Patents

Literature

1389results about "Fluid pressure control without auxillary power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

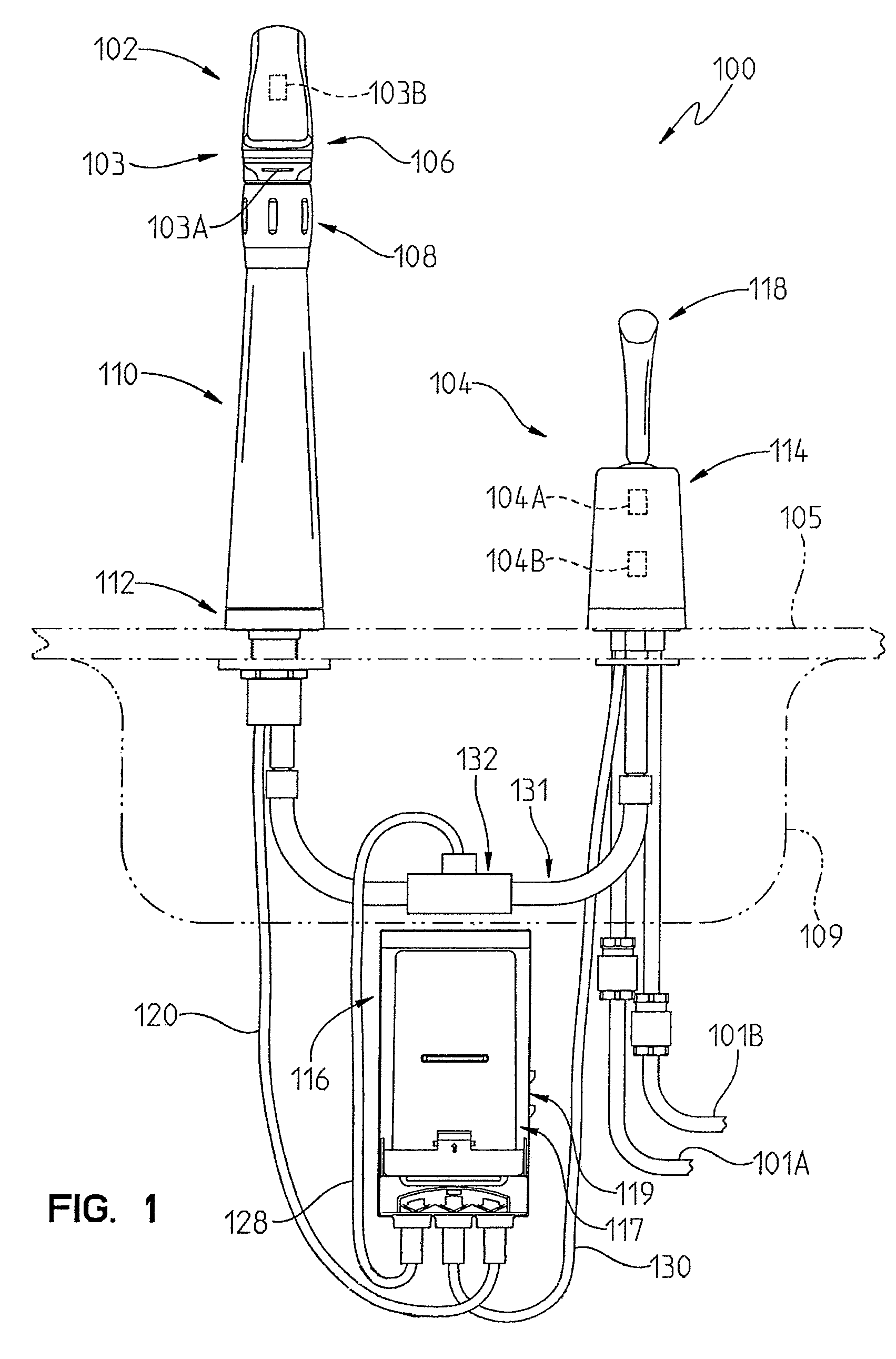

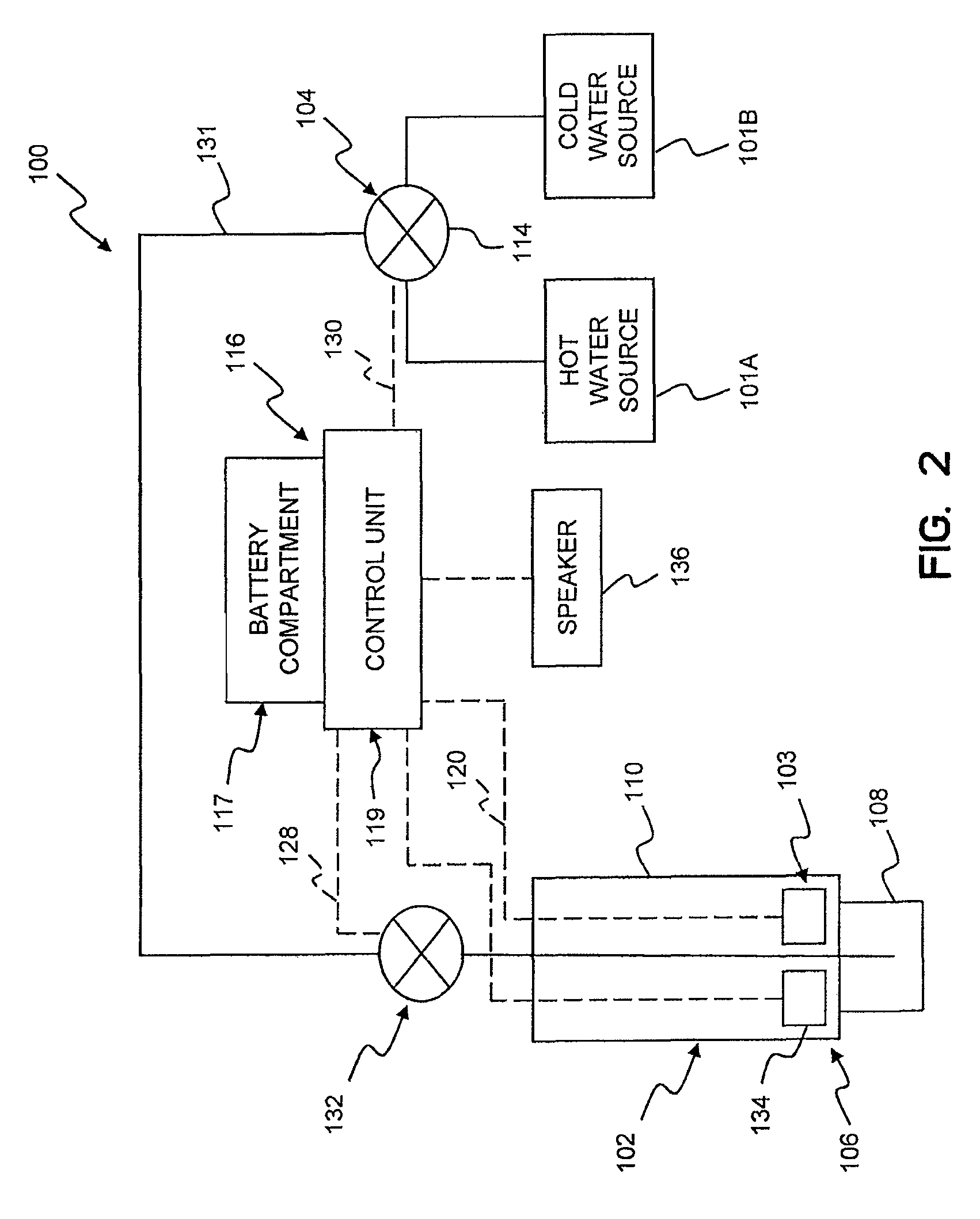

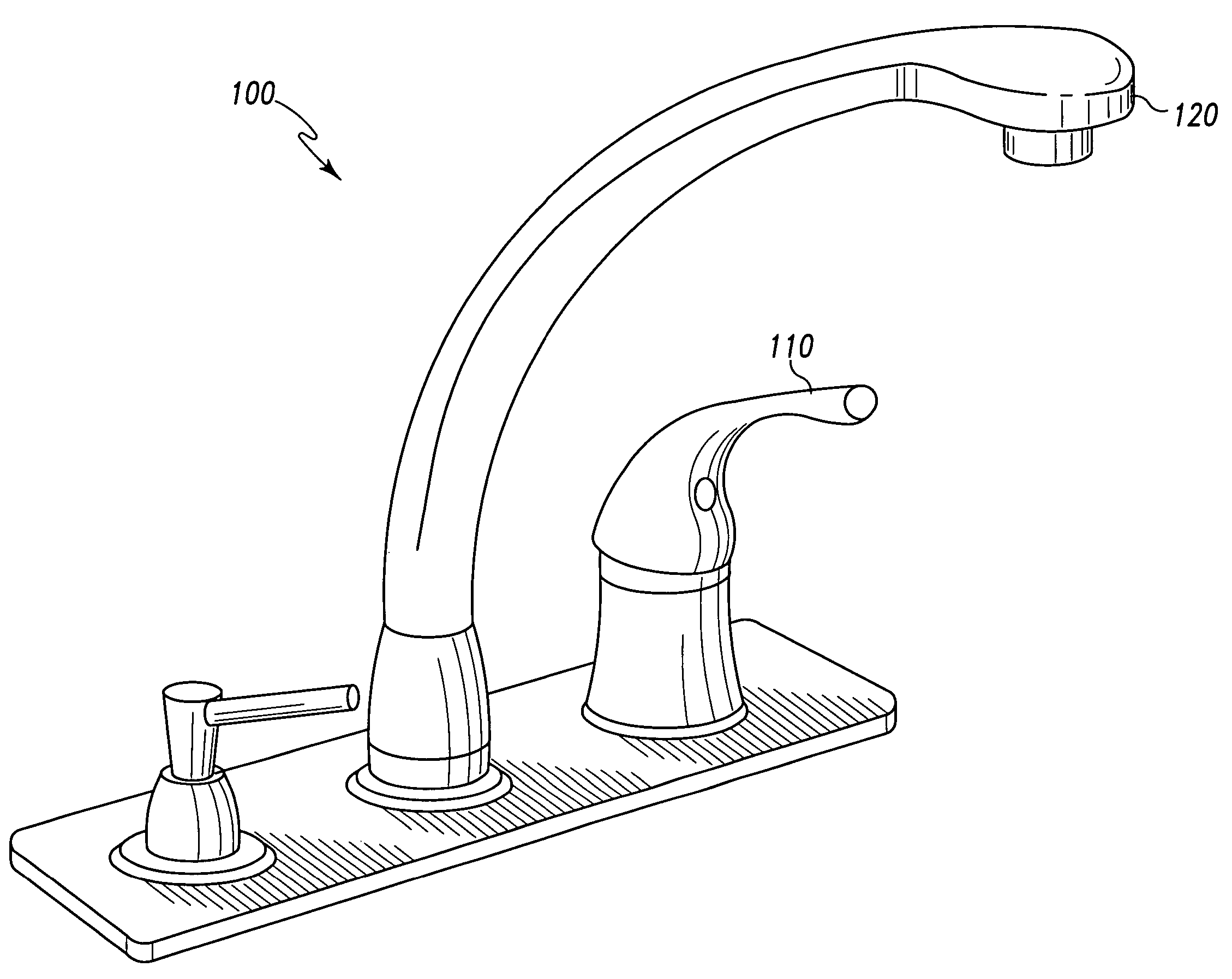

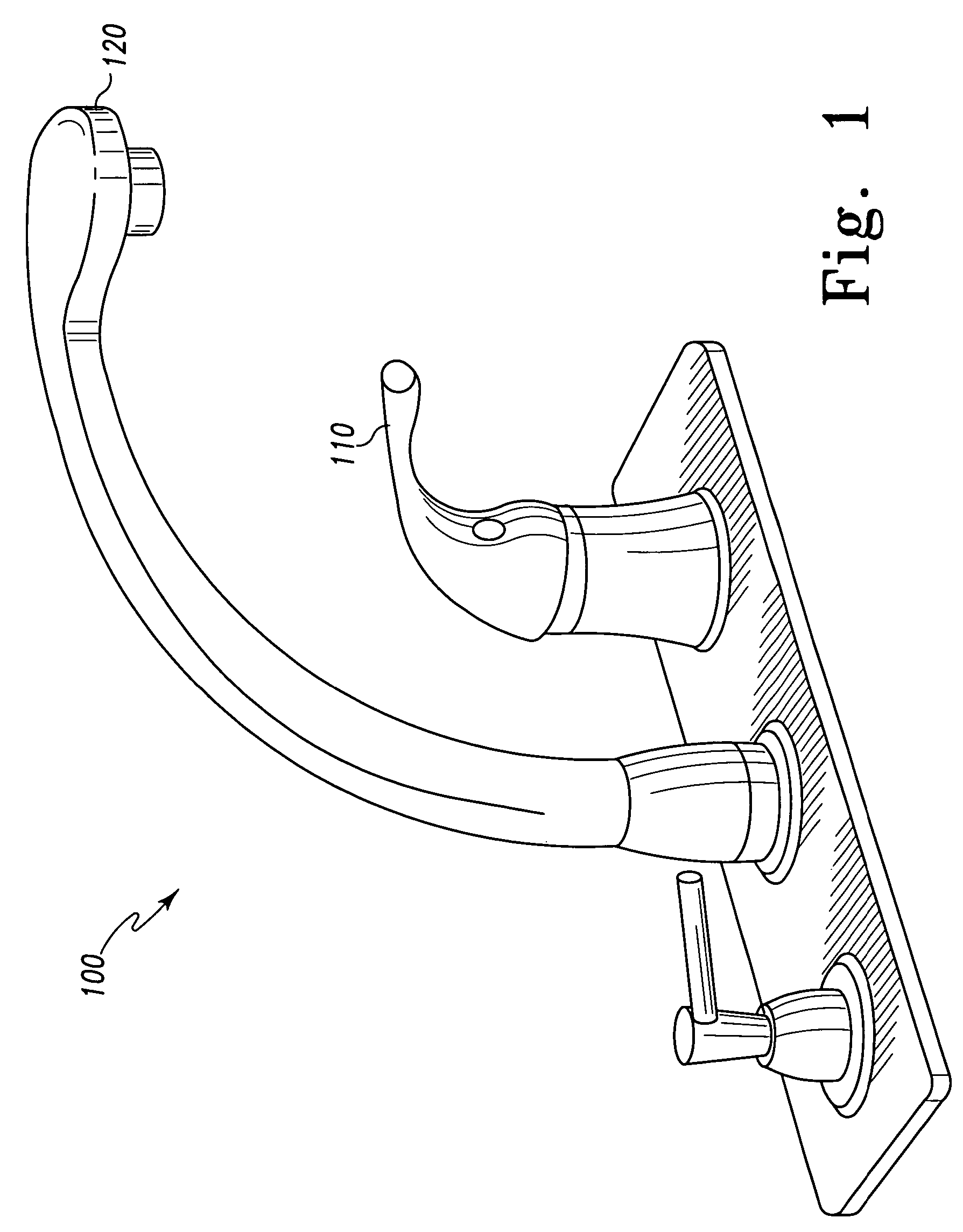

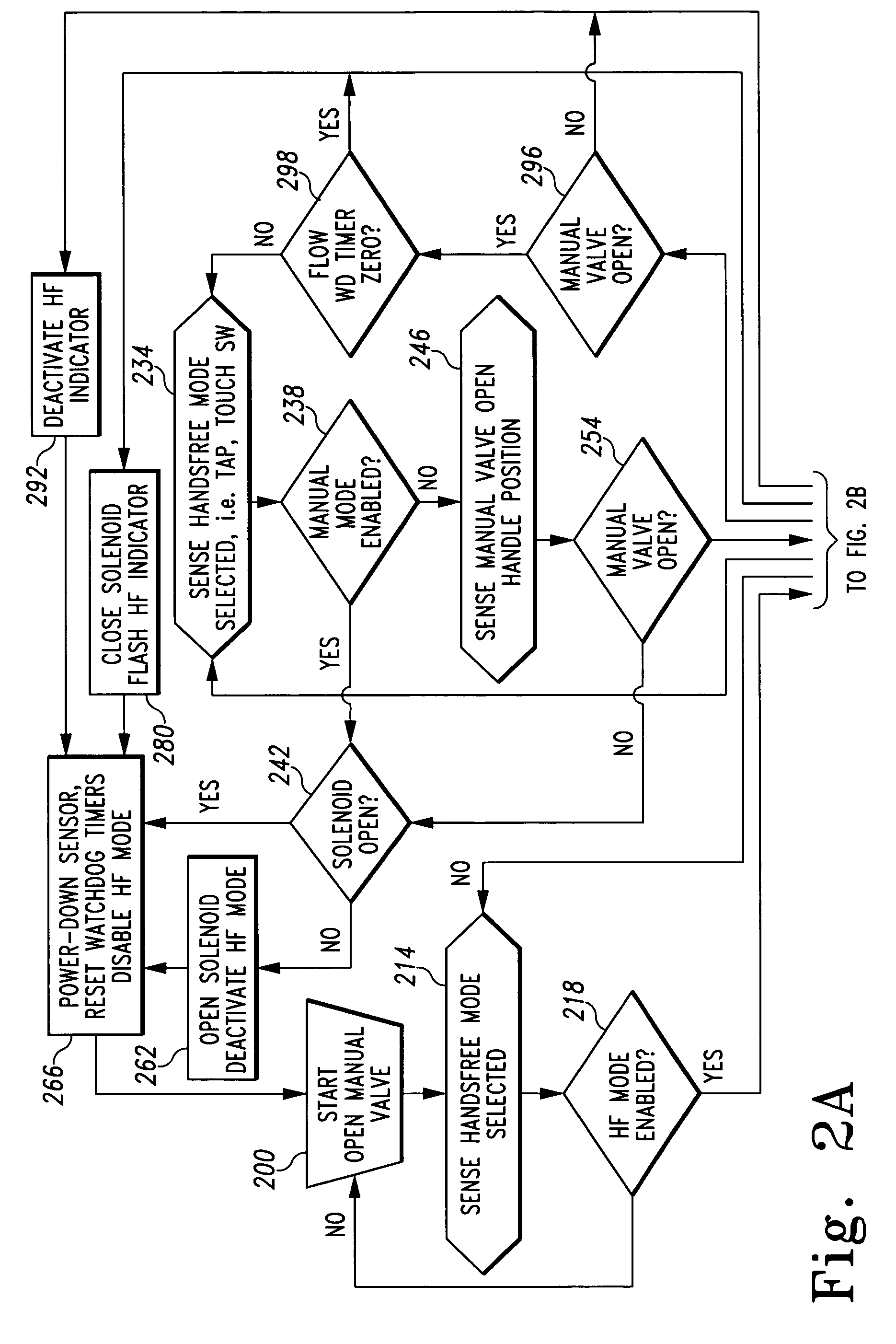

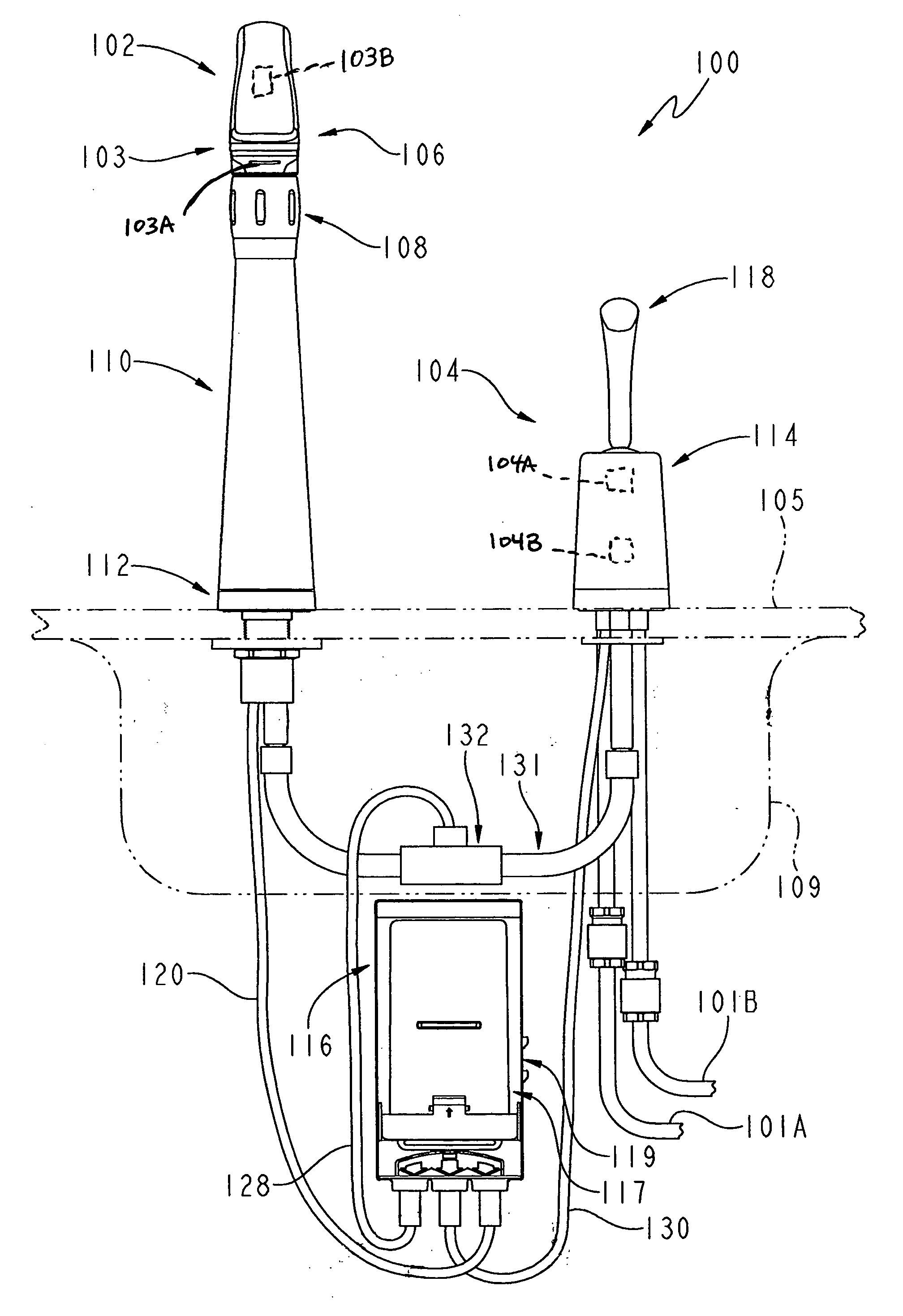

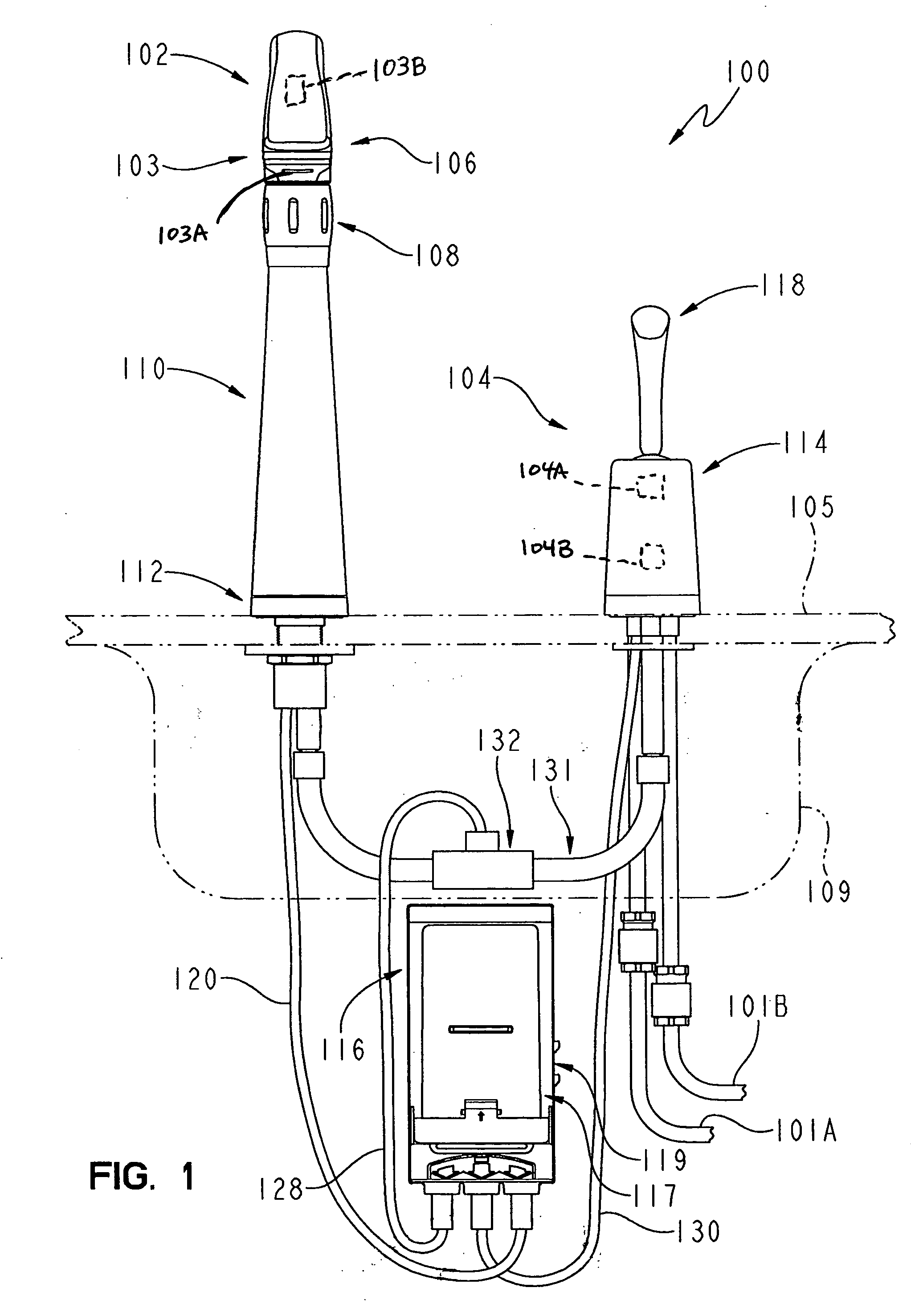

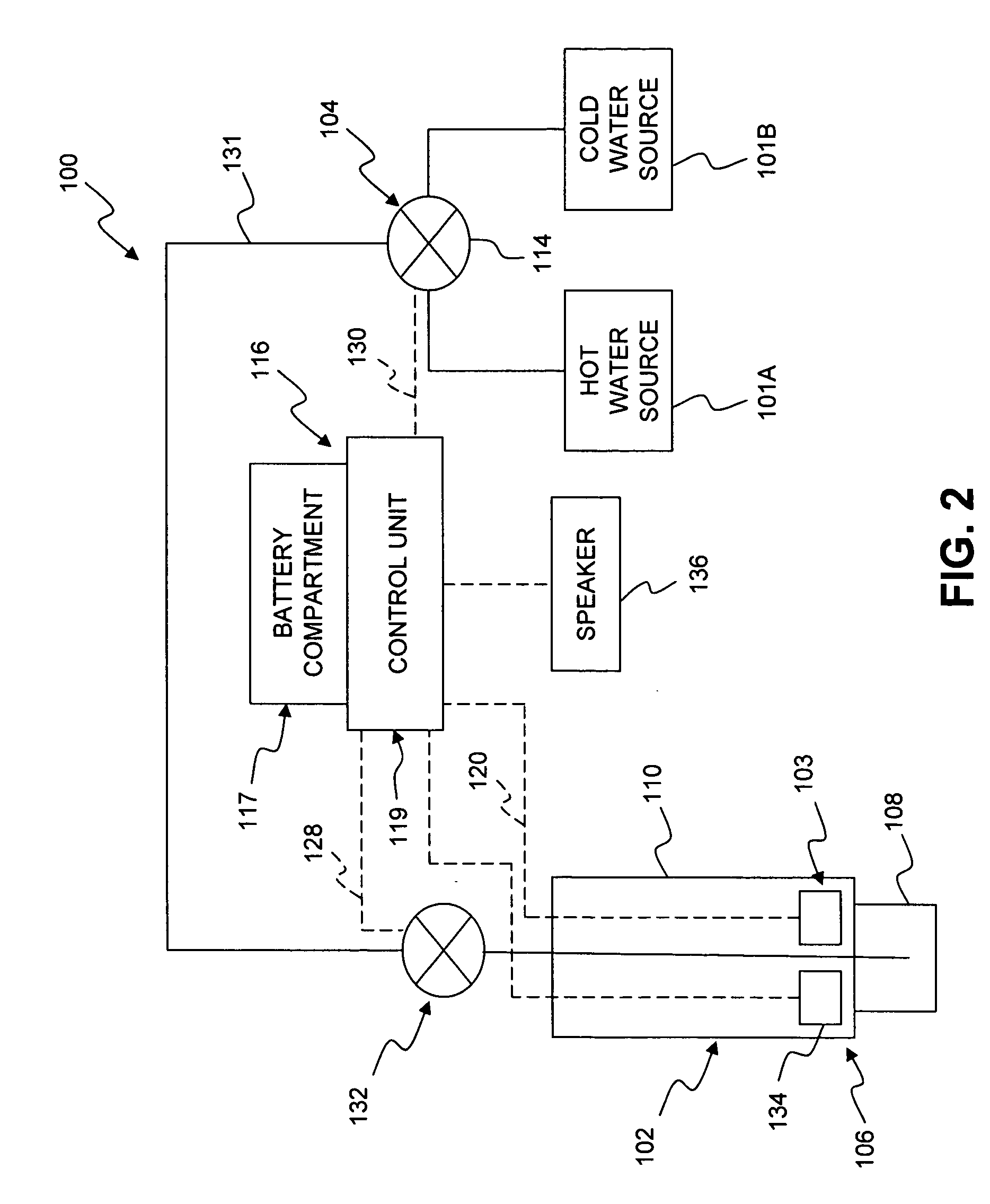

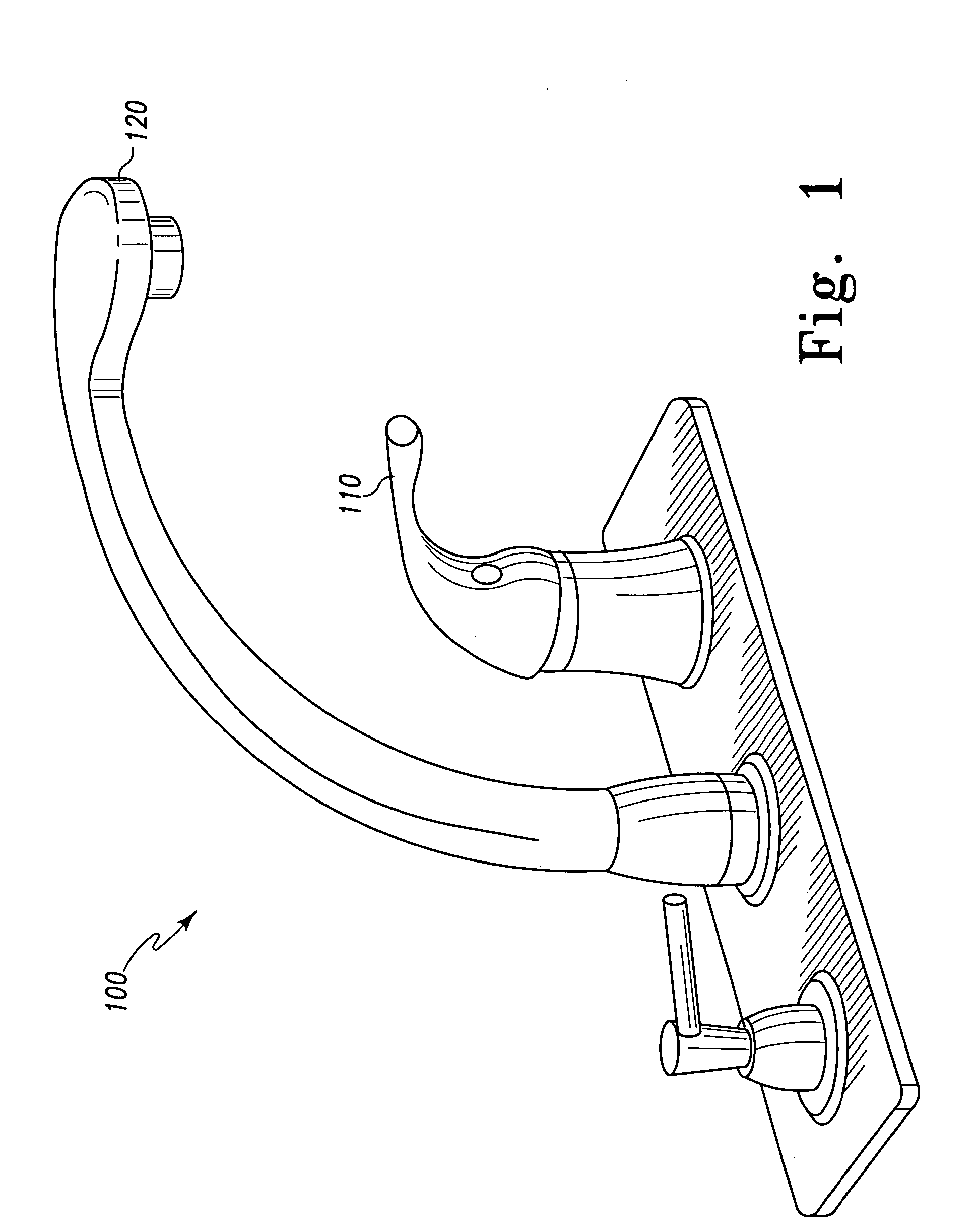

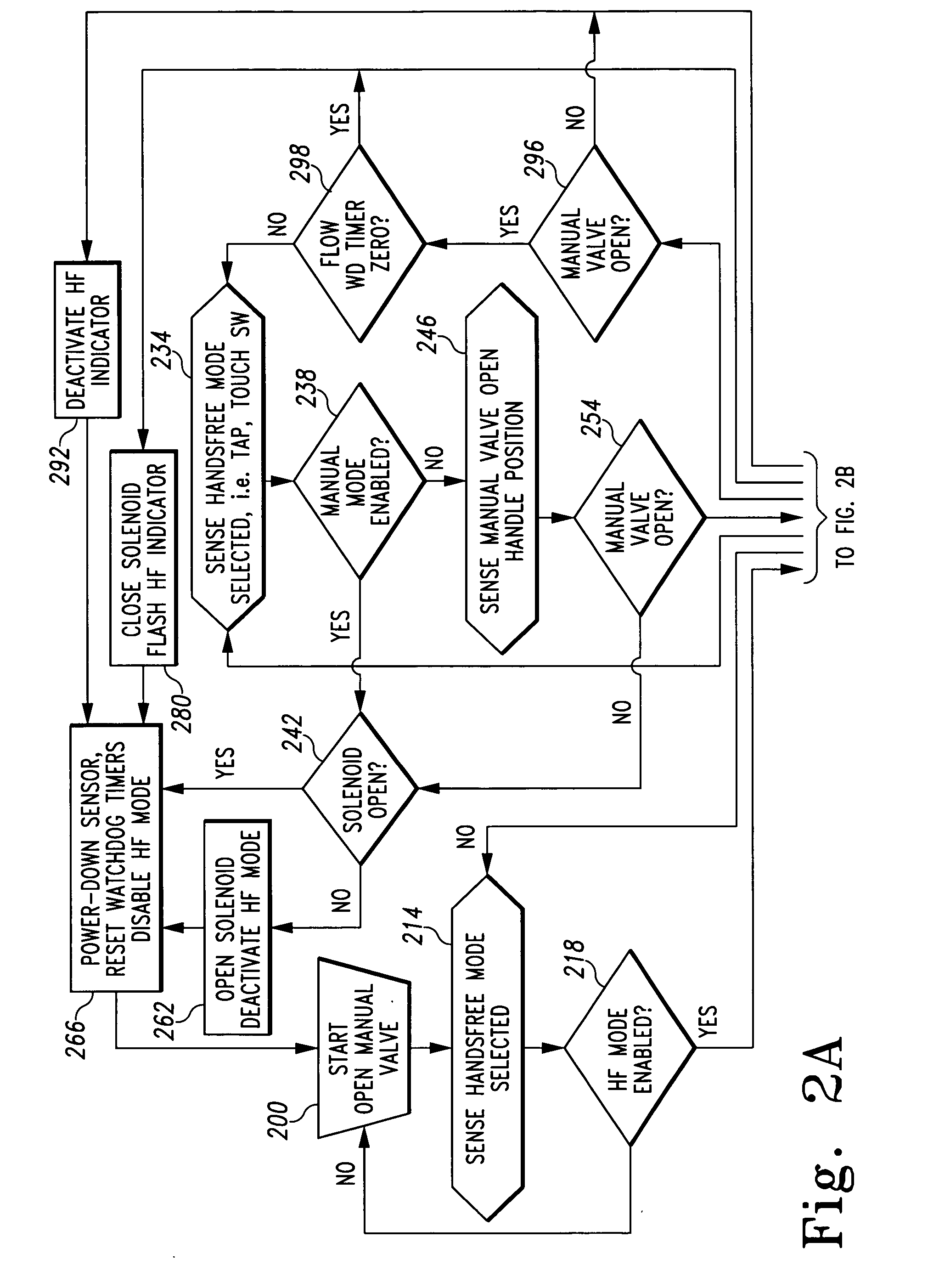

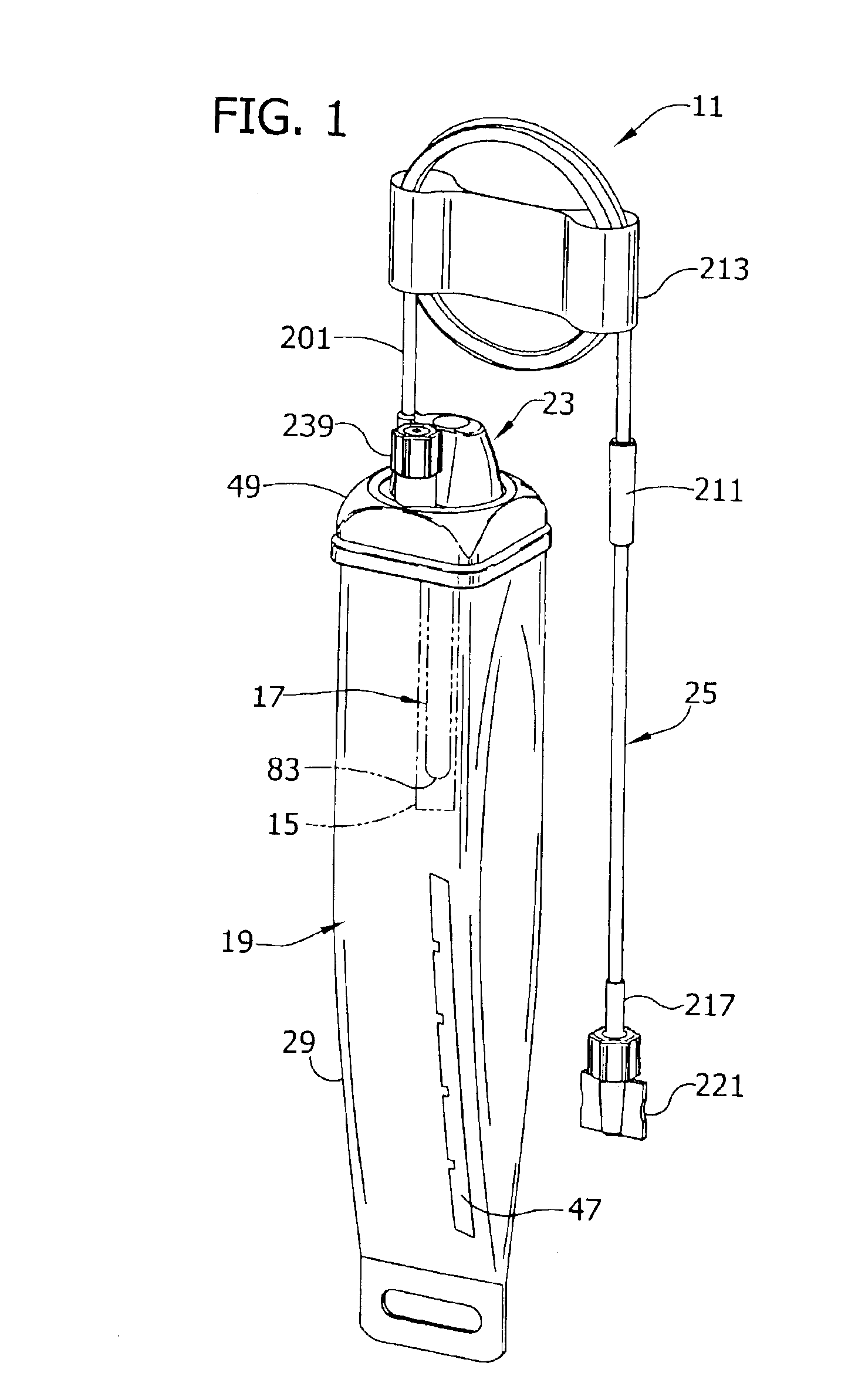

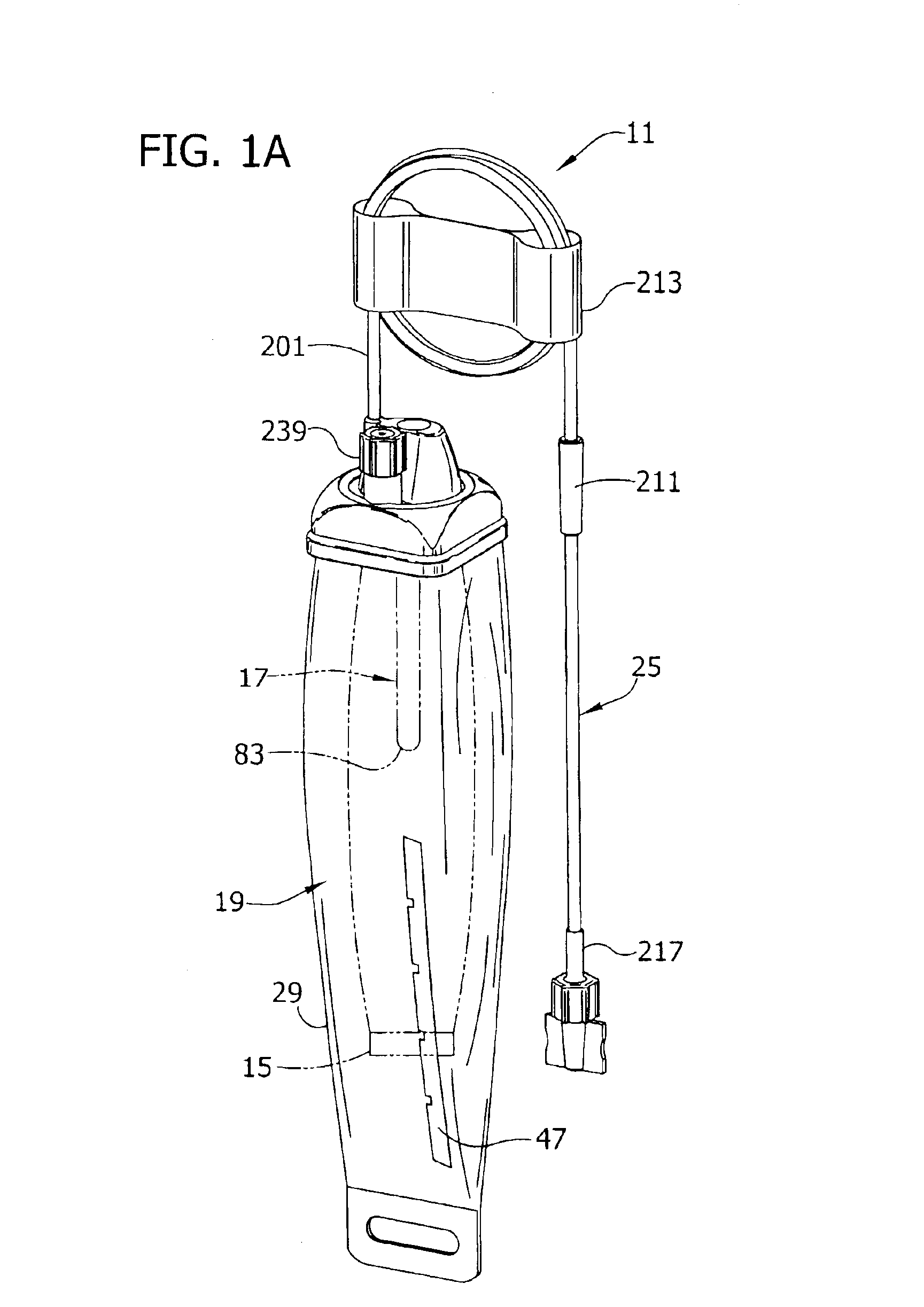

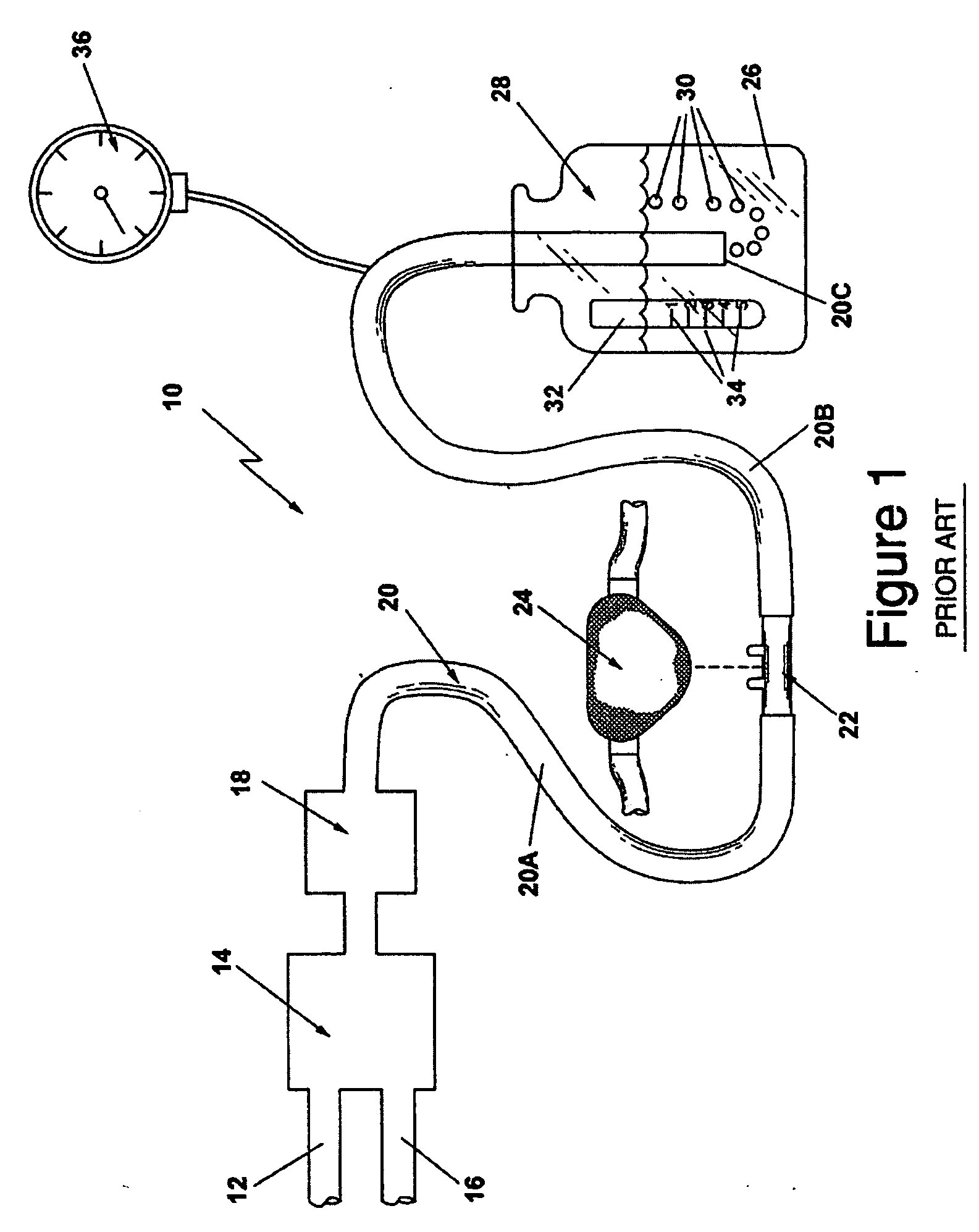

Multi-mode hands free automatic faucet

ActiveUS7690395B2Operating means/releasing devices for valvesFlow control using electric meansProximity sensorEngineering

