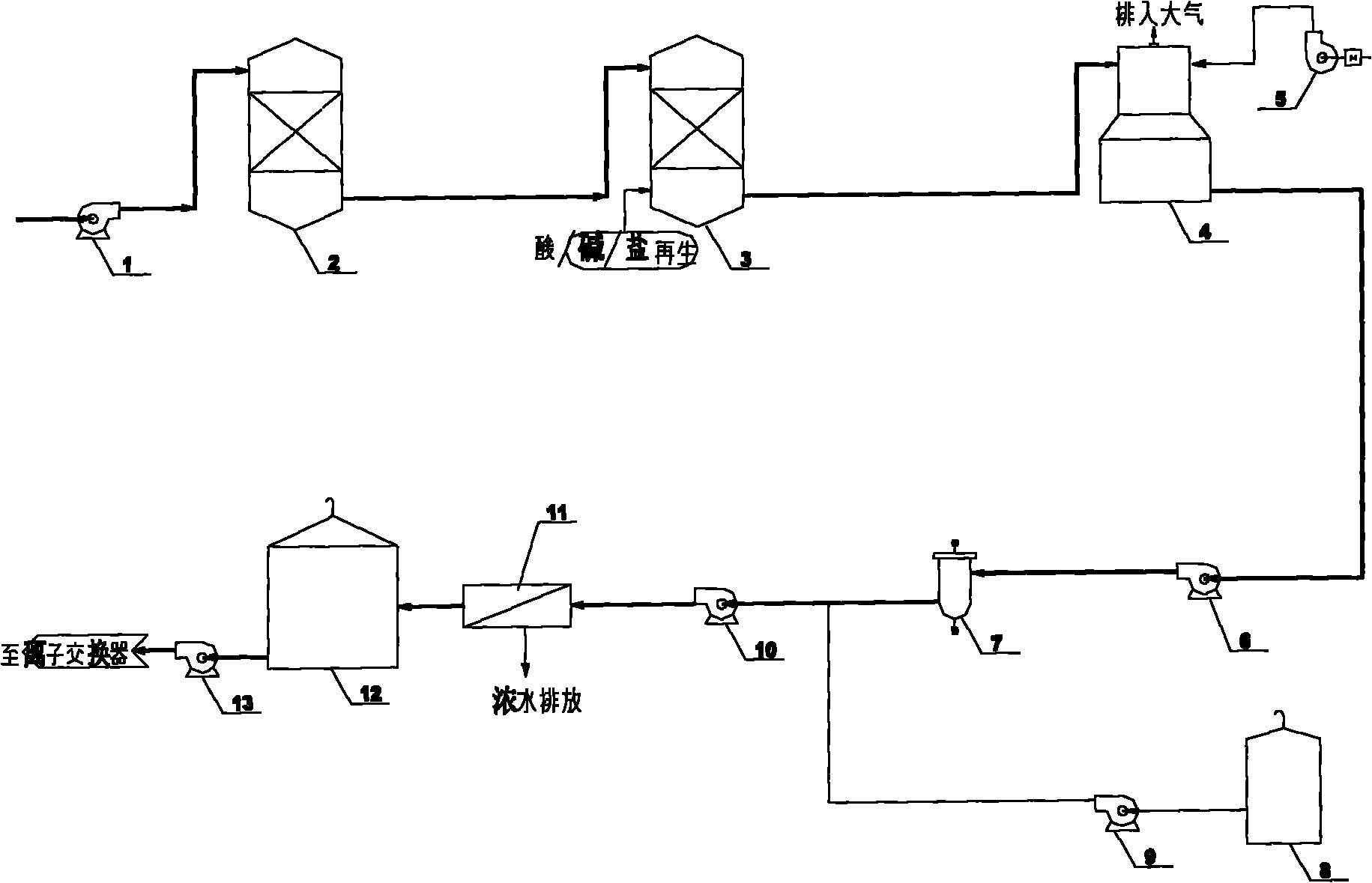

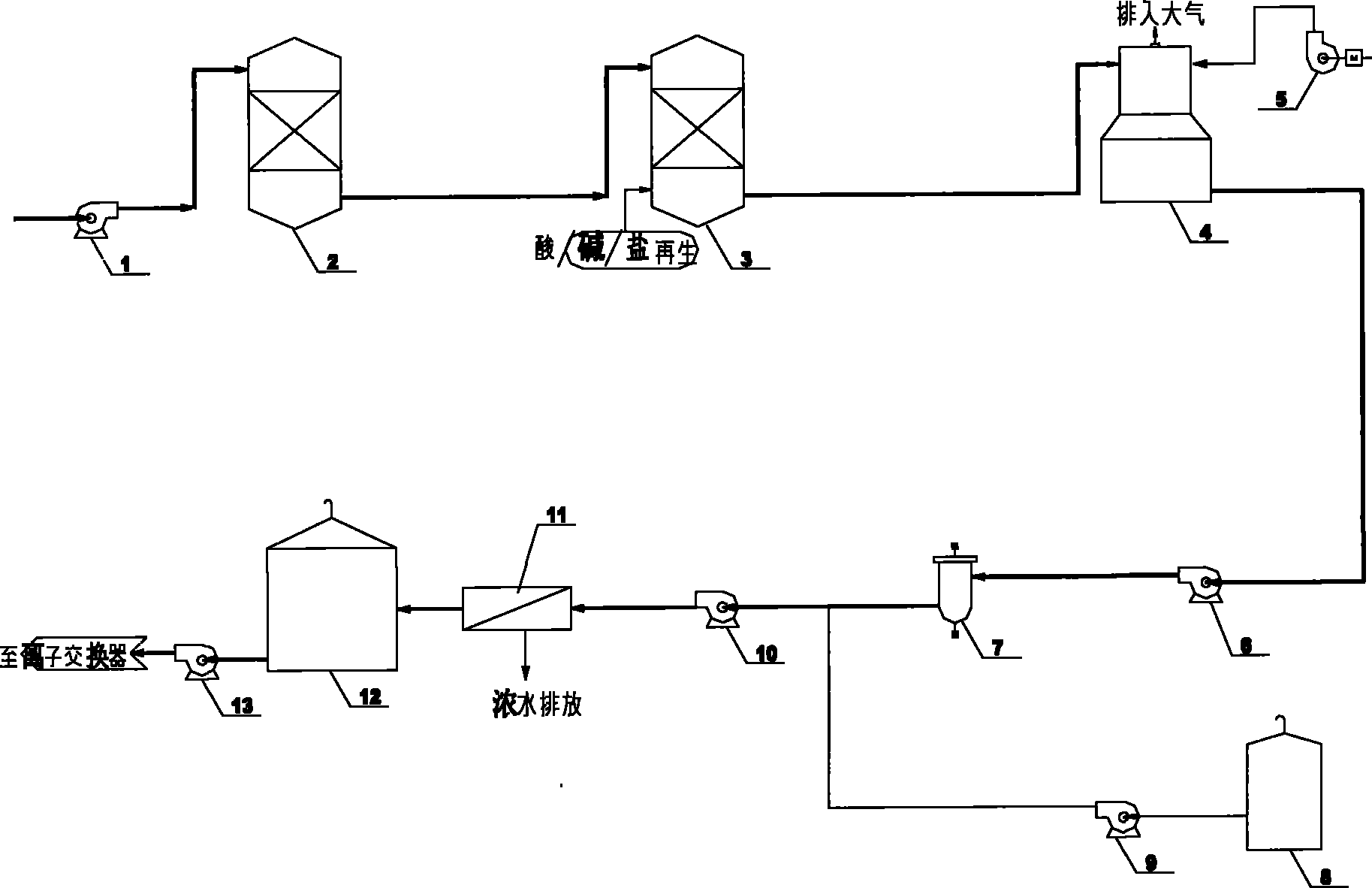

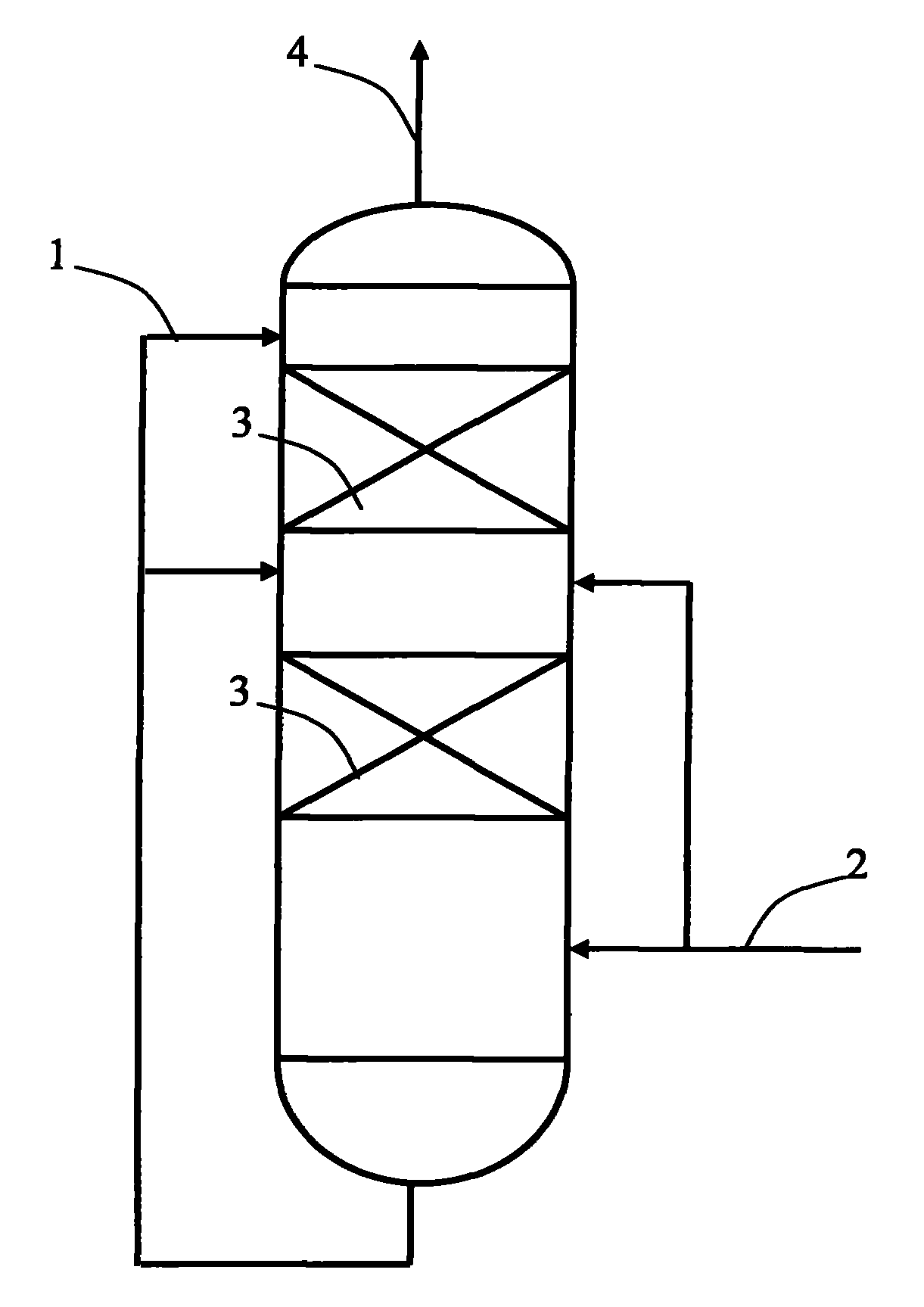

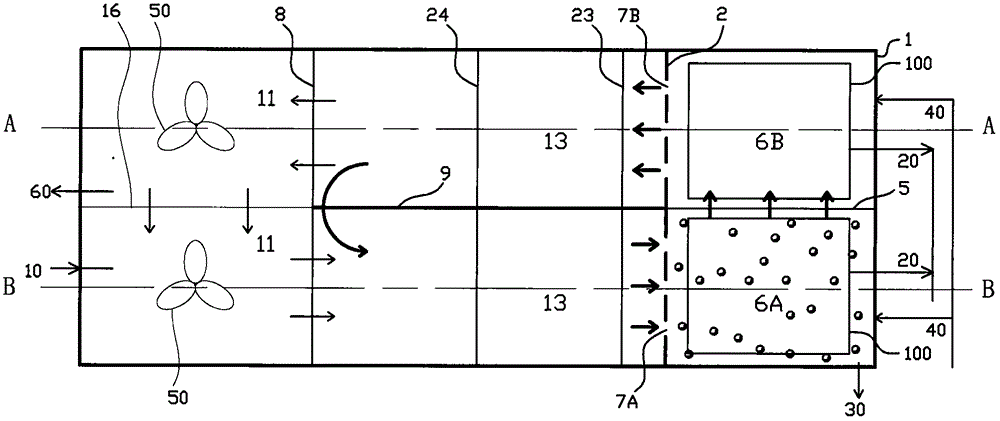

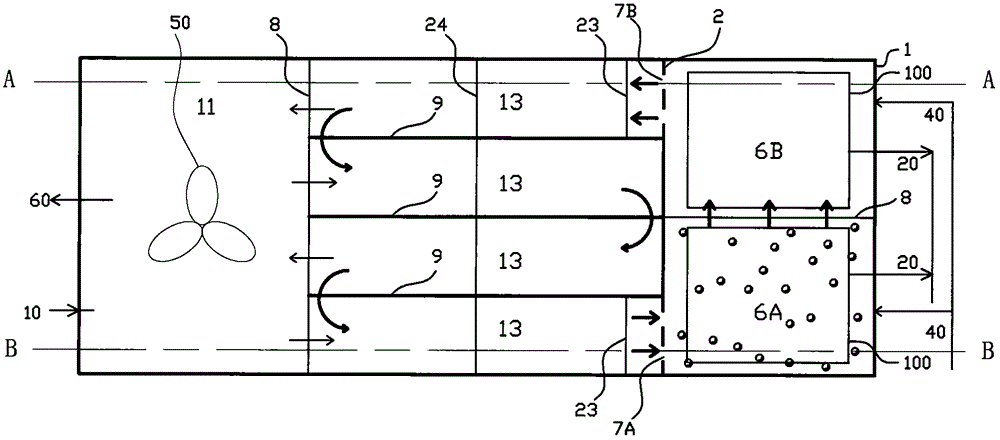

Wastewater recycling treatment process

InactiveCN101767888AImprove throughputEliminate scalingWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltration membraneReverse osmosis

The invention discloses a wastewater recycling treatment process, which comprises the following steps: leading raw water to pass through a filter for removing suspended matters and solid particles in the raw water, leading outlet water of the filter to enter into an ion exchanger, removing calcium and magnesium ions in the raw water through ion exchange, further removing the hardness in the water, leading the outlet water of the ion exchanger to enter into a decarbonizing tower, and removing the alkalinity of the raw water under the air stripping action of a rotary fan; leading the raw water out of the decarbonizing tower to enter into a precision filter under the action of a lifting pump, lifting the outlet water of the precision filter to a nano-filtration / reverse osmosis system which is mainly formed by parallel connection and / or series connection of a nano-filtration membrane and a reverse osmosis membrane under the action of a high pressure pump, leading the nano-filtration / reverse osmosis system to discharge concentrated water, leading the nano-filtration / reverse osmosis system to drain produced water into a produced water tank, and becoming the final outlet water. The process can effectively avoid the membrane pollution, improve the recycling rate, further greatly reduce the discharge amount of wastewater, simultaneously reduce the using amount of membranes due to the improvement of running conditions of a membrane system and further reduce the investment and the running cost.

