Clutch control method of hybrid vehicle

A hybrid vehicle and clutch control technology, which is applied to hybrid vehicles, clutches, road vehicle drive control systems, etc., can solve problems such as difficult torque transmission, vibration, excessive clutch slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

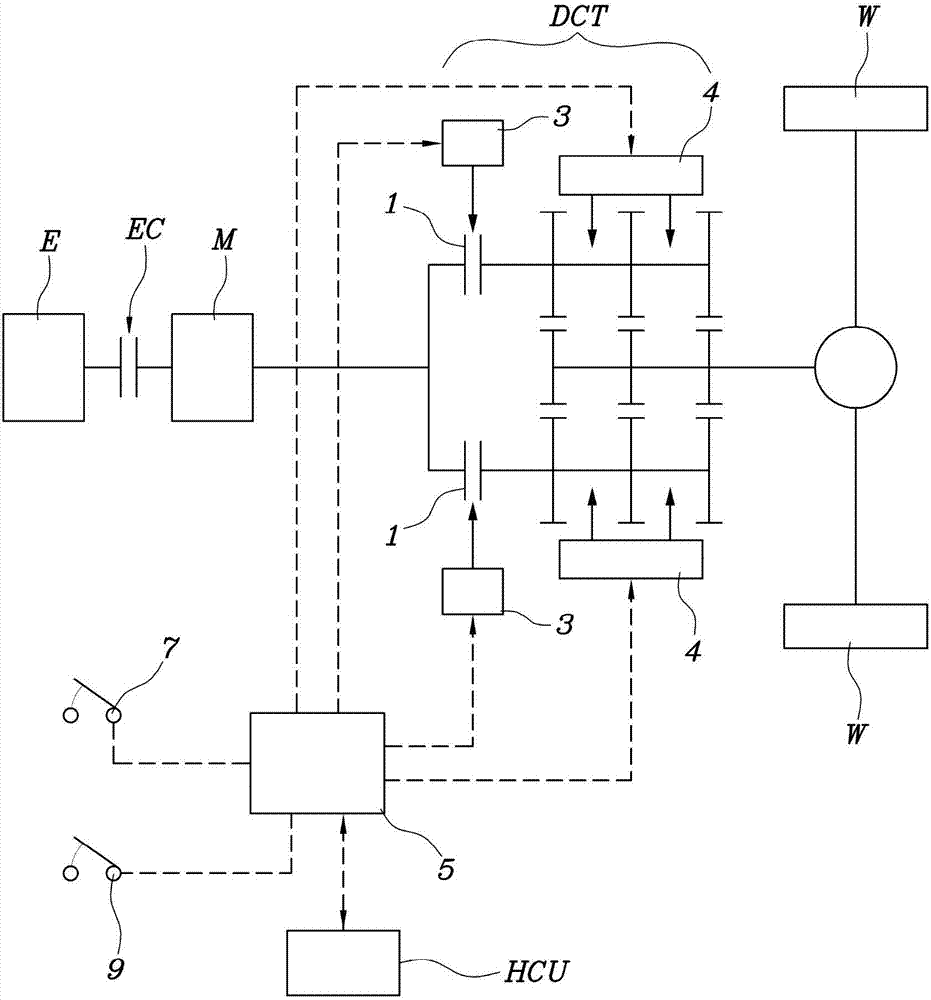

[0025] The following description is exemplary in nature and is not intended to limit the invention, the application or uses of the invention. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

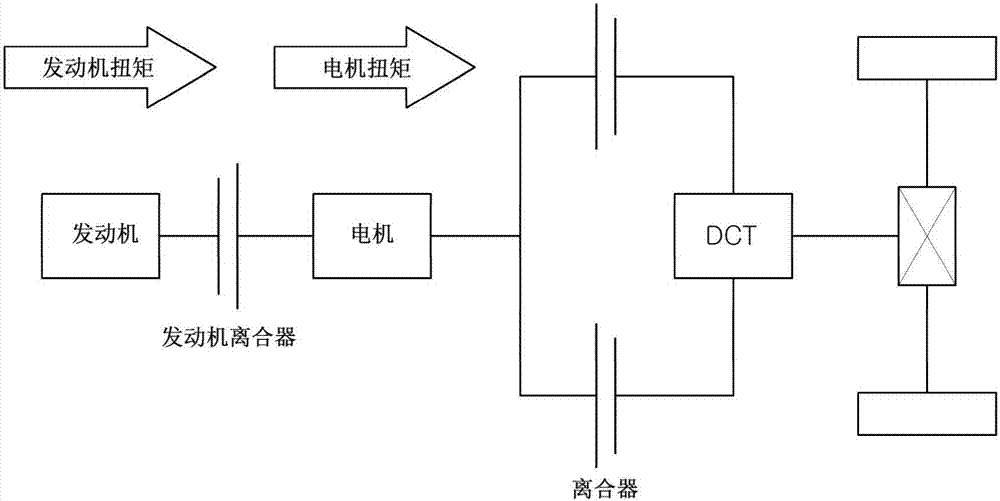

[0026] During regenerative braking in electric vehicle mode (EV mode), braking is performed by utilizing only the reverse drive of the electric motor, and it is assumed that the clutch transmits reverse torque between the transmission and the electric motor, as figure 2 As shown, the rearward transfer torque applied to the clutch results in a different behavior than the forward transfer torque.

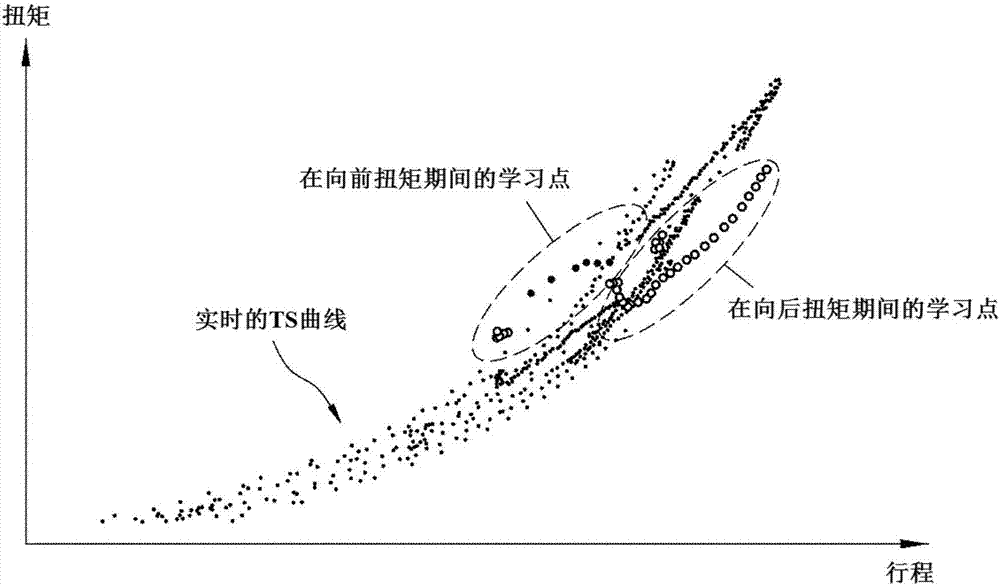

[0027] figure 2 An example of learning the transmission torque characteristic in real time according to the stroke of the clutch actuator used to control the clutch is shown. refer to figure 2 , it can be seen that the forward torque (which is the torque transmitted from the engine and motor to the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com