Method of checking design size of wind power locking disc

A technology for designing dimensions and locking discs, applied in computer-aided design, calculation, electrical digital data processing, etc., can solve problems such as not considering the influence of bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

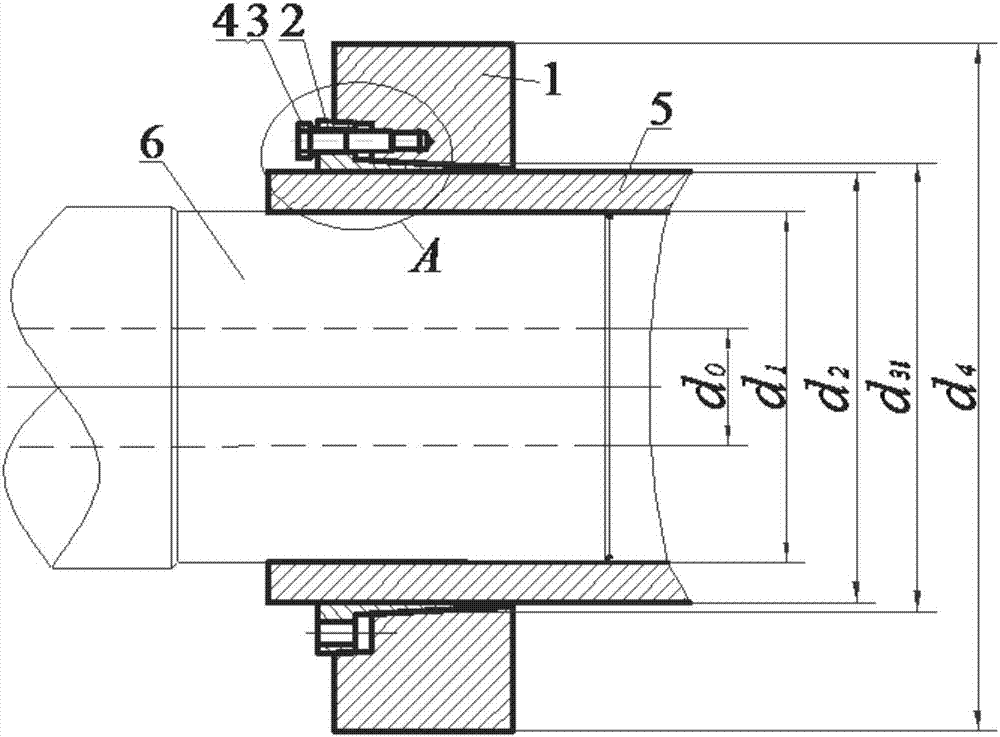

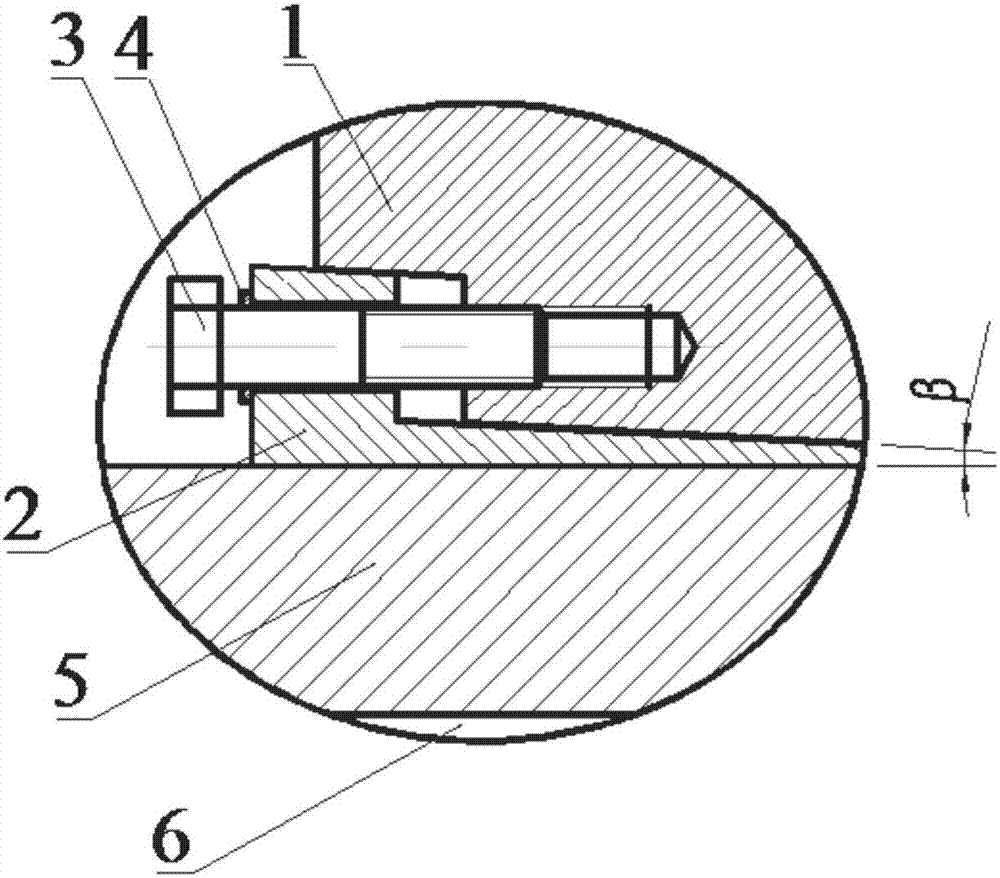

[0070] An implementation example of the present invention is to use a certain type of wind power locking disc, and the parameters of the locking disc are: the inner diameter of the main shaft d 0 75mm, outer diameter d 1 520mm, shaft sleeve outer diameter d 2 is 640mm, and the average diameter of the long cone surface of the inner ring is d 3l is 660.96mm, and the outer diameter of the outer ring is d 4 It is 1020mm. Design maximum fit clearance R between main shaft and bushing 1max is 0.136mm, the maximum fit clearance R between the sleeve and the inner ring is designed 2max is 0.240mm. The contact length L between the shaft sleeve and the inner ring is 245mm, and the inclination angle β of the conical surface of the inner ring is 2.8°. The modulus of elasticity of the spindle E 1 is 205Gpa, the elastic modulus E of the bushing 2 is 176Gpa, the elastic modulus E of the inner ring and the jacket 3 ,E 4 Both are 210GPa. Bolt tightening torque M 0 is 1660KN·m, the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com