Patents

Literature

246results about How to "Increase pressure ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

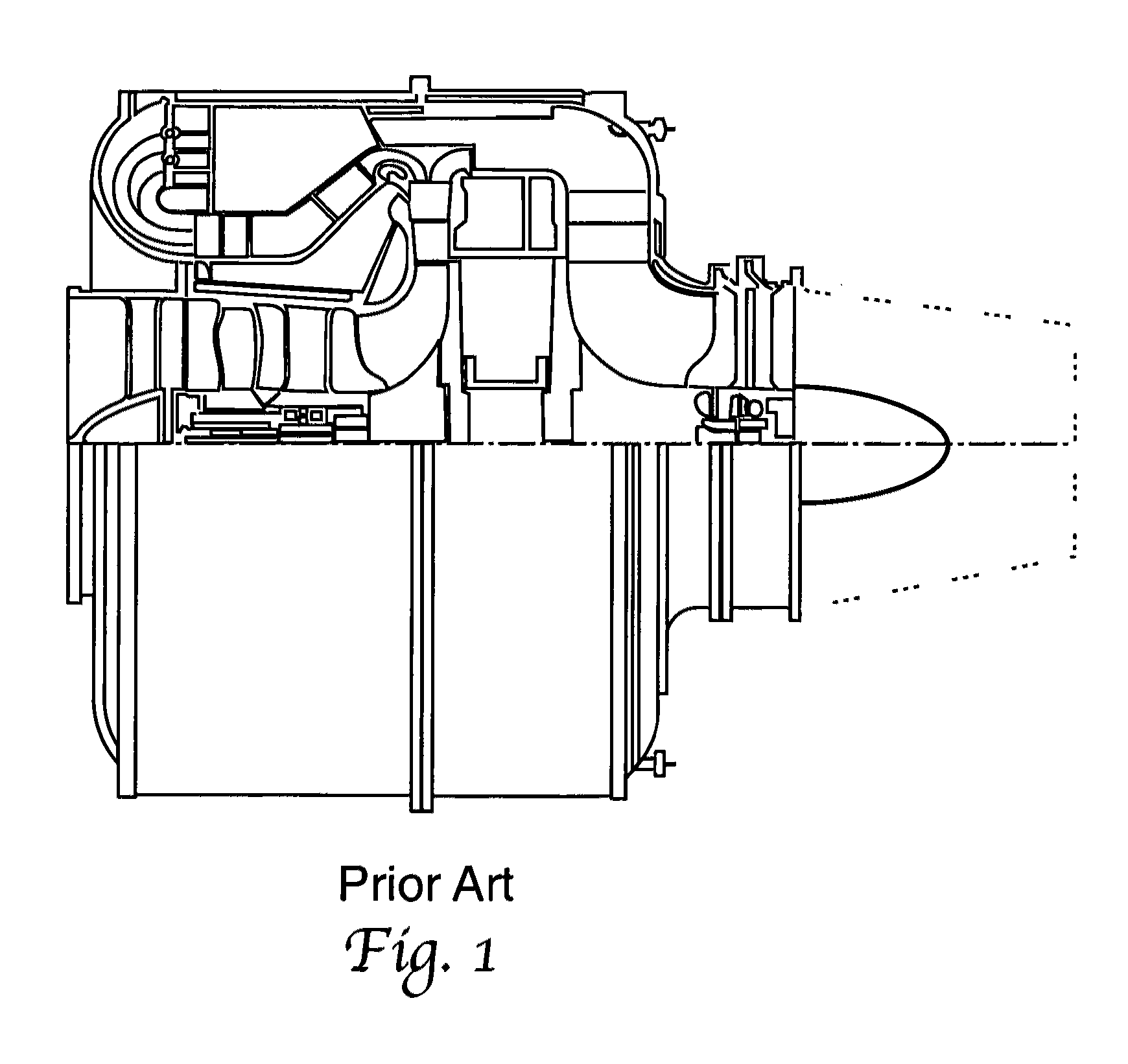

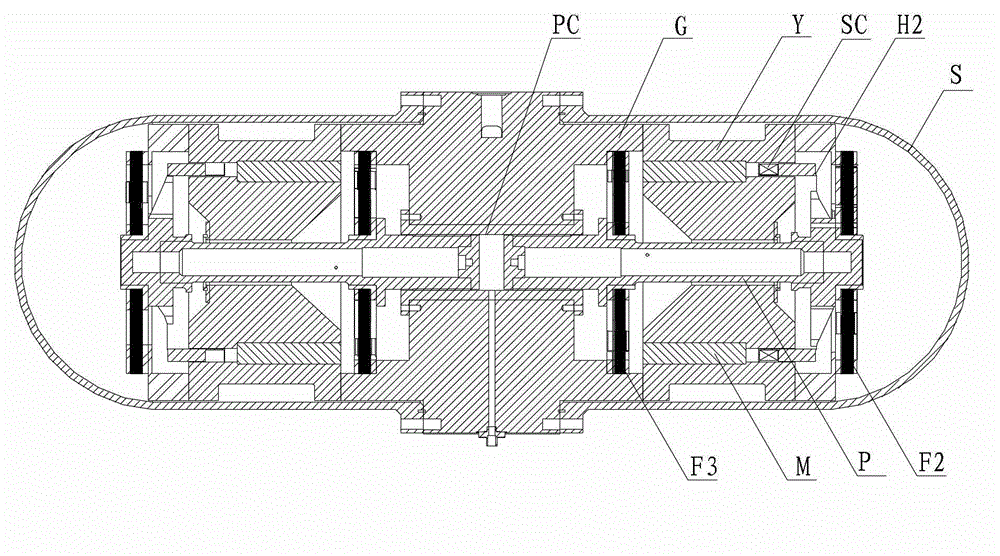

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

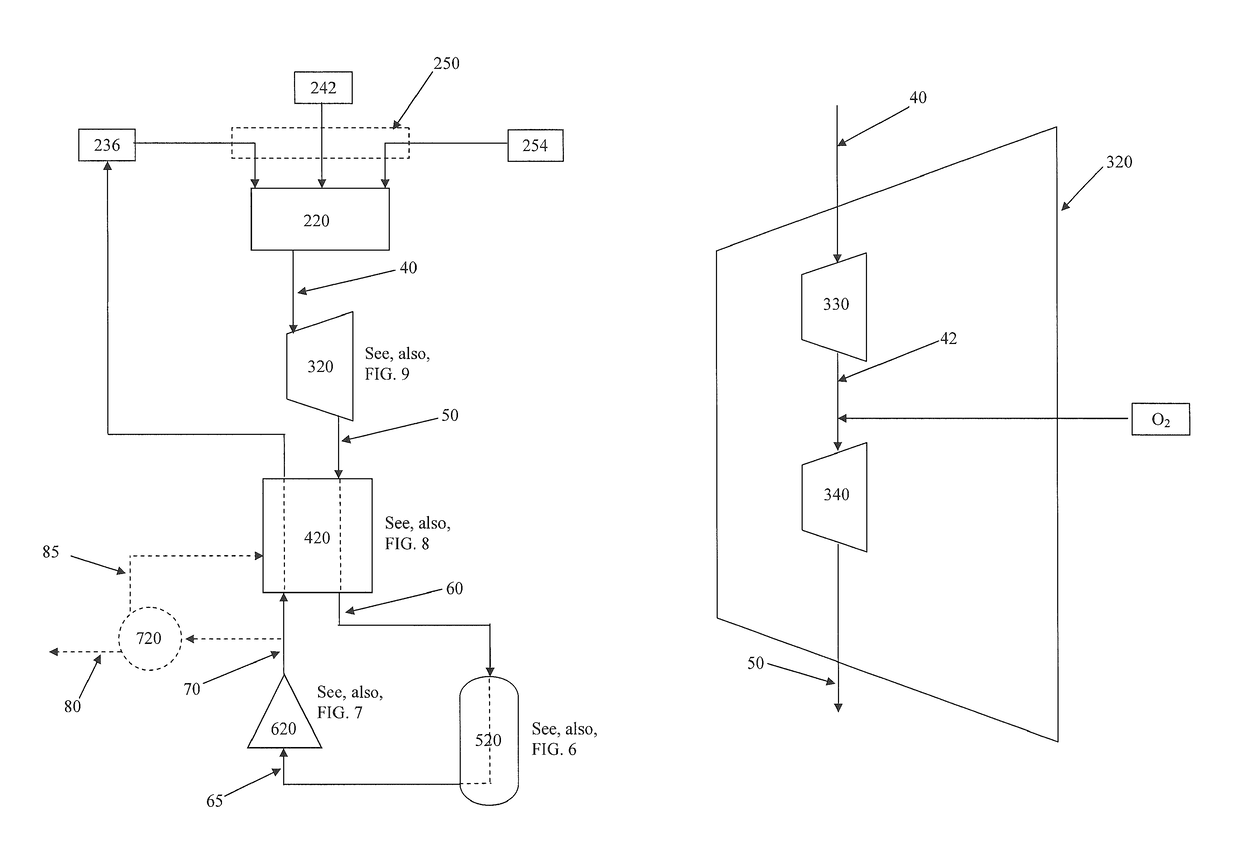

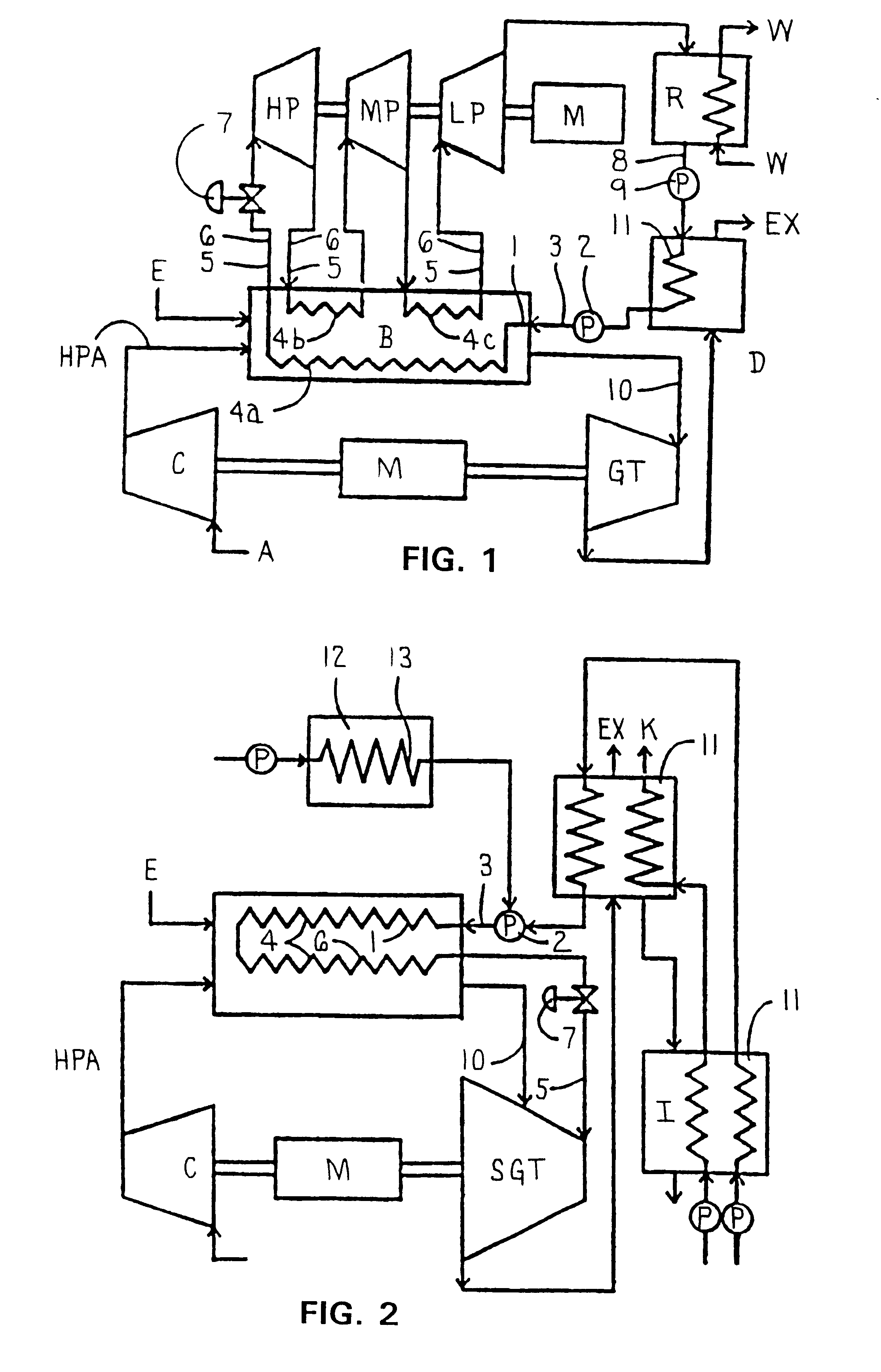

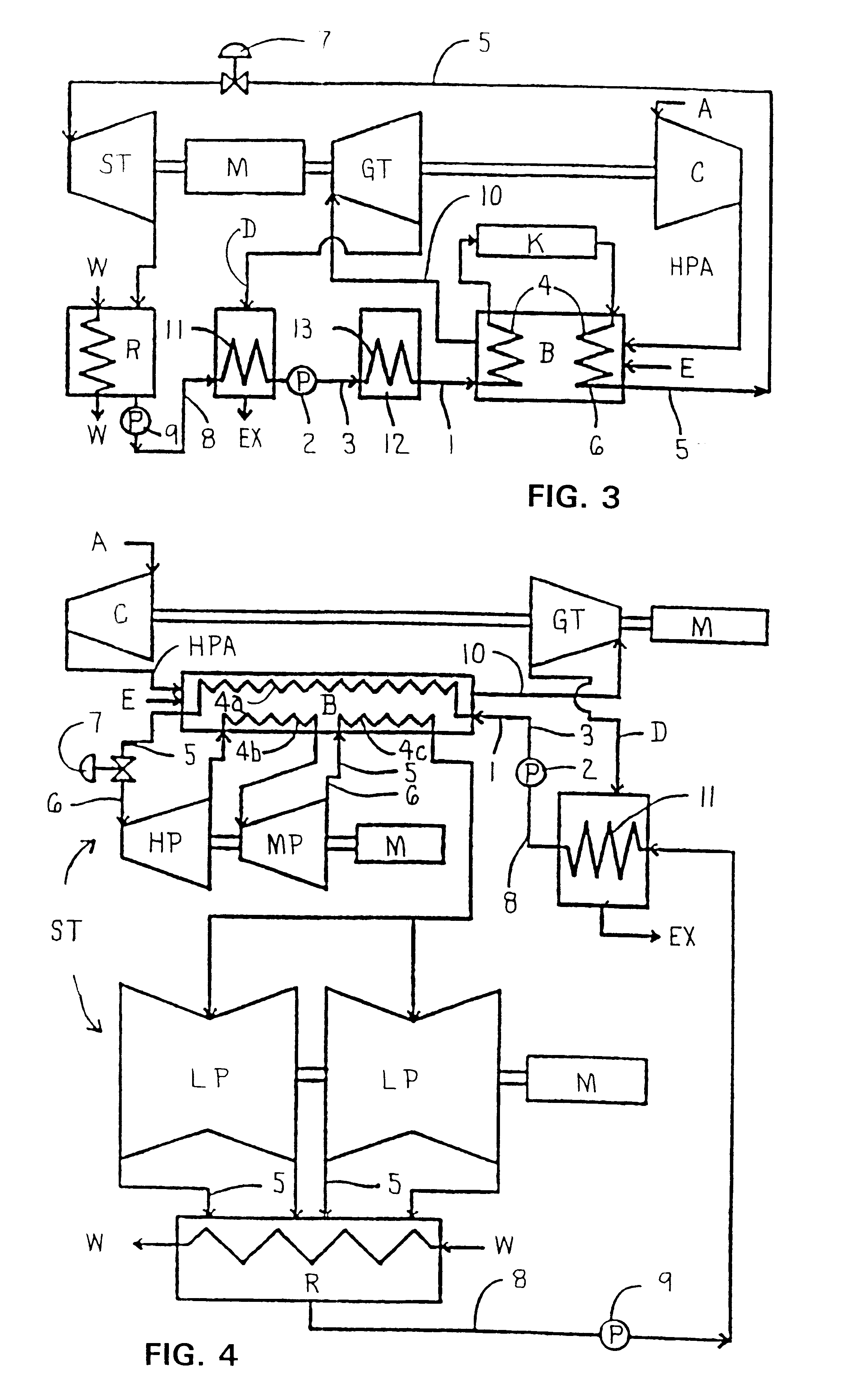

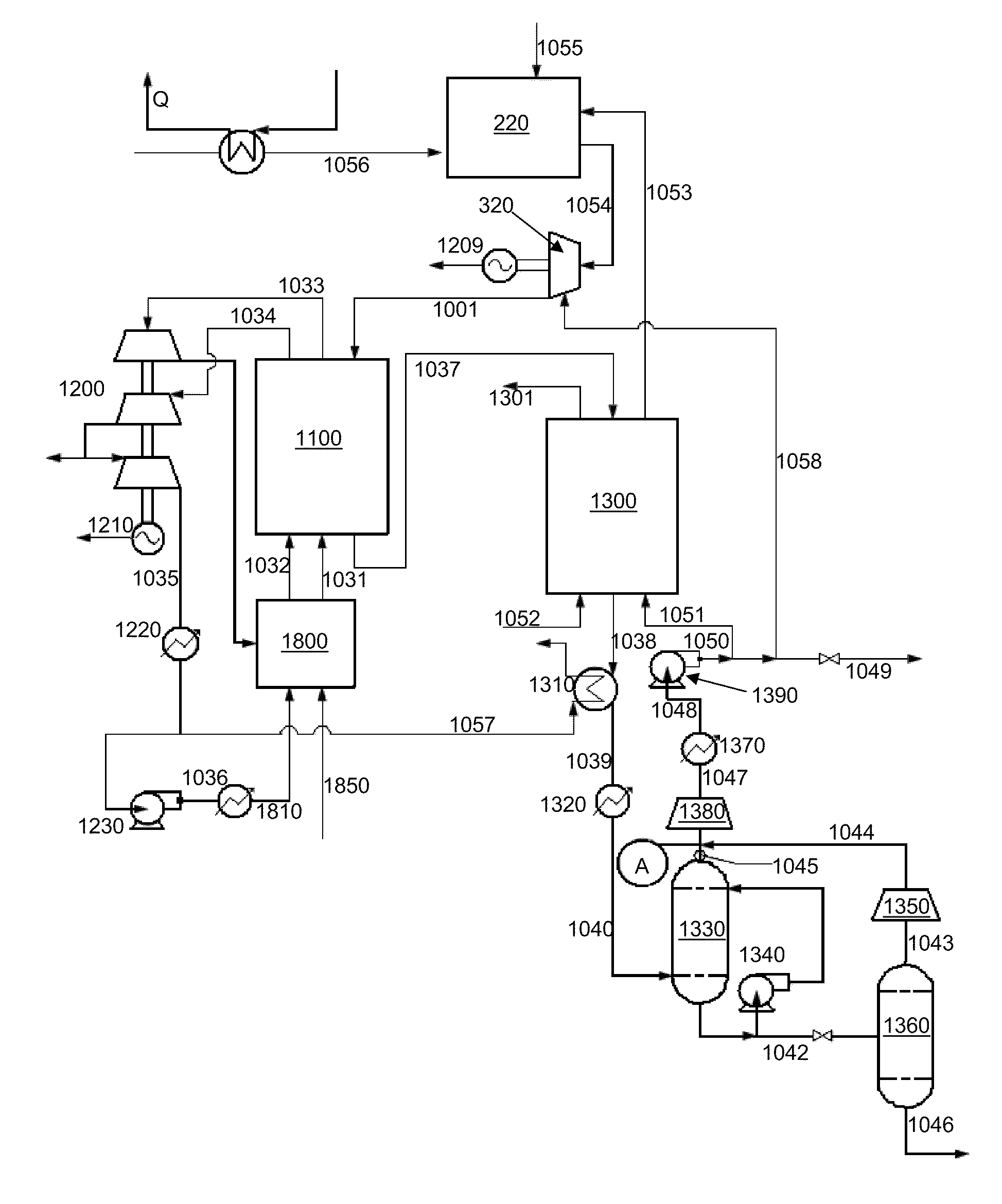

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

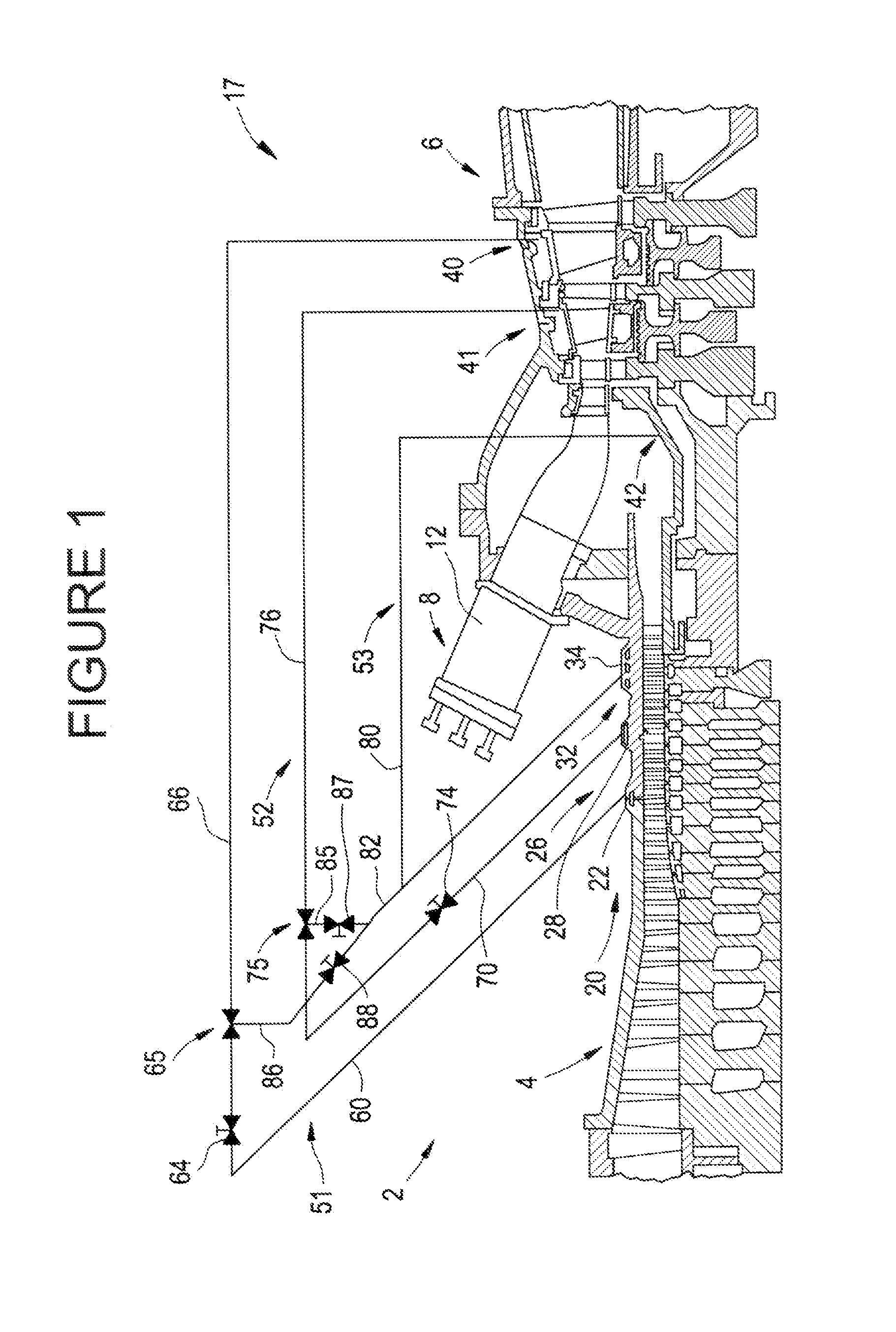

Method and apparatus for boosting gas turbine engine performance

InactiveUS8616005B1Improve performanceIncrease fluid pressureGas turbine plantsJet propulsion plantsAtmospheric pressureTurbine

A method and apparatus for boosting the performance of gas turbine engines, pipelines, and other applications using gas turbine engine systems. A pressurizing device or other source is preferably used to deliver an intake air stream to the gas turbine engine at at least 2% above atmospheric pressure. The pressurizing device of other source is preferably not mechanically driven by the gas turbine engine itself.

Owner:COUSINO SR DENNIS JAMES

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

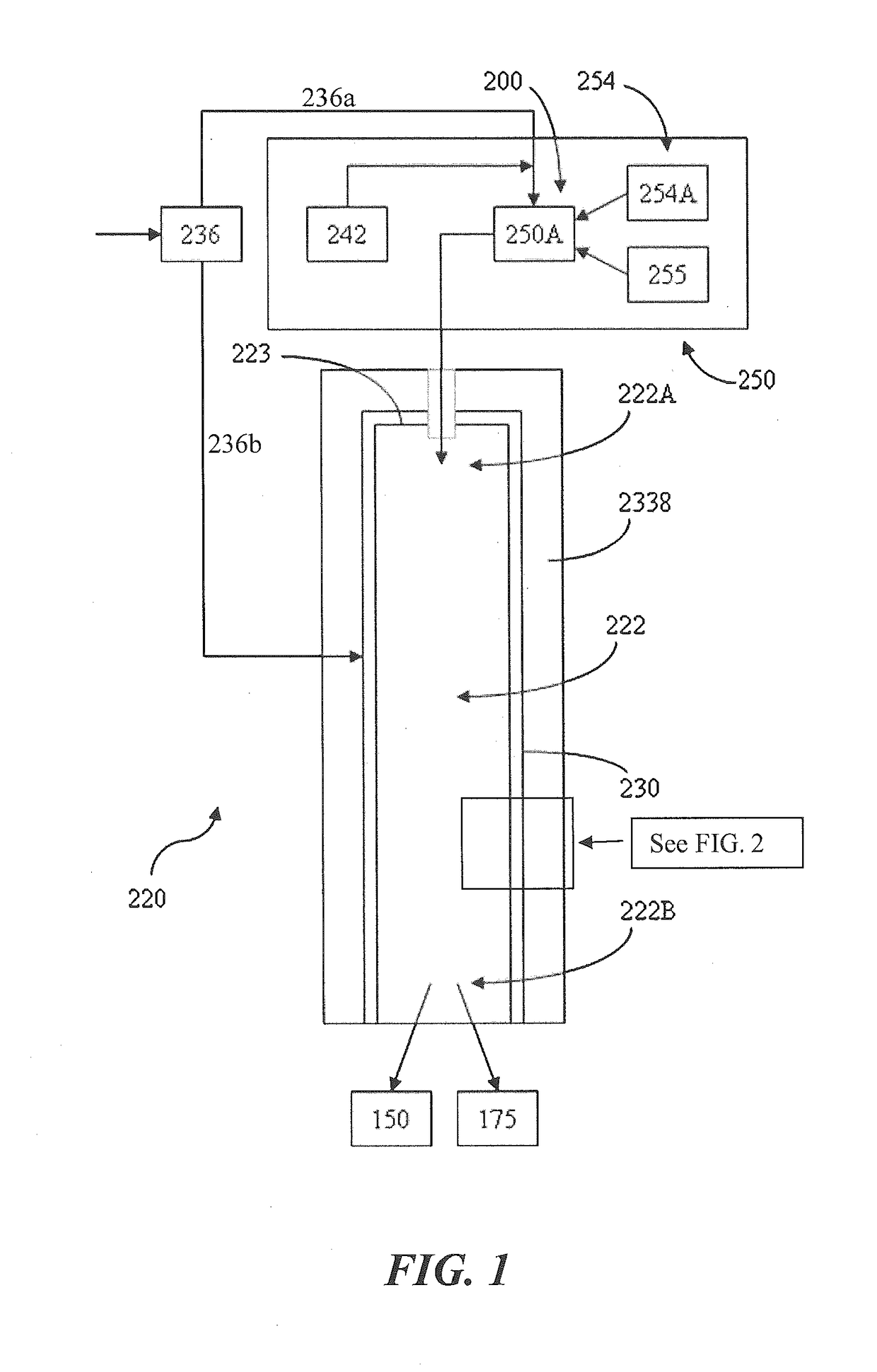

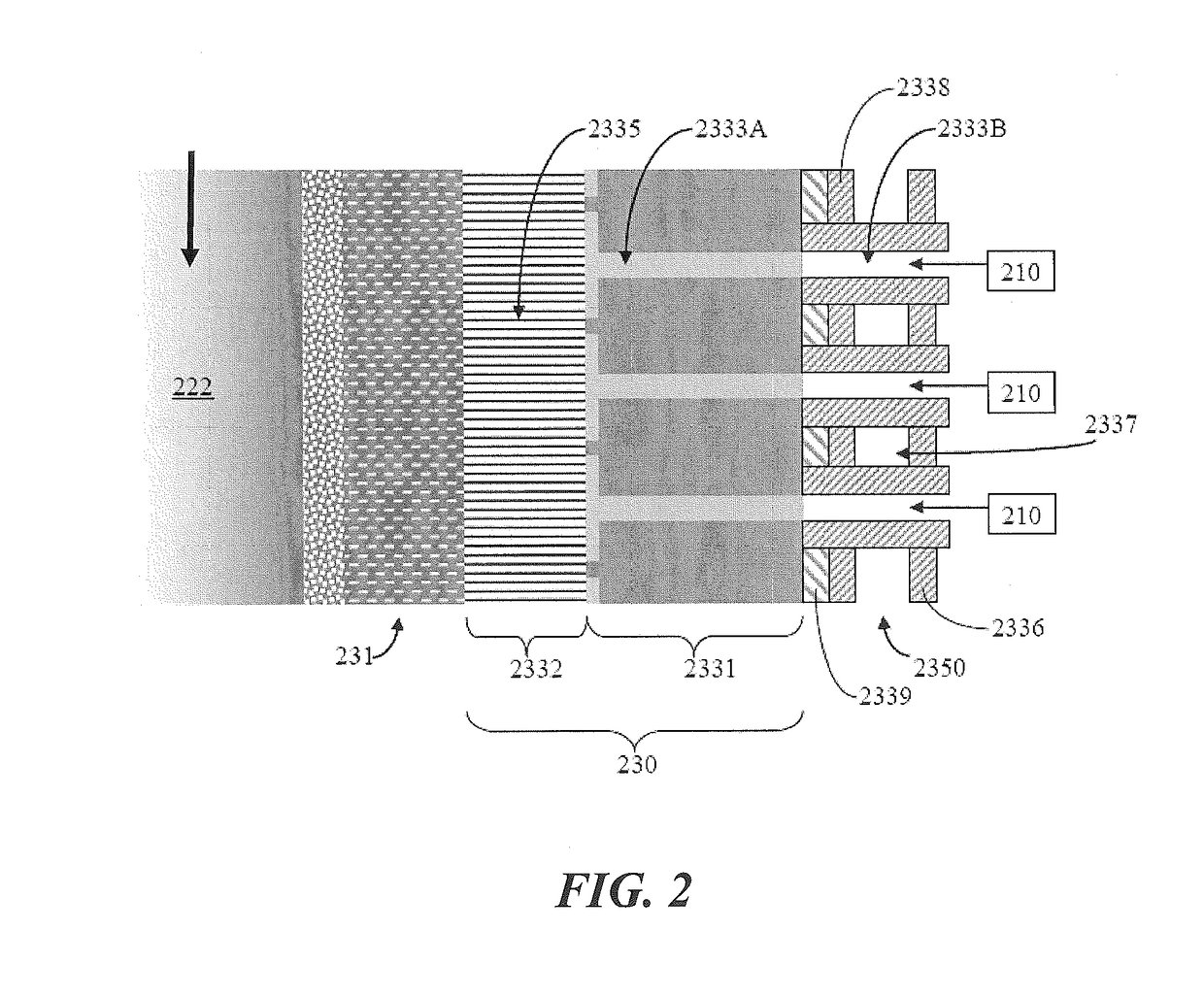

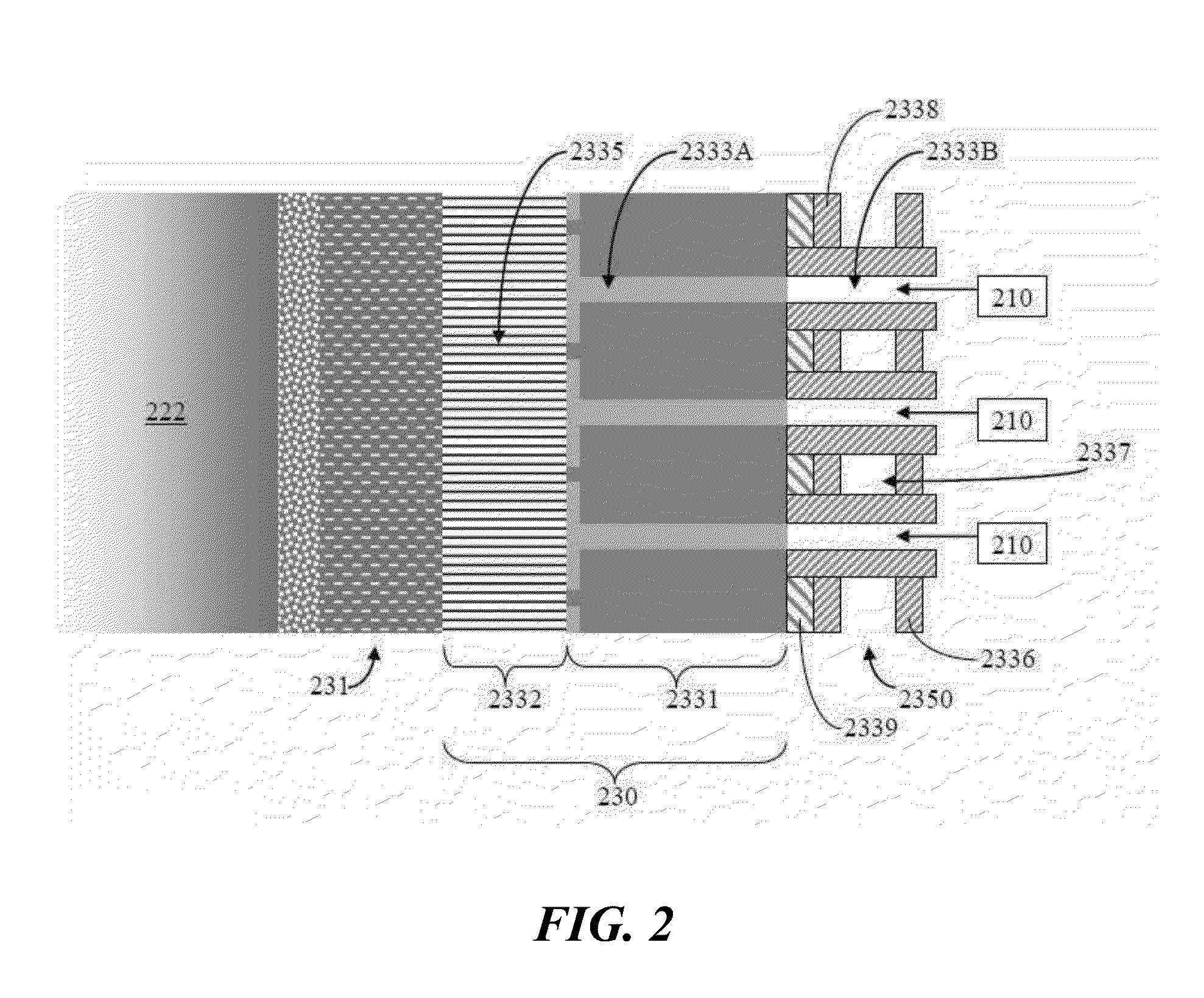

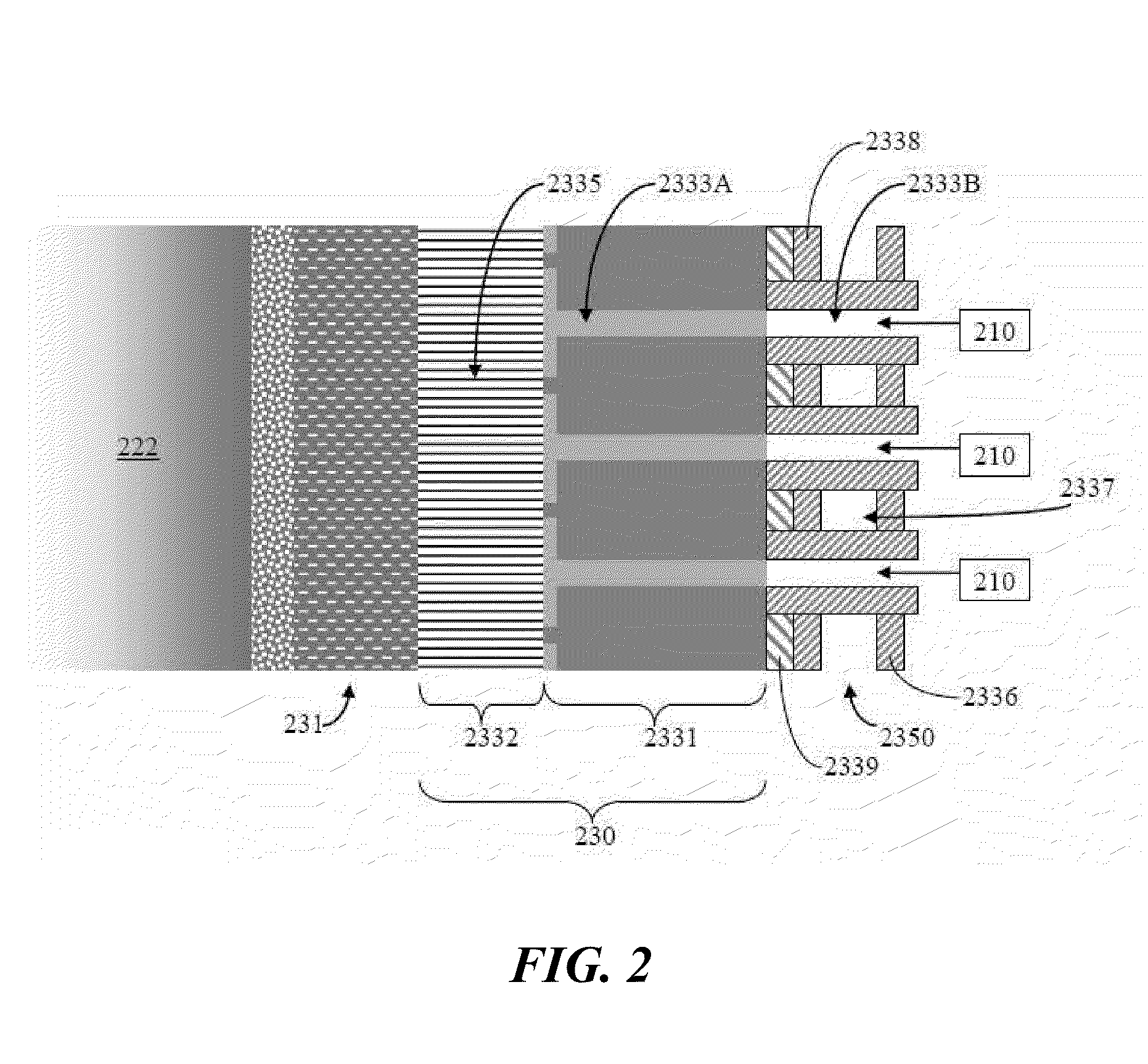

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS9068743B2Reducing and eliminating needEliminate damage to and build-upGas turbine plantsDirect carbon-dioxide mitigationCombustion chamberWorking fluid

