Chain type harvest header for composite feed crop straw

A crop straw, chain technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of short blade life, low cutting speed of reciprocating cutters, and high rotational speed of disc cutters, and achieve stubble cutting. Flattening, to achieve the effect of horizontal laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

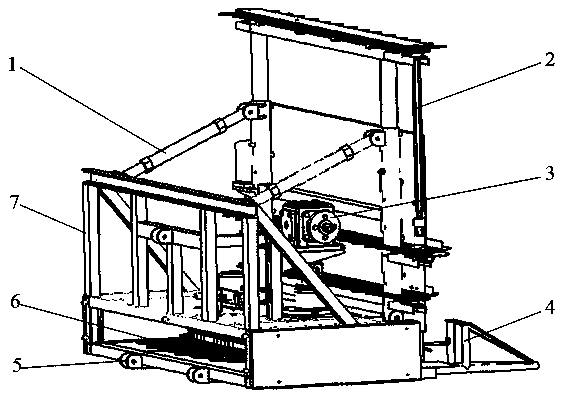

[0026] Such as figure 1 A chain-type forage crop stalk harvesting platform is shown, including a frame 7, a chain cutter 6 and a stalk transverse conveying device 2 installed on the frame, and the stalk transverse conveying device 2 is located above the cutter , the rear side of the frame is welded with a three-point suspension support 5, which is used to hang the header on the front suspension tractor, and the front side of the frame is fixedly connected with the grain divider 4 positioned at the chain cutter both sides.

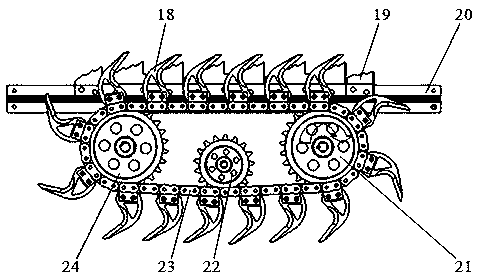

[0027] Such as image 3 As shown, the chain cutter 6 includes a fixed knife mechanism 40 fixed to the frame, a number of movable blades 18 fixed on the outer surface of the endless chain 23, and a driving device that drives the rotation of the endless chain. The fixed knife rod fixed to the frame and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com