Patents

Literature

79results about How to "Prevent bouncing up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

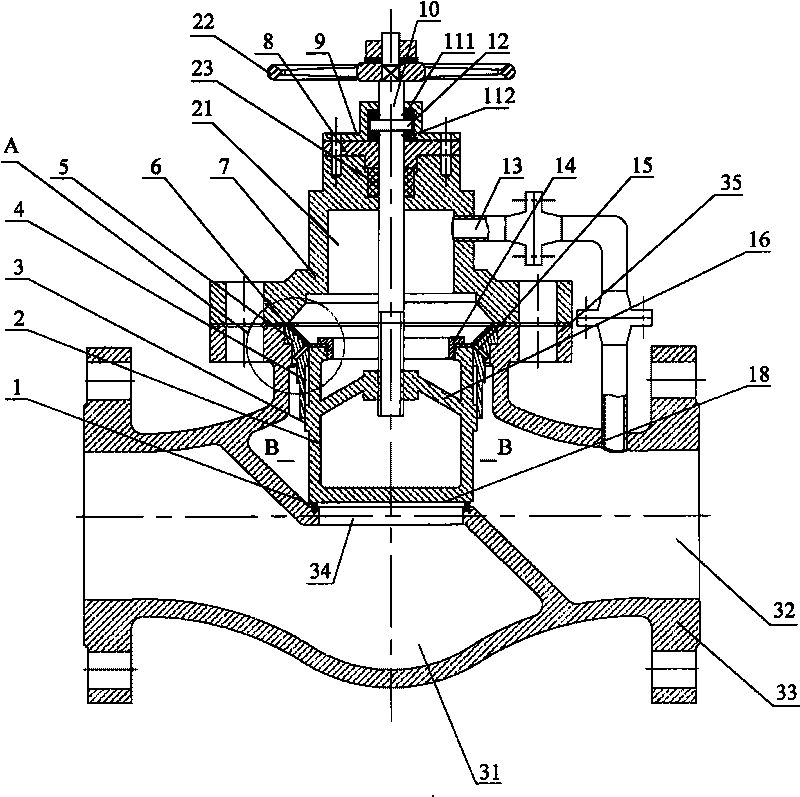

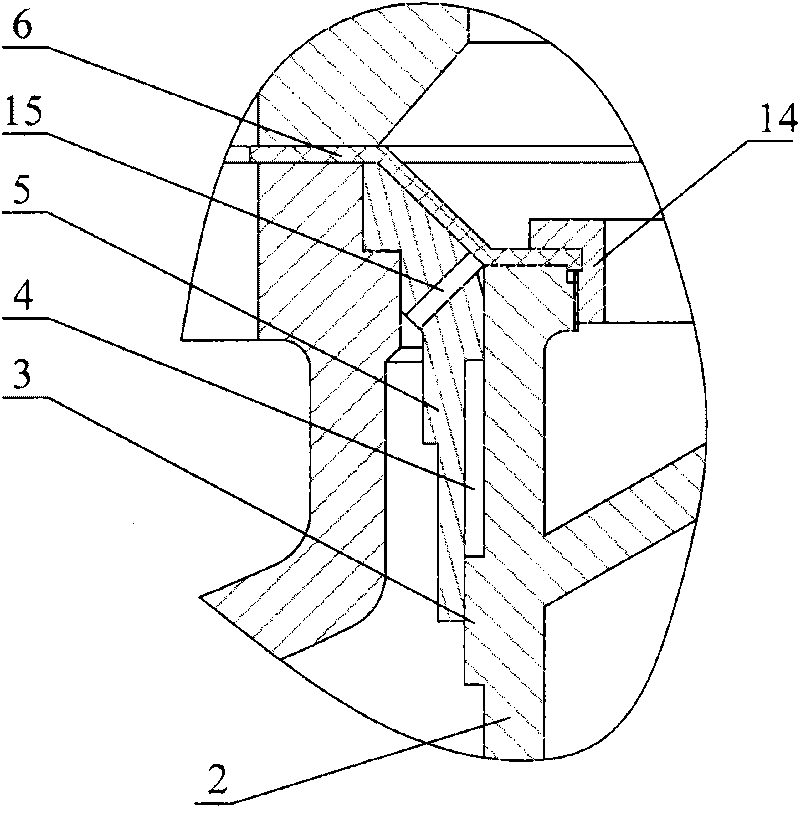

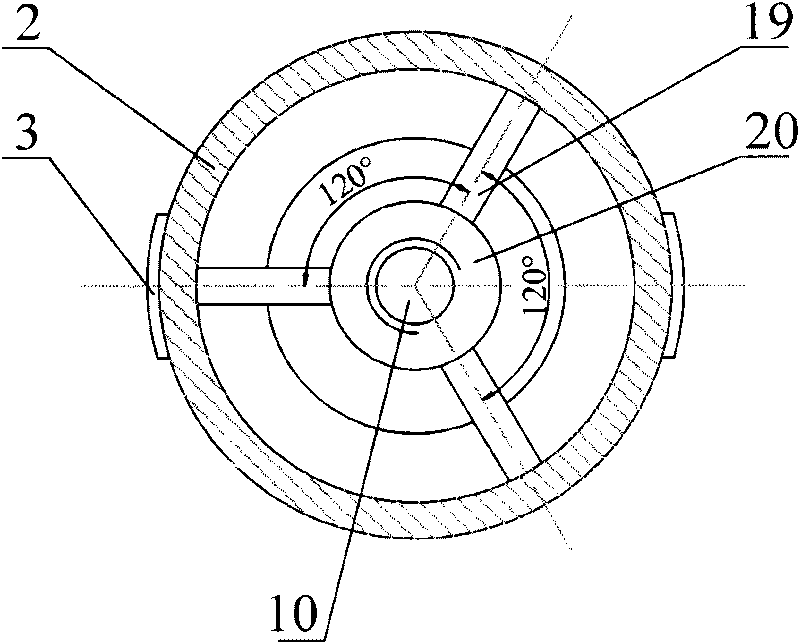

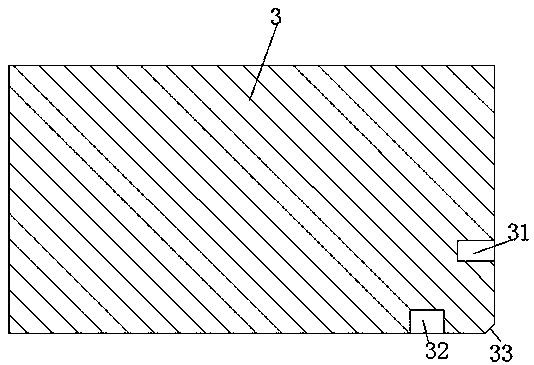

Self-balancing stop valve with piston type valve core and hidden rod

The invention discloses a self-balancing stop valve with a piston type valve core and a hidden rod, which comprises a valve cover (7) and a valve body (33) provided with a front valve cavity (31) and a rear valve cavity (32), wherein a passage (34) is formed between the front valve cavity (31) and the rear valve cavity (32). Guide sleeves (5) in vertical sealed sliding connection and the piston type valve core (2) in which a cavity is formed are arranged in the rear valve cavity (32); the bottom surface (18) of the piston type valve core (2) is used for blocking the passage (34); the guide sleeves (5) are hermetically and fixedly connected with the valve body (33); a lifting component is connected with the piston type valve core (2); the valve cover (7) is hermetically connected with the valve body (33); the inner surfaces of the piston type valve core (2), the guide sleeve (5) and the valve cover (7) encircle an upper chamber (21); and the upper chamber (21) is communicated with the rear valve cavity (32) through a guide pipe component (13). The self-balancing stop valve has the characteristic of remarkable energy-saving effect.

