Patents

Literature

105 results about "Computed torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torque Calculation. A practical way to calculate the magnitude of the torque is to first determine the lever arm and then multiply it times the applied force.

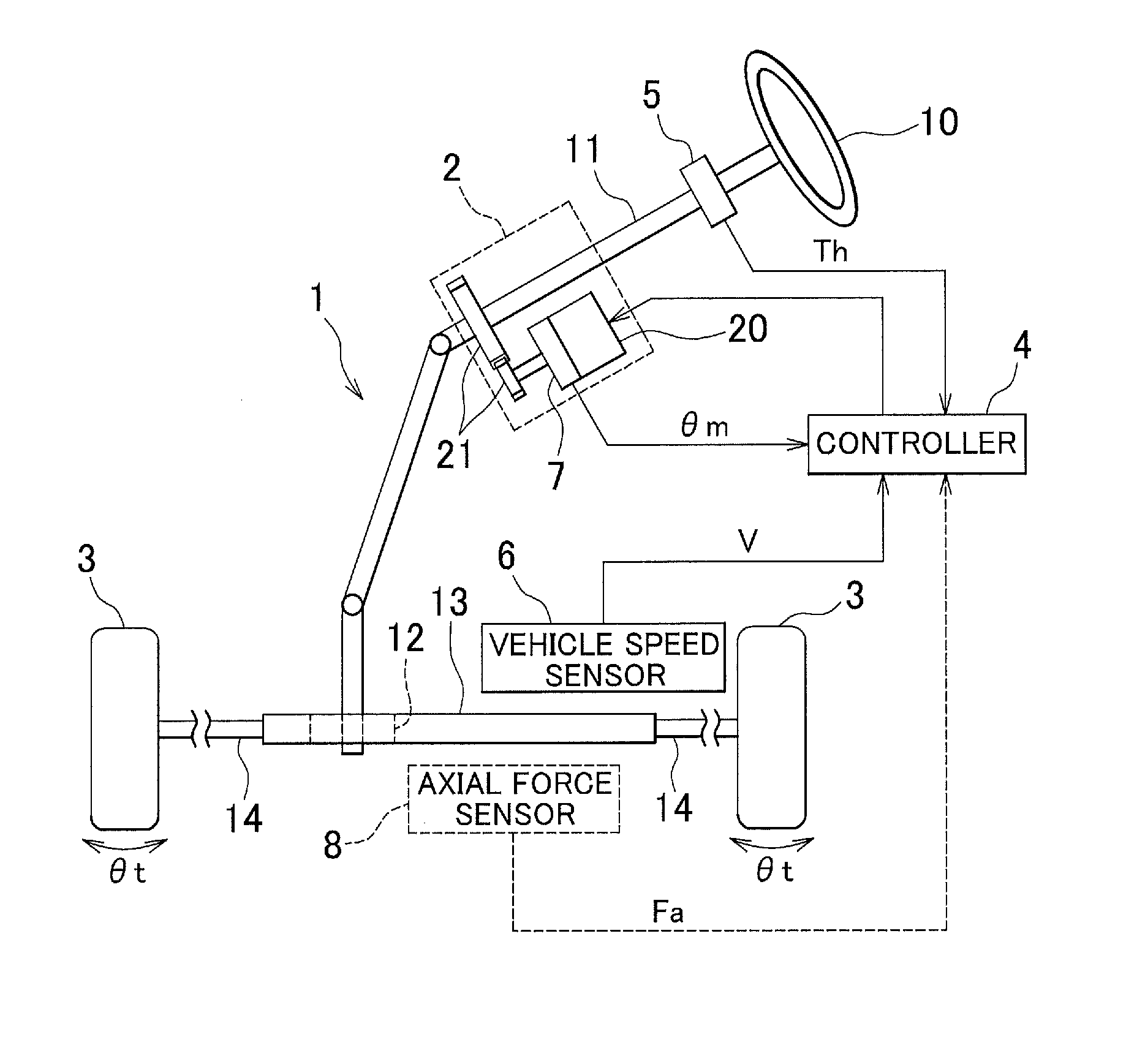

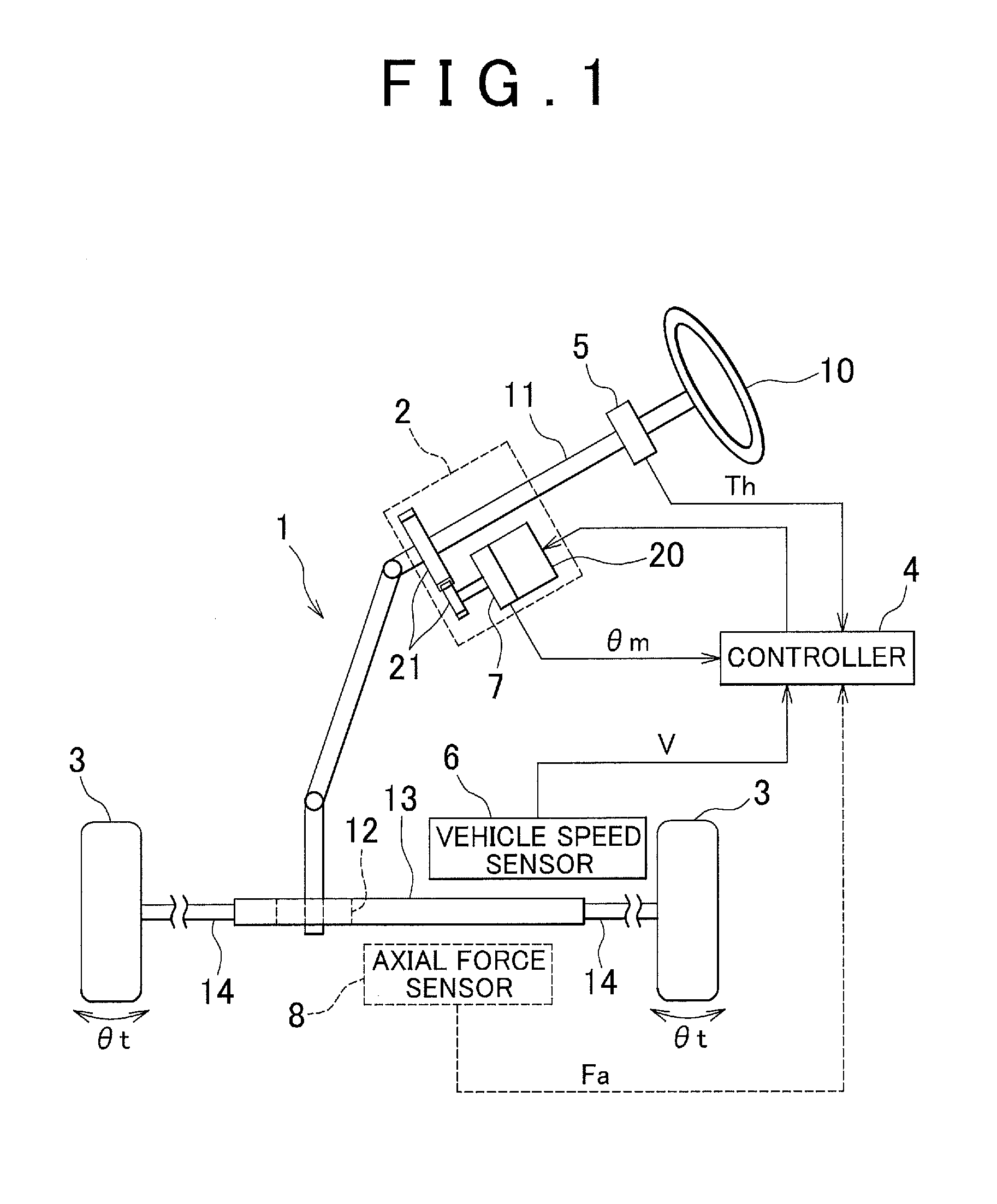

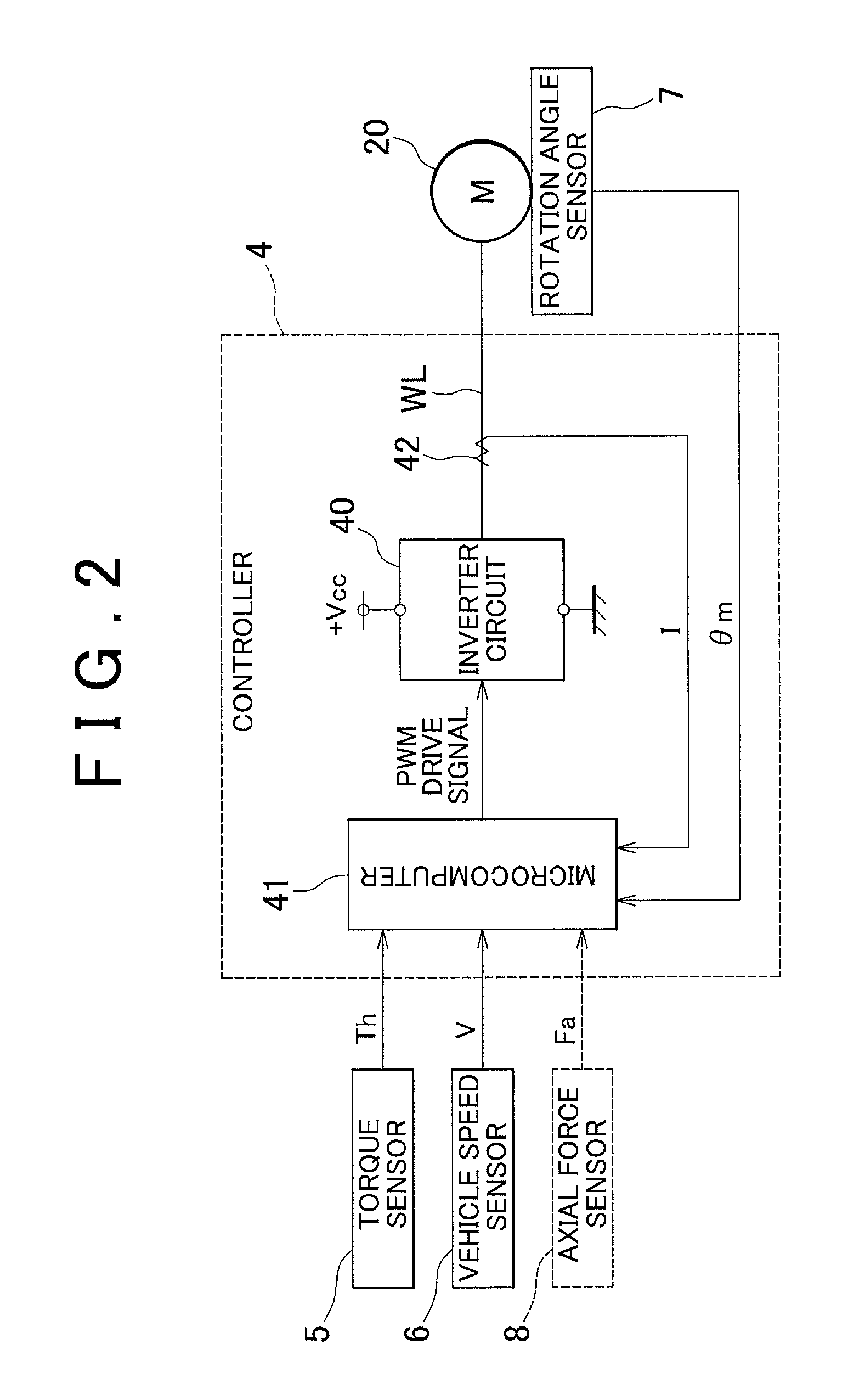

Electric power steering system

ActiveUS20140343794A1Improve a driver's steering feelImprove the driver's steering feelSteering initiationsDigital data processing detailsElectric power steeringDriver/operator

There is provided an electric power steering system that makes it possible to improve the driver's steering feel, and that includes a controller that controls driving of a motor. The controller computes a first assist component based on a steering torque. The controller computes a torque command value based on a basic drive torque that is the sum of the steering torque and the first assist component, and computes an assist compensation component through feedback control based on the torque command value. The controller computes a steered angle command value based on a value obtained by adding the assist compensation component to the basic drive torque, and computes a second assist component through feedback control based on the steered angle command value. The controller controls driving of the motor based on an assist command value that is the sum of the first assist component and the second assist component.

Owner:JTEKT CORP

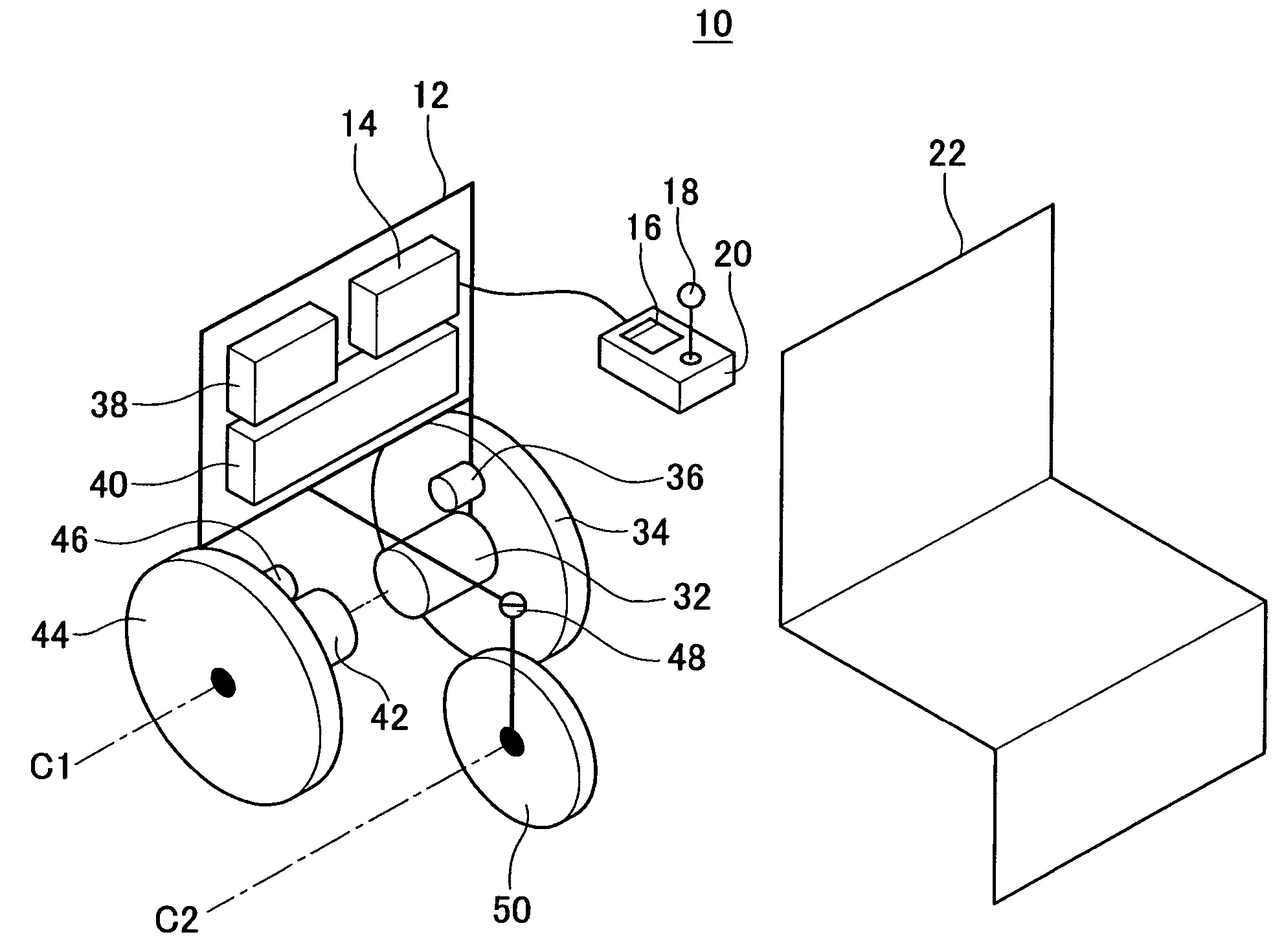

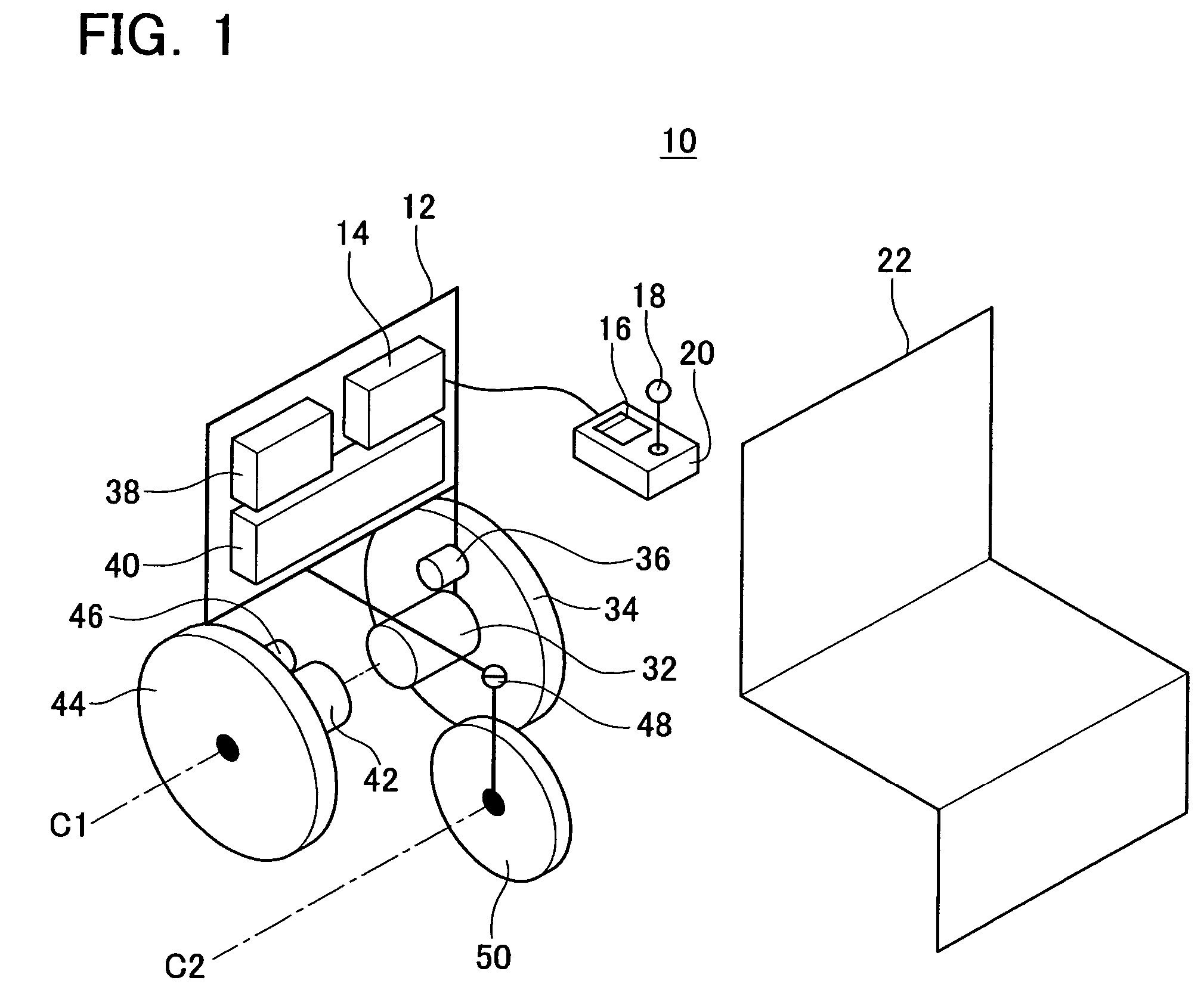

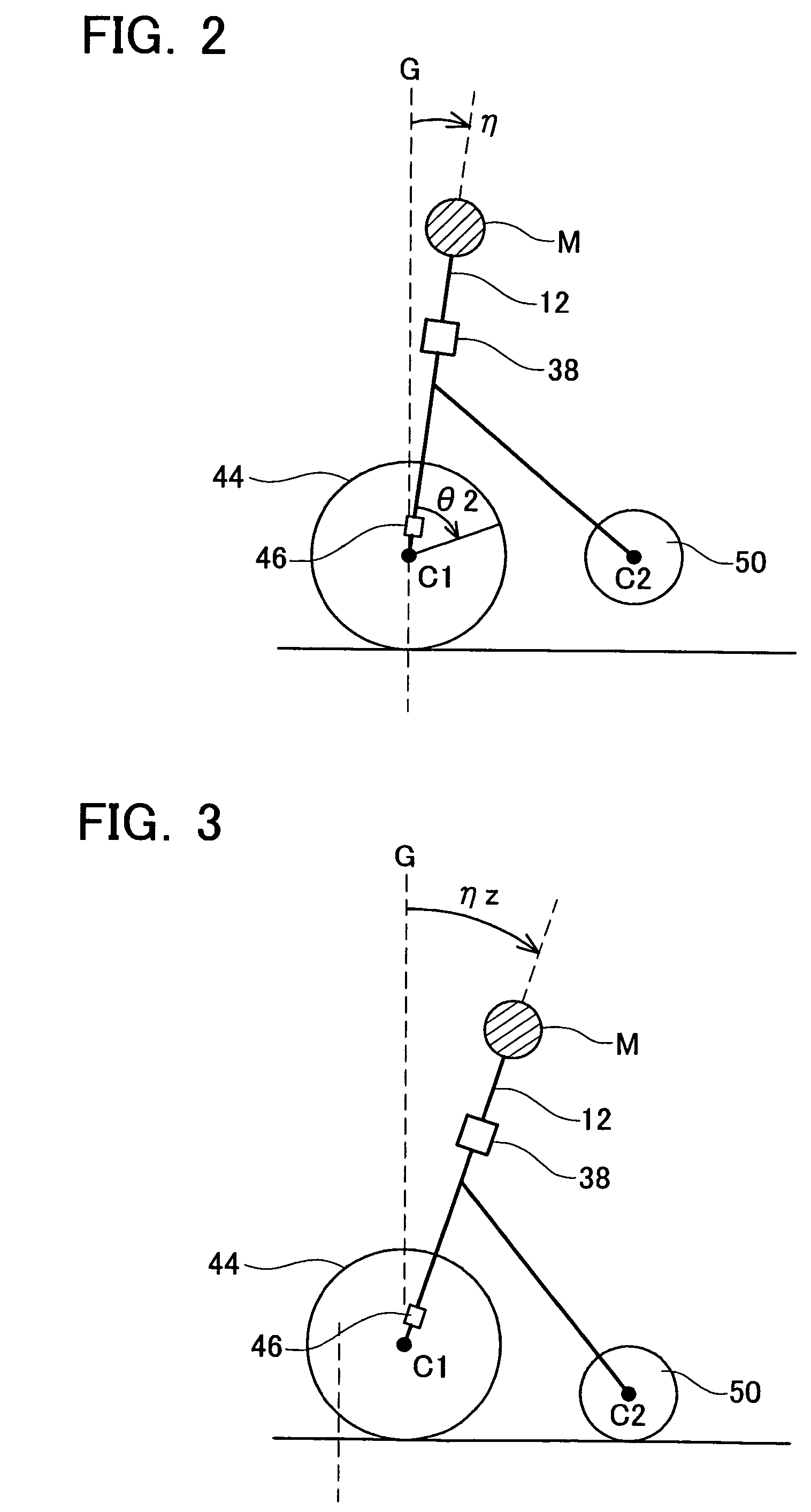

Running object and method of controlling the same

InactiveUS7640086B2Easy rideDigital data processing detailsWheelchairs/patient conveyanceDrive wheelAngular velocity

A running object includes a body, at least two drive wheels disposed on a first axle, and at least one driven wheel disposed on a second axle. The running object is capable of switching between a standing posture in which the driven wheel is suspended in the air and a stable posture in which the driven wheel is placed on the ground. The running object includes a storing device that stores a target incline pattern that chronologically describes the target incline angle of the body during a transition from the standing posture to the stable posture; a detecting device that detects the incline angle and / or the incline angular velocity of the body; a torque calculating device that calculates torque based on a deviation between the target incline pattern stored in the storing device and a detection value detected by the detecting device; and an actuator for applying the torque calculated by the calculating device to the drive wheels.

Owner:TOYOTA JIDOSHA KK

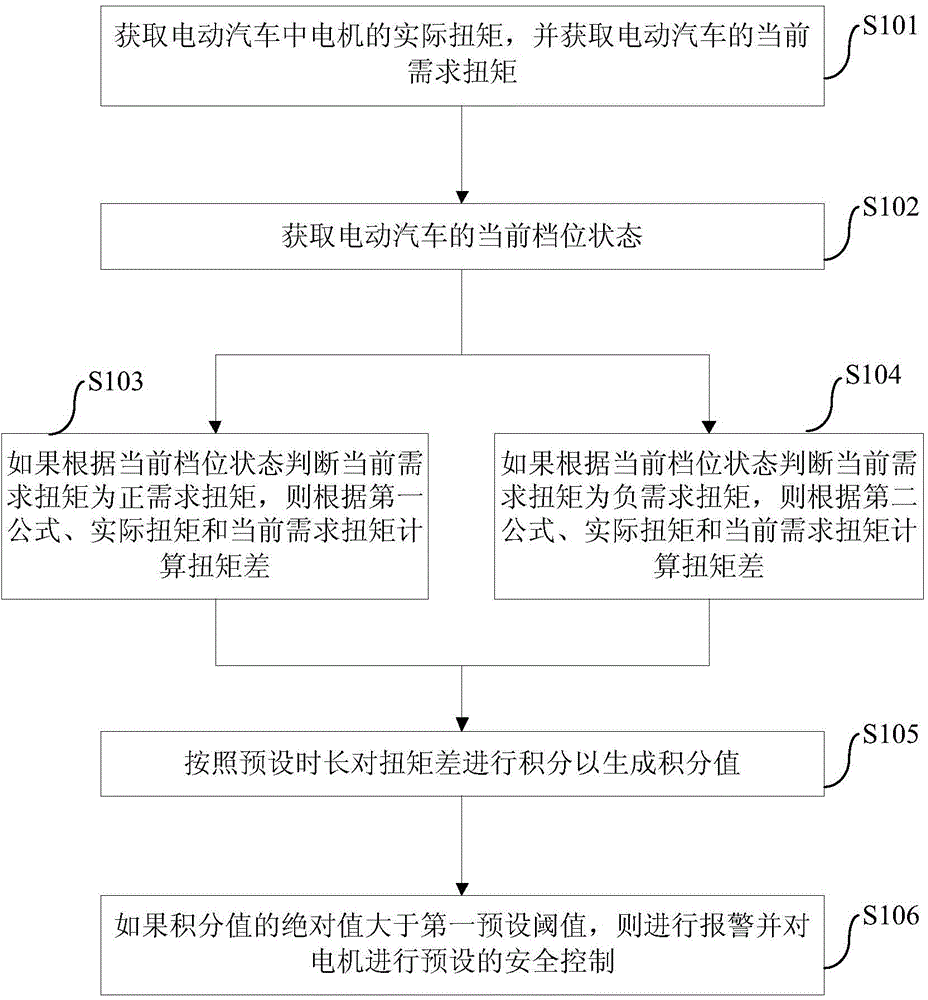

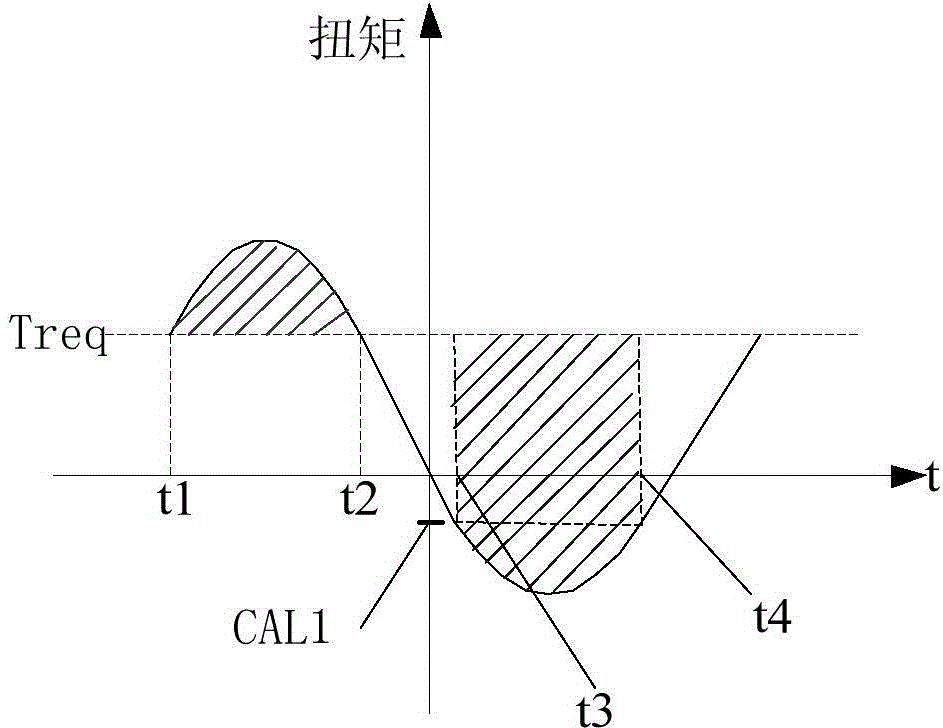

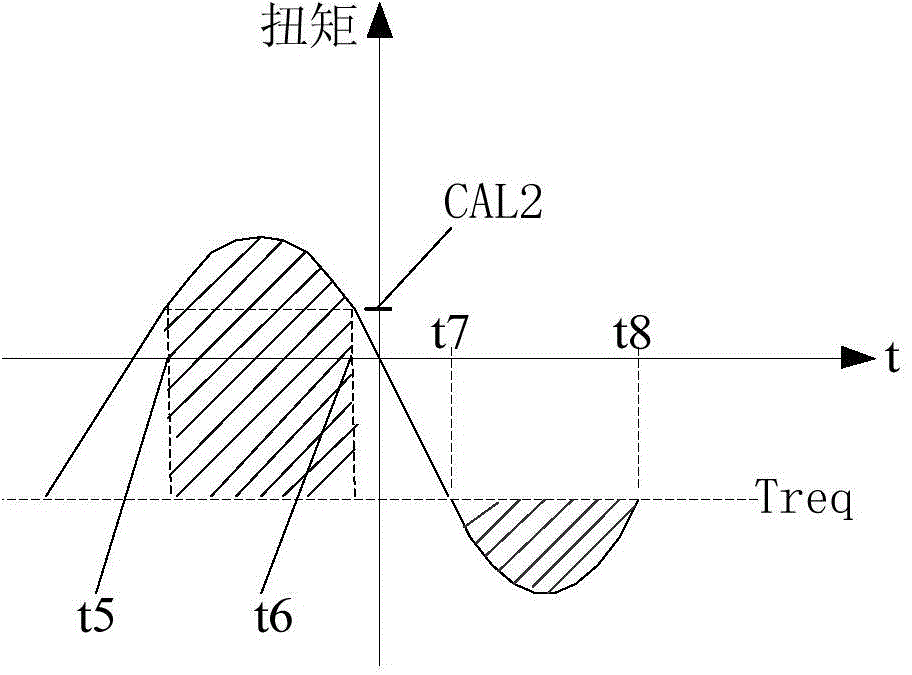

Electric vehicle and torque safety monitoring and controlling method and device thereof

ActiveCN106143162AExpand the scope of safety monitoringImprove Security Monitoring PerformanceSpeed controllerElectric devicesElectric machineComputed torque

The invention discloses a torque safety monitoring and controlling method and device of an electric vehicle. The method includes the steps that actual torque of a motor in the electric vehicle is obtained, and current demand torque of the electric vehicle is obtained; the current gear state of the electric vehicle is obtained; if it is judged that the current demand torque is positive demand torque according to the current gear state, torque difference is calculated according to a first formula, the actual torque and the current demand torque; if it is judged that the current demand torque is negative demand torque according to the current gear state, torque difference is calculated according to a second formula, the actual torque and the current demand torque; integration is carried out on the torque difference according to preset duration to generate an integral value; if absolute value of the integral value is larger than a first preset threshold value, an alarm is given, and preset safety control is carried out on the motor. According to the torque safety monitoring and controlling method in the embodiment, the torque safety monitoring range is enlarged, torque safety monitoring capacity is improved, the larger the torque difference is, the higher response speed is, and misjudgment caused by unstable currents is avoided.

