Surge-preventing structure for aero-engine compressor

A technology of aero-engine and air compressor, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of three-rotor structure, supporting force transmission, complicated lubrication, high cost and so on, and achieve the expansion of stable working range and low cost Effect of low, axial velocity and increased flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

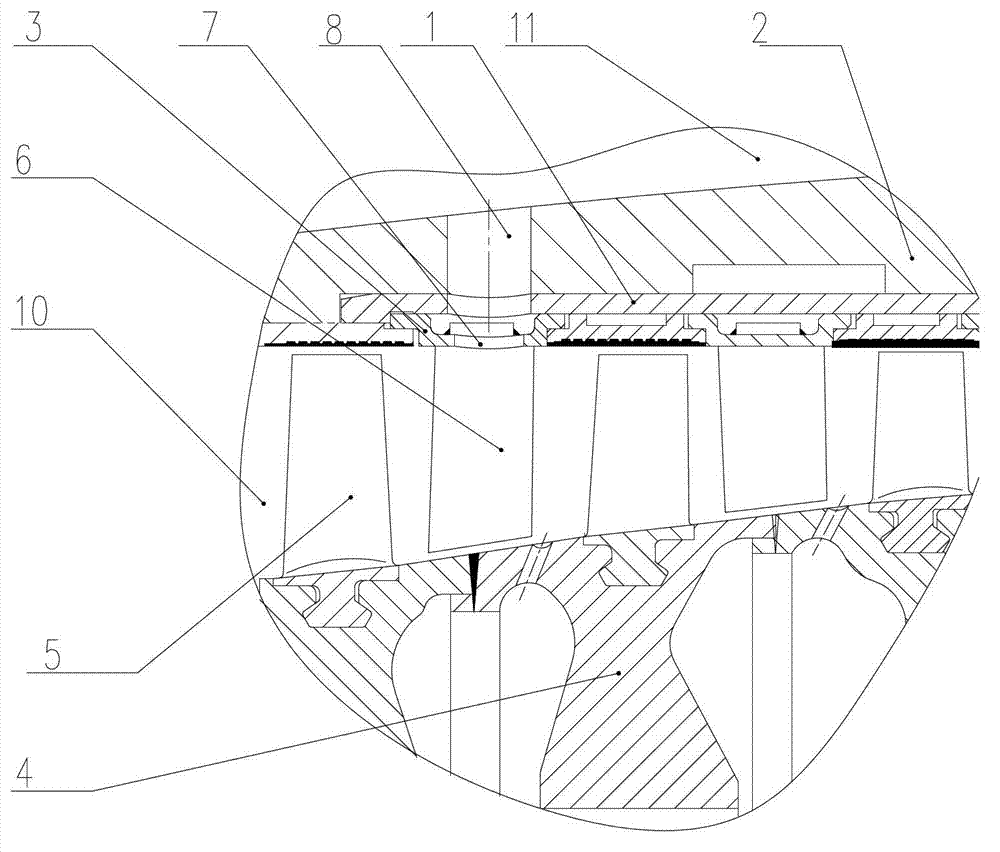

[0008] As shown in the figure, the anti-puff structure of an aero-engine compressor includes a compressor casing 1, an intermediate casing 2, and a stator ring 3. The intermediate casing 2 is installed on the compressor casing 1, and the stator ring 3 is installed inside the compressor casing 1. , the stator ring 3 is provided with stator blades 6 evenly distributed in the circumferential direction, the compressor rotor 4 is located in the compressor casing 1 and is equipped with rotor blades 5, the rotor blades 5 and the stator blades 6 are interlaced to form an inner channel 10, and the intermediate casing 2 The outside is the outer duct 11, which is located at the position of the stator vanes 6 on the stator ring 3. There are radial vent holes 7 in the middle of every two stator vanes 6, and there are holes in the corresponding positions on the compressor casing 1 and the intermediate casing. The diameter is greater than the air release hole 8 of the radial air release hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com