Patents

Literature

48results about How to "Leak won't" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

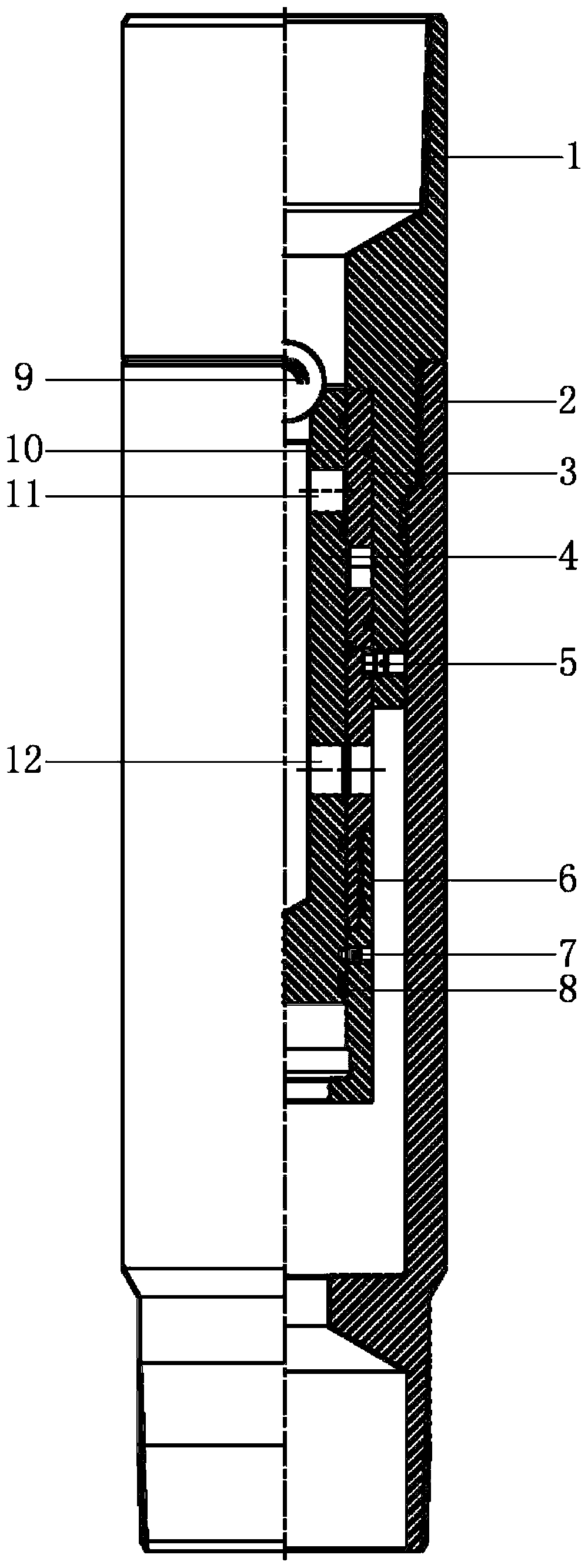

Starting pup joint with second-time opening function

PendingCN110080707AWith secondary opening functionAvoid resetFluid removalUpper jointDifferential pressure

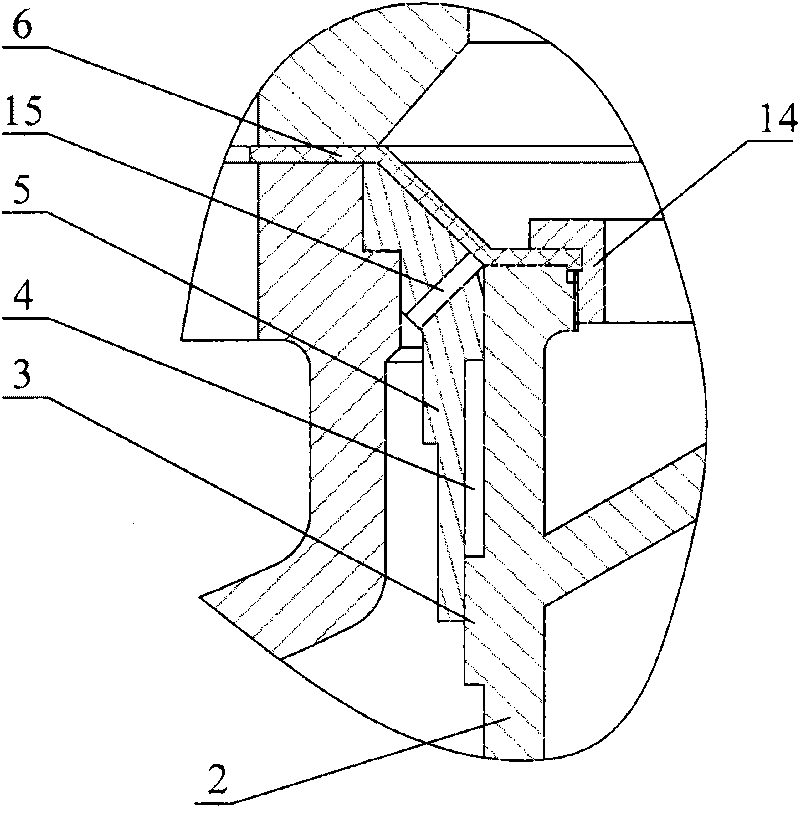

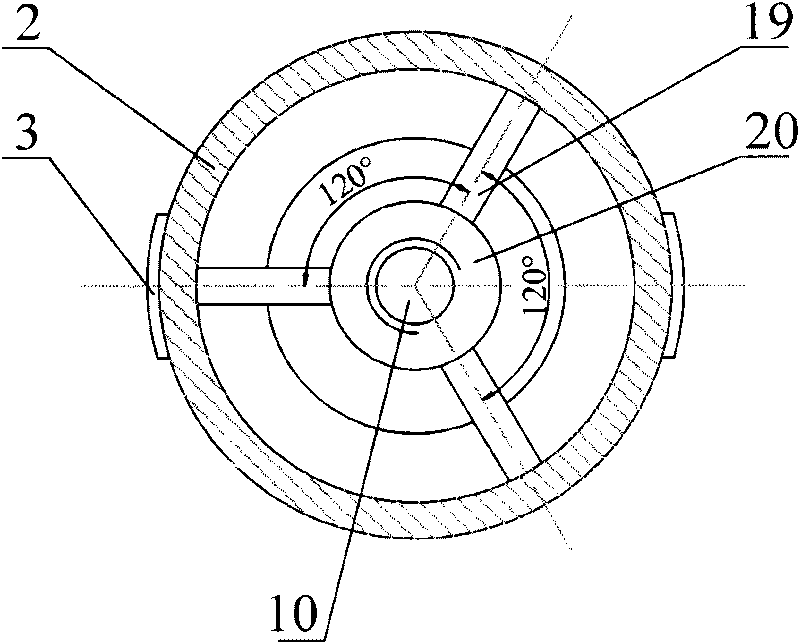

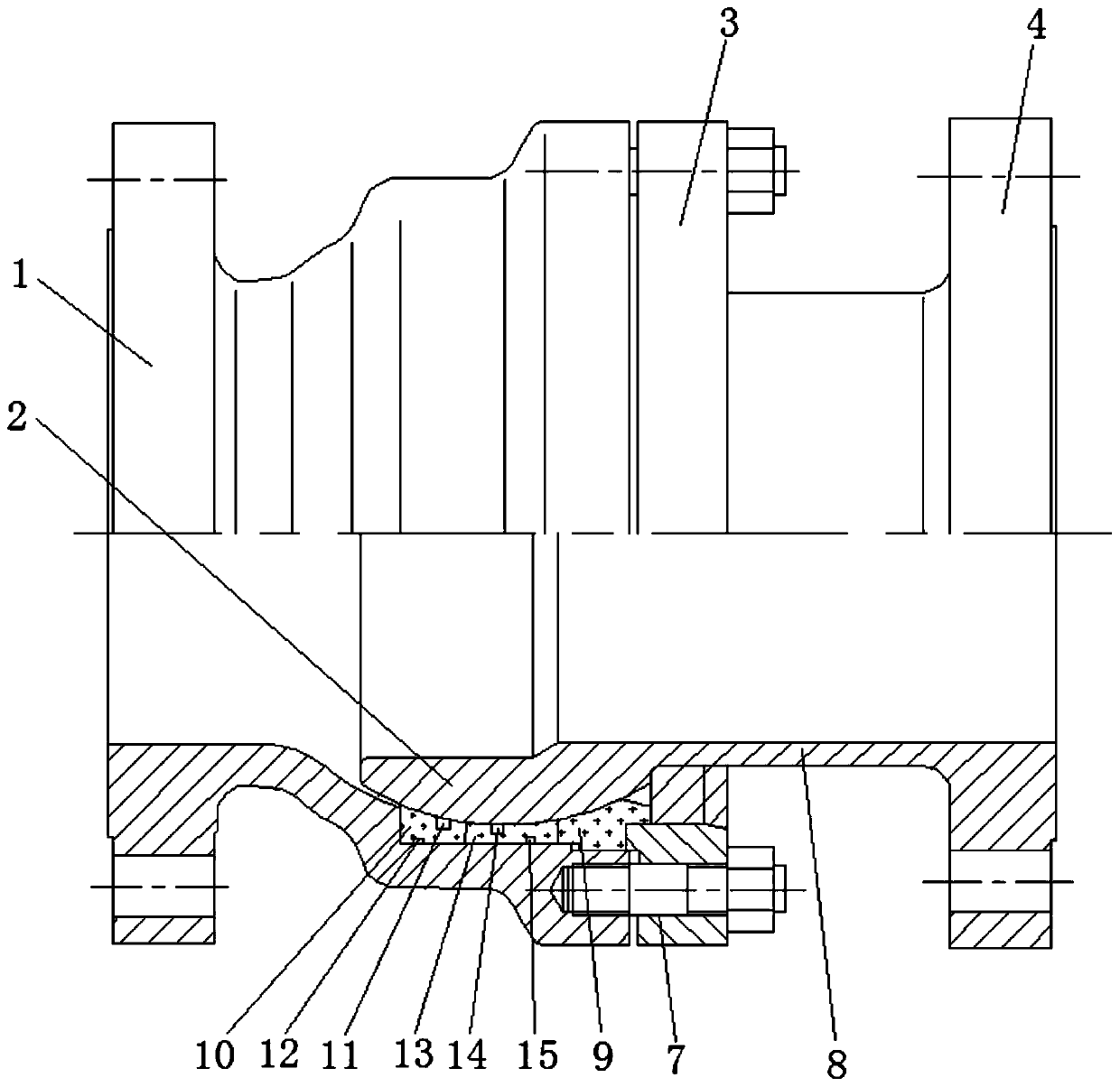

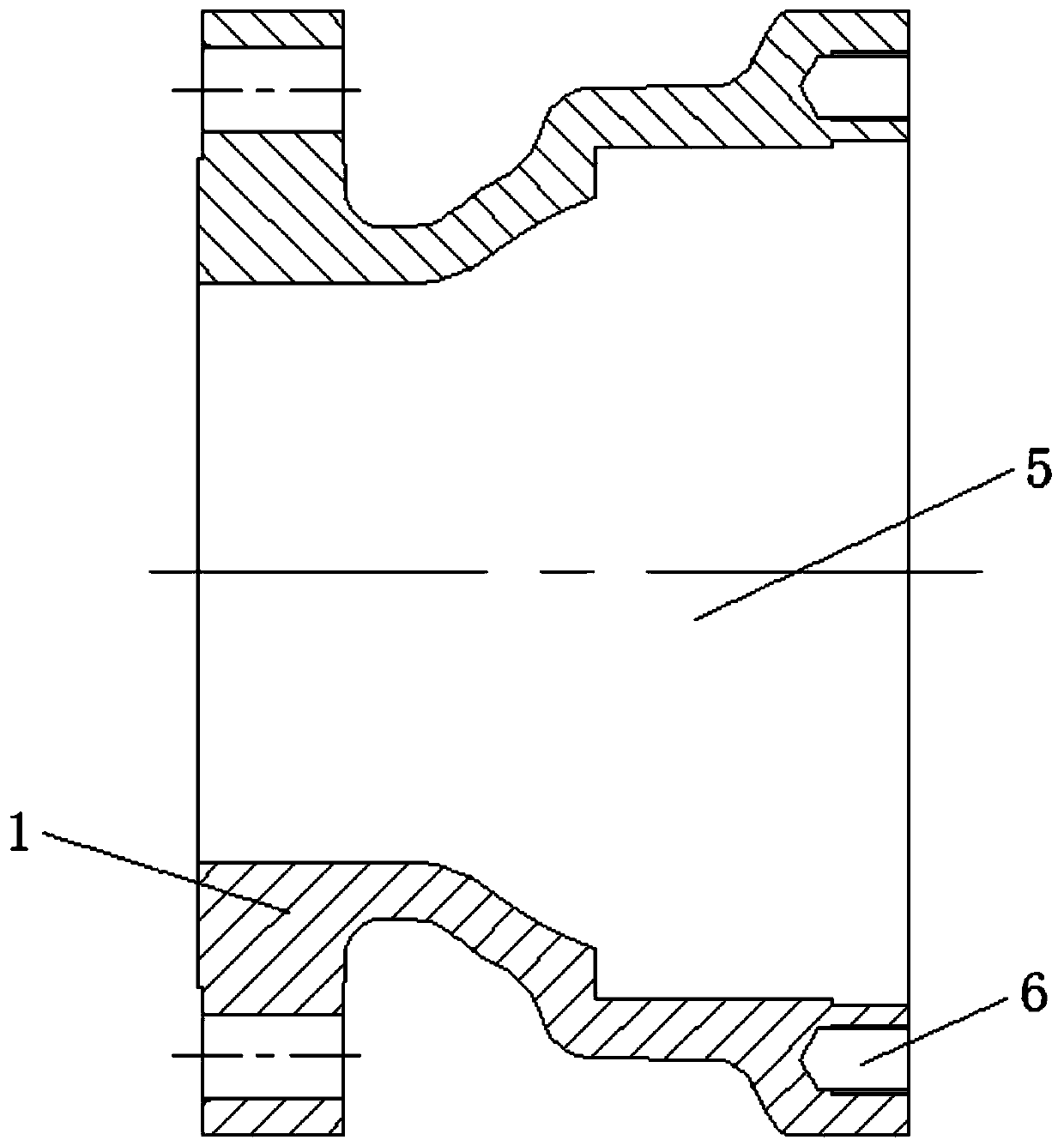

The invention discloses a starting pup joint with a second-time starting function. The starting pup joint comprises a core shaft and a setting ball. The core shaft is connected with a sliding sleeve,the setting ball is connected with the core shaft, the sliding sleeve is connected with an outer sleeve, the outer sleeve is connected with the core shaft through a first-stage shear pin, a groove isformed in the core shaft, a baffle ring can be embedded into the groove, the baffle ring is in contact with the outer sleeve, the sliding sleeve is connected with an upper joint, the upper joint is connected with a lower joint, the upper joint, the sliding sleeve and the core shaft are sequentially connected in a step mode, the core shaft is provided with a fluid channel and a fracturing channel,and the sliding sleeve is provided with a fluid channel and a fracturing channel. Setting of a packer can be achieved when the packer is opened for the first time, and when the differential pressure sliding sleeve cannot be opened normally, the starting pup joint is started for the second time, and the fracturing channel is opened.

Owner:JEREH ENERGY SERVICES

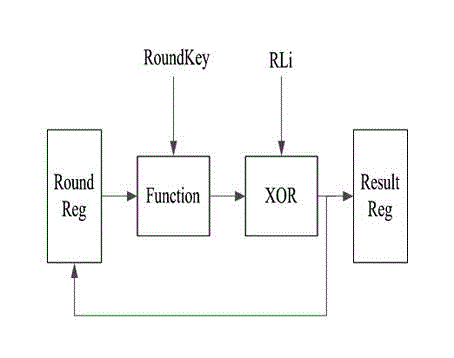

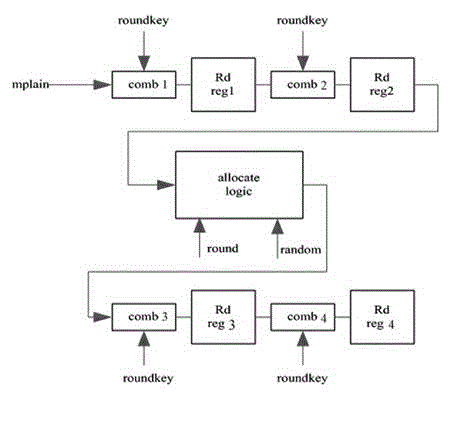

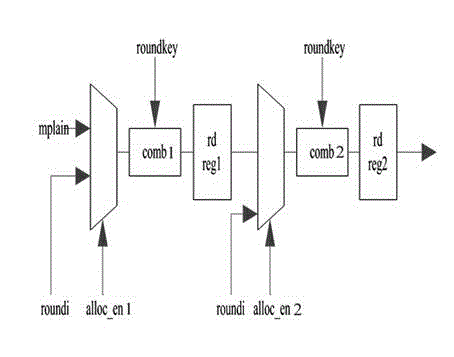

Enhanced MASK code method for resisting DES (data encryption standard) power consumption attack

ActiveCN102752103AWon't leakSmall design areaEncryption apparatus with shift registers/memoriesLogical operationsOperation mode

The invention relates to an enhanced MASK code method for resisting DES (data encryption standard) power consumption attack, comprising the steps as follows: step 1, realizing two rounds of DES (data encryption standard) calculations with a pipeline operation mode, realizing a calculating circuit by means of a first calculating circuit and a second calculating circuit which are mutually independent and isolated; step 2, realizing the DES (data encryption standard) calculation processes from the third round to the fourteenth round by means of a random positioning logical operation mode; step 3, realizing the last two rounds of DES (data encryption standard) calculations by means of a pipeline operation mode, and realizing the calculating circuit by means of a third calculating circuit and a fourth calculating circuit which are mutually independent and isolated, wherein each round of the DES (data encryption standard) calculations in step 1 to 3 is calculated with a MASK code method. The method provided by the invention not only reduces the design area of the chip, but also completely solves the problem in the prior art in which the two adjacent rounds of the MASK code solutions have a Hamming distance leakage, and keeps the sensitive information between wheels from leakage, and simultaneously keeps the Hamming distance and other sensitive information between two adjacentwheels from leakage, and effectively resists the power consumption attack.