Owner:ZHEJIANG UNIV

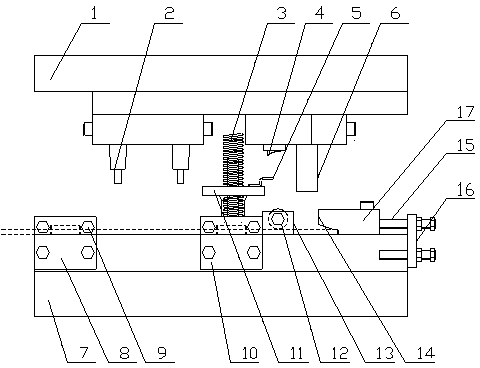

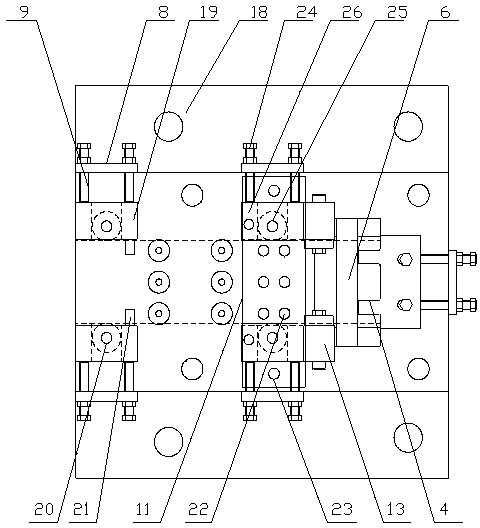

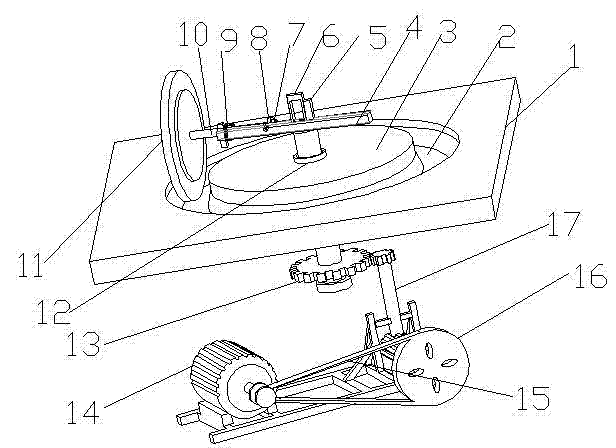

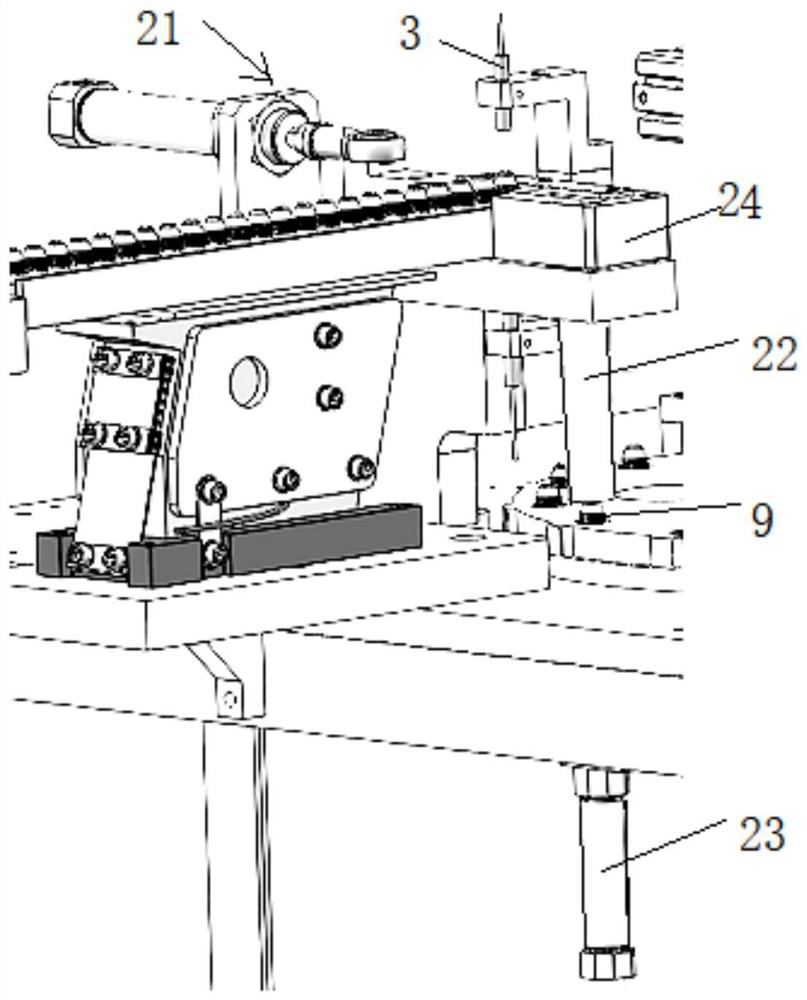

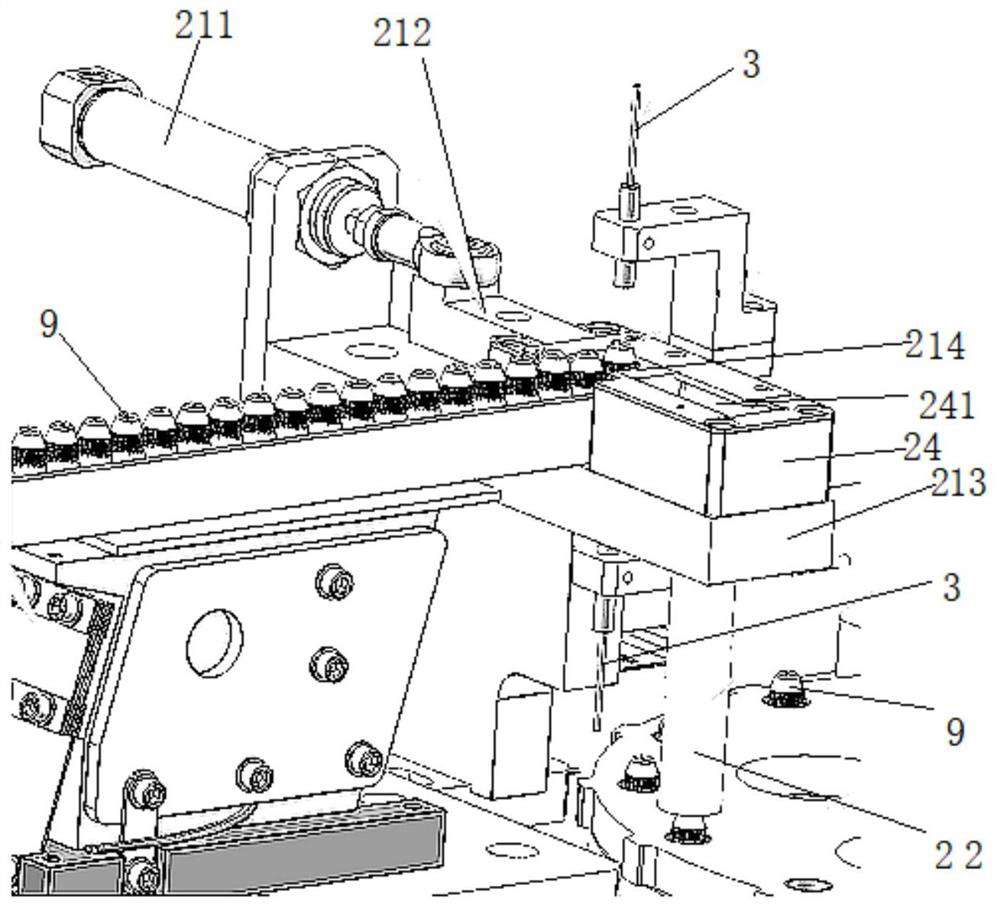

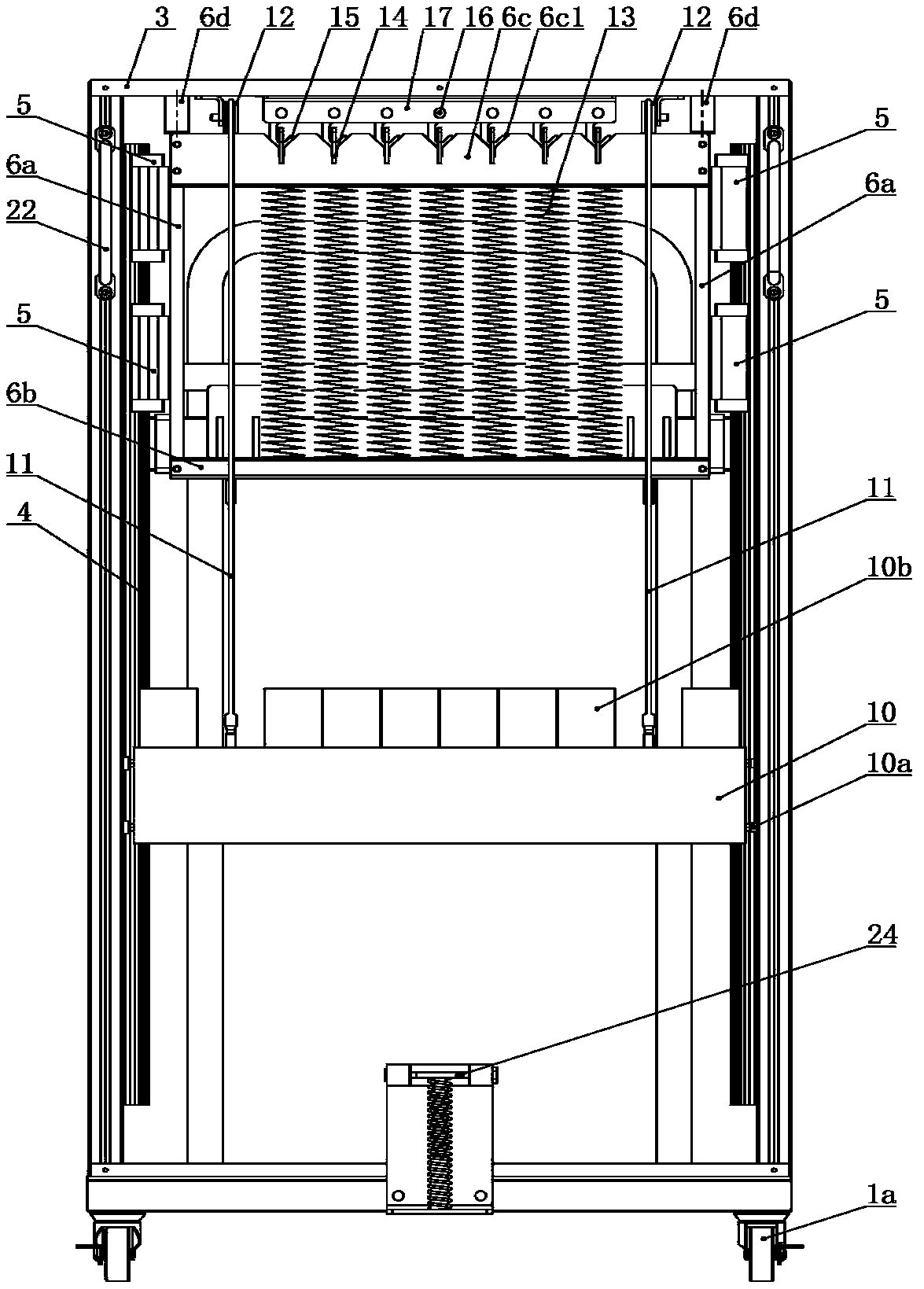

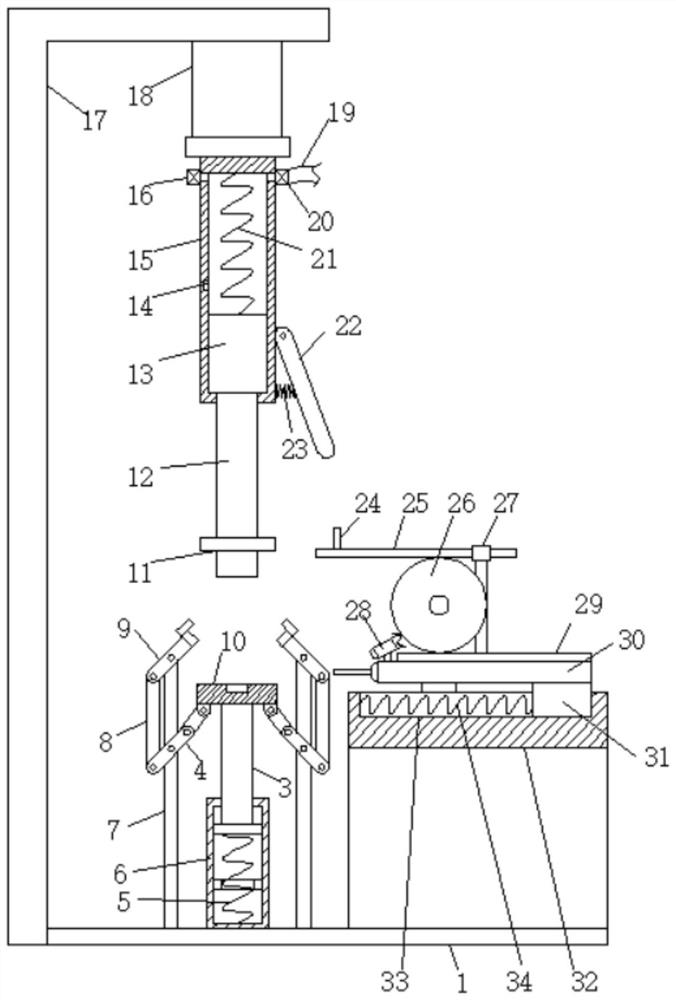

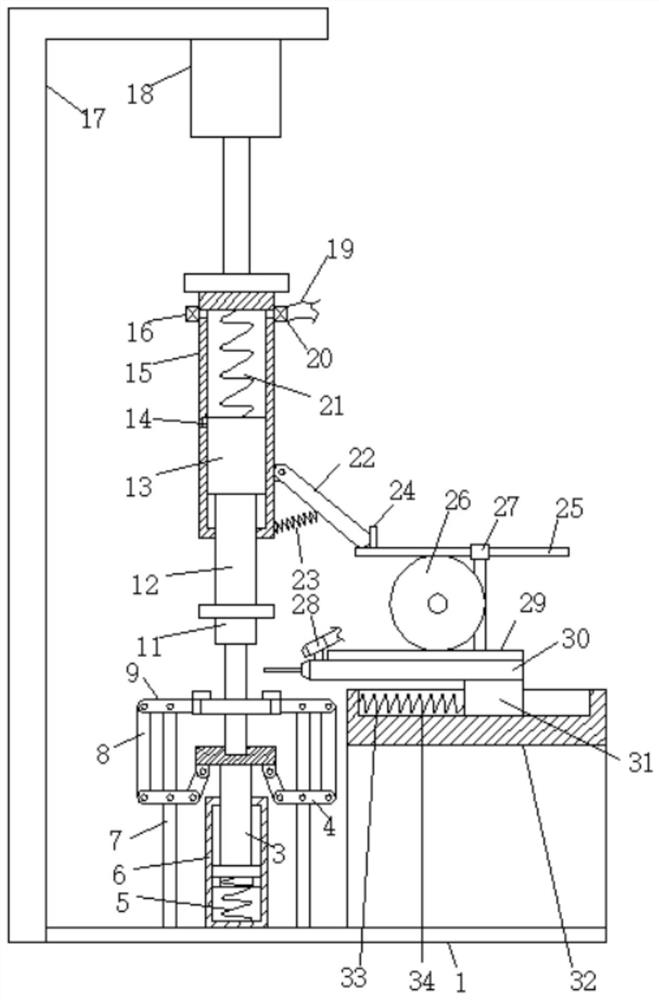

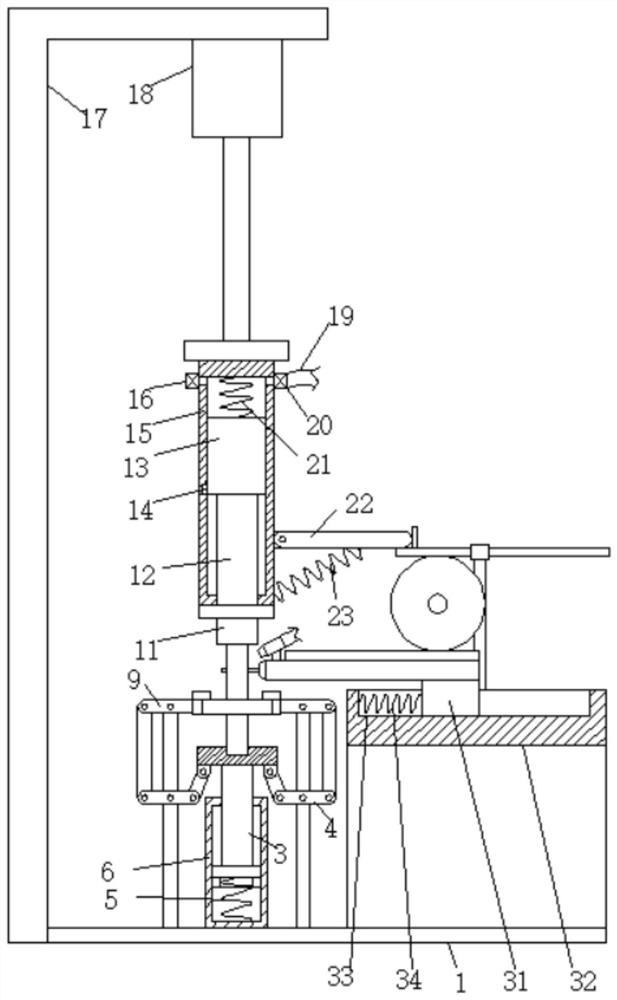

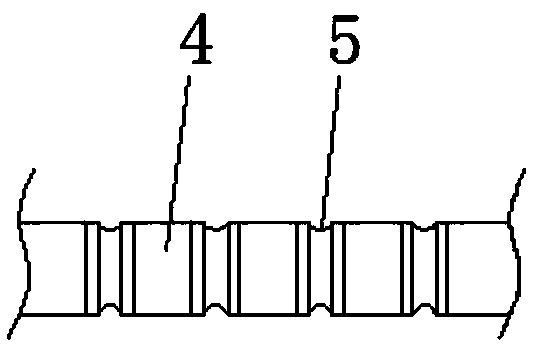

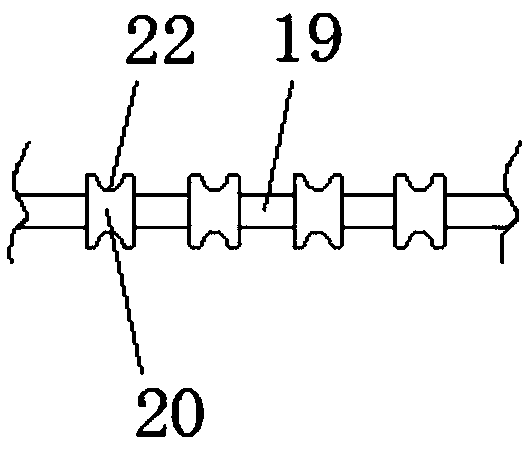

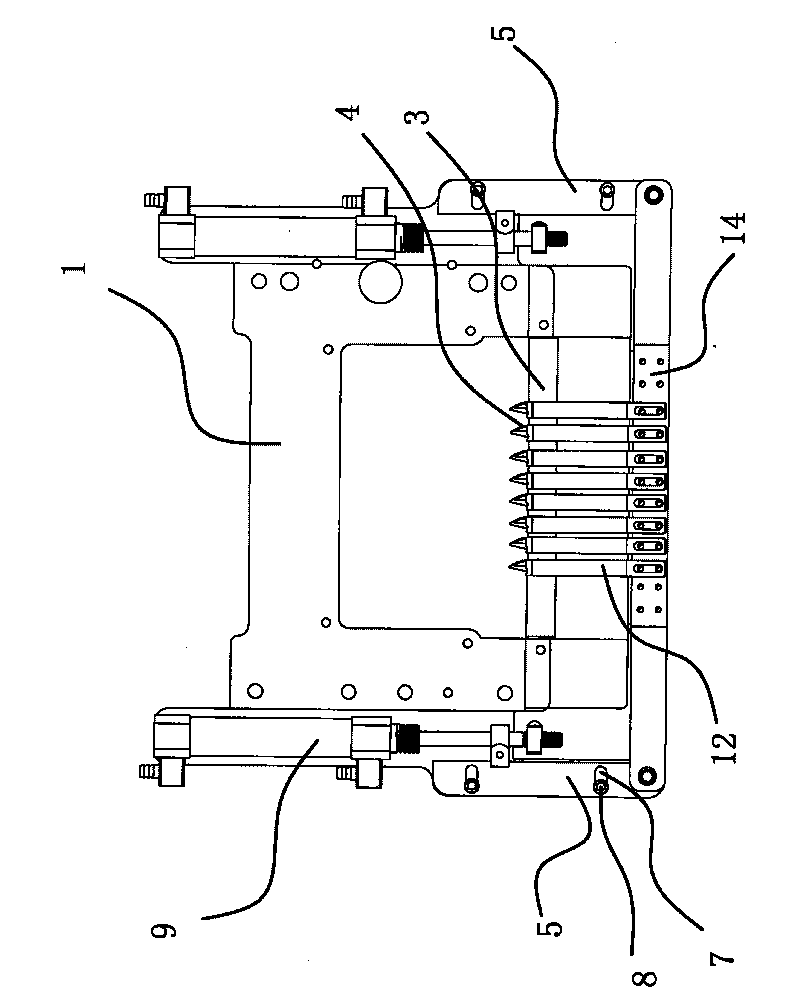

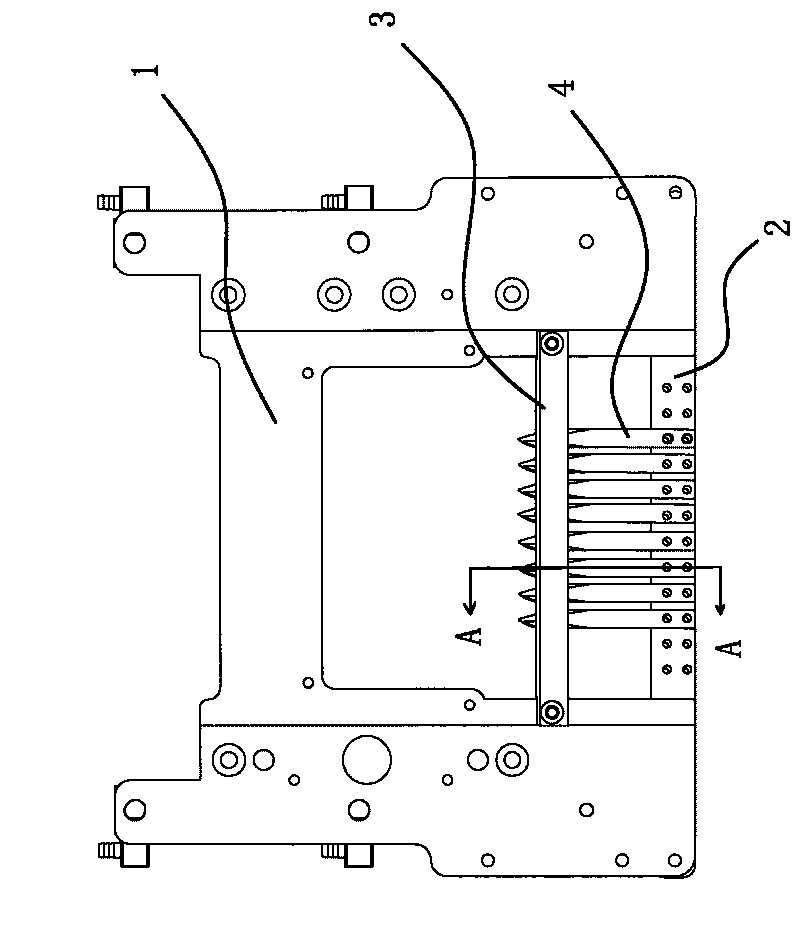

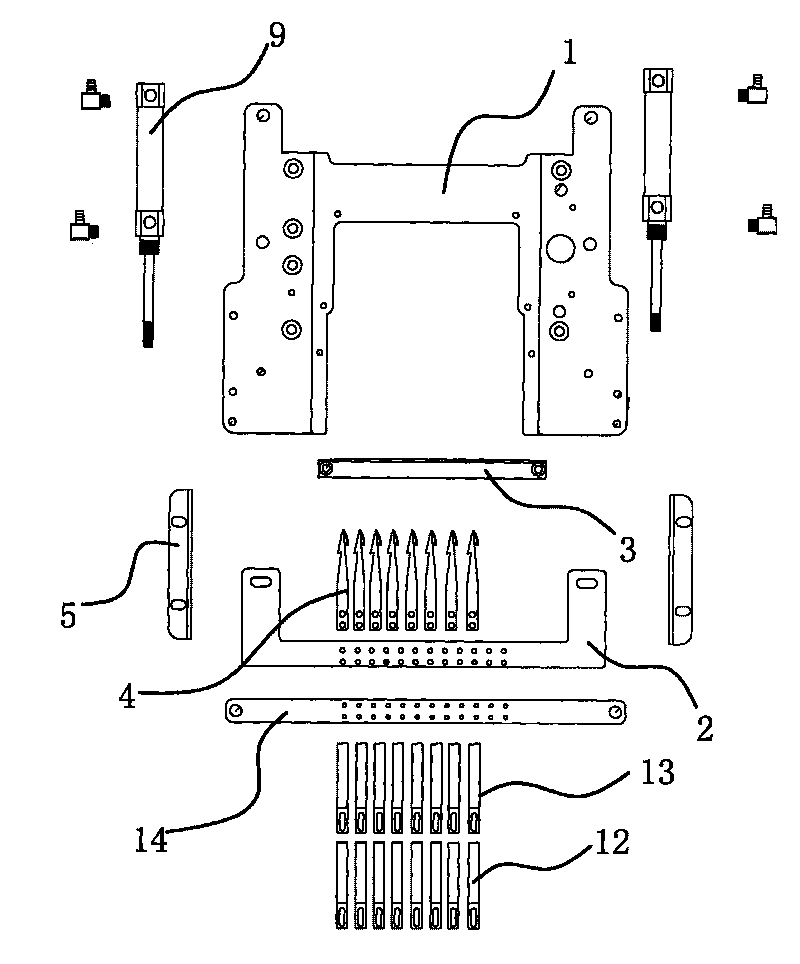

Progressive die for C-shaped clamping frame

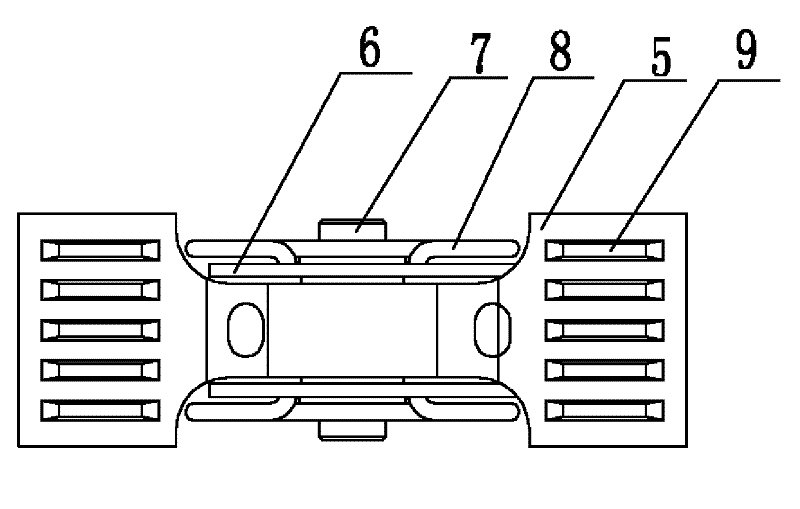

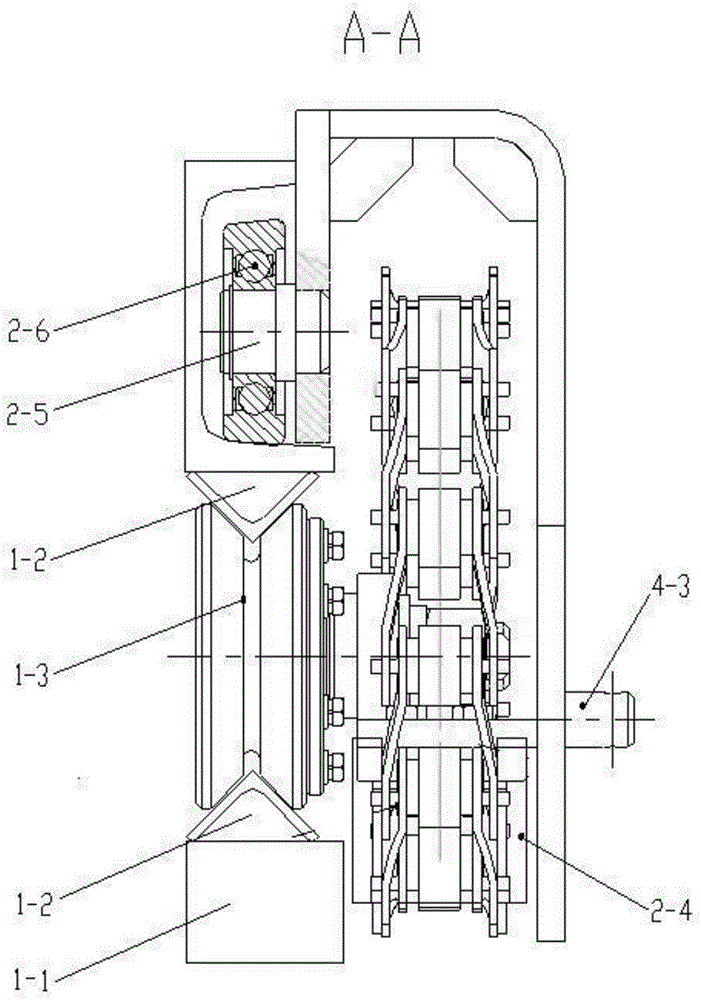

ActiveCN104028651AImprove work efficiencyPrevent bouncing up and downShaping toolsPerforating toolsPush outEngineering

The invention relates to a progressive die for a C-shaped clamping frame. The progressive die comprises a framework, an upper die, a lower die, a stamping mechanism, a detecting mechanism, a cutting mechanism, a pushing mechanism and a stock stop mechanism. The upper die and the lower die are mounted on the framework, and the stamping mechanism, the detecting mechanism, the cutting mechanism, the pushing mechanism and the stock stop mechanism are sequentially distributed between the upper die and the lower die. The progressive die for the C-shaped clamping frame has the advantages that stamping punches arranged parallelly in two rows are capable of punching materials on two workstations at one time, feed length of the materials is controlled each time so as to guarantee that each time materials are arranged on the different workstations to be punched, and operation efficiency is improved. The detecting mechanism provided is used for detecting whether the materials on the workstations are punched or not, and the materials are ensured to be punched. The cutting mechanism provided is used for cutting off the materials, cutoff materials can fall from a blanking passage, and the materials at front end of cutoff bulks are pushed out by the pushing mechanism, and discharge of the materials of the workstations is completed, and operation efficiency is improved.

Owner:RUGAO KK TELECOM MATERIALS

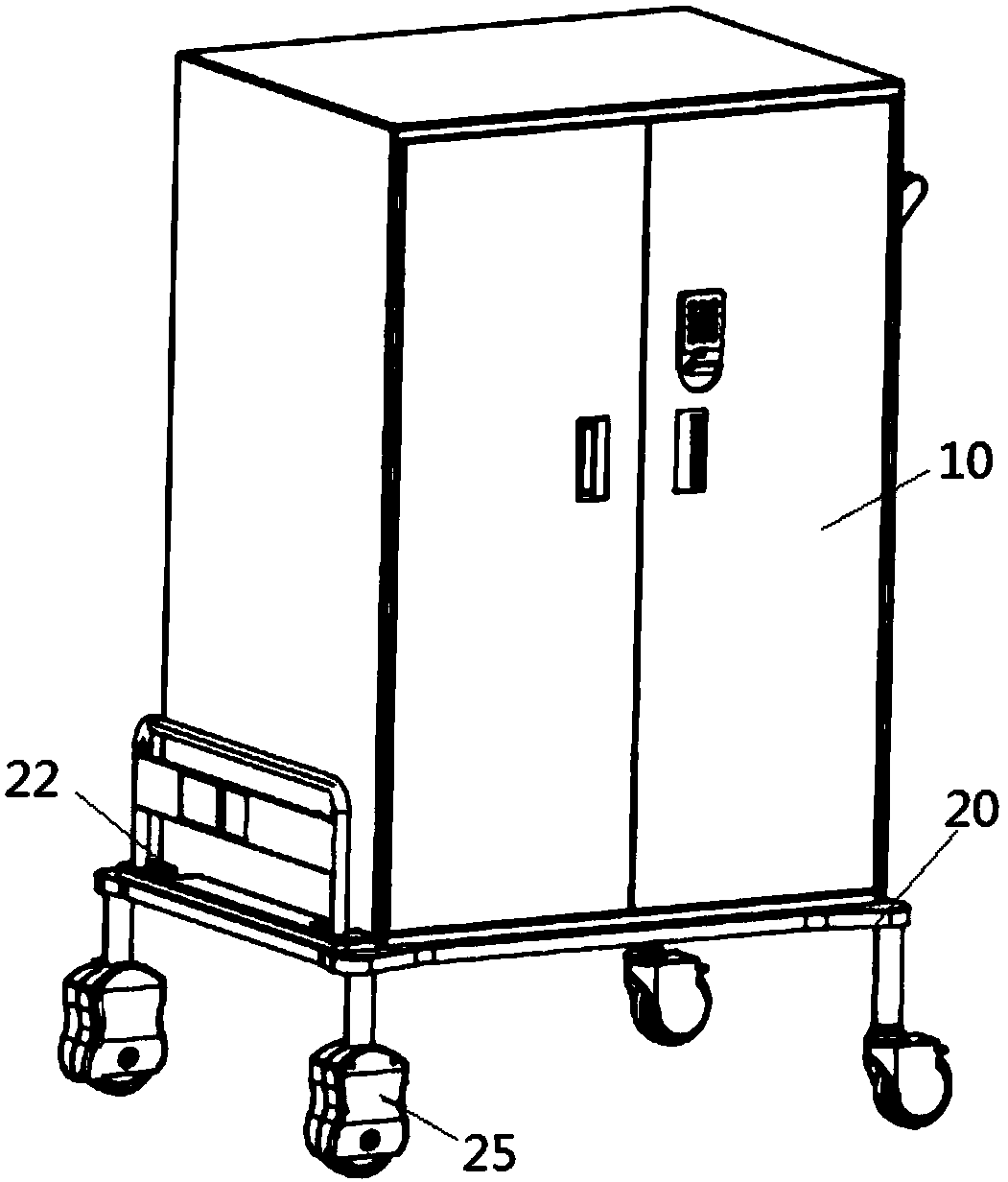

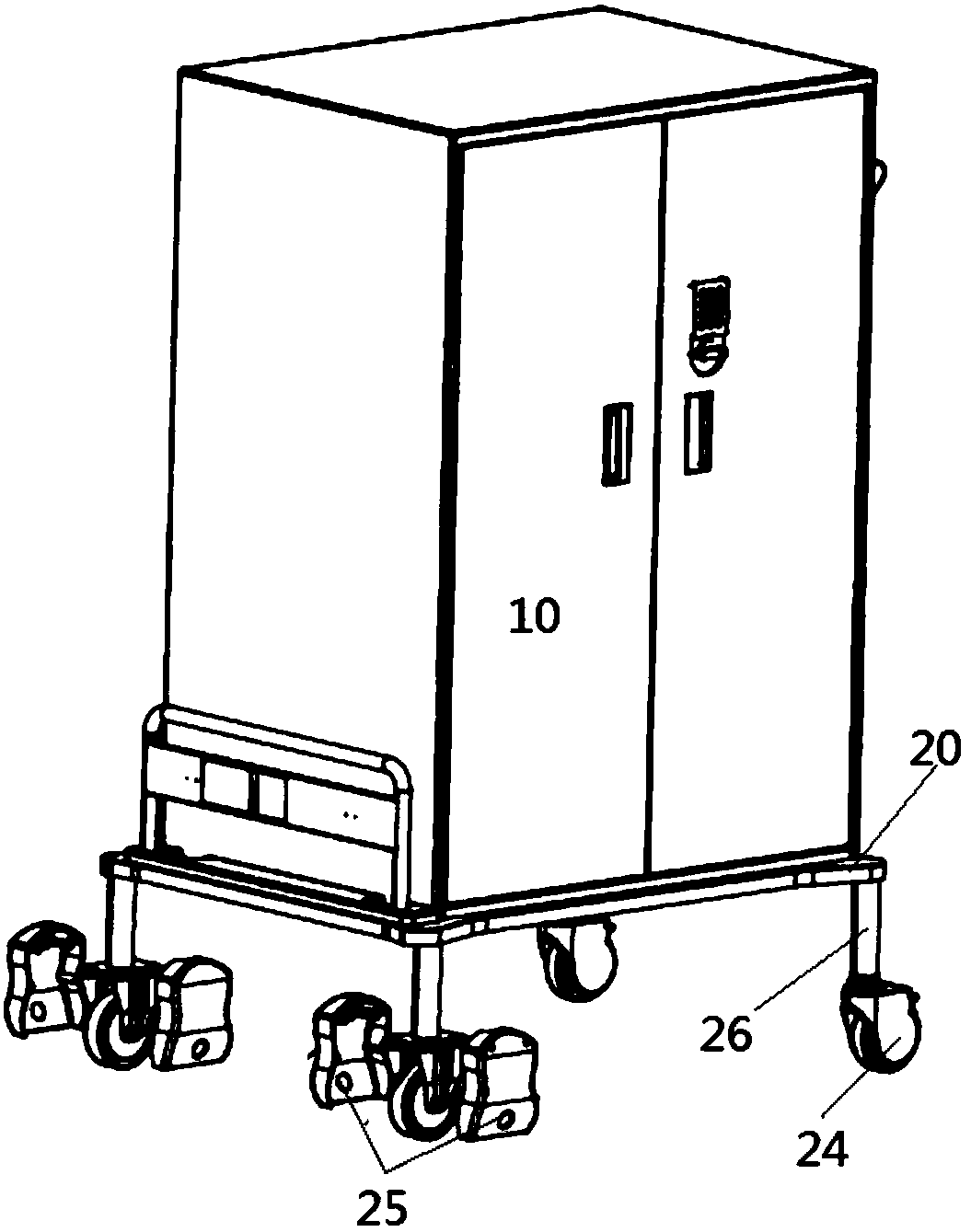

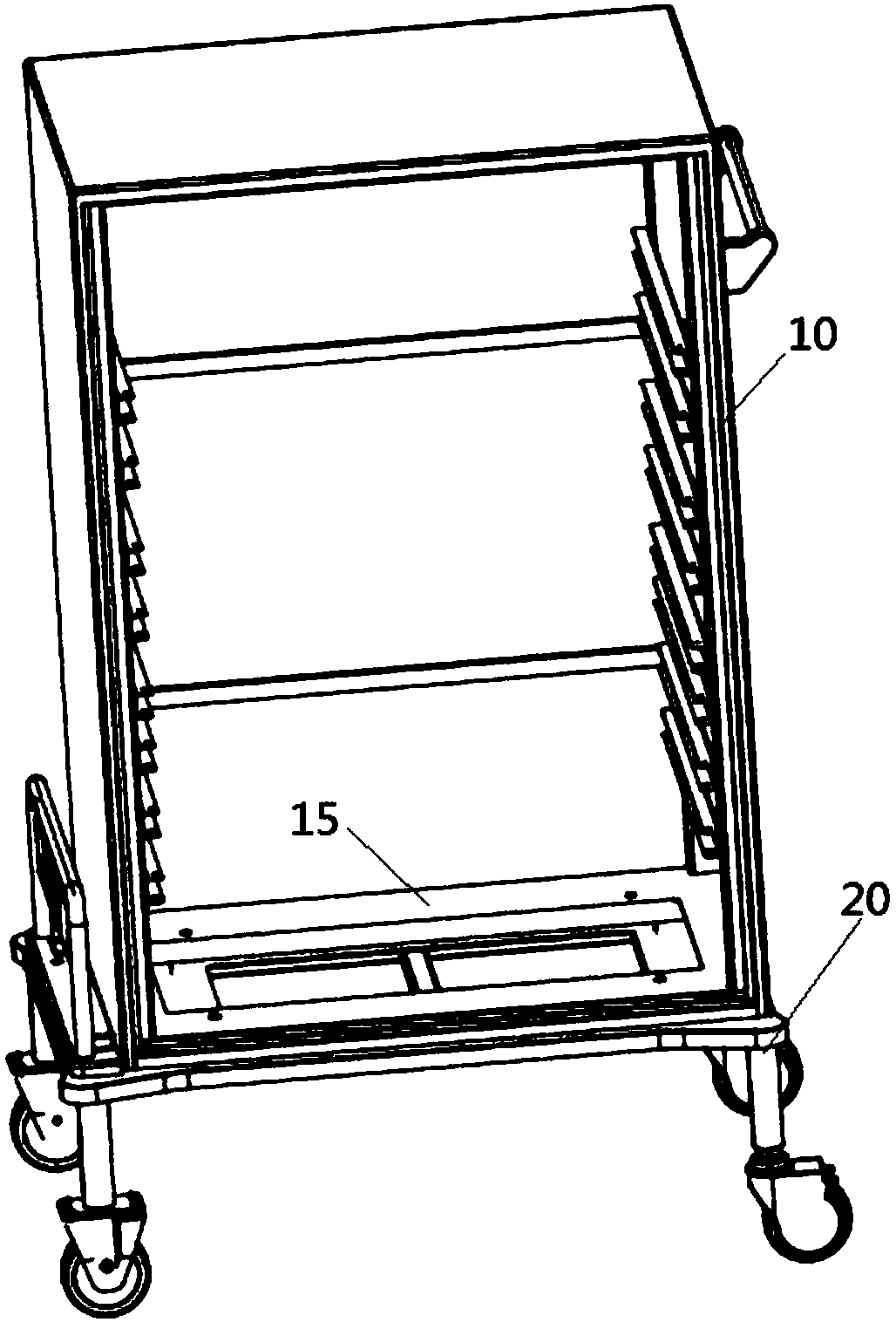

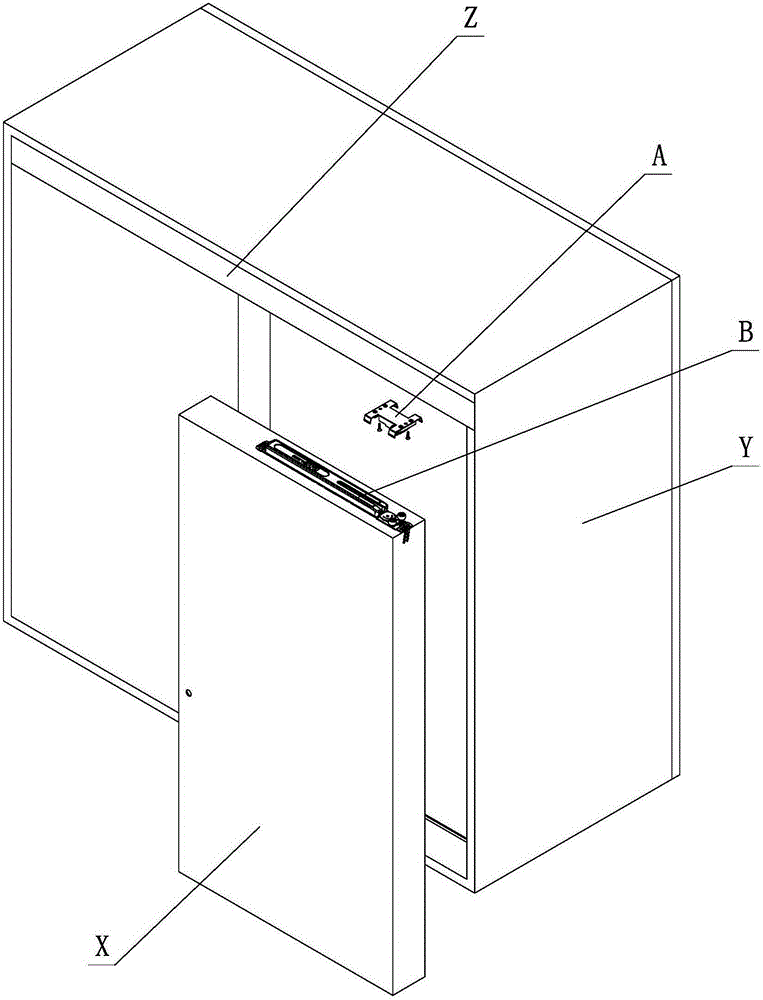

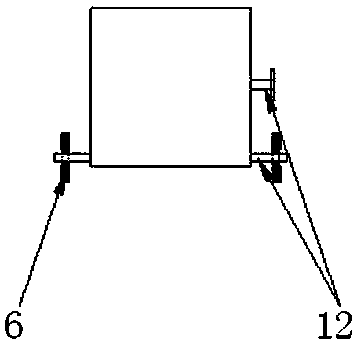

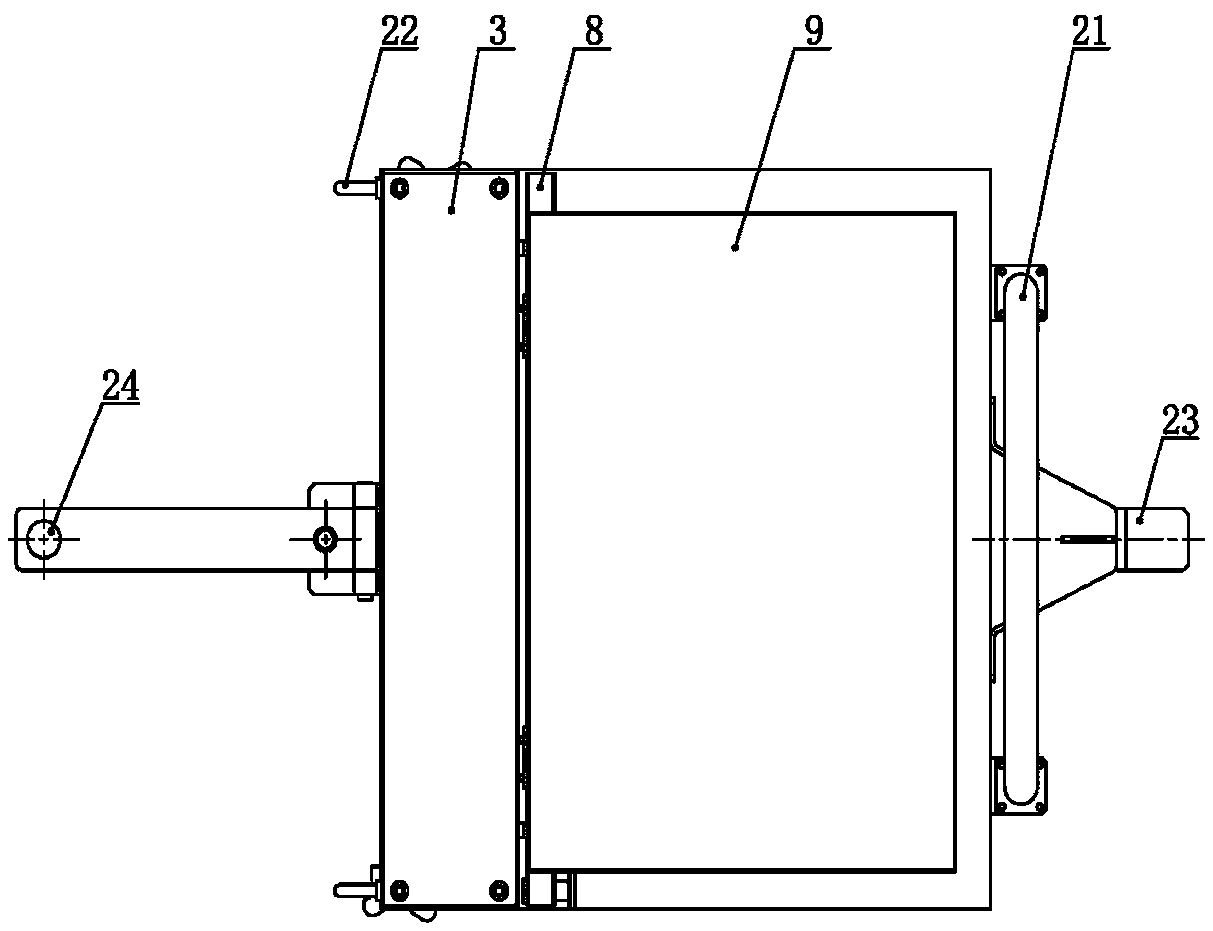

Storage cabinet and robot for shifting storage cabinet

PendingCN107826414APrevent slippingInhibit sheddingManipulatorExternal fittingsPulleyElectrical and Electronics engineering

The invention discloses a storage cabinet and a robot for shifting the storage cabinet. The storage cabinet comprises a cabinet body; a baseplate is arranged at the bottom of the cabinet body; and part of the baseplate extends out of the cabinet body to form an extension end for providing a clamping groove. The robot comprises a main body and a chassis; the main body is arranged at one end of thechassis, and is provided with a control board; pulleys are arranged at the bottom of the chassis; a jacking device is arranged in the chassis; the pulleys and a driving mechanism in the jacking deviceare electrically connected with the control board in the main body; a lifting plate is arranged at an output end of the jacking device; the main body is provided with a clamping hook; the clamping hook is matched with the clamping groove; and when the jacking device drives the lifting plate to ascend to a preset position, the clamping hook is inserted in the clamping groove of the storage cabinetfor vertically and horizontally limiting the storage cabinet. The storage cabinet can be singly used; the robot can automatically transport the storage cabinet; the robot and the storage cabinet arestably connected and matched; and in the transportation process of the robot, the storage cabinet is not easy to fall, and can be effectively prevented from stealing.

