Patents

Literature

100 results about "Double check" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double Check is a 1982 sculpture by John Seward Johnson II, located in Zuccotti Park in Manhattan, New York City. In July 2018, the statue was relocated to the northwest corner of Broadway and Liberty.

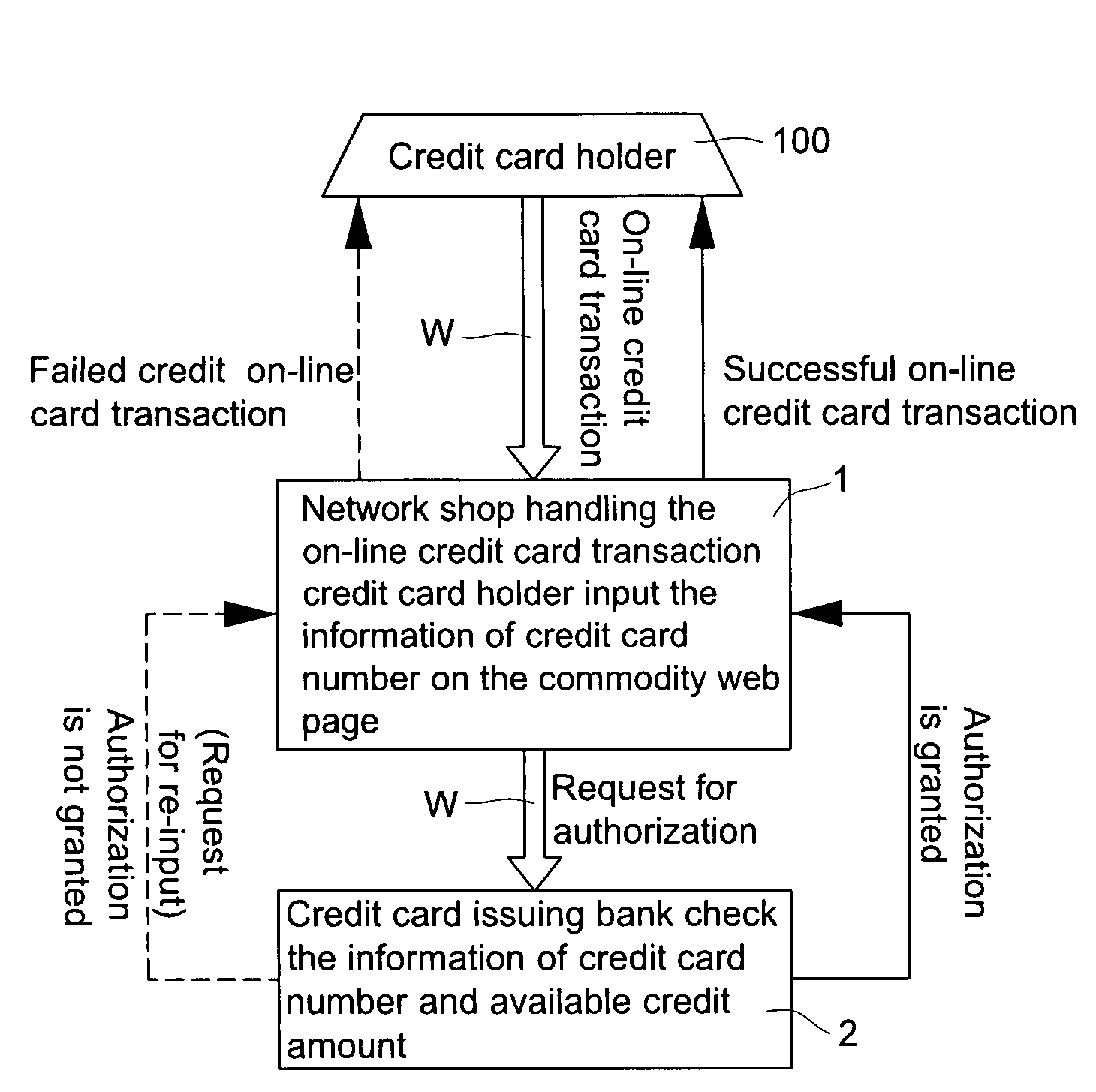

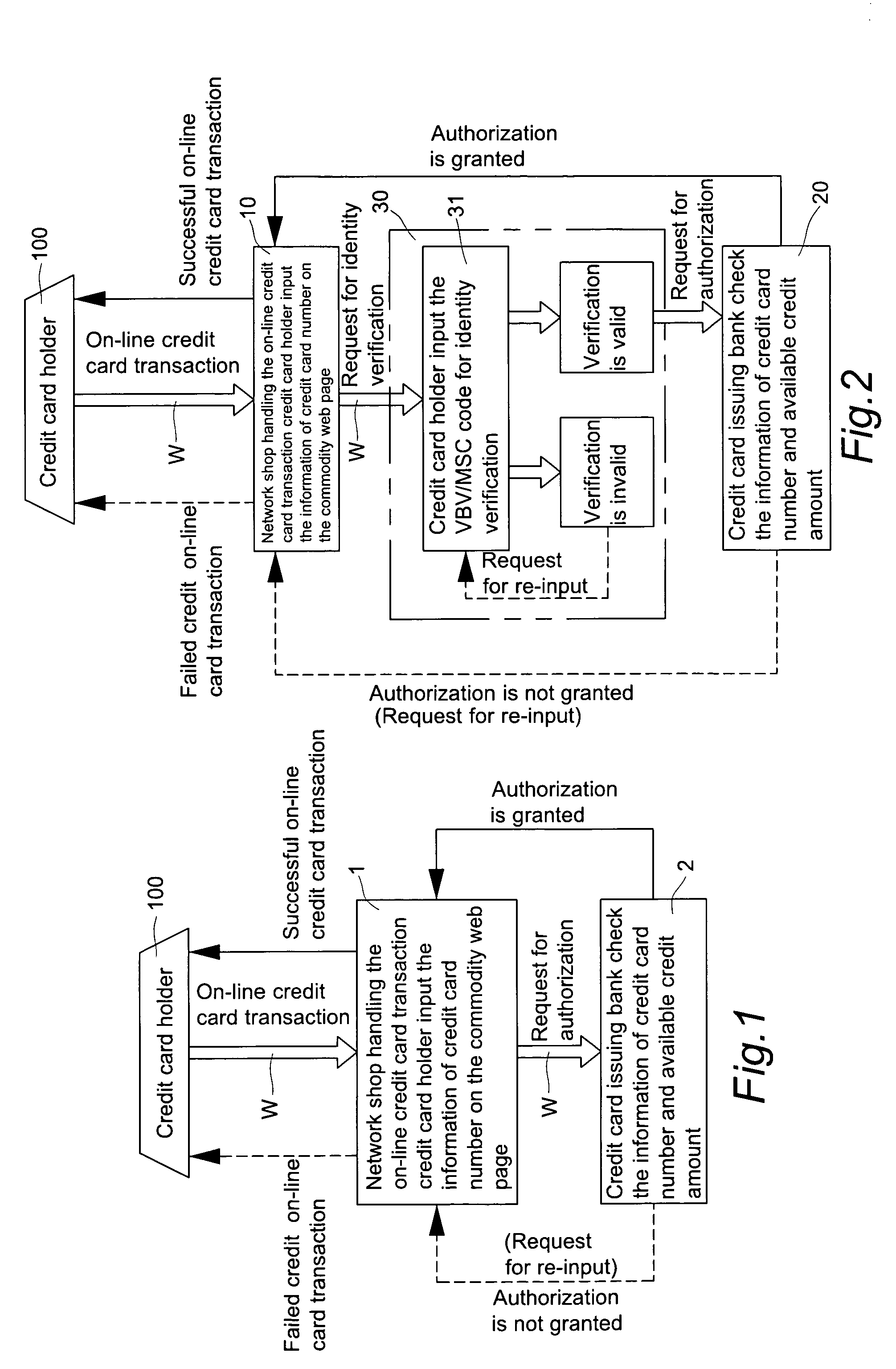

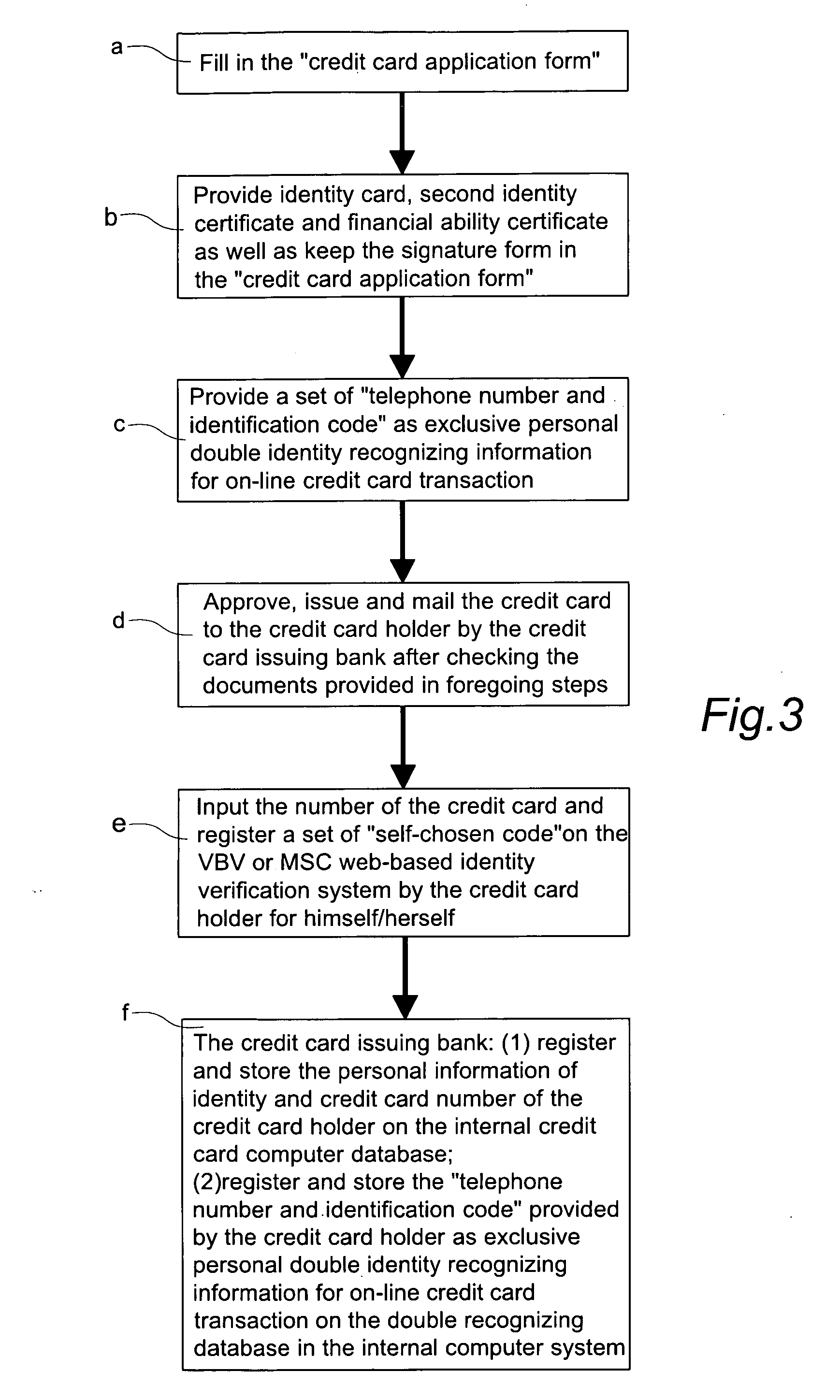

Double recognizing method by means of telephone number and identification code for online credit card transactions over the internet

The present invention relates to a “double recognizing method by means of telephone number and identification code for online credit card transactions over the internet,” in which the credit card holder not only registers a “self-chosen code” by himself / herself for VBV (Verified By VISA) or MSC (MasterCard SecureCode) network identity verification but also registers another set of “telephone number and identification code” by himself / herself for serving as an exclusive personal double identity recognizing information for online credit card transactions. The credit card issuing bank registers and stores the set of “telephone number and identification code” on a double recognizing database after checking truth of the related identity certificate provided by the credit card holder. When the credit card issuing bank handles the online credit card transaction of the credit card holder over the network, the credit card issuing bank not only proceeds the check on the “self-chosen code” used in the original VBV or MSC verification system but also performs the double check on the “telephone number and identification code” used in the telecommunications transceiving processor platform of the internal credit card double recognizing computer system, for example by sending out a short message to the credit card holder for requesting him / her to immediately reply by another short message to his / her “telephone number and identification code.”

Owner:LIN CHUNG YU

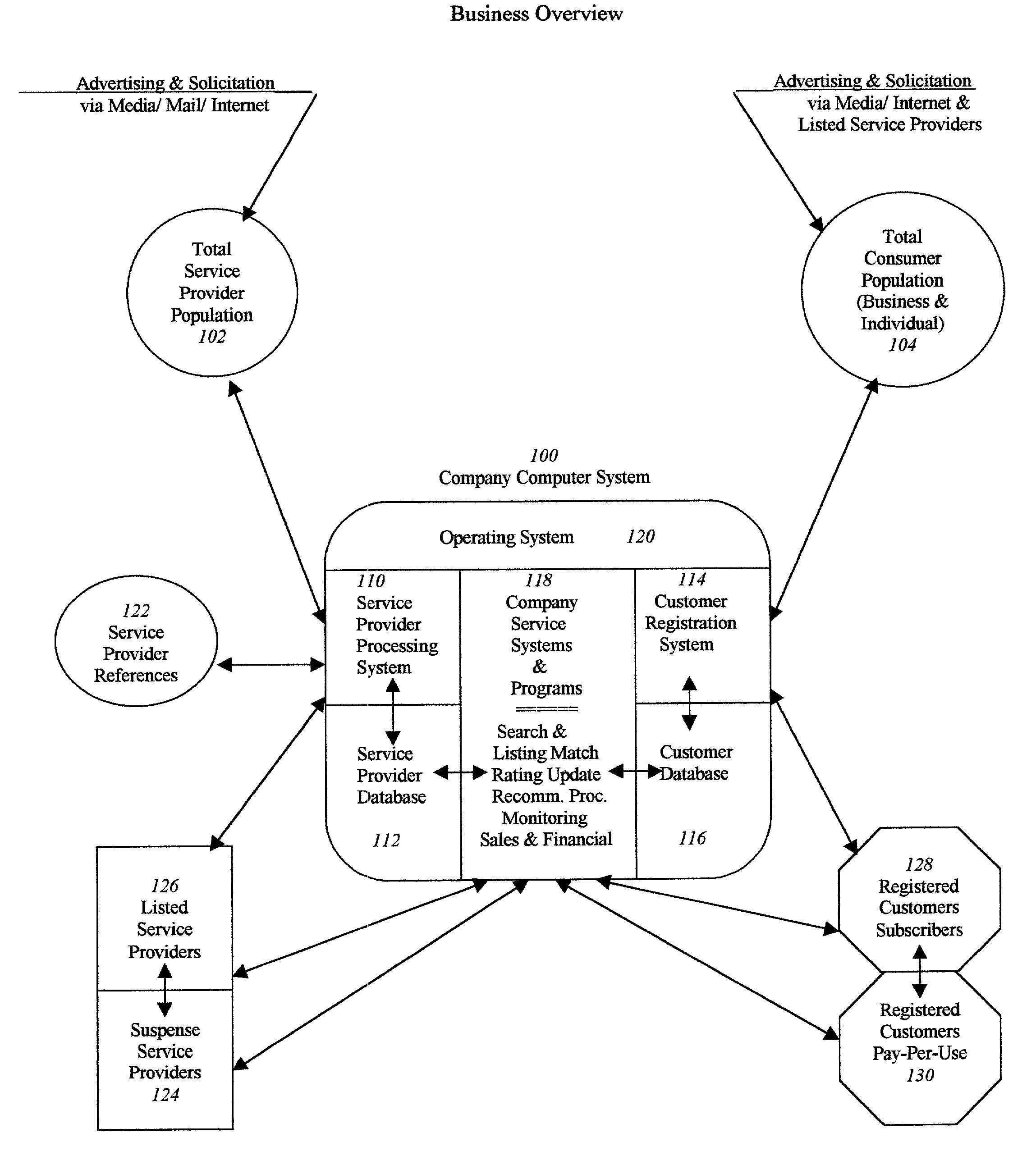

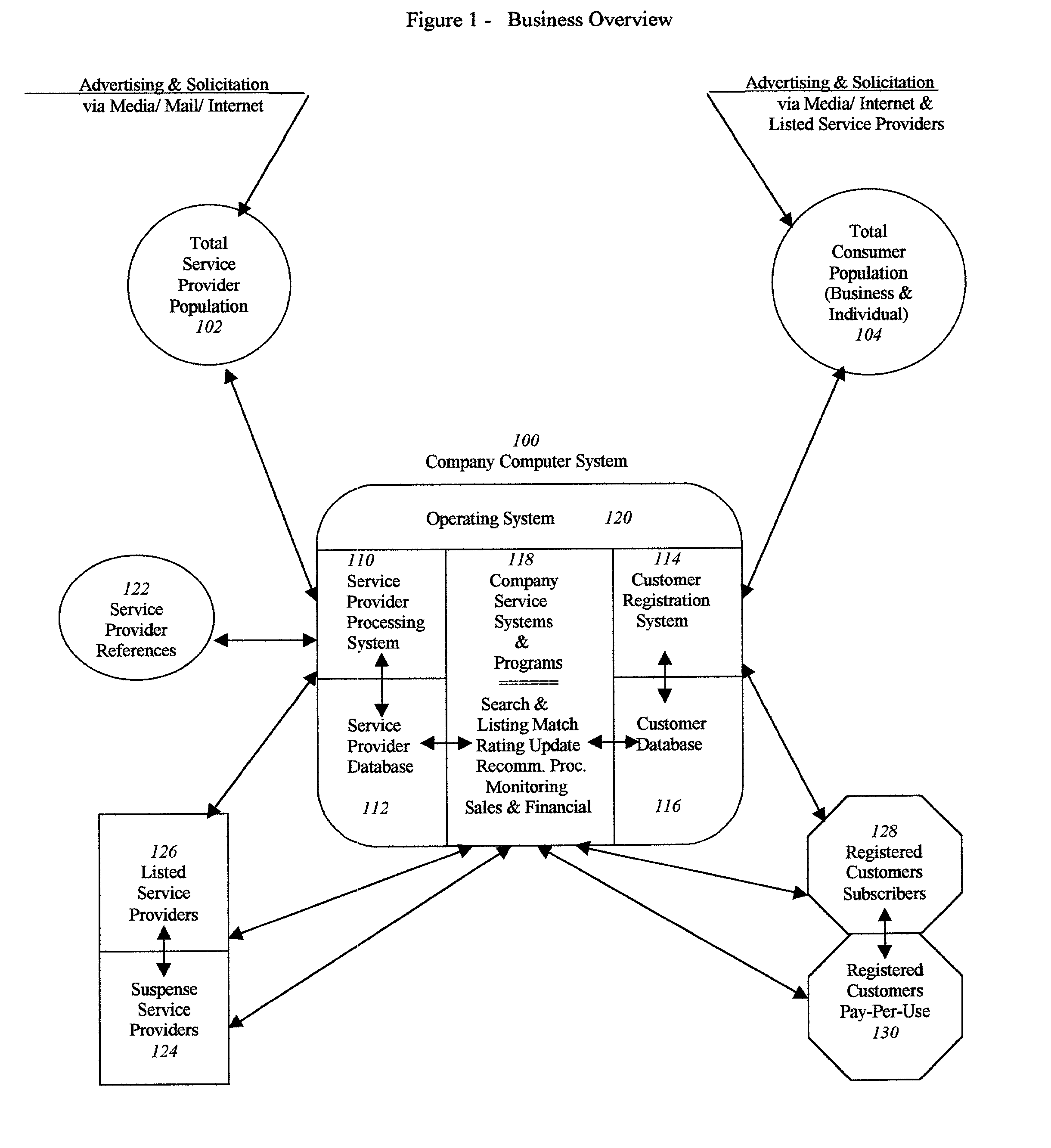

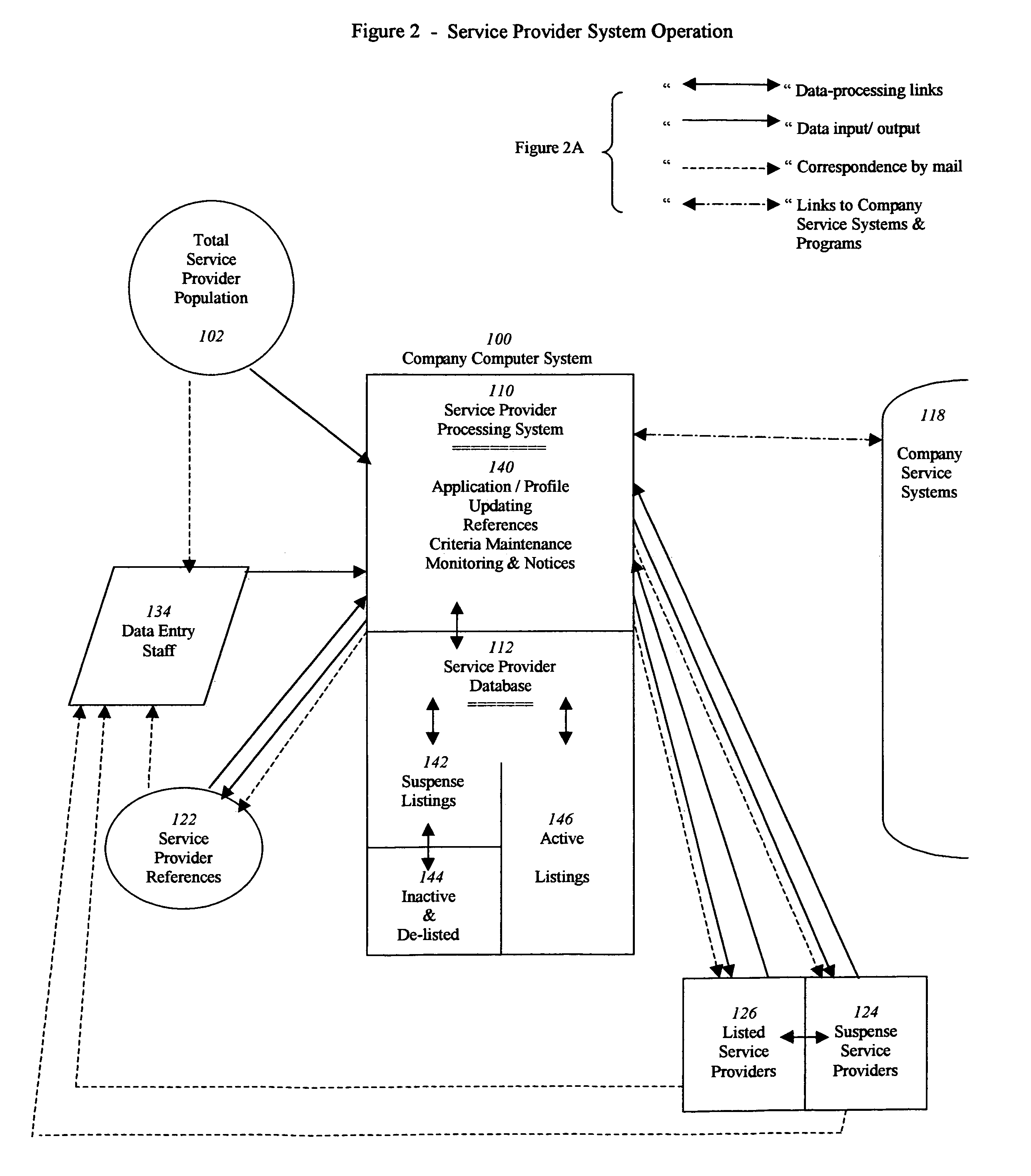

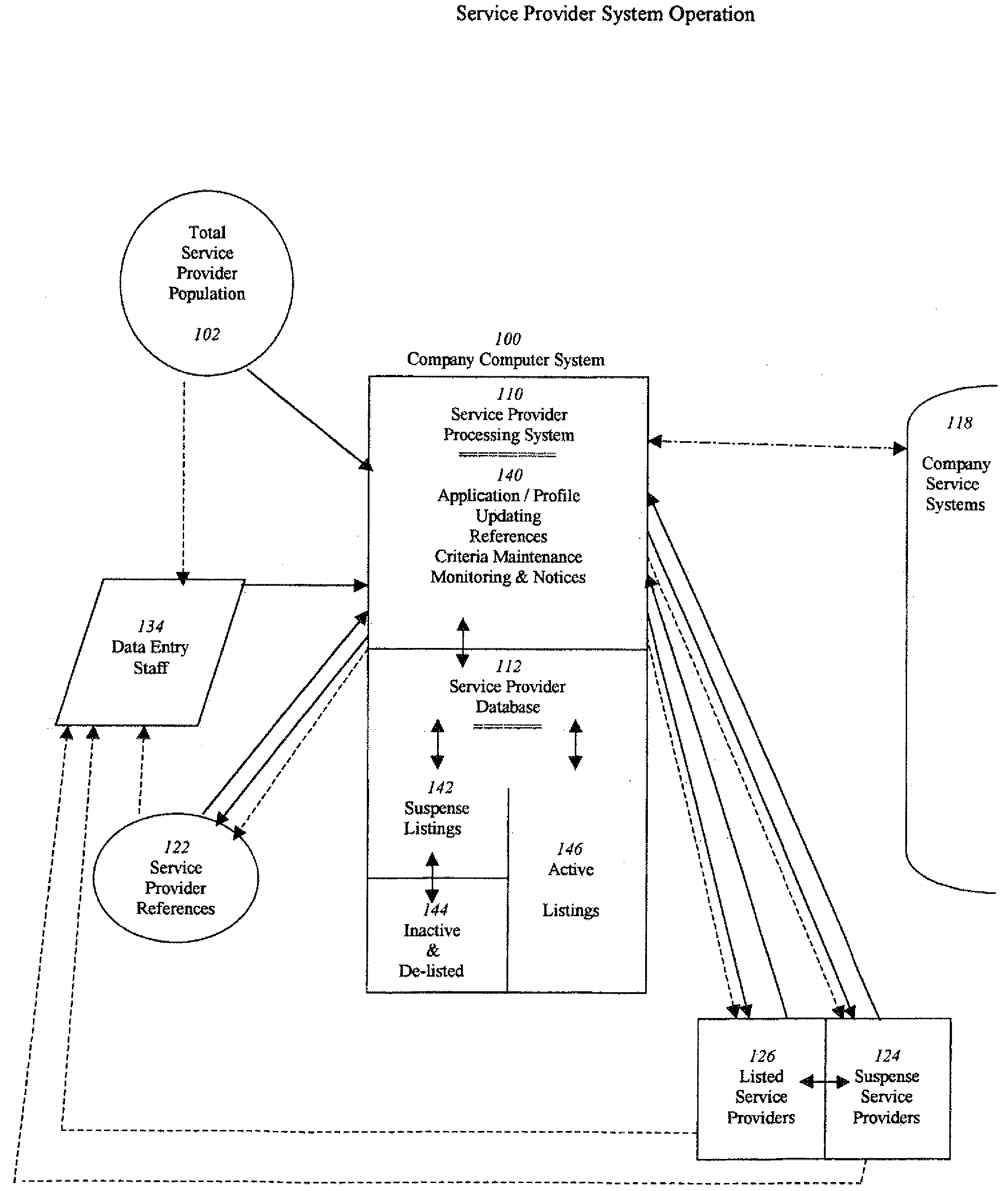

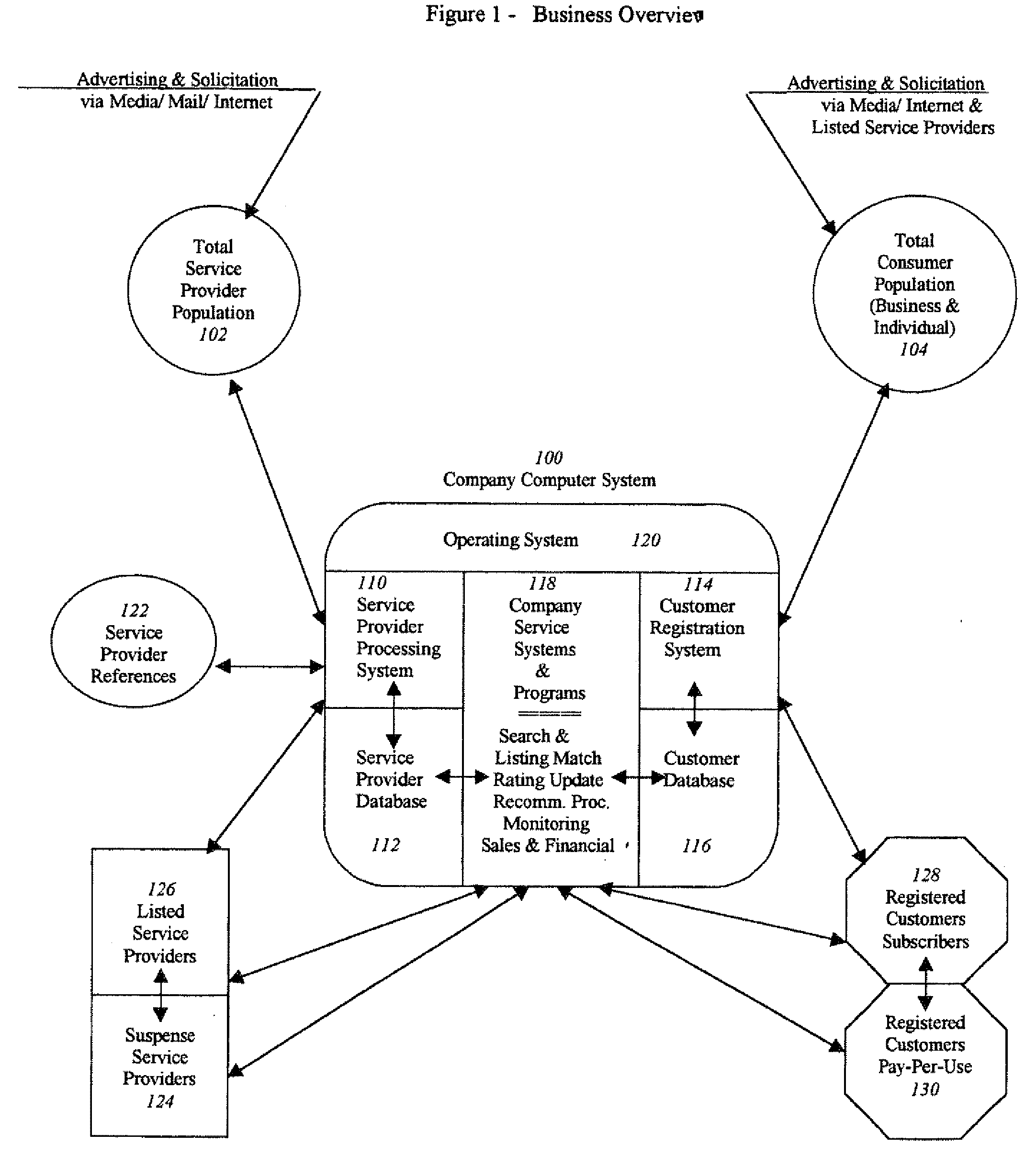

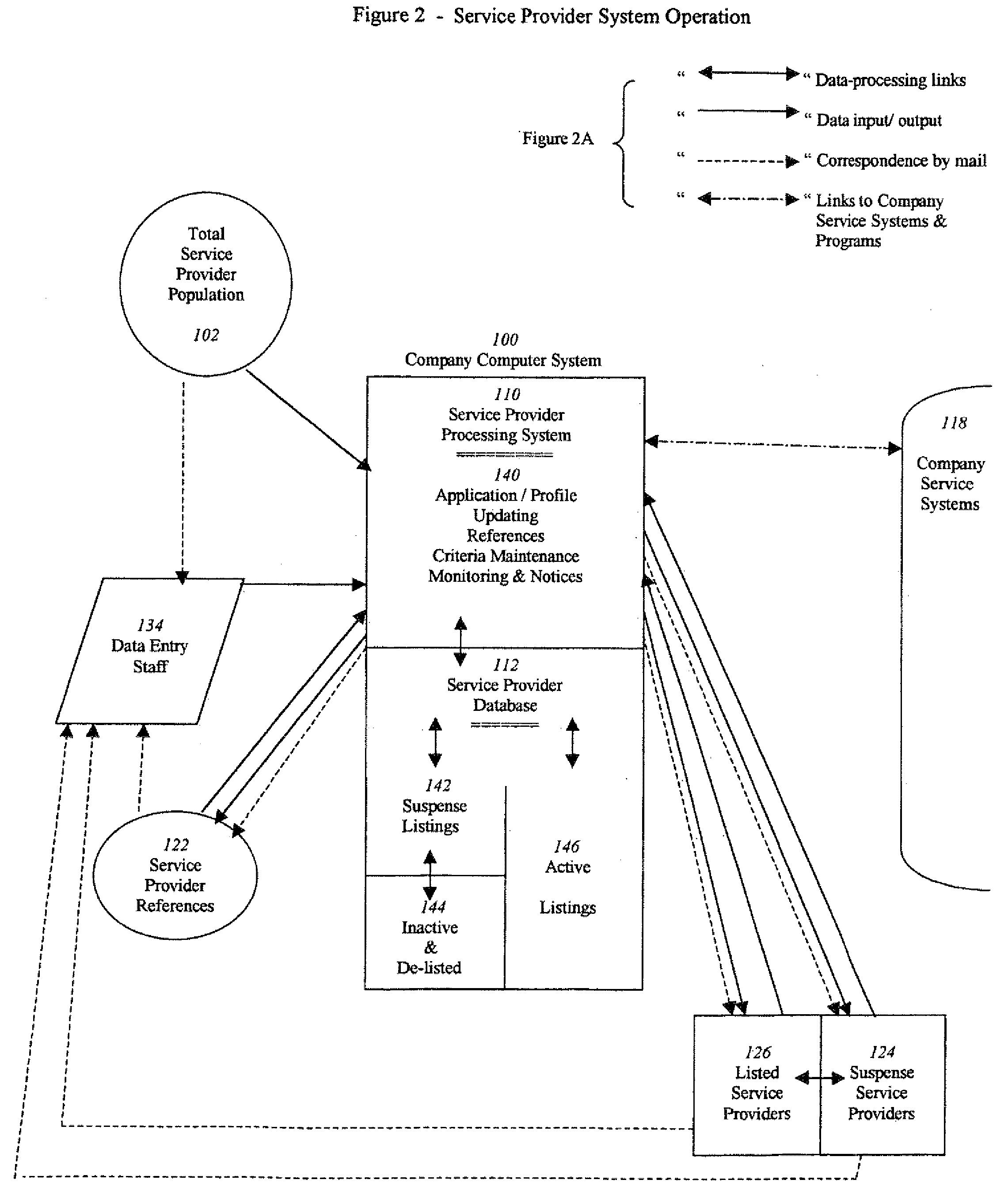

Accessible service provider clearinghouse

A service that maintains a minimum criteria level for service providers to be listed and available for public access. It can list not only the service provider's credentials and insurance support (with monitored expiration dates), but may also provide a current up-to-date rating system by the users themselves, as to the satisfaction level of the quality and reliability of the work performed. It can also offer a double-check of the credentials by customer verification input. Furthermore, the example service can be easily accessible by the general public (for individual or business use) on the Internet, or by printed text directories sold direct or in bookstores.