Owner:SHANGHAI AISINOCHIP ELECTRONICS TECH

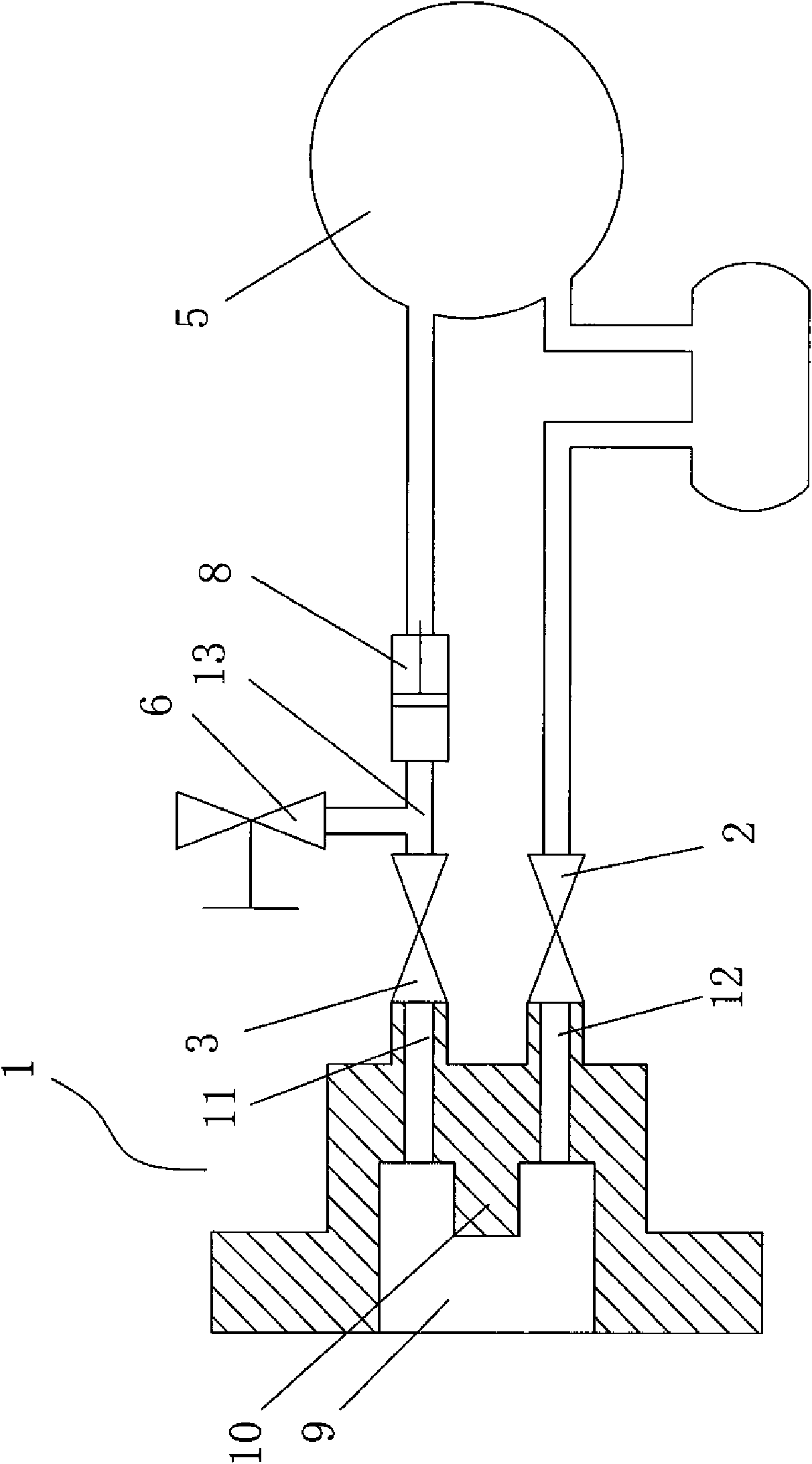

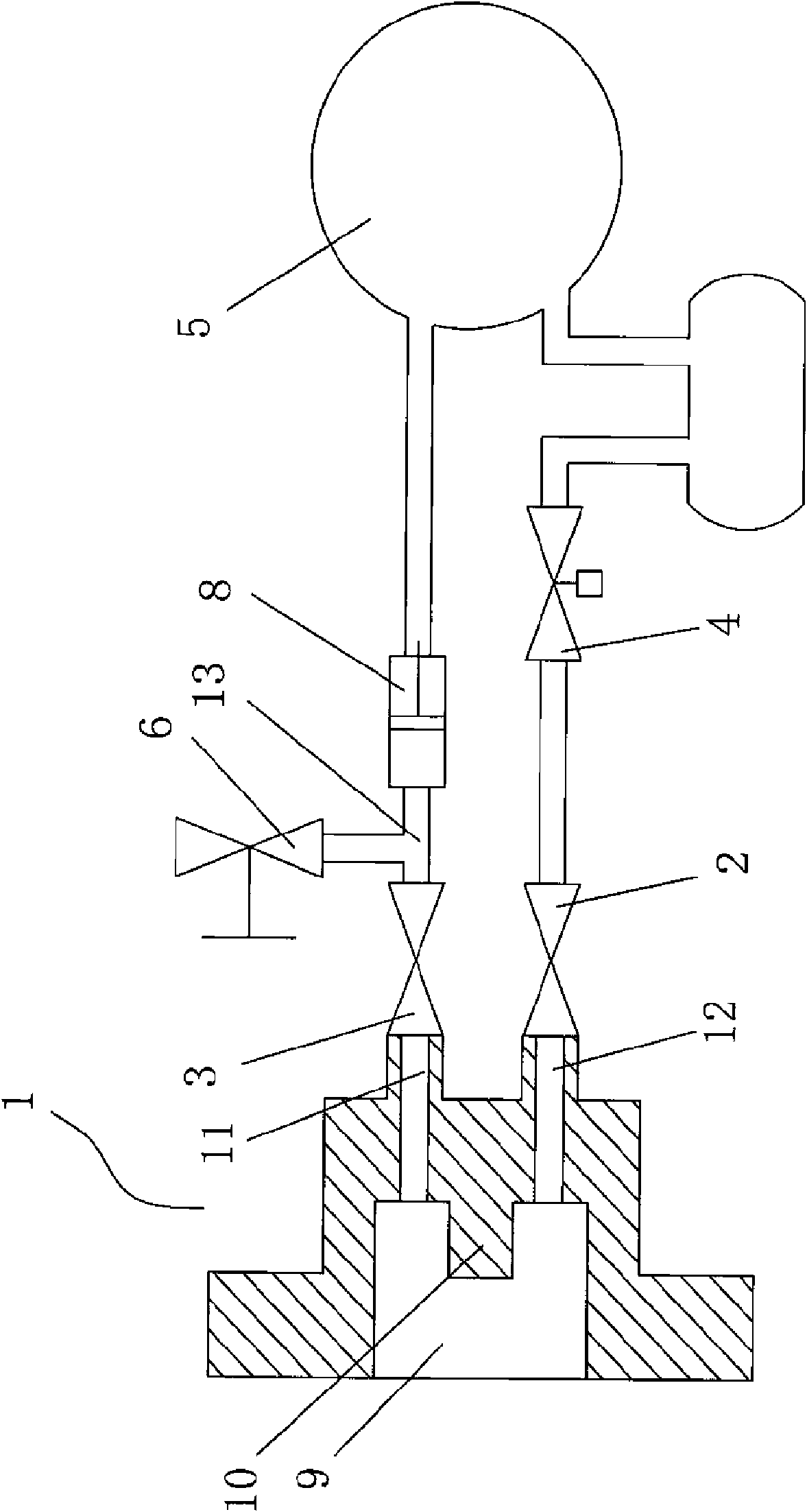

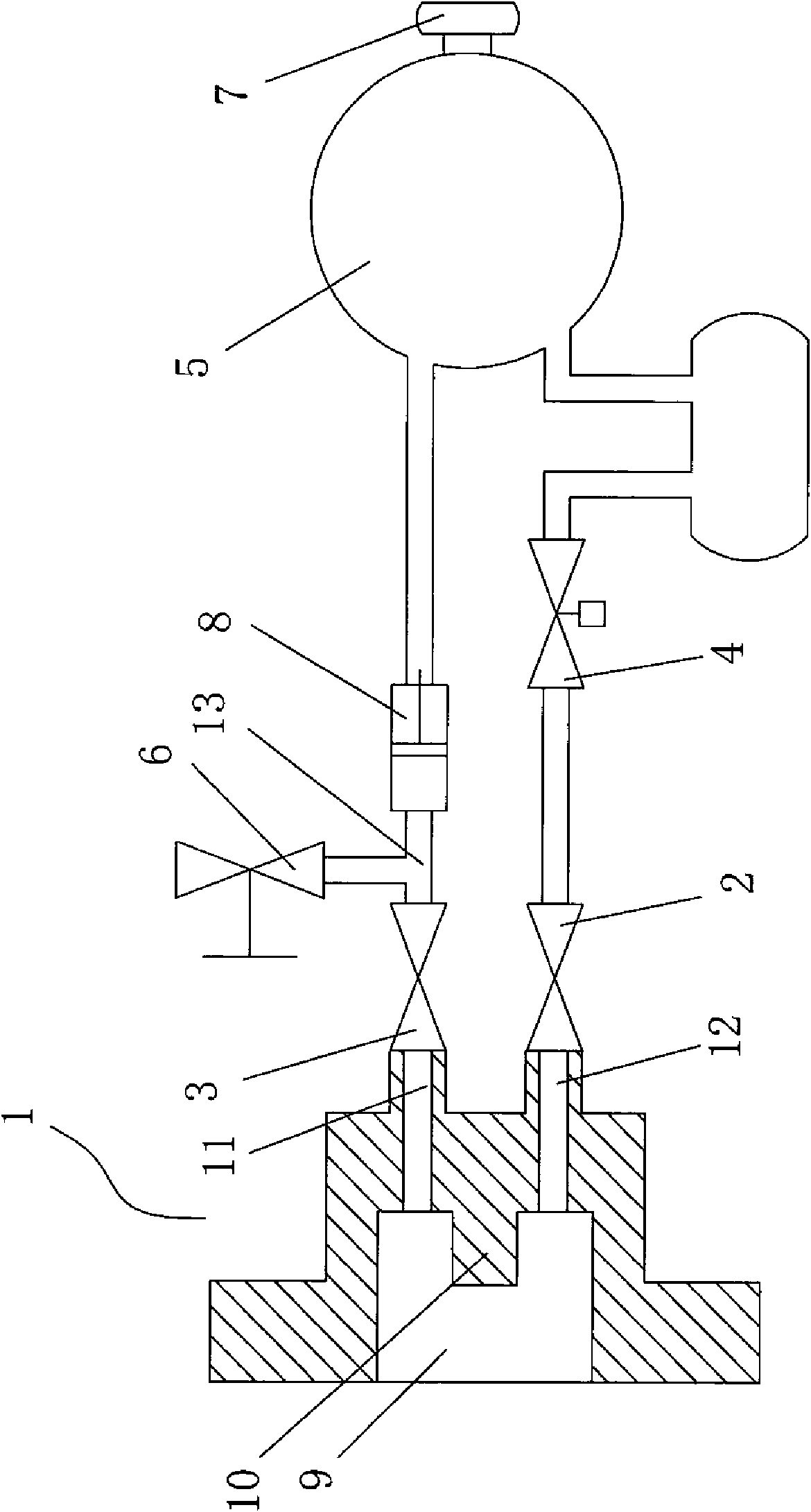

Sealing gas sampling apparatus

InactiveCN101587031AConducive to environmental protectionAvoid economic lossWithdrawing sample devicesEngineeringElectromagnetic valve

The invention discloses a sealing gas sampling apparatus, including an adapter, a first electromagnetic valve, a second electromagnetic valve, a gas container, a vent valve and a minisize high-pressure air pump. One end of the adapter is provided with a connecting column and a convex column and the other end is provided with an air inlet and an air outlet. The air outlet of the adapter is connected with the inlet of the first electromagnetic valve. The outlet of the gas container is connected with the inlet of the minisize high-pressure air pump. The outlet of the minisize high-pressure air pump is respectively connected with the inlet of the second electromagnetic valve and the vent valve via a tee joint. The outlet of the second electromagnetic valve is connected with the air inlet of the adapter. An interface is arranged on the gas container. The sealing gas sampling apparatus can sample the sealing gas. The gas passing through the sampling and analysis instrument can be charged to the electrical apparatus or the gas tank timely to realize the effective sampling of the measured gas, thus benefiting environmental protection and avoiding the economic loss.

Owner:施宏

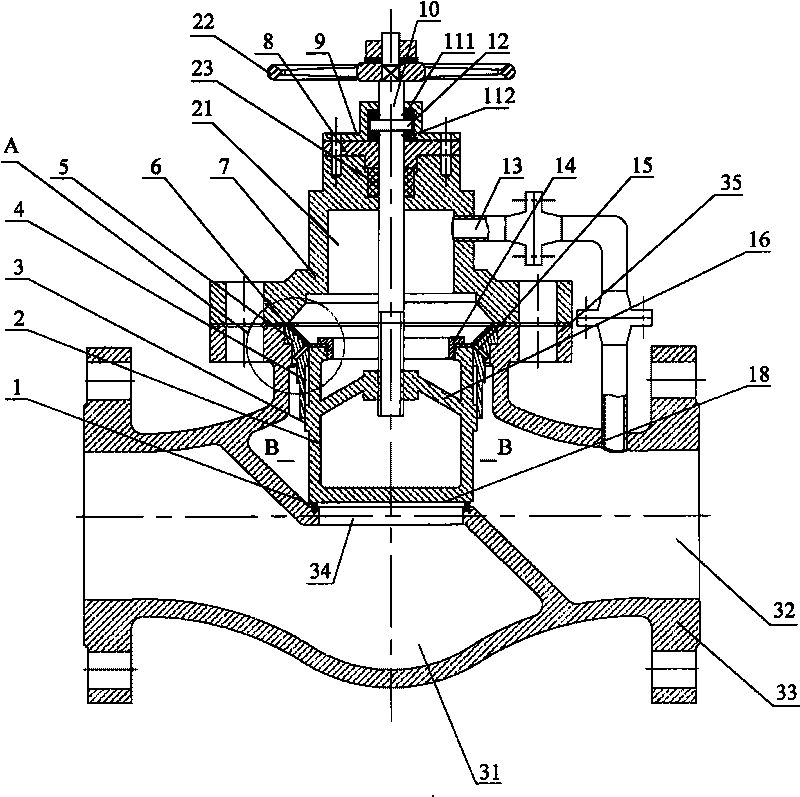

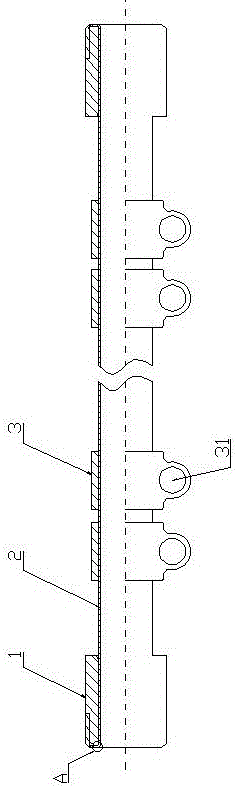

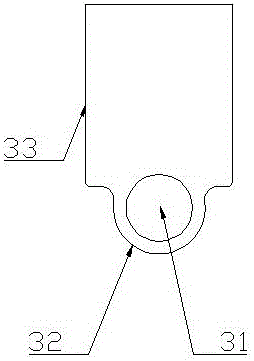

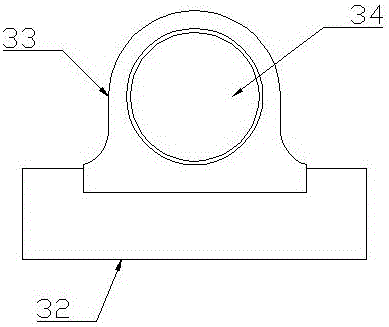

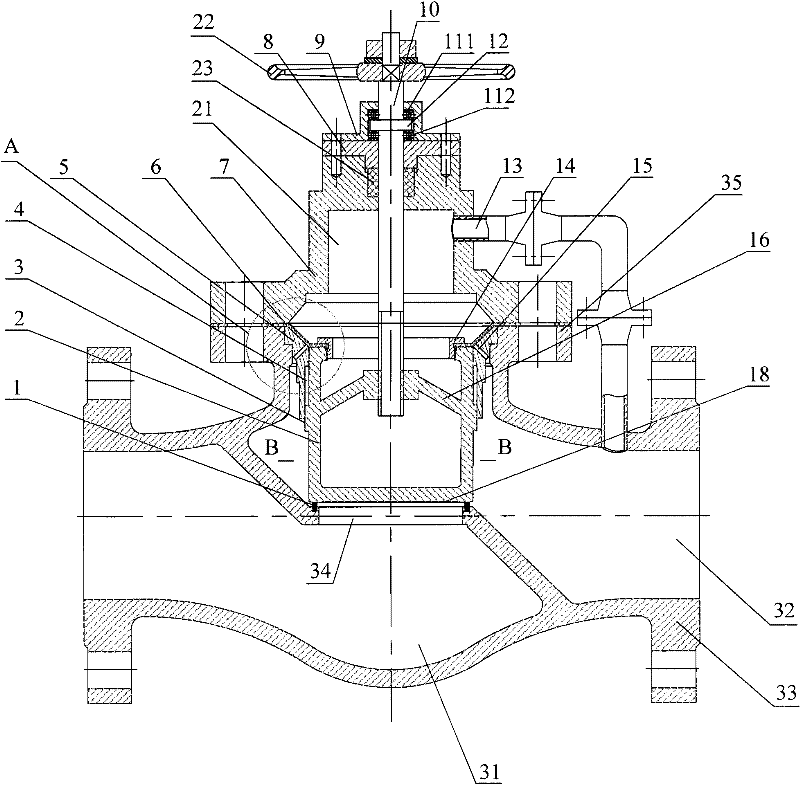

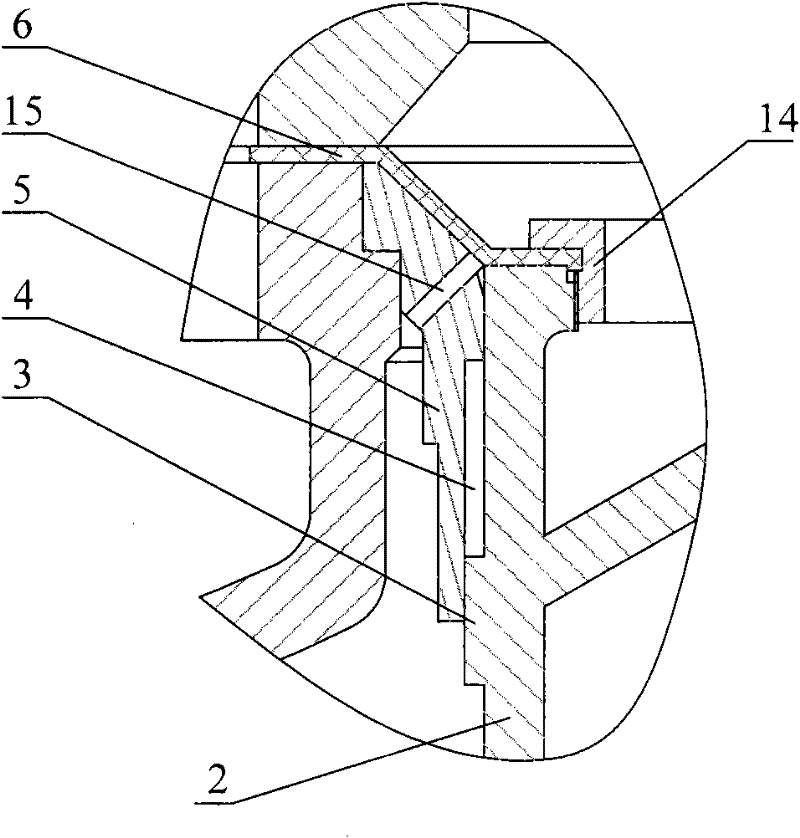

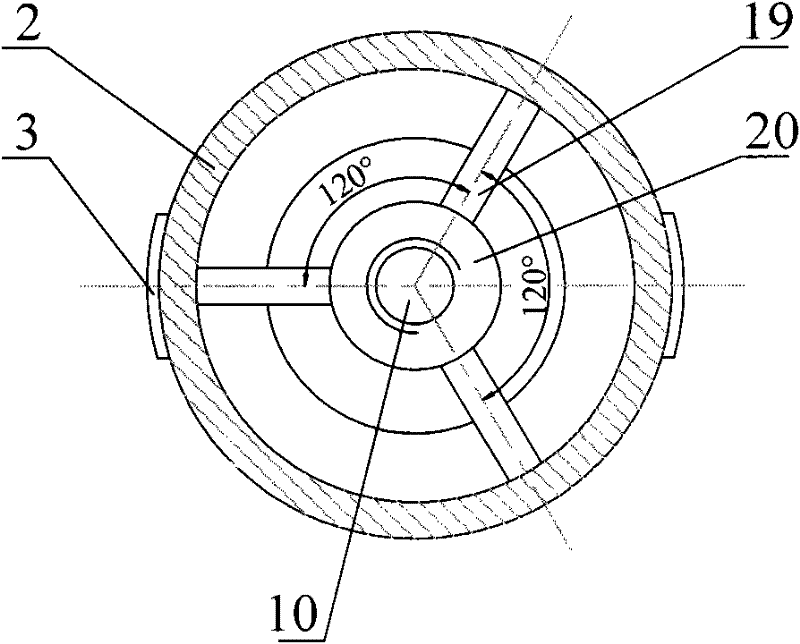

Self-balancing stop valve with piston type valve core and hidden rod

The invention discloses a self-balancing stop valve with a piston type valve core and a hidden rod, which comprises a valve cover (7) and a valve body (33) provided with a front valve cavity (31) and a rear valve cavity (32), wherein a passage (34) is formed between the front valve cavity (31) and the rear valve cavity (32). Guide sleeves (5) in vertical sealed sliding connection and the piston type valve core (2) in which a cavity is formed are arranged in the rear valve cavity (32); the bottom surface (18) of the piston type valve core (2) is used for blocking the passage (34); the guide sleeves (5) are hermetically and fixedly connected with the valve body (33); a lifting component is connected with the piston type valve core (2); the valve cover (7) is hermetically connected with the valve body (33); the inner surfaces of the piston type valve core (2), the guide sleeve (5) and the valve cover (7) encircle an upper chamber (21); and the upper chamber (21) is communicated with the rear valve cavity (32) through a guide pipe component (13). The self-balancing stop valve has the characteristic of remarkable energy-saving effect.

Owner:ZHEJIANG UNIV

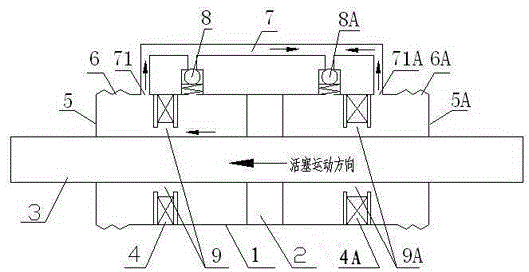

Leakage-free seal-ring-free two-way controllable magnetorheological damper

ActiveCN102359536APrevent leakageReduced concentricity requirementsSpringsNon-rotating vibration suppressionEngineeringCylinder block

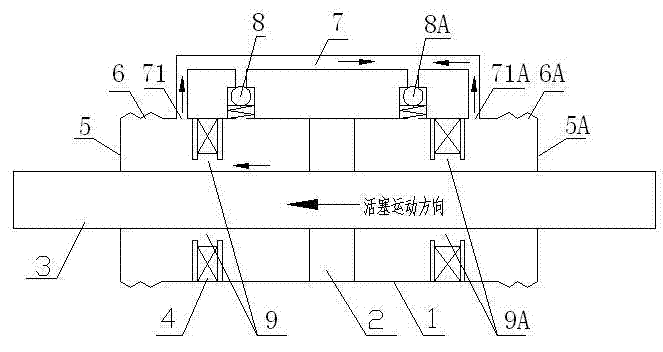

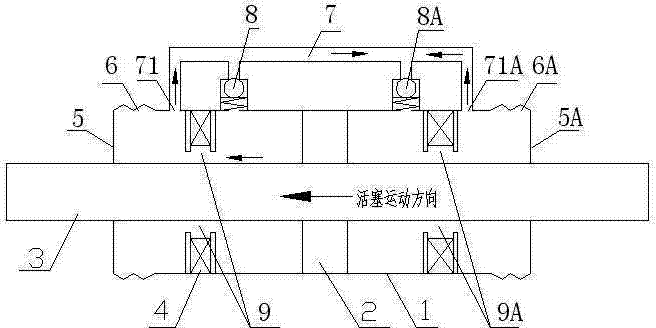

The invention discloses a leakage-free seal-ring-free two-way controllable magnetorheological damper which comprises a cylinder body, a piston and a piston rod, wherein the left end and the right end of the cylinder body are respectively connected with a left corrugated pipe and a right corrugated pipe hermetically, the left corrugated pipe is hermetically connected with a left end cover, the left end cover and a right end cover are hermetically connected with the piston rod, the left corrugated pipe and the right corrugated pipe are hermetically connected with the left end cover and the right end cover, and the centers of the left end cover and the right end cover are hermetically connected with the piston rod; a communicating pipe is arranged on the cylinder body; a left circular coil and a right circular coil are fixedly connected inside the cylinder body, and gaps between the inner holes of the circular coils and the piston rod form a damping channel; and a left one-way valve and a right one-way valve are arranged on the communicating pipe, and the piston rod is located between the left one-way valve and the right one-way valve. In the invention, the corrugated pipes are used as sealing elements, leakage caused by wearing between the piston rod and a seal ring is avoided, and the corrugated pipes do not bear working pressure. The damper can not leak within the service life of the corrugated pipes.

Owner:CHONGQING MATERIALS RES INST

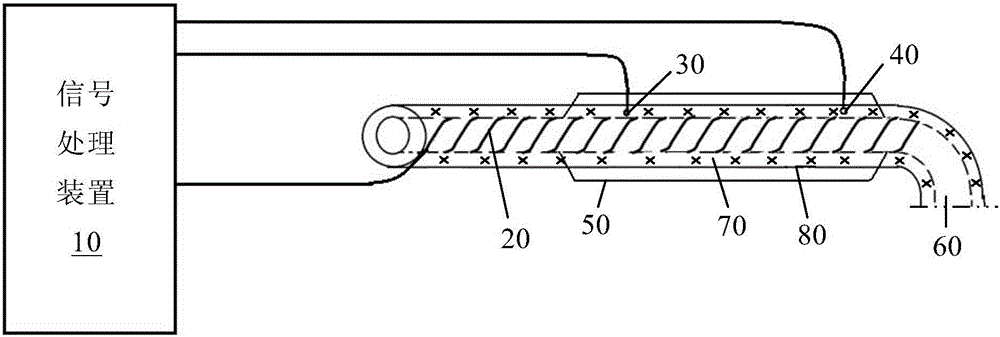

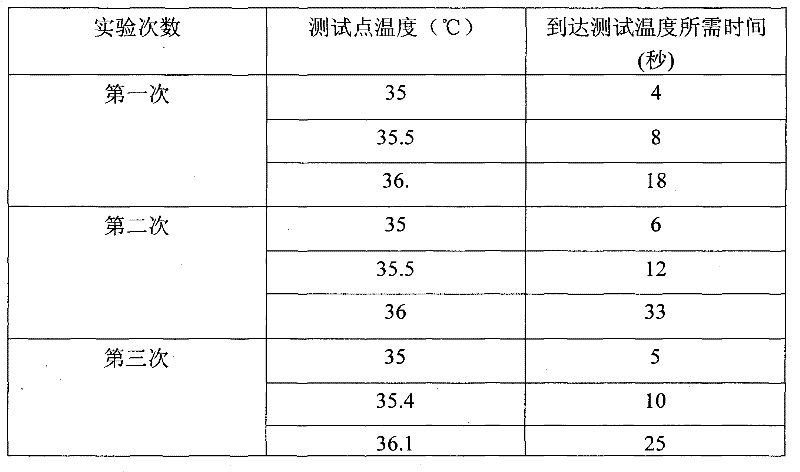

Coal dust conveying device leakage monitoring and early warning device and method

ActiveCN106338365AGuaranteed uptimeEnsure safe productionMeasurement of fluid loss/gain rateFluid-tightness measurement using lightDevice leakageCoal dust

The invention discloses a coal dust conveying device leakage monitoring and early warning device and method. The leakage monitoring and early warning device comprises distributed temperature sensitive optical fibers which are wound and adhered on the external wall of a conveying steel pipe. The conveying steel pipe is externally wrapped by a heat insulation layer and a protective sleeve. The conveying steel pipe is divided into multiple continuous monitoring areas along the axis. The protective sleeve in each monitoring area is externally provided with a jacket. The two ends of the jacket stretch into the protective sleeve and the heat insulation layer and then are connected with the conveying steel pipe in an adhesive way. The jacket and the external wall of the conveying steel pipe form an enclosed pressure detection cavity. In the pressure detection cavity, an optical fiber grating vibration sensor is arranged on the external wall of the conveying steel pipe, and an optical pressure sensor is installed in the heat insulation layer. Leakage of the coal dust conveying device caused by holes or cracks at the early stage of leakage can be accurately judged and early warning can be performed, leakage of the coal dust conveying device caused by friction of the coal dust in conveying can also be accurately judged and the leakage points can be accurately captured and located and early warning can be performed so that safe production of enterprises can be ensured.