Owner:SHANGHAI MROBOT TECH CO LTD

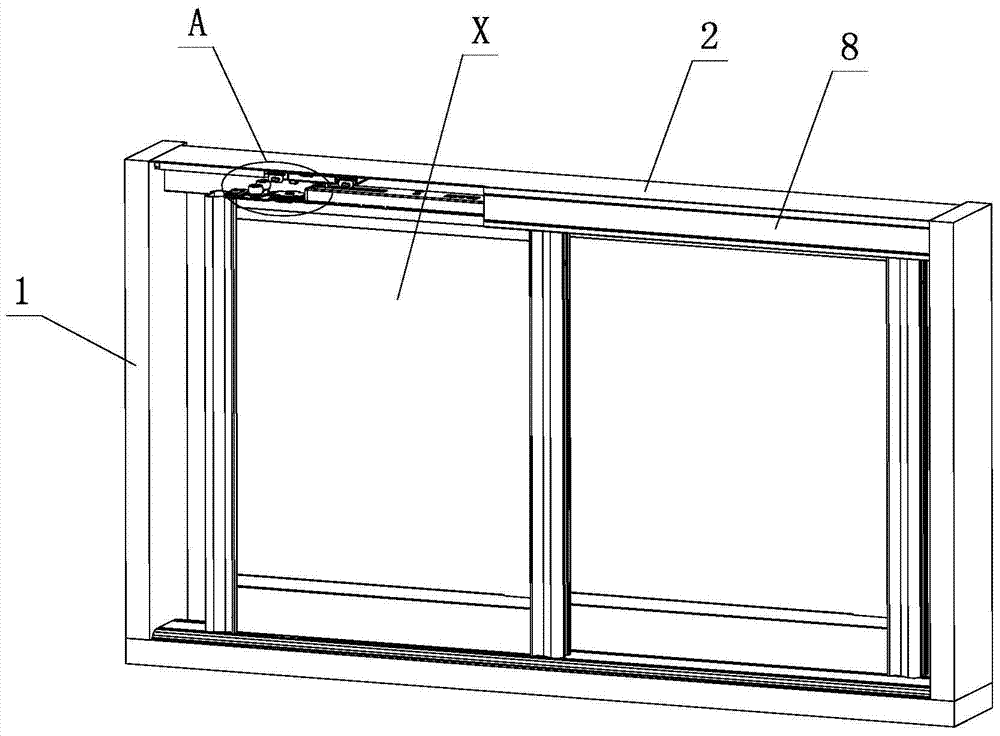

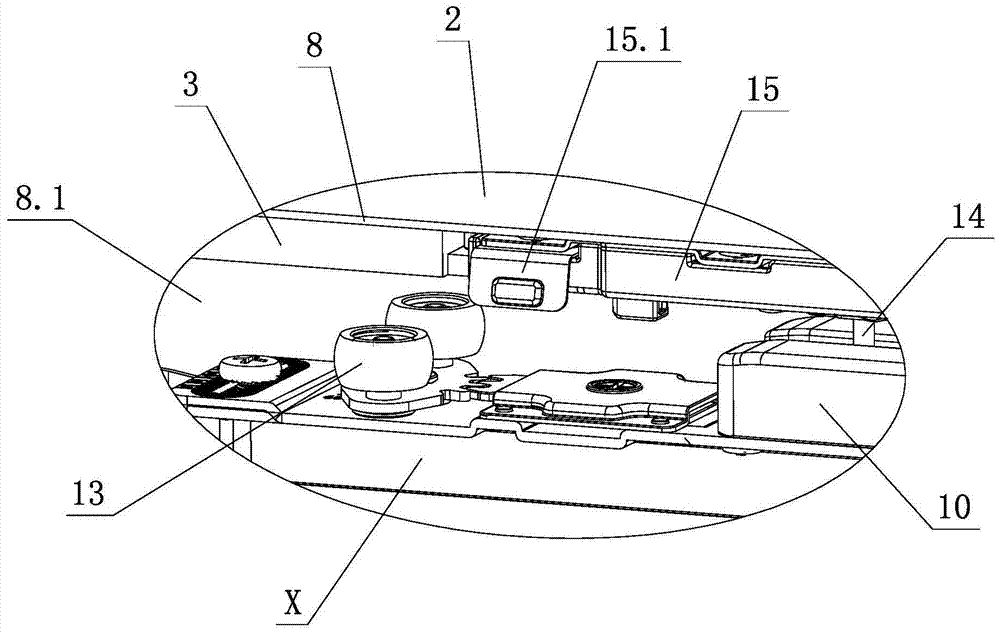

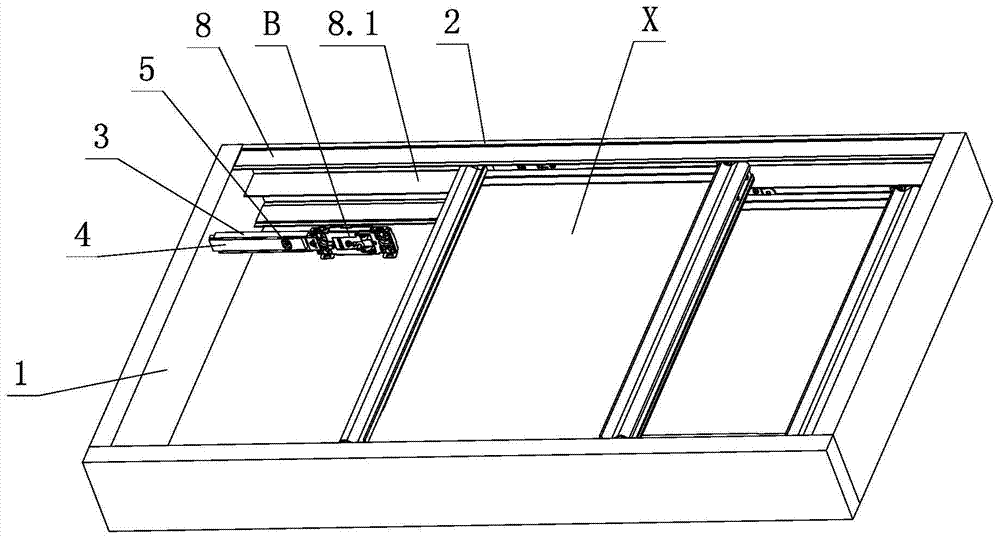

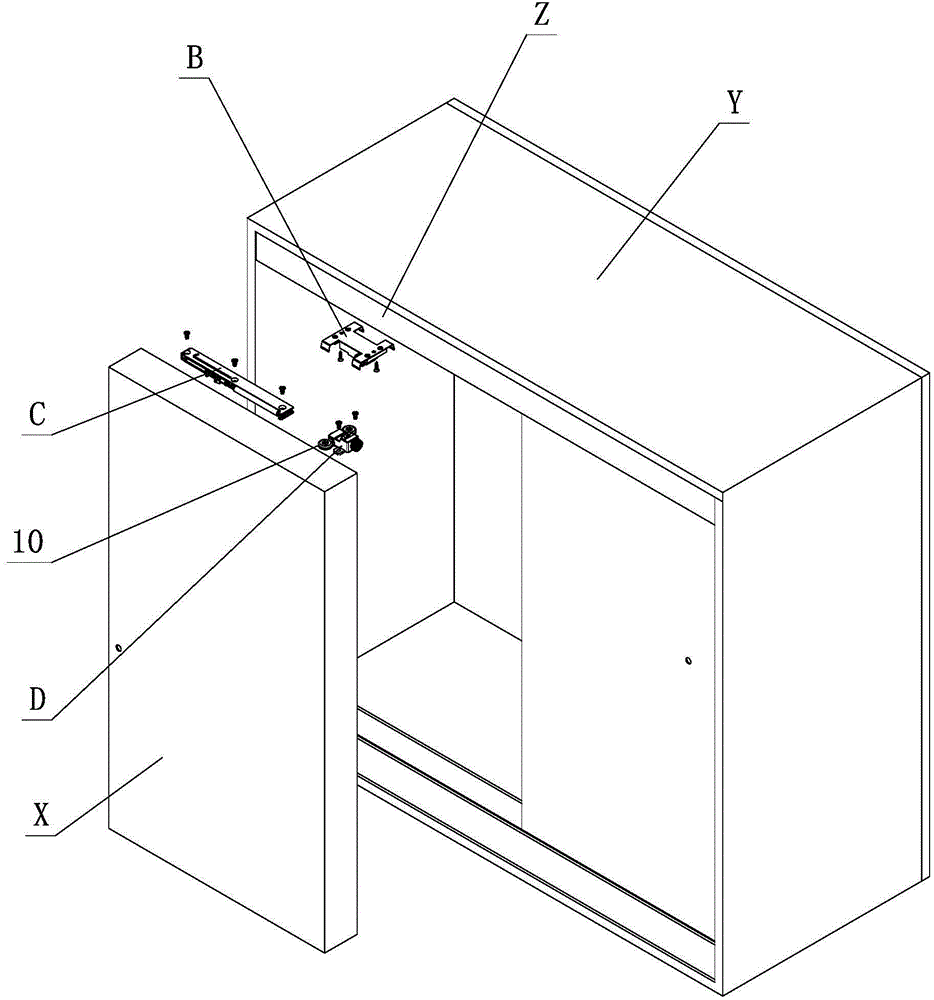

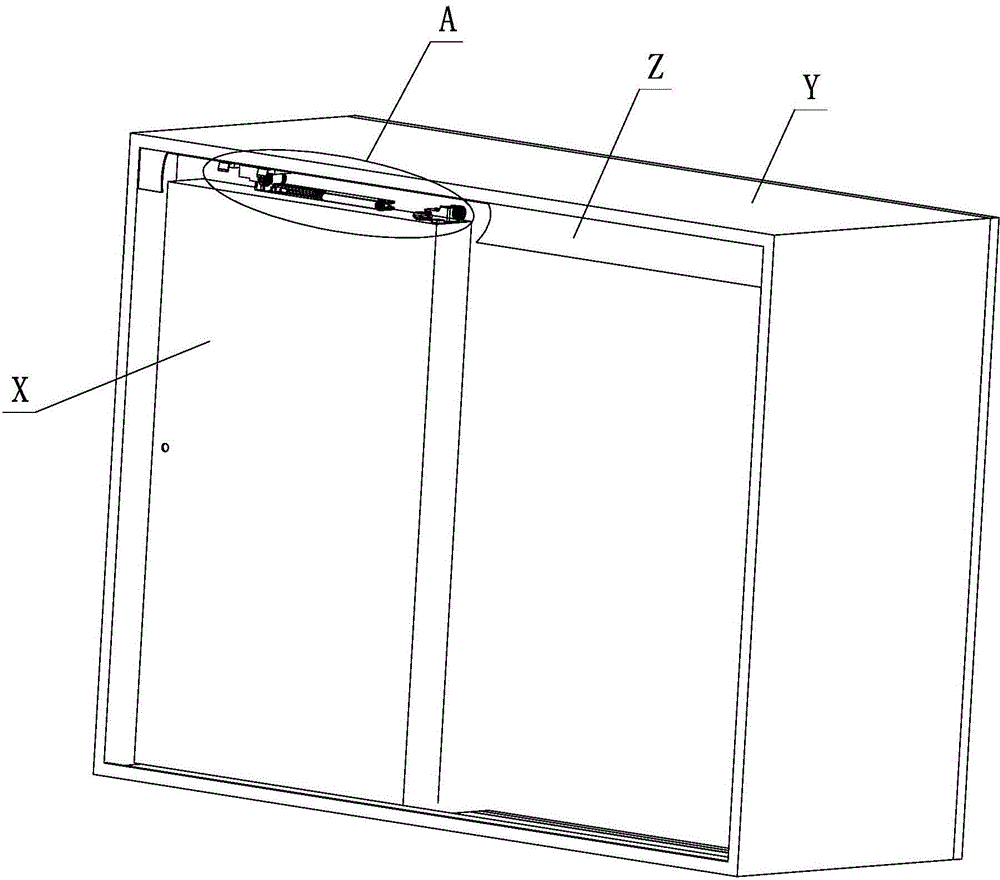

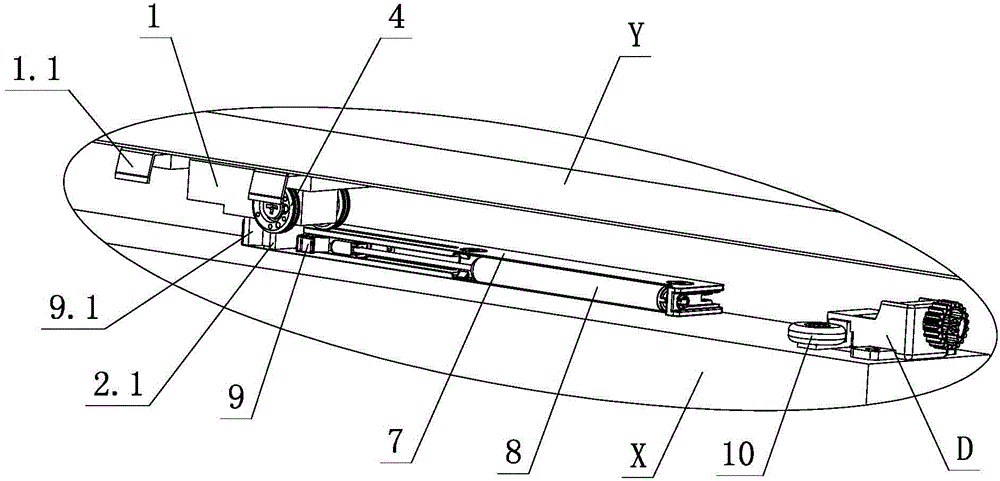

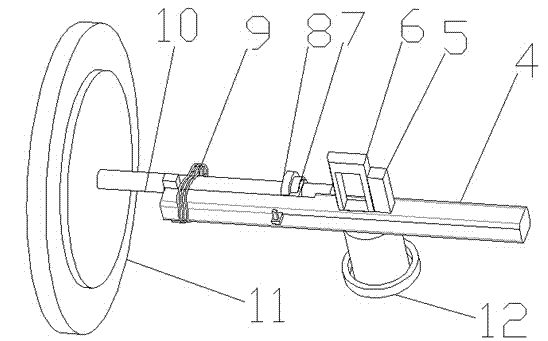

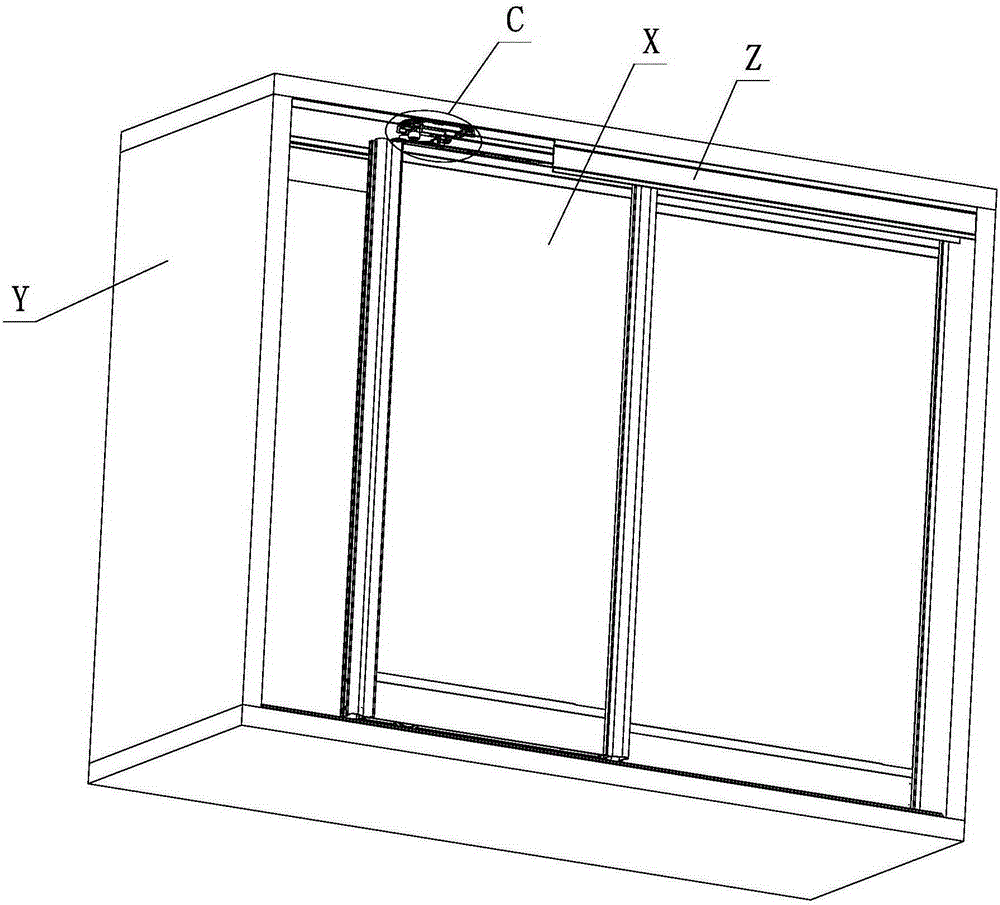

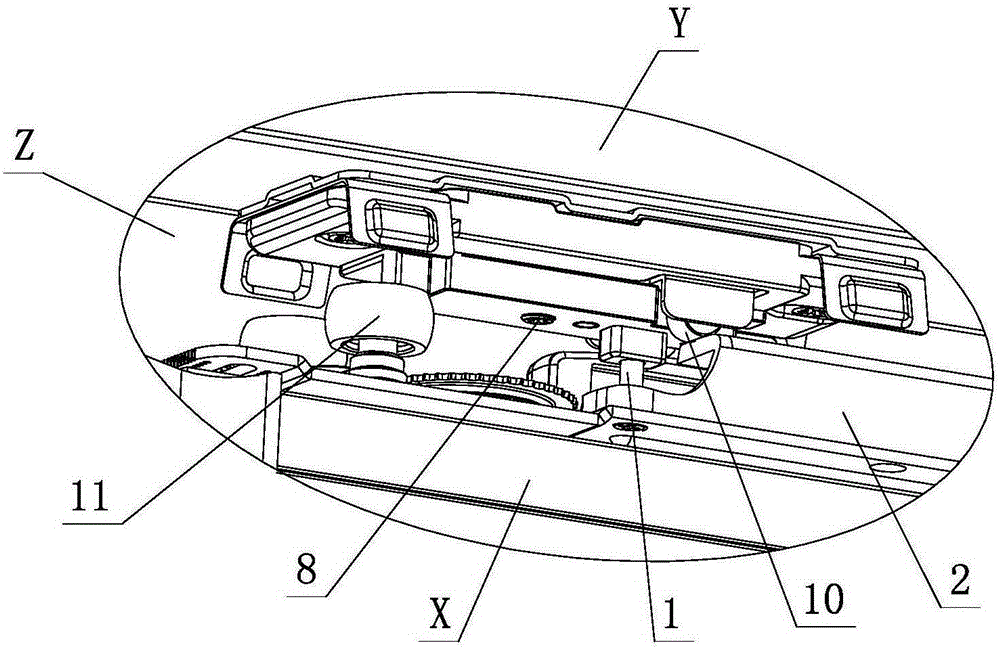

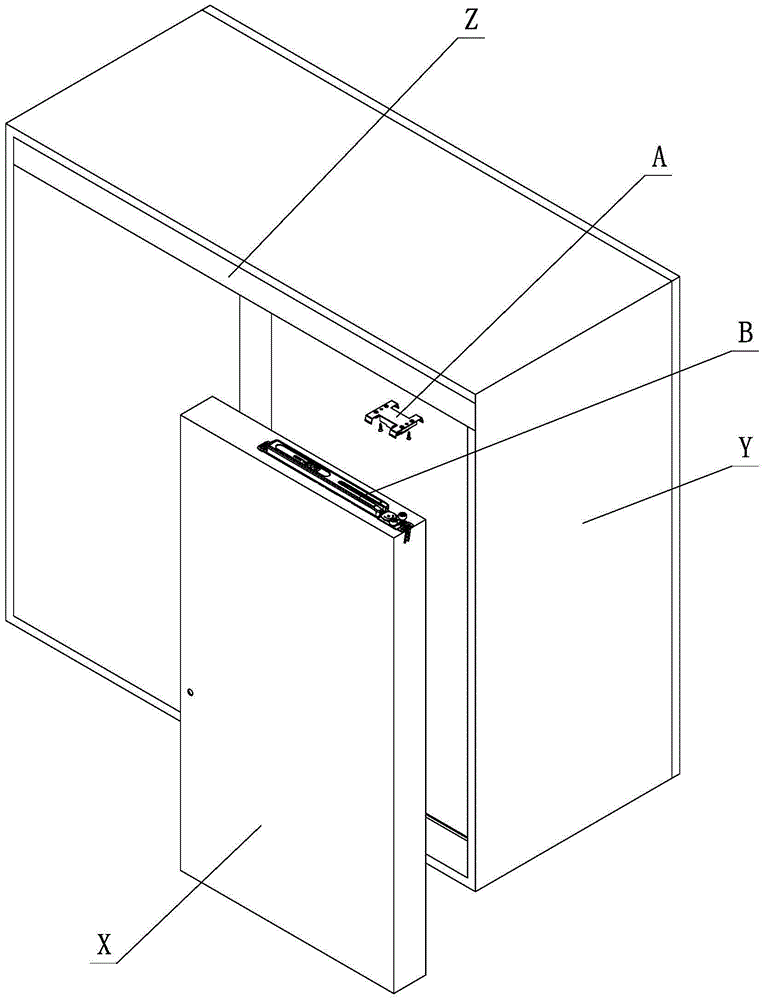

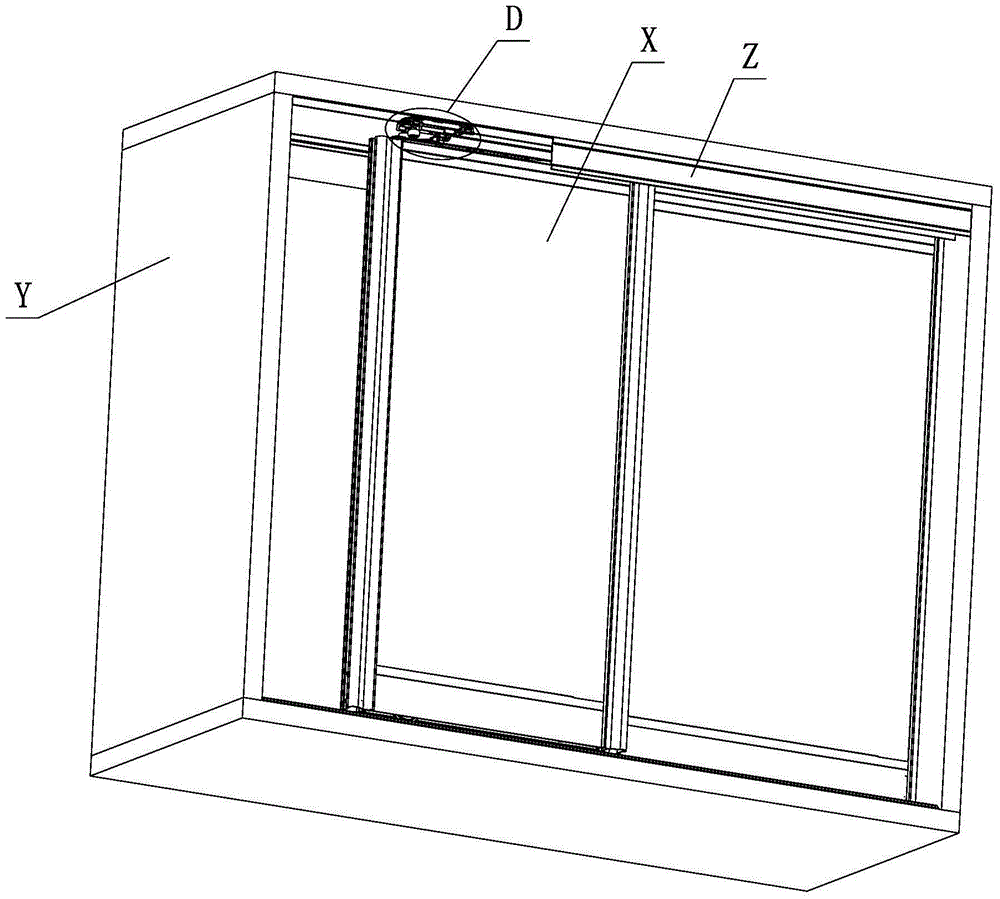

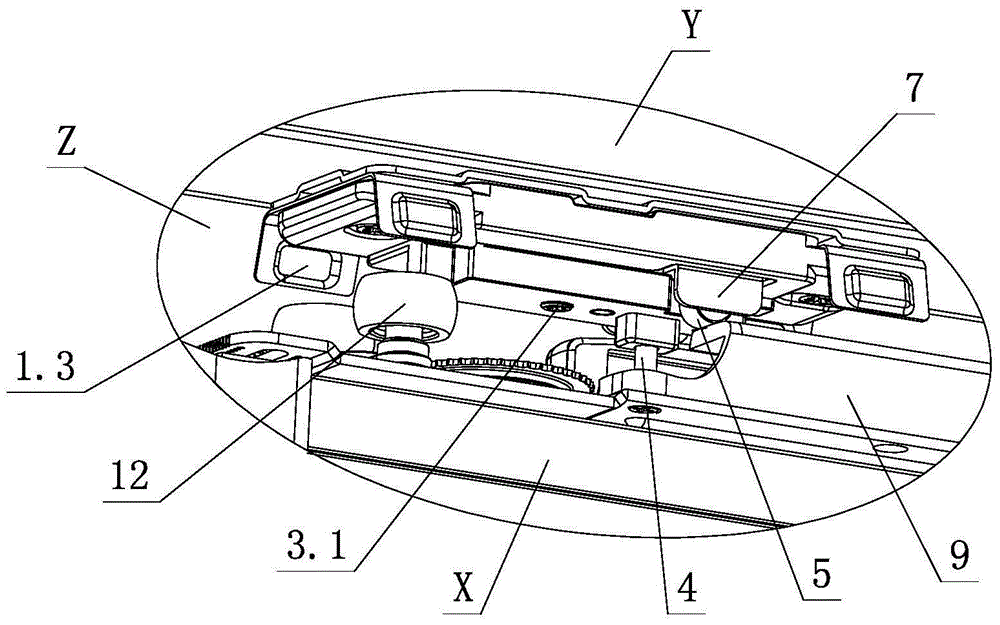

Adjustment and positioning mechanism of furniture side sliding door

ActiveCN105442991BSliding opening and closing force is smallMeet the needs of useBuilding braking devicesWing arrangementsEngineeringMechanical engineering