Owner:LOKITZ SHEILA

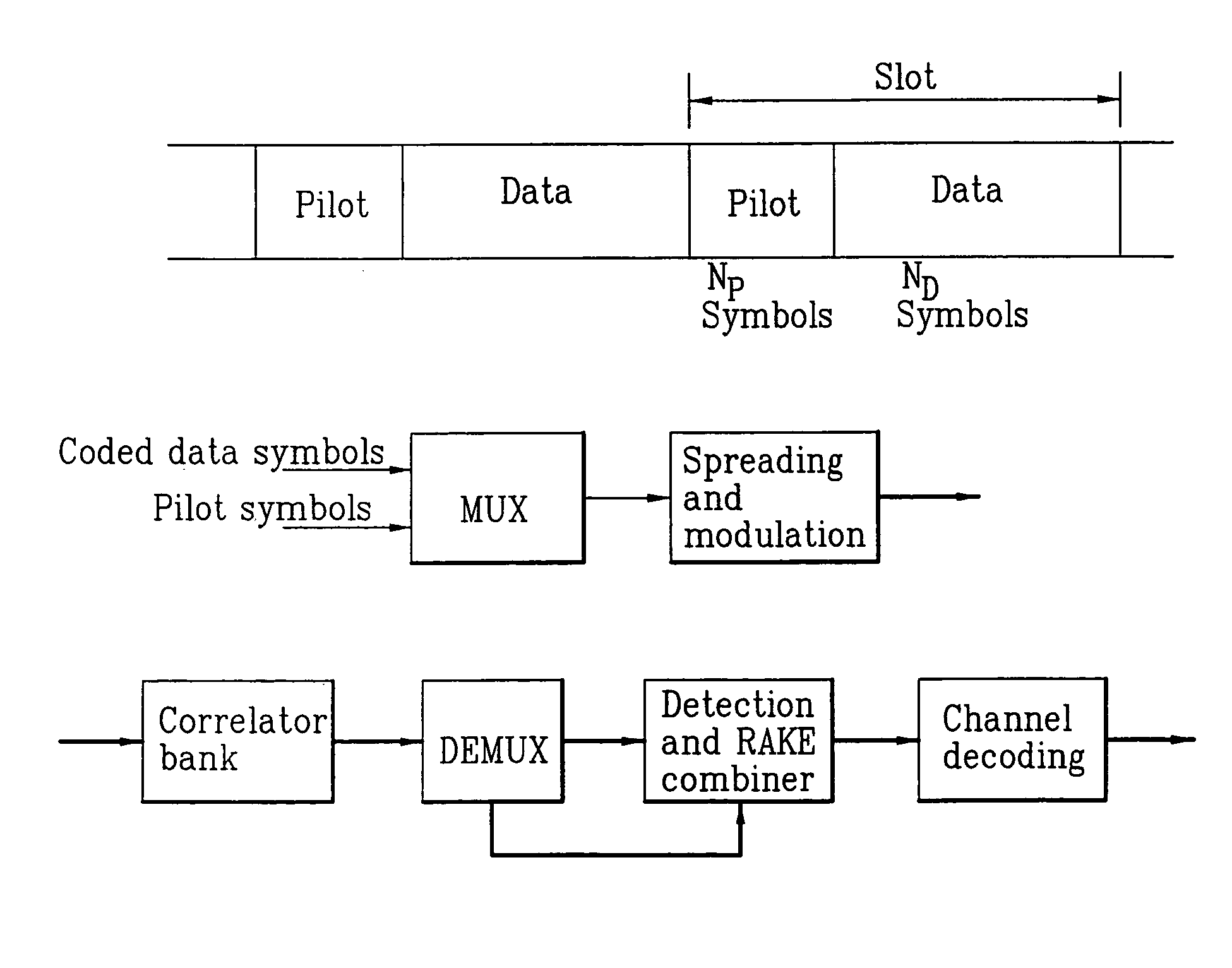

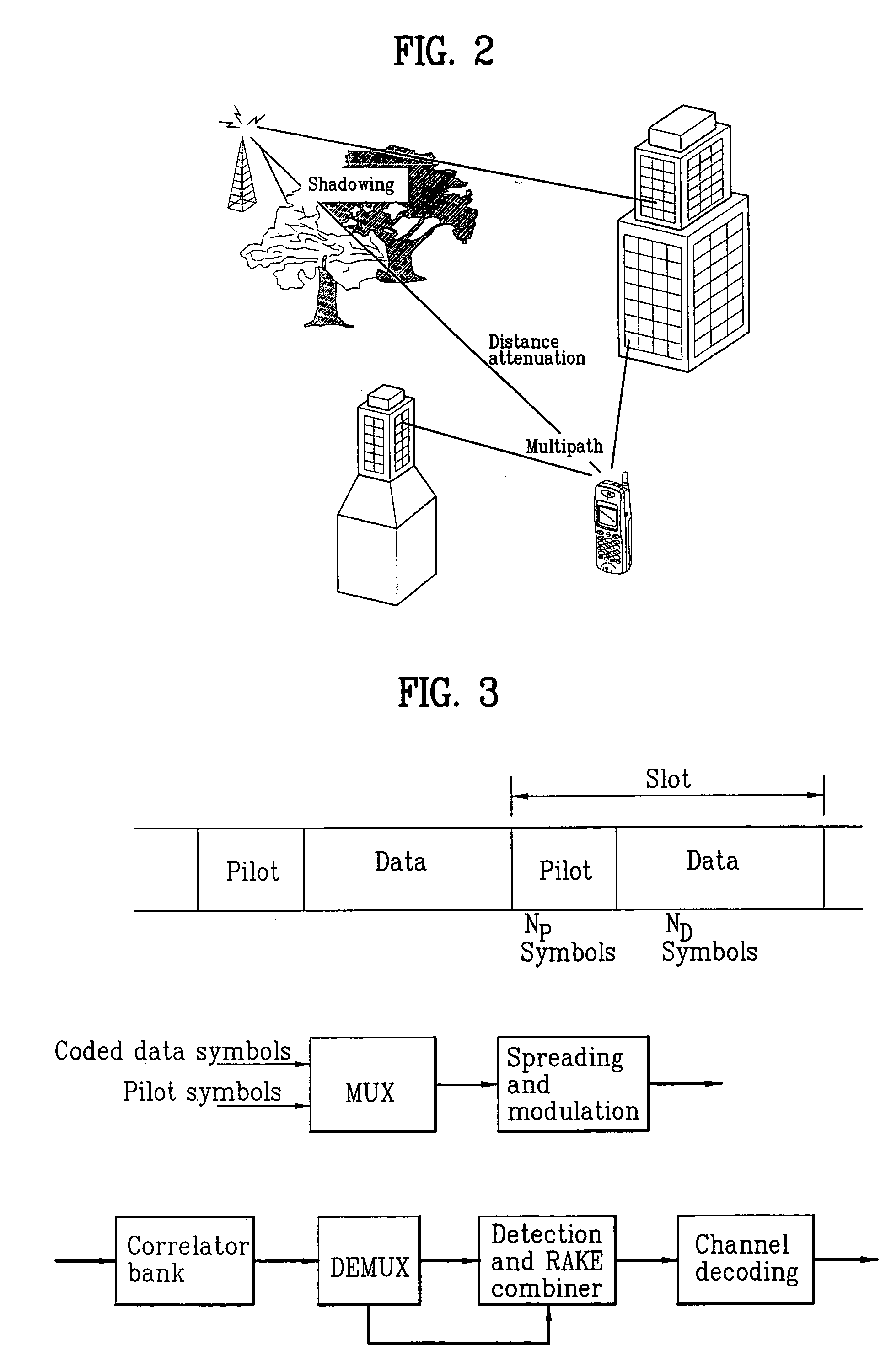

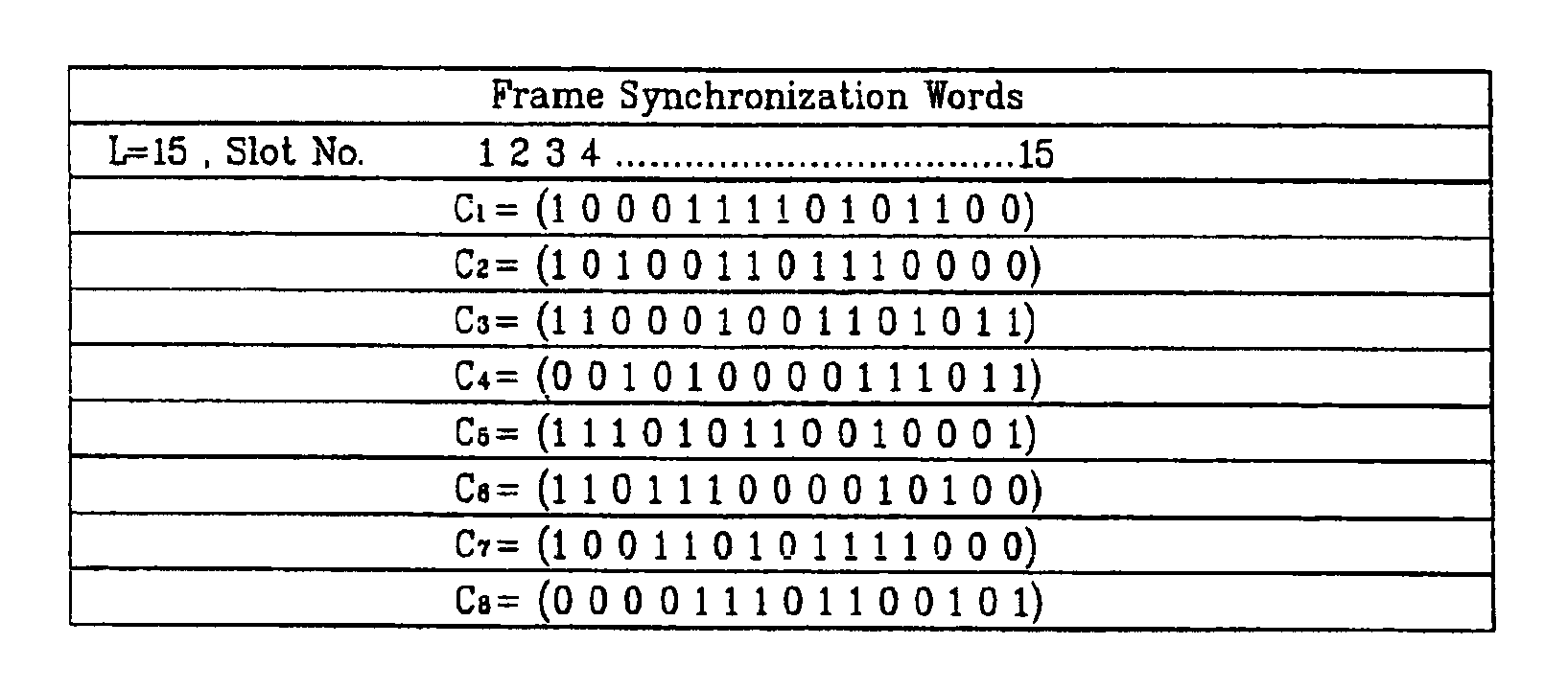

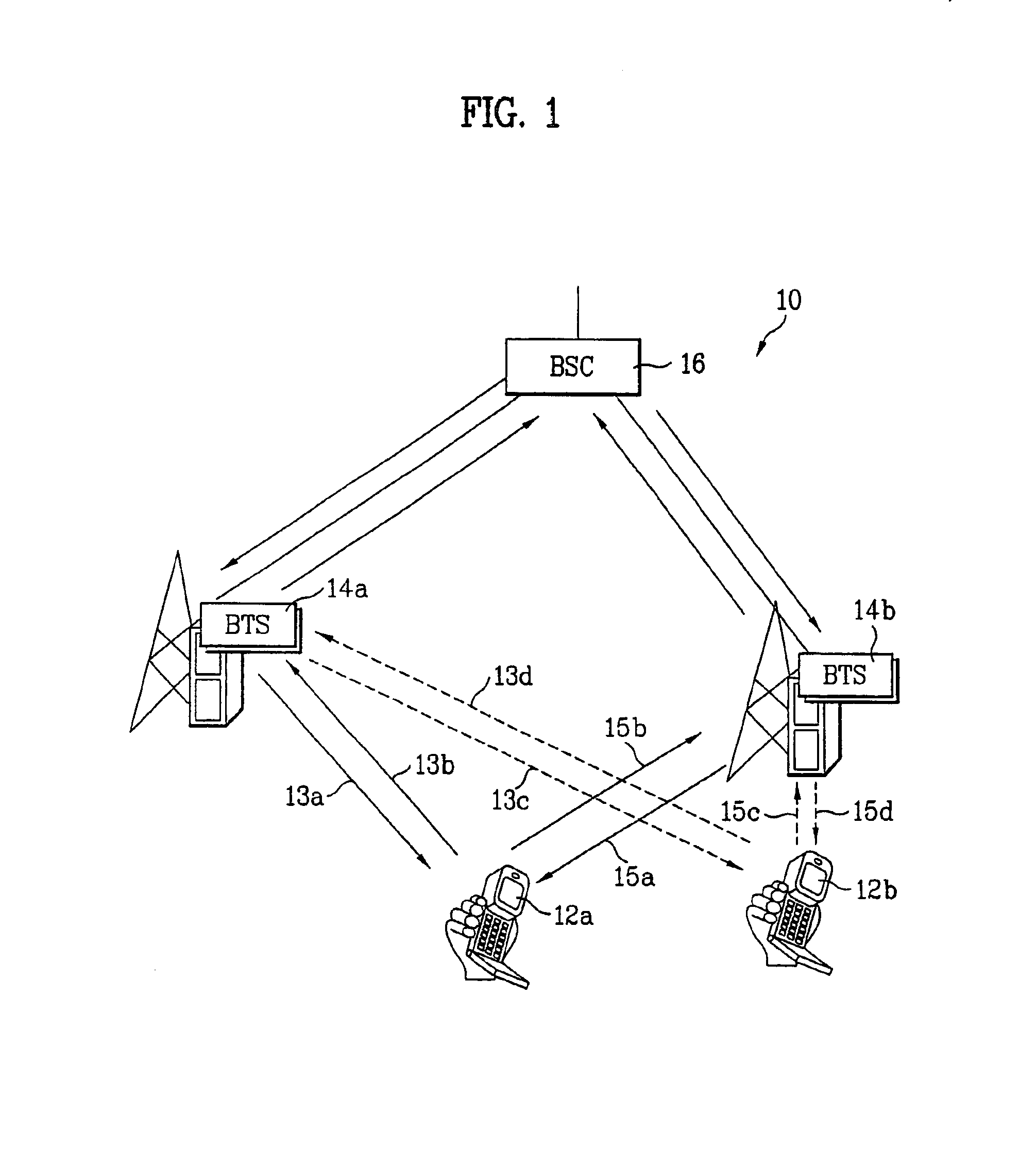

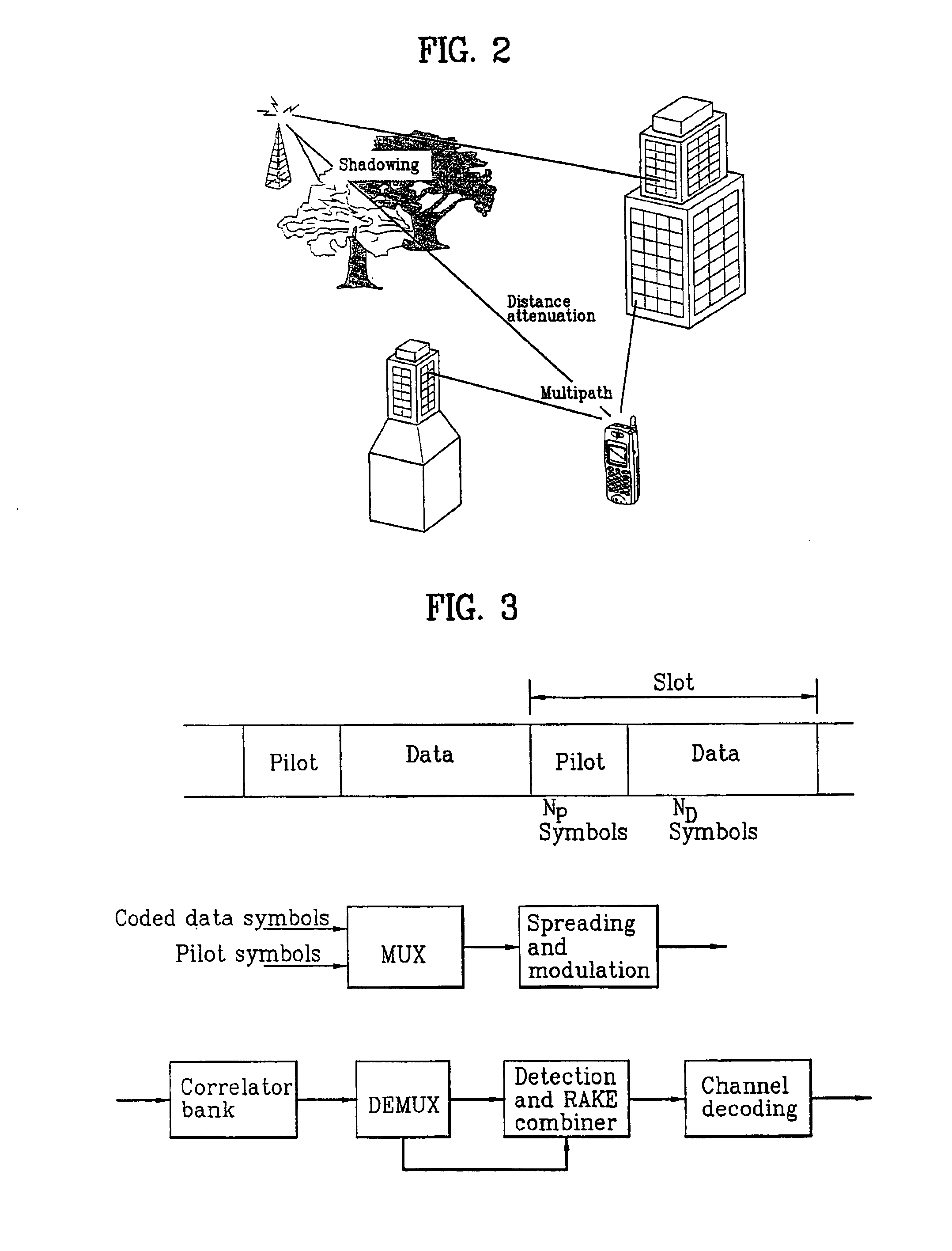

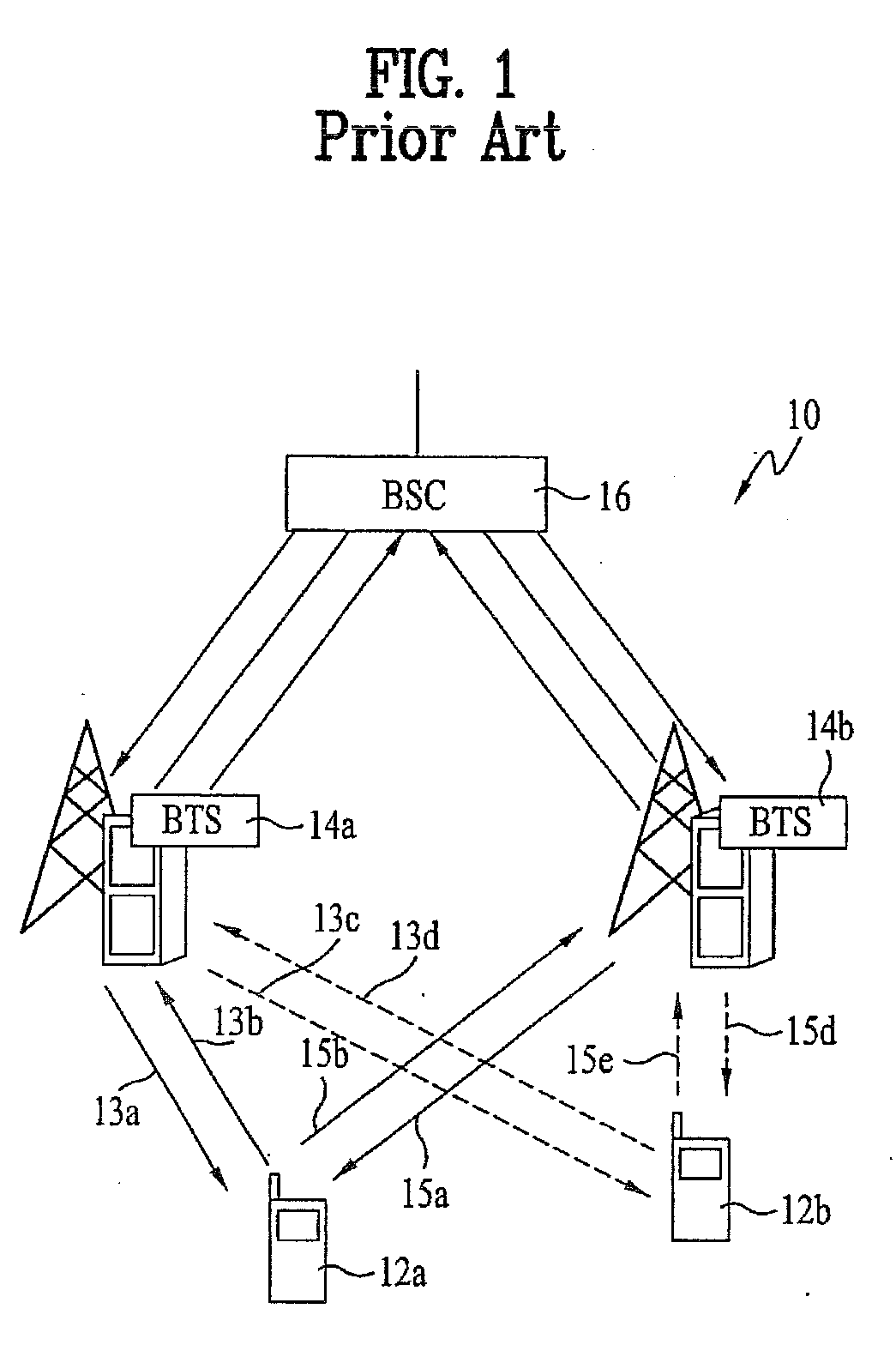

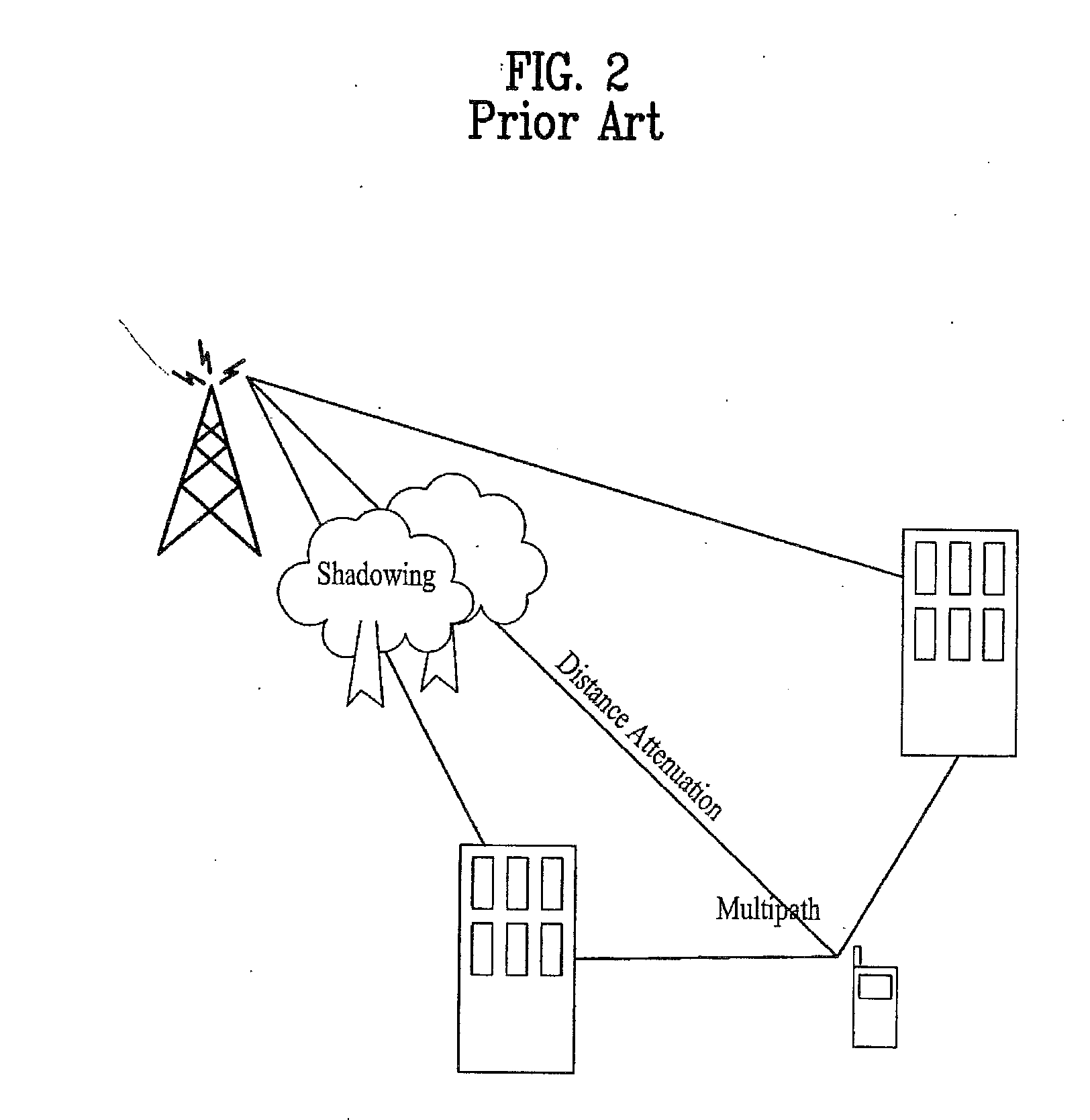

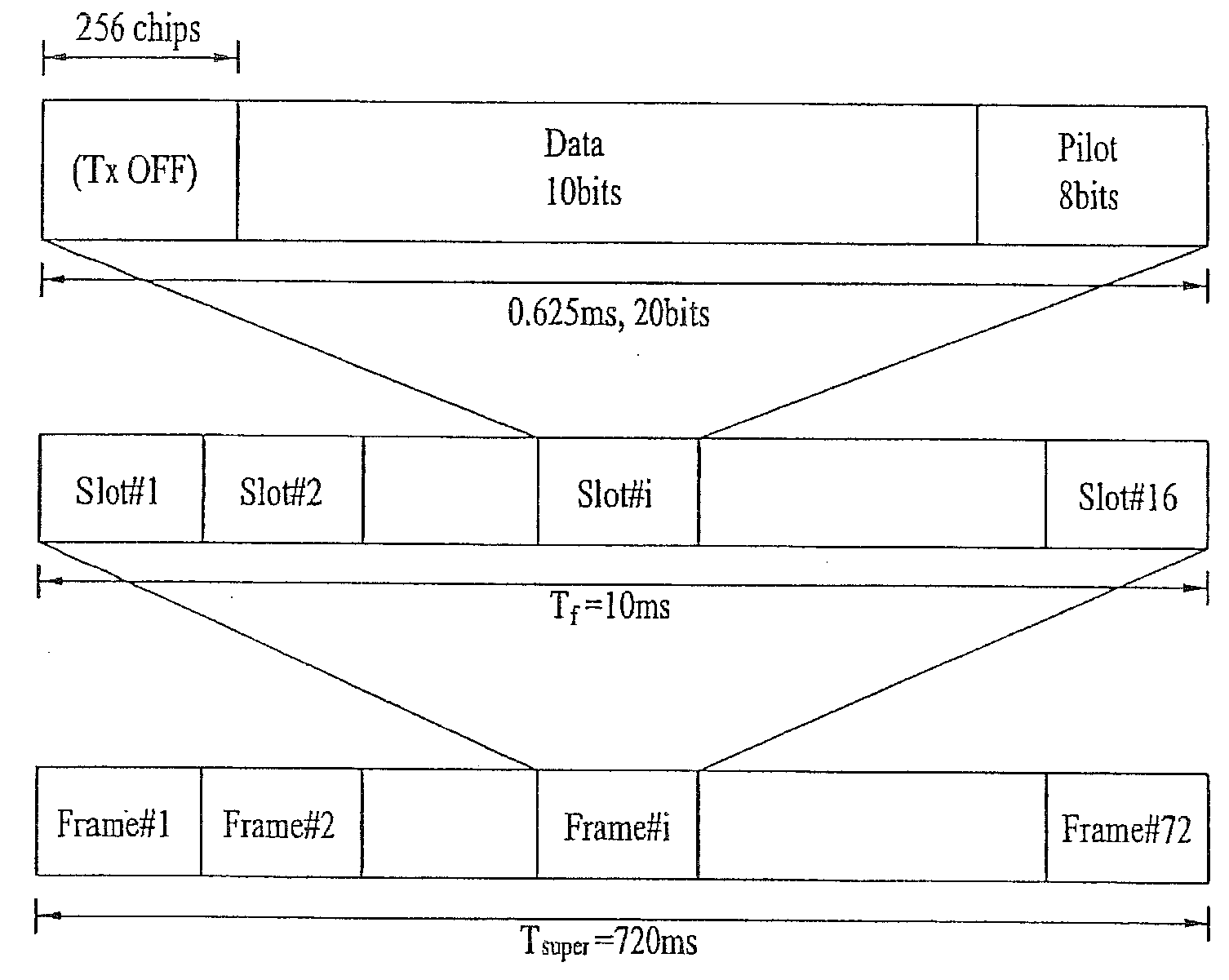

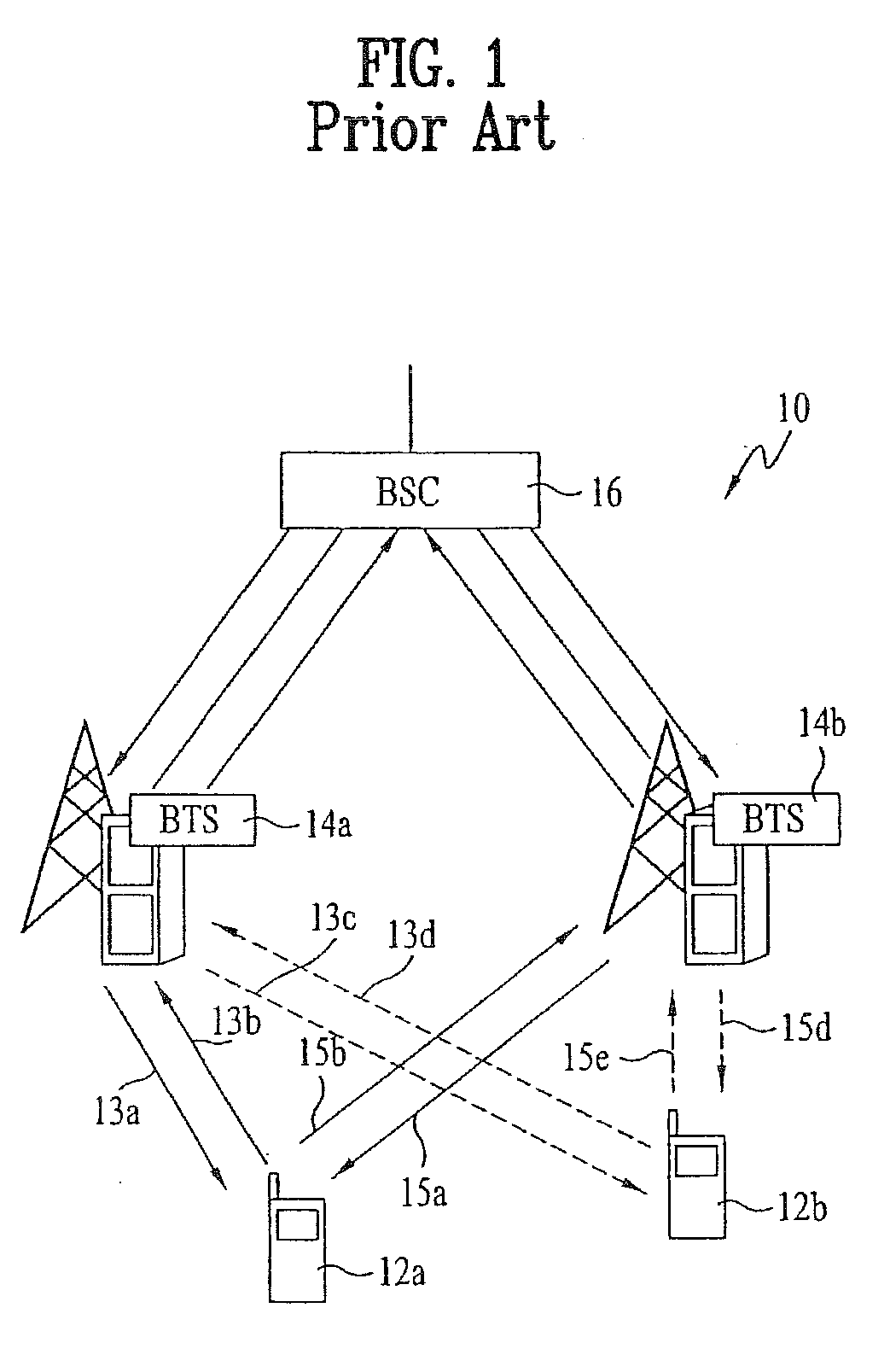

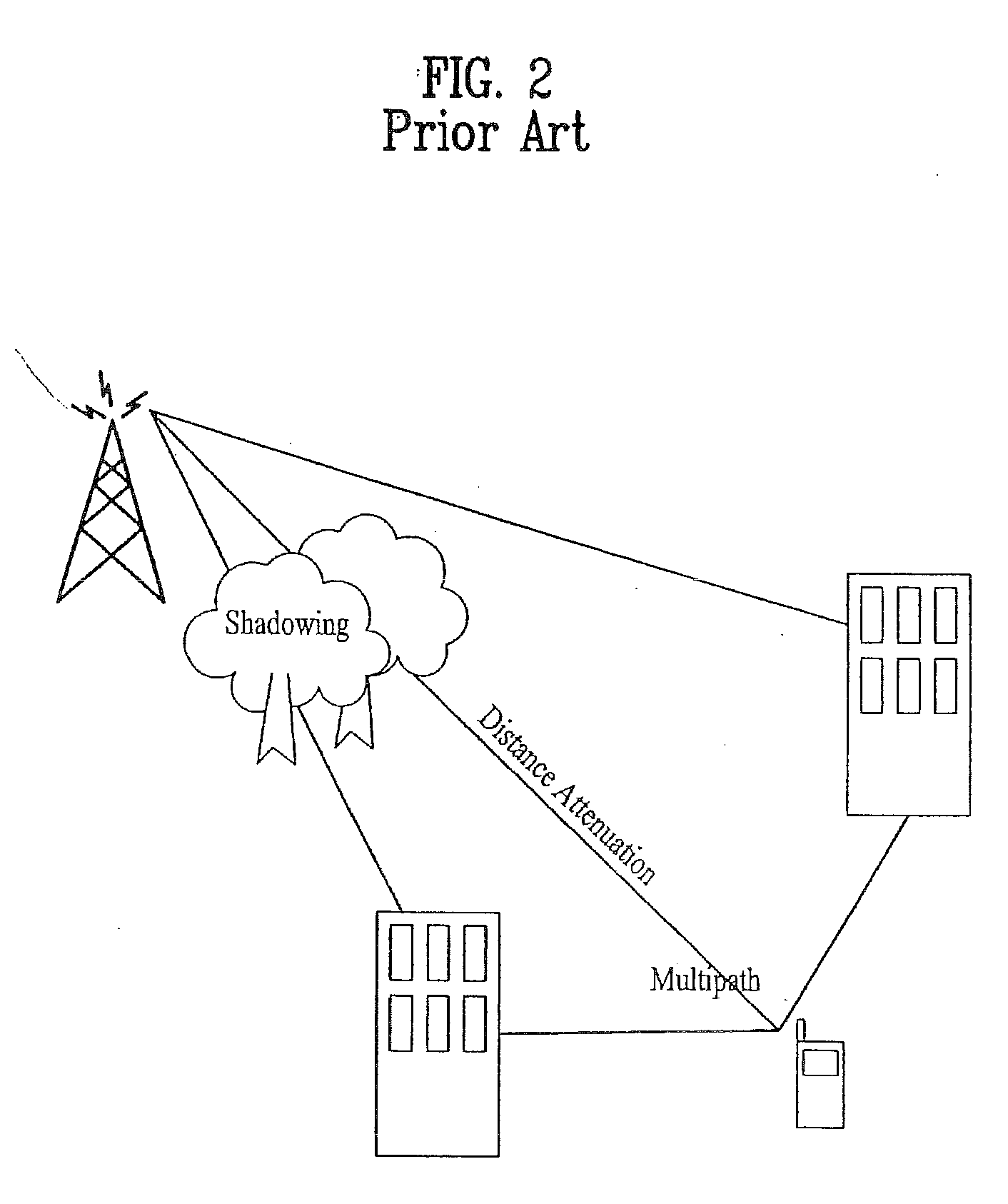

Pilot signals for synchronization and/or channel estimation

InactiveUS20050018754A1Avoid poor resultsEliminate and prevent sidelobesBaseband system detailsTime-division multiplexCorrelation functionSelf correlation

The frame words of the preferred embodiment are especially suitable for frame synchronization and / or channel estimation. By adding the autocorrelation and cross-correlation functions of frame words, double maximum values equal in magnitude and opposite polarity at zero and middle shifts are obtained. This property can be used to slot-by-slot, double-check frame synchronization timing, single frame synchronization and / or channel estimation and allows reduction of the synchronization search time. Further, the present invention allows a simpler construction of a correlator circuit for a receiver.

