Sampling device for well-inside in-situ fluid in deep well

A sampling device, an in-situ technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of narrow downhole space, formation fluid pollution, formation fluid disturbance, etc., and achieve small size, stable performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

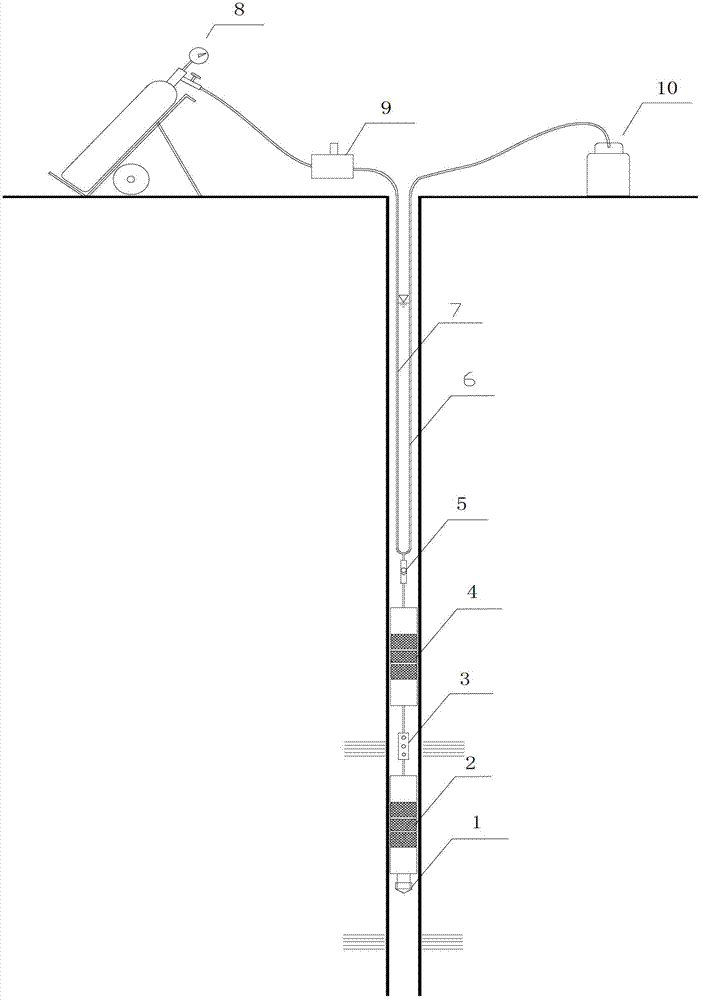

[0031] see figure 1 As shown, it is an embodiment of the in-situ fluid sampling device in a deep well of the present invention. In this embodiment, the in-situ fluid sampling device in a deep well is composed of a downhole unit and an uphole unit. The downhole unit is responsible for positioning the sampling target layer and isolating non-sampling Fluid, allowing sampling fluid to enter the sampling system, etc., mainly including plug 1, lower packer 2, filter screen 3, upper packer 4, water inlet window 5, sampling pipe 6 and gas supply pipe 7. The uphole unit is responsible for controlling the sampling and receiving the sampling fluid collected to the surface, mainly including high-pressure N 2 Gas cylinder 8, air conditioner 9 and aseptic sampling bottle 10.

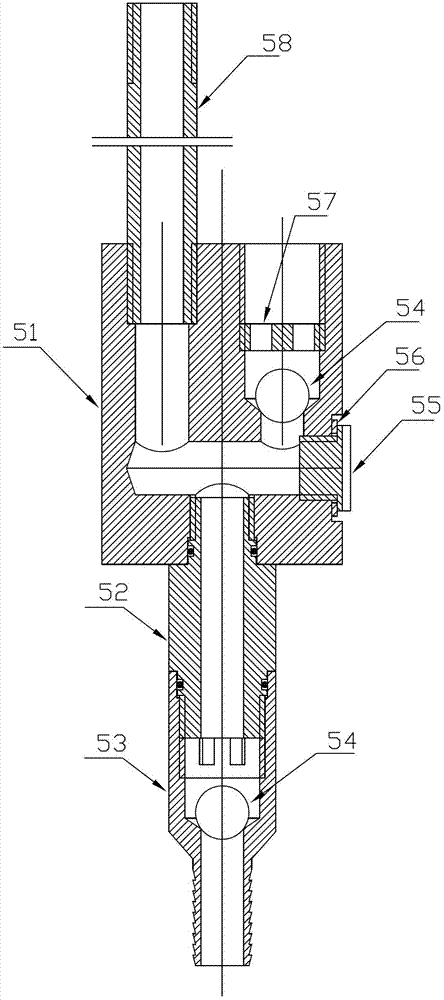

[0032] The water inlet window 5 is processed from stainless steel. Inlet window allows sample fluid to enter sampling line 6 and prevents backflow, see figure 2 , The water inlet window is made up of base 51, chec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com