Owner:伍志勇

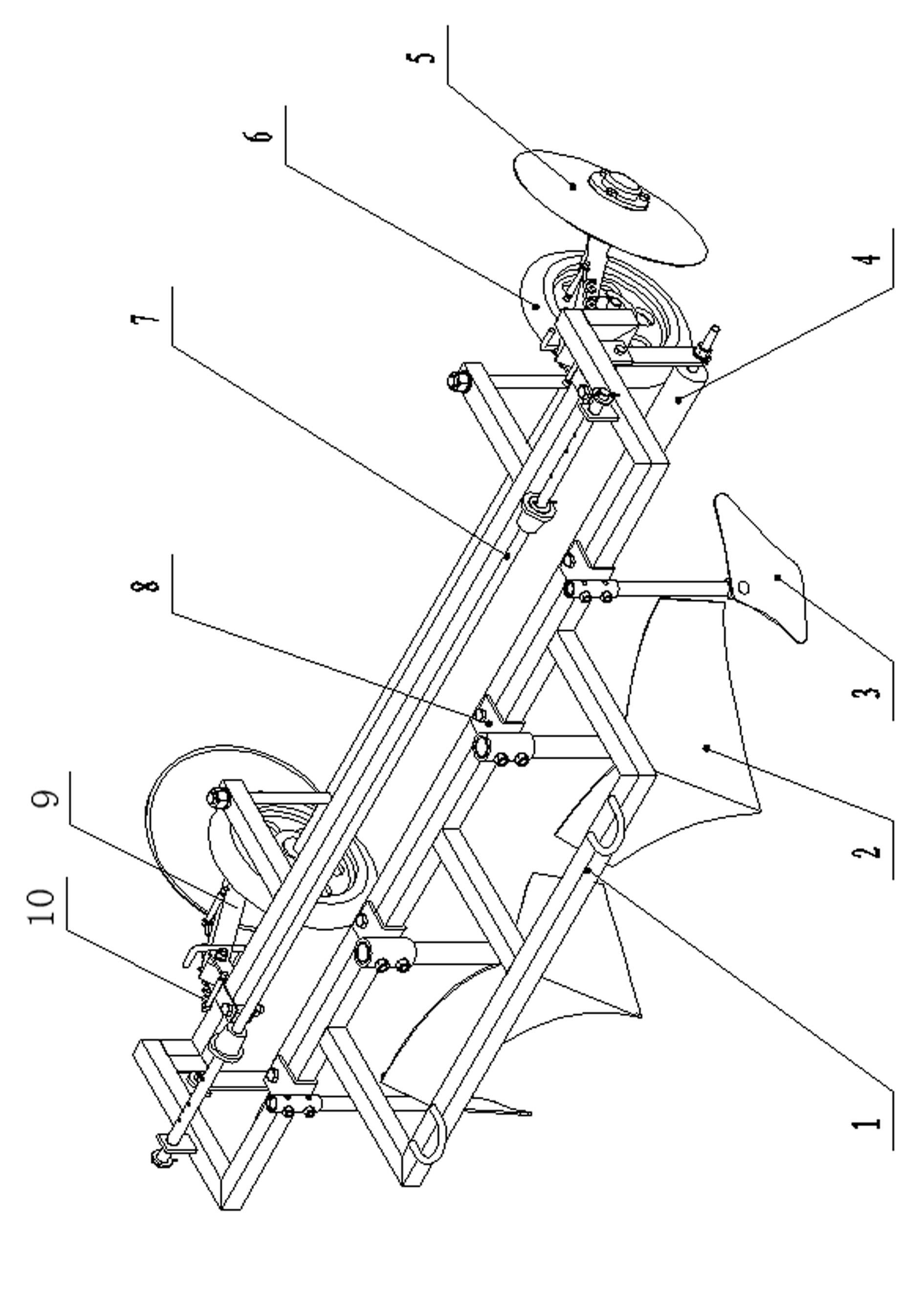

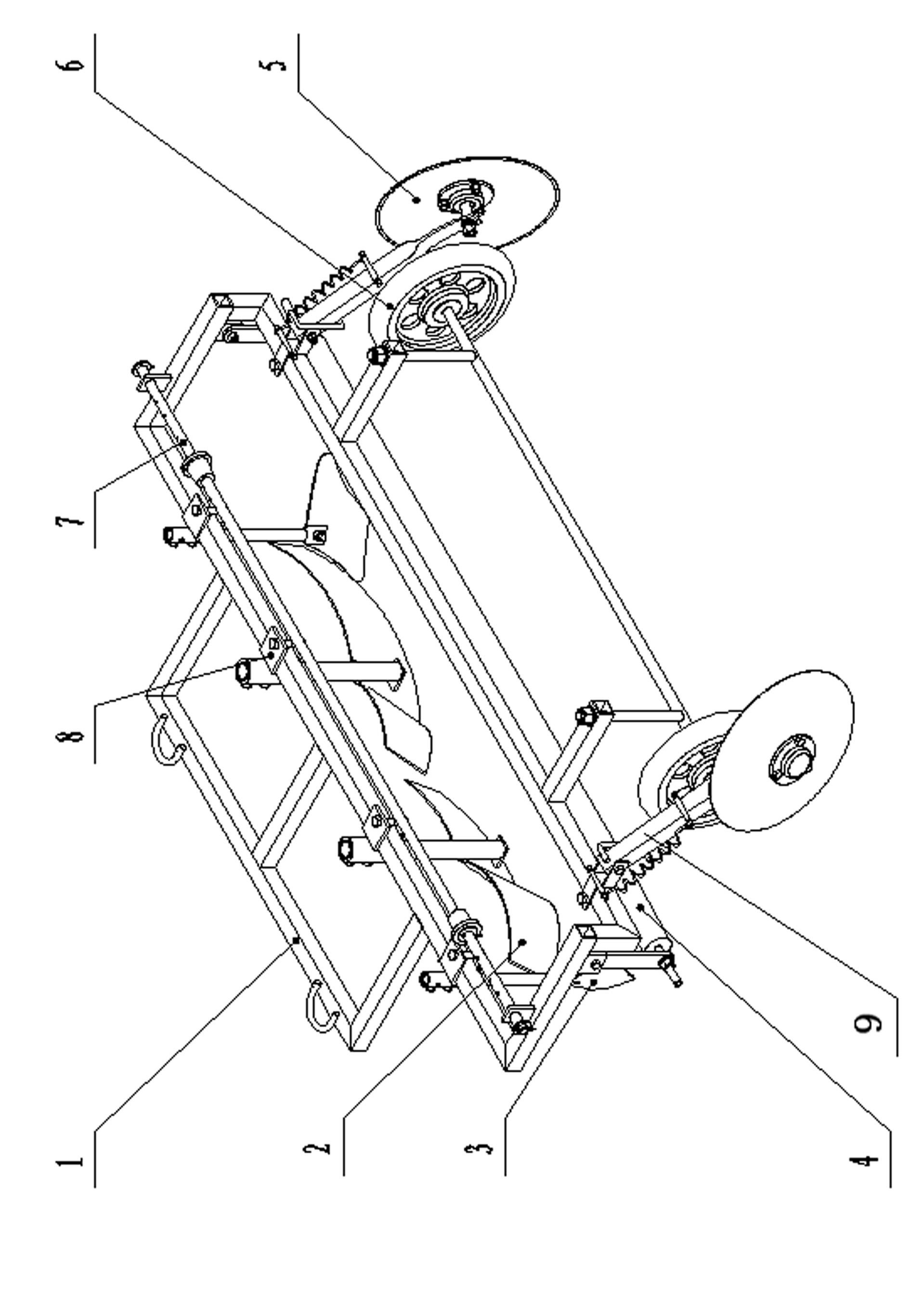

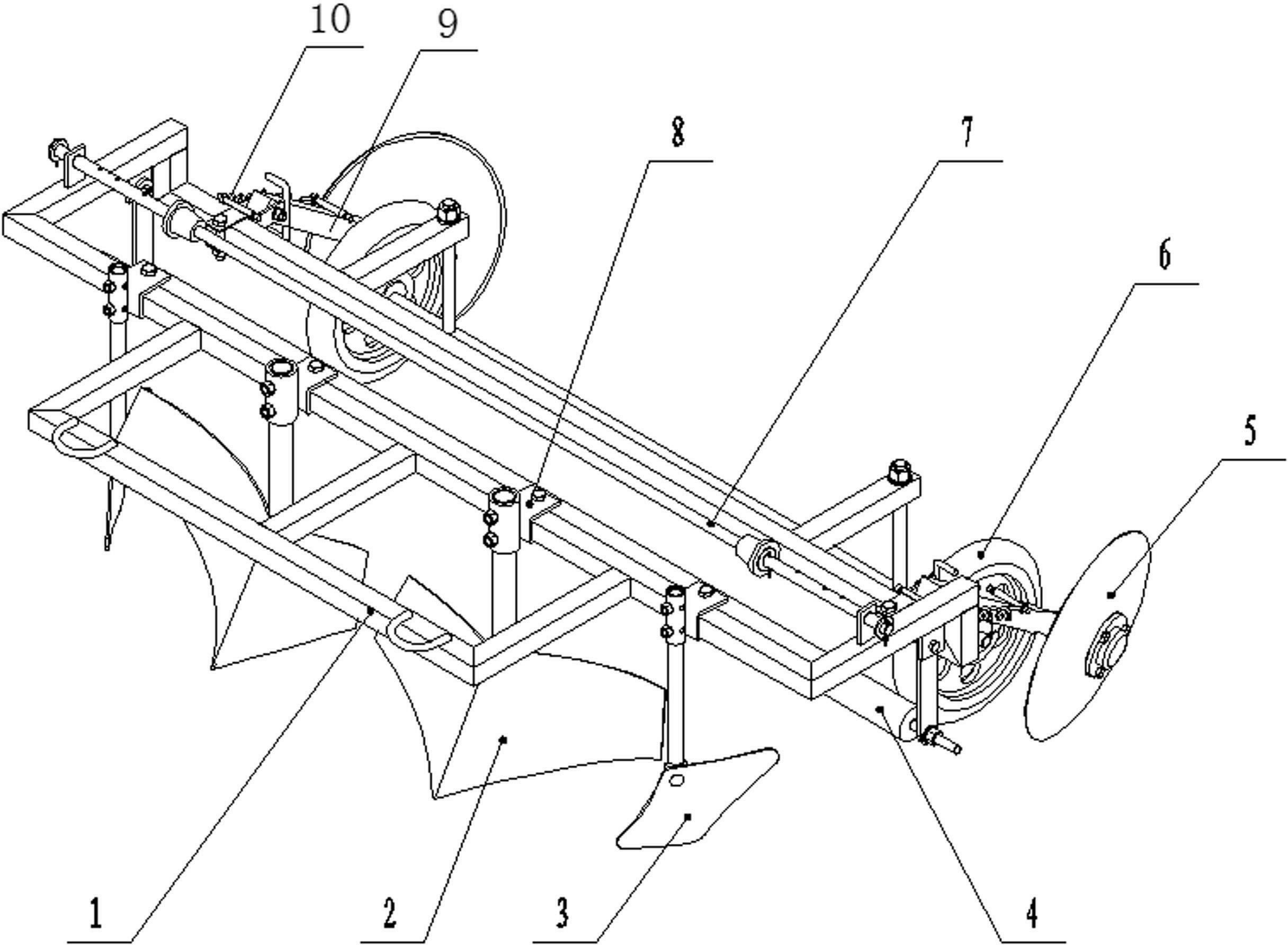

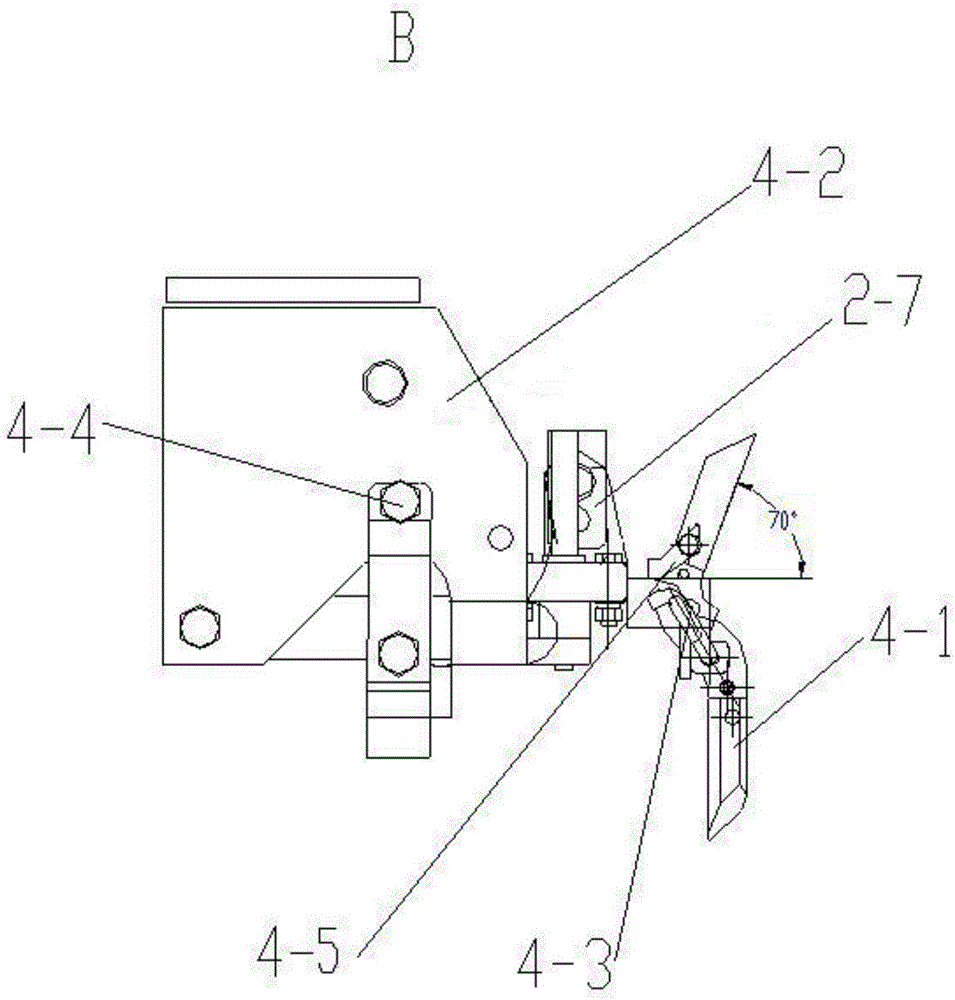

Trailed combined working machine for ridging, furrowing, paving films and covering soil on film edges

ActiveCN102656968ASimple machine structureReduce weightSpadesPloughsAgricultural engineeringSoil cover

The invention discloses a trailed combined working machine for ridging, furrowing, paving films and covering soil on film edges. The trailed combined working machine comprises a machine frame, two ridging blades, two furrowing blades, a film unfolding roller, two soil covering plates, two film pressing wheels and a film hanging frame, wherein the two symmetrical ridging blades are arranged in the center of a middle transverse beam of the machine frame; the two furrowing blades are symmetrically arranged outside the ridging blades; the film hanging frame is arranged on a rear longitudinal beam of the machine frame; the film unfolding roller is arranged at the lower rear end of the film hanging frame; the two film pressing wheels corresponding to the furrowing blades are arranged on the rear longitudinal beam of the machine frame; and the two soil covering plates are arranged outside the two film pressing wheels respectively. The trailed combined working machine can perform a plurality of processes of ridging, furrowing, paving the films and covering the soil on the film edges once by taking animal power and man power as trailing power. The ridging blades can be adjusted by moving leftwards, rightwards, upwards or downwards according to the sizes and heights of ridges; and the furrowing blades can be adjusted by rotating leftwards, rightwards, upwards or downwards according to the amount of the soil to be covered on the film edges. The trailed combined working machine is simple in structure, light in weight and convenient to adjust and can be moved flexibly.

Owner:GANSU TAOHE TRACTOR MFG

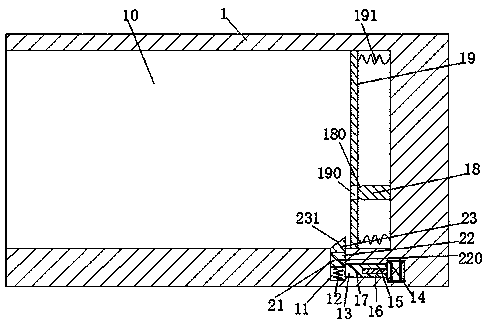

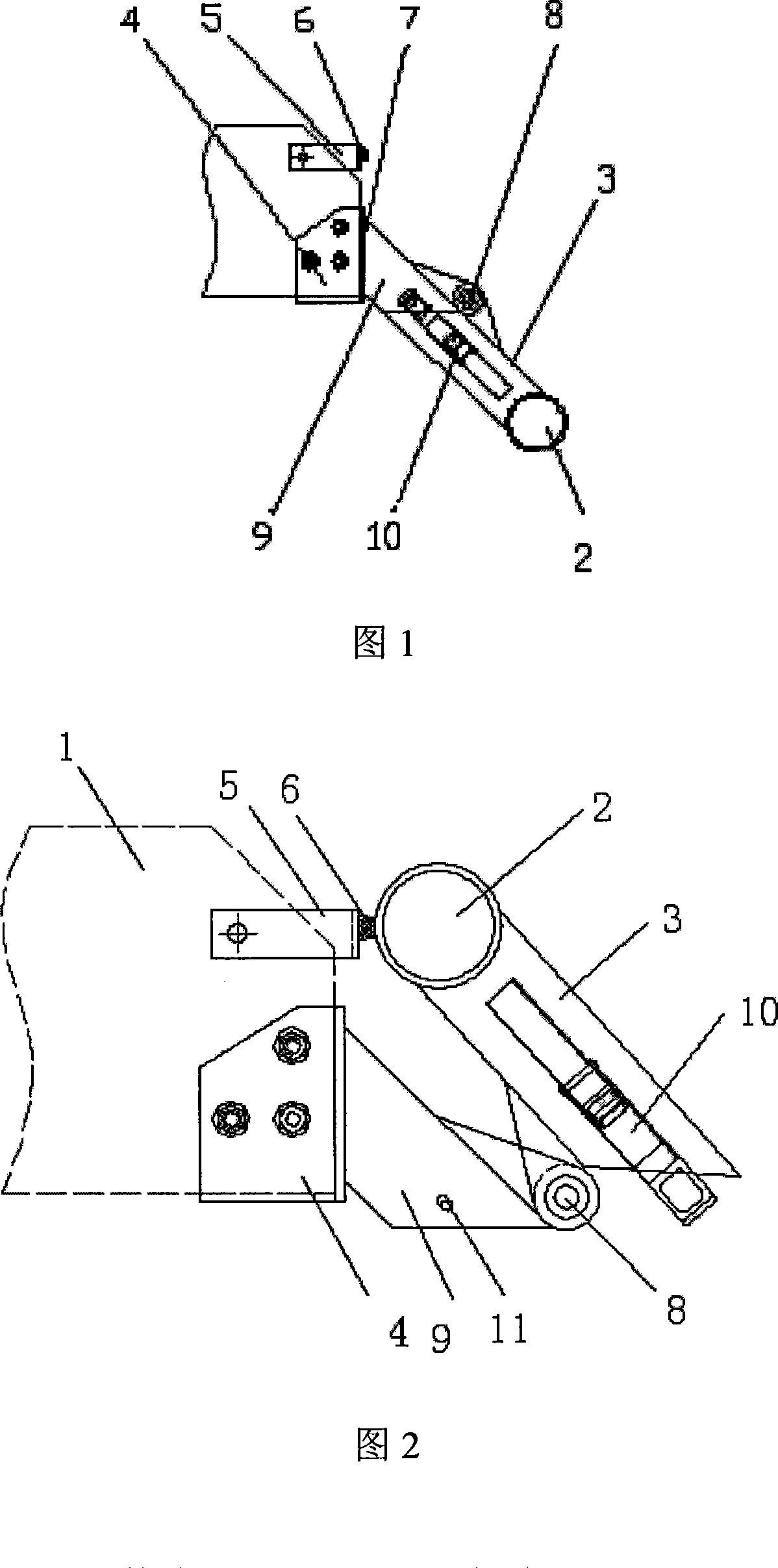

Anti-jumping stable adjusting structure for furniture sliding door

ActiveCN104806101APrevent bouncing up and downSliding opening and closing force is smallBuilding braking devicesWing openersMechanical engineeringEngineering

The invention discloses an anti-jumping stable adjusting structure for a furniture sliding door. The anti-jumping stable adjusting structure comprises a stable adjusting device, wherein the stable adjusting device comprises a fixed seat, a shifting element and an adjusting element; the shifting element and the adjusting element are arranged on the fixed seat. The anti-jumping stable adjusting structure is characterized in that rollers are arranged on the fixed seat; an acting part is arranged on the adjusting element; a tool acts on the acting part of the adjusting element; the adjusting element rotates in a positioned way, and is used for driving the rollers and the shifting element to slide upwards and downwards in a positioned way relative to the fixed seat simultaneously and / or synchronously. Through the structural improvement, the anti-jumping stable adjusting structure has the characteristics of simple and reasonable structure, reliable performance, rapidness in adjustment, convenience in operation, long service life, high connection compactness among members, silence, stability and smoothness in an opening / closing process, small force and the like, and has high practicability.