Owner:郑理慎

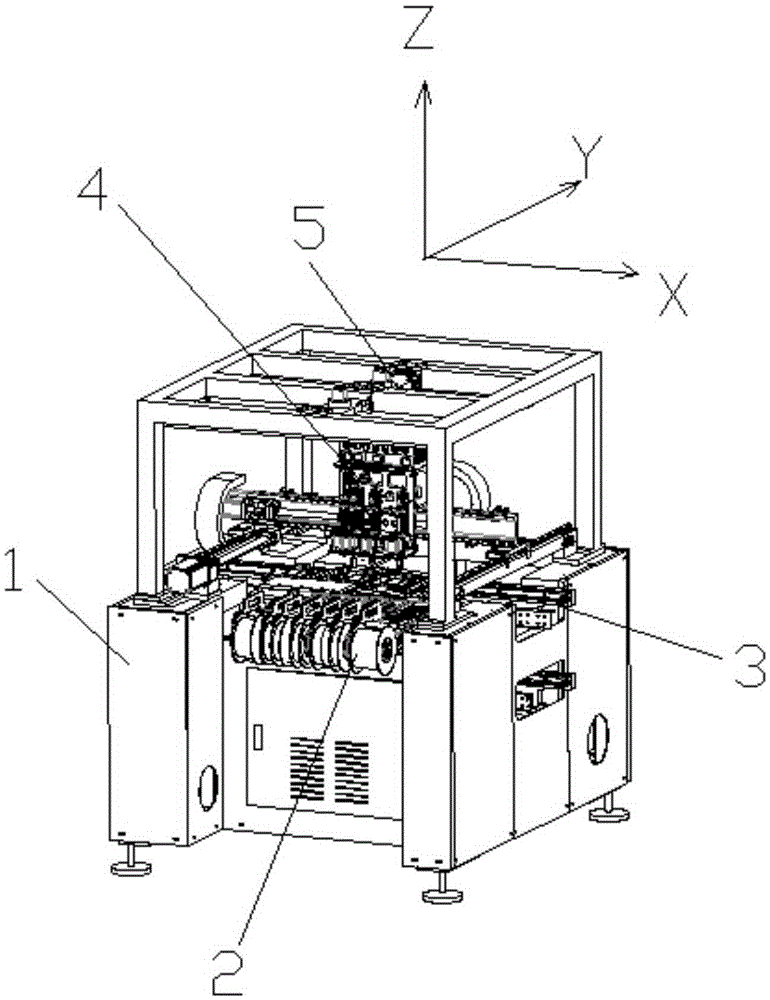

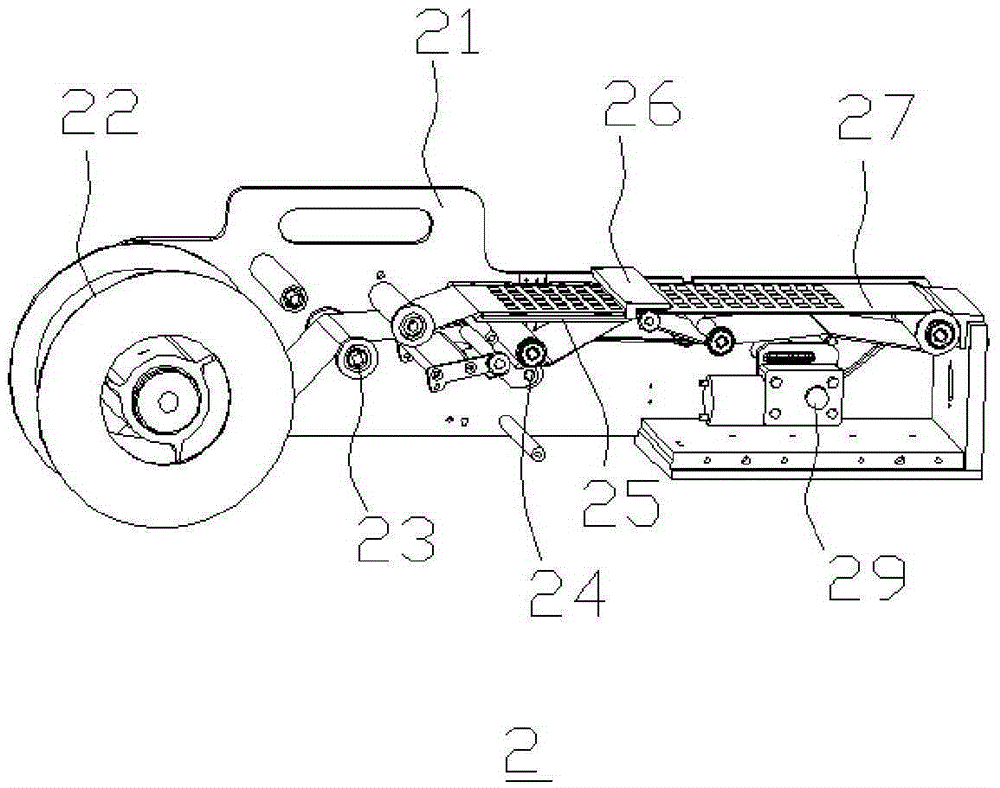

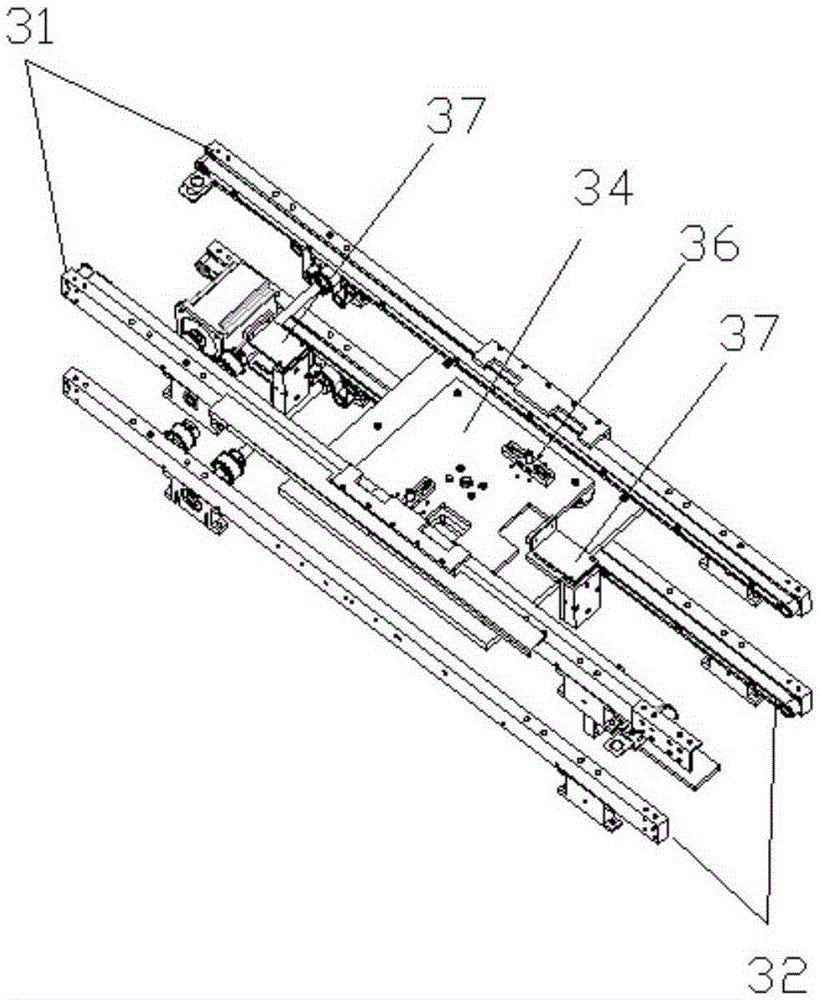

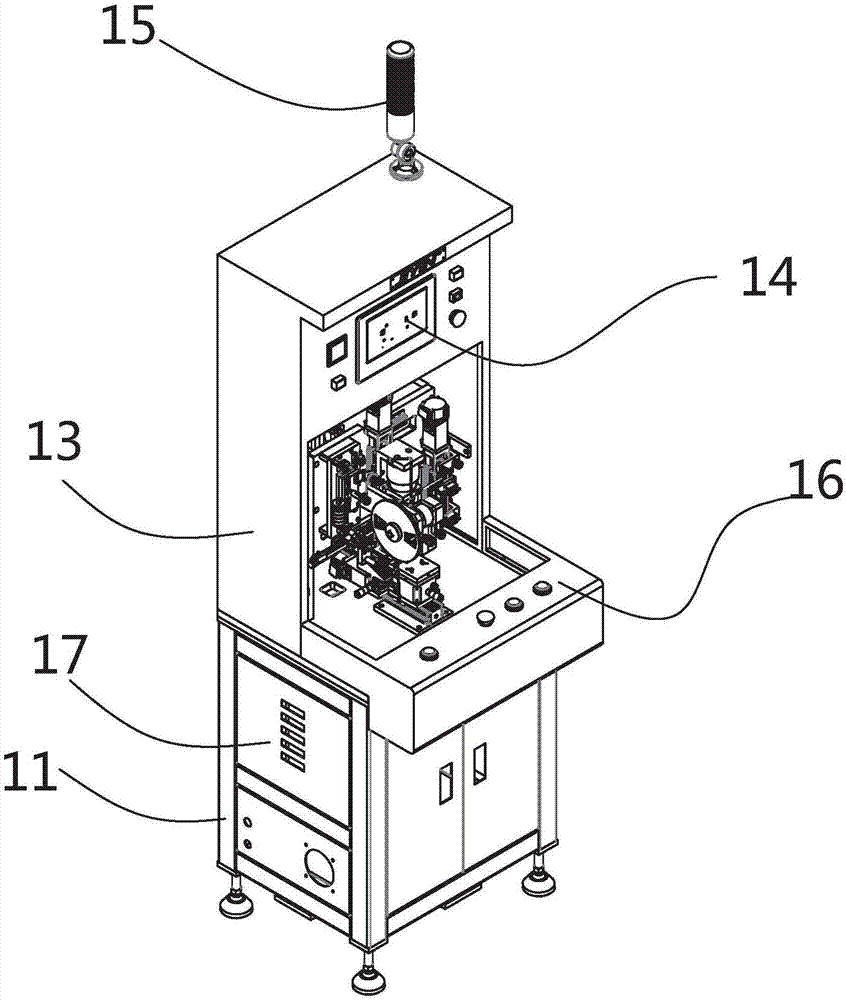

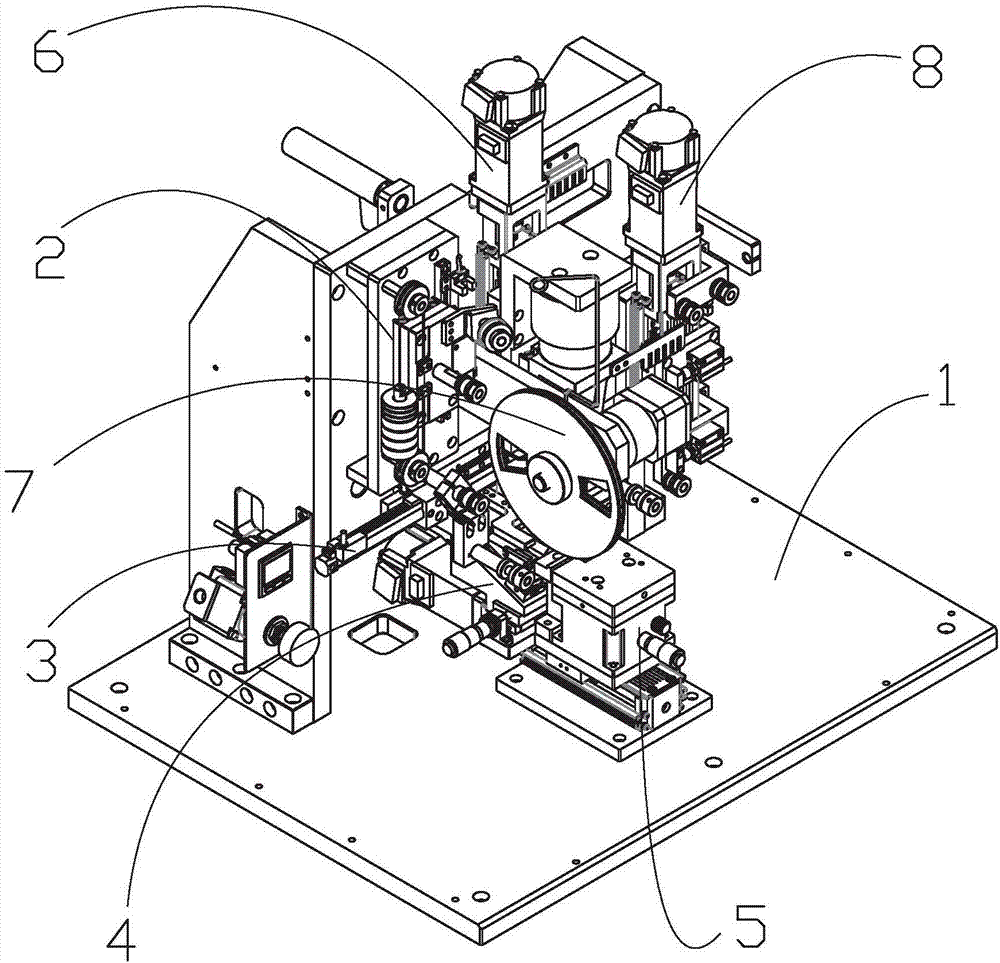

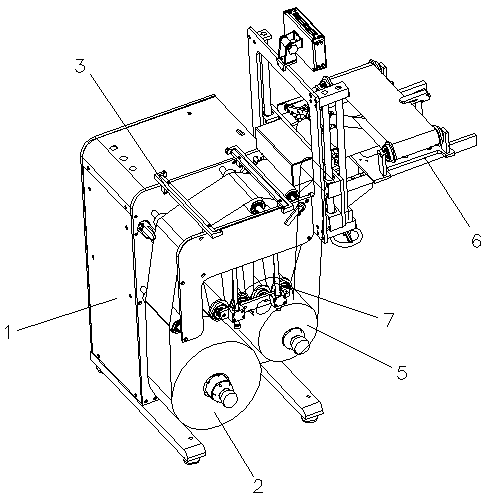

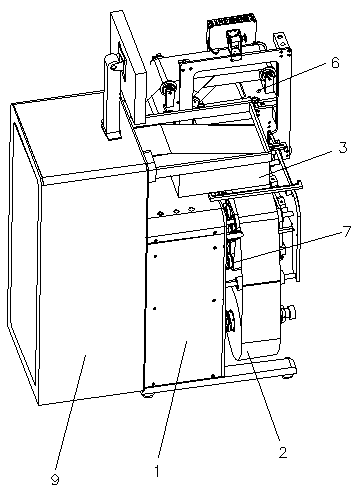

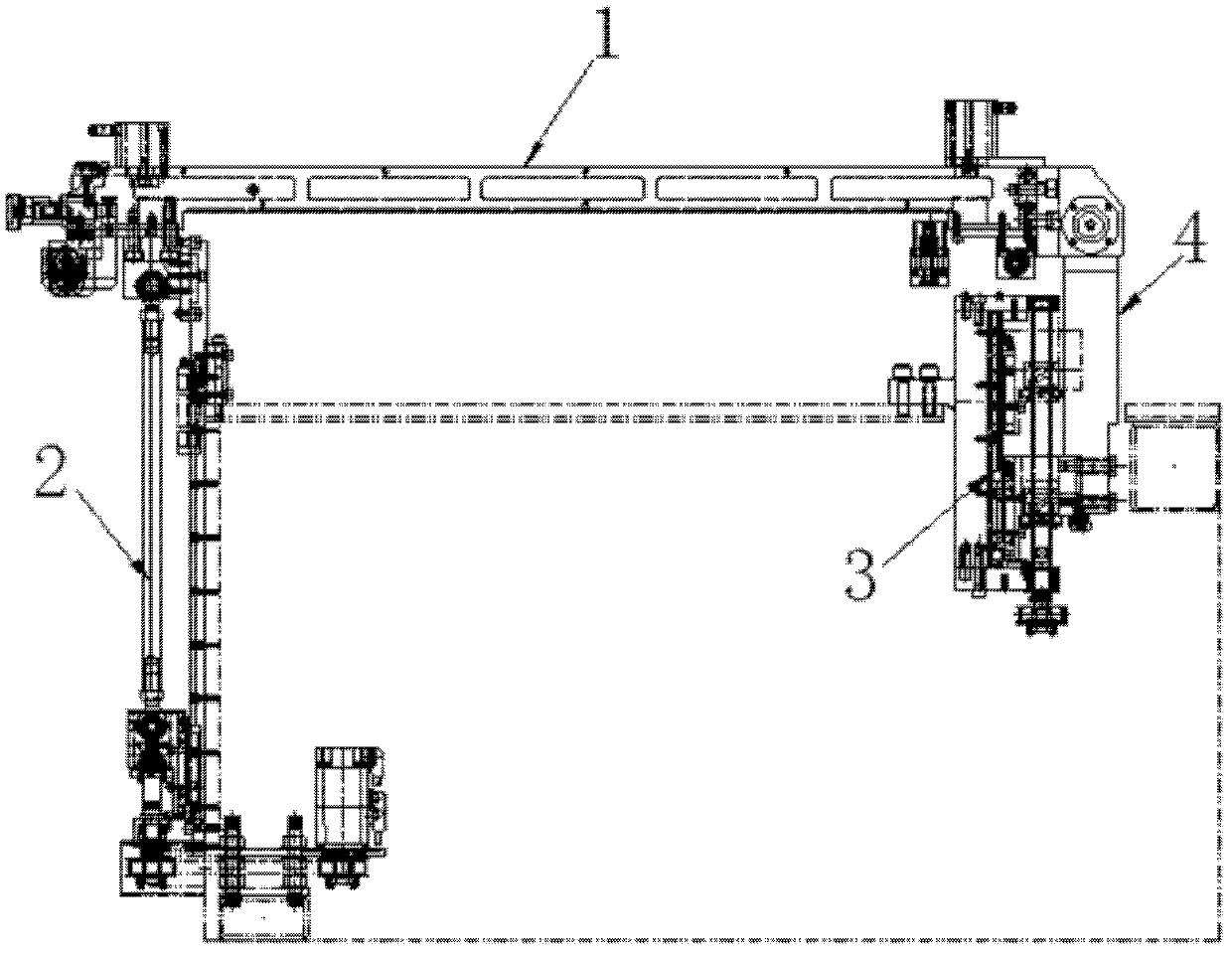

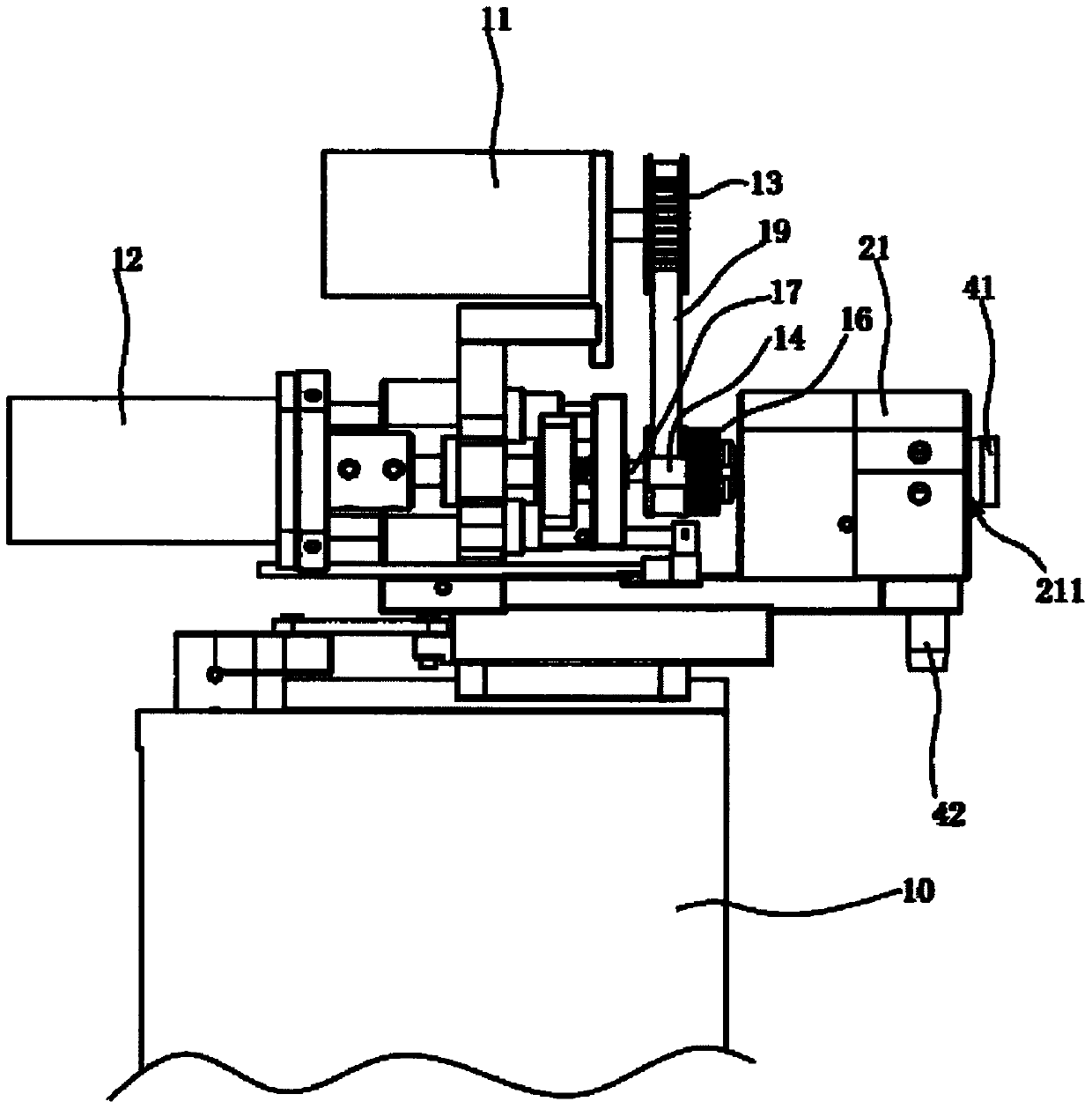

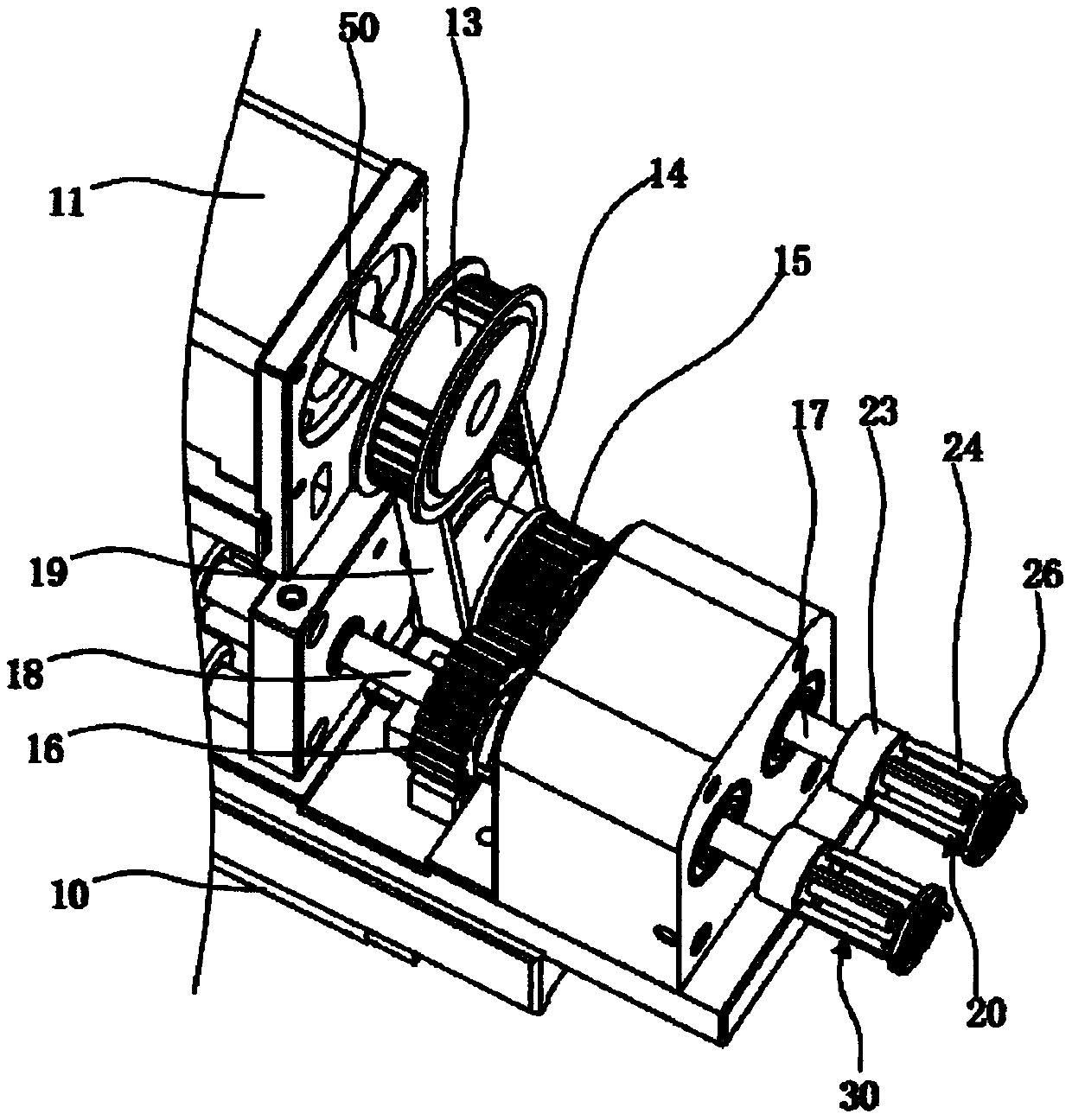

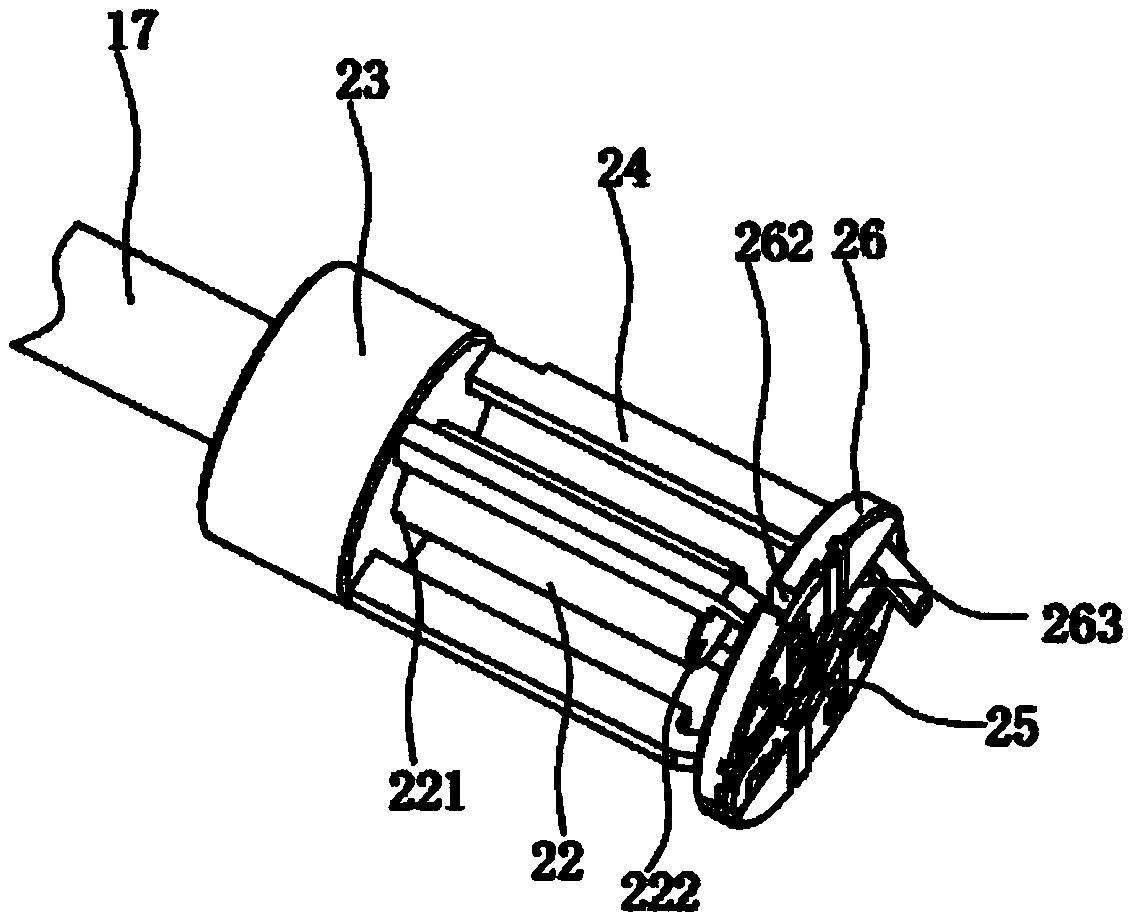

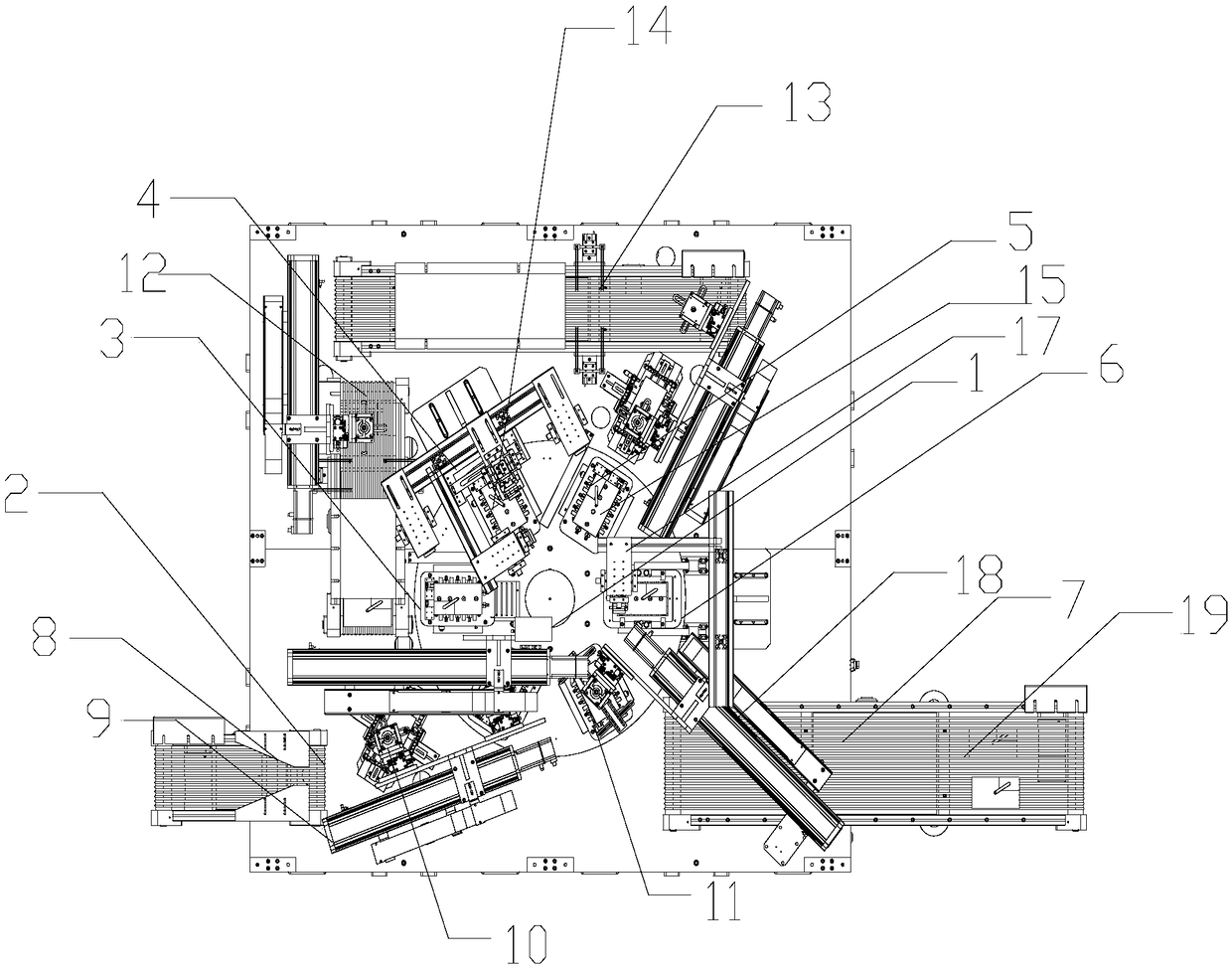

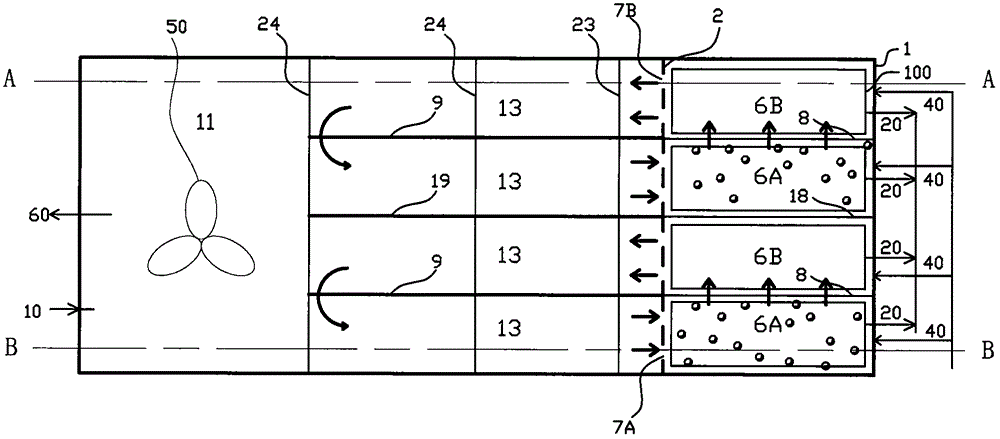

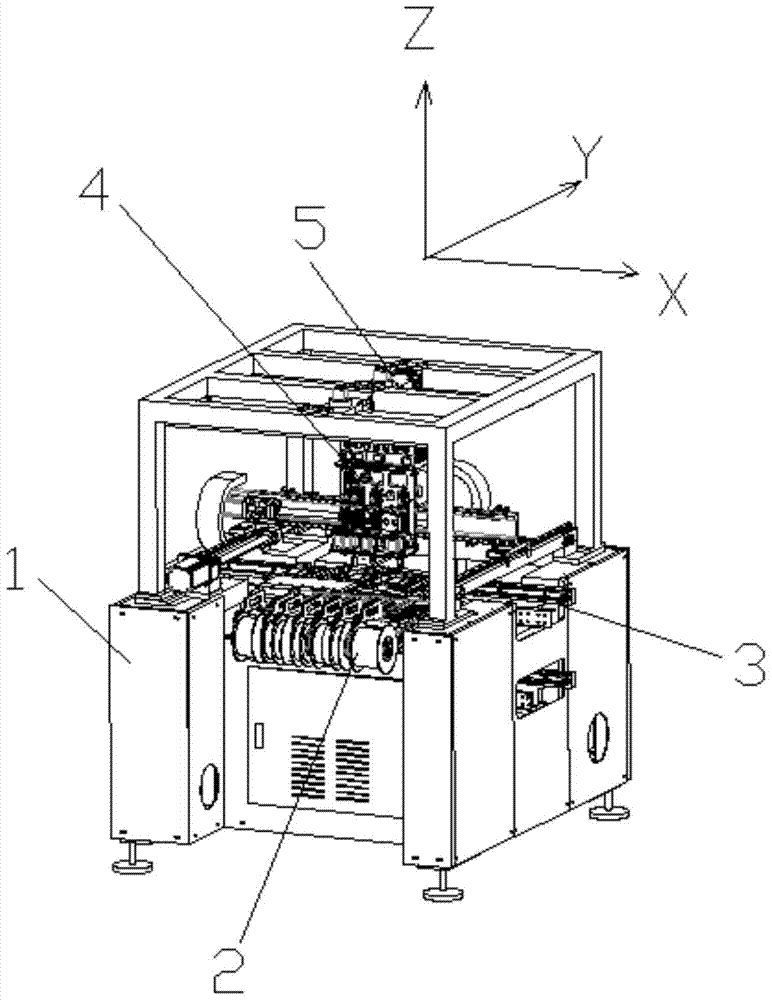

Visual-positioning mobile phone accessory attaching system

ActiveCN105292657AReduce movementImprove placement efficiencyLabelling machinesEmbedded systemStripping - action

The invention belongs to the field of mobile phone shell assembling equipment, and particularly relates to a visual-positioning mobile phone accessory attaching system. The visual-positioning mobile phone accessory attaching system comprises a hardware part and a software part. The hardware part comprises a main rack, a plurality of accessory stripping mechanisms, a feeding and discharging mechanism, an attaching executing mechanism, a visual-positioning mechanism and a controller. The software part comprises a hard configuration management module, a mobile phone accessory management module, a hand and eye calibration module and a work driving module. According to the visual-positioning mobile phone accessory attaching system, the manner that the accessory stripping mechanisms and the attaching executing mechanism with a plurality of suction nozzles are integrated on the main rack, attaching of various accessories can be completed at a time through one machine, and in addition, due to the fact that the accessory stripping action and the attaching action are independent from each other and work is completed in a division manner, the visual-positioning mobile phone accessory attaching system has the remarkable beneficial effects that precision is high, accessory waste is small, the requirement for the accessory manufacturing technology is low, the wire change cost is low, accessory stripping and accessory attaching are conducted in parallel and efficiency is high compared with a traditional accessory attaching system. In the traditional accessory attaching system, one machine is used for attaching one accessory; accessory stripping and accessory attaching are conducted in series; no machine vision exists, or a simple vision system is arranged, and generally, a camera is installed on a mechanical arm; and photographing is needed before each time of material taking.

