Side guide plate of recoiling machine

A technology of side guide plate and coiler, which is applied in the field of steel rolling side guide plate, can solve the problems of the liner wear of the side guide plate of the coiler, the instability of the coiler plate, etc., so as to improve production efficiency, prevent up and down jumping, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

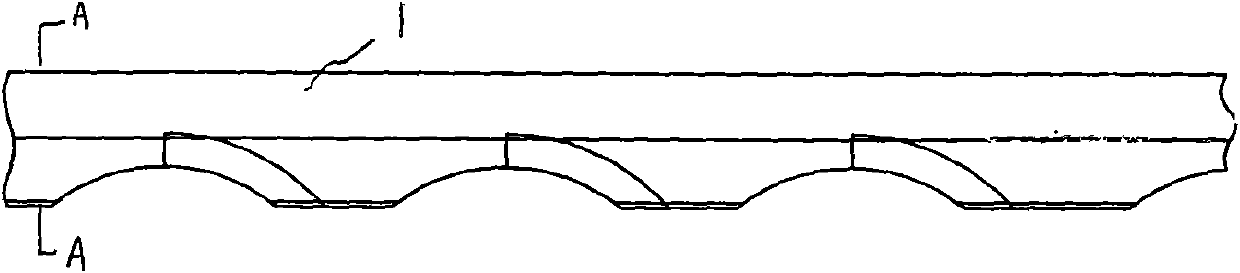

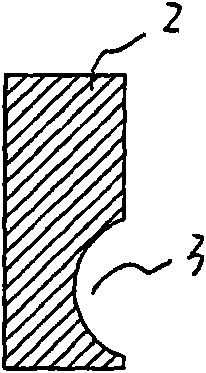

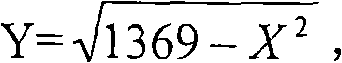

[0013] refer to figure 1 , 2 , a side guide plate of a coiler, comprising a side guide plate body 1 and a liner plate 2, and an arc-shaped guide groove 3 is provided near the lower end of the liner plate. Arc-shaped guide groove 3 is to utilize on the former take-up side guide plate backing plate to realize with the guide hole pattern of planer processing certain radian. The thickness is 60mm; the width is 150mm, the distance between the lower edge of the arc pass and the bottom of the liner is 10mm; the arc is an arc with a radius of 37, the arc depth is 25mm, and the opening of the arc pass is 70mm; the arc pass curve formula is: Y = 1369 - X 2 , X ∈ [-35, 35].

[0014] After the strip is finished rolling, the head of the strip first enters the slanted part of the side guide plate of the coiler, and due to the existence of the arc guide pass, the strip grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com