Owner:伍志勇

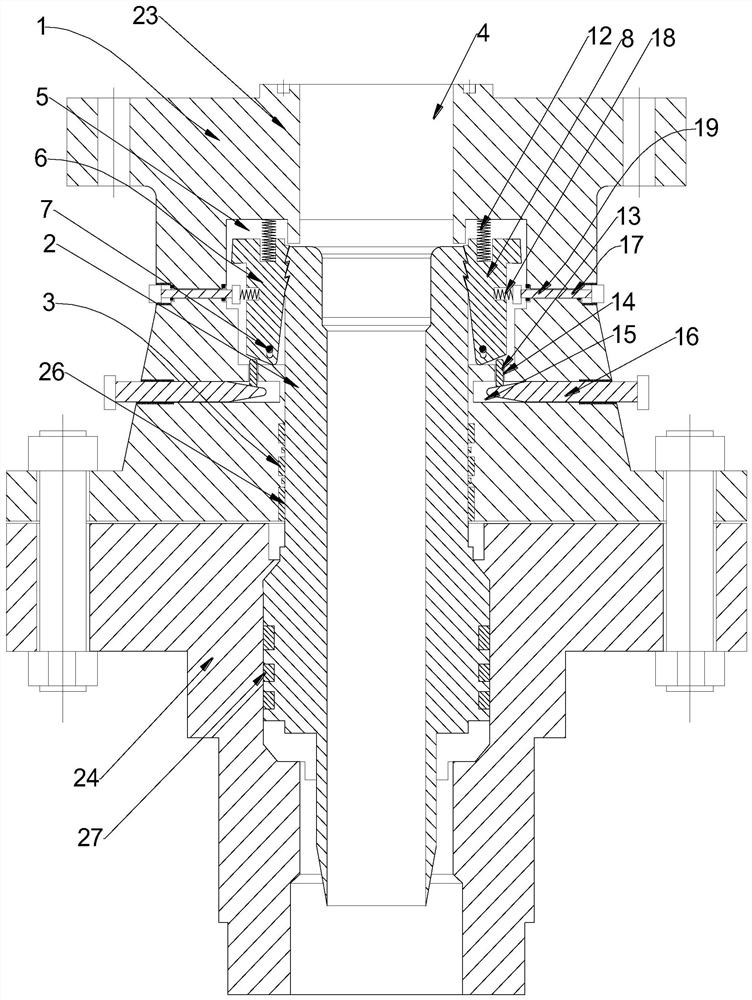

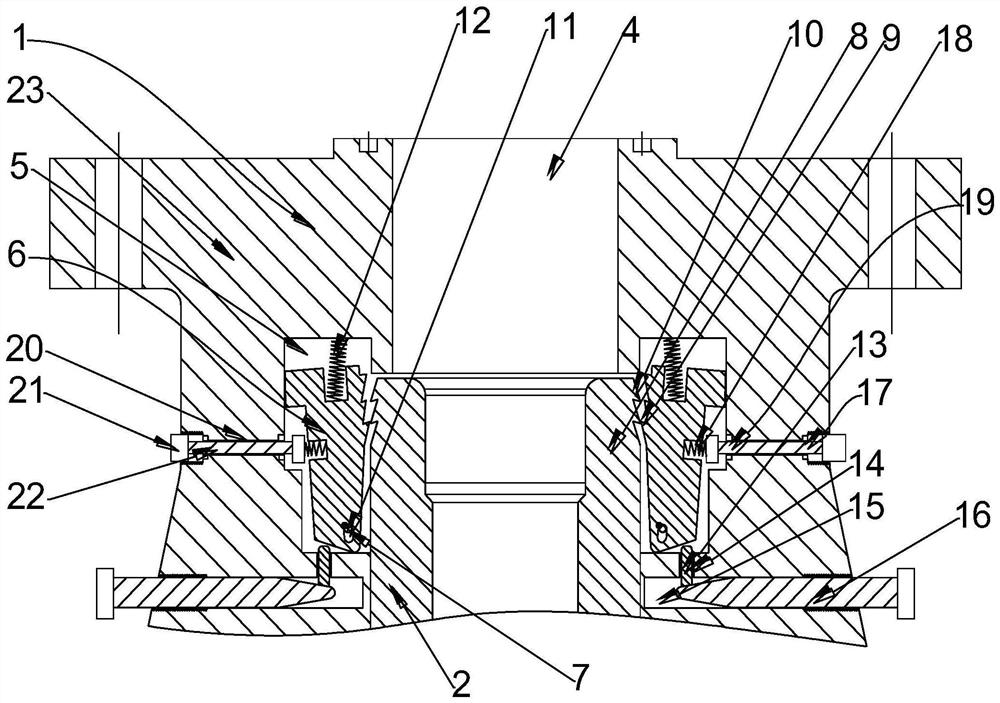

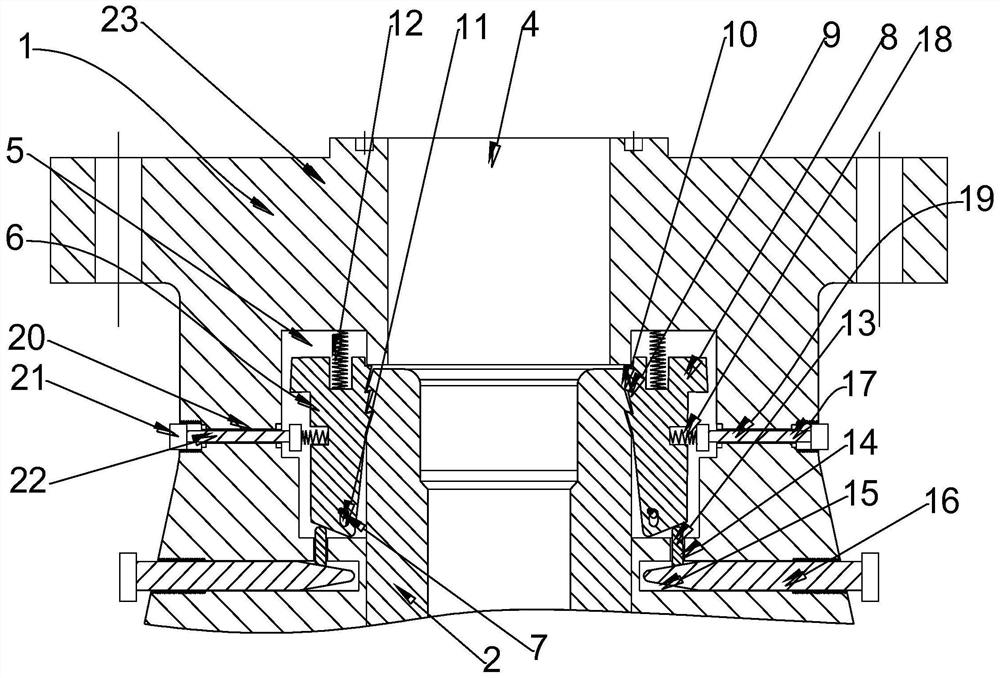

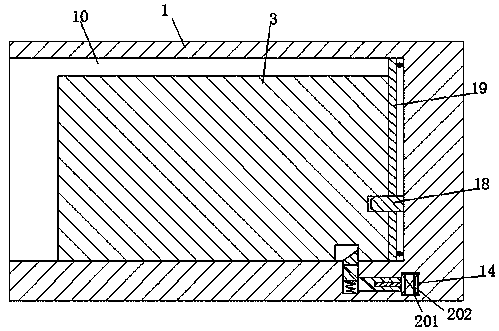

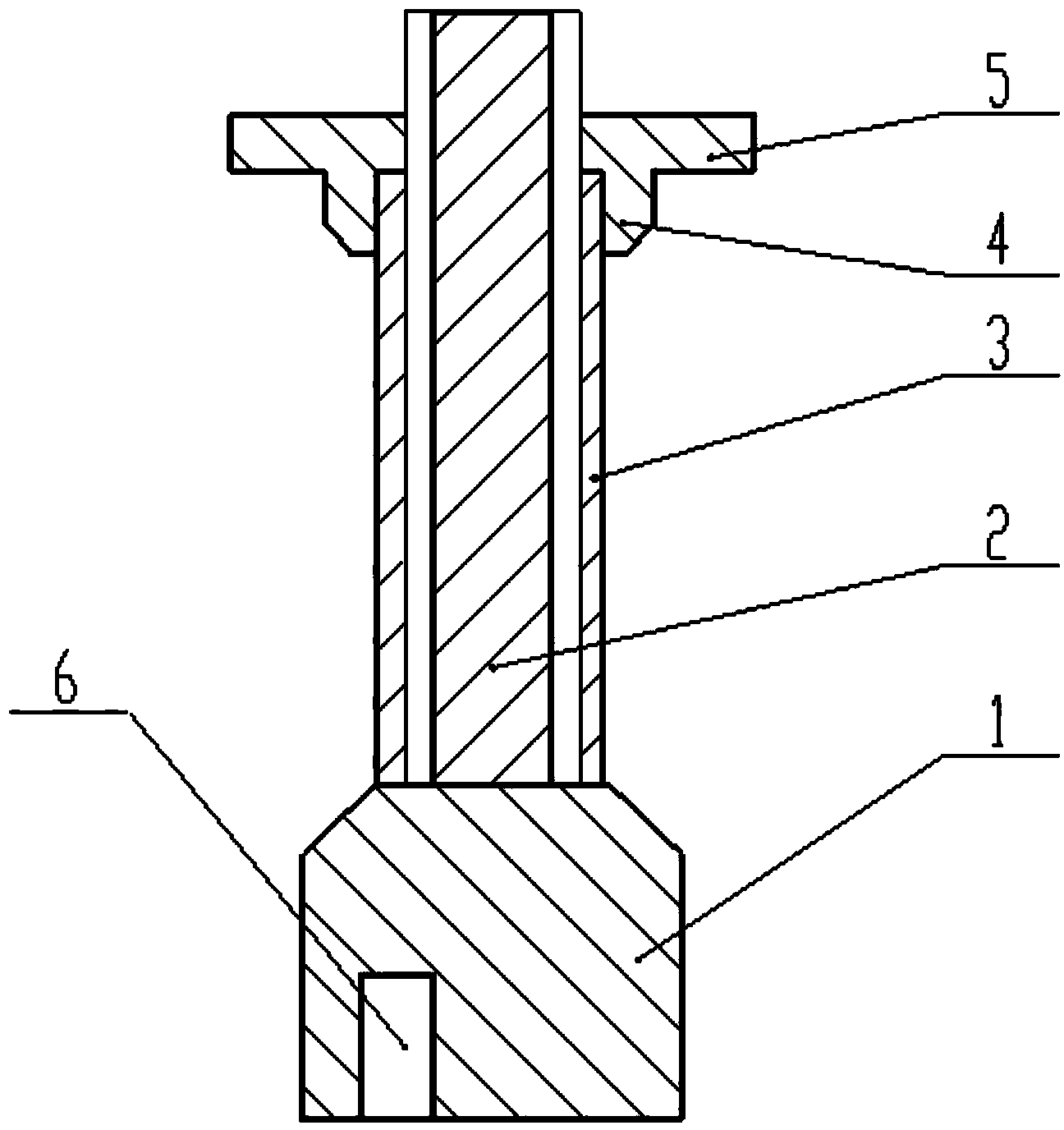

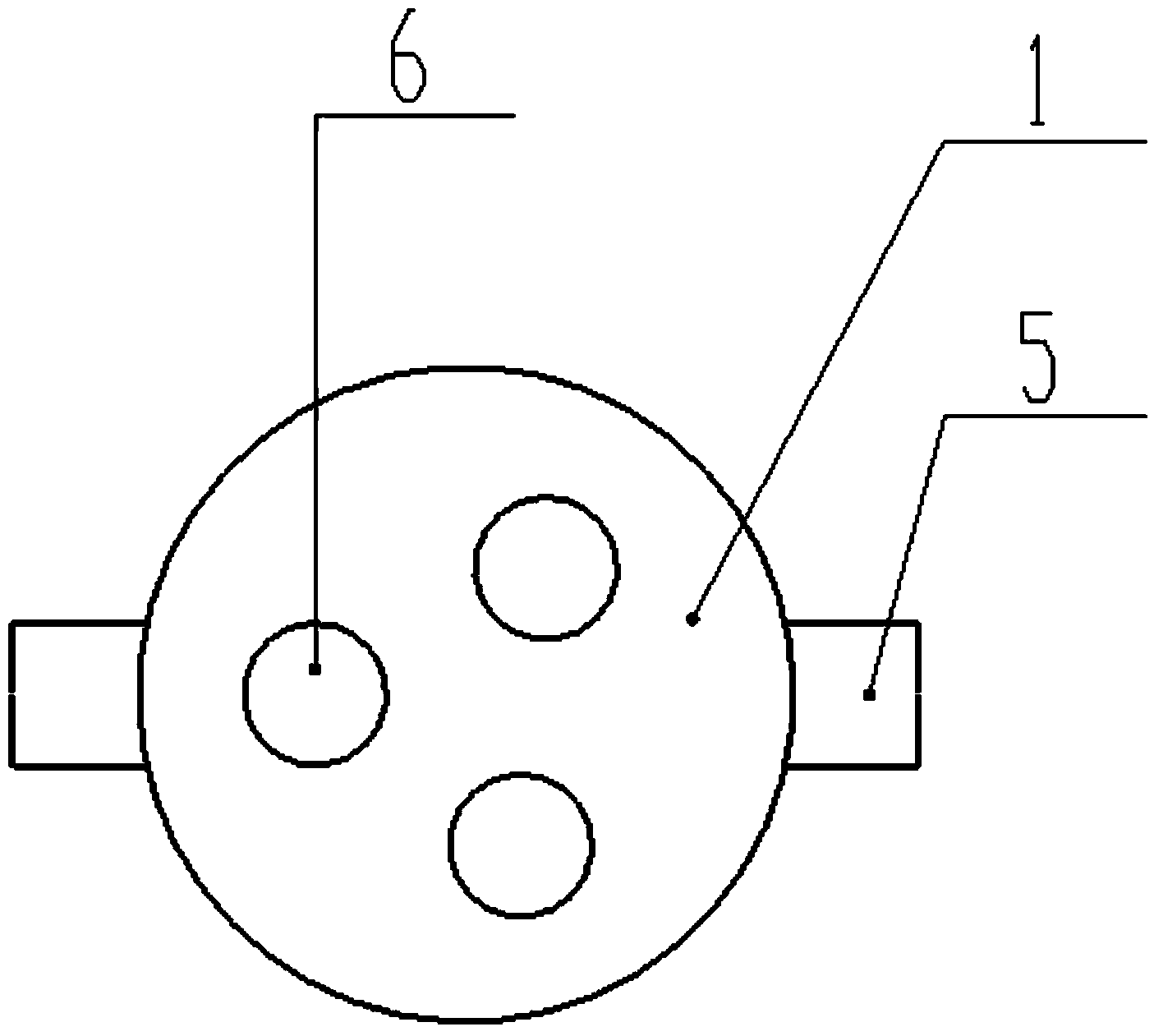

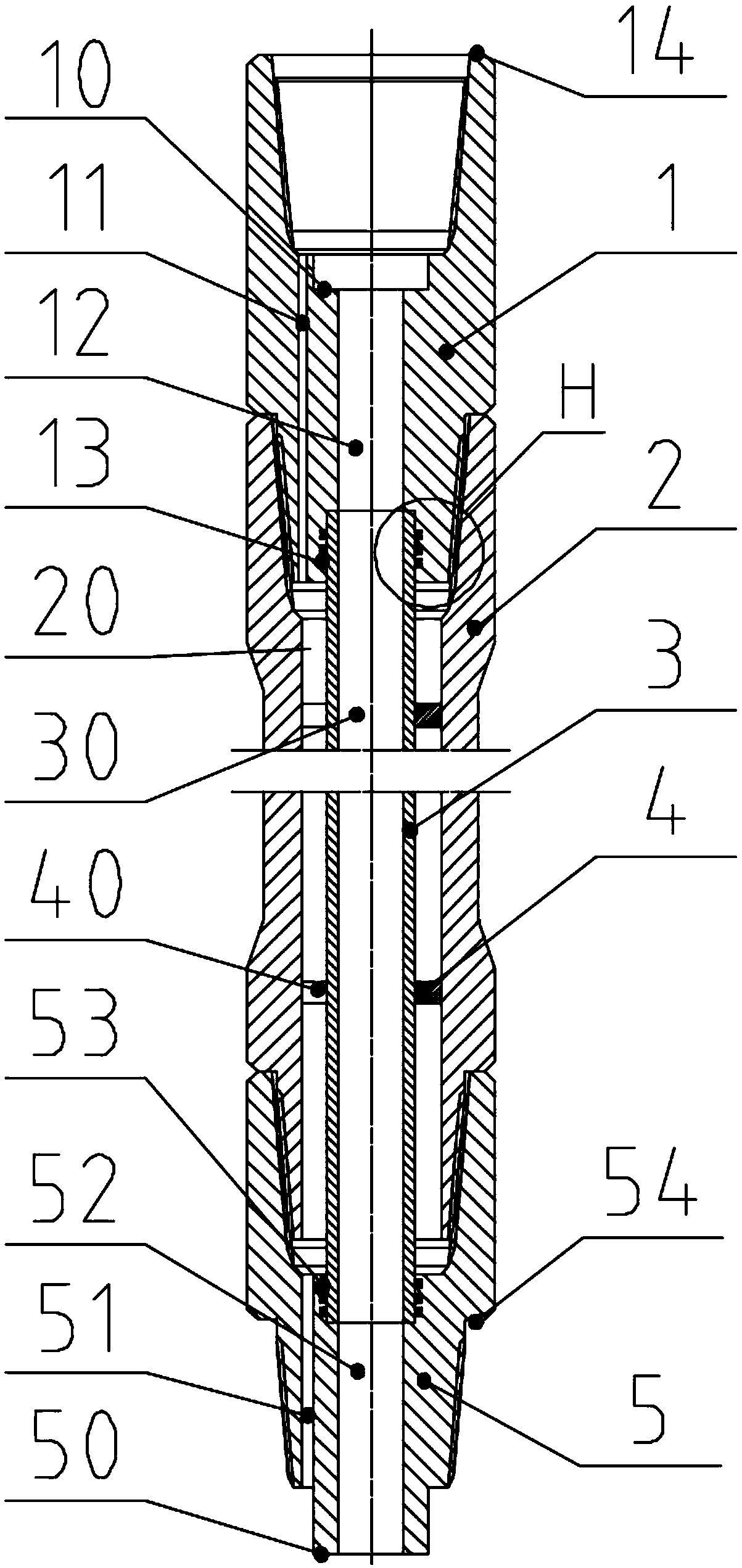

Self-locking casing head

ActiveCN113006731APrevent rotationPrevent bouncing up and downSealing/packingStructural engineeringPetroleum oil

The invention relates to the technical field of petroleum drilling and production equipment, and provides a self-locking casing head. The self-locking casing head comprises a casing head body, wherein the casing head body is provided with a mounting hole; a hanger is arranged in the mounting hole; a sealing assembly is arranged between the hanger and the mounting hole; the casing head body is further provided with a mounting groove; the mounting groove communicates with the mounting hole; a plurality of clamping pieces are uniformly distributed at intervals in the circumferential direction of the mounting hole; the clamping pieces are provided with inverted teeth; the end of the hanger is provided with positive teeth; the inverted teeth are matched with the positive teeth; the clamping pieces are provided with vertical long-strip holes; a rotating shaft penetrates through the long-strip holes; reset elastic pieces are arranged on the clamping pieces; the upper ends of the clamping pieces are connected with the mounting groove through the reset elastic pieces; the lower ends of the clamping pieces abut against the inner wall of the bottom surface of the mounting groove; the bottom surface of a locking piece mounting groove is provided with a locking hole; a locking piece is arranged in the locking hole in a sliding mode in the vertical direction; and the clamping piece is jacked up after sliding. According to the technical scheme, the problem that an oil pipe is prone to loosening in the prior art is solved.

Owner:京鸿石油钻采工程技术有限公司

Roller used in rice production

InactiveCN104741163AUniform processingStable speedGrain huskingGrain polishingPulp and paper industry

The invention relates to the field of milled cereal, in particular to a roller used in rice production. The roller comprises a grinding base and a grinding roller; the grinding base comprises a round boss and an annular groove, and the grinding roller comprises a roller body and a driving rod; the annular groove is formed in the ground surface at the periphery of the round boss, the cross section of the annular groove is in an inverted trapezoid shape, a vertical shaft is arranged on the round boss, the driving rod is inclined relative to the horizontal level, the driving rod comprises a fixed rod and a moving rod, the fixed rod is connected with the vertical shaft, a guide sleeve is arranged on the fixed rod, the moving rod passes through the guide sleeve and is bound to the fixed rod through a rope, and the roller body is vertically arranged at the tail end of the moving rod; a motor is connected with a decelerator through a belt, a vertical revolving shaft and a horizontal revolving shaft are arranged on the decelerator, the belt is connected to the horizontal revolving shaft of the decelerator, and the vertical revolving shaft of the decelerator is in gear connection with the vertical shaft. The roller used in rice production has the advantages that the processing speed is steady, the service life of the grinding roller is prolonged, and the rice processing quality is improved.

Owner:贵州省湄潭县富通米业有限公司

Disengaging-preventing maintaining mechanism of furniture movement parts

ActiveCN105275294AOff constant speedClose smoothlyWing arrangementsWing suspension devicesClose relativesEngineering

The invention discloses a disengaging-preventing maintaining mechanism of furniture movement parts. The disengaging-preventing maintaining mechanism comprises a movable component, a fixed component, a striking device and a damping stabilizing device. The damping stabilizing device is arranged on the movable component, the striking device is arranged on the fixed component, and when the movable component is closed for a section of a stroke relative to the fixed component, the striking device acts on the damping stabilizing device and generates buffering force. The striking device comprises a striking piece. The damping stabilizing device comprises a sliding groove base and a swinging element. A linear sliding area and a curve command awaiting area are arranged on the sliding groove base, the swinging element is arranged on the sliding groove base in a sliding manner and provided with a guide part and an elastic part, and a notch is formed between the guide part and the elastic part. When the movable component is closed relative to the fixed component and the swinging element is located in the linear sliding area, the striking piece acts on the elastic part, and the elastic part is elastically deformed and then penetrates the notch; and when the movable component is opened relative to the fixed component, and after the striking piece penetrates the notch, the striking piece acts on the elastic part and drives the swinging element to slide from the linear sliding area to the curve command awaiting area.

Owner:伍志勇

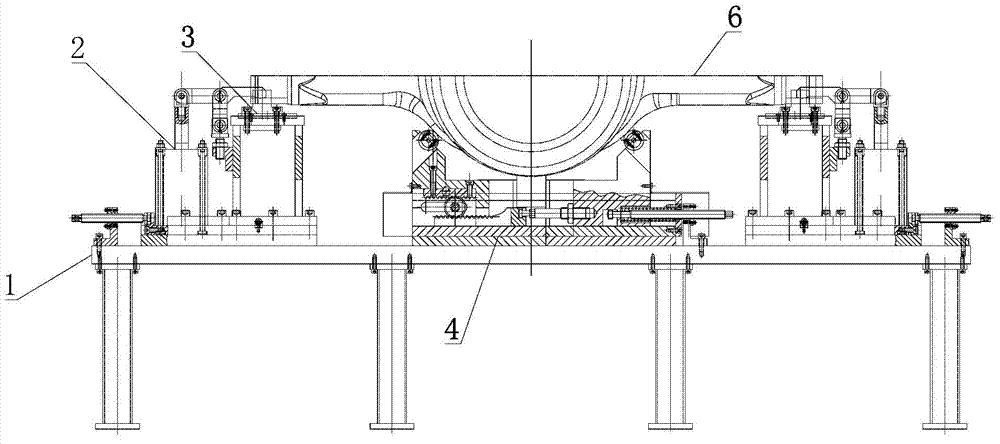

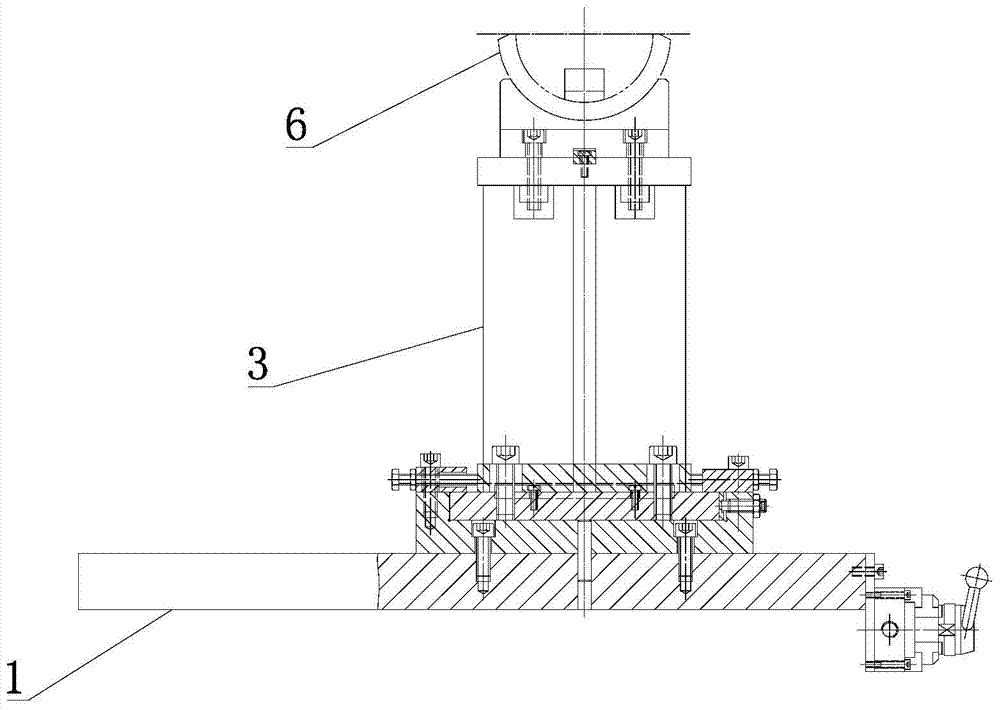

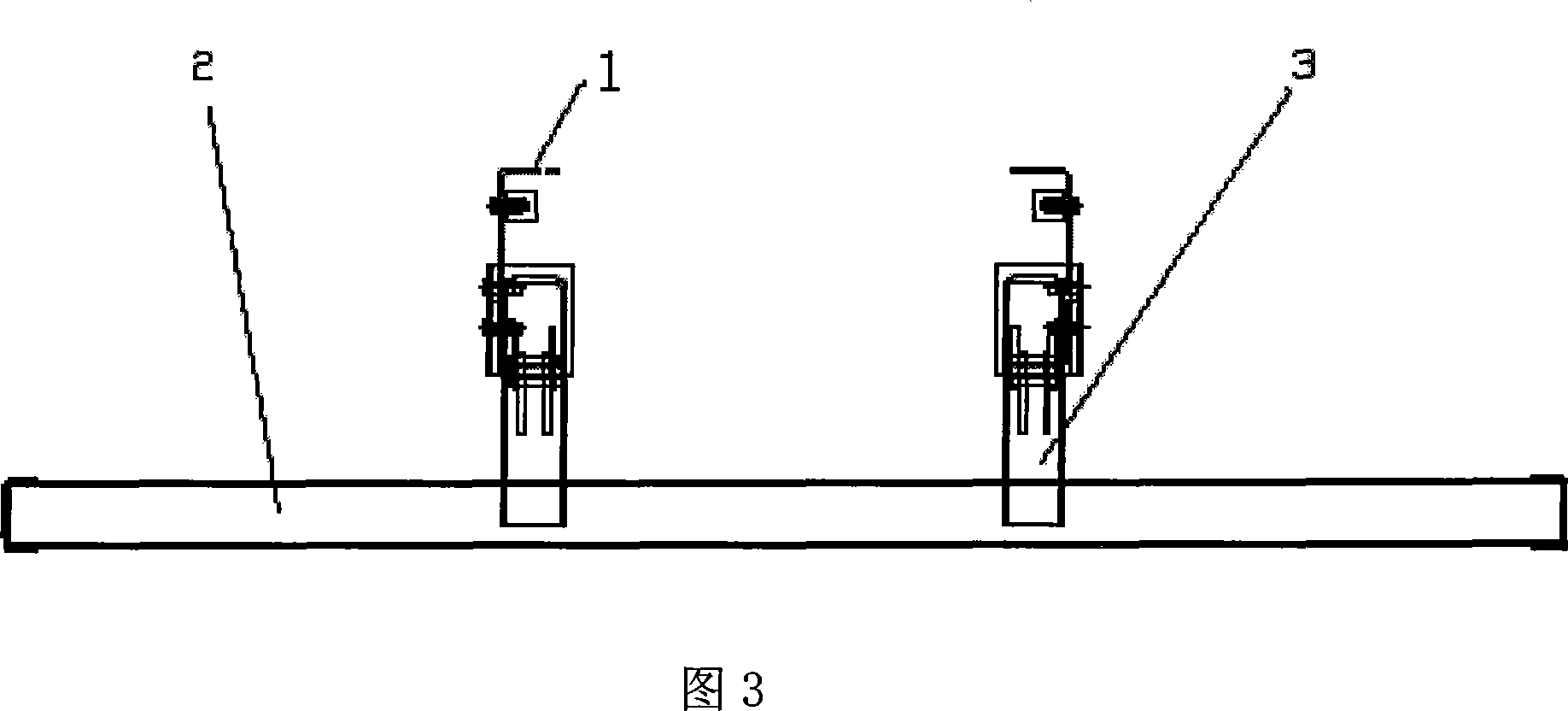

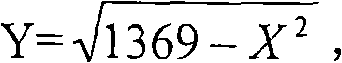

Work fixture for cutting groove at axle housing midpiece

ActiveCN103692133APrevent bouncing up and downPrevent radial movementWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringCushion

The invention discloses a work fixture for cutting a groove at an axle housing midpiece. The work fixture comprises a platform, a supporting structure and a clamping structure, wherein the supporting structure comprises end shaft supporting structures arranged at the two sides of the platform and a middle supporting structure arranged between the end shaft supporting structures, each end shaft supporting structure comprises a pedestal, a cushion block support arranged on the pedestal and a cushion block arranged on the cushion block support, the end face of each cushion block is provided with an arc-shaped inner groove, the middle supporting structure comprises a base, and a first supporting block and a second supporting block arranged at the left and right sides, the base is provided with a self-centering positioning mechanism for ensuring the synchronous movement of the first supporting block and the second supporting block, and the clamping structure comprises end shaft clamping mechanisms arranged at the two ends of an axle housing and used for clamping the two ends of the axle housing and a middle clamping mechanism for clamping the middle part of the axle housing. Through supporting and clamping the two ends and the middle of the axle housing midpiece for positioning, the positioning is accurate, the clamping is firm, the adjusting is convenient, and clamping and positioning for axle housing midpieces of different specifications and models can be realized.

Owner:GUANGDONG FUWA HEAVY IND

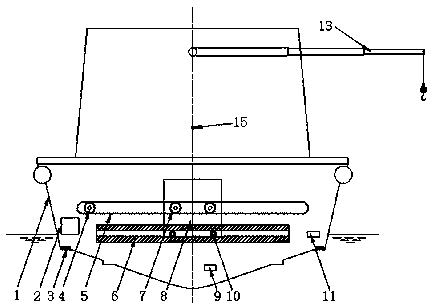

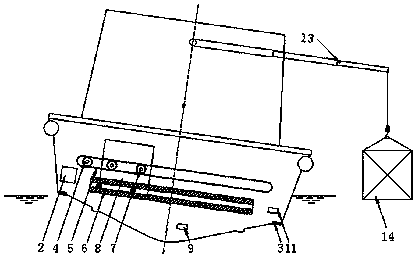

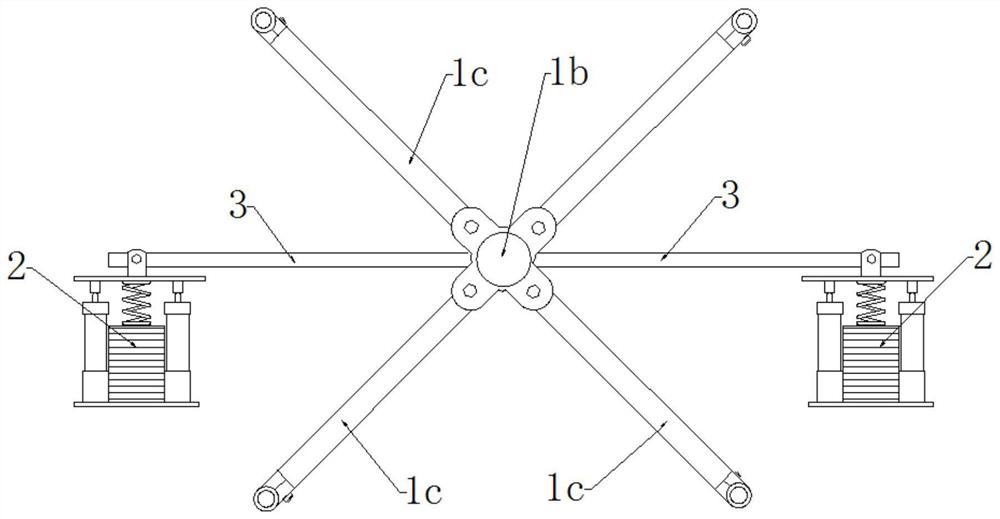

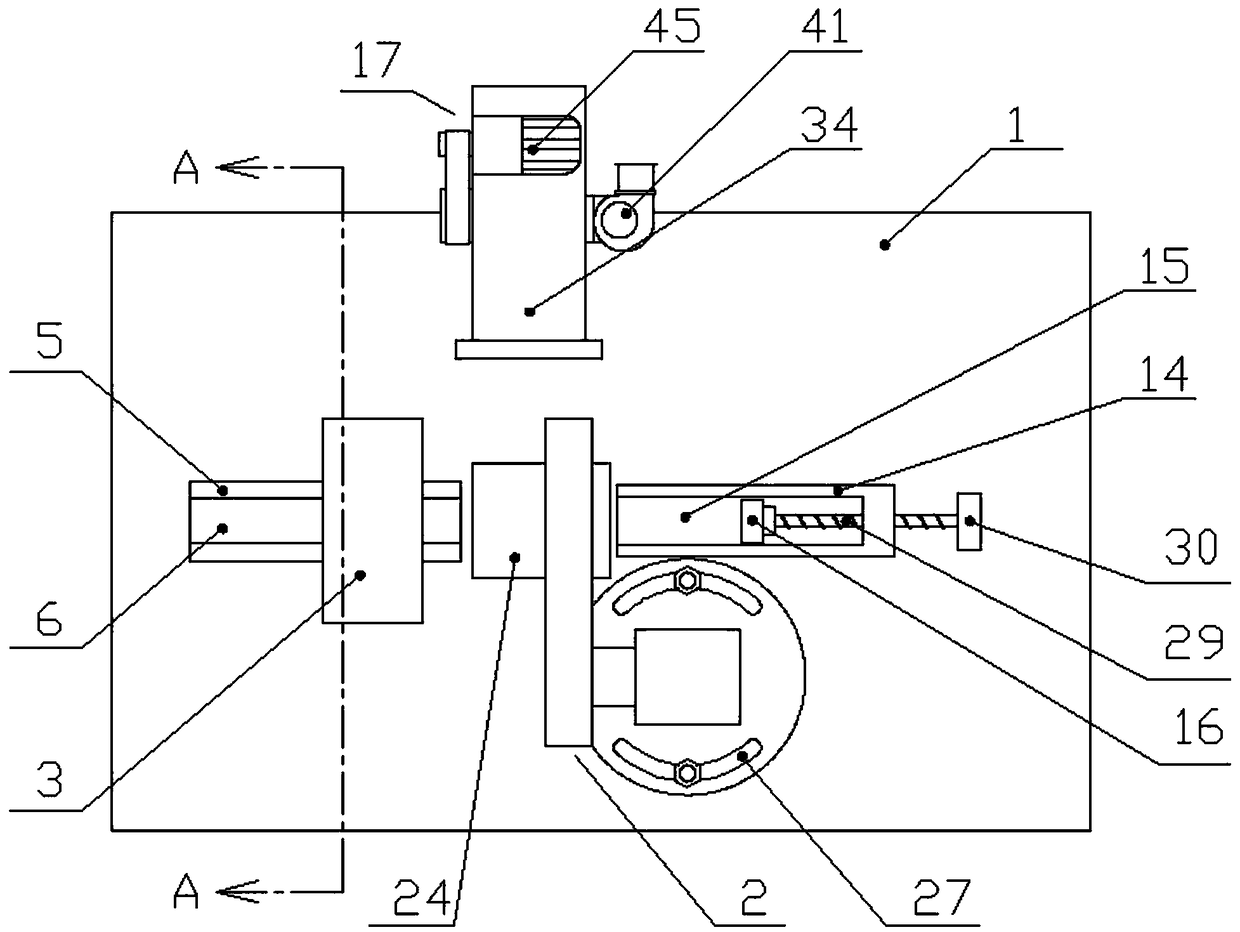

Posture automatic balancing device for a fast rescue unmanned boat

ActiveCN109263824APrevent bouncing up and downGuaranteed stabilityVessel movement reduction by mass displacementMotor driveElectric machinery

The invention discloses a posture automatic balancing device of a fast rescue unmanned boat, including a hull; a telescopic fold arm is arranged on that hull, the hull of the boat is provided with a movable balance water tank, Motor, guide rail, PLC controller and balance sensor are arranged on the guide rail, and the balance water tank is connected with the motor drive, and the motor and balancesensor are connected with the PLC controller, and the balance water tank moves left and right on the guide rail through the motor drive, so as to balance the attitude of the boat hull. By balancing the lateral position of the water tank, providing restoring moments to balance the attitude of the boat, the invention has the advantages of simple structure, low cost, convenient operation and control,automatic adjustment and balance, good safety and high practical value, and can ensure the stability of the boat, greatly reduce the phenomenon of non-elastic sliding and skidding by adopting chain transmission, and effectively prevent the water tank from jumping up and down due to the bumping of the boat.