Owner:BYD CO LTD

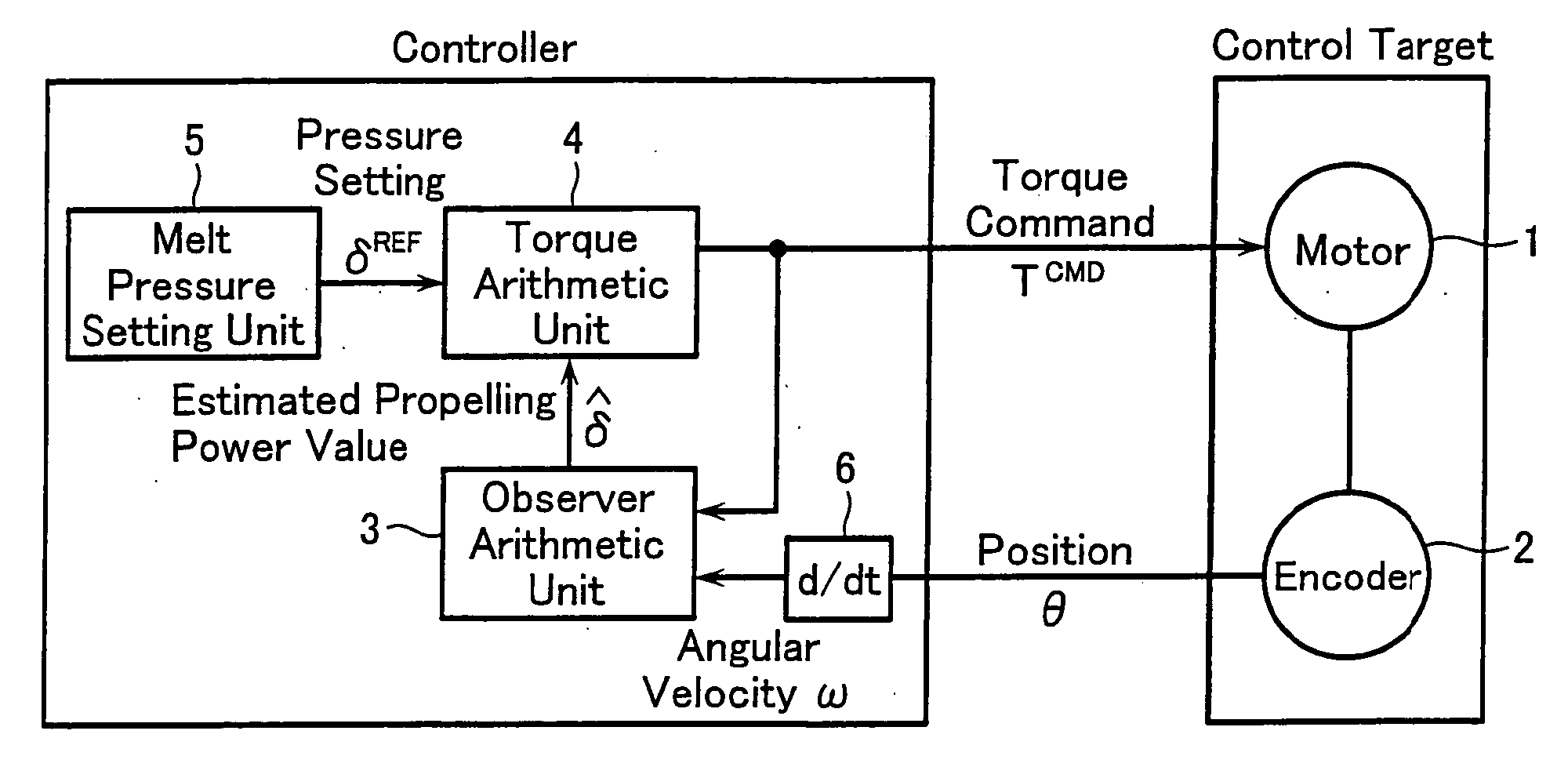

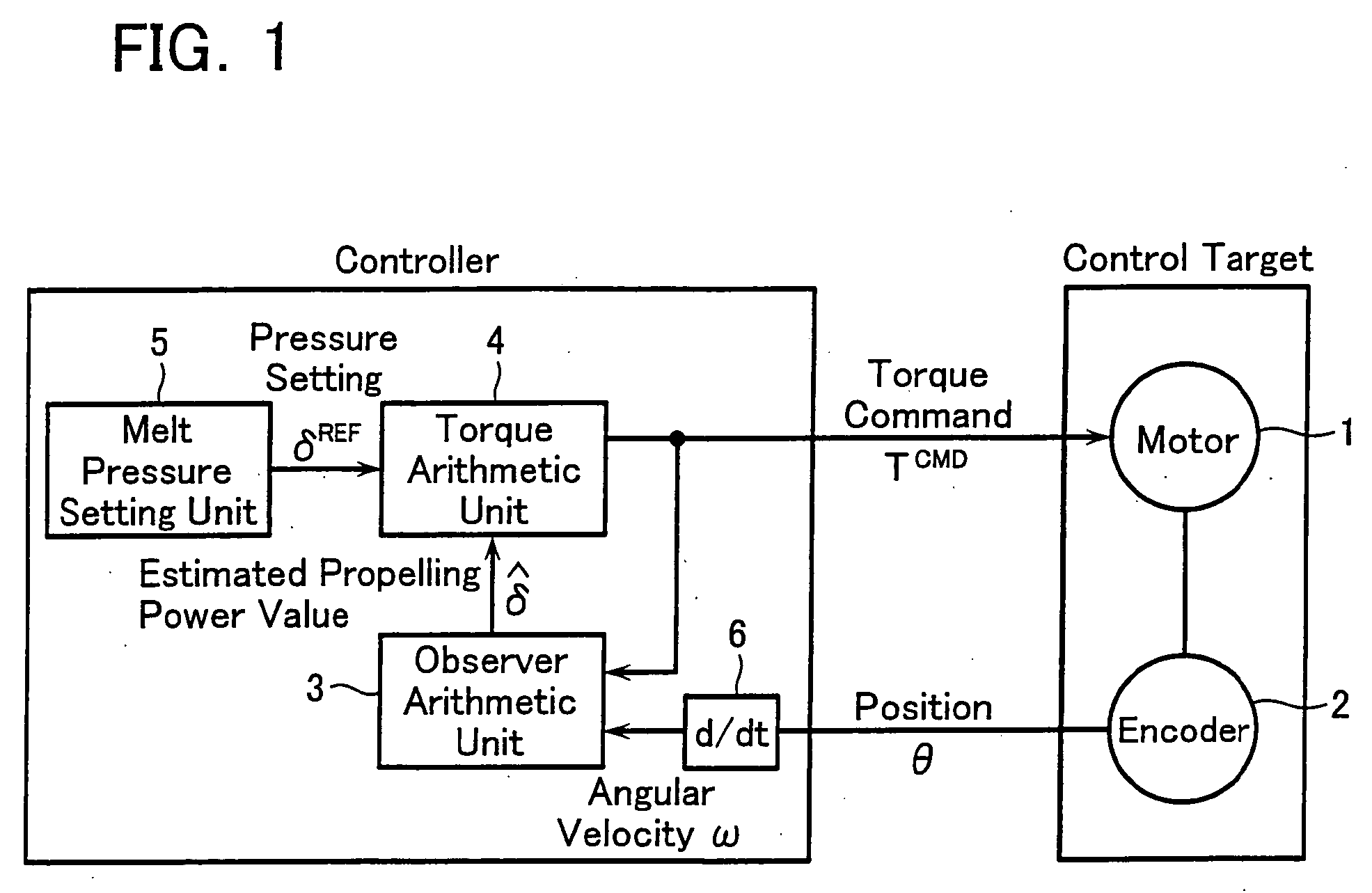

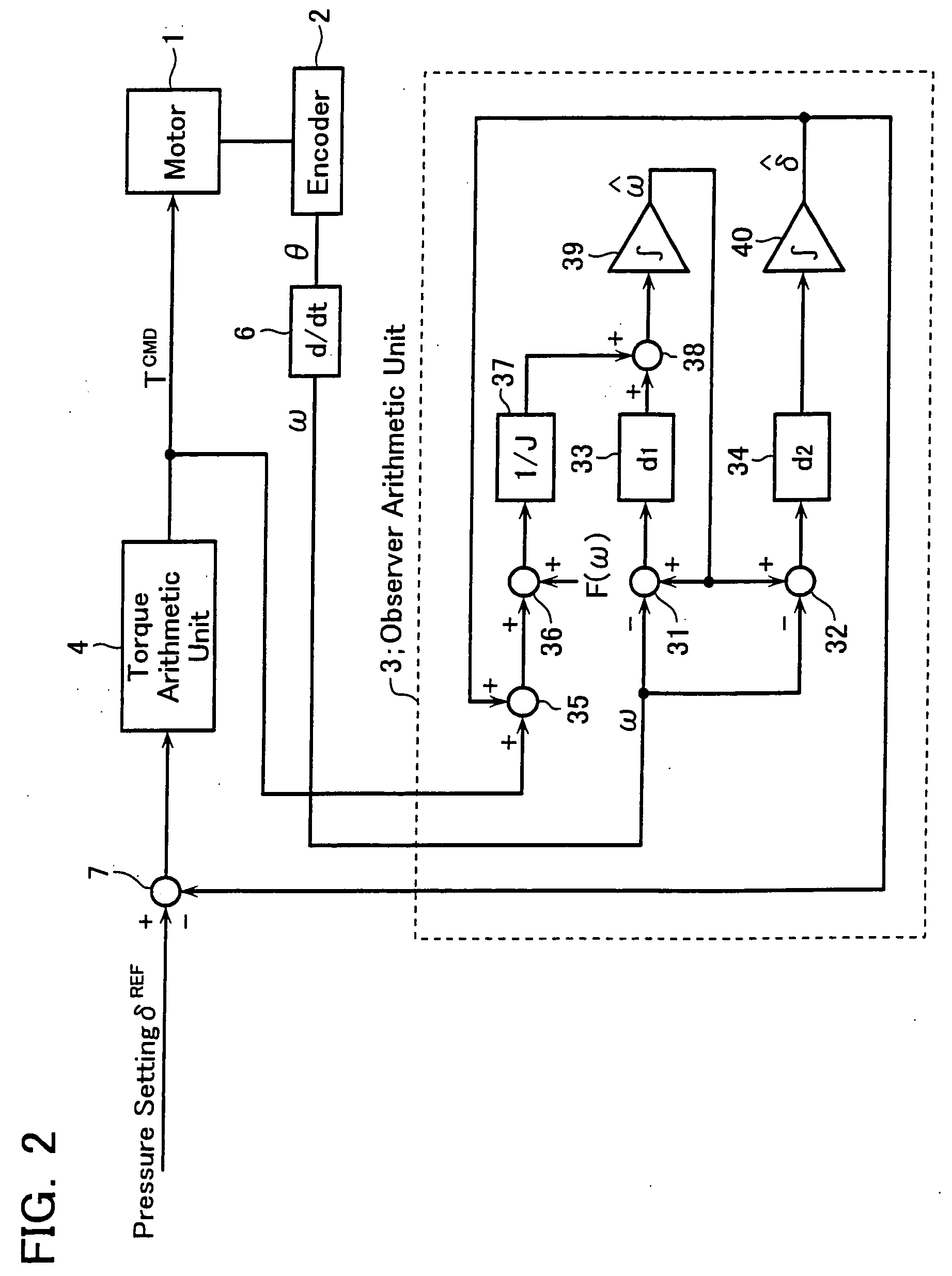

Method and device for pressure control of electric injection molding machine

A rotational angle of a motor operative to propel forward a screw in an injection molding machine is detected at an encoder. An output from the encoder is employed to obtain an angular velocity ω of the motor. From the obtained angular velocity ω, an estimated melt pressure value δˆ that contains no differential term is derived using a certain observer theory. The estimated melt pressure value δˆ is employed to calculate a torque command value TCMD for the motor, which is fed back to the motor. Thus, precise propelling power control unaffected by noises can be executed without the use of a pressure sensor such as a load cell.

Owner:UBE MASCH CORP LTD

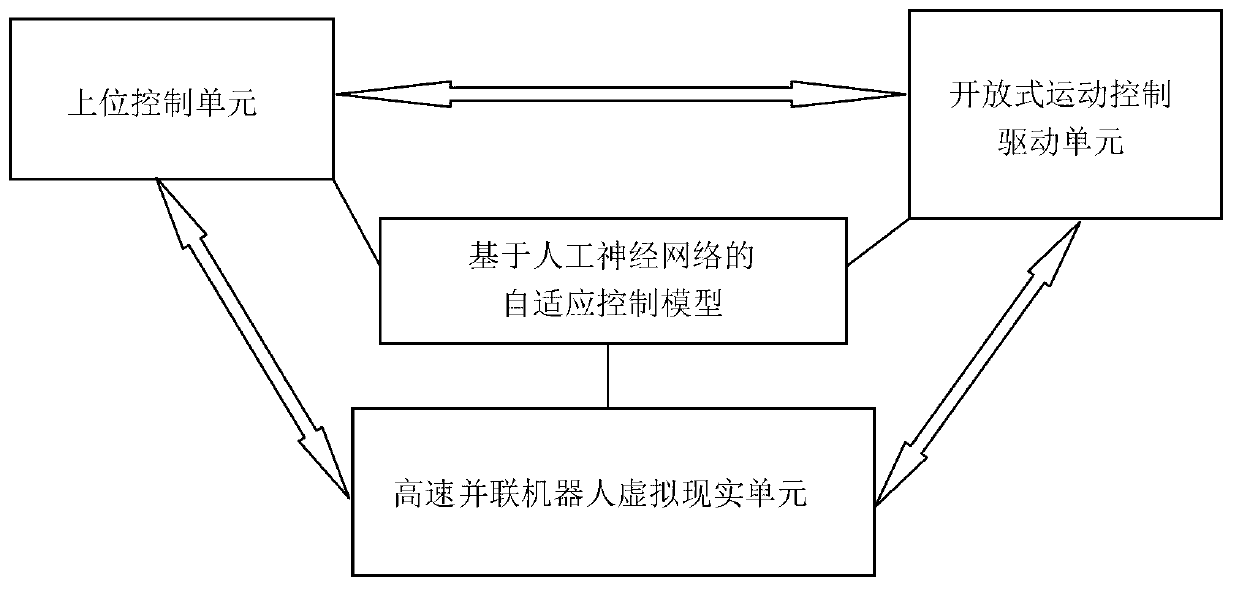

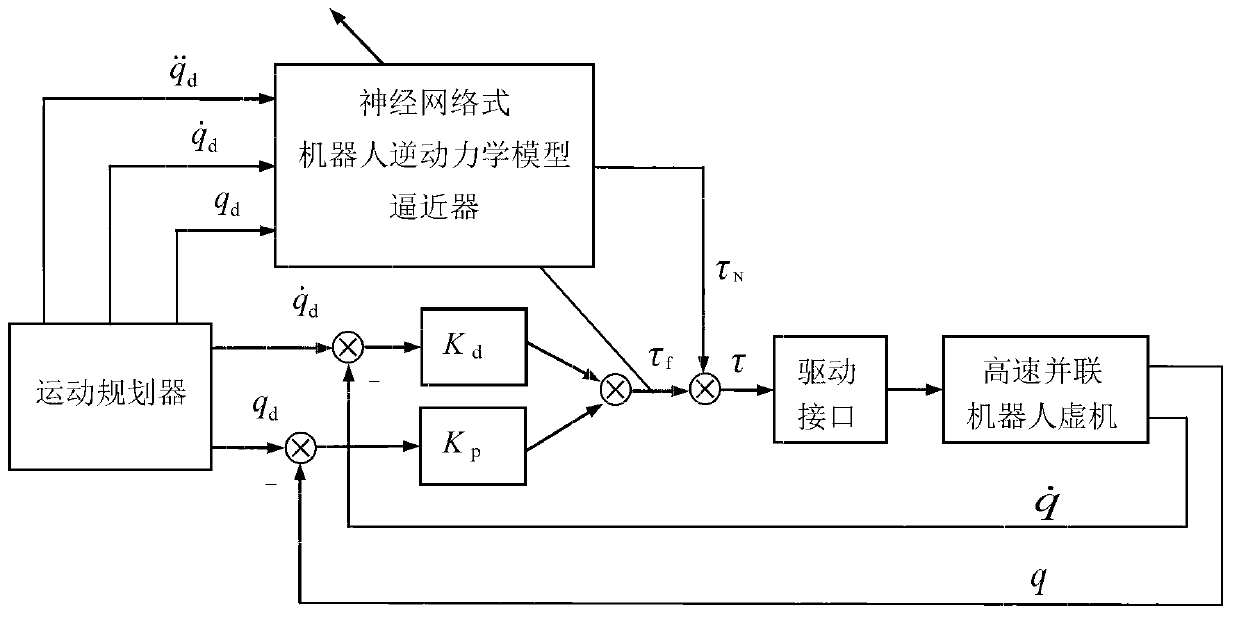

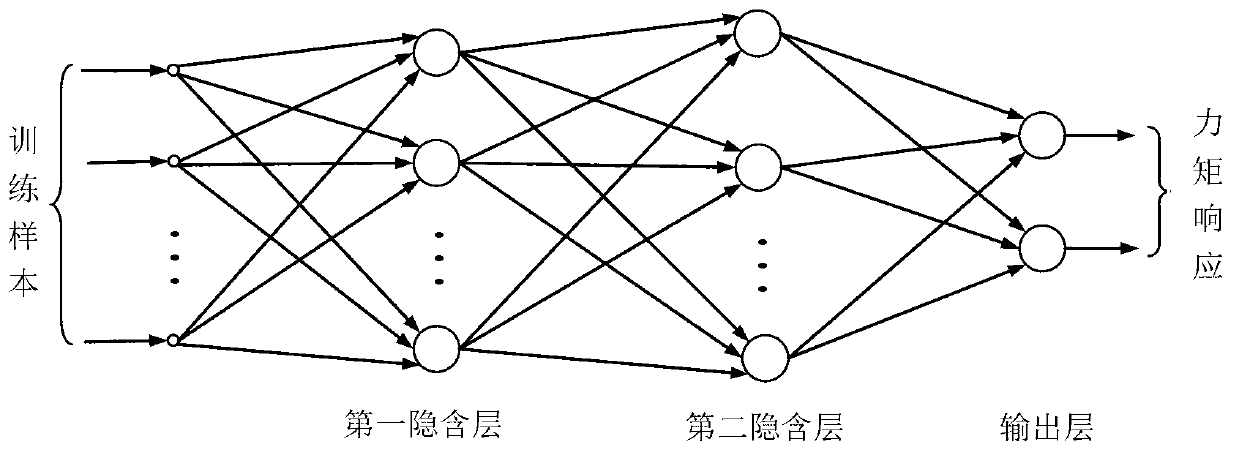

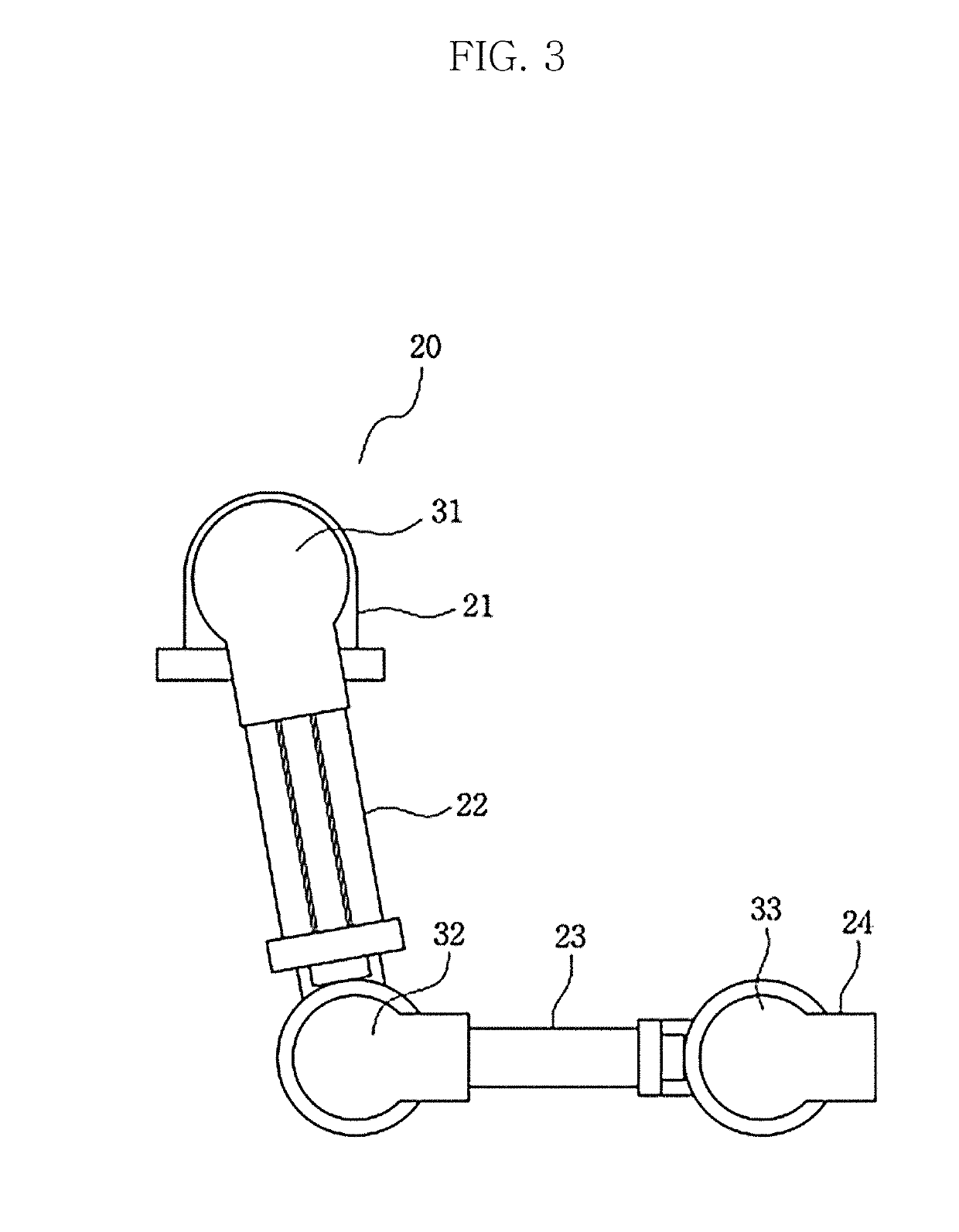

Robot neural network type computed torque controller training platform and training method

InactiveCN103279039AAvoid economyAvoid investing timeMechanical power/torque controlSimulator controlSystems designData acquisition

The invention discloses a robot neural network type computed torque controller training platform and training method, belonging to the technical field of robot control. The training platform consists of an upper control unit, an open type motion control driving unit, a high-speed parallel robot virtual reality unit, a data acquisition and communication unit and an artificial neural network-based adaptive control model, wherein motion planning and process monitoring are finished by the upper control unit; the open type motion control driving unit is an actual electrical part which finishes a control command of the upper control unit to convert to electrical control driving; the high-speed parallel robot virtual reality unit is used for realizing construction of a high-speed parallel robot virtual machine and a related three-dimensional scene; the data acquisition and communication unit realizes data communication and can collect a training sample required by the artificial neural network; and the artificial neural network-based adaptive control model consists of a neural network type robot inverse dynamic model approximator and a linear proportional differential feedback controller which work in parallel. The robot neural network type computed torque controller training platform and training method can realize trace tracking control of the high-speed parallel robot and have the characteristics of wide fitness, low system design cost and the like.

Owner:ANHUI HUACHUANG INTELLIGENT EQUIP

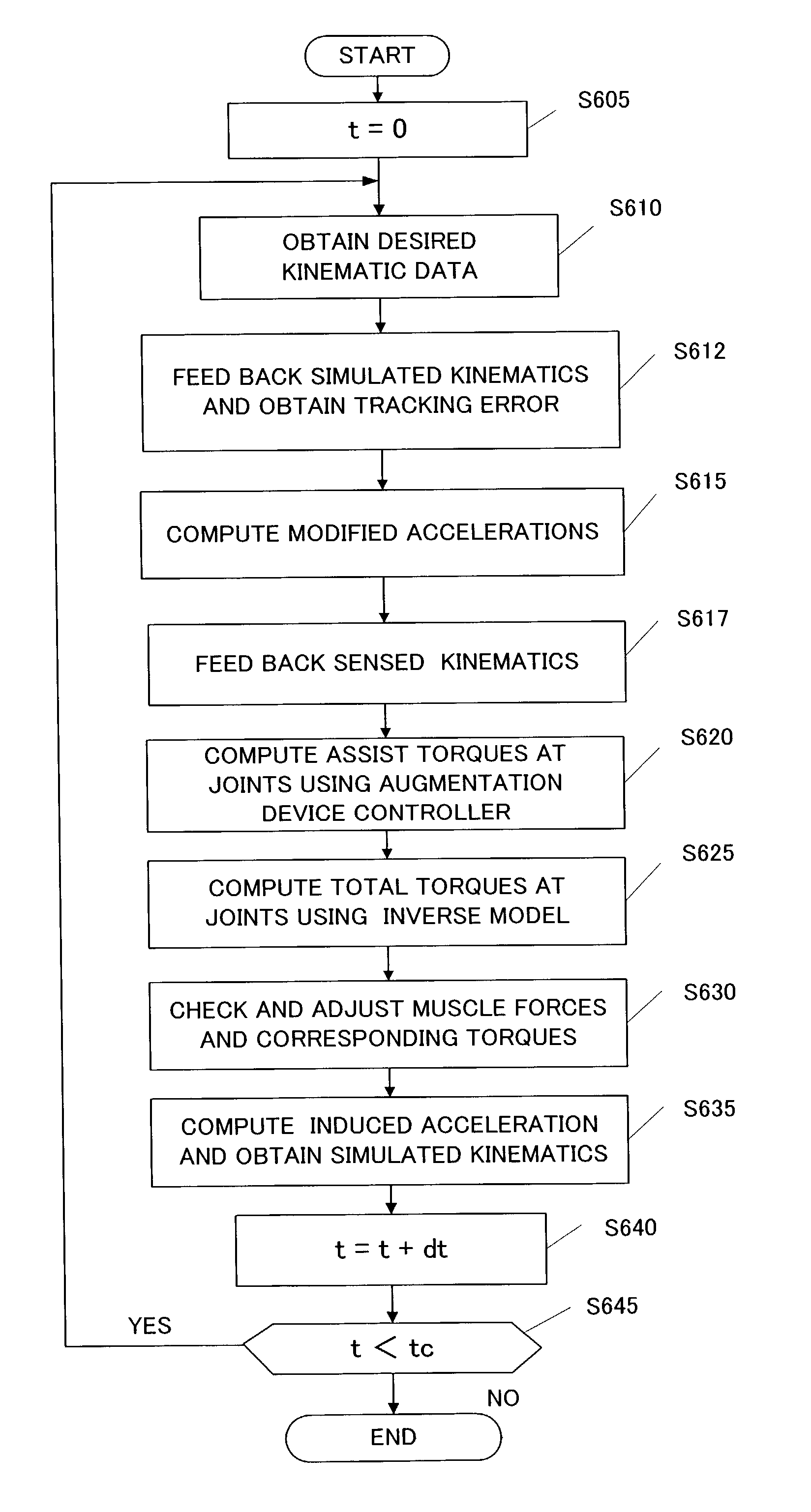

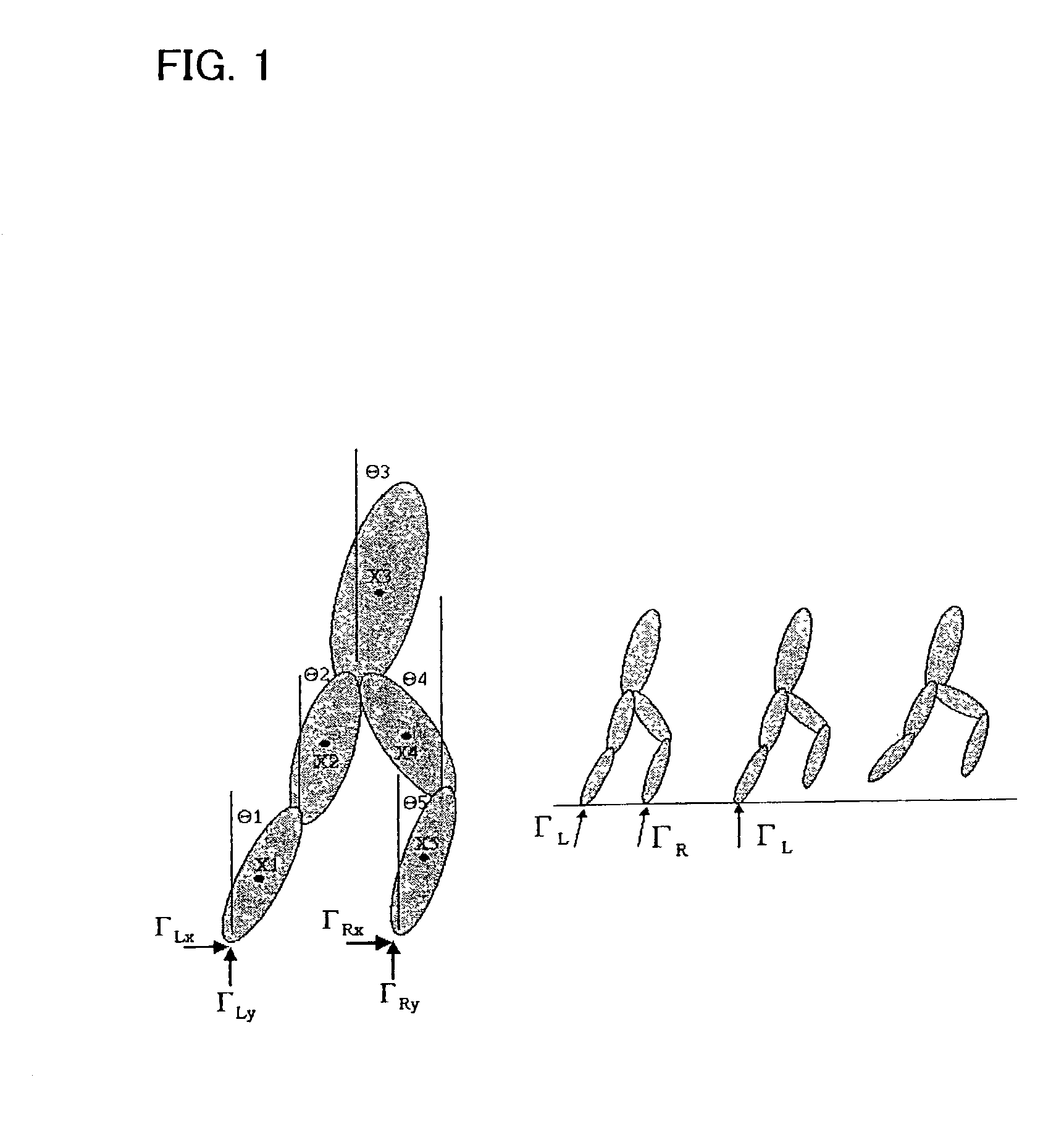

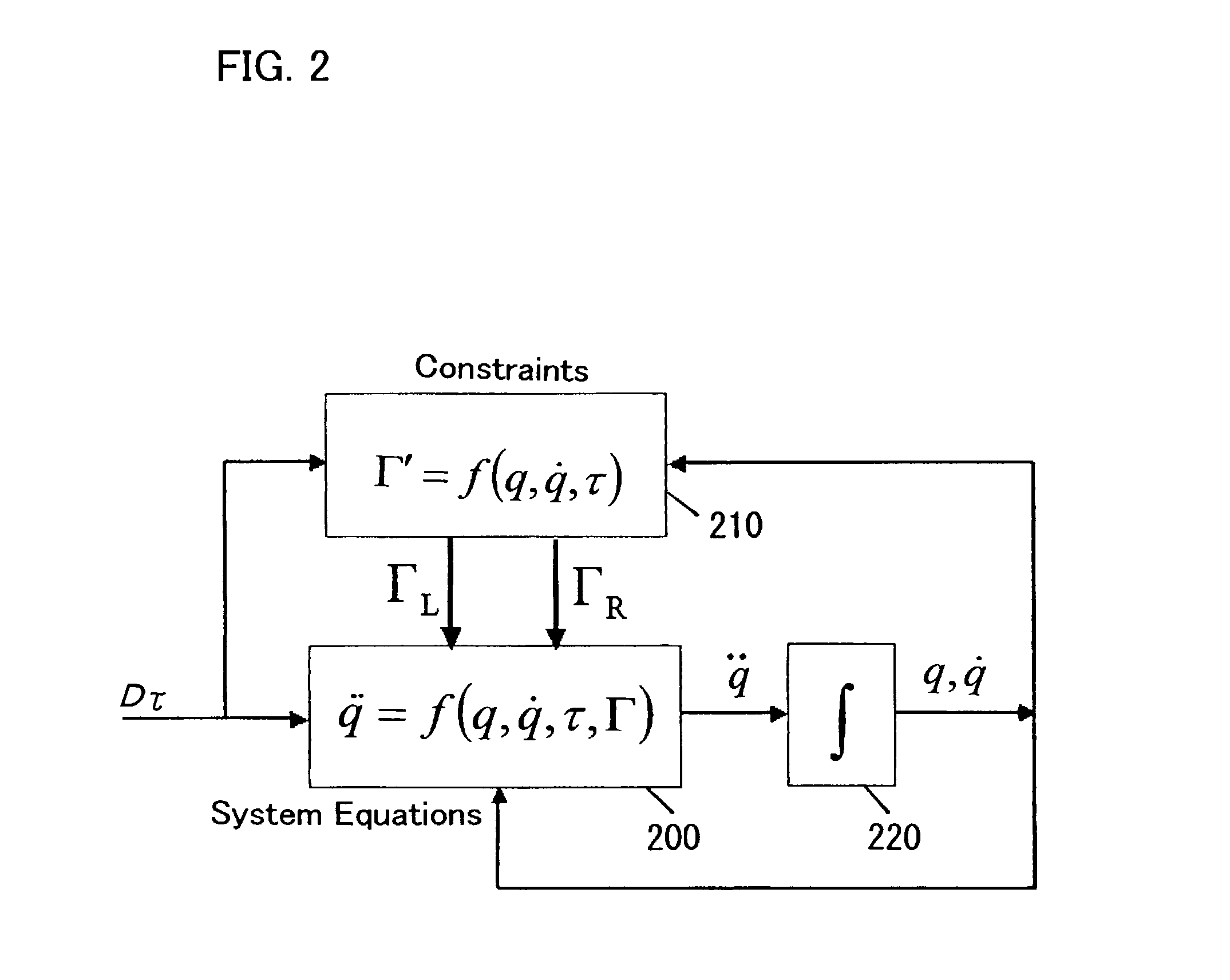

Simulation system, method and computer-readable medium for human augmentation devices

InactiveUS7251593B2Physical therapies and activitiesDigital data processing detailsMuscle forceInverse dynamics

A system, a method and a computer readable medium are provided for simulating a combined musculoskeletal and augmentation device system. The dynamics model of the combined musculoskeletal and augmentation device system receives computed torques at the joints as inputs and delivers simulated kinematic data of the segments as outputs. The augmentation device controller for control of the augmentation device, receives the simulated kinematic data as inputs and delivers assist torques as outputs. The inverse dynamics model for the musculoskeletal and augmentation device system, receives the simulated kinematic data, desired kinematic data of the segments and the assit torques as inputs and delivers the computed net joint torque and muscle torque. The muscle force and muscle capacity module for checking and adjusting the computed torques, receives the computed torques as inputs and delivers computed torques as outputs after the checking and adjustment.

Owner:HONDA MOTOR CO LTD

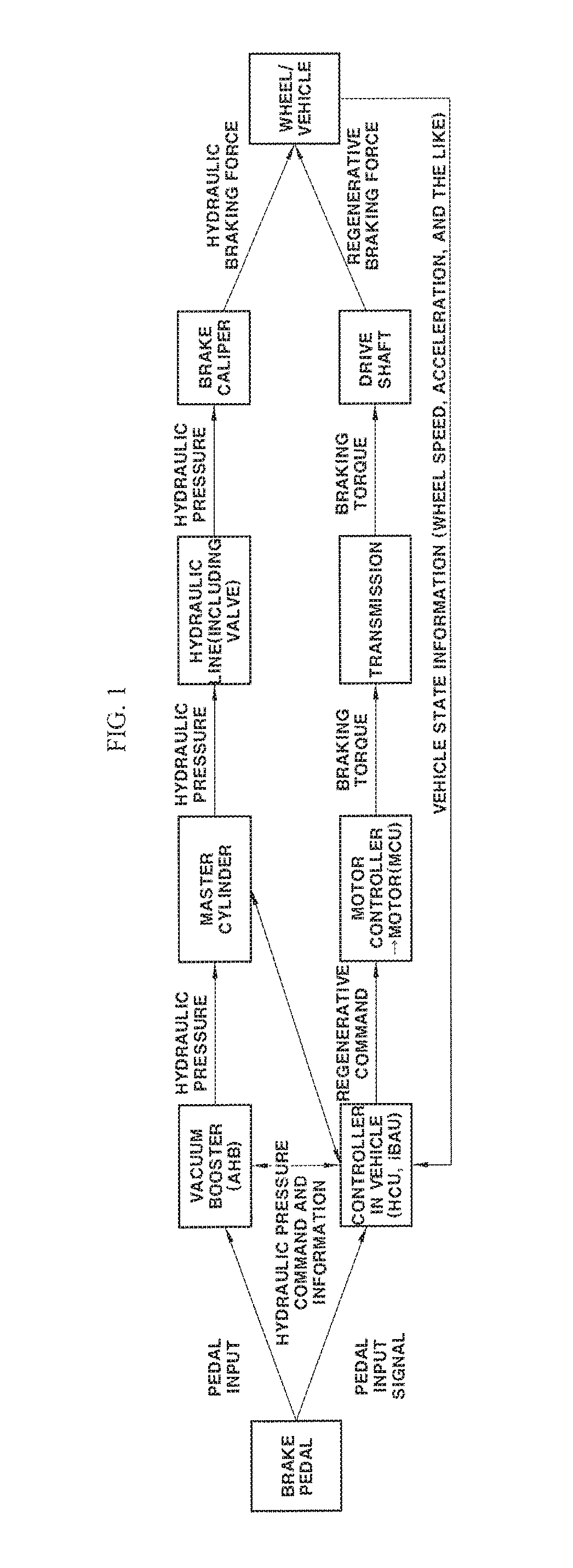

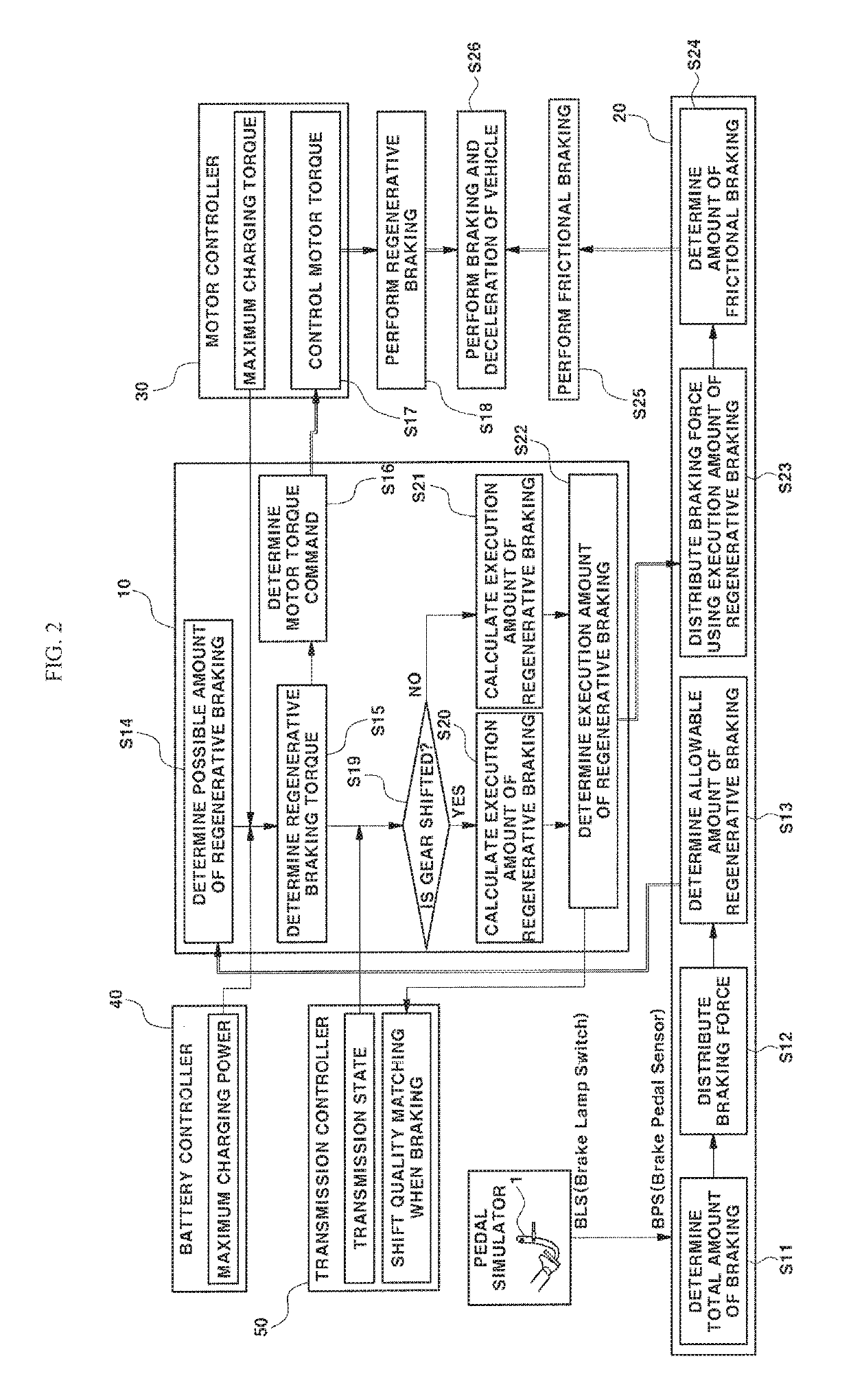

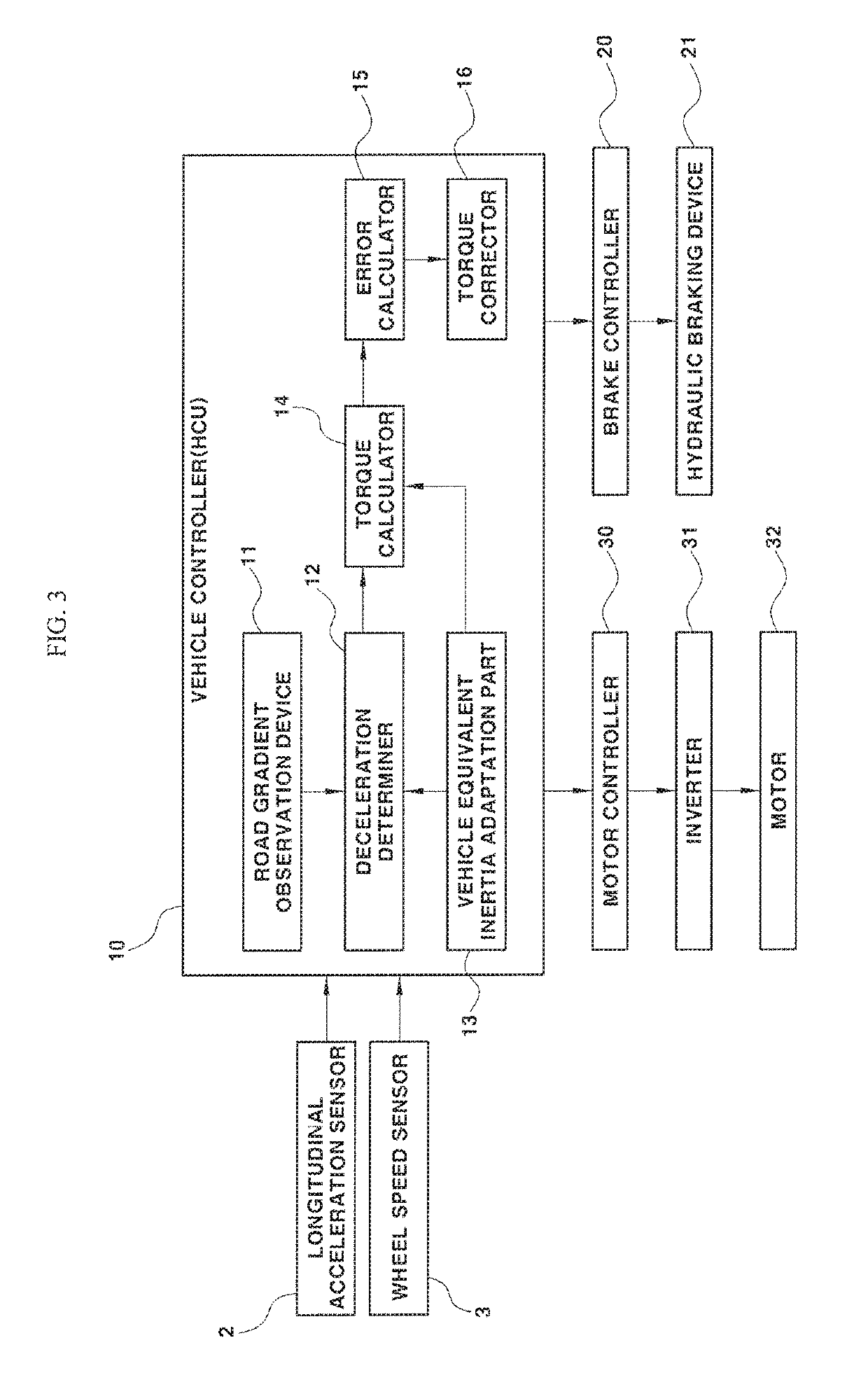

Braking control system and method for eco-friendly vehicle

ActiveUS20190193569A1Resolving discrepancy in braking force occurringHybrid vehiclesSpeed controllerRegenerative brakeControl system

A braking control system and a method for an eco-friendly vehicle are provided to resolve discrepancy in braking force occurring during switching between hydraulic braking and regenerative braking. The system includes a deceleration determiner that determines target and actual decelerations of the vehicle based on collected information when braking and a torque calculator that calculates target and actual deceleration torques from the determined target and actual decelerations of the vehicle using vehicle equivalent inertia information. An error calculator calculates a torque error and a torque corrector corrects a pre-correction target regenerative braking torque by the calculated torque error and calculates a post-correction target regenerative braking torque. A motor controller adjusts a regenerative braking torque of a motor according to the calculated post-correction target regenerative braking torque.