Owner:LG ELECTRONICS INC

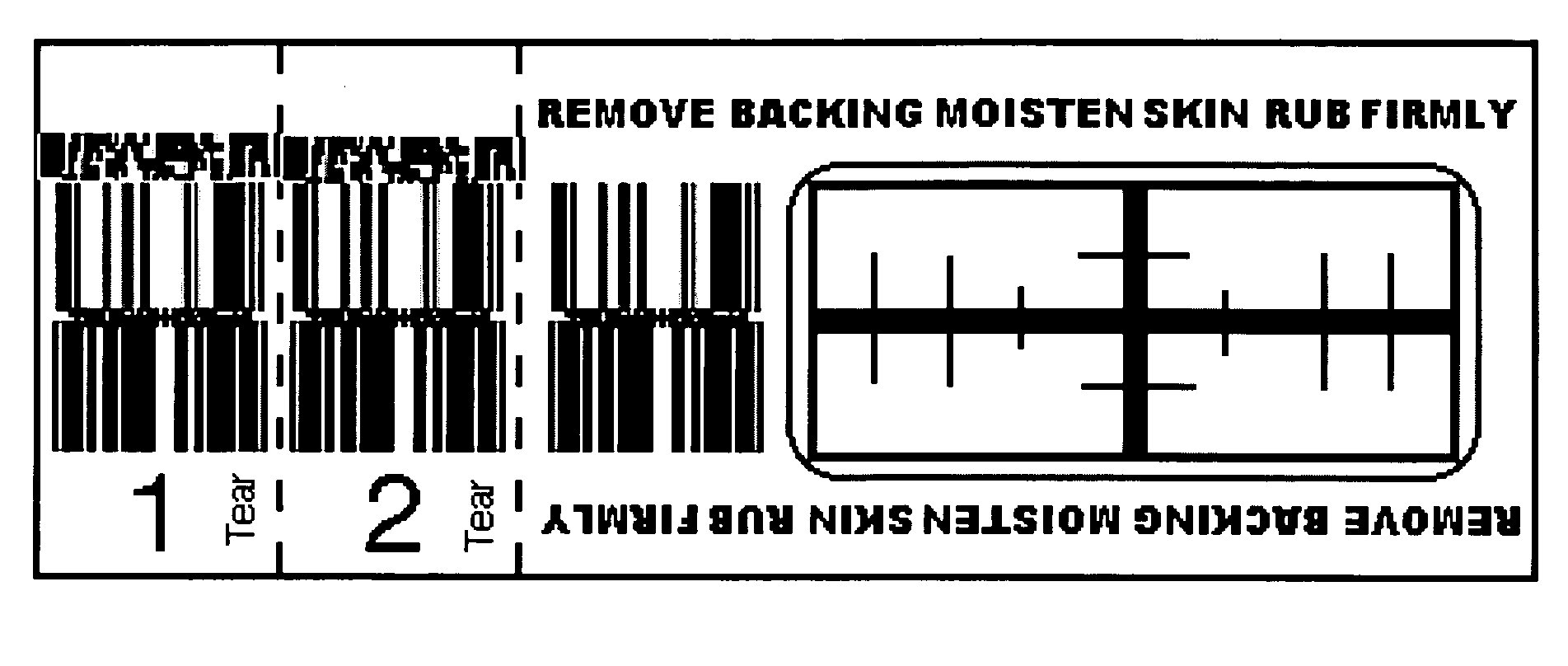

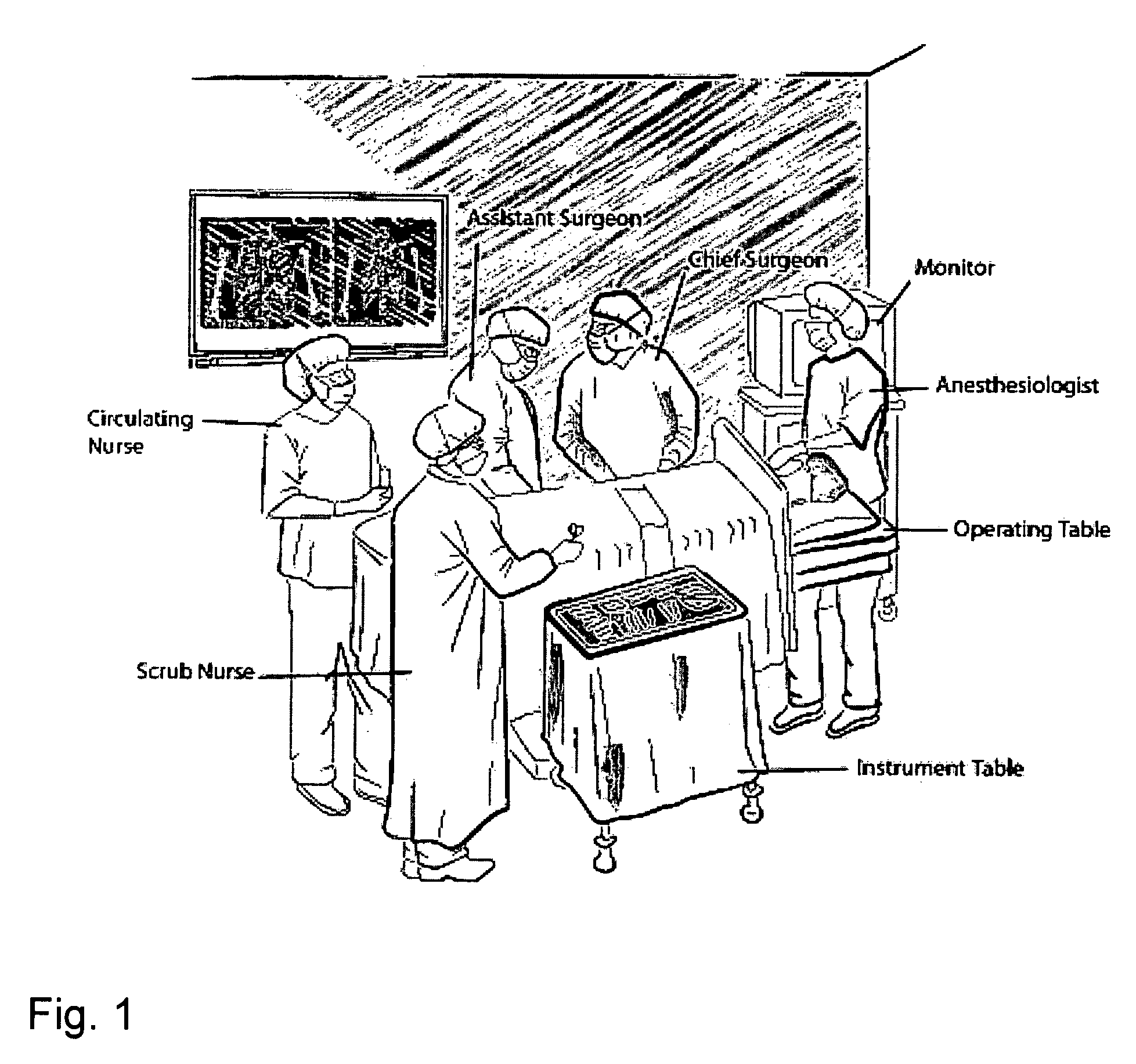

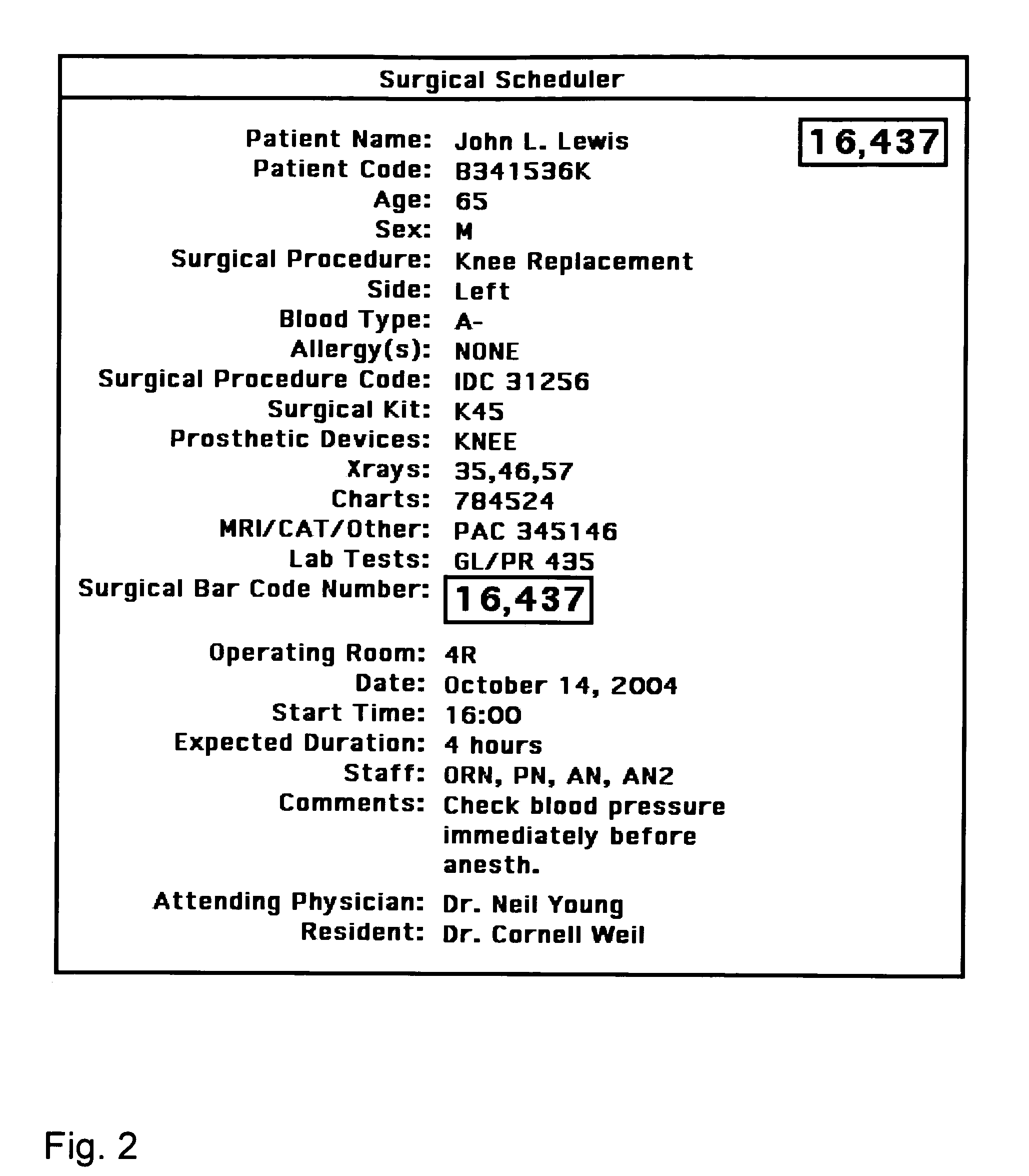

System and method of utilizing a machine readable medical marking for managing surgical procedures

InactiveUS7389928B2Increase elasticityMechanical/radiation/invasive therapiesDiagnosticsSurgical incisionCombined use

The method and system include marking a surgery site (e.g., location of surgical incision) or a site of other medical action with a machine-readable medical marking (e.g., bar code or a dot pattern), which may be used in conjunction with (1) a scanner for reading the machine-readable medical marking and (2) a controller for controlling medical actions in response to the read machine-readable medical marking. The system and method ensure the validation of the surgical procedure, the patient awaiting the surgical procedure, and the site or location on the patient where the surgery is to be performed. Utilizing a scanning device for reading machine-readable medical markings, and a controller, there are additional means to check and double check the medical action before the actual medical action (e.g., surgery) is performed.

Owner:INT BARCODE CORP

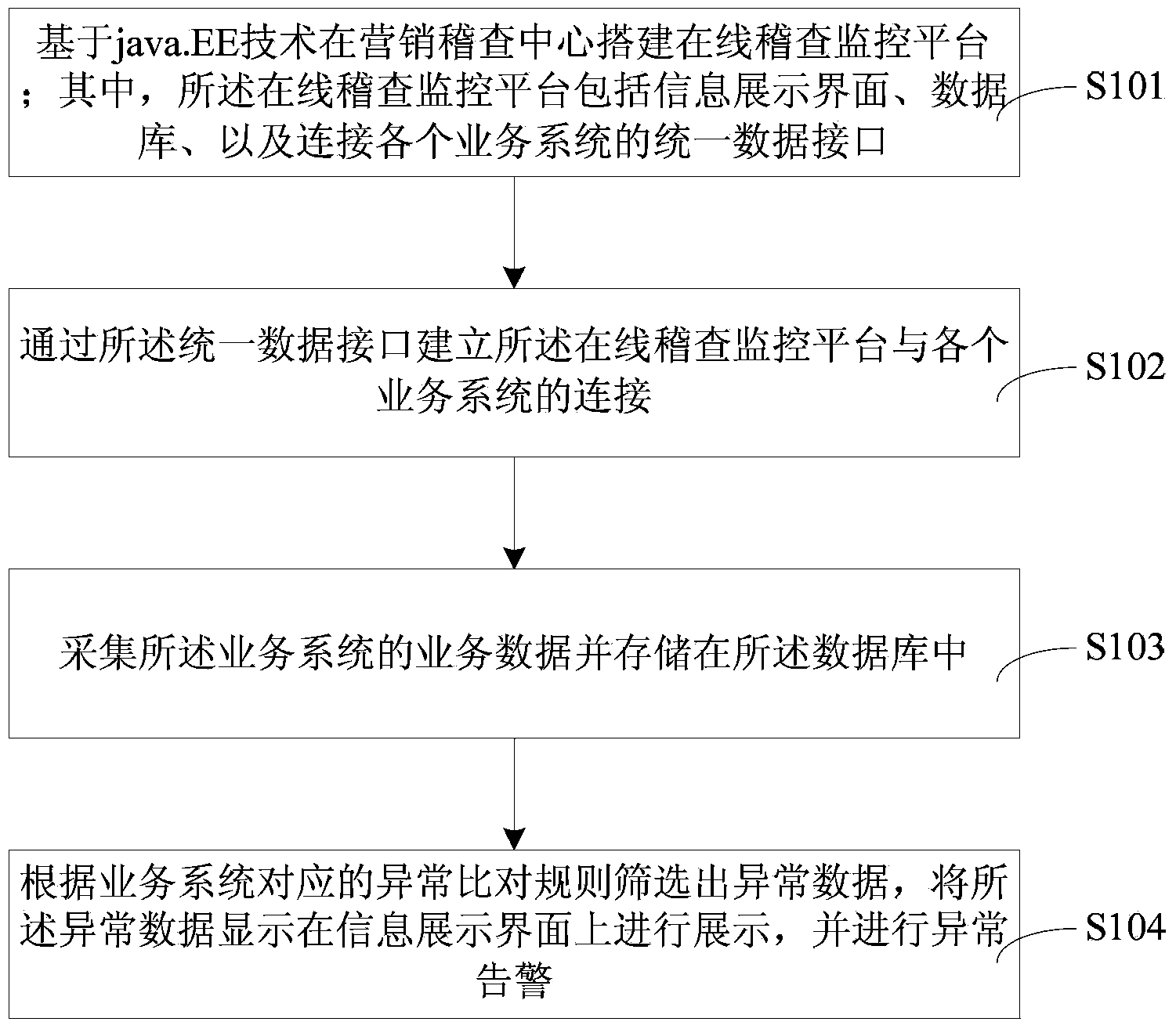

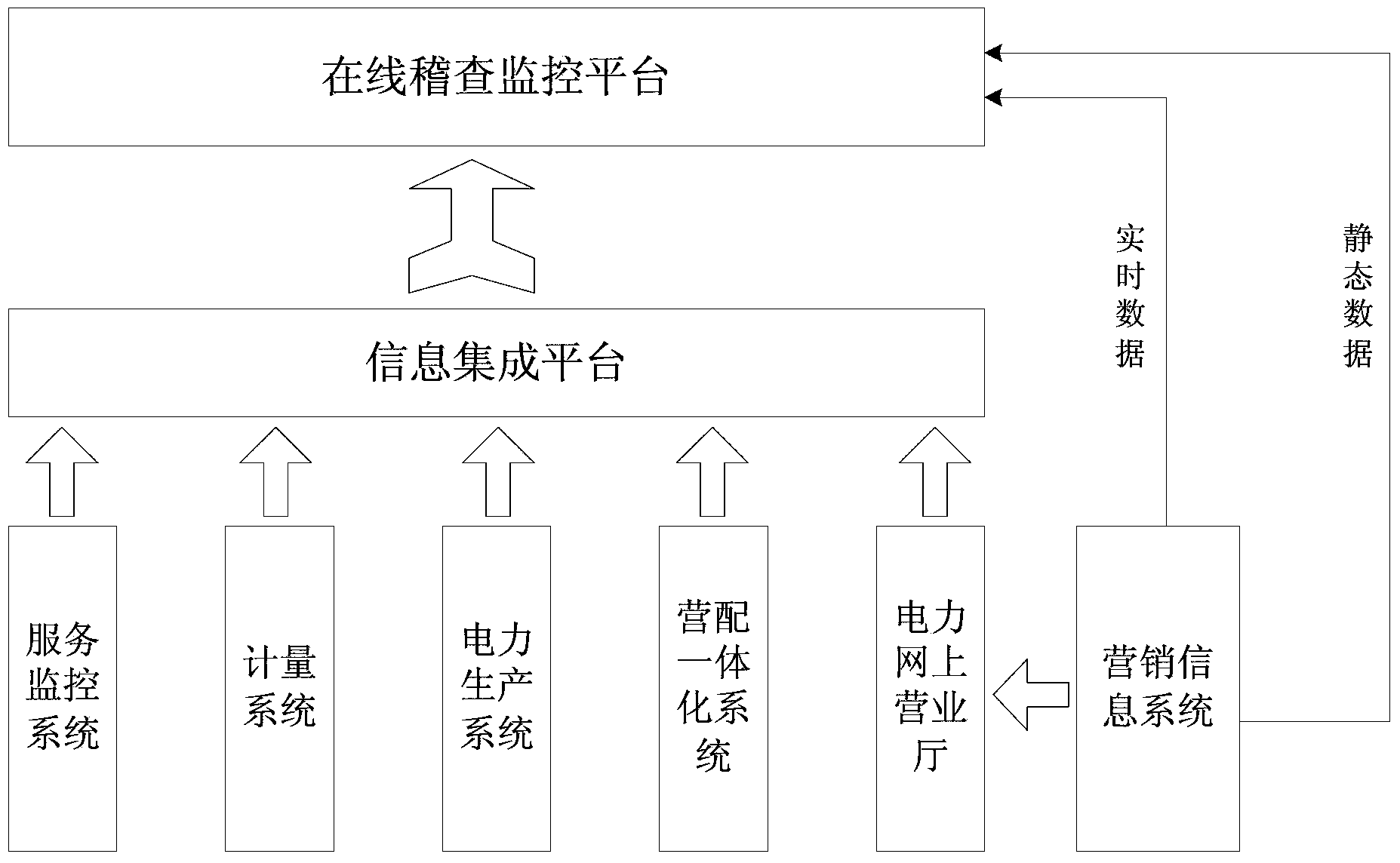

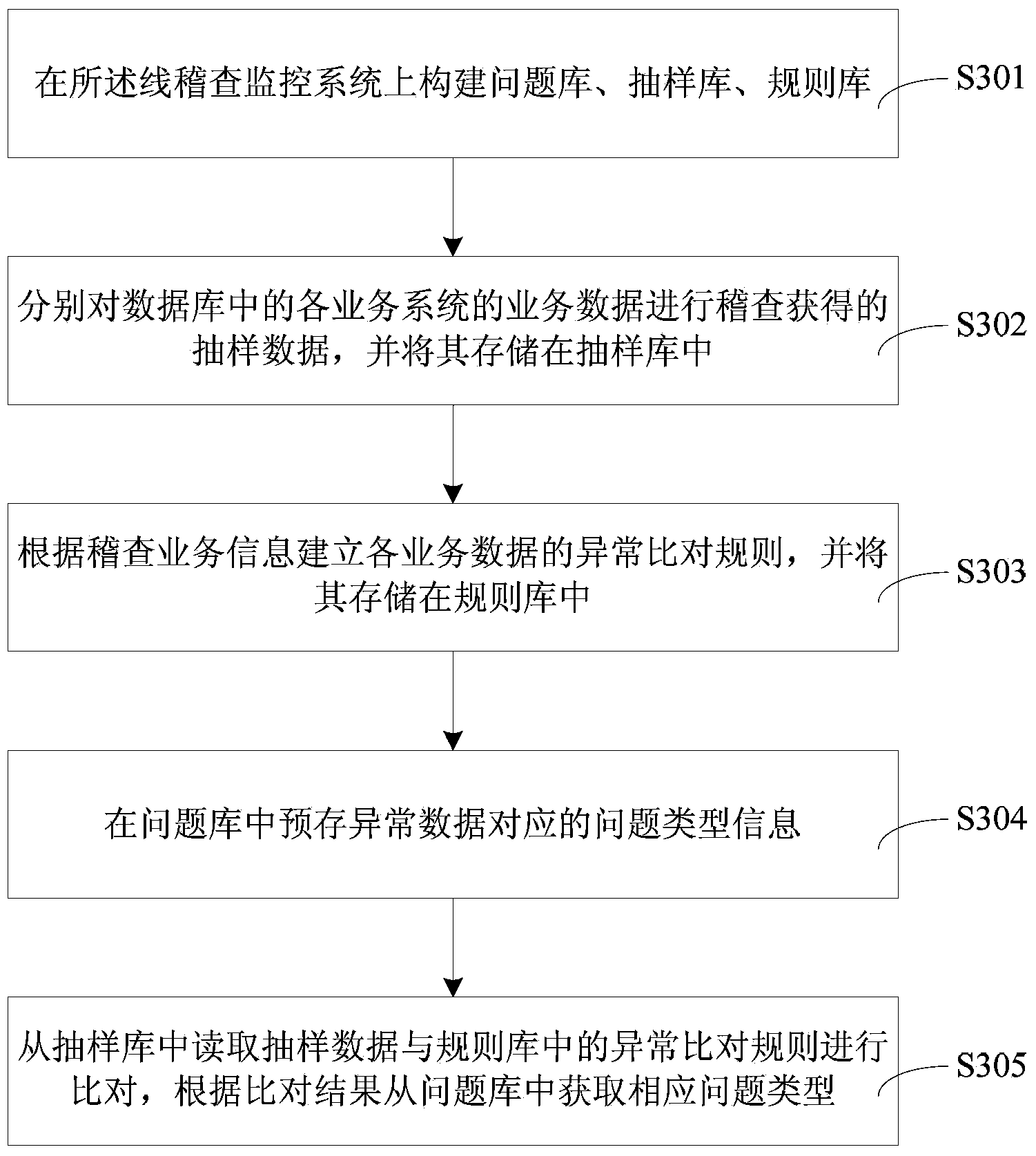

On-line monitoring method for electricity marketing business data

Provided is an on-line monitoring method for electricity marketing business data. The method is characterized by comprising the following steps that an on-line audition monitoring platform is established at a marketing audition center on the basis of java EE technology, wherein the on-line audition monitoring platform comprises an information display interface, a data base and a uniform data interface connected with various business systems; the uniform data interface establishes connection of the on-line audition monitoring platform and the various business systems; business data of the service systems are acquired and stored in the data base; abnormal data are screened out according to an abnormal comparison rule corresponding to the business systems, and the abnormal data are displayed on the information display interface for display and abnormal warning. According to the technology of the on-line monitoring method for electricity marketing business data, data monitoring efficiency is high, the data monitoring effect is good, uniform monitoring can be conducted on the electricity marketing business data of a whole power grid, and important technical support can be provided for an electricity marketing audition, supervision and double-check mechanism.

Owner:GUANGZHOU POWER SUPPLY CO LTD

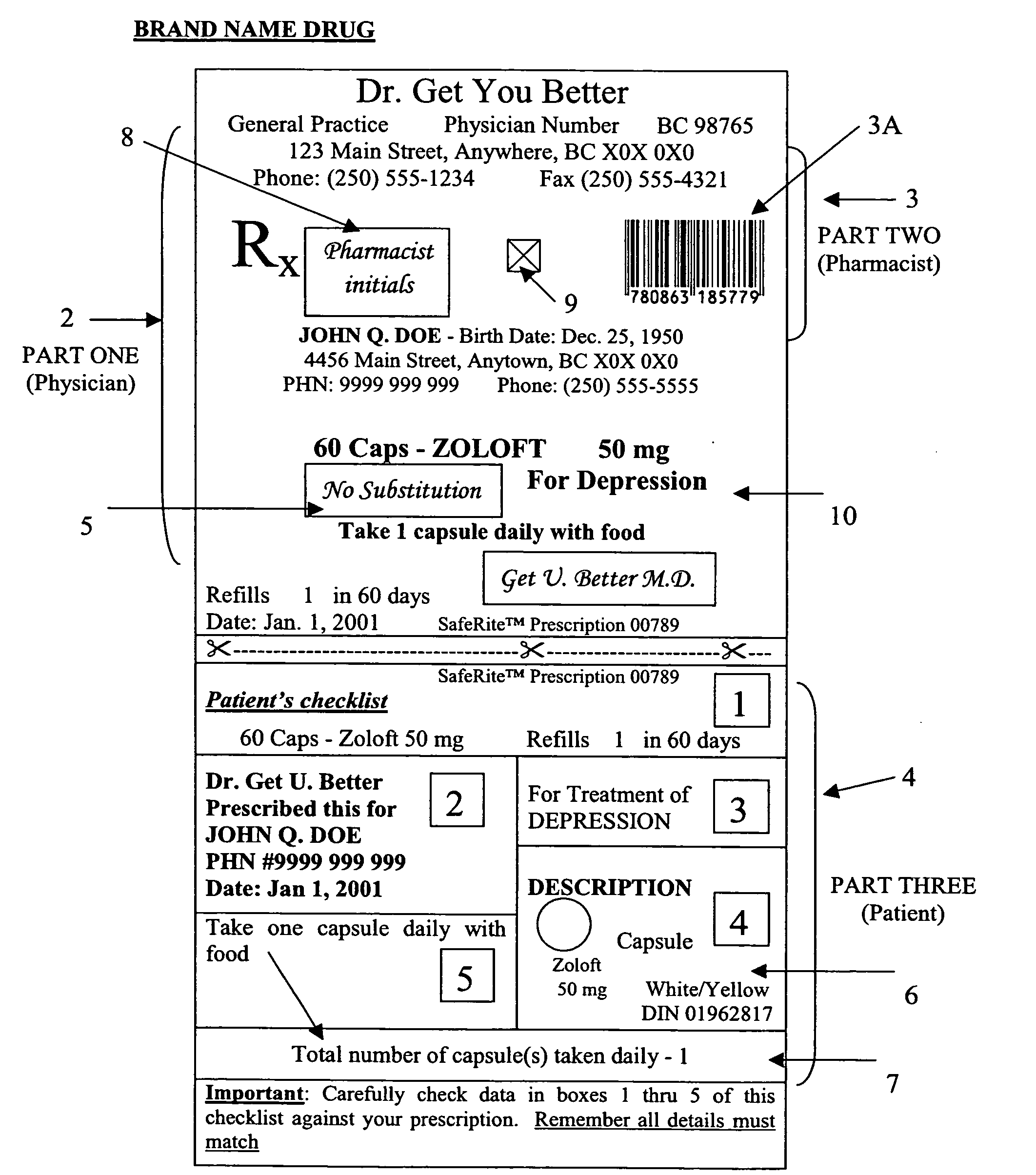

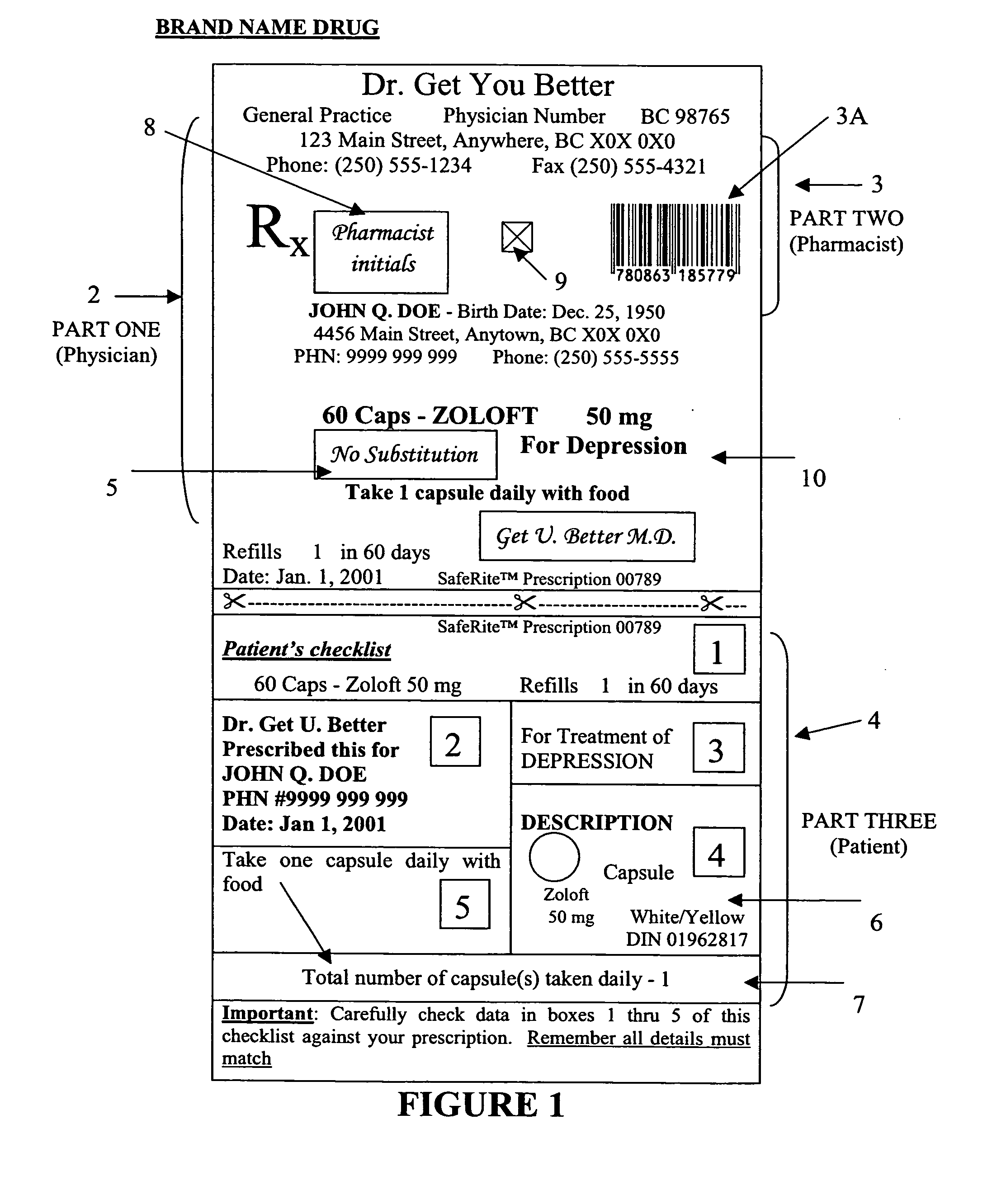

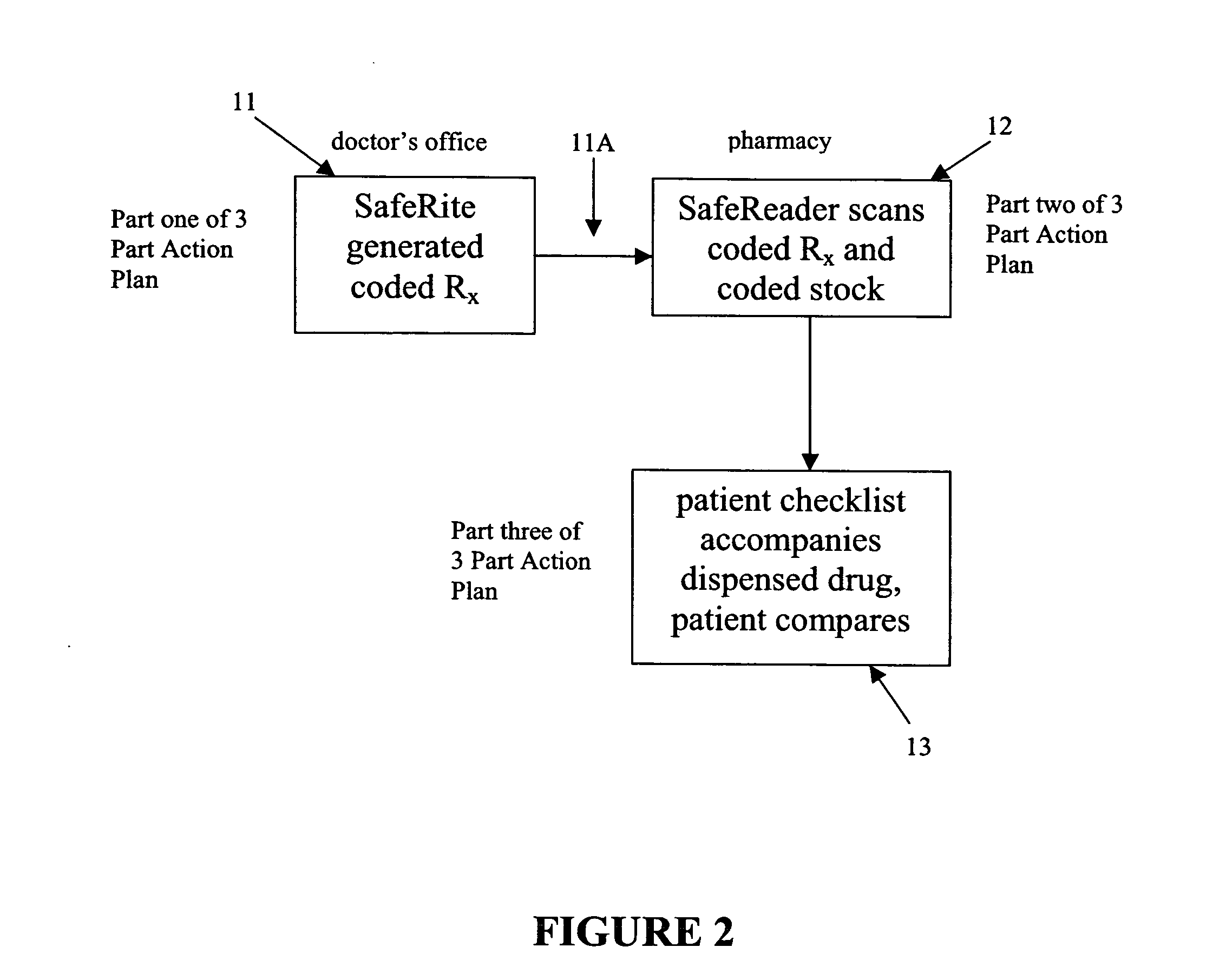

Saferite system

InactiveUS20080288287A1Substantial financial savingReduce deathDrug and medicationsOffice automationGraphicsBarcode

A system for allowing a user, such as a physician, to prepare a prescription form in multiple parts: one part encoding the prescription information (such as through a bar code, radio frequency identification, or other encoding means), and a second part containing a graphic or physical representation of the medication being prescribed. The encoded part is used by a pharmacist to compare the coded information on the prescription with coded information on the medication selected by the pharmacist to confirm if the codes match. The graphic representation portion is used by a patient to double-check that the medication provided by the pharmacy matches the physician's prescription.