Owner:DONGGUAN GOSUNM MACHINERY EQUIP CO LTD

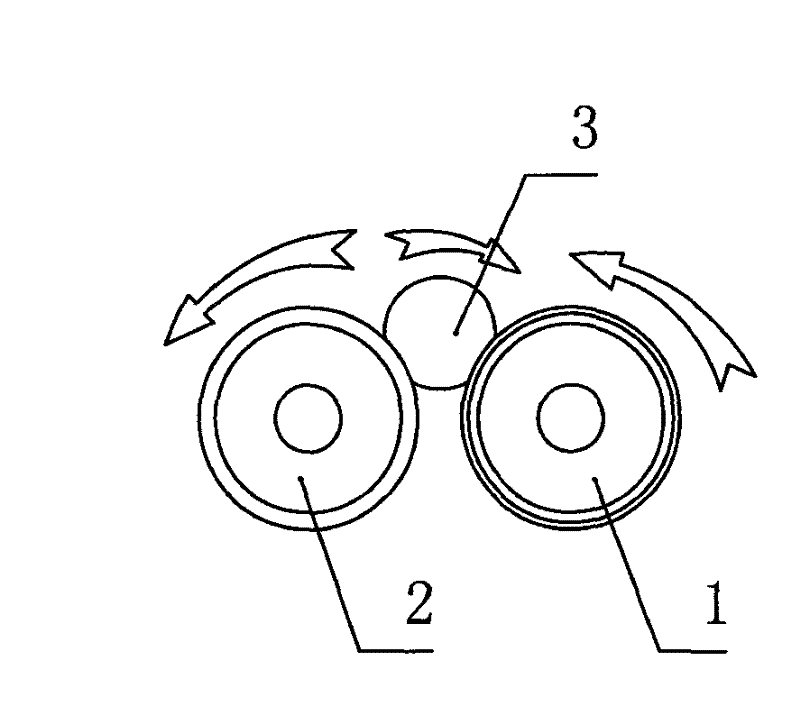

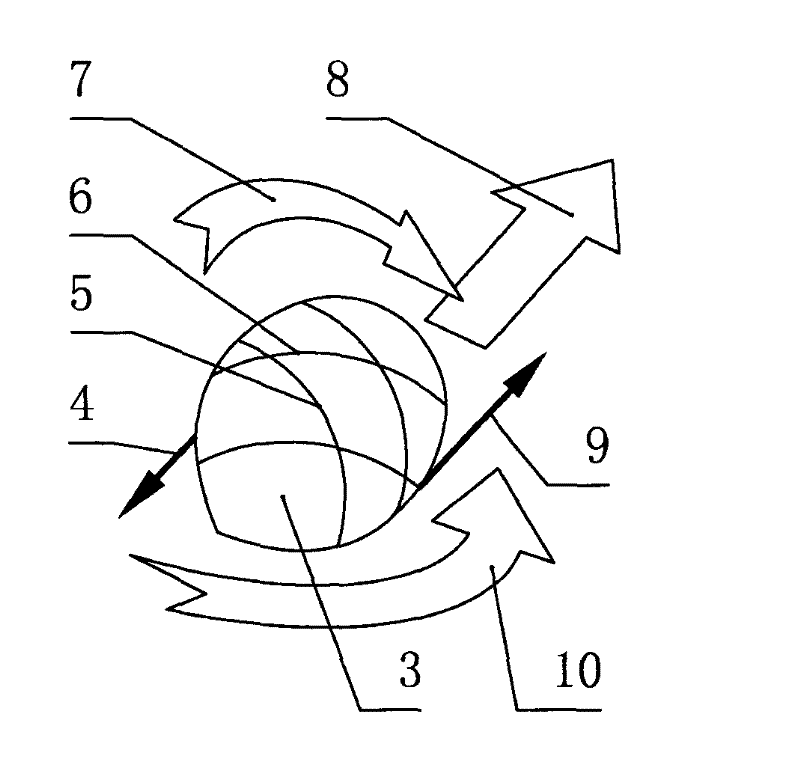

Cashmere combing method

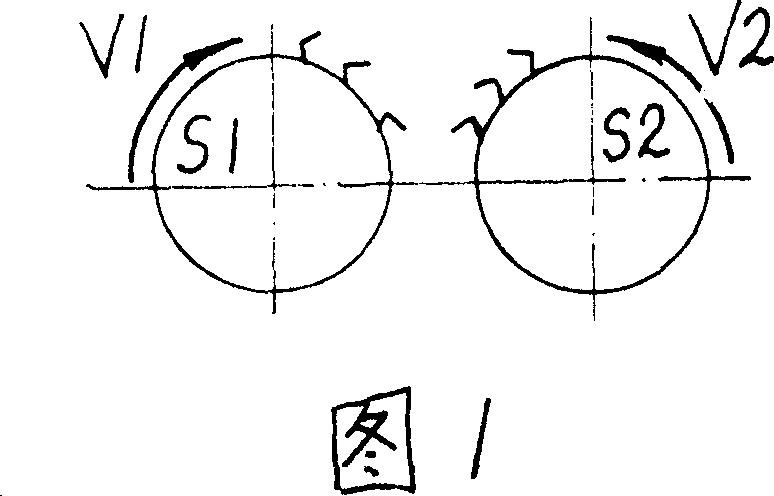

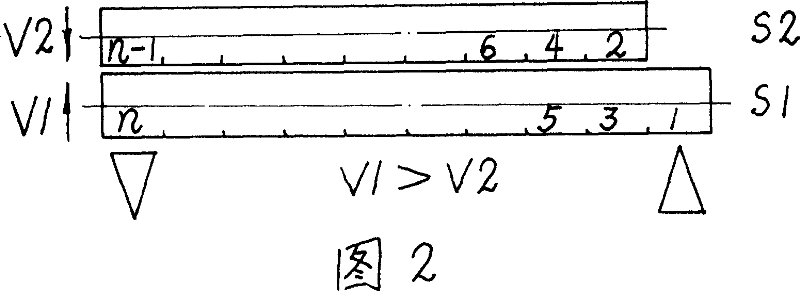

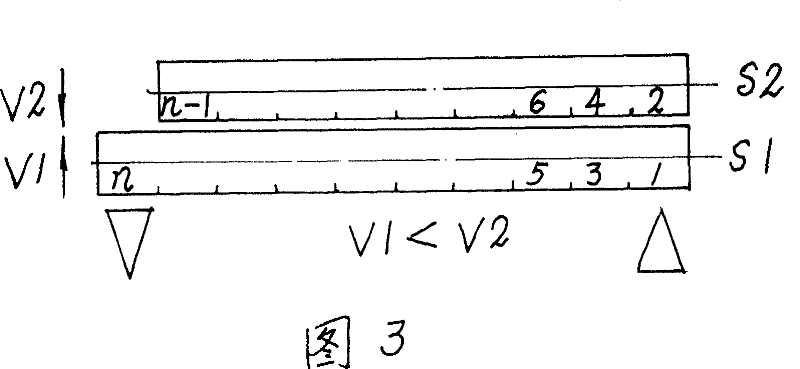

The invention discloses a cashmere combing device which belongs to the field of wool manufacture raw material preparation, characterized by that two combing rollers are arranged in parallel with the same needle direction for achieving the stripping action, the movement between the two rollers includes both periodic high and low speed motion and axial motion, and the dehaired wool is obtained through repeated striping, drawing, and trash extraction. Compared with the conventional roller carding machine or cover board hackling machine, the advantages of the device according to the present invention are simple structure and less damage to fiber length.

Owner:黄金山

ACF laminating machine for hot pressing laminating, and laminating method using ACF laminating machine

The invention relates to an ACF laminating machine for hot pressing laminating. The ACF laminating machine includes a machine housing, a machine big bottom plate, and a buffer gravity hammer mechanism, an ACF laminating precision mechanism, an ACF stripping mechanism, an ACF semi-cutting mechanism, and an LCD placement platform which are arranged on the machine big bottom plate; the ACF laminating precision mechanism includes a pressure Z axial assembly, an ACF tape winding automatic feeding mechanism, and an ACF receiving precision mechanism; during laminating, the ACF tape winding automatic feeding mechanism and the ACF receiving precision mechanism work at the same time, a material tape of the ACF adhesive tape moves under the pressure Z axial assembly. In this feeding process, the buffer gravity hammer mechanism tensions the material tape, a first buffer guide ring and a second buffer guide ring correctly guide, a vacuum suction pipe receives waste materials, and the ACF semi-cutting mechanism performs cutting; the pressure Z axial assembly performs precision laminating; the ACF stripping mechanism performs ACF stripping action, and a placement vacuum bottom plate is moved out. A quality uniform effect is improved, and processing of high precision quality products is facilitated.

Owner:SHENZHEN JIYIN TECH

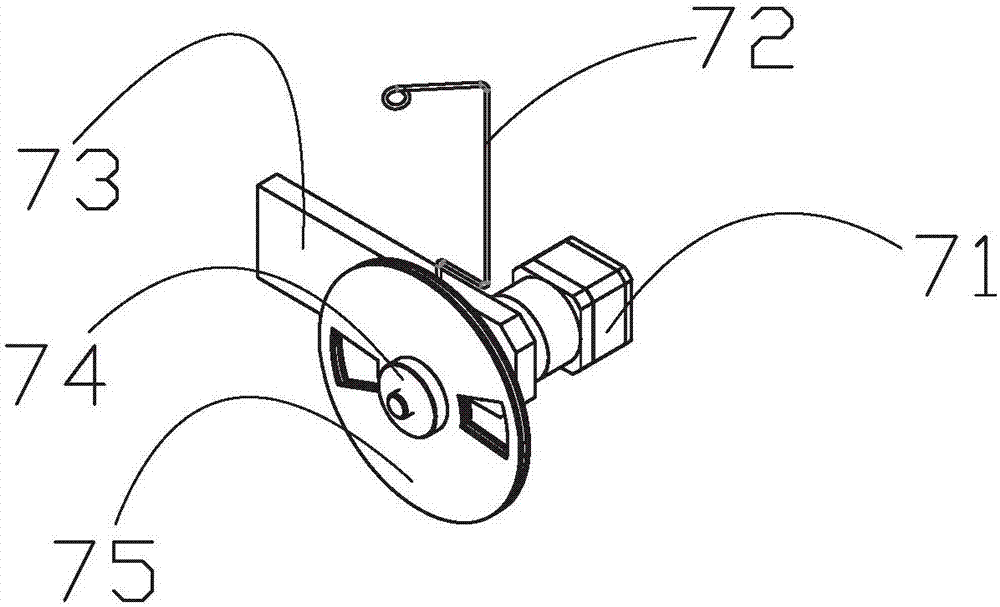

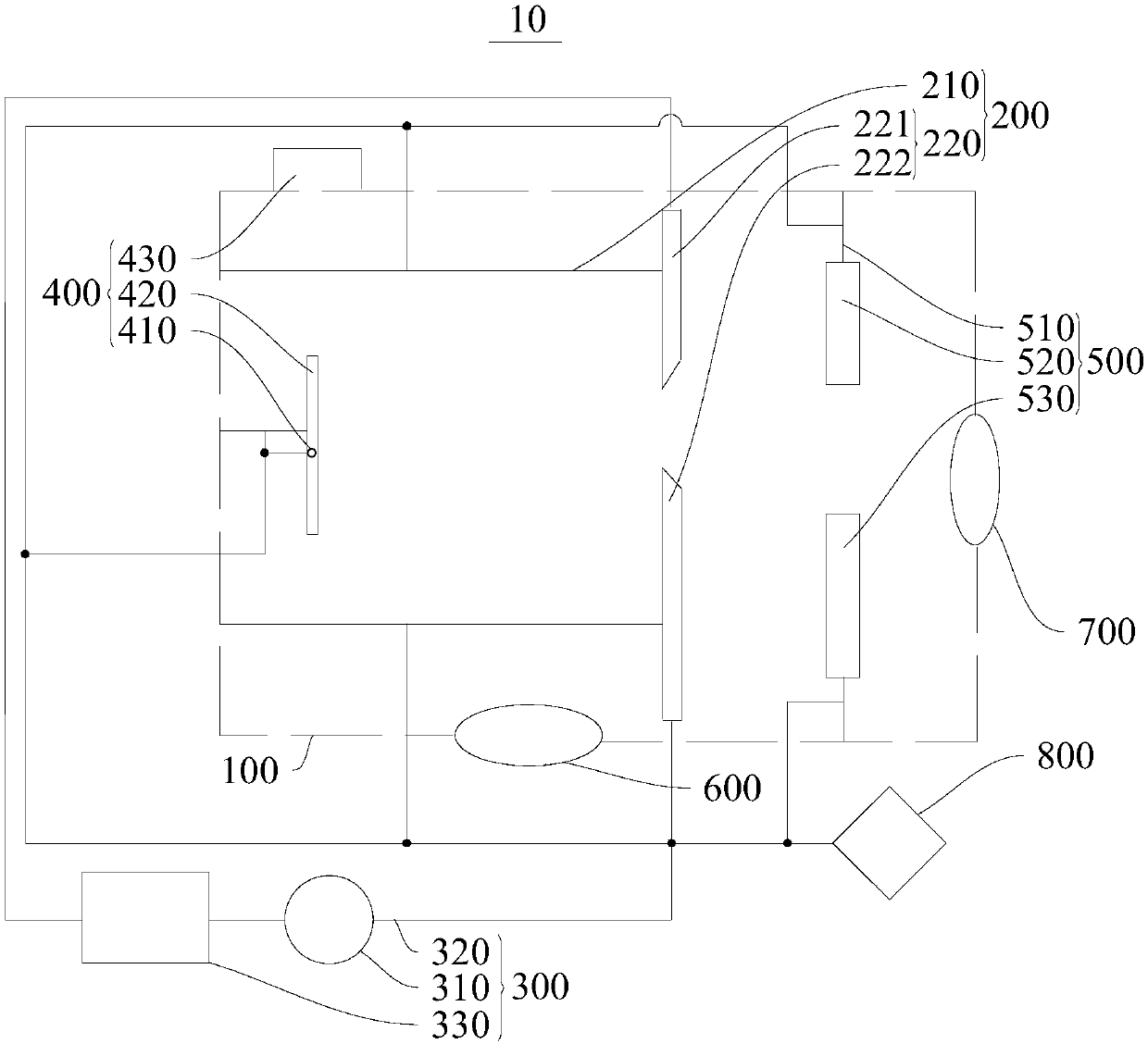

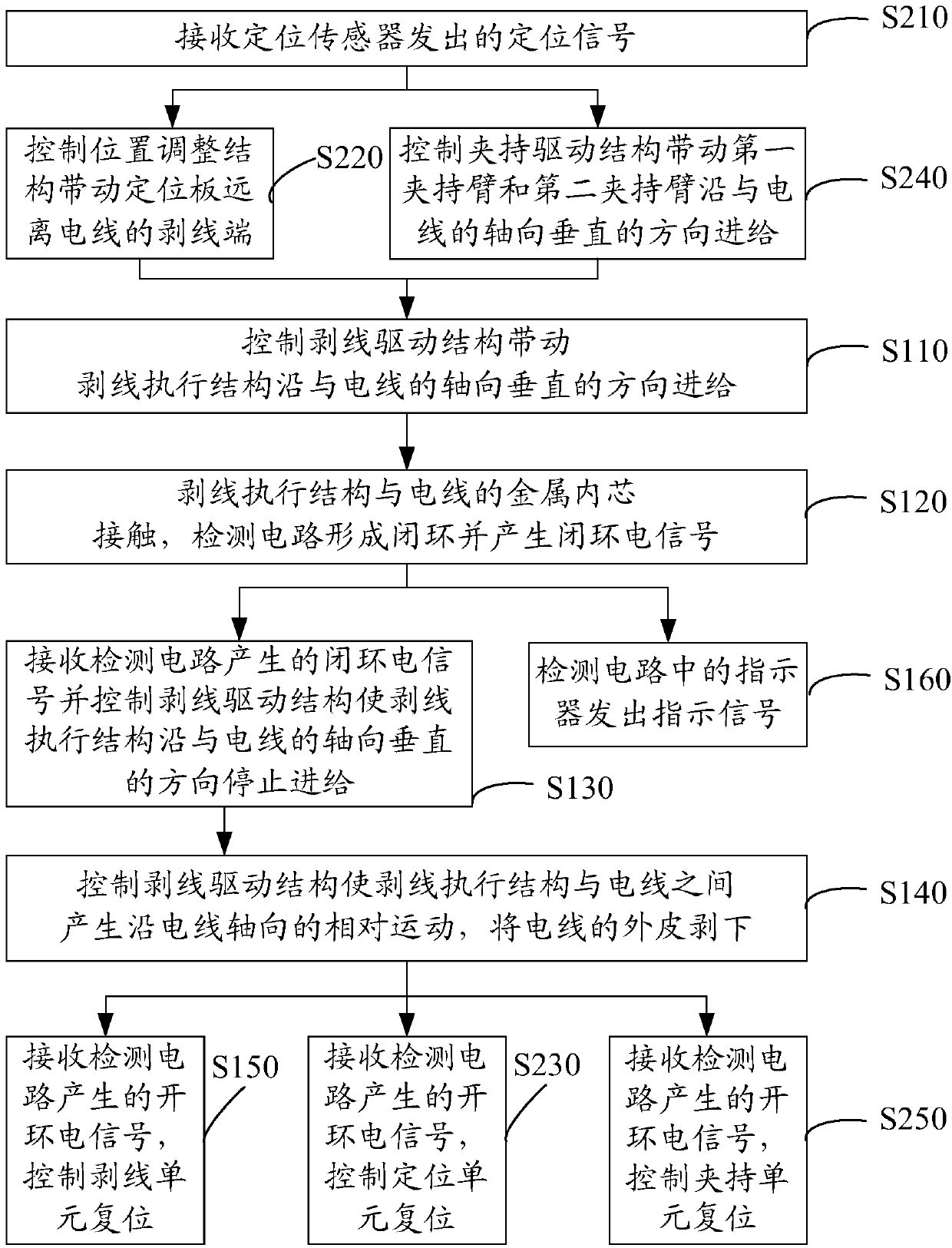

Stripping machine

PendingCN107611859AImprove stripping efficiencyImprove strip qualityLine/current collector detailsApparatus for removing/armouring cablesStripping - actionEngineering

The invention relates to a stripping machine, and includes a support structure, a stripping unit, a detection circuit, and a controller. The stripping unit arranged in the support structure includes astripping driving structure and a stripping performing structure. The stripping driving structure is connected with the stripping performing structure in a transmission way to drive the stripping performing structure to complete a stripping action. The detection circuit is electrically connected with the stripping unit. The stripping performing structure can form a loop and open circuit with thedetection circuit. The controller is respectively electrically connected with the stripping driving structure and the detection circuit. The stripping machine detects whether the stripping performingstructure is contacted with a metal inner core or not through the detection circuit in the stripping process of the stripping machine. When the stripping performing structure is contacted with the metal inner core, the controller controls the stripping unit to complete the subsequent stripping process. The stripping process is all controlled and completed by the controller, has the advantage of high efficiency stripping, and formed stripping mouths after processing by the stripping performing structure can be always matched with the metal inner core. The stripping is in high quality.

Owner:GREE ELECTRIC APPLIANCES INC

Integrated water scale removal equipment

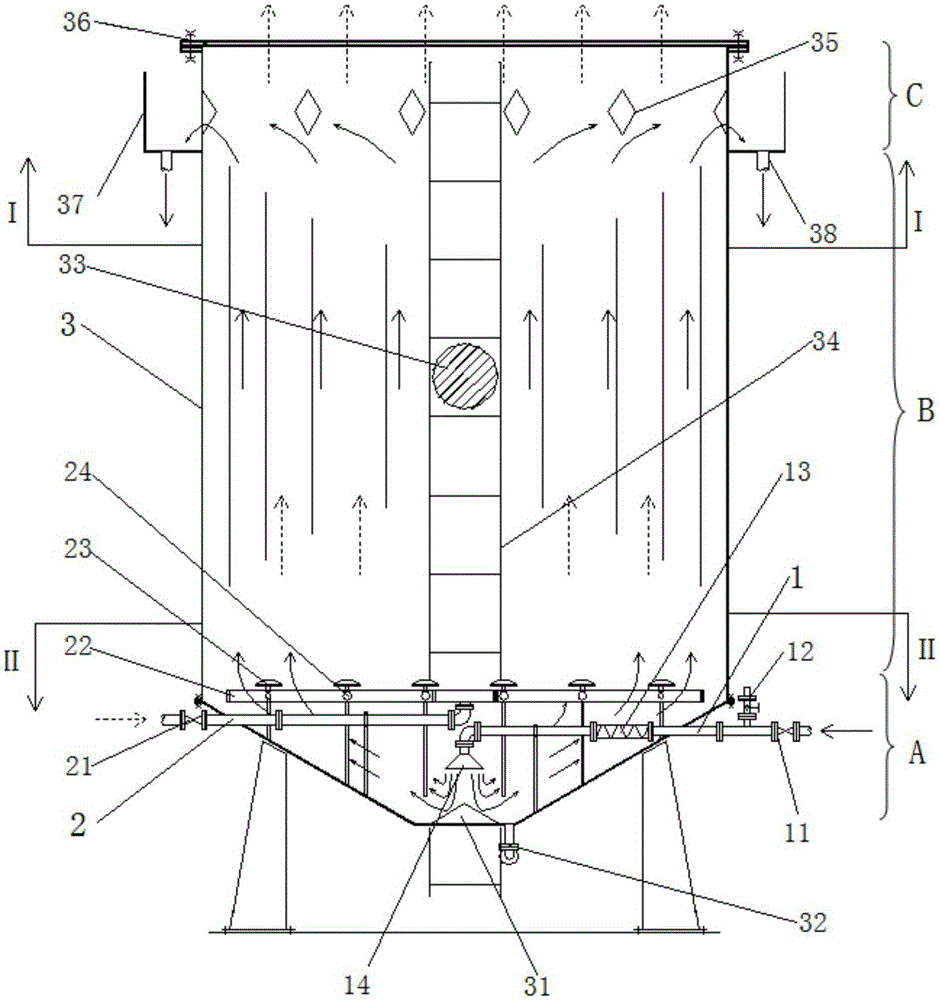

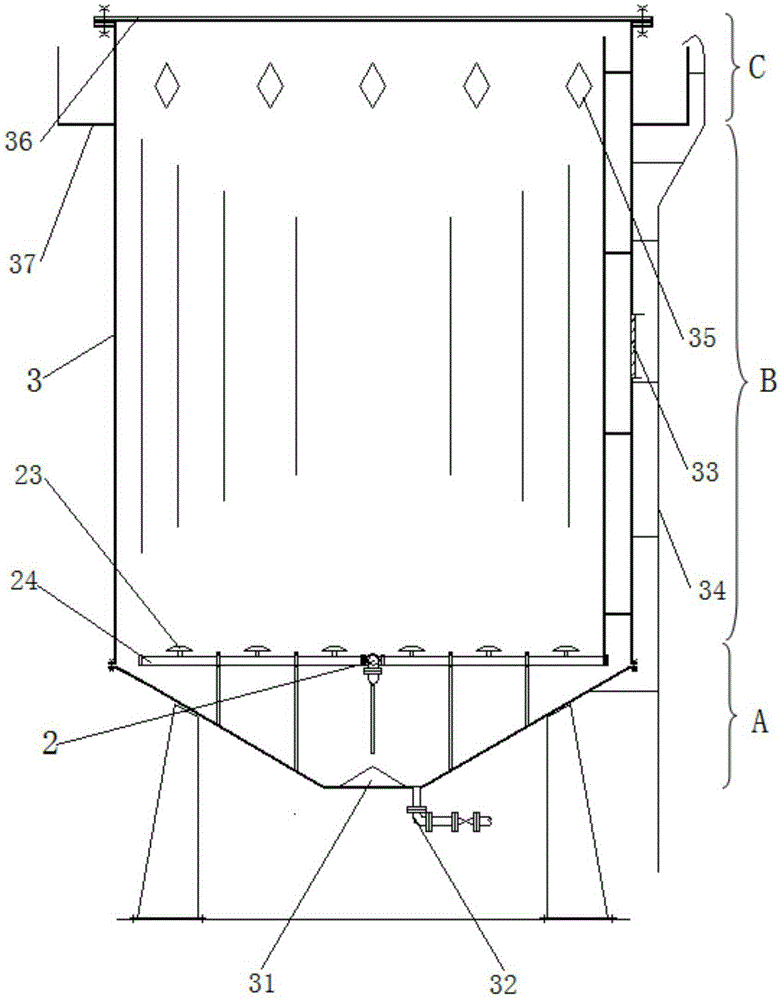

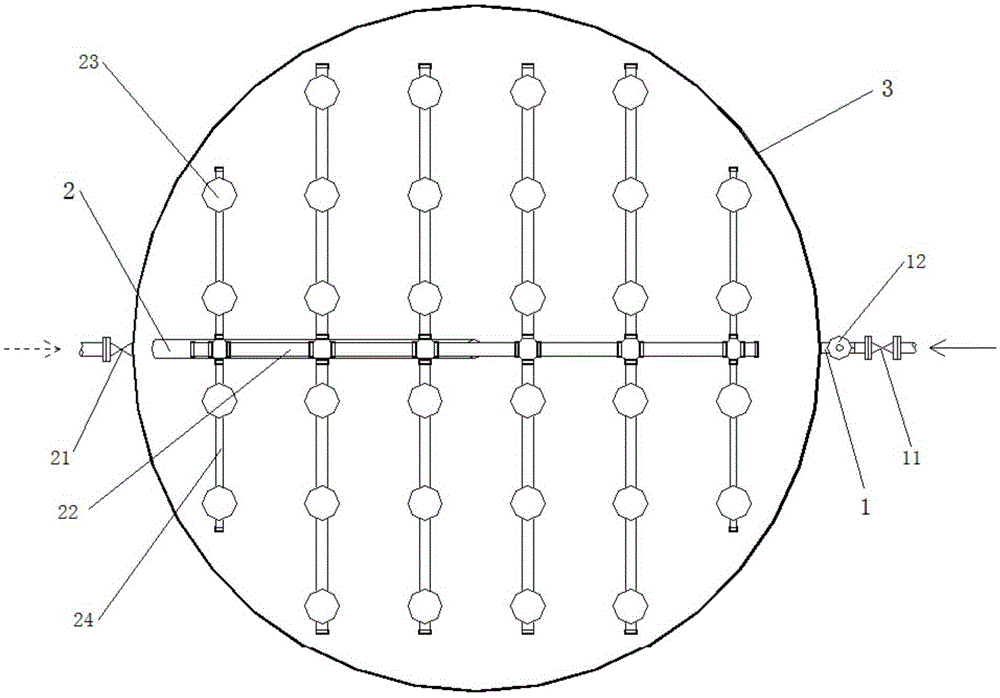

ActiveCN105314769AClosely connectedReduce lossesMultistage water/sewage treatmentStripping - actionWater flow

The invention discloses integrated water scale removal equipment, and solves the problem that a scaling phenomenon is generated caused by the fact that a precipitate is formed after water with high temporary hardness is boiled. The integrated water scale removal equipment comprises a water-collecting area, an aeration stripping area and an acid adjusting area from top to bottom; water to be treated and acid are subjected to hybrid reaction in the acid adjusting area to generate CO2 gas, water containing CO2 gas flows to the aeration stripping area, through an aeration stripping action, CO2 gas in water can escape into air, and through the water-collecting area, water in CO2 gas is collected and removed. The equipment is simple in integral structure, all functional units are compactly connected, the flat space utilization rate is high, the principle is simple, the operation is convenient, and the water scale removal rate to raw water with large temporary hardness is relatively high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