Owner:HYUNDAI MOTOR CO LTD +1

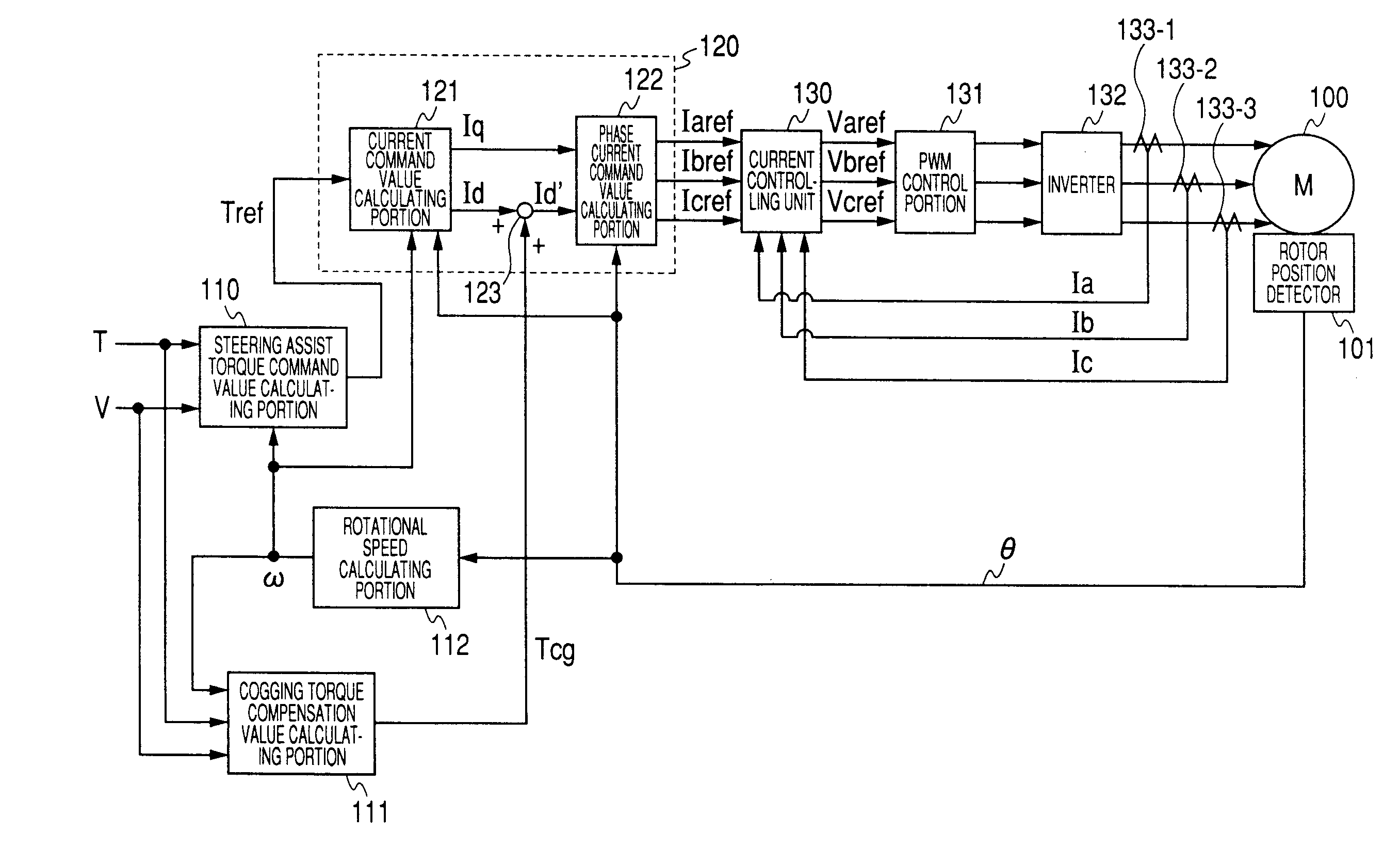

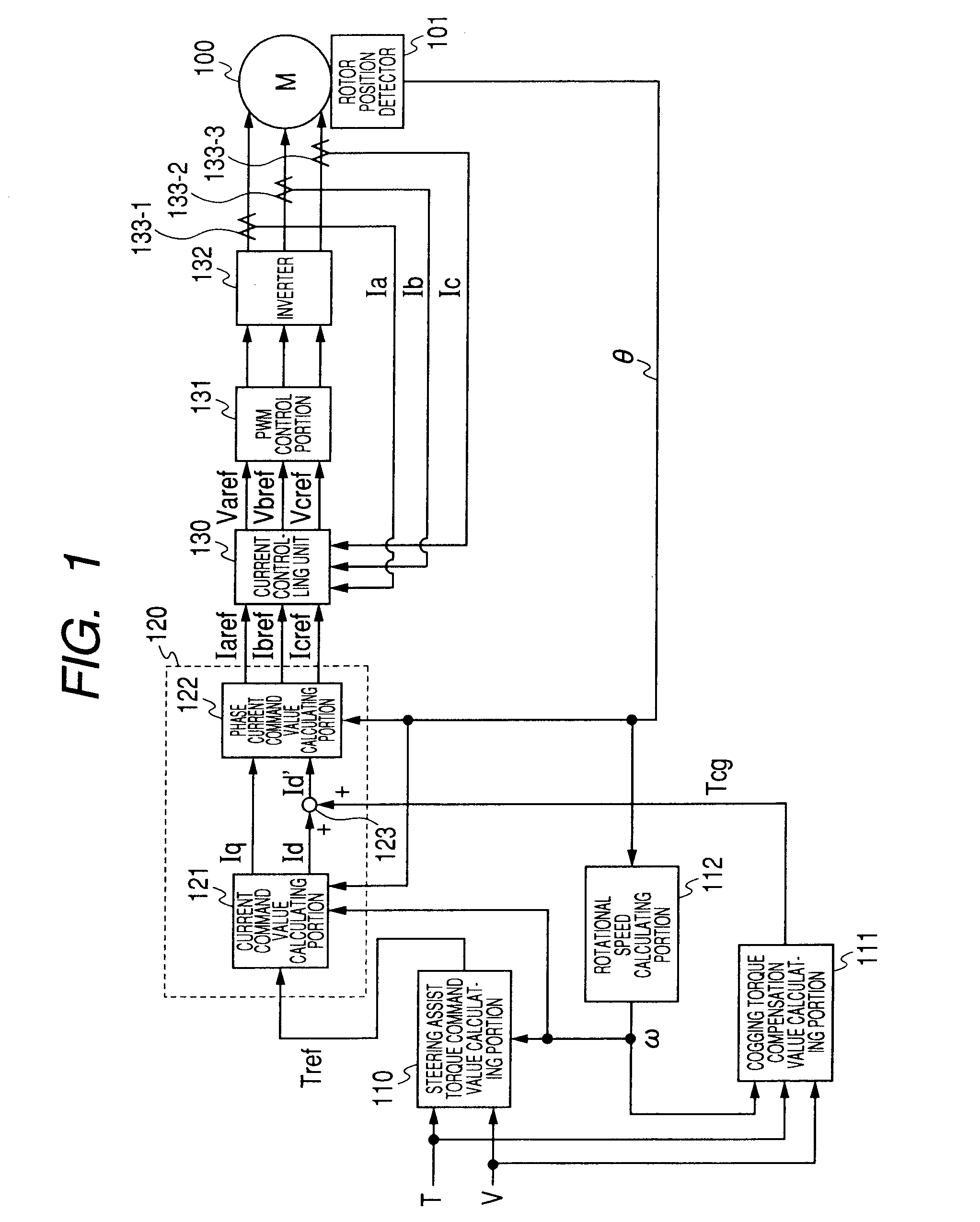

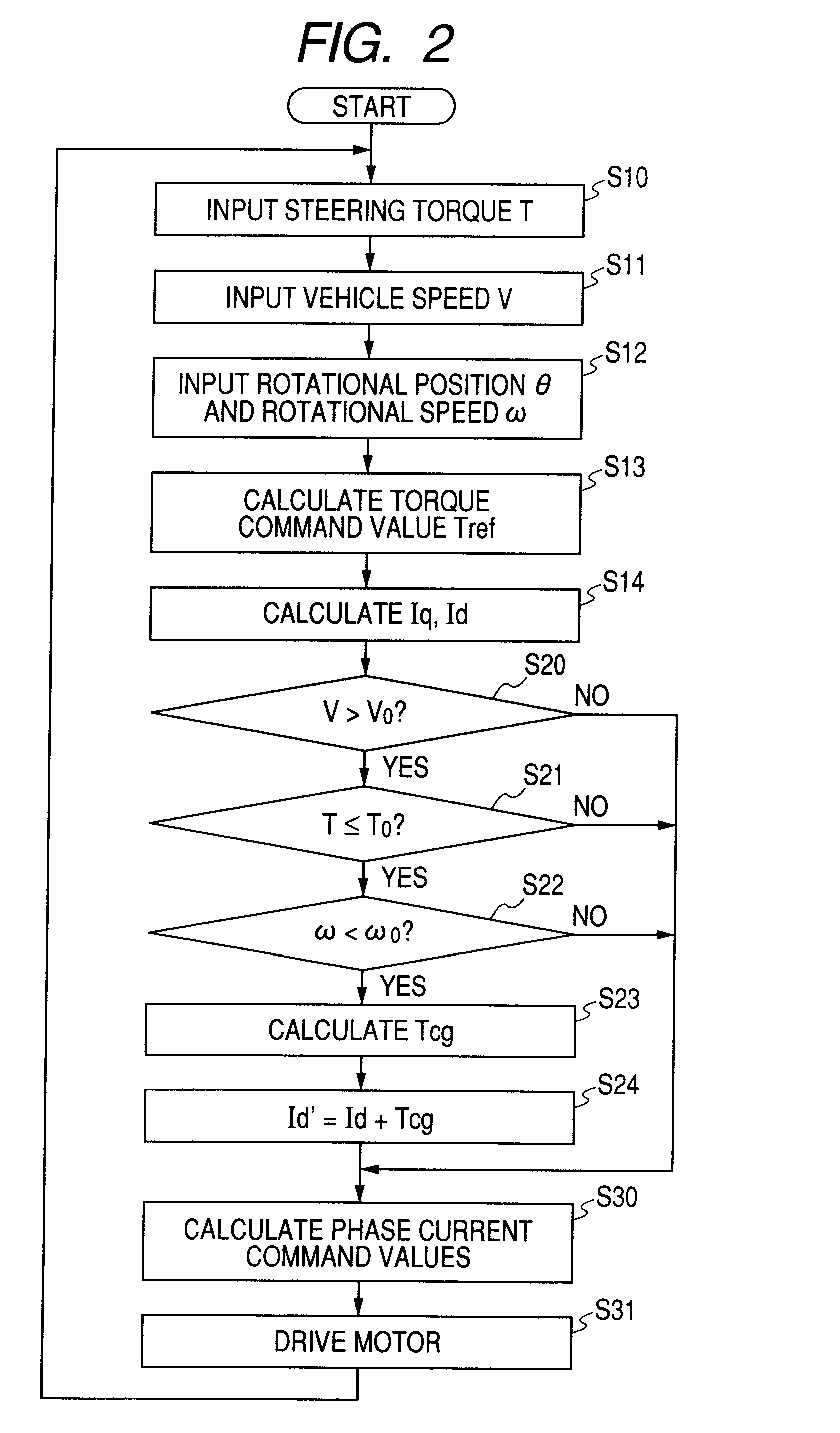

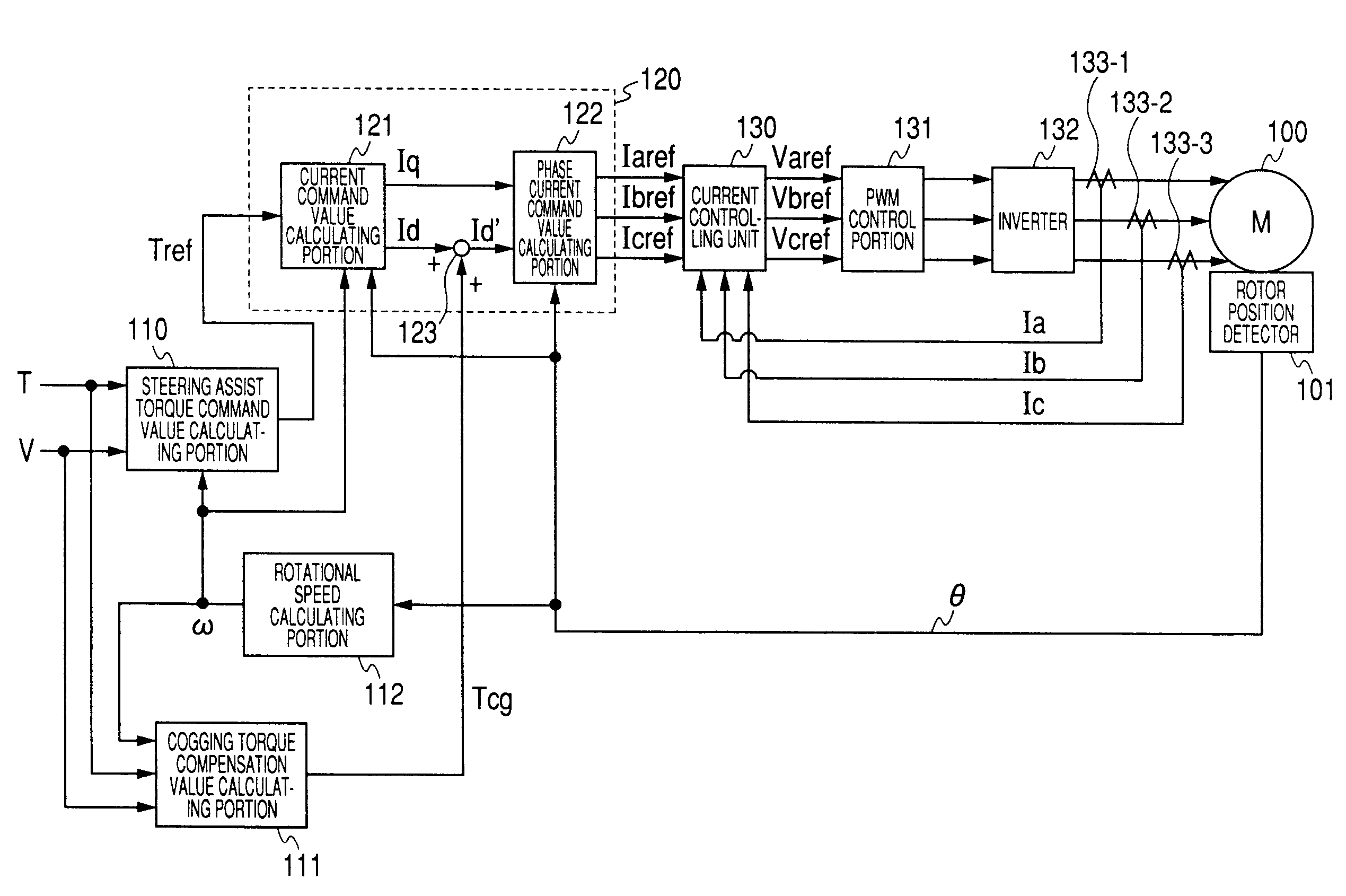

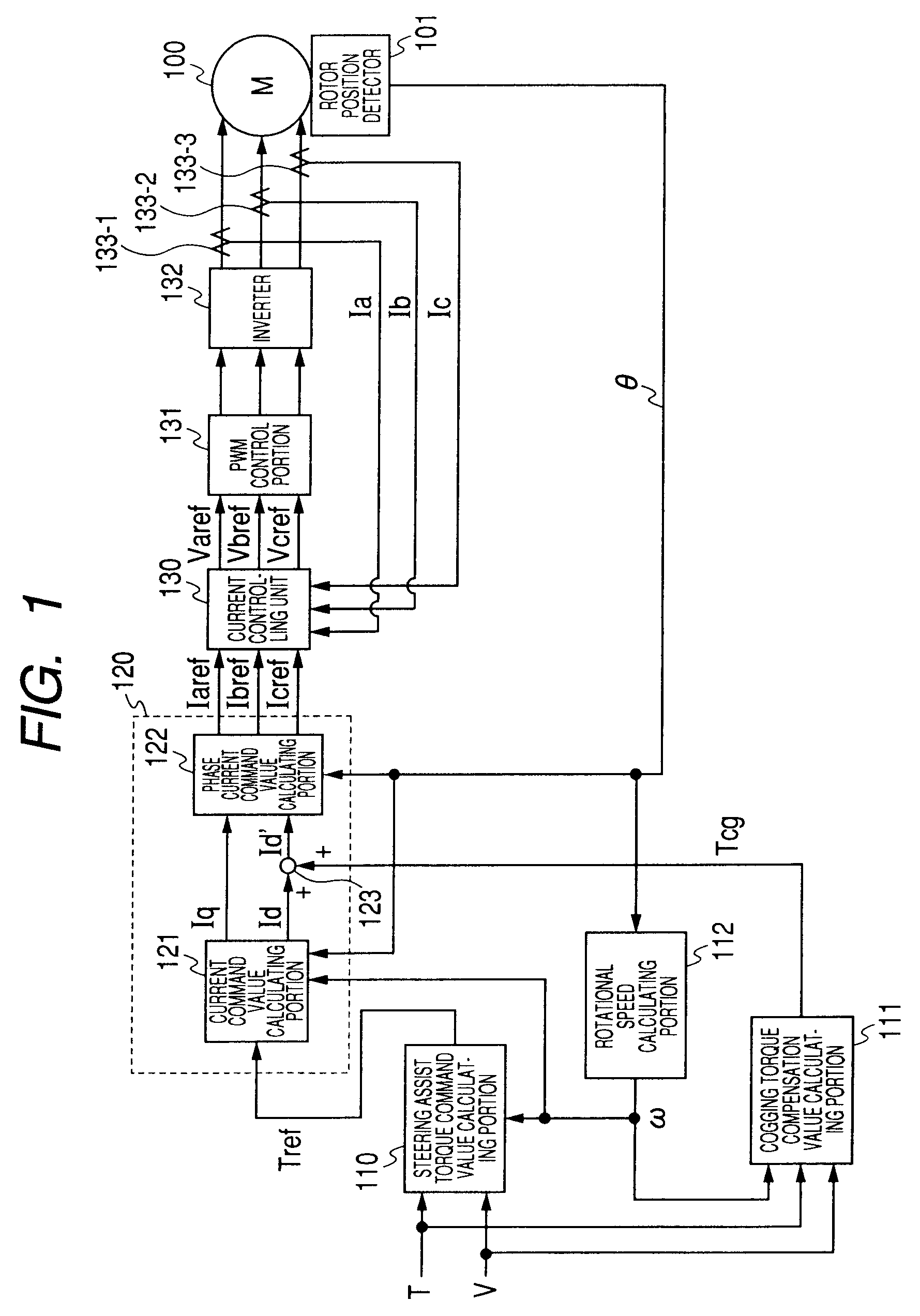

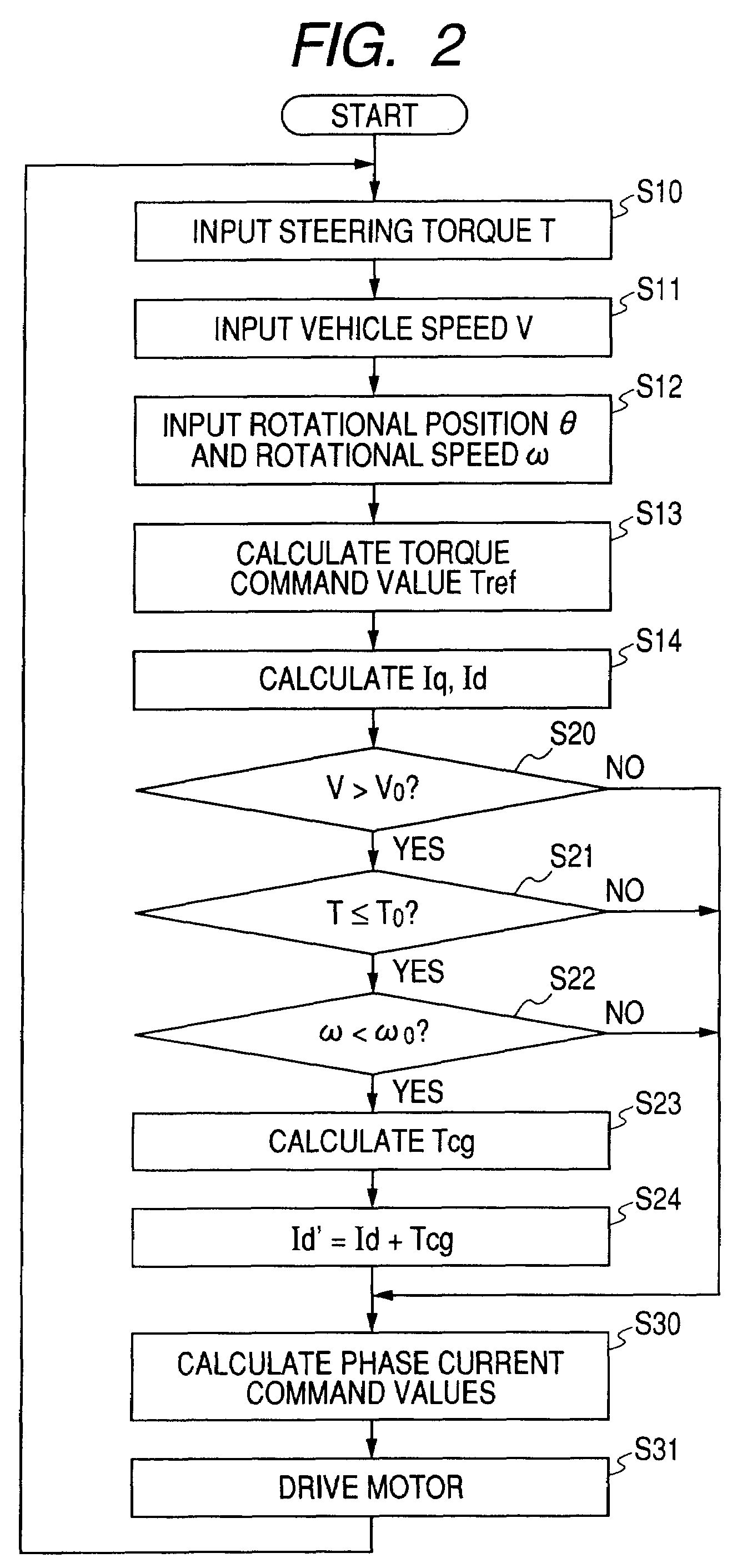

Electric power steering apparatus and controller therefor

InactiveUS20070096672A1Low costReduce loss torqueDC motor speed/torque controlElectric motor controlElectric power steeringElectric machine

There is provided a controller for an electric power steering apparatus having a motor which applies a steering assist force to a steering mechanism. The controller includes a torque command value calculating portion which calculates a torque command value based on steering torque generated in a steering shaft, and a vehicle speed and a current command value calculating portion which calculates a current command value for the motor based on the torque command value. The controller controls the motor based on the current command value. In the apparatus, the controller has a cogging torque compensation value calculating portion which calculates a cogging torque compensation value for the motor, and corrects the current command value based on the cogging torque compensation value.

Owner:NSK LTD

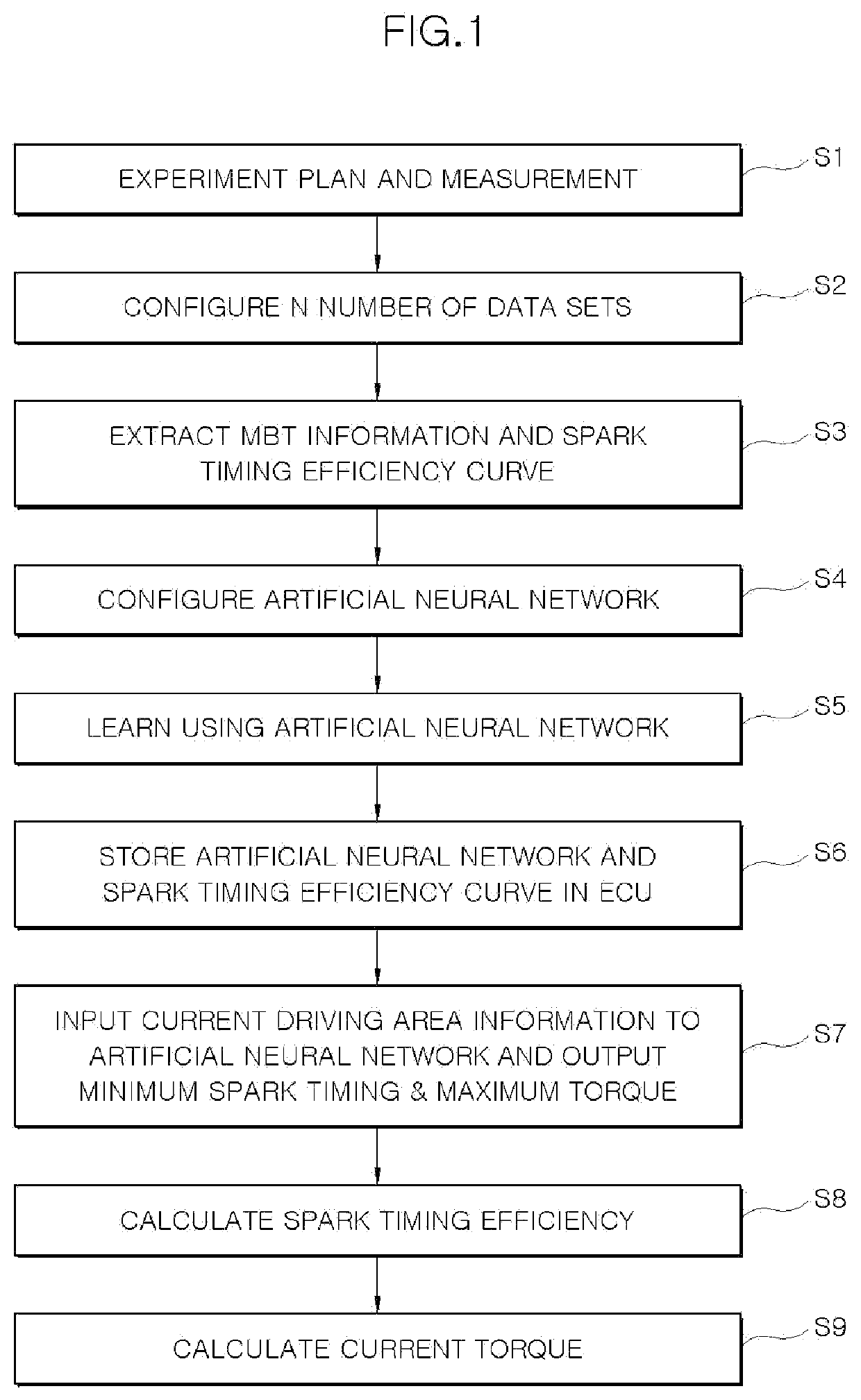

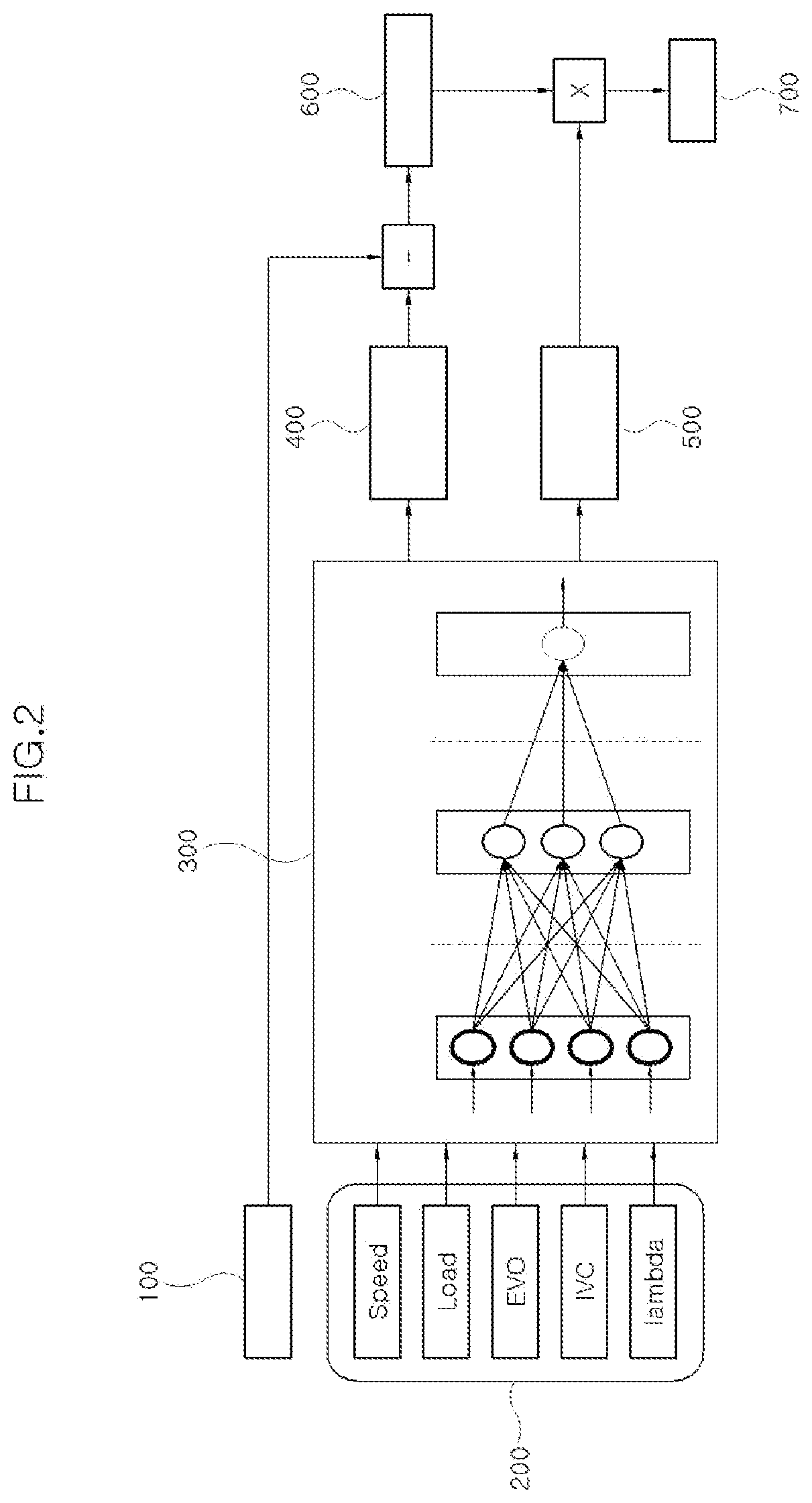

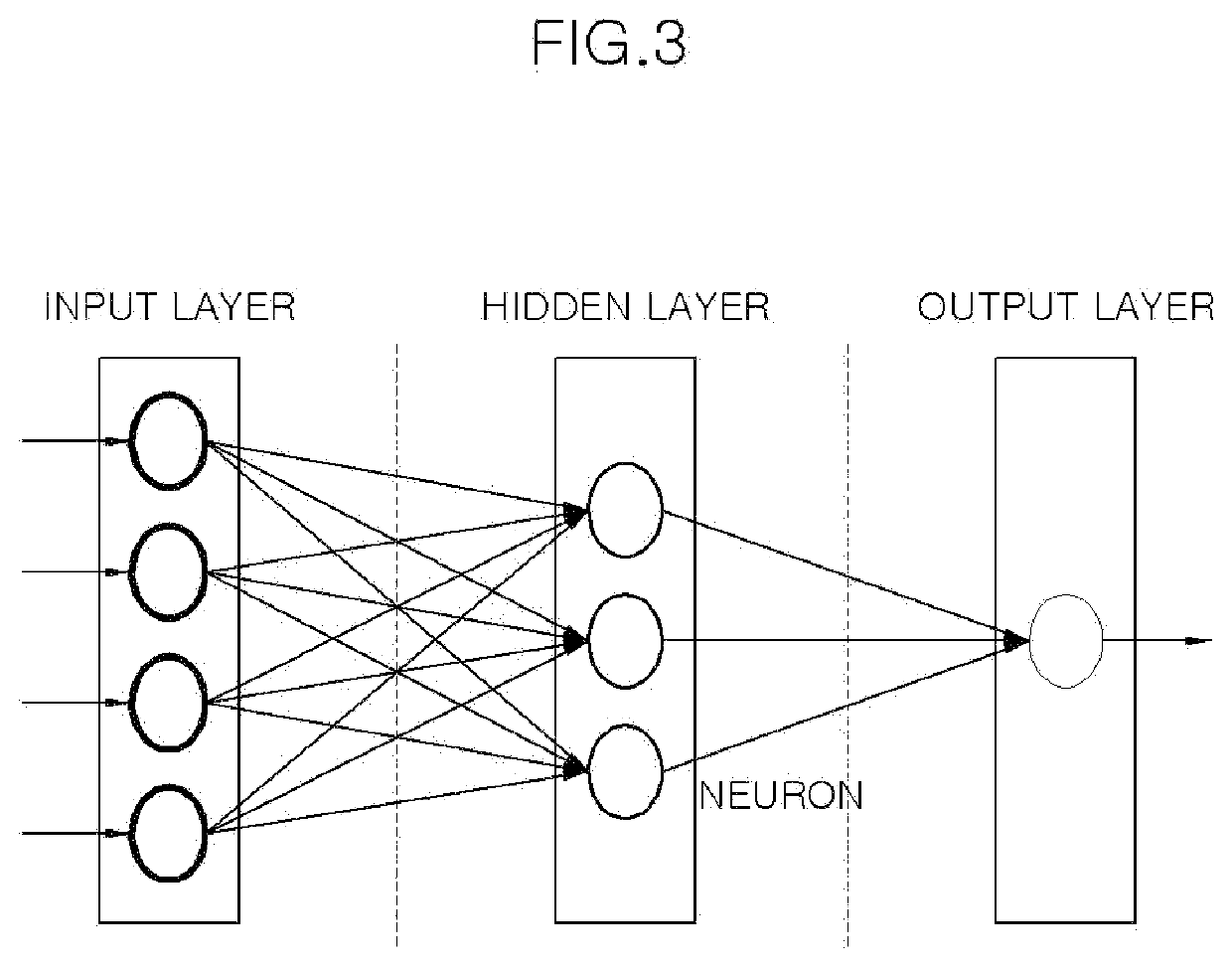

System and method of predicting vehicle engine torque using artificial neural network

ActiveUS20210222662A1Improve accuracyReduce development costsValve arrangementsAutonomous decision making processComputed torqueEngineering

A method of predicting vehicle engine torque using an artificial neural network is provided. A data-based artificial neural network model is applied to more accurately calculate. torque and reduce development costs for calibration and logics.