Owner:STANNERS SYDNEY D

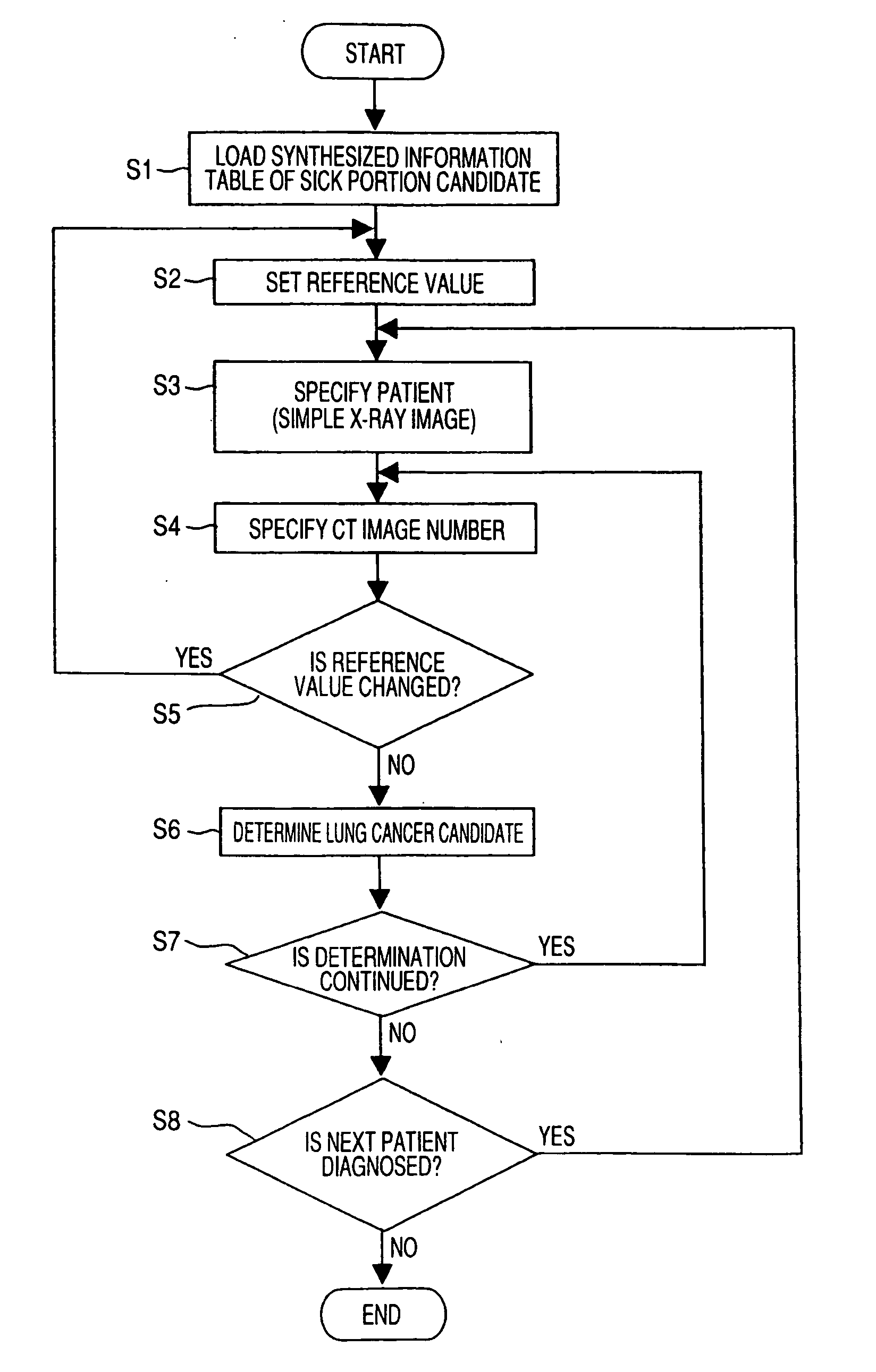

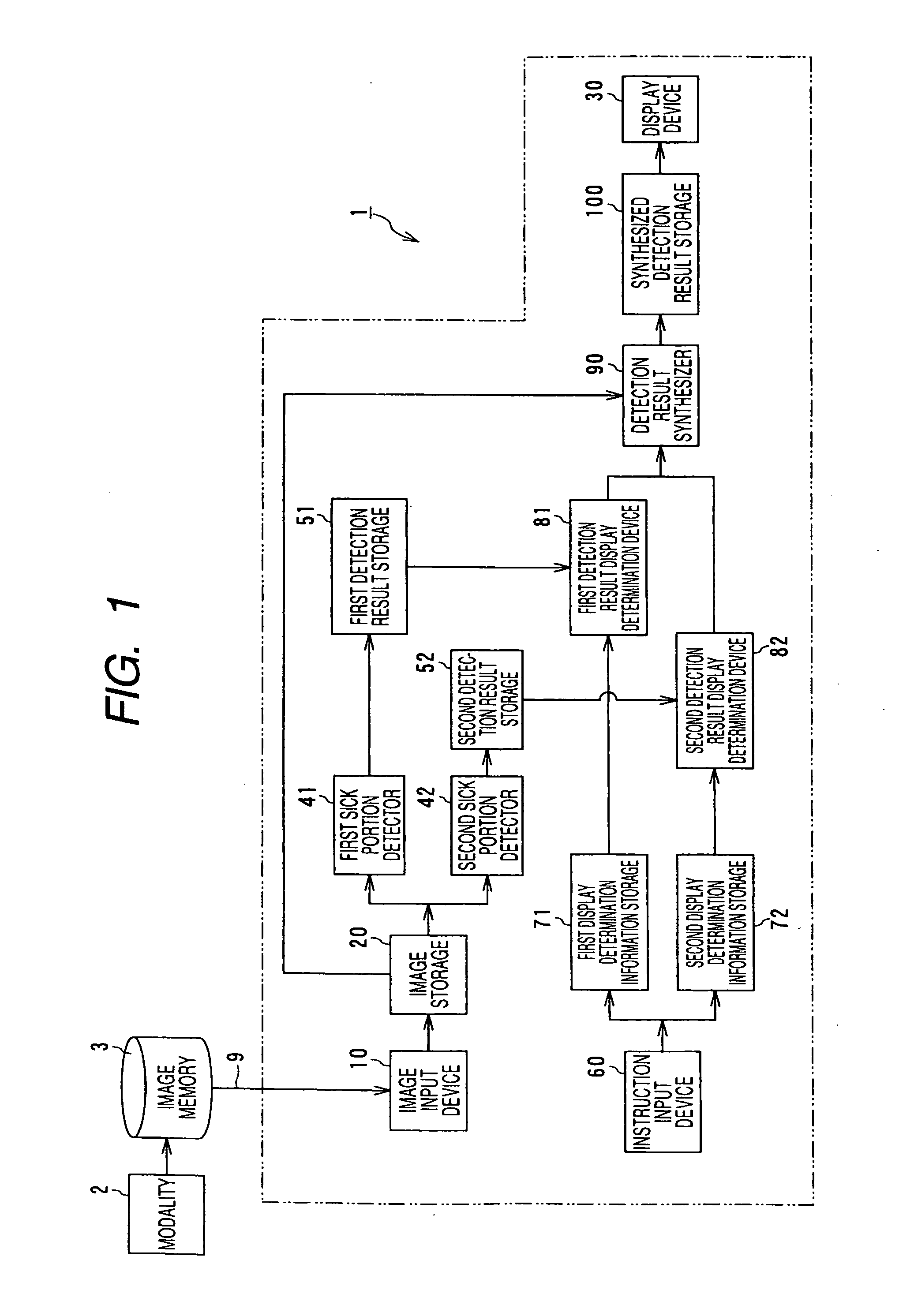

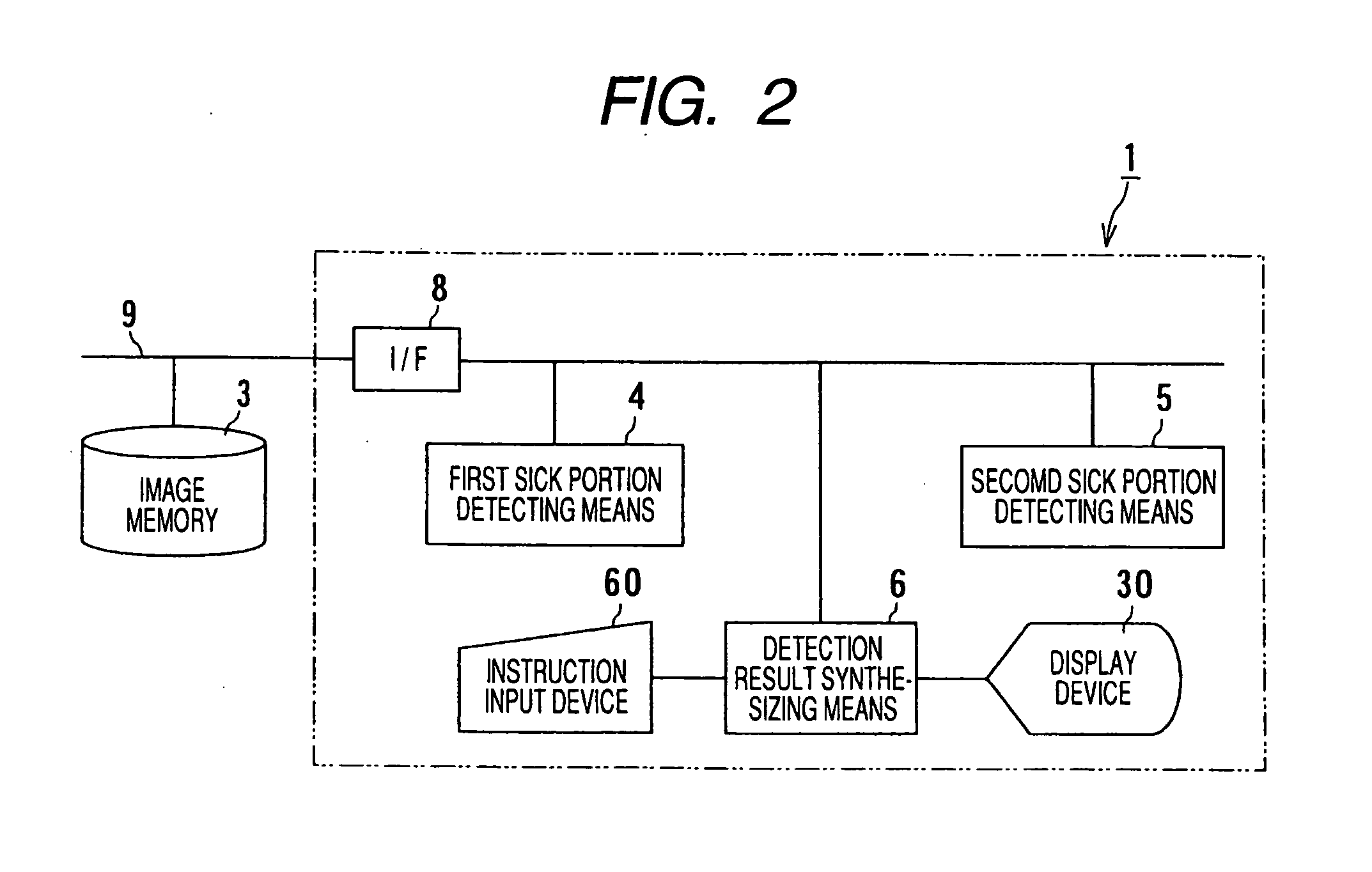

Computer-aided diagnostic apparatus

ActiveUS20060050943A1Easy to checkImage enhancementImage analysisComputer aided diagnosticsImage detection

A computer aided diagnostic system according to the invention is characterized in that first sick portion detecting means for detecting a sick portion candidate based upon an image acquired by a first modality, second sick portion detecting means for detecting a sick portion candidate based upon an image related to the same region of interest of the same subject and acquired by a second modality different from the modality, detection result synthesizing means for comparing the results of detection by the first and second sick portion detecting means and correspondence displaying means for relating the position of the sick portion candidate detected by the first sick portion detecting means on an image analyzed by the second sick portion detecting means and displaying it and for relating the position of the sick portion candidate detected by the second sick portion detecting means on an image analyzed by the first sick portion detecting means and displaying it are provided. According to the above-mentioned configuration, the computer aided diagnostic system that enables a double check comparing images acquired by plural apparatuses can be provided.

Owner:TOSHIBA MEDICAL SYST CORP

Pilot signals for synchronization and/or channel estimation

InactiveUS7012906B1Avoid poor resultsEliminate and prevent sidelobesSynchronisation arrangementTime-division multiplexCorrelation functionSelf correlation

The frame words of the preferred embodiment are especially suitable for frame synchronization and / or channel estimation. By adding the autocorrelation and cross-correlation functions of frame words, double maximum values equal in magnitude and opposite polarity at zero and middle shifts are obtained. This property can be used to slot- by-slot, double-check frame synchronization timing, single frame synchronization and / or channel estimation and allows reduction of the synchronization search time. Further, the present invention allows a simpler construction of a correlator circuit for a receiver.

Owner:LG ELECTRONICS INC

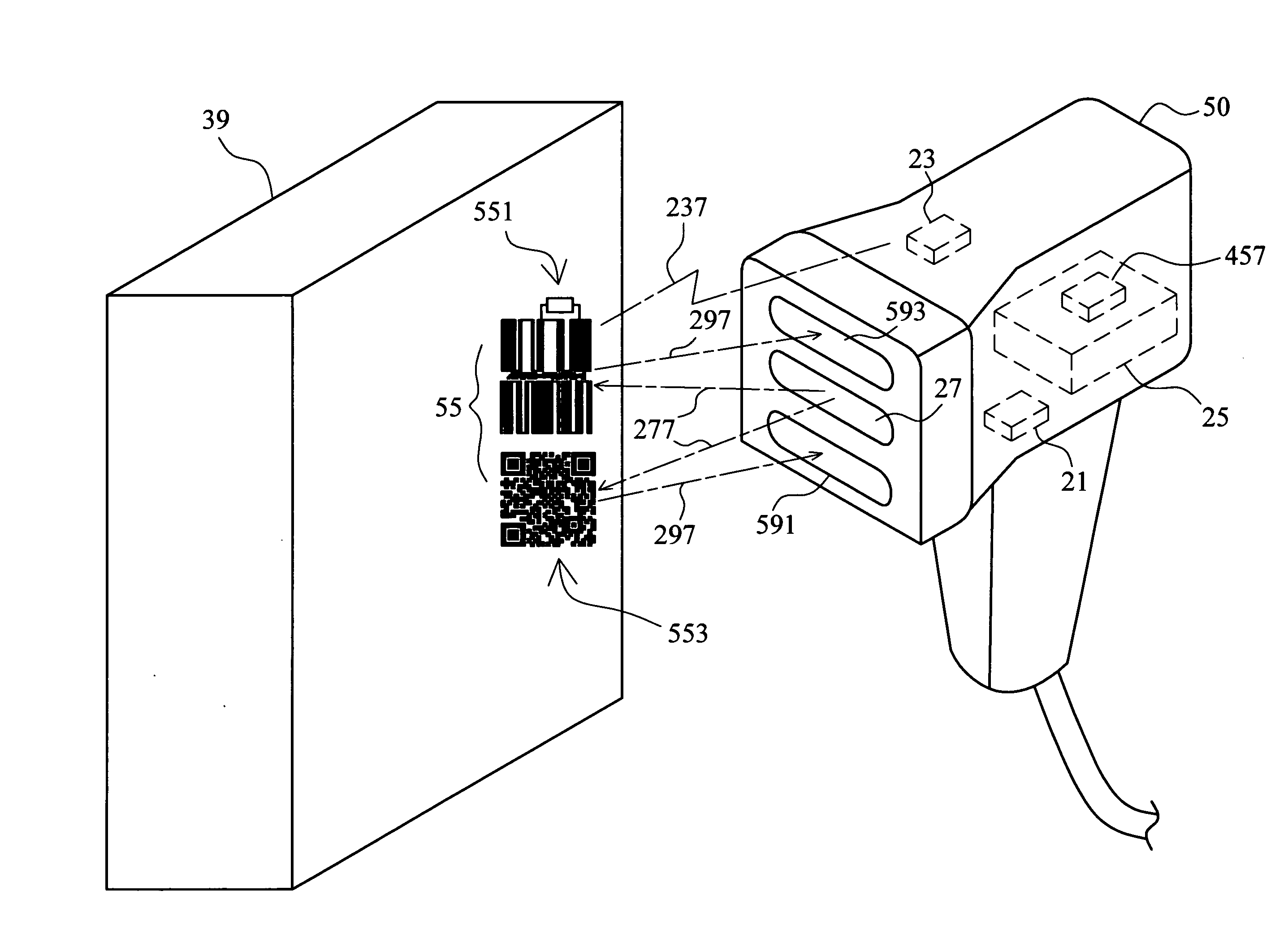

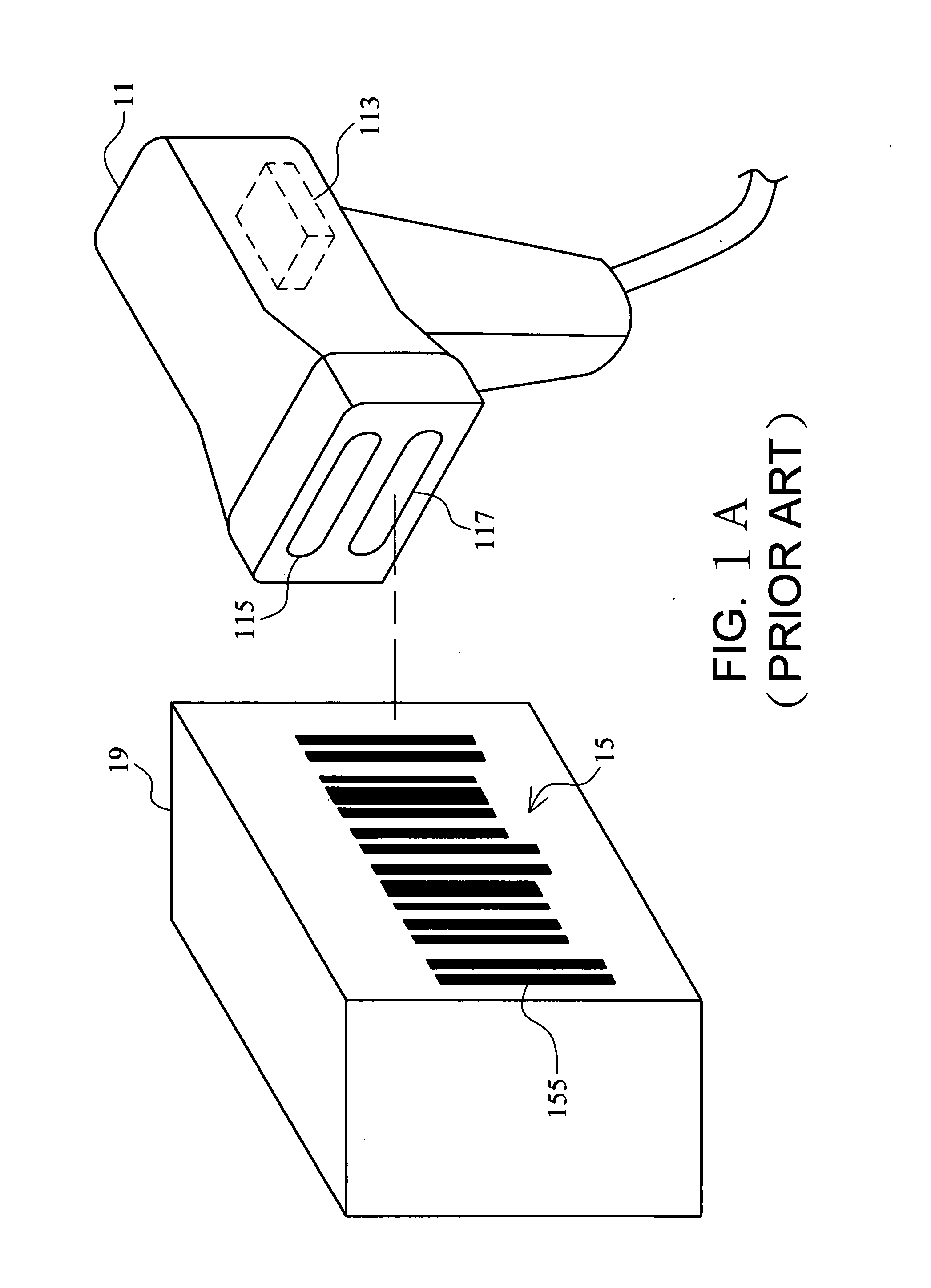

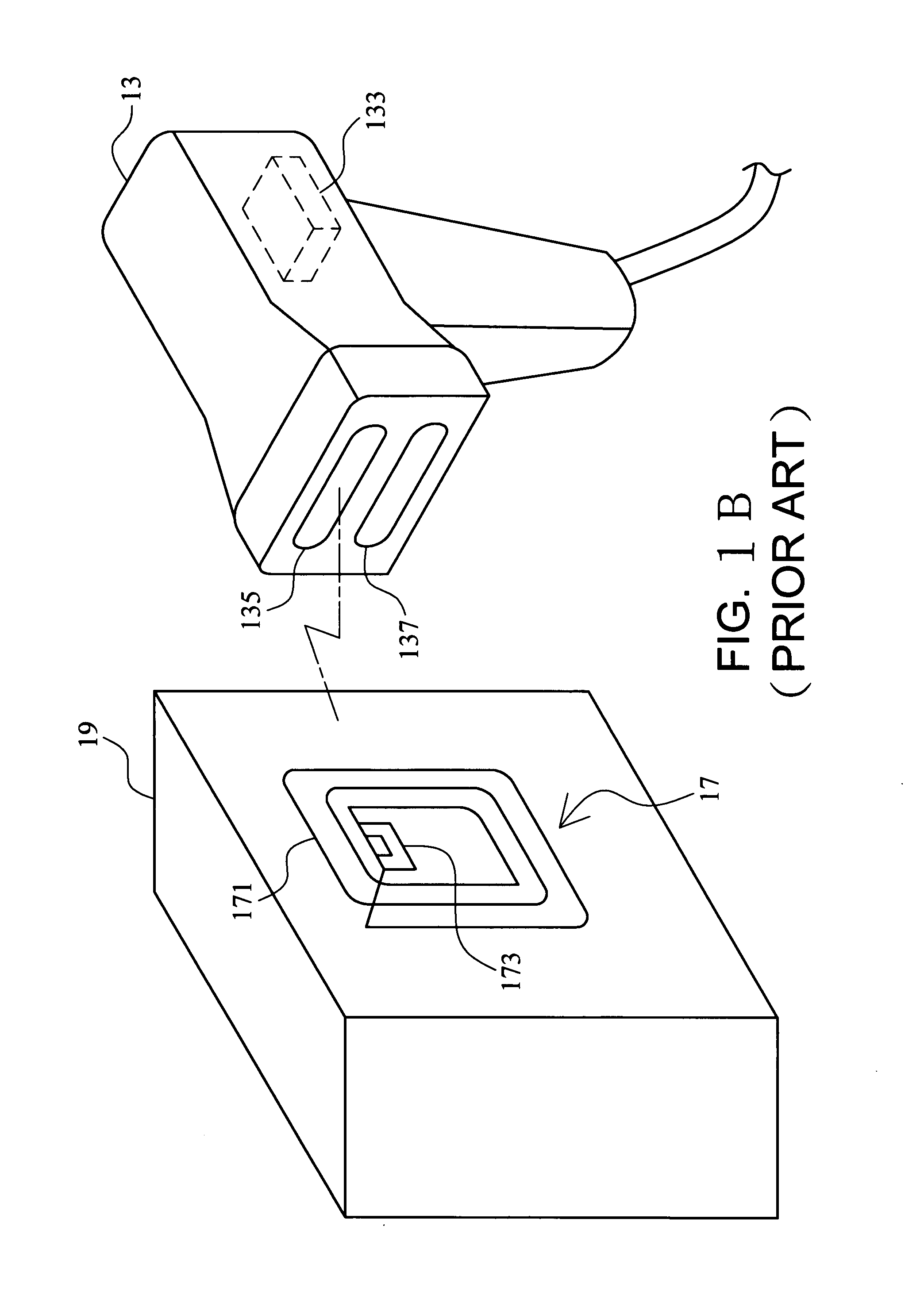

Tag reader and the tag

InactiveUS20090039162A1Convenient for peopleTransmission systemsRecord information storageBarcodeEngineering

Owner:YEN LEEWAY +1

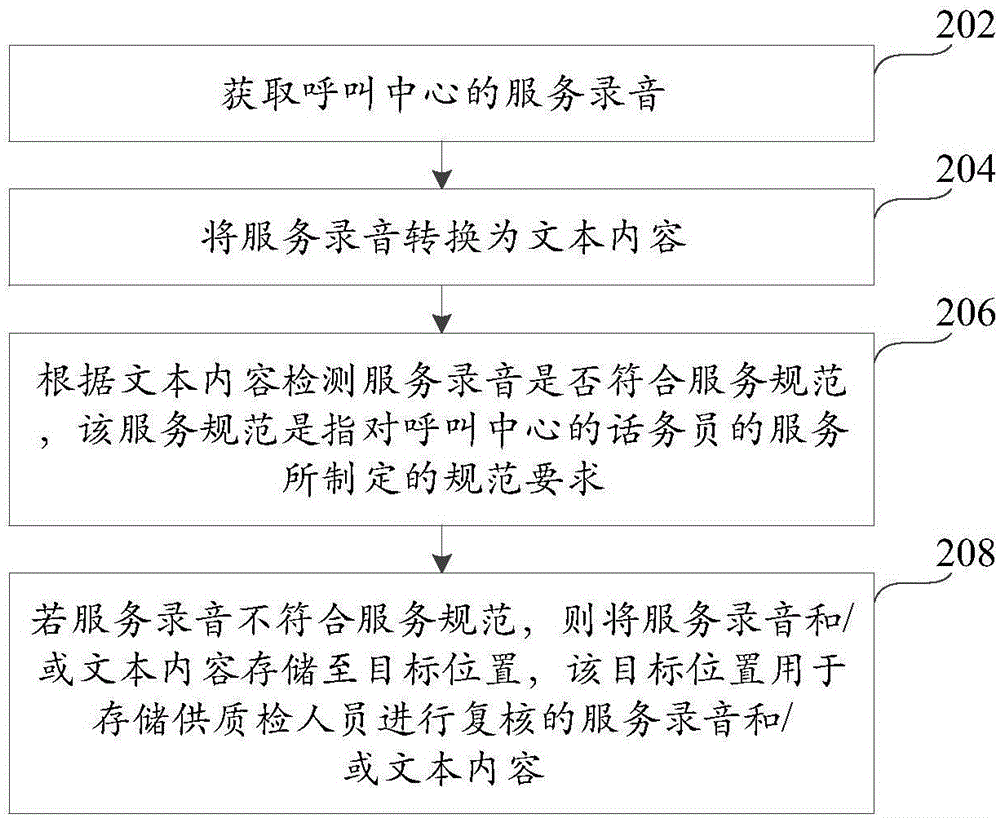

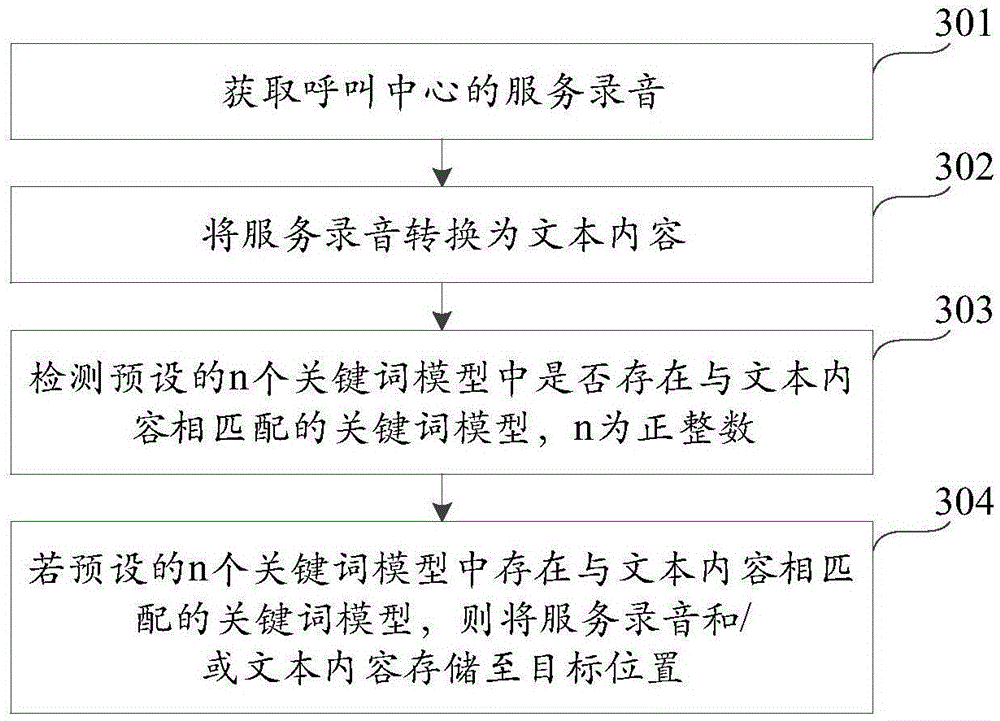

Service record compliance checking method and device

InactiveCN105141787ASolve efficiency problemsReduce missed detectionSpecial service for subscribersSupervisory/monitoring/testing arrangementsDouble checkDatabase

The invention discloses a service record compliance checking method and device and belongs to the technical field of communications. The method comprises: obtaining a service record of a call center; converting the service record into text content; detecting whether the service record complies with service specifications according to the text content, wherein the service specifications are specification requirements established for the services of operators of the call center; and if the service record does not comply with the service specifications, storing the service record and / or the text content to a target position that is used for storing the service record and / or the text content for double-check by the quality inspection personnel. The service record compliance checking method is used for solving the problem of existence of plenty of missing inspections and low efficiency if a random extraction manner is adopted in the prior art; on one hand, the missing inspections can be reduced thoroughly, and on the other hand, as only the service records which are detected by the system as being not compliant are provided for the quality inspection personnel, the quality inspection personnel only needs to re-check the service records, and therefore, the quality inspection personnel can perform targeted checking and the checking efficiency can be improved.