Owner:SHENZHEN HISPEED BOATS TECH +2

Stable logistic allocation and transportation device

InactiveCN107792650APrevent bouncing up and downPrevent slidingConveyorsConveyor partsLogistics managementEngineering

A stable logistic allocation and transportation device comprises a transportation carriage and a cargo cabinet. A storage cavity with an opening facing leftwards is formed in the transportation carriage. Longitudinal limiting arms are fixedly arranged on the right end wall of the storage cavity in a front-back symmetric mode. A top pressing plate is slidably mounted on the storage cavity. Throughgrooves matched with the longitudinal limiting arms are arranged in the top pressing plate in a front-back symmetric mode. A transverse limiting device is arranged in the bottom wall of the storage cavity and comprises a longitudinal sliding groove and a sliding block slidably mounted in the longitudinal sliding groove, wherein the longitudinal sliding groove is fixedly formed in the bottom wall of the storage cavity, and an opening of the longitudinal sliding groove faces upwards. The sliding block is provided with transverse limiting arms arranged in a front-back symmetric mode. An unlockinggroove with an opening facing rightwards is further formed in the sliding block. An unlocking device matched with the unlocking groove is further arranged in the bottom wall of the storage cavity. Longitudinal limiting grooves matched with the longitudinal limiting arms are formed in the right end face of the cargo cabinet in a front-back symmetric mode, and openings of the longitudinal limitinggrooves face rightwards. Transverse limiting grooves matched with the transverse limiting arms are formed in the bottom wall of the cargo cabinet in a front-back symmetric mode, and openings of the transverse limiting grooves face downwards.

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

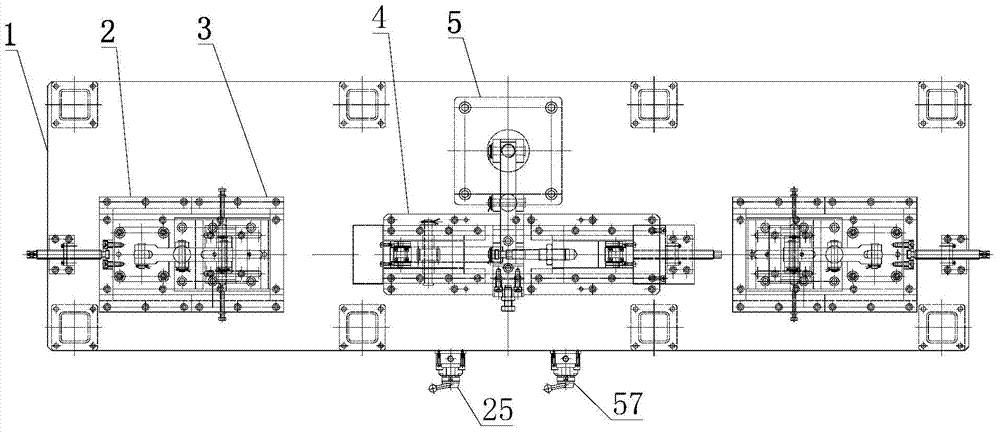

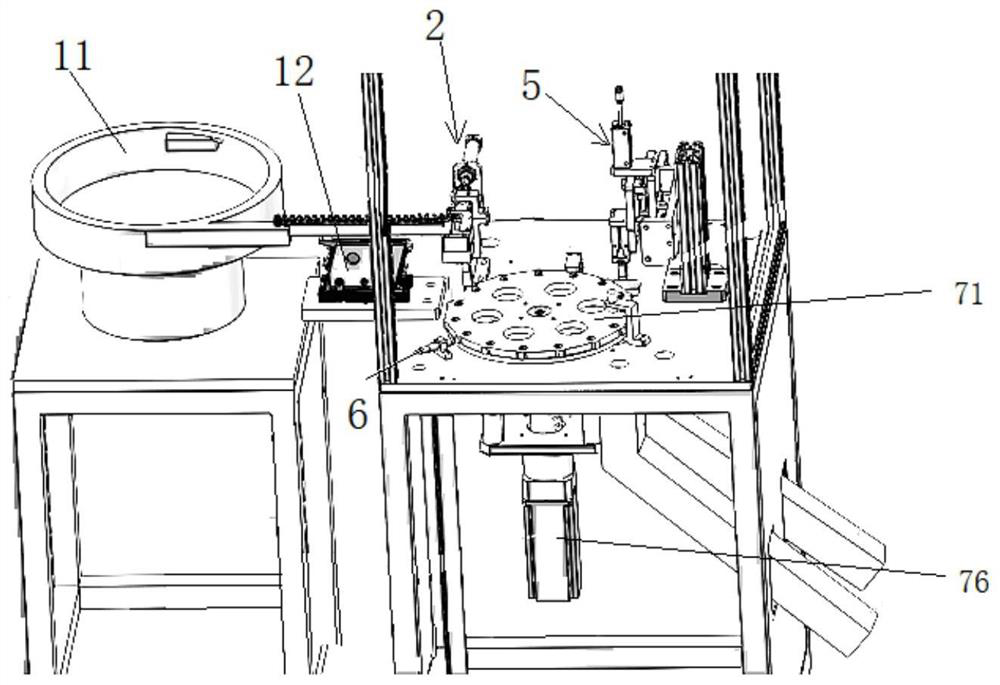

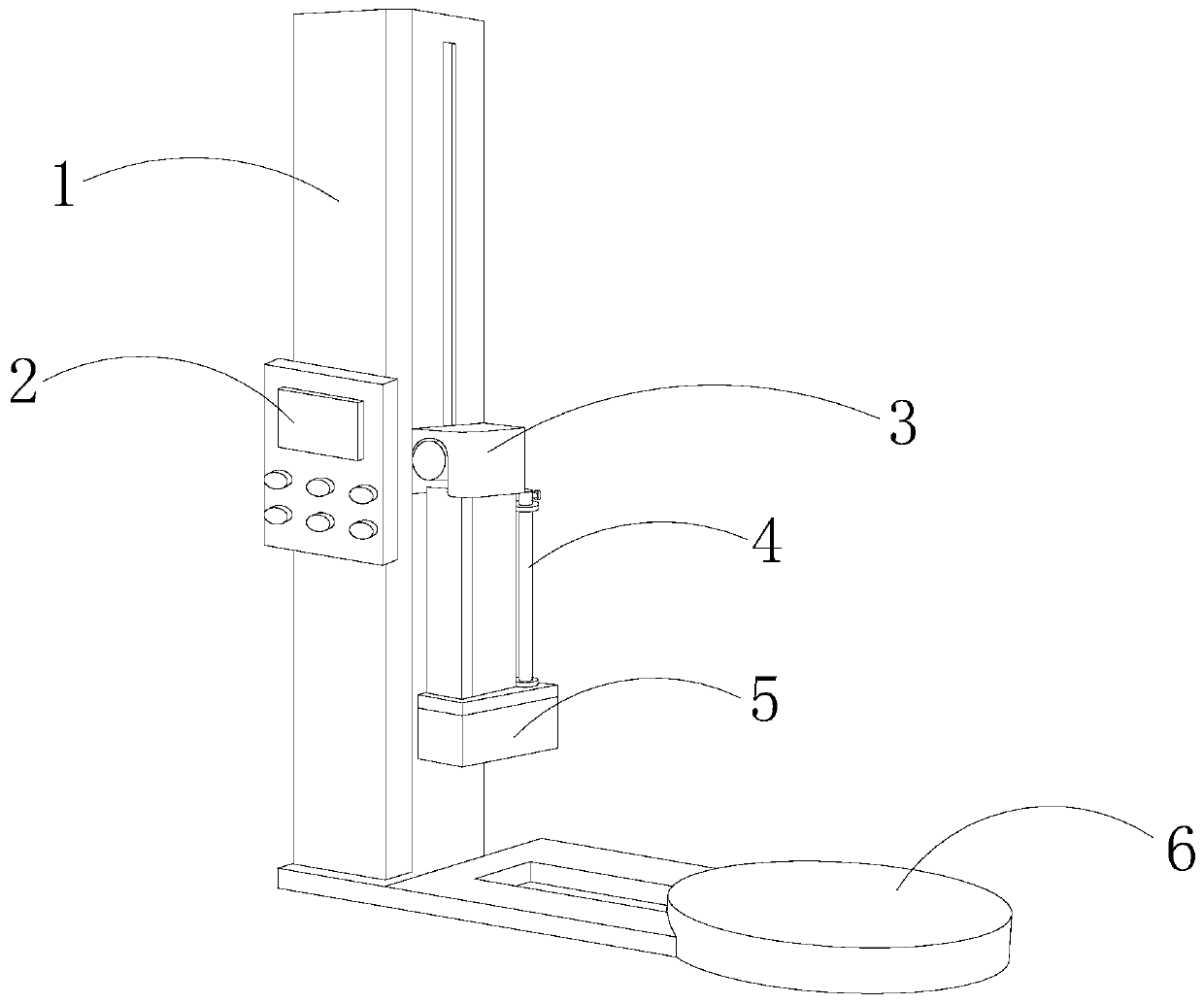

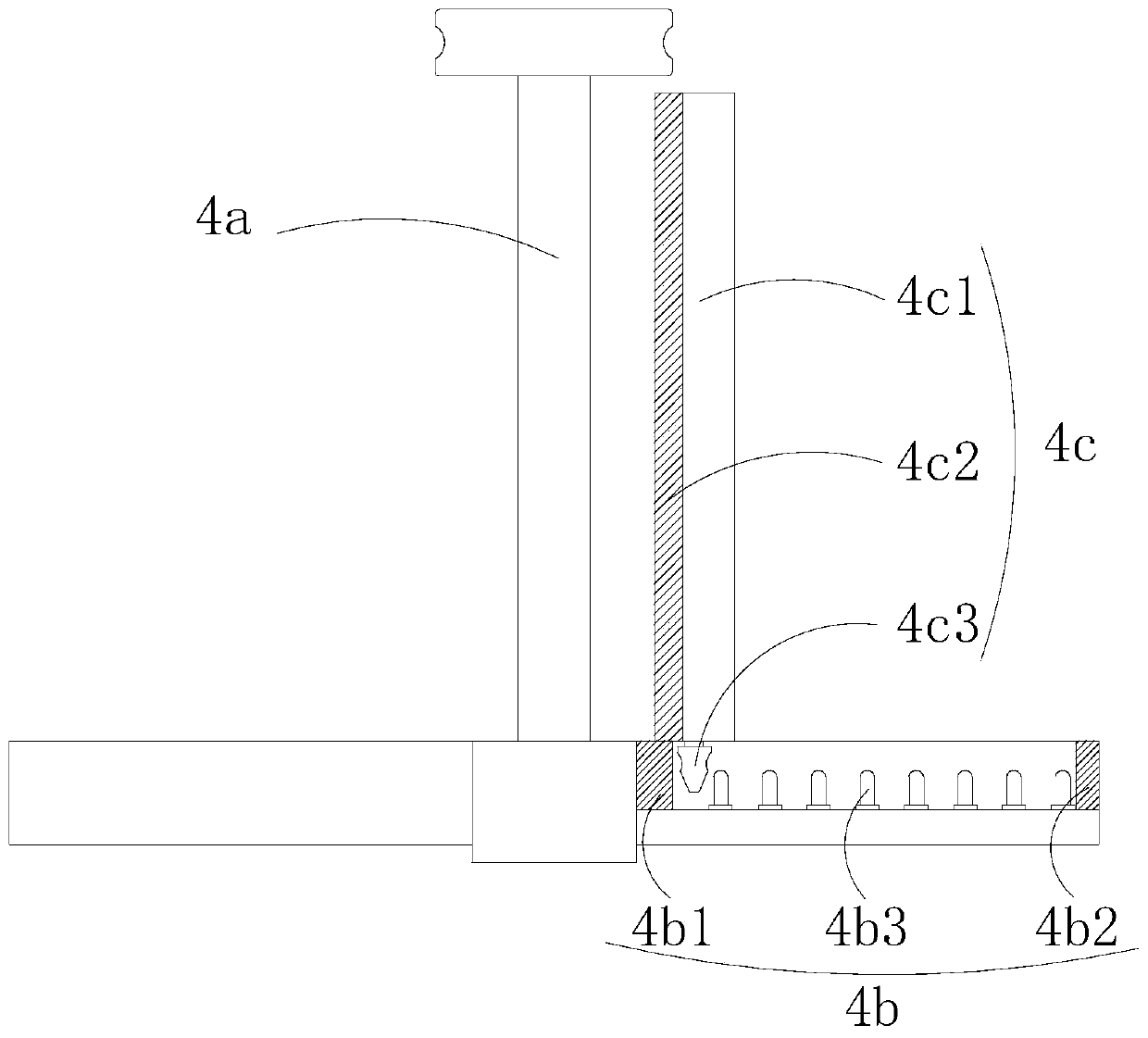

Automatic electrode detection device

PendingCN111958238ARealize automatic feeding processQuick Auto DetectAssembly machinesTransmissivity measurementsEngineeringManipulator

The invention discloses an automatic electrode detection device. The automatic electrode detection device comprises an automatic feeding component, an automatic mounting component, a hafnium wire detection component, a brass core detection component and a knurling detection manipulator. The automatic feeding component is used for conveying an electrode to be mounted to the automatic mounting component; the automatic mounting component is used for mounting the electrode in a station hole of a multi-station turntable; the hafnium wire detection component is used for detecting whether a hafnium wire is mounted on the electrode; the brass core detection component is used for detecting whether a brass core is mounted on the electrode; and the knurling detection manipulator is used for detectingwhether the surface of the electrode is knurled. According to the device, automatic feeding can be achieved, and a PLC system is combined with a mechanical structure, so that rapid, efficient and accurate automatic detection is achieved; and the installation condition or qualified condition of knurls, brass cores and hafnium wires can be detected at a time, and qualified products and unqualifiedproducts can be automatically classified.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

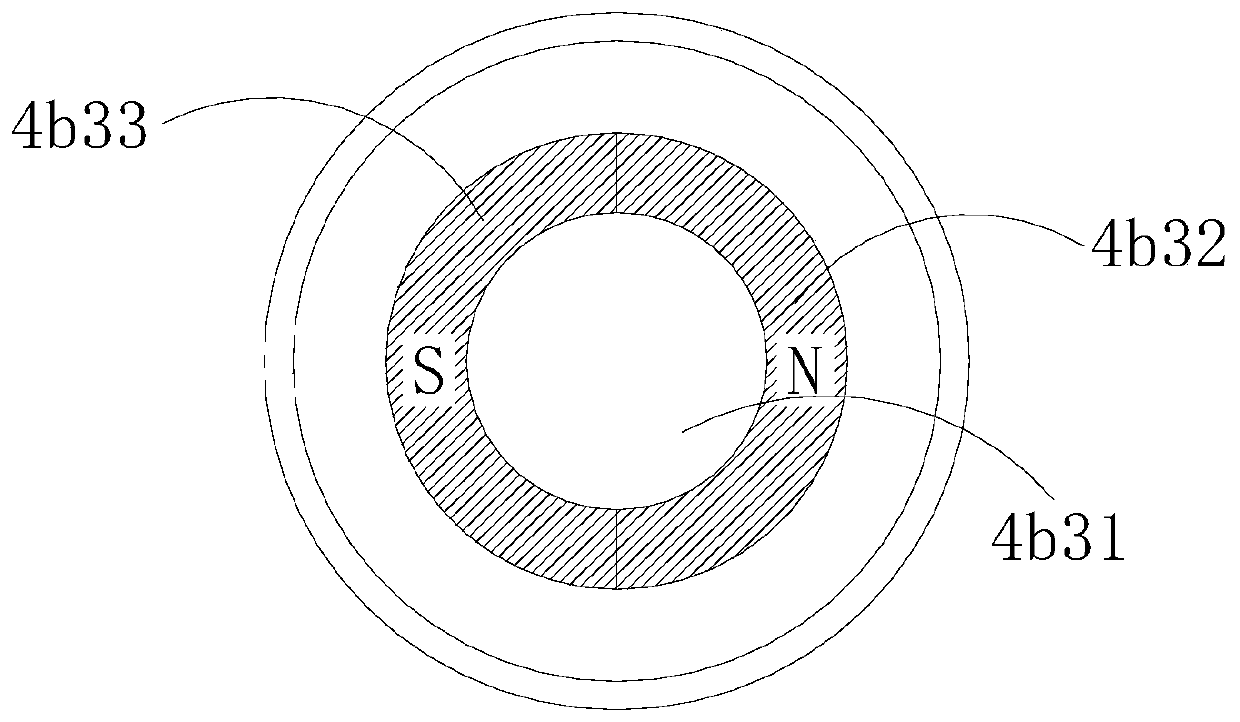

PVC transparent film winding machine with film string-proof and overlap prevention function

ActiveCN110451020APrevent bouncing up and downWrapping material feeding apparatusWrappingWinding machineStripping - action

The invention discloses a PVC transparent film winding machine with a film string-proof and overlap prevention function. The film winding machine structurally comprises a machine main body, a controller, a lifter, a film sleeve part, an exhaust fan and a rotating plate. The film winding machine has the beneficial effects that a straightening through structure is arranged and utilized, under the action of an electrostatic layer, a transparent film roll is adsorbed and fixed in an attachment mode, the transparent film which is unfolded and used is matched through a rectangular groove formed in the middle part of an arc-shaped plate to adsorb the transparent film, an adsorption effect is carried out on the upper end and the lower end of the transparent film which is unfolded and used so as toavoid the phenomenon that an object cannot be completely wrapped due to the fact that the transparent film is easily folded when the transparent film is used, a clamping piece is arranged and utilized to clamp the PVC transparent film roll during use, so that the situation that when the PVC transparent film is used until only a little is remained, the PVC transparent film roll runs up and down due to lighten self gravity and rapid film stripping action, and the PVC transparent film roll is broken away from the film sleeve part is avoided,

Owner:杭州杭邦塑胶有限公司

Spinning machine yarn bobbin

The invention relates to a spinning machine part, in particular to a spinning machine yarn bobbin which comprises a base. A threaded vertical shaft is fixed onto the base, a sleeve is sleeved on the threaded vertical shaft, and a fixed shaft sleeve is sleeved on the upper portion of the threaded vertical shaft, connected with the threaded vertical shaft in a threaded manner and arranged on the upper portion of a shaft sleeve. The spinning machine yarn bobbin has the advantages that the bobbin is sleeved outside the sleeve in the using process, fixed by screwing the fixed shaft sleeve and prevented from bouncing up and down in the spinning process, the height of the fixed shaft sleeve can be adjusted as the fixed shaft sleeve is connected with the threaded vertical shaft in the threaded manner, and the fixed shaft sleeve is applicable to bobbins with different heights.

Owner:王云荣

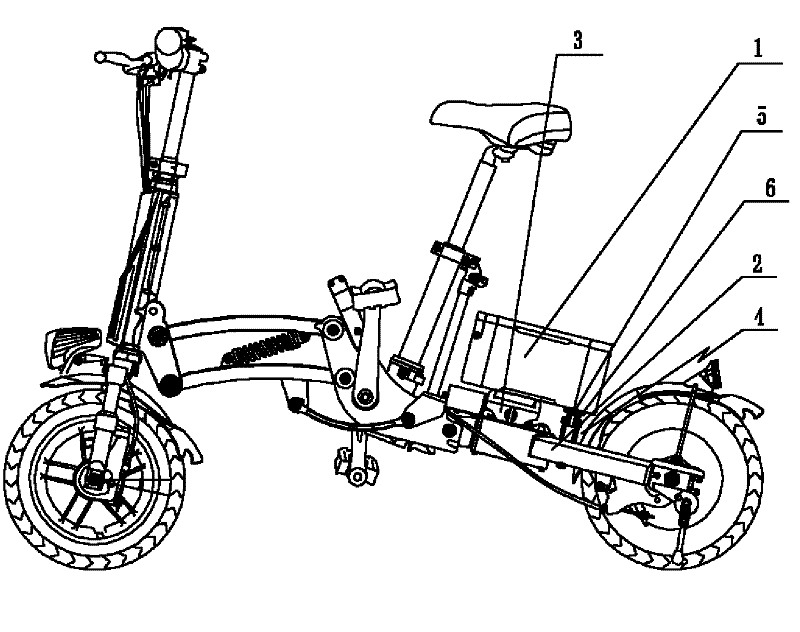

Supporting structure for battery box of foldable electric power-assisted bicycle

InactiveCN102407916APrevent bouncing up and downAvoid breakingRider propulsionEngineeringElectric power

The invention provides a supporting structure for a battery box of a foldable electric power-assisted bicycle, which avoids up-and-down vibration of the battery box caused by the rocky road in riding the electric bicycle and effectively prevents the battery box being broken and damaged; the supporting structure comprises a rear fork and a battery box; the battery box is mounted on the back fork through a battery box seat; the suspended part of the battery box out of the battery box seat is provided with a battery box supporting rack; and the battery box supporting rack is mounted on the rear fork.

Owner:WUXI SOUTHEAST VEHICLE TECH

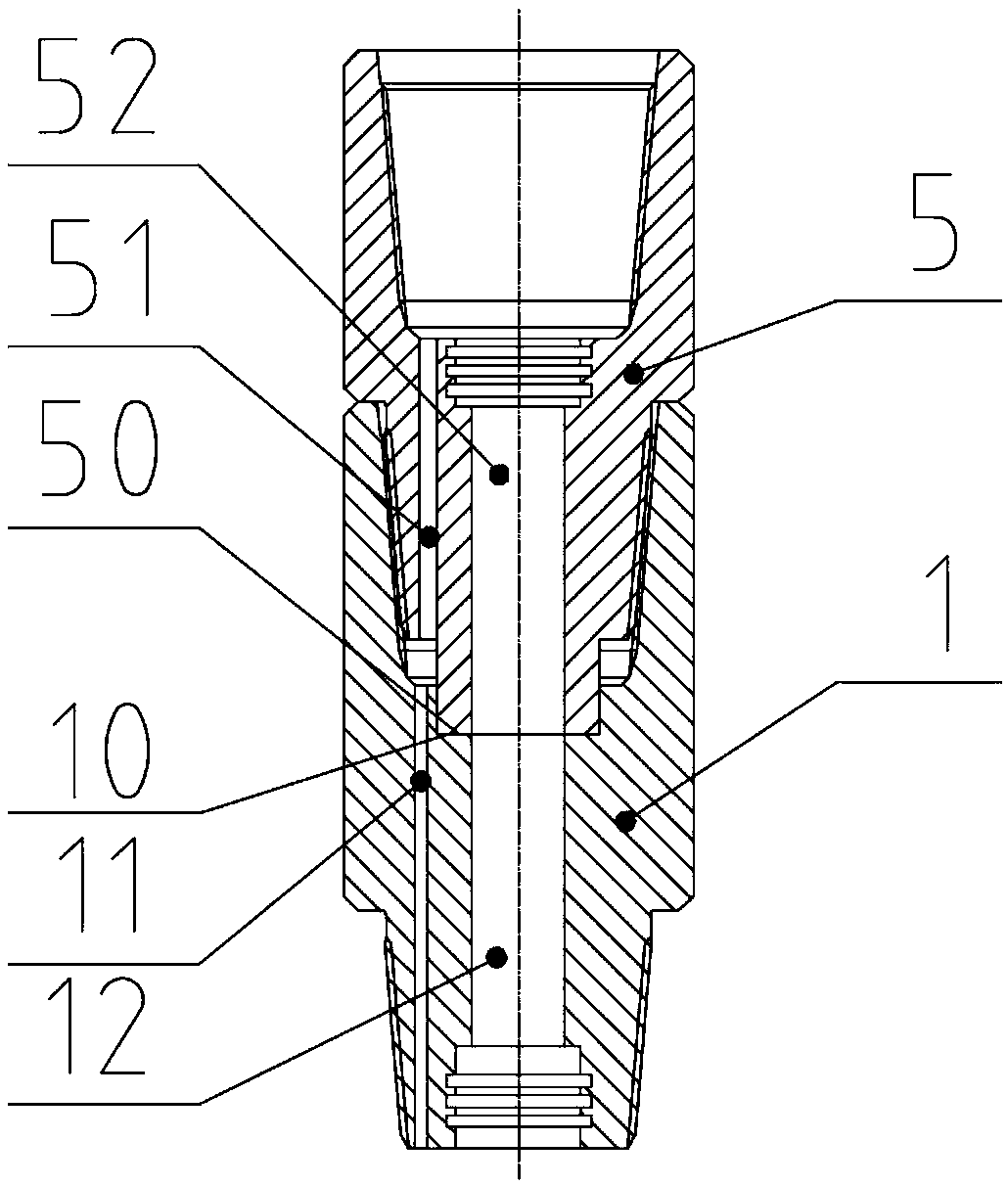

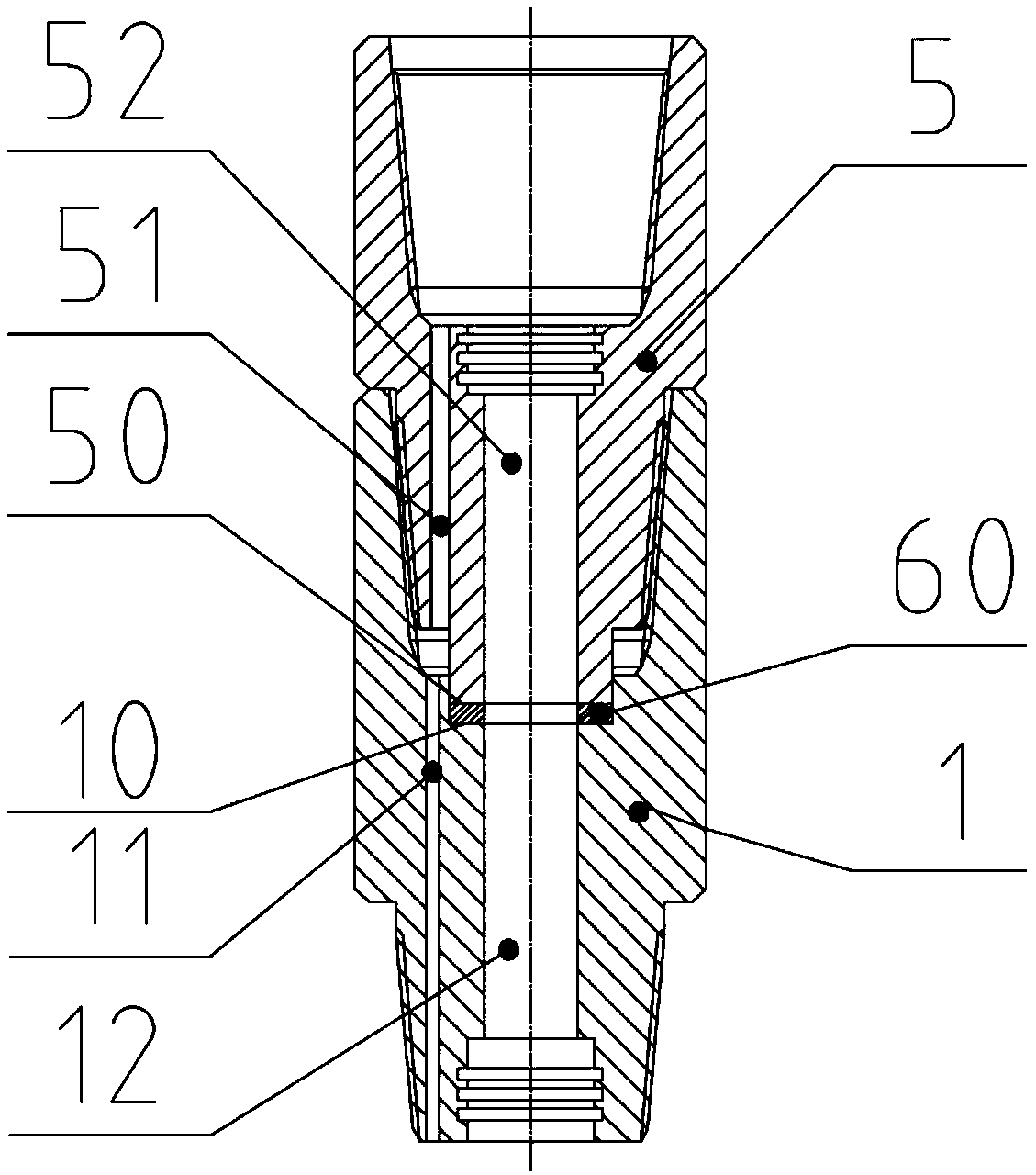

Double-wall drill pipe

PendingCN108894732AImprove seal pressure bearing capacity and reliabilityImprove machining accuracyEngine sealsDrilling rodsAnnular ductEngineering

The invention discloses a double-wall drill pipe which comprises an upper pup joint, an outer pipe, a lower pup joint and an inner pipe, wherein the upper pup joint, the outer pipe and the lower pup joint are sequentially connected in a threaded manner from top to bottom, and the inner pipe is arranged in a center duct of the outer pipe. Center ducts and eccentric ducts are axially formed in the upper pup joint and the lower pup joint, the inner pipe is mounted in the outer pipe in a gapped mode to form a double-wall pipe with a center duct and an annular duct, two ends of the double-wall pipeare fixed onto walls of the center ducts of the upper pup joint and the lower pup joint, the center ducts of the upper pup joint and the lower pup joint are communicated with the center duct of the inner pipe to form a first liquid passing channel, the eccentric ducts of the upper pup joint and the lower pup joint are communicated with the annular duct formed between walls of the inner pipe and the outer pipe to form a second liquid passing channel, and a shoulder seal is formed between two components in threaded connection, so that the first liquid passing channel is not connected with the second liquid passing channel. According to the double-wall drill pipe, up-down bounce of the inner pipe in the use process is effectively prevented, and sealing pressure-bearing capacity and reliability between the inner pipe and the outer pipe which are long can be greatly improved.