Owner:HYUNDAI KEFICO CORP

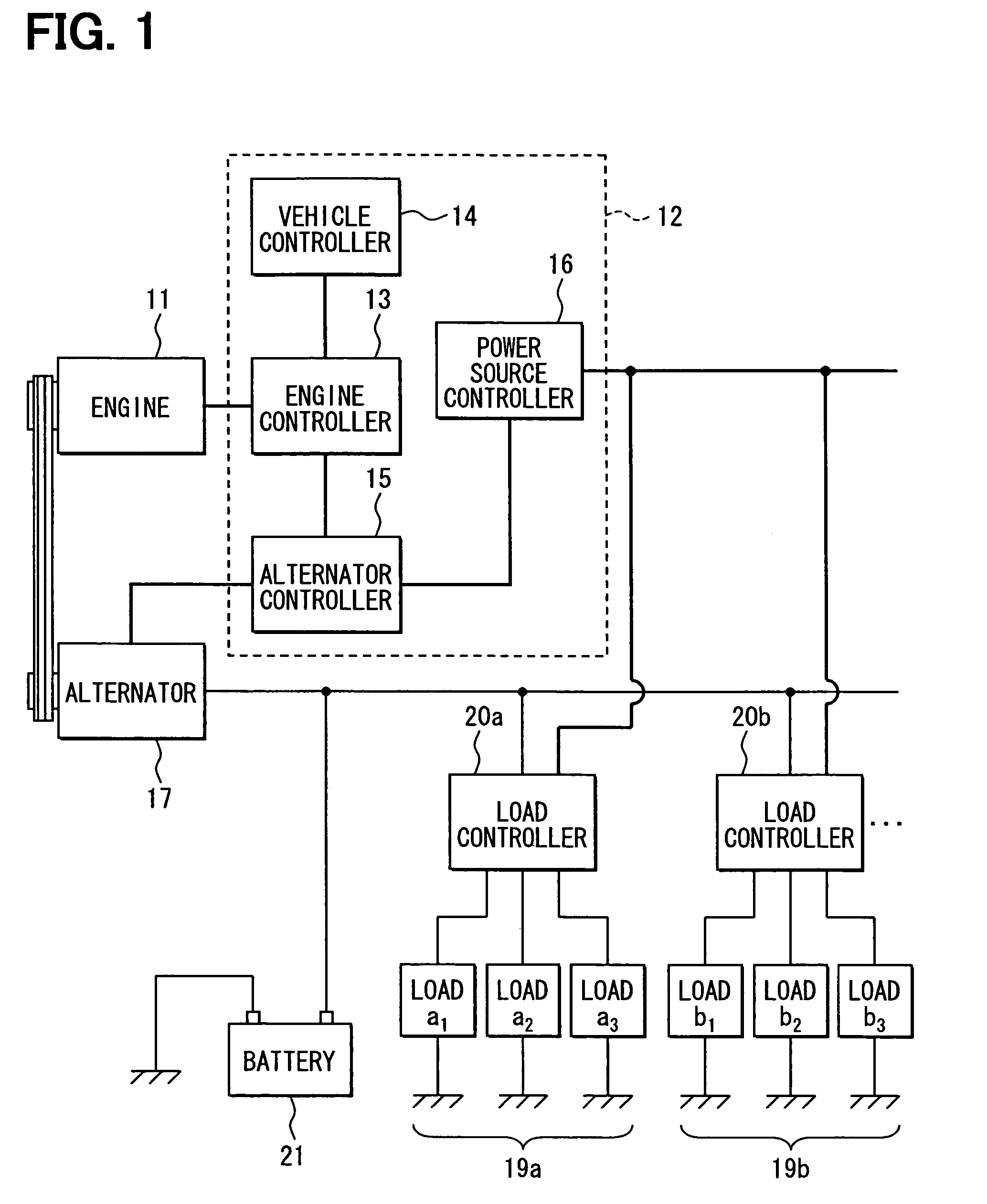

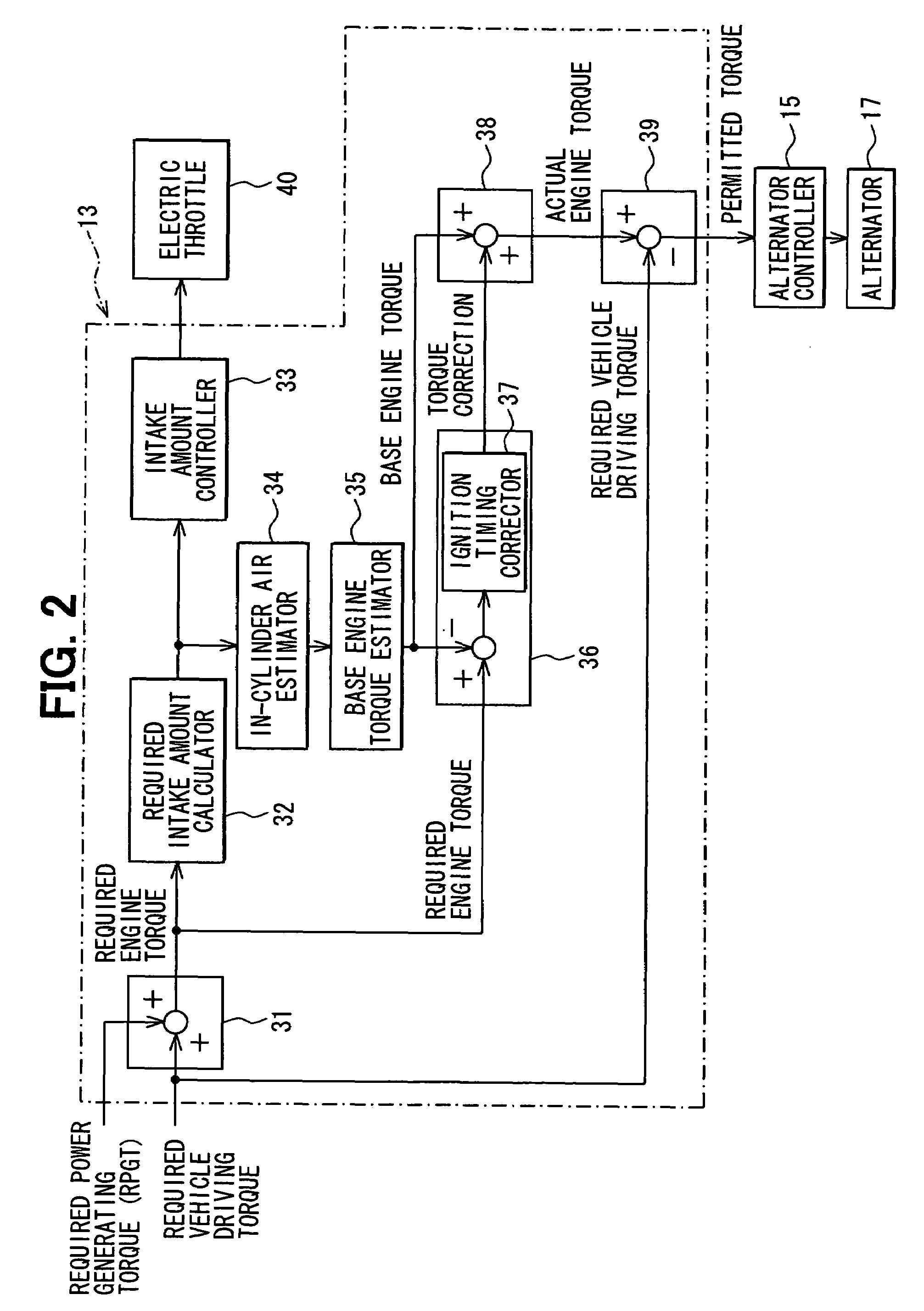

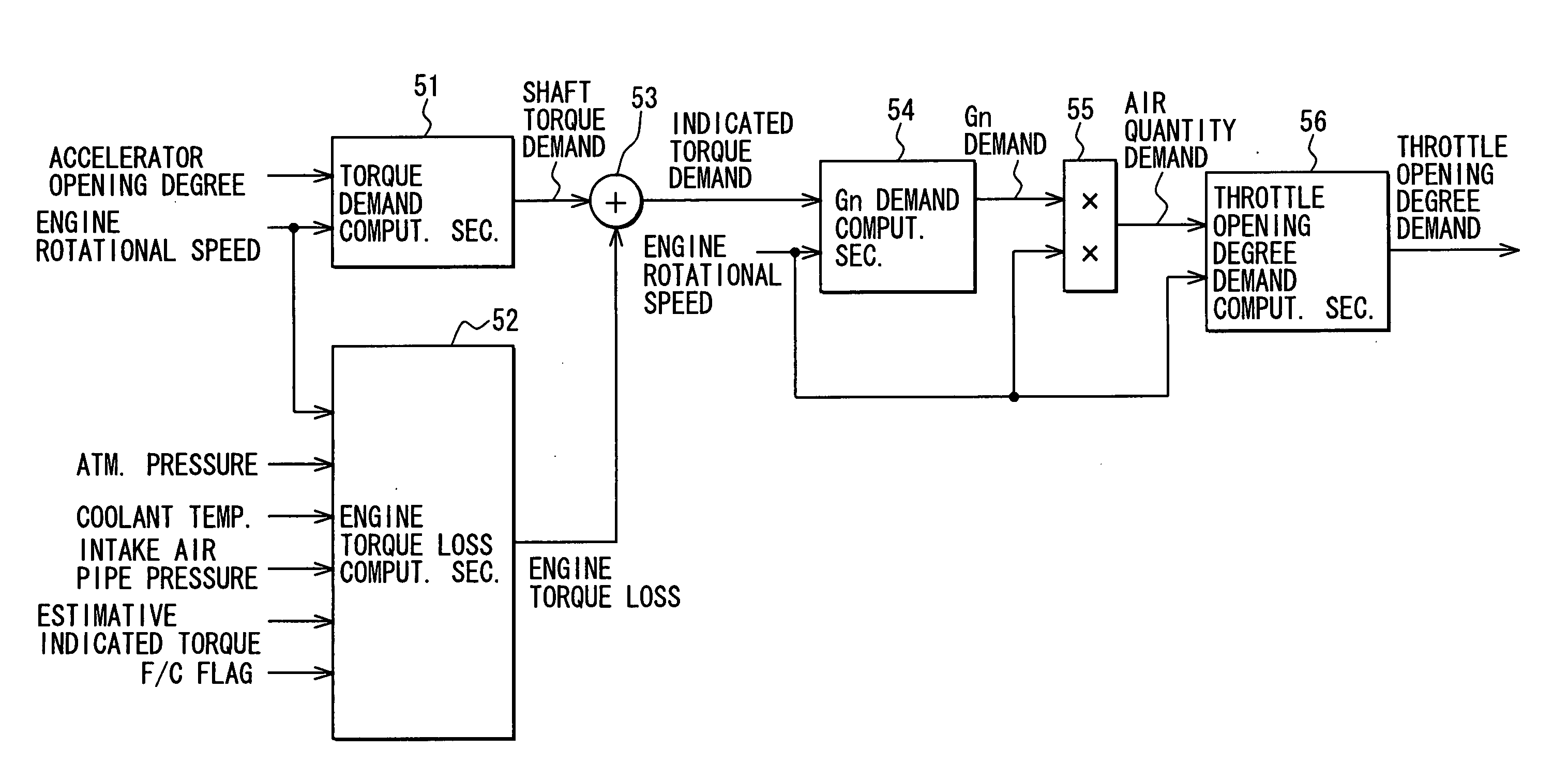

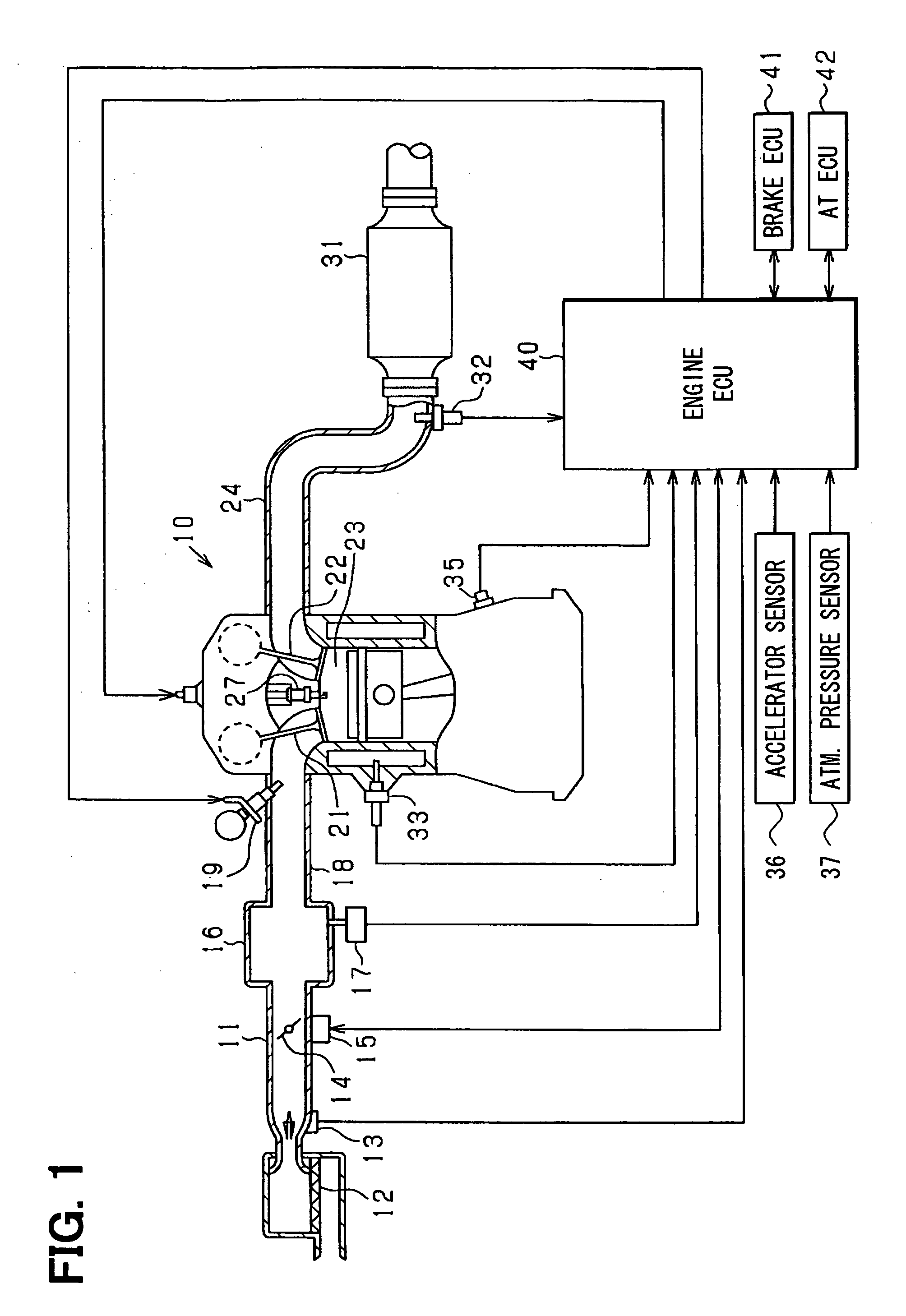

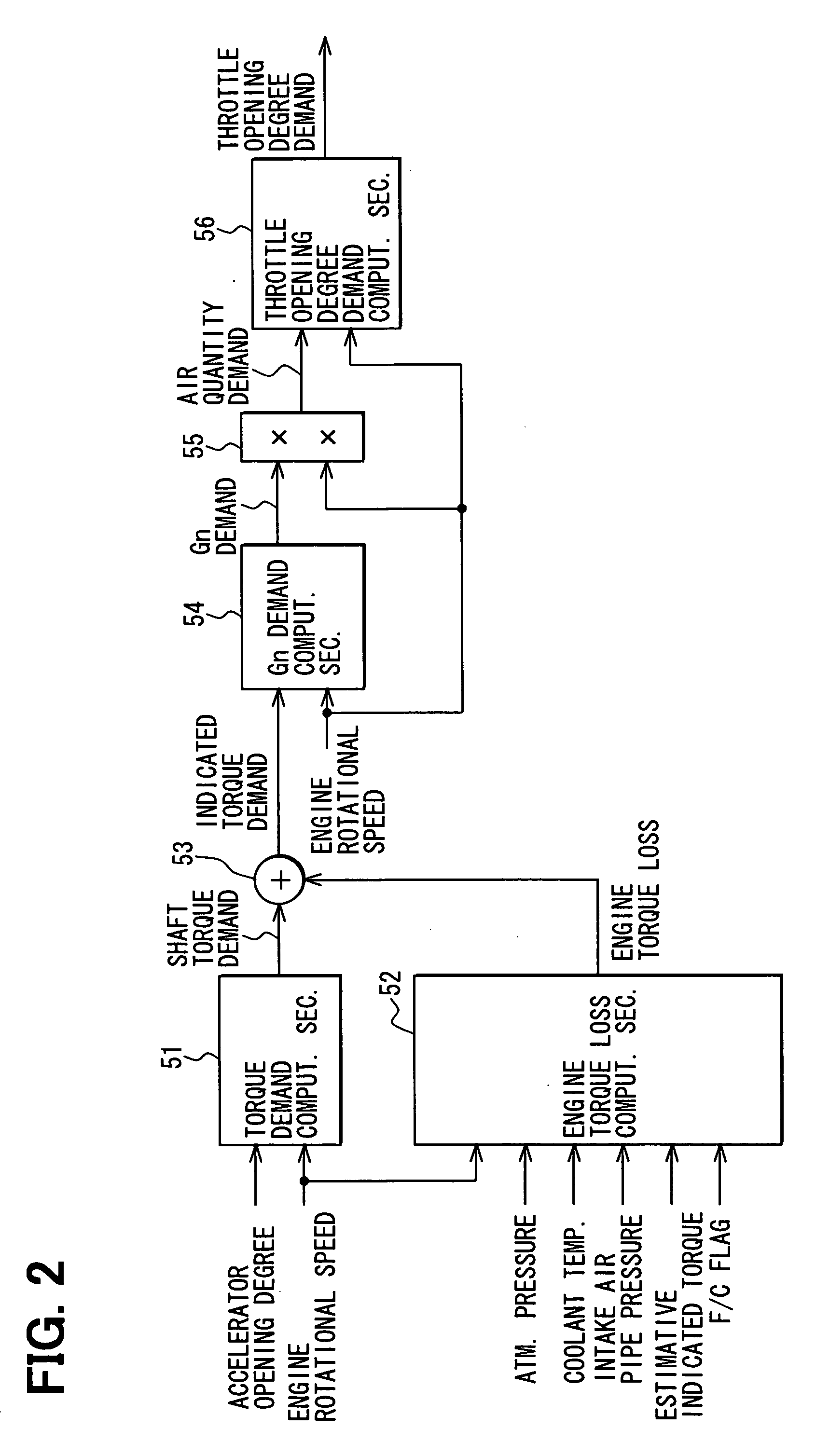

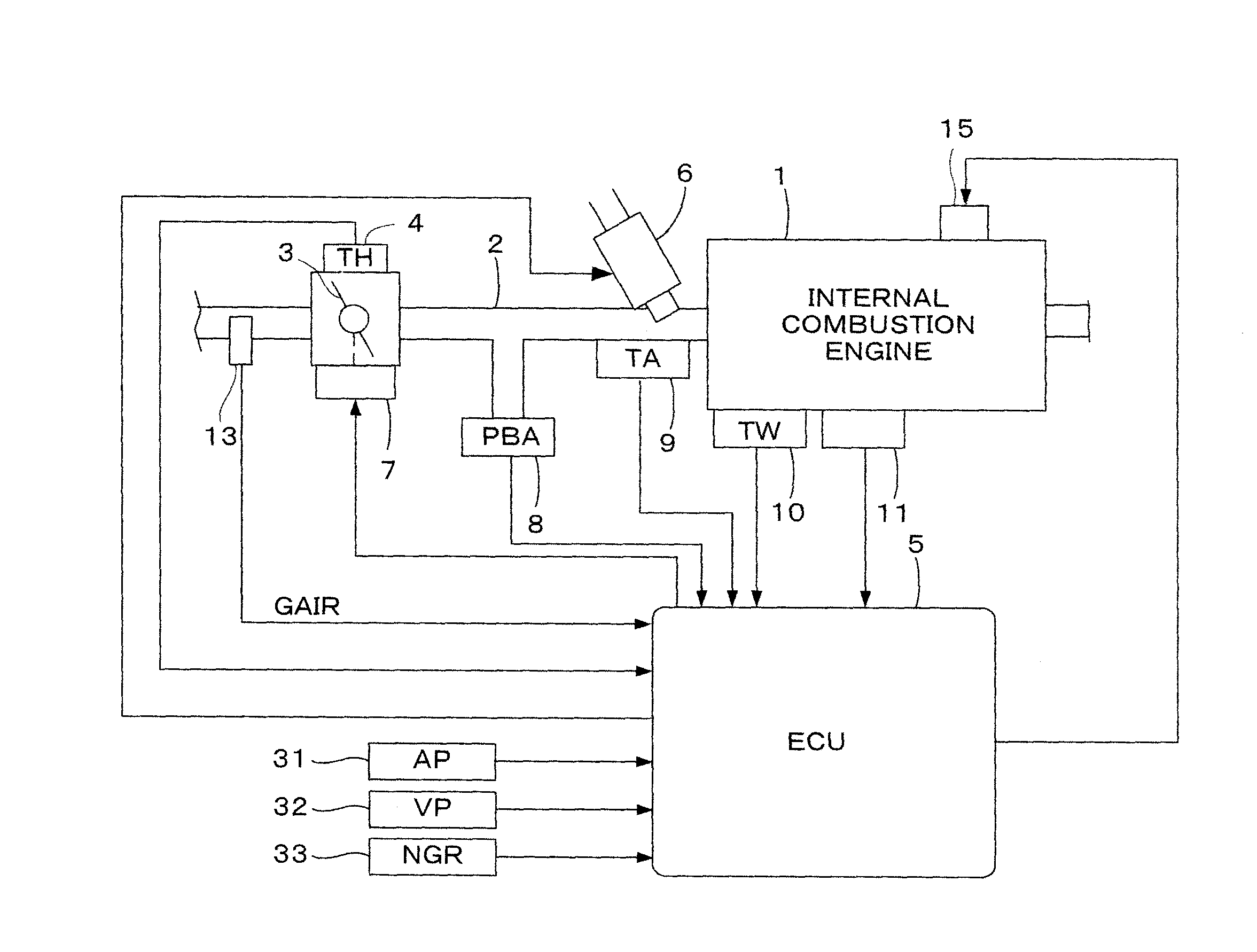

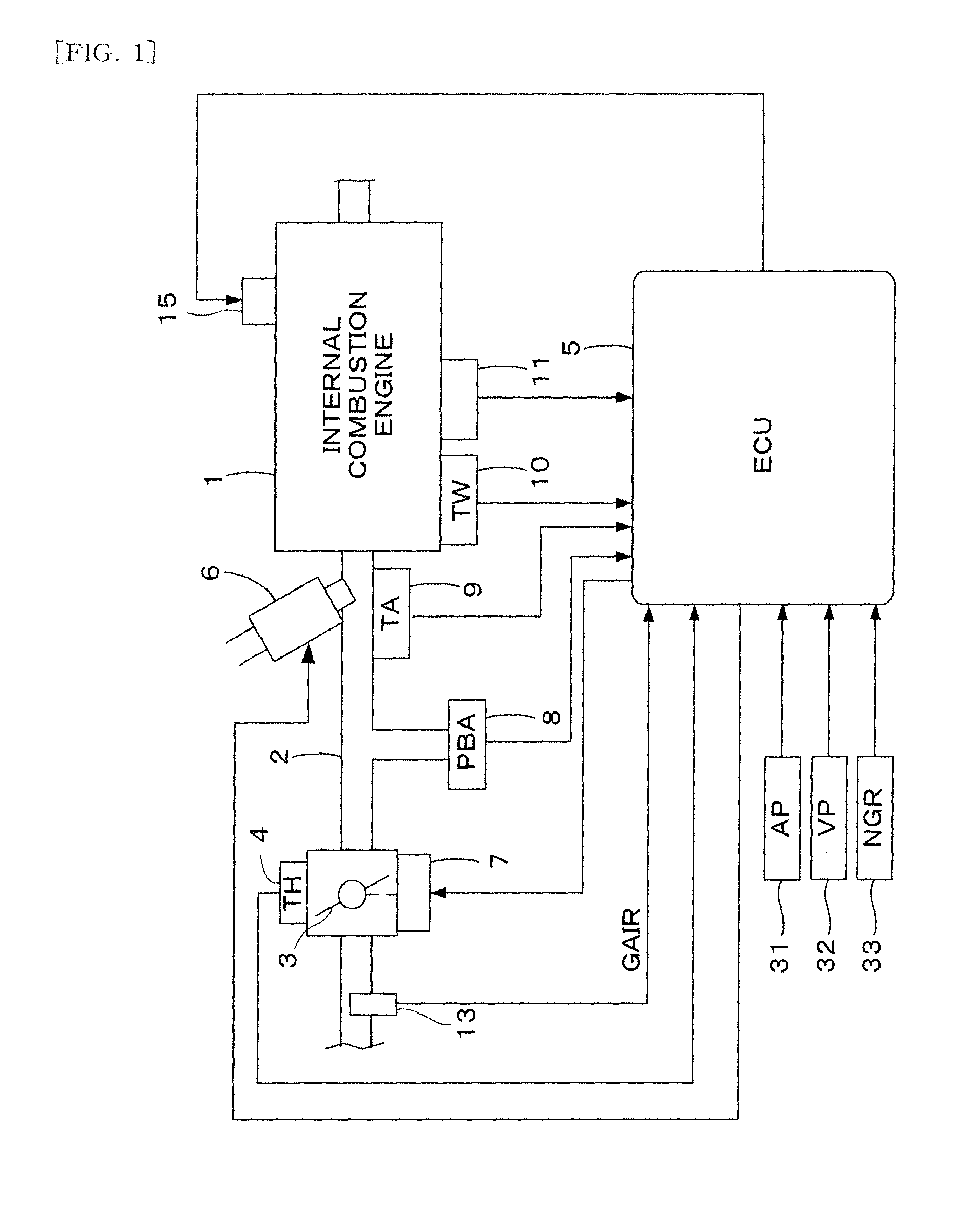

Controller and controlling method for internal combustion engine

ActiveUS7347184B2Control fluctuationsElectrical controlInternal combustion piston enginesComputed torqueEngineering

A base engine torque generated with an estimated intake air amount is estimated. An engine torque is corrected by correcting an ignition timing based on a difference between a required engine torque and the base engine torque. A torque correction amount is calculated based on a correction amount of the ignition timing. An actual engine torque is estimated based on the calculated torque correction amount and the base engine torque. A permitted component driving torque is a difference between the actual engine torque and the required vehicle driving torque. A component is controlled based on the permitted component driving torque.

Owner:DENSO CORP

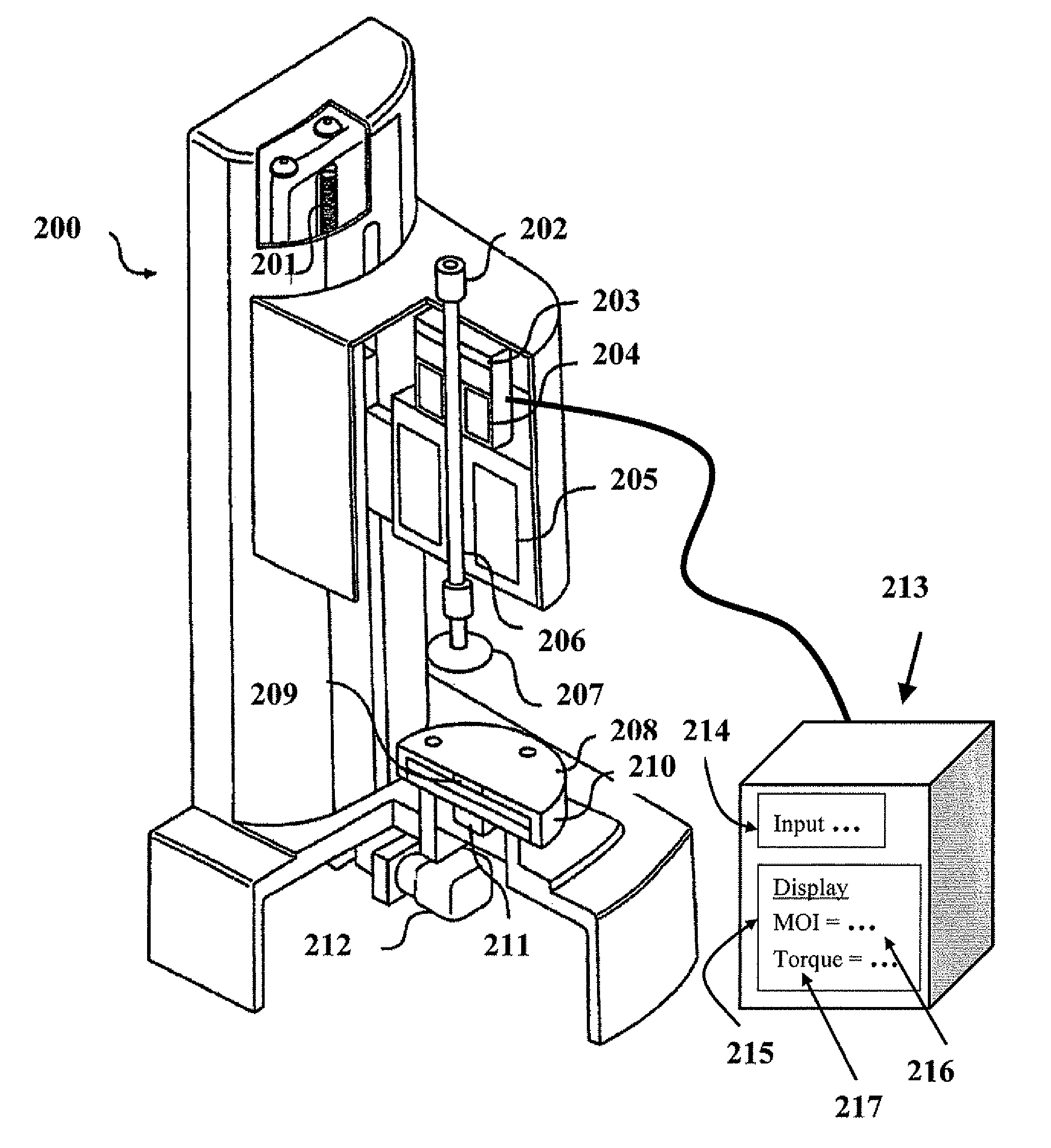

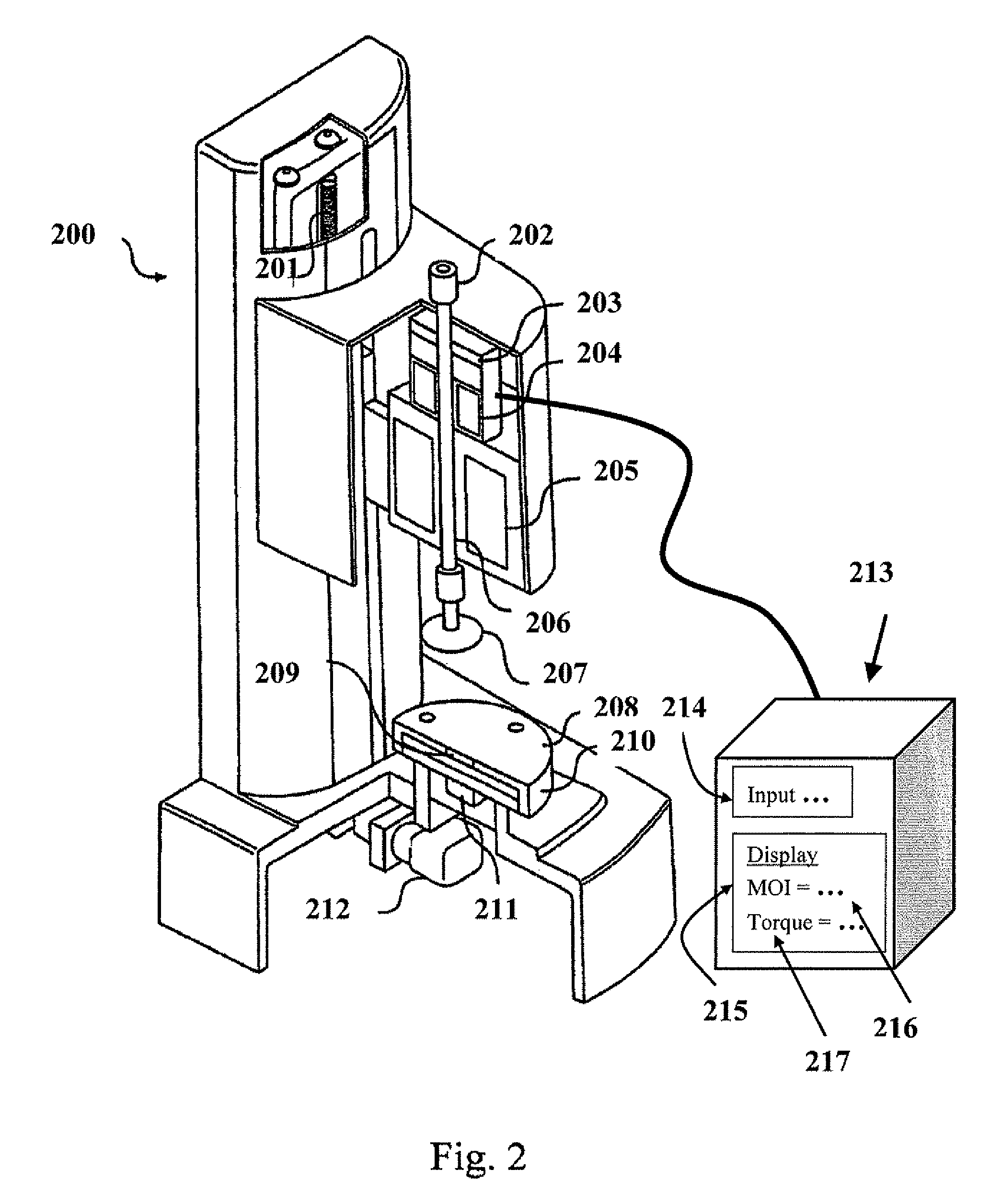

Rheometer torque calibration fixture

InactiveUS20070295055A1Low costImprove accuracyFlow propertiesMaterial analysis by electric/magnetic meansComputed torqueEngineering

A method of calibrating the torque outputs of a rheometer by using a calibrating object with a certified moment of inertia, measuring the moment of inertia of the calibrating object using the rheometer, and calculating the torque adjustment factor by dividing the certified moment of inertia value by the measured moment of inertia value. The torque adjustment factor is applied to correct subsequent measurements of rheological properties conducted using the rheometer. The torque adjustment factor may be double-checked for reproducibility by measuring the moment of inertia of the calibrating object, correcting it with the torque adjustment factor, and comparing it with its certified moment of inertia value.