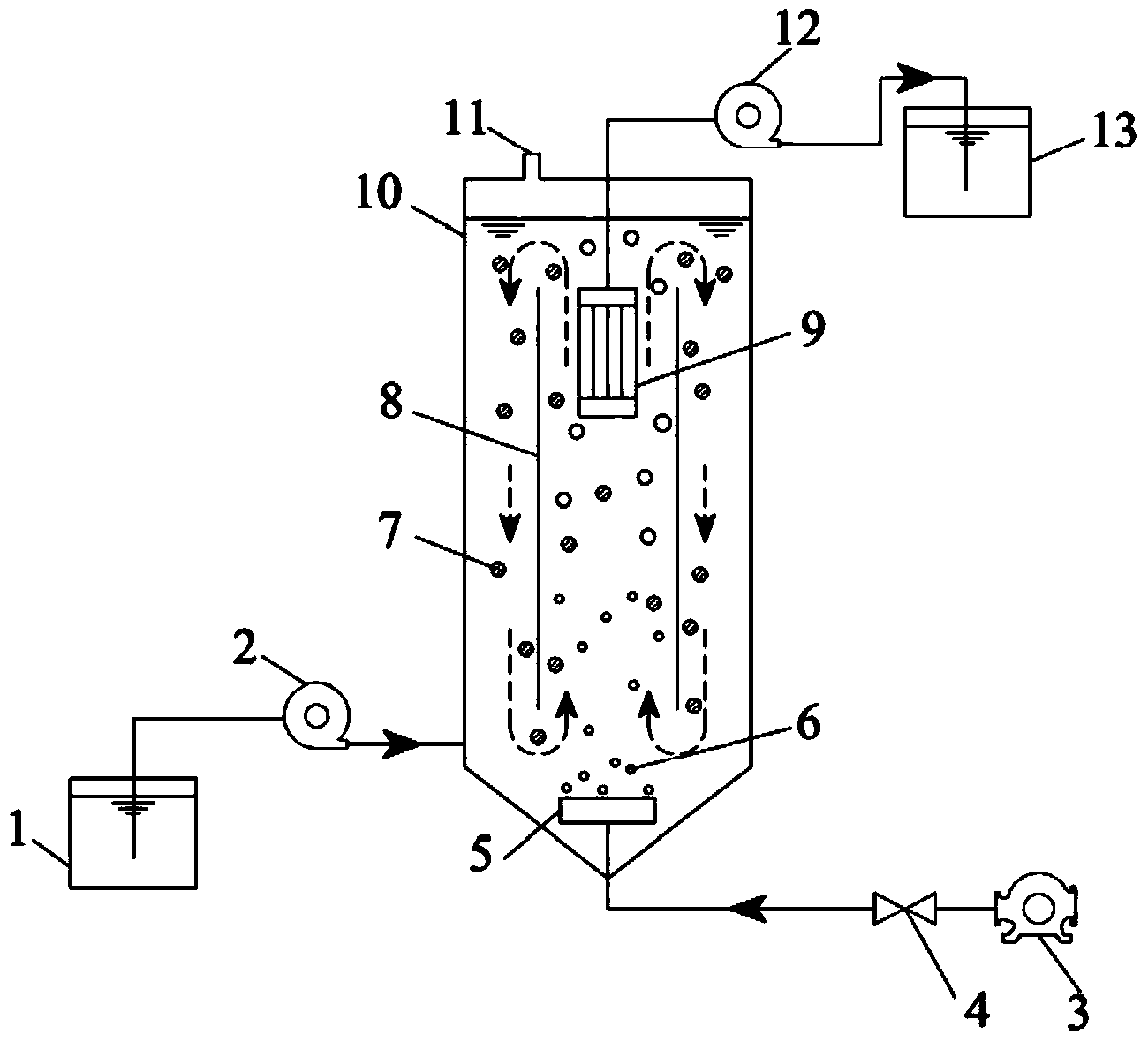

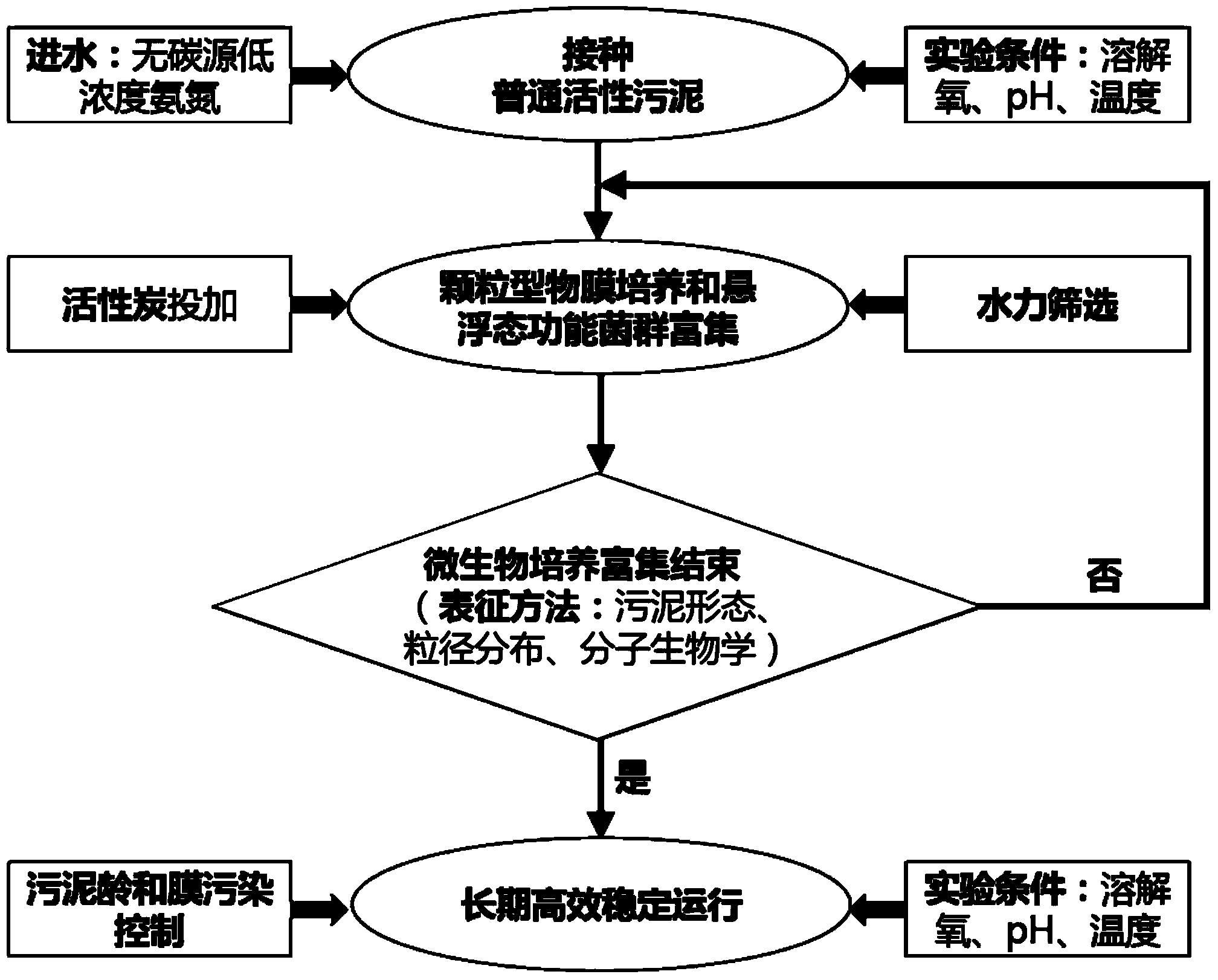

Intensifying sewage whole-course autotrophic nitrogen removal reactor and intensifying sewage whole-course autotrophic nitrogen removal method

ActiveCN104045158ASolve the difficulty of enrichmentSolve efficiency problemsWater contaminantsTreatment with aerobic and anaerobic processesForming gasWater quality

The invention relates to an intensifying sewage whole-course autotrophic nitrogen removal reactor and an intensifying sewage whole-course autotrophic nitrogen removal method, and belongs to the technical field of environmental protection and sewage treatment. The intensifying sewage whole-course autotrophic nitrogen removal reactor mainly comprises a reaction tank, a micropore aerator, a flow guide cylinder and a membrane assembly, wherein the micropore aerator, the flow guide cylinder and the membrane assembly are arranged in the reaction tank; the micropore aerator is arranged just below the flow guide cylinder and generates microbubbles for forming gas stripping action and controlling membrane pollution; the flow guide cylinder is arranged on the central position of the reaction tank; the membrane assembly is arranged in the flow guide cylinder. According to the intensifying sewage whole-course autotrophic nitrogen removal reactor, the culture and enrichment of internal functional microbes are fast completed through granular activated carbon addition and hydraulic screening modes; on the one hand, the microbes are immobilized through a granular type biological membrane, on the other hand, the microbes are enriched in a suspended state form by dint of the high-efficiency interception effect of the membrane assembly; all microbes take circulating motion up and down inside and outside the flow guide cylinder with sewage under the gas stripping action. The intensifying sewage whole-course autotrophic nitrogen removal reactor disclosed by the invention can greatly enhance the whole-course autotrophic nitrogen removal biomass and the reaction activity and ensure the higher effluent water quality.

Owner:TSINGHUA UNIV

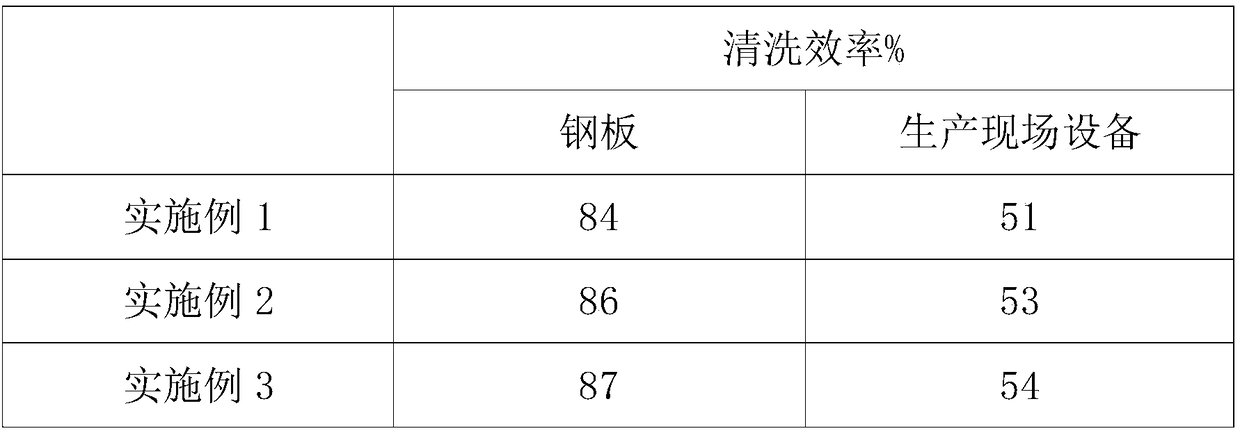

Cleaning agent used for eliminating radioactive pollutant on surface of object

PendingCN109504561AReduce corrosionReduce the level of radioactive contaminationDetergent mixture composition preparationOrganic non-surface-active detergent compositionsPhysical well beingStripping - action

The invention discloses the technical field of cleaning agents and particularly relates to a cleaning agent used for eliminating a radioactive pollutant on the surface of an object, the cleaning agentcomprises the following components by volume: 35-45 parts of an EHS0106 cleaning agent, 1-2 parts of a mixture, and 150-300 parts of a solvent, the cleaning agent finishes cleaning the dirt by usingthe chemical dissolving action and the physical stripping action, the scale, the rust and the radioactive dirt on the surface of the object are separated from an iron body, the ions like Ca<2+>, Mg<2+>, Fe<2+>, UO22+ and U4+ rapidly form a complex and a chelate through the mixture, the dirt is promoted to dissolve rapidly, the dirt enters a cleaning fluid, the degree of the radioactive pollution of steel and iron materials and equipment on the production field are greatly reduced, the reuse ratios of the steel and iron materials and the equipment on the production field are increased, the level of radioactive pollution is reduced, the working environment is improved, and the cleaning agent is favorable for the body health of an operation staff.

Owner:沈阳泰琦科技有限公司

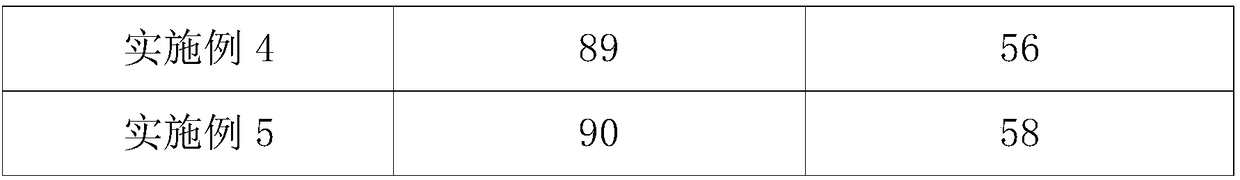

Quality closed-loop control method for automatic machining

InactiveCN110434672AEasy to reproduce clamping and alignmentAvoid quality problemsAutomatic control devicesMeasurement/indication equipmentsLoop controlStripping - action

The invention discloses a quality closed-loop control method for automatic machining, and belongs to the technical field of quality detection. The method comprises the following steps that feeding motion for a workpiece is carried out by a robot, and clamping for the workpiece is completed on a machine tool; on-machine detection is carried out on clamping data of the workpiece through an on-machine detection head, and feedback is sent to a MES system, if clamping precision requirements are not met, an instruction is sent to the robot through the MES system, and the robot performs stripping action, thus finishing the flow; if clamping precision requirements are met, the machine tool is started, then the workpiece is sent to a three-coordinate measuring machine for size detection after beingmachined, and feedback is sent to the MES system for judging whether the workpiece meets requirements on size and precision, if yes, the flow is finished; and if not, cutter compensation informationis acquired by the MES system, and the information is sent to the machine tool. According to the method, quality closed-loop control is carried out on the machining flow of the workpiece, thus improving quality control of thin-wall shell pieces during the automatic machining process so as to achieve the purpose of machining precision improvement.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

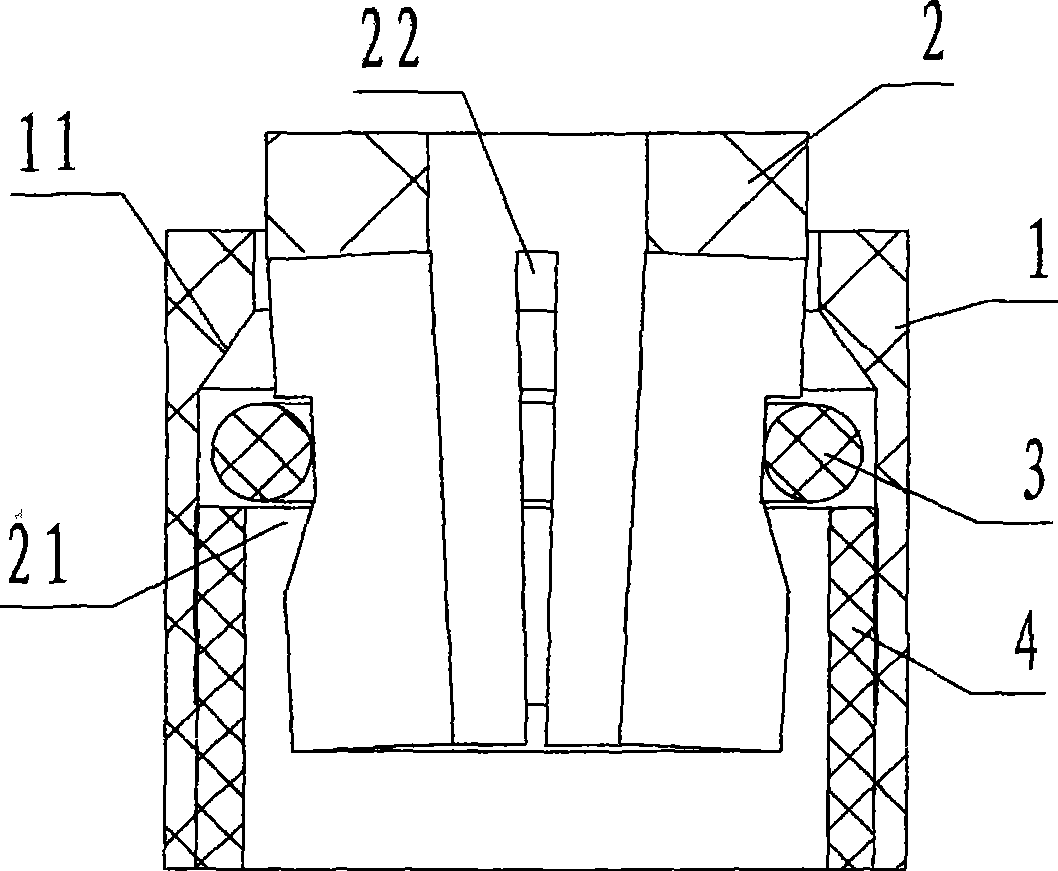

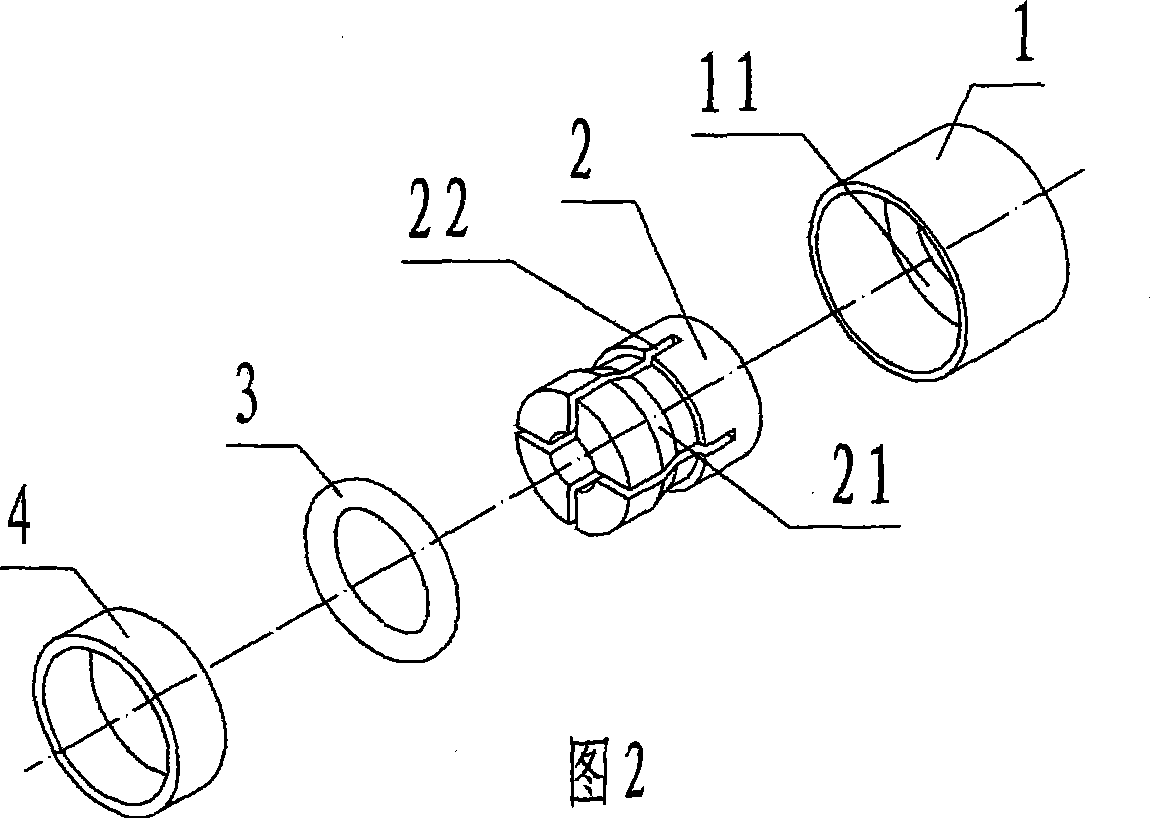

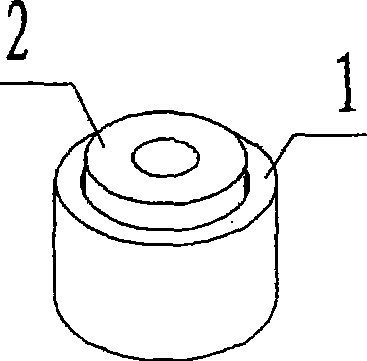

Capsule detachment conjoined device

The present invention discloses a capsule pulling integral device which comprises a casing (1), a flexible clamping head (2), an O-shaped ring (3) and a linear bushing (4). The invention adopts a technical scheme of flexible clamp head which can be clamped and loosened controllably, overcomes the problems and insufficiencies of larger machine body of capsule mould stripper matched with the capsule pulling device, low mould stripping efficiency and unsuitability for matching with large-scale product line in the capsule pulling device of prior art. The capsule pulling integral device provided by the invention realizes repeated one-time completion of mould stripping action. Therefore the capsule mould stripper which is matched with the capsule pulling integral device and operates in a repeated one-time action program obtains the purposes of compact and elaborate of machine body, high-efficient mould stripping, and suitability for matching with large-scale product line.

Owner:徐家业

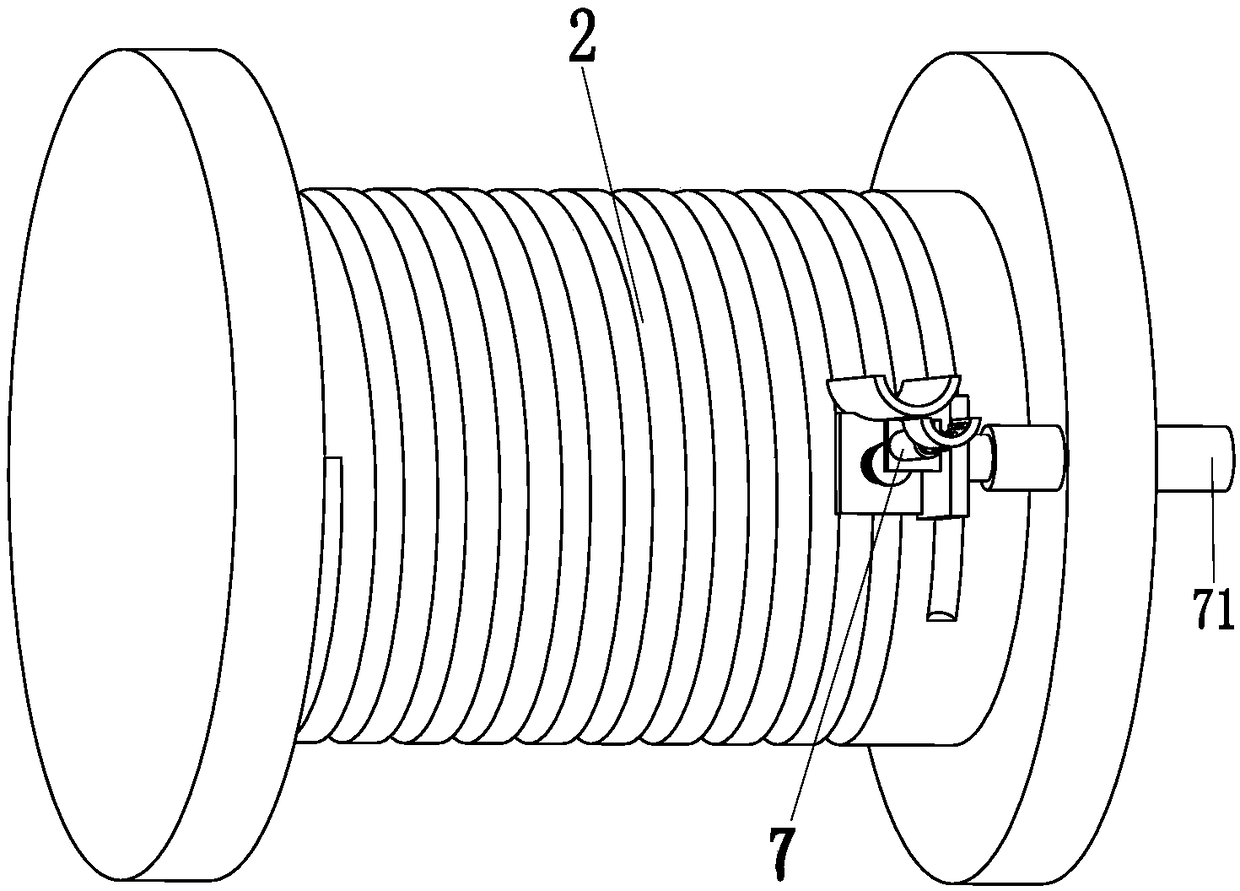

PVC transparent film winding machine with film string-proof and overlap prevention function

ActiveCN110451020APrevent bouncing up and downWrapping material feeding apparatusWrappingWinding machineStripping - action

The invention discloses a PVC transparent film winding machine with a film string-proof and overlap prevention function. The film winding machine structurally comprises a machine main body, a controller, a lifter, a film sleeve part, an exhaust fan and a rotating plate. The film winding machine has the beneficial effects that a straightening through structure is arranged and utilized, under the action of an electrostatic layer, a transparent film roll is adsorbed and fixed in an attachment mode, the transparent film which is unfolded and used is matched through a rectangular groove formed in the middle part of an arc-shaped plate to adsorb the transparent film, an adsorption effect is carried out on the upper end and the lower end of the transparent film which is unfolded and used so as toavoid the phenomenon that an object cannot be completely wrapped due to the fact that the transparent film is easily folded when the transparent film is used, a clamping piece is arranged and utilized to clamp the PVC transparent film roll during use, so that the situation that when the PVC transparent film is used until only a little is remained, the PVC transparent film roll runs up and down due to lighten self gravity and rapid film stripping action, and the PVC transparent film roll is broken away from the film sleeve part is avoided,