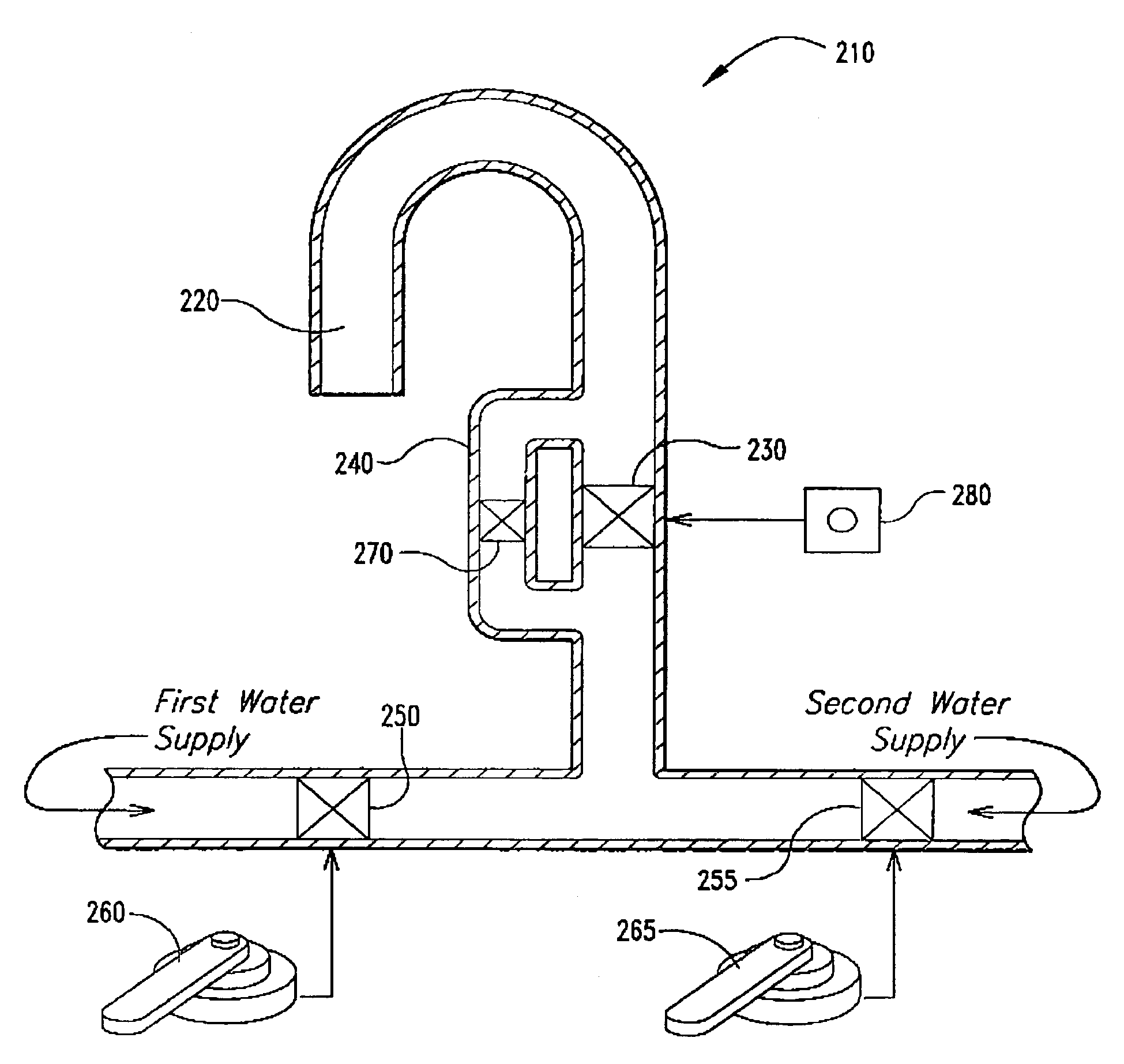

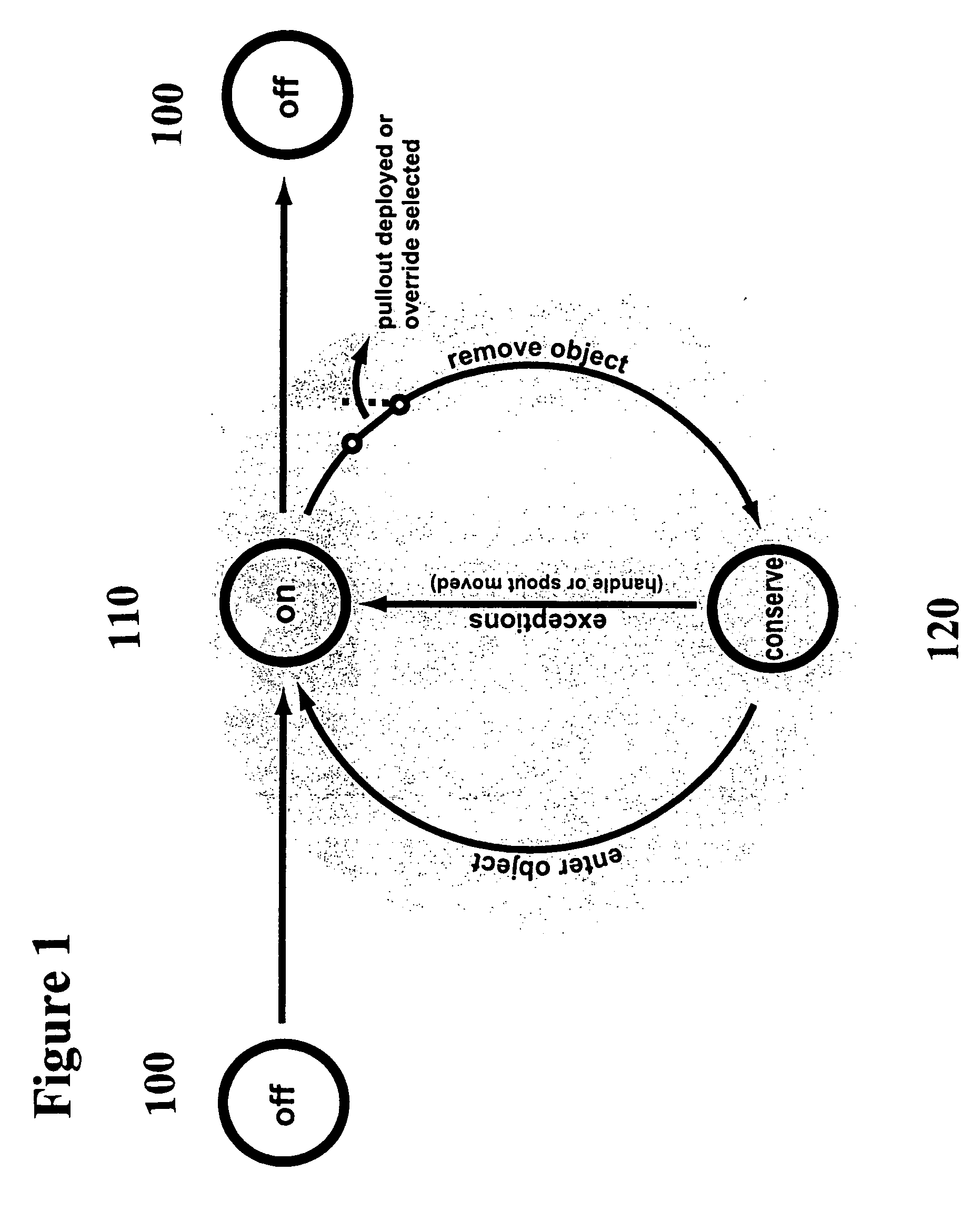

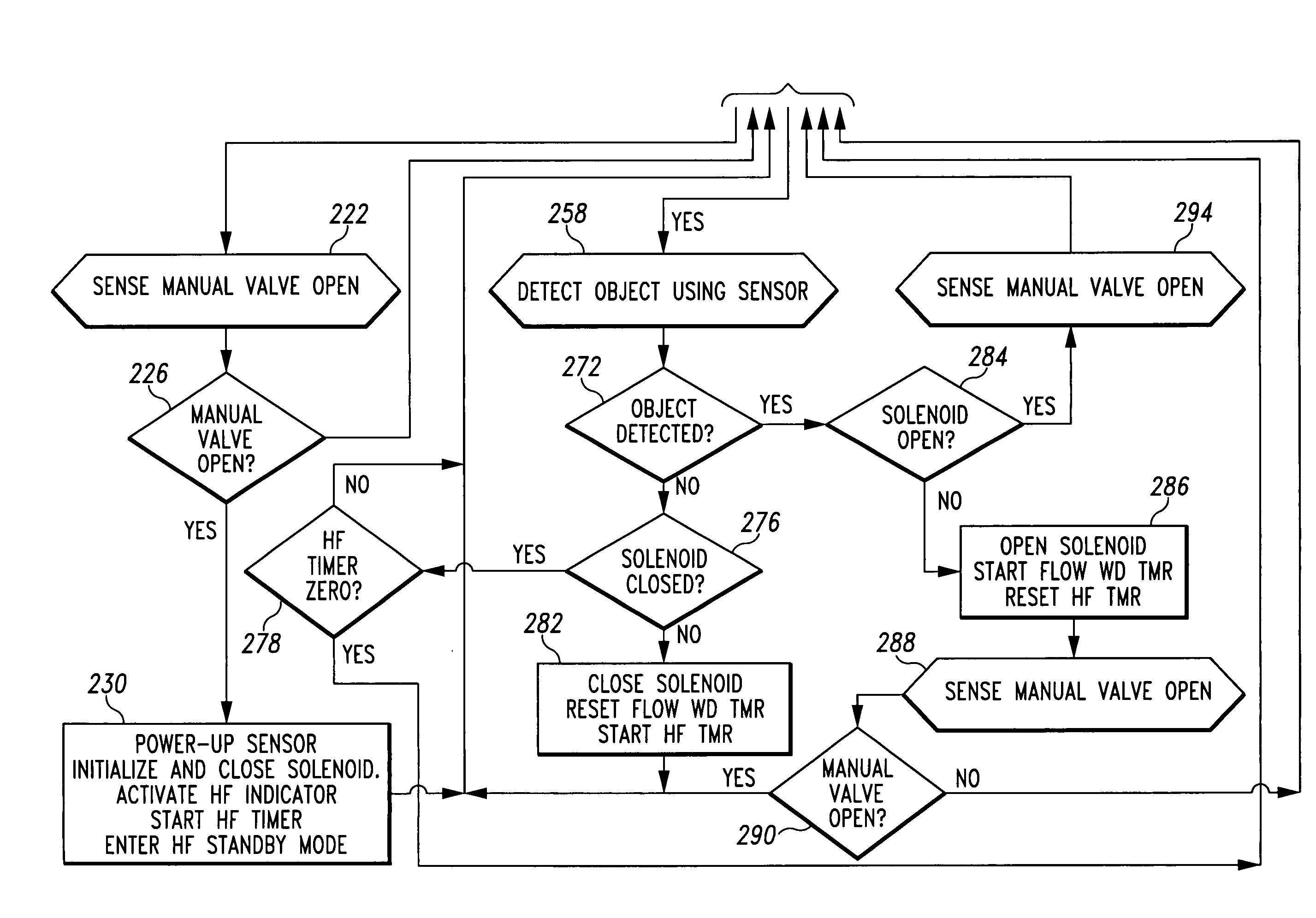

A hands-free faucet comprises a proximity sensor, a logical control, a handle, a spout, and a touch control operably coupled to at least one of the spout and the handle.

Owner:DELTA FAUCET COMPANY

Multi-mode hands free automatic faucet

ActiveUS7150293B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

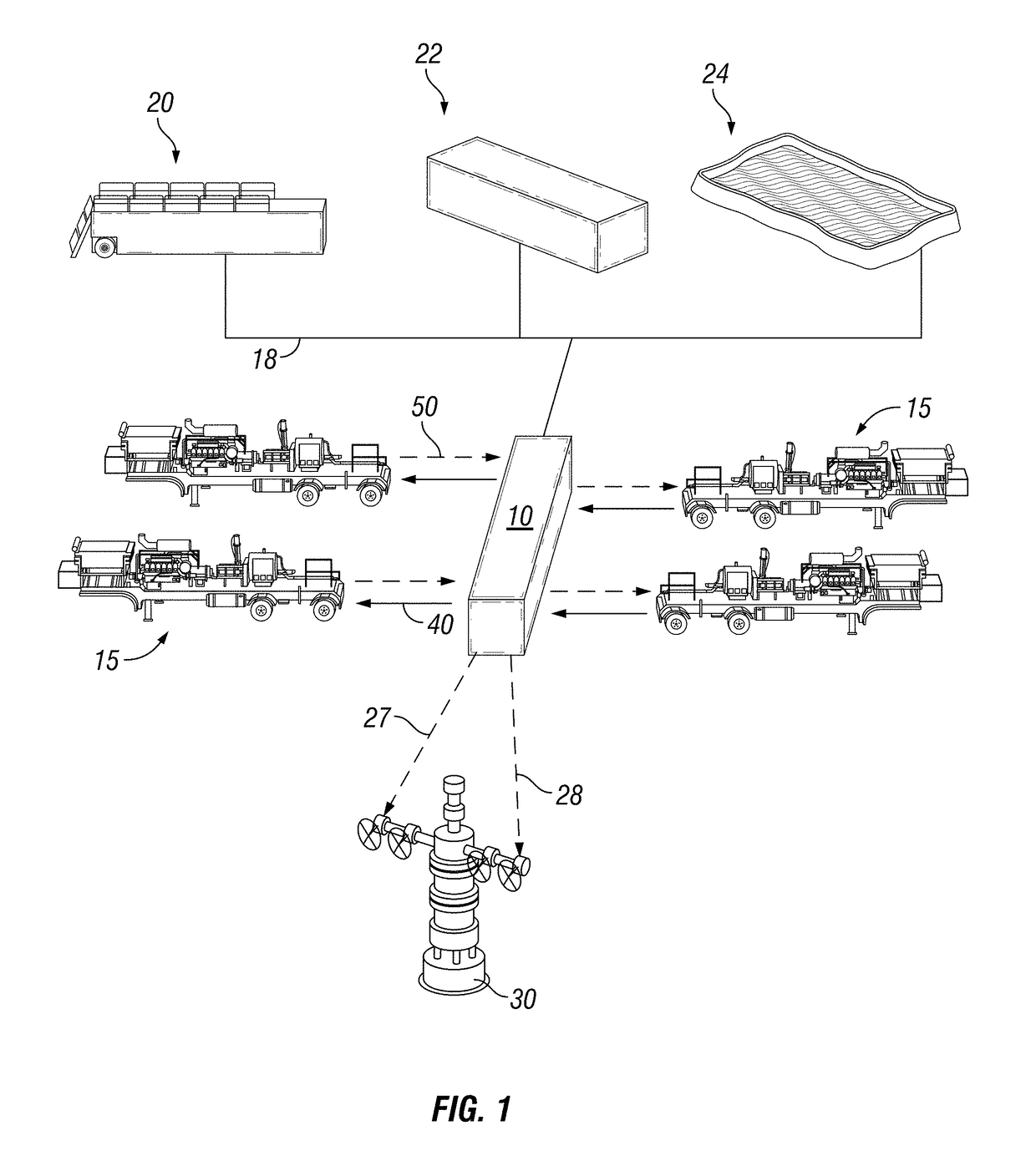

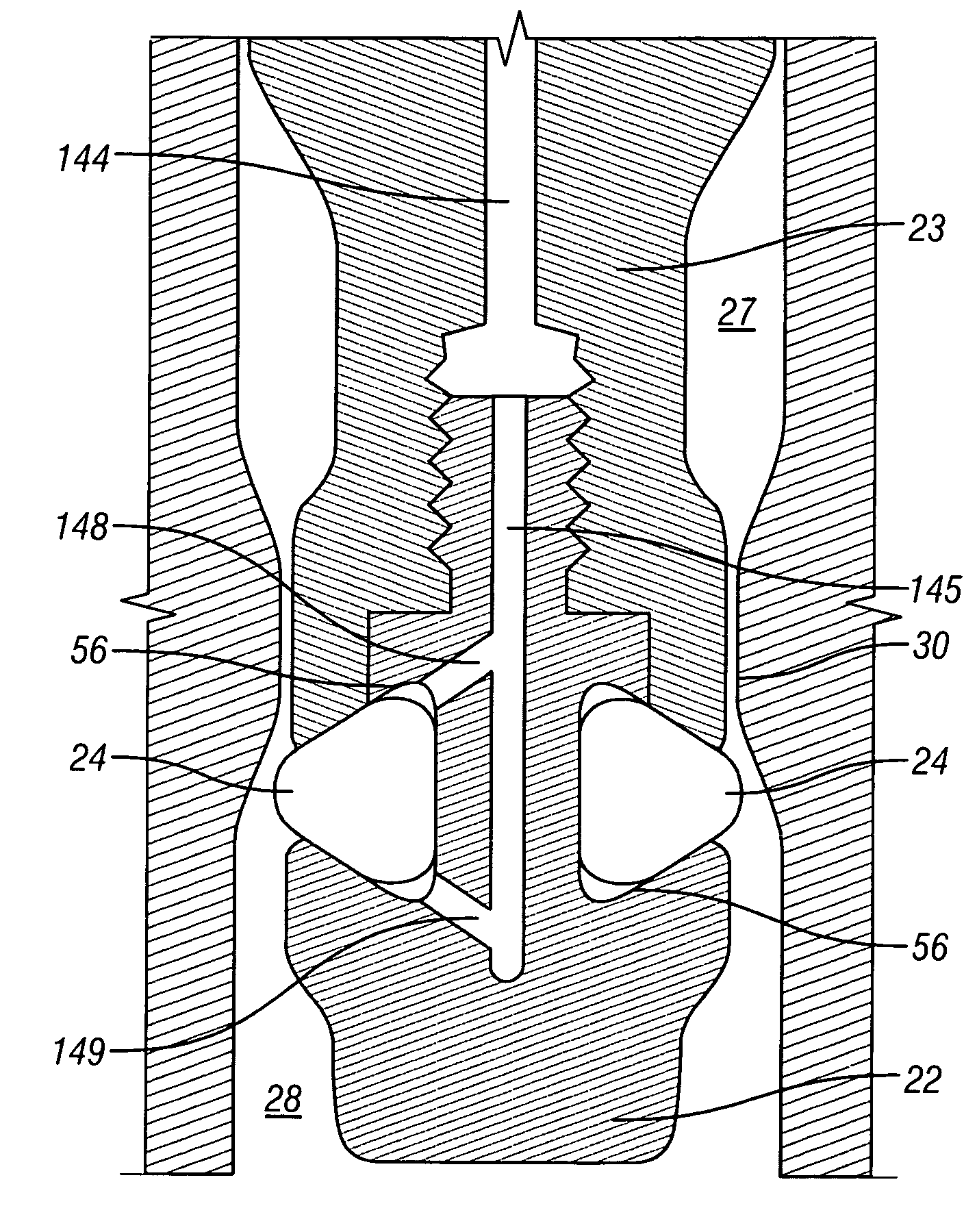

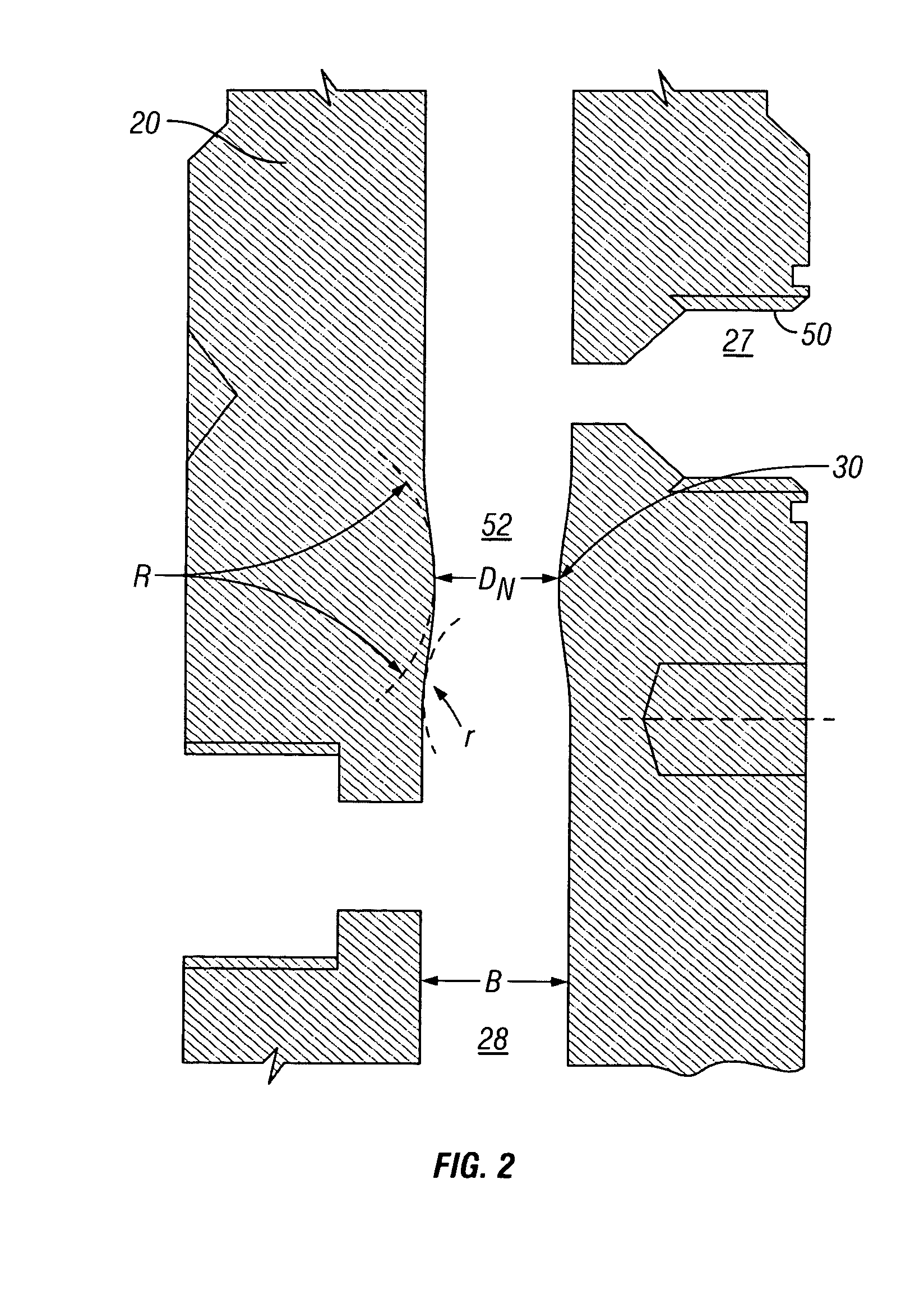

High pressure manifold, assembly, system and method

The present application is directed to a manifold system for low pressure and high pressure fluids. The manifold system may include one or more manifold sub-assemblies that may be assembled together, separated apart and replaced as desired. In oil and gas hydraulic fracturing operations, each manifold sub-assembly includes two or more low pressure fluid lines and two or more high pressure fluid lines for fluidly communicating with hydraulic fracturing pumps. High pressure fluid may exit the manifold system via a single line or multiple lines.

Owner:MGB OILFIELD SOLUTIONS LLC

Multi-mode hands free automatic faucet

ActiveUS20070157978A1Without impactOperating means/releasing devices for valvesDomestic plumbingProximity sensorEngineering

A hands-free faucet comprises a proximity sensor, a logical control, a handle, a spout, and a touch control operably coupled to at least one of the spout and the handle.

Owner:DELTA FAUCET COMPANY

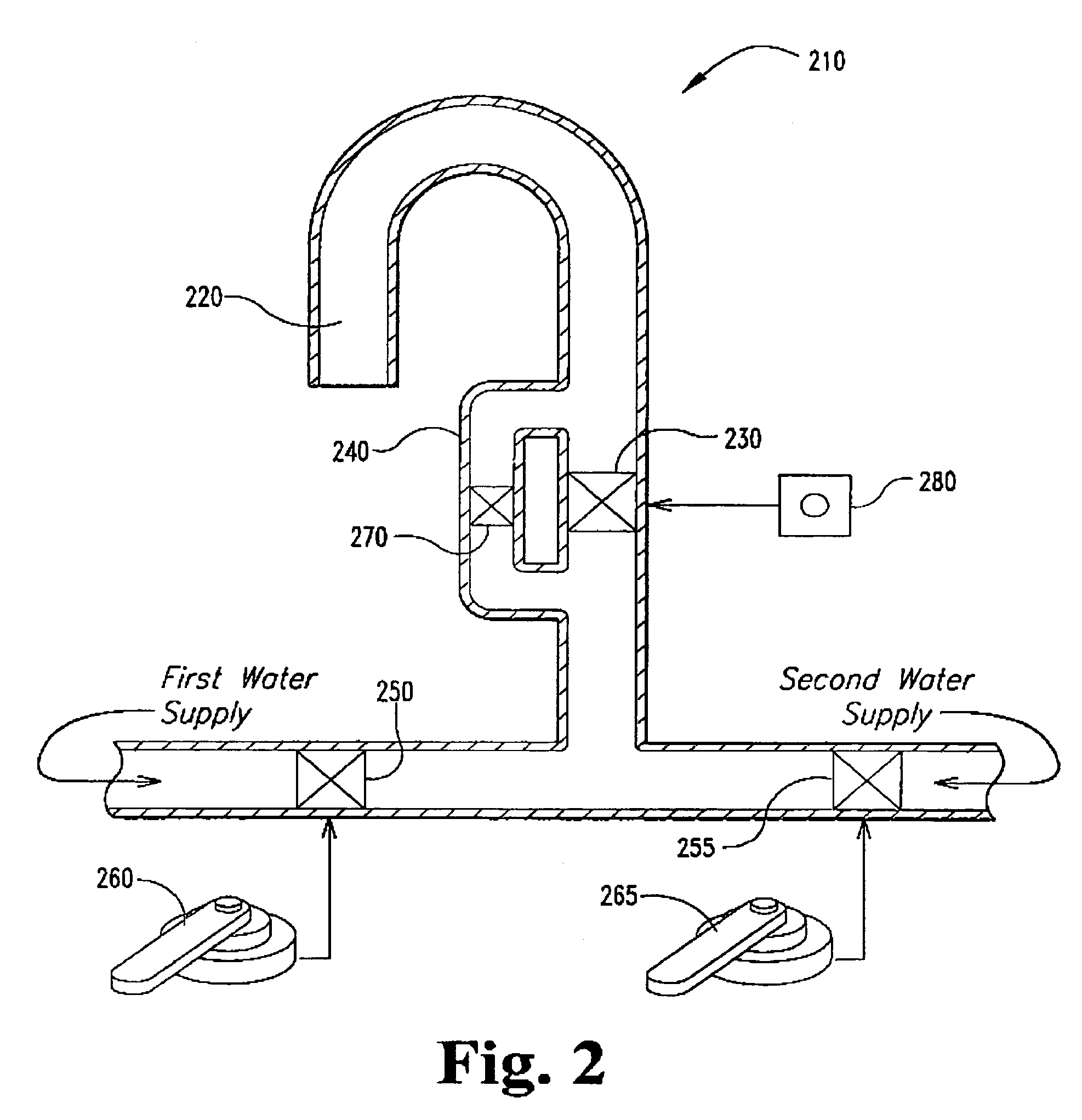

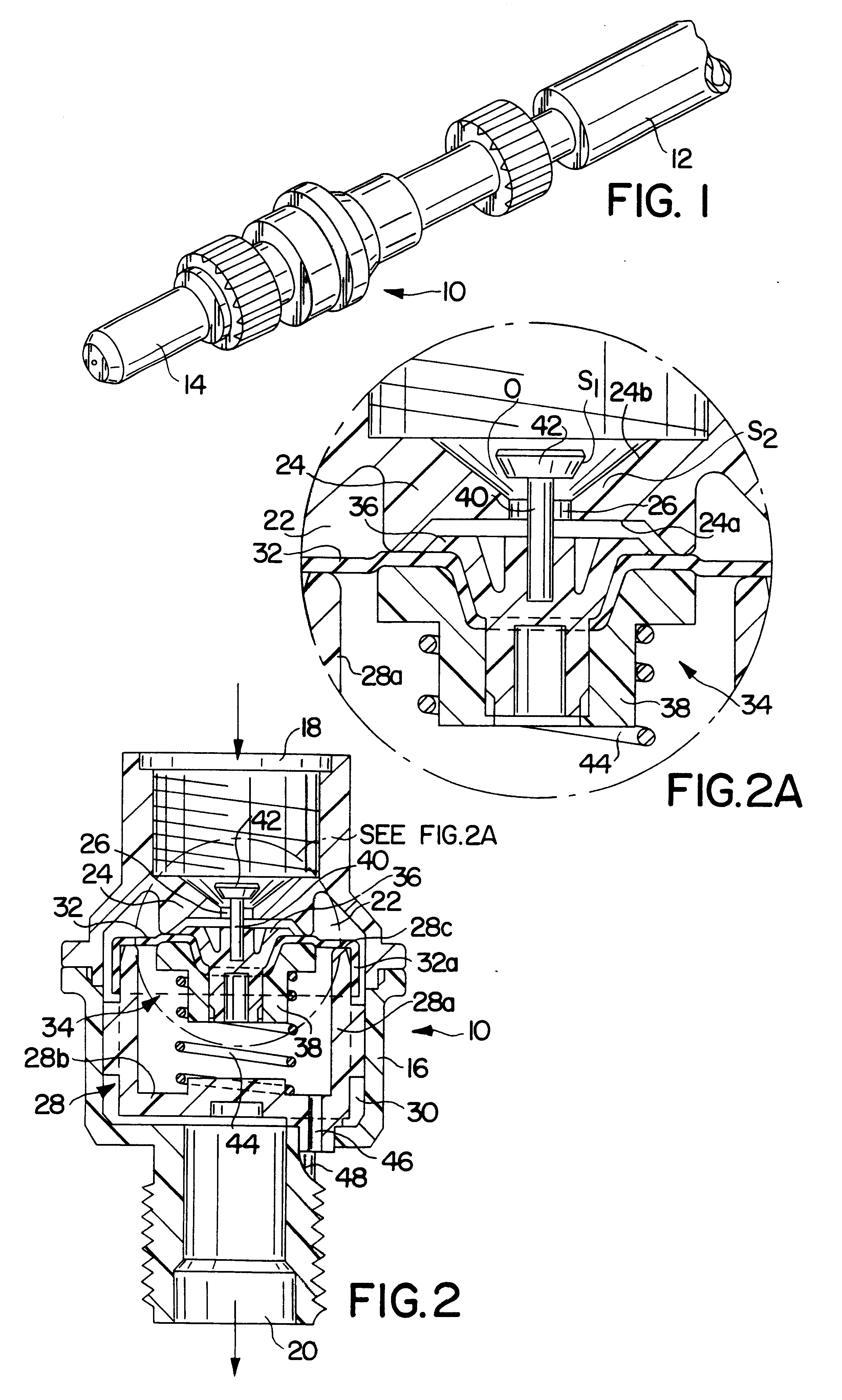

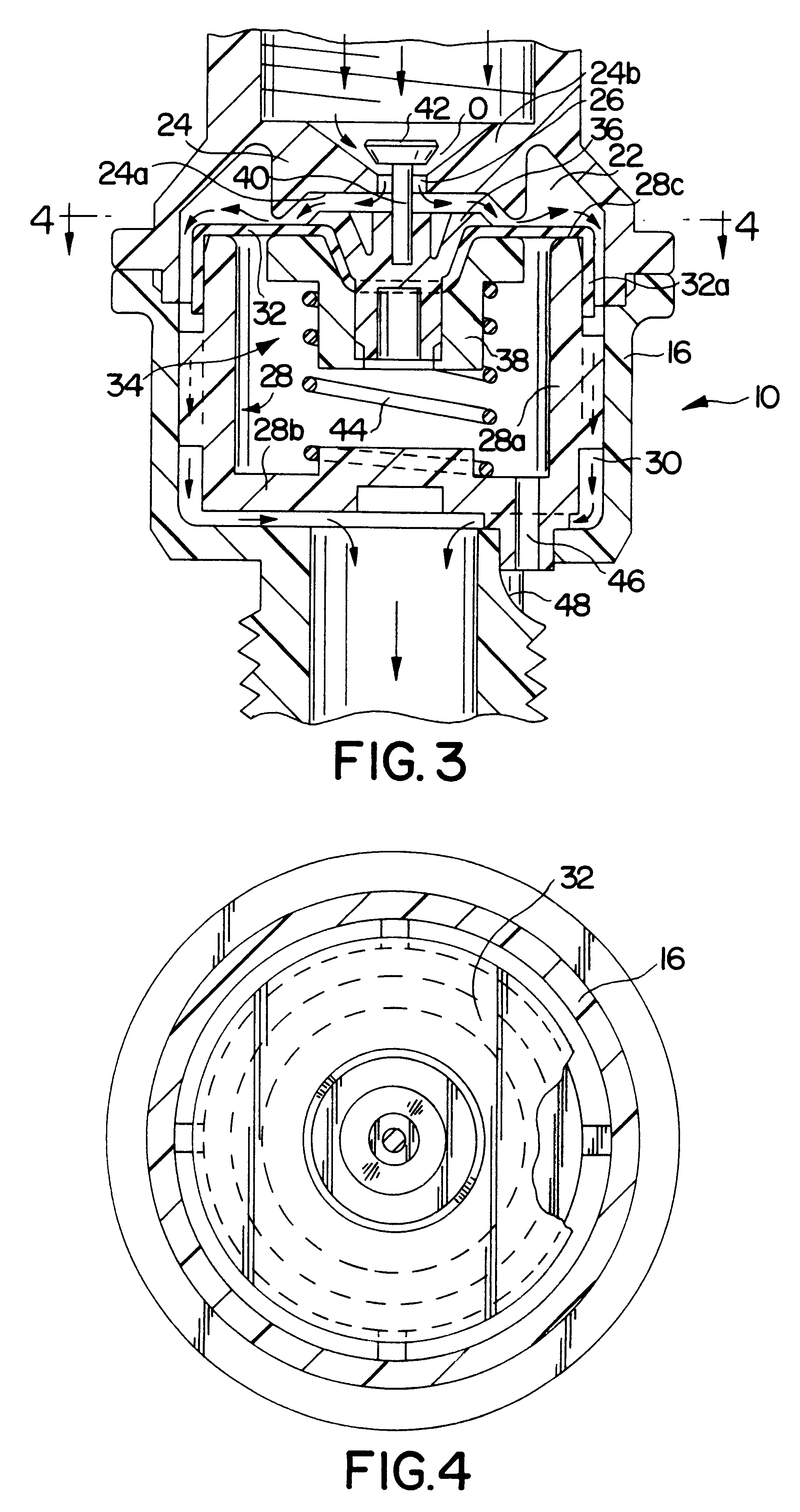

Restricted flow hands-free faucet

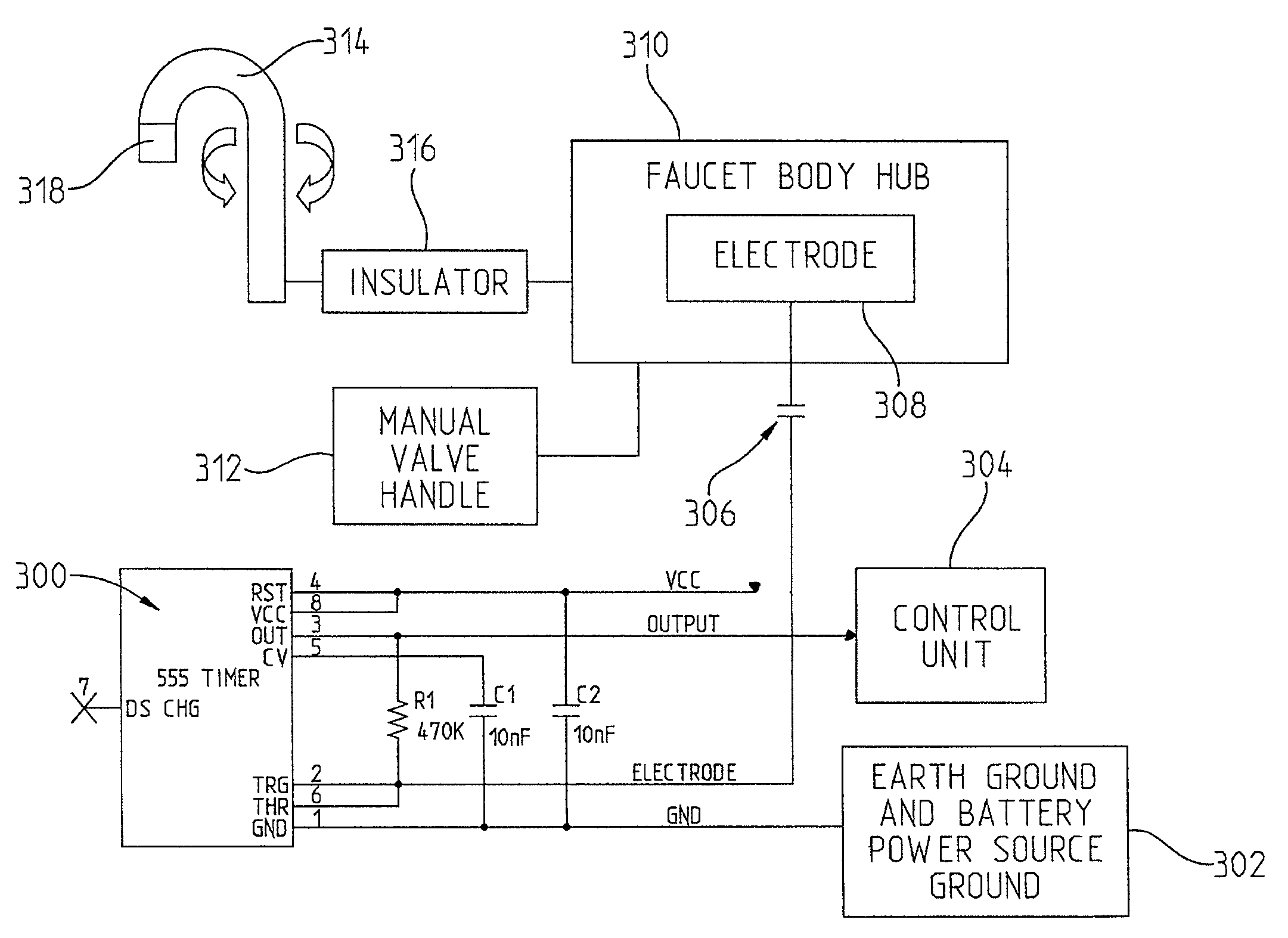

ActiveUS6968860B1Operating means/releasing devices for valvesServomotor componentsElectricityWater flow

A faucet comprising a spout, a passageway, an electrically operable valve; a first manual valve; a first manual handle; and a bypass. The passageway conducts water flow through the spout. The electrically operable valve is disposed within the passageway. The first manual valve disposed within the passageway in series with the electrically operable valve. The first manual handle that controls the first manual valve. The bypass has a first end above the electrically operable valve, relative to the water flow, and a second end below the electrically operable valve, such that a portion of the water flow bypasses the electrically operable valve.