Owner:黄桂霞

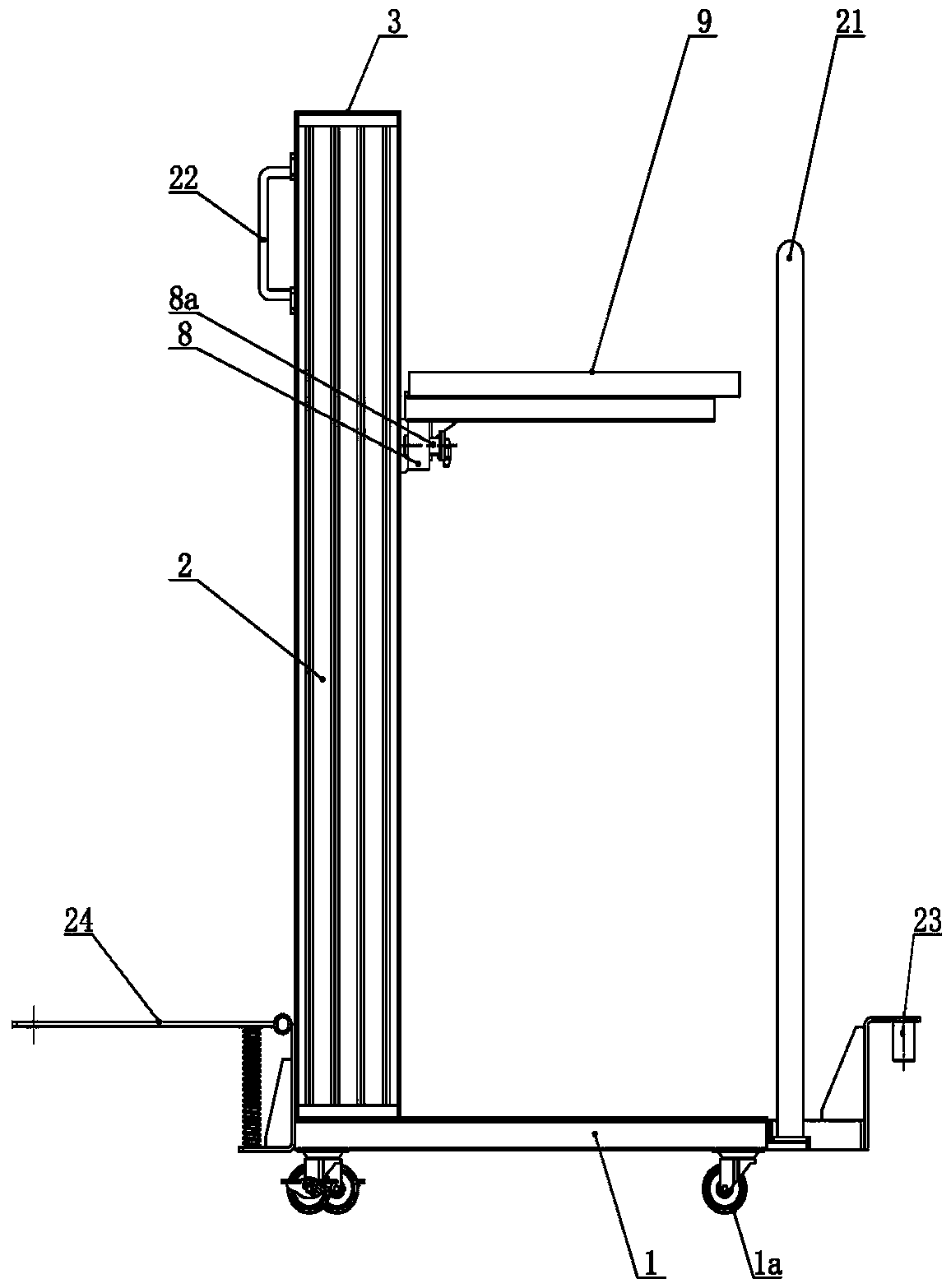

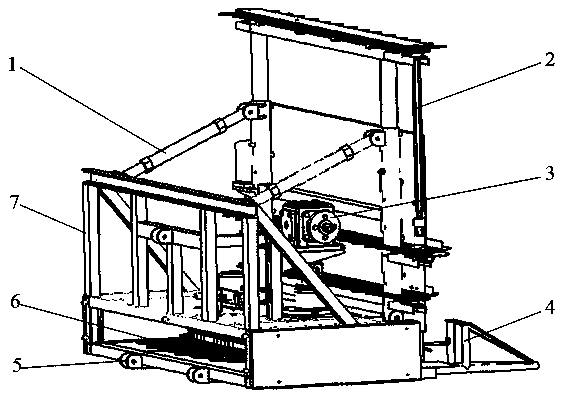

Self-balancing material vehicle

ActiveCN109941915AProtect your healthAvoid raising armsCounterweightsLifting framesEngineeringFastener

Owner:高尚

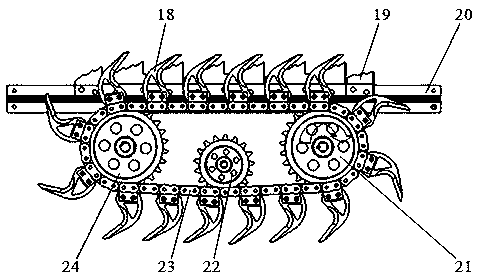

Bituminous pavement maintenance truck and raking device thereof

ActiveCN105672105AImprove transmission efficiencyHigh control precisionRoads maintainencePavement maintenanceRoad surface

The invention discloses a bituminous pavement maintenance truck and a raking device thereof. The raking device comprises a connecting frame surrounding the periphery of a heating wall and a raking frame transversely erected at the rear end of the connecting frame. The raking frame comprises connecting boards arranged on the left side and the right side, a rake tooth shaft connecting the two connecting boards and rake tooth sleeves arranged on the rake tooth shaft side by side. Rake teeth are installed in the rake tooth sleeves. Chain transmission mechanisms for driving the raking frame to move forwards and backwards are arranged on the left side and the right side of the connecting frame. A drive mechanism capable of driving the chain transmission mechanisms to rotate is arranged at the front end of the connecting frame. A supporting shaft is arranged between the left chain transmission mechanism and the right chain transmission mechanism. Idler wheels are arranged at the shaft ends of the supporting shaft and connected with the raking frame. Forward and reverse rotation of the drive mechanism is adopted, the rake teeth are driven through the chain transmission mechanisms to conduct left-and-right raking operation, a two-way raking effect is achieved, the chain transmission efficiency is high, the control accuracy is high, and the raking process is safe and reliable.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

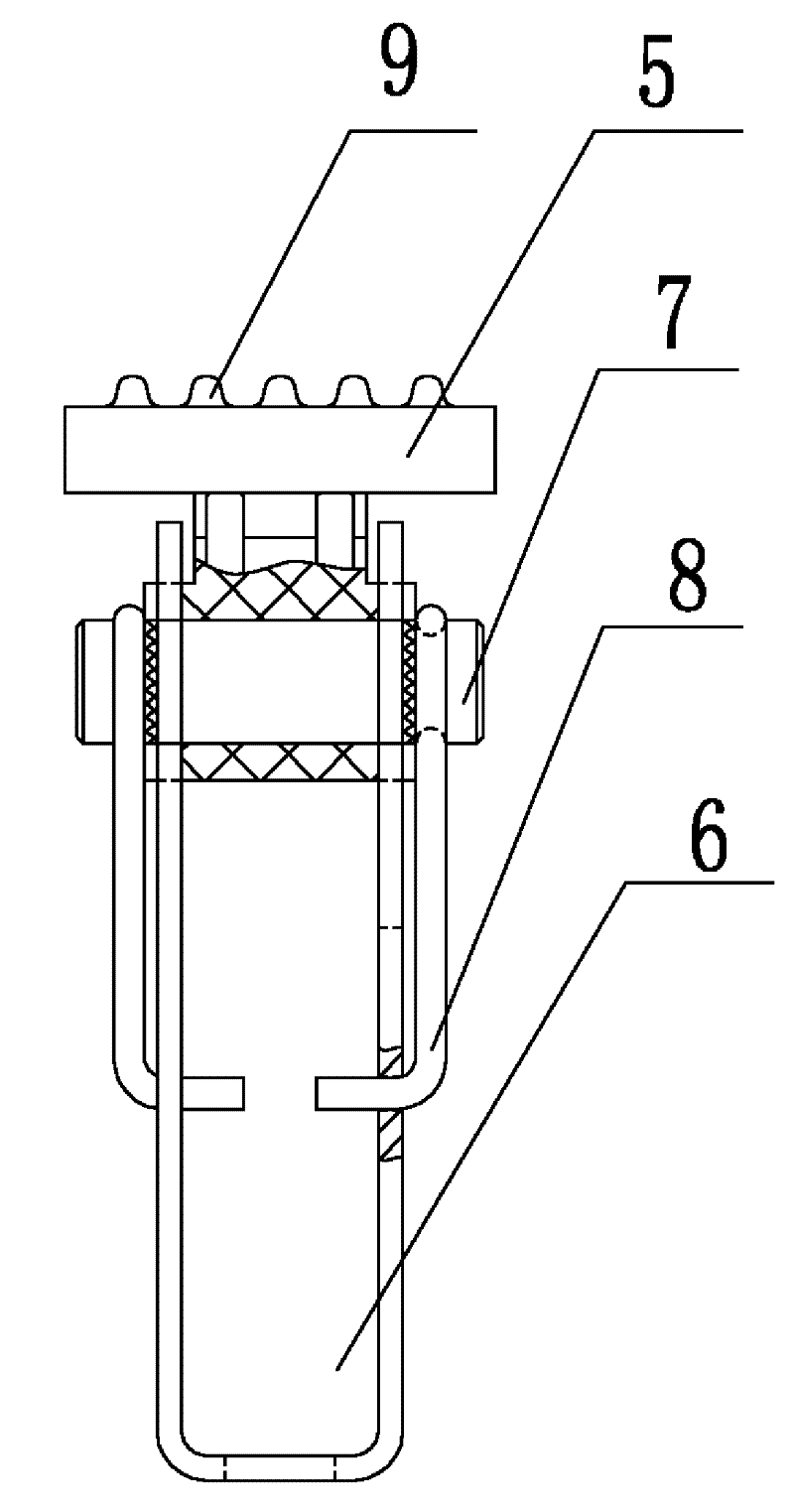

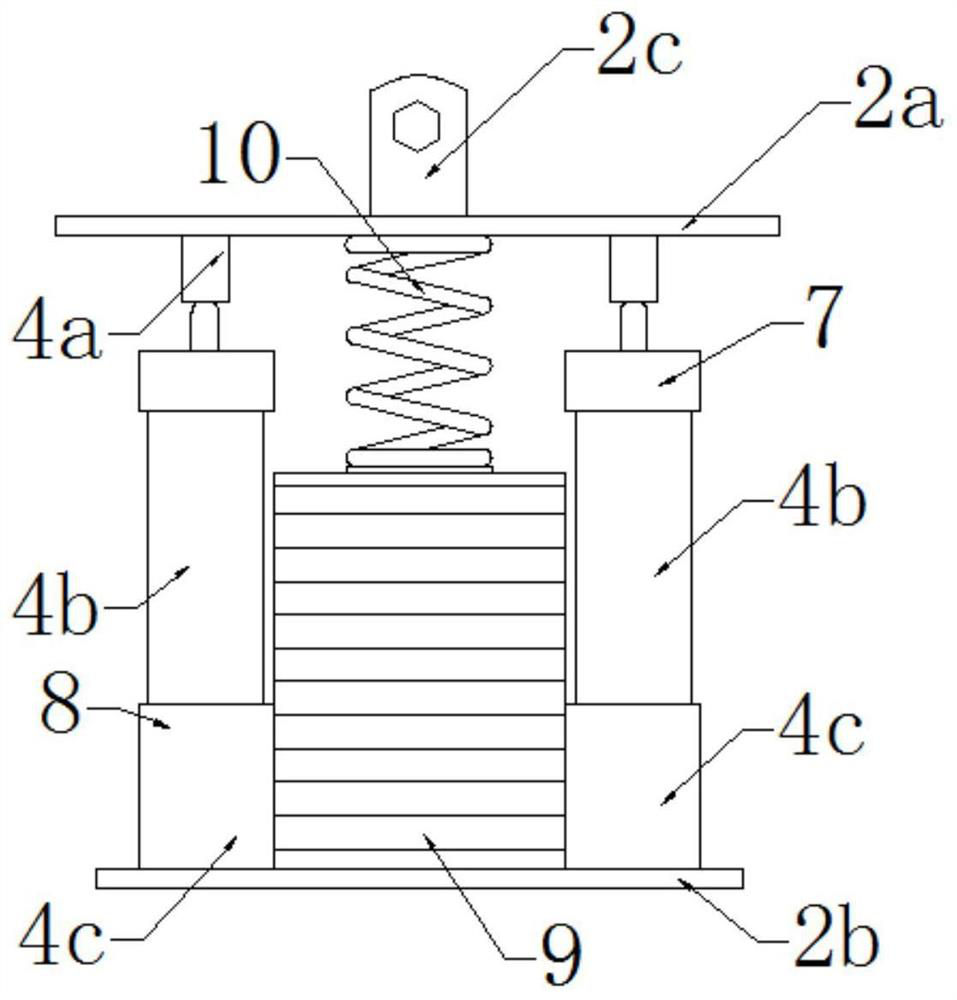

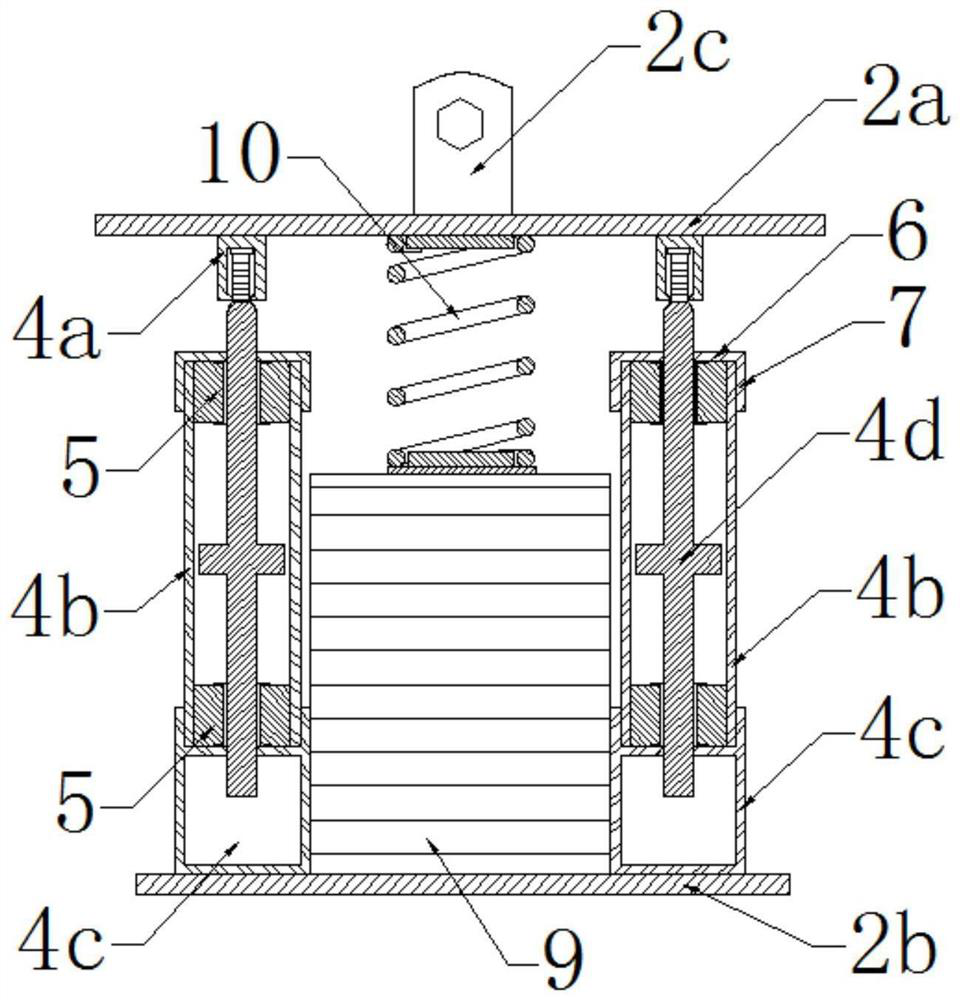

Floating type shock absorber with rigidity

ActiveCN111834969APrevent Attractive CollisionsPrevent bouncing up and downDevices for damping mechanical oscillationsSpringsEngineeringEnergy consumption

The invention discloses a floating type shock absorber with rigidity. The shock absorber comprises a rigidity device and two stabilizing devices. The rigidity device comprises a connecting rod, the connecting rod is horizontally arranged, the two stabilizing devices correspond to the two ends of the connecting rod in a one-to-one mode, the stabilizing devices are installed at the ends of the corresponding connecting rod, and each stabilizing device comprises an upper installation plate, a lower installation plate and at least two damping devices. The shock absorber has the advantages that theself-vibration frequency of the damper is adjusted through the rigidity device, so that the movement of the mass unit and the controlled structure generates displacement and speed difference, nonlinear energy consumption is conducted through the damping device, the wires are restrained through the multiple spacers, mutual attraction and collision of the wires are prevented, wire harness vibrationis eliminated and reduced, and up-down waving of the wire harness is prevented. And the torsional rigidity of the split power transmission line is improved by utilizing the two stabilizing devices, sothat the torsional motion of the electric wire is also consumed while the vertical motion is controlled, and the safety of the power transmission line is protected to a greater extent.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Chain type harvest header for composite feed crop straw

The invention relates to a chain type harvest header for composite feed crop straw. The harvest header comprises a rack and a chain type cutter mounted on the rack, wherein the chain type cutter comprises a fixed knife mechanism fixedly connected with the rack, a plurality of moving blades fixedly connected to the outer side face of a annular chain, and a driving device for driving the annular chain to rotate, and a cutting surface is formed between the moving blades and fixed blades. According to the chain type harvest header for the composite feed crop straw, the moving blades are driven bythe annular chain to move at a high speed, cutting of crop stalks is completed through mutual cooperation of the moving and fixed blades, and the moving blades are prevented from bouncing up and downthrough a knife pressing rod, so that the gap between moving and fixed knives is ensured, cut stubbles are flat and smooth, re-germination of composite feed crops such as imperatoria and protein mulberry is facilitated, and cutting, harvesting and horizontal laying of the composite feed stalks can be realized by arranging a stalk horizontal conveying device.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Foldaway back bumper

InactiveCN101224732APrevent bouncing up and downEnsuring Collision AvoidanceBumpersVehicle with tipping movementVehicle frameRoad condition

The invention discloses a fold-typed rear bumper, which comprises a rear bumper and a supporting beam, and the rear bumper is fixed on a car frame by the supporting beam, the supporting beam is composed of a fixed upper supporting beam and a reversible lower supporting beam, the lower supporting beam that is turned down combines with the upper supporting beam into the integrated structure, and the lower end of the lower supporting beam is used for fixing the rear bumper. The invention can lead the rear bumper to be folded in bad road condition or when unloading goods, thus avoiding the damage of the rear bumper and having convenient and simple use.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

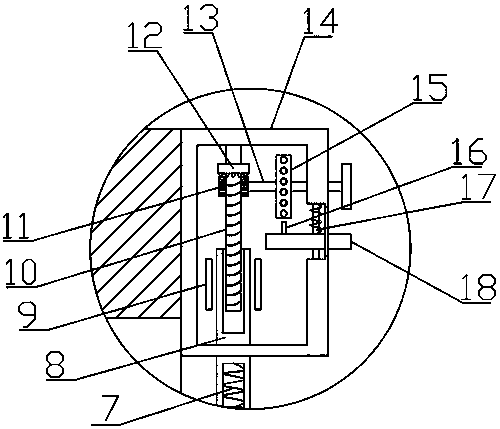

Centrifugal equipment for manufacturing cement telephone pole

InactiveCN108327065APrevent bouncing up and downFast molding speedNon-rotating vibration suppressionCeramic shaping apparatusEngineeringCircular cavity

The invention discloses centrifugal equipment for manufacturing a cement telephone pole. The centrifugal equipment comprises a base; two supporting plates are fixedly connected to the upper end of thebase; a hollow chute is formed in the side wall of each supporting plate and is internally provided with a mounting block; a buffer device is fixedly connected to the inner wall of each hollow chute;the upper end of each buffer device is fixedly connected to the lower end of the corresponding mounting block; a shell is fixedly connected to the side wall of each supporting plate; two limiting blocks are fixedly connected to the inner wall of each shell; a strip plate is movably connected between two adjacent limiting blocks; a first circular cavity is arranged at the upper end of each strip plate and is internally provided with a threaded rod; inside threads which are matched with each threaded rod are formed in the inner wall of the corresponding first circular cavity; and the upper endof each threaded rod is rotationally connected to the internal top of the corresponding shell. The centrifugal equipment provided by the invention has the effects of reasonability in structure design,simpleness in operation, rapidness in formation speed of a cement pole, capability of saving manpower and time and no capability of brushing a hand to hurt.

Owner:盐城市新驰工贸有限公司

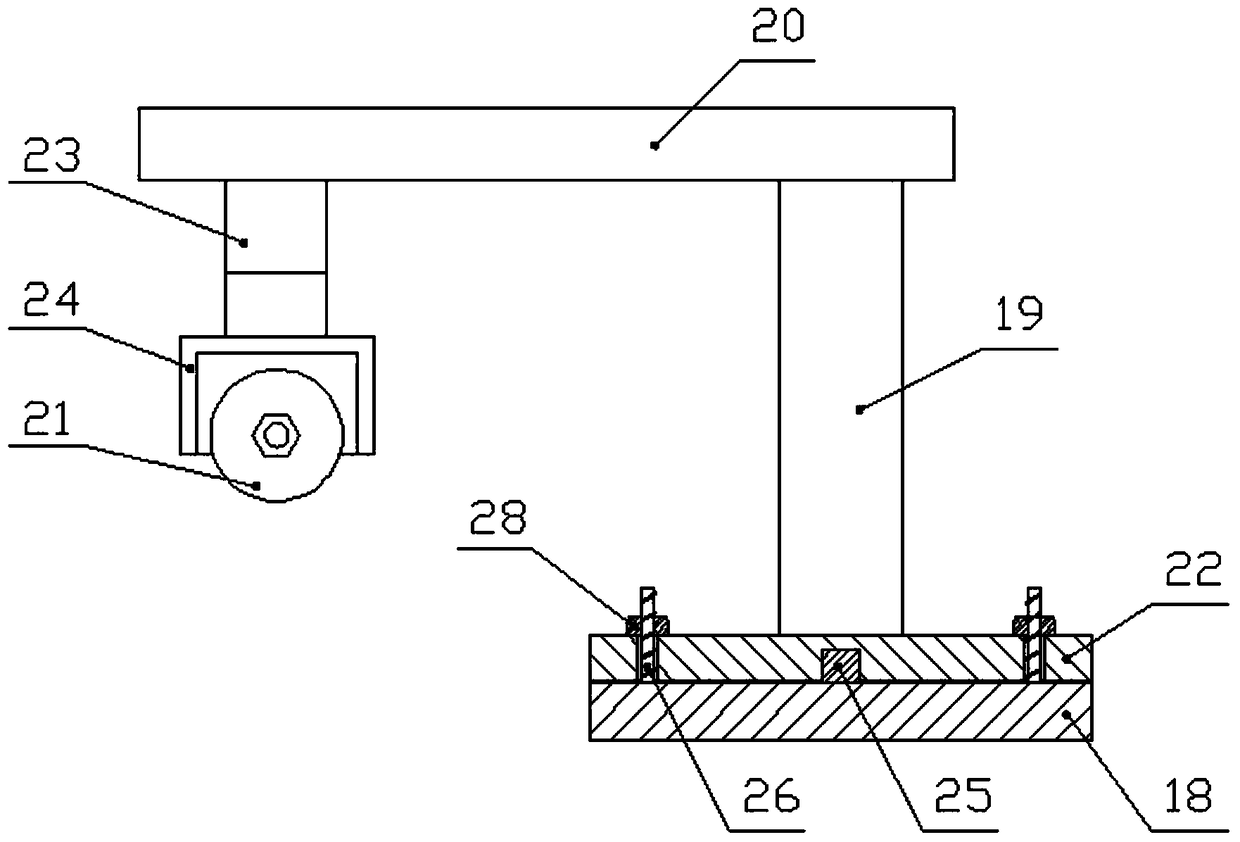

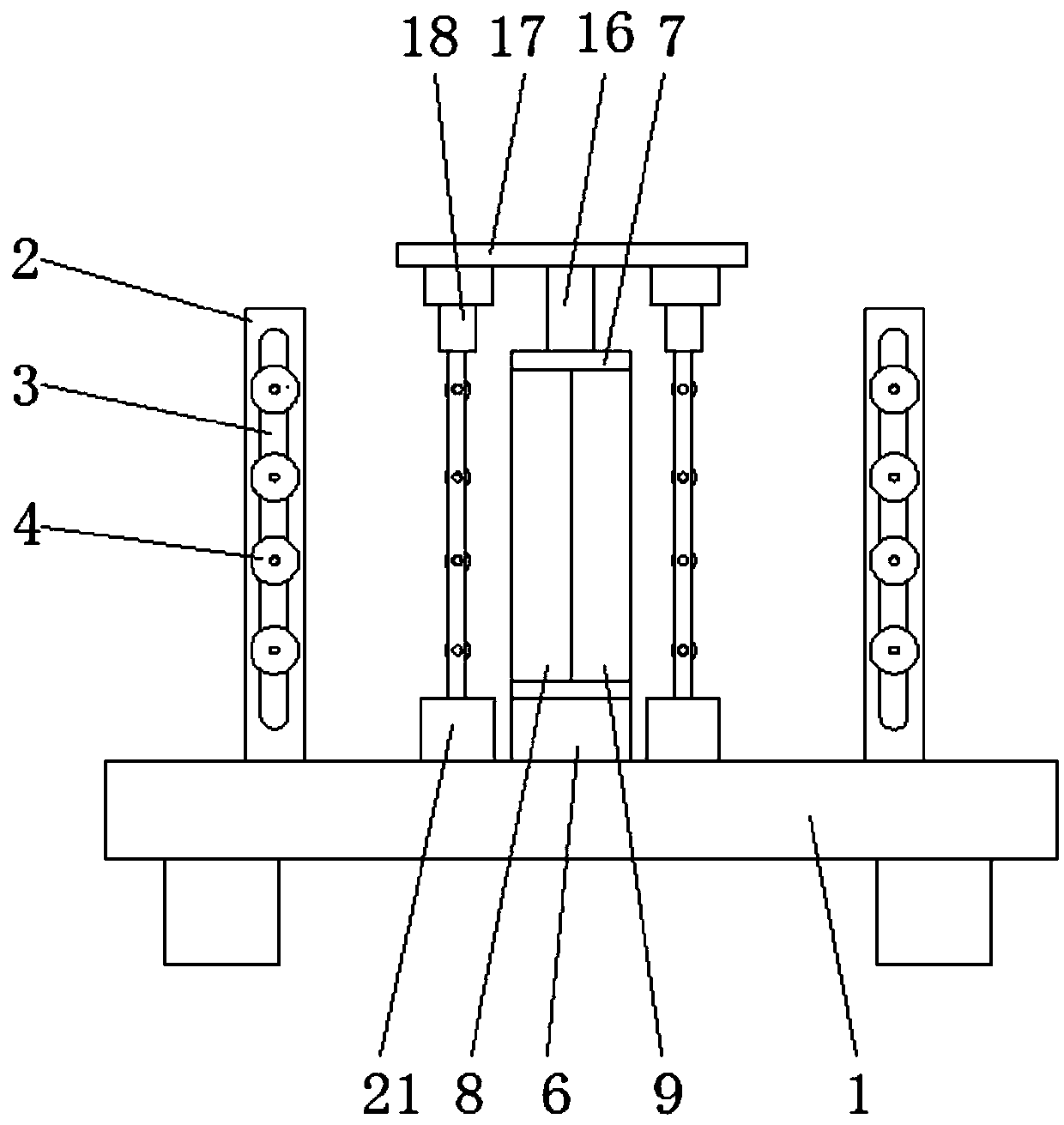

Part machining device for automobile gear shaft pin hole and using method of part machining device

InactiveCN112894434APrevent rotationPrevent bouncing up and downMetal working apparatusPositioning apparatusStructural engineeringMachining

The invention relates to the field of automobile part machining equipment, in particular to a part machining device for automobile gear shaft pin holes and a using method thereof.The part machining device comprises a base and a vertical frame fixed to one end of the base, and the base is provided with a clamping mechanism used for positioning, clamping and fixing a gear shaft. The base is further provided with a drilling mechanism used for conducting pin hole machining on the gear shaft, a pressing mechanism is fixed to the lower surface of the horizontal section of the upper end of the vertical frame, the pressing mechanism drives the clamping mechanism through the gear shaft and enables the clamping mechanism to position, clamp and fix the gear shaft, and the pressing mechanism can be in transmission connection with the drilling mechanism. The drilling mechanism is driven to drill the gear shaft on the clamping mechanism. According to the part machining device for the automobile gear shaft pin hole and the using method of the part machining device, the gear shaft is automatically positioned, clamped and fixed, the stability of the gear shaft during machining is ensured, the machining quality of the gear shaft pin hole is improved, operation is easy and convenient, safety and reliability are achieved, the automation degree is increased, and the machining efficiency is greatly improved.