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

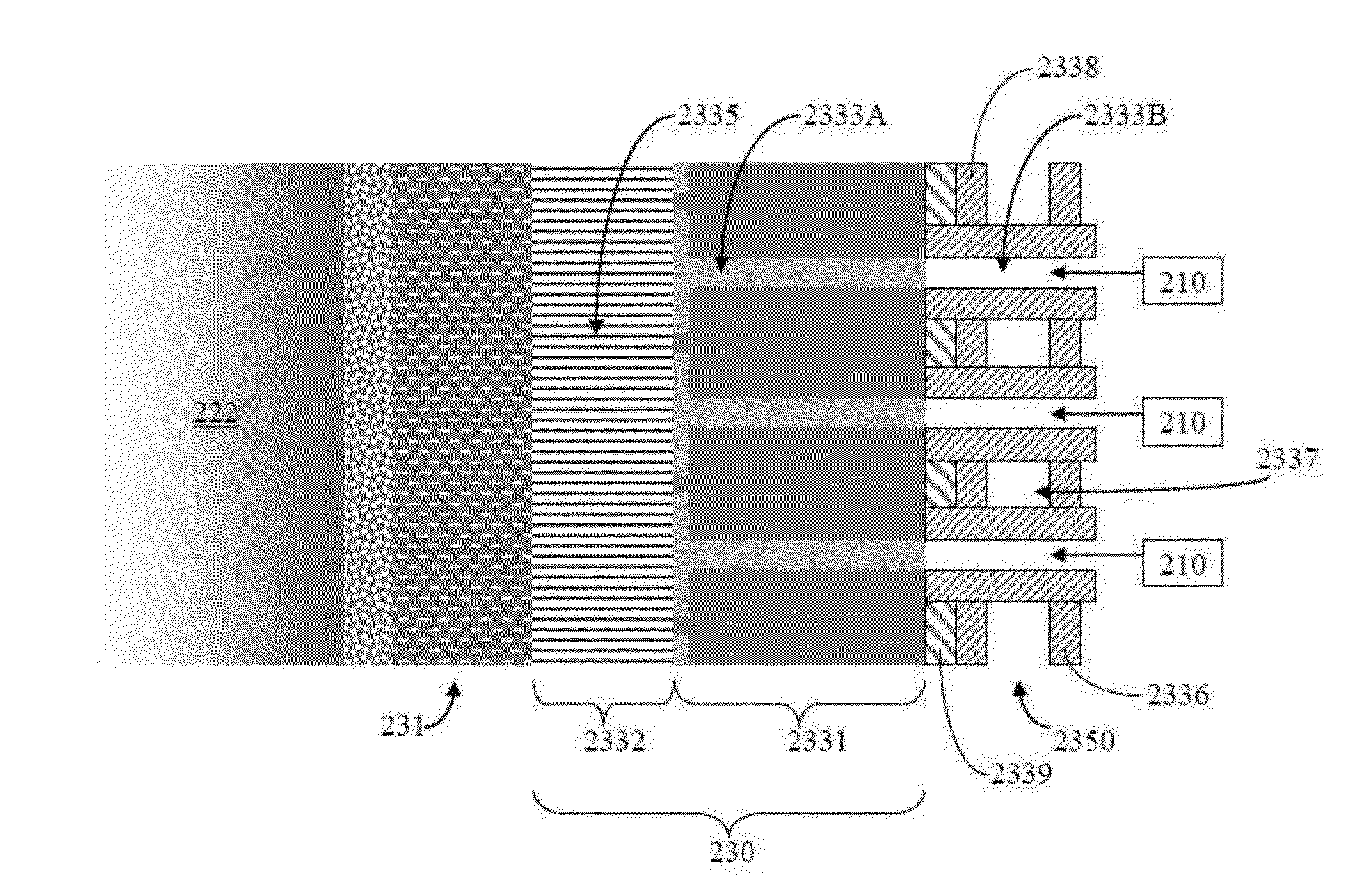

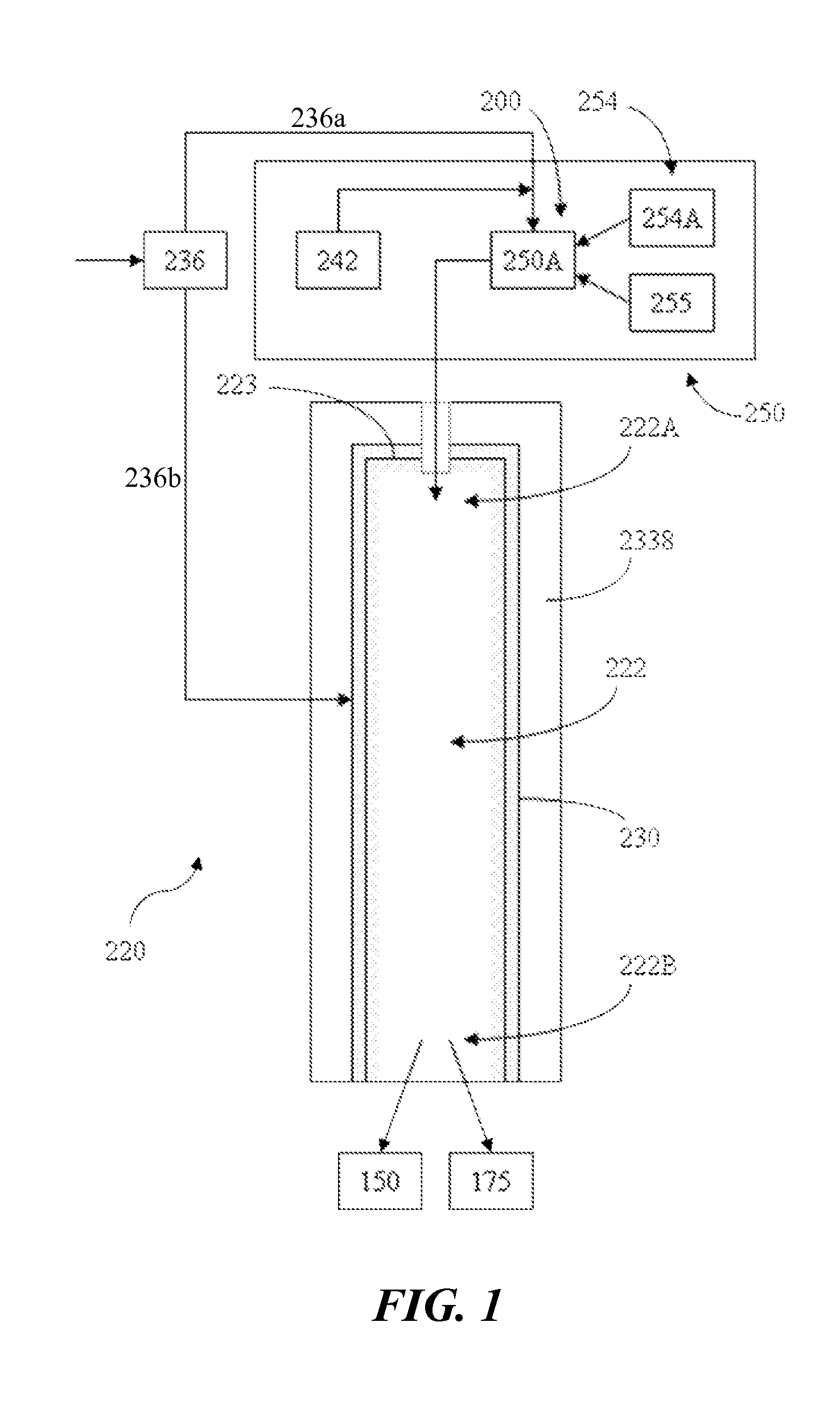

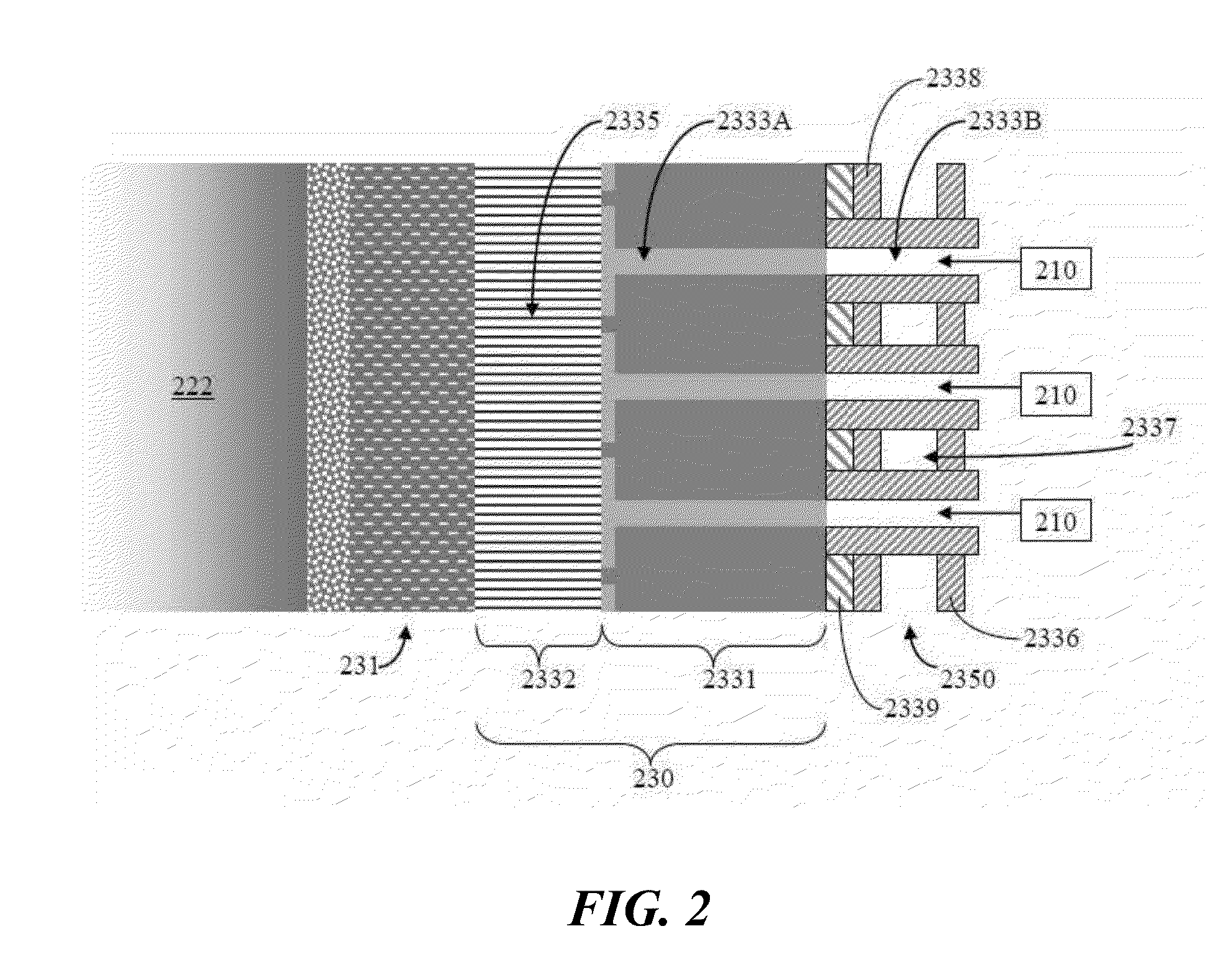

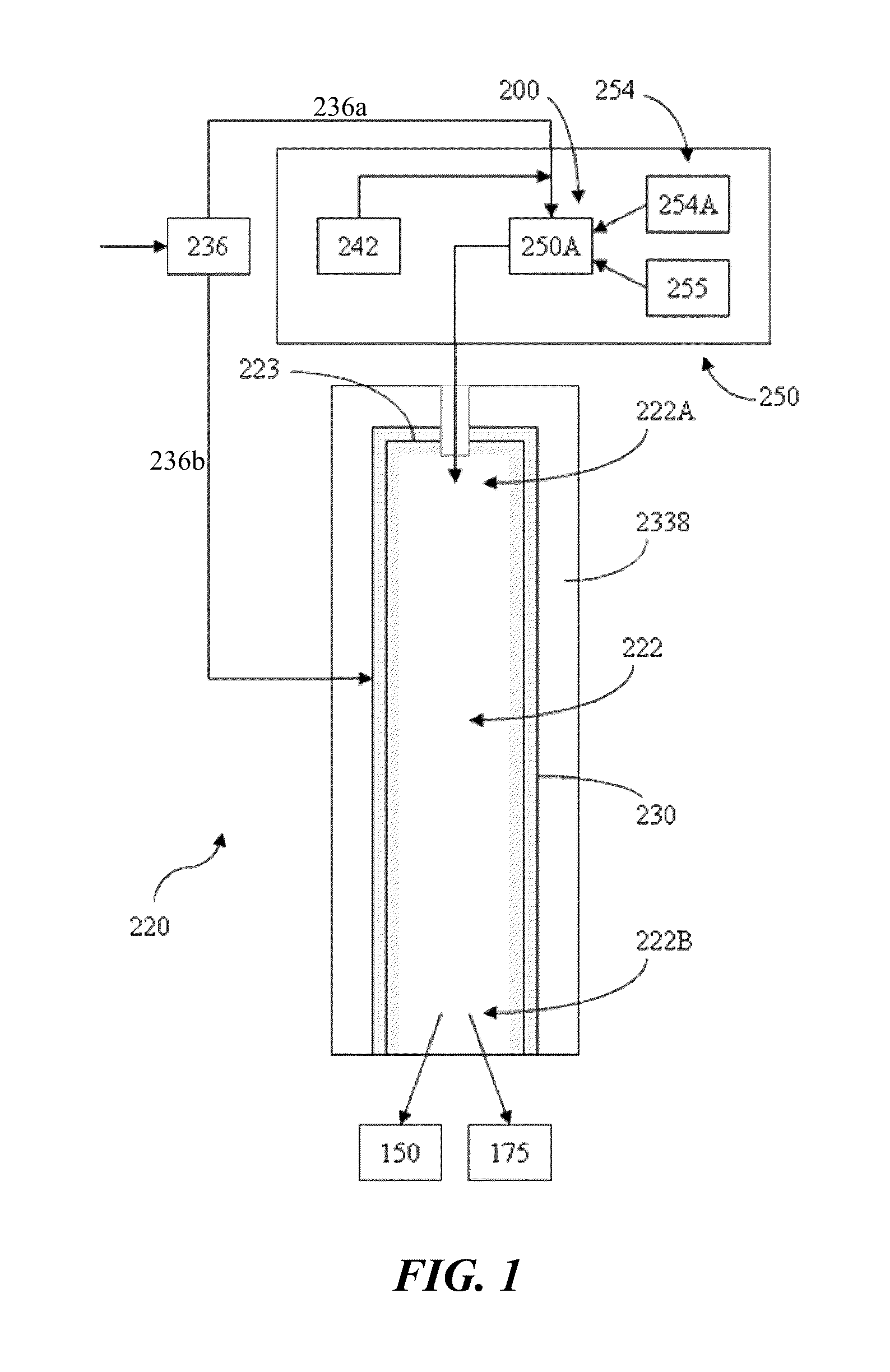

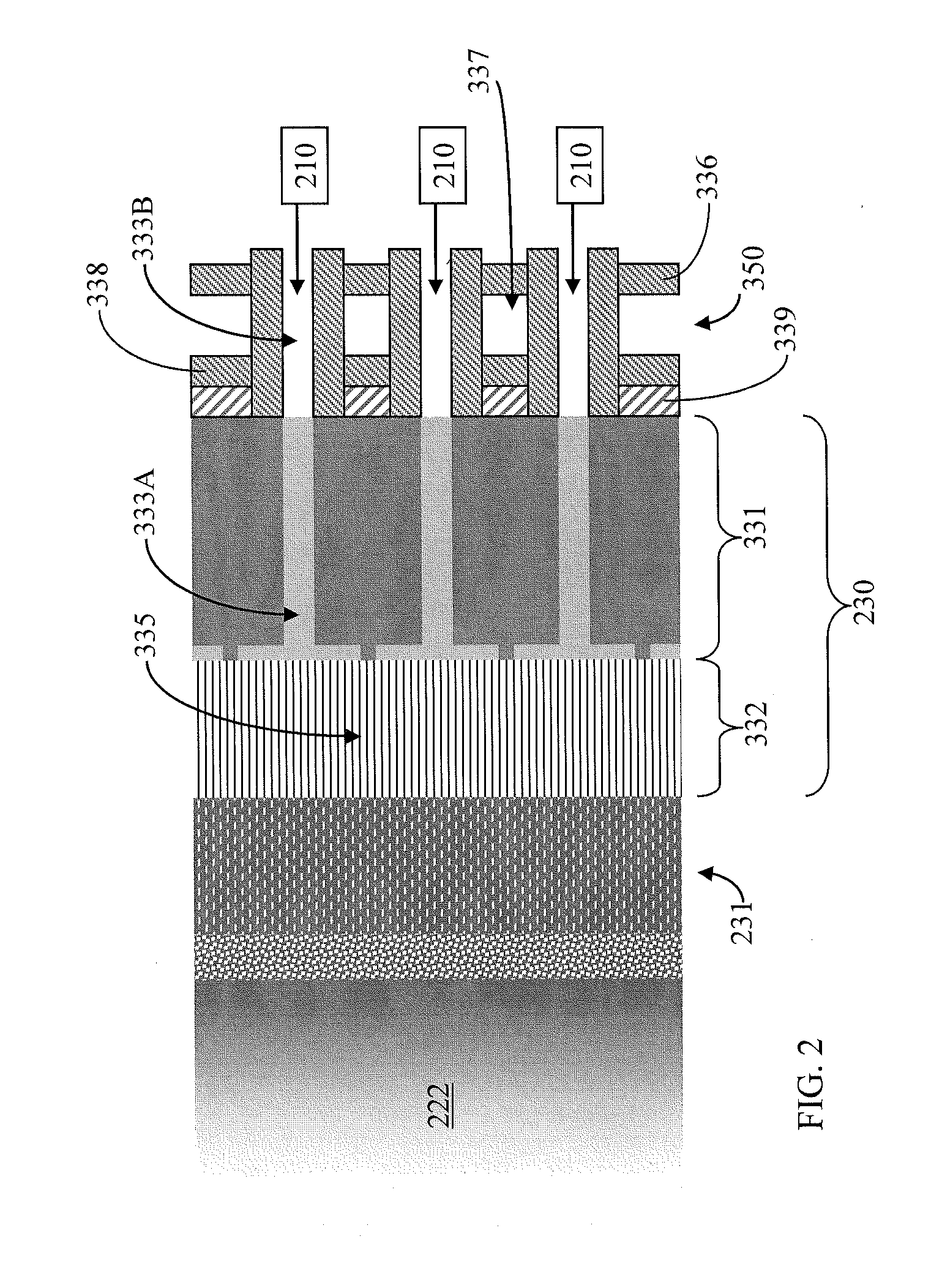

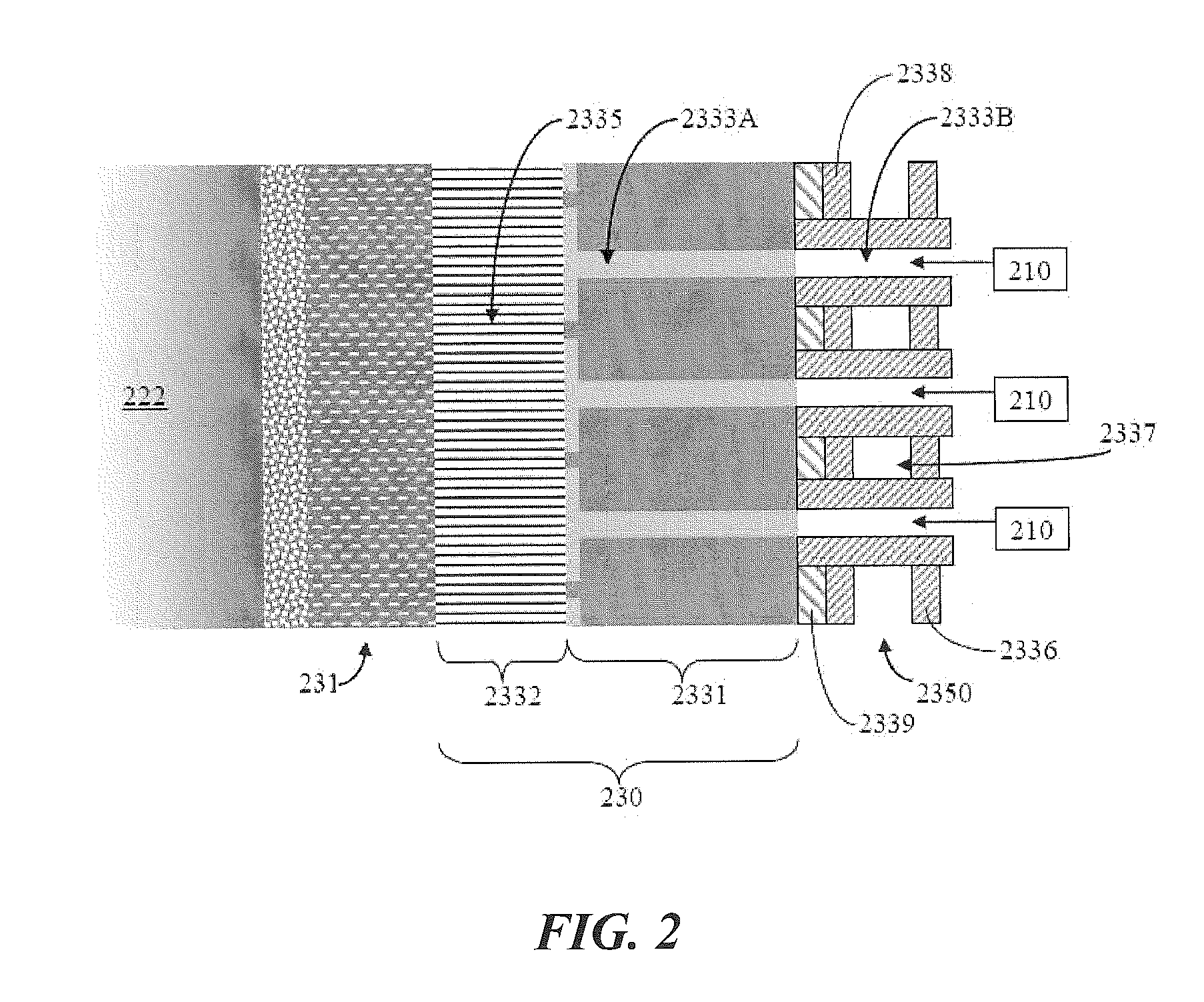

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130213049A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