Owner:DELTA FAUCET COMPANY

Multi-mode hands free automatic faucet

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

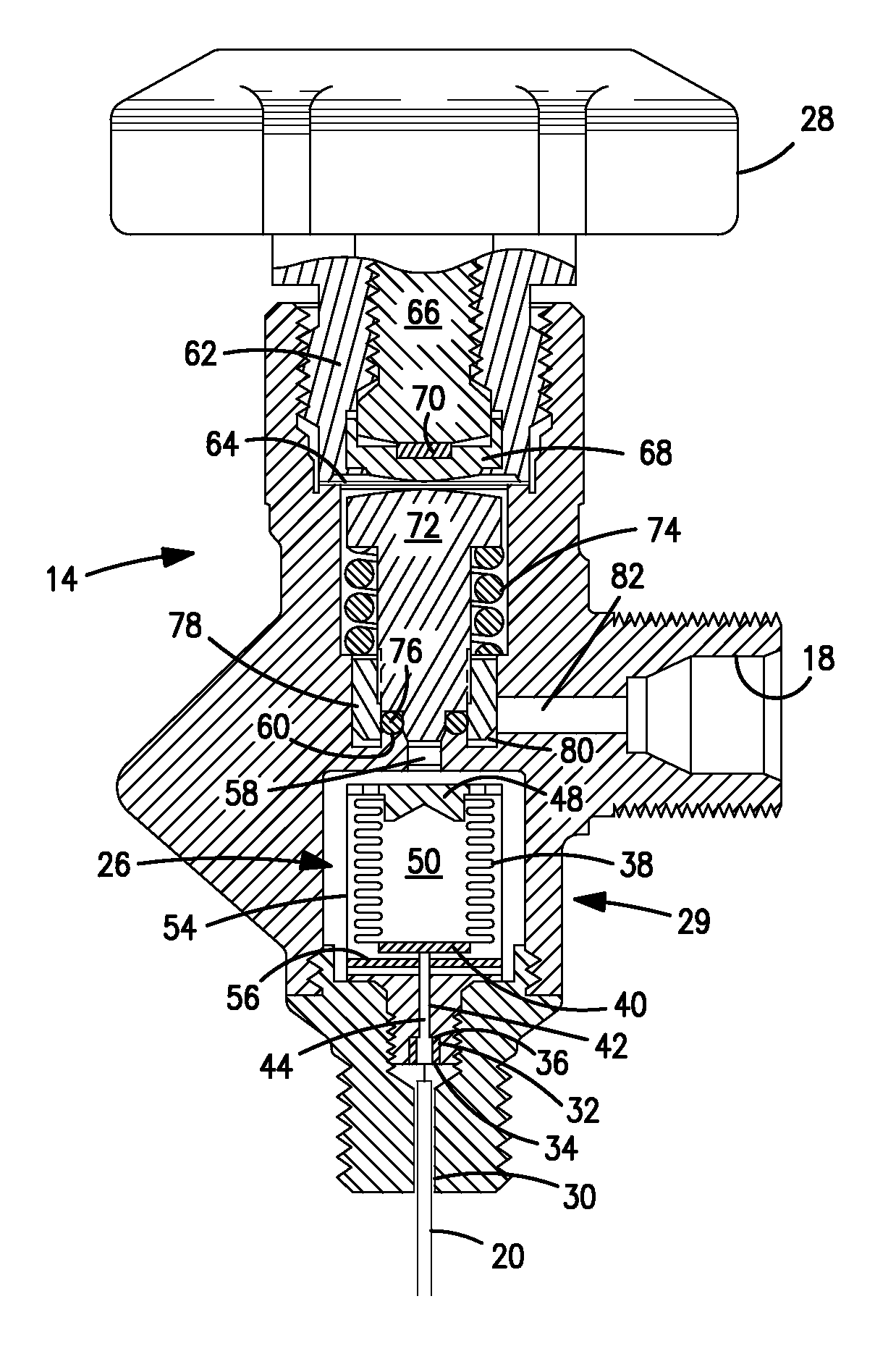

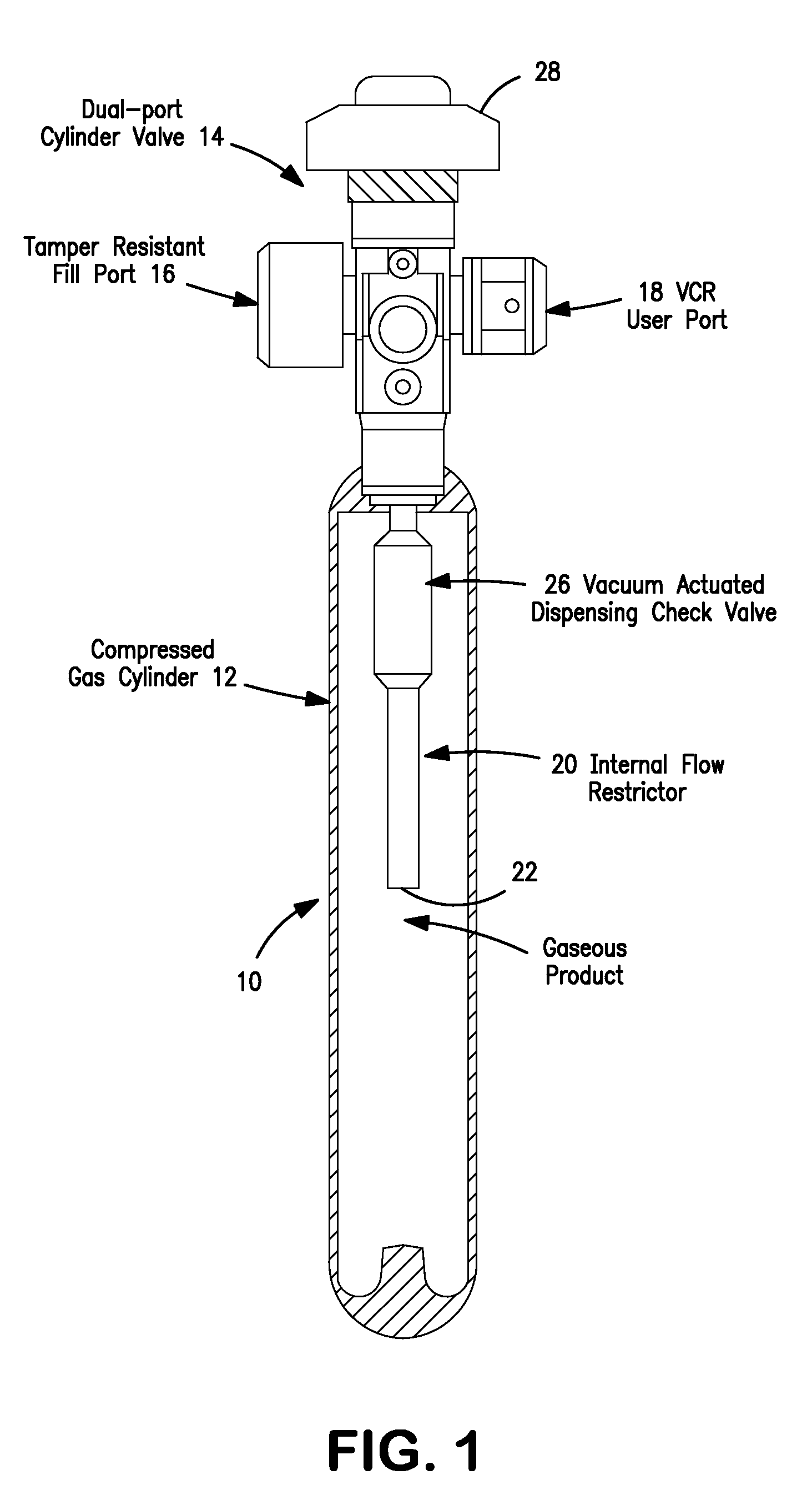

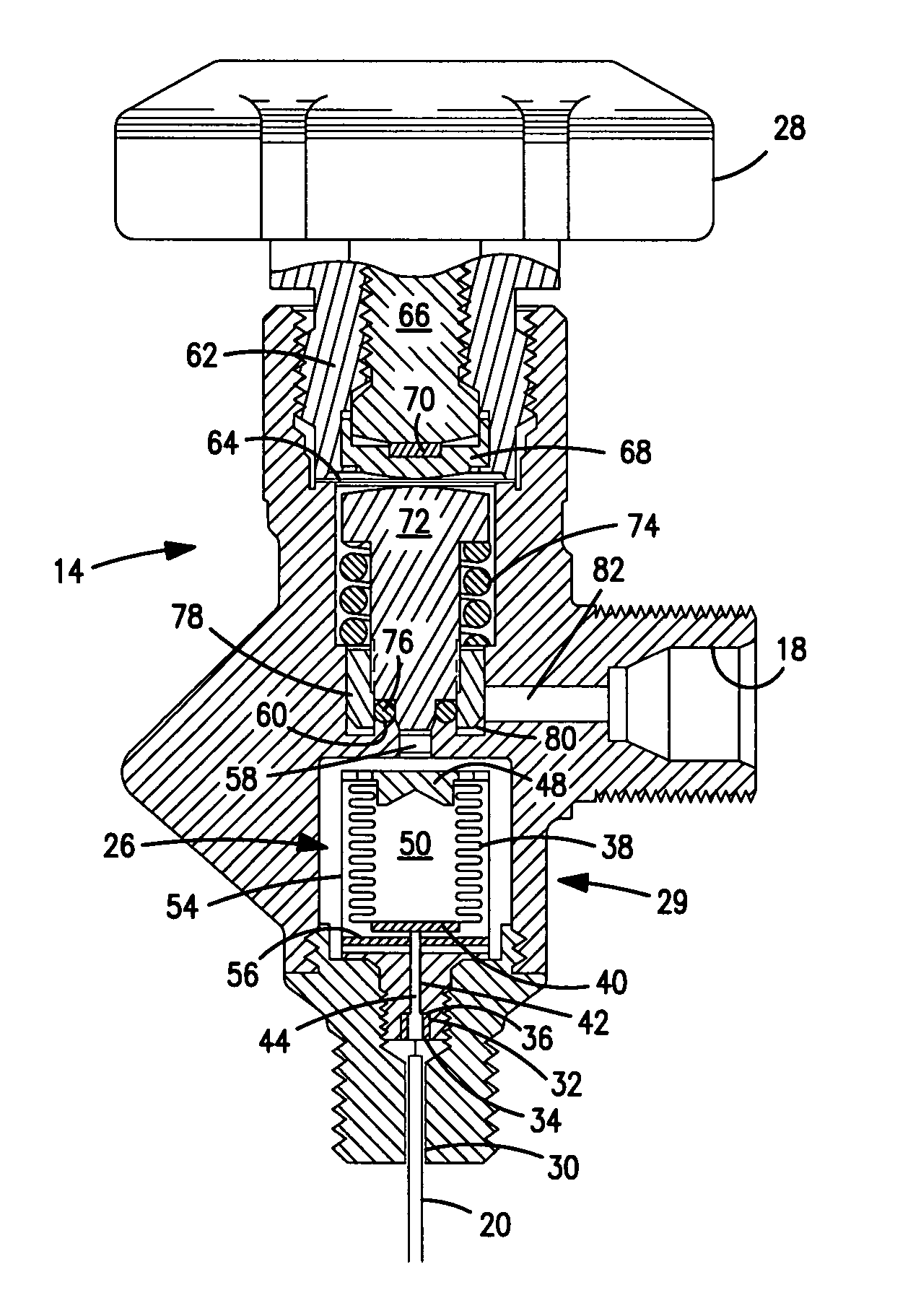

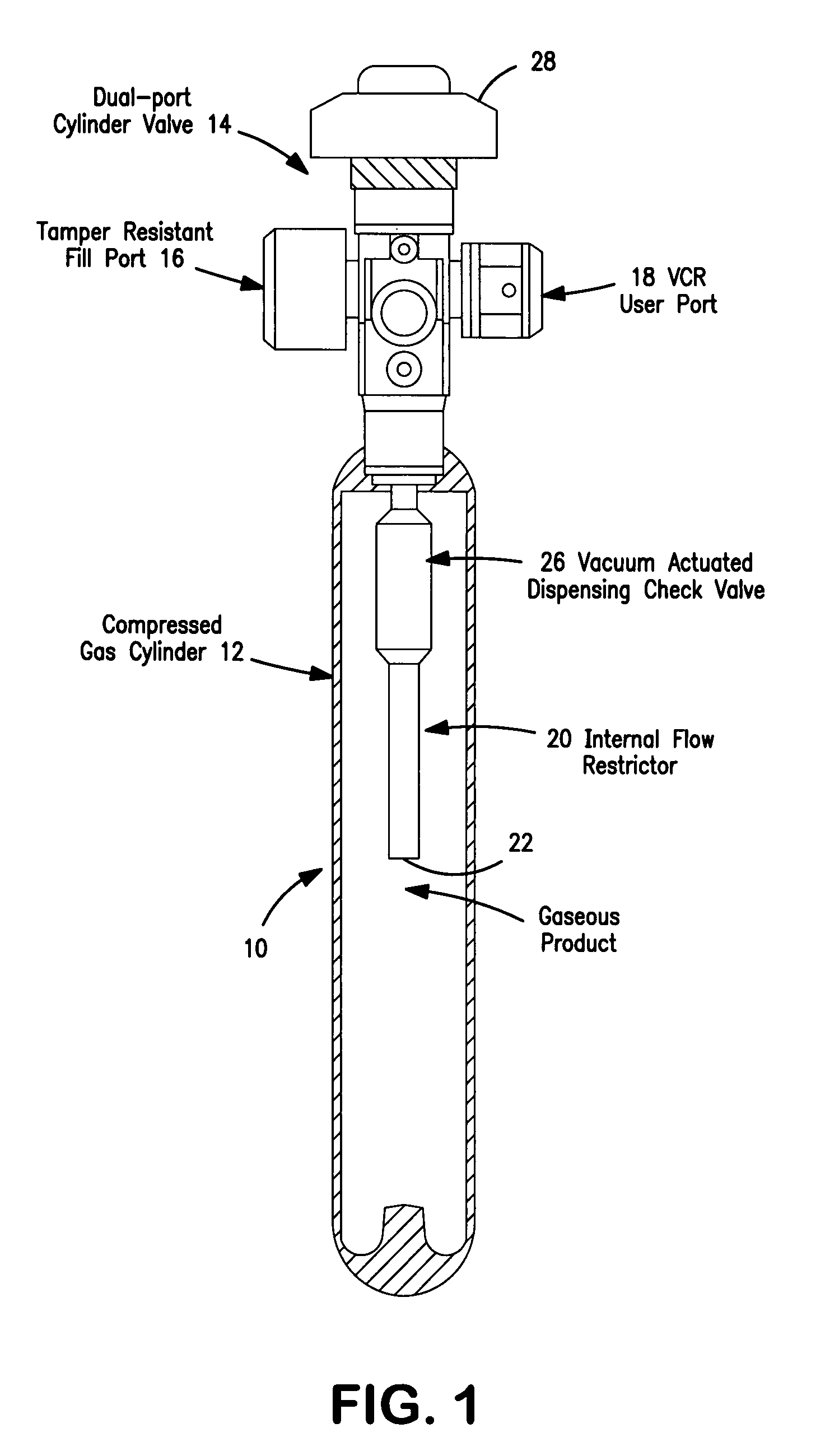

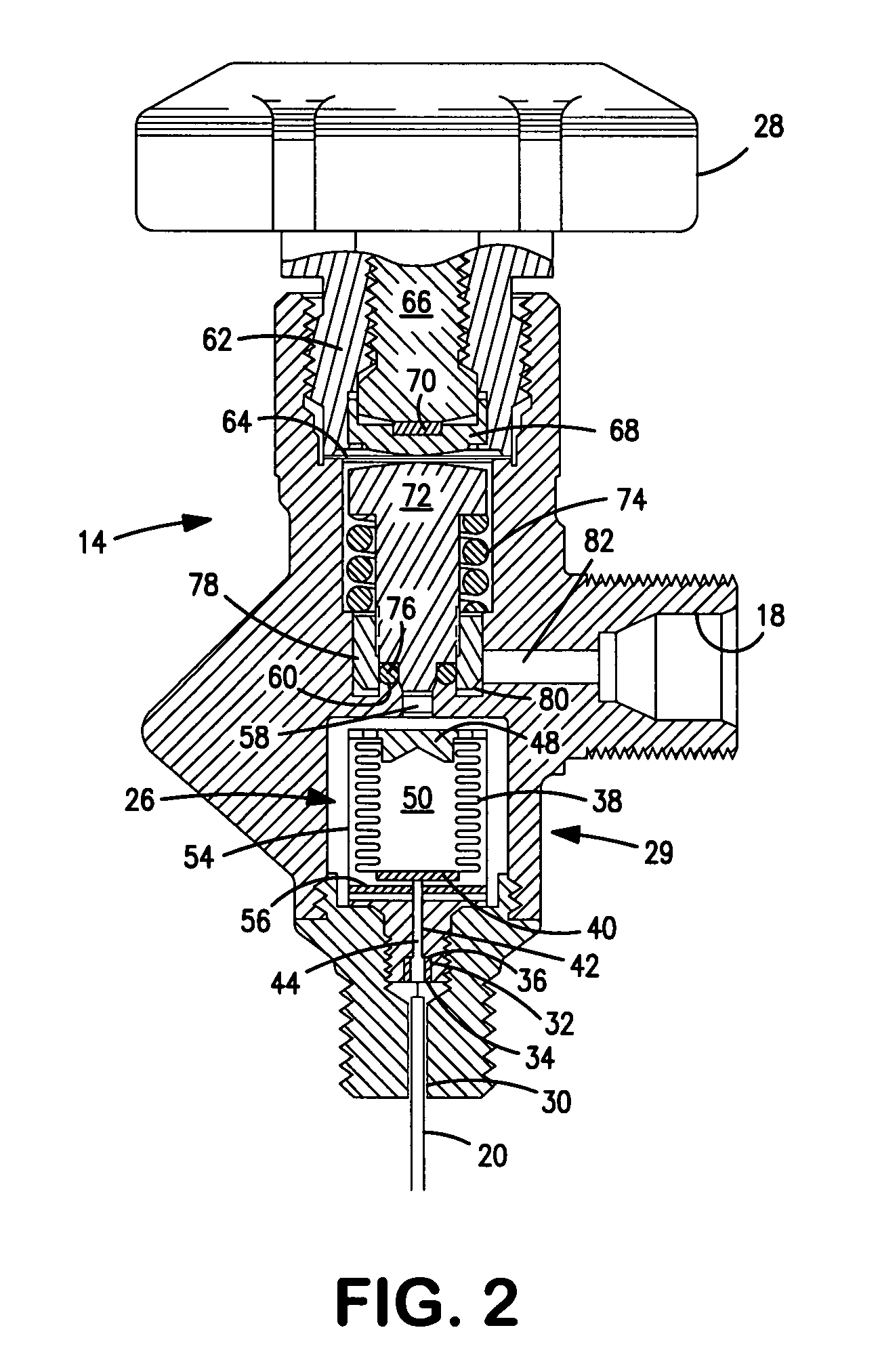

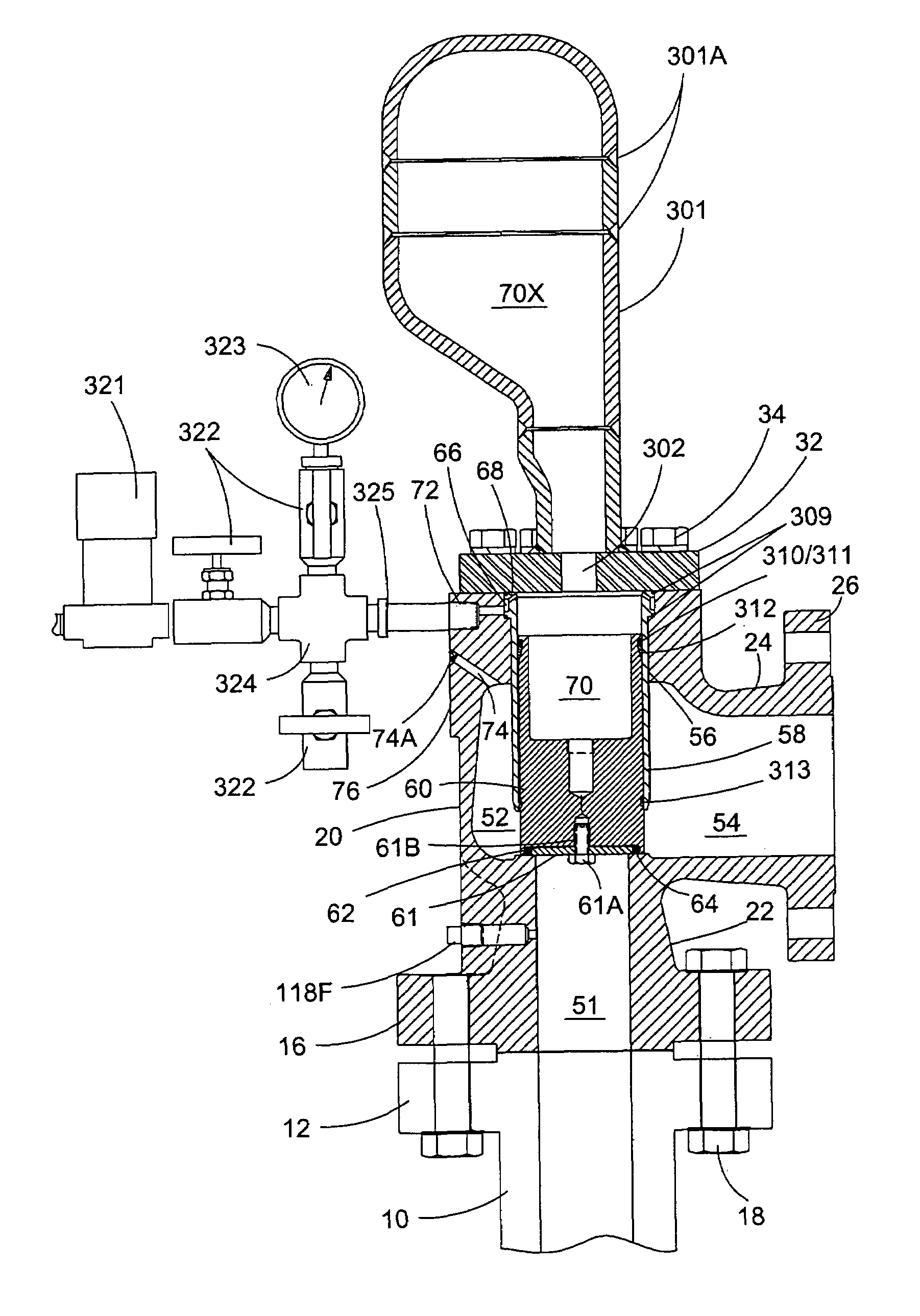

Vacuum actuated valve for high capacity storage and delivery systems

The invention relates to a re-configured valve design to accommodate a high volume of product in the delivery system and the dispensation of product upon the application of a predetermined vacuum condition on the downstream side of the valve.

Owner:PRAXAIR TECH INC

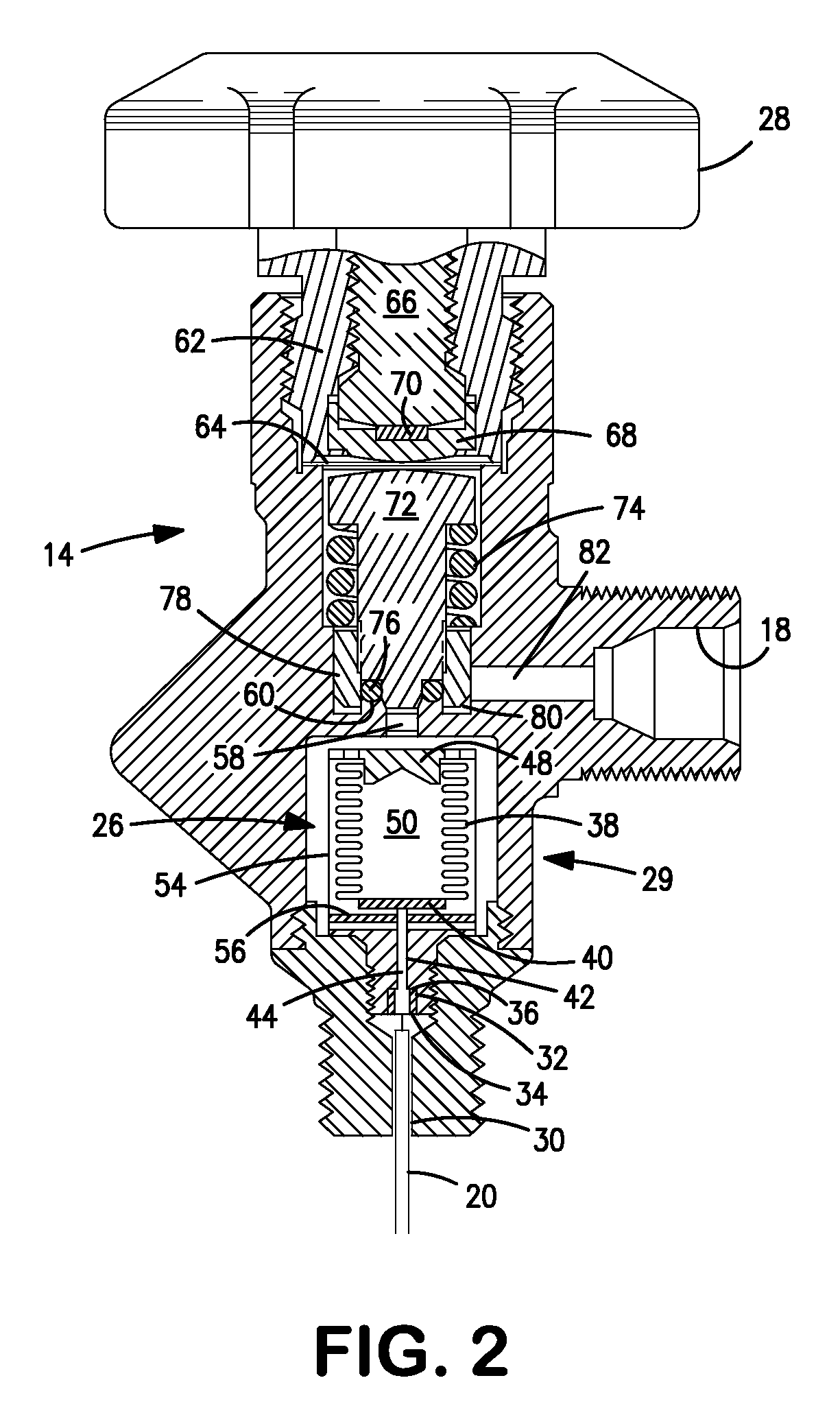

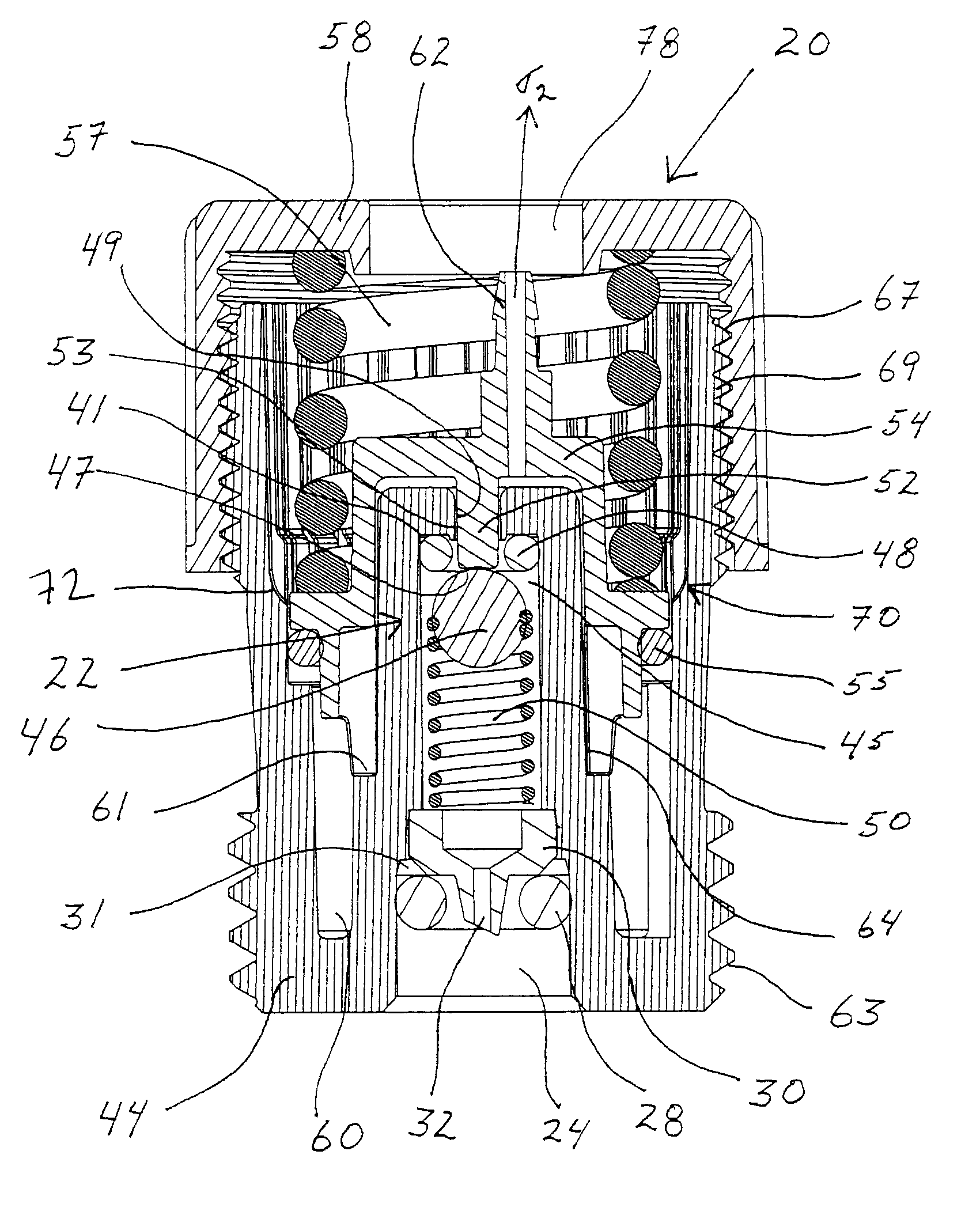

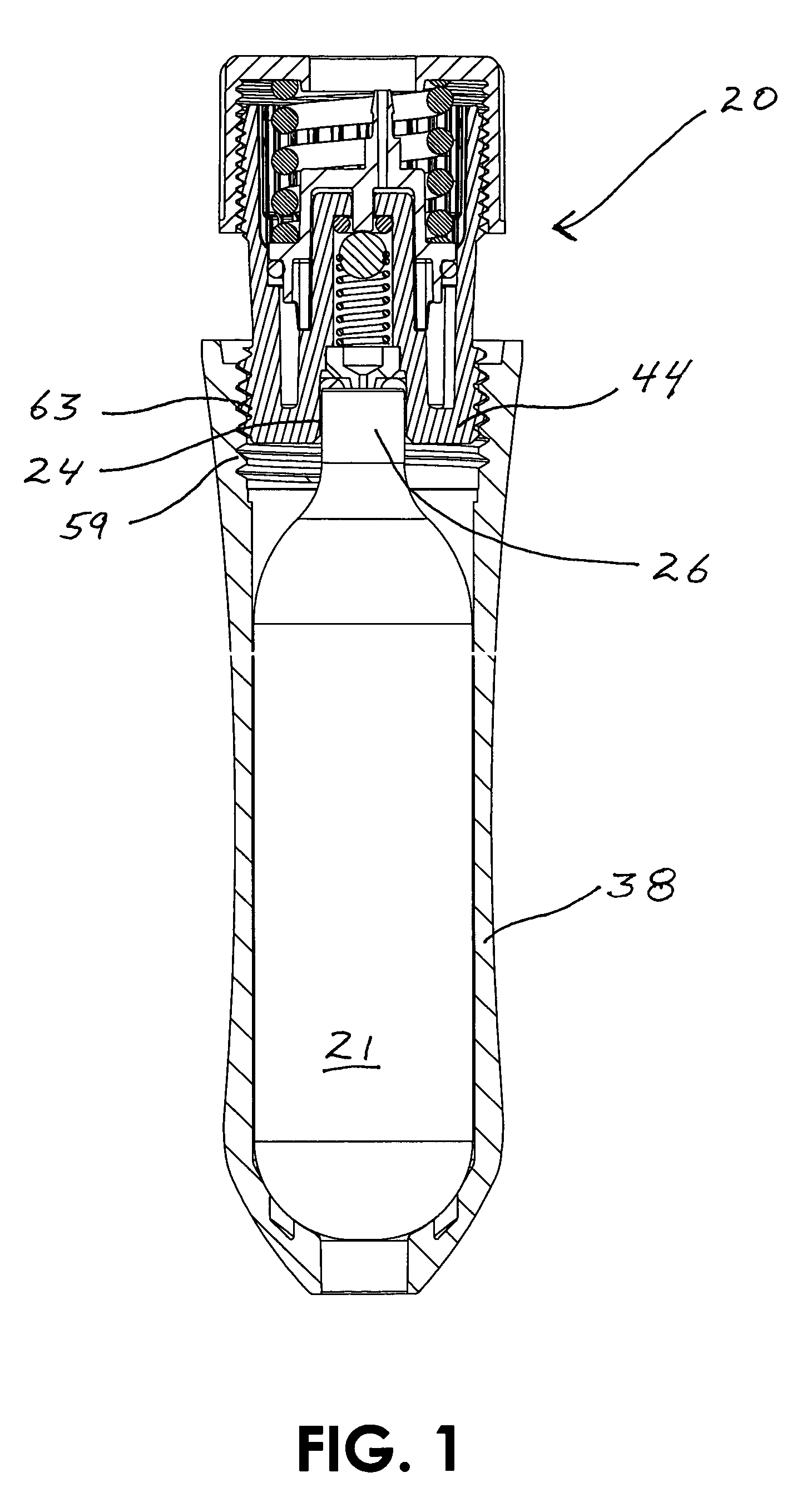

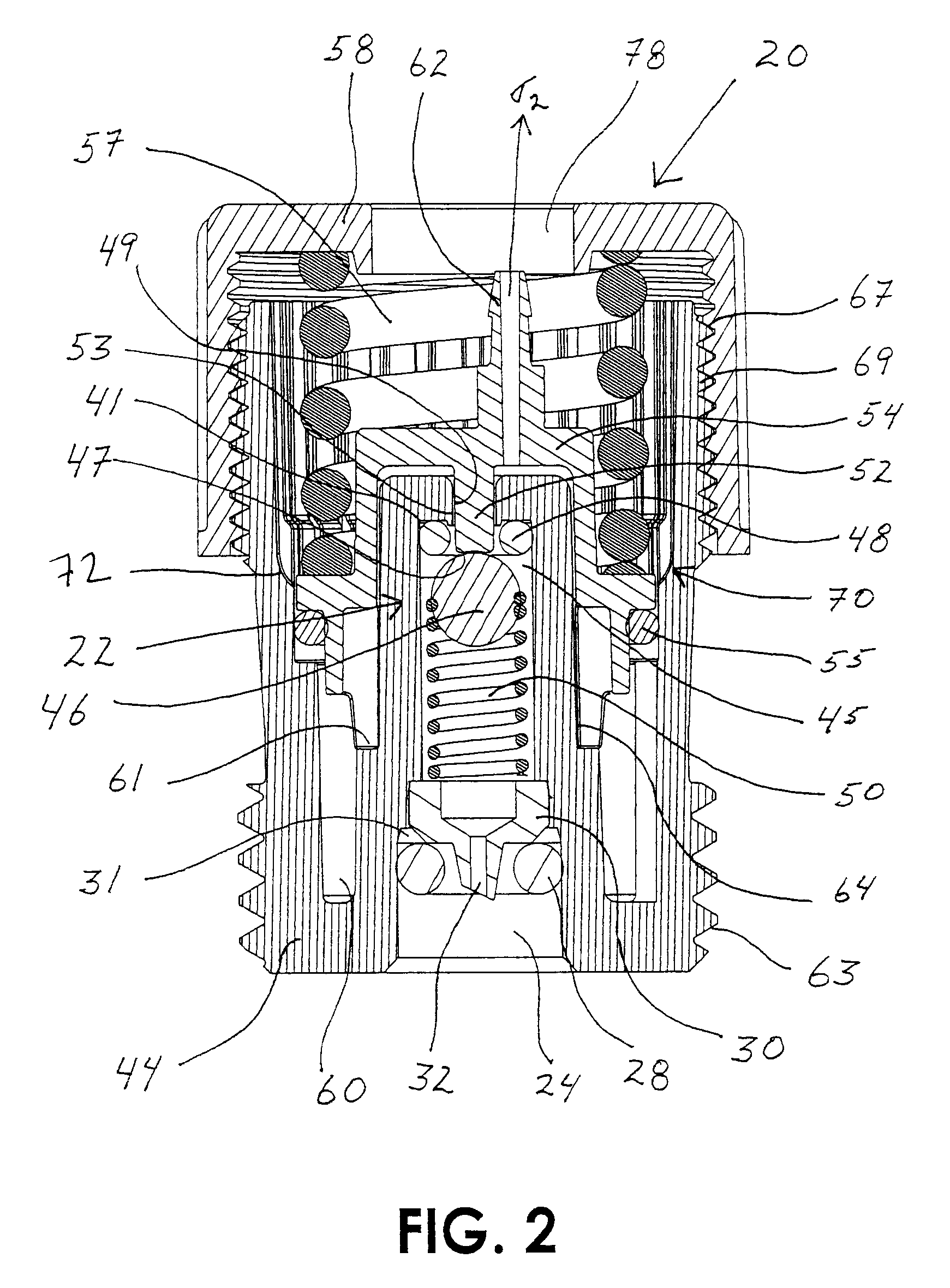

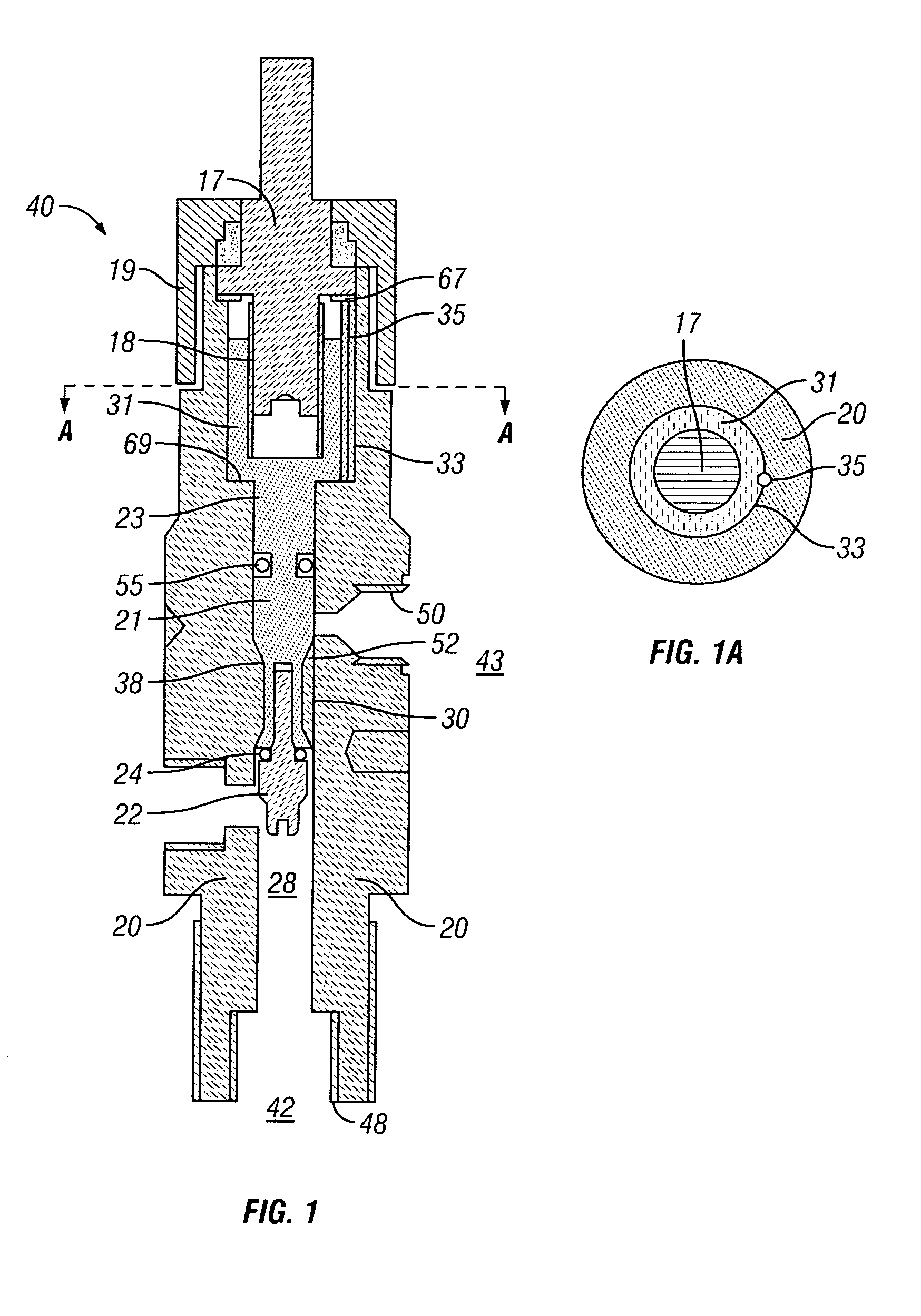

Pressure regulator adaptable to compressed gas cartridge

ActiveUS7334598B1Reduce manufacturing costImprove reliabilityContainer filling methodsGas handling applicationsEngineeringHigh pressure

This pressure regulator is specifically designed to operate with a portable compressed gas cartridge thus reducing the high vapor pressure found in compressed gas cartridges down to a substantially consistent outlet pressure. Due to the nature of the crowded regulator art, the soon to be embodied pressure regulator has been specifically embodied for use in the portable compressed gas cartridge harnessing art and this specific use is carried into the claims. Exemplified in the pressure regulator embodiments is a reduced amount of components over existing designs. Additionally, safety and reliability features have been integrated into the design and will shortly be taught in the following paragraphs. A burp-off feature in all embodiments will be exemplified that vents back-pressure spikes as well as a method of adjusting the burp-off back-pressure spikes independent of regulated pressure in some embodiments.

Owner:HOLLARS ANTHONY SCOTT

Fail-safe vacuum actuated valve for high pressure delivery systems

A high pressure storage and delivery system having a fail-safe vacuum actuated valve is provided. In particular, through the innovative design of the vacuum actuated check valve, the system can accommodate up to three times the volume of product in similar size cylinders.

Owner:PRAXAIR TECH INC

Constant flow valve

InactiveUS6209578B1Operating means/releasing devices for valvesFlow control without auxillary powerEngineeringVariable pressure

A regulating valve is disclosed for controlling the flow of fluid from a variable pressure fluid supply. The valve includes a diaphragm which is resiliently biased into a normally closed position, and which shifts to an open position when exposed to a fluid pressure above a predetermined minimum level.

