Fixed geometrical supersonic-speed and high supersonic-speed adjusting air inlet

A hypersonic and air inlet technology, applied to jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems such as complex configuration and high flow coefficient, and achieve high flow coefficient, fixed geometry, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

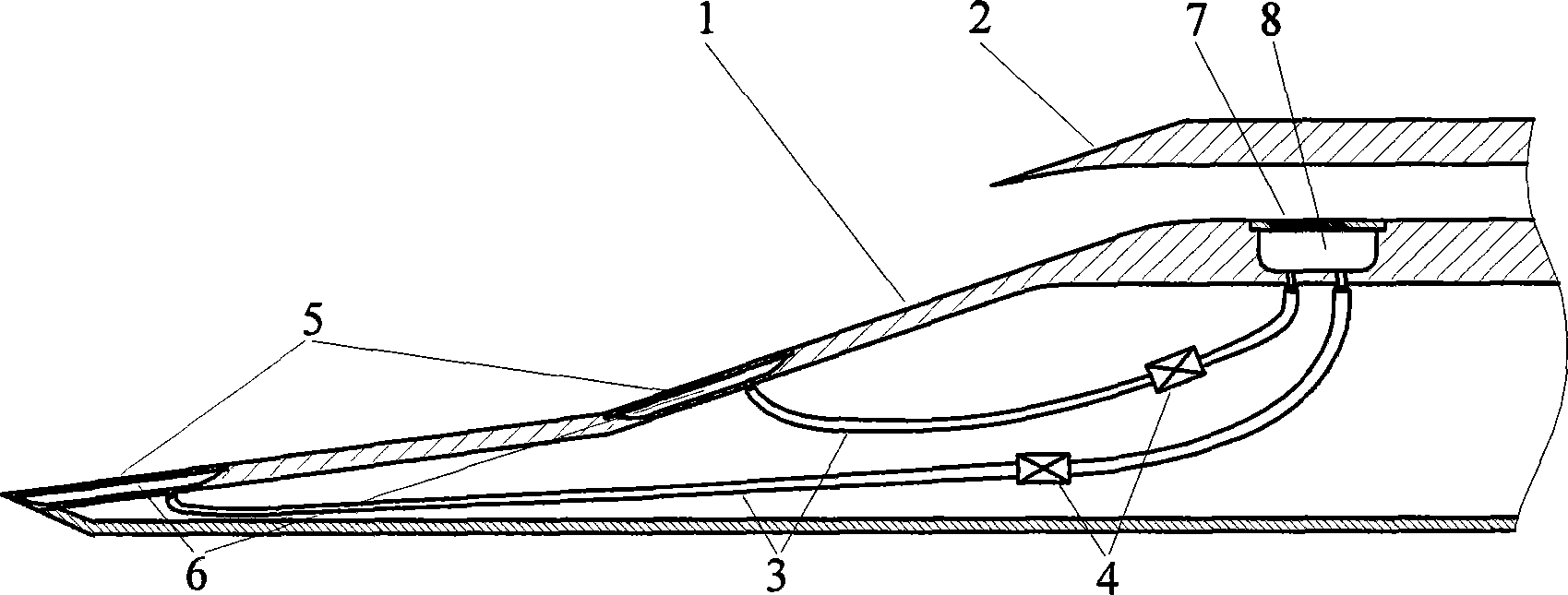

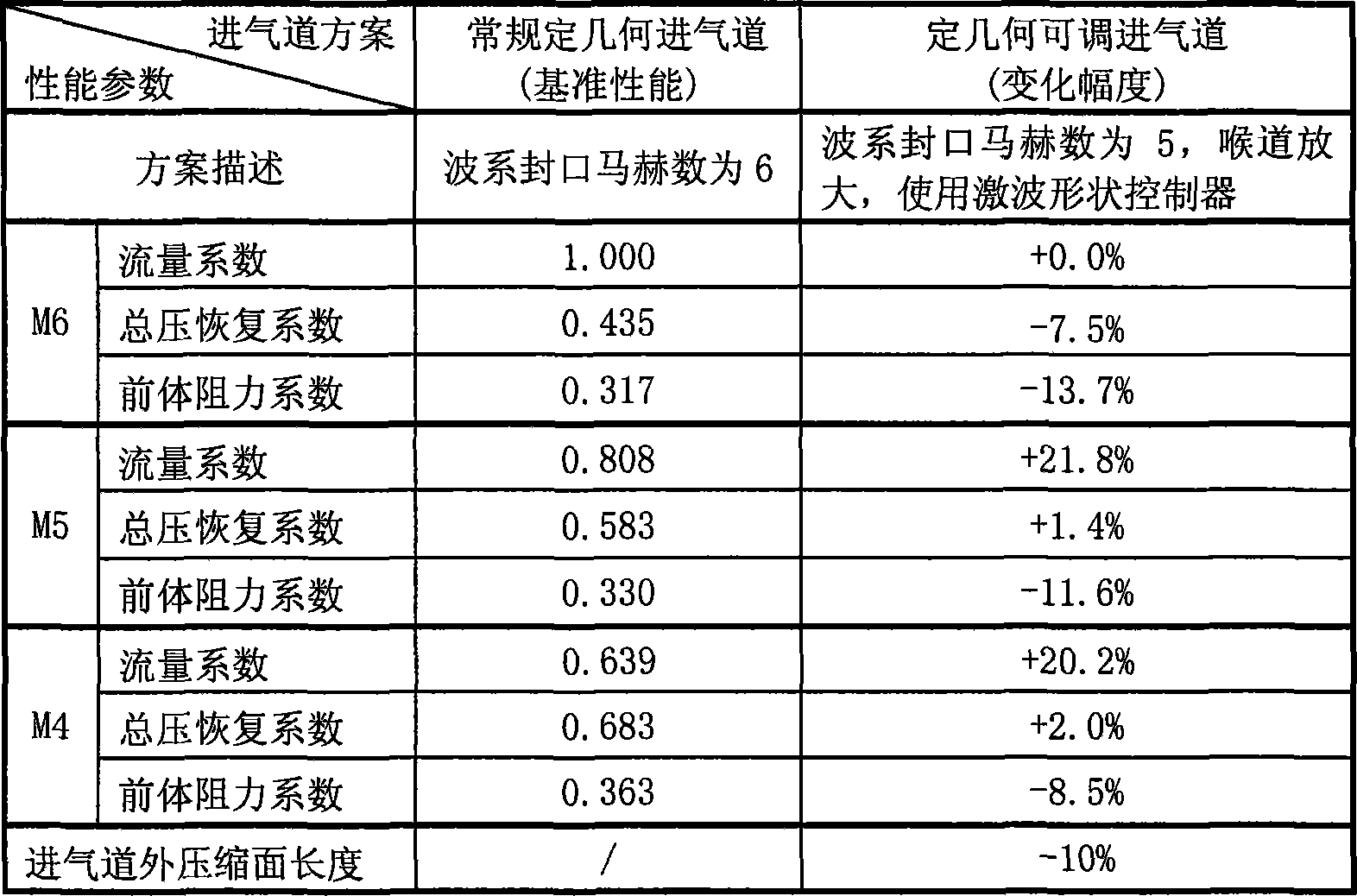

[0017] Under the design conditions of the working Mach number range of 4~6, a hypersonic adjustable inlet with a certain geometry is designed. The adjustable inlet is designed with Mach number 5 as the Mach number of the wave system seal. It has two-stage external compression slopes, and the wave system at the mouth can be maintained by injecting an appropriate amount of secondary flow within the range of Mach number 5-6. At this time, the secondary flow consumed is 0.0-1.5% of the capture flow of the inlet (recycling), and the adjustment range of the effective throat cross-sectional area is more than 15% when the Mach number is 6. Table 1 compares the main performance parameters of the fixed geometry hypersonic adjustable inlet and the regular defined geometry inlet. The starting Mach number of the two schemes is 4.0, and the difference of the outlet Mach number is within 2.0%. It can be seen that the fixed-geometry hypersonic adjustable inlet has significant advantages in te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com