Owner:杭州杭邦塑胶有限公司

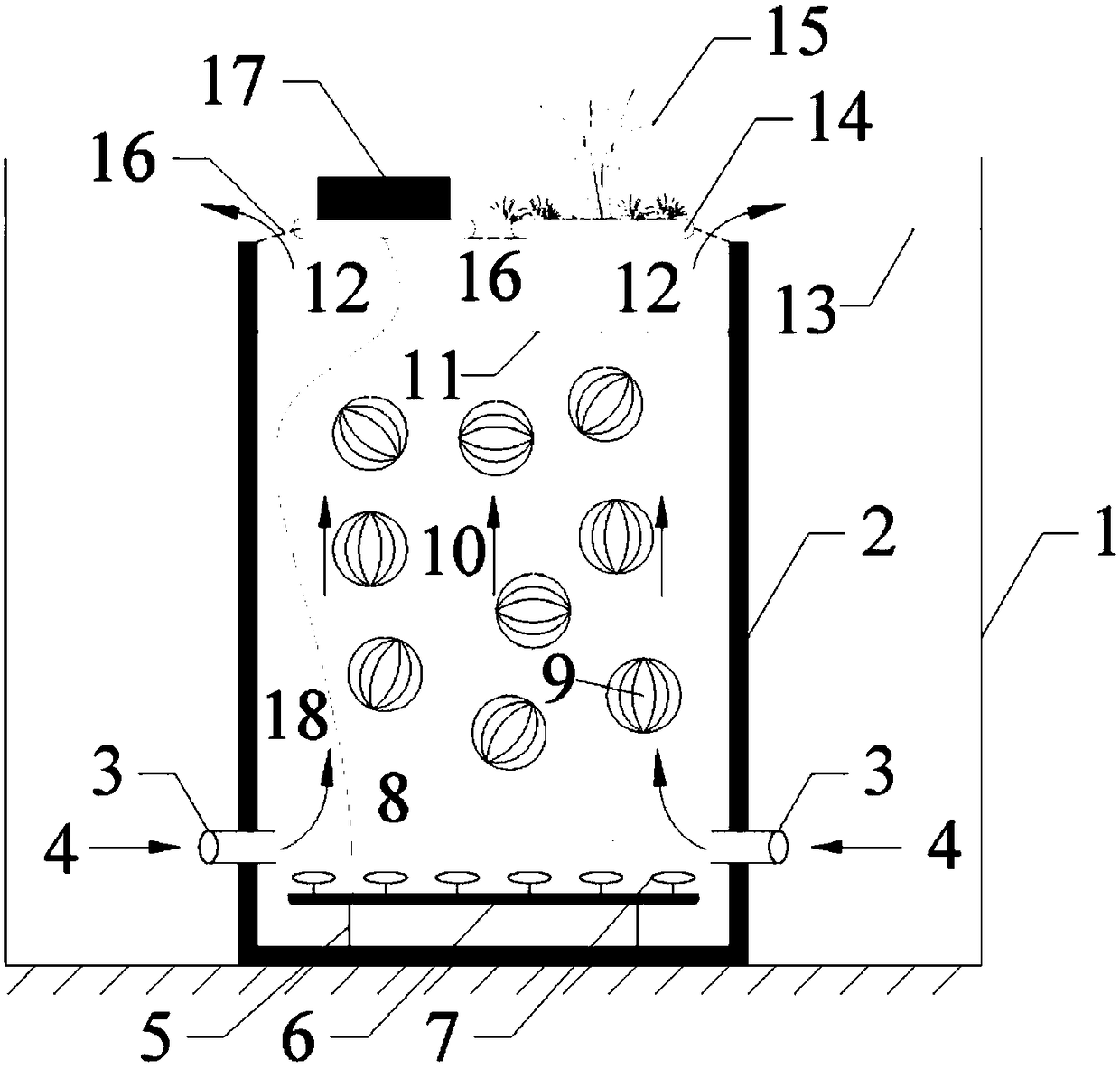

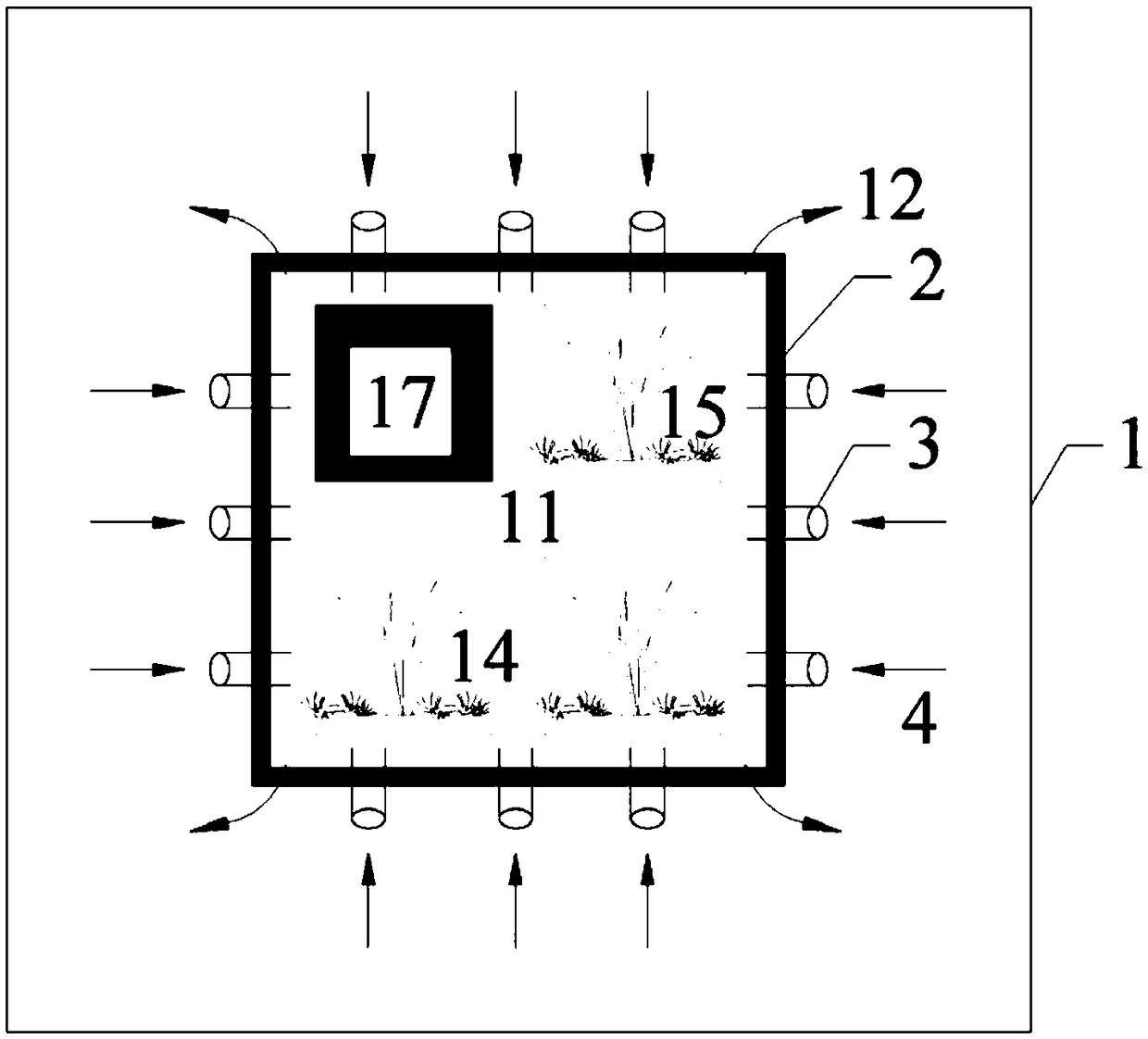

Air-floating type suspension filler in-situ water purifying device and water purifying method

InactiveCN108892249AExtend the life cycleAvoid cloggingTreatment using aerobic processesTreatment involving filtrationElectricityAeration system

The invention provides an air-floating type suspension filler in-situ water purifying device and a water purifying method thereof. The device is composed of components of a device groove body, a waterinlet, an aeration system, micro porous filtering cloth, suspending fillers, an ecological floating bed, a solar air pump and the like, the water inlet and the aeration system are located at the bottom of the device groove body, the micro porous filtering cloth is located on the top of the device groove body, the suspending fillers are located between the aeration system and the filtering cloth,and the ecological floating bed and the solar air pump are located above the device groove body. The device is placed in the water body which needs to be purified, water inlet and guiding of the device are achieved through the steam stripping action of the aeration system, and water body purification is achieved by comprehensively utilizing aeration, microorganism conversion of the suspending fillers, the filtering of the micro porous filtering cloth and the absorbing effect of ecological floating bed plants. The device and the method have significant advantages of being low in cost, free fromelectric consumption, free from floor occupation, excellent in purification effect, high in comprehensive benefit and the like compared with the prior art.