Owner:北京百世通管道科技有限公司

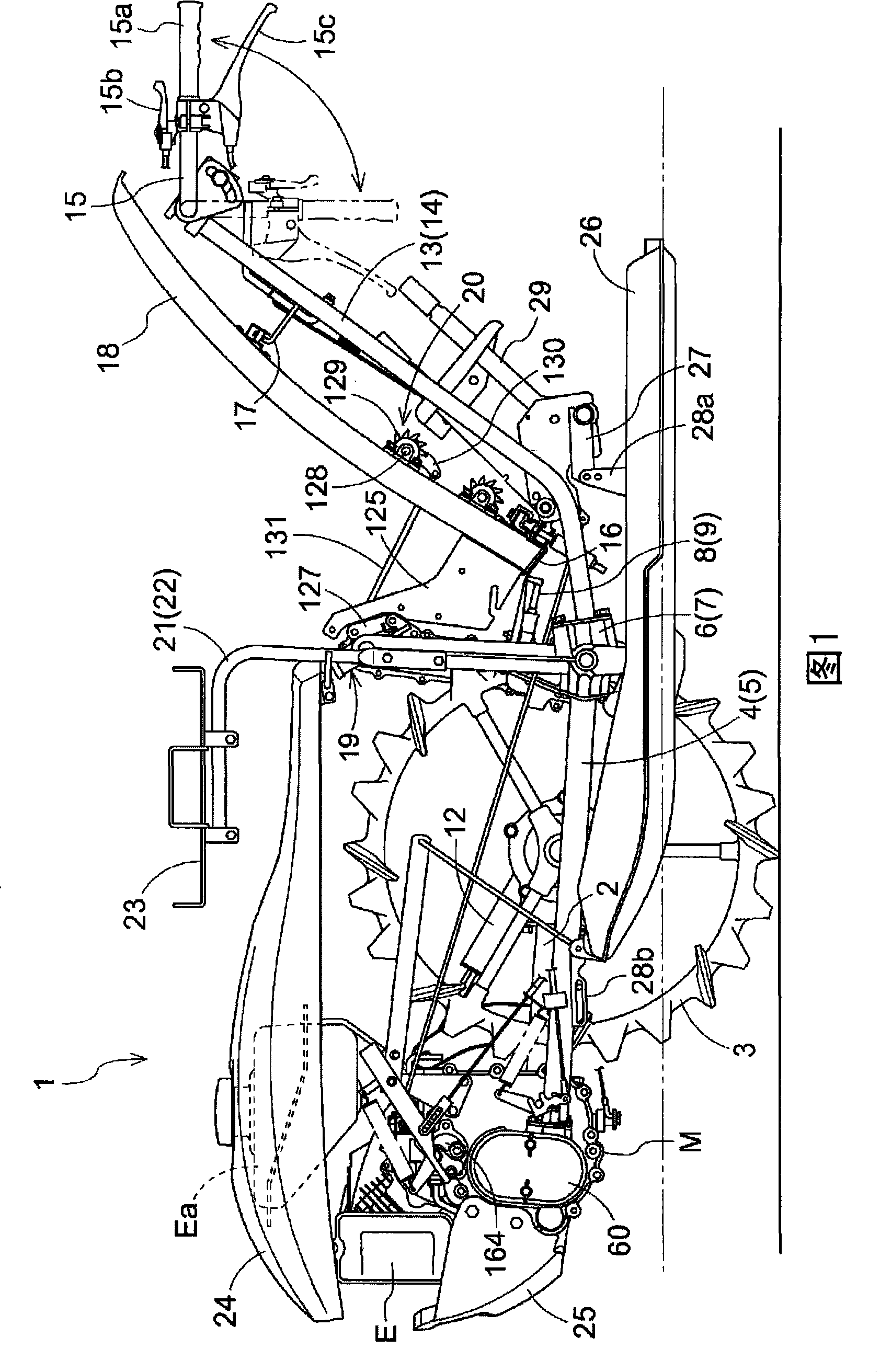

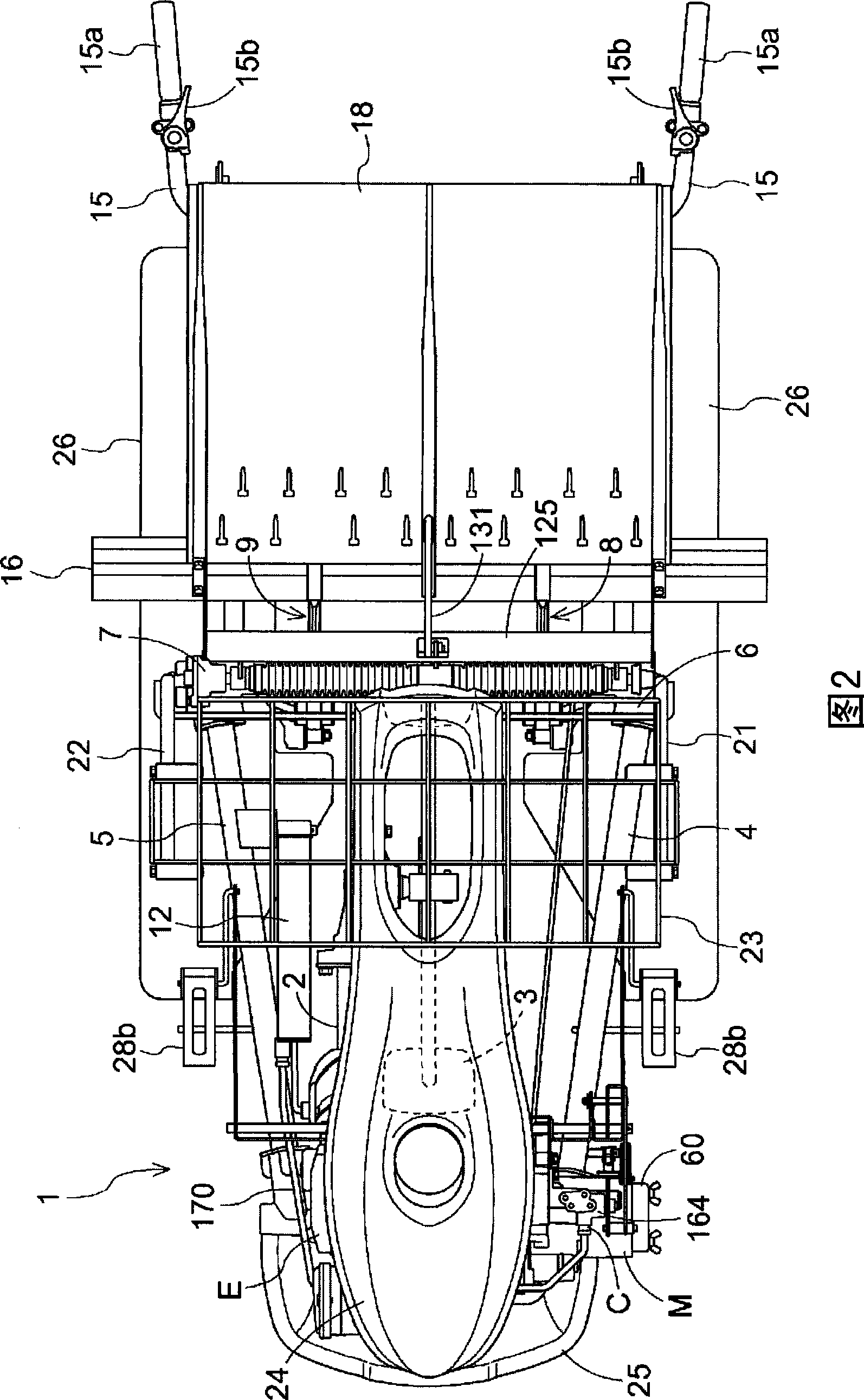

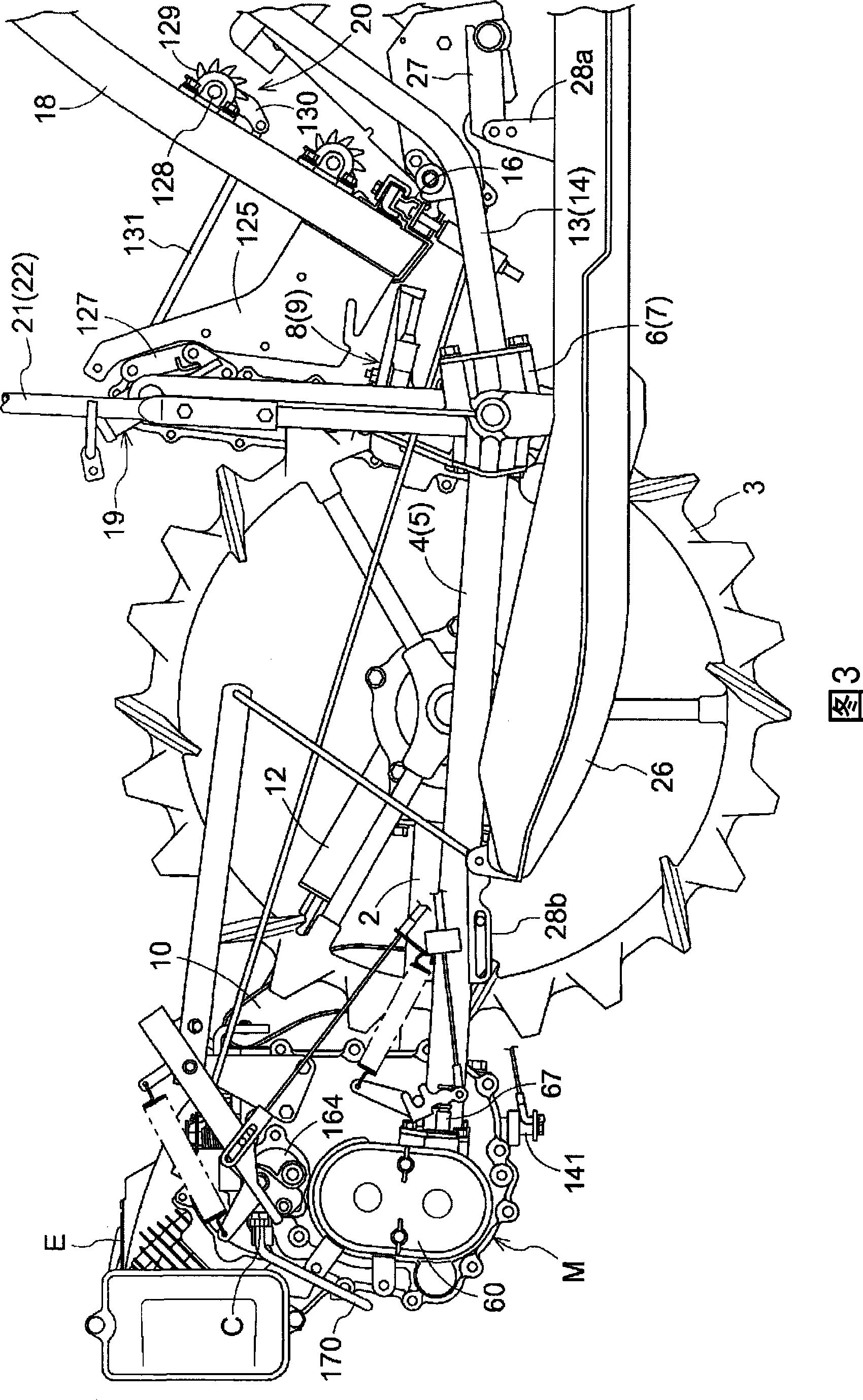

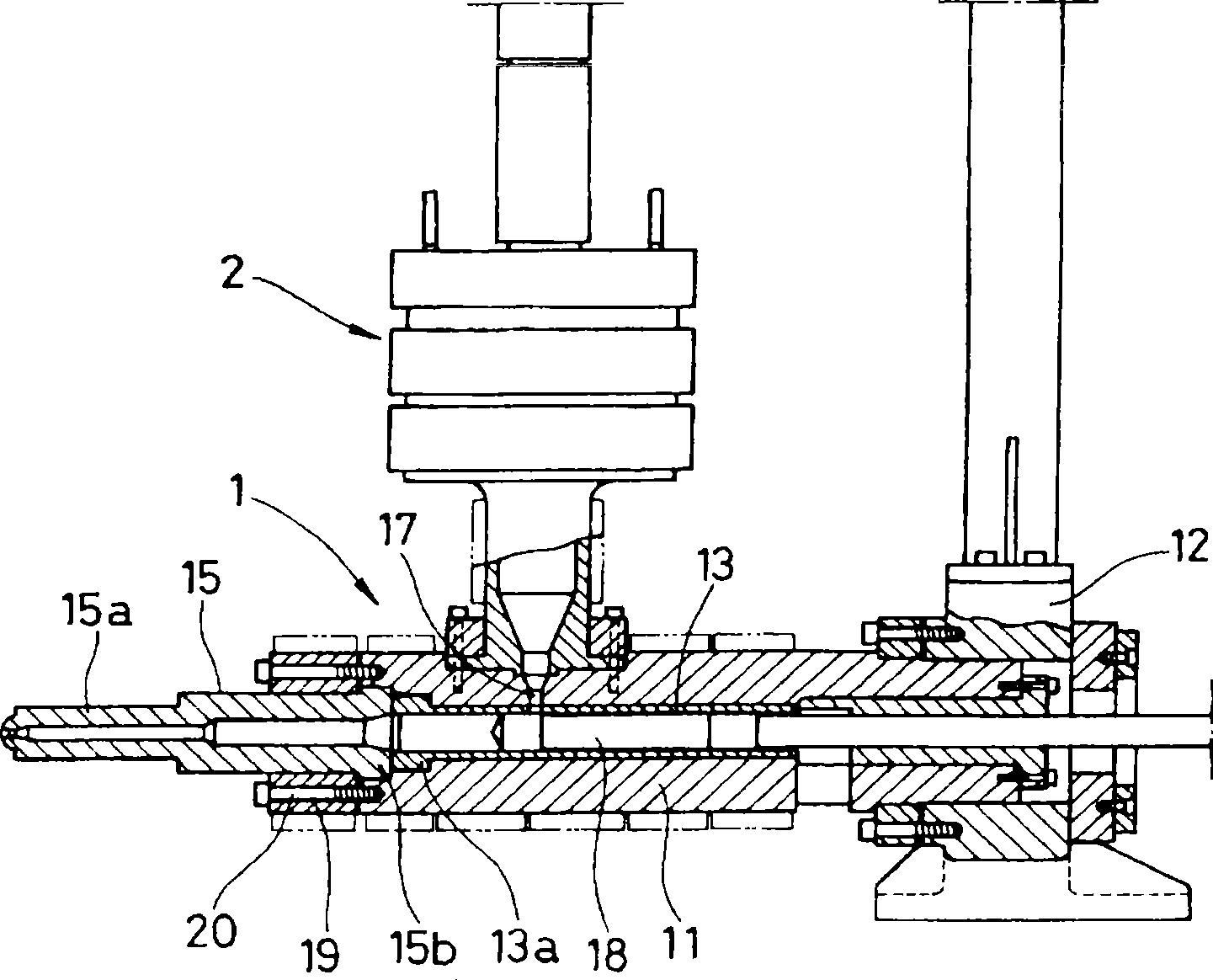

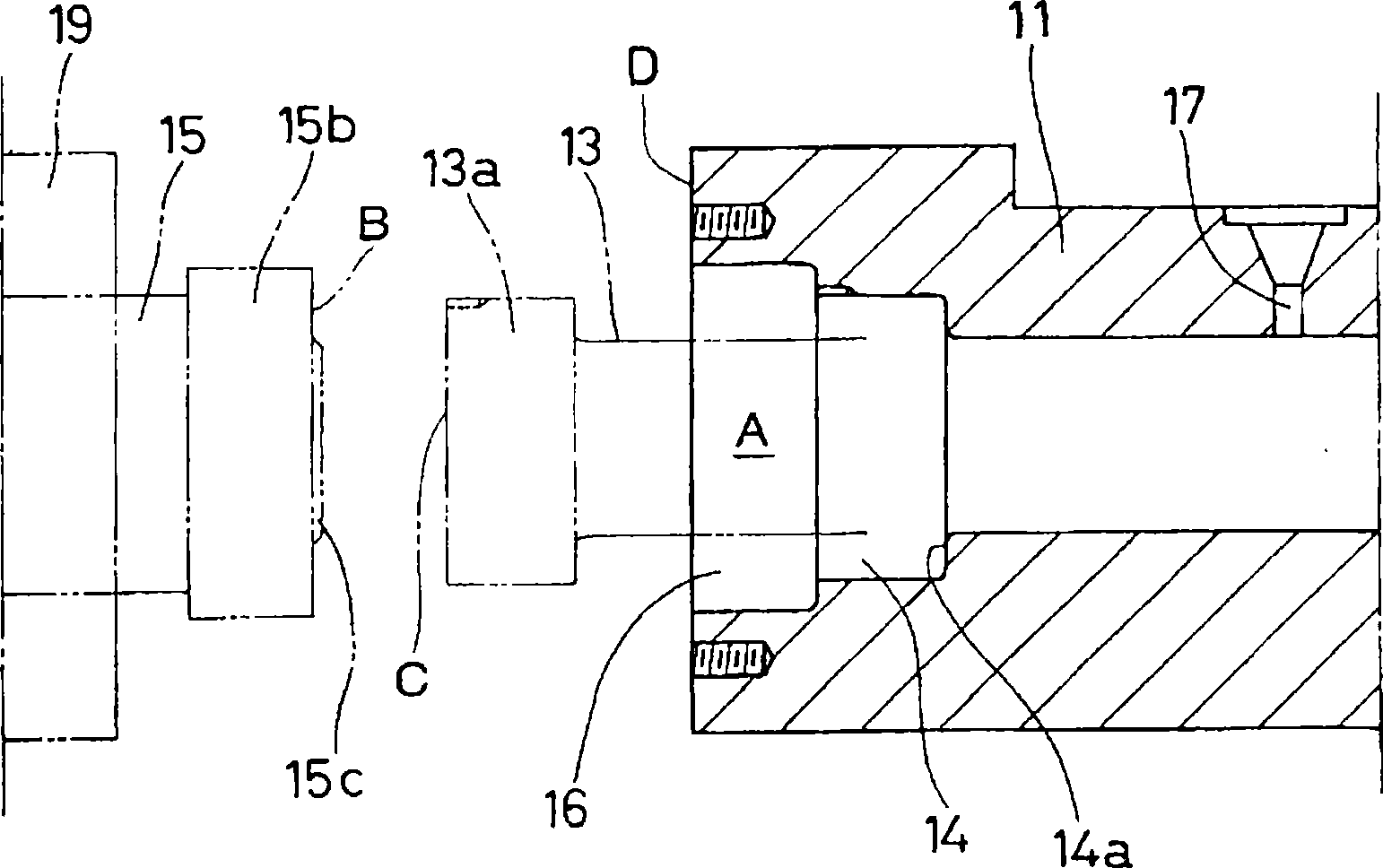

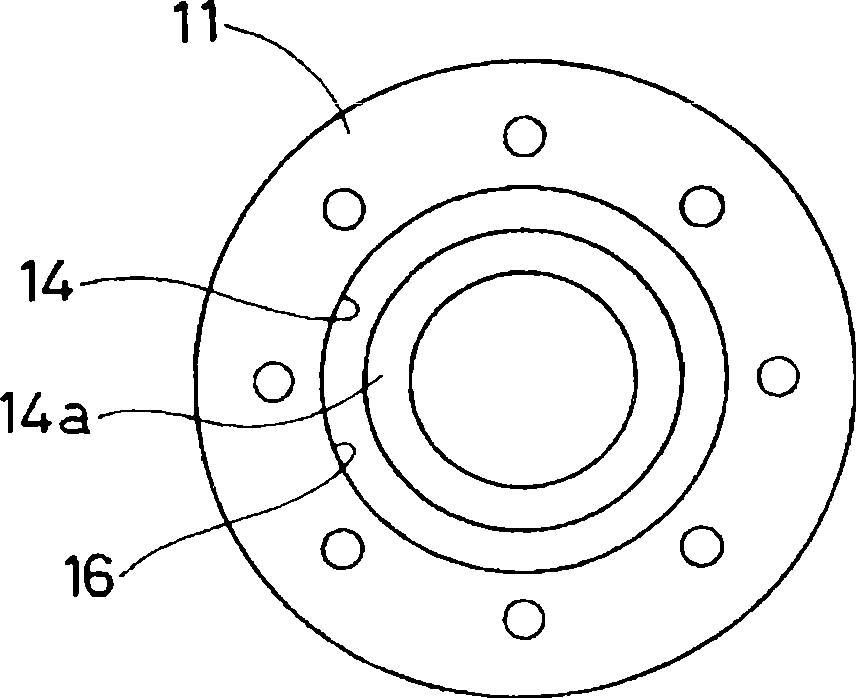

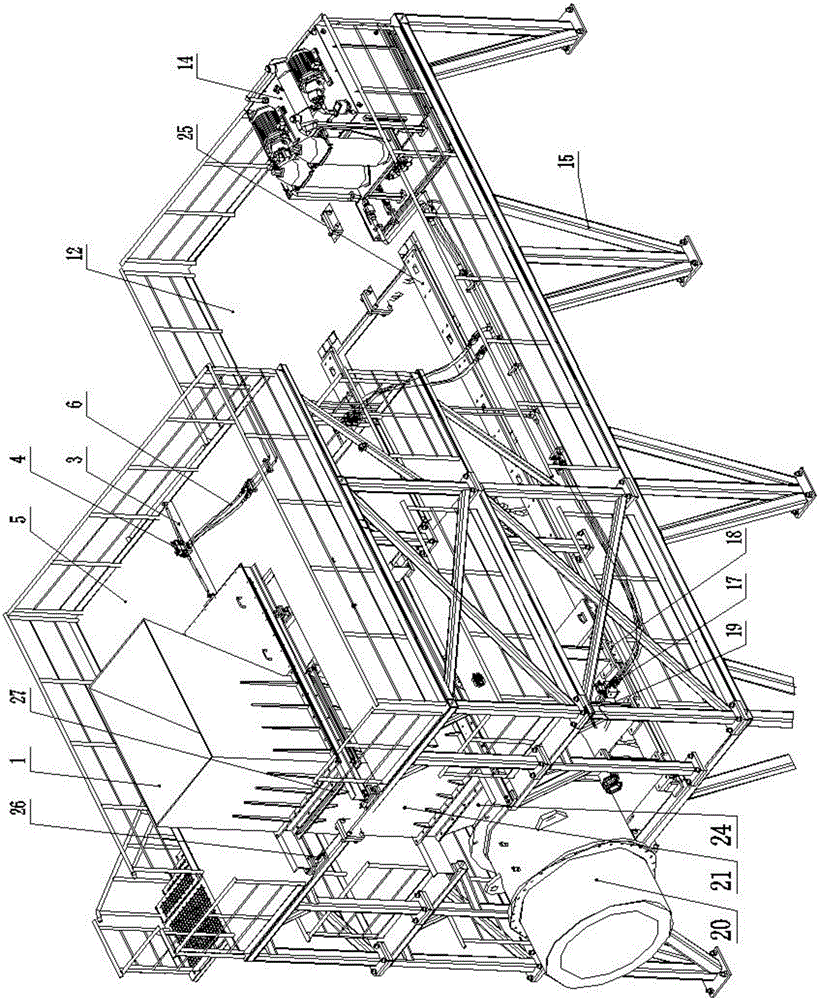

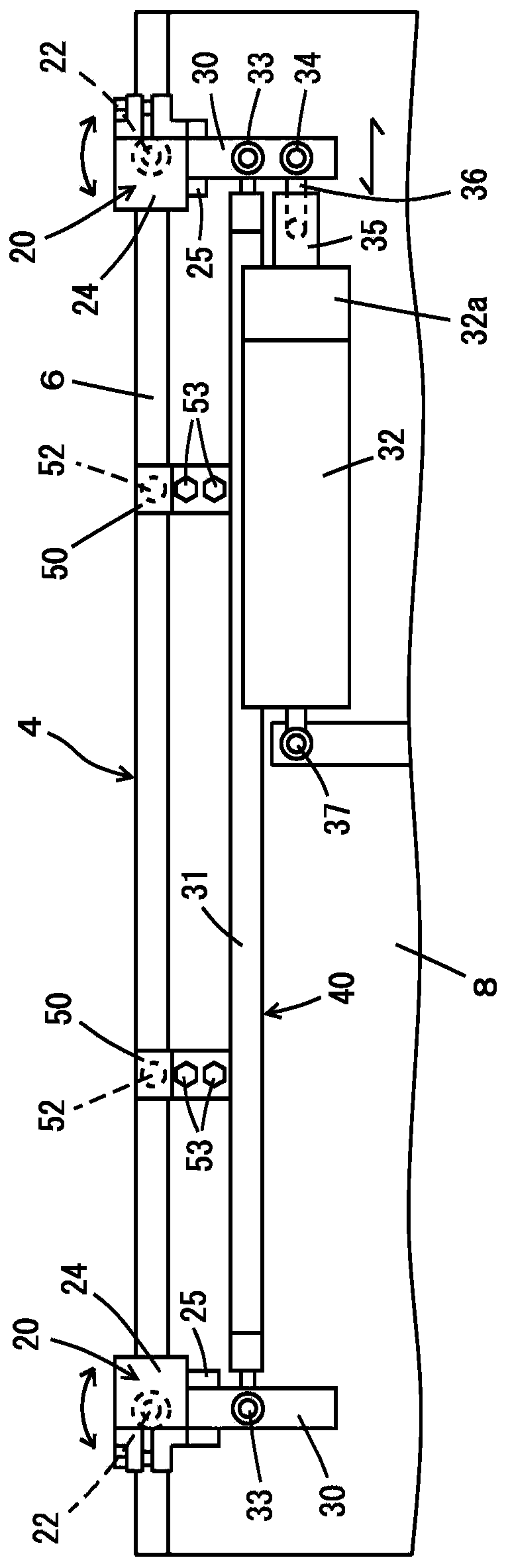

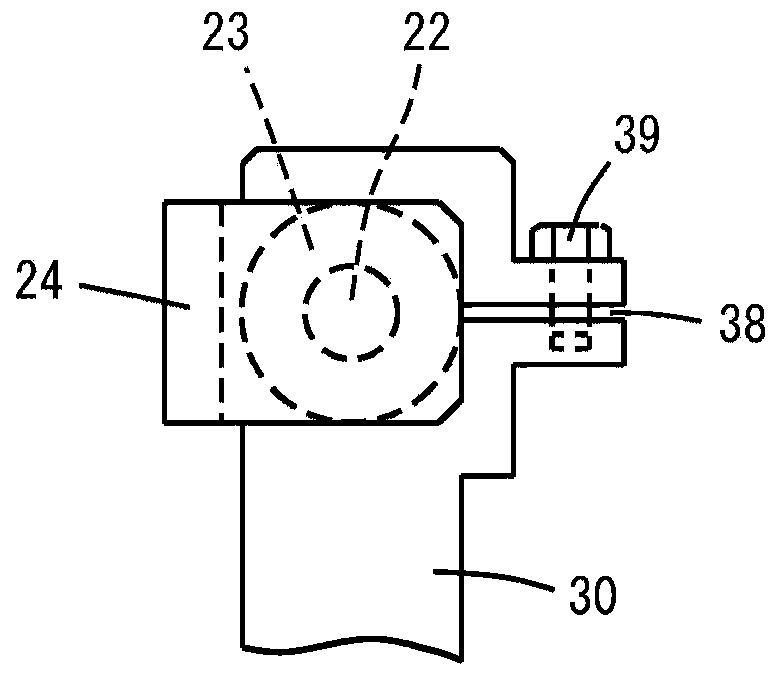

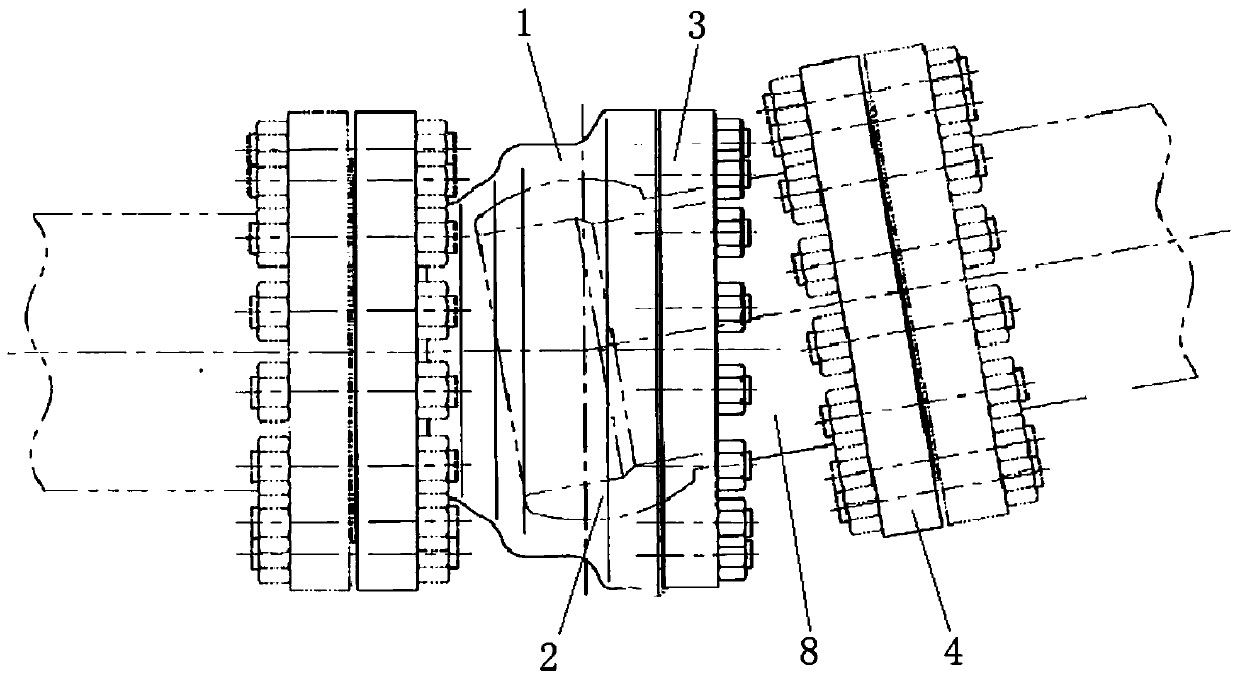

Transmission mechanism of walk-behind type paddy-field work machine

ActiveCN101455148ASimple structureSimple transmission structureTransplantingGearing detailsDrive shaftPaddy field

The invention provides a drive structure of a walking type transplanter, capable of simplifying the drive structure in a gear box and shifting a running drive system and a transplantation drive system. In the drive structure of the walking type transplanter, a first drive axle (33) into which the power of an engine (E) is input and a second drive axle (37) for branching the power from the first drive axle (33) to the running drive system and the transplantation drive system is set on a gear box (M) and a gear shifting part (39) is set across the first drive axle (33) and a second drive axle (37) and the gear shifting part (39) shifts the power transferred into the running drive system and the transplantation drive system.