Owner:蔡豪杰

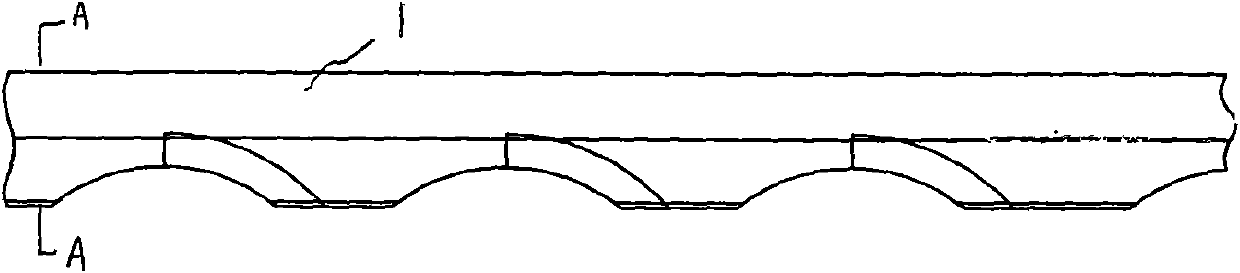

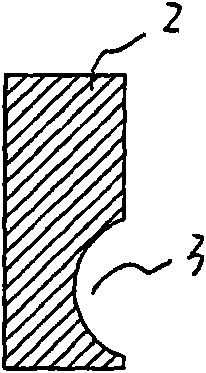

Side guide plate of recoiling machine

The invention relates to a steel rolling side guide plate, in particular to a side guide plate of a recoiling machine, aiming at solving the technical problems of unsteady through plate of a current recoiling machine and liner wear of the side guide plate of the recoiling machine. The technical proposal of the invention is as follows: the side guide plate of the recoiling machine comprises a guide plate body and a liner plate, which is characterized in that an arc-shaped guide slot is arranged near the lower end of the liner plate. The inner concave surface of the arc-shaped guide slot is an arc-shaped curve, the formula of the arc-shaped curve is as follows: Y=square root (1369-X), X is an element of a set [-35, 35]. A hard alloy layer can be bead welded on the concave surface in the arc-shaped guide slot.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Aluminum alloy fixed-distance cutting device

PendingCN109290637APrevent bouncing up and downAvoid shakingPositioning apparatusMaintainance and safety accessoriesAluminium alloyMachining

The invention discloses an aluminum alloy fixed-distance cutting device. The aluminum alloy fixed-distance cutting device comprises a machining table top; a cutting mechanism is arranged at the upperend of the machining table top; a bracket is arranged the part, on one side of the cutting mechanism, of the upper end of the machining table top; a clamping pushing device for pushing a vertical clamping plate to ascend and descend is arranged on the bracket; a placing seat is arranged below the vertical clamping plate; a placing groove is formed in the upper end of the placing seat; a horizontalclamping plate and a bearing plate are arranged on the placing groove; an object carrying plate opposite to the placing seat is arranged at the part, on the other side of the cutting mechanism, of the upper end of the machining table top; an object carrying groove in the same direction as the placing groove is formed in the upper end of the object carrying plate; a positioning plate which can slide horizontally and be locked is arranged in the object carrying groove; and a dust suction device is arranged at the upper end of the machining table top. The aluminum alloy fixed-distance cutting device can clamp an aluminum alloy profile to prevent the aluminum alloy profile from shaking in the cutting process; and at the same time, fixed-distance cutting on the aluminum alloy profile is convenient.

Owner:湖南千源铝业有限公司

Yarn conveying and carding device

The invention discloses a yarn conveying and carding device. The yarn conveying and carding device comprises a worktable. Two brackets are arranged on the worktable. Strip-shaped mounting holes are formed in the two sides of the brackets. First yarn guiding rollers are mounted in the strip-shaped mounting holes and provided with first yarn guiding grooves. A yarn carding mechanism is arranged between the two brackets and comprises a supporting frame, a frame, a first carding plate and a second carding plate. The first carding plate and the second carding plate are slidably connected with the frame. Vertical plates are arranged on the first carding plate and provided with first yarn guiding holes. Horizontal plates are arranged on the second carding plate and provided with second yarn guiding holes. A supporting column is arranged at the top of the supporting frame. A top cover is arranged at the top of the supporting column. Telescopic rods are fixedly connected to the positions, on the two sides of the supporting column, of the lower end of the top cover and fixedly connected with a plurality of second yarn guiding rollers. The second yarn guiding rollers are provided with yarn guiding pulleys. According to the yarn conveying and carding device, yarn can be prevented from being wound together, and it is ensured that the yarn is wound around a yarn barrel evenly and trimly.

Owner:XIANGSHUI YONGTAI TEXTILE GARMENT CO LTD

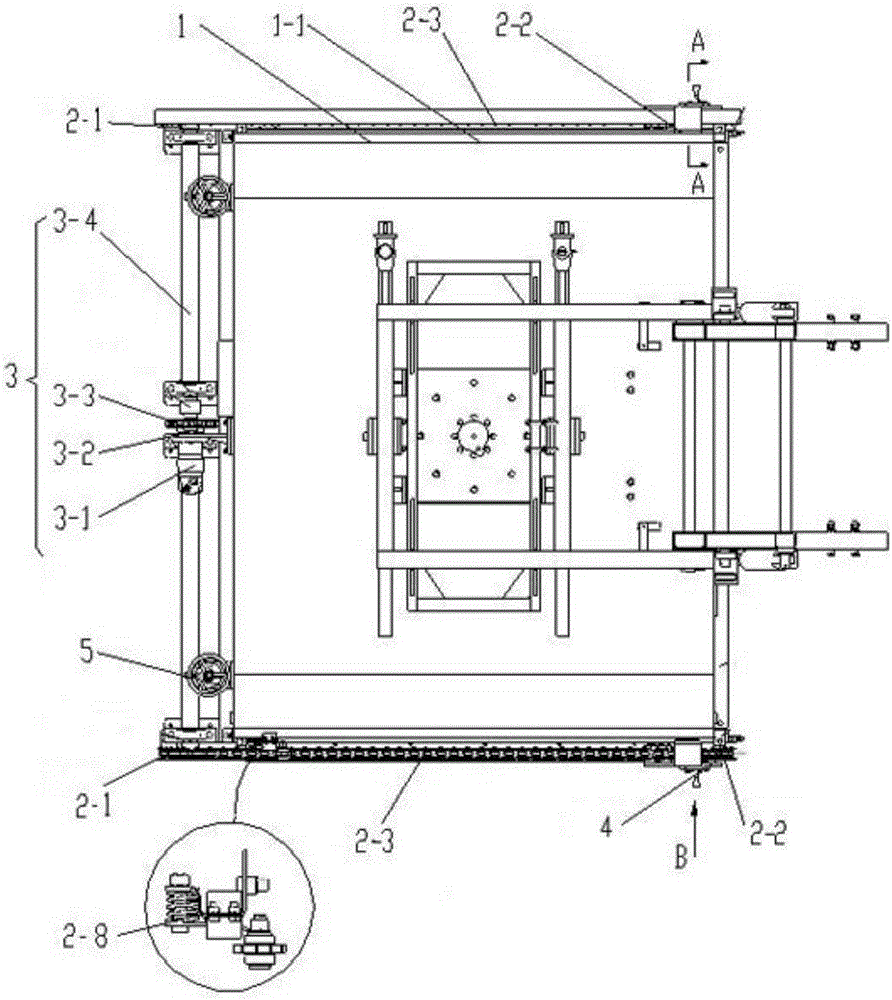

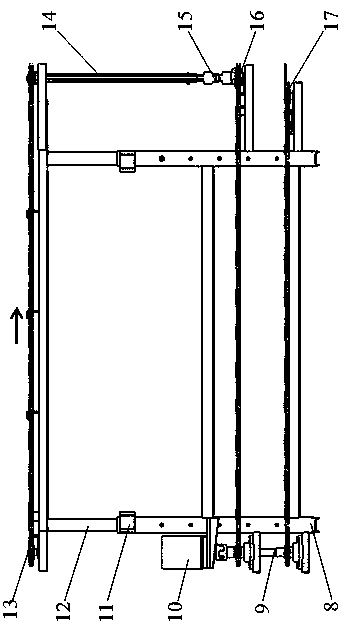

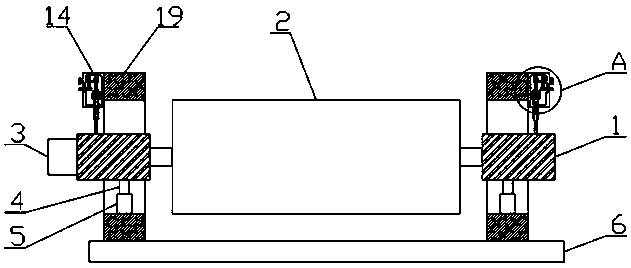

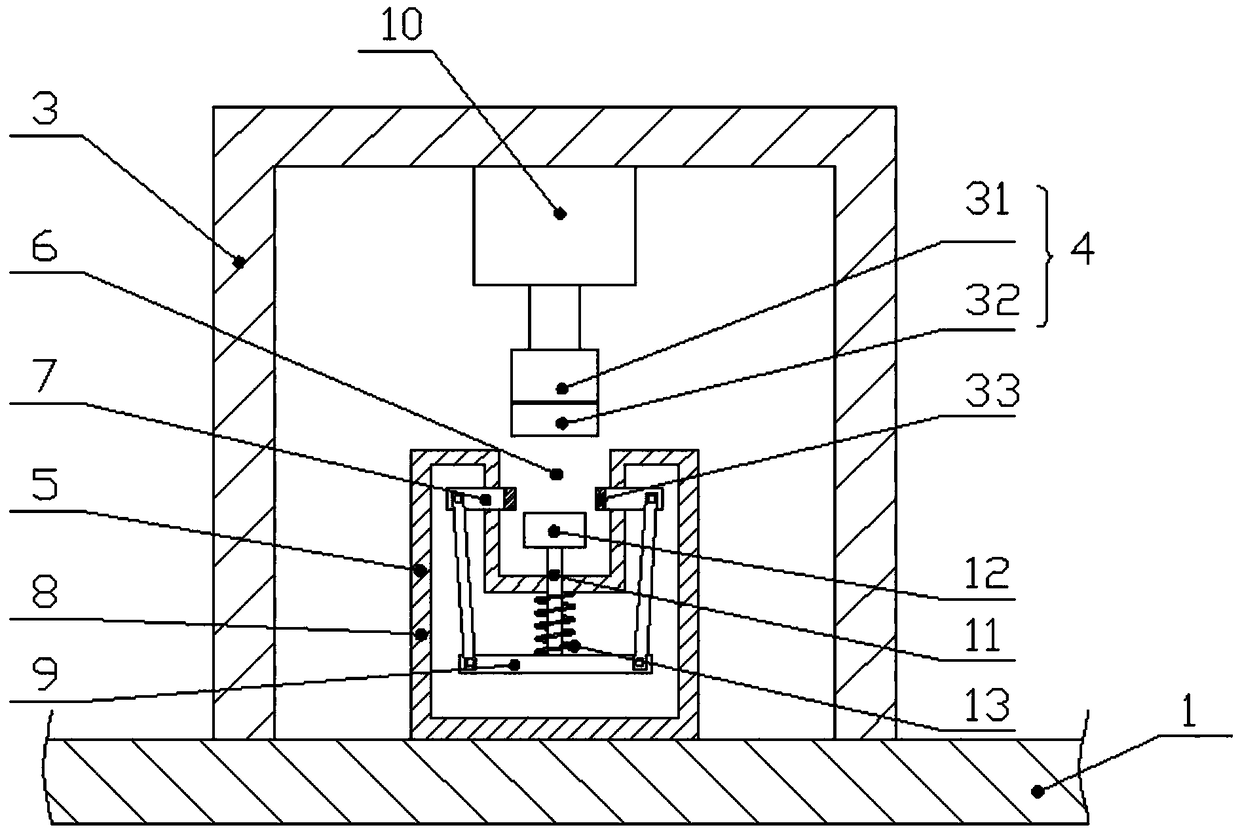

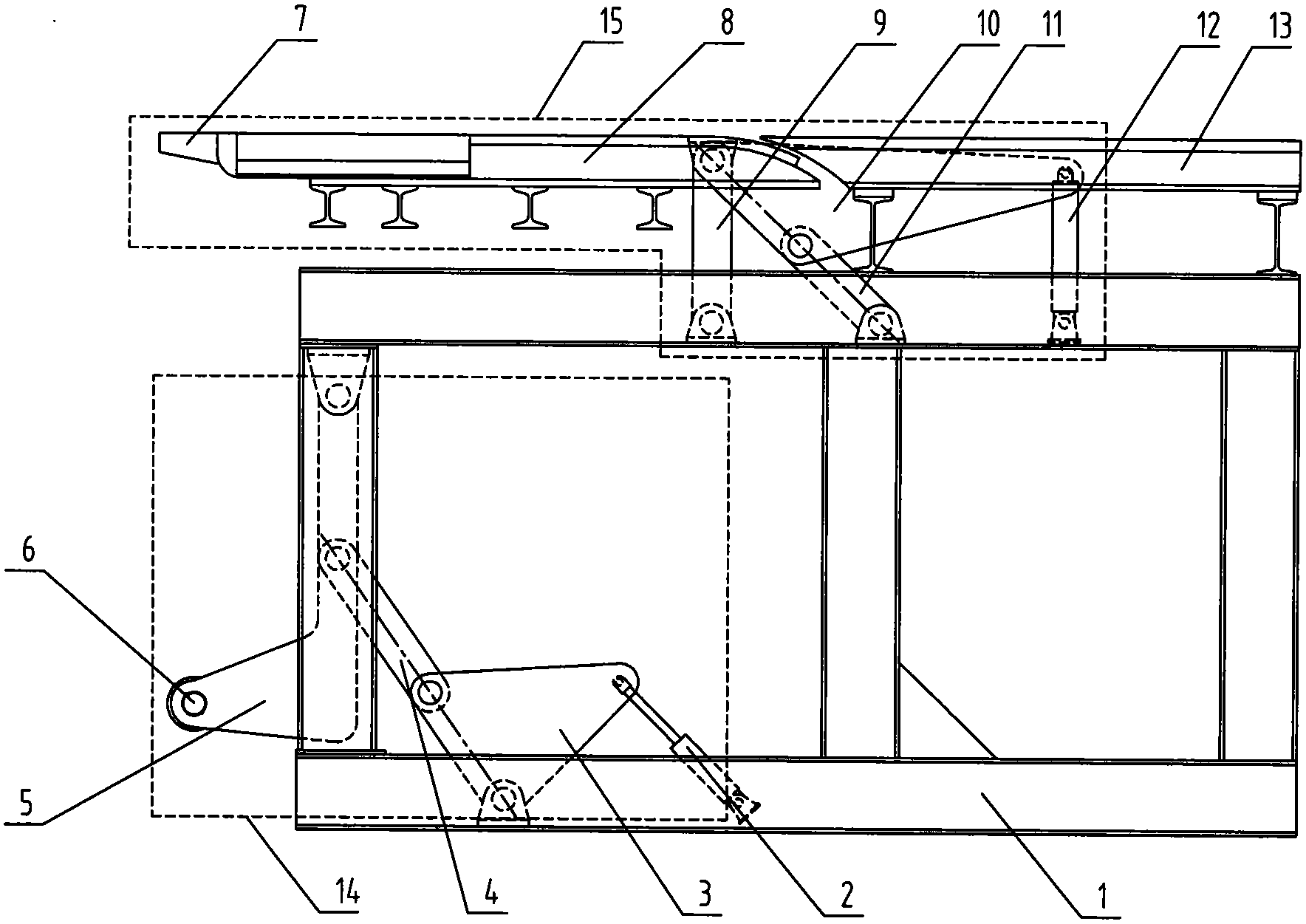

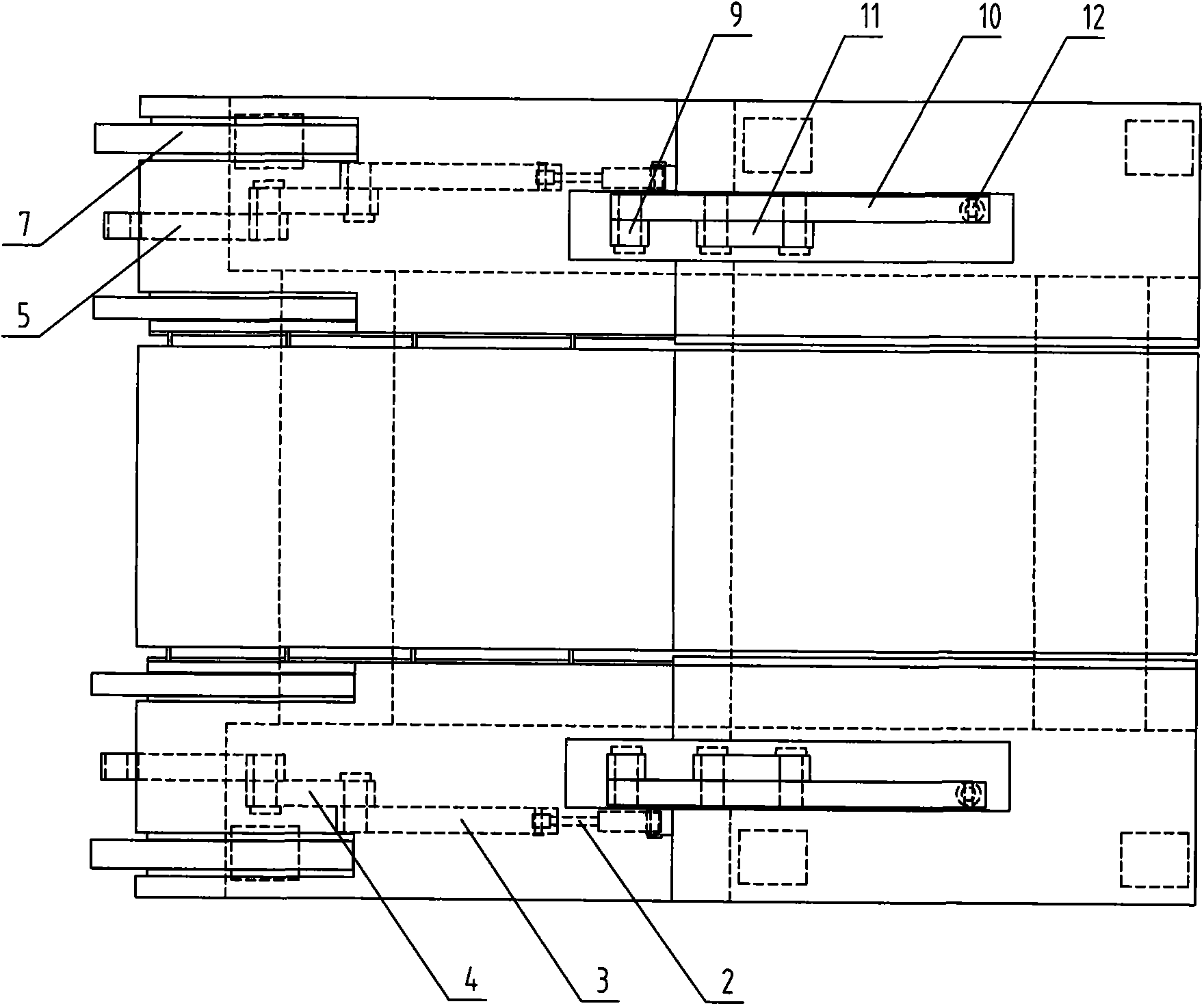

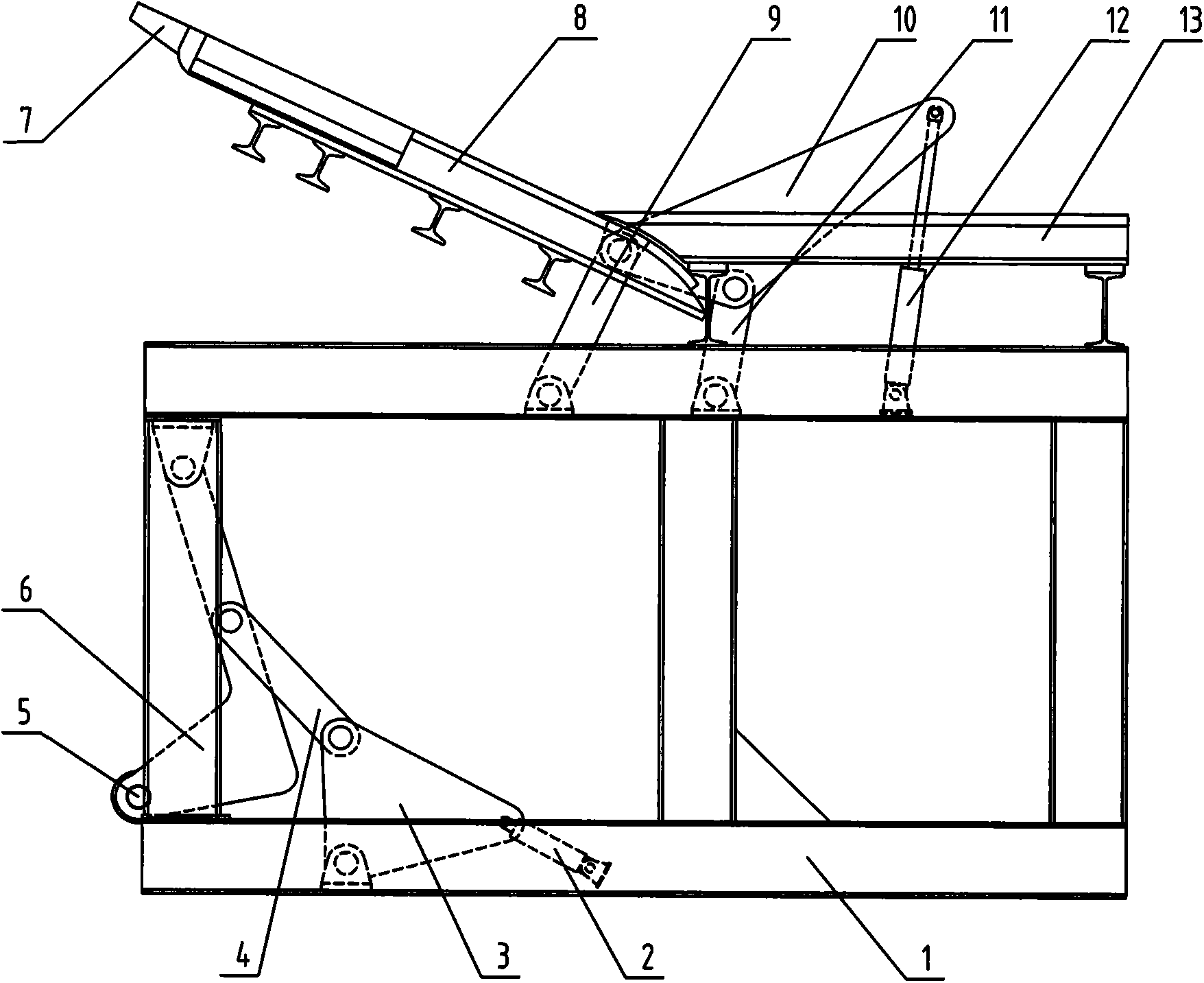

Cage supporting and stabilizing device based on dead points of two four-bar mechanisms

ActiveCN103818812APrevent bouncing up and downRealize the undertakingElevatorsMine liftsEngineeringRocker arm

The invention discloses a cage supporting and stabilizing device based on dead points of two four-bar mechanisms. The cage supporting and stabilizing device based on the dead points of the two four-bar mechanisms comprises a machine frame (1), a supporting four-bar mechanism (14), a stabilizing four-bar mechanism (15) and a rocker arm rear platform (13). According to the cage supporting and stabilizing device based on the dead points of the two four-bar mechanisms, by means of the dead point characteristic of the four-bar mechanisms, a cage can be supported smoothly and safely and stabilized firmly, the situation that the cage moves up and down due to the elasticity of suspension steel wire ropes is effectively avoided, the cage can be loaded and unloaded more stably and more reliably, the safety performance of equipment is effectively improved, the structure is simple and reliable, operation is flexible, a large power source is omitted, and the effect is obvious.

Owner:CHINA UNIV OF MINING & TECH +1

Automatic thread cutting device in multi-needle machine

ActiveCN101696536ASmooth slidingImprove sliding accuracyNeedle severing devicesEngineeringKnife holder

The invention provides an automatic thread cutting device in a multi-needle machine, which belongs to the technical field of machines. The invention solves the technical problems of low guide precision of a movable blade, poor stability of thread cutting and the like in the traditional thread cutting devices of multi-needle machines. The automatic thread cutting device arranged at the needle head of the multi-needle machine comprises a needle plate pad and a movable blade holder arranged on the needle plate pad, wherein a fixed blade is fixed on the needle plate pad and a plurality of movable blades are fixed on the movable blade holder. The movable blade holder is connected with a driving mechanism, a guide mechanism which enables the movable blade holder to slide in the plane direction under the driving of the driving mechanism is arranged on the needle plate pad, and the sliding of the movable blade holder enables the movable blades to be in a position tangental to the fixed blade. The automatic thread cutting device ensures that the movable blade holder is more stable and precise in sliding, and enhances the stability of thread cutting.

Owner:浙江振盛缝制机械有限公司

Adjustable Toggle Mechanism for Furniture Sliding Doors

ActiveCN105133983BSliding opening and closing force is smallReasonable cooperationBuilding braking devicesWing arrangementsEngineeringMechanical engineering

Owner:伍志勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com