Pressure regulator

A regulator and pressure technology, applied in the direction of fluid pressure control, instrumentation, fluid pressure control without auxiliary power, etc., can solve the problems of diaphragm and sheet components, and achieve the effect of preventing heat insulation compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

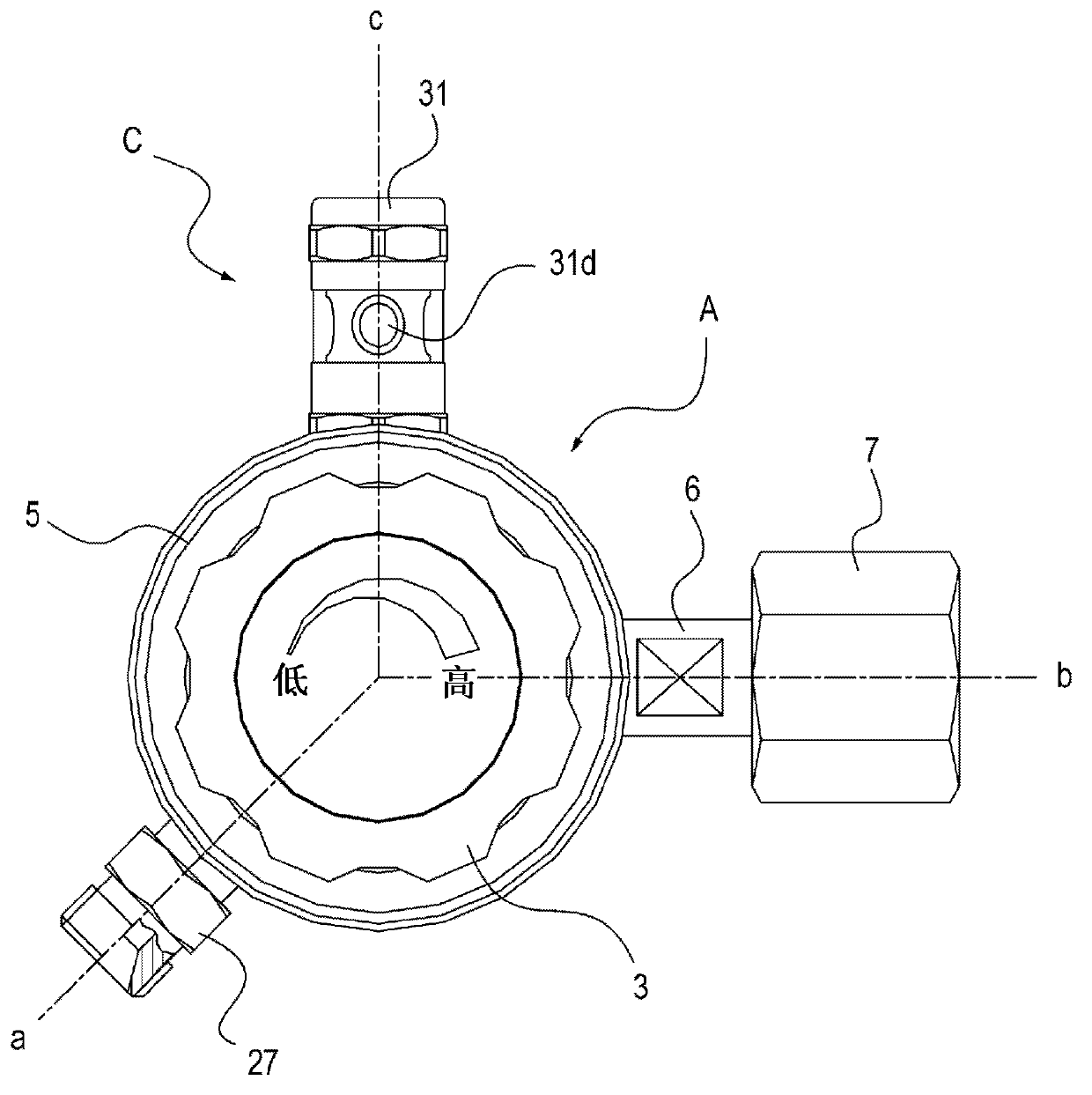

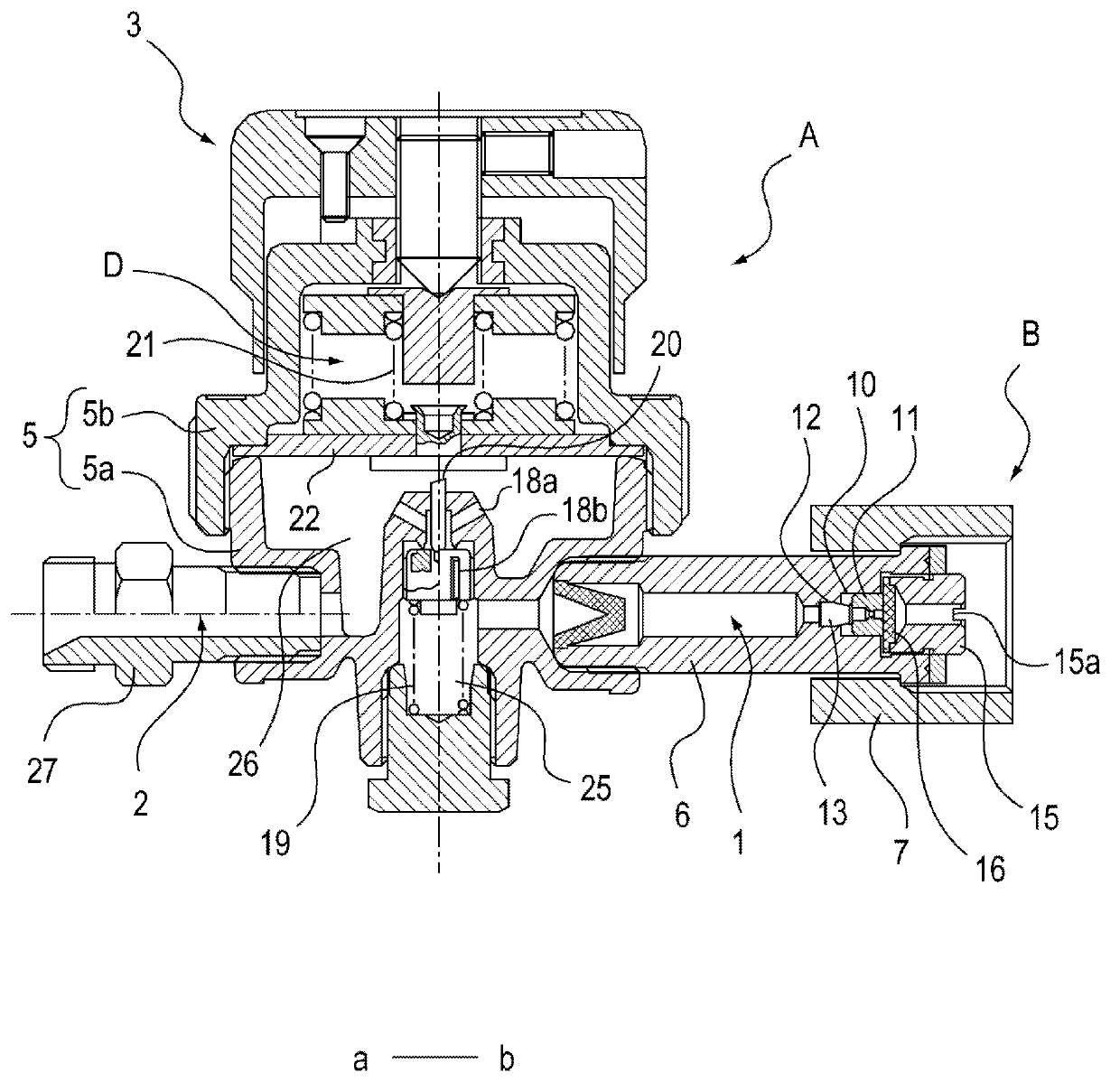

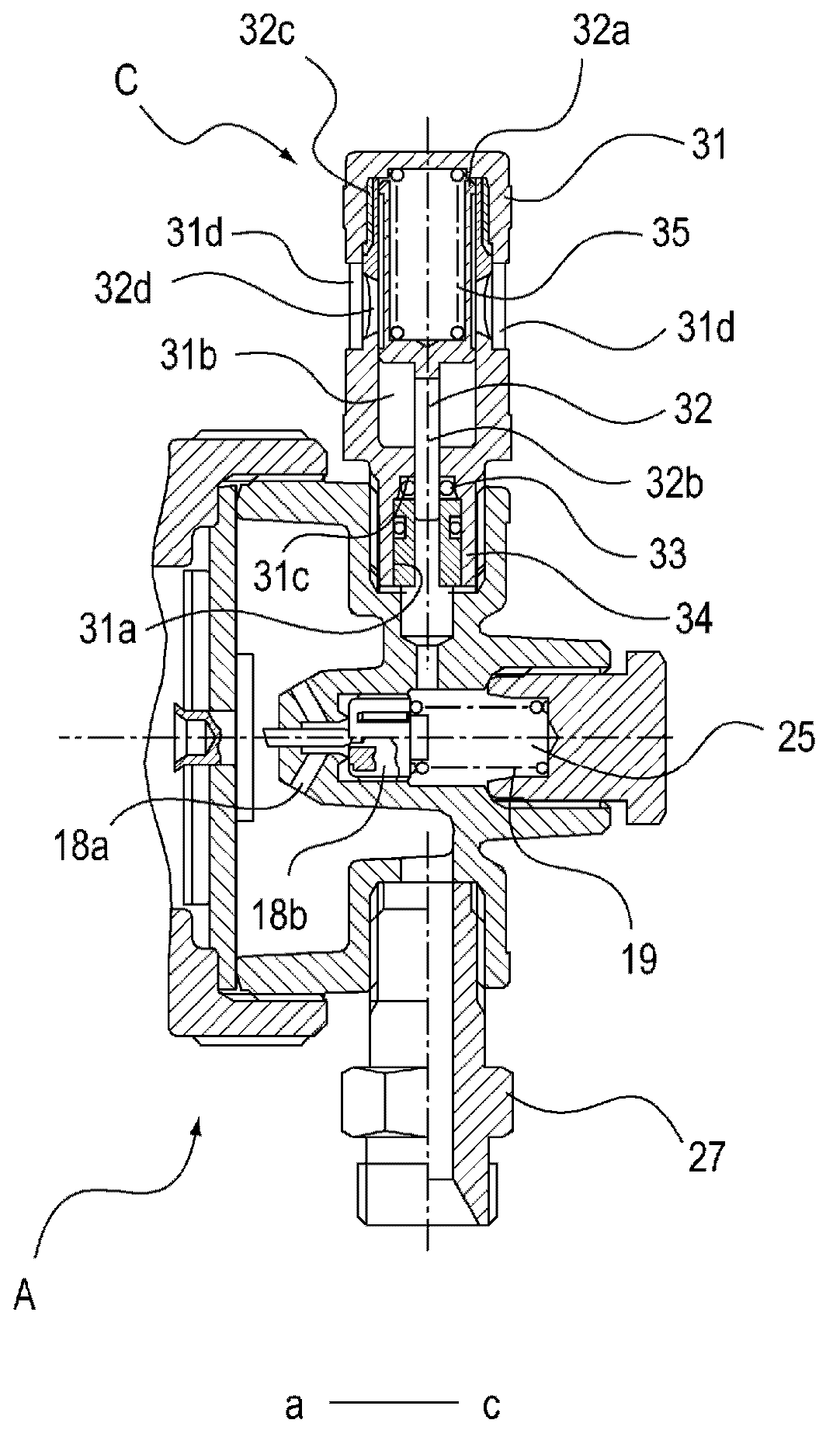

[0080] use Figure 1 ~ Figure 4 The structure of the pressure regulator of this embodiment will be described.

[0081] First, the structure of the pressure regulator A will be briefly described. This pressure regulator A is configured as an oxygen supplier for supplying medical oxygen to a patient, and is detachably attached to a medical oxygen cylinder (not shown) as a supply source of primary gas having a relatively high pressure. . Furthermore, this pressure regulator A can decompress high-pressure oxygen (primary gas) supplied from an oxygen cylinder into low-pressure oxygen (secondary gas), and the secondary gas can be supplied to a patient through an oxygen mask and a cannula.

[0082] Such as Figure 1 ~ Figure 3 As shown, the pressure regulator A has a primary side passage 1 , an adiabatic compression preventing mechanism B and a pressure indicating mechanism C, a secondary side passage 2 , a decompression mechanism D and an operating member 3 . The primary side pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com