Owner:KUBOTA LTD

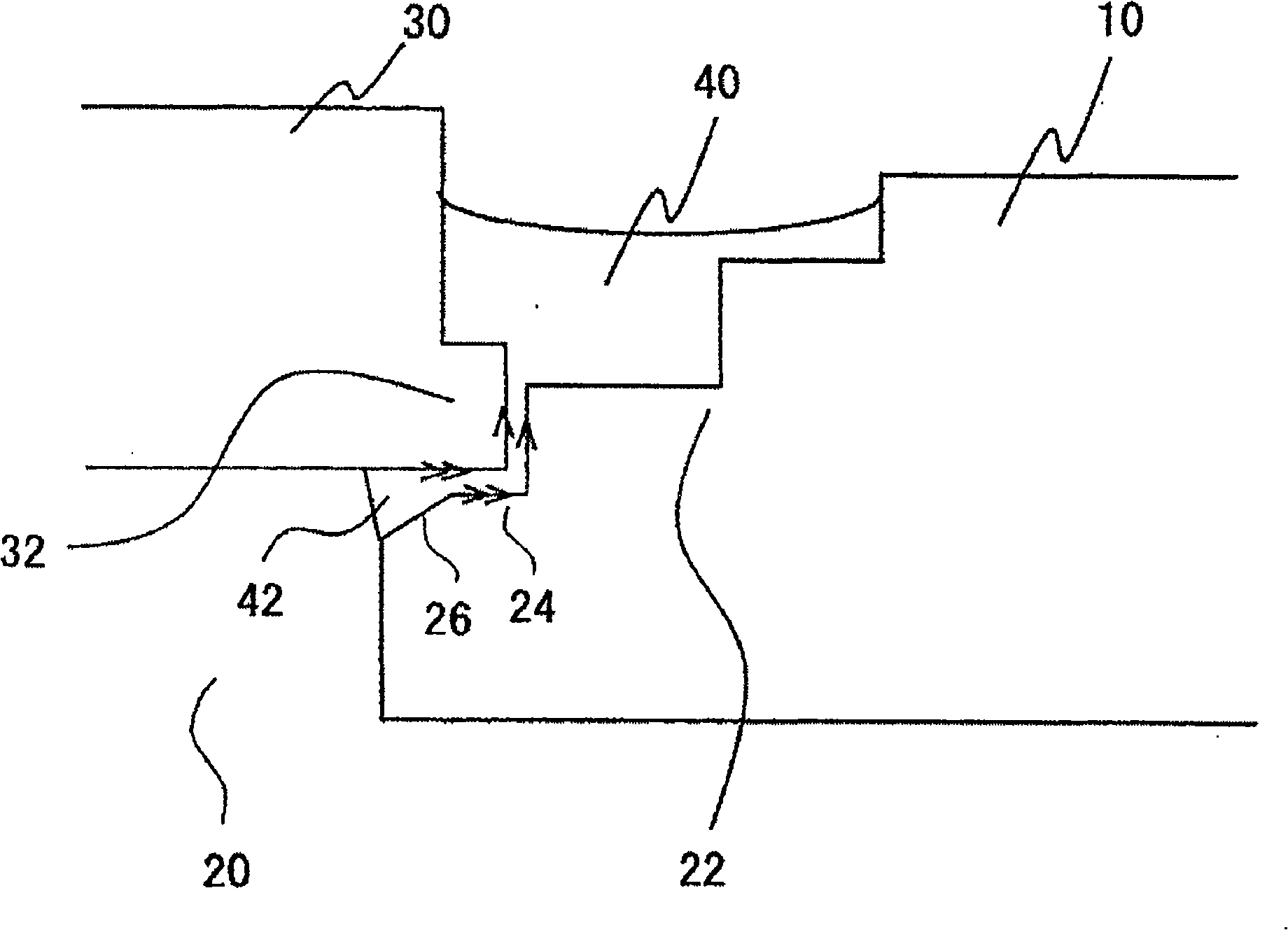

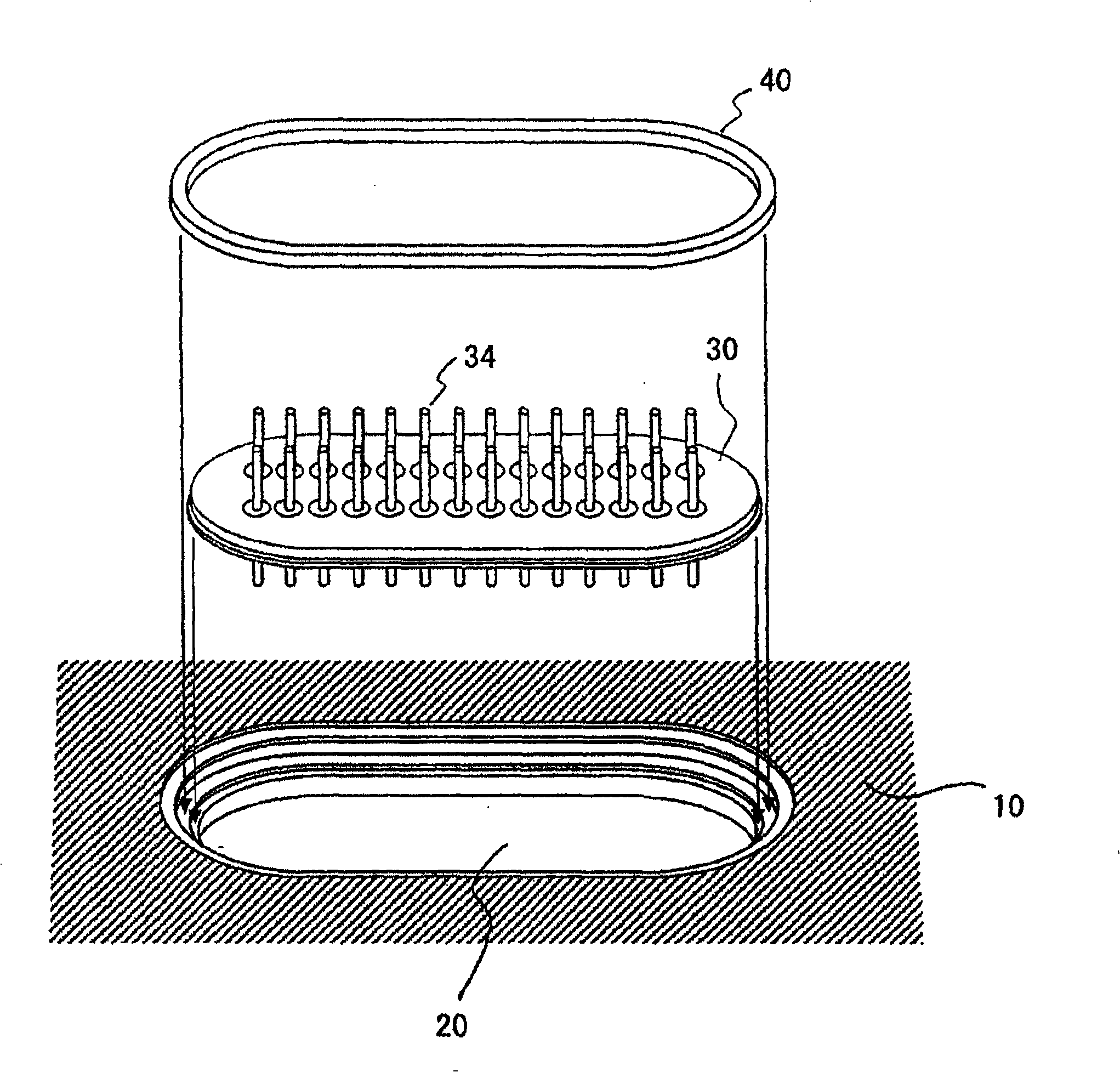

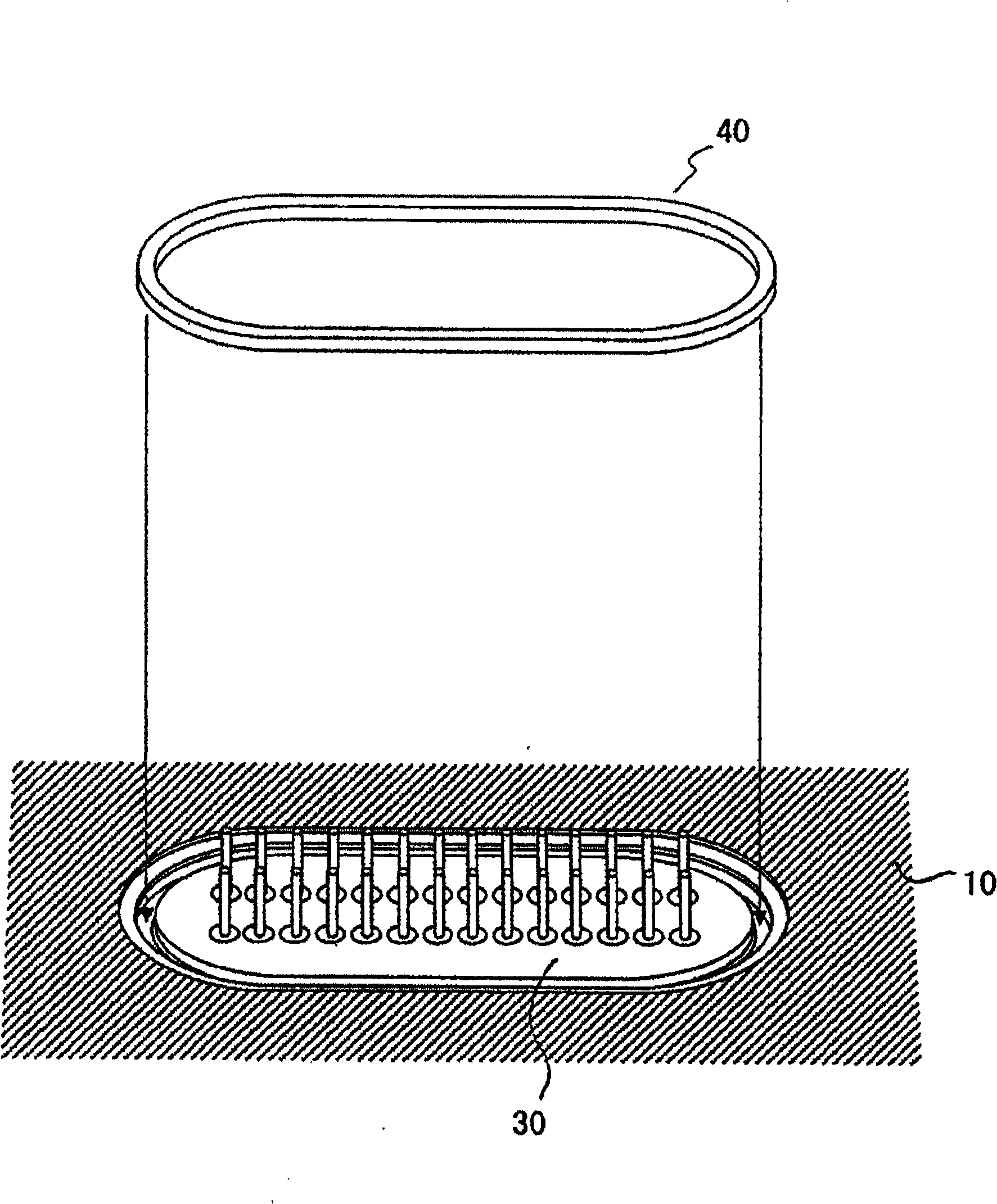

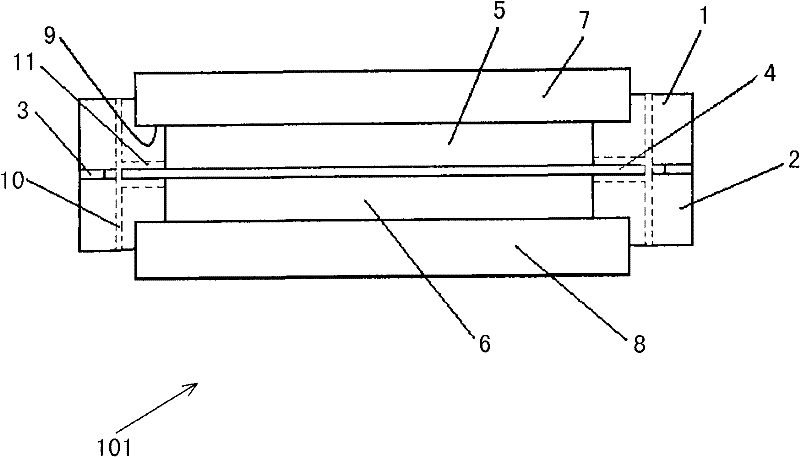

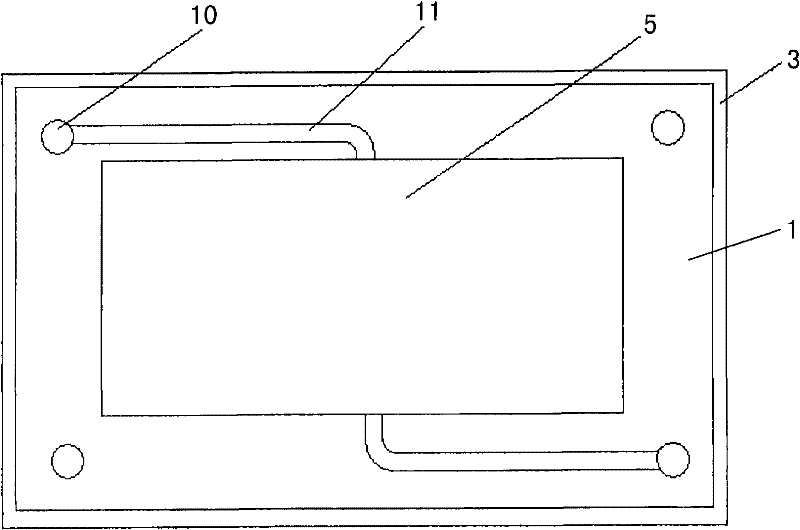

Magnetic disk drive and soldering method of feed-through

InactiveCN101290791ALeak won'tReliable sealing structureUndesired vibrations/sounds insulation/absorptionRecord information storageLow densitySoldering

The invention provides a solder connecting structure with high reliability, characterized in that, even if the flange of lead wire of sealed disk driver is made of kovar that is an iron-based material, the low density gas may almost not leak out; and a base of the driver is made of aluminium-based alloy. The base 10 has a step-shaped portion 22 located inside the periphery of an opening 20; a bevel 26 extending out of the base 10 is formed at the edge of a surface 24 of the step-shaped portion; a flange 32 of the lead wire 30 is placed on the bevel 26; therefore, a round corner of the solder 42 is not only formed inside of the base 10, but also formed outside of the same, when the step-shaped portion 22 of base is connected with the flange 32 of lead wire by welding.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Liquid flow battery unit, battery stack and manufacturing method thereof

Owner:ENN SCI & TECH DEV

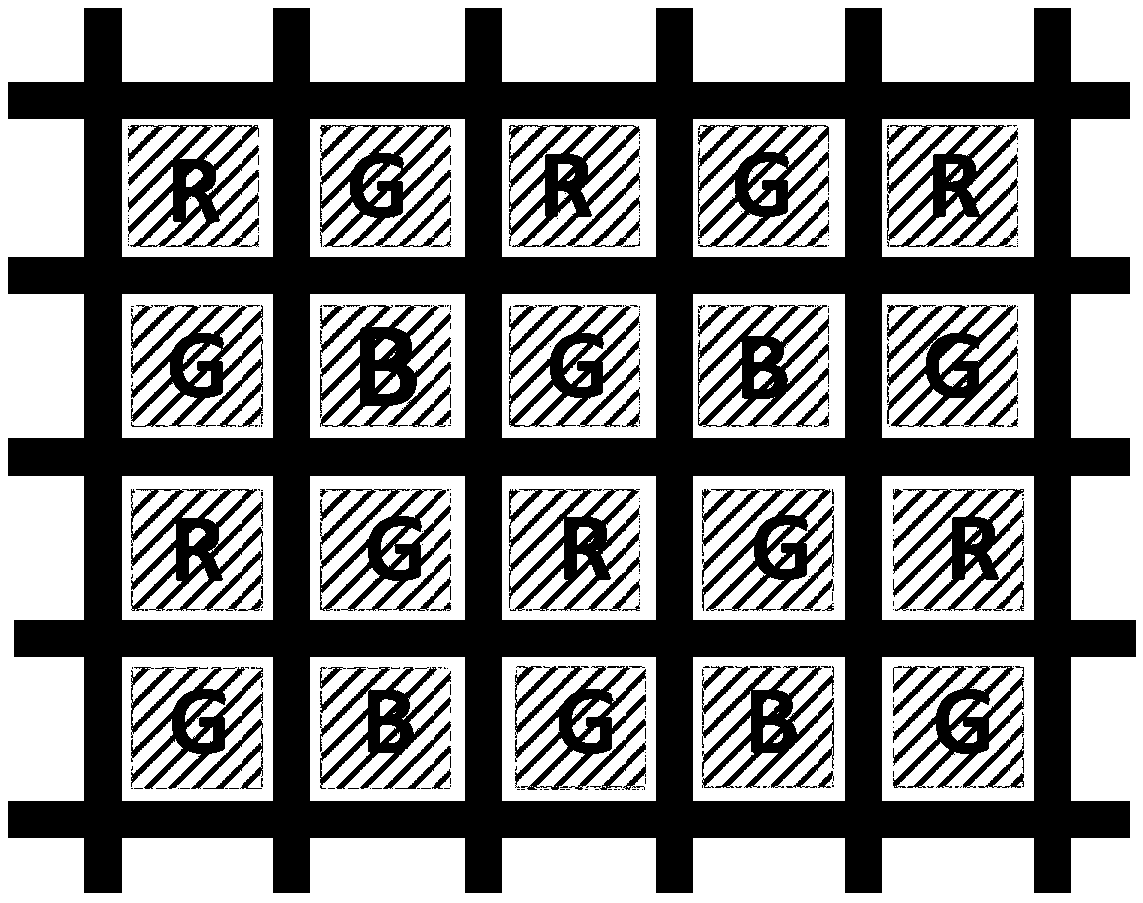

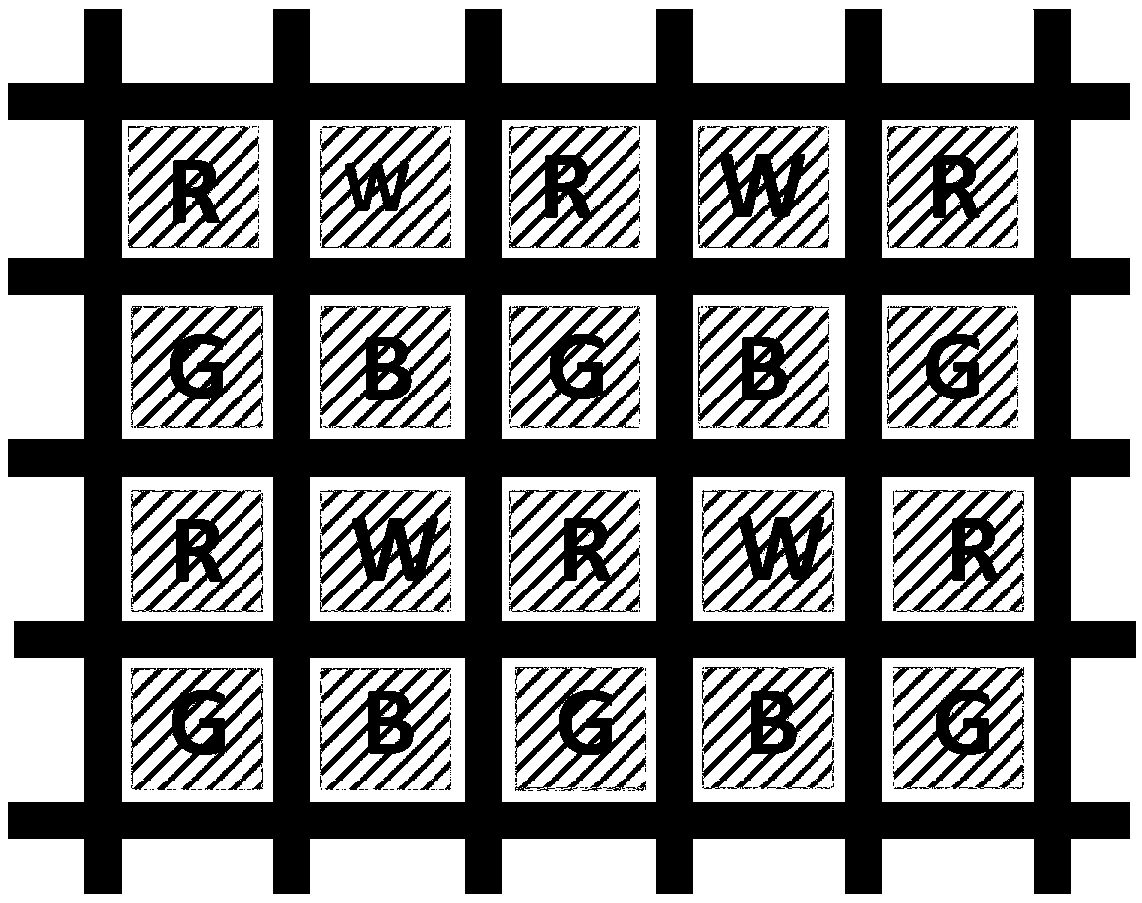

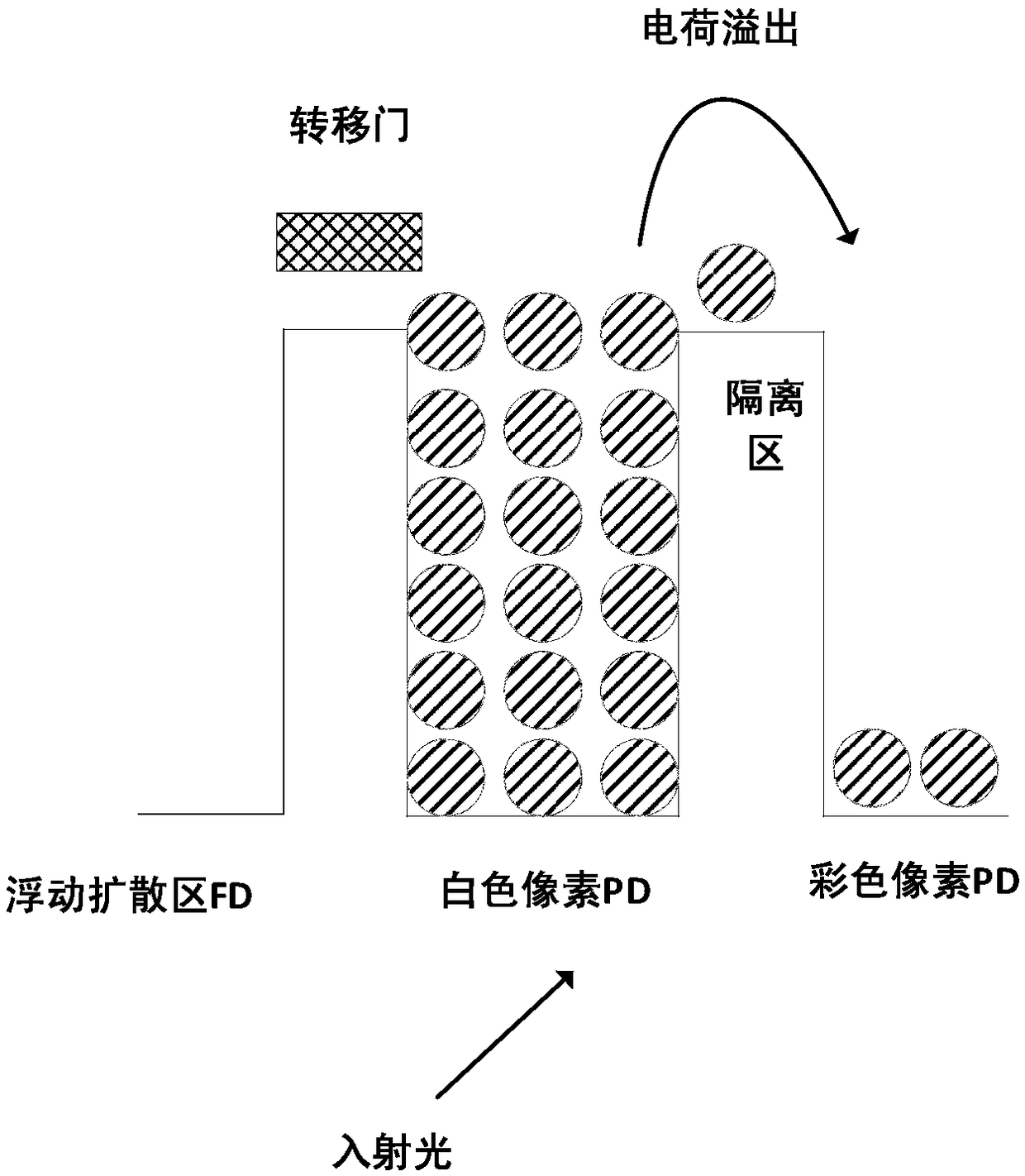

Image sensor, electronic device and manufacturing method thereof

InactiveCN109087926AReduce in quantityPrevent leakageSolid-state devicesRadiation controlled devicesEngineeringElectron

