Roller used in rice production

A technology of rolling and rice, which is applied in the field of rolling for rice production, can solve the problems affecting the quality of rice, affecting the quality of products, reducing the service life of rolling, etc., to improve efficiency and fineness, improve space utilization, and improve processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described;

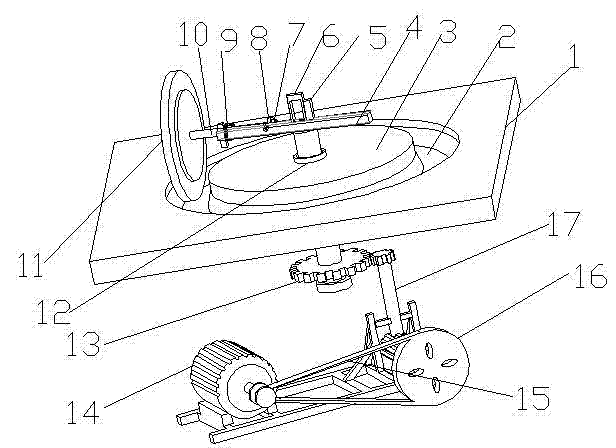

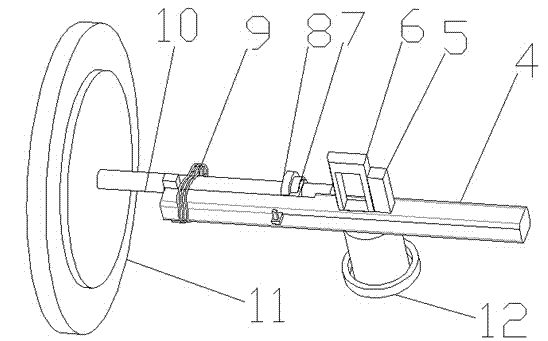

[0015] Such as figure 1 and figure 2 The rice production roller shown is that the circular boss 3 with a diameter of 300cm is arranged on the concrete pouring ground 1, and the edge of the circular boss 3 is provided with an annular groove 2 with a groove depth of 50cm, and the annular groove 2 The cross section is an inverted trapezoid, the inclination angle between the inner surface of the annular groove 2 and the horizontal plane is 70 degrees, the inclination angle between the outer surface of the annular groove 2 and the horizontal plane is 45 degrees, and the center of the circular boss 3 is provided with a circular The vertical shaft 6 of the boss 3 and the ground 1, the upper end of the vertical shaft 6 is flat and inserted into the fixed rod 4, so that the vertical shaft 6 and the fixed rod 4 are connected more firmly, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com