Owner:上海银赛计算机科技有限公司

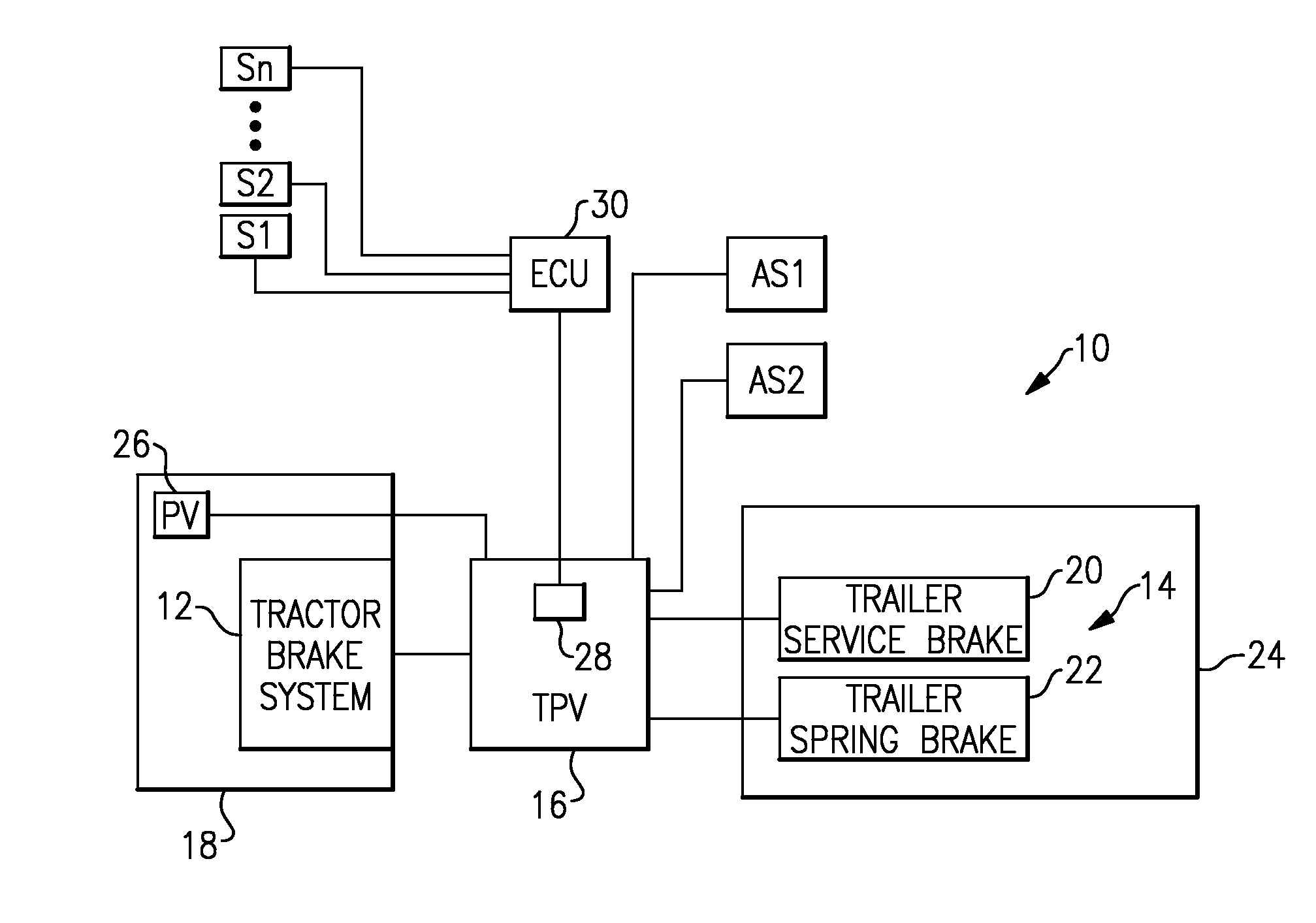

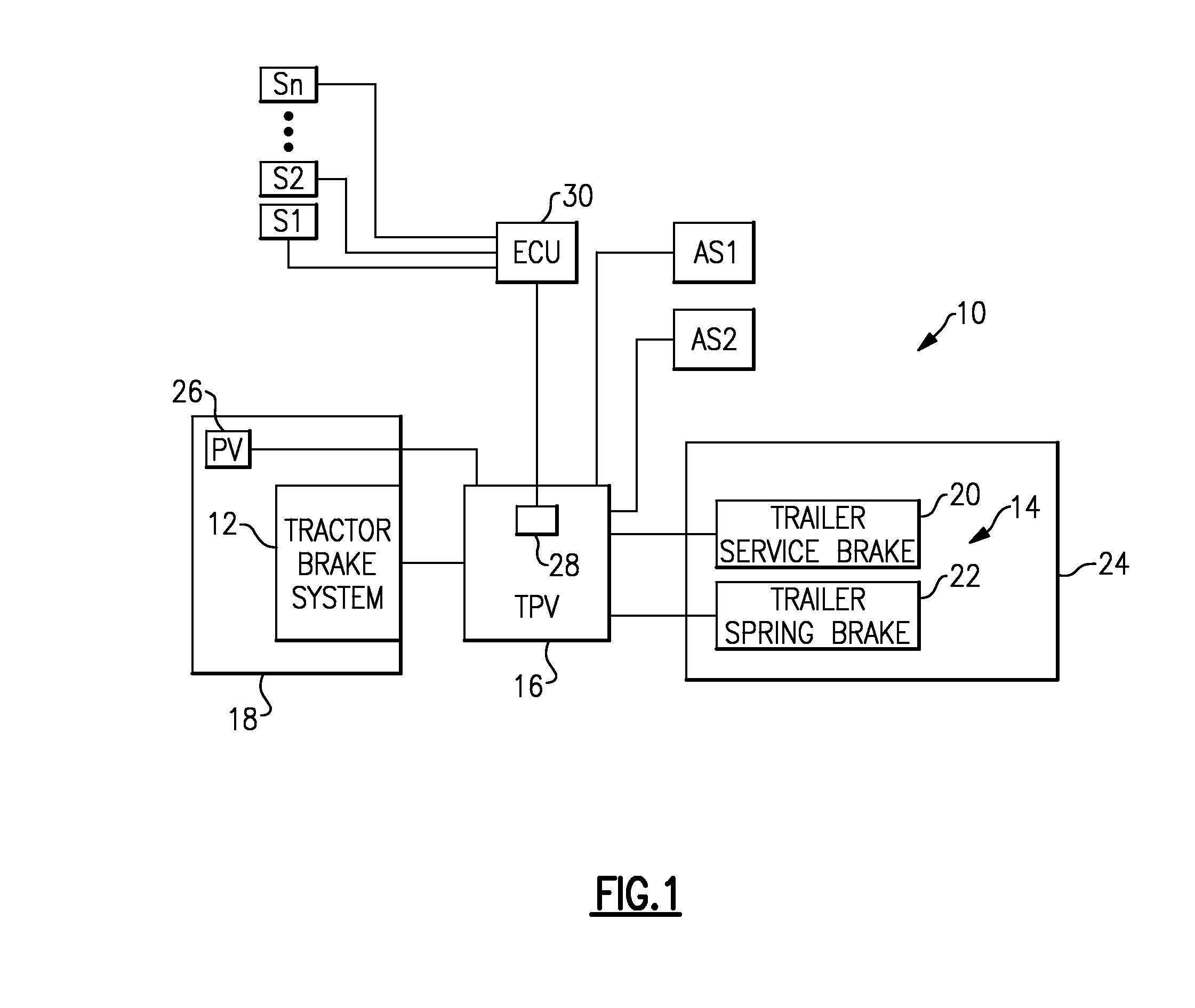

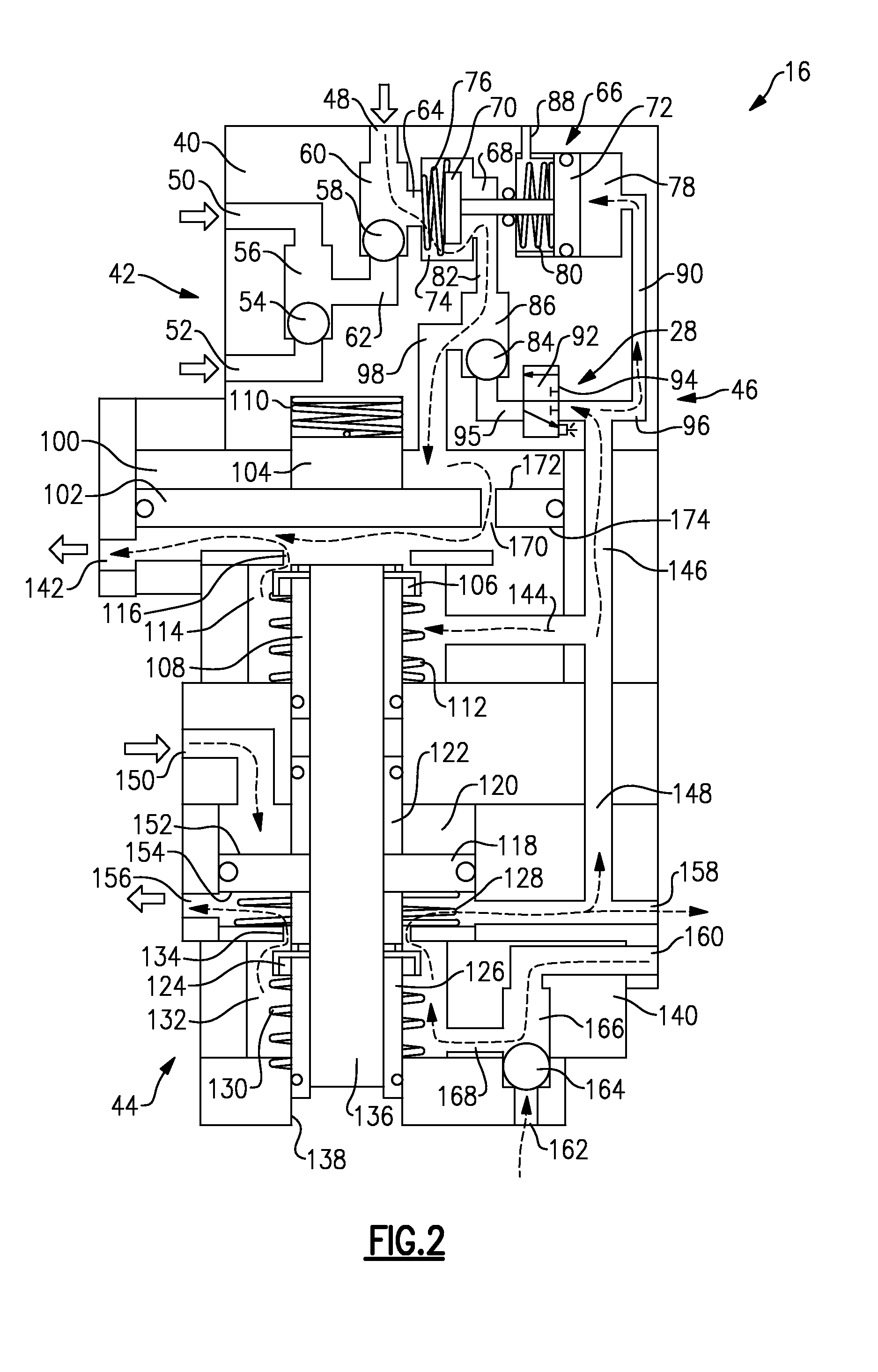

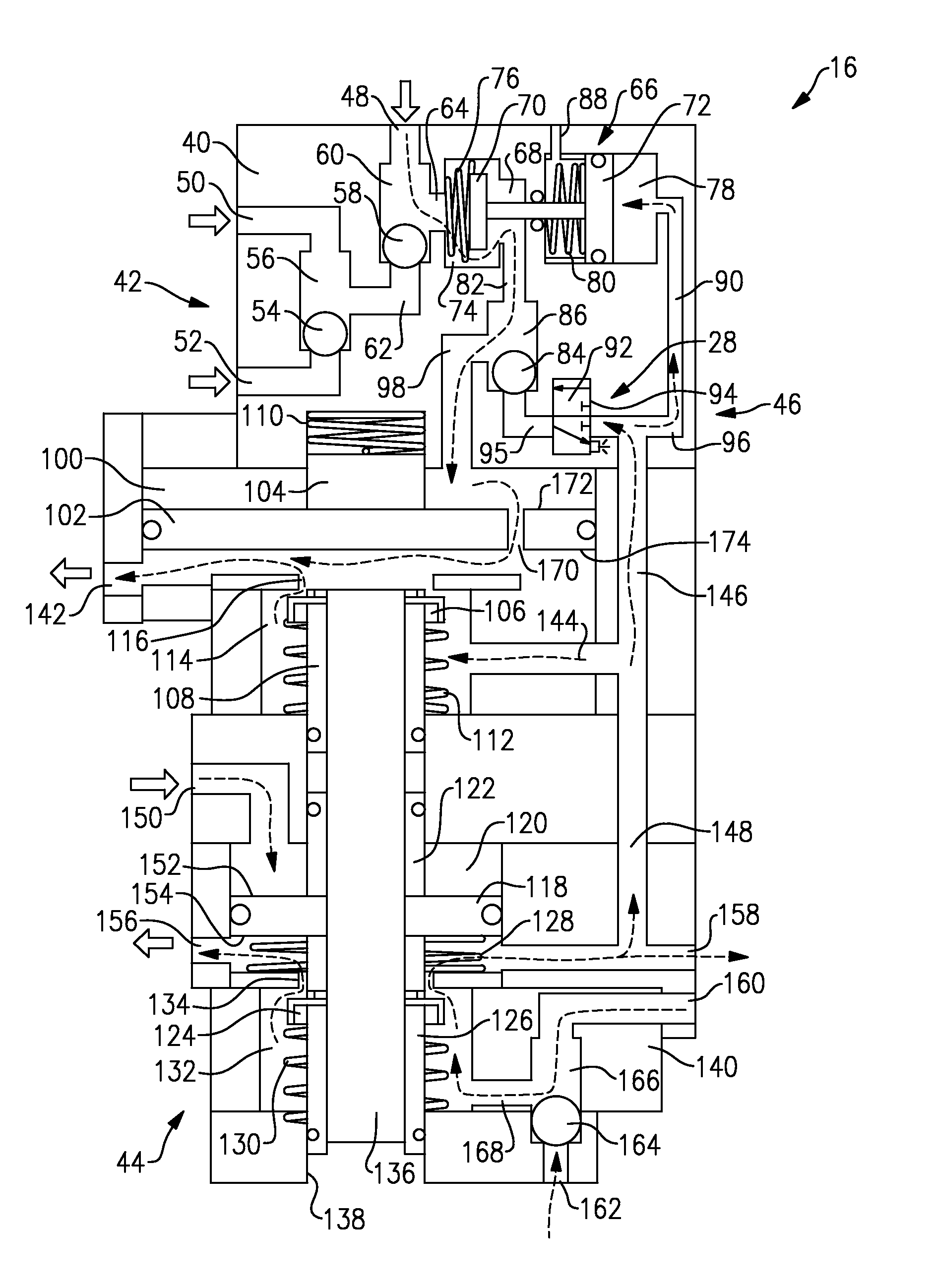

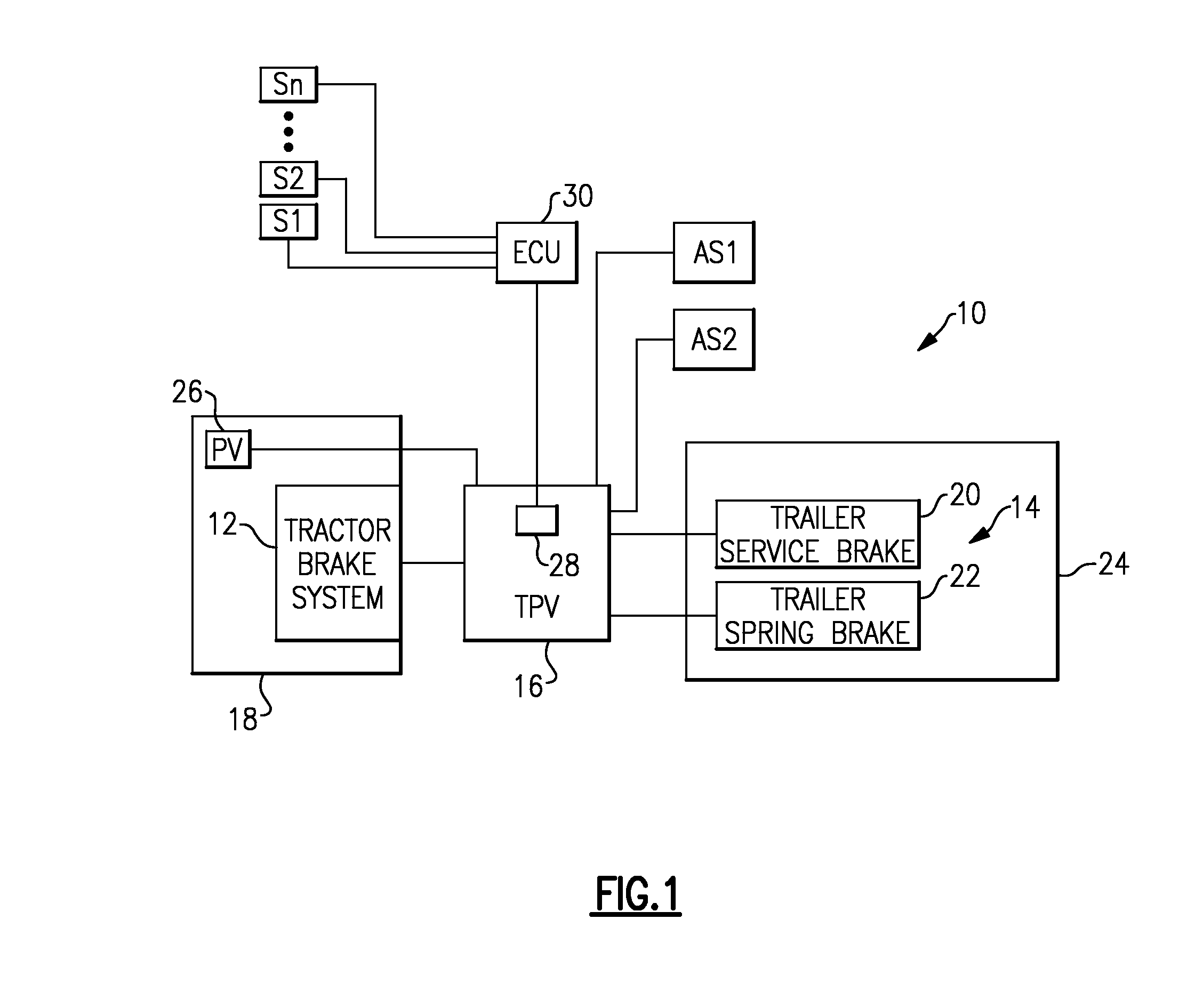

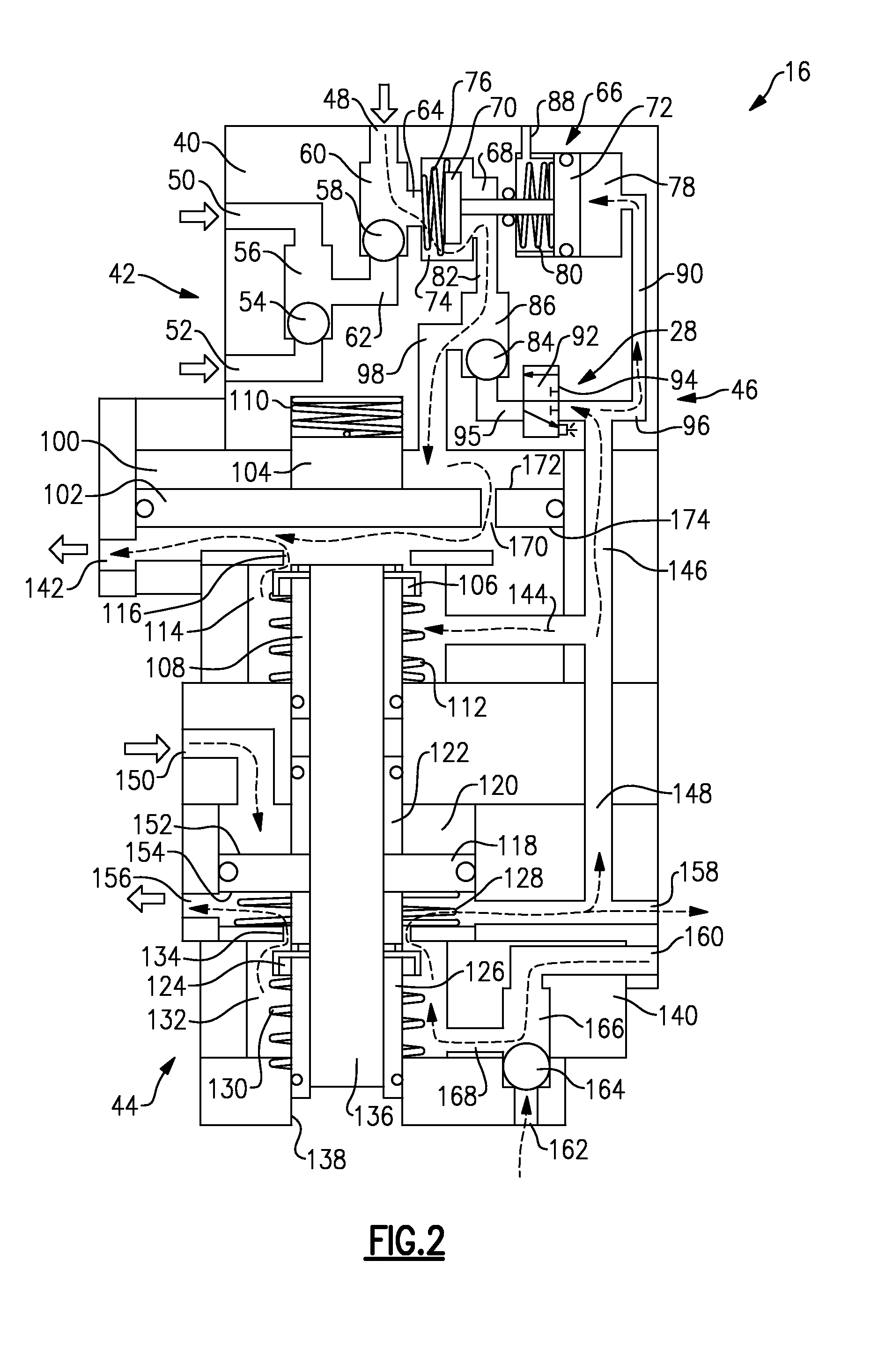

Full function tractor protection valve

InactiveUS20080258542A1Reduce in quantityQuick releaseBraking action transmissionAutomatic initiationsControl signalDouble check valve

A tractor protection valve includes a trailer service brake portion, a trailer parking brake portion, and a stability control portion that are each formed within a common valve body. In one example, the trailer service brake portion includes three inlets that can be used to apply a trailer service brake. The three inlets cooperate with a service brake blocking piston, a service brake relay piston, and double check valves to apply the trailer service brakes as needed. The stability control portion includes a solenoid that can direct air to apply the trailer service brakes in response to a stability control signal. The trailer parking brake portion also includes multiple ports that cooperate with a parking brake piston and valve to control application and release of the trailer parking brakes.

Owner:MERITOR WABCO VEHICLE CONTROL SYST

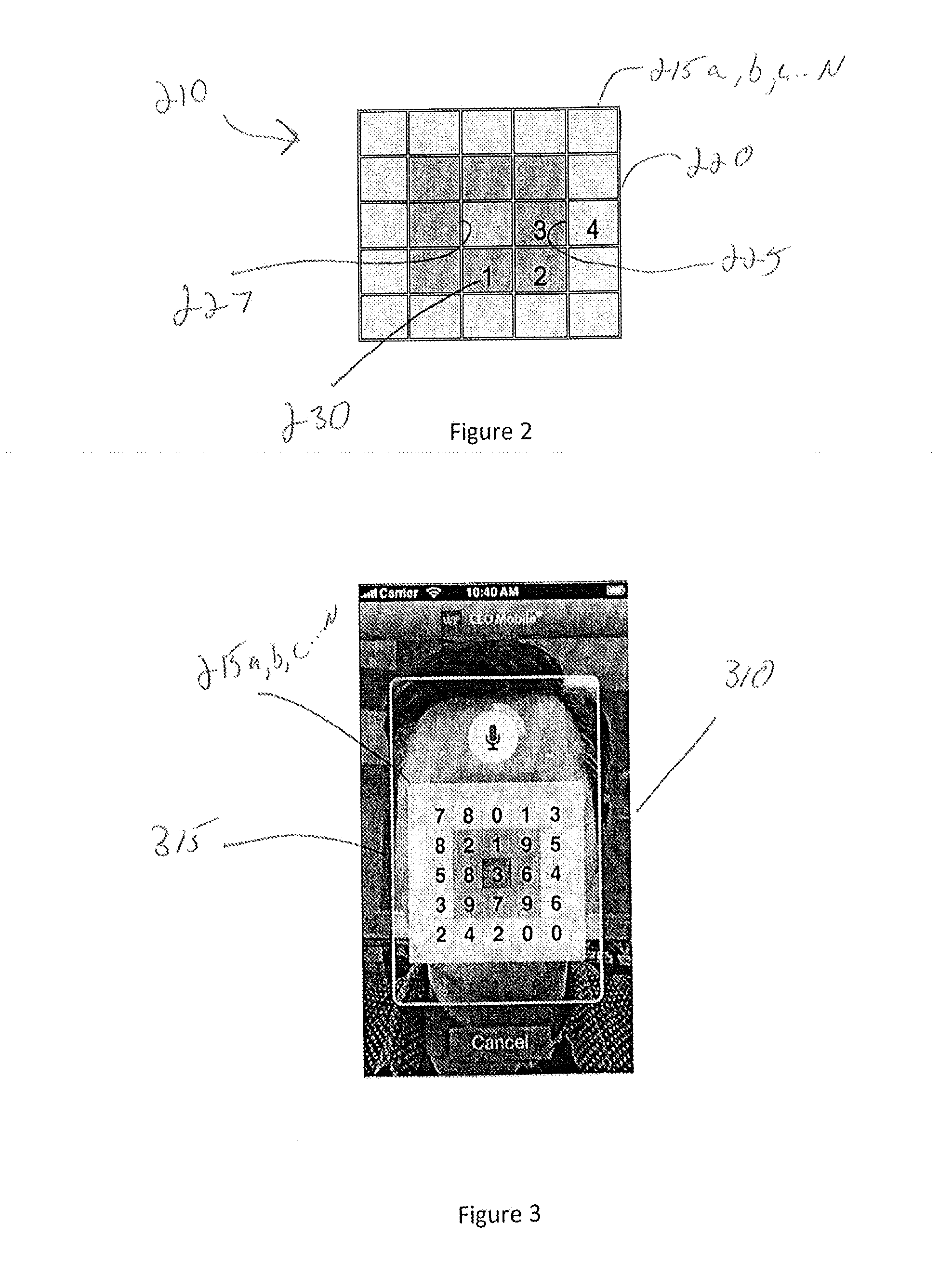

System, method and apparatus for voice biometric and interactive authentication

InactiveUS20160148012A1Increase capacityReduce the possibilityDigital data processing detailsUnauthorized memory use protectionGraphicsPassphrase

A system, method and apparatus is disclosed for voice biometric and interactive authentication including the obtaining of a voice authentication file and a sequence of user's face images and making a decision about the presence of a dummy on the images. A distinctive feature of invention combine pronunciation of a phrase (in addition to physically typing in) taken from this grid with the voice biometrics that will double check not only if the voice is correct, but if the numbers are correct as well. This passphrase is secured during pronunciation because the numbers are changing randomly and frequently while the same numbers are also placed in the other places along the selected graphic, grid, pattern or a combination thereof.

Owner:SPEECHPRO INC

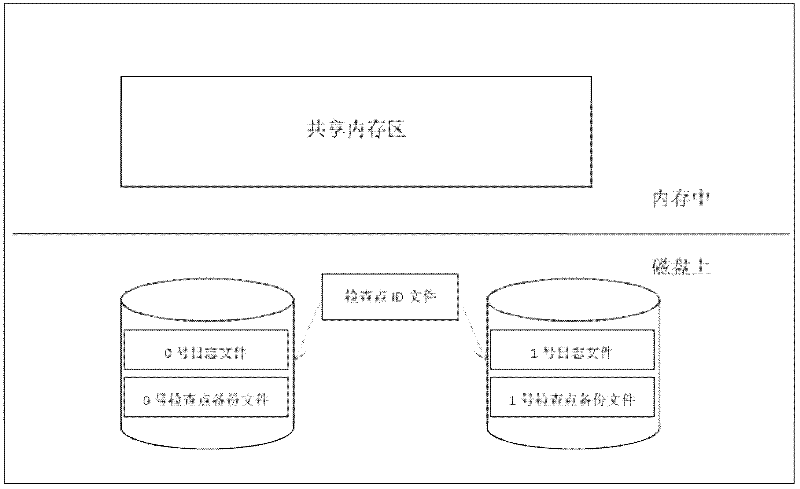

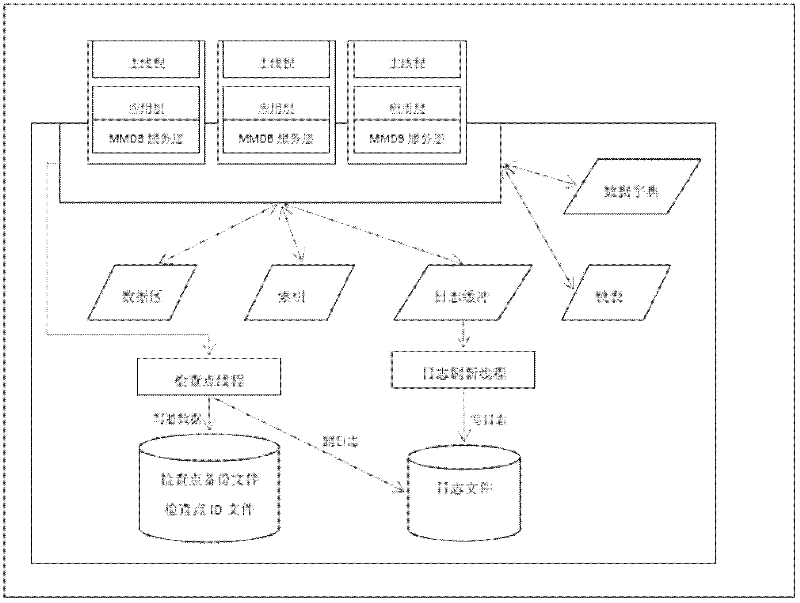

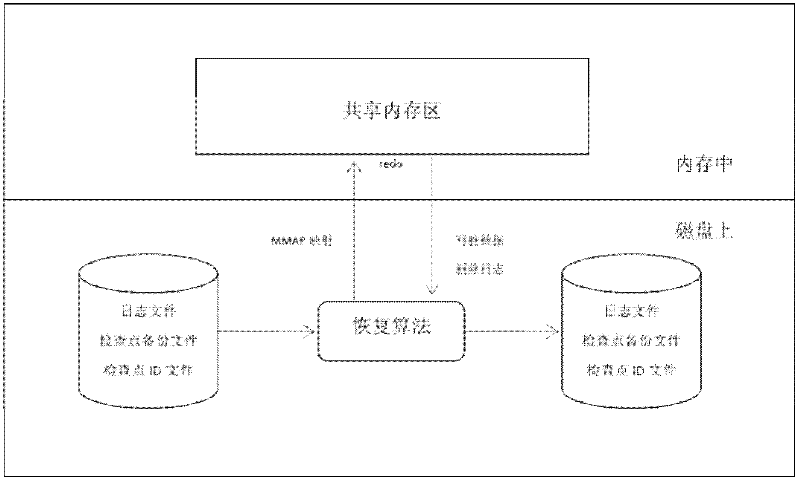

Log check point recovery method applied to memory data base OLTP (online transaction processing)

ActiveCN102541691AHigh speedReduce the burden onRedundant operation error correctionSpecial data processing applicationsRecovery methodMmap

The invention discloses a log check point recovery method applied to memory data base OLTP (online transaction processing), which uses the log check point technique based on double-log double-check-point backup. Two backup files can be used in turn, and a data base can recover to a latest uniform state no matter in a transaction process, a check point executive process or breakdown in a recovery process. Meanwhile, an MMAP (memory-mapped analog page) sharing mechanism is used for quickly setting up the mapping from a check point standby file to a memory, and rapid recovery of massive data bases is realized.

Owner:北京人大金仓信息技术股份有限公司

Accessible service provider clearinghouse

InactiveUS20080263016A1Minimal levelEasy accessDigital data processing detailsCustomer communicationsRating systemService provision

A service that maintains a minimum criteria level for service providers to be listed and available for public access. It can list not only the service provider's credentials and insurance support (with monitored expiration dates), but may also provide a current up-to-date rating system by the users themselves, as to the satisfaction level of the quality and reliability of the work performed. It can also offer a double-check of the credentials by customer verification input. Furthermore, the example service can be easily accessible by the general public (for individual or business use) on the Internet, or by printed text directories sold direct or in bookstores.

Owner:LOKITZ SHEILA

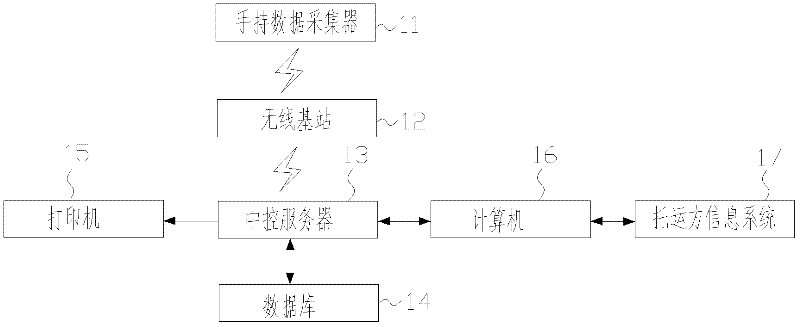

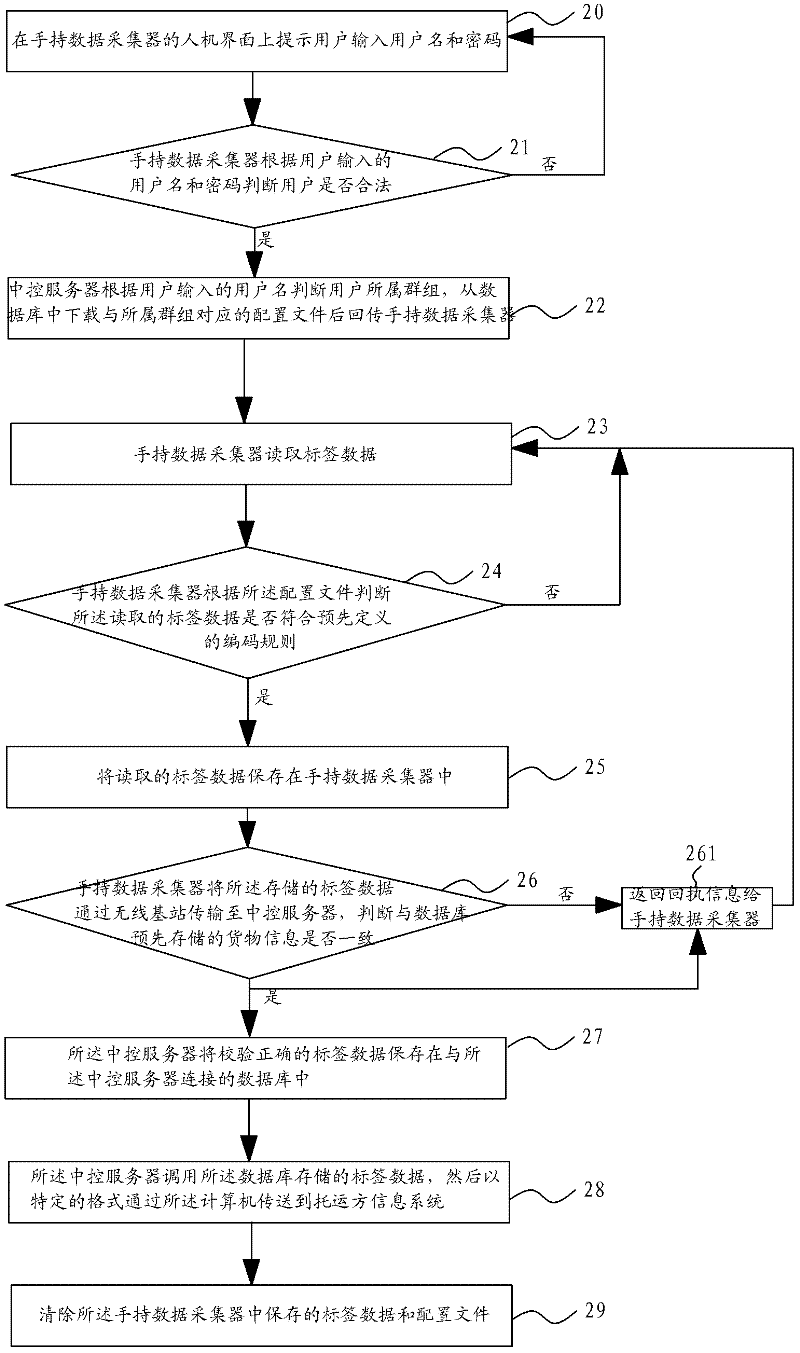

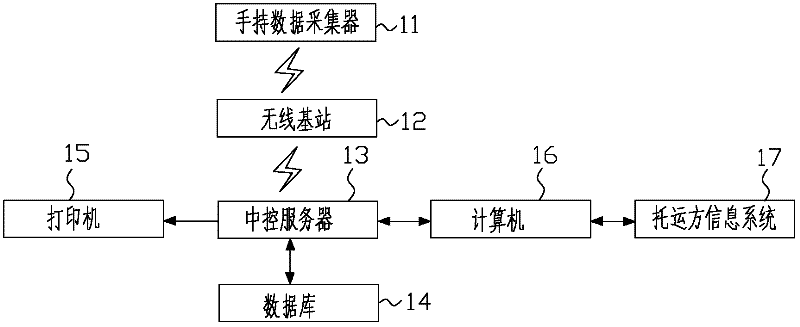

Warehouse entry system and method based on wireless network

The embodiment of the invention provides a warehouse entry system based on a wireless network. The system comprises a data collector, a wireless base station, a central control server and a database; the data collector is connected with the central control server via the wireless base station; and the database is connected with the central control server. The embodiment of the invention also provides a warehouse entry method based on the wireless network. According to the embodiment of the invention, whether a read code rule of label data is fitted or not can be judged according to the code rule in a downloaded configuration file so that it is easy to clear and check. After receiving the label data uploaded by the handheld data collector, the central control server is used for further checking the label data with the cargo information pre-stored in the database so that the accuracy of the information is ensured through double checks and errors in each link are reduced; and the central control server is also used for returning receipt information to the handheld data collector according to the judging result during the comparison so as to bring convenience to site personnel to purposefully re-inputting the label data so that the work efficiency of warehouse entry is greatly improved.

Owner:SHANGHAI RUANFU INFORMATION TECH

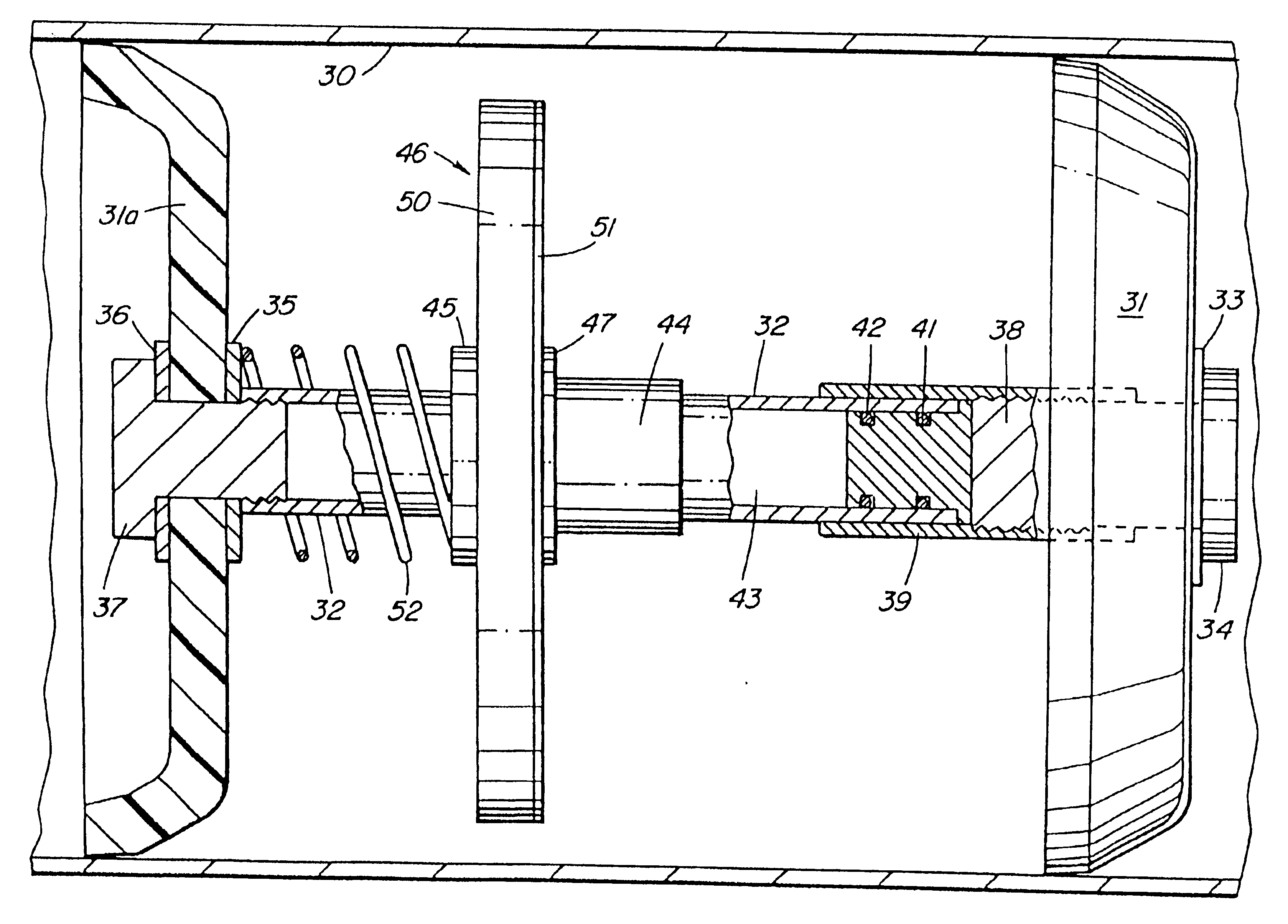

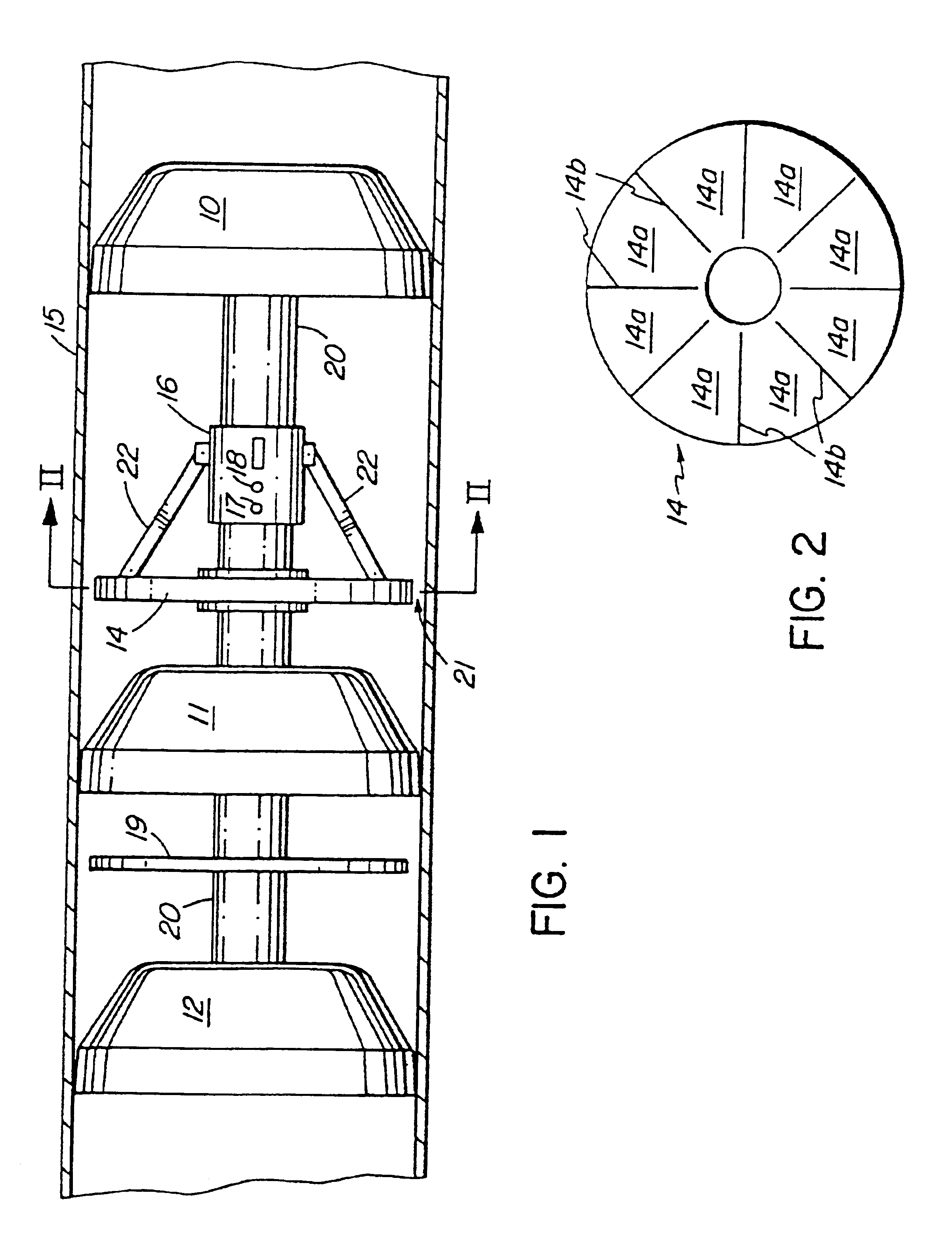

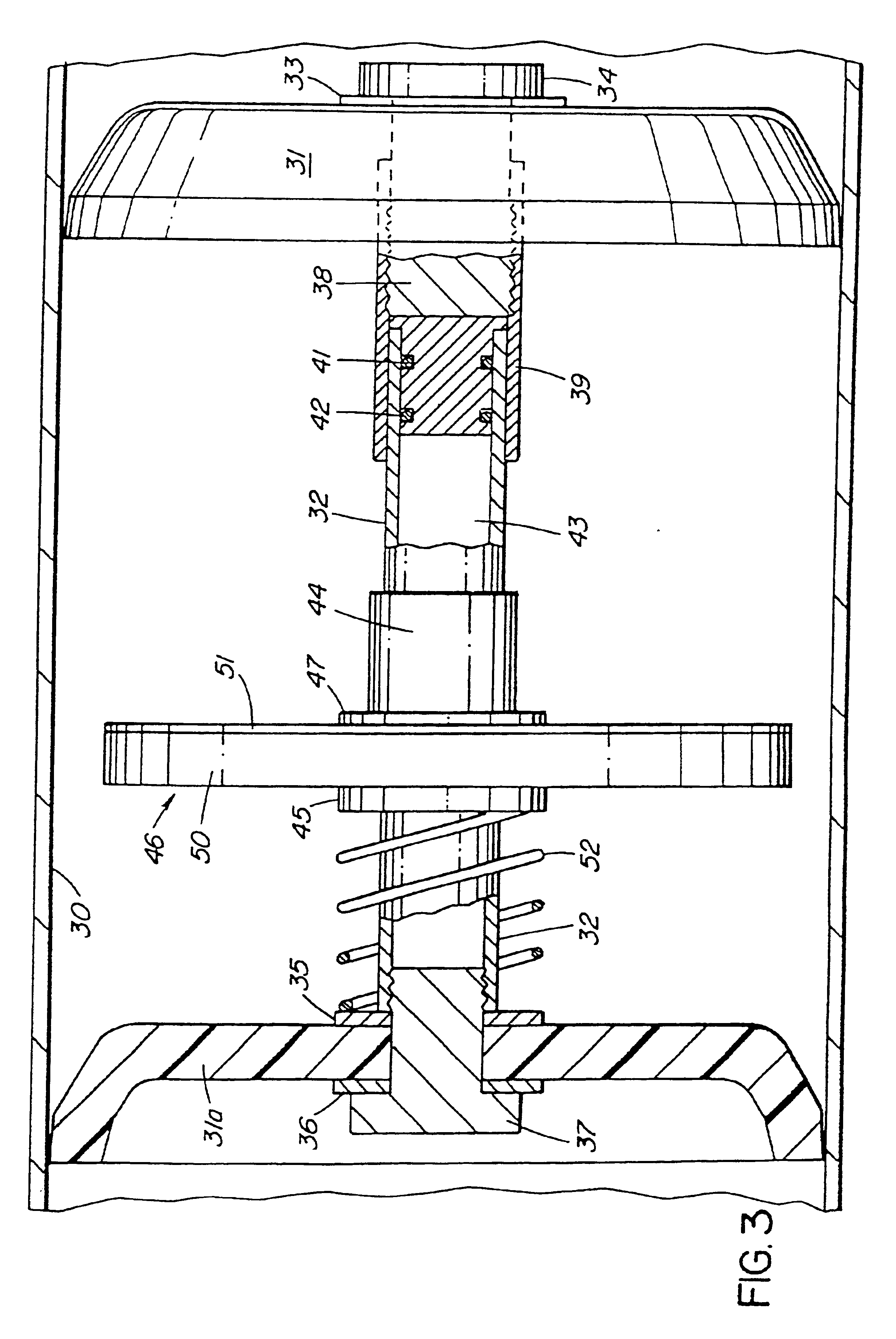

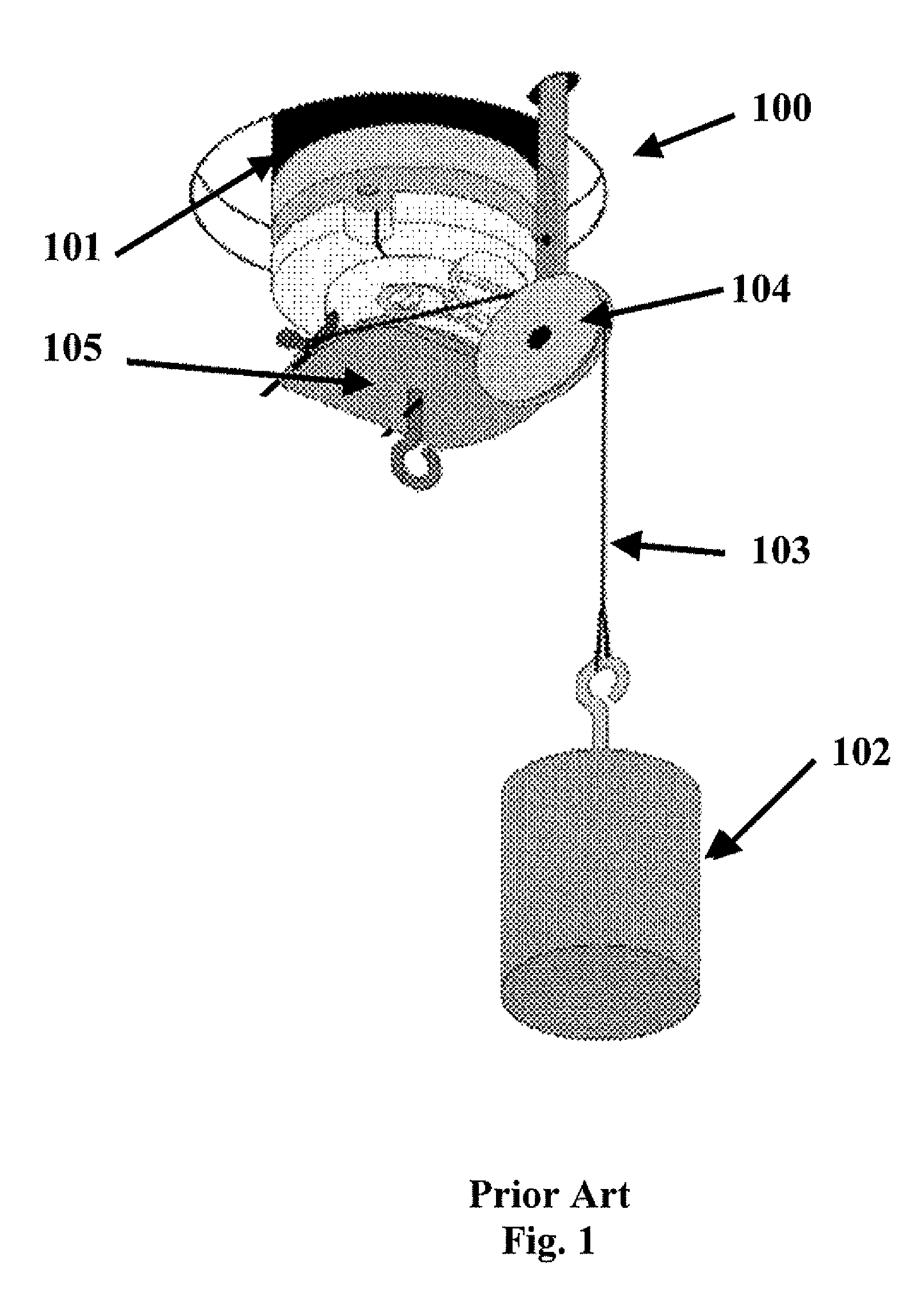

Pig for detecting an obstruction in a pipeline

InactiveUS6857329B2Sufficient resiliencySimple structurePipe elementsElectrical/magnetic diameter measurementsElastomerEngineering