The present disclosure relates to an image sensor, an electronic device, and a manufacturing method thereof. In one embodiment, the present disclosure relates to a substrate of an image sensor, the substrate comprising a first substrate; and a second substrate; the first substrate has a groove, the second substrate is formed in the groove of the first substrate, and the band gap of the second substrate is wider than the first substrate.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

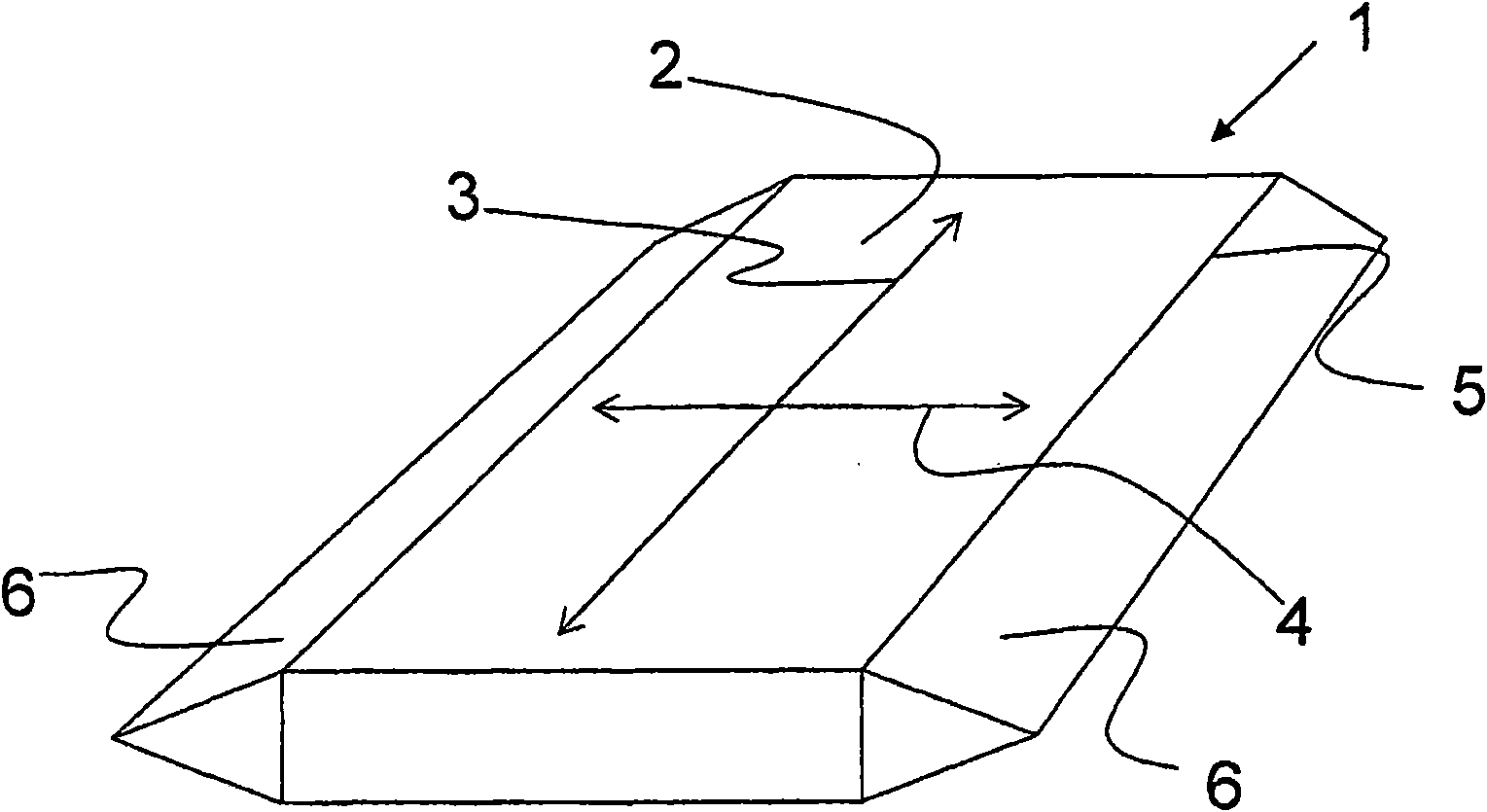

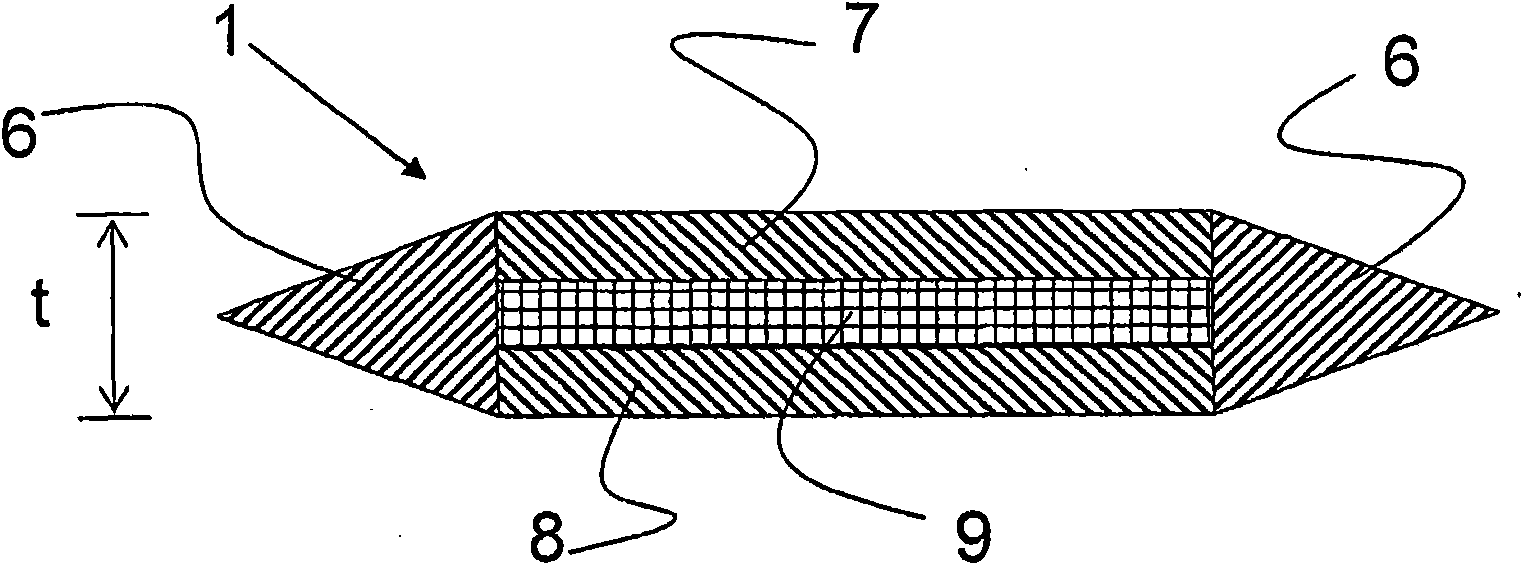

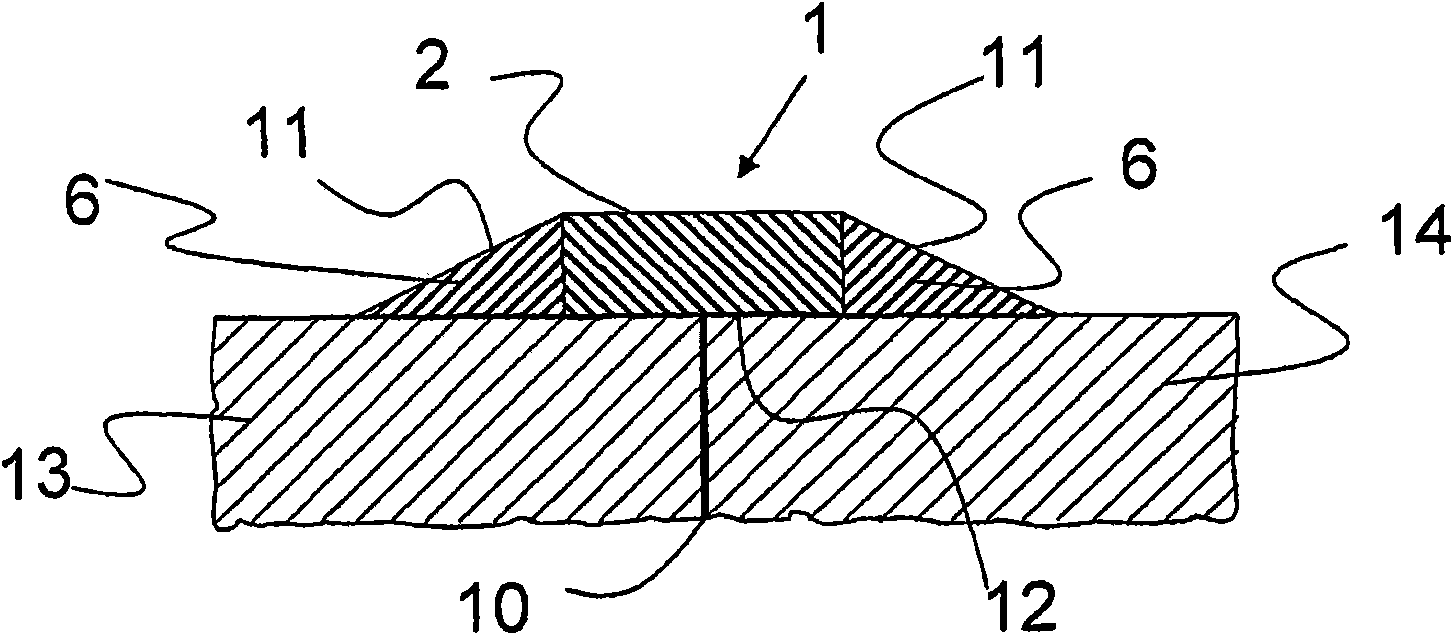

Strip for connecting and/or sealing a joint

InactiveCN101663162AHigh strength propertiesPrevent leakageEngine sealsFilm/foil adhesivesMechanical engineeringEngineering

Owner:VIKING LIFE SAVING EQUIP

Injection cylinder in injection apparatus for molding metal material

InactiveCN101468389APrevent leakageEasy to replaceMelt-holding vesselsMolten metal conveying equipmentsMetal deviceSpray nozzle

An injection device of a molded metal material prevents a melt metal device from leaking between a cylinder and a spray nozzle piece when a cylinder liner is closely arranged in the cylinder. A pressure-injection cylinder of the injection device comprises the components as follows: a cylinder-shaped cylinder: the cylinder-shaped cylinder is provided with a first installing part in an opening in the front end, a second installing part with a larger diameter and an opening for delivery formed in the top area of the cylinder; a cylinder-shaped cylinder liner: the cylinder-shaped cylinder liner is provided with a flange in a circumference in the front end and a hole for delivery in the preset area of the top area, after plugged in the cylinder from the opening side the cylinder liner closely contacts an inner surface of the cylinder through heat expansion to install the flange in the first installing part, and the hole for delivery in the same position with the opening; a cylinder-shaped spray nozzle piece: the cylinder-shaped spray nozzle piece is provided with a spray nozzle in the end, a flange which is arranged in the second installing part in a circumference in the end, and a back surface of the flange contacts the front surface of the flange in the cylinder liner; a connection ring surrounding the cylinder of the spray nozzle piece: the back surface of the connection ring is connected with the front surface of the spray nozzle piece and is fastened in the surface in the front of the cylinder through a bolt, and the spray nozzle piece is fastened with the flange of the cylinder liner used on the cylinder and plugged between the two elements.

Owner:NISSEI PLASTIC IND CO LTD

Mercury-leakage-resistant thermometer

InactiveCN102221414APrevent leakageLeak won'tThermometer detailsThermometers using material expansion/contactionThermometerEngineering

The invention relates to a mercury-leakage-resistant thermometer which is used for daily life and medical service. The common thermometer has the defects that the mercury bulb part of the thermometer is extremely easy to smash; the mercury after being smashed is not easy to collect and clean up; the mercury which remains in a room is slowly and completely volatilized in the air; and the mercury stream is exactly the main reason of mercurialism. Because the common thermometer influences the health of people because of the reason of the mercurialism, particularly the health and intelligence development of children, parents are increasingly worried about the problem. The mercury-leakage-resistant thermometer provided by the invention solves the problem that the common thermometer influences the health and intelligence development of the children. The mercury-leakage-resistant thermometer provided by the invention is characterized in that the mercury bulb part of the thermometer is tightly wrapped by metals, thereby protecting the mercury bulb part which is the easiest smashed part of the thermometer and avoiding the mercury from leaking after the mercury bulb is smashed. If the other parts are smashed, the mercury does not leak because the mercury column is thin. Simultaneously, the heat conduction of the mercury bulb part is not influenced, and the indication of the part with scales is not influenced.

Owner:王长永

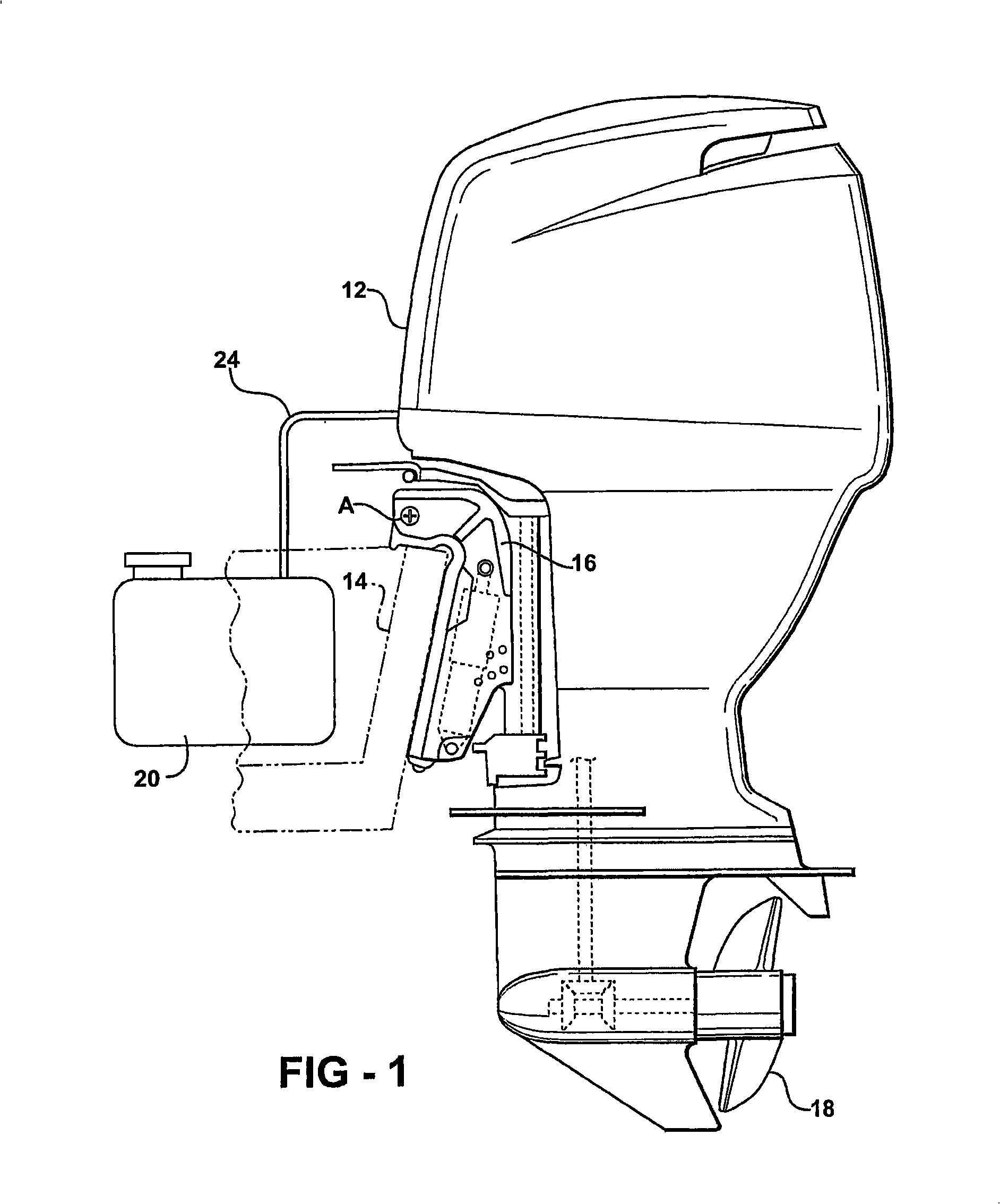

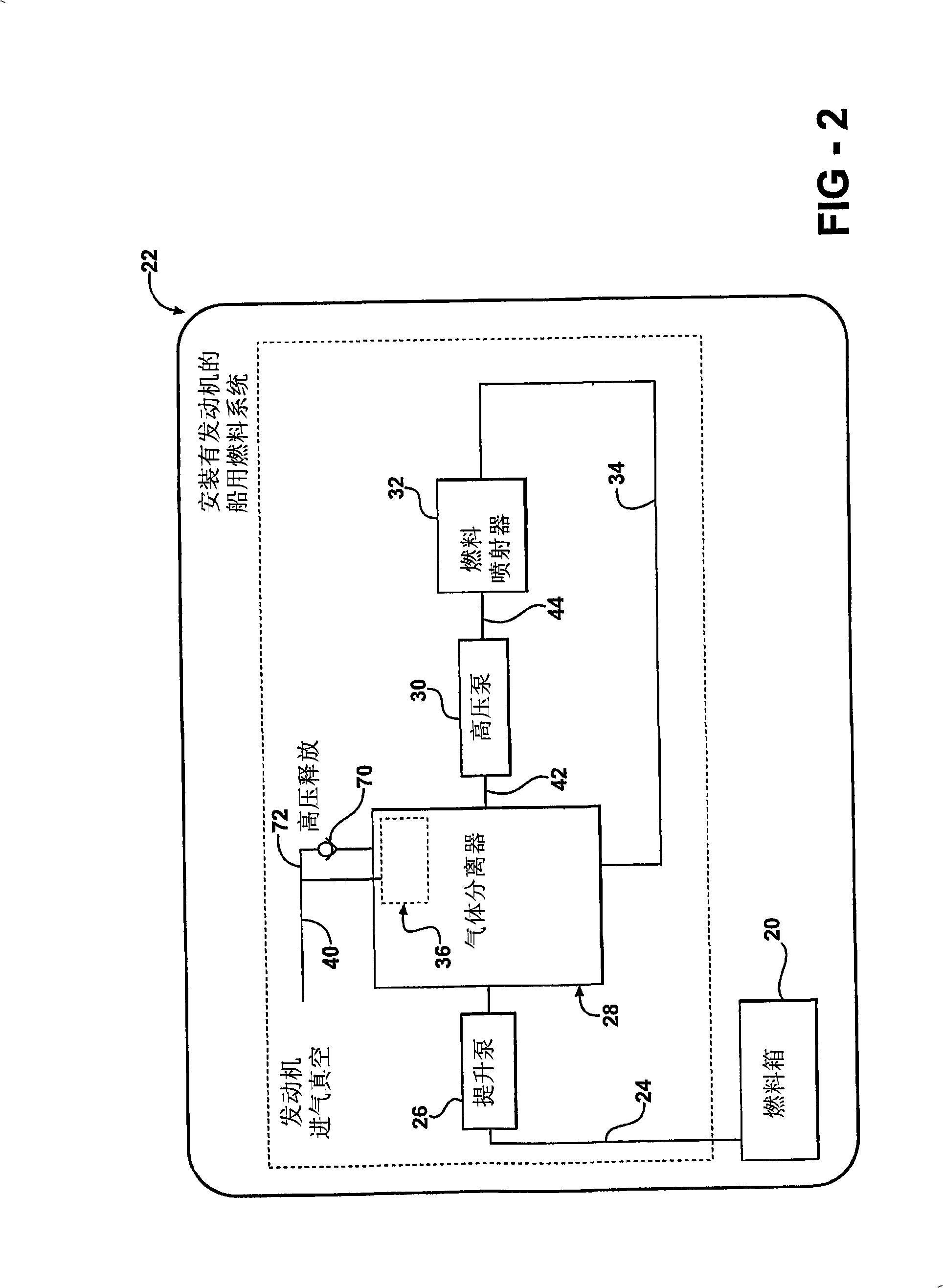

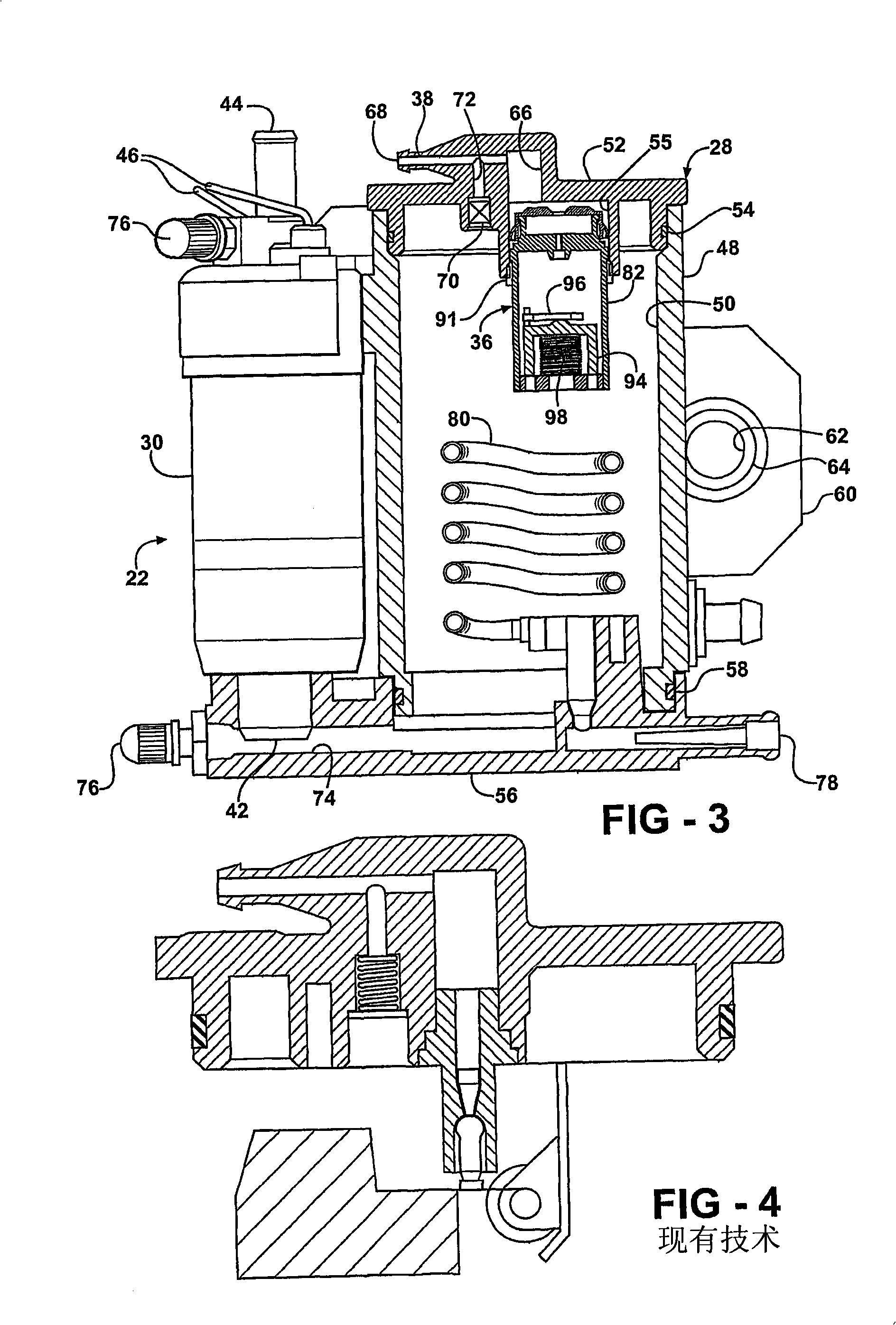

Marine fuel vapor separator with vent control device

InactiveCN101331311APrevent leakageLeak won'tMachines/enginesLiquid fuel feedersLiquid fuelEngineering

A fuel supply system for an outboard marine engine includes a vapor separator (28) having a uni-directional vapor vent device (36) for preventing fuel leakage when the engine (12) is tipped on its side. The vapor separator (28) includes an enclosed interior chamber (50) which is filled with liquid fuel by a suction pump. A separate, high pressure pump transfers the liquid fuel from the interior chamber (50) to a fuel injection system (32) of the engine (12). The vapor vent device (36) includes a generally tubular casing having an enclosed top end permeated by an escape passage (84), and a float (94) slidably disposed within the casing (82) for movement toward and away from sealing engagement with the escape passage (84).