Owner:SHANGHAI SHUIPINGHENG ENVIRONMENT TECH DEV CO LTD

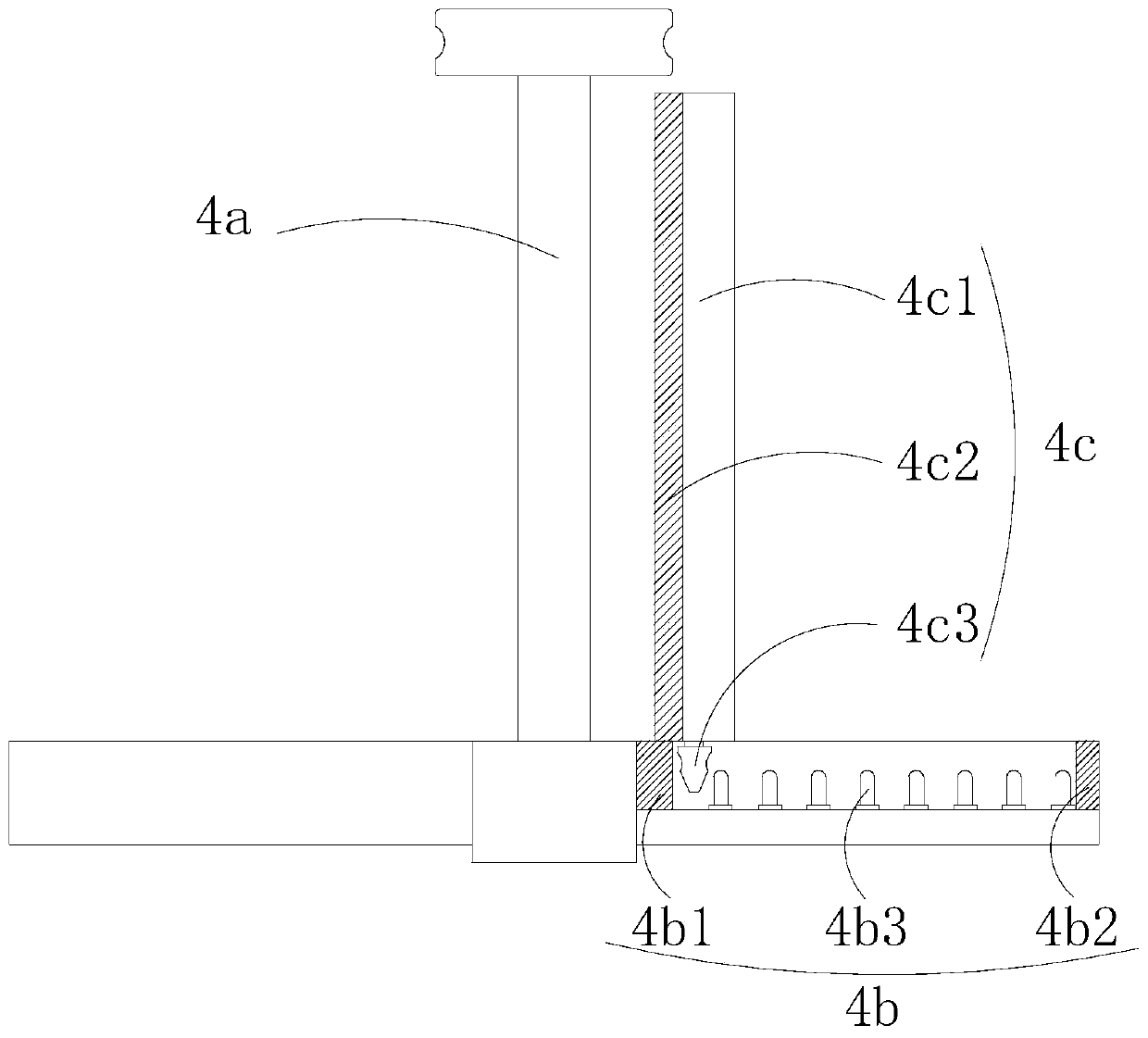

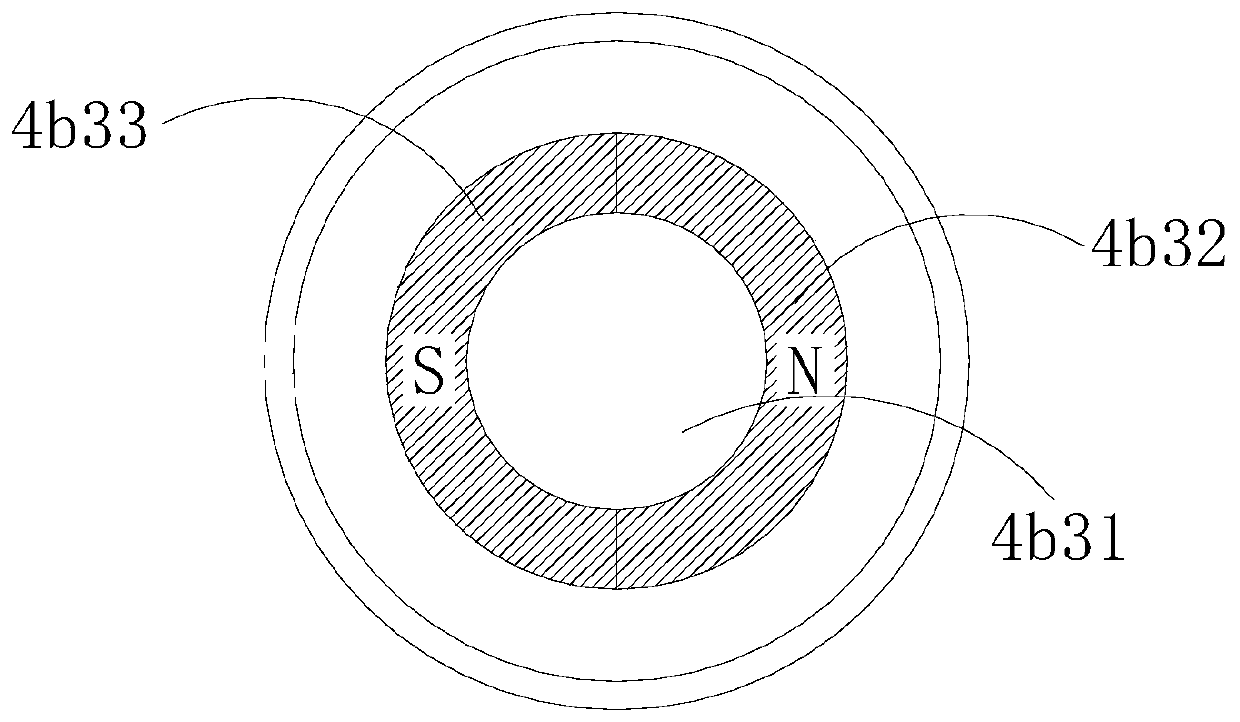

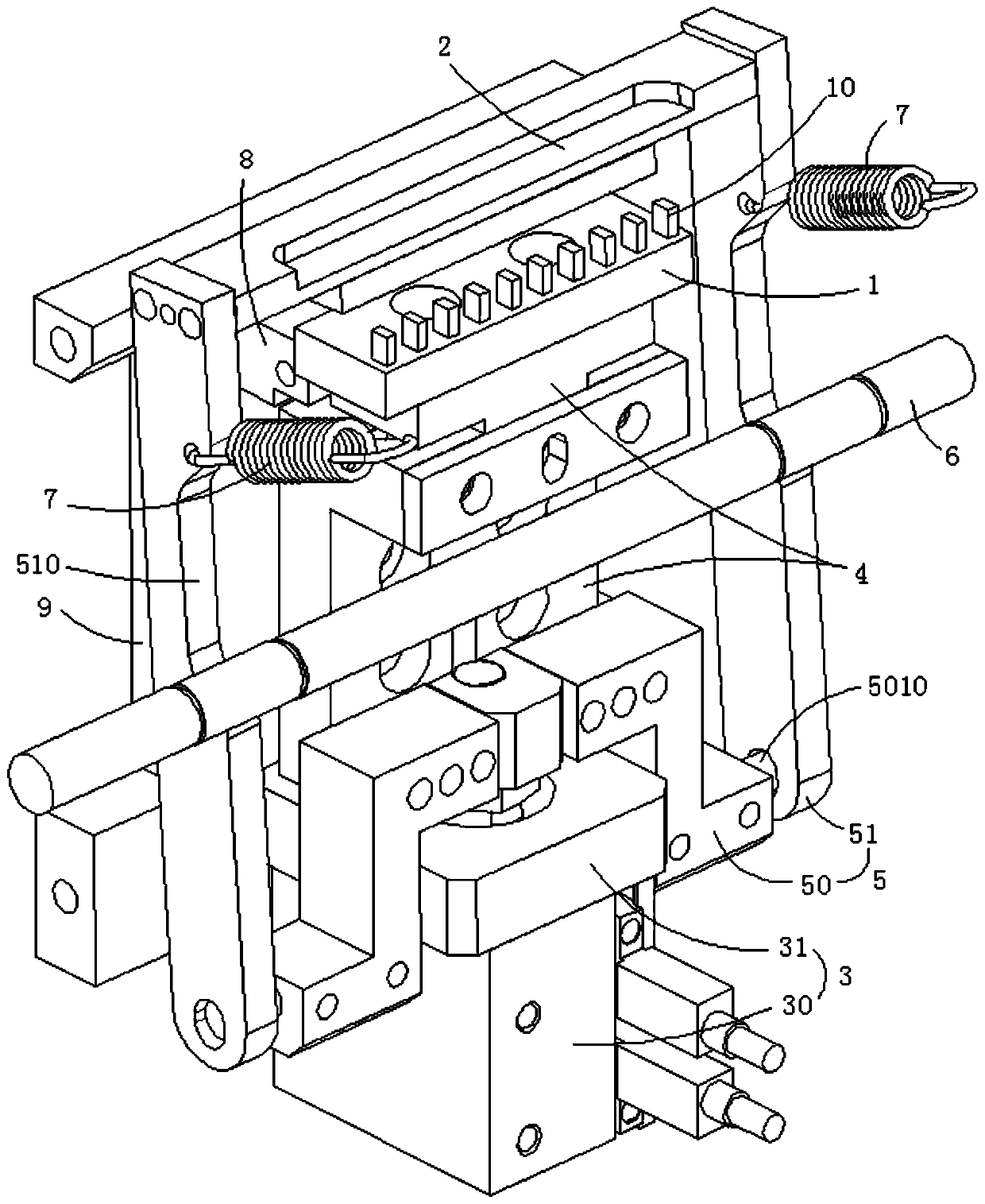

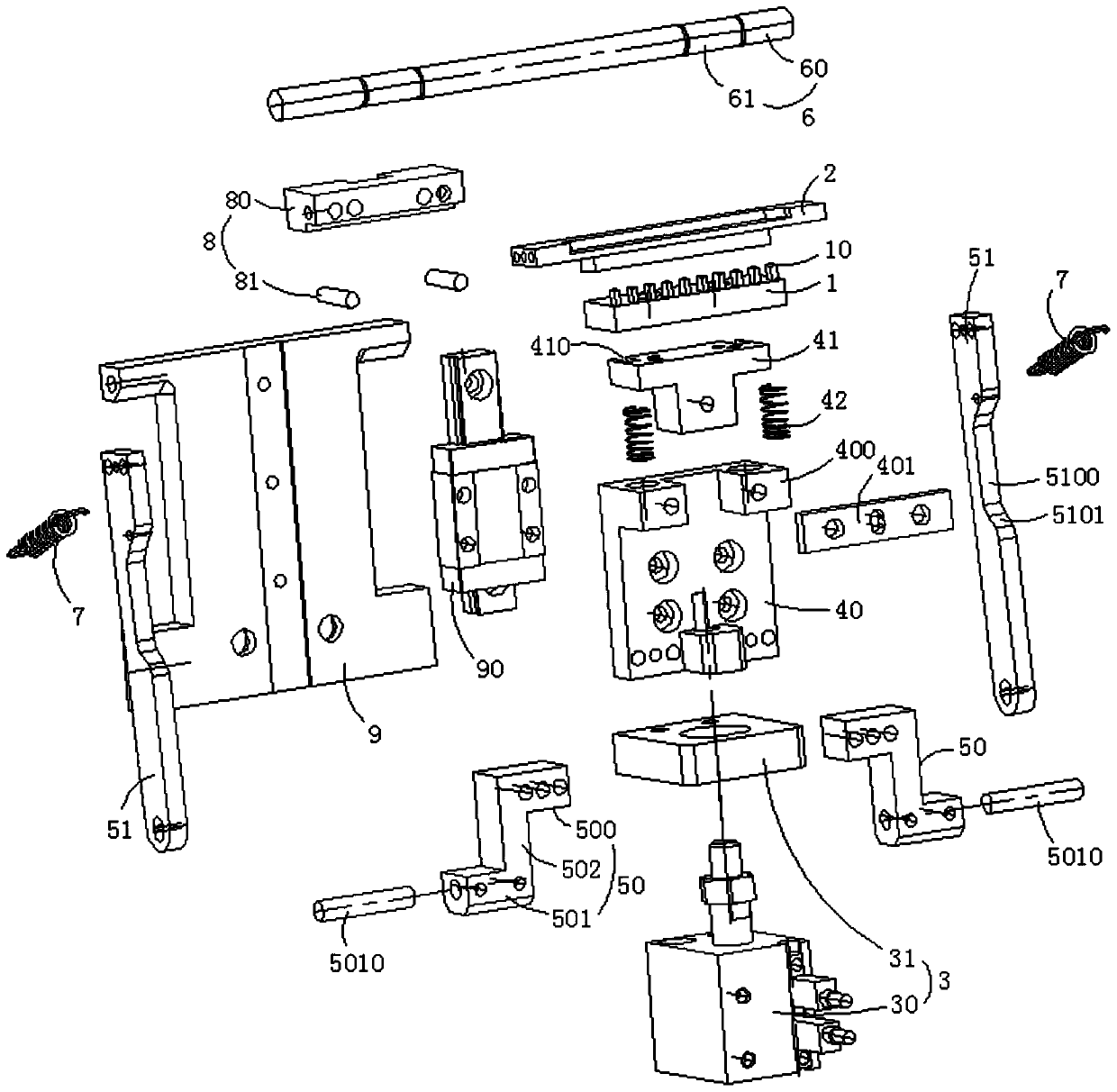

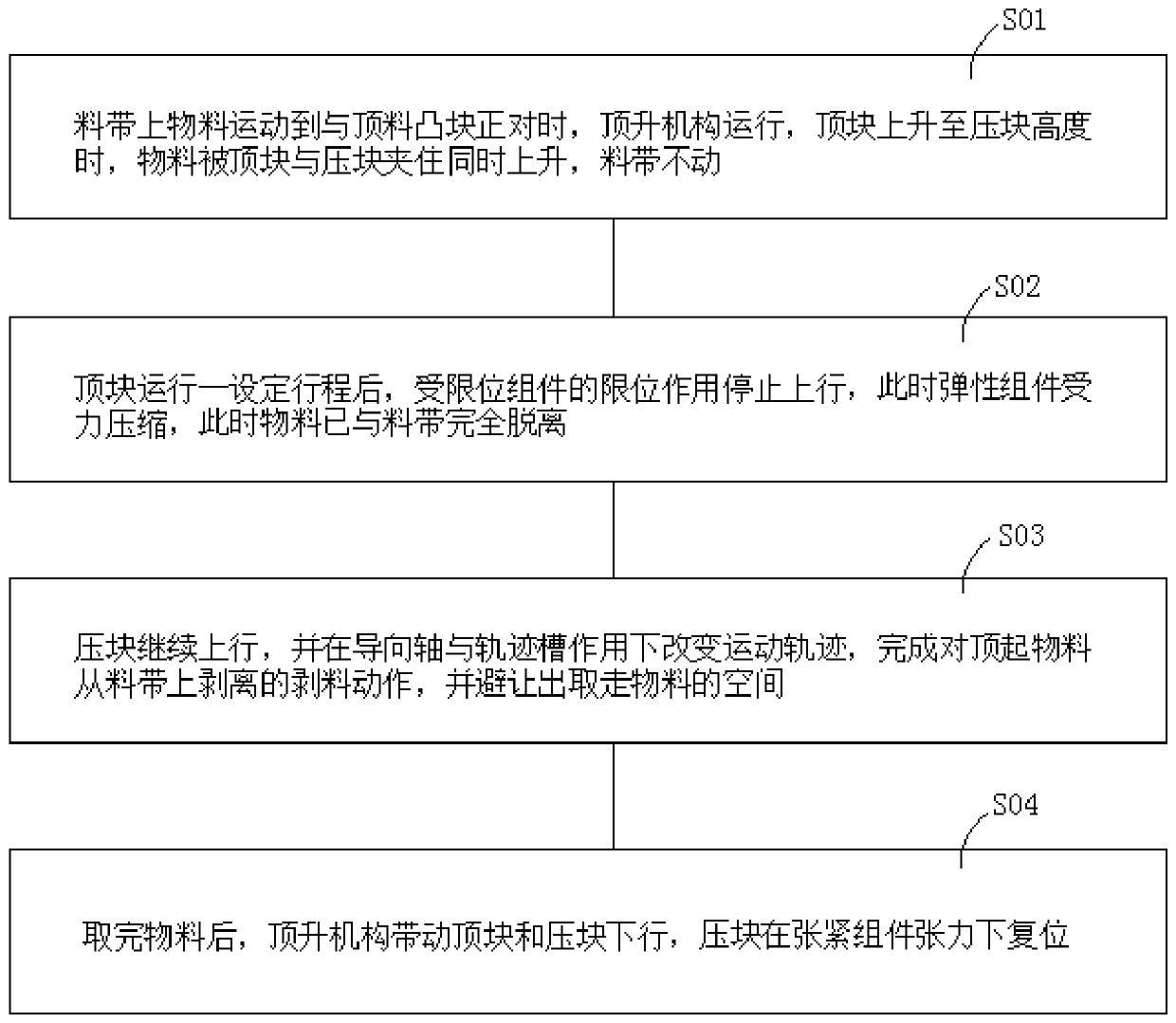

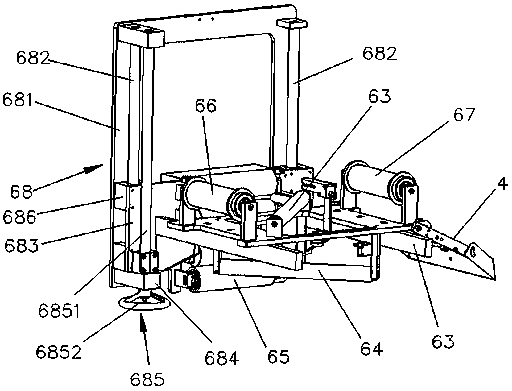

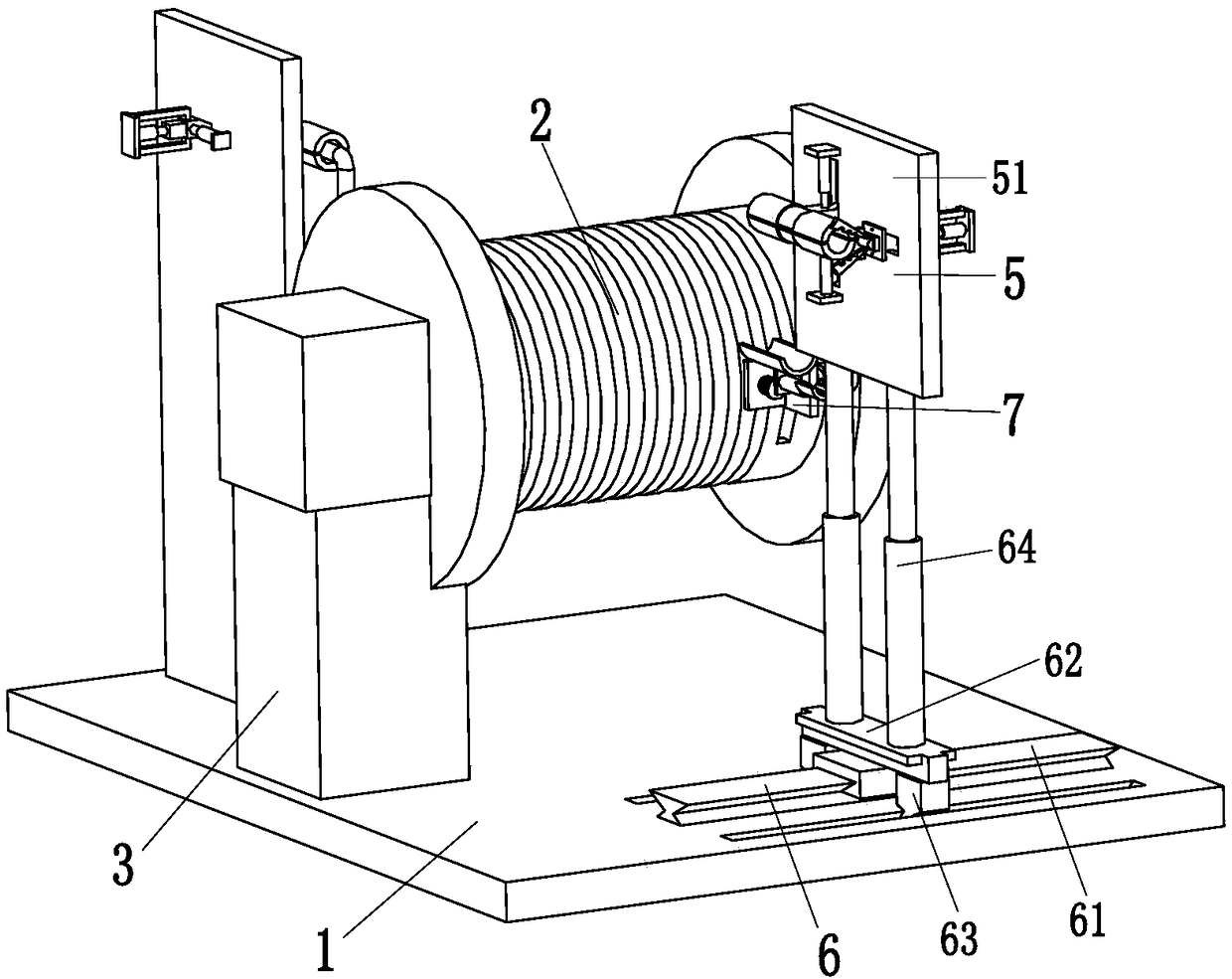

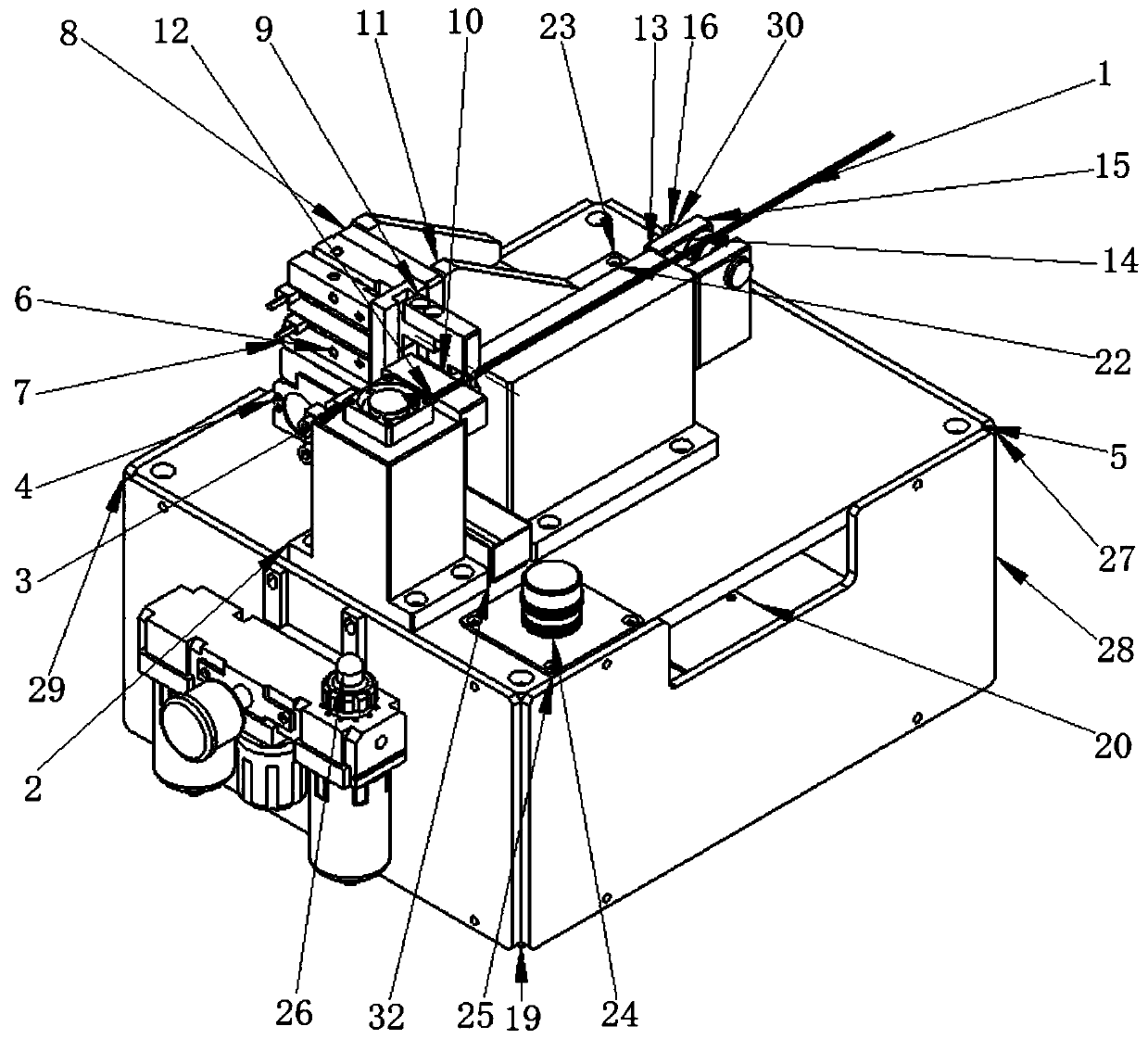

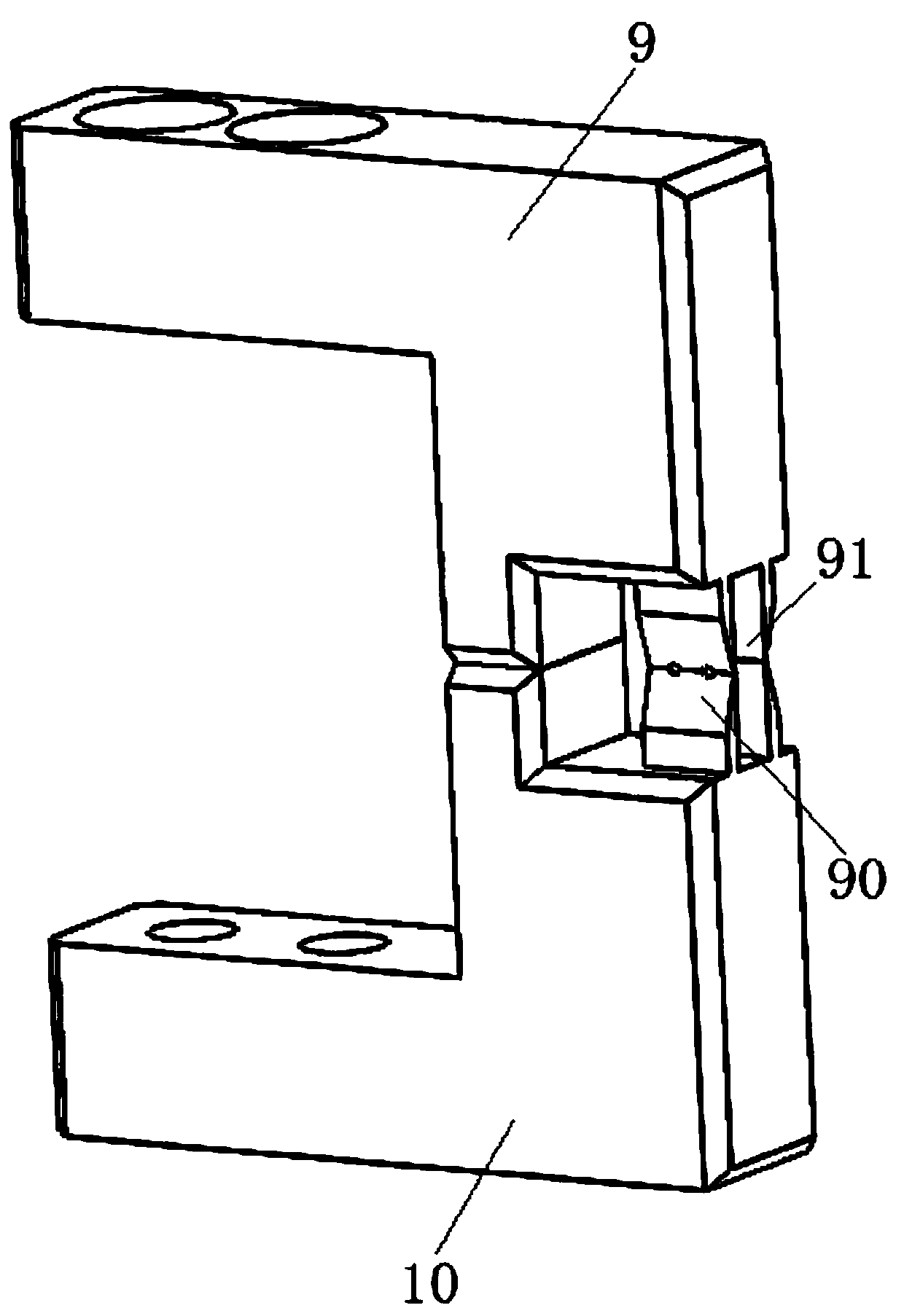

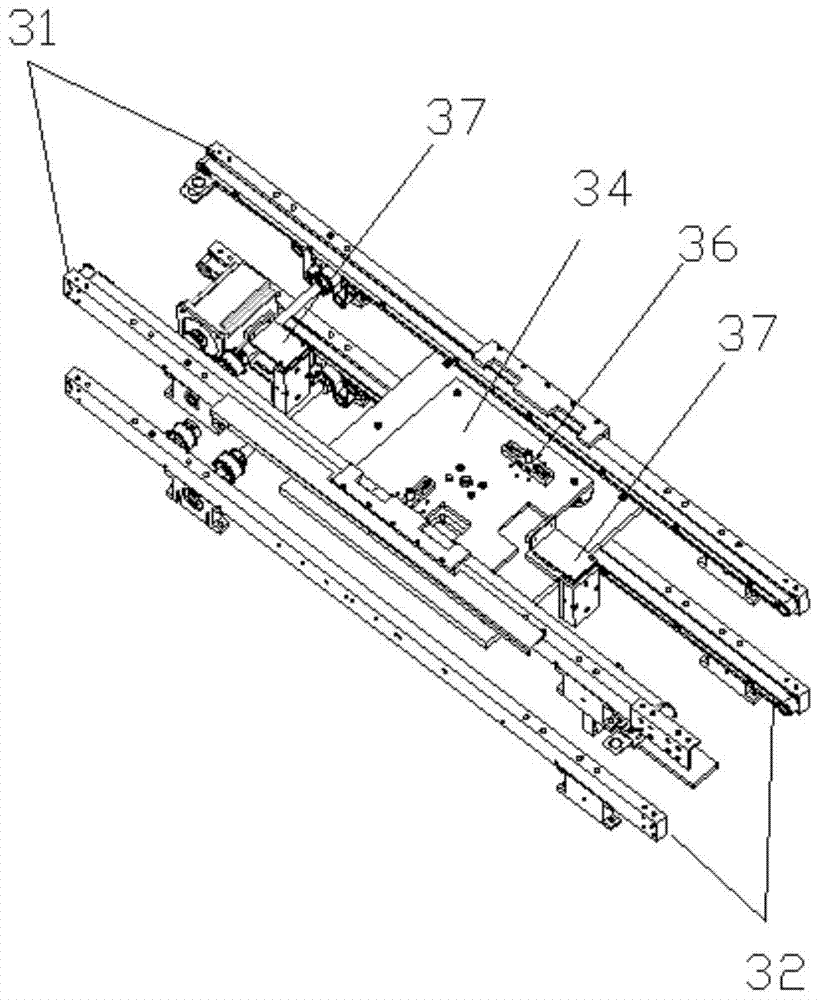

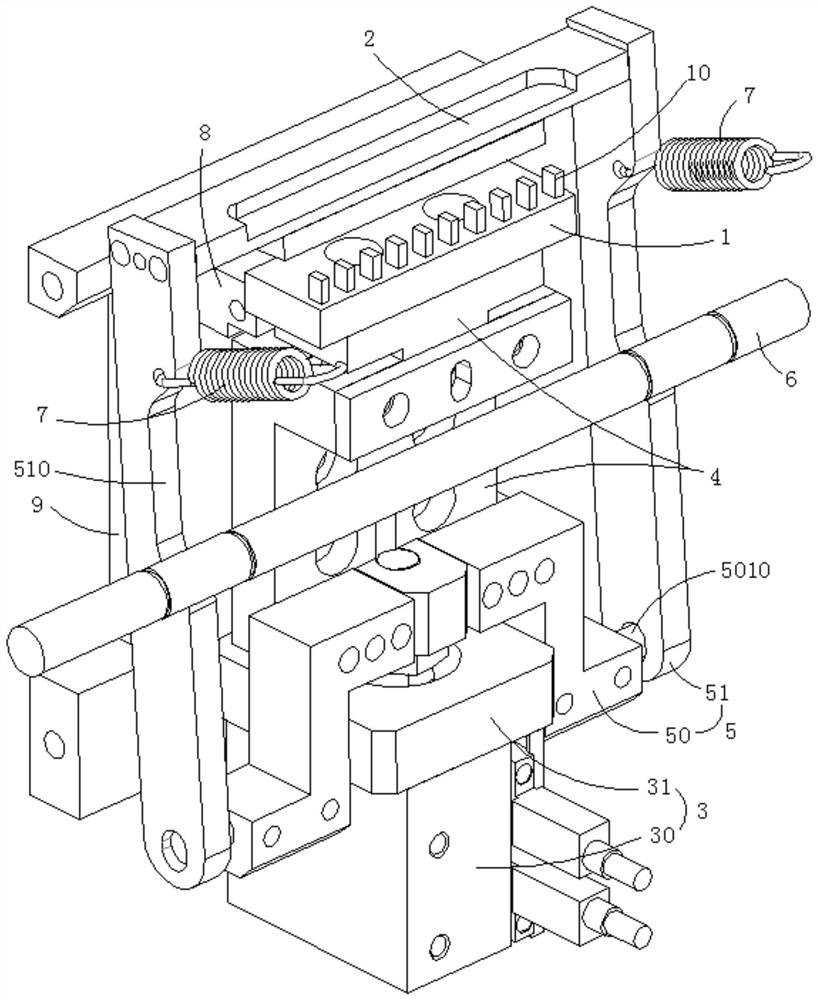

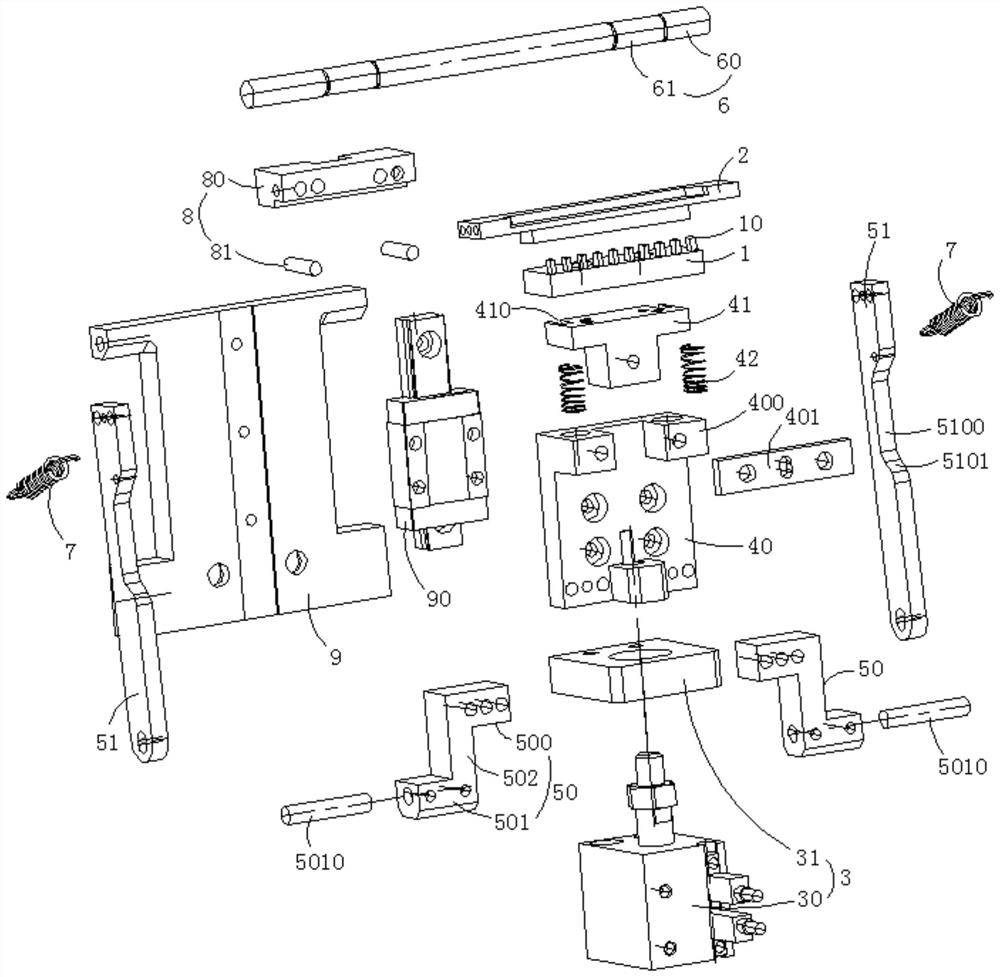

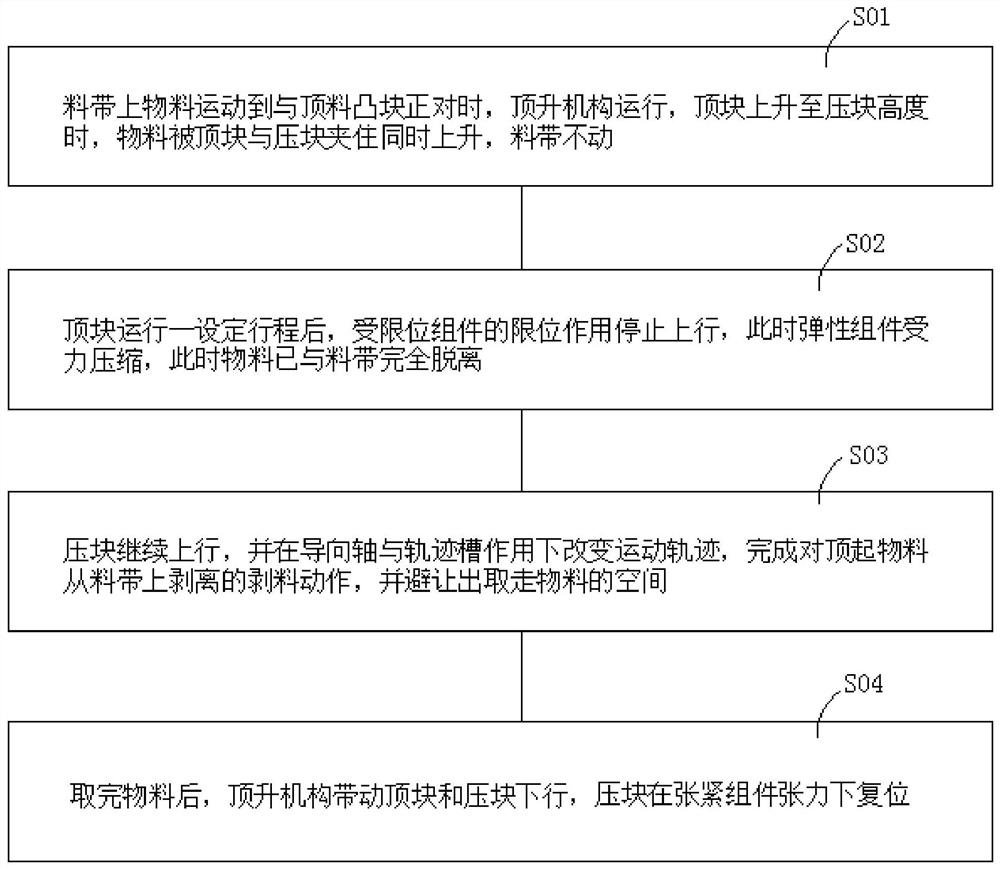

Jacking and stripping mechanism and implementation method

The invention relates to a jacking and stripping mechanism. The jacking and stripping mechanism comprises an ejecting block, a pressing block and a jacking mechanism; one or more material ejecting raised blocks are arranged on the ejecting block; under an original state, the pressing block and the ejecting block are correspondingly located above a material belt and under the material belt; the jacking end of the jacking mechanism is connected with the ejecting block through an elastic assembly, and the jacking end of the jacking mechanism is connected with the pressing block through a connecting assembly; the connecting assembly comprises connecting arms fixedly connected to the jacking end of the jacking mechanism and pressing block connecting rods; one ends of the pressing block connecting rods are rotatably connected with the connecting arms, the other ends of the pressing block connecting rods are fixedly connected with the pressing block, track grooves are formed in the positions,located between the connection points of the pressing block connecting rods and the connecting arms and the connection points of the pressing block connecting rods and the pressing block, of the pressing block connecting rods; and the jacking and stripping mechanism further comprises a guiding shaft matched with the track grooves, tensioning assemblies for applying tensioning force on the pressing block or the ends, connected with the pressing block, of the pressing block connecting rods and a limiting assembly for limiting the rising stroke of the ejecting block. According to the jacking andstripping mechanism, the ejecting action and the stripping action of materials on the material belt can be completed in one step, and the structure is compact, the speed is high, and the efficiency is high.

Owner:深圳市瓦力自动化有限公司

Concentration homogenization method of hydrocarbon-containing waste gas

ActiveCN102039080AEasy to operateLarge buffer capacityDispersed particle separationDesorptionStripping - action

The invention discloses a concentration homogenization method of hydrocarbon-containing waste gas. The method comprises the following steps: contacting the hydrocarbon-containing waste gas with high boiling point solvent oil, then performing gas-liquid separation, using the separated gas phase to perform the post-treatment, and recycling the separated liquid phase, wherein the high boiling point solvent oil is a distillate with the initial boiling point of more than 200 DEG C. In the method disclosed by the invention, the solvent oil with high boiling point and low volatility is used as the absorbent, when the concentration of hydrocarbon in the gas is higher, hydrocarbons are absorbed by the absorbent and the hydrocarbon concentration of the discharged gas is reduced; when the concentration of hydrocarbon in the gas is lower, the hydrocarbons absorbed by the absorbent are released under the gas stripping action and the hydrocarbon concentration of the discharged gas is increased; andthe concentration homogenization treatment of the gas can be realized through the absorption-desorption process of hydrocarbons. The method disclosed by the invention, the high boiling point solvent oil is used as the concentration homogenization medium of the hydrocarbon-containing waste gas, thus the method has the advantages of large buffer capacity, good concentration homogenization effect and the like and the method is especially suitable for the concentration homogenization treatment of the waste gas with higher hydrocarbon concentration.

Owner:CHINA PETROLEUM & CHEM CORP +1

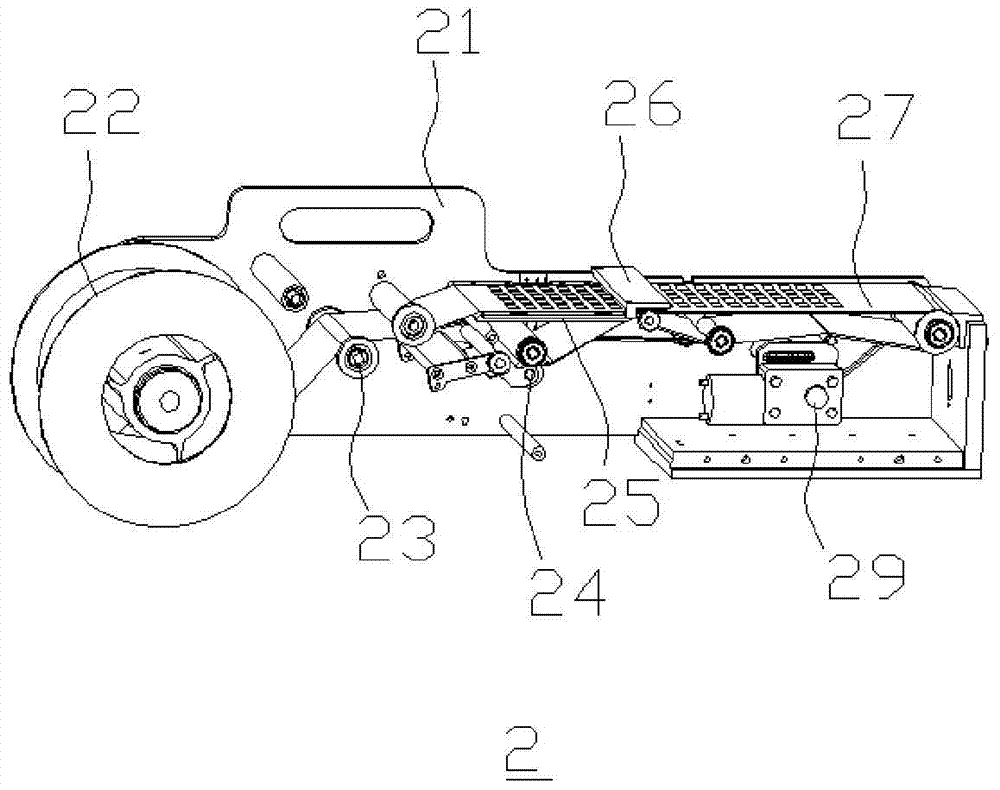

Label printing, stripping and sticking all-in-one equipment

ActiveCN109795762AImprove intelligenceImprove versatilityLabelling machinesStripping - actionPower module

The invention provides label printing, stripping and sticking all-in-one equipment, which comprises a base, an unwinding module arranged on the base, a printing module, a label stripping module, a power module and a winding module, the unwinding module and the winding module are adjacentlyarranged on the side face of the base, the power module is arranged inside the base, the printing module and the label stripping module are located above the unwinding module and the winding module, a steering module is arranged between the printing module and the label stripping module, and the label stripping module comprises a supporting frame and a label stripping knife arranged on the supporting frame. According to the label printing, stripping and sticking all-in-one equipment, required patterns canbe printed on labels in real time, and the label stripping action and the sticking action are conducted through the label stripping module; and a real-time printing technology is achieved, and thus the intelligence of the label printing, stripping and sticking all-in-one equipment is greatly improved.

