Multi-stage pulse tube refrigerator adopting relay linear compressor

A linear compressor, pulse tube refrigerator technology, applied in refrigerators, compressors, refrigeration components and other directions, can solve the problems of low refrigeration efficiency, difficult to obtain temperature zones, etc., to achieve improved efficiency, compact structure, and reduced heat generation. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

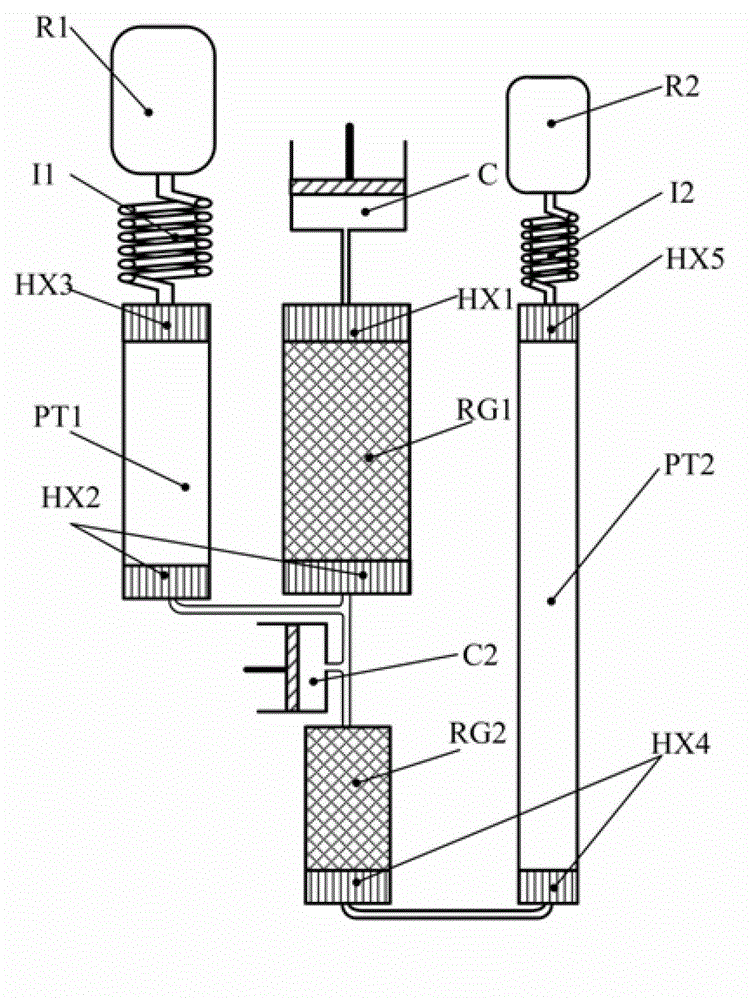

[0029] Such as figure 1 Shown: a multi-stage pulse tube refrigerator using a relay linear compressor, including: compressor C, heat exchanger HX1 at the hot end of the regenerator, regenerator RG1 at the high temperature section, heat exchange at the cold end of the regenerator at the high temperature section HX2, primary pulse tube PT1, primary pulse tube hot end heat exchanger HX3, primary inertial tube I1, primary gas storage R1, superconducting relay linear compressor C2, low temperature section regenerator RG2, low temperature section regenerator Heater cold end heat exchanger HX4, secondary pulse tube PT2, secondary pulse tube hot end heat exchanger HX5, secondary inertia tube I2, secondary gas storage R2, compressor C and regenerator hot end heat exchanger HX1, high temperature section regenerator RG1, high temperature section regenerator cold end heat exchanger HX2, primary pulse tube PT1, primary pulse tube hot end heat exchanger HX3, primary inertia tube I1 and prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com