Owner:FEDERAL MOGUL CORP

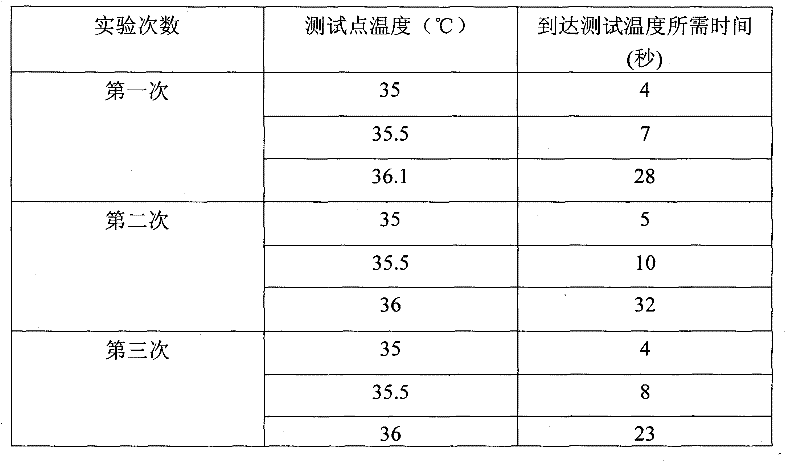

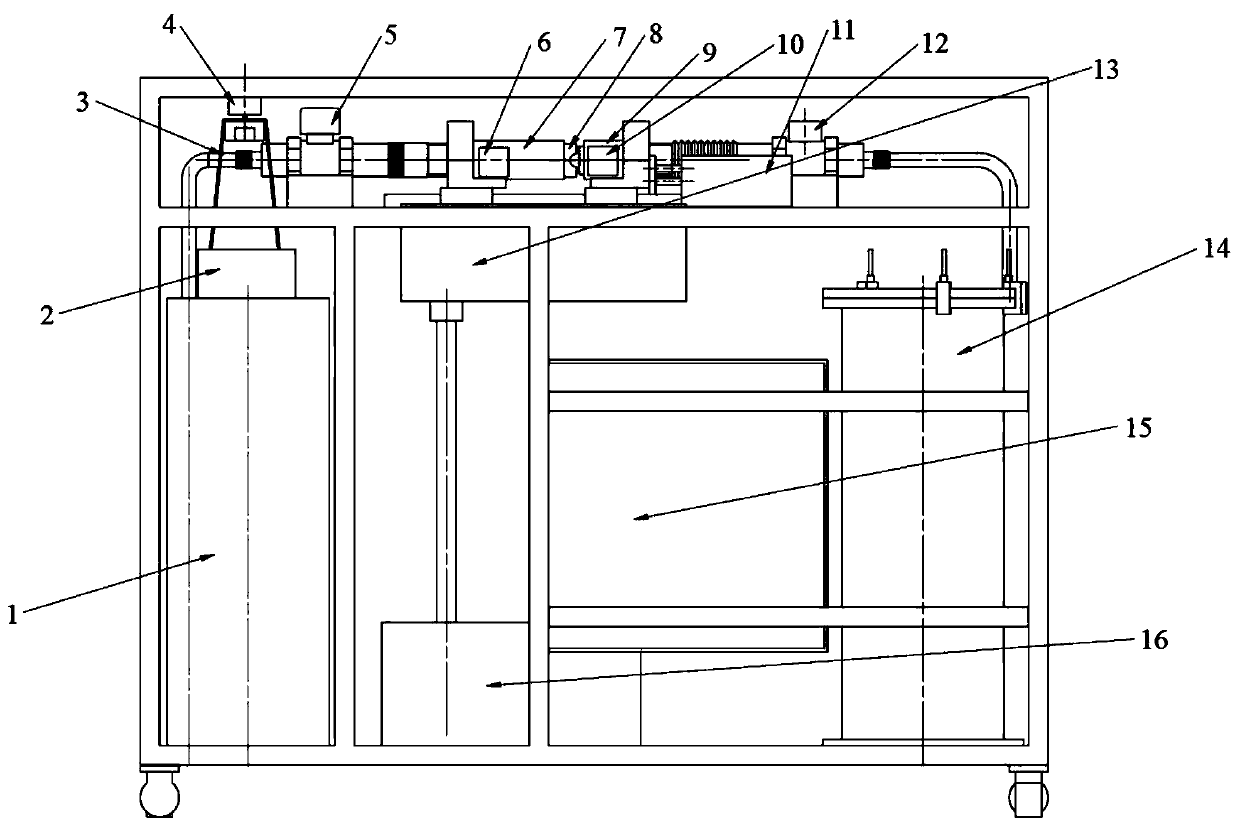

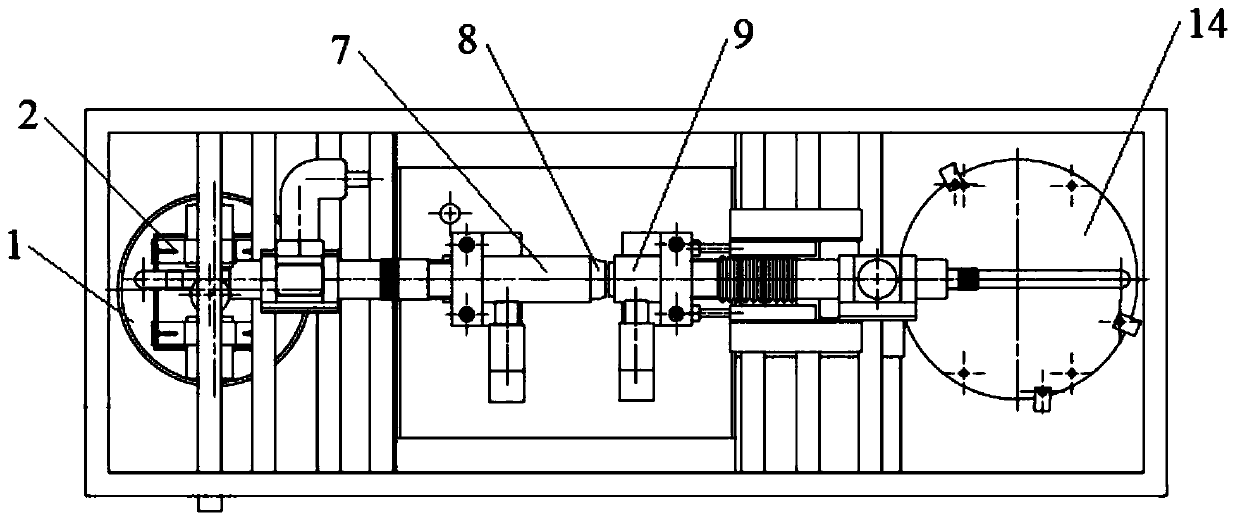

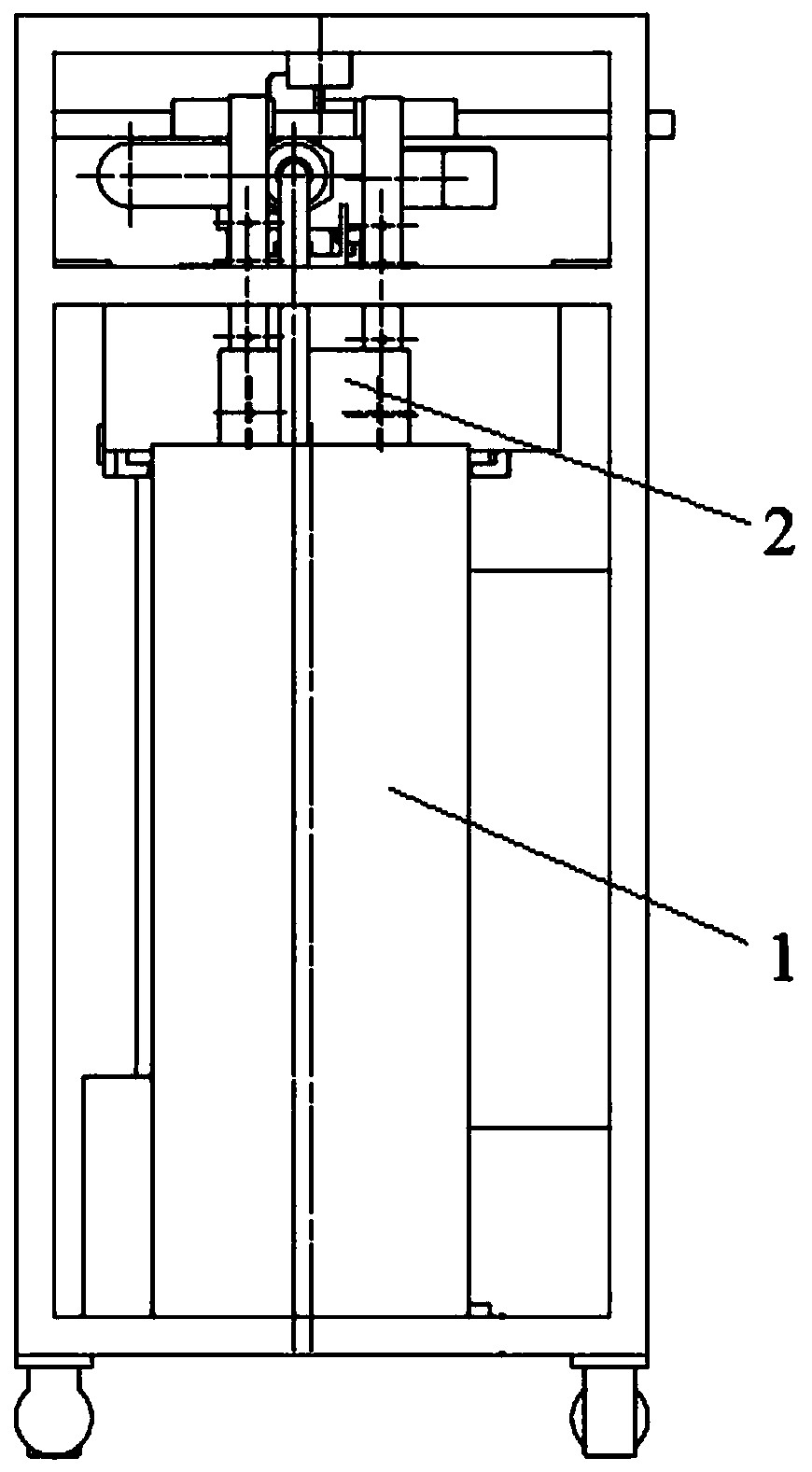

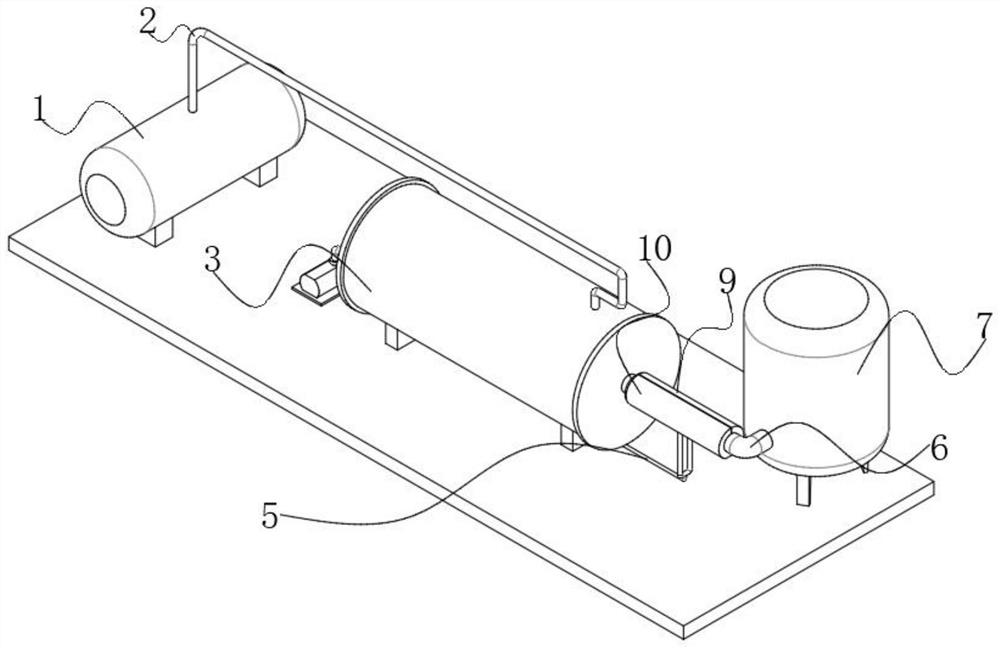

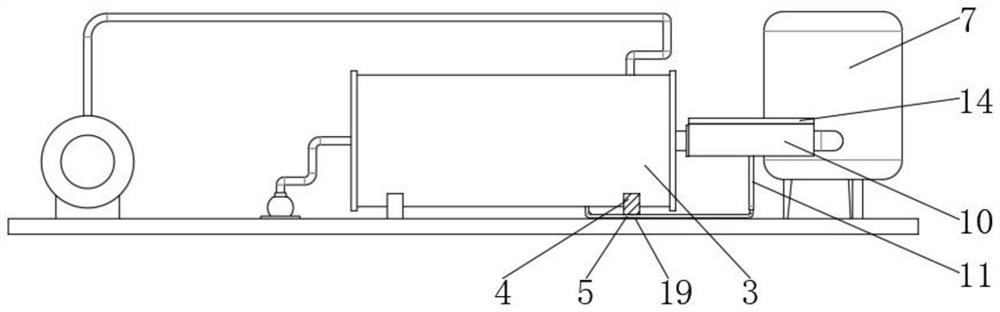

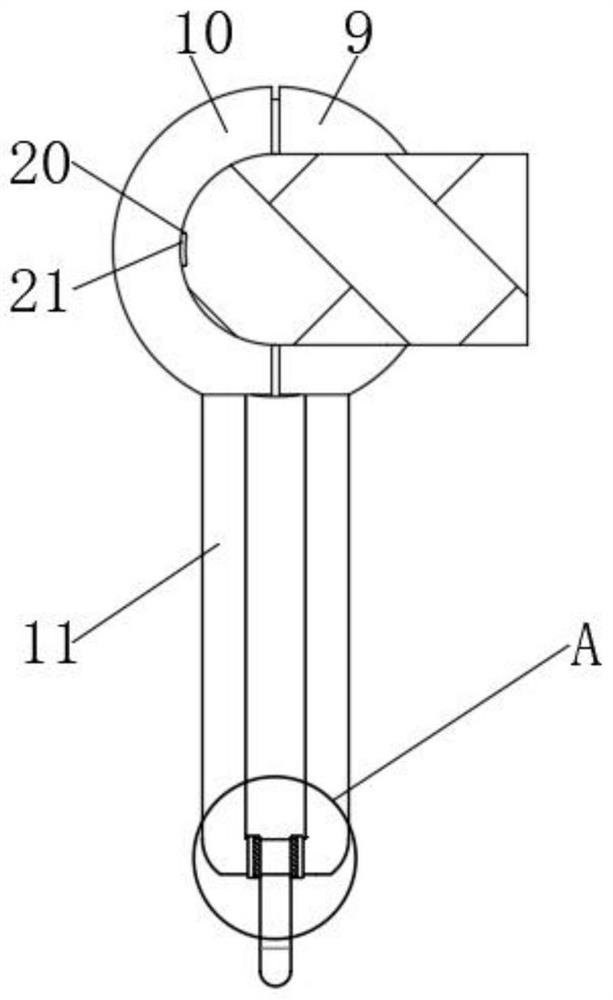

Heart valve steady-state leakage test device and use method thereof

PendingCN111174989AReduce mistakesNo continuous impactMeasurement of fluid loss/gain rateProsthesisRat heart

The invention discloses a heart valve steady-state leakage test device and a use method thereof, which belongs to the technical field of medical instrument inspection and comprises a water storage barrel and a water storage barrel which are communicated through a pipeline, and a test part tool for mounting a heart valve prosthesis is arranged on the pipeline so as to enable the heart valve prosthesis to be communicated with the pipeline. A front-end pressure sensor is installed on the front side of the test part tool, a rear-end pressure sensor is installed on the rear side of the test part tool, the water storage barrel is connected with an air source, and the water storage barrel is provided with a weighing device for weighing the mass change of liquid in the water storage barrel. The working method comprises the steps of calibrating, mounting the test part and measuring the static leakage rate. The technical scheme provided by the embodiment of the invention is used for carrying outthe steady-state leakage test of the artificial heart valve, is convenient to operate, meets standard requirements, and is accurate and reliable in result.

Owner:山东省医疗器械产品质量检验中心

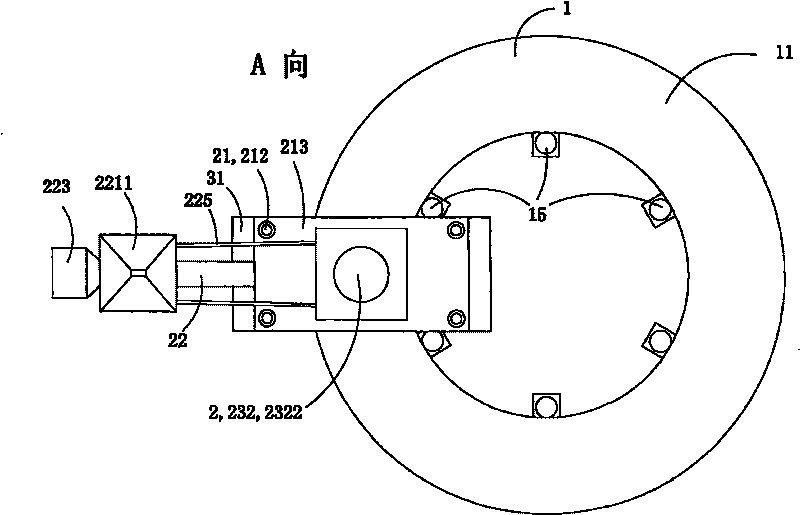

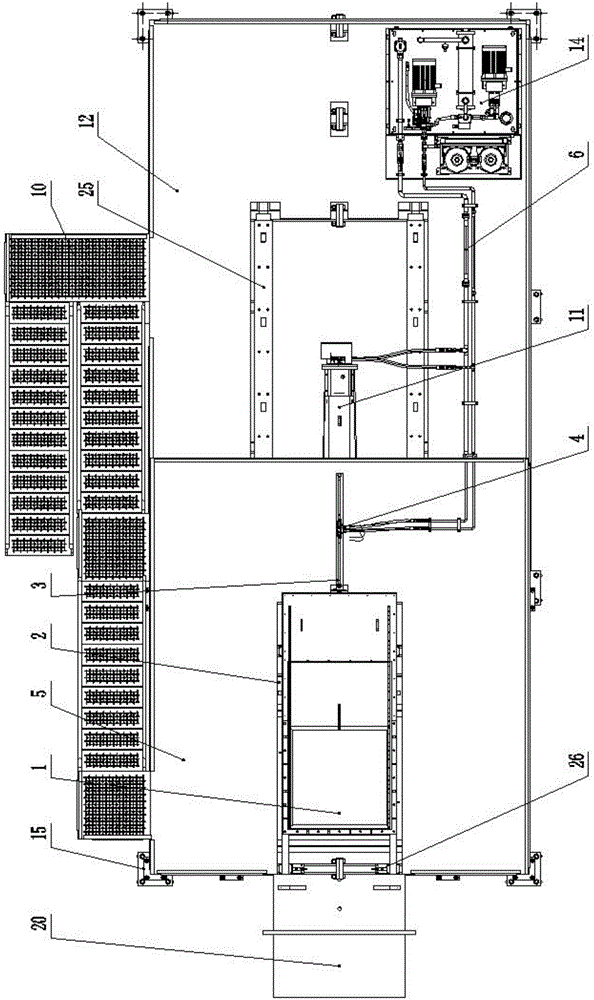

Horizontal disc plastic injection forming machine

The present invention discloses a horizontal disc-type plastic injection molding machine, comprising a turntable device, an injecting device and a die closing device. The turntable device consists of a rotary disc and a driving unit which drives the disc to rotate; the injecting device comprises an injecting stand, a horizontal pre-plasticizing mechanism , a vertical pre-plasticizing mechanism and an injecting head which are arranged on the injecting stand; the die closing device comprises a die closing stand and a die closing cylinder which is arranged on the die closing stand beneath the disc; the piston of the die closing cylinder which can move up and down, is fixedly connected to the injecting head through the injecting stand to drive the injecting head to move up and down. The invention can shorten the journey of the piston of the die closing cylinder and shorten the time on the journey, thus production efficiency is effectively improved.

Owner:金孝禹

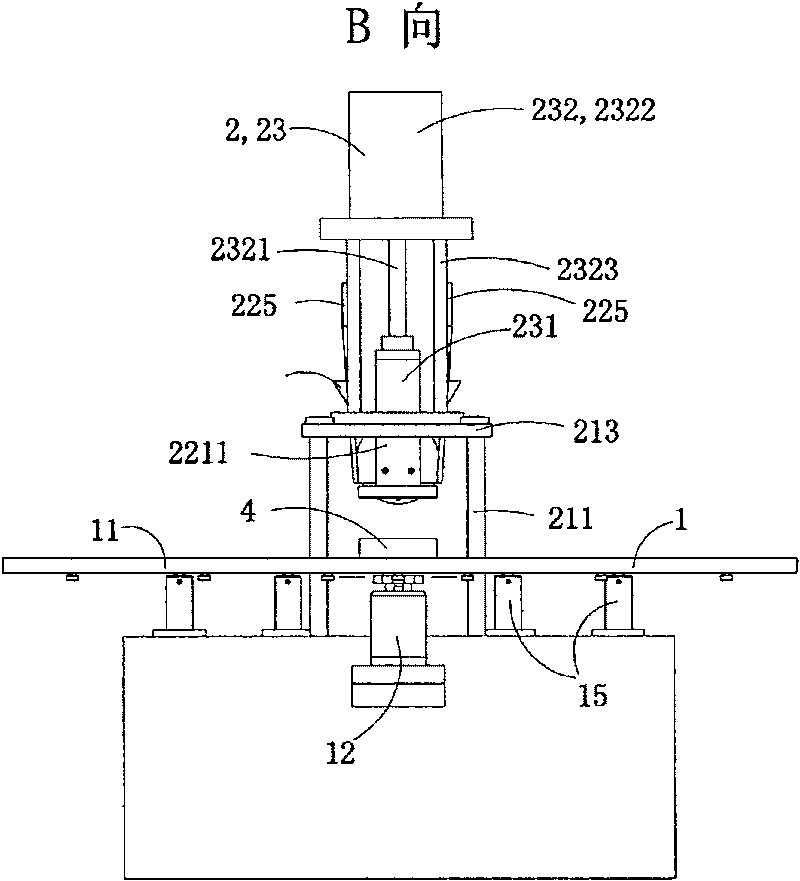

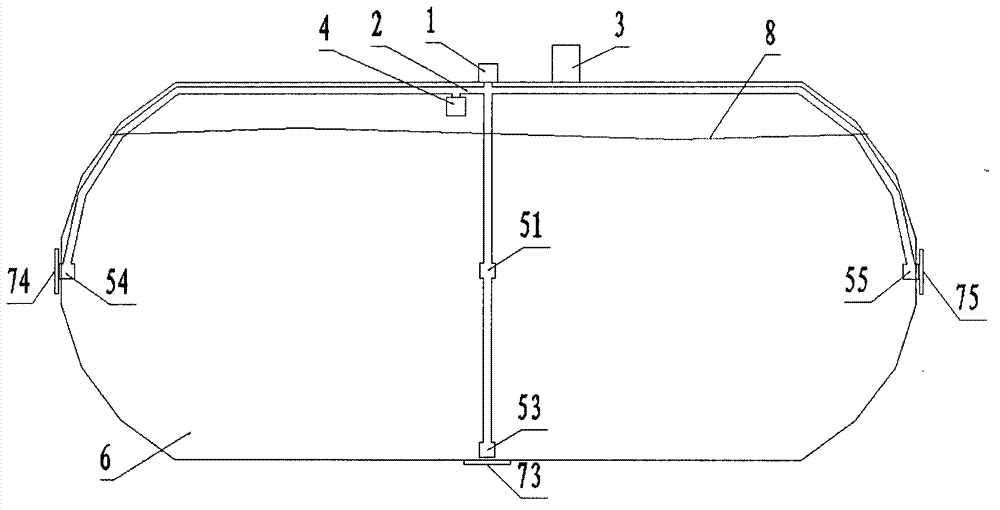

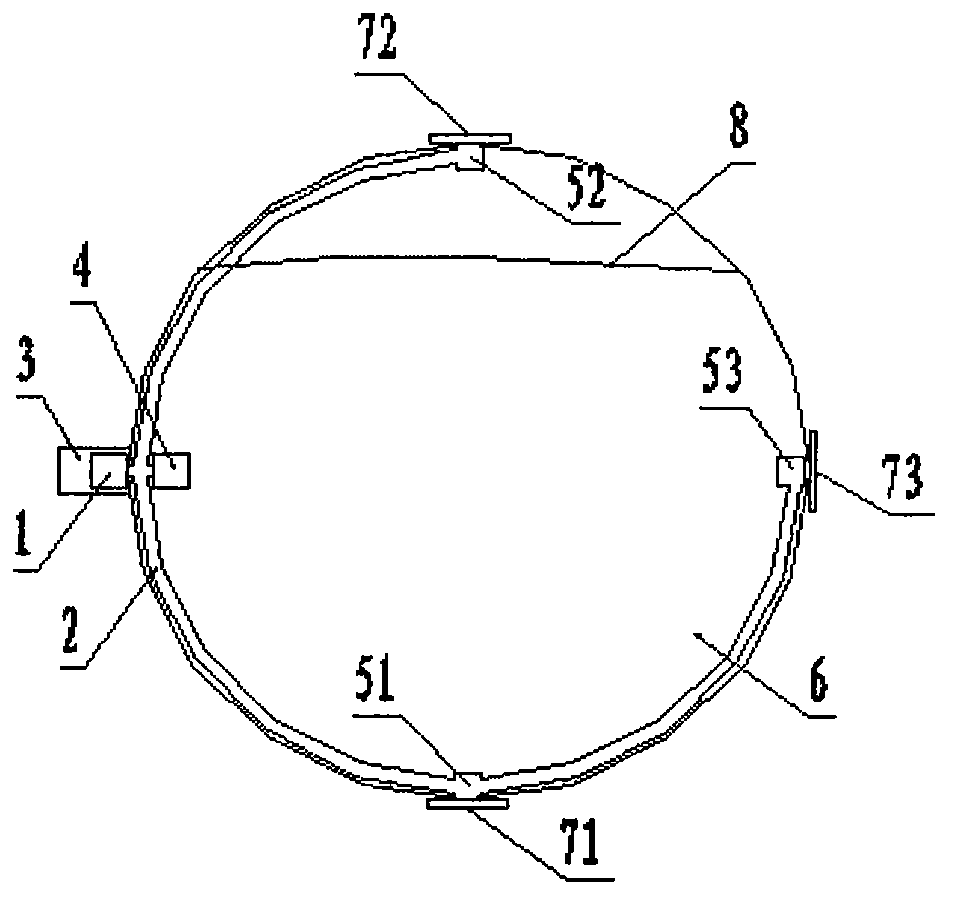

Tank truck safe breathing system and tank truck tank body

ActiveCN104724416AEasy installation, maintenance and testingNormal breathingLarge containersTank truckBreathing system

The invention relates to a tank truck safe breathing system and a tank truck tank body. The tank truck safe breathing system comprises a breather valve arranged over the tank truck tank body, a through communication pipeline arranged on the tank body, a self-closing valve arranged in the tank body and one or more buoyant valves or gravity valves distributed at different positions in the tank body and communicated with ports, correspondingly formed at the different positions, of the communication pipeline respectively. One end of the breather valve is communicated with the outside of the tank body, and the other end of the breather valve is communicated with the corresponding port of the communication pipeline. The tank truck safe breathing system has the advantages of being safe and efficient in use; especially when a tank truck rolls over in accidents, it can be guaranteed that liquid in the tank truck does not leak outside, the tank truck breathing system normally operates, and various safety and environment protection problems caused by the breathing system are ingeniously avoided. The tank truck safe breathing system can be widely applied to various tank trucks.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

Leakage test method for anti-corrosion tanks

InactiveCN106969886ALeak won'tFit tightlyDetection of fluid at leakage pointFluid-tightness measurement using electric meansPreservativeEngineering

The invention discloses a anti-leakage test method for an anti-corrosion tank, which comprises the following steps: drilling, heating, vacuuming, and testing with an ethanol solution. The concept is ingenious, the operation is simple, and one person can complete the test. The method is special and can accurately judge anti-corrosion. Whether there is a leakage point in the layer, and at the same time adjust the limit stretch of the anti-corrosion layer to make it more suitable for the impact and corrosion of acid-base solution, and extend the service life by 60%.