An obstacle detecting pig for preliminary inspection of a section of a pipeline travels through the section and determines if there are any restrictions that exceed industry guidelines or that might damage other pigs that require the full bore of the pipe. In a first embodiment, a disk-shaped segmented resilient member (14) is mounted in the body of the pig. Its outside diameter is smaller by a spacing (21) than the inside diameter of the pipeline (15). The spacing is set at the maximum tolerable size of the obstacle encountered. The deformation of the member (14) is transmitted by a linkage (22) to a slider (16) activating a switch system signaling that an obstacle has been encountered. A non-resiliently deformable checkup disk (19) may be provided at the rear end of the pig, to double check that a no-signal passage through the pipe is not due to failure of the switching system. In a particularly preferred embodiment, the resilient member is a disc-shaped detector (46) made from an elastomer and provided at its leading surface with a scratch recording layer (51), for instance a layer of lead which is thin enough to follow resilient deformations of the elastomeric ring (50) as it encounters an obstacle, and return of the ring back to its regular, shape. The scratches caused on the recording layer are evaluated after the passage of the pig through the examined pipeline section. The detector is mounted directly on a slider (44) or the like operating device designed to produce electric signal when an anomaly is encountered. Preferably, the detector (46) is a replaceable element of the pig.The device is structurally simple thus providing low manufacturing and operation costs and simple operation.

Owner:DONSA

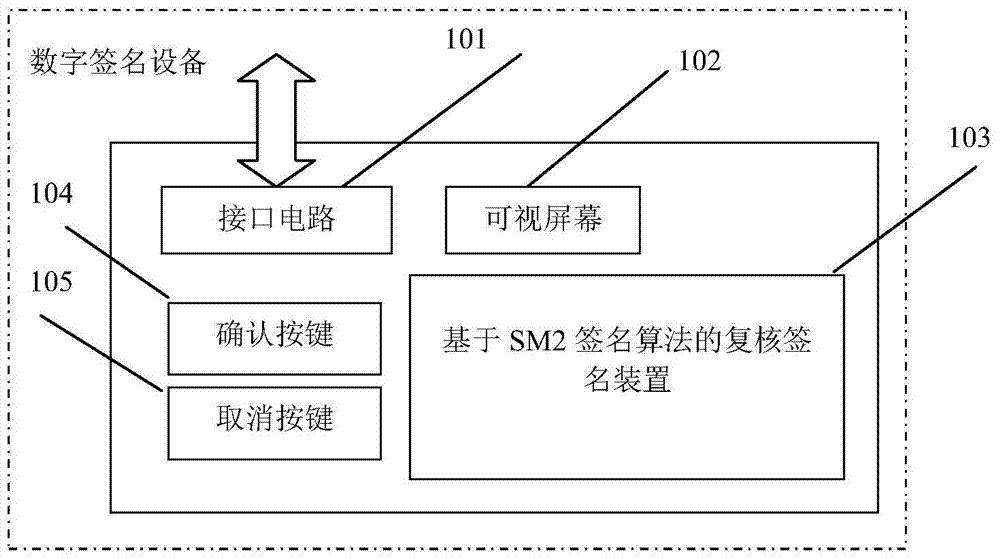

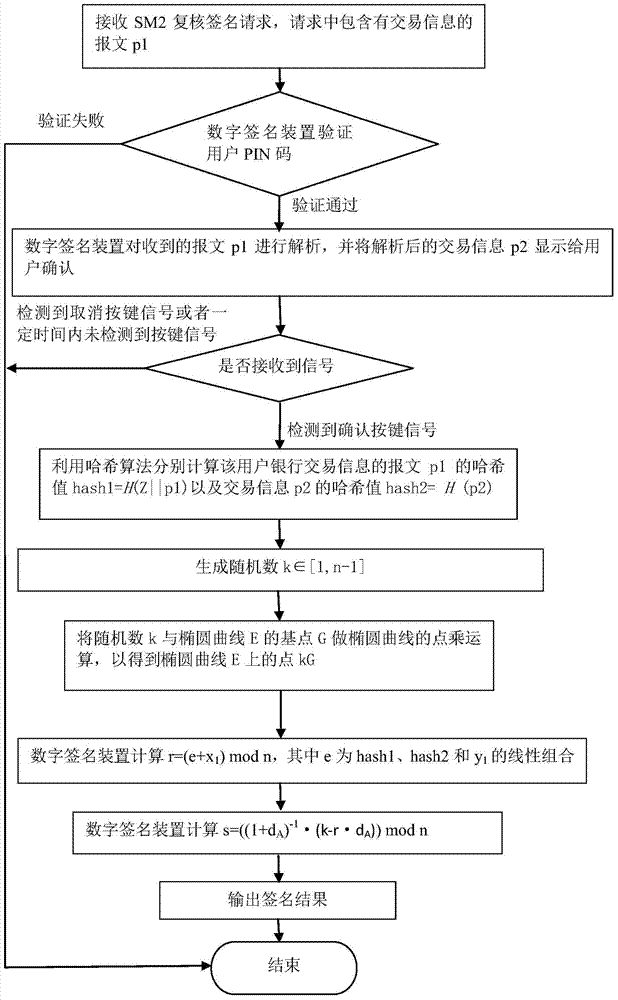

SM2 signature algorithm-based double-check signature method and digital signature equipment

ActiveCN103701598AImprove security levelImprove implementation efficiencyUser identity/authority verificationProtocol authorisationRemote controlDigital Signature Algorithm

The invention discloses an SM2 signature algorithm-based double-check signature method. The method comprises the following steps: receiving an SM2 double-check signature request from a user, wherein the SM2 double-check signature request comprises a message p1 of bank transaction information of the user; analyzing the message p1 of the bank transaction information of the valid user to generate transaction information p2; displaying the analyzed transaction information p2 to the user for check and confirmation; detecting whether a confirmation signal from the user is received, if so, respectively calculating a hash value hash1=H(Z, p1) of the message p1 of the bank transaction information of the user and a hash value hash2=H(p2) of the transaction information p2 by using a hash algorithm, and generating a random number k which belongs to [1, n-1]; performing a point multiplication operation of an elliptic curve on a random number k and a base point G of the elliptic curve E to obtain a point kG on the elliptic curve E. By adopting the SM2 signature algorithm-based double-check signature method, the technical problem that user fund is stolen by online banking transaction hijacking, transaction manipulation and remote control which easily happen in the conventional method is solved.

Owner:WUHAN ARGUSEC TECH

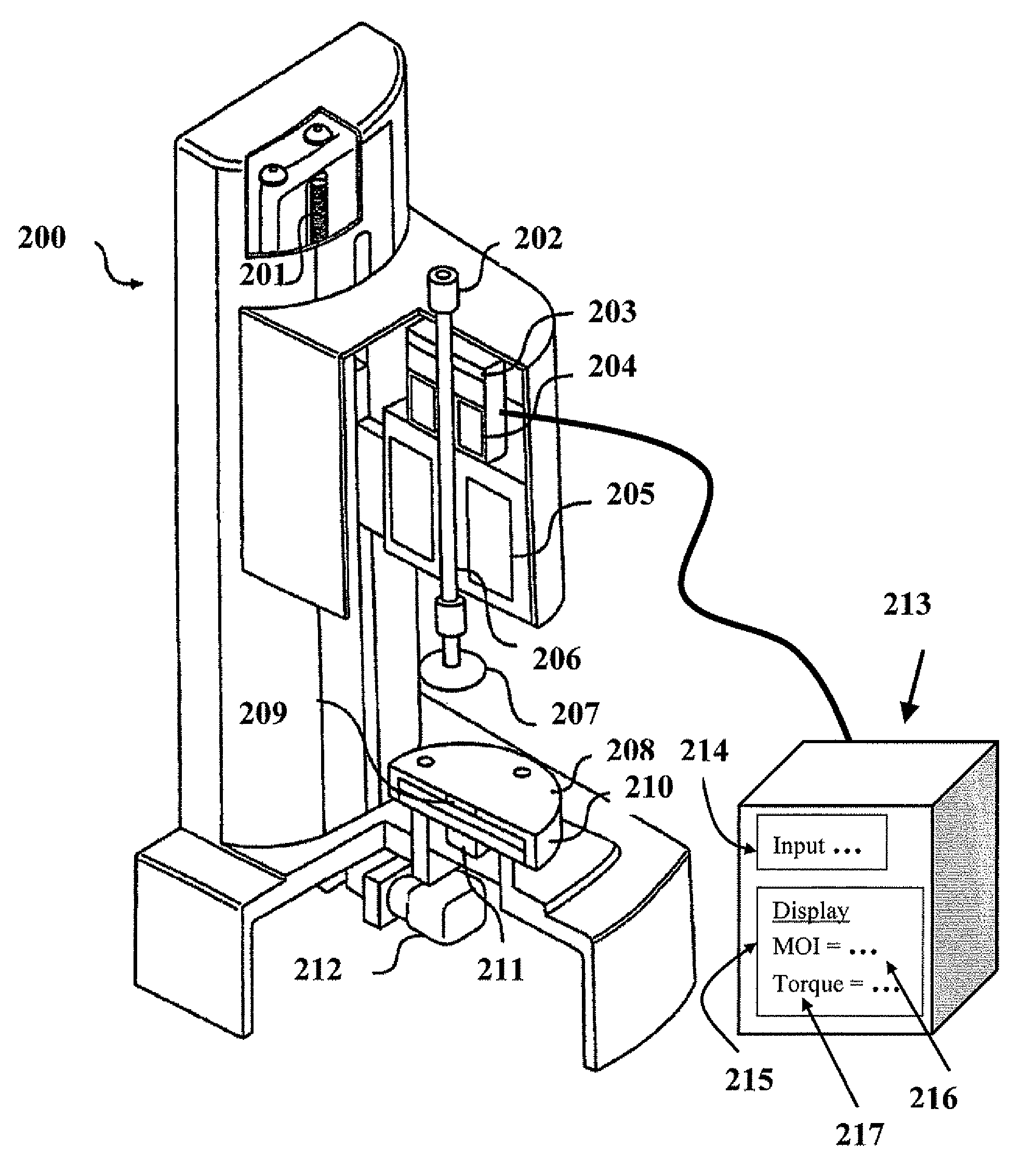

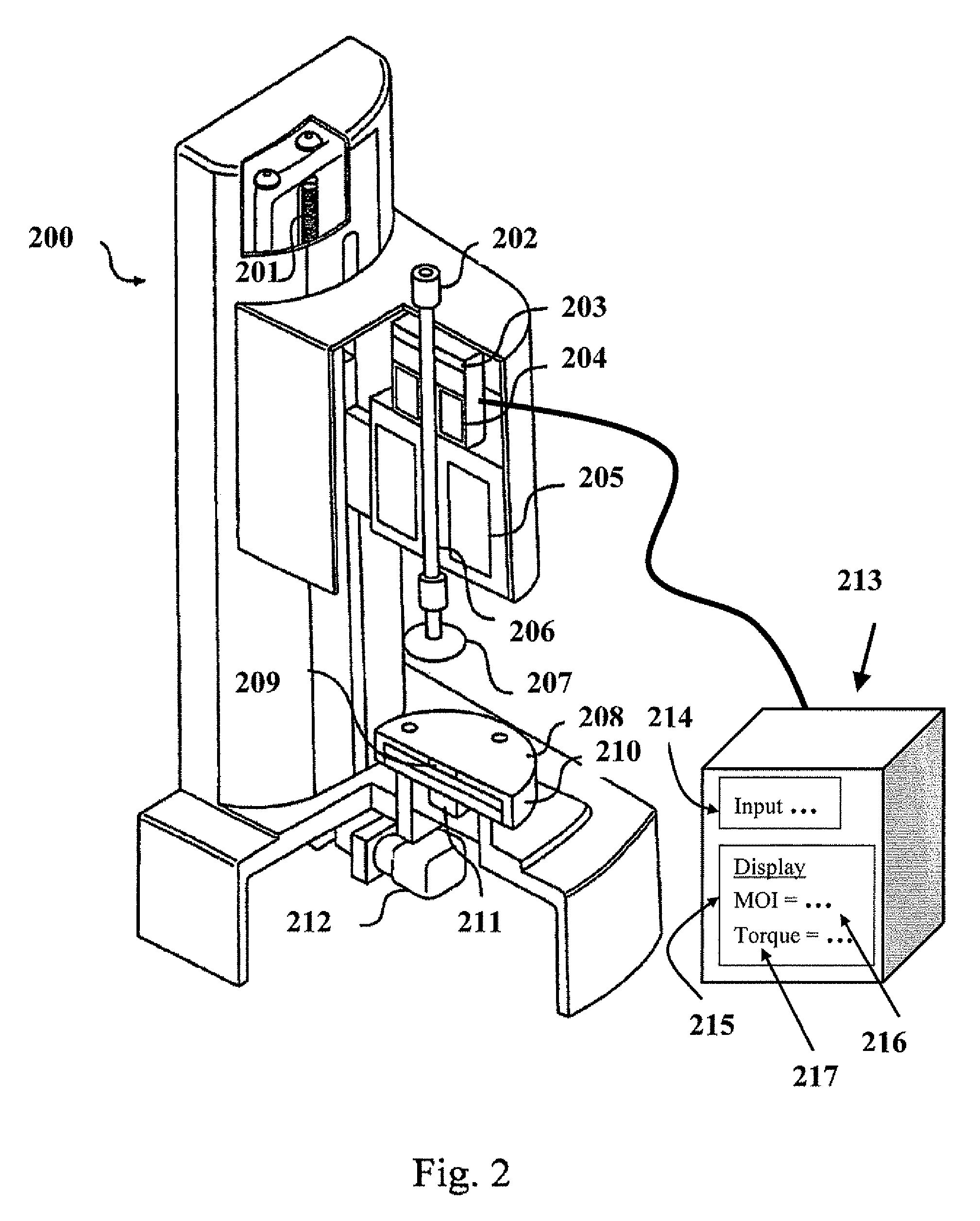

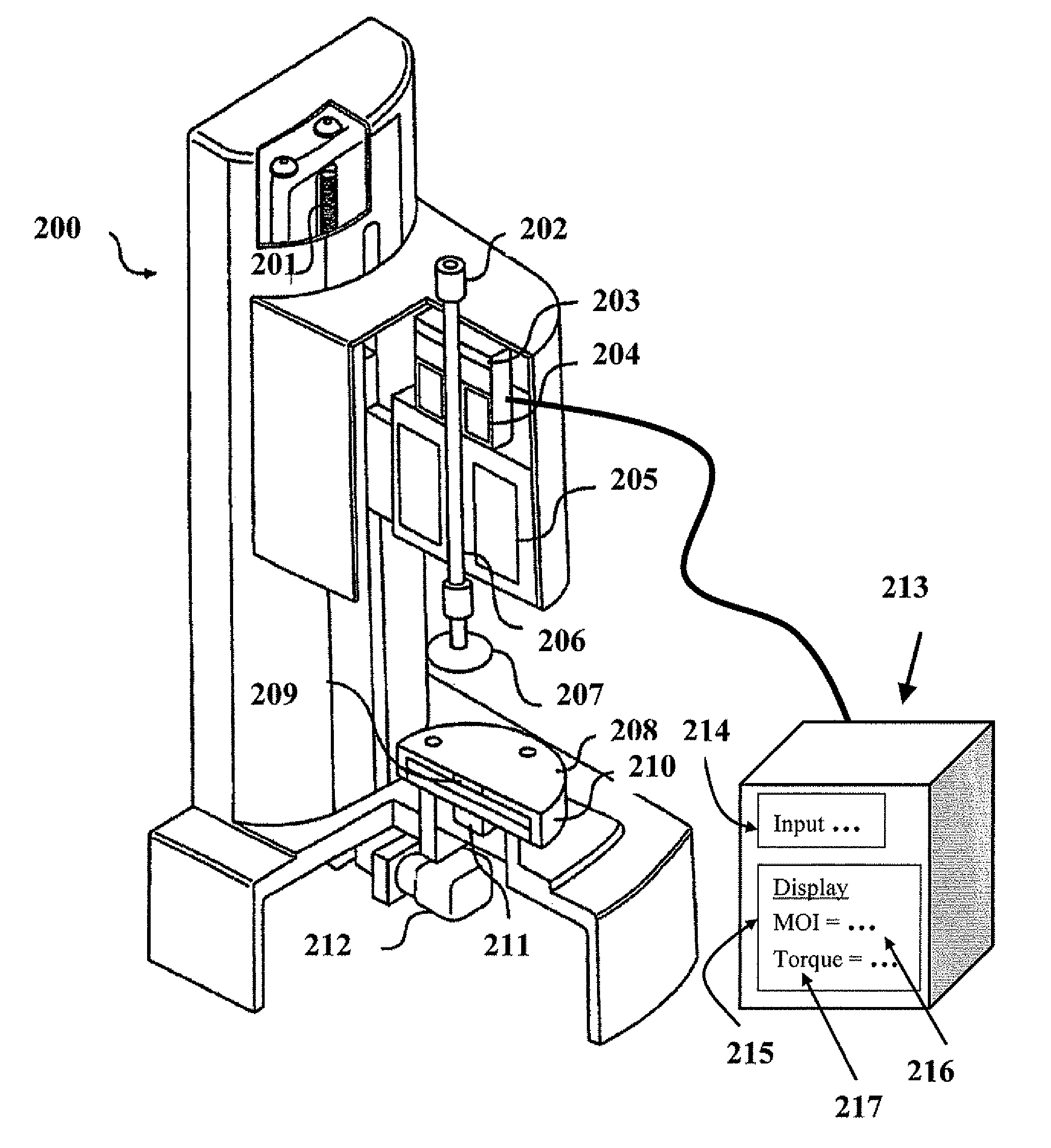

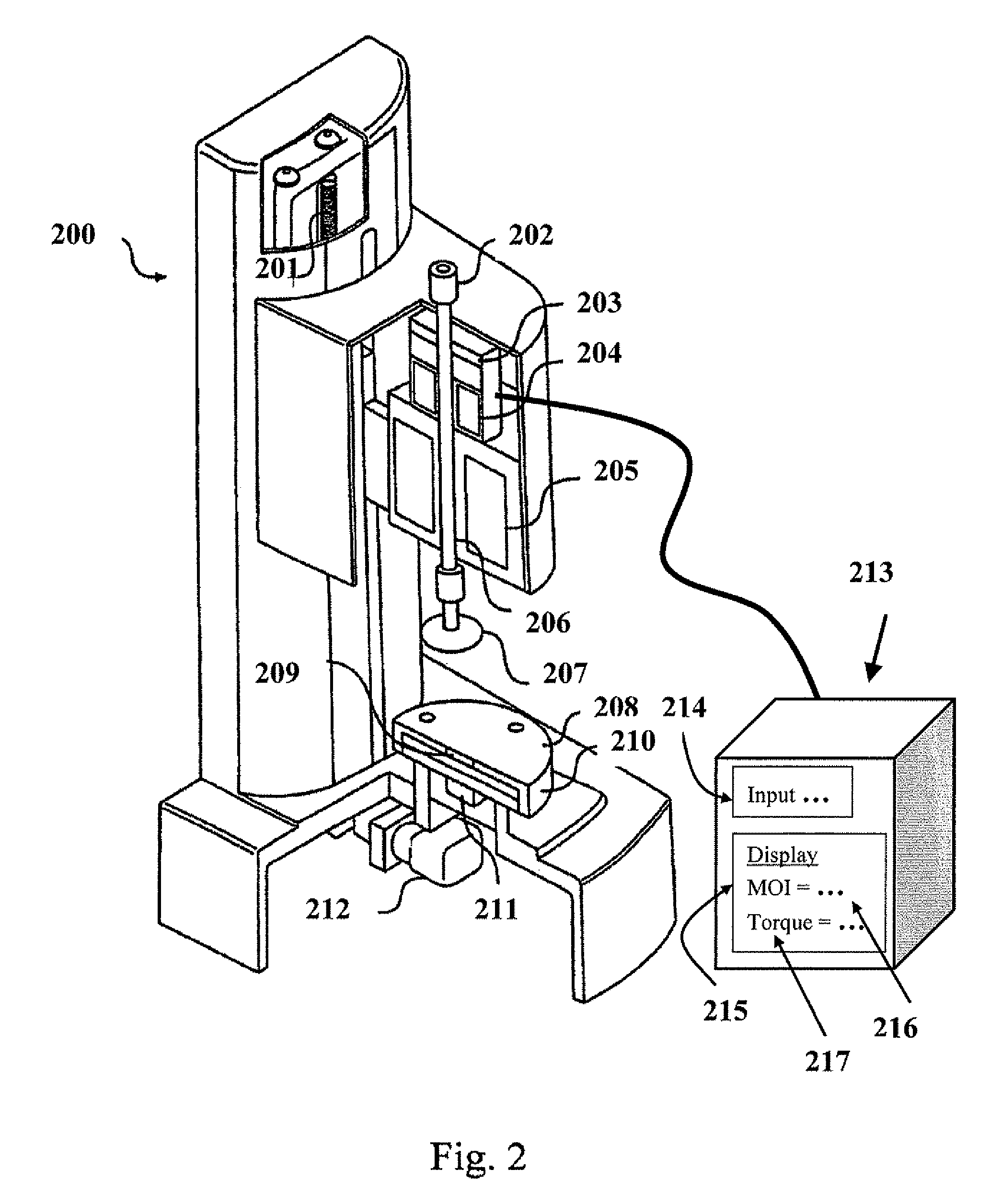

Rheometer torque calibration fixture

InactiveUS7526941B2Low costHigh measurement accuracyFlow propertiesMaterial analysis by electric/magnetic meansMoment of inertiaControl theory

A method of calibrating the torque outputs of a rheometer by using a calibrating object with a certified moment of inertia, measuring the moment of inertia of the calibrating object using the rheometer, and calculating the torque adjustment factor by dividing the certified moment of inertia value by the measured moment of inertia value. The torque adjustment factor is applied to correct subsequent measurements of rheological properties conducted using the rheometer. The torque adjustment factor may be double-checked for reproducibility by measuring the moment of inertia of the calibrating object, correcting it with the torque adjustment factor, and comparing it with its certified moment of inertia value.

Owner:WATERS TECH CORP

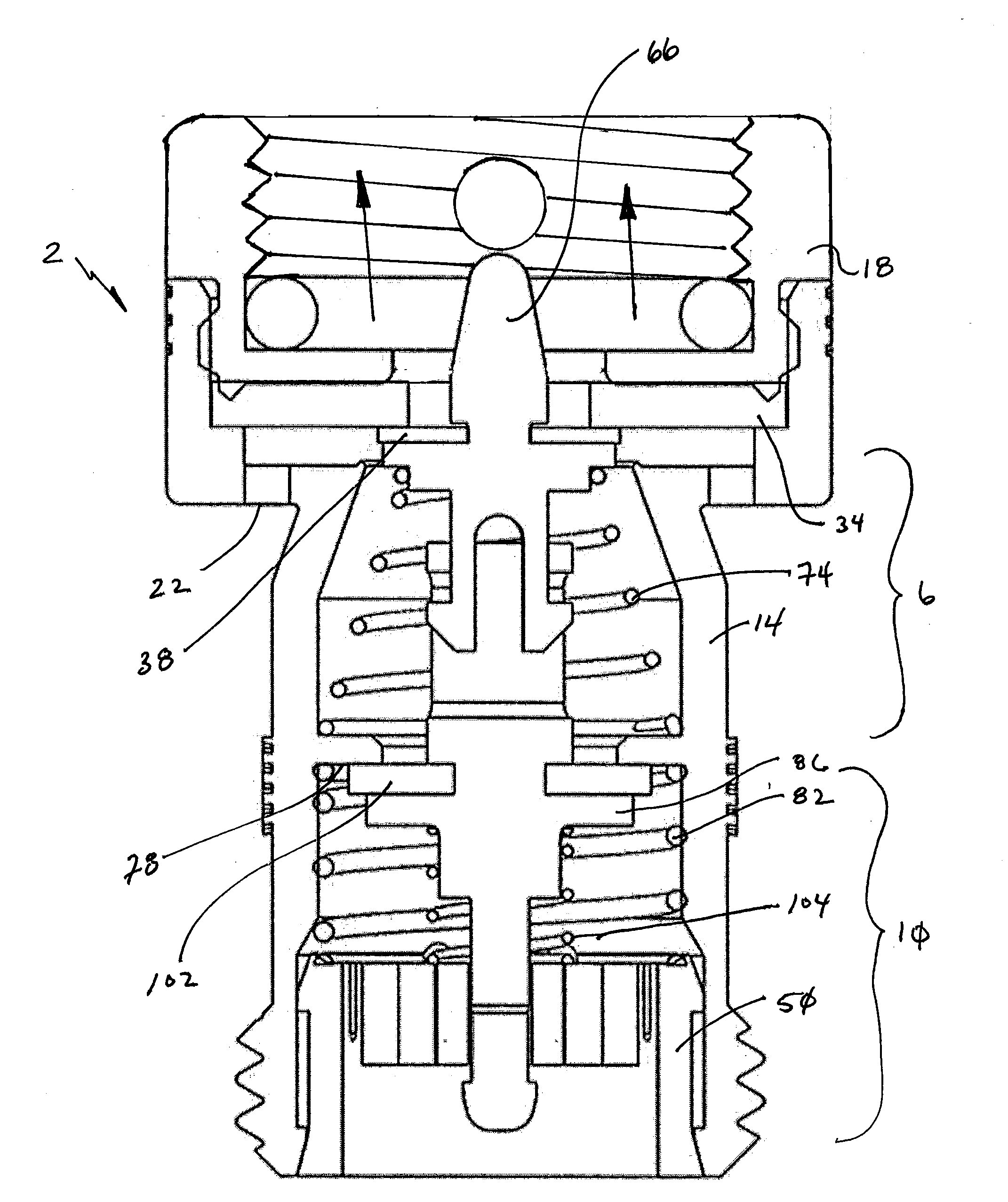

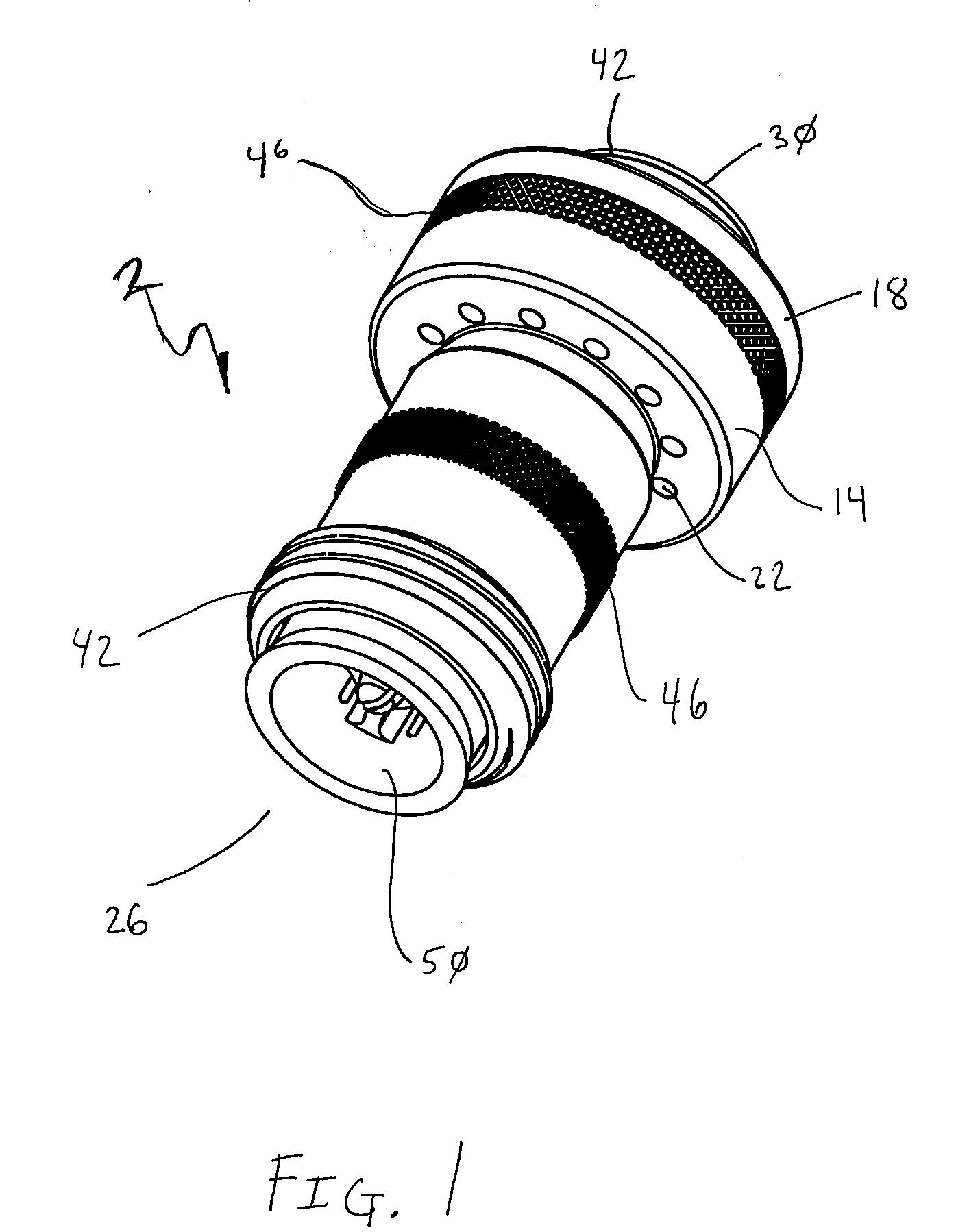

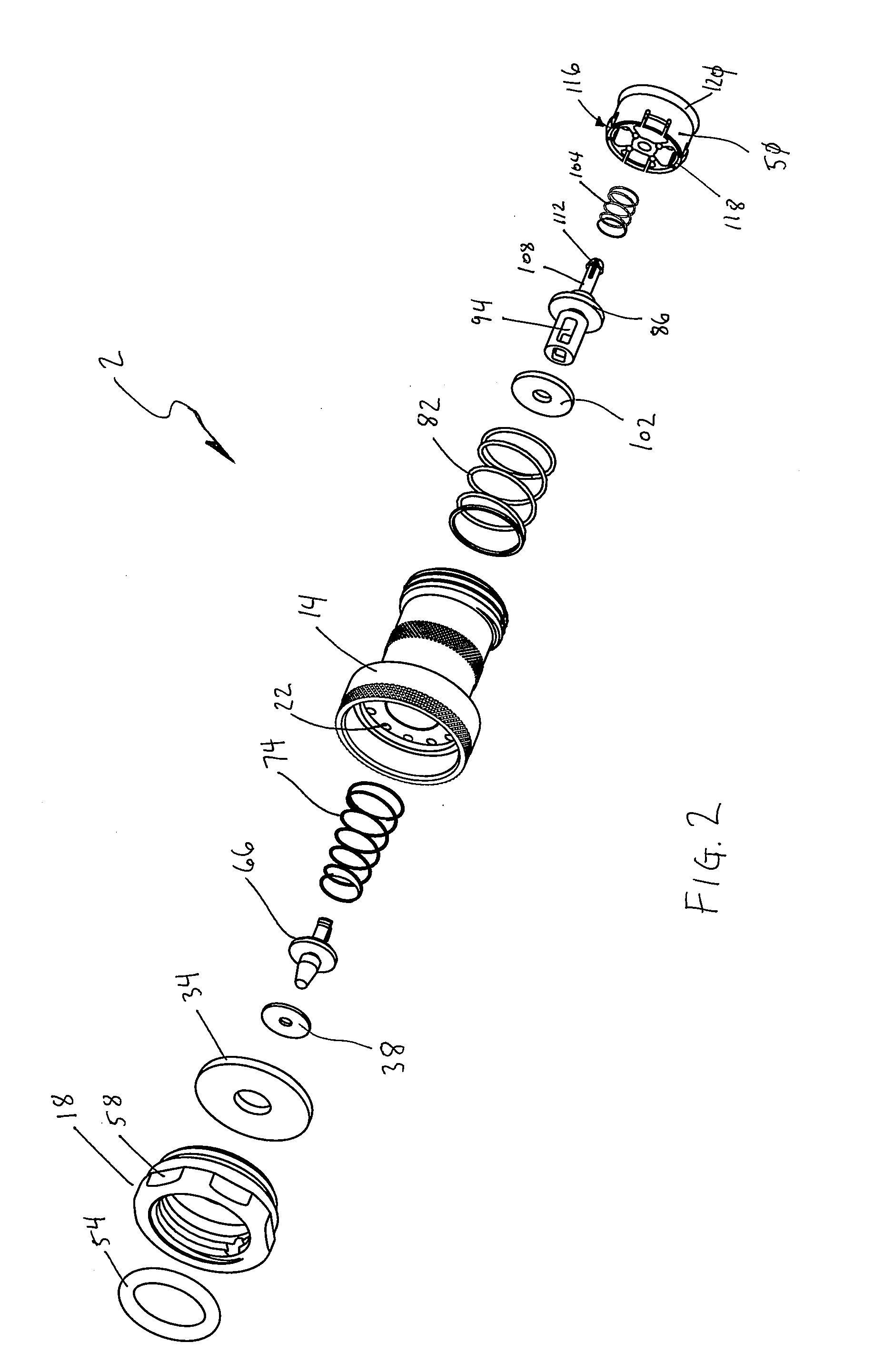

Double Check Back Flow Prevention Device

ActiveUS20090288722A1Prevent backflowEasy and less-expensive to manufactureCheck valvesDomestic plumbingDouble check valveEngineering

A double check valve is provided that includes an in-line inlet check valve and an outlet check valve that cooperate to prevent back flow of fluid through the valve. The check valve also includes at least one vent that allows for fluid trapped within the check valve to drain, thereby preventing freezing of the check valve and hydrant to which it is interconnected. The check valve provided omits many superfluous components and thus is smaller and easier to install than check valves of the prior art.