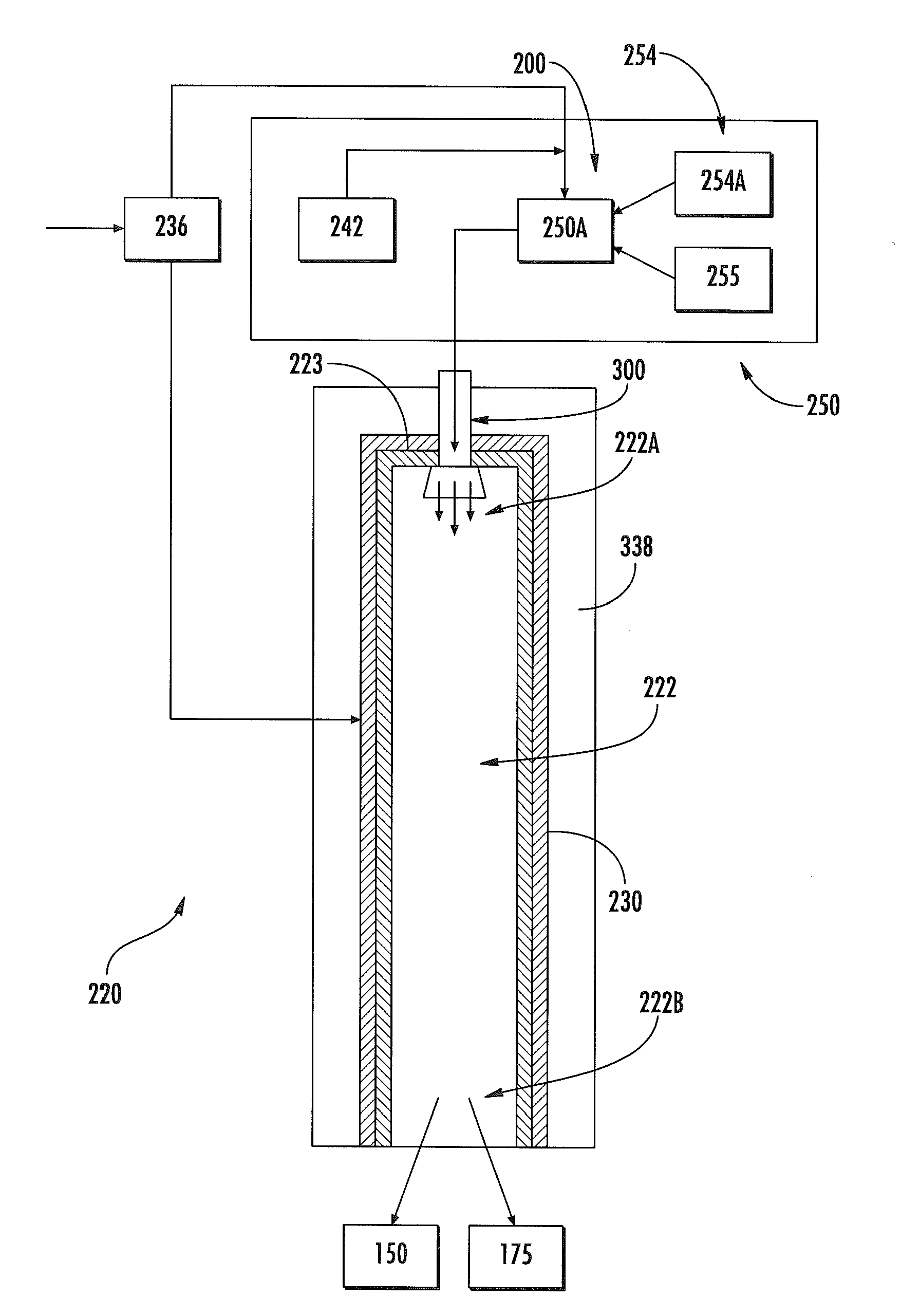

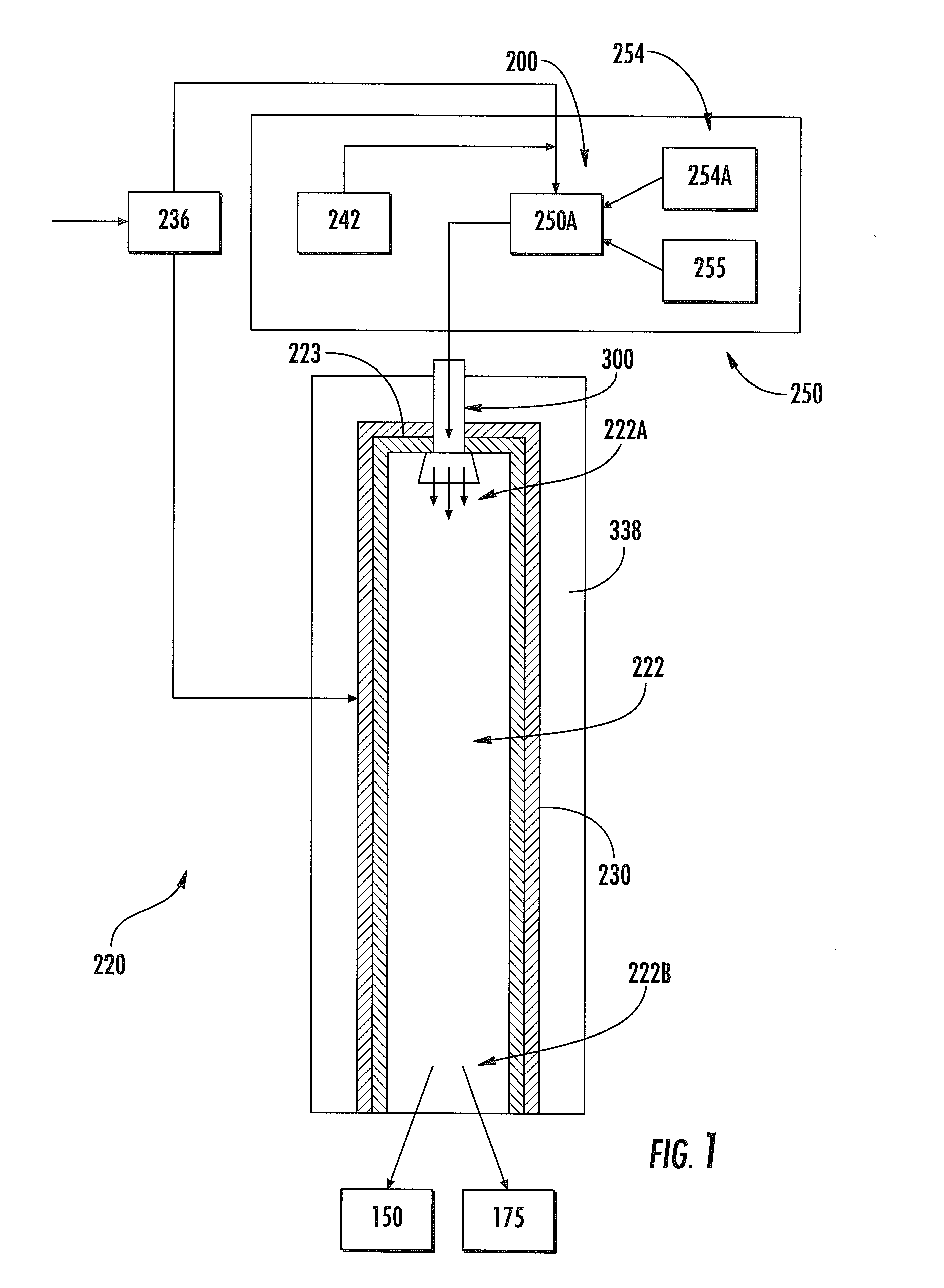

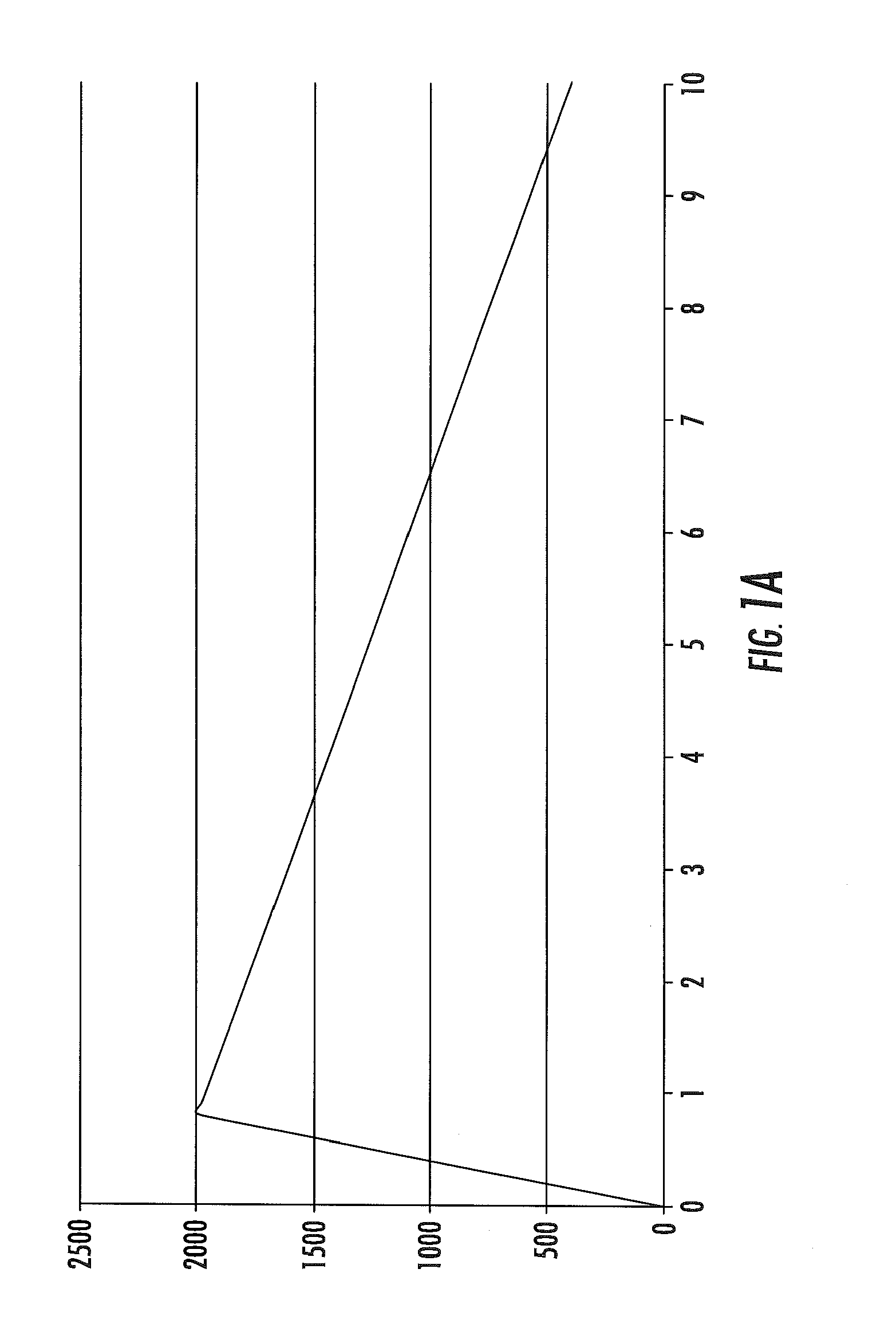

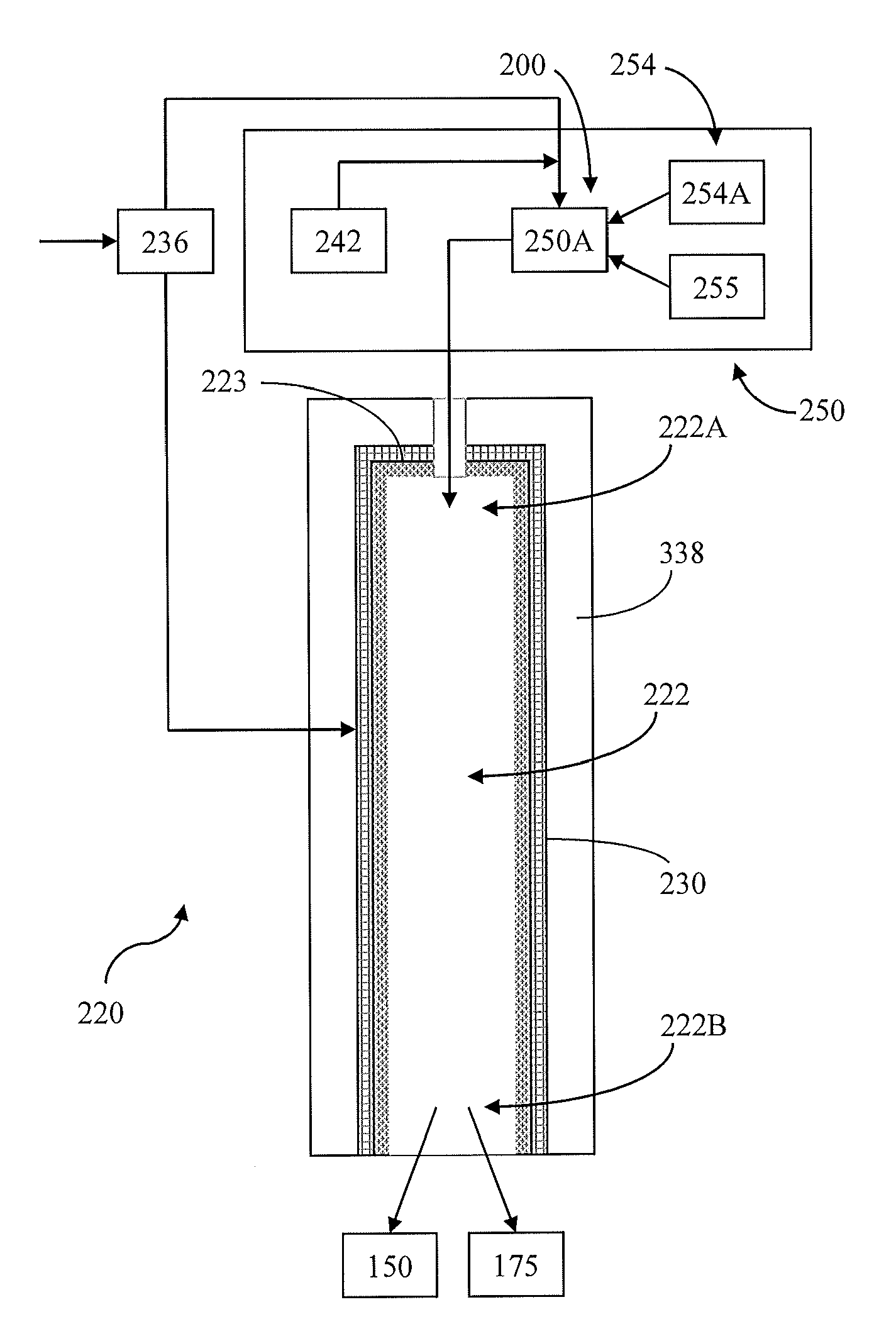

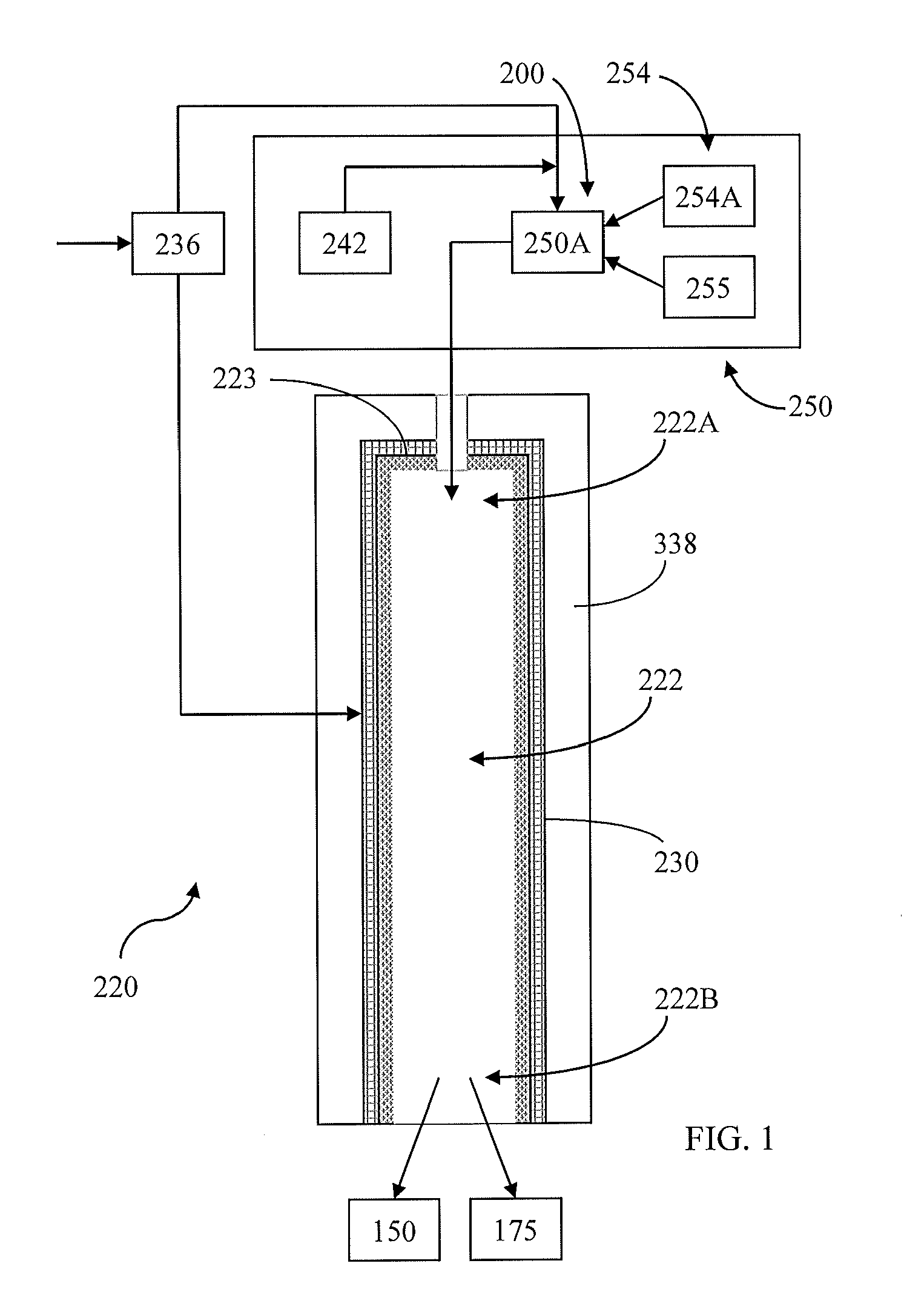

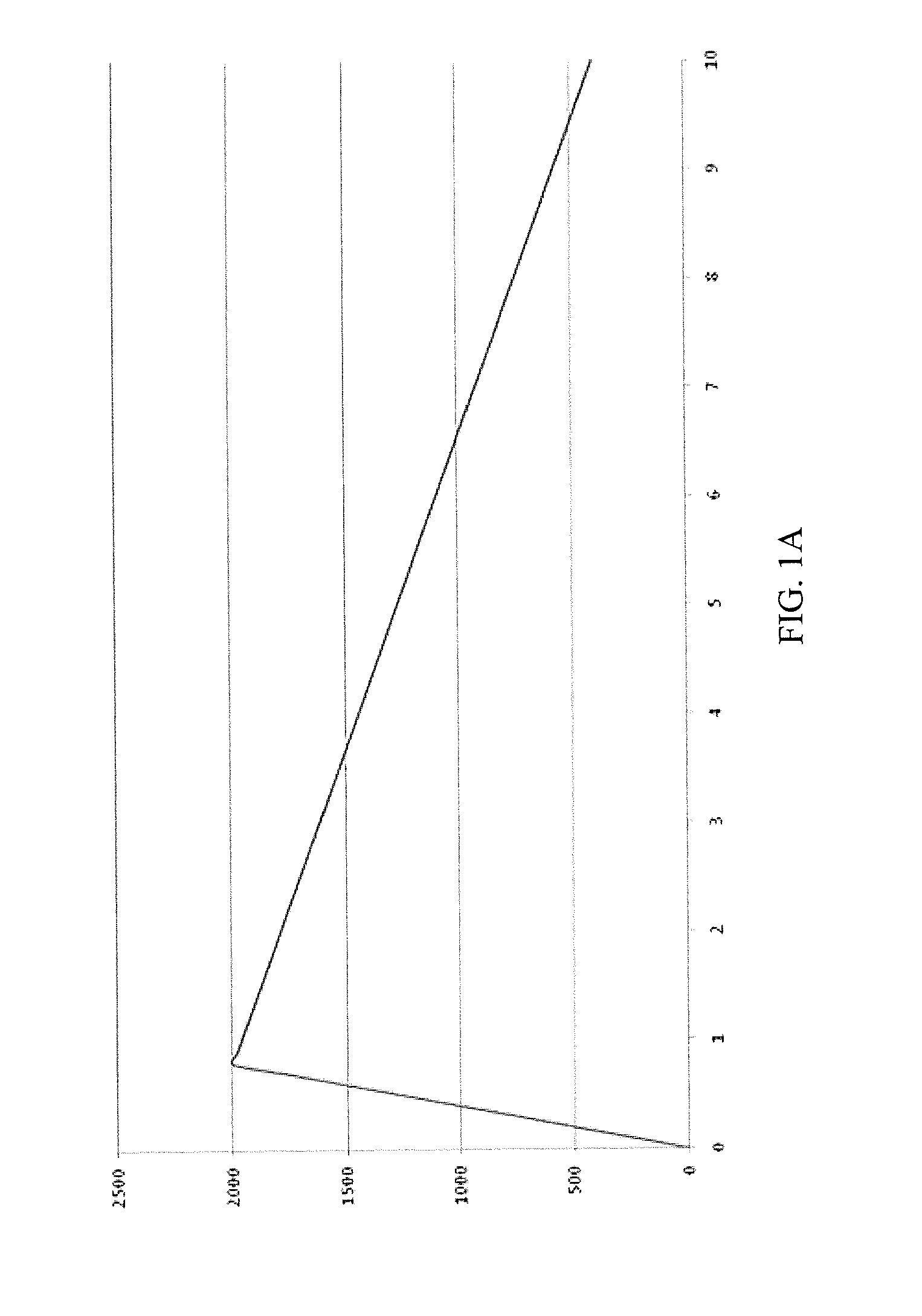

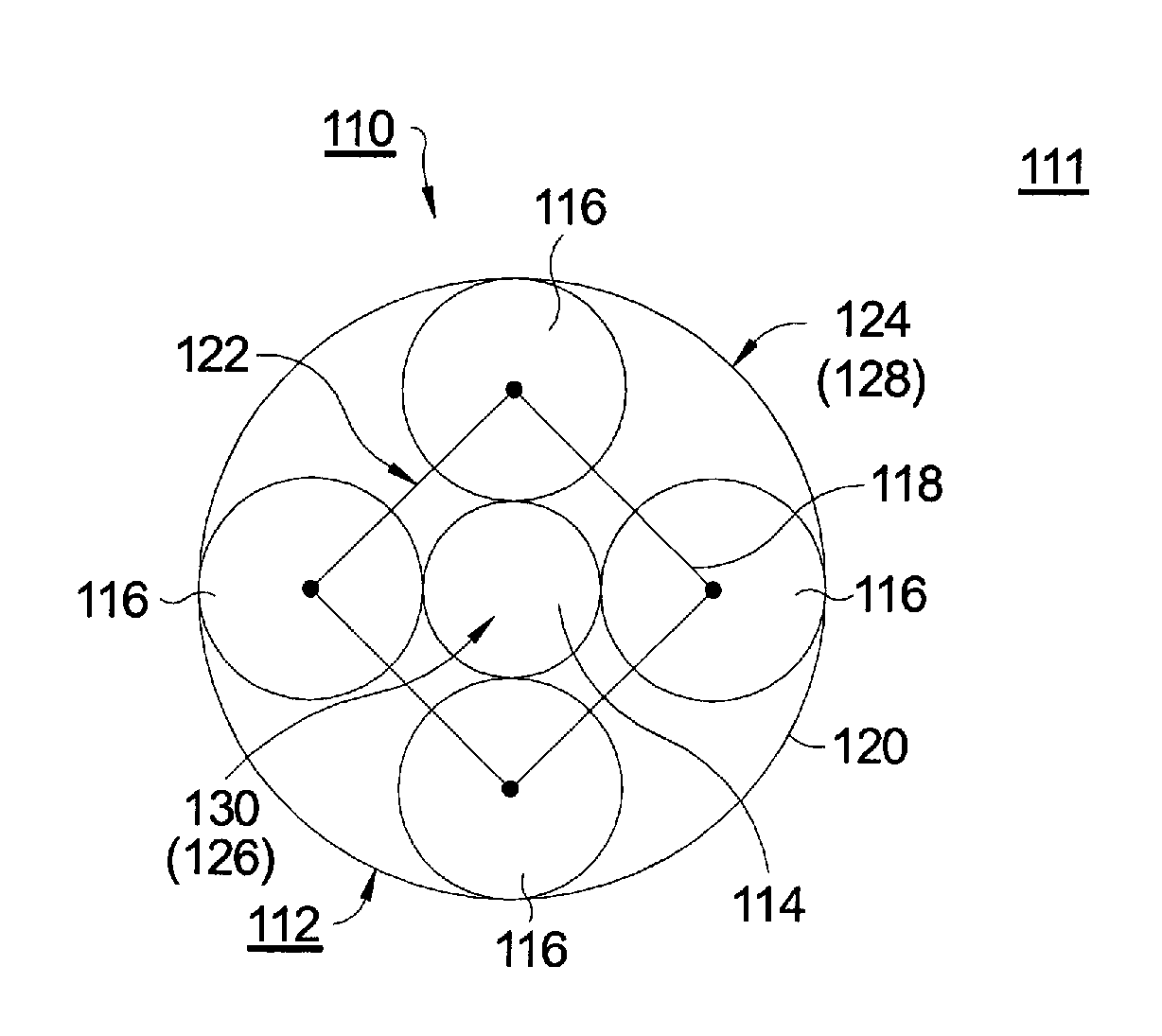

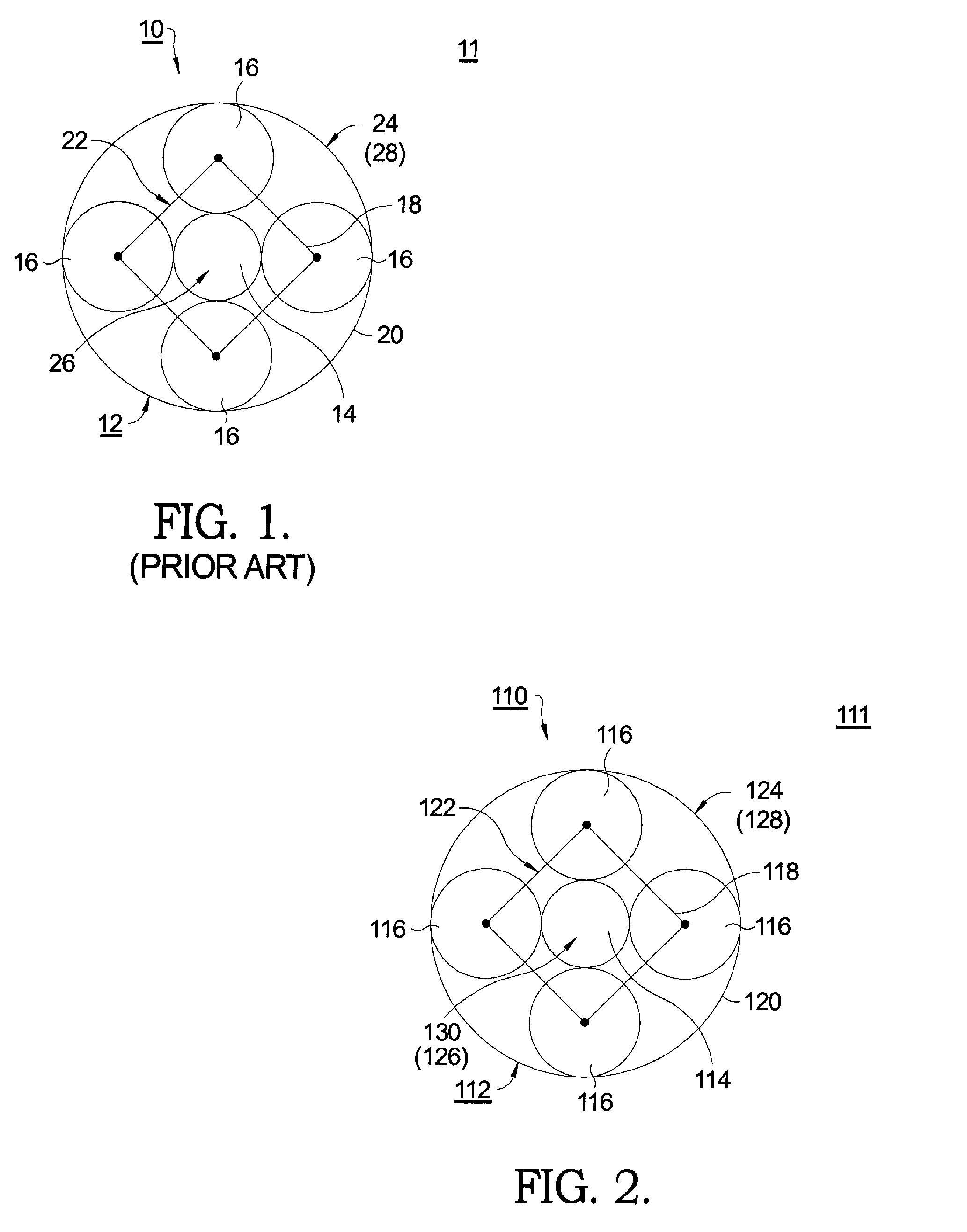

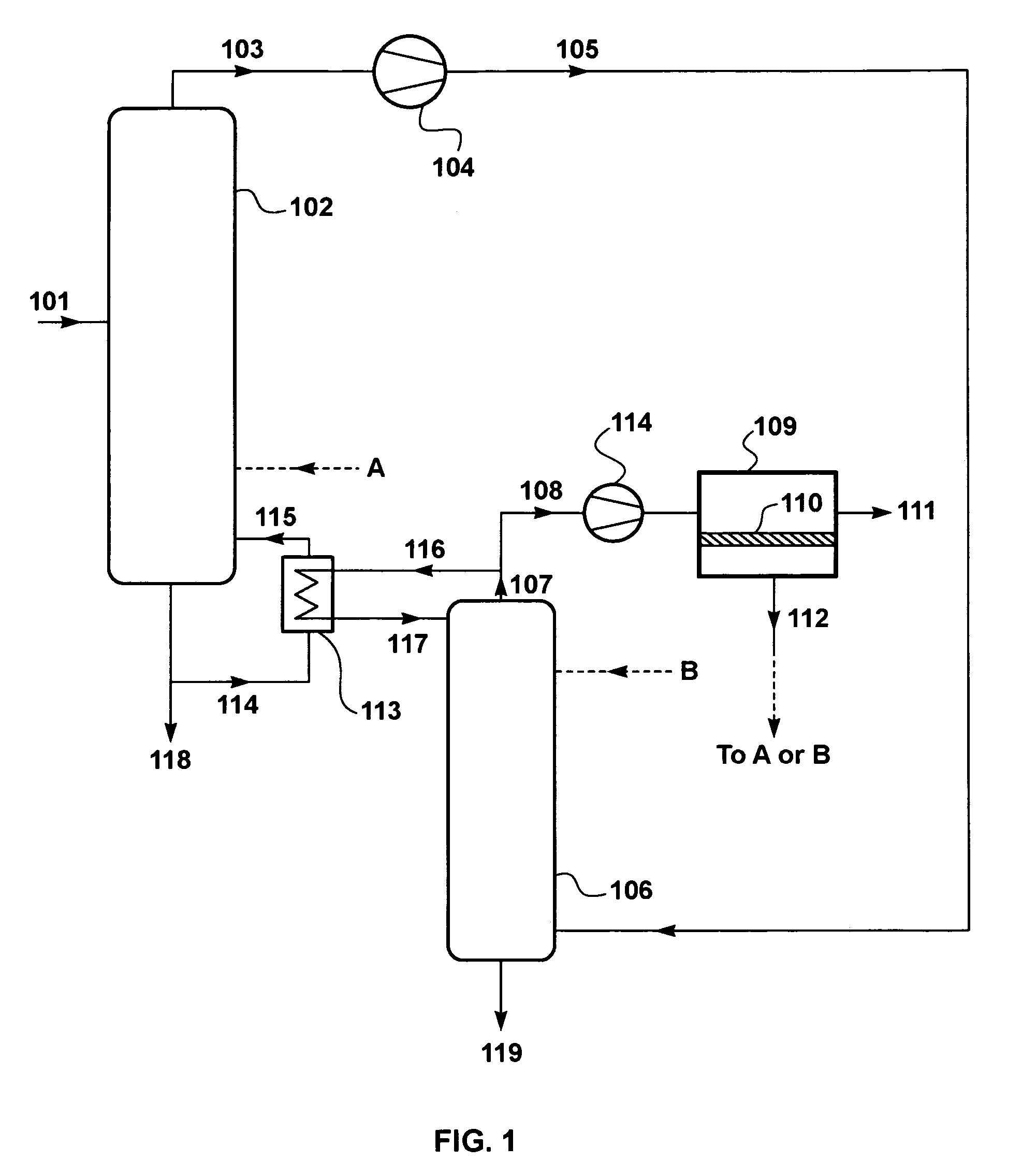

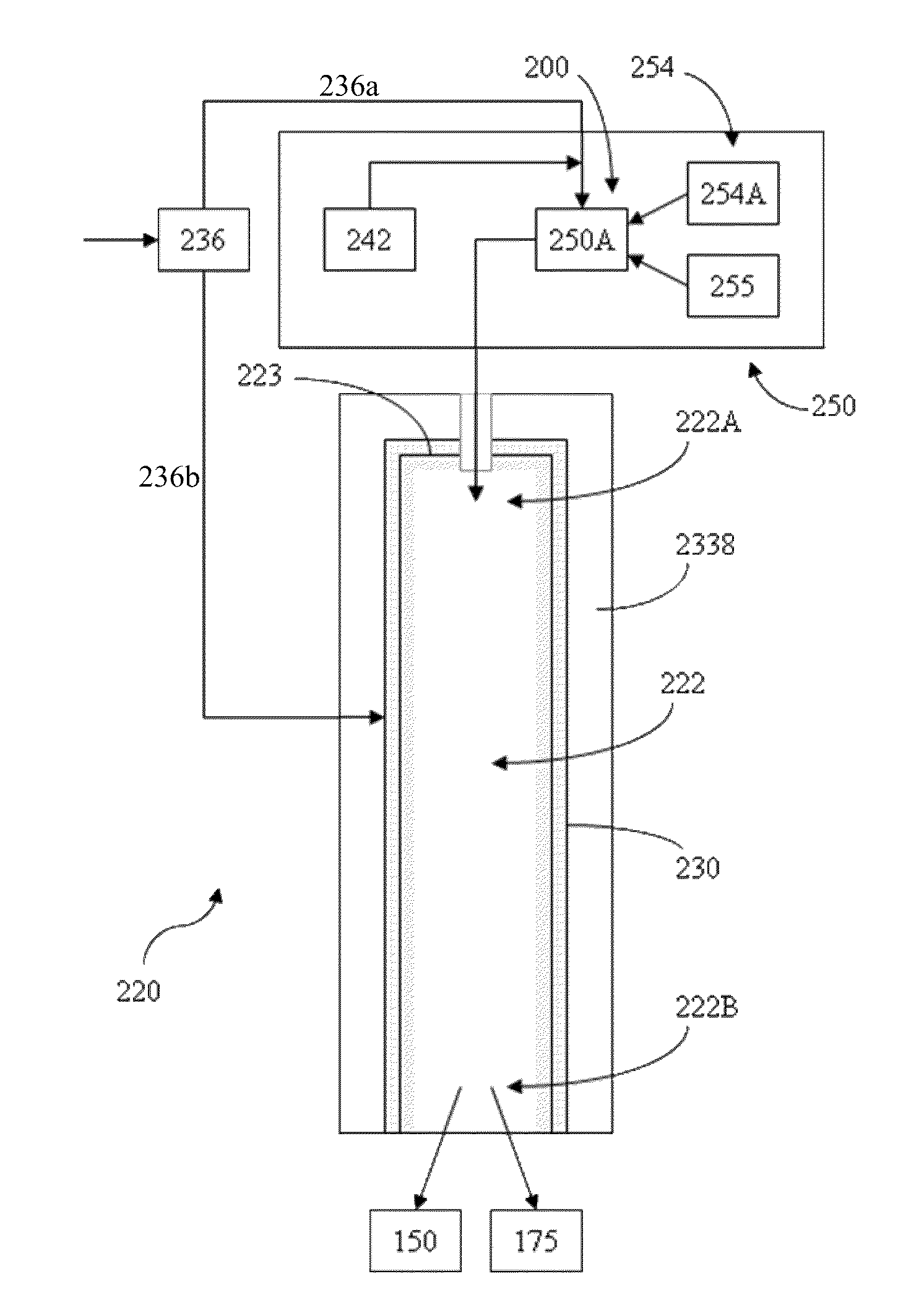

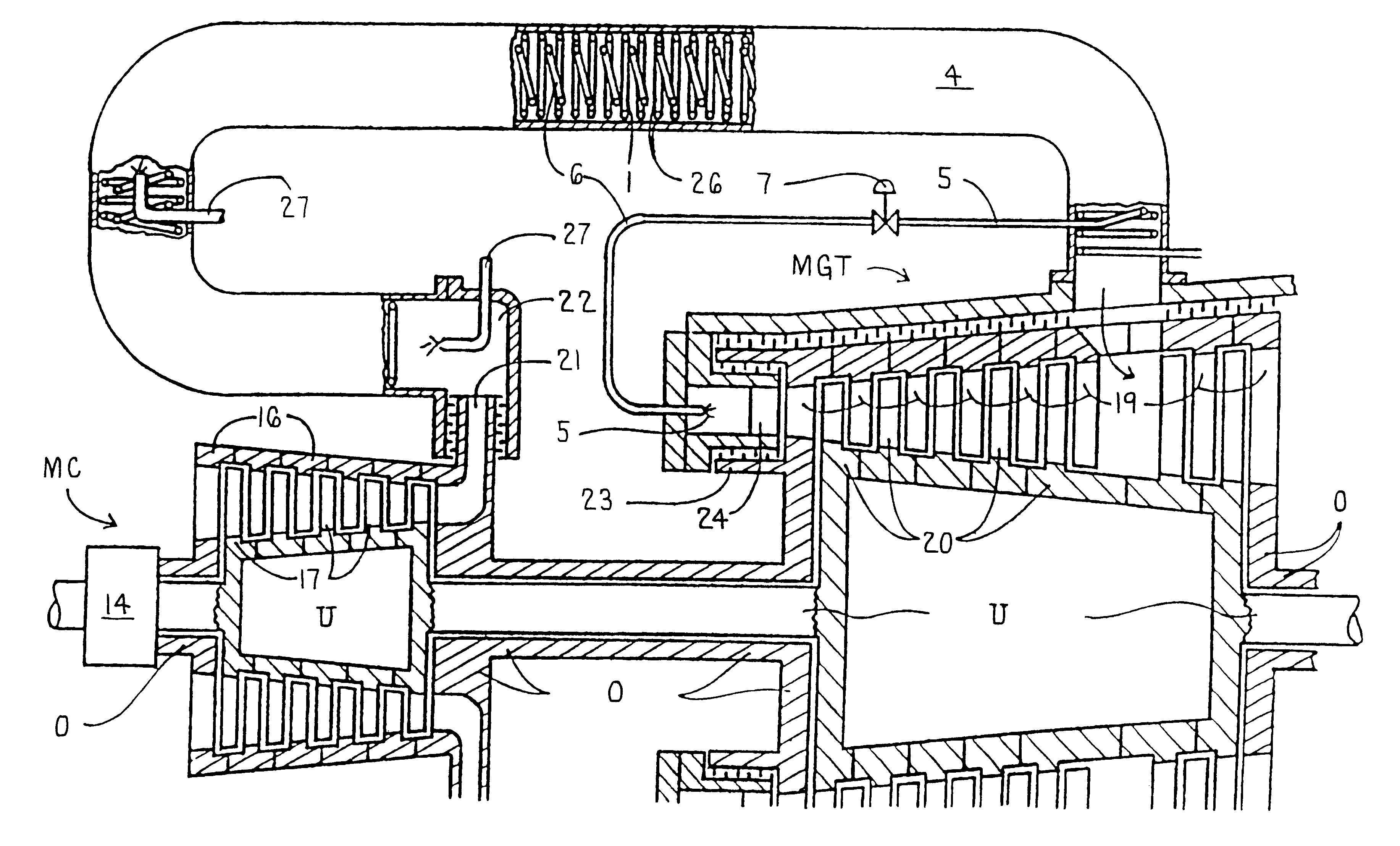

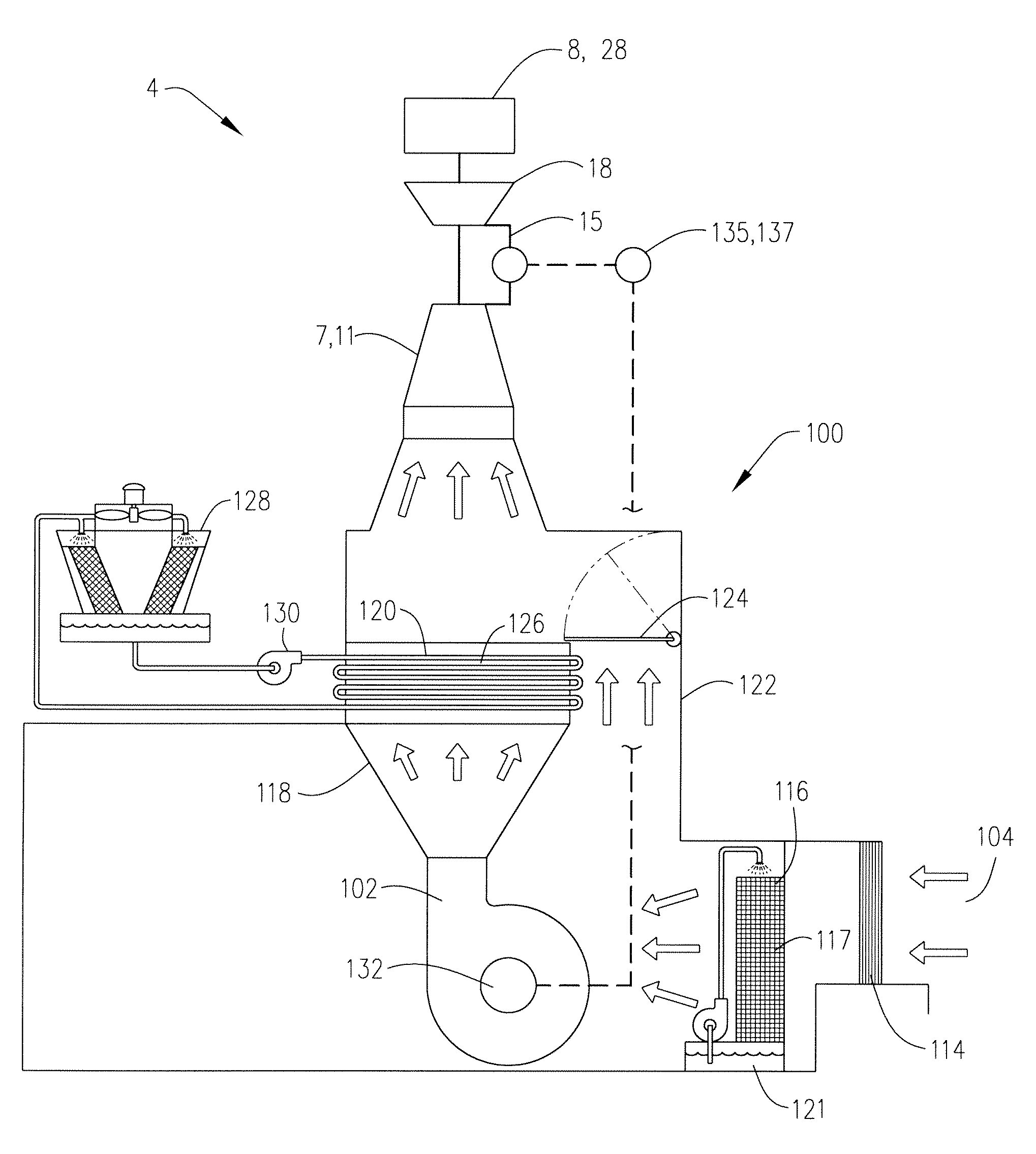

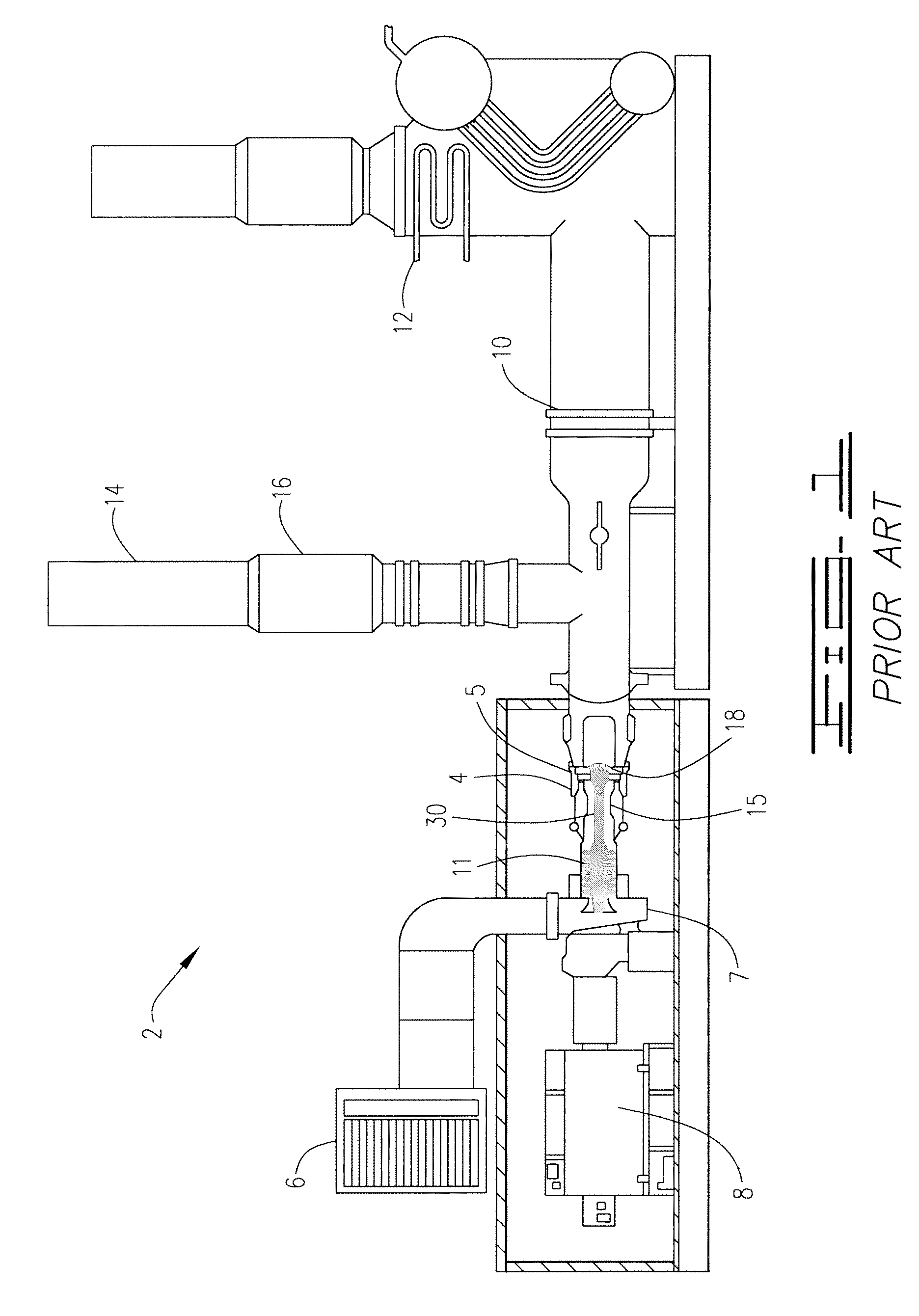

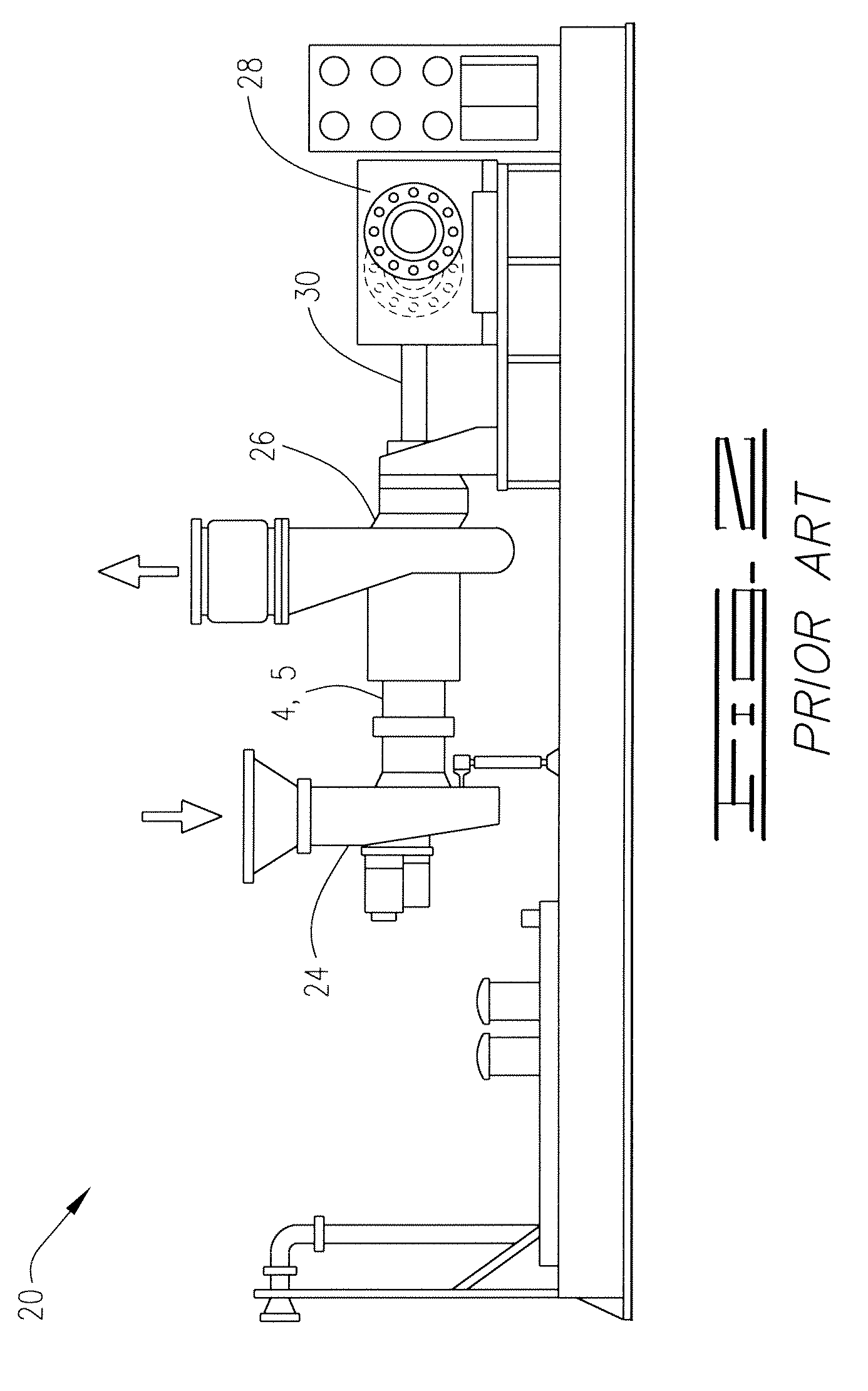

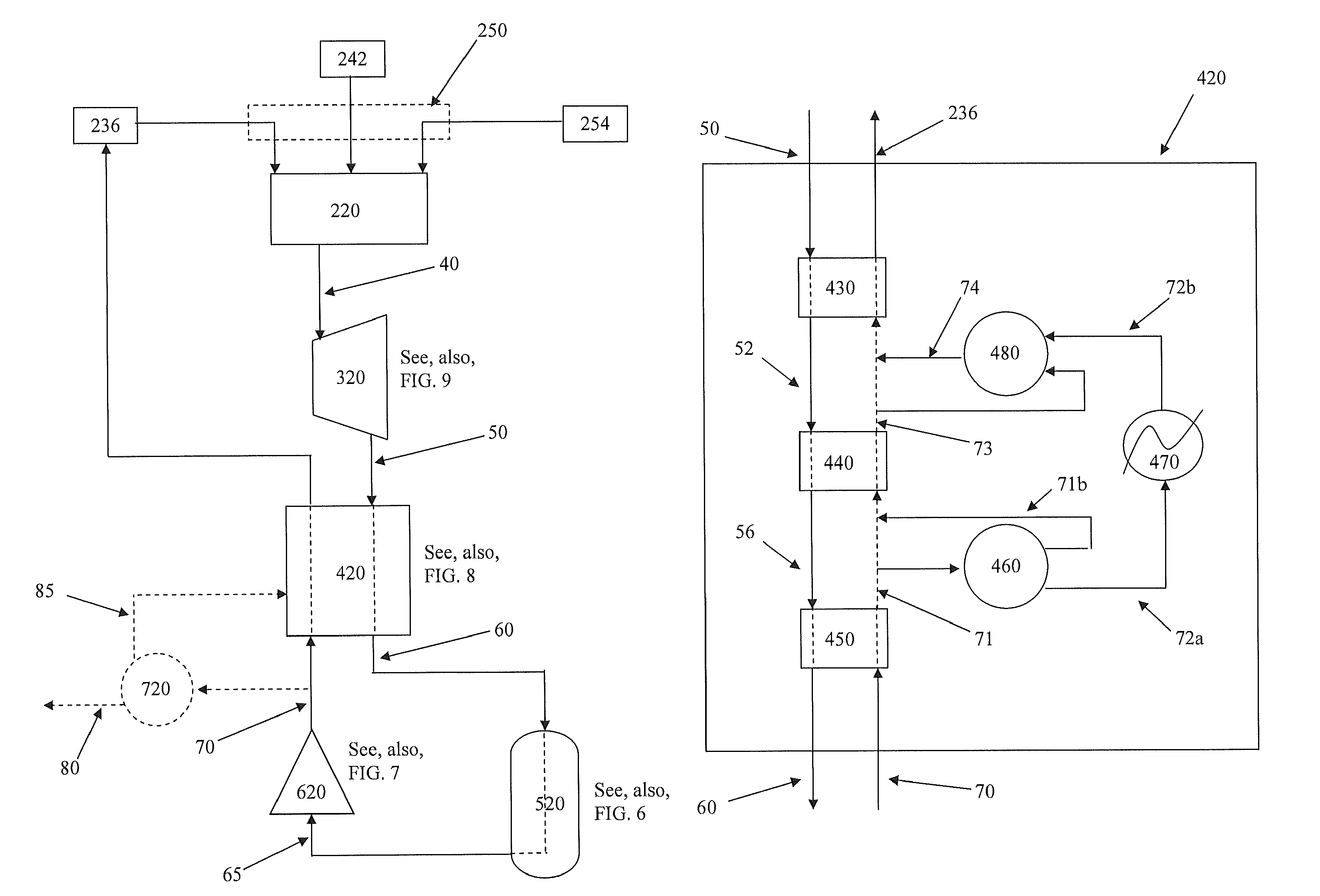

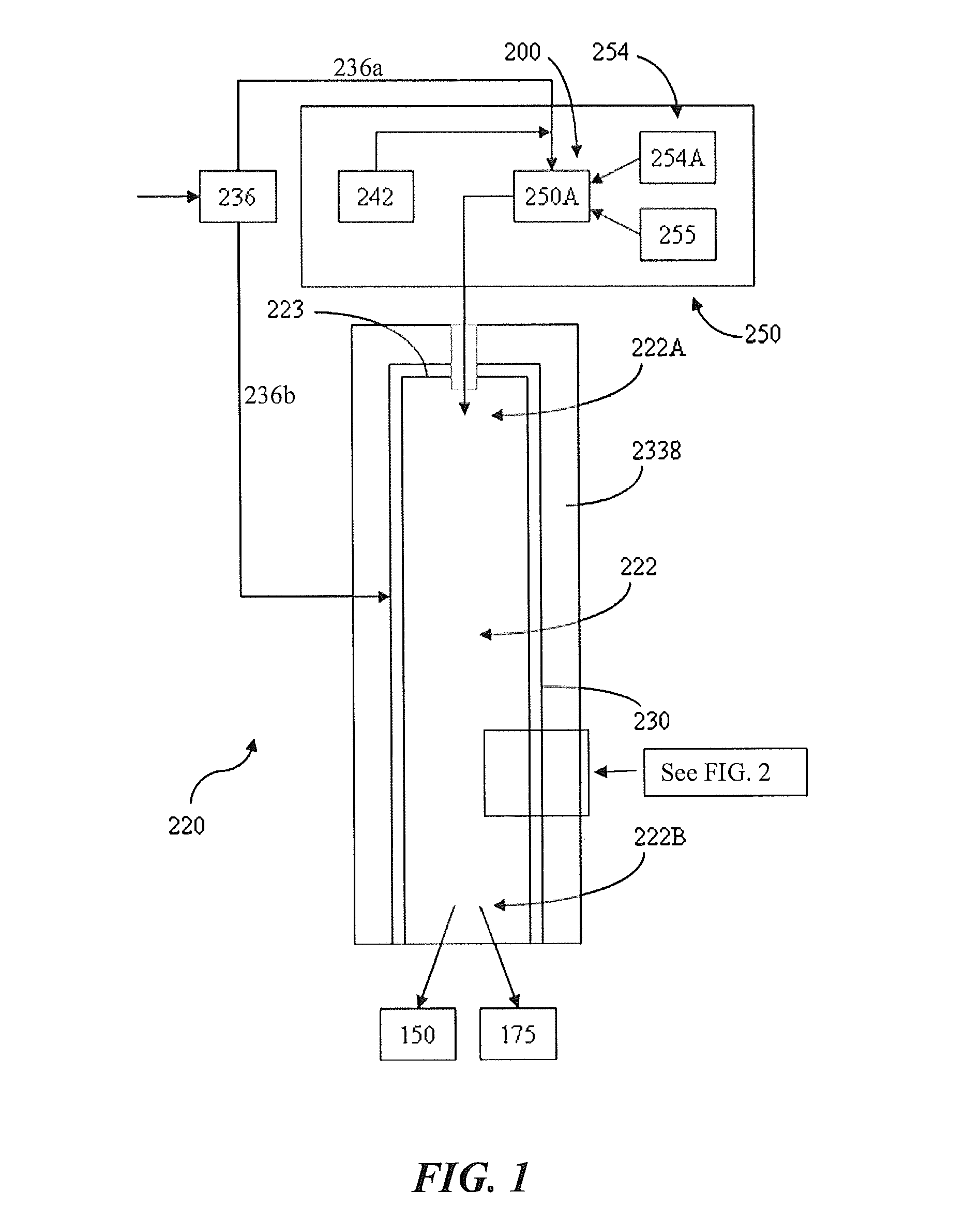

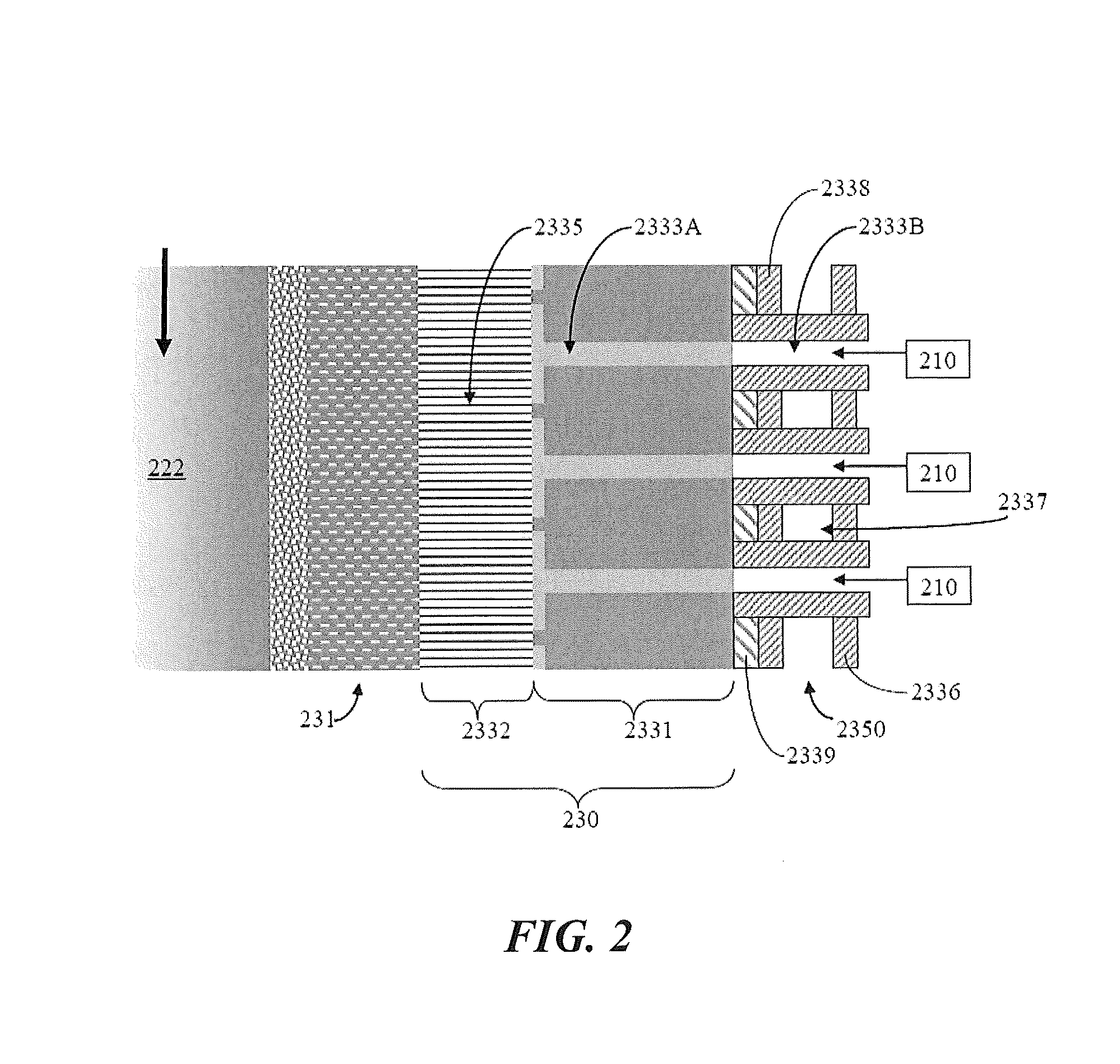

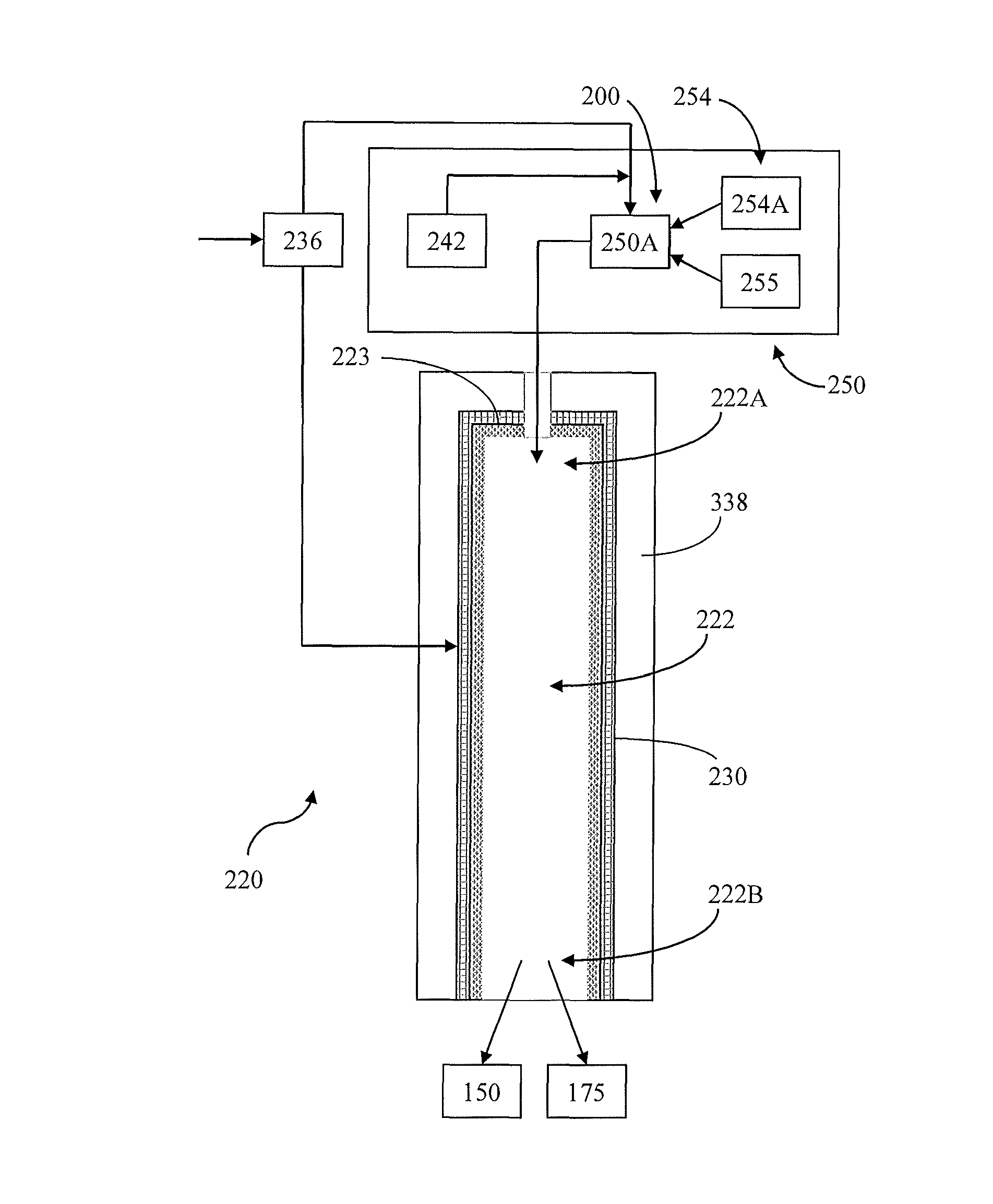

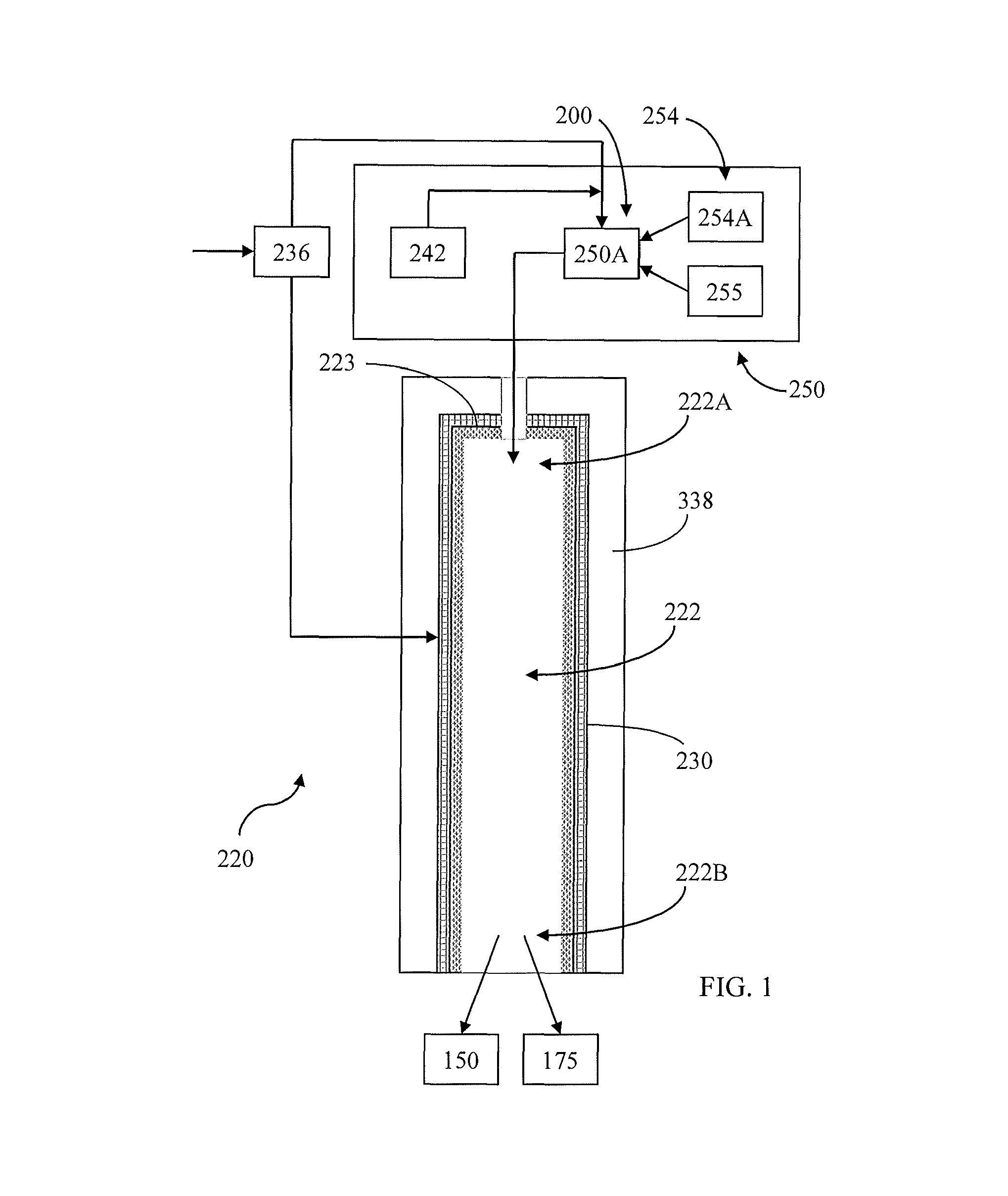

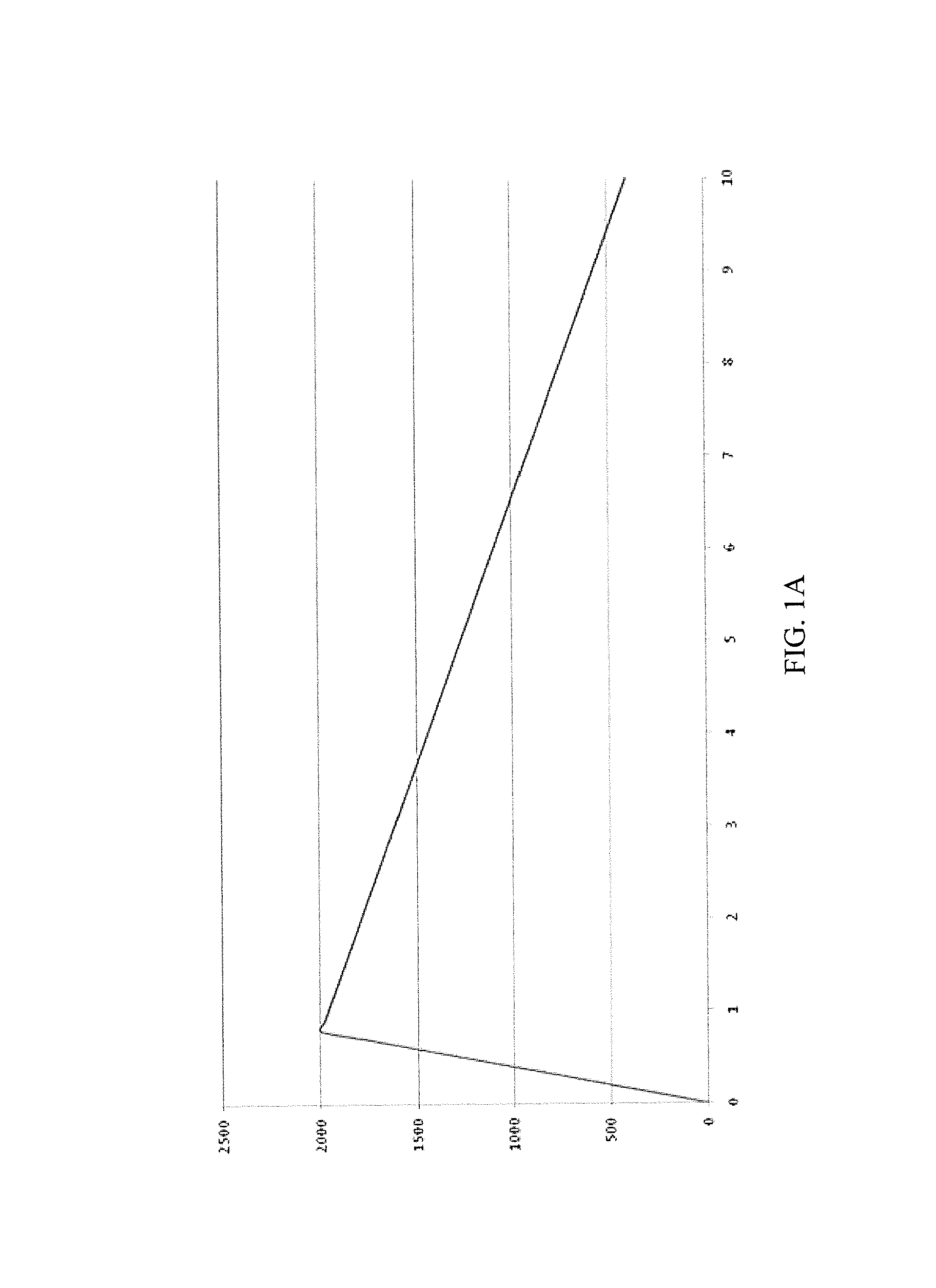

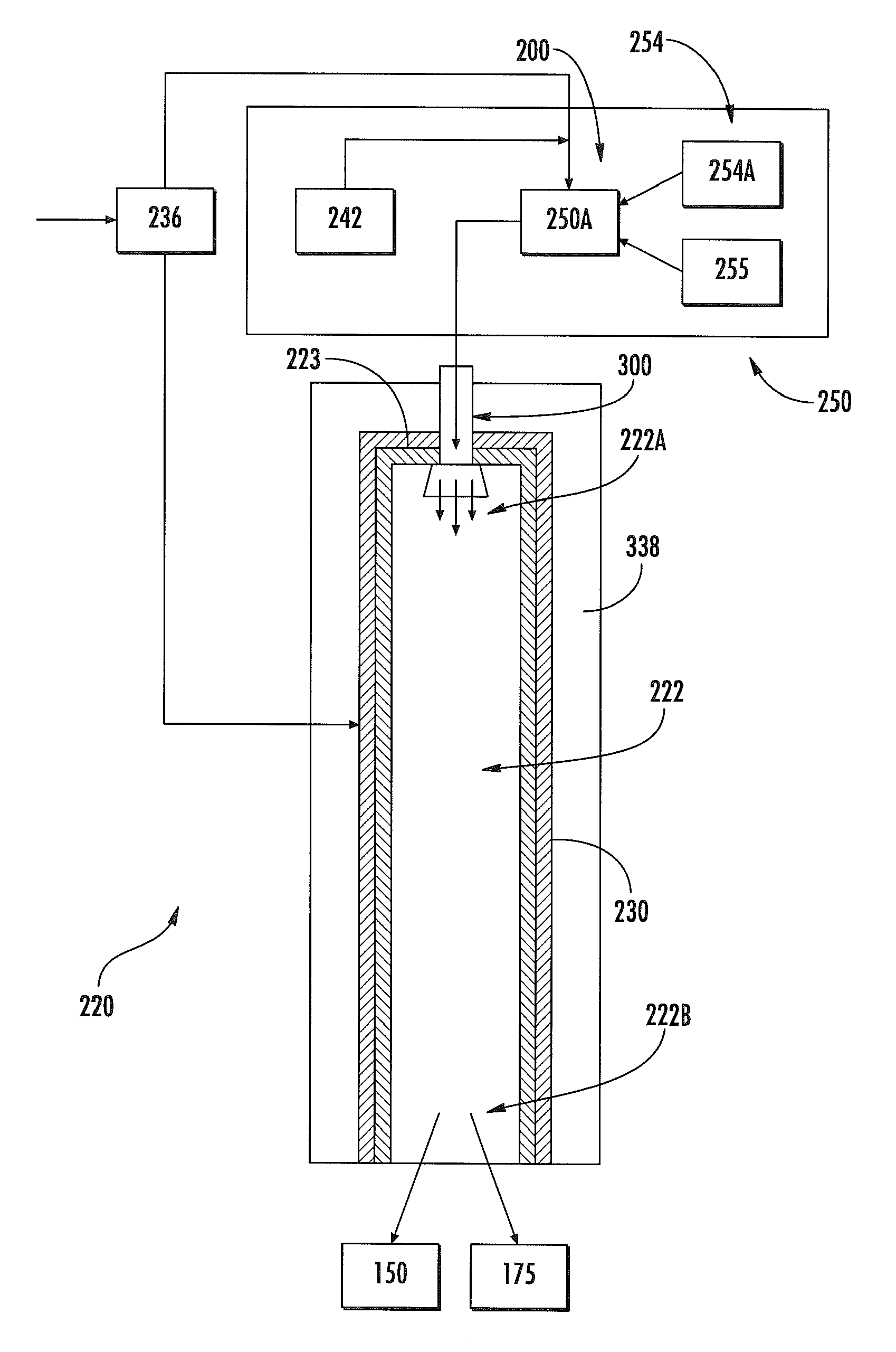

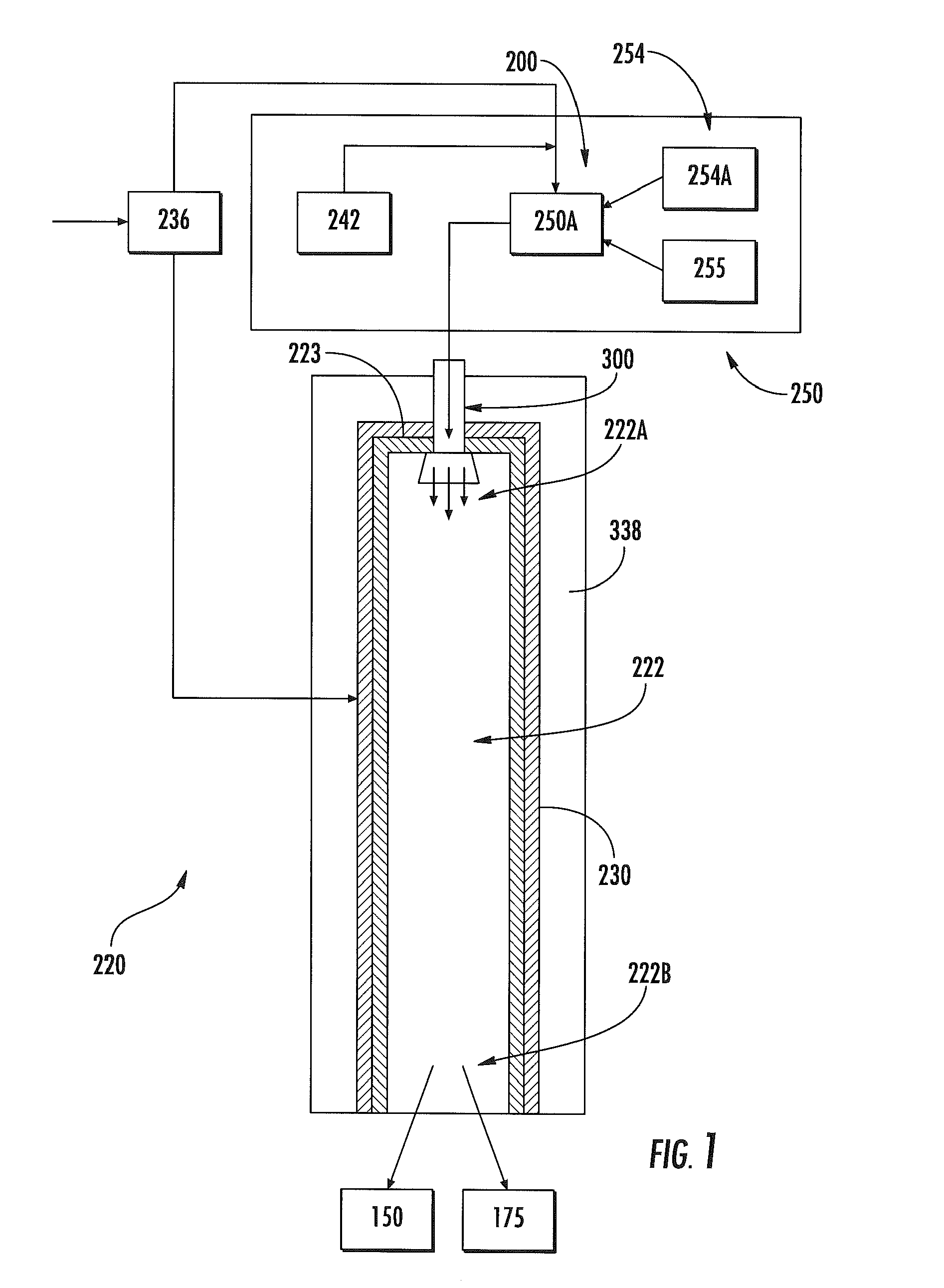

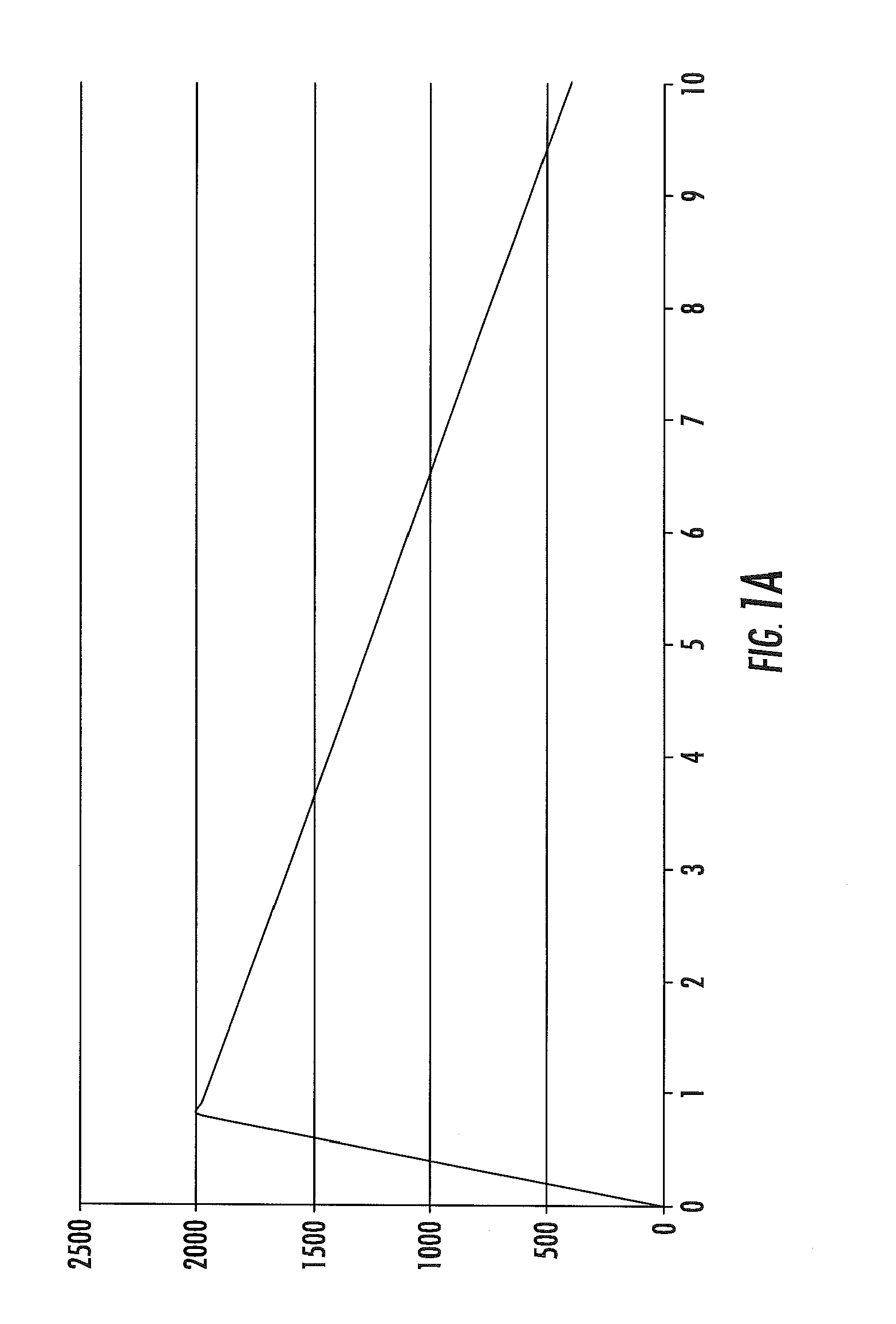

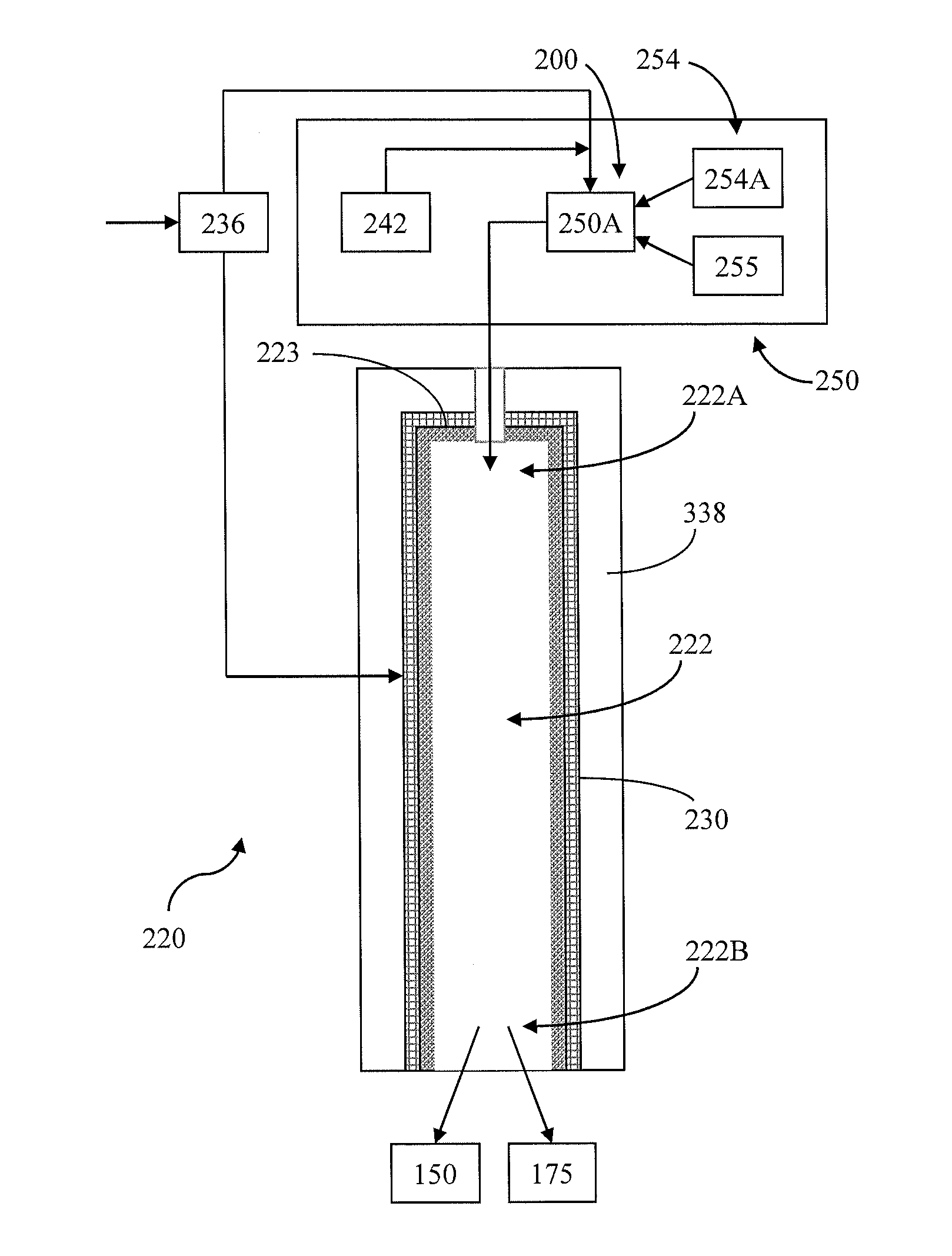

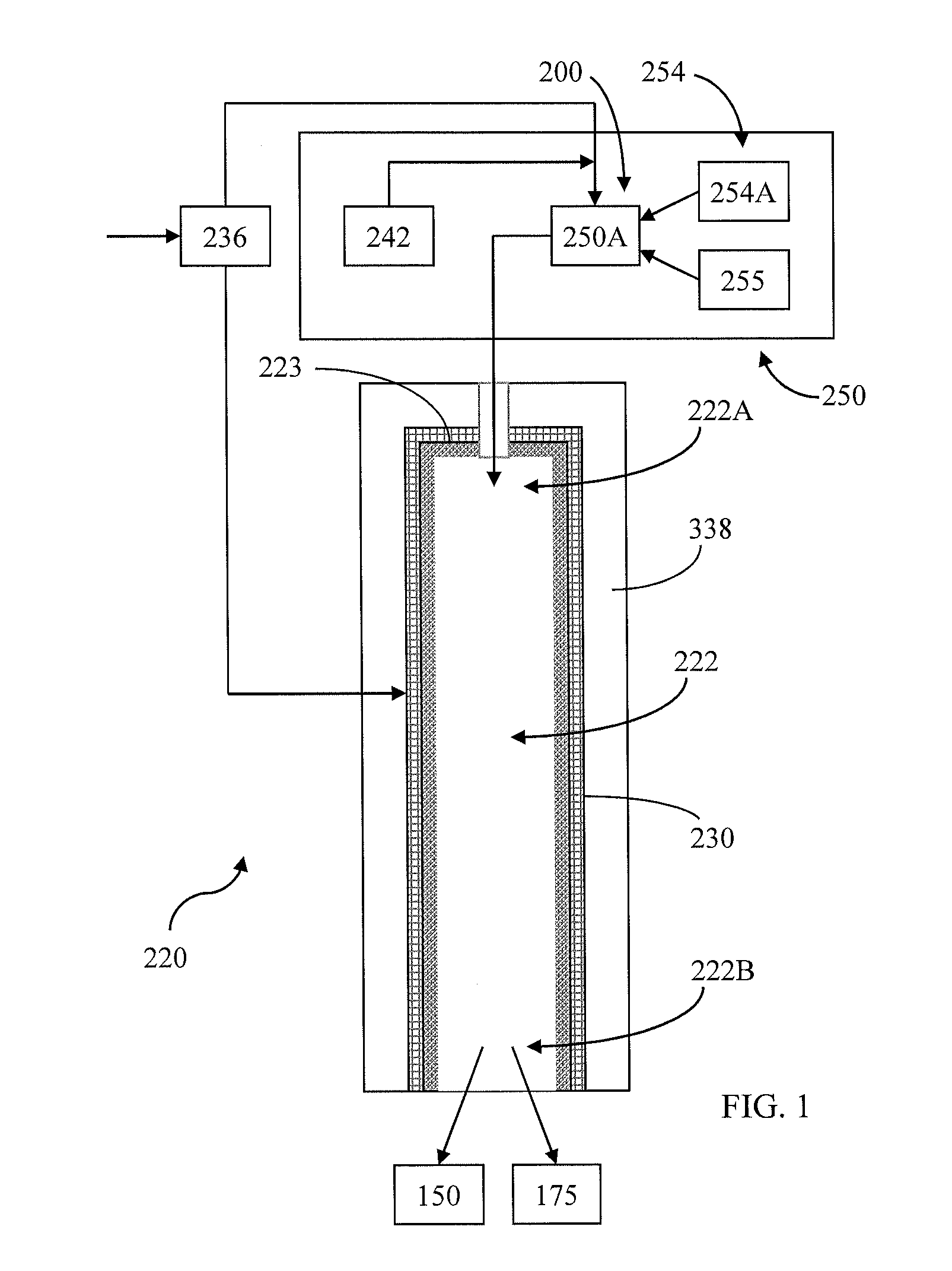

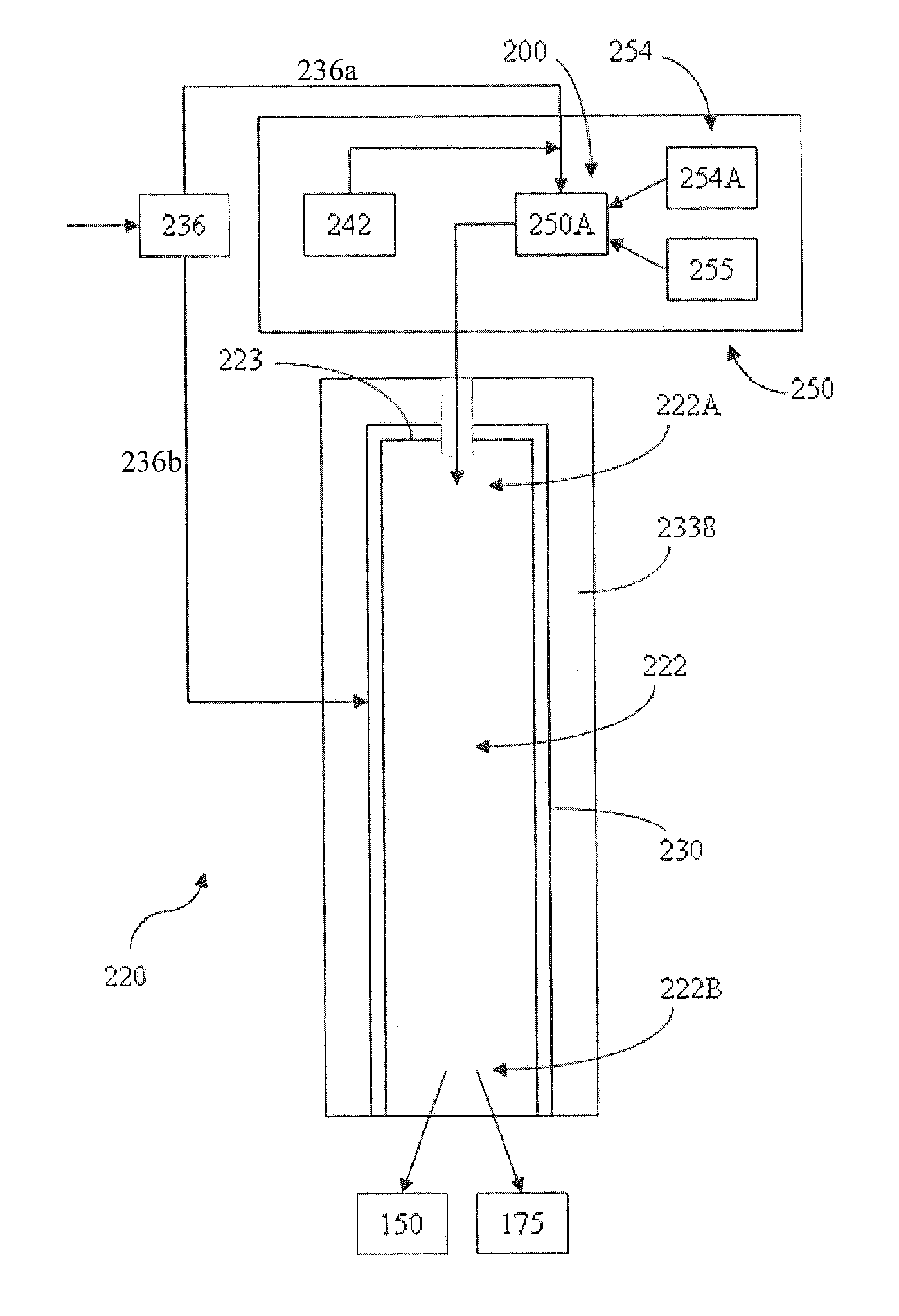

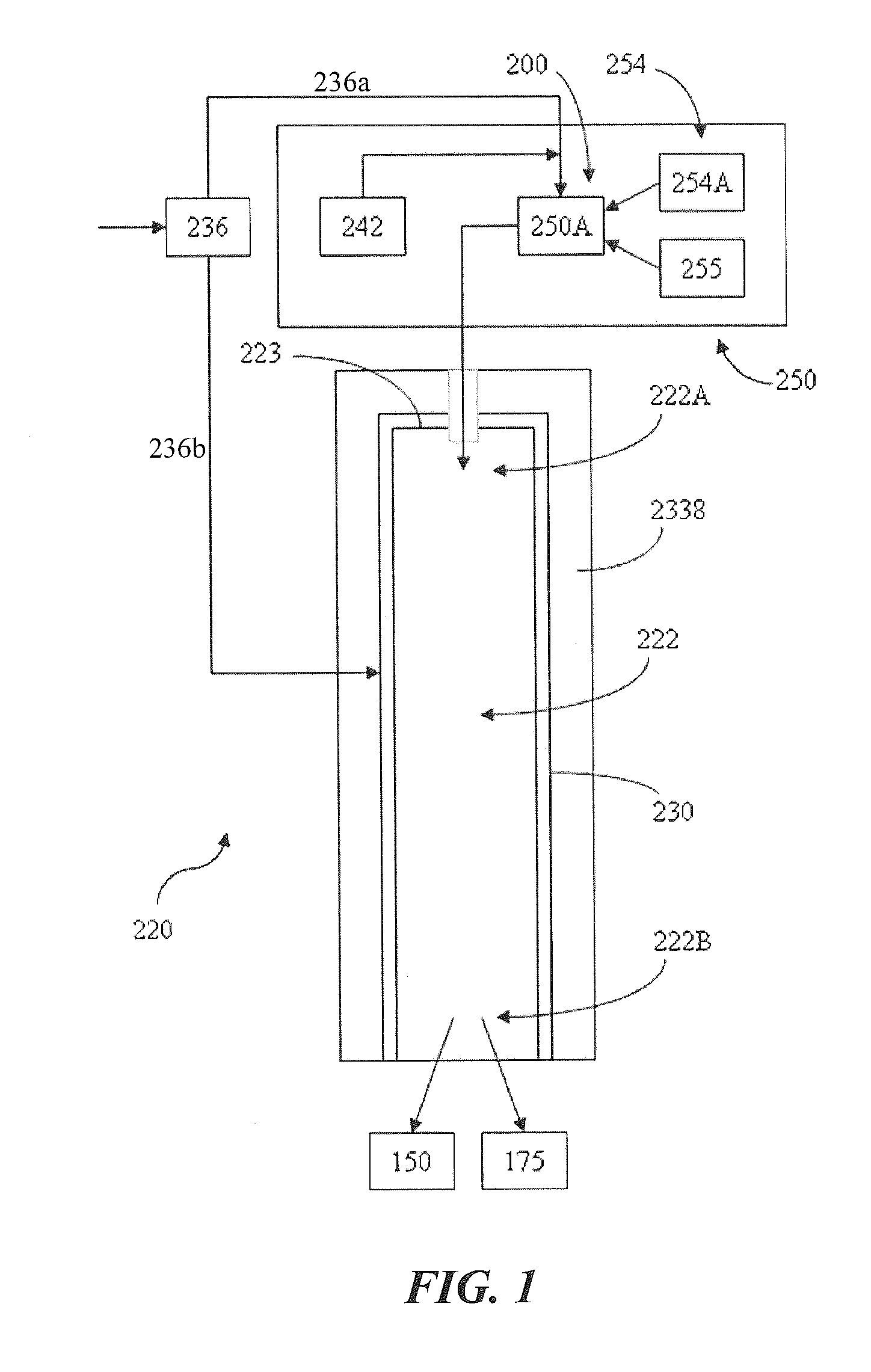

Induced symbiotic osmosis [iso] for salinity power generation

ActiveUS20110044824A1Reduce excessive wasteMaximizing membrane efficiencyFlexible member pumpsServomotorsHigh concentrationConcentration ratio