Owner:张丹丹

Liner for solar heat collective header

InactiveCN105910309AReduce wall thicknessFirmly connectedSolar heating energySolar heat devicesYarnSolar water

The invention discloses a liner for a solar heat collective header and belongs to the technical field of solar water heaters. The liner comprises a cooper tube liner and a plurality of heat exchange modules, wherein yarn ends used for being connected with the cooper tube liner are fixed to the two ends of the cooper tube liner respectively; the heat exchange modules sleeve and are fixed to the cooper tube liner and are also provided with heat collective tube cooper tube fixing holes respectively; an axis of each heat collective tube cooper tube fixing hole is perpendicular to that of the cooper tube liner; a plurality of heat exchange modules sleeve and are fixed to the cooper tube liner at a certain interval; and the axes of the heat collective tube cooper tube fixing holes of all the heat exchange modules after being sleeved and fixed are mutually parallel and arranged in a same plane. According to the liner, with addition of the heat exchange modules, opening brazing does not need to be carried out on the cooper tube liner, and the problem of leakage caused by opening brazing is prevented; meanwhile, as opening does not need to be carried out on the cooper tube liner, the thickness of the wall of the cooper tube liner can be reduced, the cost is saved, the pressure bearing capacity is improved, connection of the heat exchange modules and the cooper tube liner is firm, the contact is tight, and the contact area is large; and with adoption of gapless heat conduction, the heat exchange efficiency is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

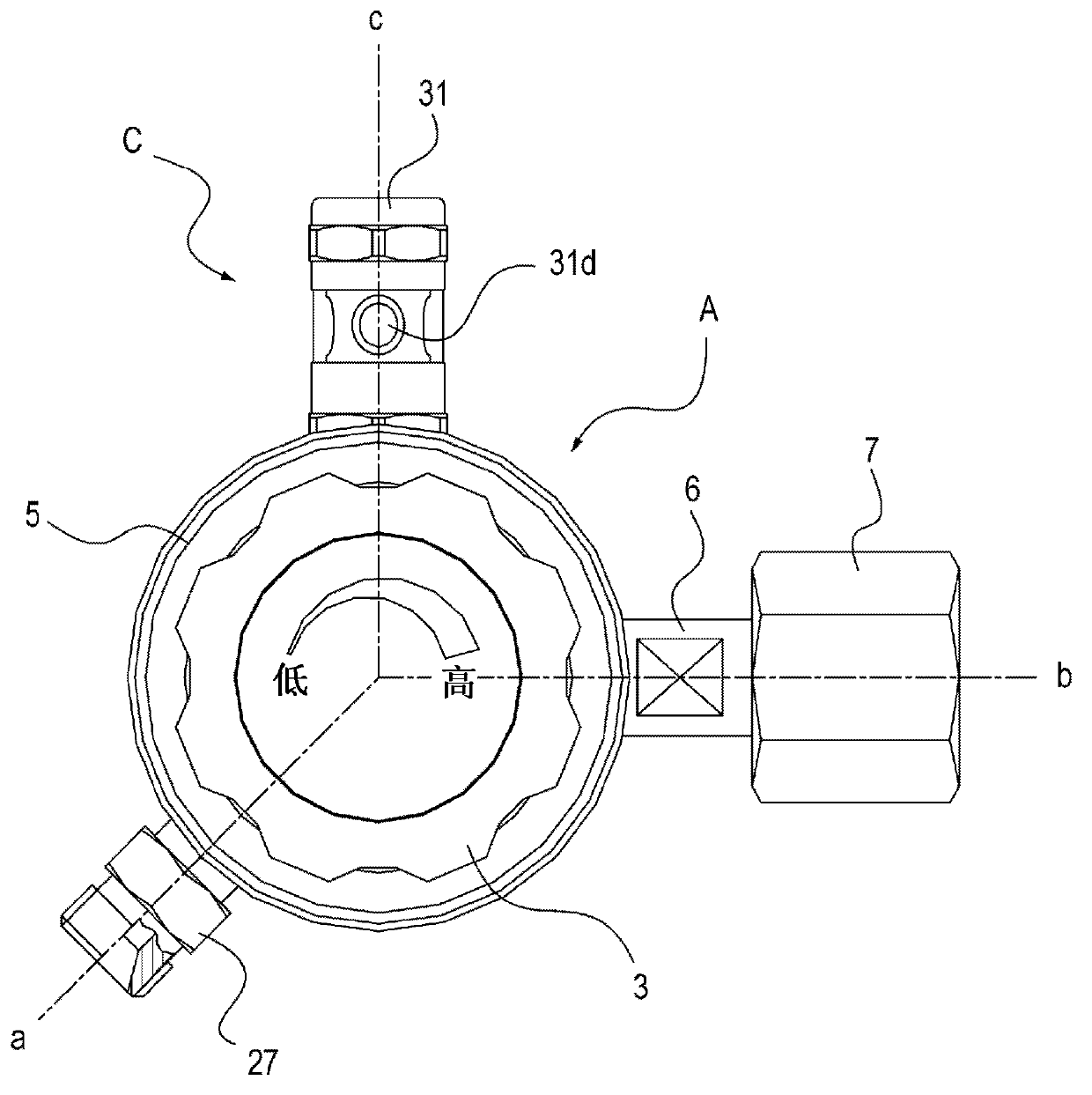

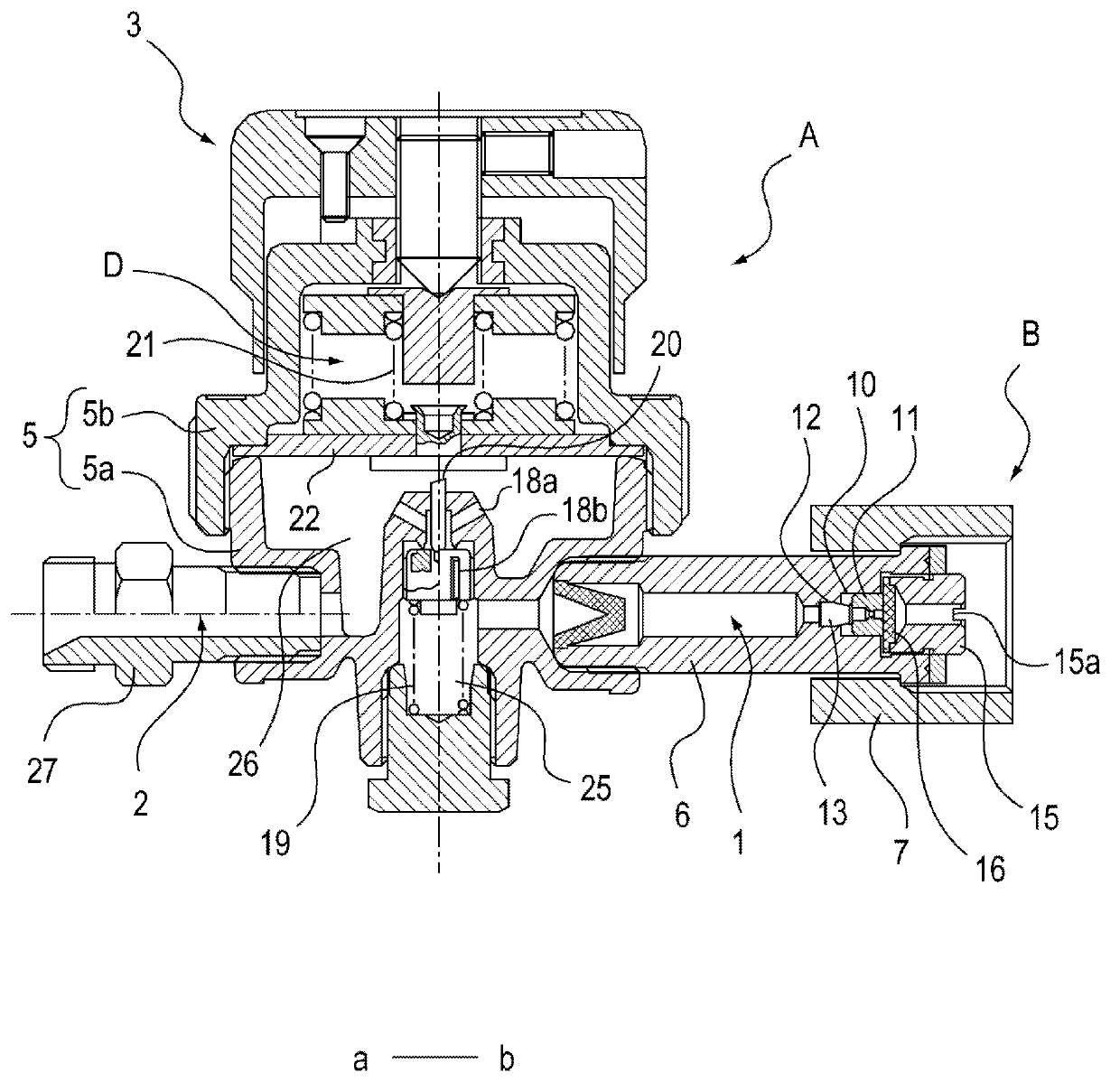

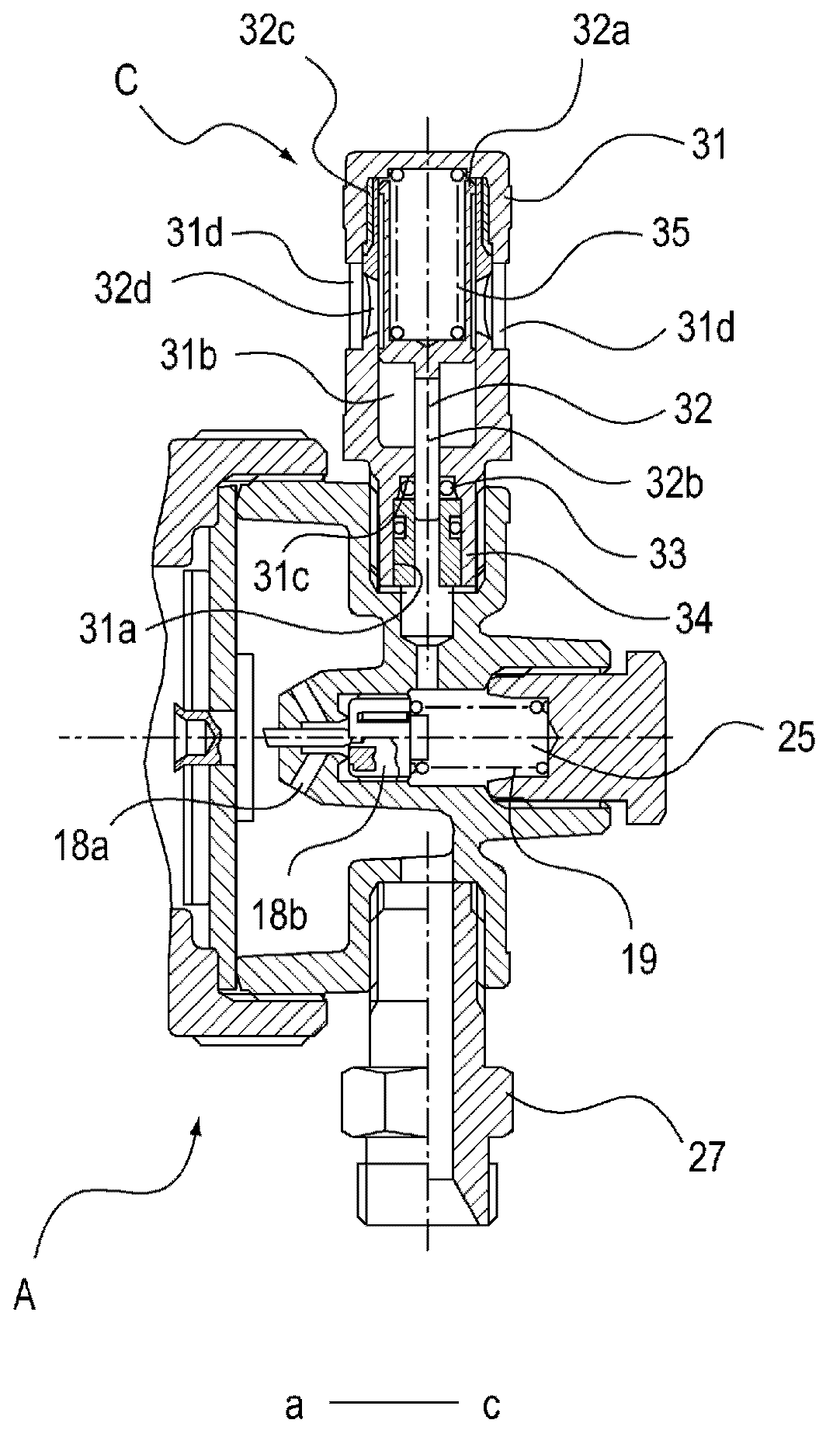

Pressure regulator

InactiveCN103299248AInsulation to prevent compressionPrevent leakageEqualizing valvesSafety valvesEngineeringPressure regulator

Provided is a pressure regulator comprising an adiabatic compression preventing mechanism and a pressure indicating mechanism. A pressure regulator comprises an adiabatic compression preventing mechanism (B) and a pressure indicating mechanism (C). The adiabatic compression preventing mechanism (B) comprises: a partitioning member (11) slidably disposed on a stepped part (10) at a primary-side passage (1) of the pressure regulator (A), the partitioning member (11) including a central small flow passage (11a) and a circumferential large flow passage (11f), the large flow passage being blocked when the partitioning member (11) makes contact with the stepped part (10), the partitioning member (11) further including a connection passage (17) formed at a downstream side of an upstream-side end surface (11d) so as to connect the small flow passage and the large flow passage; and a first spring (12) urging the partitioning member toward an upstream side in a gas flow direction. The pressure indicating mechanism (C) comprises: a cylindrical part (31) in which a first relief chamber (31a) having a small diameter and a second relief chamber (32b) having a large diameter are formed with an opening (31d) crossing the second relief chamber; a sliding member (32) including an indicating part (32a) and a pressure receiving part (32b), the sliding member (32) being slidably inserted in the cylindrical part (31); an O-ring (33) disposed on an end part of the first relief chamber; and a second spring (35) urging the sliding member toward the pressure receiving part.

Owner:KOIKE SANSO KOGYO CO LTD

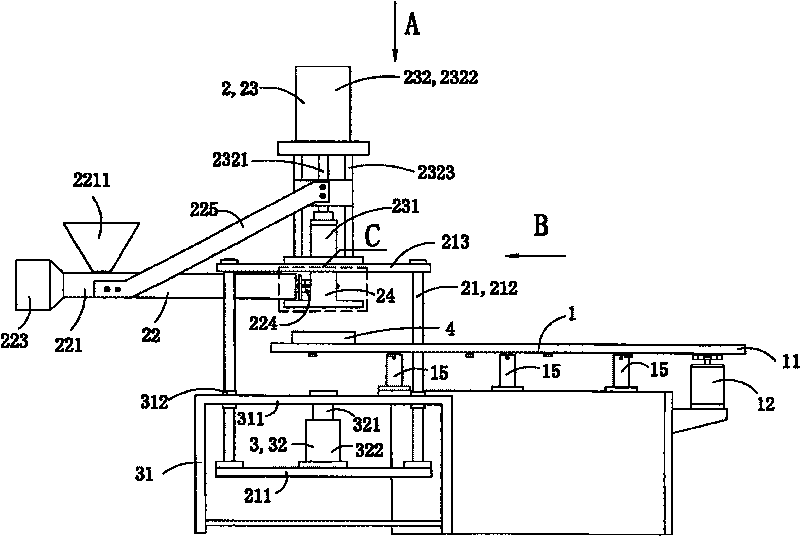

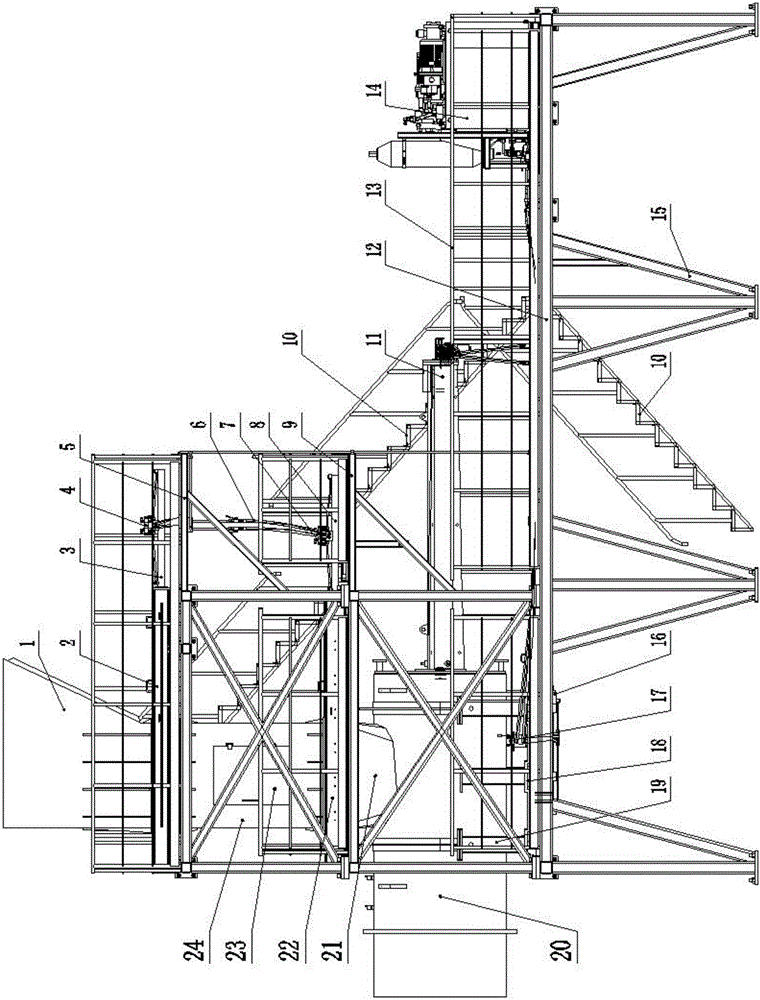

Feeding system of dangerous waste incinerator

ActiveCN105841158APrevent leakageImprove leakageCharge manipulationIncinerator apparatusCombustionExhaust fumes

The invention relates to a feeding system of a dangerous waste incinerator. A main material pushing cylinder is installed on a support. A feeding port of the main material pushing cylinder is provided with a hopper for dangerous waste to enter. A material pushing oil cylinder is installed on the end face, located in the support, of the main material pushing cylinder. An opening used for a material pushing piston to push the dangerous waste out is formed in the end face, located outside the support, of the main material pushing cylinder, and a feeding flashboard is embedded in the lower end of the hopper. In the feeding system, both the feeding flashboard and a material conveying flashboard are in a closed state, flames and heat, generated from the main material pushing cylinder, due to combustion of the dangerous waste are isolated, leakage of waste gas is also avoided, and the material pushing piston in the main material pushing cylinder can generate ten-ton pushing force so as to push the dangerous waste into a combustion section from the opening in the end face of the outer side of the main material pushing cylinder; a maintaining oil cylinder can push the main material pushing cylinder to move towards the interior of the support, equipment maintaining can be conveniently conducted by maintaining personnel; and to sum up, the whole process can be conducted automatically or manually, the automation degree is high, the dangerous waste is conveniently conveyed, waste gas generated in combustion cannot leak, and the system works safely and reliably.

Owner:TIANJIN URANUS HYDRAULIC MACHINERY +1

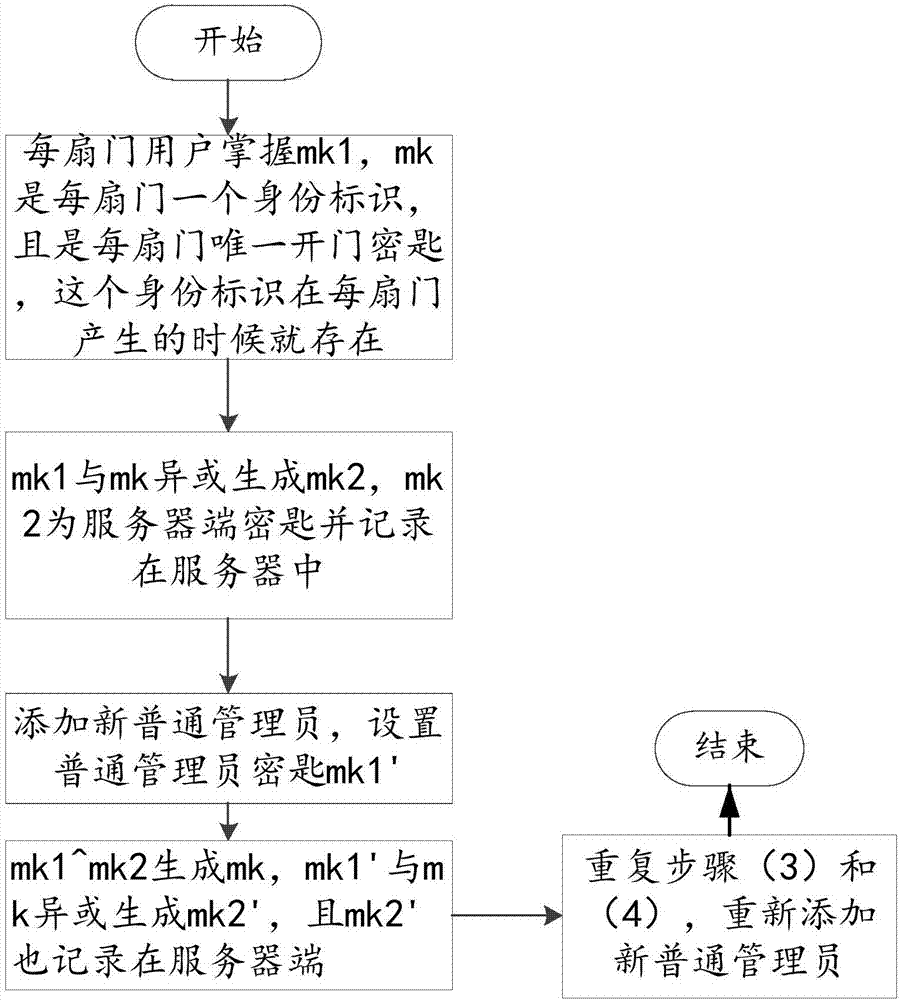

Communication encryption method and system

The invention relates to a communication encryption method and system. Each door has a fixed identity mark mk, this identity exists in the production of each door, and the mk is an only communication key to each door. The user can set an own (user 1) private password mk1, the exclusive or operation between mk1 and mk is carried out to get mk2, and the mk2 is saved to a server. Then the user 1 sets a key mk1' for other general administrators (user 2), the exclusive or operation between mk1 and mk2 is carried out to obtain mk, the exclusive or operation between mk and mk1' is carried out to obtain mk2', and mk2' is stored in the server. The addition mode of each new user is identical, and the key to each user' room is unique. When the user needs to open the door, the user sends their own private password mk1 to the server, the server combines the user's mk1 and mk2 stored in the server to get the final key mk, and the mk is destroyed immediately after use. Therefore, mk cannot be leaked when the user' key is leaked or the server is broken by the hacker.

