Storage cabinet and robot for shifting storage cabinet

A technology for storage cabinets and robots, which is applied to manipulators, manufacturing tools, and external accessories. It can solve the problems of complex fixing structure, poor fixing effect, and low work efficiency, and achieve simple fixing structure, good fixing effect, and convenient and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

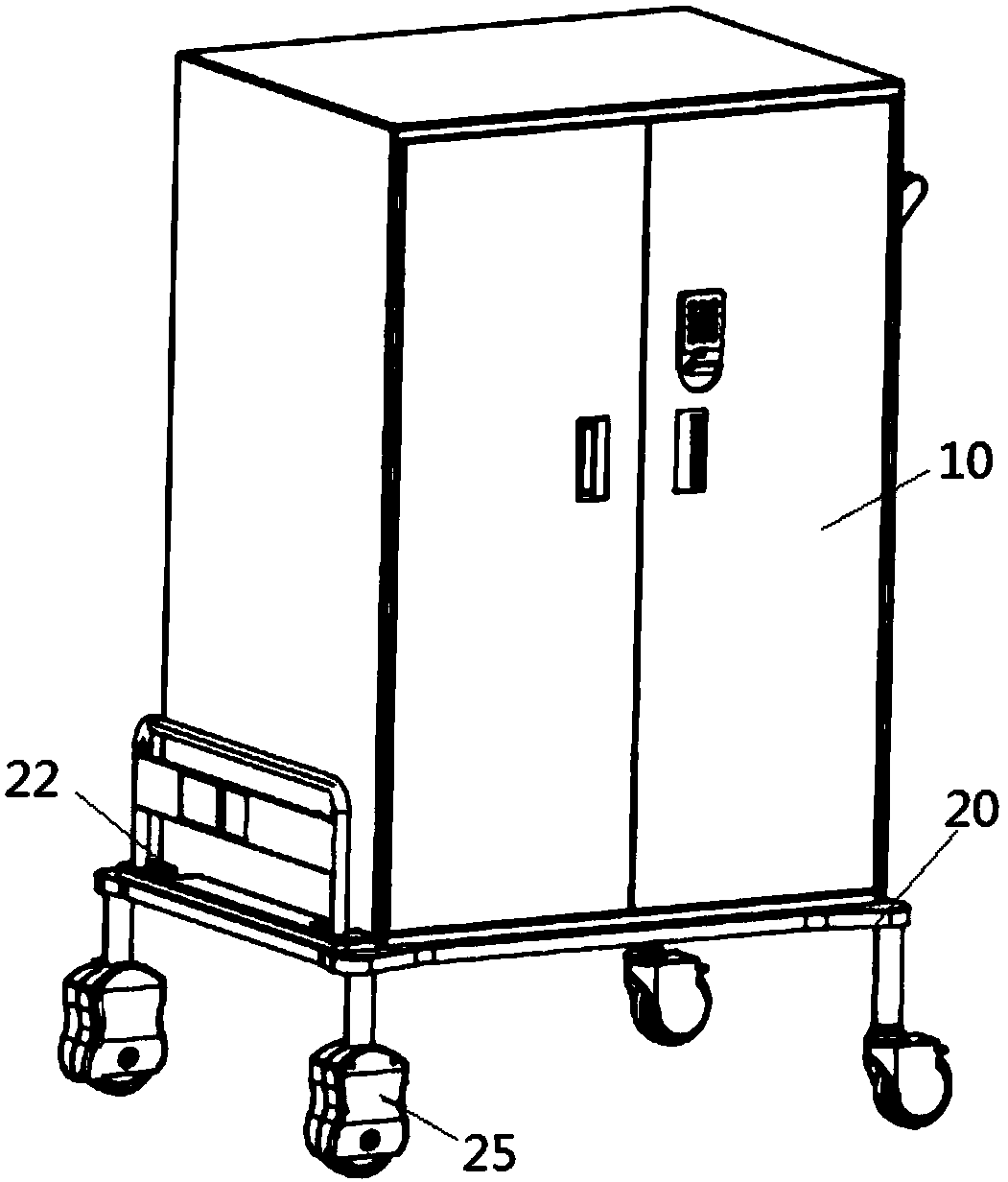

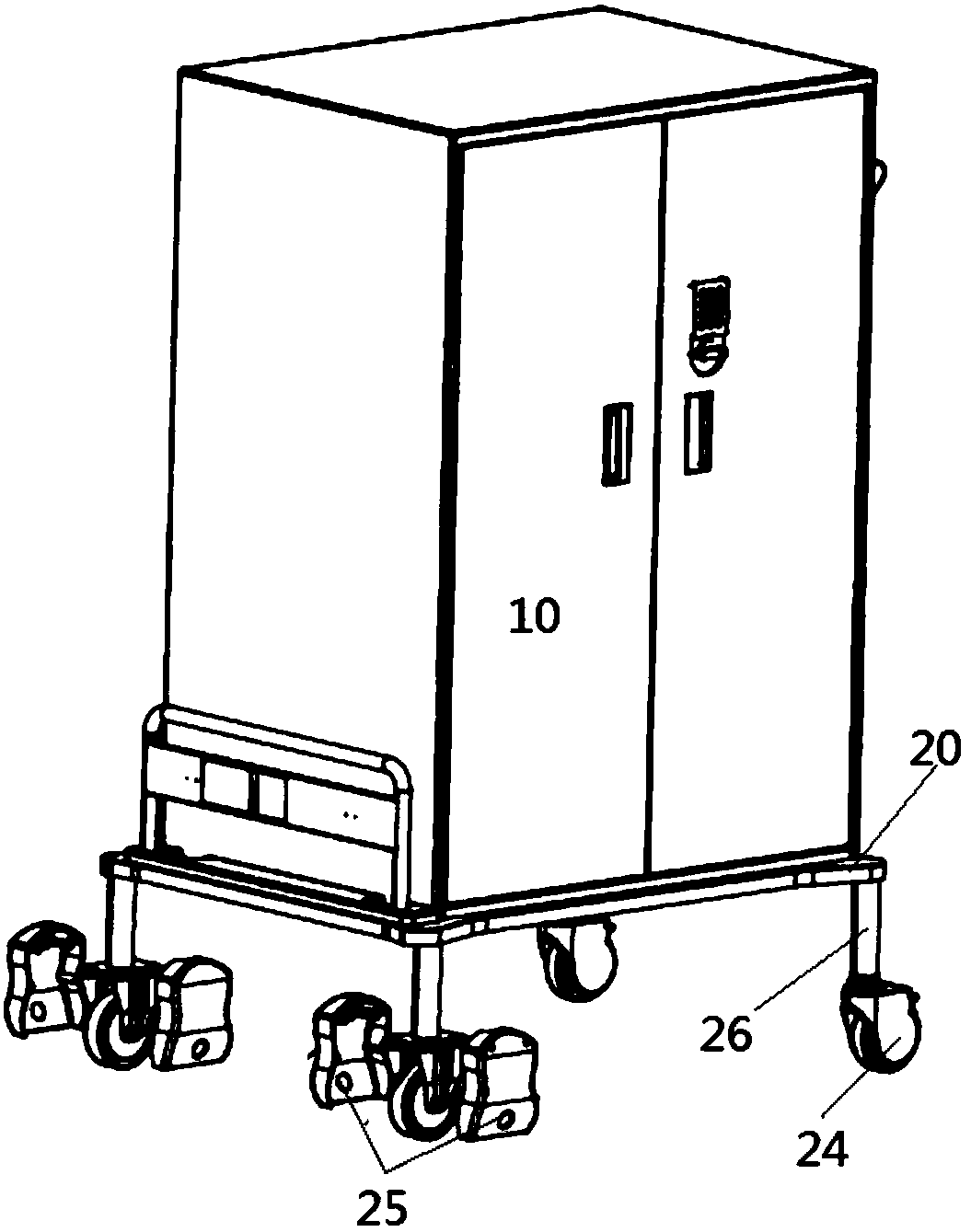

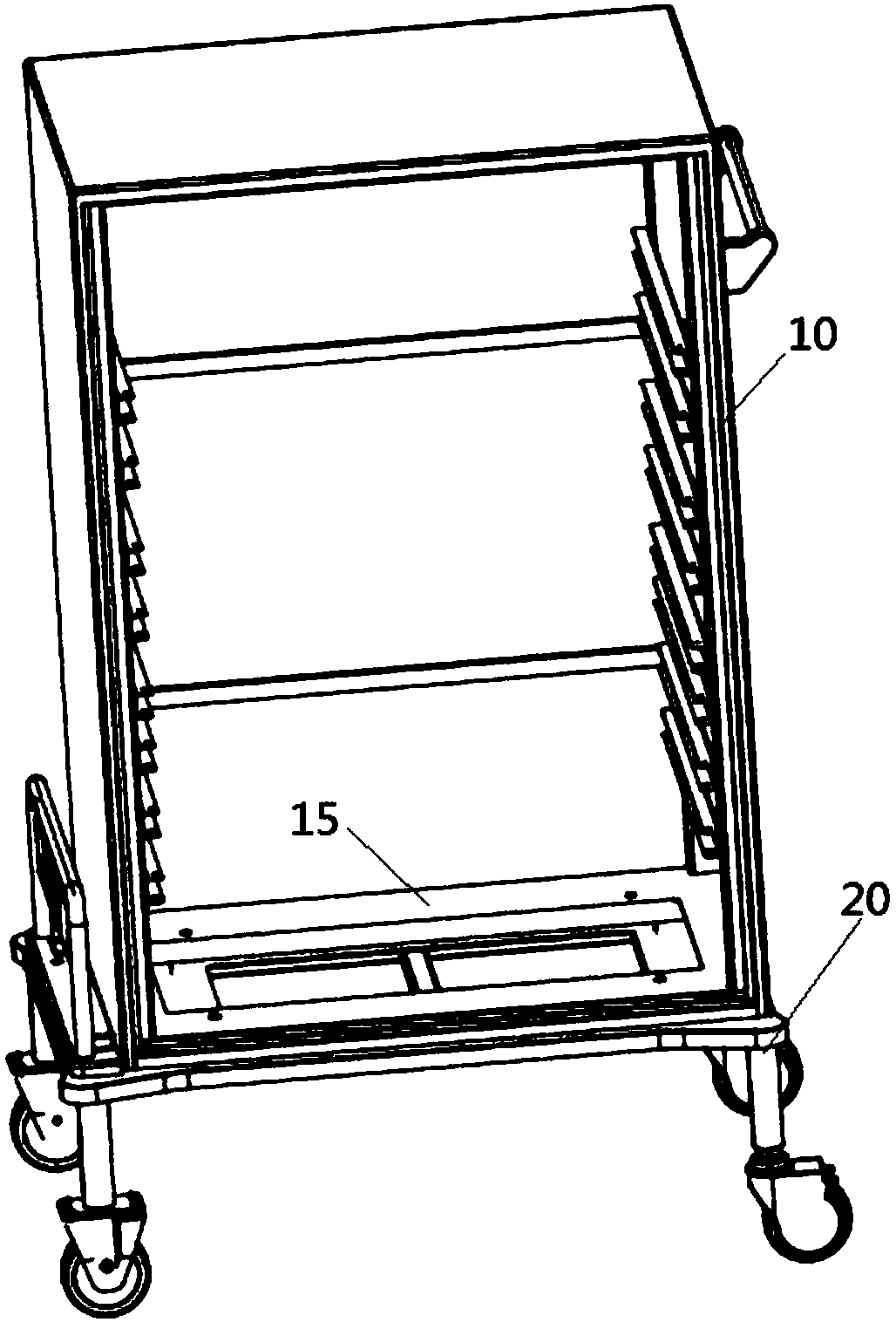

[0047] Such as Figure 1-8 As shown, this specific embodiment discloses a storage cabinet, the storage cabinet includes a cabinet body 10, a storage chamber for storing articles is provided in the cabinet body 10, an extension end is provided on one side of the cabinet body 10, and an extension end is provided on the extension