Owner:WATERS TECH CORP

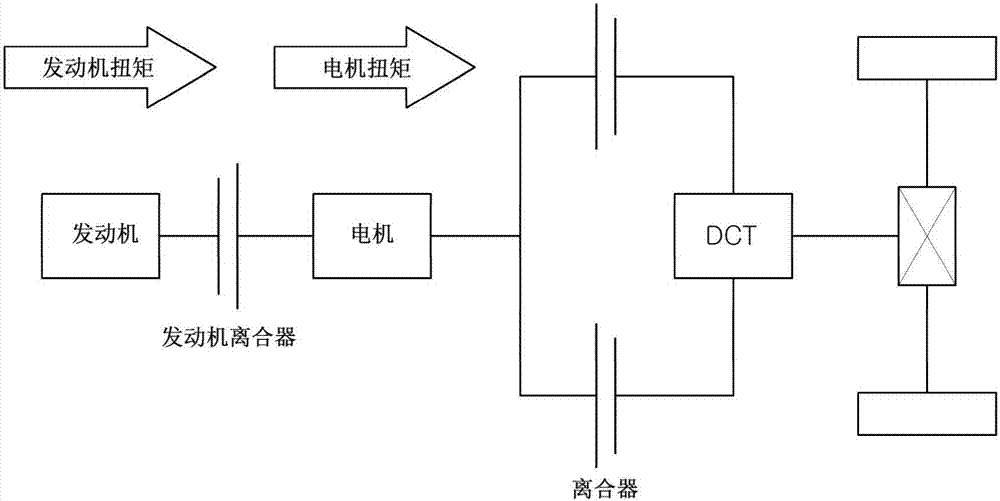

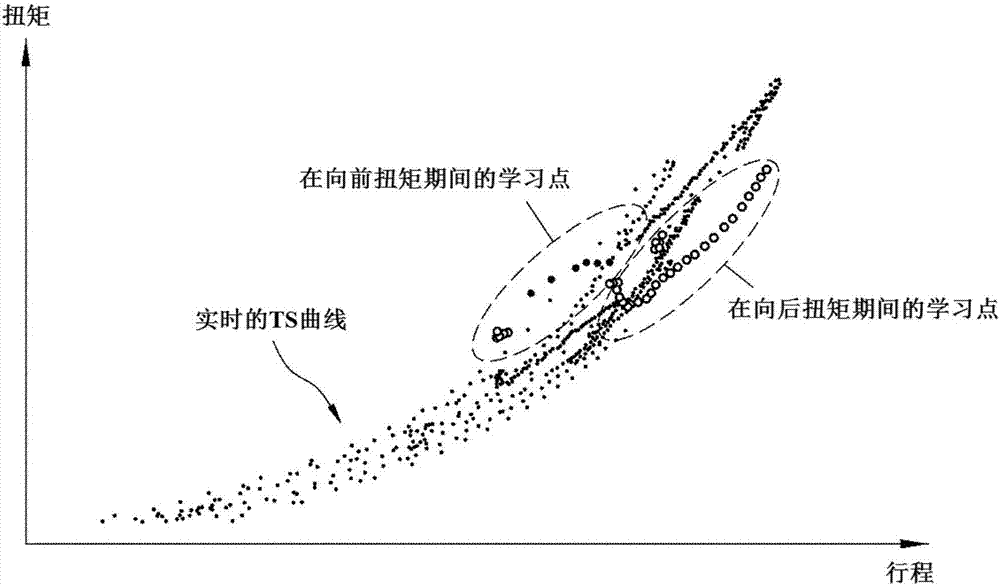

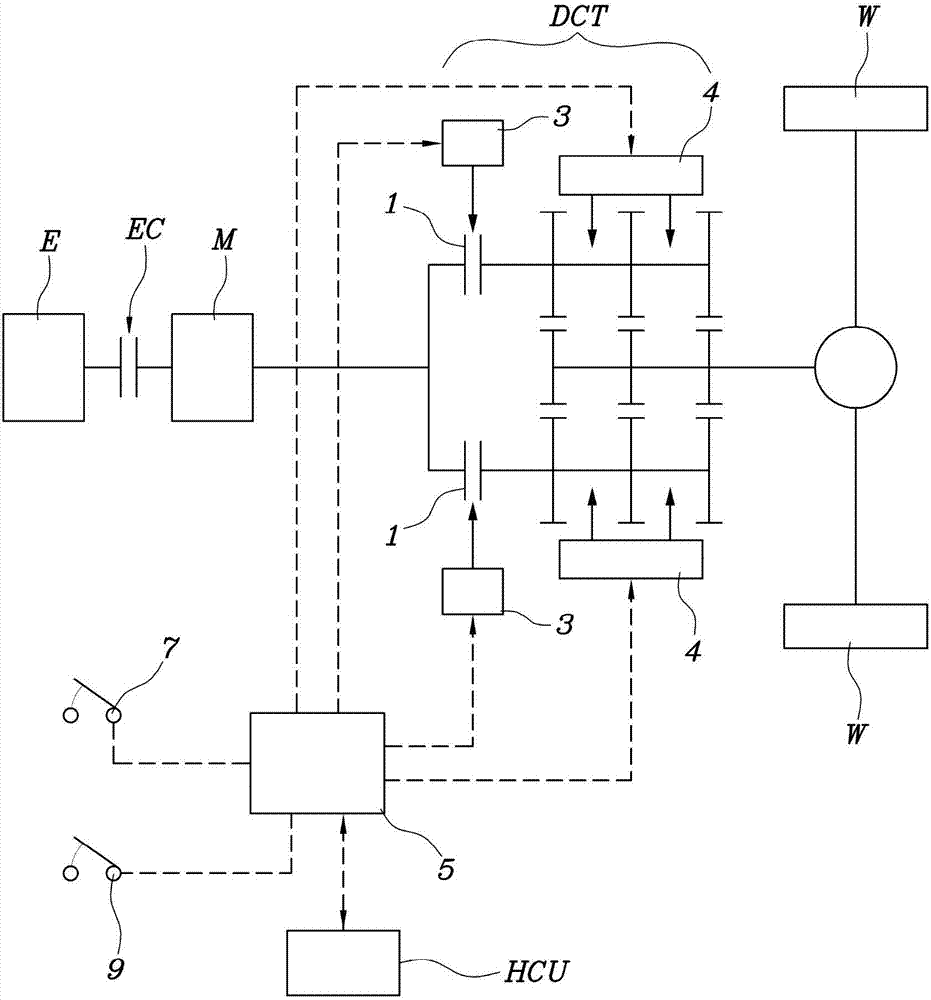

Clutch control method of hybrid vehicle

ActiveCN107401561APrevent or reduce variationPrevent or reduce shift vibrationHybrid vehiclesClutchesMotor speedClutch control

The present disclosure provides a clutch control method of a hybrid vehicle of the including an entering condition determining step in which a controller determines whether shifting is being performed during regenerative braking; an error calculating step in which the controller calculates a torque error by subtracting observer torque, which is clutch transfer torque calculated by a clutch torque estimator receiving transmission input torque and motor speed, from map torque, which is clutch transfer torque calculated based on a clutch transfer torque map for clutch actuator strokes learned in advance, when shifting is being performed during regenerative braking; a correcting step in which the controller corrects the clutch transfer torque map for the clutch actuator strokes using the torque error calculated in the error calculating step; and a clutch control step in which the controller controls a clutch using the map corrected in the correcting step.

Owner:HYUNDAI MOTOR CO LTD

Torque Overcorrection Model

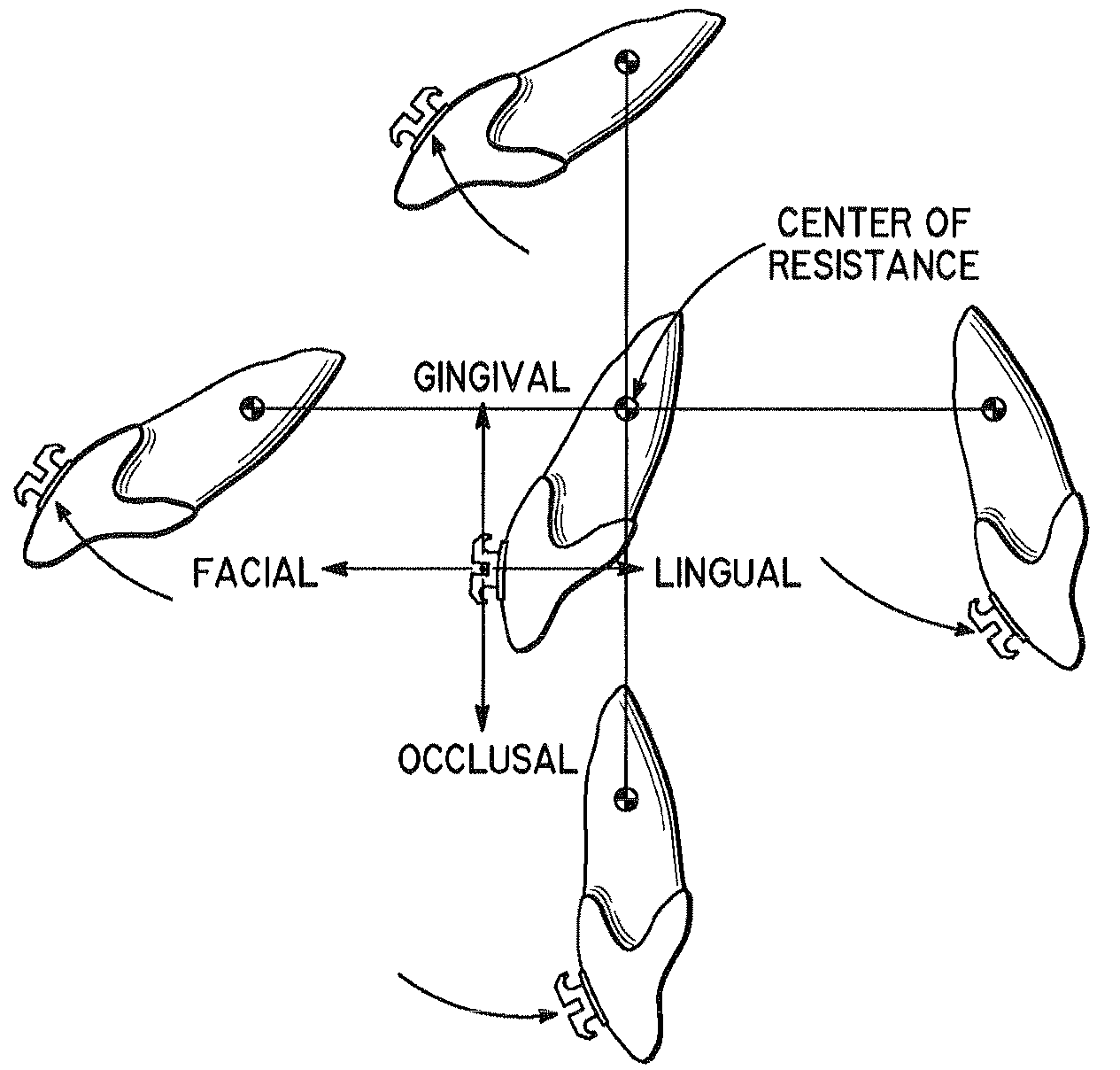

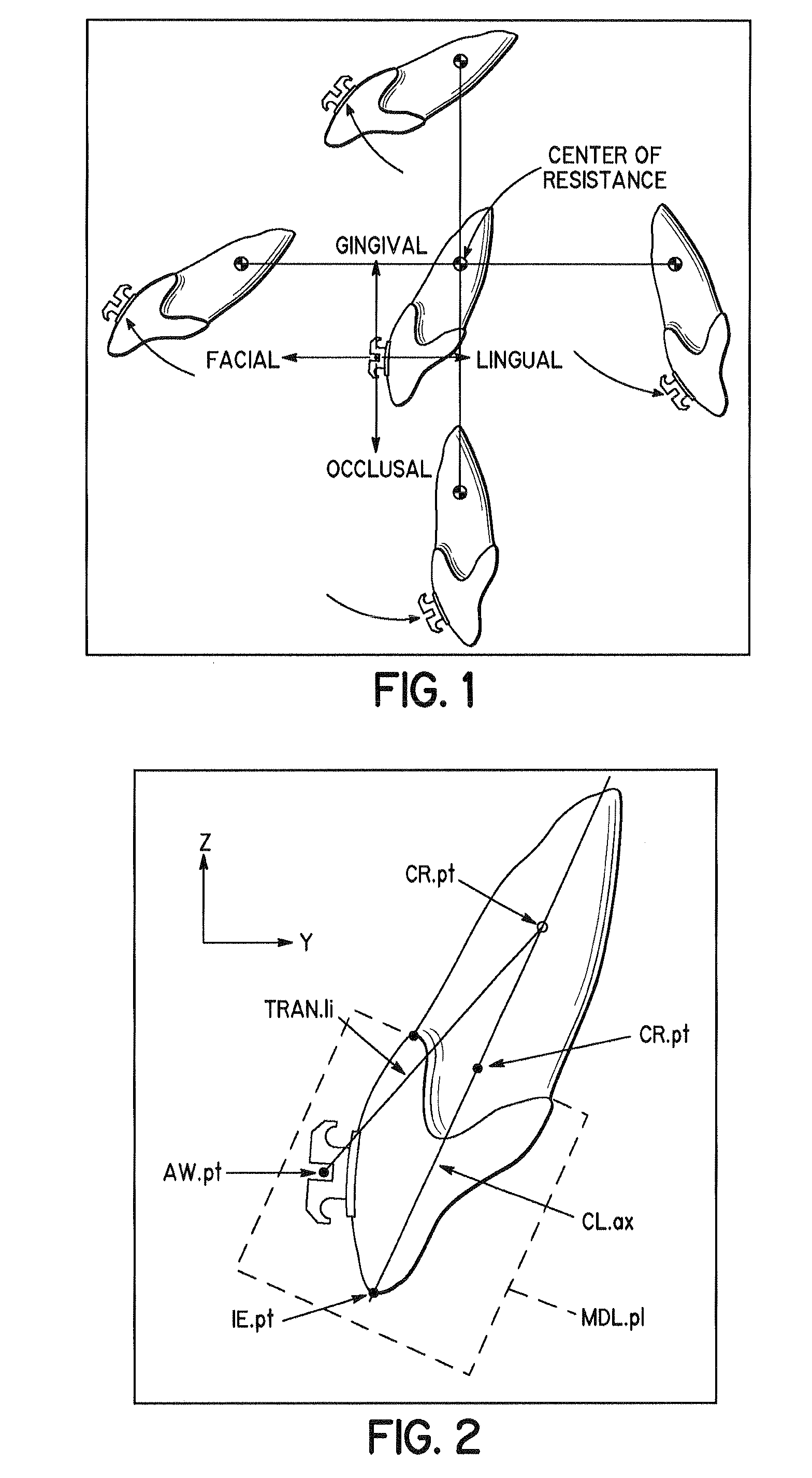

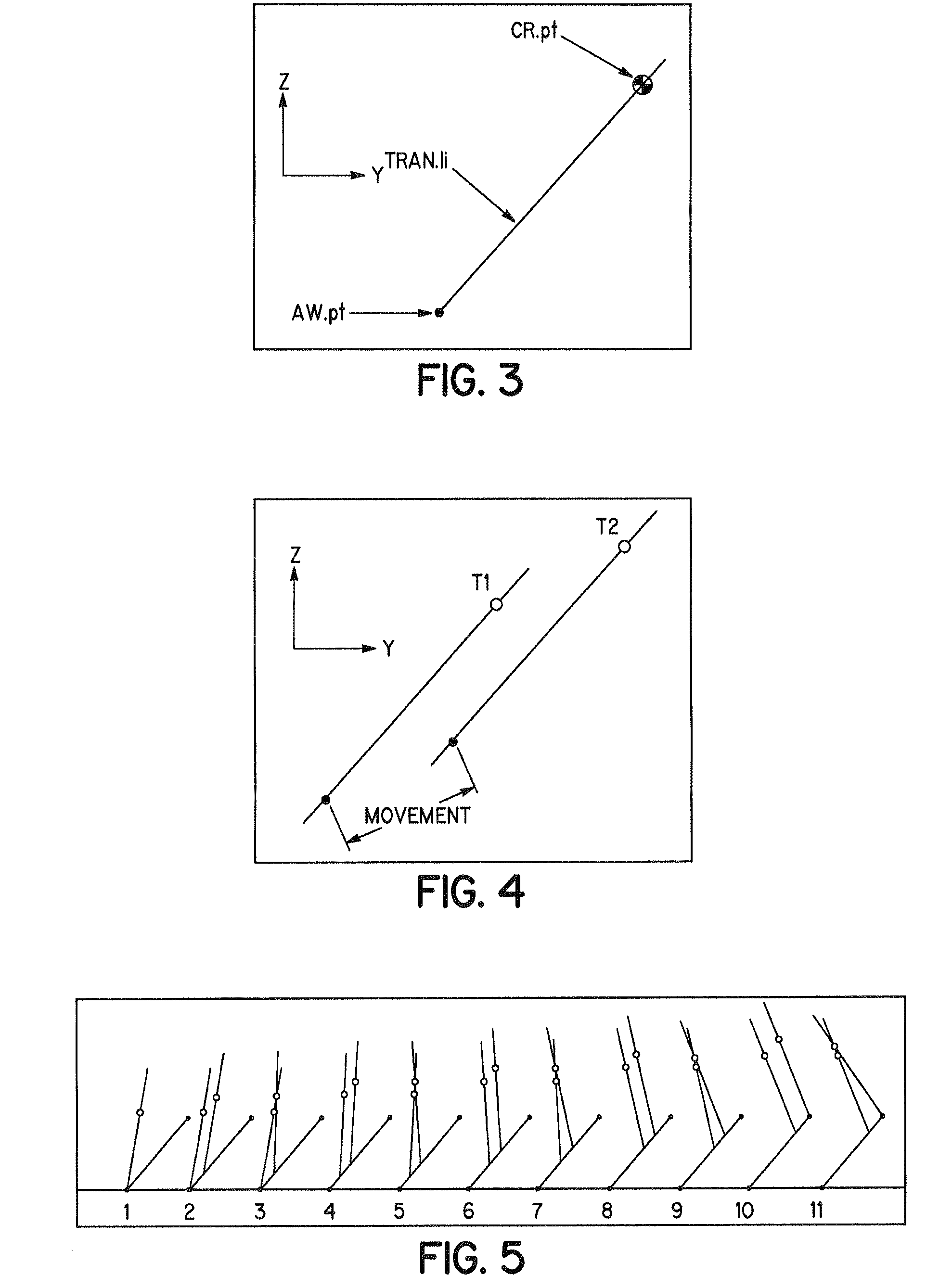

A custom orthodontic appliance comprised of brackets to be positioned on a patient's teeth, and an archwire, is customized to provide a desired torque to a tooth by selecting an angle for the slot of at least one bracket so as to provide a torque interaction between that bracket slot and the archwire. The torque interaction is computed to compensate for tooth tilt resulting from misalignment of the force vector applied by the archwire with the tooth center of resistance. The torque interaction is computed at the desired final position of the teeth, and may be computed to provide for an applied torque even where the tooth is positioned in the desired final tooth position to compensate for force diminution. Material properties of the archwire and the relative archwire slot geometry are evaluated to determine an archwire / slot angular offset in which torque is applied to the bracket.

Owner:ORMCO CORP

Electric power steering apparatus and controller therefor

InactiveUS7696709B2Low costCogging torque is reducedDC motor speed/torque controlElectric motor controlElectric power steeringElectric machine

There is provided a controller for an electric power steering apparatus having a motor which applies a steering assist force to a steering mechanism. The controller includes a torque command value calculating portion which calculates a torque command value based on steering torque generated in a steering shaft, and a vehicle speed and a current command value calculating portion which calculates a current command value for the motor based on the torque command value. The controller controls the motor based on the current command value. In the apparatus, the controller has a cogging torque compensation value calculating portion which calculates a cogging torque compensation value for the motor, and corrects the current command value based on the cogging torque compensation value.

Owner:NSK LTD

Torque control apparatus and vehicle control system having the same

InactiveUS20060229158A1Improved control of internalAnalogue computers for vehiclesElectrical controlControl systemComputed torque

In an engine torque loss computing section, a pump loss computing section computes a pump torque loss, and a frictional loss computing section computes a frictional torque loss. The pump torque loss and the frictional torque loss are summed to obtain an engine torque loss. Furthermore, a torque loss correction amount computing section computes a torque loss correction amount, and a correction amount changing section changes the torque loss correction amount based on a result of determination of whether fuel cut-off is currently executed. The torque loss correction amount is added to the uncorrected initial engine torque loss to obtain a corrected engine torque loss.

Owner:DENSO CORP

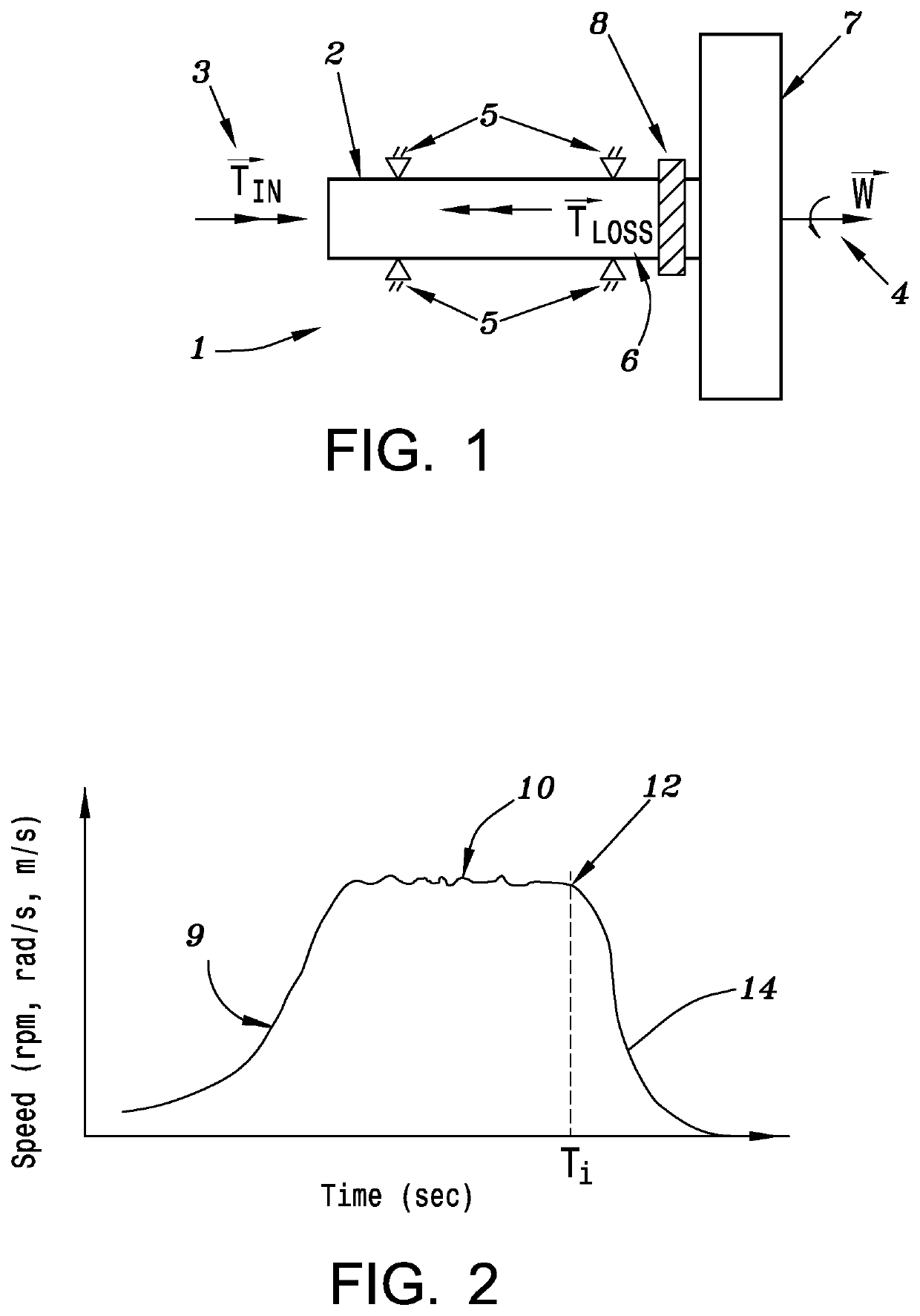

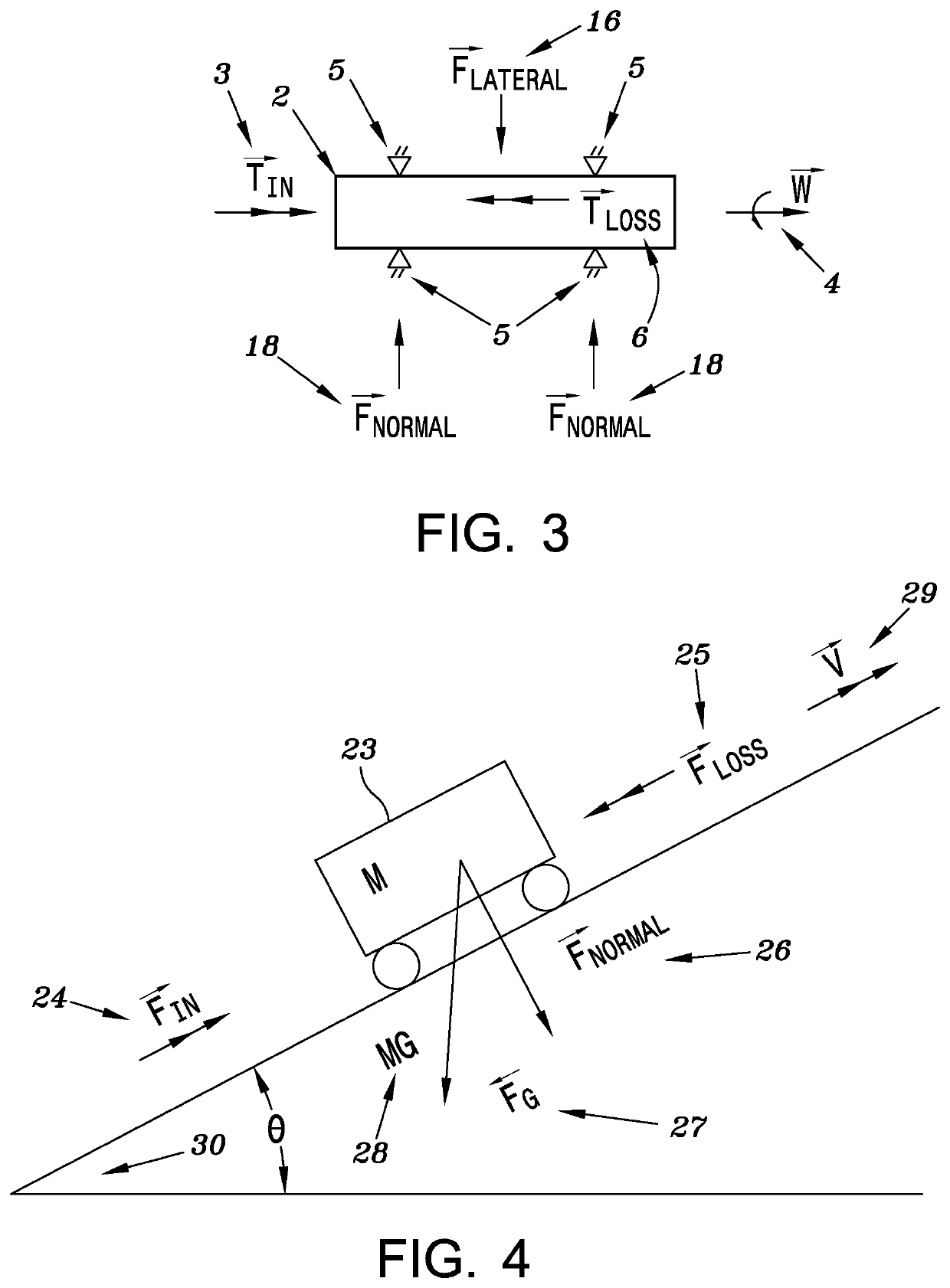

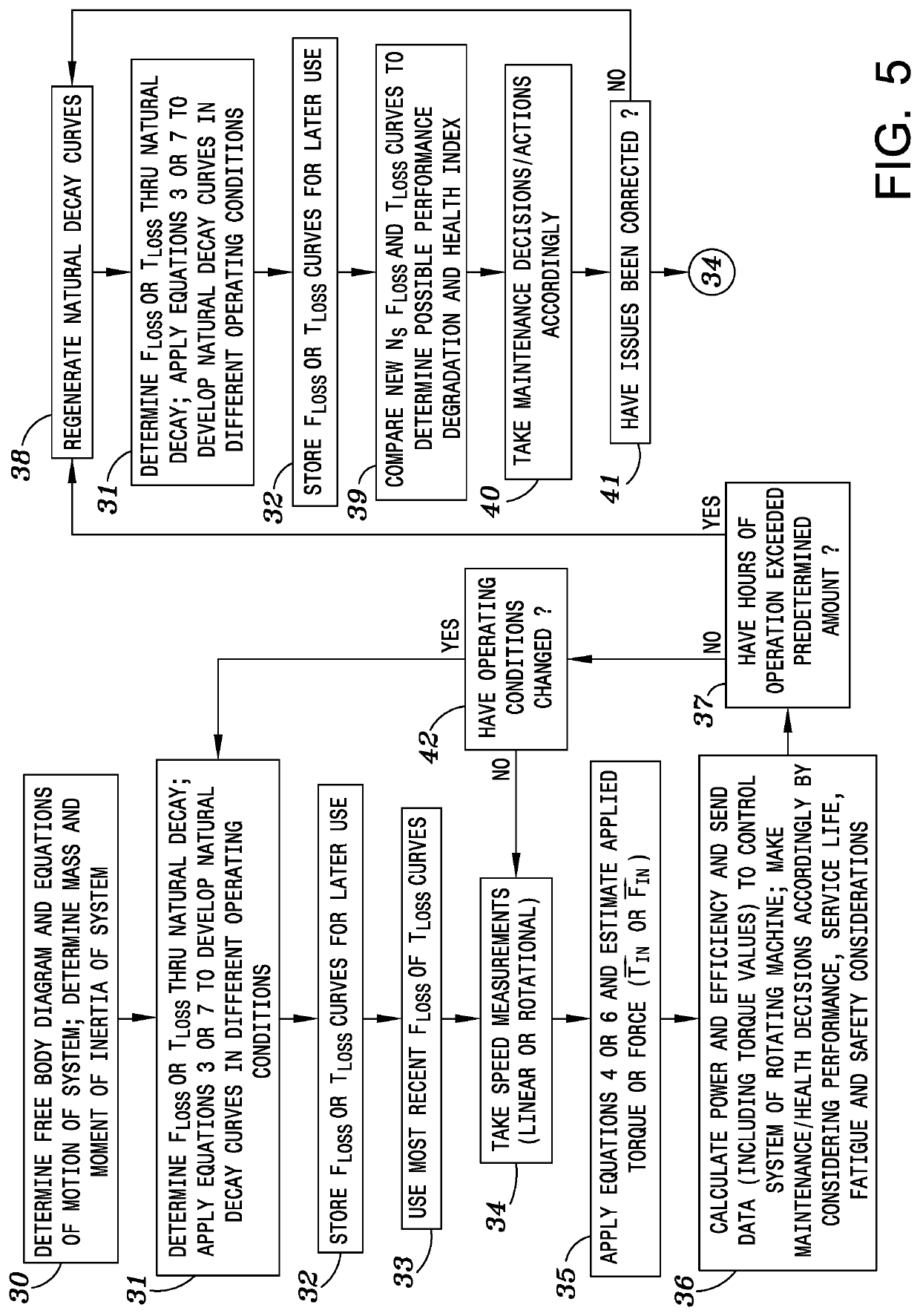

Speed driven method for calculating torque, power and energy efficiency in the control, health assessment and maintenance of rotating equipment and turbo machinery

ActiveUS10690556B1Increase speedIncrease frictionWork measurementEmergency protection detectionHealth indexMachine

Method for measuring torque in rotating-equipment, turbo-machinery, pumps, turbines, and compressors. The measured torque can be used as an input to control torque, power, or energy efficiency. The method can also measure force (or torque) in traversing-machinery or vehicles such as automobiles, ships, aircraft, bicycles and motorcycles. The method takes real-time rotating (or linear) speed measurements, applies the discrete form of equations of motion, captures the natural decay curve(s) of the machine to estimate the torque (or force) associated with the losses of the power sink, and then solves for the driving torque of the power source. The method relates to monitoring and control systems used to safely and efficiently operate rotating-equipment and traversing-machinery. The method can be used to determine a health index of a machine to make predictive and corrective maintenance, reliability, performance, safety, and efficiency-related decisions. It is accurate, robust, lightweight, space-saving, and low cost.

Owner:QUINTANA MAURICIO F

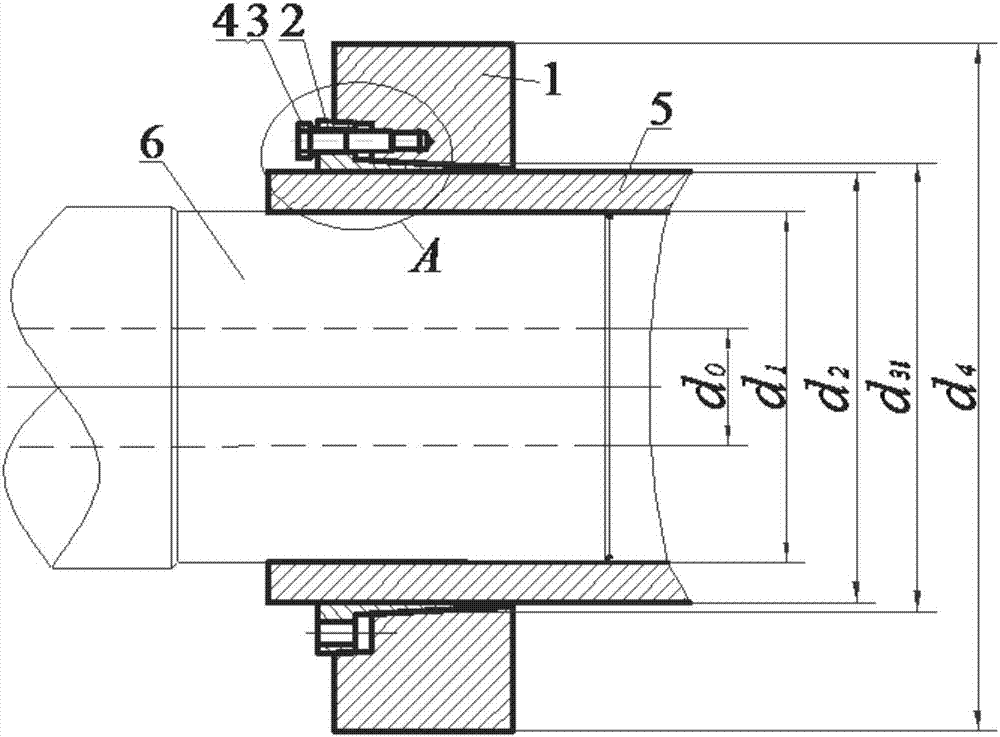

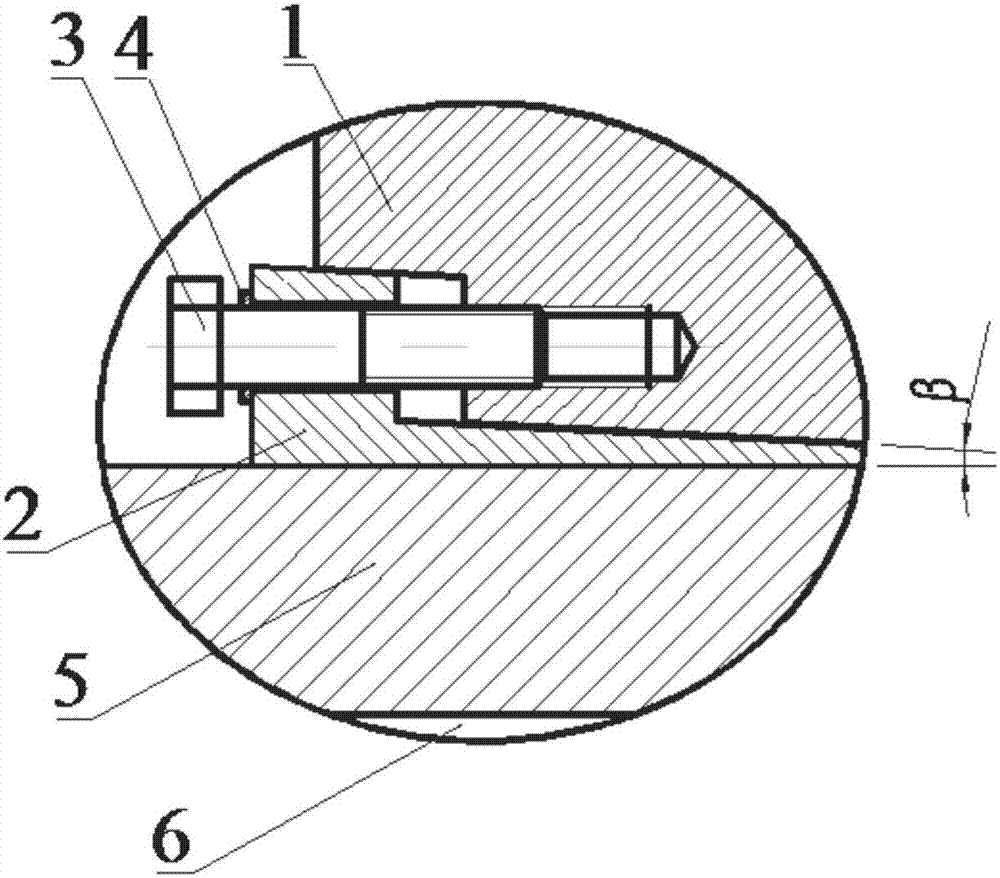

Method of checking design size of wind power locking disc

ActiveCN107403043AIn line with the actual situationThe calibration result is stable and reliableGeometric CADSpecial data processing applicationsMaximum torqueElectricity

The invention discloses a method of checking design size of a wind power locking disc, and belongs to the technical field of wind generator design and manufacture. The method is characterized by: calculating pressure of each contact surface and torque, which a main shaft and a shaft sleeve can transmit, after locking of the locking disc through a selected bolt number and given bolt tightening moment, carrying out comparison with designed transmitted maximum torque, and calculating a torque safety coefficient; then calculating composite stress of each component under a condition of the maximum torque and maximum bending moment, carrying out comparison with yield strength of each component material, and calculating a safety coefficient of each component; and finally, calculating tightening moment, which is required by bolts, according to the maximum torque and the maximum bending moment, carrying out comparison with the given tightening moment, and calculating a safety coefficient of the bolts. The method has the advantages that: whether the shaft sleeve and the main shaft can transmit the maximum torque and bear the maximum bending moment after locking of the wind power locking disc and whether plastic damage occurs on each component material can be verified; and the rationality of the design size of the locking disc is effectively verified, manufacture risks are reduced, and a rate of finished products is increased.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