A method and apparatus for renewable power generation utilizes the chemical potential dissimilarity between solutions of differing ionic formulations. A train is formed by a sequentially ordered set of a plurality of cells in which each successive cell is related to the preceding cell. Each cell has pumping means and hydro-power generation turbine means to form a closed hydraulic loop configured for specified volumetric and flow capacity. Adjacent cells share semipermeable membranes. Each cell is charged with a brine of specified ionizable inorganic salt quantity and type with the brine being cycled in a controlled concentration-pressure loop, with each of the cells operating at progressively increasing concentration and osmotic pressure ratio. A continuous and constant flow rate of substantially salt-free permeate flux is maintained across each cell, the flux being osmotically induced from low salt concentration water being fed at the first cell in the train and exiting at the last cell along with the discarded high concentration water brine. The salt-free permeate flux is continuously induced, in symbiotic mode, through the shared membranes, driven by the chemical influence of concentration potential field bounded by water of low to no salt concentration on one end of the train and by brine of high salt concentration on the other end of the train with sufficient concentration difference to provide driving force for said plurality of cells, while maintaining adequate concentration difference between adjacent cells to enhance osmosis function, as well as defining a concentration ratio within each cell to ensure a net positive power generation.

Owner:KELADA MAHER ISAAC

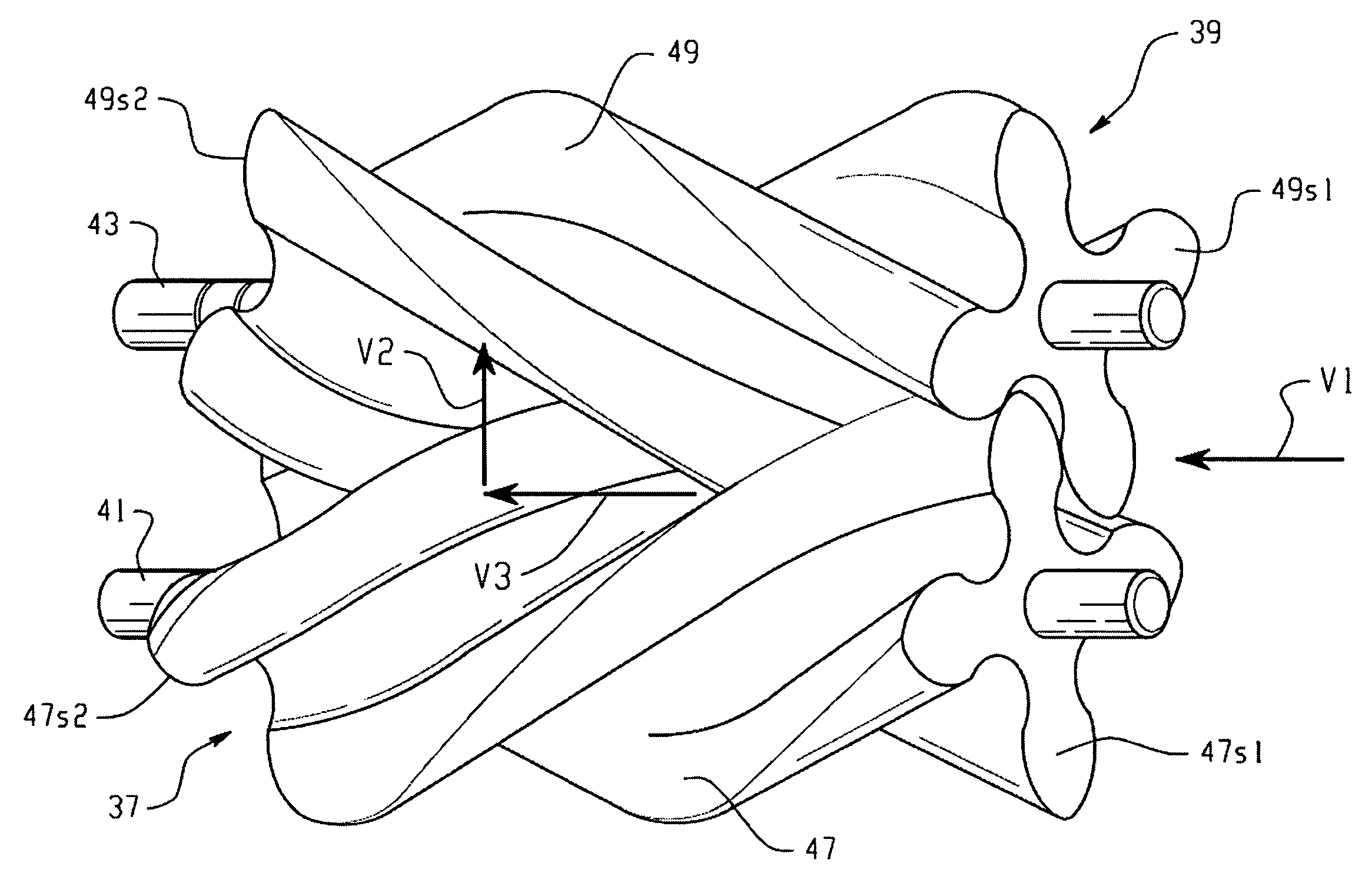

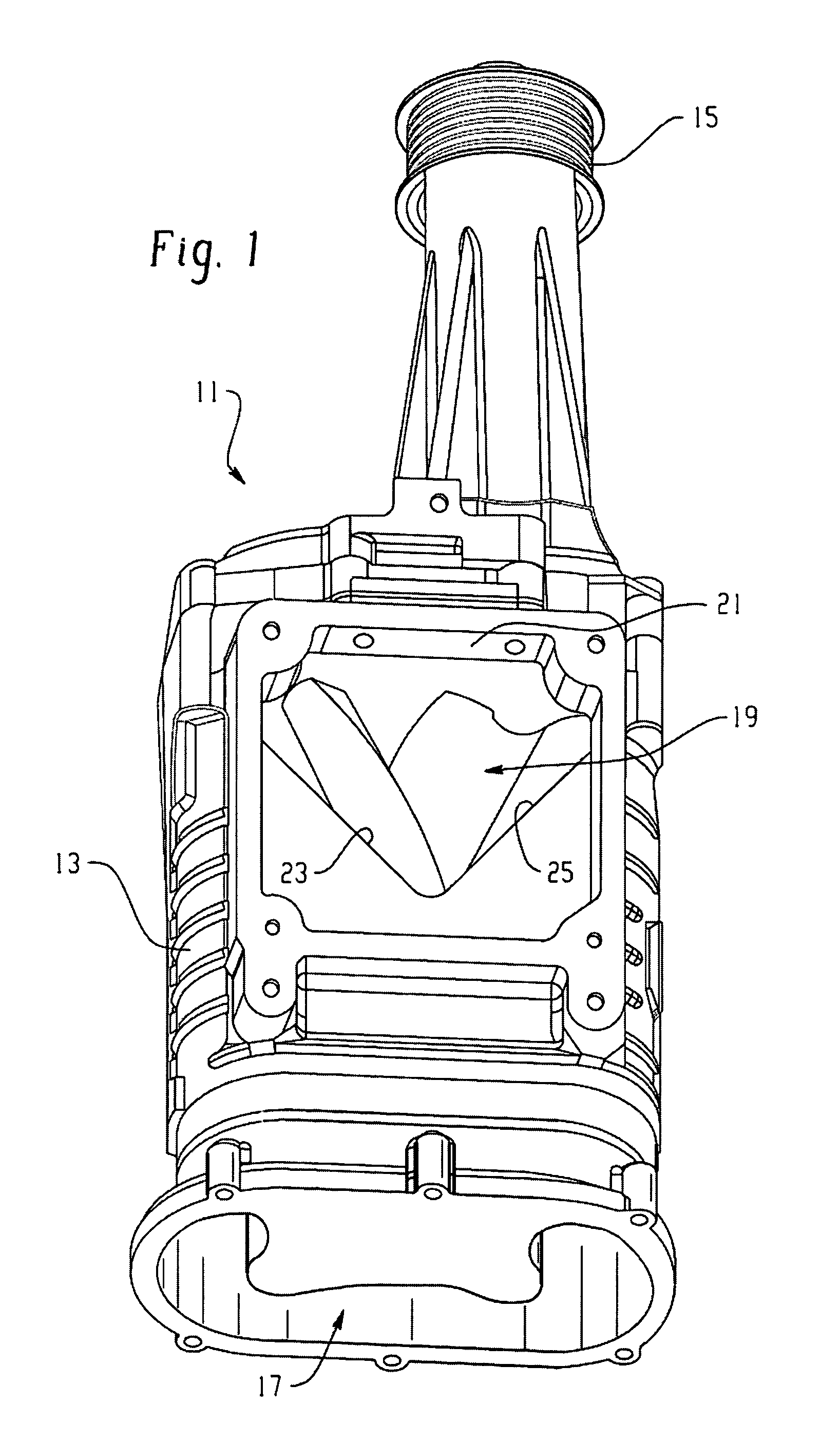

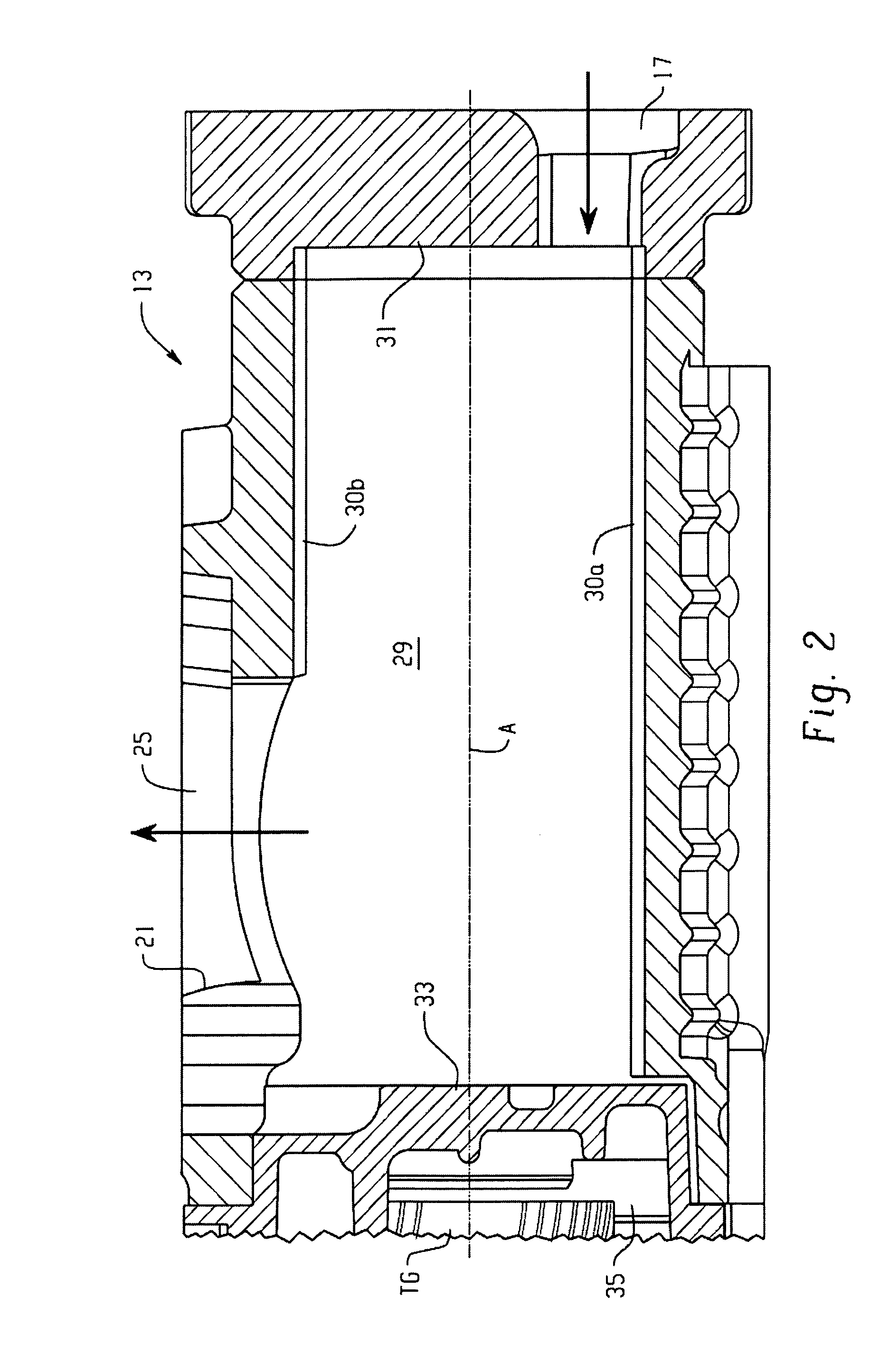

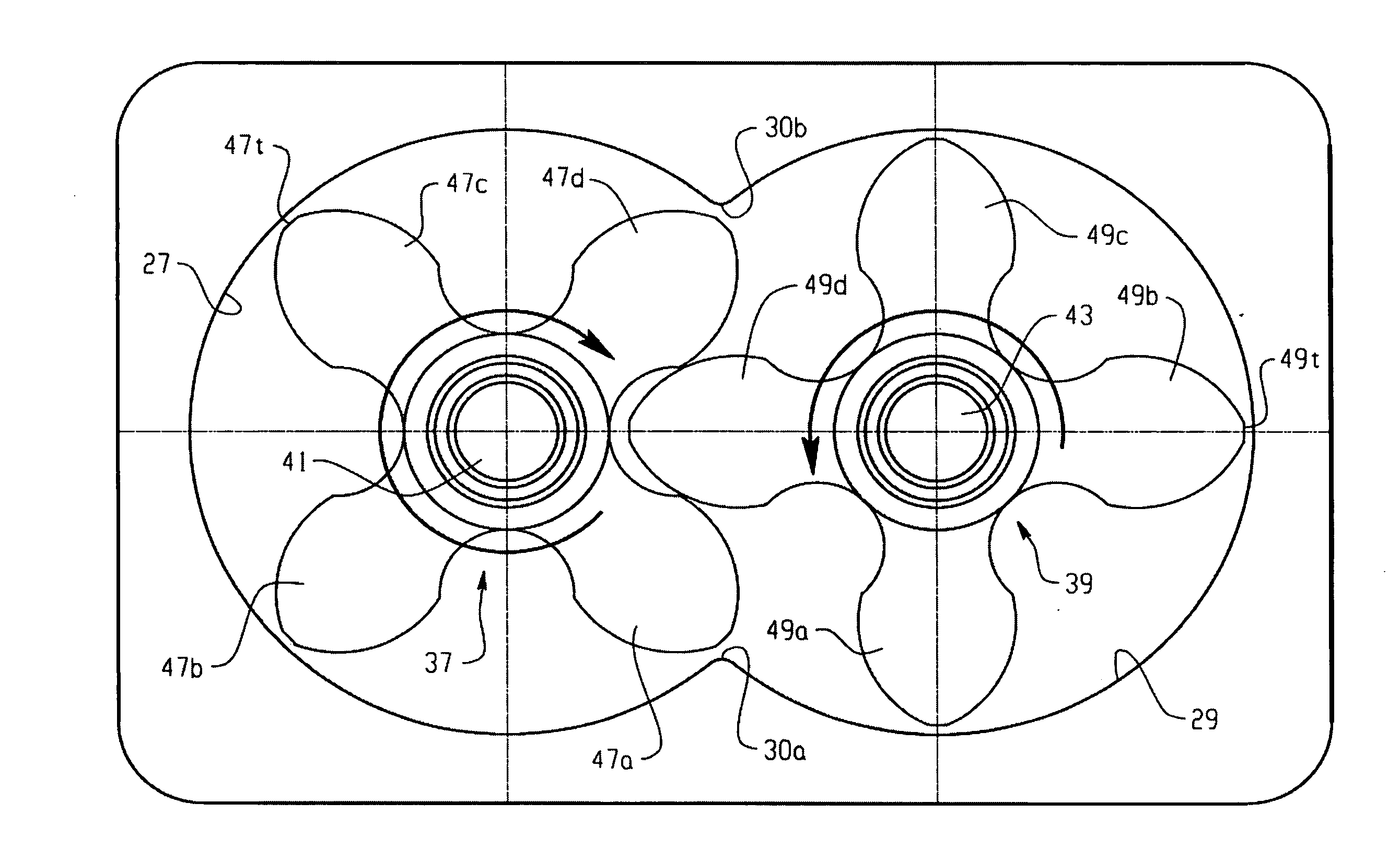

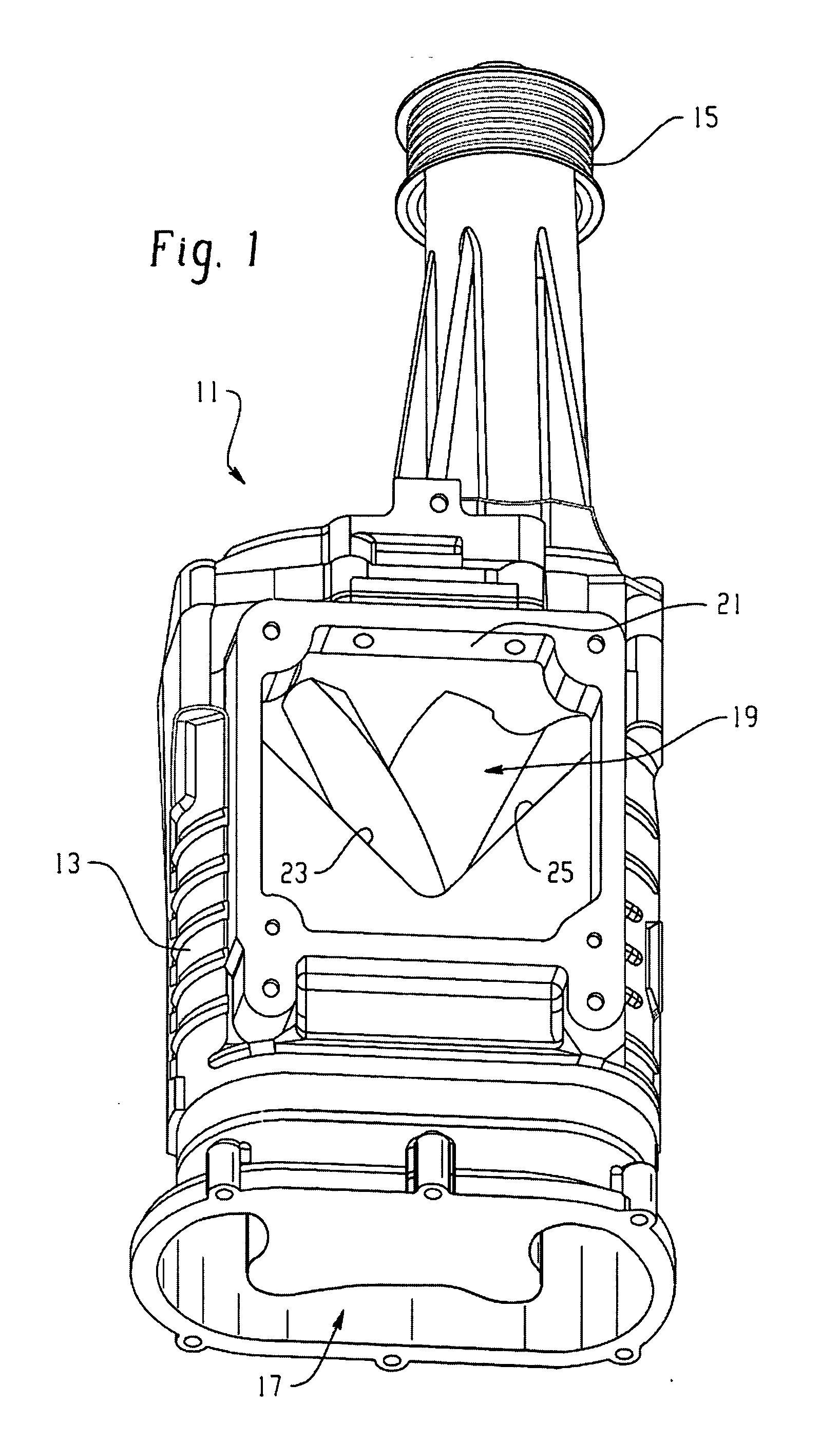

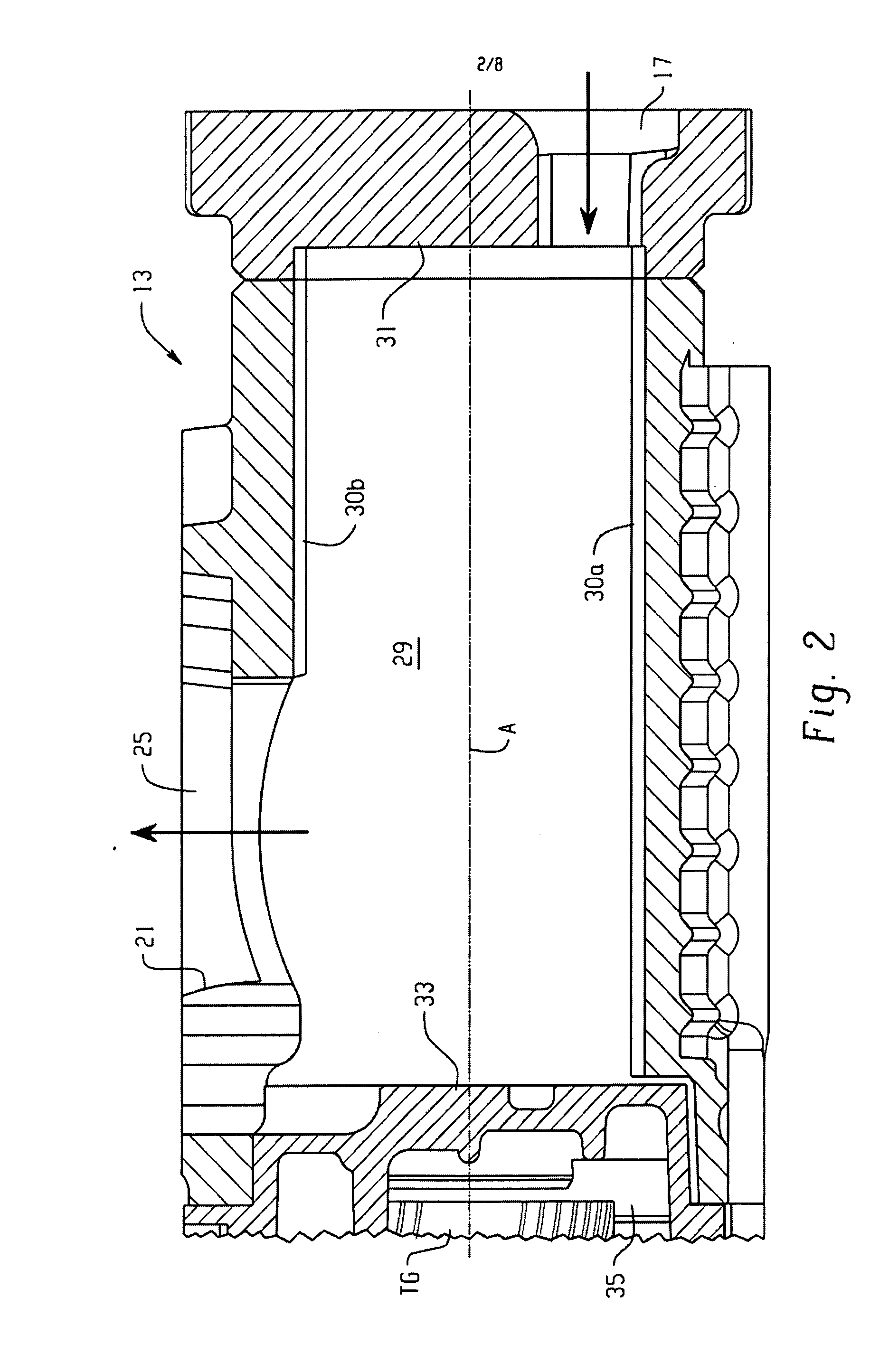

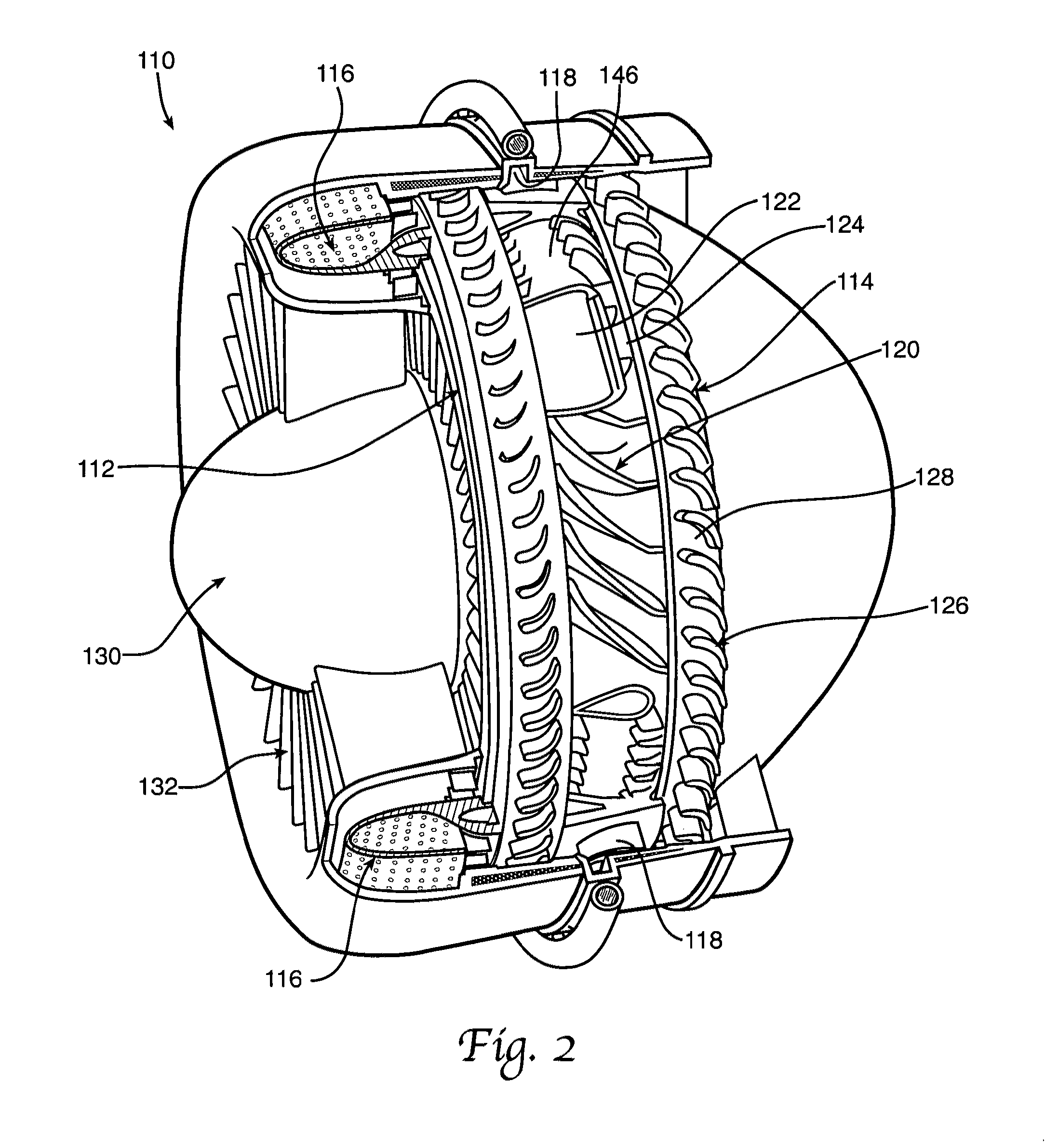

Optimized helix angle rotors for Roots-style supercharger

ActiveUS7488164B2Improve blower efficiencyImprove thermal efficiencyOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

A method of designing rotors for a Roots blower comprising a housing having cylindrical chambers, the housing defining an outlet port (19). The blower includes meshed, lobed rotors (37,39) disposed in the chambers, each rotor including a plurality N of lobes (47,49), each lobe having first (47a,49a) and second (47b,49b) axially facing end surfaces. Each lobe has its axially facing surfaces defining a twist angle (TA), and each lobe defines a helix angle (HA). The method of designing the rotor comprises determining a maximum ideal twist angle (TAM) for the lobe as a function of the number N of lobes on the rotor, and then determining a helix angle (HA) for each lobe as a function of the maximum ideal twist angle (TAM) and an axial length (L) between the end surfaces of the lobe. A rotor designed in accordance with this method is also provided.