Owner:GLOBAL AGRI TECH & ENG

Combination valve and regulator with vented seat for use with pressurized gas cylinders, particularly oxygen cylinders

Owner:LUXFER INC

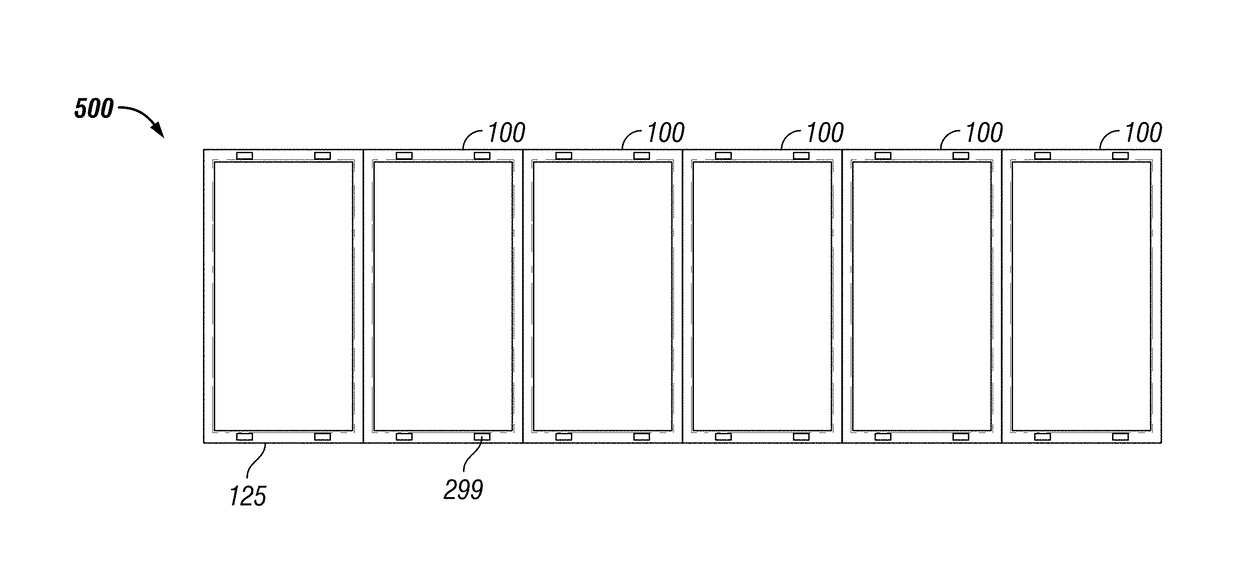

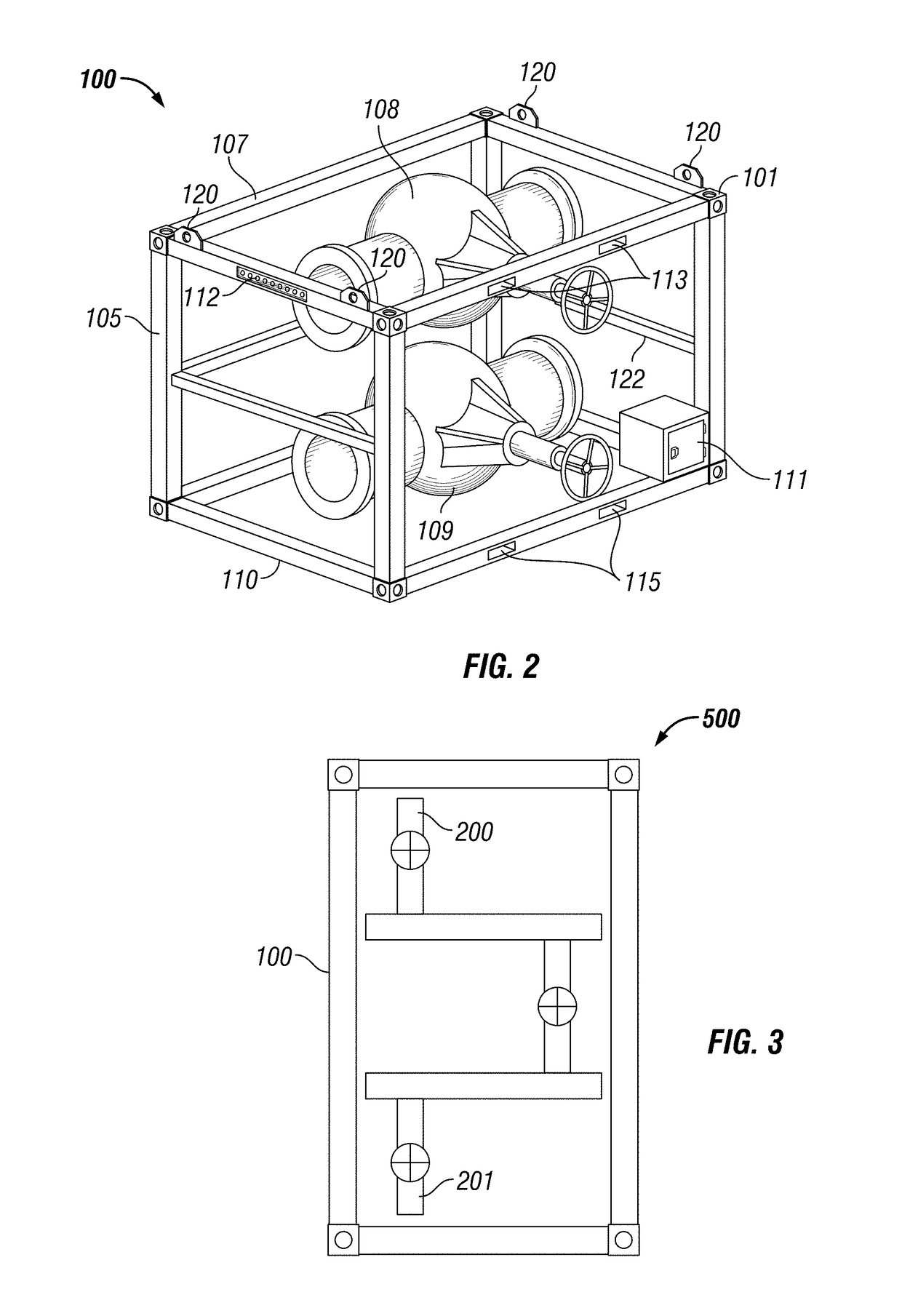

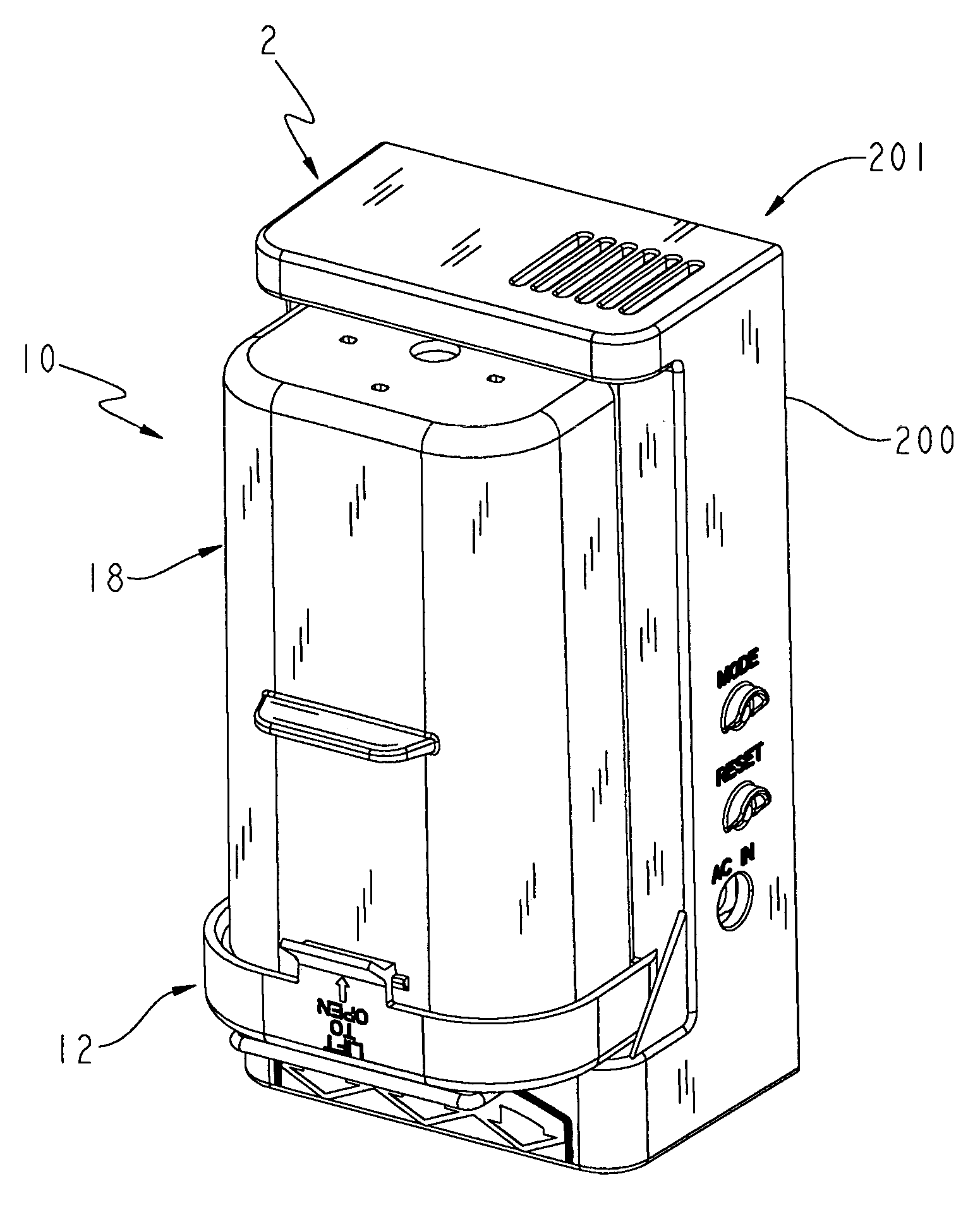

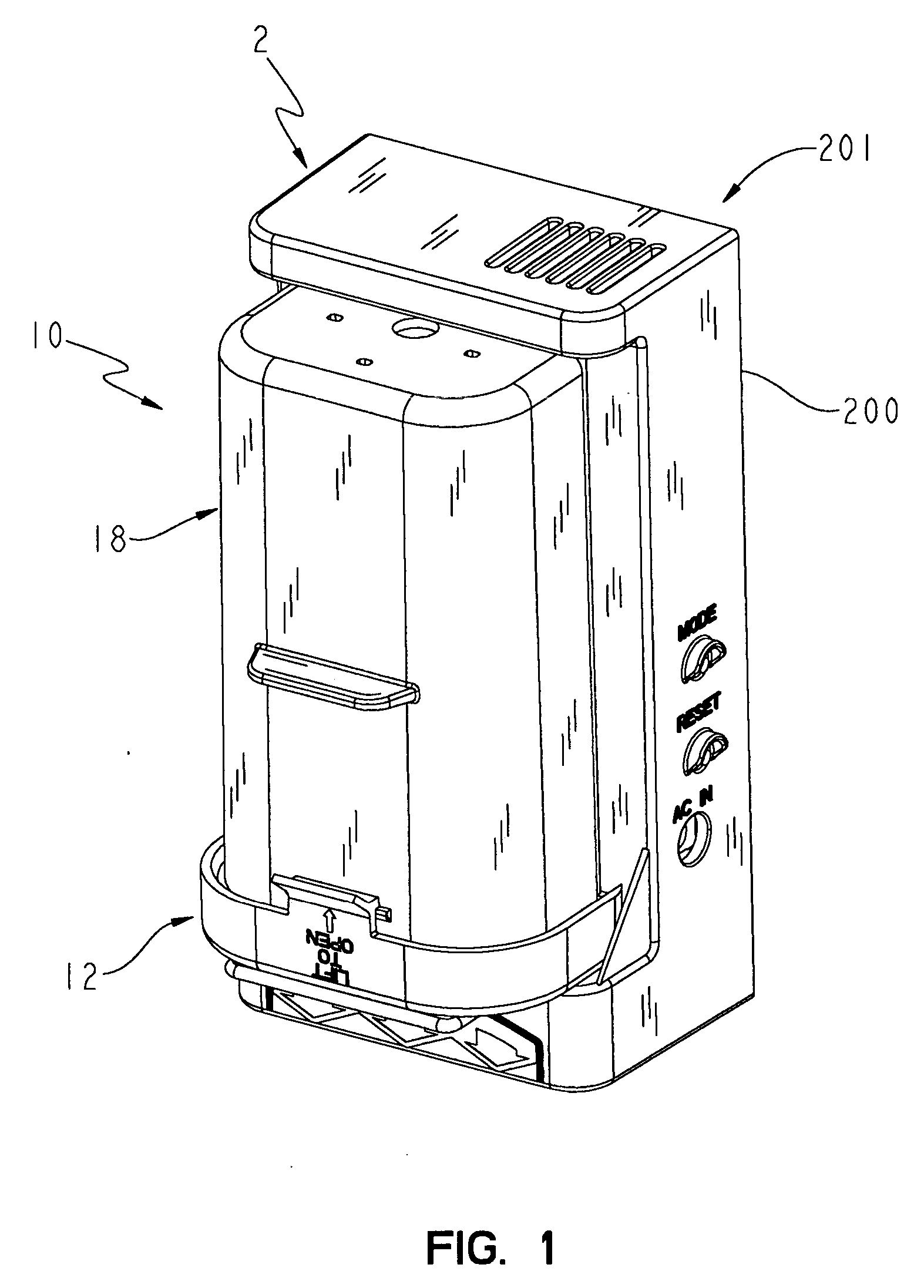

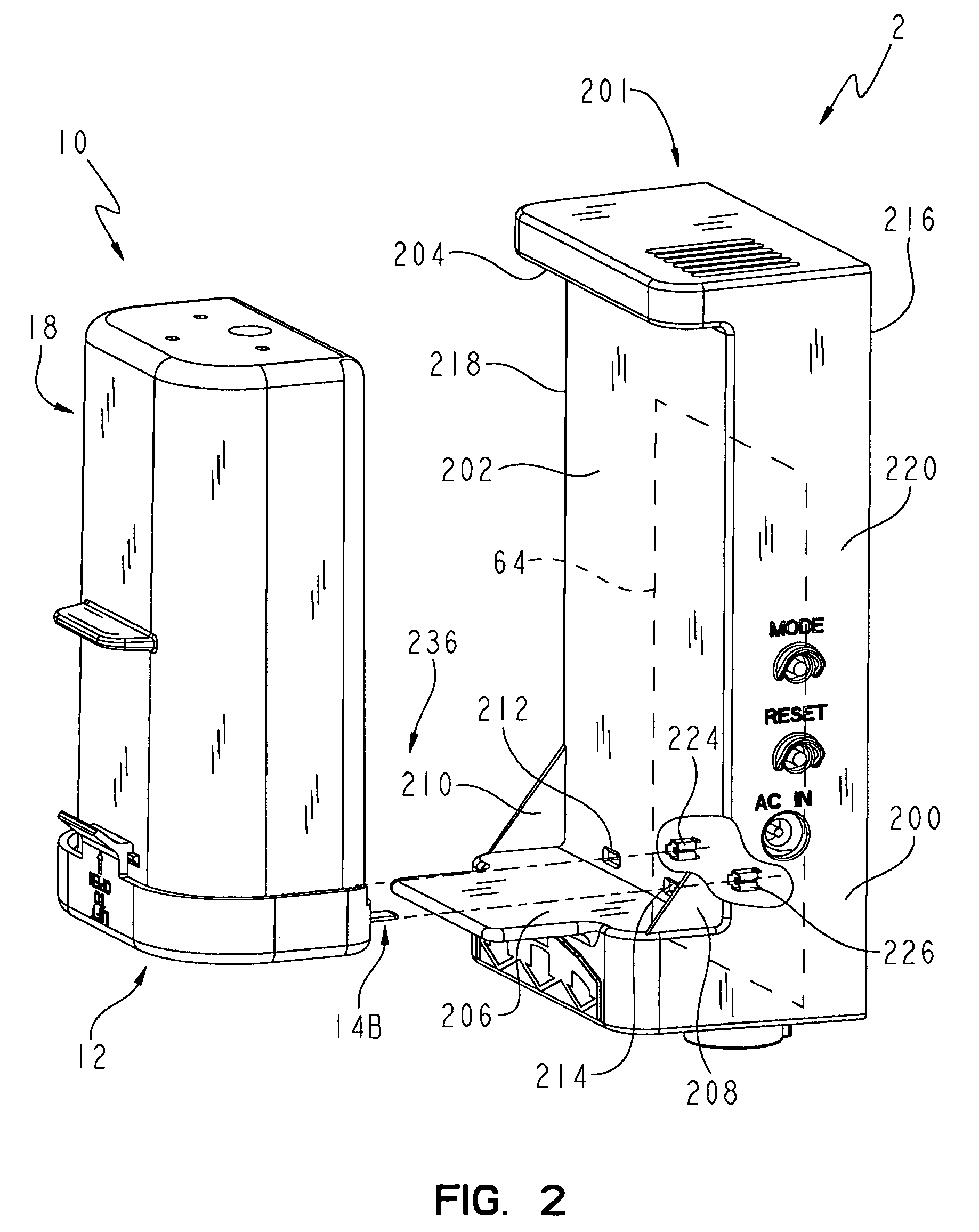

Battery box assembly

InactiveUS20060201558A1Easy to replaceDomestic plumbingCell lids/coversElectrical batteryEngineering

A battery compartment assembly includes a housing and a lid configured to be removably attached to the housing. The lid includes a pair of hinges that engage a corresponding pair of openings in the housing, and a latch that engages a ridge on the housing when the lid is in the closed position. The lid also includes a pair of contacts that extend from the lid to mate with connectors of a control unit to be powered by the batteries in the assembly. A spring is included in the housing for connecting to a positive terminal of a first battery and a negative terminal of a second battery.

Owner:MASCO CORP

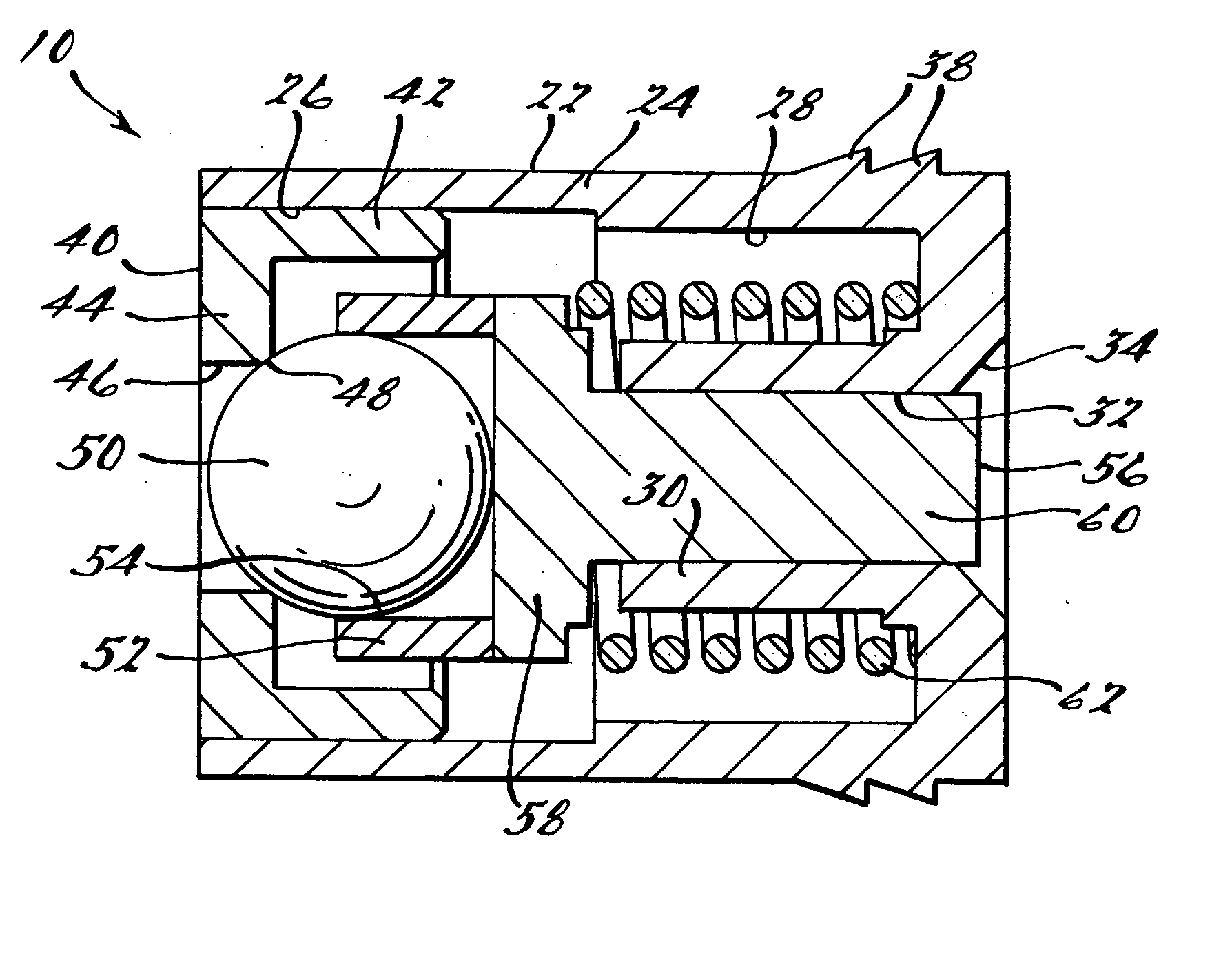

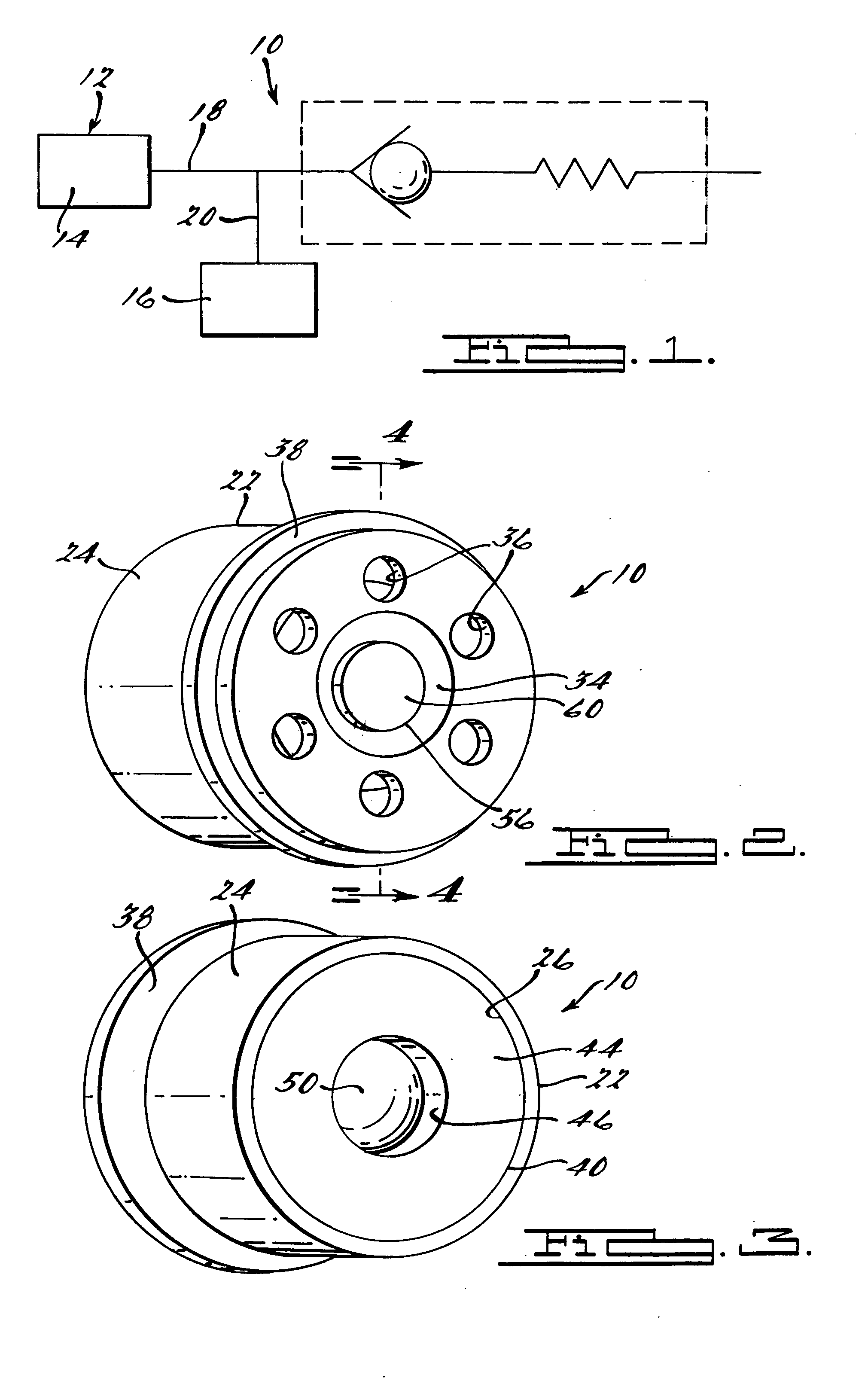

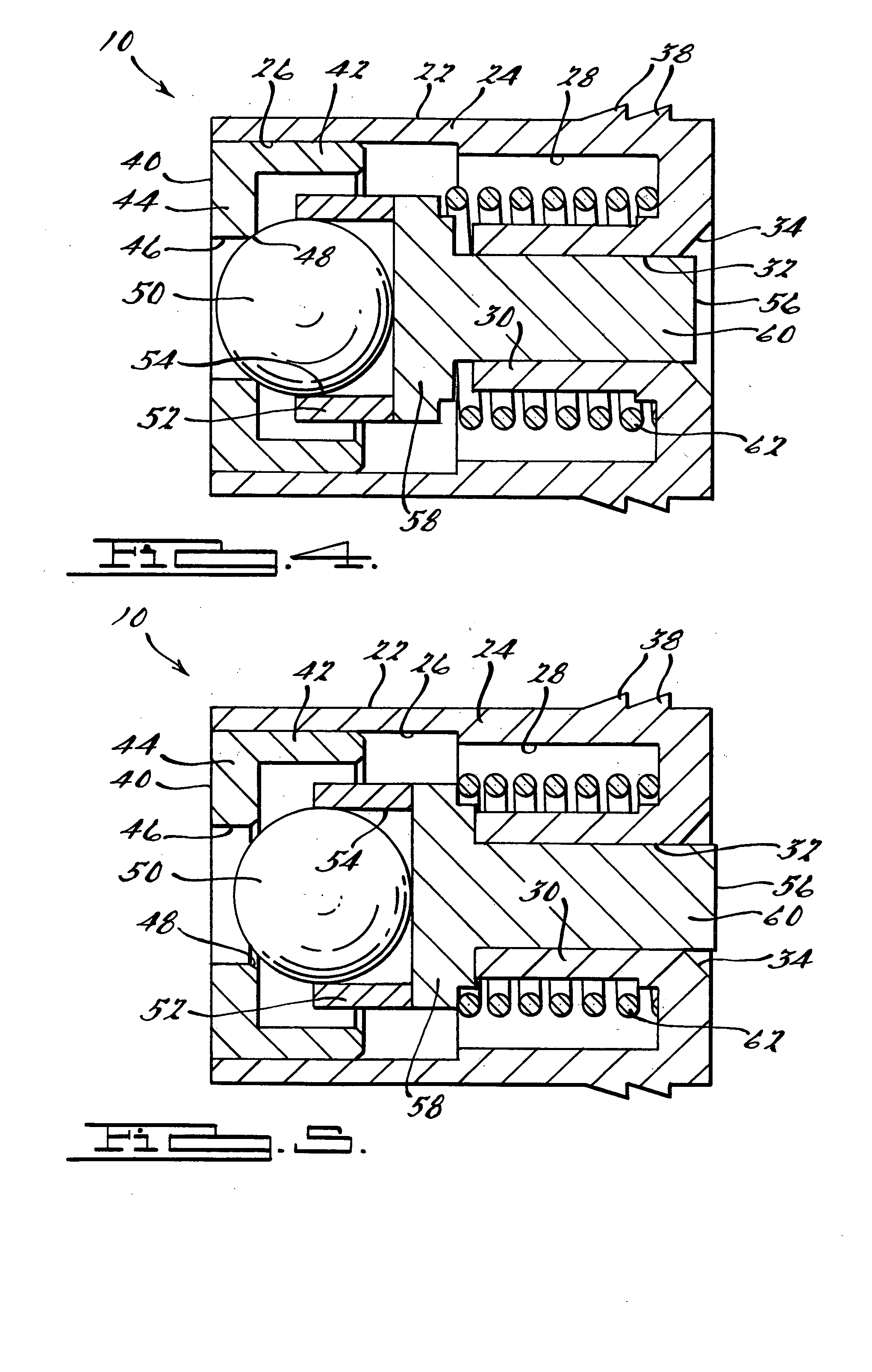

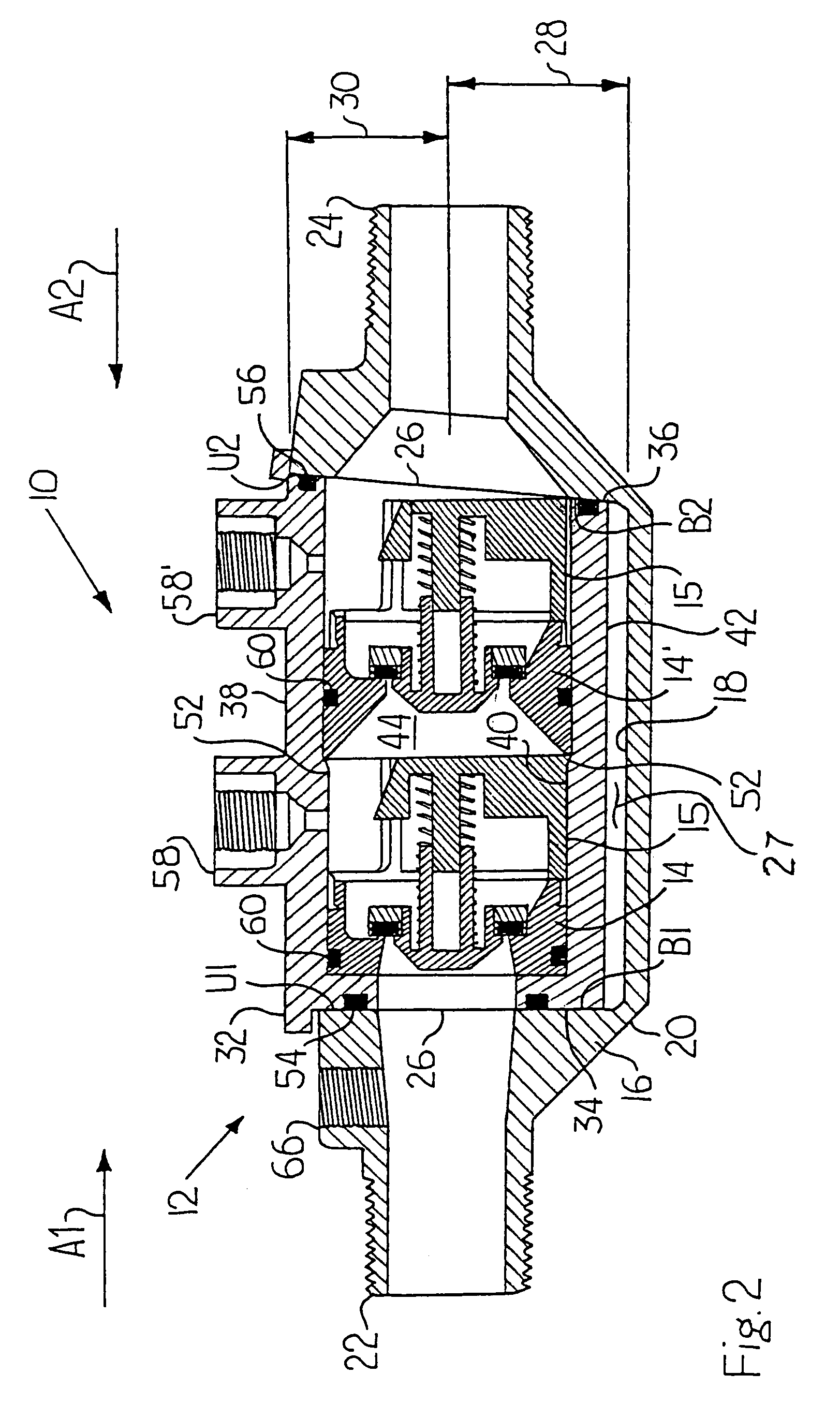

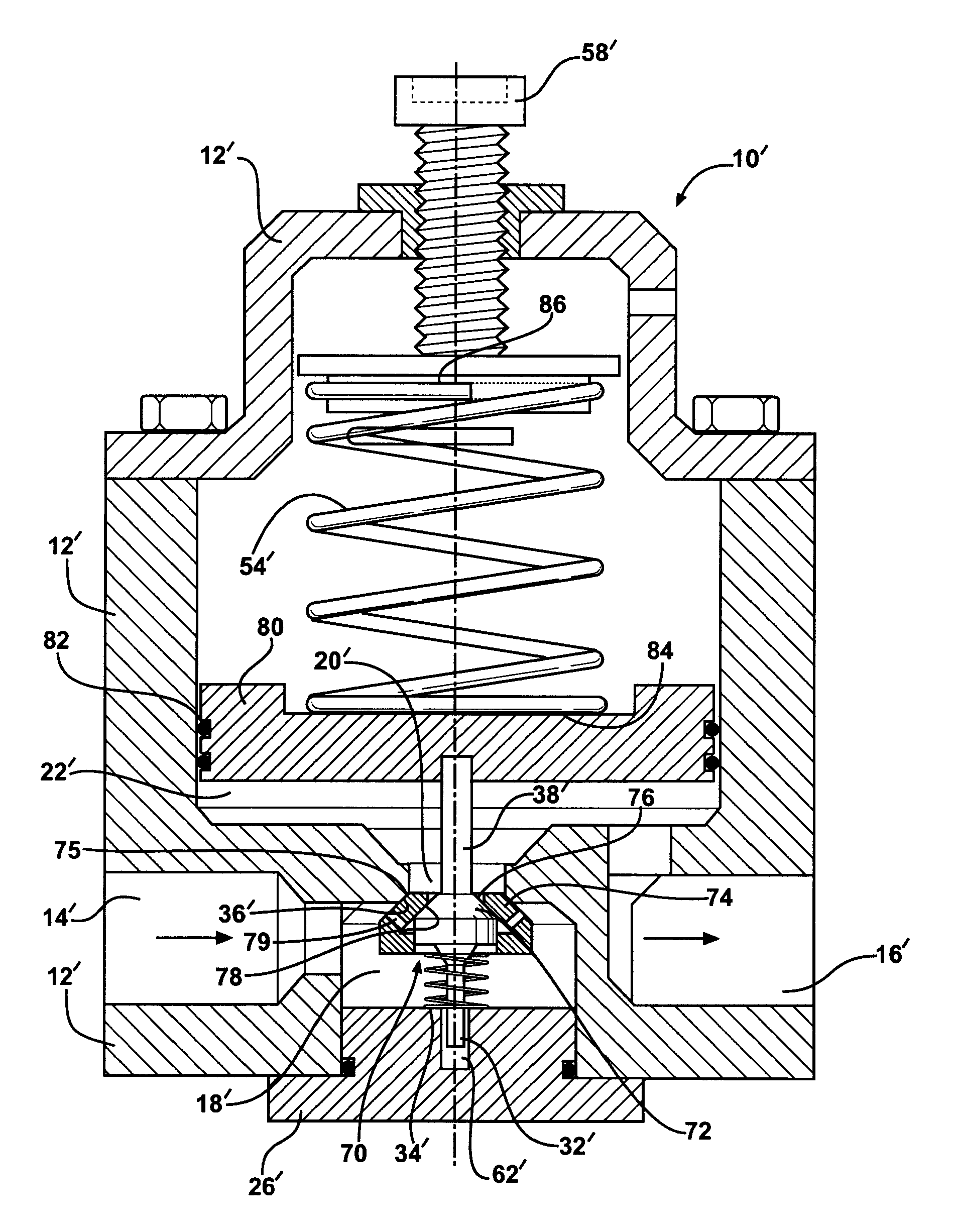

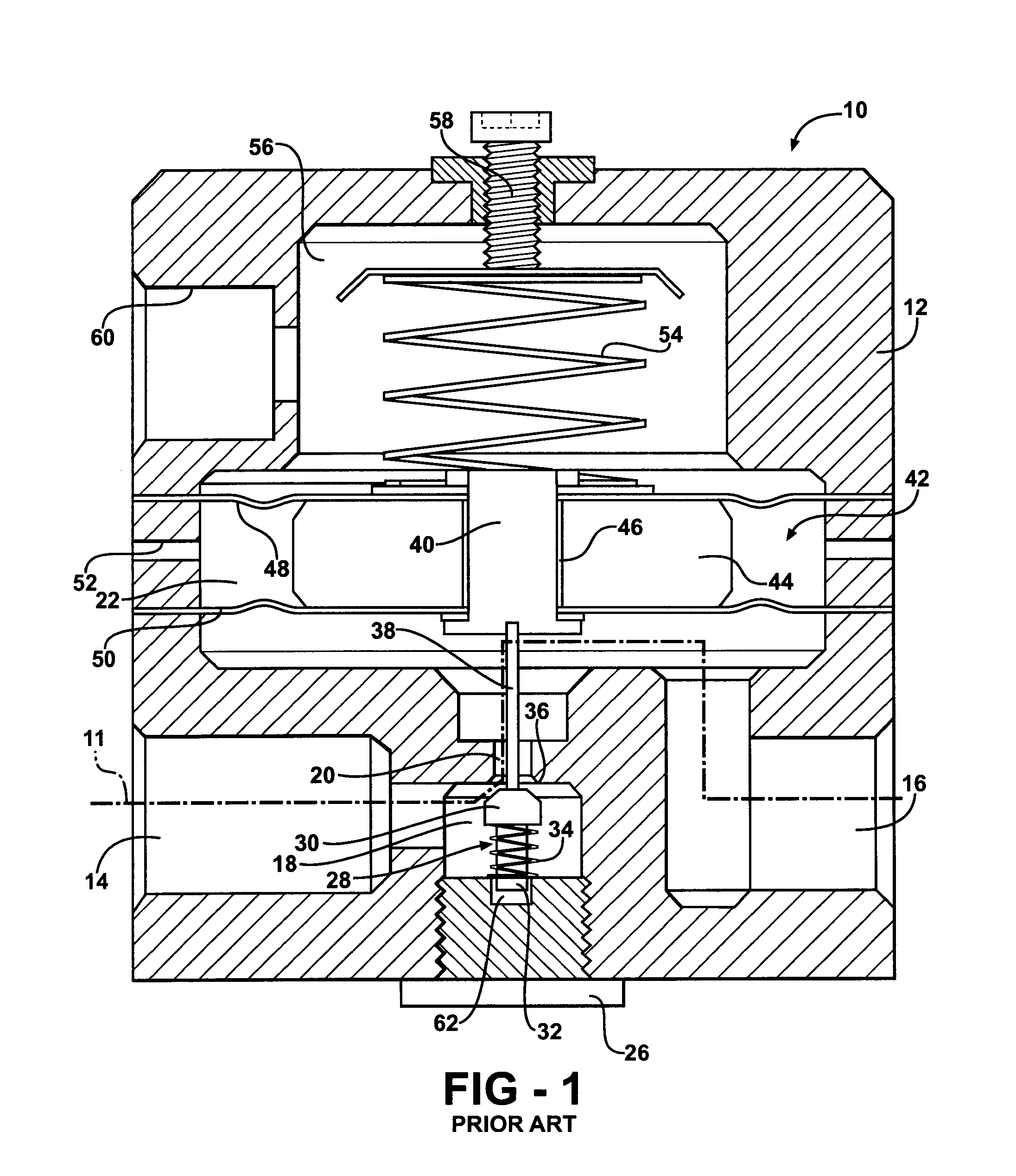

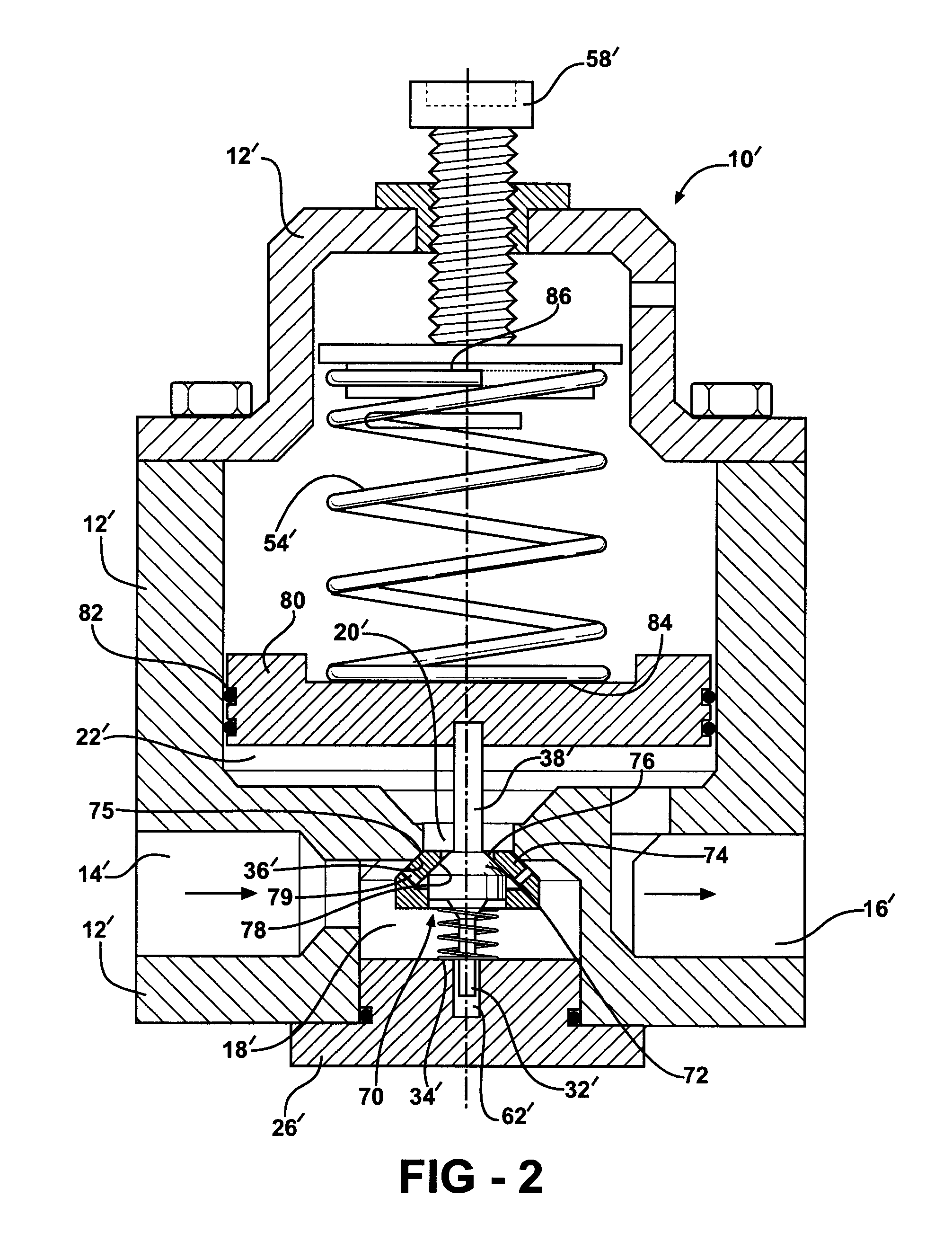

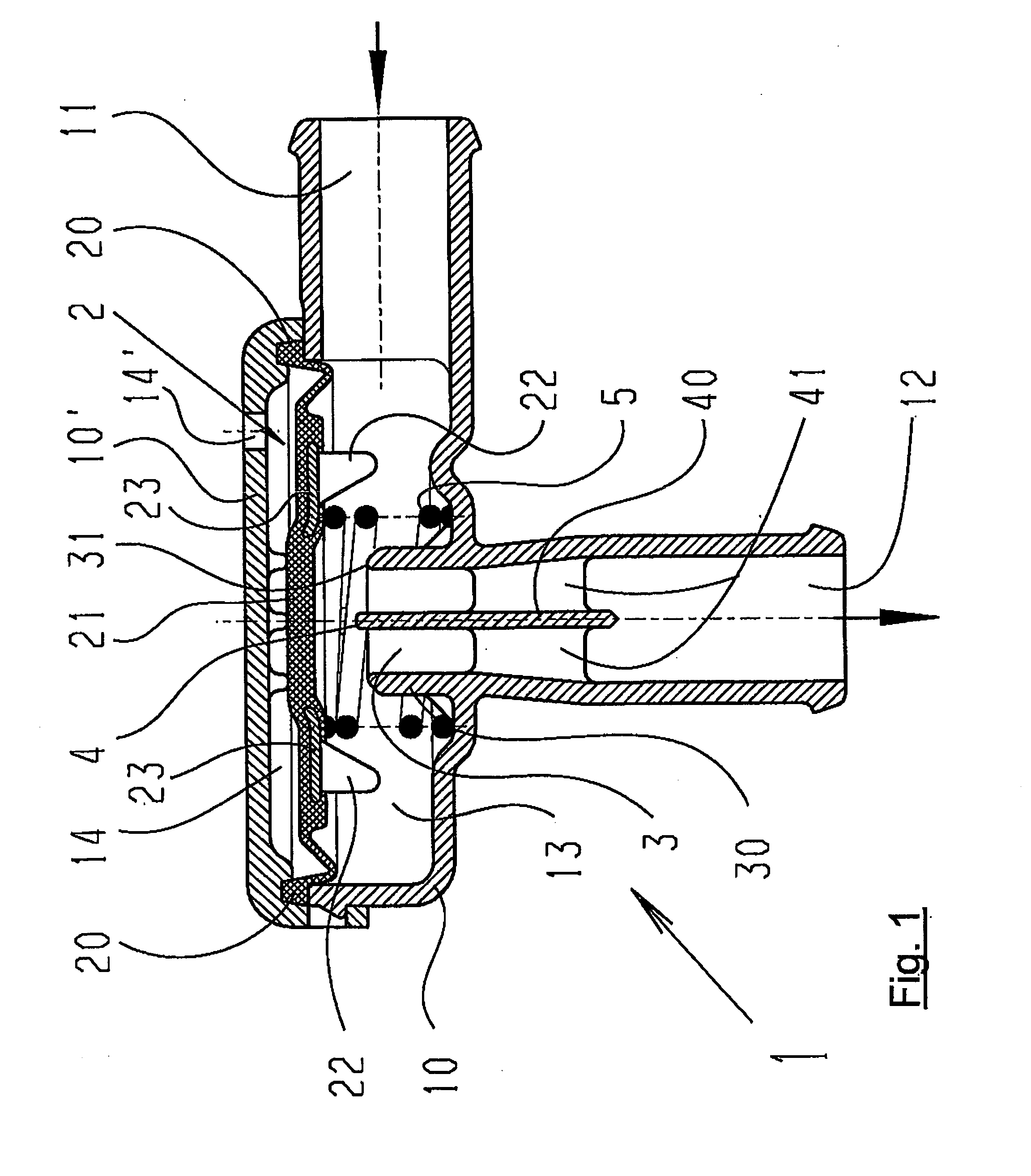

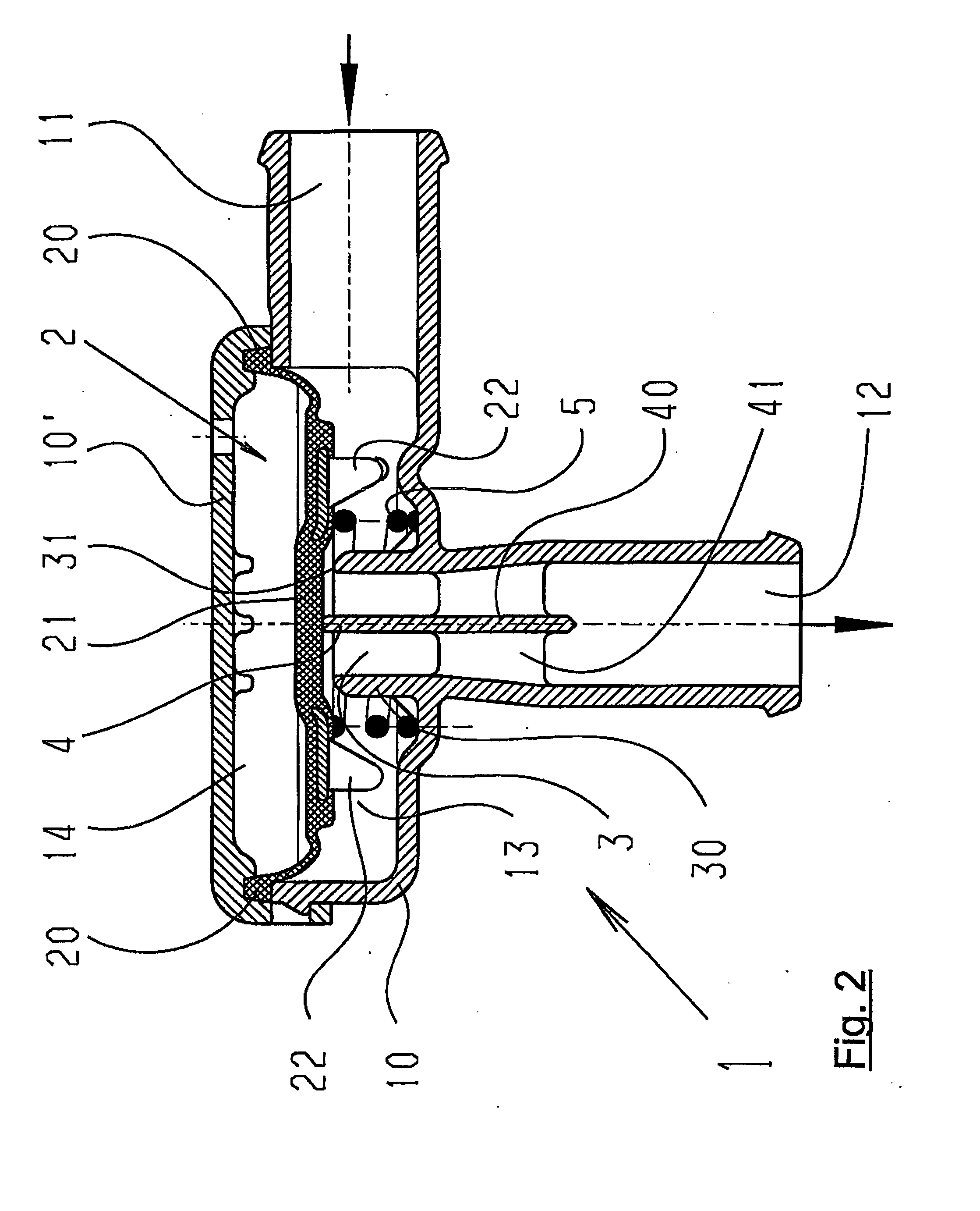

Pressure regulator assembly

InactiveUS20050061372A1Reduce in quantityLow costCheck valvesLow pressure fuel injectionEngineeringCavity pressure

A pressure regulator assembly for a fluid system includes a housing having at least one cavity therein and a valve seat disposed in the at least one cavity and having an aperture extending therethrough. The pressure regulator assembly also includes a movable valve member disposed in the at least one cavity of the housing. The valve member has a closed position to engage the valve seat to prevent fluid from flowing into the at least one cavity and an open position to disengage the valve seat to allow fluid to flow into the at least one cavity. The pressure regulator assembly further includes a biasing mechanism disposed in the at least one cavity to bias the valve member toward the valve seat to close the aperture. The valve seat and the valve member and the biasing mechanism are aligned linearly along an axis of the valve housing.

