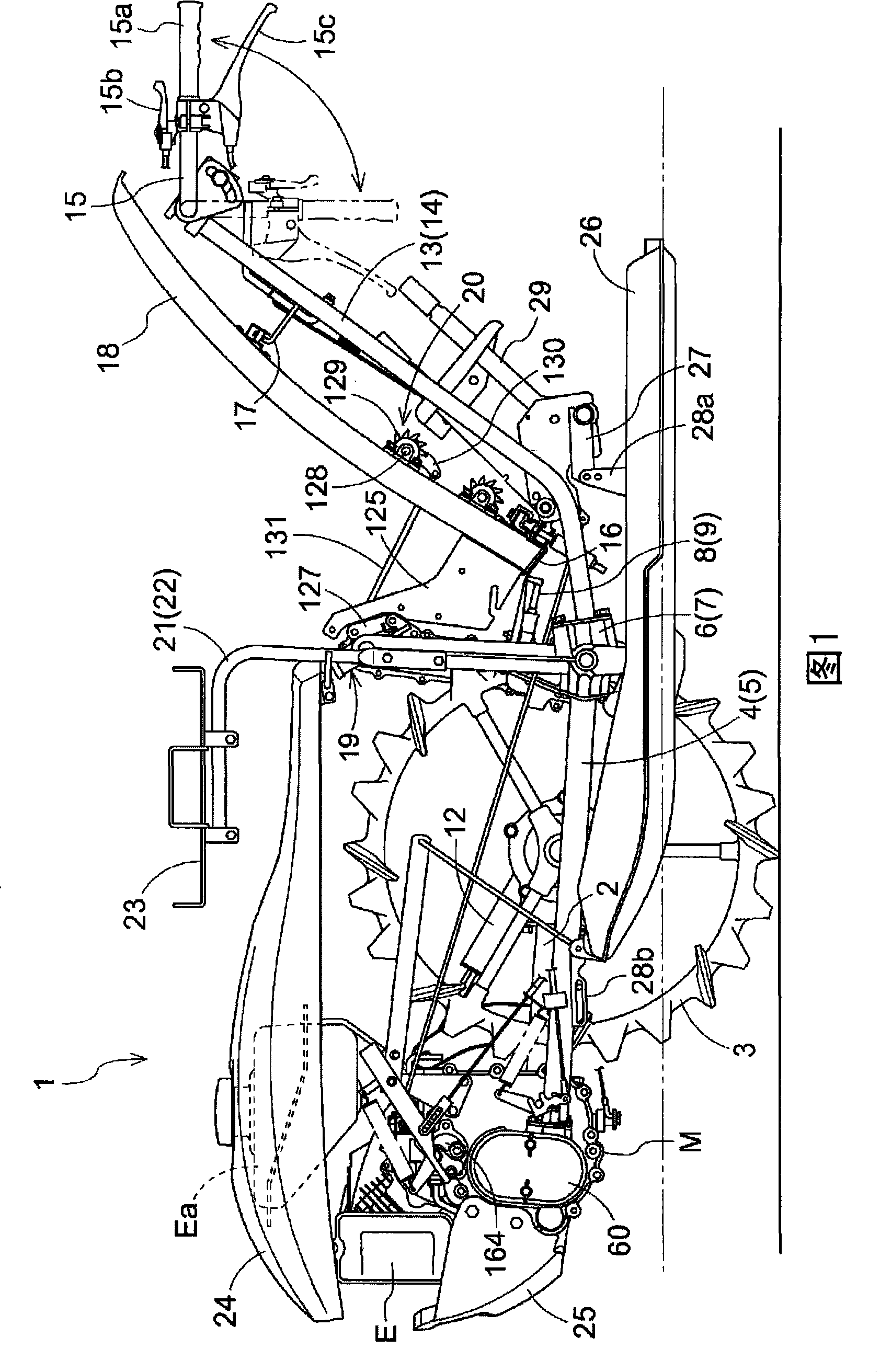

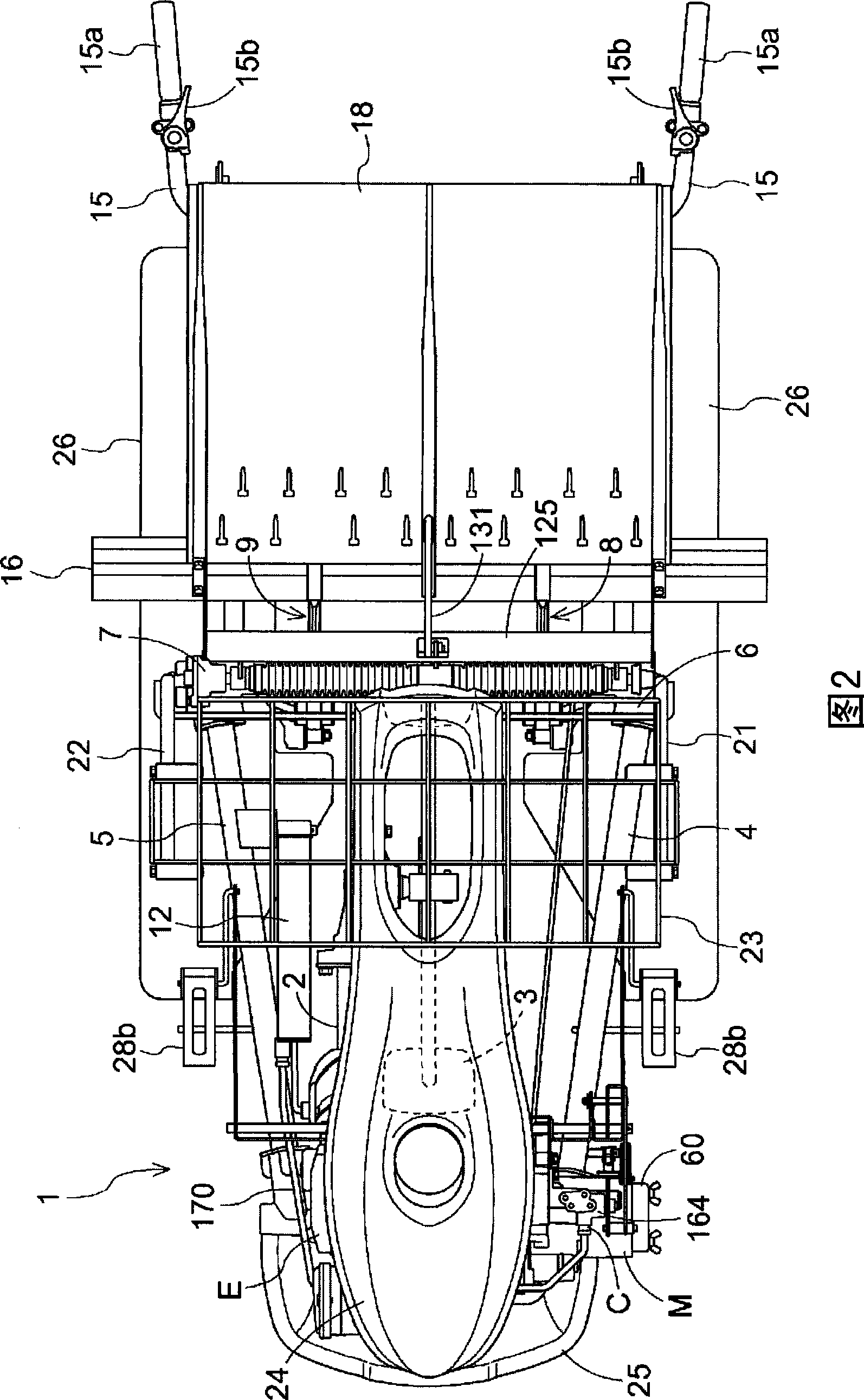

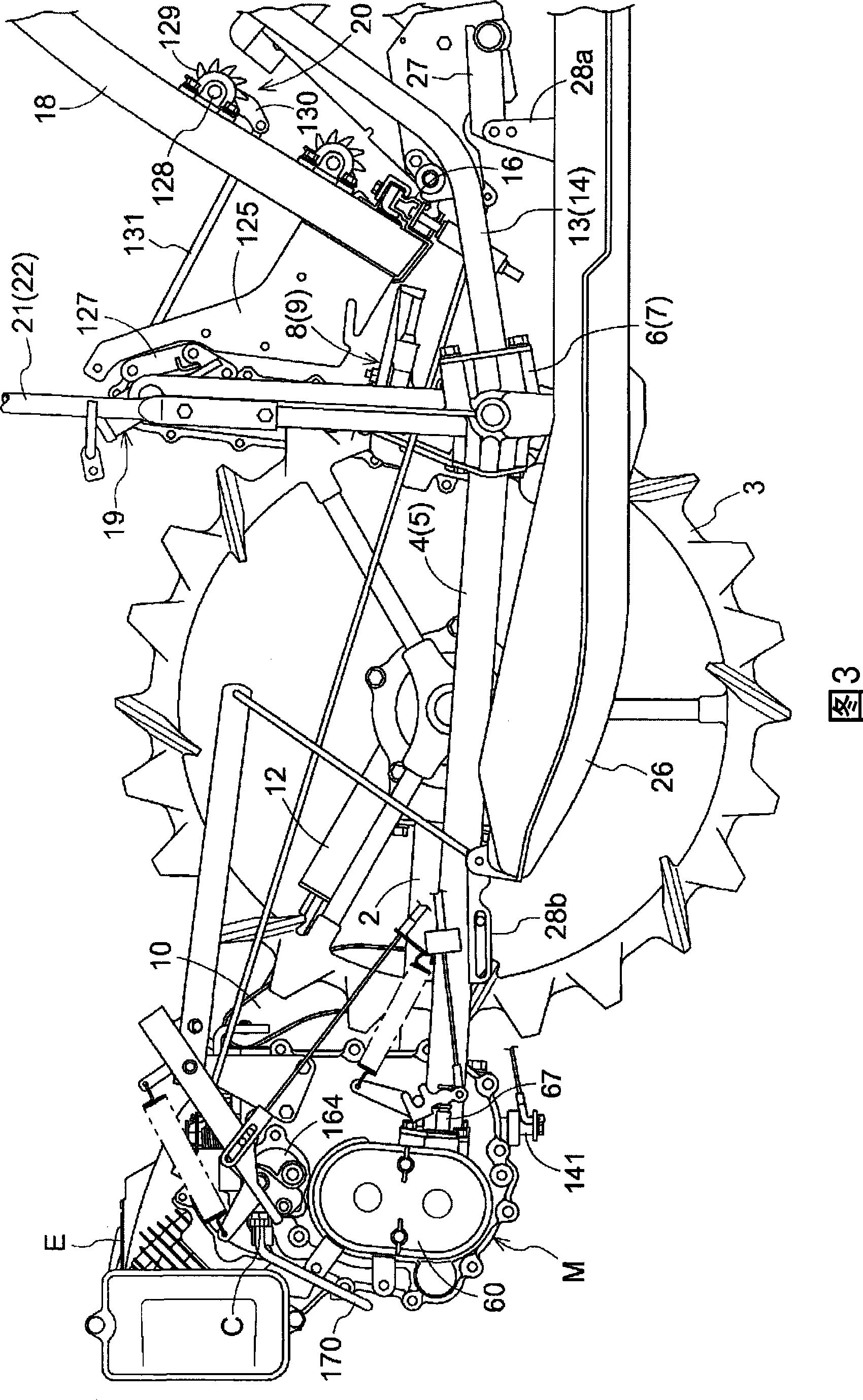

Transmission mechanism of walk-behind type paddy-field work machine

A technology of transmission structure and rice transplanter, which is applied in the directions of transmission device parts, transplanting machinery, mechanical equipment, etc., can solve the problems of complicated transmission structure of gearbox, no speed change device, increased manufacturing cost, etc., and achieve simplified structure and compactness. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0184] In the above [Best Mode for Carrying Out the Invention], the first transmission shaft 33 is overlapped with the output shaft 30 of the engine E, but it is not necessary to make the first transmission shaft 33 and the output shaft 30 of the engine E on the same axis. They are arranged overlappingly in the direction of the heart P1 and connected in series. In this case, for example, the first propeller shaft 33 can be connected to the output shaft 30 of the engine E via a coupling member or the like (not shown).

[0185] In the above [Best Mode for Carrying out the Invention], the first transmission shaft 33 and the output shaft 30 of the engine E are arranged concentrically, but the axis center of the first transmission shaft 33 and the output shaft of the engine E may also be arranged concentrically. The axes of 30 are eccentrically connected side by side. In this case, for example, the output shaft 30 of the engine E may be connected to the first transmission shaft 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com