Owner:EATON INTELLIGENT POWER LTD

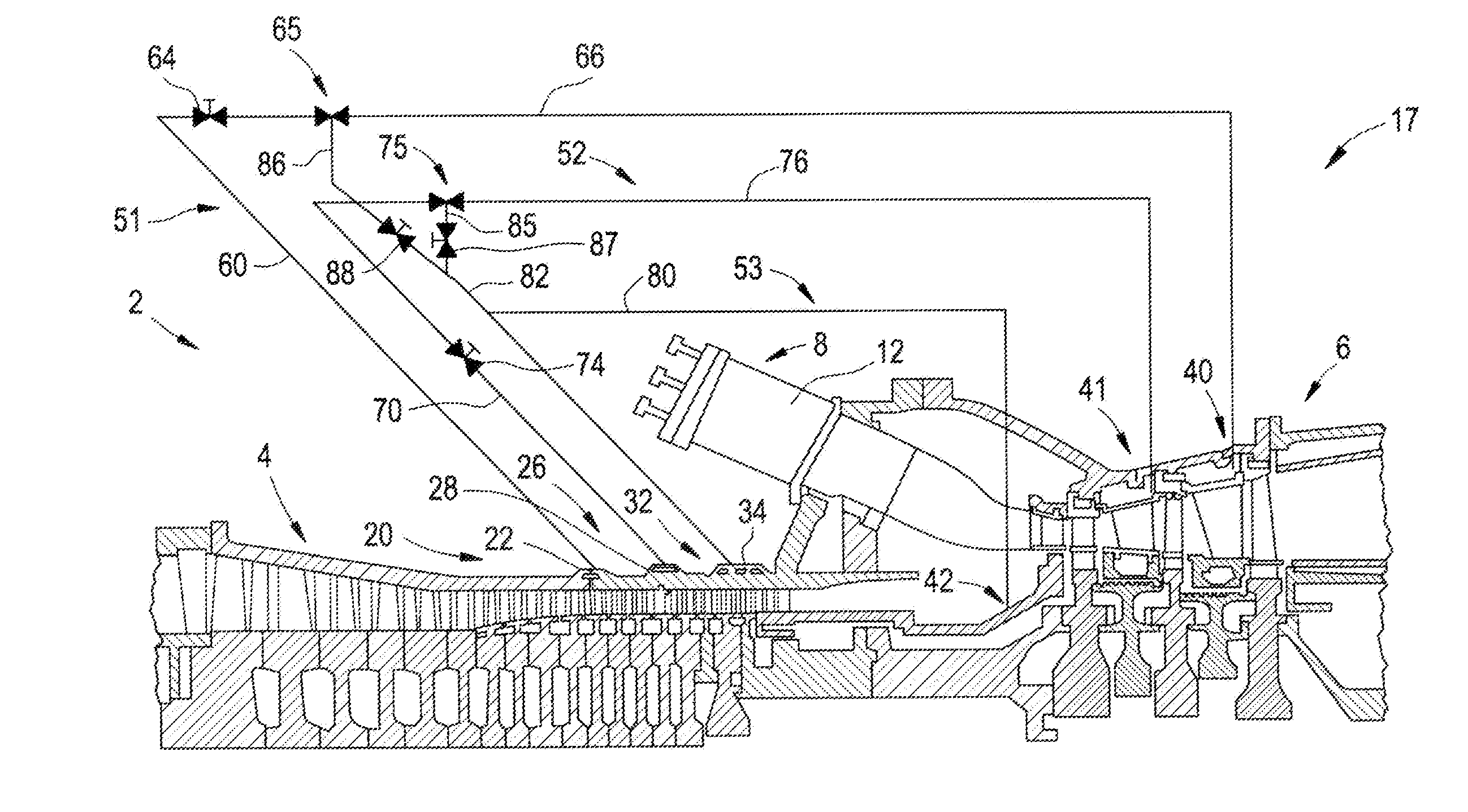

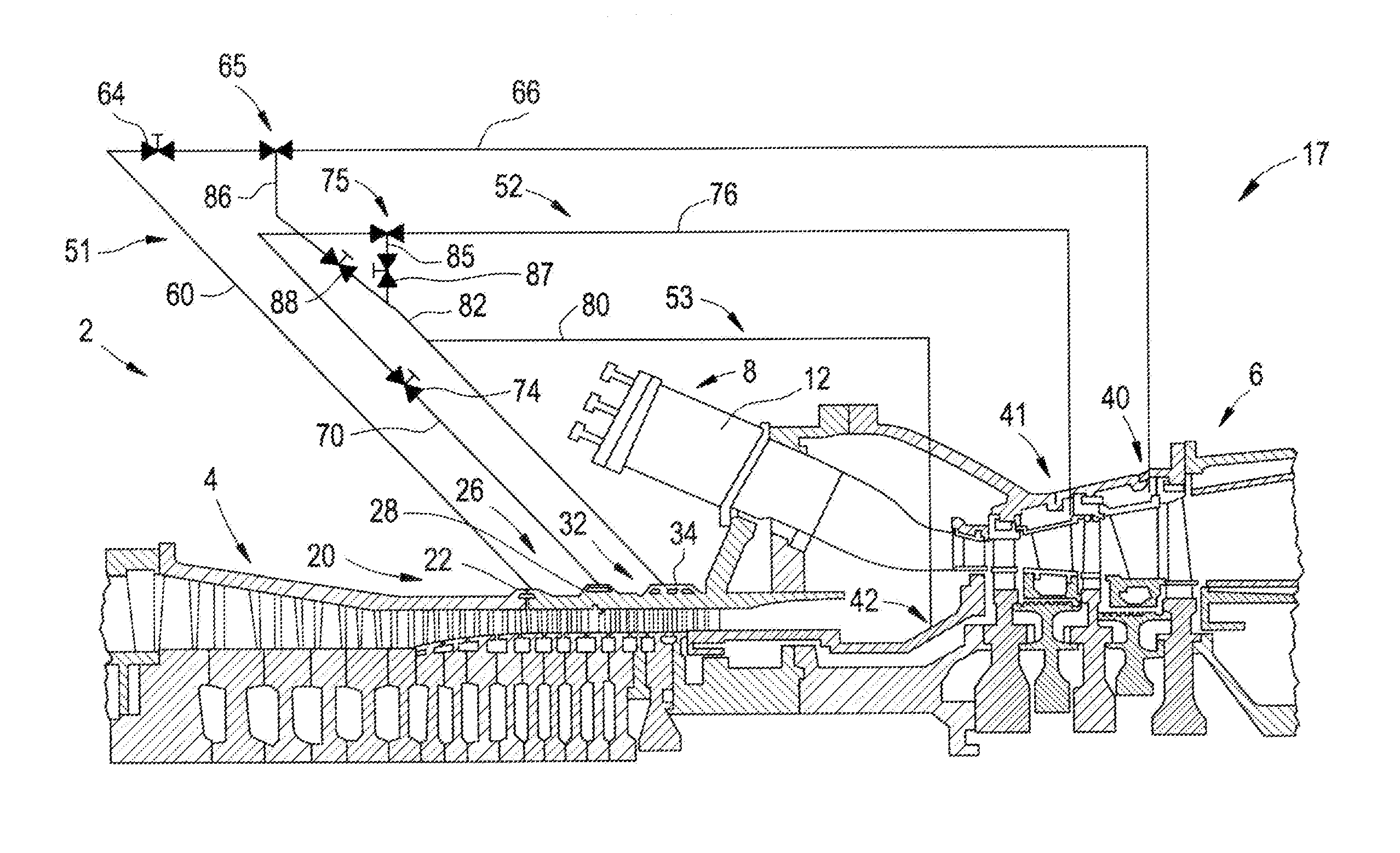

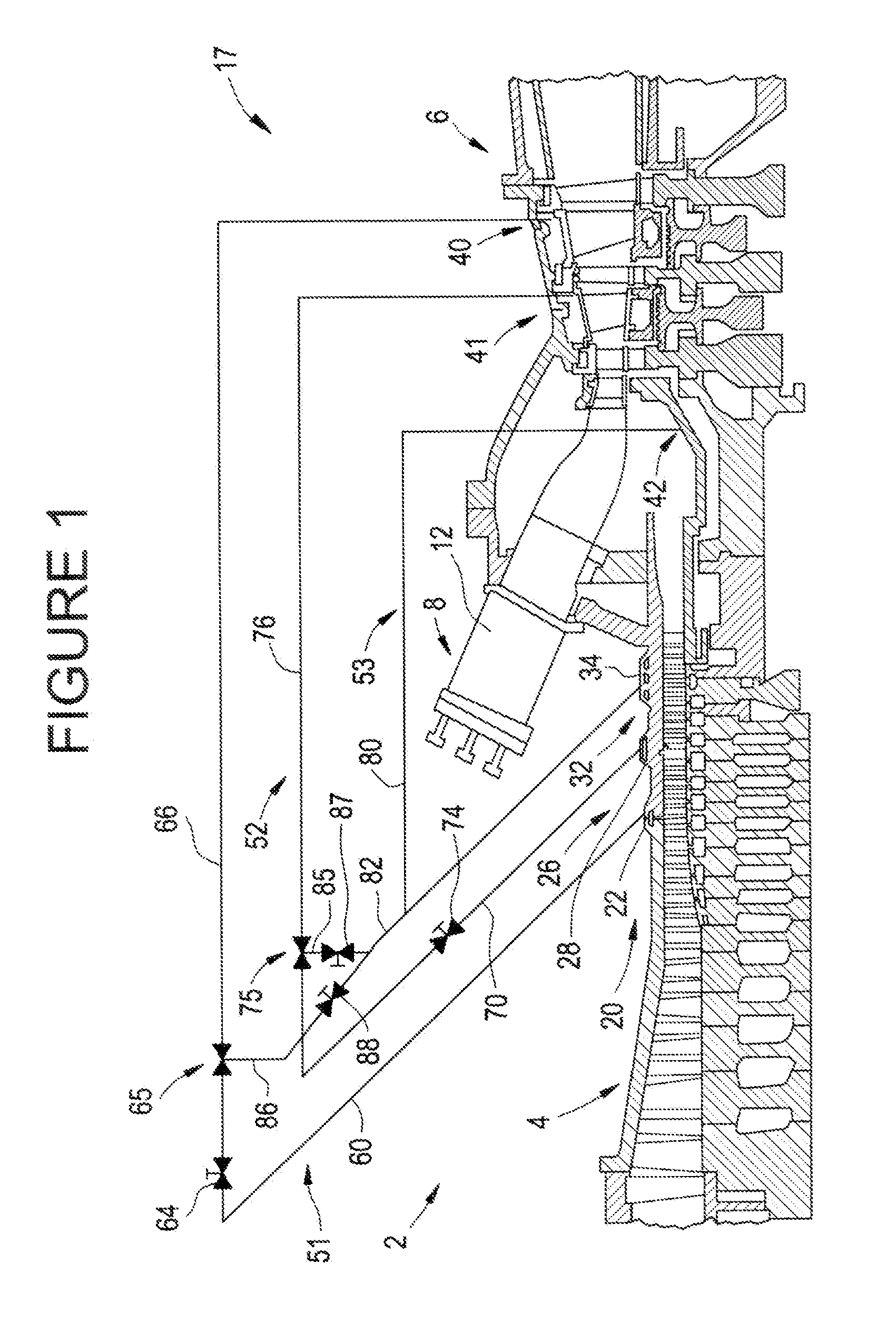

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveUS20090104020A1Lower fuel bum rateReduce outputPump componentsWind motor controlHigh pressureTurbine

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC CO

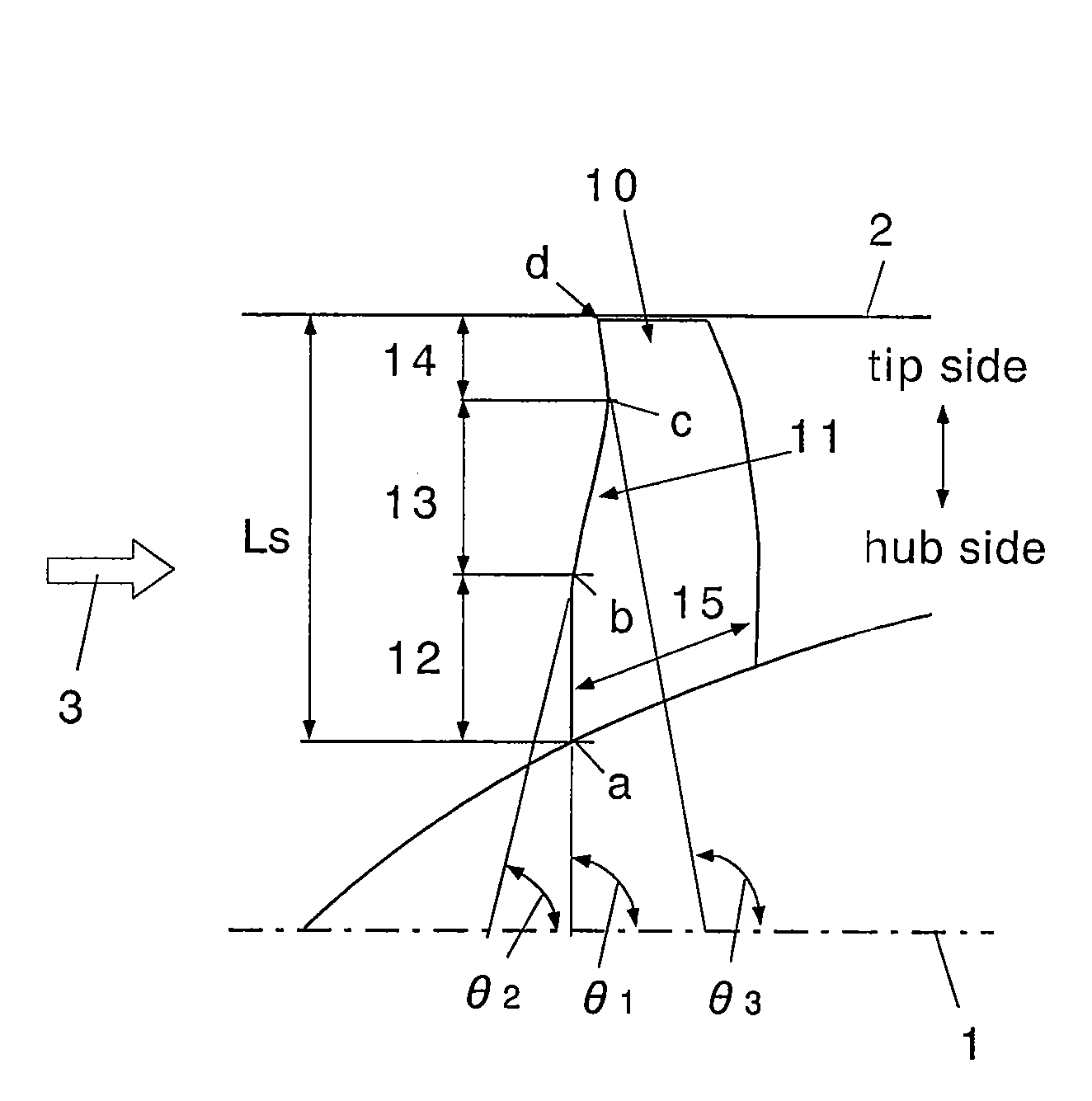

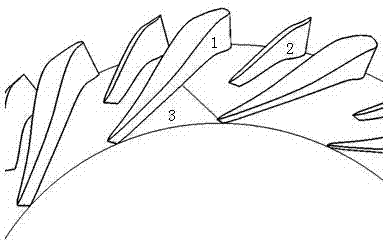

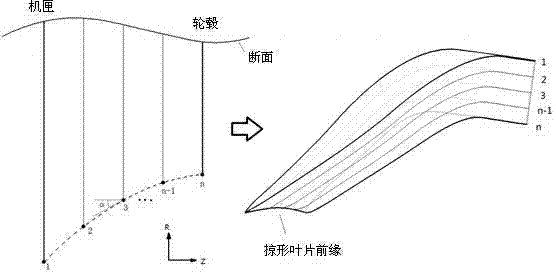

Fan rotating blade for turbofan engine

ActiveUS20100232970A1Relieve pressureIncrease pressure ratioPump componentsBlade accessoriesLeading edgeEngineering

[Object]An object of the invention is to provide a fan rotating blade for a turbofan engine capable of increasing a bypass ratio by increasing an intake air flow rate without enlarging a diameter of a fan and an inner diameter of a casing and of realizing a decrease in weight of an engine as well as a decrease in fuel consumption and noise.[Means for Solving the Problems]A leading edge part 11 of a fan rotating blade 10 for taking air thereinto is provided with a vertical hub portion 12 positioned on the hub side so as to be substantially perpendicular to a fan rotary shaft, a backward mid-span portion 13 inclined toward the downstream side from the hub side to the mid-span portion, and a forward inclined tip portion 14 inclined toward the upstream side from the mid-span side to the tip portion.

Owner:IHI CORP

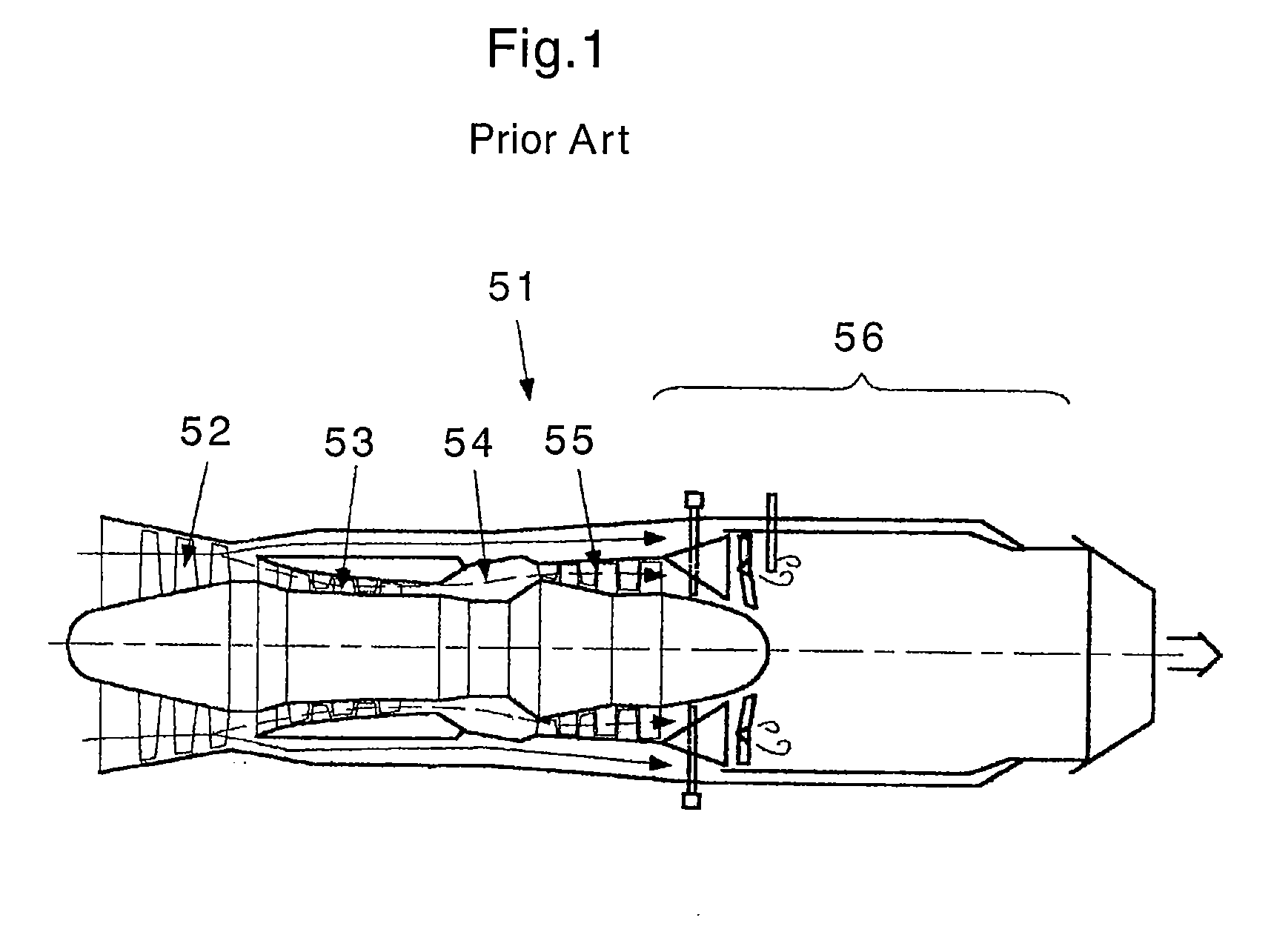

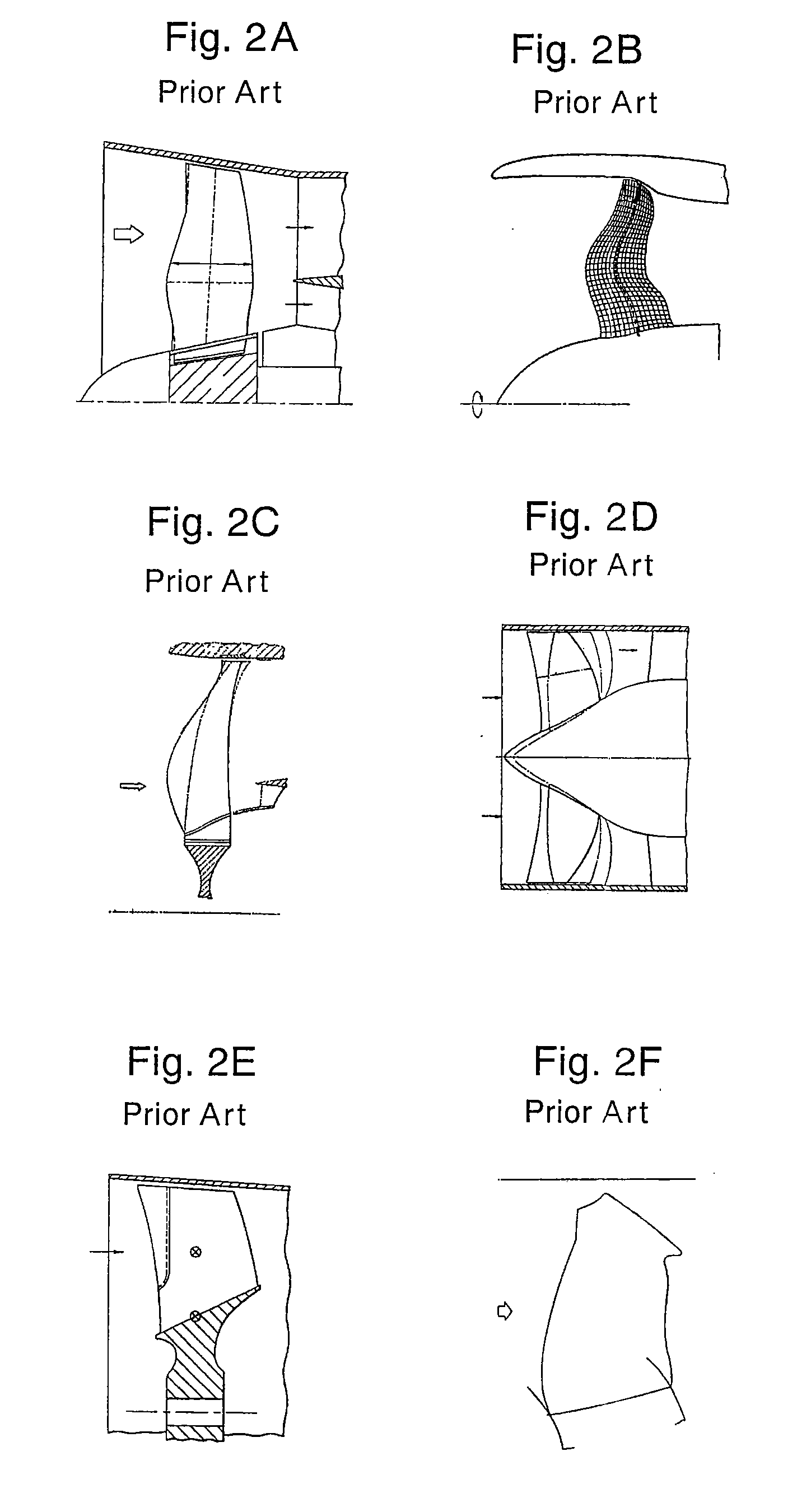

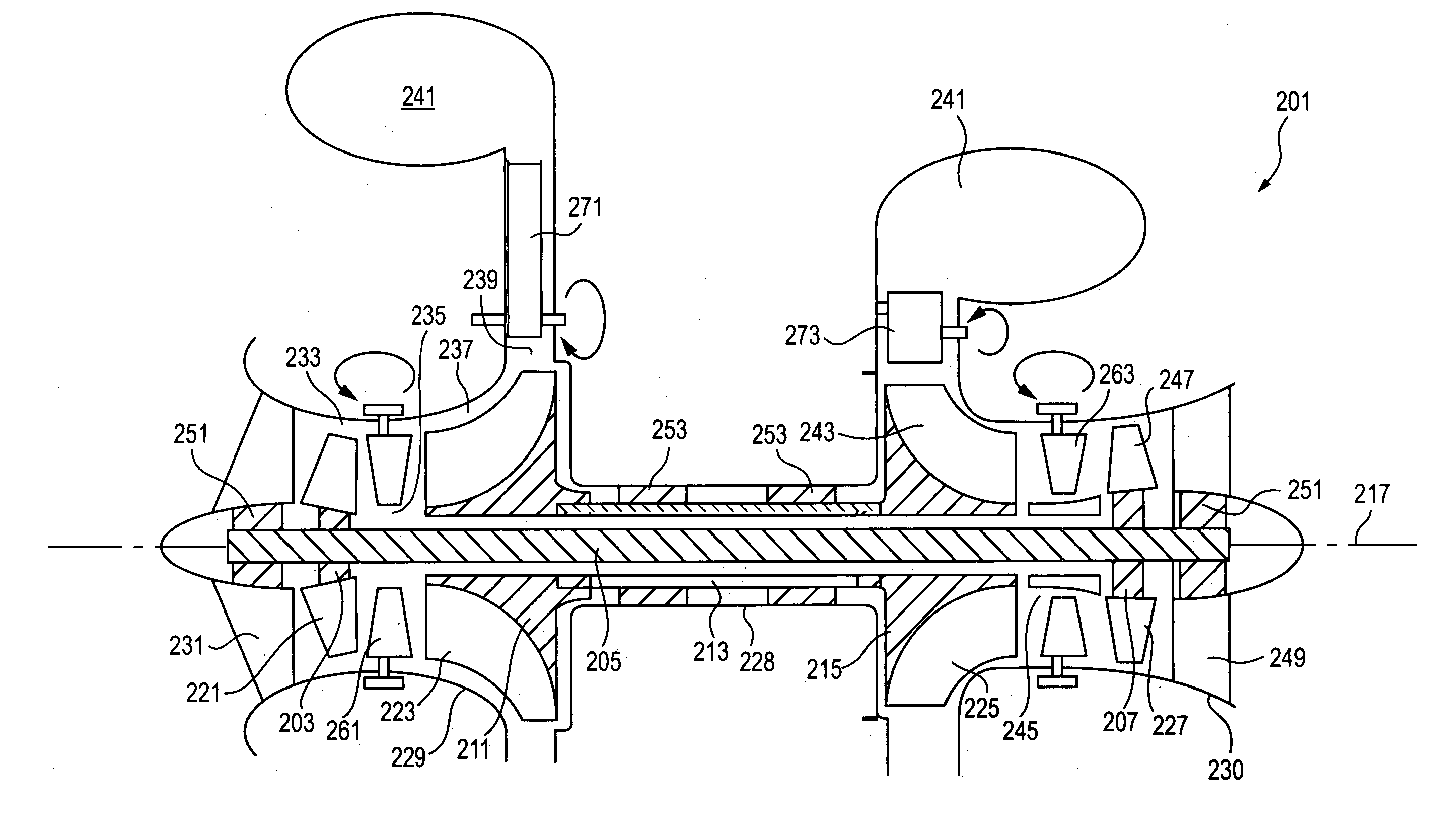

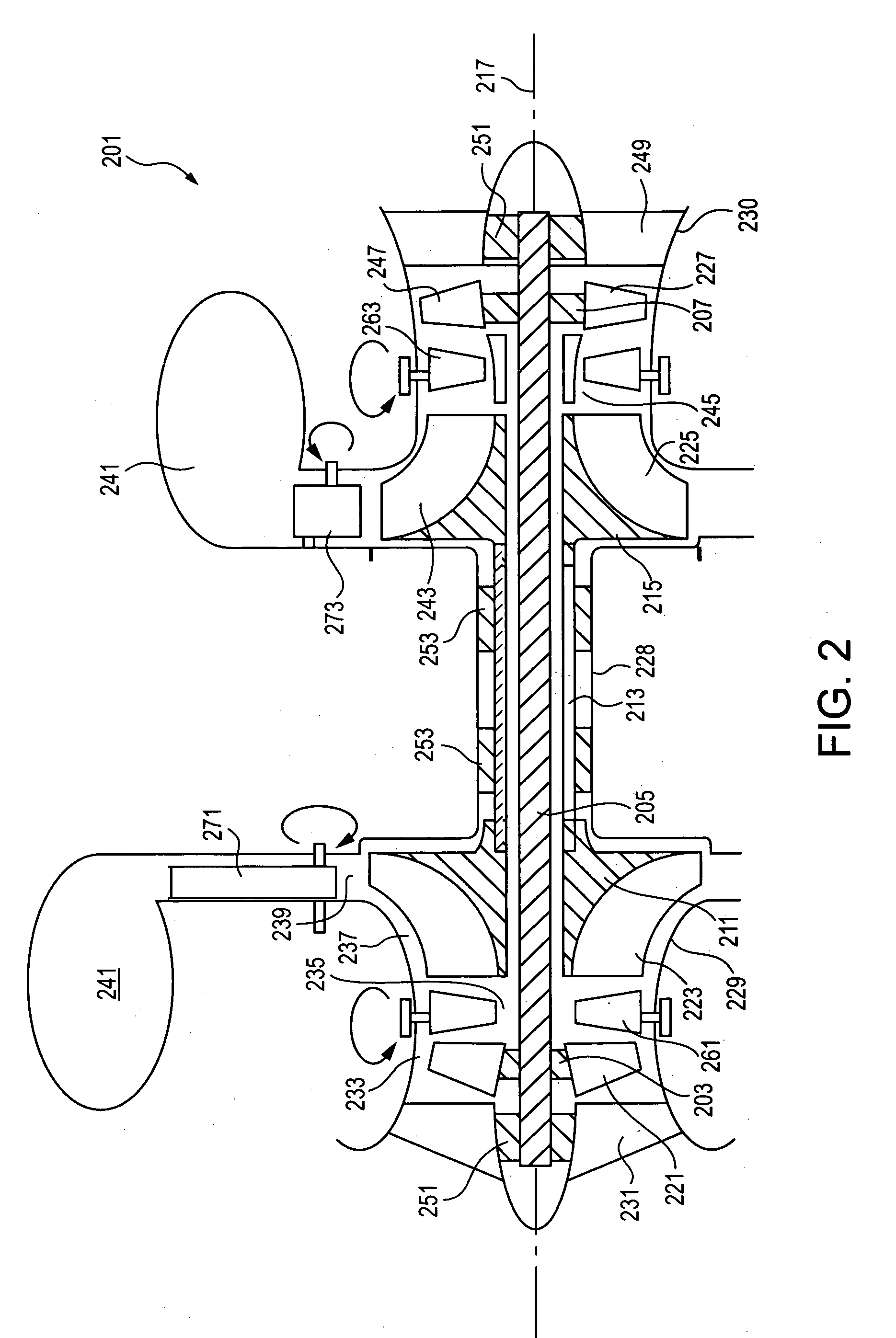

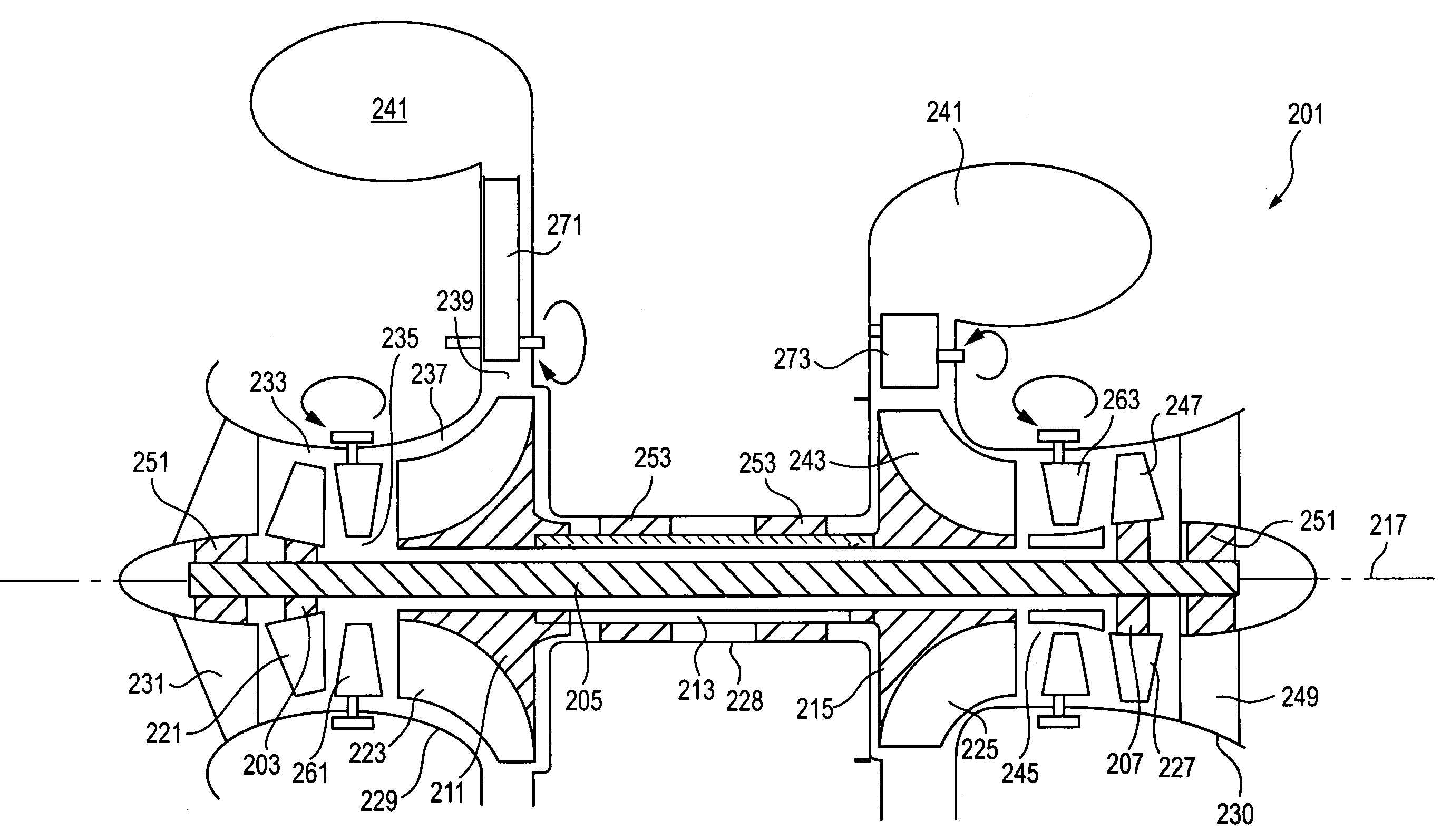

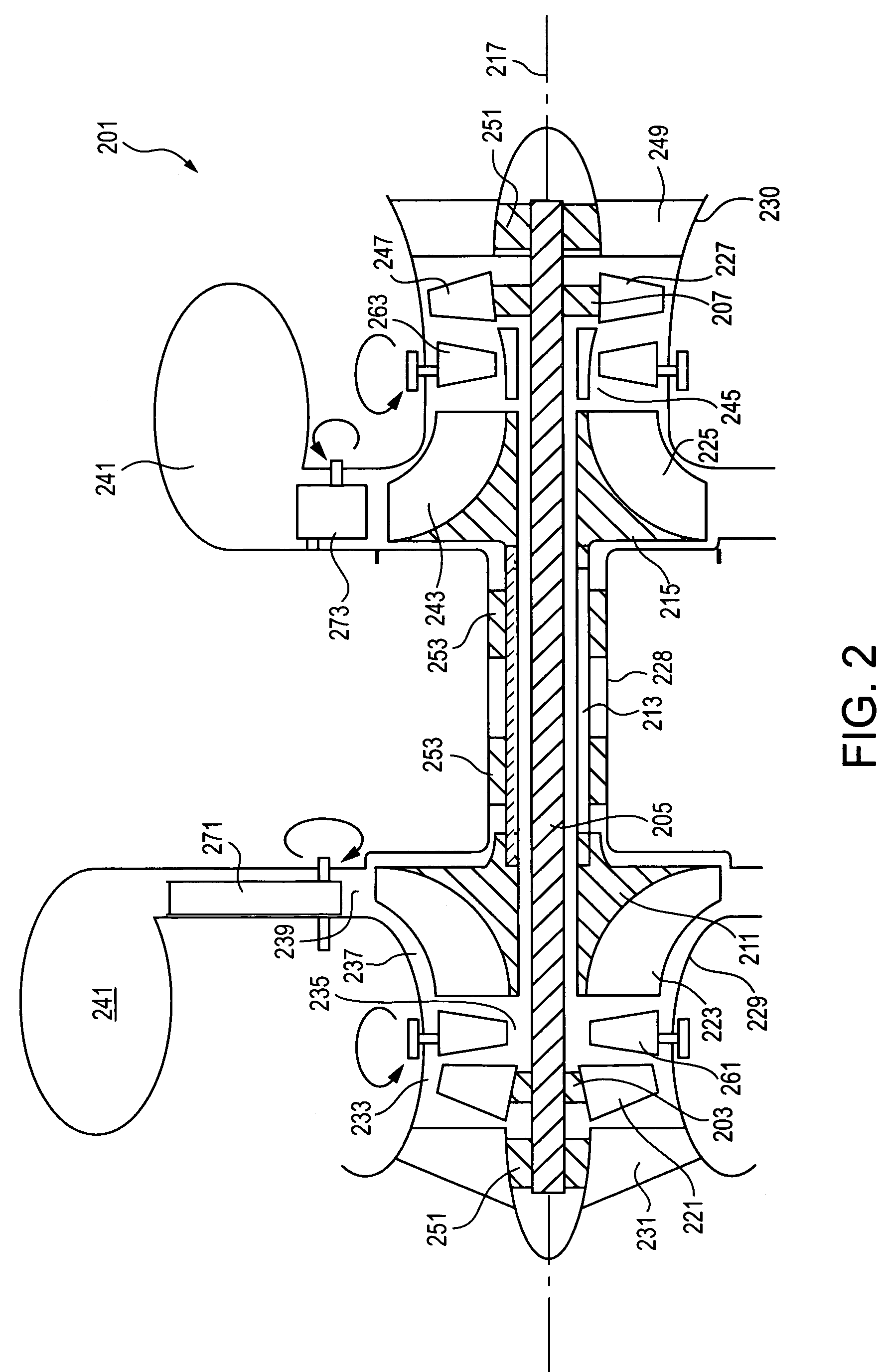

Two-shaft turbocharger

InactiveUS20070204615A1Improve transient response timeReduce morbidityInternal combustion piston enginesCombination enginesAxial compressorTurbine blade

A turbocharger, having an axial compressor wheel and an axial turbine wheel mounted on a first shaft supported by a housing, and a radial compressor wheel and a radial turbine wheel mounted on a second shaft, the second shaft concentrically extending around the first shaft and being supported by the housing. The housing defines a first duct extending axially from the exducer of the axial compressor to the inducer of the radial compressor, and a second duct extending axially from the exducer of the radial turbine to the inducer of the axial turbine. A plurality of controllable compressor guide vanes extend through the first duct, and a plurality of controllable turbine stator vanes extend through the second duct. The housing is provided with variable diffuser vanes at the exducer of the radial compressor, and with variable turbine vanes at the inducer of the radial turbine. The variable turbine vanes and the turbine stator vanes are controlled to accurately control the rotation rate of the radial and axial turbines. The compressor guide vanes are controlled to minimize surge and maximize choke flow rate.