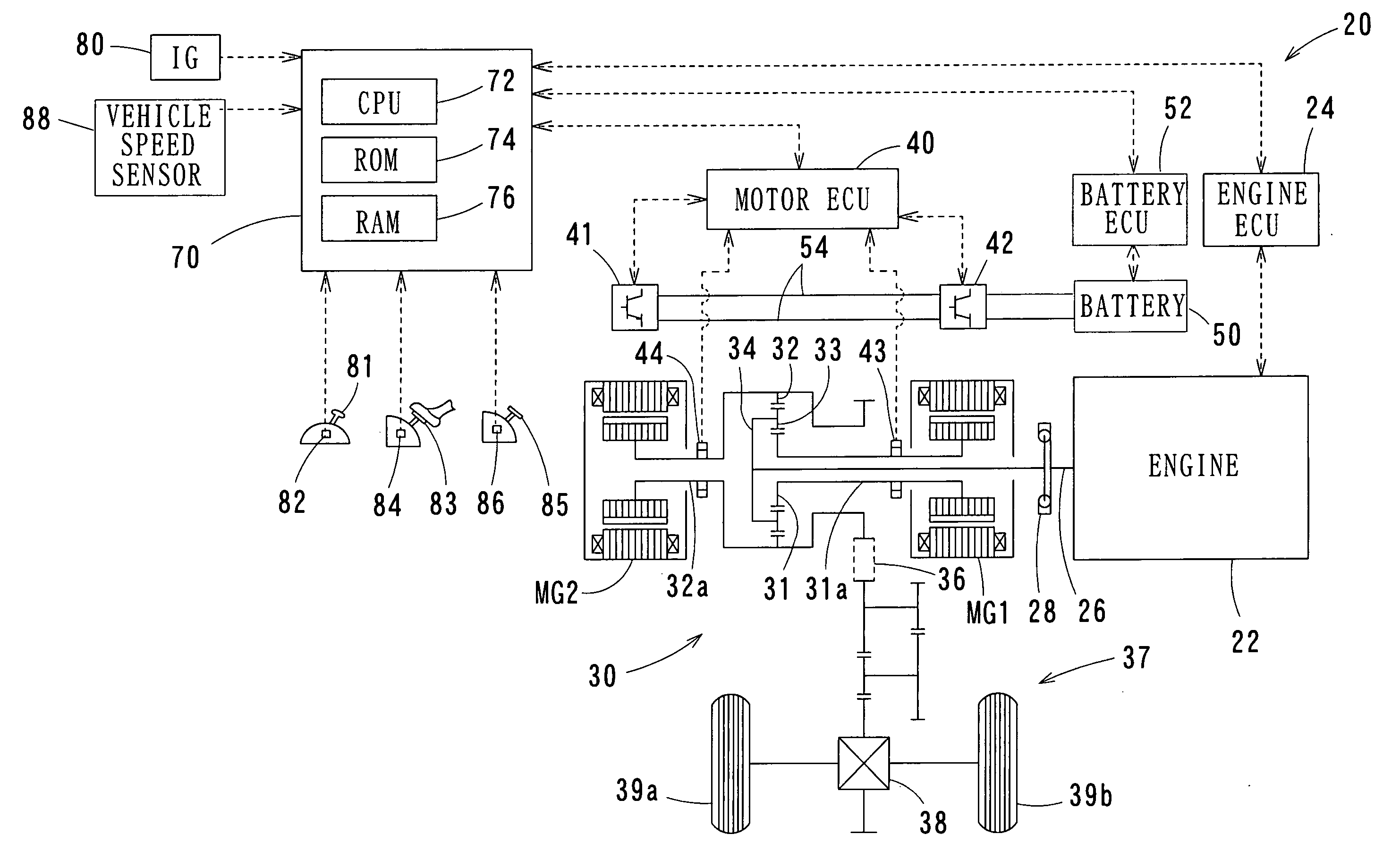

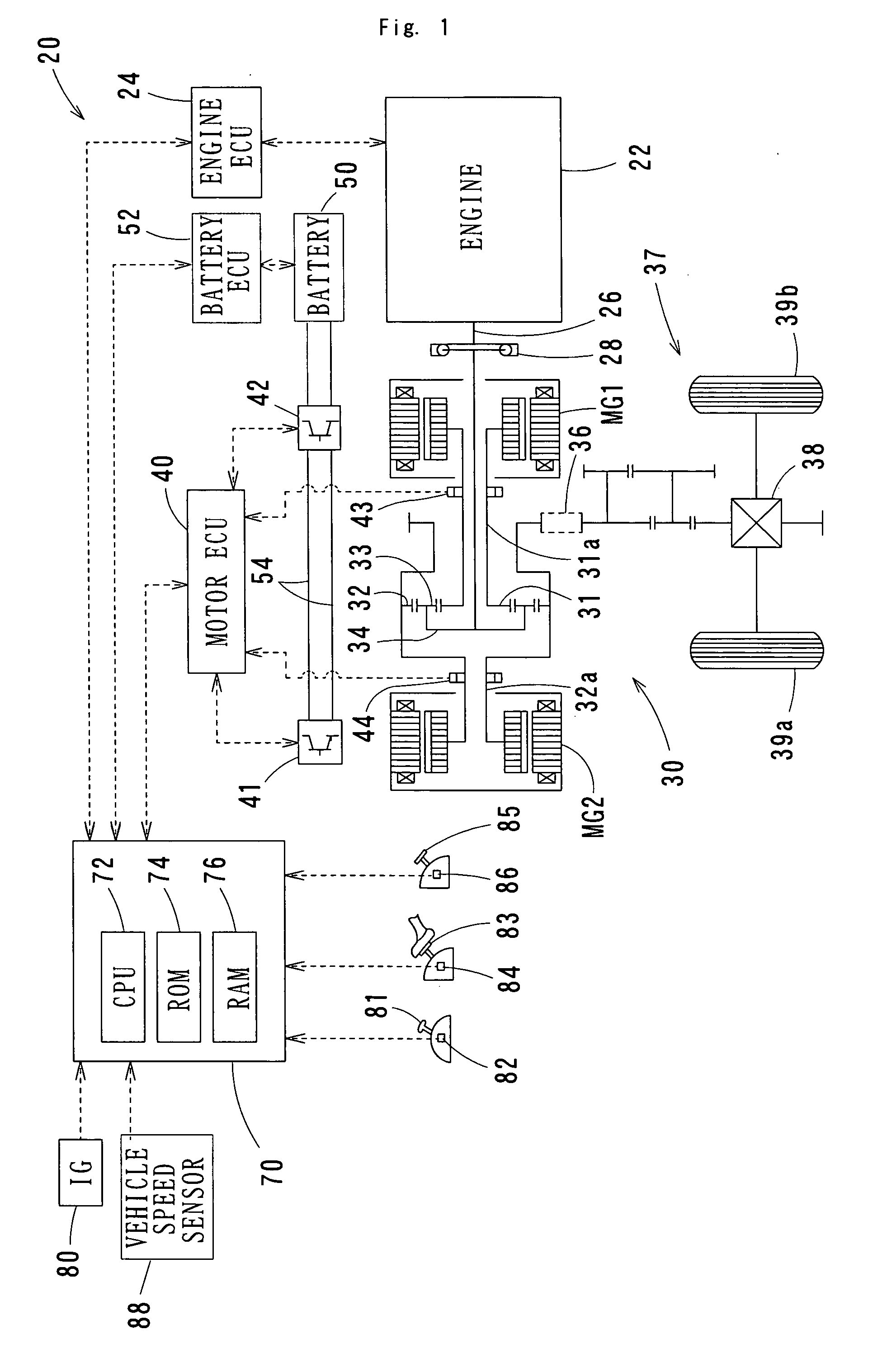

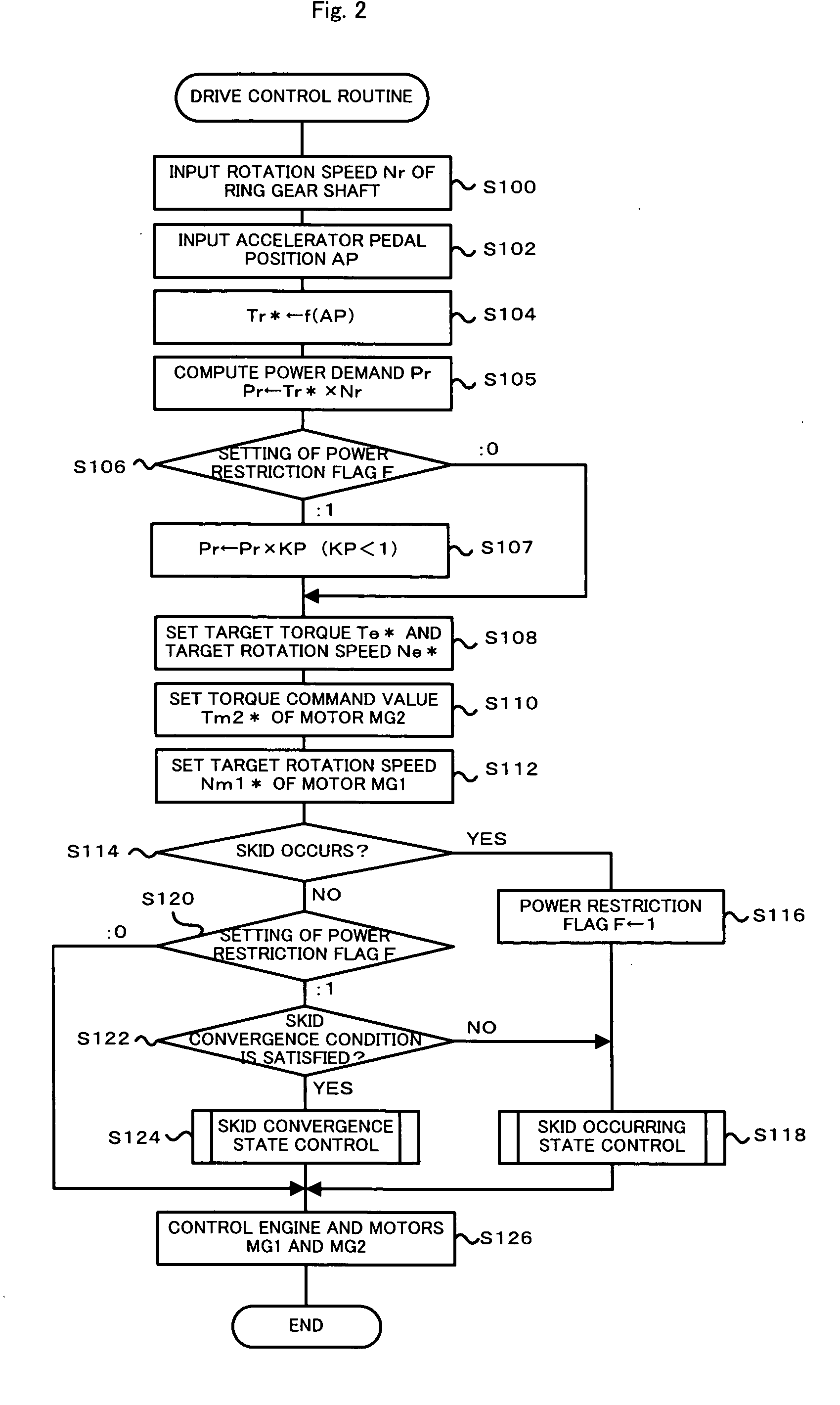

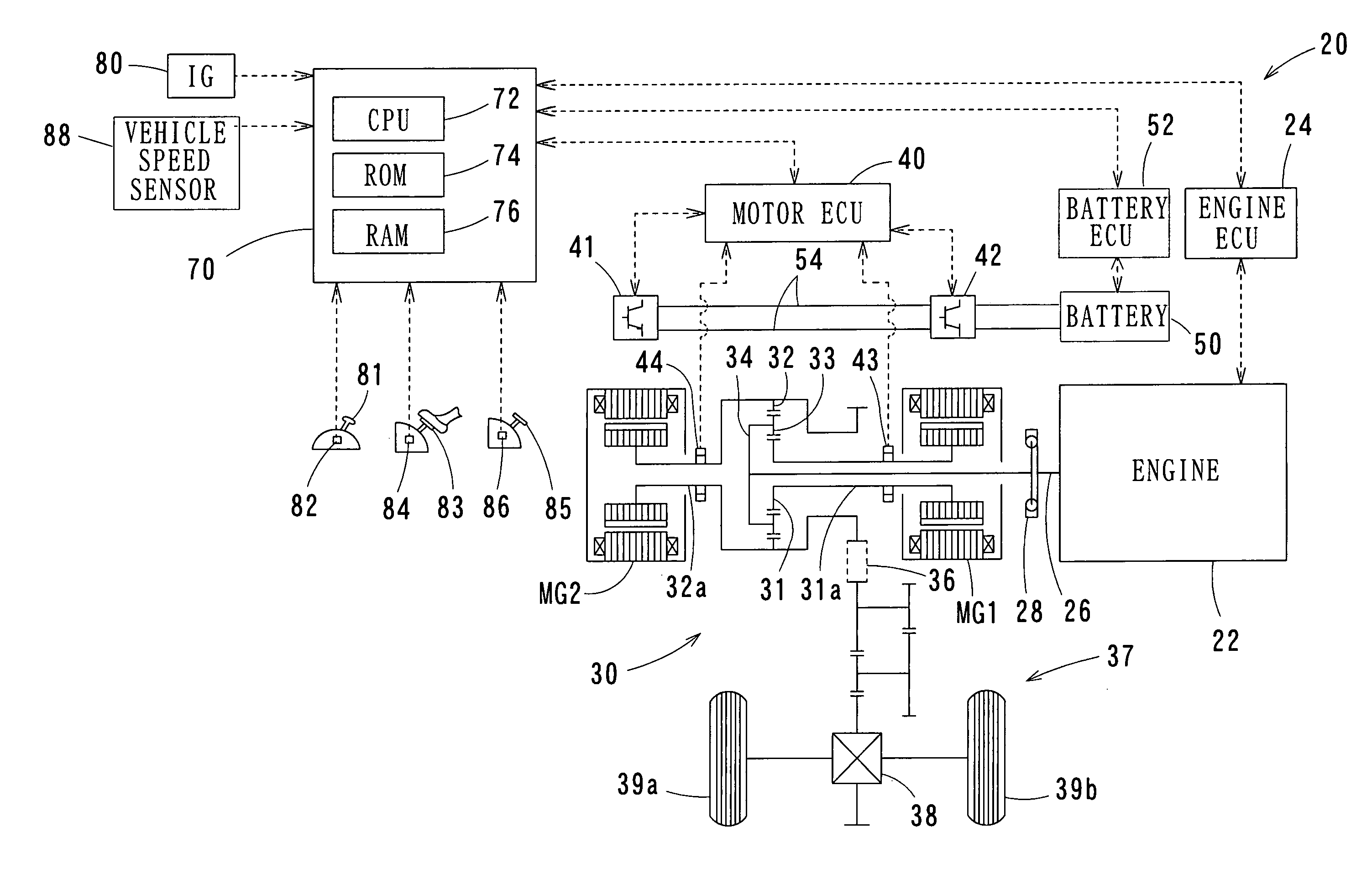

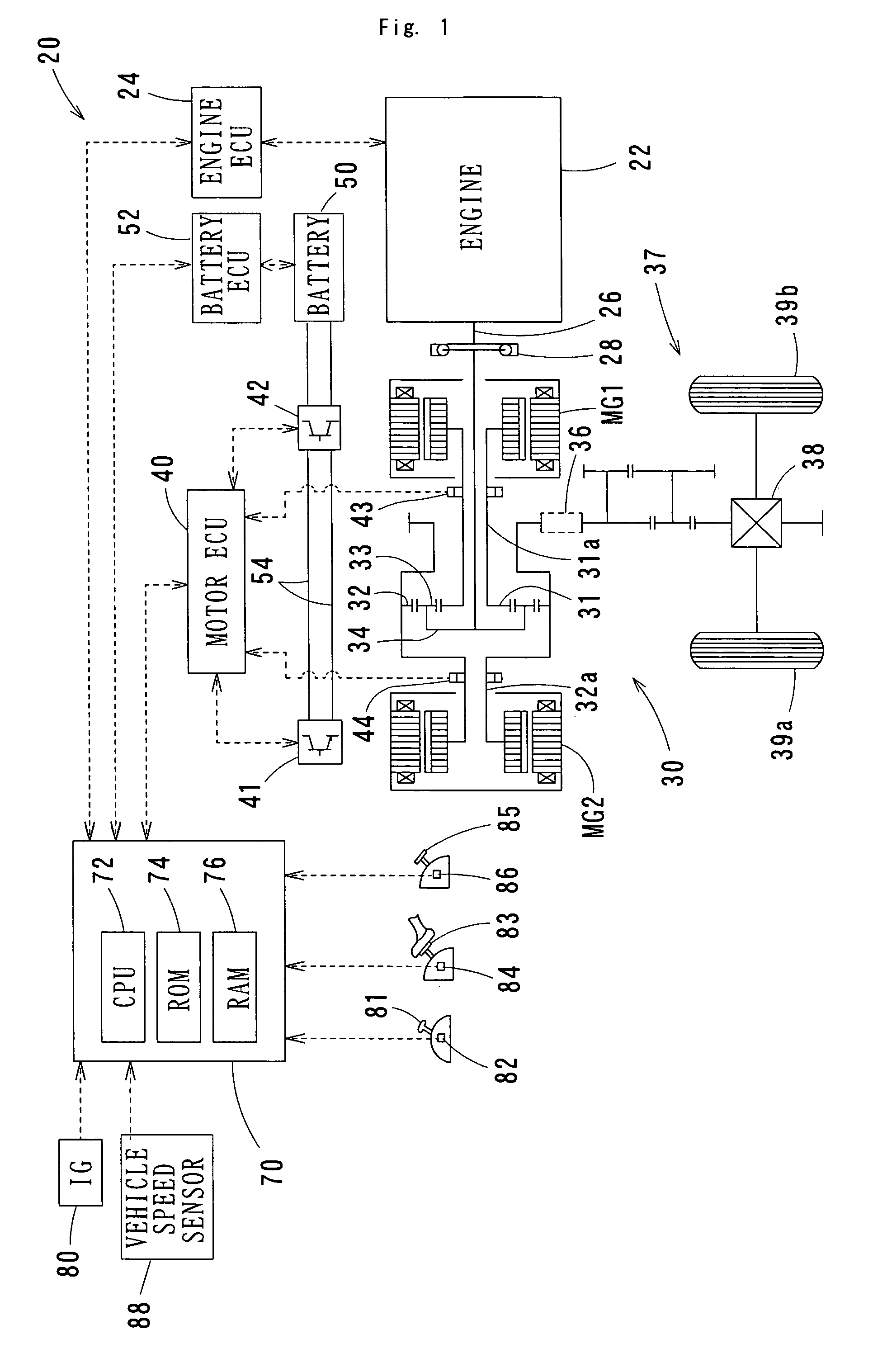

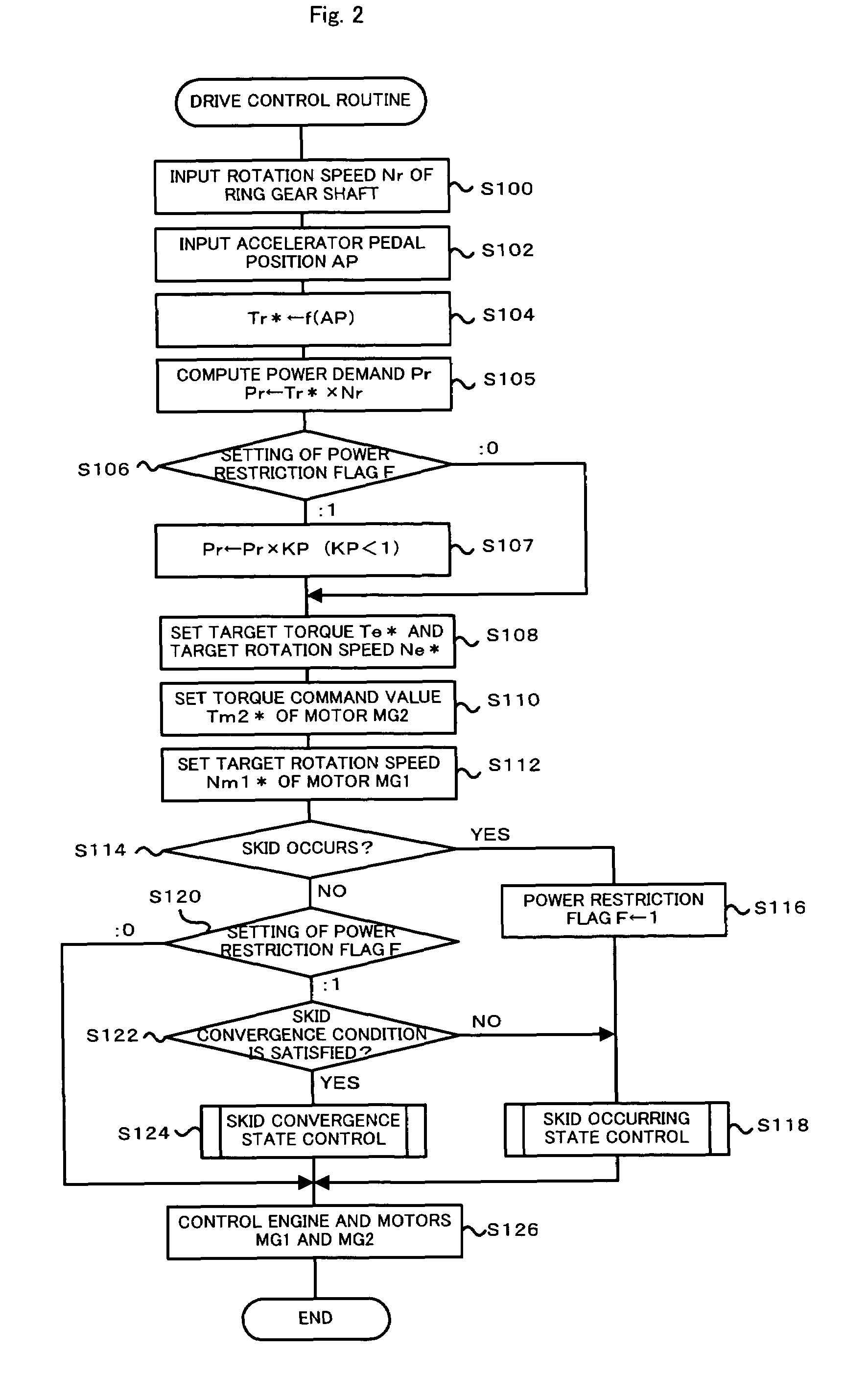

Vehicle control device, car having the device, and method of controlling the car

InactiveUS20050241868A1Large engine noiseAvoid discomfortDigital data processing detailsPlural diverse prime-mover propulsion mountingMaximum torqueDrive shaft

When a computed torque command value Tr* of a ring gear shaft as a drive shaft exceeds a maximum torque Tmax, skid occurring state control (step S118) triggered by detection of the occurrence of a skid calculates a torque restriction rate KT (=Tmax / Tr*) and restricts the torque output to the ring gear shaft to a maximum torque Tmax. In a next cycle of a drive control routine, a power demand Pr, which is calculated from inputs of accelerator pedal position AP and vehicle speed V at step S105, is limited to the product of the power demand Pr and a power restriction rate KP (=KT) at step S107. The control with the limited power demand Pr desirably prevents a large engine noise beyond the driver's expectation based on the vehicle driving state.

Owner:TOYOTA JIDOSHA KK

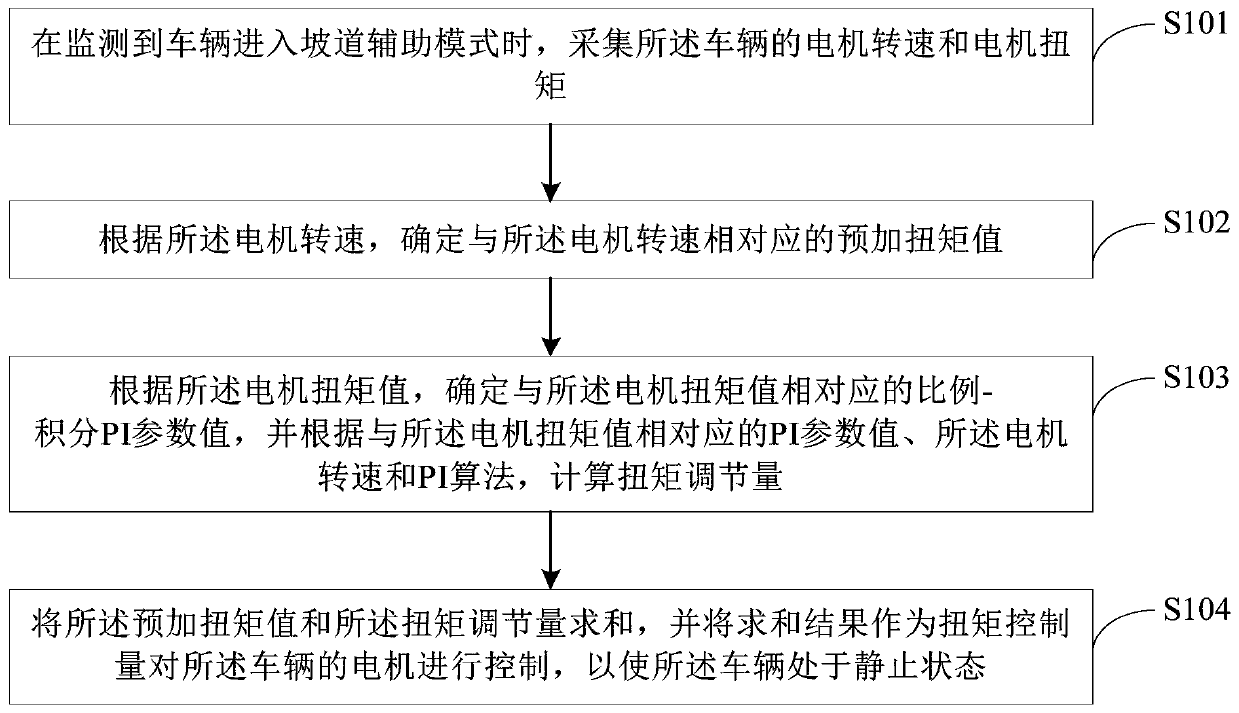

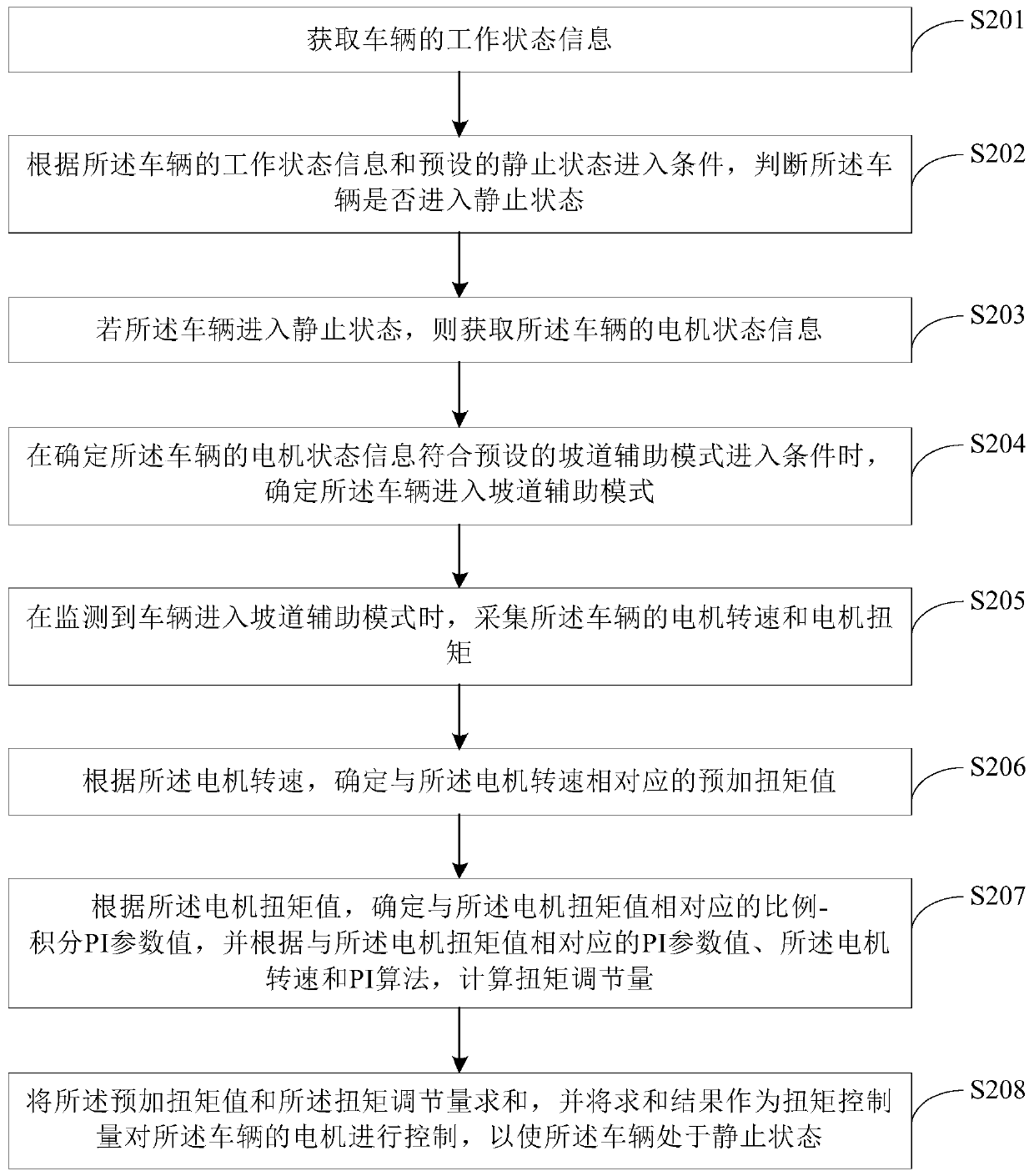

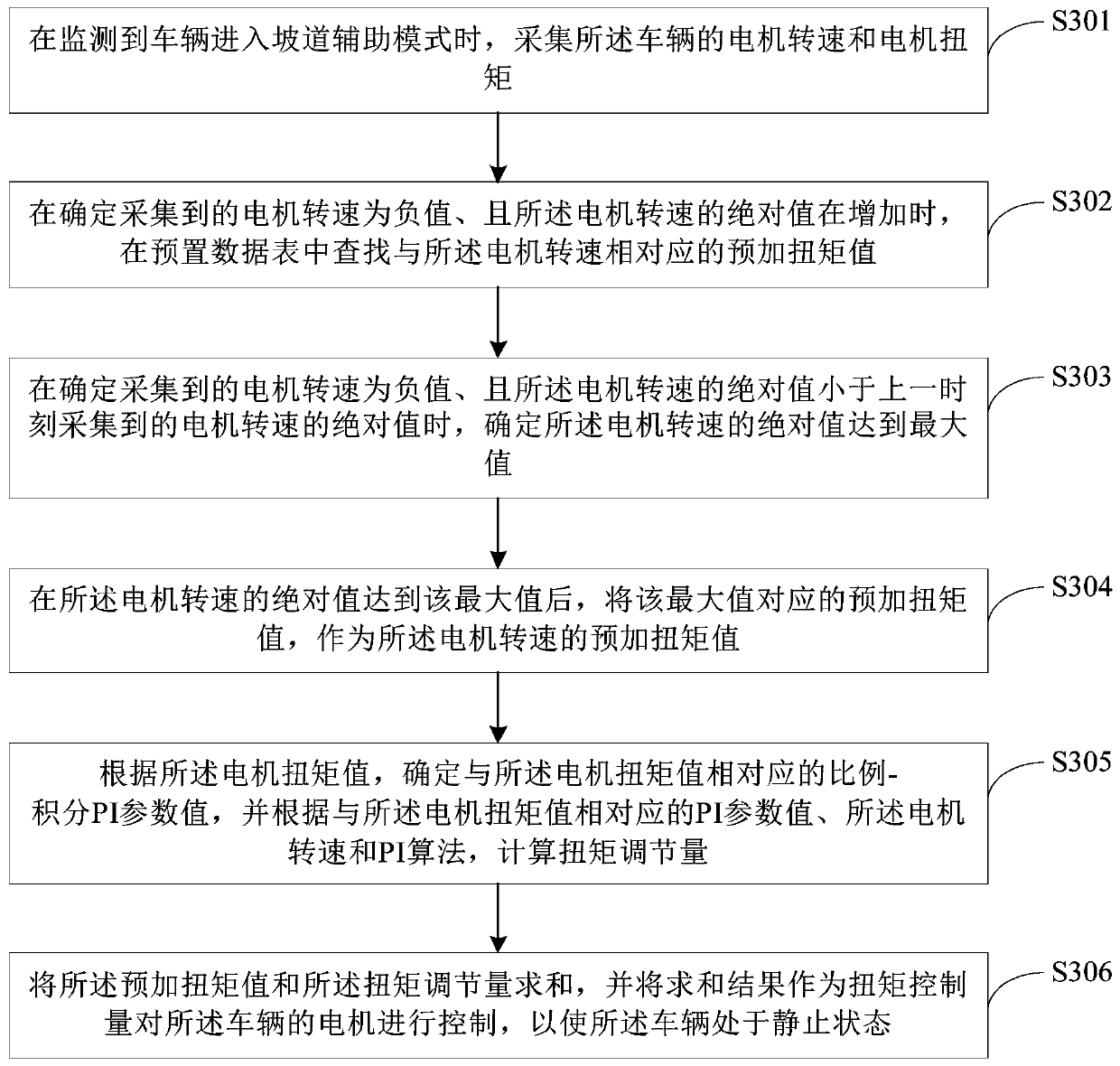

Motor control method, device and equipment and computer readable storage medium

ActiveCN111483327AMeets requirementsImprove stabilitySpeed controllerOperating modesMotor speedElectric machinery

The embodiment of the invention provides a motor control method, device and equipment and a computer readable storage medium. The method comprises the steps: collecting the motor rotating speed and motor torque of a vehicle when the vehicle is monitored to enter a ramp auxiliary mode; determining a pre-added torque value corresponding to the rotating speed of the motor according to the rotating speed of the motor; determining a PI parameter value corresponding to the motor torque value according to the motor torque value, and calculating a torque adjustment amount according to the PI parametervalue corresponding to the motor torque value, the motor rotating speed and a PI algorithm; and summing the pre-added torque value and the torque adjustment amount, and controlling a motor of the vehicle by taking a summing result as a torque control amount to enable the vehicle to be in a static state. According to the embodiment of the invention, factors in two aspects of the motor rotating speed and the motor torque value can be considered in the motor control process, so that the torque control quantity better meets the vehicle requirements, and the vehicle stability is improved.

Owner:GREAT WALL MOTOR CO LTD

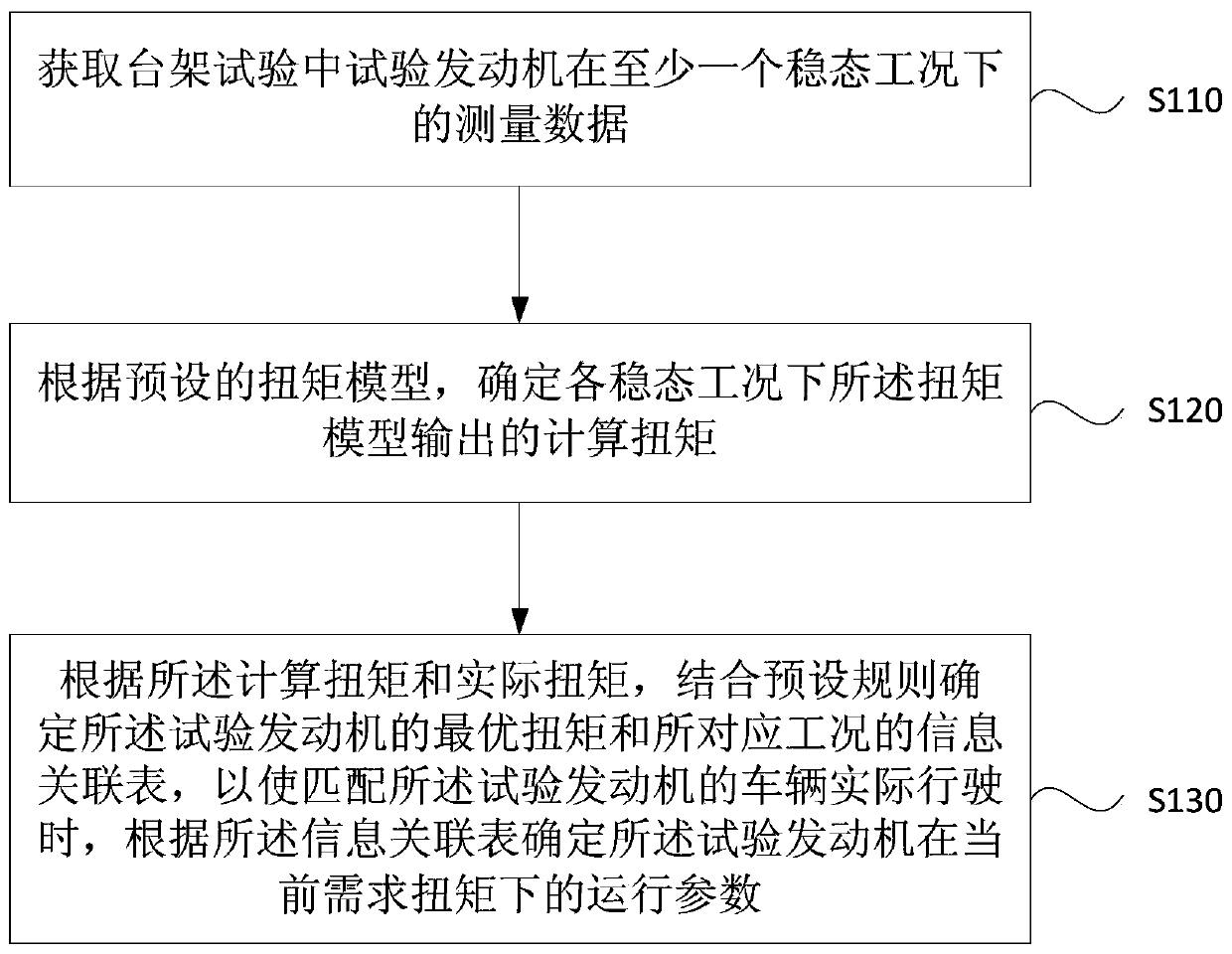

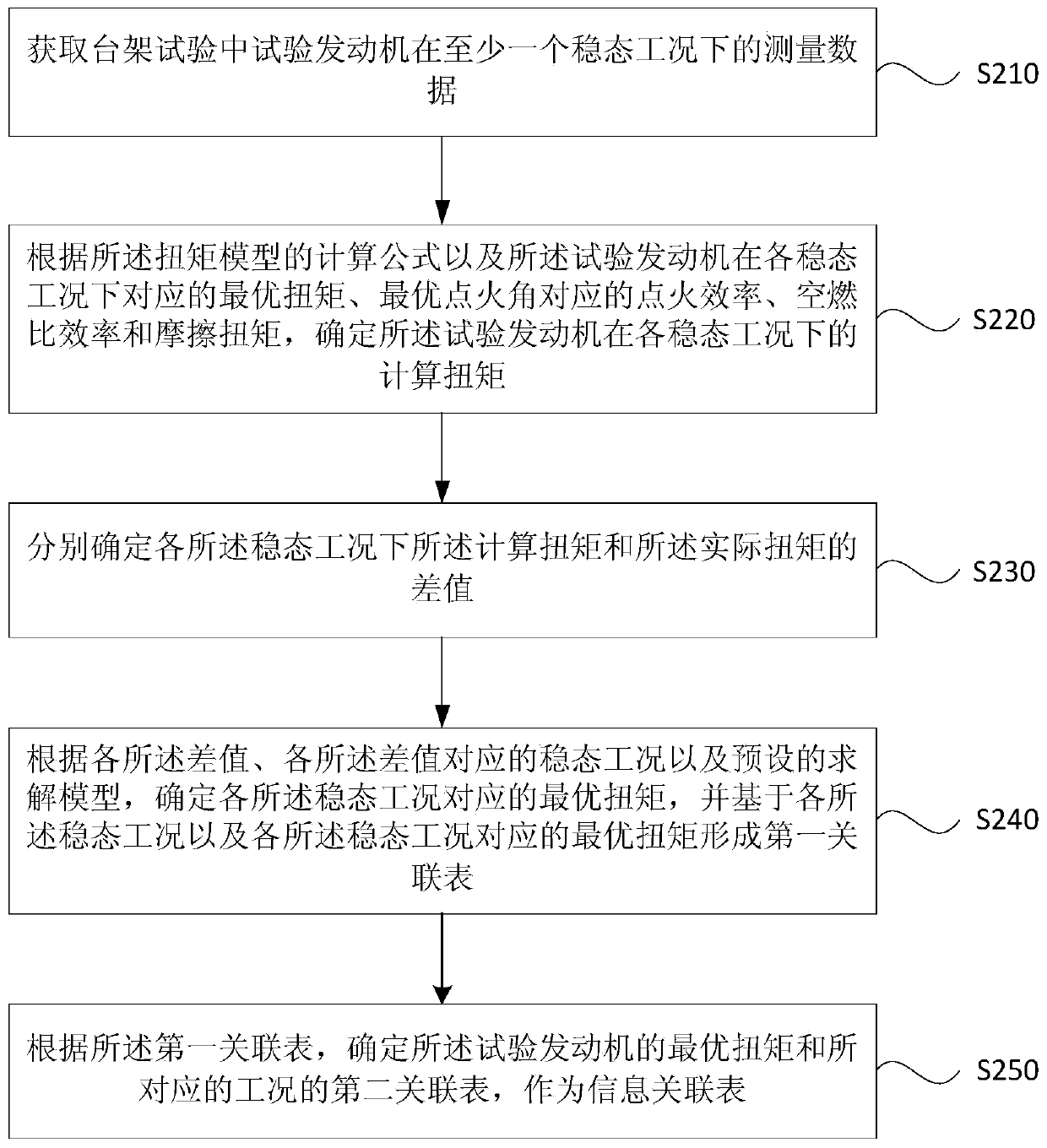

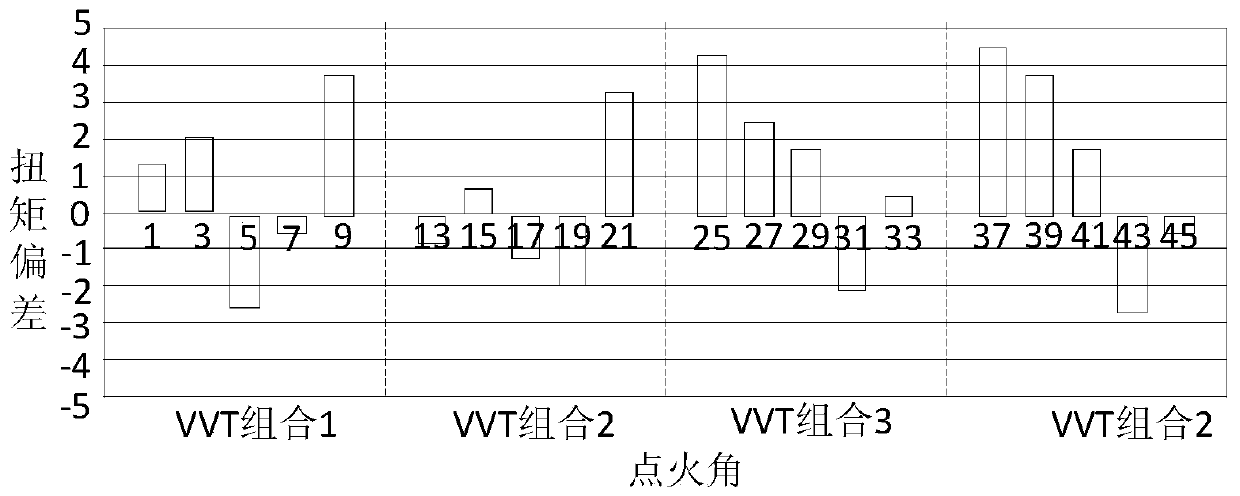

Torque model-based data processing method and device, rack and storage medium

The embodiments of the invention disclose a torque model-based data processing method and device, a rack and a storage medium. The method comprises the steps that the measurement data of a test enginein at least one steady-state working condition is acquired in a rack test; and according to a preset torque model, the calculation torque output by the torque model under each steady-state working condition is determined, an information association table of the torque of a test vehicle and the corresponding working conditions is determined according to the calculated torque and the actual torquein combination with a preset rule, so that the running parameters of the engine of the test vehicle under the current demand torque are determined according to the information association table duringactual driving of the test vehicle. Compared with the prior art, the measurement data of the test engine under different steady-state working conditions are utilized in the embodiments of the invention, and then the torque model is combined to obtain the information association table of the torque and the working conditions, thereby providing a basis for the form of a vehicle for subsequently installing the test engine, and meeting the driving demand; and in addition, manual execution is not needed in the process, the automatic processing of the data is realized, and the processing time is shortened.