end At least one card slot. Specifically, a bottom plate 20 is provided at the bottom of the cabinet body 10 , and part of the bottom plate 20 protrudes from the cabinet body 10 to form an extension end.

[0048] In this specific embodiment, the bottom plate 20 includes a body 21, the body 21 is used to connect with the bottom of the cabinet body 10, a handle 23 is provided on the body 21, the handle 23 is used to pull the body 21, and the bottom of the body 21 is provided with a plurality of wheels. The body 24 and the wheel body 24 are used to move the body 21, the cabinet body 10 is arranged on the bottom plate 20, and the cabinet body 10 can be easi...

specific Embodiment 2

[0053] Such as Figures 9 to 11 As shown, this specific embodiment discloses a robot for moving the above-mentioned storage cabinet. The robot includes a main body 30 and a chassis 40. The main body 30 is fixedly arranged at one end of the chassis 40. A control panel is arranged in the main body 30. The bottom of the chassis 40 A pulley is provided, and a jacking device is provided in the chassis 40 , and the driving mechanism of the pulley and the jacking device are both electrically connected to the control board in the main body 30 . The output end of the jacking device is provided with a lifting plate 41, and the lifting plate 41 is used for installing and lifting the storage cabinet. The slots 22 are in one-to-one correspondence. When the lifting device drives the lifting plate 41 to the preset position, the hook 50 is inserted into the slot 22 on the bottom plate 20 of the storage cabinet. The hook 50 is used to vertically lift the storage cabinet. The direction and hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com