Owner:广州里工实业有限公司

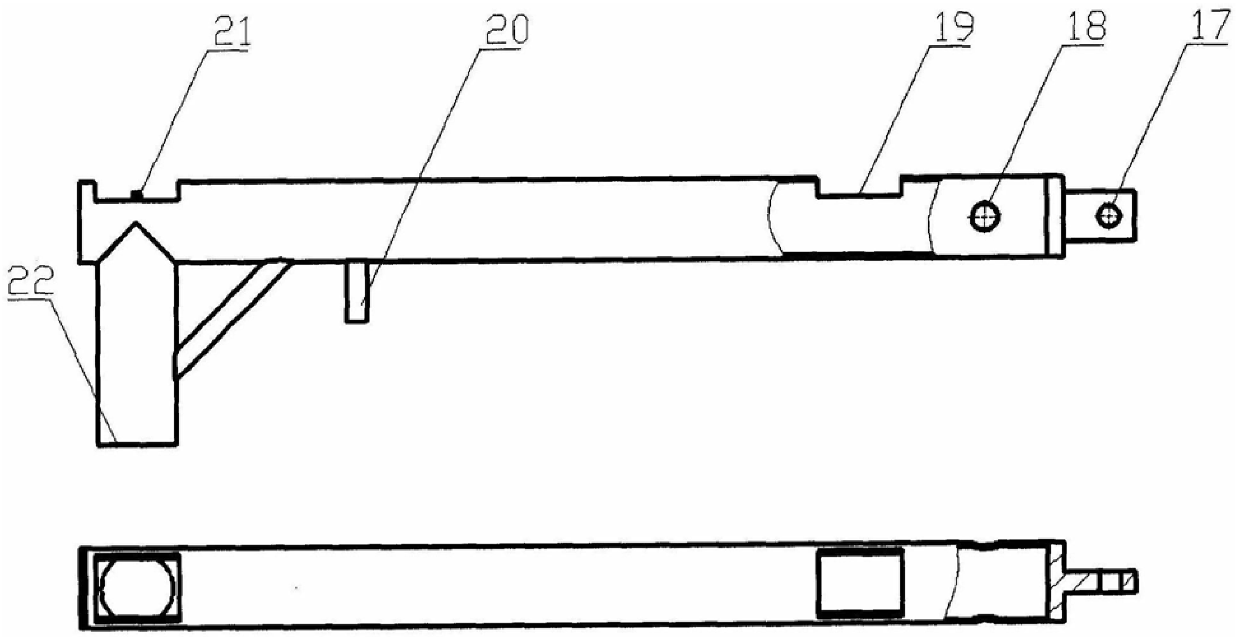

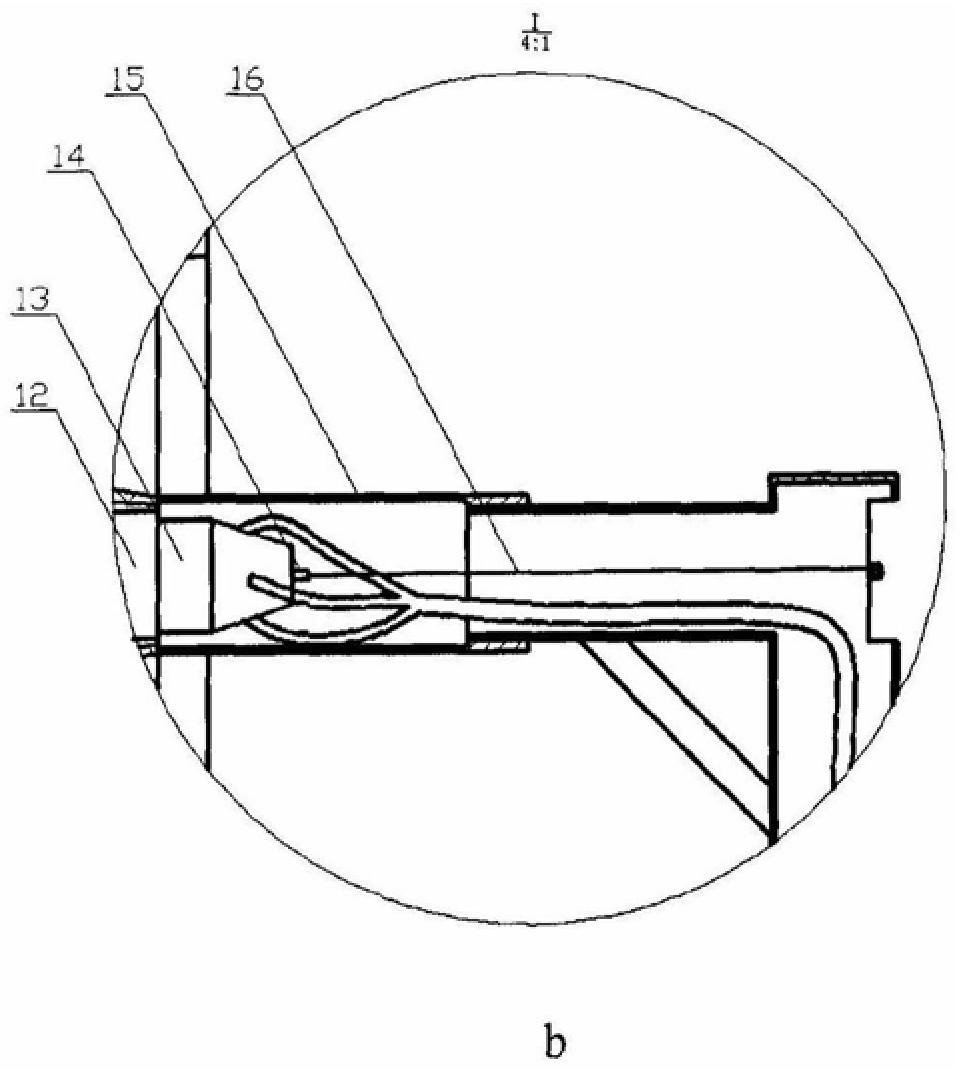

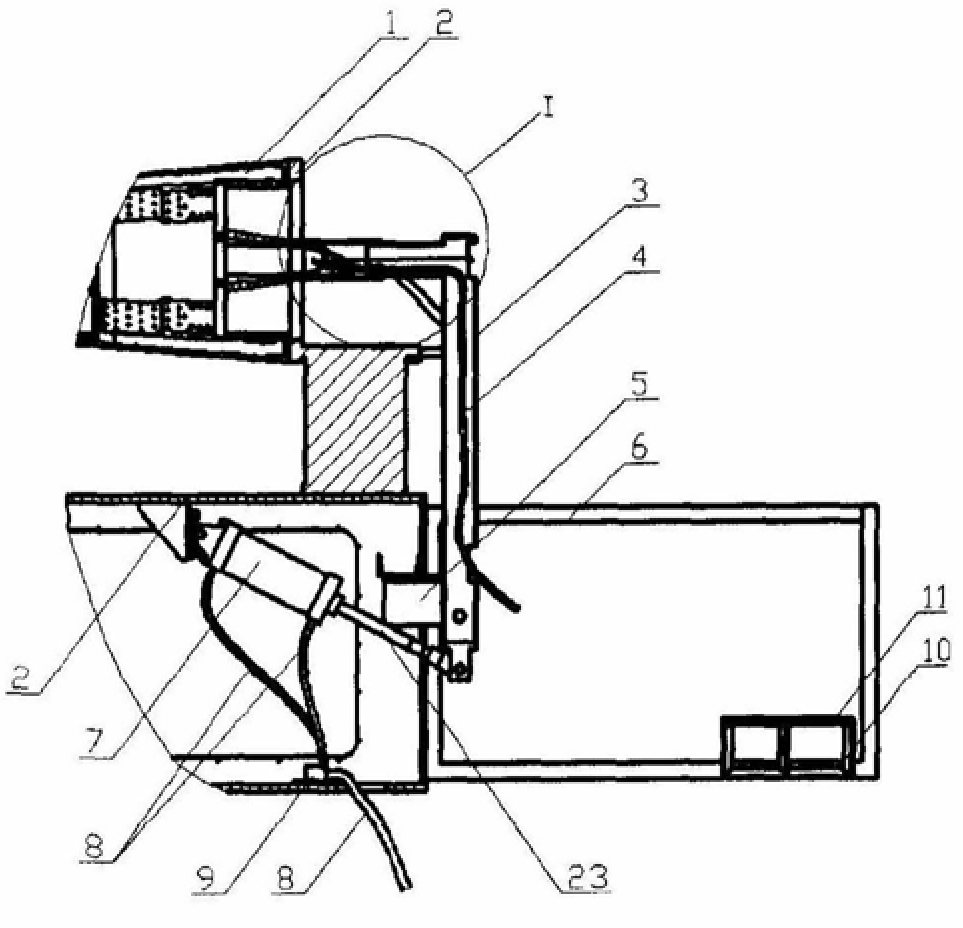

A free jet test cable pull-out device

ActiveCN106507936BSimulation is accurateEngine testingSelf-propelled projectilesStripping - actionRotating hinge

The invention provides a free jet test cable removal device, which is composed of a removal connecting rod 3, a rotary hinge support 5, and an actuating mechanism; the removal connection rod 3 is hollow L-shaped, and one end of the removal connection rod 3 It is connected with the plug protection sleeve 15; the pull-out plug 13 and the cable 4 are located in the plug protection sleeve 15 and the pull-out connecting rod 3; the pull-out plug 13 is connected with the pull-out connecting rod 3, and the actuating mechanism drives the pull-out connecting rod 3 Do rotary motion, will take off and pull out plug 13 and pull out. The invention can accurately complete the unplugging action of the cable during the free jet test, accurately simulate the separation of the cable when the aircraft is separated from the booster stage; It is ablated and destroyed by the high-temperature gas of the nozzle and the airflow of the flow field.

Owner:NAT UNIV OF DEFENSE TECH

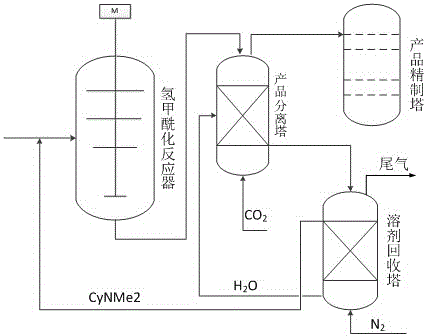

Polar-reversible transformation solvent for isobutylene hydroformylation reaction

ActiveCN104557488AEasy to separateSeparation increases the realizationPreparation by carbon monoxide reactionCarbonyl compound separation/purificationChemical industryChemical reaction

The invention belongs to the field of chemical industry, relates to solvents with different polarities used in different steps of the chemical reaction process, and in particular relates to a polar reversible transformation solvent for an isobutylene hydroformylation reaction. According to the reaction, N,N-dimethyl cyclohexyl amine (CyNMe2) serves as a solvent for generating isovaleraldehyde in the isobutylene hydroformylation reaction, and the polarity of the CyNMe2 is increased in a production separation tower under the actions of water and CO2 so as to realize separation of the product from the solvent; in a solvent recycling tower, CyNMe2 is dissociated from the aqueous phase by virtue of the gas stripping action of inert gases such as N2, and the solvent is recovered so as to be recycled. The traditional solvent and product separation process needs to be finished by distillation, and therefore the problems such as high energy consumption, solvent volatilization and loss and the like are caused. By utilizing the polar reversible transformation properties of the solvent under the normal temperature and normal pressure conditions, the aims of separating the solvent from the product and recycling the solvent are achieved, the energy consumption is reduced, and the solvent loss is avoided.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

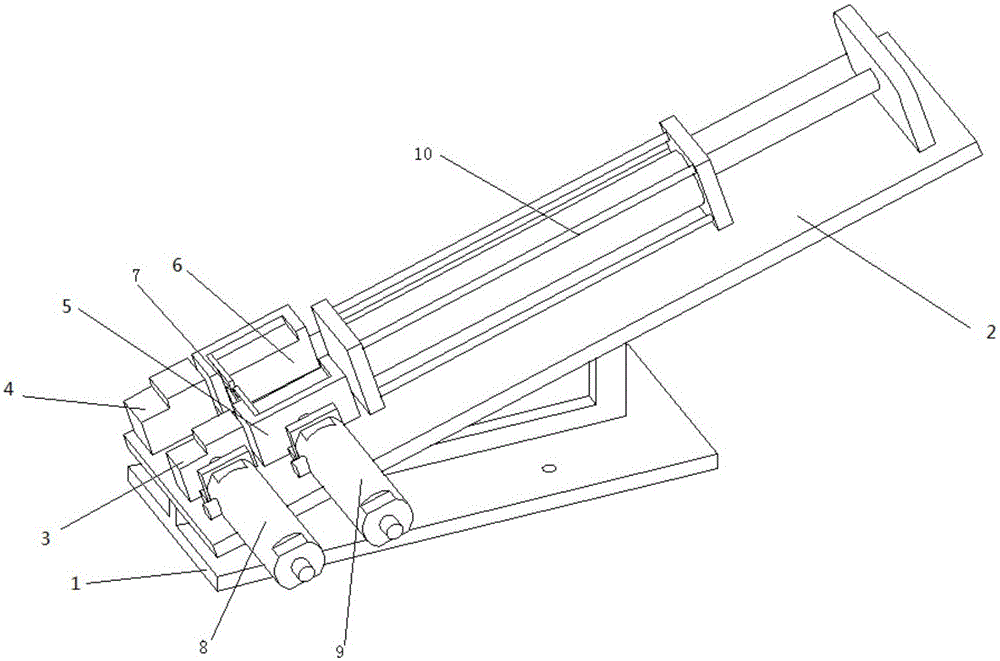

Automatic cable stripping machine

InactiveCN105071305AQuick removalImprove peeling efficiencyApparatus for removing/armouring cablesStripping - actionEngineering

The invention discloses an automatic cable stripping machine. The automatic cable stripping machine comprises a base. An inclined base plate is installed on the base. The bottom end of the base plate is provided with a fixed clamping block and a fixed positioning block in a corresponding manner. A stripping sliding seat is installed on the base plate in a sliding manner. The stripping sliding seat is provided with a sliding clamping block and a sliding positioning block in a corresponding manner. The sliding clamping block and the sliding positioning block are respectively provided with a blade, and the blades are matched with each other. A fixed cylinder and a sliding cylinder are respectively installed at the outer sides of the fixed clamping block and the sliding clamping block. The outer side of the stripping sliding seat is connected with a stripping cylinder. The automatic cable stripping machine is mainly used in an electrical appliance workshop and is capable of rapidly removing an external packaging skin of a cable. The movement of unidirectional cylinders drives the blades, so that the stripping action is completed, the cable stripping efficiency is substantially increased, and the stripping quality is improved.

Owner:HEFEI HEAN MACHINERY MFG

Joint elbow type lifting device of screen plate frame fixing rack

The invention discloses a joint elbow type lifting device of a screen plate frame fixing rack. The device comprises the screen plate frame fixing rack, a front lifting mechanism and a rear lifting mechanism, wherein the rear lifting mechanism is connected with a traction pillar; the traction pillar is pivoted with the rear end of the screen plate frame fixing rack; and the front end of the screen plate frame fixing rack is placed on a rack. The rear end of the screen plate frame fixing rack and the traction pillar adopt a joint elbow type pivoting manner, and the front end of the screen plate frame fixing rack is placed on the rack and not fixed, so that the front end and the rear end of the screen plate frame fixing rack can be lifted synchronously or asynchronously, tilt stripping action can be performed, the screen plate frame fixing rack is suitable for printing workpieces with higher accuracy requirements, and the problems that a screen plate frame fixing rack of an ordinary printing device shakes during lifting motion and workpieces shift are solved. The joint elbow type lifting device of the screen plate frame fixing rack reasonably utilizes the space of the device, and is simple and compact in structure, and easy to implement.

Owner:DENBISHI FINE CHEM KUSN

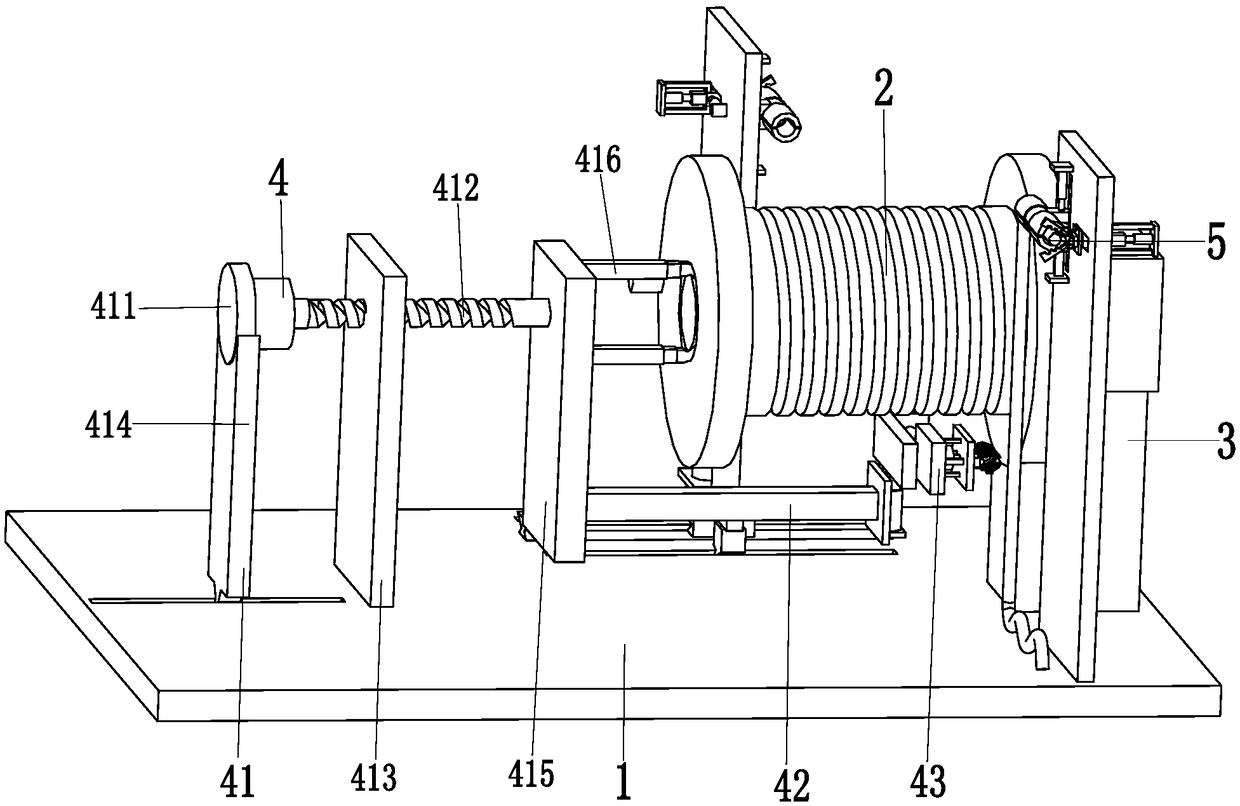

Power cable stripping equipment

InactiveCN108649495AEasy to fixSliding doesn't happenApparatus for removing/armouring cablesPower cableStripping - action

The invention relates to power cable stripping equipment, which comprises a supporting bottom plate, a winding frame, a winding support, a rotating device, cable stripping devices, a cable stripping adjusting mechanism and a conveying mechanism, wherein the right end of the winding frame is arranged on the top of the right end of the supporting bottom plate through the winding support; the conveying mechanism is arranged on the left end of the winding frame; the rotating device is arranged on the top of the left end of the supporting bottom plate; the cable stripping adjusting mechanism is arranged on the top of the rear end of the supporting bottom plate; the number of the cable stripping devices is two, one cable stripping device is arranged on the top of the front end of the supportingbottom plate, and the other cable stripping device is arranged on the top of the cable stripping adjusting mechanism. According to the power cable stripping equipment, the problems that the fixation is not firm and the two ends of the cable cannot be subjected to cable stripping action at the same time when the cable is stripped, the cable is easy to slide and the cable cannot be wound automatically when the cable is wound, a head of the cable cannot be fixedly transferred after the cable is wound and the like in an existing cable stripping process can be solved.

Owner:湖南多稳移动供电科技有限公司

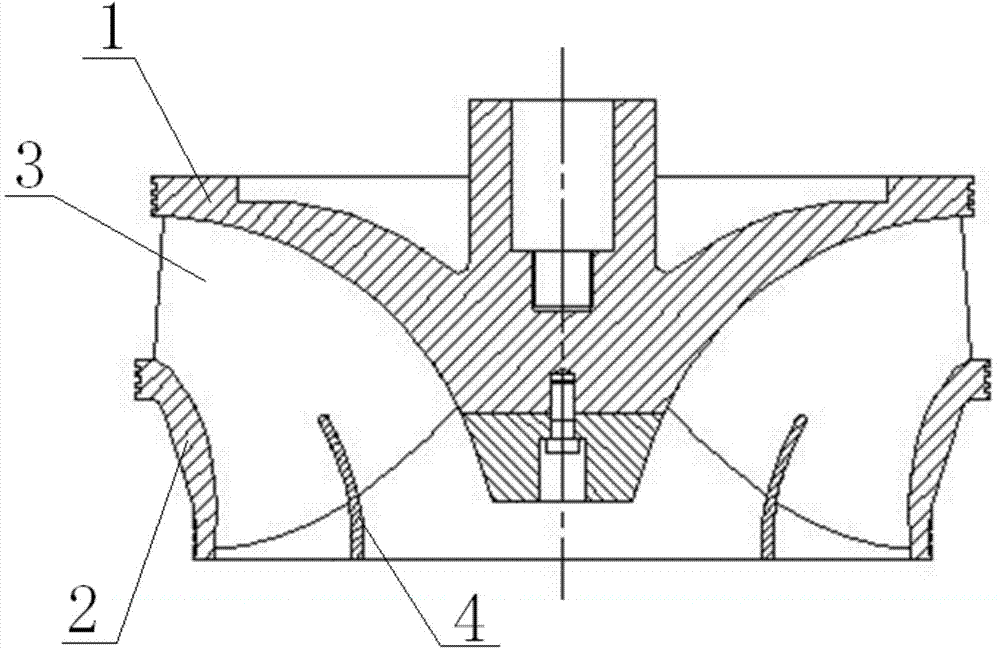

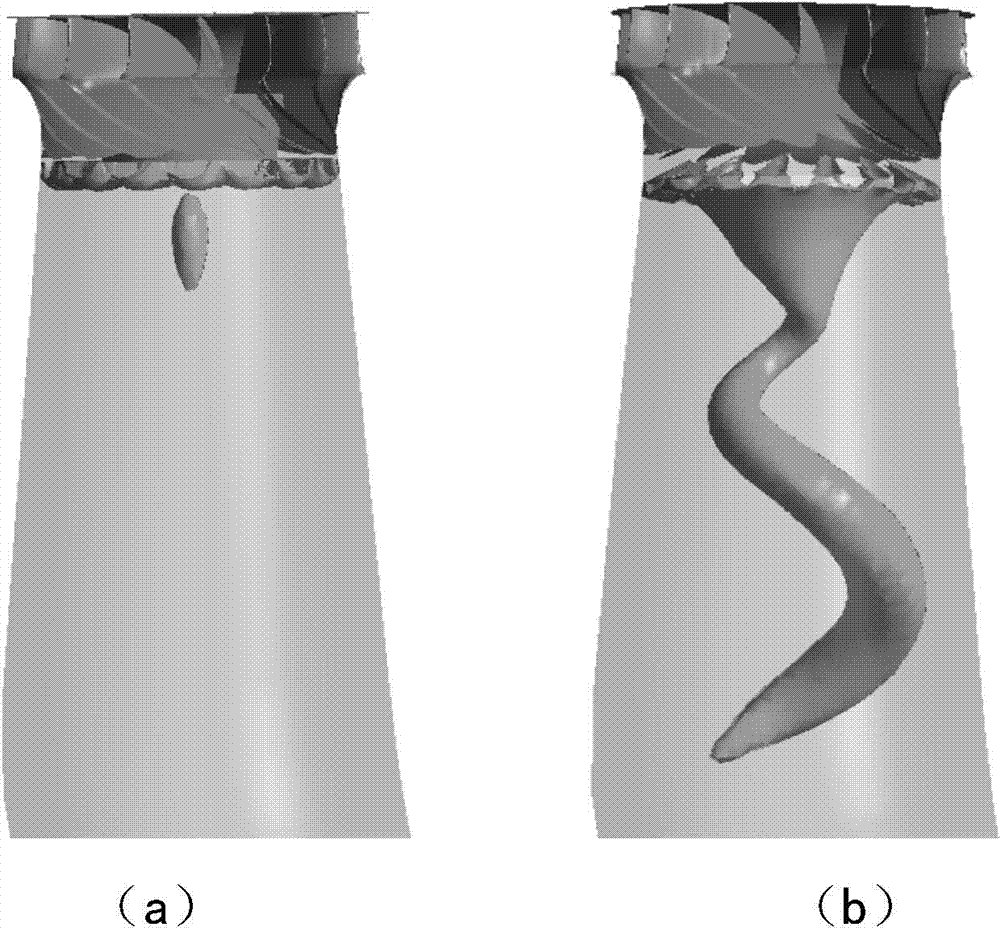

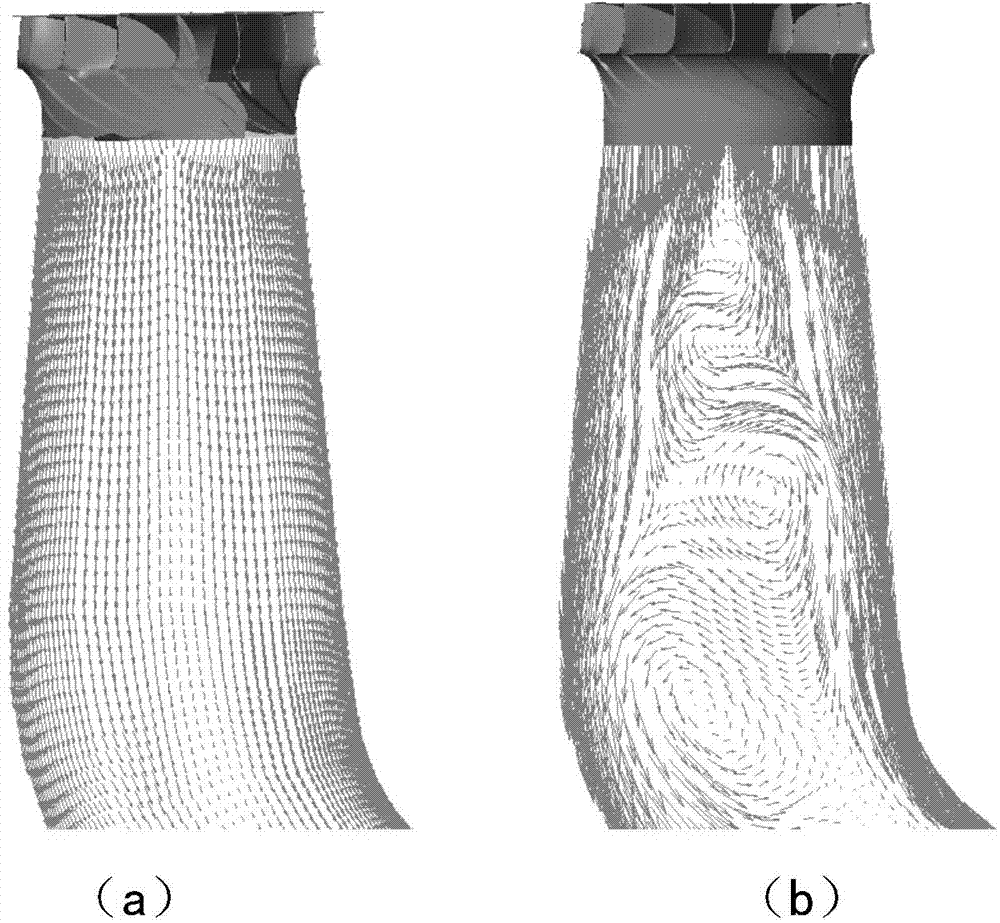

Mixed-flow water turbine runner with double flow channels on outlet

InactiveCN104847568AReduced radial velocityOutflow smoothlyHydro energy generationReaction enginesMixed flowWater turbine

The invention relates to a mixed-flow water turbine runner with double flow channels on an outlet. The mixed-flow water turbine runner is characterized by comprising an upper crown, a lower ring, multiple blades fixed between the upper crown and the lower ring and a splitter plate, the splitter plate is formed by thickening a gyration surface, the gyration center of the gyration surface coincides with the rotation center of a water turbine, and the upper portion of the splitter plate intersects with the lower portions of all the blades and is connected to the lower portions of all the blades in a fastened mode. The radial flow rate on the outlet of the water turbine runner can be reduced greatly, so that it is ensured that the flow rate on the outlet of the water turbine runner is evenly distributed under the working condition of vortex strips; compared with a common runner, the flow in the rotation center of the vortex strips is increased, the pressure of the region close to an axis center region and located between outlets of the blades and an inlet of a draft tube is increased, and therefore the spiral vortex strip action of the draft tube is eliminated at the source.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

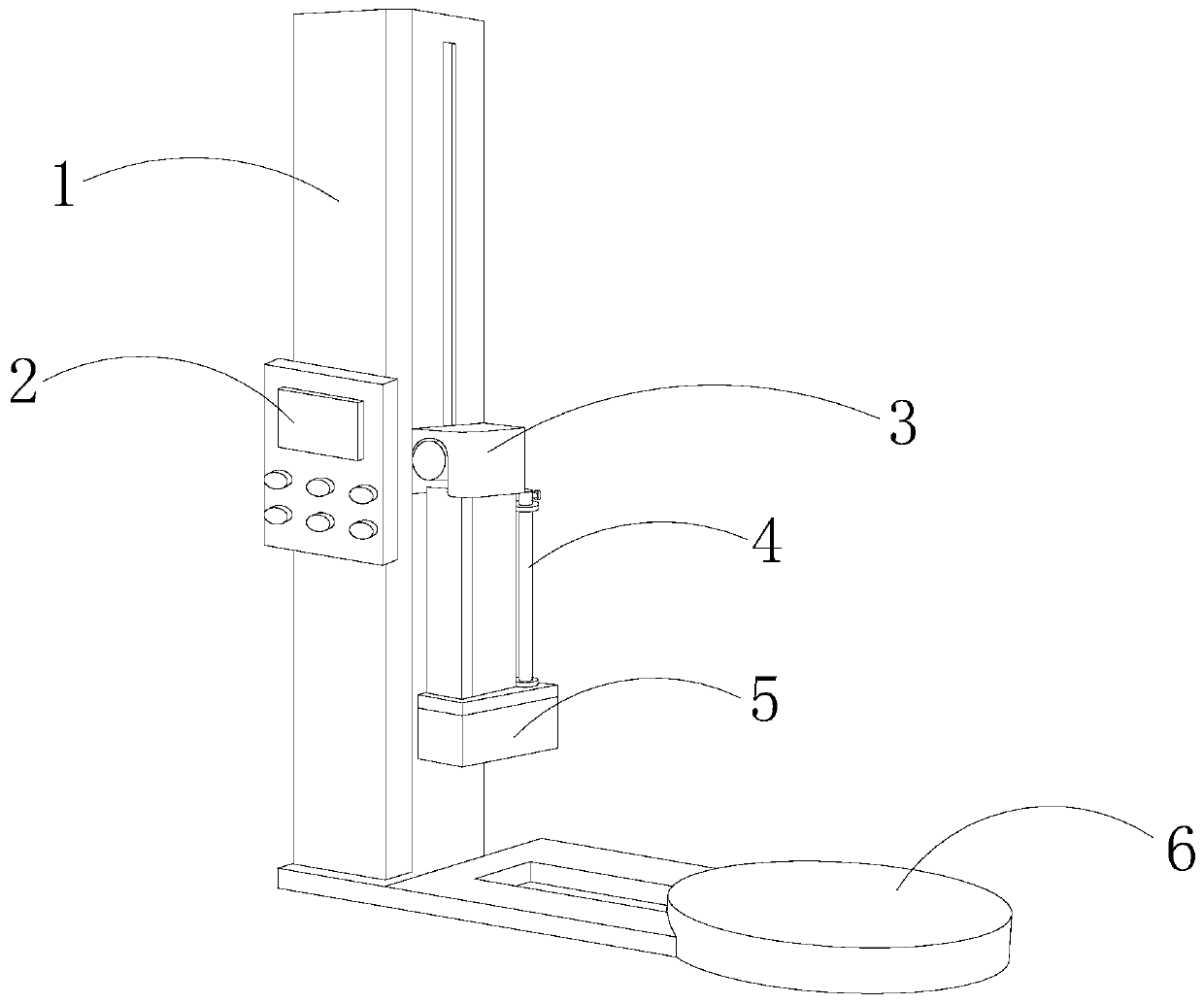

Wire stripping device

InactiveCN110021896ARealize mechanization, automation and intelligenceIncreased stripping length rangeApparatus for removing/armouring cablesStripping - actionEngineering

The invention discloses a wire stripping device. The wire stripping device comprises a wire stripping structure. The wire stripping structure comprises a cutter head driving assembly, a first cutter head assembly, a second cutter head assembly and a control module. The controlled end of a first driving structure of the cutter head driving assembly and the controlled end of a second driving structure are connected with the control end of the control module. The first driving structure drives a first connecting shaft to rotate so as to drive the first cutter head assembly and the second cutter head assembly to rotate; the second driving structure drives the first connecting shaft and a second connecting shaft to move along the axis; and a wire stripping knife on the cutter head assembly is controlled to be opened and closed by rotating and moving along the axial direction, so that the wire stripping action is realized. The wire stripping device can solve the problems of low wire stripping efficiency, low precision and the like in the prior art.