Owner:HONEYWELL INT INC

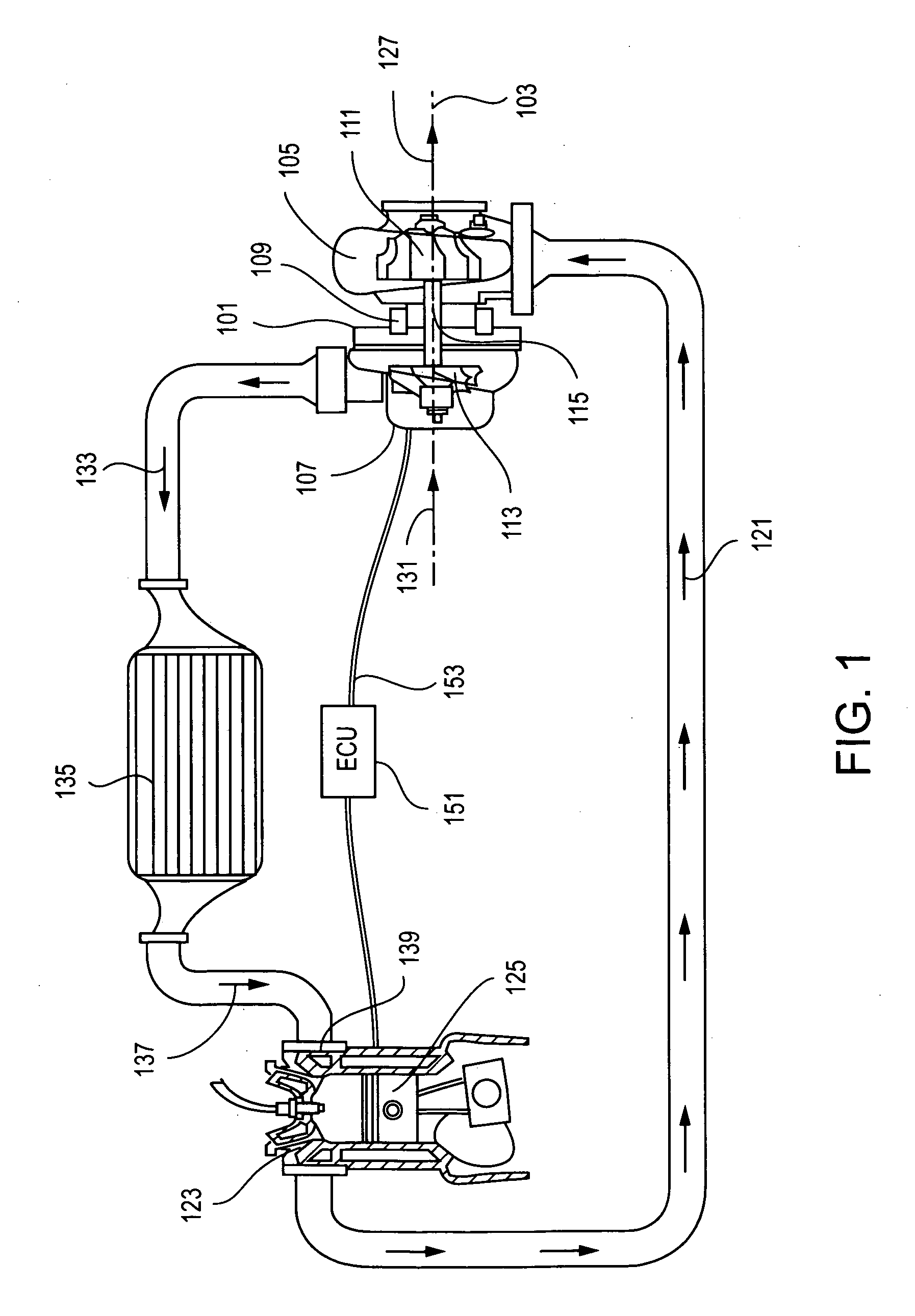

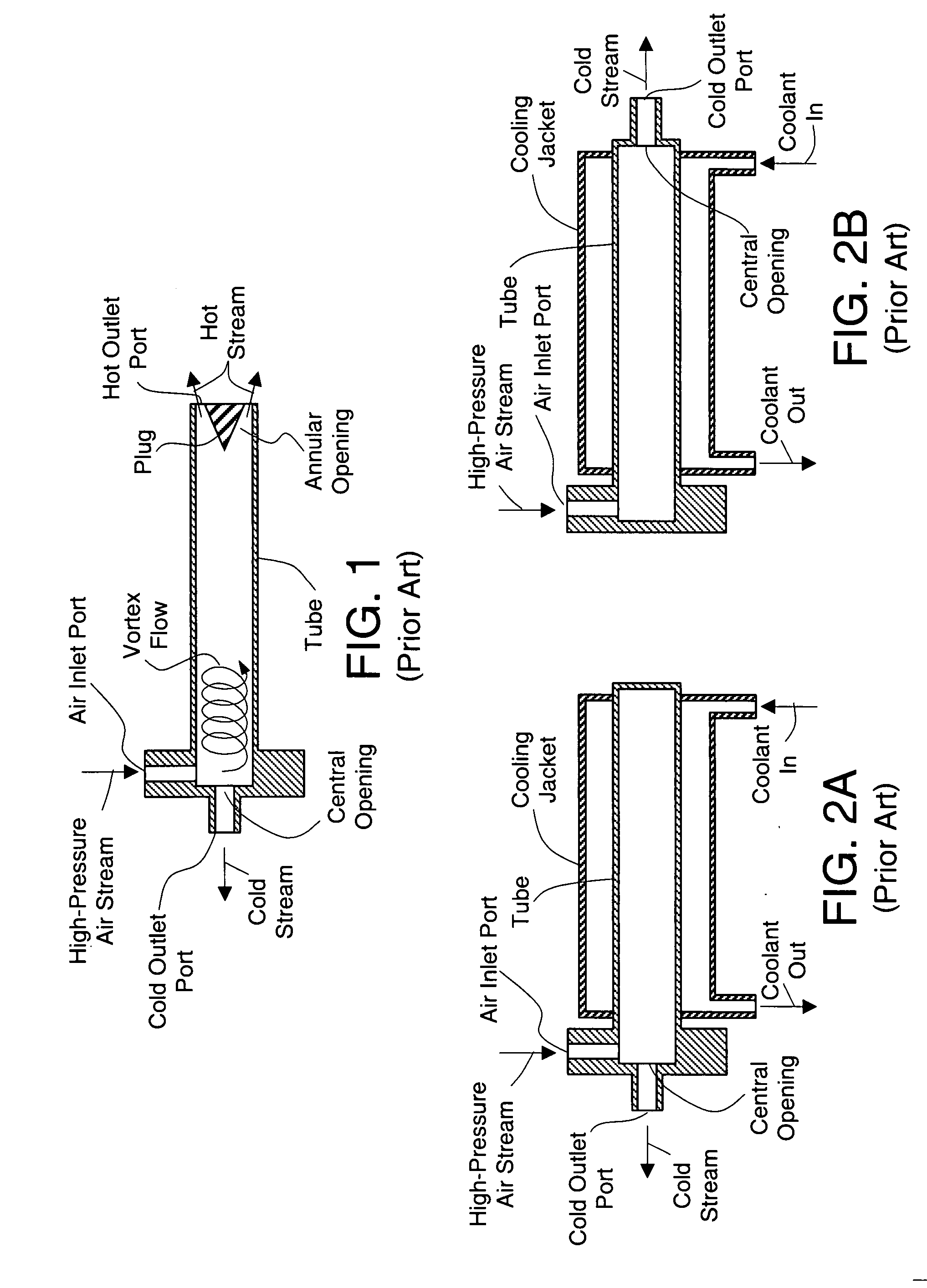

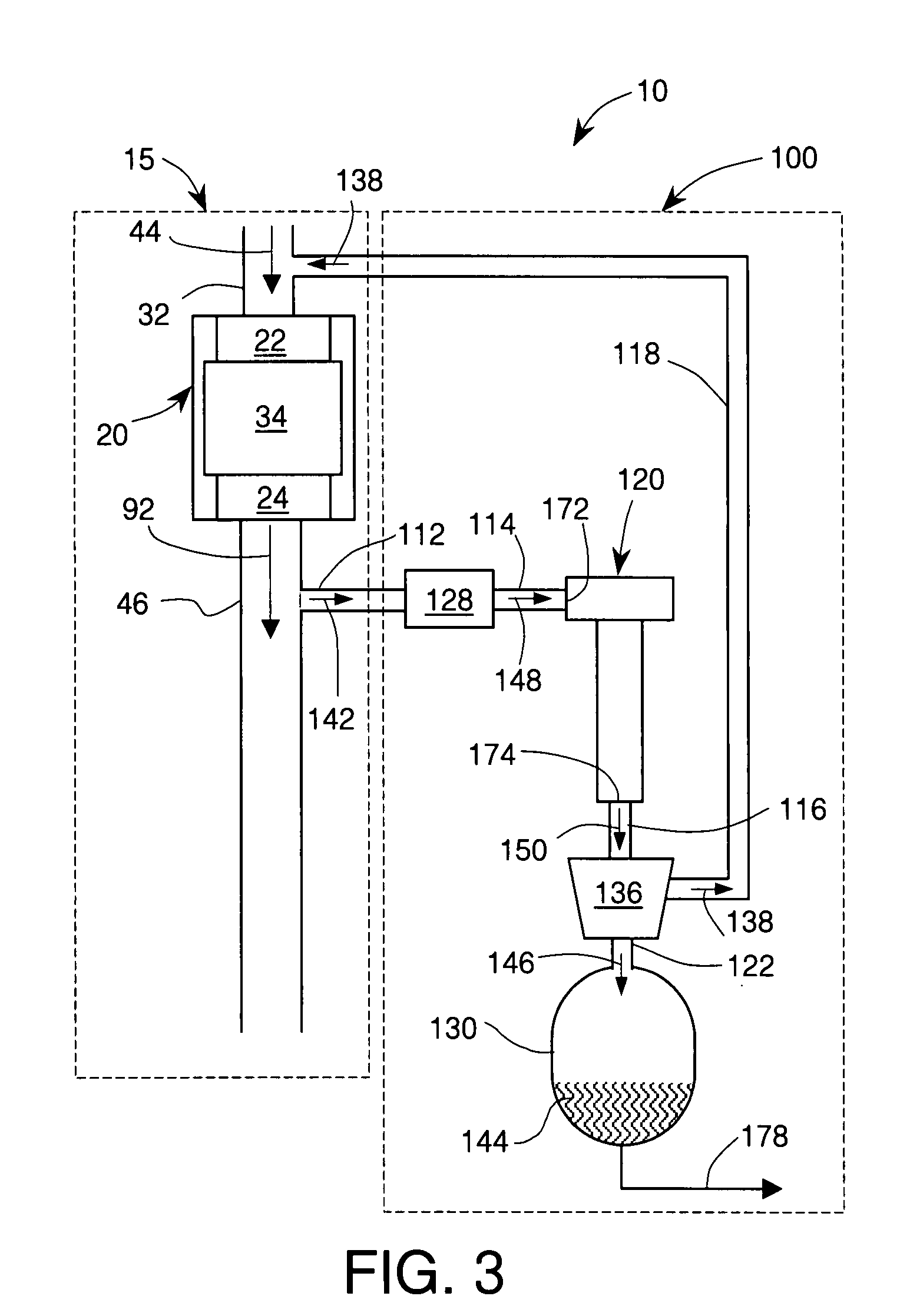

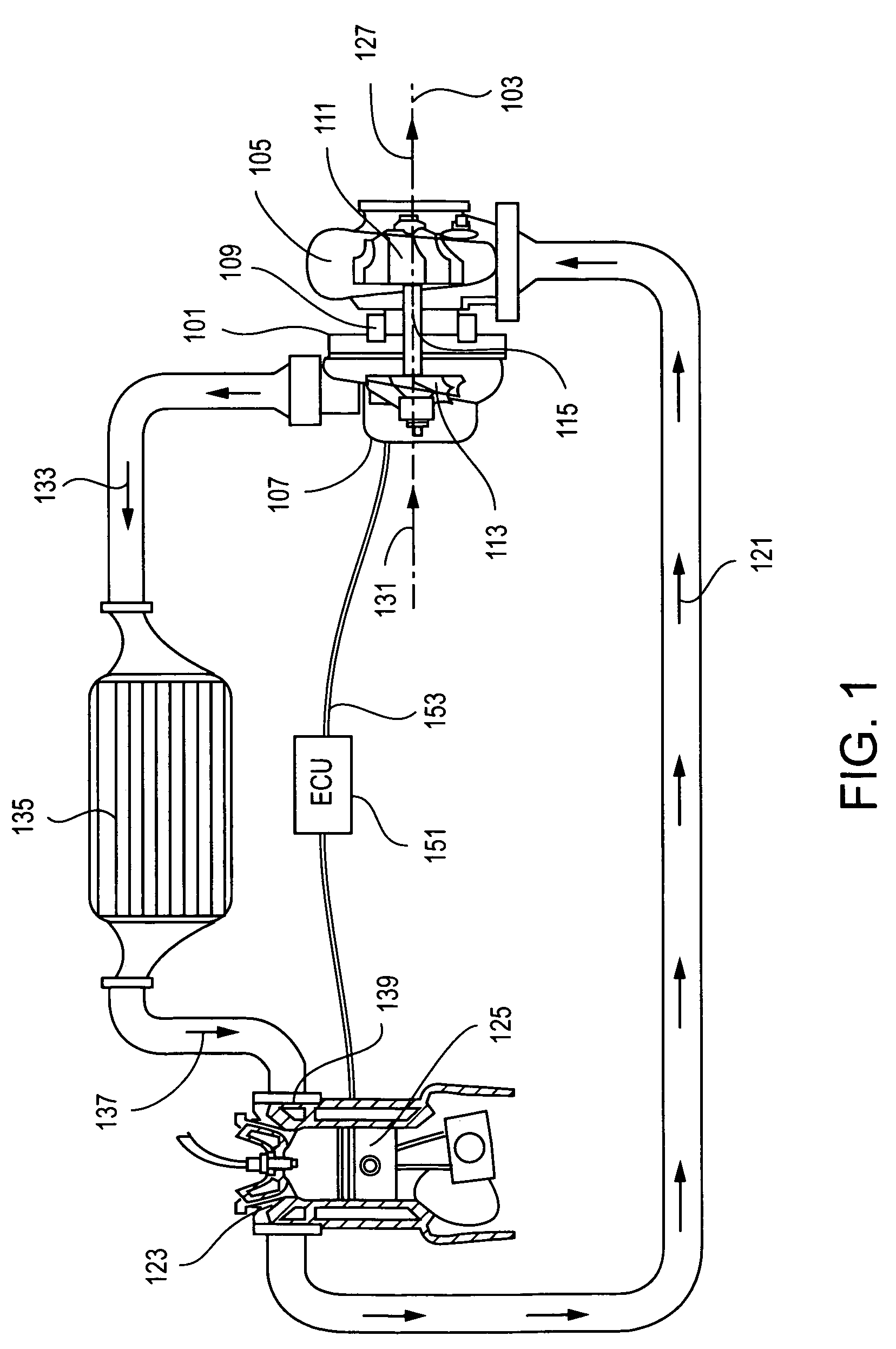

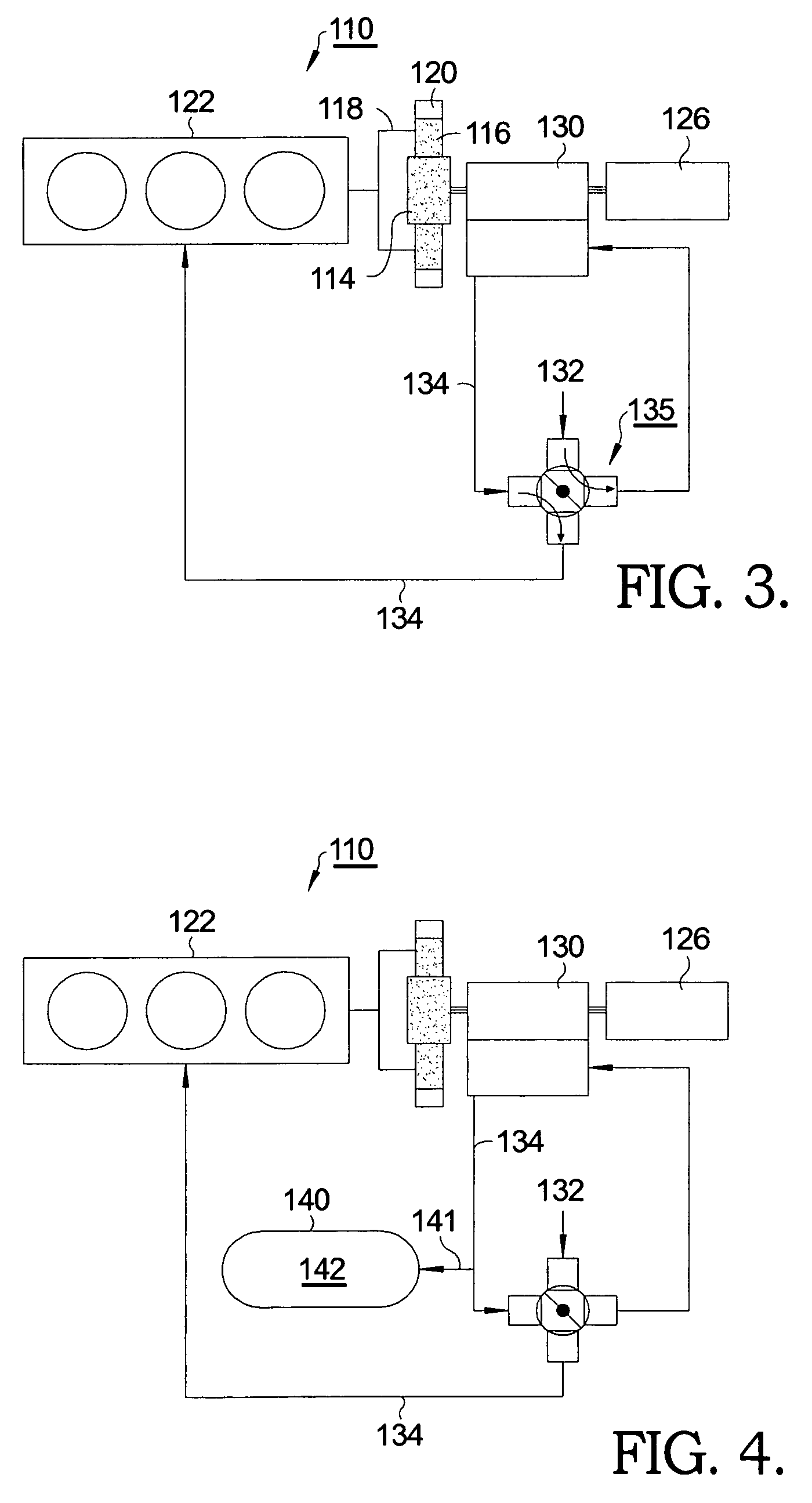

Internal combustion engine/water source system

InactiveUS20070137590A1Easy to operateReduce pollutantsElectrolysis componentsInternal combustion piston enginesExternal combustion engineWater source

An internal combustion engine / water source system for a vehicle powered by a internal combustion engine wherein liquid water is produced by cooling a portion of engine exhaust gases in a vortex tube to induce condensation. In one embodiment, engine exhaust gases are pumped into the vortex tube by a compressor. After removing a portion of water vapor, cooled exhaust gases may be re-introduced to engine's combustion chamber thereby providing an exhaust gas recirculation. In an automotive vehicle, liquid water generated by the invention may be collected and provided to an electrolytic cell for electrolysis into gaseous hydrogen to reduce exhaust pollutants during cold engine start. Alternatively, water generated by the invention may be injected into engine combustion chamber to increase power and to reduce production of nitrogen oxides.

Owner:VETROVEC JAN

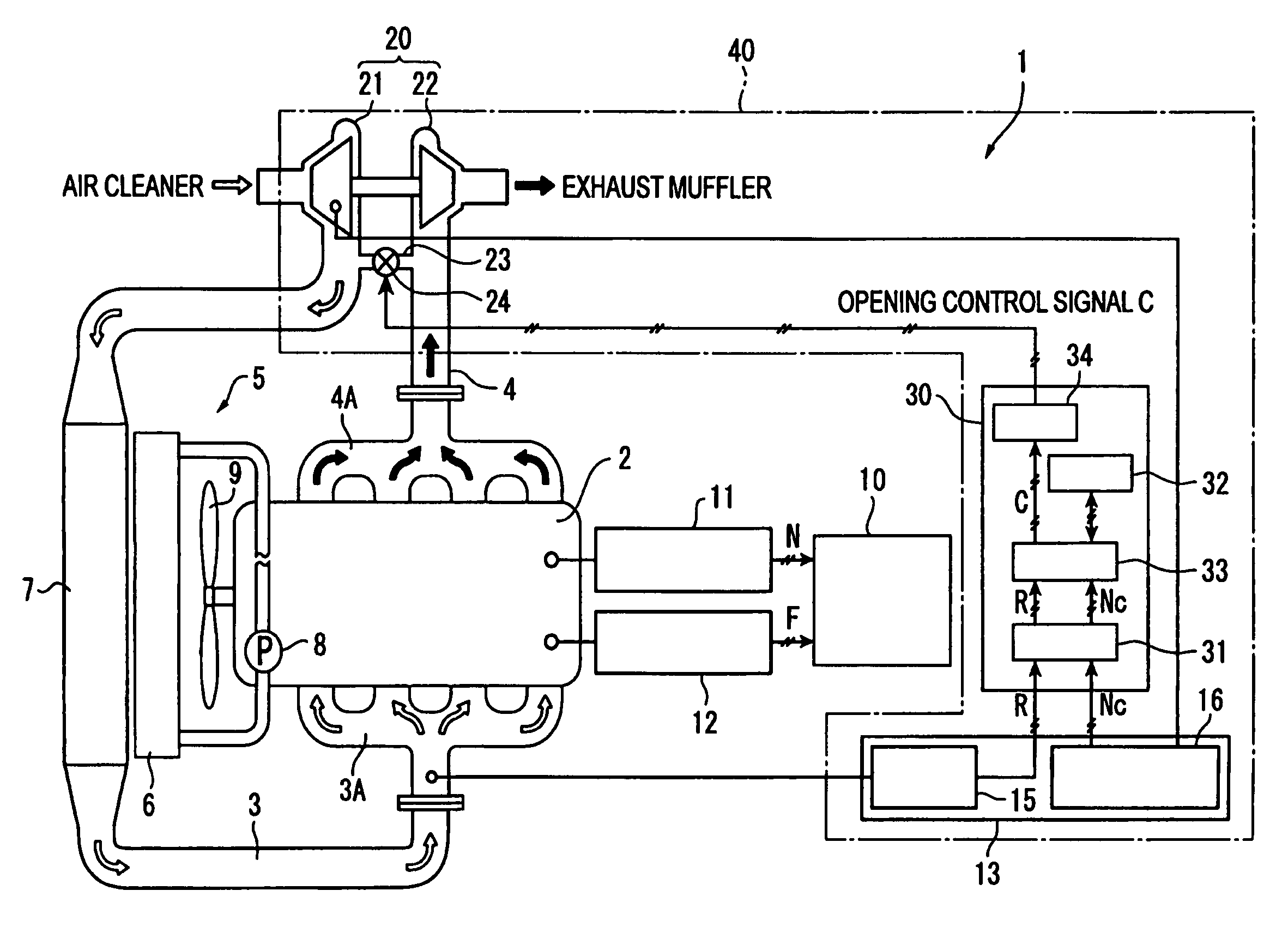

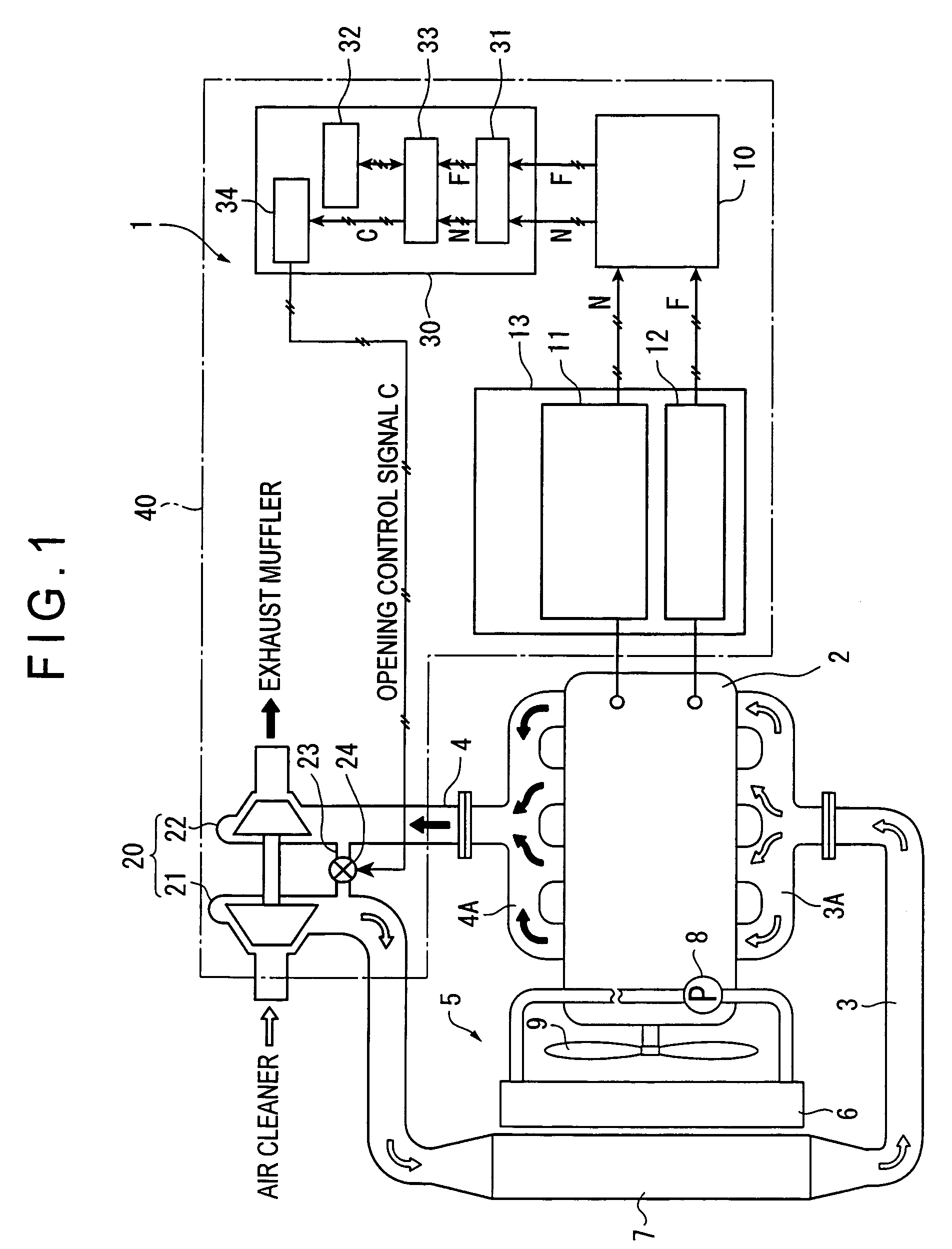

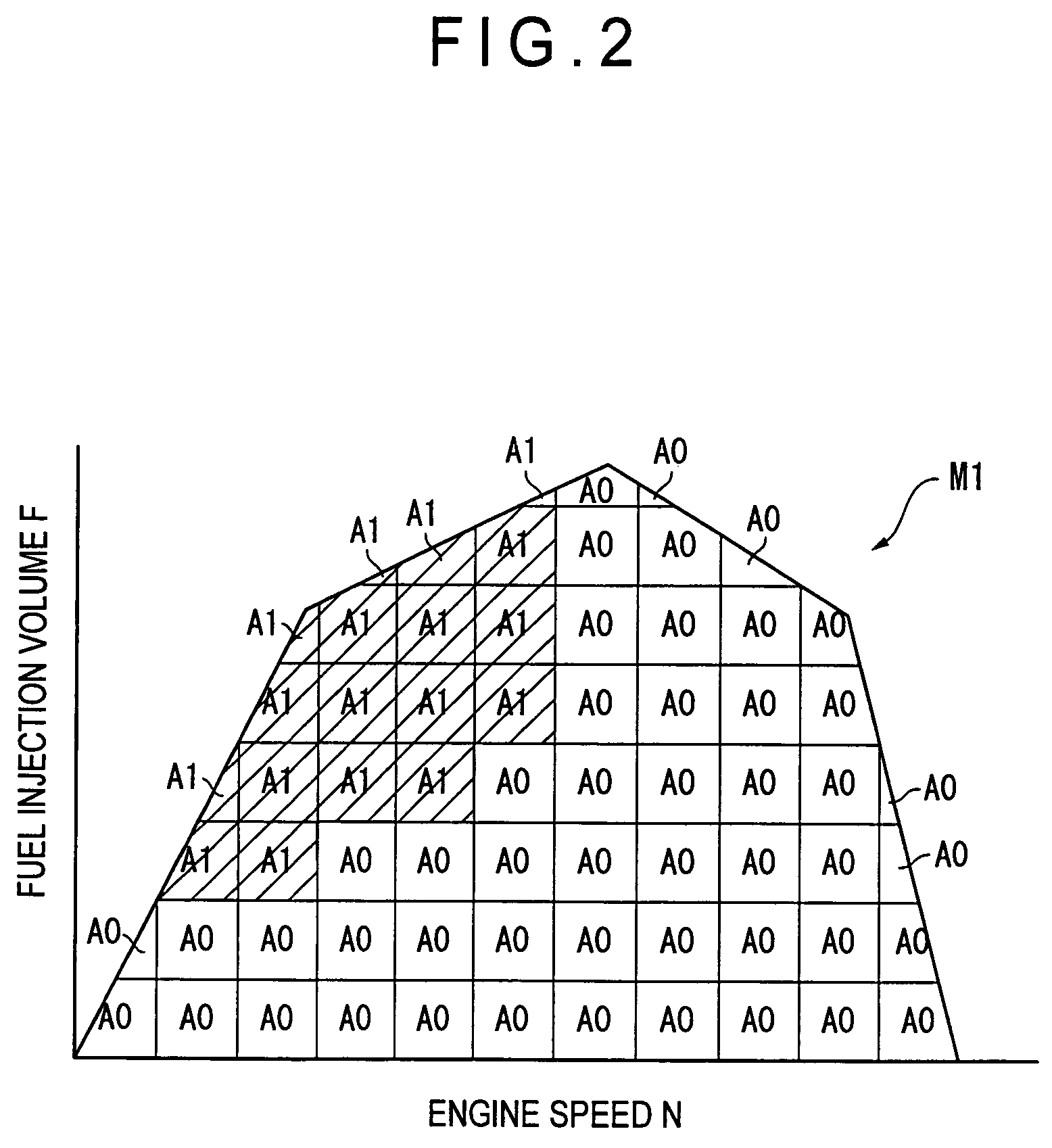

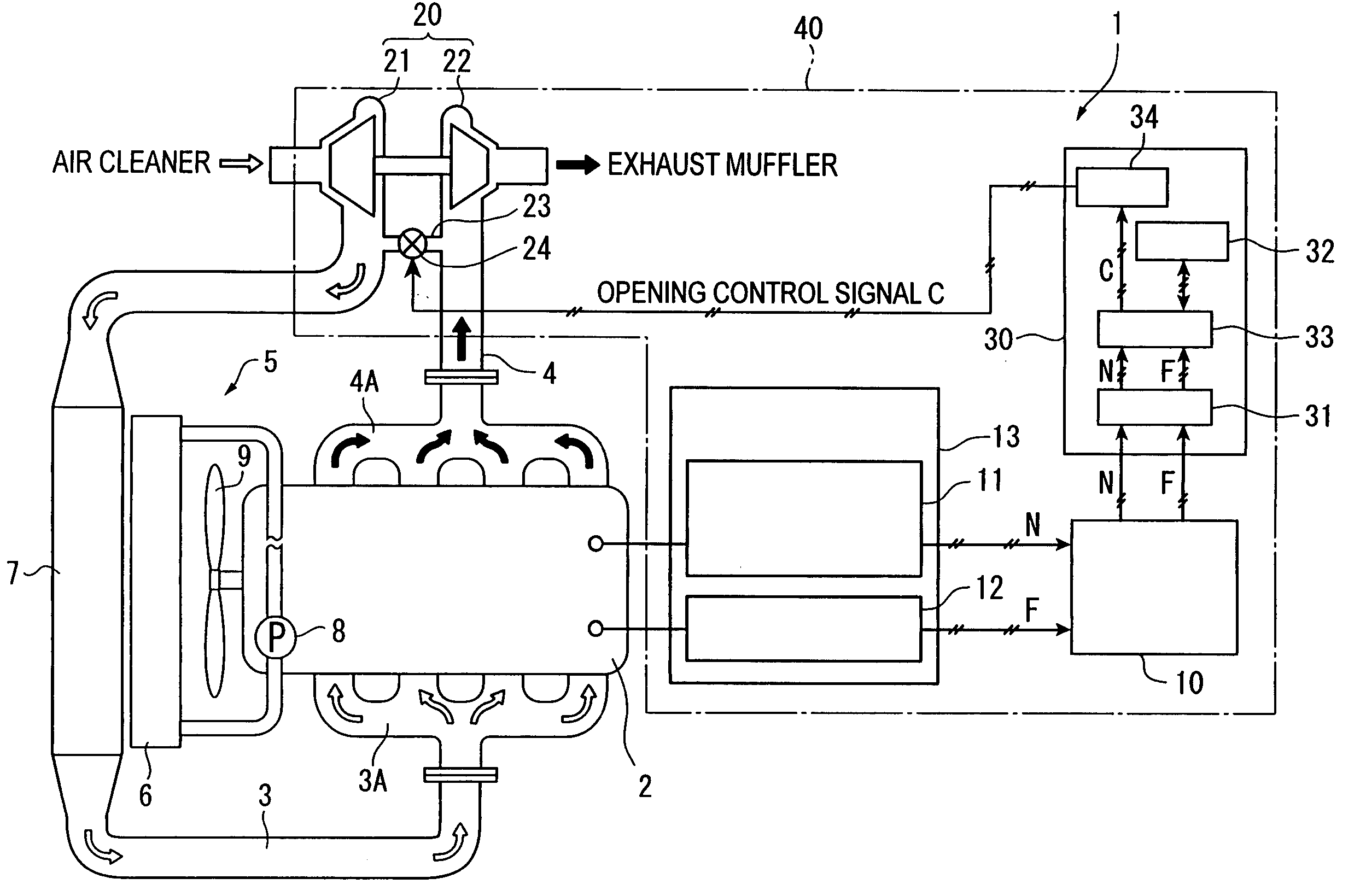

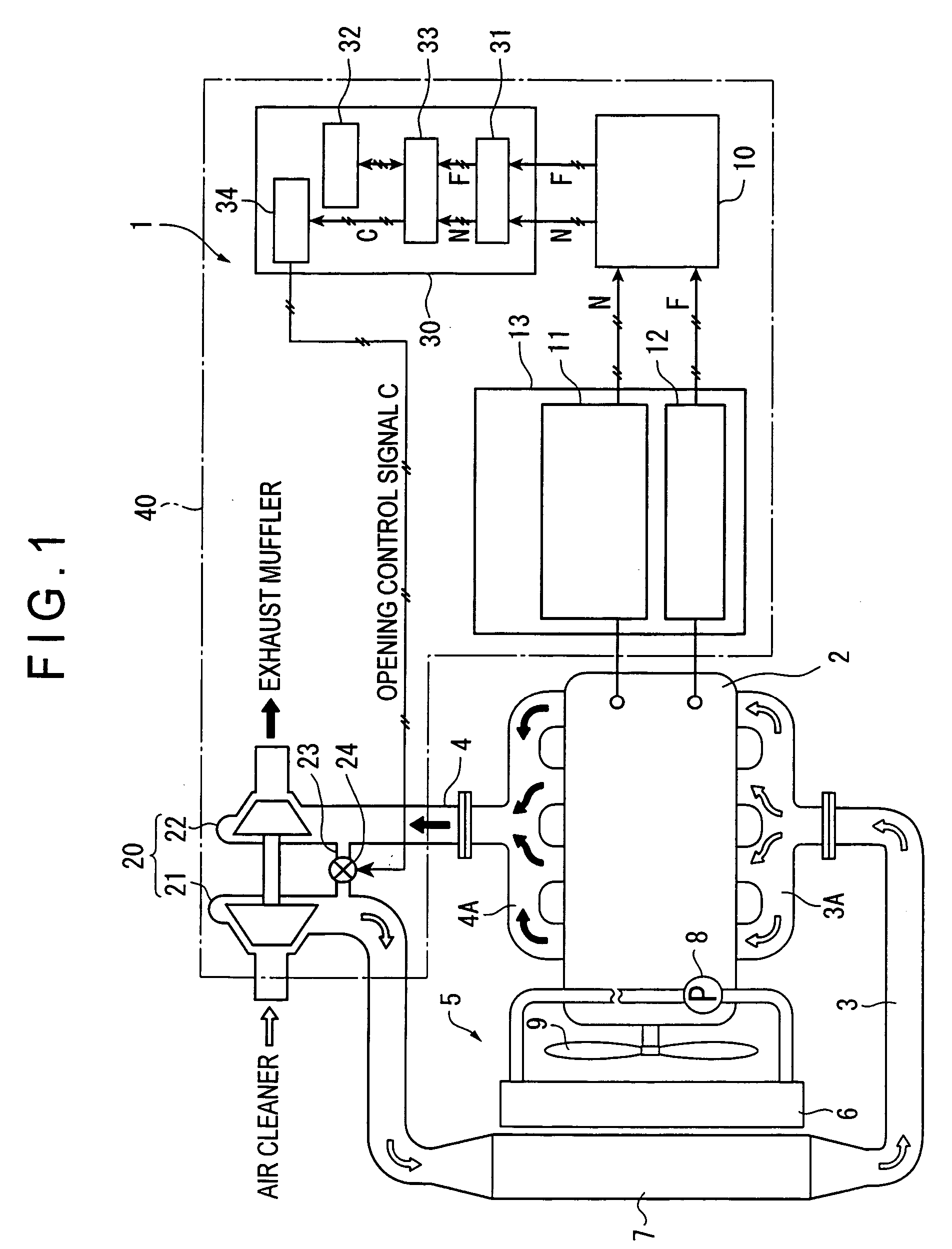

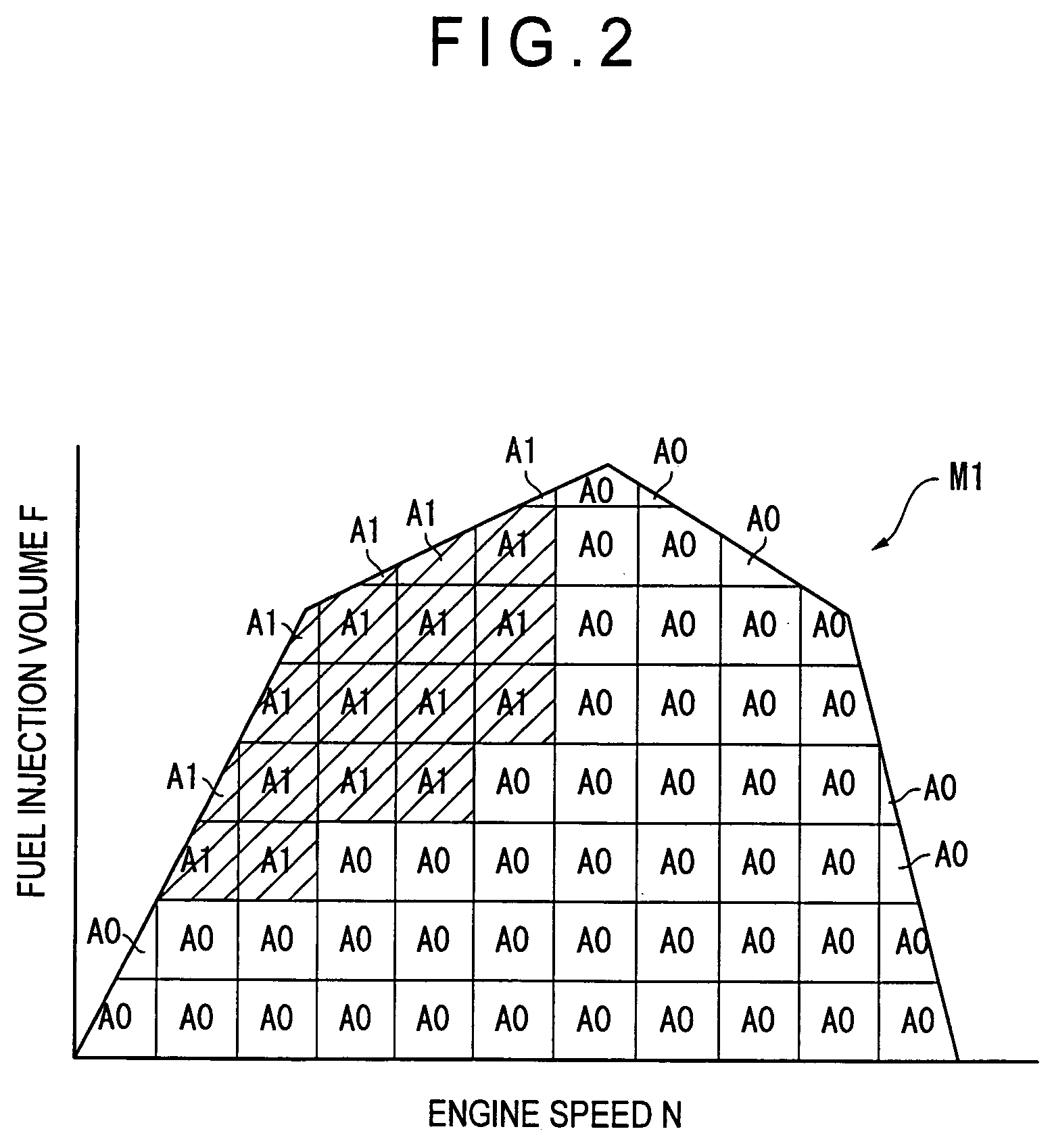

Internal combustion engine provided with intake bypass control device

InactiveUS7032382B2Prevent surgeIncrease pressure ratioElectrical controlInternal combustion piston enginesTurbochargerDieseling

A bypass conduit (23) connects an outlet passage of a compressor (21) of an exhaust gas turbocharger (20) and an inlet passage of an exhaust turbine (22), and a bypass valve (24) is provided therein. When the operating condition of a diesel engine (1) is found to be in a low-speed and high-load region, the bypass valve (24) is controlled by means of a valve controller to adjust the bypass conduit (23) so as to open it. Then, the charge air partly flows into an exhaust conduit (4) to increase the rotational speed of the exhaust turbine (22) and hence the charge air flow rate raises the output of the diesel engine (1). Additionally, as the charge air flow rate is increased, the operating condition of a compressor (21) is prevented from approaching the surging range.