Owner:南京优尼科软件有限公司

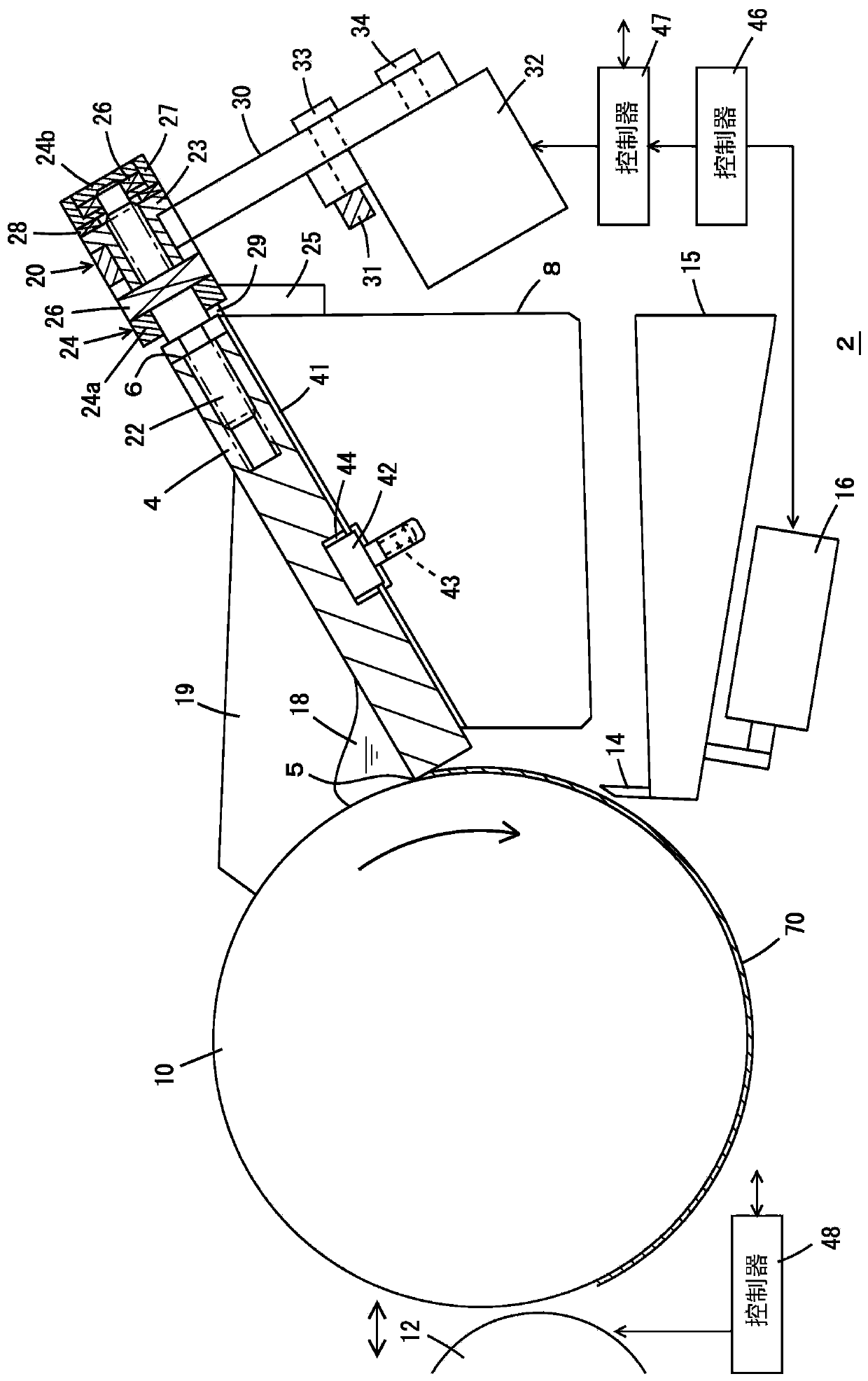

Device for cleaning ink reservoir, printing machine, and method for cleaning ink reservoir

In a printing machine, an ink reservoir is formed between an ink fountain and an ink fountain roller, and then ink is supplied to a plate cylinder via a ductor roller that is capable of moving forwardand backward with respect to the ink fountain roller. The printing machine is provided with: a base which supports the ink fountain; the ink fountain; a slide mechanism which controls a gap between the tip of the ink fountain and the ink fountain roller by sliding the ink fountain along the base; a cleaner which removes ink from the ink fountain roller; a forward / backward motion mechanism which moves the cleaner back and forth between a position at which the cleaner comes into contact with the ink fountain roller and a non-contact position; and a controller. The controller performs control onthe slide mechanism and the forward / backward motion mechanism, expands the gap so as to allow both ink and impurities therein to pass through the gap, and brings the cleaner into contact with the inkfountain roller to remove the ink and impurities therein from the roller.

Owner:I MAR PLANNING INC

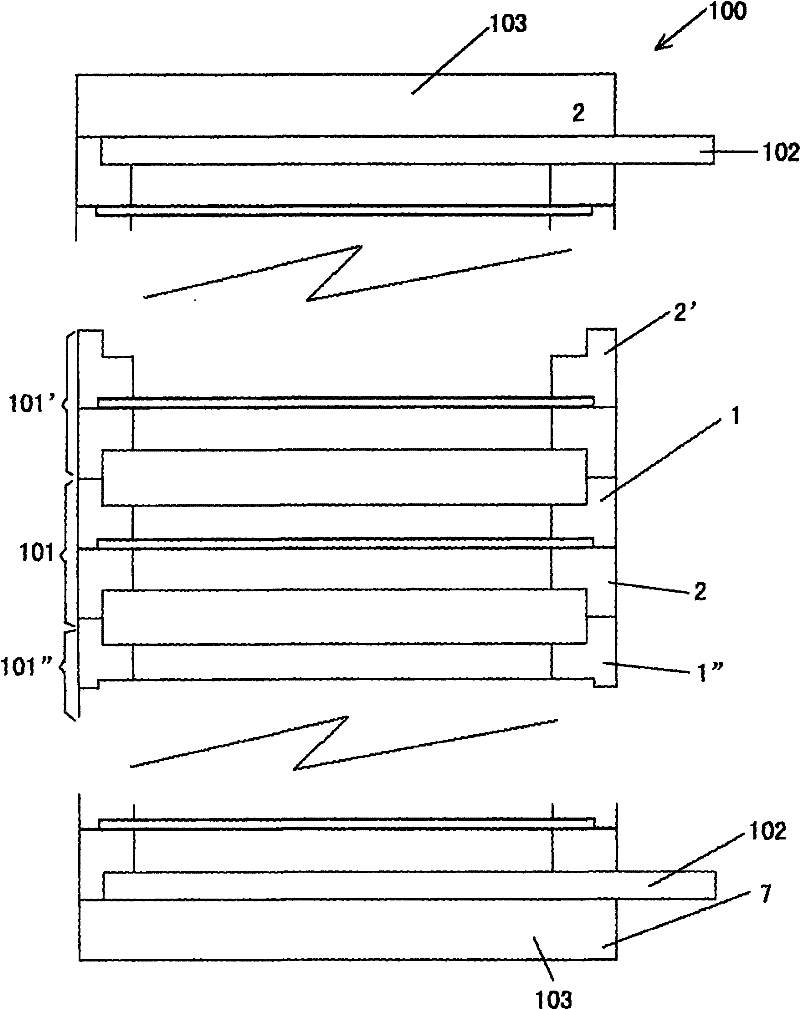

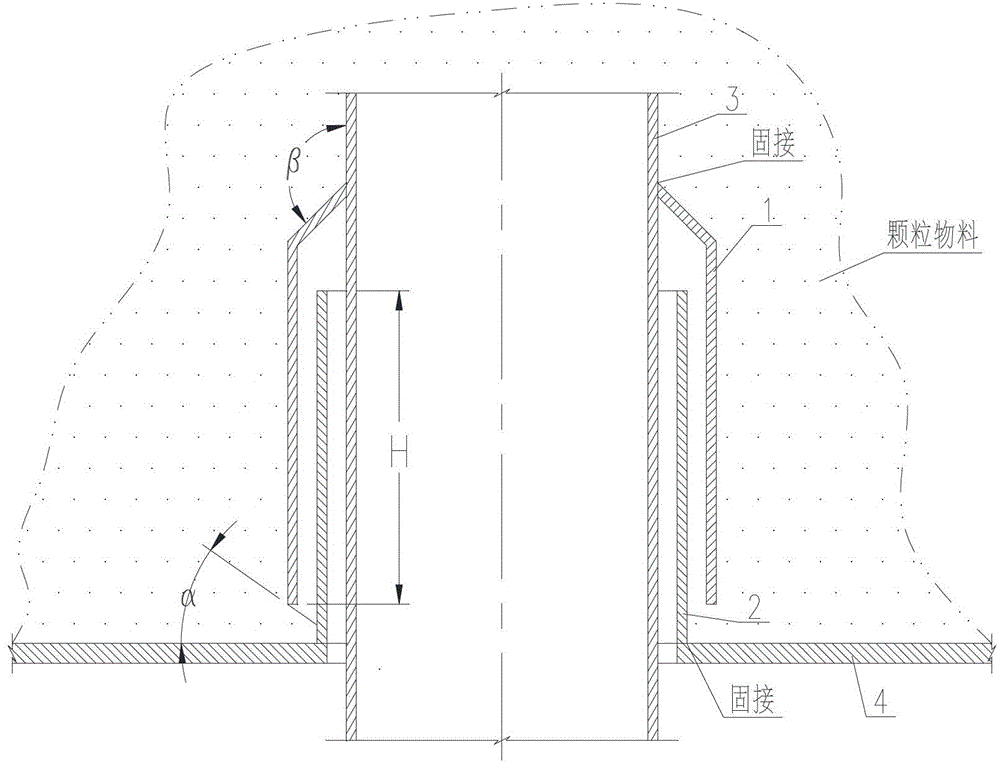

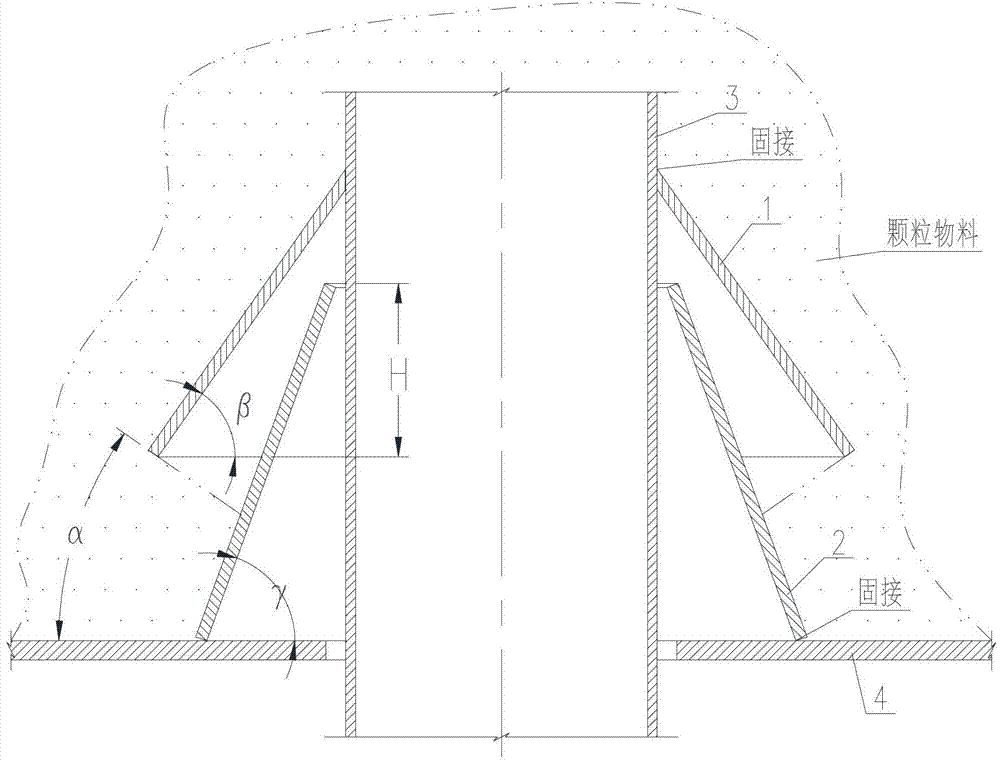

Sleeve sealing device

The invention relates to a sleeve-type material sealing device. The sleeve-type material sealing device comprises M upper sleeves (1), N lower sleeves (2), a pipeline (3) and a material layer bearing device (4), wherein M is greater than or equal to 1, and N is greater than or equal to 1. The upper ends of the upper sleeves (1) are fixedly connected with the pipeline (3); the lower ends of the upper sleeves (1) are open pipe ends; the upper ends of the lower sleeves (2) are open pipe ends; the lower ends of the lower sleeves (2) are fixedly connected with the material layer bearing device (4); and the material layer bearing device (4) is sleeved on the pipeline (3). According to the invention, through a mutually and loosely sleeved cylindrical structure, the pipeline is prevented from being fixedly connected with the material layer bearing device, the pipeline and the material layer bearing device can perform relative movement in a certain range, and materials cannot be leaked.

Owner:北京清新环境工程技术有限公司

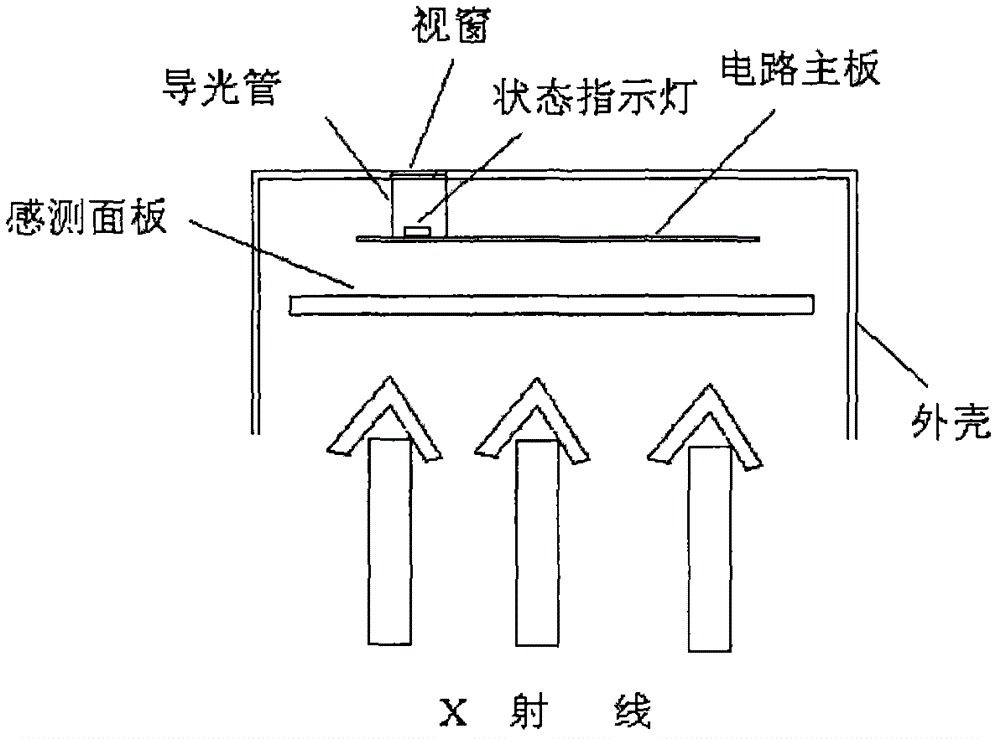

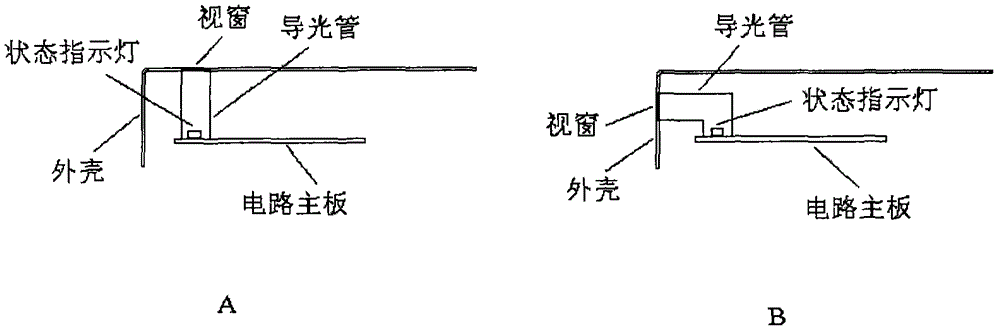

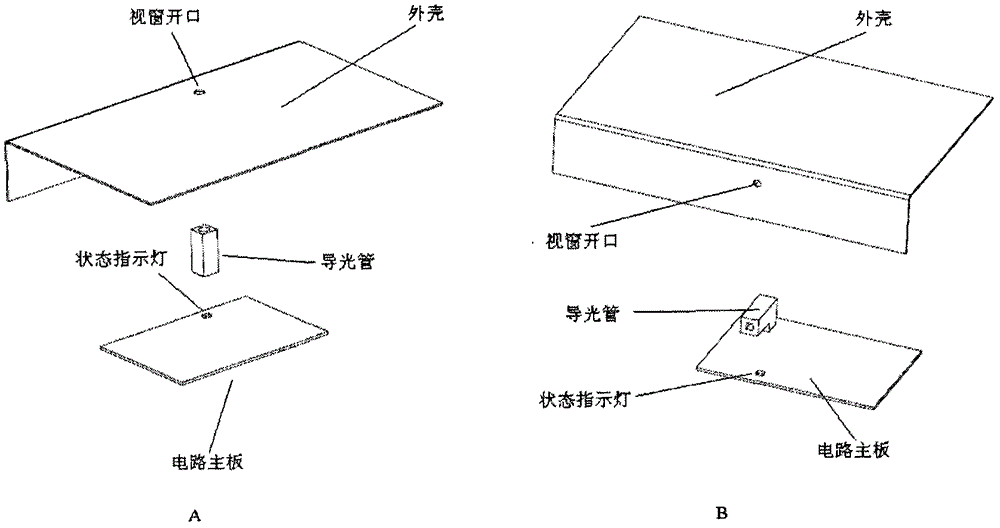

X-ray detectors and X-ray imaging equipment

ActiveCN103445797BLeak won'tPrevent image quality from being compromisedRadiation diagnosticsLight guideImaging quality

The invention discloses an X-ray detector and an X-ray imaging device. The X-ray detector includes: a status indicator light, located on the circuit board of the X-ray detector, used to indicate the status of the circuit board; and a light guide tube, connected between the X-ray detector shell and the circuit board, and The status light is housed inside a light pipe to direct the light from the status light out of the housing. Wherein, the light pipe includes an inner layer part and an outer layer part that encapsulates the inner layer part inside, and the inner layer part forms a hollow light channel, so that the light emitted by the status indicator light passes through it, and the outer layer part is made of flexible and light-shielding Composition of materials used to prevent light from the status indicator light from leaking into the interior space enclosed by the housing of the X-ray detector. The X-ray detector according to the present invention can effectively prevent the light emitted by the status indicator light from being leaked onto the sensing panel of the X-ray detector so as to affect the imaging quality.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Self-balancing stop valve with piston type valve core and hidden rod

The invention discloses a self-balancing stop valve with a piston type valve core and a hidden rod, which comprises a valve cover (7) and a valve body (33) provided with a front valve cavity (31) and a rear valve cavity (32), wherein a passage (34) is formed between the front valve cavity (31) and the rear valve cavity (32). Guide sleeves (5) in vertical sealed sliding connection and the piston type valve core (2) in which a cavity is formed are arranged in the rear valve cavity (32); the bottom surface (18) of the piston type valve core (2) is used for blocking the passage (34); the guide sleeves (5) are hermetically and fixedly connected with the valve body (33); a lifting component is connected with the piston type valve core (2); the valve cover (7) is hermetically connected with the valve body (33); the inner surfaces of the piston type valve core (2), the guide sleeve (5) and the valve cover (7) encircle an upper chamber (21); and the upper chamber (21) is communicated with the rear valve cavity (32) through a guide pipe component (13). The self-balancing stop valve has the characteristic of remarkable energy-saving effect.

Owner:ZHEJIANG UNIV

Canopy type material sealing device

The invention relates to a canopy type material sealing device which comprises an upper canopy (1), a lower canopy (2), a pipeline (3) and a material layer bearing device (4), wherein the upper end of the upper canopy (1) is fixedly connected with the pipeline (3); the lower end of the upper canopy (1) is sheathed outside the lower canopy (2); the lower end of the lower canopy (2) is fixedly connected with the material layer bearing device (4); the upper end of the lower canopy (2) is sheathed on the pipeline (3) to ensure that the lower canopy (2) is capable of relatively moving along the axial direction of the pipeline (3); and the material layer bearing device (4) is sheathed on the pipeline (3) to ensure that the material layer bearing device (4) is capable of relatively moving along the axial direction of the pipeline (3). Through the upper and lower canopies which are sheathed in a loosening manner, the fixed connection between the pipeline and the material layer bearing device is avoided, so that the pipeline and the material layer bearing device are capable of relatively moving in a certain range and the materials do not leak.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Angle-adjustable pipeline connecting structure, installing method and long-line pipeline

The invention belongs to the field of sludge treatment equipment, and discloses an angle-adjustable pipeline connecting structure. The angle-adjustable pipeline connecting structure comprises a valvebody, a valve ball, a first flange and a second flange; the inner side of one end of the valve body is provided with a connecting inner cavity, and the end is provided with a port with the small innerside and the large outer side; the valve body is further provided with a first connecting portion; the first flange is provided with a second connecting portion; the second connecting portion is connected with the first connecting portion through a fixing part; the valve ball is located in the connecting inner cavity; and the second flange penetrates through the first flange and the port througha water supply pipeline to be connected with the valve ball. The invention further discloses an installing method of the pipeline connecting structure and a long-line pipeline with the pipeline connecting structure. Therefore, connection of the long-line pipeline can be applied to the high-pressure work condition, and the pipeline angle steering problem can be solved.

Owner:蓝钿(北京)流体控制设备有限公司

Matched heat storage equipment for molten salt tank and use method of matched heat storage equipment

PendingCN114484575AAvoid dischargeAvoid breakingMechanical apparatusLighting and heating apparatusHeat flowMolten salt

The invention belongs to the technical field of molten salt tank heat storage, and particularly relates to matched heat storage equipment for a molten salt tank, which comprises a tank body and a heat conduction pipe. Through cooperative use of a heat conduction pipe, a heat exchanger, a supporting block, a heat discharge pipe, a hot water outlet pipe, a heat preservation tank, a first butt joint block, a first heating shell, a second heating shell, a connecting pipe and a second butt joint block, then the heat exchanger discharges hot air into the heat discharge pipe, and the hot air in the heat discharge pipe enters the first heating shell and the second heating shell through the connecting pipe; when the first heating shell and the second heating shell reach a certain temperature, the surface of the hot water outlet pipe can be heated, heat recovery and utilization are completed through the steps, and the problems that hot air discharged into the heat exchanger by the molten salt tank is discharged out of the machine during circulation, the discharged hot air has extremely high temperature, and the heat exchange efficiency is improved are solved. In order to solve the problem that energy is wasted when hot air is discharged due to the fact that an existing heat exchanger is not provided with a device for recycling the hot air, the invention further provides a using method of the equipment.

Owner:QINGHAI SUPCON SOLAR POWER GENERATION

A two-way controllable magneto-rheological damper without leakage and without sealing ring

ActiveCN102359536BPrevent leakageLeak won'tSpringsNon-rotating vibration suppressionWorking pressureMagneto

The invention discloses a two-way controllable magneto-rheological damper without leakage and without sealing ring, which comprises a cylinder body, a piston, and a piston rod. The left and right ends of the cylinder body are respectively airtightly connected with a left bellows and a right bellows. The left bellows is airtightly connected with the left end cap, the left and right end caps are airtightly connected with the piston rod, the left and right bellows are airtightly connected with the left and right end caps, and the centers of the left and right end caps are airtightly connected with the piston rod; Connecting pipe; a ring-shaped left coil and a ring-shaped right coil are fixedly connected inside the cylinder, and the gap between the inner hole of the ring-shaped coil and the piston rod forms a damping channel; the connecting pipe is provided with a left one-way The valve and the right check valve piston are located between the left check valve and the right check valve. The present invention adopts the bellows as the seal, which avoids the leakage between the piston rod and the sealing ring due to wear, and the bellows does not bear the working pressure, as long as the bellows is within the fatigue life of the damper, the damper will not leakage.

Owner:CHONGQING MATERIALS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com