Owner:彩美伟业精密电子(昆山)有限公司

Wire cutting and stripping device

PendingCN111403991AReduce investmentControl precisionLine/current collector detailsApparatus for removing/armouring cablesControl systemStripping - action

The invention relates to the technical field of wire cutting and stripping, and provides a wire cutting and stripping device, which comprises a machine body; the machine body is provided with a wire groove for a power line to pass through, a cutting and stripping assembly used for cutting and stripping the power line and a control system used for controlling the cutting and stripping assembly to act. A receiving position for a machined power line is arranged at an outlet of the wire groove, and the cutting and stripping assembly comprises a cutting and stripping knife used for cutting and stripping the power line and a driving mechanism used for driving the cutting and stripping knife to do wire cutting action and wire stripping action. Automatic wire cutting and stripping are achieved through cooperation of the wire groove, the cutting and stripping assembly and the control system, so that the efficiency is improved compared with manual wire cutting and stripping, and safety is higher; through the layout of an electric control area, a power line processing area and a staff operation area, a staff pulls a wire harness with one hand and straightens the wire harness in a wire slot during production, and the other hand operates the control system, so that both hands of the staff are far away from the power line processing area during production, and industrial accidents are avoided.

Owner:XIAOGAN HUAGONG GAOLI ELECTRONICS

Color changing paint and varnish remover

InactiveUS7304021B2Good anti-sag performancePrevent the excessive bubbling, blistering and swellingDetergent dyesChemical paints/ink removersStripping - actionLacquer

A color change paint and varnish removal formulation is provided. The formulation comprises: at least one penetrant, at least one carrier and at least one colorant whereby the formulation is applied to the target area and as the surface of the formulation dries, the carrier partially dehydrates emitting white light as the colorant migrates away from the dehydrating surface and there is a color change to indicate that the stripping action of the formulation has ceased and is ready for the scraping and removal step.

Owner:DYNACRAFT INDUSTRIES INC

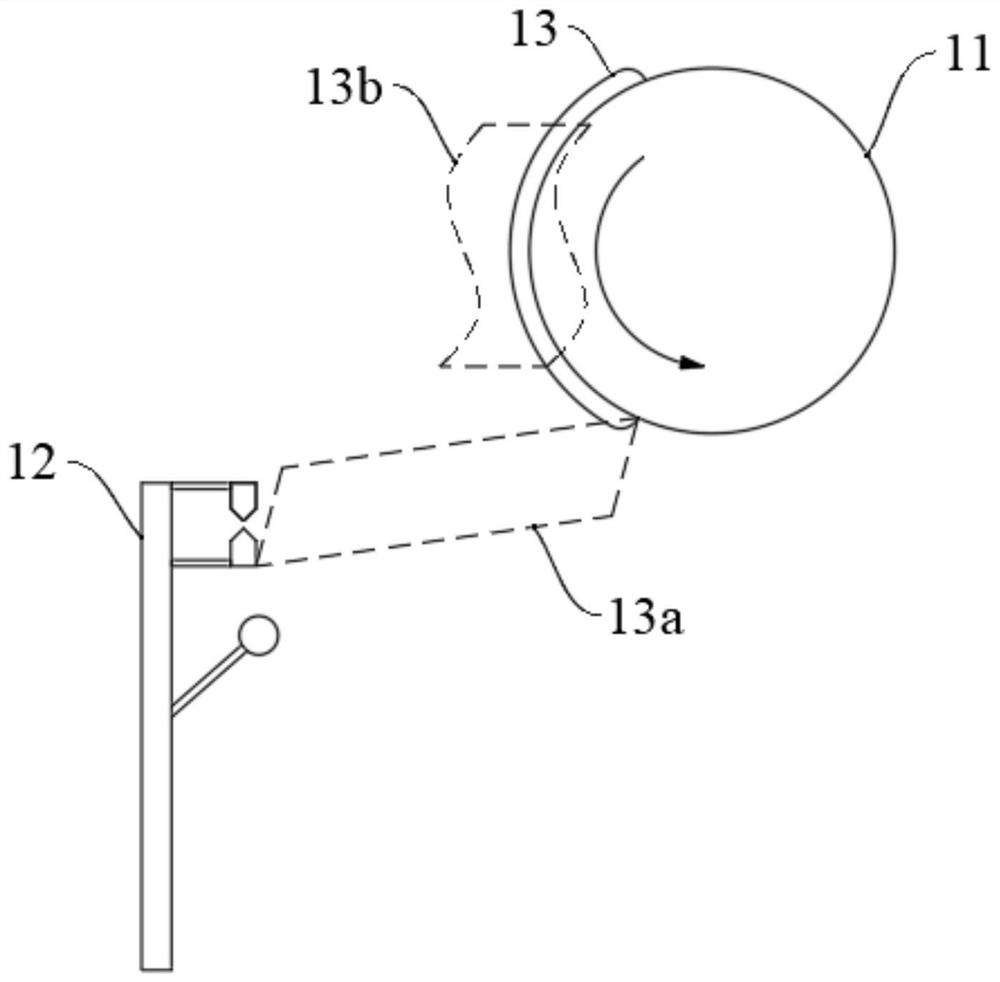

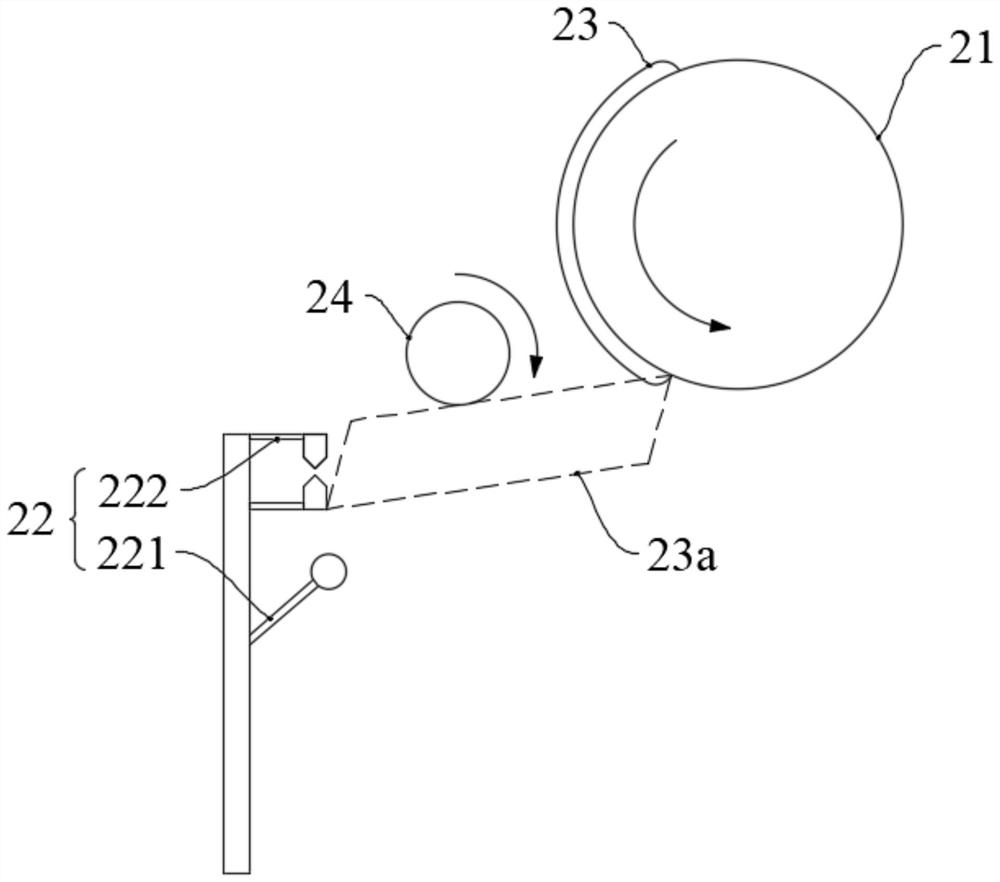

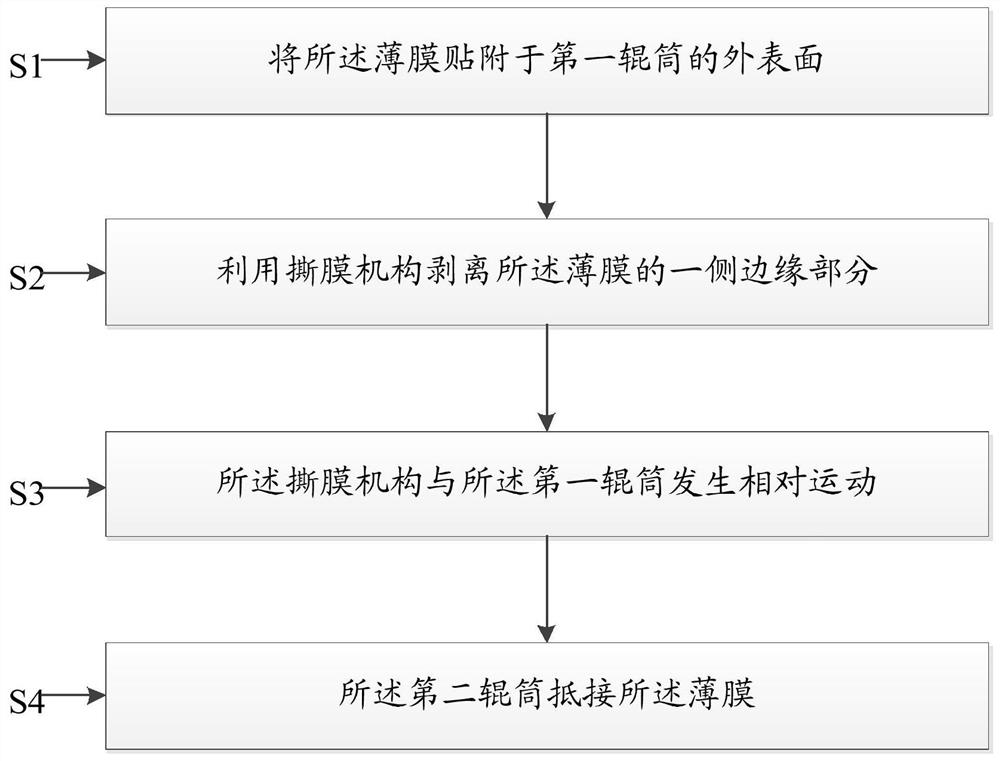

Stripping device and stripping method

ActiveCN113086739APrevent adhesionSmooth peeling actionElectrostatic chargesArticle deliveryStripping - actionThin membrane

The invention discloses a stripping device and a stripping method. The stripping device is used for stripping films and comprises a first roller, a first film tearing mechanism and a second roller, wherein the films are attached on the outer surface of the first roller; the film tearing mechanism is arranged below the first roller; and the second roller is arranged between the first roller and the film tearing mechanism and is used for abutting against the films during stripping. Compared with the existing stripping device and stripping method, the stripping device has the advantages that the second roller is additionally arranged in the stripping device and is arranged between the first roller and the film tearing mechanism; when the films rebound and curl due to tension, the second roller can block the rebounding tracks of the films, so that the films are attached on the second roller and are prevented from being attached on the first roller; and the stripping action is smoothly completed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

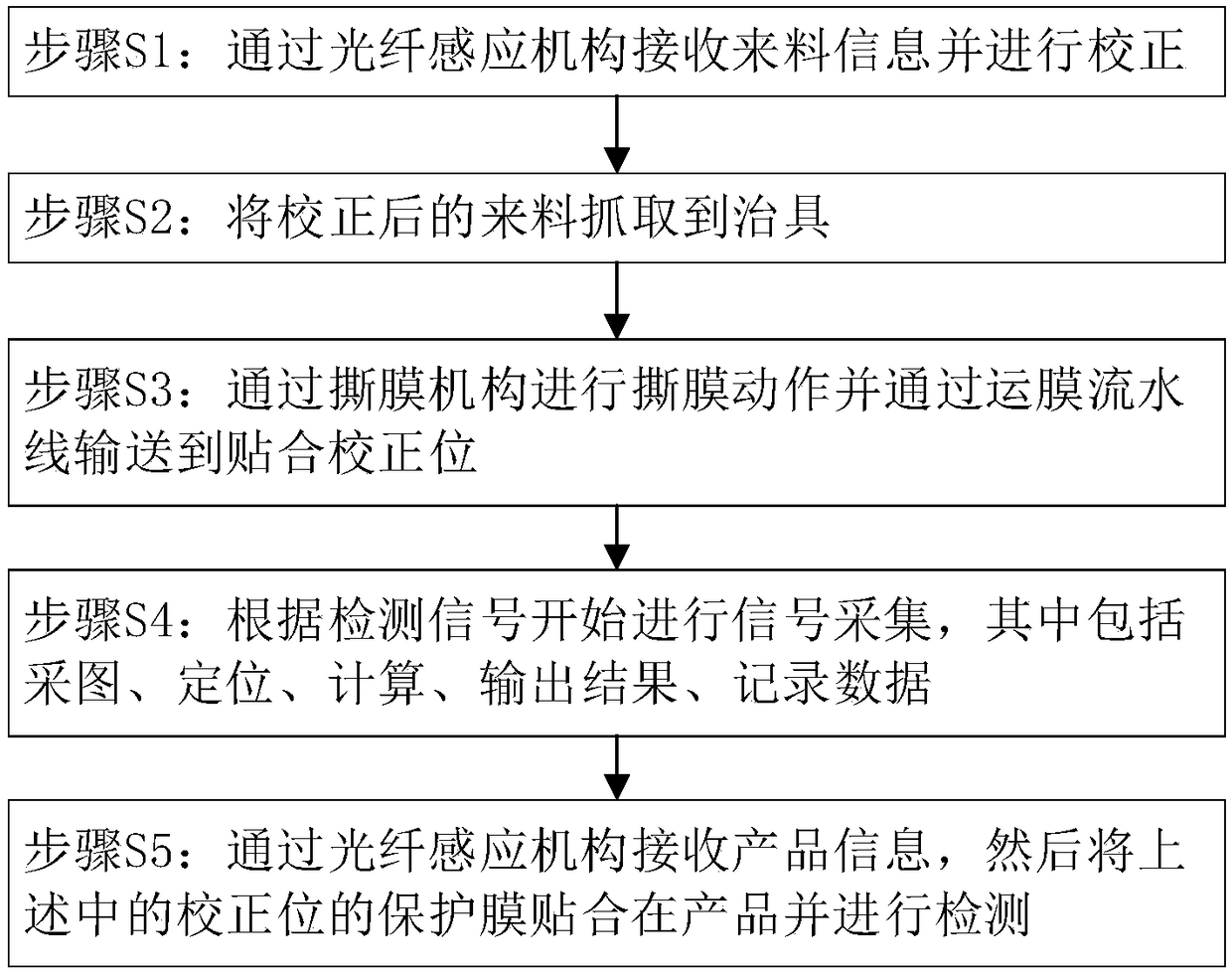

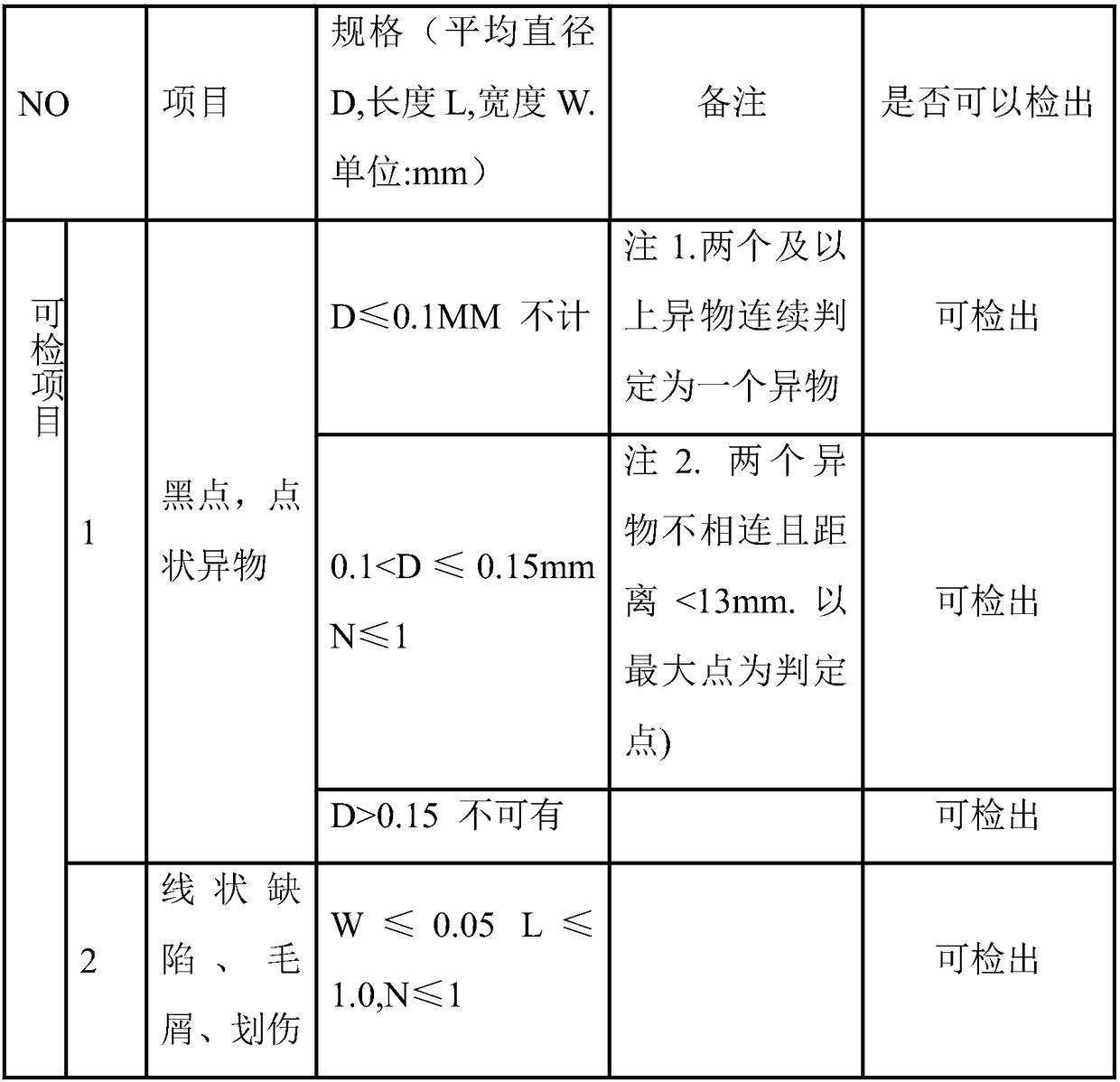

Detection method of full-automatic background module detector

InactiveCN108375587AImprove detection efficiencyOptically investigating flaws/contaminationStripping - actionEngineering

The invention provides a detection method of a full-automatic background module detector. The detection method includes: step S1, receiving incoming material information and correcting through an optical fiber sensing mechanism; step S2, grabbing corrected incoming materials to a jig; step S3, adopting a film stripping mechanism for carrying out film stripping action, and conveying to a laminationcorrection position through a film transport line; step S4, starting signal acquisition according to detection signals, namely acquiring images, positioning, calculating, outputting results and recording data; step S5, receiving product information through the optical fiber sensing mechanism, laminating a protective film at the correction position to a product, and detecting; step S6, performingdistinguished discharging according to detection results. The detection method of the full-automatic background module detector has advantages that existing manual lamp detection can be replaced withthe method, and high detection precision and high detection efficiency are realized.

Owner:FREESENSE IMAGE TECH

Low energy consumption anaerobic-oxic coupled membrane bioreactor and sewage treatment method

PendingCN106830327AEfficient degradationFlush aeration savingsTreatment with aerobic and anaerobic processesStripping - actionMembrane bioreactor

The invention relates to a low energy consumption anaerobic-oxic coupled membrane bioreactor (LE-AOCMBR) and a sewage treatment method, and relates to the technical field of sewage treatment. The LE-AOCMBR comprises at least one membrane pool A, at least one membrane pool B, at least one aerobic area and at least one anoxic area; the bottoms of the membrane pool A and the membrane pool B communicate with the two ends of the aerobic area correspondingly; an aerobic pool communicate with an anoxic pool through an anoxic channel; and produced water is produced by an MBR (membrane bioreactor) positioned in the membrane pool A and the membrane pool B. Repeated circular flowing of water in the membrane pools, the aerobic area and the anoxic area is realized by switching aeration on the membrane pool A or the membrane pool B and through gas stripping circular flow, dissolved oxygen is provided for aerobic reaction of the aerobic area, and large-flow denitrification liquid is provided for the anoxic area. Double-direction flushing of the membrane is realized by switching aeration on the membrane pool A or the membrane pool B. Anoxic, aerobic and membrane separation are organic combined through membrane aeration gas stripping action, energy consumption is one third of the traditional MBR energy consumption, energy-saving effect is remarkable, and a denitrification effect is obvious.

Owner:GELANTE ENVIRONMENTAL PROTECTION ENG BEIJING CO LTD

A visual positioning mobile phone accessories placement system

ActiveCN105292657BReduce movementImprove placement efficiencyLabelling machinesManufacturing technologyMachine vision

The invention belongs to the field of mobile phone shell assembling equipment, and particularly relates to a visual-positioning mobile phone accessory attaching system. The visual-positioning mobile phone accessory attaching system comprises a hardware part and a software part. The hardware part comprises a main rack, a plurality of accessory stripping mechanisms, a feeding and discharging mechanism, an attaching executing mechanism, a visual-positioning mechanism and a controller. The software part comprises a hard configuration management module, a mobile phone accessory management module, a hand and eye calibration module and a work driving module. According to the visual-positioning mobile phone accessory attaching system, the manner that the accessory stripping mechanisms and the attaching executing mechanism with a plurality of suction nozzles are integrated on the main rack, attaching of various accessories can be completed at a time through one machine, and in addition, due to the fact that the accessory stripping action and the attaching action are independent from each other and work is completed in a division manner, the visual-positioning mobile phone accessory attaching system has the remarkable beneficial effects that precision is high, accessory waste is small, the requirement for the accessory manufacturing technology is low, the wire change cost is low, accessory stripping and accessory attaching are conducted in parallel and efficiency is high compared with a traditional accessory attaching system. In the traditional accessory attaching system, one machine is used for attaching one accessory; accessory stripping and accessory attaching are conducted in series; no machine vision exists, or a simple vision system is arranged, and generally, a camera is installed on a mechanical arm; and photographing is needed before each time of material taking.

Owner:DONGGUAN GOSUNM MACHINERY EQUIP CO LTD

A lifting and peeling mechanism and its realization method

ActiveCN109795758BImprove efficiencyCompact structureArticle unpackingStripping - actionStructural engineering

The invention relates to a jacking and stripping mechanism. The jacking and stripping mechanism comprises an ejecting block, a pressing block and a jacking mechanism; one or more material ejecting raised blocks are arranged on the ejecting block; under an original state, the pressing block and the ejecting block are correspondingly located above a material belt and under the material belt; the jacking end of the jacking mechanism is connected with the ejecting block through an elastic assembly, and the jacking end of the jacking mechanism is connected with the pressing block through a connecting assembly; the connecting assembly comprises connecting arms fixedly connected to the jacking end of the jacking mechanism and pressing block connecting rods; one ends of the pressing block connecting rods are rotatably connected with the connecting arms, the other ends of the pressing block connecting rods are fixedly connected with the pressing block, track grooves are formed in the positions,located between the connection points of the pressing block connecting rods and the connecting arms and the connection points of the pressing block connecting rods and the pressing block, of the pressing block connecting rods; and the jacking and stripping mechanism further comprises a guiding shaft matched with the track grooves, tensioning assemblies for applying tensioning force on the pressing block or the ends, connected with the pressing block, of the pressing block connecting rods and a limiting assembly for limiting the rising stroke of the ejecting block. According to the jacking andstripping mechanism, the ejecting action and the stripping action of materials on the material belt can be completed in one step, and the structure is compact, the speed is high, and the efficiency is high.

Owner:深圳市瓦力自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com