Owner:MCGRATH DENNIS P +3

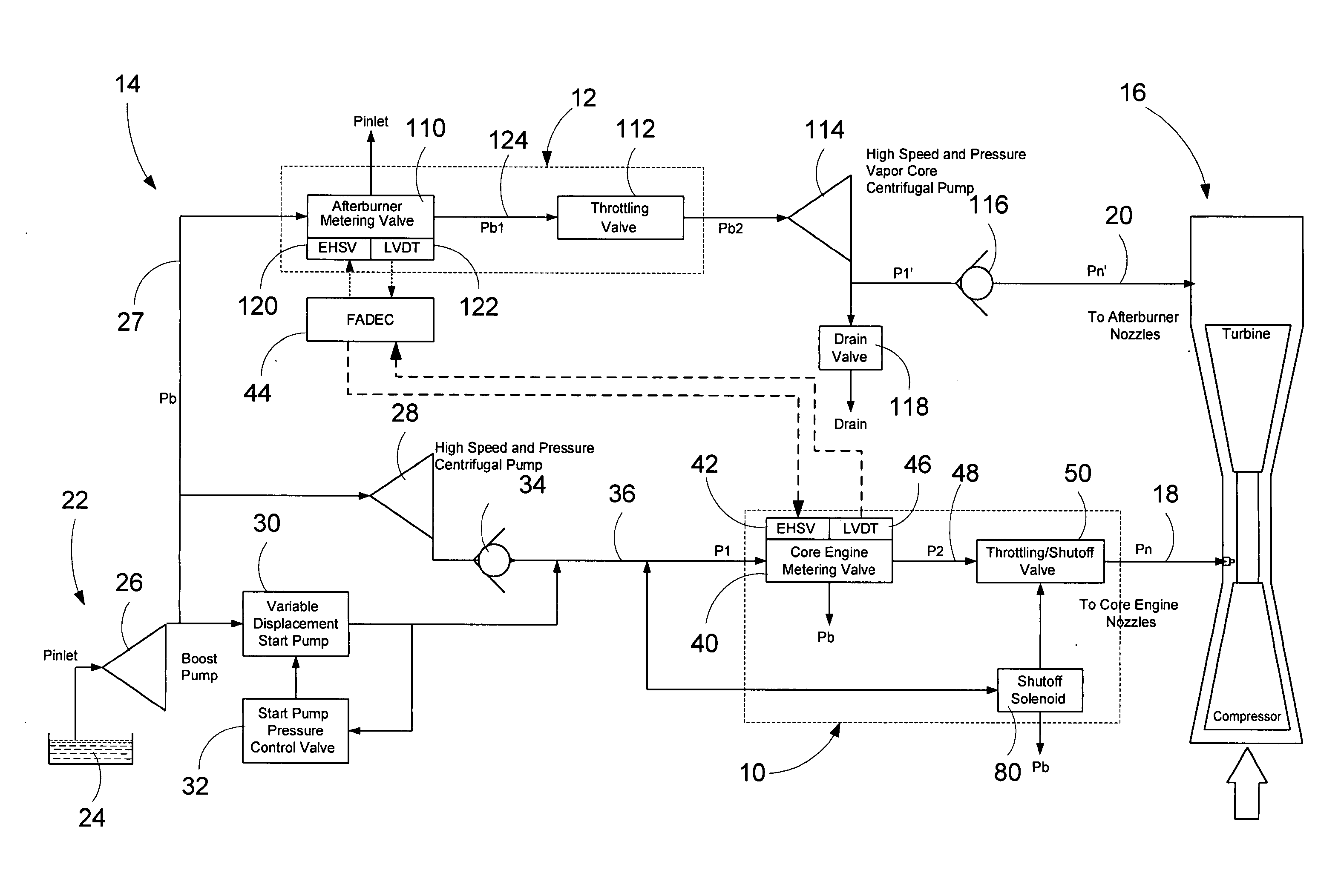

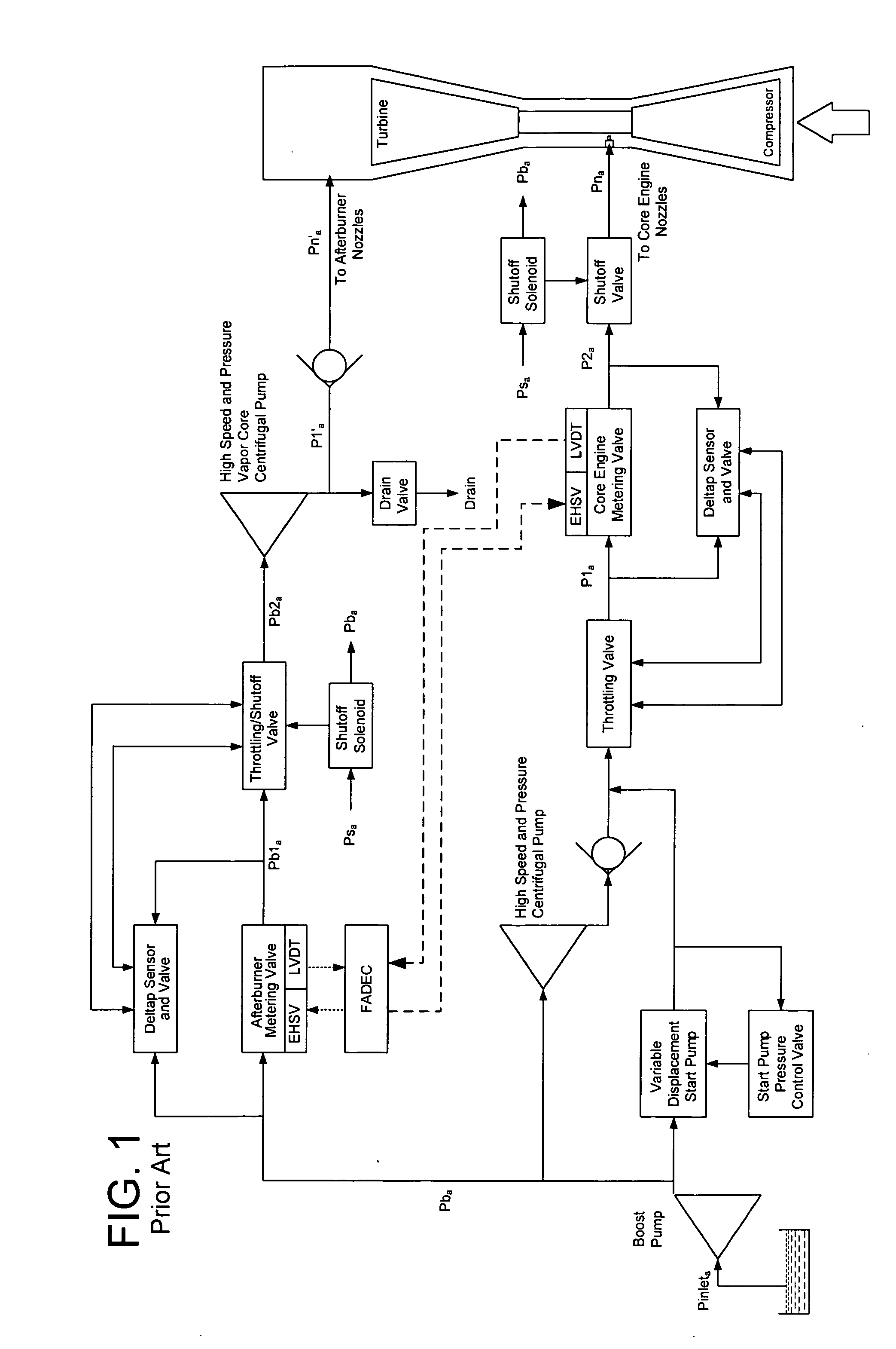

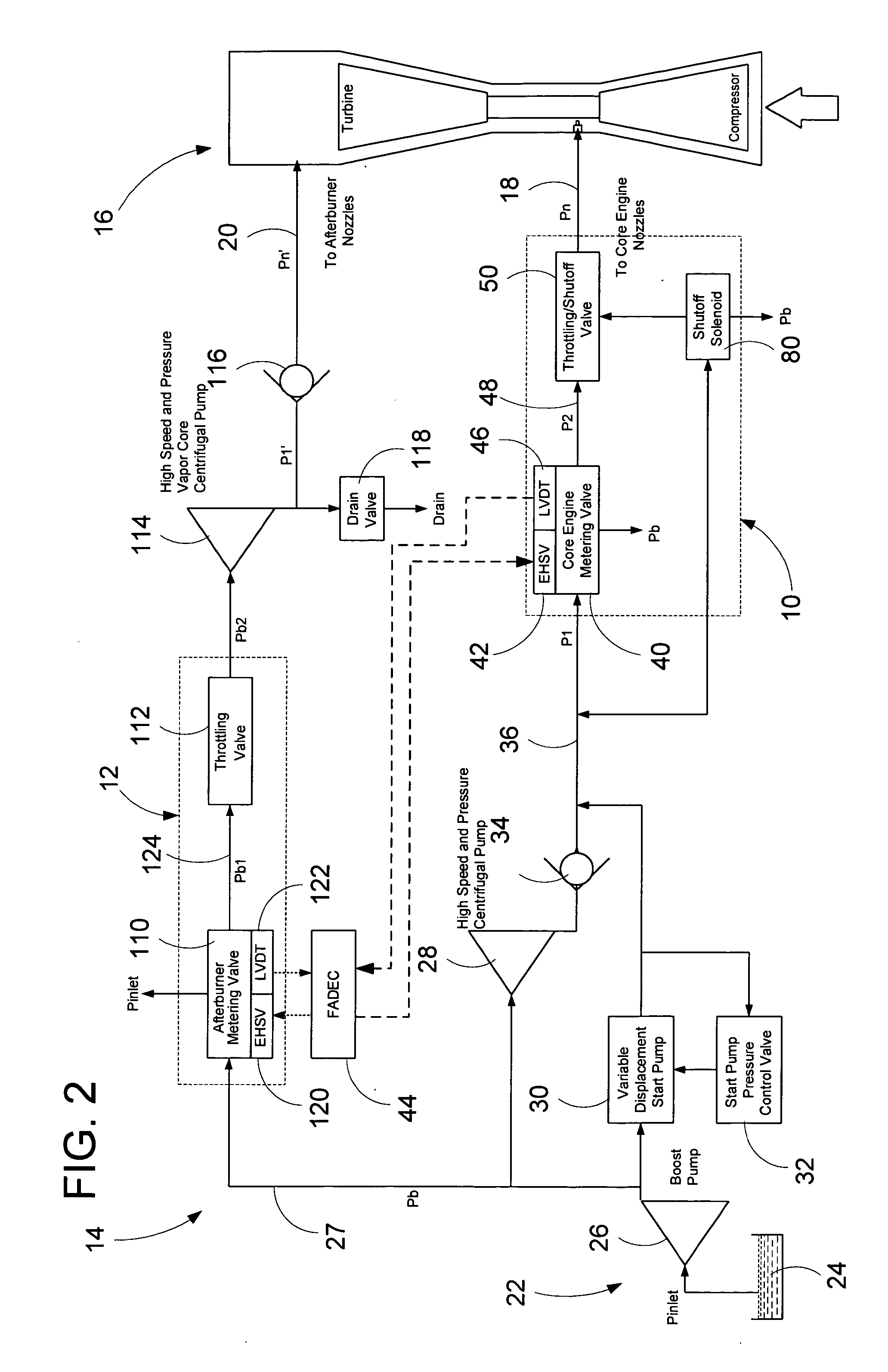

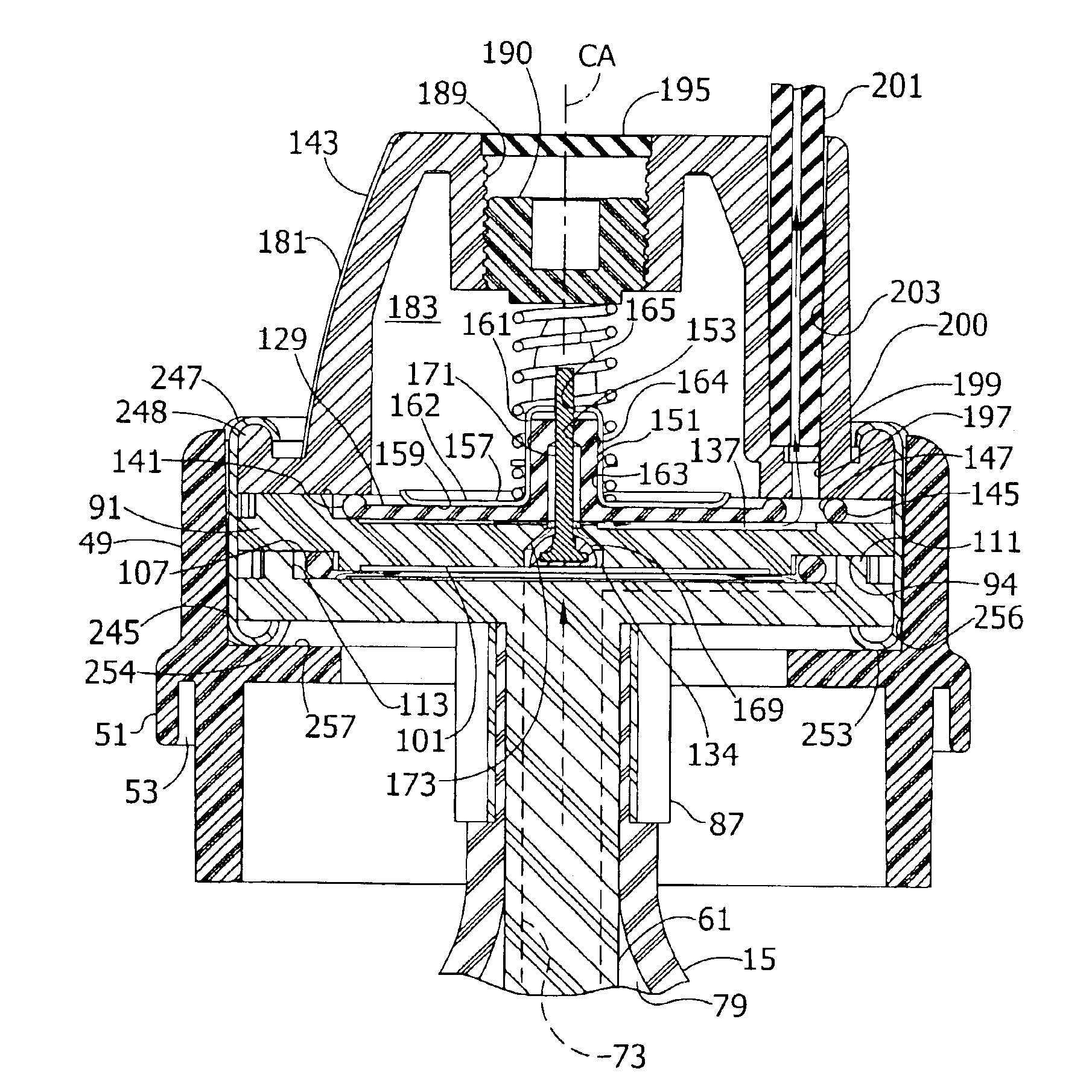

Centrifugal pump fuel system and method for gas turbine engine

InactiveUS20050217236A1Turbine/propulsion fuel deliveryTurbine/propulsion fuel valvesEngineeringAxial force

A fuel system for a gas turbine engine that utilizes a centrifugal pump is presented. The system includes a fuel metering valve that is adapted to set a metered flow of fuel, and a throttle valve that is adapted to accurately control pressure drop across the fuel metering valve. The throttle valve has at least two variable orifices and a compensation chamber between the variable orifices. The throttle valve includes a differential valve piston slidable in a valve body. The differential valve piston comprises working surfaces of at least two different diameters such that changes in chamber pressures effect different axial forces upon the piston.

Owner:WOODWARD GOVERNOR CO

Pressure regulator for infusor

InactiveUS6892755B2Operating means/releasing devices for valvesMedical devicesInfusion setInlet pressure

An improved ambulatory infusion device for dispensing a fluid into a patient includes a flexible bladder enclosure having a first open end a closed second end. The closed second end of the sheath is free to conform to the body of the patient so that the device is comfortable when worn. In other aspects, a pressure regulator of the device is adapted to maintain the outlet pressure within a predetermined range of pressures so that the fluid flow rate is substantially constant during fluid flow. A flow restrictor of the device is formed of flexible tubing.An ambulatory infusion device for dispensing a fluid at a predetermined fluid flow rate includes an elastic bladder having an interior volume for storing the fluid under pressure and an opening for dispensing the fluid. A pressure regulator is in fluid communication with the opening of the bladder and includes an inlet for receiving fluid from the bladder at an inlet pressure and an outlet for discharging the fluid at a predetermined outlet pressure. A valve at the inlet has a hemispheric-shaped head adapted to cooperate with a frustoconic-shaped seat to promote uniform fluid flow therebetween. A movable diaphragm is connected to the valve, and a valve plate opposite a surface of the diaphragm has channels or texture therein. The diaphragm and the valve are movable in response to the fluid pressure acting on the diaphragm surface.

Owner:BAXTER INT INC

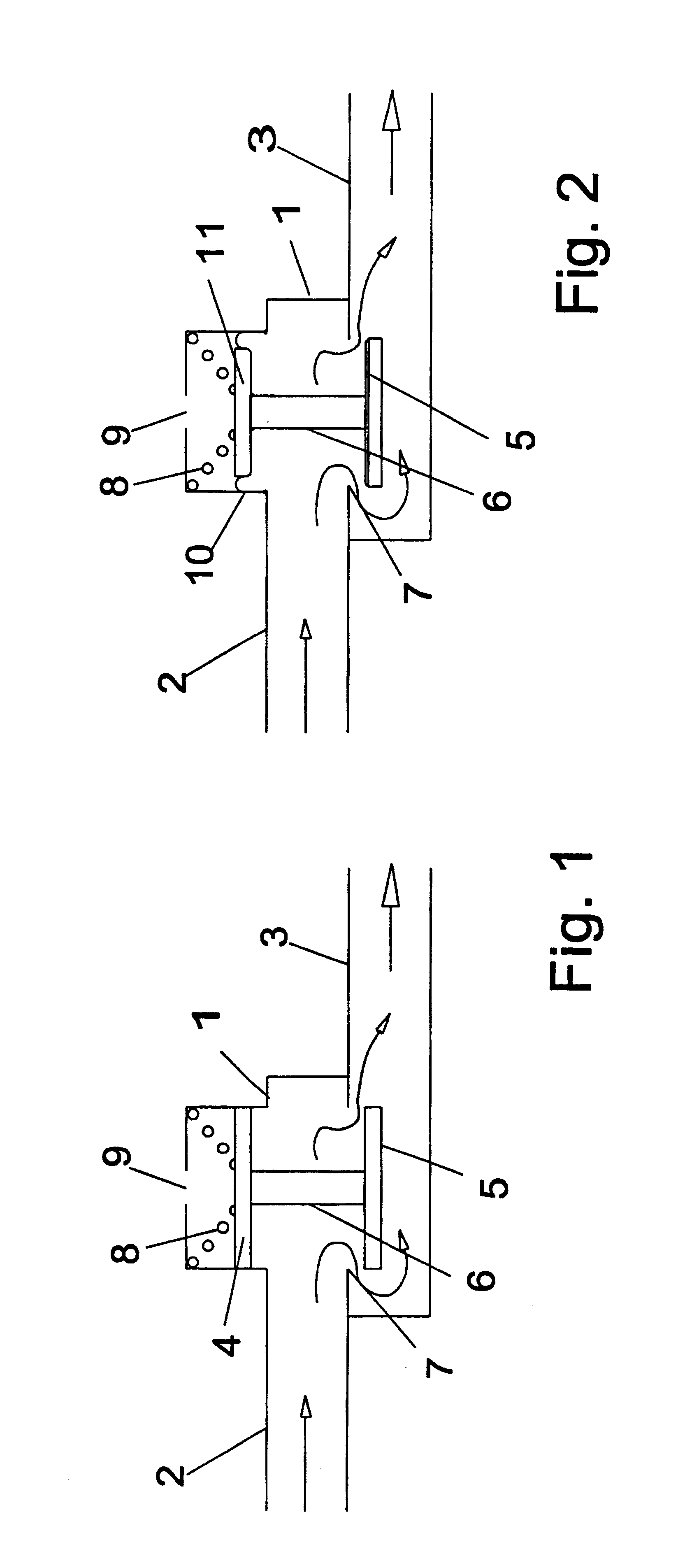

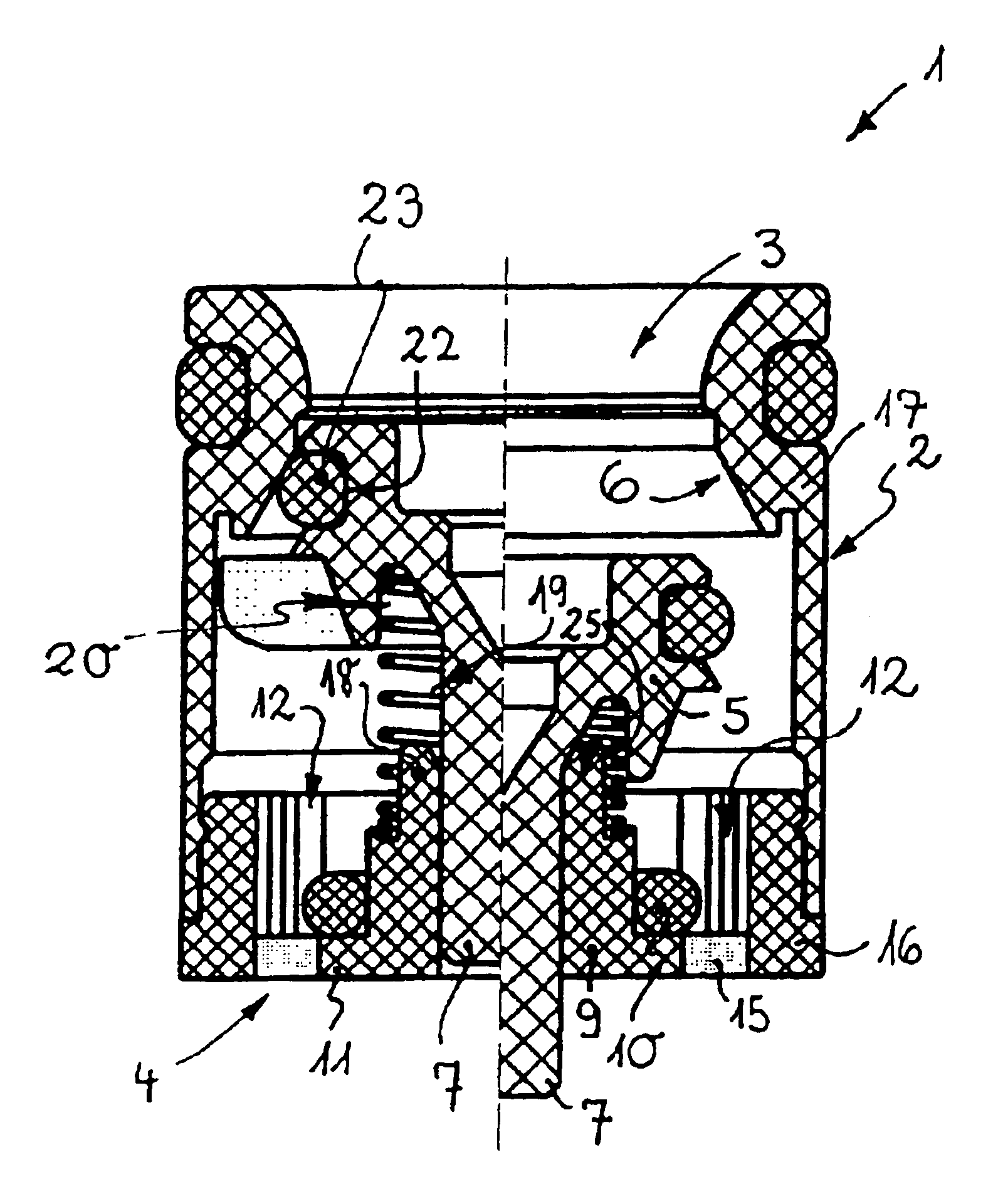

Pressure independent control valve

InactiveUS6827100B1Operating means/releasing devices for valvesFlow control without auxillary powerLine tubingAtmospheric air

Simple APCV, ADPCV and PICV's are provided. The APCV's are referenced to the atmosphere and control the gauge pressure, either upstream or downstream. The ADPCV's are the same as the APCV's, differing in that they are not referenced to the atmosphere. They are instead referenced to a second point in the fluid flow system and control the differential pressure. The PICV's are control valves connected in series with ADPCV's and control the fluid flow rate through the valve independently of variations in the line pressure. A preferred APCV has a valve body (1) with connections for a single-phase fluid line and a flow passage between the inlet (2) and the outlet (3) of said fluid line, with an opening having a defined seat orifice (7) intersecting the flow passage. A moveable assembly, comprising a disk (5) or cup is connected to a pressure sensing member (4), having essentially the same effective surface area. The moveable assembly, is biased by a force, and is free to automatically move to any intermediate position between fully open and closed, producing a desired outlet pressure which minus the reference pressure, times the effective surface area of the disk or cup generates an opposing force equal to the biasing force.

Owner:BELIMO HOLDING AG

Direct acting gas regulator

InactiveUS6851447B1Improve accuracyLow costOperating means/releasing devices for valvesFluid pressure control without auxillary powerEngineeringHigh pressure

A direct acting pressure regulator controls the flow of a gas from a high pressure source to a low pressure device. Gas is delivered from the regulator at a predetermined outlet pressure. The regulator includes a body having a high pressure inlet and defining a seat. A bonnet is engageable with the body to define a piston chamber within the body and the bonnet. The bonnet has a regulated gas outlet. A piston is disposed within the piston chamber and defines a gap between the piston and a wall defining the chamber. The piston is movable between an open regulator condition and a closed regulator condition. The piston includes a plug having a sealing surface engageable with the seat and movable toward the seat to the closed regulator condition and away from the seat to the open regulator condition. The plug includes axially disposed openings therein for communicating gas from around the plug to a central longitudinal bore in the piston. The piston has an impingement surface in flow communication with the central bore such that gas pressure on the impingement surface exerts a force on the piston to move the piston to the closed regulator condition. A spring urges the piston to the open regulator condition.