Owner:KOMATSU LTD

Two-shaft turbocharger

InactiveUS7571607B2Easy to controlIncrease pressure ratioInternal combustion piston enginesCombination enginesAxial compressorImpeller

Owner:HONEYWELL INT INC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS20120073261A1Improve efficiencyLower cost of capitalGas turbine plantsDirect carbon-dioxide mitigationNuclear engineeringCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS20110083435A1Enhance oil recoverySave powerGas turbine plantsDirect carbon-dioxide mitigationNuclear engineeringCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Supercharged hybrid input differential engine system

InactiveUS8196686B2Increase torqueIncrease pressure ratioElectric propulsion mountingCombustion enginesHydraulic motorElectric machine

A hybrid input differential engine system comprising a planetary gear set. Preferably, an ICE is connected to the planet gear carrier, the output shaft is connected to the ring gear, and the sun gear is connected to a supercharger / expander and an electric or hydraulic motor / generator. As engine torque increases, the supercharger speeds up, increasing torque still further, enabling a small displacement engine to have very high torque at low RPM. In cruise conditions, the sun gear direction is reversed by the motor / generator, causing the supercharger to act as an expander for efficiently throttling the engine. The motor / generator modulates the speed / torque relationships between the engine and the supercharger / expander. A second motor / generator may be used on the output shaft. The electric machines and electric storage may be downsized because less electrical power is needed for the operation of the system.

Owner:DELPHI TECH IP LTD

Optimized helix angle rotors for Roots-style supercharger

ActiveUS20060263230A1Improve blower efficiencyReduce input powerOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

A method of designing rotors for a Roots blower comprising a housing having cylindrical chambers, the housing defining an outlet port (19). The blower includes meshed, lobed rotors (37,39) disposed in the chambers, each rotor including a plurality N of lobes (47,49), each lobe having first (47a,49a) and second (47b,49b) axially facing end surfaces. Each lobe has its axially facing surfaces defining a twist angle (TA), and each lobe defines a helix angle (HA). The method of designing the rotor comprises determining a maximum ideal twist angle (TAM) for the lobe as a function of the number N of lobes on the rotor, and then determining a helix angle (HA) for each lobe as a function of the maximum ideal twist angle (TAM) and an axial length (L) between the end surfaces of the lobe.

Owner:EATON INTELLIGENT POWER LIMITED

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20140053529A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

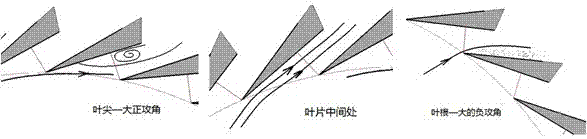

Sweeping and twisting type three-dimensional blade diffuser and design method thereof

The invention relates to a sweeping and twisting type three-dimensional blade diffuser. According to the structure, the front edges of blades are designed into a sweeping shape, the sweeping angle ranges from -45 degrees to 45 degrees, and the blades are suitable for incoming flow and are twisted to be expanded into different air flow angles. The main blade is designed into a three-dimensional integral structure from an inlet to an outlet in the axial direction. The flow-dividing blades are arranged on the rear section in a main blade channel. The sweeping and twisting type three-dimensional blade diffuser has the advantages that interaction of shock waves and a boundary layer is relieved, so that flow in the diffuser is modified; blade surface air flow separation and load loss which are caused by a relative large positive / negative attack angle in part of the blades in the high portion are eliminated, flow loss is reduced, and therefore a stator part diffuser of a centrifugal / oblique flow gas compressor can reach the higher efficiency and the larger pressure ratio. The strength of the shock waves is changed and the shock waves are even eliminated and influence caused by interaction of the shock waves and the boundary layer is relieved; flow loss caused by the overlarge positive attack angle or the overlarge negative attack angle is avoided, the expansion capacity and the operation range of the diffuser are improved, and therefore the improvement in the performance of the whole-level gas compressor is assisted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Internal combustion engine provided with intake bypass control device

InactiveUS20050160733A1Avoid rangePrevent surgeElectrical controlNon-fuel substance addition to fuelExhaust gasOperant conditioning

A bypass conduit (23) connects an outlet passage of a compressor (21) of an exhaust gas turbocharger (20) and an inlet passage of an exhaust turbine (22), and a bypass valve (24) is provided therein. When the operating condition of a diesel engine (1) is found to be in a low-speed and high-load region, the bypass valve (24) is controlled by means of a valve controller to adjust the bypass conduit (23) so as to open it. Then, the charge air partly flows into an exhaust conduit (4) to increase the rotational speed of the exhaust turbine (22) and hence the charge air flow rate raises the output of the diesel engine (1). Additionally, as the charge air flow rate is increased, the operating condition of a compressor (21) is prevented from approaching the surging range.

Owner:KOMATSU LTD

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS10018115B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

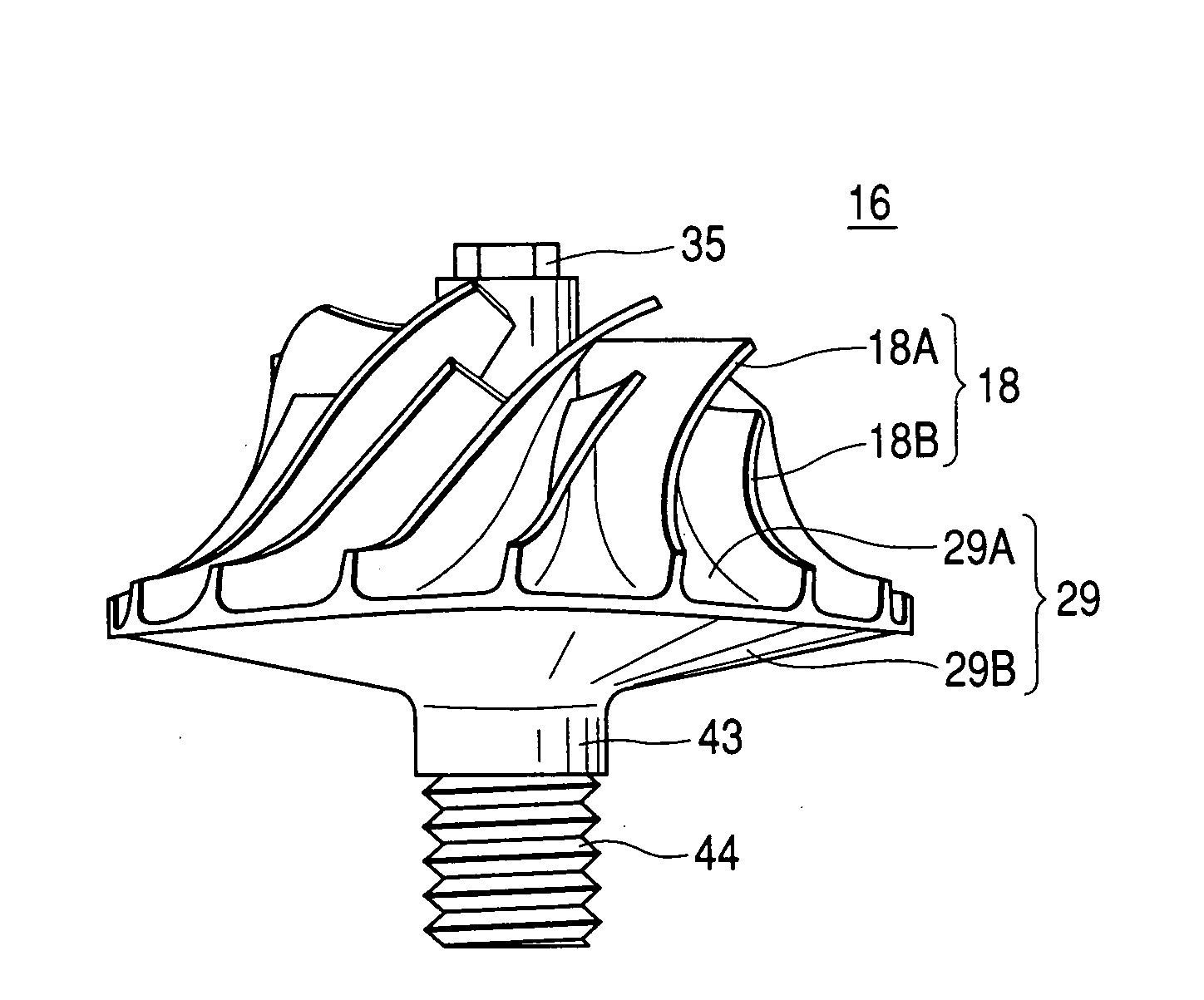

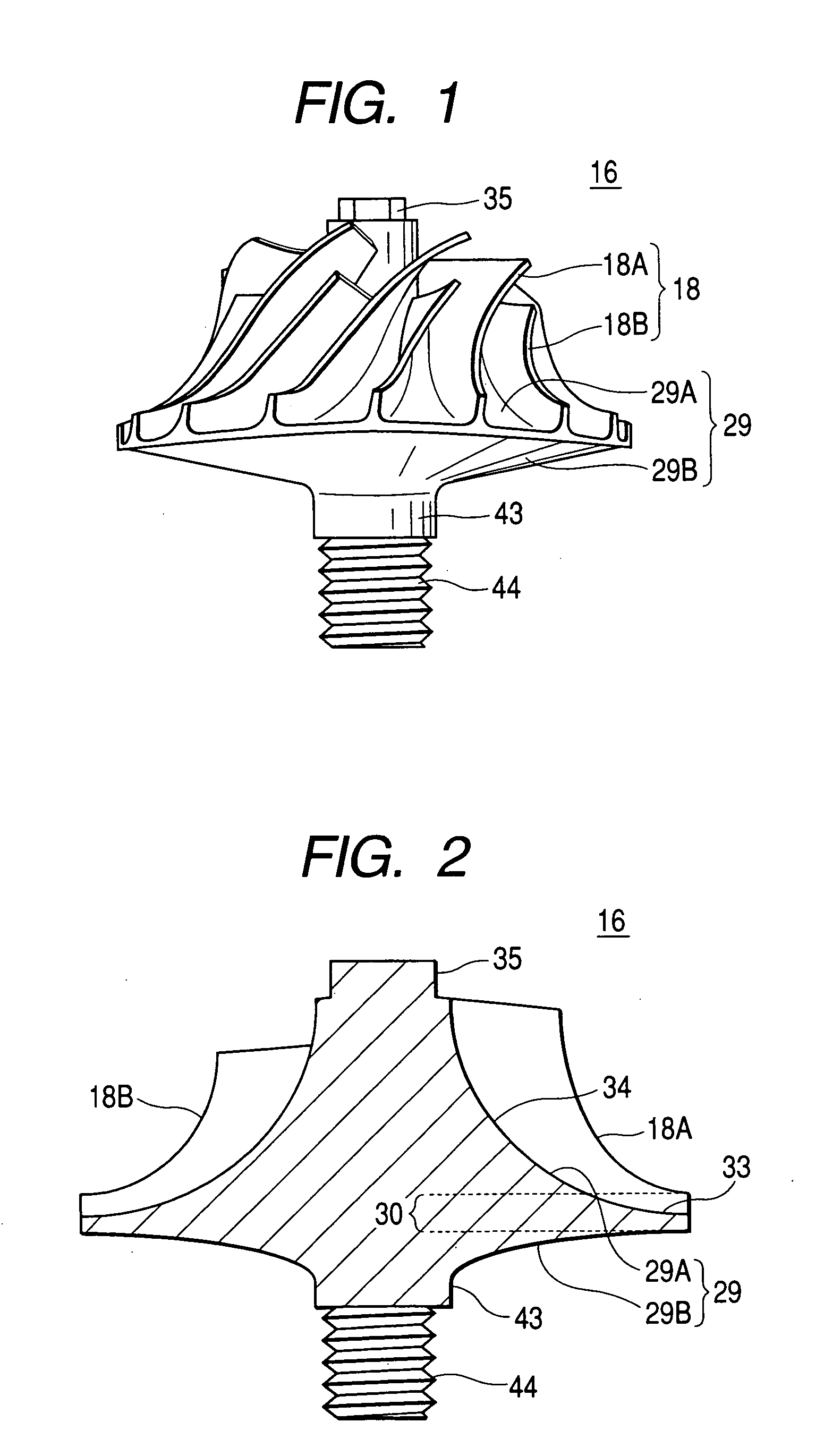

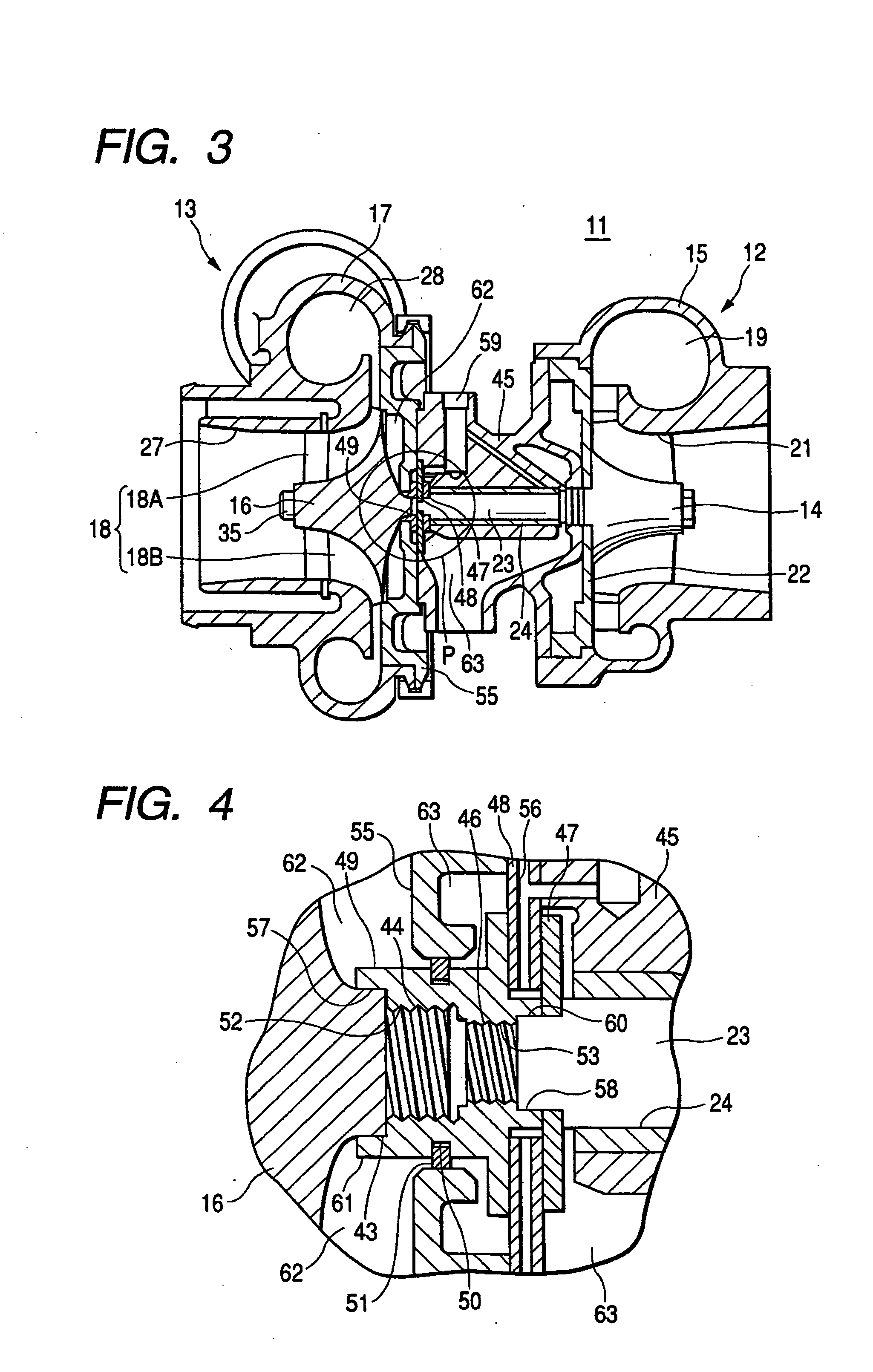

Compressor of turbo machine and its compressor wheel

The invention provides a compressor of a turbo machine and its compressor wheel that do not easily undergo breaking even when rotated at a high number of revolutions. The compressor of the turbo machine includes a male screw portion integrally formed on a main body portion of the compressor wheel and a male screw portion disposed at a distal end of a shaft for driving the compressor wheel that are coupled with each other through a sleeve equipped at one of the ends thereof with a female screw portion capable of meshing with the male screw portion of the compressor wheel and at the other end with a female screw portion capable of meshing with the male screw portion of the shaft.

Owner:KOMATSU LTD

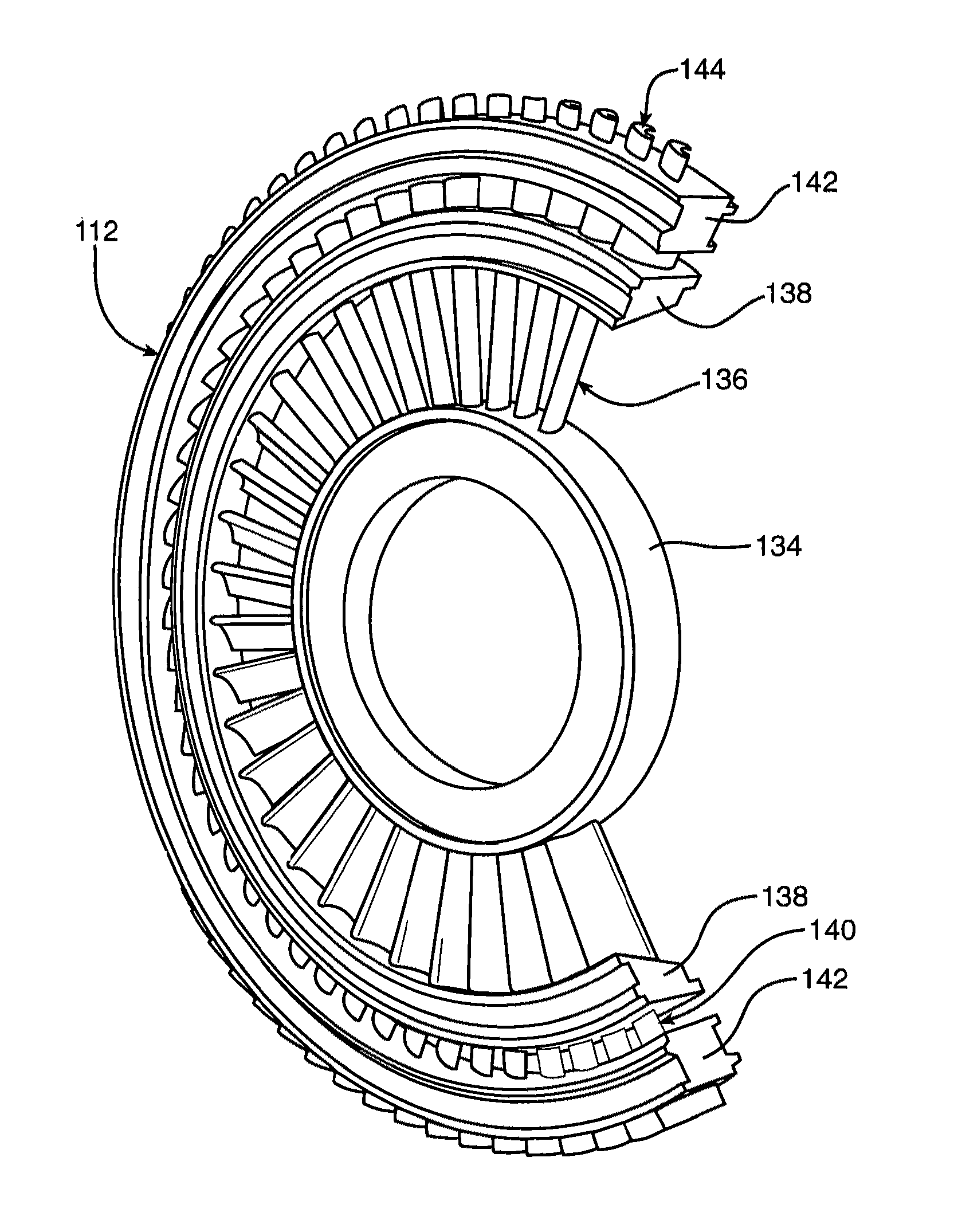

Dual compression rotor

InactiveUS8192141B1Lack capabilityVersatile mission capabilitiesPump componentsGas turbine plantsAxial compressionGas turbines

The present invention provides a gas turbine rotor having a first axial compression stage for compressing air in a first direction and a second axial compression stage for compressing the air in a second direction, the second direction being generally opposite the first direction.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

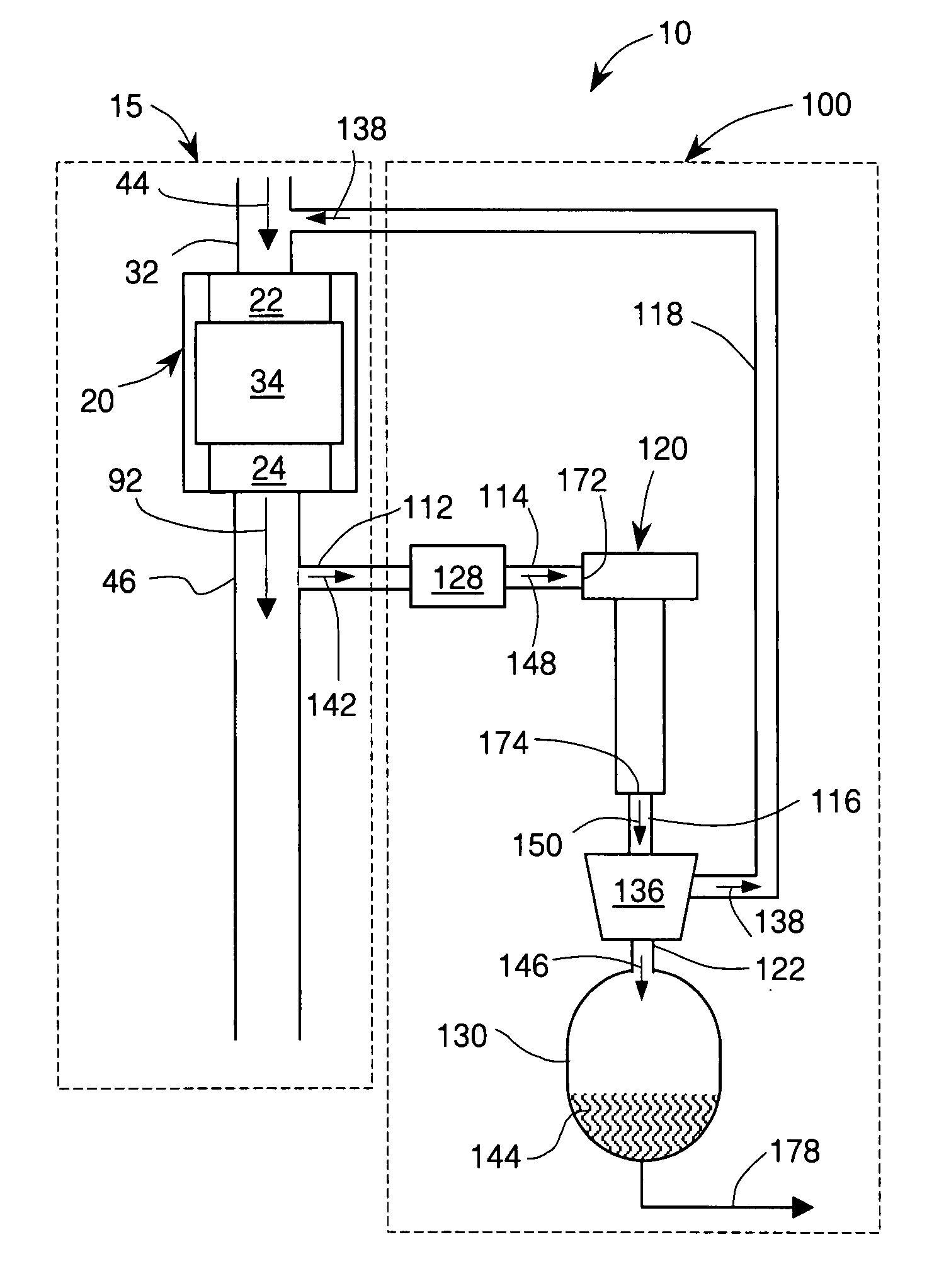

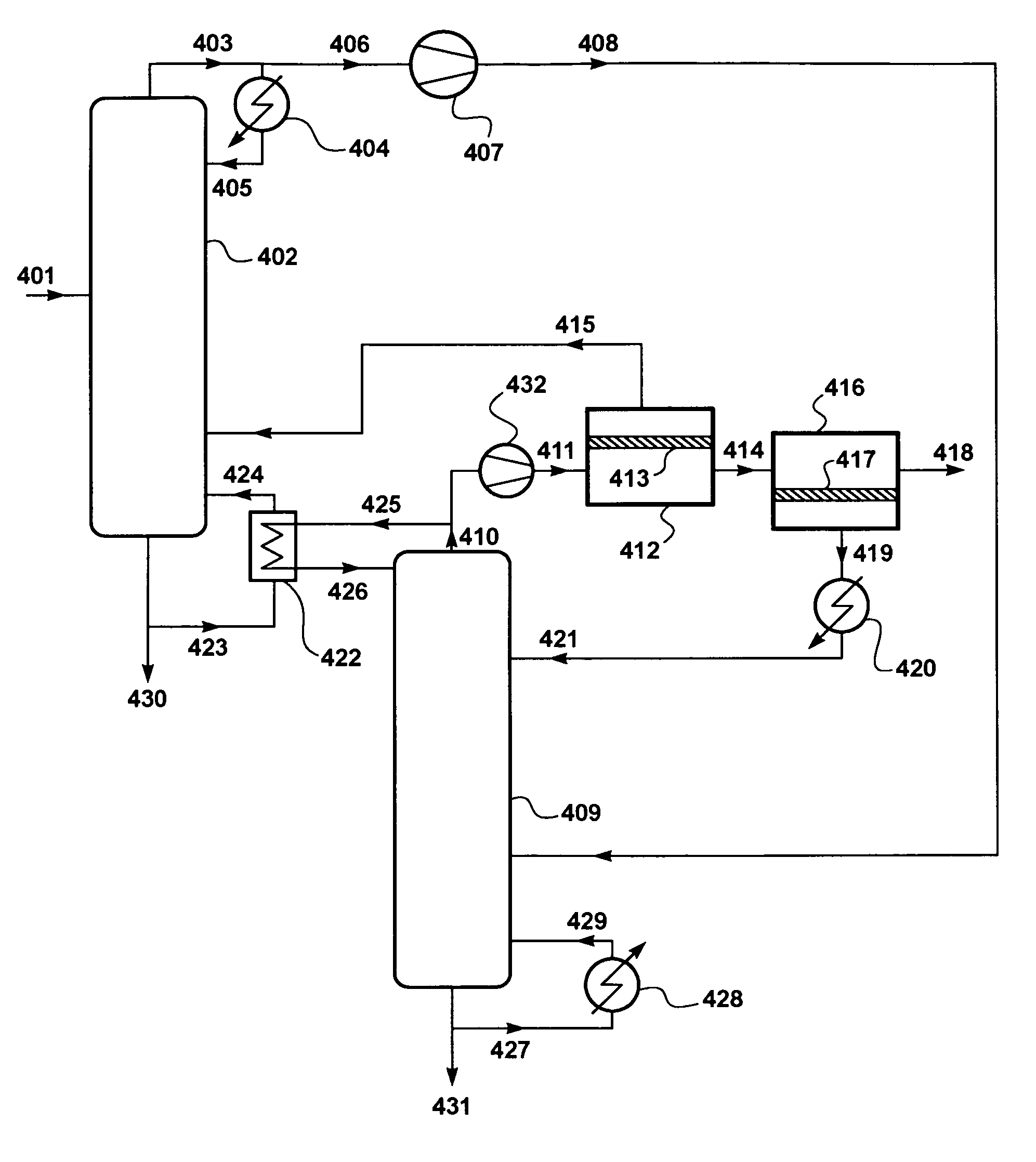

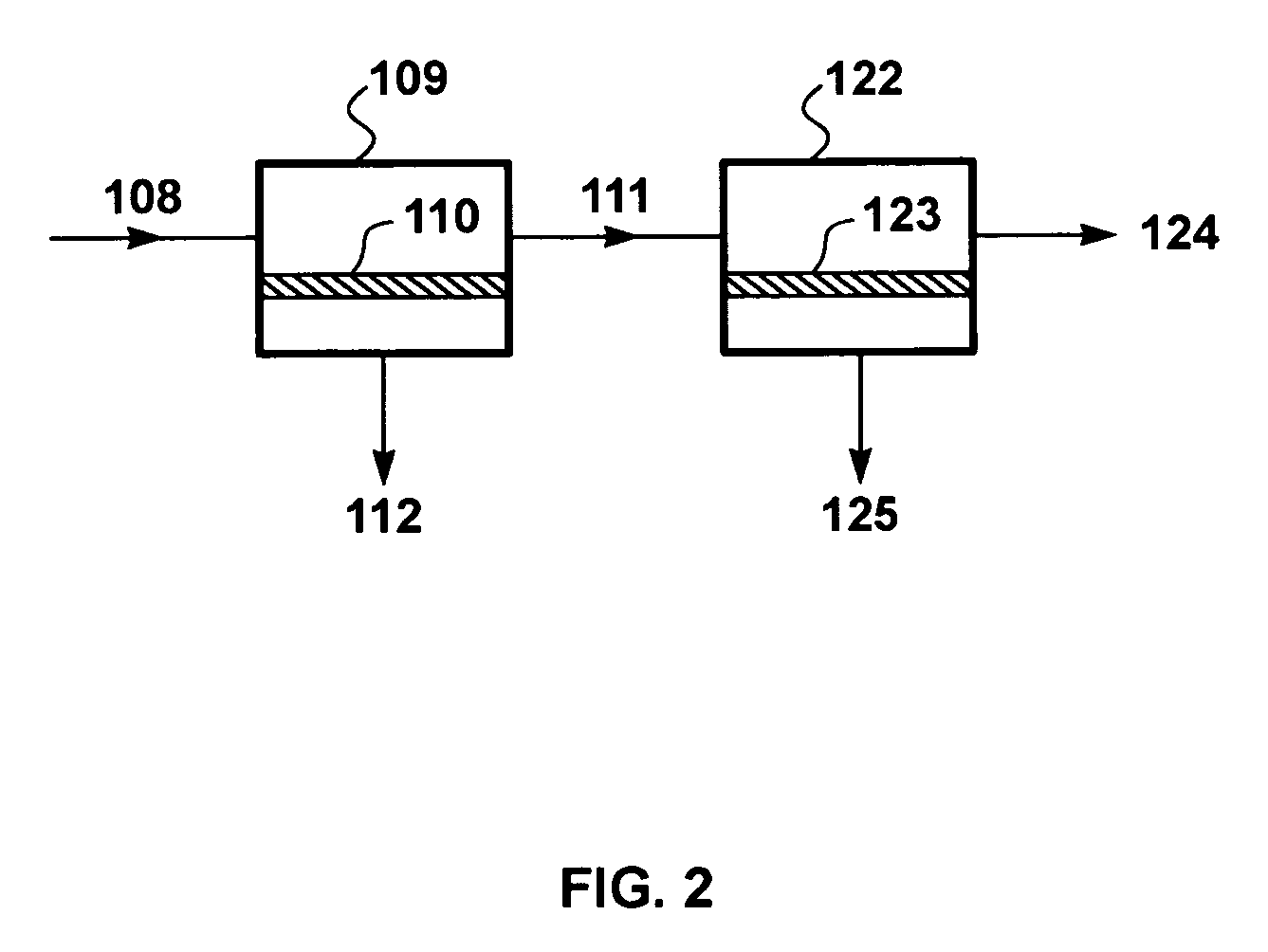

Membrane-augmented distillation with compression to separate solvents from water

ActiveUS8114255B2Low costImprove efficiencyOrganic compound preparationBiofuelsOrganic solventDistillation

Processes for removing water from organic solvents, such as ethanol. The processes include distillation in two columns operated at sequentially higher pressure, followed by treatment of the overhead vapor by one or two membrane separation steps.

Owner:ENVIRONMENTAL PROTECTION AGENCY US +1

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveUS8057157B2Improve performanceLow turn downPropellersWind motor controlGas compressorHigh pressure

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC CO

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130199195A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

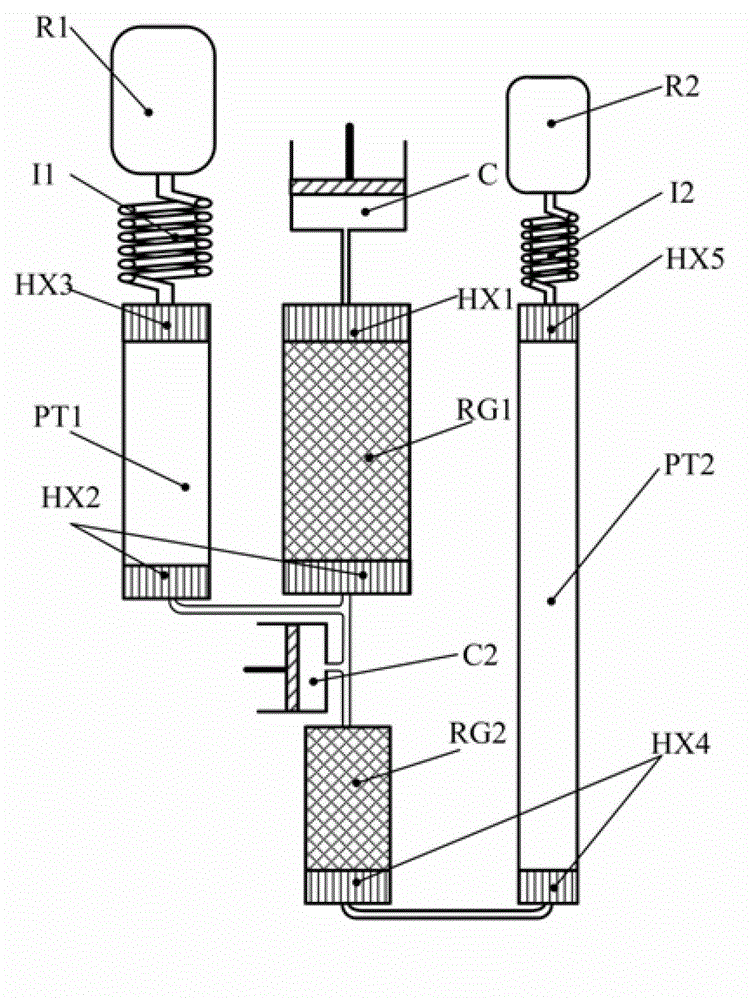

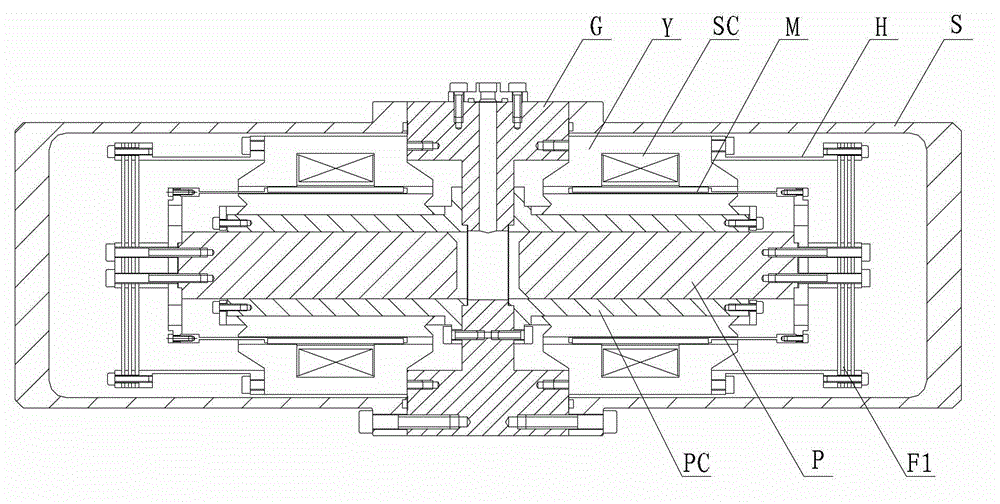

Multi-stage pulse tube refrigerator adopting relay linear compressor

ActiveCN102980321AOptimize layoutEasy to installCompression machinesFluid circulation arrangementLinear compressorPulse tube refrigerator

The invention discloses a multi-stage pulse tube refrigerator adopting a relay linear compressor. The multi-stage pulse tube refrigerator comprises a compressor, a regenerator hot end heat exchanger, a high-temperature section regenerator, high-temperature section regenerator cold end heat exchangers, a first-stage pulse tube, a first-stage pulse tube hot end heat exchanger and first-stage phase-modulating parts, which are sequentially connected, the multi-stage pulse tube refrigerator also comprises a low-temperature section regenerator, low-temperature section regenerator cold end heat exchangers, a second-stage pulse tube, a second-stage pulse tube hot end heat exchanger and second-stage phase-modulating parts, which are sequentially connected, the cold end of the high-temperature section regenerator is also connected with the hot end of the low-temperature section regenerator through a pipeline, and the pipeline is provided with the relay linear compressor which is used for compressing the air passing through the pipeline. The pressure ratio of the cold end of the high-temperature section regenerator of the multi-stage pulse tube refrigerator adopting the relay linear compressor is further increased, consequently, a high pressure ratio is obtained at the cold end of the multi-stage pulse tube refrigerator, and the efficiency of the multi-stage pulse tube refrigerator is ultimately increased; and meanwhile, the multi-stage pulse tube refrigerator has the advantages of compact structure, long service life, high reliability and the like.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00000.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00001.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00002.png)