Automatic cable stripping machine

A stripping machine and cable technology, which is applied in the direction of equipment for disassembling/armoring cables, etc., can solve the problems of low stripping efficiency, low degree of automation, and unsuitable production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

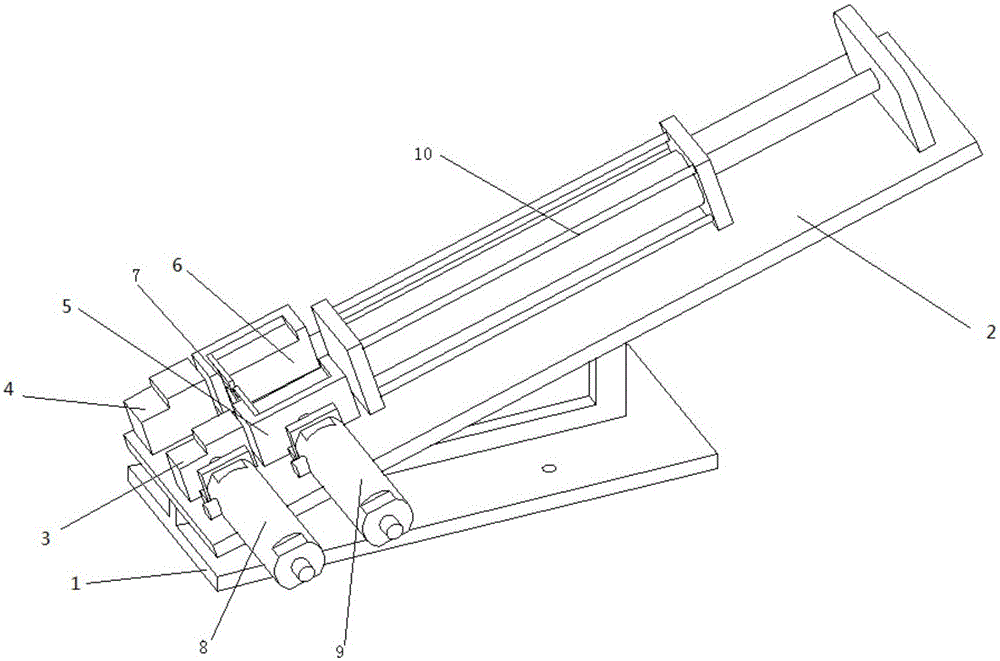

[0010] The automatic cable stripping machine includes a base 1, an inclined base plate 2 is installed on the base 1, a corresponding fixed clamping block 3 and a fixed positioning block 4 are installed on the bottom of the base plate 2, and a stripping slide is installed on the base plate 2. Seat, the peeling slide seat is equipped with corresponding sliding clamping block 5, sliding positioning block 6, and the sliding clamping block 5, sliding positioning block 6 are installed with matching blade 7 respectively, and the blade has semicircle groove respectively, and fixing clip Tight block 3, sliding clamping block 5 outsides are equipped with fixed cylinder 8, sliding cylinder 9, and peeling slide seat outside is connected with peeling cylinder 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com