Owner:PRESSURE SPECIALIST

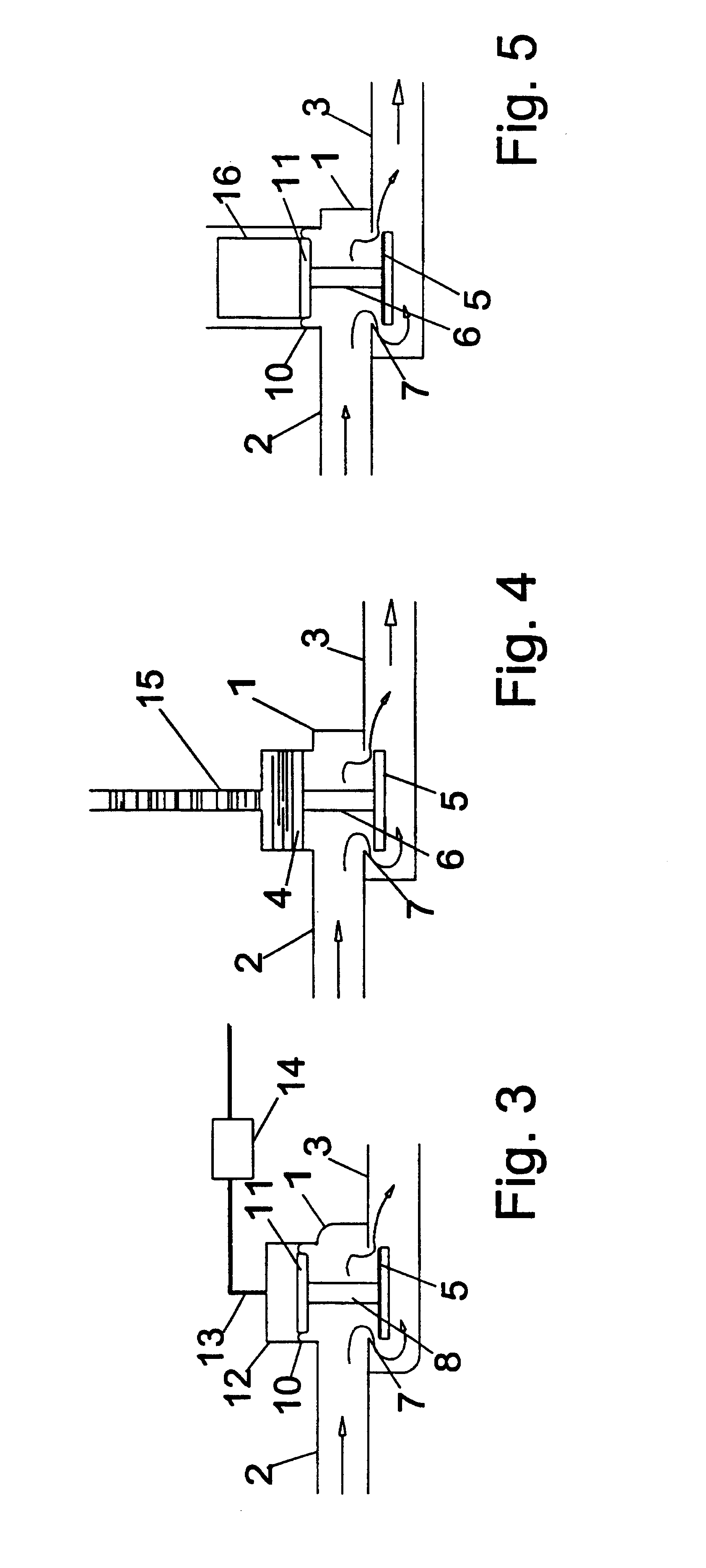

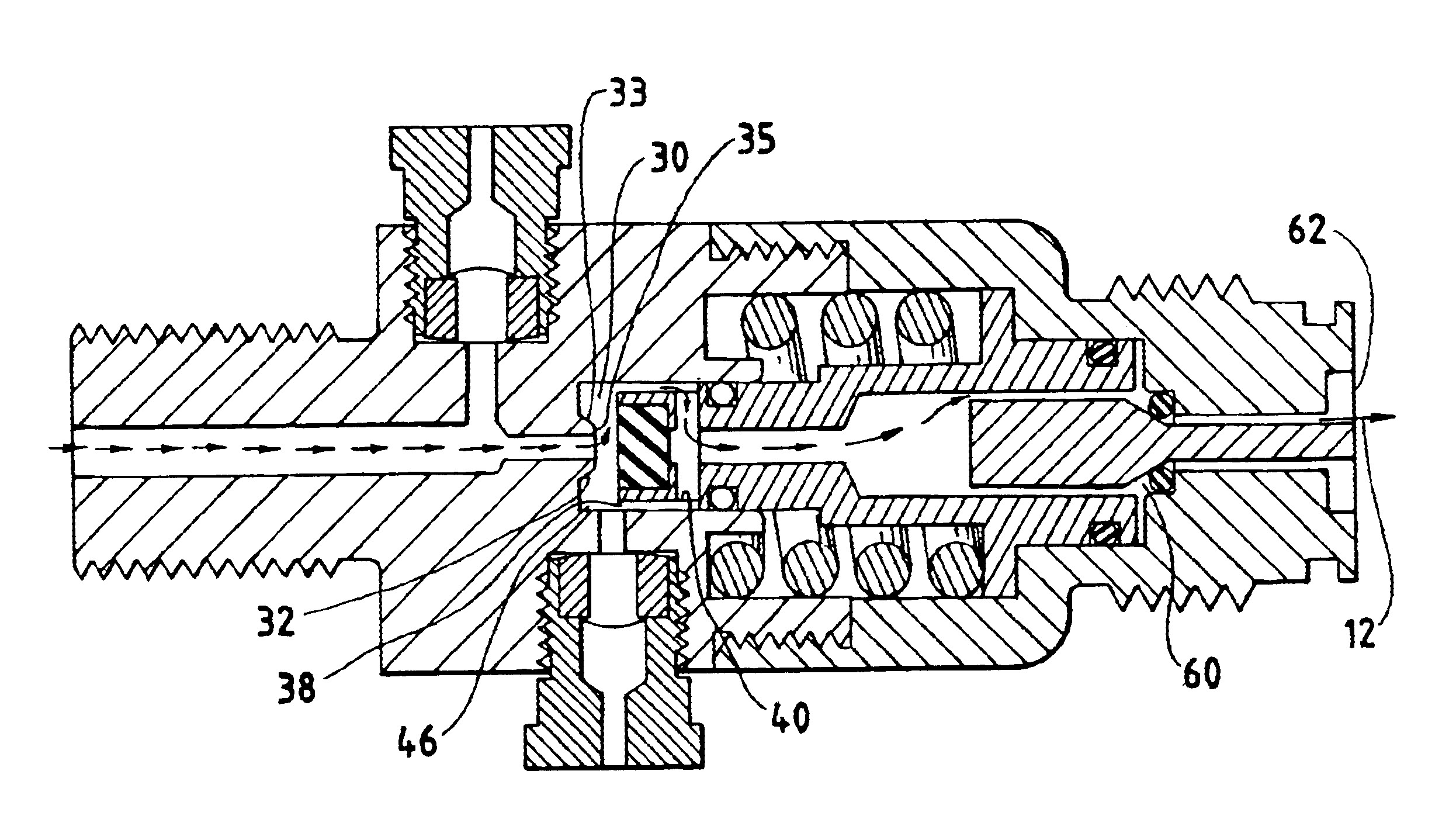

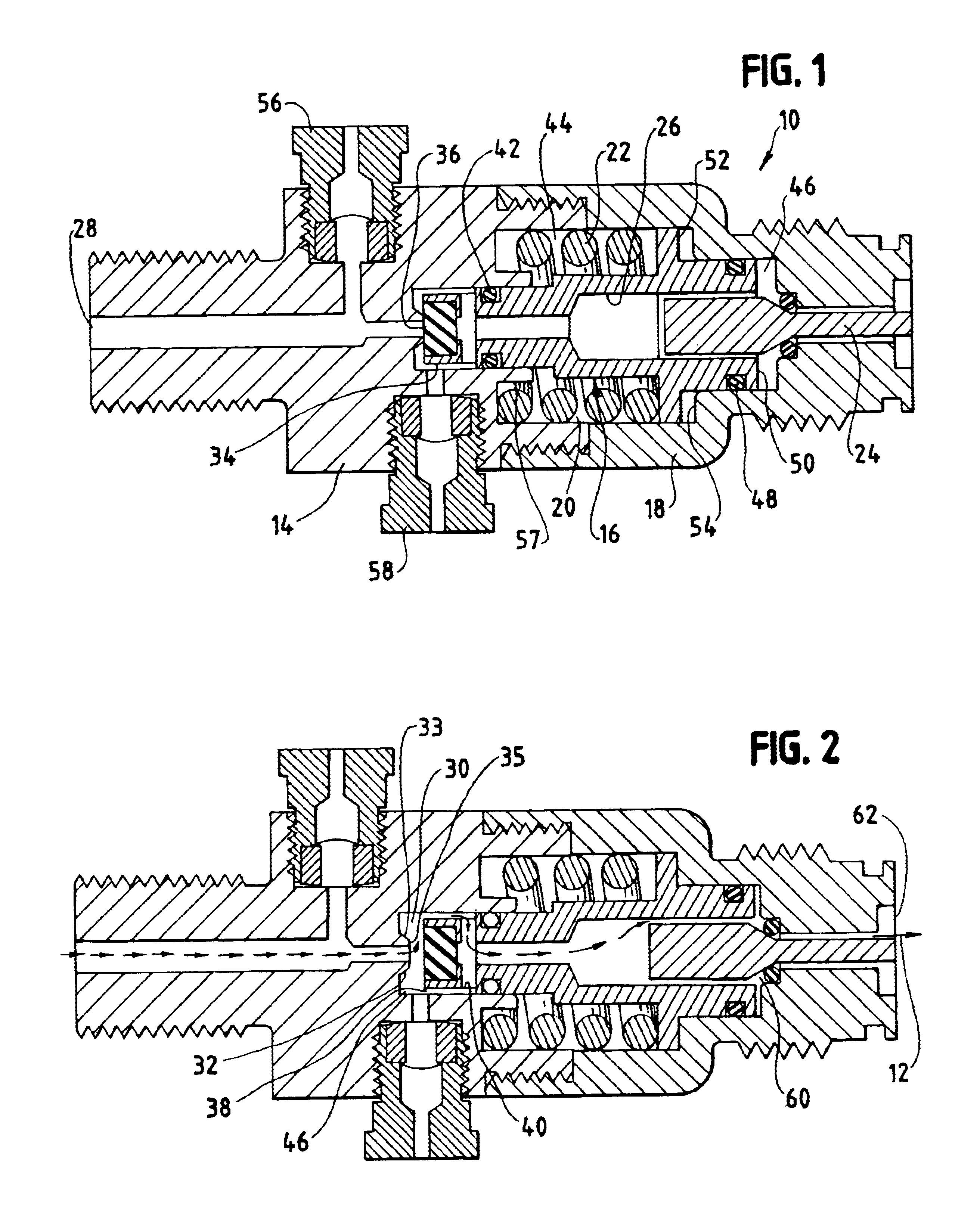

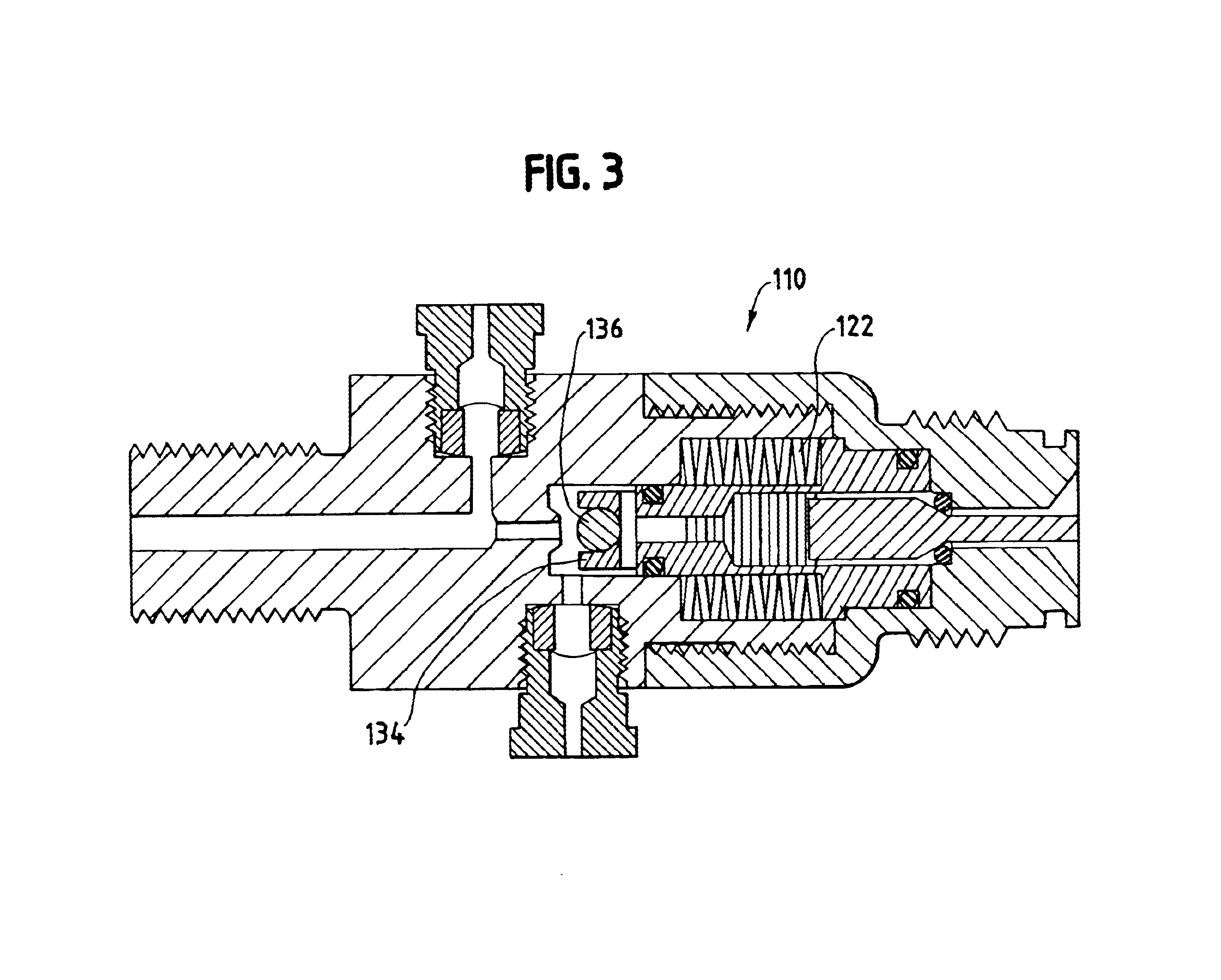

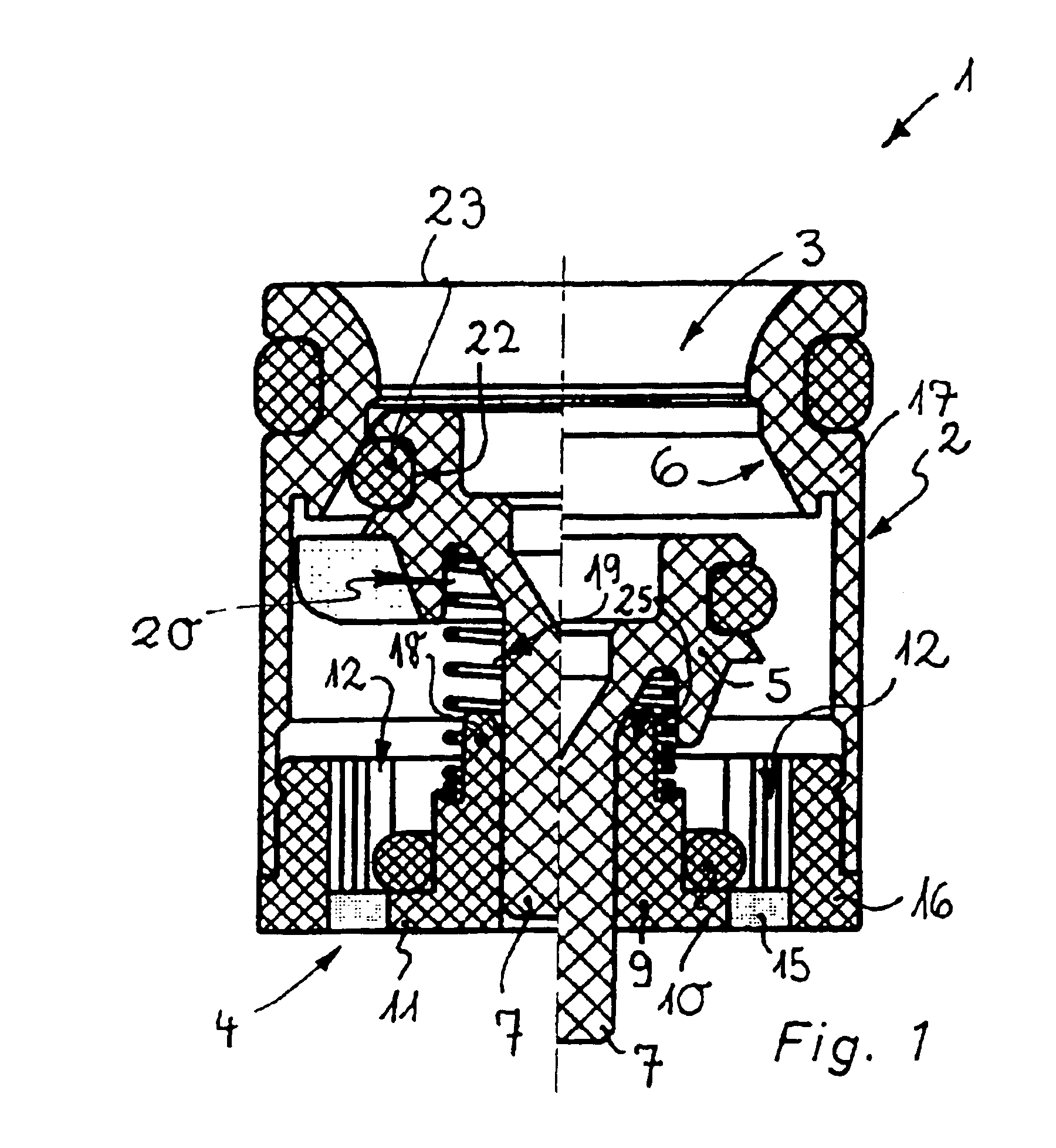

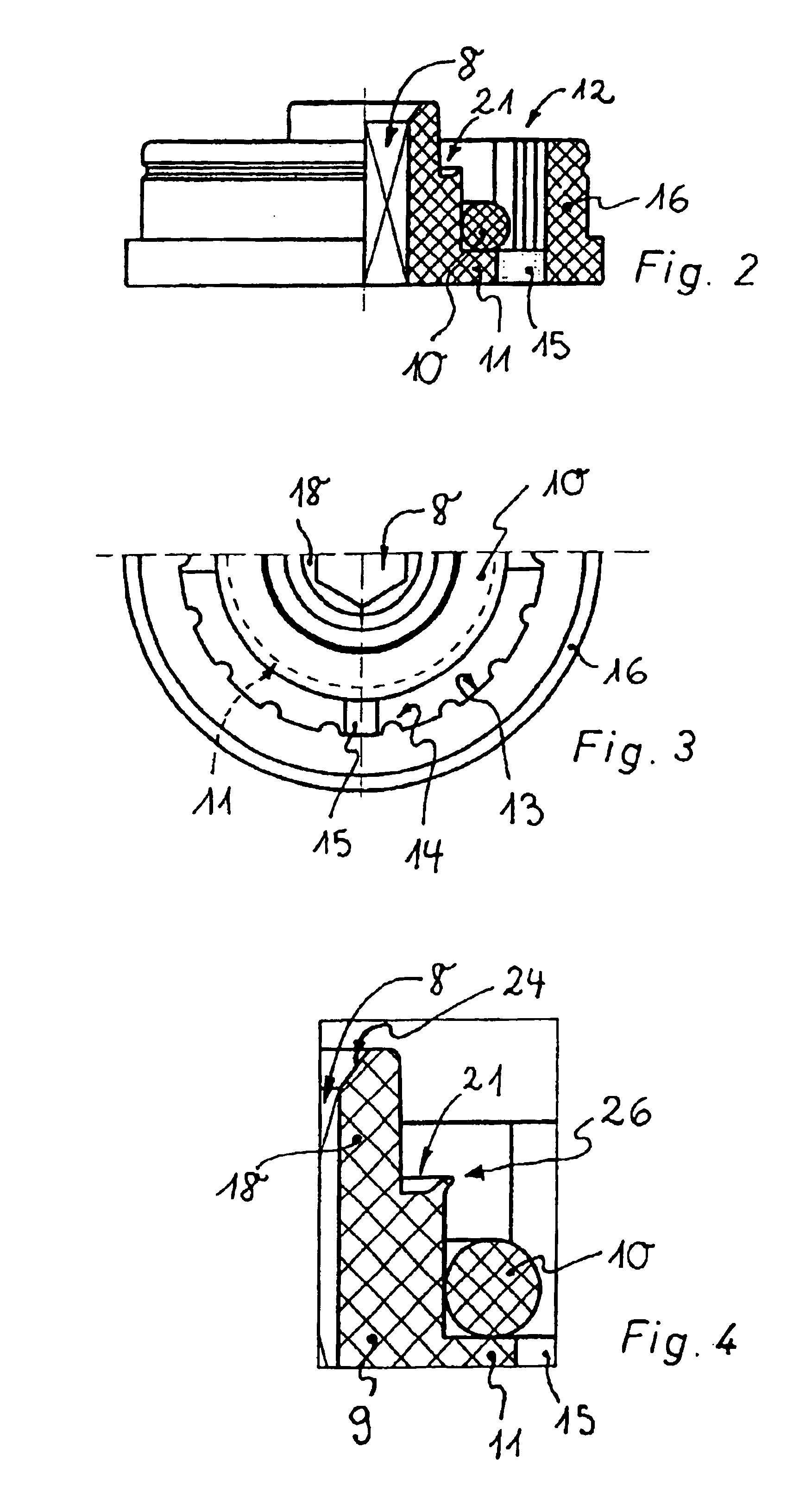

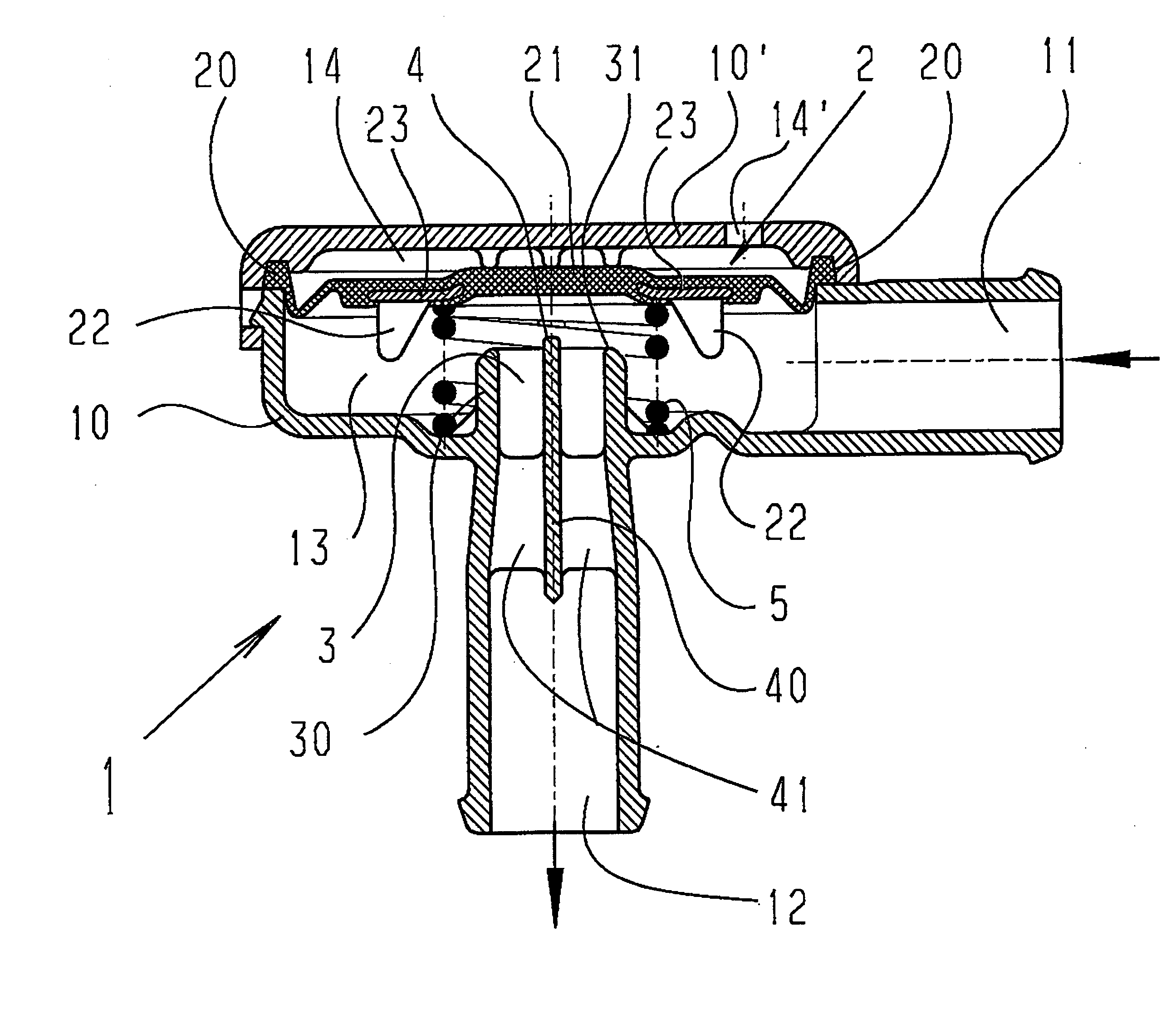

Cartridge insert for a fluid line

InactiveUS6837267B2Small space requirementEconomically manufacturedServomotor componentsCheck valvesValve seatCentral governor

A cartridge insert for insertion in a fluid line is provided having a cartridge housing within which is located at least one backflow inhibitor and downstream at least one flow regulator. The backflow inhibitor has a closing element, which, in a closed position thereof, lies tightly sealed on a valve seat of the cartridge housing and which may be displaced from the closed position against a return force into an open position. A downstream guide pin projects from the closing element, and extends into a guide opening of a central regulator core of the flow regulator, and the flow regulator is formed from a regulator element made from an elastic material that surrounds the regulator core, which rests on an annular shoulder and defines a control gap, which changes with pressure between the above and an opposing enclosing wall. The cartridge insert is compact and space saving in that the flow regulator terminates generally flush with the downstream side of the cartridge and the annular shoulder projects from the regulator core and the control gap is provided between the regulating element and an inside of the cartridge housing which forms the enclosing wall.

Owner:NEOPERL

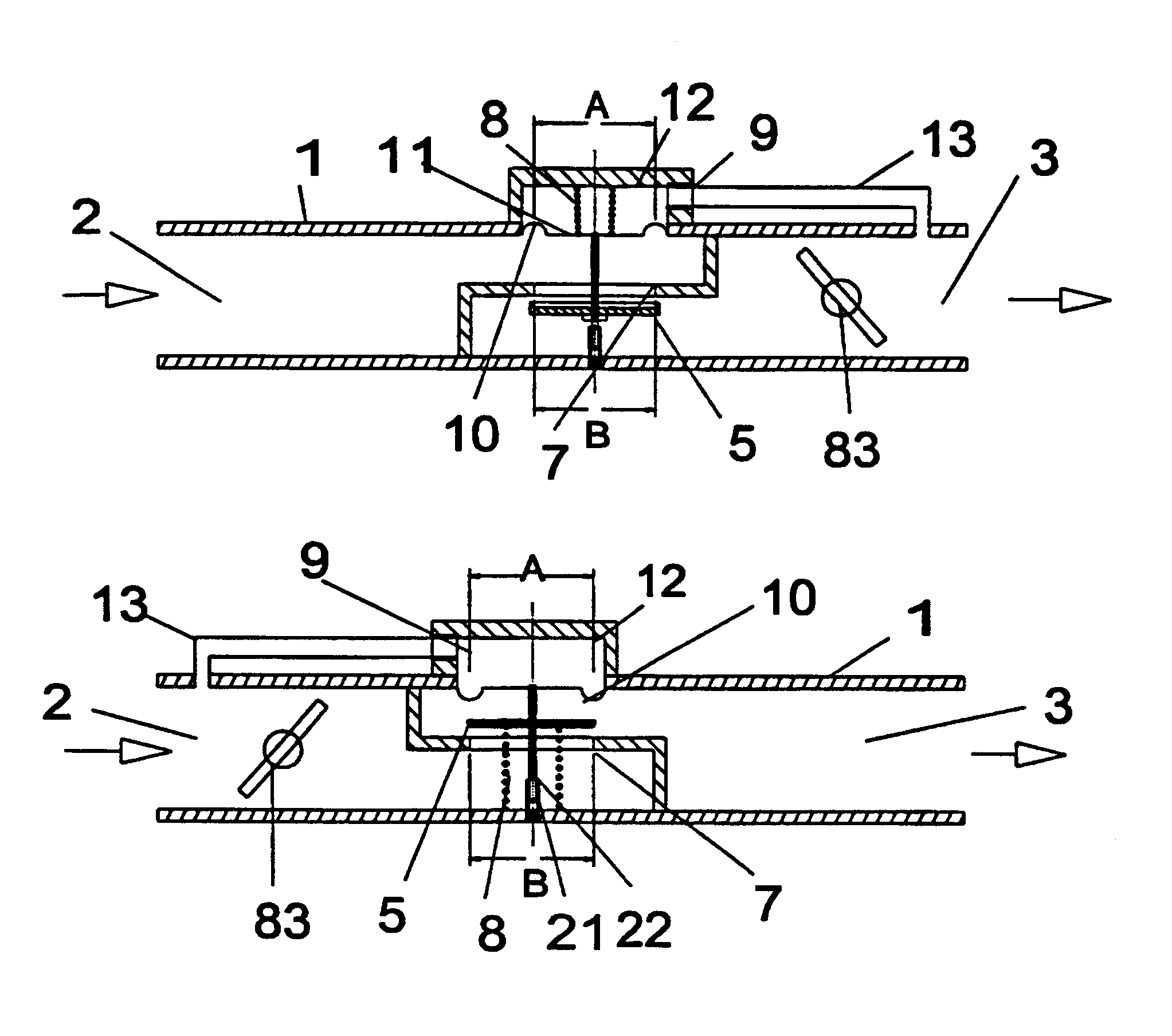

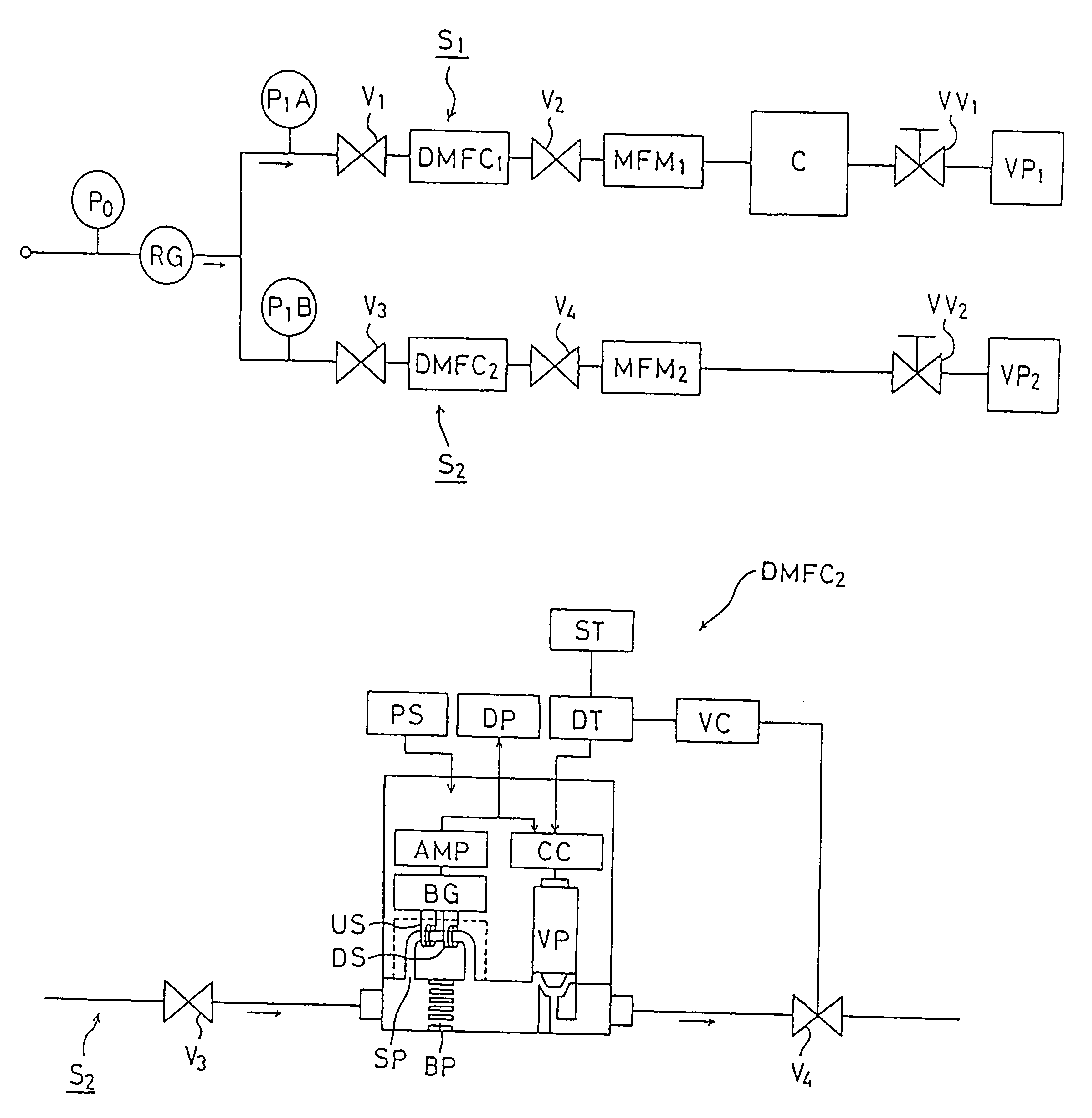

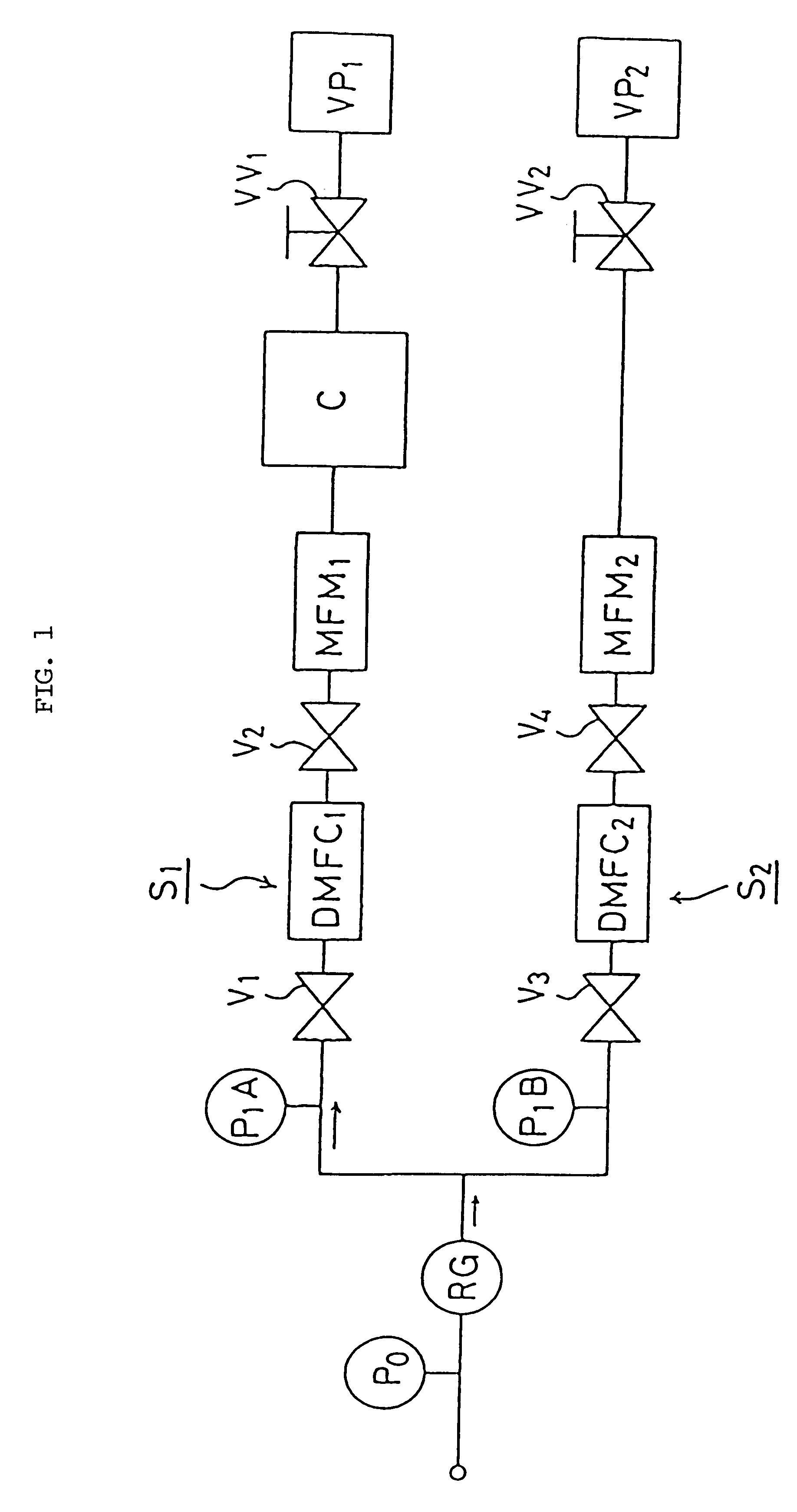

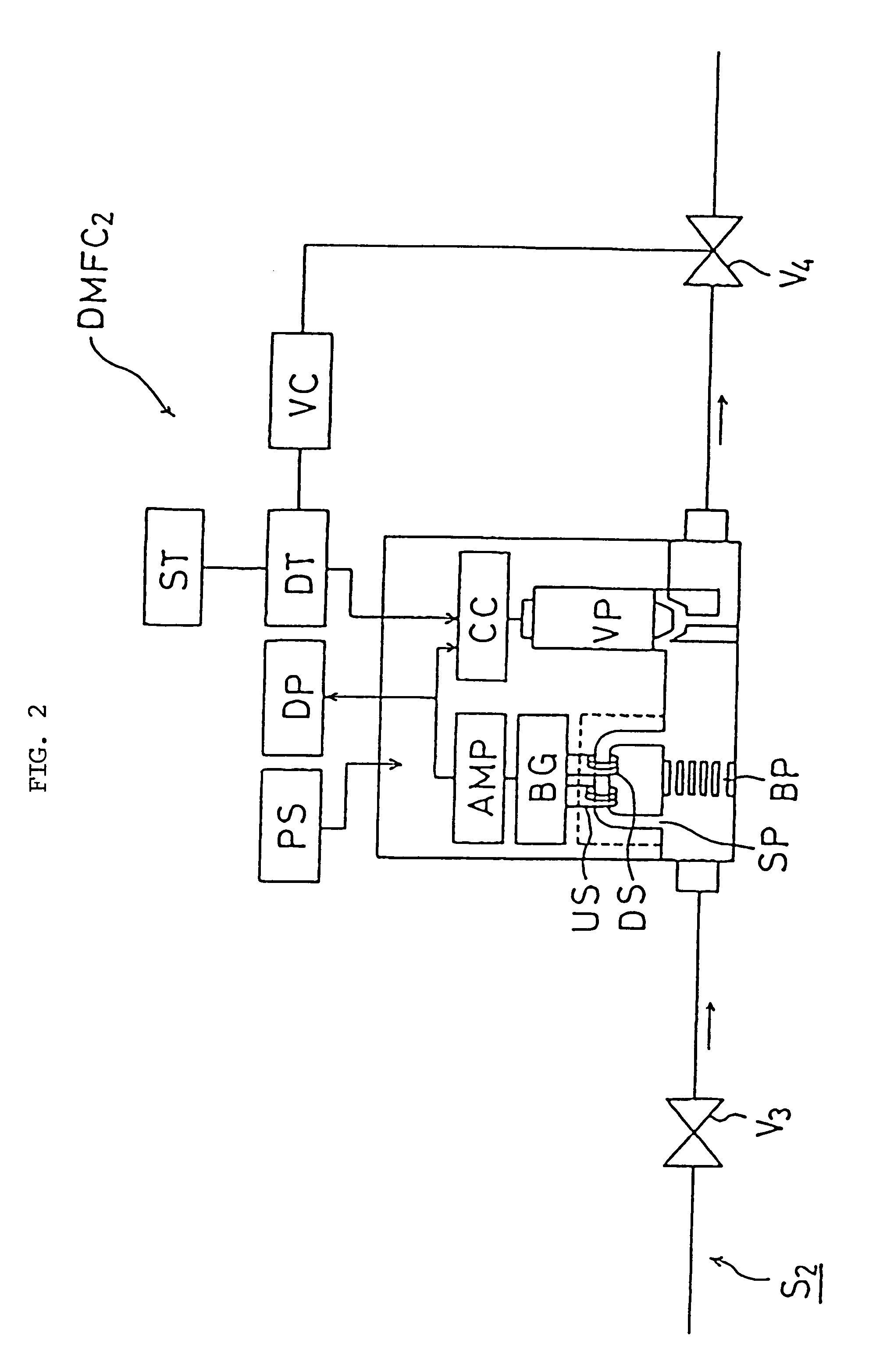

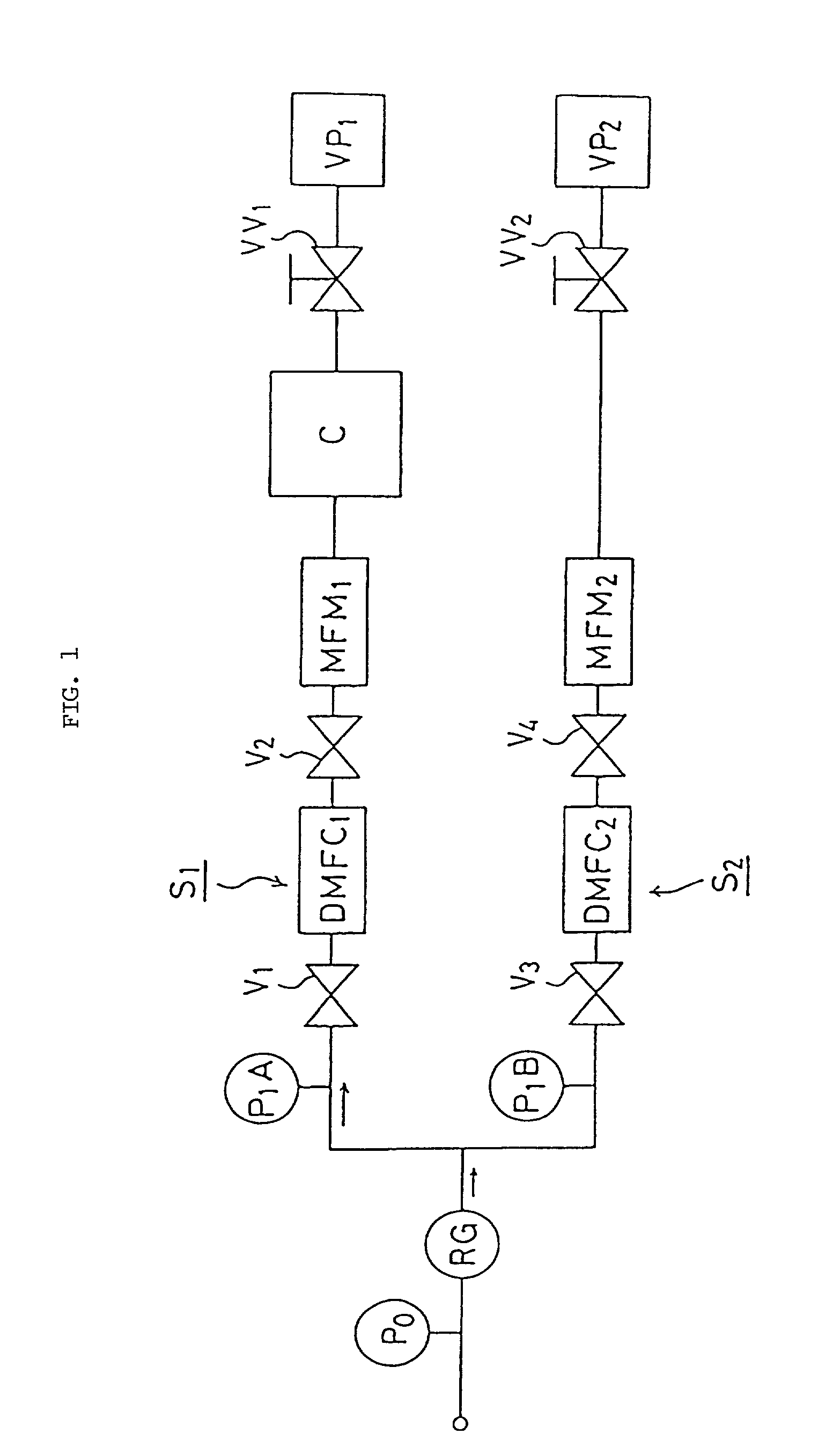

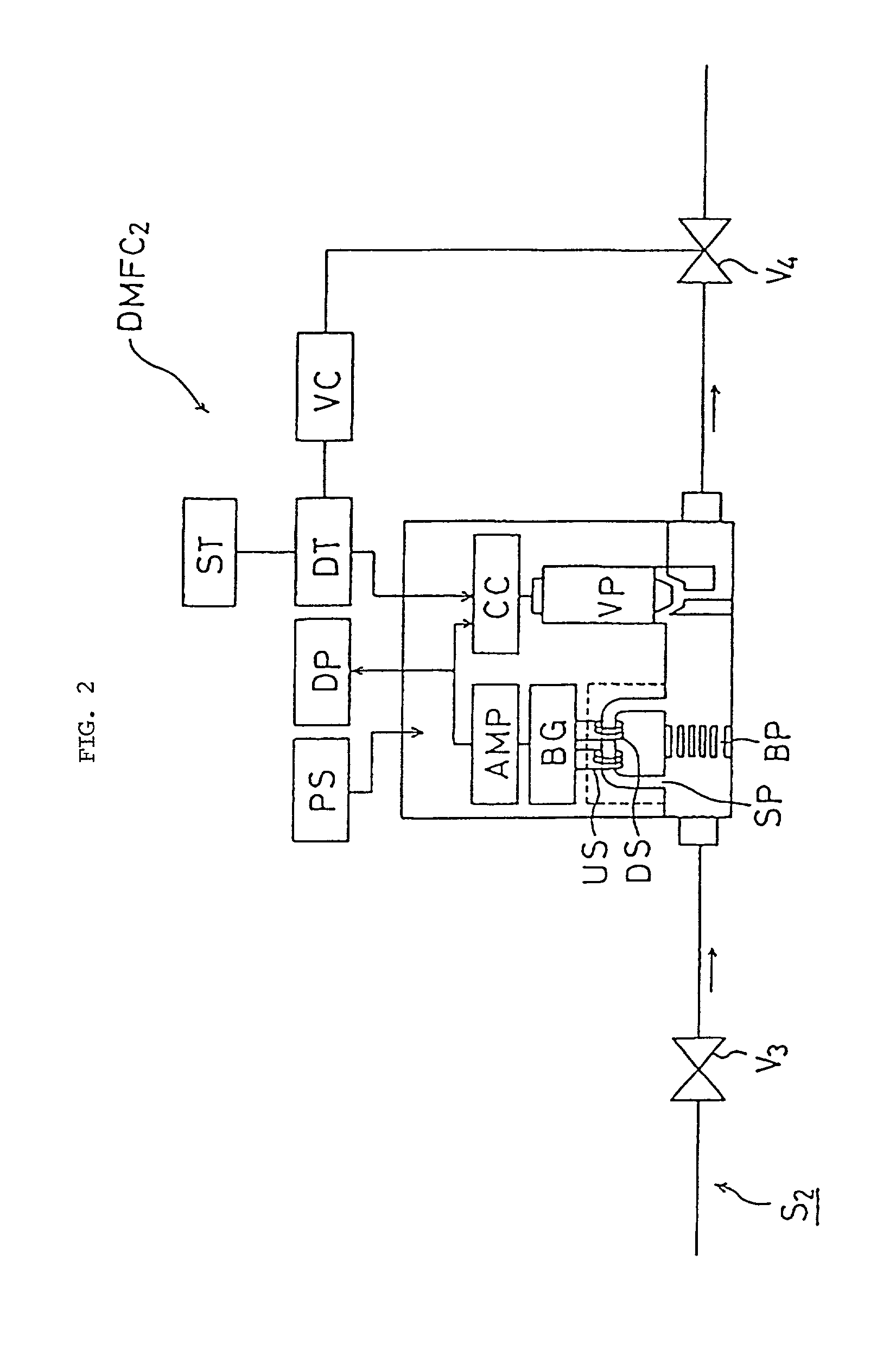

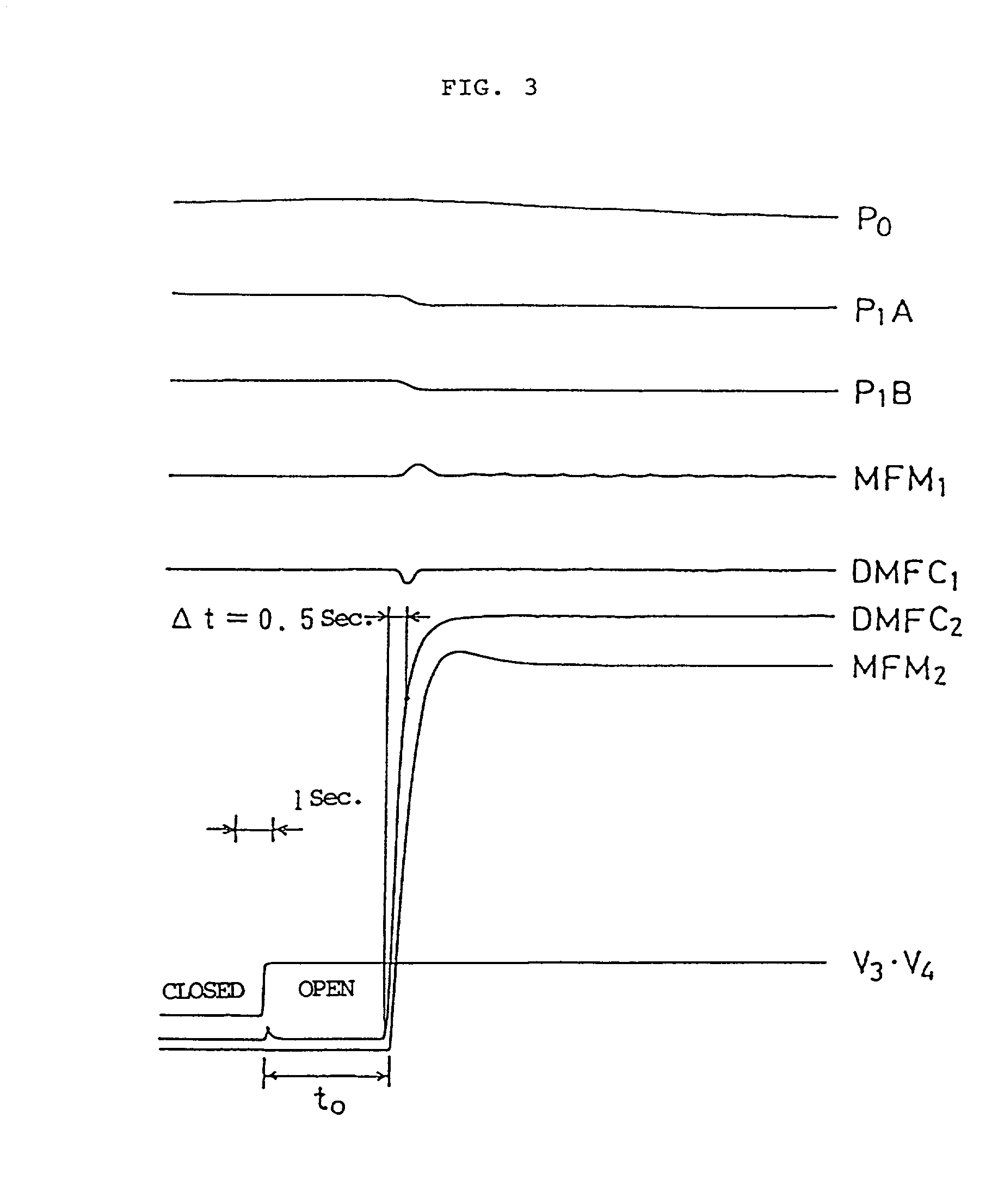

Parallel divided flow-type fluid supply apparatus, and fluid-switchable pressure-type flow control method and fluid-switchable pressure-type flow control system for the same fluid supply apparatus

InactiveUS6422264B2Operating means/releasing devices for valvesTime-programme switchesLine tubingControl system

A fluid supply apparatus with a plurality of flow lines branching out from one pressure regulator with the flow lines arranged in parallel and constructed so that opening or closing one flow passage will have no transient effect on the steady flow of the other flow passages. Each flow passage is provided with a time delay-type mass flow controller MFC so that when one closed fluid passage is opened, the mass flow controller on that flow passage reaches a set flow rate Qs in a specific delay time DELTAt from the starting point.The invention includes a method and an apparatus in which a plurality of gas types can be controlled in flow rate with high precision by one pressure-type flow control system.