Owner:WCM IND INC

Full function tractor protection valve

InactiveUS8297713B2Reduce in quantityQuick releaseBraking action transmissionAutomatic initiationsControl signalDouble check valve

A tractor protection valve includes a trailer service brake portion, a trailer parking brake portion, and a stability control portion that are each formed within a common valve body. In one example, the trailer service brake portion includes three inlets that can be used to apply a trailer service brake. The three inlets cooperate with a service brake blocking piston, a service brake relay piston, and double check valves to apply the trailer service brakes as needed. The stability control portion includes a solenoid that can direct air to apply the trailer service brakes in response to a stability control signal. The trailer parking brake portion also includes multiple ports that cooperate with a parking brake piston and valve to control application and release of the trailer parking brakes.

Owner:MERITOR WABCO VEHICLE CONTROL SYST

Rheometer torque calibration fixture

InactiveUS20070295055A1Low costImprove accuracyFlow propertiesMaterial analysis by electric/magnetic meansComputed torqueEngineering

A method of calibrating the torque outputs of a rheometer by using a calibrating object with a certified moment of inertia, measuring the moment of inertia of the calibrating object using the rheometer, and calculating the torque adjustment factor by dividing the certified moment of inertia value by the measured moment of inertia value. The torque adjustment factor is applied to correct subsequent measurements of rheological properties conducted using the rheometer. The torque adjustment factor may be double-checked for reproducibility by measuring the moment of inertia of the calibrating object, correcting it with the torque adjustment factor, and comparing it with its certified moment of inertia value.

Owner:WATERS TECH CORP

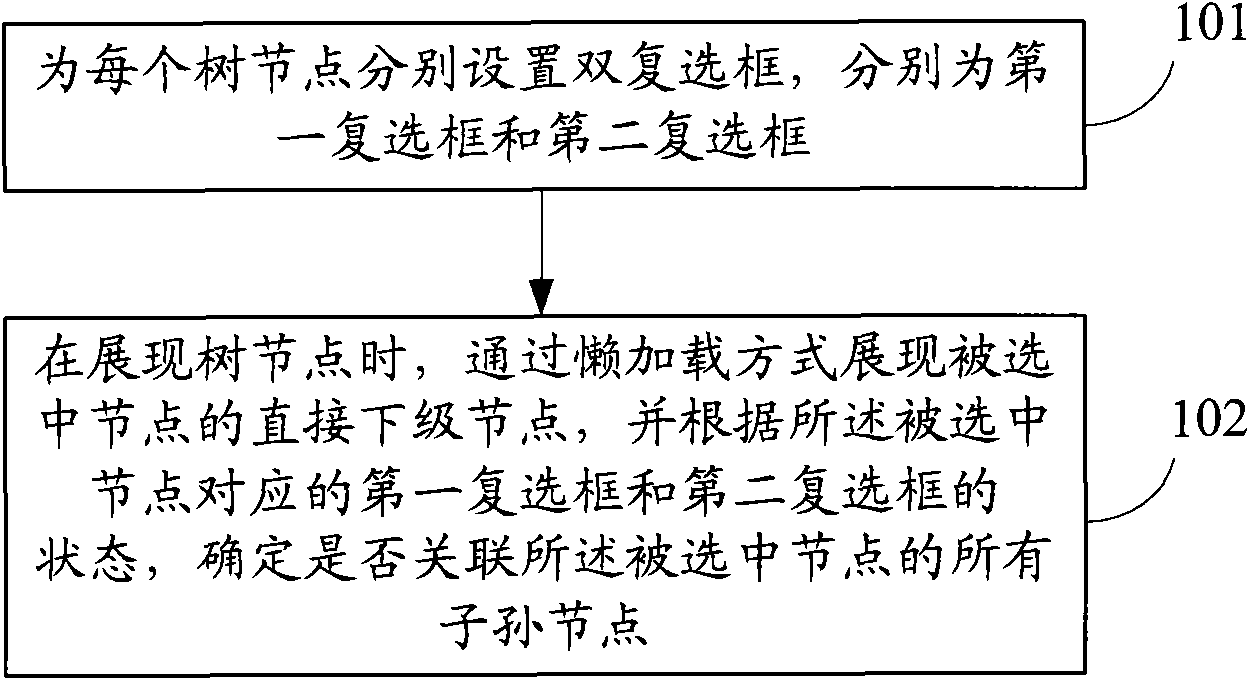

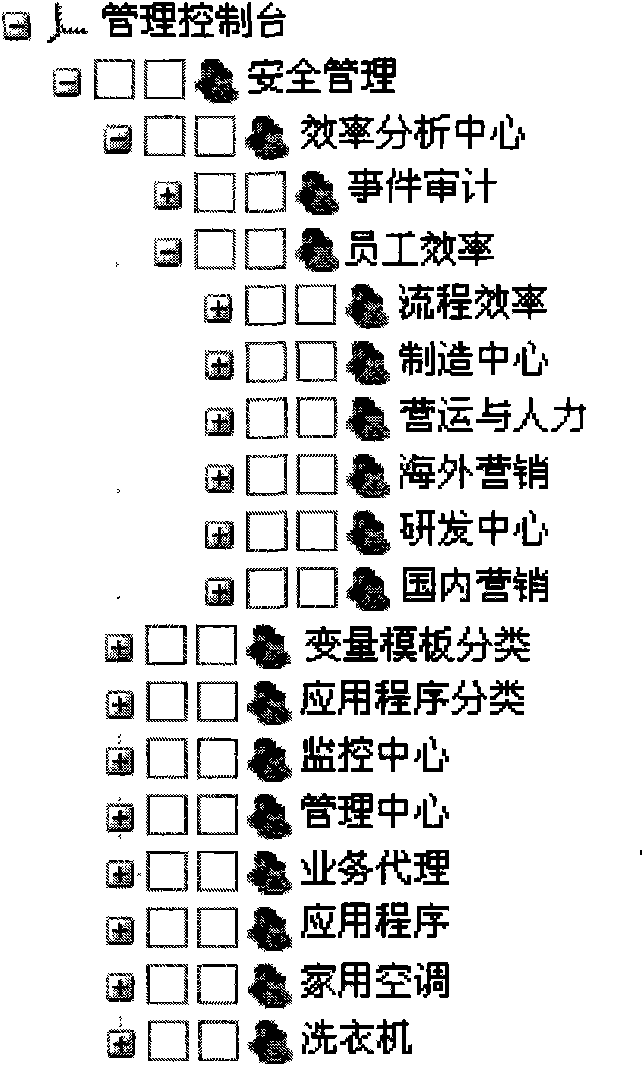

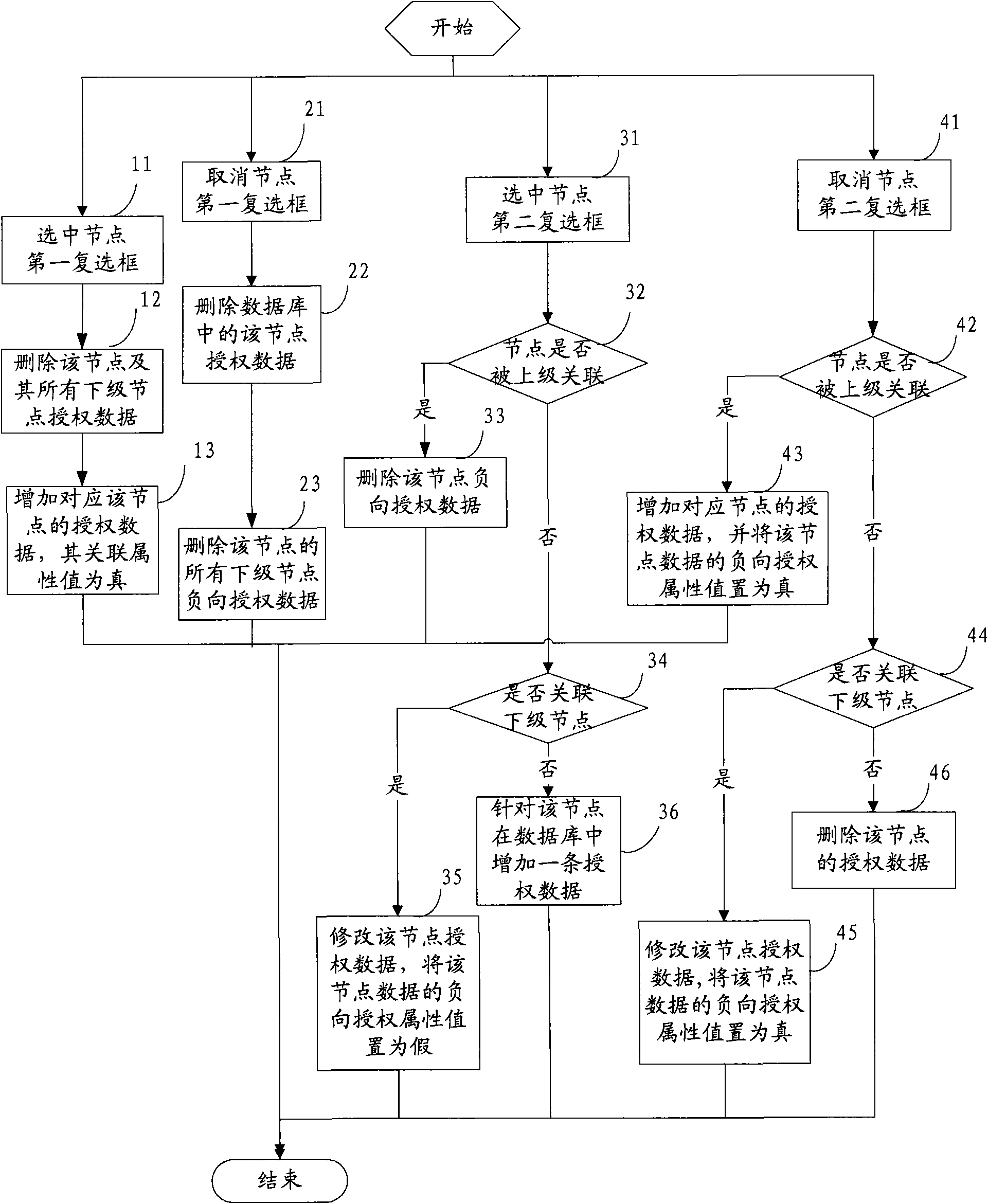

Tree-node displaying method and device

InactiveCN101639845AImprove loading speedImplement check logicSpecial data processing applicationsTheoretical computer scienceAssociate - relationship

The invention discloses a tree-node displaying method and a device thereof. The method comprises the steps of setting a double-check box for each tree node, respectively named as a first check box anda second check box, wherein, the first check box indicates whether the node is associated with all descendant nodes thereof or not; the second check box indicates whether the node has associated relationship with superior nodes or indicates the state whether the node is selected or not when the node is not associated with the superior nodes; when tree nodes are displayed, direct subordinate nodesof the selected nodes are displayed by a lazy load way, and whether all subordinate nodes of the selected nodes are associated or not is determinated according to the state of the first check box andthe second check box corresponding to the selected node. By using the invention, tree nodes can be displayed on the basis of lazy load, business display performance is provided, and meanwhile, the association of all descendent nodes is realized.

Owner:NEUSOFT CORP

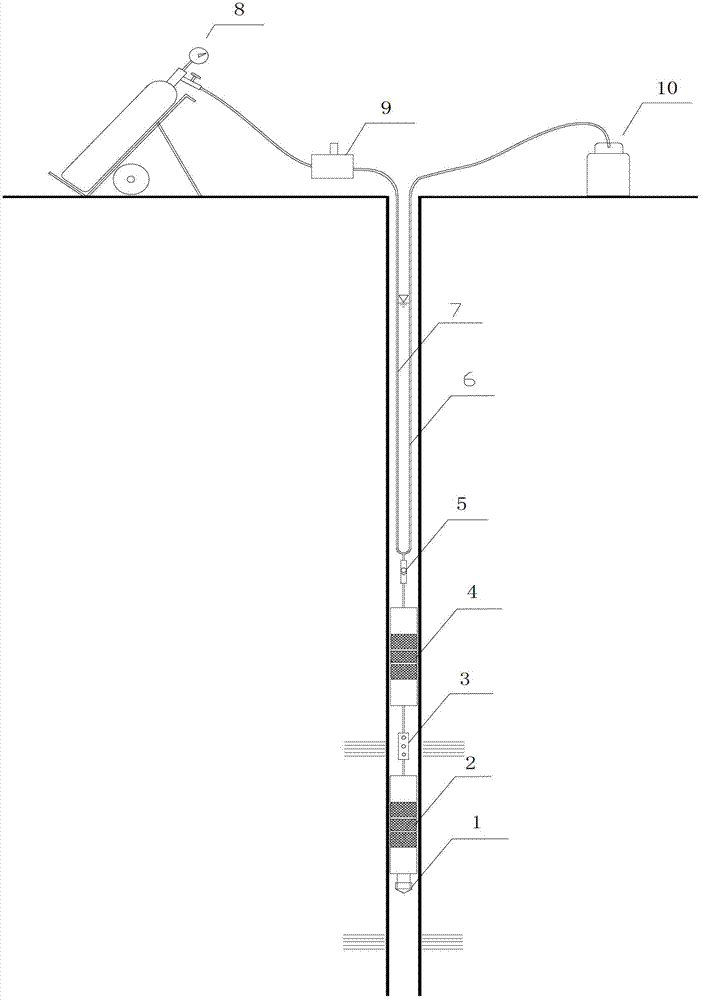

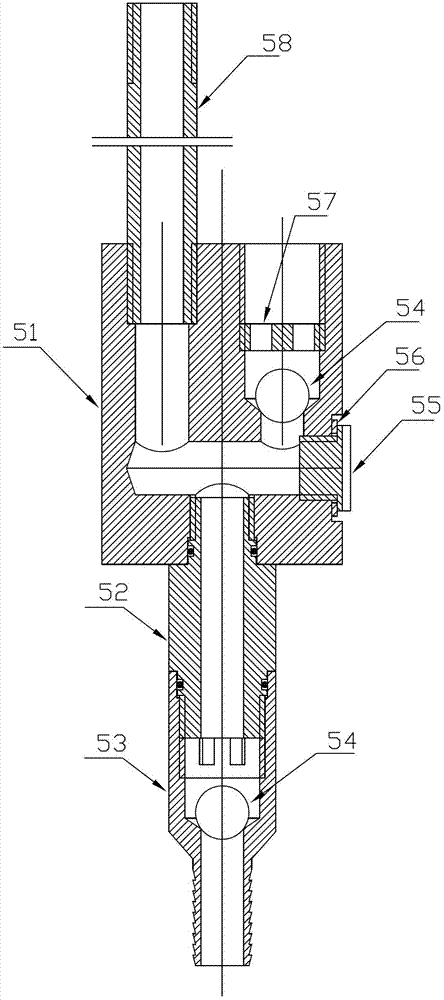

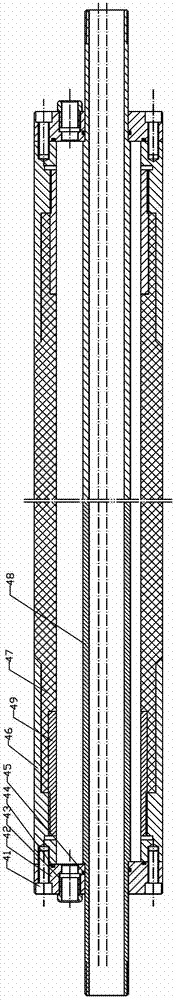

Sampling device for well-inside in-situ fluid in deep well

ActiveCN103174414AMonitor the risk of leakageMonitor leak pathsBorehole/well accessoriesInlet channelEngineering

The invention discloses a sampling device for well-inside in-situ fluid in a deep well. The sampling device is composed of a downhole sampling unit and a pit unit. The pit unit comprises a set of air supply sources controlled by an air regulator and a set of containers used for collecting samplings. The downhole sampling unit is provided with a water inlet window, an upper packer, a filtering screen unit and a lower packer, wherein the water inlet window, the upper packer, the filtering screen unit and the lower packer are sequentially arranged from top to bottom, and the water inlet window has a double-check function. The water inlet window comprises a base seat, wherein three channels are formed on the base seat and include a water inlet channel with a downward opening, a water outlet channel with an upward opening and an air supplying channel with an upward opening. The water inlet channel is controlled by a lower one-way valve, and sampling flow liquid flows in unidirectionally. The water outlet channel with the upward opening is controlled by an upper one-way valve, the sampling flow liquid flows out unidirectionally, and the water outlet channel is connected to the containers used for collecting the samplings through sampling pipes. The air supplying channel with the upward opening is communicated with the air supply sources of the pit unit through air supply pipes. The sampling device can conveniently and rapidly extract the samplings of the well-inside in-situ fluid in the deep well.

Owner:天津星通九恒科技有限公司

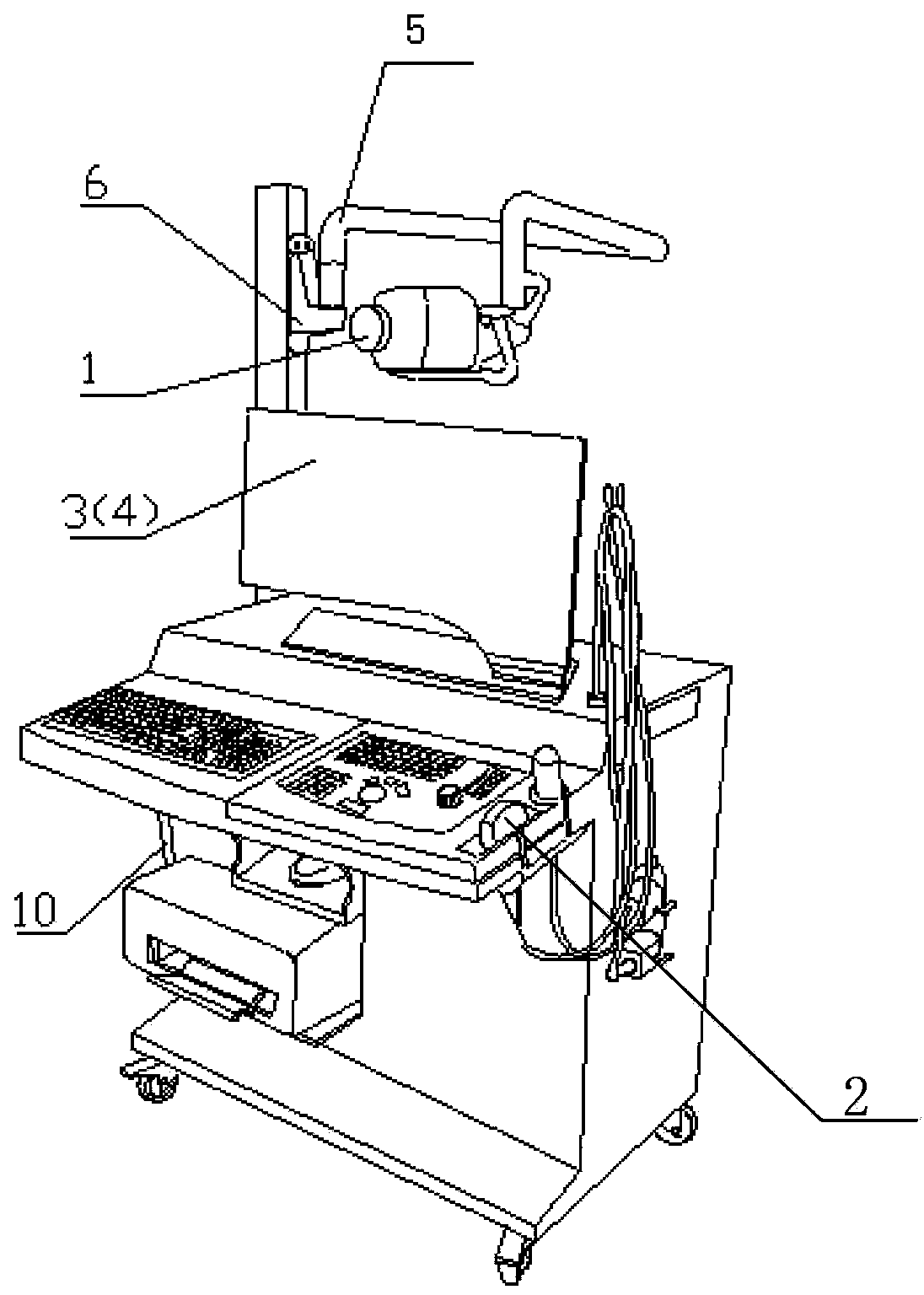

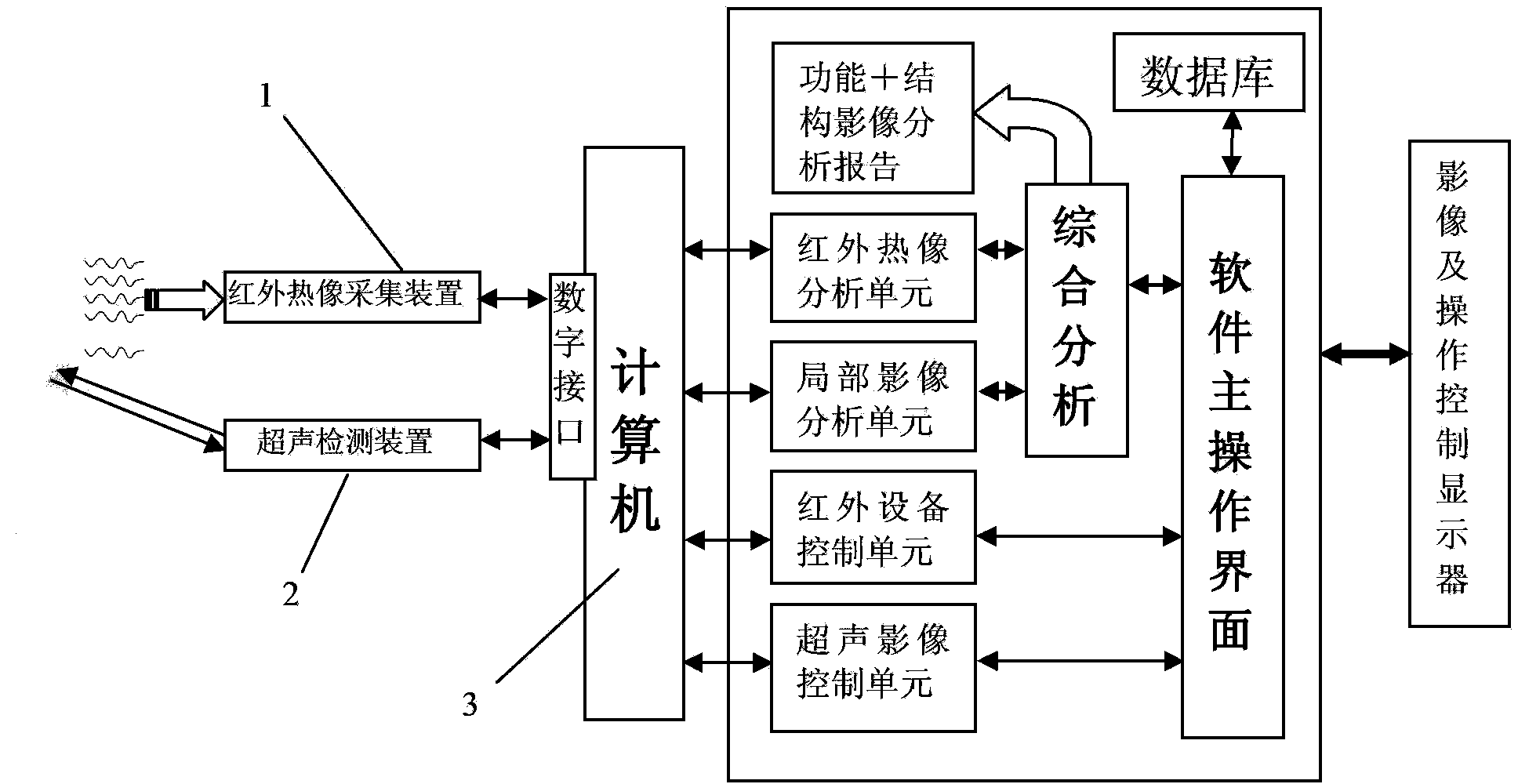

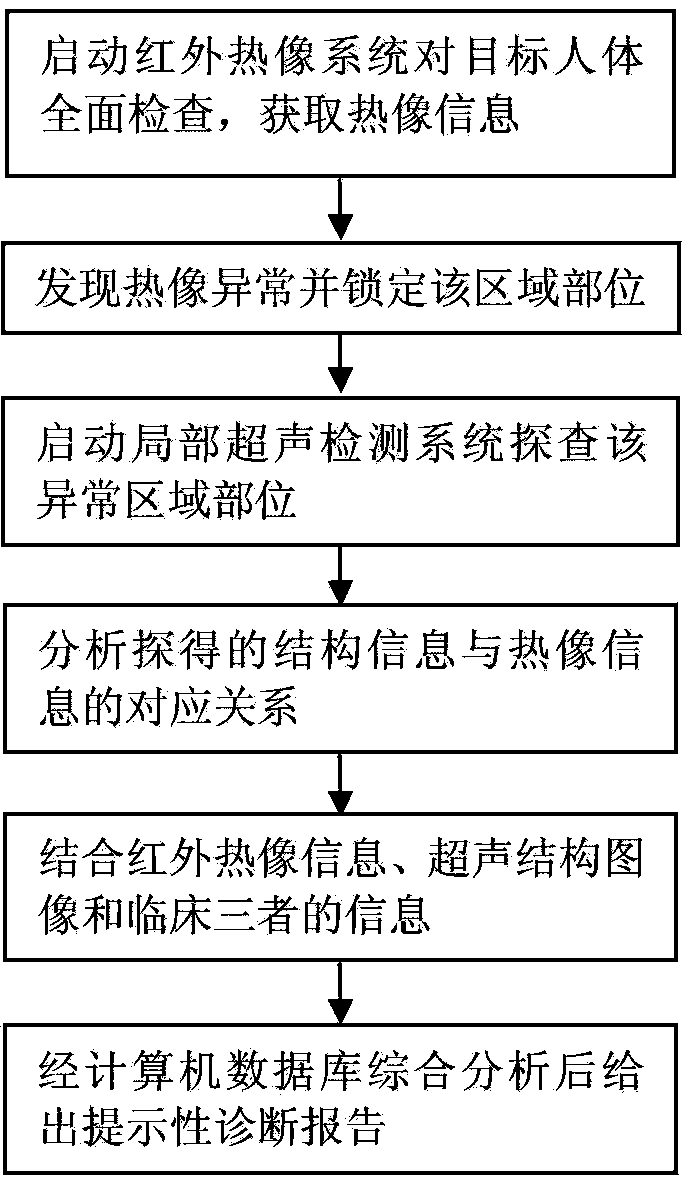

Double check comprehensive diagnostic apparatus guiding ultrasound by infrared thermography and detection method of diagnostic apparatus

ActiveCN103385734AImprove convenienceTimely treatmentUltrasonic/sonic/infrasonic diagnosticsSurgeryDiseaseWhole body

The invention belongs to the technical field of medical diagnosis, and particularly discloses a double check comprehensive diagnostic apparatus guiding ultrasound by infrared thermography and a detection method of the diagnostic apparatus. The diagnostic apparatus comprises a worktable which is provided with an infrared thermographic collecting device for general check-up and an ultrasonic detection device for precise check of local areas as well as a computer and an image display connected with the two devices. The computer has software which can simultaneously or respectively control the two devices. The software has the function of analyzing and processing infrared and ultrasonic data image information and is provided with a database. The diagnostic apparatus can obtain and mutually corroborate functional and structural image check results by adequately using advantages of the infrared thermographic technology and the ultrasonic detection technology so as to quickly and effectively diagnose or pre-warn diseases more specifically, so that patients can be immediately and accurately treated in the early stage of diseases. The medical cost is lowered, and the misdiagnosis rate, the rate of missed diagnosis and the death rate of the diseases can be greatly reduced.

Owner:广州呼研所红外科技有限公司 +1

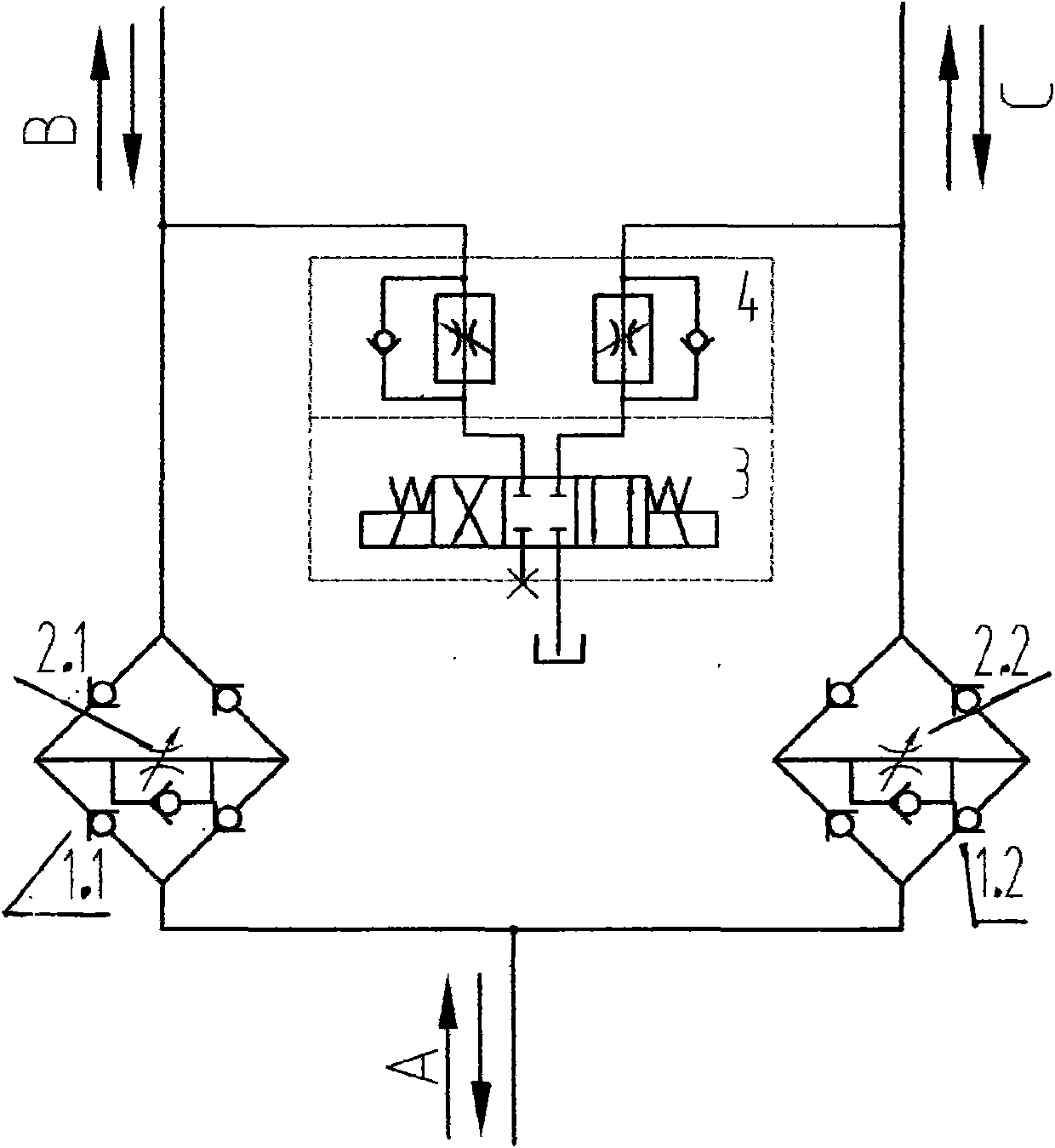

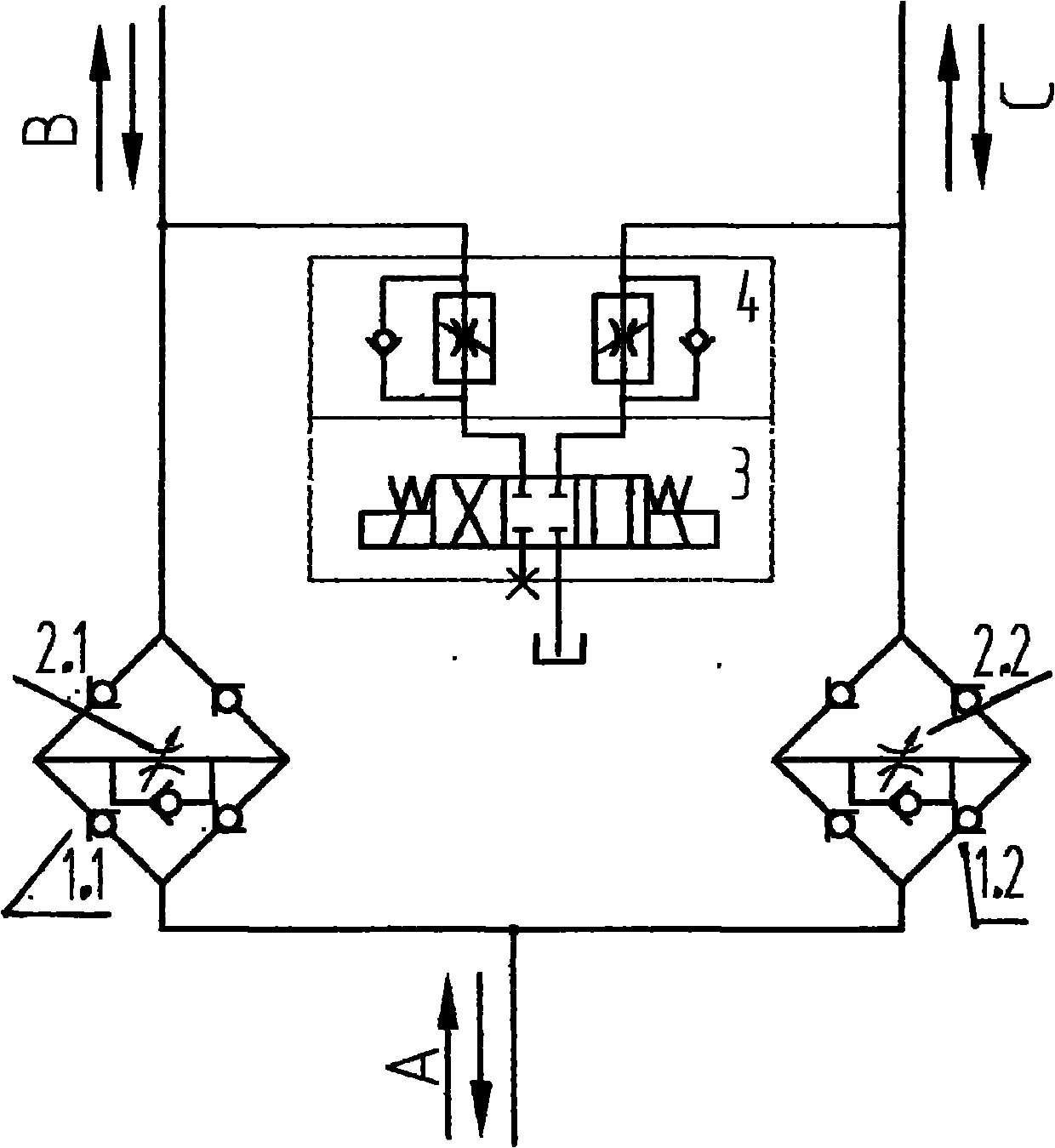

Synchronizing circuit applicable to double suspension hoist

The present invention relates to a synchronizing circuit applicable to a double suspension hoist, which comprises two rectifying plates, two speed-regulating valves, an electromagnetic change valve, and a double check throttle. The electromagnetic change valve and the double check throttle are connected in parallel between the two regulating valves and left and right cylinder oil circuits. The principle is that the pressure oil from an oil pump enters into the left and right oil cylinders of the hoist separately through the two speed-regulating valves and the two rectifying plates, enabling hoisting movements of the gate. By adjusting the two speed-regulating valves, the two cylinders can reach a preliminary synchronous state which is synchronous in speed. Then, by correcting the deviations through the small-sized electromagnetic directional valve and the small-sized double check throttle, the two cylinders can be in synchronous positions within an acceptable deviation range, and the route terminal will not get accumulated.