Owner:CHINA FIRST AUTOMOBILE

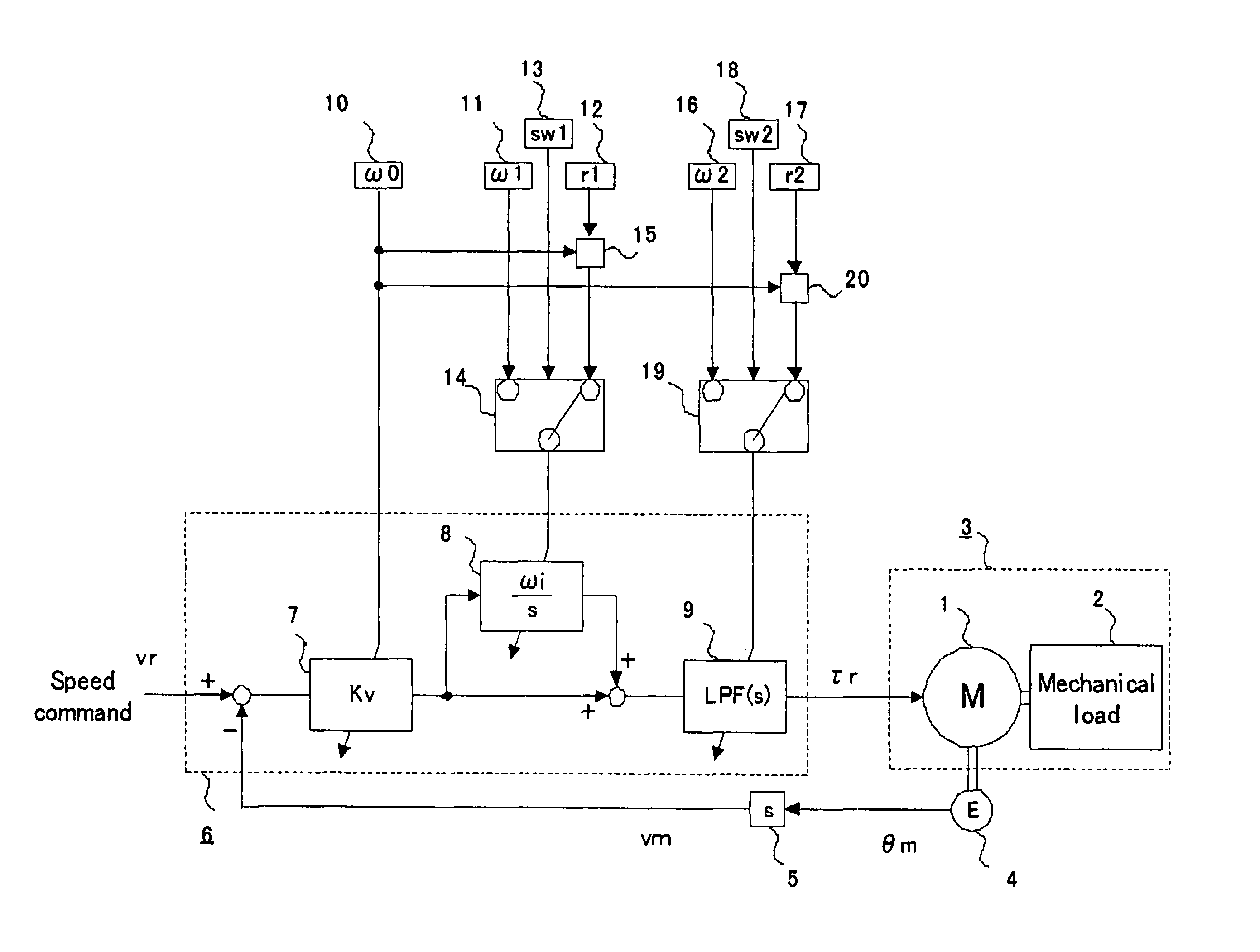

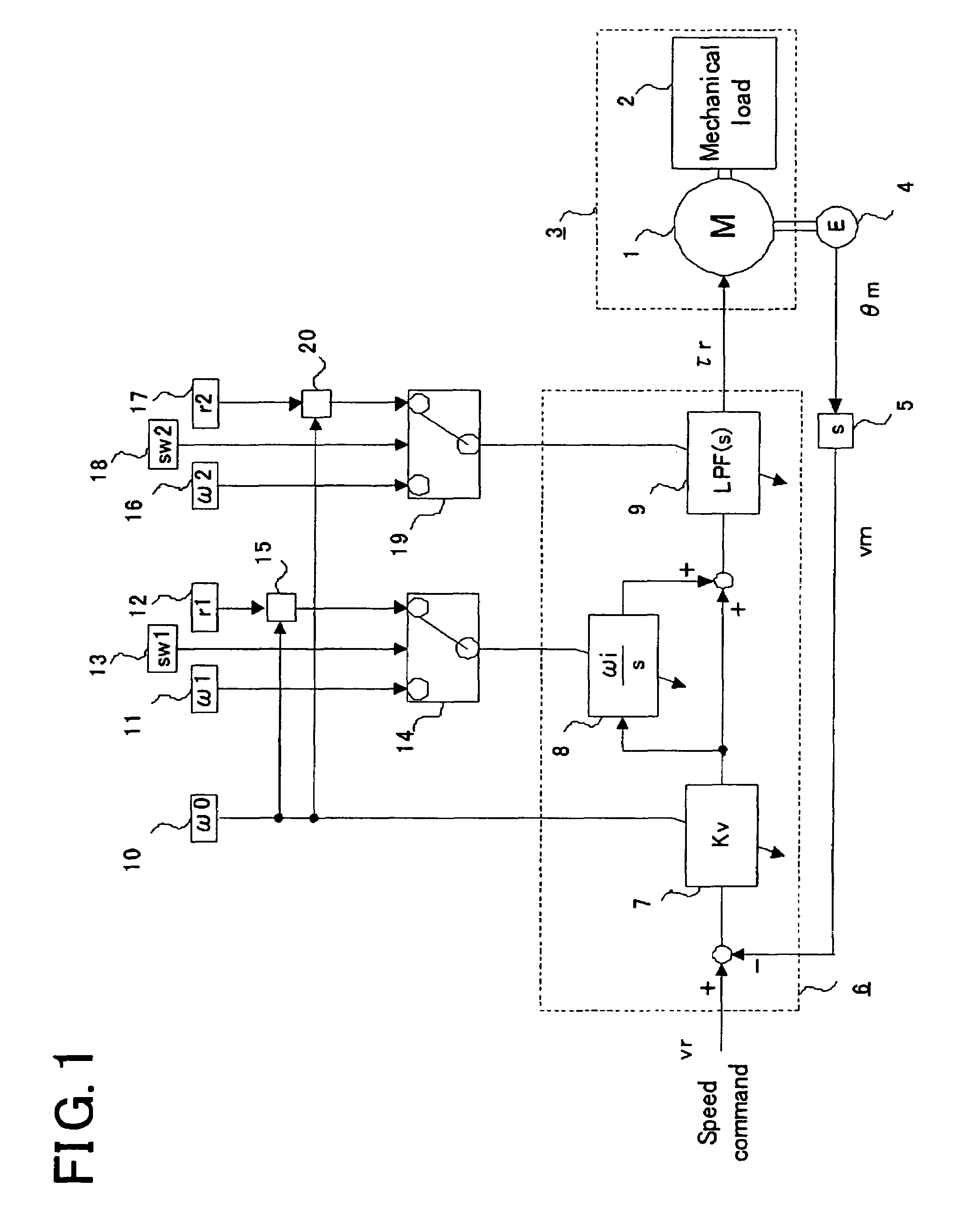

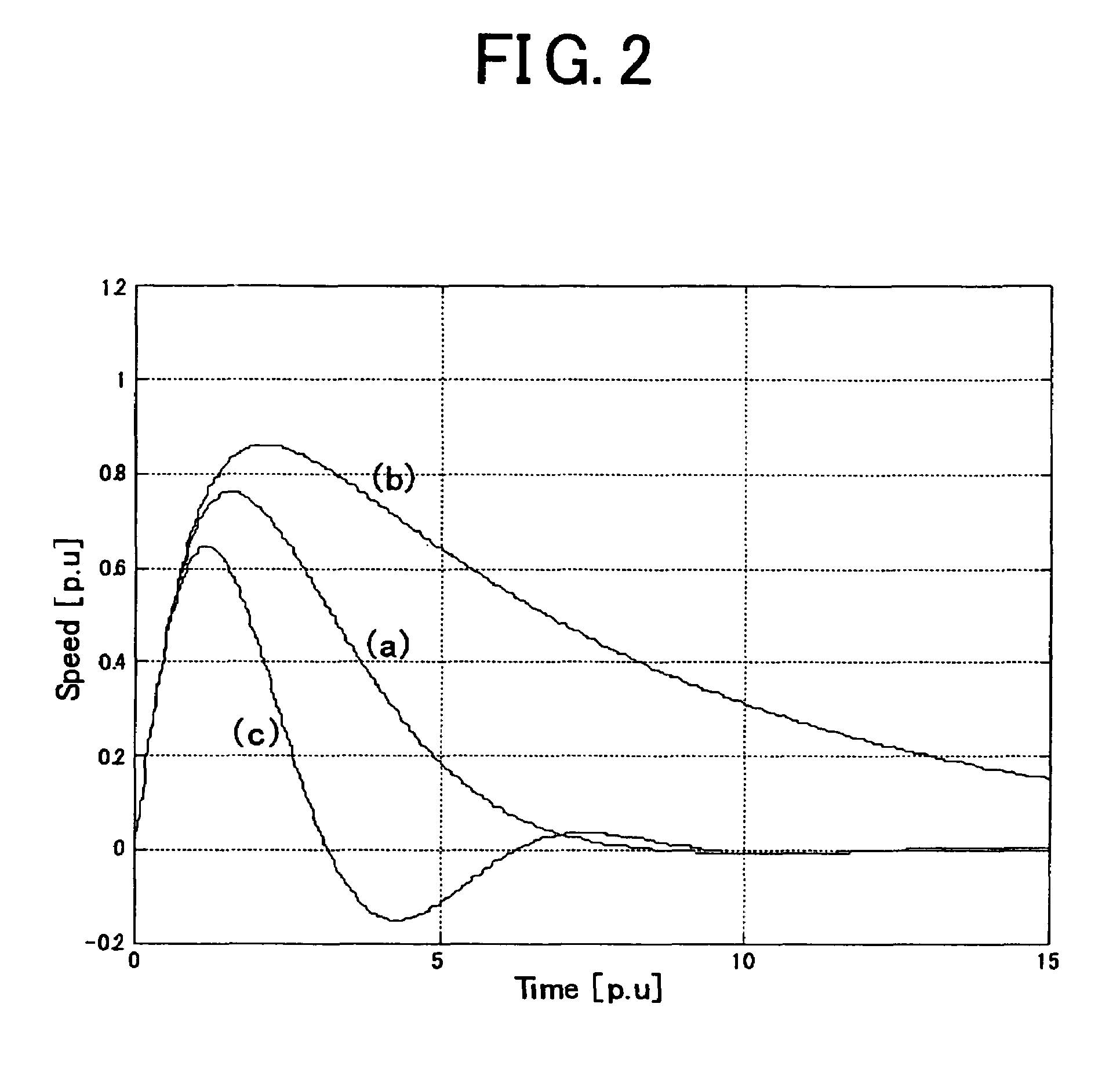

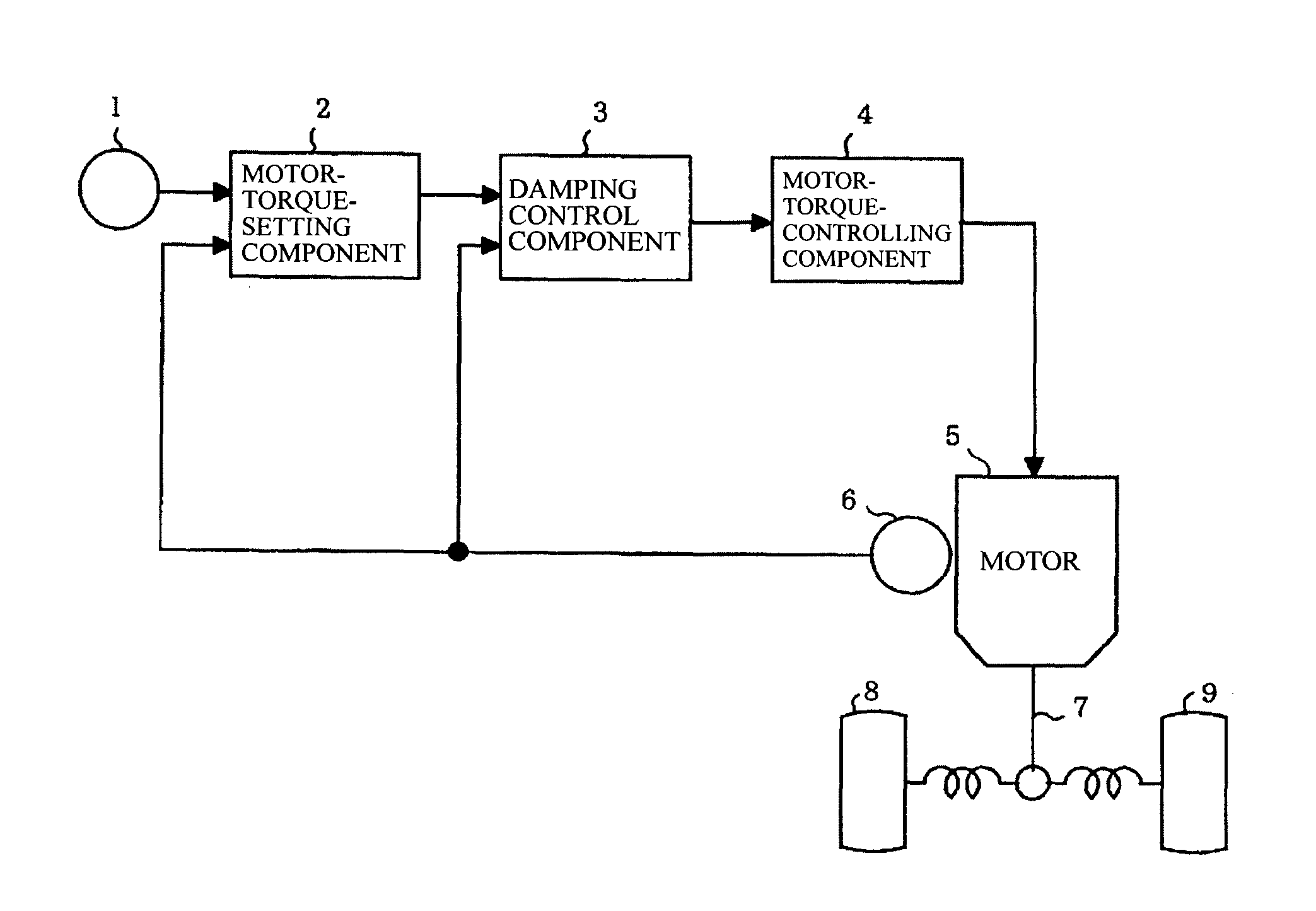

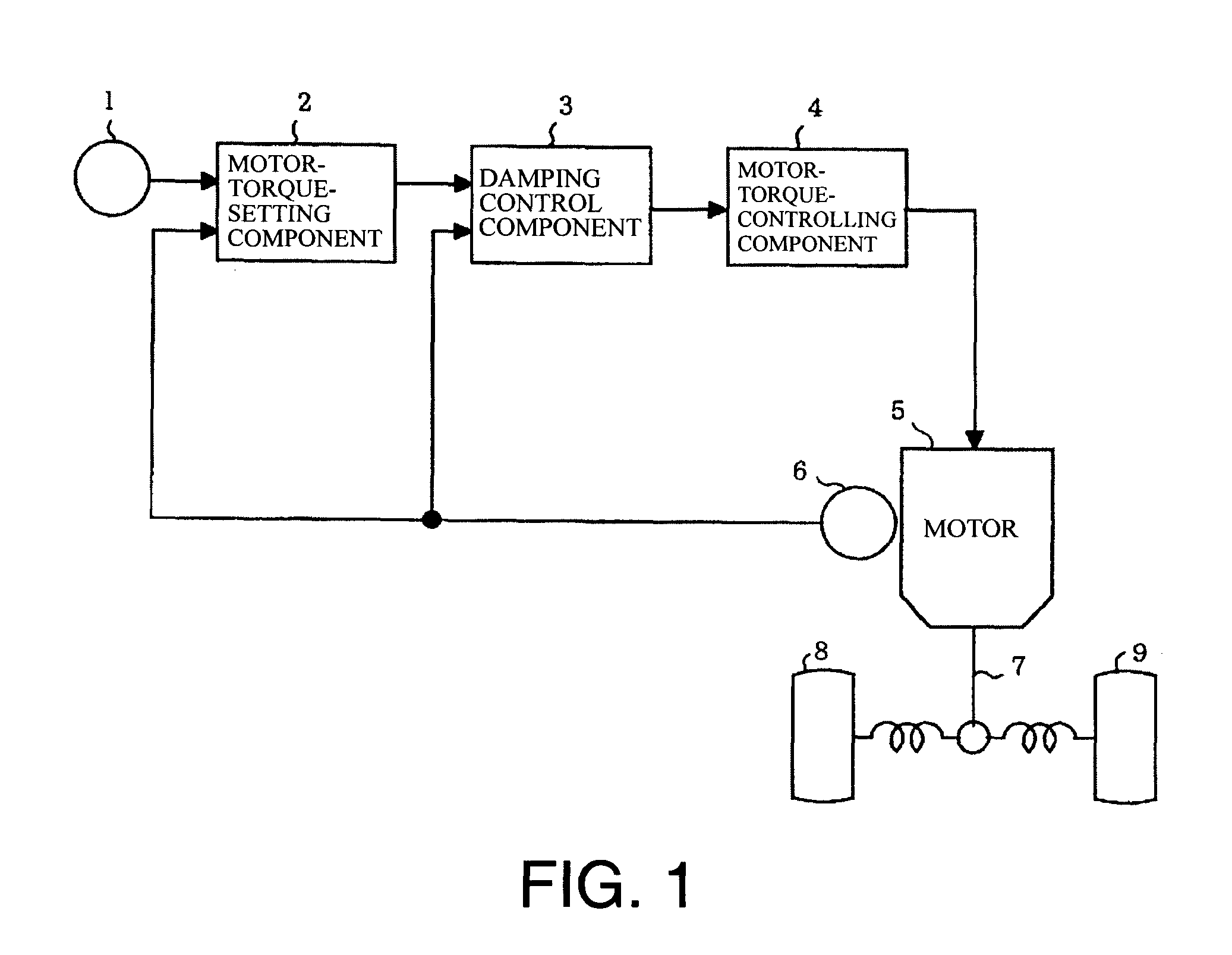

Motor controller

InactiveUS7030581B1Short timeEasy to adjustAC motor controlDC motor speed/torque controlComputed torqueResponse Frequency

This invention relates to a motor controller for driving an object to be controlled by torque from a motor responding to a computed torque command, the object being provided with the motor and a mechanical load. The motor controller includes: a feedback computation unit into which is inputted a positional command signal or a speed command signal, and a motor rotational signal which is a detected value of the motor's rotational angle or speed, the feedback computation unit being for computing the torque command by a computation in which the transfer function for a feedback loop from the motor rotational signal to the torque command includes a pole or a zero point; a response parameter input unit for inputting a response parameter; and a ratio parameter input unit for inputting a ratio parameter. A loop gain which is the gain of the feedback loop is determined based on the response parameter. The pole or the zero point of the feedback loop is determined based on the response parameter and the ratio parameter in such a way that the ratio of a response frequency which is quotient of the loop gain divided by an inertia value of the controlled object to a frequency corresponding to the pole or the zero point of the feedback loop is the value determined by the ratio parameter.

Owner:MITSUBISHI ELECTRIC CORP

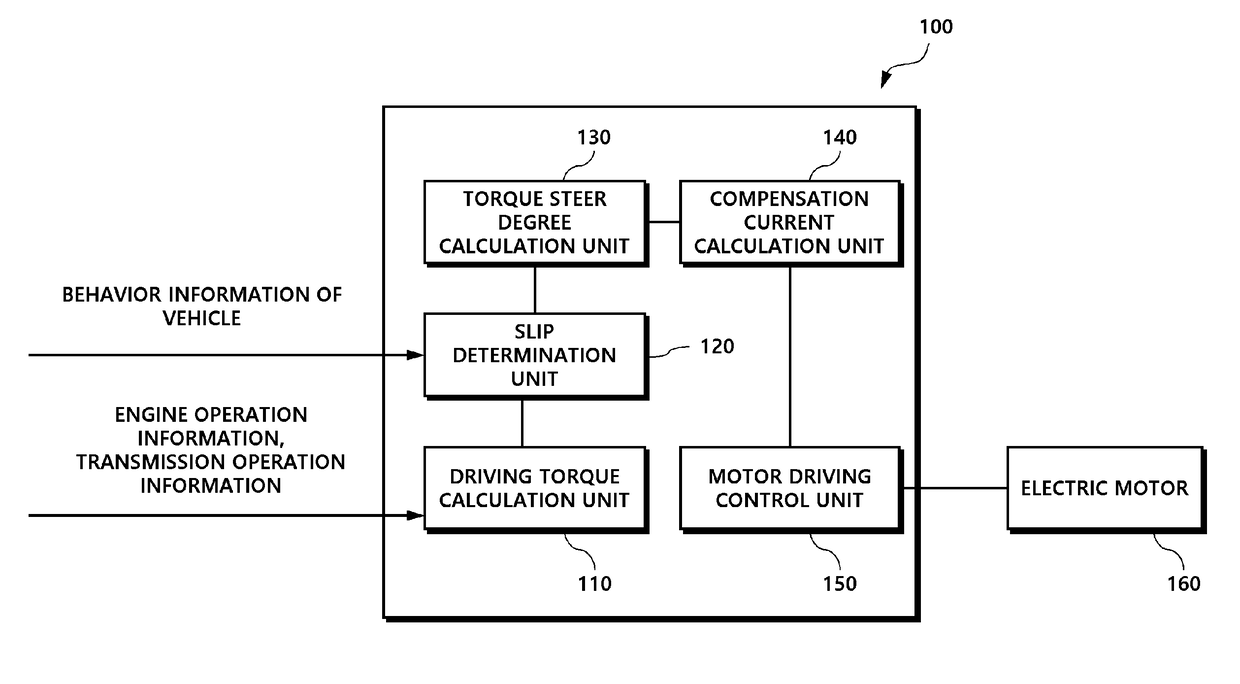

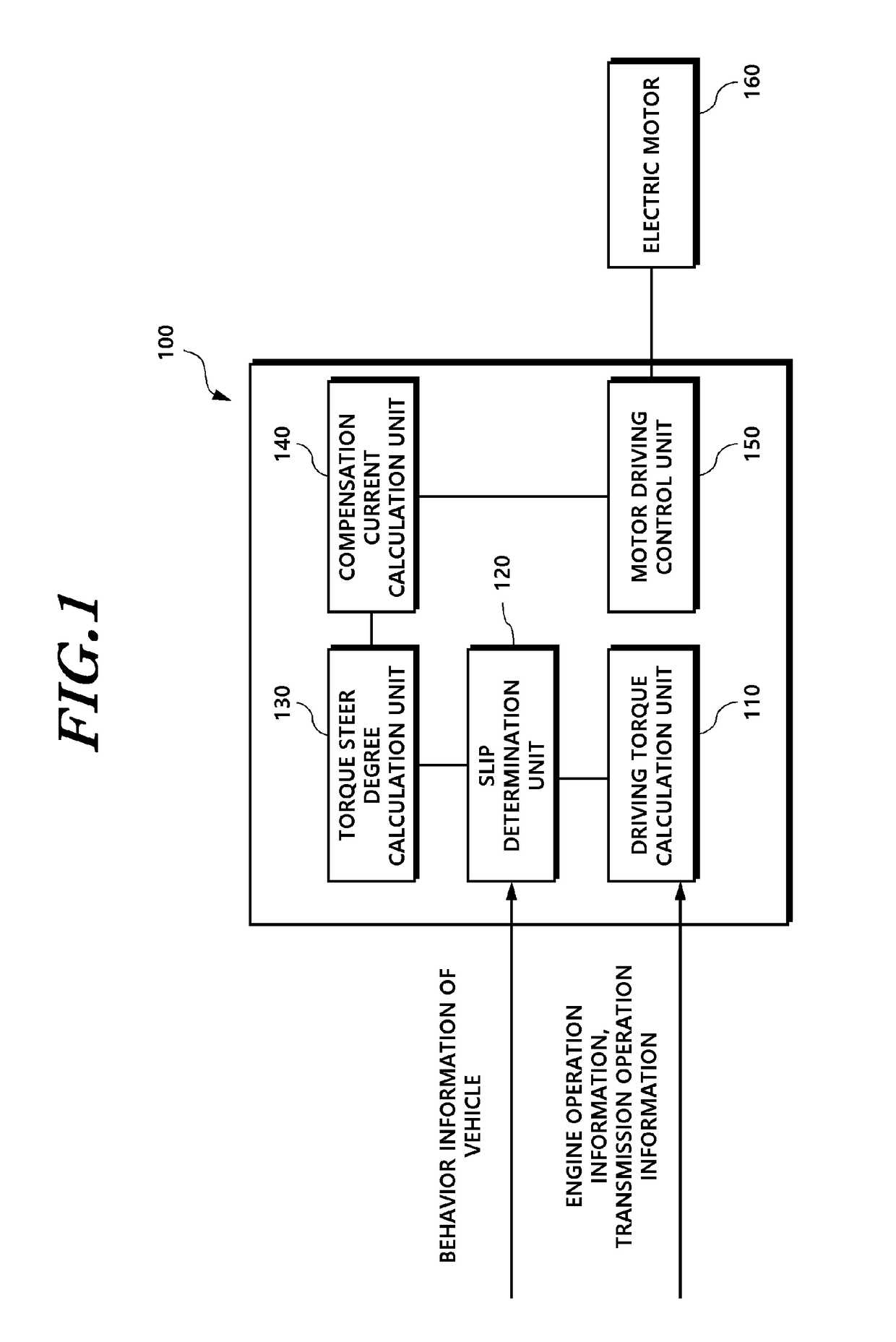

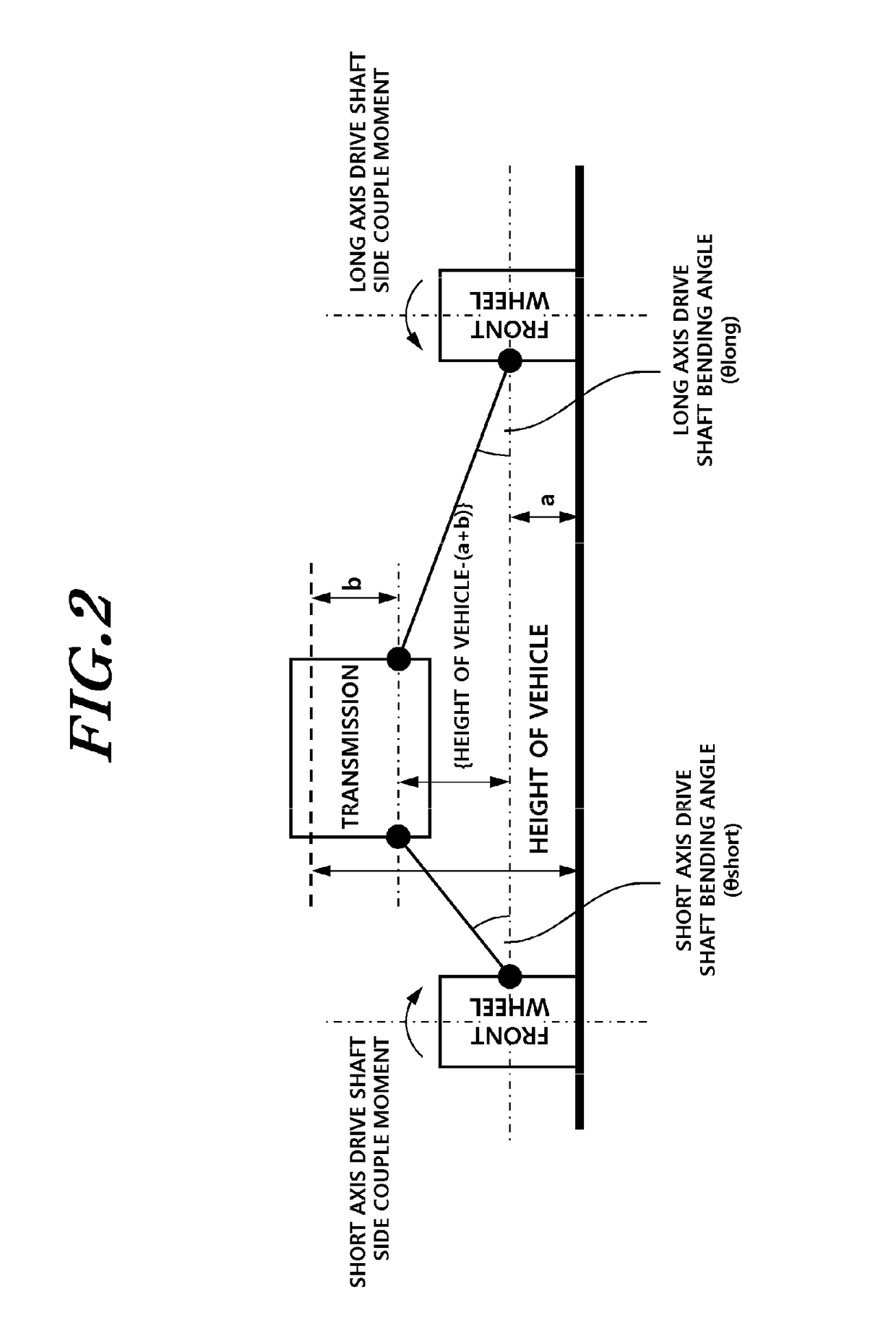

Electronic control unit and method for compensating for torque steer

The present invention relates to an electronic control unit and a method for compensating for a torque steer. The electronic control unit includes: a driving torque calculation unit that calculates a drive shaft driving torque value using engine operation information and transmission operation information; a torque steer degree calculation unit that calculates the actual driving torque value of a vehicle based on the drive shaft driving torque value, and calculates a torque steer degree by using the actual driving torque value; a compensation current calculation unit that calculates a torque steer compensation current value that compensates for the torque steer using the torque steer degree; and a motor driving control unit that calculates a basic control current value using a steering angle and a steering torque value, calculates the final control current value by adding the torque steer compensation current value to the basic control current value, and generates a control current according to the final control current value in order to supply the control current value to an electric motor.

Owner:HL MANDO CORP

Vehicle control device, car having the device, and method of controlling the car

InactiveUS7445066B2Torque level of the drive wheels is restrictedLarge engine noiseDigital data processing detailsPlural diverse prime-mover propulsion mountingMaximum torqueDriver/operator

When a computed torque command value Tr* of a ring gear shaft as a drive shaft exceeds a maximum torque Tmax, skid occurring state control (step S118) triggered by detection of the occurrence of a skid calculates a torque restriction rate KT (=Tmax / Tr*) and restricts the torque output to the ring gear shaft to a maximum torque Tmax. In a next cycle of a drive control routine, a power demand Pr, which is calculated from inputs of accelerator pedal position AP and vehicle speed V at step S105, is limited to the product of the power demand Pr and a power restriction rate KP (=KT) at step S107. The control with the limited power demand Pr desirably prevents a large engine noise beyond the driver's expectation based on the vehicle driving state.