Owner:FUJIKIN INC +2

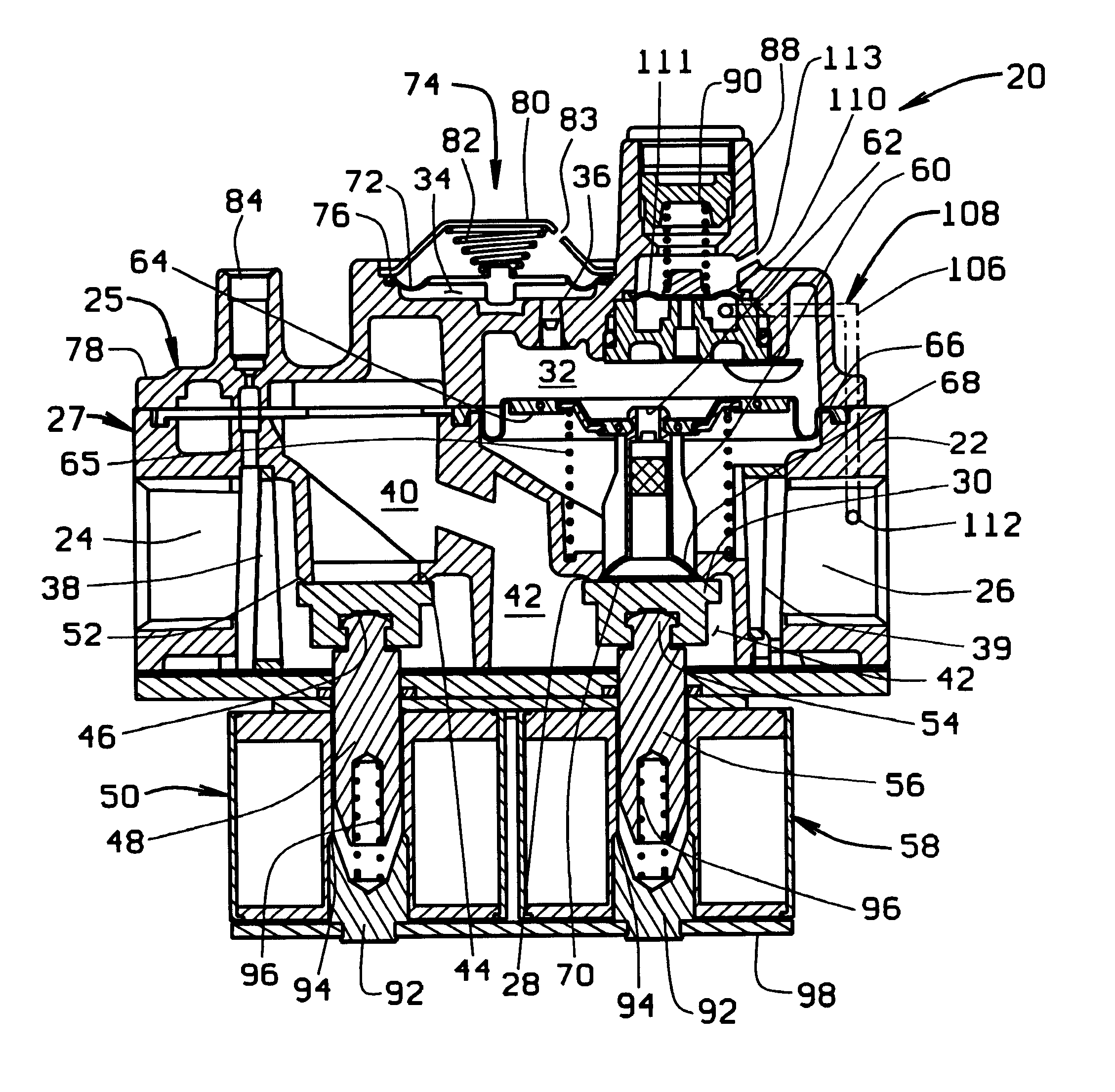

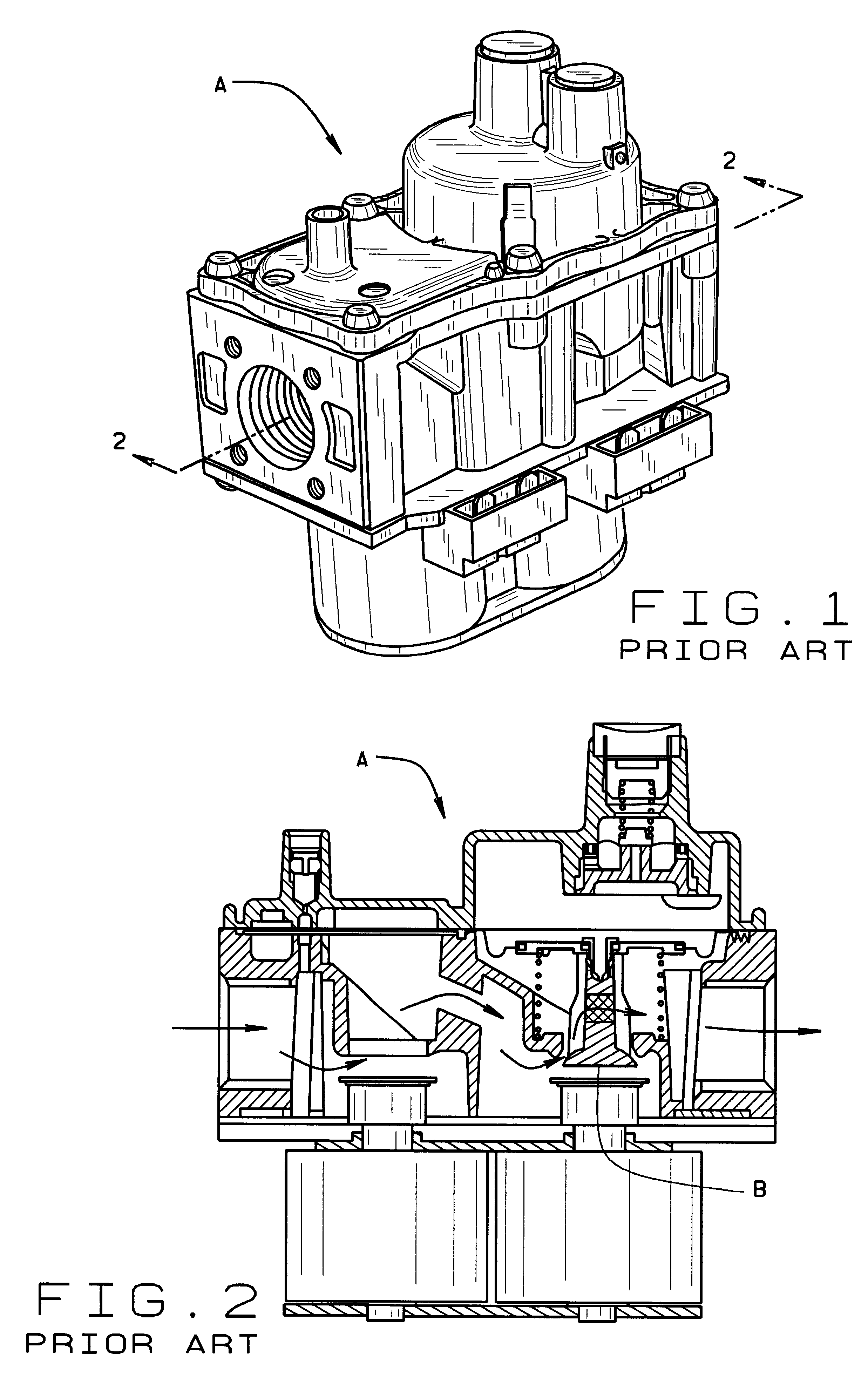

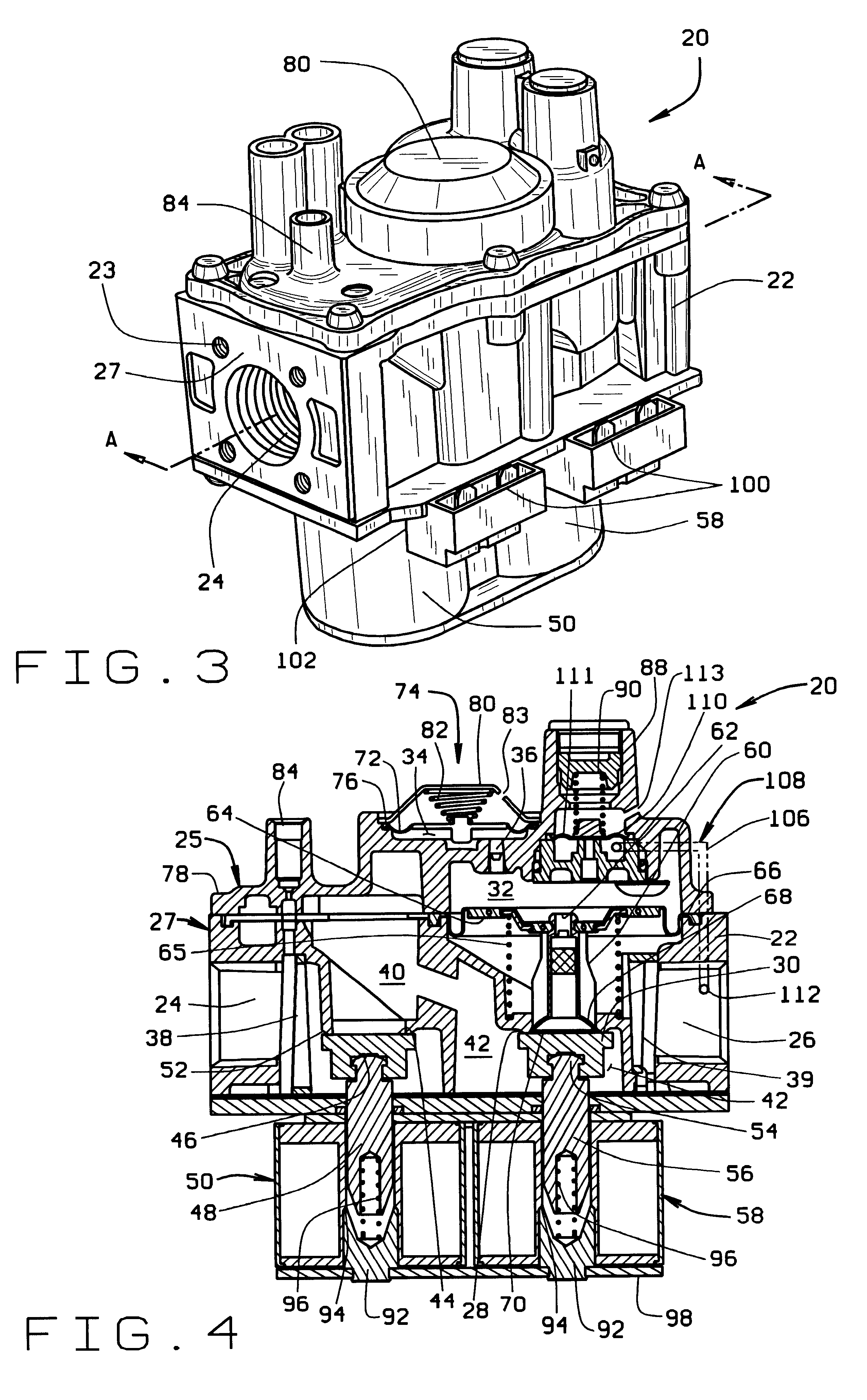

Slow opening gas valve

InactiveUS6263908B1Fuel supply regulationOperating means/releasing devices for valvesProduct gasEngineering

An improved slow opening gas valve providing for continuous gradual and smooth opening of the gas valve includes an expansible auxiliary chamber connected to an expansible control chamber by a metering orifice. The expansible auxiliary chamber slows expansion of the expansible control chamber, thereby slowing opening of the gas valve and allowing gas to ignite at a lower pressure with a much less audible sound. The gas valve is provided with a normally closed valve member for controlling flow of gas through the gas valve and a diaphragm forms a movable wall of the expansible control chamber that is operable upon expansion of the chamber to move the valve member to an open position. The expansible auxiliary chamber also comprises a movable diaphragm to control the opening of the gas valve and provide gas flow gradually and smoothly. In an alternate embodiment, a gas valve is configured to provide an initial gas flow through a bypass orifice in the closed valve member, which enables ignition of the gas at an optimum gas pressure instantly, followed by a gradual and smooth opening of the valve member. This arrangement provides a "step" function followed by the desired slow opening of the valve member.

Owner:EMERSON ELECTRIC CO

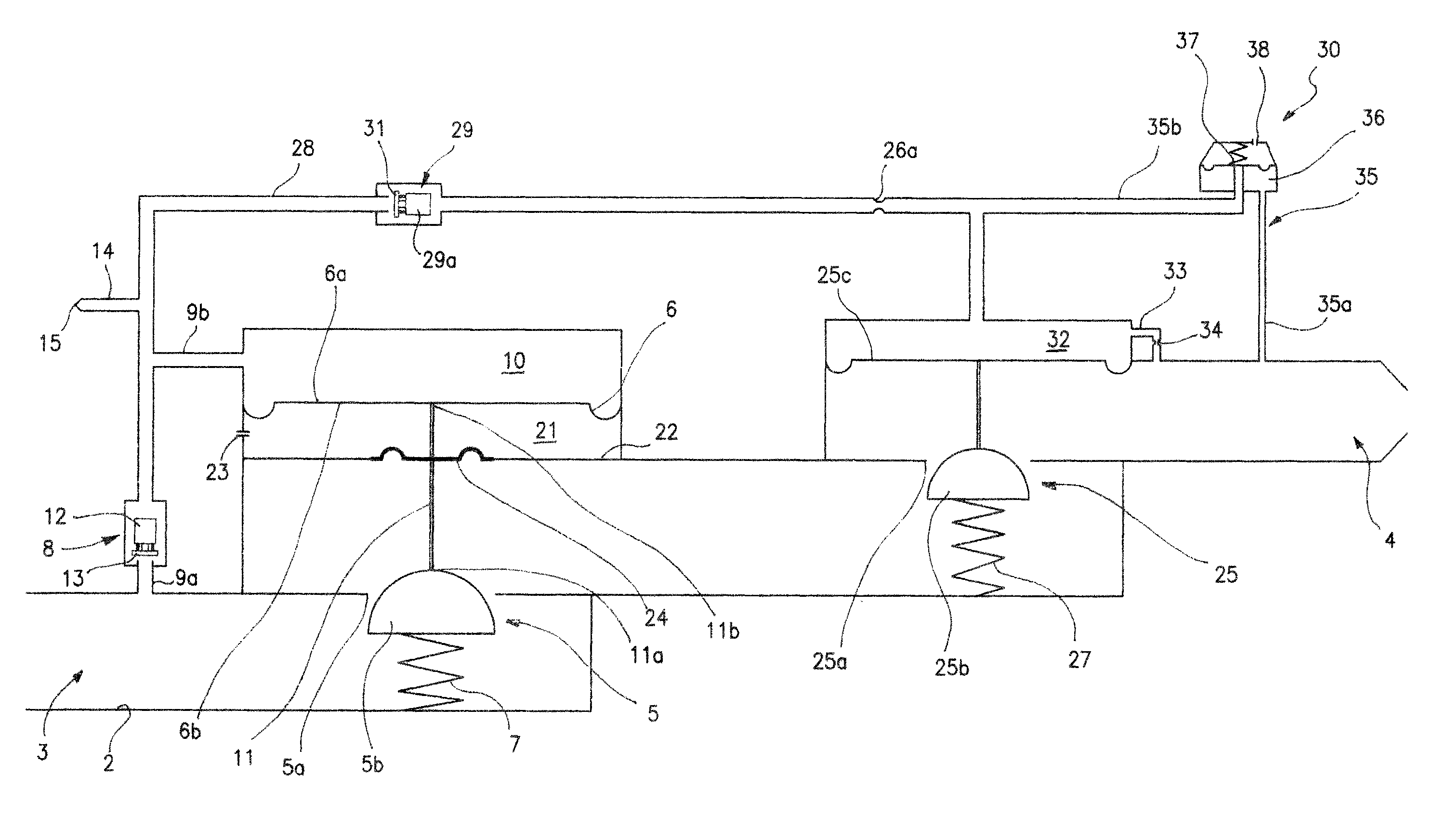

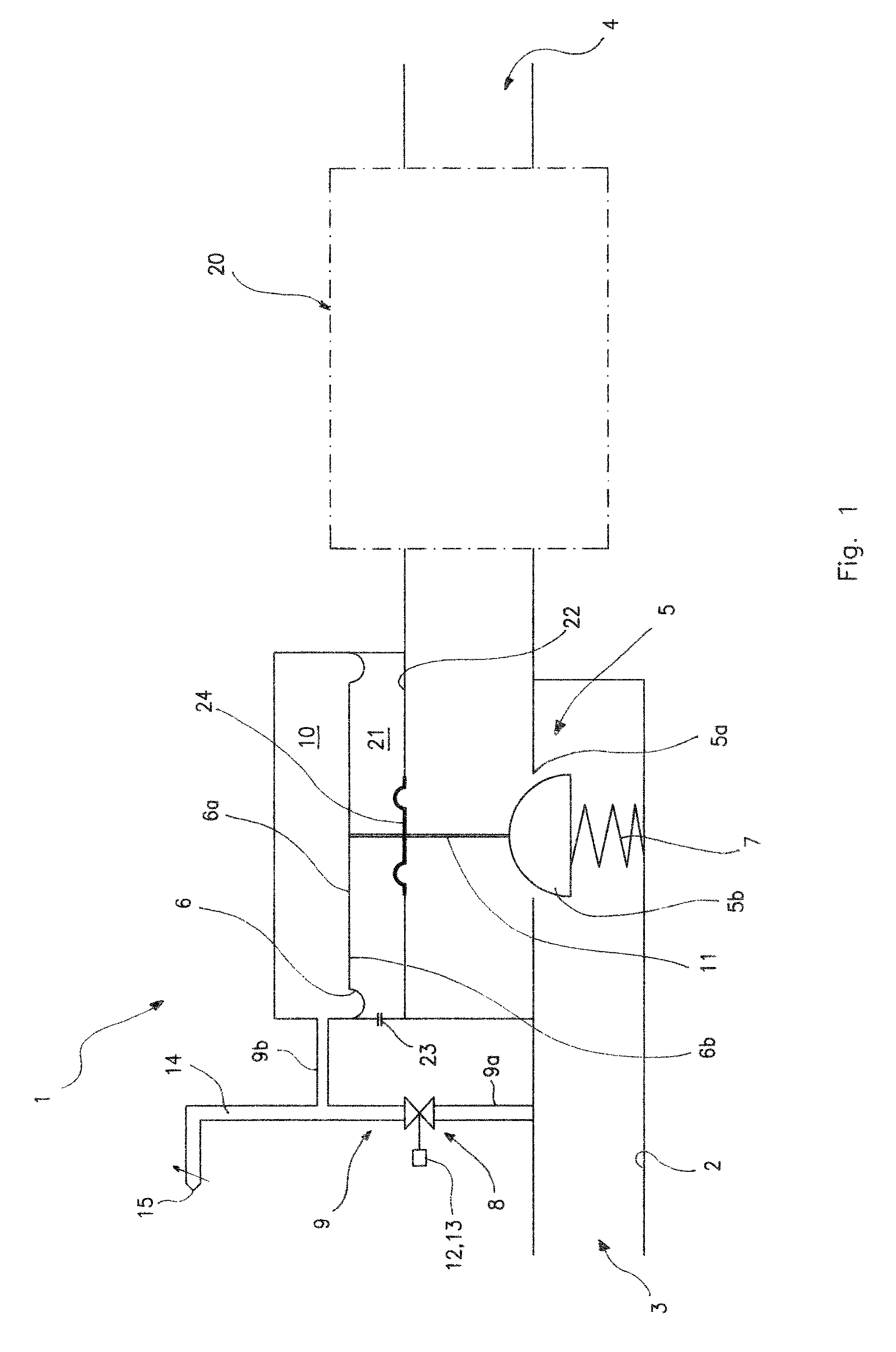

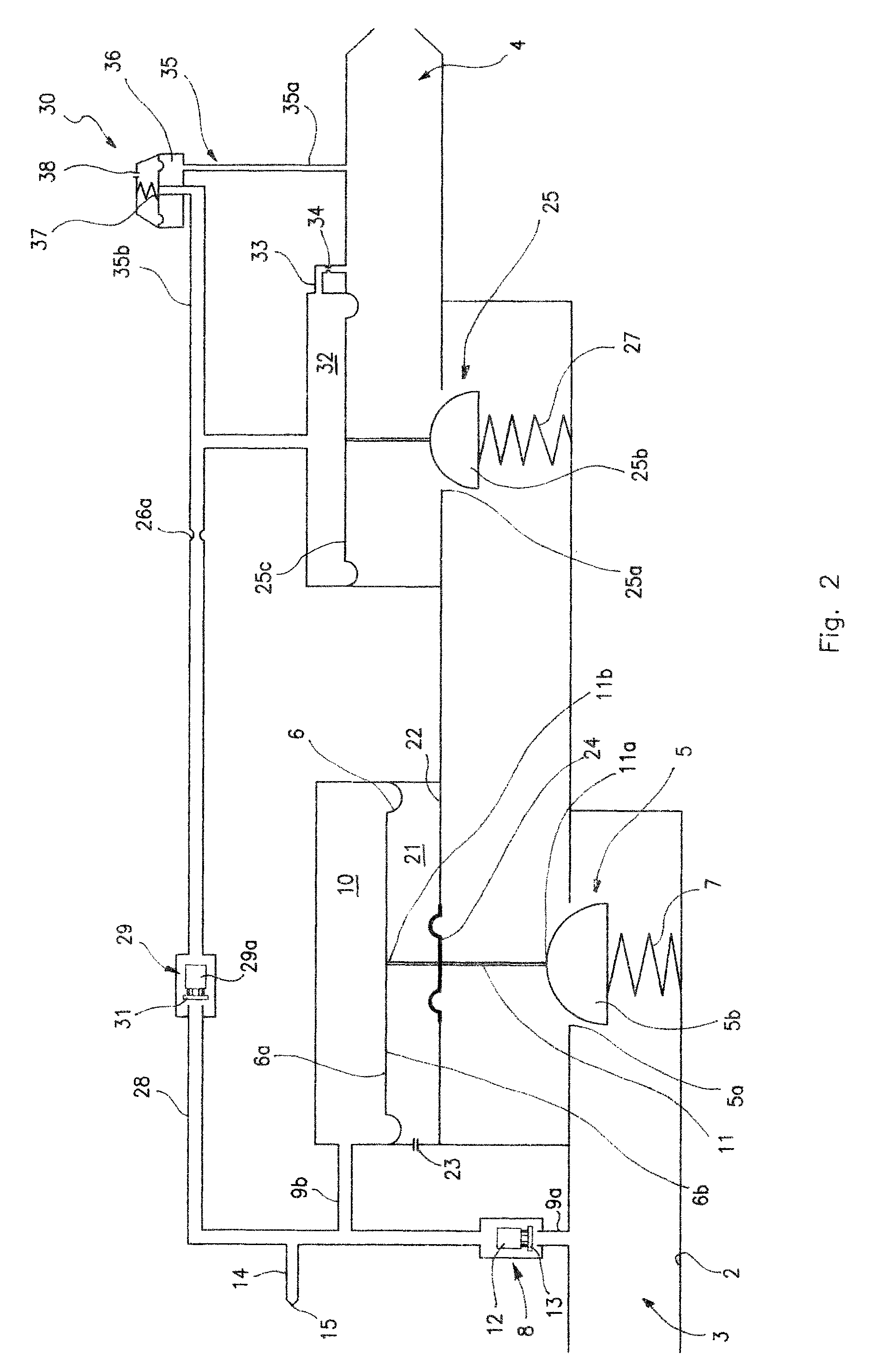

Device for controlling the delivery of a combustible gas to a burner apparatus

ActiveUS8162002B2Fuel supply regulationOperating means/releasing devices for valvesCombustorSolenoid valve

A device for controlling the delivery of a combustible gas to a burner apparatus is provided including a main gas-delivery duct in which there is at least one servo-assisted diaphragm valve including a valve seat associated with a corresponding closure member with diaphragm control for opening the seat against the action of a resilient biasing member. The diaphragm valve includes a respective control solenoid valve with an electromagnetic operator for controlling the corresponding valve, the solenoid valve being arranged to bring about the opening / closure of a duct of a respective servo-assisted control circuit so as to operate the closure member of the valve indirectly, by the diaphragm control. The duct of the control circuit putting a portion of the main duct that is disposed upstream of the valve seat with respect to the direction of the gas-flow into flow communication with a respective control chamber of the diaphragm valve.

Owner:SOC ITALANA TECNOMECCANICA

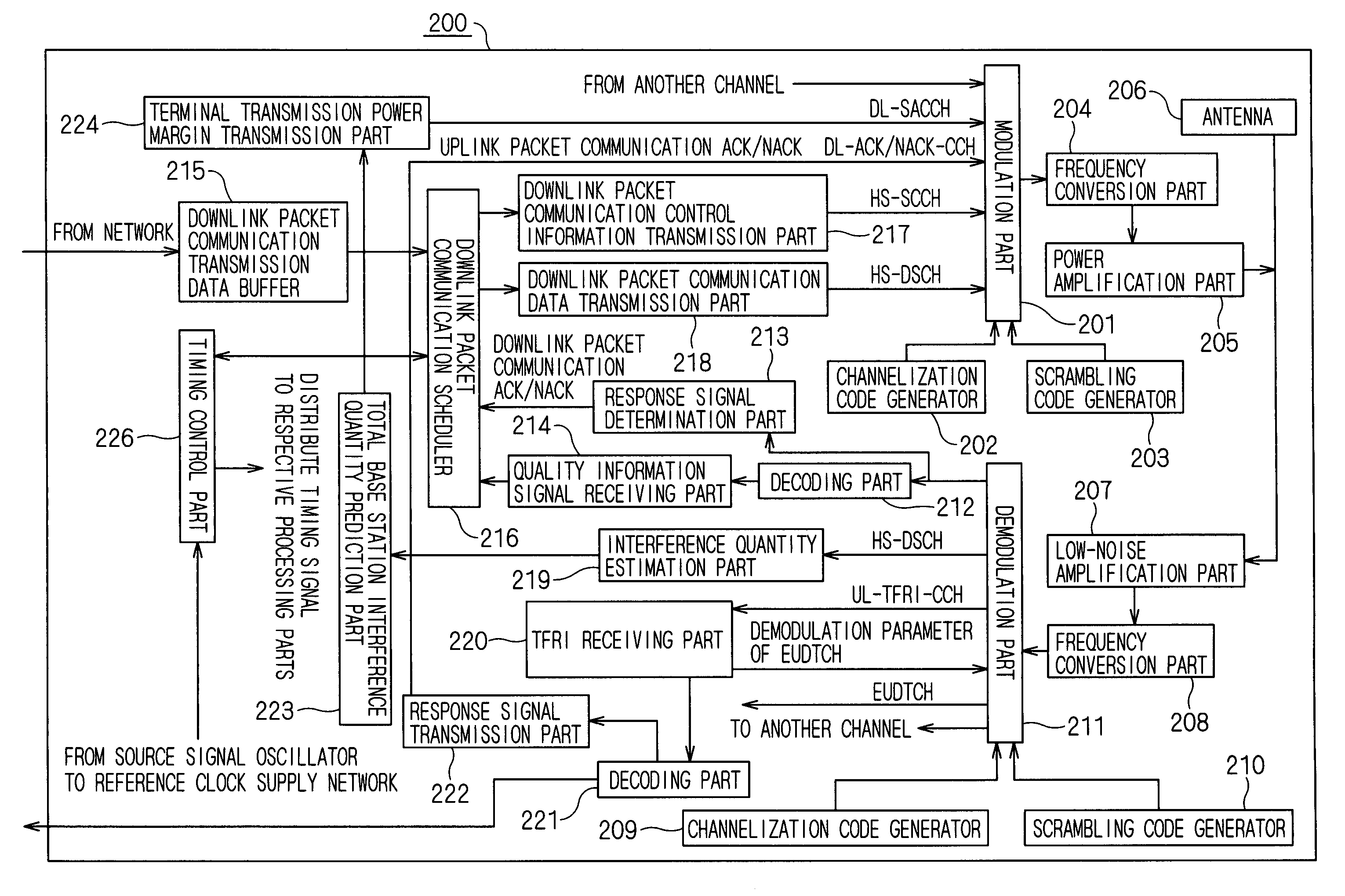

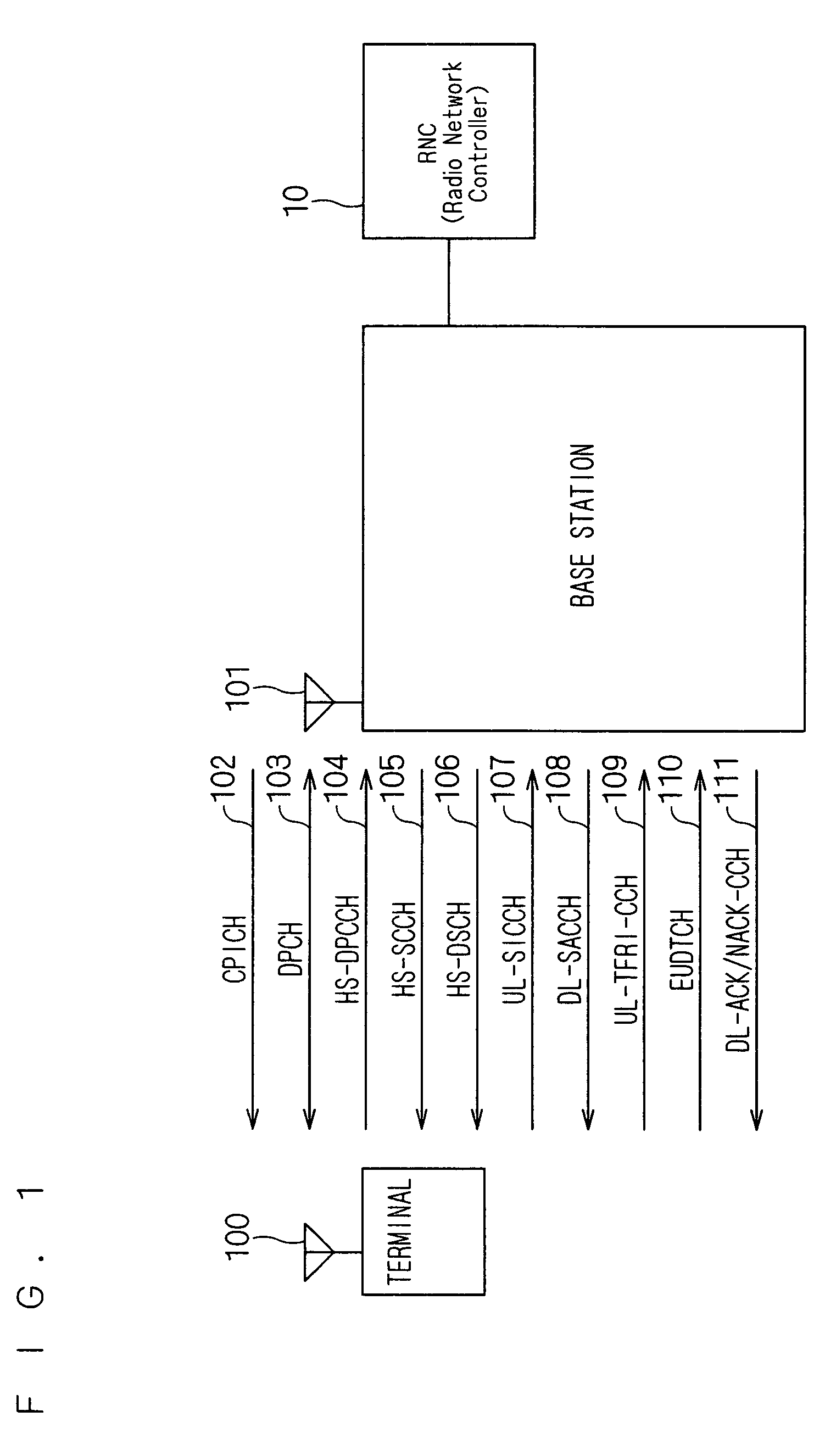

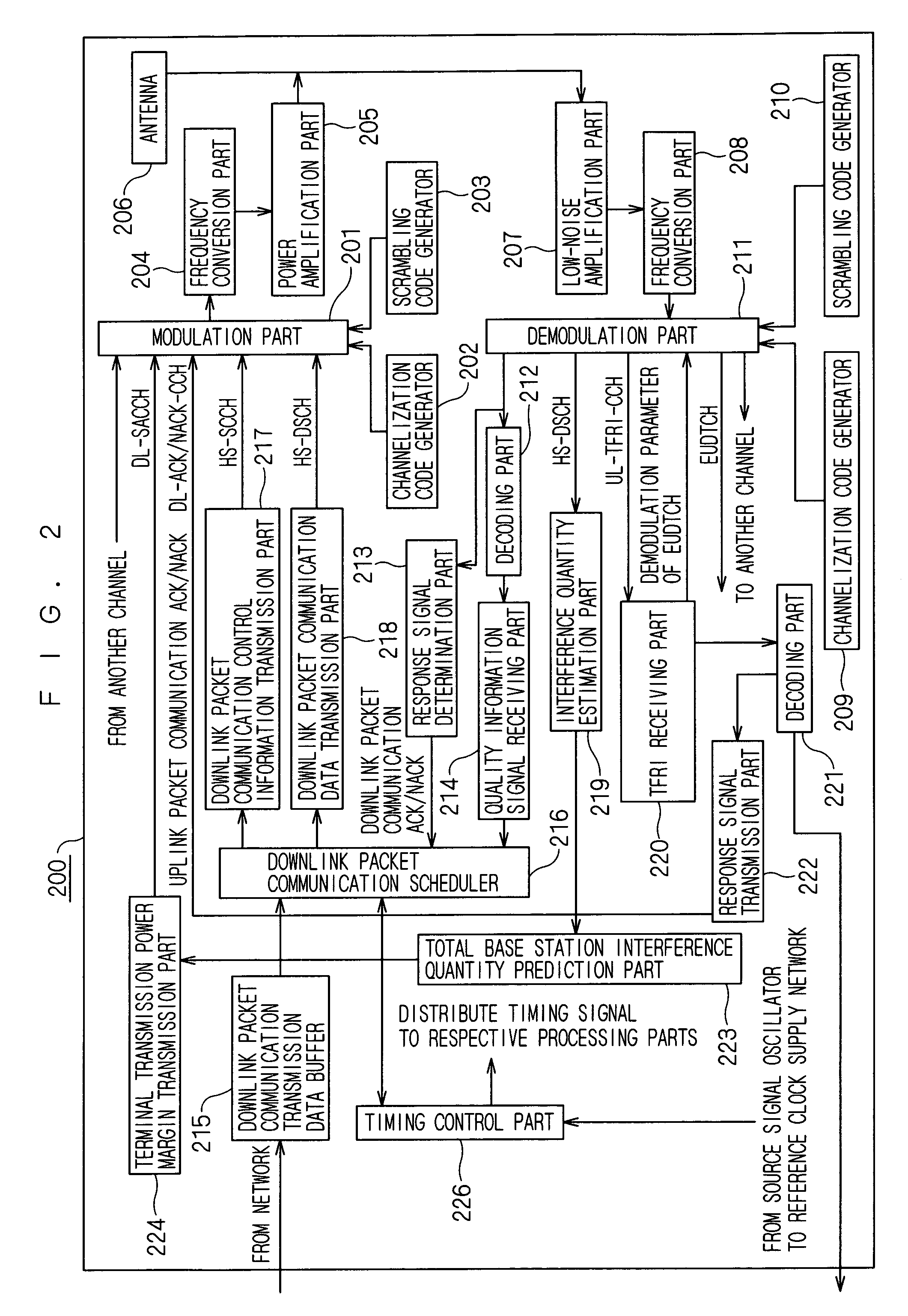

Communication terminal and communication system

InactiveUS7352709B2Improve communication qualityError preventionFrequency-division multiplex detailsCommunication qualityCommunications system

A communication system including a base station and a communication terminal transmitting / receiving data to / from this base station, in which the base station transmits downlink packet data to the communication terminal and receives an information signal related to the downlink packet data from the communication terminal that has received the downlink packet data, and the communication terminal includes an overflow estimation mechanism estimating a simultaneous transmission of uplink data and the information signal to the base station and a transmission signal control controlling transmission of the information signal in response to the result of estimation of this overflow estimation mechanism. The communication system is capable of selectively improving communication quality of either uplink communication or downlink communication by avoiding an overflow caused in a power amplification part of the communication terminal.