Owner:SHAOYANG VICTOR HYDRAULICS

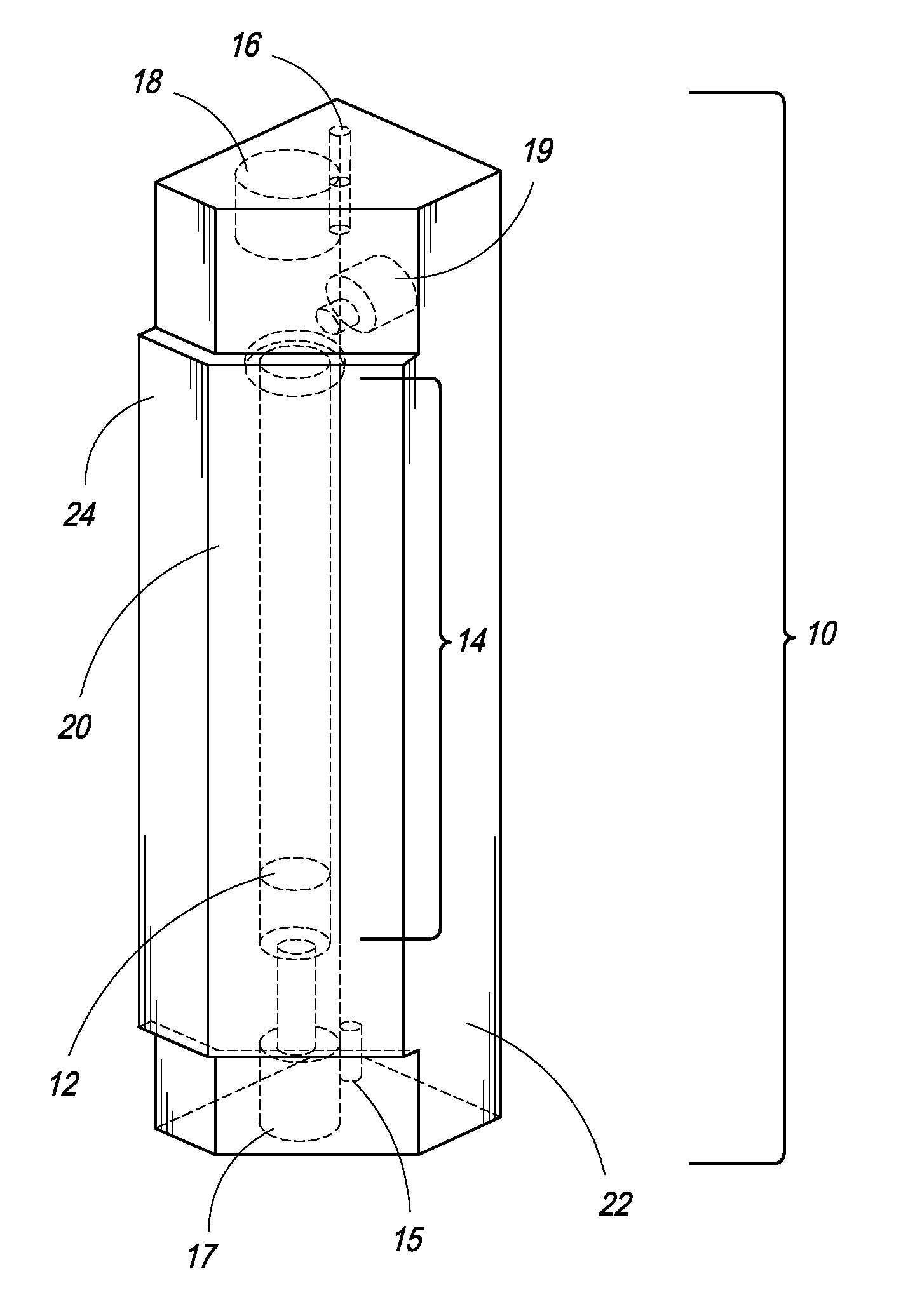

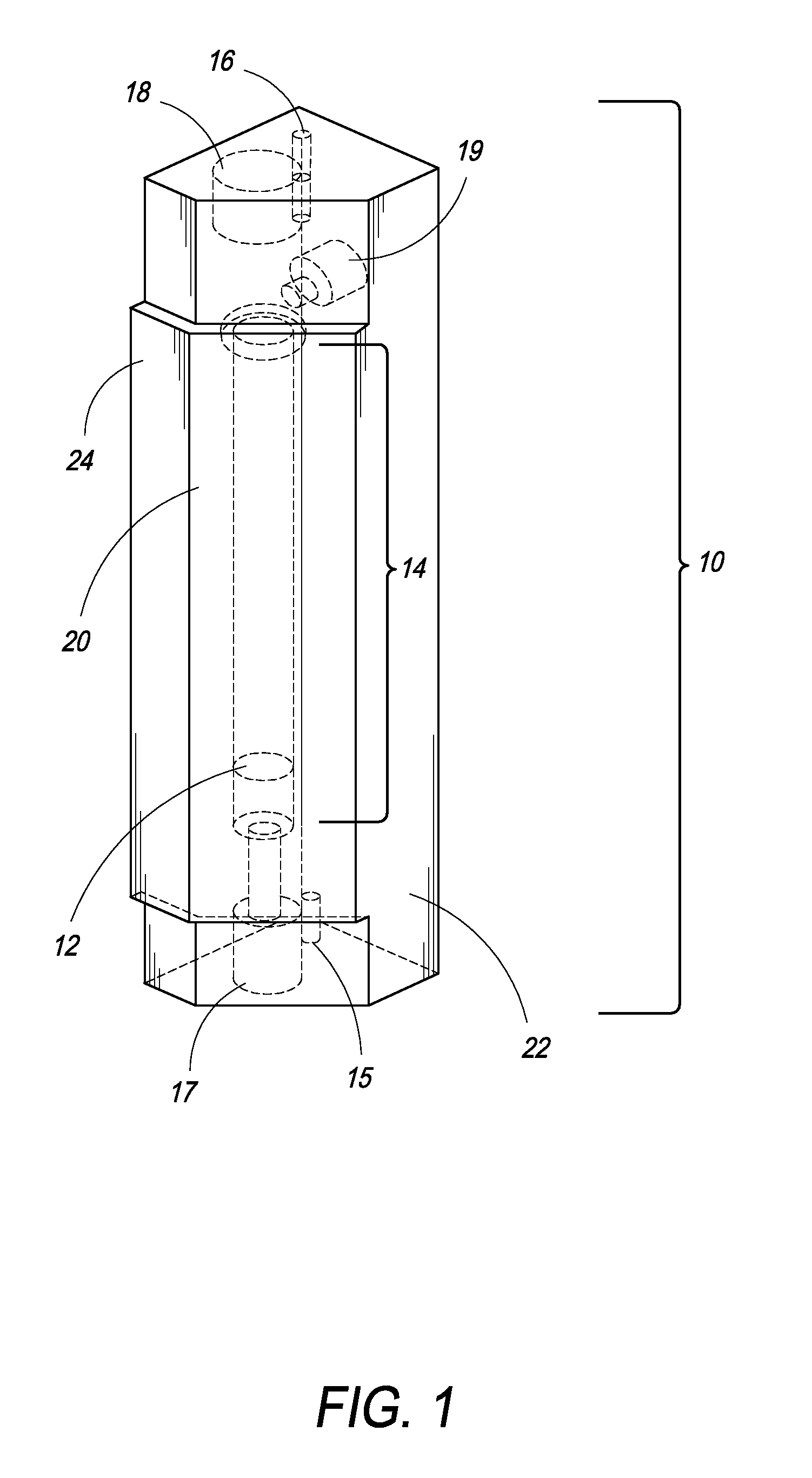

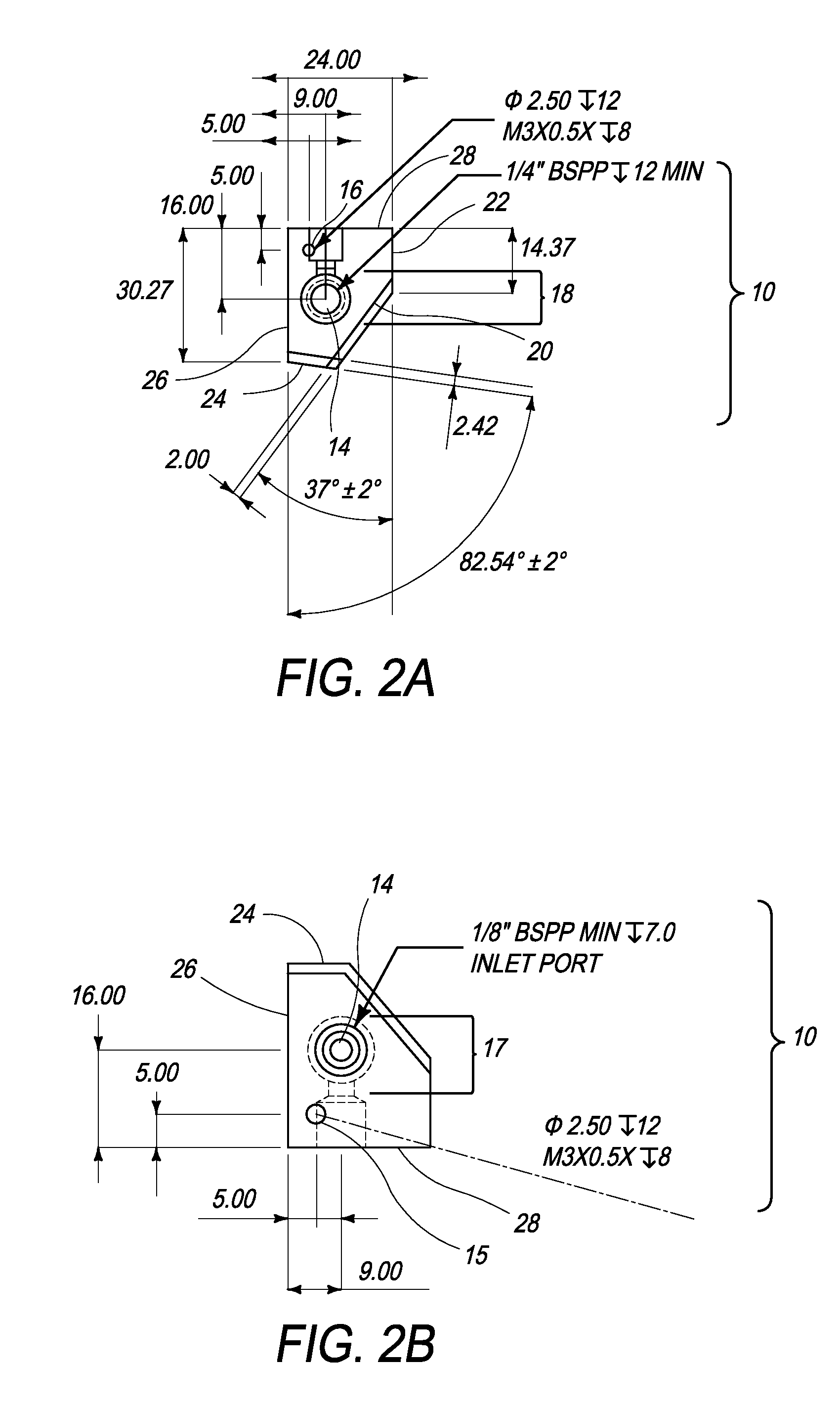

Light Enhanced Flow Tube

An improved fluid flow gauging device includes a light enhanced acrylic block flow tube to optimize visualization of pressure readings. An LED or other light source is fitted to the top of the flow tube and illuminates a float or bobbin from above to provide more accurate readings, especially in low light conditions such as modern operating rooms. In addition, the light enhanced flow tube provides a mechanical backup in the case of failure of newer electronic systems and visually matches the graphical flow display, simultaneously providing a double-check of the electronic system.

Owner:SPACELABS HEALTHCARE INC

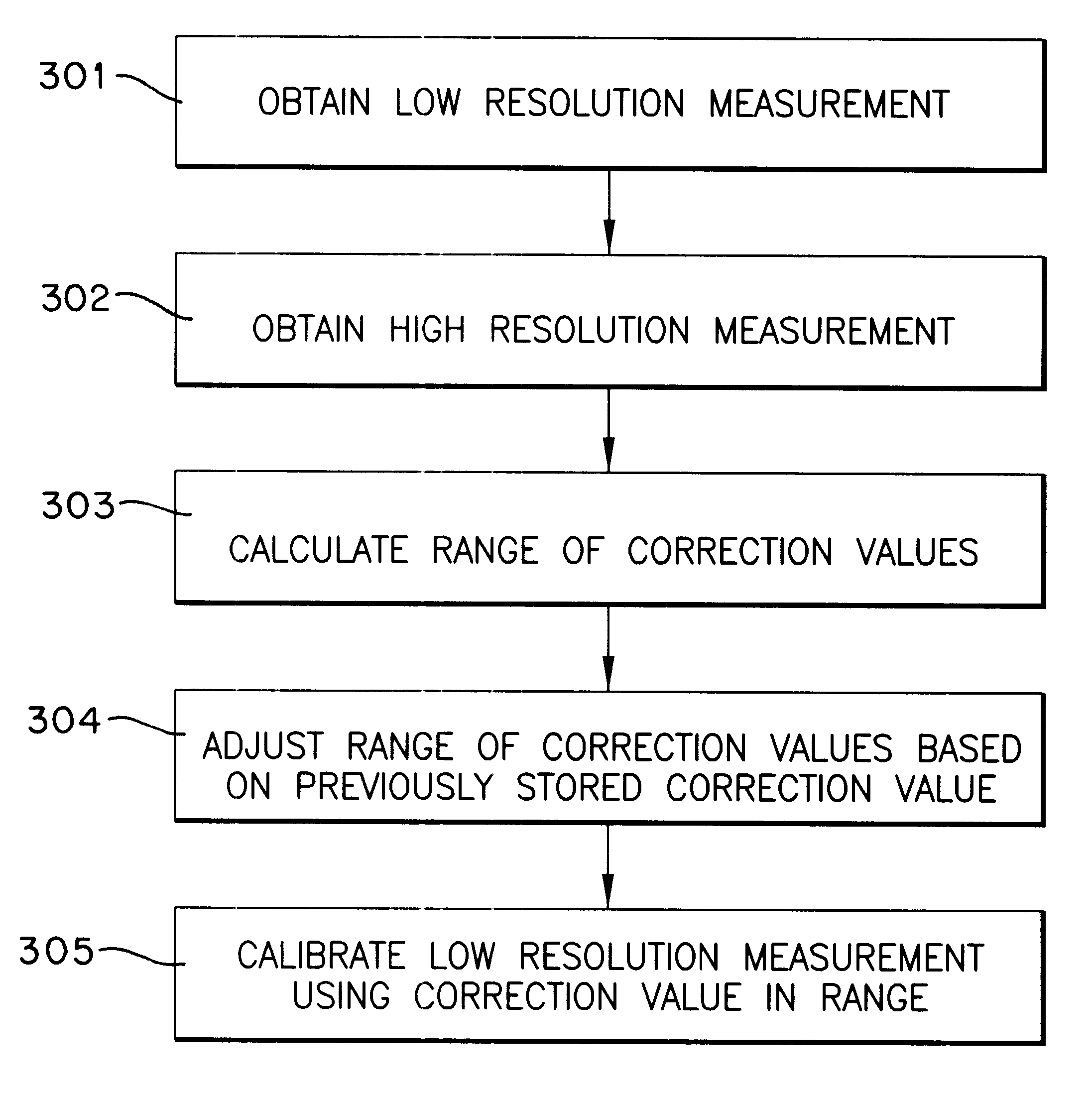

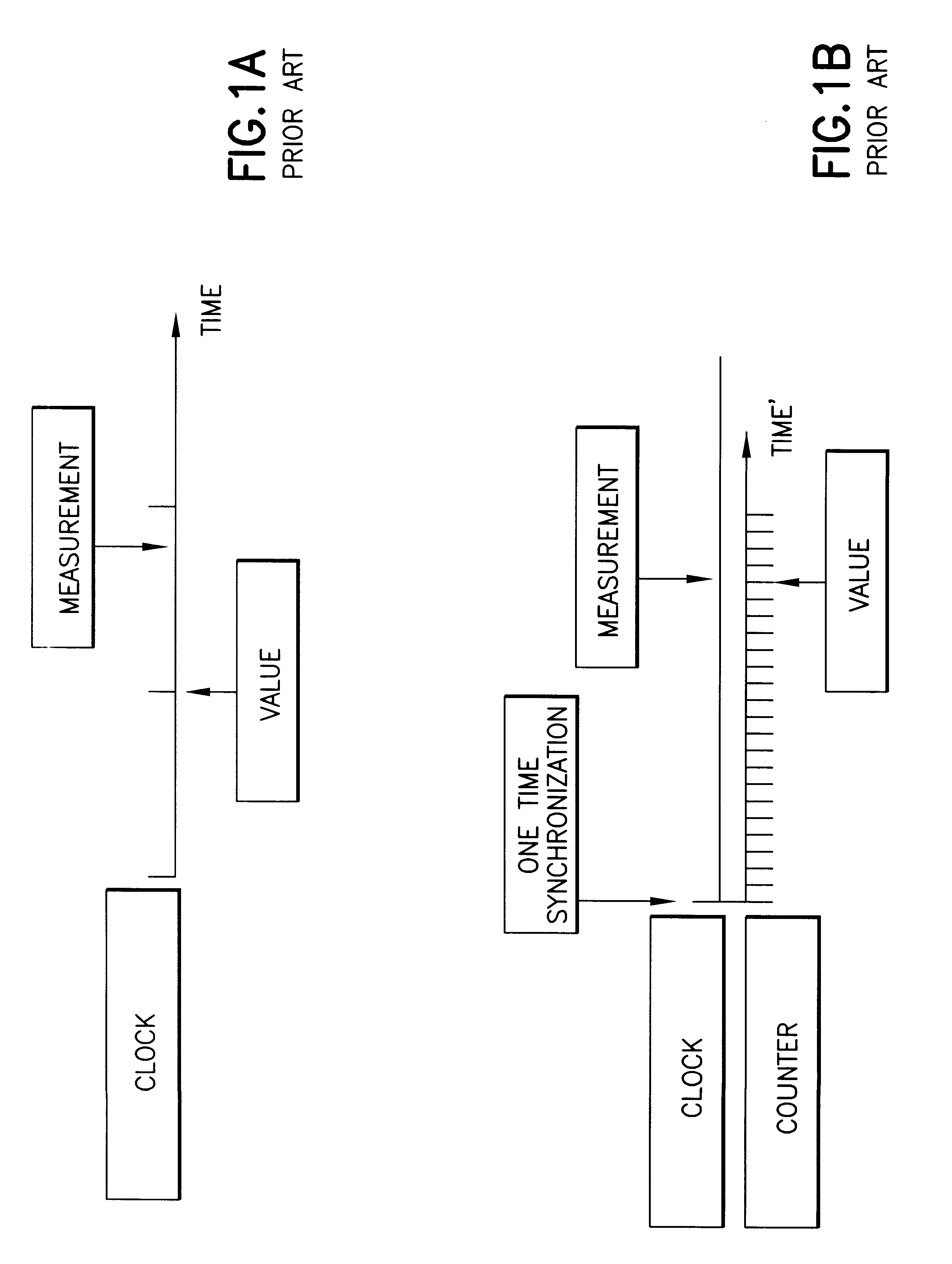

Calibrating high resolution measurements

InactiveUS6266625B1Improve accuracyGood precisionTime indicationSynchronous motors for clocksImage resolutionDouble check

There is described a method and system for calibrating measurements, in particular for calibrating a high resolution counter against an accurate real time calibrated clock signal. The method comprising obtaining the calibrated low resolution clock measurement and the corresponding high resolution counter measurement and calculating a range of possible corrections to the counter measurement to align it with the clock measurement. The correction range is adjusted to make it consistent with a previously stored correction range and a value is taken from it to calibrate the counter measurement. If the calculated range and the stored range are inconsistent then only the calculated range is used. A further measurement of the clock or counter is taken to double check.

Owner:IBM CORP

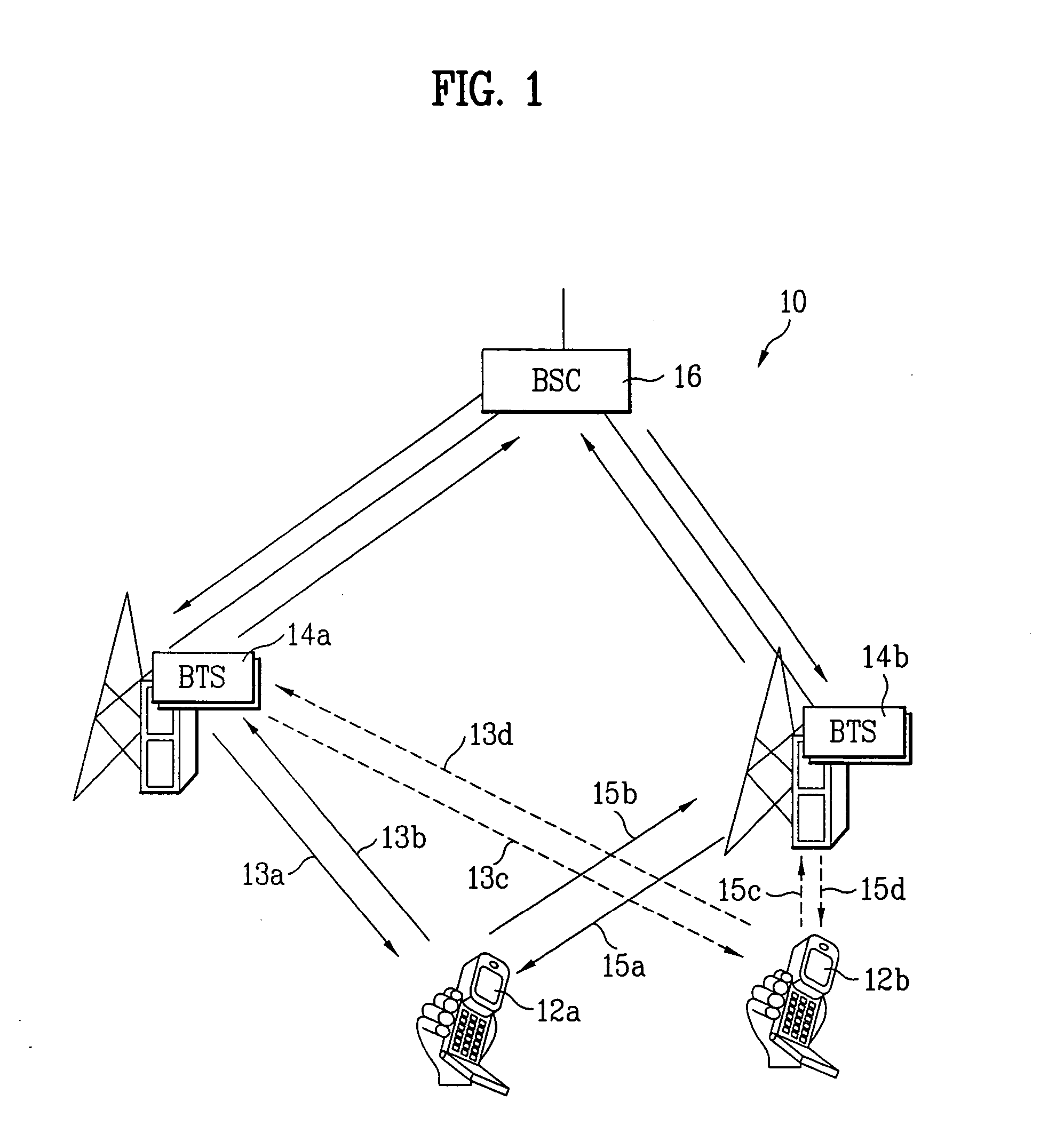

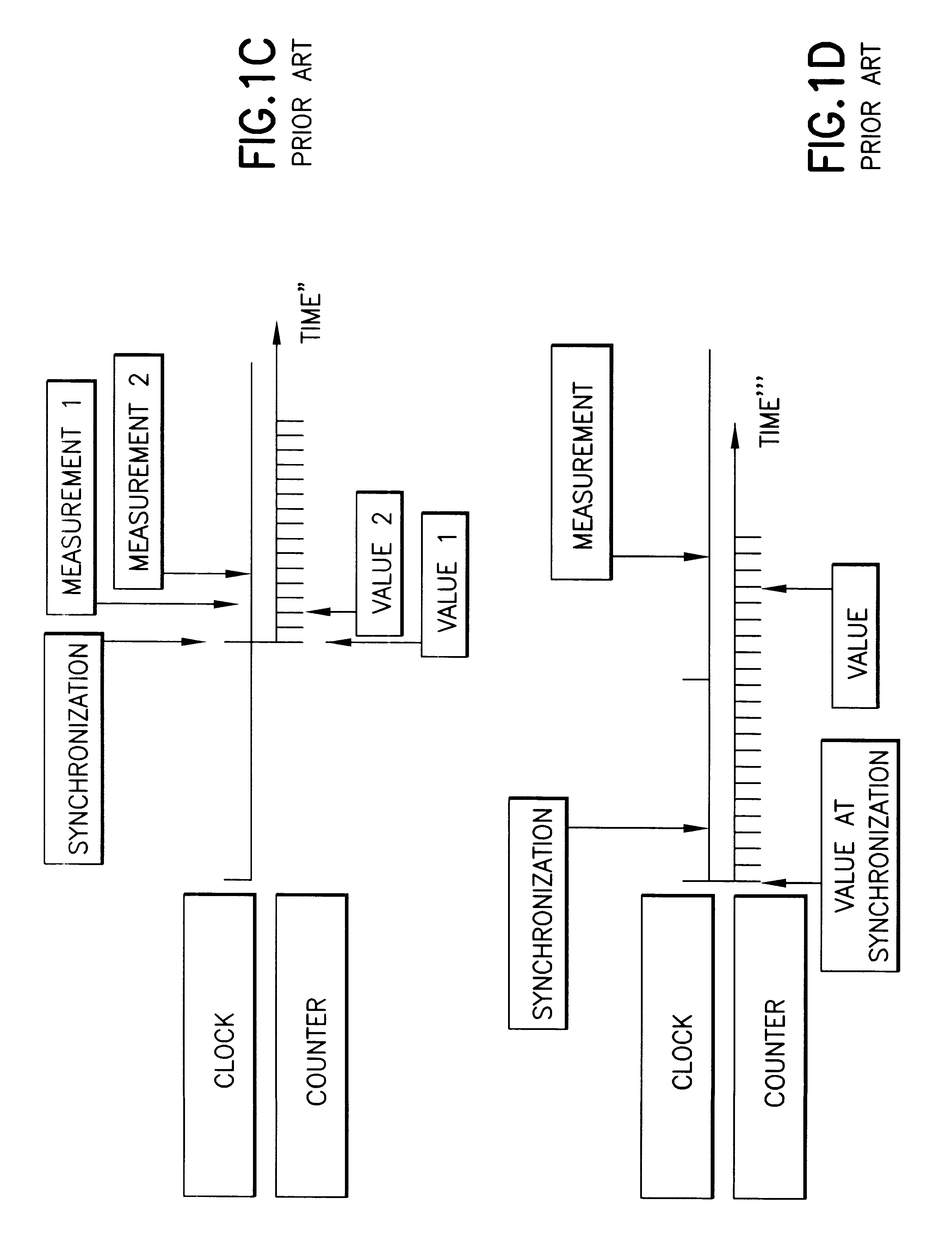

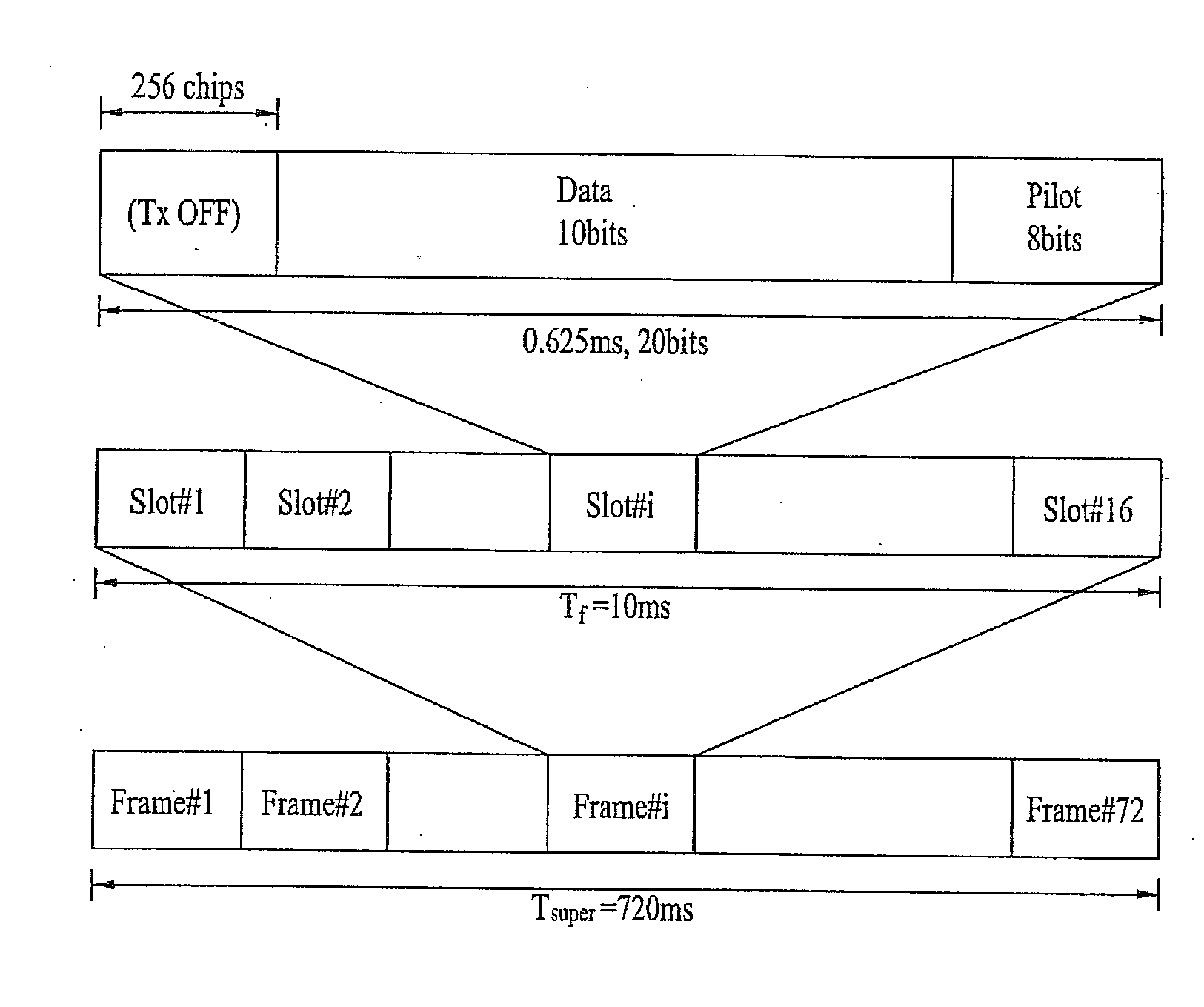

Pilot signals for synchronization and/or channel estimation

InactiveUS20080298438A1Avoid poor resultsEliminate and prevent sidelobesTransmission control/equlisationTime-division multiplexCorrelation functionSelf correlation

The frame words of the embodiments are suitable for frame synchronization and / or channel estimation. By adding the autocorrelation and / or cross-correlation functions of frame words, double maximum values equal in magnitude and opposite polarity at zero and middle shifts are obtained. This property can be used to slot-by-slot, double-check frame synchronization timing, single frame synchronization and / or channel estimation and allows reduction of the synchronization search time. Further, the present invention allows a simpler construction of a correlator circuit for a receiver. A frame synchronization apparatus and method using an optimal pilot pattern is used in a wide band code division multiple Access (W-CDMA) next generation mobile communication system.

Owner:LG ELECTRONICS INC

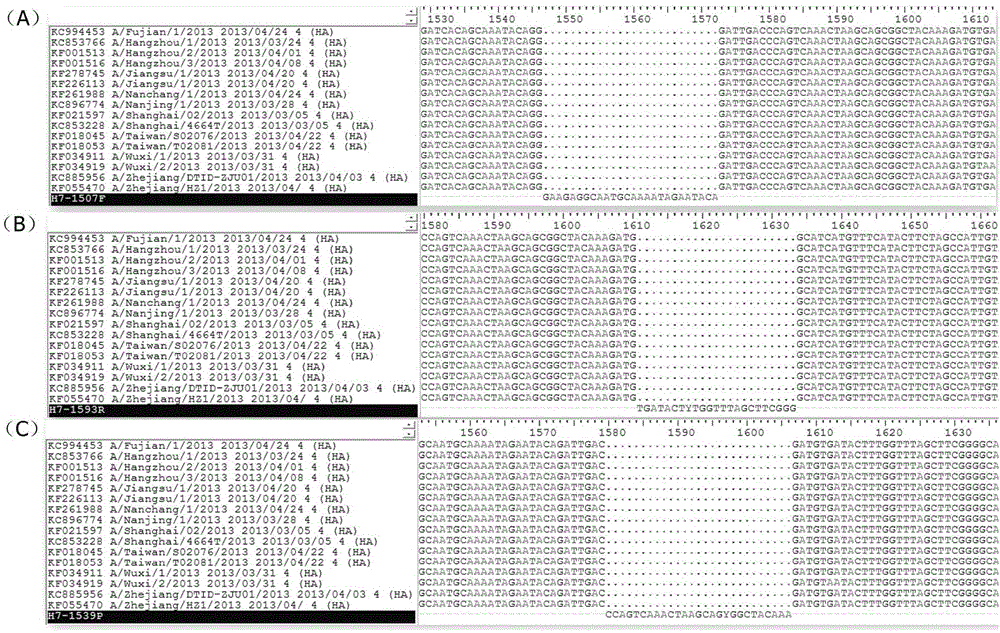

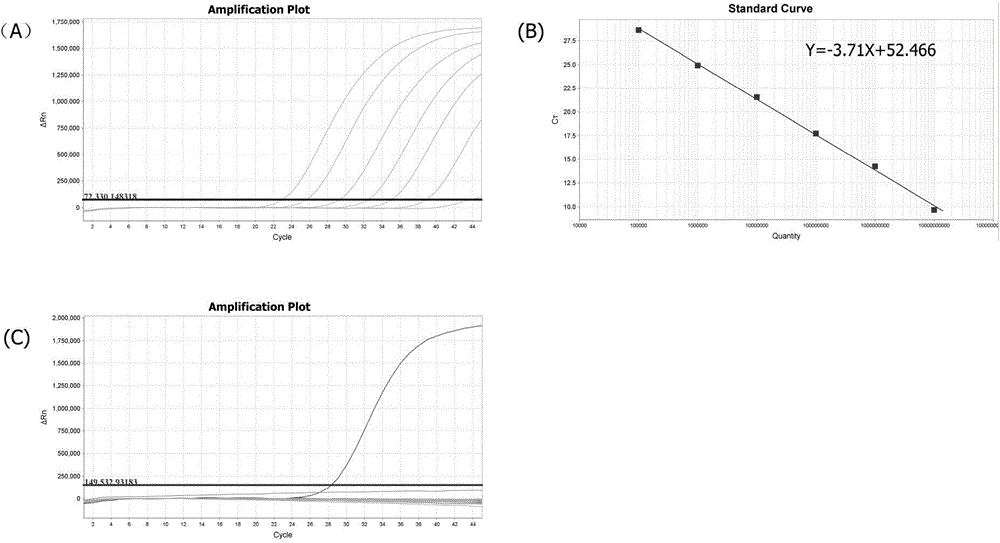

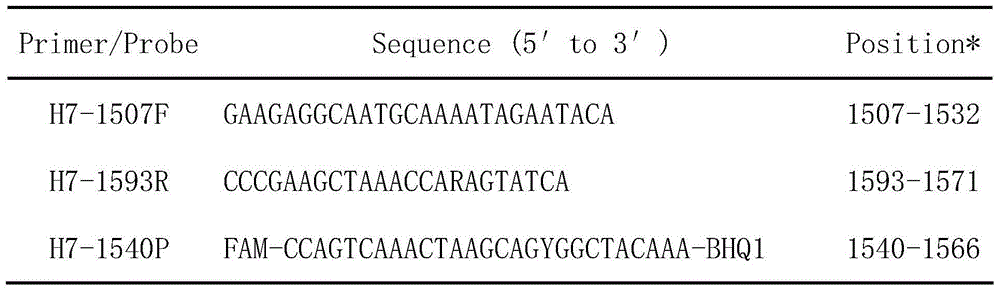

Real-time fluorescence RT-PCR method for quantitatively detecting human-infected avian influenza virus (A/H7N9)

InactiveCN105200161ARapid diagnosisSuitable for large-scale detectionMicrobiological testing/measurementFluorescenceRespiratory infection virus

The invention belongs to the field of virus detection, and particularly relates to a real-time fluorescence RT-PCR method for quantitatively detecting a human-infected avian influenza virus (A / H7N9). According to comparative analysis with an existing human-infected H7N9 virus in a Genbank database, it is shown that a synthesized and designed primer and probe are completely conservative to the epidemic H7N9 virus. According to the method, a higher detection sensitivity is achieved on the condition that five genes are copied in each reaction, a cross reaction on 17 common respiratory tract infection viruses does not occur, and the H7N9 can be specifically detected; contrast detection between the method and a national CDC detection method is conducted on 80 clinical specimens, double-check is conducted on 13 inconsistent specimens by adopting rRT-PCR recommended by WTO for detecting an influenza A virus, detection results are all positive, and it is shown that the detection results are accurate and reliable. The method can conduct quantitative analysis on the copy number of the H7N9 virus in the clinical specimens, the specificity, the sensitivity and the accuracy are achieved, the method is suitable for large-scale detection of the clinical specimens, and an important basis is provided for optimizing clinical treatment strategies.

Owner:SHANGHAI PUBLIC HEALTH CLINICAL CENT

Pilot signals for synchronization and/or channel estimation

InactiveUS20090196271A1Optimal autocorrelation resultEliminate and prevent sidelobesSynchronisation arrangementTransmission control/equlisationCode division multiple accessCorrelation function

The frame words of the embodiments are suitable for frame synchronization and / or channel estimation. By adding the autocorrelation and / or cross-correlation functions of frame words, double maximum values equal in magnitude and opposite polarity at zero and middle shifts are obtained. This property can be used to slot-by-slot, double-check frame synchronization timing, single frame synchronization and / or channel estimation and allows reduction of the synchronization search time. Further, the present invention allows a simpler construction of a correlator circuit for a receiver. A frame synchronization apparatus and method using an optimal pilot pattern is used in a wide band code division multiple Access (W-CDMA) next generation mobile communication system.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com