Owner:TOYOTA JIDOSHA KK

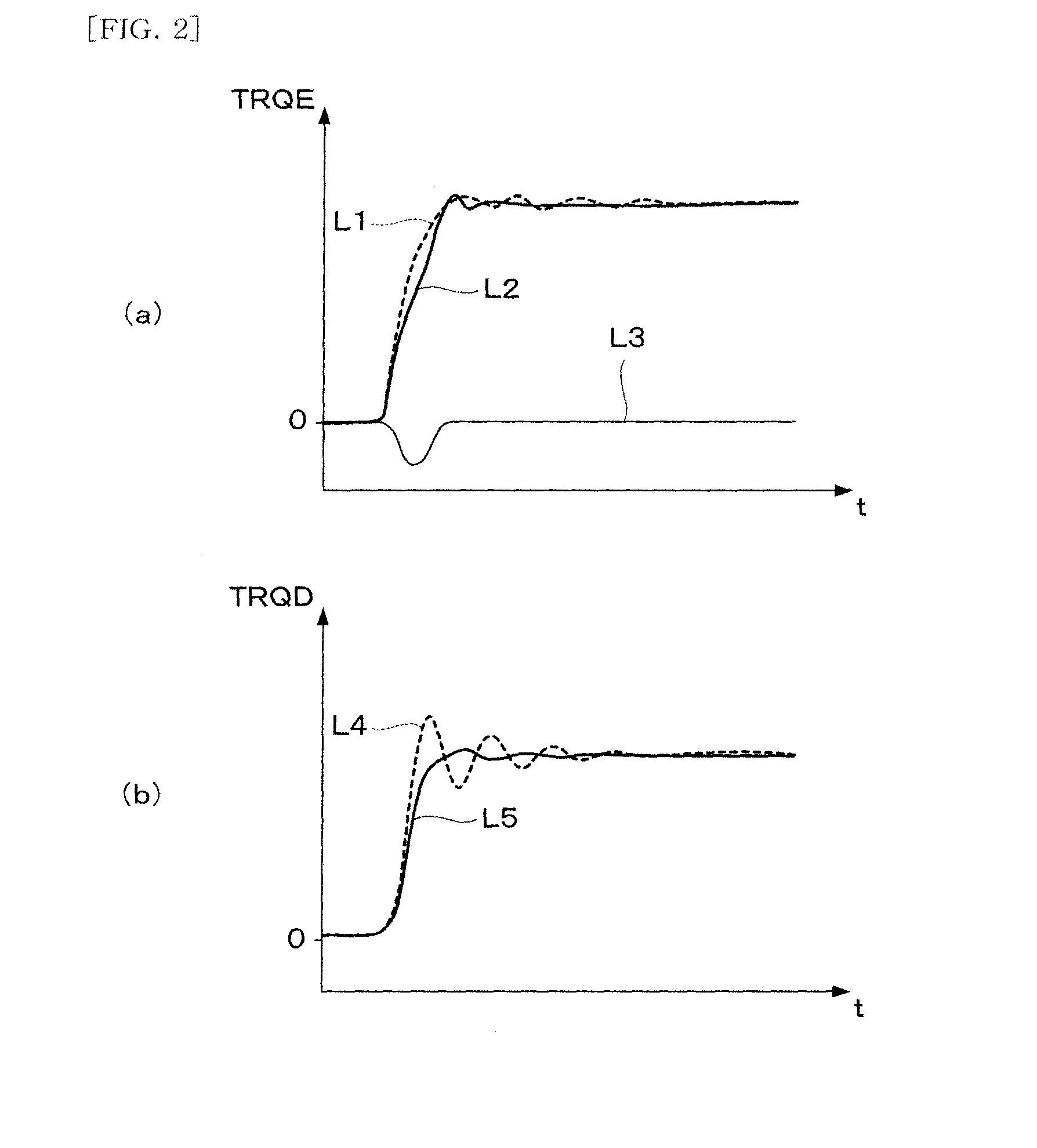

Control system for internal combustion engine

InactiveUS20100116247A1Lower Detection LatencyReduce vibrationElectrical controlFuel injection apparatusResonanceControl system

A control system for an internal combustion engine for driving a vehicle, which controls an output torque of the engine, is provided. In this control system, a rapid change in a demand torque of the engine is detected, and a feedforward correction amount is generated during a correction period which is substantially equal to a resonance period of a powertrain of the vehicle, from a time when the rapid change in the demand torque is detected. An output torque control amount of the engine is corrected with the feedforward correction amount. A torque change amount integrated value is calculated by integrating an amount of change in the demand torque, and the feedforward correction amount is generated according to the torque change amount integrated value.

Owner:HONDA MOTOR CO LTD

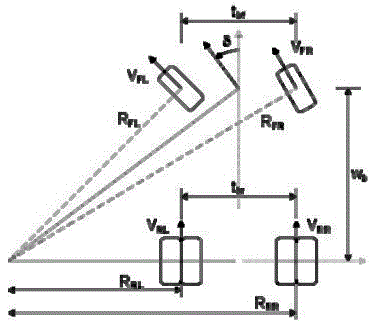

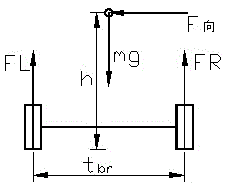

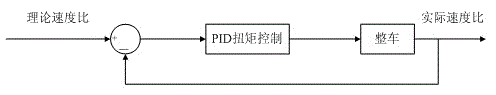

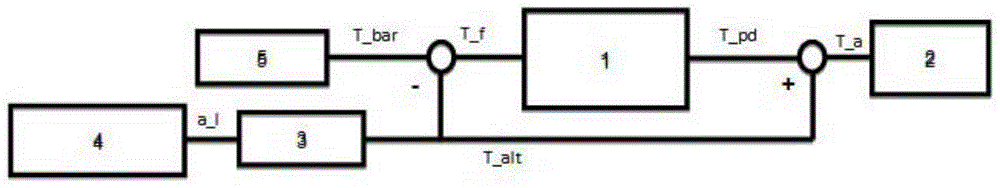

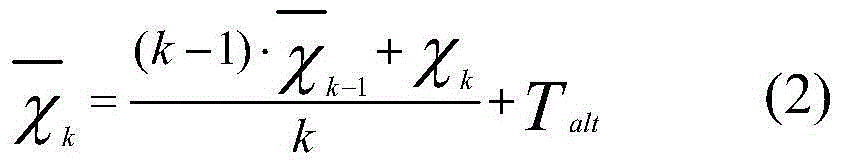

Electronic differential control method and electrically driven mine car using same

The invention discloses an electronic differential control method and electrically driven mine car using the same, belonging to the technical field of vehicle control systems. The method comprises the following steps of: carrying out open-loop control by using a torque distribution curve, wherein the torque distribution curve is computed through analog; estimating a wheel corner when entering the steering and then obtaining a torque distribution ratio by means of a torque distribution curve graph; and carrying out a closed-loop control by using a rear wheel theoretical velocity and a rear wheel actual velocity, wherein the rear theoretical velocity is computed through the wheel corner and the rear actual velocity is actually measured by a sensor. The invention also discloses an electrically driven mine car using the electronic differential control method. According to the invention, the torque during the steering is divided into two stages, open-loop control is carried out firstly by using the computed torque distribution curve and then closed-loop control is carried out by using the rear wheel theoretical velocity and the rear wheel actual velocity, so that the auxiliary steering is realized through a simple and easy control method and mass complicated control algorithms are saved.

Owner:SANYI ROBOT TECH CO LTD

Method for controlling the directional stability of a vehicle, associated steering system and vehicle

A steering system to control a directional stability of a vehicle may include an active power steering assistance system, a sensor to detect vehicle dynamics data of the vehicle, a sensor to detect a torque of a steering system of the vehicle, and a controller. The controller may be configured to determine a torque value based on the vehicle dynamics data, calculate a torque component based on a difference between the torque value and the torque of the steering system, calculate a preliminary compensation torque on a basis of the torque component, calculate a final compensation torque by adding the preliminary compensation torque and the torque value, and actuate the active power steering assistance system based upon the final compensation torque. Systems and methods for controlling directional stability of a vehicle may compensate for short-term pull / drift and long-term pull / drift.

Owner:FORD GLOBAL TECH LLC

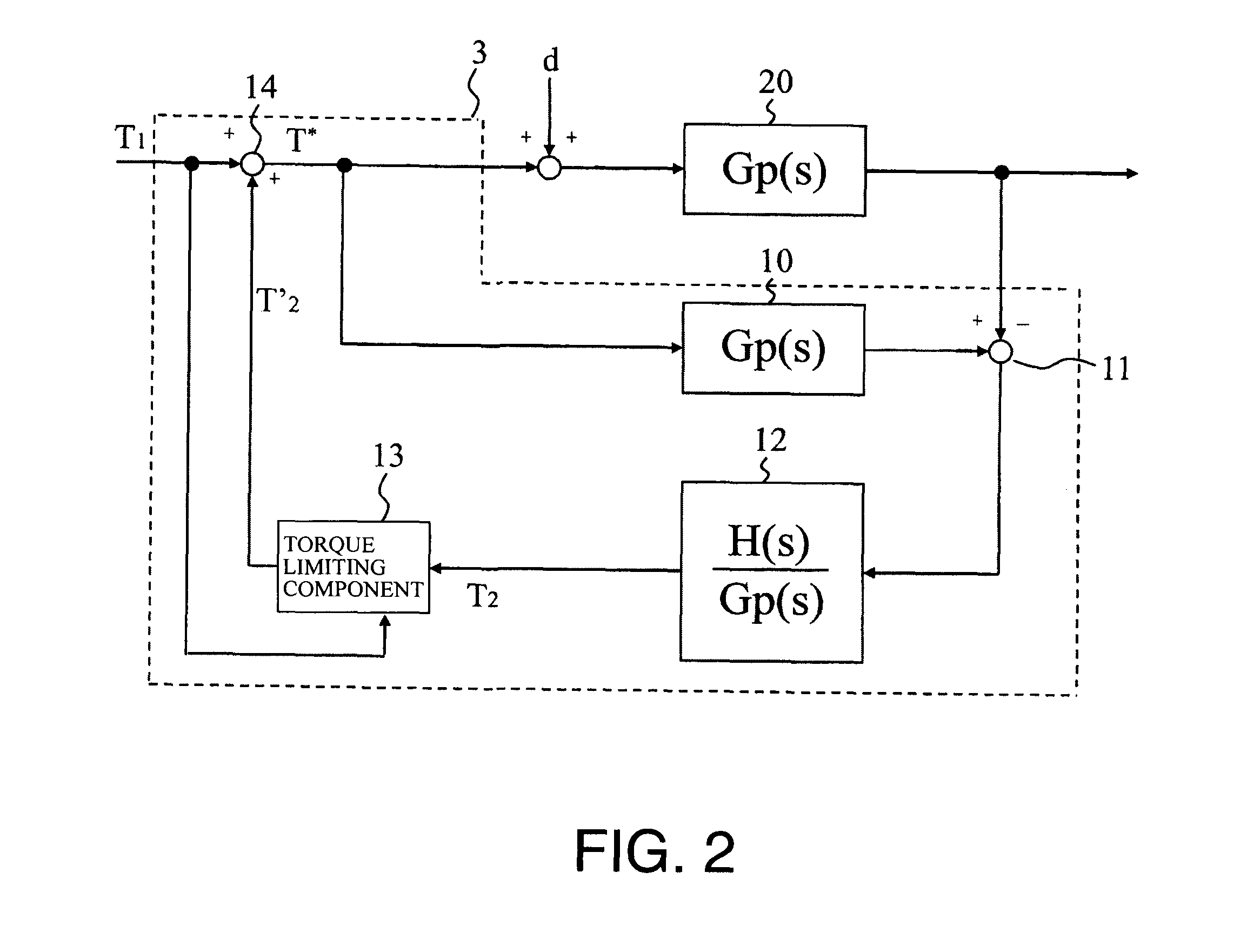

Motor controlling apparatus

ActiveUS20130141028A1Minimize any anomalous soundSpeed controllerDC motor speed/torque controlComputed torqueControl theory

A motor controlling apparatus includes a first target torque value calculator, a frequency detector, a second target torque value calculator, a torque command value calculator, a torque limiter, and a controller. The first target torque value calculator calculates a first target torque value, which is a target value of an output torque of a motor. The frequency detector detects a motor rotational frequency. The second target torque value calculator calculates a second target torque value based on the rotational frequency. The torque command value calculator mathematically combines (e.g., adds) the first and target torque values to calculate a torque command value. The torque limiter sets the signs of the first target torque value and the torque command value to be equal to limit the torque command value according to the first target torque value. The controller controls the motor based on the limited torque command value.

Owner:NISSAN MOTOR CO LTD

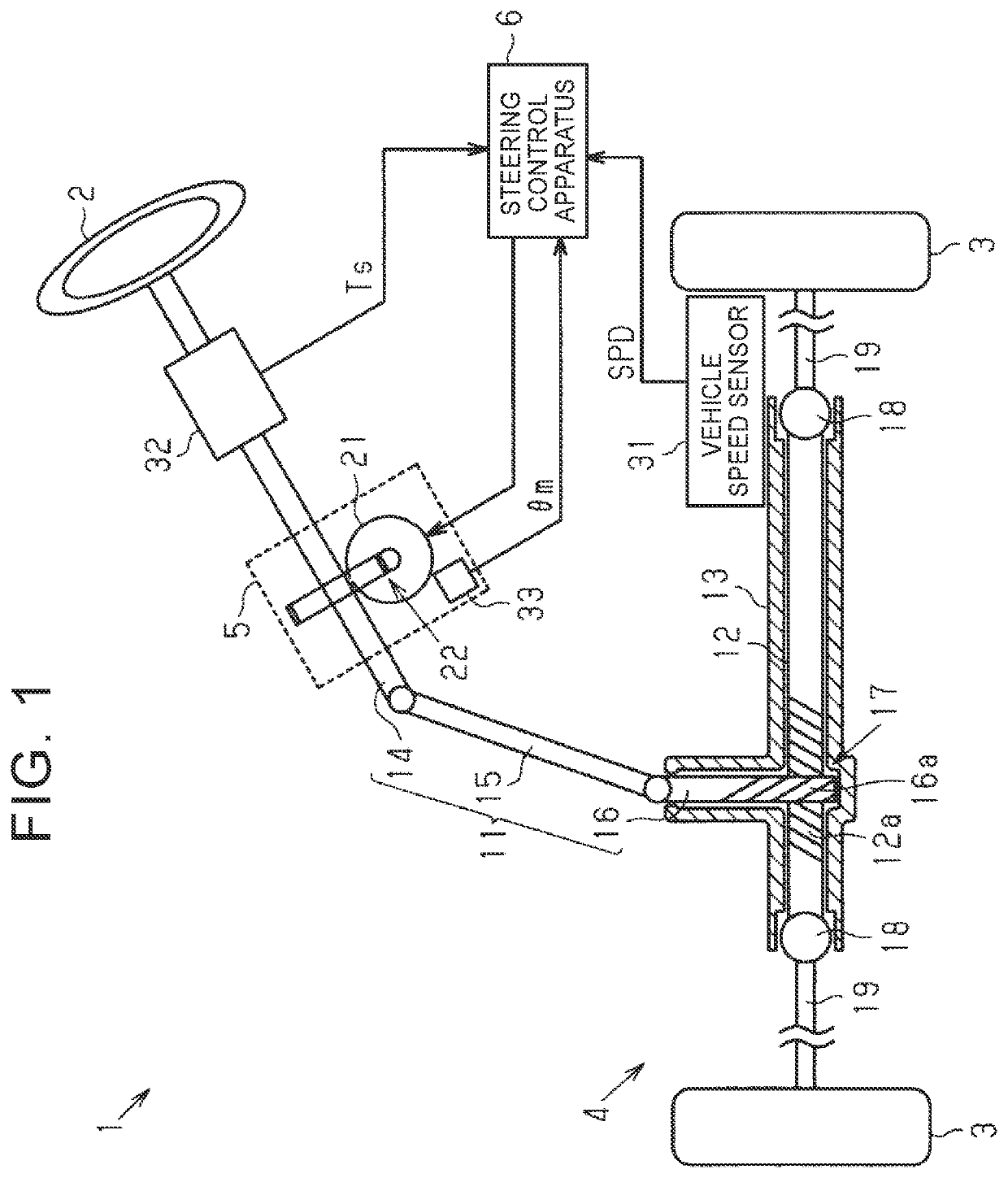

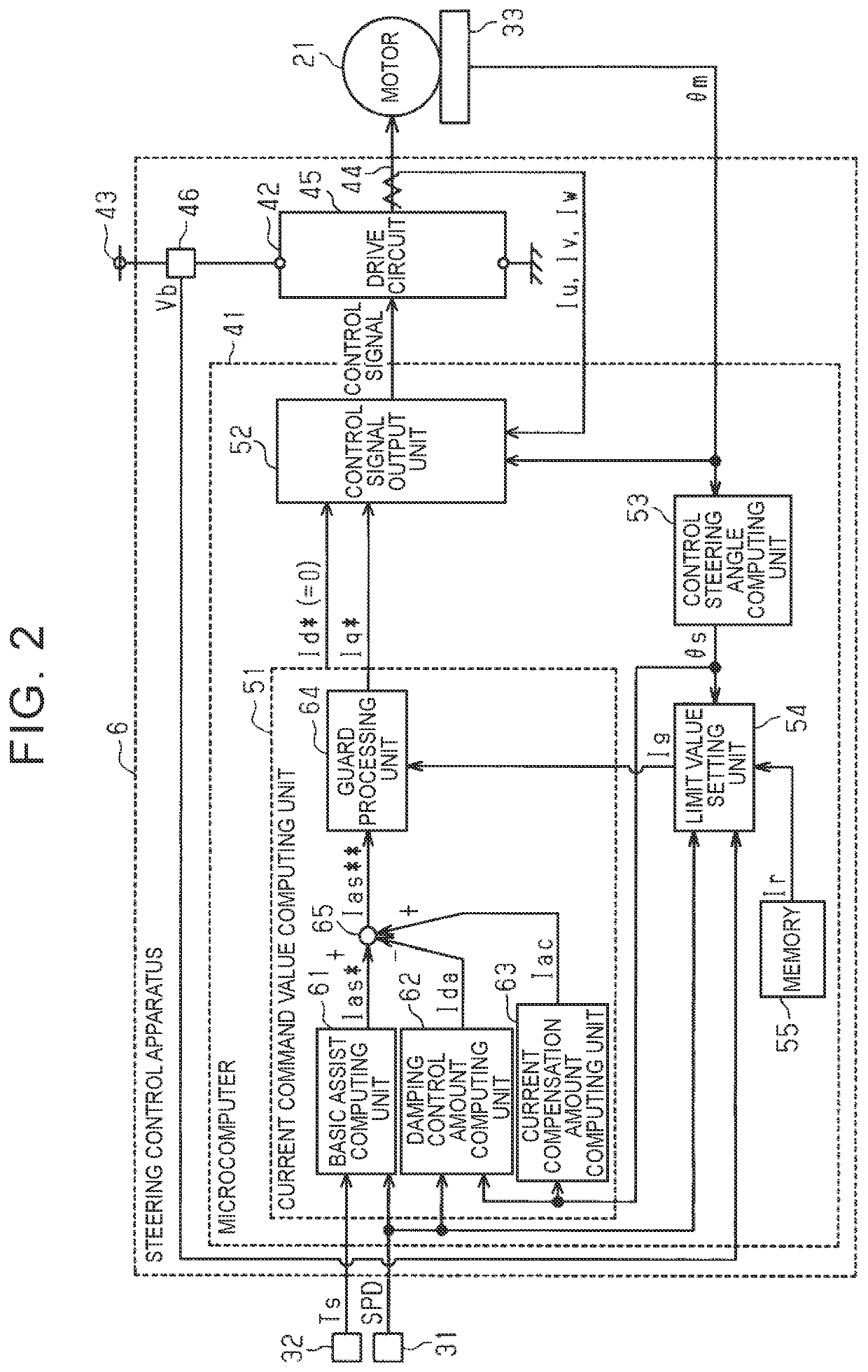

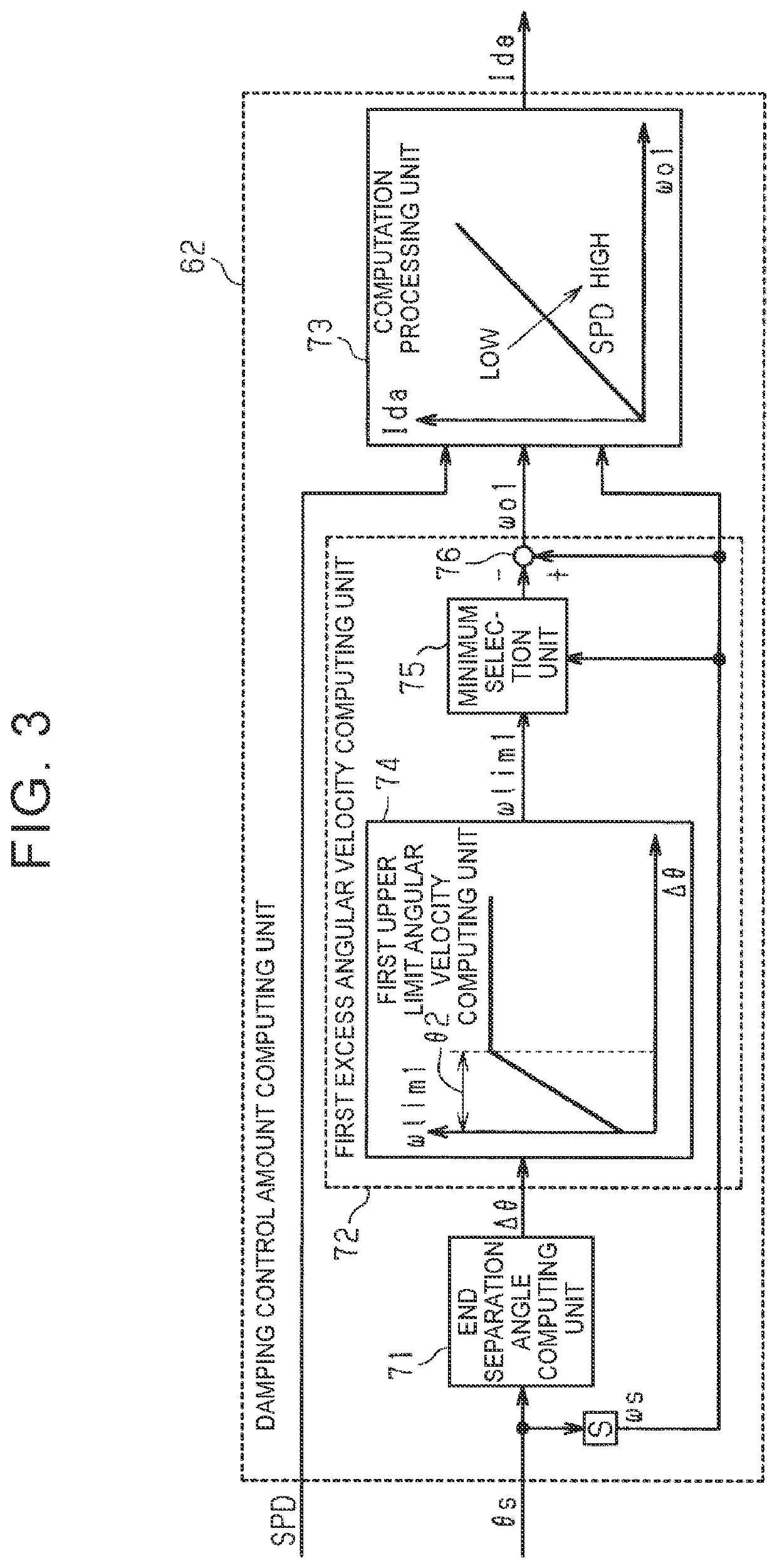

Steering control apparatus and steering control method

ActiveUS20200010112A1Suitable for downsizingReduce the impactElectrical steeringRotational axisSteering angle

A steering control apparatus for a steering system includes a controller. The controller sets a limit value to less than or equal to a steering angle limit value, the limit value being an upper limit of an absolute value of a torque command value, and controls a motor such that a motor torque follows the torque command. When the absolute value of a rotation angle of a rotary shaft exceeds a steering angle threshold, the controller computes a damping control amount such that the damping control amount increases with an increase in an excess of an angular velocity of the rotary shaft over a first upper limit angular velocity. The controller computes the torque command value based on a value obtained by combining the basic command value and the damping control amount such that an absolute value of the basic command value is reduced.

Owner:JTEKT CORP +1

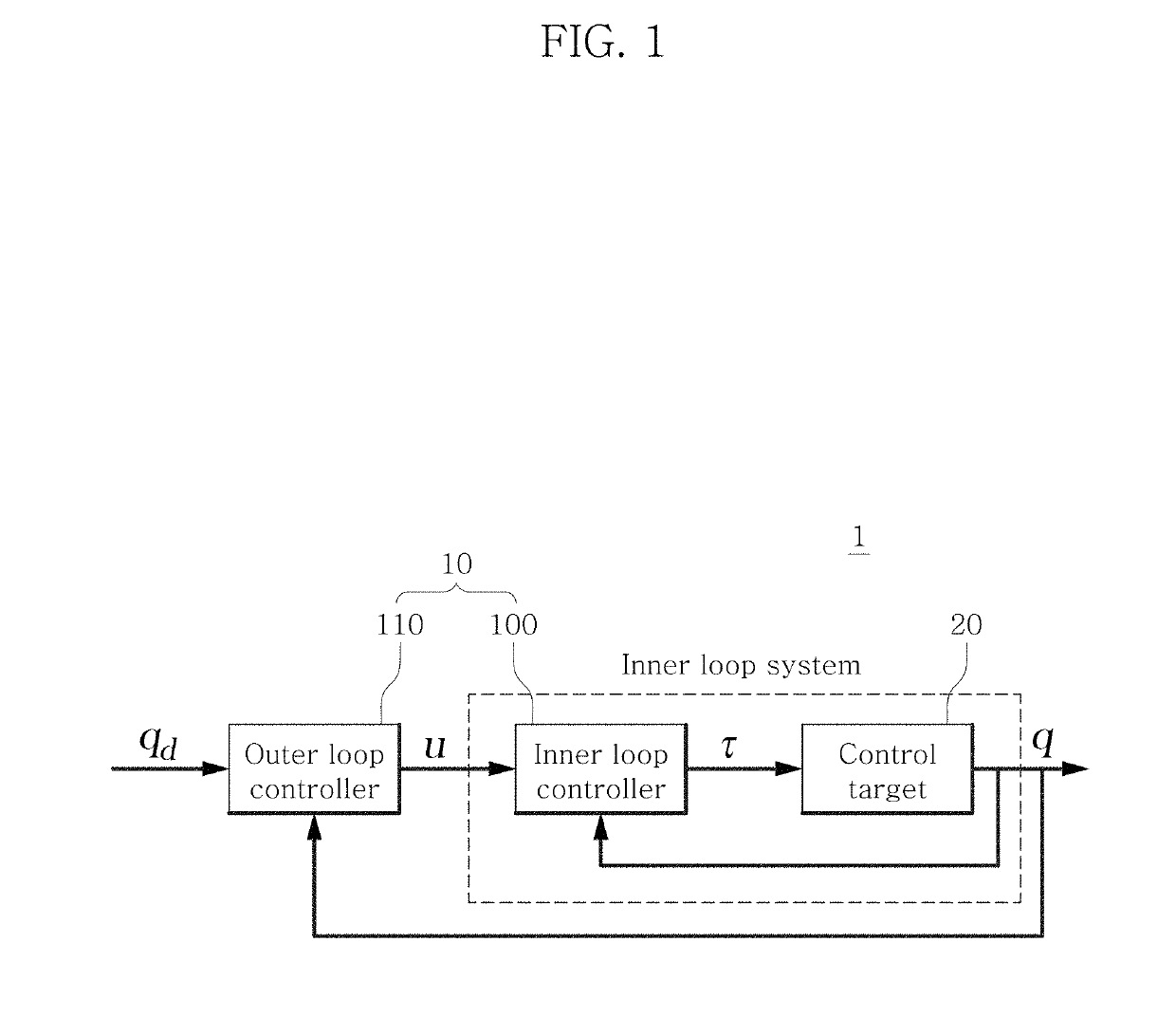

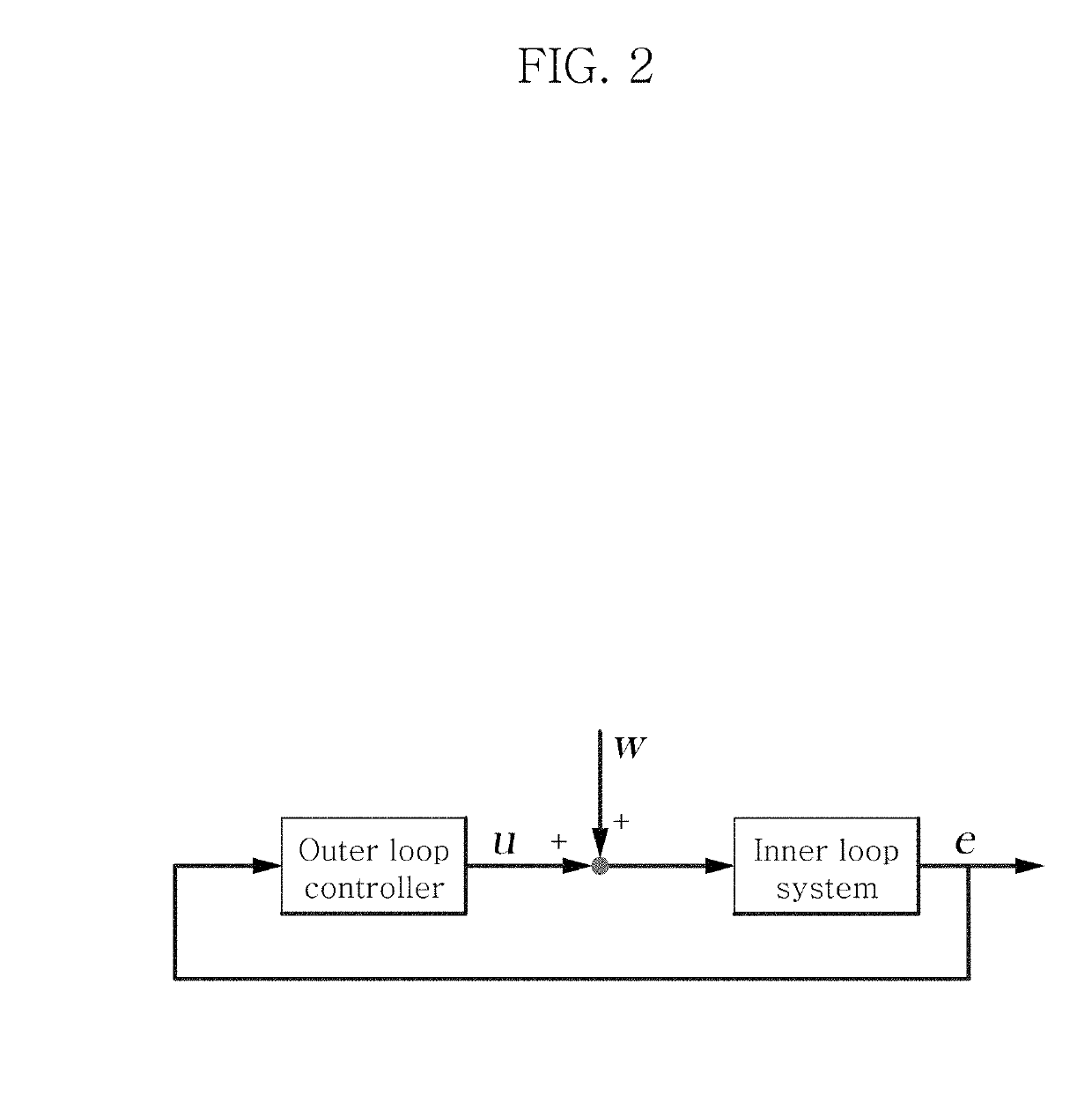

Computed-torque based controller, parameter determination method thereof and performance analysis method thereof

ActiveUS20190321972A1Improve controlReduce non-linearityProgramme controlProgramme-controlled manipulatorInner loopControl objective

Provided is a controller of a robot manipulator, a performance analysis method thereof and a parameter determination method thereof. The controller computes an error value of an output value of a control target for a target value through a computational equation and provides a control input value of the control target, and includes an outer loop controller which constitutes closed loop control of the control target, and an inner loop controller which performs feedback linearization to remove nonlinearity of the control target, wherein the computational equation is a linear differential equation designed considering exogenous disturbance acting in the controller and a computational error.

Owner:KOREA INST OF SCI & TECH

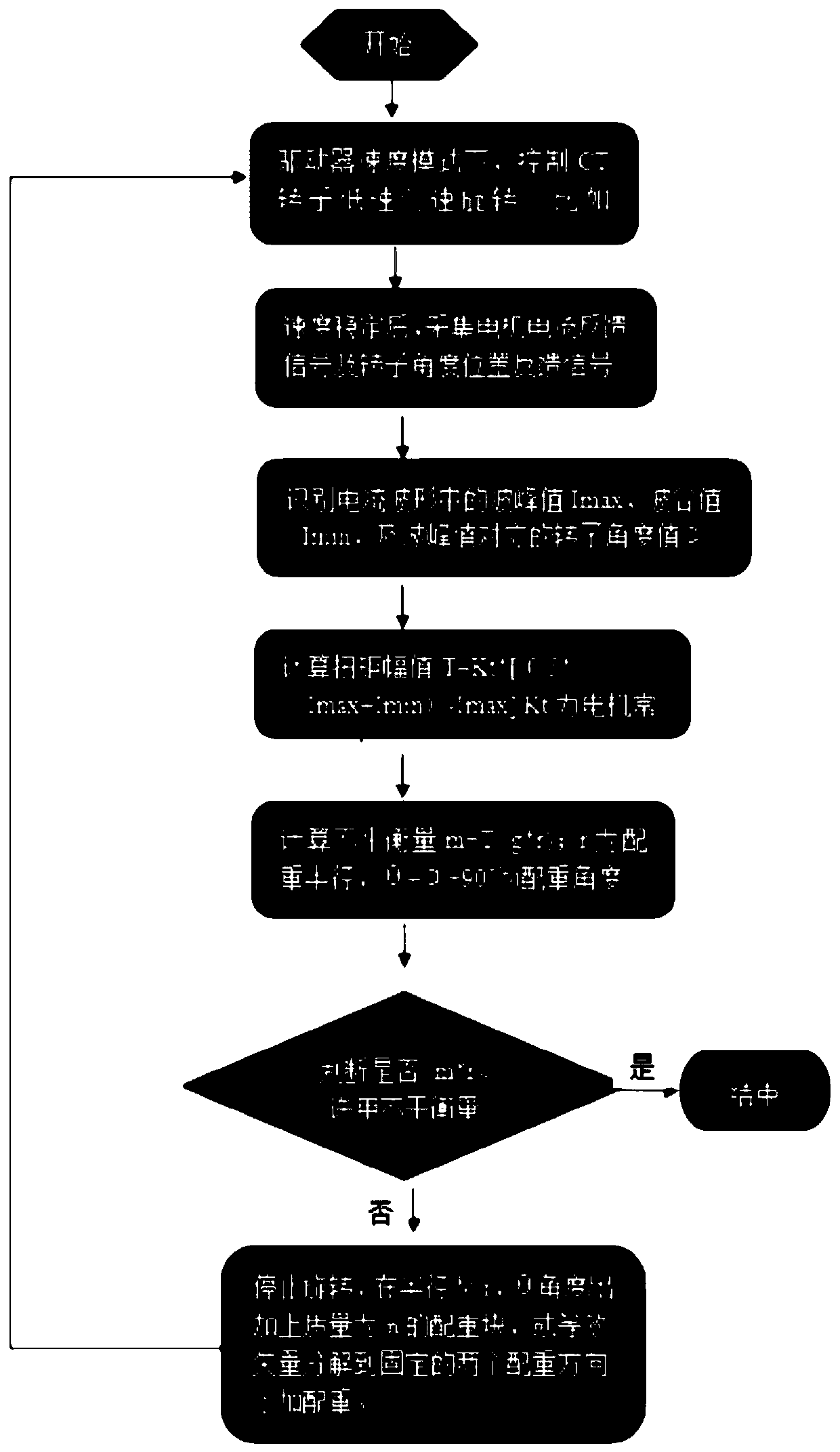

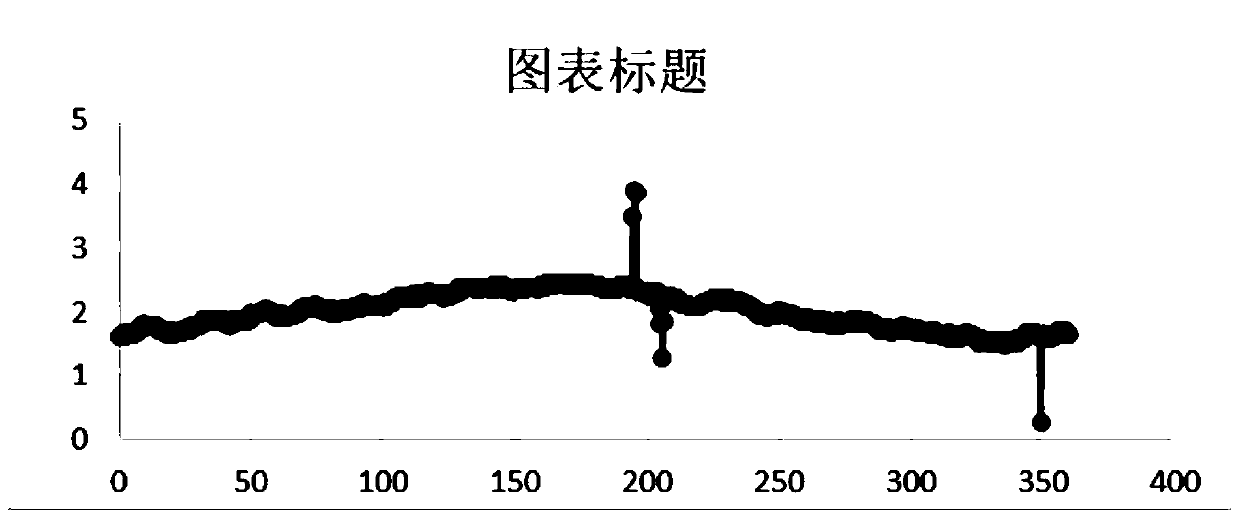

Static balancing method of a CT rotor

InactiveCN110763399AEasy to operateImprove efficiencyStatic/dynamic balance measurementLow speedComputed torque

The invention discloses a static balancing method of a CT rotor. The method comprises the following steps of (1) controlling the CT rotor to rotate at the constant low speed of 4-6rpm in a driver speed mode, (2) collecting a motor current feedback signal and a rotor angle position feedback signal after the speed is stabilized, (3) identifying a wave peak value Imax, a wave trough value Imin, and arotor angle value alpha corresponding to the wave peak value in a current waveform; (4) calculating torque amplitude T=Kt*[0.5*(Imax+Imin)-Imax], wherein Kt is a motor constant; and (5) calculating the amount of unbalance m=T / (g*r), wherein r is balance weight semi-diameter, and the theta is equal to alpha+90 degrees as the balance weight angle. Through the static balancing method of the CT rotordisclosed by the invention, the amount of the unbalance and the position can be automatically identified, an additional extra instrument is unnecessary, the operation is simple, and the efficiency ishigh; and the method is free from the influence of a human factor, the amount of unbalance factor interface can be eliminated, and the precision is high.

Owner:FMI MEDICAL SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com