Owner:MITSUBISHI ELECTRIC CORP

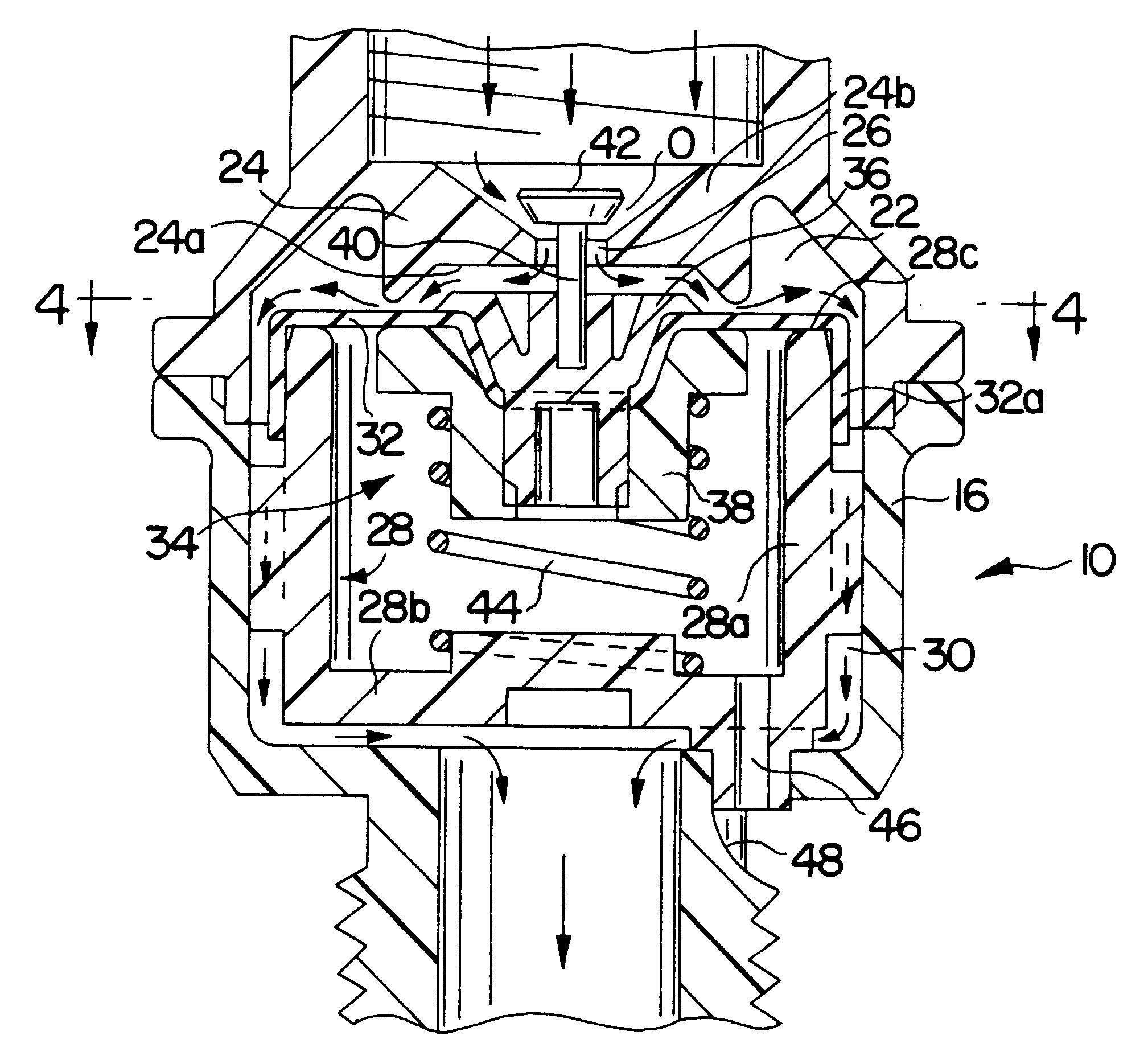

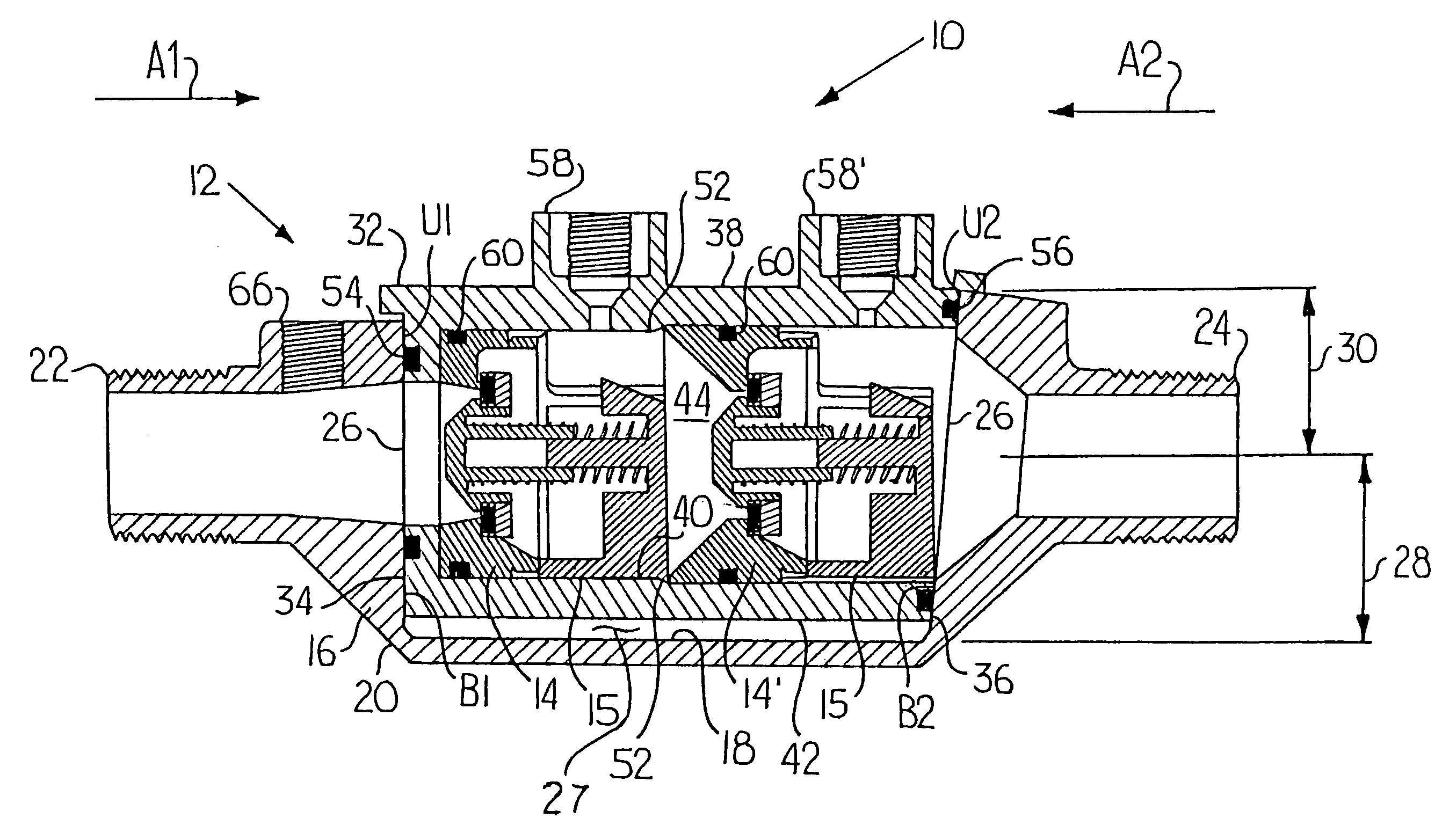

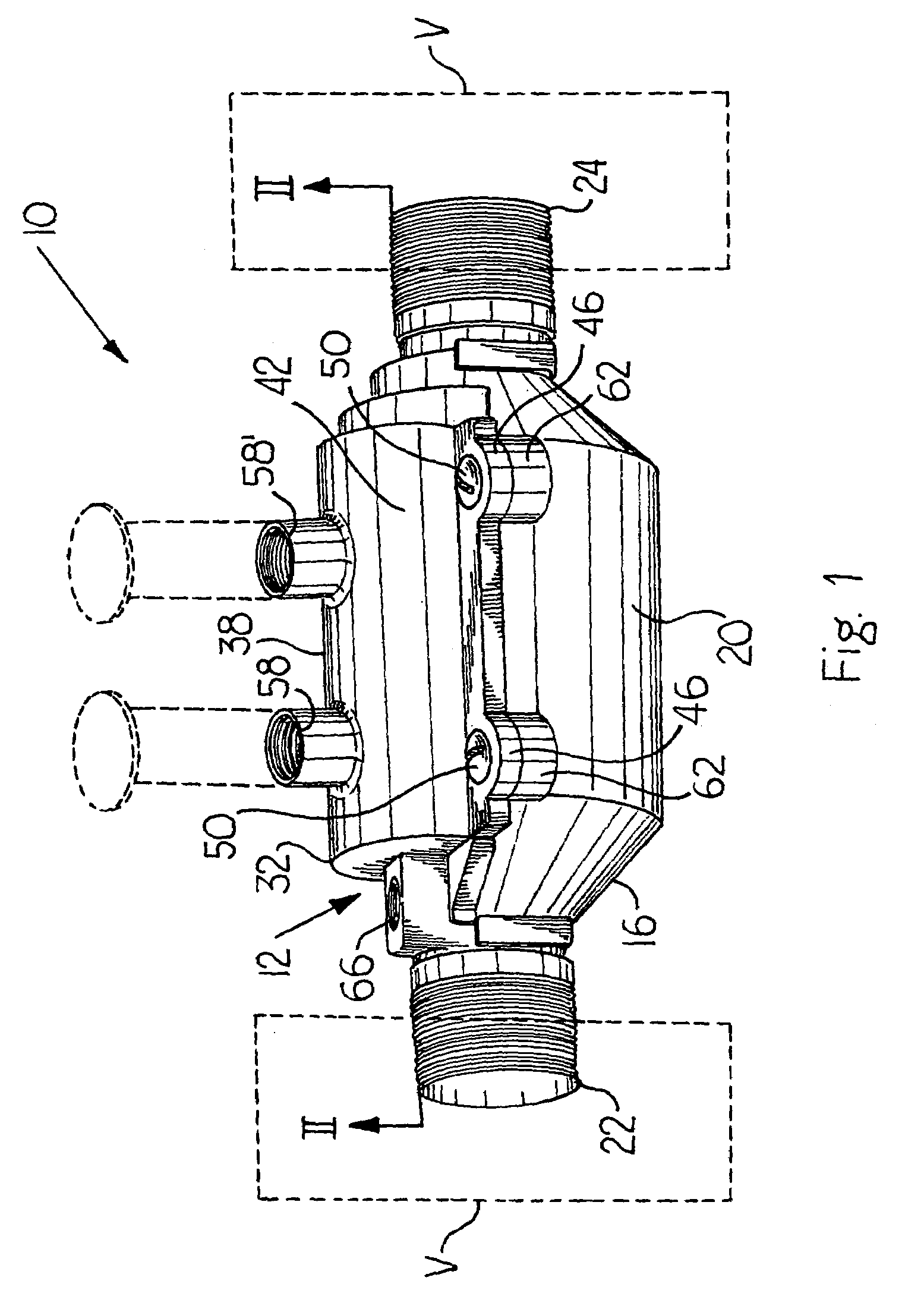

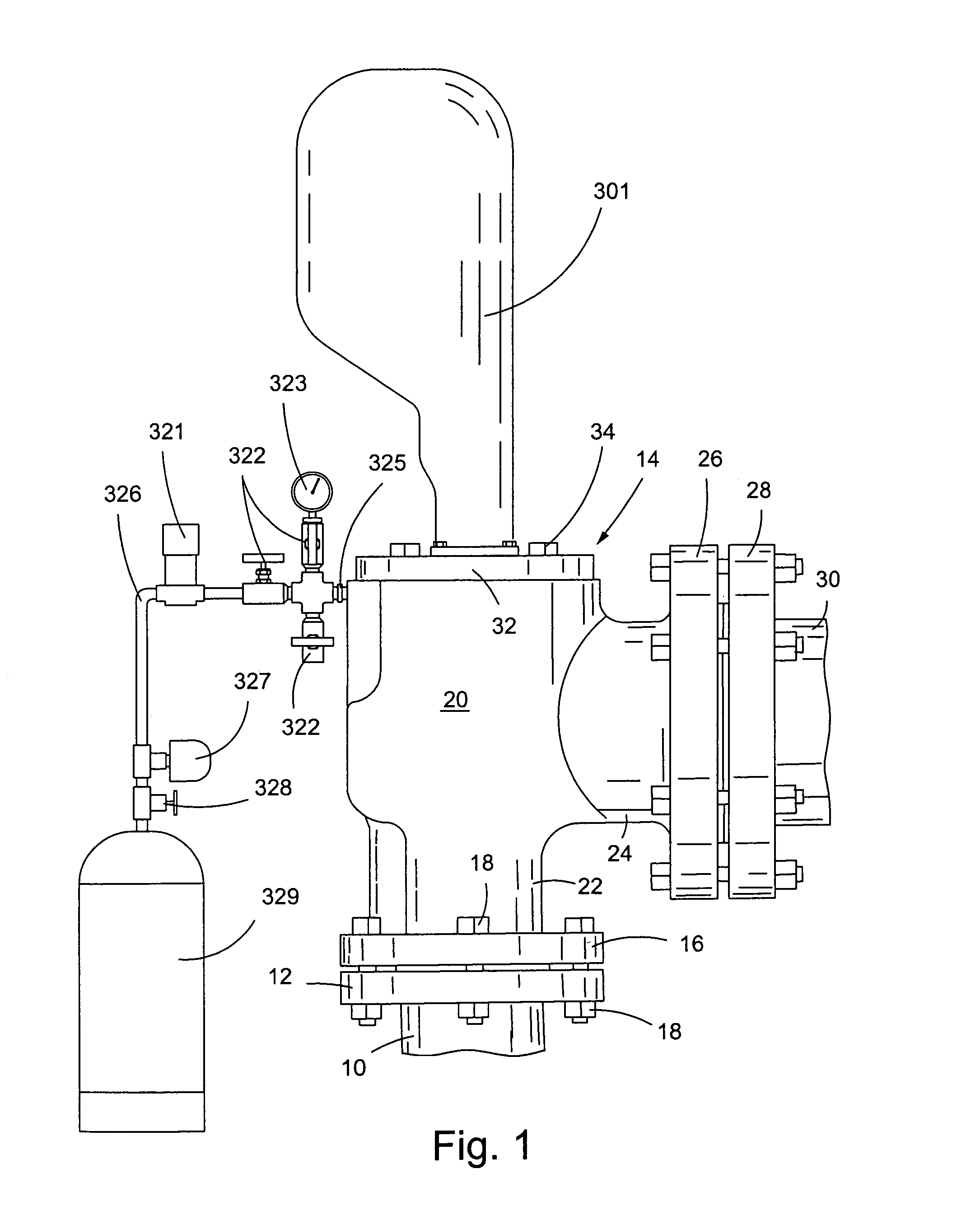

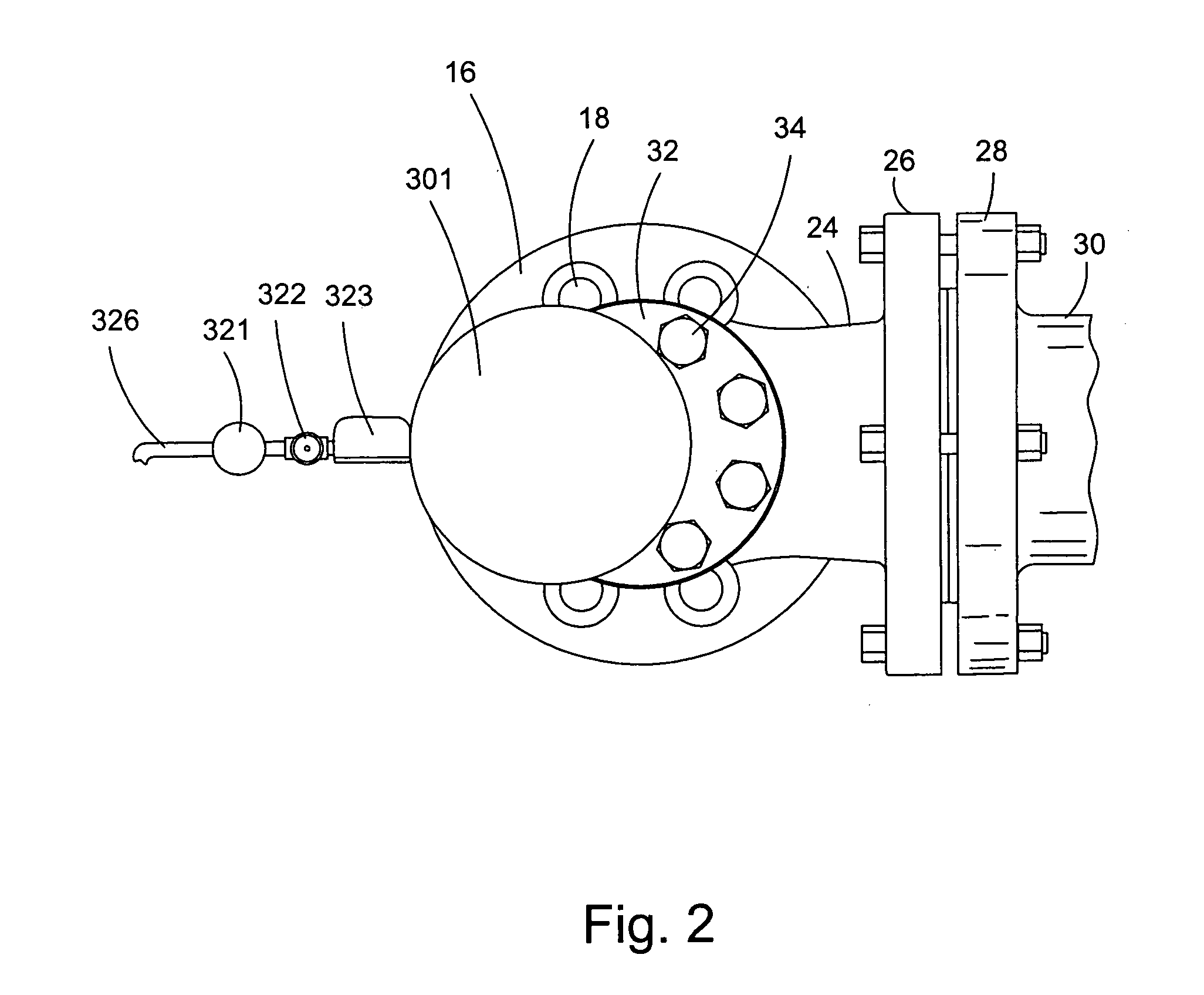

Double check valve assembly

A double check valve that generally includes a modular fluid casing having a main housing, a one-piece modular cage, and at least one in-line check valve removably housed in the modular cage.

Owner:ZURN INDS

Multi stage pressure regulator

InactiveUS20080047619A1Reduce flow rateIncrease flow rateOperating means/releasing devices for valvesCircuit elementsEngineeringPressure regulator

A pressure regulator is disclosed wherein multiple valve stages are used to accommodate low flow rates and to maximize a turn-down ratio of the regulator.

Owner:GM GLOBAL TECH OPERATIONS LLC

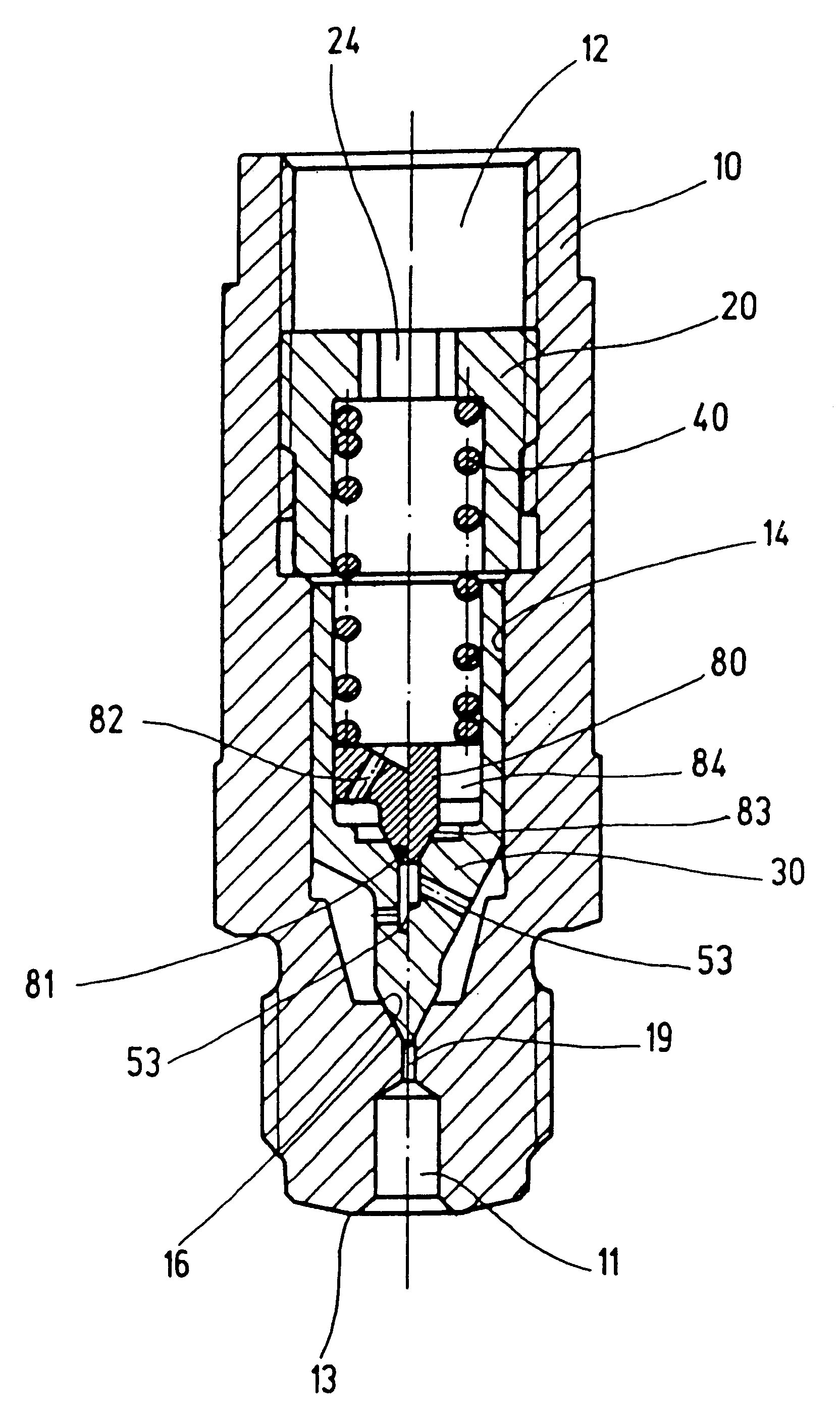

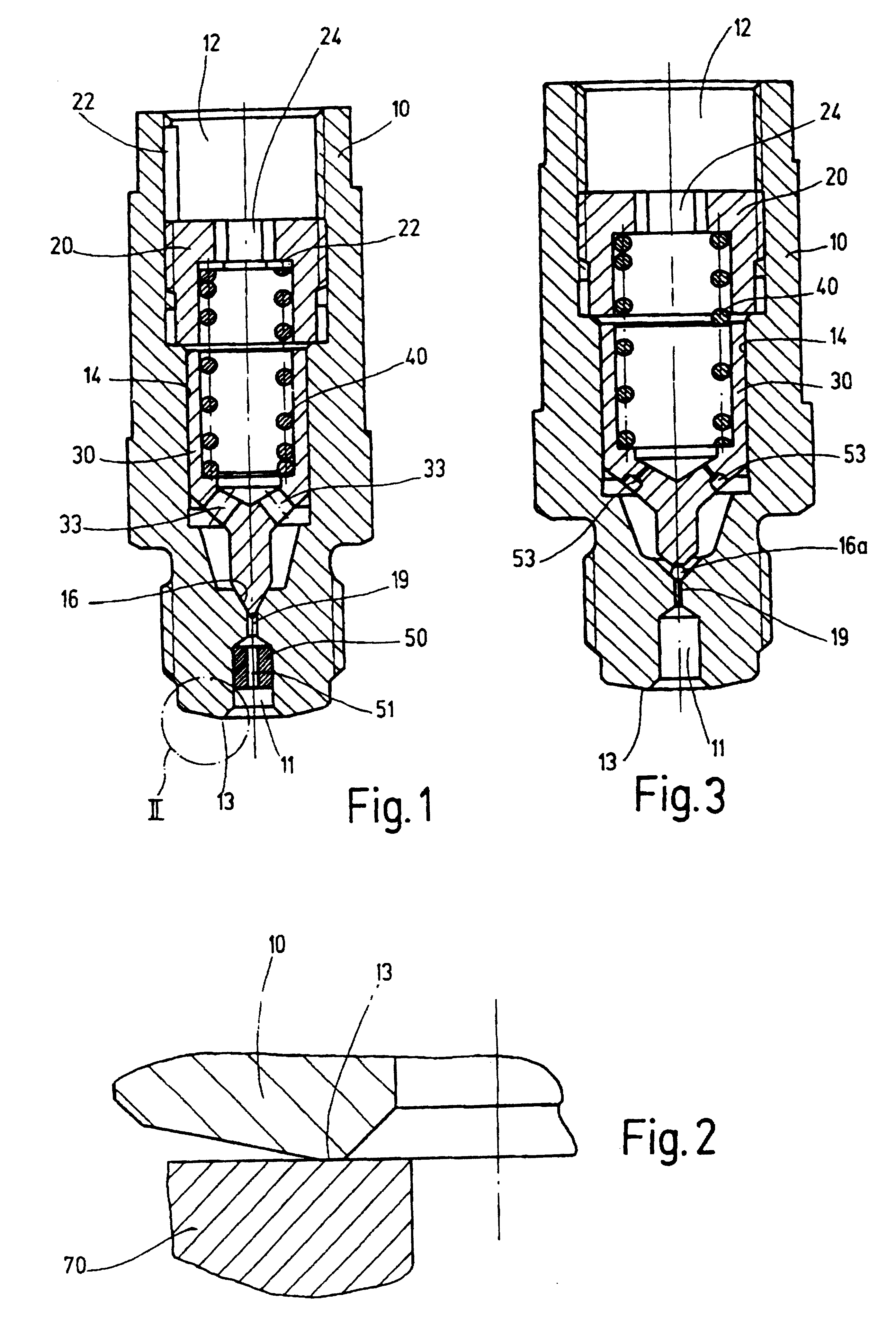

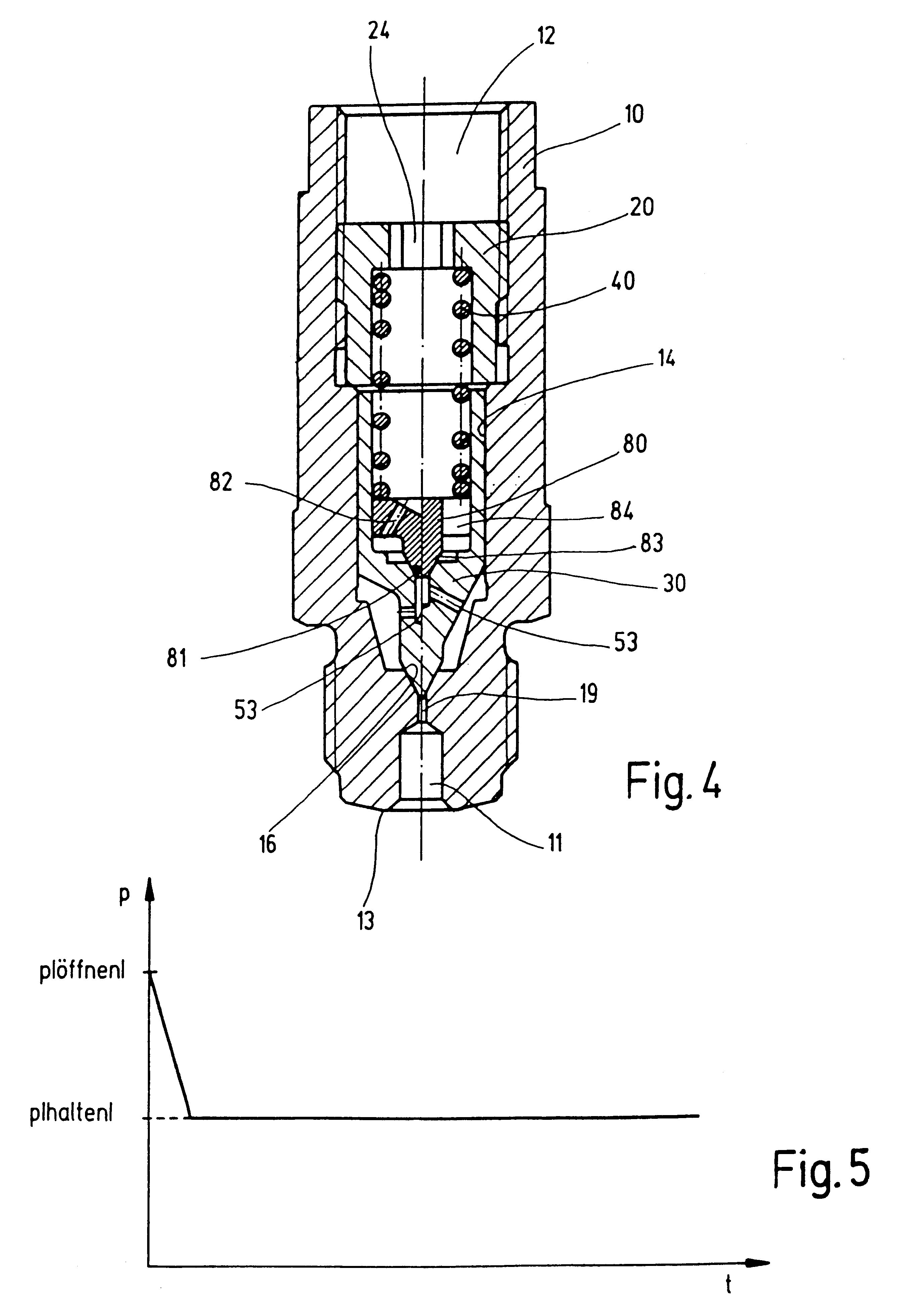

Pressure control valve

A pressure control valve for a fuel injection apparatus for internal combustion engines, including a housing with a high-pressure connection and a return connection and including a cup-shaped piston, which is disposed in a housing bore, can be moved axially between a valve seat oriented toward the high-pressure connection and a stop oriented toward the return connection, counter to the spring force of a spring acting in the direction of the valve seat, and has at least one through opening that connects the inside of the cup-shaped piston to the housing bore, is characterized in that at least one throttle element is disposed upstream and / or downstream of the valve seat in the flow direction of the fuel.

Owner:ROBERT BOSCH GMBH

Pneumatic Pressure Regulation Valve

ActiveUS20080142091A1Guaranteed uptimePrevent freezingDiaphragm valvesOperating means/releasing devices for valvesDifferential pressureEngineering

A pneumatic pressure regulating valve, the opening of which can be automatically changed in a pressure-related manner, including a control diaphragm that is subjected to a reference pressure, to the gas pressure as well as to a governor spring, wherein a change in the differential pressure causes an adjustment of the control diaphragm and the latter itself or a closing element actuated by it changes the opening through an outflow cross-section, and wherein a structure that is arranged adjacent to the outflow cross-section on the diaphragm side forms a stop for the control diaphragm or for the closing element in the closed position of said control diaphragm. At least one preliminary stop is arranged in the pressure regulating valve such that, when the control diaphragm is moving in its closing direction, the control diaphragm or the closing element first comes into contact with the preliminary stop and that, when the control diaphragm is moving further in its closing direction, the control diaphragm or the closing element will then, while being subjected to elastic and flexible deformation or being further subjected to elastic and flexible deformation respectively, further reduces the opening and, in a final position, also comes into contact with the stop.

Owner:HENGST WALTER

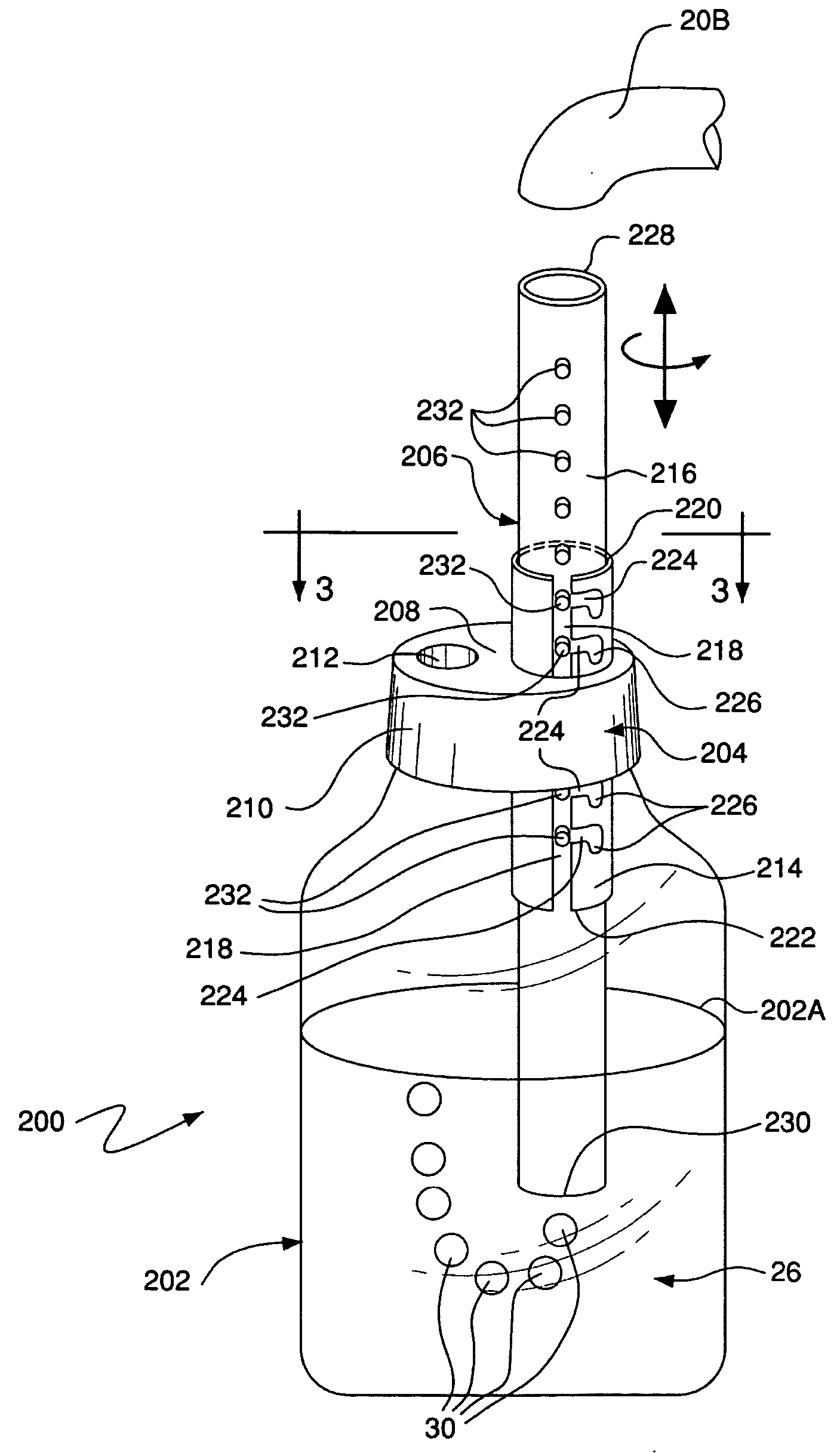

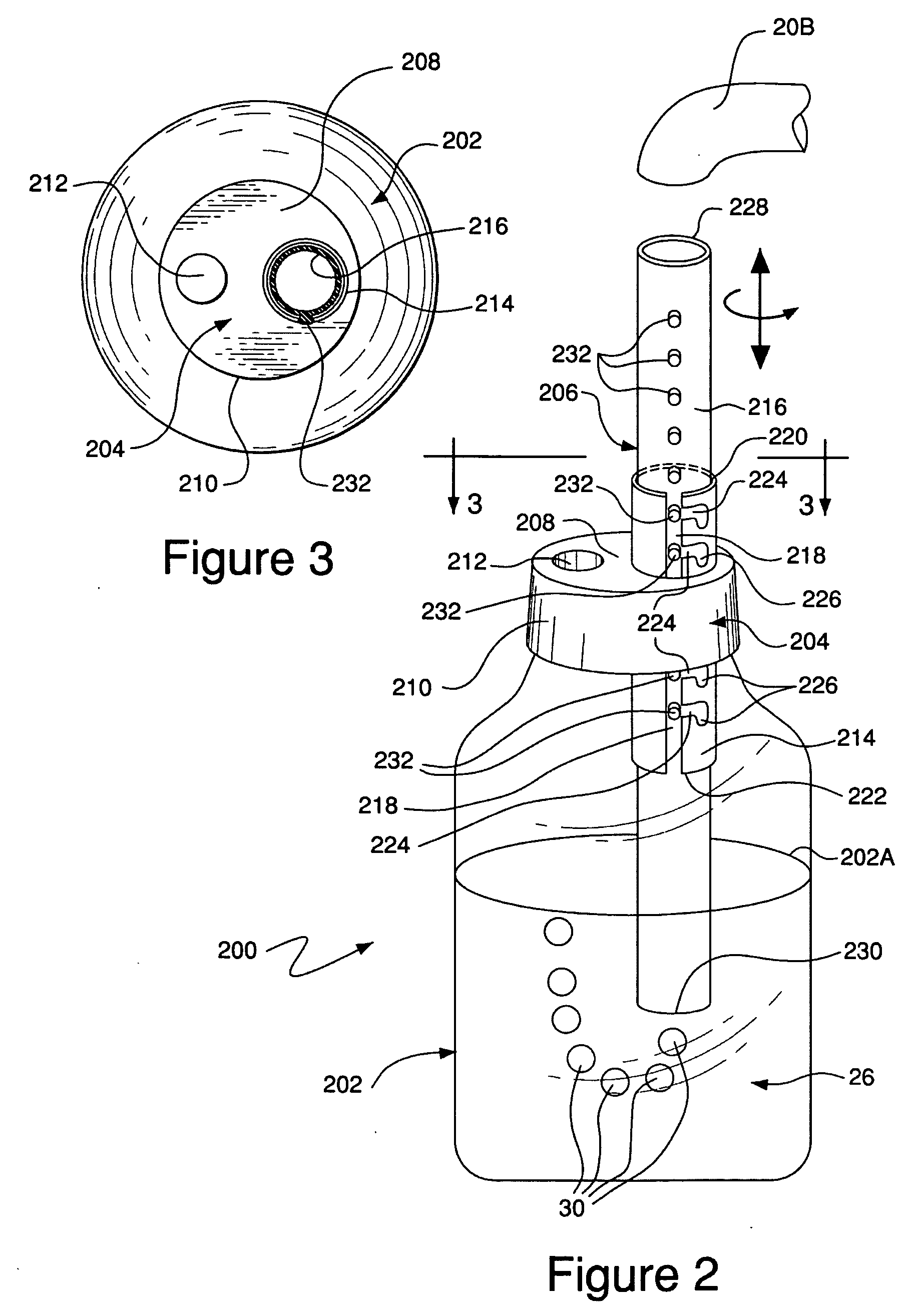

Apparatus for controlling the pressure of gas by bubbling through a liquid, such as bubble CPAP

InactiveUS20050072470A1Operating means/releasing devices for valvesRespiratory masksEngineeringGuide tube

Apparatus for effecting bubble CPAP. The apparatus includes a hollow vessel holding a liquid, a cap, and a positionable tube assembly. The positionable tube assembly comprises a guide tube and a positionable tube. The positionable tube is arranged to have a gas introduced through it and is located within the guide tube. The positionable tube is arranged to be slid to various discrete longitudinal positions with respect to the guide tube and to be held in any one of those discrete positions against accidental displacement so that the lower free end of the positionable tube is held at a desired position below the surface of the liquid.

Owner:JACOBS HARRIS C +1

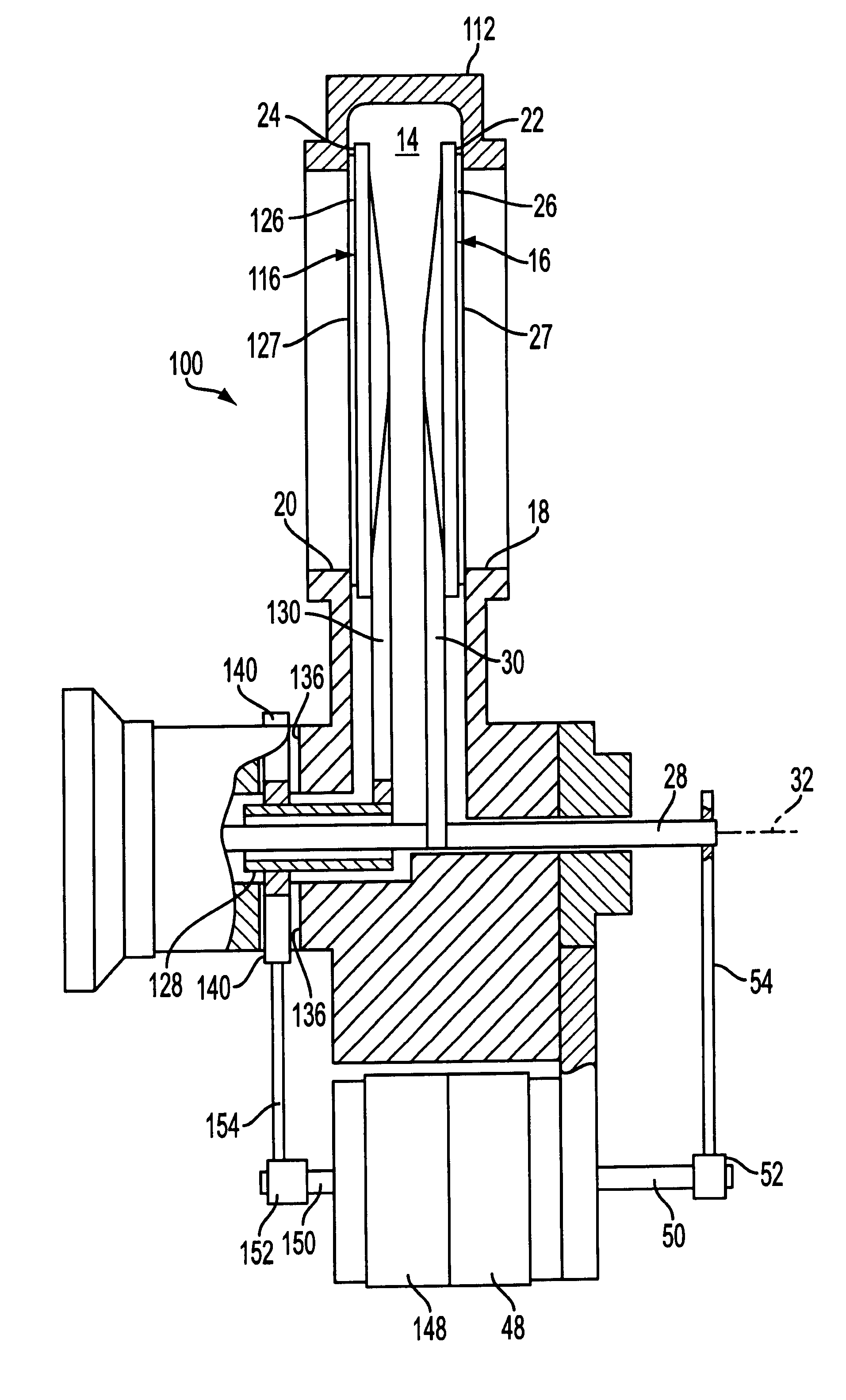

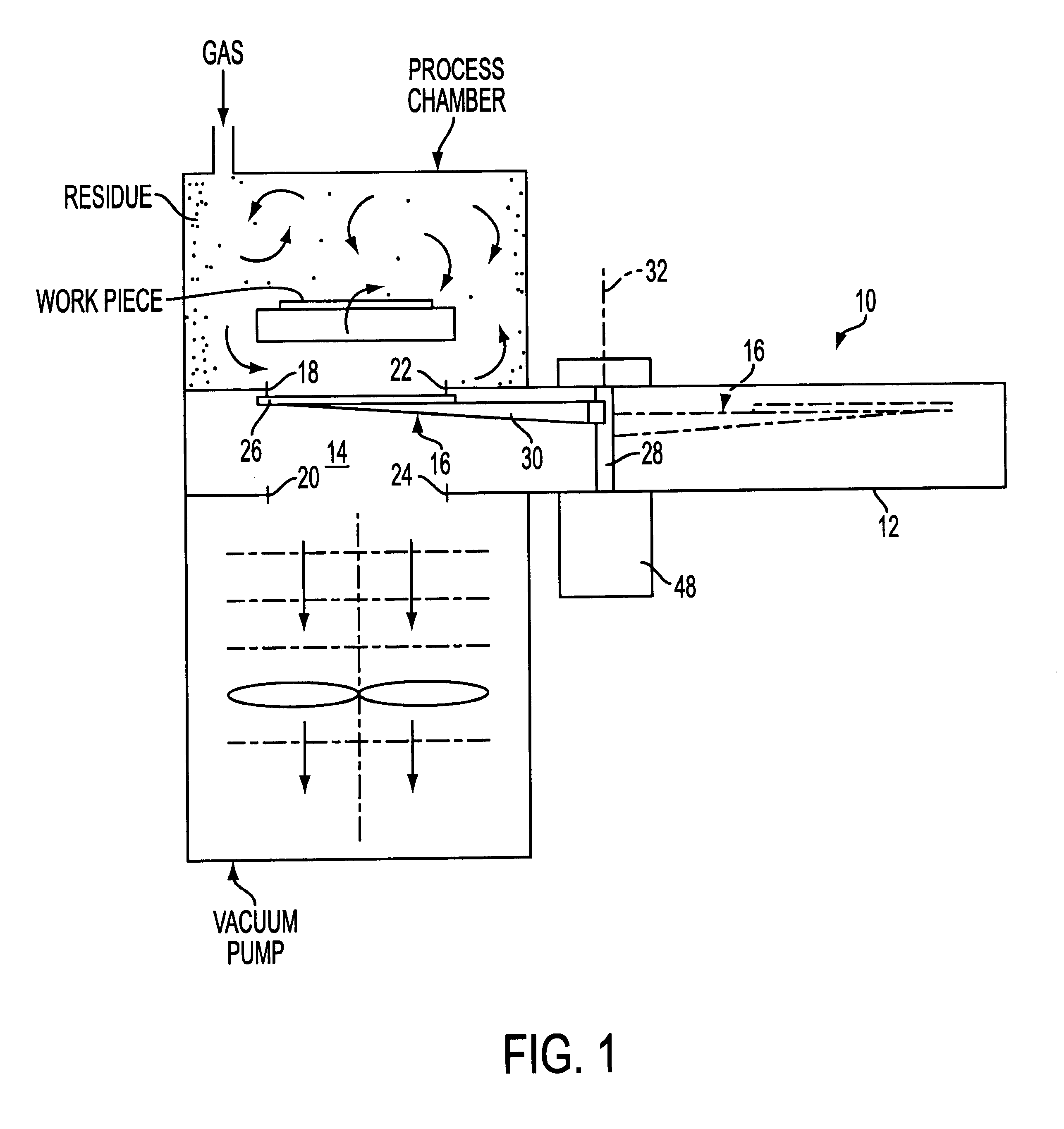

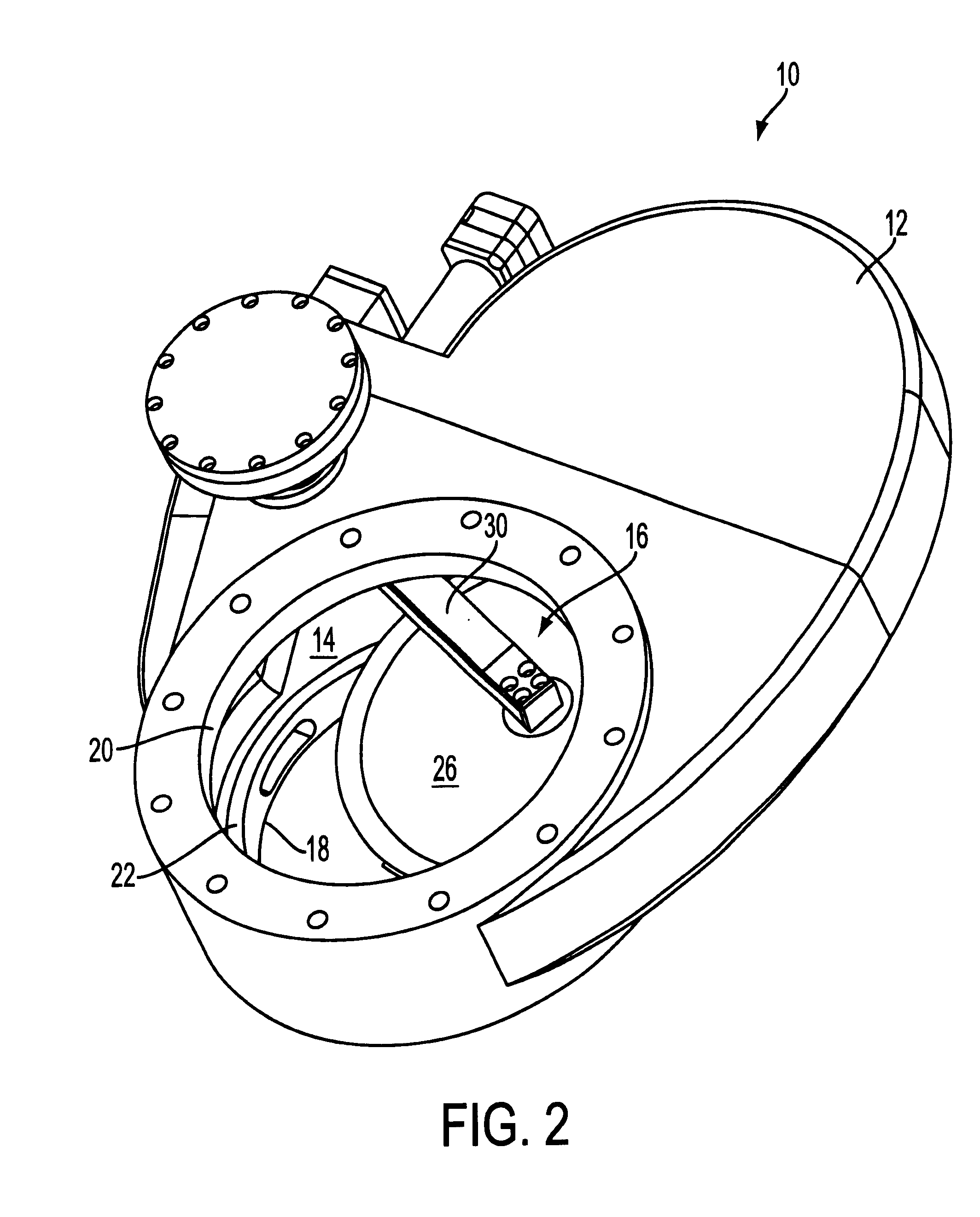

Dual pendulum valve assembly

InactiveUS6328051B1Easy to controlOperating means/releasing devices for valvesPositive displacement pump componentsInterior spaceVacuum pressure

A dual pendulum valve assembly including a housing having an interior space and first and second openings through which fluid can enter and exit the interior space; valve seats disposed in the interior space around the edges of the openings; and first and second pendulum valves for opening and closing, respectively, the first and second openings. Each pendulum valve is independently movable and includes a valve body mounted relative to the housing so that the valve body is movable between a completely opened position wherein fluid is allowed to pass through its respective opening and a completely closed position wherein the valve body seals the opening so that fluid can not pass therethrough. Each pendulum valve also includes a shaft fixedly coupled to the valve body through at least one pivot arm and at least partially mounted within the housing so that the valve body can rotate about a longitudinal axis of the shaft between a first angular position where the first valve body is in the completely opened position and a second angular position where the valve body is substantially axially aligned with its respective opening, and move substantially parallel to the longitudinal axis of the shaft, so that the valve body can move between the second angular position and the completely closed position as the pendulum valve continues to rotate. The present disclosure also provides a method of precisely controlling vacuum pressure within a process chamber of a semi-conductor wafer fabricator.

Owner:MKS INSTR INC

Parallel divided flow-type fluid supply apparatus, and fluid-switchable pressure-type flow control method and fluid-switchable pressure-type flow control system for the same fluid supply apparatus

InactiveUS20010004903A1Operating means/releasing devices for valvesTime-programme switchesStandard stateControl system

A fluid supply apparatus with a plurality of flow lines branching out from one regulator for adjustment of pressure, the flow lines being arranged in parallel, wherein a measure is taken that the operation, that is, opening or closing of one flow passage will have no transient effect on the steady flow of the other flow passages. For this purpose, each flow passage is provided with a time delay-type mass flow controller MFC so that when one closed fluid passage is opened, the mass flow controller on that flow passage reaches a set flow rate Qs in a specific delay time DELTAt from the starting point. Also provided are a method and an apparatus for the above in which a plurality of gas types can be controlled in flow rate with high precision by one pressure-type flow control system. To that end, a formula for calculating the flow rate of a gas is theoretically derived that flows with a pressure ratio not higher than the critical pressure ratio. From that formula, the flow factor is defined, so that the formula may be applied to a number of gas types using flow factors. The method includes calculating the flow rate Qc of a gas passing through an orifice according to formula Qc=KP1 (K=constant) with a pressure P1 on an upstream side of the orifice set at twice or more higher than pressure P2 on a downstream side, wherein the flow factor FF for each kind of gas is calculated as follows: <paragraph lvl="0"><in-line-formula>FF=(k / gammas){2 / (kappa+1)}1 / (kappa-1)[kappa / {(kappa+1)R}]½< / in-line-formula>and wherein, if the calculated flow rate of gas type A is QA, and, when gas type B is allowed to flow through the same orifice under the same pressure on the upstream side and at the same temperature on the upstream side, the flow rate QB is calculated as follows: <paragraph lvl="0"><in-line-formula>QB=(FFB / FFA)QA < / in-line-formula>where gammas=concentration of gas in standard state; kappa=ratio of specific heat of gas; R=constant of gas; K=proportional constant not depending on the type of gas; FFA=flow factor of gas type A; and FFB=flow factor of gas type B.

Owner:FUJIKIN INC +2

Surge relief valve

ActiveUS7302961B2Quick reliefEliminate and reduce incidenceOperating means/releasing devices for valvesCheck valvesEngineeringVALVE PORT

A surge relief valve comprising a main valve body having a dome port and an inlet port. The inlet port is in fluid communication with a first fluid. The invention further includes a dome reservoir connected to the main valve body via the dome port and arranged to hold a second fluid, a piston located in the main valve body, the piston in fluid communication with the reservoir, and a dampening ring positioned around the circumference of the piston operatively arranged to dampen the piston, wherein the first fluid exerts an upward force on the piston, the second fluid exerts a downward force on the piston, and the piston is arranged to move in response to a differential in the upward and downward forces, wherein the first and second fluids are isolated from one another.

Owner:FLOW SAFE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com